Patents

Literature

1018results about "Flower-pot filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

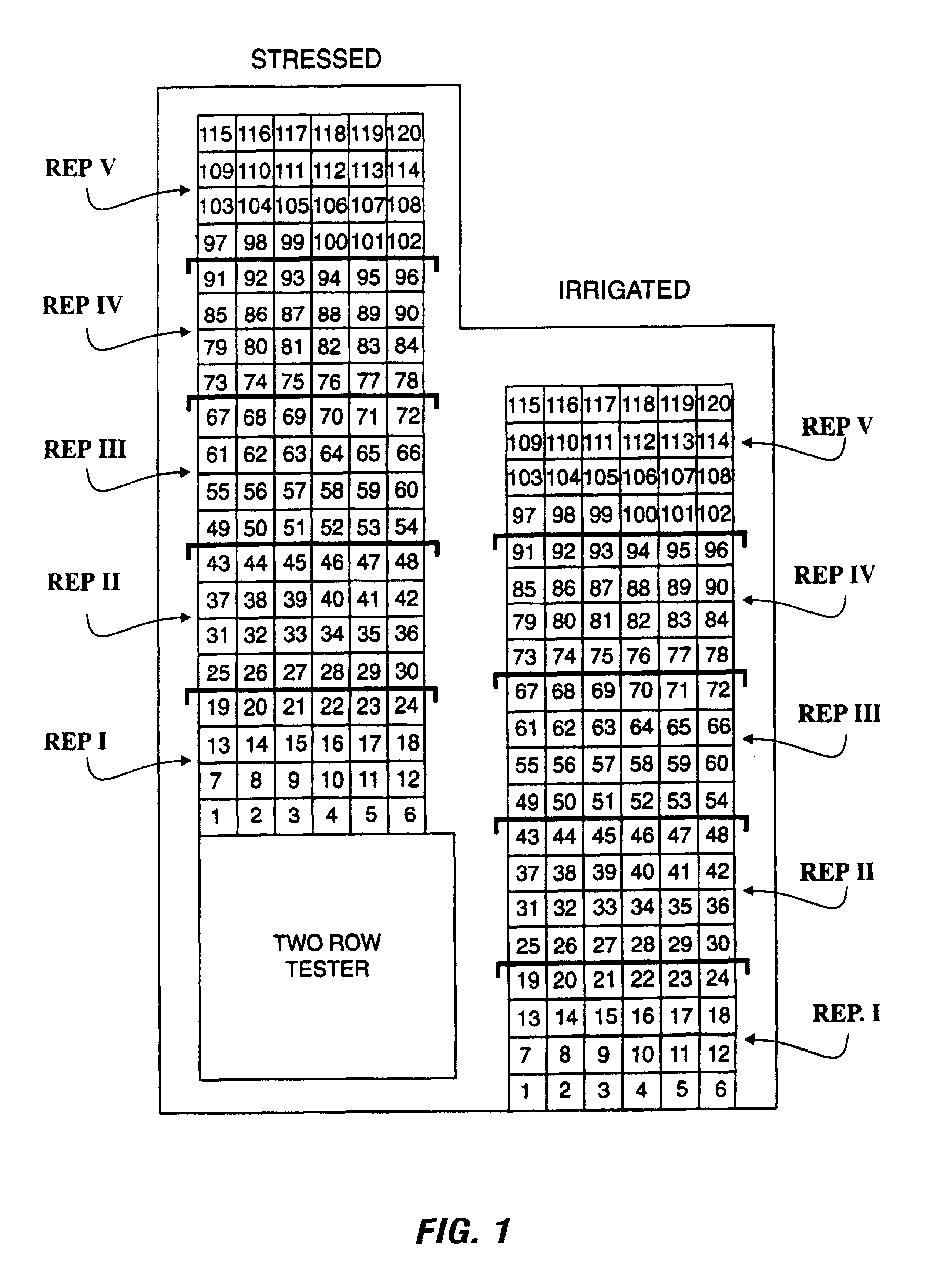

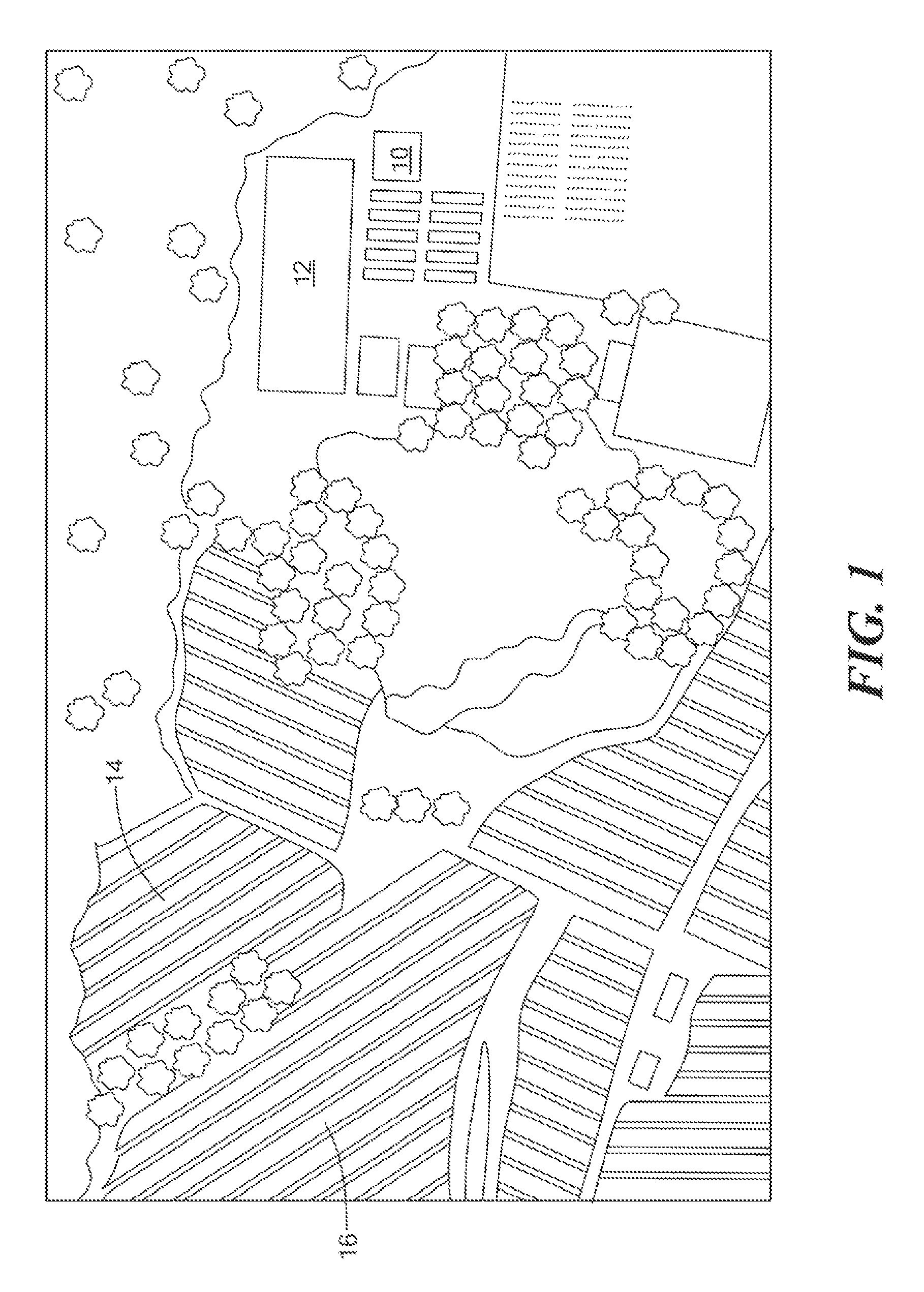

Methods for classifying plants for evaluation and breeding programs by use of remote sensing and image analysis technology

InactiveUS6212824B1Improve performanceLow costSeed and root treatmentPhotogrammetry/videogrammetryImaging analysisBreeding program

Methods for classifying plants by remote sensing and image analysis technology are presented. These methods are useful for evaluating plants and for selecting plants for a plant breeding program which has as its goal to selectively alter phenotype. The methods combine the newer techniques of remote sensing technology to obtain indirect correlates of the traits of interest, with classical pedigree breeding strategies. Thermal and infrared reflectance measures of plant canopies are examples of energy values measured by remote sensing, used to indirectly predict the selected traits.

Owner:MONSANTO TECH LLC

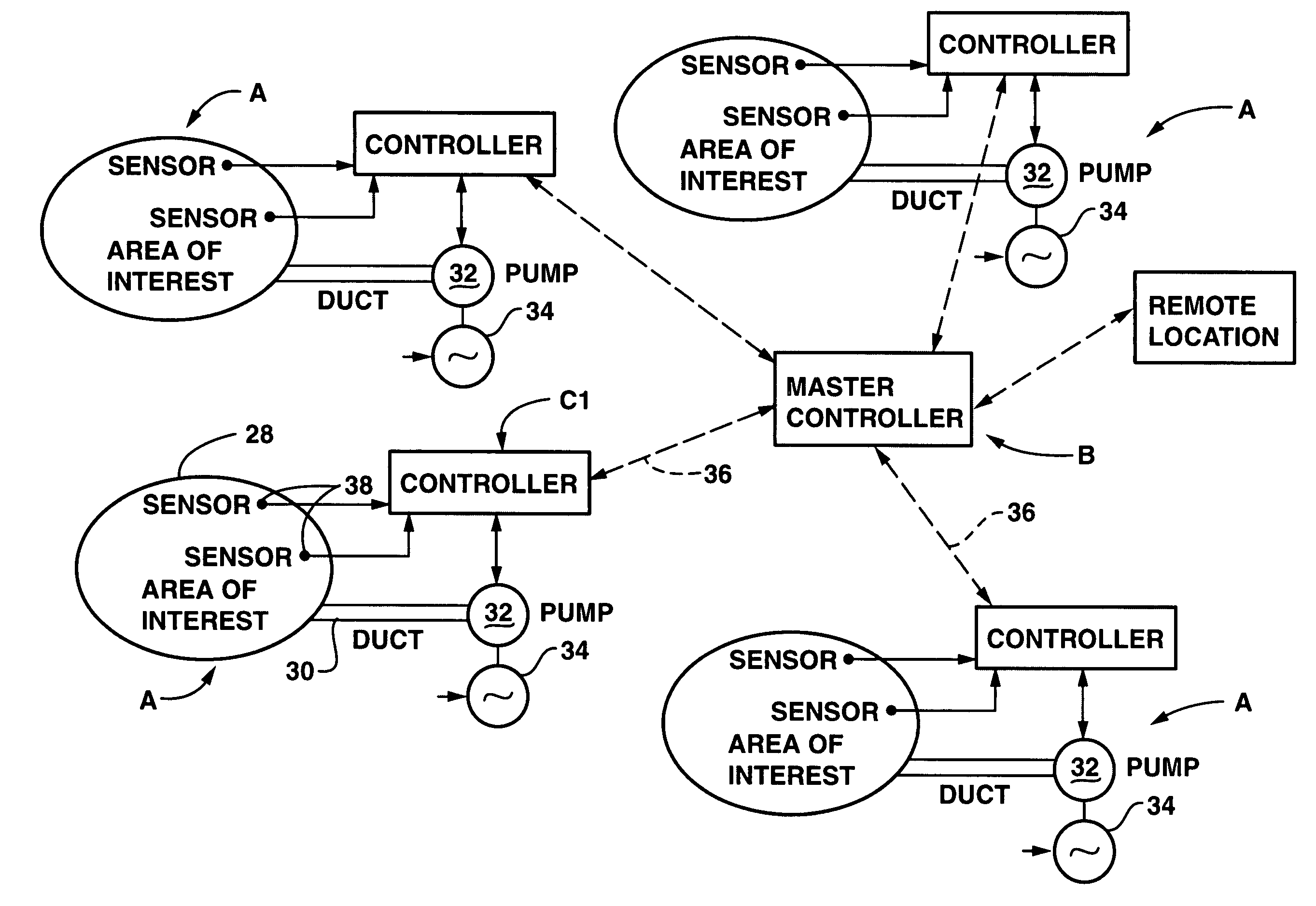

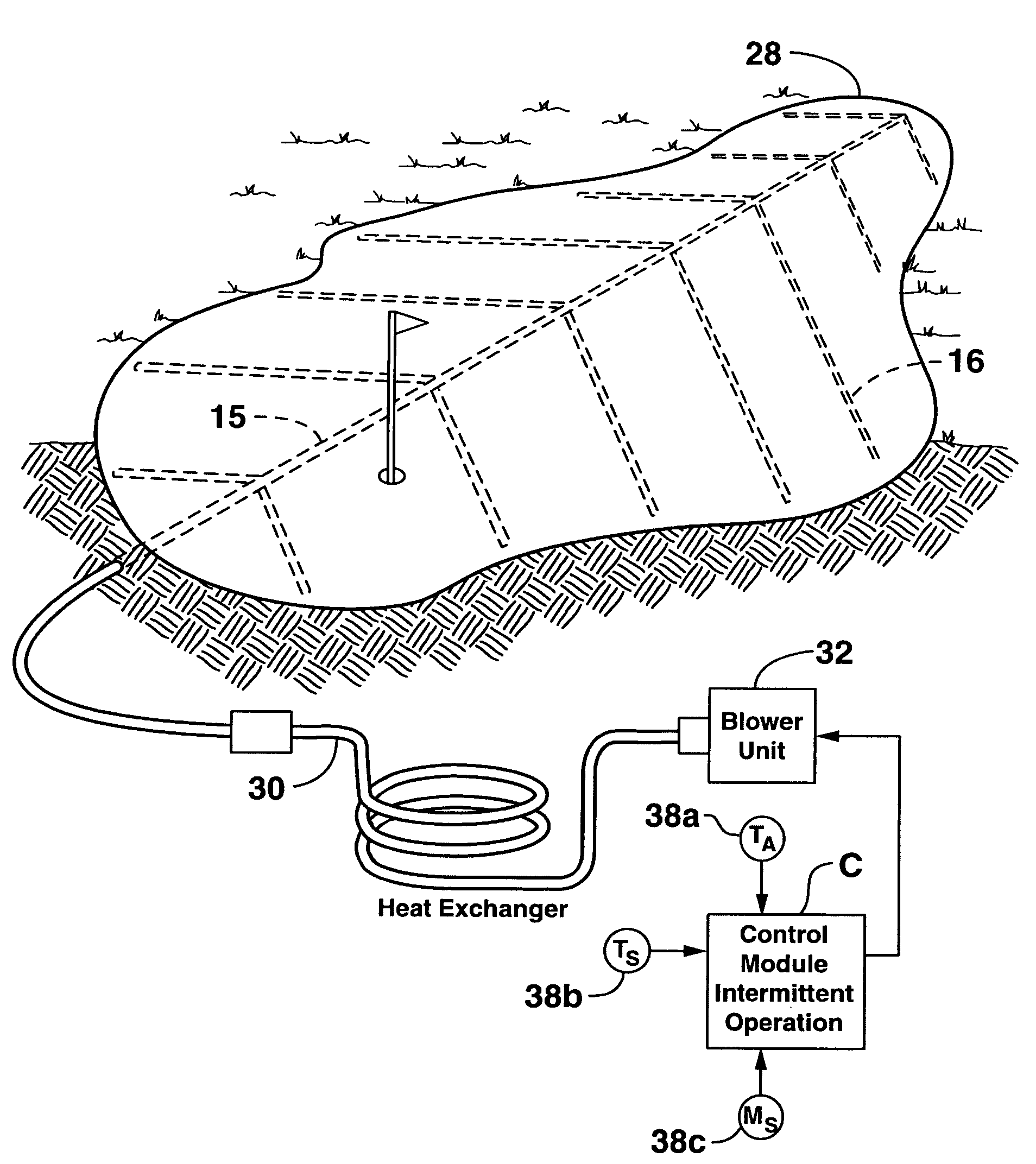

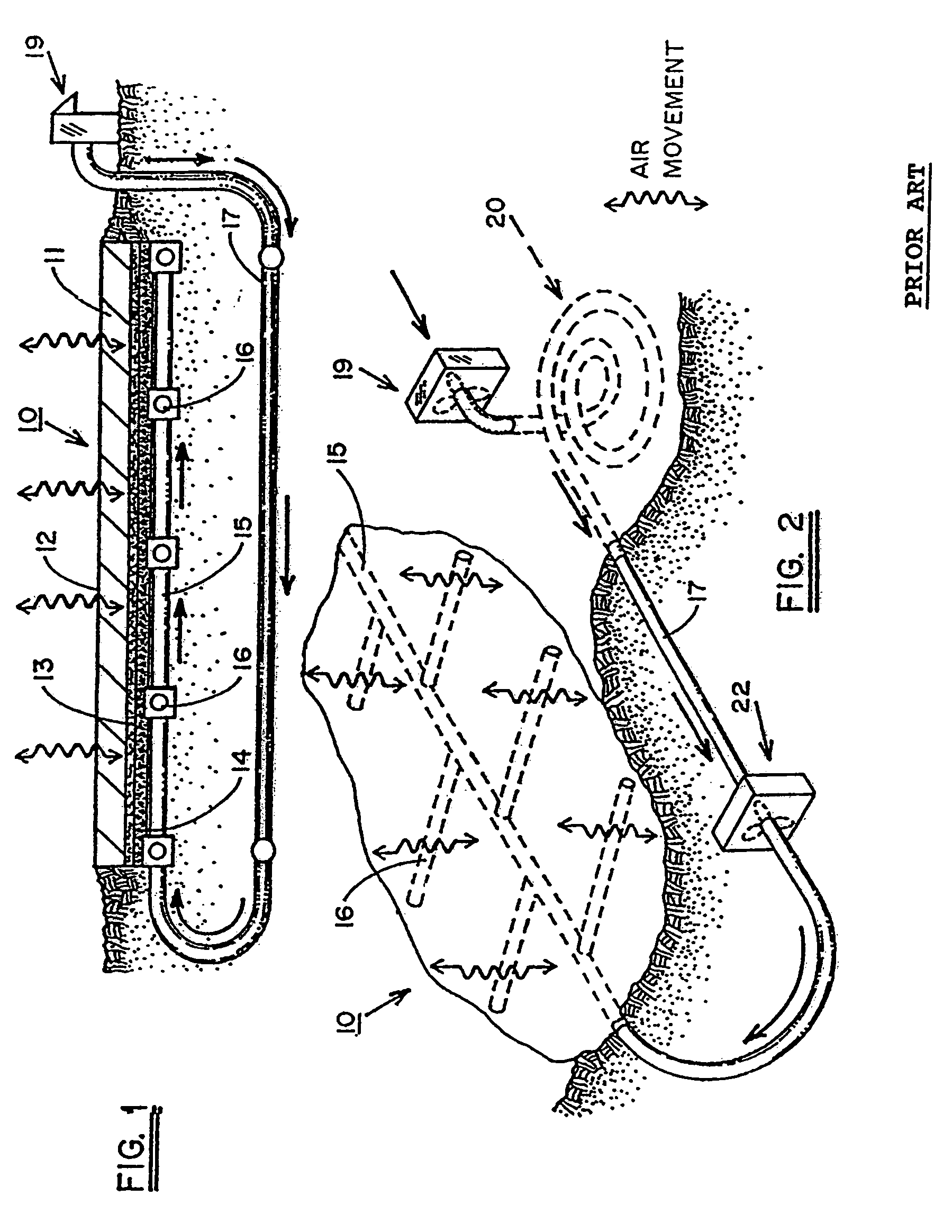

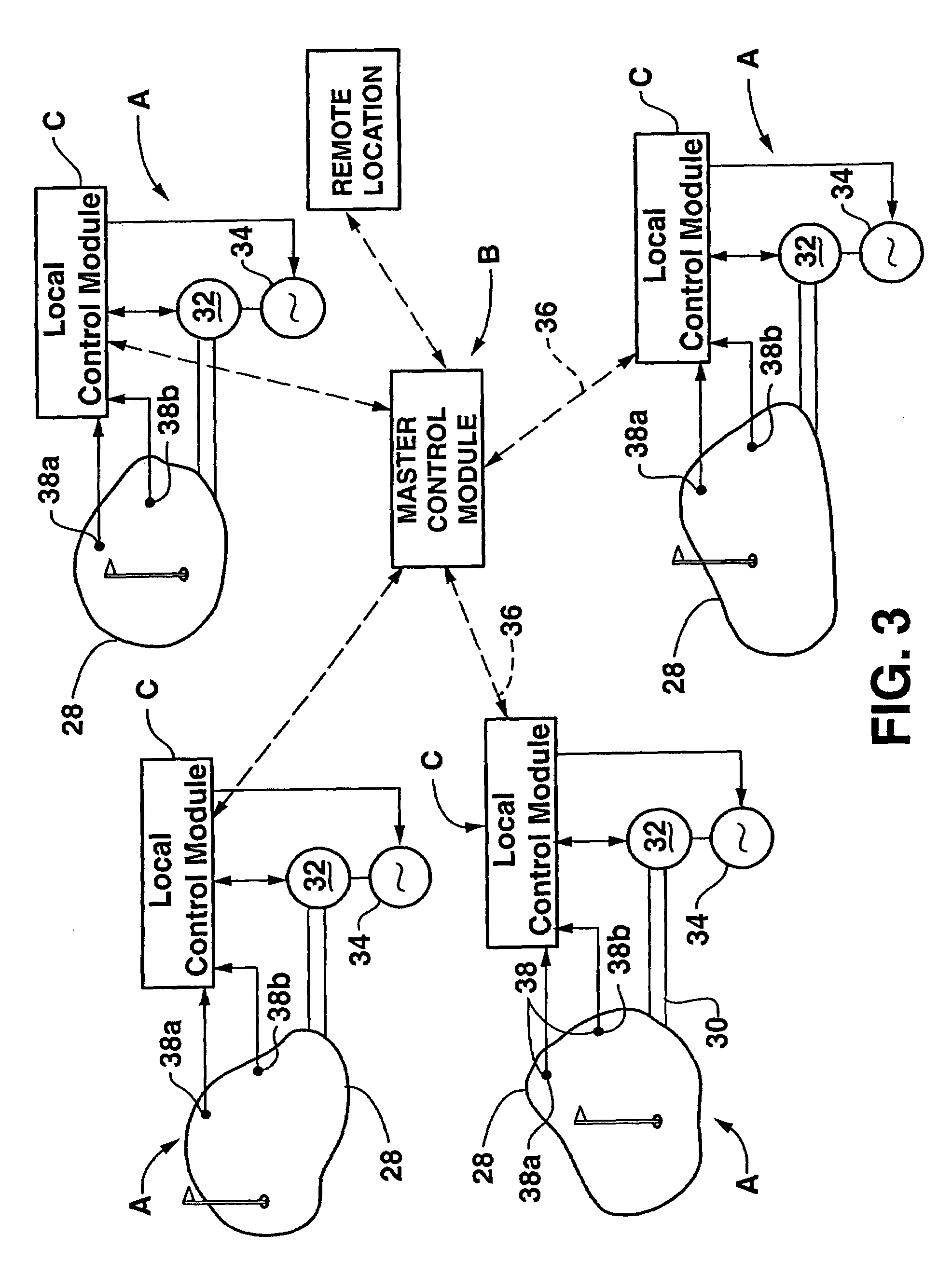

Golf course environmental management system and method

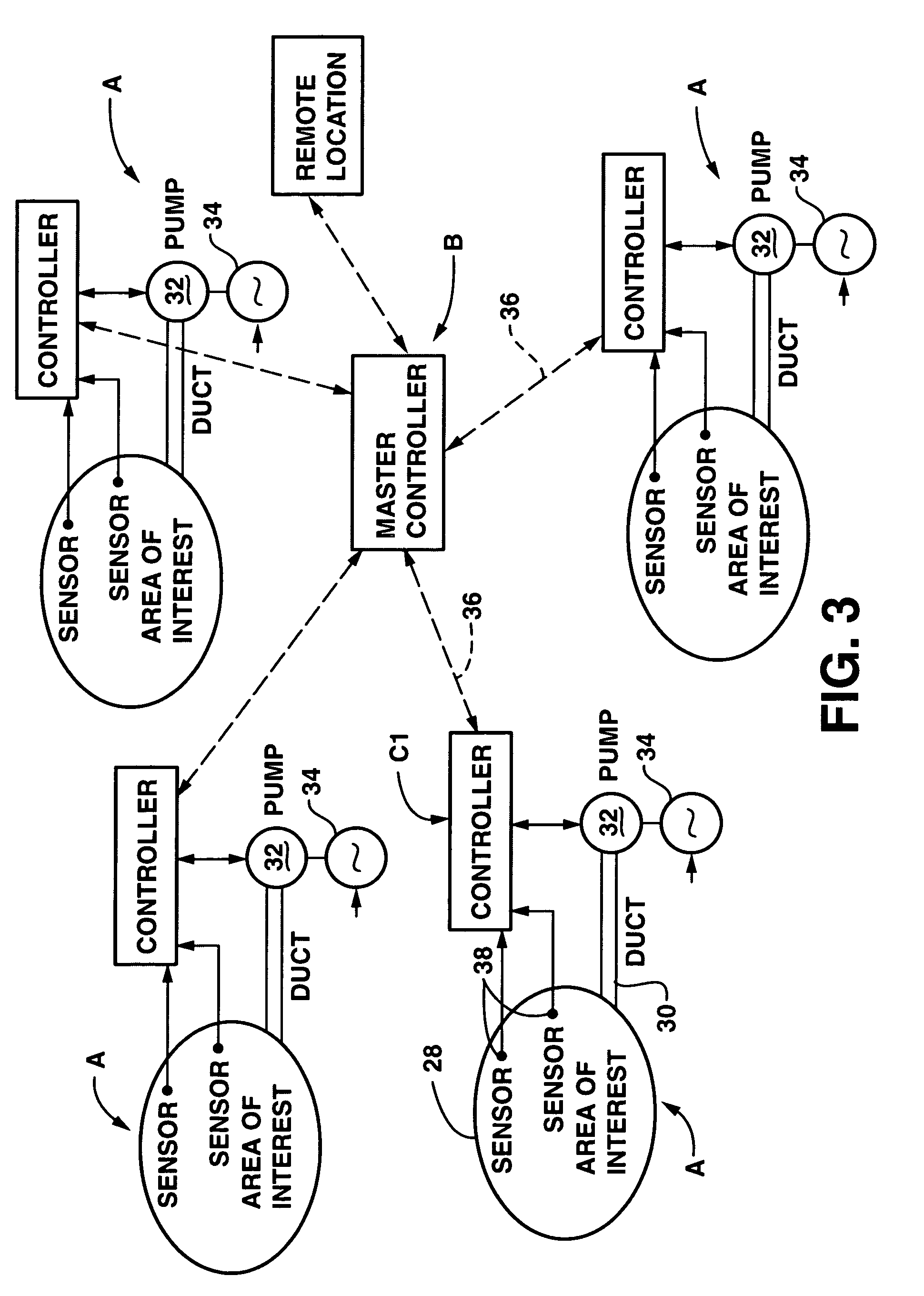

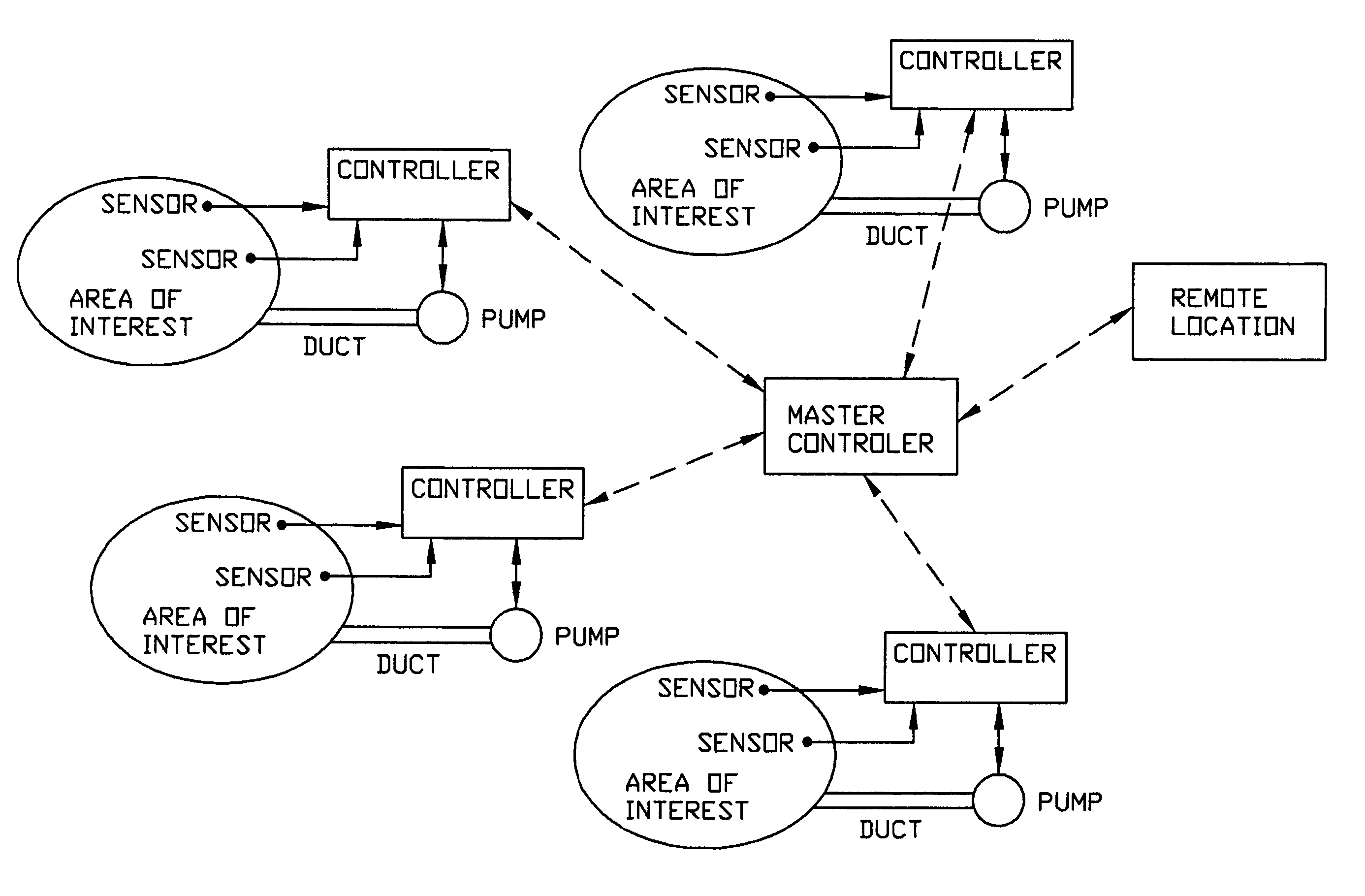

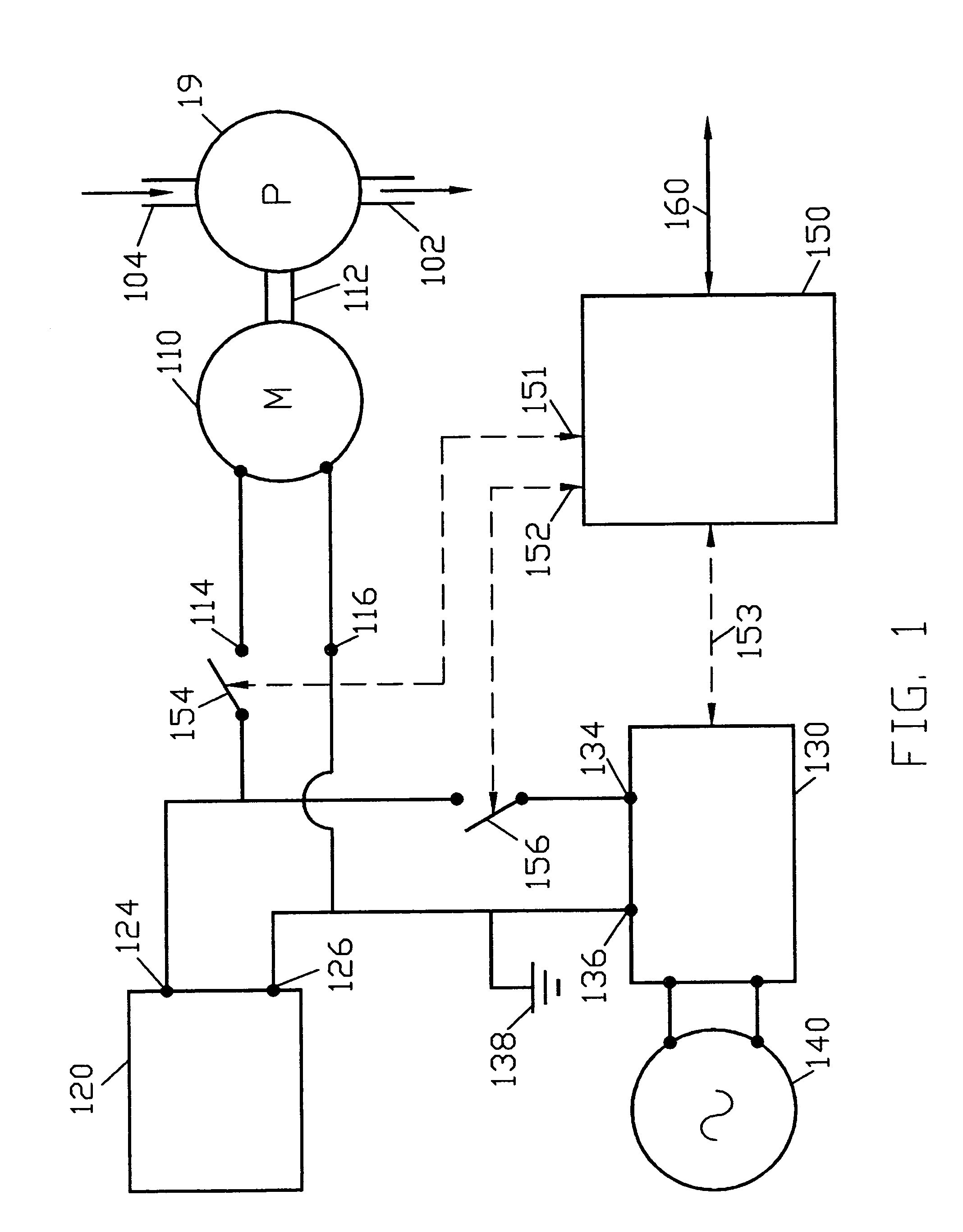

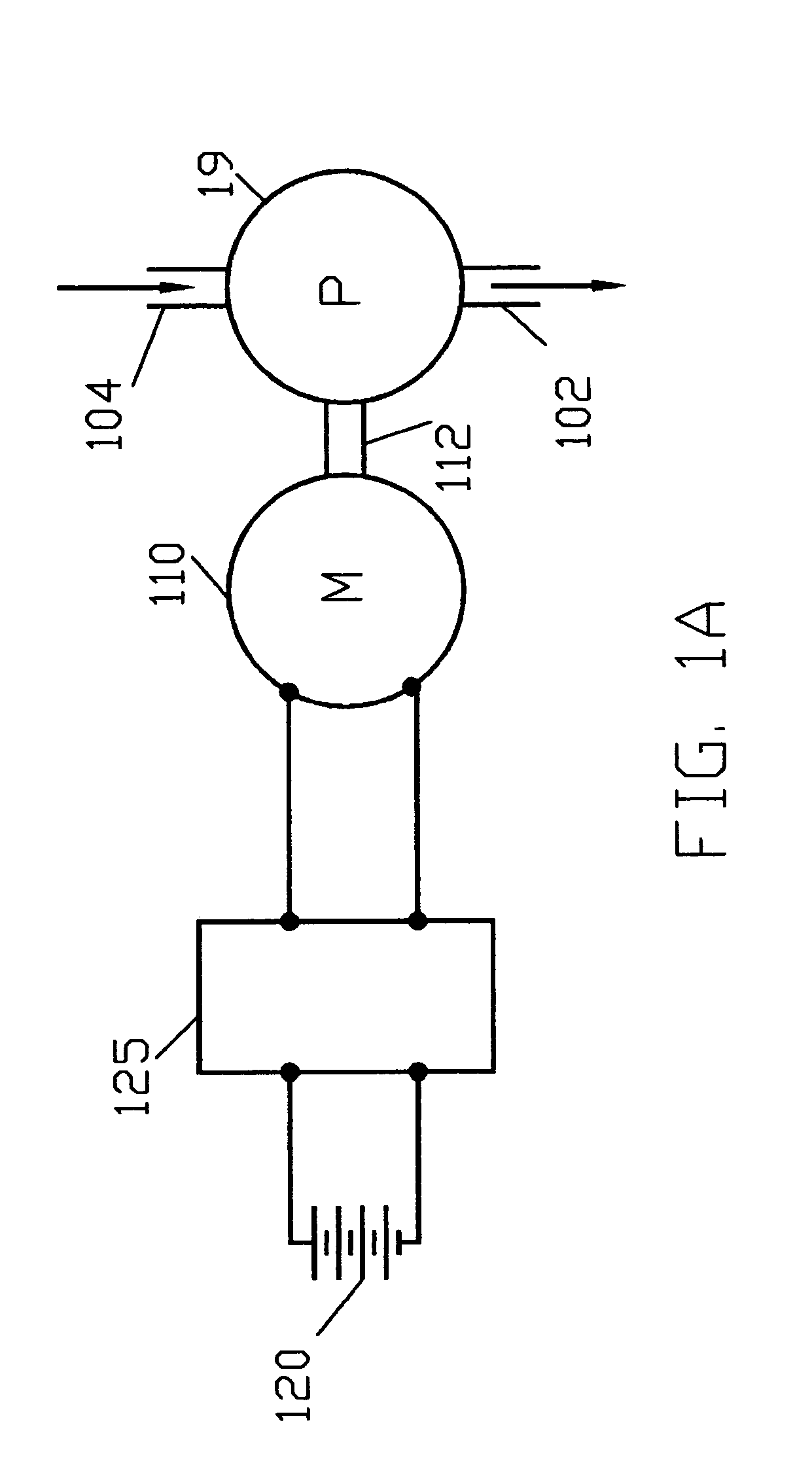

The invention is a system and method for managing a plurality of areas of interest of a golf course. The system comprises a plurality of subsurface aeration subsystems and a programmable master control module. Each subsystem provides to a specific area at least one of air under pressure and a partial vacuum. In each area of interest, a local control module is responsive to a directive and to a datum (environmental or operational parameter). The local control module is configured to operate the subsystem and is in communication with the programmable master control module. The programmable master control module receives from the local control modules area information representing a status of the respective specific area to which the local control module is dedicated, and in response to the area information and to a command, the programmable master control module issues a directive to the local control module to operate the subsurface aeration subsystem.

