Patents

Literature

73results about How to "Quick and accurate installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

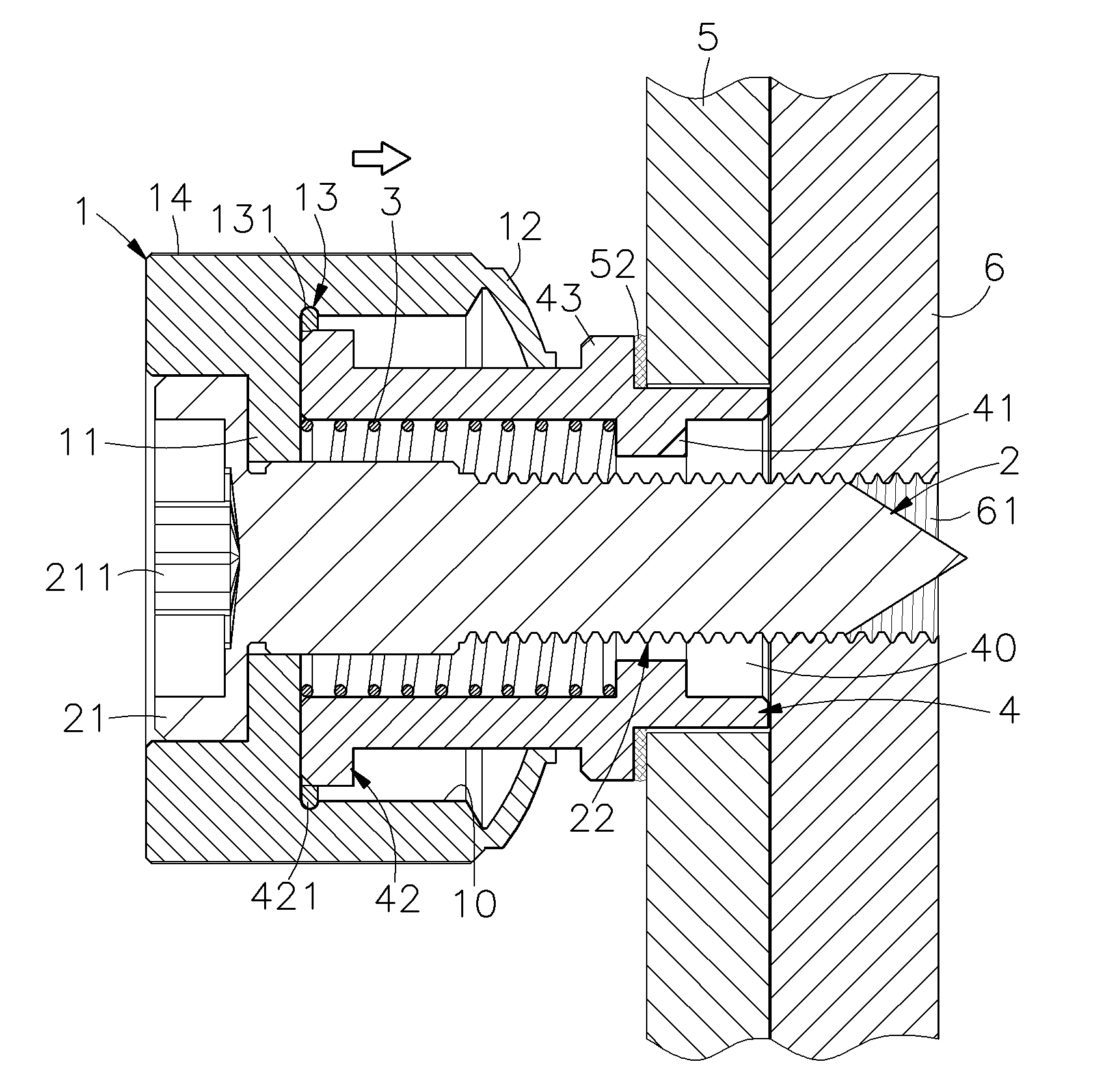

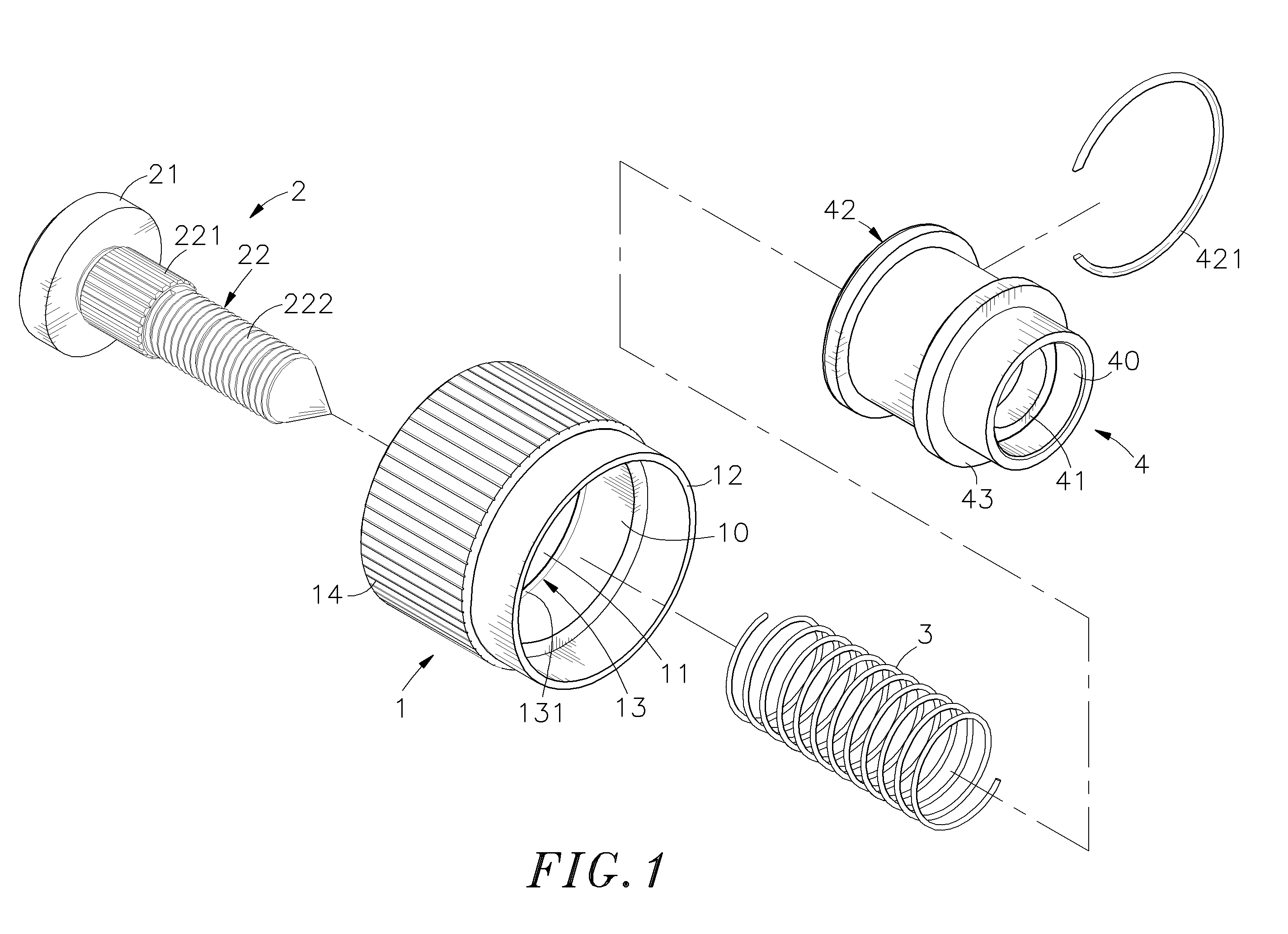

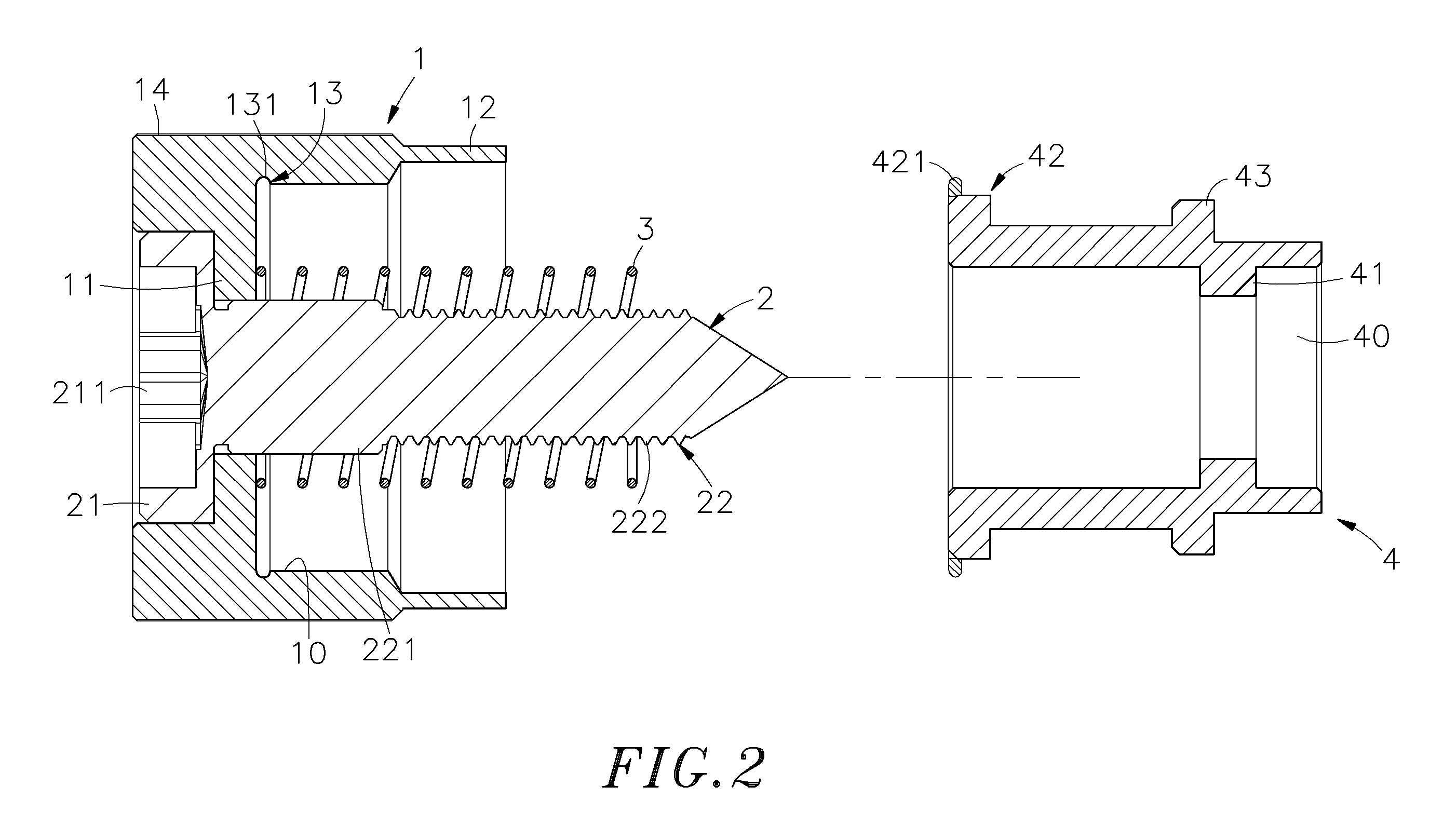

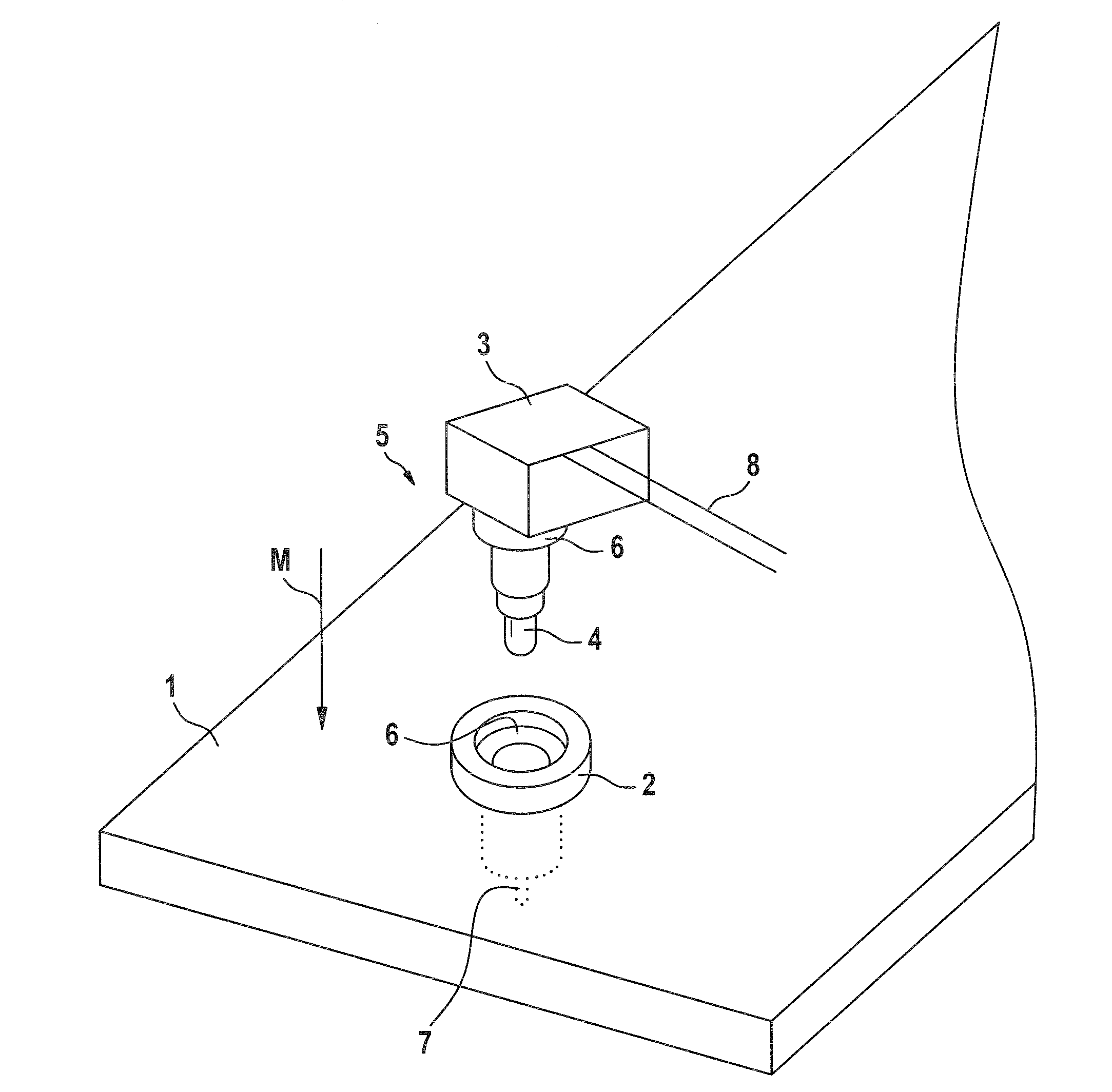

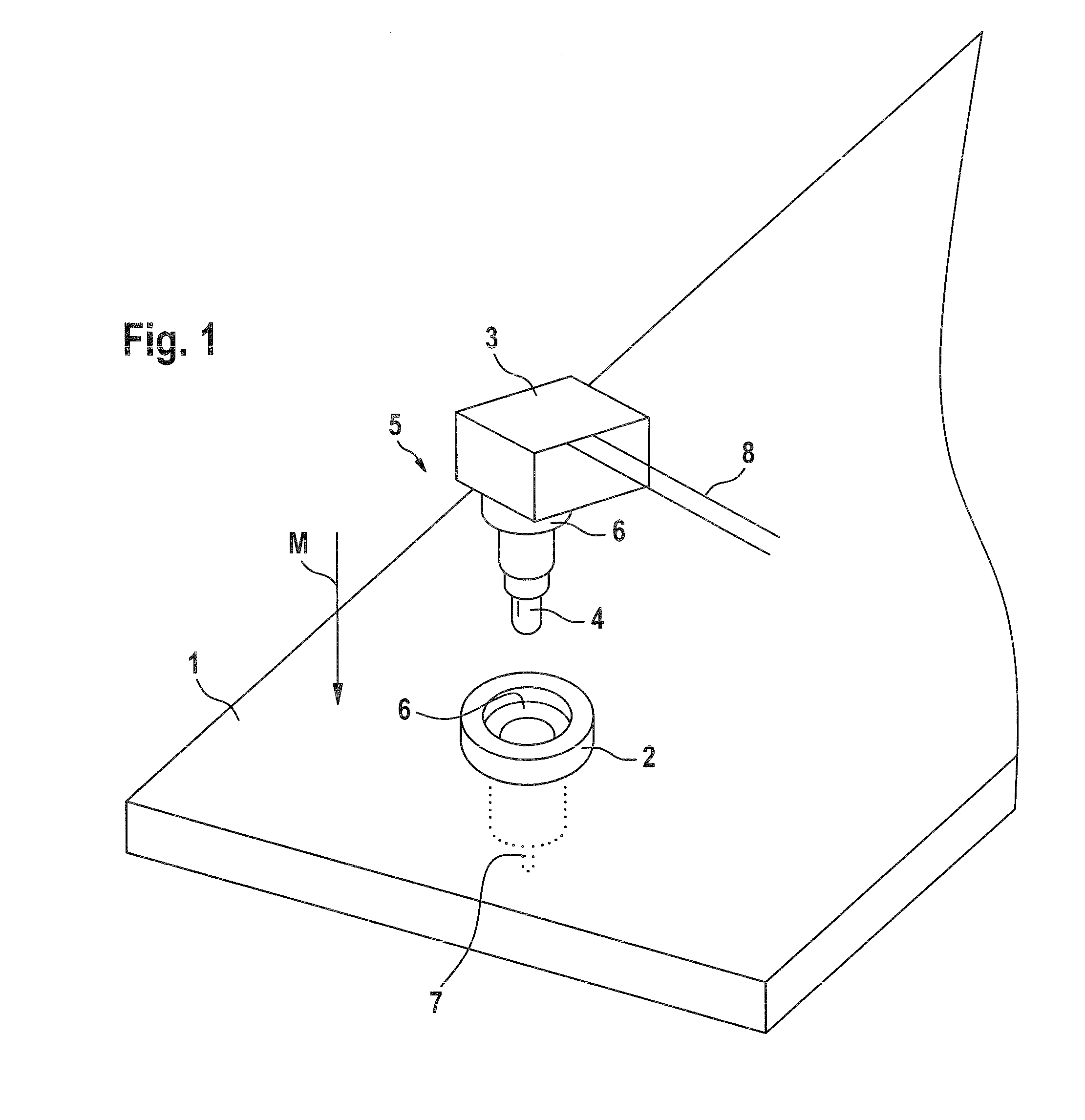

Quick-positioning screw assembly

InactiveUS20100132178A1Quick and accurate installationPrevent fallingNutsBoltsEngineeringScrew press

A quick-positioning screw assembly includes a cap having an inside annular flange and a locating groove or locating rib extending around the inside wall, a mounting socket bonded to a mounting through hole of a first plate member and having a top positioning flange extending around the periphery and detachably forced into engagement with the locating groove or locating rib of the cap, a screw press-fitted into the inner diameter of the inside annular flange of the cap for threading into a screw hole on a second plate member to secure the first plate member to the second plate member, and a compression spring mounted in the cap around the screw and stopped between the inside annular flange of the cap and an inside annular flange of the mounting socket.

