Patents

Literature

75results about How to "Avoid tangled rope" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crane disorderly rope alarm method and device, and crane using the same device

InactiveCN101264851AAvoid damageExtended service lifeWinding mechanismsSafety gearLate stageEngineering

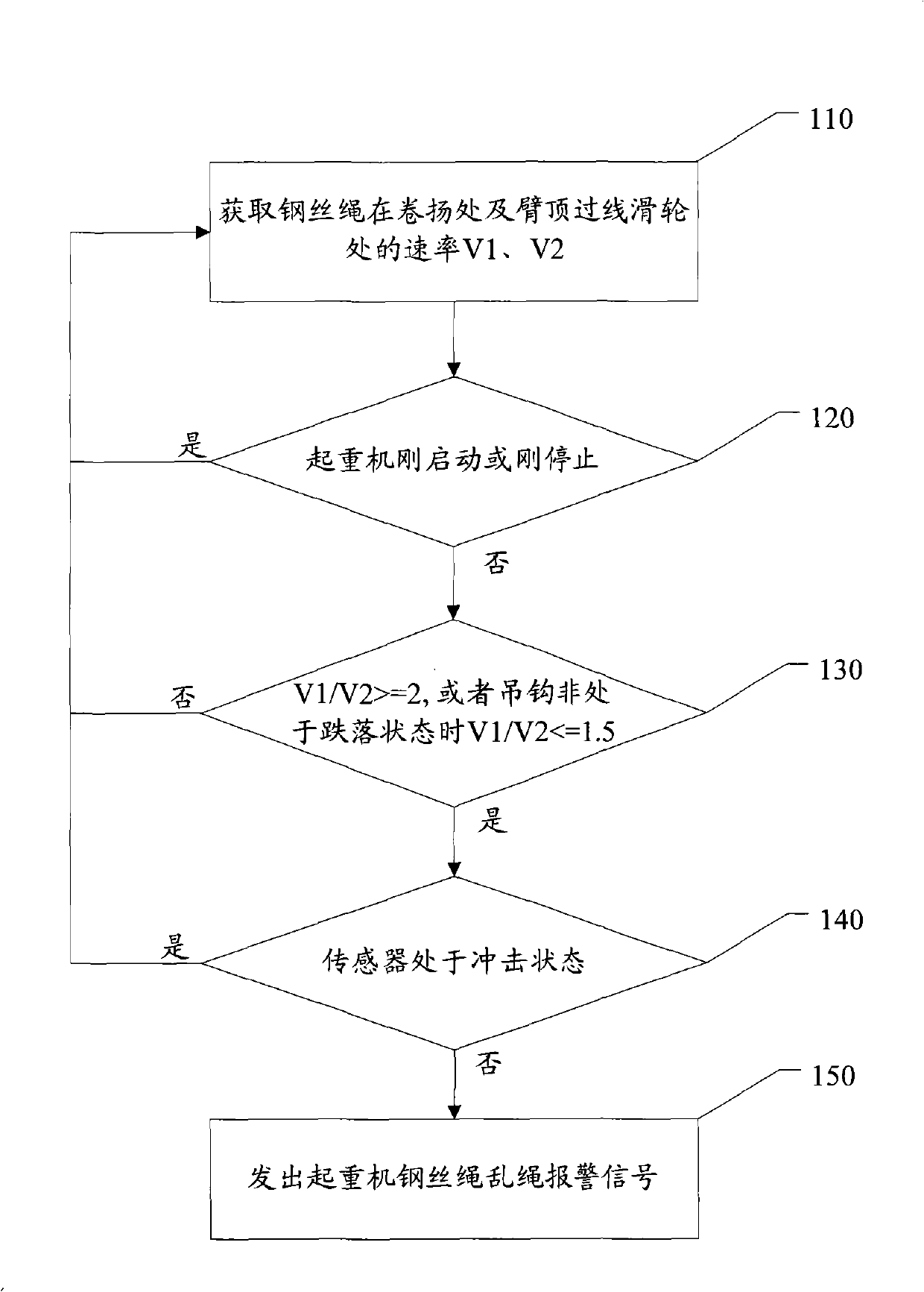

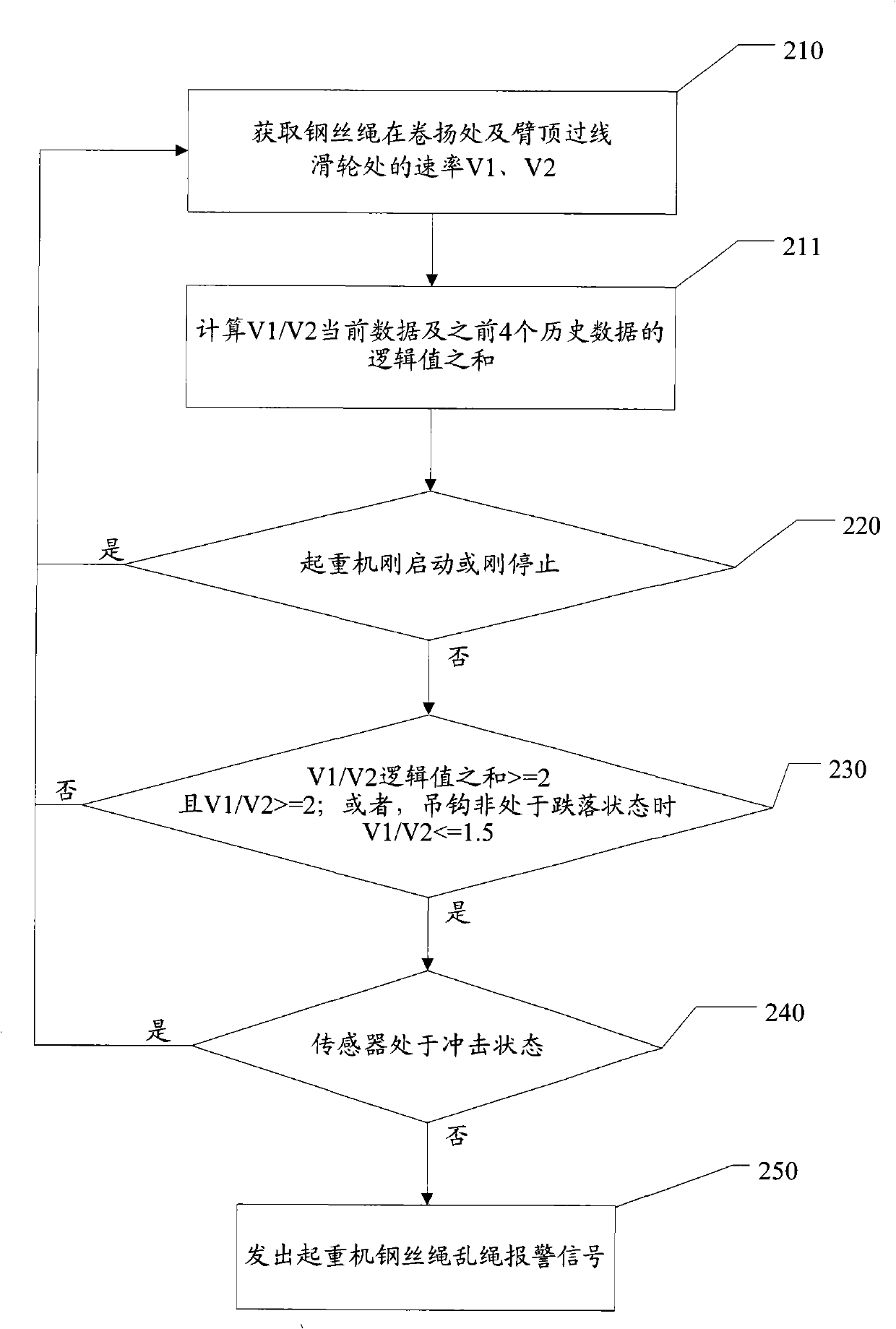

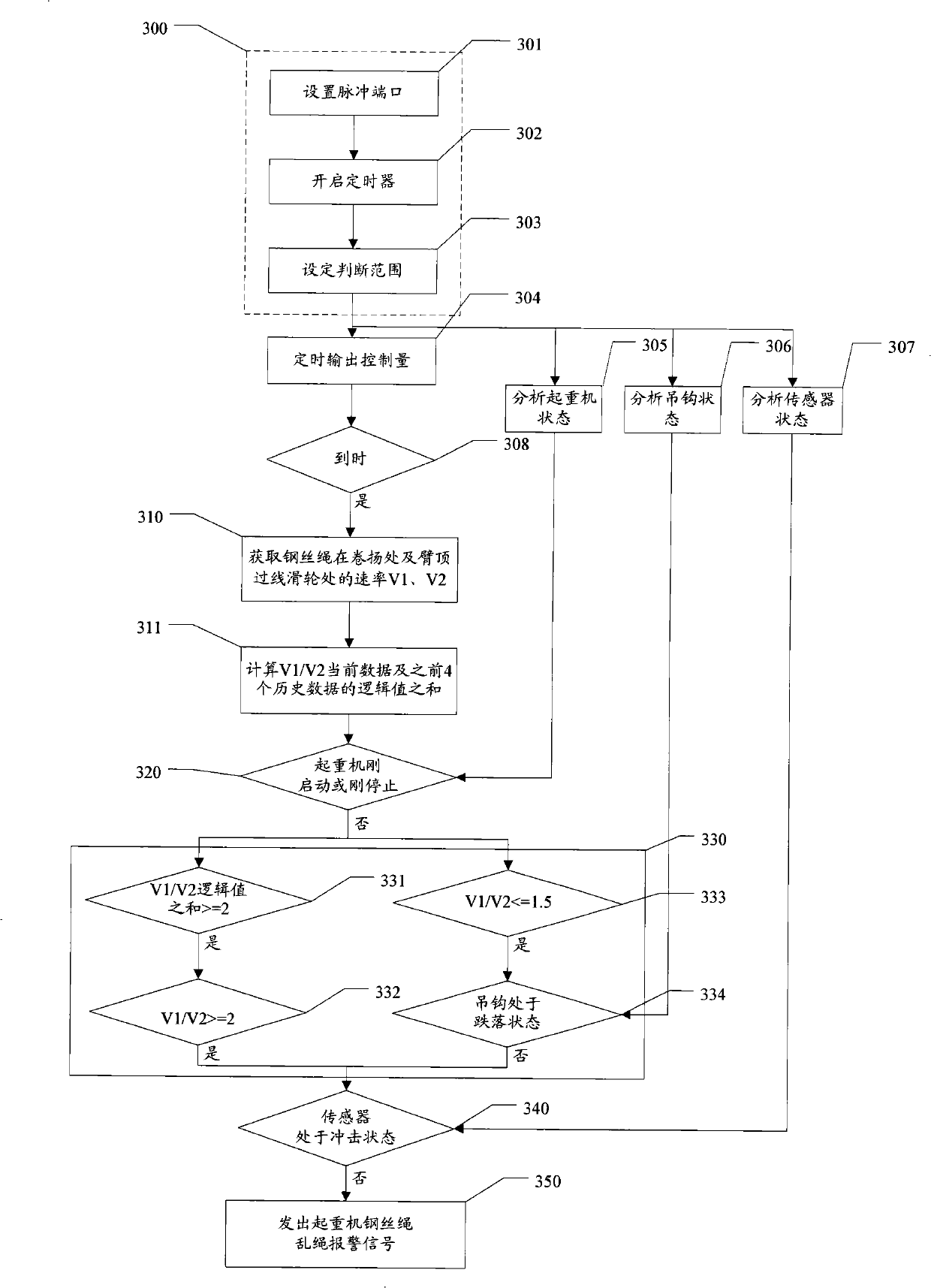

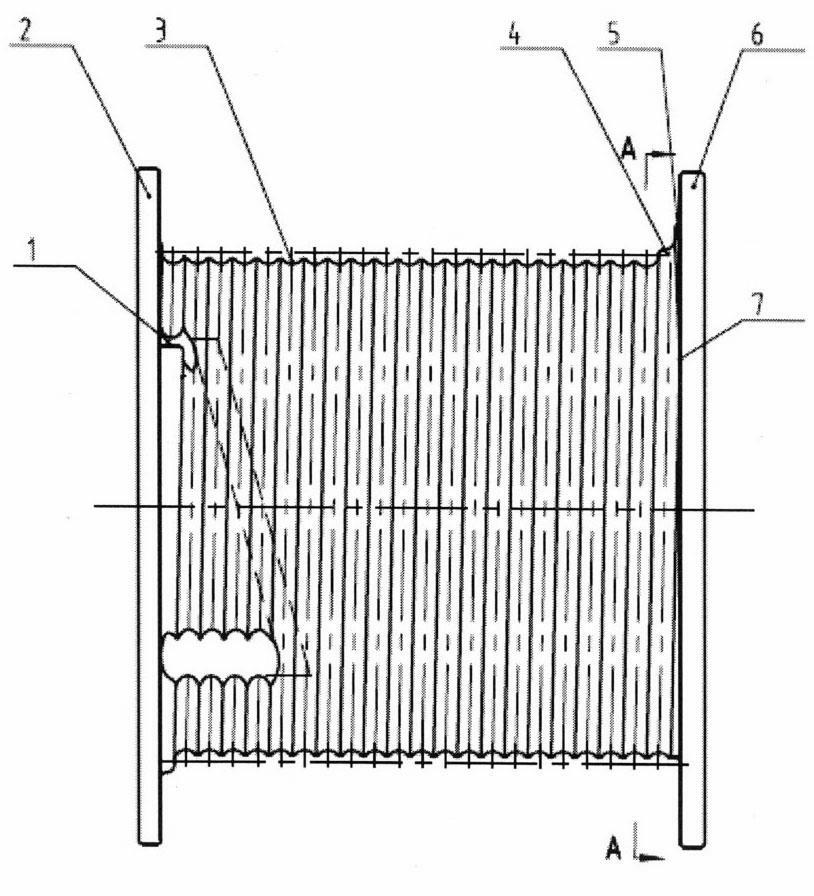

The invention discloses a disorder cable alarming method for cranes, comprising steps as follows: S10, acquiring a velocity V1 of hoisting cables at a hoisting place and a velocity thereof V2 at a pulley part on top of a crane arm where the hoisting cables pass through; S20, judging whether a ratio between V1 and V2 is in a zone of disorder cables or not while the crane is just started or stopped and a sensor is free of impacts. Either of the following factors is applied for the judgment of the zone of disorder cables: a ratio between V1 and V2 is equal or greater than two; or a ratio between V1 and V2 is equal or less than 1.5 when a lifting hook is not in a falling state. If in a zone of disorder cables, the step S10 is needed; if not, a step S30 is needed; S30, giving off alarm signals for the disorder cables of the crane. With the disorder cable alarming method for cranes, alarms can be given at the early stage the disorder cables occur, so as to avoid the disorder of hoisting cables in the middle and the late stages, and effectively eliminate the dangers caused by disorder of the hoisting cables. Based on the disorder cable alarming method for cranes, the invention also discloses a disorder cable alarming device for cranes, and a crane with the disorder cable alarming device.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

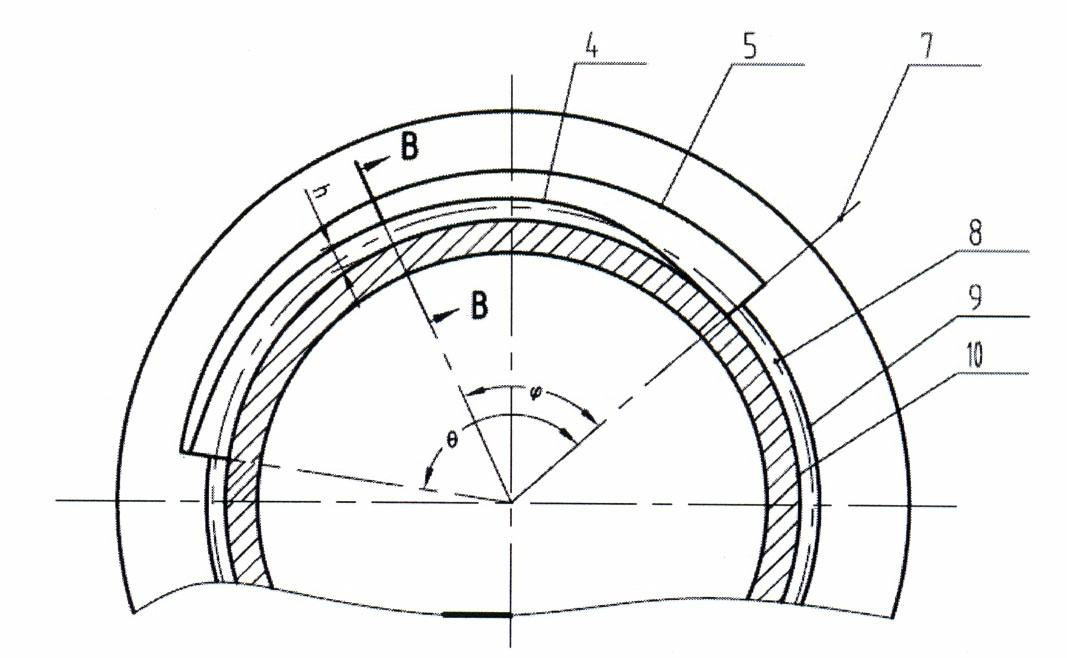

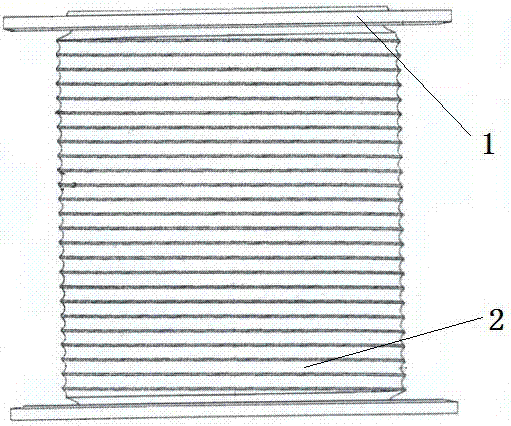

Double-layer winding steel wire rope reel

InactiveCN102107824AReduce contact stressReduce wearWinding mechanismsArchitectural engineeringSpiral line

The invention relates to a double-layer winding steel wire rope groove reel. The double-layer winding steel wire rope groove reel is provided with a reel body with a left flange and a right flange, wherein a rope groove is formed on the circumferential surface of the reel body; a steel wire rope fixing groove is formed at the starting end of the rope groove on the circumferential surface of the reel body; the rope groove is a spiral line rope groove; a climbing boss is arranged on the reel circle, at the tail end of the rope groove, of the reel body; the height of the climbing boss is gradually increased on the circumferential surface of the reel body along the circumferential extension angle; a guide baffle ring is arranged on the inner side, corresponding to the climbing boss, of the right flange; and the thickness of the guide baffle ring is gradually increased in the circumferential direction along with the extension angle. In the process of the steel wire rope climbing among layers, the guide baffle ring can guide the steel wire rope to change the winding direction, so that rope skipping and rope disordering are avoided and the rope can be tidily and tightly arranged on the second layer of the reel; the climbing boss has the effects of supporting and positioning, so that the contact stress between the steel wire ropes in the climbing process is effectively reduced and abrasion is reduced; the reel has a simple structure; the rope groove is easy to process; and precision is high and cost is low.