Owner:SUBAIR SYST

Golf course environmental management system

ActiveUS6997642B2Functional valve typesSelf-acting watering devicesElectronic systemsGolf course turf

The invention is a system for managing a plurality of areas of interest of a golf course. The system comprises a plurality of electromechanical subsystems and a programmable master control module. Each subsystem provides to a specific area at least one of air under pressure and a partial vacuum. In each area of interest, a local control module is responsive to a directive and to a datum. The local control module is configured to operate the subsystem and is in communication with the programmable master control module. The programmable master control module receives from at least two of the plurality of local control modules information representing a status of the respective specific area to which the local control module is dedicated, and in response to the information and to a command, the programmable master control module issues a directive to the local control module to operate the electromechanical subsystem.

Owner:SUBAIR SYST

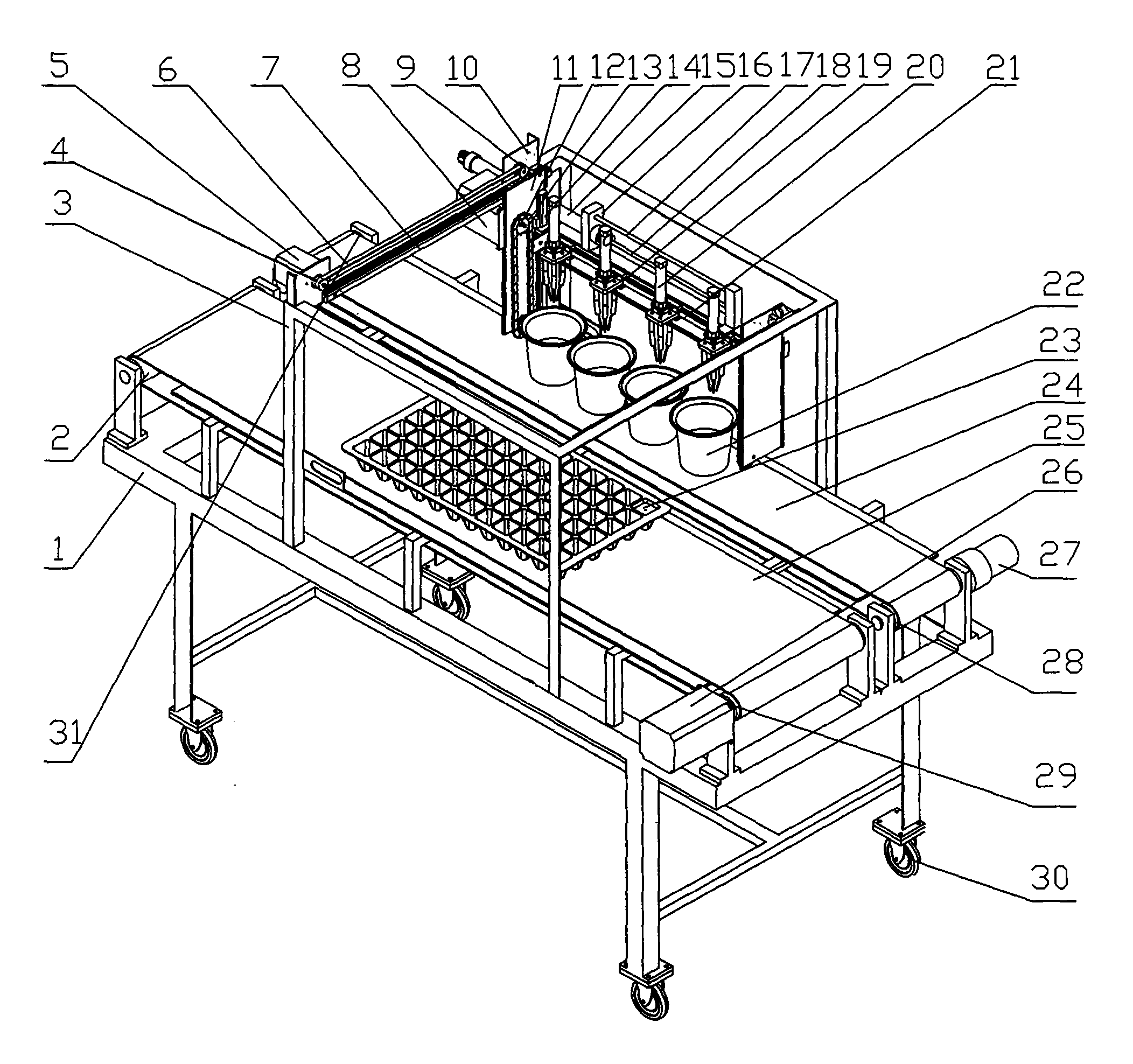

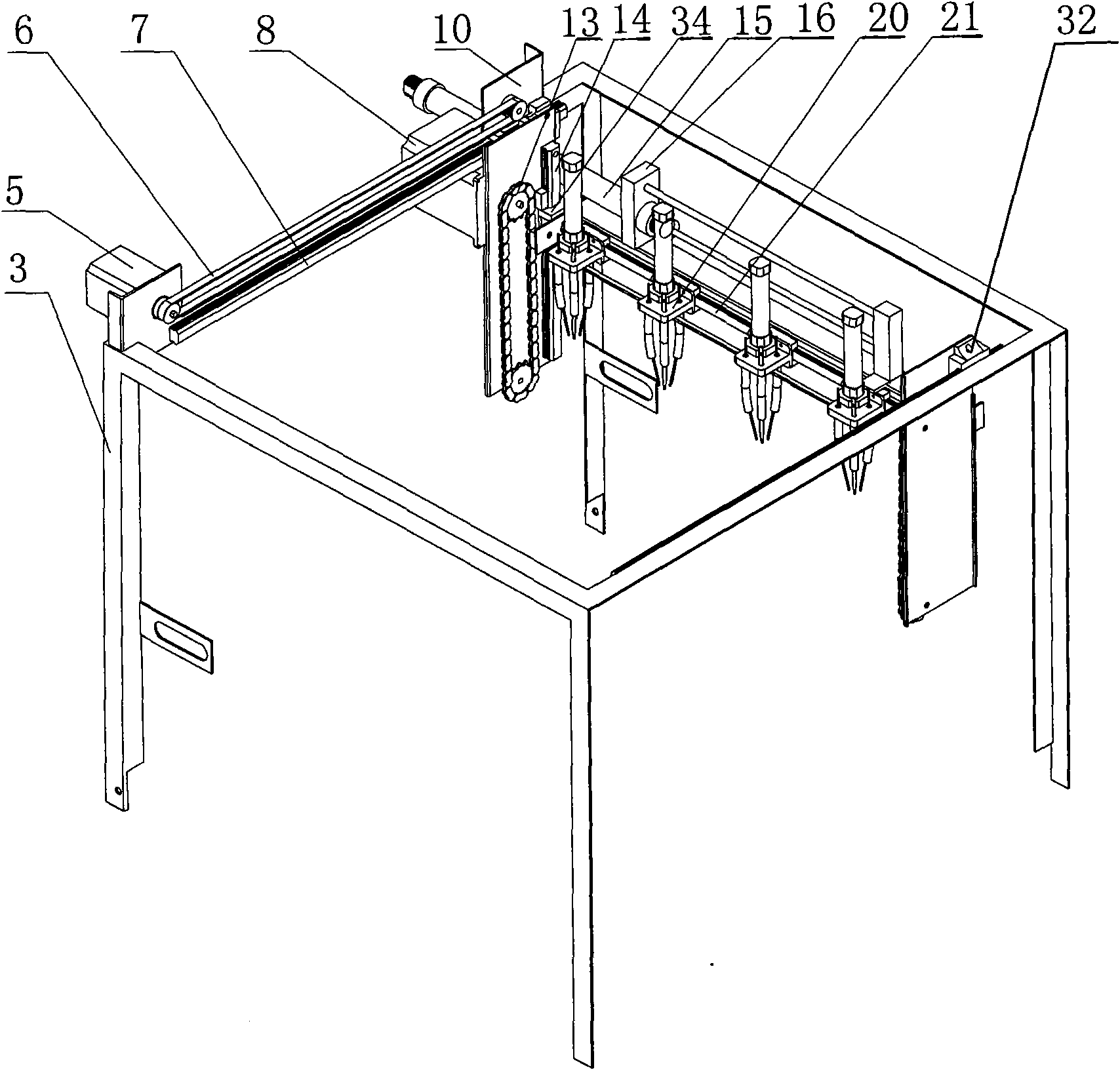

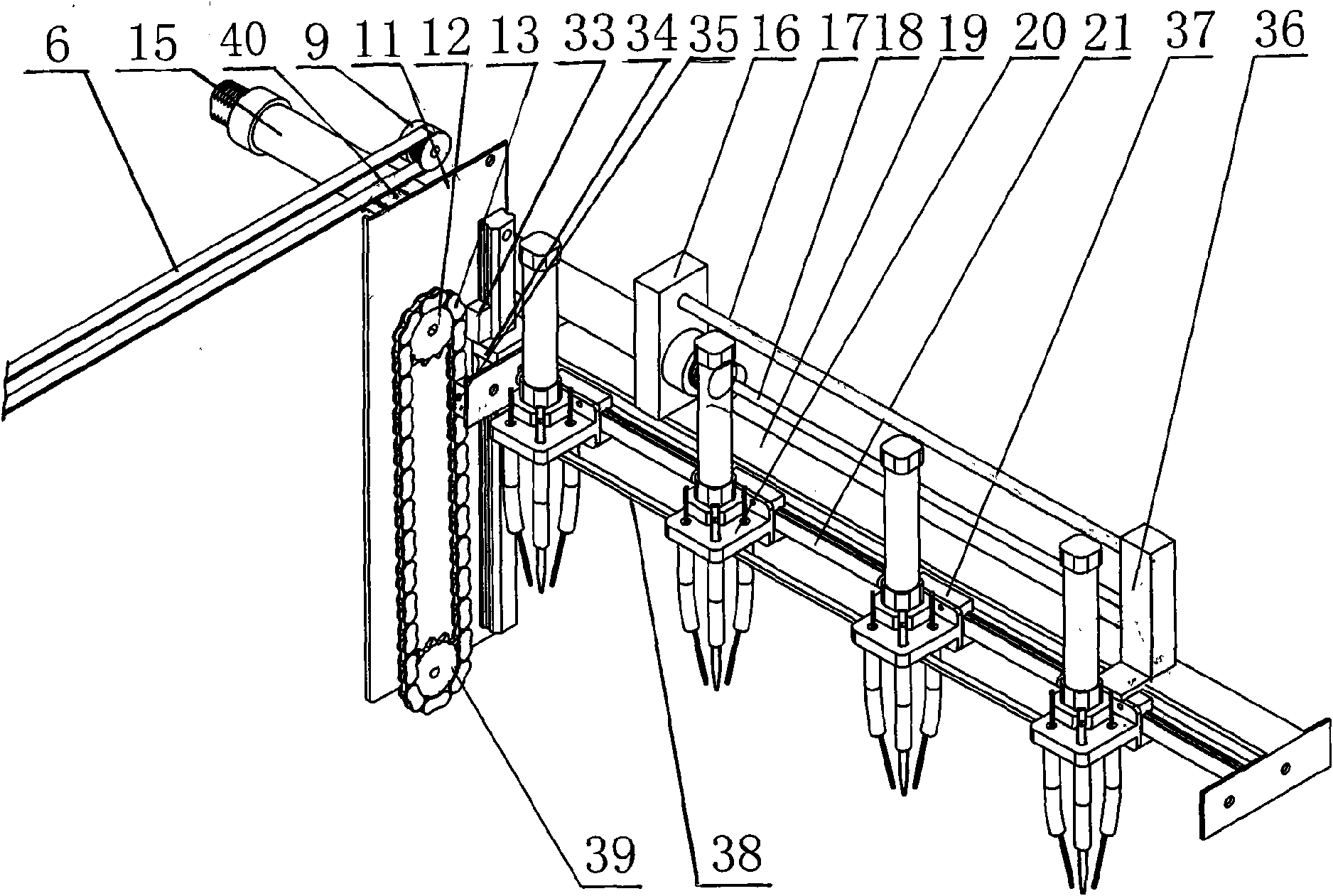

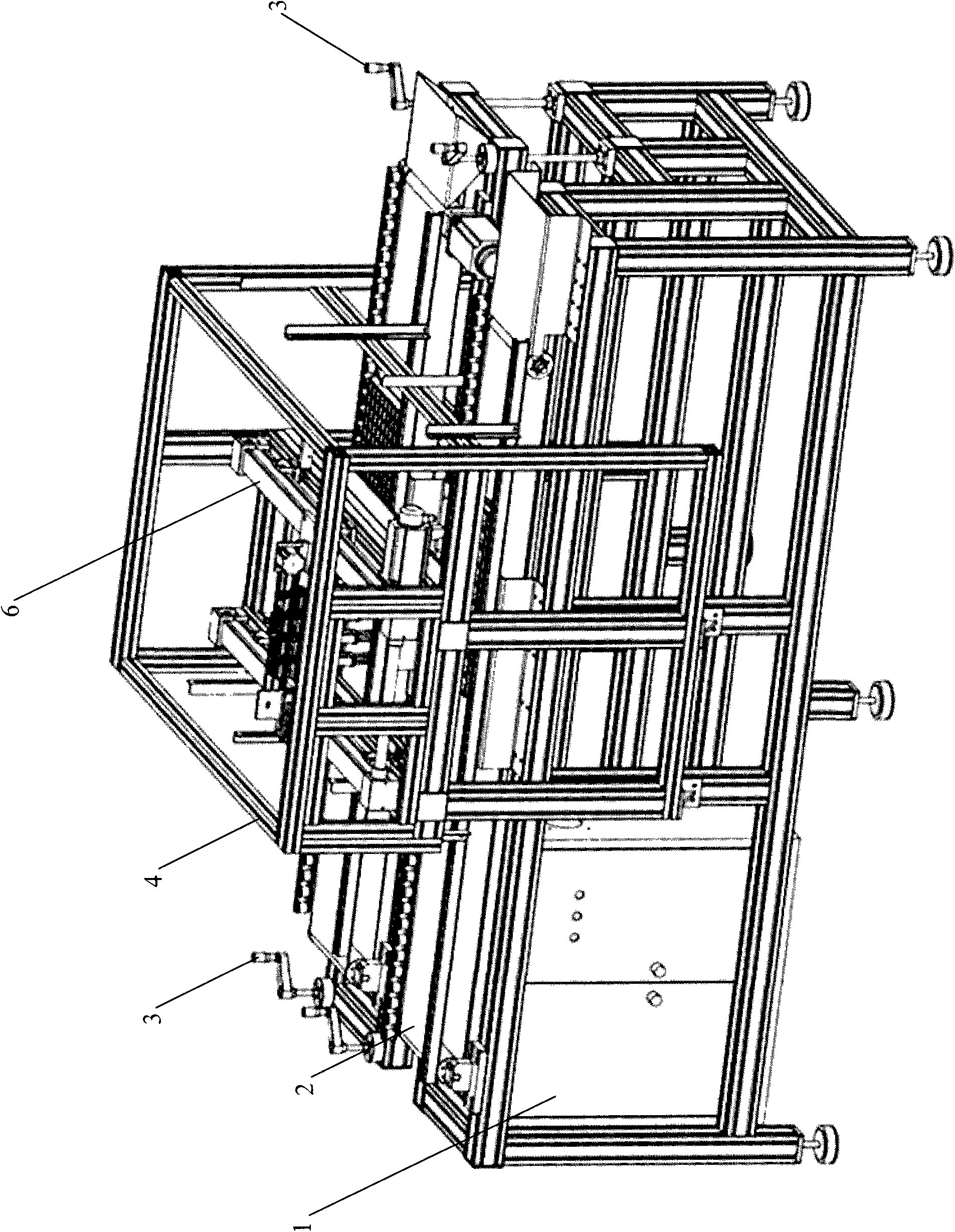

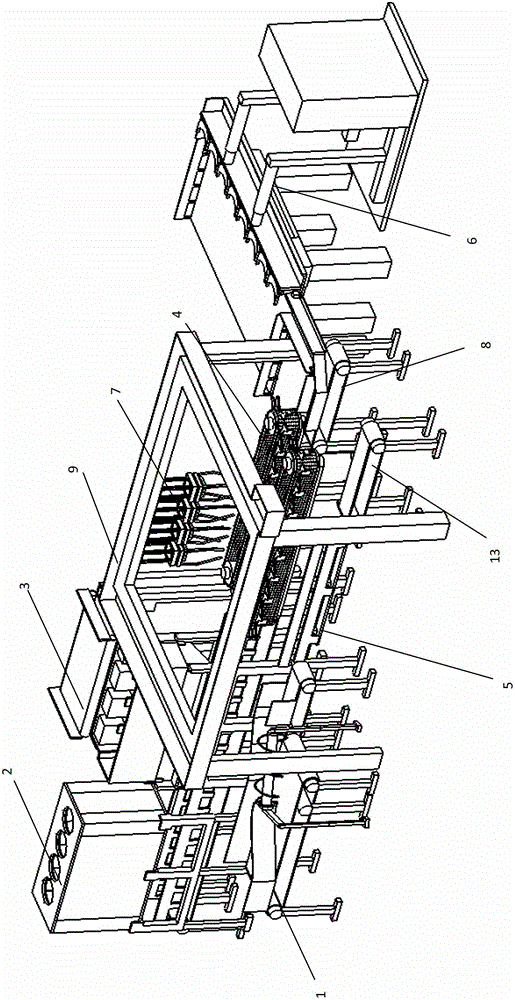

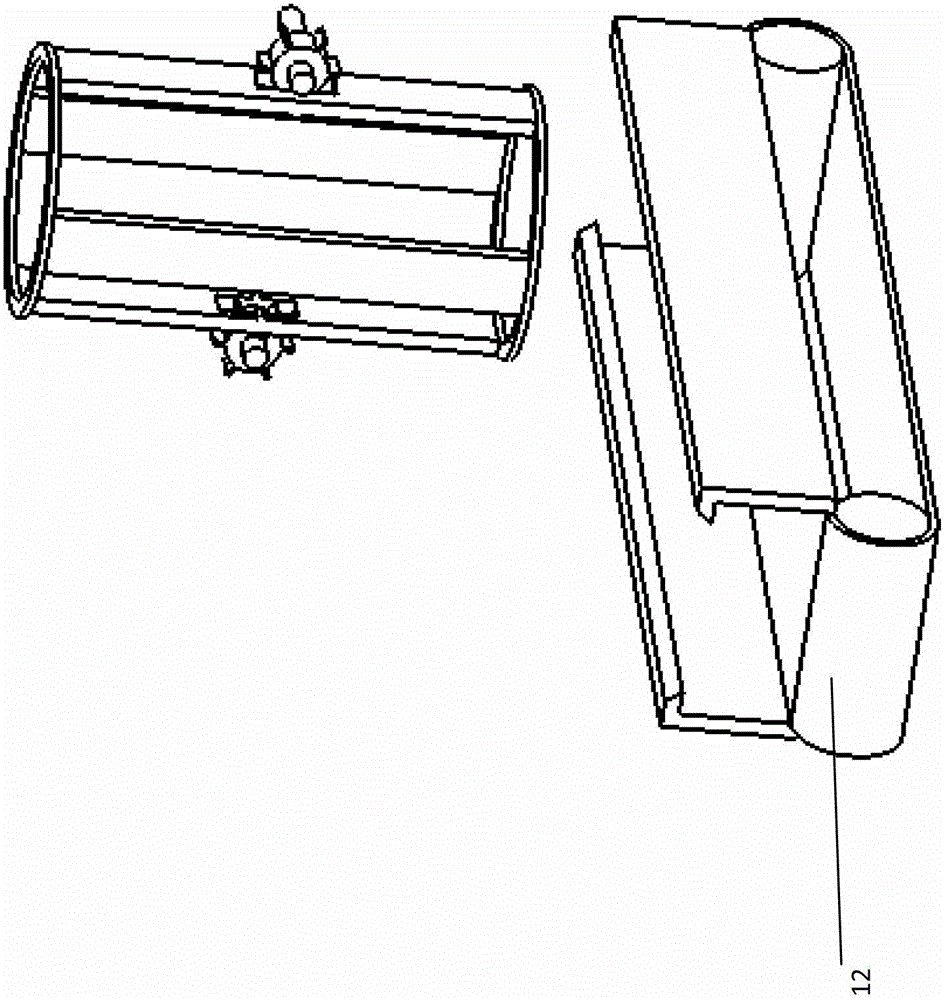

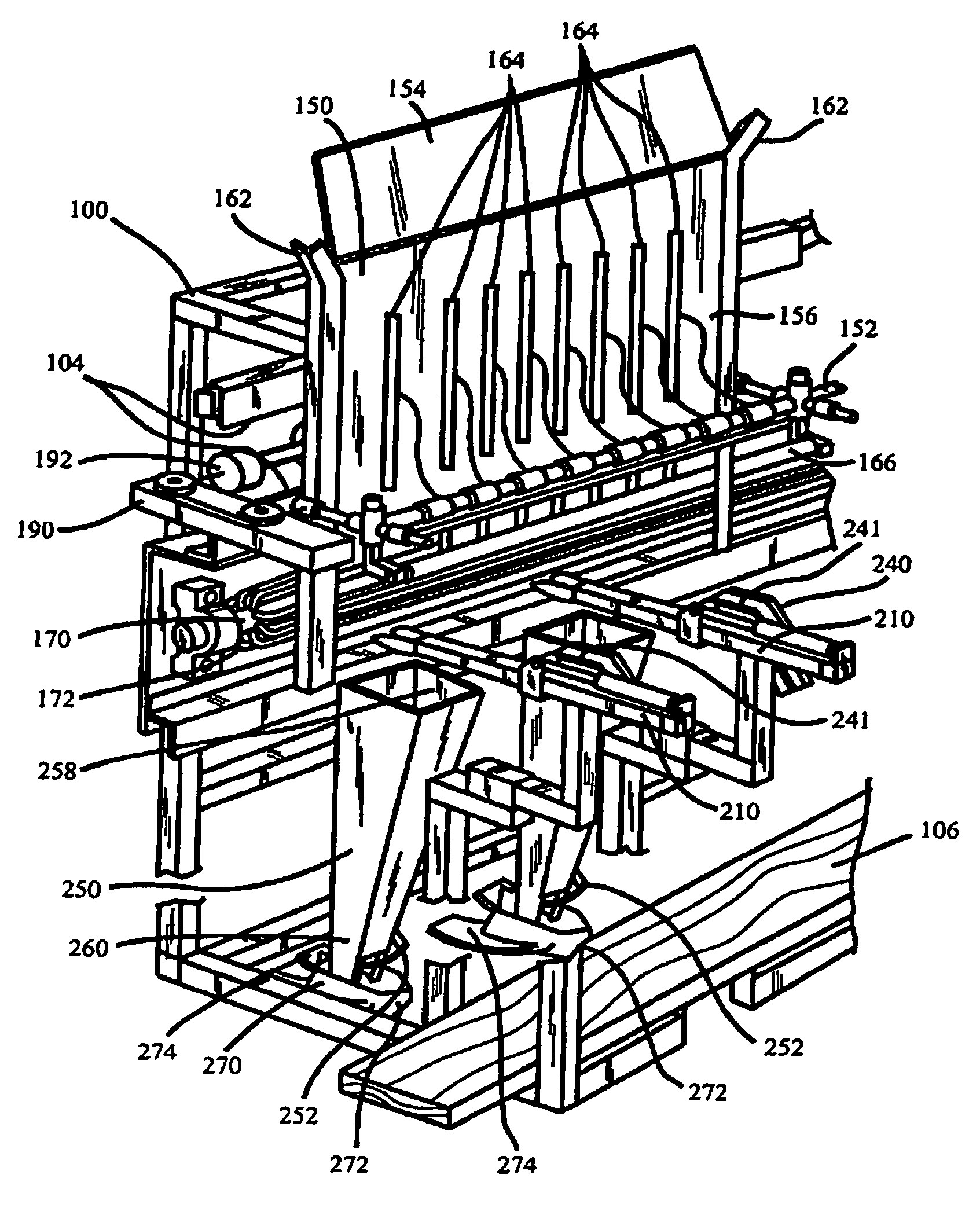

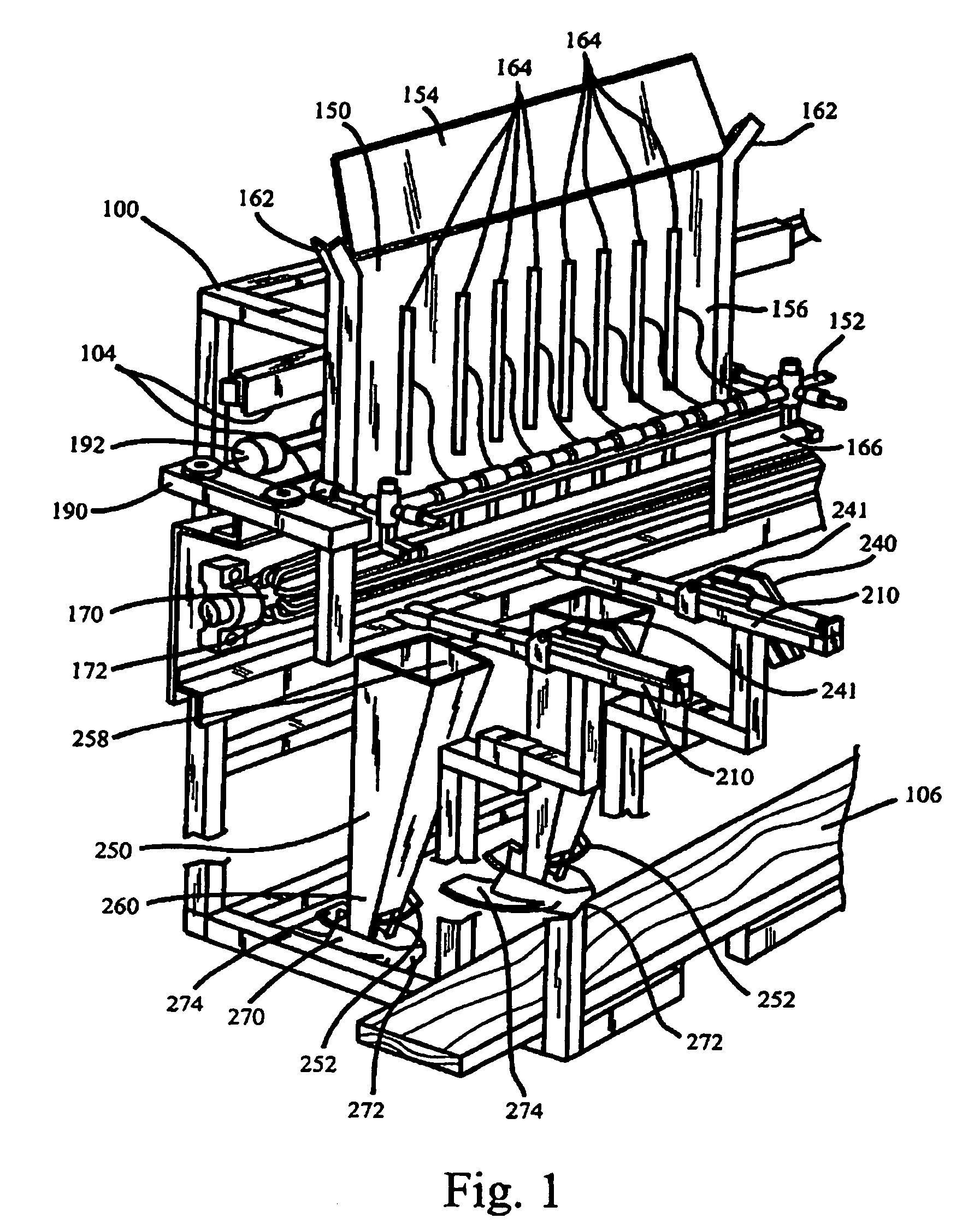

Automatic transplanter for plug seedling

InactiveCN101663972ARealize the transplanting operationSimple structureTransplantingFlower-pot fillingManipulatorEngineering

The invention provides an automatic transplanter for plug seedlings, comprising a transplanting mechanical hand mechanism, a planer-type mechanical arm mechanism, a seedling plug, a flowerpot conveying mechanism and a stand. The automatic transplanter for the plug seedlings is characterized in that the planer-type mechanical arm mechanism is provided with a mechanical arm horizontal movement guiderail and a synchronous belt on the upper part of the stand, the mechanical arm horizontal moving guide rail is connected with a mechanical arm connection plate in a sliding way, and the mechanical arm connection plate is connected with the synchronous belt and provided with a mechanical arm vertical movement guide rail and a transmission chain, and both ends of the mechanical arm are respectivelyarranged on the mechanical arm vertical movement guide rail and respectively connected with the transmission chain; a mechanical hand split-joint movement guide rail is assembled with a plurality ofmechanical hands in a sliding way, the end part of a cylinder piston rod is connected with a fore-end mechanical hand, and inelastic connection belts are arranged among the mechanical hands; the transplanting mechanical hand mechanism is fixedly connected with a mechanical finger installation positioning block at the lower end of a cylinder, the cylinder piston rod is fixedly connected with a mechanical hand installation positioning block which is fixedly connected with a finger sleeve, and a mechanical finger penetrating through the finger sleeve and the mechanical hand installation positioning block is fixedly connected on the mechanical finger installation positioning block. The automatic transplanter is characterized by replacing the manual operation with the machine to automatically complete transplantation of the plug seedlings of vegetables and flowers and plants and having simple structure, convenience, practicality and reliable property.

