Initiator assembly

a technology of initiator and assembly, which is applied in the direction of pedestrian/occupant safety arrangement, electric fuze, vehicular safety arrangement, etc., can solve the problems of large molding-shrinkage that a molding-shrinkage rate exceeds 1%, no improvement is considered concerning the reliability of operation, and the effect of forming a gap between

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 2

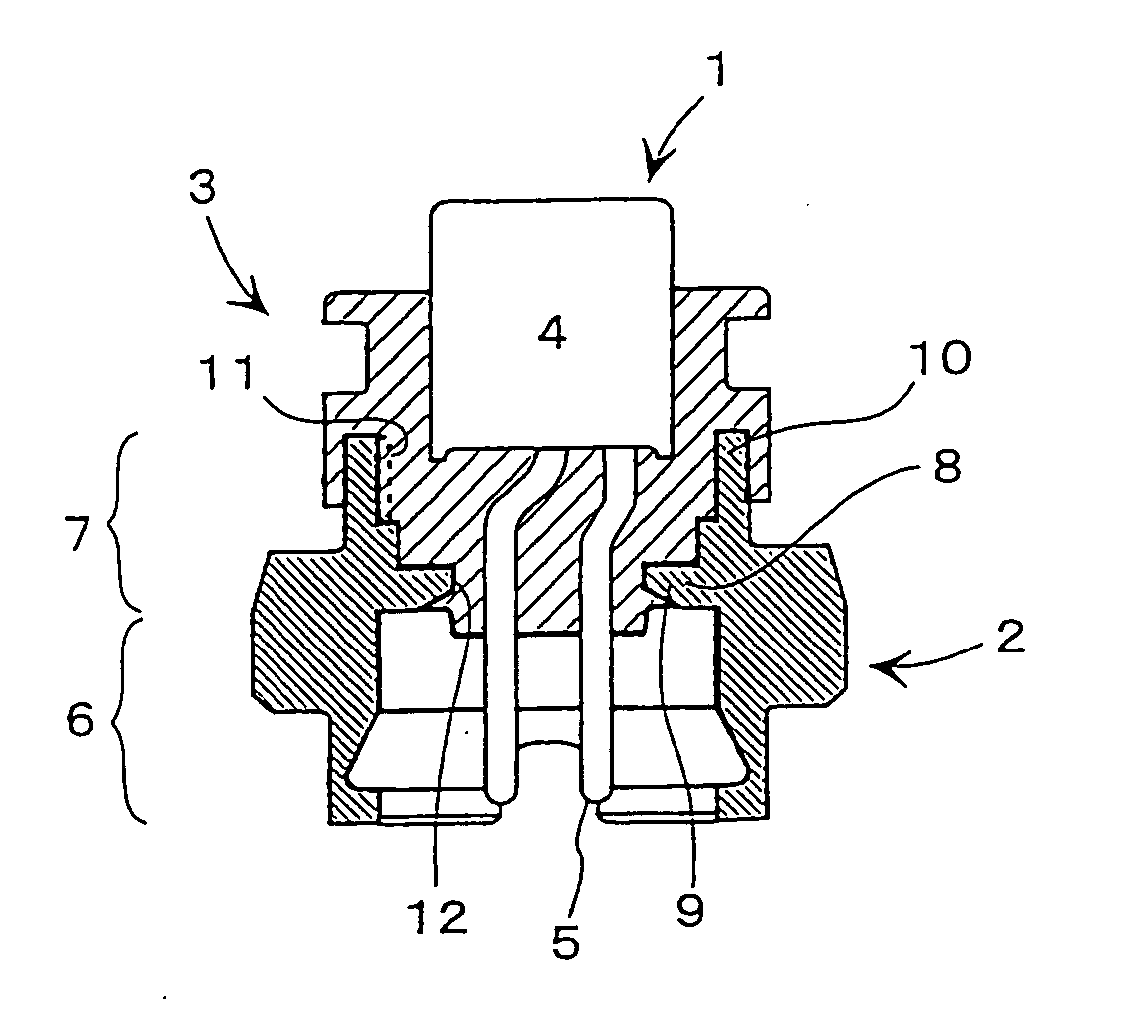

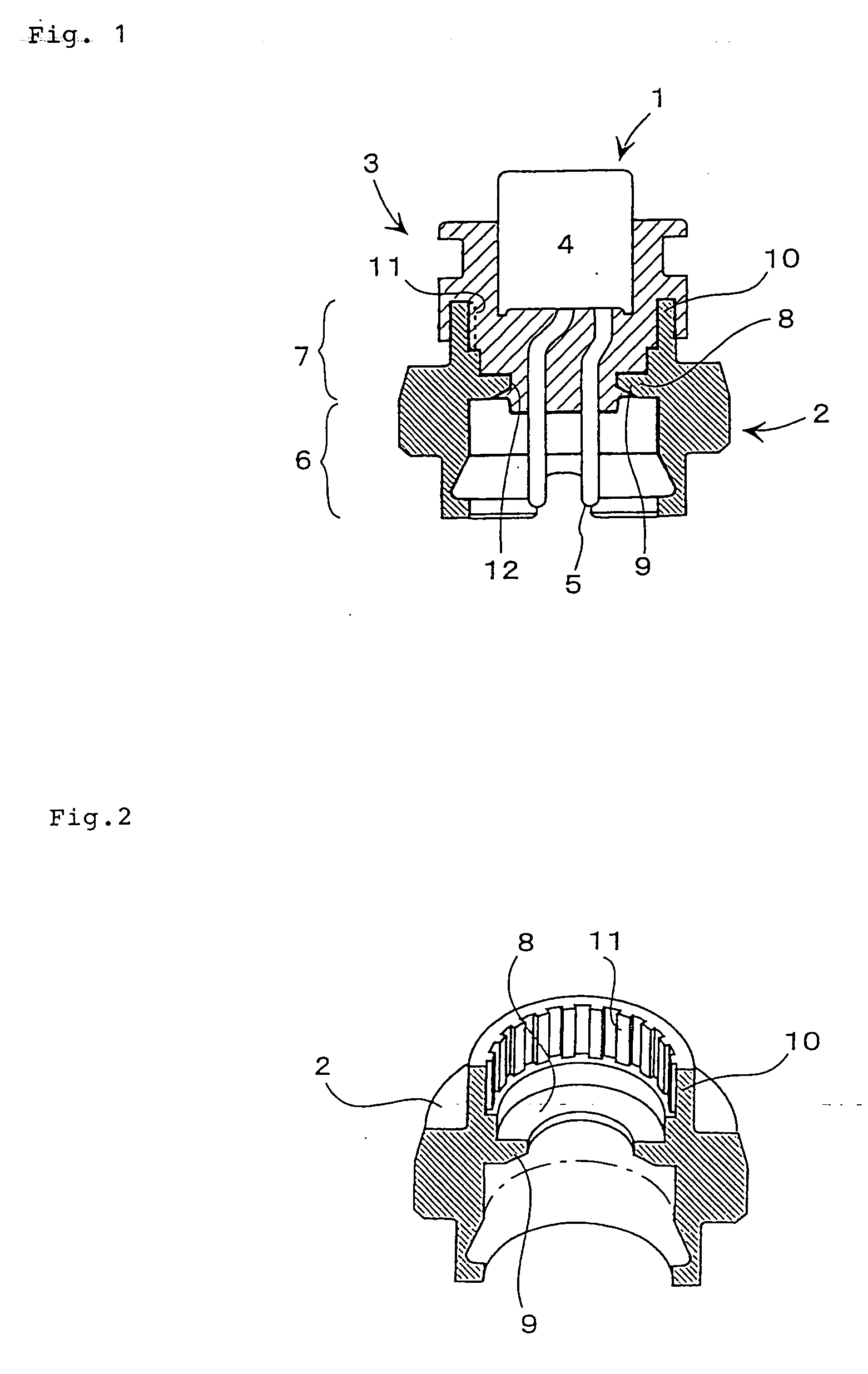