Owner:HANWIT PRECISION IND LTD

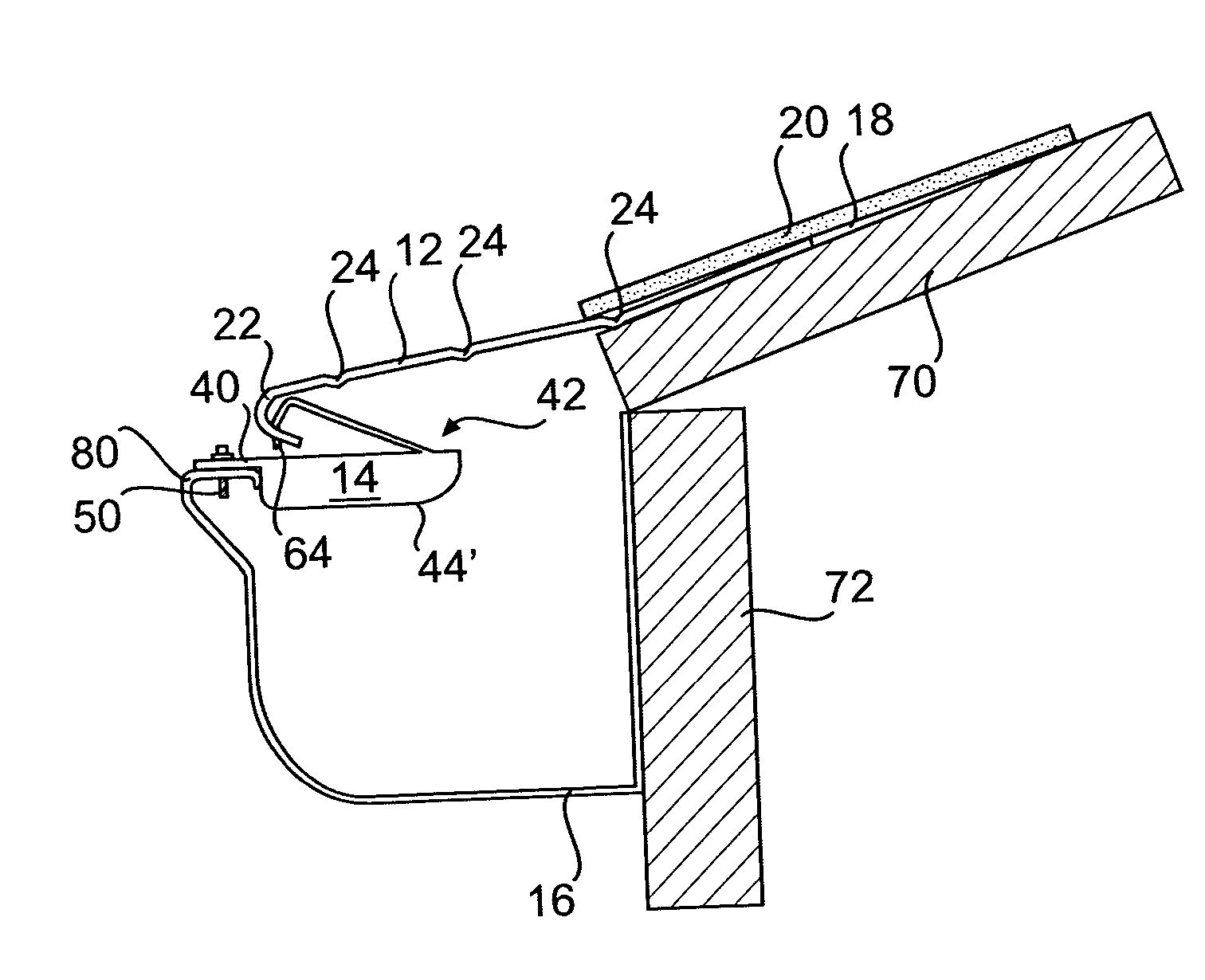

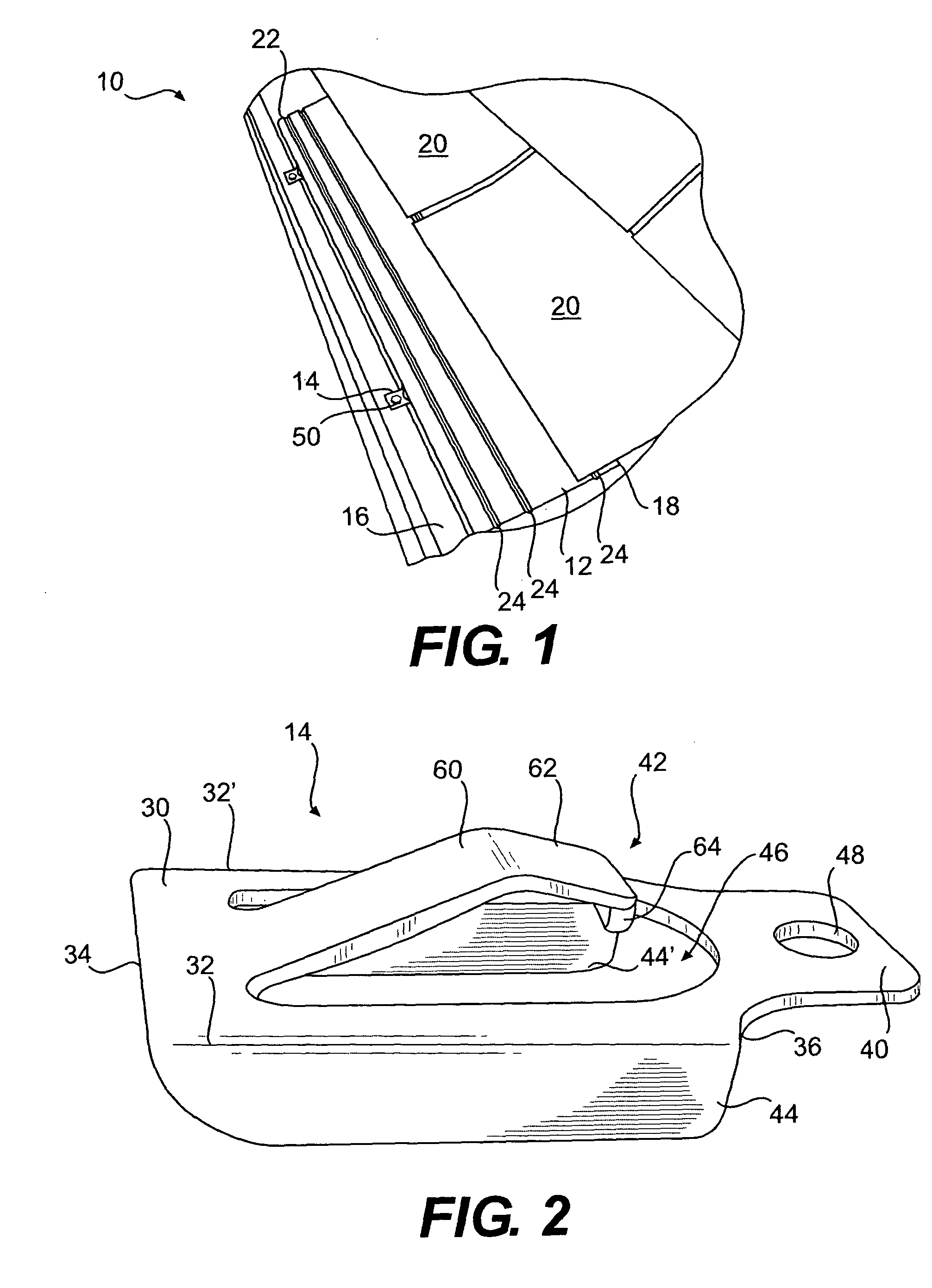

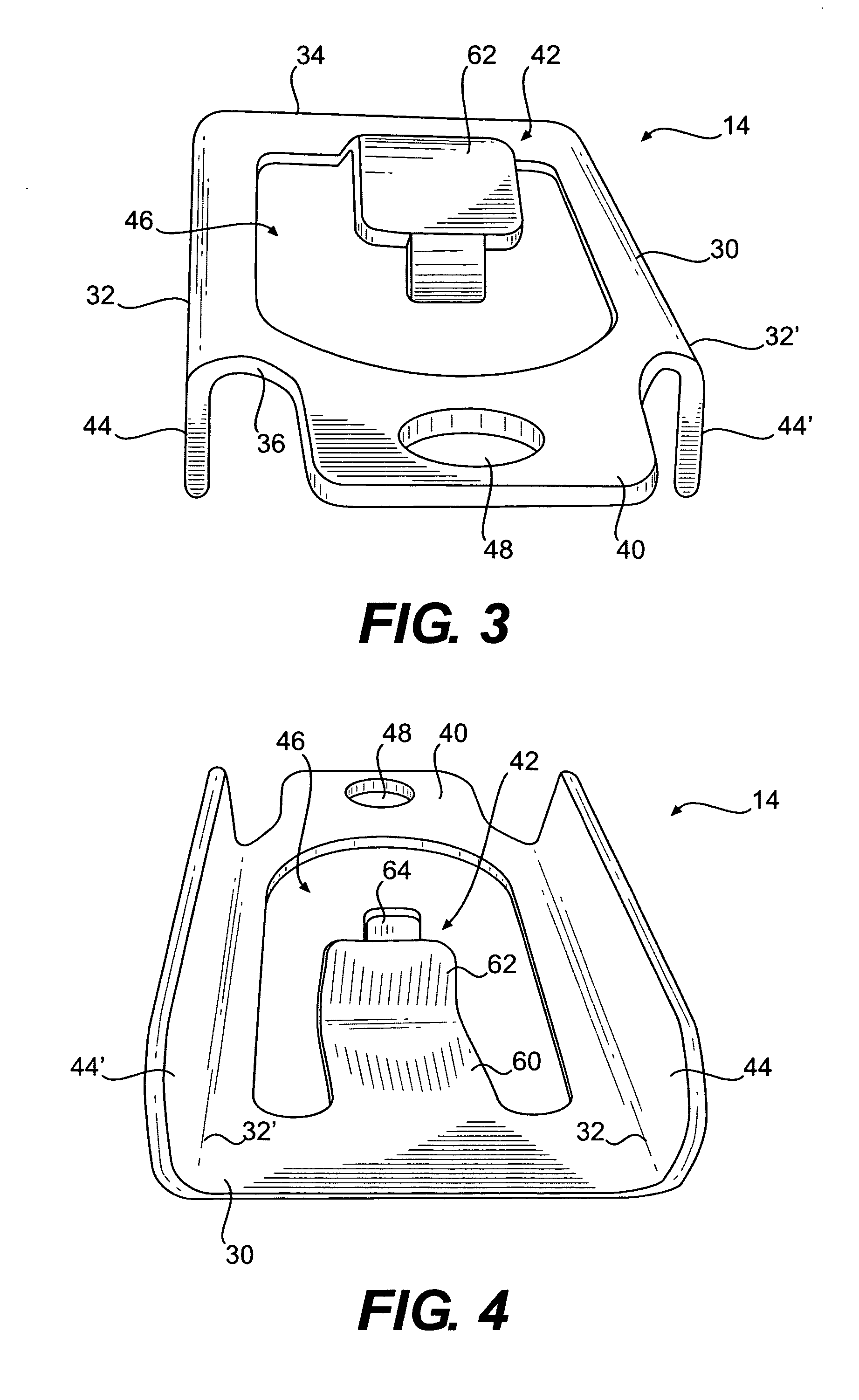

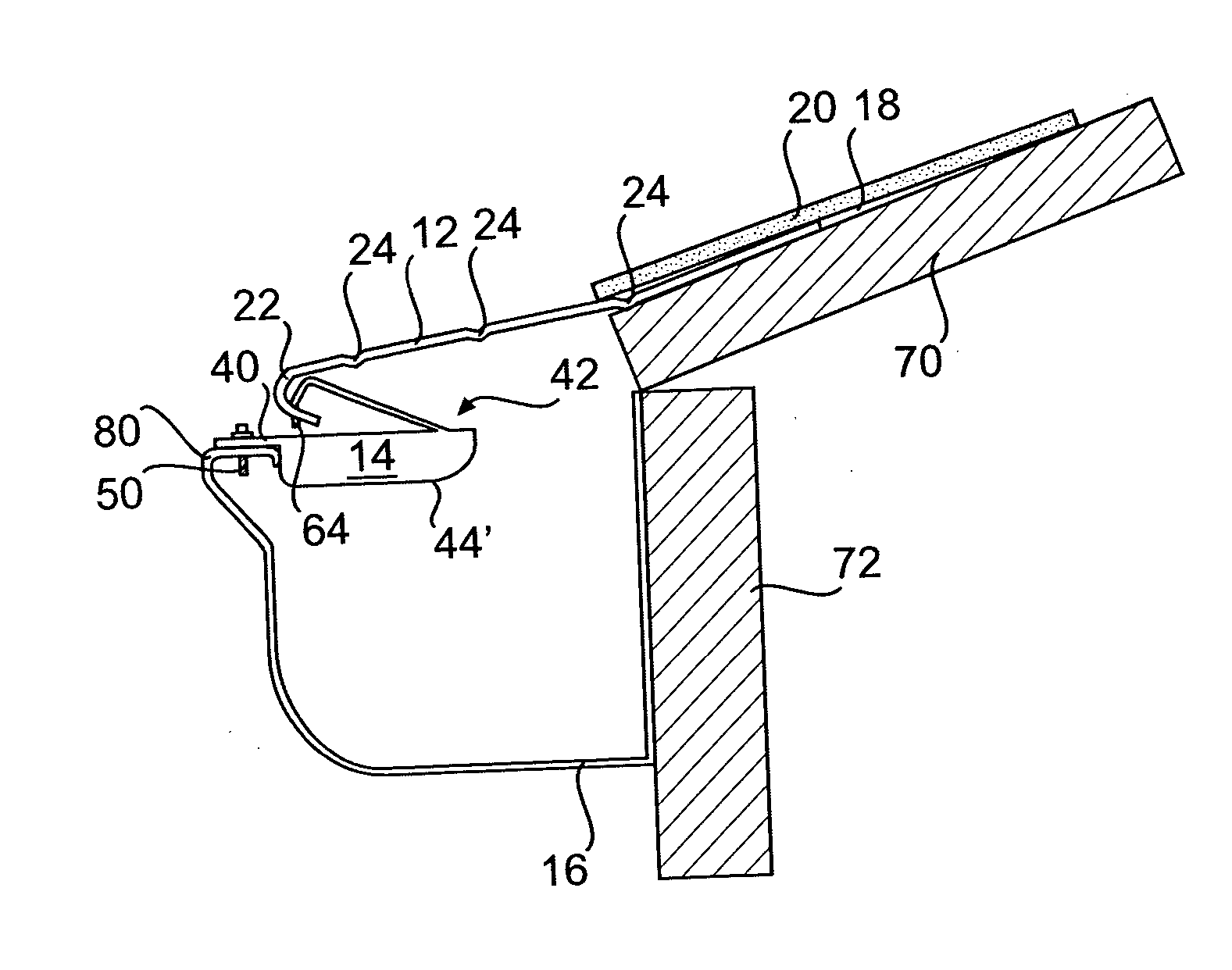

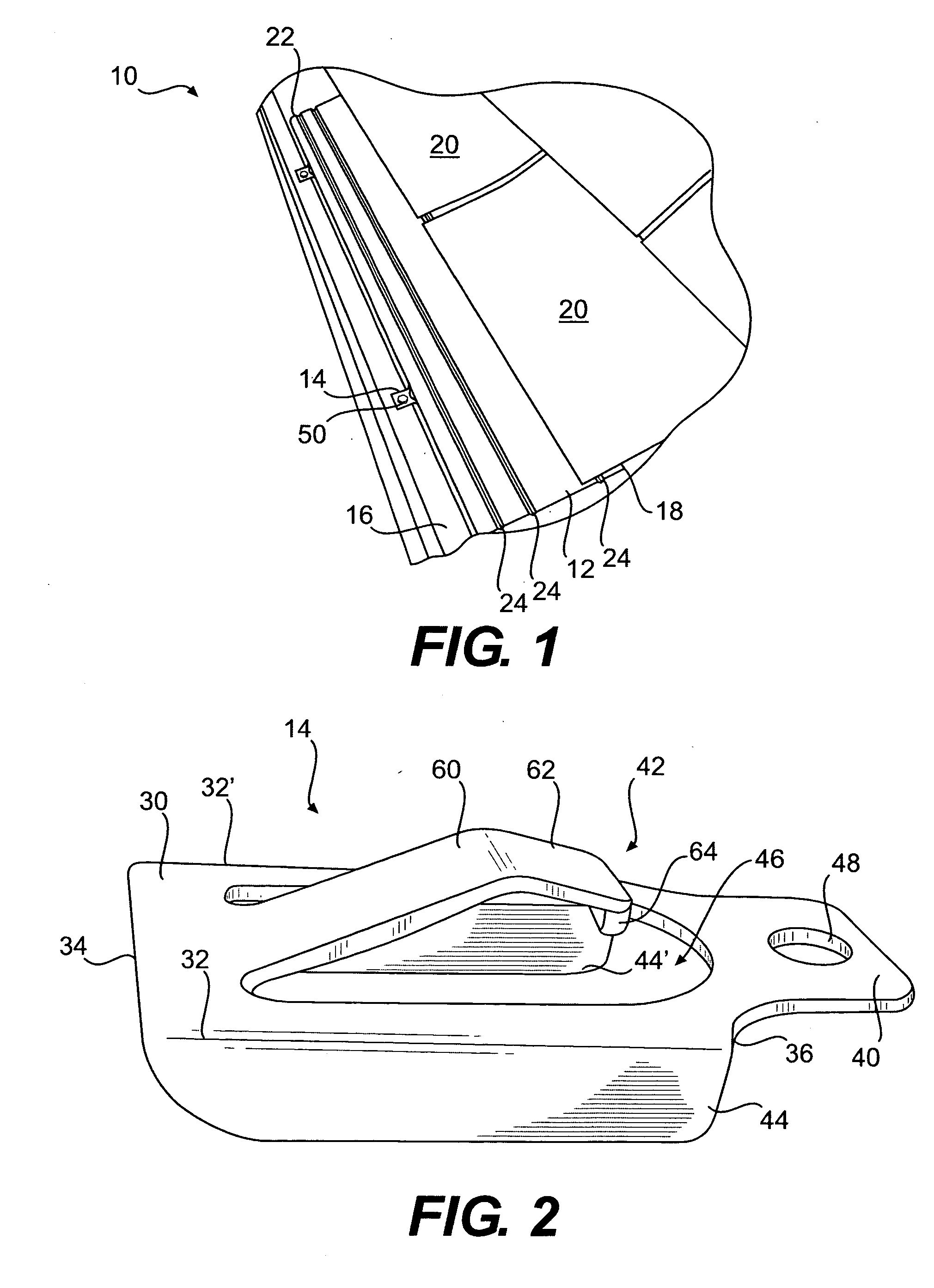

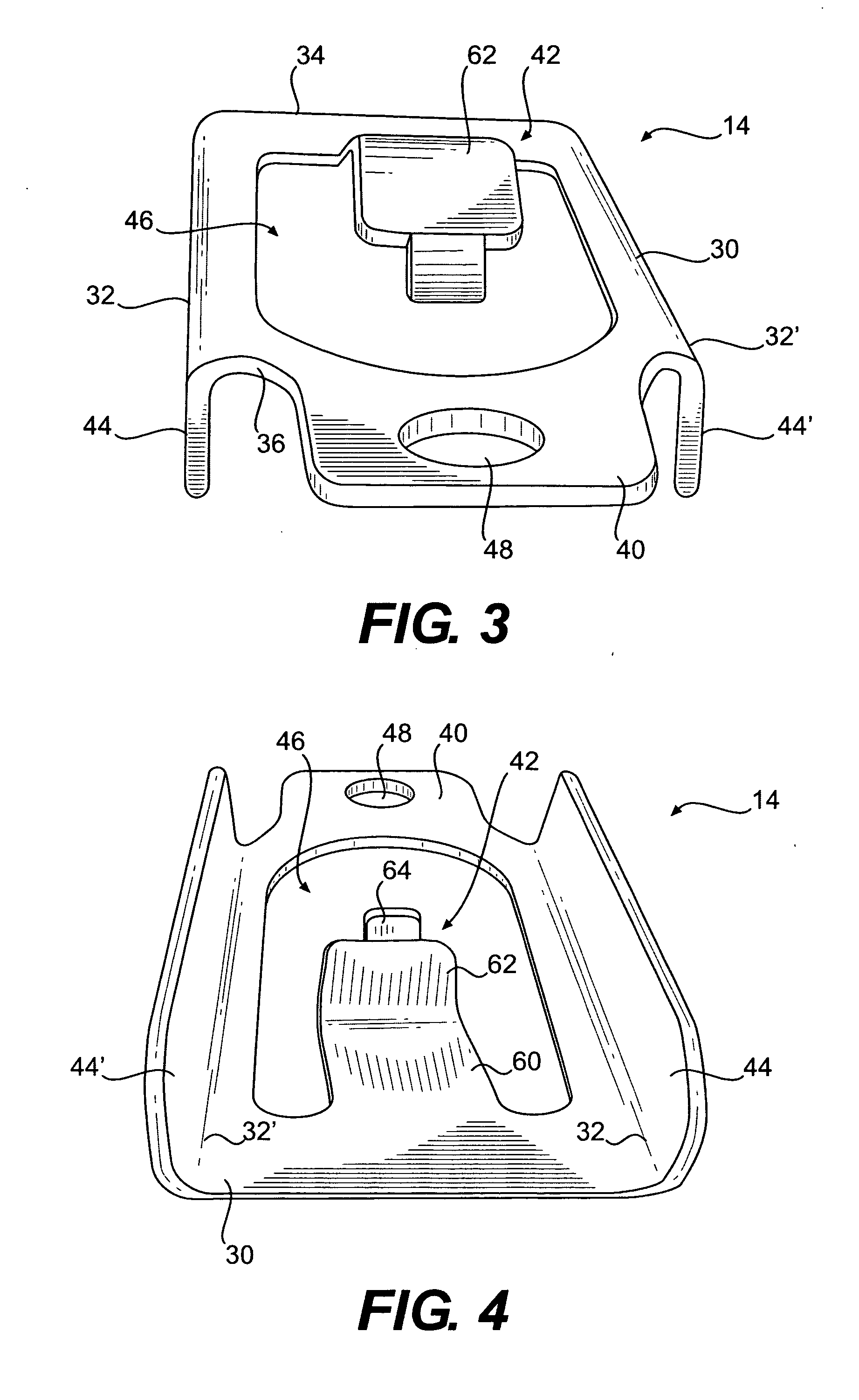

Gutter cover with a clip and method of installing the same

InactiveUS7726076B2Quick and accurate installationIncrease flexibilityRoof coveringRoof runoffEngineering

A gutter cover with clip is provided that operates with a variety of gutter styles to capture roof runoff while preventing debris from entering the gutter. The gutter cover is an elongated panel of sufficient width to bridge a roof to the far side of the gutter. A radiused edge is provided to direct roof runoff into the gutter. The clip includes a mounting tab and an upward rising arm. A tooth on the arm positively engages an aperture in the radiused edge to facilitate extremely accurate, fast, and resilient installation of a gutter cover system.

Owner:STAUB TIMOTHY G

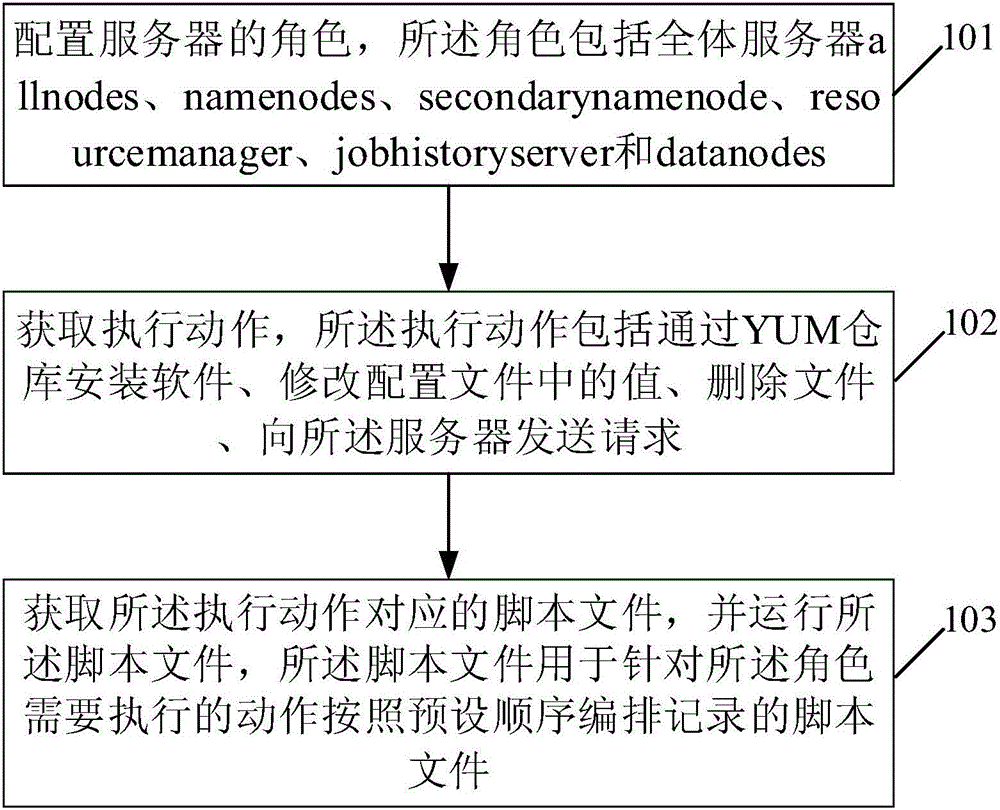

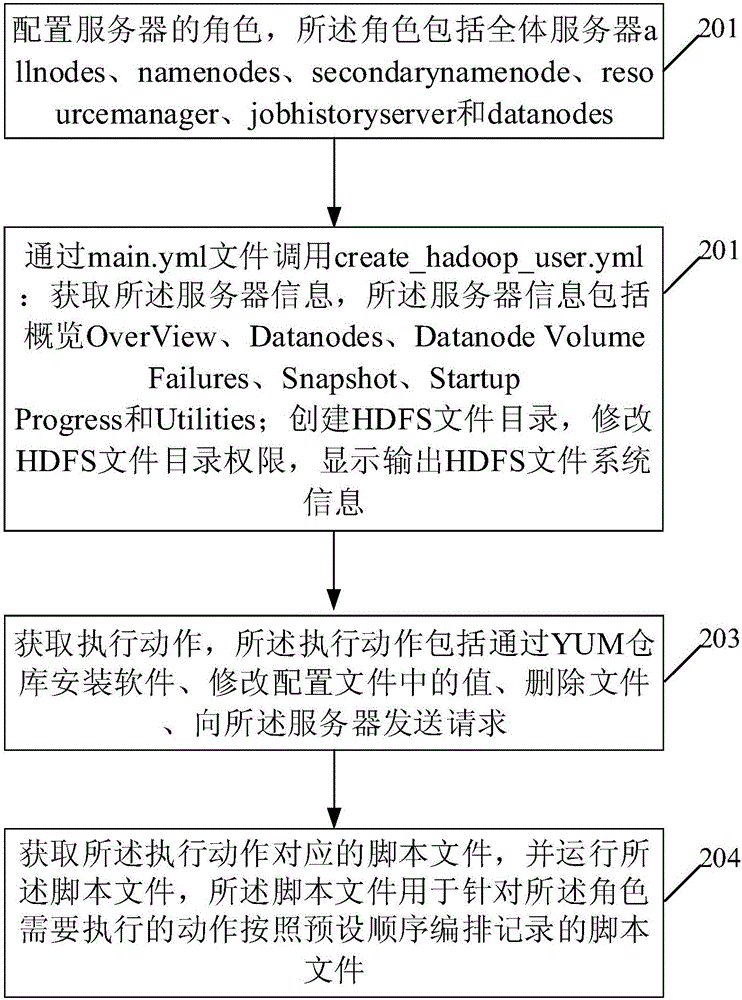

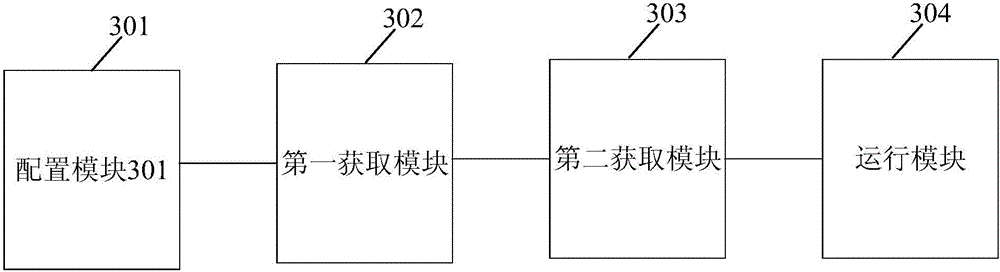

Method and device for operating large-scale computer cluster

InactiveCN106681956AQuick and accurate installationMultiple digital computer combinationsProgram loading/initiatingComputer clusterSoftware

The embodiment of invention discloses a method and device for operating a large-scale computer cluster. The method comprises the steps of configuring roles of servers, the role comprises all the servers including allnodes, namenodes, econdarynamenode, resourcemanager, jobhistoryserver and datanodes, obtaining an execution action which includes the steps of installing a software though YUM warehouse, modifying the value of a configured file, deleting the file, sending request to servers; obtaining a script file corresponding to the execution action, running the script file, wherein, the script file is used for arranging the recorded script file based on a preset sequence for the action that the role needs to perform. Thus, the ansible automatic operation and maintenance component encapsulates the complex operation and maintenance operations, and a normal operator can quickly and accurately conduct the installation operation of clusters.

