Patents

Literature

58results about How to "Neatly coiled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

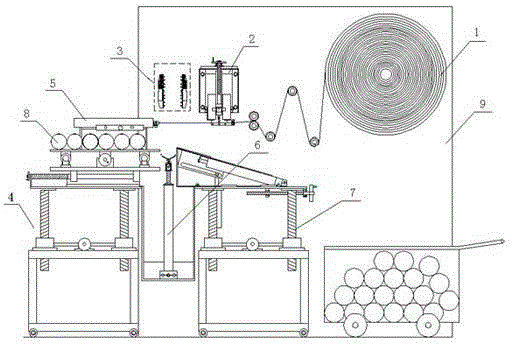

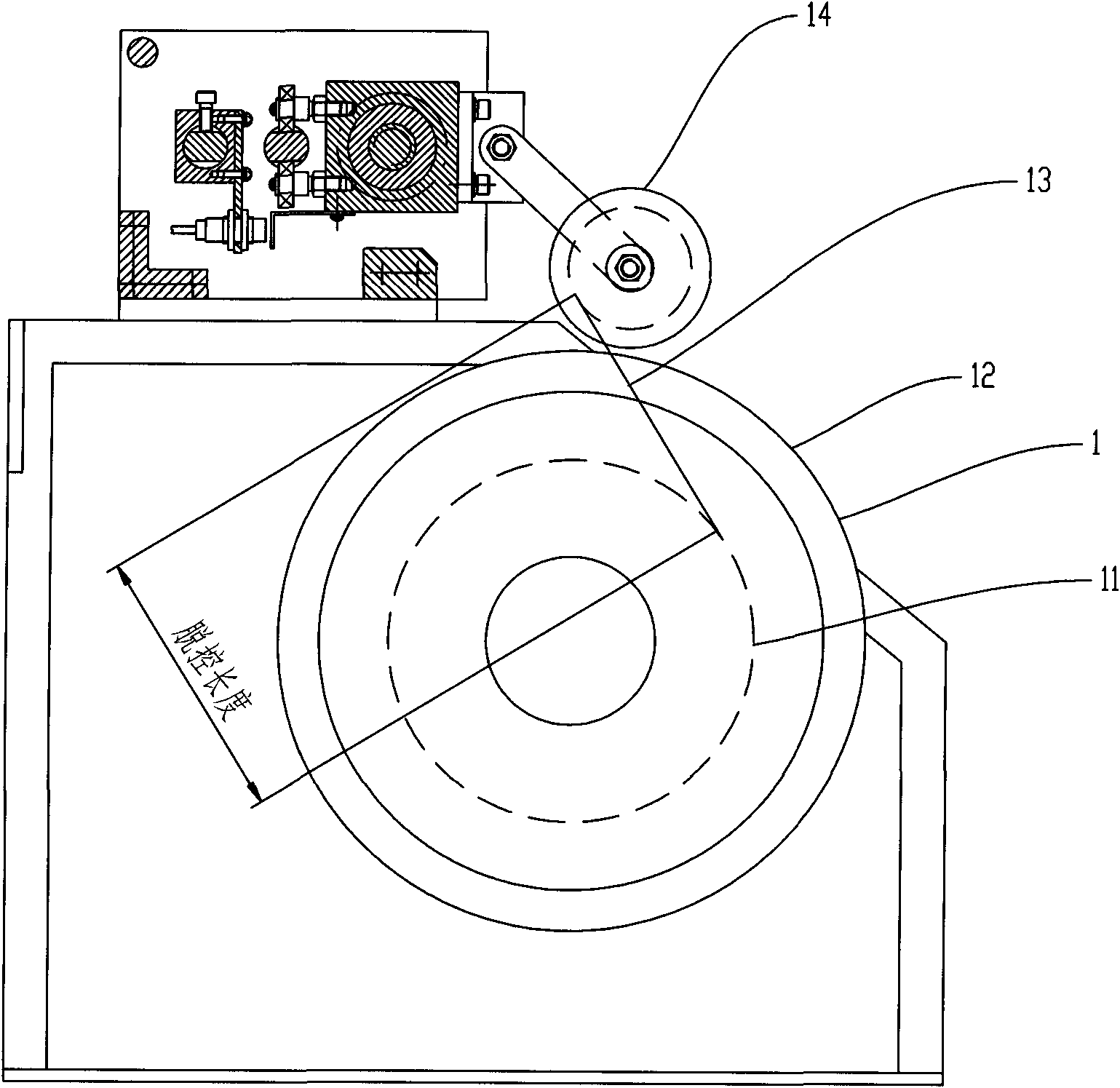

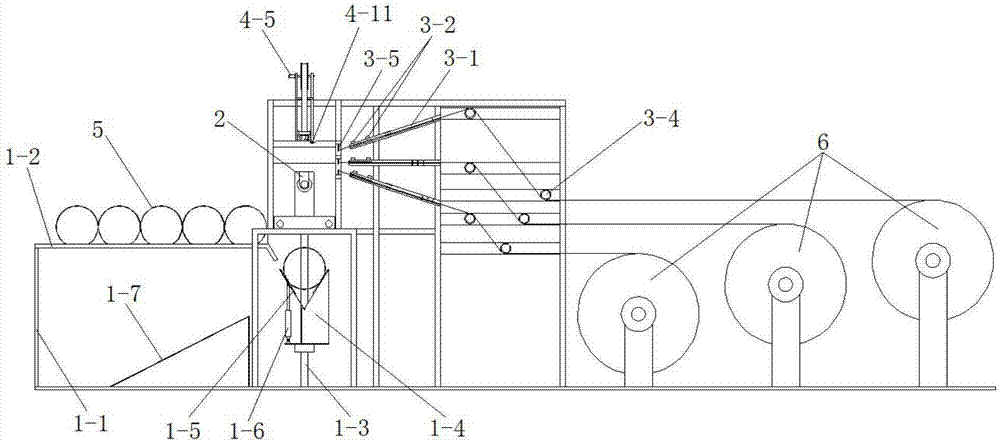

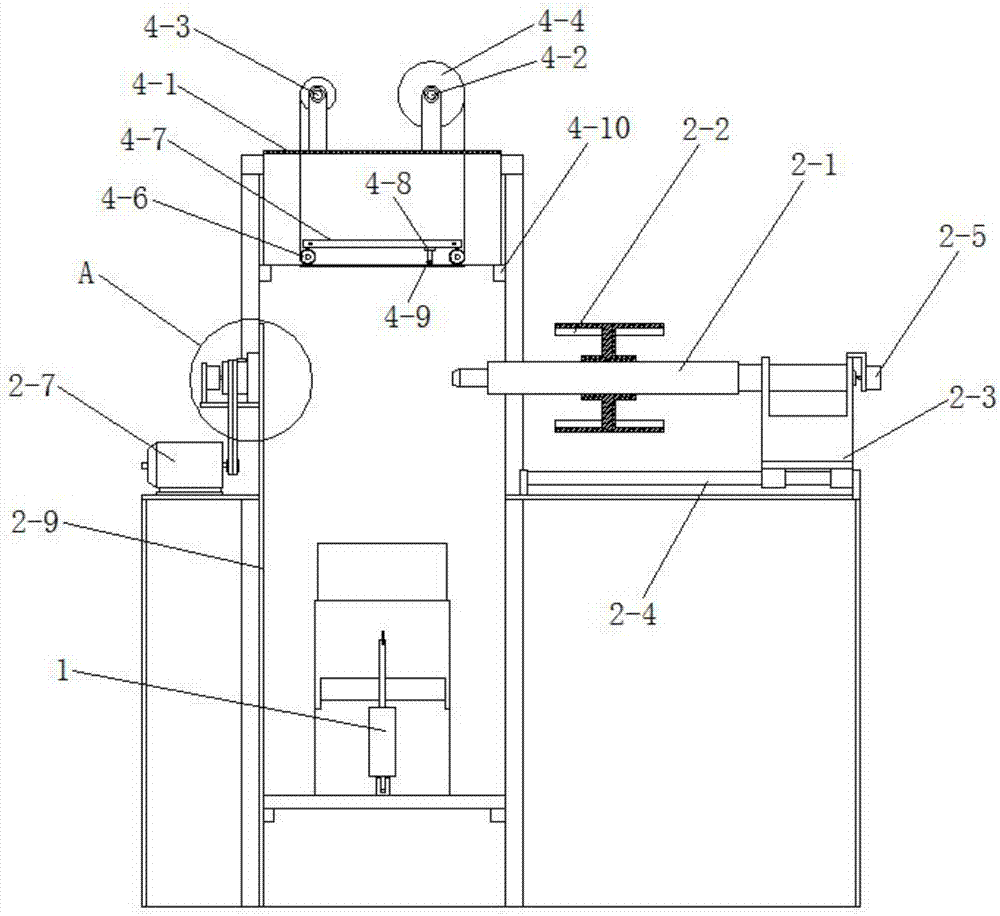

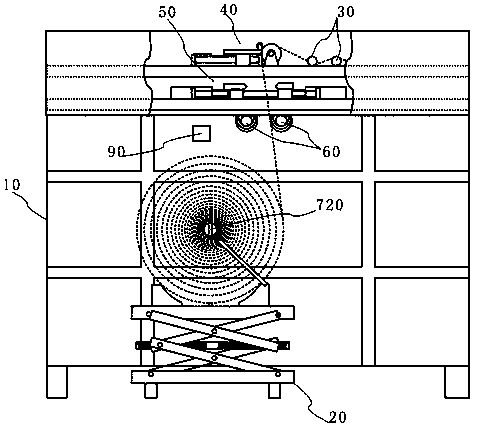

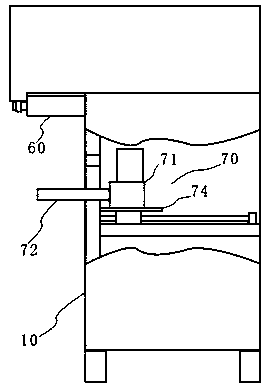

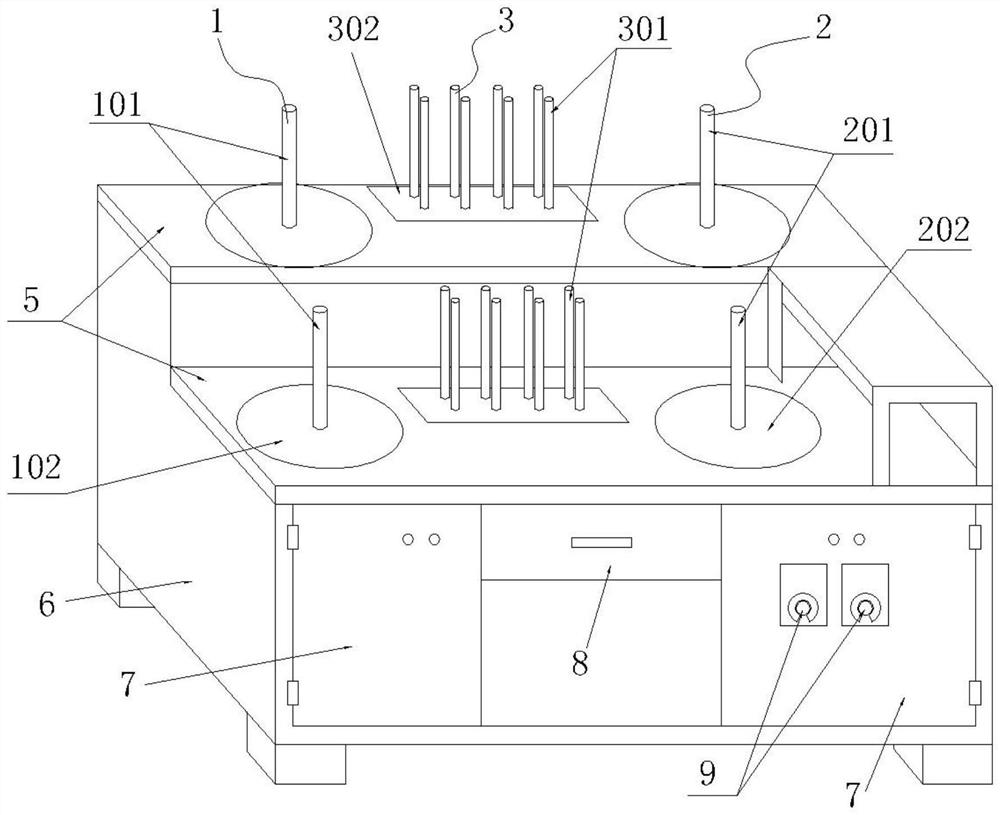

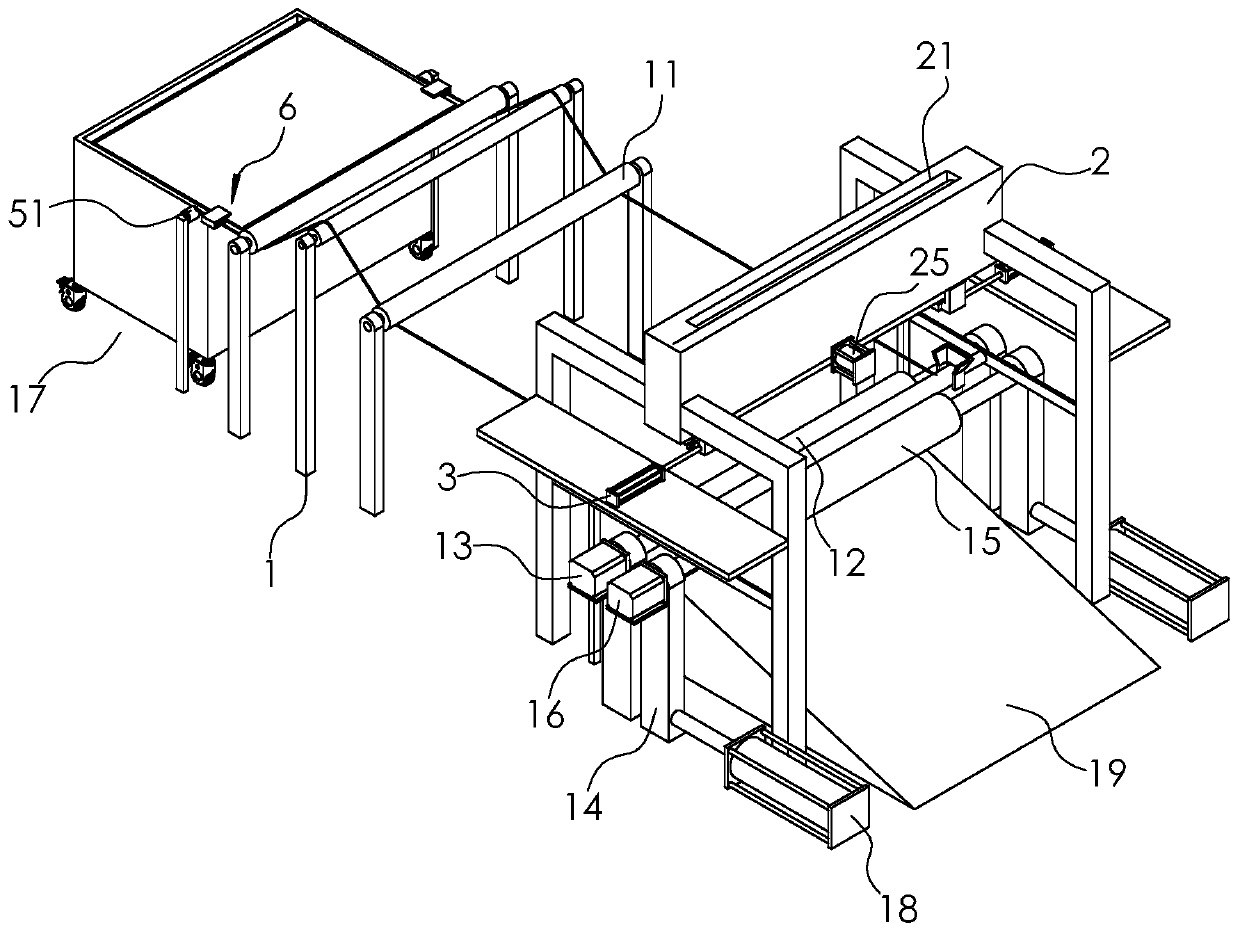

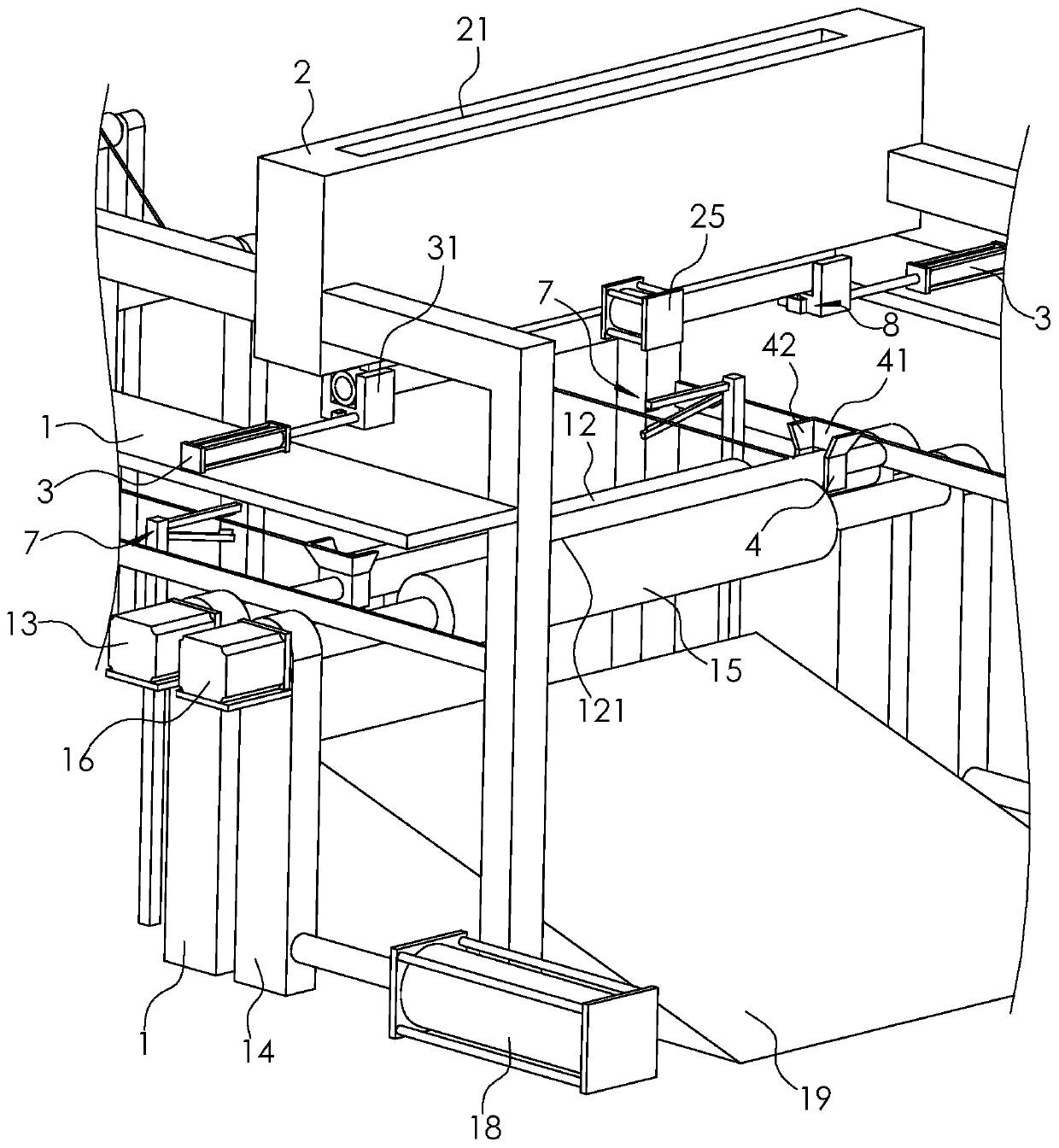

Full-automatic filter element winding machine

ActiveCN104925558AAchieve clampingSolve the thickness of the wallWebs handlingWinding machineAdhesive

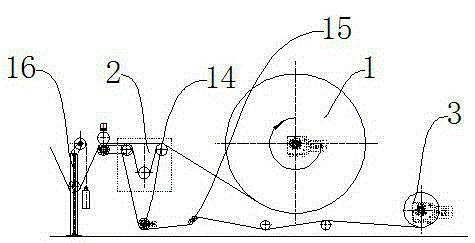

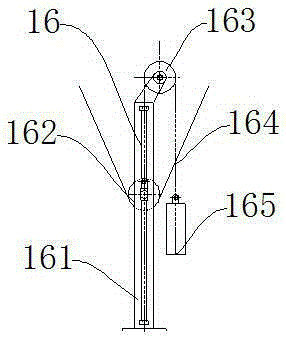

The invention relates to a full-automatic filter element winding machine which comprises a filter element paper unreeling mechanism, an adhesive-dispensing cutting mechanism, a clamping drive mechanism, a three-dimensional lifting platform, a filter screen jacking mechanism, an oblique jacking and discharging mechanism and a central control cabinet. A filter paper clamping traction device adjusts the filter element paper position corresponding to the inlet point adhesive-dispensing cutting mechanism and performs filter element paper traction. An adhesive-dispensing of the adhesive-dispensing cutting mechanism performs adhesive dispensing on filter element paper, and the filter element paper is cut off through the cutting device after winding is completed. The filter screen jacking mechanism lifts a filter element screen to the clamping drive mechanism. The clamping drive mechanism is used for clamping the filter element screen and drives the filter element screen to rotate and to be wounded with the filter element paper. The filter element screen completing winding through the clamping drive mechanism drops to the oblique jacking and discharging mechanism and is moved out of a winding machine through the oblique jacking and discharging mechanism. The full-automatic filter element winding machine has a full-automatic multi-azimuth adjusting function, completely replaces manual operation to wind the filter paper on the filter element screen, production efficiency and product quality are improved, and production cost is reduced.

