Automatic transplanter for plug seedling

A technology for transplanting machines and plug seedlings, which is applied in the field of automatic transplanting machines, can solve the problems of complex opening and closing structure of transplanting hands, low degree of automation, poor versatility, etc., and achieves transplanting operations of plug seedlings with simple structure , Practical and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

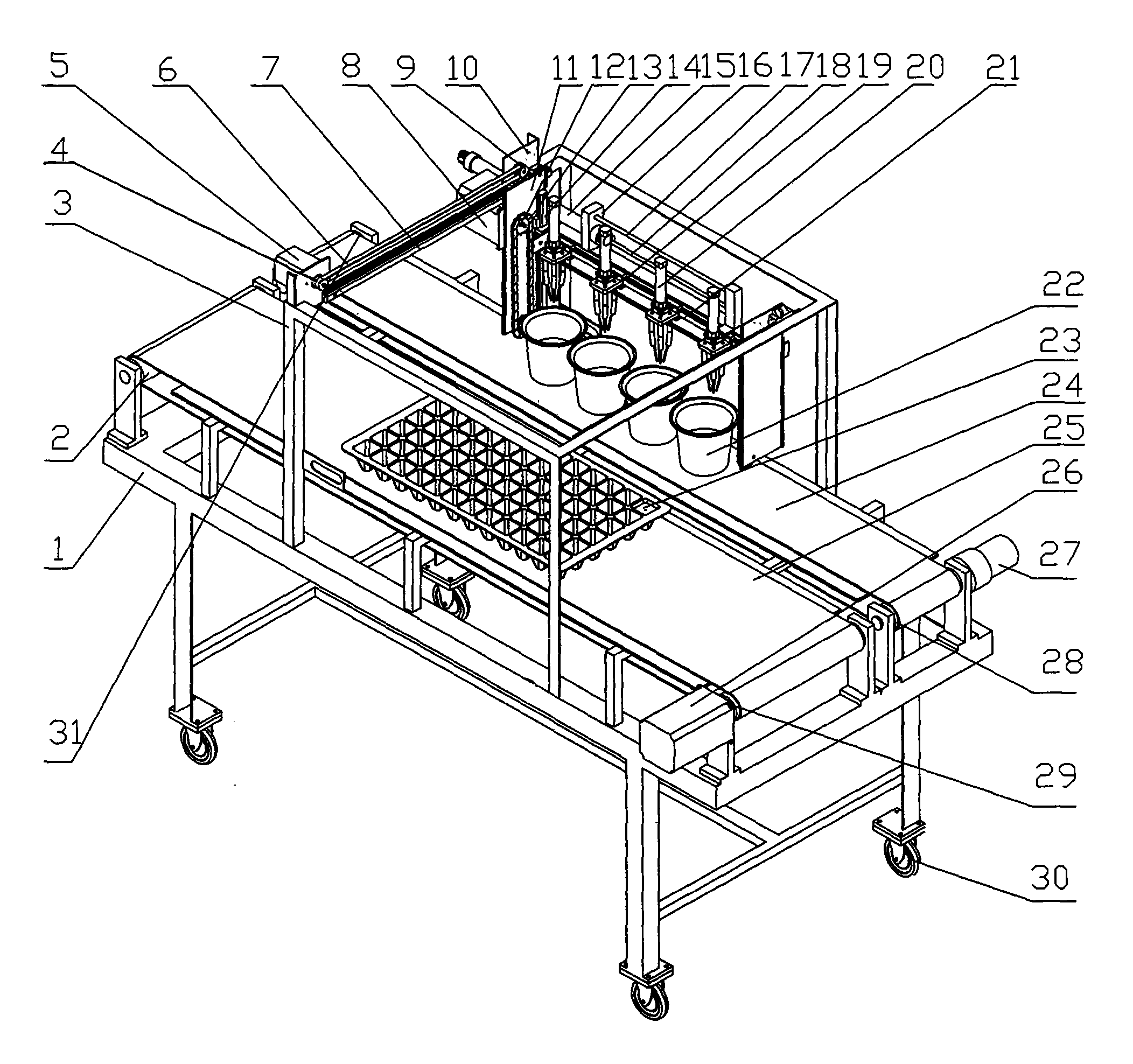

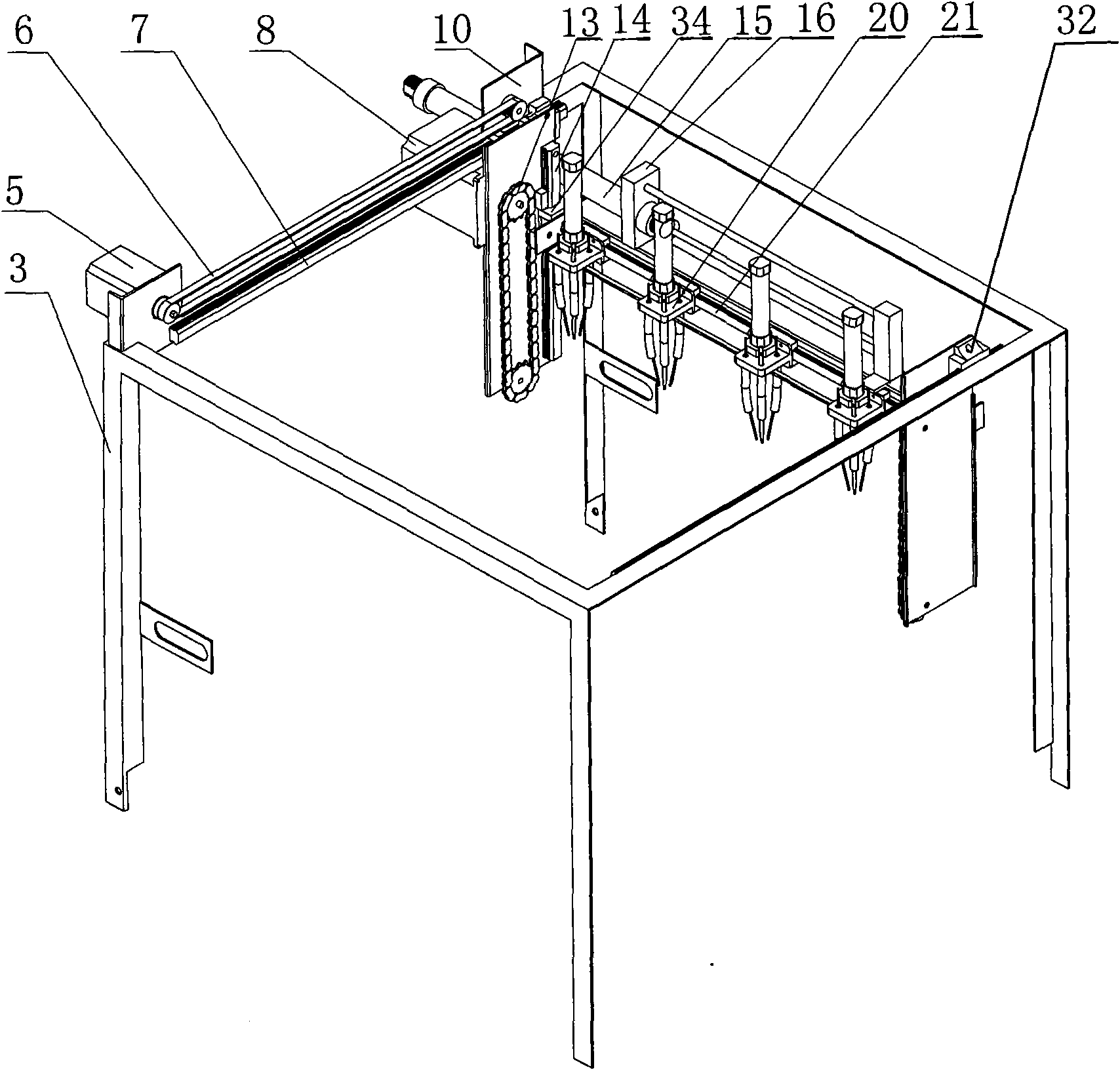

[0023] See figure 1 , the present invention mainly comprises a transplanting manipulator mechanism, a gantry-type mechanical arm mechanism, a seedling tray and a flower pot conveying mechanism and a frame.

