Patents

Literature

215 results about "Moisture penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

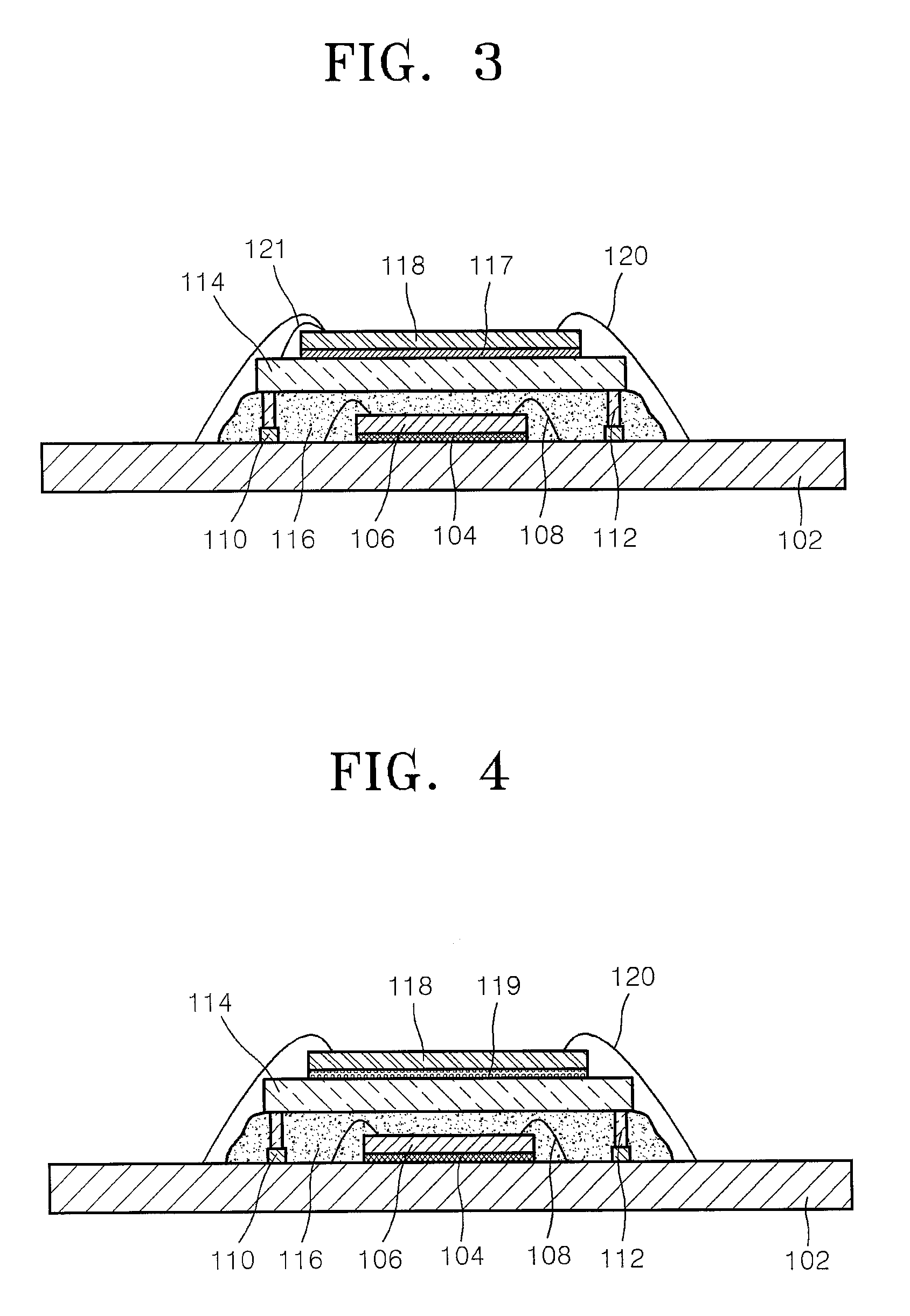

Encapsulating OLED devices

InactiveUS20050248270A1Discharge tube luminescnet screensElectroluminescent light sourcesMoisture penetrationFrit

An encapsulated OLED device includes a substrate having a predetermined glass seal area and defining a sealed region and one or more OLED unit(s) provided over the substrate, each OLED unit having a light-emitting portion including at least one first electrode, at least one second electrode spaced from the first electrode, and an organic EL media layer provided between the first and second electrodes, wherein the light-emitting portion is provided within the sealed region. The device also includes an inorganic protection layer provided over the glass seal area and over at least a portion of the sealed region, a cover provided over the substrate and OLED unit(s), and sintered glass frit seal material provided in the glass seal area and in contact with both the cover and the inorganic protection layer to bond the cover to the inorganic protection layer and provide sealing against moisture penetration into the sealed region.

Owner:EASTMAN KODAK CO

Epoxy coating

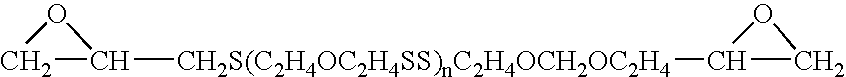

InactiveUS7037958B1Improve adhesionAvoid corrosionLiquid surface applicatorsAircraft carriersEpoxyGlass fiber

This invention concerns an epoxy coating for use as a non-skid surface for applications such as the deck of an aircraft carrier. The epoxy coating can be formulated from (a) an amine curing agent, (b) an epoxide-containing toughening agent such as a polysulfide and / or a polythioether, (c) an epoxy resin, (d) a rubber toughening agent, and (e) an optional fire retardant, a glass fiber thixotrope and impact toughening agent, an optional pigment, an optional corrosion inhibitor, an optional moisture penetration inhibitor, an optional ultraviolet light stabilizer, an optional abrasive aggregate, or a combination thereof.

Owner:TEXAS RES INT

Absorbent sheet exhibiting resistance to moisture penetration

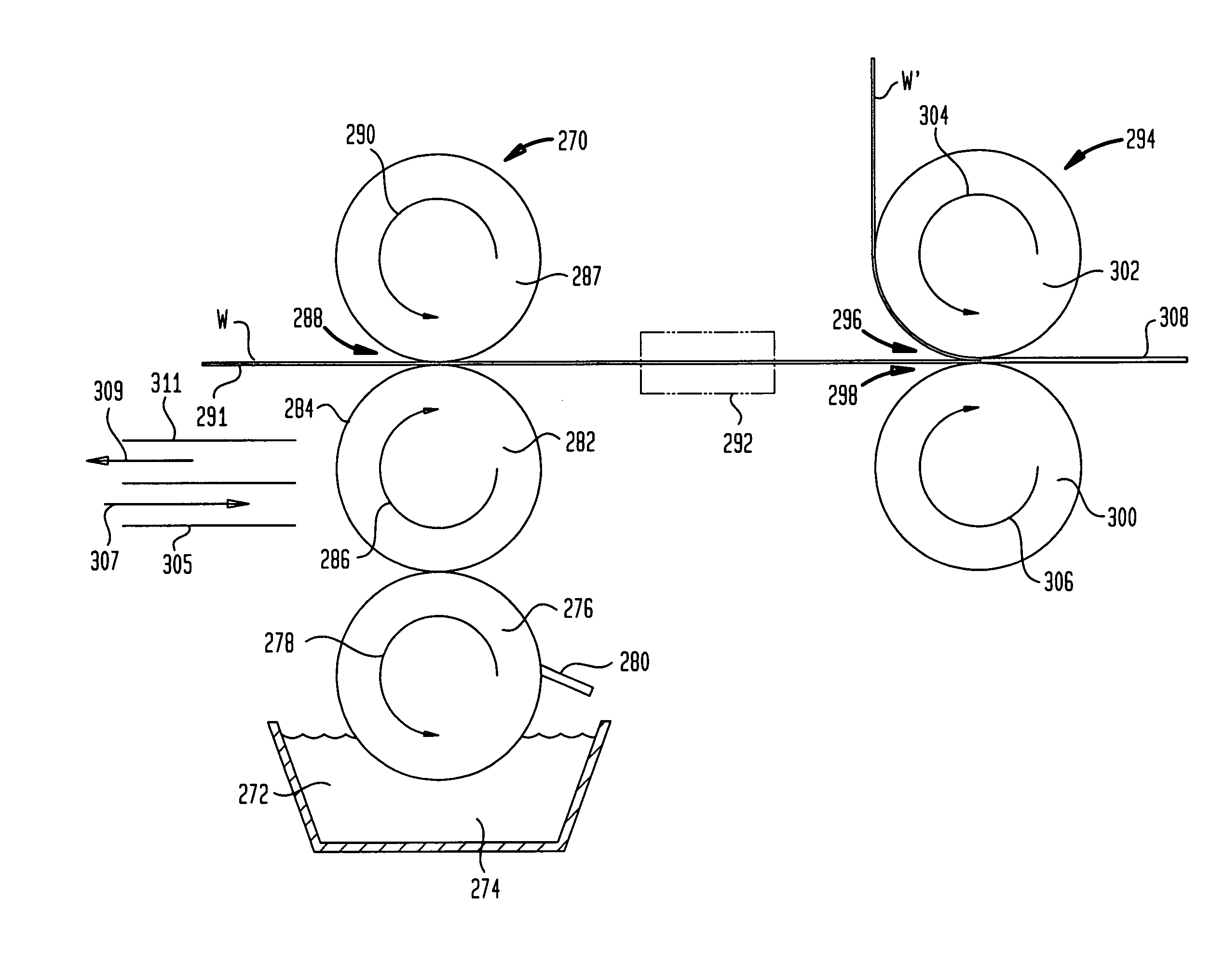

ActiveUS20040250969A1Reduce feelingsReduce wetted areaNatural cellulose pulp/paperMechanical working/deformationWaxFiber

An absorbent paper sheet is treated with an aqueous wax dispersion such that the sheet includes a fused wax and emulsifier residue in an amount of from about 1 to about 20 weight percent of the sheet based on the combined weight of the fiber, wax residue and an emulsifier residue in the sheet. The fused wax emulsion operates to make at least one surface of the sheet laterally hydrophobic, exhibiting a moisture penetration delay of at least about 2 seconds and less than about 40 seconds as well as a typical contact angle with water at one minute of at least about 50 degrees. There is thus provided absorbent products which exhibit both absorbency and resistance to moisture penetration. The treated sheet further exhibits microbial barrier properties, impeding transfer of bacteria, for example, through the sheet. There are produced tissue products which resist moisture penetration from propelled liquids as well as sequester sorbed liquids in the interior of the tissue.

Owner:GPCP IP HLDG LLC

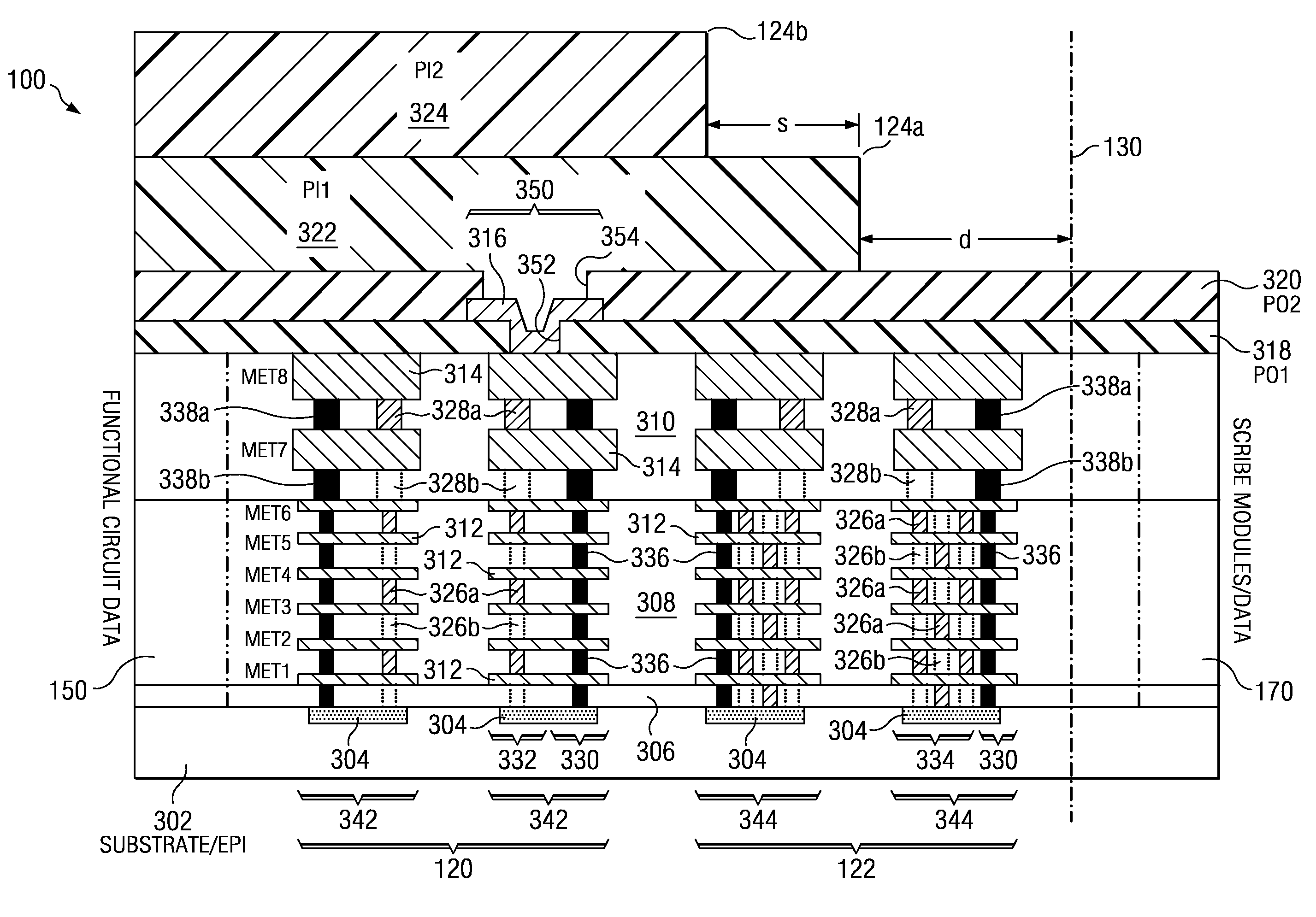

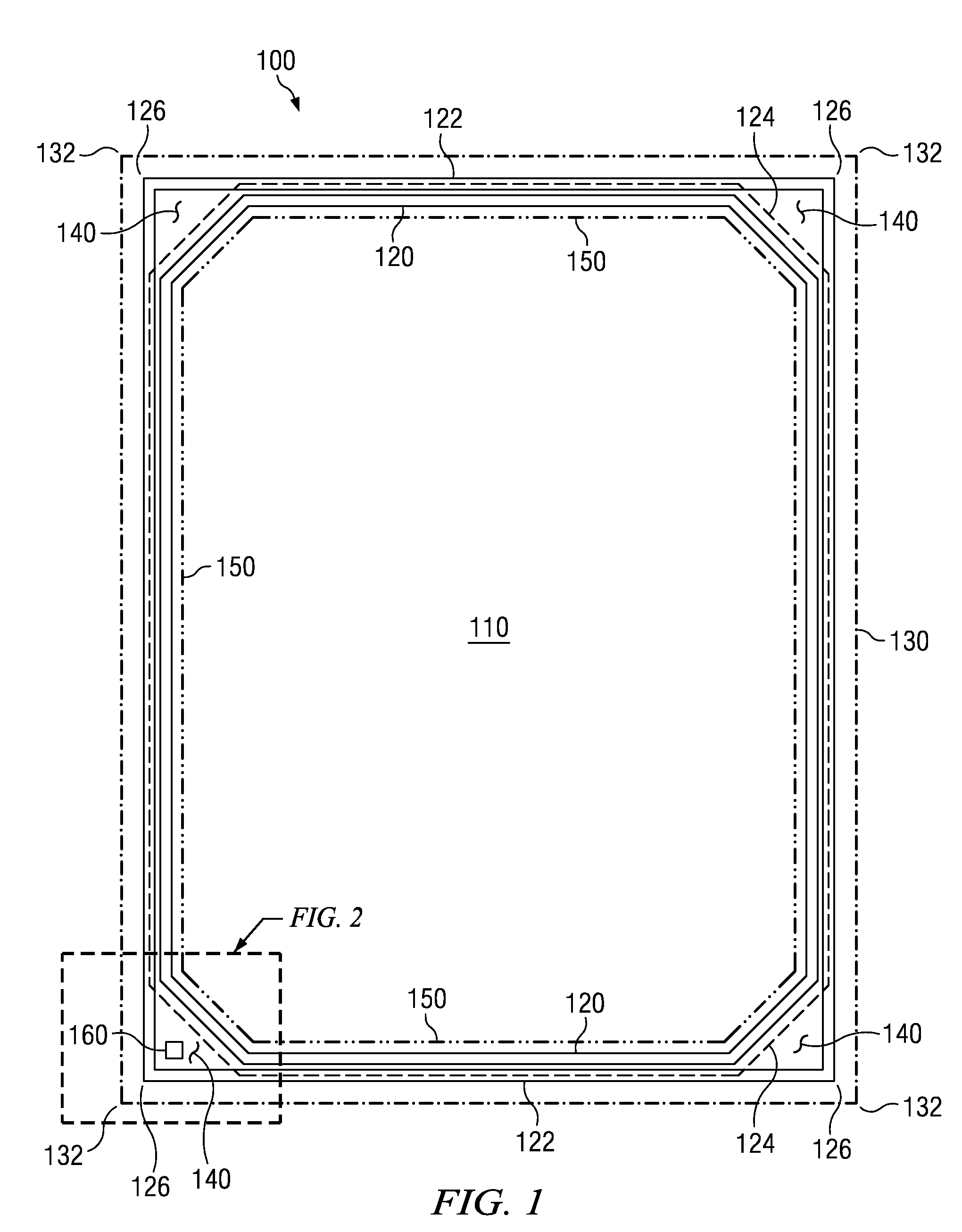

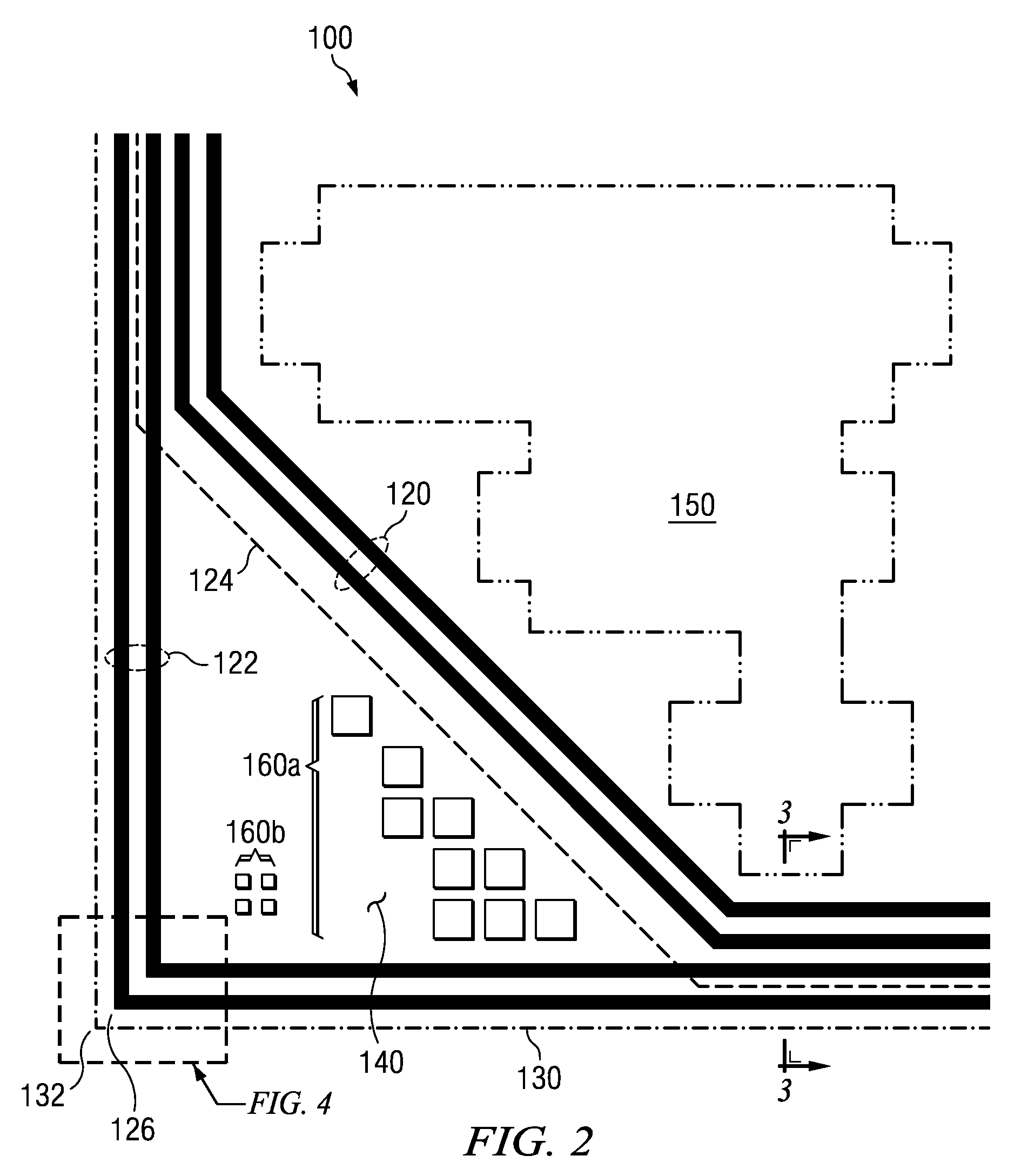

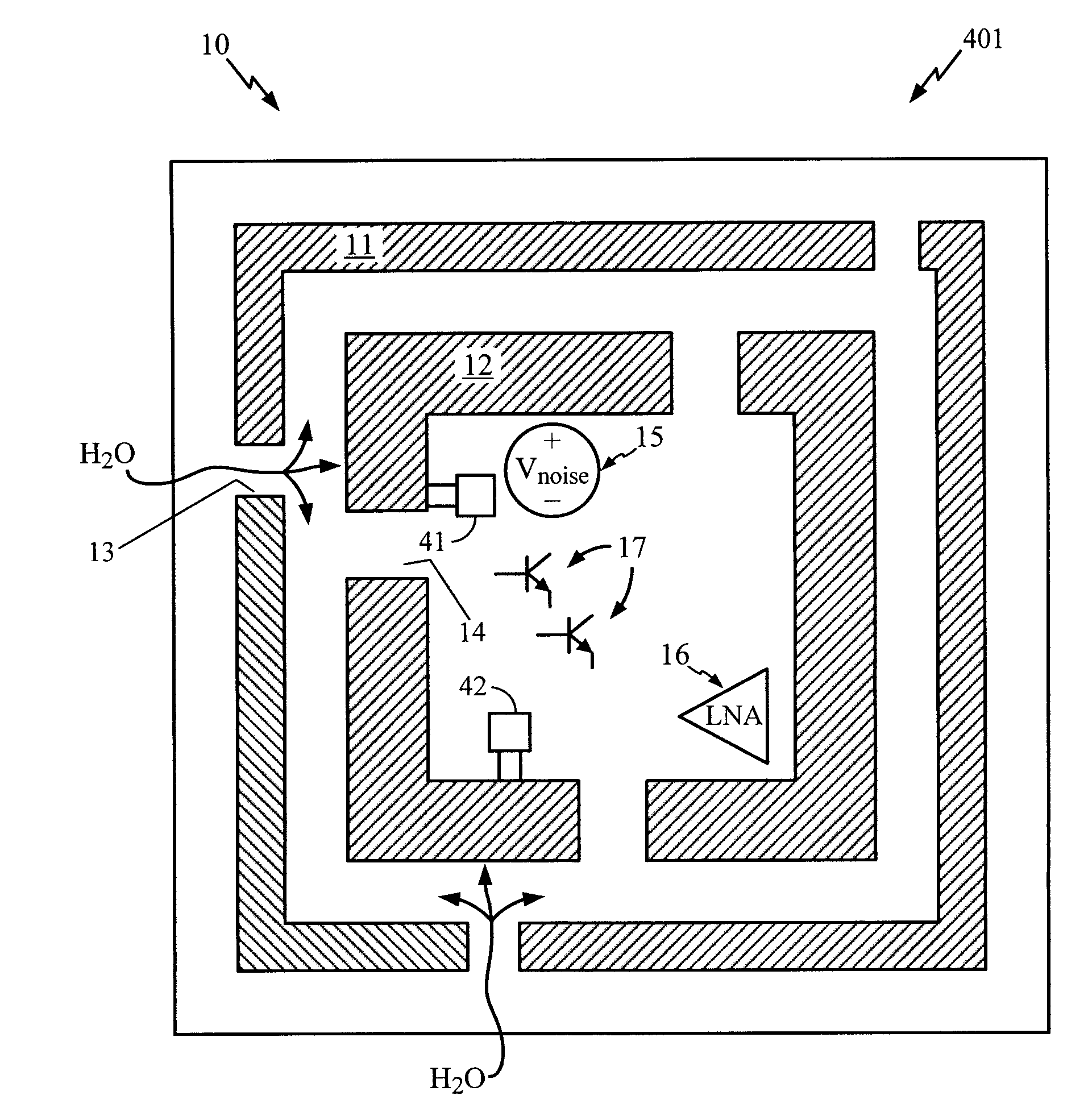

Environmental die seal enhancement for wafer level chip scale packages

ActiveUS20100078769A1Improve barrier propertiesImprove strength propertiesSemiconductor/solid-state device detailsSolid-state devicesMoisture penetrationEngineering

In a semiconductor device for use in a wafer level chip scale package (WLCSP) and a method for fabrication, an inner scribe seal is formed around a functional circuit area that does not extend all the way into the corners of the rectangular die, and an outer scribe seal follows the perimeter of the die and into the corners, with the outer scribe seal having a continuous barrier wall towards the die edges so that moisture penetration in dielectric layers of the die is minimized, and cracks and delamination are stopped near the die edges. Limiting the extent of the insulating layer or layers in the WLCSP to cover the functional circuit area also reduces the stresses caused by these layers near the die corners. Other features further enhance the strength and barrier properties of the scribe seals and the layers near the die corners, terminate cracks and delamination at various levels within the dielectric stack of the die and the die protective overcoat, and prevent damage during the WLCSP assembly process.