Owner:珠海圣菲玛滤清器有限公司

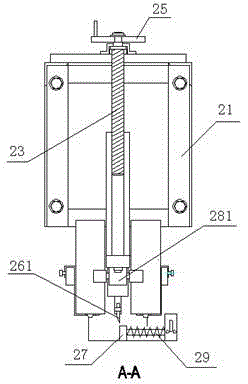

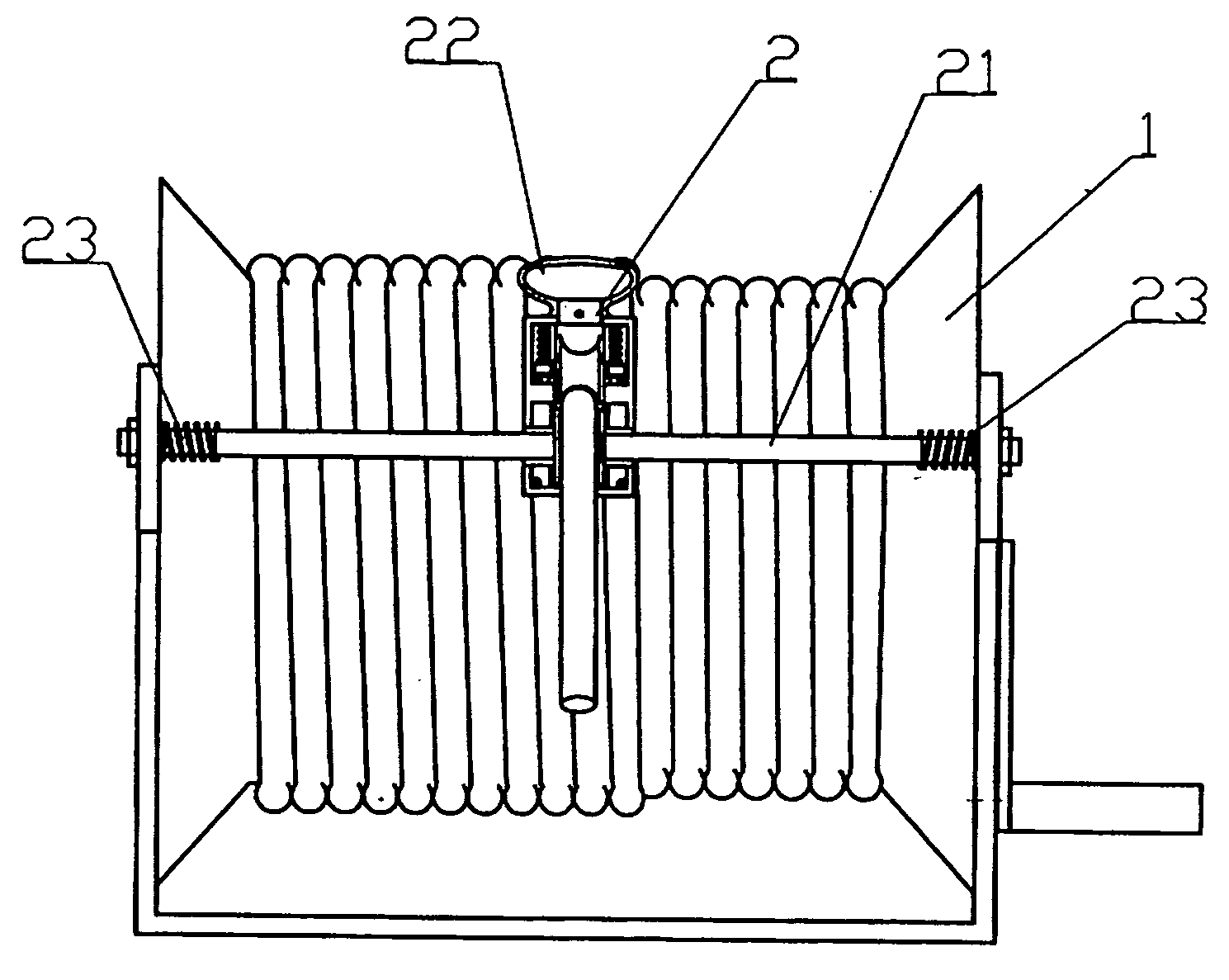

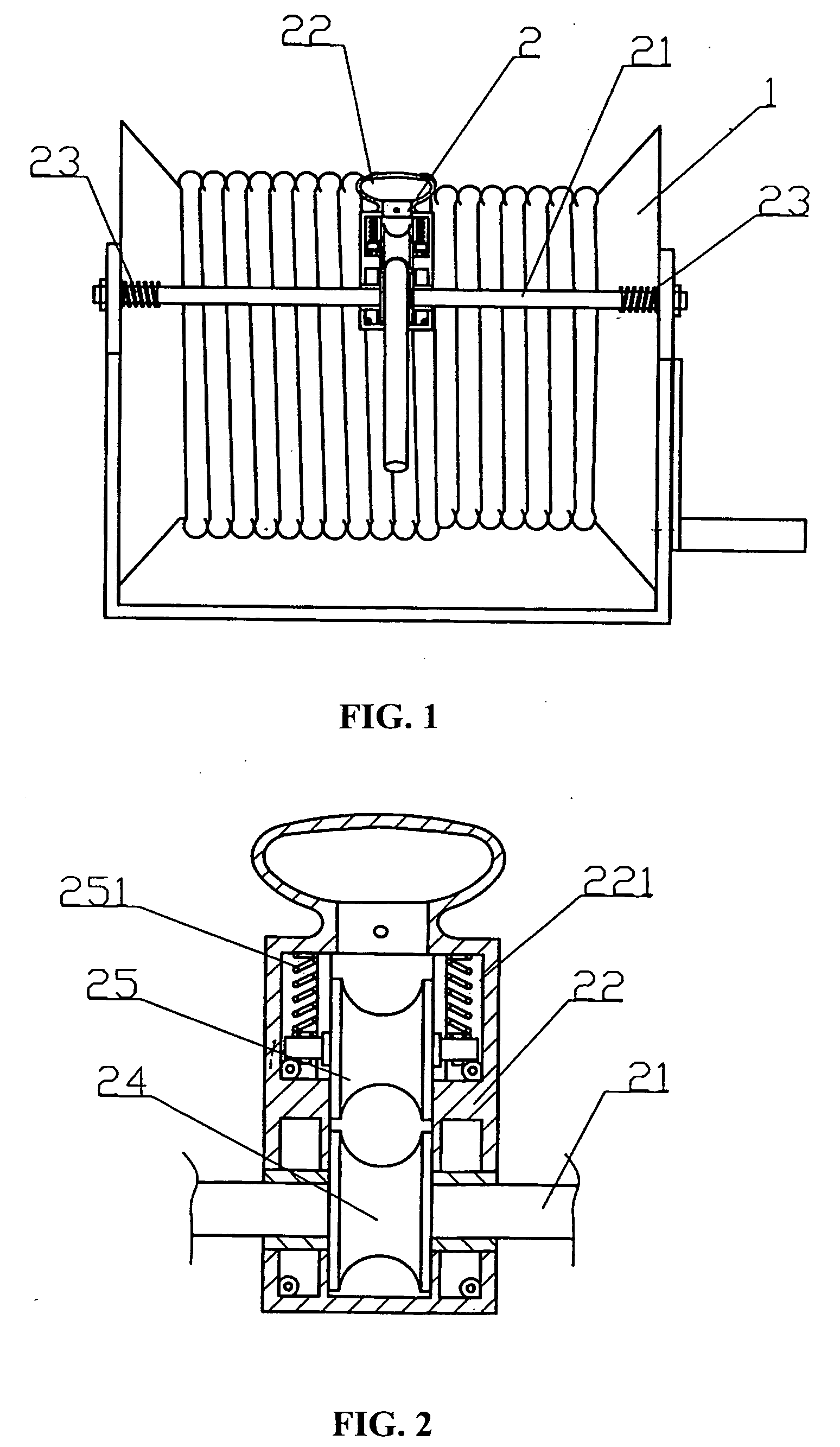

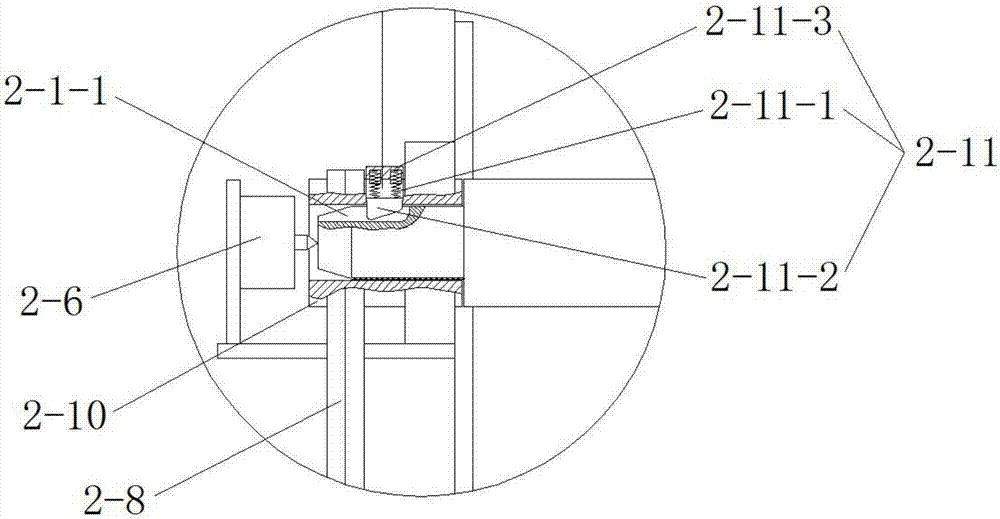

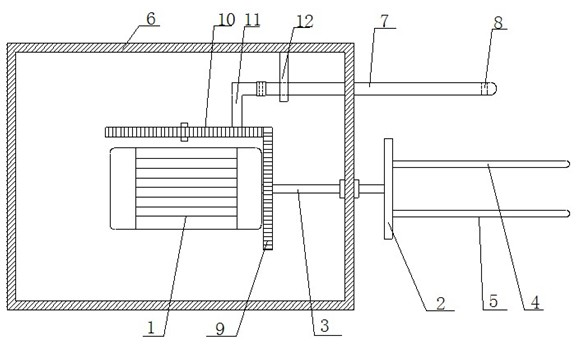

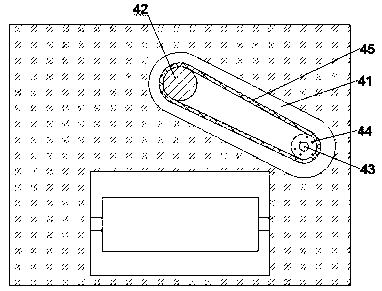

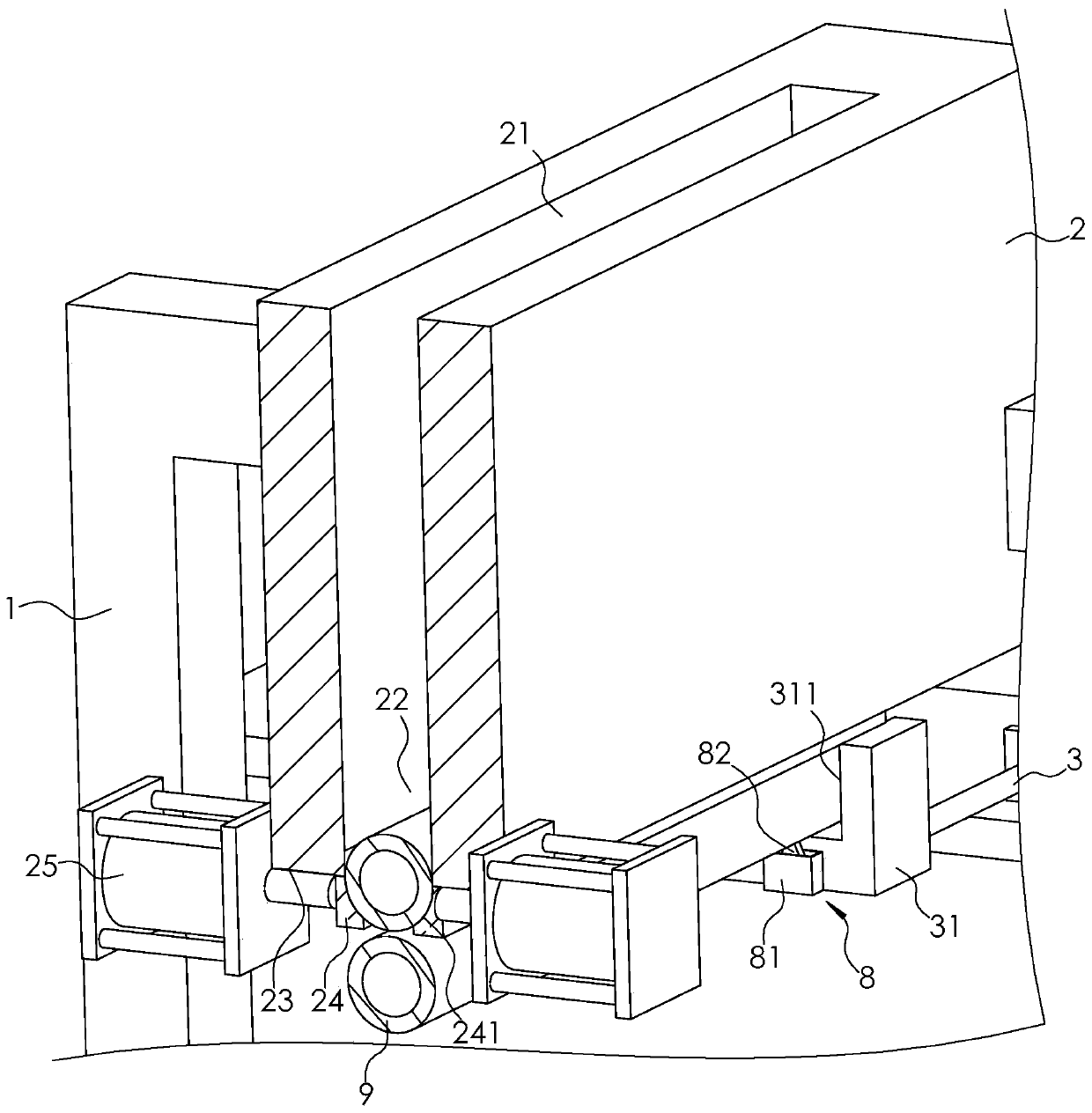

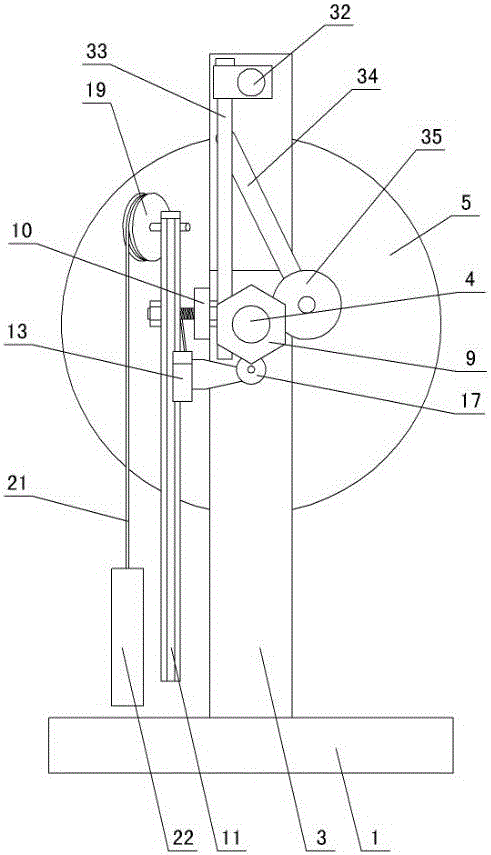

Hose reel

InactiveUS20060144986A1Easy to useSimple structureFilament handlingWebs handlingEngineeringConductor Coil

The present utility model relates to winding devices for guiding or ensuring the sequential coiling of steel cables or chains. In particular, it relates to a reel for hoses. It comprises a winding drum and a support. The winding drum is mounted on the support, and a hose is coiled around the winding drum. Its main structural elements: It further comprises a positioning assembly. The positioning assembly comprises a guide rod, a positioning unit, and two springs. The positioning unit is slidably mounted on the guide rod, and the two ends of the guide rod rest on the support. The two springs fit over the guide rod and are separately disposed on two sides of the positioning unit. The positioning unit has a hose hole, and the hose passes out through this hose hole. When the winding drum is rotated, the positioning assembly mounted on the hose reel can cause the hose to coil sequentially on the winding drum. It is characterized by neat and orderly coiling of the hose, convenience and ease of use, and simplicity of structure.

