Crane hook falling velocity adjustment apparatus

A technology of speed adjustment and hoisting, which is applied in hoisting devices, transportation and packaging, and clockwork mechanisms. It can solve problems such as messy ropes, inability to increase the speed of hook drop, and speed up the speed of hoisting and unwinding ropes, so as to improve the hoisting load. ability, preventing rope chaos, and reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

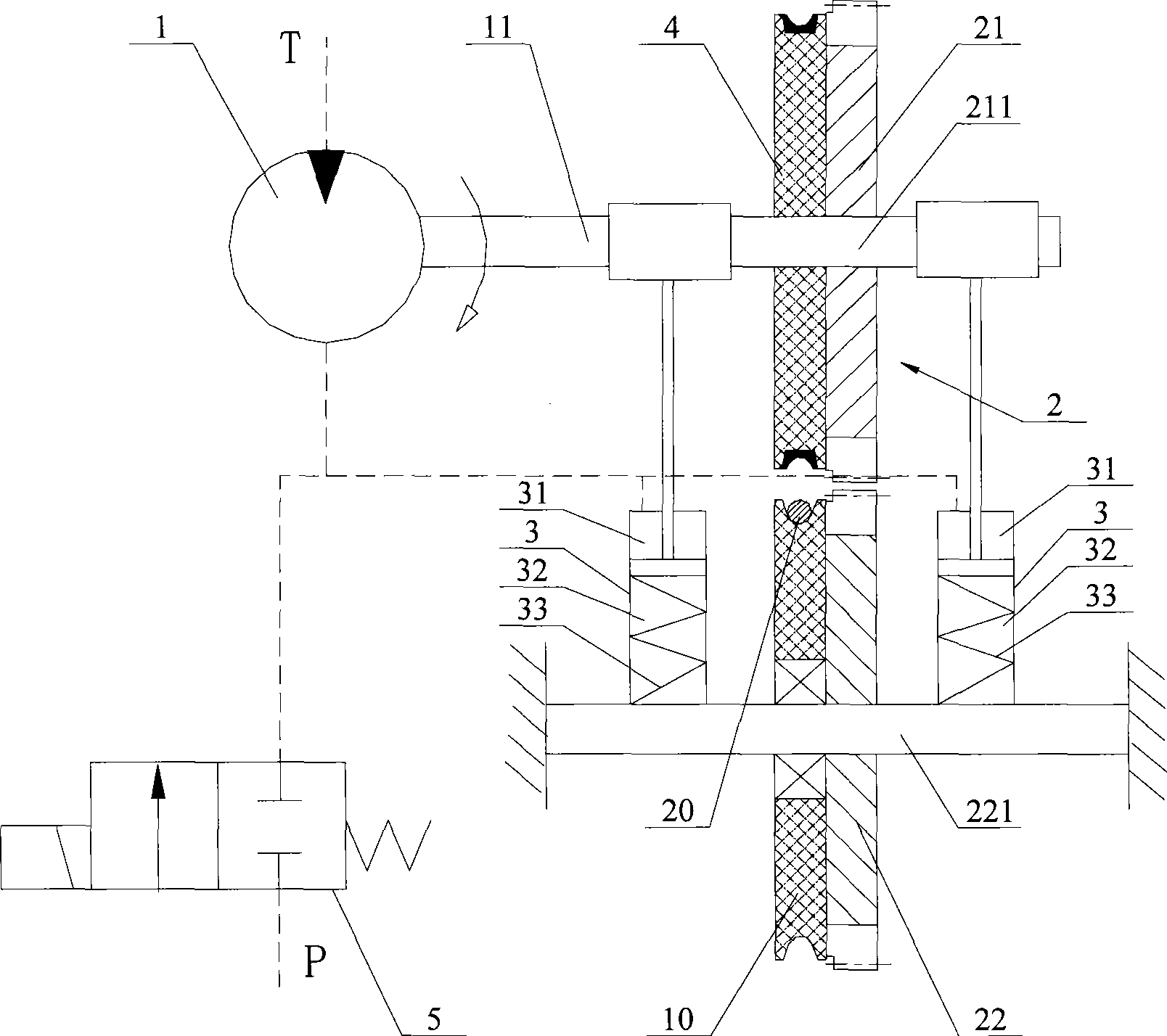

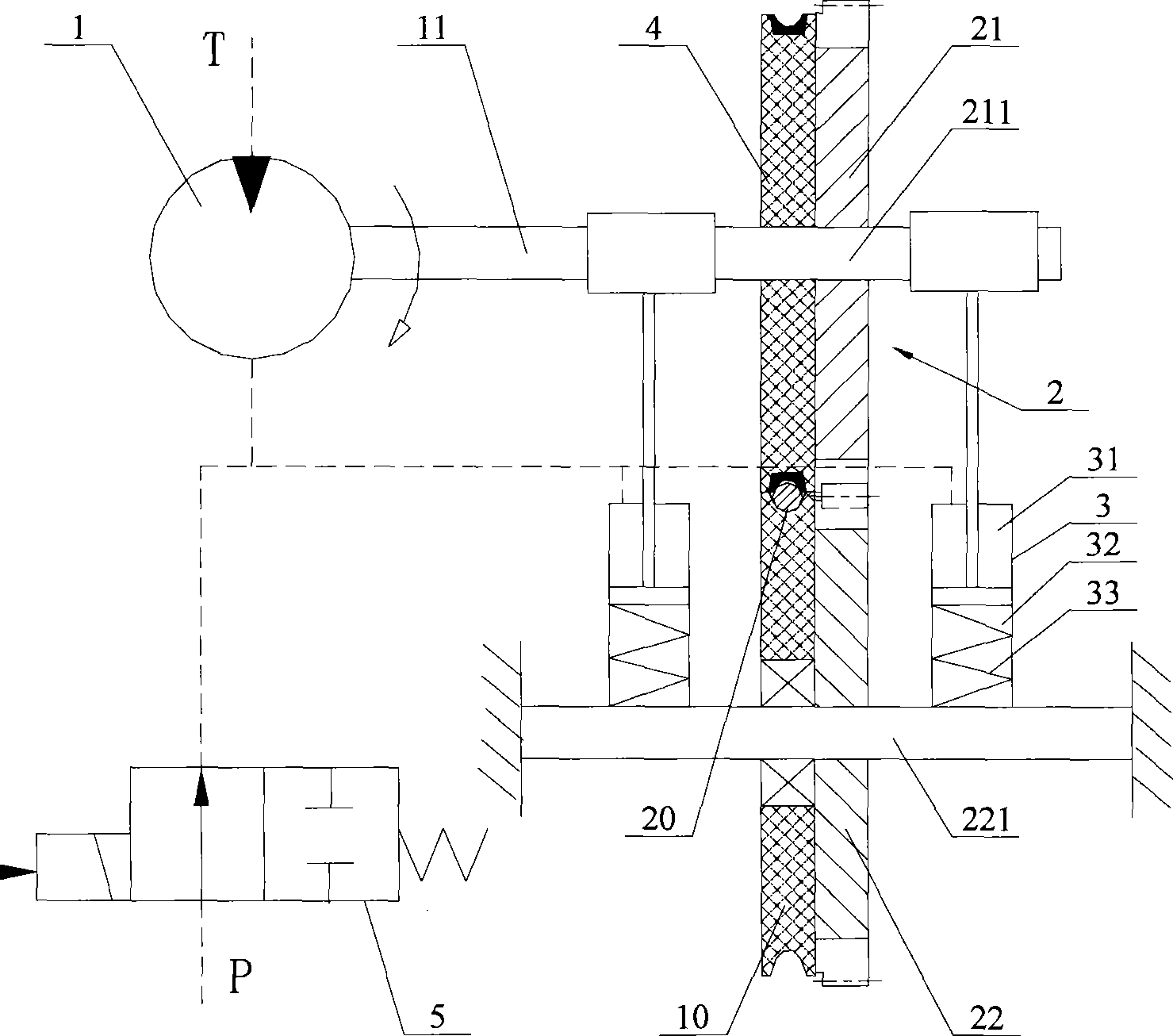

