Carbonization-resistant waterproof slurry

A waterproof slurry and anti-carbonization technology, which is applied in the direction of cement coatings, etc., can solve the problem of unsatisfactory anti-carbonization ability and achieve the effect of avoiding losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

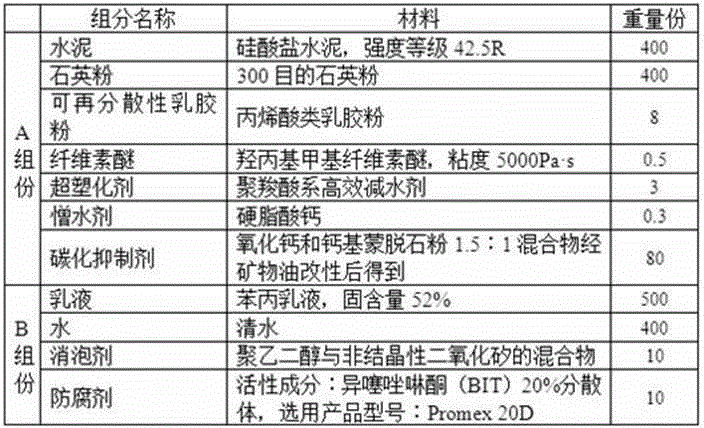

Embodiment 1

[0054] Example 1 Prepare the anti-carbonization waterproof slurry of the present invention according to the following formula and steps:

[0055] (1) Accurately weigh the following materials according to the ratio:

[0056]

[0057] (2) The carbonization inhibitor is prepared by the following steps: conduct ultrasonic atomization at a frequency of 60kHz, first atomize mineral oil in the atomization chamber; then put calcium oxide and calcium-based montmorillonite powder into a high-speed mixer according to the formula ratio Mix uniformly in the medium to obtain a mixture powder of calcium oxide and calcium-based montmorillonite powder; then pass the prepared mixture powder into the atomization chamber through the feed port, and stay for 5 seconds to obtain the carbonization inhibitor;

[0058] (3) Put the cement, quartz powder and other materials of component A into the high-speed disperser, stir for 3 minutes, until the mixture is uniform, pack it, and then it can be m...

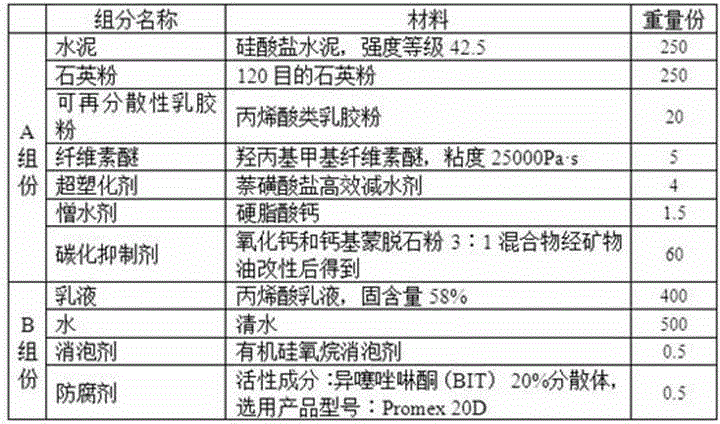

Embodiment 2

[0062] Example 2 Prepare the anti-carbonization waterproof slurry of the present invention according to the following formula and steps:

[0063] (1) Accurately weigh the following materials according to the ratio:

[0064]

[0065] (2) The carbonization inhibitor is prepared by the following steps: conduct ultrasonic atomization at a frequency of 55kHz, first atomize mineral oil in the atomization chamber; then put calcium oxide and calcium-based montmorillonite powder into a high-speed mixer according to the formula ratio Mix uniformly in the medium to obtain a mixture powder of calcium oxide and calcium-based montmorillonite powder; then pass the prepared mixture powder into the atomization chamber through the feed port, and stay for 10 seconds to obtain the carbonization inhibitor;

[0066] (3) Put the cement, quartz powder and other materials of component A into the high-speed disperser, stir for 2 minutes, until the mixture is uniform, pack it, and then it can be...

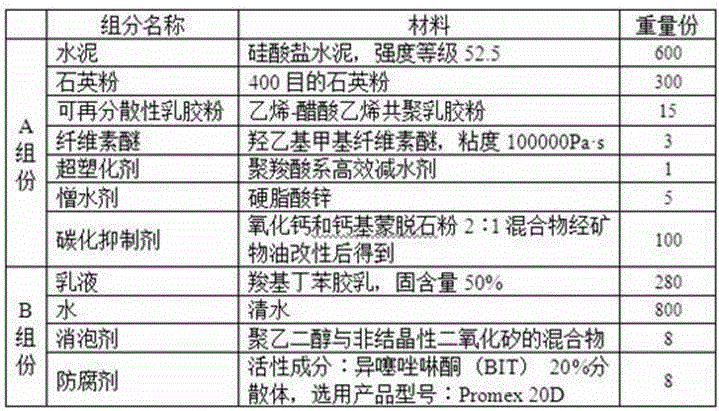

Embodiment 3

[0069] Example 3 Prepare the anti-carbonization waterproof slurry of the present invention according to the following formula and steps:

[0070] (1) Accurately weigh the following materials according to the ratio:

[0071]

[0072] (2) The carbonization inhibitor is prepared by the following steps: using compressed air atomization technology, the mineral oil is first atomized in the atomization chamber with a pressure of 0.25 MPa; then calcium oxide and calcium-based montmorillonite powder are placed in the high-speed Mix evenly in a mixer to obtain a mixture powder of calcium oxide and calcium-based montmorillonite powder; then pass the prepared mixture powder through the feed port into the atomization chamber, and stay for 1 second to obtain a carbonization inhibitor;

[0073] (3) Put the cement, quartz powder and other materials of component A into the high-speed disperser, stir for 3 minutes, until the mixture is uniform, pack it, and then it can be made into powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com