Owner:LEGACY MFG

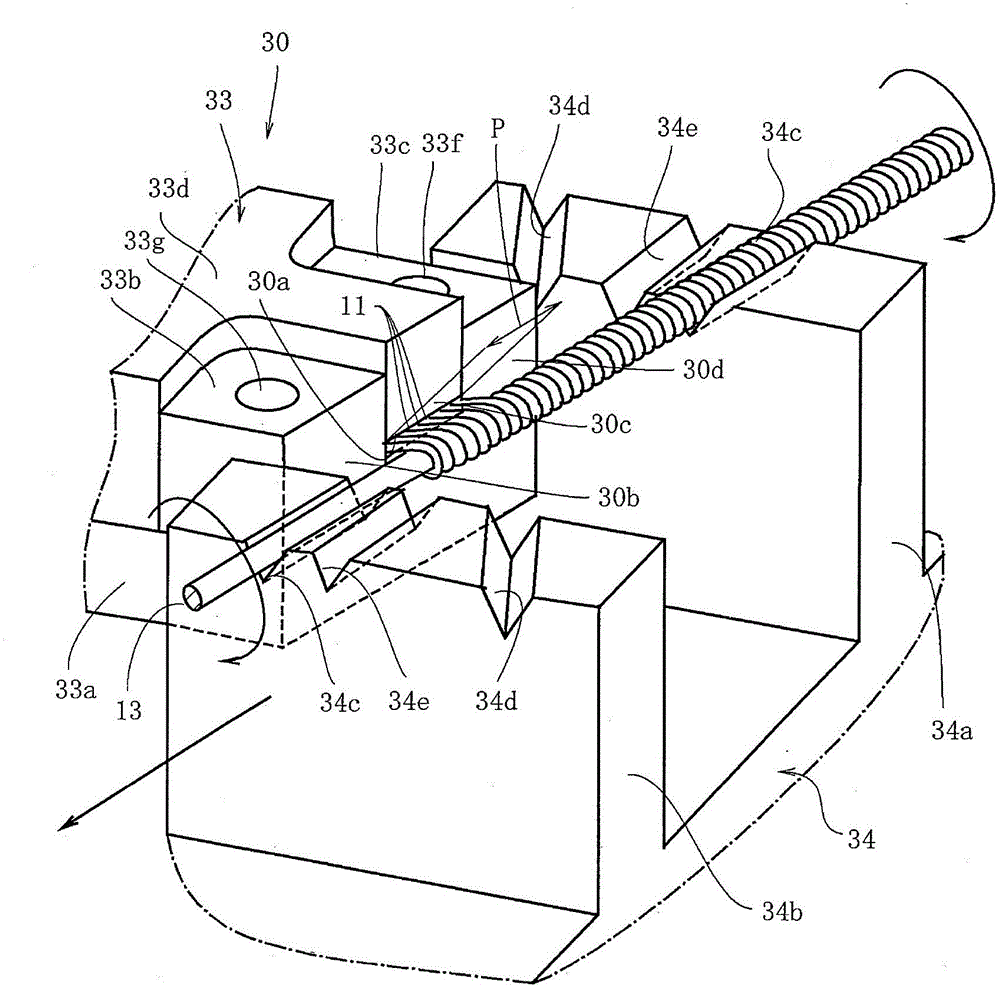

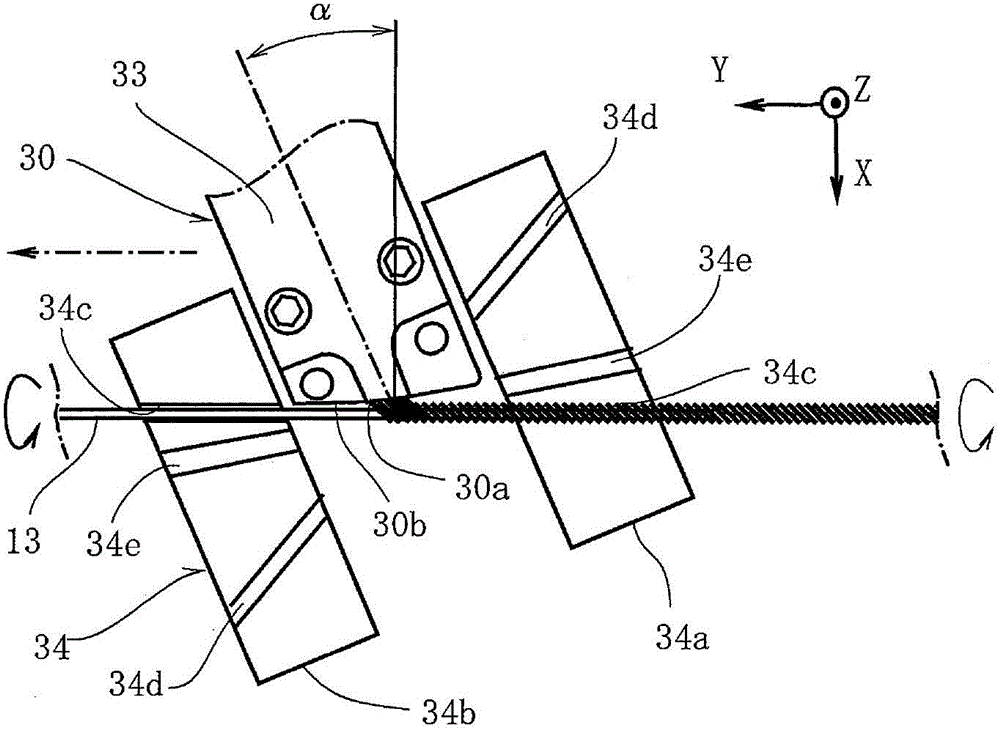

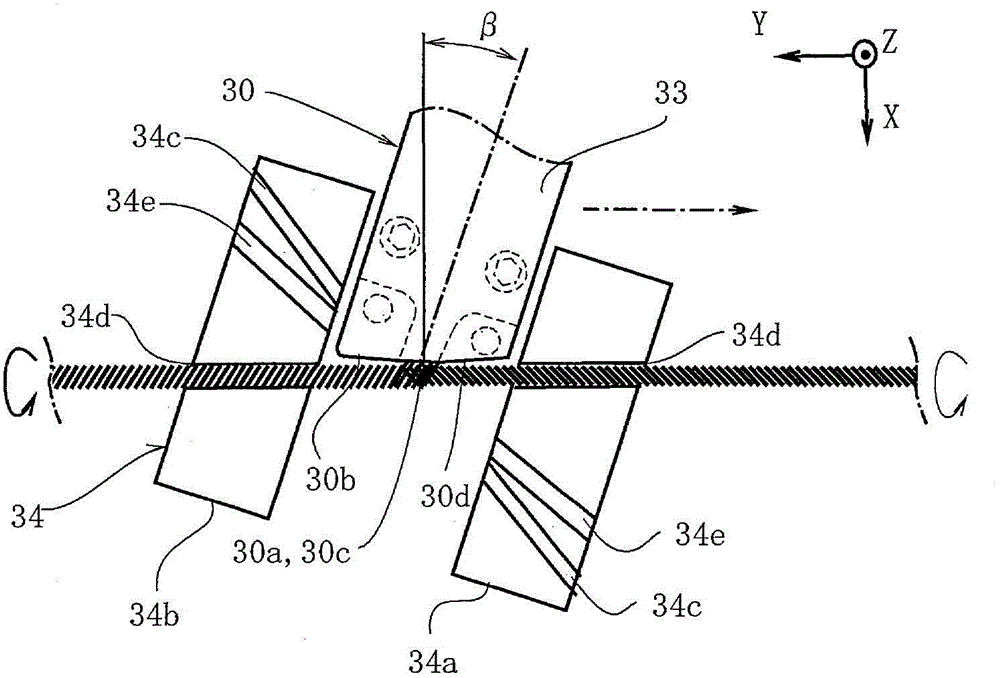

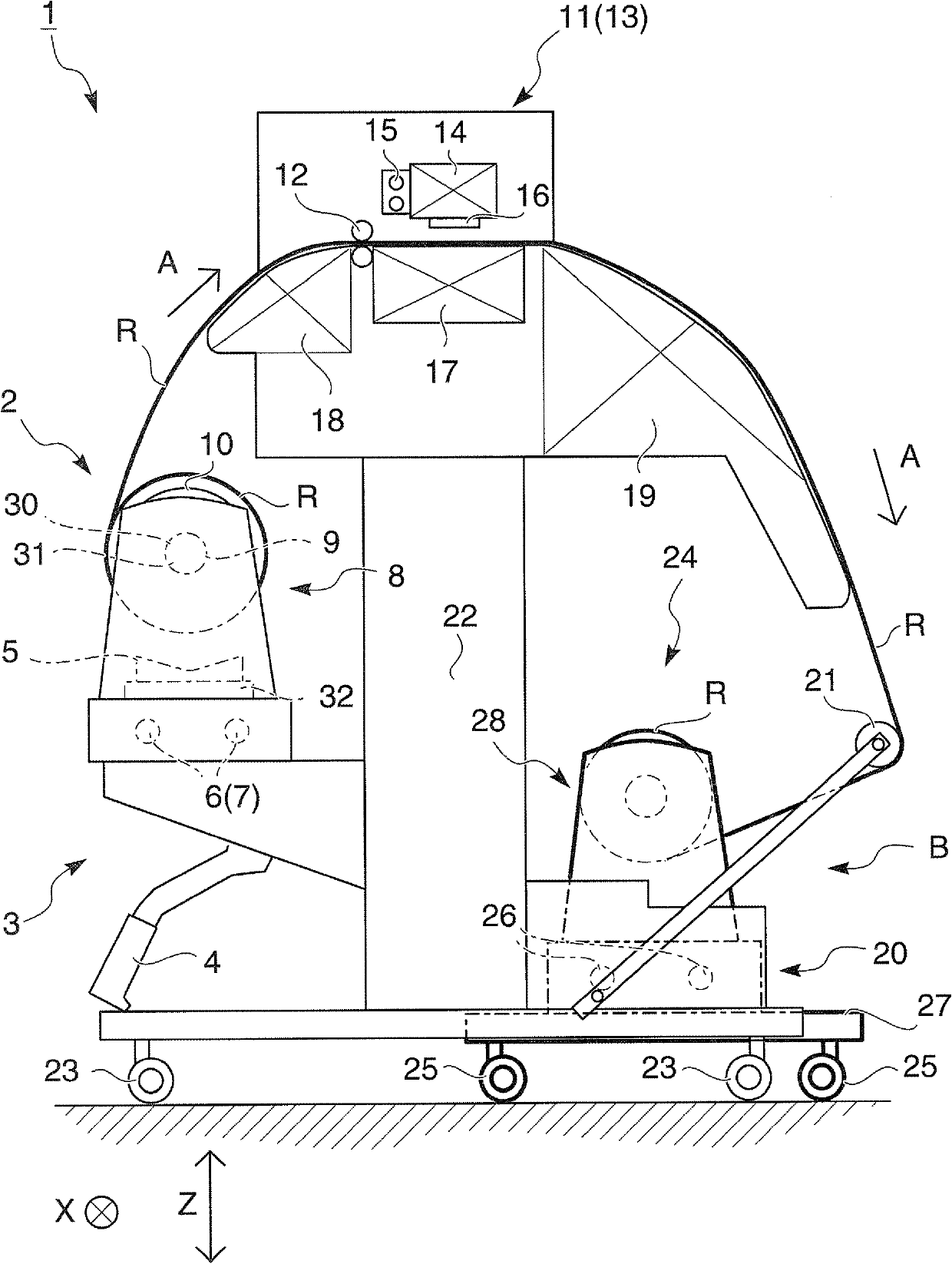

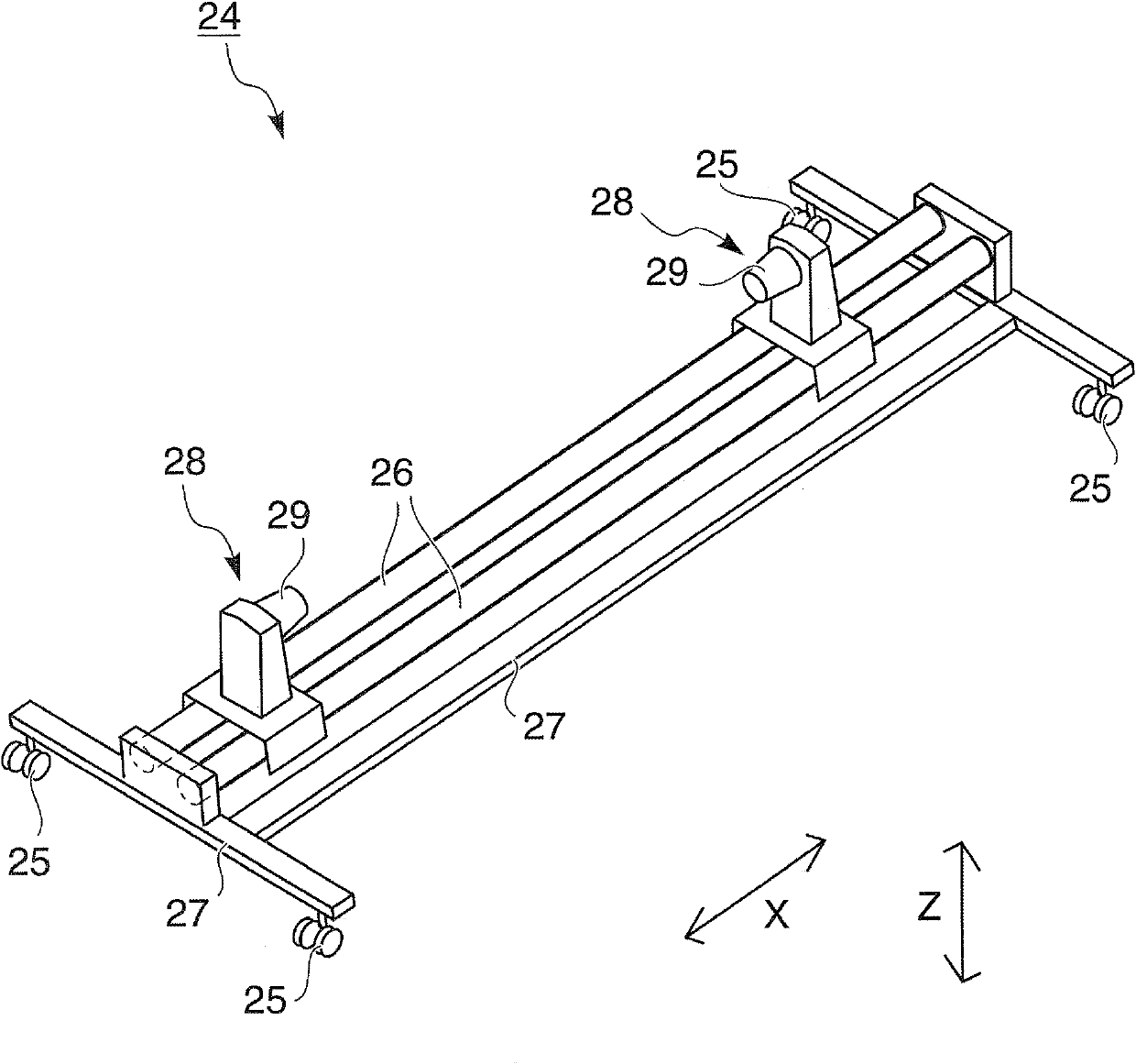

Plural-wire coiling device and plural-wire coiling method

InactiveCN102867642AReduce gapIncrease the gapManufacturing dynamo-electric machinesCoils manufactureEngineeringMechanical engineering

