Patents

Literature

250results about How to "Increased lifting capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

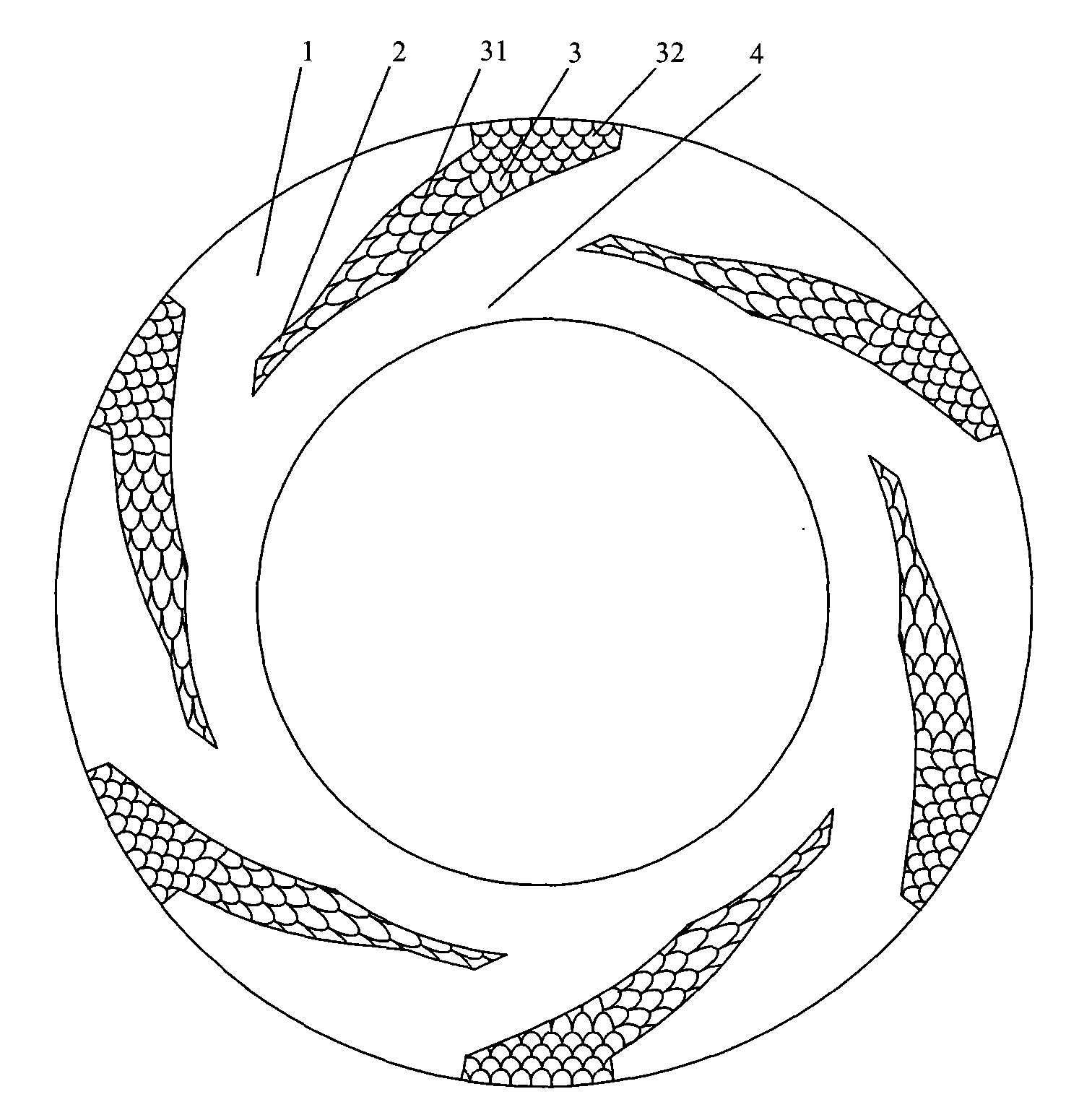

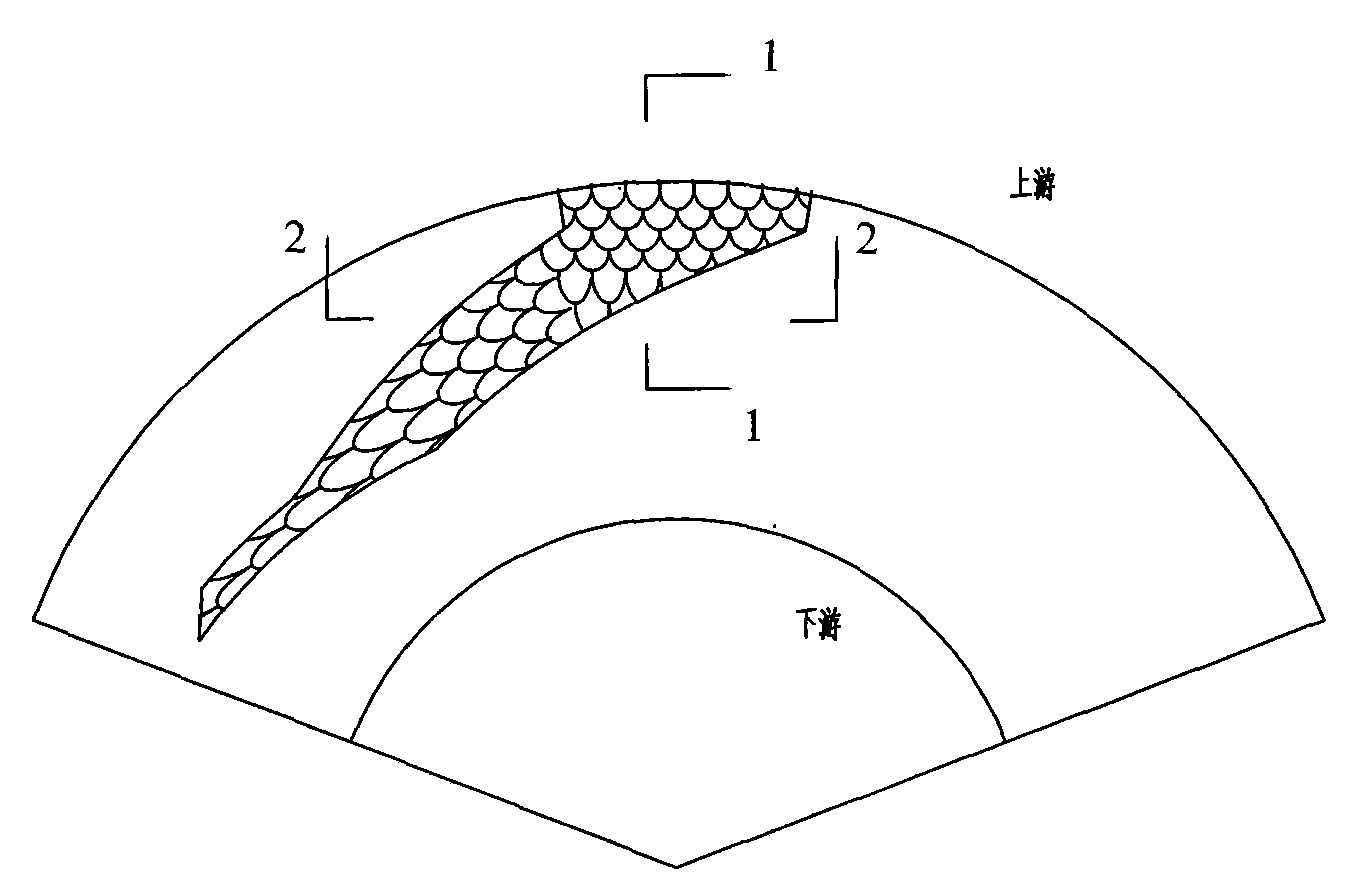

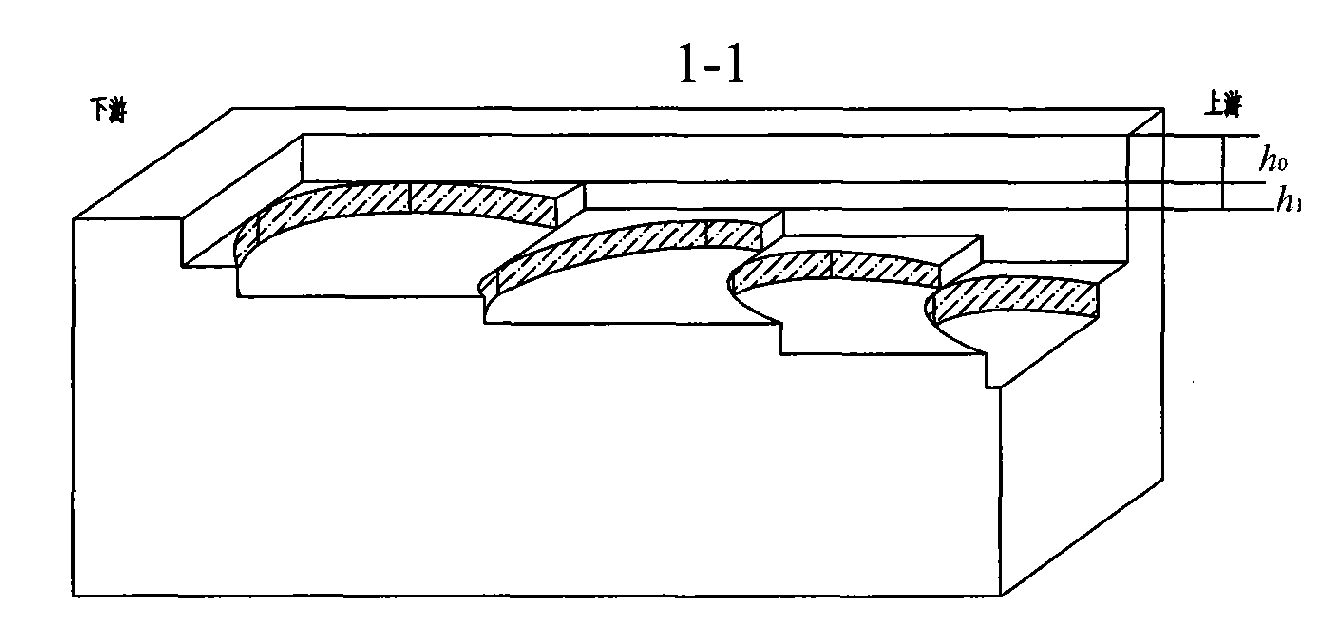

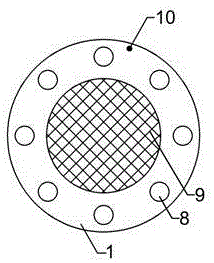

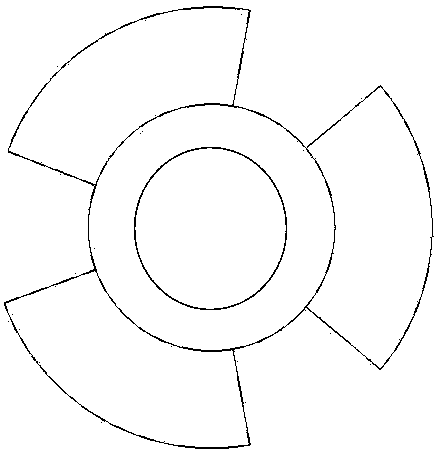

Gas end surface sealing structure with three-dimensional feather-like textured bottom shaped grooves

A gas end surface sealing structure with three-dimensional feather-like textured bottom shaped grooves comprises a dynamic ring and a static ring which are used for sealing a mechanical end surface. As for the dynamic ring and the static ring, at least one sealed end surface is provided with a plurality of three-dimensional shaped grooves. Non-grooved areas among the three-dimensional shaped grooves serve as sealing weirs. Each three-dimensional shaped groove consists of a pumping groove and a spiral groove which are provided with bottoms similar to feather texture features. The pumping grooves are radially distributed and positioned at the upstream part of the sealed end surface. The depths of the pumping grooves are gradually reduced from upstream parts to downstream parts. The pumping groove is connected with the spiral groove. Spiral angles of spiral lines at windward lateral walls of the spiral grooves are greater than the spiral angles of spiral lines at leeward lateral walls. The depths of the spiral grooves are gradually reduced from upstream parts to downstream parts. A continuous planar ring-band sealing dam is arranged at downstream parts of the spiral grooves. The gas end surface sealing structure has the advantages of strong static pressure and dynamic pressure effect of fluid on the end surface, good low-speed start-up performance, excellent pressure resistibility, strong anti-articulation capability, little leakage and good wearability.

Owner:ZHEJIANG UNIV OF TECH

Multiple arms telescopic device automatically controlled by single telescopic cylinder

InactiveCN1418805AIncrease the cross-sectional areaHigh strengthCranesAutomatic controlCylinder head

The automatic controlled multi-joint boom telescopic equipment is characterized by that the left and right two sides of cylinder head the cylinder pins are connected, the boom pin drawing-out device is connected in the upper portion of the cylinder head, a detection switch for detecting its end and initial positions of set nearby boom-pin drawing-out device, in the lower end of left and right cylinder pins there is an end and initial position detection proximity switch respectively, and in both sides of rear end of every telescopic boom a boom position detection proximity switch is set respectively, and the upper portion of the rear end of the telescopic boom is equipped with boom pin, and both sides of cylinder head and cylinder are equipped with float telescopic oil cylinder slideway and the left and right positions of rear end of every boom have sliding way chute respectively.

Owner:XUZHOU HEAVY MASCH CO LTD

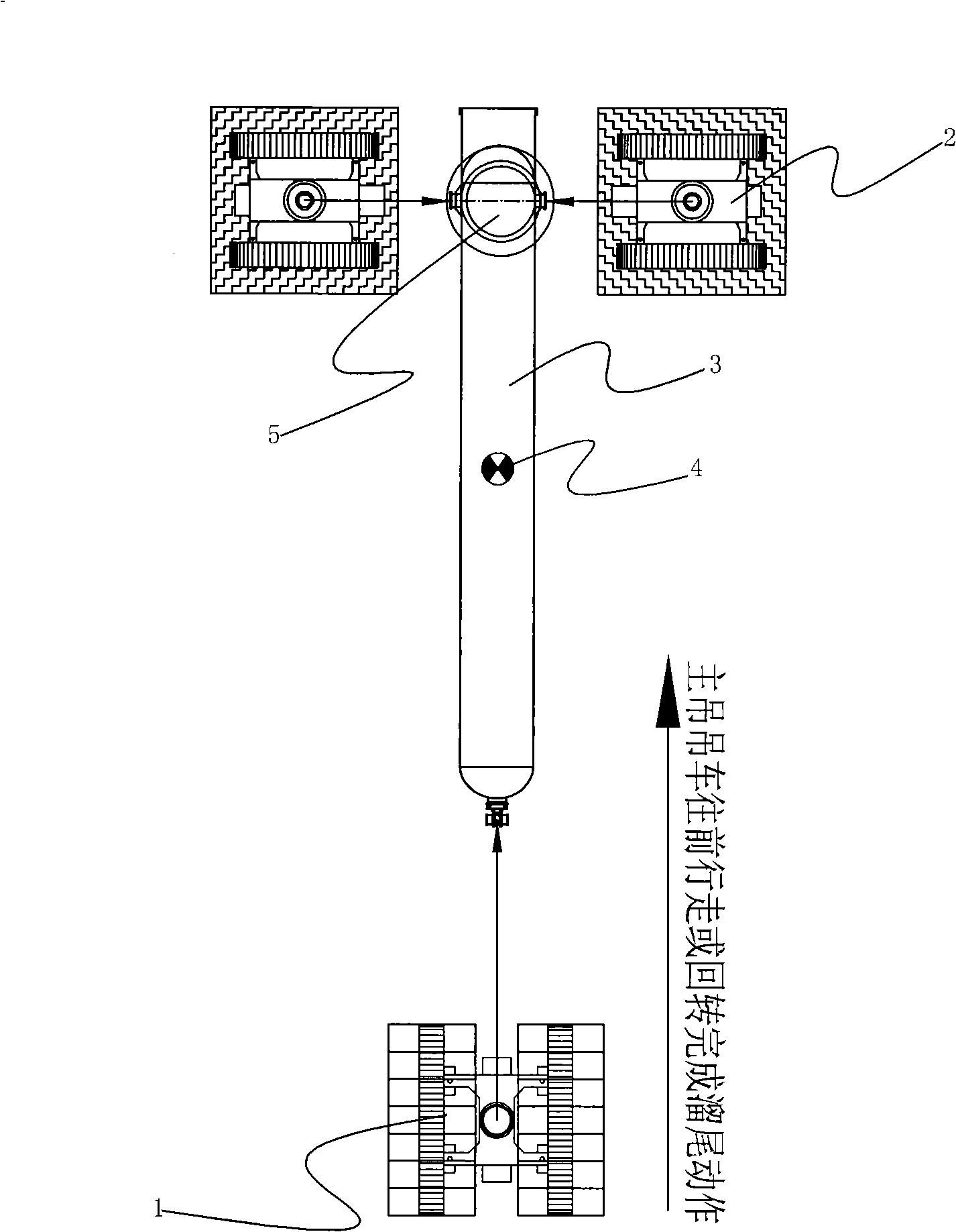

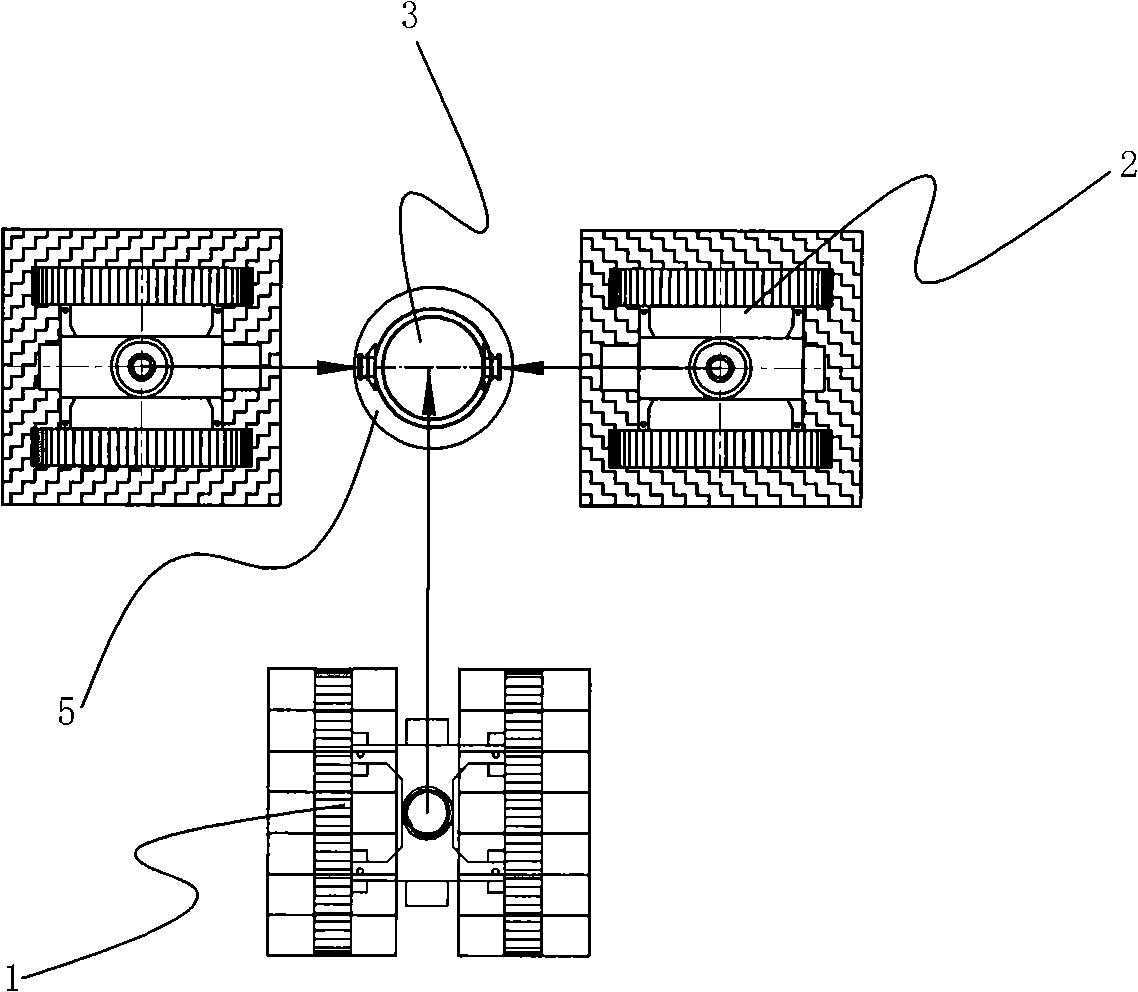

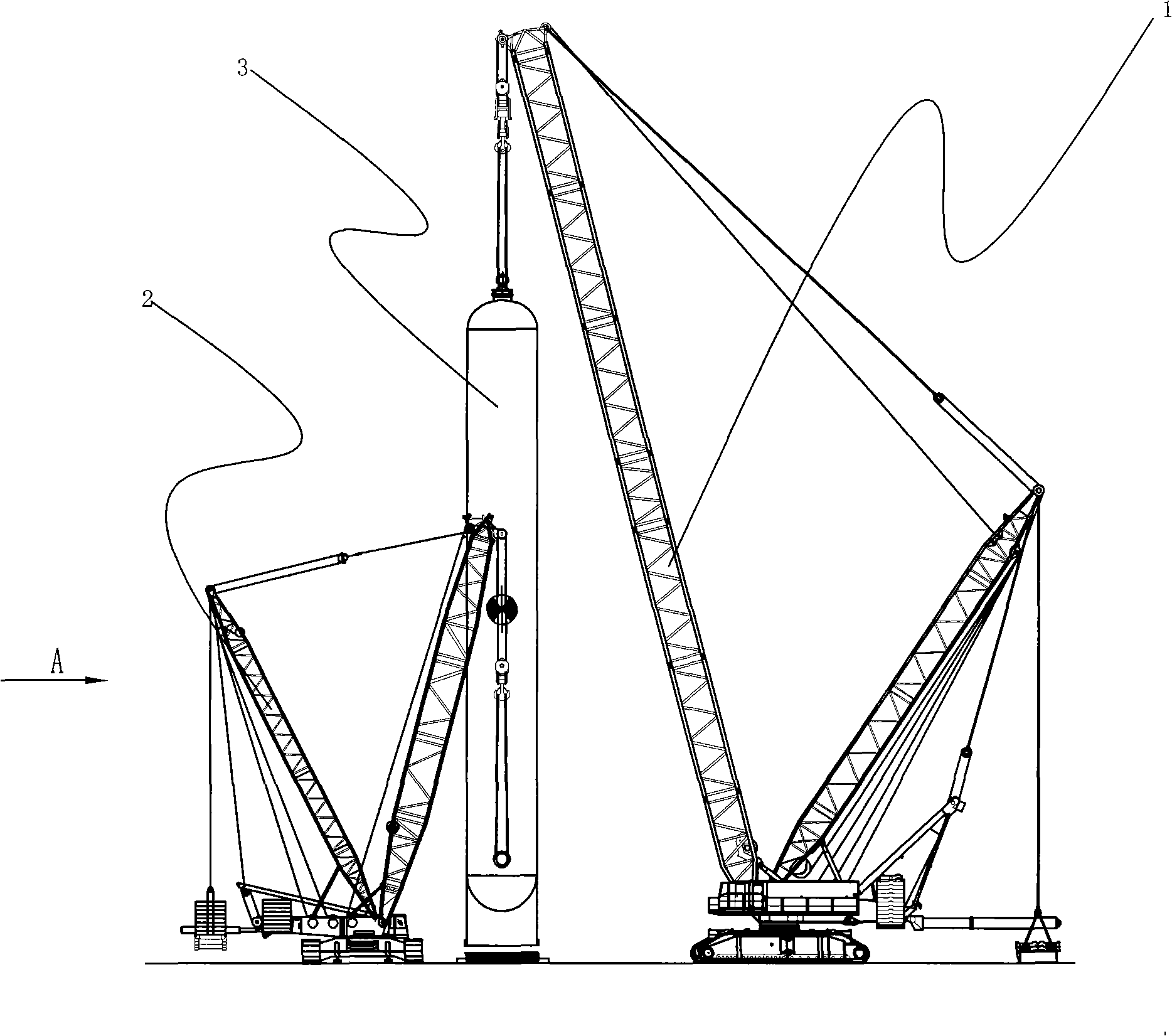

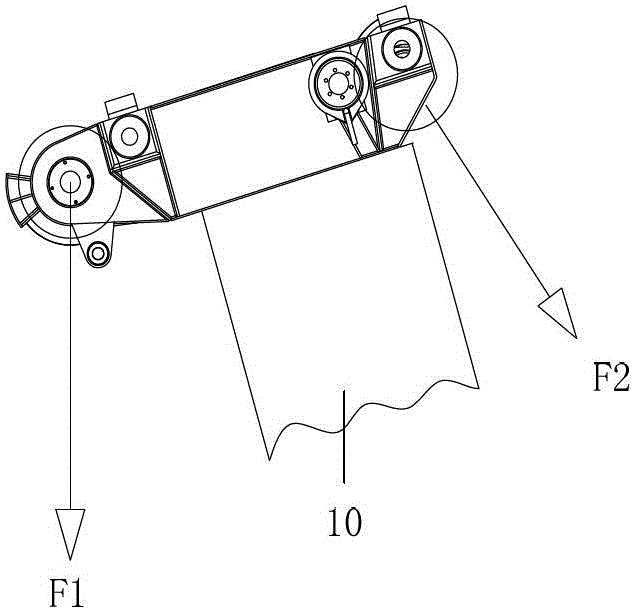

Hoisting method

ActiveCN101301981AIncreased lifting capacityShort construction periodCranesLoad-engaging elementsLifting capacityIndustrial engineering

The invention relates to a lifting method which is characterized in the following steps: a) the lifting points of two sliding tail cranes are arranged under the centre of gravity of the equipment lifted and the lifting point of at least one main crane is arranged above the centre of gravity of the equipment lifted; b) the main crane is driven forward or turned to allow the equipment to become erective gradually from horizontal state and the reverse sliding tail of the equipment lifted is completed; c) two sliding tail cranes and at least one main crane are used to lift the equipment lifted in place simultaneously after the equipment lifted is completely erective. The lifting capacity of the lifting method provided by the invention is the sum of the lifting capacity of the main crane and the sliding tail crane; thus the lifting capacity of the method can be greatly increased without increasing the crane.