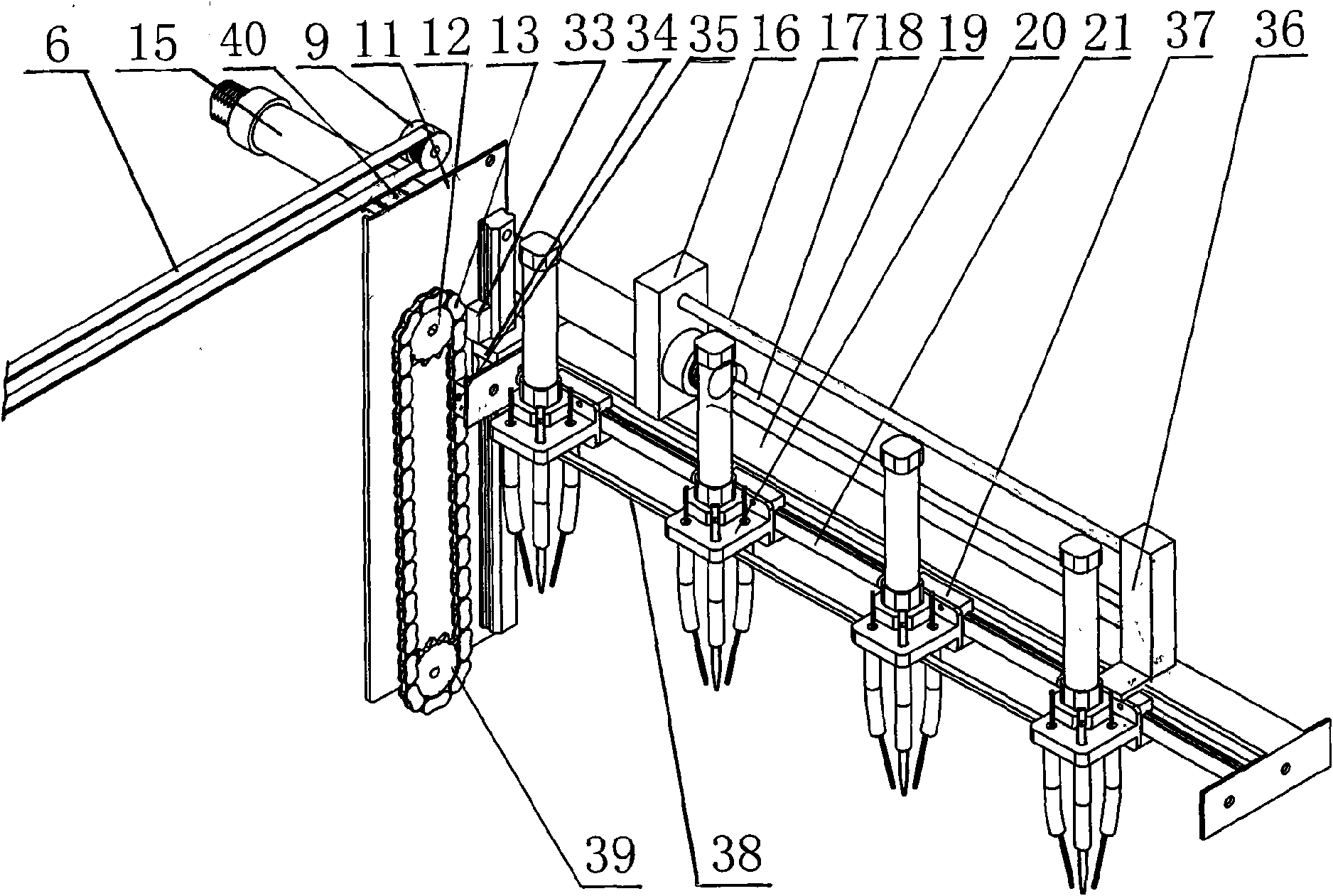

[0024] See Figure 1-3 , the gantry-type mechanical arm mechanism: the mechanical arm horizontal movement guide rail 7 is installed on the inner wall of the arms on both sides of the frame top 3, and the synchronous pulley support plate 10 is fixed on the frame top 3, and the upper part of the synchronous pulley support plate 10 is assembled. Driven belt pulley 4,9, and synchronous belt 6 is assembled thereon, and stepper motor 5 drives and connects driving belt pulley 4. Horizontal sliders 32 are installed on the horizontal movement guide rails 7 of the mechanical arms on both sides, and the horizontal sliders 32 are affixed to the connecting plate 11 of the mechanical arm, and the connecting plate 11 is affixed to the synchronous b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com