Owner:NITTOKU ENG CO LTD

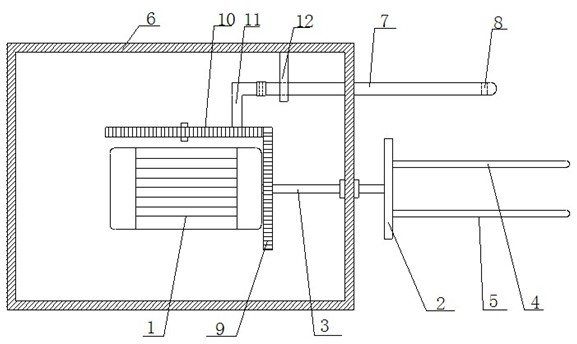

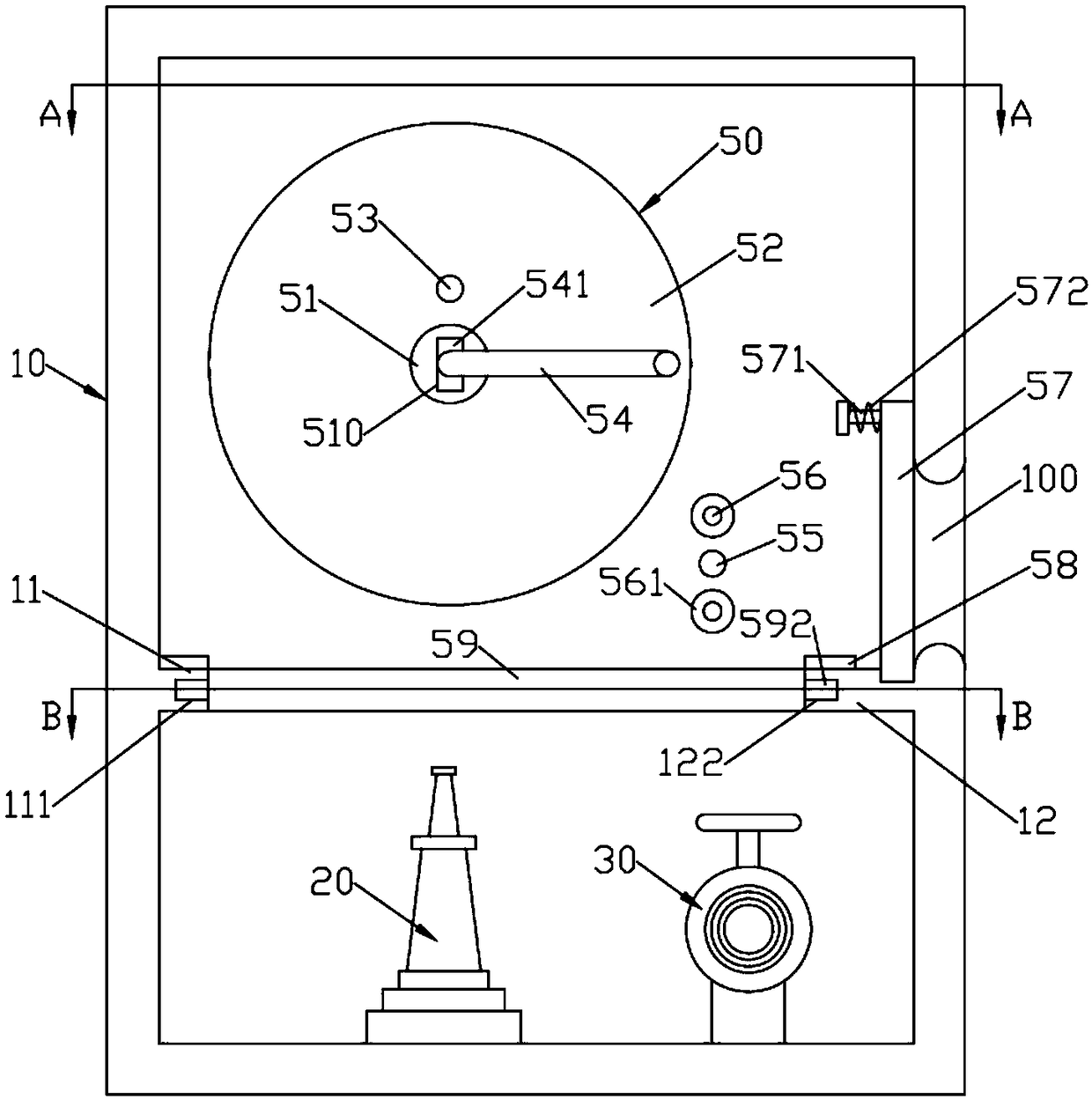

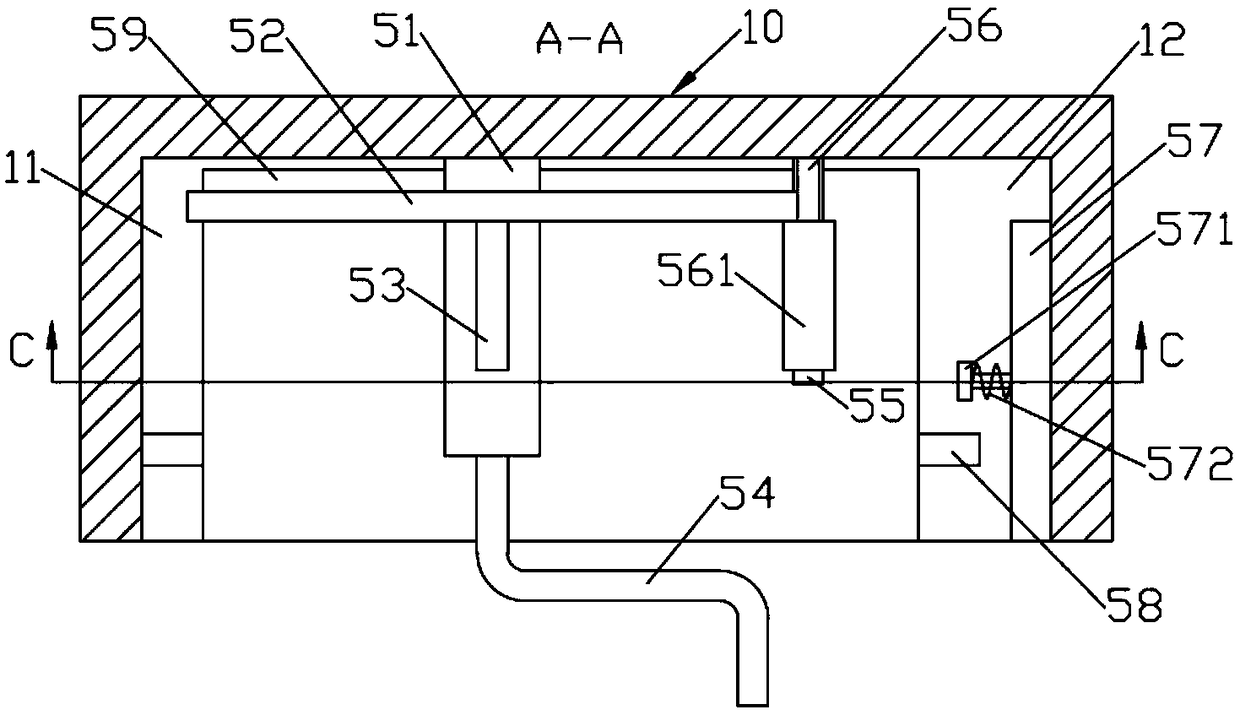

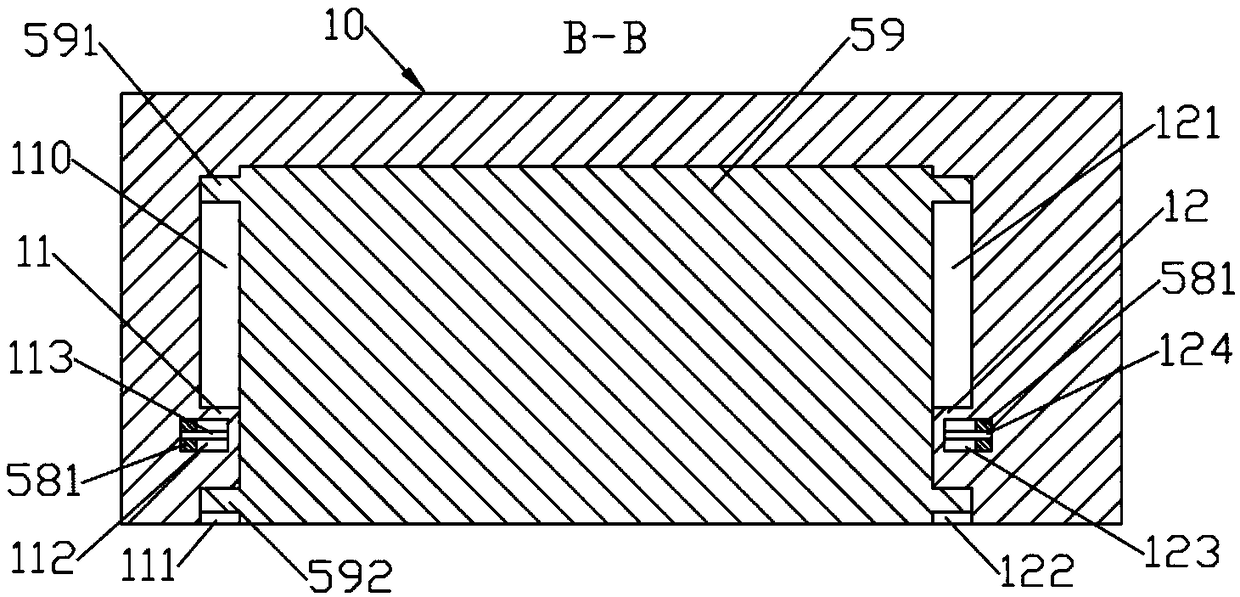

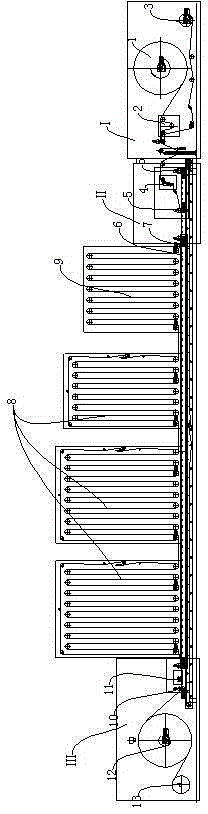

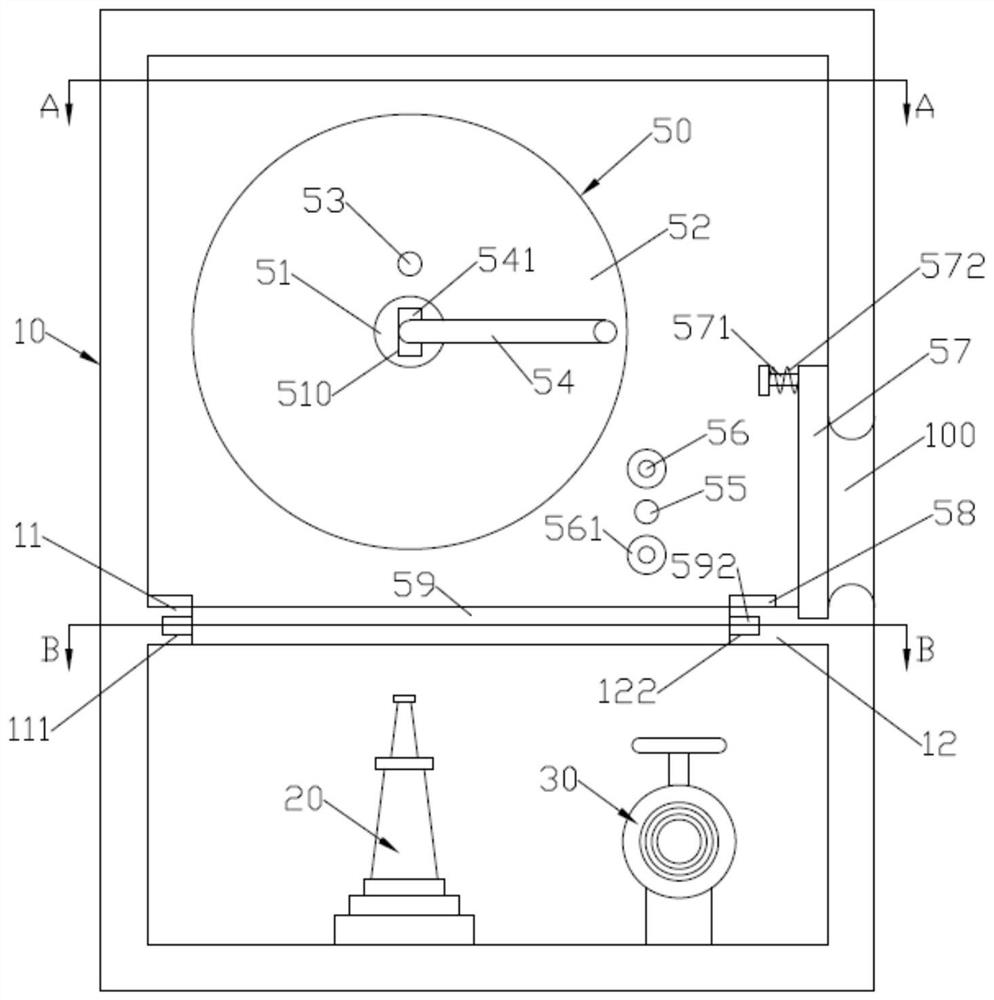

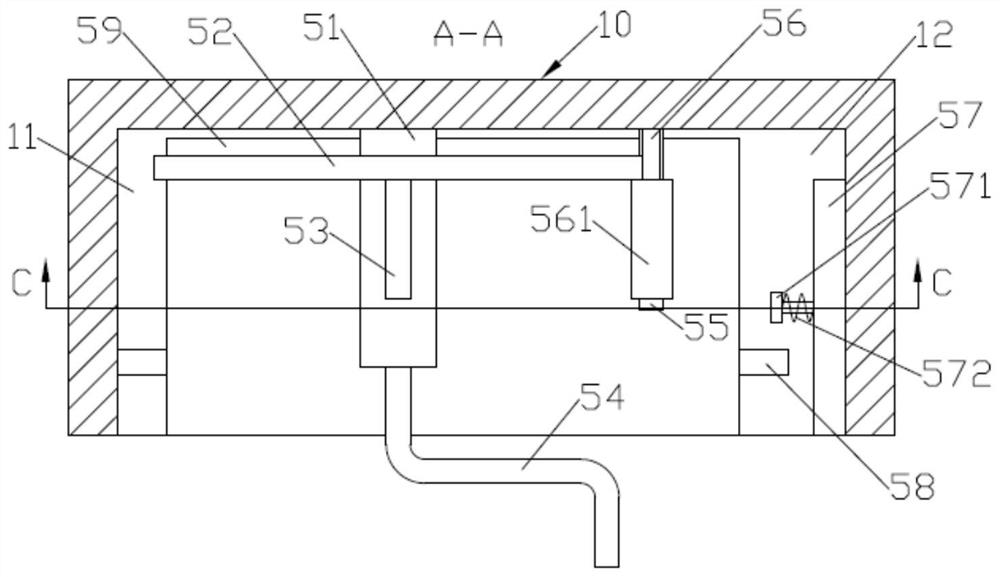

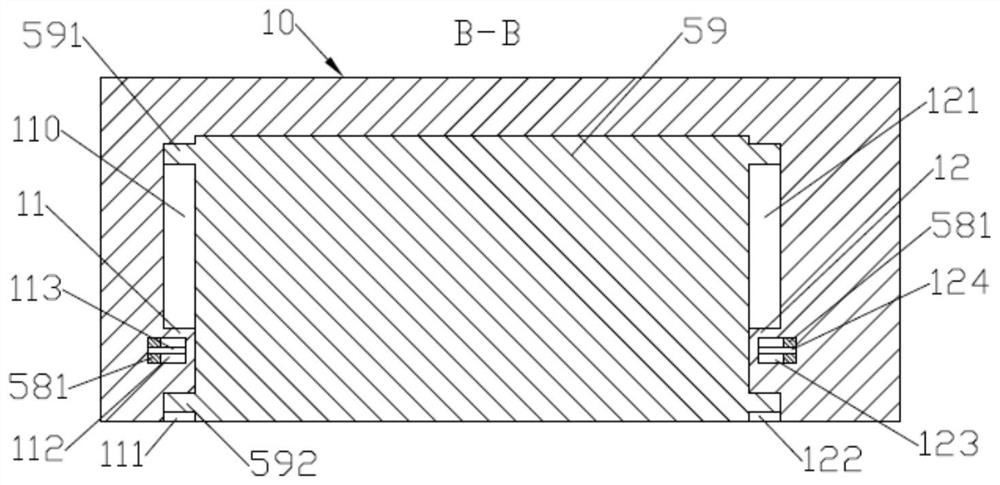

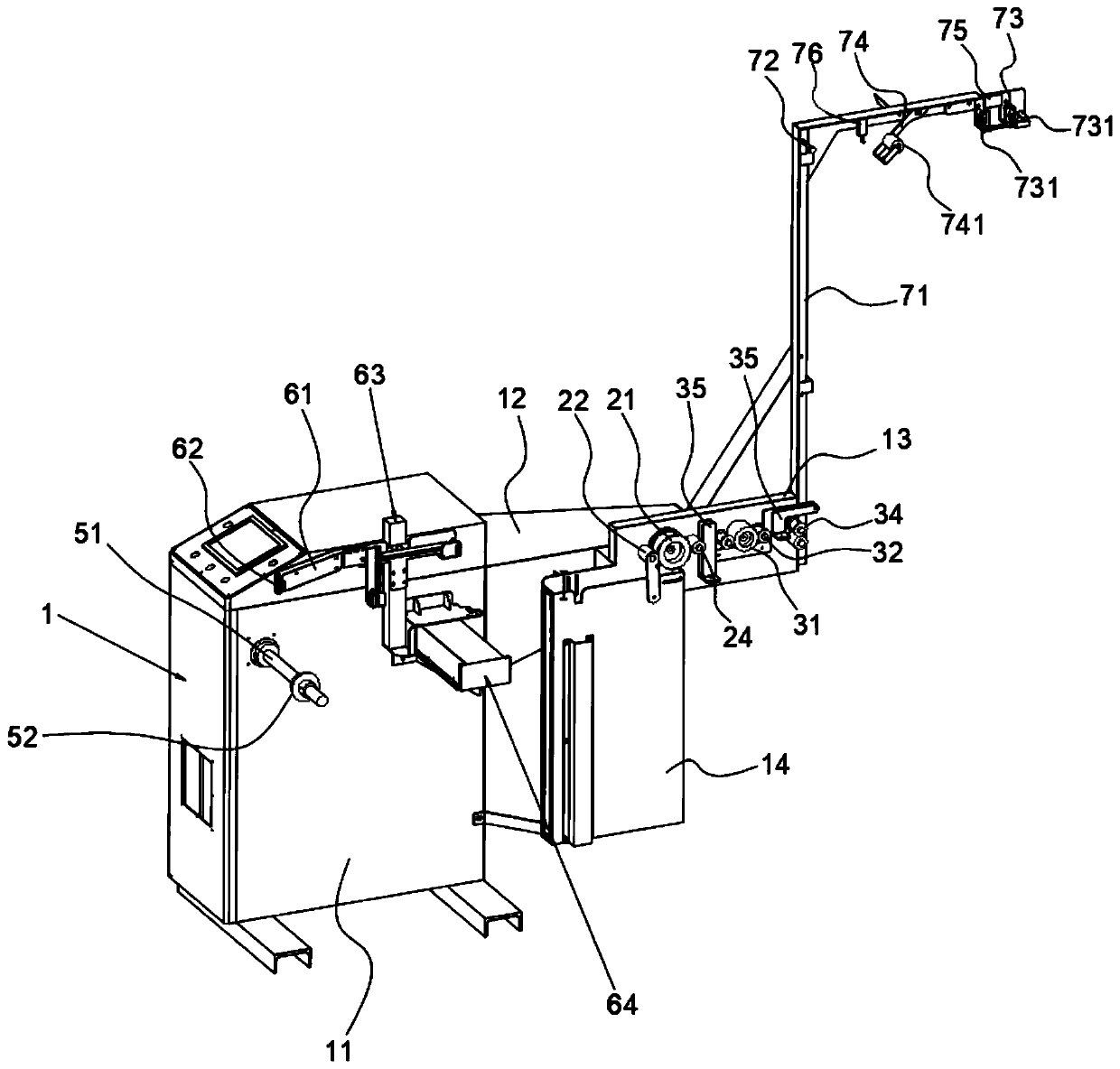

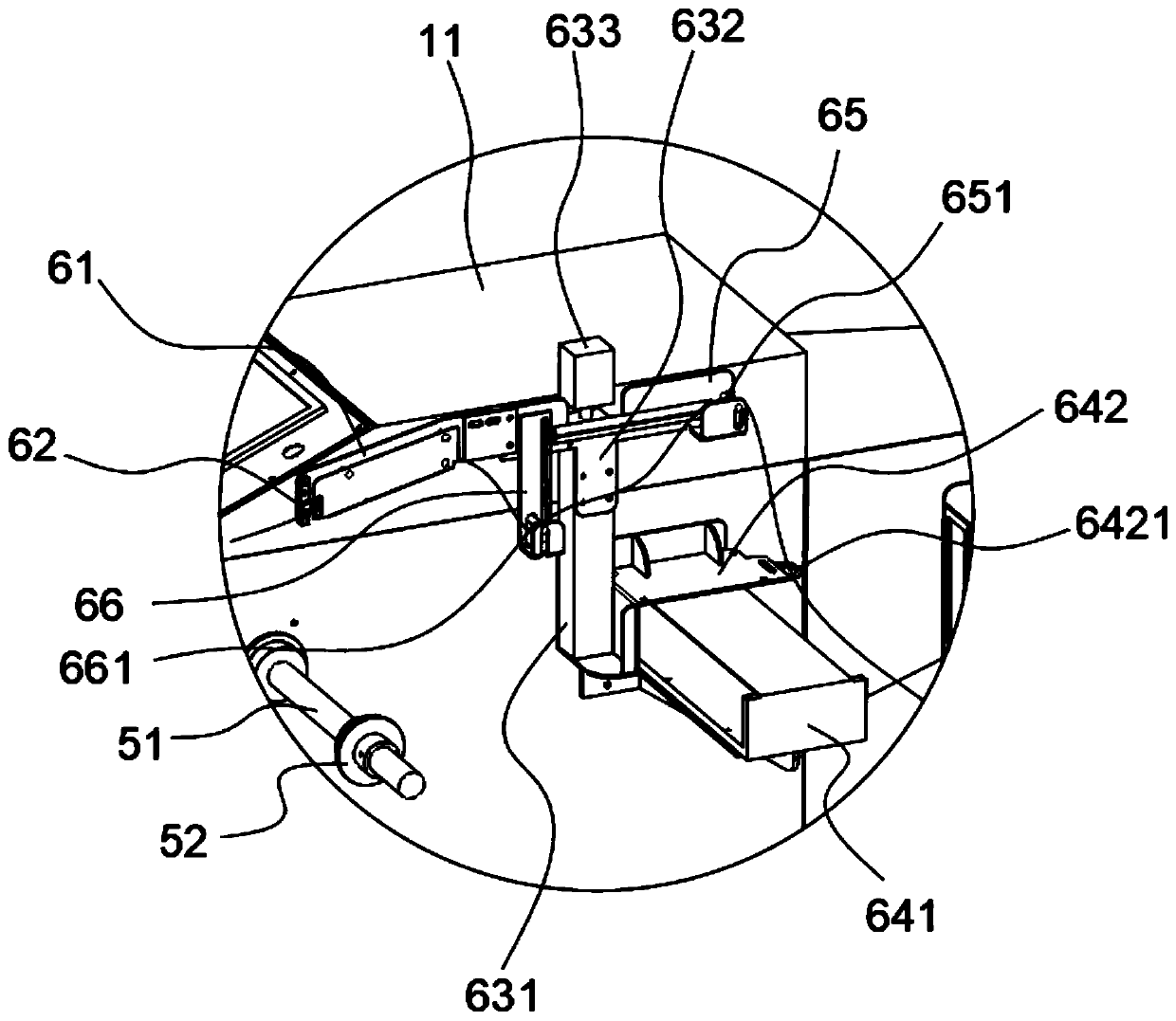

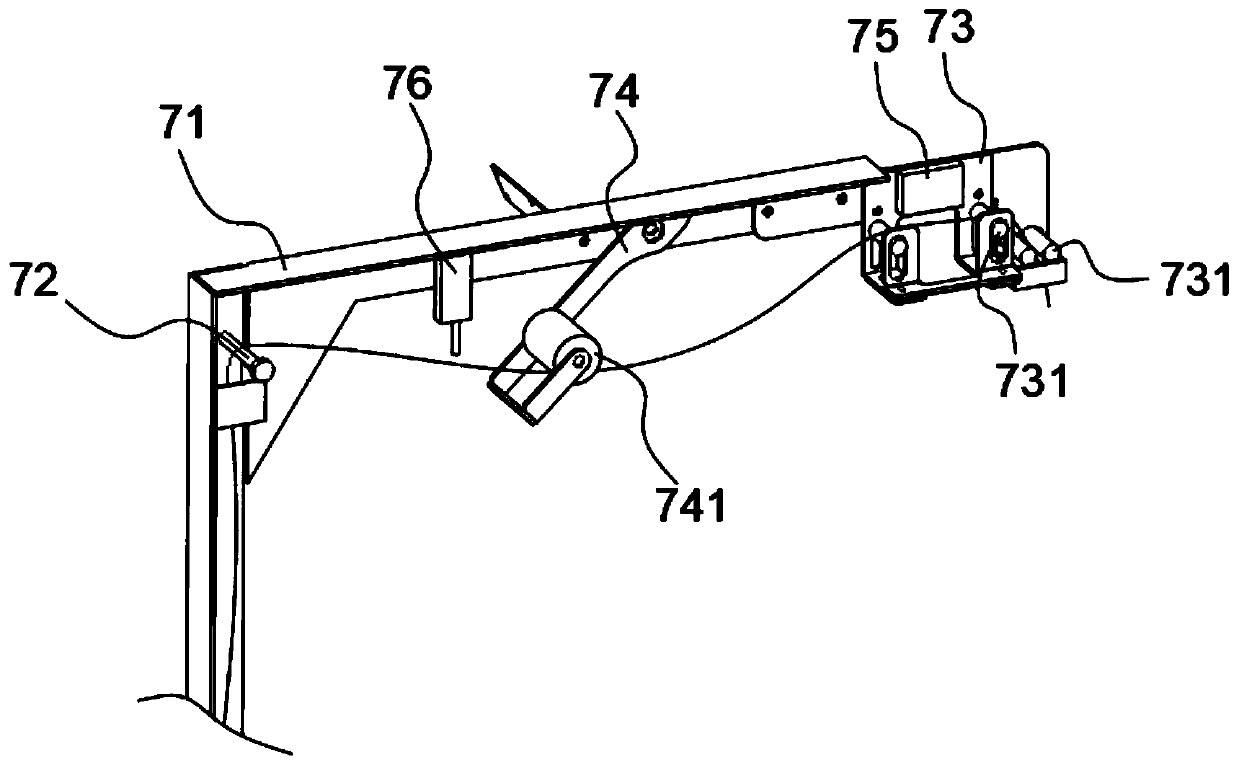

Automatic infusion apparatus packaging production line

PendingCN111717469AEvenly loadedNeatly coiledWrapper twisting/gatheringIndividual articlesInfusion setProcess engineering

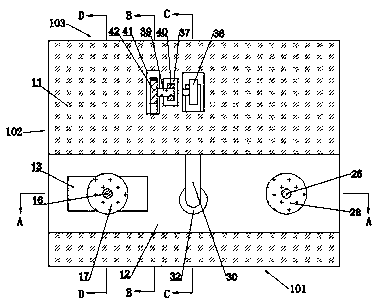

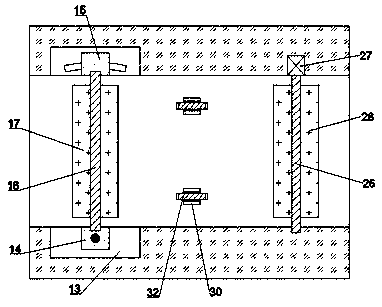

The invention relates to the technical field of packaging equipment, in particular to an automatic infusion apparatus packaging production line. The automatic infusion apparatus packaging production line comprises automatic packaging bag feeding and position correcting equipment, automatic packaging bag transferring and opening equipment, automatic packaging bag taking, winding and bagging equipment and automatic packaging bag sealing equipment; the automatic feeding and position correcting equipment is arranged in front of the automatic packaging bag transferring and opening equipment in theX-axis direction; the automatic packaging bag taking, winding and bagging equipment is arranged behind the automatic packaging bag transferring and opening equipment in the X-axis direction; and the automatic packaging bag sealing equipment is arranged on one side of the automatic packaging bag transferring and opening equipment in the Y-axis direction. The automatic infusion apparatus packaging production line is reasonable in overall structure arrangement, high in structural operation relation continuity, high in process continuity, high in automation degree, high in packaging efficiency andhigh in packaging success rate.

Owner:YANTAI KAIBO AUTOMATION TECH

Wire guiding member

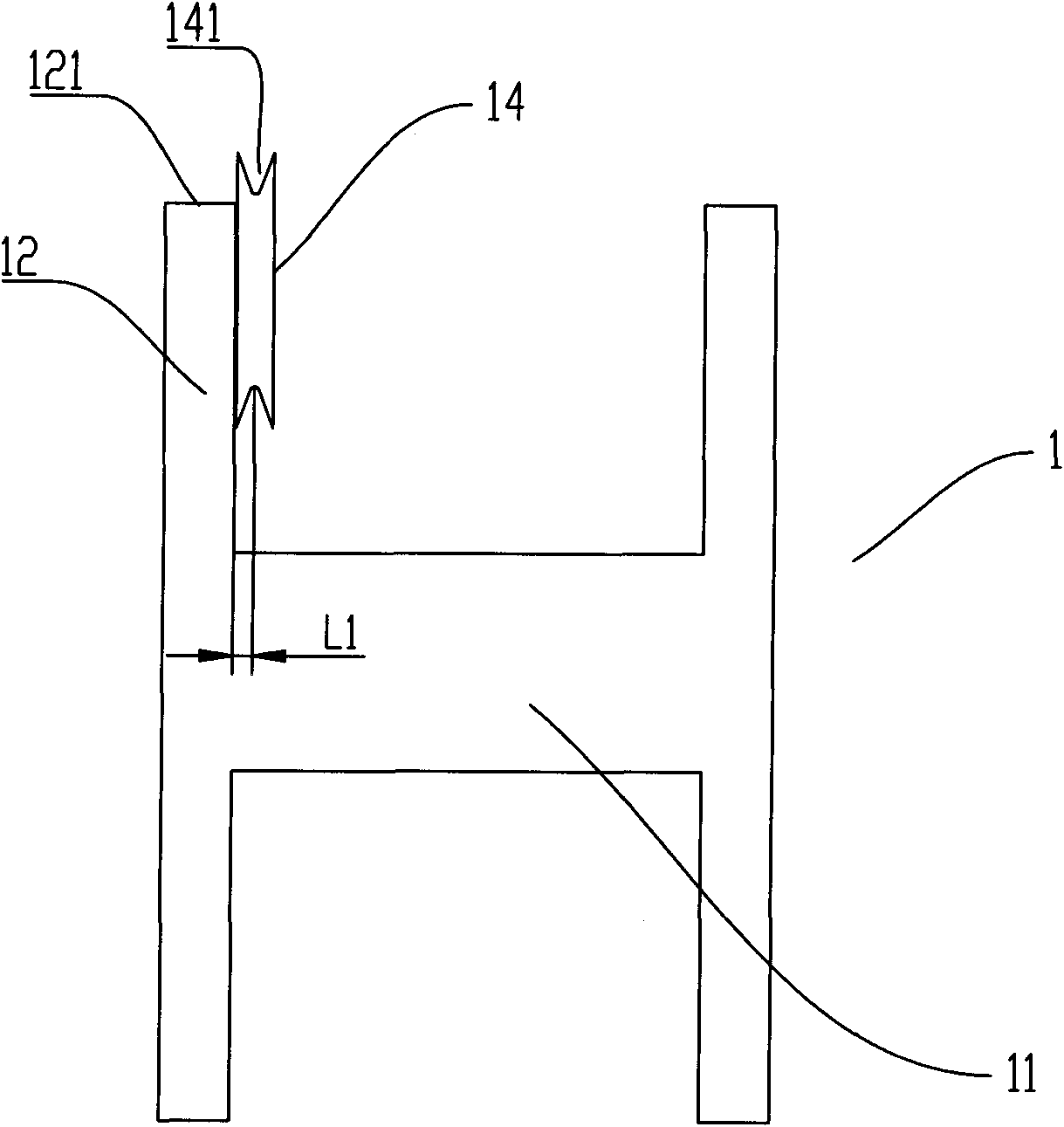

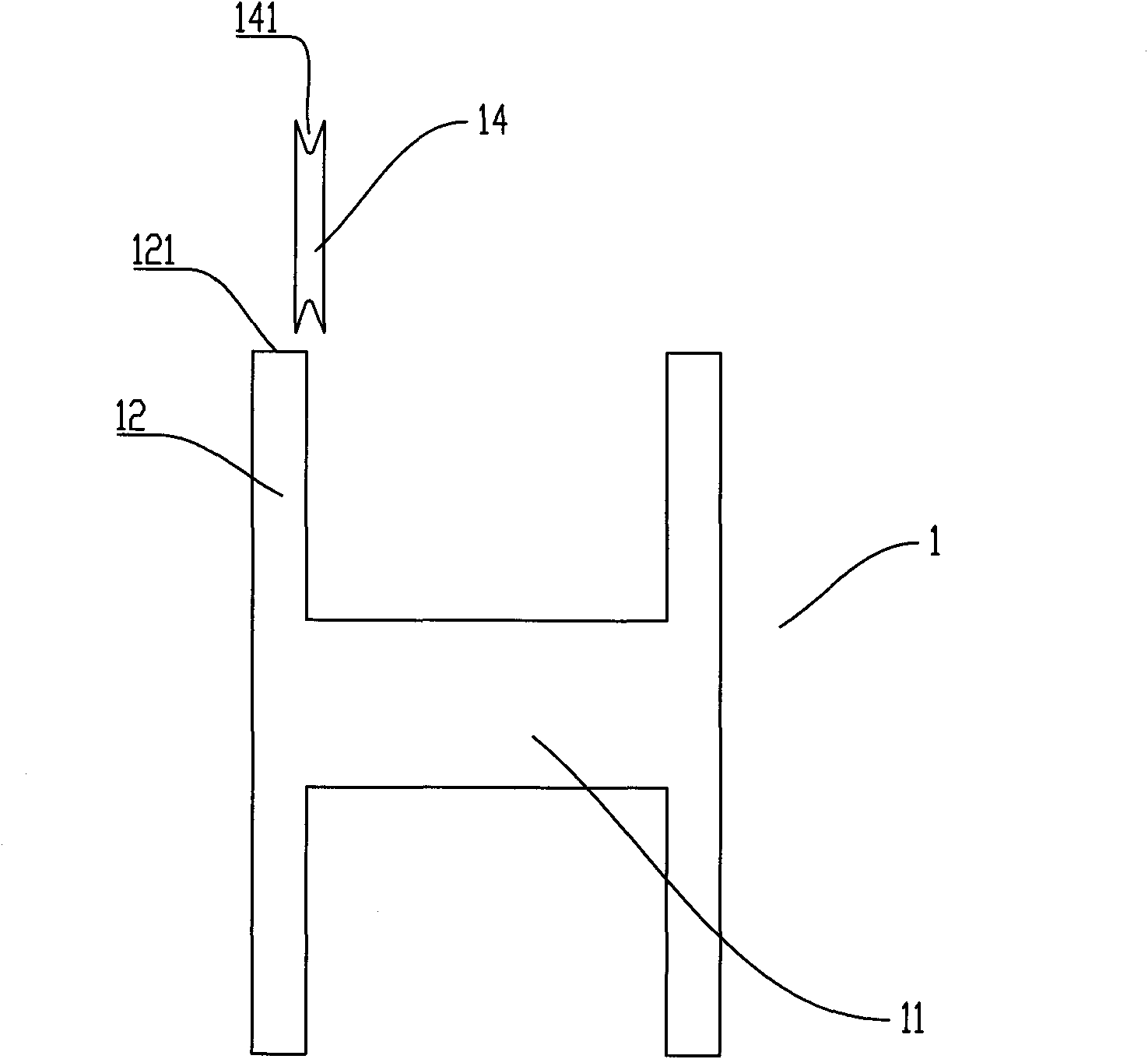

The invention discloses a wire guiding member characterized by comprising a fixed frame and a spacing device with a slit, wherein the spacing device is installed on the fixed frame which is movably installed on a first support. The wire guiding member adopts steel wires or slices to guide wires. The wires have small diameters, the slices have small thicknesses, and therefore, the steel wires or the slices can be put between the outer circle of a plate edge and a plate center to be close to a winding layer as far as possible. The wire guiding member can prevent control-release length from being overlong to affect the winding precision. When the steel wires or the slices axially move along a wire plate, the wire guiding member can be close to the plate edge of the wire plate as far as possible so as to ensure that the wires close to the plate edge of the wire plate can still be orderly winded.