Owner:SINOPEC NINGBO ENG

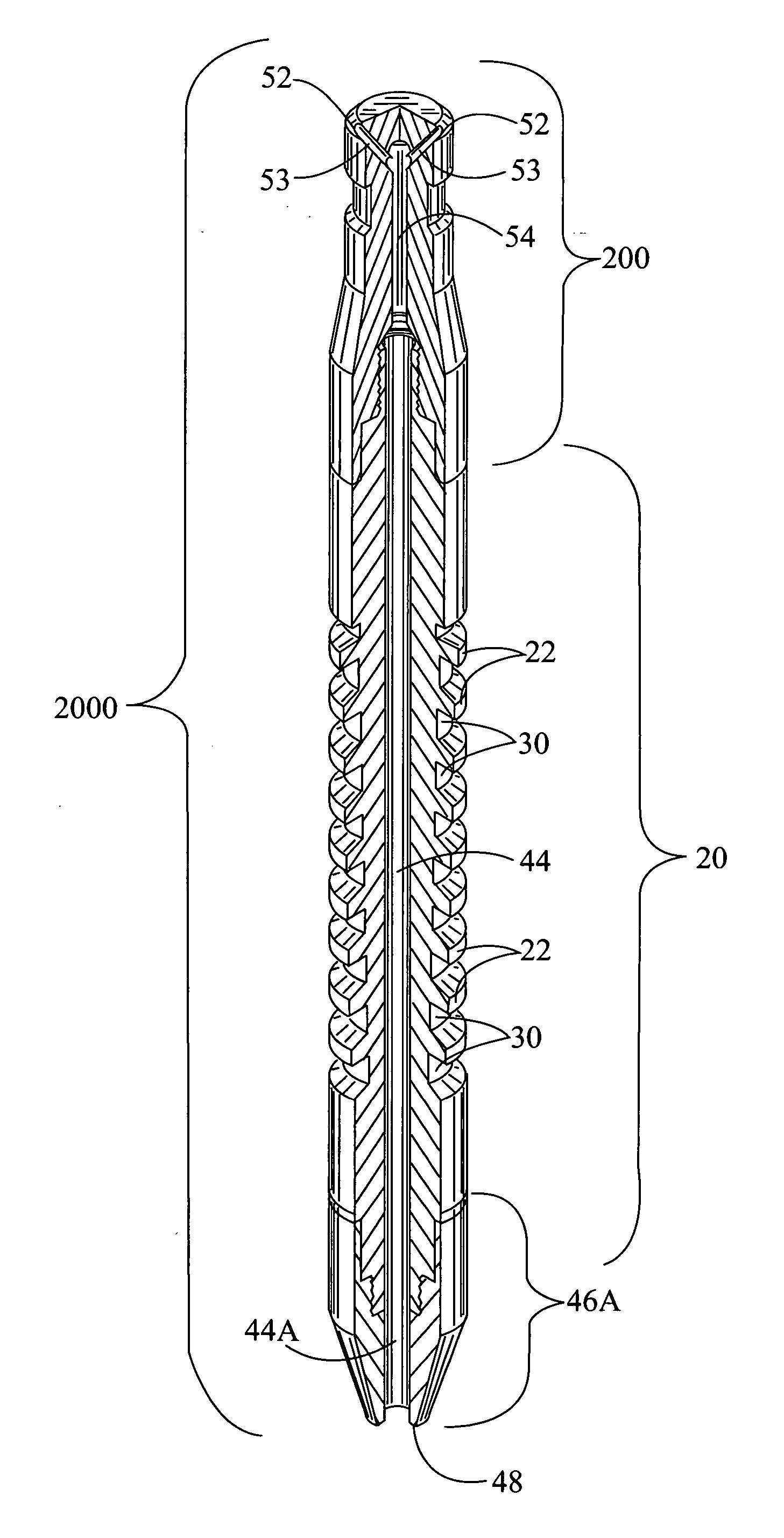

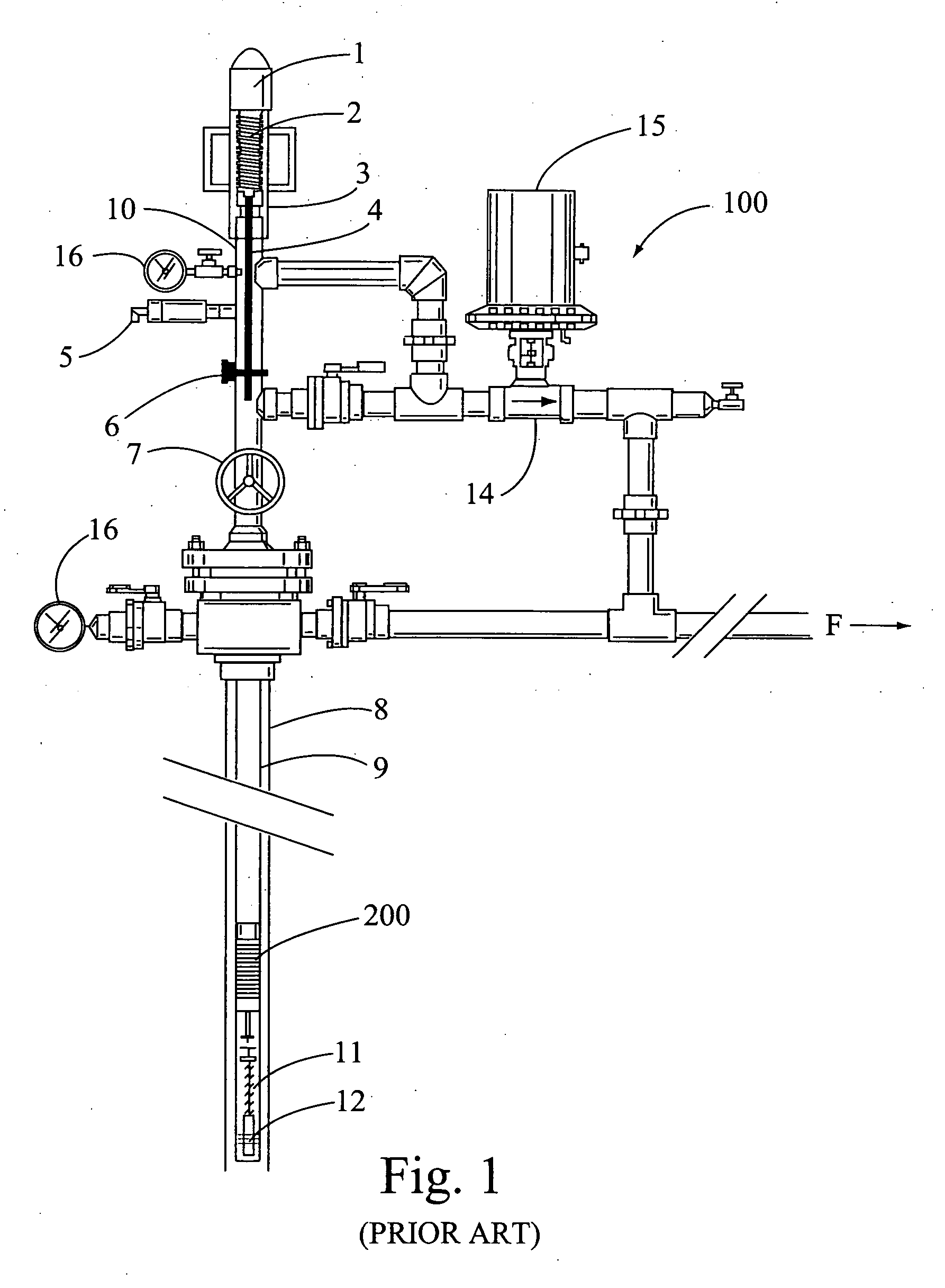

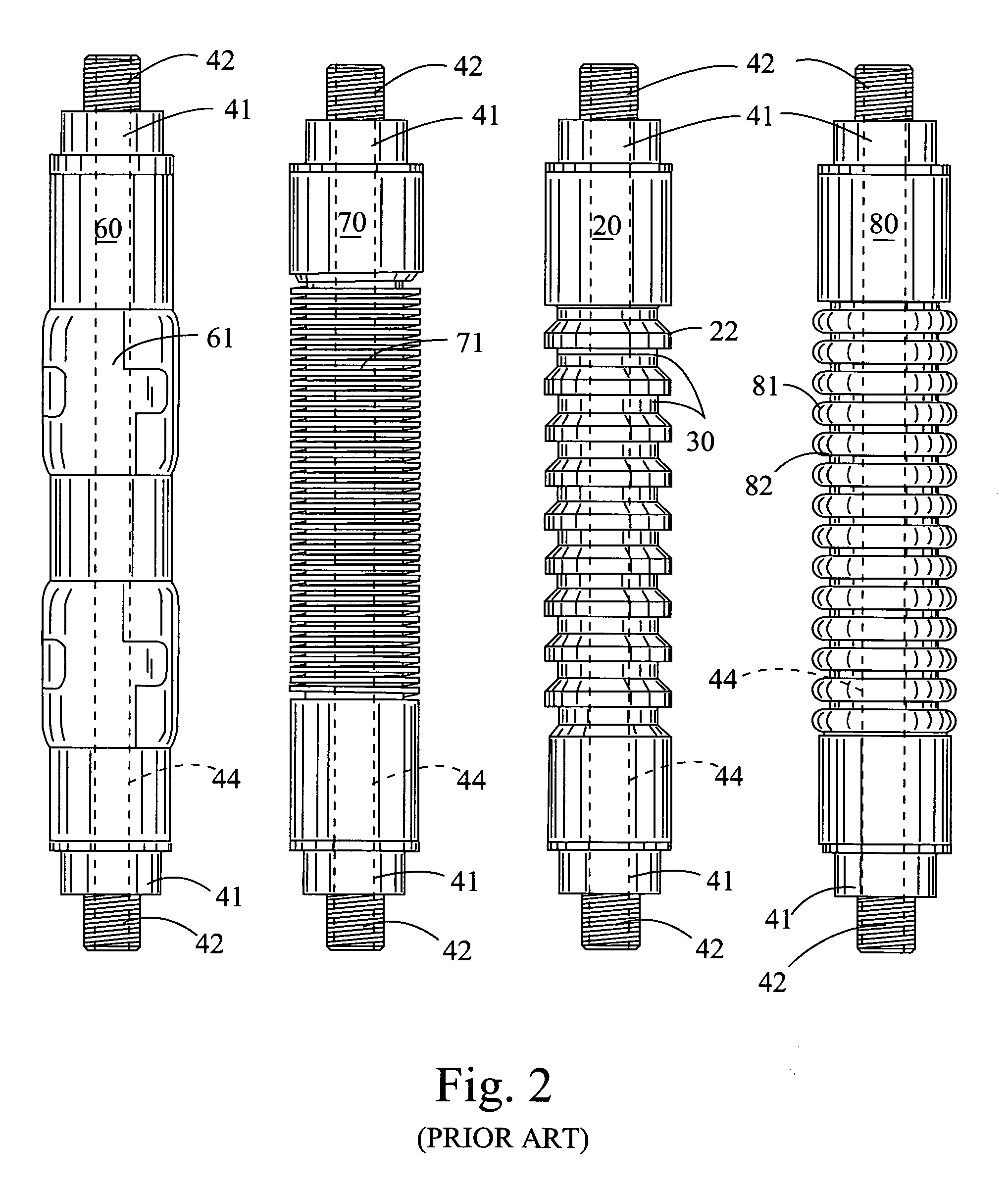

Liquid aeration plunger

ActiveUS20060249284A1Improve productivityLifting efficiencyFlexible member pumpsFluid removalProduction rateEngineering

An improved plunger lift apparatus having an internal orifice, nozzles and exit apertures. The present invention relates to an improved plunger lift apparatus for the lifting of formation liquids in a hydrocarbon well. More specifically the improved plunger consists of a plunger apparatus that operates to propel one or more jets of gas through one or more internal orifices and / or nozzles, out through an aperture and into the liquid load formation, thereby providing a momentum transfer of the gas into the liquid load and causing a gaseous and turbulent aeration to the formation during lift. This action allows a large liquid formation load to be carried to the well top by the plunger at an increased level of efficiency resulting in an improved well productivity level.

Owner:PCS FERGUSON

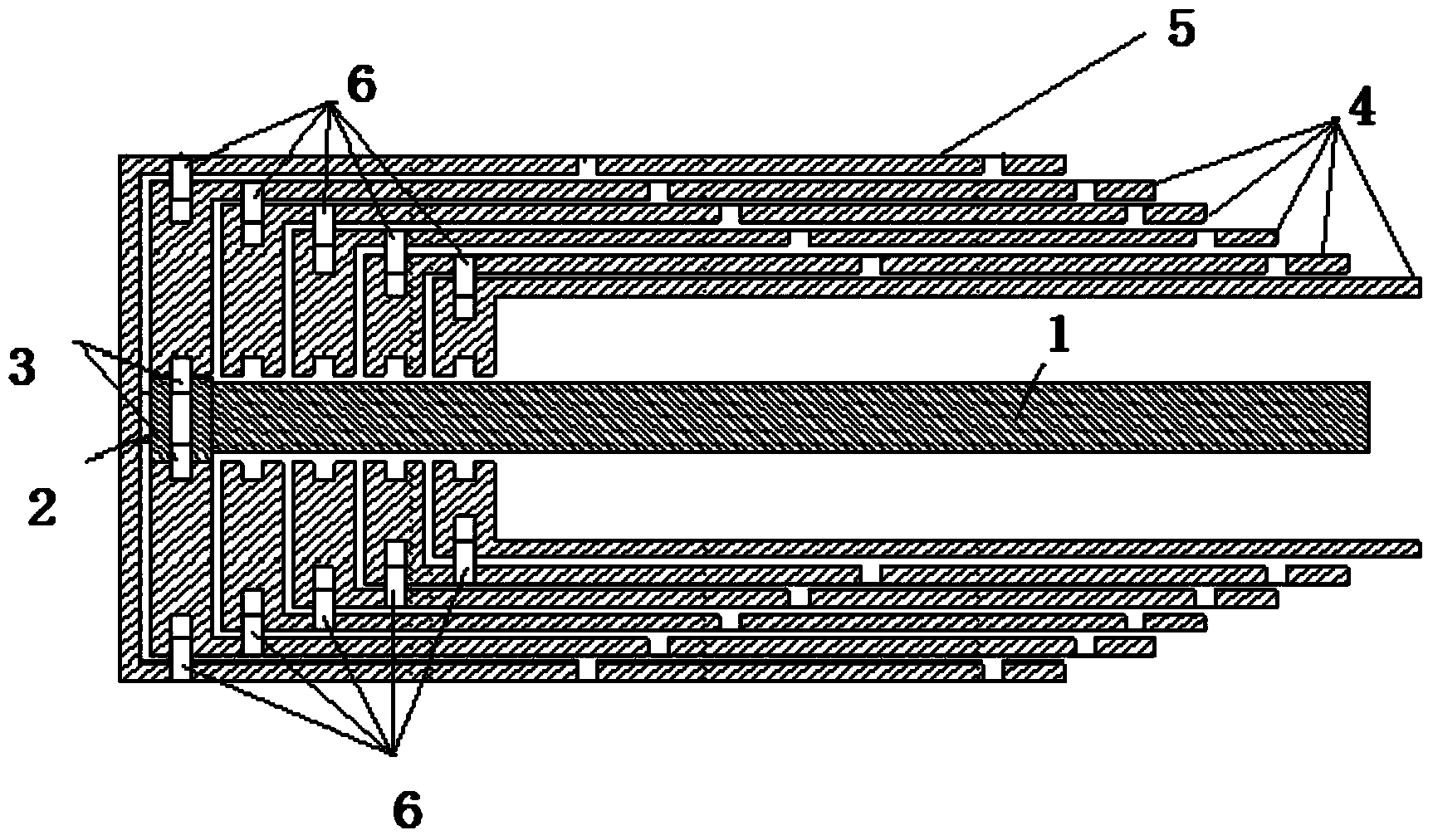

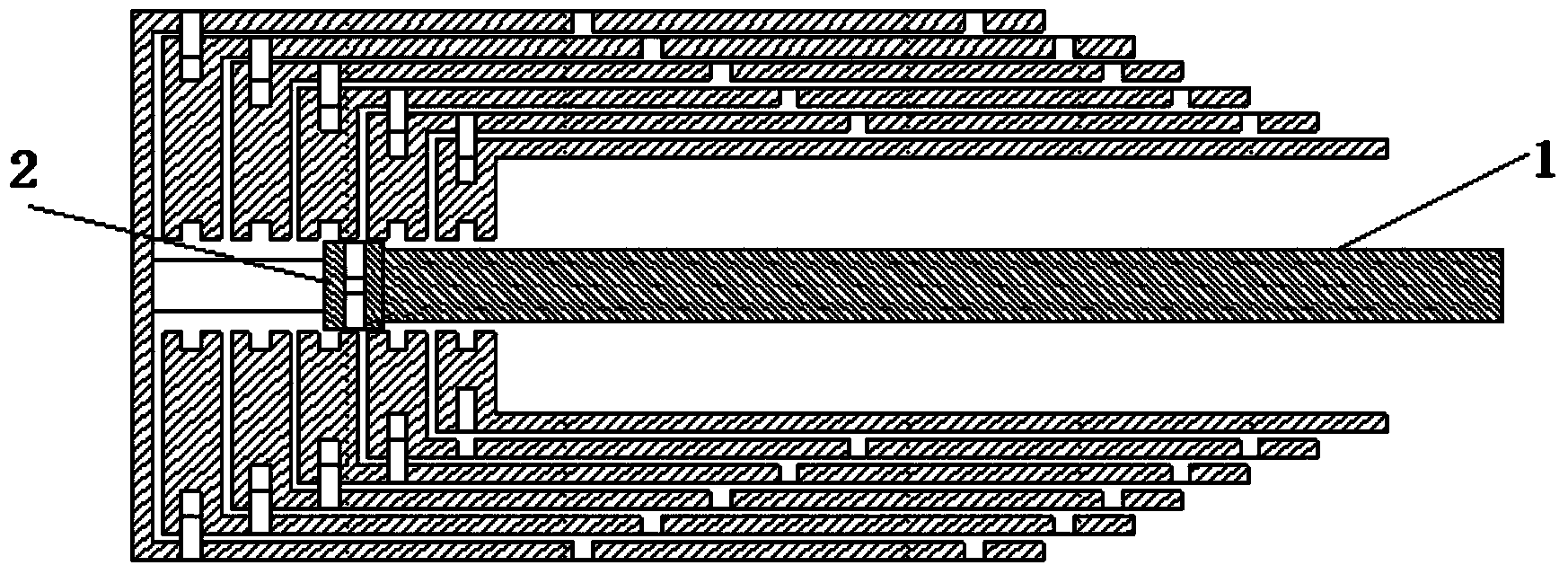

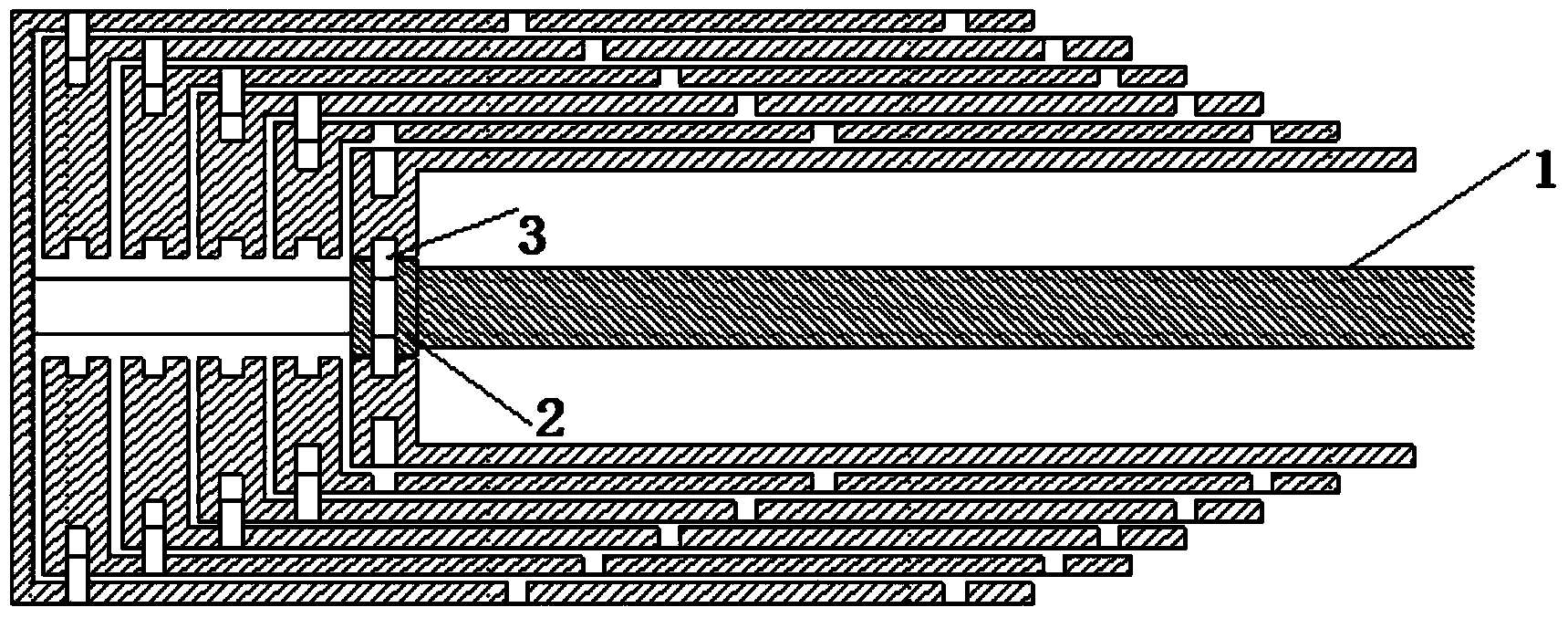

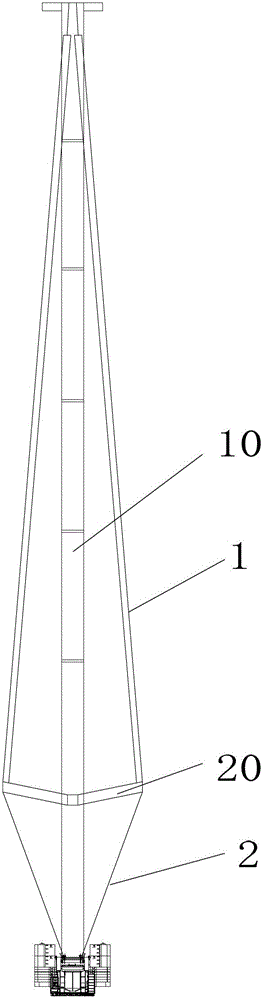

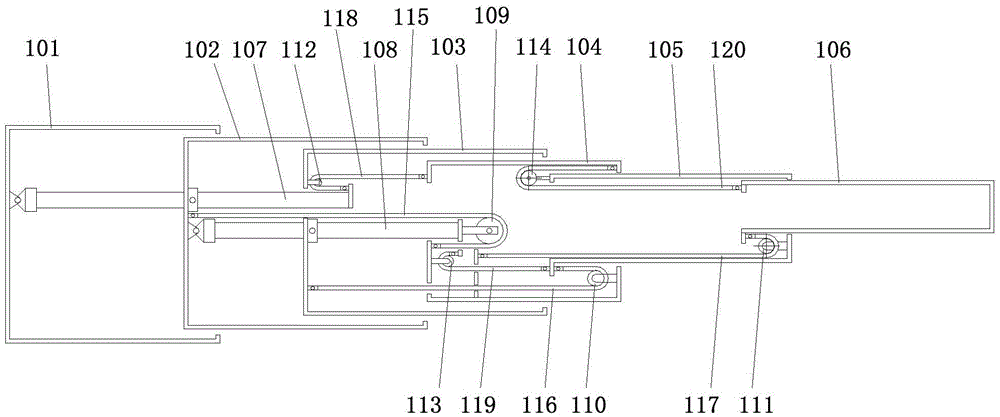

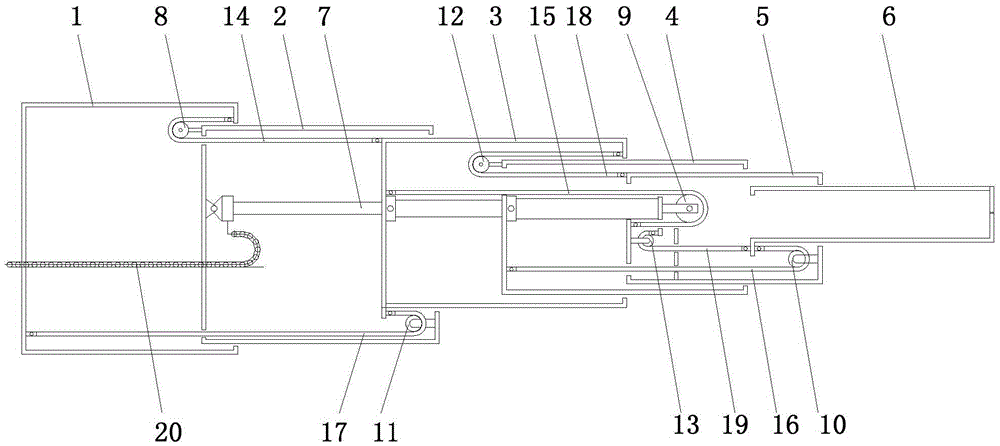

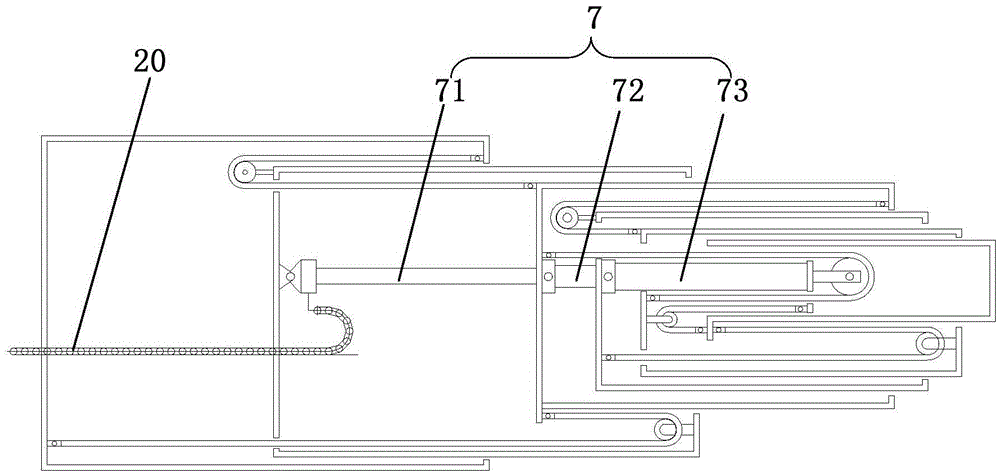

Single-cylinder plug pin type telescopic arm, crane and telescoping method of single-cylinder plug pin type telescopic arm

The invention relates to a single-cylinder plug pin type telescopic arm, a crane and a telescoping method of the single-cylinder plug pin type telescopic arm. The single-cylinder plug pin type telescopic arm comprises a basic arm and at least one section of telescopic arm which is sleeved in the basic arm, wherein coaxial central holes are formed in the tails of the telescopic arms; a telescopic oil cylinder is arranged in the central holes and comprises a cylinder rod and a cylinder barrel; at least two cylinder heads are fixedly sleeved outside the cylinder barrel in the longitudinal direction; at least three arm pin holes are respectively formed in the basic arm and the telescopic arm in the longitudinal direction. The single-cylinder plug pin type telescopic arm provided by the invention adopts the telescopic oil cylinder and the at least two cylinder heads; each cylinder head can be used for locking and unlocking the telescopic oil cylinder and any one telescopic arm; in a relay manner, the telescopic arms stretch or shrink; telescoping of the single-cylinder plug pin type telescopic arm is realized; the length of the oil cylinder is reduced; the cylinder diameter and the rod diameter of the oil cylinder are reduced; the cost of the oil cylinder is lowered; the loading weight is reduced; the hoisting capability is improved; the design capability of the crane is improved.

Owner:XUZHOU HEAVY MASCH CO LTD

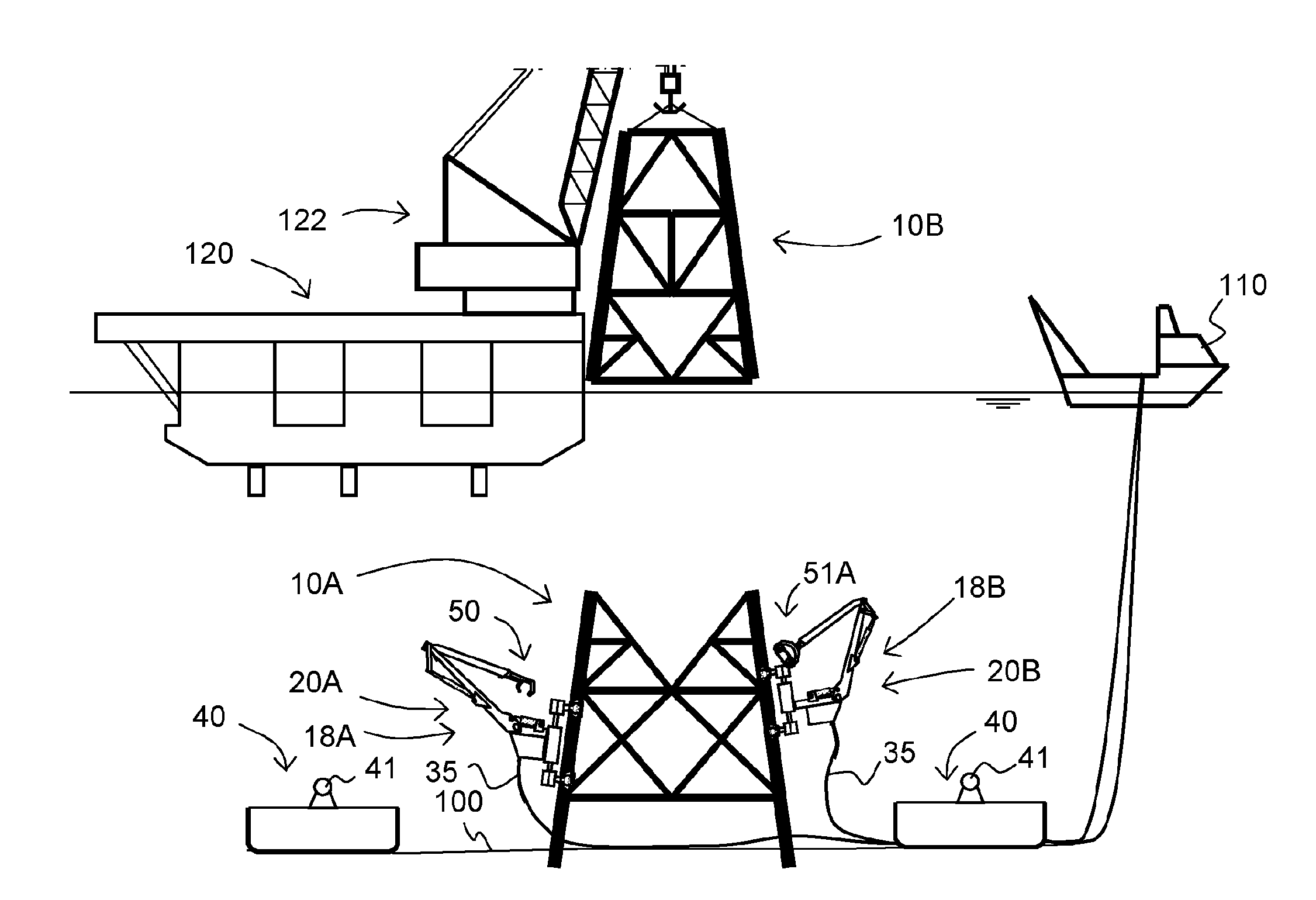

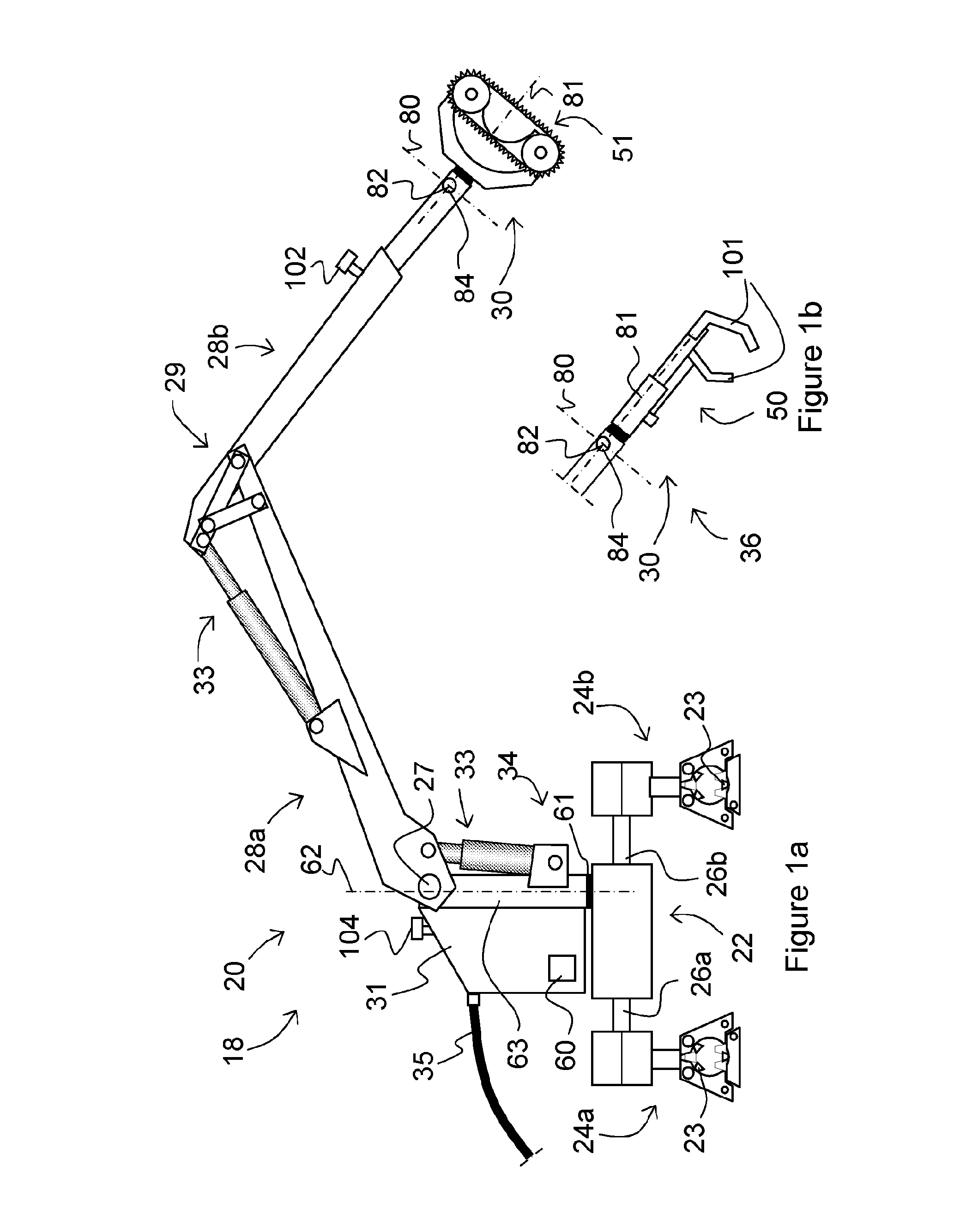

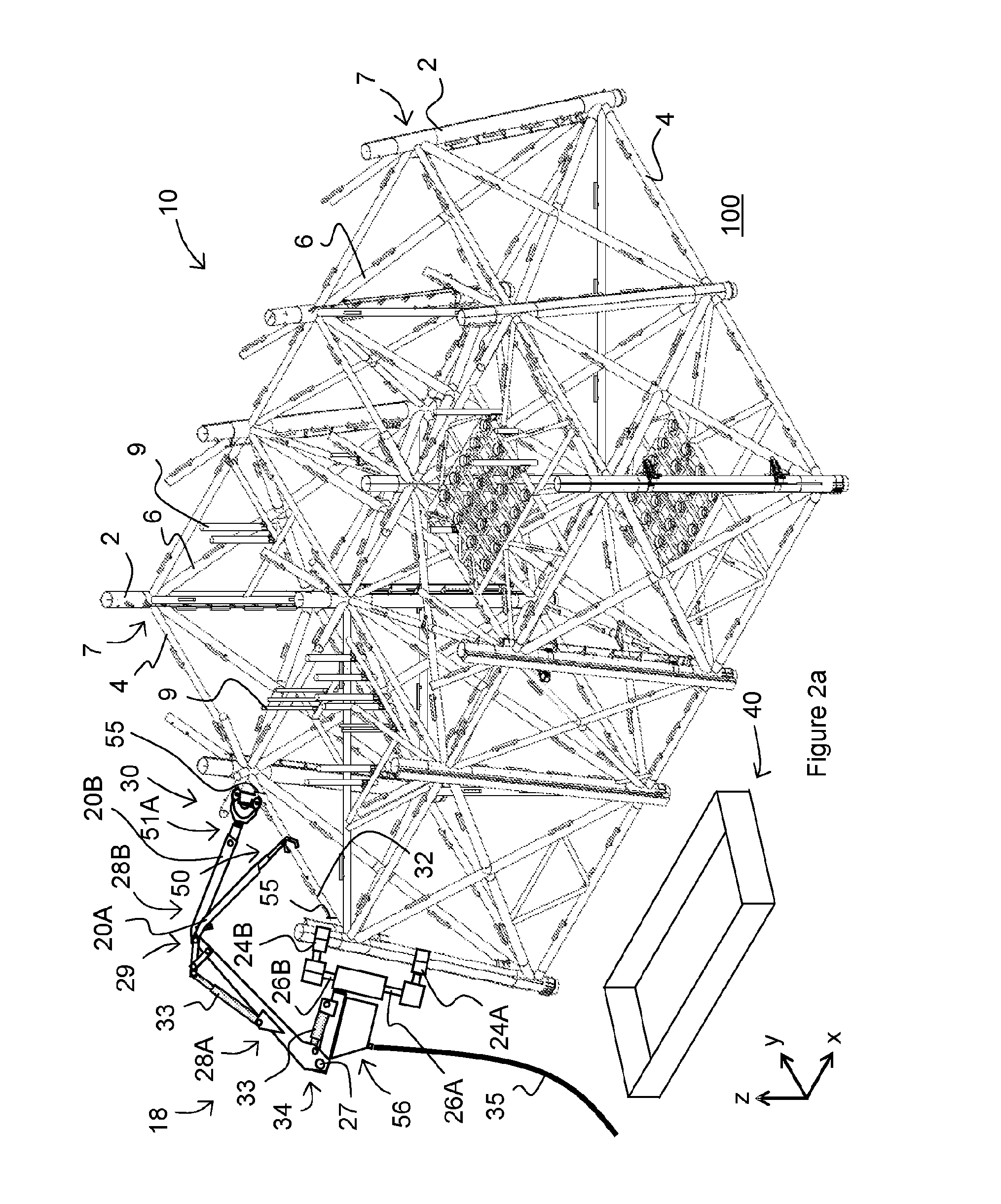

Method and device for assembling or disassembling a structure under water

InactiveUS20140147217A1Efficient and reliableIncreased lifting capacityMetal sawing devicesArtificial islandsWorking rangeEngineering

A method of performing an under water operation on a structure (10) or in the vicinity of the structure includes providing a device (18) having a movable arm (20) and at least a first support (22) constructed to be connected to the structure, the movable arm (20) directly or indirectly connected at a proximal end (34) to the support, the first movable arm having a first tool (30) connected to a distal end (36) of the first movable arm, at least one actuator (33) configured to controllably move the first tool (30) in a three dimensional working range in order to position the first tool at a target location, attaching the device to the structure via the at least one support, and-moving the tool in three dimensions and performing an operation under water.