Owner:SHANDONG SHANTUI MASCH CO LTD

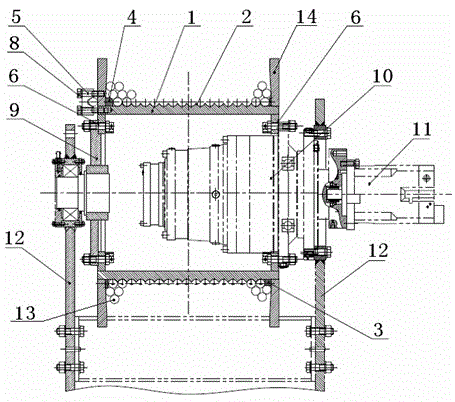

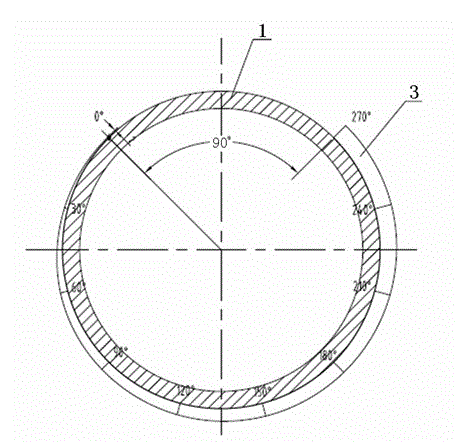

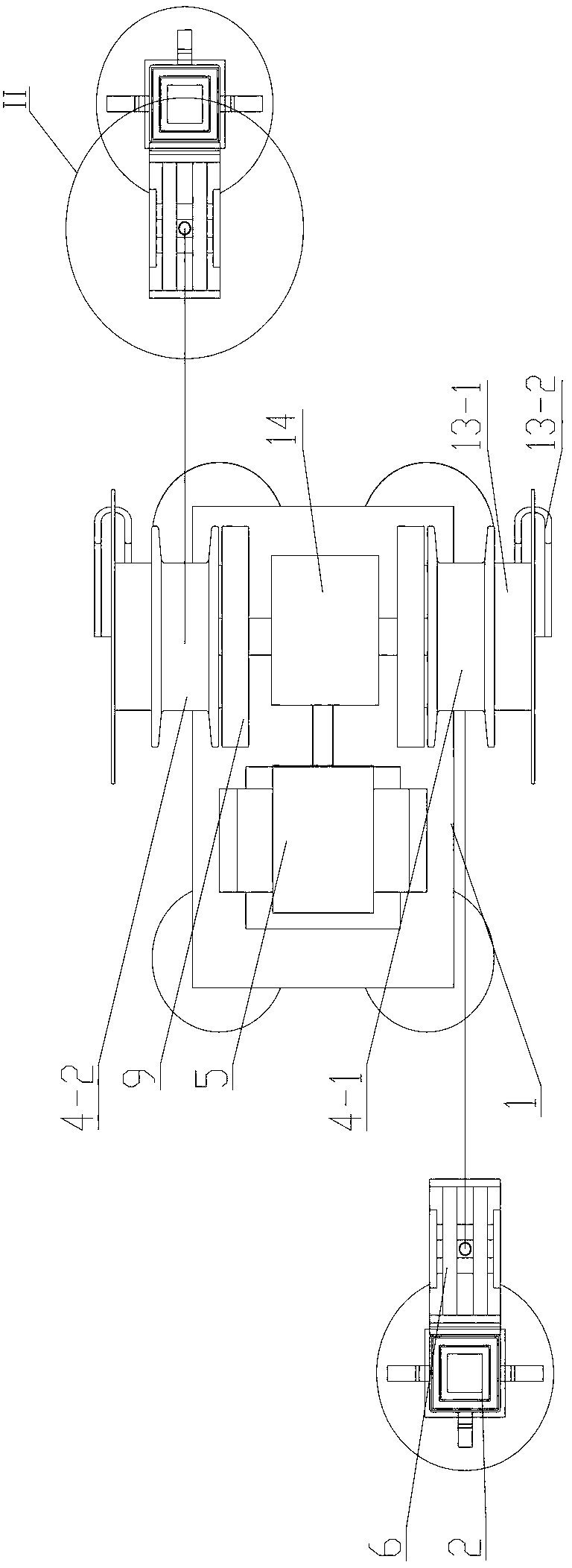

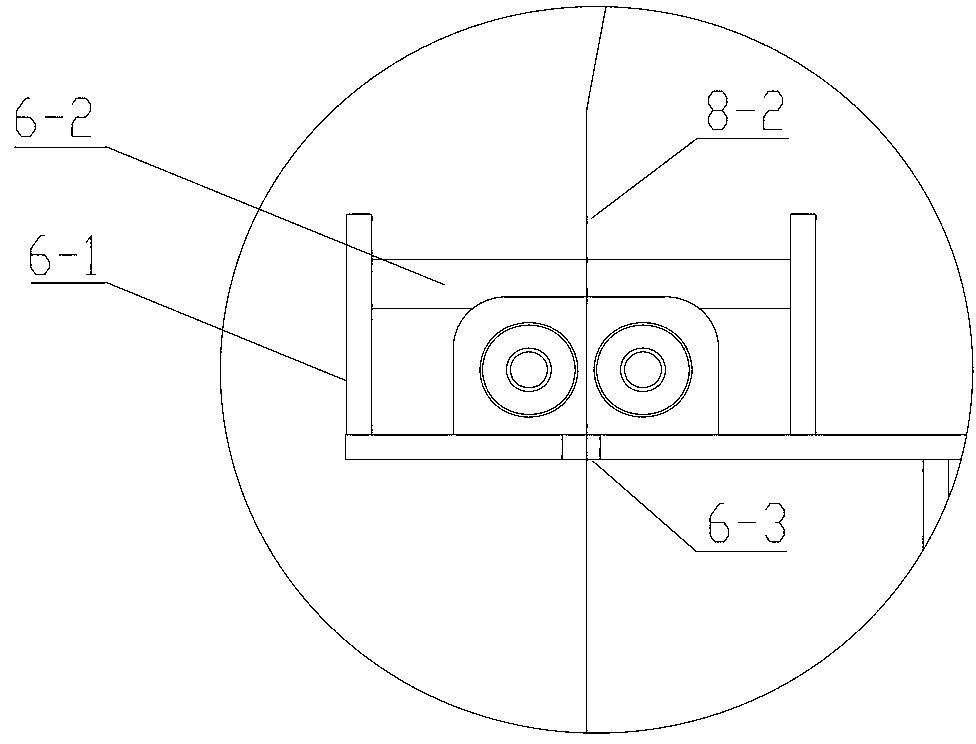

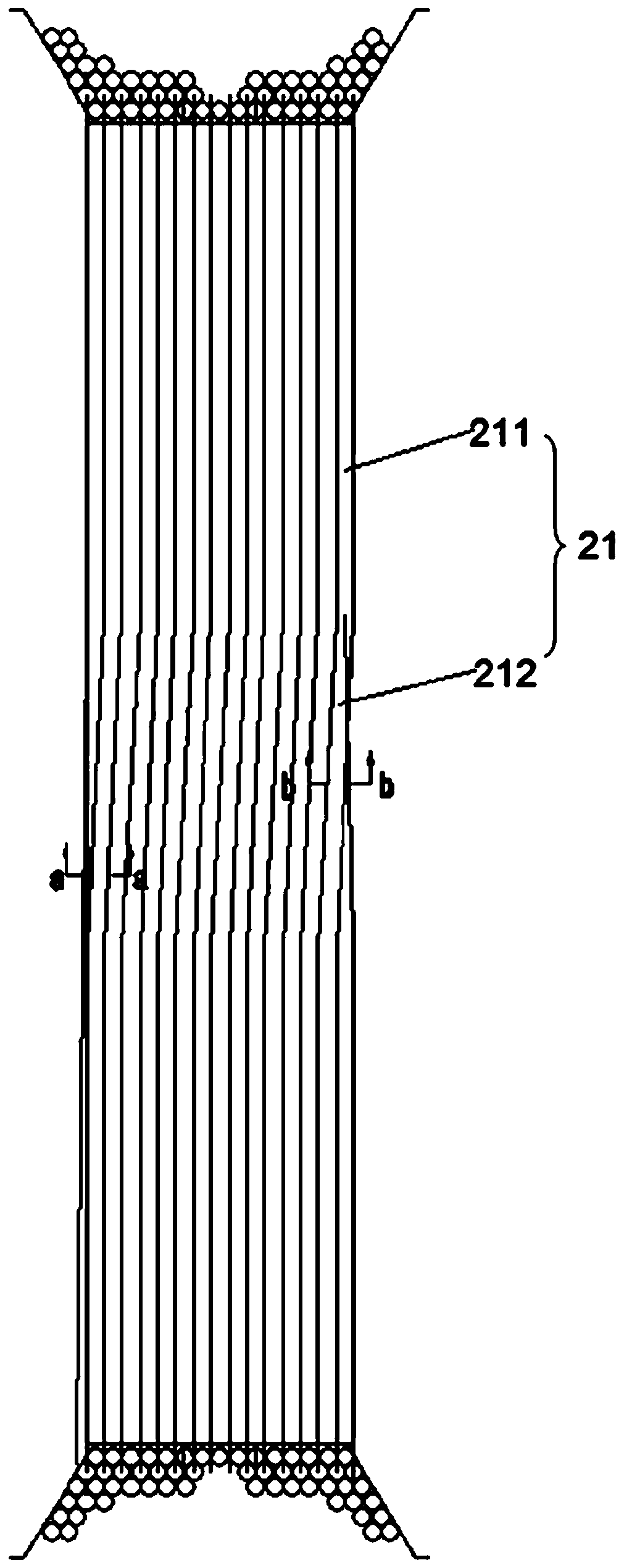

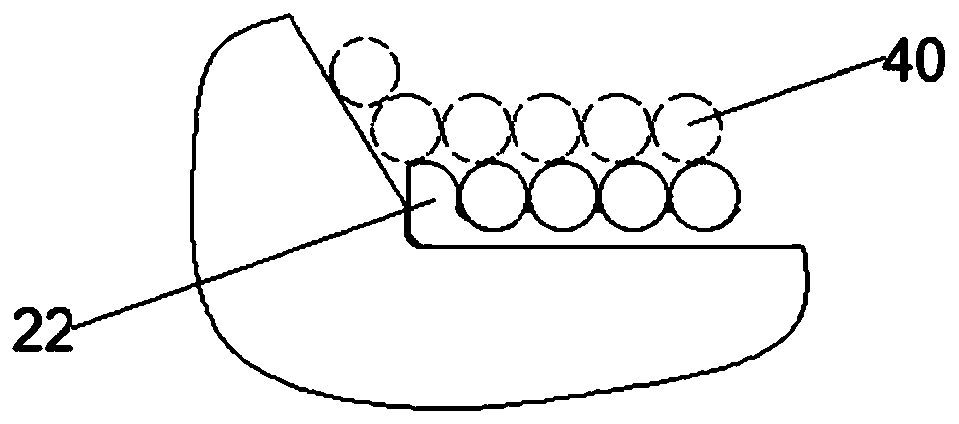

Multi-layer helix rope winding groove coiling barrel

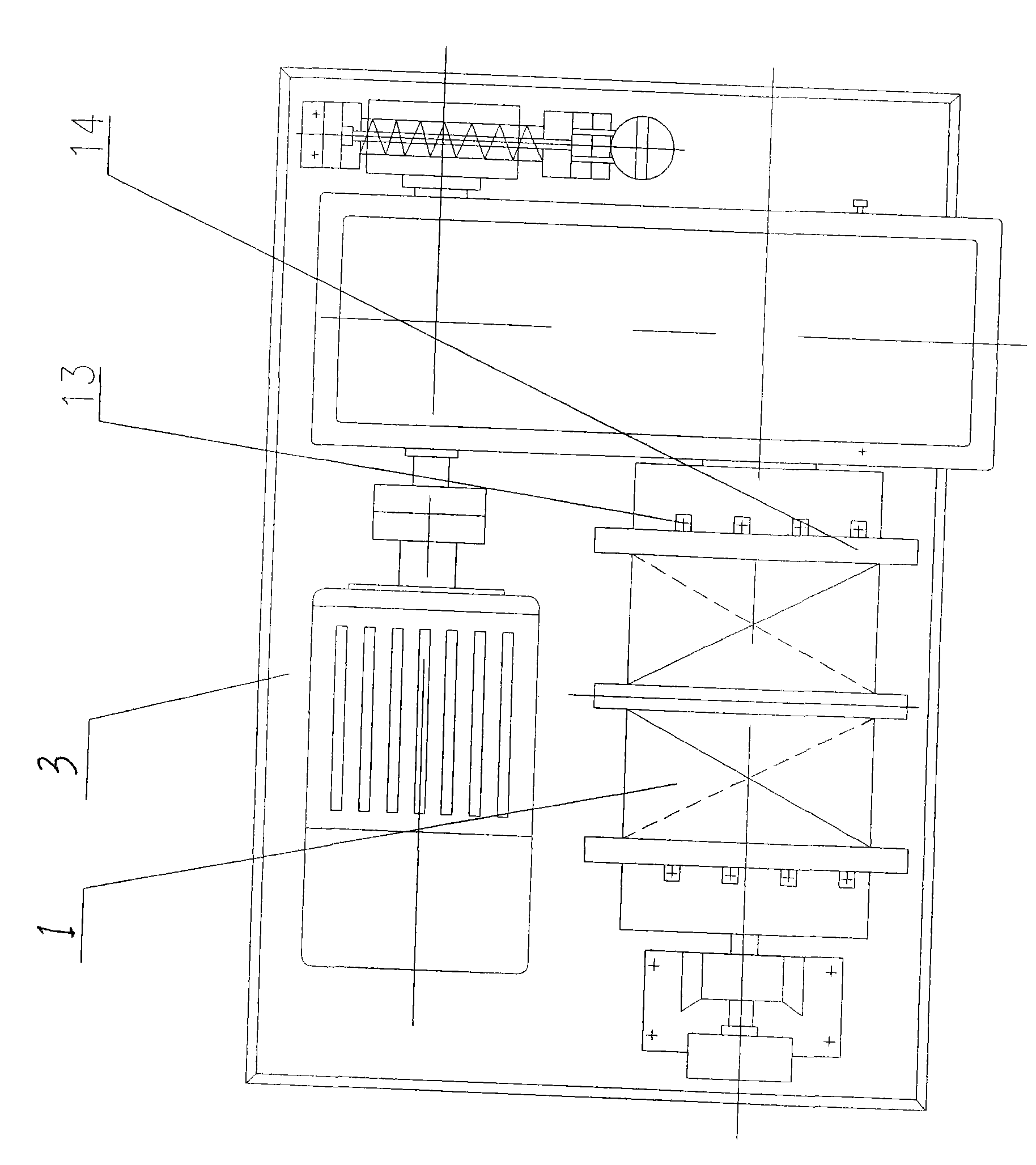

The invention discloses a multi-layer helix rope winding groove coiling barrel, which comprises a coiling barrel (1), a helix rope groove (2), a steel wire rope (13) ad a coiling barrel side plate (14), wherein two ends of the coiling barrel (1) are used as the installation interfaces (6); a rope through hole (7) is formed in the coiling barrel side plate (14); a rope climbing block (3) is arranged at the tail end of the helix rope groove (2); a wedge-shaped block (4) is arranged at the beginning end of the steel wire rope (13); the wrap angle alpha of the rope climbing block (3) ranges from 0 degree to 270 degrees; the height of the rope climbing block (3) is increased from 2mm to the diameter of the steel wire rope (13) gradually; the width of the rope climbing block (3) is reduced from being equal to the diameter of the steel wire rope (13) to the 1 / 4 of the diameter of the steel wire rope (13); the wrap angle alpha 2 of the wedge-shape block (4) ranges from 0 degree to 320 degrees; the height of the wedge-shape block (4) is equal to the diameter of the steel wire rope (13); and the width of the wedge-shape block (4) is reduced from being equal to the diameter of the steel wire rope (13) to the 1 / 9 of the diameter of the steel wire rope (13).

Owner:WUHAN MARINE MACHINERY PLANT

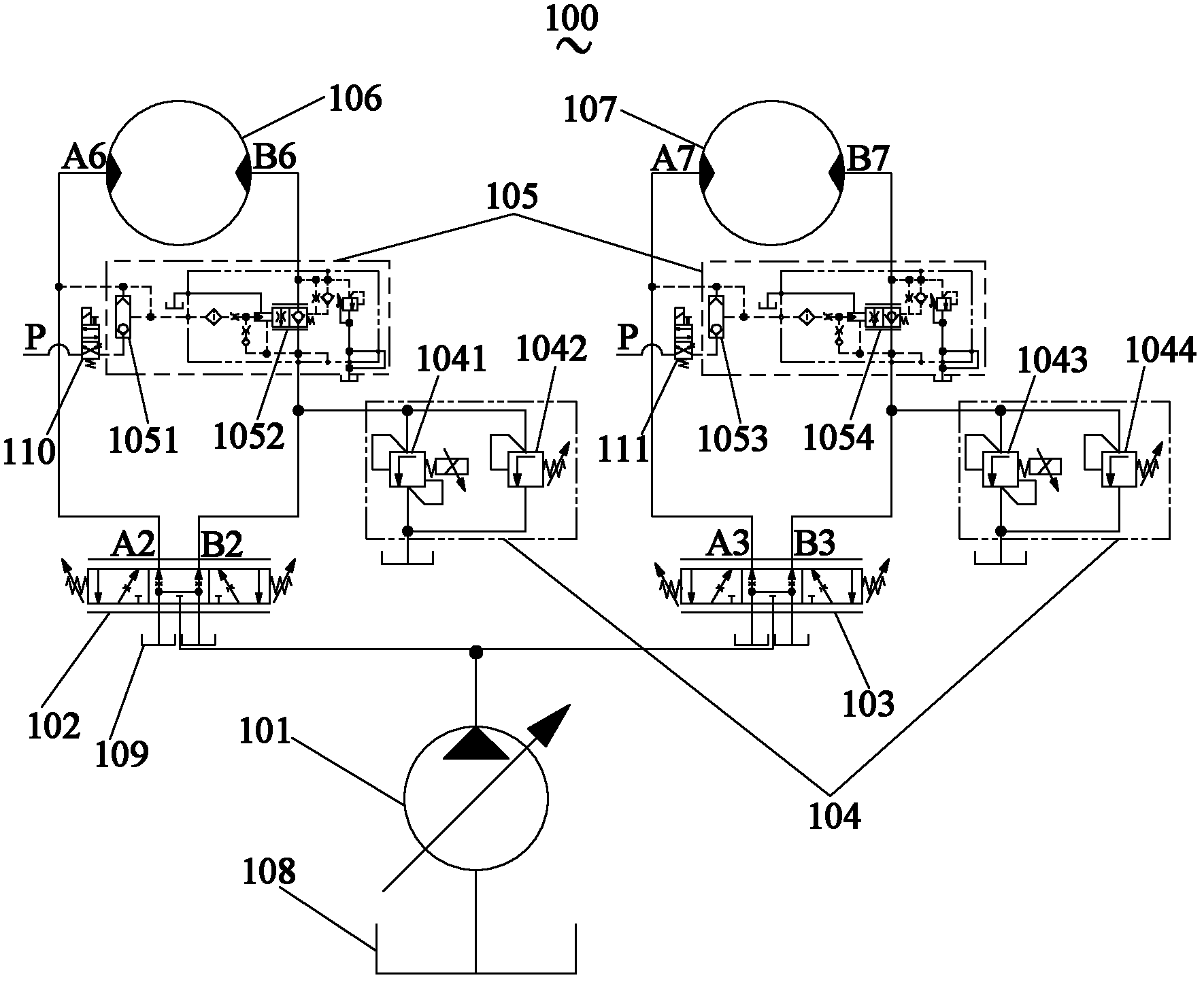

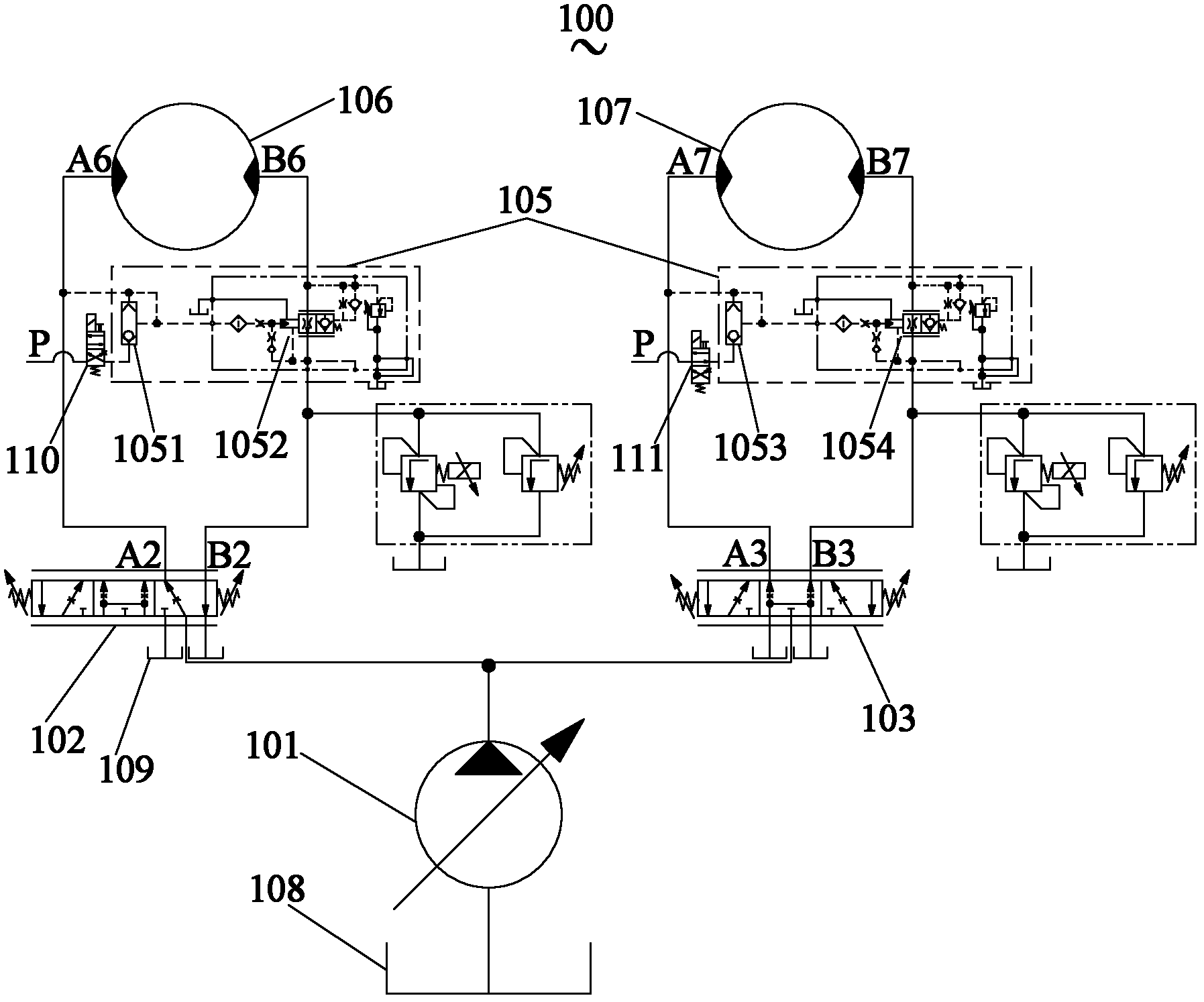

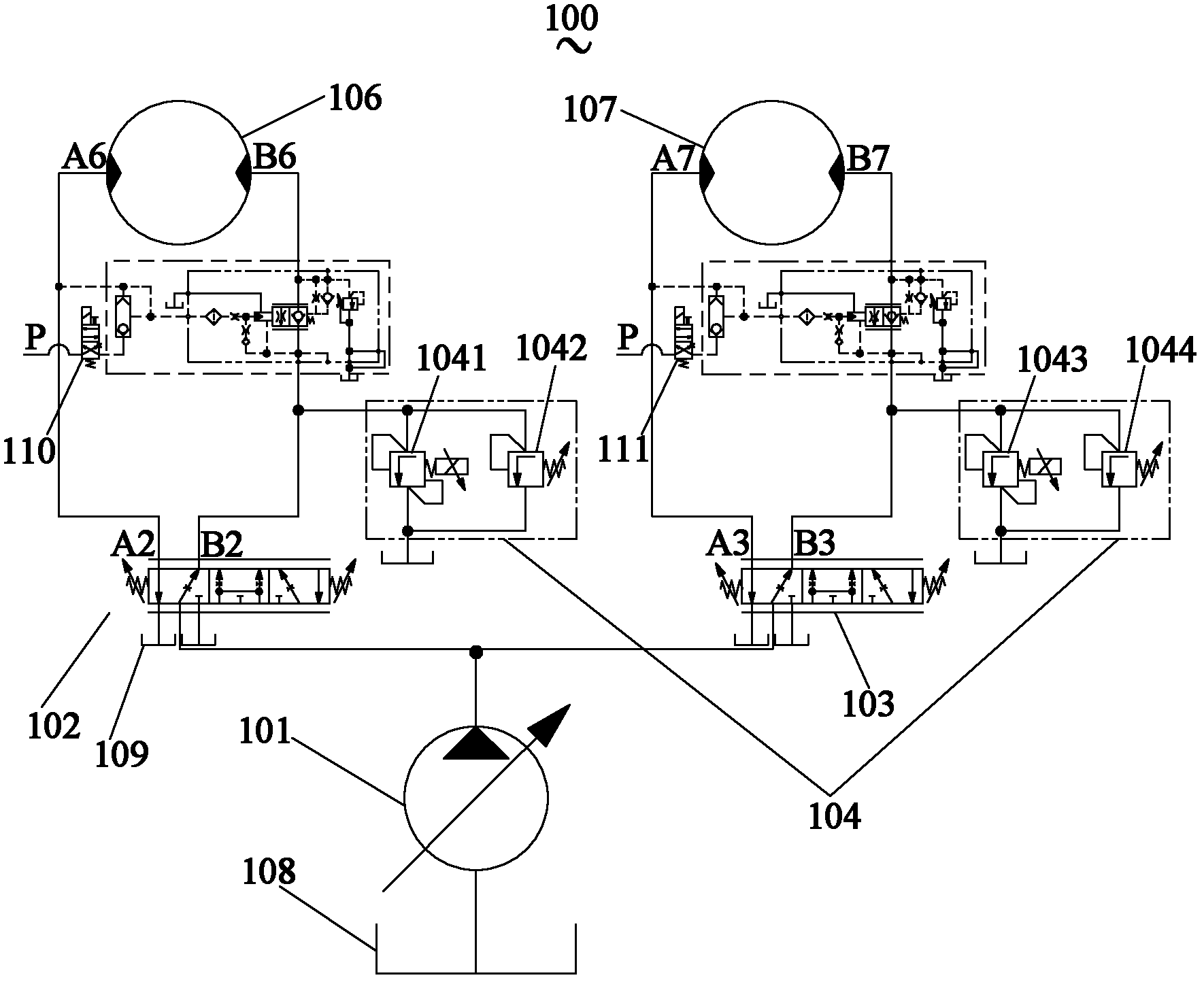

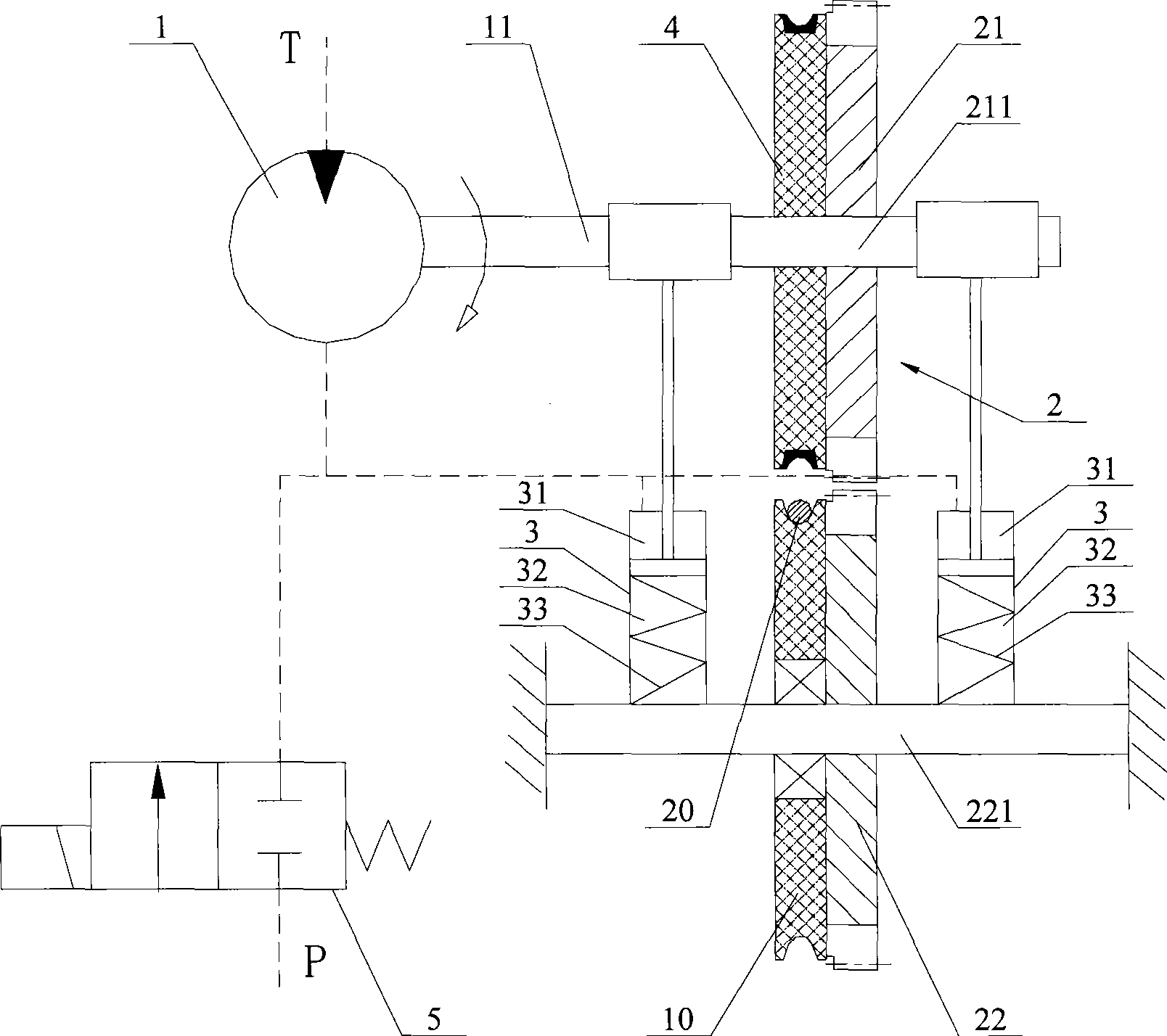

Hydraulic rope unreeling control system, hydraulic rope reeling control system and crane

ActiveCN102556872AAvoid tangled ropeEasy to debugWinding mechanismsLoad-engaging elementsHydraulic brakeControl system

The invention discloses a hydraulic rope unreeling control system and a hydraulic rope reeling control system, which respectively comprise an oil pump, a first reversing valve, a second reversing valve, a first motor, a second motor and a control unit. The oil pumps are connected with system oil sources, the first reversing valves and the second reversing valves, and the first reversing valves and the second reversing valves are connected with the first motors and the second motors. The hydraulic rope unreeling control system further comprises a rope unreeling unit which comprises a first balance valve unit and a second balance valve unit. The hydraulic rope reeling control system further comprises a rope reeling unit which comprises a first pressure regulating valve unit and a second pressure regulating valve unit. The control units are used for controlling the first reversing valves, the second reversing valves, the rope unreeling unit and / or rope reeling unit. The invention further discloses a crane. By the aid of coordination of the two motors, rope reeling and unreeling of two winches can realize non-linear synchronization reliably, rope disordering can be avoided, operators can debug conveniently and cost is saved.