Owner:上海颐尚电气科技股份有限公司

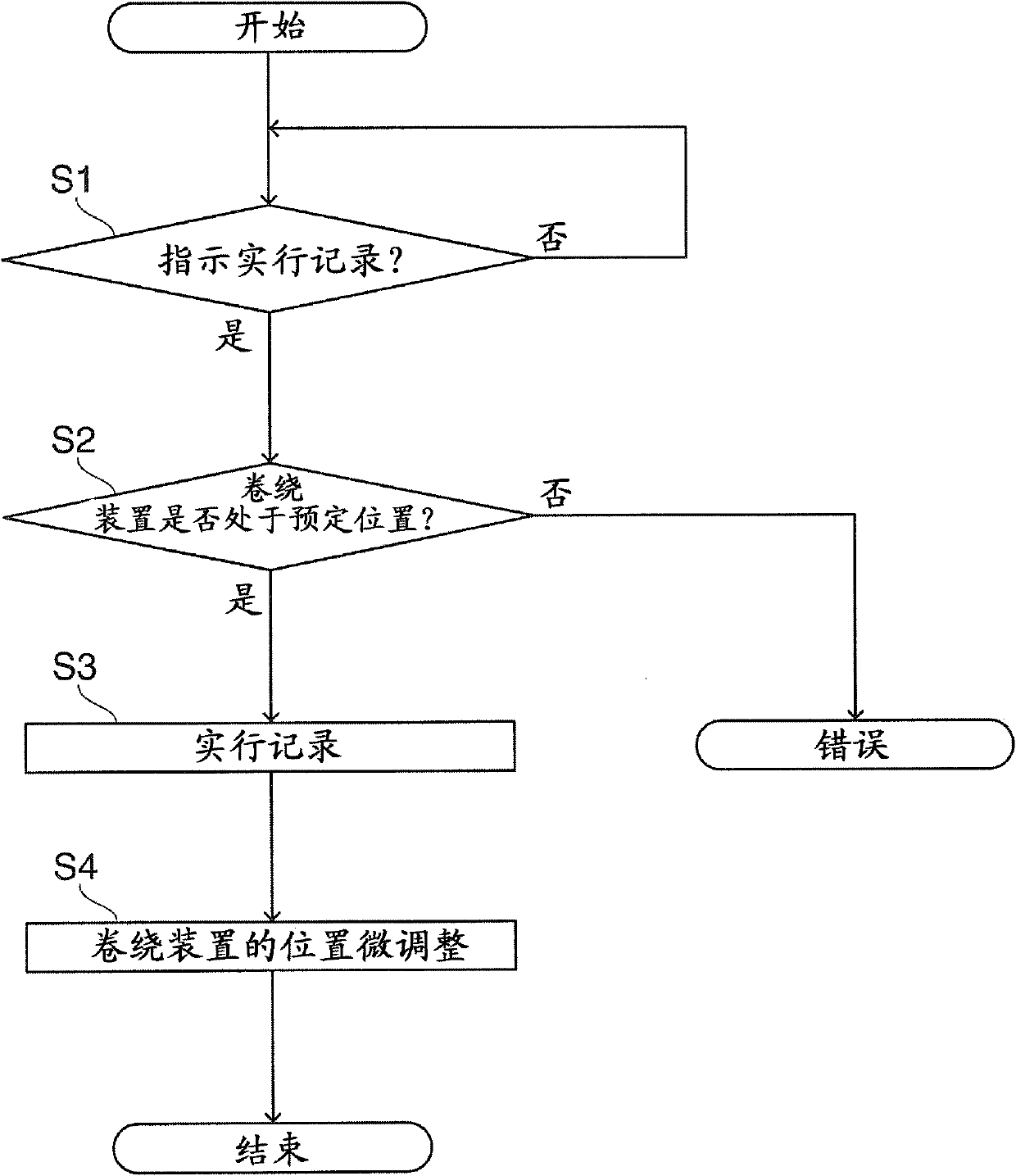

Recording apparatus

ActiveCN102642410ANeatly coiledOther printing apparatusEngineeringElectrical and Electronics engineering

Owner:SEIKO EPSON CORP

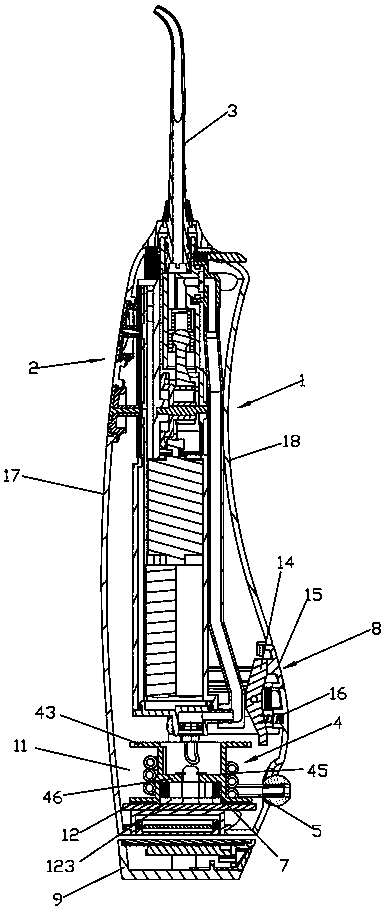

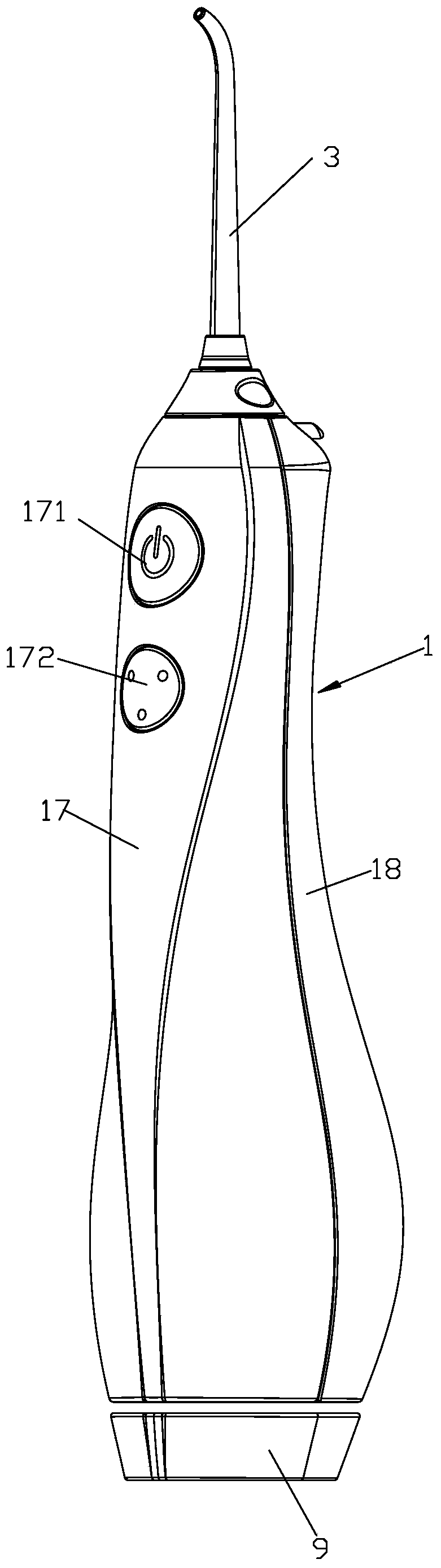

Oral irrigator

The invention discloses an oral irrigator. The oral irrigator comprises a shell, an oral irrigation part and a water nozzle part, the oral irrigation part is mounted in the shell and provided with a water inlet and a water outlet, and the water nozzle part communicates with the water outlet of the oral irrigation part; and a winding mechanism and a water pipe capable of being bent and wound are further included. The water pipe can be wound through the winding mechanism, the occupied space of the water pipe is reduced, carrying, packaging and transporting are convenient, and the loss of the water pipe can further be avoided; and the water pipe capable of being bent and wound is adopted, thus the second end of the water pipe is conveniently placed in a container filled with water or connected with a water source, and using occasions are wide.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

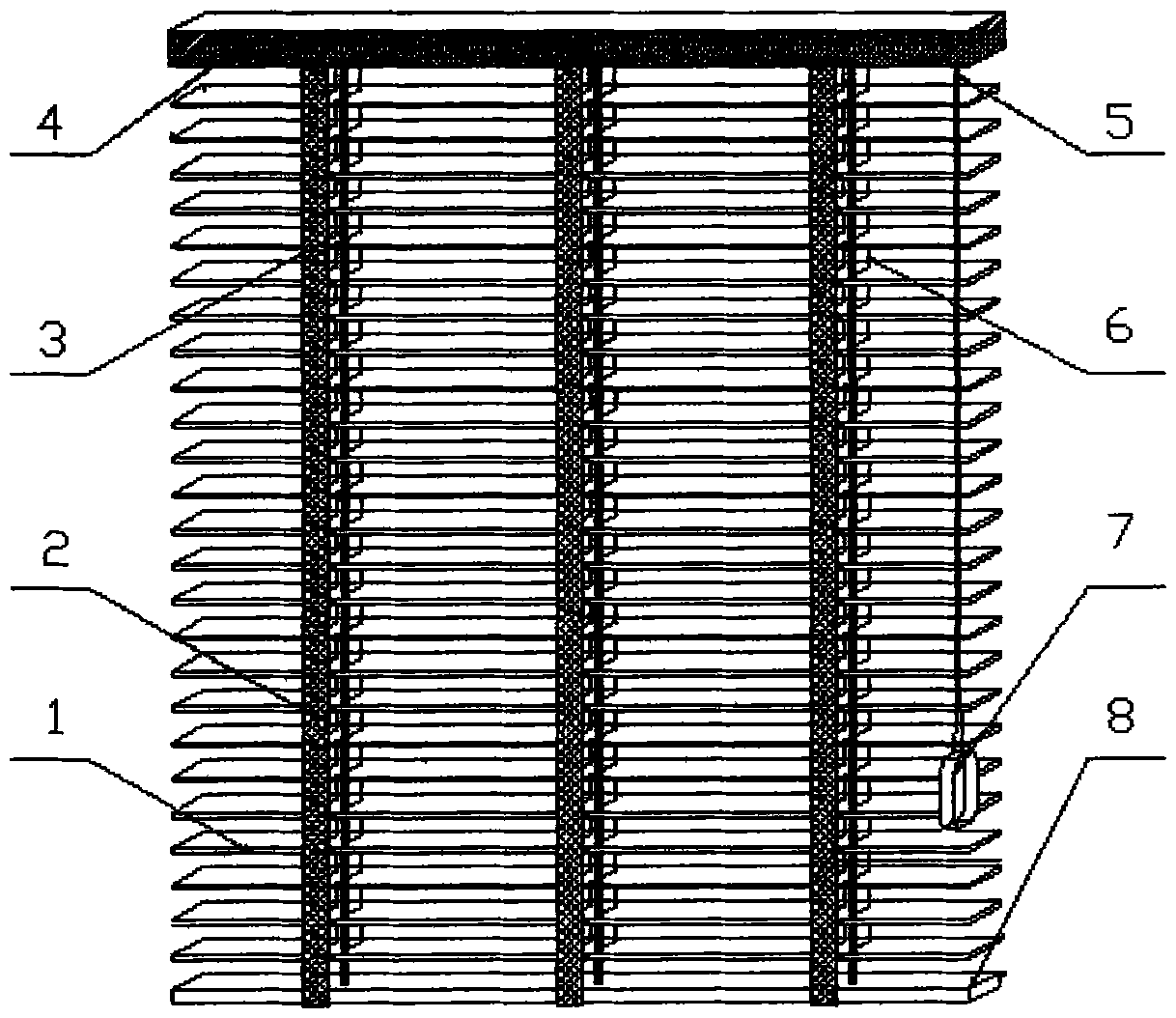

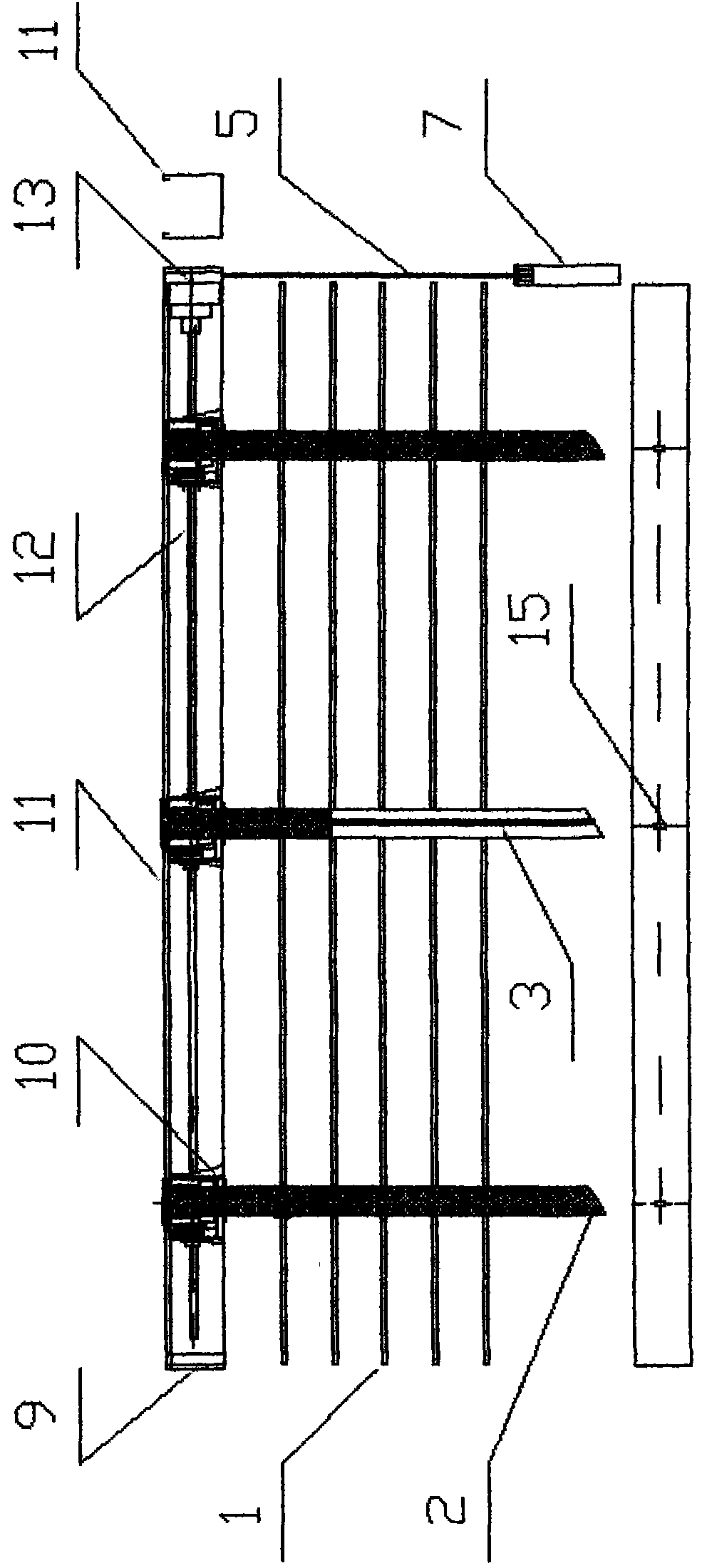

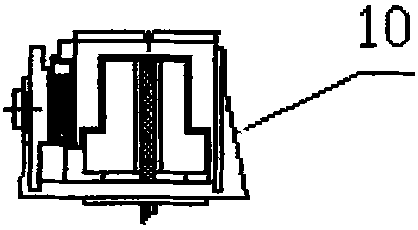

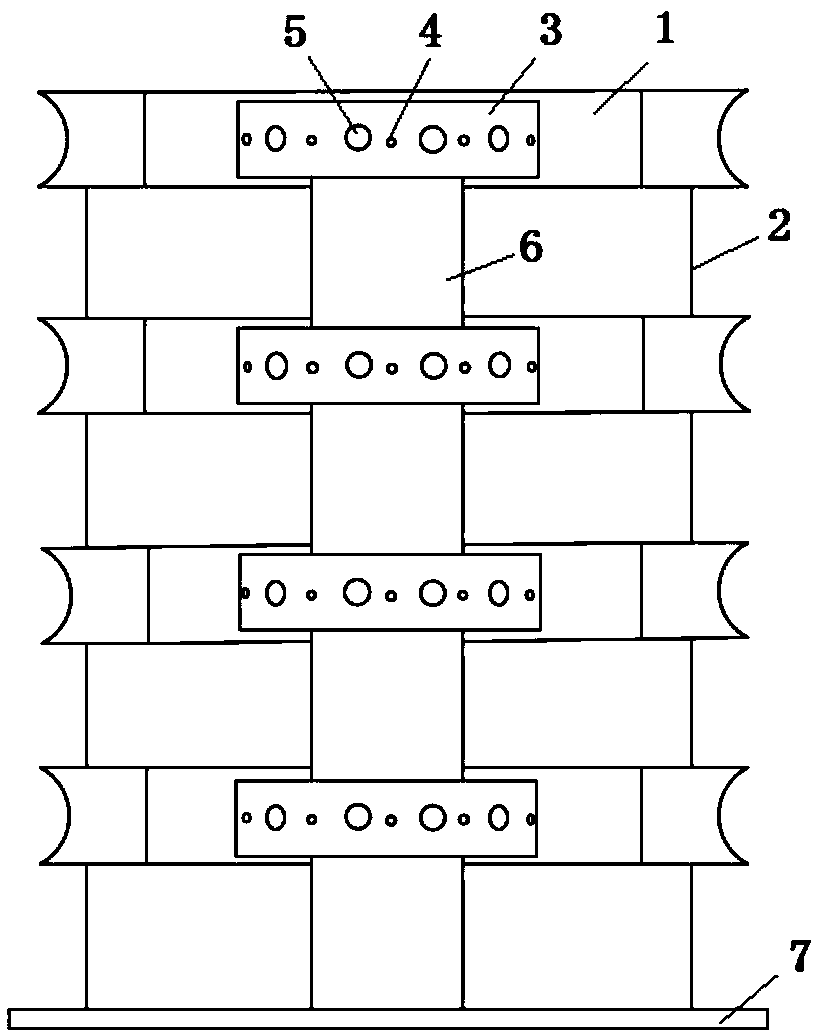

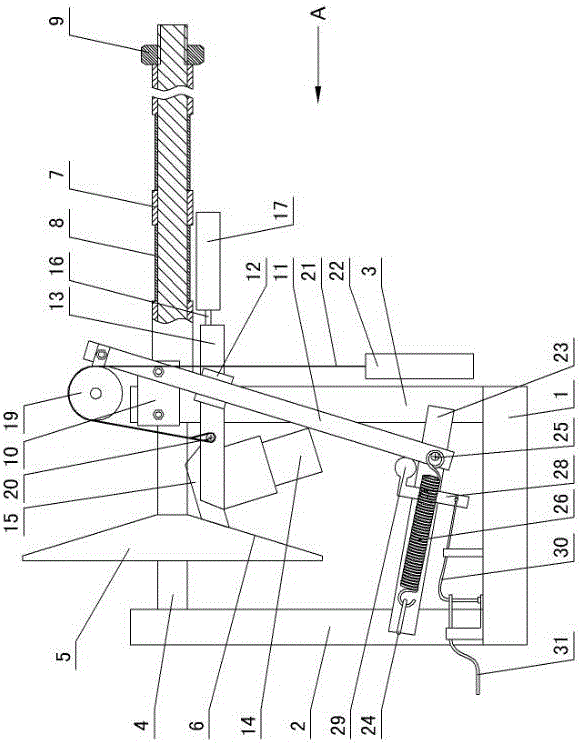

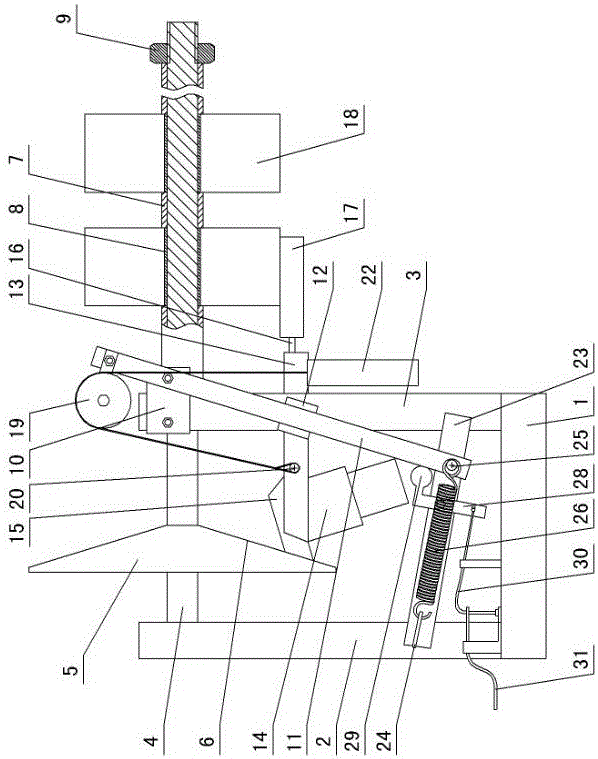

Lift venetian blinds

ActiveCN101886516AReasonable structureClosely connectedLight protection screensElectric machineryEngineering

The invention discloses venetian blinds, wherein one end of an upper beam (11) is provided with a rope-locking device (13), the other end is provided with a side cover (9); the inside of an upper beam assembling system is provided with a cross shaft (12); a rope-locking device is arranged at one end of the cross shaft, the other end is assembled with a lifter; and a lifter component (10) is assembled by a lifter connecting base (16), a cloth ladder wheel brake shaft (17), a cloth wheel stop elastic device (18), a cloth ladder wheel (19), a bearing seat (20), a bearing (21), an elevating belt rotating wheel (22) and the like. The venetian blinds provided by the invention furthest solves the problem that rope holes on the strips of the blinds leak light; and the lifting belts can be freely retractable in the lifting or dropping process of the venetian blinds, the venetian blinds can not twist together, the operation is easy, convenient and labor-saving and has no noise, the track space is saved, and the venetian blinds of the electric motor is easy to hide.