Owner:HEEREMA MARINE CONTRACTORS NEDERLAND SE

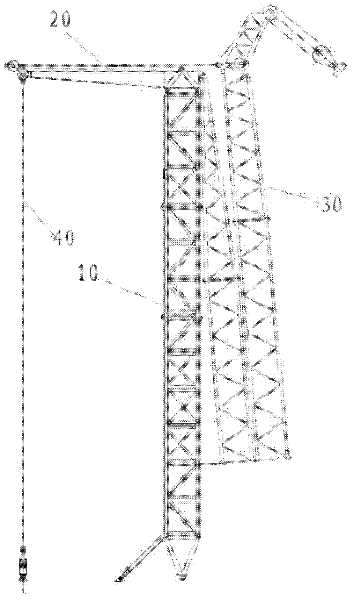

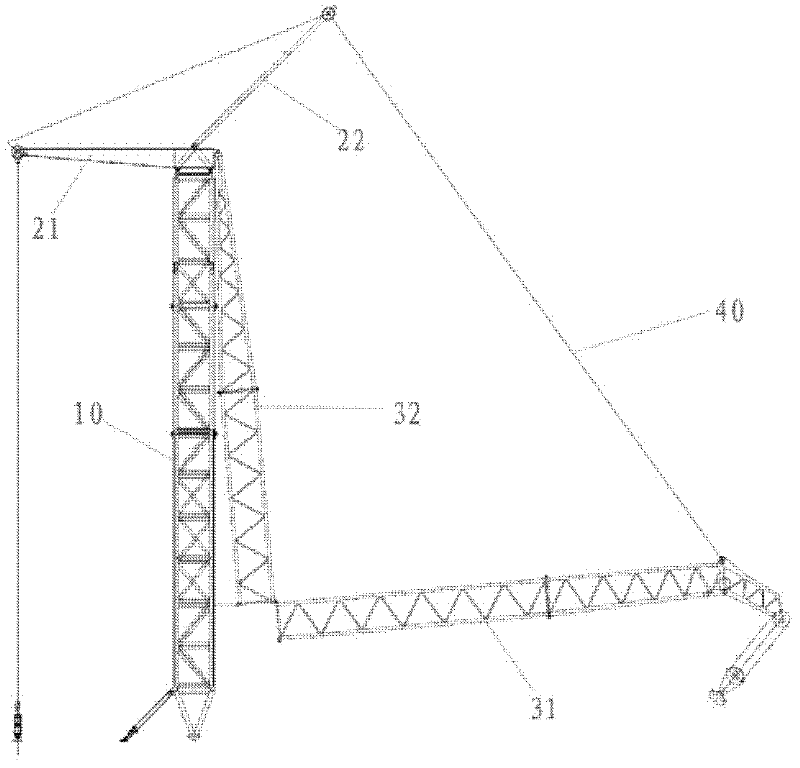

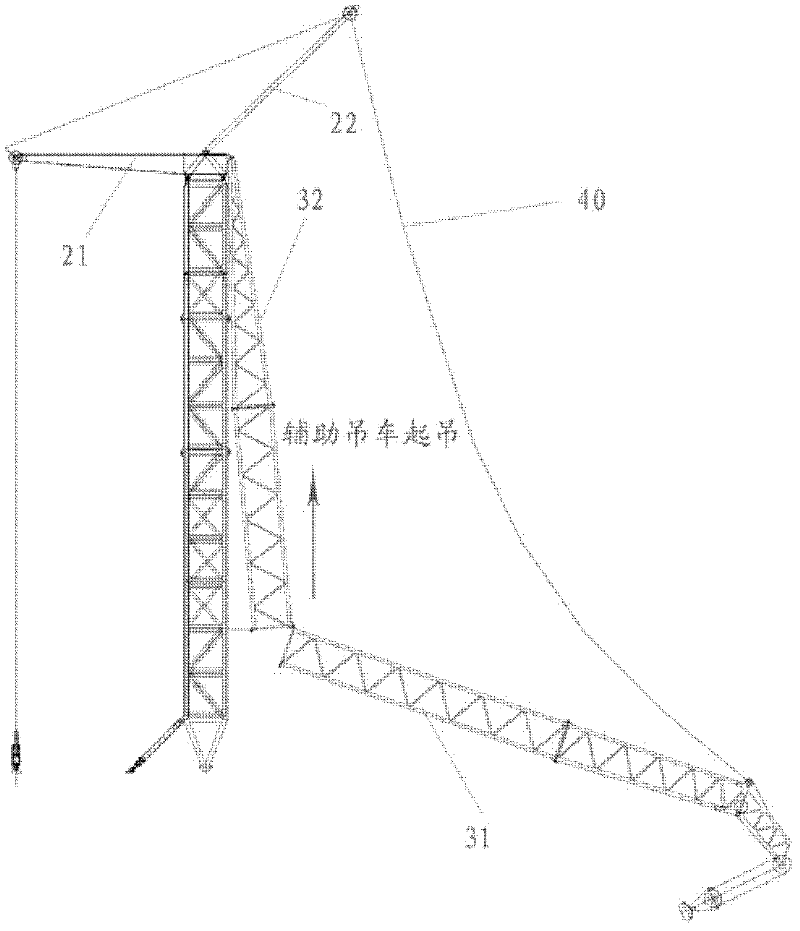

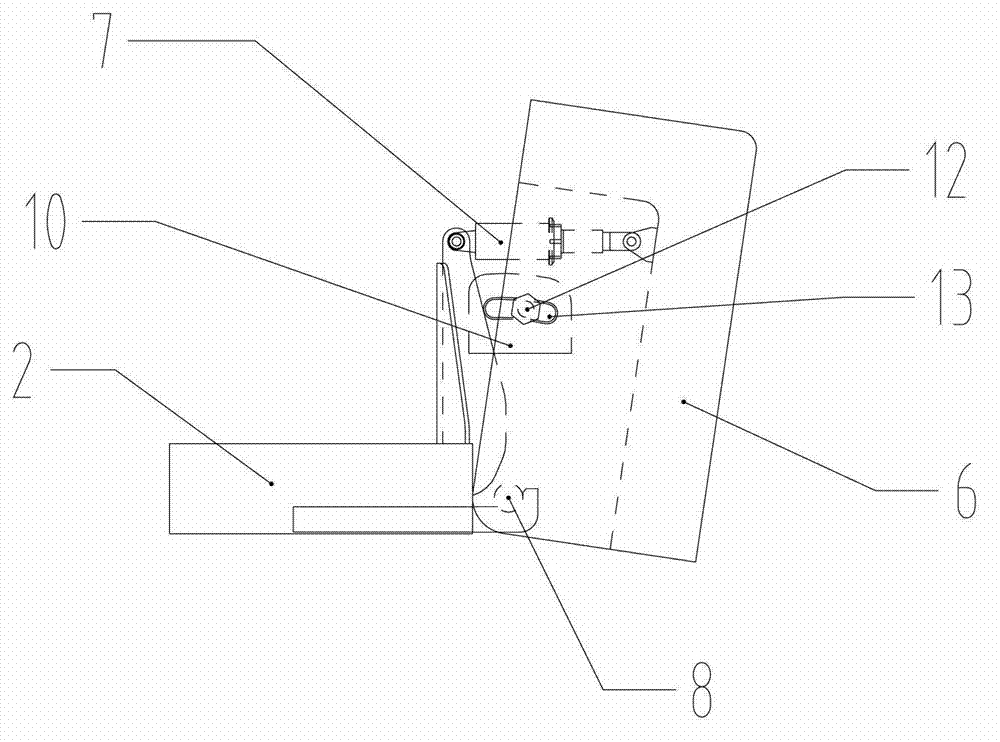

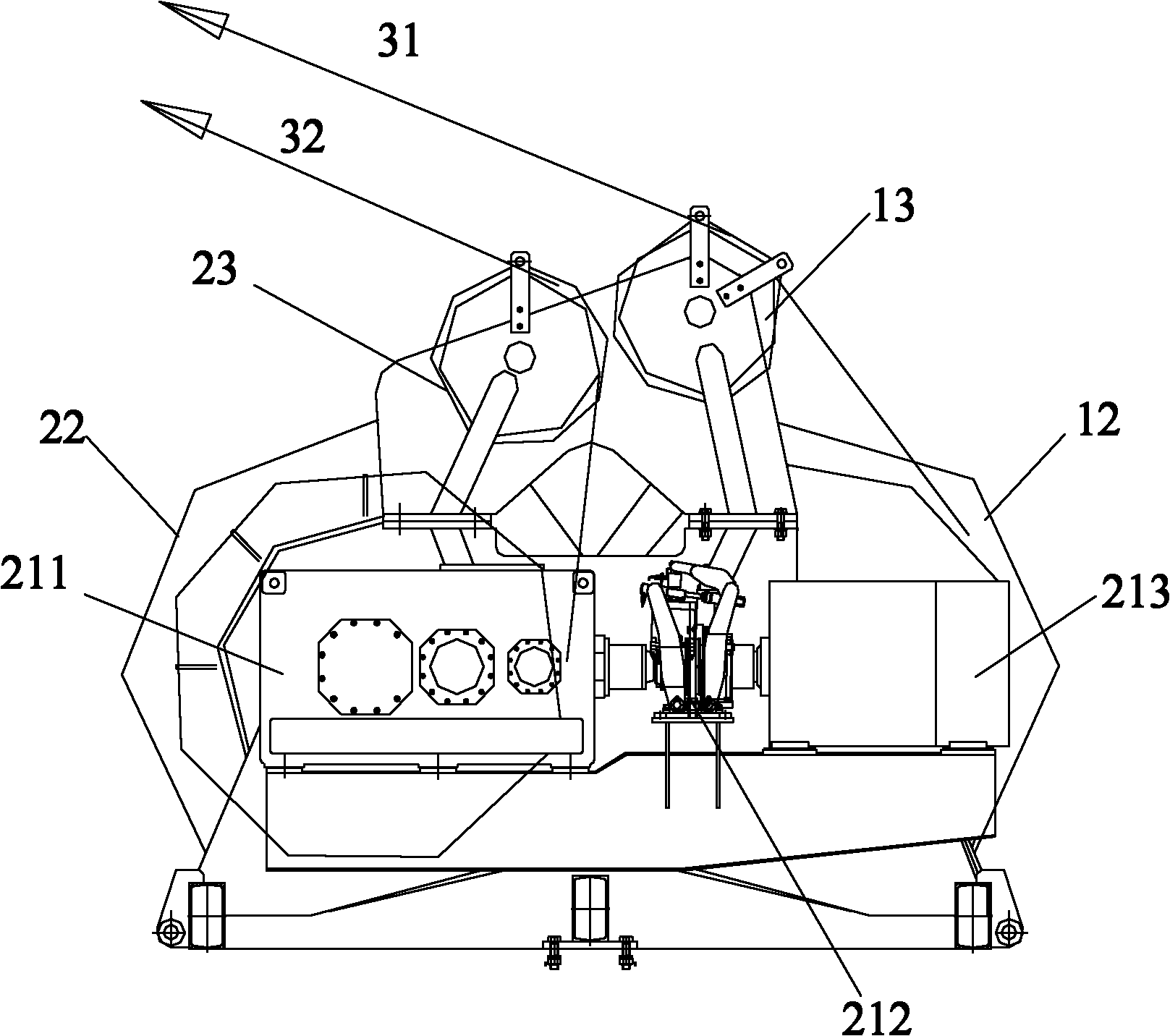

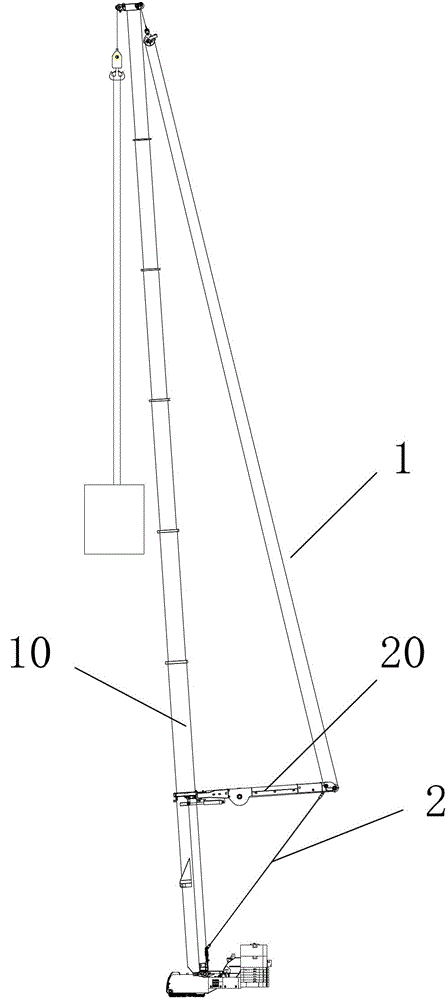

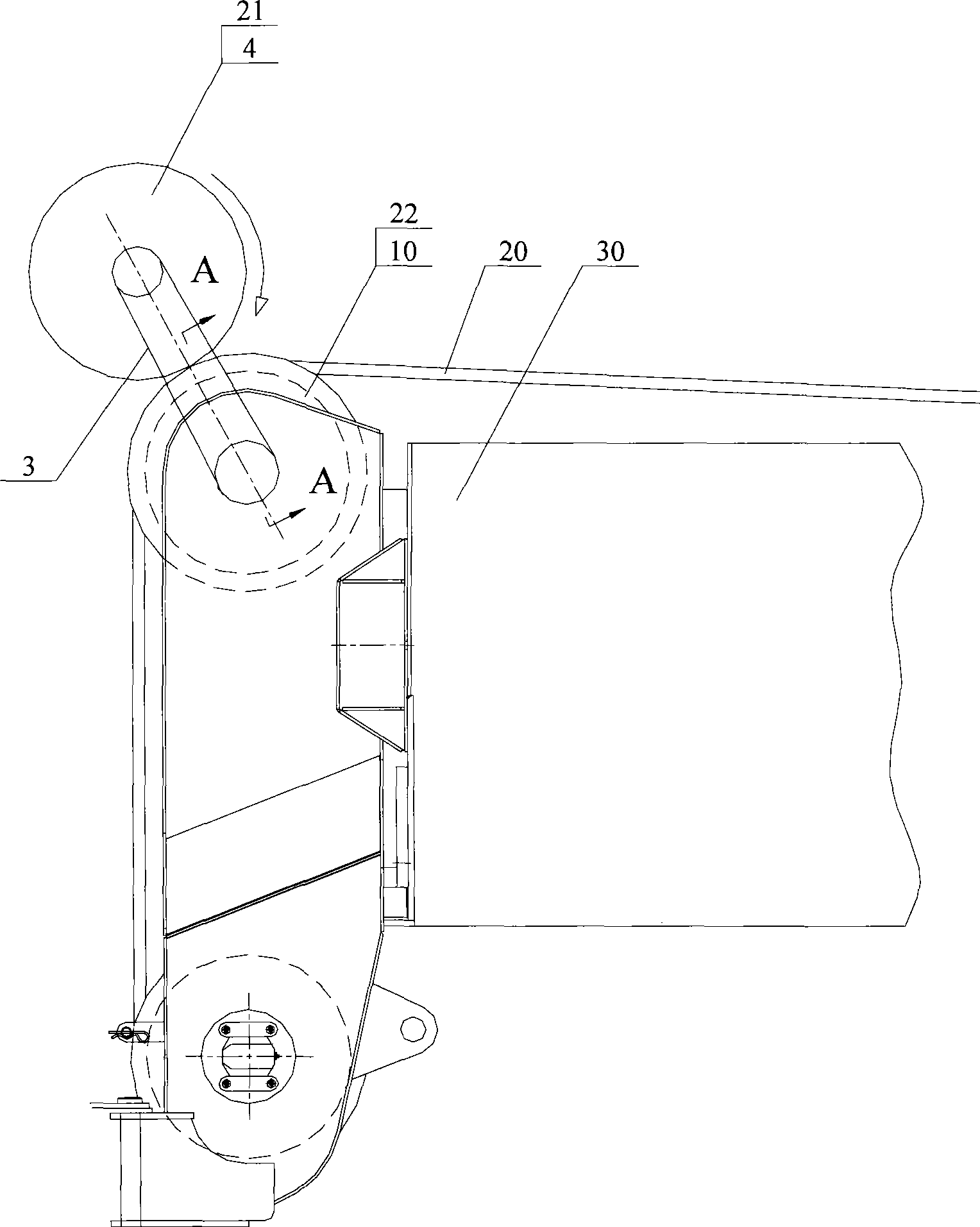

Folding jib structure and method for unfolding and folding the same

The invention discloses a folding jib structure and a method for unfolding and folding the same. The folding jib structure comprises a principal arm (10), a support bar mechanism (20) and a fly jib (30) that are arranged on the principal arm, and a steel rope (40) reeled by a hoist and supported by the support bar mechanism support. The fly jib comprises a fly jib front segment (31) and a fly jibrear segment (32) that are in pivotal connection with each other; and one end of the steel rope is detachably connected to the fly jib. The folding jib structure also comprise a pulling plate (50), which includes at least a first portion (51) and a second portion (52) that are in detachable and pivotal connection; and the first portion and the second portion are respectively connected with the fly jib front segment and the support bar mechanism. According to the above technical scheme, the fly jib can be folded or unfolded through the pulling plate and the steel rope, so as to enhance hoisting performance and lower requirements on the steel rope strength. Besides, auxiliary equipment like an auxiliary crane is omitted, and manual dangerous operation is not needed.

Owner:ZOOMLION HEAVY IND CO LTD

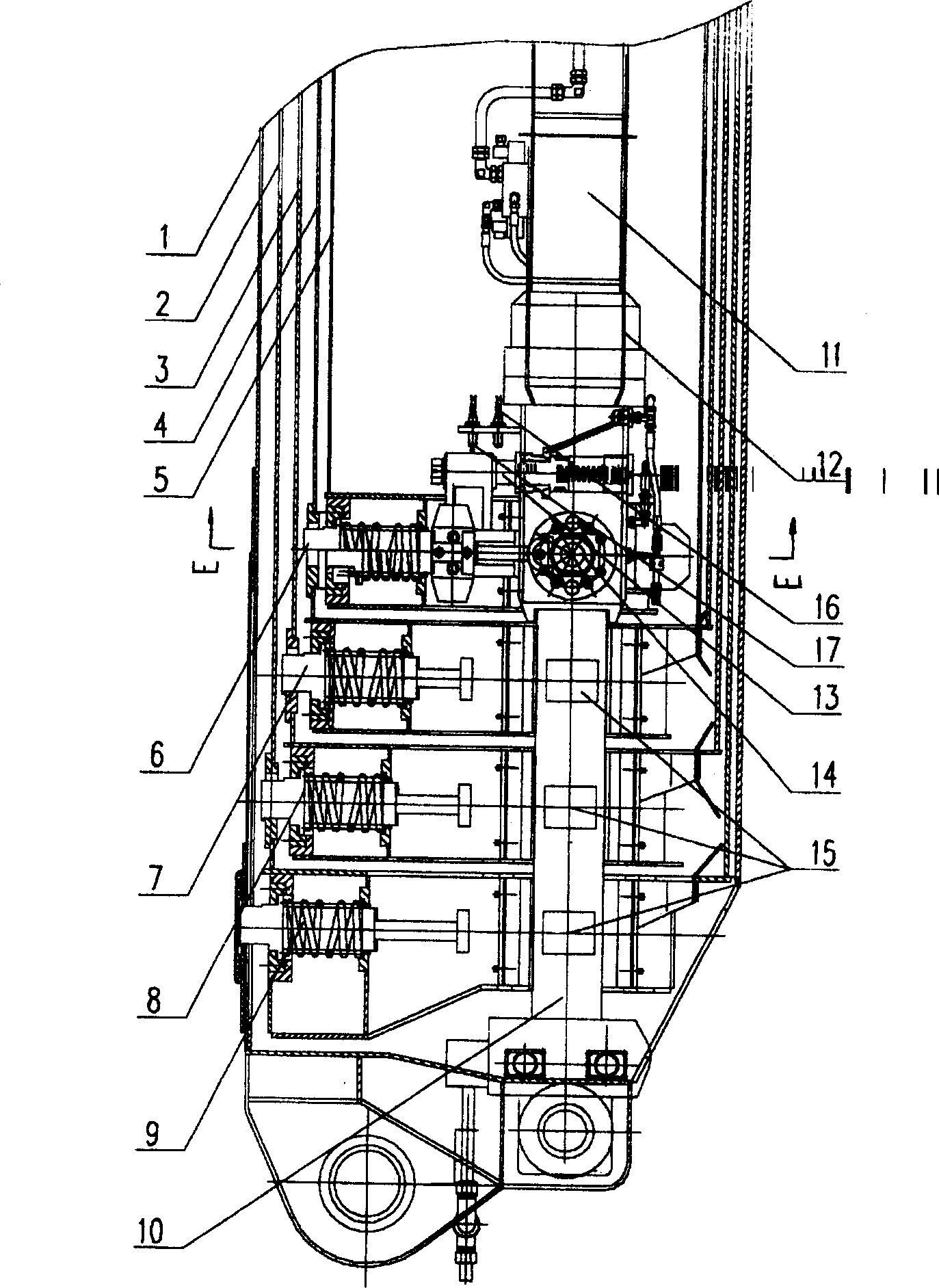

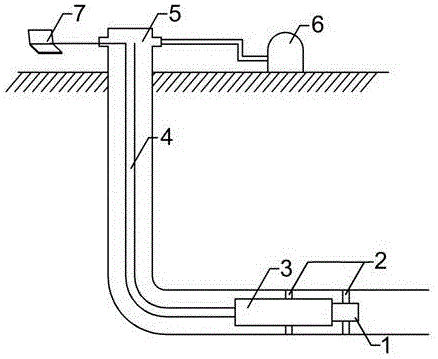

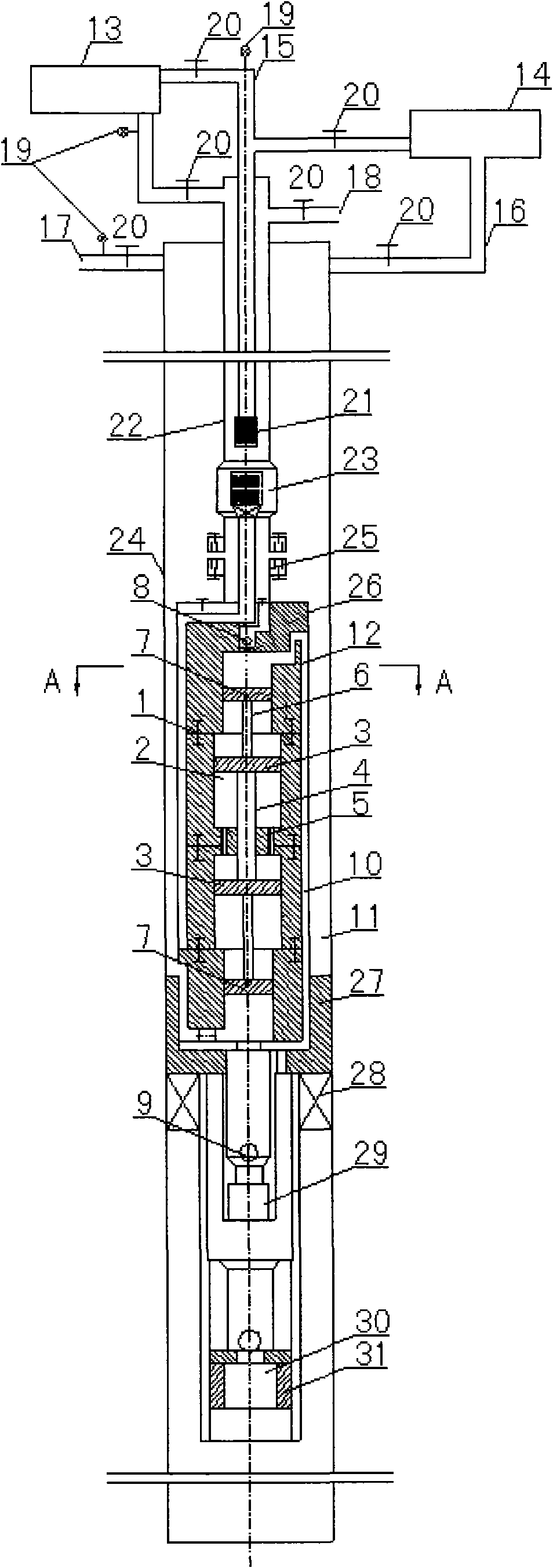

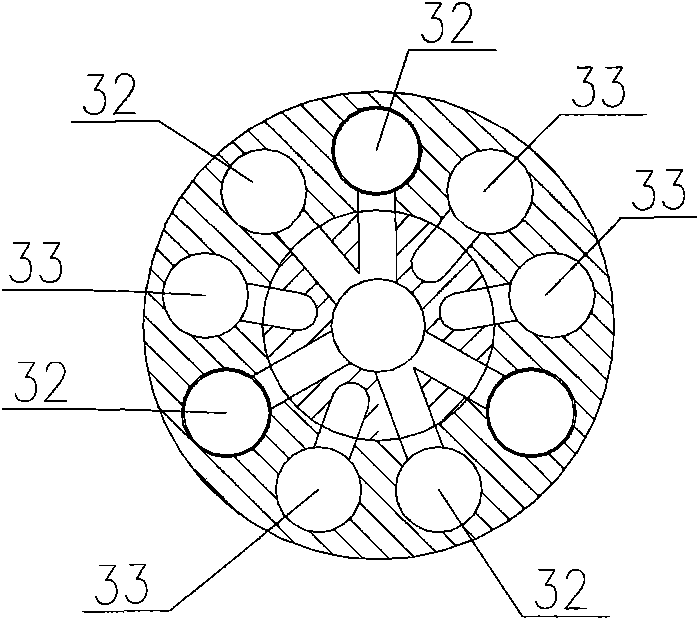

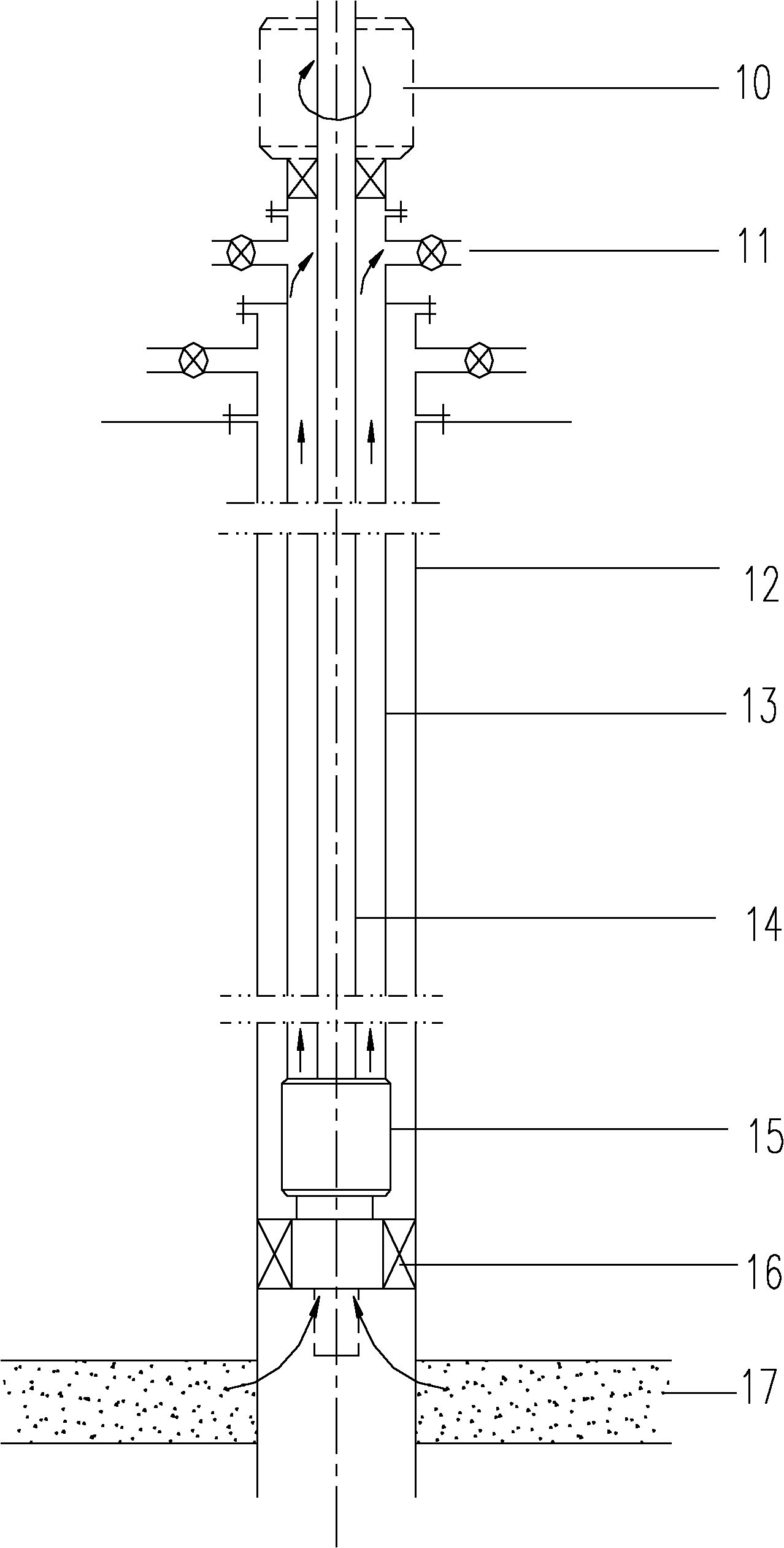

Water pumping and draining and gas producing system of horizontal gas well machine

The invention relates to a water pumping and draining and gas producing system of a horizontal gas well machine, which is used for underground water drainage and gas production. By adopting the system, normal production of a gas well can be kept, the productivity of the gas well is increased, and the lifting capacity of a pump to formation water is increased. The system adopts the technical scheme that in an underground gas-liquid separation lifting part, a gas-water separator is connected and fixed with a linear motor pump by a fixator at a production interval of the well; in a ground treatment operation part, the linear motor pump is connected with a gas producing tree by an intelligent coiled tubing, and then the gas producing tree is connected with a ground treatment device by a pipeline; in an intelligent control device, a cable is arranged in the intelligent coiled tubing, one end of the cable is connected with the linear motor pump and the inlet cross section of the gas-water separator, the other end of the cable is connected with a ground intelligent control terminal, and a set of intelligent control program and microcomputer equipment are installed in the intelligent control terminal. The water draining and gas producing system has the functions of preventing sand jamming, increasing the lifting capacity to the formation water and optimizing the productivity of the gas well and is used for water drainage and gas production operation, and maintenance is convenient.