Owner:TEXAS INSTR INC

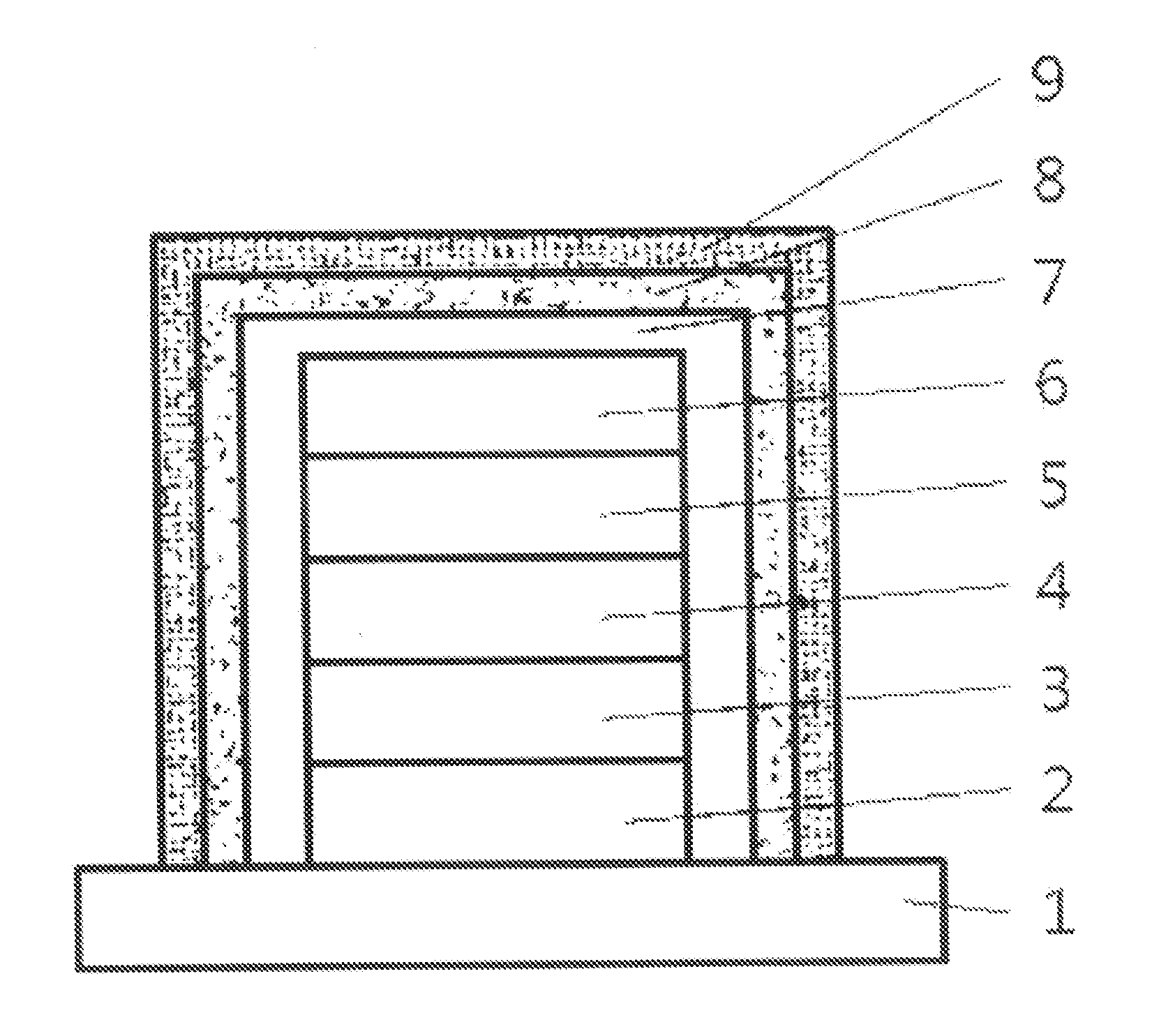

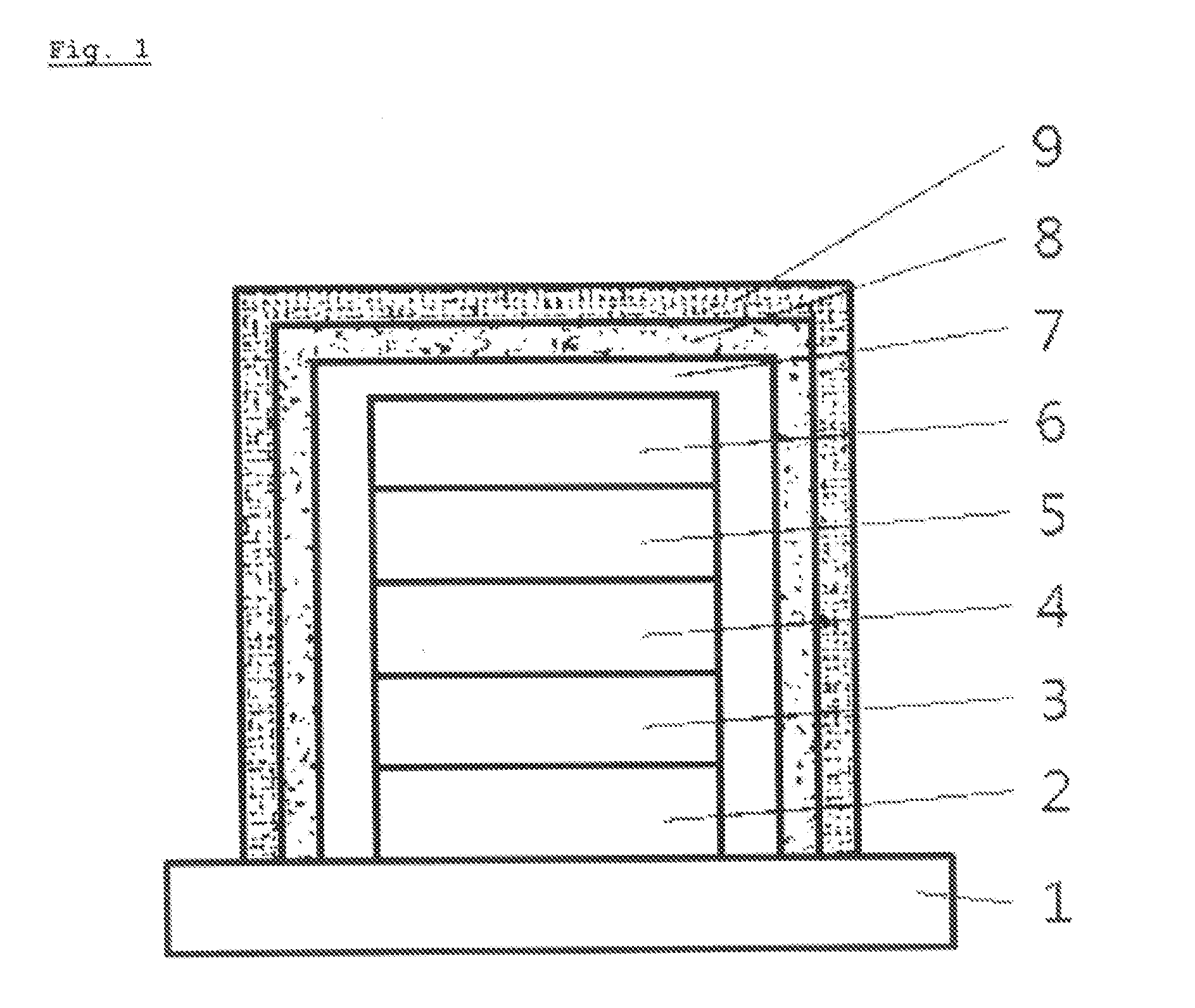

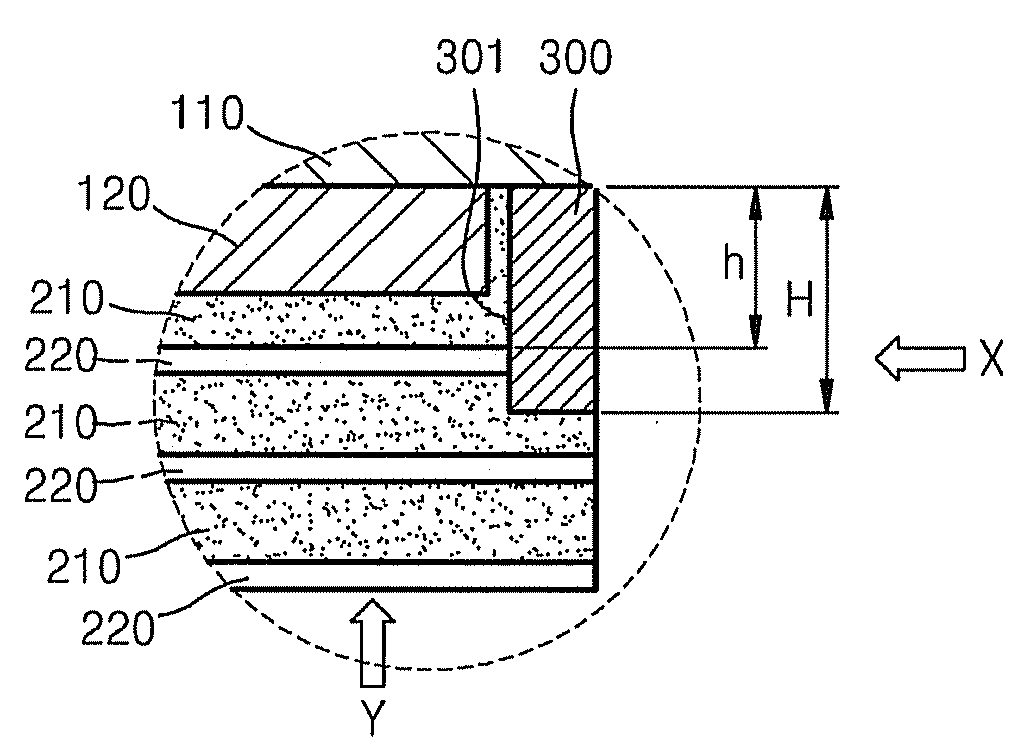

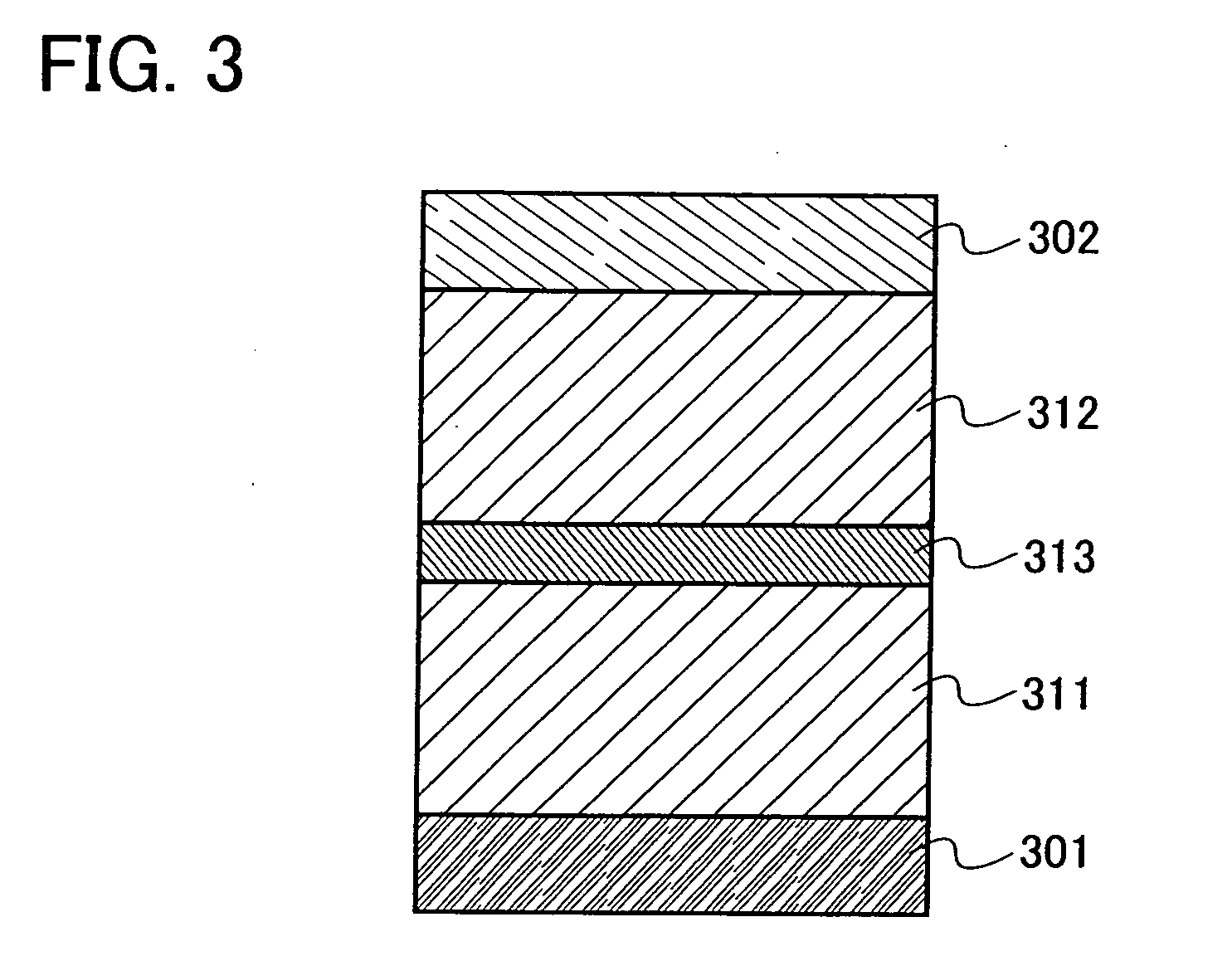

Multi-layer thin film for encapsulation and method thereof

InactiveUS20110100458A1Increase brightnessLow level of moistureLiquid surface applicatorsFinal product manufactureHigh resistanceMoisture penetration

A multi-layer thin film for encapsulation and the method thereof are provided. The multi-layer thin film for encapsulation includes a protective layer composed of aluminum oxide, a single or double barrier layer composed of silicon nitride (SiNx), and a mechanical protective layer composed of silicon dioxide (SiO2). The multi-layer thin film can be economically fabricated by using the existing equipment, and has a high level of light transmission over 85% while showing a low level of oxygen and moisture penetration. Additionally, due to superior adhesive strength between the thin films, and high resistance against impacts by heat or ion during a fabricating process, reliability of fabrication is enhanced, and it can thus efficiently used in encapsulating an organic light-emitting device (OLED), a flexible organic light emitting device (FOLED) in a display field, and the cells such as a thin film battery and a solar cell.

Owner:KOREA INST OF MASCH & MATERIALS

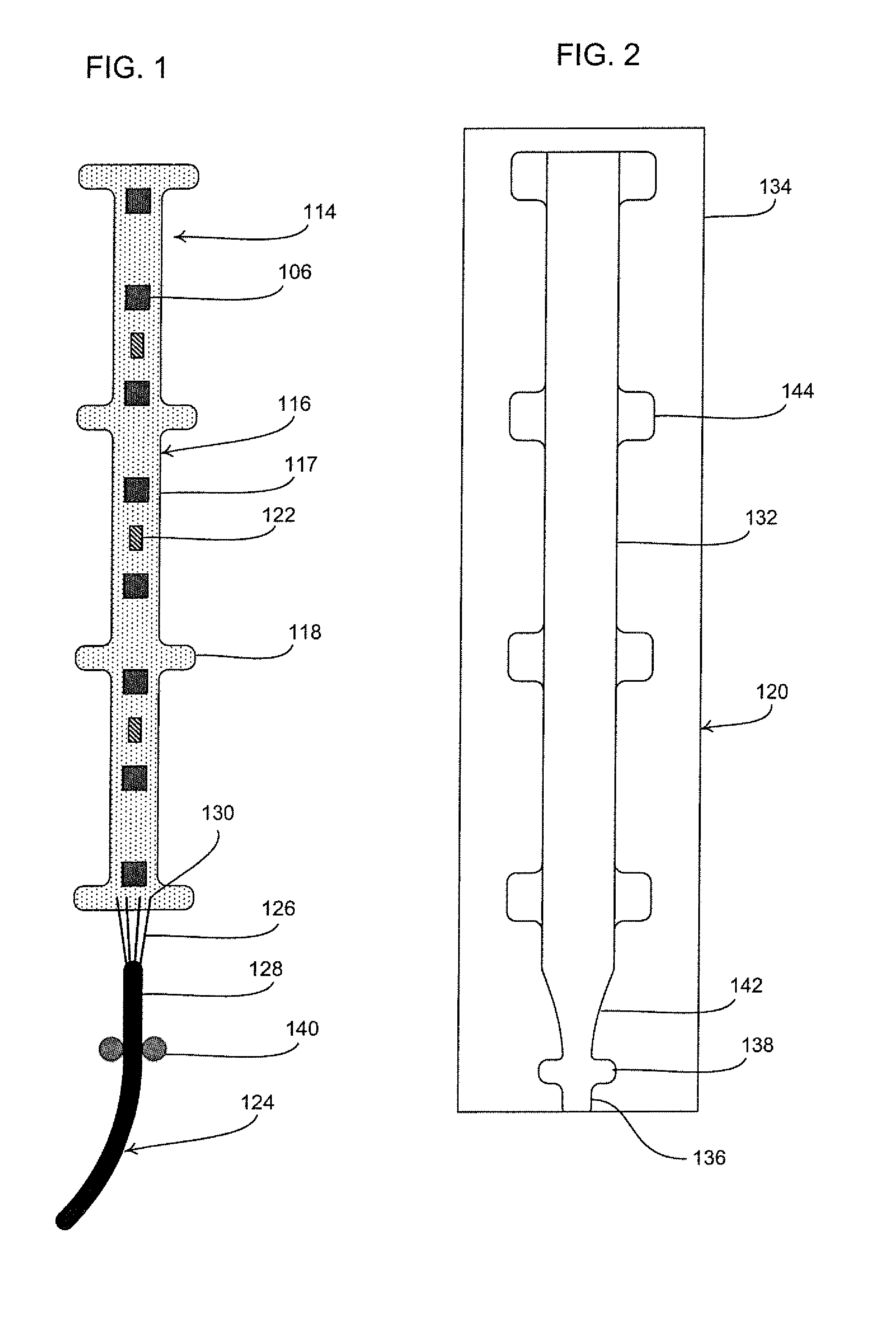

Flexible LED light strip for a bicycle and method for making the same

ActiveUS20130021811A1Minimal flexibilityPoint-like light sourceLighting support devicesVehicle frameMoisture penetration

An integrally-formed single-piece flexible light strip includes a substrate populated with at least one LED light circuit. A clear flexible plastic housing is molded around the LED light circuit to completely encapsulate the light circuit. A flexible electrical cable and contoured strain relief for the electrical cable are also integrally formed as part of the light strip to maintain complete environmental and physical protection and eliminate any non-flexible portions of the light strip such as when a connector is used. The light strip is manufactured in a cost efficient manner, and is impervious to moisture penetration and highly resistant to physical damage, thereby allowing the light strip to be used in a variety of applications and environments. The shape of the illustrated light strip is specially designed for attachment to the round tubing of a bicycle frame. The light strip includes an electrical circuit allowing a reduction in the number of wires between the strip and its associated external control and power.

Owner:LKRB IND LLC

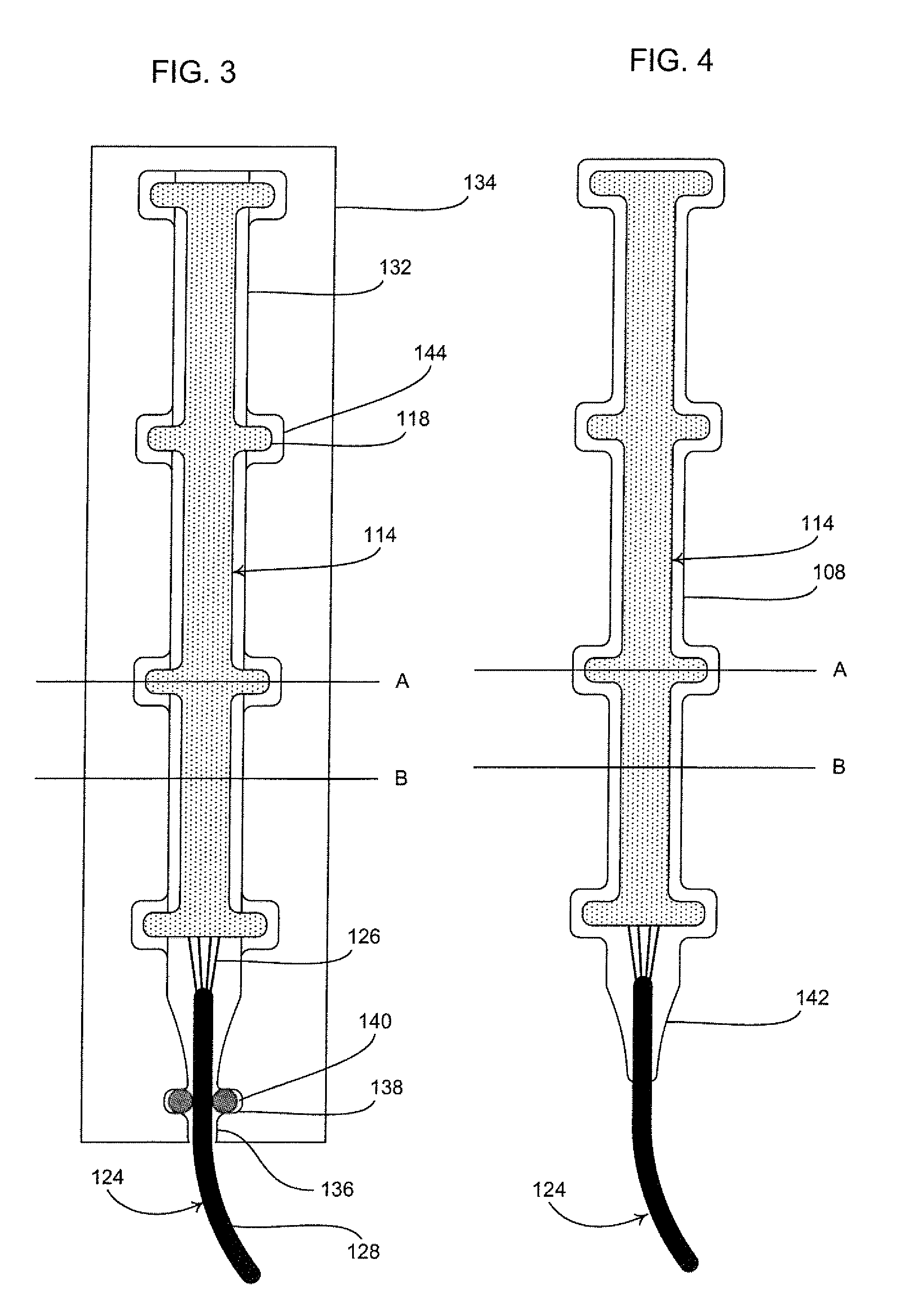

Vertical stack type multi-chip package having improved grounding performance and lower semiconductor chip reliability

ActiveUS20080029869A1Good grounding effectSmall sizeSemiconductor/solid-state device detailsSolid-state devicesMoisture penetrationSolder ball

A vertical stack type multi-chip package is provided having improved reliability by increasing the grounding performance and preventing the decrease in reliability of the multi-chip package from moisture penetration into a lower semiconductor chip. The vertical stack type multi-chip package comprises an organic substrate having a printed circuit pattern on which a semiconductor chip is mounted. A first semiconductor chip is mounted on a die bonding region of the organic substrate and is electrically connected to the organic substrate through a first wire. A metal stiffener is formed on the first semiconductor chip and connected to the organic substrate by a first ground unit around the first semiconductor chip. An encapsulant is used to seal the first semiconductor chip below the metal stiffener. A second semiconductor chip, which is larger in size than that the first semiconductor chip, is mounted on the metal stiffener and connected by a second ground unit. The second semiconductor chip is connected to the organic substrate by a second wire. A mold resin seals the second semiconductor chip and a solder ball is bonded to a solder ball pad below the organic substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

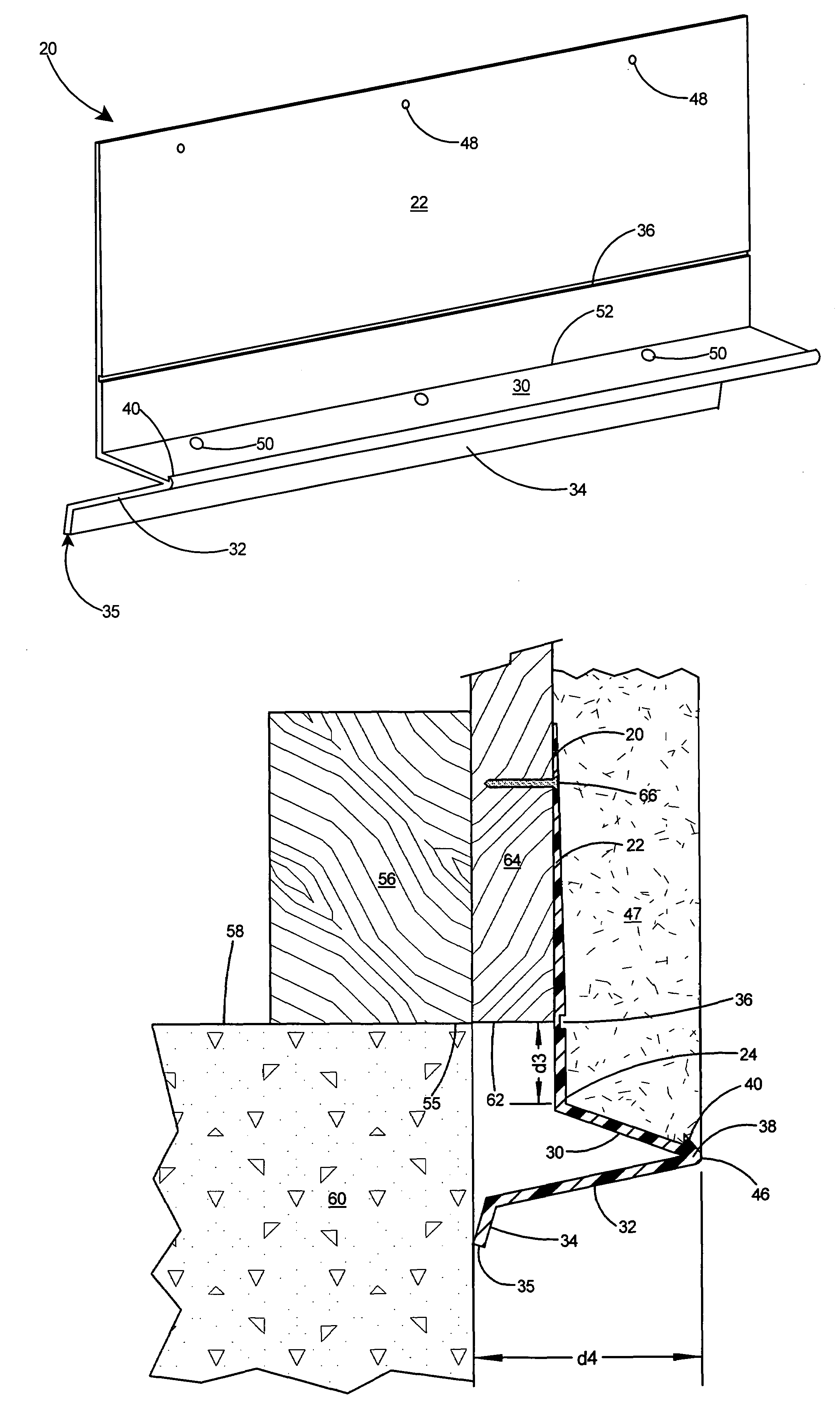

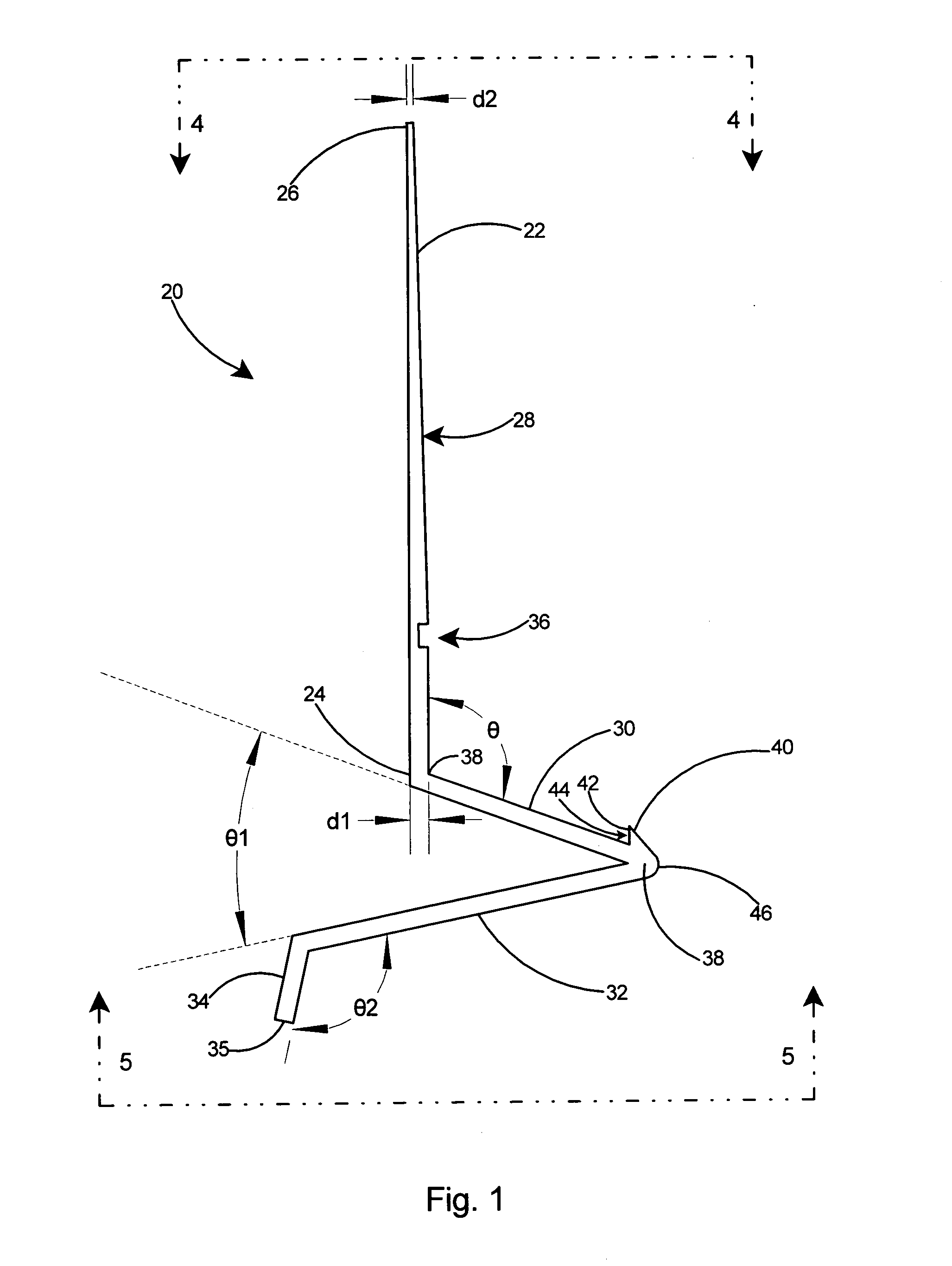

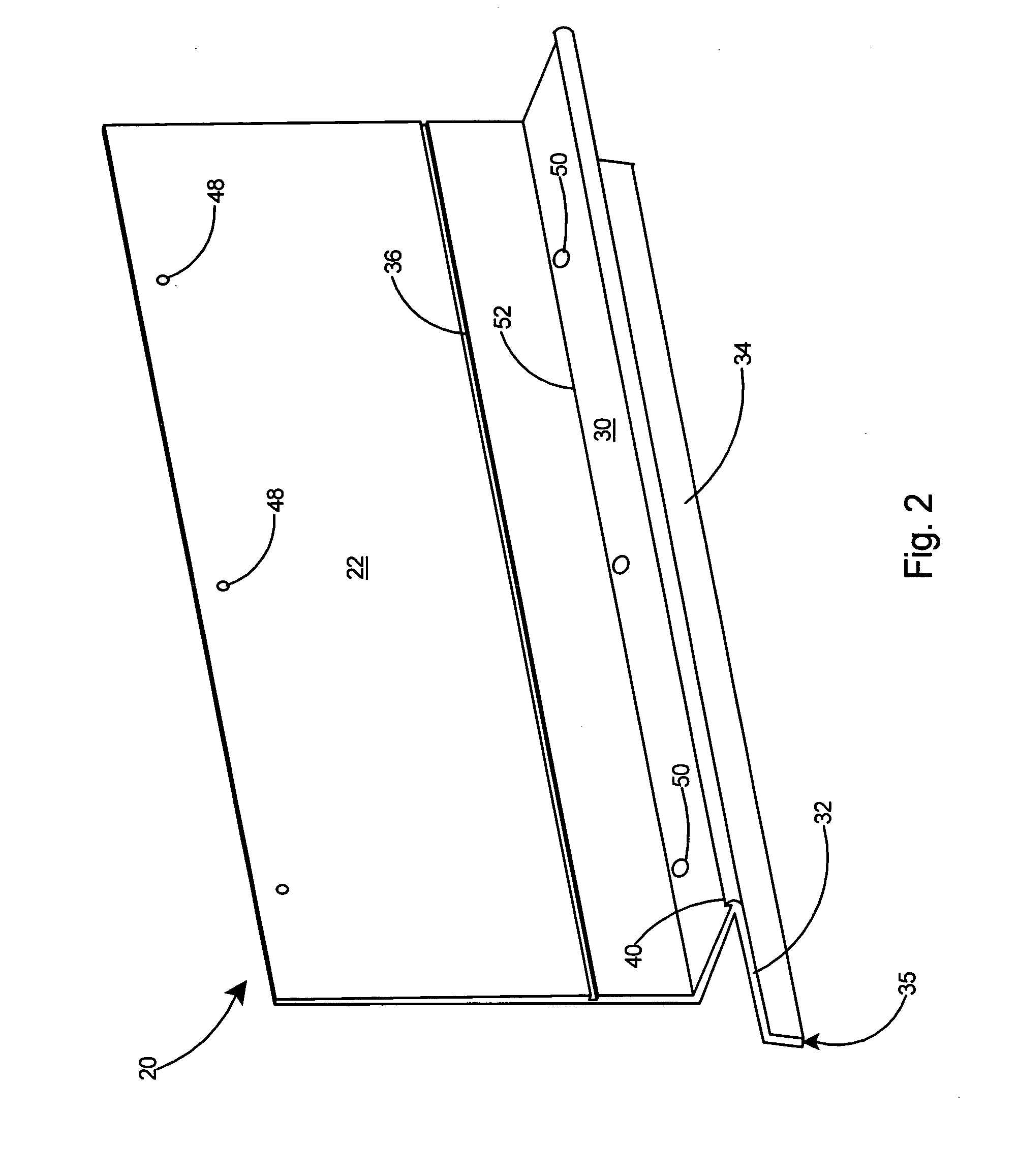

Foundation sill screed having tapering thickness vertical flange and alignment guide in front face of vertical flange for alignment of screed with respect to sill plate line

ActiveUS7546719B1Quick and accurate installationCovering/liningsBuilding componentsScreedMoisture penetration

A foundation sill screed with a vertical flange having a top end and a bottom end and a thickness that is tapered from a minimum at the top end to a maximum at the bottom end. The foundation sill screed includes a first leg extending downwardly and outwardly from the bottom end of the vertical flange, a second leg extending downwardly and inwardly from the stucco ledge, and a lip extending downwardly and inwardly from the inwardly extending member. The foundation sill screed includes a floor line alignment guide extending longitudinally along the vertical flange to provide accurate positioning of the foundation sill screed with respect to the sill plate of a building in order to properly protect the sill plate against moisture penetration and pest infestation.