Owner:LANTEX WINDOW FASHIONS CO LTD

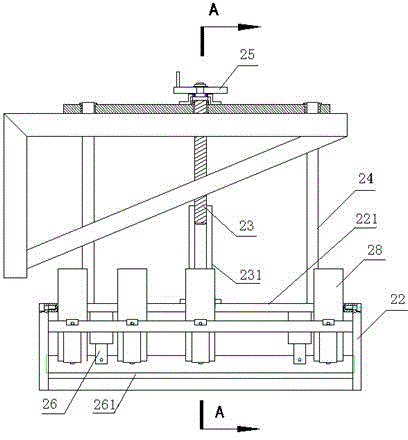

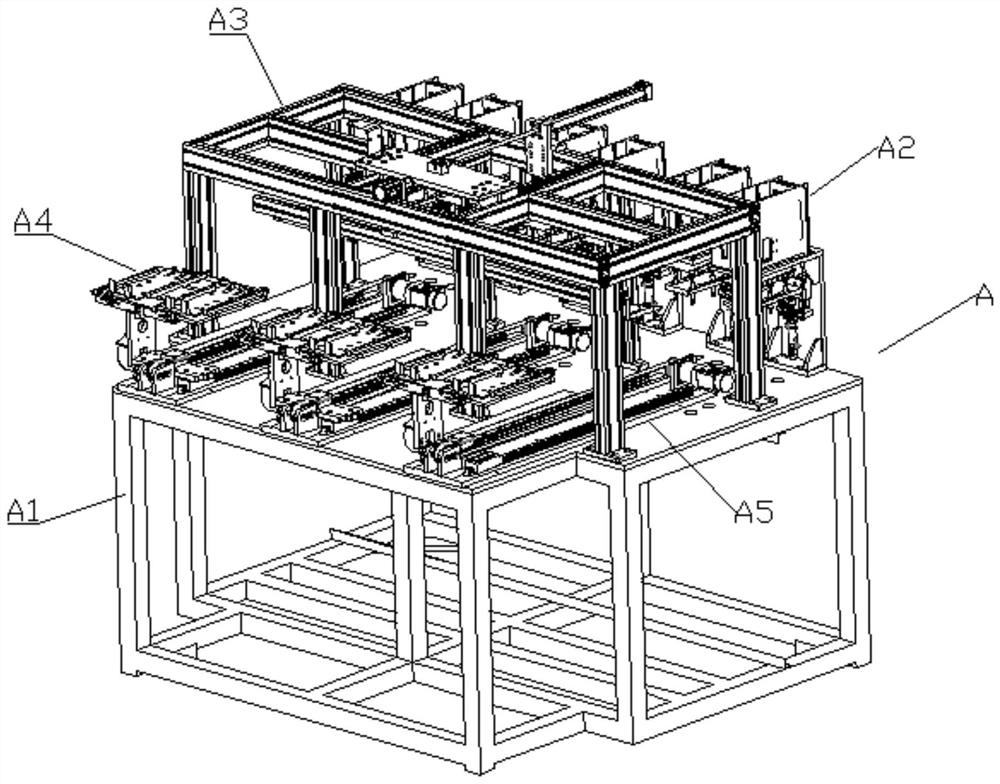

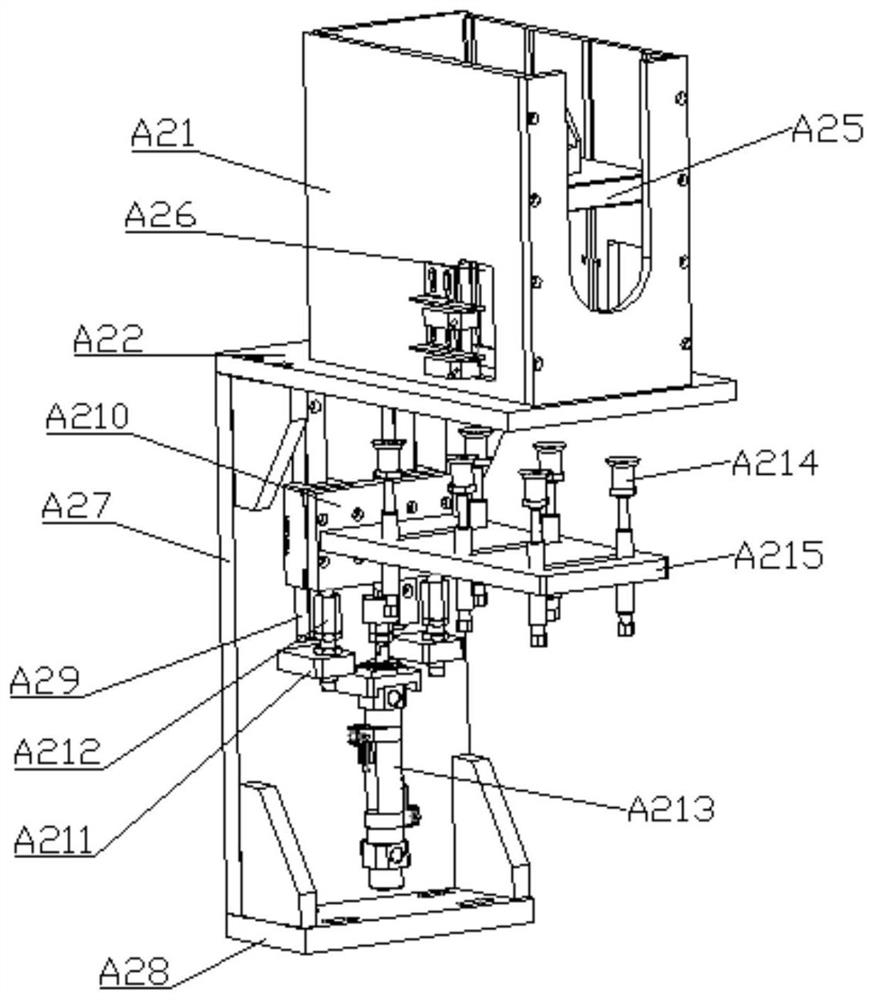

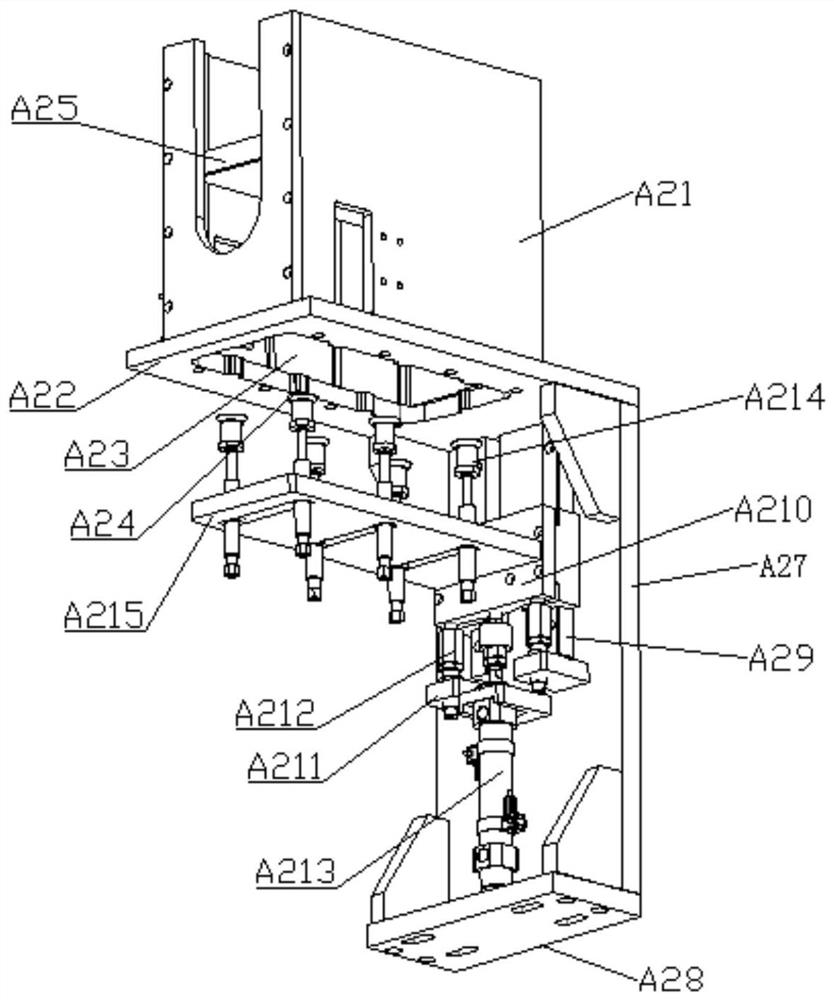

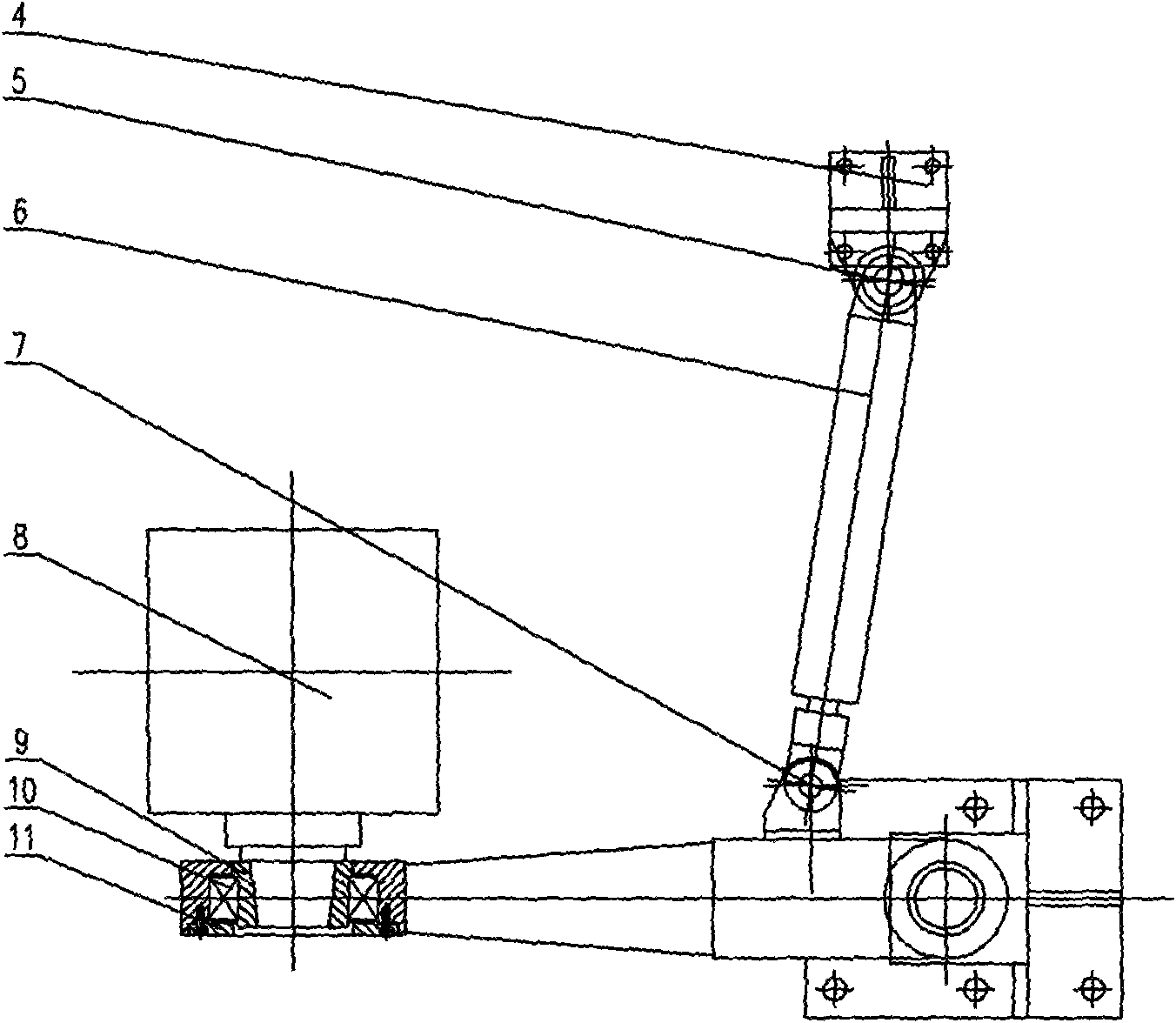

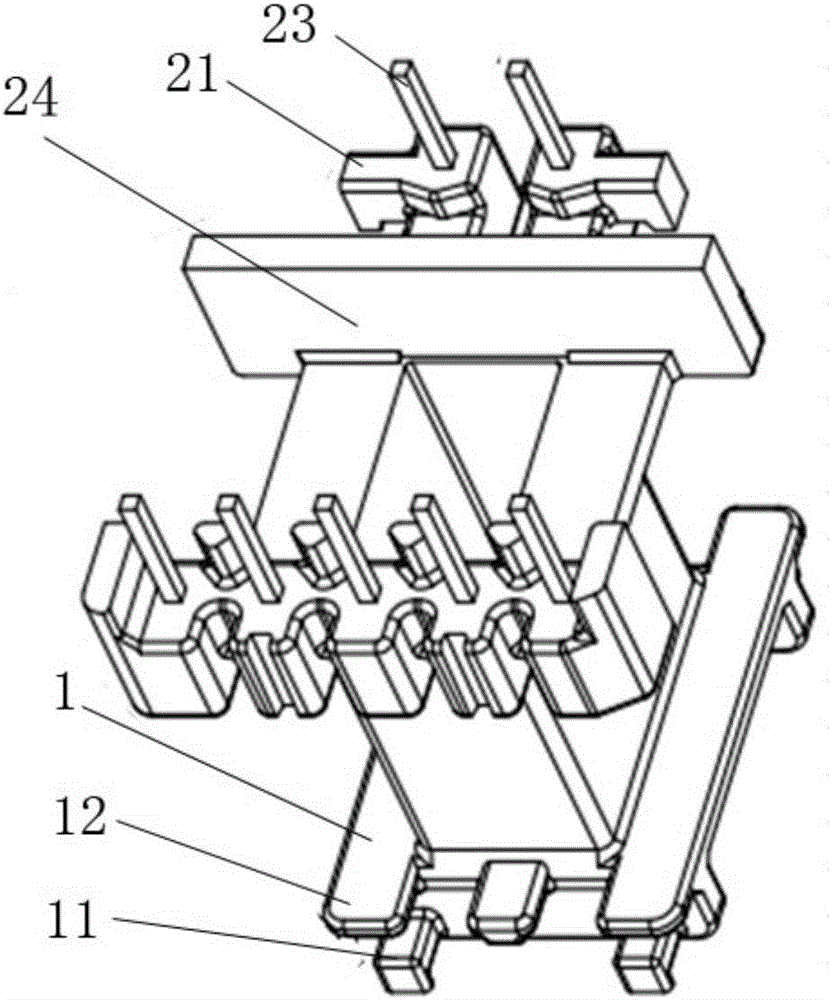

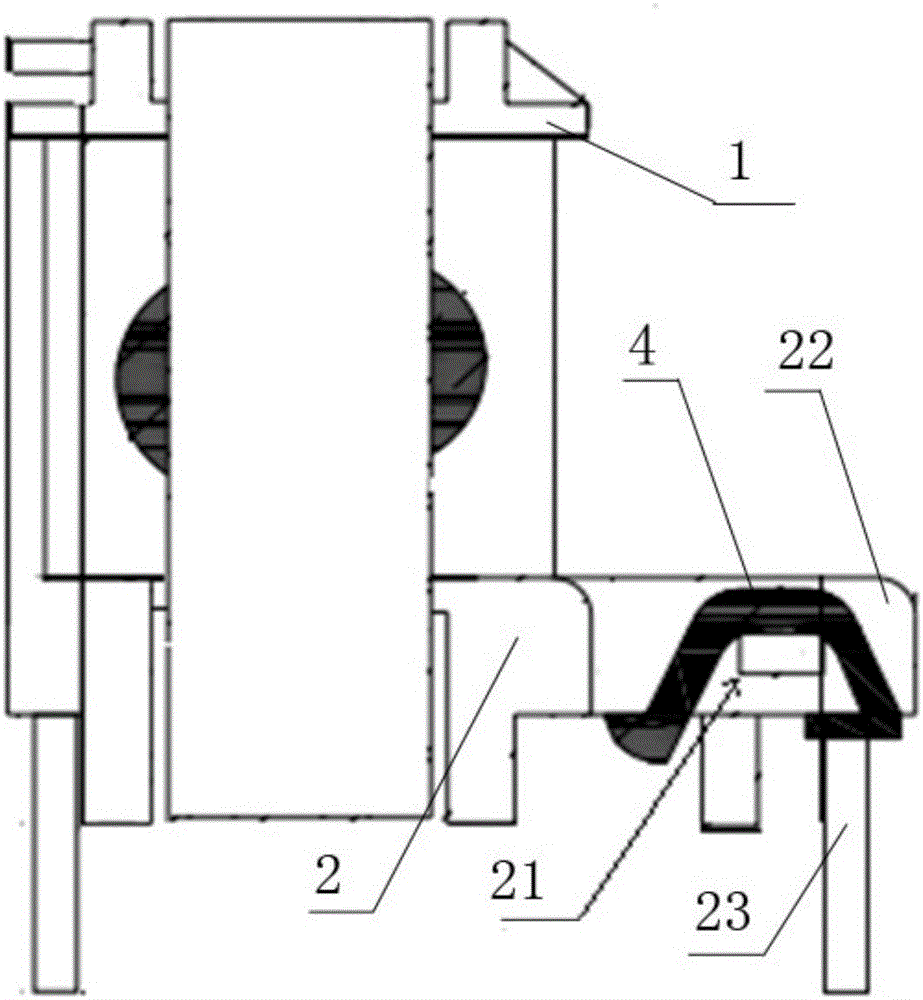

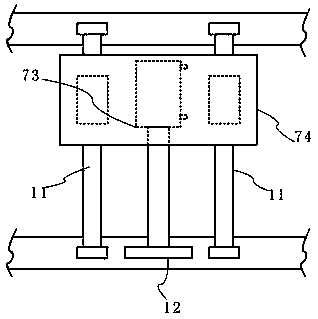

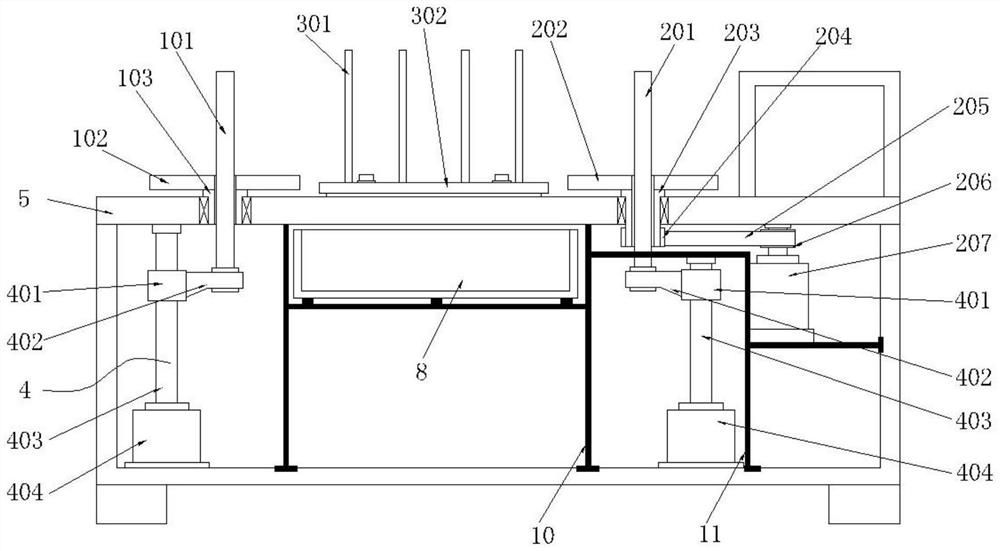

Full-automatic winding machine for multiple filter papers

InactiveCN107298337AFully automatedReduce labor intensityStationary filtering element filtersArticle deliveryWinding machineBobbin