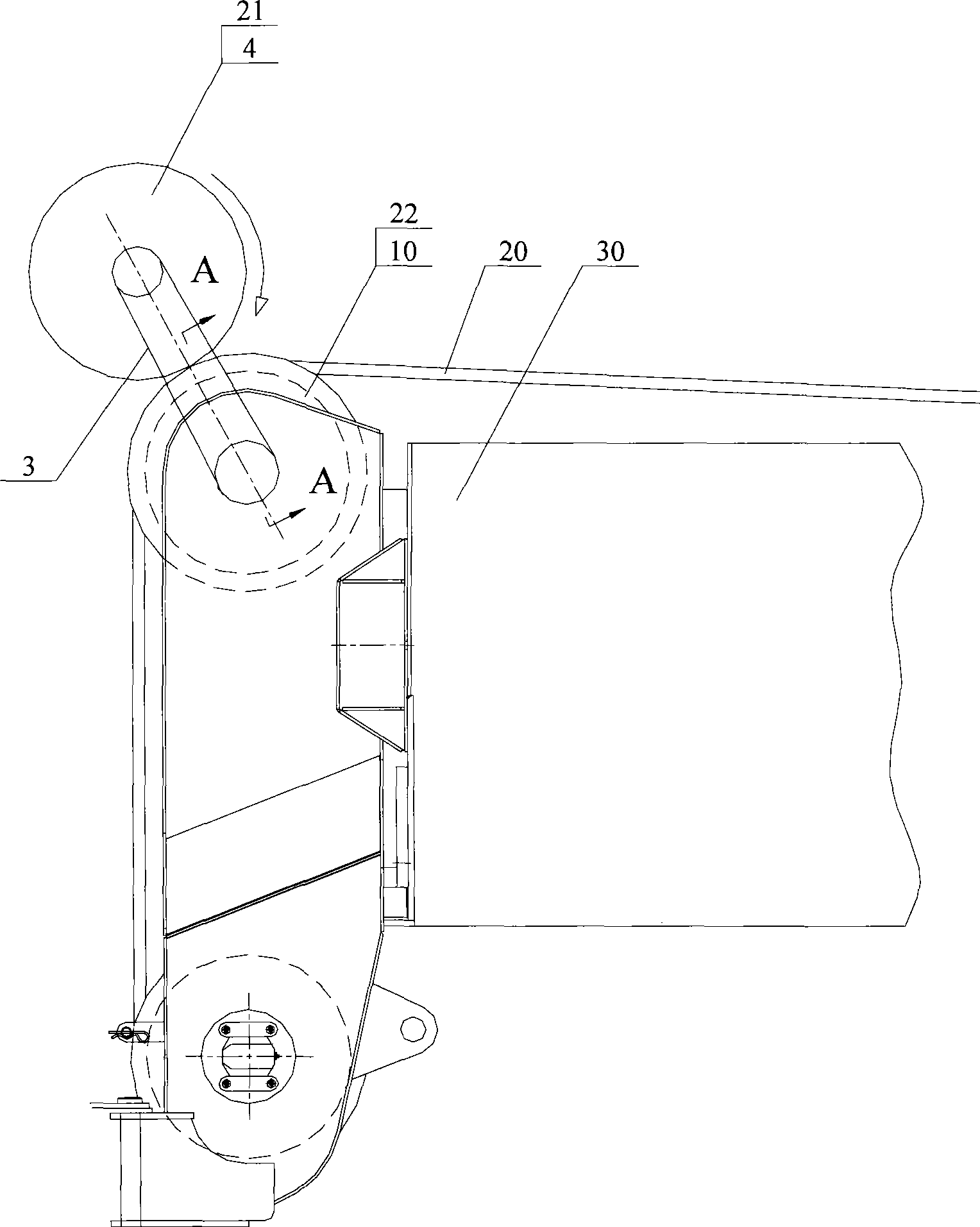

[0030] The present embodiment will be described in detail below in conjunction with the accompanying drawings.

[0031] The present invention is an improved design made on the basis of the existing crane arm head pulley structure. The wire rope of the existing crane traction hook is arranged in the wheel groove of the arm head pulley, and there is friction between the arm tip pulley and the wire rope. Under the action of friction, the arm tip pulley and the wire rope rotate approximately synchronously, and the linear velocity of the contact surface between the arm tip pulley and the wire rope is approximately equal to the speed of the wire rope.

[0032] Based on the structural characteristics between the crane arm pulley and the hook traction wire rope, the main idea of the present invention is to drive the arm pulley through an external power to appropriately increase the rotation speed of the arm pulley and the speed of the wire rope, and then adjust the crane's suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com