Owner:PLASTIC COMPONENT

Absorbent sheet exhibiting resistance to moisture penetration

ActiveUS7300547B2Reduce feelingsReduce wetted areaNatural cellulose pulp/paperMechanical working/deformationWaxFiber

An absorbent paper sheet is treated with an aqueous wax dispersion such that the sheet includes a fused wax and emulsifier residue in an amount of from about 1 to about 20 weight percent of the sheet based on the combined weight of the fiber, wax residue and an emulsifier residue in the sheet. The fused wax emulsion operates to make at least one surface of the sheet laterally hydrophobic, exhibiting a moisture penetration delay of at least about 2 seconds and less than about 40 seconds as well as a typical contact angle with water at one minute of at least about 50 degrees. There is thus provided absorbent products which exhibit both absorbency and resistance to moisture penetration. The treated sheet further exhibits microbial barrier properties, impeding transfer of bacteria, for example, through the sheet. There are produced tissue products which resist moisture penetration from propelled liquids as well as sequester sorbed liquids in the interior of the tissue.

Owner:GPCP IP HLDG LLC

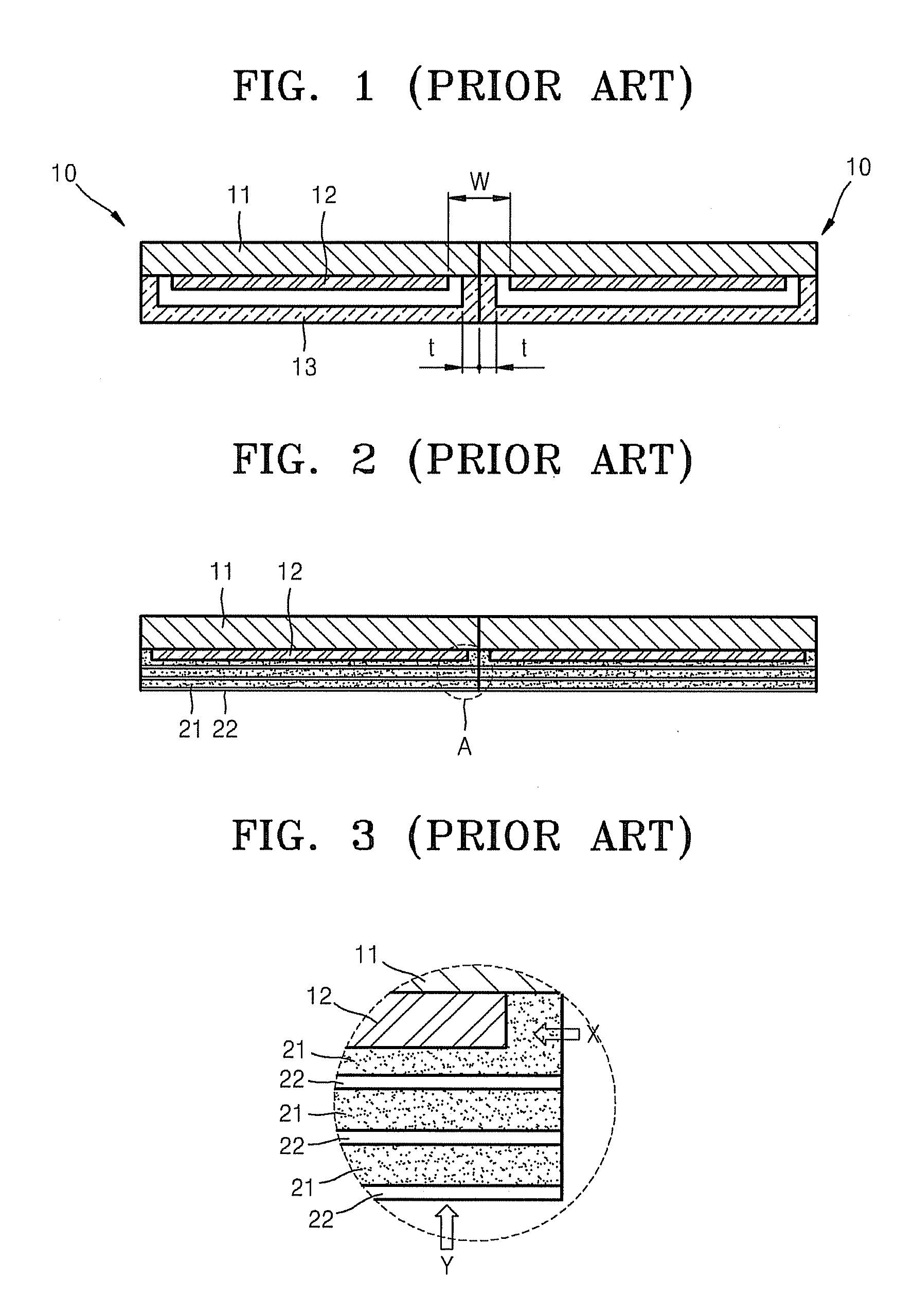

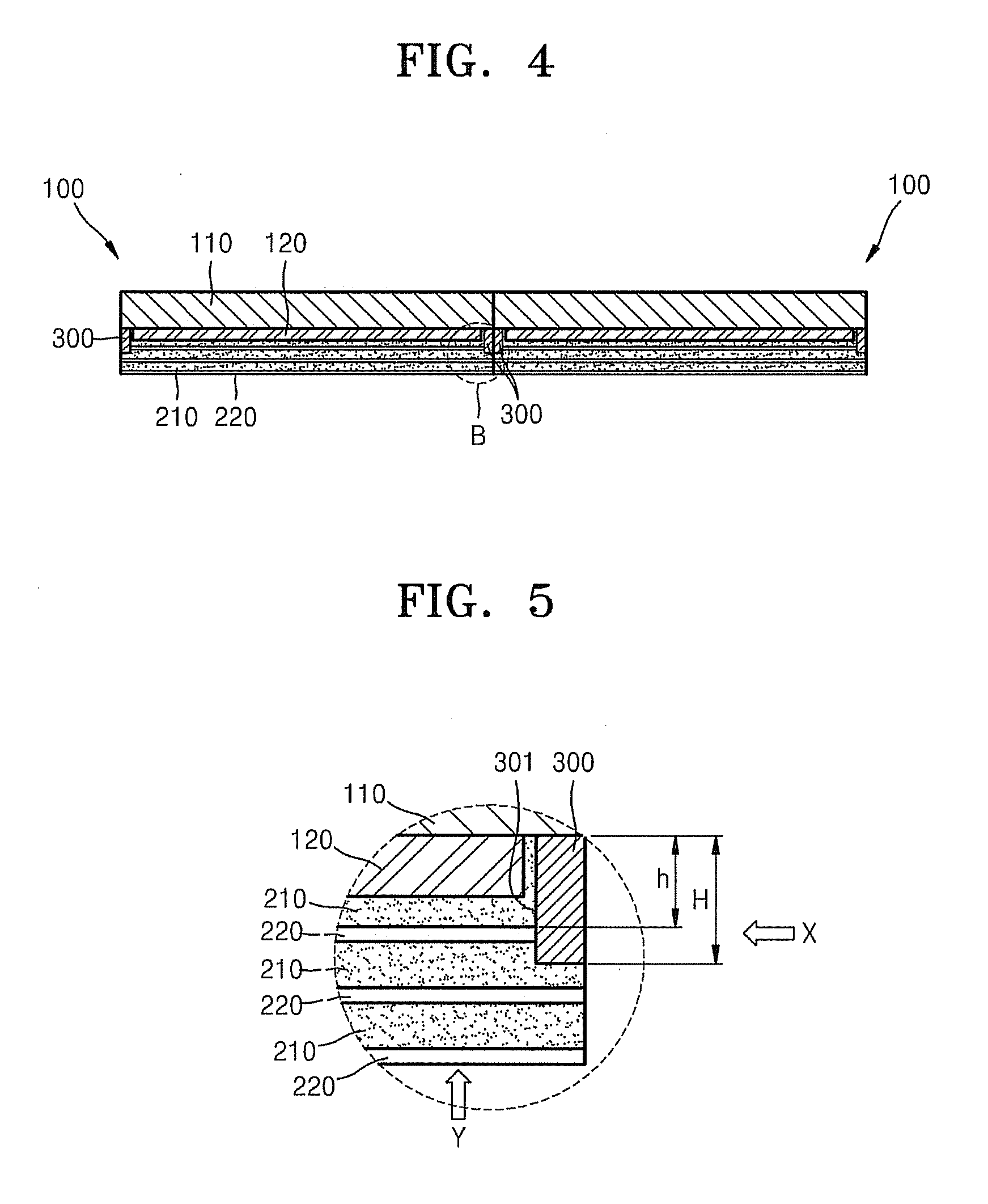

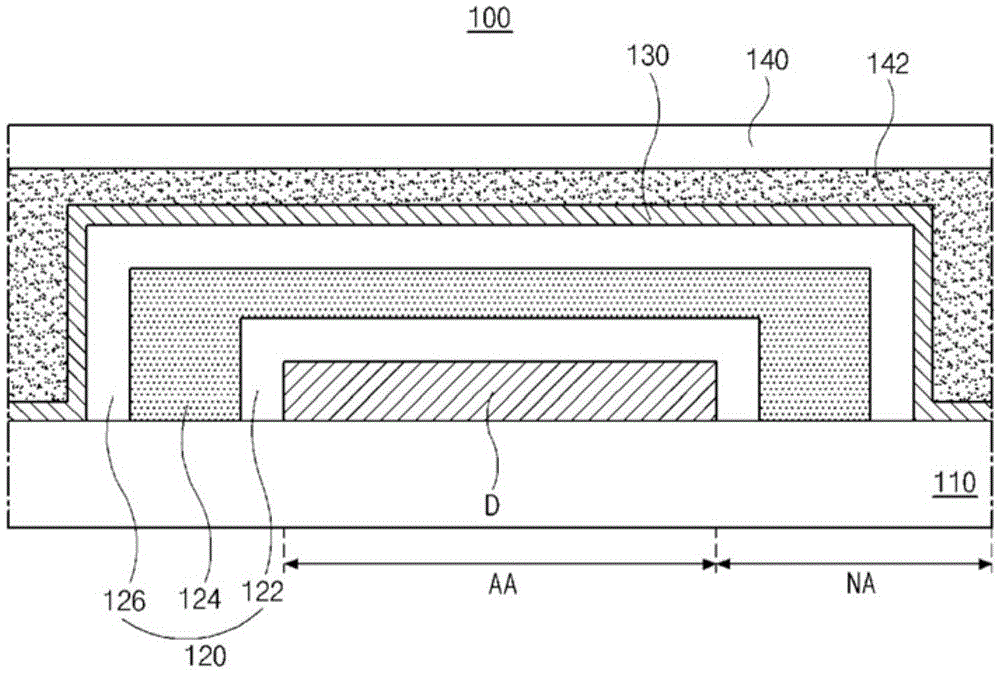

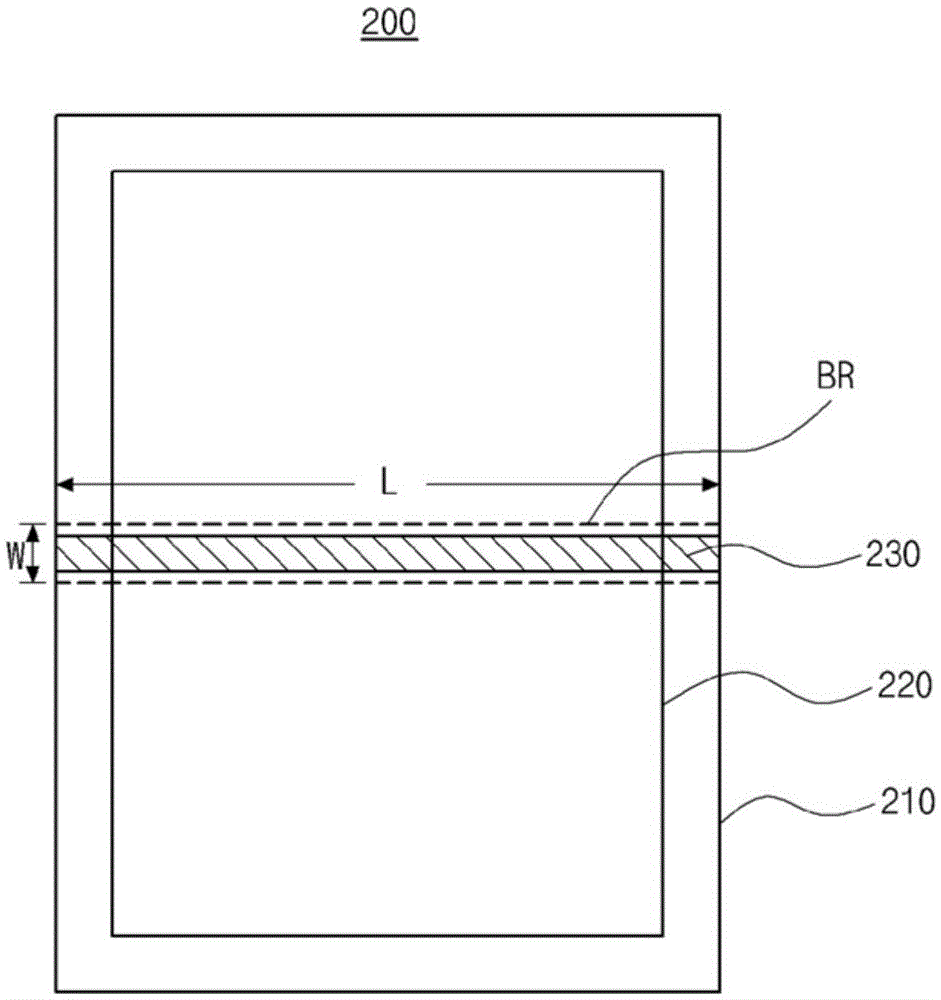

Multi-display apparatus and methods thereof

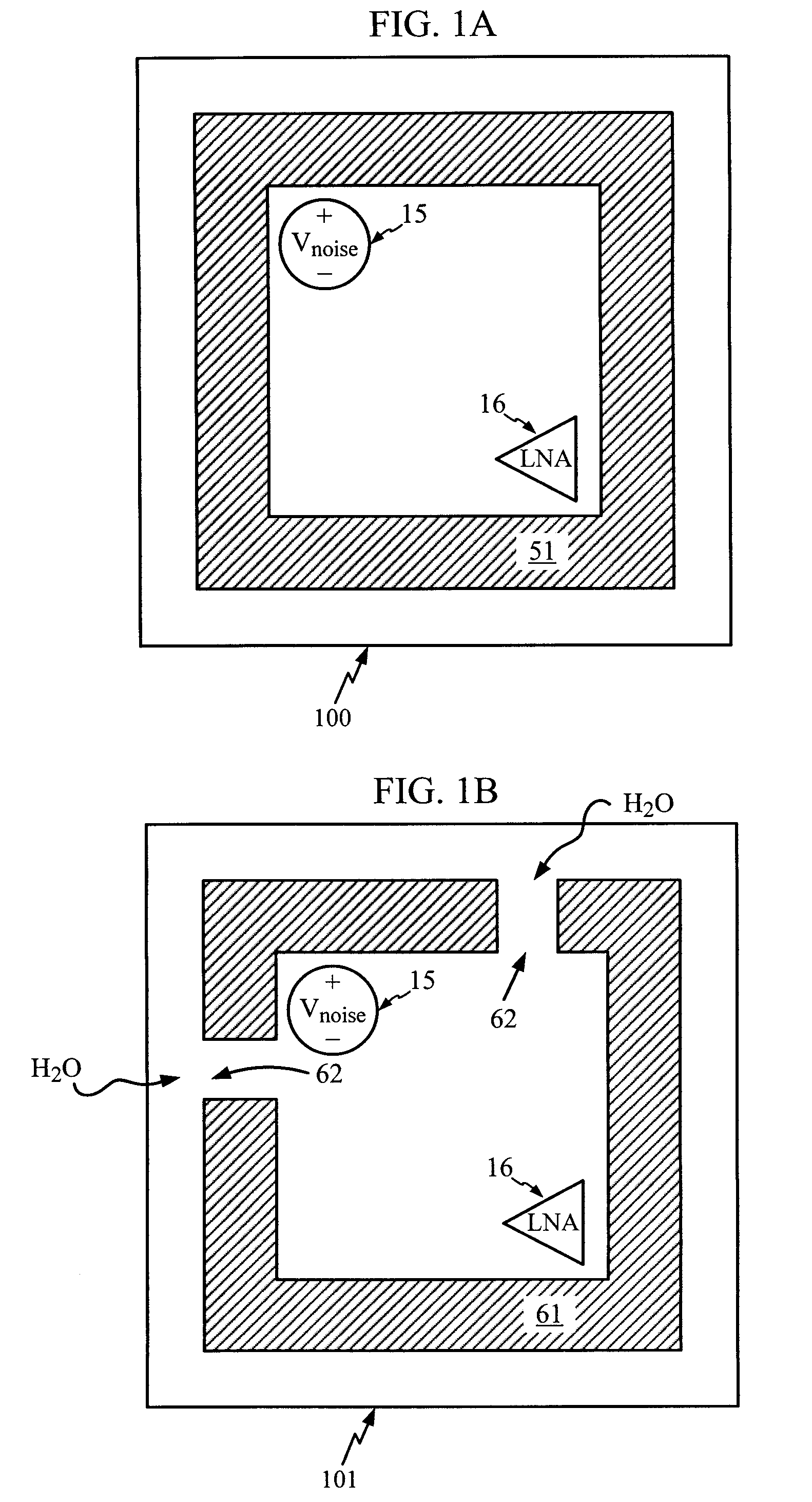

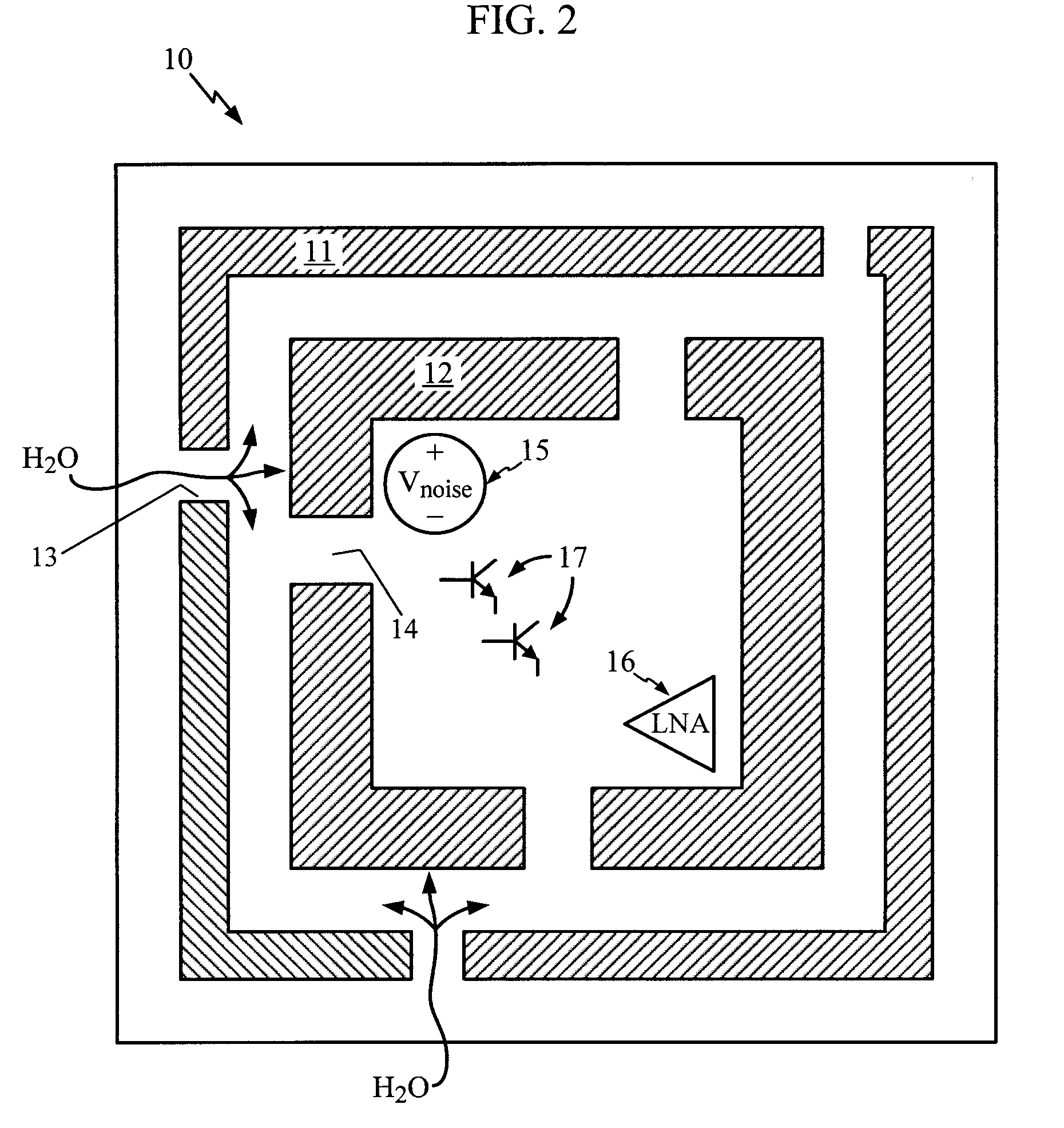

InactiveUS20080203907A1Reduce widthPrevent moisture penetrationDischarge tube luminescnet screensLamp detailsMoisture penetrationDisplay device

A multi-display apparatus includes a thin film encapsulating structure to prevent moisture penetration through sides of the encapsulating structure. Each of a plurality of unit panels of the multi-display apparatus includes a substrate, a display device formed on the substrate, an organic material layer formed on the substrate to bury the display device, an inorganic material layer stacked on the organic material layer, and a moisture barrier wall that is formed outside the display device on the substrate and has a height greater than a thickness of the organic material layer. The multi-display apparatus having a thin film encapsulating structure can realize a stable, smooth, and large image screen since the thin film encapsulating structure can reduce a width of seams between the unit panels and can prevent moisture penetration.

Owner:SAMSUNG ELECTRONICS CO LTD

Initiator assembly

InactiveUS20040226472A1Original performancePedestrian/occupant safety arrangementBlasting cartridgesElectricityMoisture penetration

The present invention provides an initiator assembly in which a metallic collar and an electric type initiator are combined securely to block a moisture penetration into the inside of the gas generator, thereby obtaining operation reliability of the gas generator. An initiator assembly in which an electric type initiator and a metallic collar surrounding at least part of the electric type initiator are integrated with a resin, wherein at least either of an annular protrusion and a cylindrical protrusion provided in the direction to surround the electric type initiator is formed on the metallic collar, and the protrusion is covered with the resin.

Owner:DAICEL CHEM IND LTD

Method of treating sandy soils to reduce water repellency therein

Certain novel formulations of turf additives that act in such a manner as to permit proper amounts of moisture to contact root systems in order to reduce dry spots within highly managed turf areas and / or lawns. It is theorized that the accumulation of humic acid (and other natural byproduct deleterious compounds) at the topsoil surface in most cultivated grassy areas including sandy soils (such as, in particular, golf greens), results in the production of an effective organic waxy coating on the soil components. Such a coating is hydrophobic in nature and thus dries out the soil itself. The inventive formulation thus permits removal of such accumulated humic acid (and other compounds) from the topsoil to the level necessary to provide effective moisture penetration for sustained grass growth therein (hereinafter referred to as "redistributes"). Methods of providing such beneficial removal of humic substances from target sandy soils are also contemplated within this invention, as well as specific test hydrophobic sand formulations.

Owner:MILLIKEN & CO

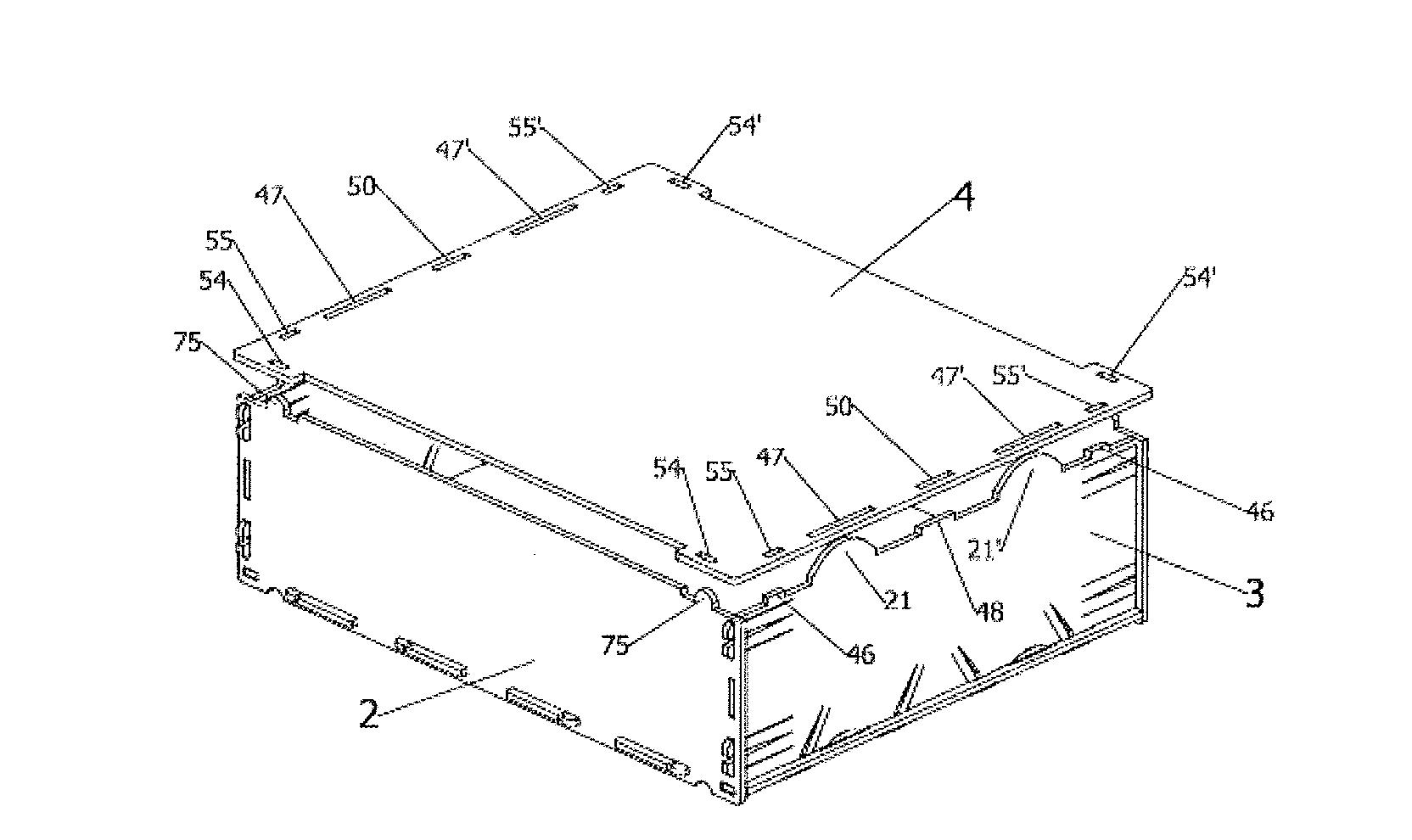

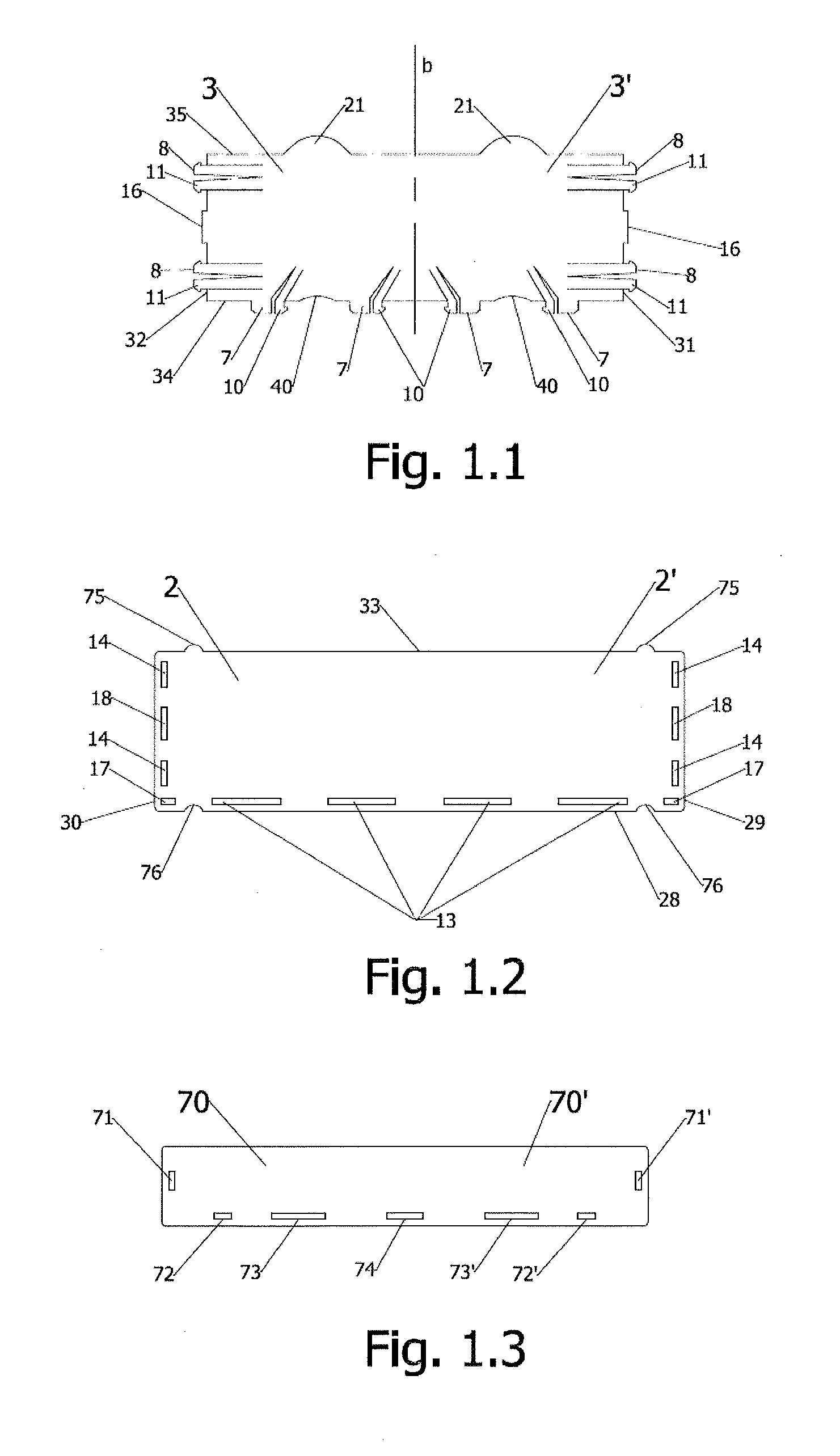

Self-assemblable container for generic use and manufacturing method thereof

ActiveUS20110309072A1Ensure structural stabilityAvoid disassemblyBoxes/cartons making machineryPaper-makingNatural resinMoisture penetration

The present invention refers to a self-assemblable container, preferably manufactured from ecologic materials such as standard fiberboard, comprising as its main structural elements a bottom, two longitudinal sides and two transverse sides of a basically rectangular shape having cauterized perimetrical faces to prevent moisture penetration into the structural elements that make up the container, thus providing long term structural stiffness to the perimetrical faces of the container's structural elements comparable to that of the fiberboard surface. Each of the main structural elements comprises in one side adjacent to another corresponding main structural element, tensile-resistant flexible tabs or receiving slots, the other corresponding main structural element in said side adjacent to the first main structural element respectively comprising slots or flexible tensile resistant tabs, said main structural elements being assembled together by the insertion of the flexible tabs into the receiving slots. In addition, the container may comprise an antisagging brace, a lid and / or two transverse laths. The invention also refers to a method of manufacturing the structural elements of a self-assemblable container by means of perimetrical laser cutting that by reason of the extremely high cutting temperature causes a reaction of the natural resins contained in the raw material and the resulting perimetrical cauterization.