Owner:RUN TECH CO LTD BEIJING

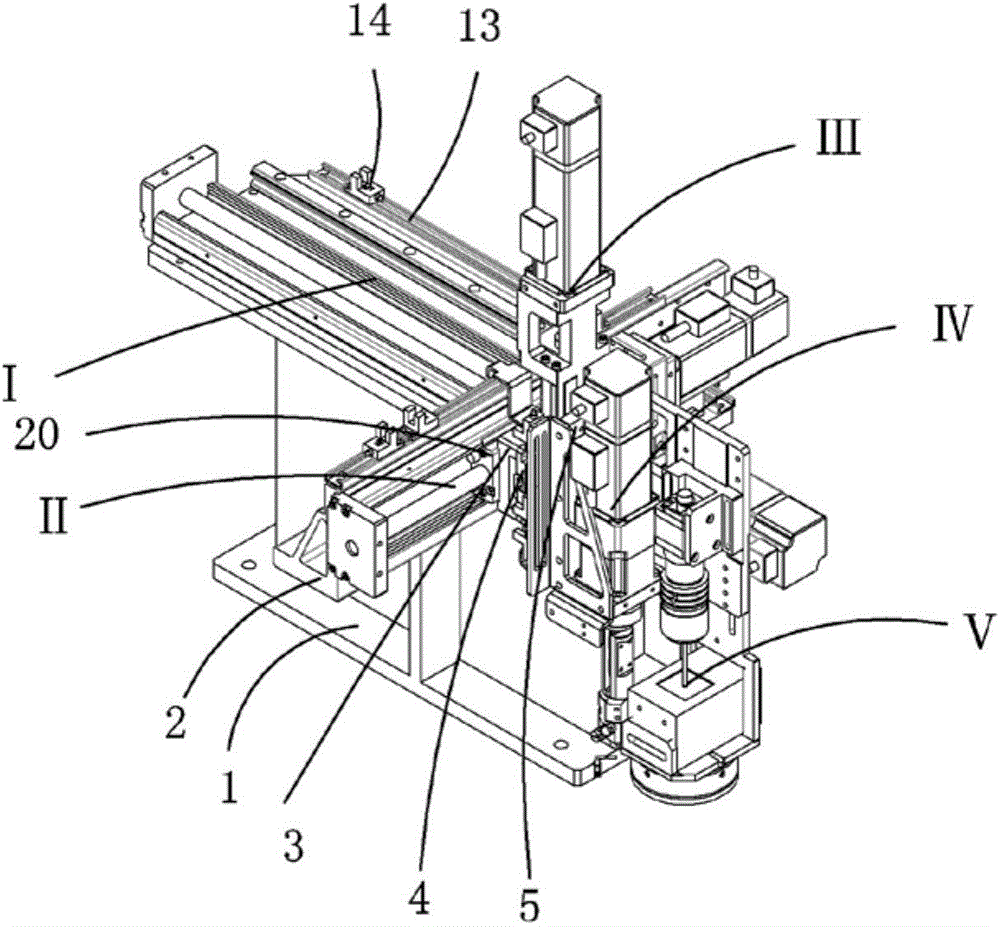

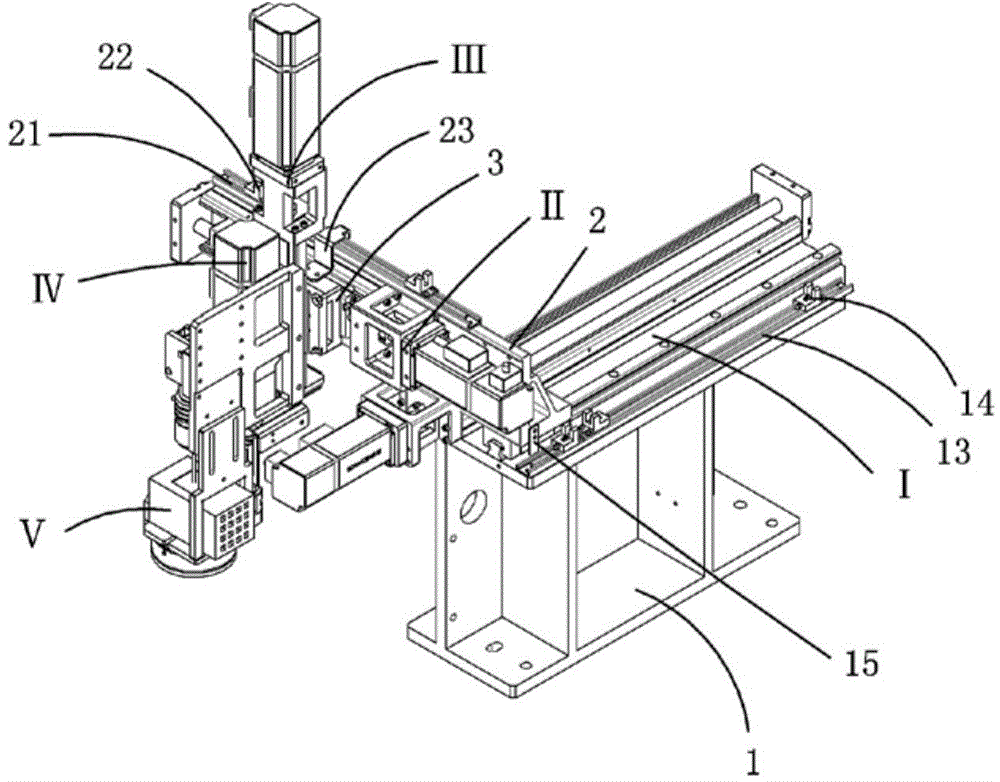

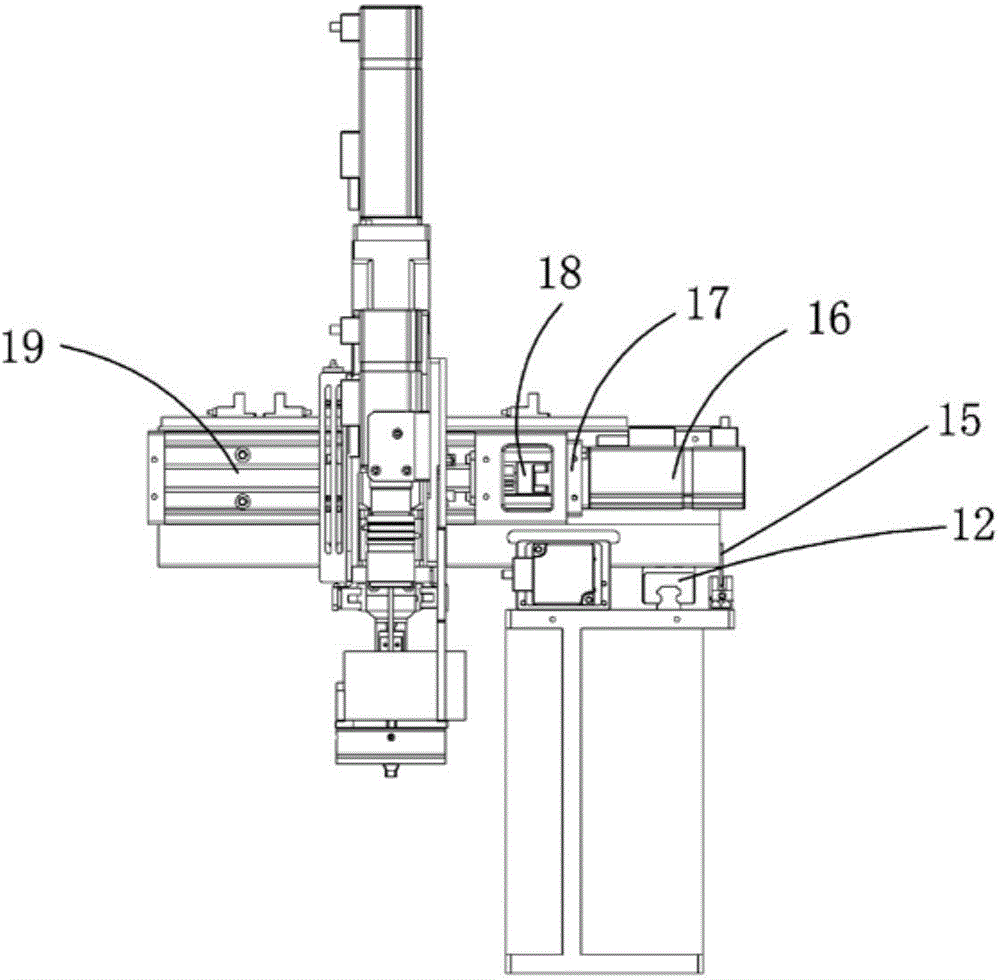

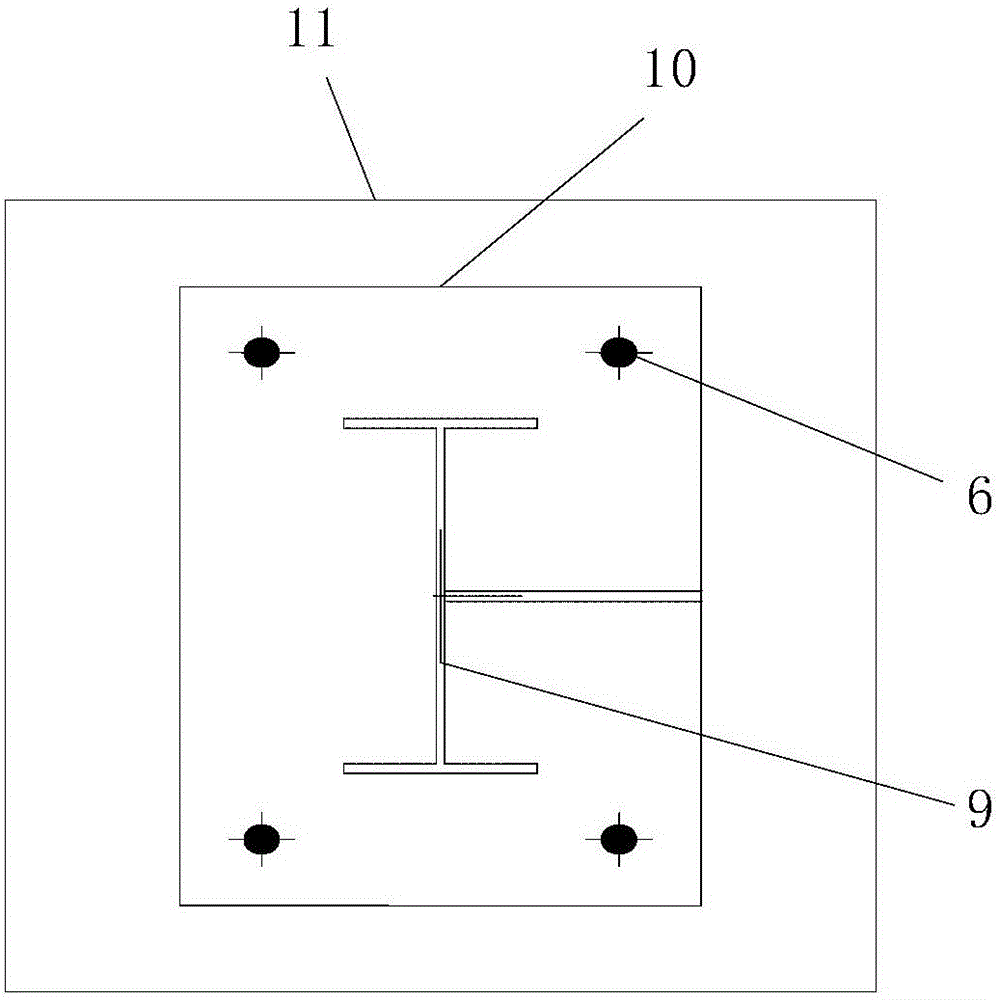

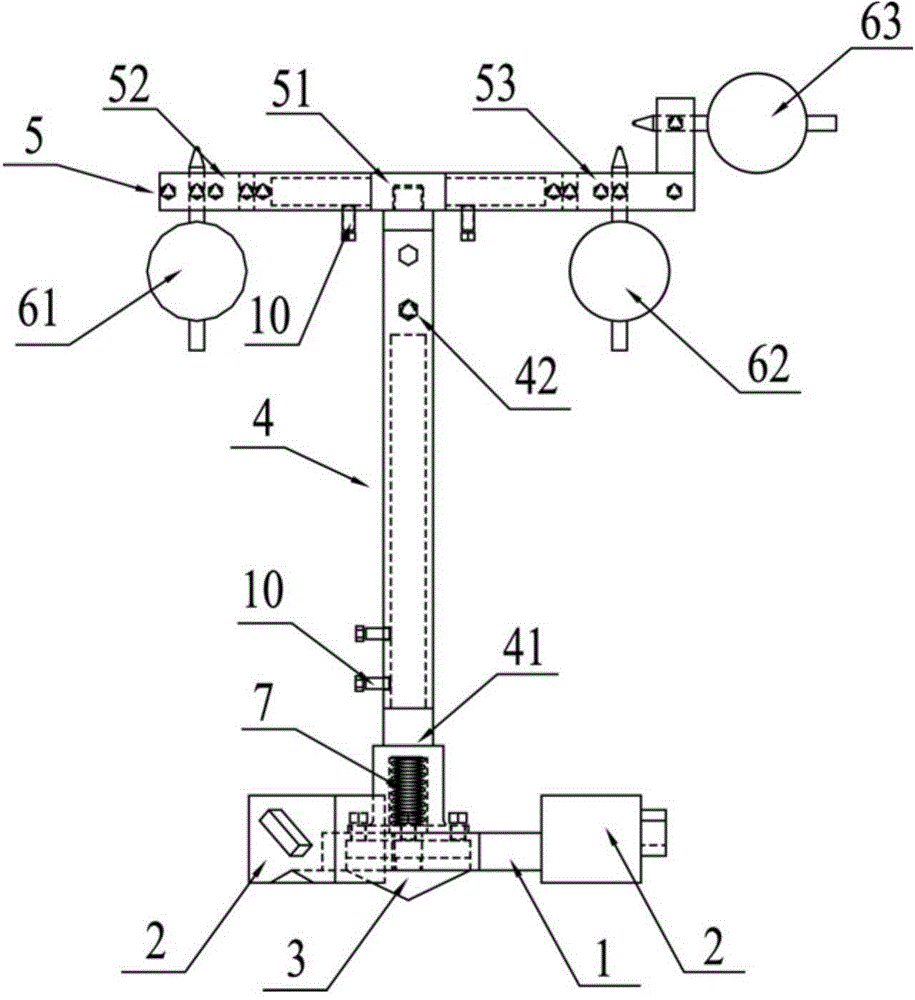

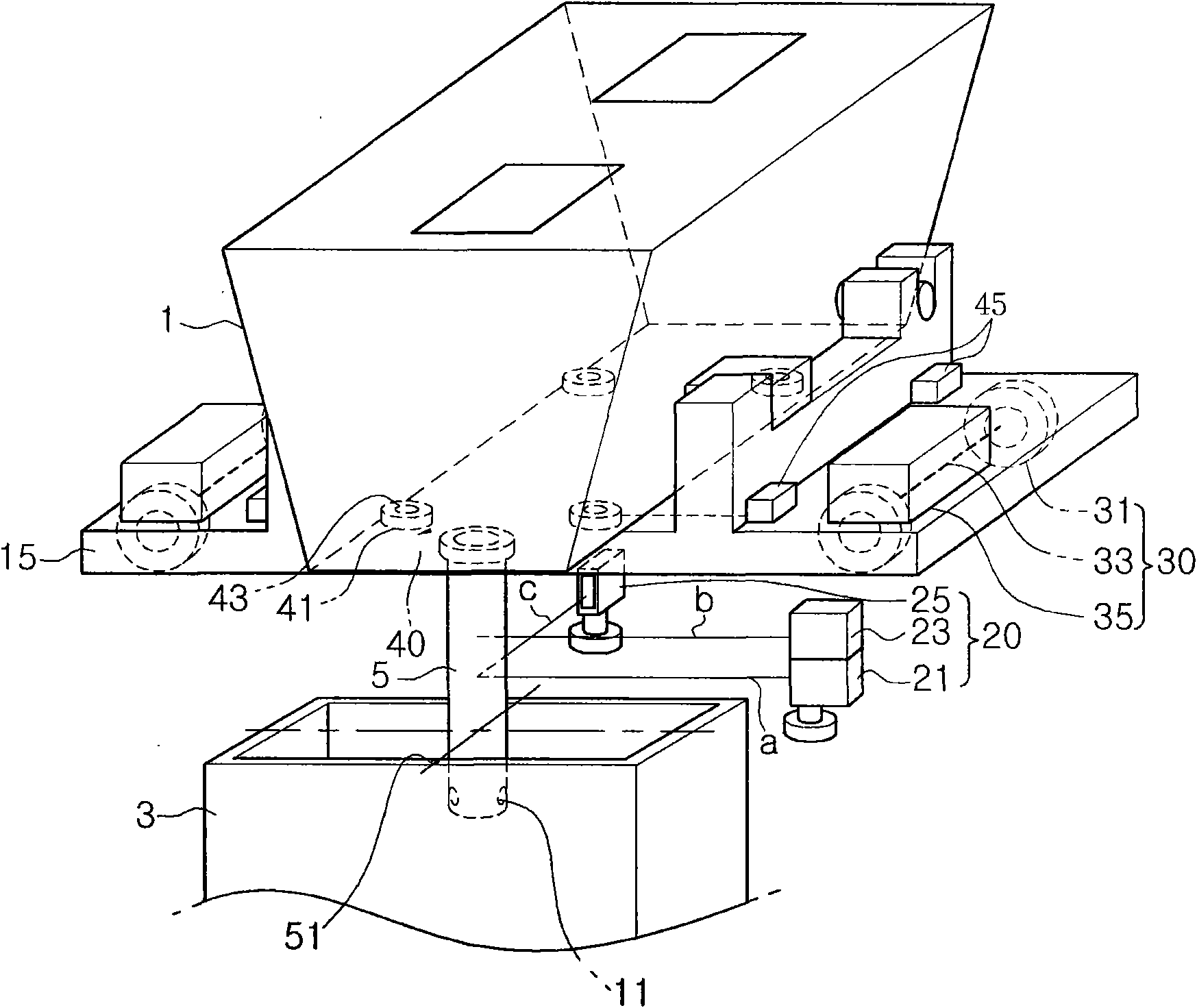

Four-axis direction-adjustable component mounting mechanism

InactiveCN104668952AQuick and accurate installationReduce manufacturing costAssembly machinesEngineeringLoad cell

The invention relates to a four-axis direction-adjustable component mounting mechanism. A Y-axis mechanism is mounted on a base; an X-axis mechanism is mounted on the Y-axis mechanism through an XY connecting plate; a Z-axis mechanism is mounted on the front part of the X-axis mechanism through an XZ connecting block a and an XZ connecting block b. The four-axis direction-adjustable component mounting mechanism further comprises an R-axis mechanism and a CCD (charge coupled device) mechanism, wherein the R-axis mechanism is mounted on the front part of the Z-axis mechanism through a ZR connecting plate; the CDD mechanism is mounted at the right side of the R-axis mechanism. An R-axis motor is driven to drive an R-axis suction nozzle mechanism to rotate, so that a suction nozzle can be rotated to a standard operation position; the components are sucked by the suction nozzle, and the X-axis mechanism, the Y-axis mechanism and the Z-axis mechanism are matched for mounting the components on a product; meanwhile, when the components are mounted on the product, pressure during mounting can be measured through a weighing sensor, so that the product is conveniently protected during mounting. The CCD mechanism can shoot and position positions of the components as well as to-be-mounted positions of the components, and can shoot and detect whether the mounted product is qualified or not.

Owner:BOZHON PRECISION IND TECH CO LTD

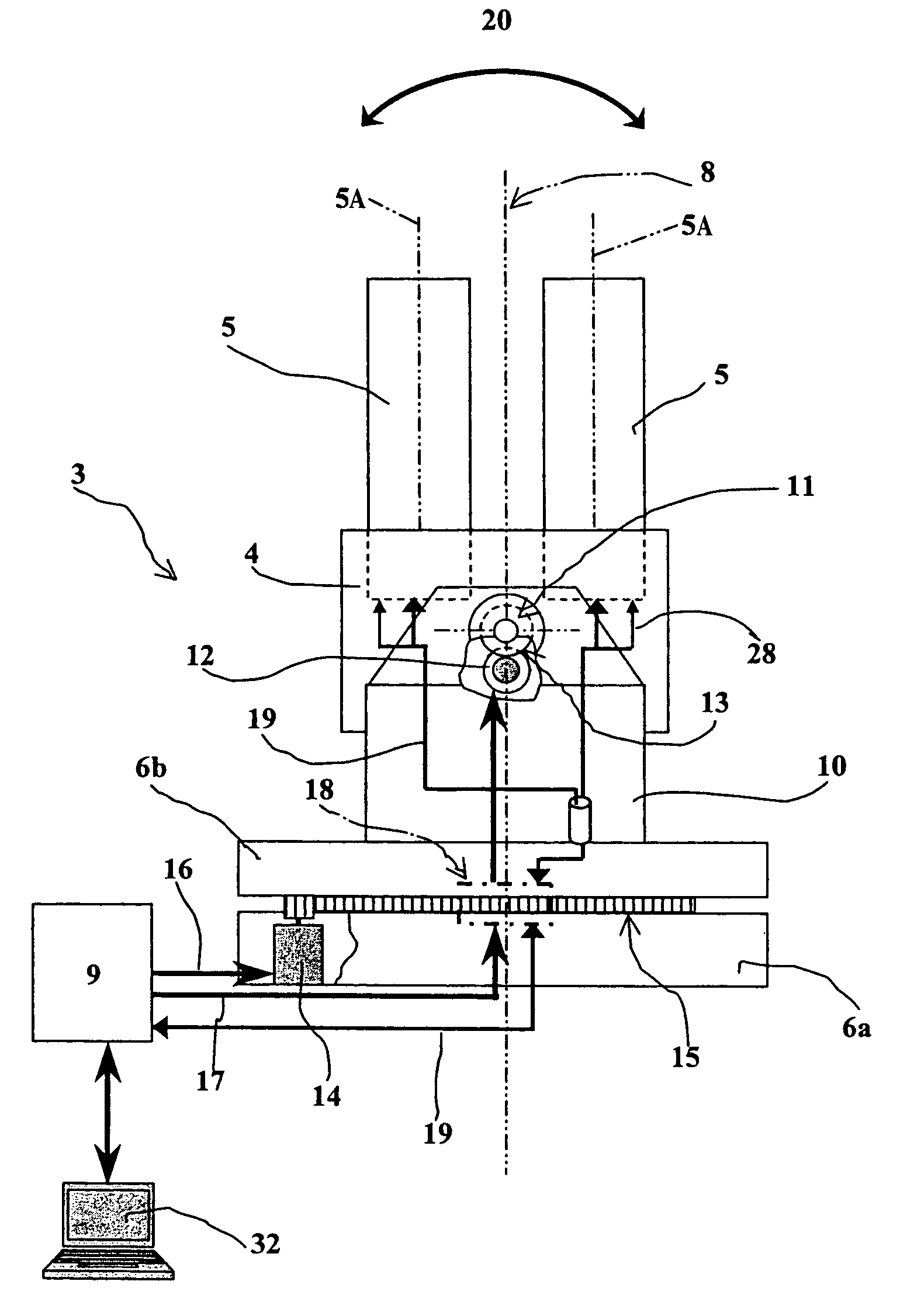

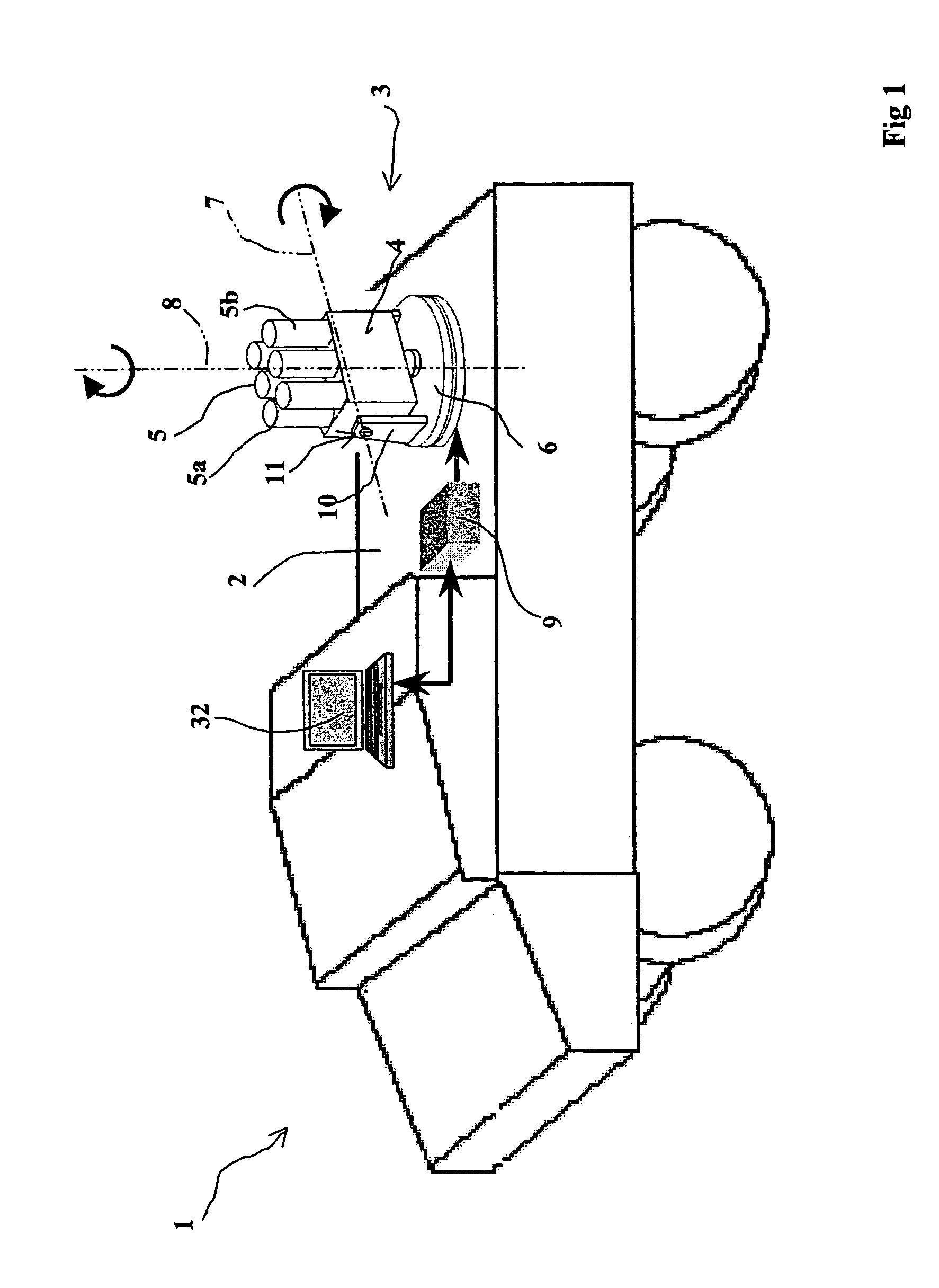

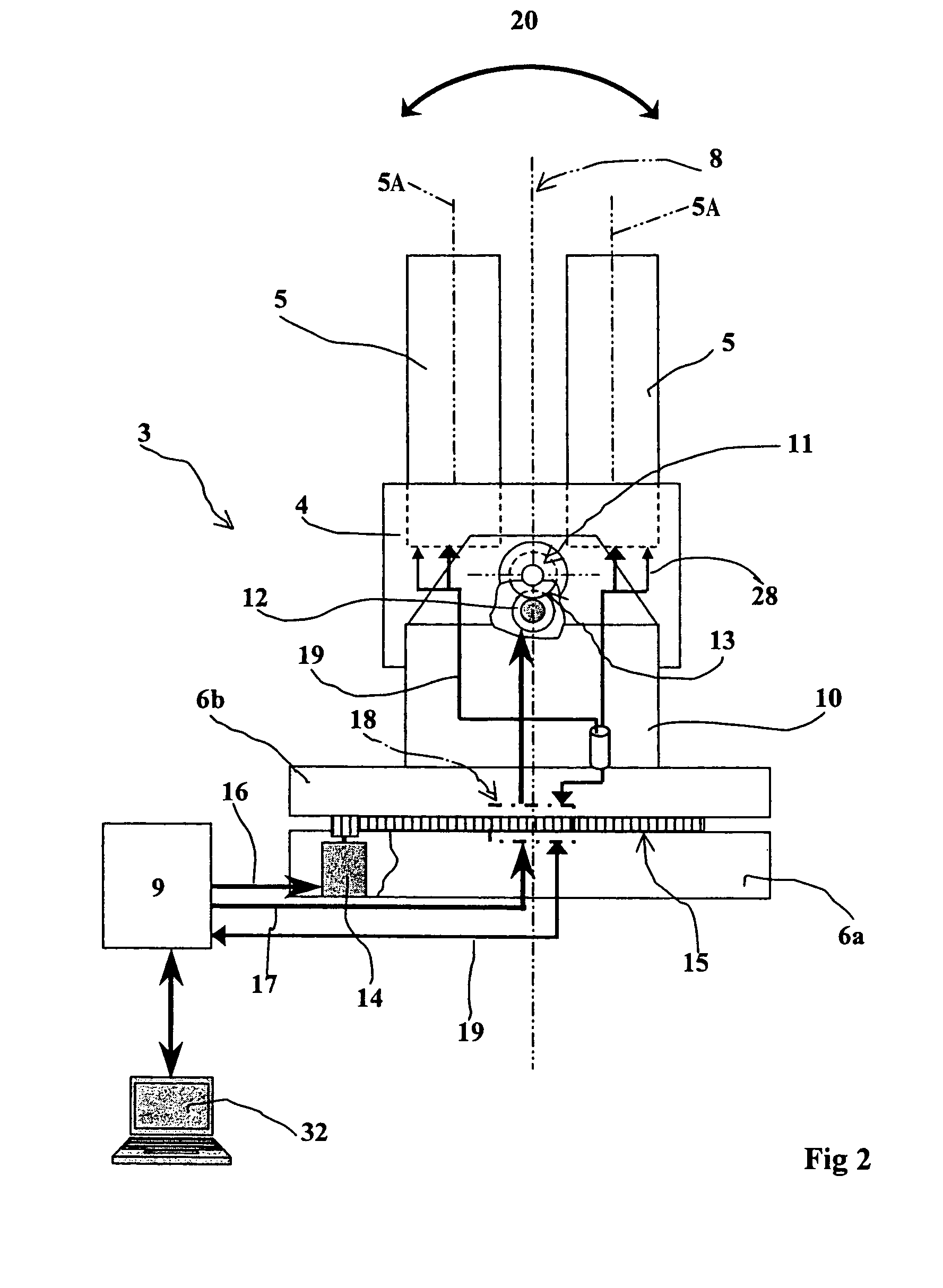

Projectile firing device

InactiveUS7237468B2Quick and accurate installationFiring/trigger mechanismsGun mountingsHorizontal axisEngineering

The invention relates to a projectile firing device used on a platform and comprising at least two tubes integral with a base.This device is characterized in that the base is mounted able to swivel on a turret around a first, substantially horizontal axis, such swiveling controlled by first drive means, the turret being able itself to pivot with respect to the platform around a second substantially vertical axis and being controlled by second drive means, the horizontal swiveling being made on either side of a median position in which the tubes are oriented with their axes substantially vertical.

Owner:NEXTER SYST SA

Gutter cover with a clip and method of installing the same

InactiveUS20070017162A1Accurate and fast and resilient installationQuick and accurate installationRoof coveringRoof runoffEngineering

A gutter cover with clip is provided that operates with a variety of gutter styles to capture roof runoff while preventing debris from entering the gutter. The gutter cover is an elongated panel of sufficient width to bridge a roof to the far side of the gutter. A radiused edge is provided to direct roof runoff into the gutter. The clip includes a mounting tab and an upward rising arm. A tooth on the arm positively engages an aperture in the radiused edge to facilitate extremely accurate, fast, and resilient installation of a gutter cover system.

Owner:STAUB TIMOTHY G

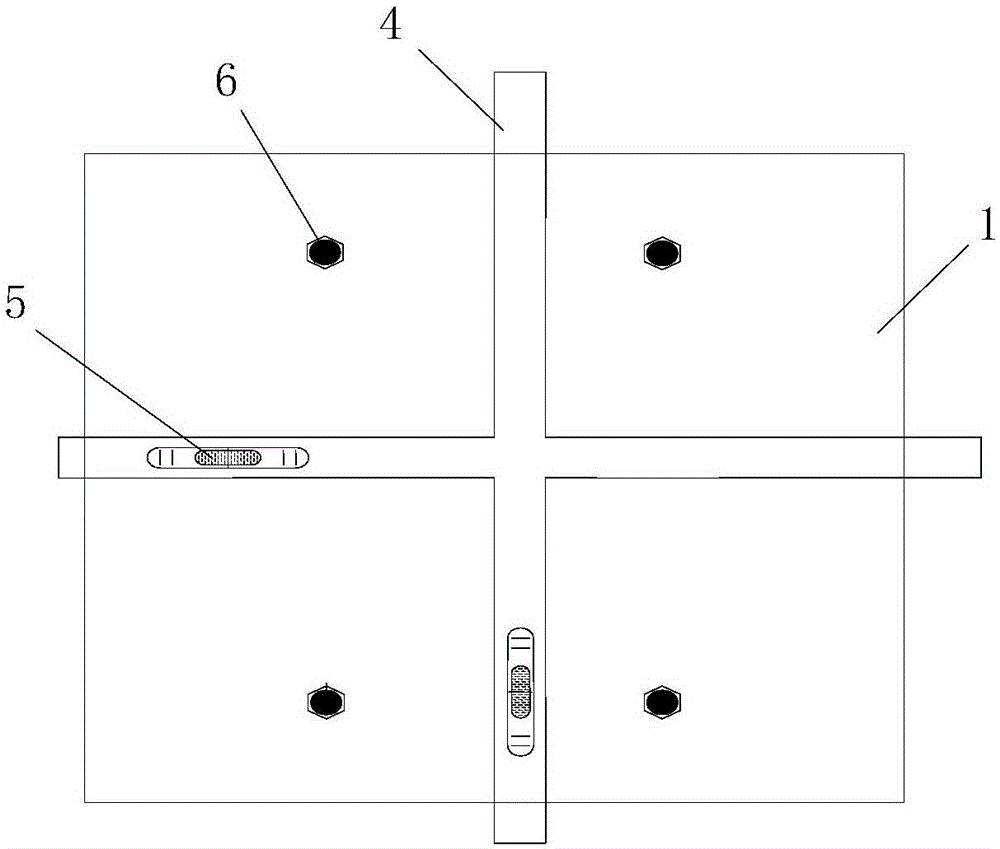

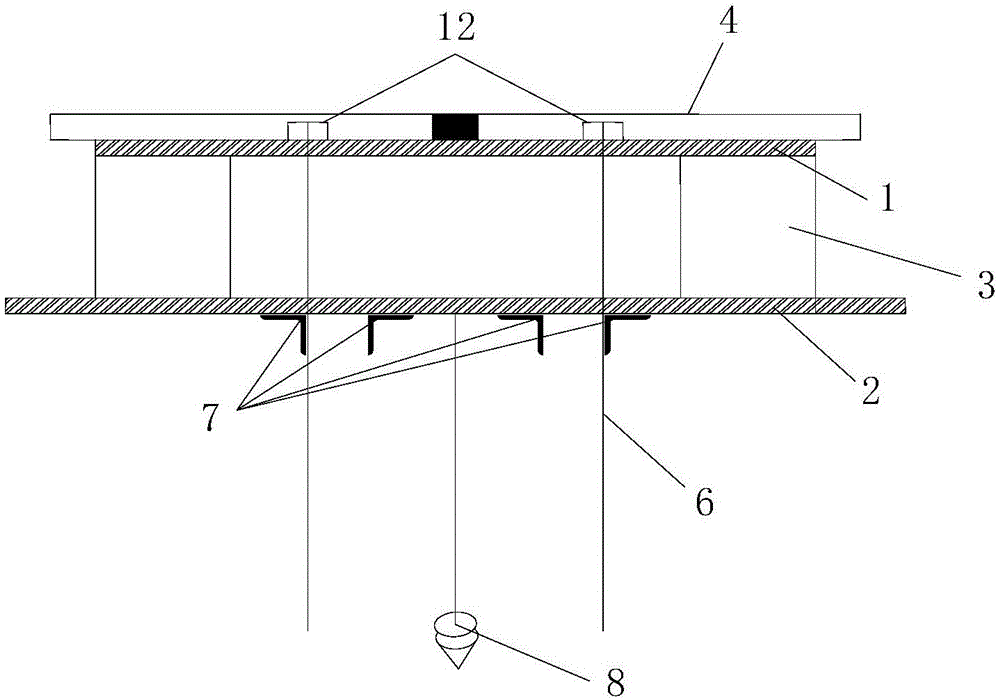

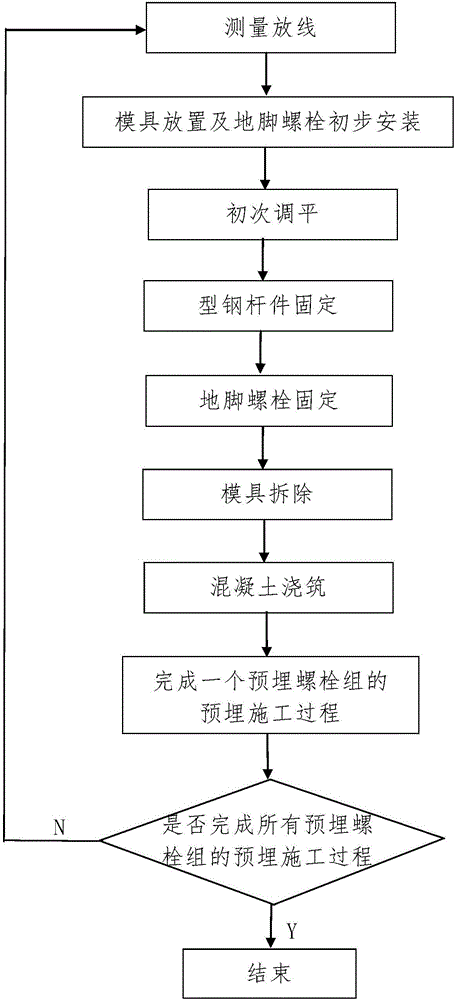

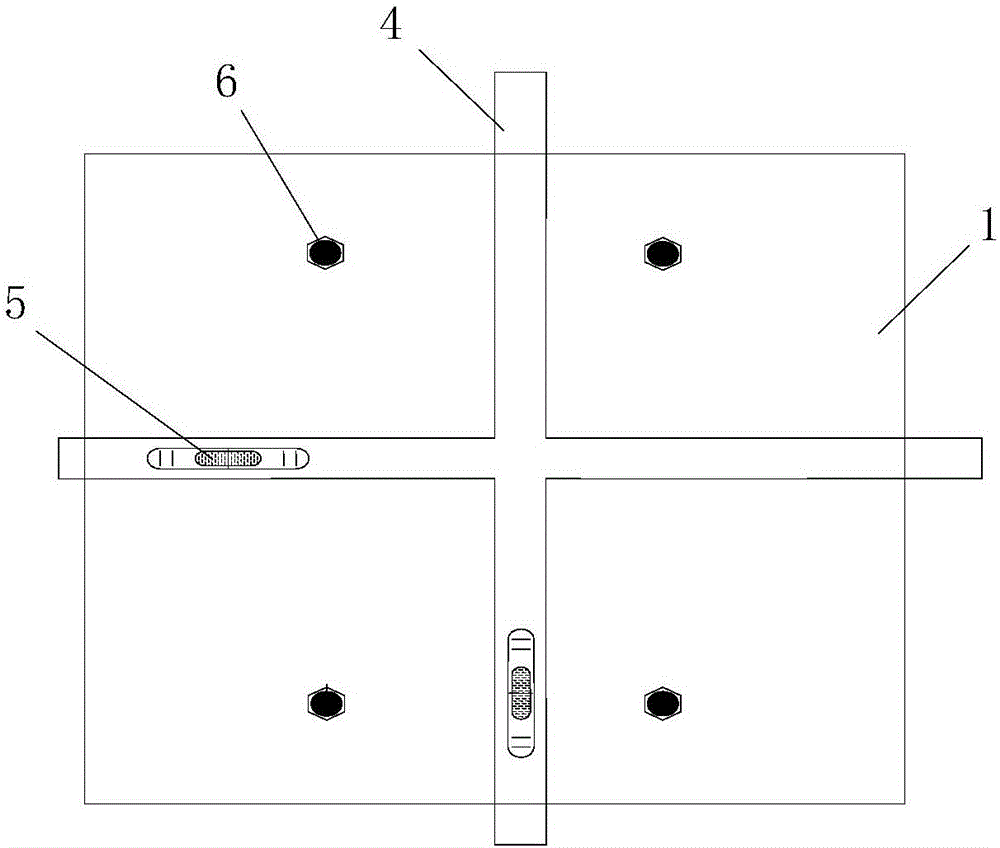

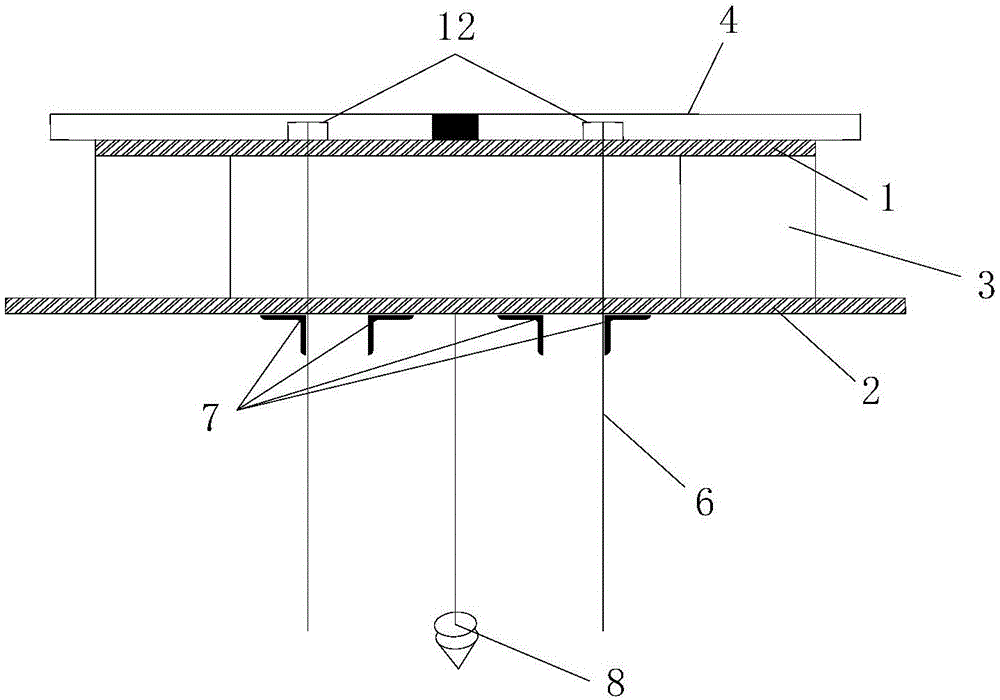

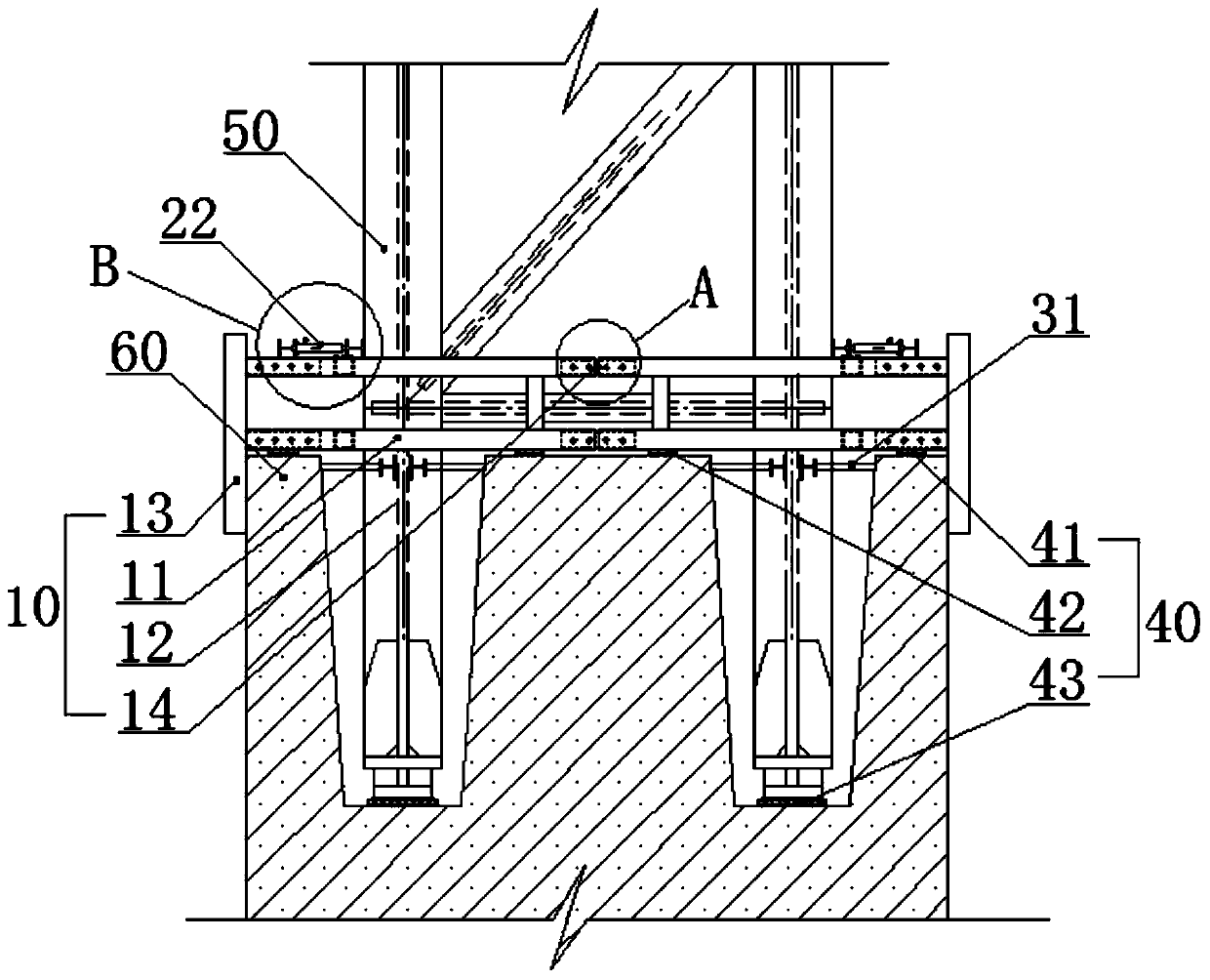

Foundation bolt embedding construction die and foundation bolt adjusting construction method

