System for hoisting steel lining module of nuclear power station

A steel lining and nuclear power plant technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of loose hoisting, deformation of steel lining modules, etc., and achieve the effects of improving economic benefits, stable and safe structures, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

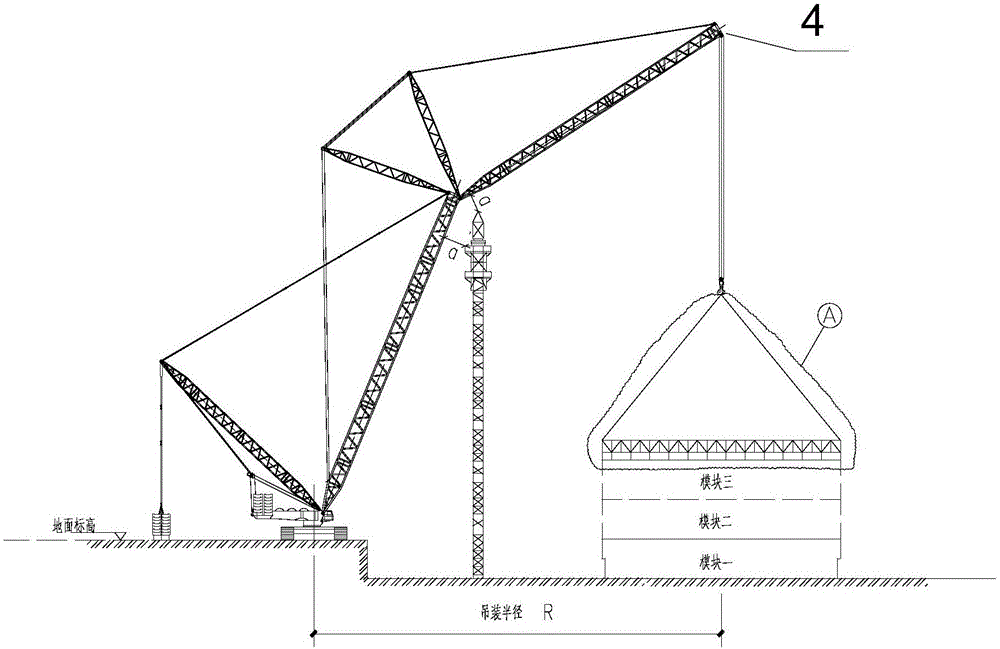

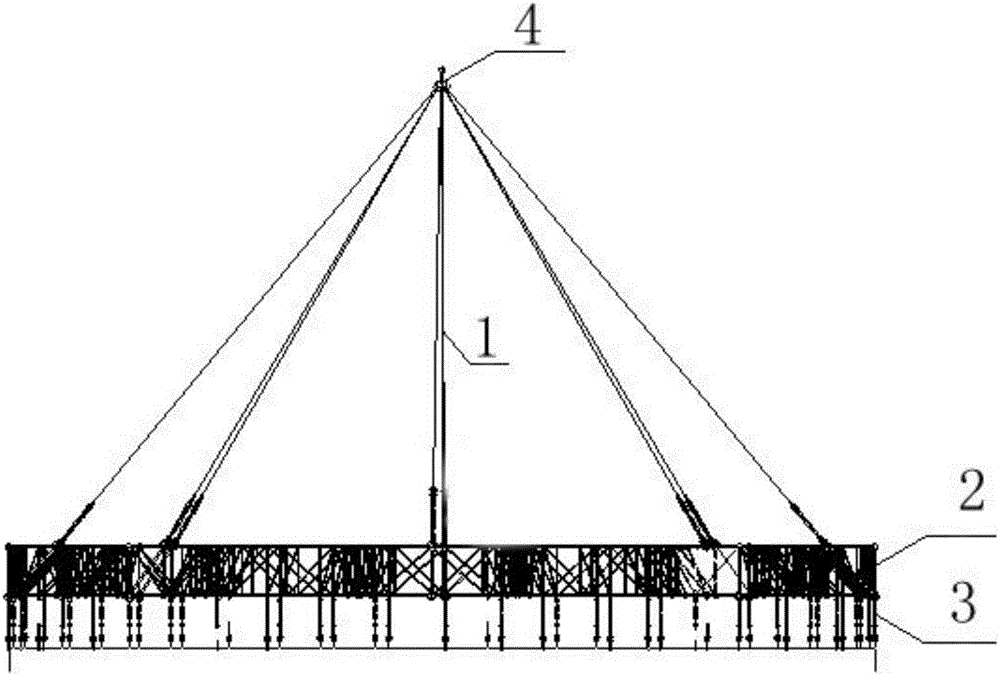

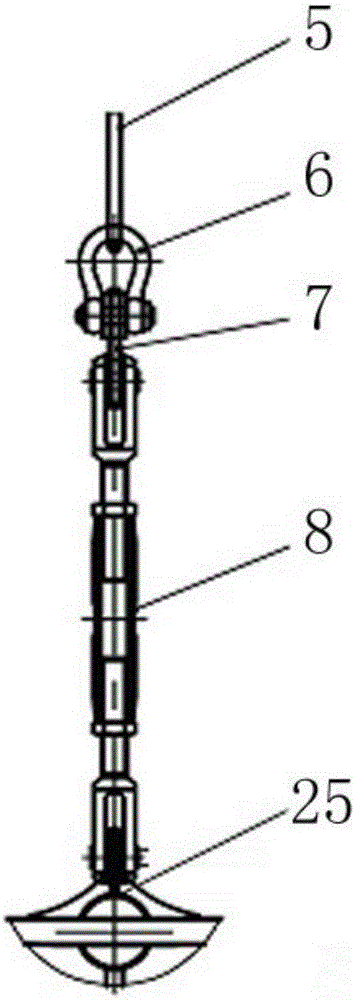

[0030] Such as Figure 1-4 As shown, a nuclear power plant steel lining module hoisting system of the present invention includes an upper sling system 1, a truss sling 2 and a lower sling system 3, and the upper sling system 1, that is, the truss sling 2 and the hoisting crane Between the hooks 4, an adjustable-length connection form consisting of a main wire rope 5, a flat shackle 6, a connecting pull plate 7 and an adjustable pull rod 8 is adopted. The lower end is connected to the truss spreader 2 through the flat shackle 6, the connecting pull plate 7 and the adjustable pull rod 8 in sequence; The difference in length between the hook and the spreader due to the elastic deformation of the harness system.

[0031] The lower sling system 3, that is, the connection between the truss sling 2 and the module lifting point 9 adopts a space-adjustable flexible connection form composed of a turnbuckle 10, a wire rope ring 11, a ring plate 12, an upper shackle 13 and a lower shackl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com