Owner:COMPANIA DE PATENTES DEL PACIFICO

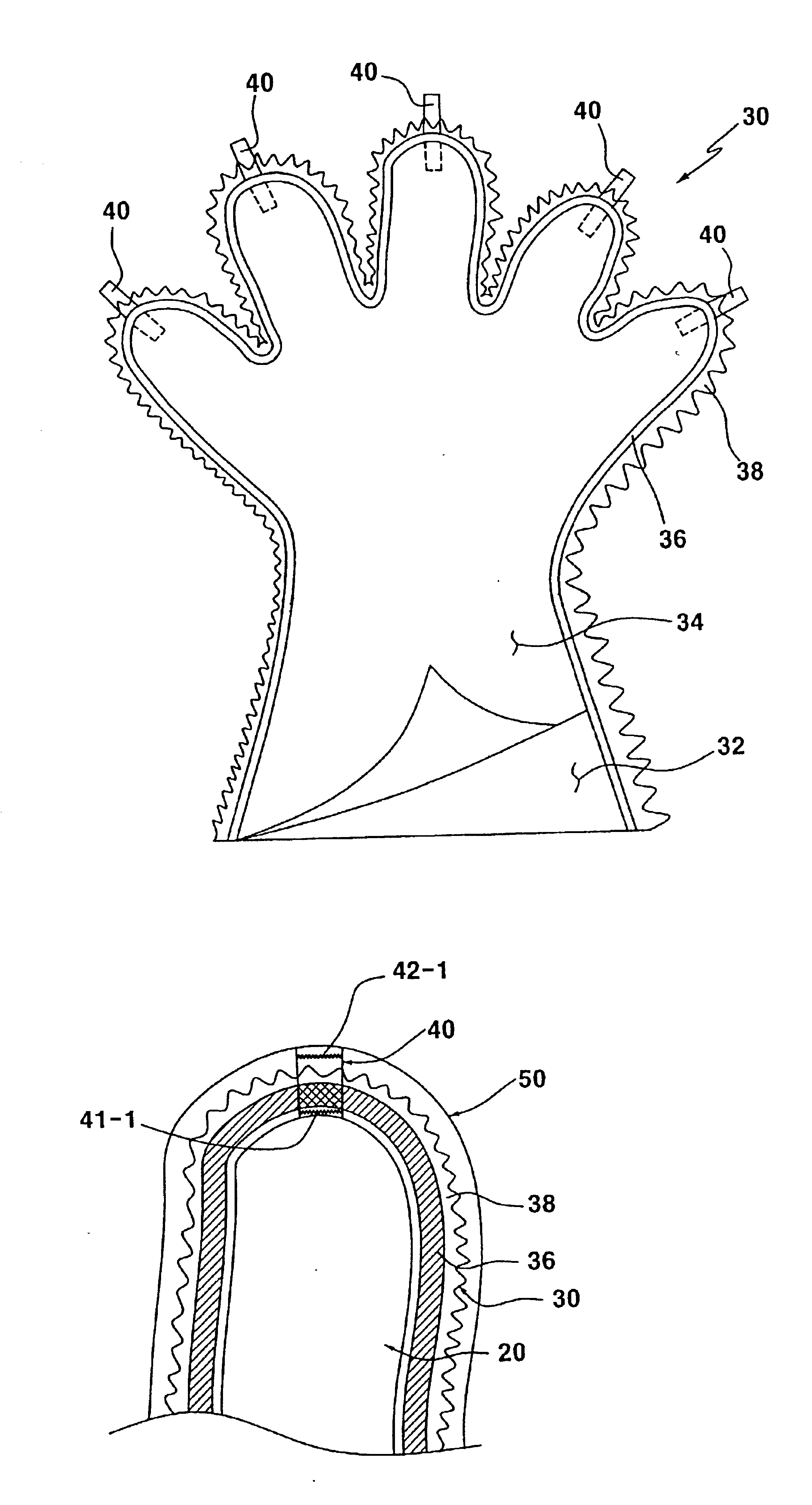

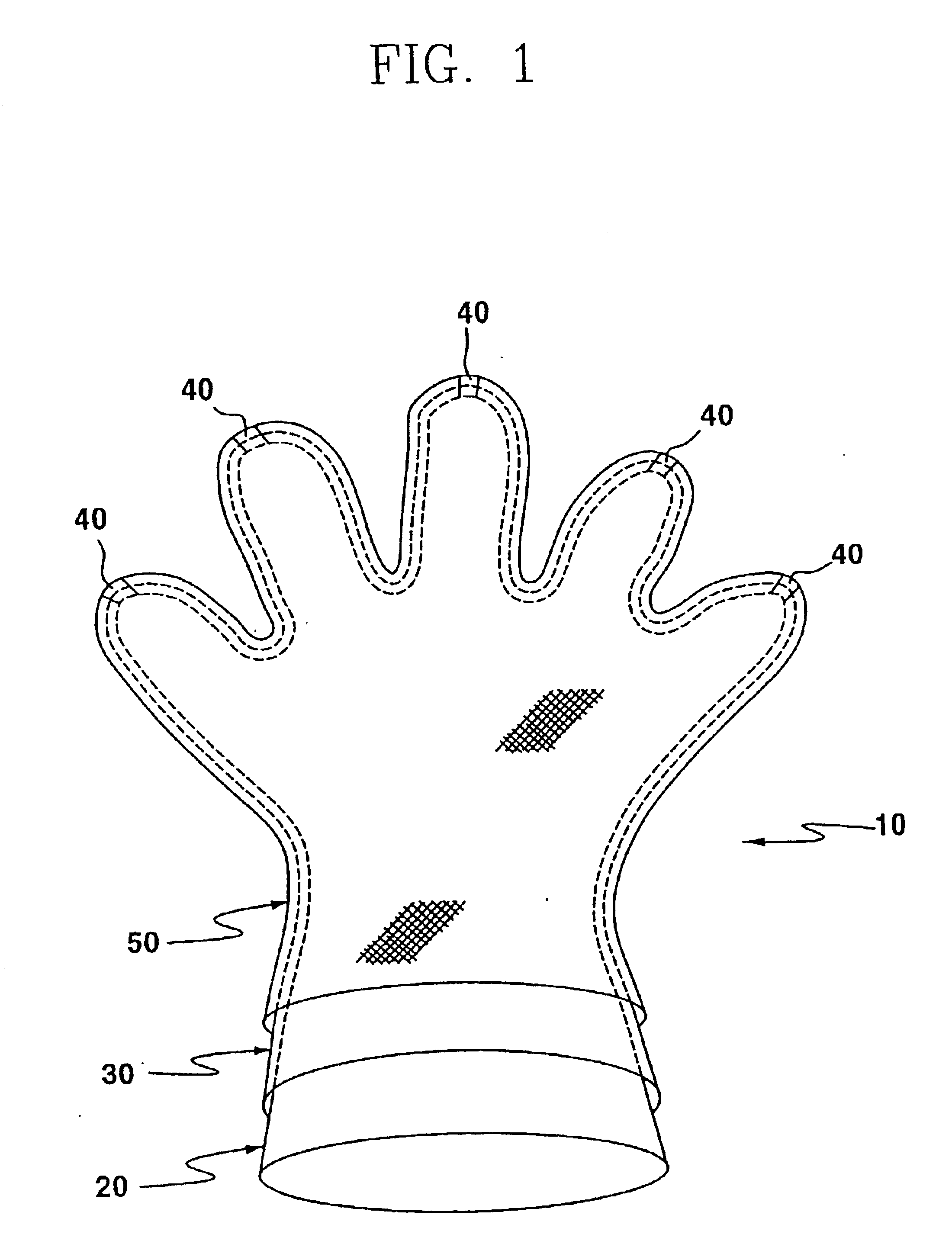

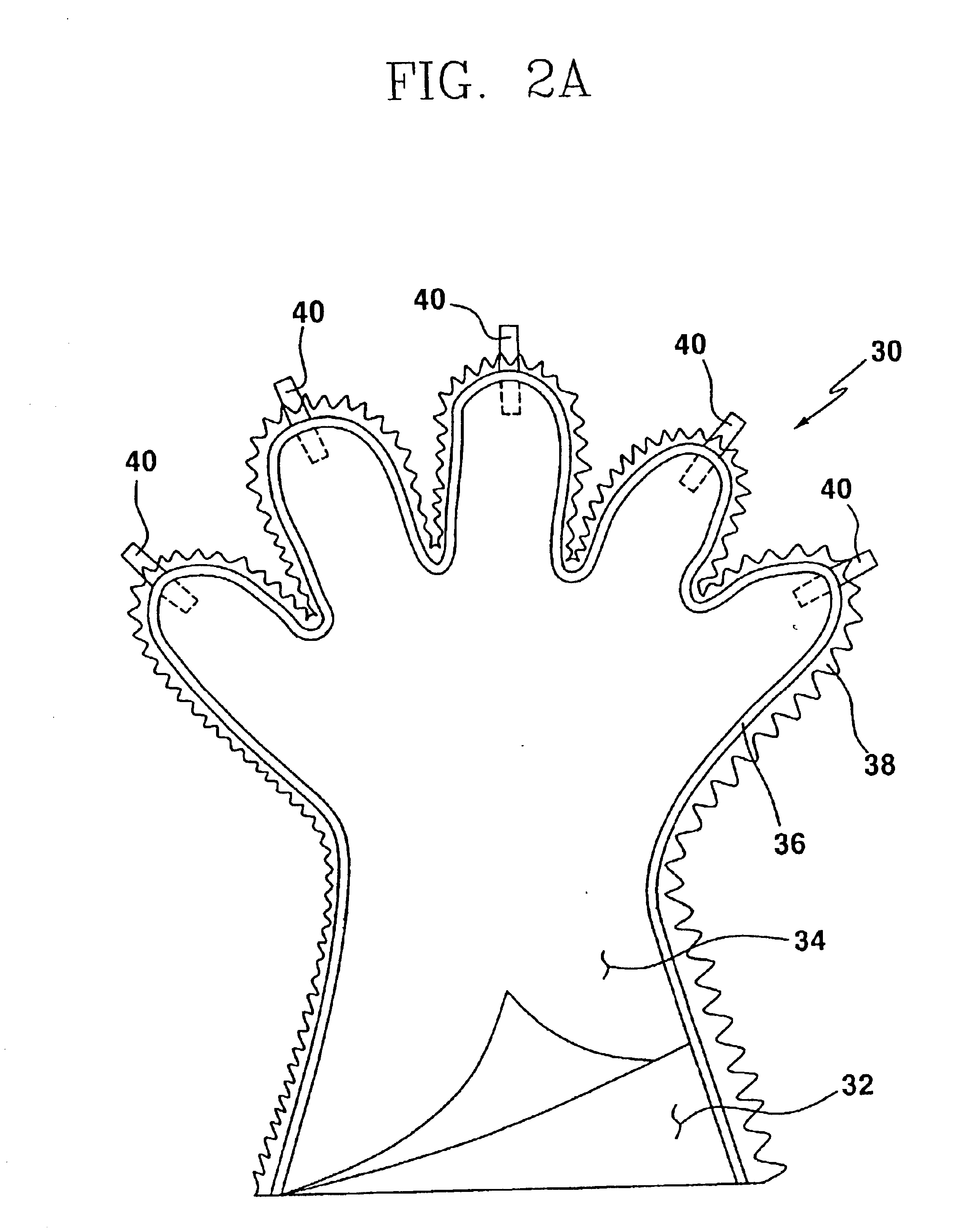

Inner cloth for glove and glove fabricated using the same

The present invention relates to an inner cloth for a glove which is inserted between a lining material contacting with a user's skin and an outer skin exposed to the outside and includes a certain connection member for thereby being fixed together with a lining material and an outer skin based on a sewing operation, so that it is possible to implement good moisture penetration, anti-cold, and waterproof functions. The inner cloth for a glove includes a pair of hand-shaped panel members which each include a certain size or area and an edge portion connected at a certain width, and a connection member which is arranged at a certain position of the pair of the panel members and is integrally formed when the panel members are connected, and is formed in a certain shape. The glove implements good moisture penetration, anti-cold and waterproof functions using the inner cloth of the present invention.

Owner:HAN DONG SIK

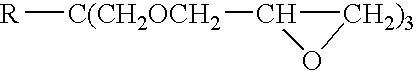

Method of treating sandy soils with multi-branched regenerating wetting agents

Certain novel formulations of turf additives that act in such a manner as to permit proper amounts of moisture to contact root systems in order to reduce dry spots within highly managed turf areas and / or lawns. The inventive formulation comprising multi-branched surfactant compounds with both hydrophobic and hydrophilic constituents within each branch attached to an oxygen-containing polyfunctional base compound permits effective moisture penetration through such localized dry spots for sustained grass growth therein. Importantly, such multi-branched wetting agents provide sustained moisture penetration over a sustained period of time since the individual branches of such compounds may become dissociated from its base polyfunctional compound. Since such branches include both hydrophobic and hydrophilic constituents themselves, and thus act as wetting agents, even after degradation of the initial surfactant compound, long-term wetting and moisture penetration, at least, are permitted. Methods of treating sandy soils with such compounds and formulations thereof are also contemplated within this invention.

Owner:MILLIKEN & CO

Flexible organic light emitting diode display device

ActiveCN106206962ASolid-state devicesSemiconductor/solid-state device manufacturingFlexible organic light-emitting diodeMoisture penetration

Embodiments relate to a flexible organic light emitting diode (OLED) display device and a method for manufacturing the flexible OLED display device. The display device includes a multi-layered encapsulation film coving pixel regions of the display device, and a metal layer on or within at least a portion of the encapsulation film, the portion in a bending region of the flexible substrate. The multi-layered encapsulation film includes at least a first inorganic layer, an organic layer, and a second inorganic layer. The metal layer is formed in the bending region such that the stress generated in the encapsulation film by folding, bending, or rolling operations in the bending region is reduced by the metal layer. The metal layer prevents generation of cracks in the encapsulation film and thus, prevents moisture penetration into the display area of the display device.