Owner:ZOOMLION HEAVY IND CO LTD

Crane hook falling velocity adjustment apparatus

InactiveCN101376486AImprove work efficiencyIncreased lifting capacityWinding mechanismsLoad-engaging elementsControl signalControl theory

The invention discloses a hook-falling speed adjusting apparatus of a crane hook, which comprises a drive mechanism and a transmission organ. The transmission organ receives the source power output by the drive mechanism, and outputs the source power to an arm head pulley so as to realize the rotation of the arm head pulley. Preferably, a speed sensor and an arm head controller which are arranged on an arm head are also included; the speed sensor is used for detecting rotational speed of the arm head pulley; the arm head controller is used for receiving rotational speed signals acquired by the speed sensor, transforming the rotational speed signals into wire rope speed signals which are then compared with a preset value, and outputting a control signal to control the source power output of the drive mechanism. By the two main components that are the drive mechanism and the transmission organ, the outside power is output to the arm head pulley which drives a wire rope to raise the speed synchronously, so as to further drive the crane hook to fall fleetly. The optimal proposal realizes the hook-falling speed control through the arm head controller and the speed sensor.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

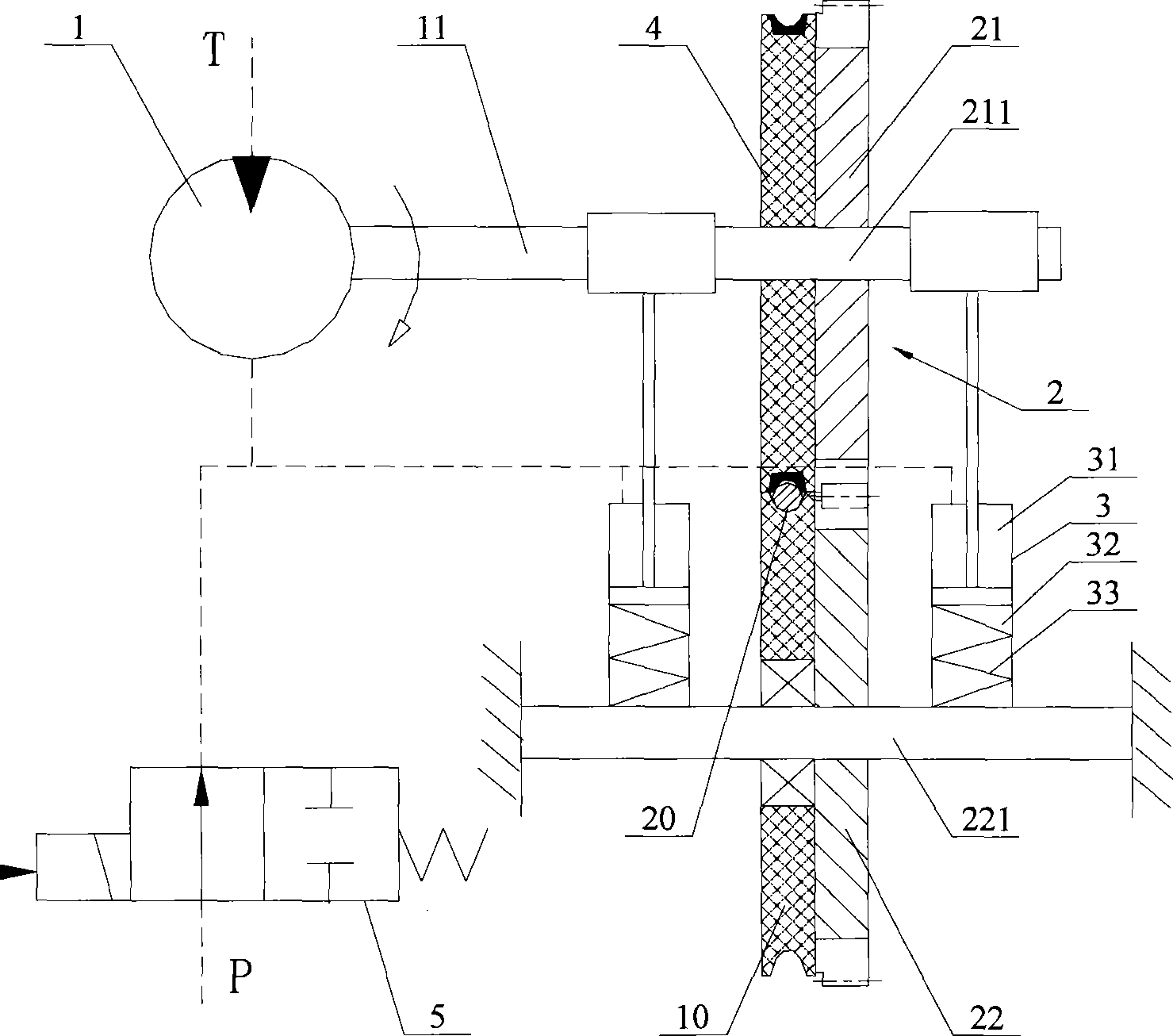

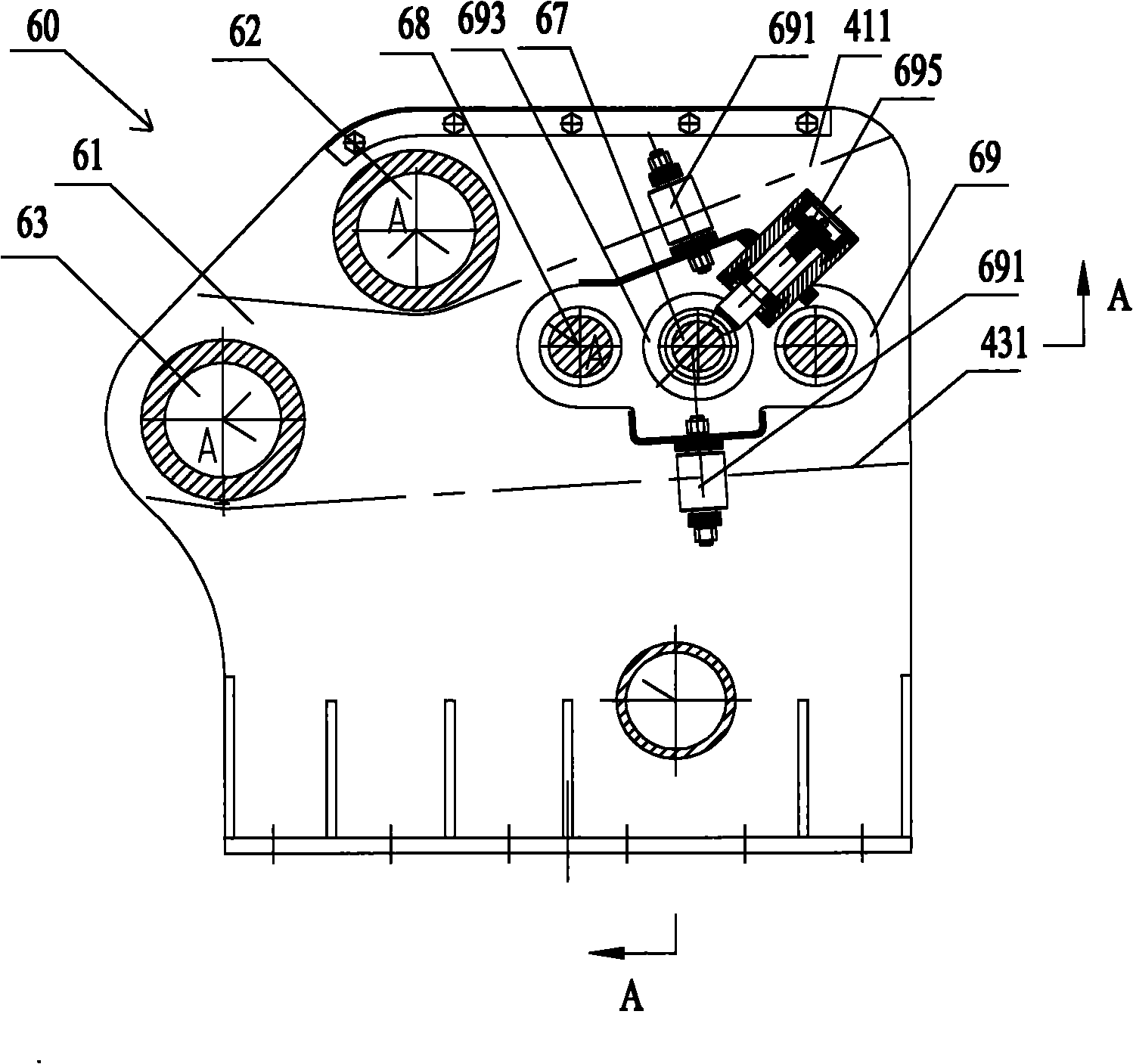

Movable manned elevator and elevator working mechanism thereof

InactiveCN101913548AAvoid tangled ropeImprove securityLifting devicesCantileverMechanical engineering

The invention discloses an elevator working mechanism for a manned elevator, which comprises a turntable bearing seat, a cantilever crane mechanism, a counter weight, a winch assembly and a cage. The cantilever crane mechanism comprises a suspension arm assembly, an amplitude cylinder, an arm head part and a leveling cylinder, wherein one end of the suspension arm assembly is hinged on the turntable bearing seat; two ends of the amplitude cylinder are connected with the turntable bearing seat and the suspension arm assembly respectively, and the amplitude cylinder is used for driving the suspension arm assembly to rotate longitudinally around the turntable bearing seat; the arm head part is pivotably connected with the second end of the suspension arm assembly; and two ends of the leveling cylinder is movably connected with the turntable bearing seat and the arm head part respectively to form a triangle structure, and the leveling cylinder is used for matching with the amplitude cylinder to control a pivot angle of the arm head part relative to the suspension arm assembly. Due to the adoption of the stable triangle structure formed among the leveling cylinder, the suspension arm assembly and the arm head part, the elevator working mechanism for the manned elevator solves the problems of low synchronicity of the suspension arms which are controlled by two elevators and low stability and safety of the cage in the prior art; meanwhile, the invention also provides a movable manned elevator.

Owner:SANY GRP +1

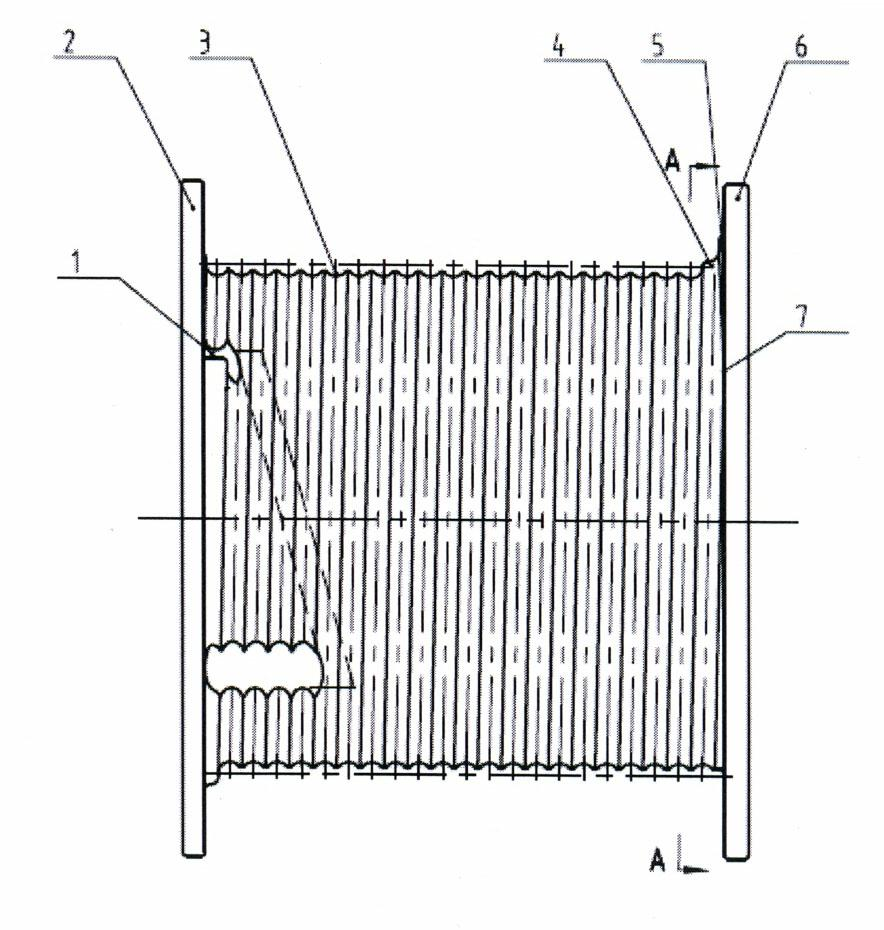

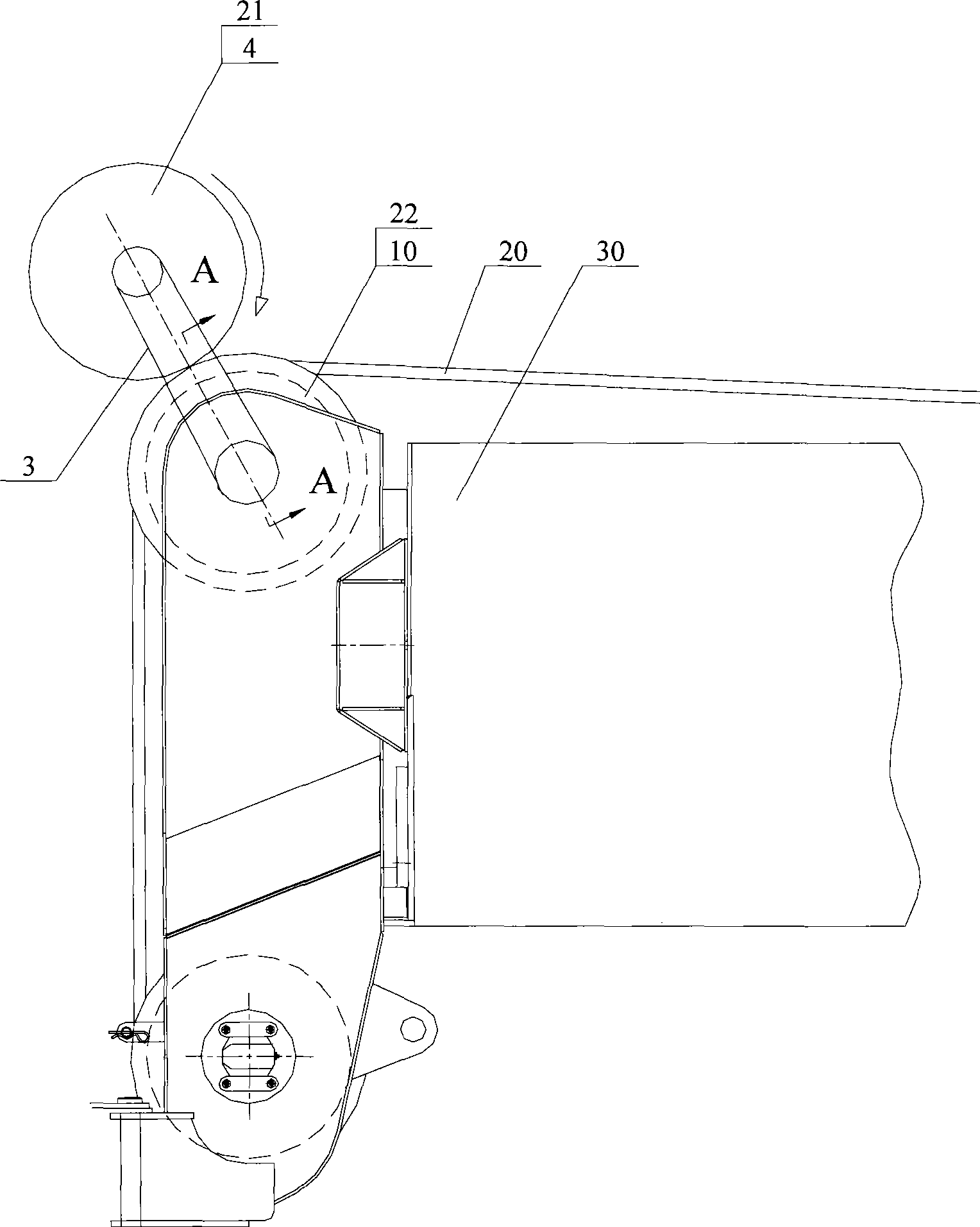

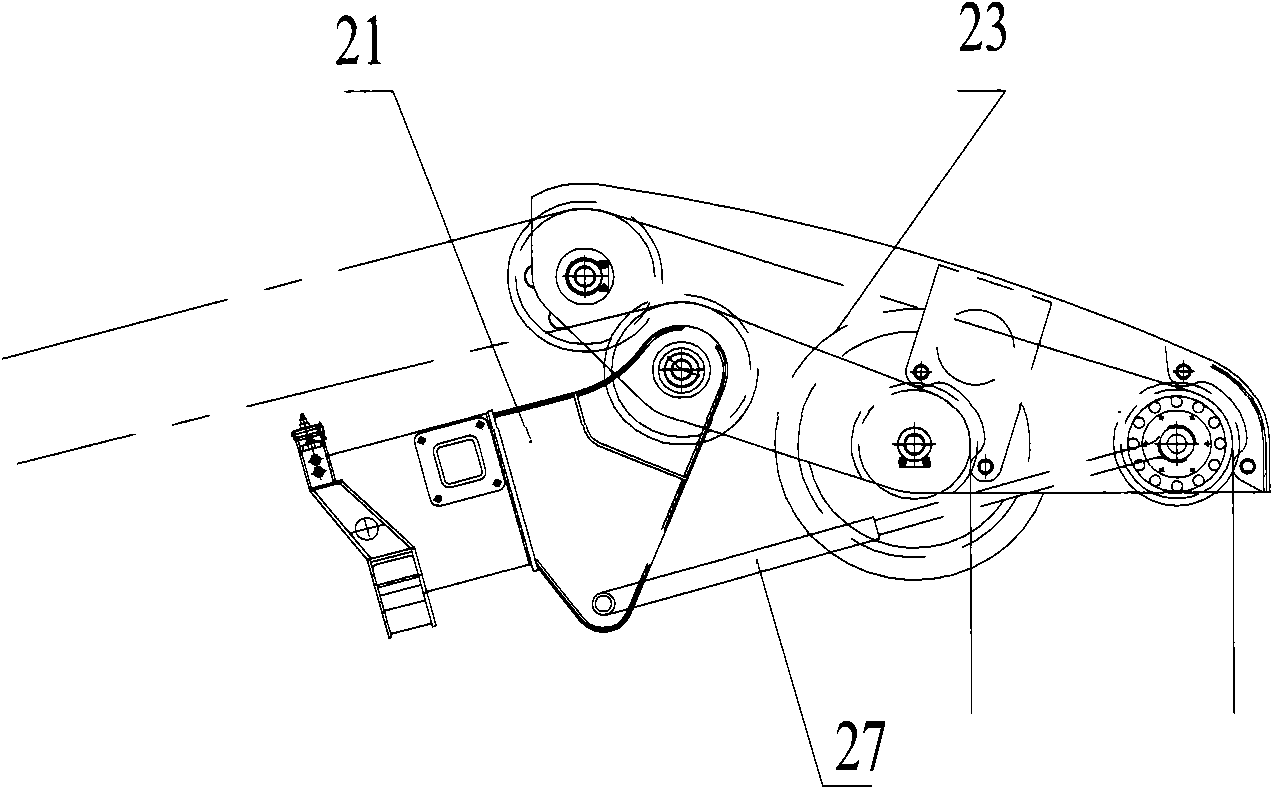

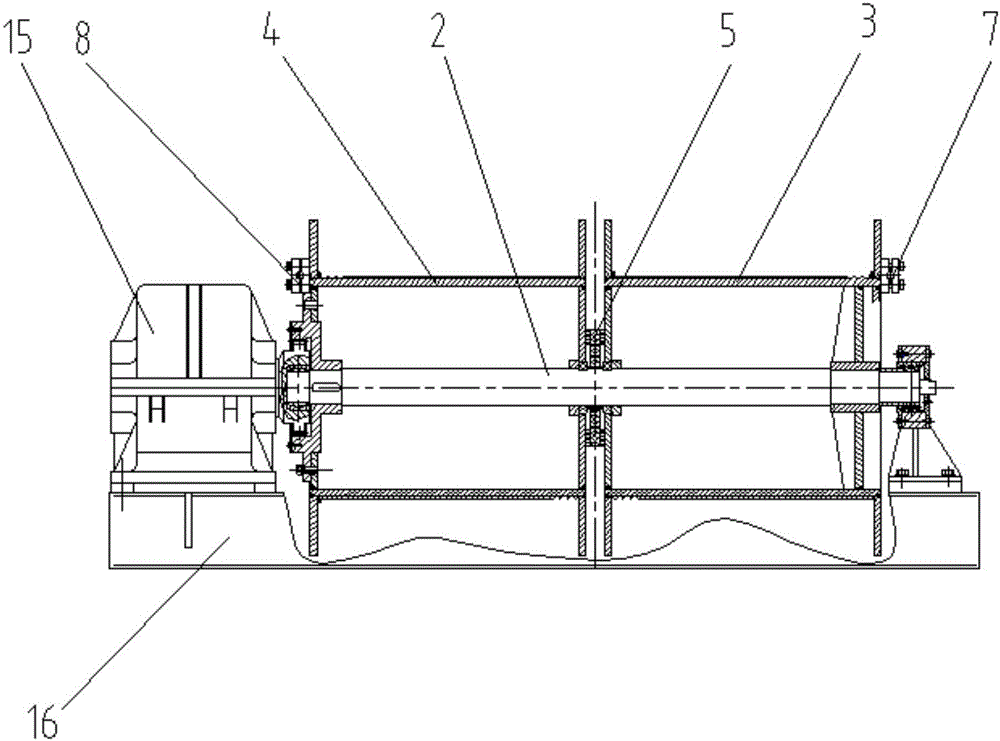

Hoisting traction mechanism of arm line-like cantilever crane

The invention discloses a hoisting traction mechanism of an arm line-like cantilever crane, which comprises a winding drum, main beams, an underframe and a hoisting hook and is characterized in that: the underframe is provided with a hoisting driving device and a winding drum, and is arranged in a neutral position in the middle of the lower parts of the two main beams, a guide pulley is fixed on one side of the winding drum, a reversing pullet is fixed at the upper end of the main beam, two fixed pulleys are fixed on a wheel box of an operating trolley, a movable pulley is assembled with the hoisting hook together, a balance pulley is arranged on a fixed frame and fixed on an end beam through connecting bolts, and wire ropes are fixed on two sides of a winding drum stop ring by pressure plates. The hoisting traction mechanism has the advantages that the hoisting traction mechanism can ensure the hoisting of the arm line-like cantilever crane, has low cost, ensures that the wire ropes entering the winding drum are arranged orderly in the hoisting process, prevents the messy ropes and prolongs the service life of the wire ropes.

Owner:WEIHUA GROUP

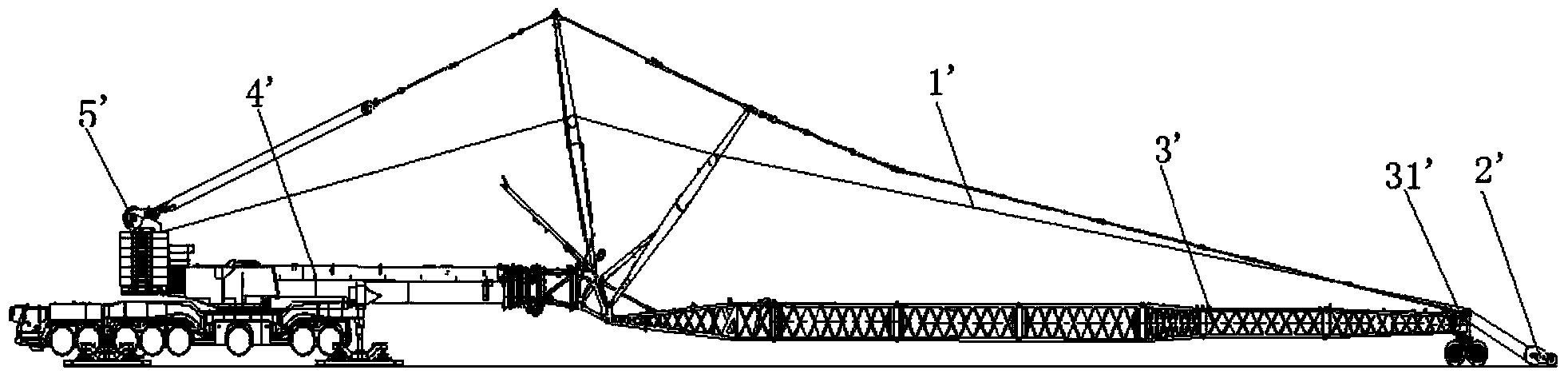

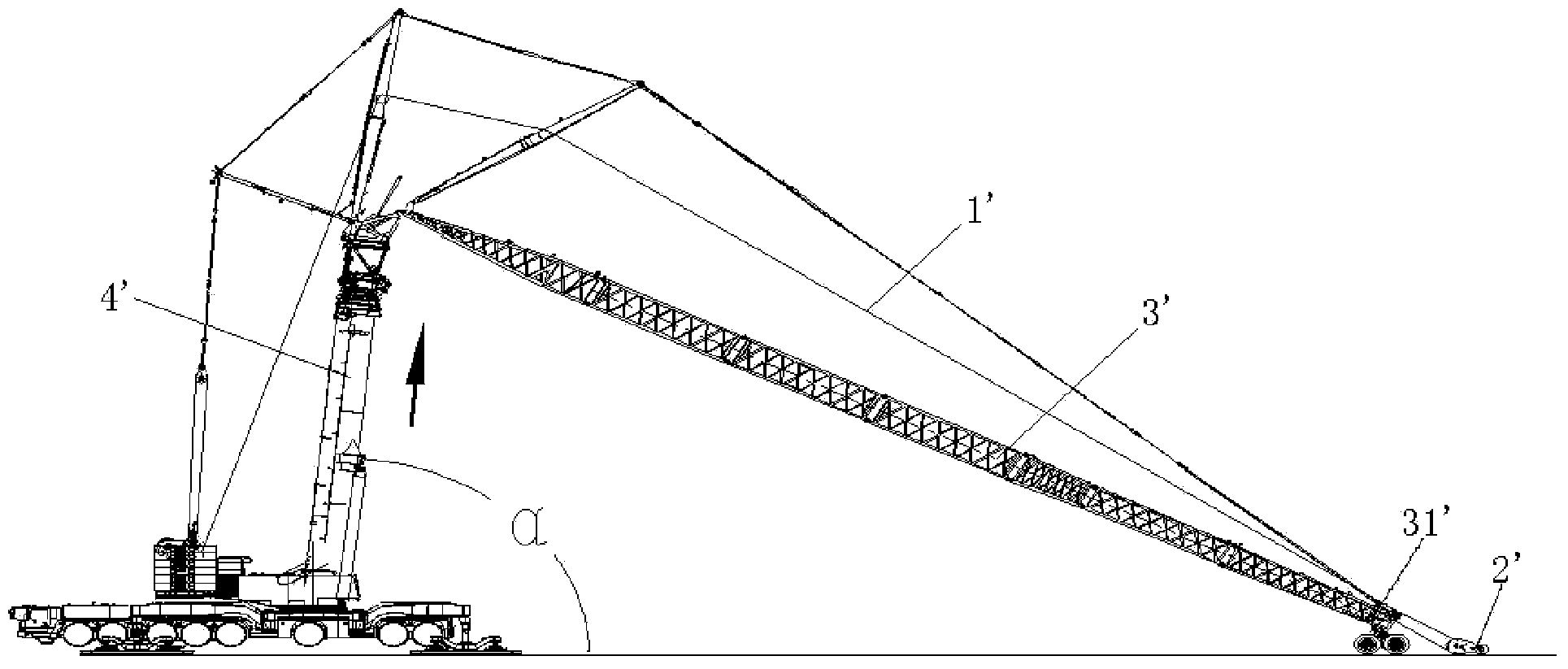

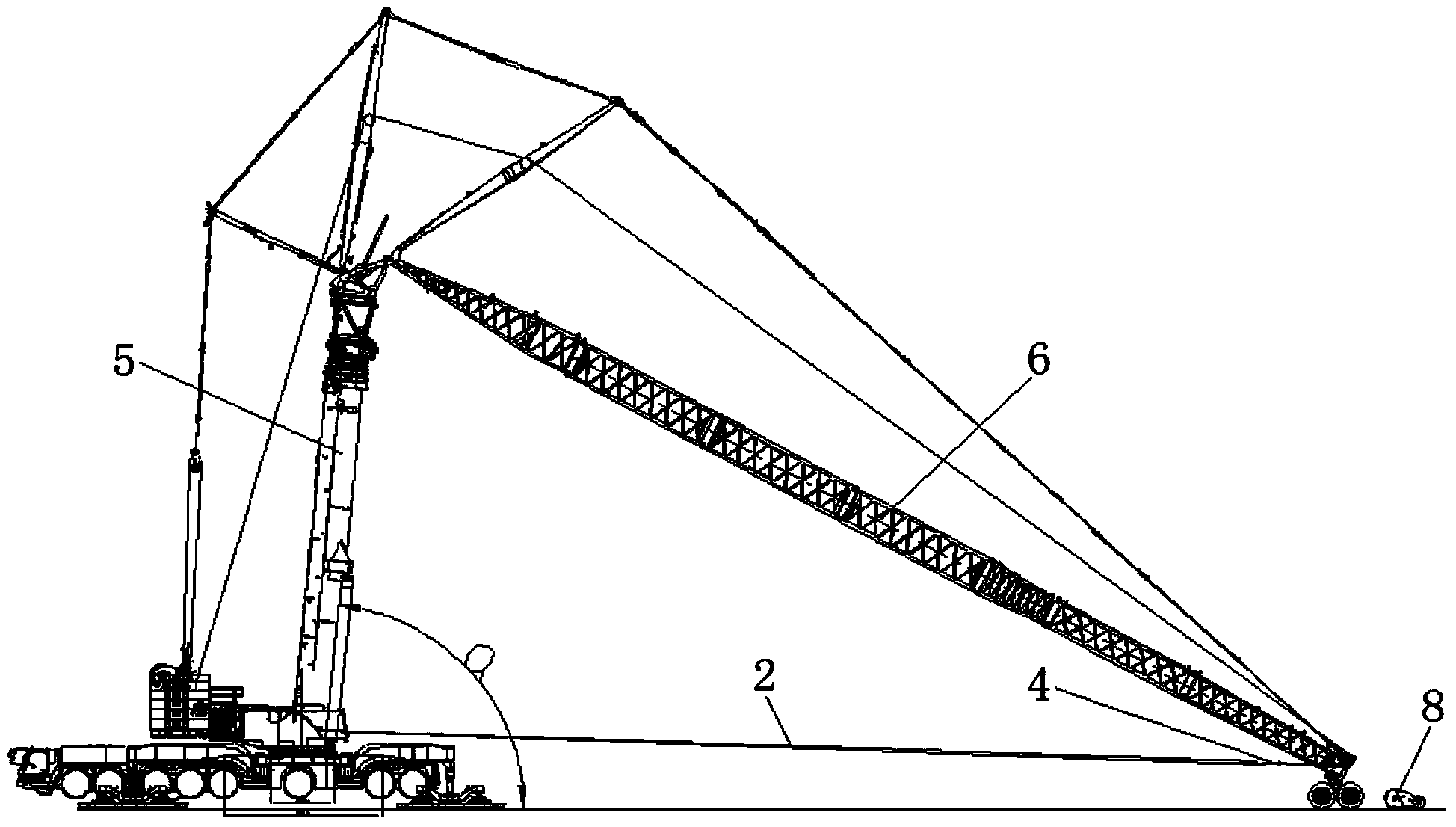

Hoisting and winching control device capable of preventing rope from messing and control method

The invention relates to a hoisting and winching control device capable of preventing a rope from messing and a control method. The hoisting and winching control device comprises a stringing winch and an auxiliary steel wire rope, wherein one end of the auxiliary steel wire rope is fixedly connected to the stringing winch, and the other end thereof winds the stringing winch and then is connected with a hoisting steel wire rope winding an arm head of a crane, so as to enable the hoisting steel wire rope to be in a tensioning state. The hoisting and winching control device disclosed by the invention enables the hoisting steel wire rope to be in the tensioning state during the arm rising and descending processes, so as to prevent the situation that the weight of the hoisting steel wire rope in front of a main arm is lighter than that of the hoisting steel wire rope in the back of the main arm, and avoid the rope messing phenomenon of the hoisting steel wire rope.