Owner:SOUTHWEST PETROLEUM UNIV

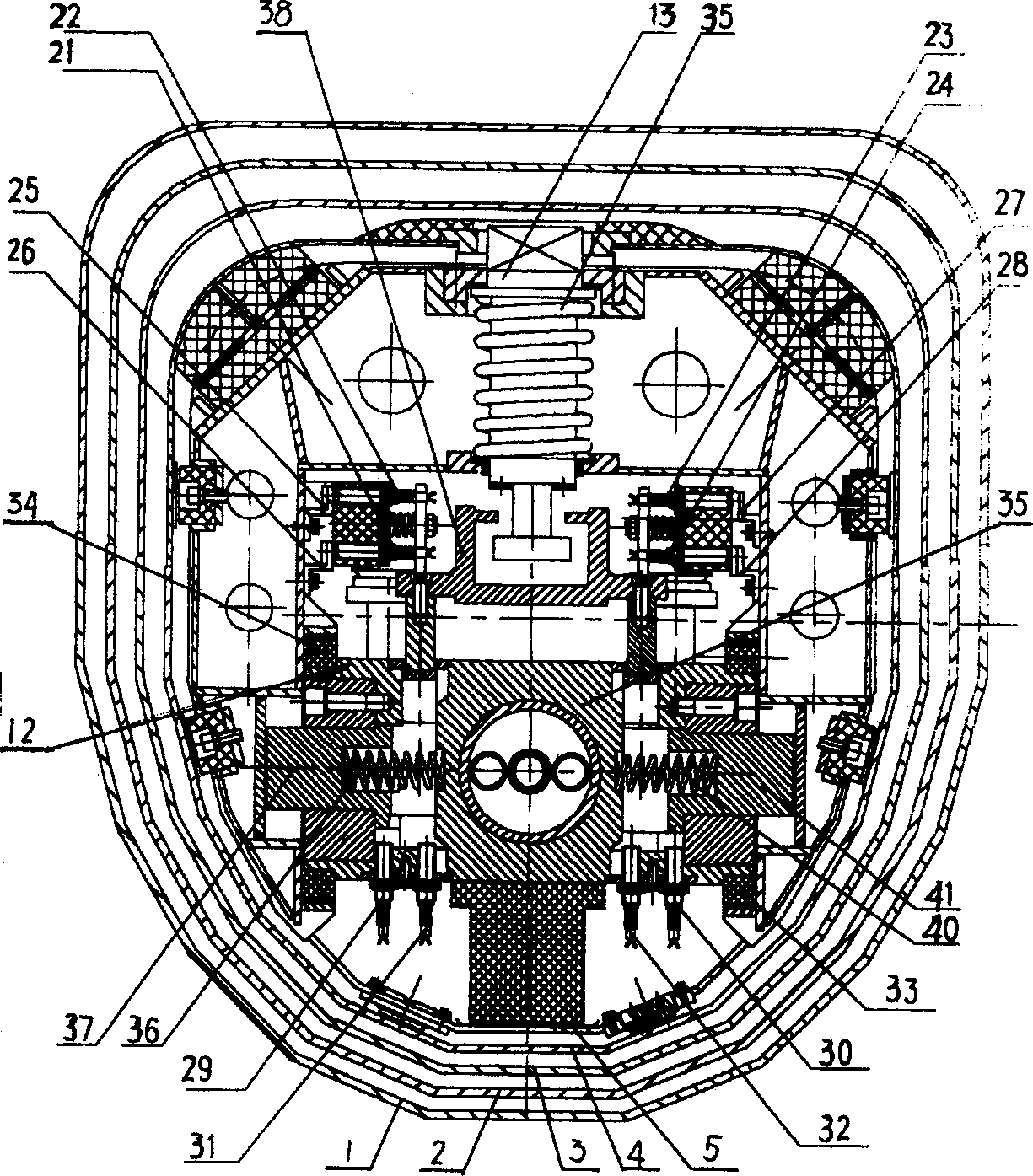

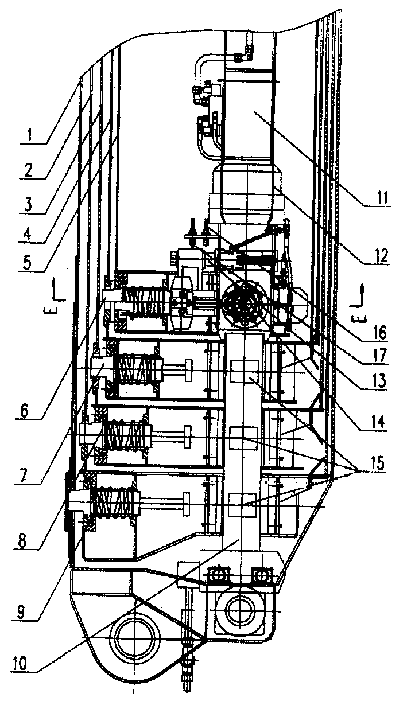

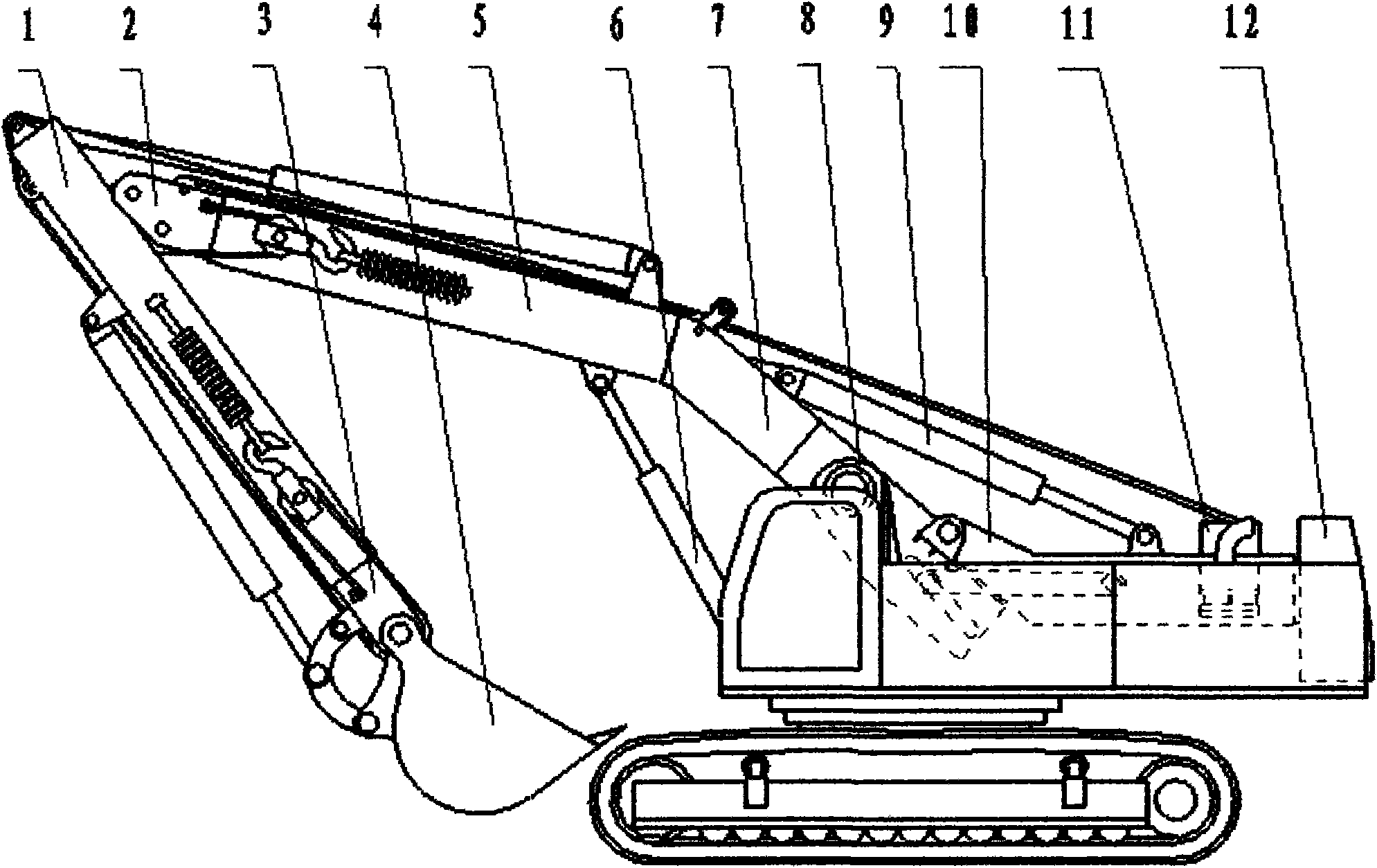

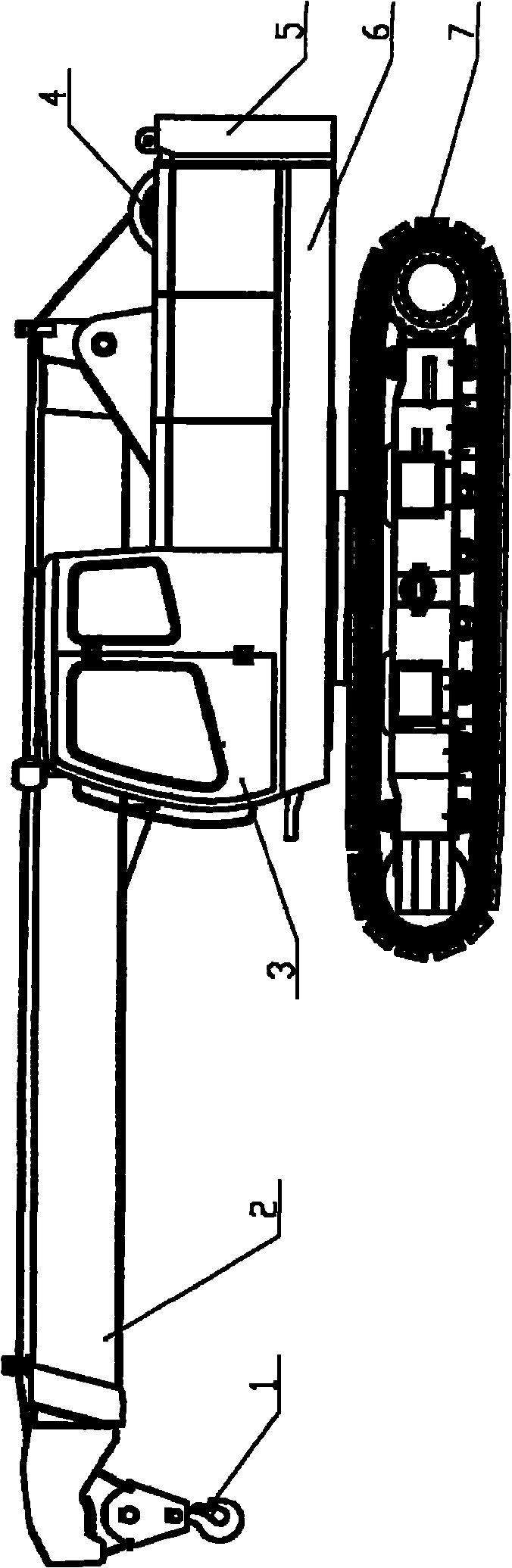

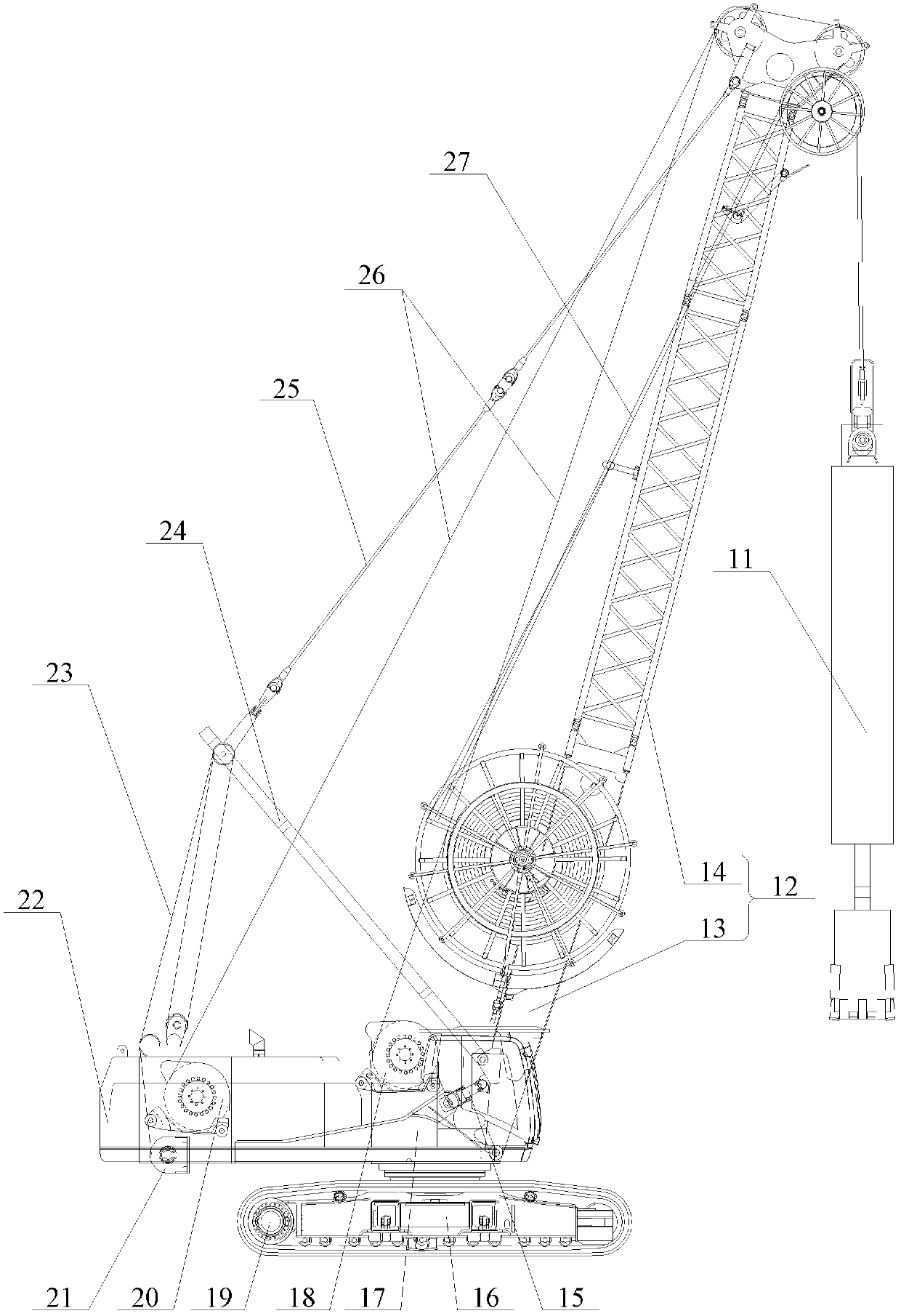

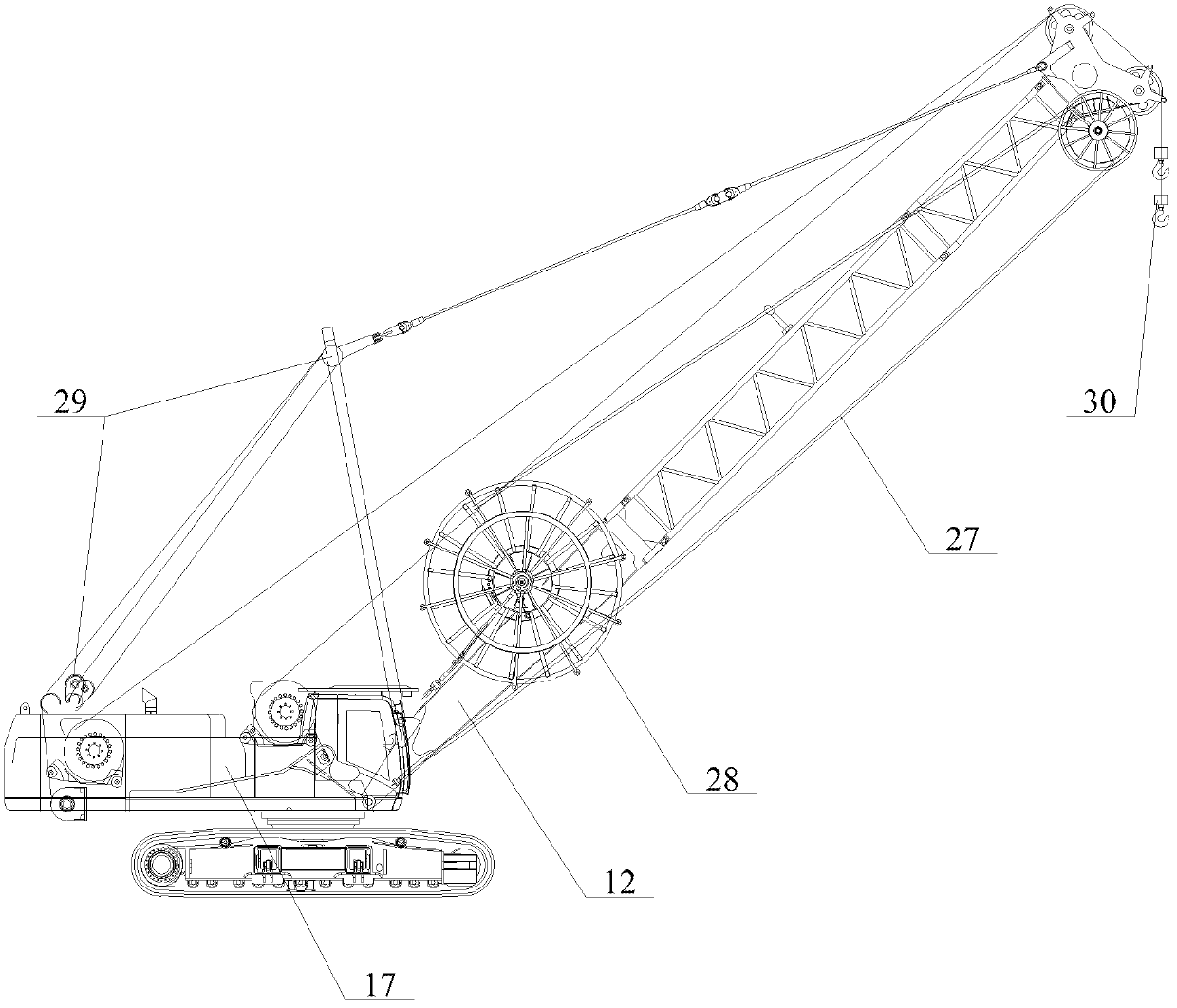

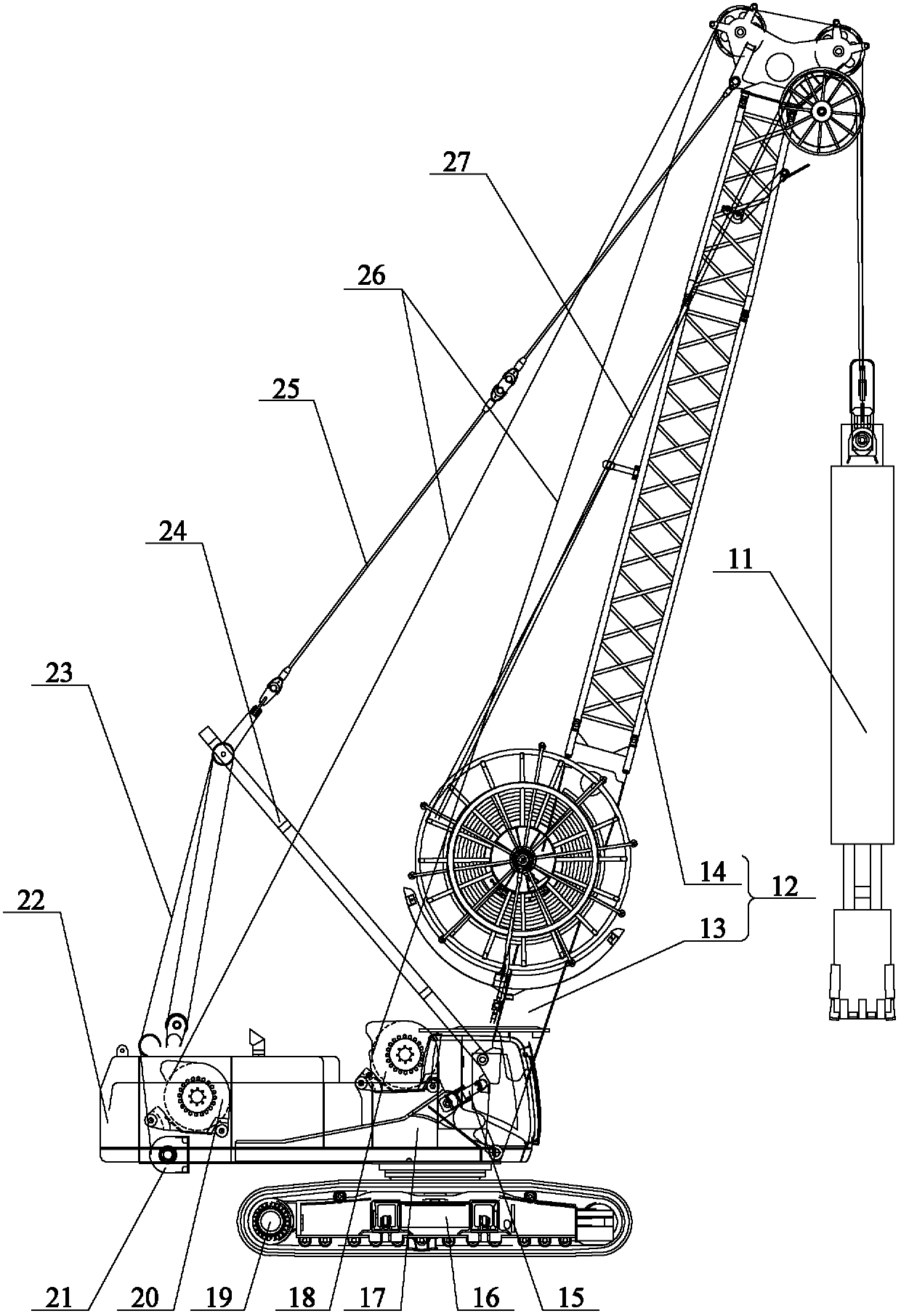

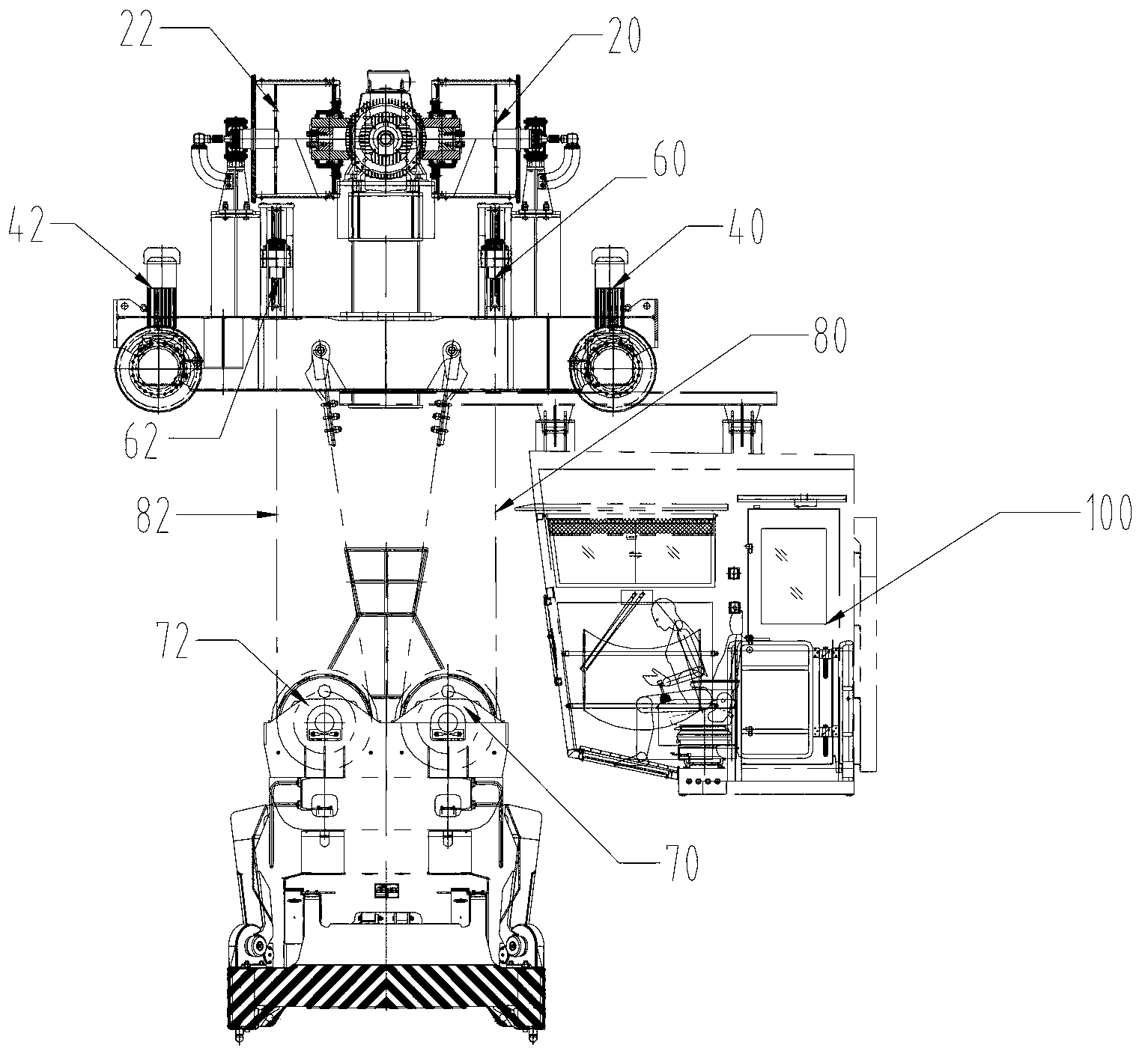

Multifunctional crane excavator

ActiveCN101839003AWith lifting functionTilting effect is smallMechanical machines/dredgersCranesHydraulic cylinderEngineering

The invention relates to a multifunctional crane excavator which has both the hoisting function and the excavating function. By using a chassis of a crawler excavator as an excavator body, the multifunctional crane excavator is provided with a main arm, an auxiliary arm, a balance arm, a supporting seat, a derricking hydraulic cylinder, a main hydraulic winch, an auxiliary hydraulic winch and a balance weight. A gravitational moment which is generated when the multifunctional crane excavator carries out lifting and excavating operations is balanced by a gravitational moment of the balance arm at the other end of the supporting seat; the gravitational moment which is generated during lifting and excavation does not act on the body of the multifunctional crane excavator fully, the roll-over action on the multifunctional crane excavator is very small, therefore, the safety under the condition of the same lifting and excavating capability is improved. Accordingly, the invention is quite suitable for application in special lifting sites and special excavating operations.

Owner:陈炯

Rotary counter weight mechanism and crane

ActiveCN102826465AIncreased lifting capacityImprove stabilityCranesMechanical engineeringWeight Unit

The invention provides a rotary counter weight mechanism comprising a rack, a counter weight unit and a driving device; the counter weight unit and the rack are hinged by using a pin shaft; and the driving device is used for driving the counter weight unit to swing relative to the rack. Therefore, the lifting property is improved without increasing the weight of the whole crane or changing the contour dimension; and the crane is simple in structure, excellent in safety and low in manufacturing cost.

Owner:SANY MARINE HEAVY IND +1

Hanging-hoisting device for wet leather conveying

InactiveCN106379703ATo achieve lifting effectEasy to operateConveyor partsMechanical conveyorsMechanical engineeringEngineering

Owner:陈明

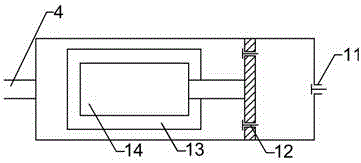

Deep well gas injection supercharging mechanical oil production method and device

InactiveCN101566057ASolve the problem of insufficient lifting capacityIncreased lifting capacityFluid removalProduct gasOil production

The invention provides a deep well gas injection supercharging mechanical oil extraction method and device, which belongs to the method or equipment technique field for extracting oil from well, and solves insufficient lifting ability problem of prior mechanical oil extraction method and device, the method uses a deep well gas injection supercharging oil extraction device, and specifically includes the steps of: connecting a sealing base, a supercharging oil extraction pump, a pump fastening rack, a packer, a filter tube valve and a filter tube to the oil conduit, placing the oil conduit into the well bore casing tube, and fastening the pump-fastening rack; injecting liquid into the annular spacing between the oil conduit and casing tube, testing pressure and relieving pressure; injecting gas into the annular spacing between the oil conduit and the air injection tube, discharging liquid from the gas injection tube; installing wellhead equipment, adjusting pressure and air flow of pumped air, sampling humidity and oil content of analysis gas, calculating quantity of production. The method and device provided by the invention use gas as power medium for periodic duty recyclablely, which causes the lifting pressure up to 2-5 times of gas pressure, and the process flow is simple and is suitable for oil extraction of deep well and mechanical oil extraction of thick oil well.