The invention discloses a multi-filter paper full-automatic winding machine, which comprises a filter core skeleton transport positioning mechanism, a skeleton tension winding mechanism, a filter paper transport positioning cutting mechanism, and a tape transport pasting mechanism; the filter core skeleton transport positioning mechanism sends the filter core skeleton to to the skeleton tensioning and winding mechanism; the skeleton tensioning and winding mechanism tightens the filter element skeleton and drives the filter element skeleton to rotate; the filter paper conveying positioning and cutting mechanism is provided with multiple, and each filter paper conveying positioning and cutting mechanism is equipped with A filter paper roll; the filter paper transport positioning and cutting mechanism sends the filter paper on the corresponding filter paper roll to the filter element skeleton expanded by the skeleton expansion and winding mechanism; the tape conveying and pasting mechanism sticks the filter paper to the filter element skeleton through tape superior. The invention realizes the full automation of the winding production of the filter element and filter paper, reduces the labor intensity of the production personnel, improves the production efficiency, and has broad market prospects.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

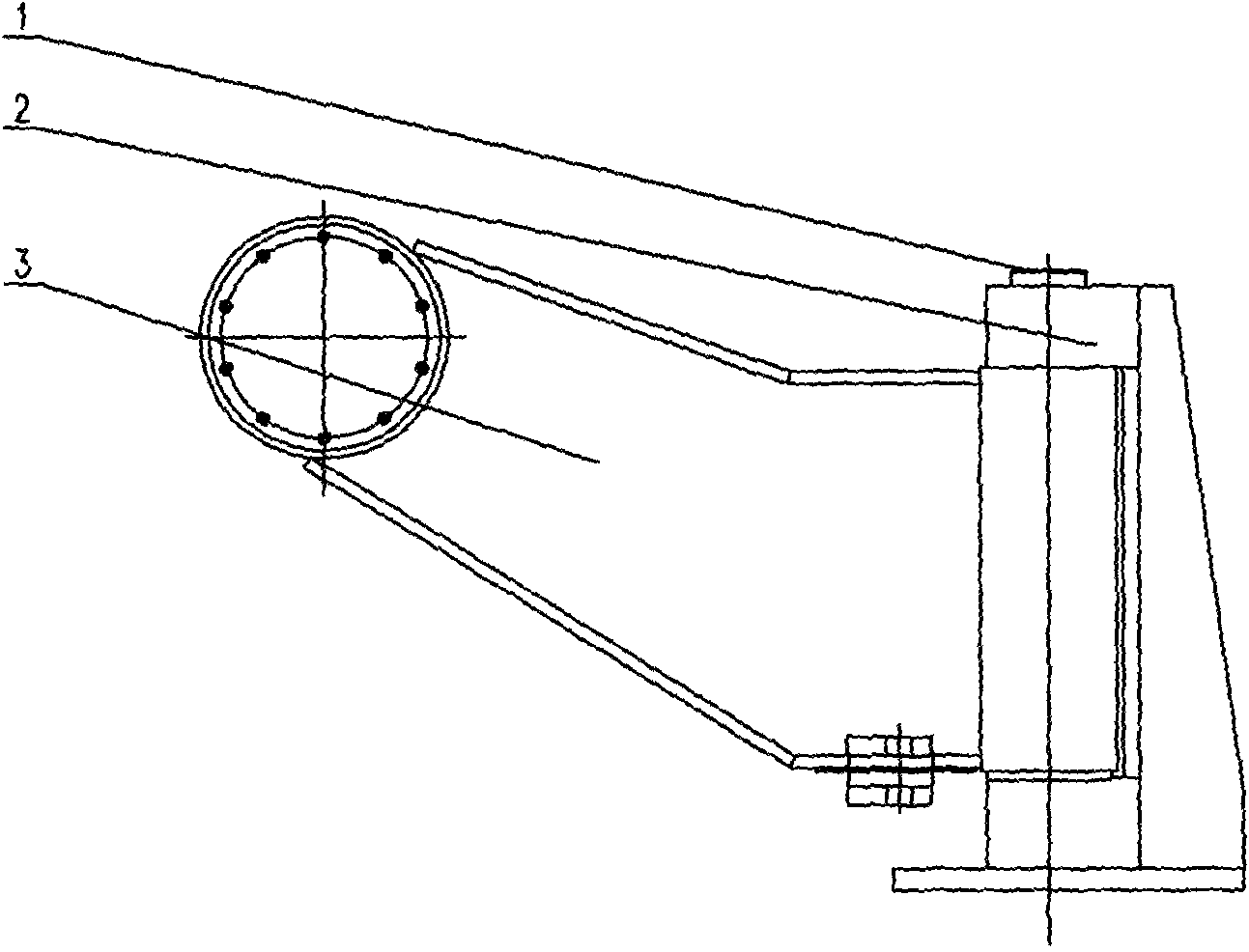

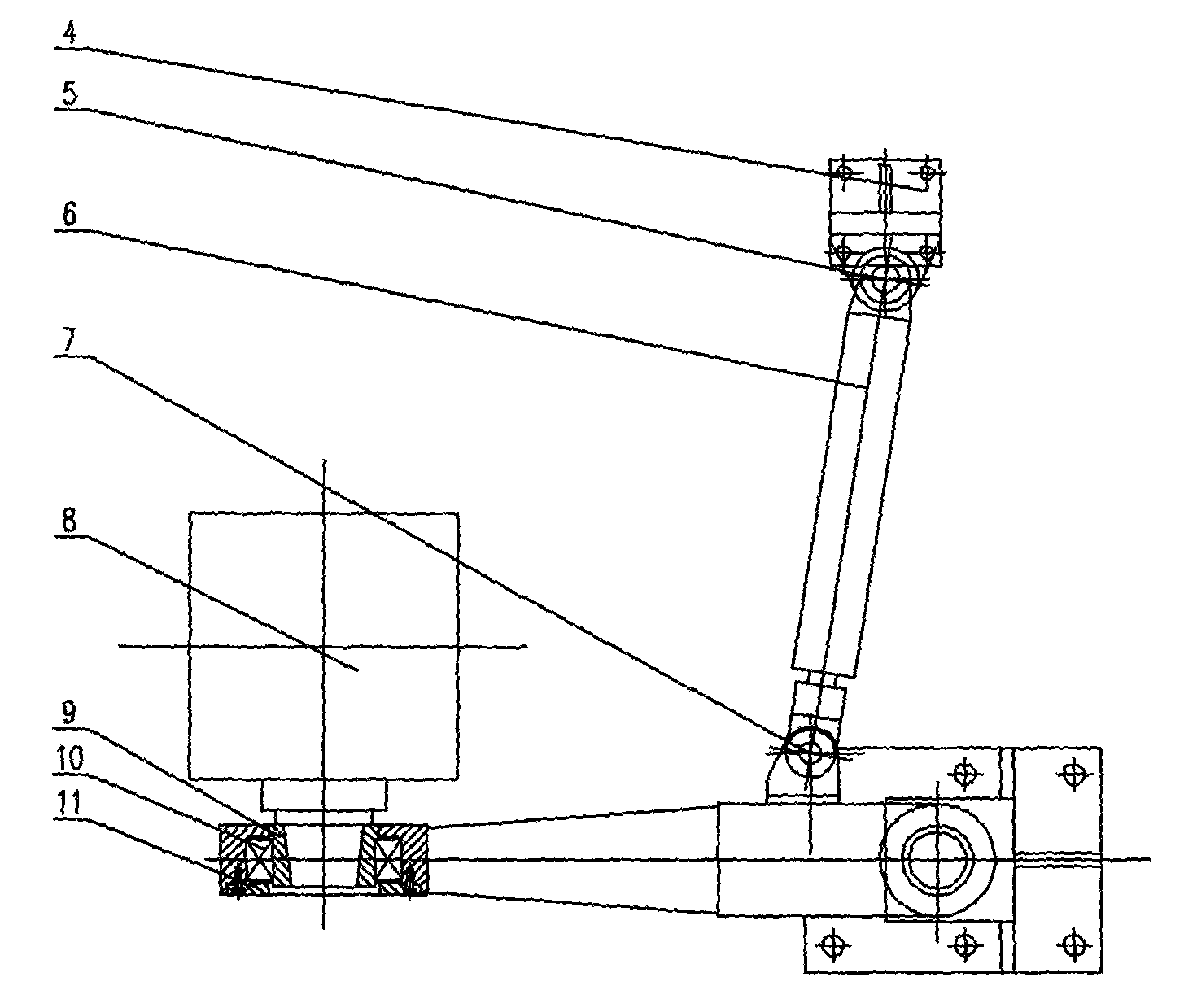

Hydraulic auxiliary support structure for recoiling machine

The invention relates to a hydraulic auxiliary support structure for a recoiling machine, which comprises a rotary shaft, an upright post, a support arm, an oil cylinder base, a first pin shaft, an oil cylinder, a second pin shaft, a taper sleeve, a bearing and a bearing cap. The bearing is arranged in an inner hole of the support arm; the taper sleeve is arranged in an inner hole of the bearing; the bearing is tightly pressed by the bearing cap and screwed by using a bolt; the support arm is in fitting joint with the upright post through the rotary shaft; the lower part of the support arm is connected with the oil cylinder through the second pin shaft; and the oil cylinder is connected with the oil cylinder base through the first pin shaft. The hydraulic auxiliary support structure of the invention has the advantages of stable recoiling in a belt material recoiling process, improvement on product quality, security guarantee, convenient operation, simple structure and convenient manufacturing.

Owner:WUXI WUYE METAL ROLLING

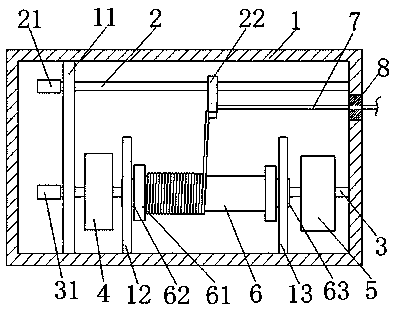

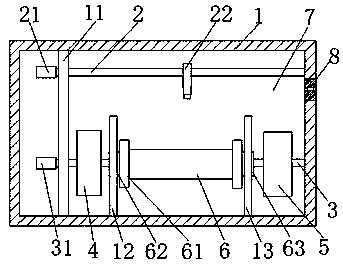

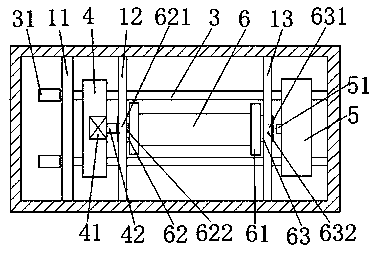

Convenient-to-maintain charging pile for electric vehicle

InactiveCN110884378APrevent looseningPrevent overwindingCharging stationsElectric vehicle charging technologyElectric machineDrive shaft

The invention belongs to the technical field of electric vehicle charging pile accessory machinery, and particularly relates to a convenient-to-maintain charging pile for an electric vehicle. The convenient-to-maintain charging pile comprises a pile body, wherein a vertical partition plate, a left partition plate and a right partition plate are arranged in the pile body; a limiting motor and a driving motor are arranged on the vertical partition plate, and the limiting motor is connected with a limiting piece through a limiting shaft; the driving motor drives the left sliding block and the right sliding block through a driving shaft, and a winding reel is arranged between the left partition plate and the right partition plate; and the cable is wound on the winding reel, penetrates throughthe limiting piece, then penetrates out of the cable through hole and is connected with the charging gun through the wiring piece. Compared with the prior art, the convenient-to-maintain charging pilehas the following advantages that the left sliding block and the right sliding block are driven by the driving motor at the same time through reasonable arrangement; limiting control over the windingreel is achieved in the non-winding state, and winding loosening caused by reverse rotation of the winding reel is avoided; the limiting piece plays a role in guiding the cable; and the whole deviceis reasonable in structural arrangement and convenient to disassemble and maintain.

Owner:界首尚嘉工业设计有限公司

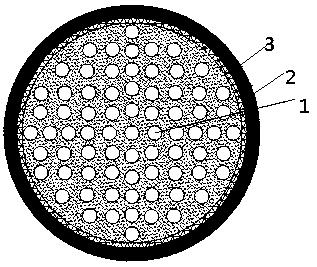

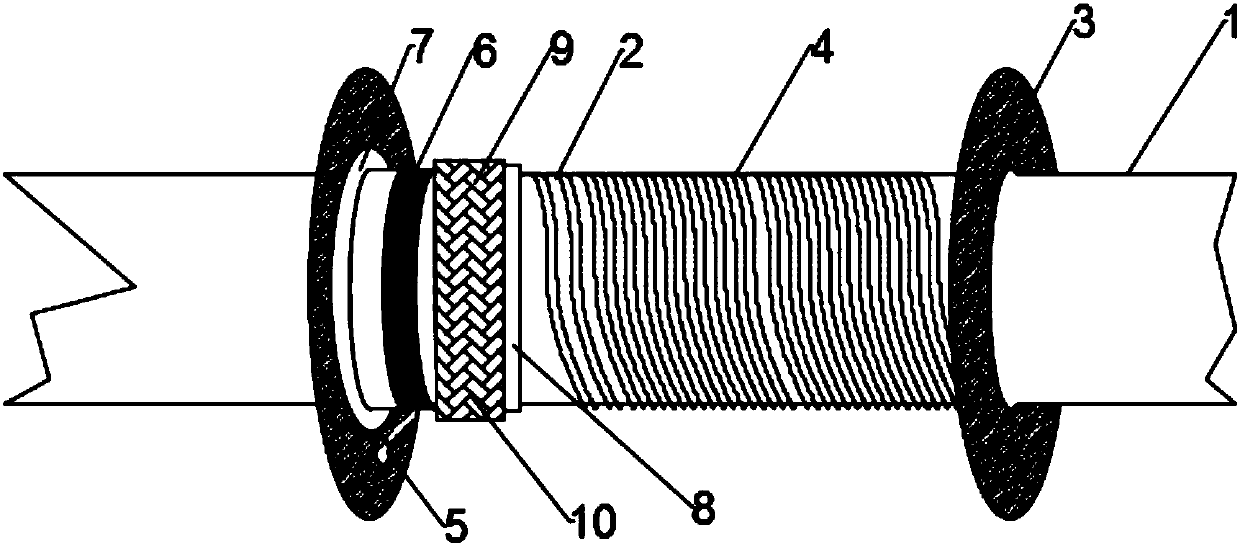

Lightweight rigid self-lubricating composite rope and preparation method thereof

The invention discloses a lightweight rigid self-lubricating composite rope and a preparation method thereof, and relates to the field of ropes. The lightweight rigid self-lubricating composite rope comprises a rope core (1), a wrapping layer (2) and a plastic-coated layer (3), wherein the rope core (1) is of a multilayer helical structure with a circular cross section formed by spirally interweaving ultrahigh-molecular-weight polyethylene fiber rope yarn, layers are spirally and reversely arranged, the outer portion of parallel rope yarn of each layer is provided with a composite finishing coating, the ingredients in a composite finishing liquid on the cross section of the rope core (1) account for 10-30%, the outer portion of the rope core (1) is provided with the wrapping layer (2), andthe outer portion of the wrapping layer (2) is provided with the plastic-coated layer (3). The lightweight rigid self-lubricating composite rope and the preparation method thereof have the advantagesthat the cross section of the rope is circular, the strength-to-weight ratio is high, and the rope can completely replace a steel wire rope in the fields of huge weight hoisting and well drilling exploration.

Owner:SHANDONG ROPE TECH CO LTD +1

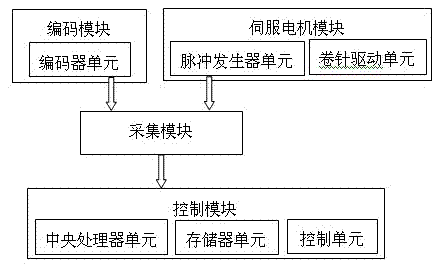

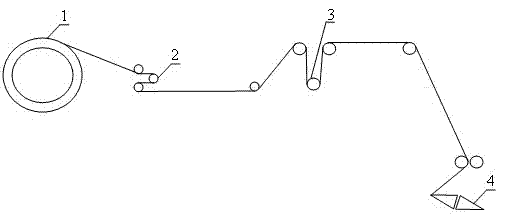

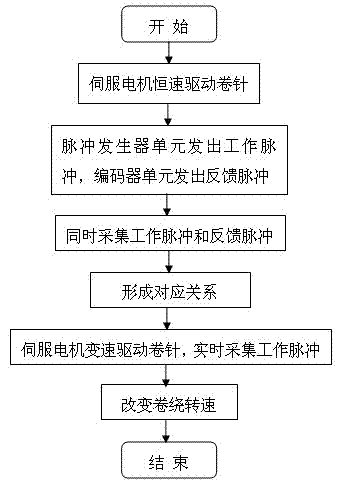

A system and method for variable speed winding of a square winder

ActiveCN102290608AReduce distortionIncrease wind speedFinal product manufactureSecondary cellsEngineeringConductor Coil

The invention provides a square winder variable-speed winding system and a method. The square winder variable-speed winding system comprises a servomotor module, a coding module, an acquisition module and a control module, the servomotor module comprises a winding pin-driving unit and a pulse generator unit, and the pulse generator unit outputs the working pulses of the servomotor module; the coding module adopts a coder unit to periodically interrupt and output feedback pulses; the acquisition module simultaneously acquires the working pulses and the feedback pulses; the control module comprises a central processor unit, a memory unit and a control unit, the central processor unit is used for calculating the winding speed corresponding to the feedback pulses and storing the corresponding relation between the winding speed, the working pulses and the feedback pulses into the memory unit, and the control unit changes the winding speed of the system according to the corresponding relation between the working pulses and the corresponding relation.

Owner:GEESUN AUTOMATION TECH

Steel wire rope rolling-up device of bridge type crane

InactiveCN107686066ANeatly coiledAvoid tangled ropeWinding mechanismsBridge typeArchitectural engineering

The invention discloses a steel wire rope rolling-up device of a bridge type crane. The steel wire rope rolling-up device comprises a reel, a rope groove is formed in the periphery of the reel in a surrounding mode, and flanges are arranged at the two ends of the rope groove correspondingly. Threads are carved on the rope groove, the distance between the threads is equal to the diameter of each steel wire rope, and a fixing hole is formed in the flange below the rope groove. A rope guiding device is arranged between one flange and the rope groove, a fixing plate is directly welded to one sideof the rope guiding device, and the fixing plate and the flanges are fixed through bolts. The steel wire ropes can be tidily rolled, disorder of the steel wire ropes is avoided, the steel wire ropes are smoothly rolled in the rope groove accordingly, thus the performance of heavy object lifting of the steel wire ropes can be brought into play, friction between the steel wire ropes is avoided, andthe service life of the steel wire ropes is prolonged accordingly.

