Crushing equipment for attapulgite

A crushing equipment and technology of attapulgite, which is applied in the field of attapulgite crushing equipment, can solve the problems of waste, lack of screening devices in equipment, and insufficient crushing in one crushing, and achieve the effect of avoiding waste and preventing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

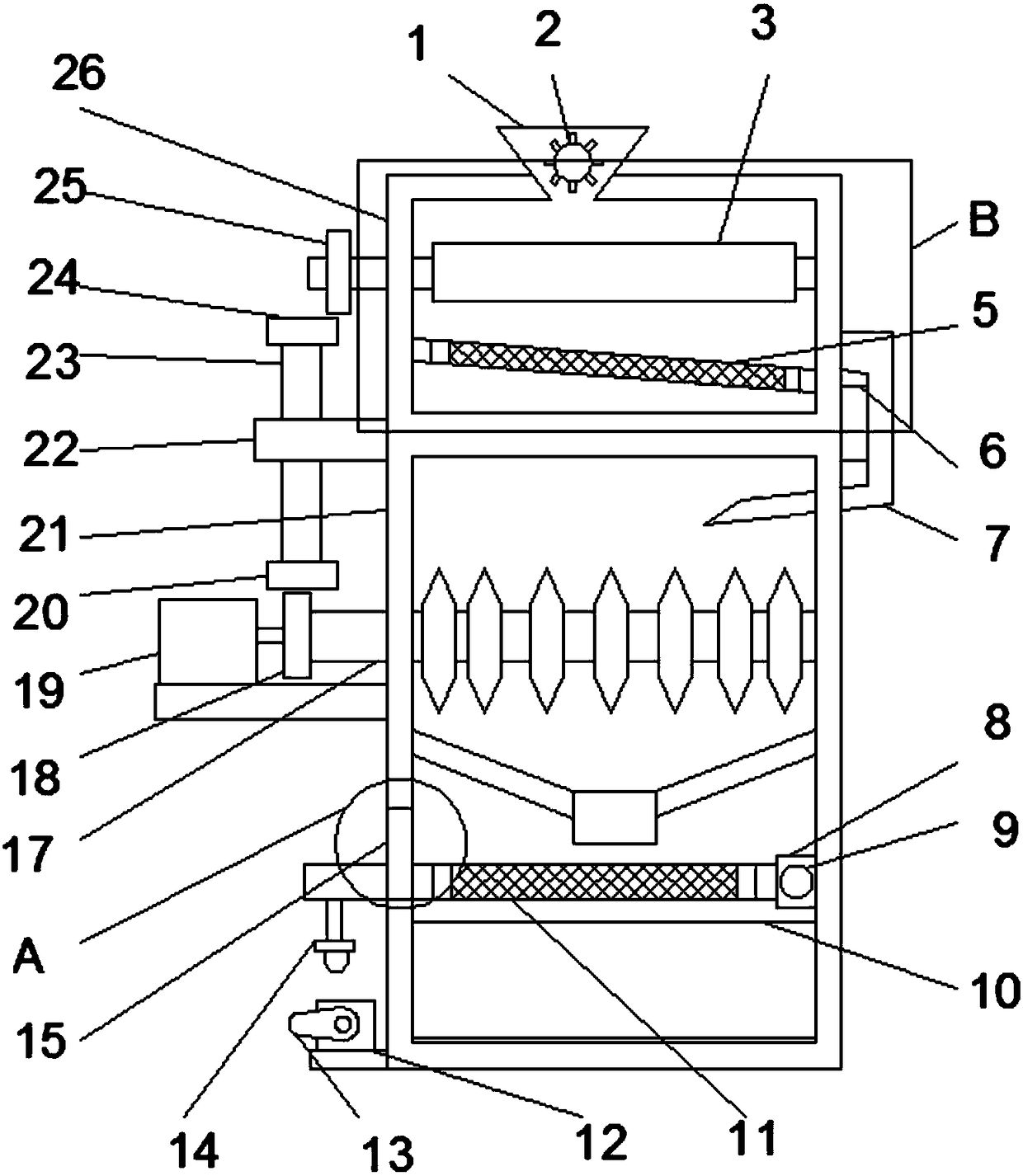

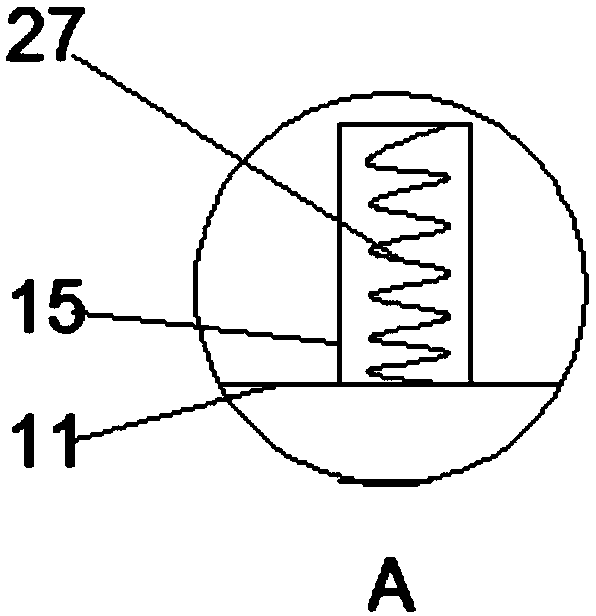

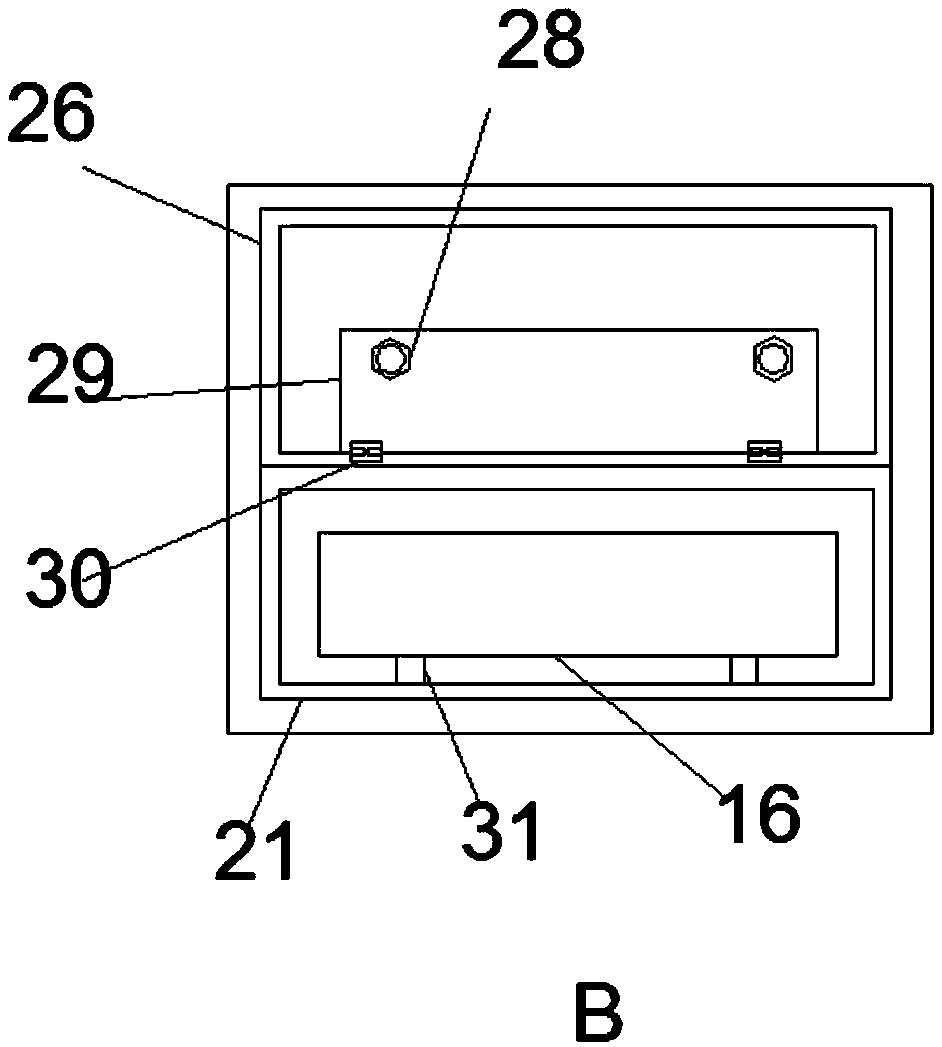

[0019] Such as Figure 1-Figure 3 As shown, a kind of crushing equipment for attapulgite clay proposed by the present invention includes a rolling box 26 and a crushing box 21. A feeding port 1 is provided at the middle of the upper end of the rolling box 26, and a buffer blade 2 is arranged inside the feeding port 1. , the inside of the rolling box 26 is pierced with a rolling roller 3, the left side of the rolling roller 3 is provided with a second gear 25, the inside of the rolling box 26 is provided with a filter plate 5, the filter plate 5 is placed obliquely, and the right side of the rolling box 26 A conduit 7 is provided. The upper end of the pipeline 7 is connected with the rolling box 26, and the lower end of the rolling box 26 is provided with a crushing box 21;

[0020] The upper right corner of the crushing box 21 is provided with an opening, and the opening communicates with the lower end of the pipeline 7. The left side of the crushing box 21 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com