Owner:SHENYANG AGRI UNIV

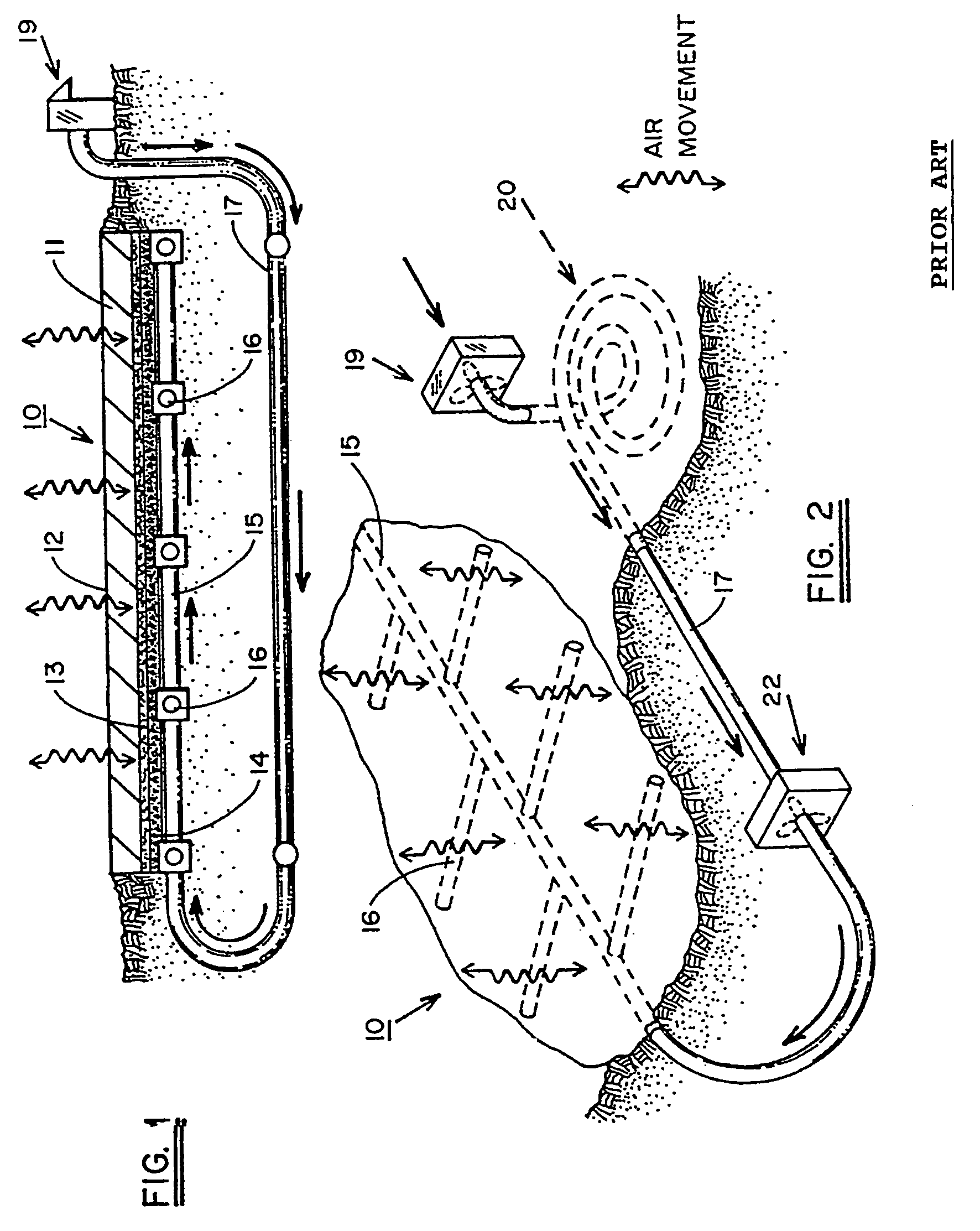

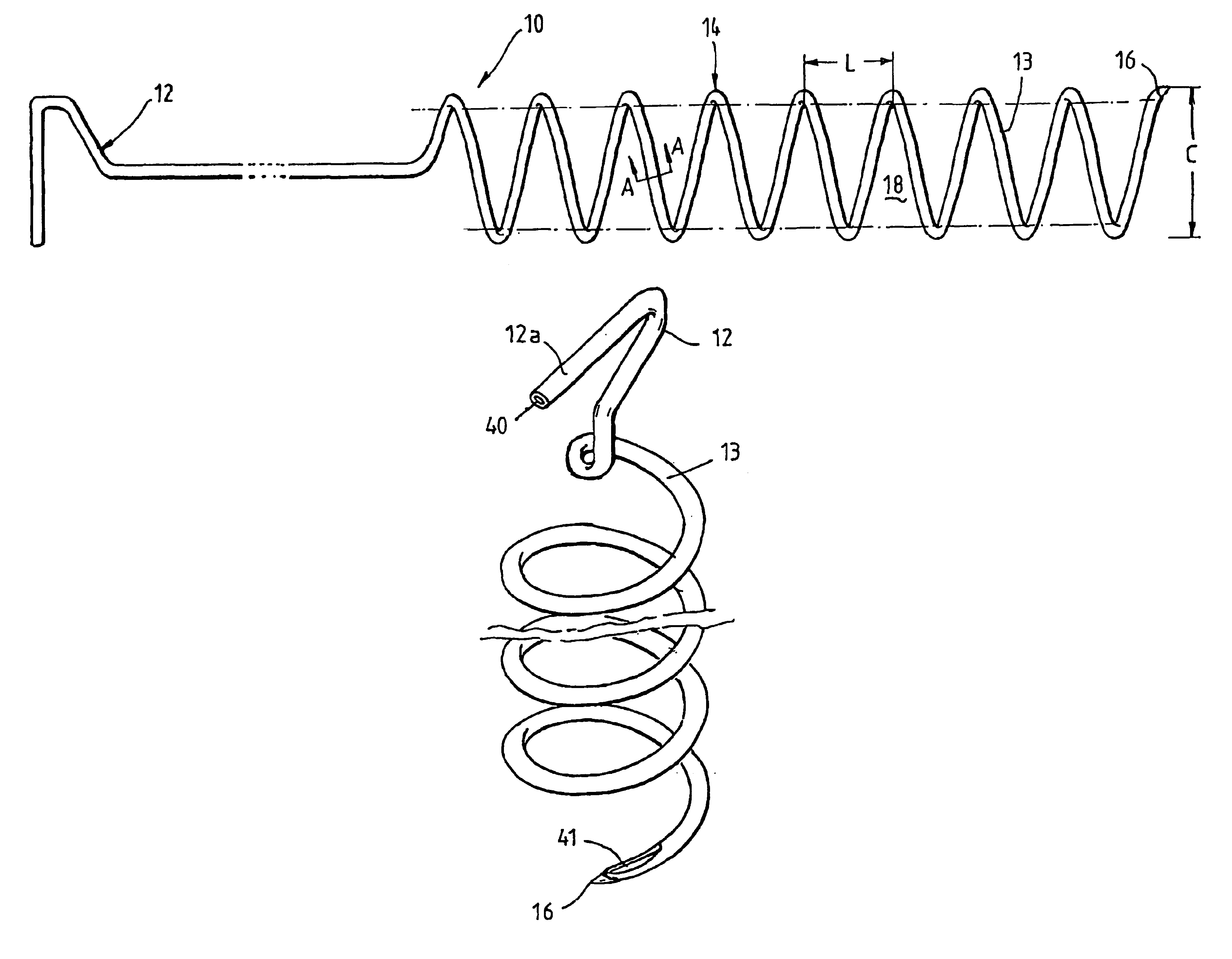

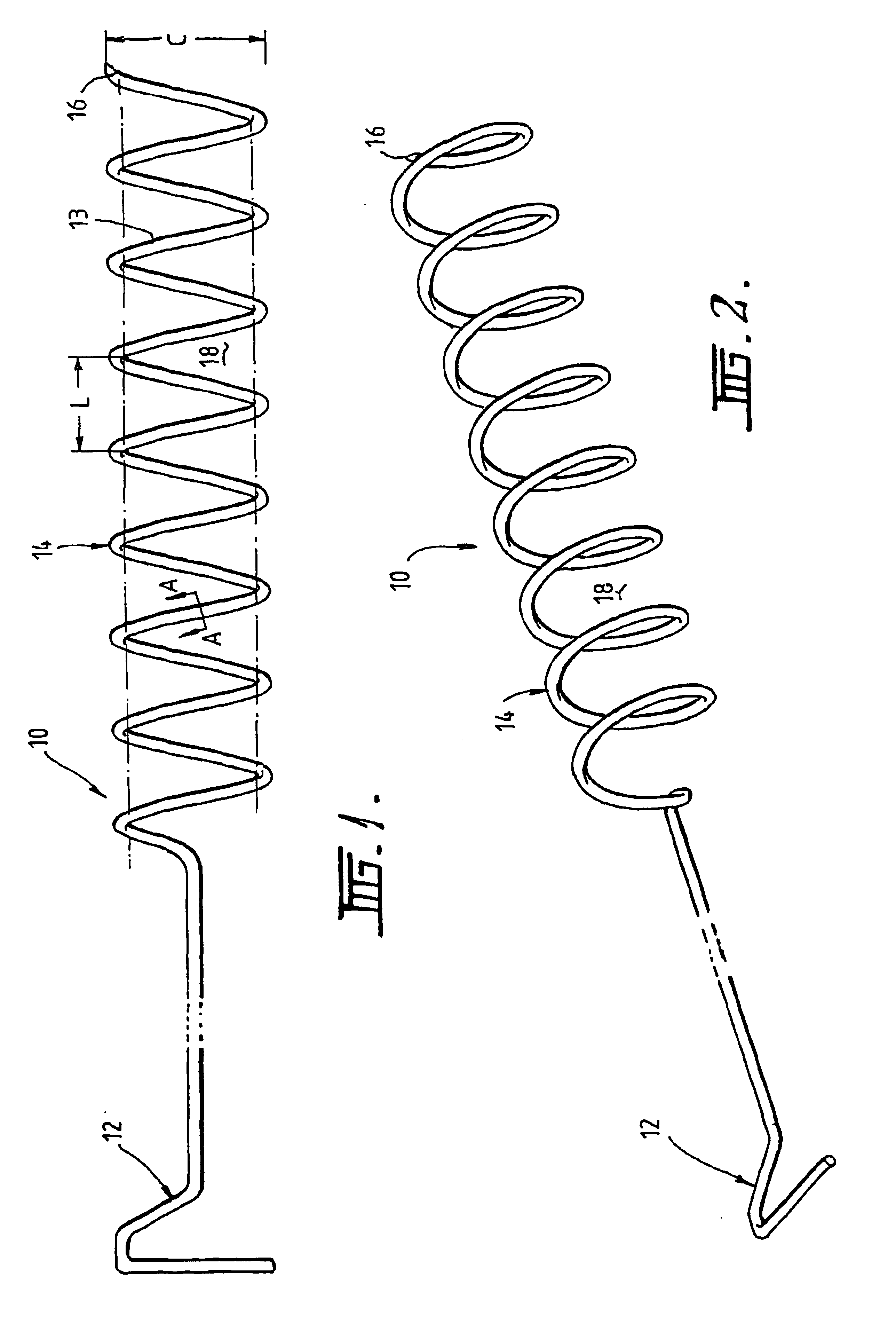

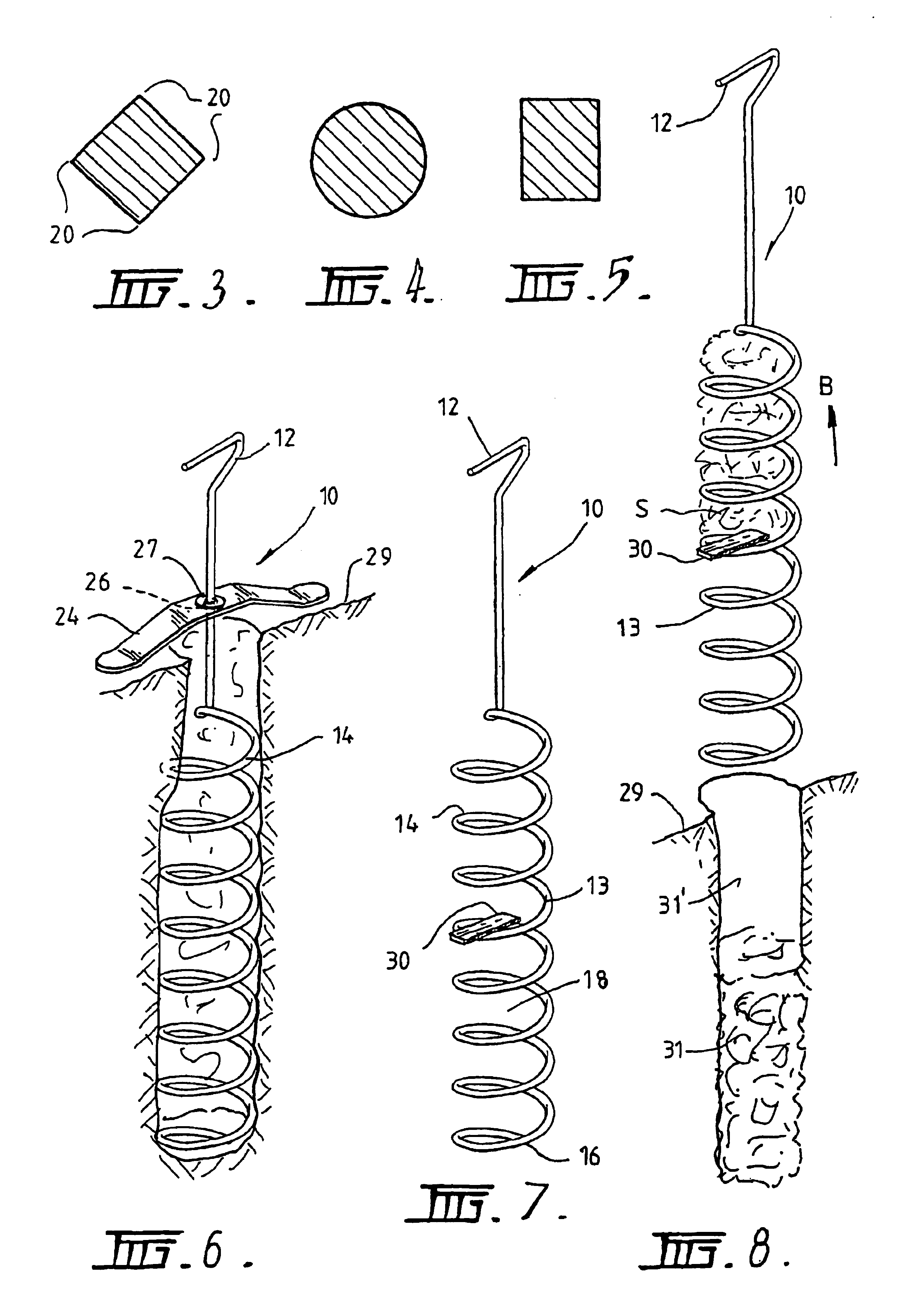

Soil manipulating tool

A soil manipulating tool is disclosed which has a handle (12) and a soil penetrating portion (14). The soil penetrating portion (14) is formed from a helical or spiral rod or wire (13) which defines a cavity (18). The rod or wire (13) may be hollow so that fertilizer or other liquid material can pass through the hollow rod wire (13) into the soil in which the tool is to be used. The tool may also include an abutment member for limiting the amount of penetration of the tool into the soil to facilitate churning up of the soil and a blade may also be provided across one of the spirals of the portion (14) to provide a chopping of soil so that a hole can be formed by removal of a plug of soil but at the same time leaving loosened soil at the bottom of the hole. The tool has particular application in aerating and manipulating composted material and the removal of composted material from a compost bin as well as garden applications for the formation of holes, and the aeration of soil facilitating plant growth.

Owner:GLOBAL ENVIRONMENT MANAGEMENT FZC

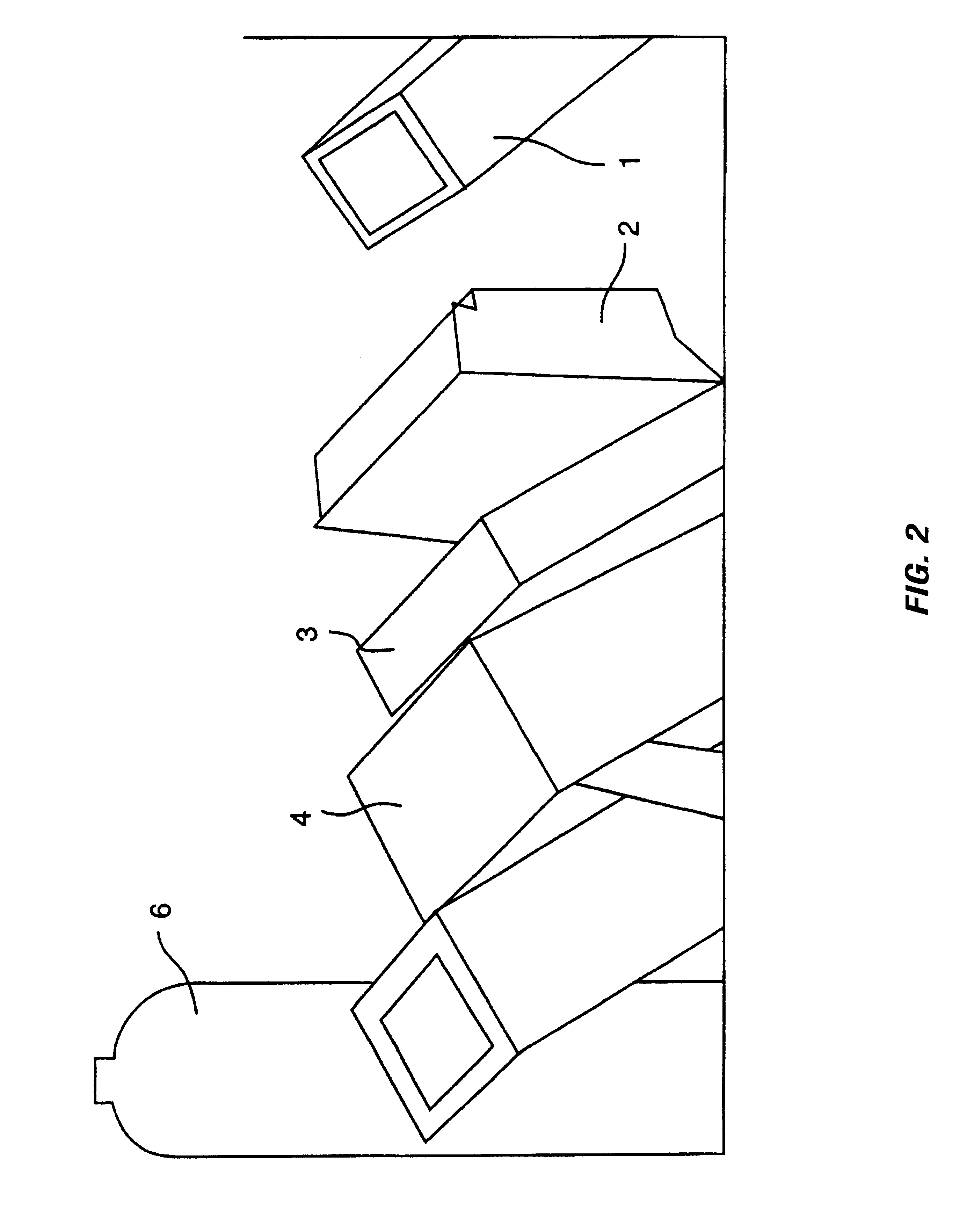

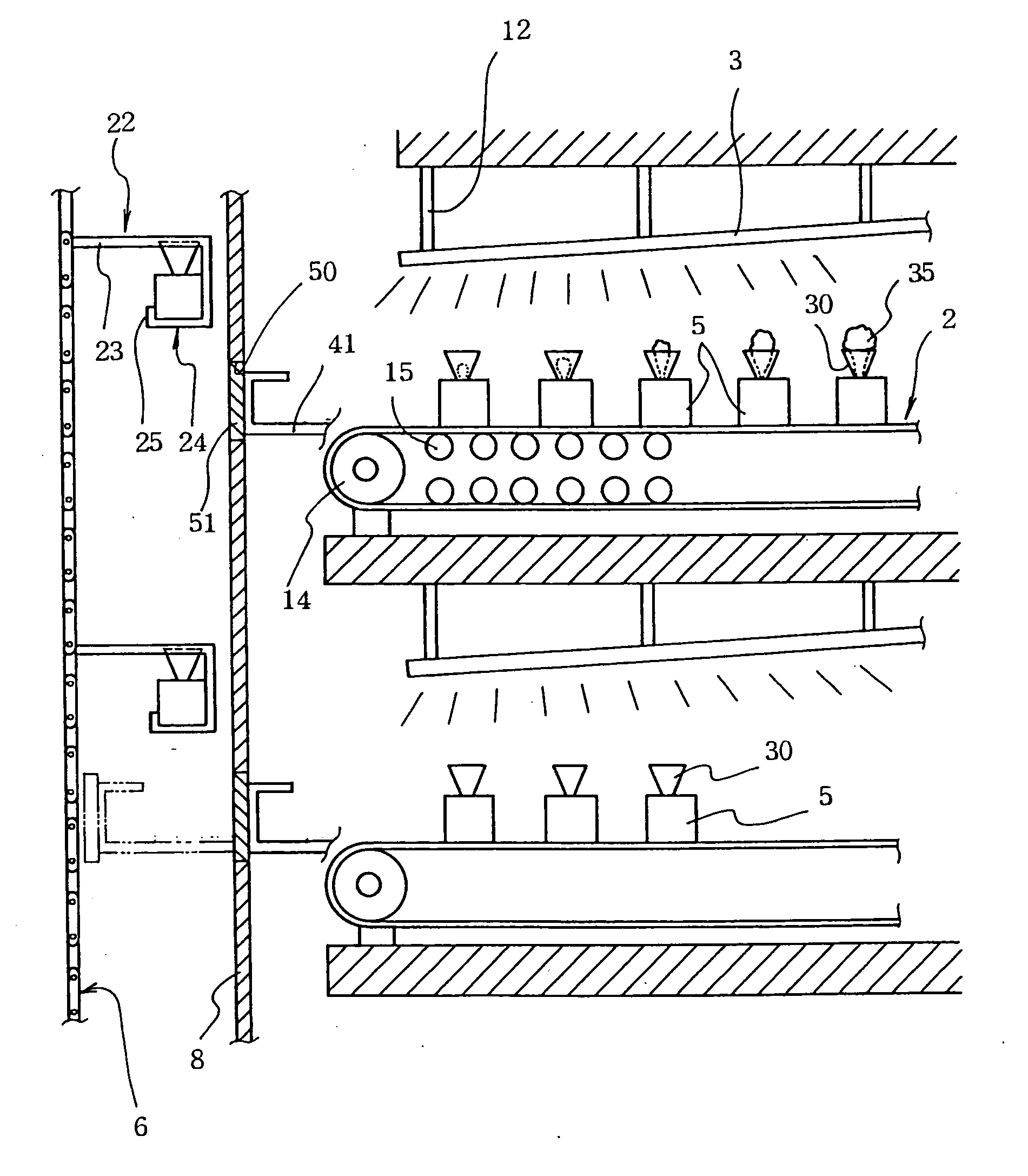

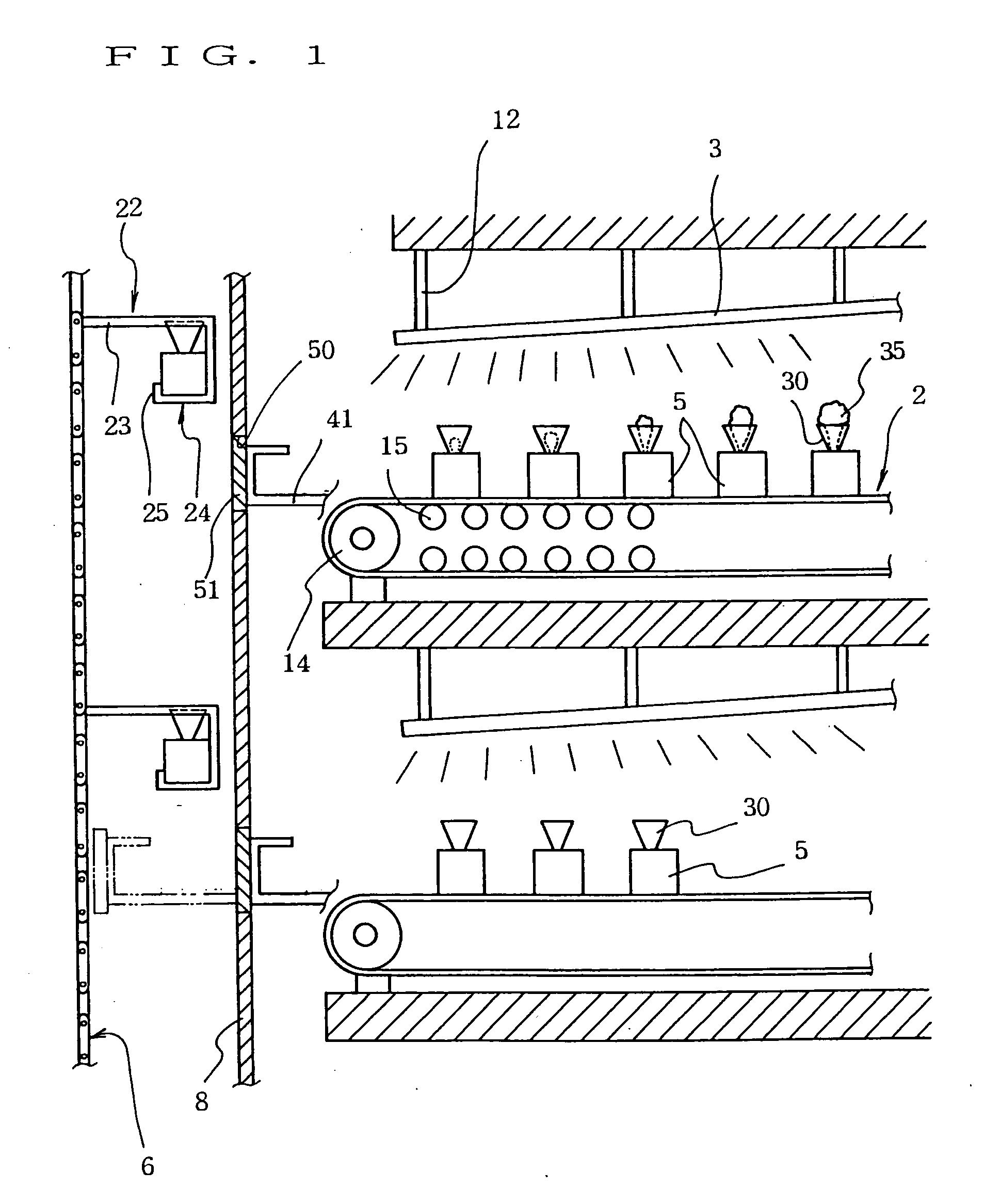

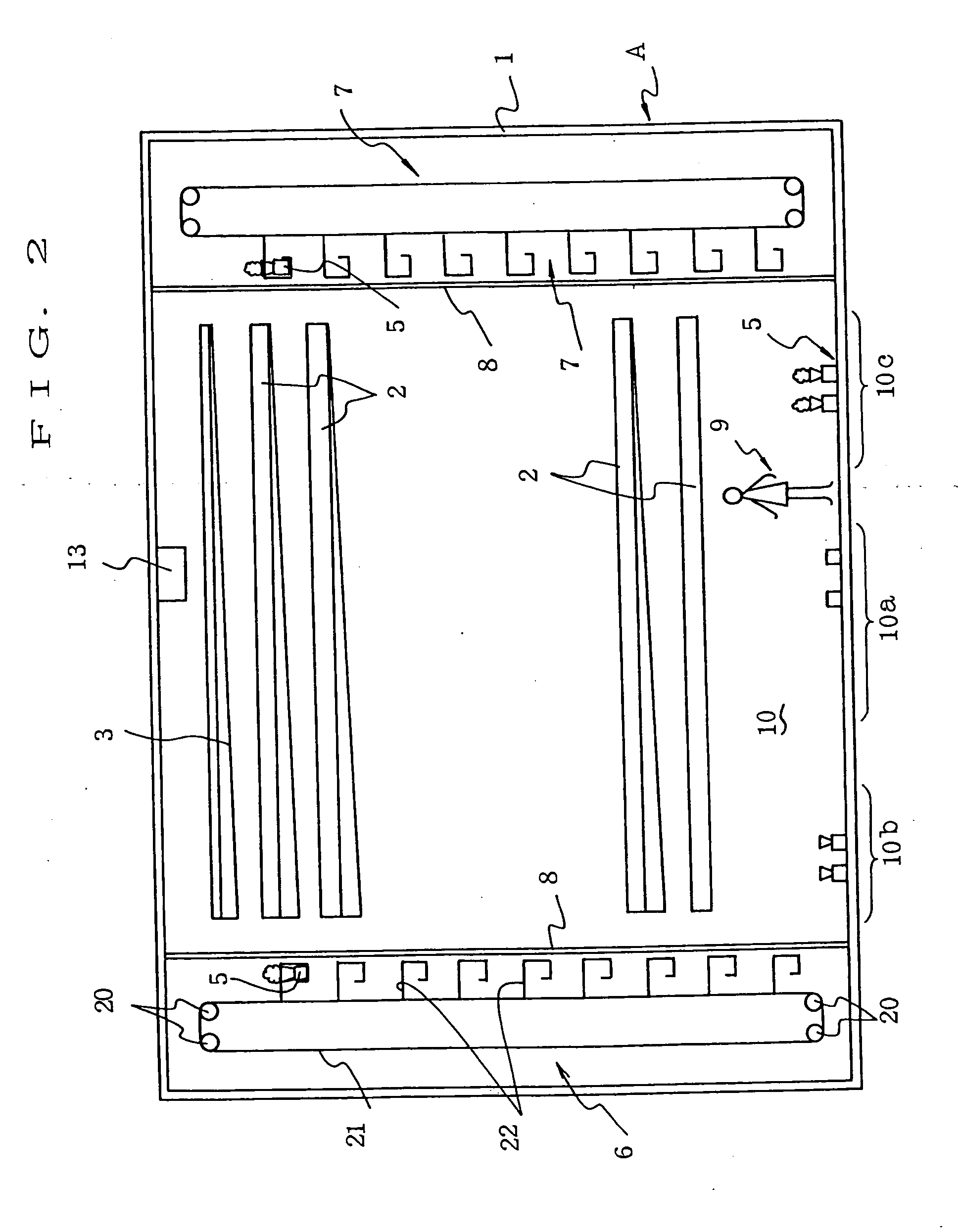

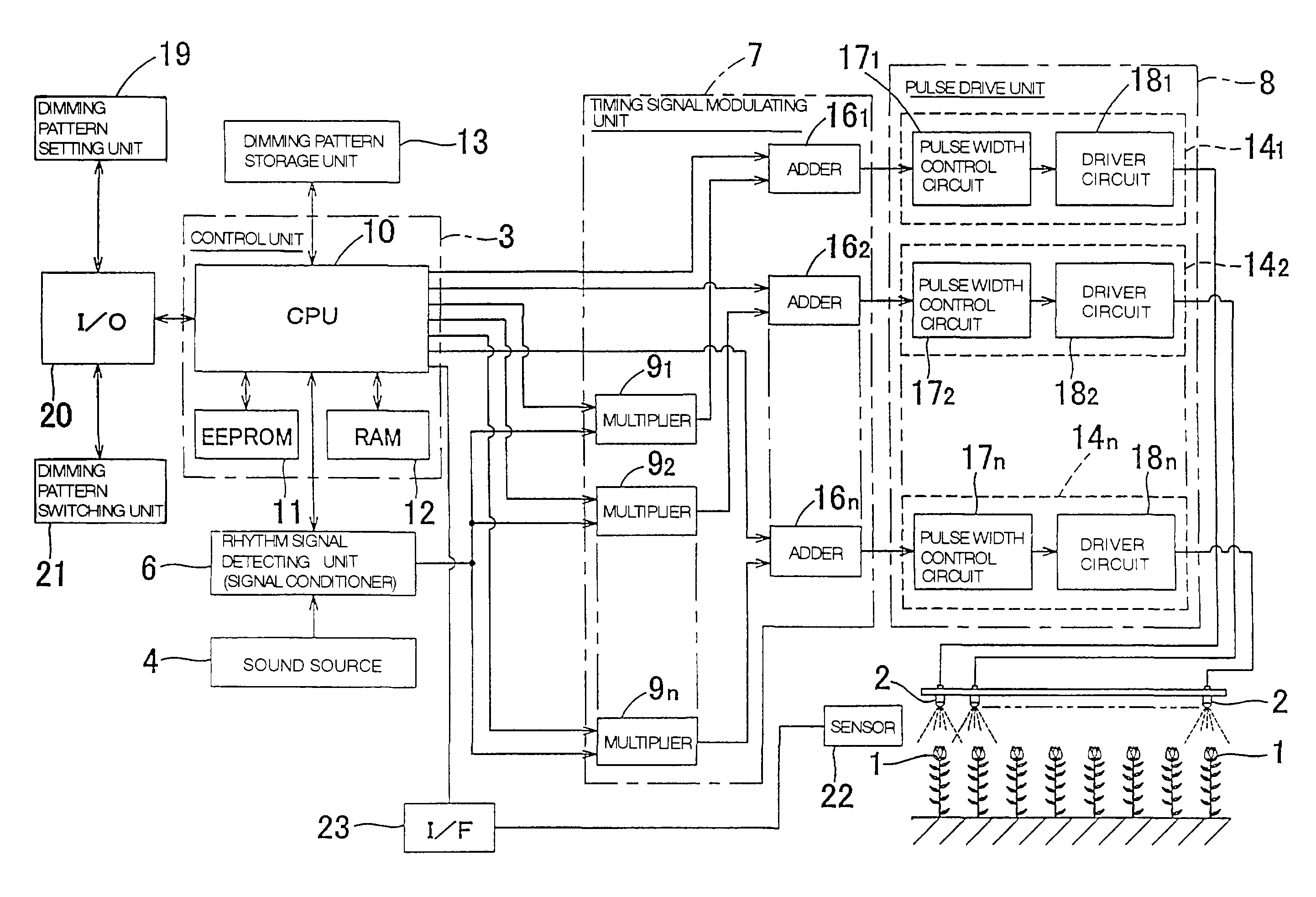

Method of producing plants, plant cultivating device, and light-emitting panel

InactiveUS20040163308A1Easy to handleEasy to manufactureSeed and root treatmentSolid-state devicesEffect lightLight-emitting diode

A plant cultivating device (A), comprising aluminum long square pipe trays (5) for storing plants (35) together with culture solution, a conveyor device (2) for feeding the trays (5) in order in lateral direction, and a lighting device (3), having a number of light-emitting diodes disposed thereon, located over the conveyor device (5), the lighting device (3) being disposed so as to be higher gradually from the upstream side to the downstream side of the conveyor device (2), wherein a funnel-shaped holder (30) holding the upper part of the plant (35) is provided on the upper surface of the tray (5), and a planting conveyor (6) and a harvesting conveyor (7) for supply and retrieval, a reflecting wall (8) provided between these conveyors and the conveyor device (2), and transfer bars (41) for transferring the trays (5) between the conveyor device (2) and the planting and harvesting conveyors (6,7) are installed on the upstream and downstream sides of the conveyor device (2).

Owner:KINPARA SHIRO

Living systems from cardboard packaging materials

InactiveUS20080046277A1Increase valueEffect shipping rateBiocideSustainable waste treatmentCardboardLiving systems

Compositions, methods and business applications of using new and recycled cardboard infused with a plurality of saprophytic (including endophytic) and mycorrhizal fungi matched with seeds of plants (including trees, vegetables, herbs and grasses) whereby the cardboard can be sprouted by end-users to start ecosystems. Such containers may have carbon-credit value for companies and consumers when planted and grown as a carbon sink or carbon offset for the photosynthetic and mycelial sequestration of carbon dioxide. The relative weight of the Life Box's added seeds and spores does not significantly affect the total weight of the infused cardboard, thus not increasing transportation costs.

Owner:TURTLE BEAR HLDG LLC

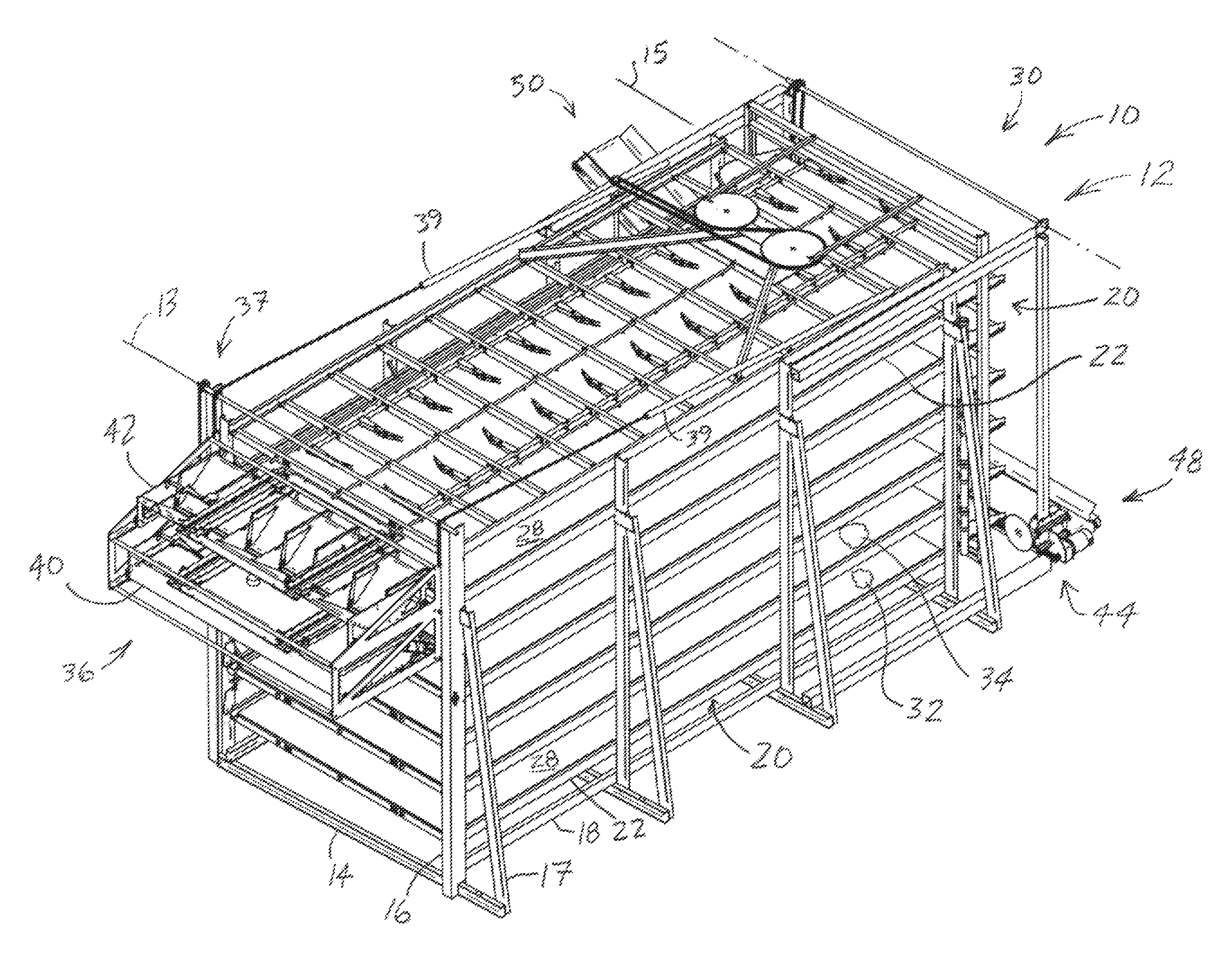

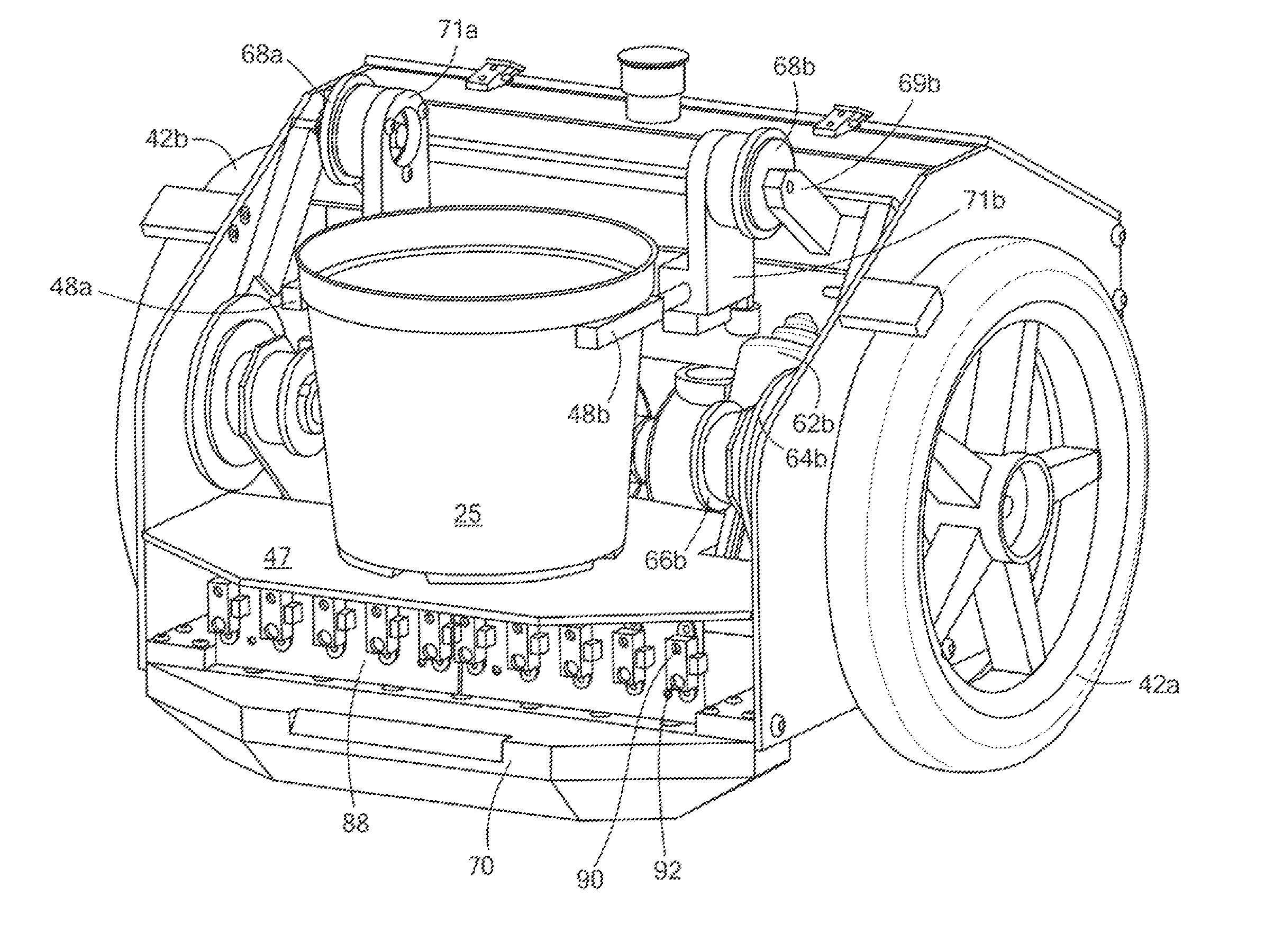

Robotic systems for handling objects

InactiveUS20050135912A1Avoid possibilityExpensive to replaceLifting devicesGreenhouse cultivationRobotic systemsEngineering

An automated handling system for moving objects from one location to another location is provided with a self-mobile system having a grabber subsystem for grasping objects, including assemblies for movement in four directions, along X, Y and Z axes and through an angle θ. The system also has a translating carriage assembly for moving the grabber subsystem and power supply and drive systems. A sensing device, such as an imager, is provided to determine the geometric position of the objects and to move the grabber subsystem accordingly. Another embodiment of the system is provided as an accessory to a prime mover. It includes an alignment articulation system, a gross advance system, a tine storage system, a loading head system, and pot grabbers. This automated handling system can be used to move plant containers in nurseries from the ground to a trailer bed and / or from a trailer bed to the ground in a variety of container configurations.

Owner:CARNEGIE MELLON UNIV

Golf course turf conditioning control system and method

A system and method for conditioning turf at of one or more golf course areas includes an aeration subsystem having subsurface aeration conduits for aerating the area, and an air blower unit in fluid communication with the aeration conduits configured to provide one of a vacuum in a vacuum mode and air under pressure in a pressure mode in the conduits. A control module is provided which responds to a directive for controlling operation of the aeration subsystem in response to sensing environmental parameters. The control module operates the blower in repetitive cycles of intermittent operation in one of the vacuum mode and pressure mode wherein each cycles includes a blower-on and blower-off mode. The blower-on mode operates the blower units for a first time interval and the blower-off mode ceases operation of the blower units for a second time interval during each cycle.