The invention discloses a foundation bolt embedding construction die and a foundation bolt adjusting construction method. The foundation bolt embedding construction die comprises an upper horizontal plate, a lower horizontal plate and a plurality of supporting pieces supported between the upper horizontal plate and the lower horizontal plate. A horizontal measuring ruler is flatly placed on the upper horizontal plate or the lower horizontal plate. The upper horizontal plate is provided with one upper bolt installing hole set. The lower horizontal plate is provided with a lower bolt installing hole set. The number of bolt installing holes included in each of the upper bolt installing hole set and the lower bolt installing hole set is equal to the number of foundation bolts needing to be constructed. Structural steel rod pieces are fixed to the bottom of the lower horizontal plate. The construction method comprises the first step of surveying and setting out, the second step of die placing and primary foundation bolt installing, the third step of the first-time leveling, the fourth step of structural steel rod piece fixing, the fifth step of foundation bolt fixing and the sixth step of die dismounting. According to the foundation bolt embedding construction die and the foundation bolt adjusting construction method, the design is reasonable, construction is easy and convenient, the using effect is good, the foundation bolts needing to be constructed can be accurately positioned easily, conveniently and rapidly, and the foundation bolt adjusting construction process is easily and conveniently finished.

Owner:CHINA RAILWAY 20 BUREAU GRP

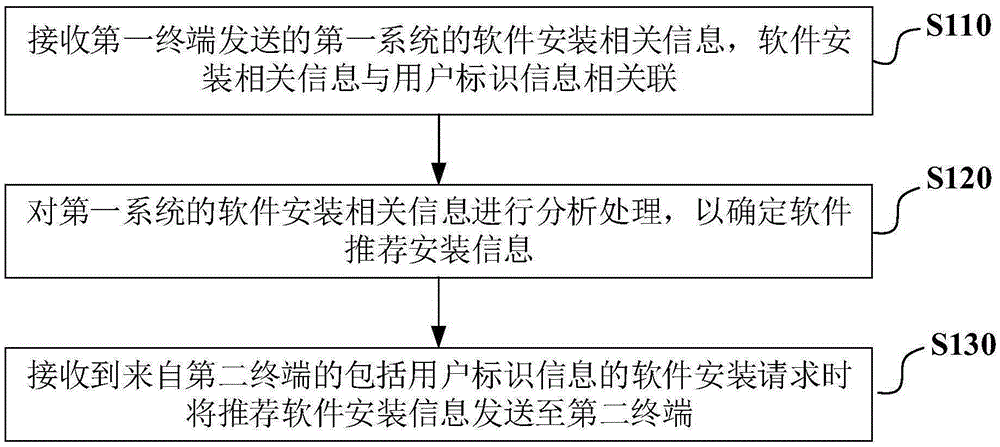

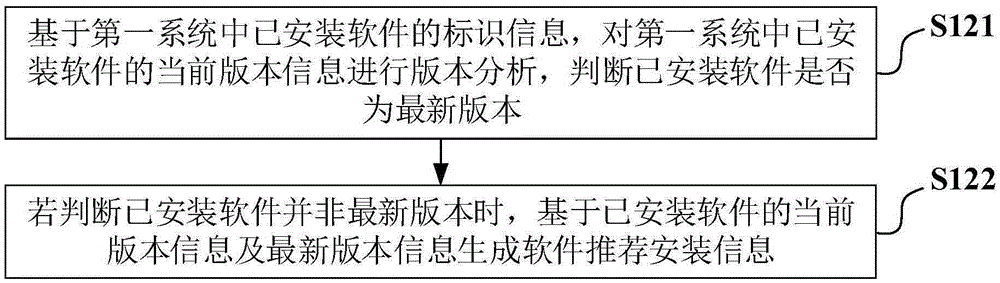

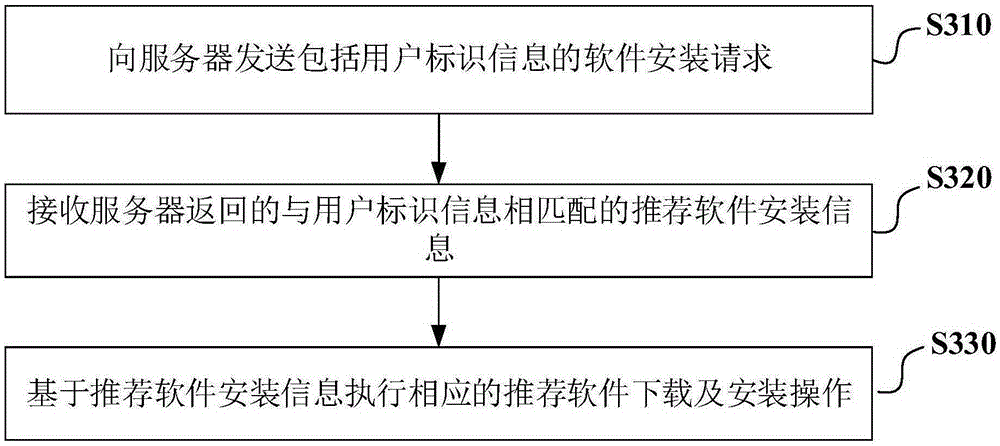

Method and device for installing software

InactiveCN105302622AQuick and accurate installationTroubleshoot installation of their commonly used softwareProgram loading/initiatingSoftware engineeringComputer terminal

The invention provides a method and device for installing software in a second terminal and a method and device for assisting in installation of software on a server side. The method for installing software in the second terminal comprises the steps of sending a software installing request carrying user identification information to a server; receiving recommended software installation information matched with the user identification information and fed back by the server, wherein the recommended software installation information is obtained based on the software installation related information, sent by a first terminal, of a first system; executing corresponding recommended software downloading and installing operation based on the recommended software installation information. By the adoption of the scheme, for users who have the requirement for replacing an old terminal unit with a new terminal unit or operate multiple terminal units, the same set of common software can be installed on different terminal units of one user in a related mode according to user identification information, and excellent user experience is guaranteed.

Owner:BEIJING QIHOO TECH CO LTD +1

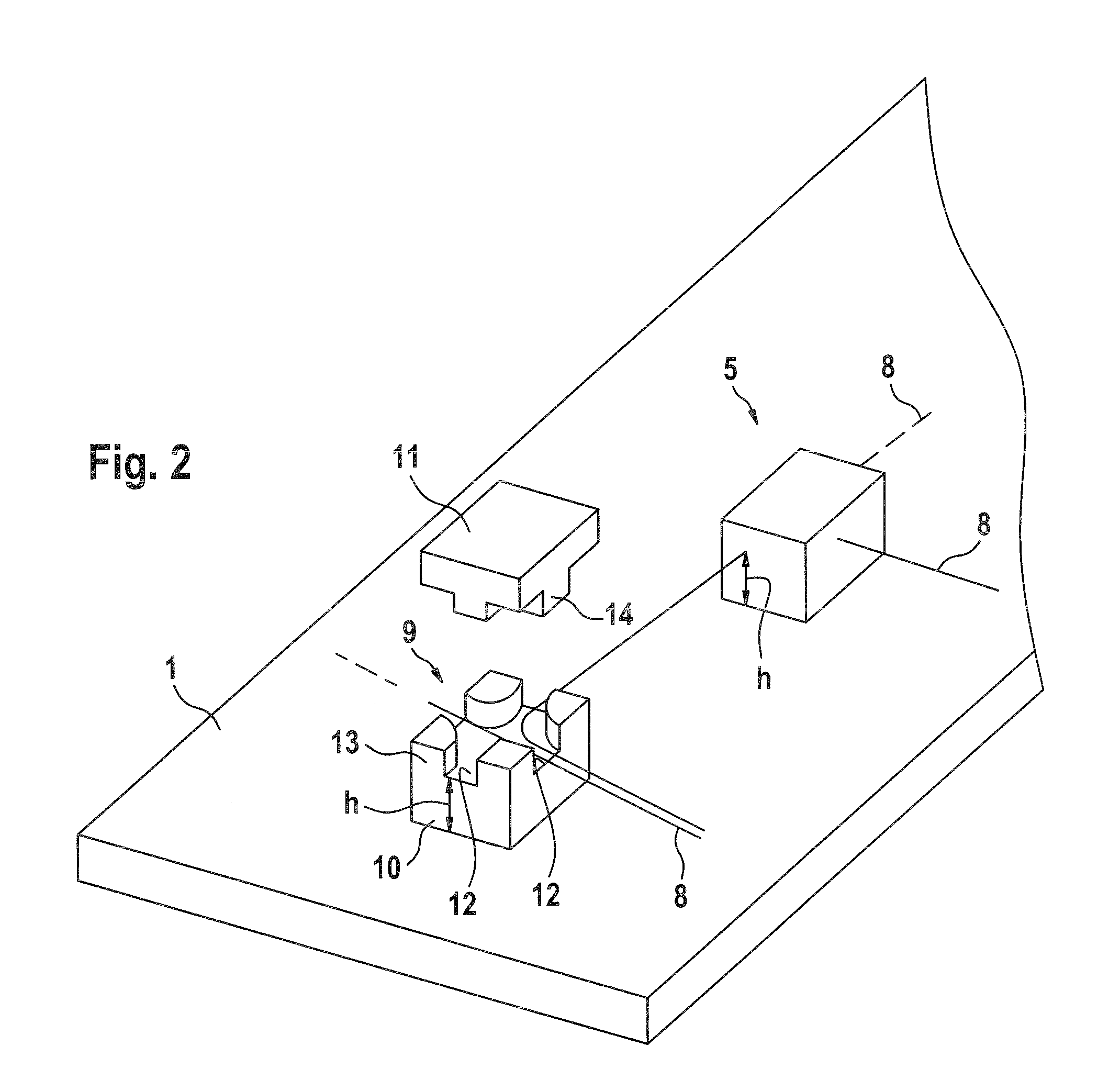

Luminous means, cable harness and interior trim element

InactiveUS20120051064A1Prevent be damageFast and precise mountingLighting support devicesPoint-like light sourceElectricityEngineering

The present invention is directed to a luminous means comprising at least one light-emitting diode which is at least partly accommodated in a connection block, wherein electrical connections of the at least one light-emitting diode exit from the connection block in an angled fashion relative to the preferred light emission direction (M). The invention is further directed to a cable harness comprising at least one of said luminous means, as well as to an interior trim element comprising said luminous means.

Owner:DIEHL AIRCABIN +1

Center alignment device for coupler

ActiveCN104567586AQuick and accurate installationImprove alignment efficiencyMechanical measuring arrangementsCouplingArchitectural engineering

The invention relates to the technical field of measurement, and discloses a center alignment device for a coupler. The center alignment device comprises a fixing base, a conical body, an axial adjusting rod, a radial adjusting rod and dial indicators. One end of the axial adjusting rod is connected with the fixing base, the other end of the axial adjusting rod is connected with the center of the radial adjusting rod, a magnetic base used for being attracted to and fixed to a motor shaft is arranged on the periphery of the fixing base, the conical body is disposed in the center of the bottom of the fixing base, the conical body and the axial adjusting rod are coaxially arranged and used for being aligned to a center hole of the motor shaft, and the dial indicators are installed at the two ends of the radial adjusting rod respectively. The conical body is designed in the center of the bottom of the fixing base so that the center hole of the motor shaft can be quickly found and aligned, and the magnetic base is attracted to and fixed to the motor shaft so that installation can be more precise and quicker. Besides, the conical body can installed in the bottom of the fixing base in a telescopic rod, center alignment is convenient to achieve, and machining difficulty is lowered.