Owner:LG DISPLAY CO LTD

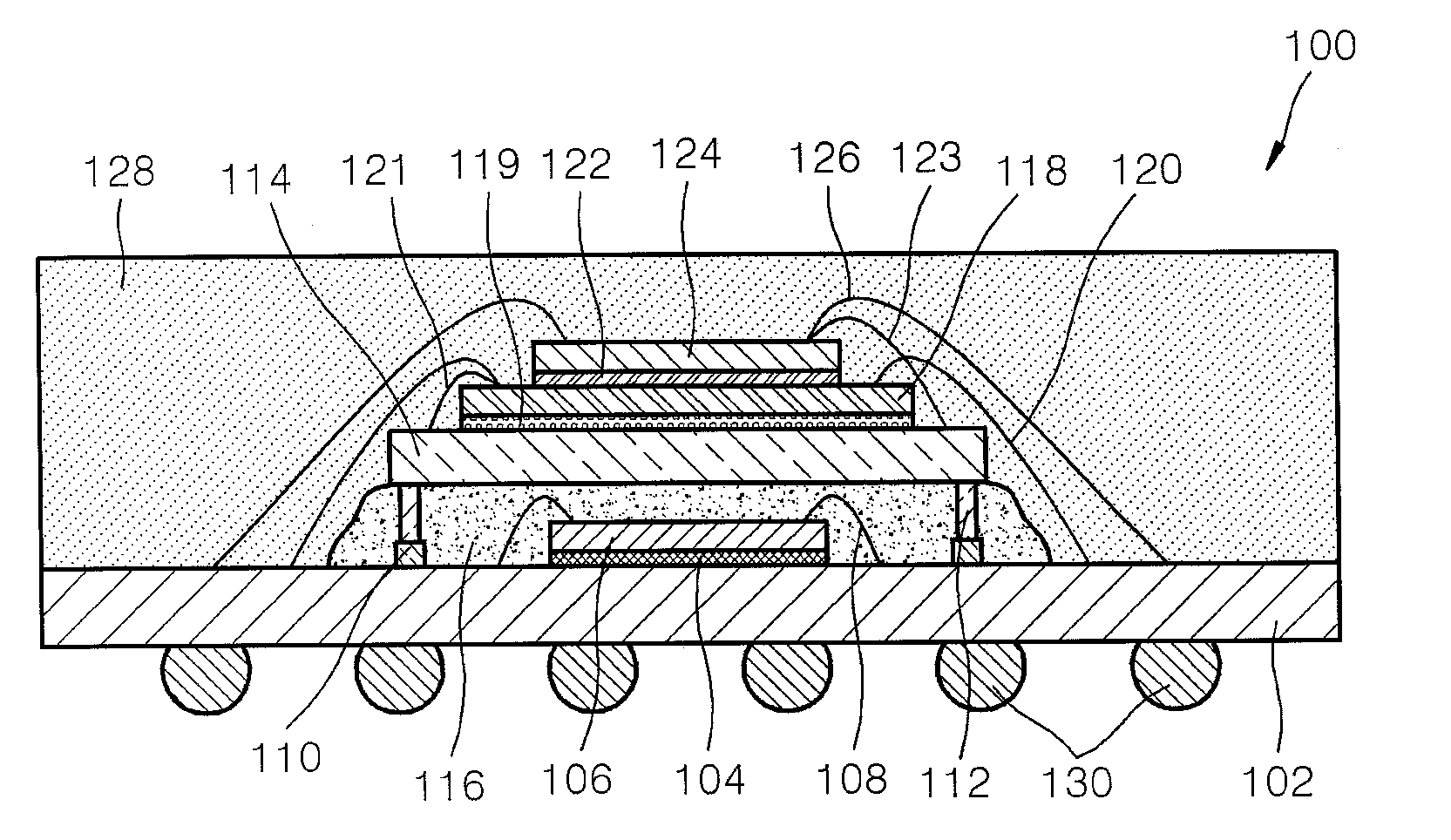

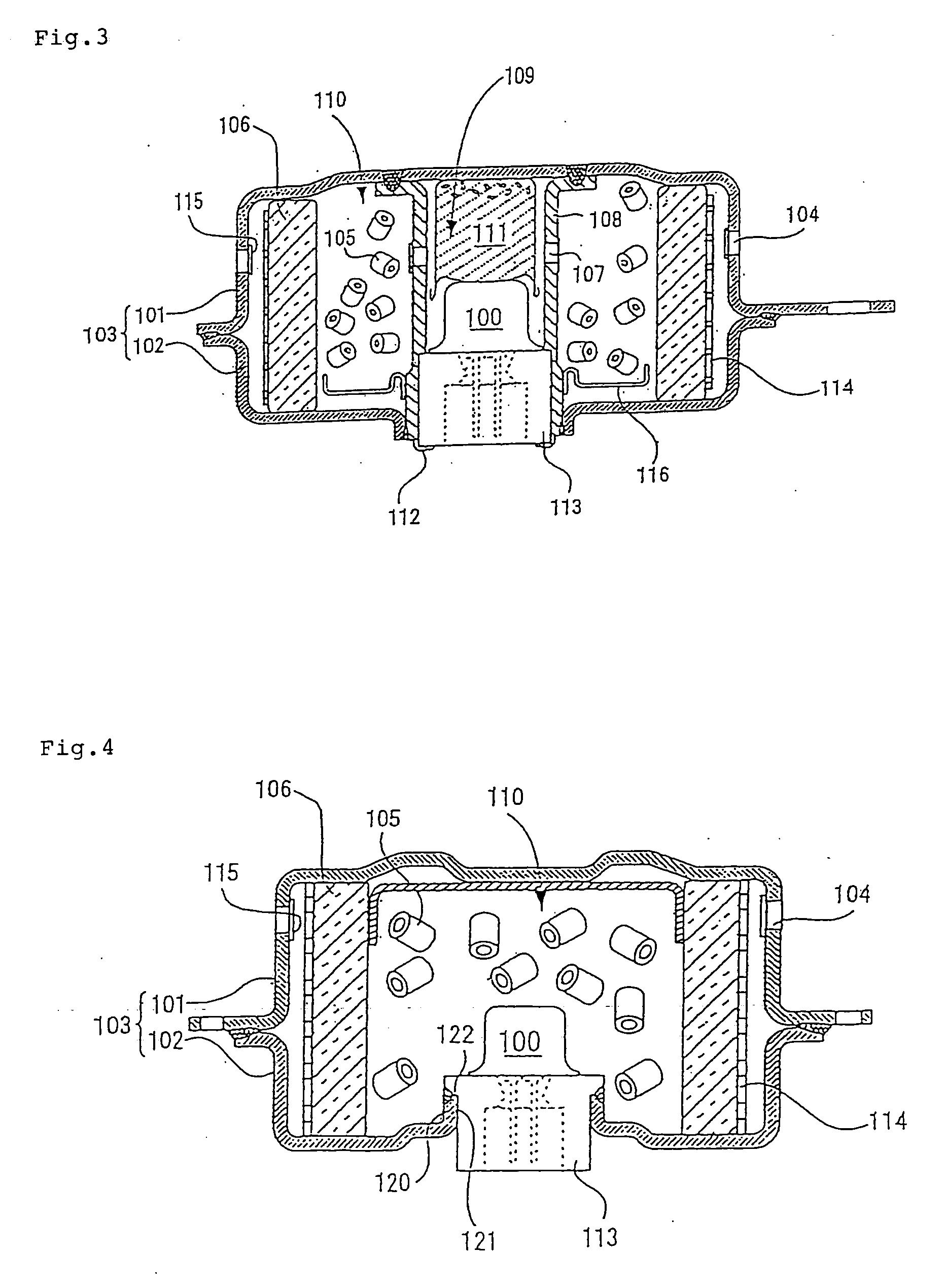

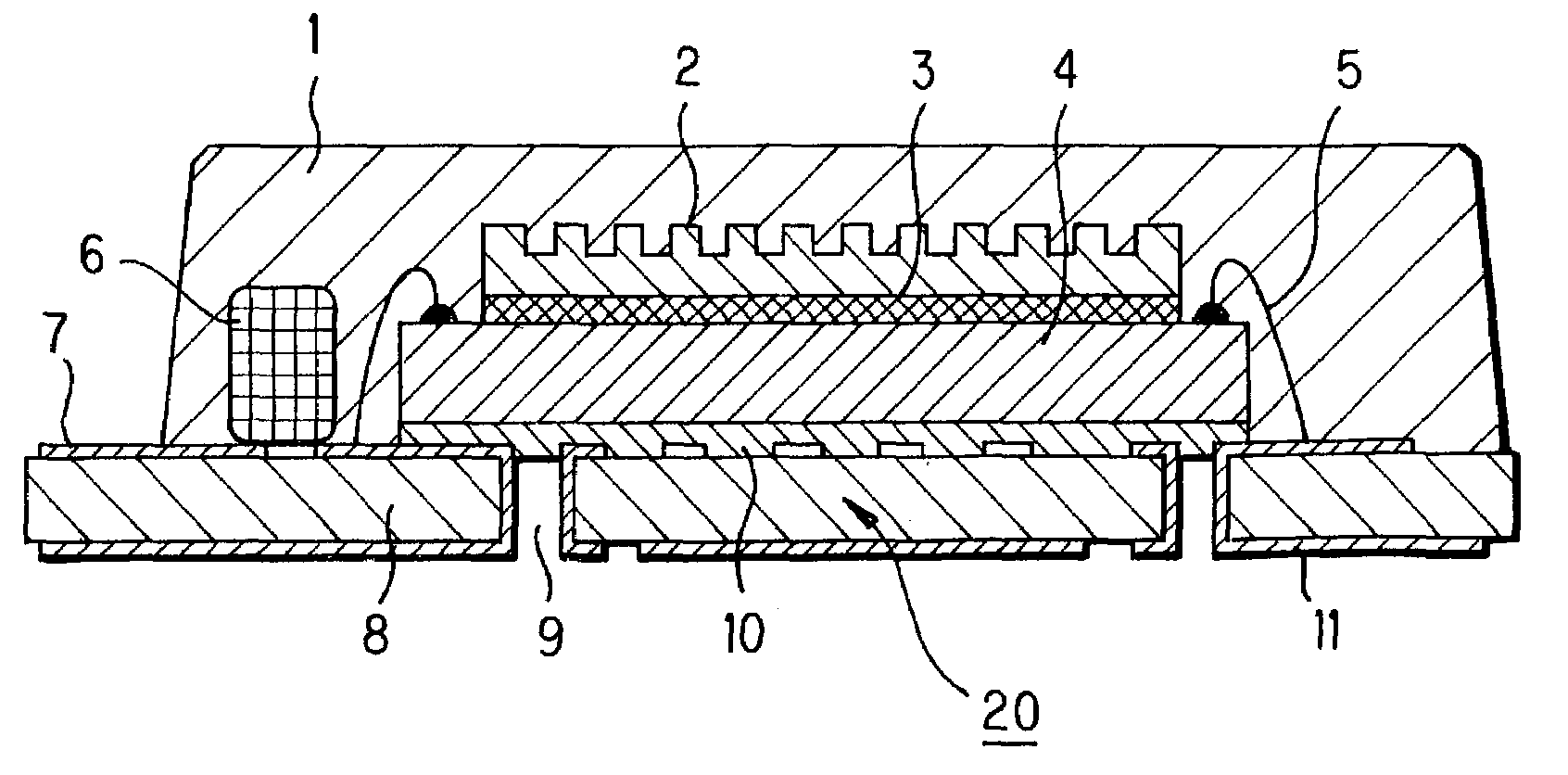

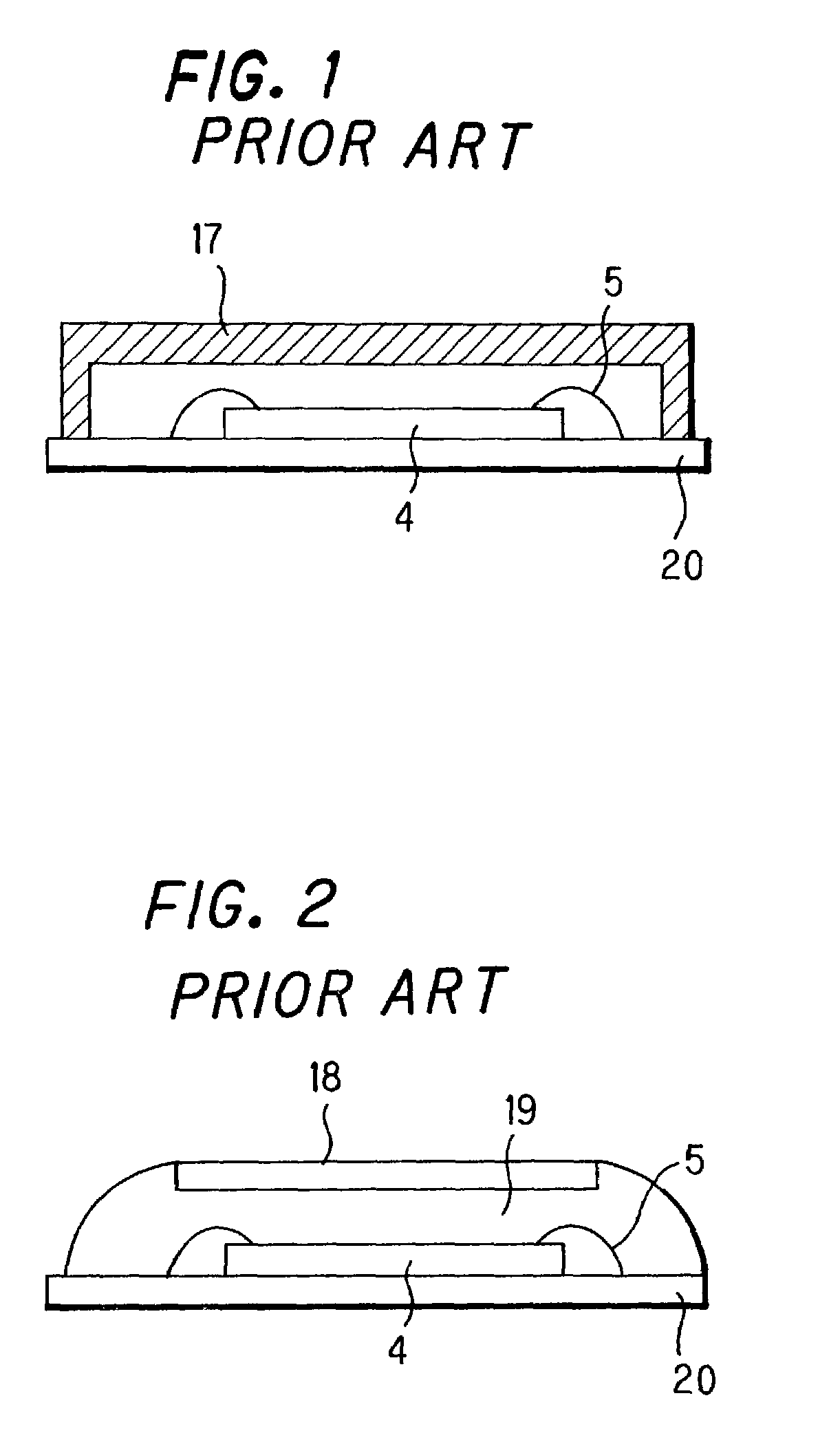

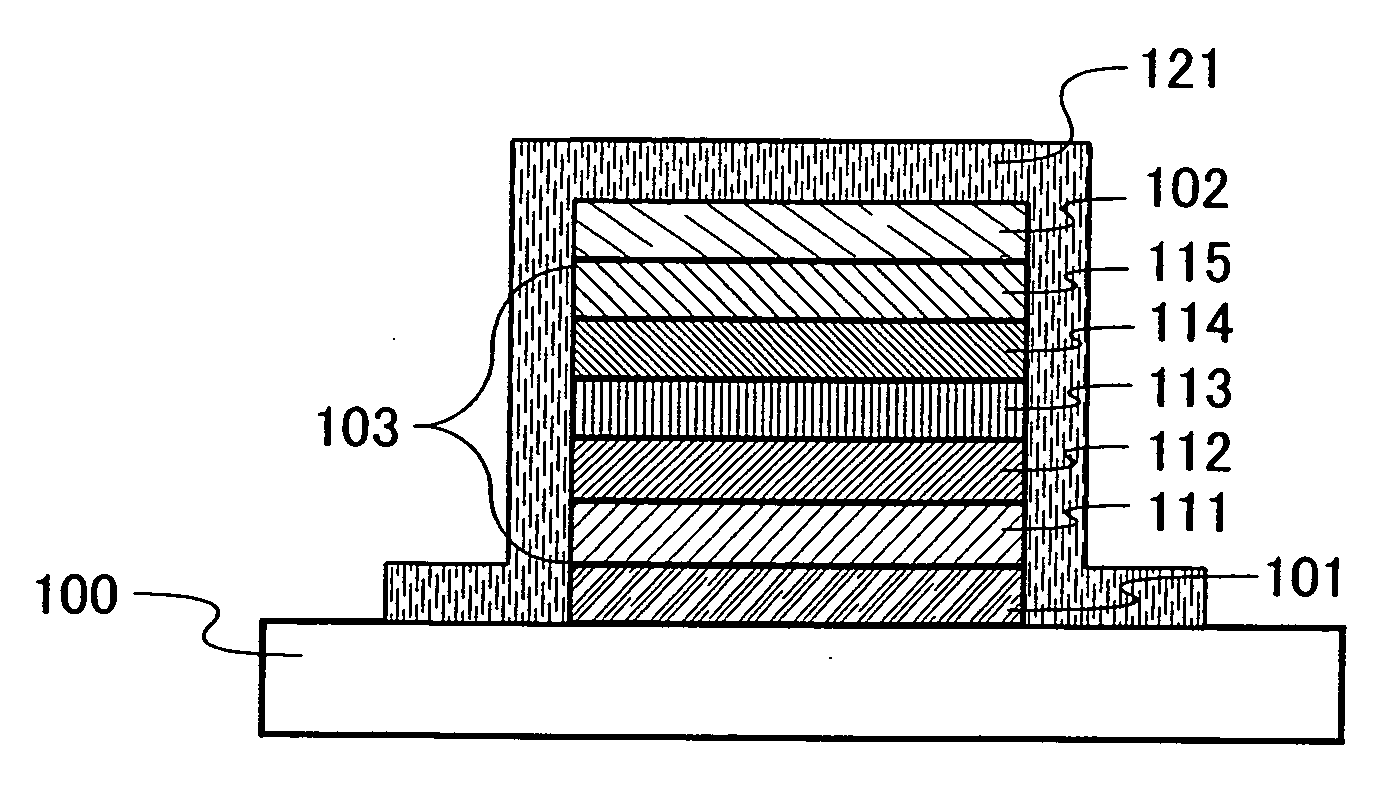

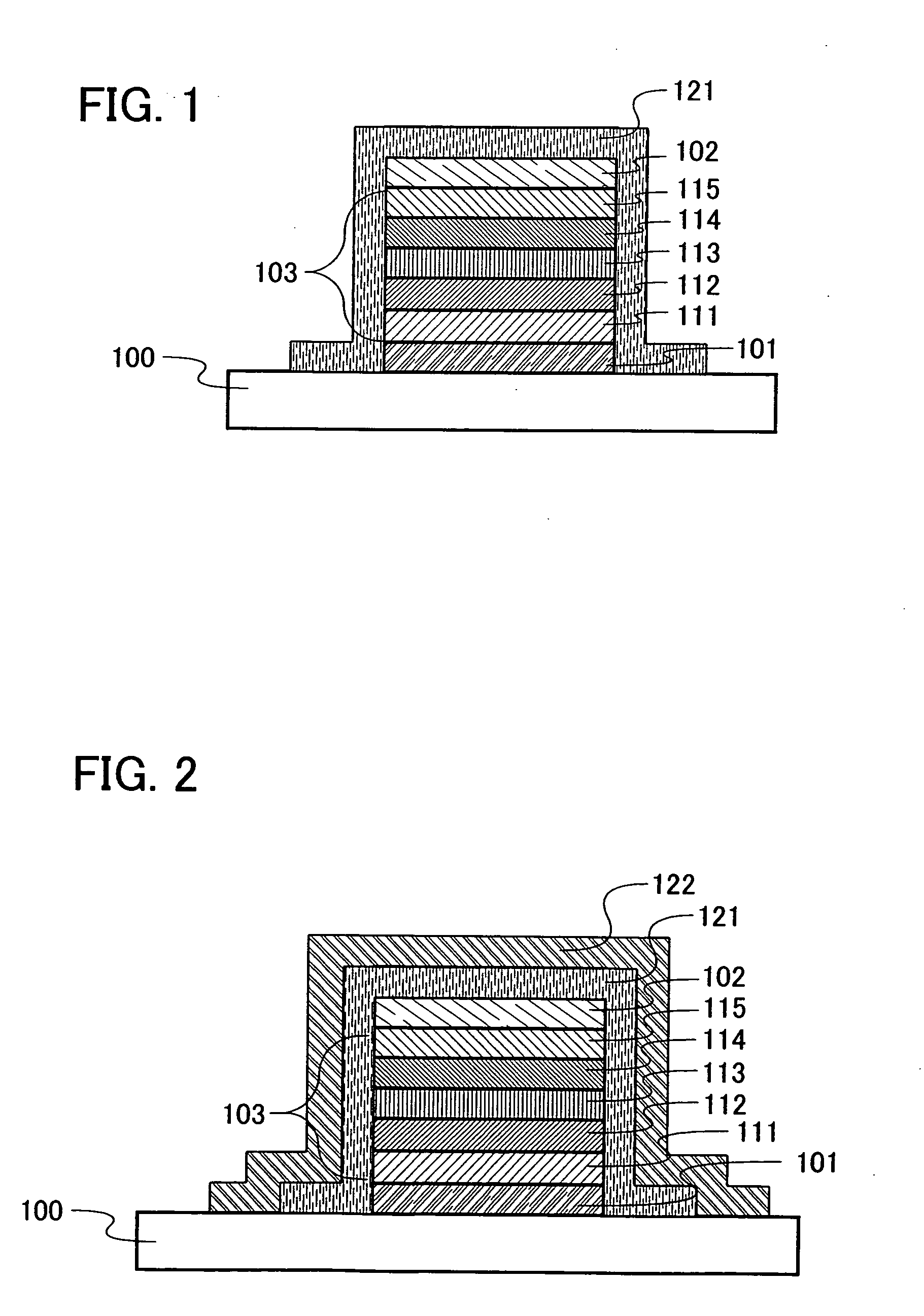

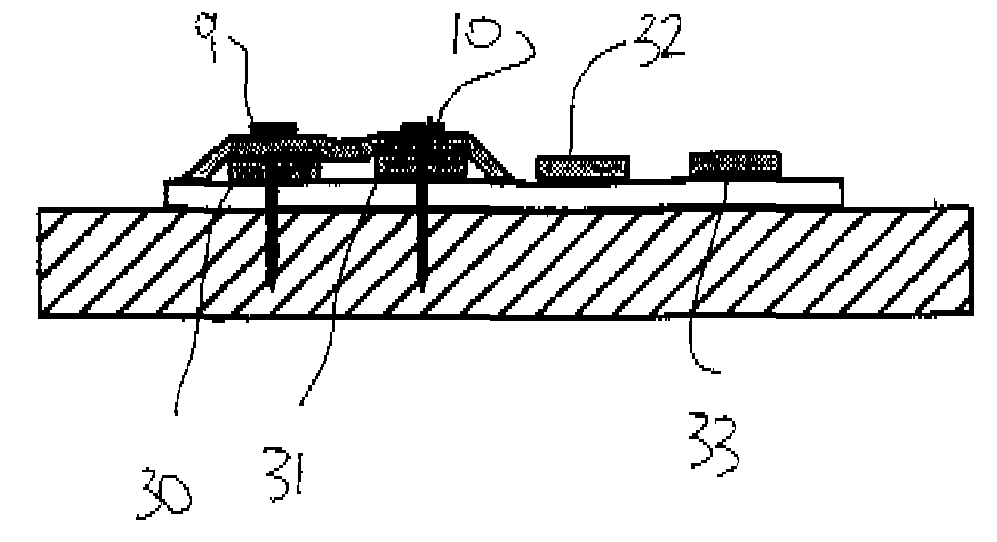

Semiconductor module and production method therefor and module for IC cards and the like

InactiveUS7135782B2Reduce generationIncrease productionOther printing matterSemiconductor/solid-state device detailsElectrical conductorMoisture penetration

A semiconductor module includes: a printed wiring board made of an insulator with conductor patterns formed on both sides thereof. An IC chip is mounted on the printed wiring board and sealed with a resin. A metallic sheet or moisture penetration blocking sheet is adhered on the IC chip surface opposite to the side that faces the printed wiring board.

Owner:SHARP KK

Light-emitting element, light-emitting device, electronic device, and method for fabricating light-emitting element

ActiveUS20090001886A1Solution to short lifePrevent moisture penetrationDischarge tube luminescnet screensLamp detailsMoisture penetrationInorganic compound

Objects of the present invention are to provide a light-emitting element that does not readily deteriorate, a light-emitting device and an electronic device that do not readily deteriorate, and a method of fabricating the light-emitting element that does not readily deteriorate. A light-emitting element having an EL layer between a pair of electrodes is covered with a layer containing an inorganic compound and halogen atoms or a layer containing an organic compound, an inorganic compound, and halogen atoms, whereby deterioration by moisture penetration can be inhibited. Thus, a light-emitting element with a long life can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

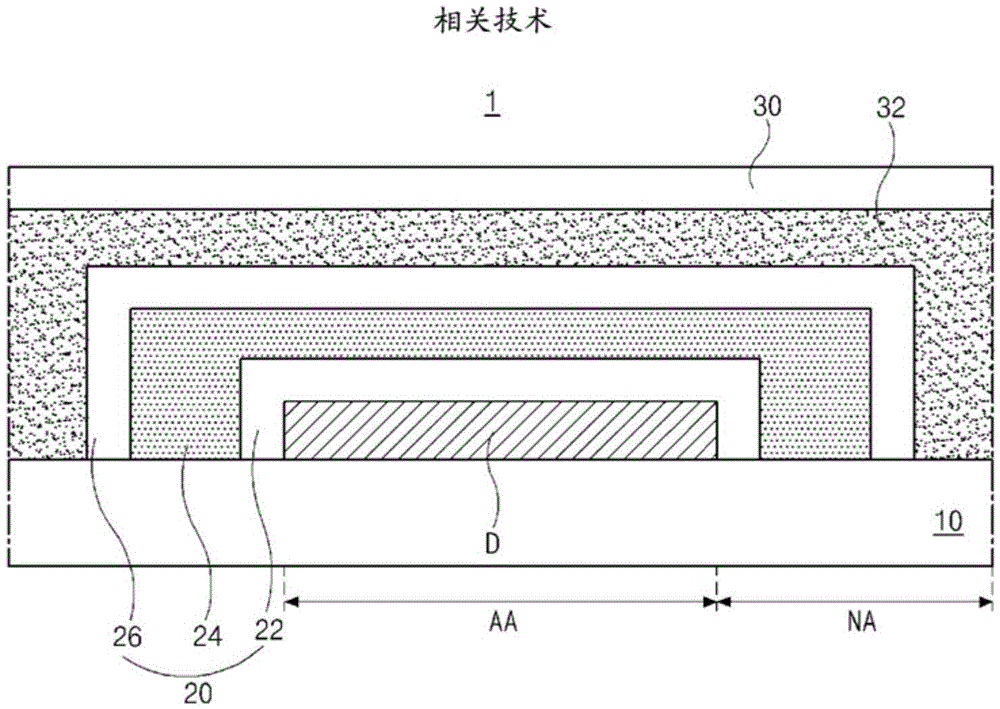

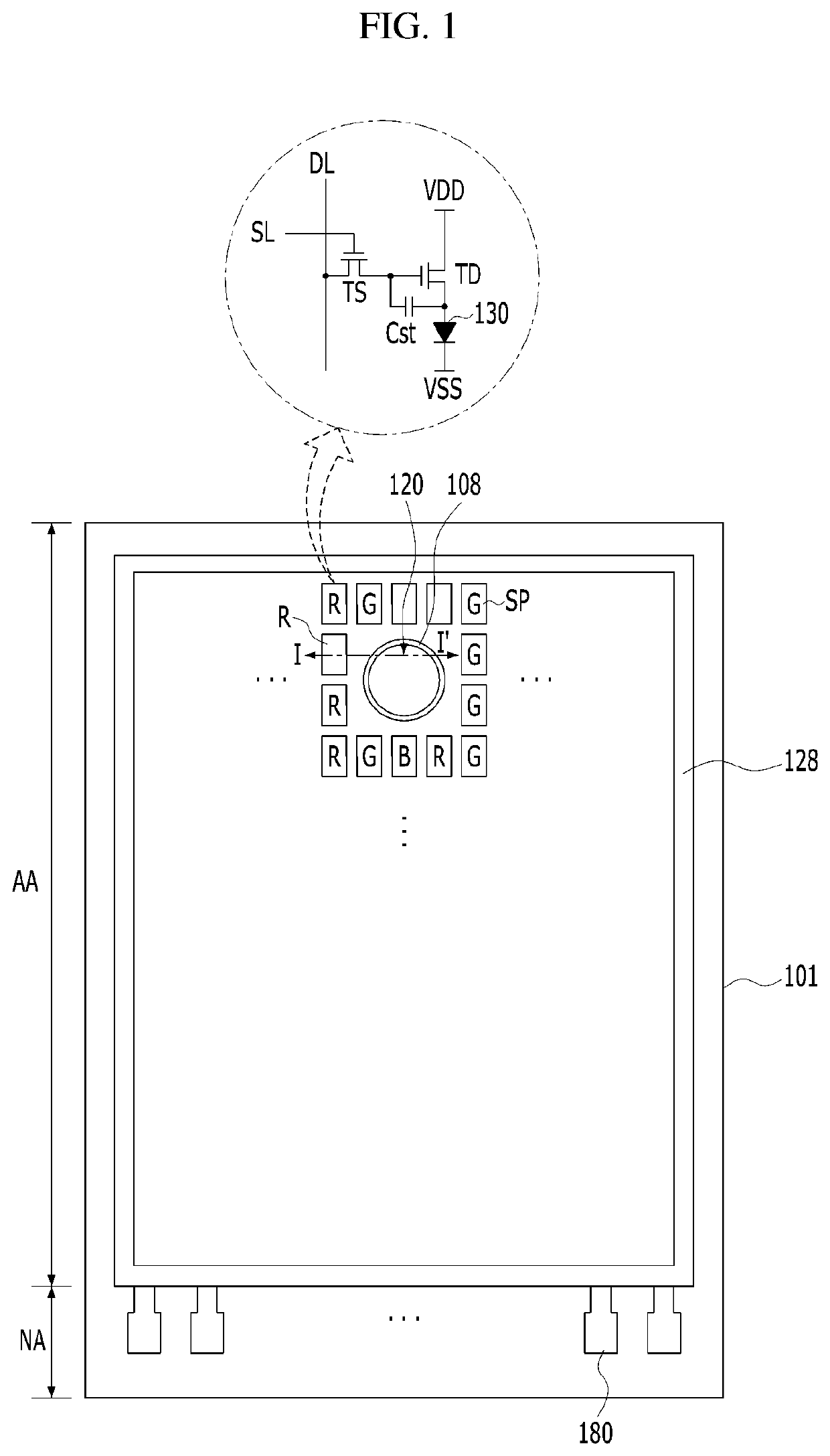

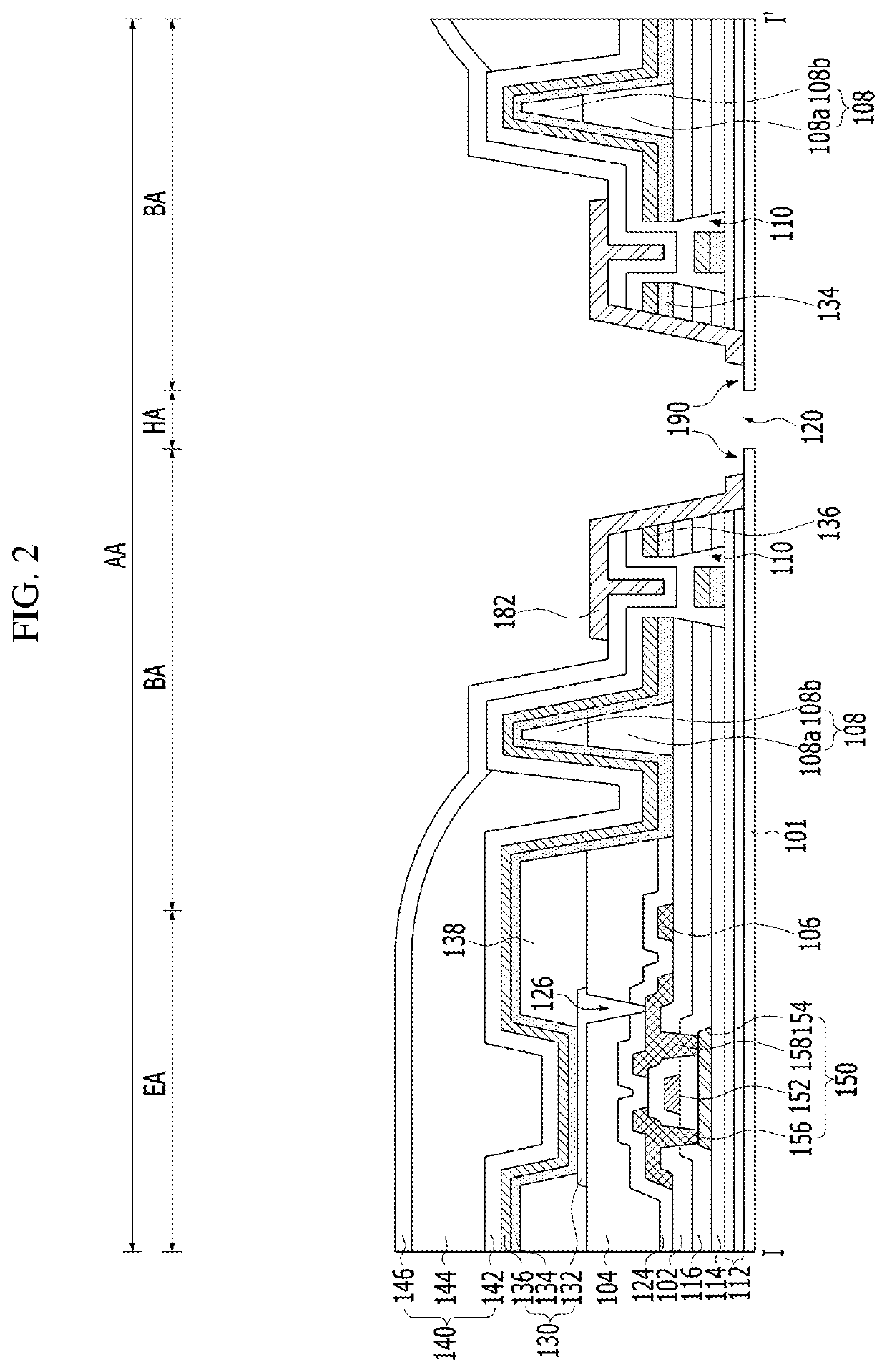

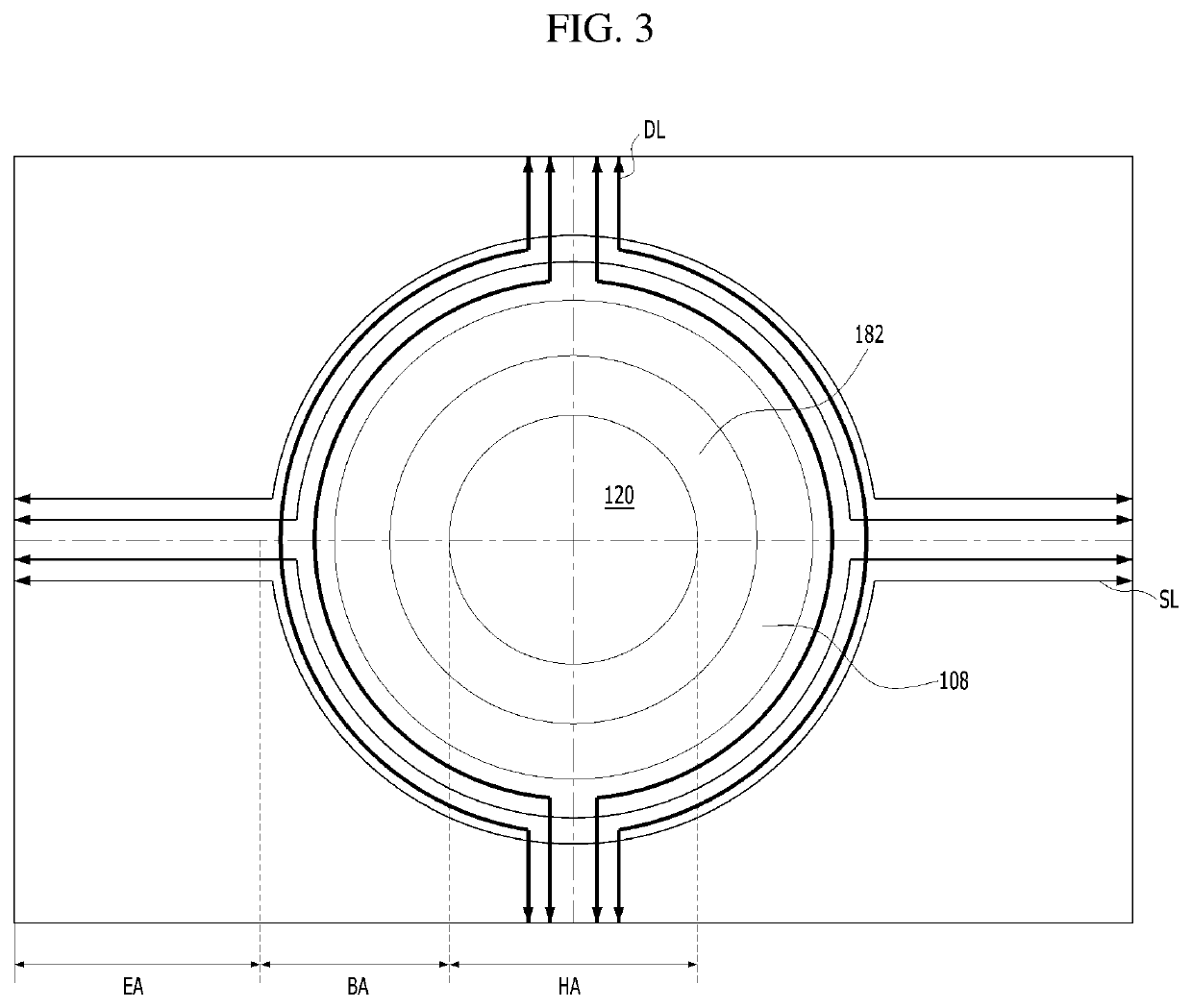

Display Device

ActiveUS20200194721A1Reduce non-display areaAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingMoisture penetrationDisplay device

A display device capable of reducing a non-display area includes a substrate hole surrounded by light emitting elements, and a moisture penetration preventing layer disposed between an inner dam surrounded by the light emitting elements and the substrate hole. Accordingly, it is possible to prevent damage to light emitting stacks caused by external moisture or oxygen. Since the substrate hole is disposed within an active area, a reduction in non-display area is achieved.