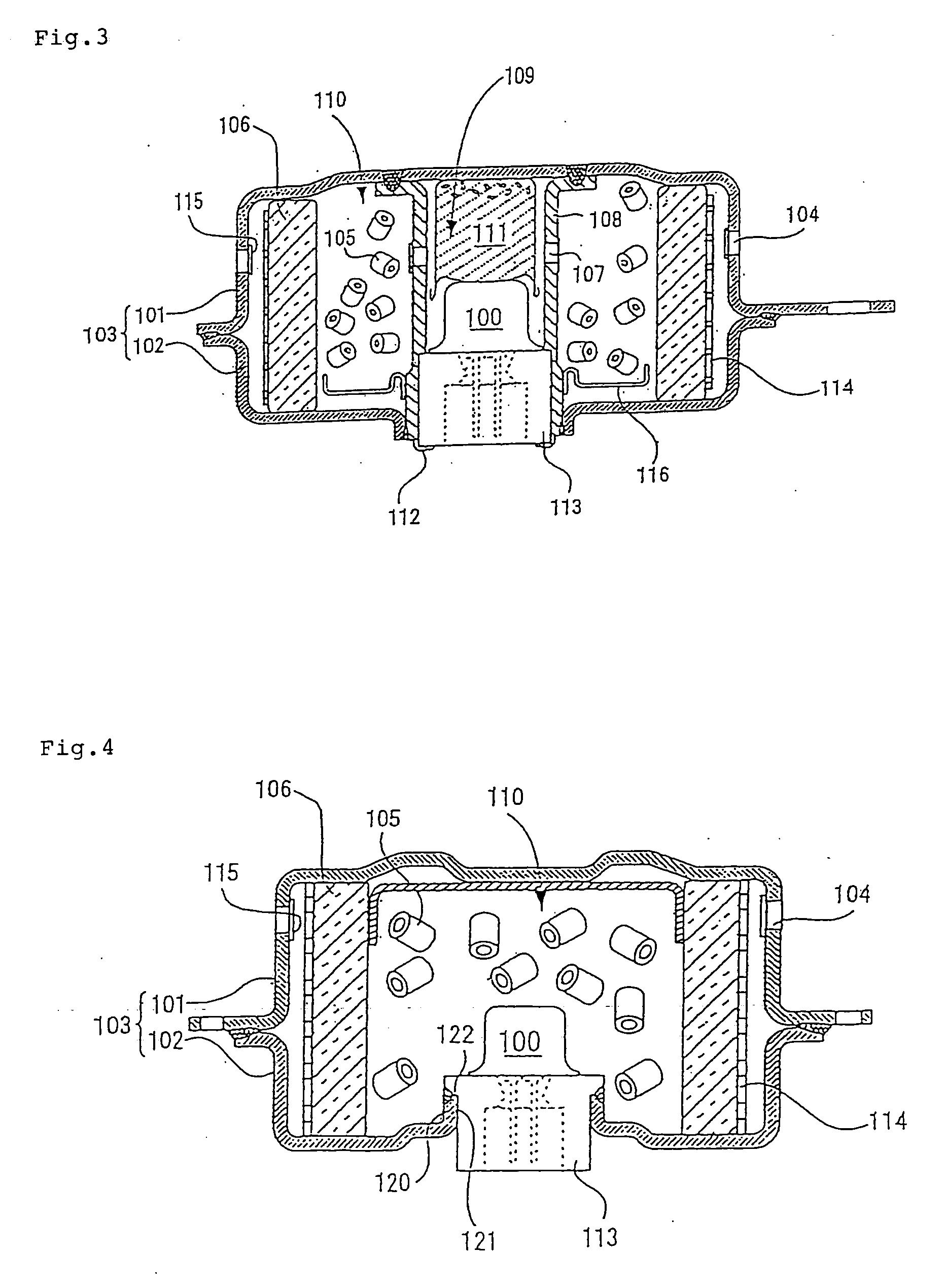

[0058] FIGS. 3 and 4 show embodiments of gas generators for air bags using an initiator assembly 100 having the same feature as the above-described initiator assembly.

[0059] The gas generator comprises, in a housing 103 formed by joining a diffuser shell 101 having a gas discharging port, and a closure shell 102 closing the diffuser shell, an ignition means including the above initiator assembly 100, a gas generating agent 105 to be ignited and burnt due to activation of the ignition means for generating a operating gas to inflate an air bag (bag body), and a filter means 106 to purify and / or cool a operating gas generated by combustion of the gas generating agent 105.

[0060] In the gas generator shown in FIG. 3, an inner cylindrical member 108 provided at its peripheral surface with a plurality of flame-transferring holes 107 is disposed at the center of the housing, a space 109 for accommodating the ignition means is formed inside the inner cylindrical member 108, and a combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com