Owner:GUANGDONG TOPKEY POWER TECHN DEV

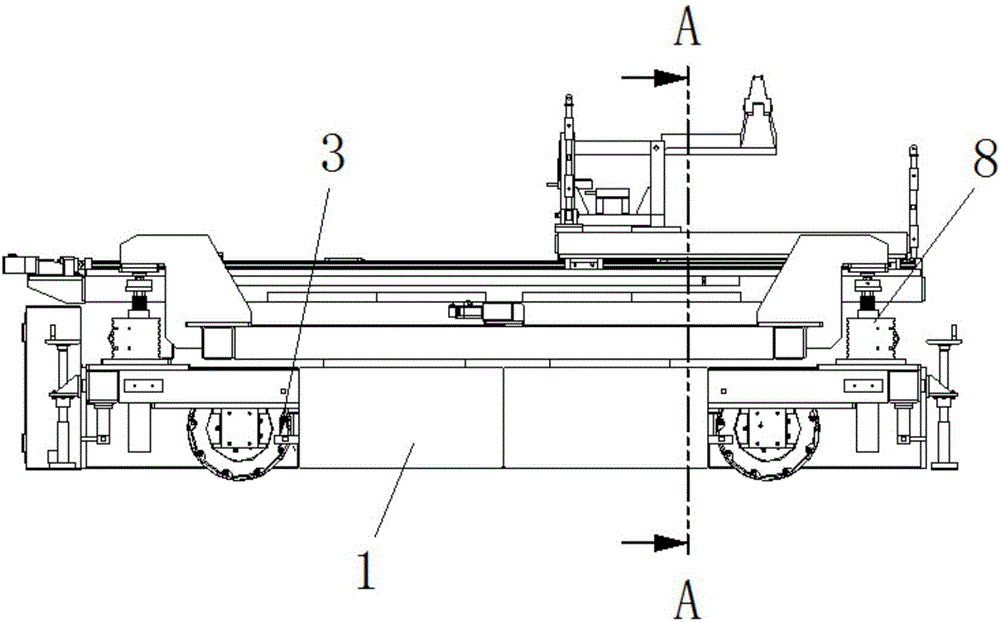

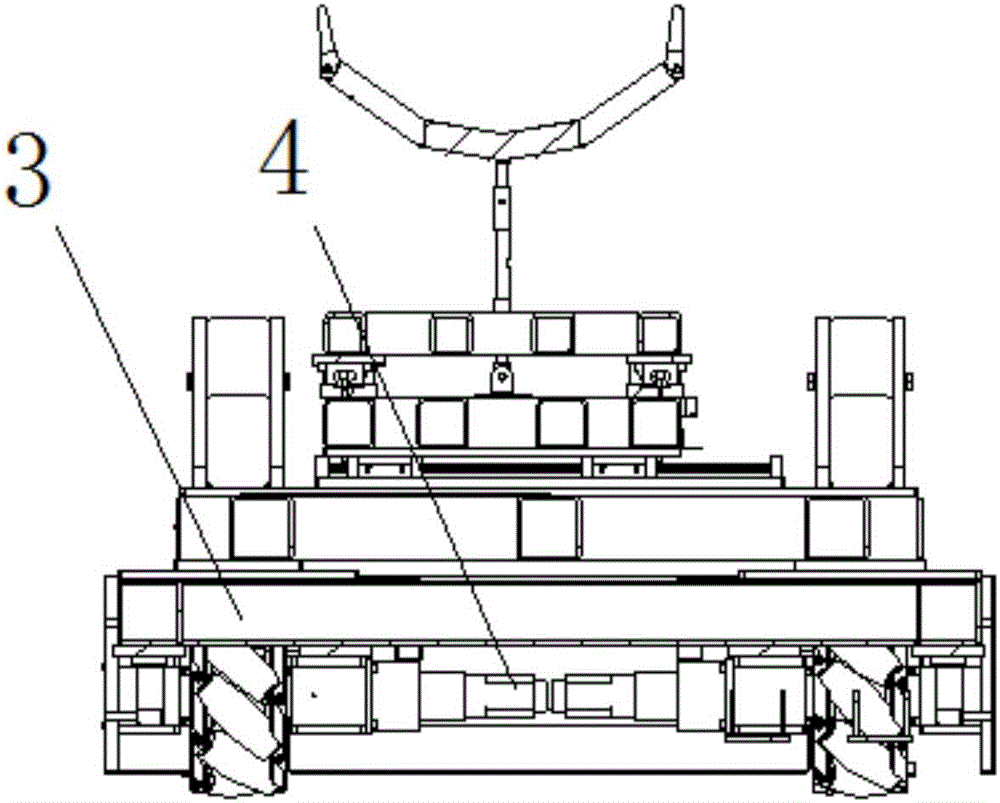

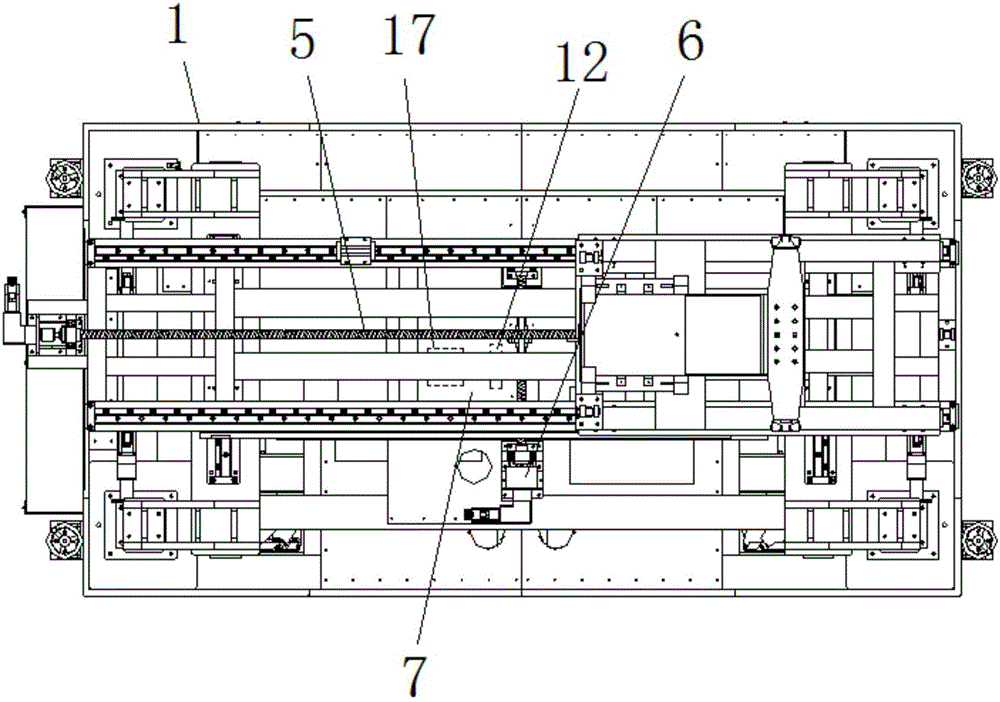

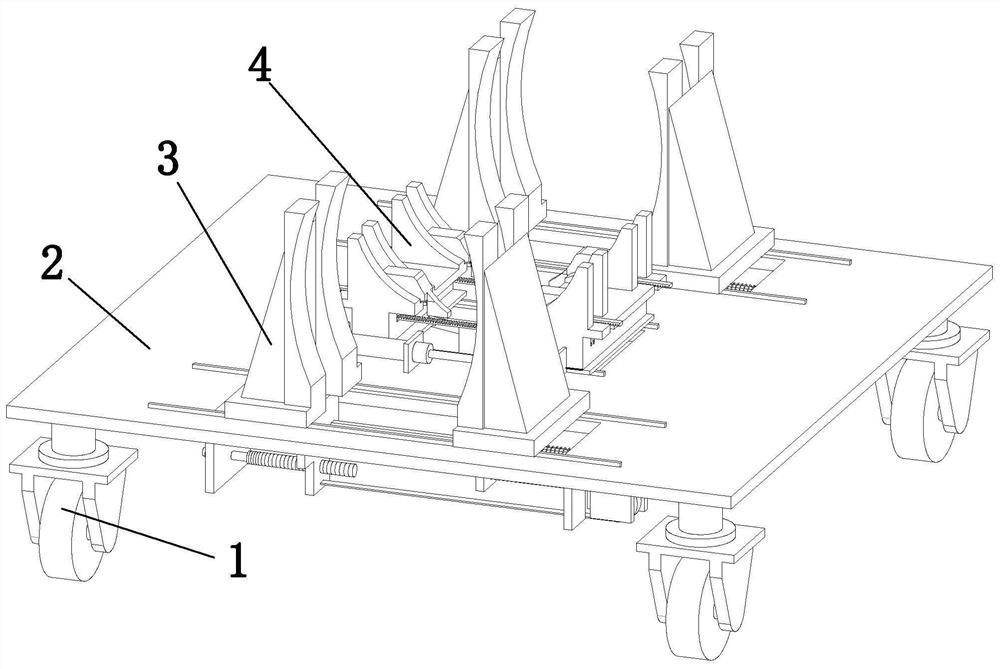

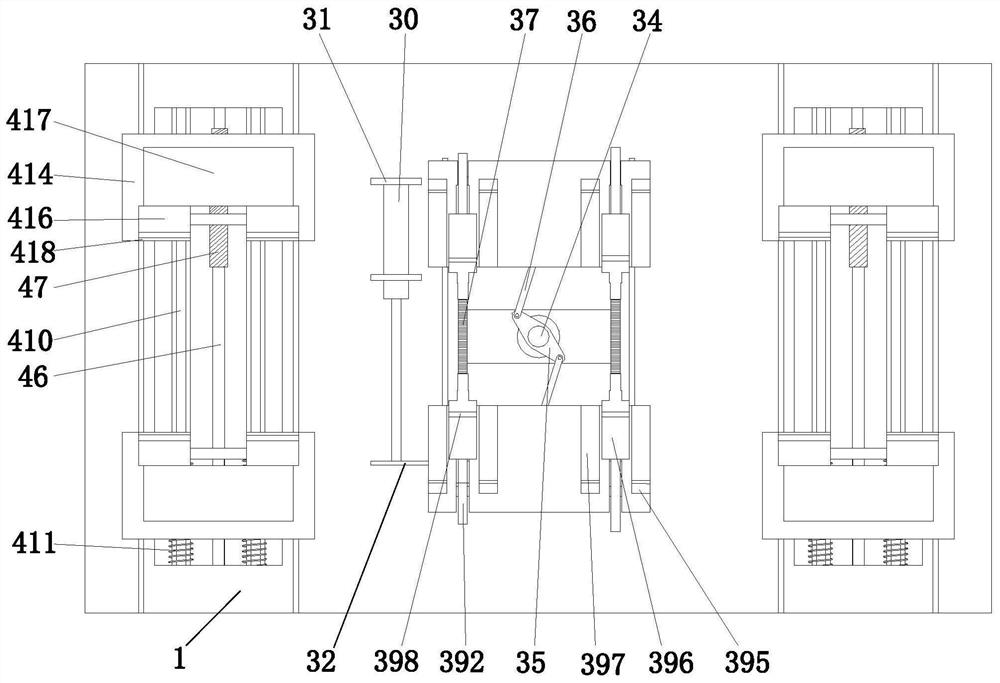

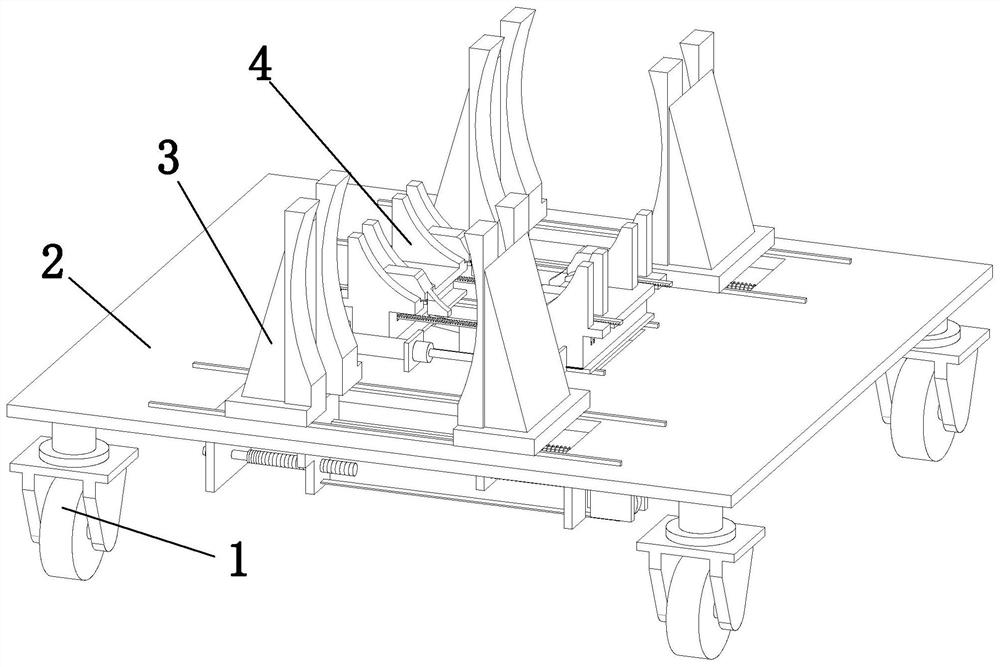

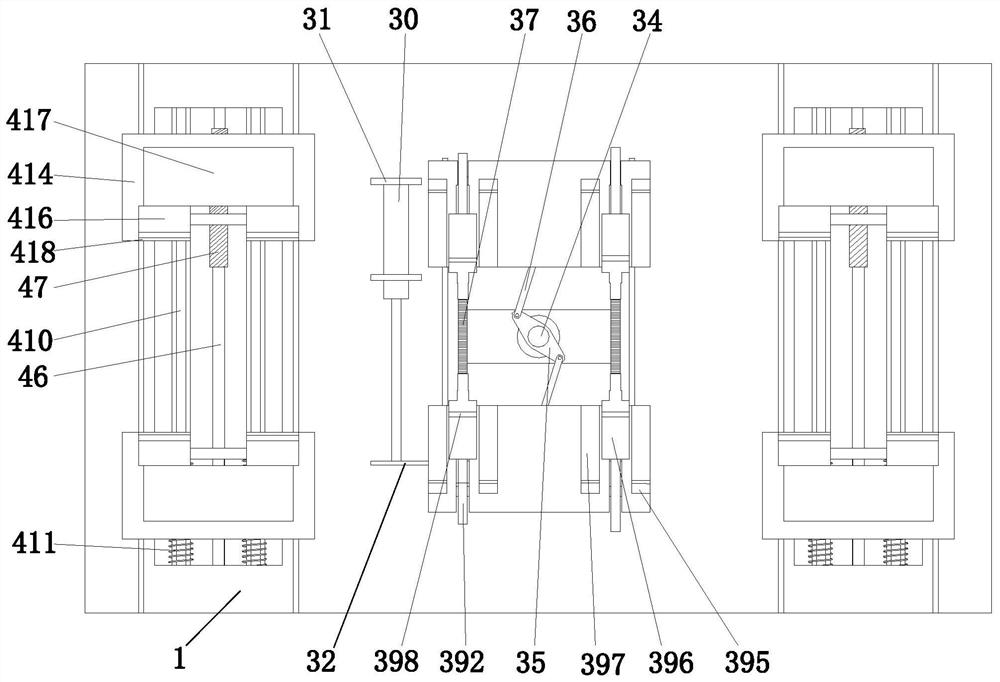

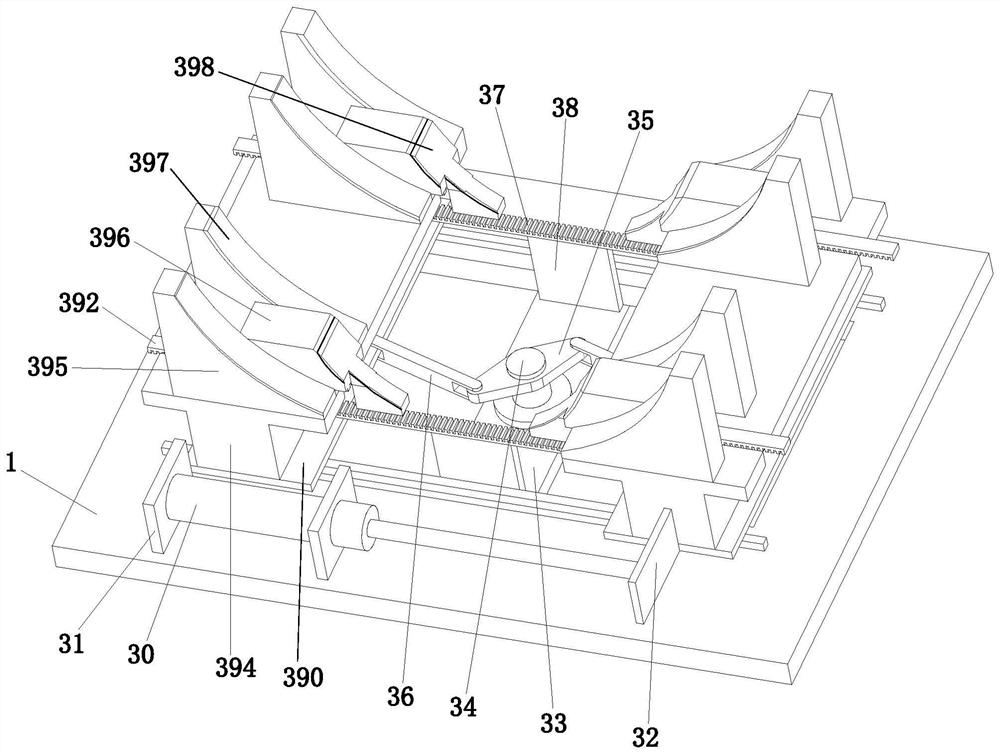

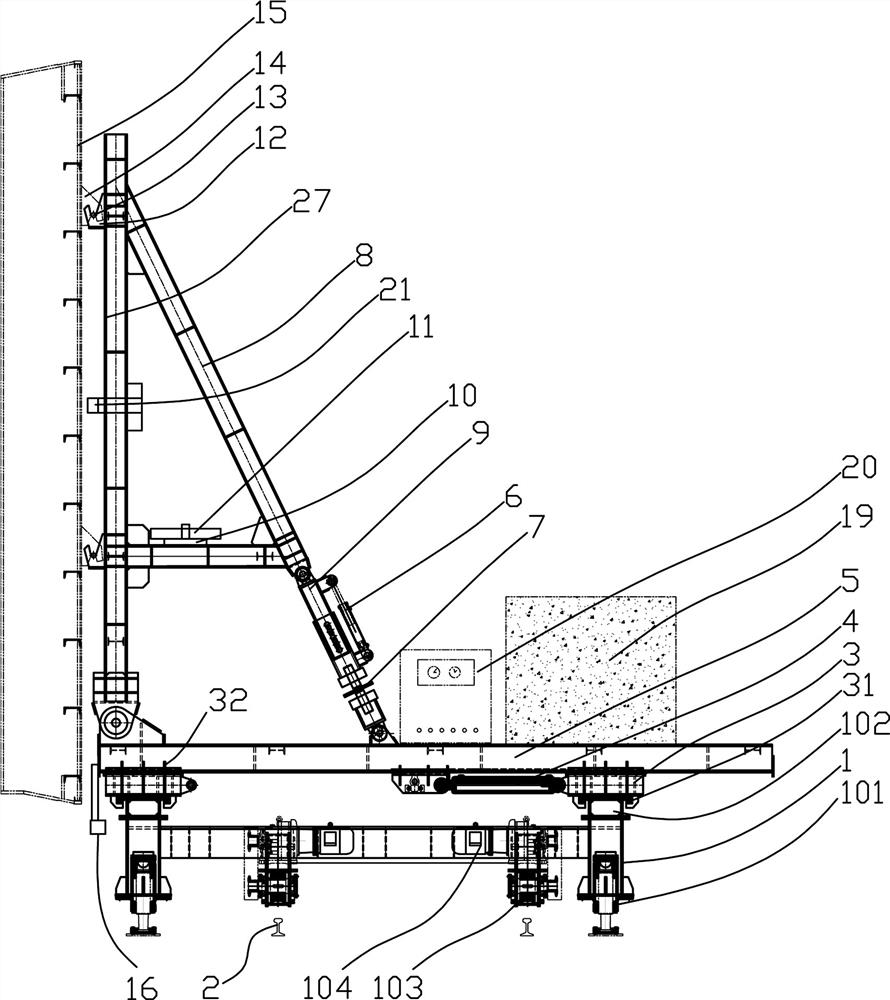

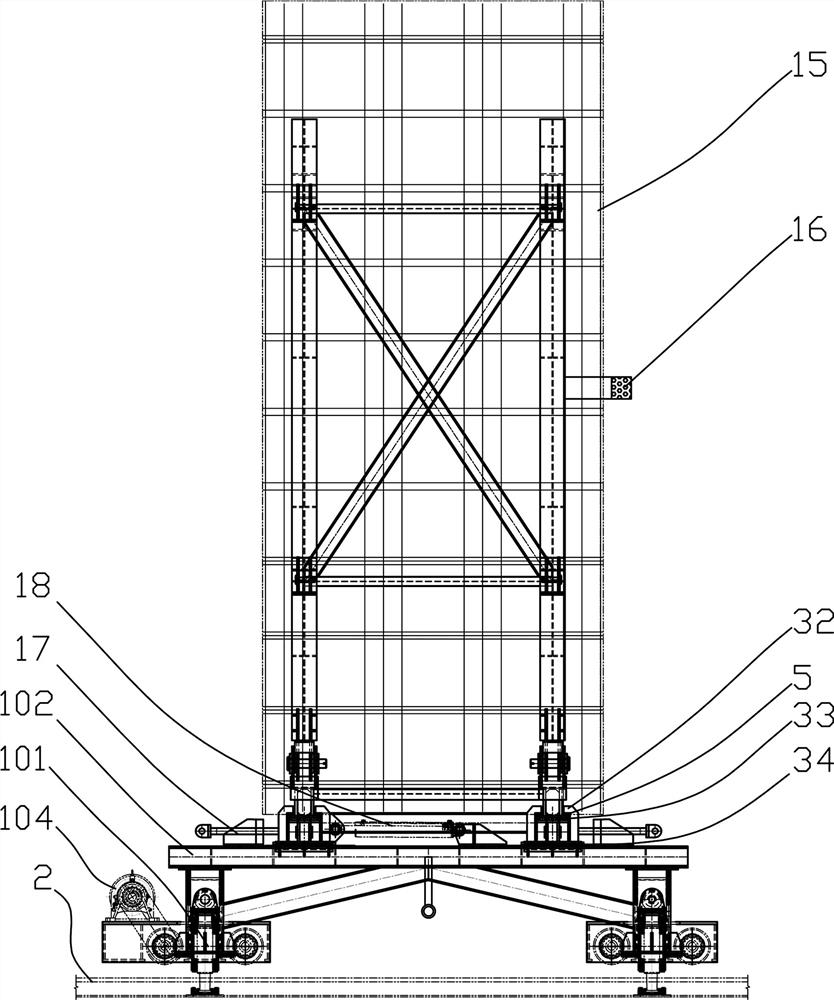

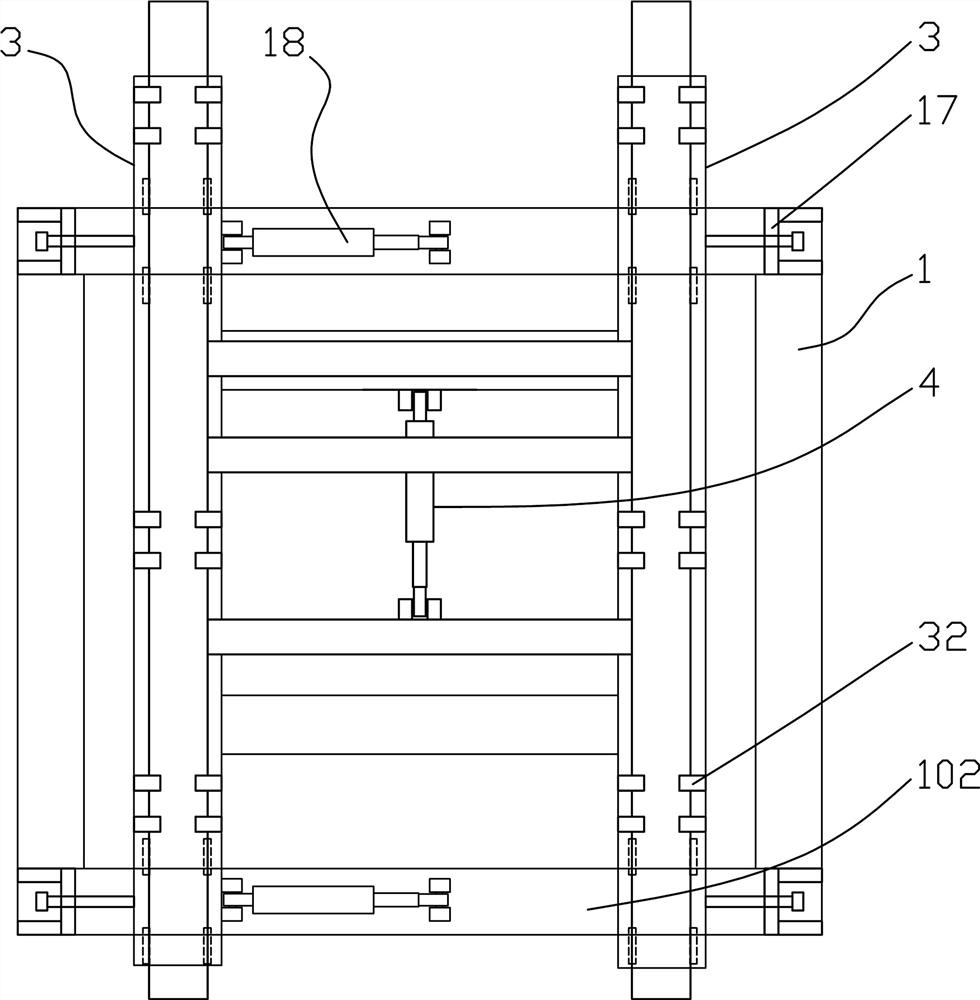

Automated sectioning platform for engine

PendingCN106742040AQuick and accurate installationReal-time and precise gap monitoringAircraft assemblyBall screwVideo processing

The invention discloses an automated sectioning platform for an engine. The automated sectioning platform comprises a vehicle body, wherein walking mechanisms are arranged at the four corners of the bottom of a first-layer platform of the vehicle body, and attitude-adjusting mechanisms are arranged at the four corners of the lower part of a second-layer platform of the vehicle body; a transversal screw adjusting mechanism is arranged on the second-layer platform of the vehicle body, and a longitudinal screw adjusting mechanism is arranged on a third-layer platform of the vehicle body; the longitudinal screw adjusting mechanism is perpendicular to the transversal screw adjusting mechanism, and the walking mechanism comprises Mecanum wheels; a rotating shaft is fixedly connected with the axis of the Mecanum wheel, and the surface of the rotating shaft is sleeved with a bearing seat; a first flange arranged on the bearing seat is fixedly connected with a second flange arranged at the bottom of the first-layer platform of the vehicle body. The automated sectioning platform for the engine has the advantages of meeting the fast and accurate installation and safe disassembly requirements of the engine by using a first servo motor, a second servo motor, a third servo motor, a screw lift, ball screws and a video processing technology and the like, saving a lot of labor force and meeting the wartime needs.

Owner:上海汇聚自动化科技有限公司

Embedment construction method for foundation bolts used for steel structure building construction

ActiveCN106193330AThe method steps are simpleReasonable designBuilding constructionsReinforced concreteEmbedment

The invention discloses an embedment construction method for foundation bolts used for steel structure building construction. A steel structure skeleton of a constructed steel structure building comprises multiple steel stand columns, each steel stand column is supported on a reinforced concrete foundation, a steel backing plate is fixedly welded to the bottom of each steel stand column, and an embedded bolt set is installed on the steel backing plate; the process of embedded construction of each embedded bolt set includes the steps of 1 surveying and setting-out; 2, mold placing and primary foundation bolt installation; 3, primary leveling; 4, profile steel rod fixing; 5, foundation bolt fixing; 6, mold disassembling; 7, concrete pouring; 8, repeating the steps from 1 to 7 until the embedded construction process of all the embedded bolt set is completed. The embedment construction method is simple in step, reasonable in design and good in use effect, construction is convenient, the embedment construction process of the foundation bolts used for steel structure building construction can be conveniently and fast completed, and embedment accuracy of the foundation bolts can be ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

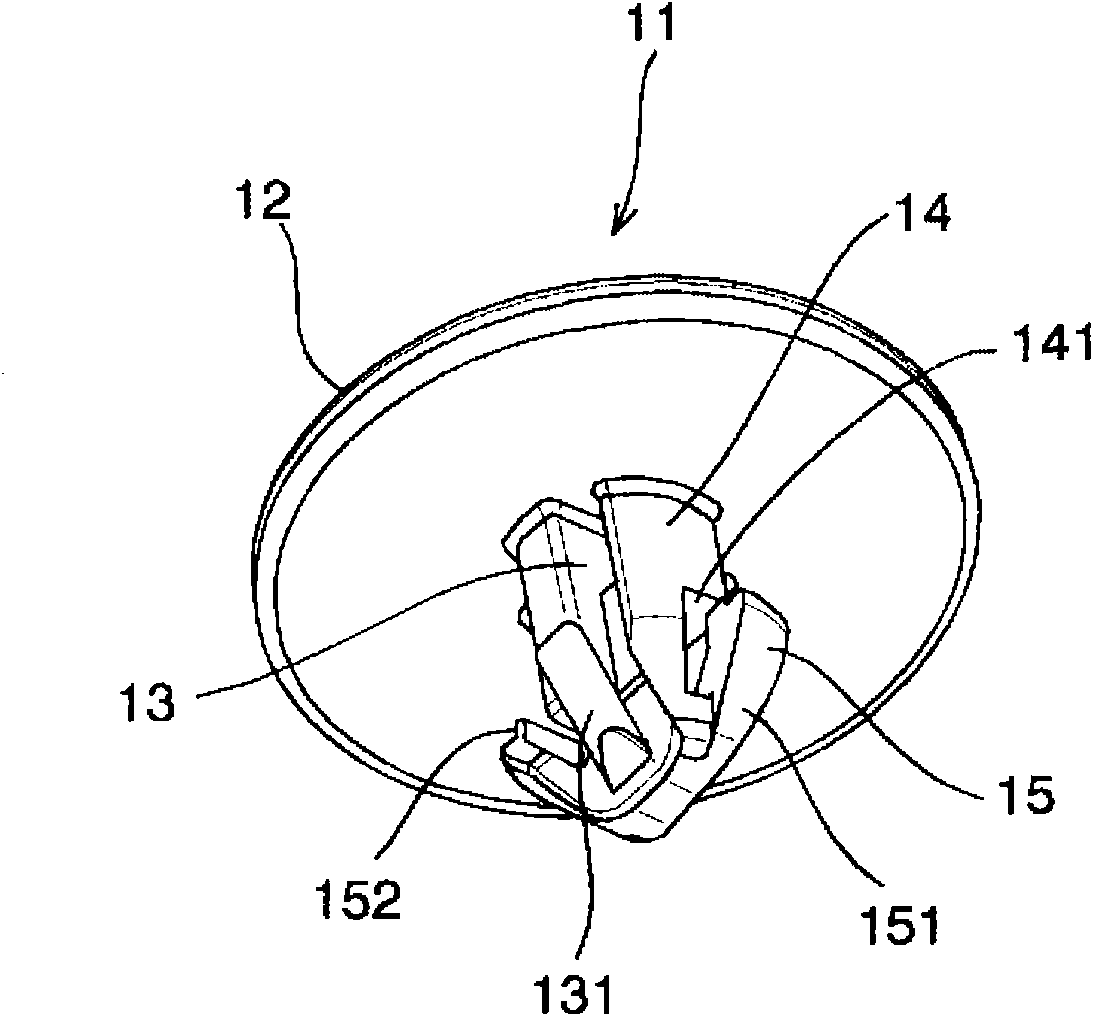

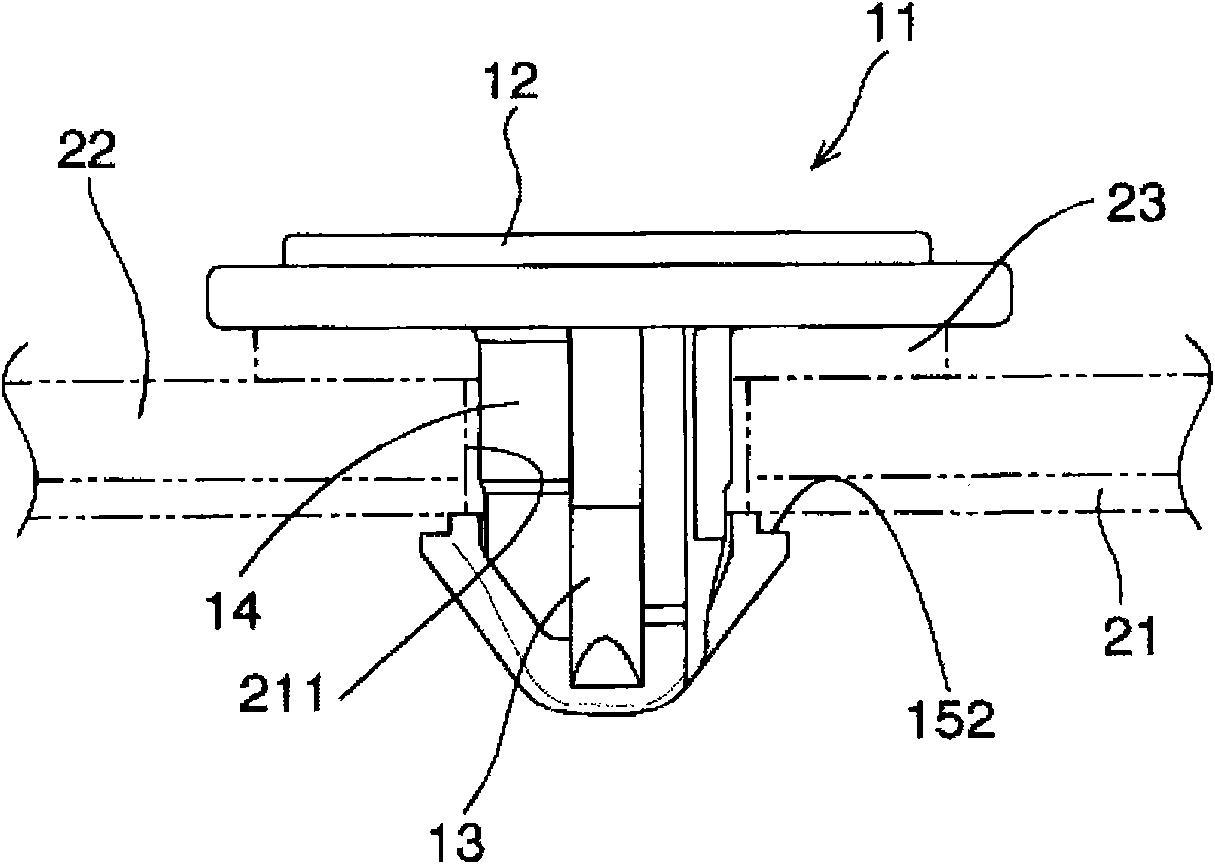

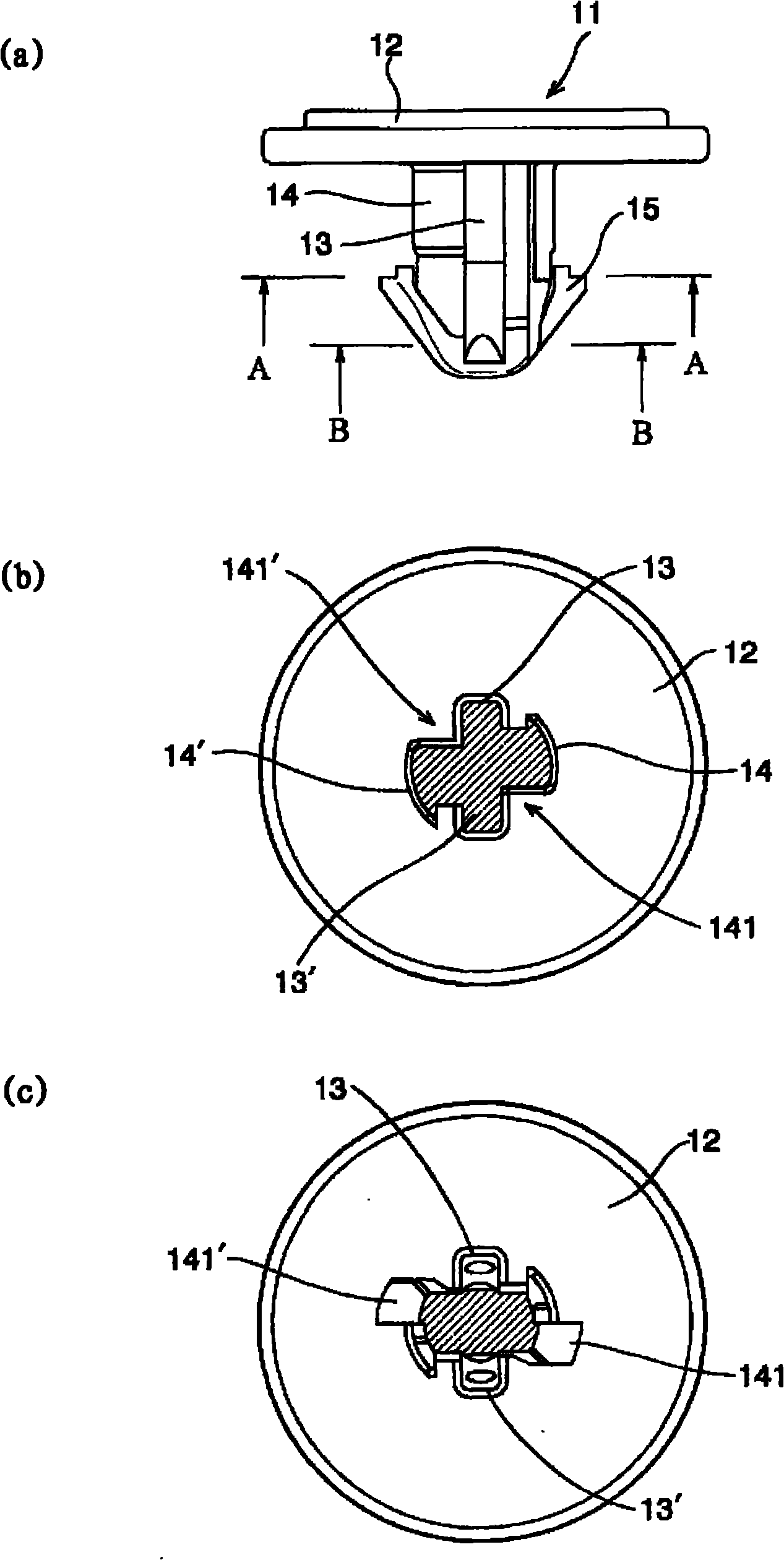

Clip

ActiveCN101893023AQuick and accurate installationEasy to installSheet joiningScrewsEngineeringMechanical engineering

The invention relates to a clip mounted on a mounting member by once through operation. The clip is provided with at least a head, a center support, an auxiliary support, elastic legs, engaging sections, and a cavity. The head has a shape capable of engaging with one surface of a member to which a mounting member is mounted. The center support is extended downward from the head and has a shape suitable to be inserted into a mounting hole. The auxiliary support is extended downward from the head in the same manner as the center support, and the base of the auxiliary support, said base being adapted to be inserted into the mounting hole, is formed integrally with both the head and the center support so as to be perpendicular to the center support. The pair of elastic legs, which expand in a V-shape, is interconnected with the tips of the center support and the auxiliary support and is formed in a shape which is turned back toward the head and the auxiliary support. The engaging sections which engage with the member to which a mounting member is mounted are provided to the tips of the elastic legs and are engaged with the mounting member or the other surface of the member to which the mounting member is mounted. The cavity is provided in the auxiliary support and is configured in such a manner that, when the elastic legs are deformed and inserted into the mounting hole, the cavity receives the deformed portions.

Owner:NIFCO INC

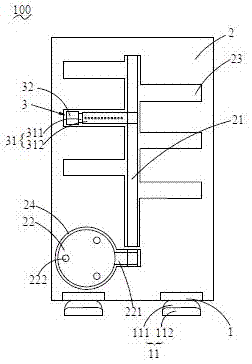

Transferring and conveying process of chemical reactors

InactiveCN111689046AImprove stabilityAvoid leaningExternal fittingsInternal fittingsChemical reactorProcess engineering

The invention provides a transferring and conveying process of chemical reactors. The transferring and conveying process is mainly completed through the cooperation of chemical reactor transferring and conveying equipment. The chemical reactor transferring and conveying equipment comprises a mounting bottom plate, a moving mechanism, a supporting mechanism and clamping mechanisms. The lower end surface of the mounting bottom plate is uniformly provided with the moving mechanism. The mounting bottom plate is provided with a sliding rail. The mounting bottom plate is symmetrically provided withthe clamping mechanisms through sliding fit. The supporting mechanism is located between the clamping mechanisms. By means of the transferring and conveying process of the chemical reactors, the problems that the outer walls and the bottoms of chemical reactors of different sizes cannot be supported at the same time during transferring and conveying of existing chemical reactors, clamping operation cannot be performed automatically while supporting tank bodies, and the impact, caused by shaking of the tank bodies, on the whole transport equipment cannot be relieved in the transportation process can be solved.

Owner:HANGZHOU DEBIAO NEW ENERGY TECH CO LTD

Chemical industry reaction still transfer transporting device

InactiveCN111703803AAvoid leaningImprove stabilityPackaging vehiclesContainers for machinesChemical industryProcess engineering

The invention provides a chemical industry reaction still transfer transporting device, and the device comprises a mounting base board, a moving mechanism, a support mechanism and a clamping mechanism, the moving mechanism is evenly mounted at a lower end face of the mounting base board, the mounting base board is provided with a sliding rail, the clamping mechanism is symmetrically mounted on themounting base board through sliding fit, the support mechanism is mounted on the mounting base board through sliding fit, and the support mechanism is located between the clamping mechanism. The chemical industry reaction still transfer transporting device can solve a problem that, in the prior art, when a chemical industry reaction still transfer transporting work is executed, an external wall and a bottom part of the chemical industry reaction still of different size cannot be supported at the same time, an automatic clamping operation cannot be executed while a tank body is supported, andimpact to the whole transporting device caused by waggling of the tank in a transporting process cannot be eased. The chemical industry reaction still transfer transporting device improves working efficiency in a chemical industry reaction still transfer transporting operation, and has the advantages of being widely applicable, excellent in adjustment performance, accurate and stable in clamping and supporting, and so on.

Owner:HANGZHOU DEBIAO NEW ENERGY TECH CO LTD

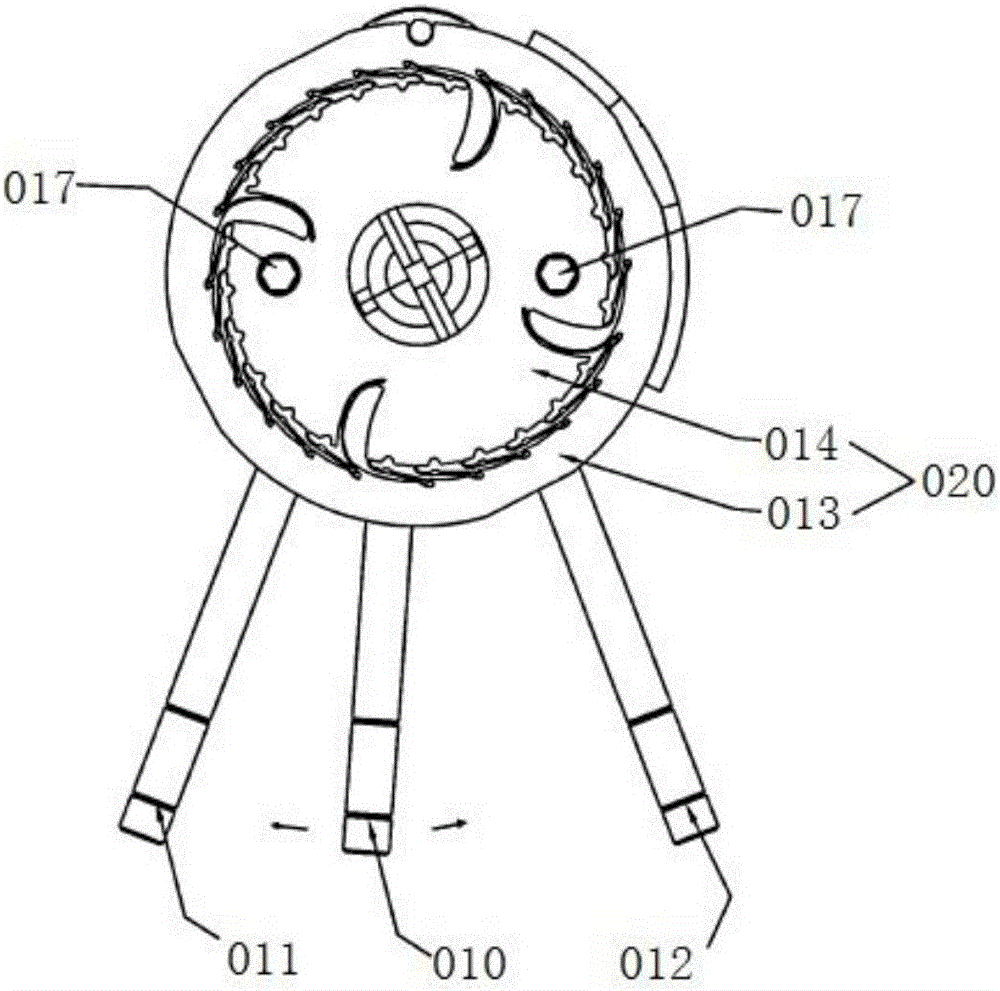

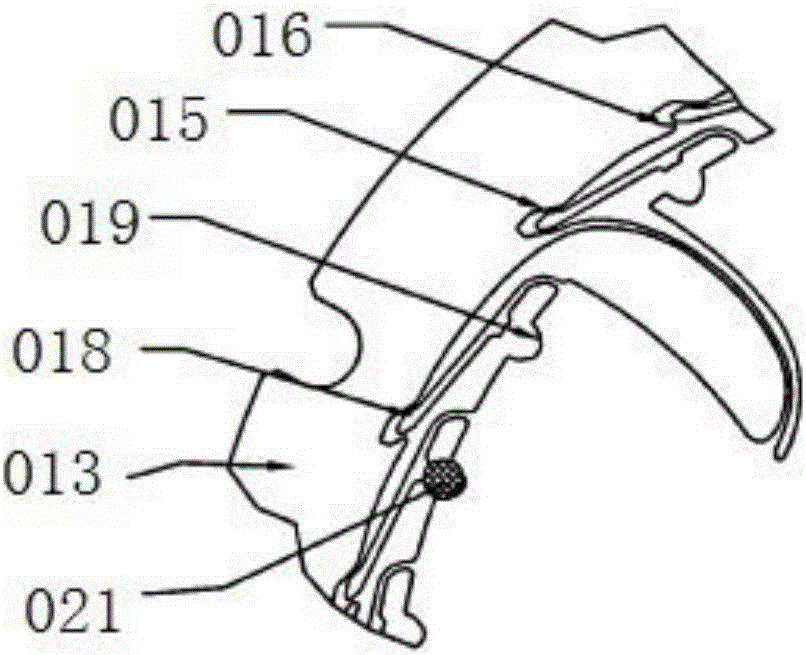

Grinding clamp and jig thereof

ActiveCN105108638AFixed fastThere will be no problems with small displacementsLapping machinesWork carriersEngineeringIliac screw

The invention provides a grinding clamp and a jig thereof. When an insertion core needs to be located and fixed, only the free end of the jig needs to be pulled towards the side away from a clamp body to enable a first extrusion face to be separated from a second extrusion face by a certain distance; then the insertion core is put between the first extrusion face and the second extrusion face, an elastic locating arm is loosened and restores to the original position under the action of elasticity of the elastic locating arm, and accordingly the insertion core can be fixed between the first extrusion face and the second extrusion face rapidly and firmly, and the fixing speed is high. As the insertion core is fixed at a time, the process of gradual extrusion of a screw is avoided in the process of fixing, small displacement due to gradual extrusion can be prevented, and the insertion core does not move any more once being extruded and fixed, so that the locating is accurate; besides, the elasticity of the elastic locating arm is large, so that the insertion core is extruded and fixed quite firmly, and position changing or falling of the insertion core due to external slight impact is prevented.