Owner:LG DISPLAY CO LTD

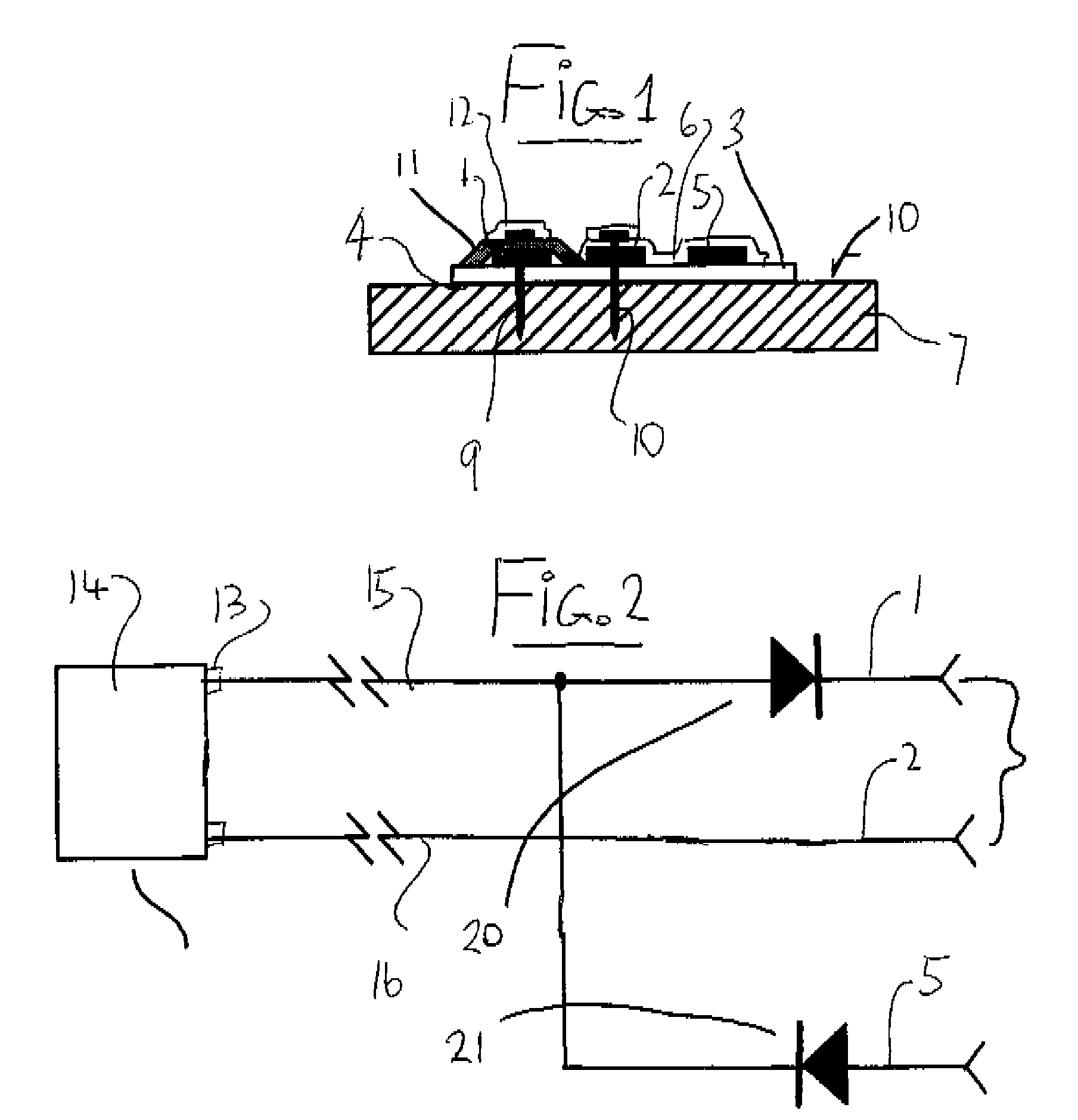

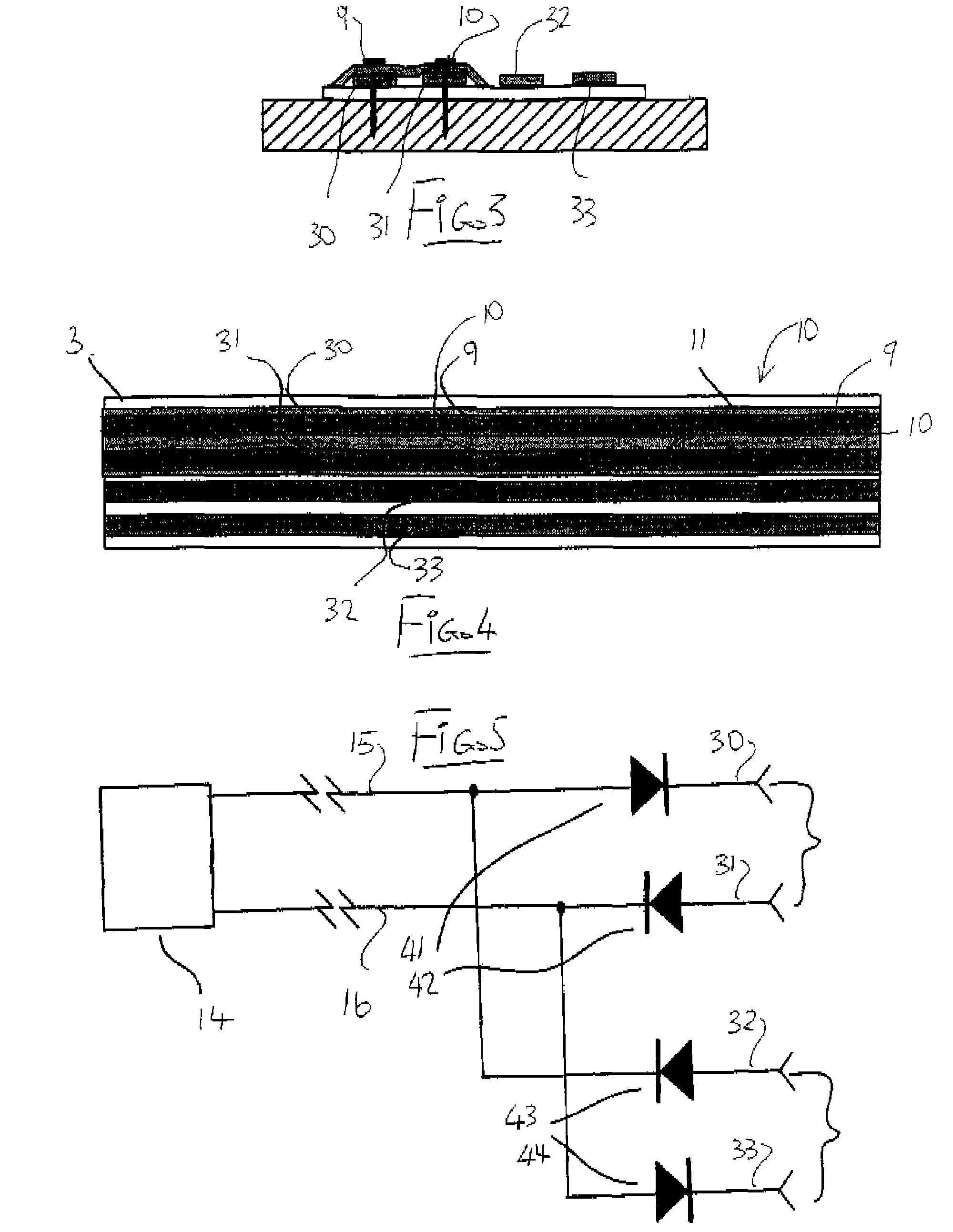

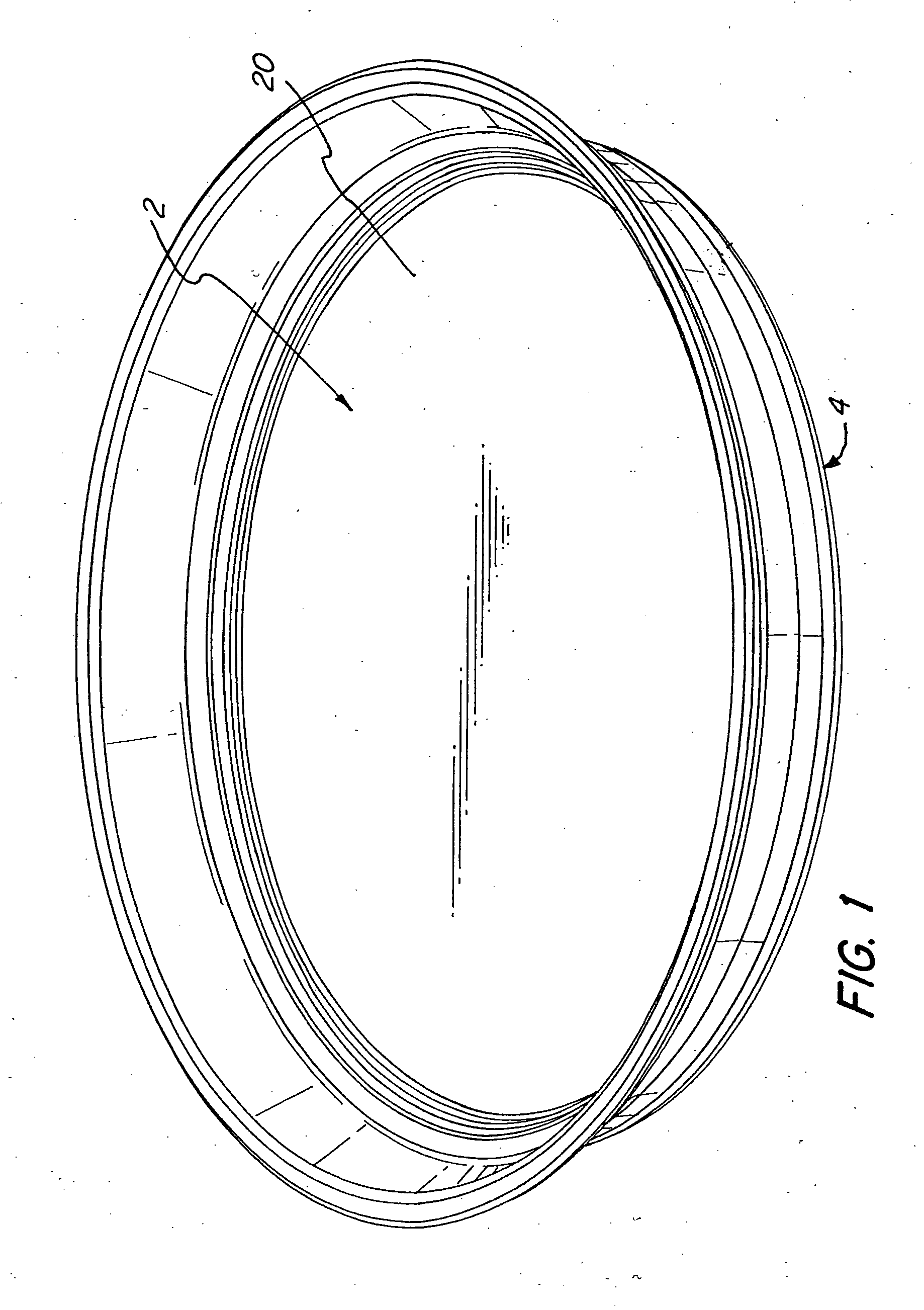

Moisture detection sensor tape and probes to determine surface moisture and material moisture levels

ActiveUS7688215B2Detection of fluid at leakage pointResistance/reactance/impedenceSurface moistureAdhesive belt

A moisture detection sensor is used in a building structure to detect moisture penetration. The sensor is a flat adhesive tape of a substrate of dielectric, hydrophobic material. Three or four elongate, parallel, conductors are secured to the top surface and a protective layer of non-hygroscopic, water pervious material is secured over two of the conductors so that they are exposed to surface moisture. One or two of the conductors are covered by an insulating layer to prevent moisture access. Pairs of moisture probes along the length of the tape penetrate the insulating layer, the respective conductors and the substrate and to extend into a building component to which the substrate has been adhered. A diode guide arrangement allows a monitoring unit to monitor the exposed conductors for surface moisture and the penetrated conductors for moisture in the component by reversing polarity of the voltage across the conductors.

Owner:DETEC SYST

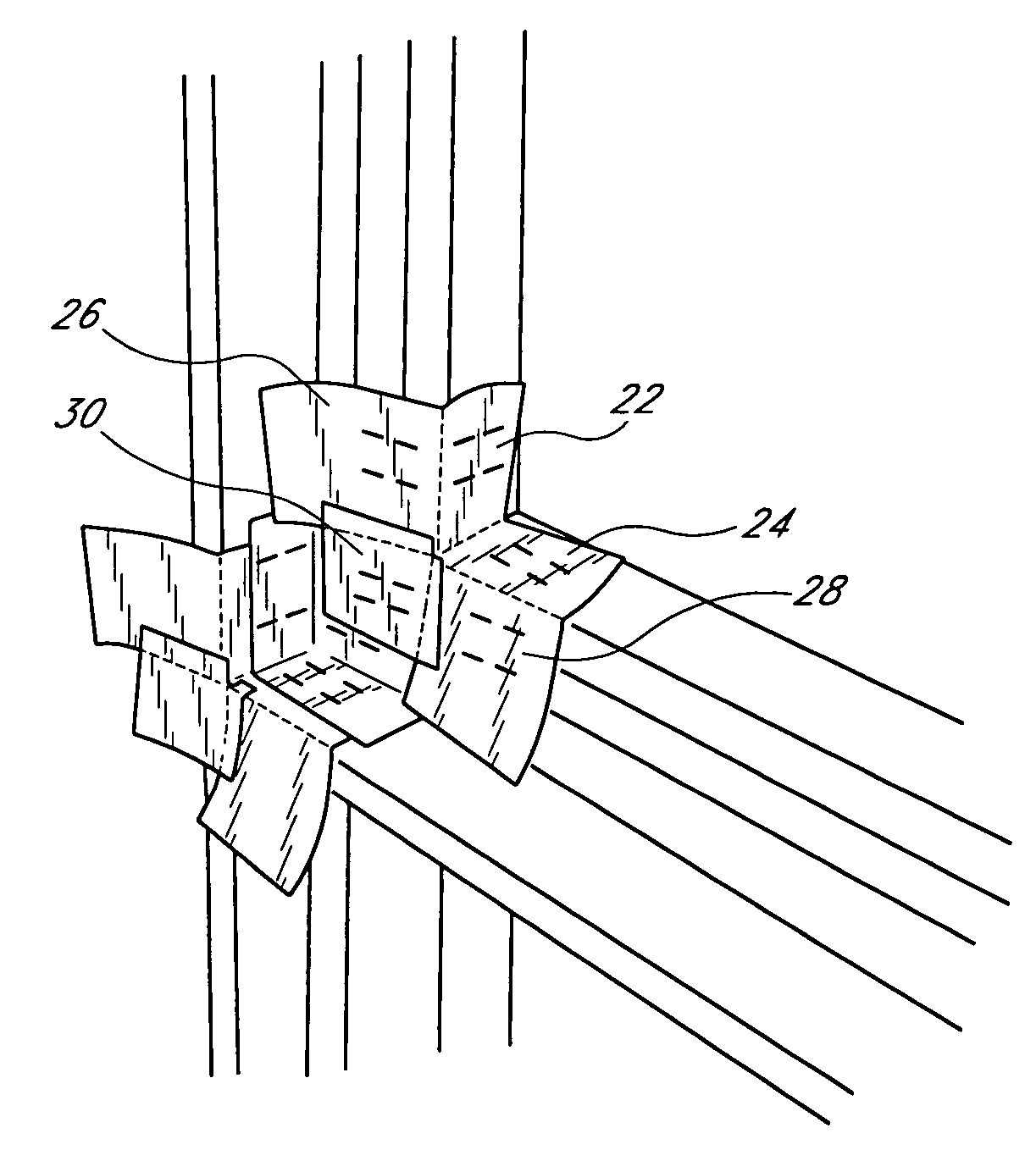

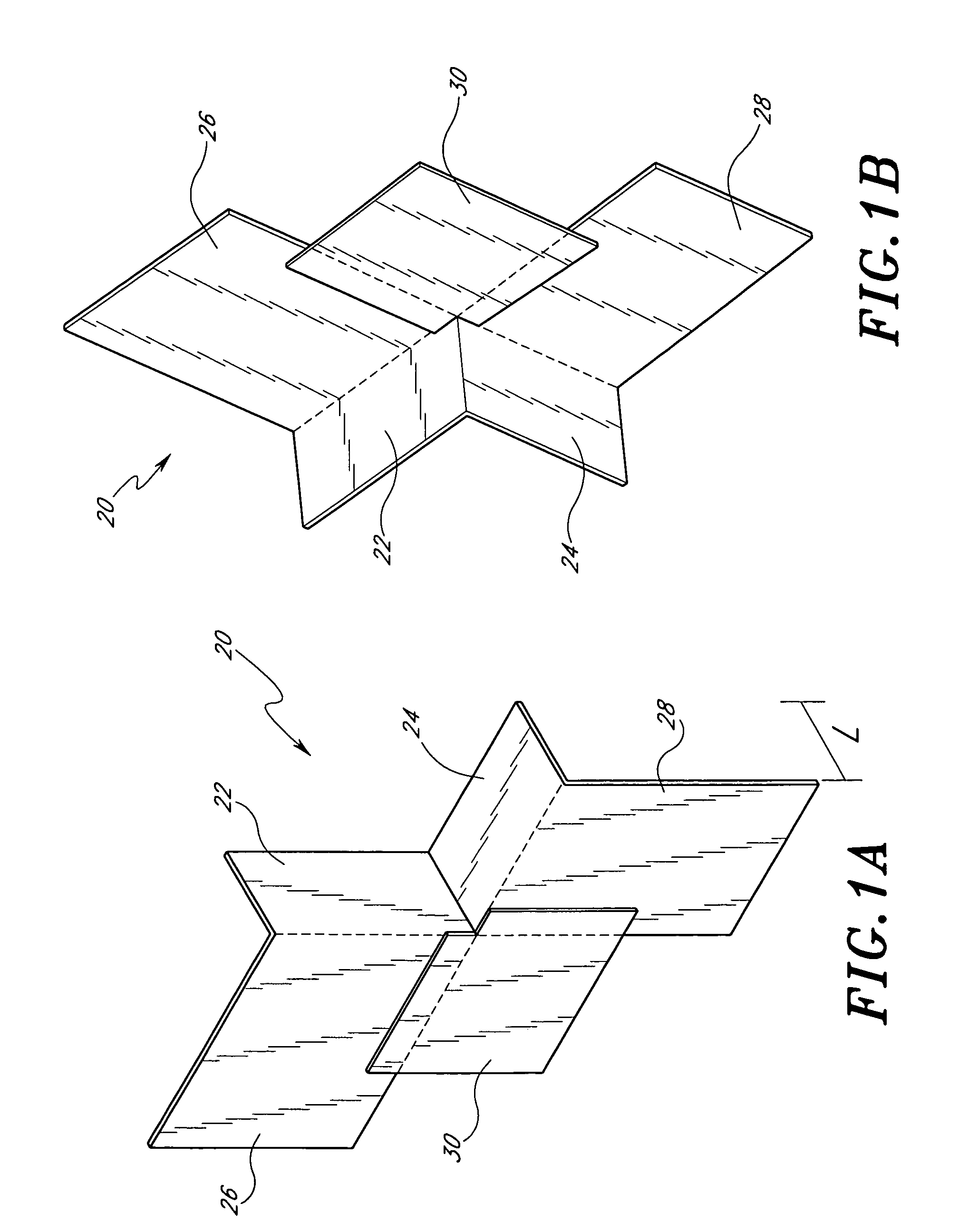

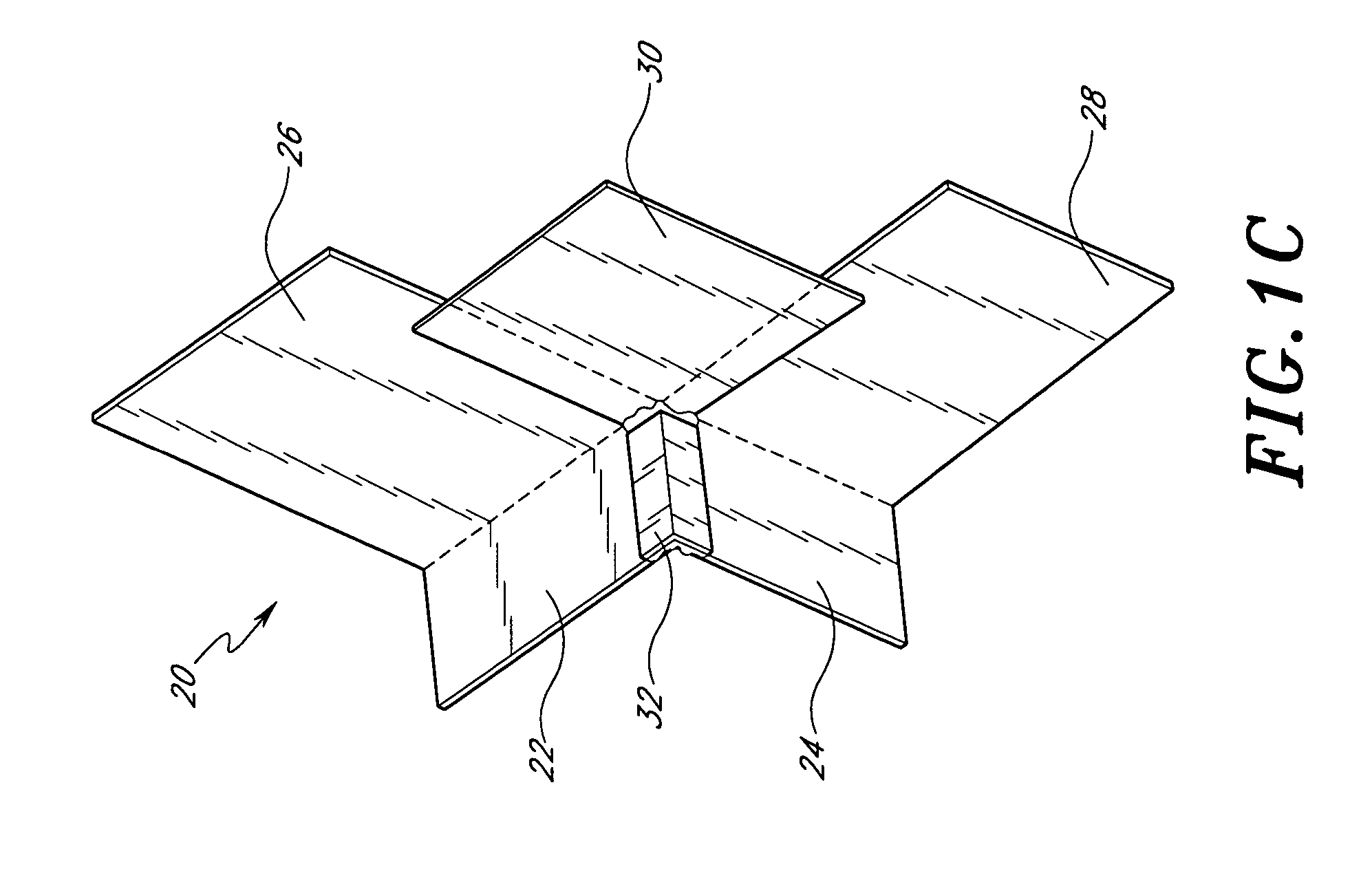

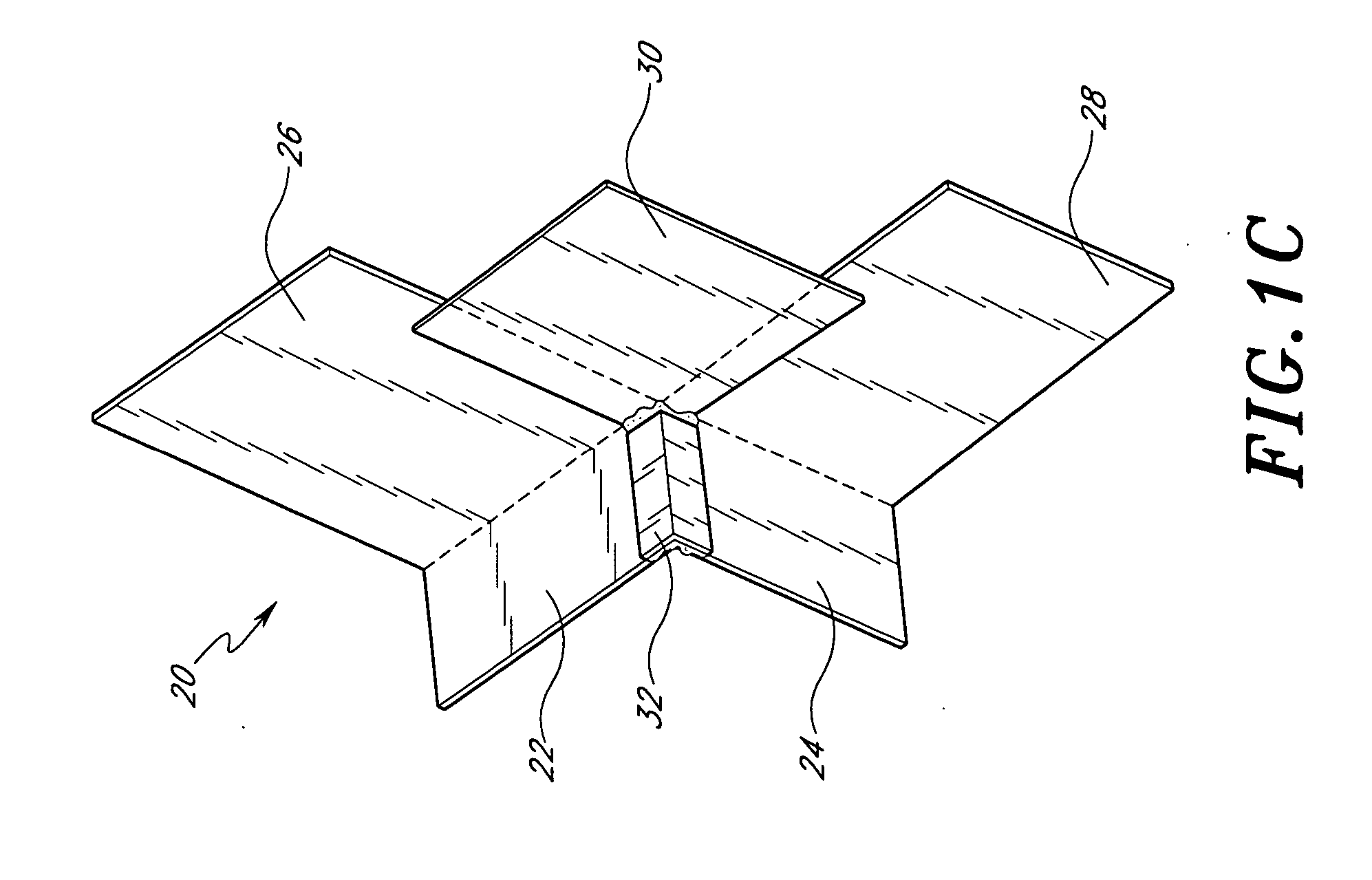

Corner flashing system

ActiveUS7735291B2Low costRoof covering using slabs/sheetsRoof covering using tiles/slatesMoisture penetrationEngineering

A corner flashing system is provided for sealing the corners of recessed window frames against moisture penetration. In a preferred embodiment, the system comprises first and second double-flap members, a half-cube member, and caulking. The first and second double-flap members, and the half-cube member are preferably made of asphalt or petroleum based material. In another preferred embodiment, the system comprises one double-flap member, a modified half-cube member, and caulking. In another preferred embodiment, the system comprises a single member that combines a double-flap member and a half-cube member, and caulking. In another preferred embodiment, the system comprises a combination member, a double-flap member, and caulking.

Owner:SUMMY GENE

Stimuli-responsive textile fabric and method for preparing same

The invention relates to an environment-response intelligent weave fabric and relative preparation. Wherein, adding the fabric which is induced by argon microwave low-temperature plasma to generate free group on surface, into the dual monomer solution of 2-acrylamide-2-methanesulfonic acid and N-isopropyl acrylamide that contains N and N'-methylene dual acrylamide cross linker to process graft polymerization reaction, while the bath ratio is 1:40, to graft the dual intelligent gel on the fiber macromolecule of fabric, to attain said inventive product. When the invention is dry, it has no difference from general fabric, but when it is wet, the gel will adsorb water to expand and block the slits between fibers, to reduce the water and gas permeability of fabric, and avoid outer penetrating into the inner layer of fabric to stop heat emission. The invention can be used to produce army waterproof clothes, heat-accumulation temperature adjustable special clothes, etc.

Owner:TIANJIN POLYTECHNIC UNIV

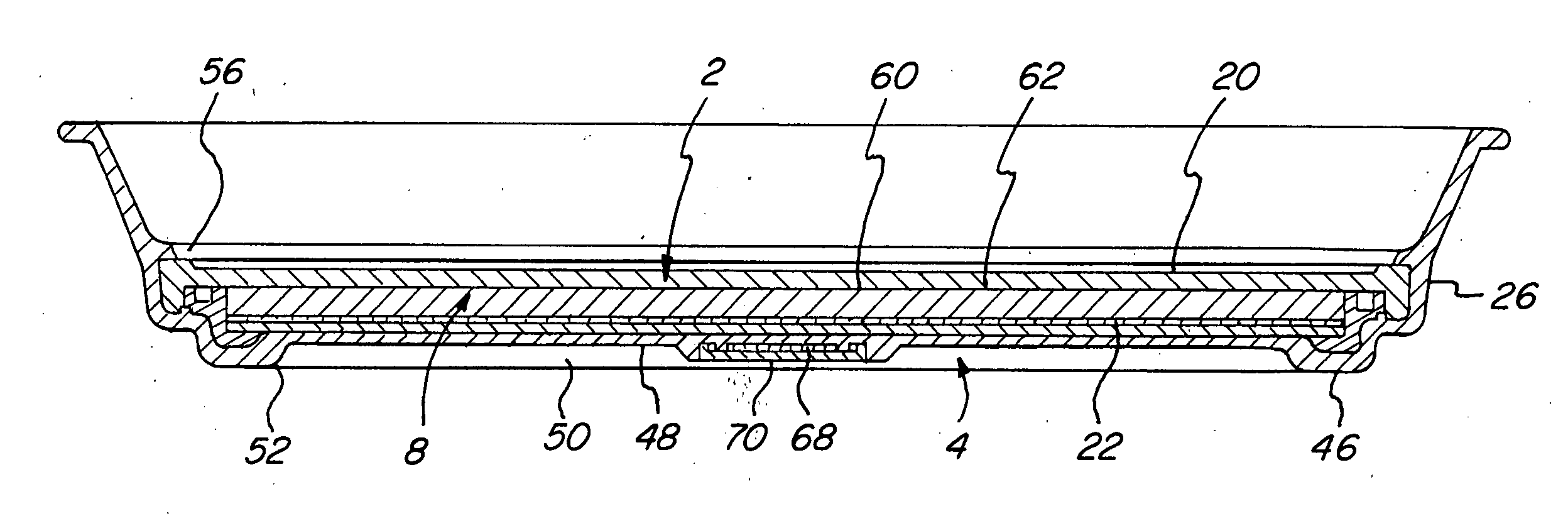

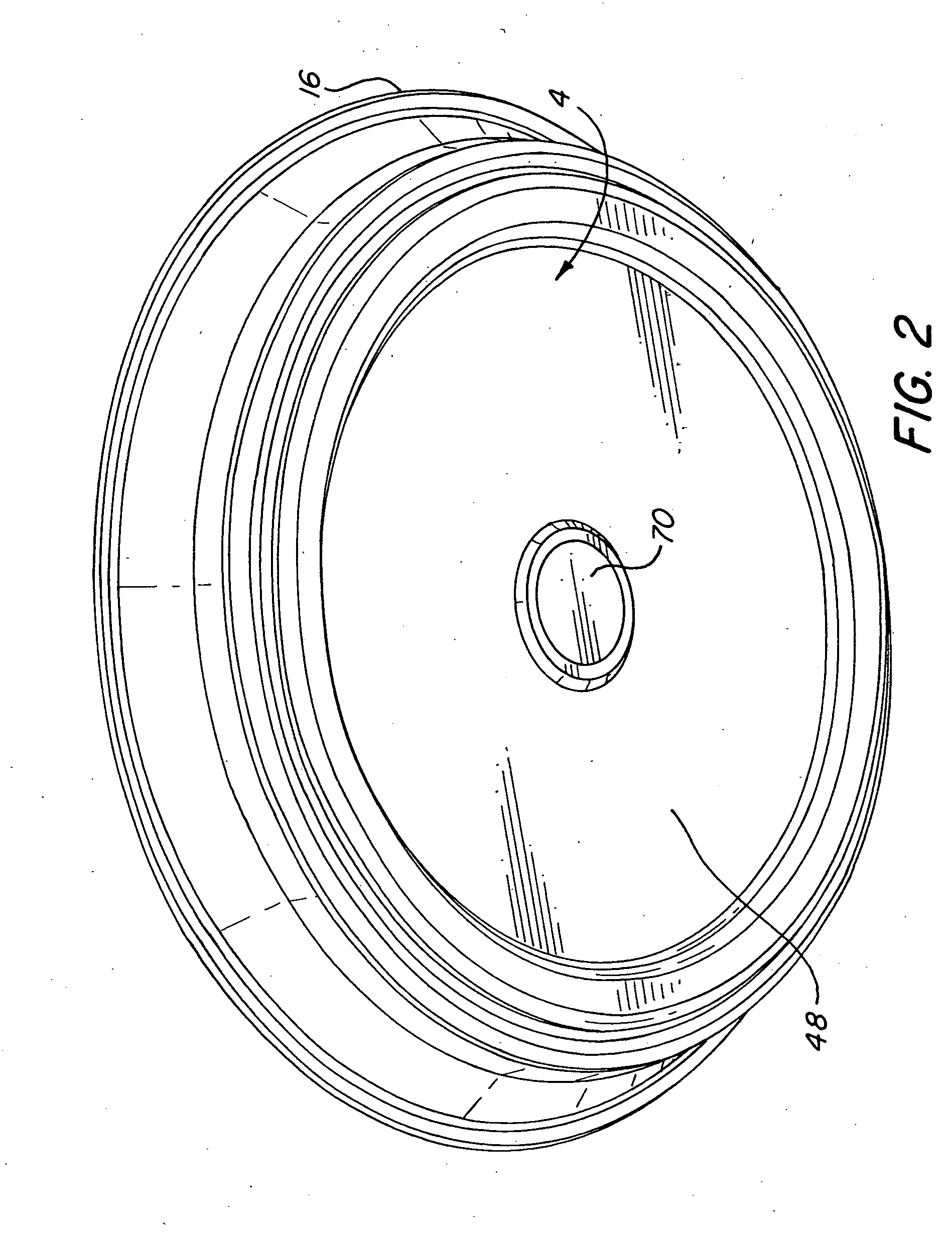

Induction heated server and method of making

InactiveUS20090188909A1Easy to reachPrevent moisture penetrationCooking-vessel materialsMetal working apparatusMoisture penetrationEngineering

An induction heatable server comprises a base element having a bottom wall and a peripheral wall defining an upwardly opening cavity in which are disposed a heat retentive disc and a ring member which is bonded to the peripheral wall. A top element extends over the ring member and seals the cavity. The top element is bonded to the peripheral wall of the base element and the ring member to preclude moisture penetration into the cavity.