Owner:SUBAIR SYST

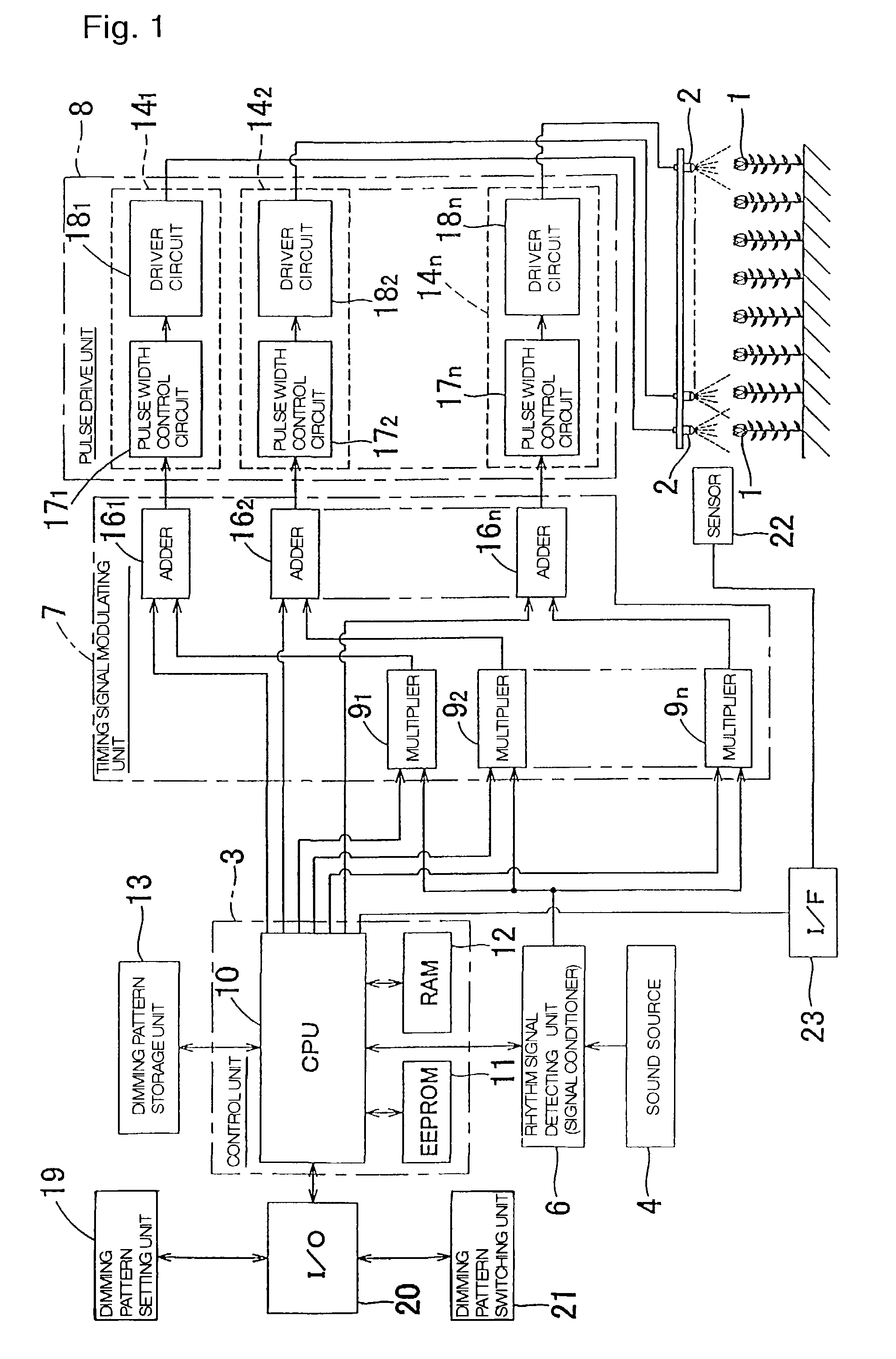

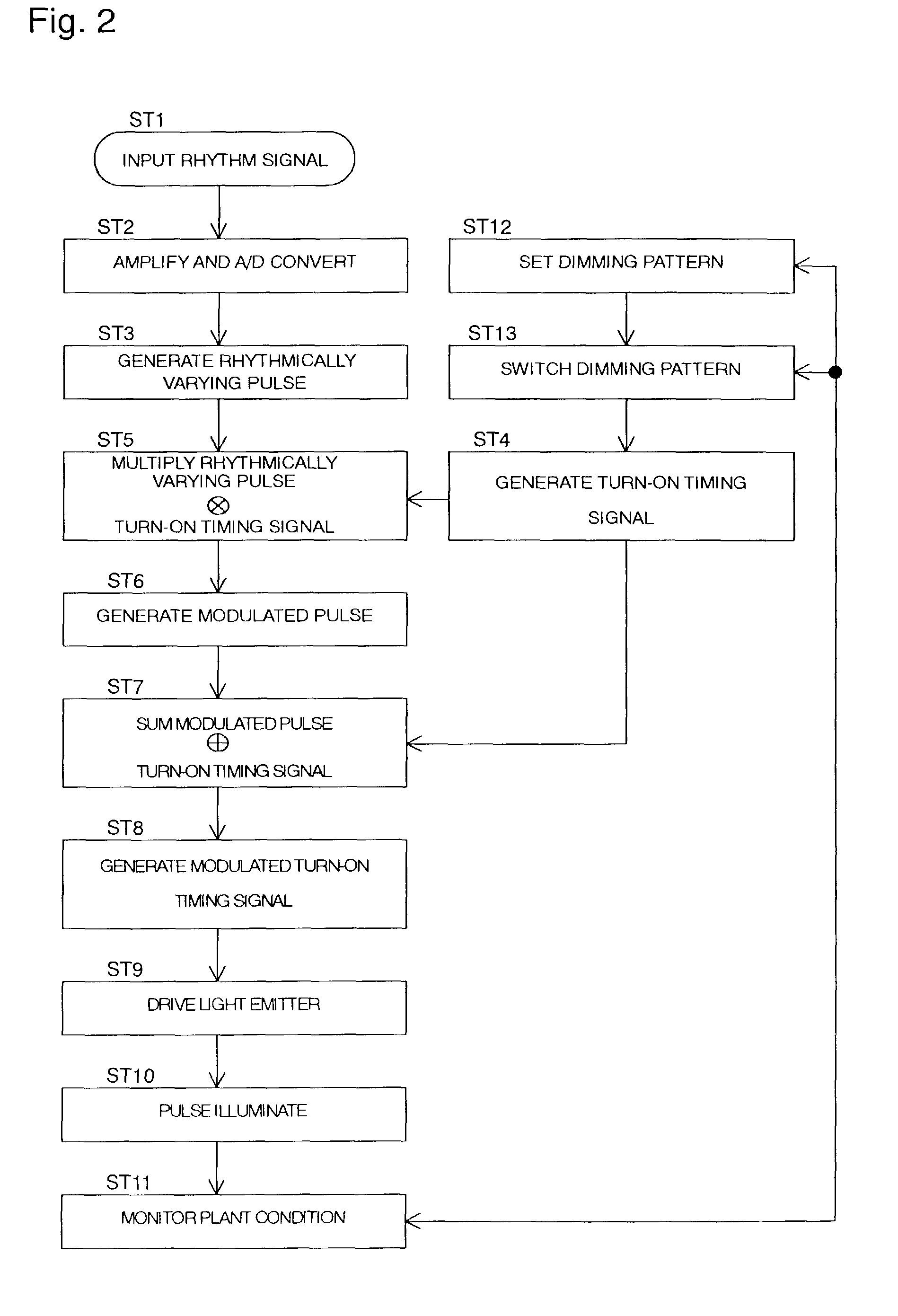

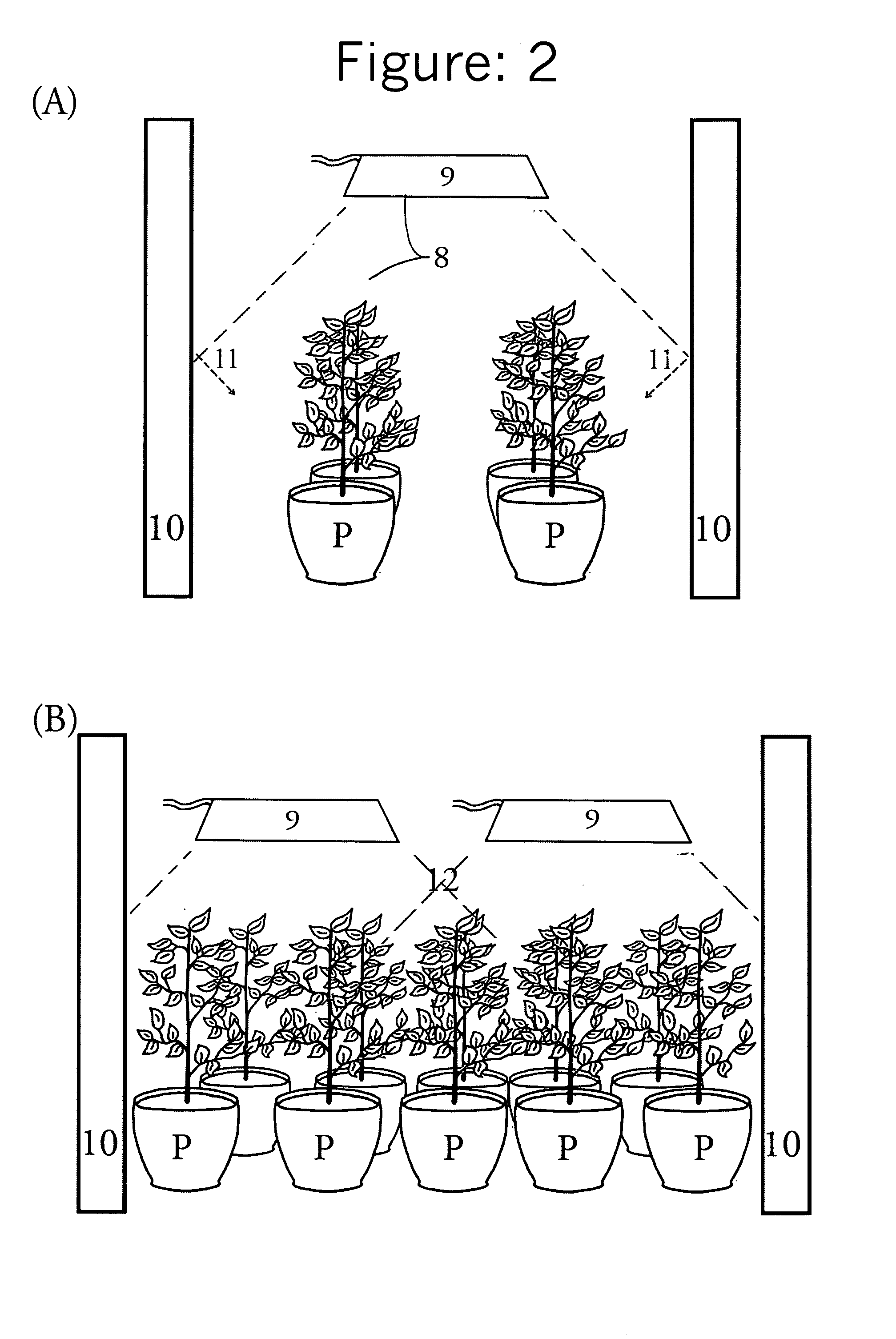

Illuminator for plant growth

InactiveUS8074397B2Promote plant growthPromote photosynthesisRoot feedersSaving energy measuresGrowth plantPlant growth

To provide an illuminator for plant growth that can illuminate a plant intermittently (pulse illumination) or continuously to cause an effect similar to sunbeam spot phenomenon, thereby accelerating photosynthetic reaction.Specifically, the illuminator for plant growth includes a light source composed of a semiconductor optical device, a control unit for outputting a turn-on timing signal for the light source, a rhythm signal detecting unit for A / D converting an input rhythm signal, a timing signal modulating unit for modulating the turn-on timing signal with the output signal from the rhythm signal detecting unit, and a pulse drive unit for pulse-modulating a power signal with the modulated turn-on timing signal outputted from the timing signal modulating unit and supplying the pulse-modulated power signal to the light source.

Owner:CCS INC

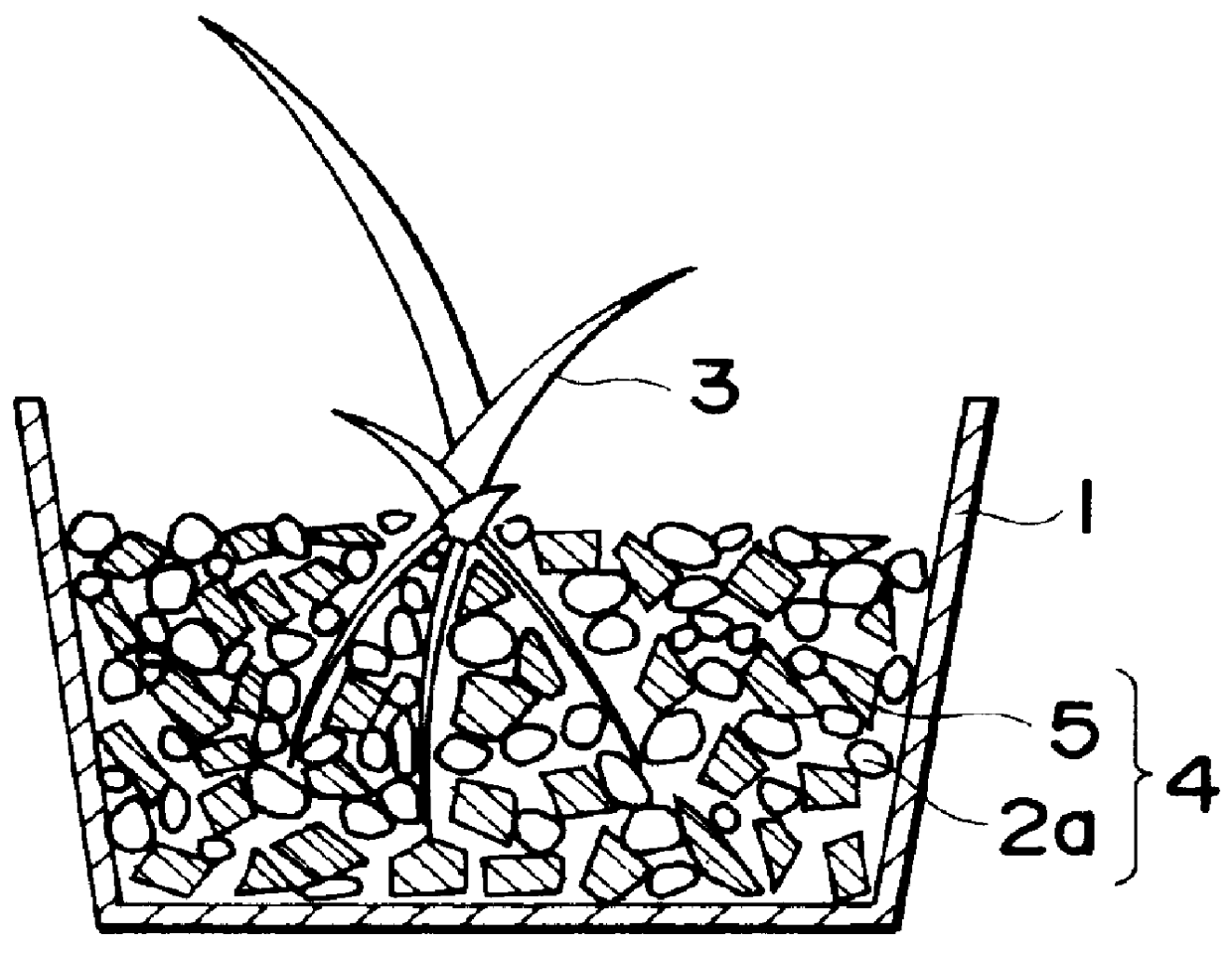

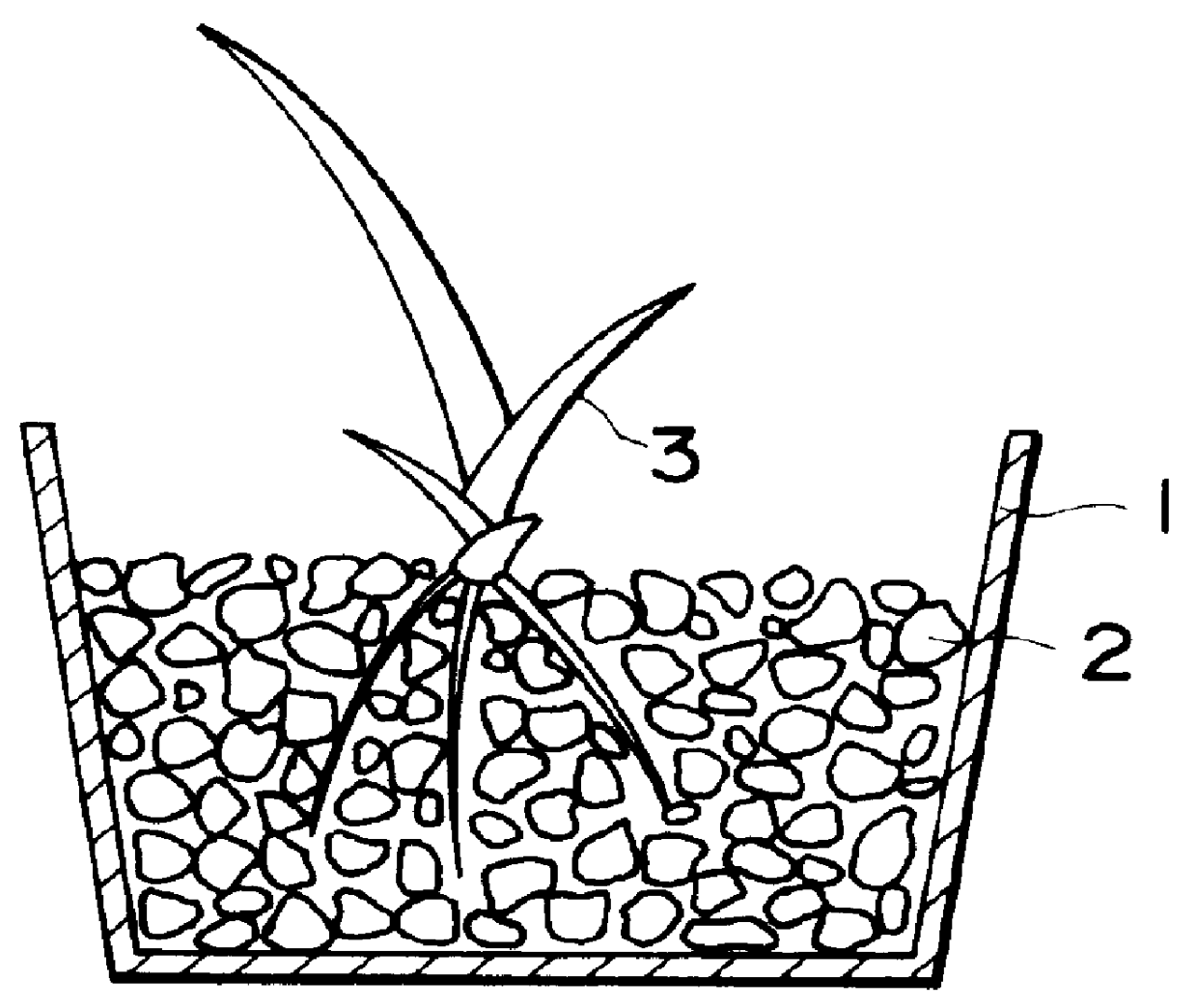

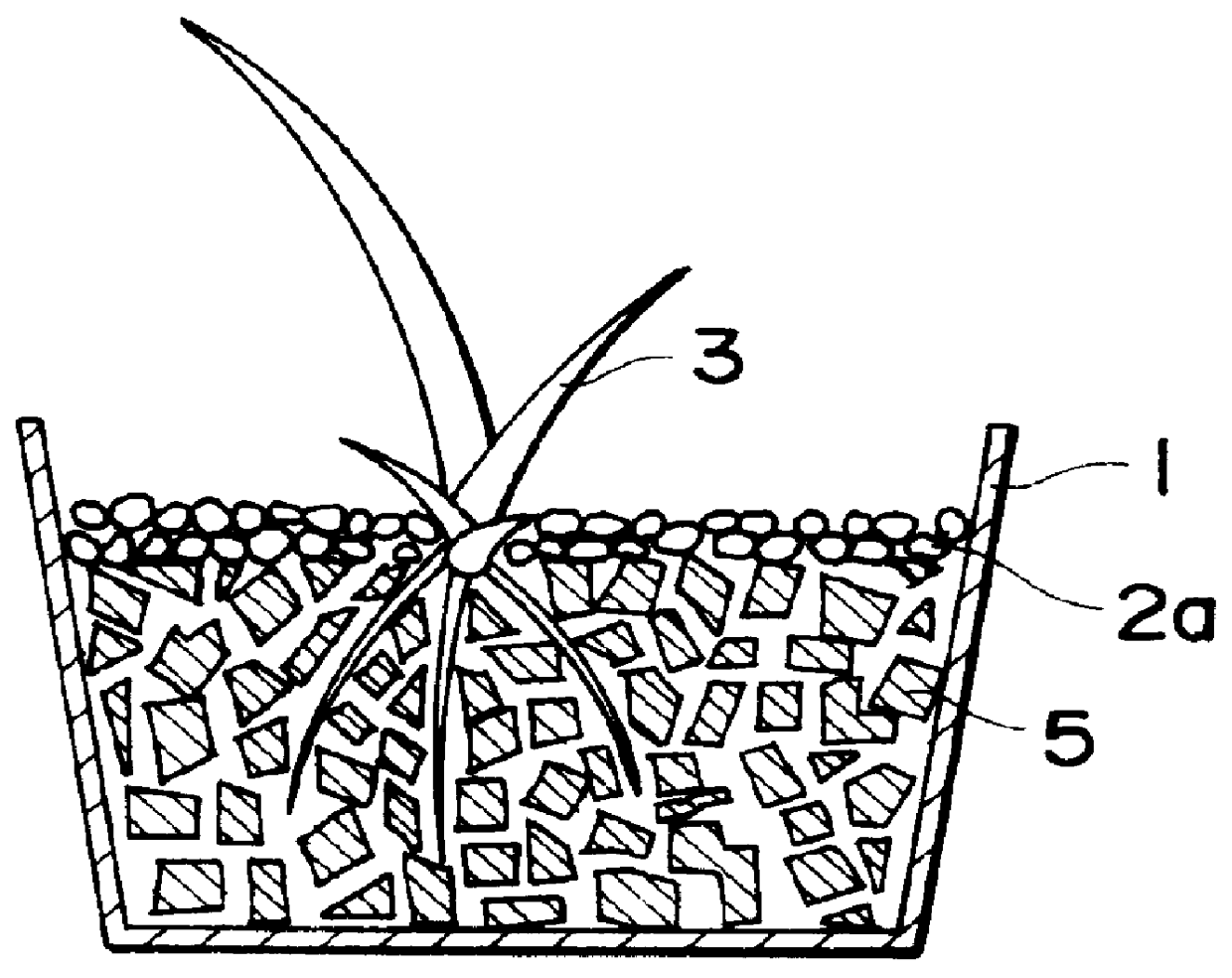

Support for cultivating plant

PCT No. PCT / JP96 / 02128 Sec. 371 Date Mar. 4, 1998 Sec. 102(e) Date Mar. 4, 1998 PCT Filed Jul. 29, 1996 PCT Pub. No. WO97 / 08938 PCT Pub. Date Mar. 13, 1997A vessel for growing a plant, comprising: a base material 11 in the form of a vessel which is capable of accommodating therein at least a part of a plant; and a hydrogel-forming polymer 12 having a crosslinked structure disposed inside of the vessel-form base material 11 is disclosed. When such a vessel is used, a transfer operation for the plant can be automated, and any damage caused by transferring the plant can be reduced.

Owner:MUKOYAMA ORCHIDS

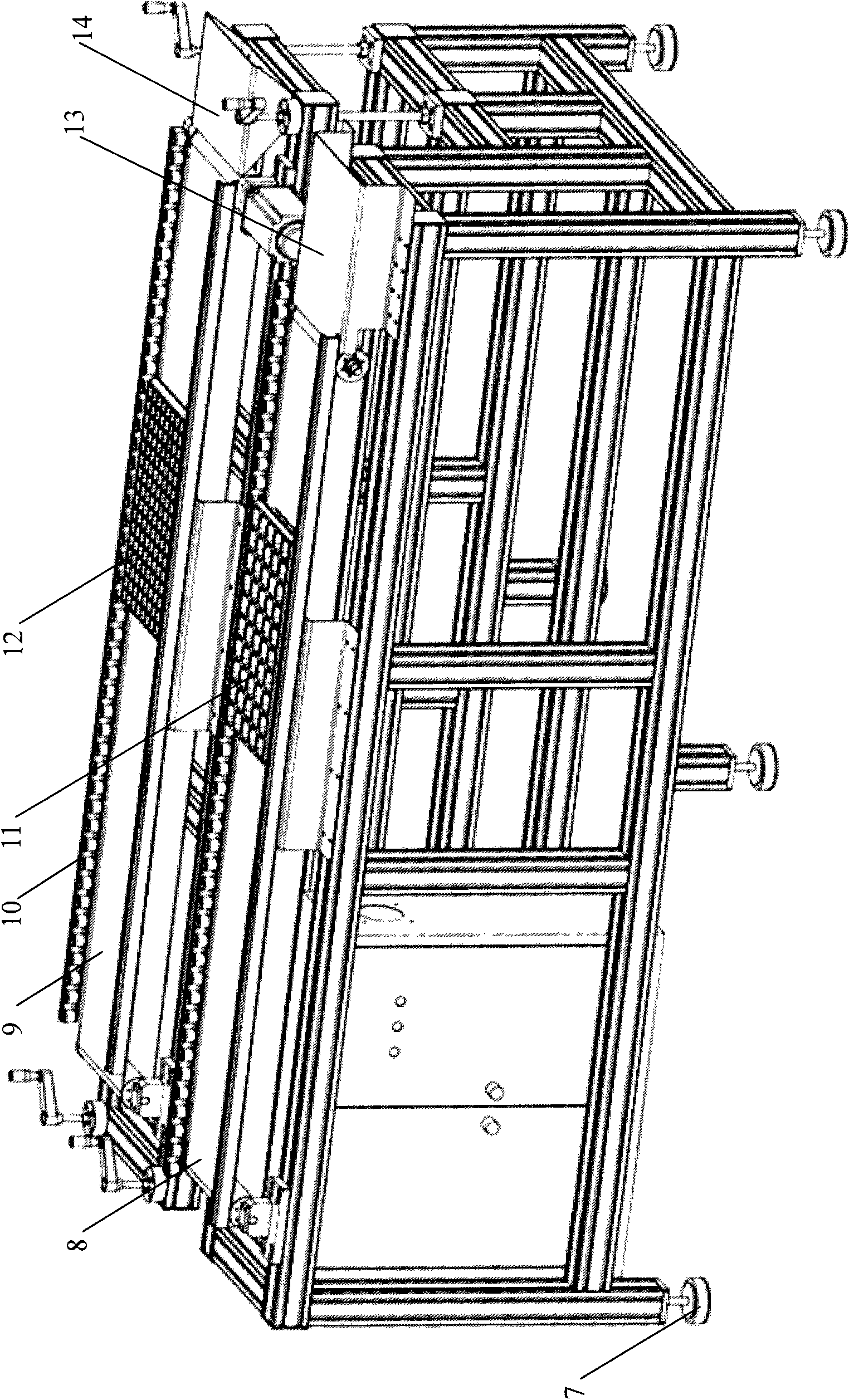

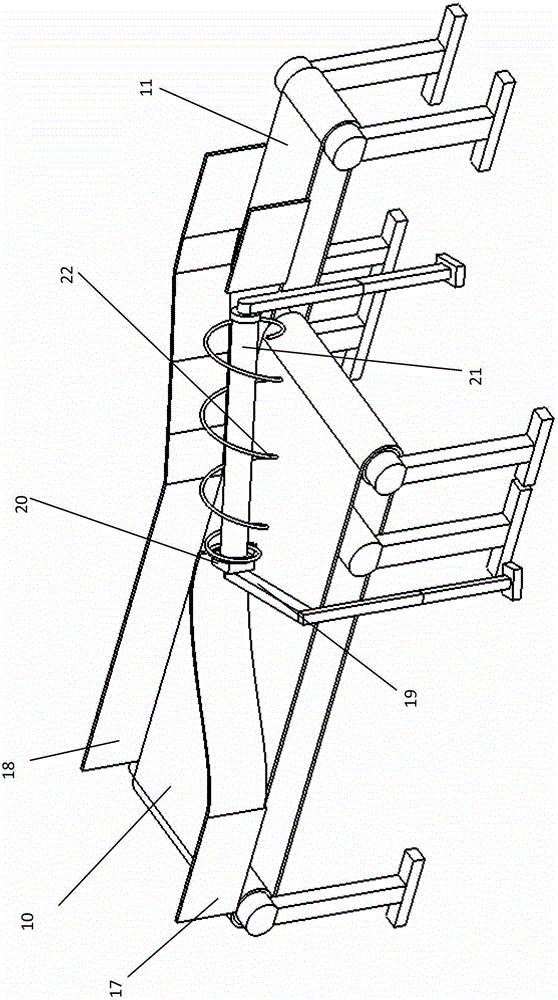

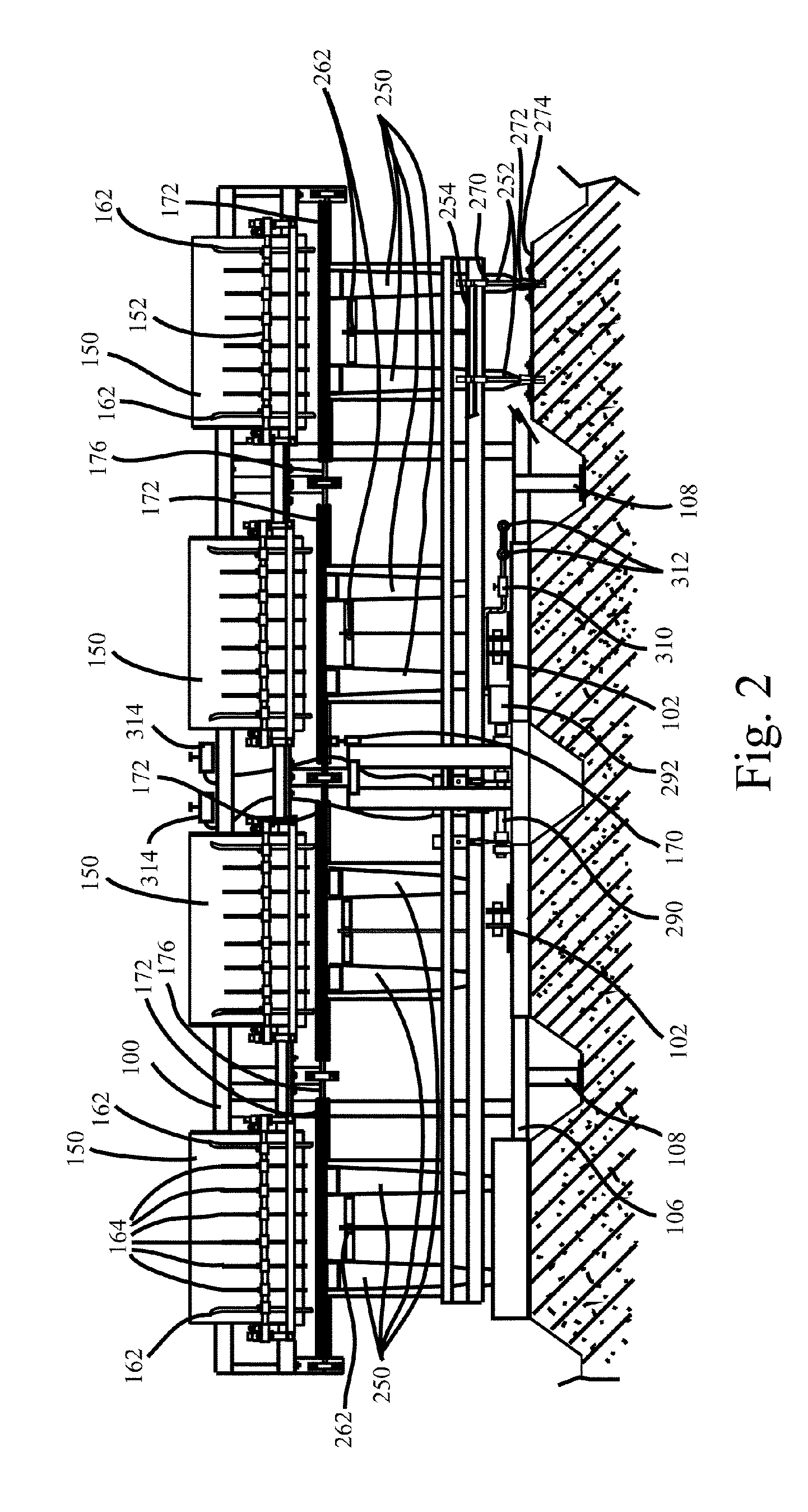

Automated potted-seedling transplanting machine for greenhouse

InactiveCN101843200AHigh degree of automationEasy to installConveyorsTransplantingGreenhouseEngineering

The invention relates to an automated potted-seedling transplanting machine for a greenhouse, belonging to the field of an automated seedling transplanting device in facility agriculture. The transplanting machine comprises a potted tray transport mechanism (2) and a potted seedling transplanting mechanism (6), wherein the potted tray transport mechanism (2) is installed on a machine frame and is used for transporting a potted tray to a specified transplanting work position; the potted seedling transplanting mechanism (6) is used for clipping a seedling out from the potted tray, transporting the seedling to a space above another empty potted tray and then implanting the seedling; and a control box (1) is arranged below the machine frame (4), an operating button for starting and stopping the complete machine is arranged in the control box (1), and the control box (1) can carry out integrating control on all the mechanisms. The transplanting machine can transplant the seedlings of multiple crops, the transplanting work can be completed by simply arranging a potted tray containing a seedling and an empty potted tray to be implanted on the potted tray transport mechanism and taking the potted tray the transplanting work of which is completed away from the potted tray transport mechanism by only one operating person, and other procedures of spraying, disinfecting and the like can be subsequently carried out after the transplanting work is completed. The transplanting machine has the advantages of high automation degree and simple and reliable operation.

Owner:BEIJING UNIV OF TECH

Agricultural apparatus and method

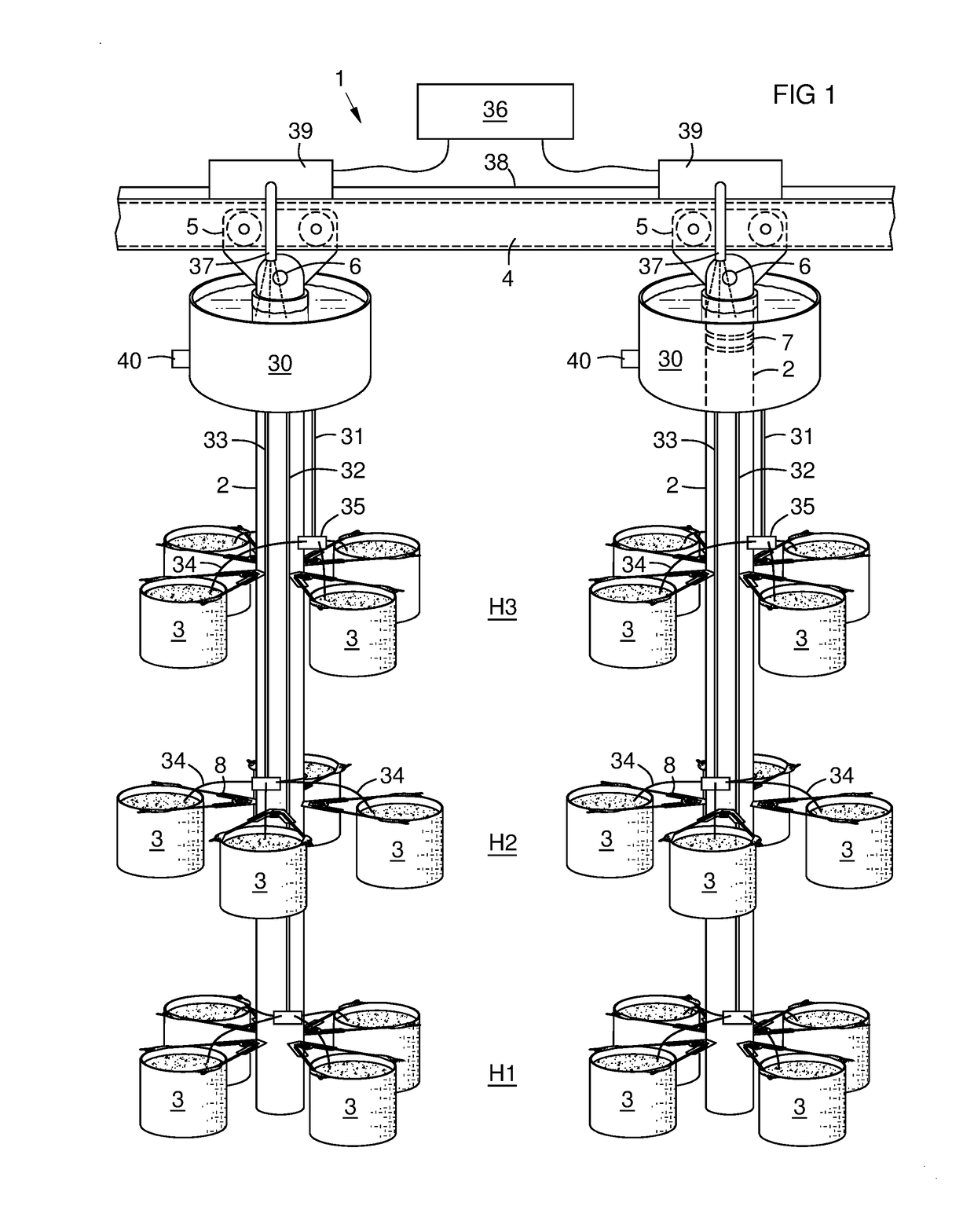

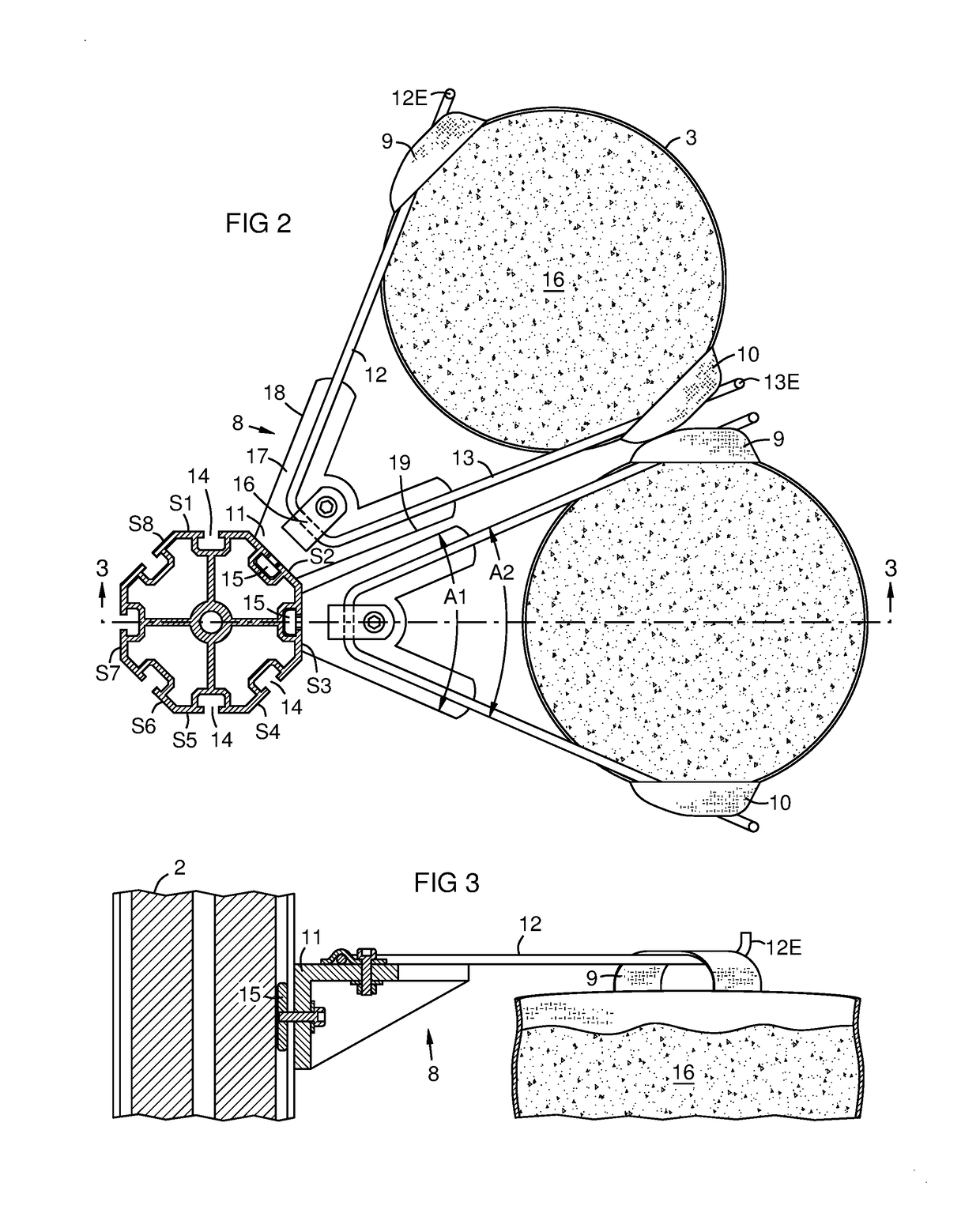

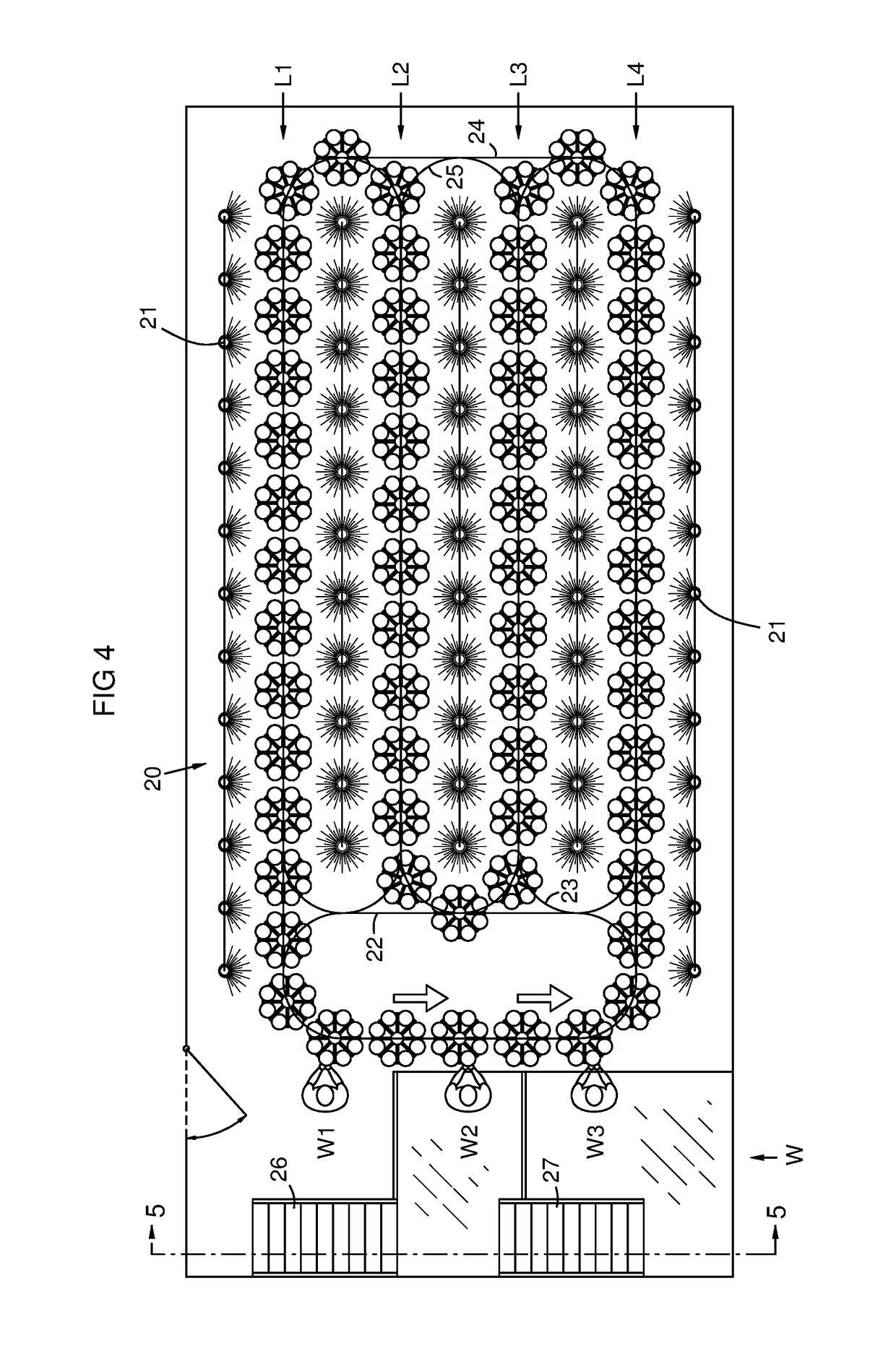

ActiveUS10136587B1Improved inventory controlEasy maintenanceSelf-acting watering devicesWatering devicesEngineeringWorkstation

A conveyor system (4, 5) moves vertical poles (2) in an agricultural facility between a growing area (20) and a workstation (W). Each pole carries plant growing containers (3) at multiple levels (H1-H9). An irrigation reservoir (30) may be mounted atop each pole. Irrigation lines (31-33) from the reservoir may be individually metered (35) at each level to compensate for differing water pressure with height. Sensors (40) in the reservoir and at each level of the poles may provide a controller (36) with data input. The controller may impose different growing conditions in different areas of the facility, including vertically different grow areas (20A, 20B), and controls pole movements and locations selectively to provide a sequence of poles at the workstation ready to harvest on a demand schedule. The workstation may have multiple heights (W1, W2, W3) for tall poles that increase plant density per facility footprint.