Owner:XUZHOU HEAVY MASCH CO LTD

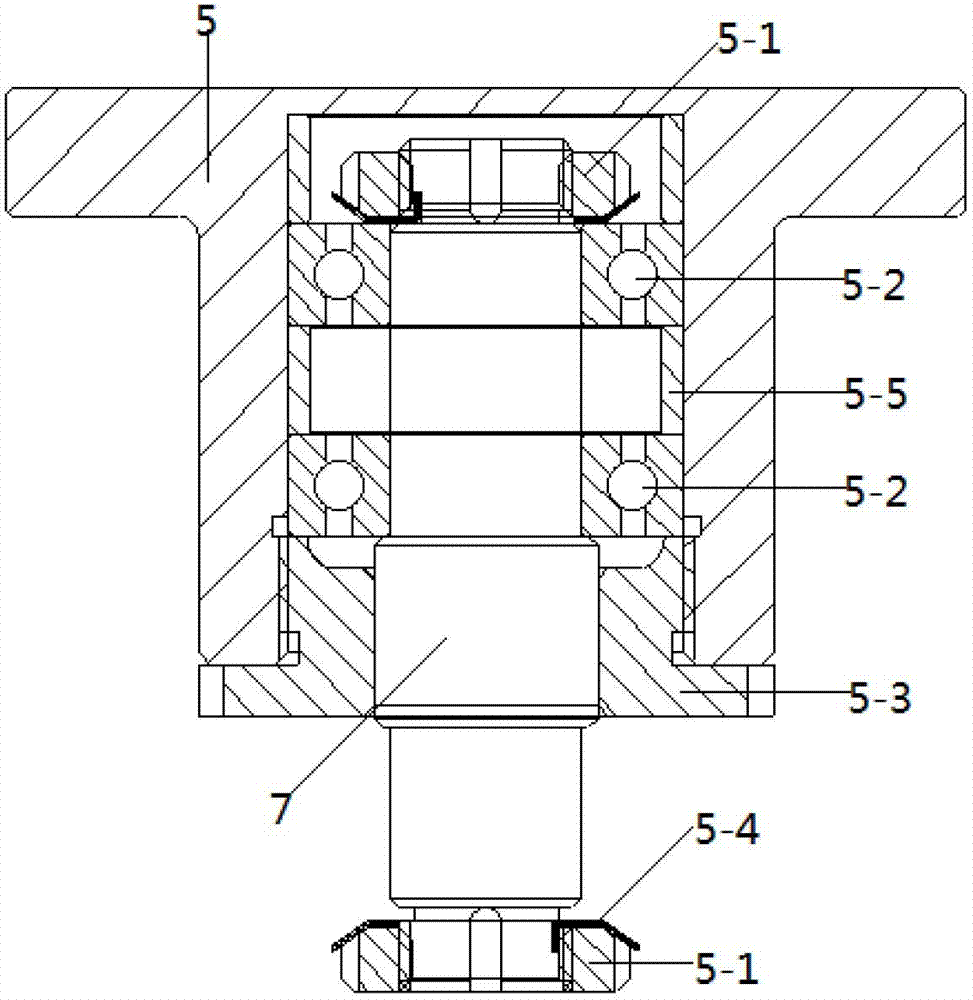

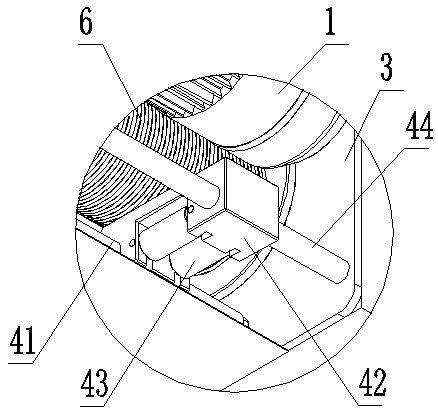

Reel device and hoisting mechanism of crane

The invention discloses a reel device and a hoisting mechanism of a crane. The reel device comprises a work rope (1) and at least two reel bodies, wherein the work rope (1) is wound on the at least two reel bodies, so that the number of layers of the work rope (1) wound on each of the at least two reel bodies can be reduced. According to the reel device, the possibility of avoiding the occurrence of a rope clutterphenomenon is provided.

Owner:ZOOMLION HEAVY IND CO LTD

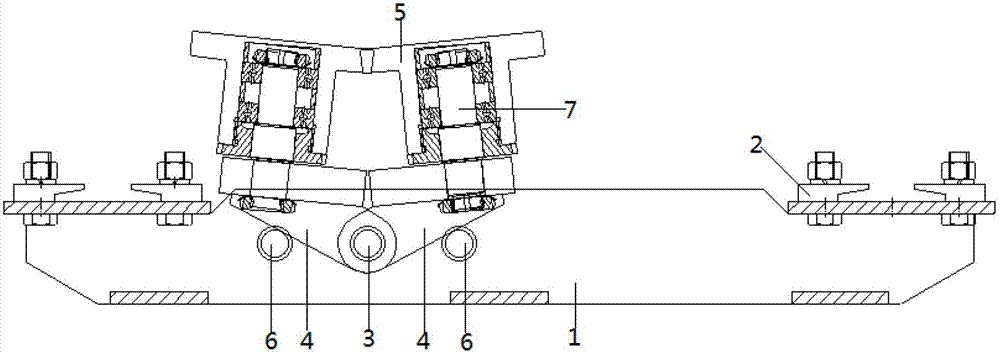

Pressing rope wheel device for endless rope continuous tractor

The invention discloses a pressing rope wheel device for an endless rope continuous tractor. The pressing rope wheel device comprises a pressing rope wheel bottom frame; rail pressing plates are fixedly arranged at two ends of the bottom frame through bolts; a group of two vertical wheel swinging frames are rotatably arranged on the pressing rope wheel bottom frame through a pin shaft; a pressing rope wheel is arranged on each swinging frame through a shaft; and pin shafts are arranged on the pressing rope wheel bottom frame and positioned below the two vertical wheel swinging frames. In the normal running process of an endless rope continuous tractor system, the pressing rope wheel device can press and position a steel wire rope, so that the phenomenon that the steel wire rope is messed, and the service life of the steel wire rope can be prolonged.

Owner:ANHUI PROVINCE SUZHOU CITY LONGHUA MACHINERY MFG

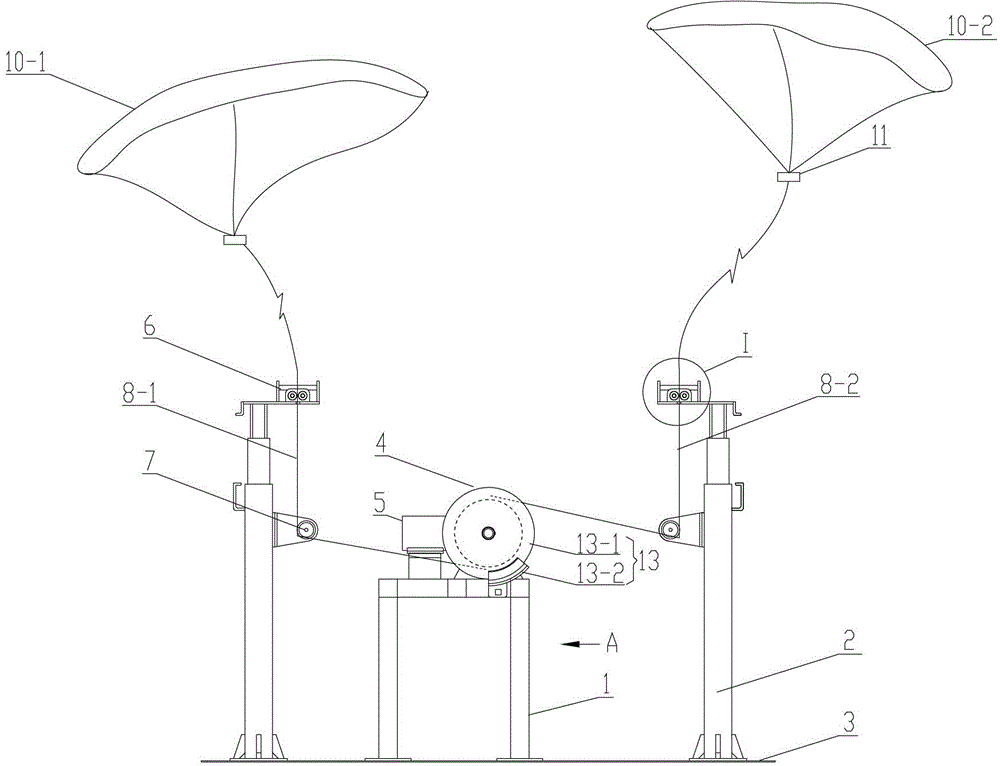

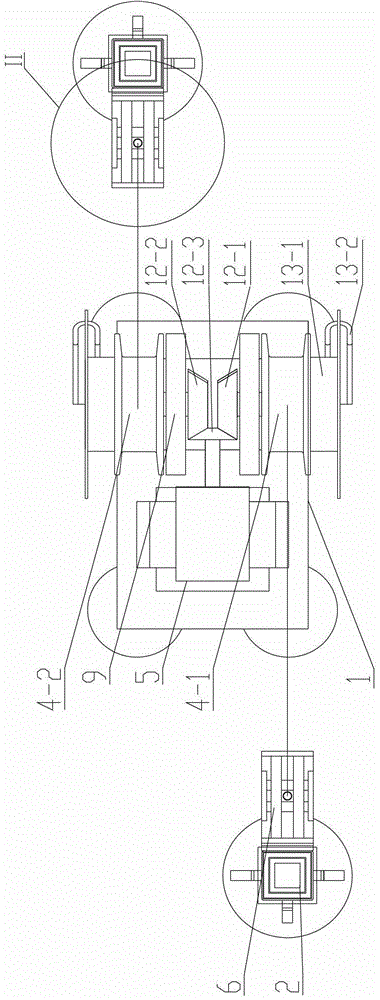

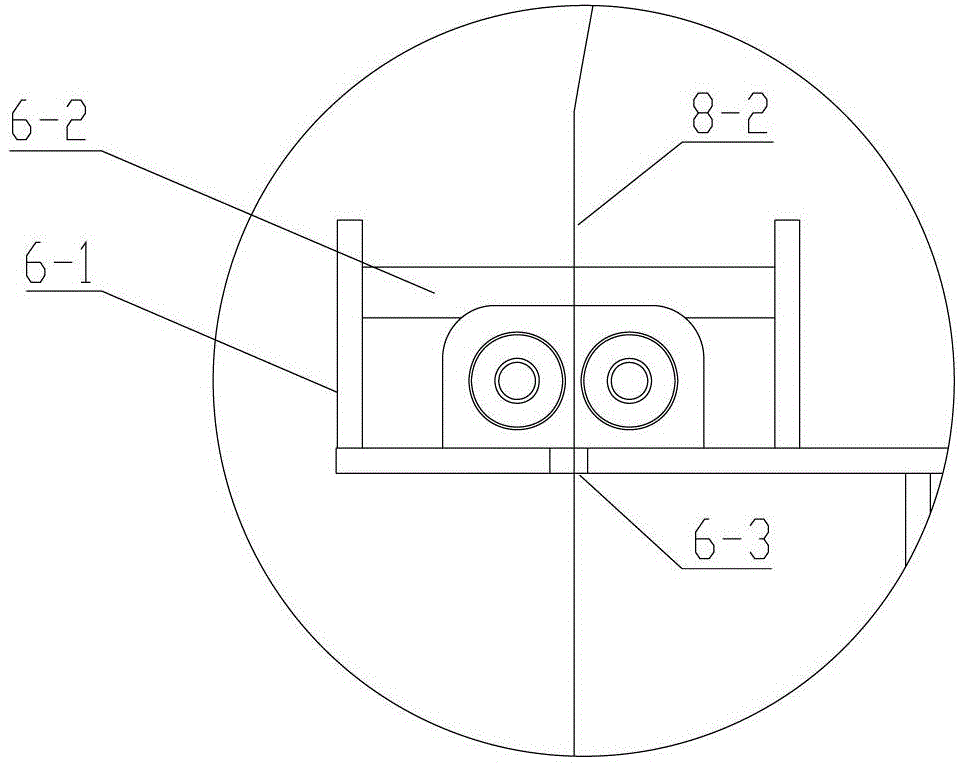

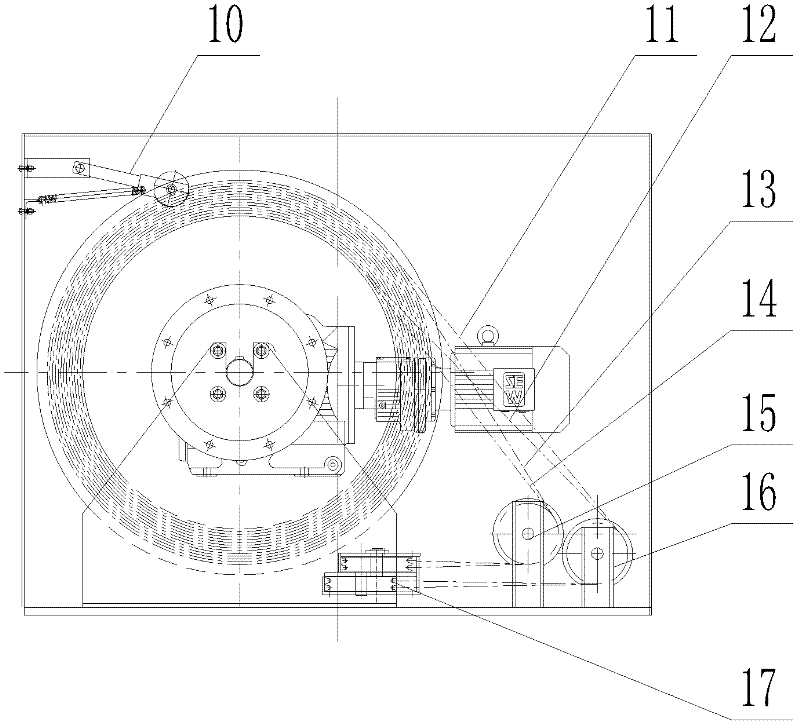

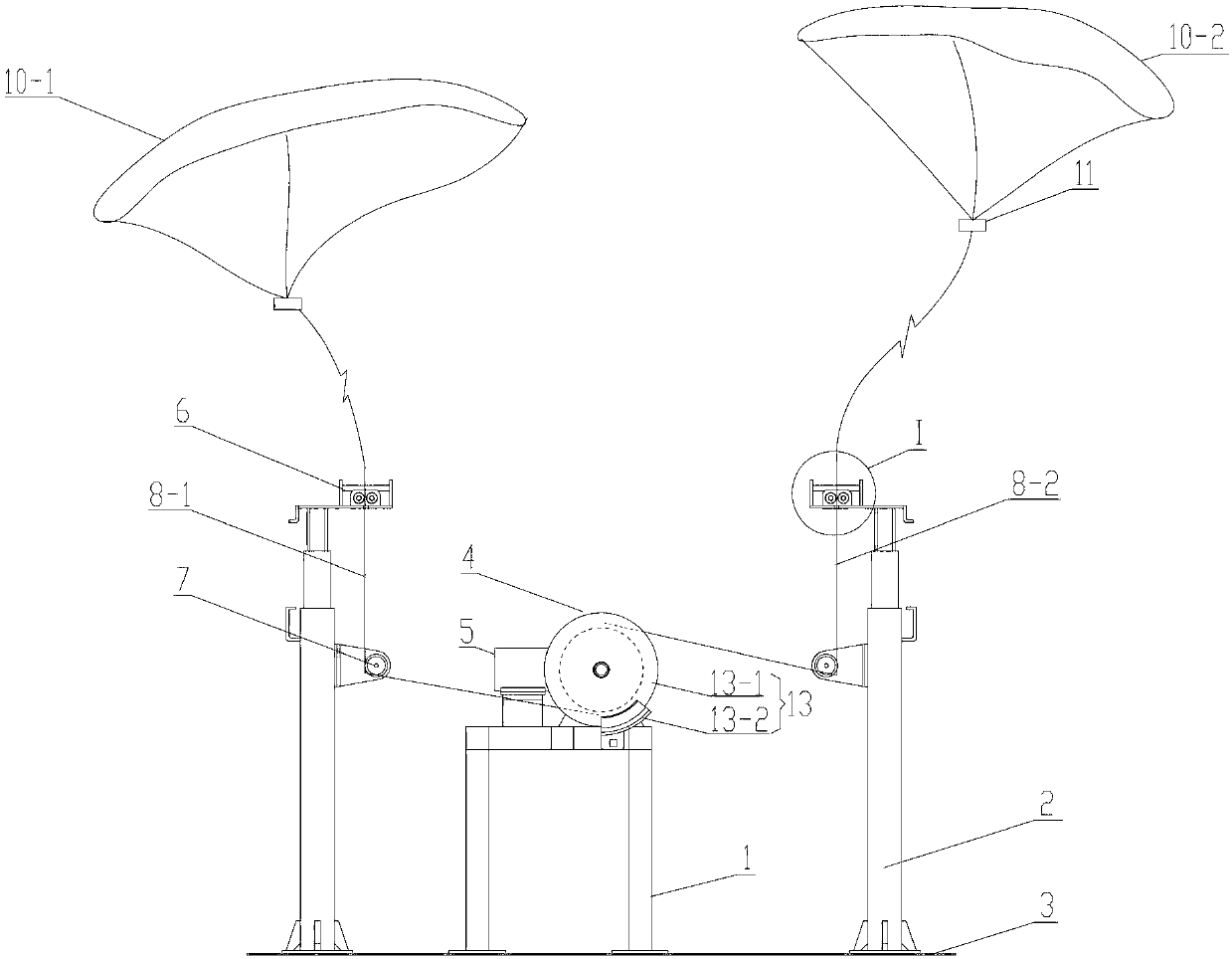

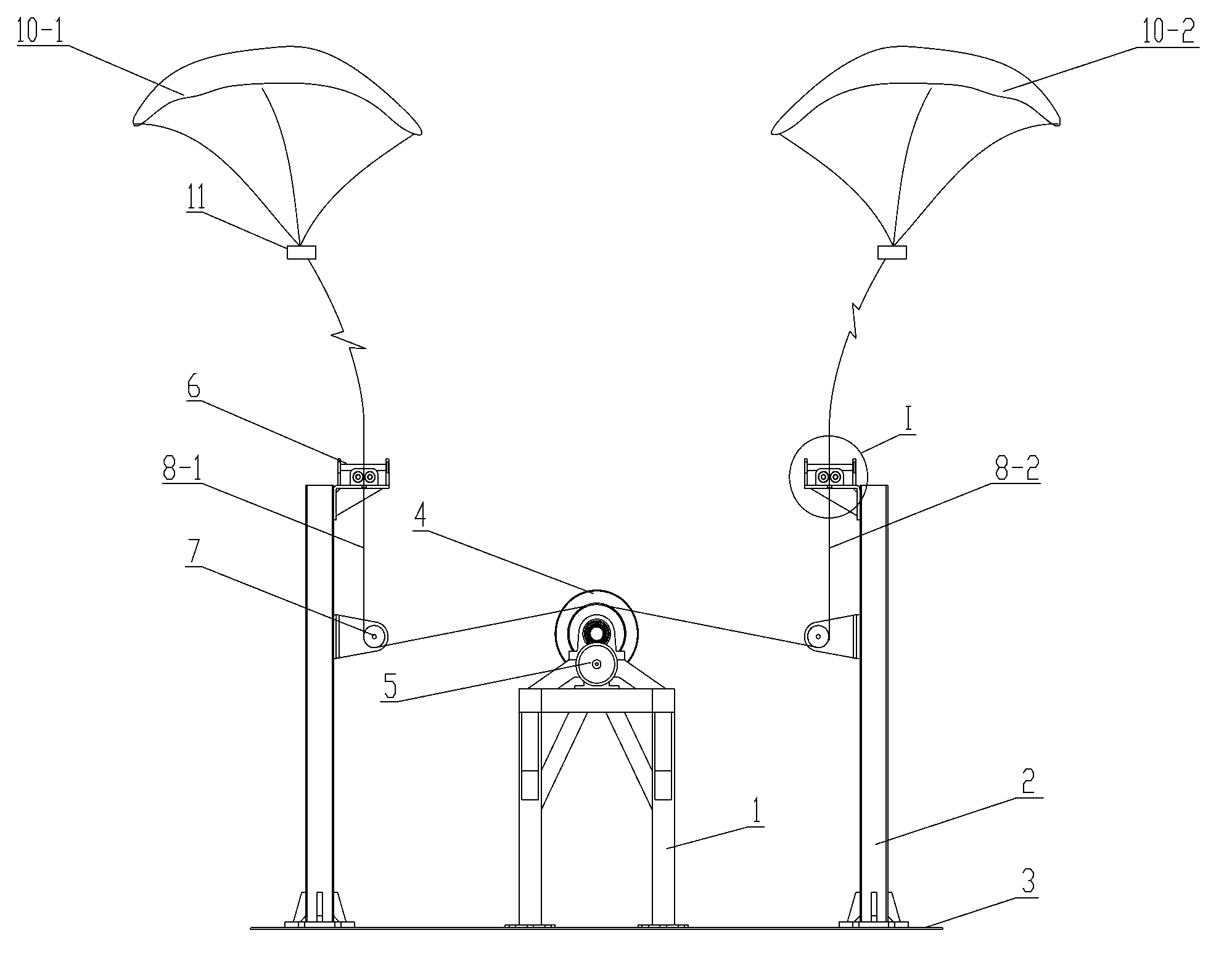

Wind power conversion mechanism and high altitude wind power generator

ActiveCN102979670ANo entanglementStable power generationWind motor controlMachines/enginesHigh-altitude wind powerWind energy conversion

The invention discloses a wind power conversion mechanism. The wind power conversion mechanism comprises reciprocating wheels, a generating-electromotion dual-purpose machine, universal rope guiding mechanisms and traction cables, wherein the reciprocating wheels comprise a first reciprocating wheel and a second reciprocating wheel; the generating-electromotion dual-purpose machine is in transmission connection with the first reciprocating wheel and the second reciprocating wheel through transmission parts; the universal rope guiding mechanisms are arranged at two sides of the reciprocating wheels; and the traction cables comprise a first cable and a second cable, the first cable is wound on the first reciprocating wheel, the second cable is reversely wound on the second reciprocating wheel, and the first cable and the second cable are used for connecting with one end of an aircraft to respectively wind the universal rope guiding mechanism at the corresponding side. The mechanism is compact in structure and stale in performance, can effectively avoid cable winding and can adapt to various wind directions, so that the wind power conversion efficiency can be obviously improved. The invention further discloses a high altitude wind power generator with the wind power conversion mechanism.

Owner:CHINA NAT COAL GROUP CORP

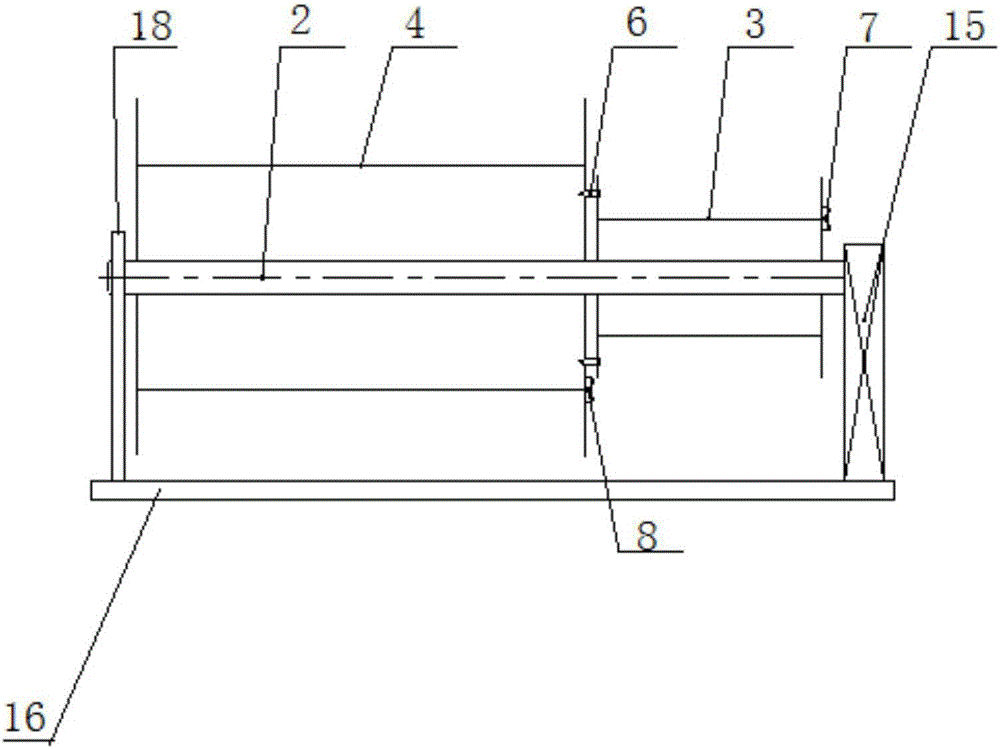

Double rope groove multi-layer hoisting mechanism

InactiveCN102283619AAvoid Rope ProblemsSimple structureCarpet cleanersFloor cleanersThird partyDrive shaft

The invention relates to a mechanical device in the technical field of building exterior wall cleaning, in particular to a double-rope groove multi-layer hoisting mechanism specially used in a window cleaning machine system. The invention mainly includes a reel supporting frame, a left bearing seat and a right bearing seat, a reel main body, a reduction motor, a left vertical pulley and a right vertical pulley, and a horizontal pulley block. The main transmission shaft of the reel is directly driven by the geared motor, and double rope grooves are used for winding, which avoids the problem of wire rope arranging, and through the effective installation of vertical pulleys, each wire rope in the two rope grooves is wound into the same A vertical pulley makes the steel wire rope passing through the first set of pulleys become the guide rope of the second set of pulleys, completely eliminating the need to use other third-party mechanisms to arrange the ropes, eliminating the phenomenon of rope chaos. Compared with the existing lifting mechanism, the lifting mechanism has the advantages of simple structure, flexible operation, safety and reliability.