Owner:NEWSTAR BUSINESS CREDIT +1

Multifunctional high-strength composite fabric coating agent, coating, and preparation method and application of multifunctional high-strength composite fabric coating agent

InactiveCN107254248AHigh strengthImprove scratch resistanceAntifouling/underwater paintsBiochemical fibre treatmentMoisture penetrationFilm-forming agent

Owner:JIANGNAN UNIV

Double Broken Seal Ring

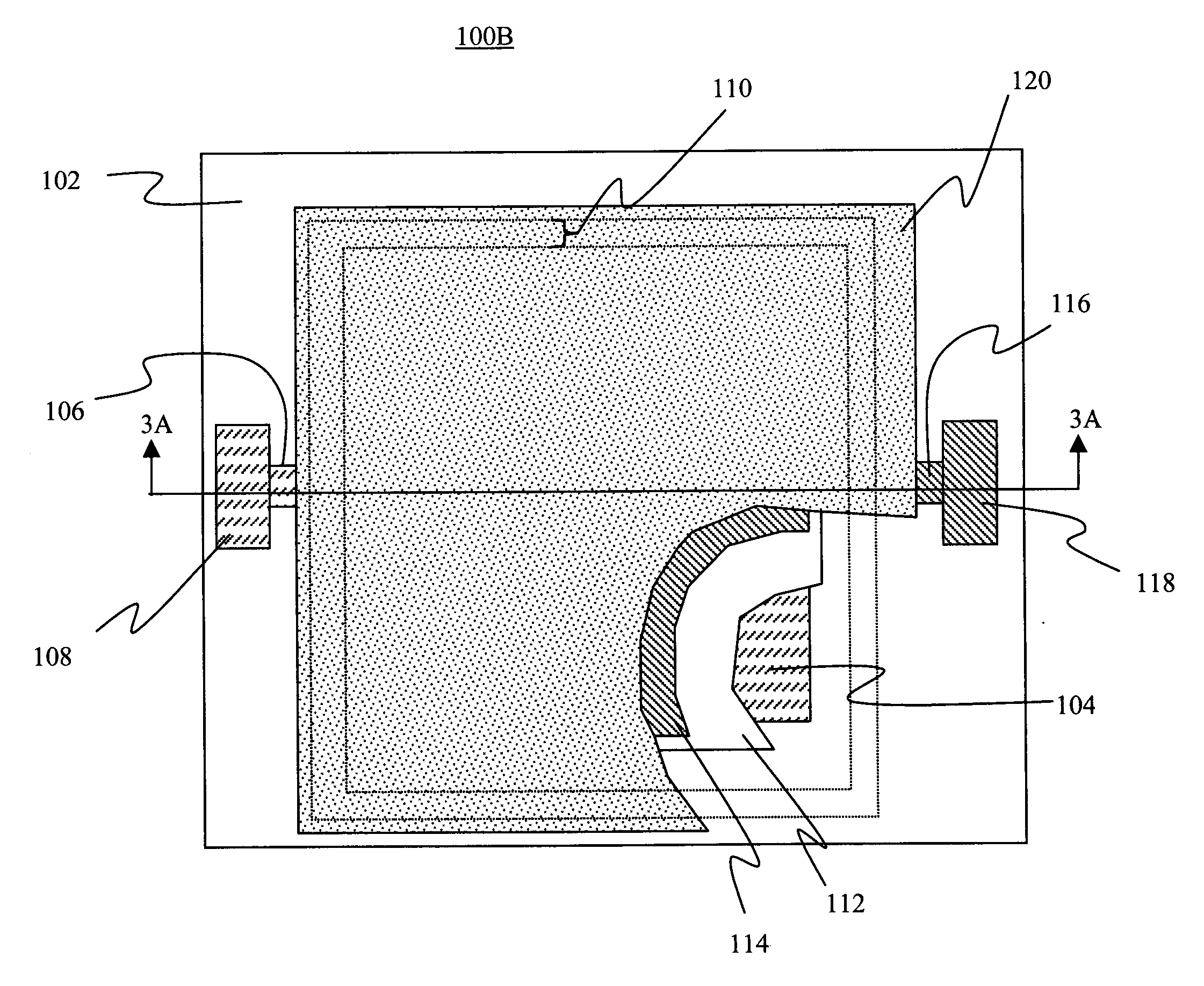

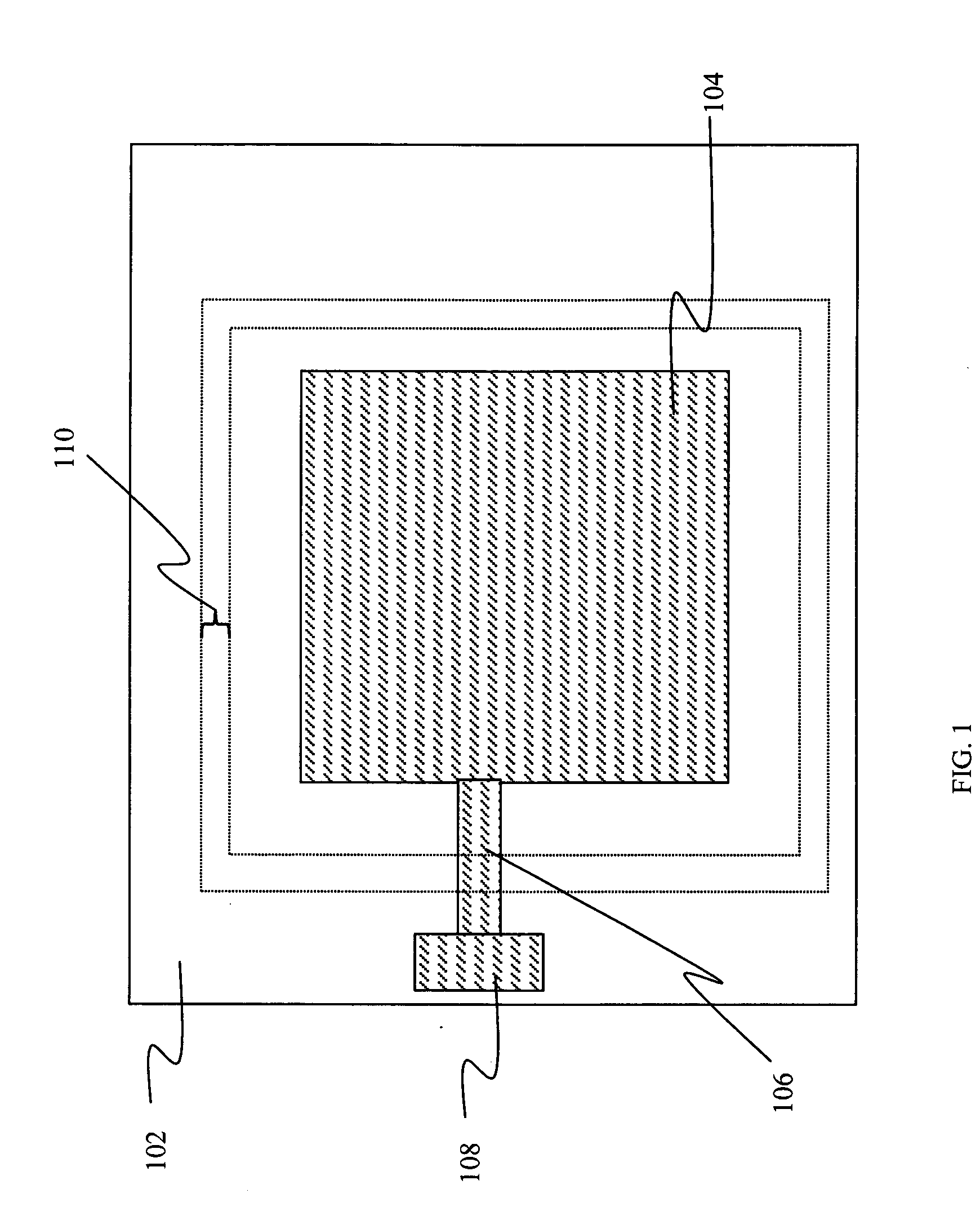

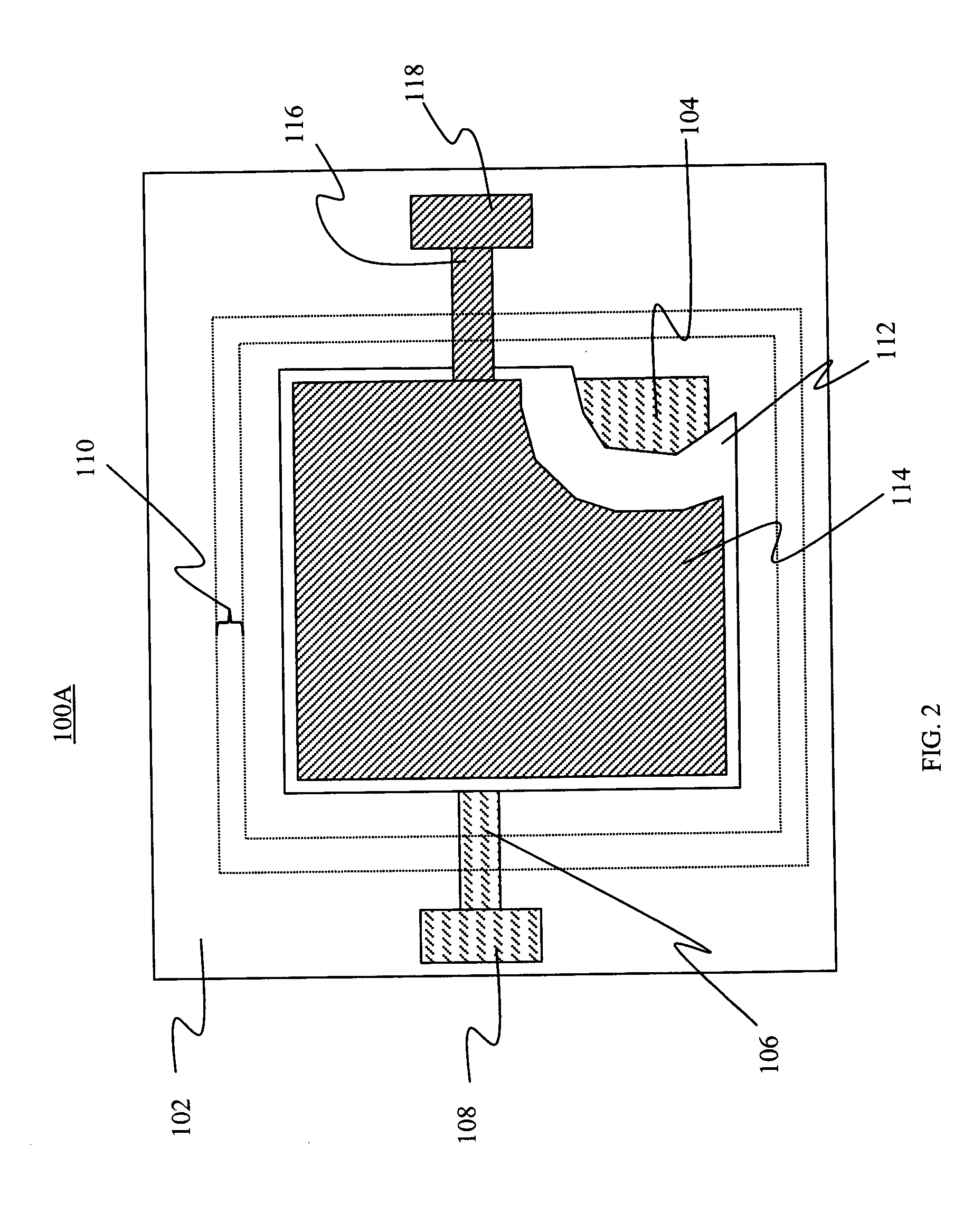

InactiveUS20100084751A1Reduce noise transmissionQuantity minimizationSemiconductor/solid-state device detailsSolid-state devicesMoisture penetrationEngineering

The amount of signal propagation and moisture penetration and corresponding reliability problems due to moisture penetration degradation in an IC can be reduced by fabricating two seal rings with non-adjacent gaps. In one embodiment, the same effect can be achieved by fabricating a wide seal ring with a channel having offset ingress and egress portions. Either of these embodiments can also have grounded seal ring segments which further reduce signal propagation.

Owner:QUALCOMM INC

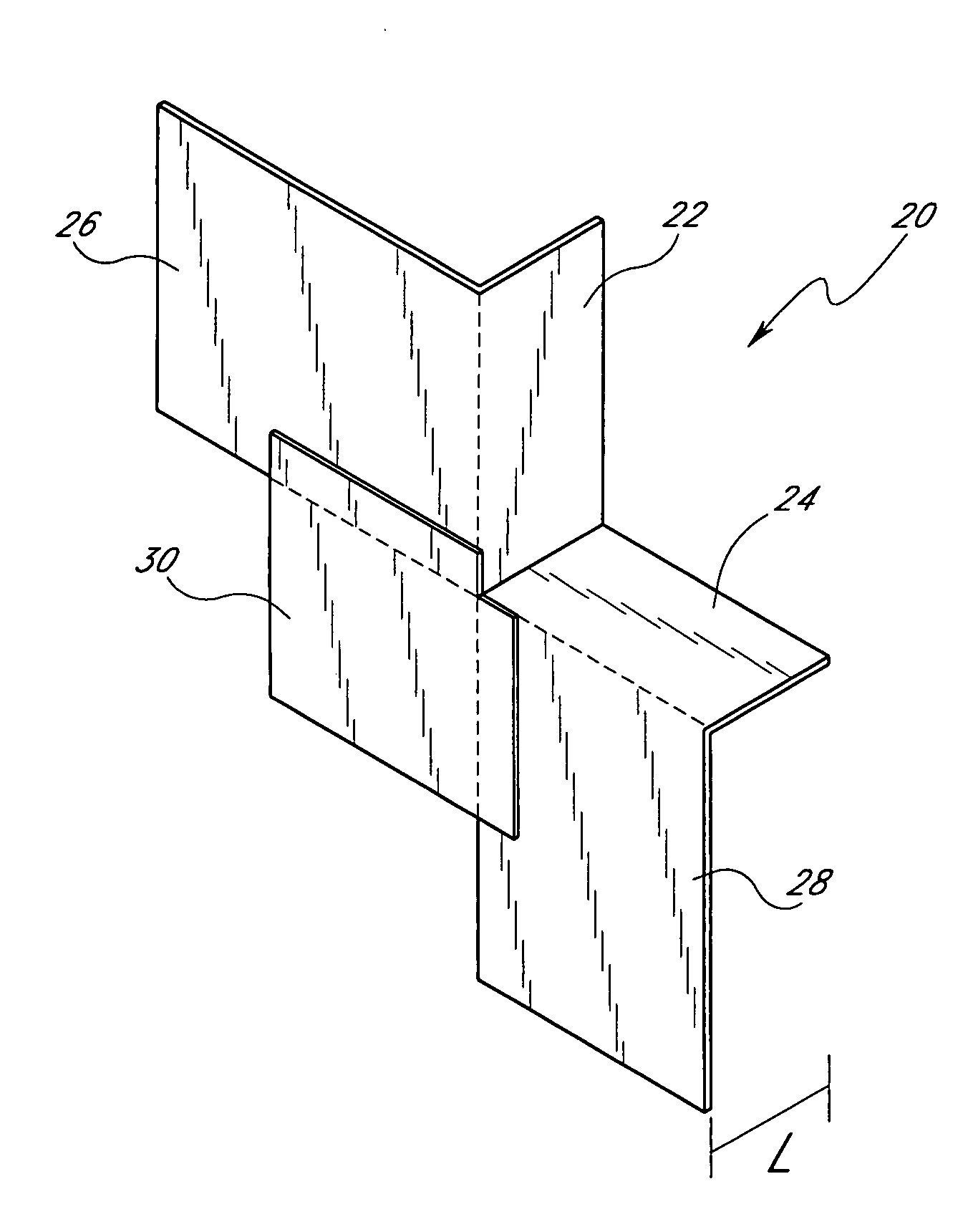

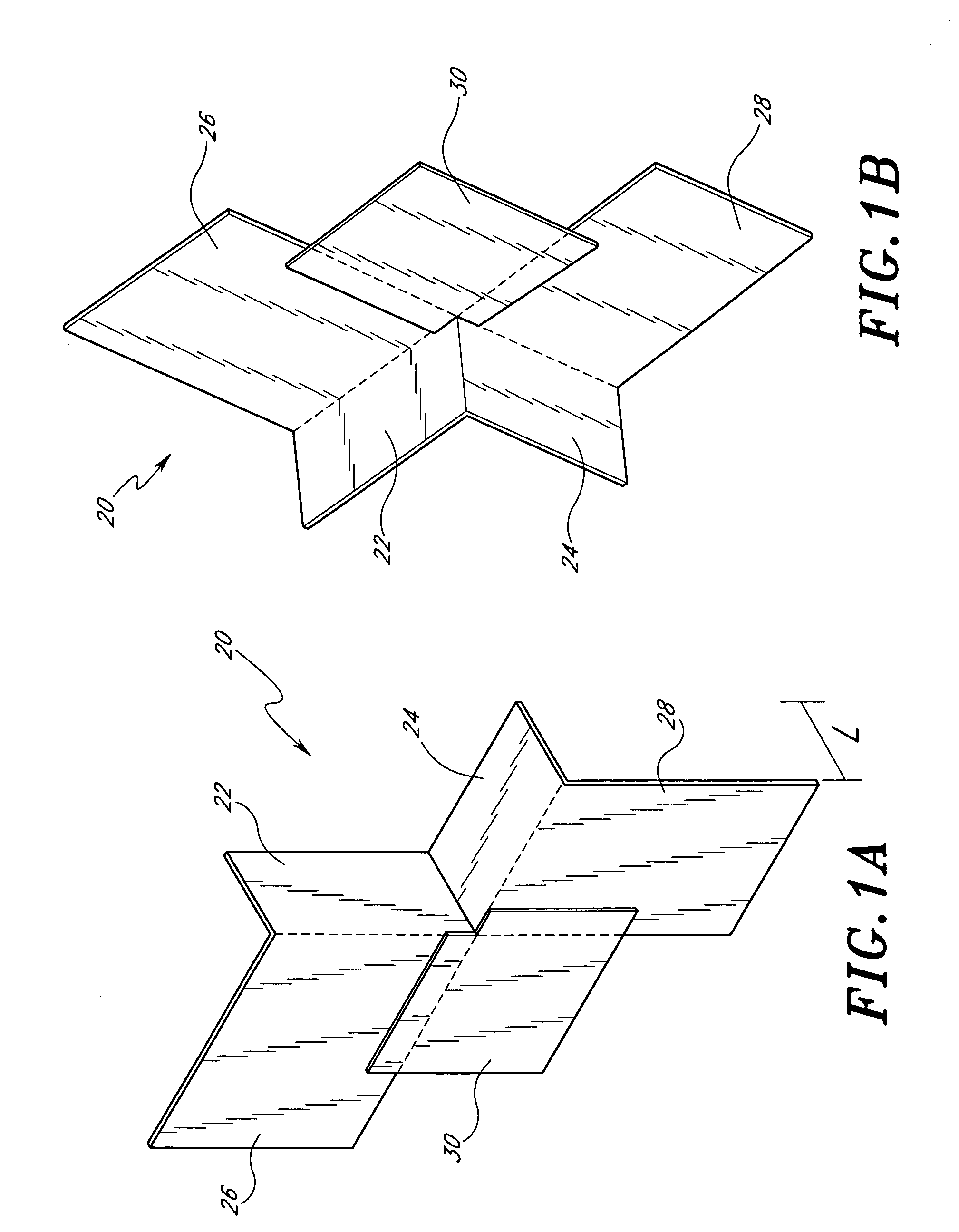

Corner flashing system

ActiveUS20050055890A1Low costRoof covering using slabs/sheetsRoof covering using tiles/slatesMoisture penetrationEngineering

A corner flashing system is provided for sealing the corners of recessed window frames against moisture penetration. In a preferred embodiment, the system comprises first and second double-flap members, a half-cube member, and caulking. The first and second double-flap members, and the half-cube member are preferably made of asphalt or petroleum based material. In another preferred embodiment, the system comprises one double-flap member, a modified half-cube member, and caulking. In another preferred embodiment, the system comprises a single member that combines a double-flap member and a half-cube member, and caulking. In another preferred embodiment, the system comprises a combination member, a double-flap member, and caulking.

Owner:SUMMY GENE

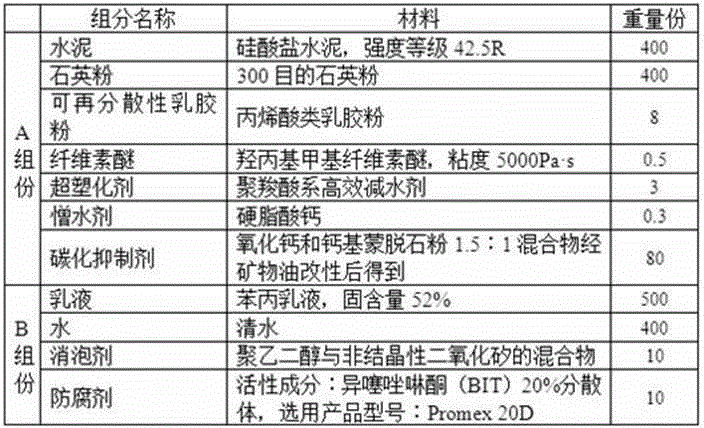

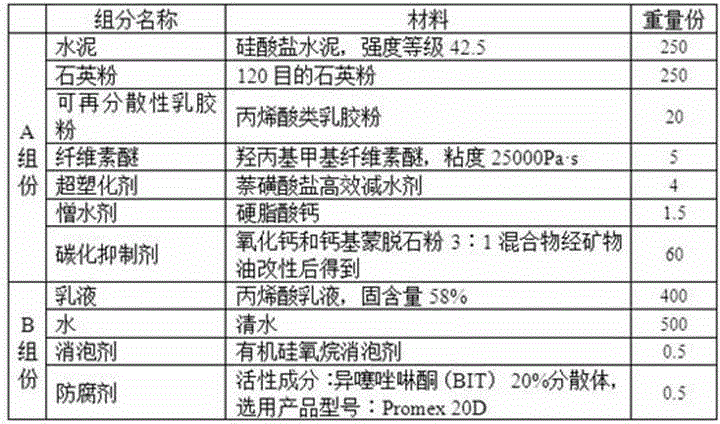

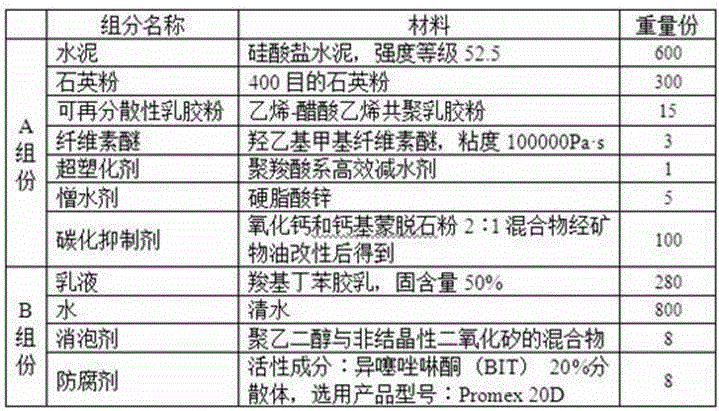

Carbonization-resistant waterproof slurry

ActiveCN103601441AAnti-carbonizationWith waterproof functionCement coatingsCelluloseMoisture penetration

The invention relates to a carbonization-resistant waterproof slurry. The carbonization-resistant waterproof slurry is a double-component organic / inorganic material composite slurry, and comprises cement, quartz powder, redispersible latex powder, cellulose ether, a super plasticizer, a water repellent, a carbonization inhibitor, an emulsion, water, an antifoaming agent, and an antiseptic. The carbonization inhibitor is prepared by modifying a mixture of calcium oxide and calcium montmorillonite powder with mineral oil, and effect controlling on release of active ingredients of the carbonization inhibitor can be realized via modification, so that compact and uniform waterproof layers are formed from the surface to the internal part of a coating thin layer, moisture penetration is prevented with high efficiency, excellent carbonization resistance and water resistance are obtained, and service life of the coating layer and concrete protection term are prolonged. Compatibility of the carbonization-resistant waterproof slurry with inorganic materials such as cement is excellent, and excellent carbonization resistance and water resistance can be obtained by a functional thin layer with a thickness of 1 to 2mm.