Owner:CHINA PETROLEUM & CHEM CORP

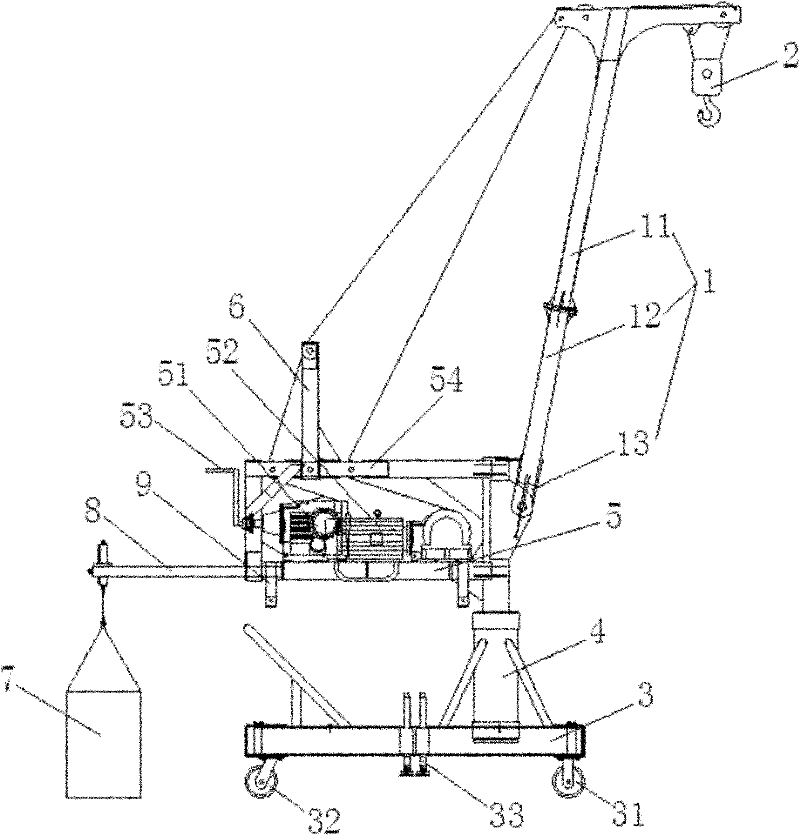

Miniature crane

The invention discloses a miniature crane, which comprises a jib and a hook. The hook is hung to the jib top by a lifting rope. The crane also includes a pedestal, a slewing mechanism and a rotary table. The slewing mechanism can slew at any angle within 360 degrees, and includes a slewing shaft and a shaft sleeve in rotation connection. The jib is hinged to the front side of the slewing shaft, the rotary table is fixed to the rear side of the slewing shaft, and the shaft sleeve is fixed on the pedestal. The pedestal and the rotary table both adopt a box structure. The inside of the rotary table is provided with a worm-gear luffing mechanism and a worm-gear hoisting mechanism. The housing of the rotary table is in rotation connection with a crank handle that is connected to the worm-gear luffing mechanism. By setting the slewing mechanism able to slew at any angle within 360 degrees, the miniature crane of the invention realizes expansion of the movement range of heavy objects from two dimensions to three dimensions.

Owner:DALIAN UNIV OF TECH +6

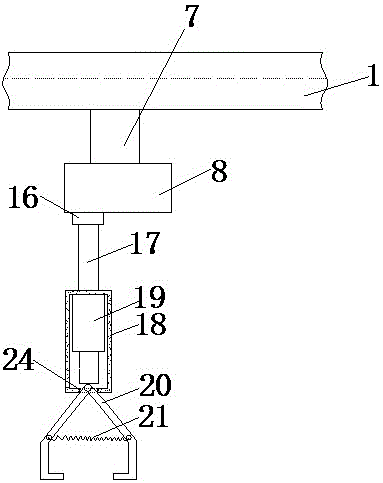

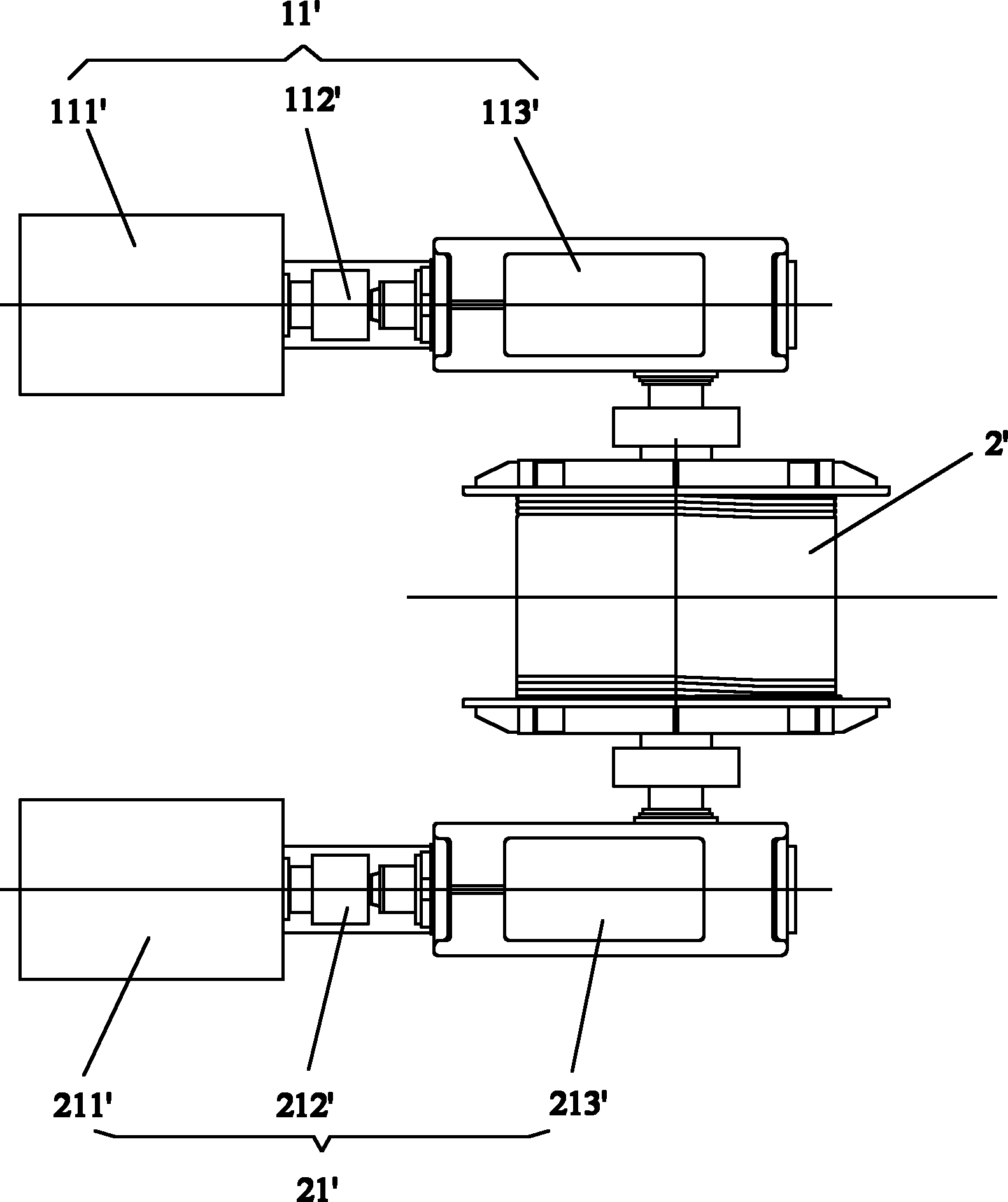

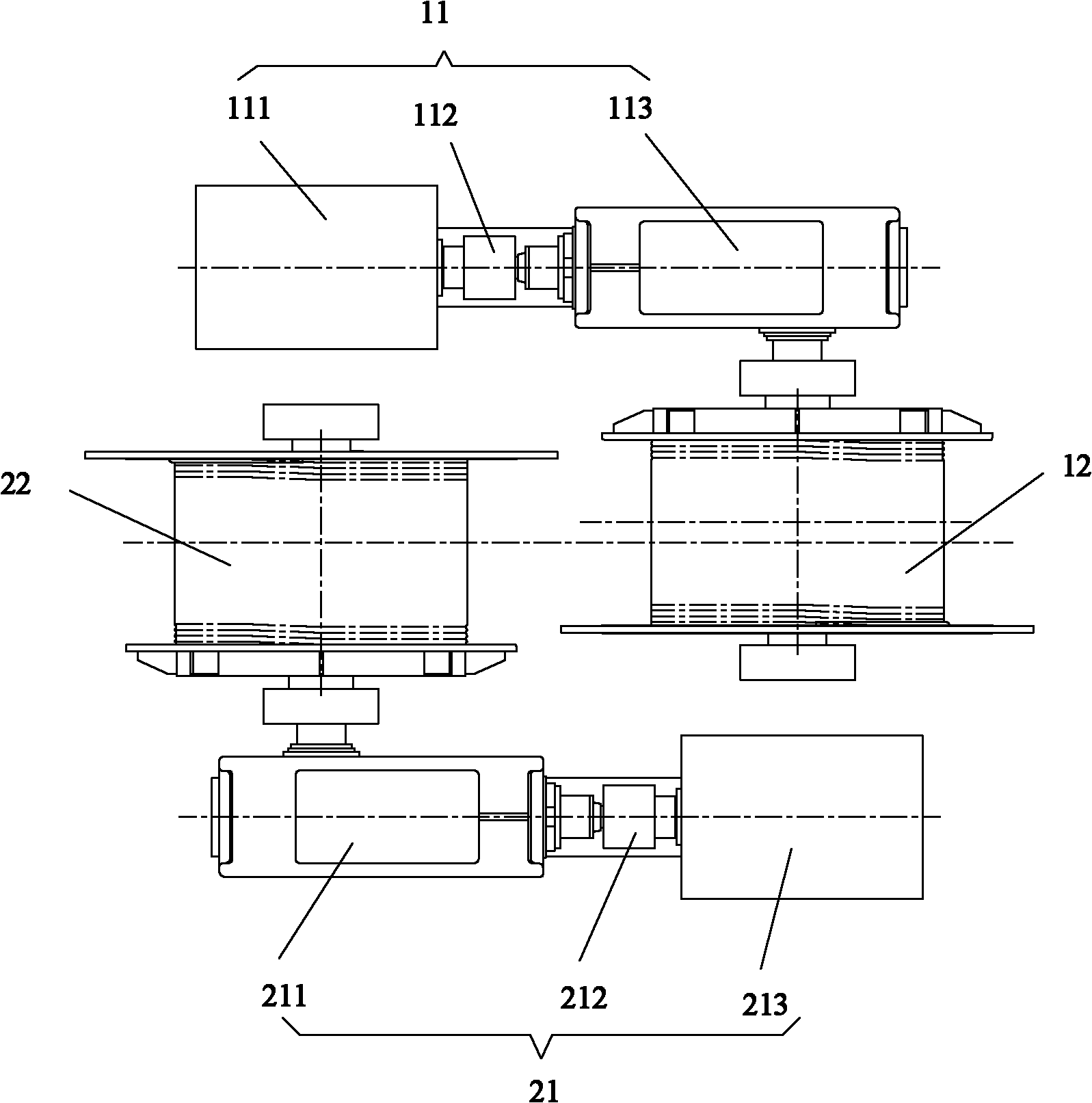

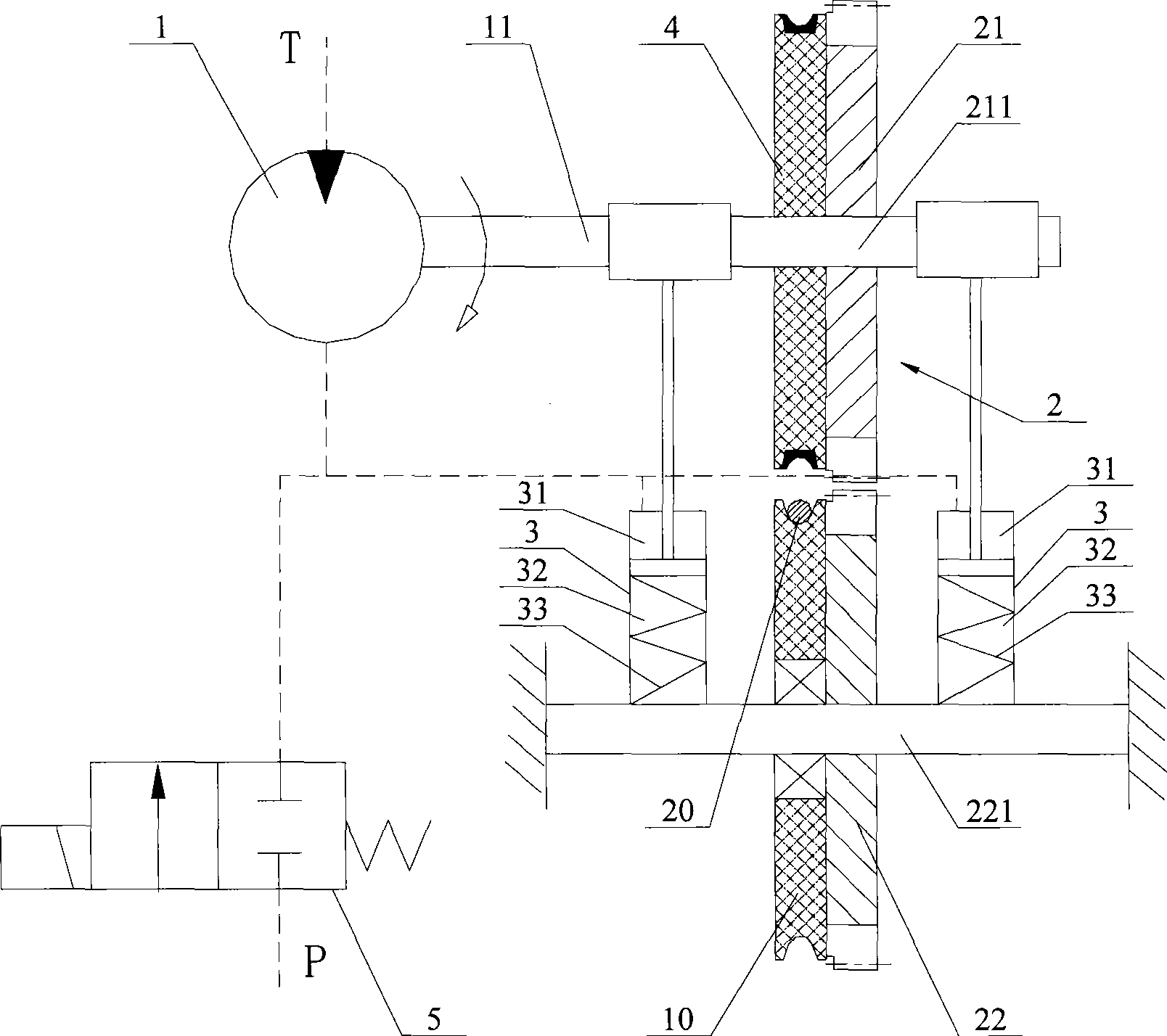

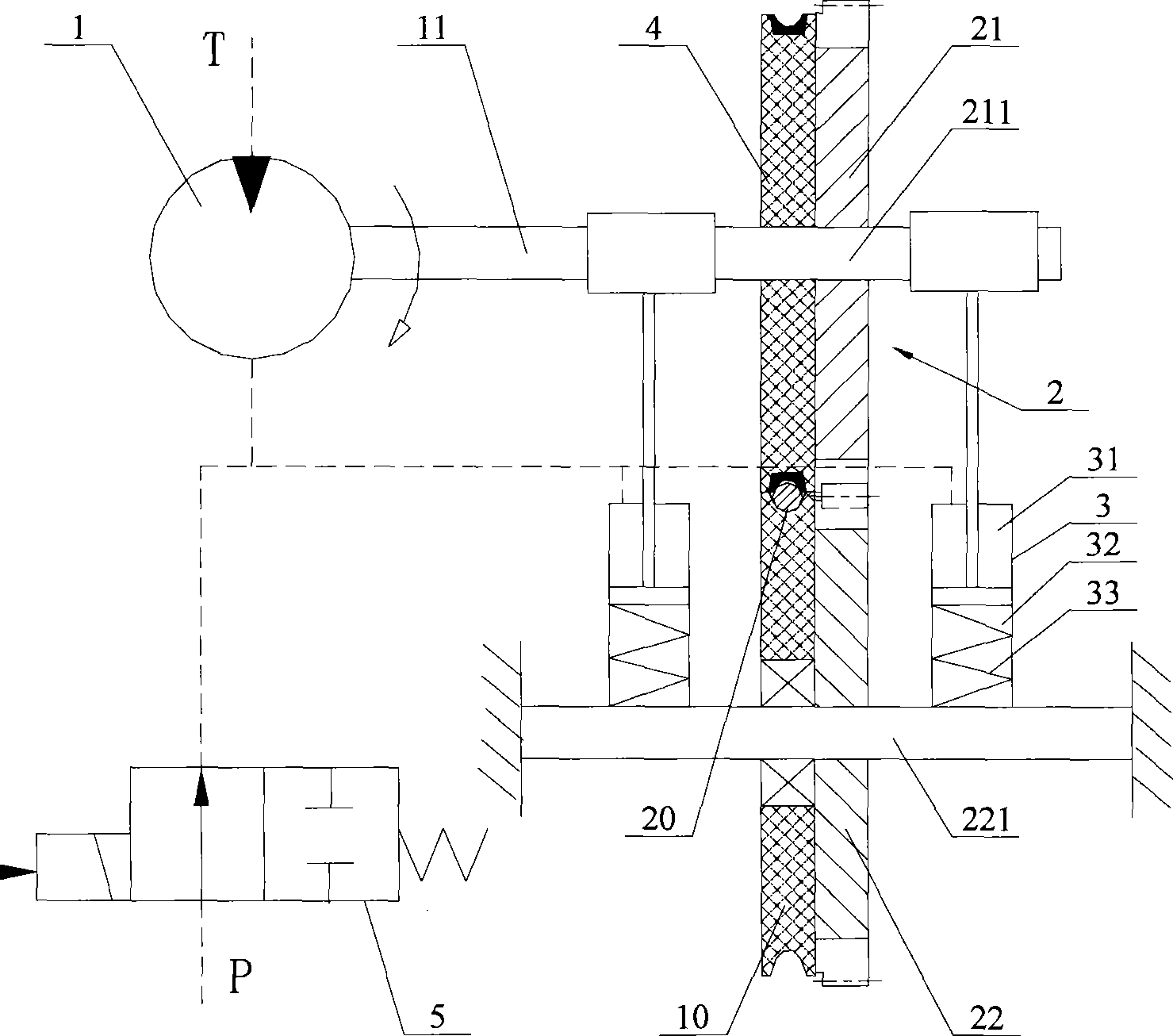

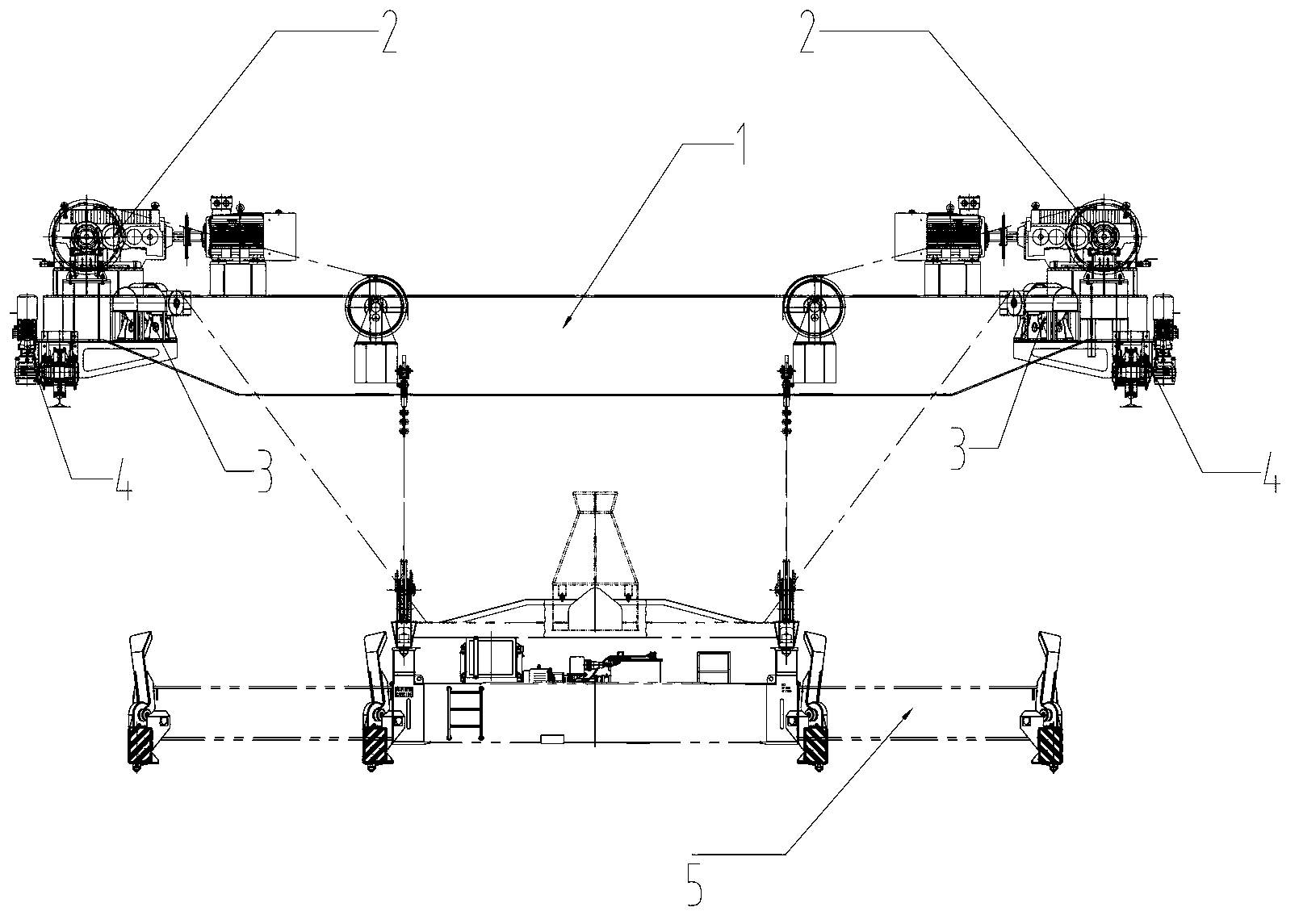

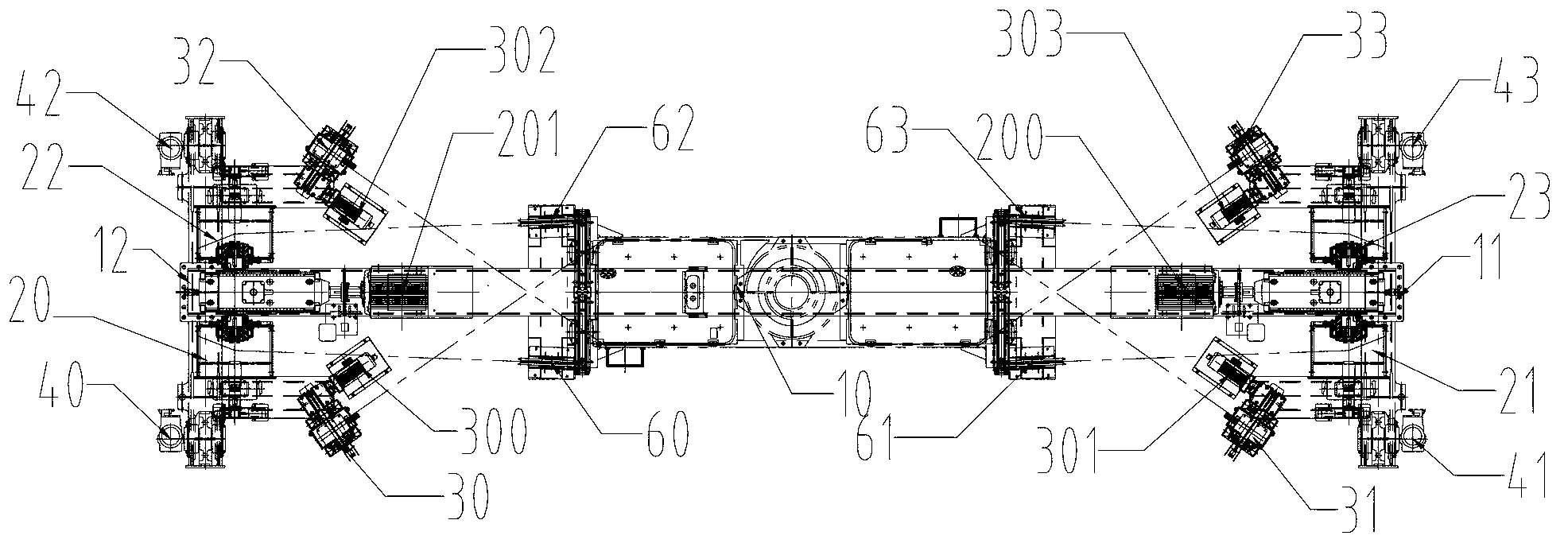

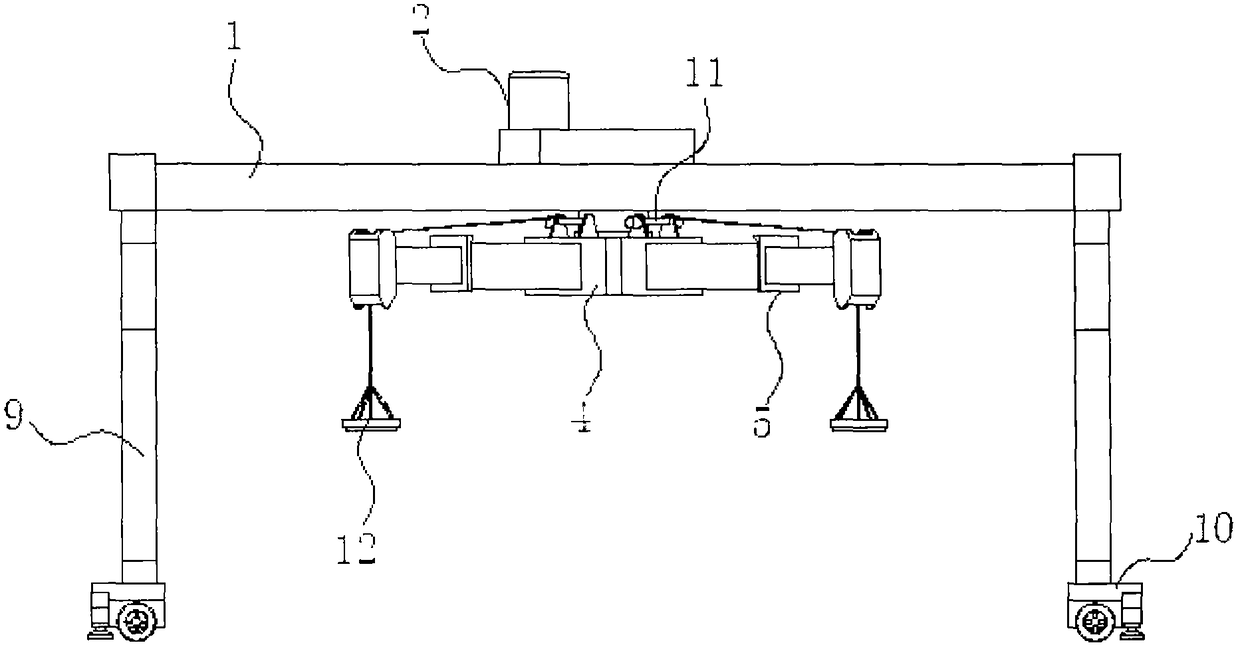

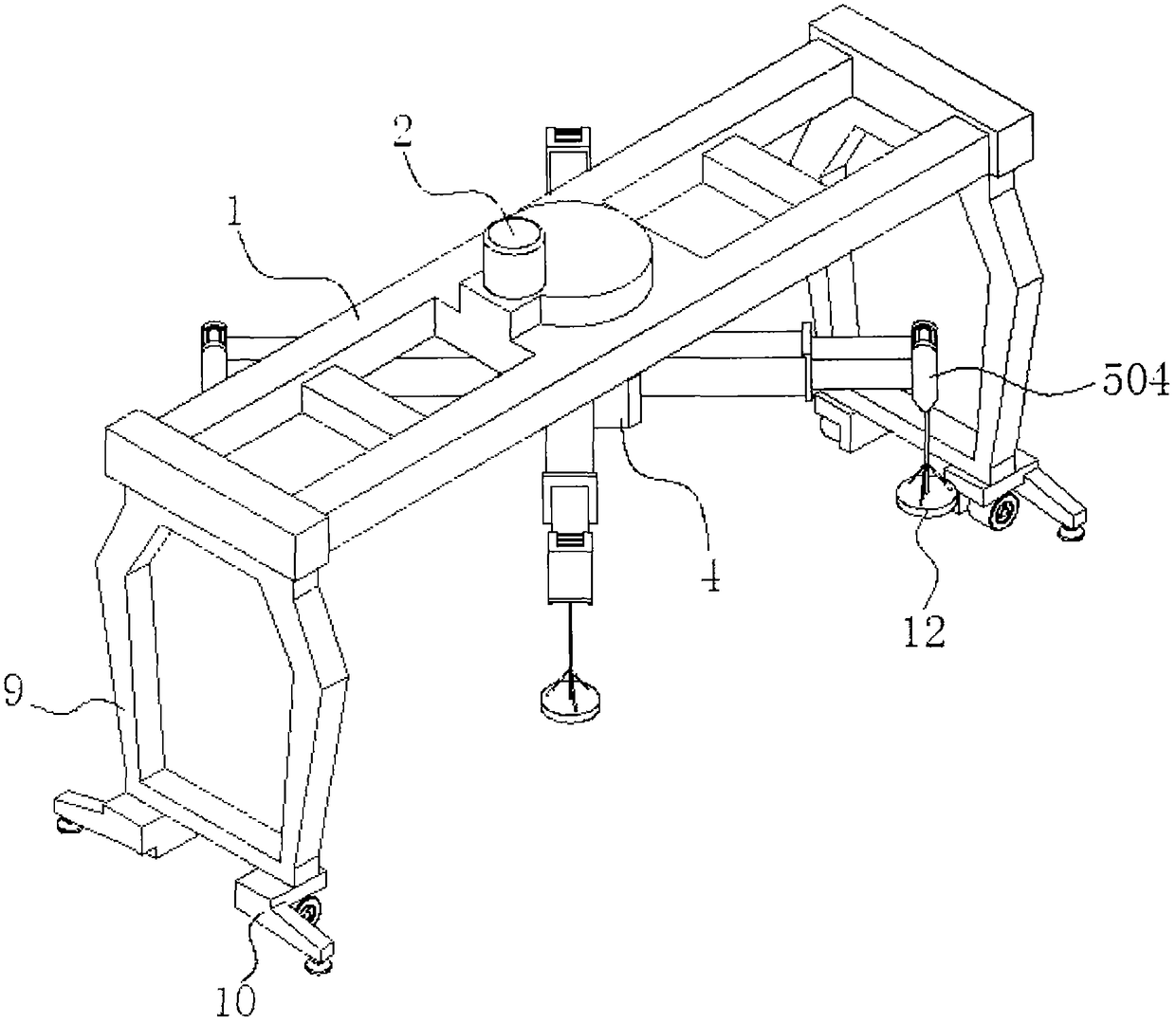

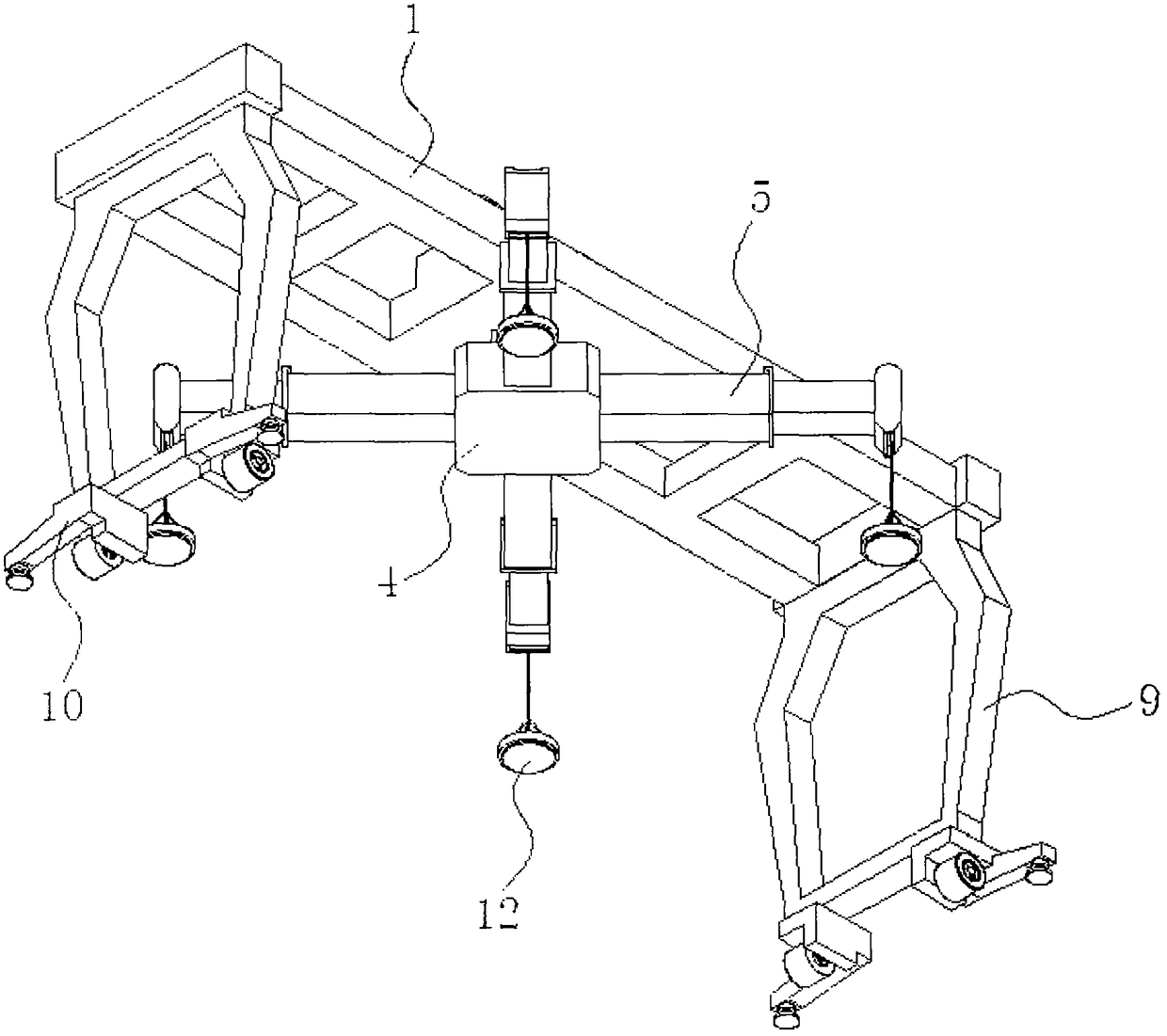

Tower crane, lifting mechanism thereof and method for leveling lifting mechanism

ActiveCN102030273AIncreased lifting capacityUse will not affectLoad-engaging elementsCranesLifting capacityTower crane