Owner:SHANGHAI POINT HIGH RISE EQUIP

Wind energy conversion mechanism and upper-air wind power generation device

ActiveCN102996333ANo entanglementStable power generationWind motor combinationsMachines/enginesHigh-altitude wind powerWind energy conversion

The invention discloses a wind energy conversion mechanism which comprises reciprocating wheels, a dual-purpose electric motor-generator, universal guide rope mechanisms and traction cable rope, wherein the reciprocating wheels comprise a first reciprocating wheel and a second reciprocating wheel; the dual-purpose electric motor-generator is connected with the first reciprocating wheel and the second reciprocating wheel through a clutch driving mechanism; the universal guide rope mechanisms are arranged on two sides of the reciprocating wheels; the traction cable ropes comprise a first cable rope and a second cable rope; the first cable rope is arranged on the first reciprocating wheel; the second cable rope is wound on the second reciprocating wheel; the first cable rope and the second cable rope are used for being connected with one end of an aircraft and come across the universal guide rope mechanisms on corresponding sides. The wind energy conversion mechanism is compact in structure and stable in performance, cable ropes are effectively prevented from being twisted, and the wind energy conversion mechanism is applicable to various wind directions, so that the wind energy conversion efficiency is remarkably improved. The invention further discloses an upper-air wind power generation device with the wind energy conversion mechanism.