Owner:西卡德高(上海)建材有限公司

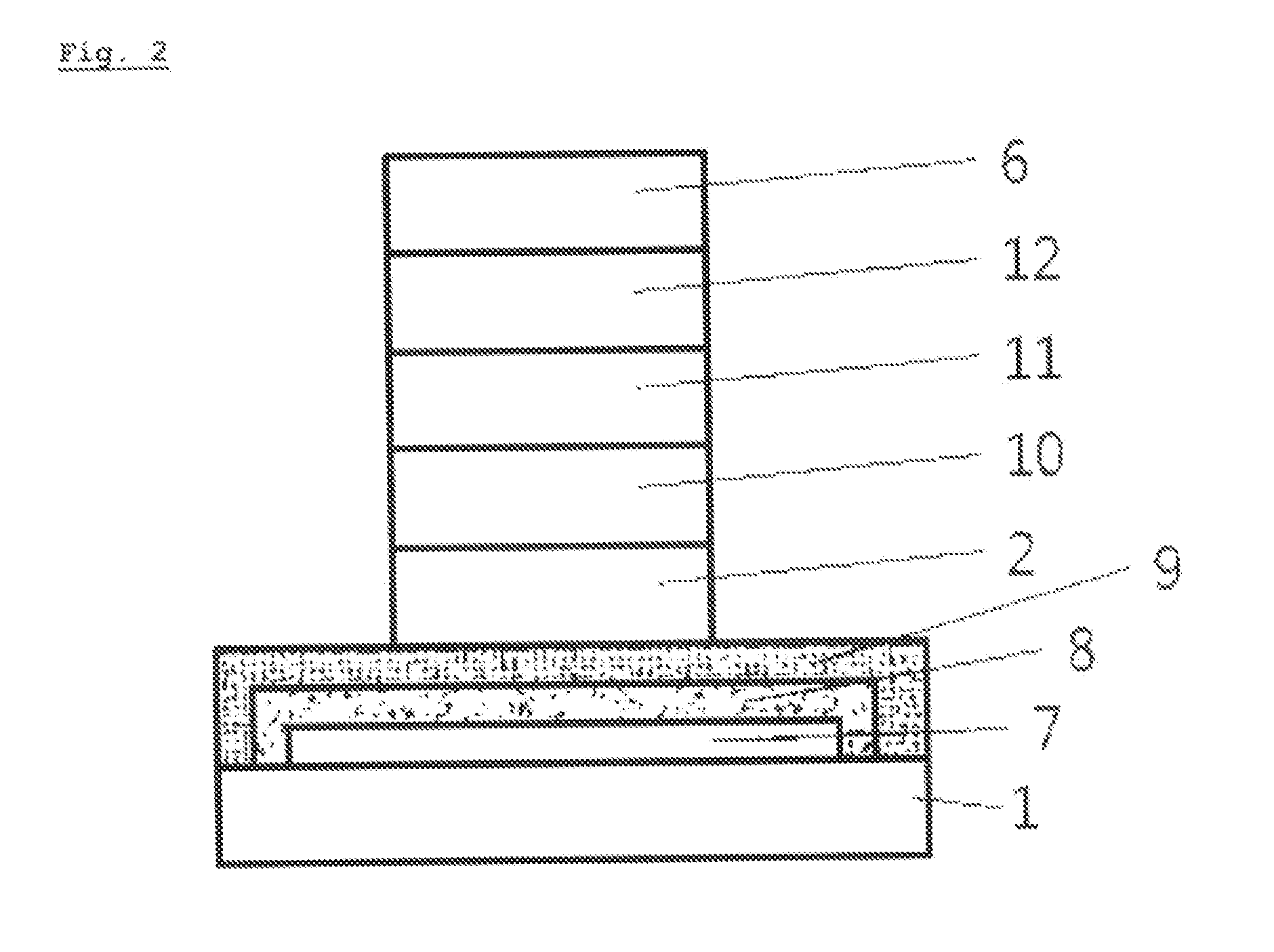

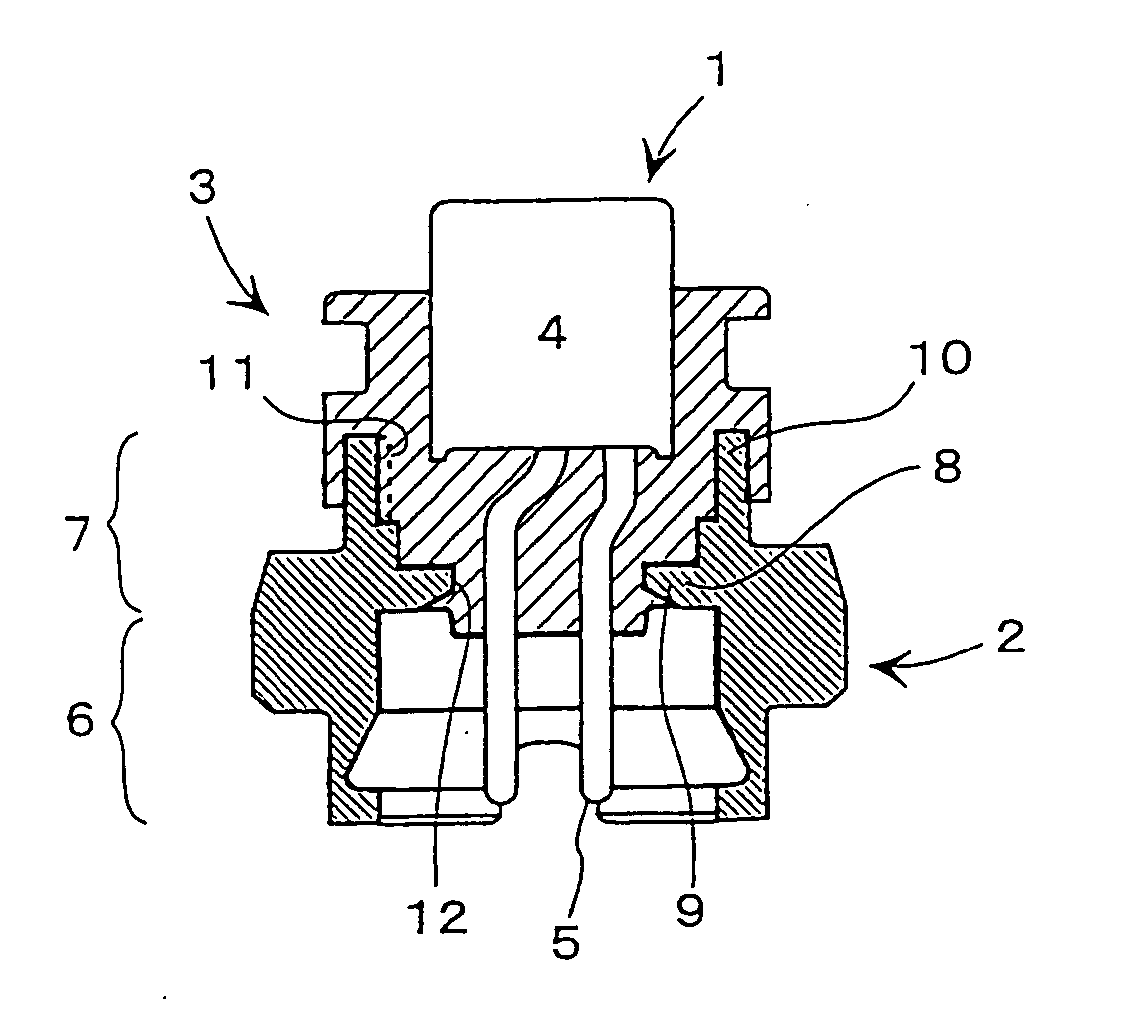

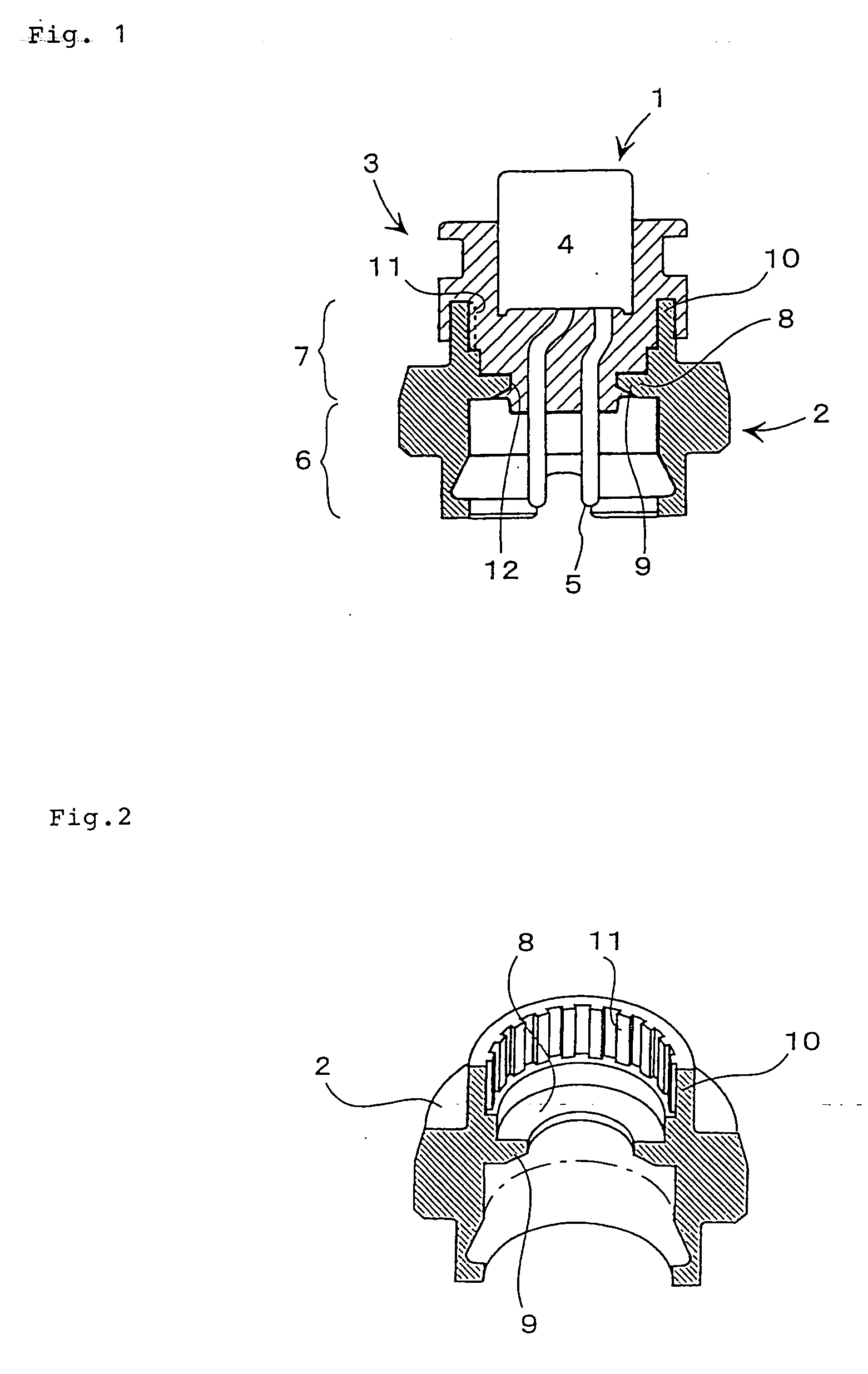

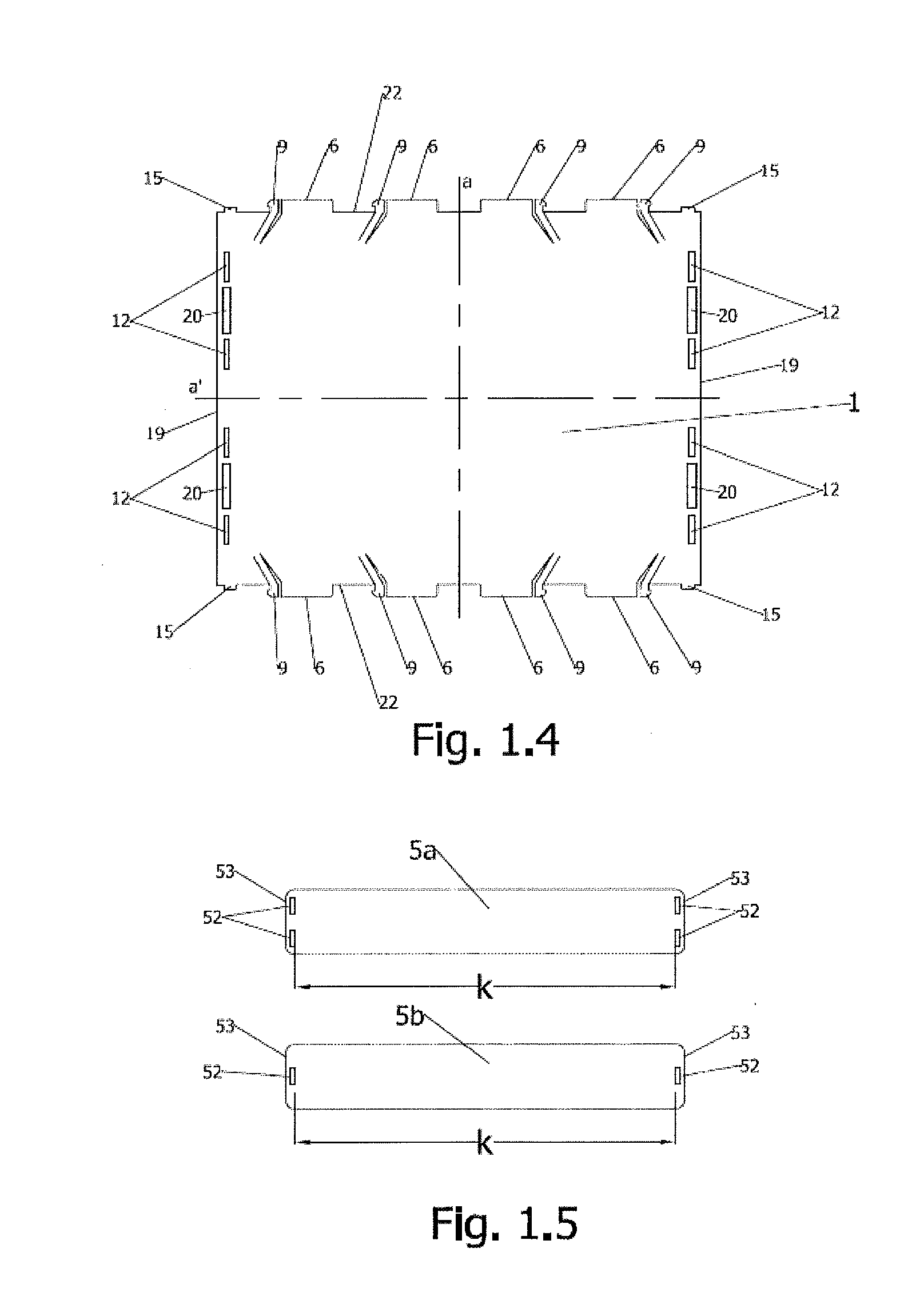

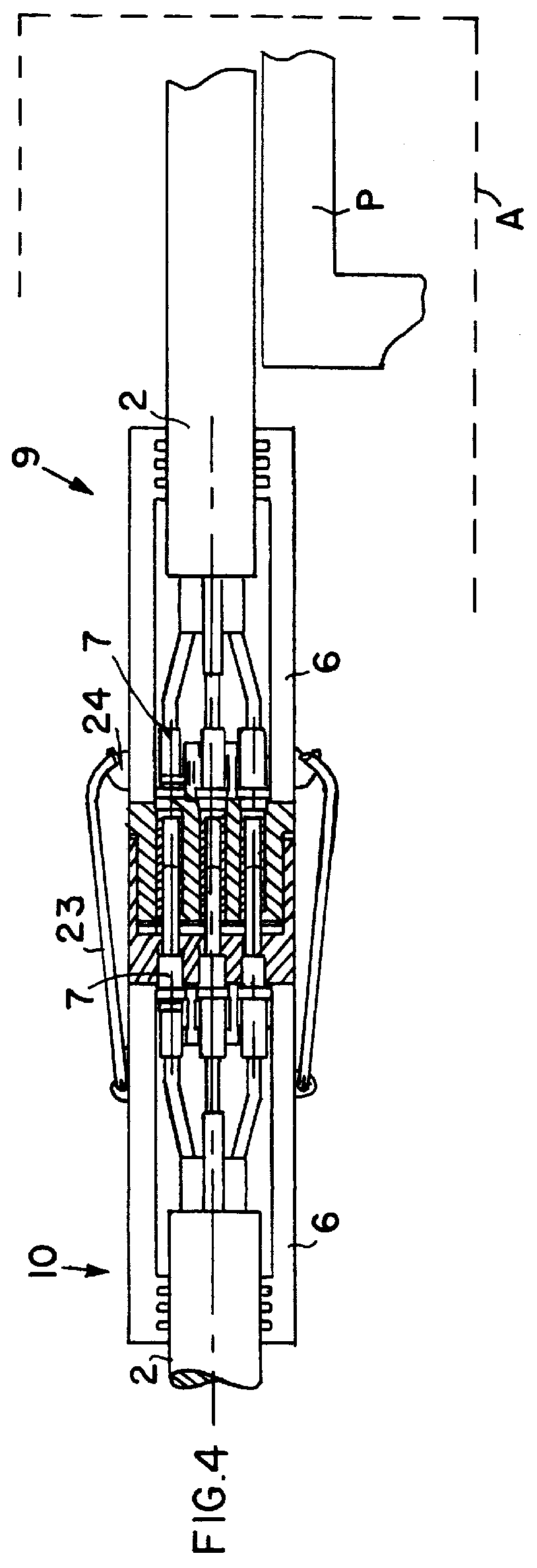

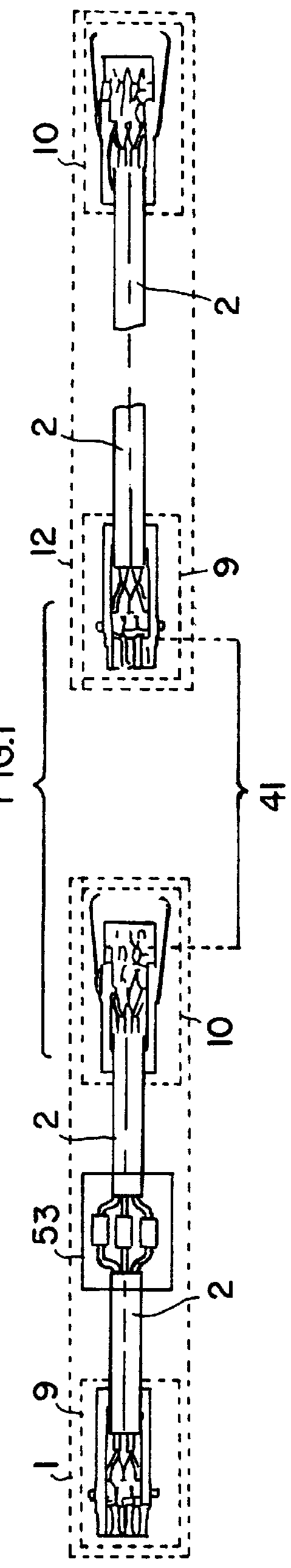

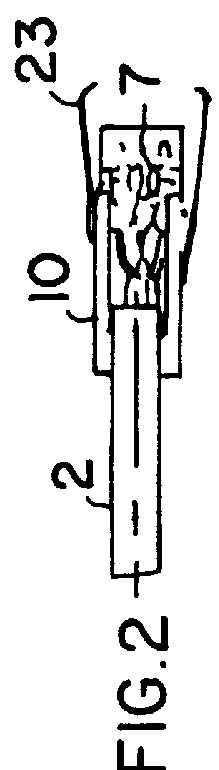

Interconnect system for heating conductors in an aircraft

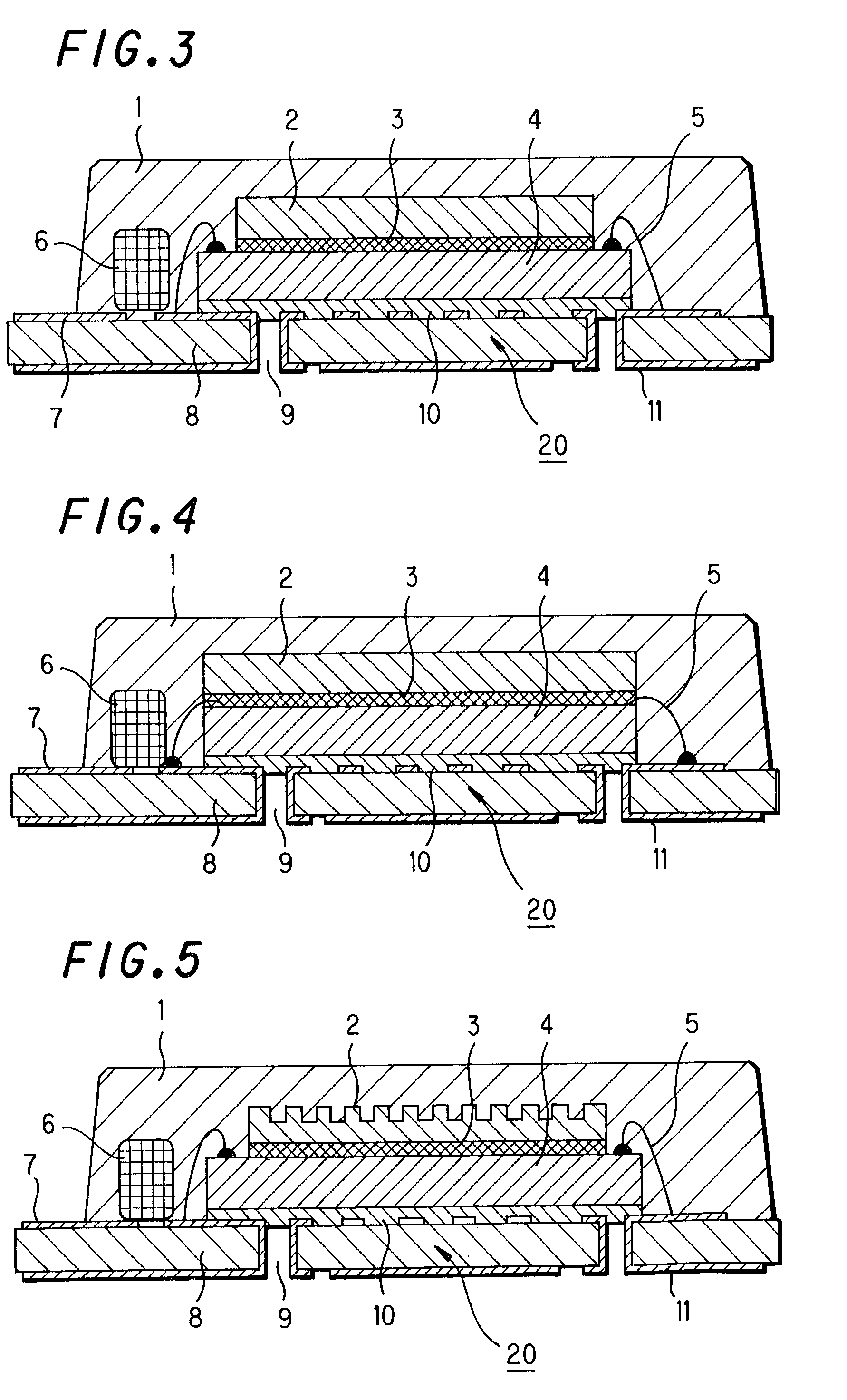

InactiveUS6126483AImprove sealingSimple processHeater elementsSecuring/insulating coupling contact membersElectricityElectrical conductor

A system of interconnected heating conductors, suitable for preventing freezing of water lines in an aircraft for example, includes a plurality of heater units (1, 12) electrically coupled together by respective coupling plugs (9, 10). Each heater unit comprises one or more heating conductor bands or cables (2, 21, 22), with a respective socket contact plug (9) connected to one end thereof and a respective pin contact plug (10) connected to the other end thereof. Each plug (9, 10) includes a housing (6) wherein the conductors of the heater band (2) are crimp-connected to electrical connectors (7), which include pin contacts (723) in the case of the pin contact plug (10) and socket contacts (77) in the case of the socket contact plug (9). The housing (6) is completely filled with a sealing compound (19) which is injected through a fill hole in the housing wall. The pin contacts (723) extend outwardly through contact chambers into a female cavity (411) of the plug (10), while the socket contacts (77) extend outwardly through contact chambers in a male plug member (412) of the plug (9). The two plugs may be matingly plugged together, and mechanically secured by locking bails (23) engaging retaining catches (24). This achieves a very effective seal against moisture penetration, and eliminates capillary action even when subjected to vibrations, shock, temperature variations, and low pressure conditions.

Owner:DAIMLER CHRYSLER AEROSPACE AIRBUS

Turf additive formulation for reduction of localized dry spots due to water repellency

Certain novel formulations of turf additives that act in such a manner as to permit proper amounts of moisture to contact root systems in order to reduce dry spots within highly managed turf areas and / or lawns. It is theorized that the accumulation of humic acid (and other natural byproduct deleterious compounds) at the topsoil surface in most cultivated grassy areas including sandy soils (such as, in particular, golf greens, pastures, lawns, and the like), as well as other non-grassy sandy areas in which such humic acid accumulation poses water repellency problems (such as beaches), results in the production of an effective organic waxy coating on the soil and / or sand components. Such a coating is hydrophobic in nature and thus dries out the soil itself. The inventive formulation thus permits removal of such accumulated humic acid (and other compounds) from the topsoil to the level necessary to provide effective moisture penetration for sustained grass growth therein (hereinafter referred to as "redistributes"). Methods of providing such beneficial removal of humic substances from target sandy soils are also contemplated within this invention, as well as specific test hydrophobic sand formulations.

Owner:MILLIKEN & CO

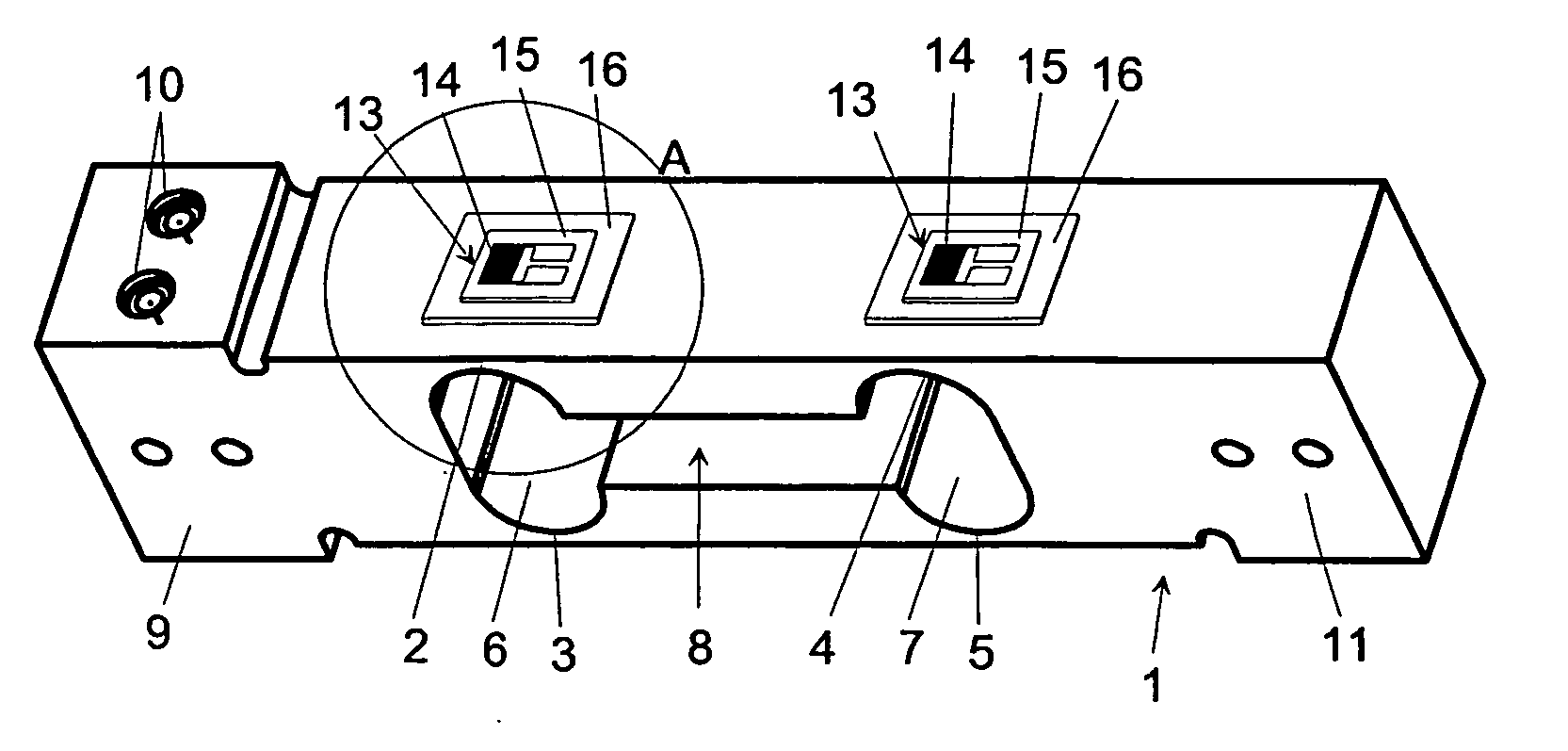

Moisture protection for an electromechanical transducer

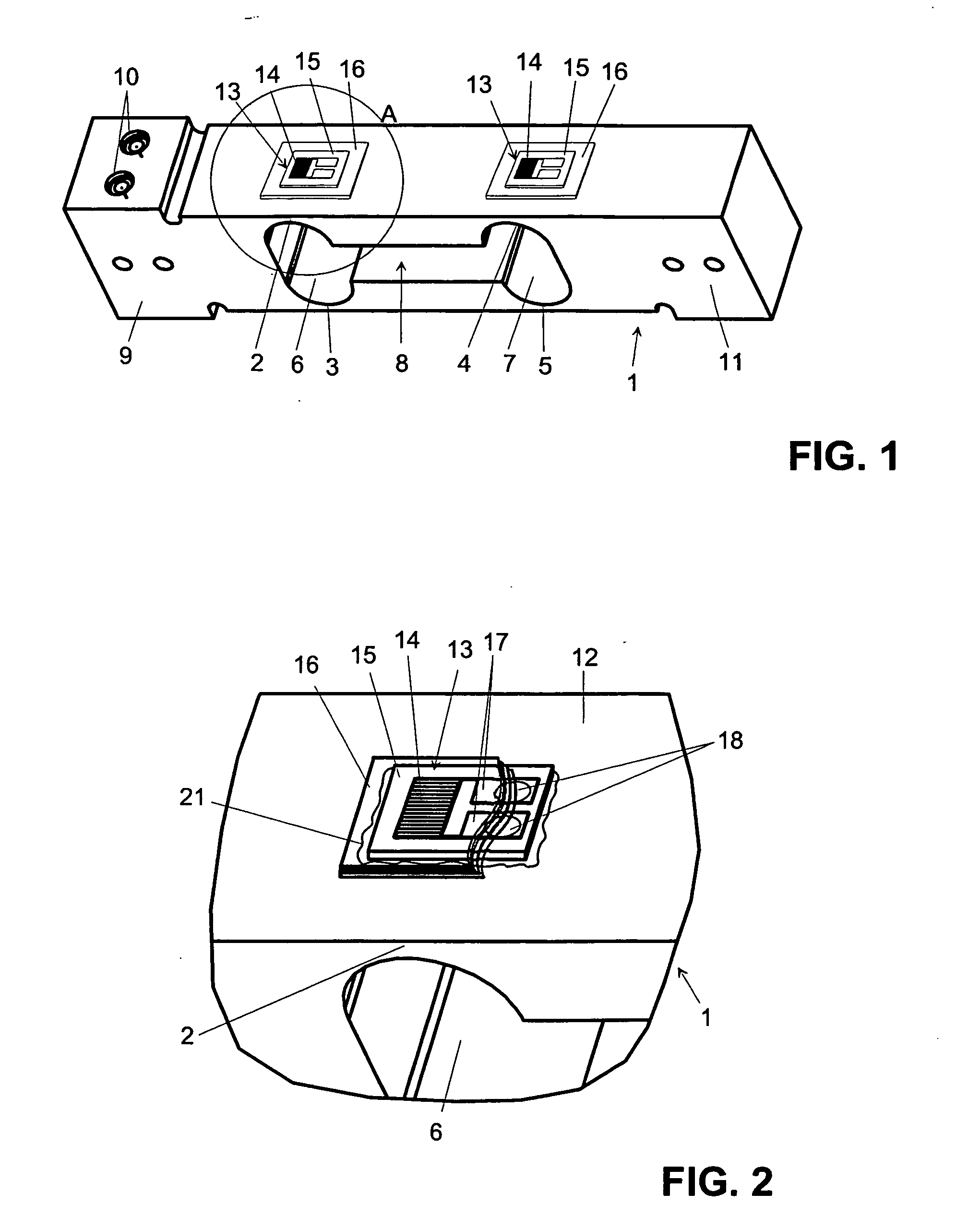

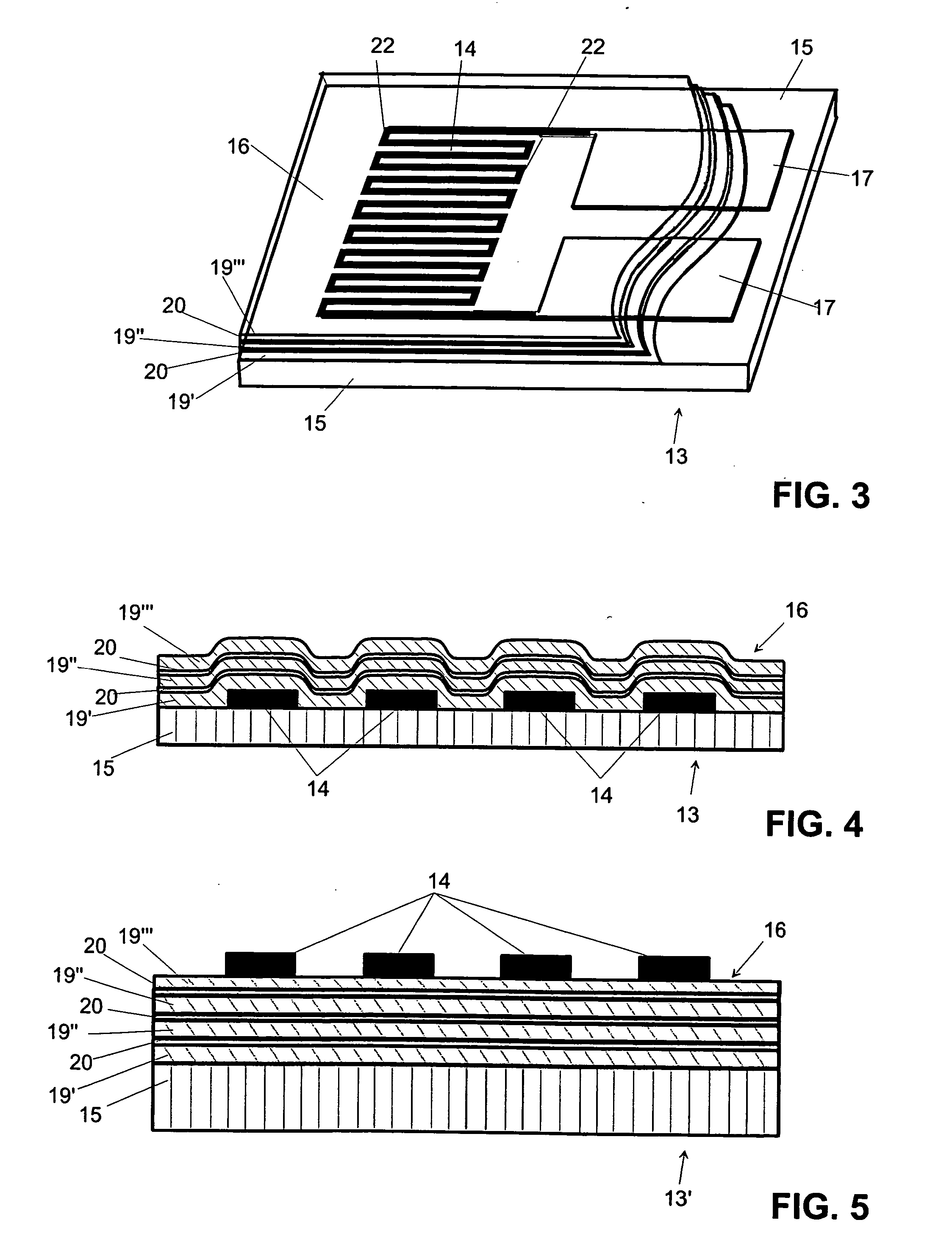

ActiveUS20050155435A1Little strengthPrevent moistureWeighing apparatus using elastically-deformable membersUsing electrical meansMoisture penetrationStrain gauge

A multilayered coating is disclosed as a protective coating against moisture penetration for strain gauges that are or can be installed on a deformable body of a force-measuring cell. A strain gauge has a strain-sensitive electrical resistor track and connector electrodes for contacting the resistor track arranged on a carrier substrate, with a multilayered coating covering at least a part of the carrier substrate and / or of the resistor track and / or of the connector electrodes as a protective coating against moisture penetration. The multilayered coating is composed of an alternating sequence of a polymer layer and a barrier layer and consists of at least three thin individual layers. In the case where a multilayered coating is applied to a strain gauge that is already installed on the deformable body of a force-measuring cell, the multilayered coating can in addition also cover a part of the deformable body.

Owner:METTLER TOLEDO GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com