The invention discloses a tower crane, a lifting mechanism thereof and a method for leveling the lifting mechanism. The lifting mechanism comprises a first lifting unit, a second lifting unit and a lifting assembly, wherein the first lifting unit comprises a first driving mechanism (11) and a first drum (12); the first driving mechanism (11) drives the first drum (12) to rotate; the second lifting unit comprises a second driving mechanism (21) and a second drum (22); the second driving mechanism (21) drives the second drum (22) to rotate; and the lifting assembly is provided with a hook crossbeam (4) and a hook arranged below the hook crossbeam (4), wherein a first rope (31) on the first drum (12) extends out of the first drum (12) and is connected to one end of the hook crossbeam (4); and a second rope (32) on the second drum (22) extends out of the second drum (22) and is connected to the other end of the hook crossbeam (4). The lifting capacity of the lifting mechanism is greatly improved, the rope capacity is improved, and the lifting mechanism can adapt to conditions of high lifting height and heavy lifting weight.

Owner:ZOOMLION HEAVY IND CO LTD

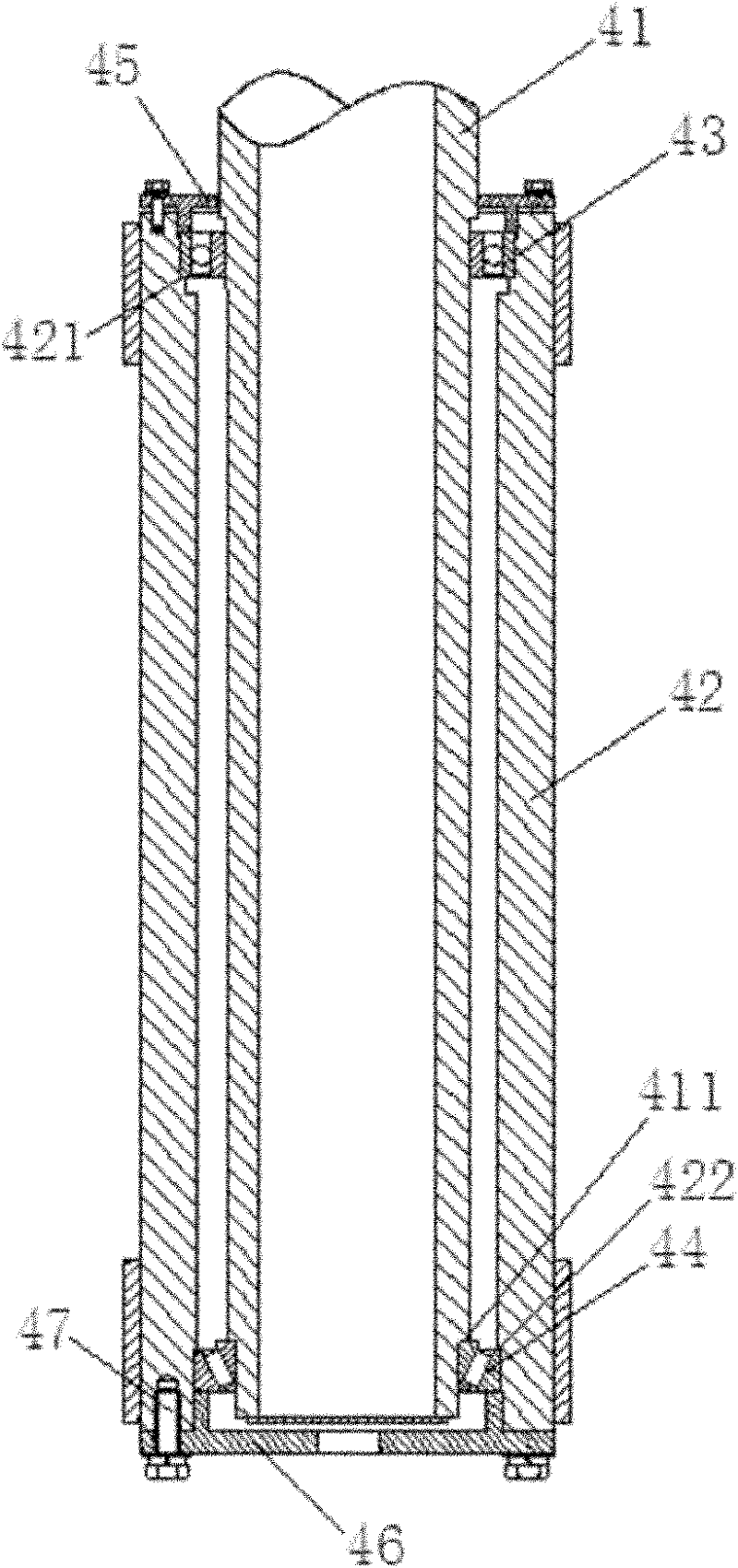

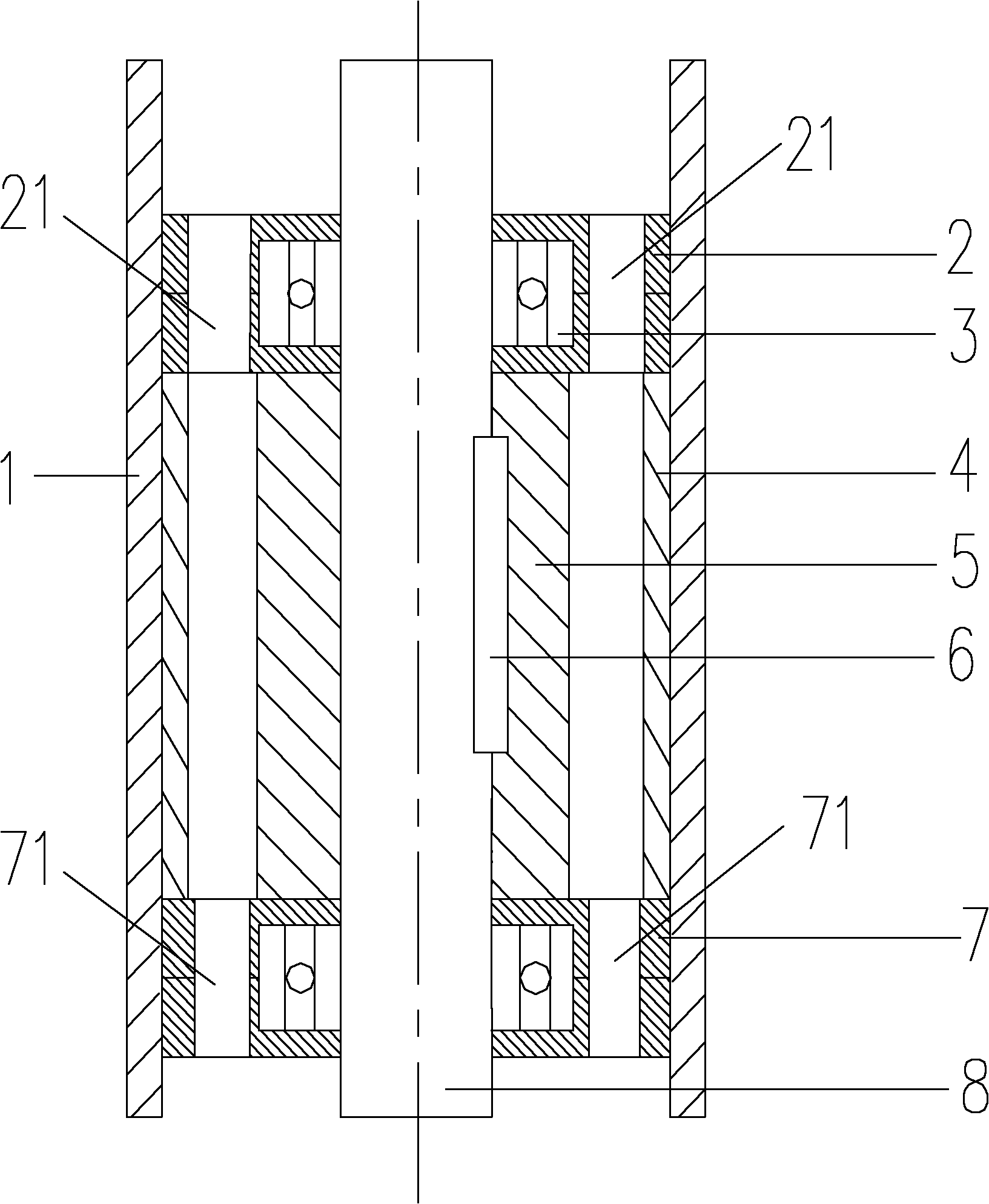

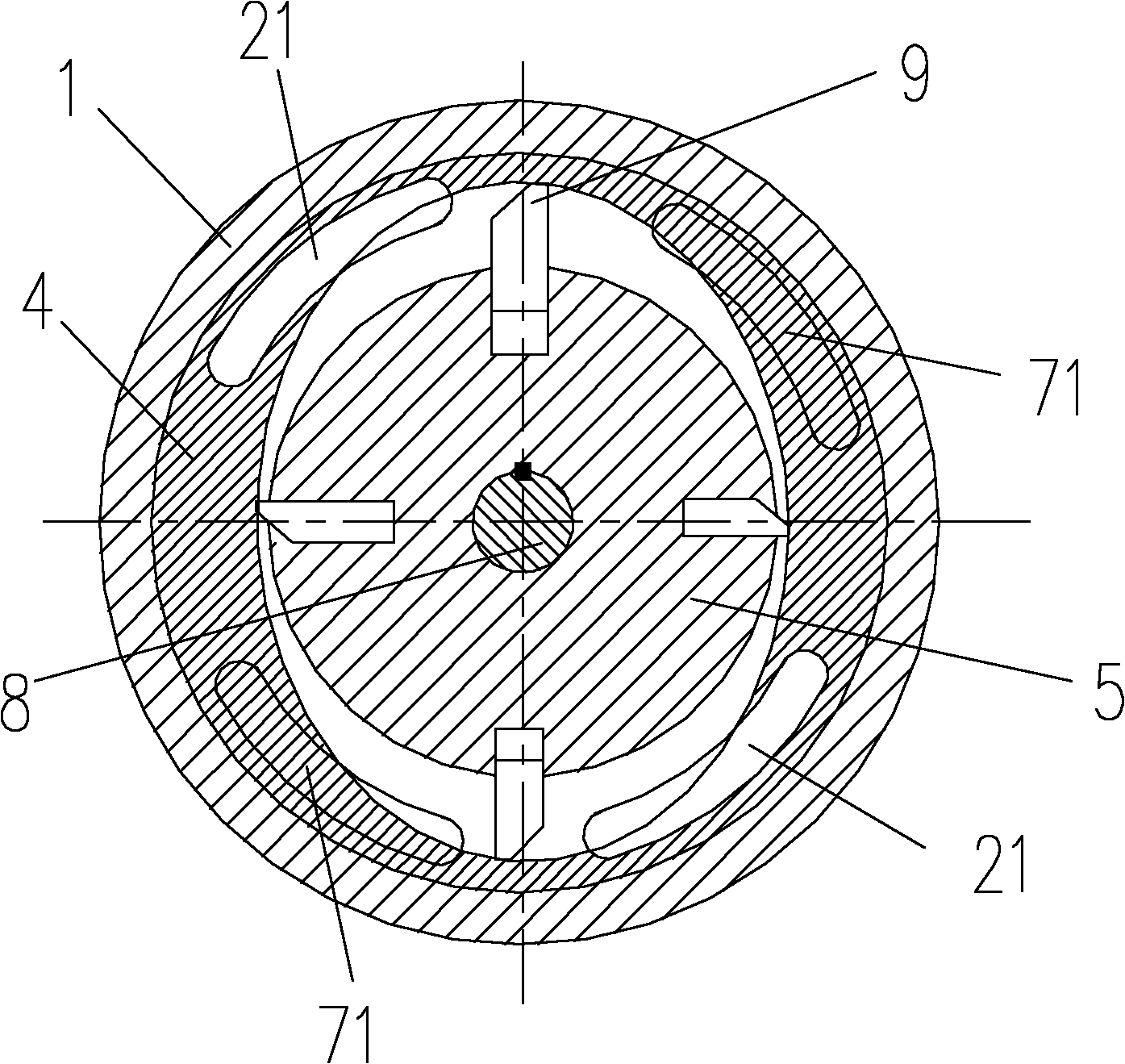

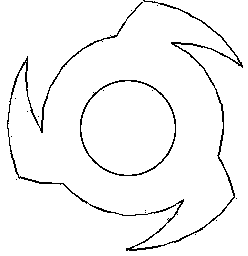

Raw oil lifting system and method for conveying fluid by utilizing sliding vane pump

The invention provides a raw oil lifting system and a method for conveying a fluid by utilizing a sliding vane pump. The raw oil lifting system comprises an oil pipe and an oil pump connected with the oil pipe, wherein the oil pump is the sliding vane pump; the sliding vane pump is provided with a barrel-shaped stator; a drive shaft arranged in the stator along a direction parallel to the length of the stator, and a rotor sleeved onto the drive shaft are arranged in the stator; the lower end of the stator is provided with a suction disk; the upper end of the stator is provided with an exhaustion disk; the suction disk, the exhaustion disk and the stator form a barrel-shaped inner cavity; the rotor is arranged between the suction disk and the exhaustion disk; the suction disk is provided with a suction hole for sucking raw oil; and the exhaustion disk is provided with an exhaustion hole for exhausting the raw oil. The method for conveying the fluid by utilizing the sliding vane pump comprises the steps of sucking and exhausting the fluid from the direction of the end part of the stator to perform a lifting process.

Owner:PETROCHINA CO LTD

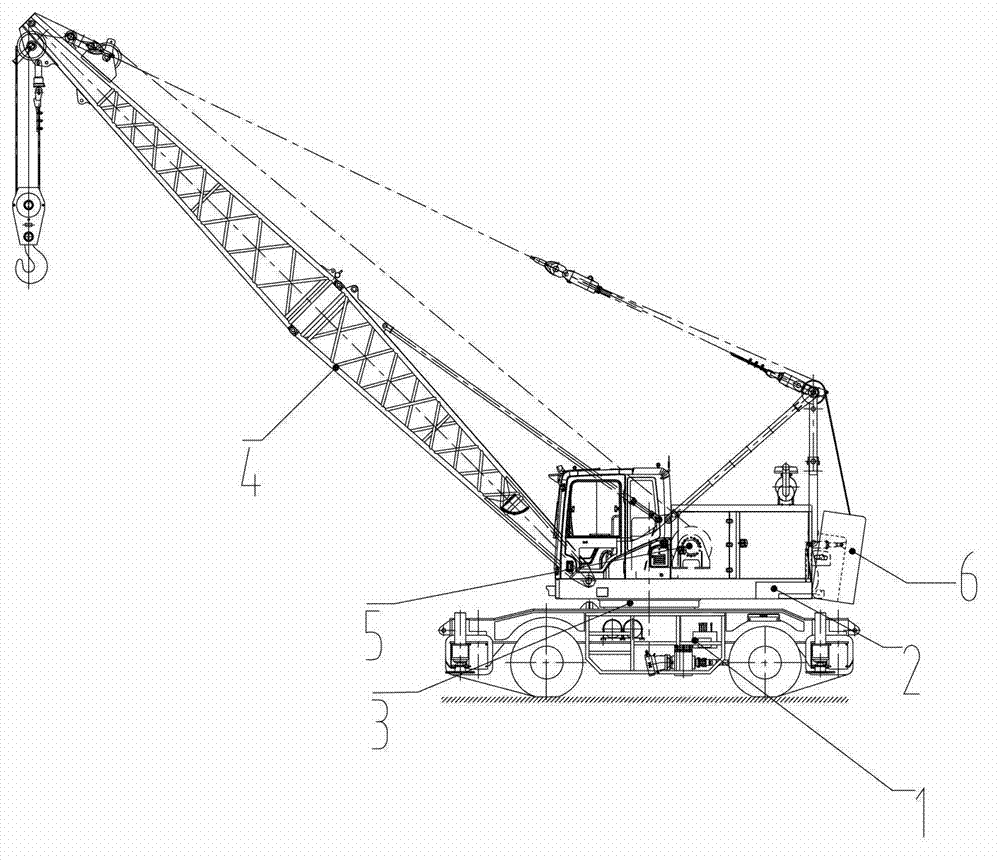

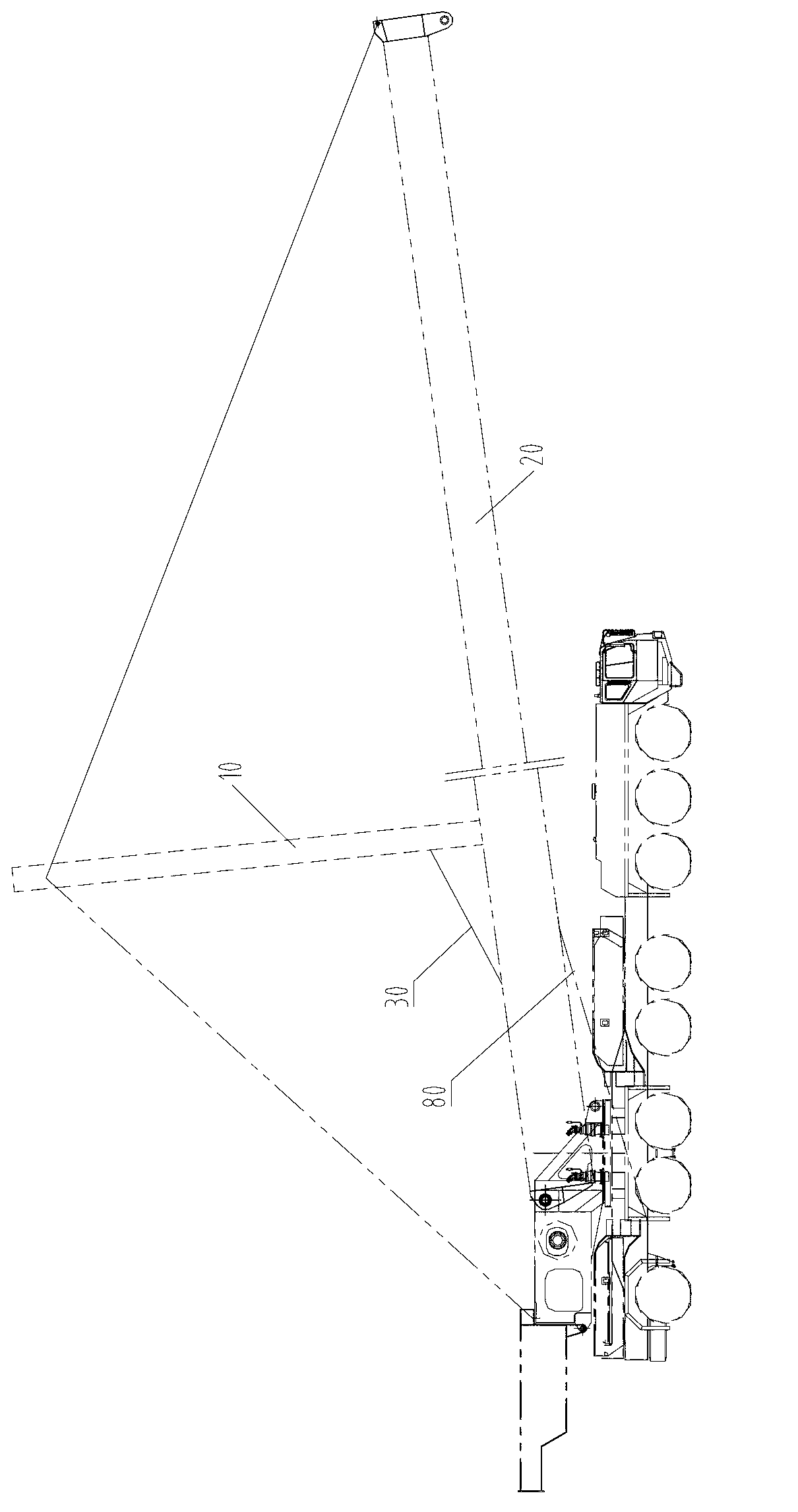

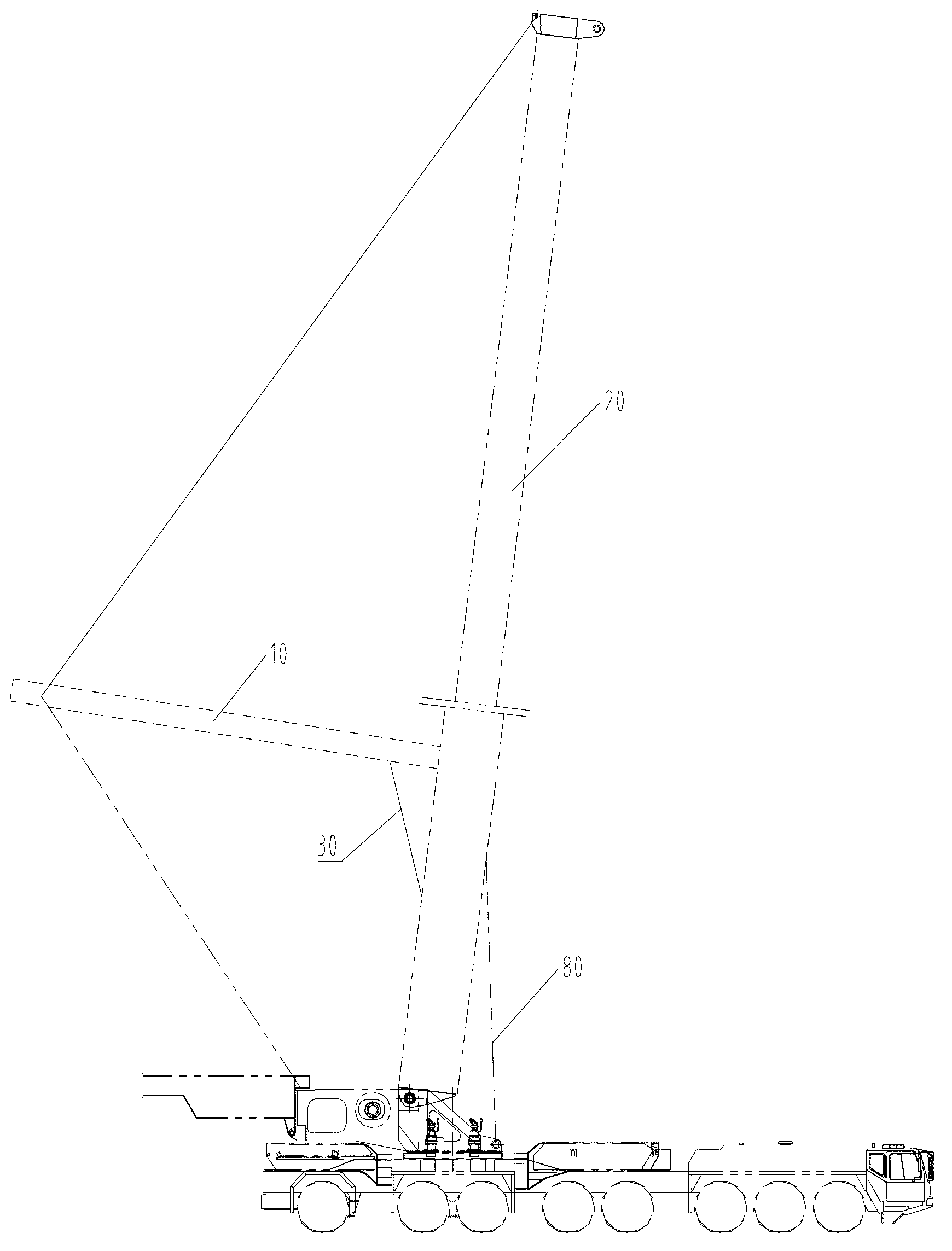

Superlift device and crane

Owner:SANY AUTOMOBILE HOISTING MACHINERY

Crane hook falling velocity adjustment apparatus

InactiveCN101376486AImprove work efficiencyIncreased lifting capacityWinding mechanismsLoad-engaging elementsControl signalControl theory

The invention discloses a hook-falling speed adjusting apparatus of a crane hook, which comprises a drive mechanism and a transmission organ. The transmission organ receives the source power output by the drive mechanism, and outputs the source power to an arm head pulley so as to realize the rotation of the arm head pulley. Preferably, a speed sensor and an arm head controller which are arranged on an arm head are also included; the speed sensor is used for detecting rotational speed of the arm head pulley; the arm head controller is used for receiving rotational speed signals acquired by the speed sensor, transforming the rotational speed signals into wire rope speed signals which are then compared with a preset value, and outputting a control signal to control the source power output of the drive mechanism. By the two main components that are the drive mechanism and the transmission organ, the outside power is output to the arm head pulley which drives a wire rope to raise the speed synchronously, so as to further drive the crane hook to fall fleetly. The optimal proposal realizes the hook-falling speed control through the arm head controller and the speed sensor.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

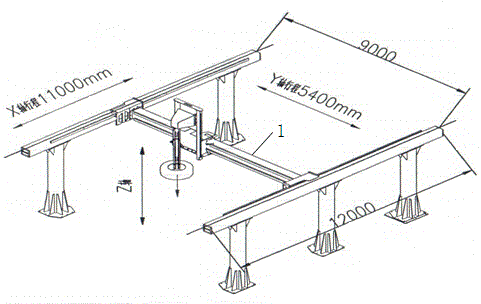

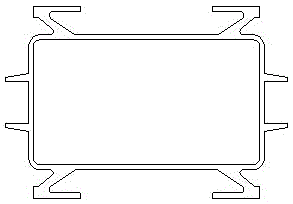

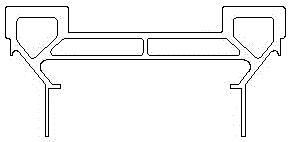

Manufacturing method of aluminum alloy mechanical arm track girder hollow profile

ActiveCN105039805AReduced risk of weakeningMeet the use requirementsUltimate tensile strengthAluminium alloy

The invention belongs to the technical field of aluminum alloy profiles and particularly relates to a manufacturing method for producing an aluminum alloy mechanical arm track girder hollow profile through an aluminum alloy replacing rolled steel. The manufacturing method comprises the steps that firstly, the intensity and the capacity of resistance to deformation of a steel cross beam are evaluated; secondly, the aluminum alloy is selected; thirdly, the structure of the aluminum alloy mechanical arm track girder hollow profile is designed; fourthly, the movement track and deformation of the aluminum alloy mechanical arm track girder hollow profile in a stressed state are simulated through a computer; fifthly, a mould of the aluminum alloy mechanical arm track girder hollow profile is manufactured; sixthly, the aluminum alloy mechanical arm track girder hollow profile is extruded and quenched online; seventhly, the aluminum alloy mechanical arm track girder hollow profile is aged; eighthly, the aluminum alloy mechanical arm track girder hollow profile is sampled; ninthly, the aluminum alloy mechanical arm track girder hollow profile is riveted; and tenthly, the aluminum alloy mechanical arm track girder hollow profile is packaged and delivered, and the aluminum replaces the steel to produce the aluminum alloy mechanical arm track girder hollow profile.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

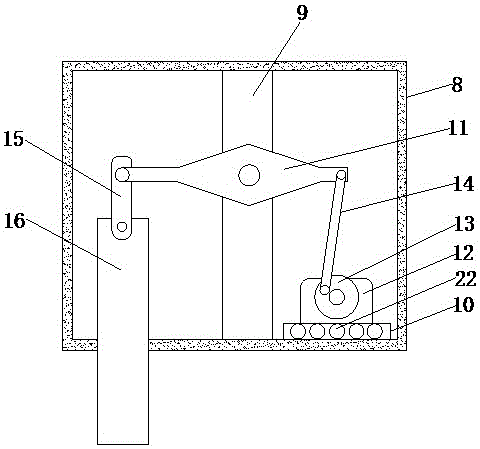

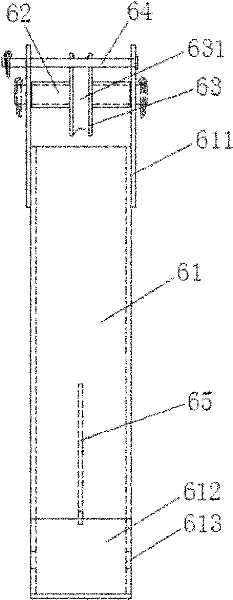

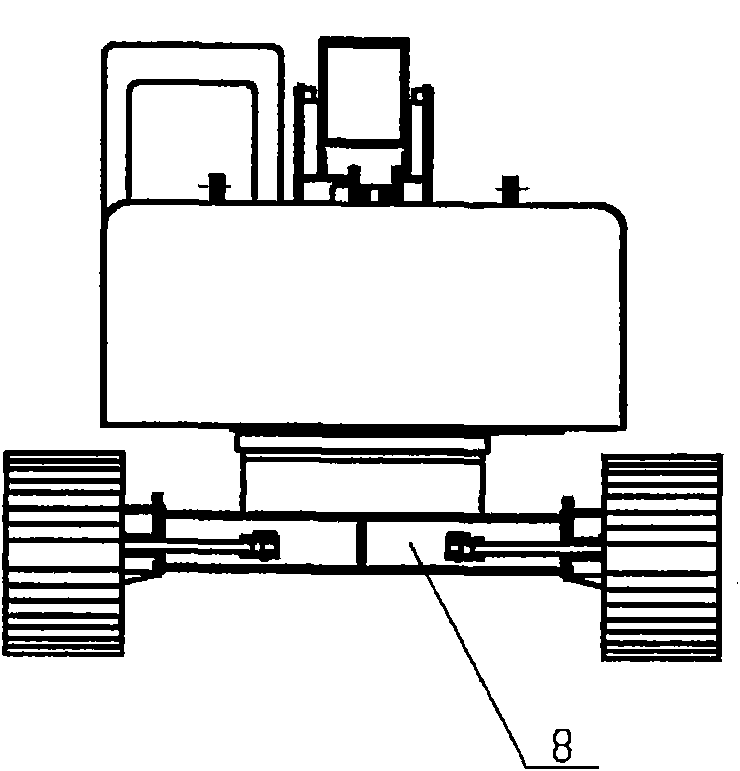

Novel lower chamber device

The invention relates to a novel lower chamber device. The lower part of the novel lower chamber device is provided with double crawler travel mechanisms. A frame is arranged between the double crawler travel mechanisms. The upper part of the frame is provided with a rotating platform. The rotating platform is provided with a cab. The rotating platform at the rear of the cab is assembly connected with the lower end of a telescopic suspension arm. The rotating platform is provided with a lifting mechanism. The lifting mechanism is matched with the telescopic suspension arm. The rotating platform is also provided with a telescopic counterweight mechanism. When the novel lower chamber device is used for operating under the cabin, two modes of complete counterweight extension and complete counterweight shrinkage can be realized, wherein the counterweight extends completely to improve the lifting performance; and the counterweight shrinks completely to improve conformability for the space.