Owner:CHINA NAT COAL GROUP CORP

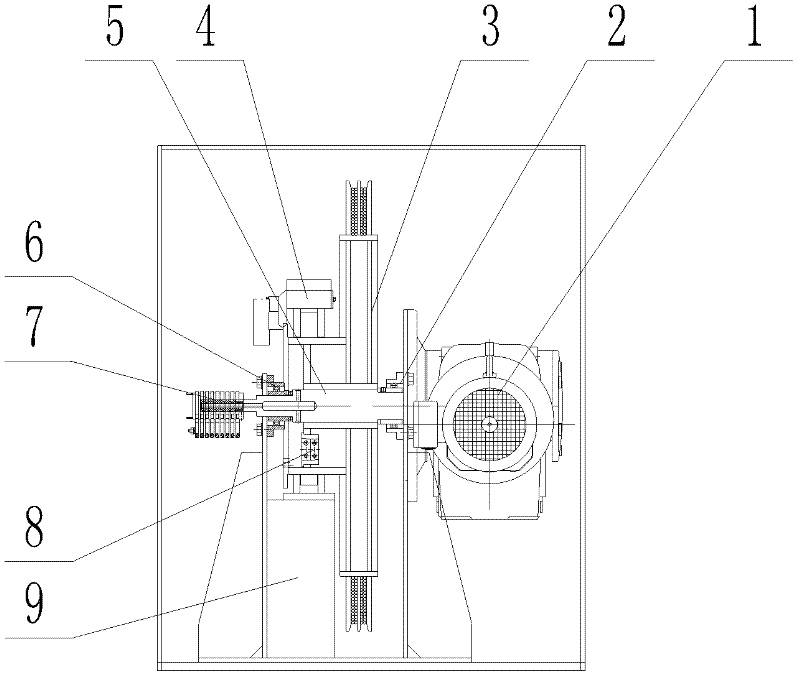

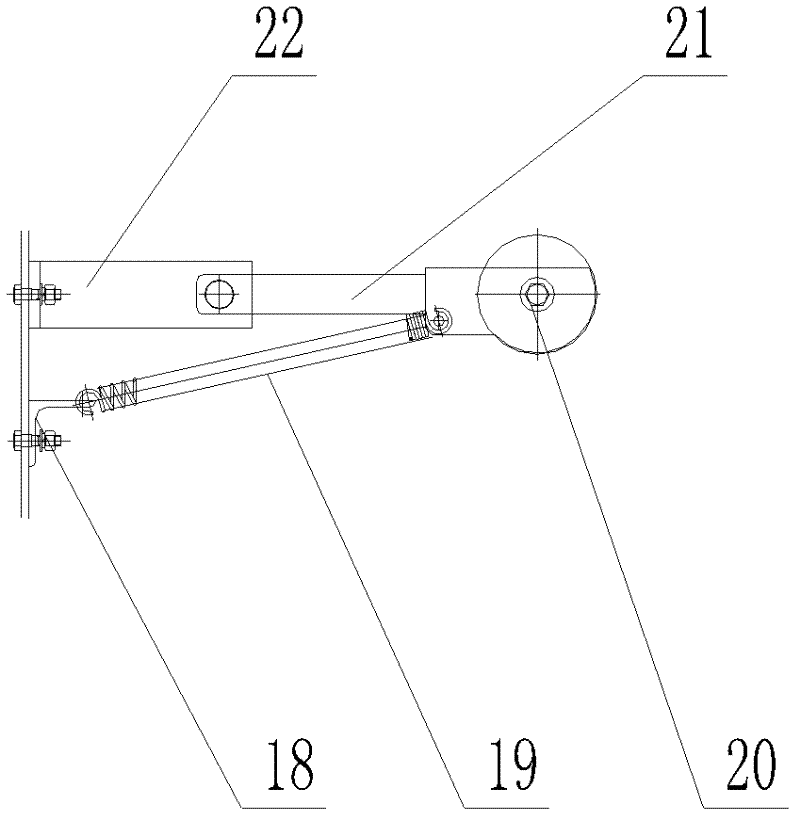

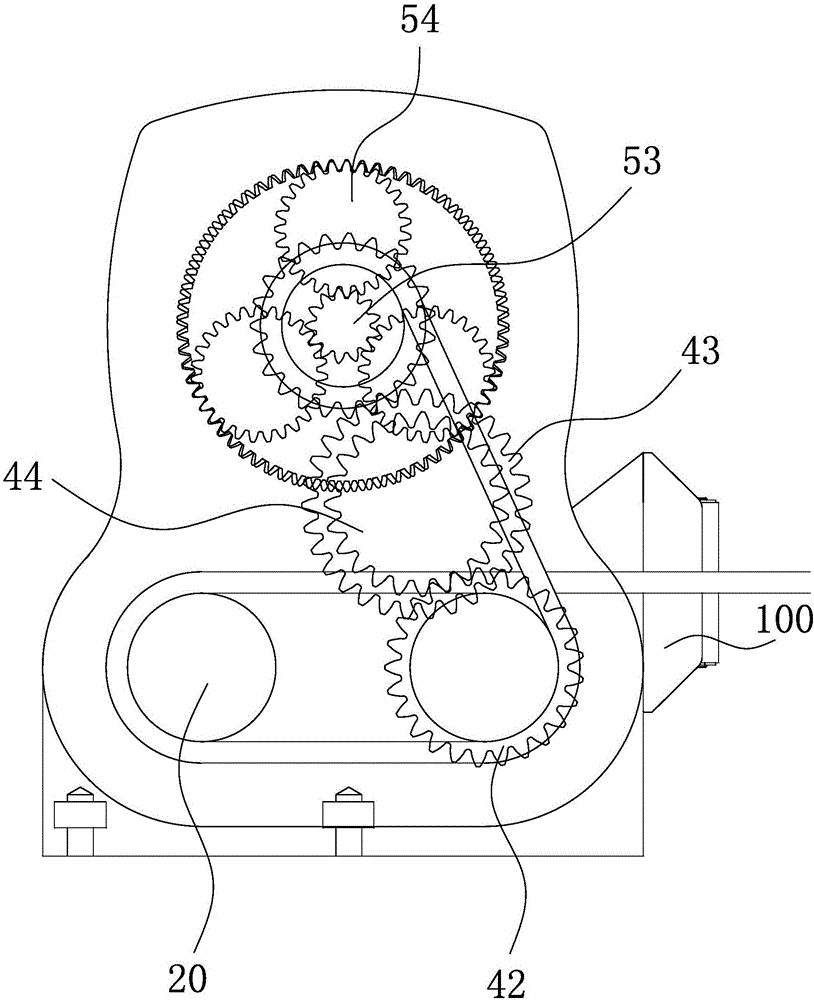

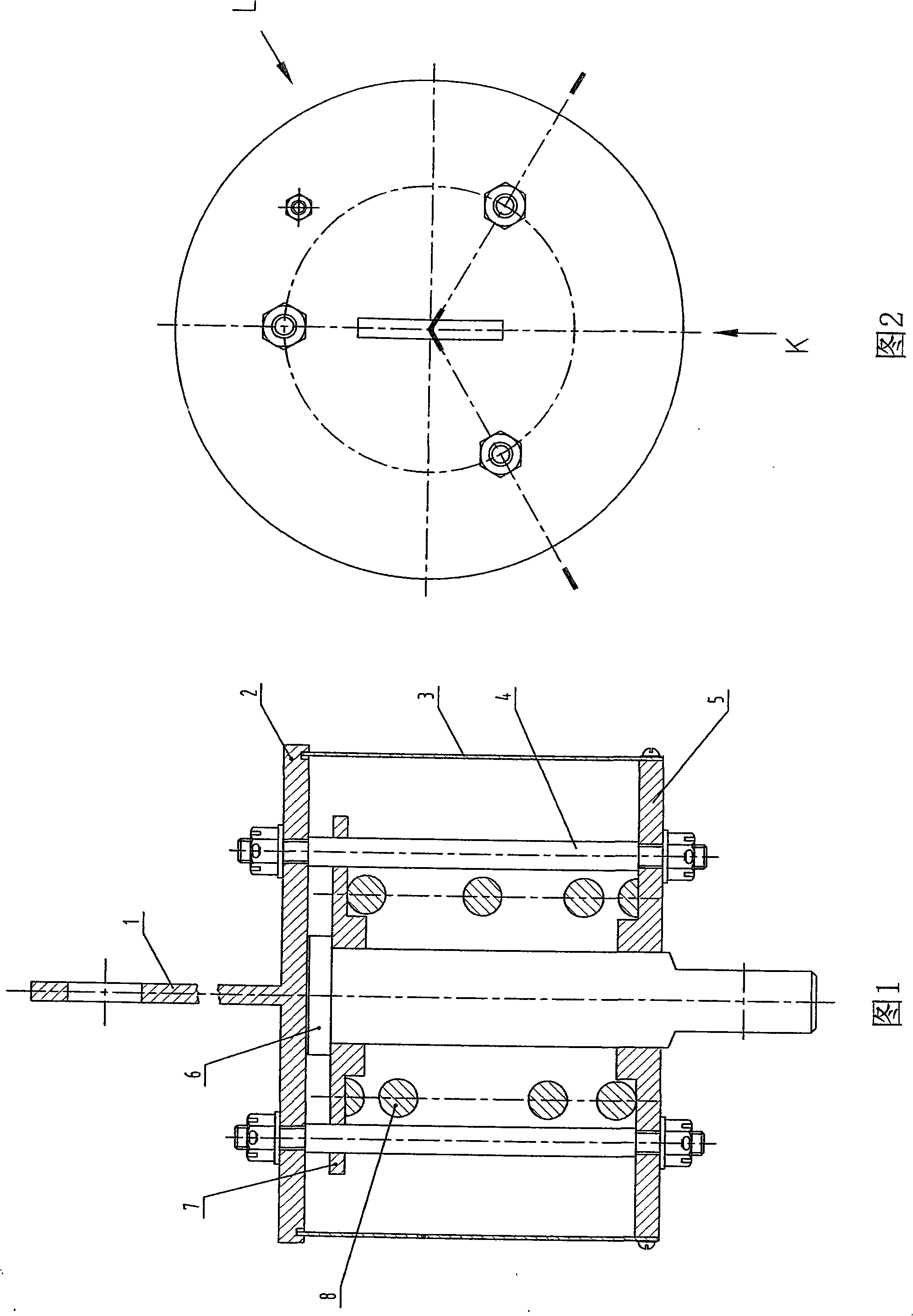

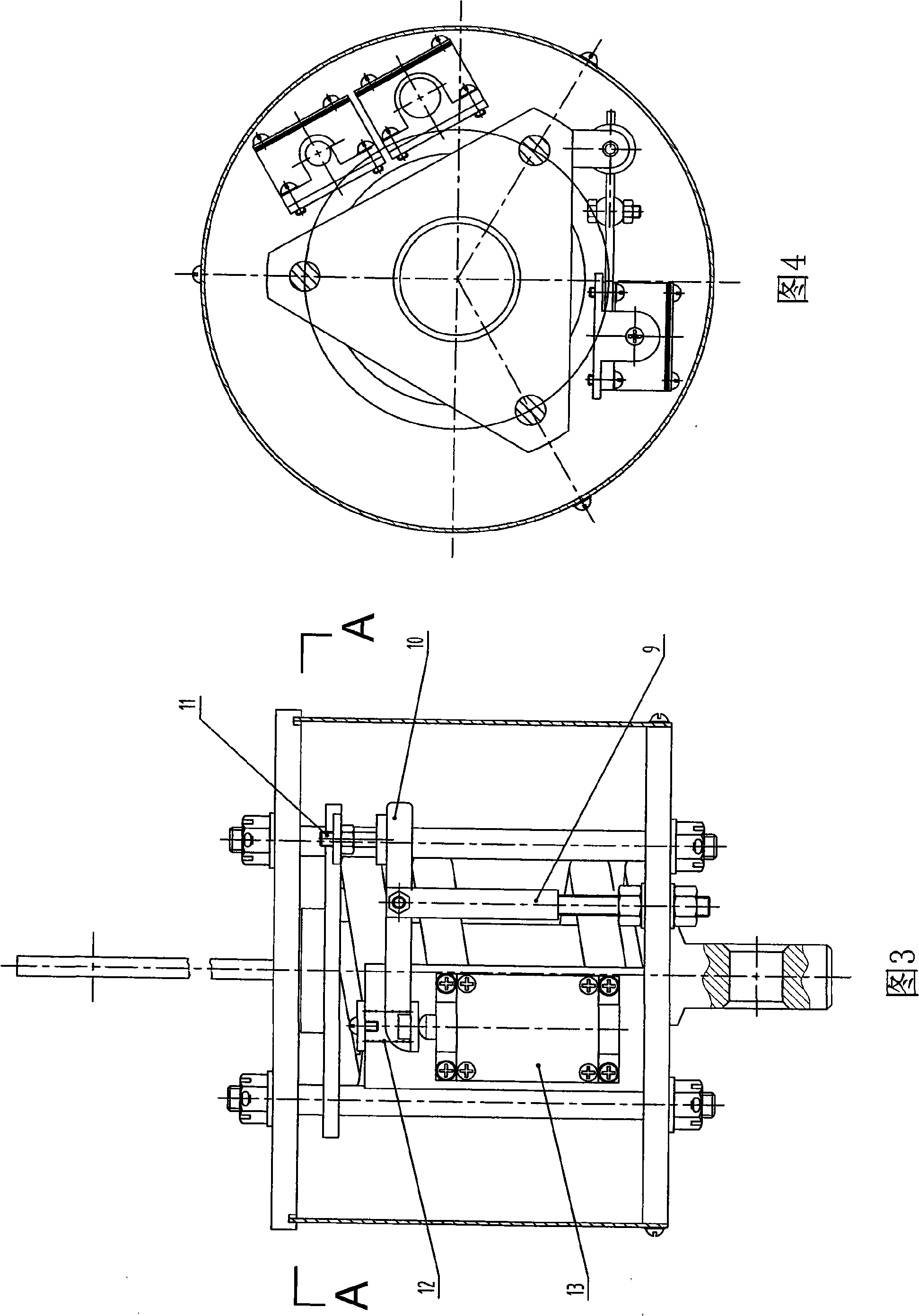

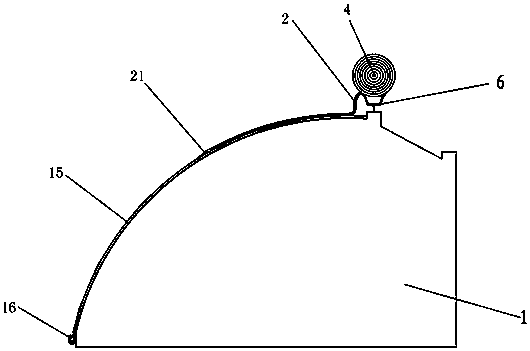

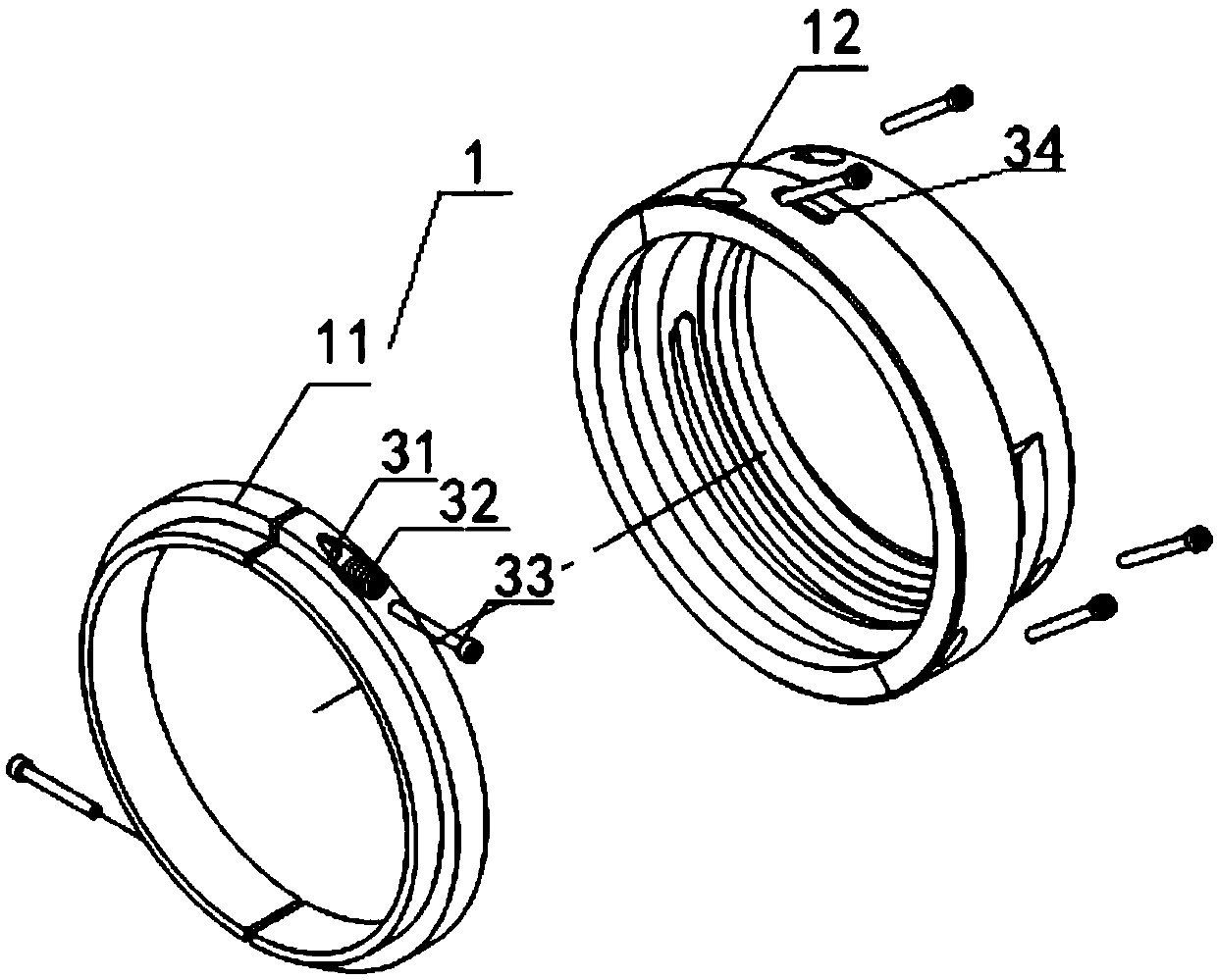

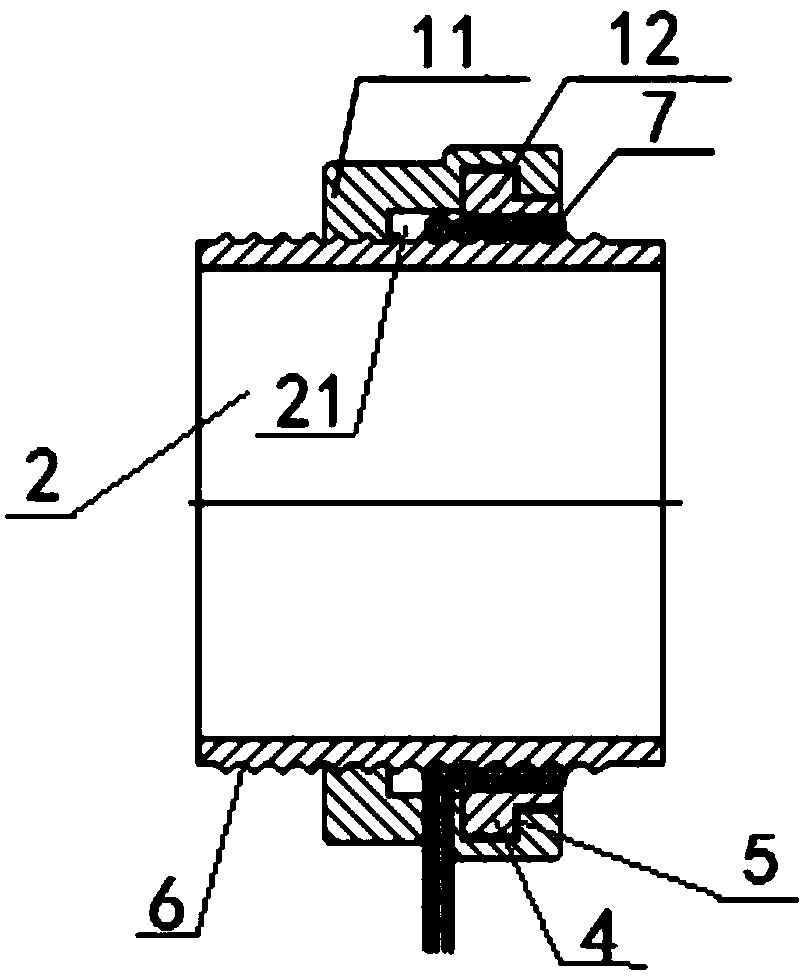

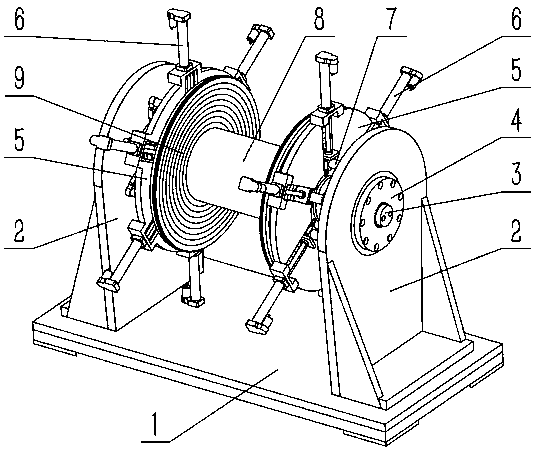

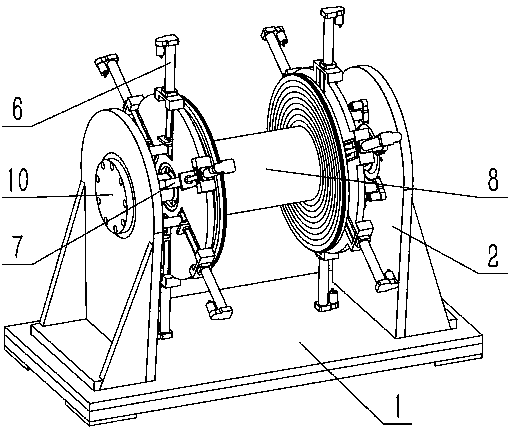

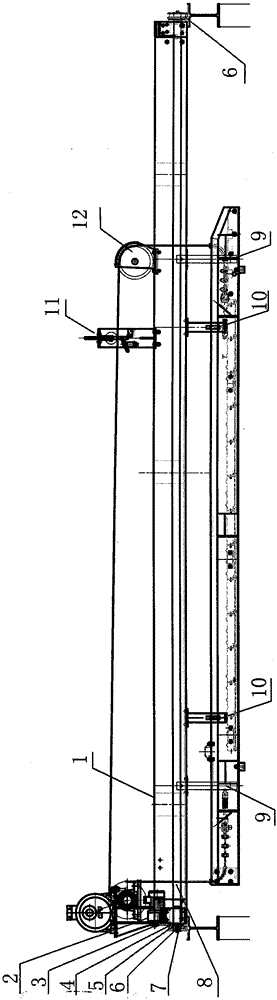

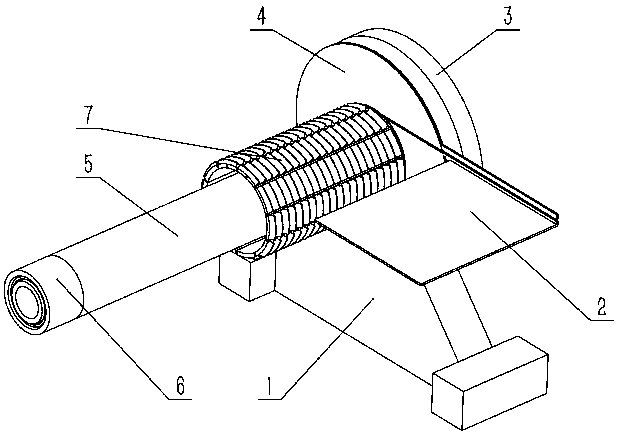

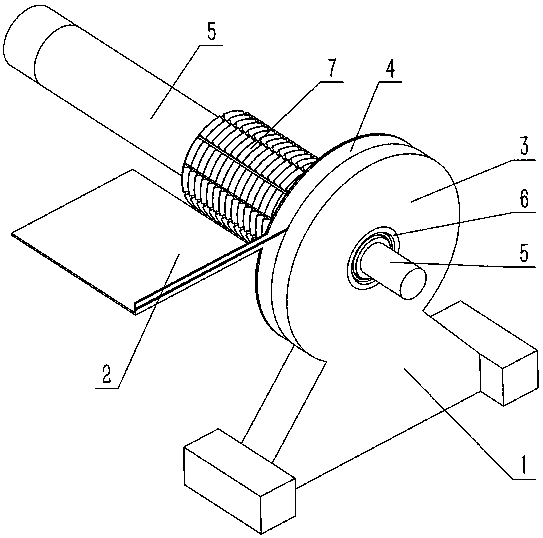

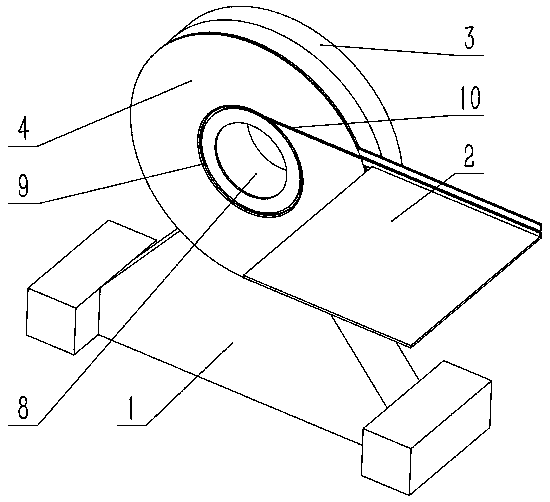

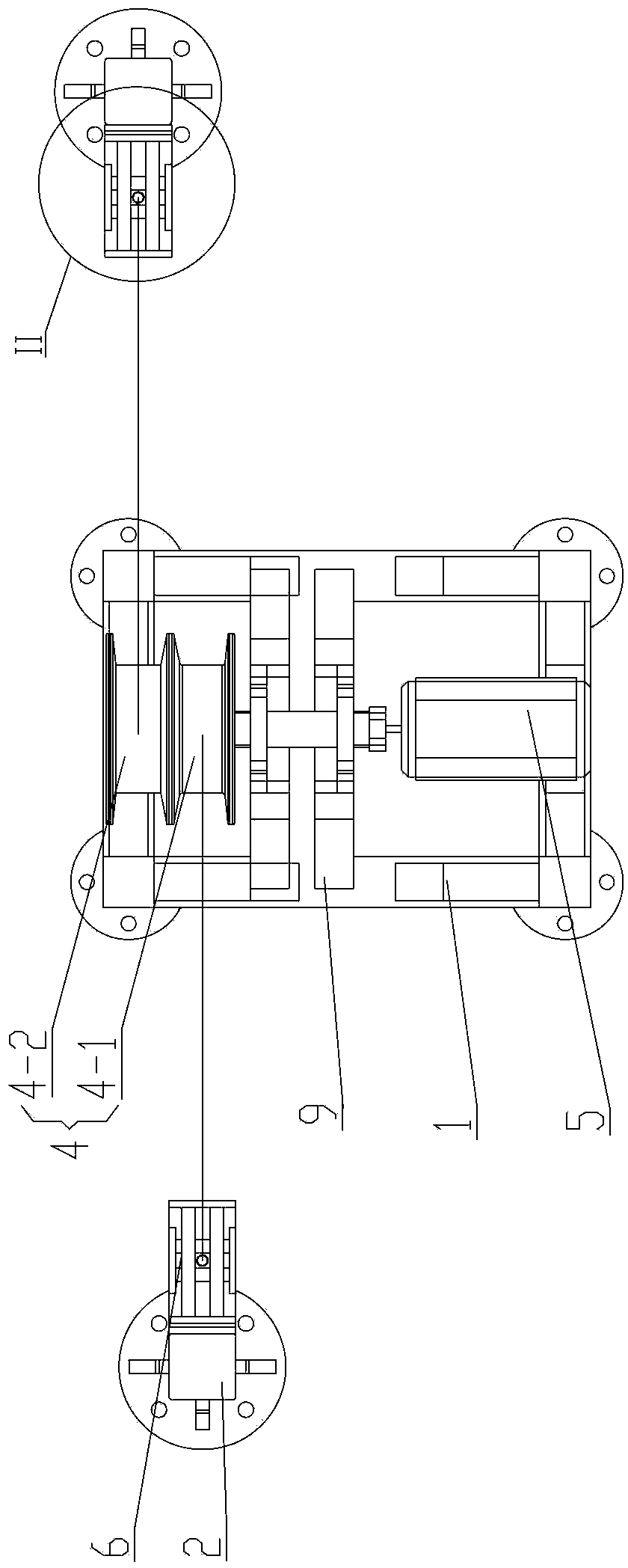

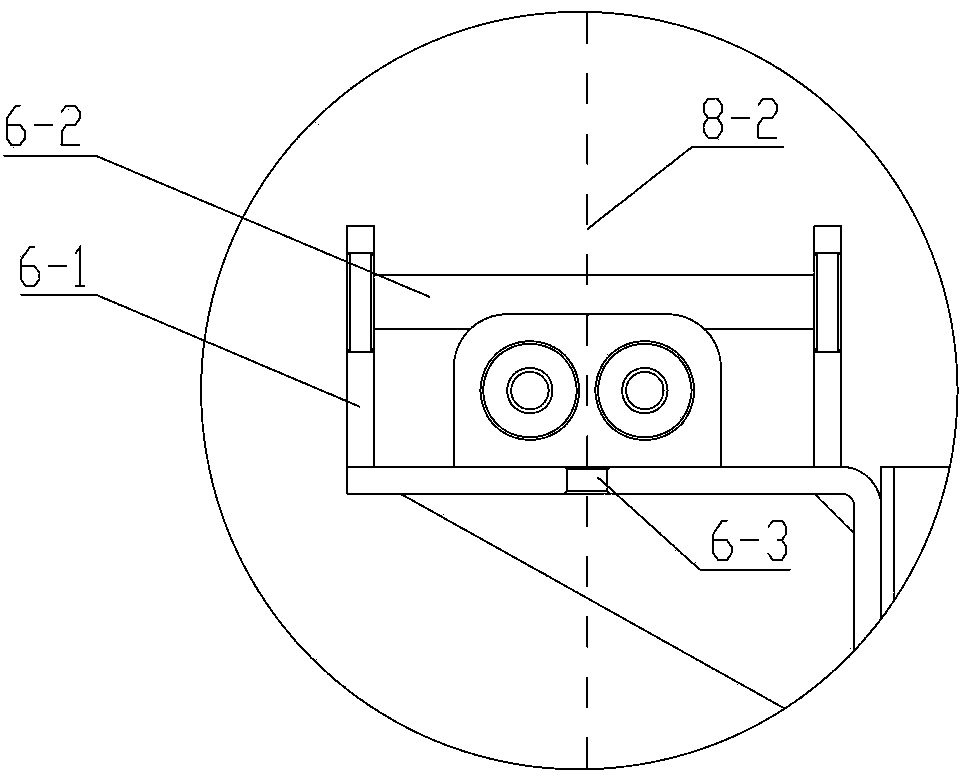

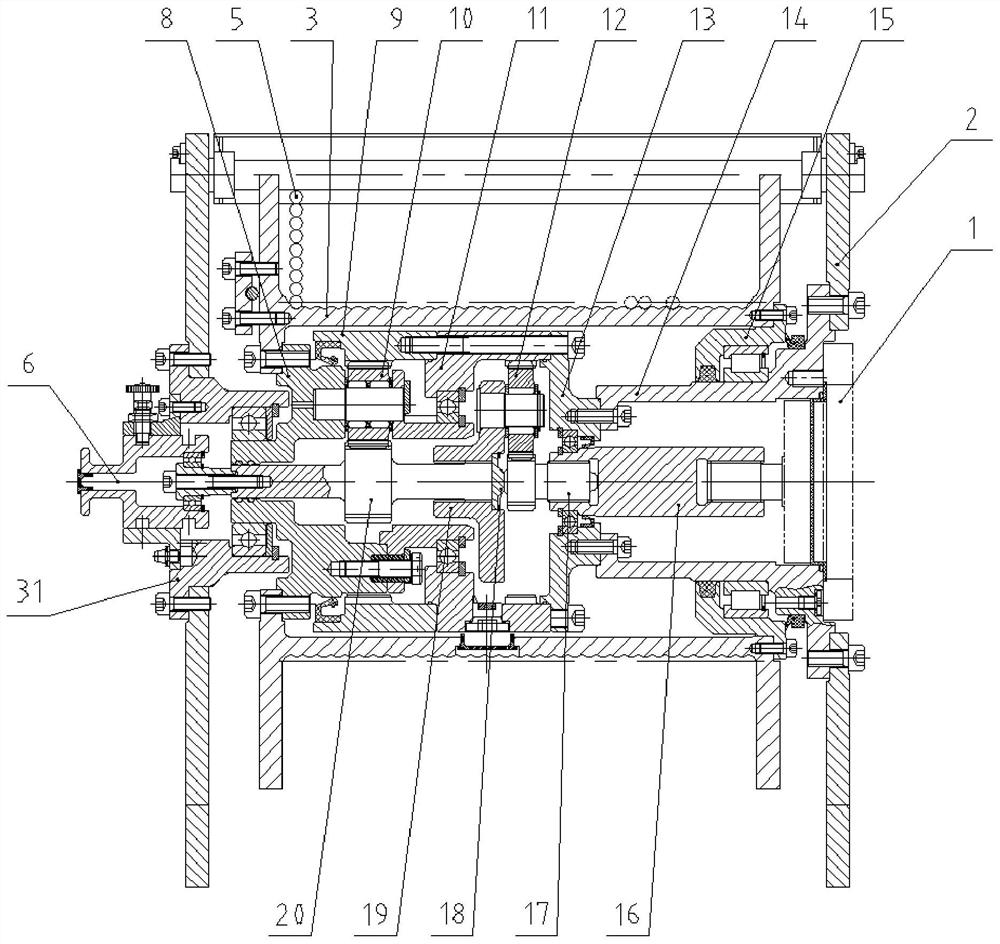

Movement speed and displacement integrated testing device and method of cable arranging device of marine winch

ActiveCN106865437ALarge measuring displacement rangeGuaranteed to be tightMeasurement devicesWinding mechanismsGear wheelCoil spring

The invention discloses a movement speed and displacement integrated testing device and method of a cable arranging device. The testing device comprises a supporting seat, a coil spring, a rope storing drum, a supporting shaft, a testing gear and a two-way hall switch, wherein the supporting shaft is mounted on a bracket, and the rope storing drum is mounted on the supporting shaft through a bearing; one end of the coil spring is fixedly connected with the bracket, and the other end of the coil spring is fixed to the rope storing drum; the testing gear which is coaxially fixedly mounted on the rope storing drum; the two-way hall switch corresponding to the testing gear is mounted on the bracket, and an axis of the two-way hall switch passes through the center of the gear; a steel wire rope end head locking device corresponding to the rope storing drum is arranged on the bracket. According to the testing device, the movement speed and displacement are measured in a way of pulling a coiling drum to test the contact mode of a steel wire rope, so that the measurement moving range is wide; a vortex type coil spring is arranged and can provide a certain tensioning force and returning force so as to ensure that the testing steel wire rope is tensioned as well as avoid disordering of the rope, and as a result, the tracking measuring accuracy is high.

Owner:HUNAN UNIV OF SCI & TECH

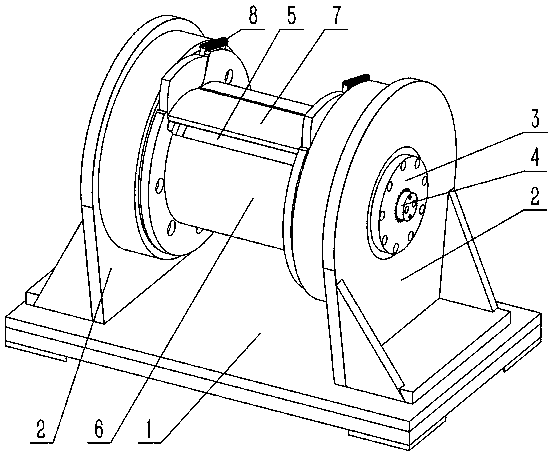

Constant-force and constant-speed electric capstan

InactiveCN106081962AConvenient for retractable workSmooth retractableWinding mechanismsReduction driveElectric machine

The invention provides a constant-force and constant-speed electric capstan, belongs to the technical field of machinery and solves the problem that a conventional capstan is instable in operation. The constant-force and constant-speed electric capstan comprises an enclosure, a winding drum, a motor, a speed reducer, at least one traction drum and a differential, wherein the winding drum is arranged in the enclosure and used for winding a wire rope; the motor is provided with a motor shaft which penetrates the winding drum, and the winding drum can horizontally move on the motor shaft when the motor rotates; the speed reducer is arranged at the end, far away from the motor, of the winding drum and connected with the motor shaft; one of the traction drums is connected with the speed reducer through a connecting shaft and used for receiving the wire rope output by the winding drum, and the received wire rope is conveyed out of the enclosure; and the differential is arranged in the enclosure and connected with the speed reducer. The constant-force and constant-speed electric capstan has the advantage of being stable in operation.

Owner:NINGBO ELEVATOR WINCH MFG

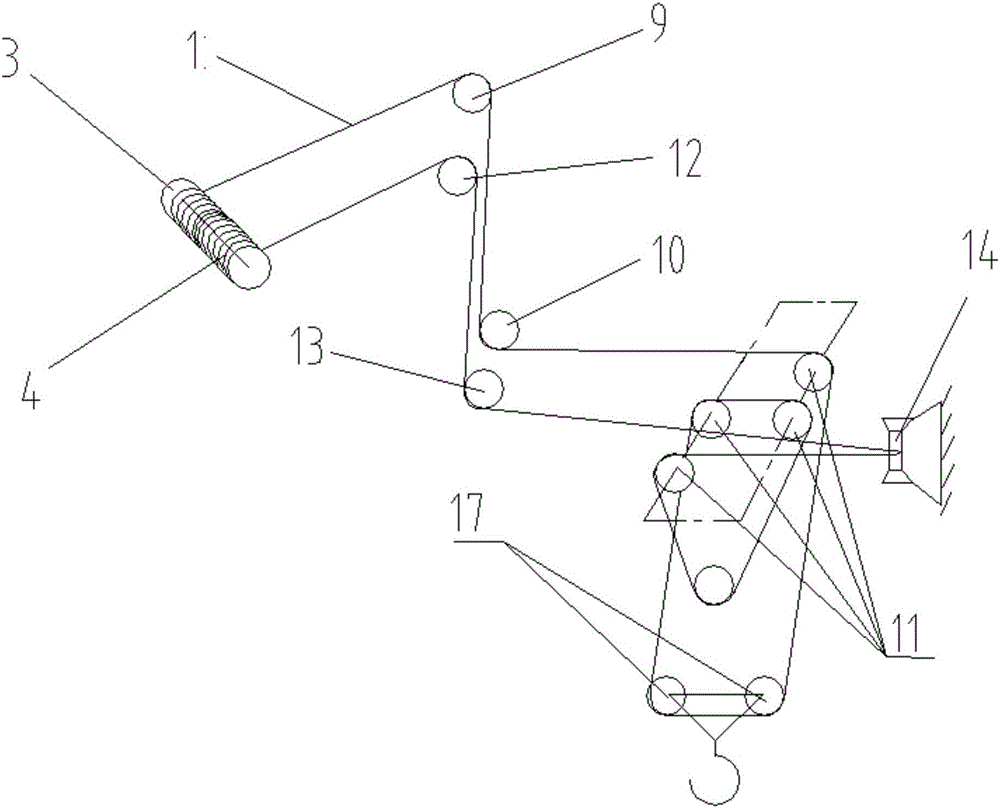

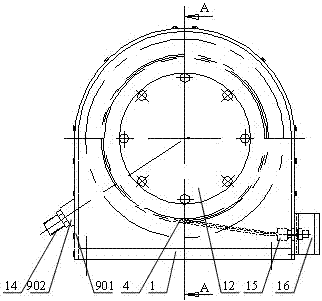

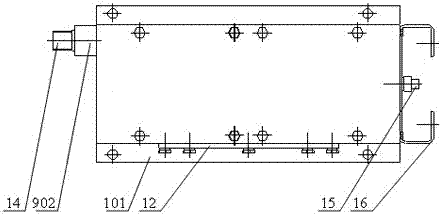

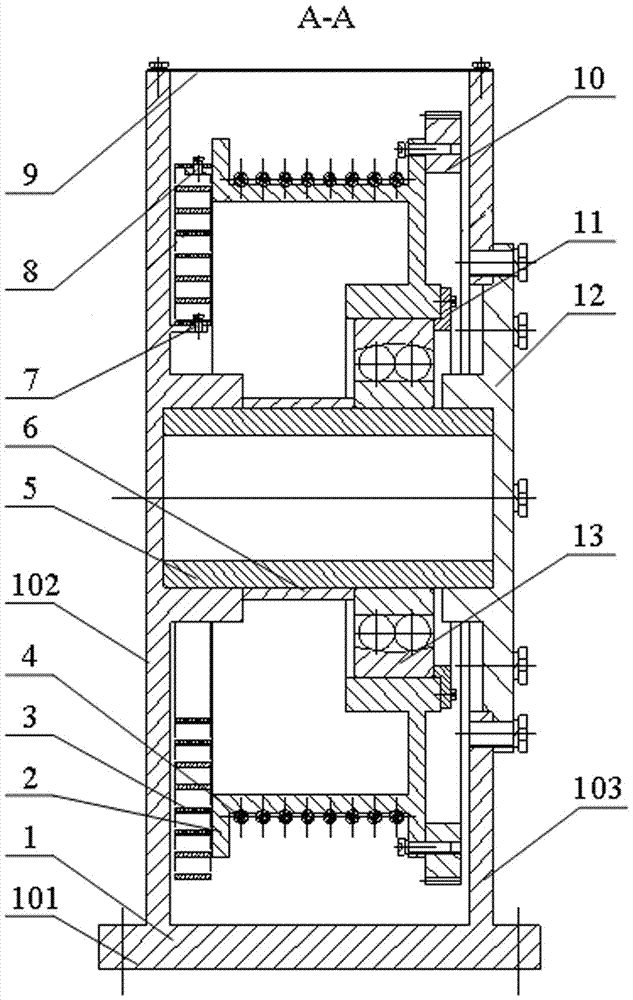

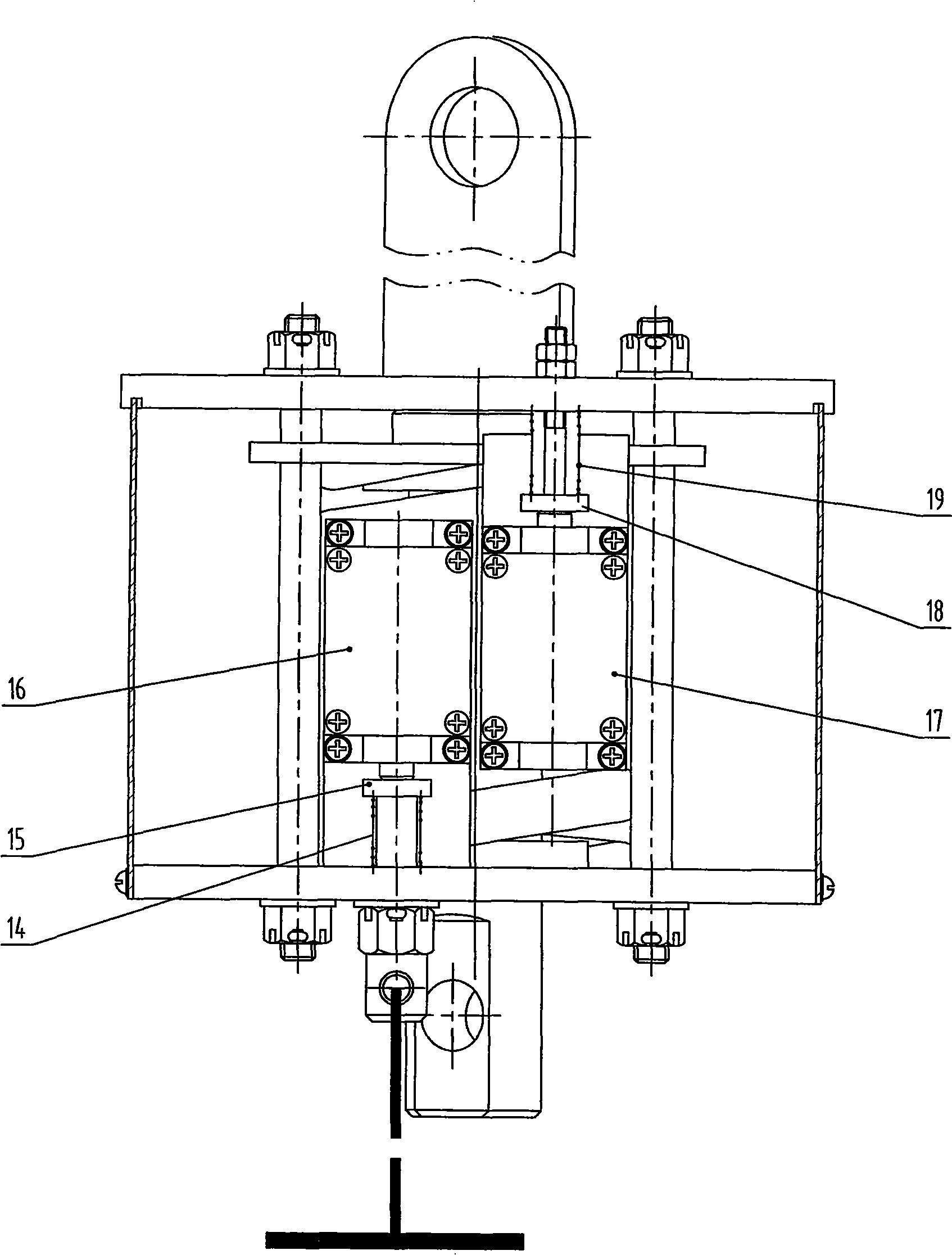

Multifunctional weight safety device

The invention relates to a multi-function weight safety device, which is mainly used for safe guarding of a material hoisting machine such as a headframe, a portal frame and the like. The safety device comprises a lifting lug (1), an upper cover (2), a protecting cap (3), a connecting rod (4), a bottom board (5), a pulling rod (6), a movable plate (7) and a main spring (8). The device is characterized in that a supporting rod (9) is arranged on the bottom board (5); a level (10) is arranged on the top end of the supporting rod (9); a trim screw rod I (11) is arranged on the upper end at one side of the level (10); a return spring I (12) is arranged on the upper end at the other side of the level (10); a travel switch I (13) is arranged on the lower end of the level (10); a push rod (15) passes through a return spring II (14) and the bottom board (5); the upper end of the push rod (15) is provided with a travel switch II (16); a trim screw rod III (18) is arranged on the upper cover (2); a vertical bar of the trim screw rod III (18) passes through the upper cover (2) and extends out of the upper plane of the movable plate (7); and the lower end of the trim screw rod III (18) is provided with a travel switch III (17) which is fixed on the movable plate (7). The device integrates an overload limiting stopper, a superior limiting stopper and an interior limit stopper into a whole, and has the advantages of compact structure, and convenient, safe and reliable use.

Owner:江阴市星联建筑机械厂

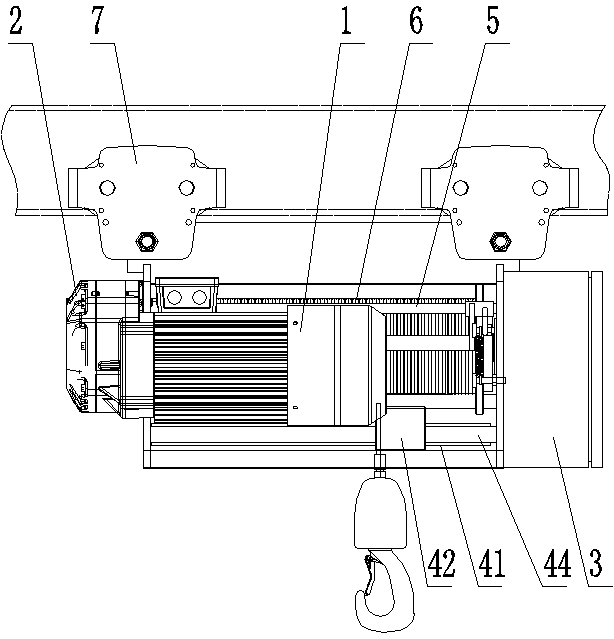

Steel wire rope rolling-up device of bridge type crane

InactiveCN107686066ANeatly coiledAvoid tangled ropeWinding mechanismsBridge typeArchitectural engineering

The invention discloses a steel wire rope rolling-up device of a bridge type crane. The steel wire rope rolling-up device comprises a reel, a rope groove is formed in the periphery of the reel in a surrounding mode, and flanges are arranged at the two ends of the rope groove correspondingly. Threads are carved on the rope groove, the distance between the threads is equal to the diameter of each steel wire rope, and a fixing hole is formed in the flange below the rope groove. A rope guiding device is arranged between one flange and the rope groove, a fixing plate is directly welded to one sideof the rope guiding device, and the fixing plate and the flanges are fixed through bolts. The steel wire ropes can be tidily rolled, disorder of the steel wire ropes is avoided, the steel wire ropes are smoothly rolled in the rope groove accordingly, thus the performance of heavy object lifting of the steel wire ropes can be brought into play, friction between the steel wire ropes is avoided, andthe service life of the steel wire ropes is prolonged accordingly.

Owner:ANHU WUHU CHANGJIANG JACK UP EQUIP CO LTD

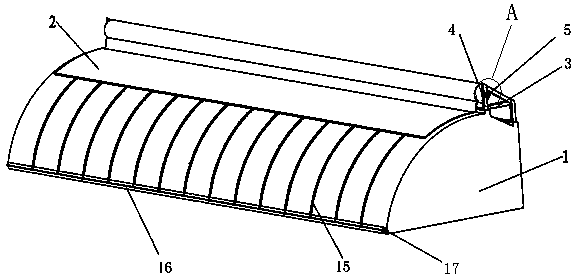

Pull-down and roll-up type solar greenhouse roller shutter device and using method

PendingCN109348934ASimple structureAvoid dangerous accidentsClimate change adaptationGreenhouse cultivationEngineeringPulley

The invention relates to a pull-down and roll-up type solar greenhouse roller shutter device and a suing method. A roller shutter shaft is arranged above a greenhouse, a plurality of auxiliary bearingdevices are arranged above a greenhouse body, a strip-shaped roller is arranged on each auxiliary bearing device, the strip-shaped rollers and the roller shutter shaft are parallel and can relativelyslide with a heat preservation quilt; a plurality of sliding ways are arranged on the face of the greenhouse, a rolling rope shaft is arranged at the bottom of the front part of the greenhouse, and asupporting pulley is arranged inside each sliding way; a plurality of rolling ropes are fixedly connected to the tail end of the heat preservation quilt, rolling rope bodies are arranged inside the sliding ways and are in overlapped connection with the supporting pulleys; when the heat preservation quilt is placed down, the rolling rope shaft rotates and drives the heat preservation quilt to slide downwards, when the heat preservation quilt is rolled up, the roller shutter shaft rotates, the heat preservation quilt and the strip-shaped rollers slide relatively so that the heat preservation quilt can be rolled up; the roller shutter shaft and the wound heat preservation quilt do not directly act on the surface of a front slope of the solar greenhouse under gravity loads, the phenomenon that peril incidents are caused by dynamic loads in the front slope greenhouse surface unfolding and folding processes is avoided, and the whole structure of the roller curtain device is improved.