Owner:SUZHOU TFC OPTICAL COMM CO LTD

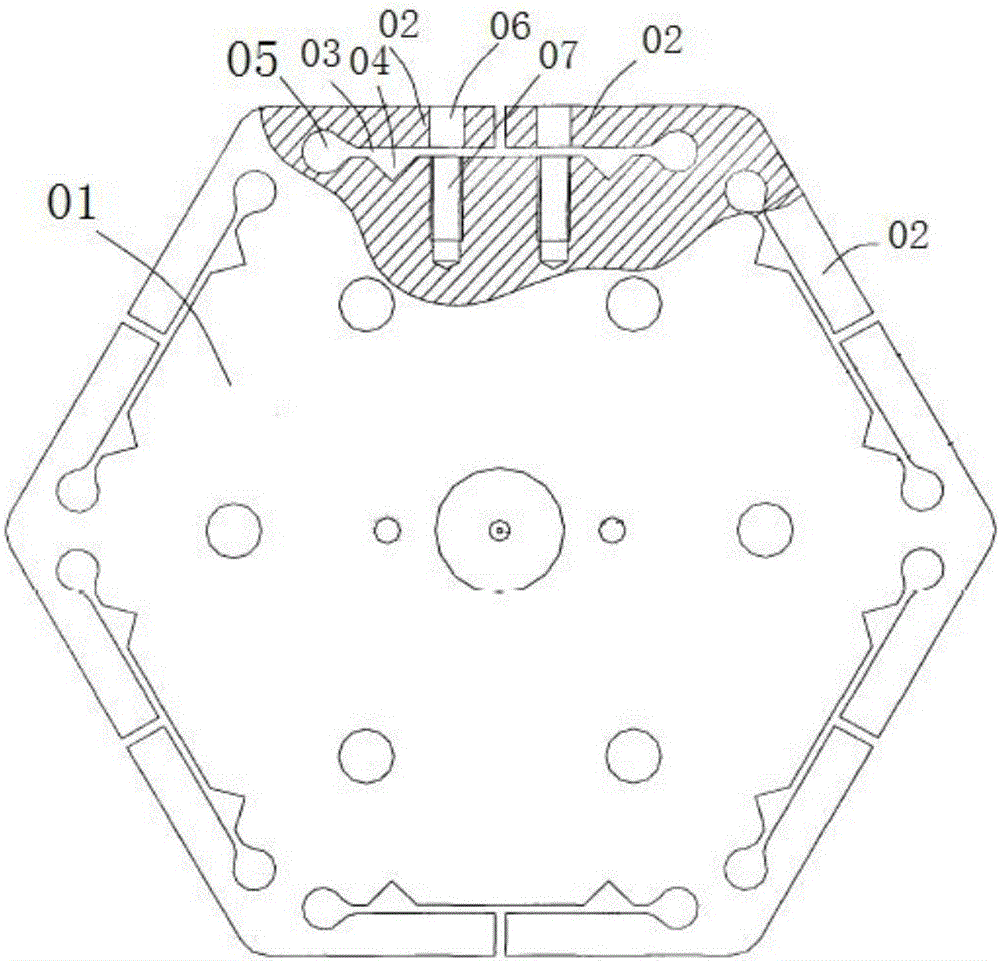

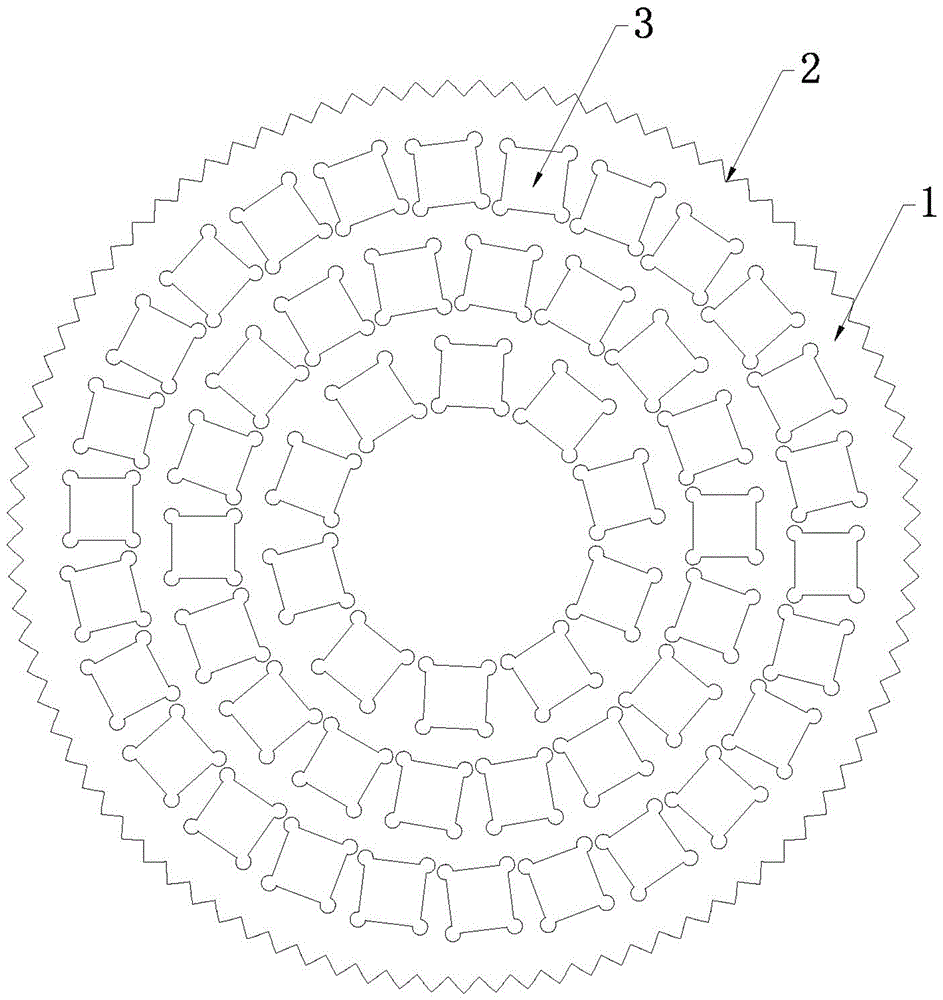

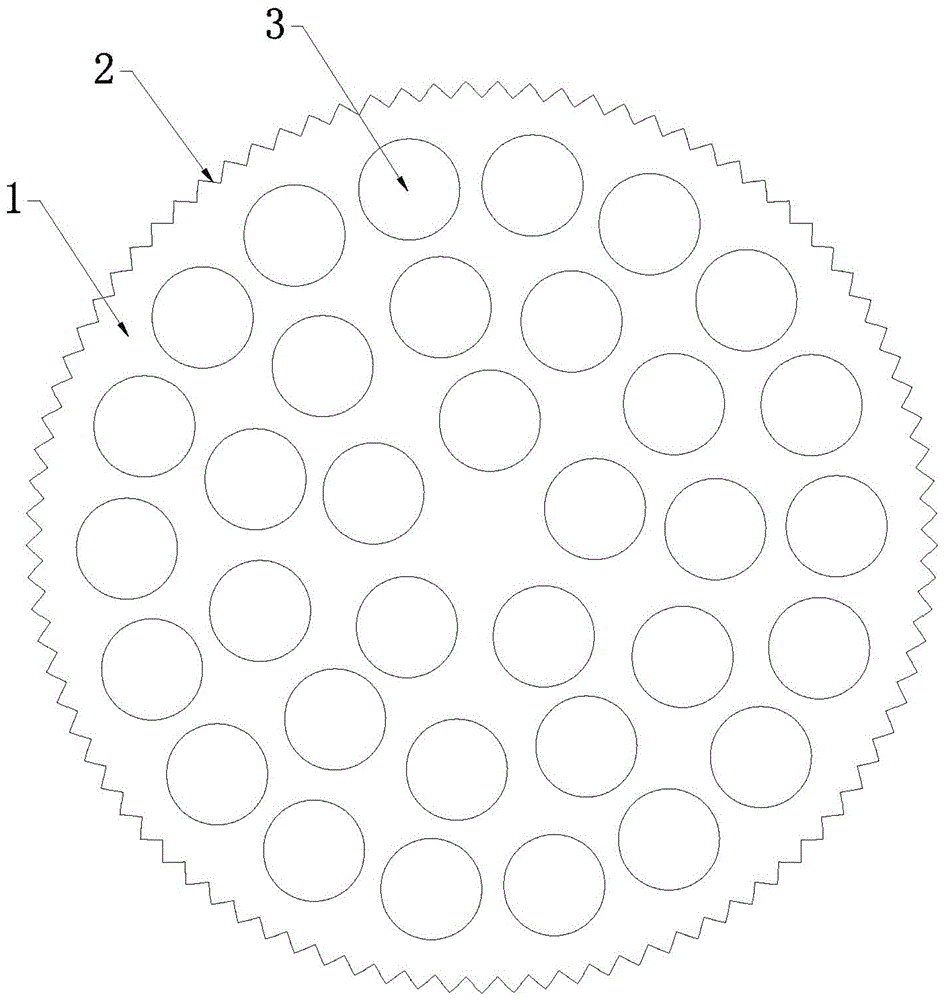

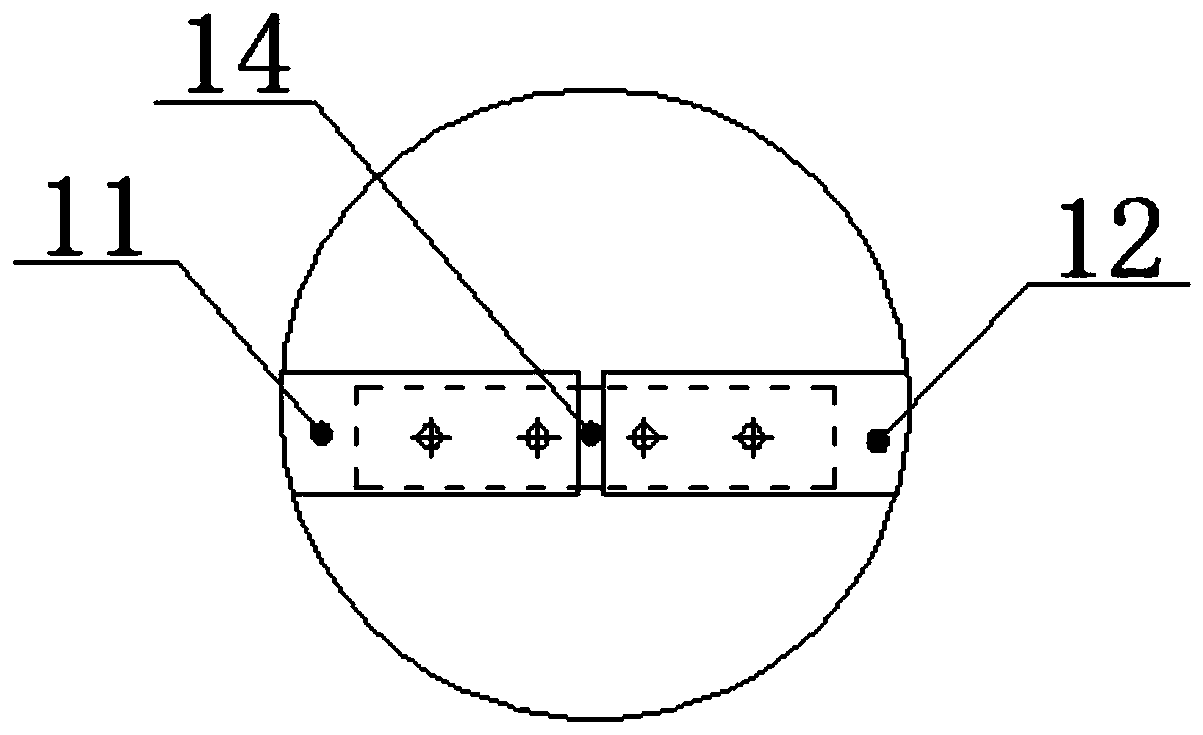

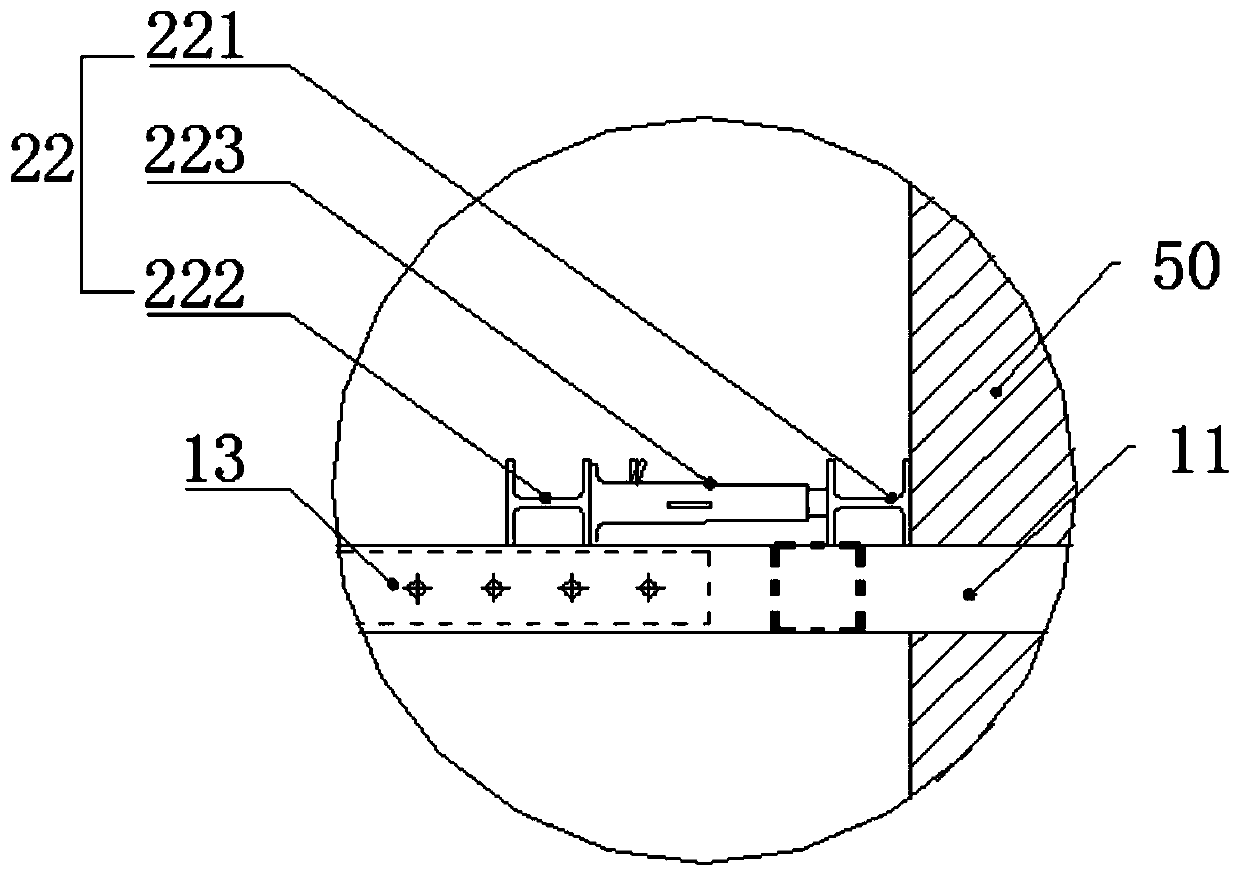

Work fixture for double-side grinding and polishing machine

InactiveCN106363529AProcessing quality meetsLow movement resistanceWork carriersEngineeringMachining process

The invention discloses a work fixture for a double-side grinding and polishing machine. The work fixture for the double-side grinding and polishing machine comprises a fixture body (1), wherein the fixture body (1) is disc-shaped; gear slots (2) which are uniformly distributed are formed in the outer edge of the periphery of the fixture body (1) and can be simultaneously engaged with a sun gear and an internal gear ring of the double-side grinding and polishing machine; and hollowed-out workpiece grooves (3) are formed in the fixture body (1), so that the upper surfaces and the lower surfaces of to-be-machined workpieces placed in the workpiece grooves (3) can be ground and polished, and the to-be-machined workpieces can rotate. The shape of the work fixture of the grinding and polishing machine is designed according to the shape of the grinding and polishing machine, and the work fixture can be engaged with the gear of the grinding and polishing machine well during running; and by the work fixture, the to-be-machined workpieces can be mounted rapidly and accurately, the workpiece grooves correspond to the to-be-machined workpieces to ensure that the to-be-machined workpieces cannot move or deviate in a machining process, and therefore, the machining quality of the to-be-machined workpieces meets requirements.

Owner:YIXING JINGKE OPTICAL INSTR

Installation jig and installation technology for guide rails of numerically-controlled machine tool

InactiveCN105500018AQuick and accurate installationReduce processing difficultyLarge fixed membersNumerical controlMachine tool

The invention provides an installation jig and an installation technology for guide rails of a numerically-controlled machine tool. The installation jig comprises an L-shaped right-angle body, a locating plate, Y-axis guide rail fixing grooves, X-axis guide rail fixing grooves, guide rail fixing guide holes and jig fixing screw holes. The installation technology comprises the steps of 1, cleaning the surface of a base of the numerically-controlled machine tool to be installed and the installation jig for the guide rails of the numerically-controlled machine tool; 2, aligning the locating plate of the installation jig for the guide rails of the numerically-controlled machine tool to one side of the base of the numerically-controlled machine tool and fixing the installation jig to the base of the numerically-controlled machine tool through eight screws M10; 3, sequentially drilling screw holes M6 in the base of the numerically-controlled machine tool by an electric hand drill through the guide rail fixing guide holes for fixing the guide rails of the numerically-controlled machine tool; 4, inserting the guide rails into the X-axis guide rail fixing grooves and the Y-axis guide rail fixing grooves respectively, and fixing the guide rails firmly through inner hexagonal socket head cap screws M6; 5, disassembling the installation jig and the screws fixing the base of the numerically-controlled machine tool and then completing installation of the X-axis guide rail and the Y-axis guide rail.

Owner:安徽省皖凯机械有限公司

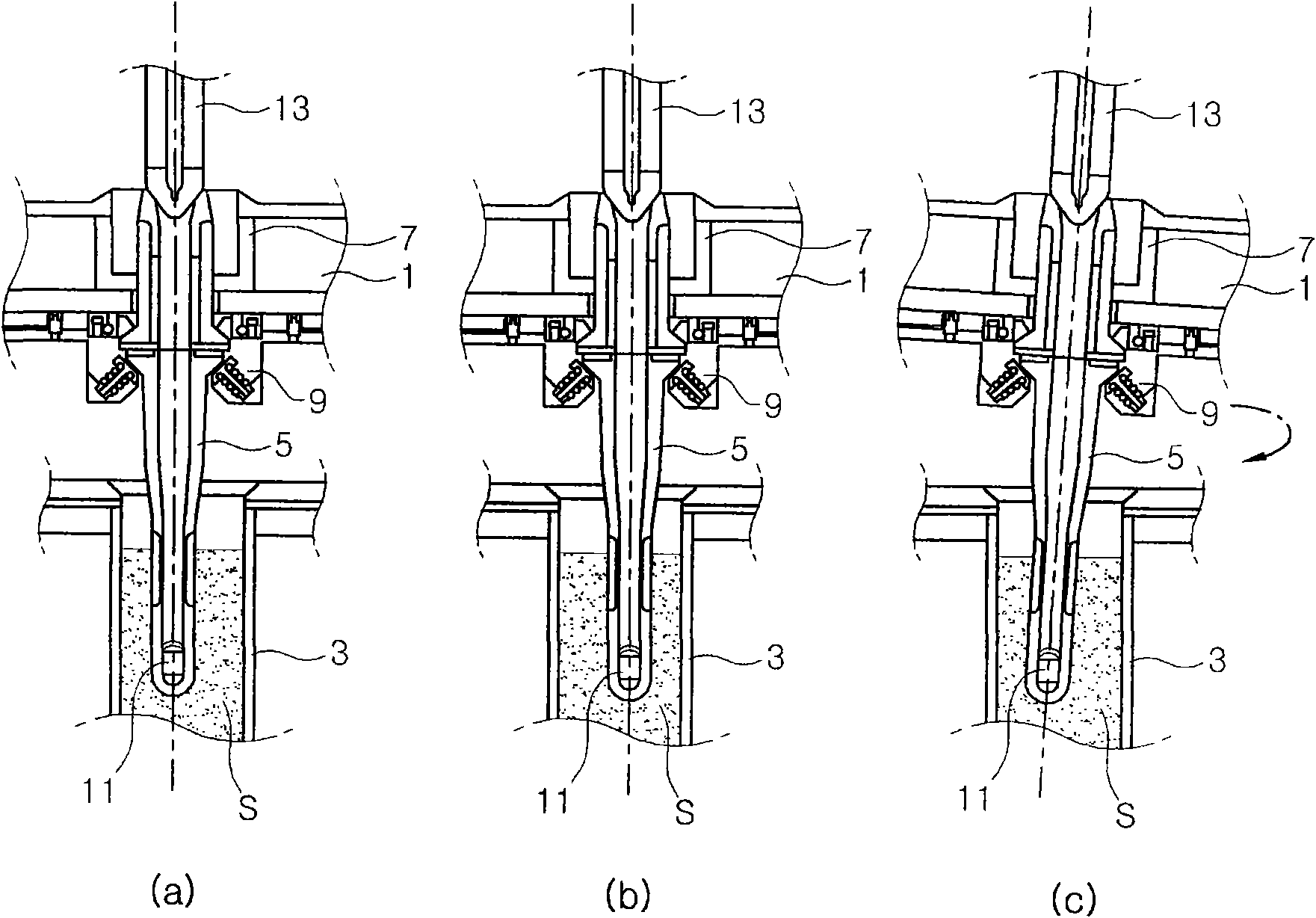

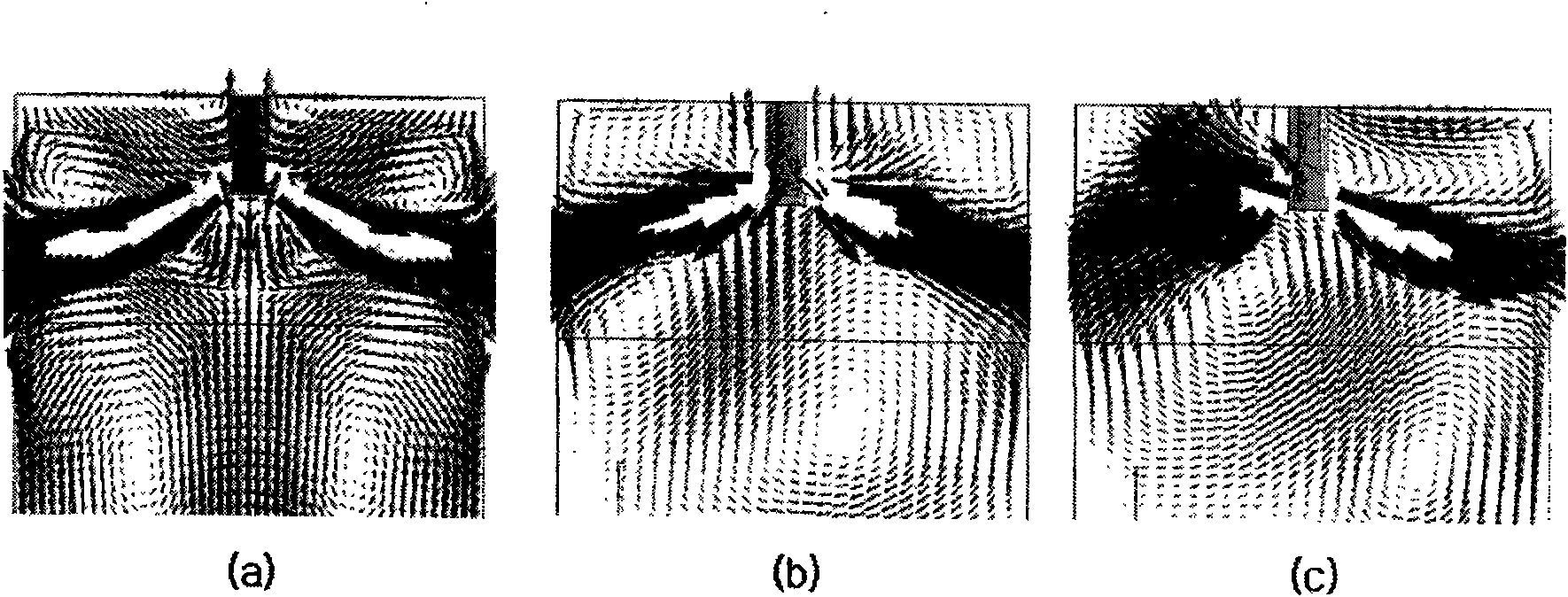

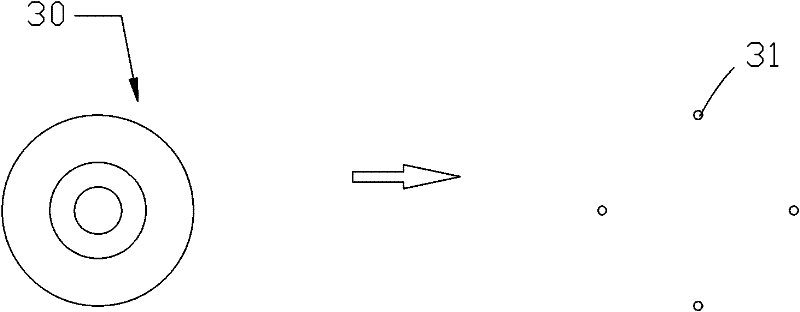

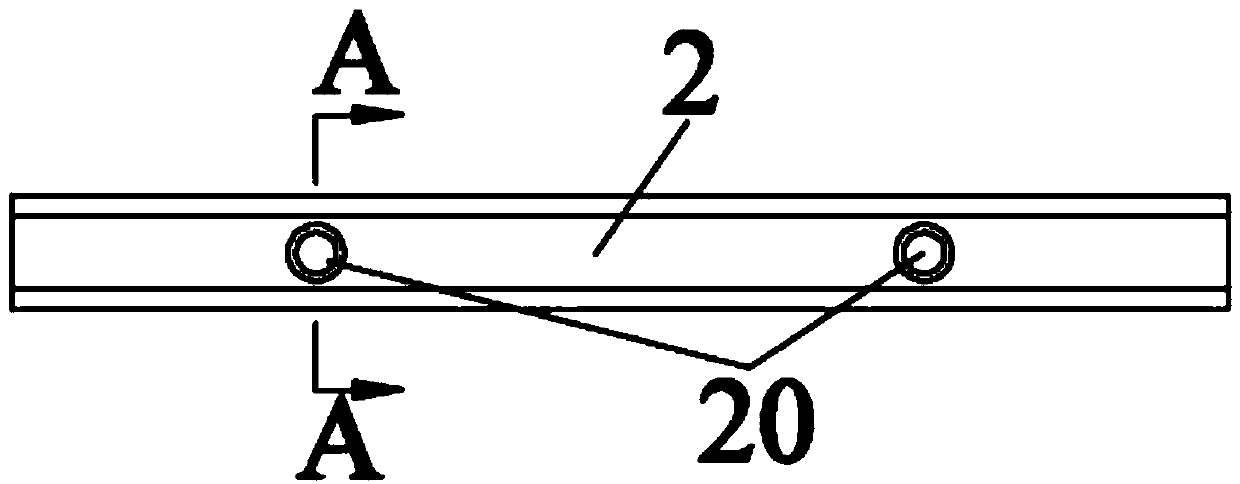

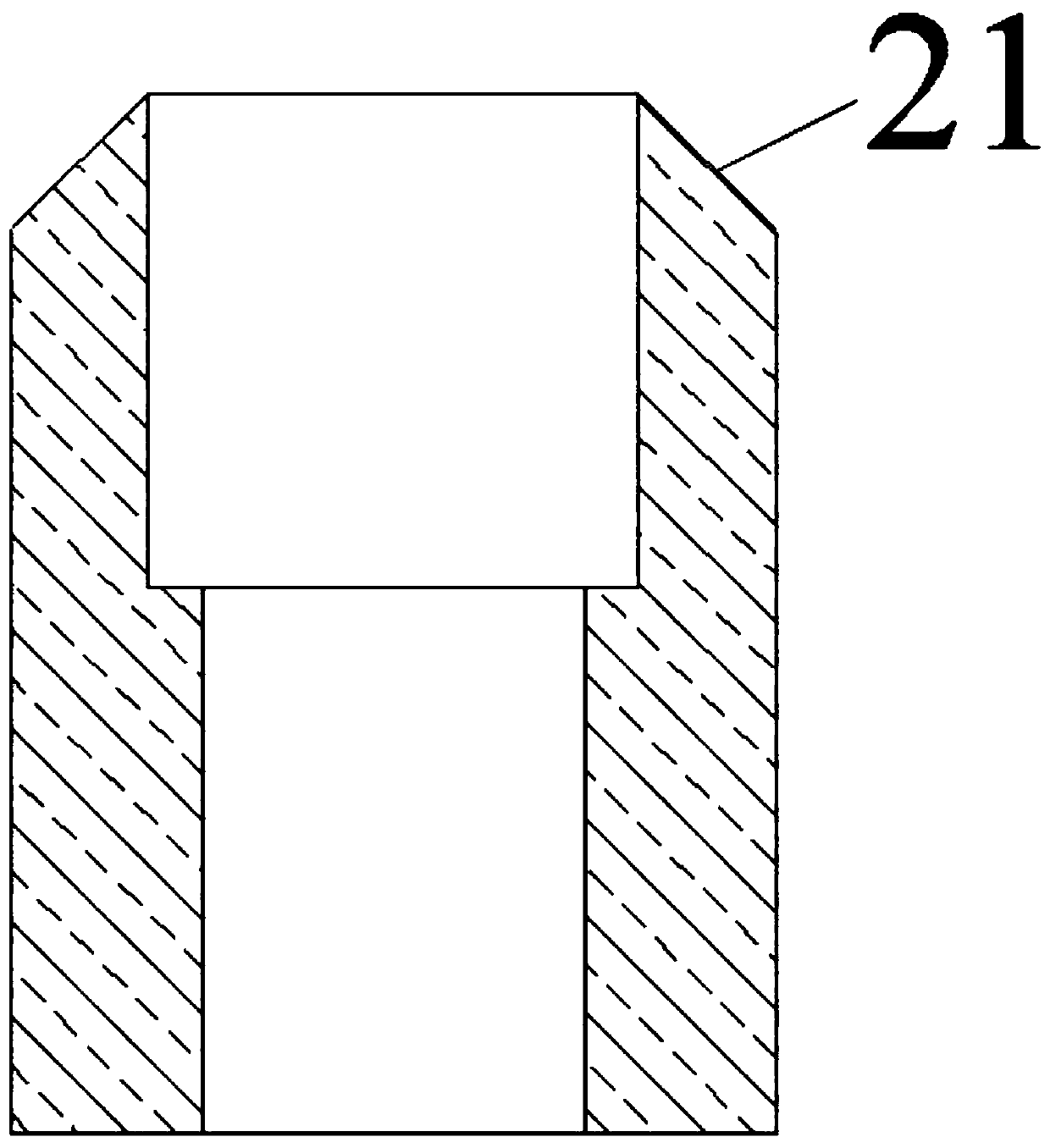

Submerged-entry nozzle centring device

InactiveCN101687252AQuick and accurate installationQuality improvementMelt-holding vesselsEngineeringLaser beams

The present invention relates to a submerged-entry nozzle centring device. The present invention comprises: a plurality of laser beam generators (20) arranged in such a way as to irradiate laser beams towards the centre of a continuous-casting mould (3) from the upper part of the mould (3); a tundish-conveying mechanism (15) for conveying a tundish (1) over the mould (3); and a control means which is connected to the laser beam generator (20), and which controls the operation of the tundish-conveying mechanism (15) in such a way as to centre the positioning of a submerged-entry nozzle (5) provided on the lower part of the tundish (1) by means of a signal received from the laser beam generator (20). The present invention can not only centre the submerged-entry nozzle (5) in a way which is both accurate and fast, but it can also maintain the submerged-entry nozzle (5) constantly fixed at the centre and can thus minimise the phenomenon of drifting of the molten steel. Consequently, it has the advantage that it can be expected to improve the quality of the slab.

