Planet wheel installation device and method

A technology for mounting devices and planetary gears, applied in transportation and packaging, load suspension components, cranes, etc., can solve the problem of inability to achieve the alignment and positioning of planetary gears and planetary frames, it is difficult to ensure the use effect, and the positioning ring is not universal To achieve the effect of improving convenience and operability, high use and promotion value, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The invention discloses a planetary gear mounting device and a mounting method suitable for aligning and positioning a planetary gear and a planetary pin hole of a planetary carrier during the mounting process.

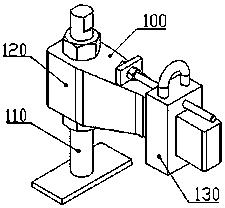

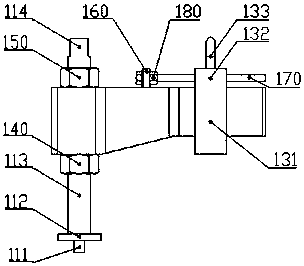

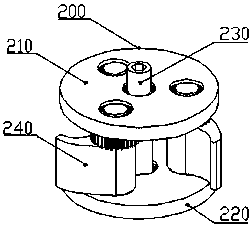

[0063] Such as Figure 1~Figure 9 As shown, a planetary wheel installation device is arranged on the planetary wheel 300 and the planetary carrier 400, including a planetary wheel hoisting mechanism 100 detachably arranged on the planetary wheel 300 for hoisting the planetary wheel 300, and The planet gear positioning mechanism 200 is movably arranged on the planet carrier 400 and is used for centering and positioning the planet gear 300 and the planet carrier 400 .

[0064] The planetary wheel hoisting mechanism 100 includes a boom 110 , a beam 120 and a lifting slider 130 , one end of the beam 120 is fixedly connected to the boom 110 , and the other end is fixedly connected to the lifting slider 130 .

[0065] The planet wheel positioning mechanism 200 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com