Owner:JOHNSON GARY LIND +1

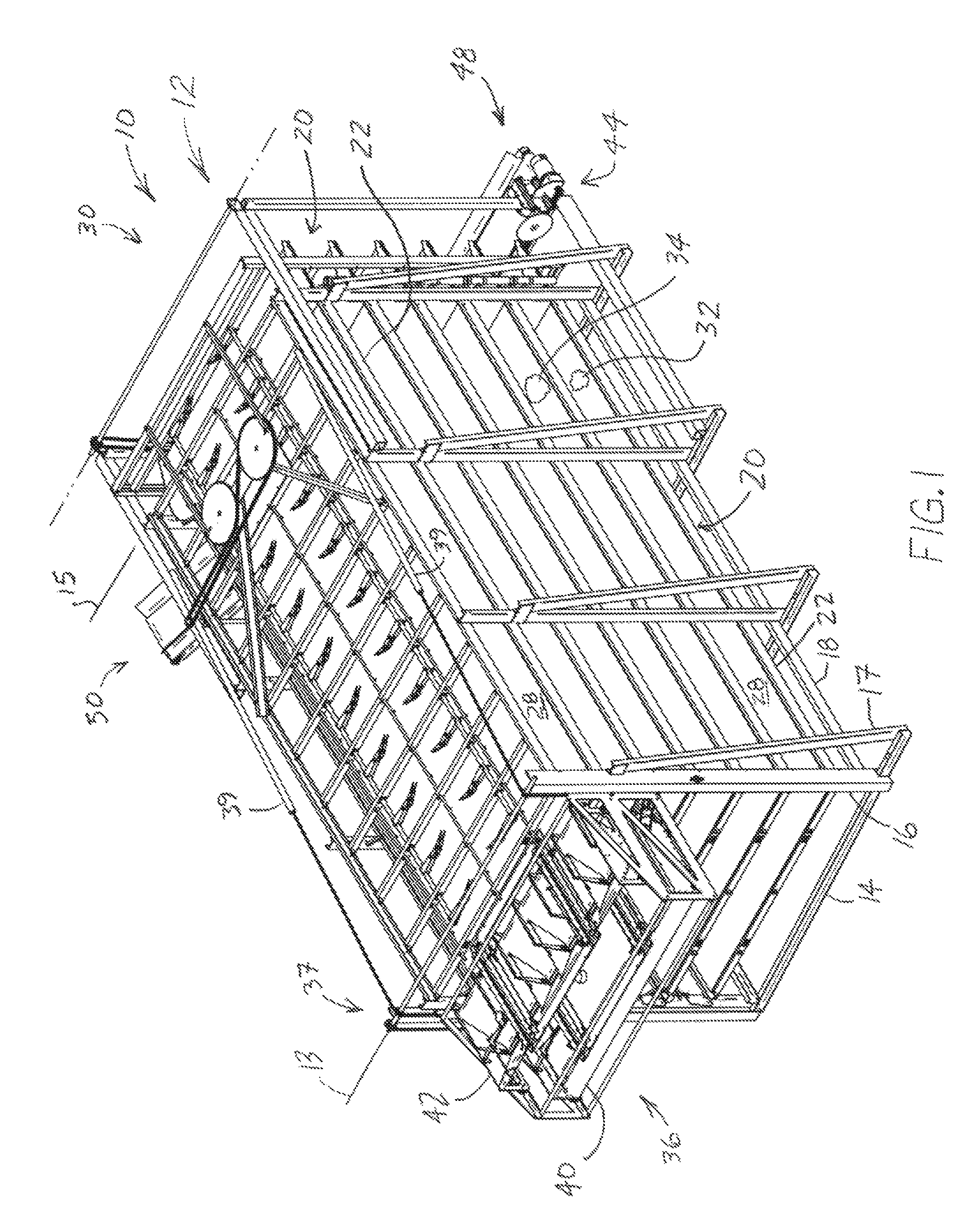

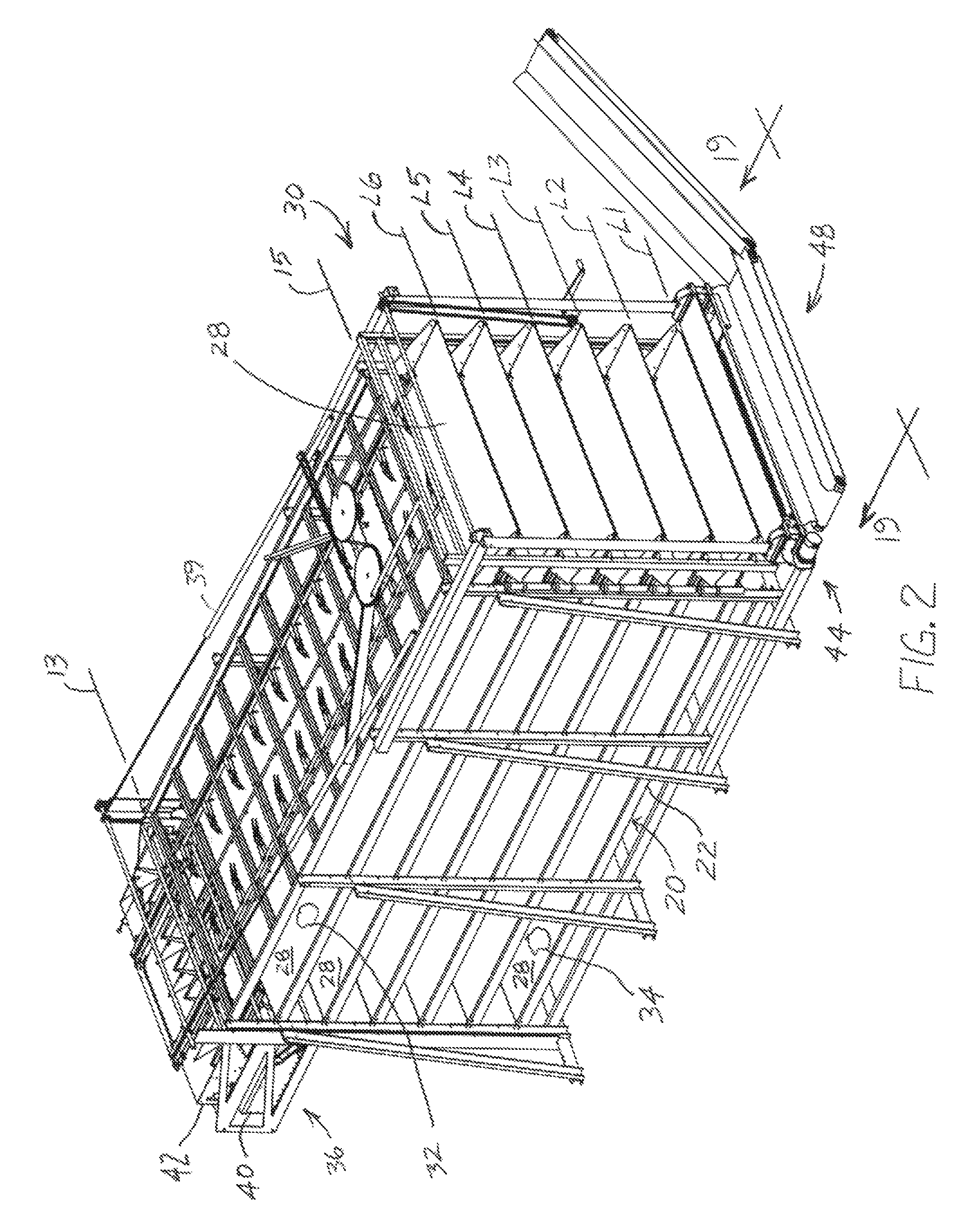

Sprouted seed grain growing and harvesting apparatus and method

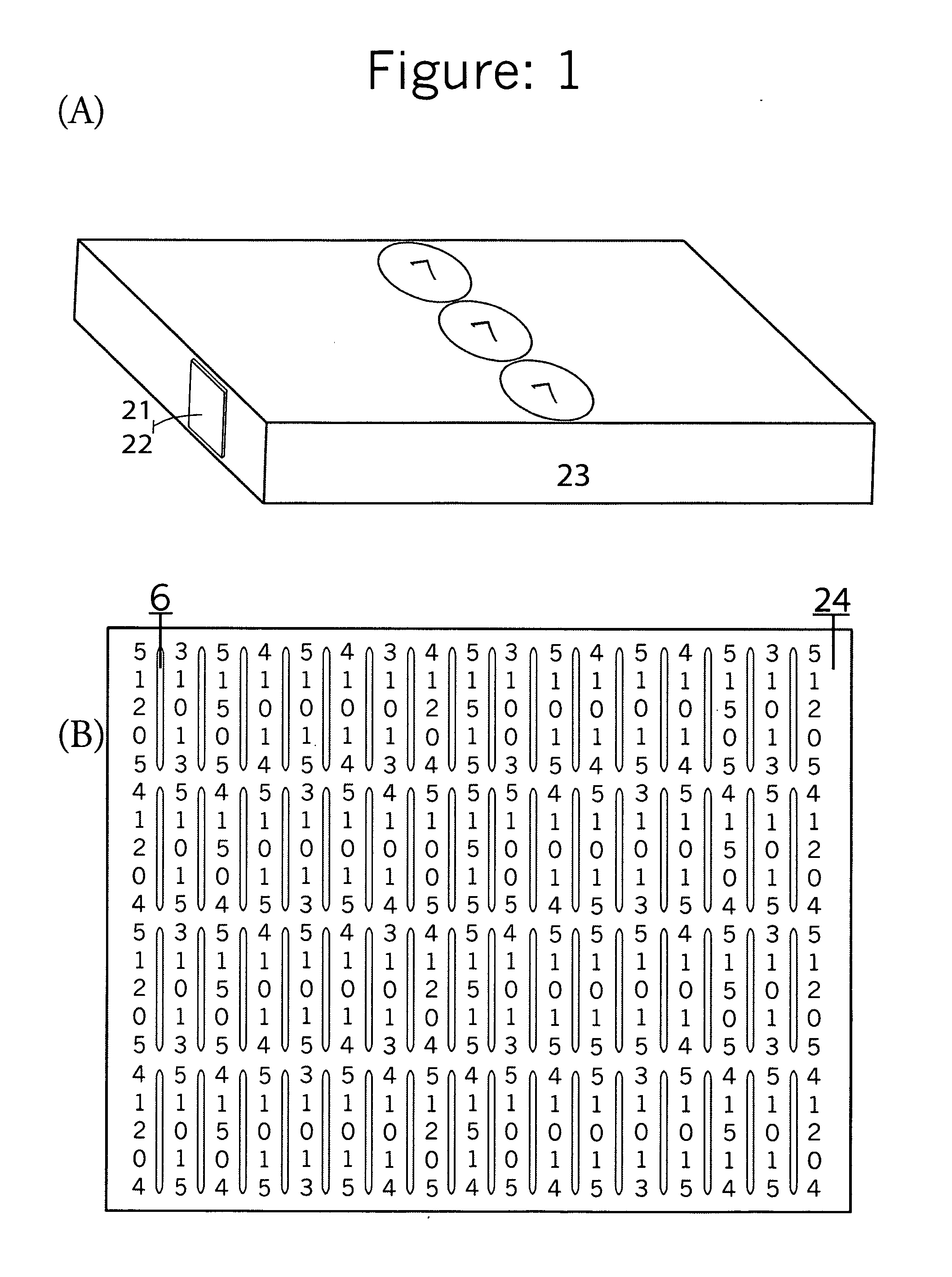

InactiveUS8627598B1Agriculture gas emission reductionCultivating equipmentsSprouted SeedsEngineering

An apparatus for growing and harvesting a tangled mass composed of sprouted seed grain includes a plurality of overlying immobile, substantially planar surfaces having a length. Each surface is configured to receive a layer of seed grain that is permitted to grow for a predetermined period of time on each surface, the layer of seed grain becoming a continuous tangled mass of sprouted seed grain. An extraction device removes the mass from each surface. A cleaning device removes debris from each surface prior to each surface receiving a subsequent layer of seed grain.

Owner:SPROUTING WORKS

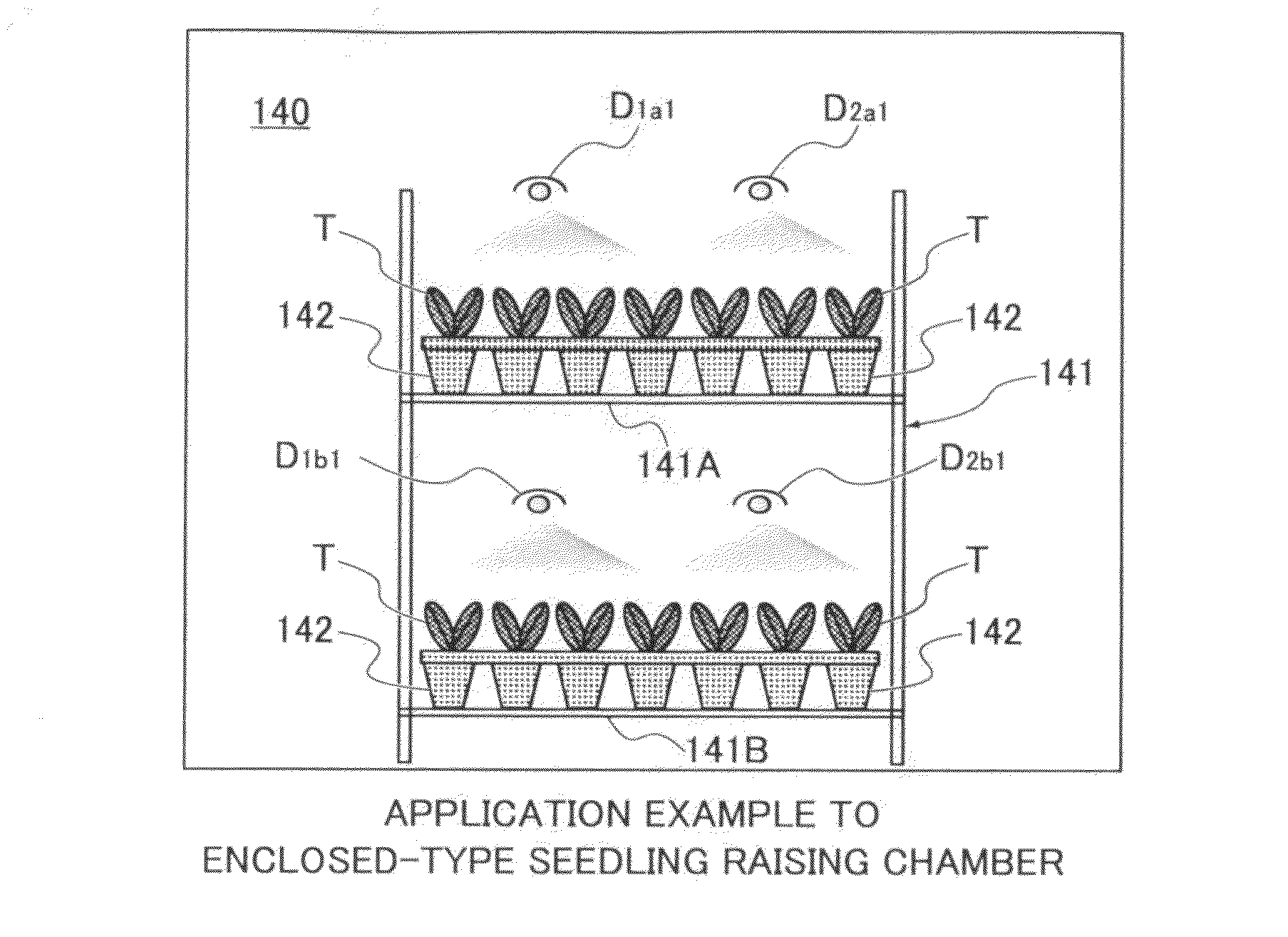

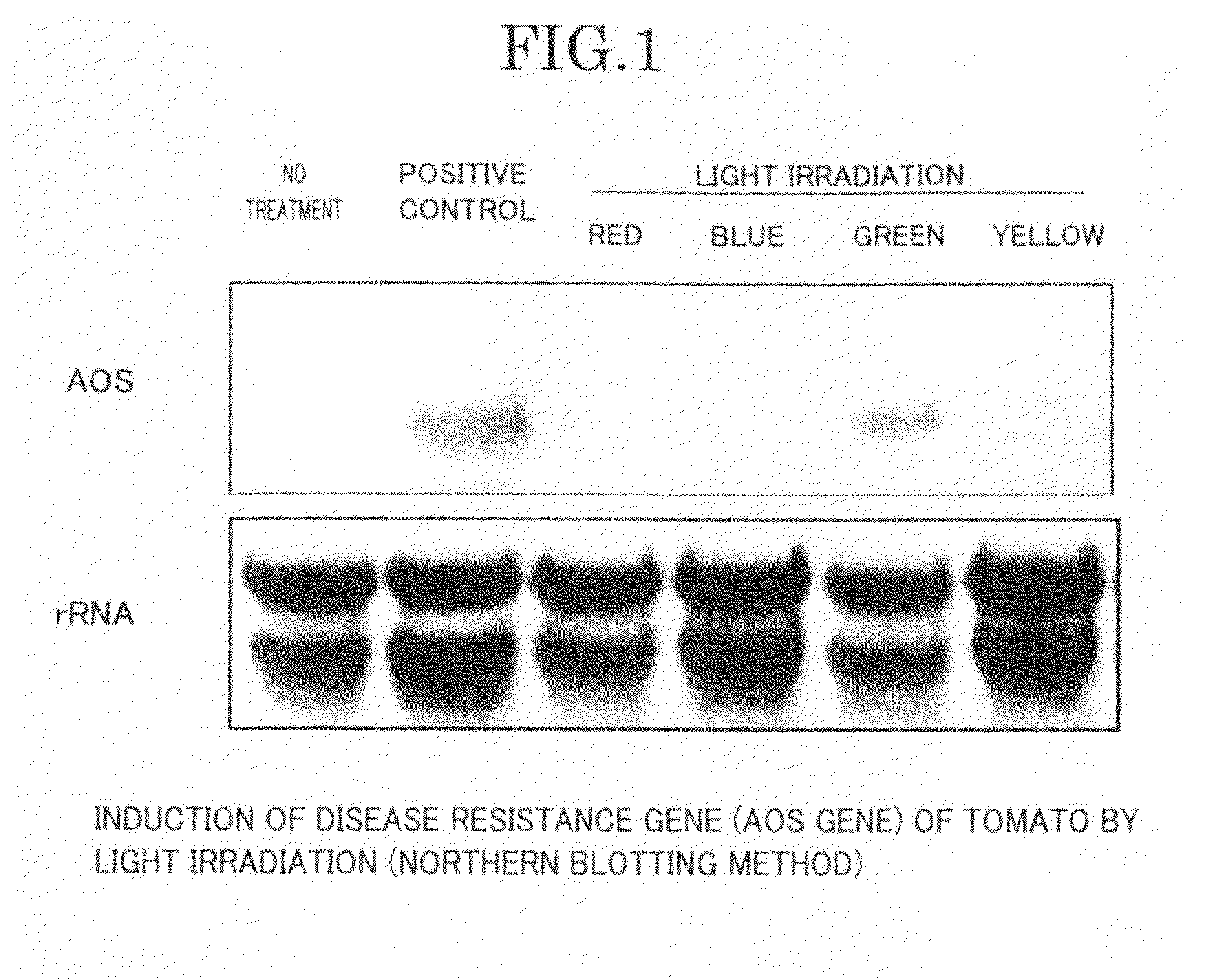

Disease Control Method and Disease Control Device

InactiveUS20100281771A1Improve plant resistanceReduce the amount requiredRoot feedersSaving energy measuresGreen-lightIrradiation

A disease control device has light emitting diodes (D1 to Dn) emitting green light and a controller (2) controlling a drive circuit (1) for turning on the light emitting diodes (D1 to Dn). The drive circuit (1) is controlled by the controller (2) to cause the light emitting diodes (D1 to Dn) to emit green light to irradiate plants with the light. The irradiation with the green light enhances resistance of the plants against diseases.

Owner:SHIKOKU RES INST +1

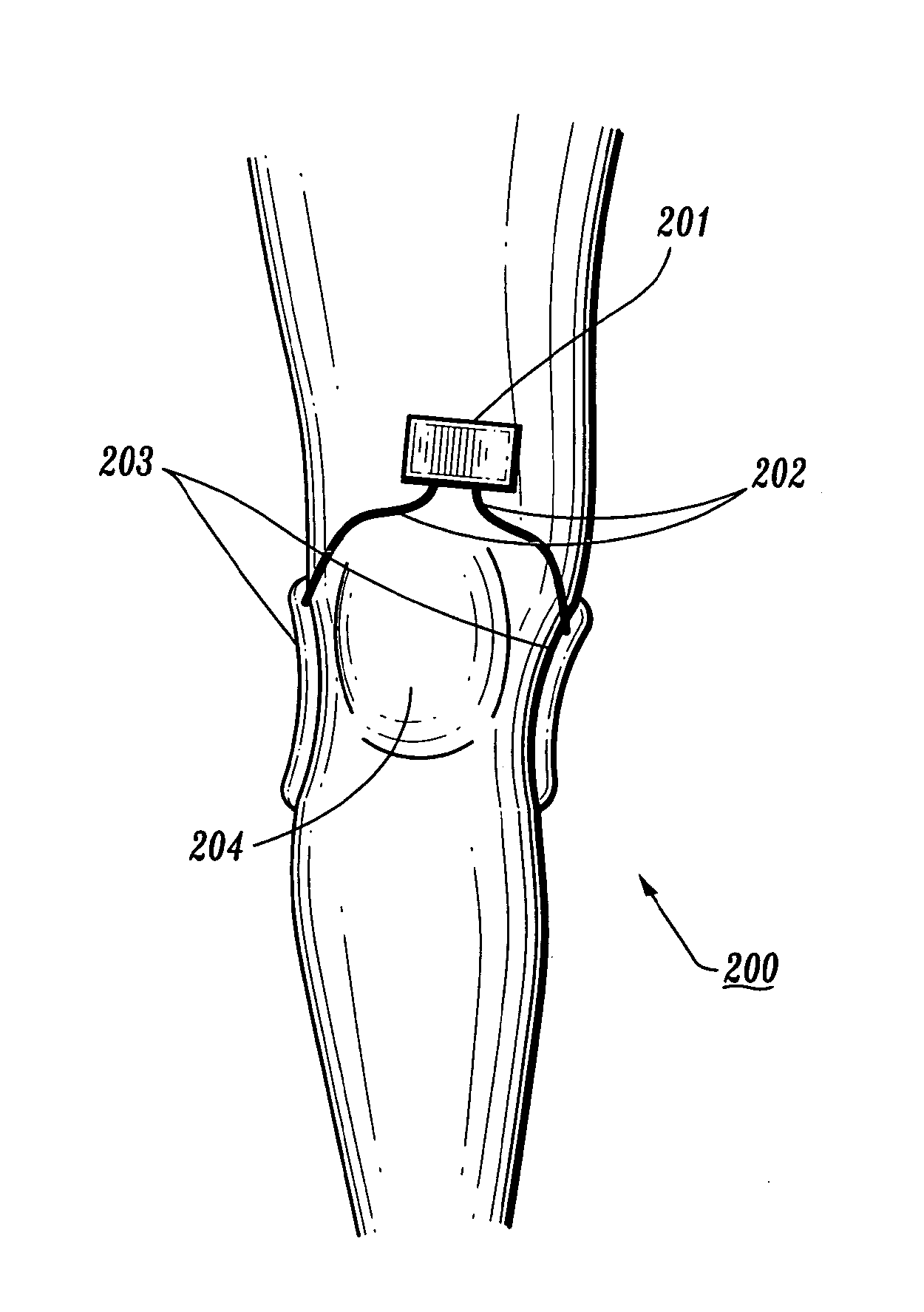

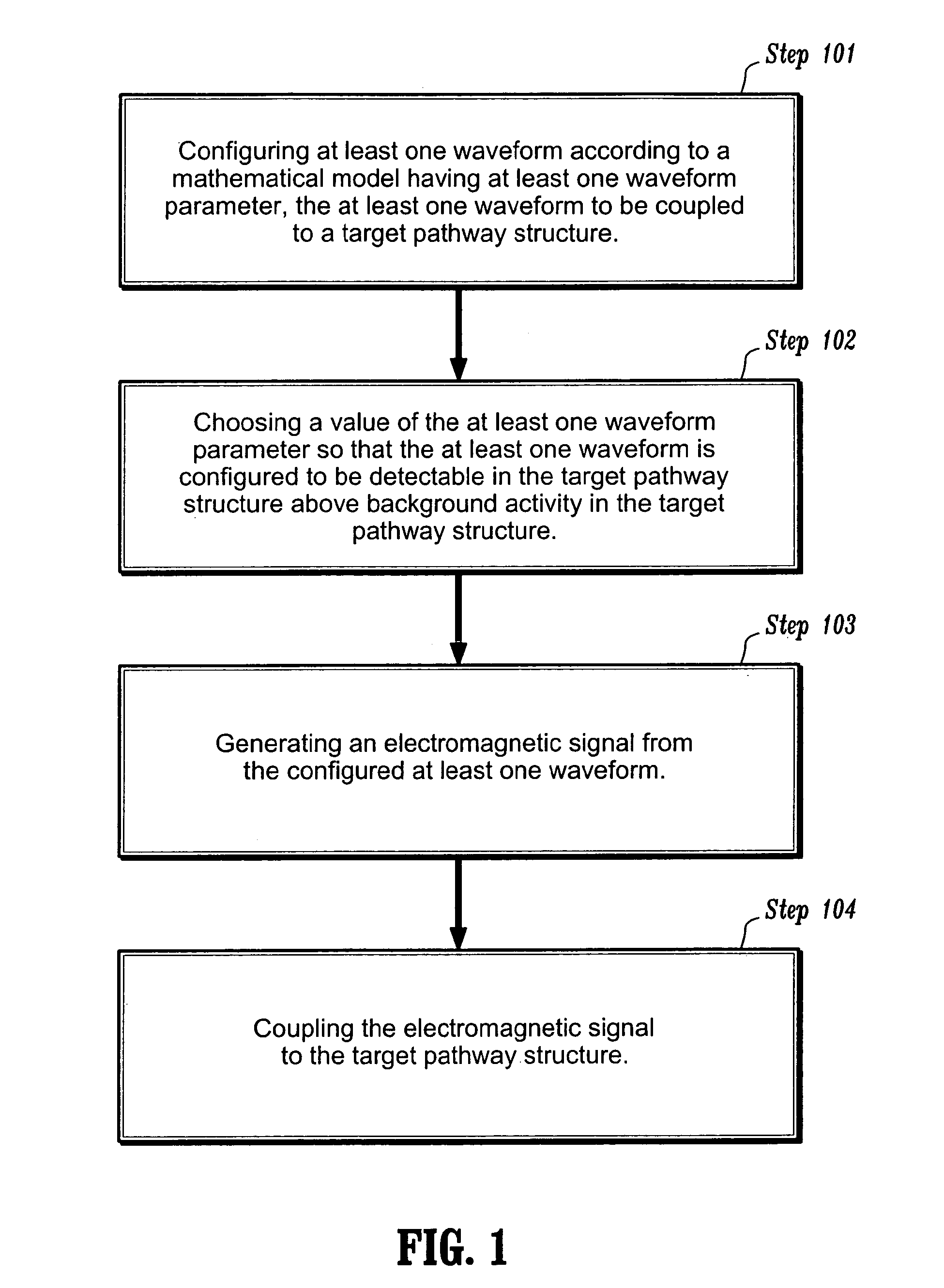

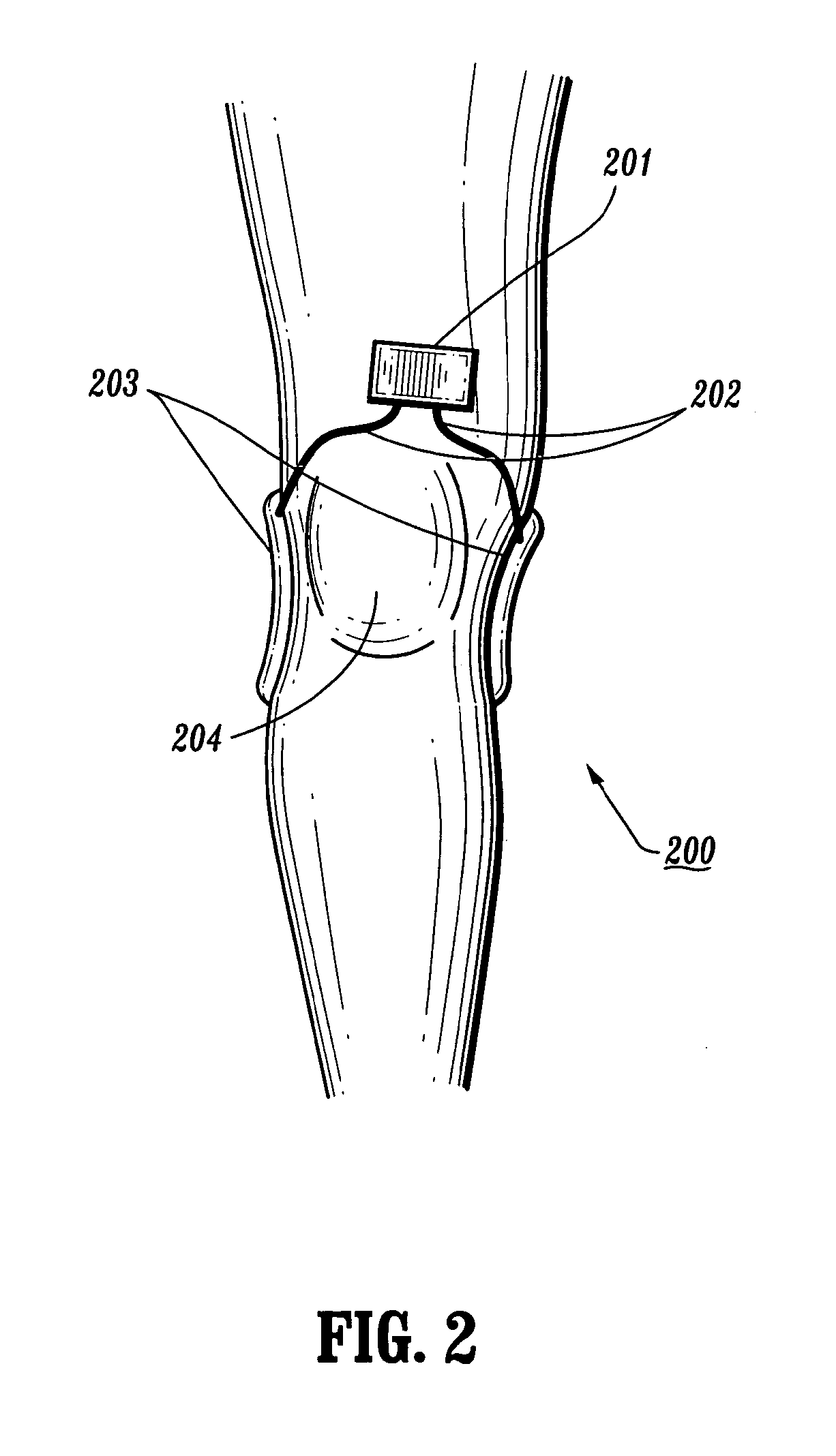

Apparatus and method for electromagnetic treatment of plant, animal, and human tissue, organs, cells, and molecules

InactiveUS20100210893A1Low peak amplitudeShort durationElectrotherapySeed and root treatmentCouplingMathematical model

Owner:RIO GRANDE NEUROSCI

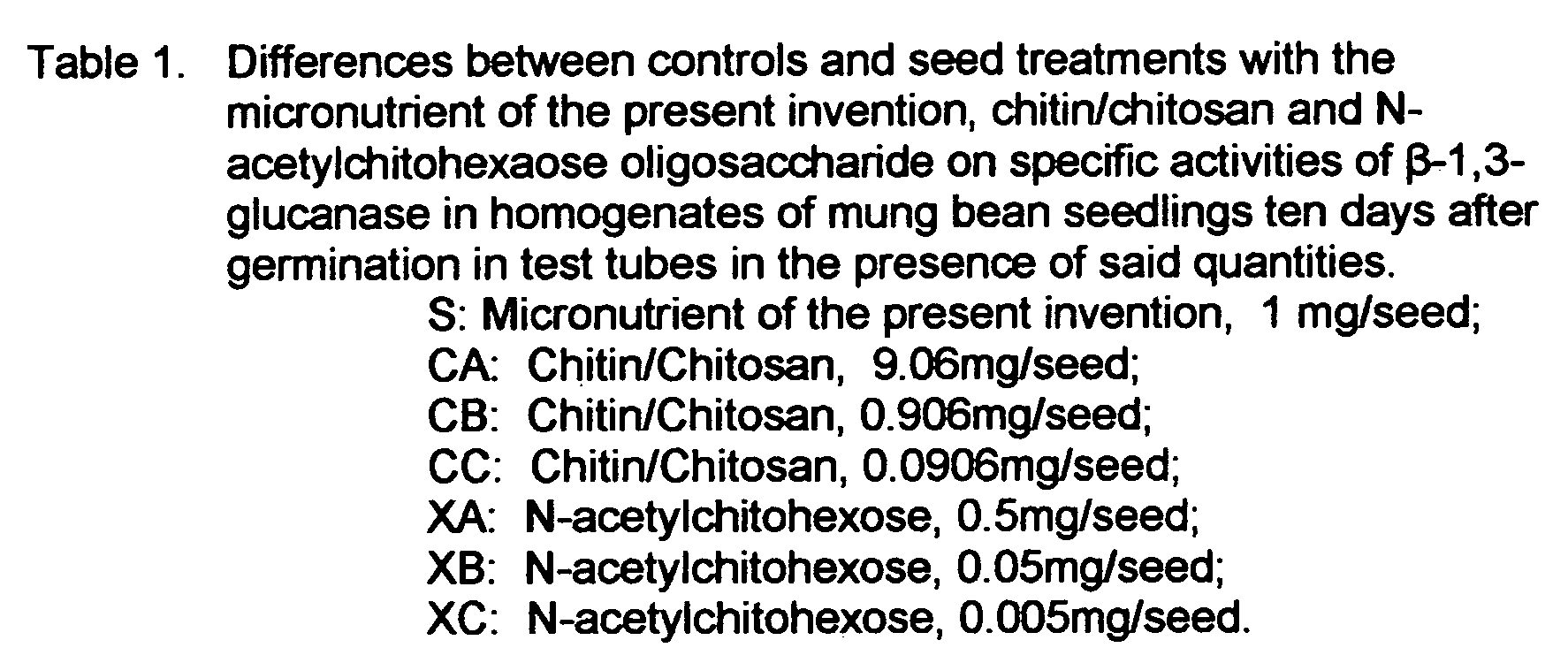

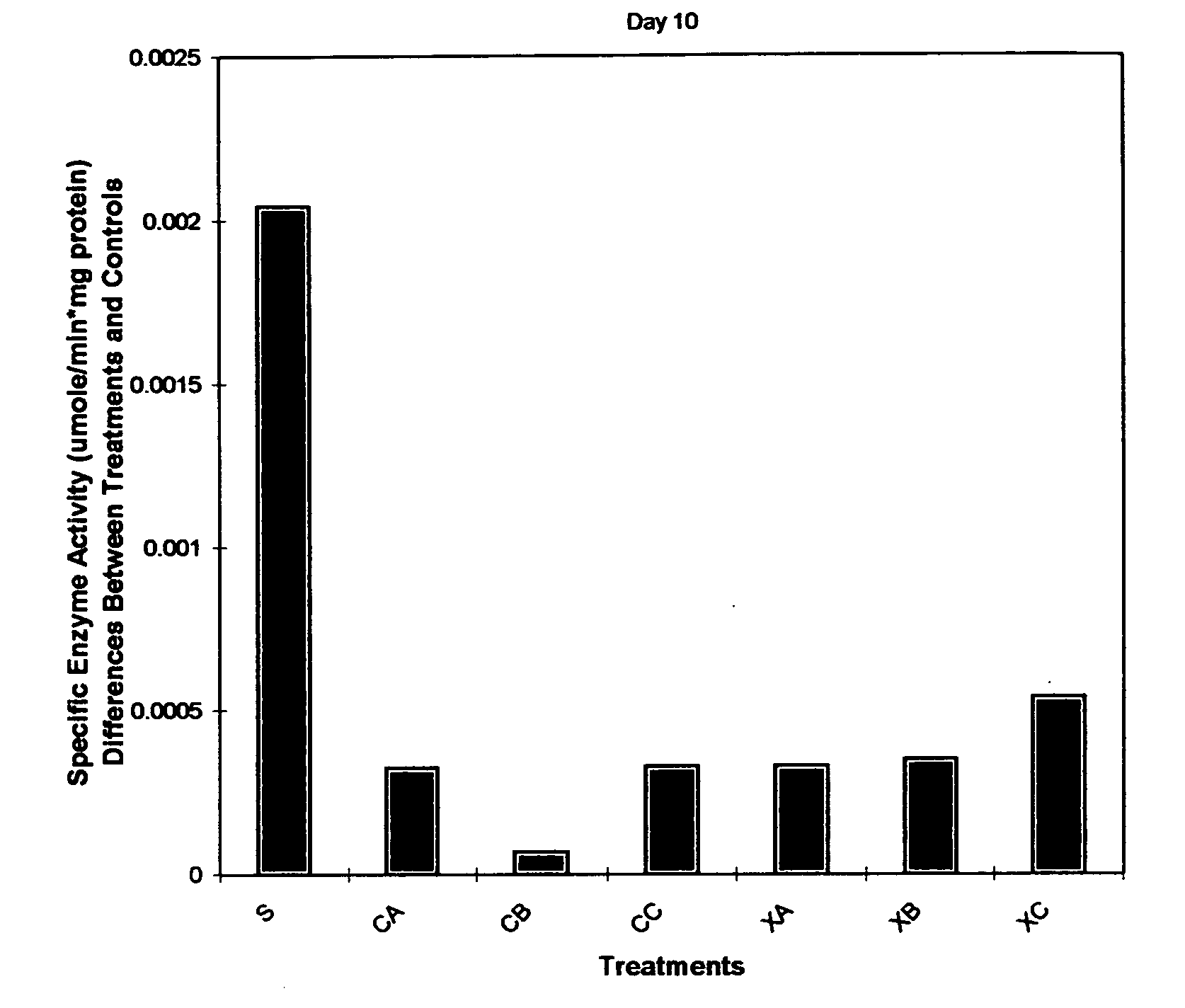

Micronutrient elicitor for treating nematodes in field crops

InactiveUS20080072494A1Disable or destroy the disease's ability to negatively impact the propaguleQuality improvementCultivating equipmentsSeed coating/dressingDiseaseField crop

A liquid micronutirent elicitor involving a cell to cell signal transduction system within a plant which is applied to propagules (seed and / or plant) causes natural defensive responses to be produced by the seed and / or plant. This substance may exist as a seed coating, irrigation water, and / or foliar spray for a period of time so that the propagules may have enhanced disease control until the propagule develops sufficiently to fend for itself against parasitic nematodes. The benefits of incorporating the solution include increased vigor, blooms, and harvests. Crops include legumes including soybeans, as well as wheat, canola, corn, peanuts, sunflowers, peppers, tomatoes, grapes, and potatoes.