Owner:HYUNDAE STEEL CO LTD

Fixing device for cup opening type concrete foundation pit stand column and mounting method thereof

PendingCN110409481AReasonable structure and safe and controllableStructure miniaturizationFoundation engineeringBuilding material handlingBuilding constructionArchitectural engineering

Owner:TIANJIN 20 CONSTR

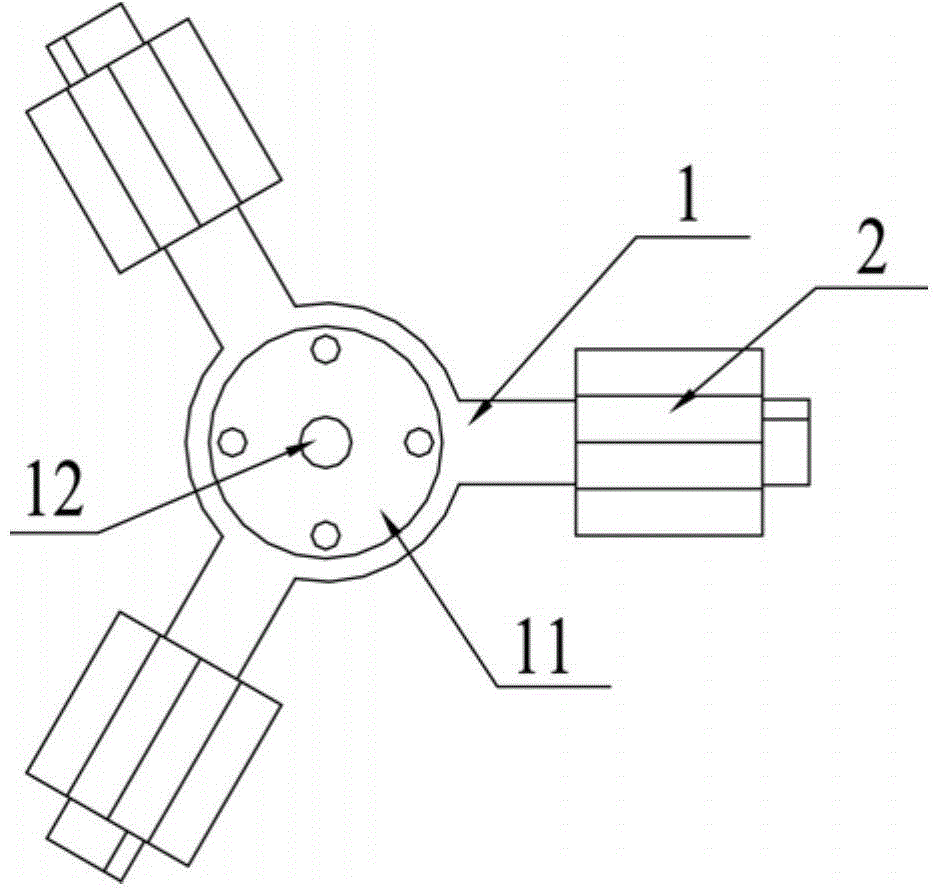

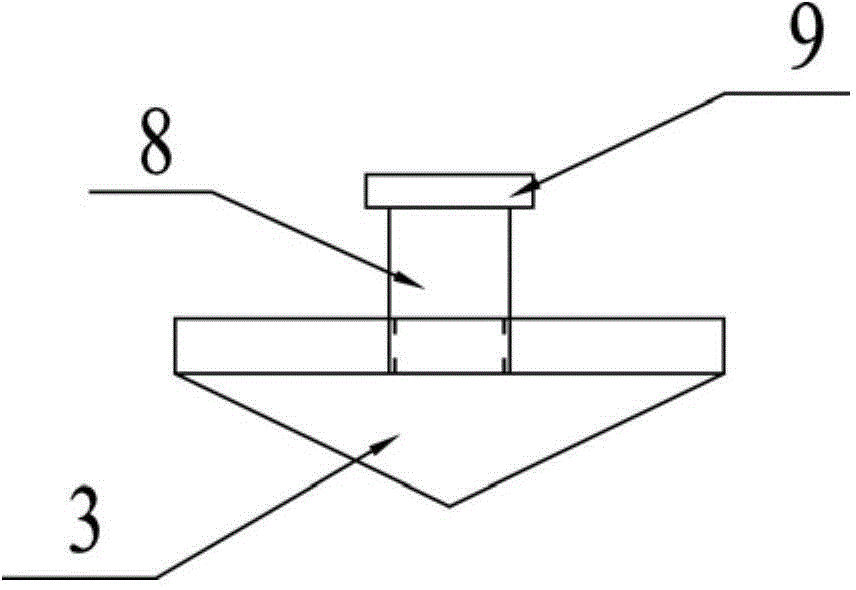

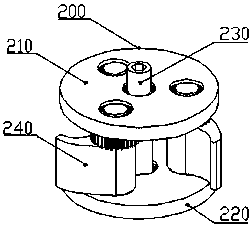

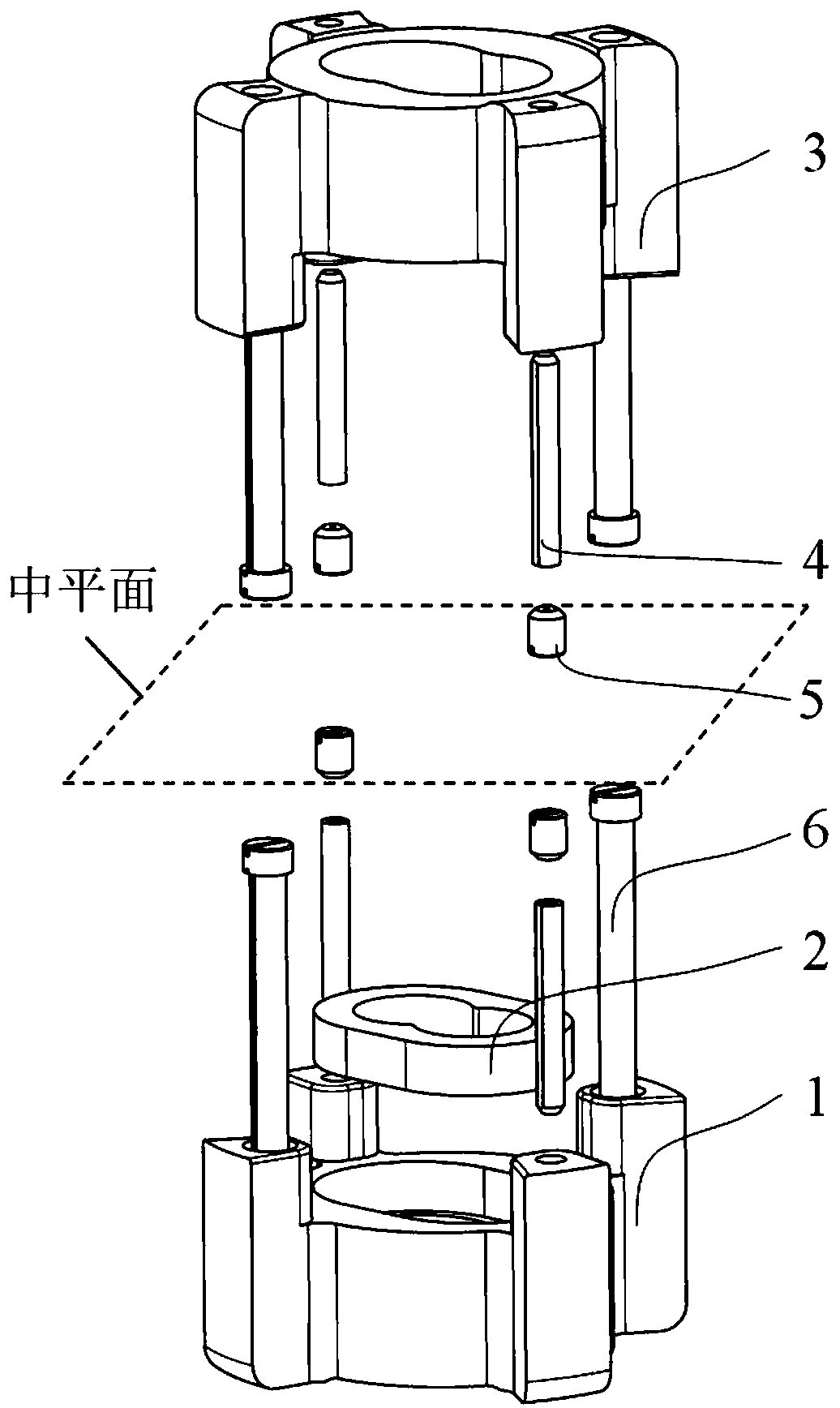

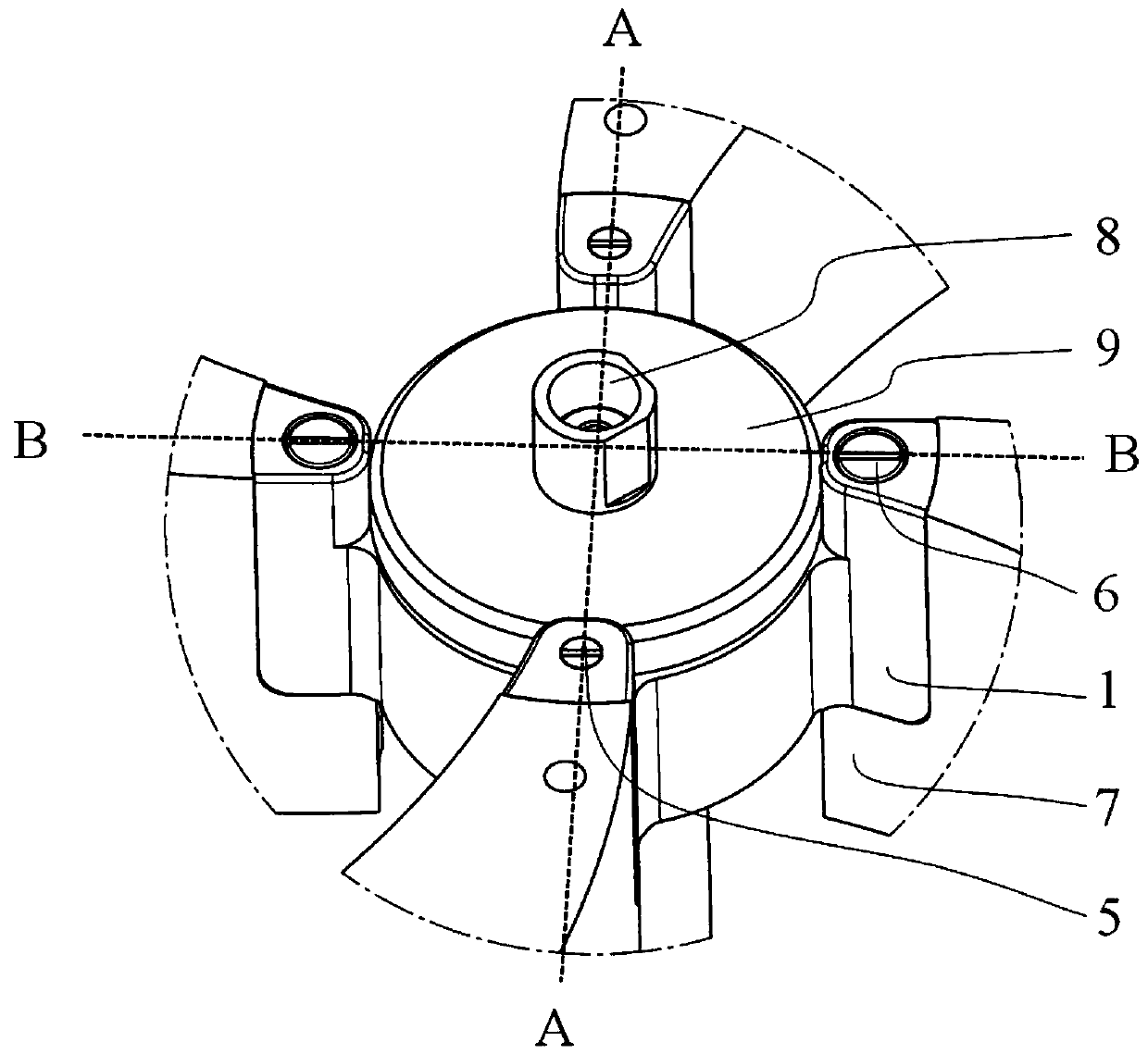

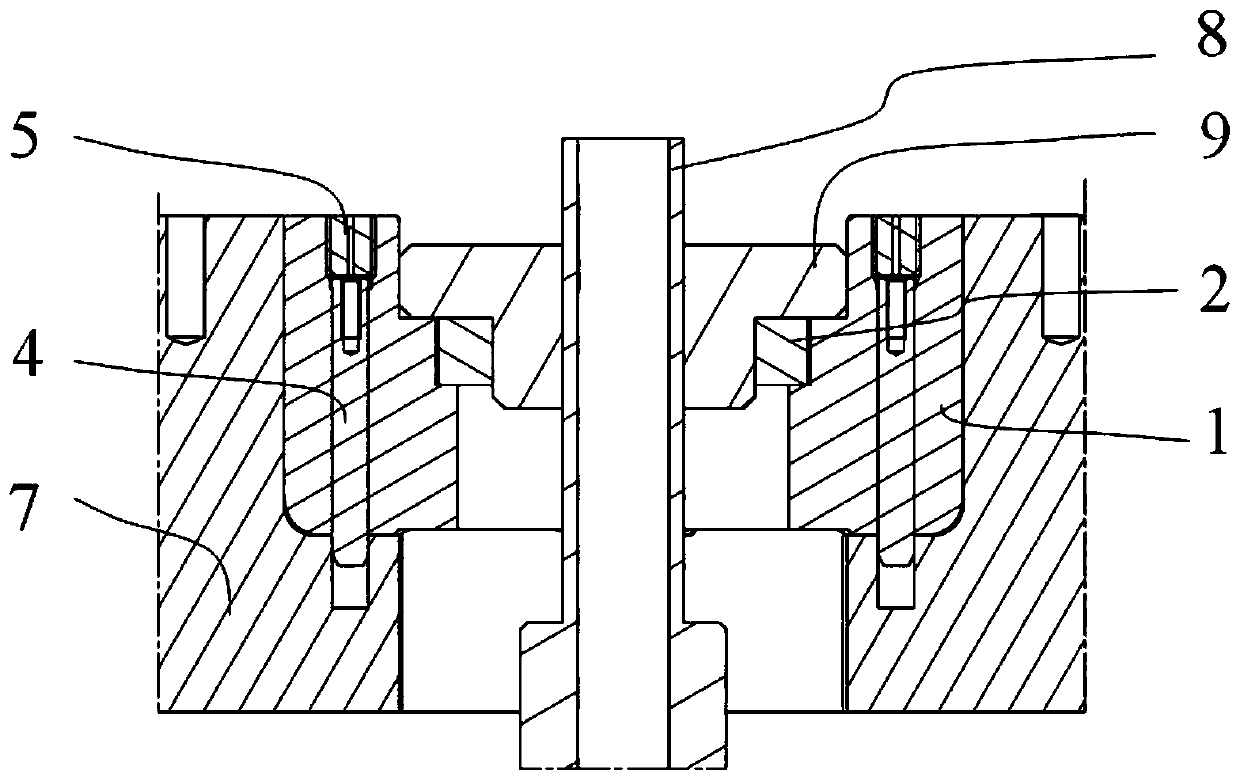

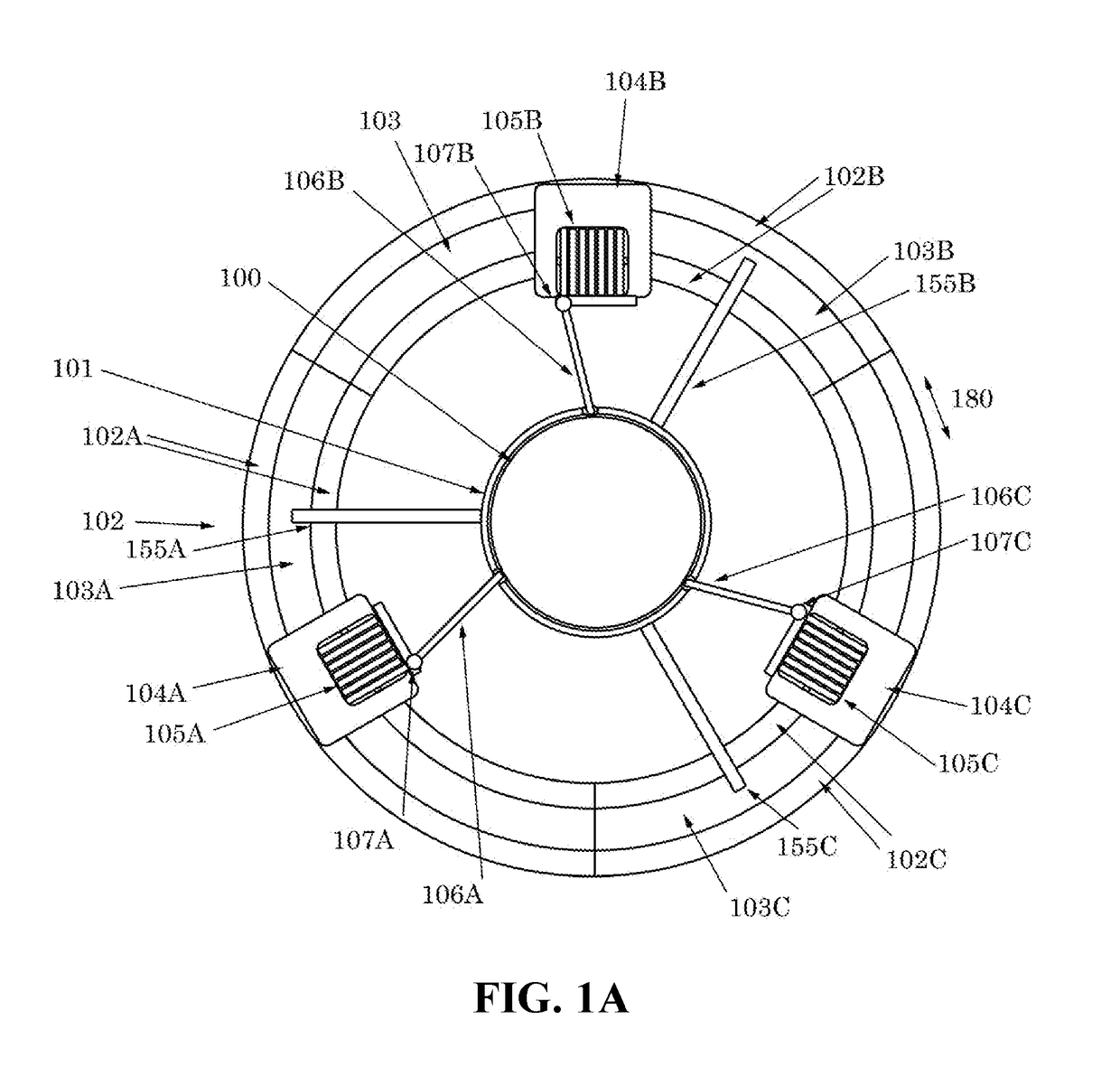

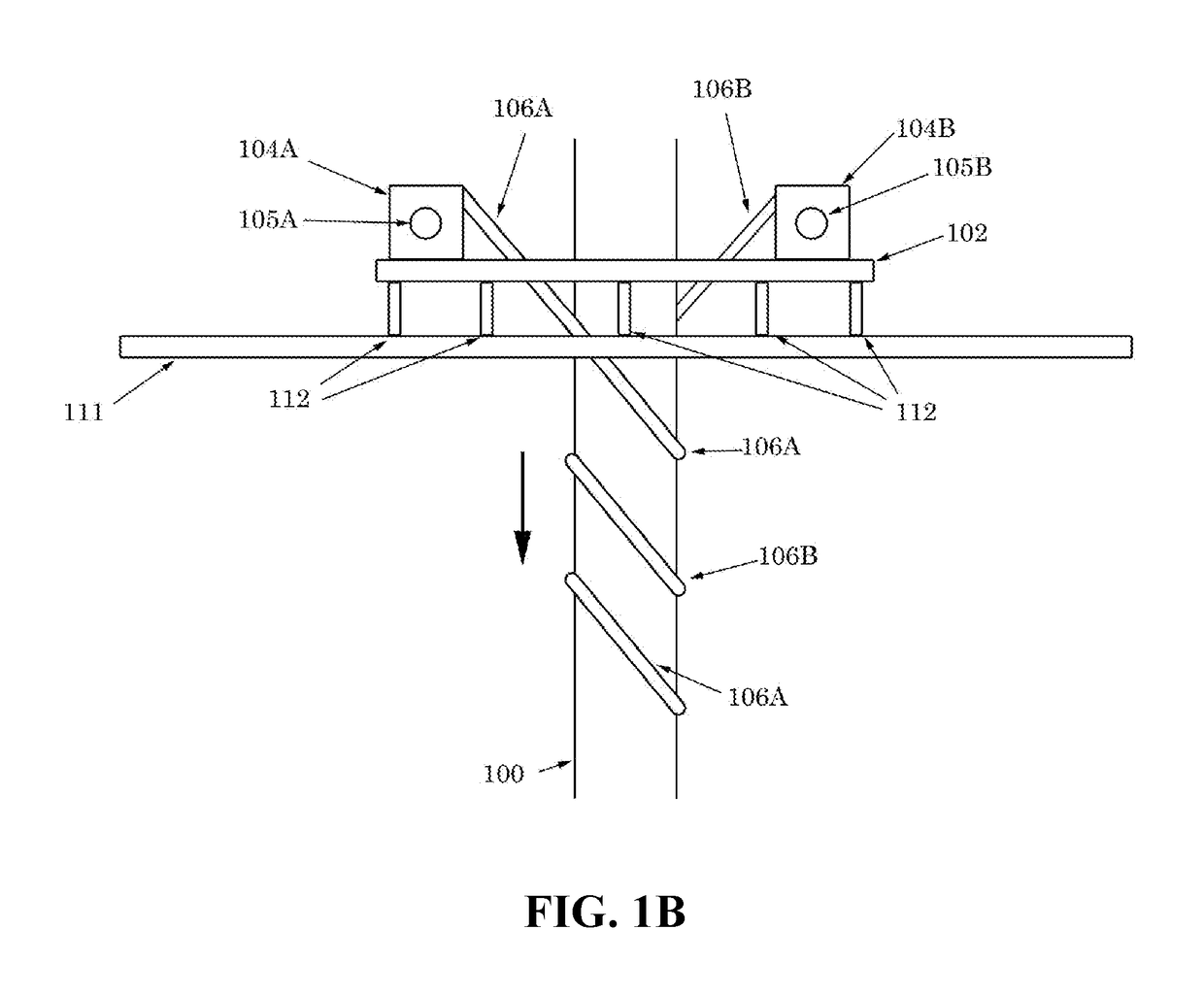

Planet wheel installation device and method

ActiveCN105668433AHoisting process safetyImprove applicabilityLoad-engaging elementsCranesEngineeringMechanical engineering

The invention discloses a planet wheel installation device. The planet wheel installation device is arranged on a planet wheel and a planet carrier, and comprises a planet wheel hoisting mechanism and a planet wheel positioning mechanism, wherein the planet wheel hoisting mechanism comprises a hoisting rod, a transverse beam and a hoisting slide block; and one end of the transverse beam is fixedly connected with the hoisting rod and the other end of the transverse beam is fixedly connected with the hoisting slide block; the planet wheel positioning mechanism comprises an upper supporting cover, a lower supporting cover, a central wheel assembly and a planet wheel assembly; the central wheel assembly and the planet wheel assembly are movably arranged between the upper supporting cover and the lower supporting cover; and the central wheel assembly and the planet wheel assembly are matched so that the planet wheel hoisting mechanism can be expanded and retracted. The planet wheel installation device is simple in structure, low in machining cost, simple and convenient in installation process, wide in applicable range and good in use effect, and has very high application and popularization values.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