Owner:天津港第二港埠有限公司 +1

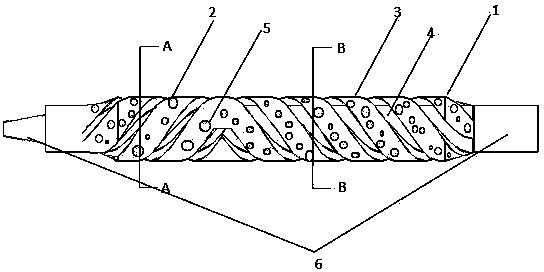

Borehole cleaning tool for horizontal-section gas drilling

The invention discloses a borehole cleaning tool for horizontal-section gas drilling. The borehole cleaning tool consists of a main body, spiral flow channels, alloy teeth and joints, wherein two ends of the main body are the joints; the spiral flow channels are located in the main body; the spiral flow channels comprise a front spiral flow channel which takes up one third of the length of the spiral flow channel and a rear spiral flow channel which takes up two thirds of the length of the spiral flow channel; unequal-diameter alloy teeth are respectively embedded into the strengthening bars of the front spiral flow channel and the rear spiral flow channel; an inclined U-shaped groove of which the cross section is 2cm to 4cm deep is formed in the rear spiral flow channel. According to the borehole cleaning tool, as the spiral flow channels which are of a composite structure respectively are adopted, the flow speed of gas is increased, and the orbiting flow of an annular air body is enhanced; the windward sides of the spiral flow channels are respectively provided with the inclined U-shaped groove, so that a great deal of rock waste is annularly hoisted in the sky; as the different-size alloy teeth are respectively embedded into the strengthening bars of the spiral flow channels, the grinding of rock waste in rotation is enhanced; the borehole cleaning tool is reliable in principle, rational in structure, and applicable for a horizontal borehole drilling technology under the working conditions of gas drilling and fluid drilling, thereby having a broad market prospect.

Owner:SOUTHWEST PETROLEUM UNIV

Grab bucket grooving machine for continuous wall

InactiveCN102605817ALight in massImprove versatilityMechanical machines/dredgersExcavationsRolling chassisOperation mode

The invention relates to the technical field of piling machinery, and discloses a grab bucket grooving machine for a continuous wall. The grab bucket grooving machine for the continuous wall comprises a chassis, an upper vehicle body arranged on the chassis, and an arm frame hinged on the upper vehicle body, wherein the arm frame comprises a fist part and a second part which are connected with each other, the first part has a box type structure, and the second part has a truss structure. The grab bucket grooving machine for the continuous wall provided by the embodiment of the invention has the functions of cranes, can work under a grooving operation mode, and also can work under a hoisting operation mode, so that the construction efficiency is improved, and the construction cost is lowered.

Owner:BEIJING SANY HEAVY MASCH CO LTD

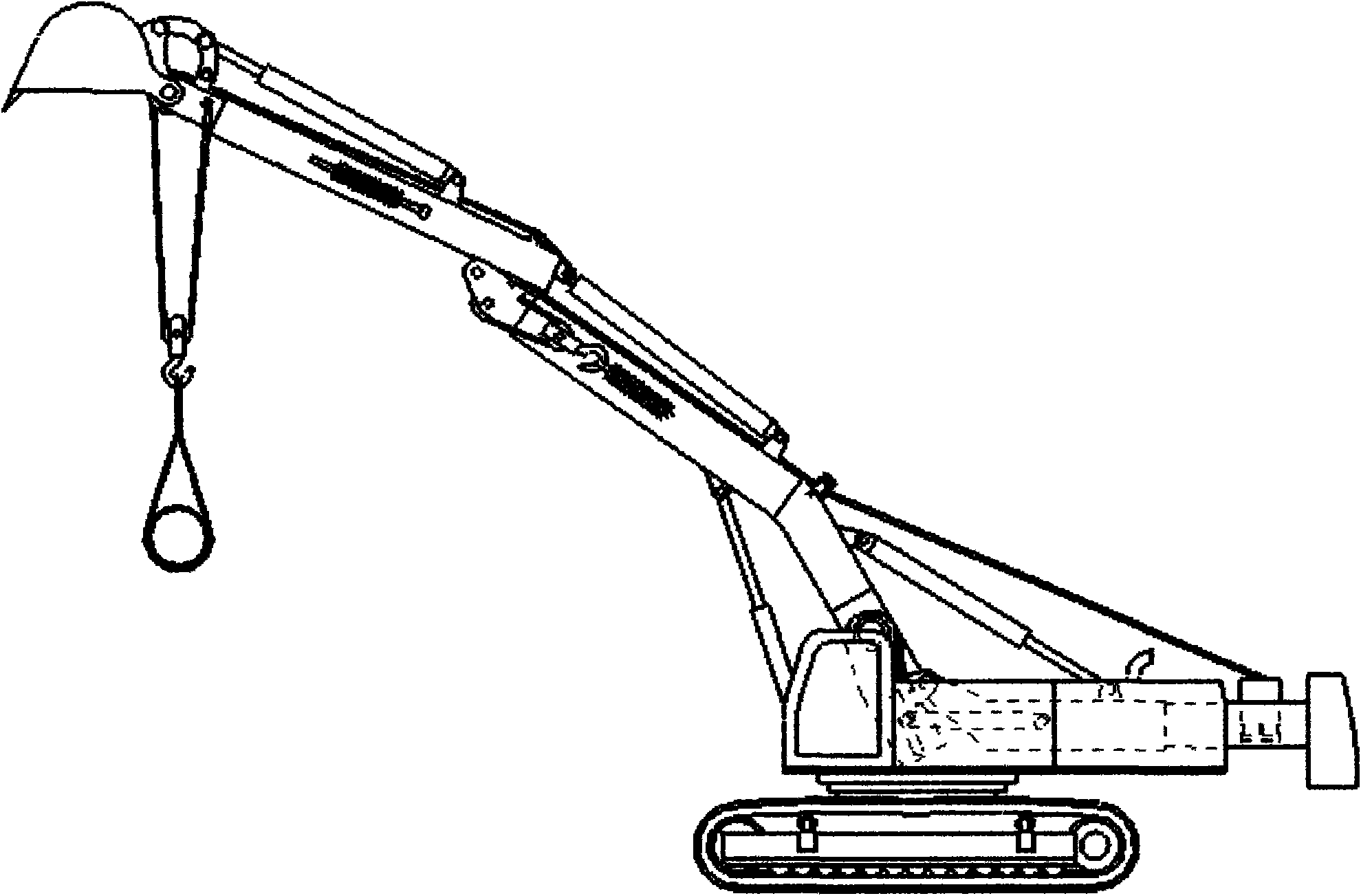

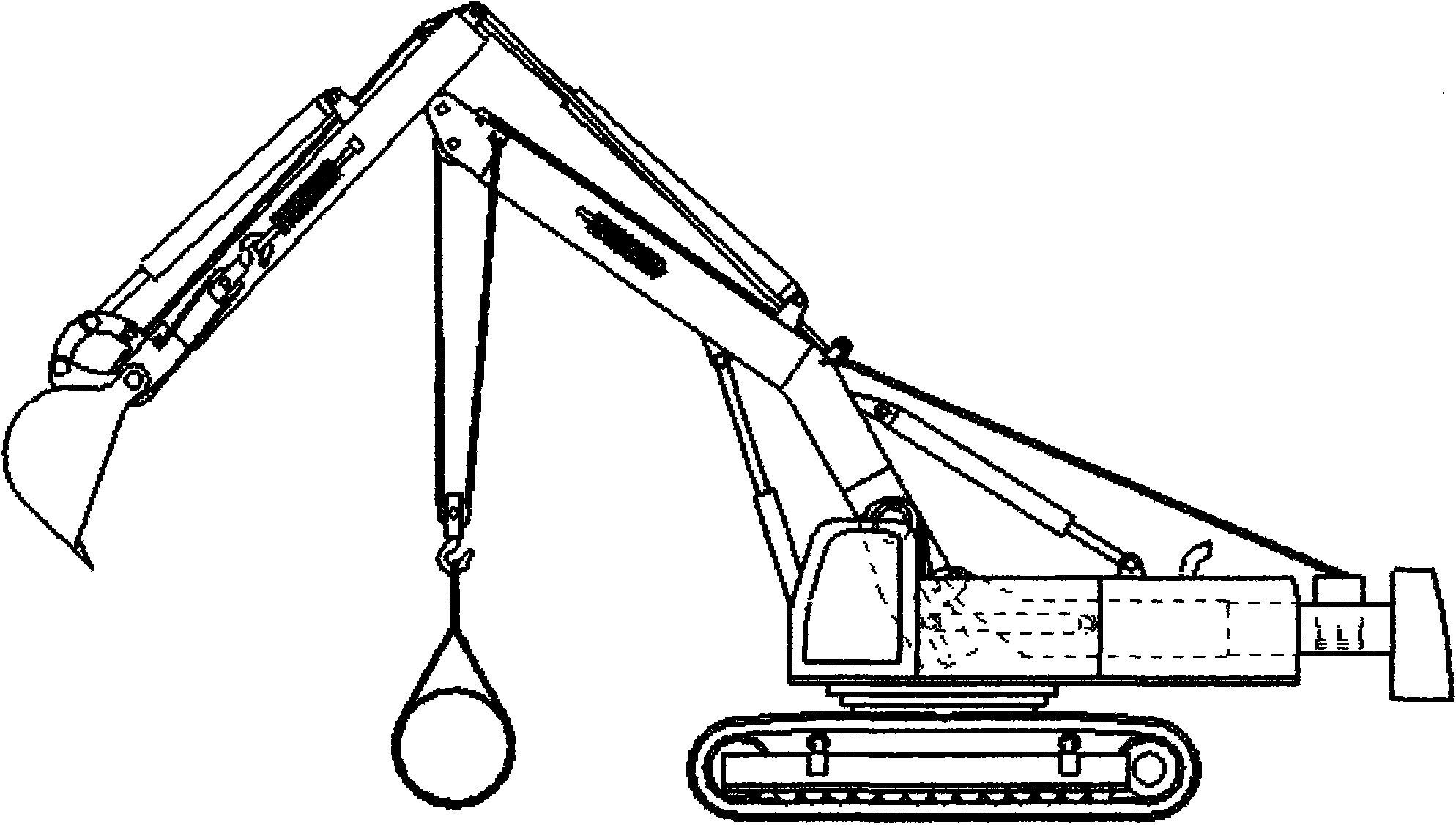

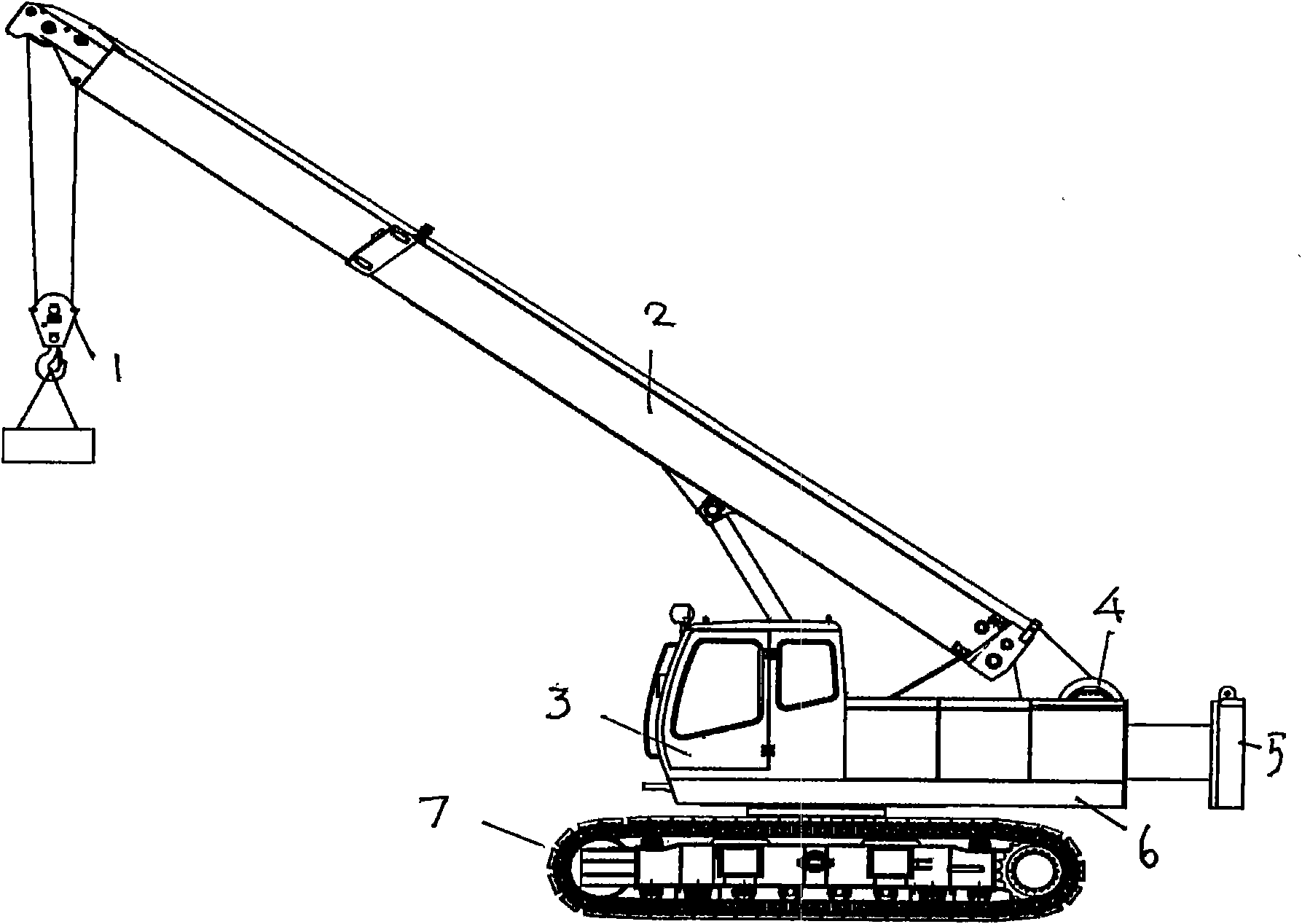

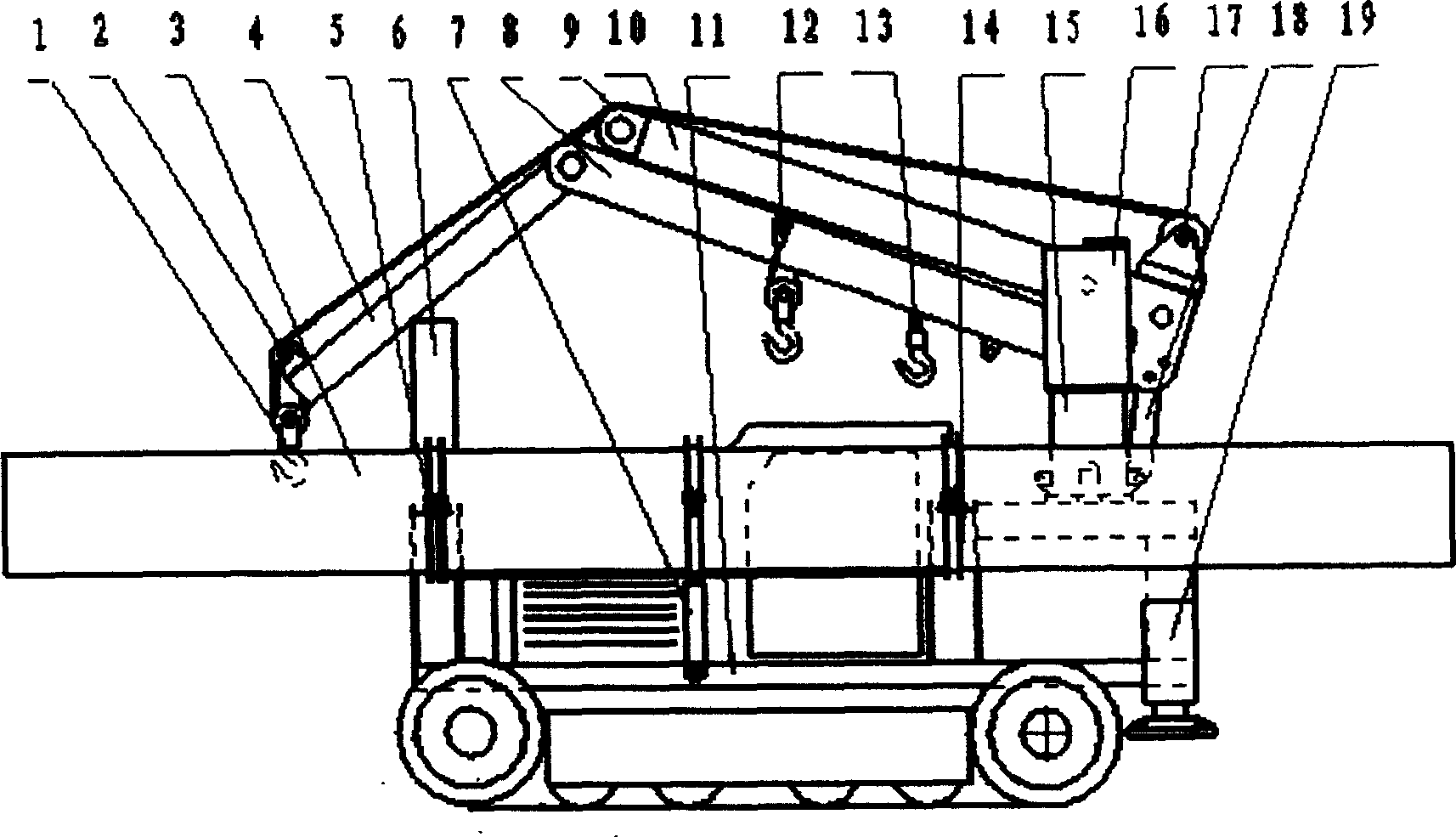

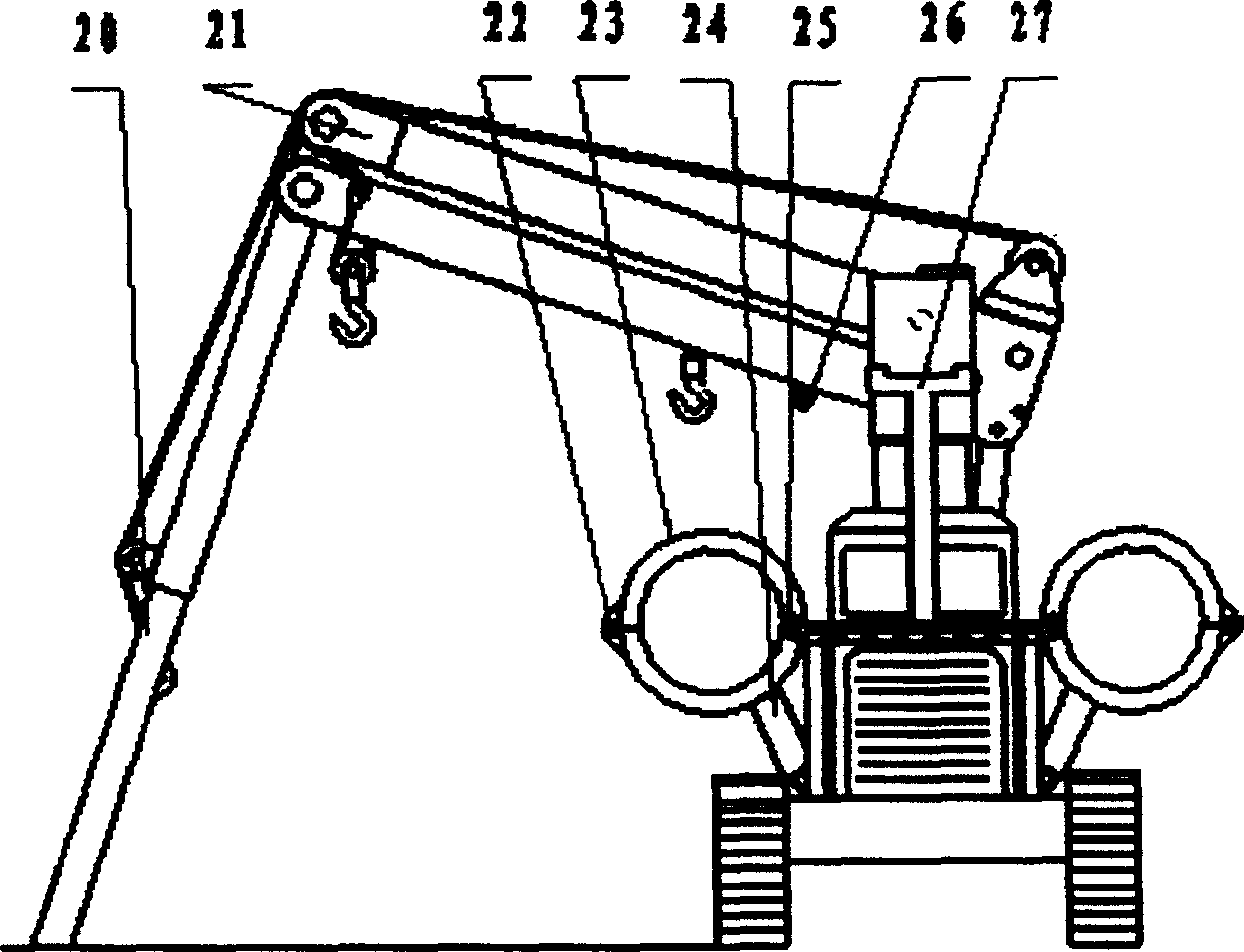

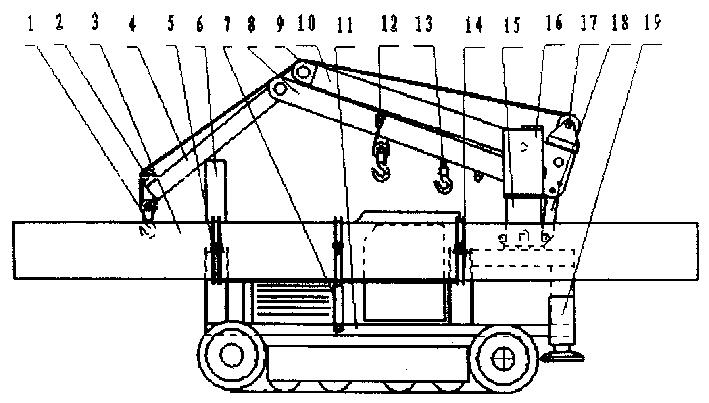

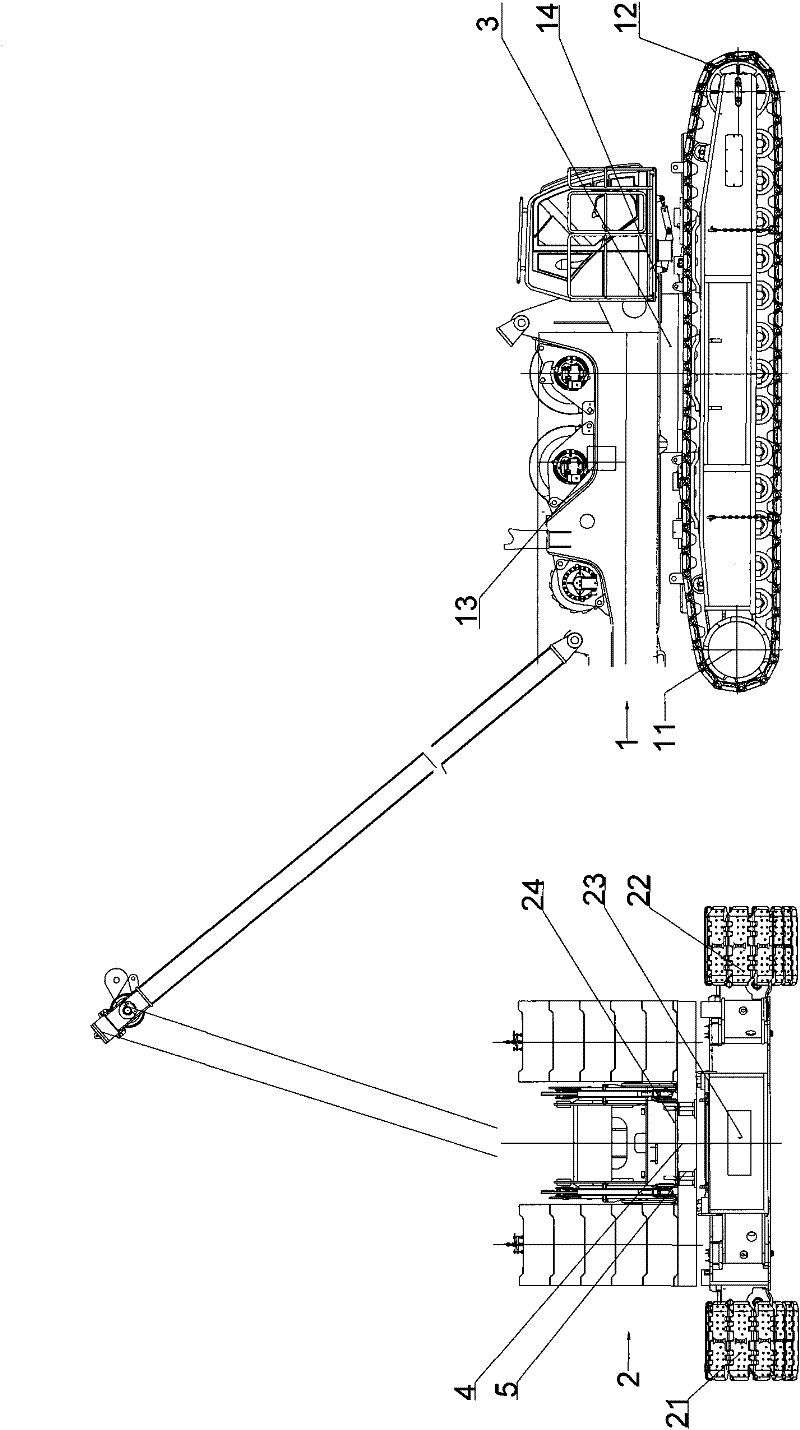

Pipe suspension transferring machine

InactiveCN1493517AGuarantee the quality of deliveryLower the ground clearanceCranesMode of transportAutomotive engineering

A pipe lifting and transporting vehicle based on caterpillar earth mover or wheel-type loader features that it has foldable hydraulic hoist and hydraulic supporting frame.

Owner:陈炯

Telescopic boom structure based on multi-stage oil cylinder and crane

InactiveCN105417411AReduce in quantityReduce the phenomenon of force multiplicationCranesStructure basedPetroleum engineering

The invention discloses a telescopic boom structure based on a multi-stage oil cylinder and a crane, and relates to the field of engineering machinery. The telescopic boom structure is used for optimizing an existing telescopic boom structure. The telescopic boom structure comprises multiple telescopic booms and the multi-stage oil cylinder; the multi-stage oil cylinder is connected with the telescopic booms and at least can directly drive two of the telescopic booms to telescope. According to the telescopic boom structure, by adopting the multi-stage oil cylinder to drive the telescopic booms to telescope, the oil cylinder number is decreased, and therefore the weight and cost of the telescopic structure are lowered; in addition, part or complete of a rope row structure can be omitted, therefore, the phenomenon that rope row stress is multiplied is reduced, and the hoisting capacity of hoisting equipment where the telescopic boom structure is located is enlarged.