Owner:STONER RICHARD J +1

Biological-Based Catalyst to Delay Plant Development Processes

ActiveUS20080236038A1Extended shelf lifeFacilitating longer-distance transportationBiocideBacteriaBacteroidesBrevibacterium ketoglutamicum

The present invention is directed to methods for delaying a plant development process comprising exposing a plant or plant part to one or more bacteria or enzymes. In specific embodiments, the one or more bacteria are selected from the group consisting of Rhodococcus spp., Pseudomonas chloroaphis, Brevibacterium ketoglutamicum, and a mixture comprising any combination of these bacteria. Apparatuses for delaying a plant development process comprising a catalyst that comprises one or more of the above bacteria.

Owner:CROWPIERCE TECH LLC

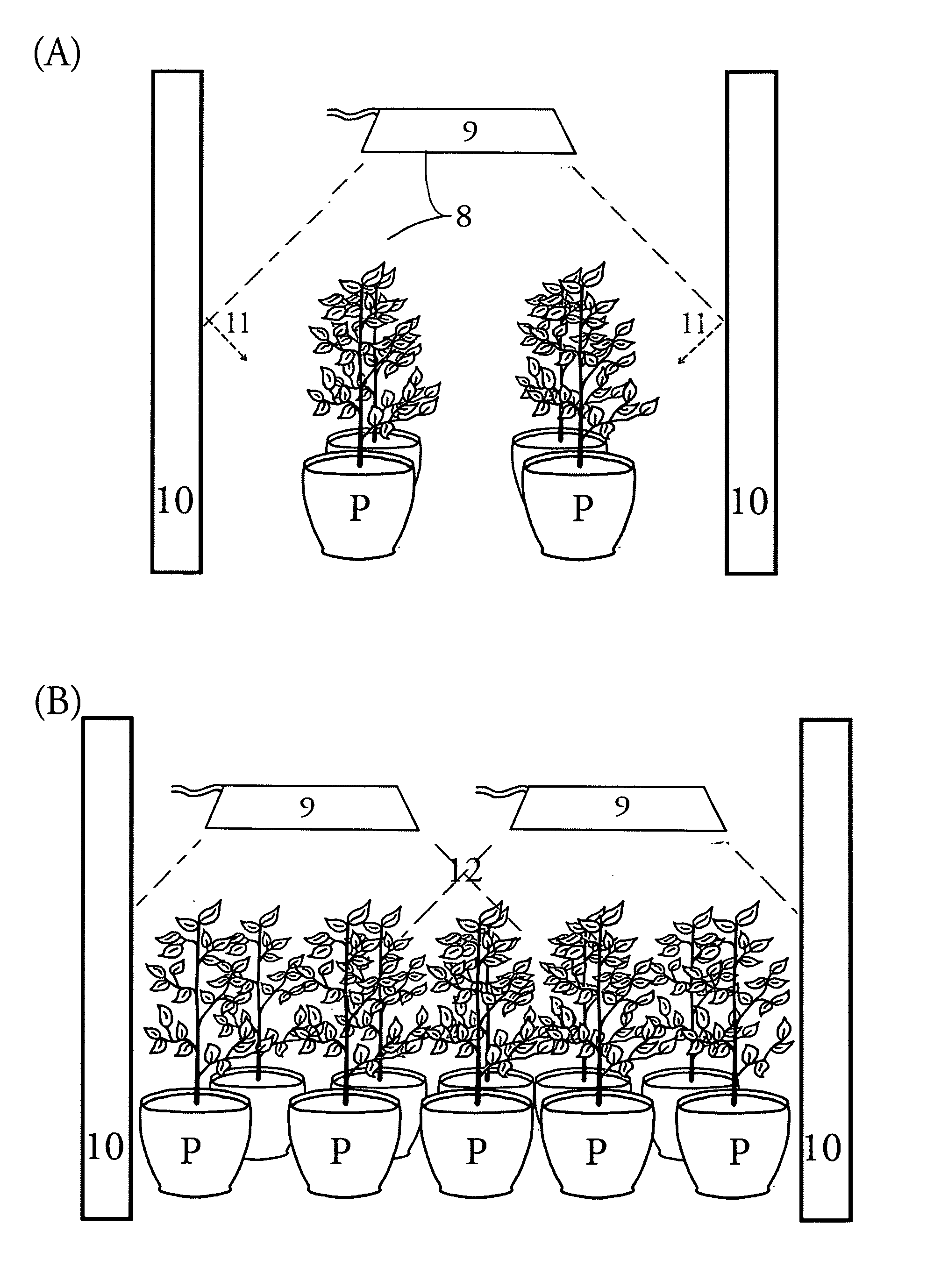

Spectural specific horticulture apparatus

A device would be desirable if it reflected directional light, and if it could stimulate the phenomena of horticulture efficiently in a place where sunlight may not be readily available. Then it could be possible to harvest desirable crops in any season. Given that the climate is right and plants are properly fed with both micro and primary nutrients; this device would propagate the best growth in green photosynthetic plants by simulating a band of magnetic frequencies that enhance the photoperiodism states. This device will use wavelengths approaching the UV and IR spectrum but will stay within the bounds of beneficial frequencies. Desired growth being: biomass gain, yield, and the metabolic integrity of the plant. The device ought to aid in biomass gain by achieving desirable light cycles, color band ratios and aid in air circulation in the vicinity of the plants (in turn affecting respiration and transpiration).

Owner:LEE RICKY

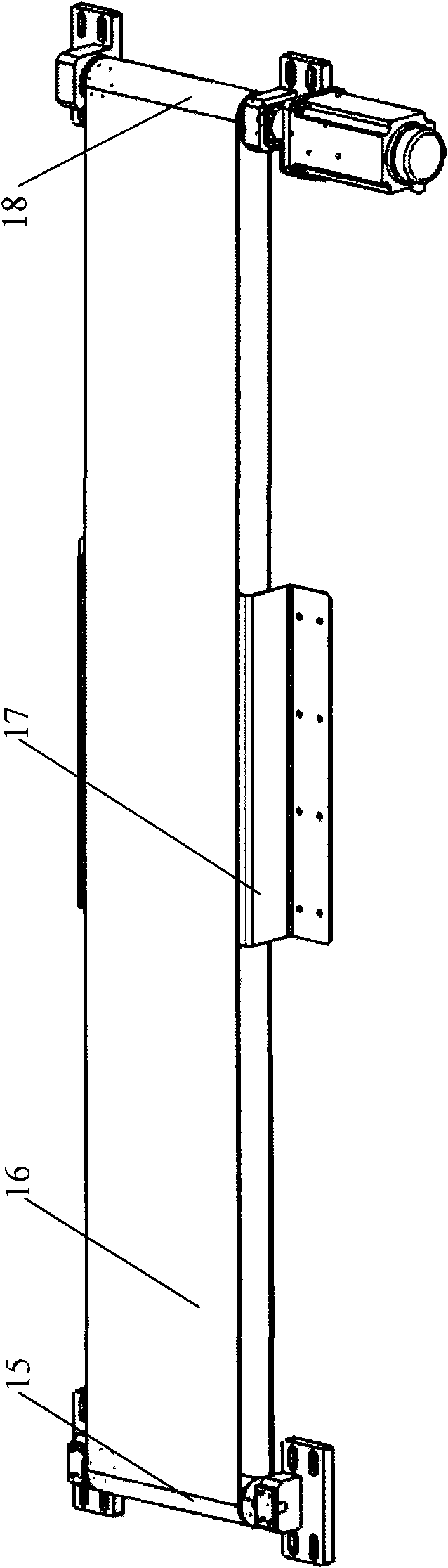

Automatic flower transplanting device

InactiveCN102715035AMeet transplantHigh degree of automationFlower-pot fillingAgricultural automationMechanical engineering

An automatic flower transplanting device belongs to the field of automatic seedling transplanting equipment in protected agriculture. A conveyor of original flowerpots and a conveyor of empty flowerpots respectively convey the original flowerpots and the empty flowerpots into a transplanted flower pot positioning device. An earthing device for empty flowerpots is used for earthing the empty flowerpots before the empty flowerpots are conveyed into the transplanted flower pot positioning device. A flowerpot rubbing device is disposed below a position, at which the transplanted flower pot positioning device positions the original flowerpots and is used for rubbing the original flowerpots being positioned. A flower transplanting gripper above the transplanted flower pot positioning device is used for transplanting flowers from the positioned and rubbed original flowerpots to the empty flowerpots. A flowerpot collecting device is adjacent to the back of the transplanted flower pot positioning device and is used for collecting the flowerpots containing the transplanted flowers and arranging and positioning the flowerpots. The automatic flower transplanting device is available for transplanting and the like of various flower plants, and is applicable to various specifications of flowerpots, high in automation level and simple and reliable to operate during transplanting.

Owner:BEIJING UNIV OF TECH

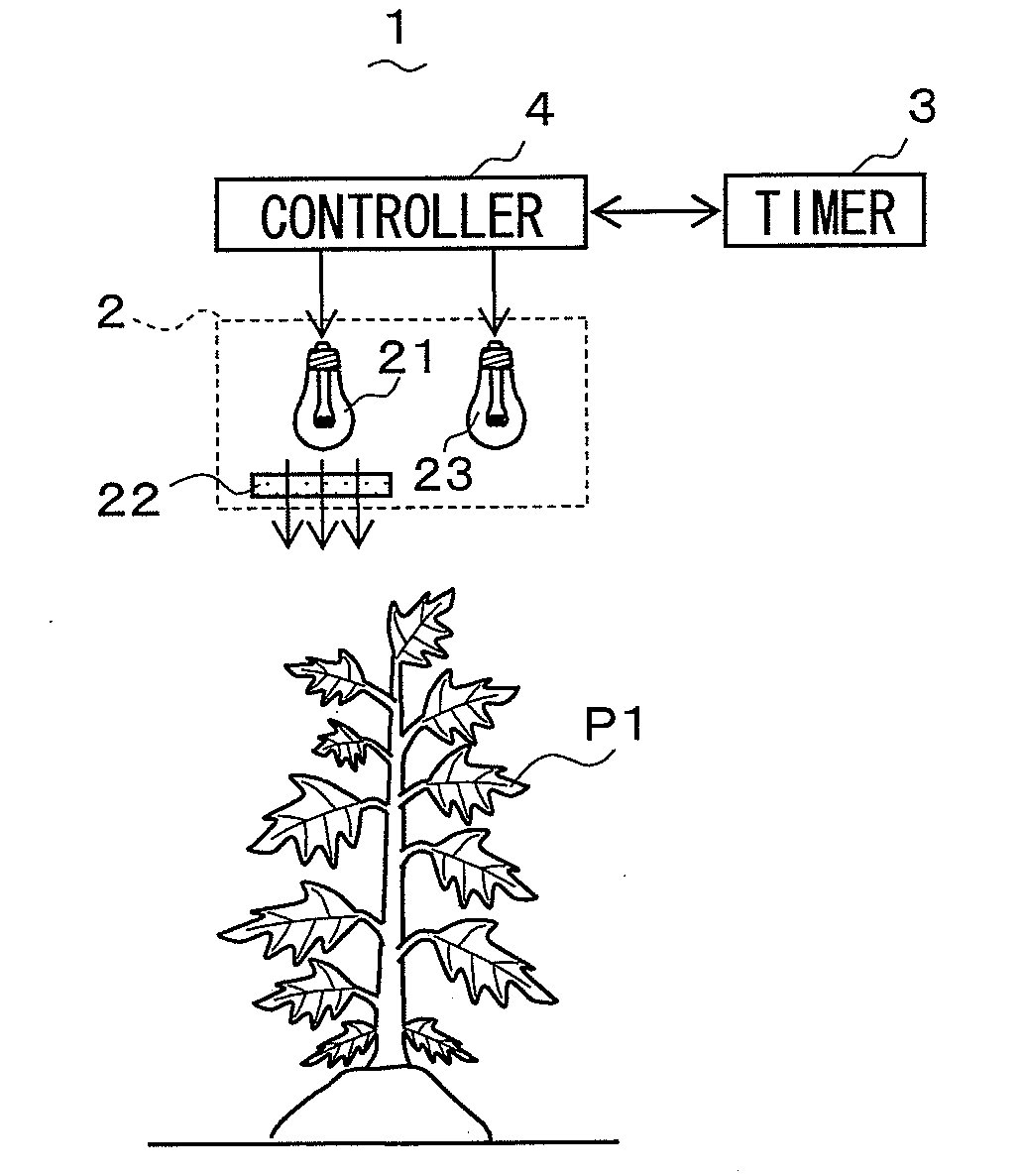

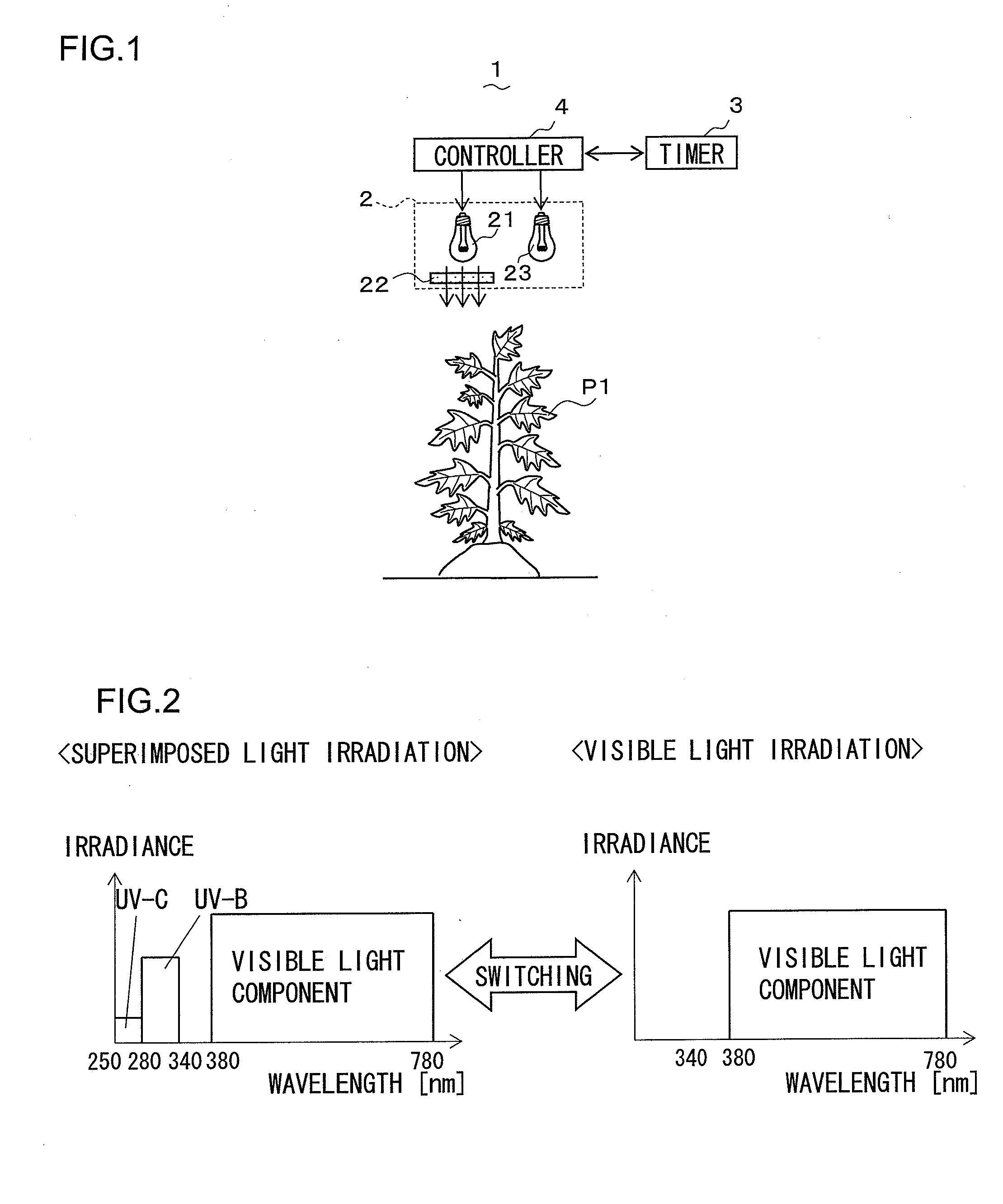

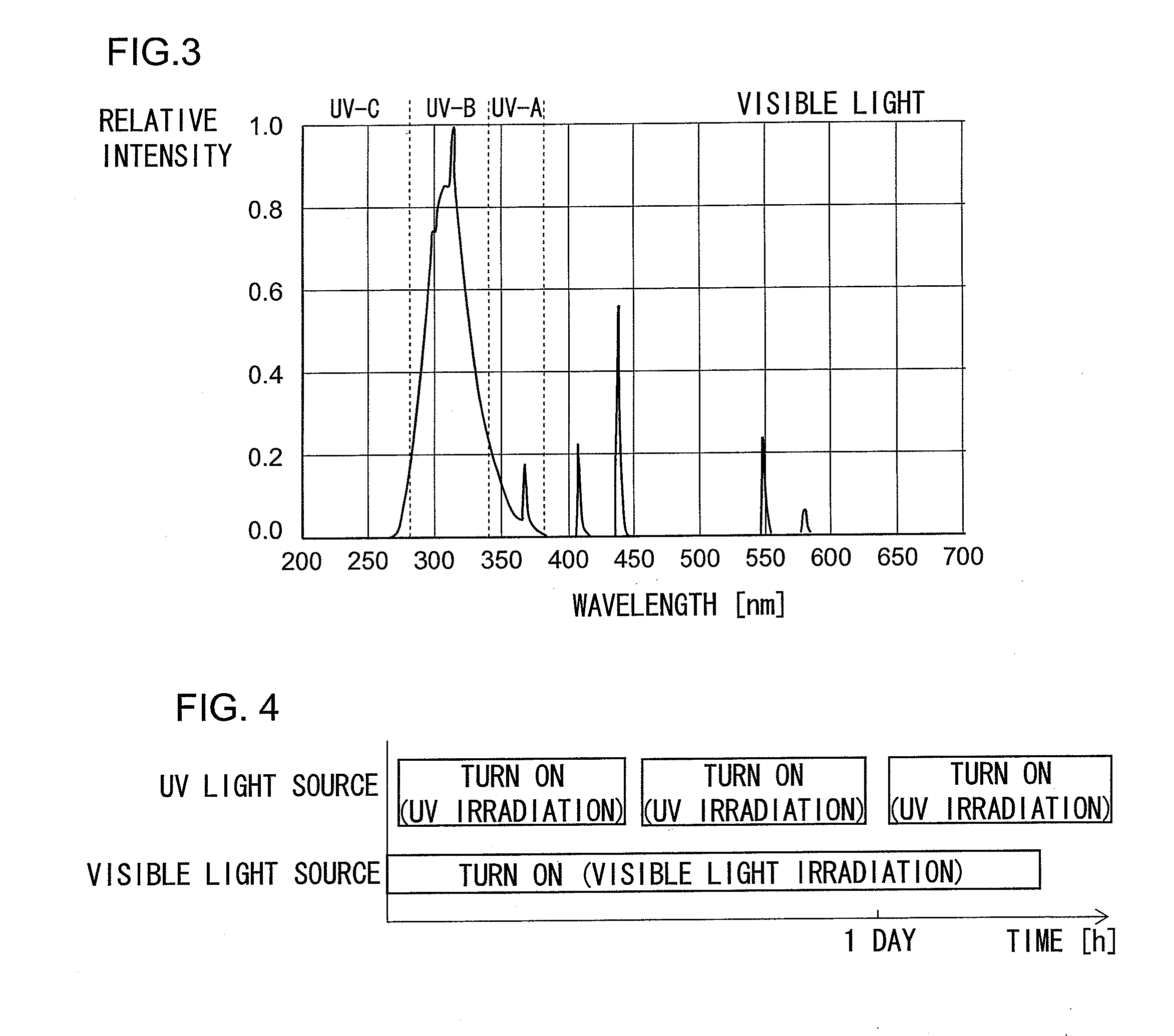

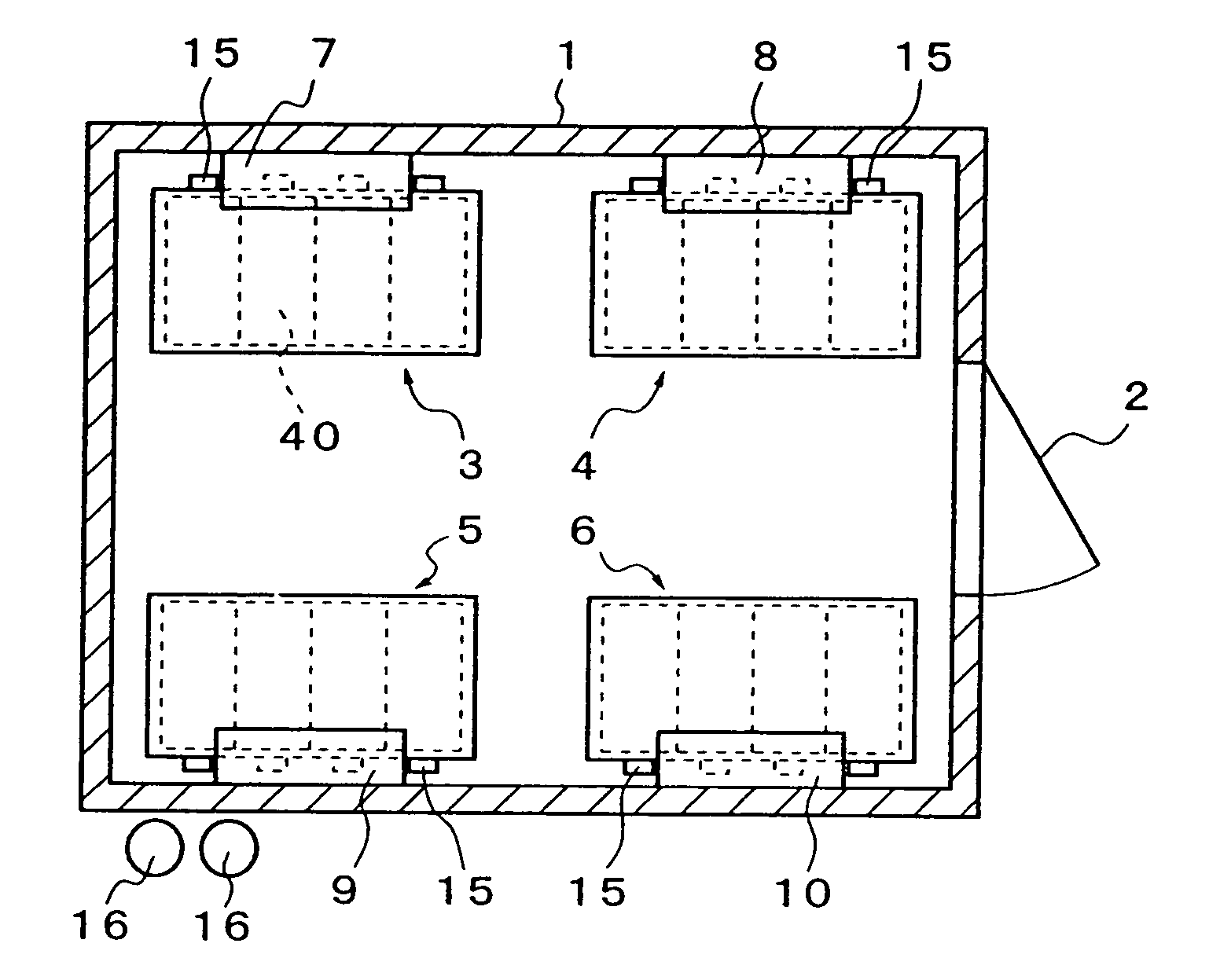

Lighting apparatus for controlling plant disease

InactiveUS20110016785A1Spread of plant can be reducedIncrease crop yieldElectrical apparatusElectric lighting sourcesDiseaseUredospore formation

A lighting apparatus for controlling a plant disease is provided to reliably inhibit a spore formation and a hyphal growth of a filamentous fungi, reliably induce a disease resistance, prevent a leaf scorch, and promote a growth of a plant. A UV light source repeats a light irradiation which has an irradiation pattern of combining a light irradiation, in which UV-C and UV-B and a visible light are superimposed, with a visible light irradiation alone at least twice a day. The emission of UV-B and UV-C enables the reliable inhibition of the spore formation of the filamentous fungi, for example. Its intermittent emission prevents a plant from getting too used to ultraviolet rays, promotes a generation of an antibacterial substance, for example, and prevents a leaf scorch. The continuous emission of the visible light enables a promotion of a growth of the plant.