Owner:SHENYANG AGRI UNIV

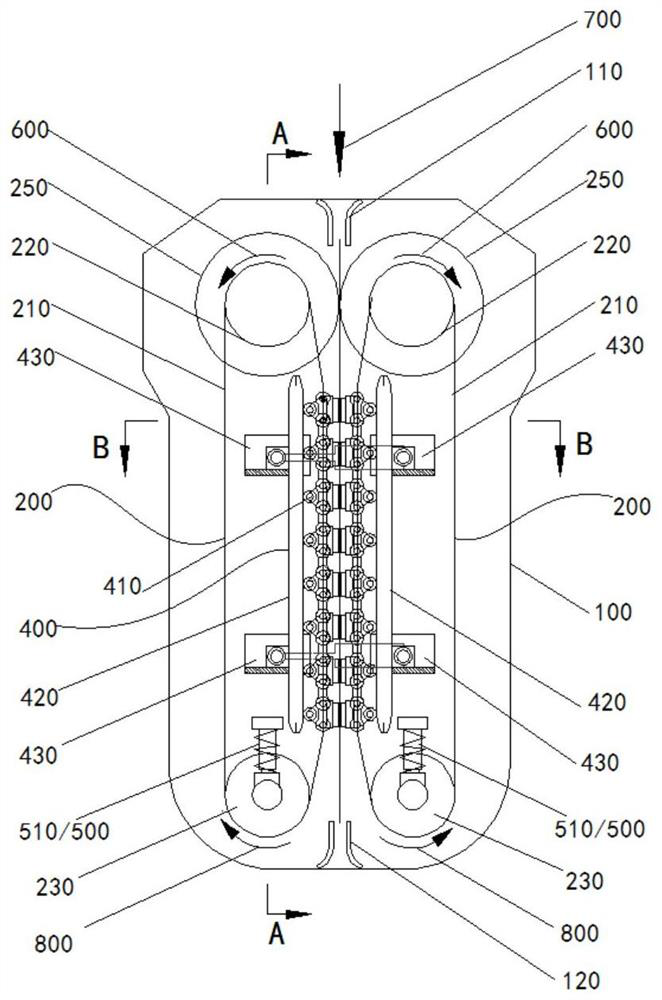

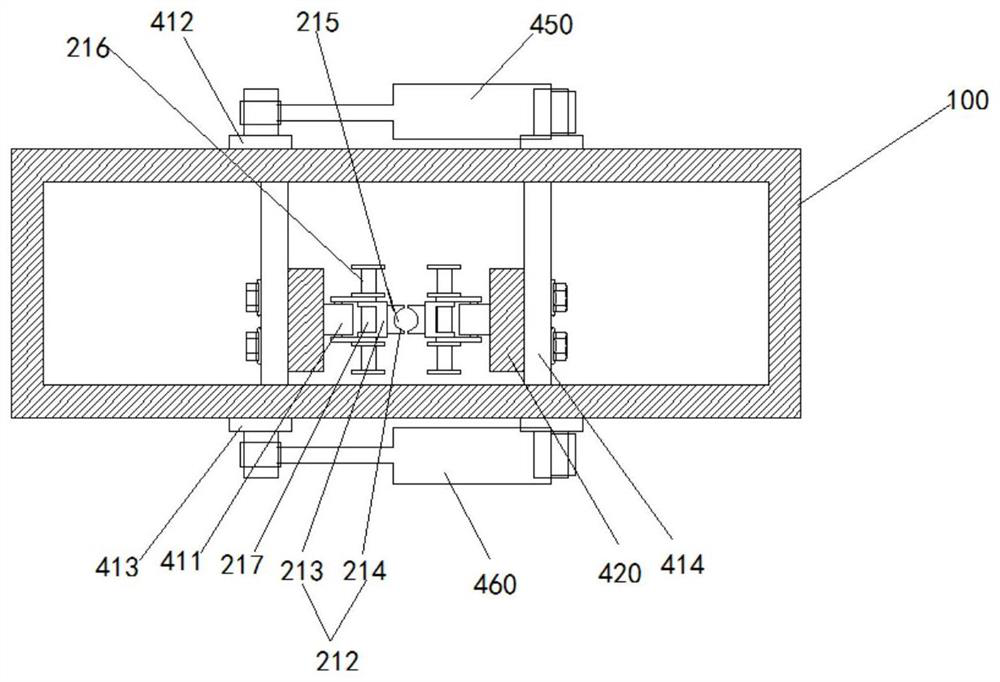

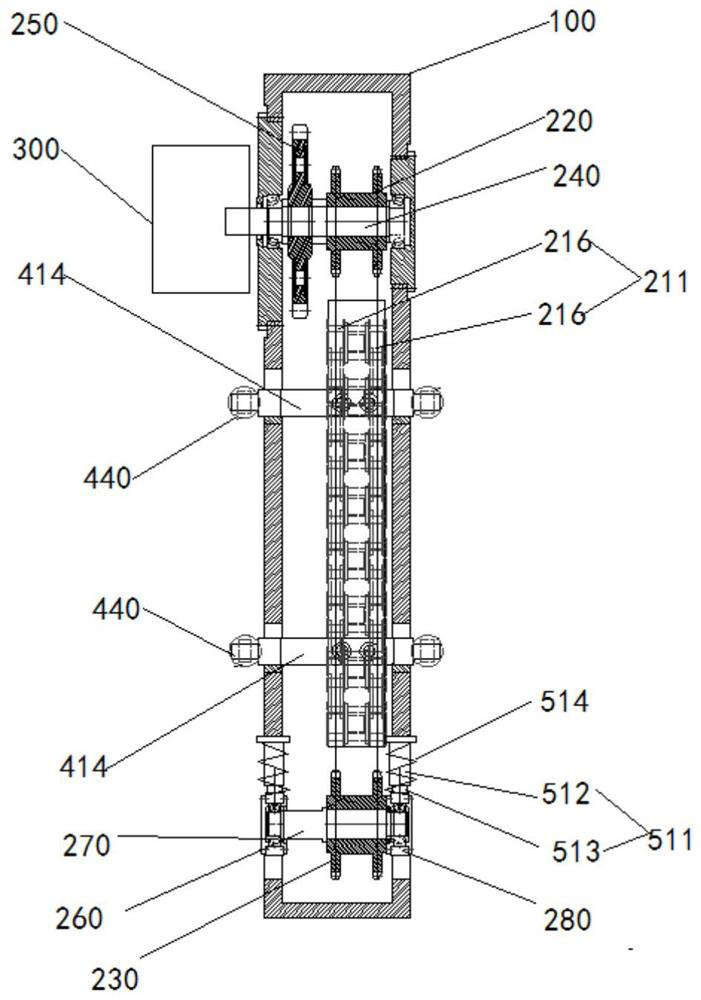

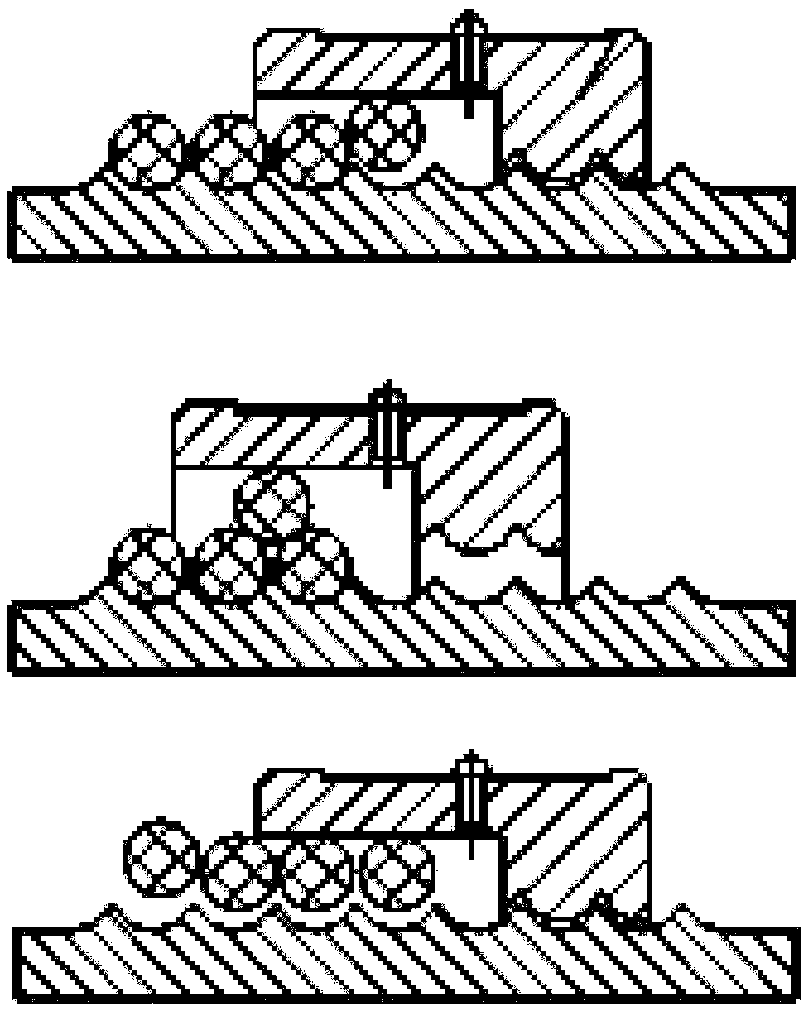

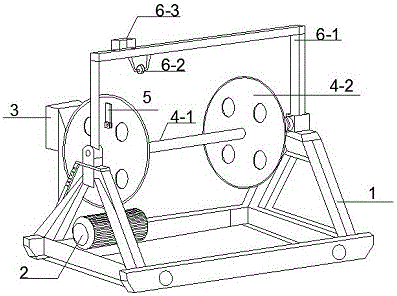

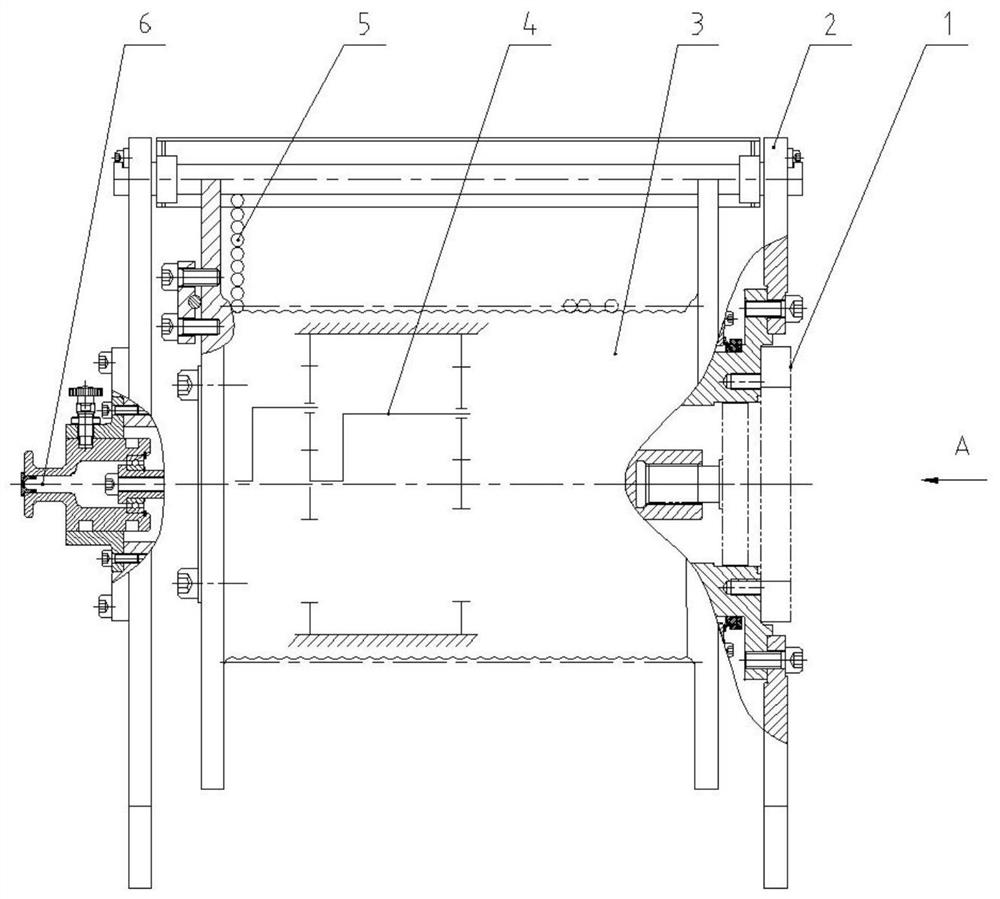

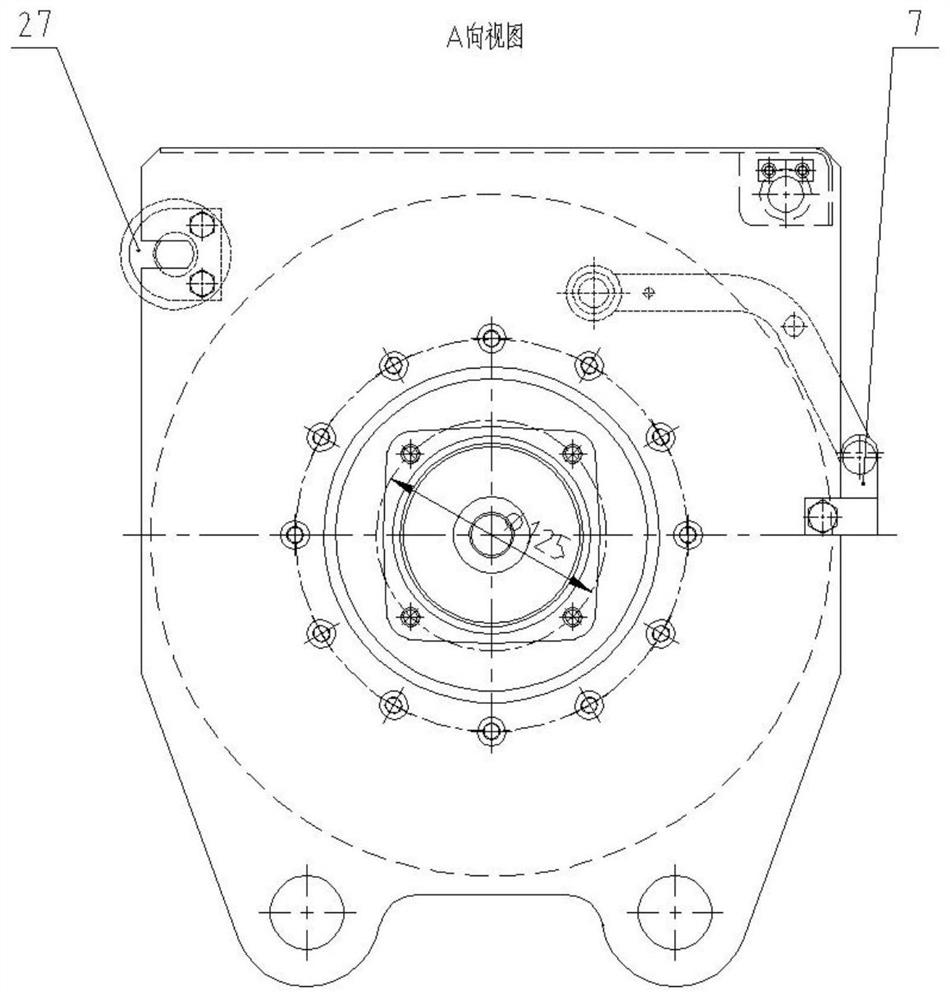

Steel wire rope pre-tightening device and crane

PendingCN111847241AAvoid tangled ropeGuarantee the quality of windingWinding mechanismsLoad-engaging elementsEngineeringWire rope

The invention provides a steel wire rope pre-tightening device and a crane. The steel wire rope pre-tightening device comprises a rack, two chain transmission devices and a driving device, wherein thetwo chain transmission devices are arranged on the rack side by side; each chain transmission device comprises a transmission chain, a chain driving wheel and a chain driven wheel; the transmission chain is arranged on the chain driving wheel and the chain driven wheel in a sleeving manner; the chain driving wheel and the chain driven wheel are rotatably arranged on the rack; and the two transmission chains are used for tightly holding a steel wire rope passing between the two chain transmission devices. When the steel wire rope is retracted, the steel wire rope can drive the two transmissionchains to drive synchronously; the driving device is arranged on the rack and is used for applying reverse moment of force to each chain driving wheel, so that each transmission chain generates pre-tightening force, the direction of which is opposite to the transmission direction of the transmission chain. The steel wire rope pre-tightening device can provide pre-tightening force when the steel wire rope is retracted, improves the quality of rope arrangement, and prolongs the service life of the steel wire rope.

Owner:ZHEJIANG SANY EQUIP

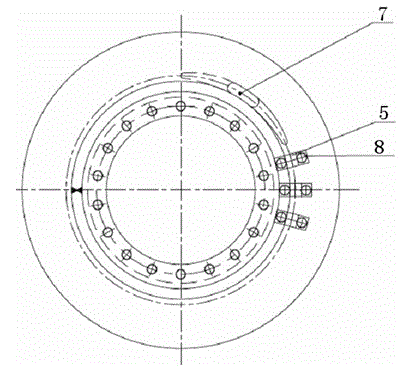

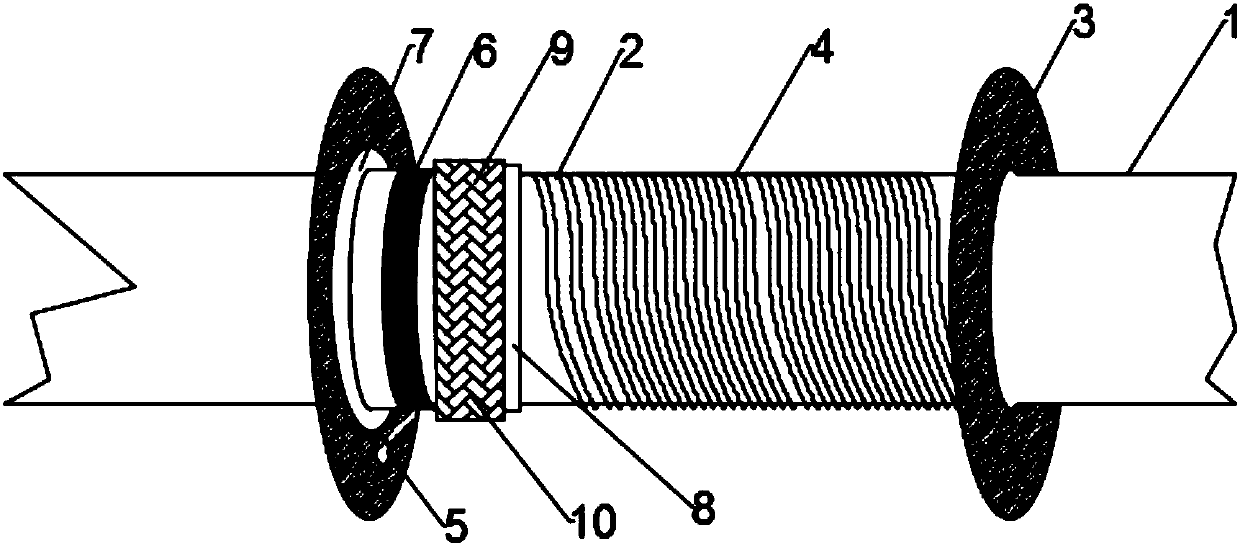

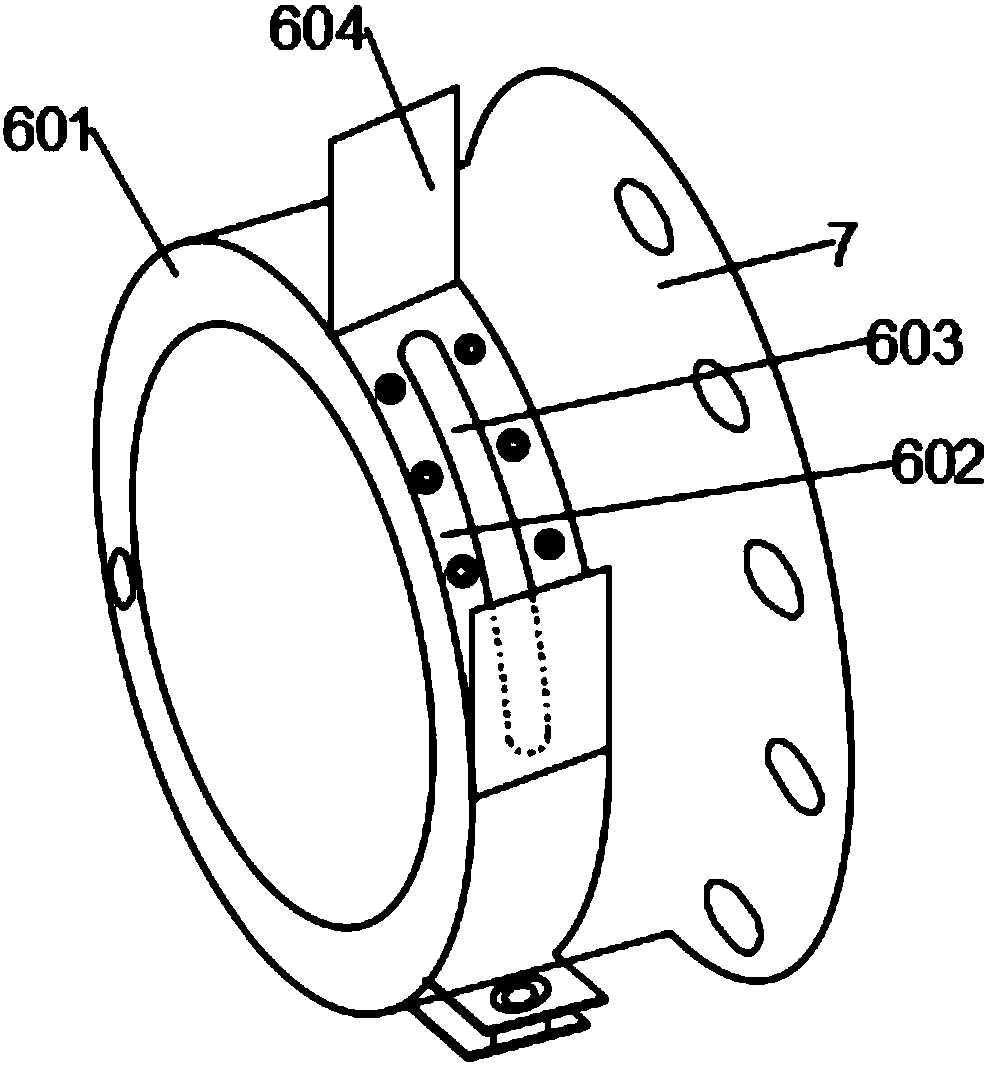

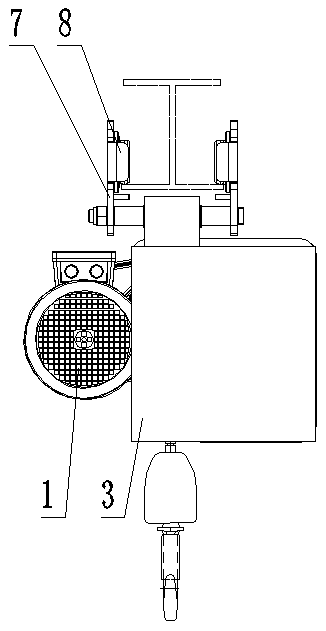

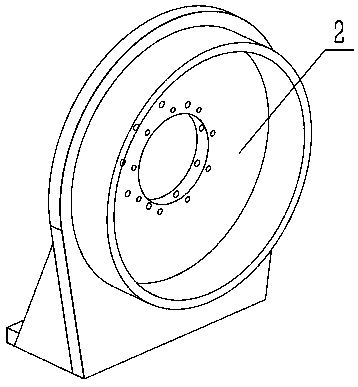

Electric hoist rope guide

PendingCN109095373ASmoothly involvedSmooth dischargePortable liftingWinding mechanismsArchitectural engineeringWire rope

The invention discloses an electric hoist rope guide, and relates to the technical field of the rope guides. The electric hoist rope guide comprises a rope guide body. The rope guide body comprises arope guide inner ring and a rope guide outer ring which are correspondingly installed and can be relatively rotated. The rope guide inner ring is mutually cooperated with the rope guide outer ring. The rope guide body is provided with a fastening mechanism for fastening a steel wire rope. The fastening mechanism comprises a rope releasing port installed on the rope guide inner ring and the rope guide outer ring, and a pressing component for pressing the steel wire rope. The pressing component bears against the steel wire rope except a position of the rope releasing port. The pressing componentcan be adjusted according to a tension degree of the steel wire rope. The electric hoist rope guide is simple in structure, convenient to install, and capable of enabling the rope guide inner ring tobe tensioned by only adjusting a bolt of a pressure spring if a steel wire rope loosening phenomenon happens after the electric hoist rope guide is used for a long time, solving problems that disordered rope and loosened rope phenomena easily happen in a weightless situation, and rolling and discharging the steel wire rope without the help of any gravity.

Owner:南京禄口起重机械有限公司

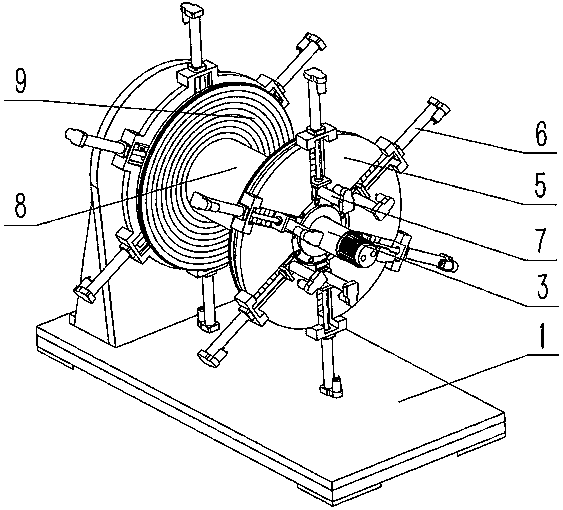

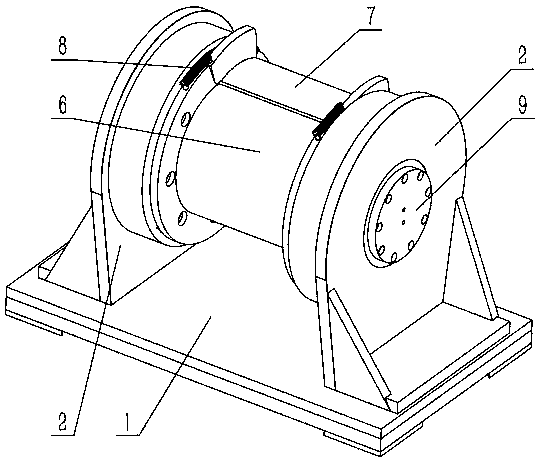

Disorderly rope prevention winch comprising roller with both ends converged

ActiveCN108100908ASolve the messy rope problemAvoid tangled ropeWinding mechanismsPulp and paper industryWinch

The invention discloses a disorderly rope prevention winch comprising a roller with both ends converged. The winch comprises a winch bracket, and is characterized in that the both sides of the winch bracket are vertically and symmetrically provided with two roller brackets separately; the middle parts of the roller brackets are provided with through holes, and the middle part of a power end seat is provided with a fixed shaft driving motor; a roller is arranged on the two roller brackets, and one end of the roller is installed on the inner side of a non-power end seat through a bearing; the other end of the roller is installed on the outside of the fixed shaft driving motor; the both sides of the roller are symmetrically provided with adjusting disks, and each adjusting slot is internallyprovided with a vertical adjusting cylinder; the end of a piston rod of each vertical adjusting cylinder is provided with a horizontal adjusting cylinder; and the inner sides of the two adjusting disks are provided with a set of adjusting systems separately, and each set of adjusting systems comprises nine baffle rings. According to the winch disclosed by the invention, through arrangement of thebaffle ring systems as well as the vertical adjusting cylinder and the horizontal adjusting cylinder, the purpose of compressing steel wire ropes in a trapezoidal shape to prevent disorderly ropes isachieved; and the winch is unique in structure, and the problem of the disorderly ropes of the winch can be solved properly.

Owner:安徽初么纸业有限公司

Winding drum with cable guide grooves

PendingCN107381391AAvoid rearrangementAvoid misalignmentWinding mechanismsStructural engineeringScrew thread

The invention discloses a winding drum with cable guide grooves. The winding drum mainly comprises an H-shaped shaft and threaded tracks. The threaded tracks which are neatly arrayed are arranged on the surface of the H-shaped shaft and are of groove-shaped structures, the widths of grooves are matched with the diameters of cables, and the depths of the grooves are matched with the radiuses of the cables. The winding drum with the cable guide grooves has the advantages that the threaded tracks can be in modes for assisting in preventing rearrangement and mistaken arrangement of the cables, and accordingly conditions such as cable compression, disorder and squeezing can be prevented by the threaded winding drum under double protection effects of inspection mechanisms and the threaded tracks; the winding drum is simple in structure, reasonable in design and suitable to be widely applied to industries with requirements on winding displacement equipment.