Owner:XUZHOU HEAVY MASCH CO LTD

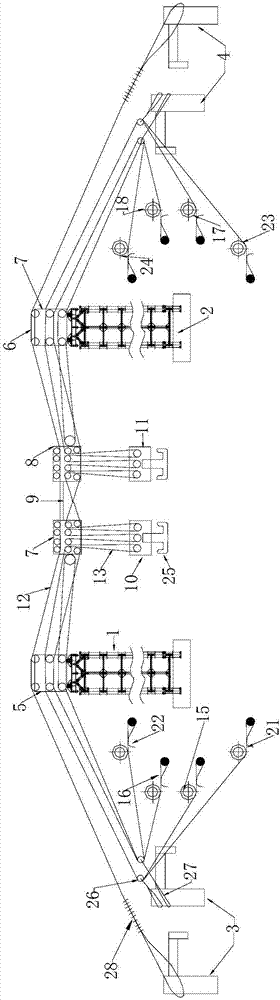

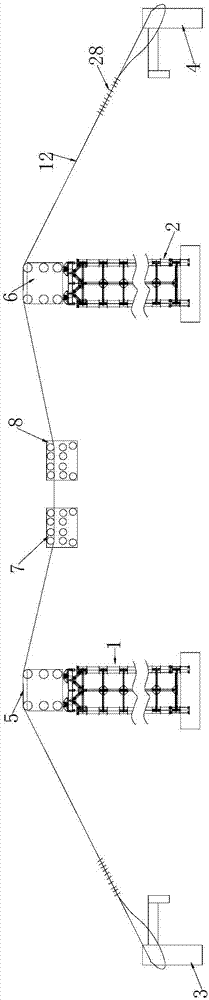

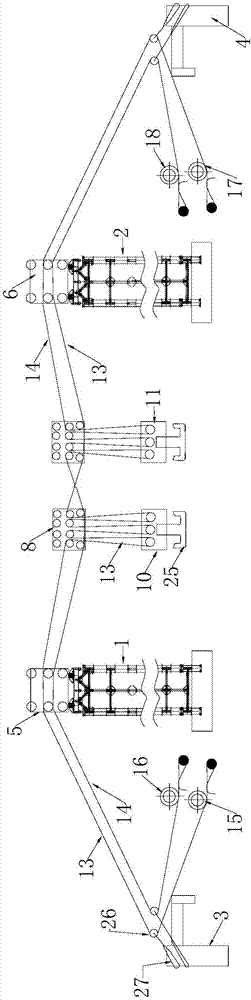

System of cable hoisting and swivel construction

PendingCN107354873AImprove construction progressImprove construction qualityBridge erection/assemblyArch-type bridgeBridge engineeringTower

The invention belongs to the technical field of bridge engineering, and relates to a system of cable hoisting and swivel construction. The system of cable hoisting and the swivel construction comprises a first tower and a second tower which are symmetrically arranged on both banks of a river respectively, and further includes a load bearing subsystem, cable saddles for supporting a load bearing cable and a running trolley arranged on the load bearing cable, wherein the load bearing subsystem comprises the load bearing cable, and two ends of the load bearing cable are fixed on a first ground anchor and a second ground anchor which are oppositely arranged on the banks of the river respectively, and the cable saddles are internally provided with three layers of cable saddle pulleys, namely an upper layer cable saddle pulley, a middle layer cable saddle pulley and a lower layer cable saddle pulley; the cable saddles include a first cable saddle disposed at the top of the first tower and a second cable saddle disposed at the top of the second tower, and the system of cable hoisting and the swivel construction also includes a hoisting subsystem, a traction subsystem and a tower top cable saddle sidesway subsystem. According to the system of cable hoisting and the swivel construction, by means of the combination of cable hoisting and the swivel construction, the construction progress and the bridge construction quality of an arch bridge can be improved, and the construction cost can be reduced.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

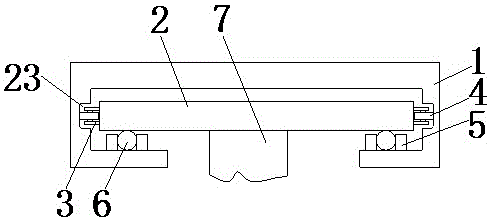

Traveling crab and crane

InactiveCN102838038AReduced tendency to gnaw railsReduce deflectionWinding mechanismsTrolleysEngineeringTrue crabs

Owner:SANY MARINE HEAVY IND

Moveable hoisting machine and construction method thereof

InactiveCN108928757AWide range of workImprove work efficiencyLoad-engaging elementsCranesDrive shaftArchitectural engineering

The invention discloses a moveable hoisting machine and a construction method thereof, belonging to the technical field of engineering machinery. The moveable hoisting machine of the invention comprises a top beam; a driving device is fixed on the top of the top beam, and is in transmission connection with a rotating seat through a transmission shaft; four lifting arms are fixed on the peripheralside surface of the rotating seat; one end of the transmission shaft penetrates the top beam and is rotatably connected with the top beam; the top of the top beam is fixedly provided with a support turntable; the top of the support turntable is connected with a revolution turntable through a revolving member; the peripheral side surface of the transmission shaft is provided with a flange; the transmission shaft is fixedly connected with the revolution turntable through the flange; the top end of the transmission shaft is fixedly provided with a fluted disc; and the bottom end of the transmission shaft is in flanged joint with the rotating seat. The moveable hoisting machine of invention can carry out revolving motion on the top beam in virtue of the rotating seat, and as the retractable lifting arms are arranged at different directions of the rotating seat, the moveable hoisting machine has the functions of revolution, retraction and multi-point simultaneous working; thus, the moveablehoisting machine has the advantages of a wider working range, higher working efficiency, stronger hoisting capacity and better flexibility in use.

Owner:WENZHOU POLYTECHNIC

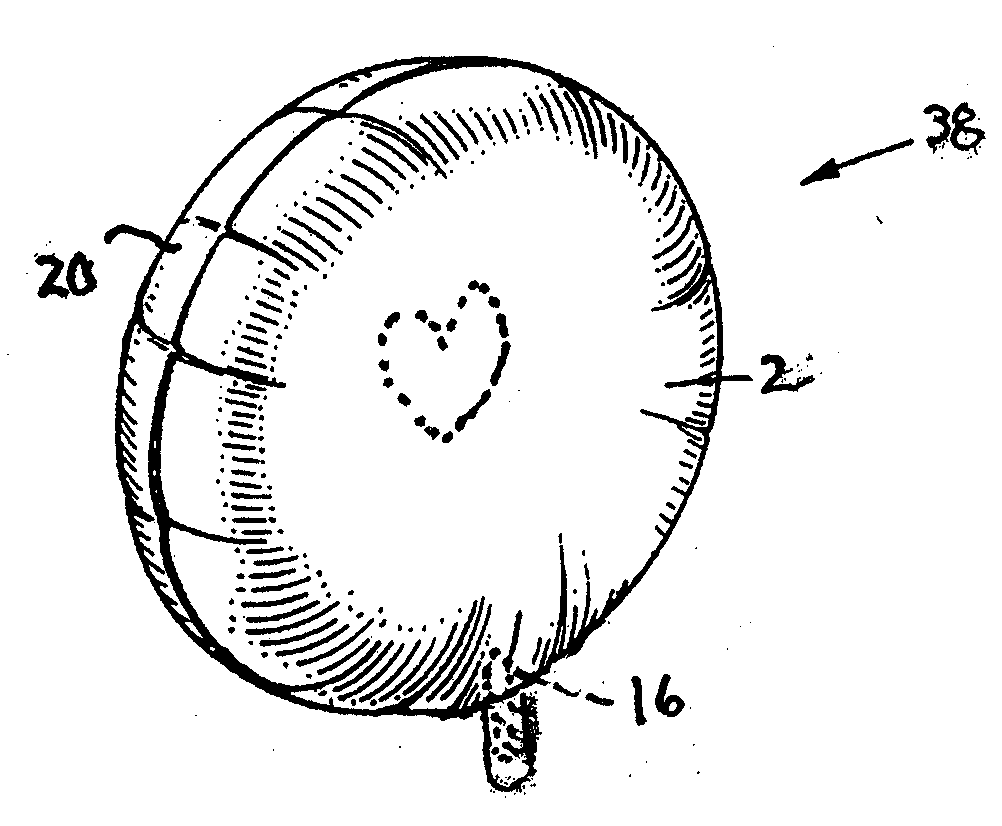

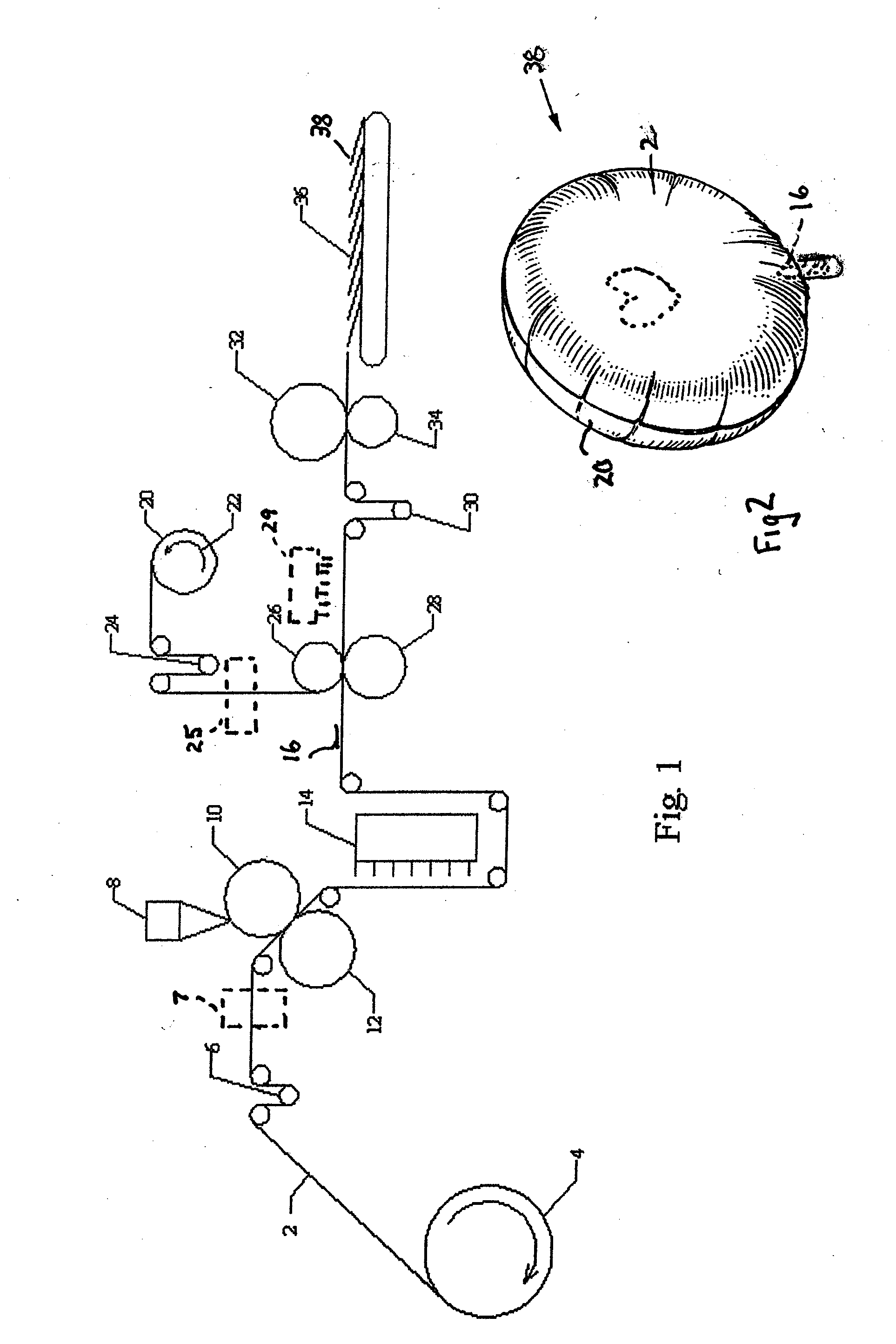

Localized sealant application in aerostats

InactiveUS20100287801A1Reduce weightImprove lifting performanceLamination ancillary operationsLaminationEngineeringSealant

Formation of an aerostat through the application of a pressure sensitive adhesive onto one or more barrier films at the desired point of bonding between the films. The adhesive is applied about the periphery prior to the point of bonding the two barrier films together. The method of the present invention results in aerostats with a bond line at the edge of the desired shape. The reduced weight, in comparison to conventional practices employing a heat sealing layer, enables intricate designs and smaller volume aerostats.

Owner:ANAGRAM INT INC

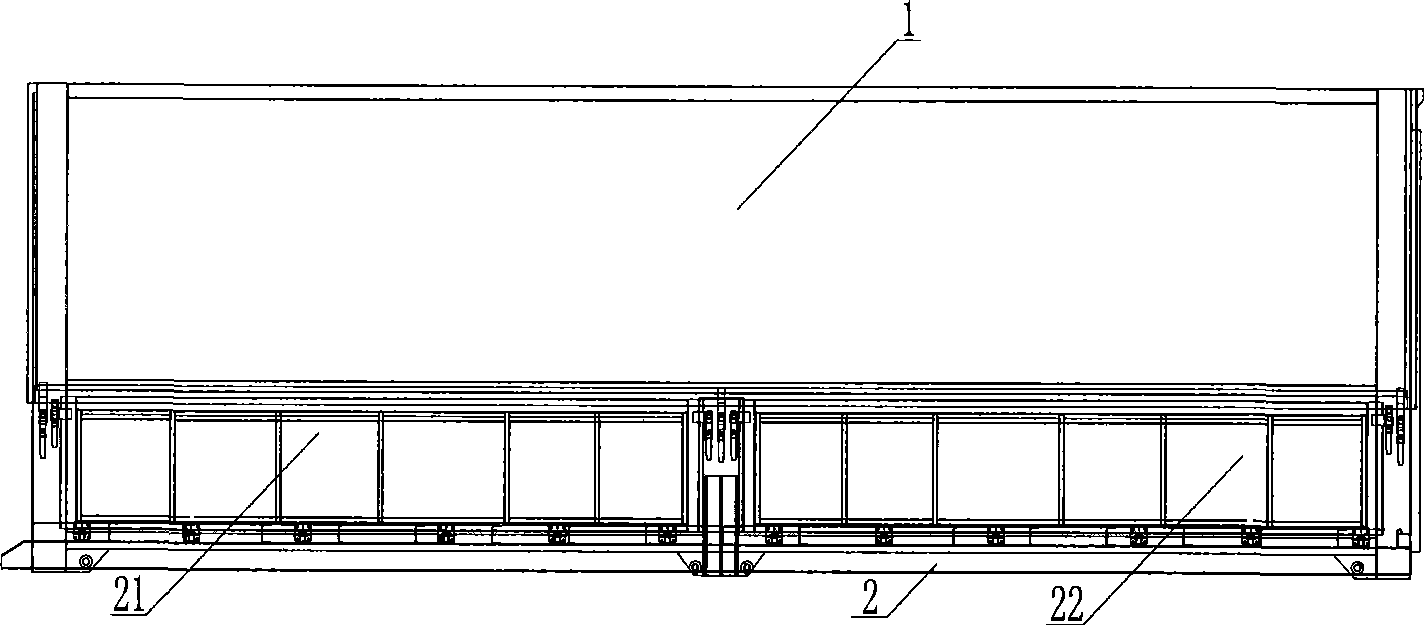

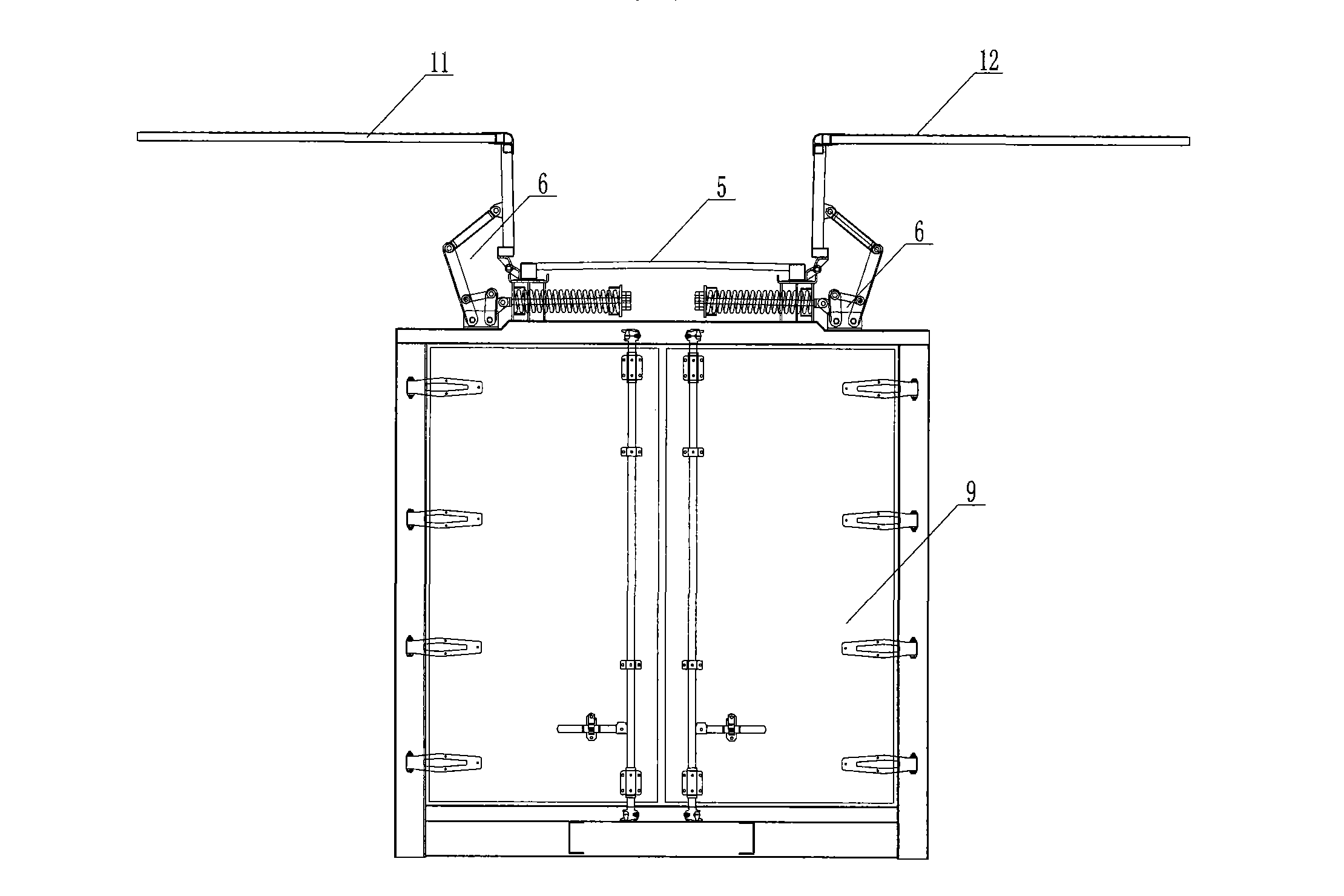

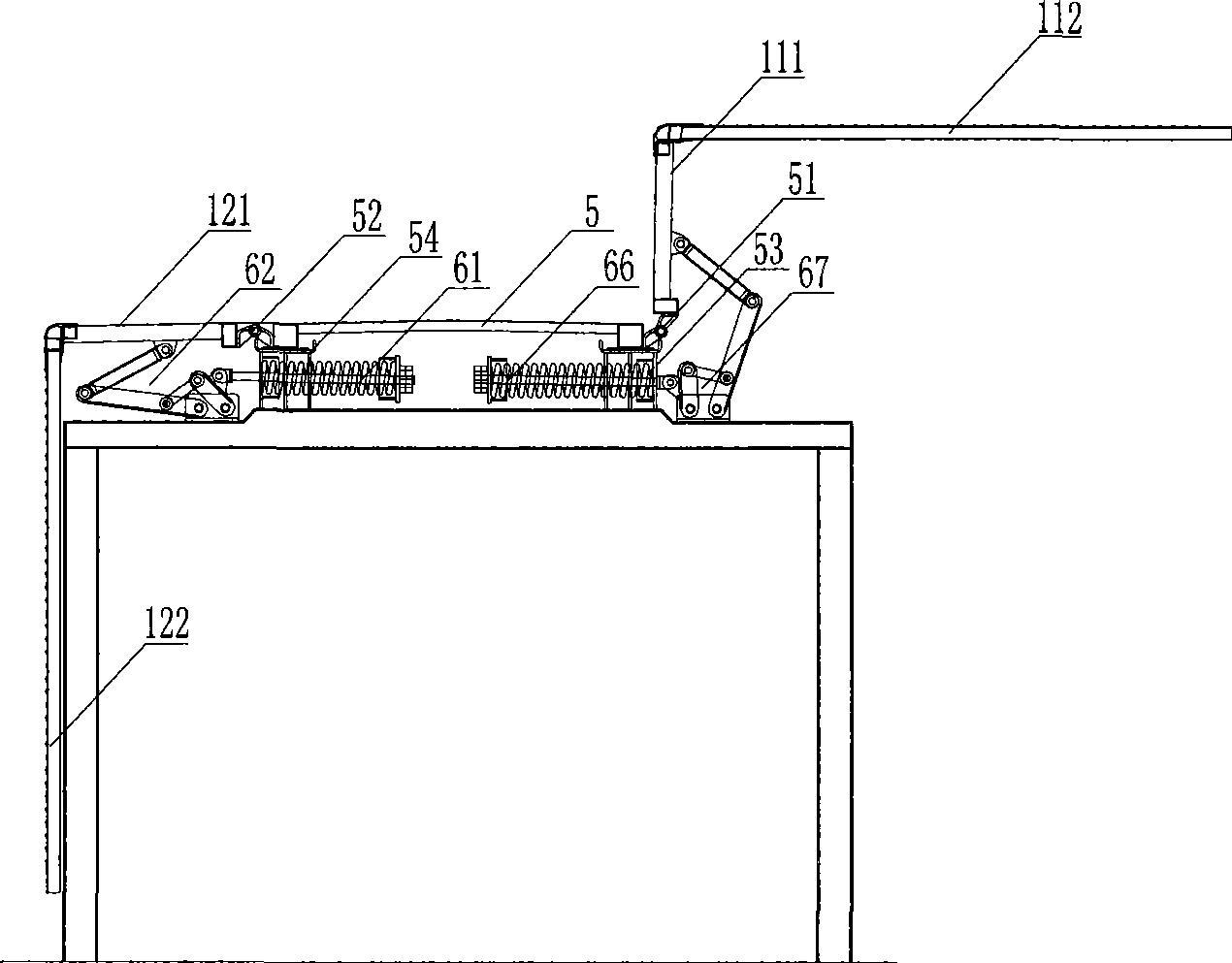

Wing opening box and trucks and container equipped therewith

ActiveCN101397036ASave installation spaceIncrease widthLarge containersLoading-carrying vehicle superstructuresTruckSelf locking

A wing opening van body comprises a bottom plate, a top plate, a side plate and openable wing plates which are arranged on both sides of the top plate. A switch device of the wing plates comprises an elastic mechanism and a manual mechanism. The elastic mechanism is arranged on the top of the van body and comprises an elastic element and an interlocking rod mechanism, when the wing plates are in closed state, the compressed elastic element generates upward thrust to the wing plates through the interlocking rod mechanism when the wing plates are opened; the manual mechanism is arranged on the outer surface of the end part of the van body and comprises a drive handle and a transmission rod mechanism, the transmission rod mechanism is equipped with a self-locking speed reducer, and the moment generated by the drive handle drives the wing plates to be opened, closed and suspended through the transmission rod mechanism. A transport vehicle and a container are provided with the wing opening van body. The wing opening van body overcomes the problem that bidirectional limitation and stable opening and closing can not be realized in the prior art, and ensures smooth and safe operation.

Owner:中集车辆(江门市)有限公司

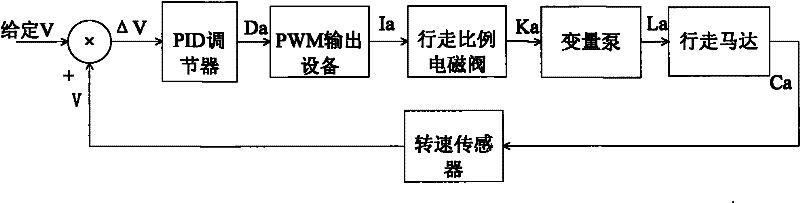

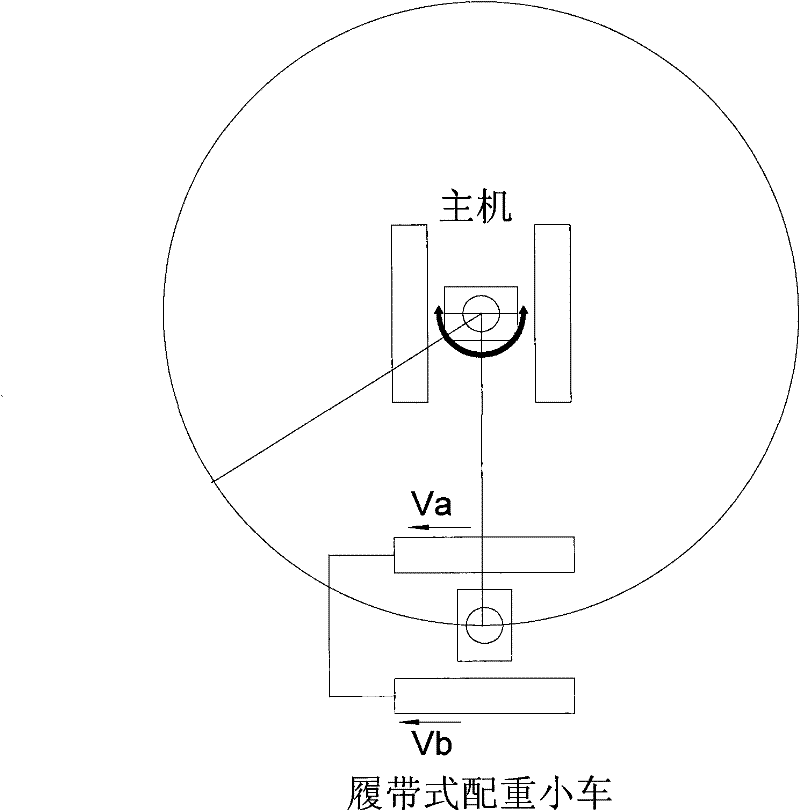

Electrical control device for crawler-type counter weight trolley and control method thereof

ActiveCN102234076AHigh automation intensityIncreased lifting capacityCranesLoad-engaging elementsElectrical controlMachine control

The invention relates to an electrical control device for a crawler-type counter weight trolley, comprising a main machine control component arranged on a main machine of a crane and a counter weight trolley control component arranged on a counter weight trolley of the crane, wherein the main machine control component comprises a right main machine crawler travelling motor rotating speed sensor, a left main machine crawler travelling motor rotating speed sensor, a main machine controller and a main machine rotation angle displacement sensor; the counter weight trolley control component comprises a right counter weight trolley crawler travelling motor rotating speed sensor, a left counter weight trolley crawler travelling motor rotating speed sensor, a counter weight trolley controller anda counter weight trolley rotation angle displacement sensor; and the main machine controller and the counter weight trolley controller are connected to communicate by virtue of a CAN bus. By adoptingthe electrical control device provided by the invention, synchronous control on the main machine and the counter weight trolley is realized, and actions of the main machine and the counter weight trolley are combined to generate diversified operating modes, thus the automation strength is improved, the lifting capacity is improved, a counter weight is convenient to move, and the problem that desynchronization is caused by adverse impact of personal factors can be avoided.

Owner:ZHEJIANG SANY EQUIP

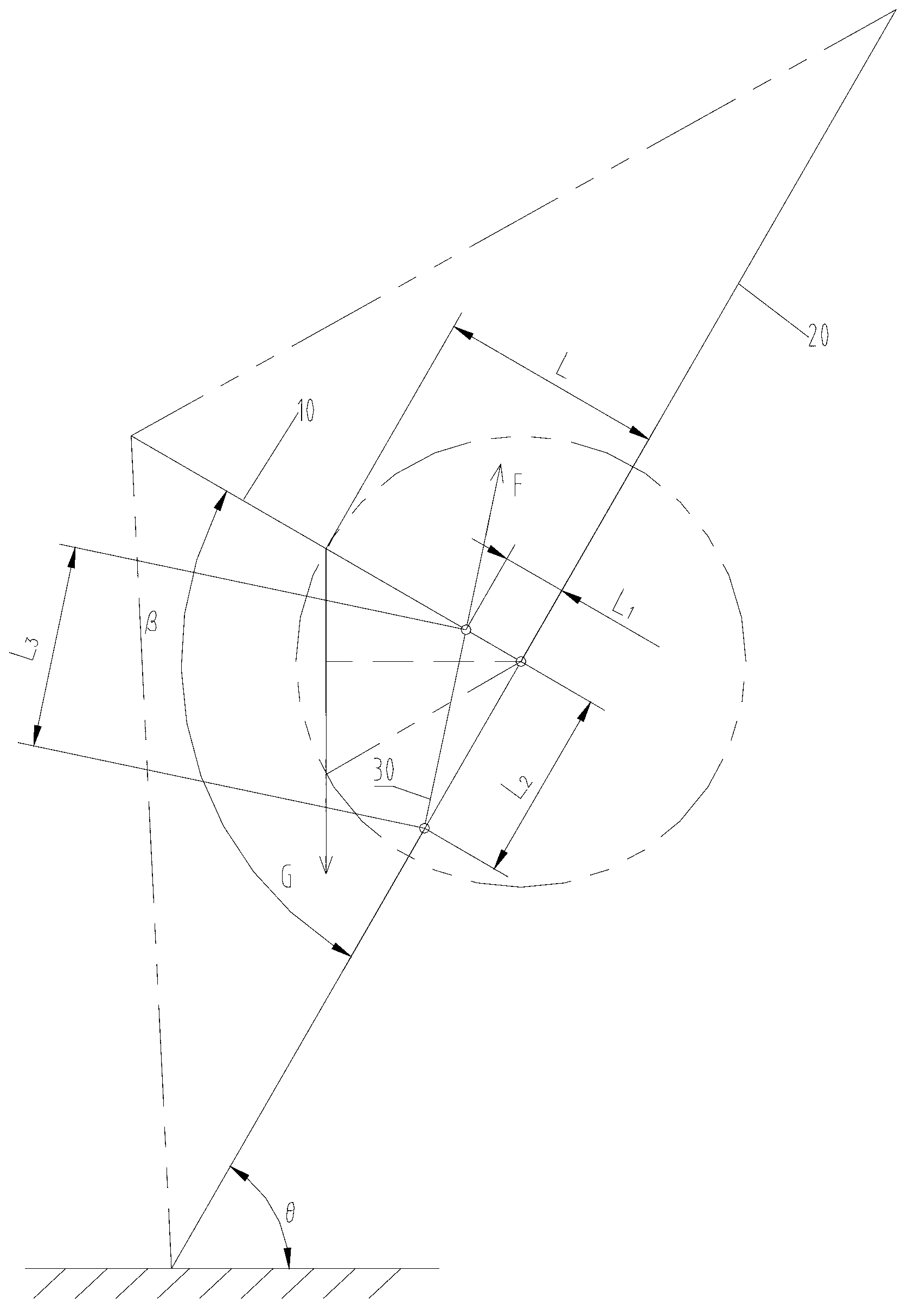

Crane, and method and device for controlling super-lifting derricking oil cylinder thereof

ActiveCN103231999AReduce forceAvoid deformationCargo handling apparatusServomotorsOil pressurePetroleum engineering

The invention provides a crane, and a method and device for controlling a super-lifting derricking oil cylinder of the crane. The control method comprises the following steps of: acquiring a first included angle between a super-lifting mast and a lifting arm of the crane and a second included angle between the lifting arm and a horizontal plane in real time; calculating a real-time oil pressure for overcoming the self weight of the super-lifting mast when the lifting arm is in the second included angle and the super-lifting derricking oil cylinder is in the first included angle; and setting a safe working pressure of the super-lifting derricking cylinder in real time according to the real-time oil pressure. According to the method provided by the invention, the safe working pressure of the super-lifting derricking oil cylinder is set according to the real-time oil pressure corresponding to the first included angle and the second included angle, so that the pressure value of the super-lifting derricking oil cylinder does not need to be kept in a maximum working pressure state of the system, deformation of structural components such as super-lifting pedestals or accidents caused by pressure surge of the system due to unexpected circumstances can be prevented, a super-lifting structure does not need to be designed large, and the lifting capability of the whole crane is improved.

Owner:ZOOMLION HEAVY IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com