Owner:PANASONIC CORP

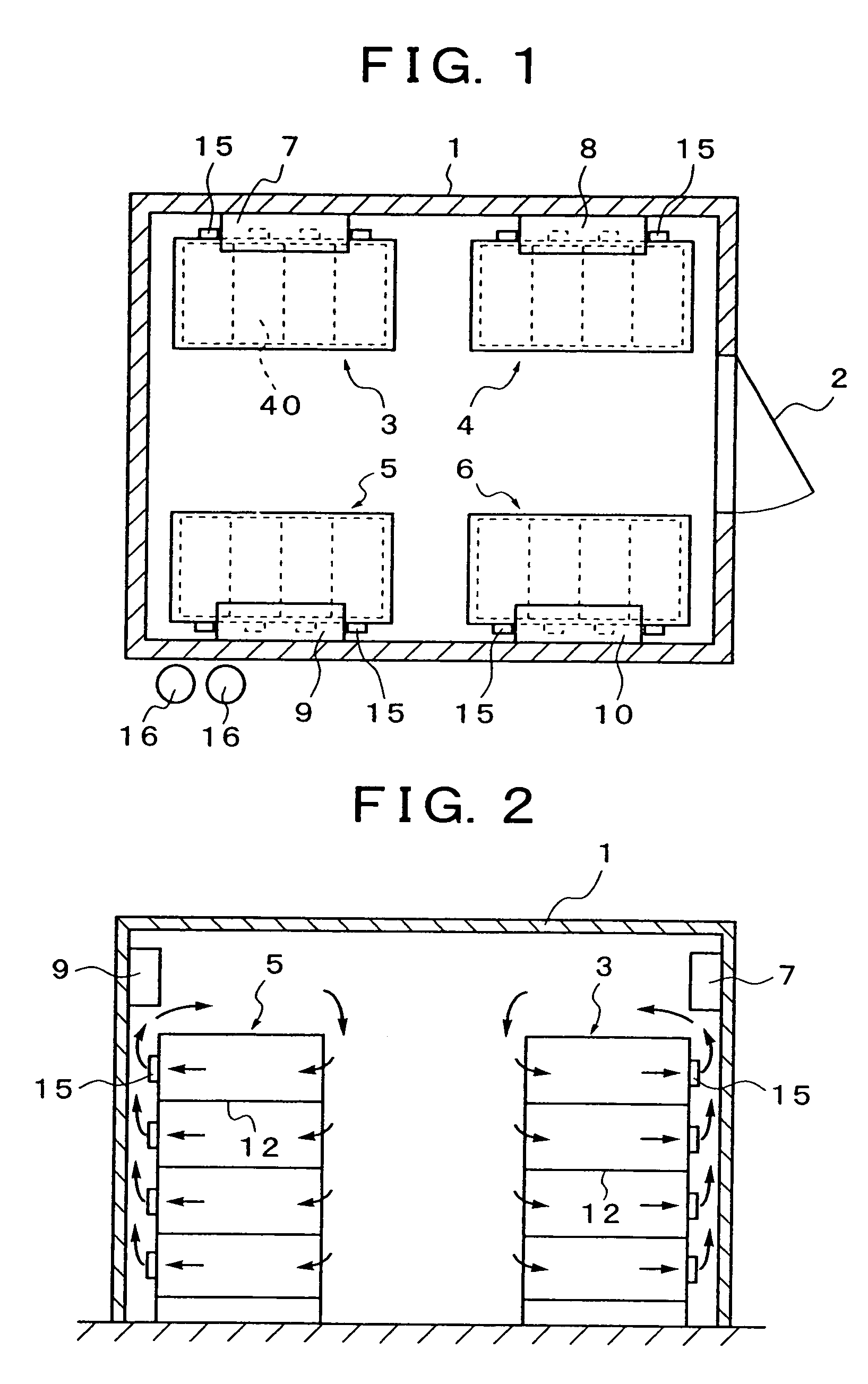

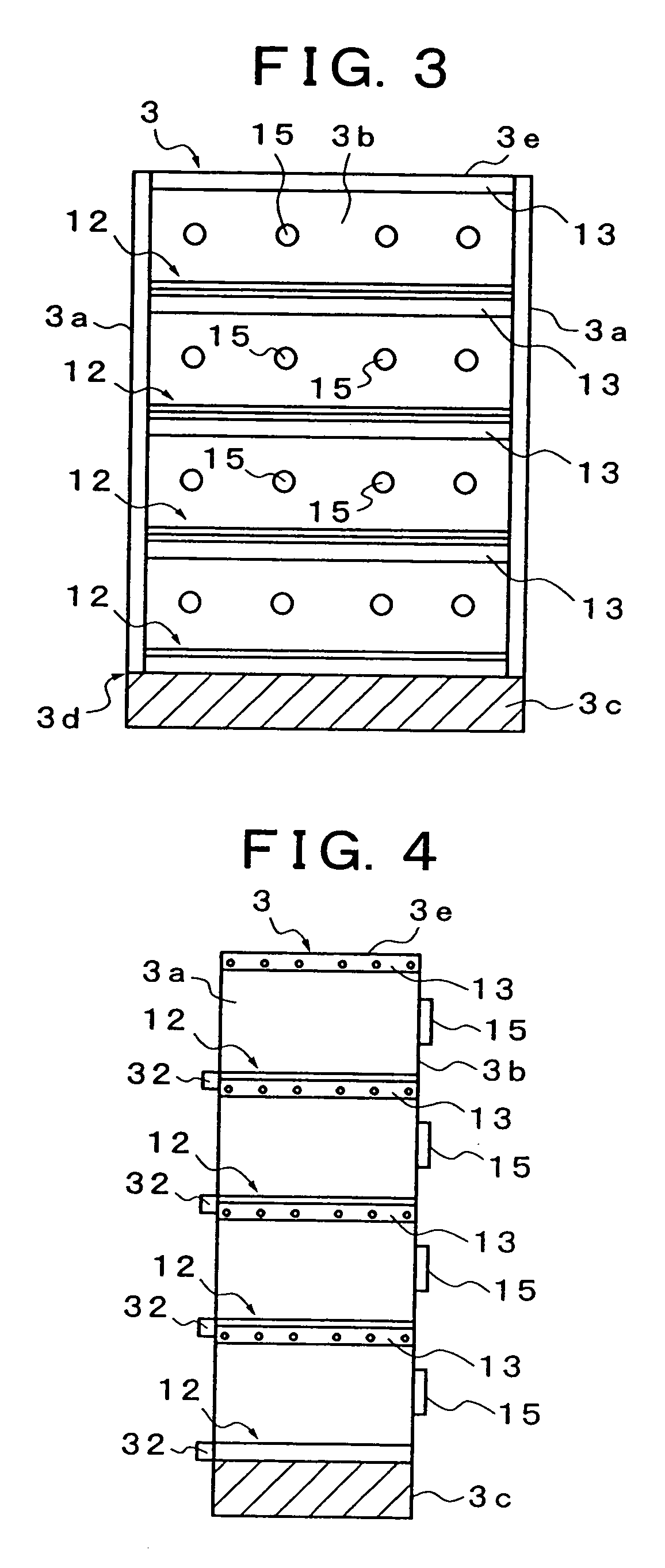

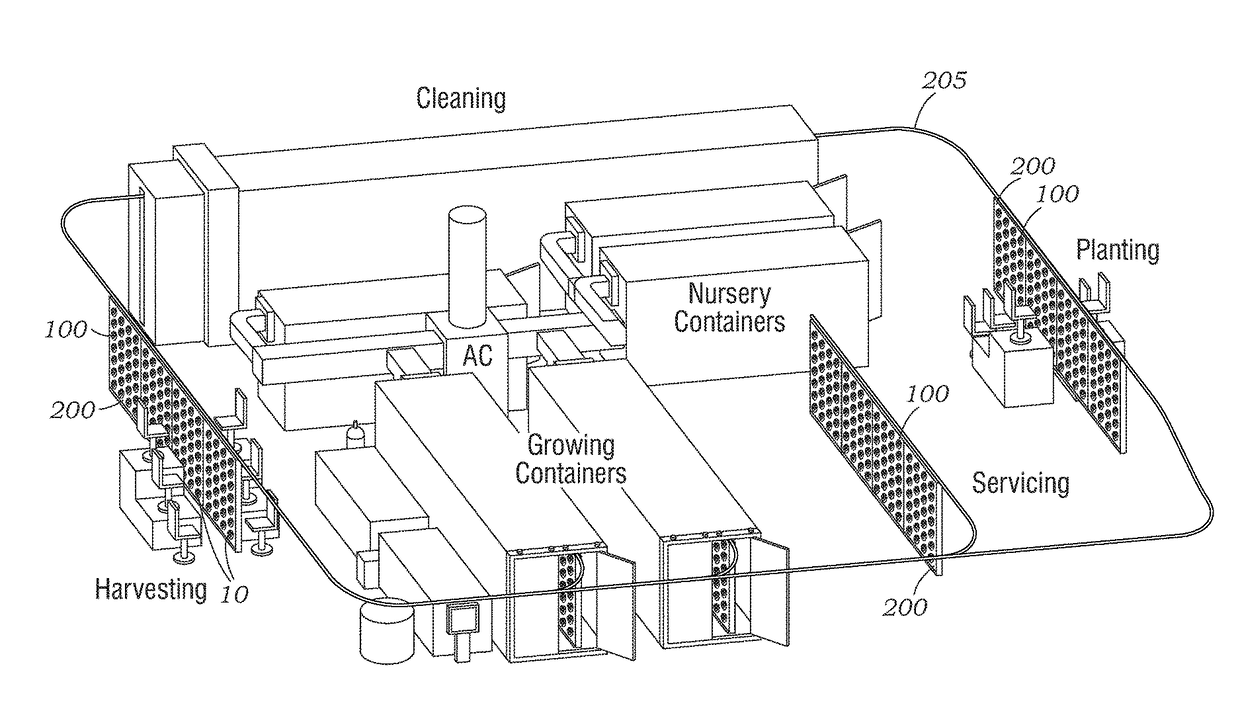

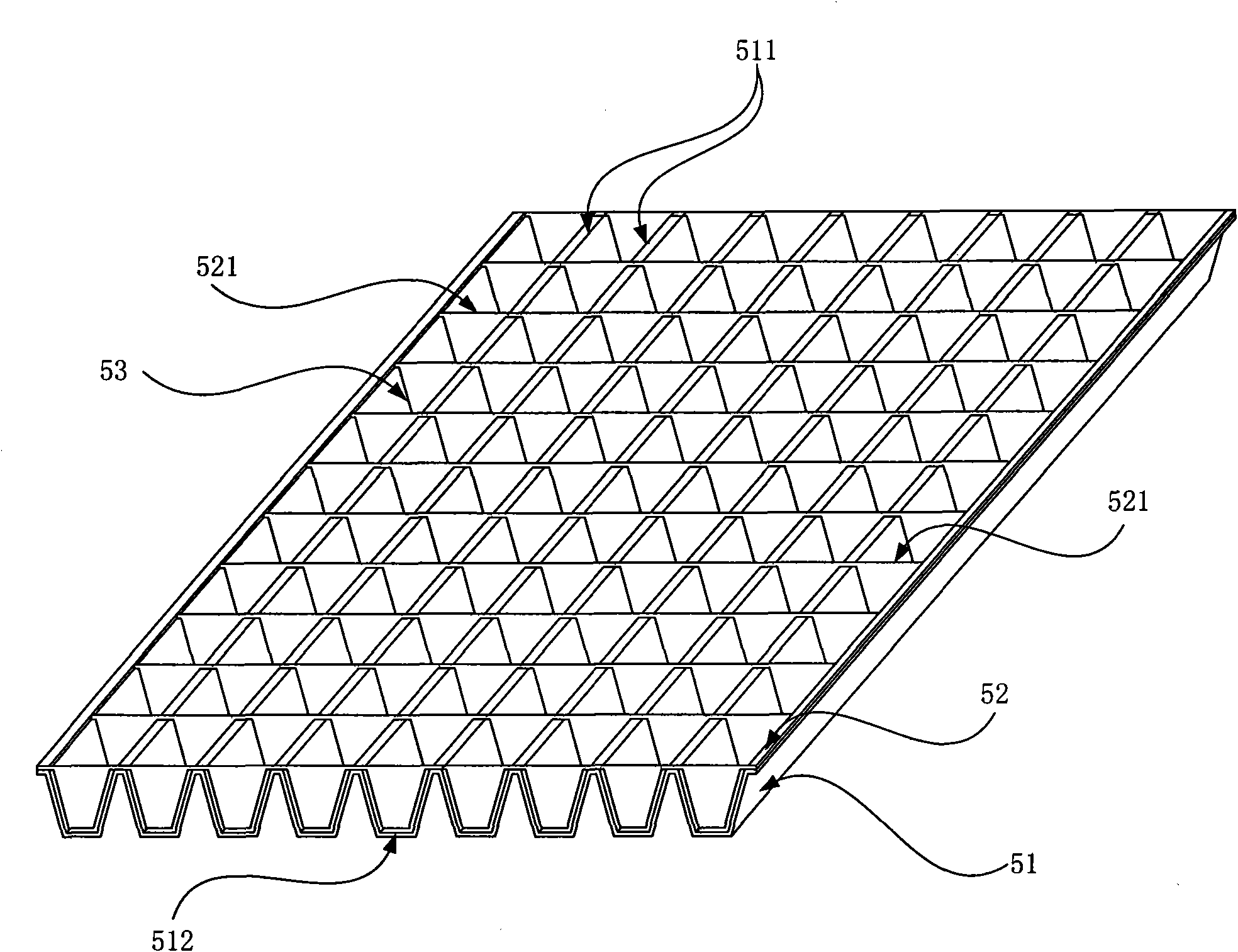

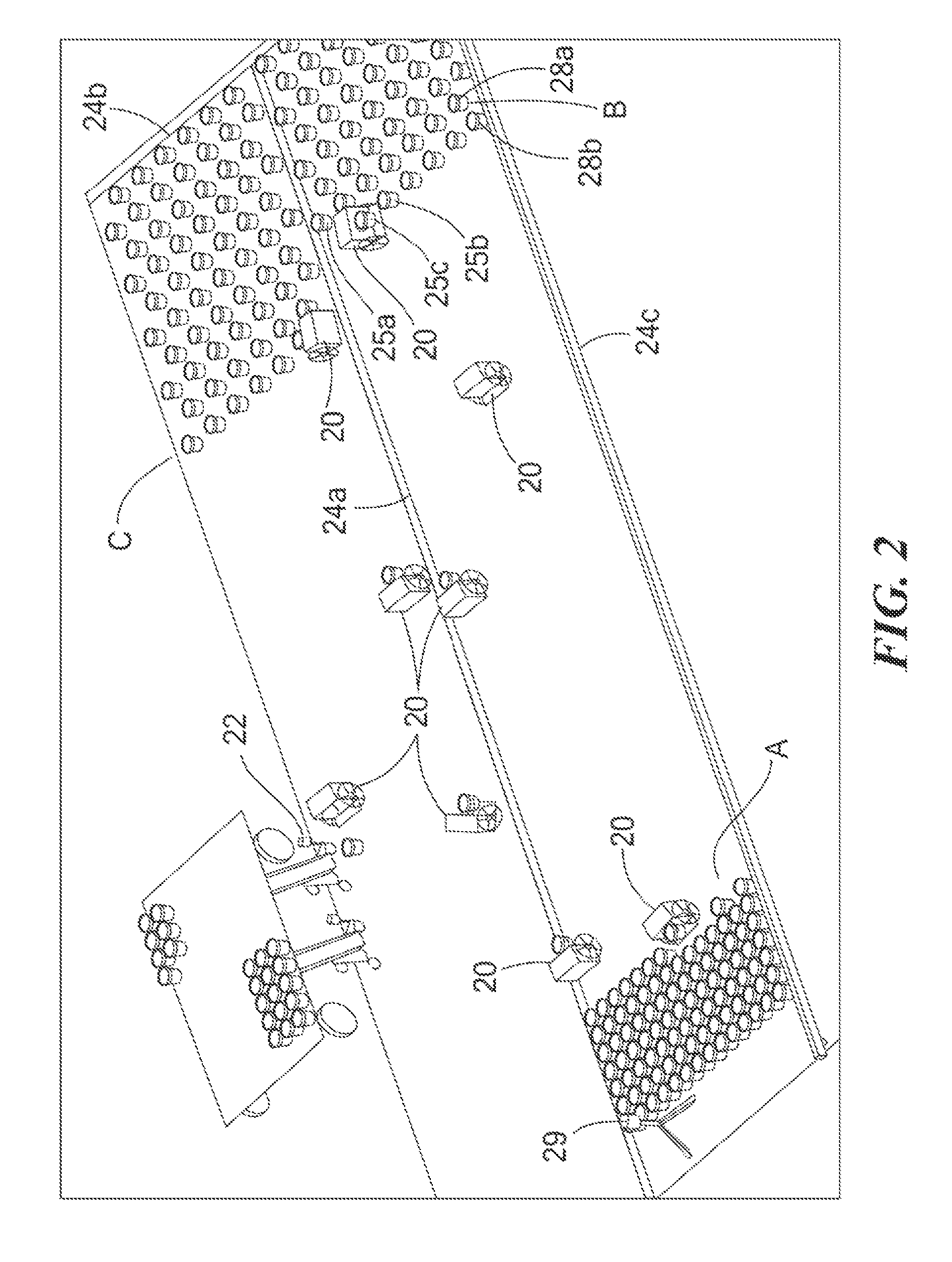

Transplant production system

InactiveUS20060162246A1Efficient productionWeaken energyClimate change adaptationTransplantingTemperature controlInterior space

A system for transplant production comprising: at least one air conditioner installed in a completely light shielding closed structure surrounded by a thermally insulated wall, the air conditioner controlling the temperature and humidity of air in the closed structure; at least one box-shaped culturing module disposed in the internal space of the closed structure, the culturing module having a front face opening which is opened to the internal space of the closed structure; a plurality of transplant production shelves arranged vertically in multi-layer in the culturing module to form a transplant production space between the upper and lower transplant production shelves; a plurality of plug trays for holding a plant growing medium mounted on each transplant production shelf; a sub-irrigation unit capable of irrigation from the bottom of the plug trays mounted on each transplant production shelf; an artificial lighting unit provided on the back of each transplant production shelf, the artificial lighting unit irradiating light to the lower plug trays; and at least one air fan fixed to the back wall of each transplant production shelf of the culturing module. By sucking the air whose temperature and humidity have been controlled by the air conditioner using the air fan from the front face opening of the culturing module and sending the air to the rear of the back wall of each transplant production shelf, temperature-controlled and humidity-controlled air can be effectively generated.

Owner:MKV DREAM

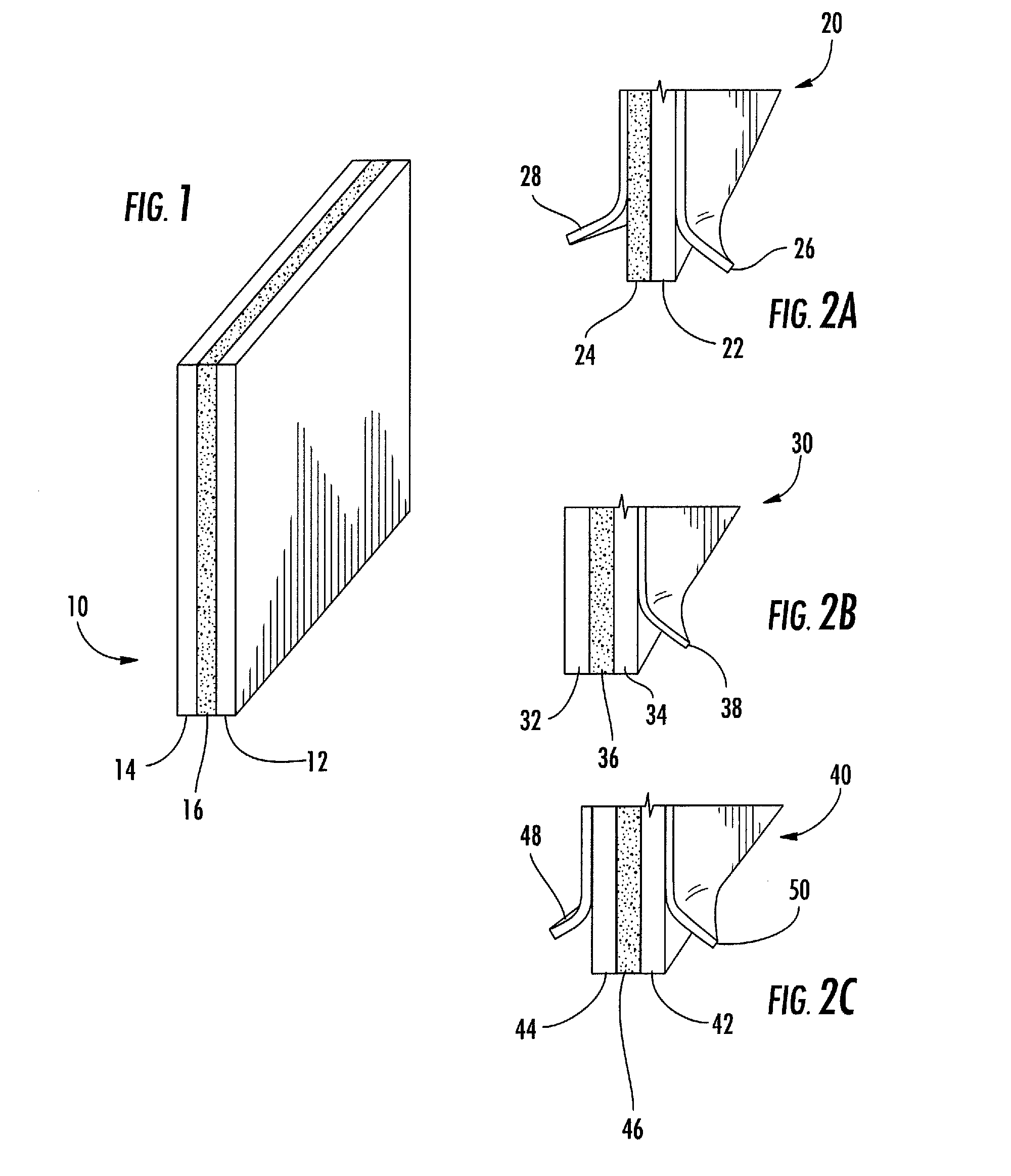

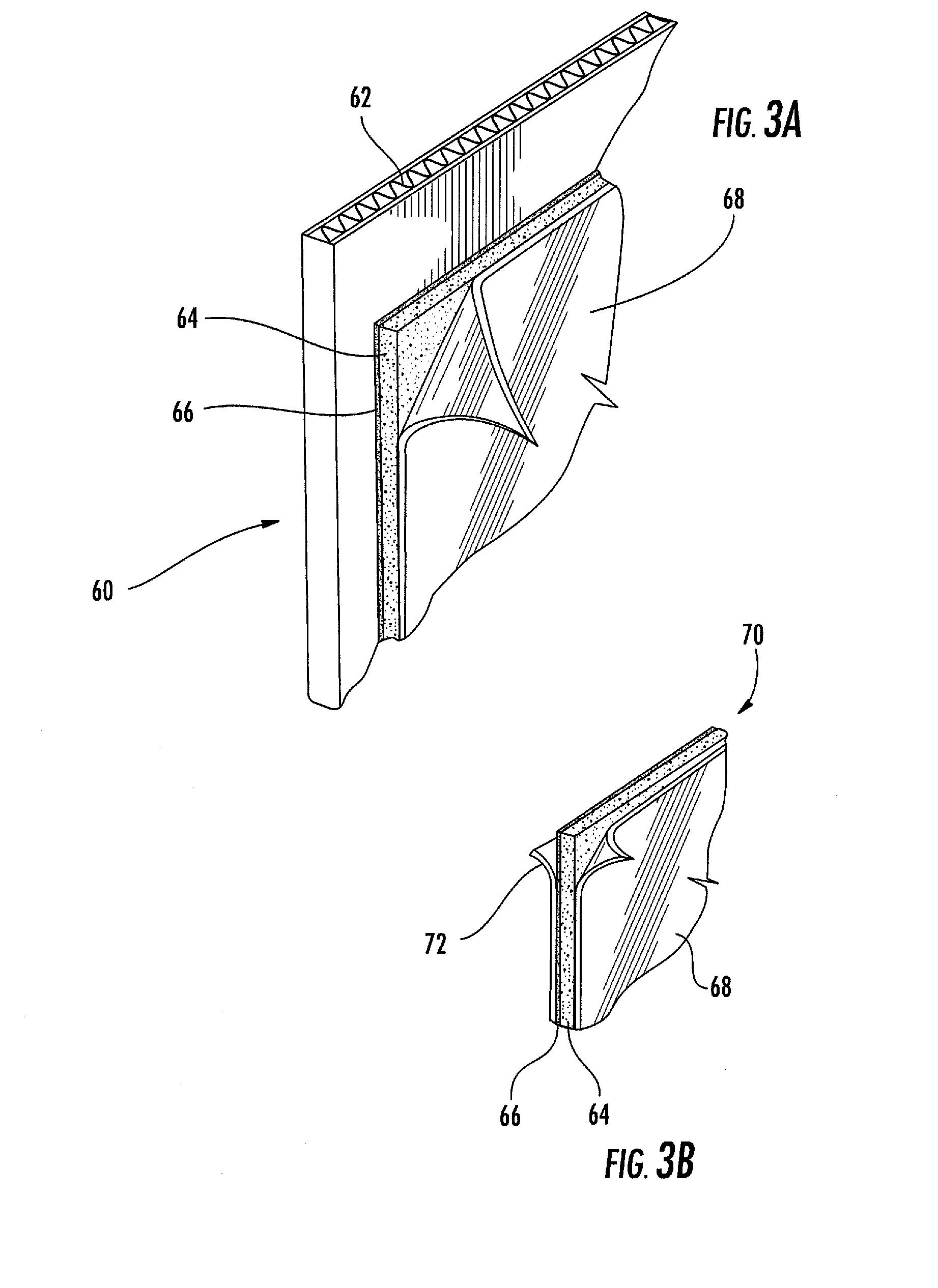

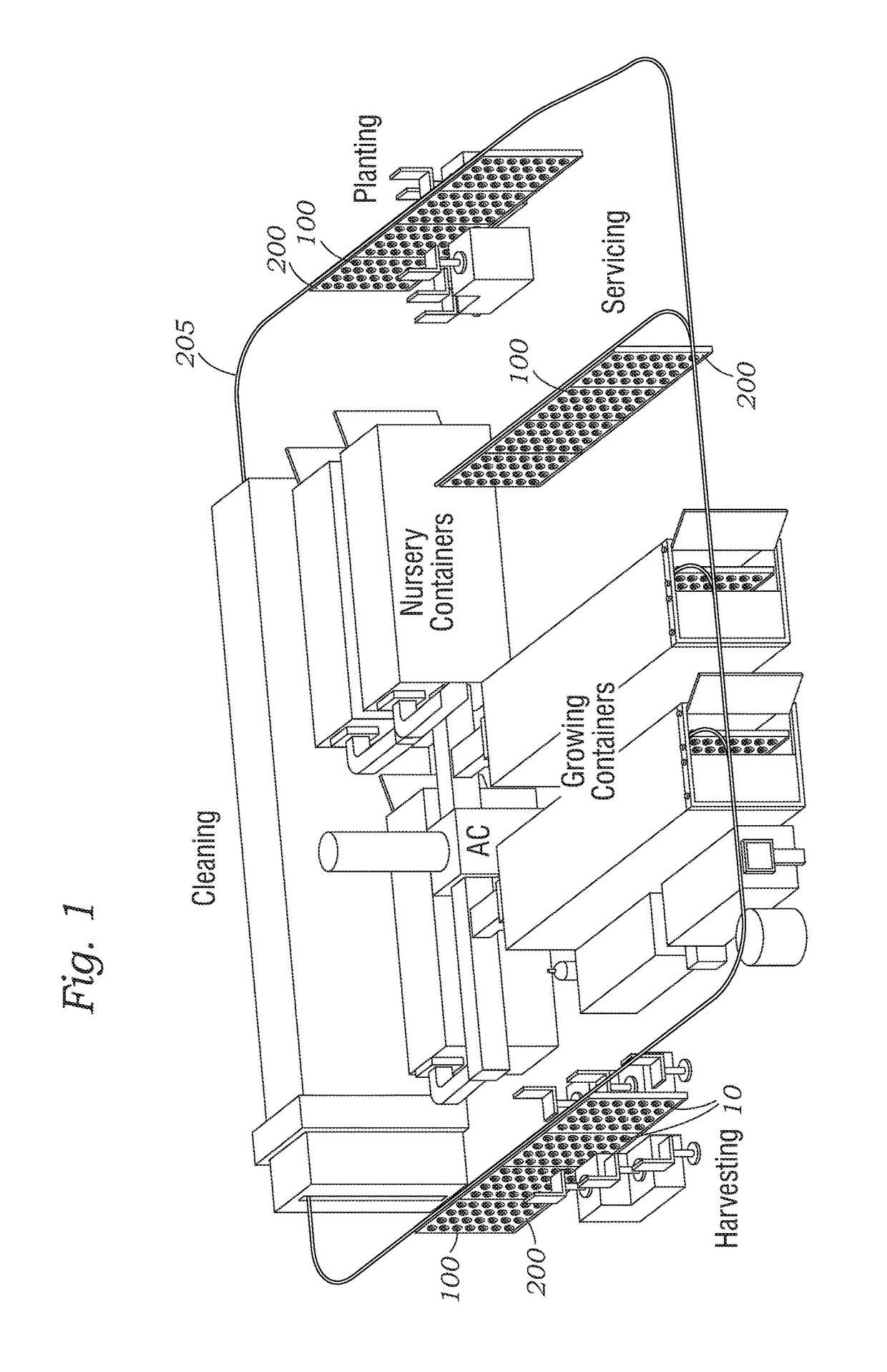

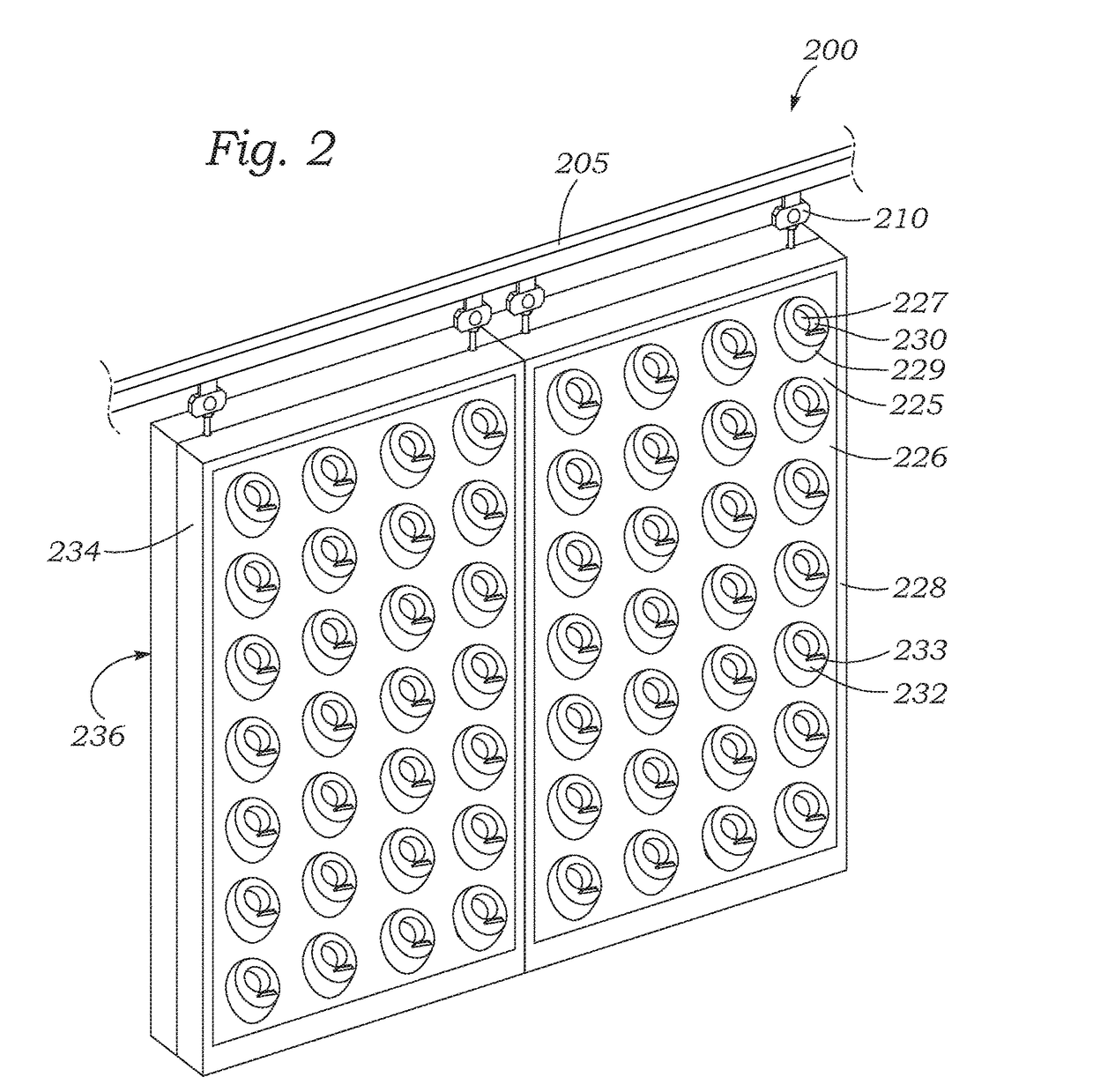

Plant growing systems and methods

A plant growing system comprising a growing panel and a porous air hose coupled to the growing panel. The growing panel includes a plurality of openings for receiving a plurality of plant receptacles. The plurality of openings are arranged in a plurality of parallel lines on the growing panel, and the porous air hose extends along the growing panel between at least two of the parallel lines.

Owner:PROTERRA AG INC

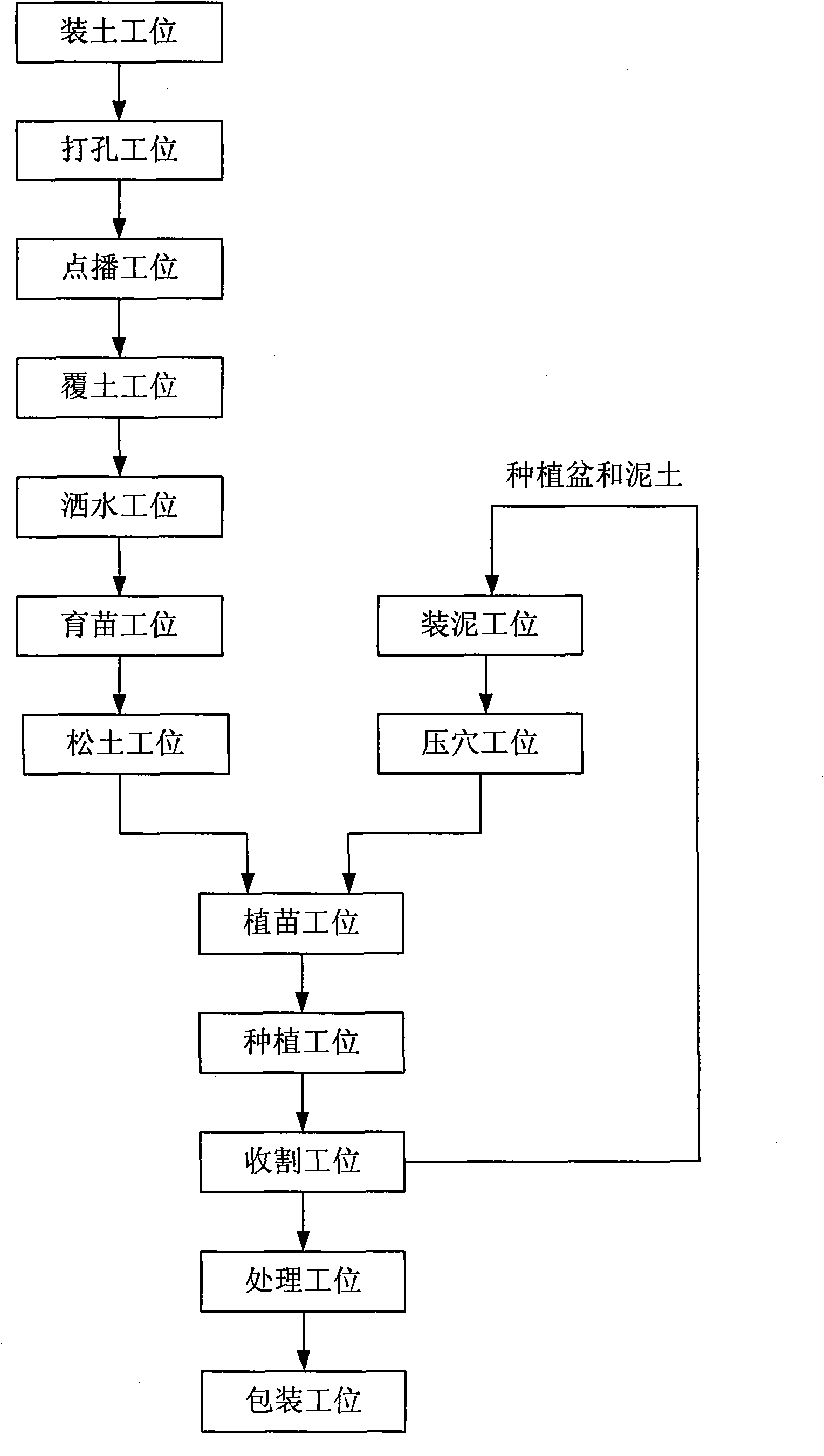

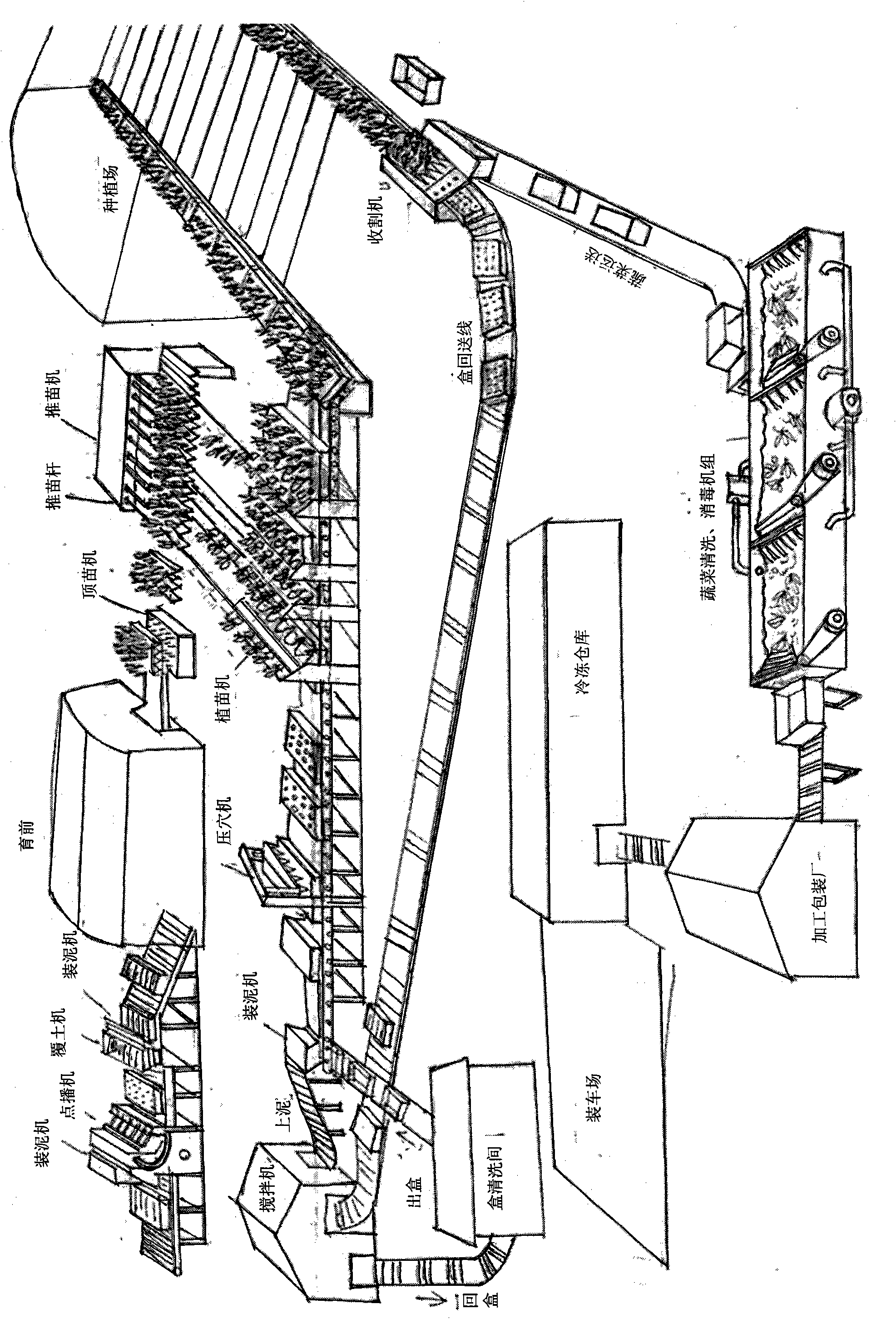

Automatic vegetable cultivation and processing method

InactiveCN102084786AUniform qualityIncrease productivityCultivating equipmentsFlower-pot fillingProduction lineEngineering

The invention provides an automatic vegetable cultivation and processing method, comprising the following steps: a first conveying mechanism loaded with a seedling disc passes through an earth filling station, a hole drilling station, a seeding station, an earth covering station, a watering station and a seedling station; the second conveying mechanism loaded with a seedling disc passes through a stocking station after a seedling loosening station; at the stocking station, a single seedling with earth moves sequentially and directionally; a third conveying mechanism loaded with a planting basin sequentially passes through the earth filling station, an indentation, the stocking station and a planting station, and the planting basin sequentially contains seedlings with earth at the stocking station; a fourth conveying mechanism loaded with the planting basin passes through a harvesting station; and a fifth conveying mechanism loaded with harvested vegetables sequentially passes through a processing station and a packing station. The method combines the planting and growing characteristics of vegetables, and the vegetables are reasonably arranged at each of the stations which are connected through a plurality of conveying mechanisms, thereby forming a continuous working production line.

Owner:林良宪

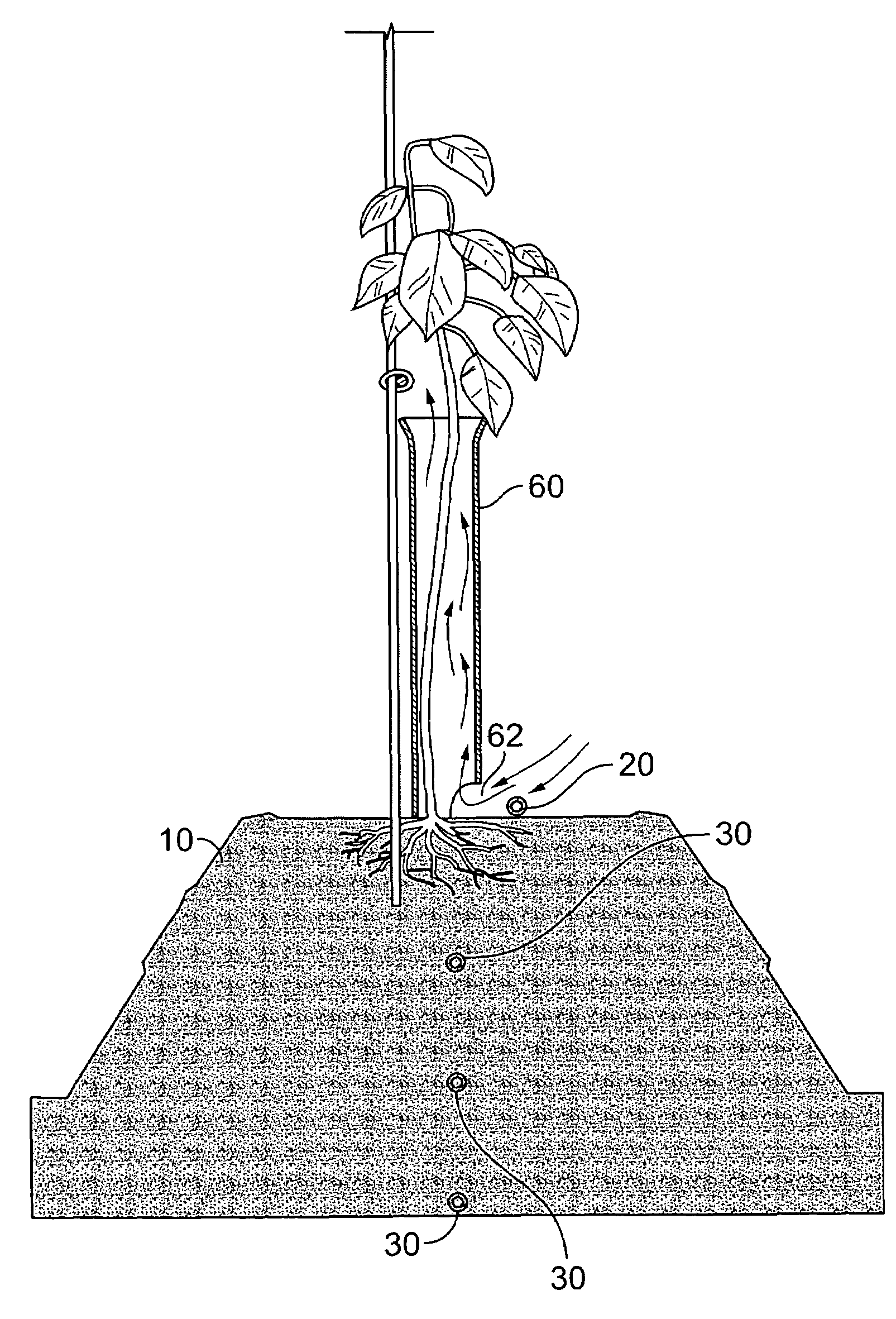

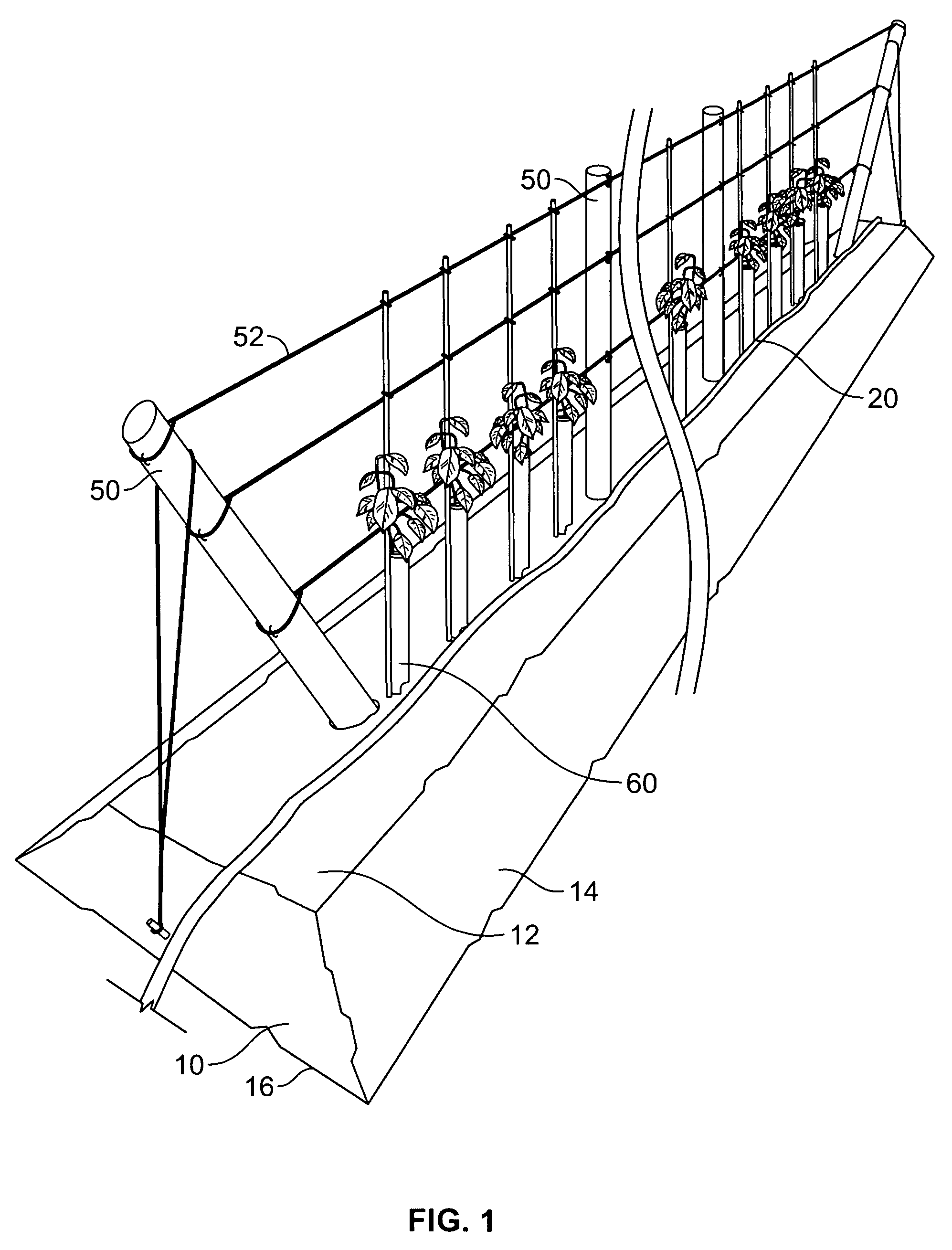

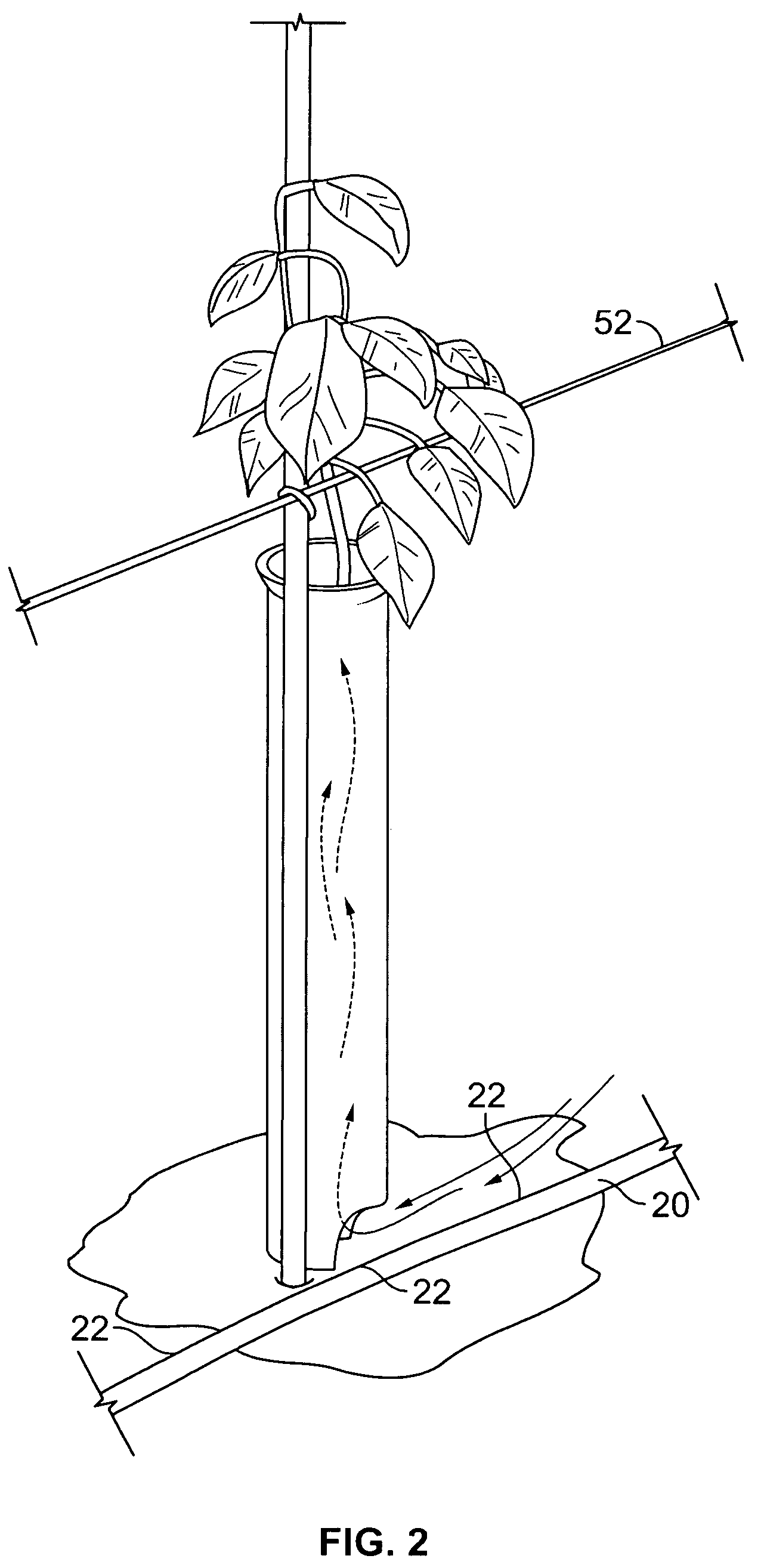

Method of cultivation and components for use therewith

ActiveUS7243459B2Increase productionIncrease planting yieldWatering devicesCultivating equipmentsSupporting systemEnvironment effect

A method and components for cultivation of plant materials. The components include enhanced berms, a confined irrigation / fertigation system, field and plant sensors, a plant support system, overcovering structure and a protective collar. Each of these components used singularly or in combination with each other enhances the growth and yield of plant material decreases the associated costs of cultivation, and decreases adverse environmental impacts.