Owner:江苏三科海洋装备有限公司

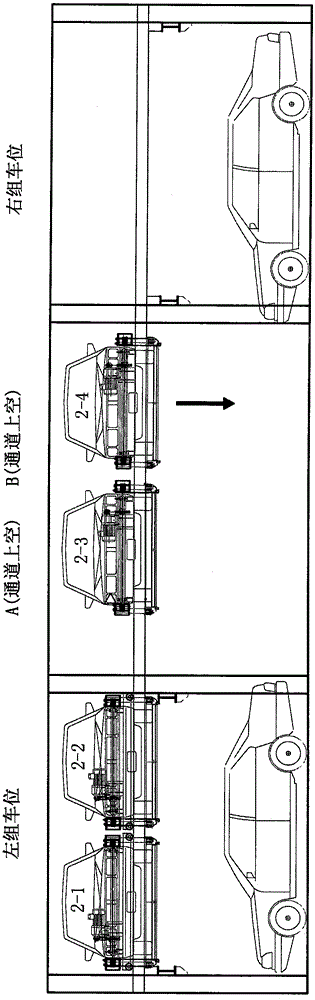

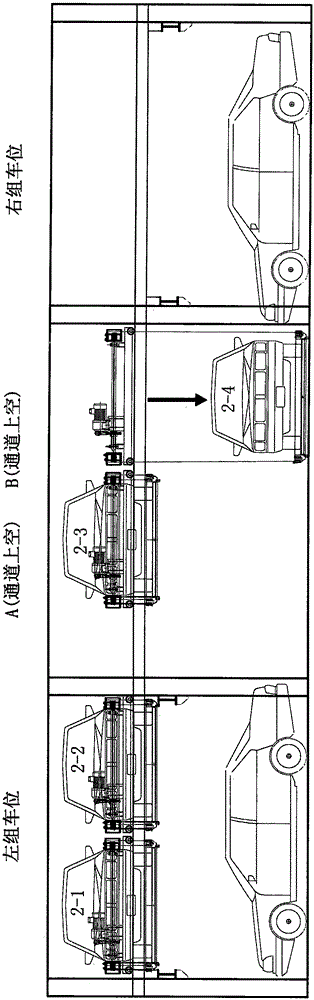

Bridge suspension and steel bar type stereo garage

InactiveCN106065722AReduce difficultyIncrease channel areaParkingsLateral moveAutomotive engineering

The invention relates to a bridge suspension and steel bar type stereo garage. The purpose of the invention is to overcome the shortcomings of a current garage by providing a new bridge suspension stereo garage that can be manufactured at a low cost and provide good performances. The stereo garbage can also be of less labor intensity and can be mounted and maintained very conveniently. The second-tier lifting mechanism is a structure made of steel ropes and rolling cylinders; the bottom layer is provided with a completely natural parking stall without a car loading plate or a lateral movement stall; the second tier is a lateral moving parking stall either lifted to the left or to the right; through the bridge suspension steel bar, a small car can be laterally moved to a path to enter or exit from. This means that the car can advance to not only park but also leave without having to be reversed to enter a parking stall. As a result, car parking becomes easier. More particularly, for an underground parking lot provided with a two-tier stereo garage, the space of parking stalls at the left group and the right group of the two tiers are in full use for cars to enter and exit, thus saving a great area of a path. And at the same time, other vehicles on the main path can pass without being impacted.

Owner:傅婉娜

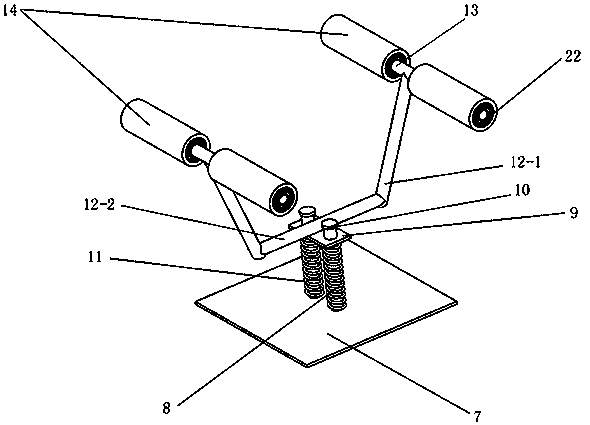

Follow-up pad chain type rope-disorder-resistant winch

ActiveCN108100909ASolve the messy rope problemAvoid tangled ropeWinding mechanismsGear wheelPush pull

The invention discloses a follow-up pad chain type rope-disorder-resistant winch. The follow-up pad chain type rope-disorder-resistant winch comprises two bases and ten pad chain units. Bearing seatsare arranged on the outer sides of the two bases correspondingly. Rotary shafts are rotationally arranged in the two bearing seats correspondingly. An adjusting plate is arranged on the inner side ofeach base. An intermediate shaft is arranged between each adjusting plate and the corresponding bearing seat. Two push-pull electric cylinders are arranged on the inner side of each bearing seat. A push-pull plate is connected with the end of a piston rod of each push-pull electric cylinder. The axis of each push-pull plate and the axis of the corresponding intermediate shaft coincide. Friction plates are arranged on notch bearings. Big gears are arranged on the outer peripheries of the friction plates. A driving plate is further arranged on each intermediate shaft and located on the inner sides of friction balls. An adjusting ring is arranged on each adjusting plate. Each pad chain unit is composed of a plurality of rope grooves. By arranging the multiple pad chain units, cushions of winch wire ropes are arranged, and the phenomenon of rope disorder caused by too large number of winding layers of wire ropes is prevented; and the follow-up pad chain type rope-disorder-resistant winch is unique in structure, and the rope disorder problem of the winch can be well solved.

Owner:山东固丝德夫金属制品有限公司

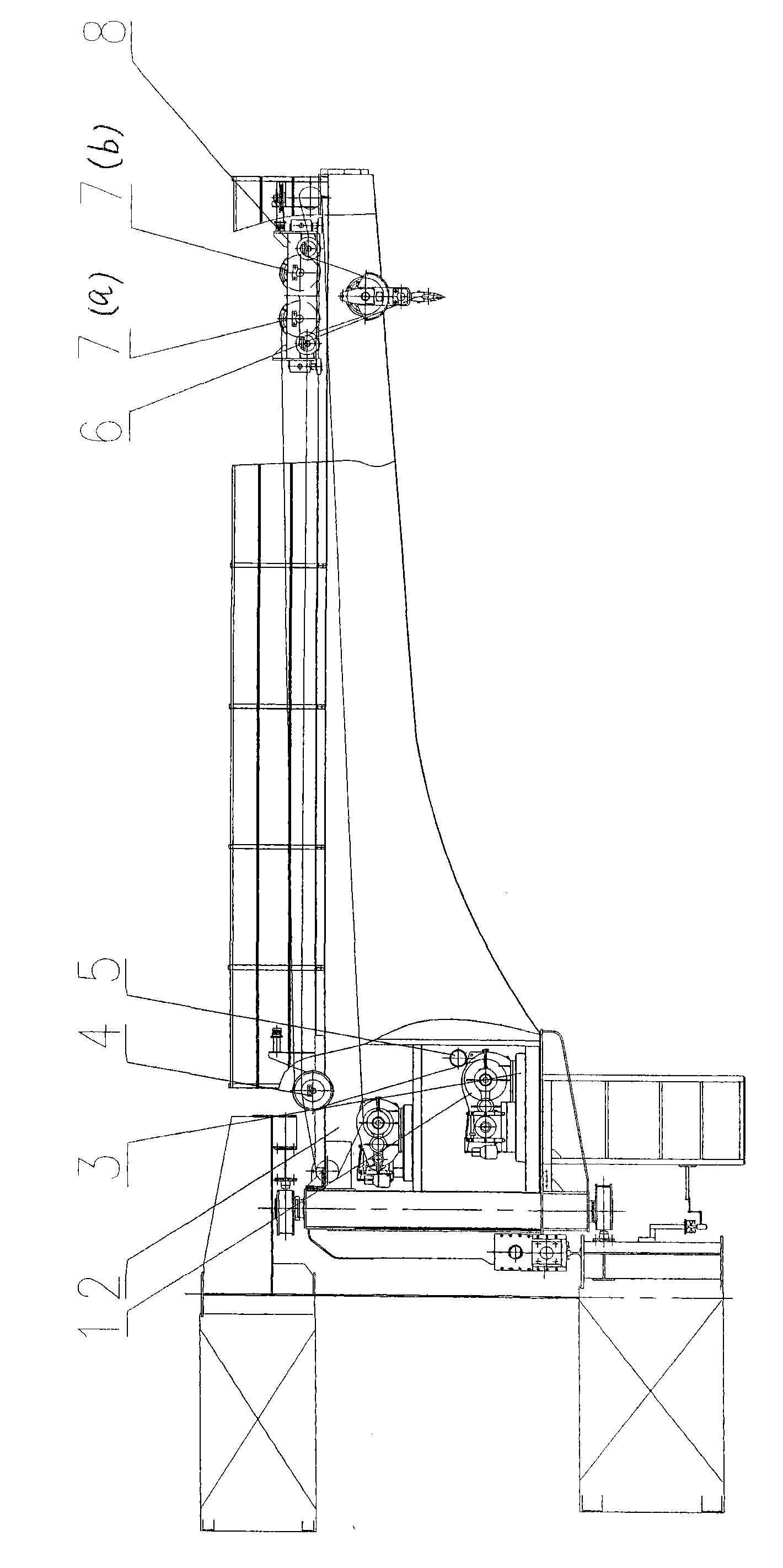

Crane elevator for wind power generator repairing

The invention discloses a crane elevator for wind power generator repairing. A speed reduction motor, a coiling block, a first transmission box, a second transmission box, a reciprocating rope arranging mechanism and a rope pressing mechanism are included. The coiling block is a folding line coiling block. The reciprocating rope arranging mechanism comprises a reciprocating lead screw and a rope arranging sliding block. The reciprocating lead screw is arranged below the folding line coiling block in parallel and is in transmission connection with the folding line coiling block through the second transmission box. Two guiding rollers are symmetrically arranged and rotationally connected to the rope arranging sliding block. The rope pressing mechanism comprises a supporting rod, a rope pressing roller and a stretching type elastic element, the supporting rod is fixedly connected between the first transmission box and the second transmission box, the rope pressing roller is rotationally connected to the supporting rod and can movably press a steel wire rope wound around the folding line coiling block, and the stretching type elastic element can apply deflecting force towards the folding line coiling block. By means of the crane elevator, multi-layer steel wire ropes can be wound tidily, the requirement of the elevating height is met, and when the steel wire ropes are wound or unwound, the phenomenon of rope disorder is avoided.

Owner:河南锐思特科技有限公司

Wind power conversion mechanism and high altitude wind power generator

ActiveCN102979672BNo entanglementStable power generationWind motor combinationsMachines/enginesHigh-altitude wind powerElectricity

The invention discloses a wind power conversion mechanism. The wind power conversion mechanism comprises a power generator, reciprocating wheels, universal rope guiding mechanisms and traction cables, wherein the reciprocating wheels drive the power generator to generate electricity and comprise a first reciprocating wheel and a second reciprocating wheel which are coaxially arranged; the universal rope guiding mechanisms are arranged at two sides of the reciprocating wheels; and the traction cables comprise a first cable and a second cable, the first cable is wound on the first reciprocating wheel, the second cable is reversely wound on the second reciprocating wheel, and the first cable and the second cable are used for connecting with one end of an aircraft to respectively wind the universal rope guiding mechanism at the corresponding side. The mechanism is compact in structure and stale in performance, can effectively avoid cable winding and can adapt to various wind directions, so that the wind power conversion efficiency can be obviously improved. The invention further discloses a high altitude wind power generator with the wind power conversion mechanism.

Owner:CHINA NAT COAL GROUP CORP

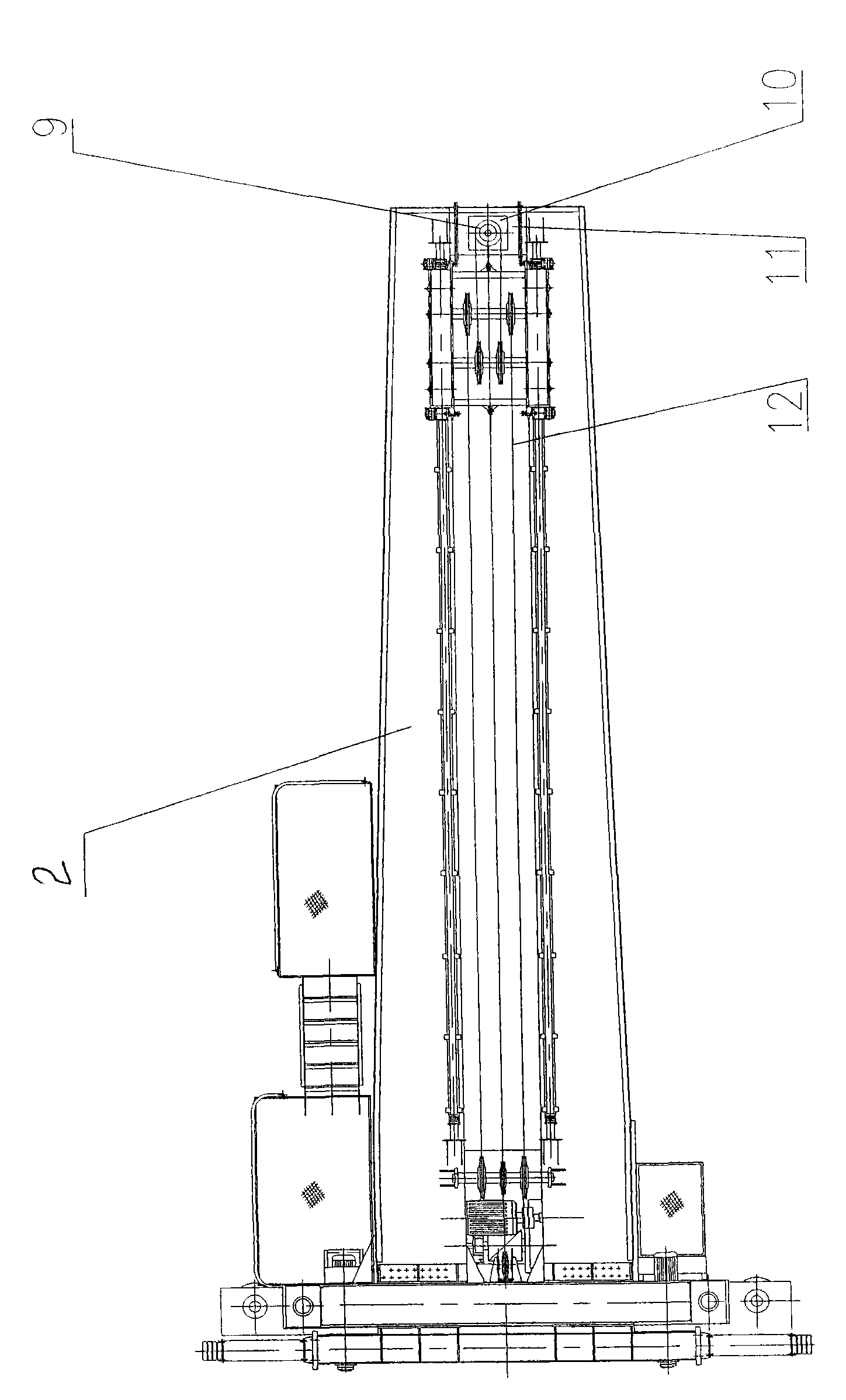

Drilling winch capable of achieving automatic rope arrangement

InactiveCN107176555ARealize the function of automatic rope unwindingLarge rope capacityWinding mechanismsEngineeringWinch

The invention discloses a drilling drawworks for automatically arranging ropes, comprising: a drawworks frame, a motor, a gearbox, a drum system, a brake system and a rope arranging device. Wherein, the drum system includes a roller and a turntable, the roller is connected to the frame, and two turntables are respectively located on both sides of the roller; the brake system is located on the turntable of the roller system; the rope arrangement includes a bracket, The pulley and the speed limiter are provided with a track on the support, the pulley is buckled in the track and can slide freely on the track, and the speed limiter is located on the support. The beneficial effects of the invention are: when the drawworks starts drilling, the wire rope passes through the pulley to connect with the drill pipe, and the speed governor guides the pulley to move on the guide rail of the bracket, so that the wire rope falls on different positions on the roller. The invention can realize the automatic rope arrangement function of the winch machine, which is convenient to control, prevents the phenomenon of disordered ropes when starting and feeding the drill, and can arrange the steel wire ropes closely and orderly on the rollers without wasting the rope arrangement space, so that the roller system can reach a larger rope capacity.

Owner:YANCHENG HUAYI GASOLINEEUM MACHINERY

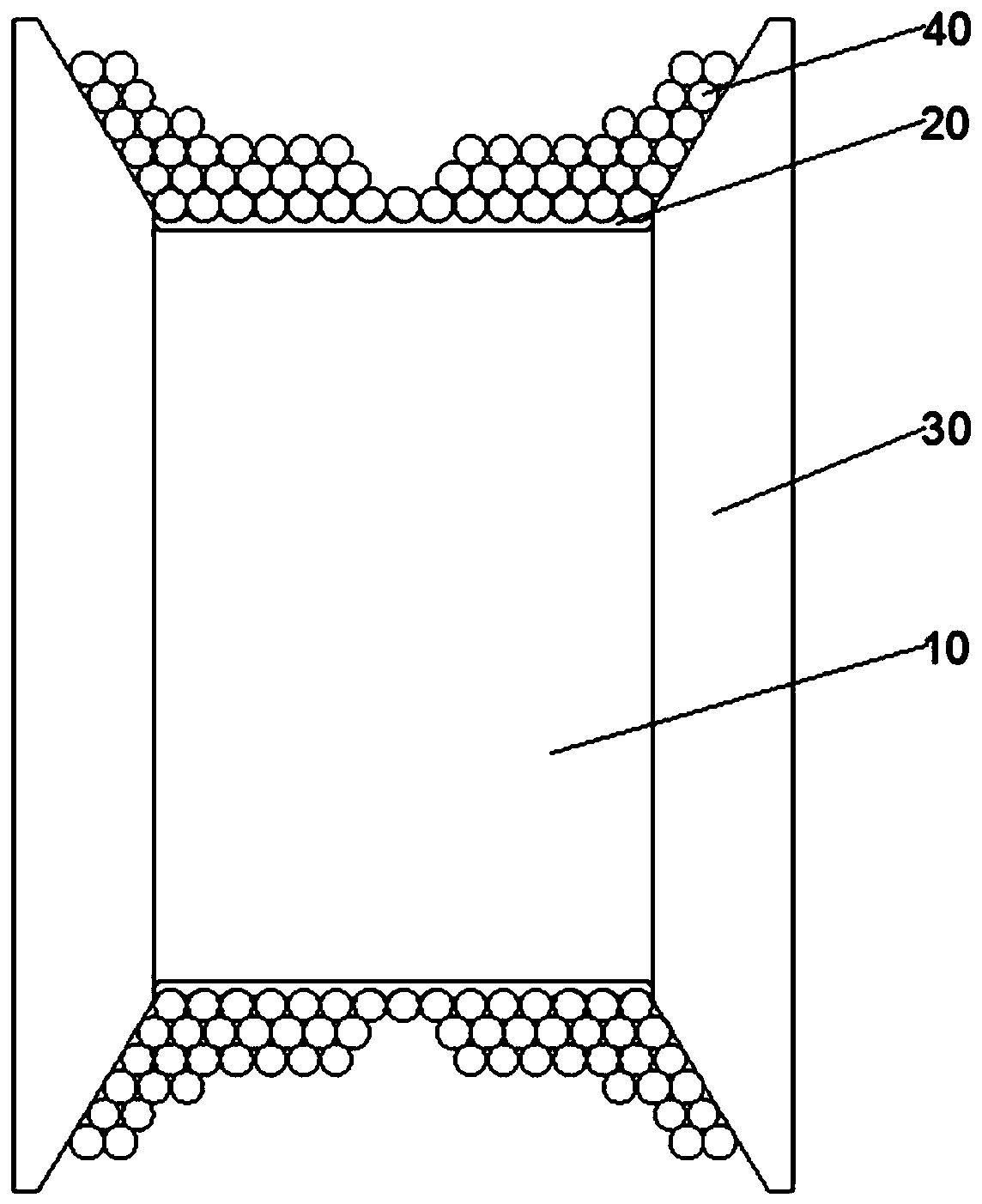

Drum and hoisting equipment

PendingCN110395673AAchieve permutationAvoid tangled ropeWinding mechanismsEngineeringElectrical and Electronics engineering

The invention provides a drum and hoisting equipment. The drum comprises a drum body, drum skin and two baffles, wherein the drum skin is arranged on the periphery of the drum body and is provided with a plurality of parallel rope grooves with the outer diameter matched with that of ropes, and the rope grooves are spirally arranged in the circumferential direction of the drum body; and the two baffles are separately arranged at the two ends of the drum body in the circumferential direction of the ends of the drum body, and an obtuse angle is formed between the side face, towards the drum body,of each baffle and the outer circumferential surface of the drum body. According to the drum provided by the embodiment of the invention, the ropes can be prevented from being out of order, the friction between the ropes and the drum body and the friction between the ropes are reduced, and the service life of the ropes is prolonged.

Owner:SHANGHAI ZHENHUA HEAVY IND

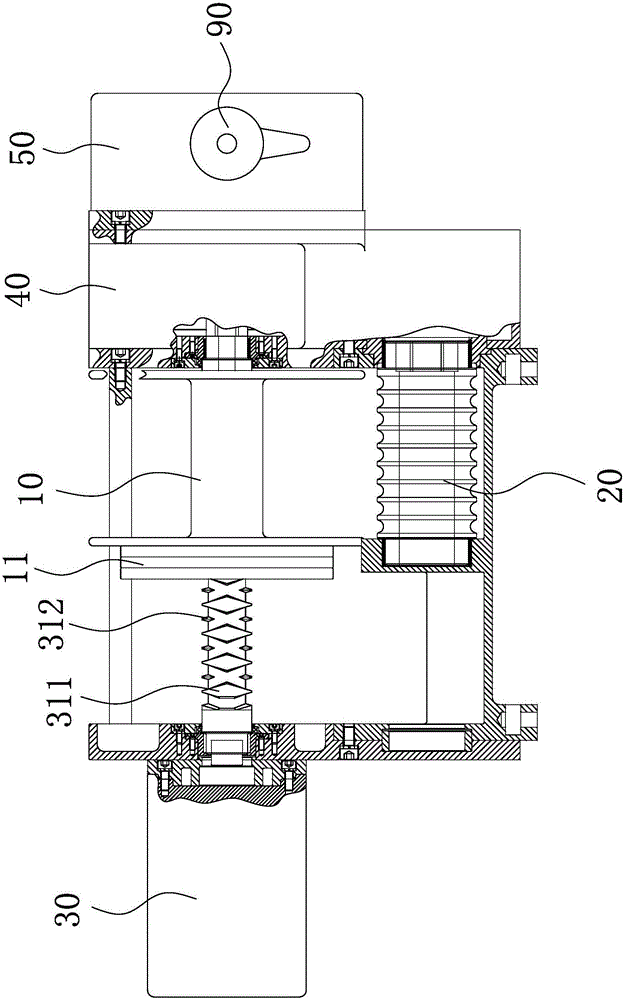

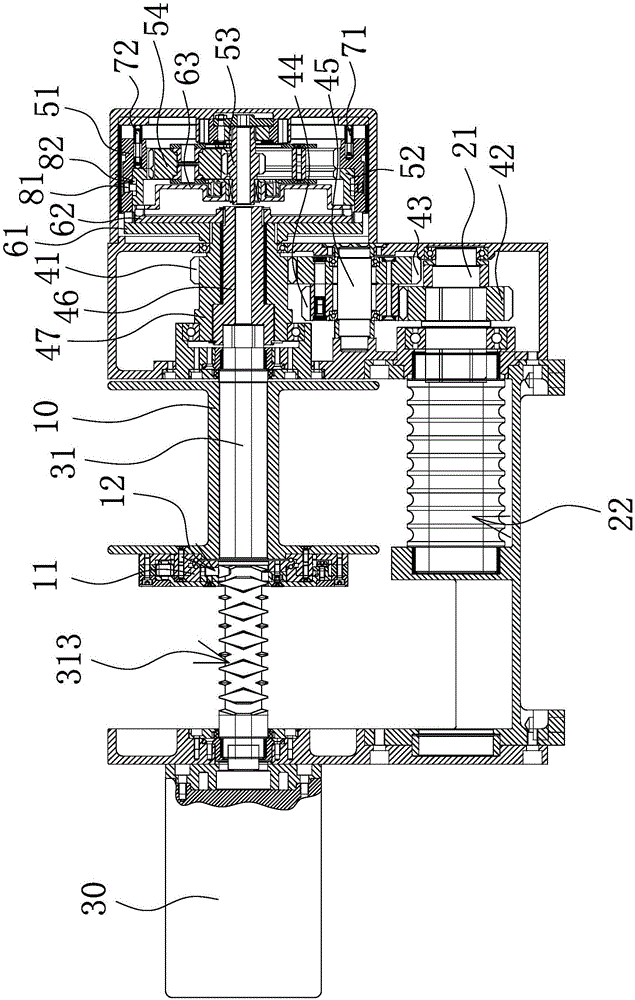

Clutch type rope threading hoisting mechanism for crane

PendingCN111924735AGuaranteed StrengthEasy to produceMechanical actuated clutchesGear lubrication/coolingClutchWire rope

The invention discloses a clutch type rope threading hoisting mechanism for a crane, relates to the technical field of clutch type hoisting mechanisms, and particularly relates to a hoisting mechanismwhich is applied to a large crane and is used for threading and tensioning a hoisting steel wire rope on an arm frame. The clutch type rope threading hoisting mechanism comprises a hydraulic motor, arack, a winding drum, a planetary gear train, a steel wire rope, a clutch, a rope pressing device and a guide device, wherein the rack is connected to the crane through a pin shaft; the winding drumis arranged inside the rack and can rotate inside the rack; the planetary gear train is arranged in the winding drum; the input end of the planetary gear train is connected with the hydraulic motor arranged on one side of the rack, and the output end of the planetary gear train is connected with the clutch arranged on the other side of the rack; the steel wire rope is wound on the outer wall of the winding drum; the guide device is arranged on the rack in the rope outlet direction of the steel wire rope; the rope pressing device is arranged on the rack on the side opposite to the rope outlet direction of the steel wire rope; and the hydraulic motor is connected with the winding drum through the planetary gear train and drives the winding drum to rotate, and after speed reduction and torqueincrease, the steel wire rope is finally output to the steel wire rope through the winding drum, so that winding and unwinding of the steel wire rope are realized.

Owner:DALIAN HUARUI HEAVY IND GROUP

Opening following roller rope-disorder-prevention winch

The invention discloses an opening following roller rope-disorder-prevention winch. The opening following roller rope-disorder-prevention winch comprises a winch support, two roller supports are vertically arranged on the two sides of the winch support, each roller support is provided with a through hole, a non-power end base is arranged on the through hole in one roller support, a power end baseis arranged on the through hole in the other roller support, an end base shaft is arranged on the inner side of the non-power end base, a roller is arranged between the two roller supports, a piston rod set is arranged in each control cylinder, a guide sleeve set is arranged at the outer end of each piston rod set, the other end is connected with an inner clutch plate which is located in a rectangular groove, the outer ends of two guide sleeve sets on the same plane are connected with an outer clutch plate, and a sleeve is fixedly arranged between the inner sides of two clutch ring frames. Through the inner clutch plates, the outer clutch plates and sleeve structures outside the roller, the aims that steel wire ropes are wound on the inner layer and the outer layer, and the ropes are prevented from being disordered are achieved, and the winch is unique in structure and can well solve the problem of winch rope disorder.

Owner:江苏蓝鹰液压科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com