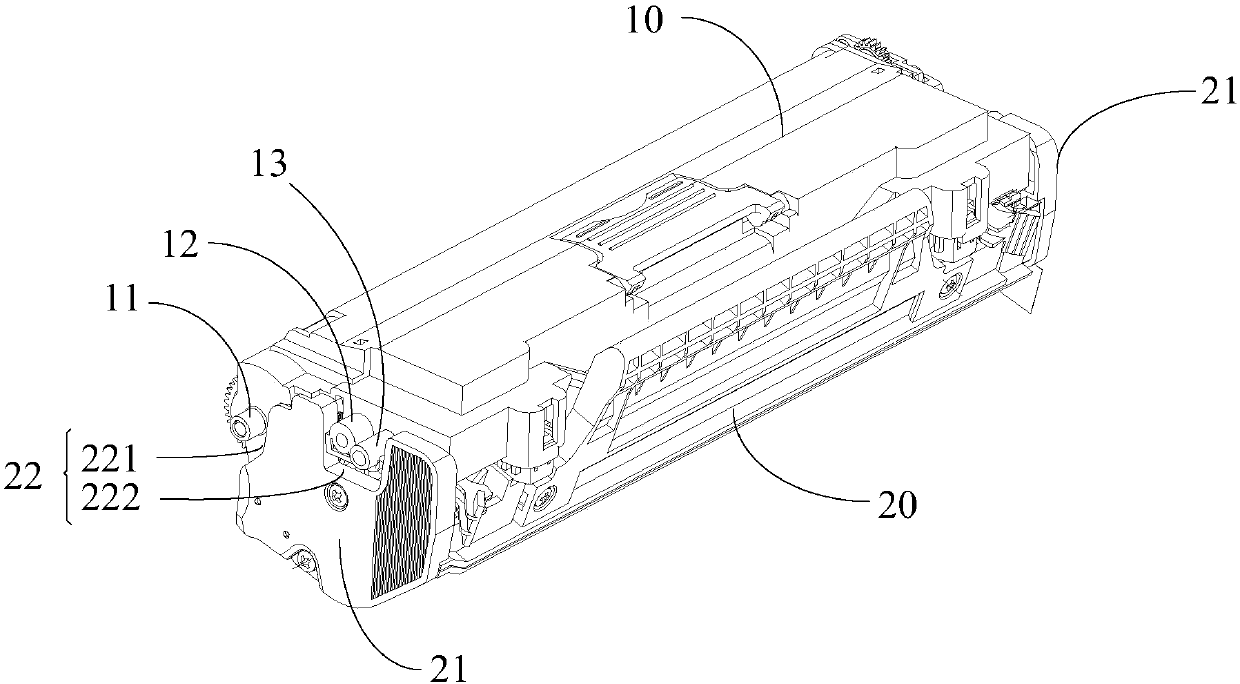

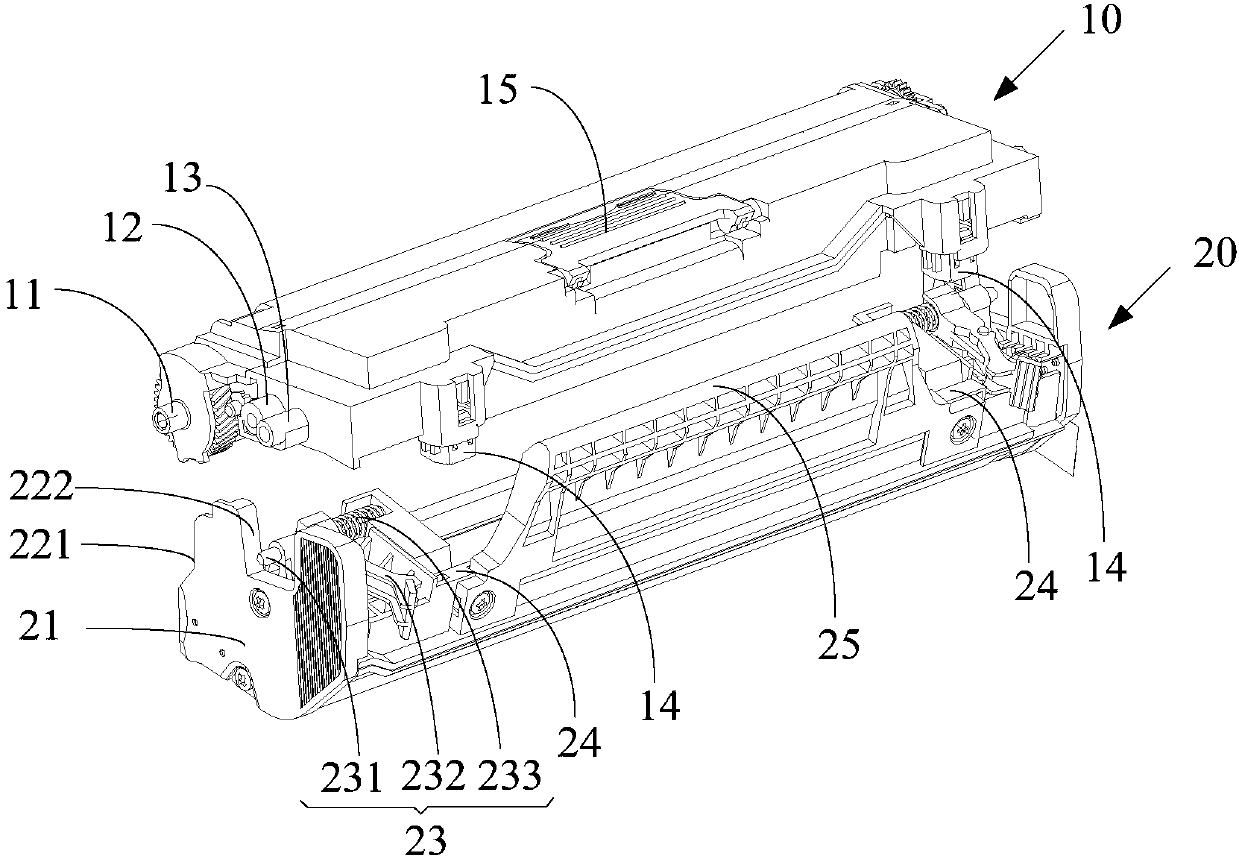

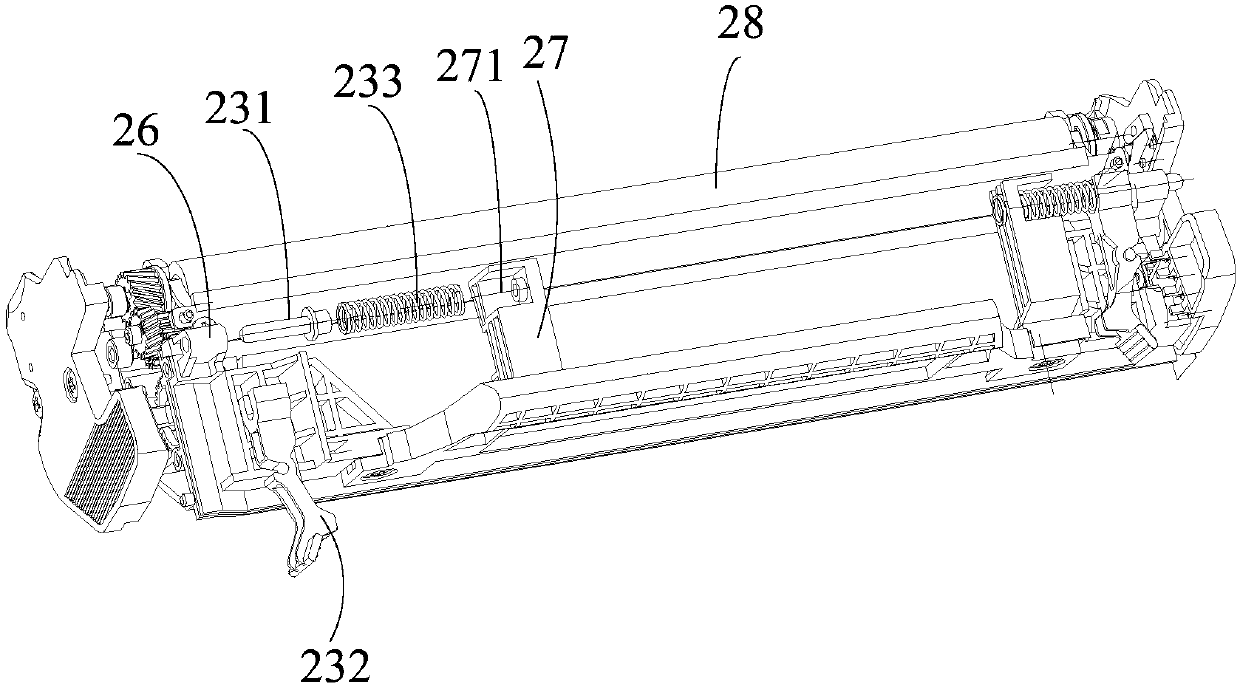

Developing box, process cartridge and electronic imaging device

ActiveCN108021011ACompact structureTroubleshoot long technical issuesElectrography/magnetographyExisting TreatmentEngineering

The invention discloses a developing box, a process cartridge and an electronic imaging device. The process cartridge comprises the developing box and a toner cartridge box, wherein the developing boxand the toner cartridge box can be mutually dismounted and mounted; a first bulge part and a second bulge part which are protruded outwards are both arranged on each of the end surfaces of two ends of the toner cartridge box; mounting parts for detachably mounting the developing box are also arranged on the end surfaces of the two ends of the toner cartridge box; end covers are respectively arranged at the two ends of the developing box; accommodating parts for accommodating the first bulge part, the mounting part and the second bulge part are formed in the end covers; the end surfaces of thefirst bulge part and the second bulge part extend out of the outer surfaces of the end covers. According to the process cartridge provided by the invention, the technical problems that a process cartridge is integrally long and a toner cartridge box has a complicated and unstable structure because spaces required by bulge parts and a slideway on the toner cartridge box need to be reserved in existing treatment are solved.

Owner:ZHUHAI PANTUM ELECTRONICS

Inner injection type superconducting cyclotron central area split and layered type magnet plug block structure

ActiveCN110430657AEnhanced Axial FocusEasy to adjustMagnetic resonance acceleratorsSuperconducting magnets/coilsMagnetic measurementsBlock structure

The invention discloses an inner injection type superconducting cyclotron central area split and layered type magnet plug block structure. The magnet plug block structure comprises an upper magnet structure and a lower magnet structure, wherein the upper magnet structure and the lower magnet structure are in mirror symmetry with respect to a midplane. The lower magnet structure comprises a magnetbody lower main body. The upper magnet structure comprises a magnet body upper main body. The magnet body lower main body is equipped with magnet positioning pins, a magnet body lower branch body, positioning pin plug screws and bolts. Under the premise of taking into account installation and operation of a magnetic measurement system and an ion source, the magnet structure can be in mirror symmetry with respect to the midplane, thereby providing a suitable Bump magnetic field for a central area, enhancing axial focusing of particles and reducing beam loss rate. The structure can realize fastand accurate installation and disassembly, has high repeated positioning accuracy, and provides great convenience for magnetic field testing and adjustment and replacement of an ion source head.

Owner:HEFEI CAS ION MEDICAL & TECHNICAL DEVICES CO LTD

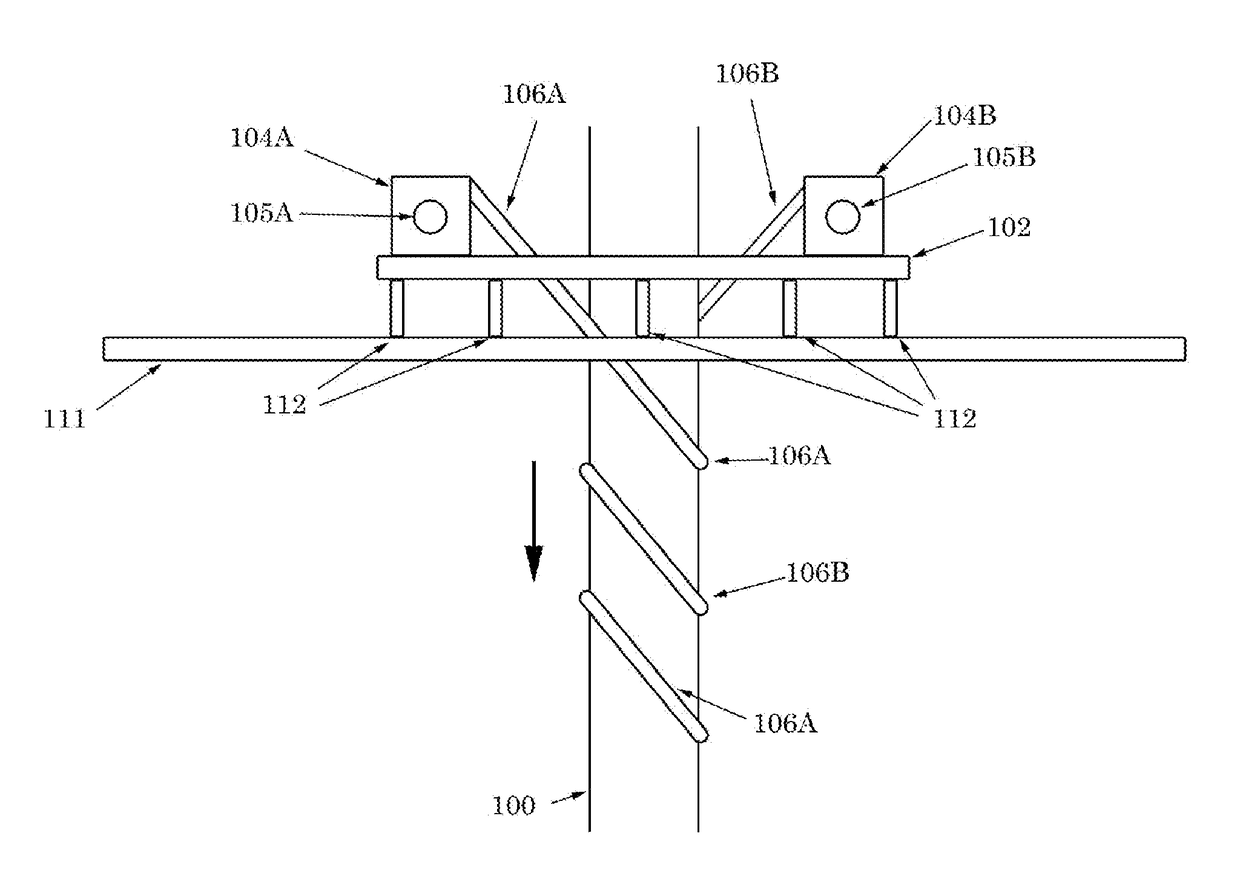

Installation systems and methodology for helical strake fins

ActiveUS20180100353A1Quick and accurate installationDrilling rodsUnderwater drillingStrakeEngineering

Owner:VIV SOLUTIONS

Method for mounting and positioning automobile glass accessory

InactiveCN102343507AQuick and accurate installationFast installationMetal working apparatusScreen printingEngineering

The invention relates to a method for mounting and positioning an automobile glass accessory. The method is characterized in that a positioning mark is printed at the corresponding mounting position of the glass accessory on automobile glass according to the shape of the glass accessory when the automobile glass is subjected to silk-screen printing. According to the method for mounting and positioning the automobile glass accessory, which is disclosed by the invention, when the automobile glass is subjected to silk-screen printing, the positioning mark is printed on the automobile glass; the accessory can be mounted according to the positioning mark, so that the automobile glass accessory can be quickly and accurately mounted and the mounting speed of the glass accessory can be effectively improved; and meanwhile, the method is beneficial to improving the mounting quality.

Owner:XINYI AUTOMOBILE GLASS (SHENZHEN) CO LTD

Quick loading and unloading construct for heavy construct and manufacturing method thereof

ActiveCN111908377AReduce time spentFacilitates fast and precise installationLifting devicesBuilding material handlingStructural engineeringManufacturing engineering

The invention provides a quick loading and unloading structure for a heavy construct and a manufacturing method thereof. The quick loading and unloading structure comprises a plurality of bearing devices fixedly arranged on the heavy construct, and the distance between every two adjacent the bearing devices is fixed. The bearing devices are used for being detachably connected with bearing bases fixedly arranged on a loading and unloading trolley; the positions of the bearing bases correspond to the positions of the bearing devices one to one; the bearing devices can be quickly separated from the bearing bases and are located at the positions close to the center of mass of the heavy construct. By using the scheme of the fixed-distance bearing devices, the time for hanging the device can beshortened, the heavy construct can be quickly and conveniently hung onto the loading and unloading trolley, the loading and unloading trolley can conveniently adjust the position and posture of the heavy construct, and the heavy construct is convenient to quickly and precisely install. And in addition, the fixed-distance bearing devices can be commonly used for the heavy constructs of different types and specifications, so that the loading and unloading trolley is less adjusted, the device and construction cost is greatly reduced, and the safety hidden risk is greatly reduced.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES

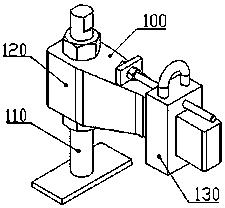

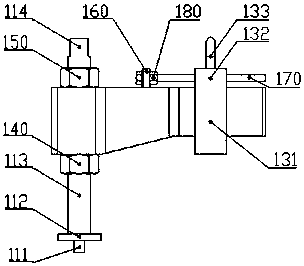

Fast assembly fixture

InactiveCN107309596ASimple structureReduce volumeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPallet

The invention provides a quick-installation clamp, which includes a base, a support plate fixedly installed on the base, and a clamp connected and installed on the support plate. The lower end of the base is provided with support feet, wherein the vertical A clamp fixing rod is directly provided, and the clamp is provided with at least one, and is fixed on the clamp fixing rod; the clamp includes a connecting rod and a replaceable fixing part, and the connecting rod can be positioned on the clamp fixing rod in the up and down direction. Sliding, and can rotate between 0° and 180° on the first layer of the support plate; the support plate is provided with a supporting plate arranged in a disc shape between the fixture fixing rod and the connection position with the base. The quick-installation jig of the present invention can accurately fix the tank body to complete the welding; at the same time, the quick-installation jig is simple to assemble, has a fast combination installation speed, is convenient and simple to store, can greatly increase the combined welding speed of the tank body, and has a high applicability.

Owner:ANHUI KAICHENG ELECTRIC APPLIANCE CO LTD

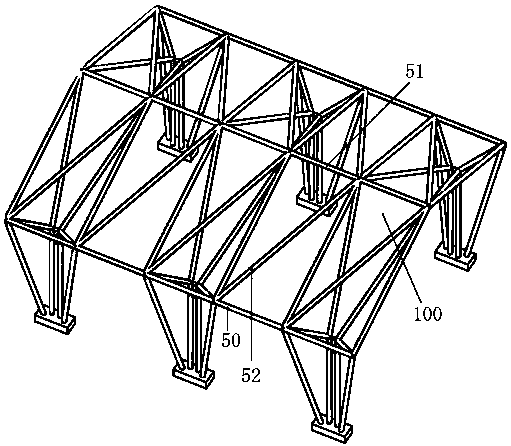

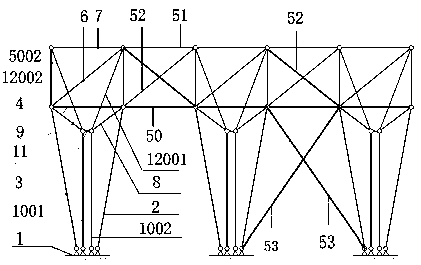

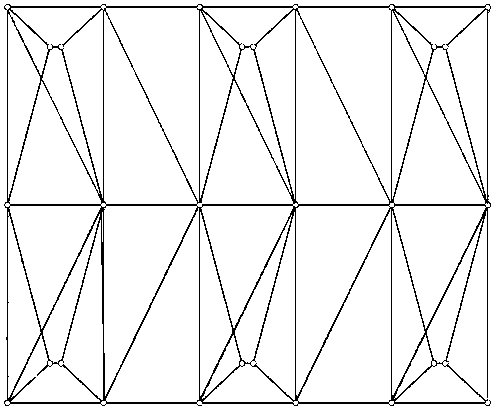

Circular bamboo space three-hinged arch structural unit and circular bamboo space three-hinged arch structural system

ActiveCN107654010AMeet the needs of useWide range of choicesBuilding roofsRoof coveringEngineeringAxial force

Disclosed are a circular bamboo space three-hinged arch structural unit and a circular bamboo space three-hinged arch structural system. The circular bamboo space three-hinged arch structural unit comprises a fixing device, a first space unit and a second space unit, wherein the first space unit and the second space unit jointly consist of vertical supporting structures and roof bearing structures. The top ends of the first space unit and the second space unit are hinged together and hinged to the fixing device at the bottom ends of the first space unit and the second space unit to form the space three-hinged arch unit. The circular bamboo space three-hinged arch structural system comprises the circular bamboo space three-hinged arch structural unit. A certain distance exists between two adjacent circular bamboo space three-hinged arch structural units. A connecting device used for connecting the every two adjacent circular bamboo space three-hinged arch structural units into a whole is arranged between every two adjacent circular bamboo space three-hinged arch structural units. According to the circular bamboo space three-hinged arch structural unit and the circular bamboo space three-hinged arch structural system, the section bending moment of a single rod part of a structure system is very small, rod parts mainly bear the axial force, and while the circular bamboo rod partsare poor in flexural performance but good in axial force, so the circular bamboo space three-hinged arch structural unit and the circular bamboo space three-hinged arch structural system are suitablefor a circular bamboo structure.

Owner:XIHUA UNIV

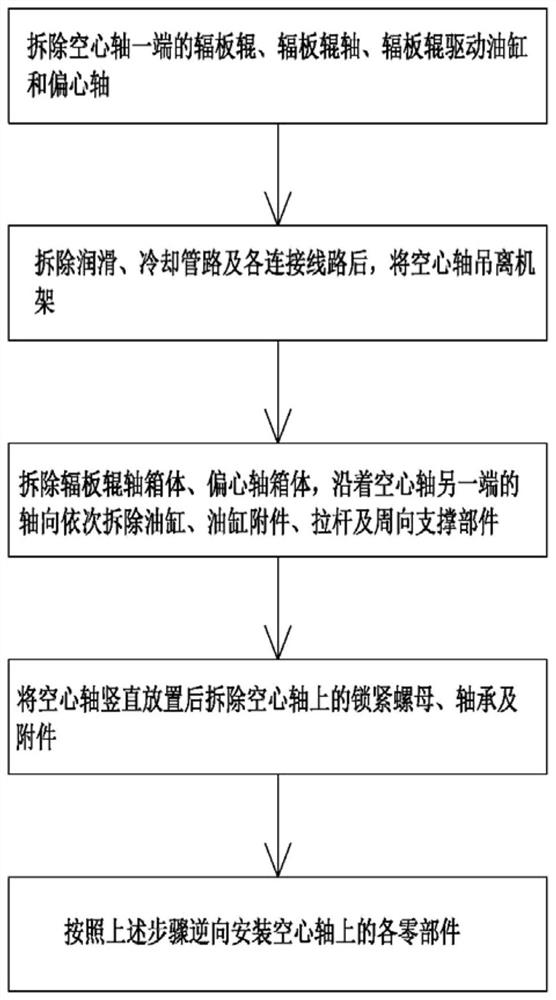

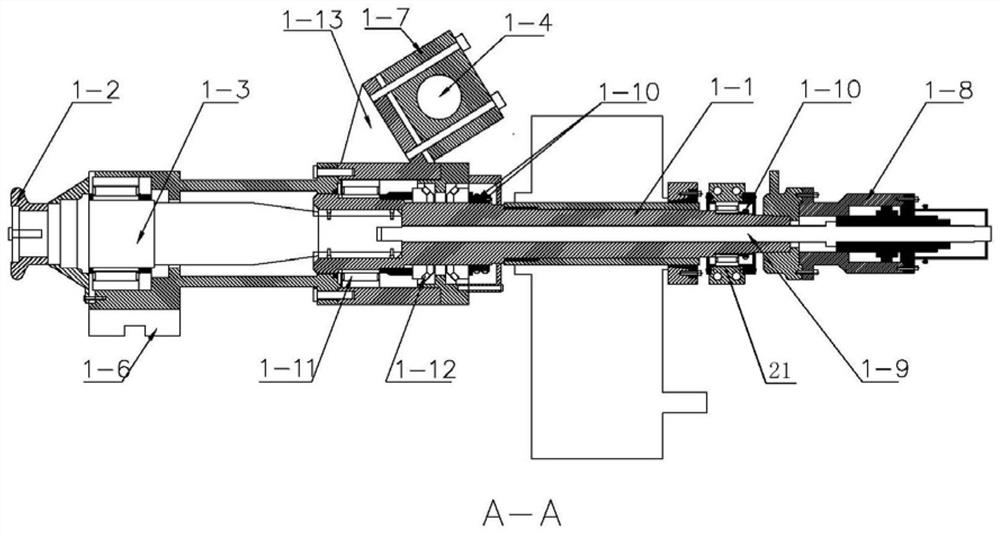

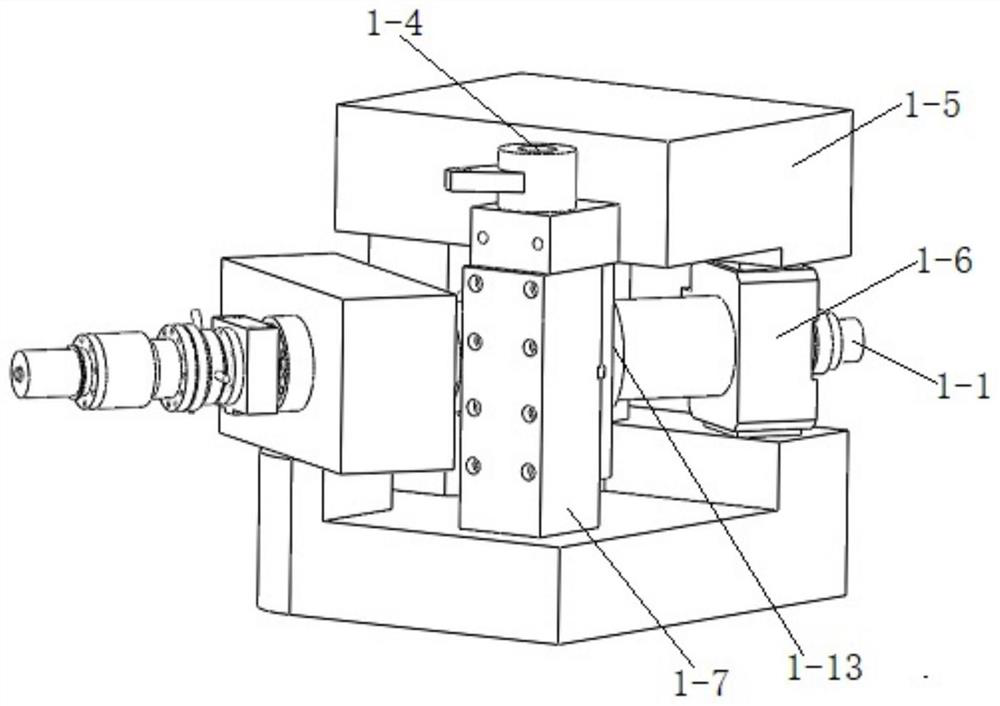

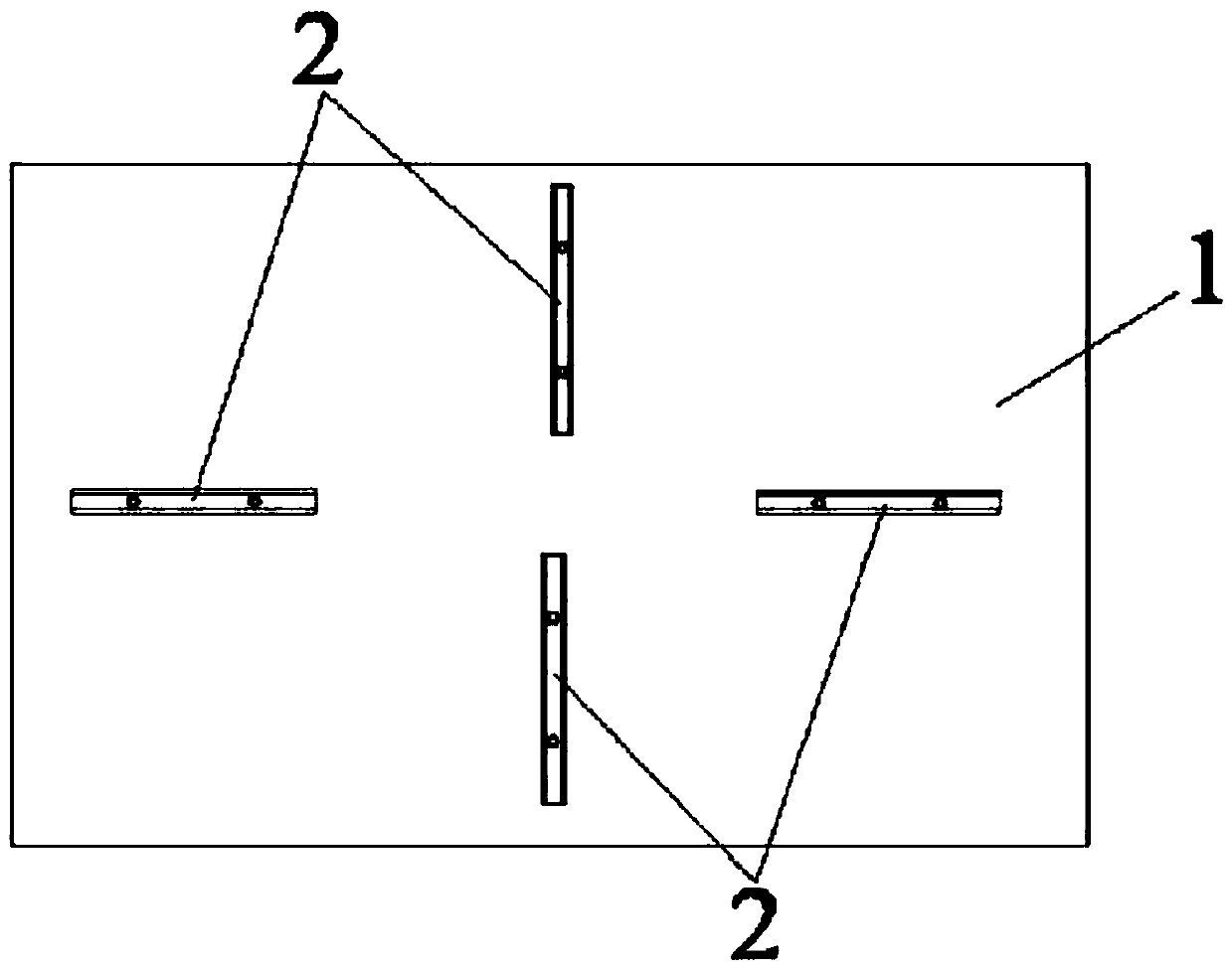

Method for disassembling and assembling hollow shaft assembly of high-speed rail wheel rolling mill

ActiveCN113770700AAvoid damageEasy to assemble and disassembleMetal working apparatusStructural engineeringCooling pipe

The invention discloses a method for disassembling and assembling a hollow shaft assembly of a high-speed rail wheel rolling mill, and belongs to the technical field of use and maintenance of high-speed rail wheel rolling mill equipment. The disassembling and assembling method comprises the following steps: a radial plate roller, a radial plate roller shaft, a radial plate roller driving oil cylinder and an eccentric shaft at one end of a hollow shaft are dismantled; after a lubricating pipeline, a cooling pipeline and all connecting lines are dismantled, the hollow shaft is lifted out to be separated from a rack; a radial plate roller shaft box body and an eccentric shaft box body are dismantled, and an oil cylinder, an oil cylinder accessory, a pull rod and a circumferential supporting component are sequentially dismantled in the axial direction of the other end of the hollow shaft; after the hollow shaft is vertically placed, a locking nut, a bearing and accessories on the hollow shaft are dismantled; and all parts on the hollow shaft are reversely mounted according to the above steps. The method has the beneficial effects that operation specifications are provided for disassembly and assembly of the hollow shaft assembly, disassembly and assembly are conducted in the axial direction of the hollow shaft in the manner that disassembly is conducted from outside to inside and assembly is conducted from inside to outside through a designed tool, the disassembly and assembly efficiency is improved, the installation cost is saved, and the mounting precision, safety and reliability are ensured.

Owner:MAANSHAN MAGANG JINXI RAIL TRANSPORT EQUIP

Mounting and positioning mechanism for stamping die

InactiveCN109570362AImprove installation positioning accuracyImprove efficiencyShaping toolsMachine pressEngineering

The invention discloses a mounting and positioning mechanism for a stamping die. The mounting and positioning mechanism for the stamping die comprises a press worktable and a lower die plate of the stamping die. A group of cross symmetrical centering keys are arranged on the press worktable. A group of keyways matched with the group of centering keys are arranged on the lower die plate of the stamping die. Through the positioning mechanism, the centering keys and the keyways can be quickly and accurately positioned and overlapped, so that the stamping die can be quickly mounted and replaced; and the stamping die has high mounting and positioning precision and does not need to be adjusted, so that the efficiency is improved, and the production cost is reduced.

Owner:湖北法科拉精密制造股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com