Owner:FW ENVIRO

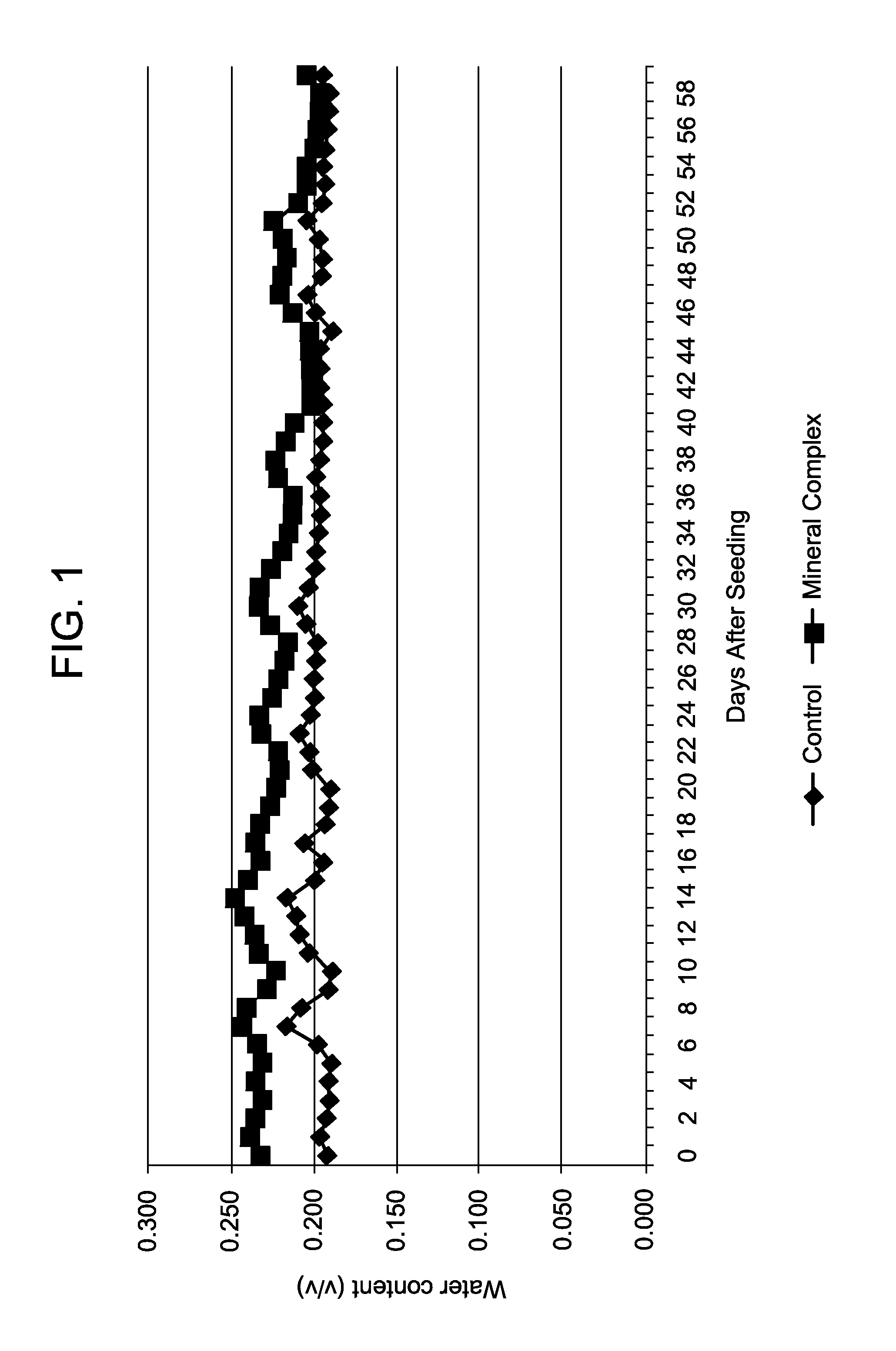

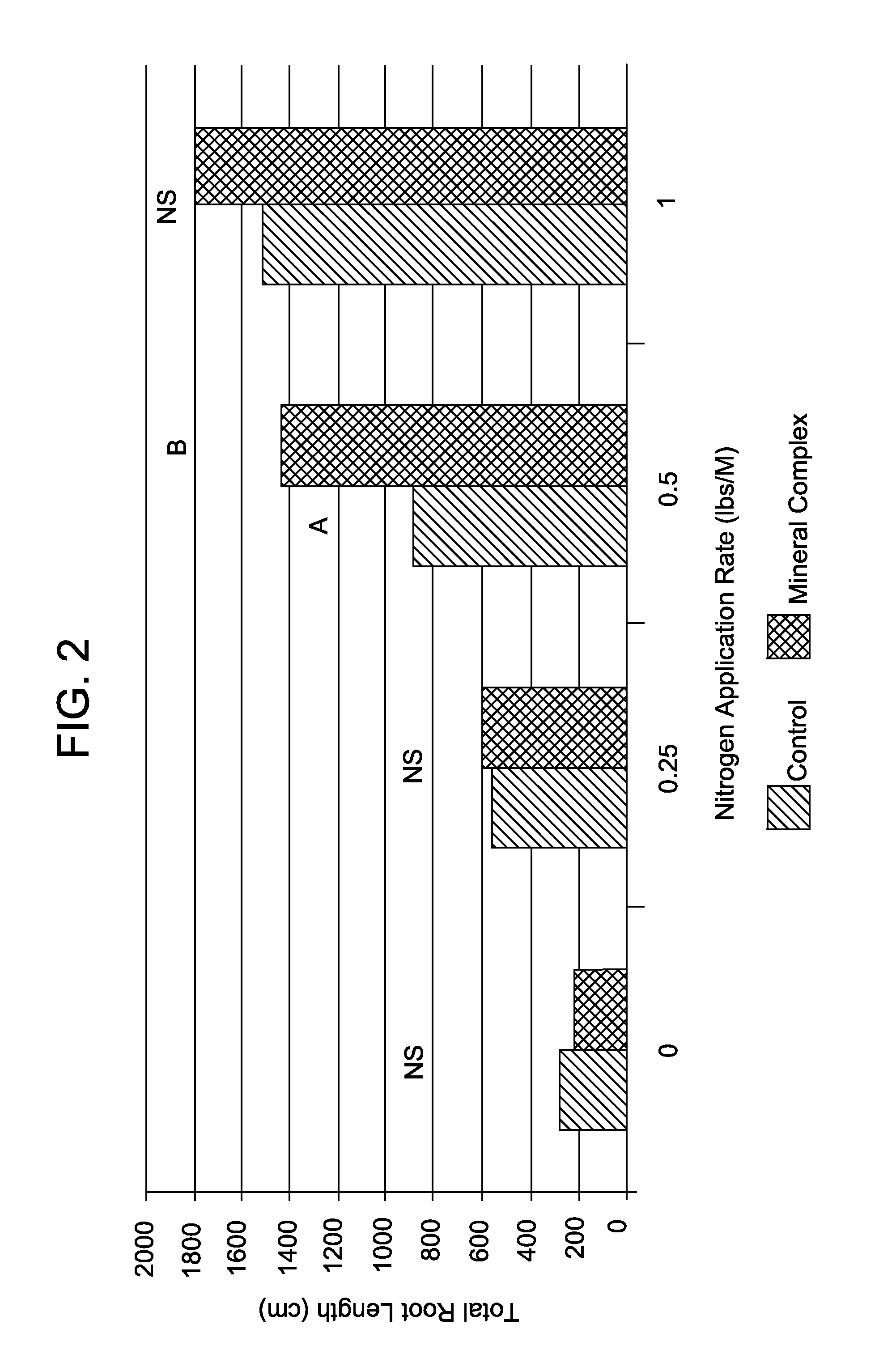

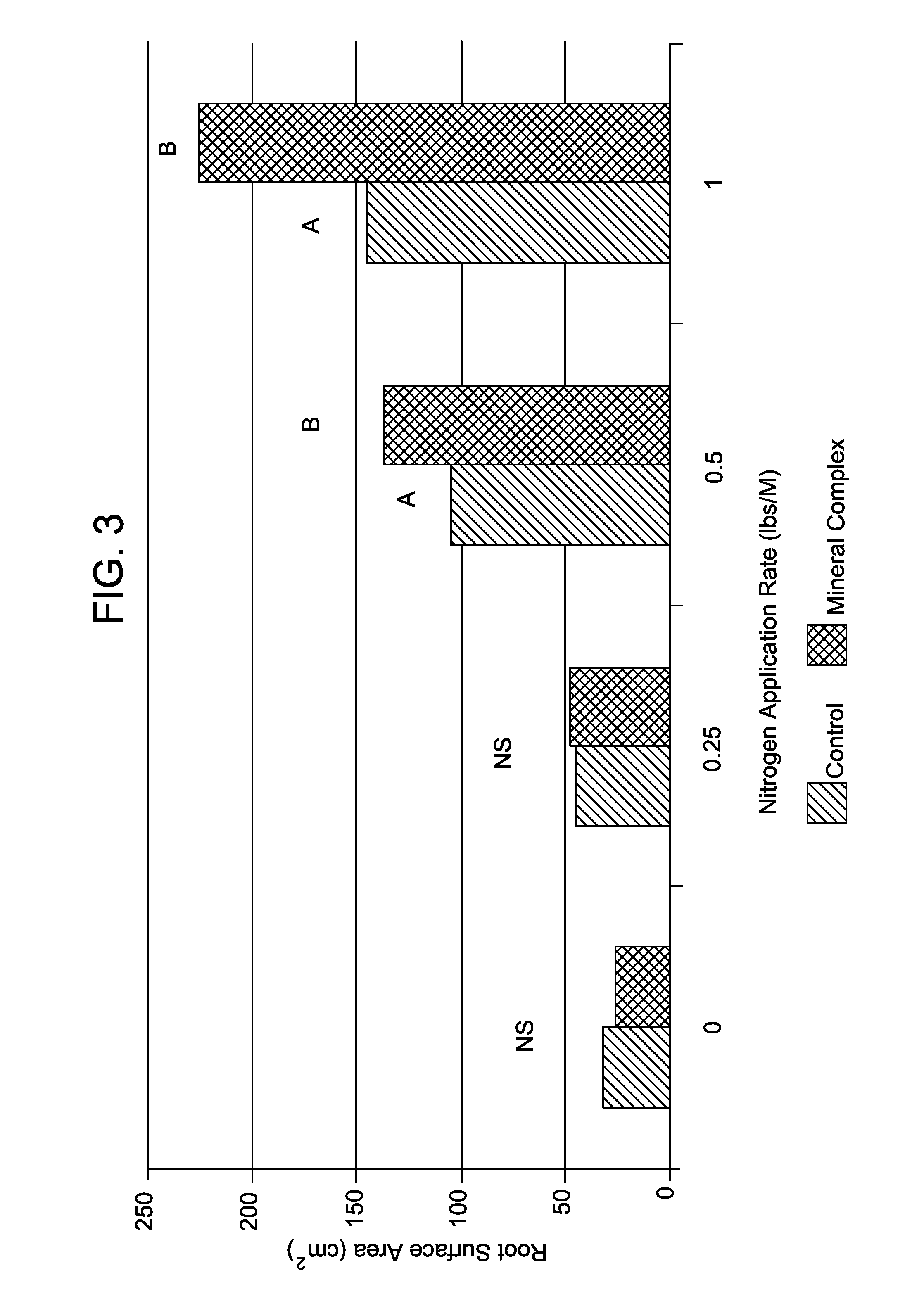

Mineral complex, compositions thereof, and methods of using the same

InactiveUS20110247273A1Good moisturizing effectCalcareous fertilisersMagnesium fertilisersMineralogyGrowth medium

The invention provides inter alia a mineral complex comprising about 40 wt. % to about 60 wt. % SiO2, about 6 wt. % to about 16 wt. % Fe2O3, about 4 wt. % to about 12 wt. %. CaO, about 2 wt. % to about 8 wt. % MgO, wherein at least 85% of the mineral complex has a particle size of about 10 to about 6000 mesh, related compositions and methods for their use, including for growth medium augmentation and remediation.

Owner:AVELIS

Turf additive formulation for reduction of localized dry spots due to water repellency

Certain novel formulations of turf additives that act in such a manner as to permit proper amounts of moisture to contact root systems in order to reduce dry spots within highly managed turf areas and / or lawns. It is theorized that the accumulation of humic acid (and other natural byproduct deleterious compounds) at the topsoil surface in most cultivated grassy areas including sandy soils (such as, in particular, golf greens, pastures, lawns, and the like), as well as other non-grassy sandy areas in which such humic acid accumulation poses water repellency problems (such as beaches), results in the production of an effective organic waxy coating on the soil and / or sand components. Such a coating is hydrophobic in nature and thus dries out the soil itself. The inventive formulation thus permits removal of such accumulated humic acid (and other compounds) from the topsoil to the level necessary to provide effective moisture penetration for sustained grass growth therein (hereinafter referred to as "redistributes"). Methods of providing such beneficial removal of humic substances from target sandy soils are also contemplated within this invention, as well as specific test hydrophobic sand formulations.

Owner:MILLIKEN & CO

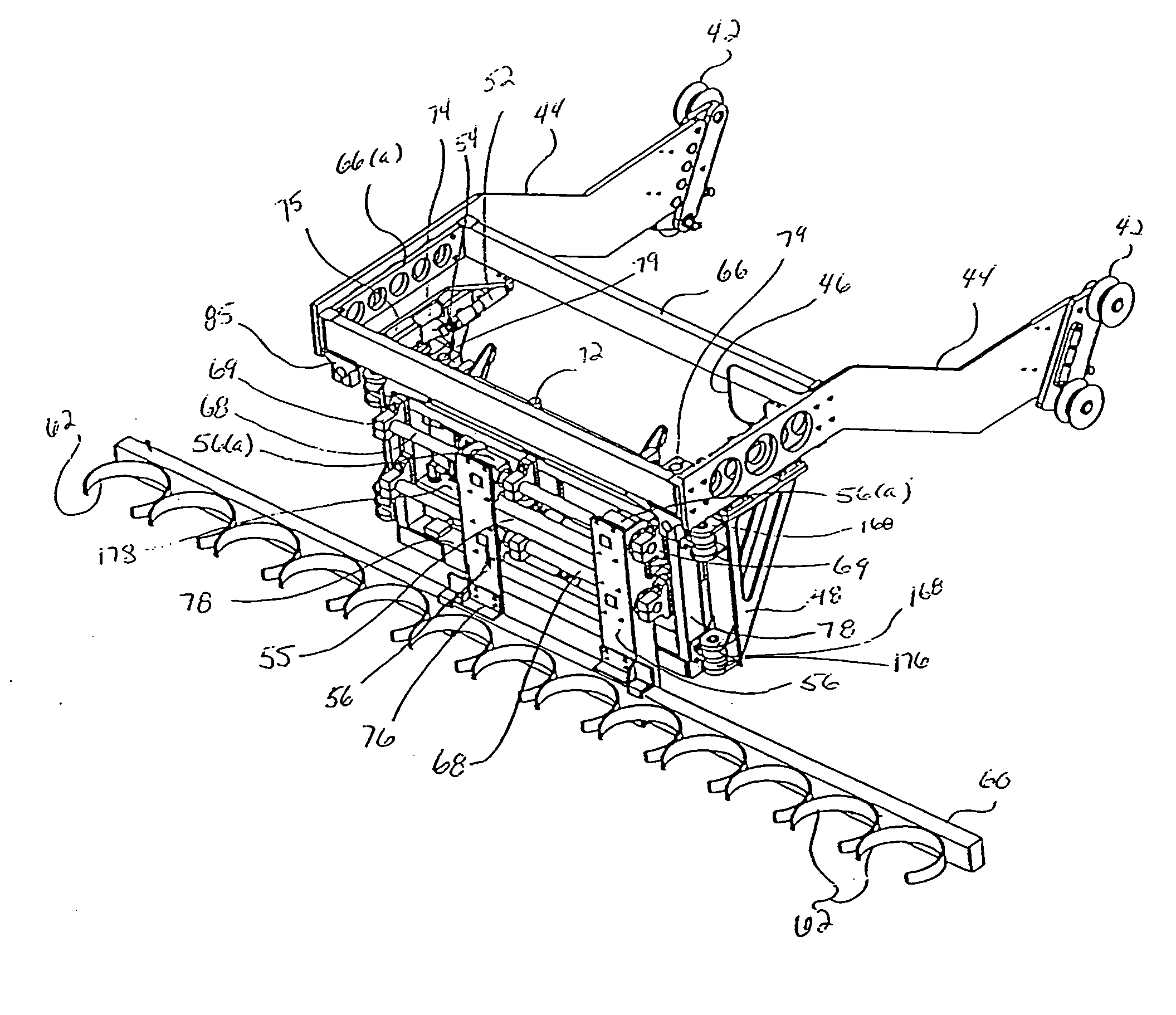

Adjustable tray size automatic seedling planting apparatus

A farm apparatus for automatically planting seedlings that have been sown in growing trays configured with multiple rows of seedling growing cells. Trays may be of various dimensions and seedling configurations. The apparatus may be adjusted in the field to accommodate these different tray sizes and configurations and also provides for adjustment of the planted seedling configuration. The apparatus is drawn by a common farm tractor and is powered by the tractor. In operation the apparatus continuously moves over a growing field while individually extracting seedlings from the trays and planting them in the desired array.

Owner:SENA GIL A

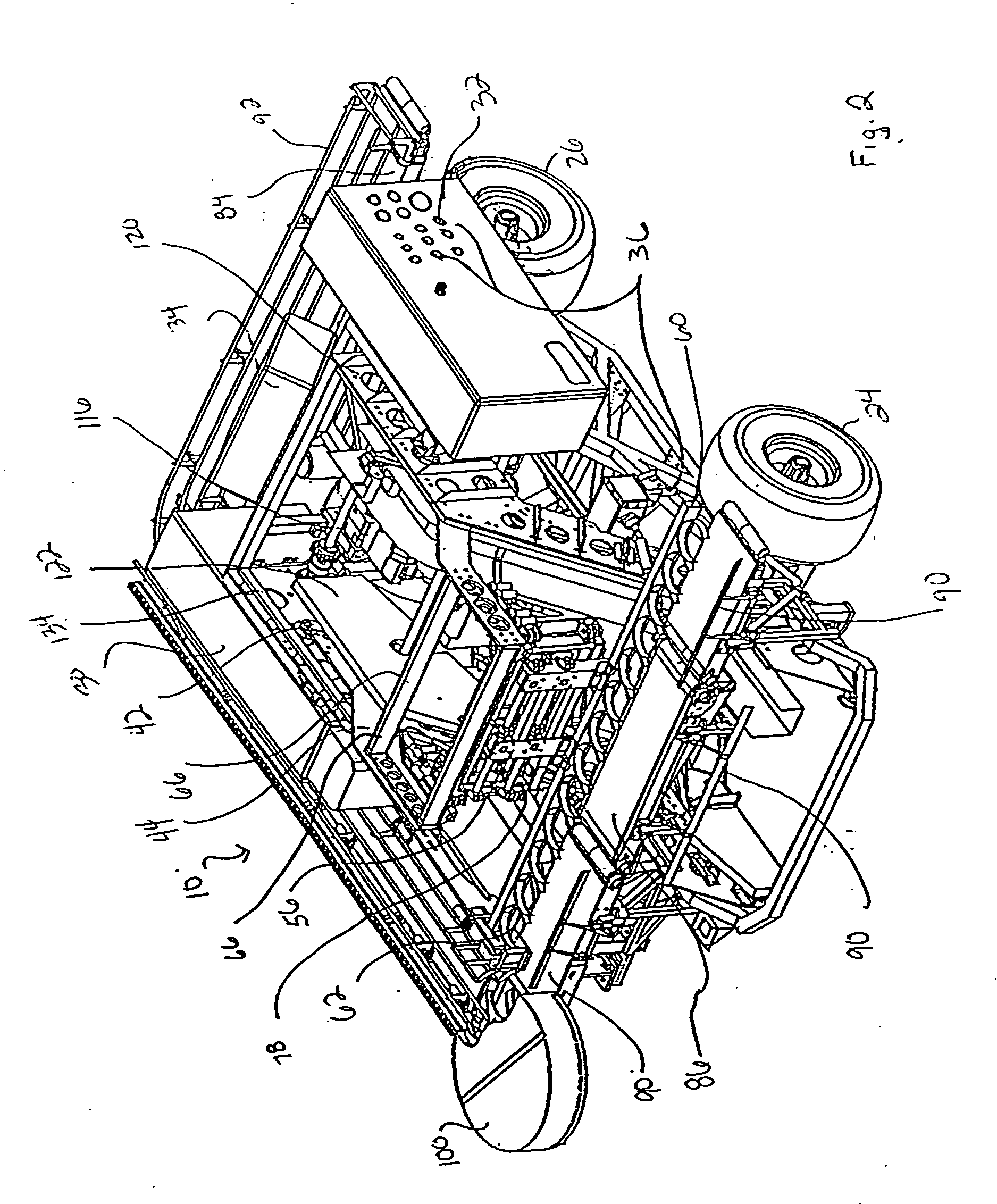

Adaptable container handling system

ActiveUS8915692B2Low costSimple and intuitive operationRailway vehiclesRefuse receptaclesHandling systemSelf adaptive

Owner:HARVEST AUTOMATION

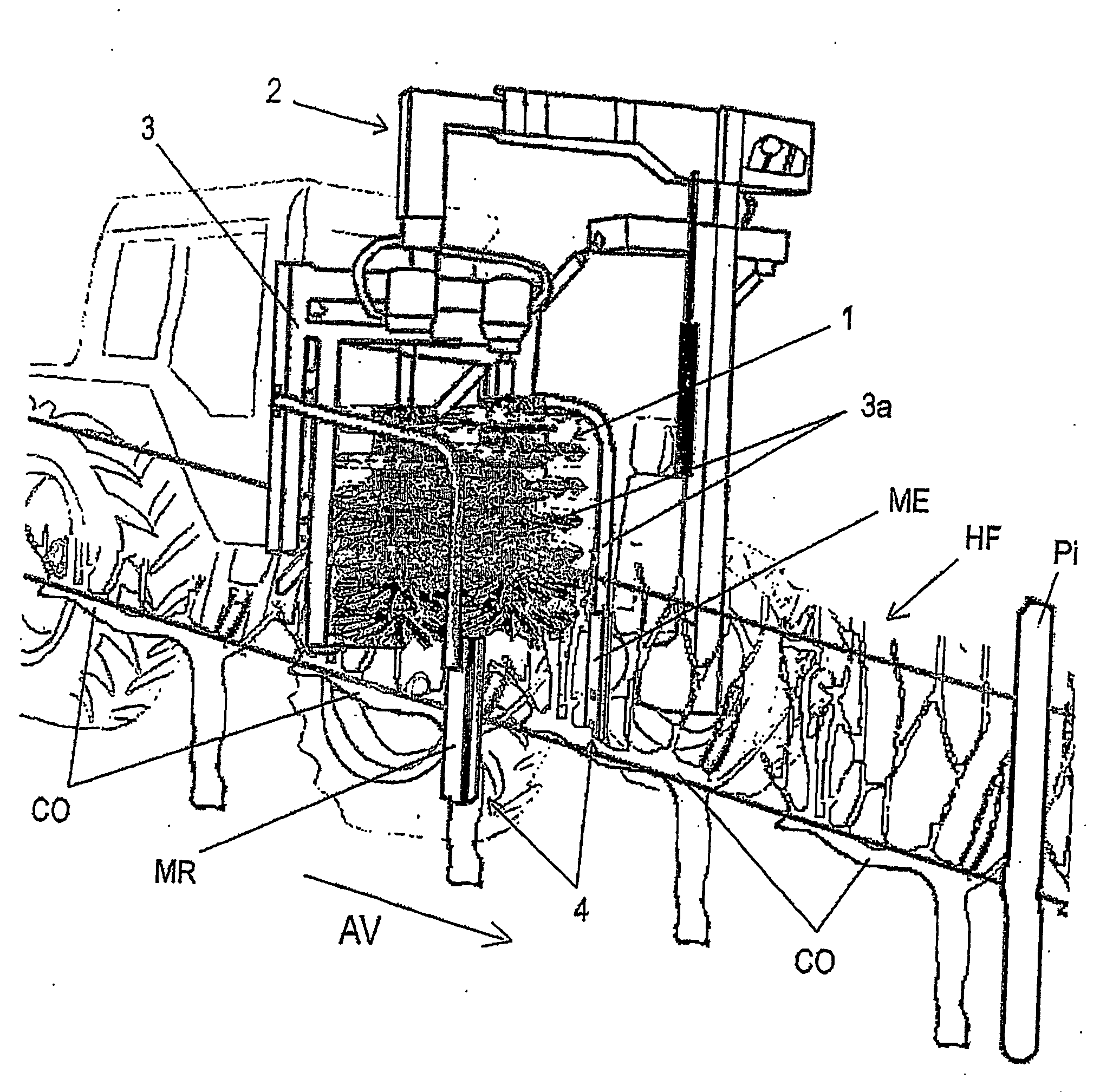

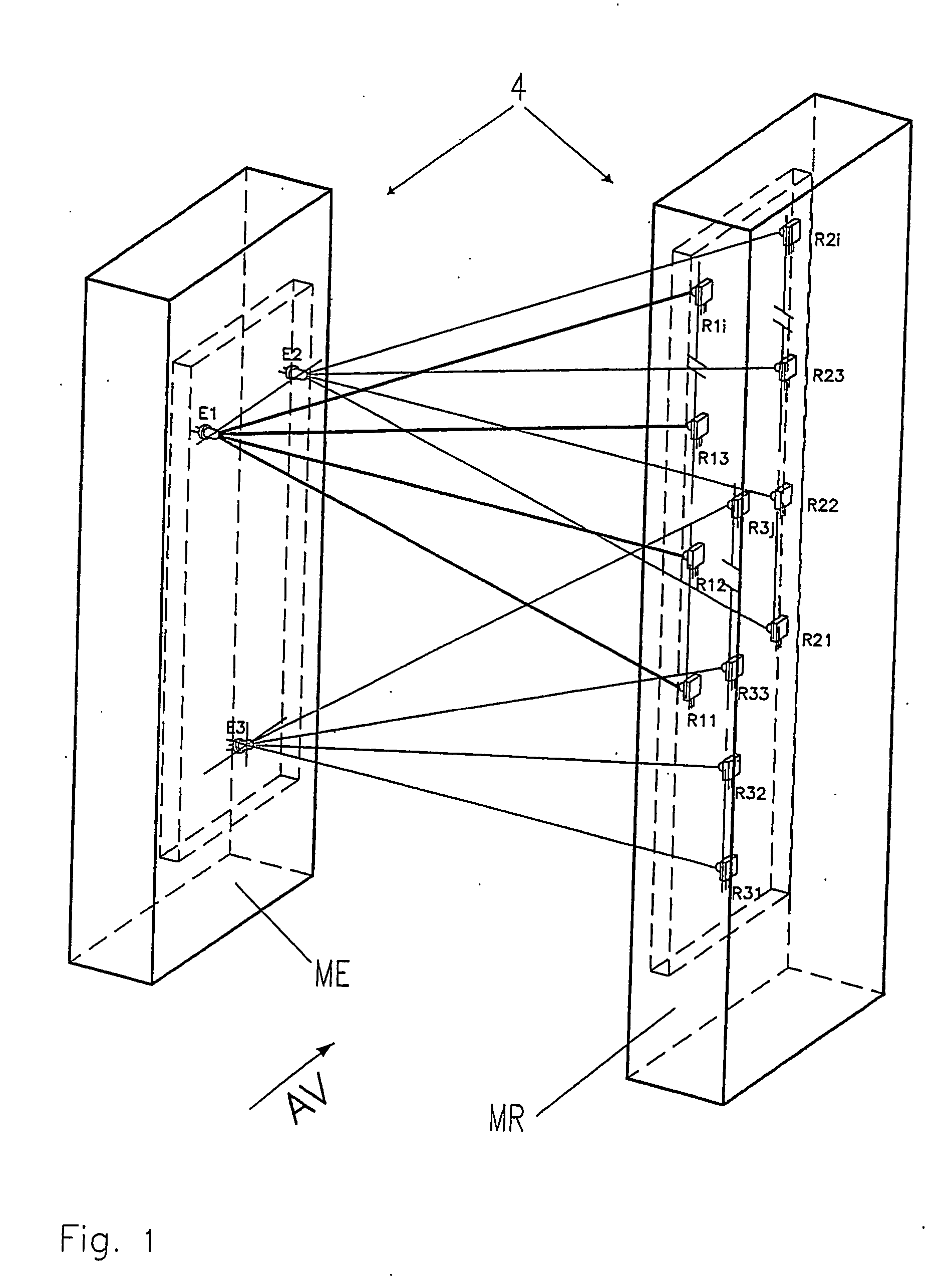

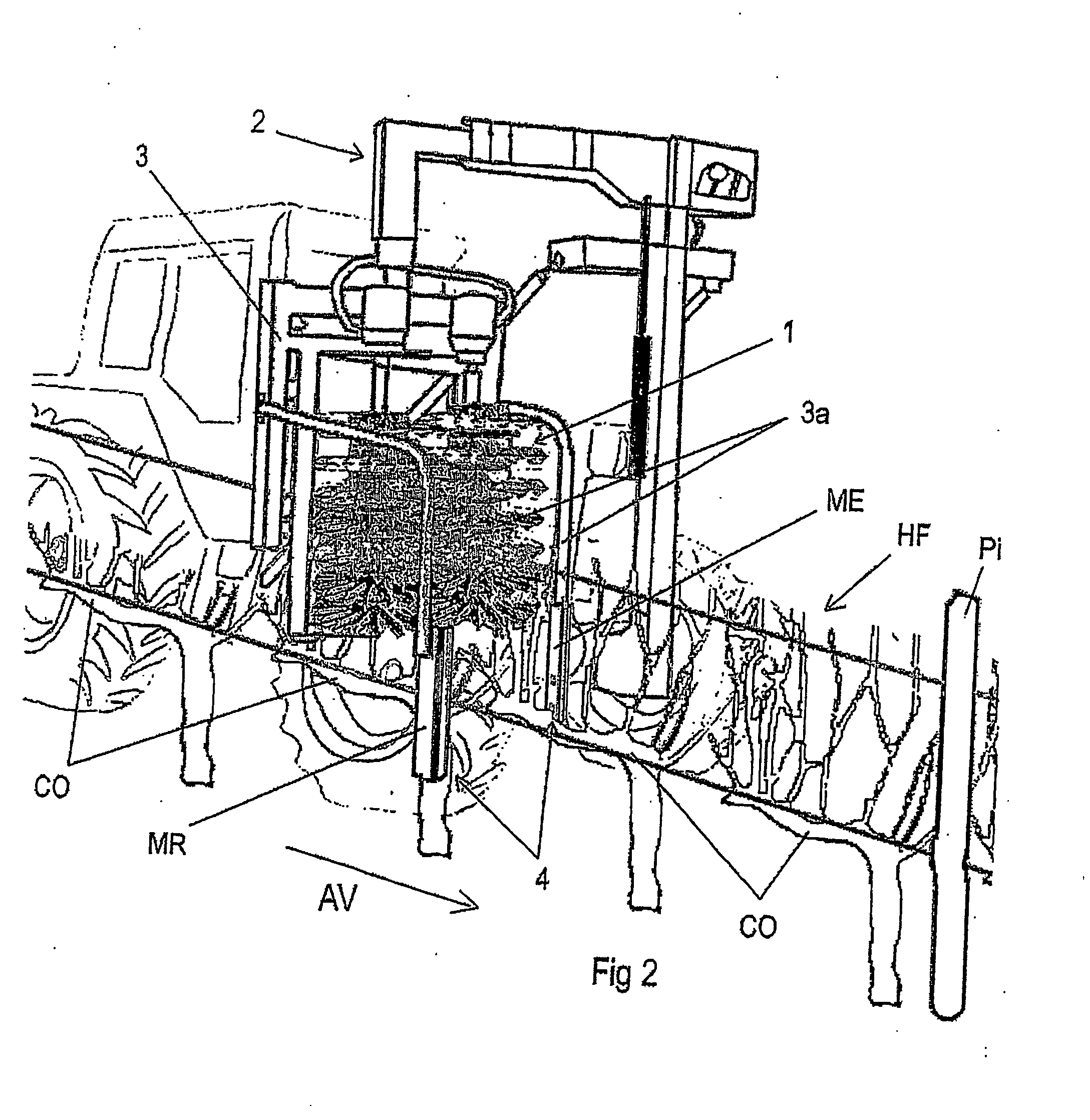

Method and device for analysis of the structure and the composition of cultured hedges such as for example rows of vines

ActiveUS20060272201A1Move fastReduce distracting lightAgricultural machinesHedge trimming apparatusShadowingsEngineering

The method for analysing the structure of cultured hedges, equally applicable by day or by night, for a mobile, continuously-moving machine in tied or staked plantations such as vineyards, includes a system using an artificial vision system, working by transmission, which permits a detection of the shadowing of the light between one or more transmitters and one or more detectors to one side and the other of the hedge. The information generated by said shadows of light are processed by an electronic analysis system, programmed or embodied to examine the elements of the structure of the hedge.

Owner:PELLENC SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com