Mashing device for agricultural processing

A technology of agricultural processing and feeding hopper, which is applied in food processing, grain processing, etc. It can solve the problems of affecting medicinal value, low processing efficiency, and high temperature of materials, so as to improve the mashing effect, increase the heat exchange effect, and ensure the mashing effect. The effect of the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

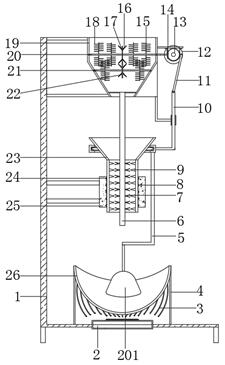

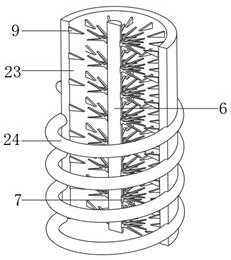

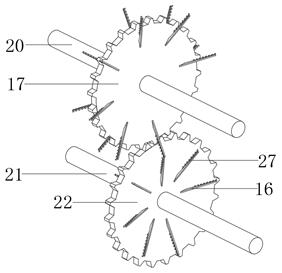

[0029] refer to Figure 1-4 , a mashing device for agricultural processing, comprising a fixed frame 1, a side of the fixed frame 1 close to the top is fixedly equipped with a feeding hopper 19, and one side of the feeding hopper 19 is equipped with a driving mechanism, the driving mechanism includes a The rotating motor 13 on the outer wall of one side of the hopper 19, and the output shaft of the rotating motor 13 are respectively keyed to be connected with the active conical gear 28 and the runner 12, and the inside of the feeding hopper 19 is connected with the driven rod 120 and the driven rod 12 through bearing rotation respectively. Rod two 21, and the middle end of driven rod one 20 and driven rod two 21 are respectively key-connected with intermeshed transmission gear one 17 and transmission gear two 22, and both sides of transmission gear one 17 and transmission gear two 22 are all fixed Equidistantly distributed oblique cutter bars 16 are installed, and the opposite...

Embodiment 2

[0039] refer to figure 1 and Figure 5 , a mashing device for agricultural processing. Compared with Embodiment 1, this embodiment also includes that the outer wall of the bottom of the mashing basin 26 is welded with equidistantly distributed heat exchange strips 3, and the specifications of the heat exchange strips 3 are as follows: The middle end increases sequentially to both sides.

[0040] In the present invention, the outer wall of the bottom of the smashing basin 26 is provided with half-circle wall grooves 29 equidistantly distributed; by setting the heat exchange strips 3 whose specifications are increased from the middle end to both sides, and cooperating with the half-circle wall grooves 29, effectively Increase the heat exchange area of the smashing basin 26, thereby increasing the heat exchange effect.

[0041] When the present invention is in use: by setting the heat exchange strips 3 whose specifications increase from the middle end to both sides in turn, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com