Owner:ANHU WUHU CHANGJIANG JACK UP EQUIP CO LTD

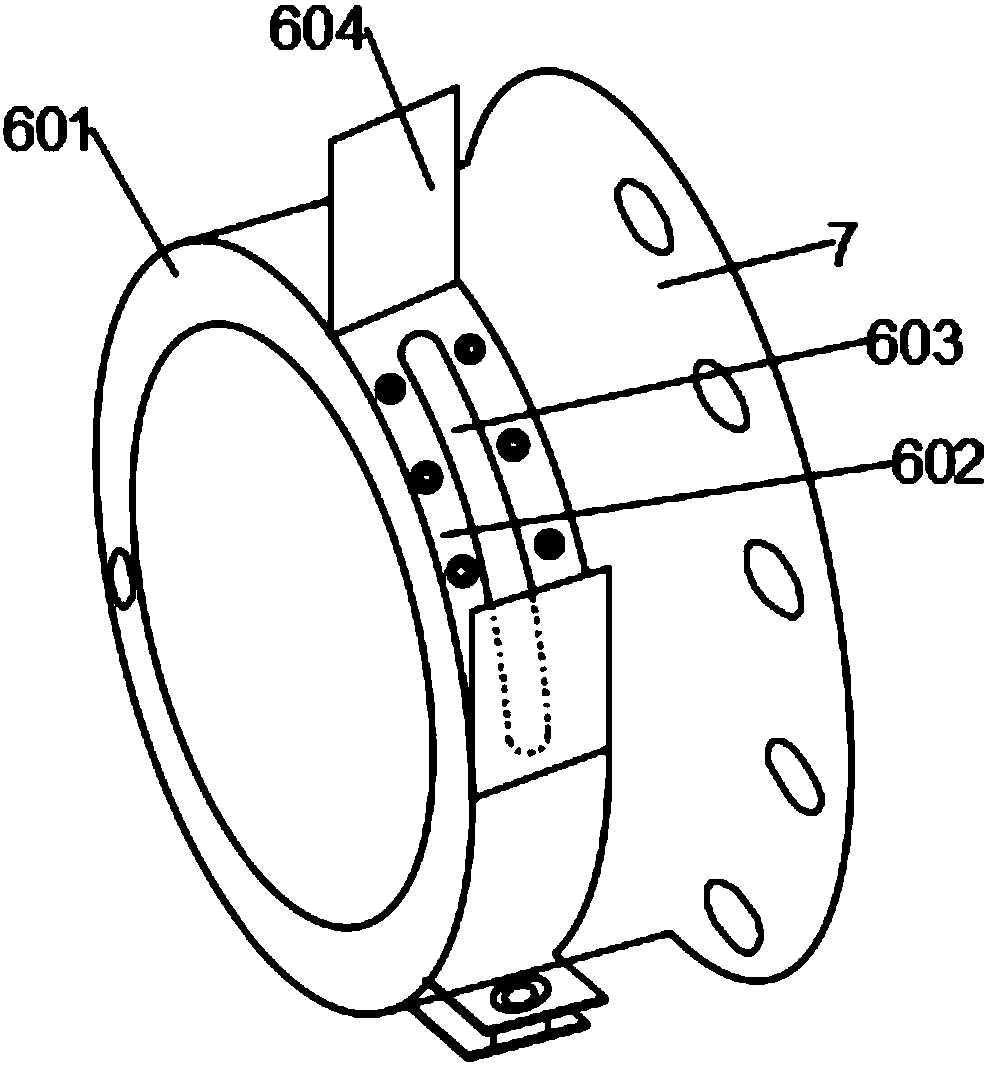

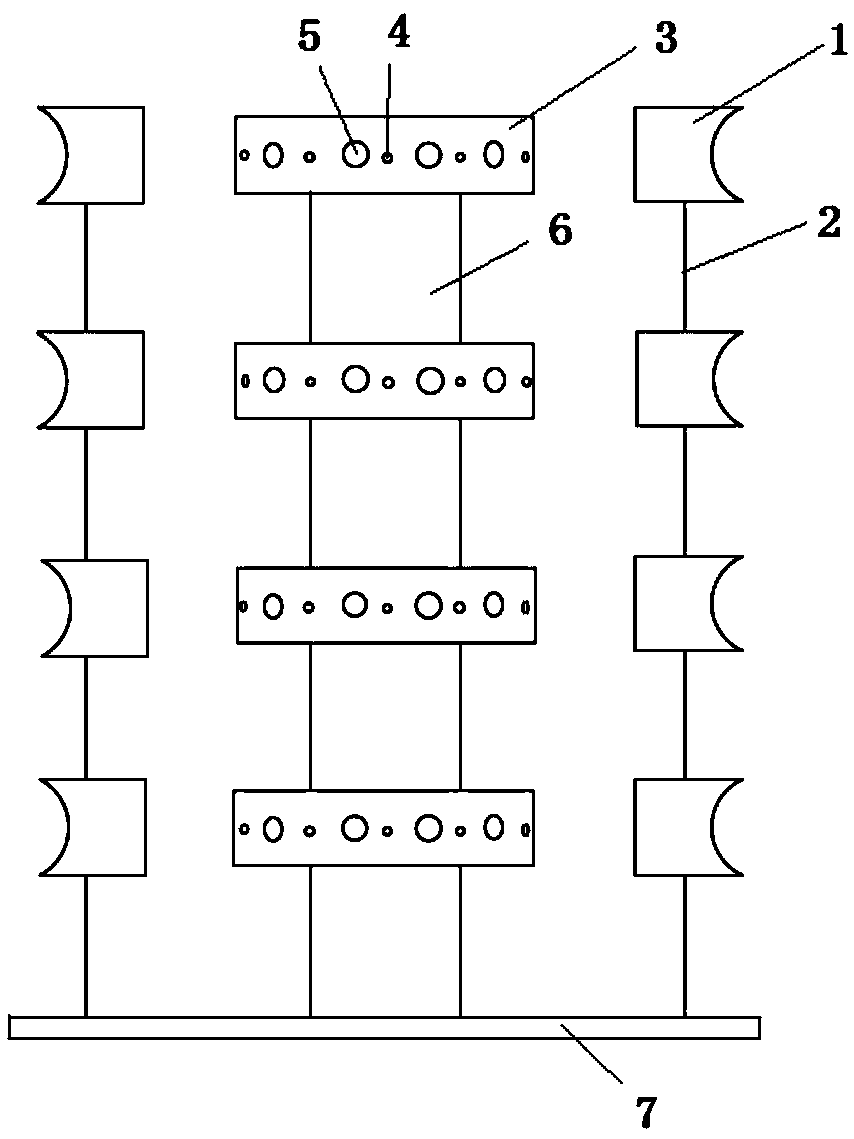

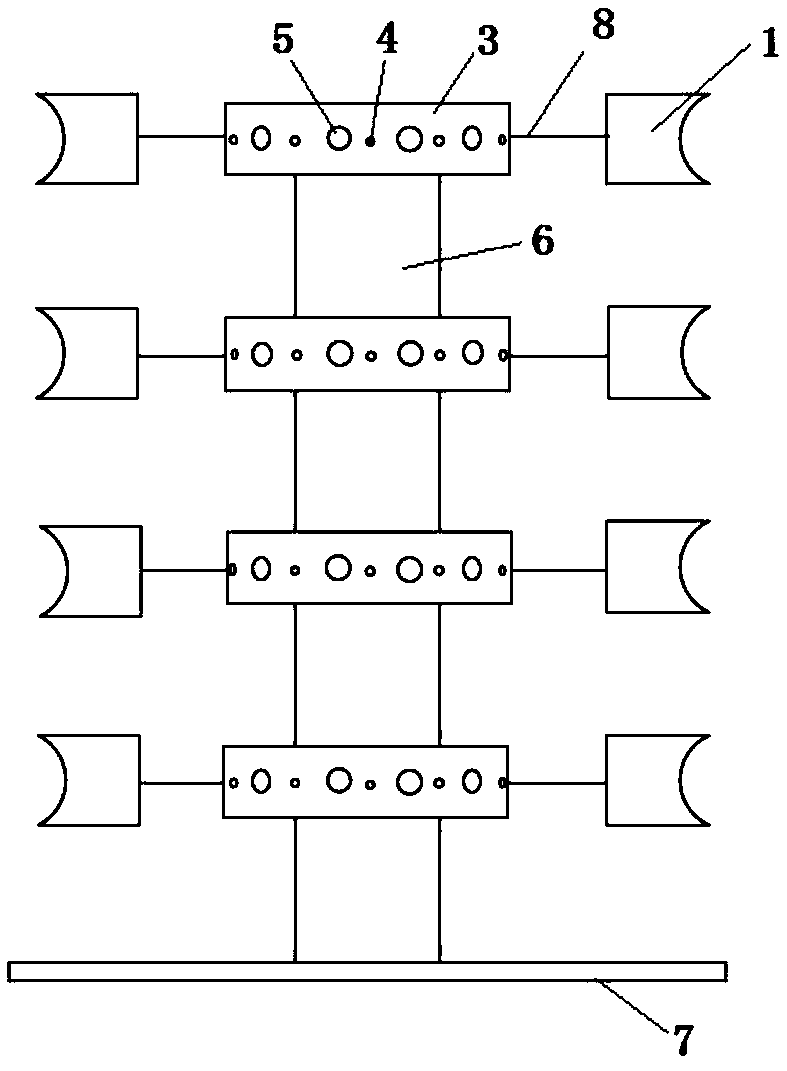

Intelligent optical distribution frame

ActiveCN109581603AFlexible pluggingRealize side jump fiber adjustmentFibre mechanical structuresDistribution frameEngineering

The invention discloses an intelligent optical distribution frame comprising a base plate, a hollow cylindrical frame vertically arranged on the base plate, wiring rings sleeved on the cylindrical frame at intervals, and cable winding racks arranged at the peripheries of the wiring rings and used for winding optical fibers; an optical fiber flange head is arranged on the annular wall of each wiring ring in a penetrating manner; the inner end of each optical fiber flange head is communicated with the interior of the cylindrical frame; a monitoring component used for monitoring the real-time state of the optical fiber is arranged in the wiring ring; and an alarm light is arranged on the outer wall of the wiring ring. The intelligent optical distribution frame provided by the invention is compact in structure and saving in space; due to the wiring rings arranged at intervals and the cable winding racks arranged at the peripheries of the wiring rings, the more optical fibers can be accommodated, and meanwhile the optical fibers can be orderly wound on the cable winding racks, and the adverse effects on the business caused by mistakenly touching the light path in running are avoided; furthermore, the running state of the light path channel can be better monitored in real time.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

Winding machine capable of winding wires uniformly

InactiveCN102568810ANeatly coiledStable windingMechanical energy handlingCoils manufactureDrive motorWinding machine

The invention discloses a winding machine, in particular a winding machine capable of winding wires uniformly. A swing arm capable of partially extending into or extending out of an enclosure back and forth is arranged on the enclosure of the winding machine; a lead hole is formed in one end of the swing arm, which is positioned outside the enclosure, and suspended outside a rotating trace of a first winding rod and a second winding rod; and the swing arm is positioned in the enclosure and connected with a driving motor through a gear component. The winding machine has the advantages that: a coil passes through the lead hole in the swing arm; due to back and forth motion of the swing arm, of which the moving frequency is matched with the rotating frequency of the first winding rod and the second winding rod, the coil can be uniformly wound on the first winding rod and the second winding rod, and looks tidy, uniform and attractive; and furthermore, the coil is very firmly wound, and cannot get loose during storage and movement.

Owner:吴江市合成电子机械厂

Transformer of small power supply

InactiveCN106057447ANeatly coiledPrevent disengagementTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresEngineeringTransformer

The invention discloses a transformer of a small power supply. The transformer comprises skeletons, wherein each skeleton comprises a first platform and a second platform, a conducting wire is wound between the first platform and the second platform, a communicating pipe for accommodating an iron core is connected between the first platform and the second platform, a first convex column for wire hanging is arranged on the first platform, the head of the first convex column extends in the direction away from the second platform to form a first blocking rib, a second convex column for wire hanging is arranged on the second platform, a second blocking rib is arranged on the head of the second convex column, a pin is arranged at the bottom of the second platform, the pin is a columnar square pin, and the iron core comprises an upper U-shaped iron core and a lower U-shaped iron core; the number of the skeletons is two; two ends of the upper iron cores are inserted into the communicating pipes of the two skeletons, two ends of the lower iron cores are inserted into the communicating pipes of the two skeletons, and the two ends of the upper irons cores and the two ends of the lower iron cores are spliced in the communicating pipes. The transformer has the advantage that the transformer is more convenient to wind, a wound coil is more regular, and the transformer is safer.

Owner:HAINING LIANFENG DONGJIN ELECTRONICS

Automatic counting winding and cutting machine and braid winding and cutting method

PendingCN108689211AAppropriate tensionDecrease the tilt angleArticle deliveryElectronic control systemEngineering

The invention relates to an automatic counting winding and cutting machine which comprises an electronic control system, a braid winding mechanism, a receiving disc lifting table, a braid guide rollerset, a fusing mechanism, a limiting assembly and a traction mechanism, the braid guide roller set, the fusing mechanism, the limiting assembly and the traction mechanism are sequentially arranged inthe braid running direction, the center of a braid winding station of the braid winding mechanism is located on any one of the left and right sides of a fusing station, the limiting assembly is located under the fusing station and is provided with a braid walking space, the receiving disc lifting table is correspondingly arranged under the braid winding station, a meter counting wheel and a photoelectric detector are electrically connected with the signal input end of the electronic control system. By means of the automatic counting winding and cutting machine, the inclined angle between a braid and the vertical line can be smaller during full winding, fusion is facilitated, the braid descending angle is limited, and accidental fusion is avoided; and a pneumatic rolling shaft is tightly attached to a traction roller to enable the braid to keep appropriate tension force without corrugation or displacement, and the smooth implementation of braid winding and orderly and attractive braid discs are guaranteed. According to the automatic counting winding and cutting machine, the braid can be automatically cut off and rolled into a disc cake shape according to the set length, the accuracyis high, and the load weight is large.

Owner:福建锦特新材料科技有限公司

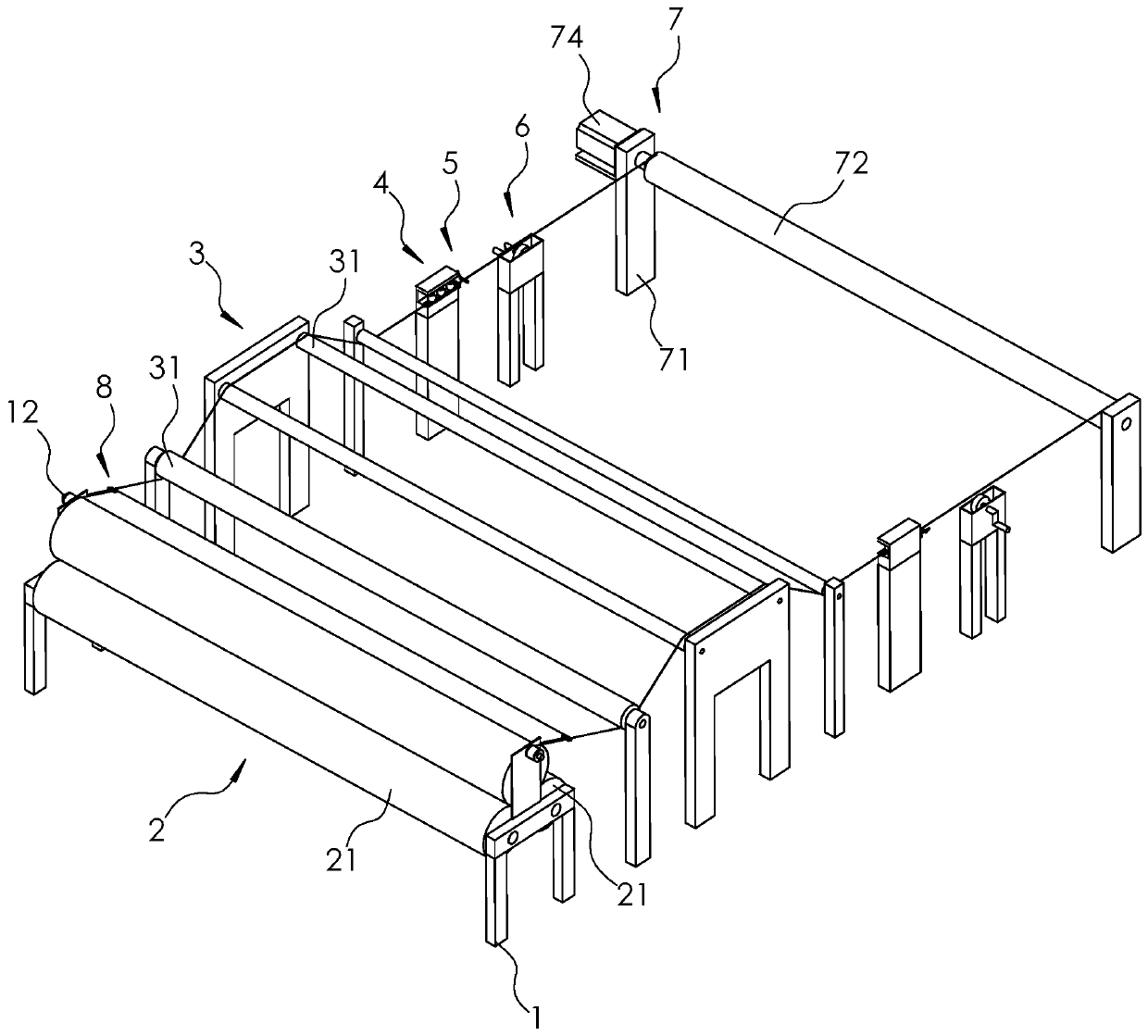

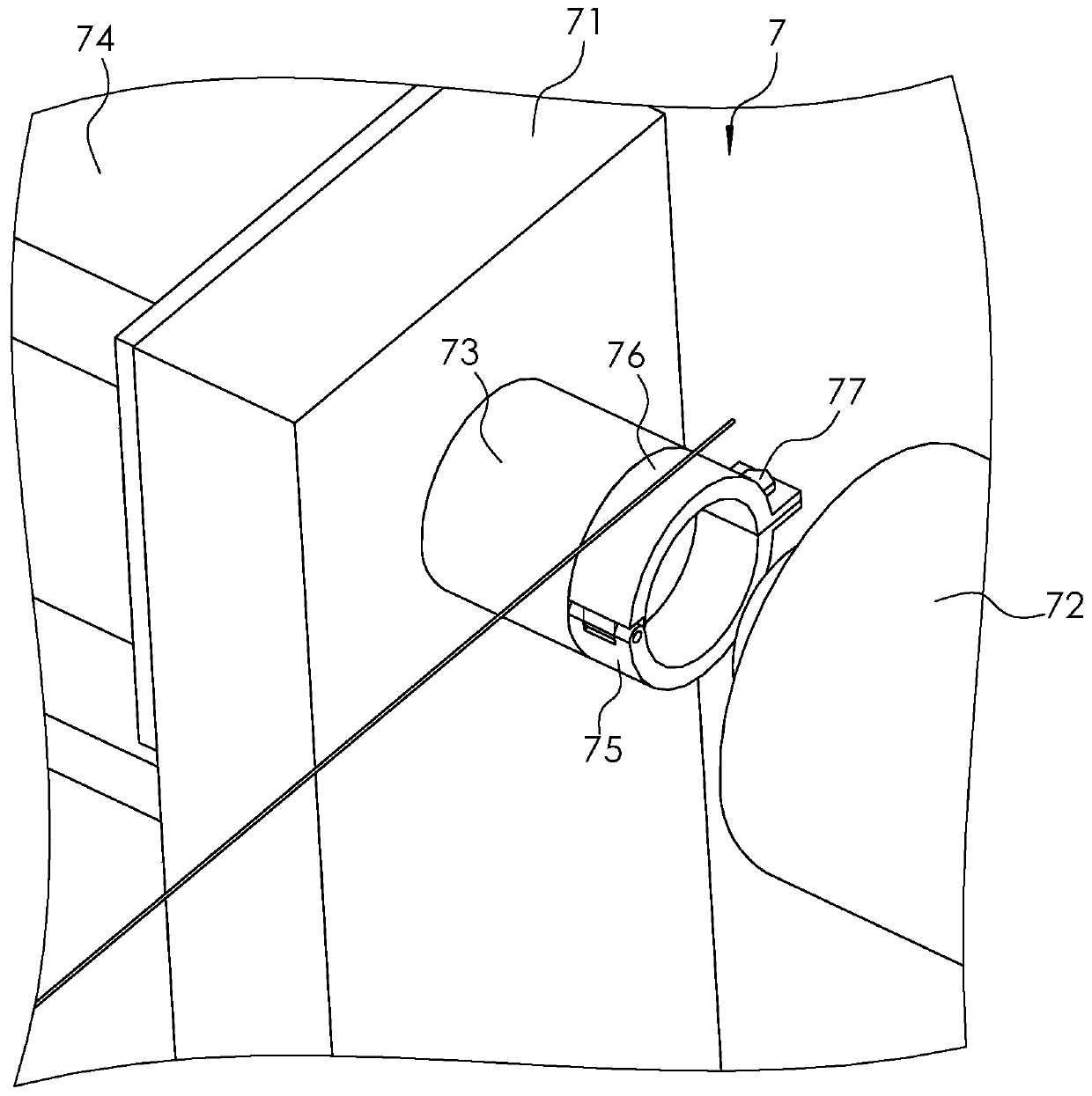

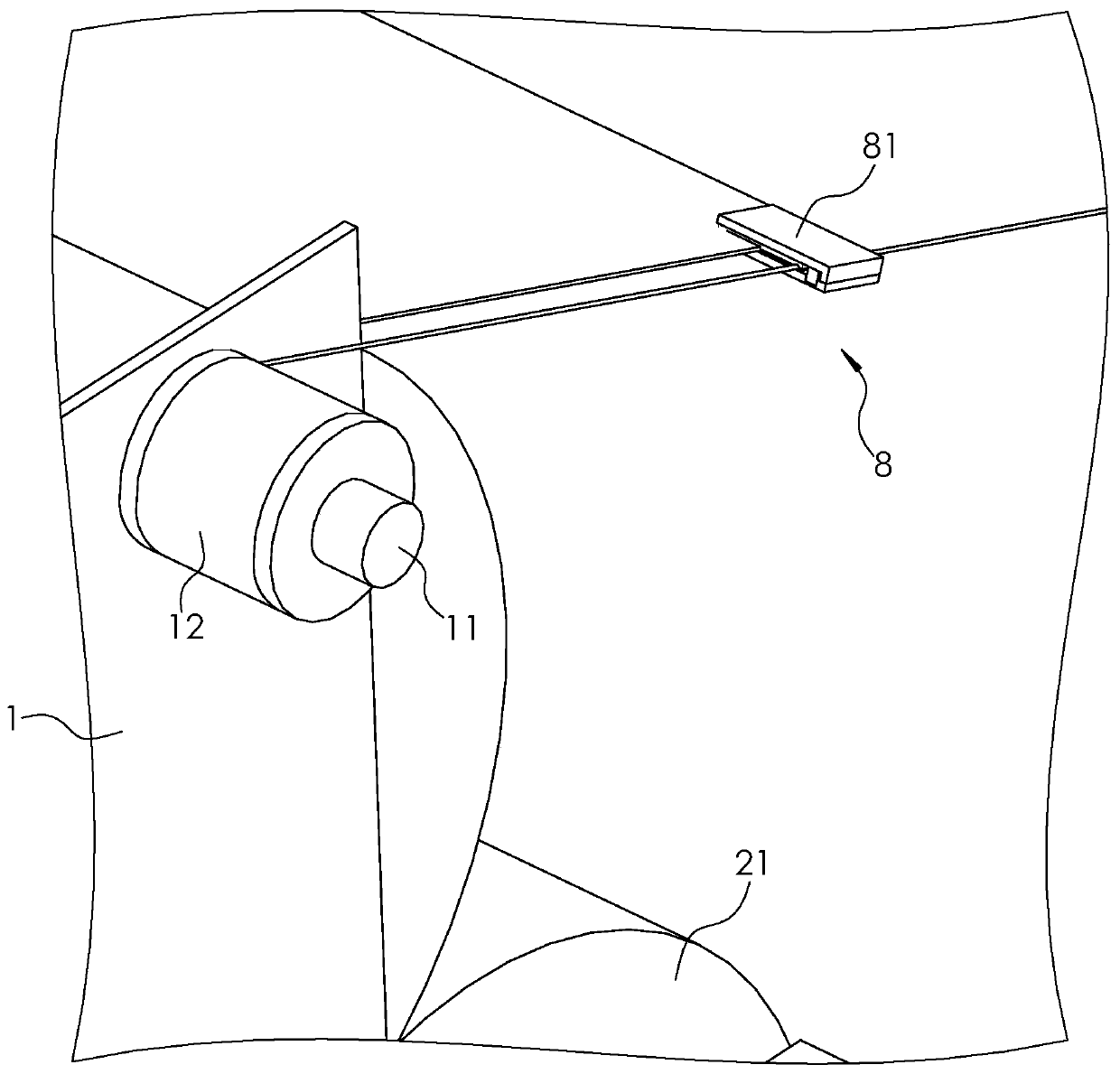

High-efficiency cloth inspection machine

ActiveCN111270504AImprove cloth inspection efficiencyGuaranteed stabilityInspecting textilesSevering textilesMechanical engineeringEngineering

The invention relates to a high-efficiency cloth inspection machine, which comprises a rack, a cloth unwinding assembly, a cloth guide assembly and a winding assembly, wherein the cloth guide assemblycomprises a plurality of cloth guide rollers; the winding assembly comprises a winding frame, winding rollers and a drive member; two groups of silk thread loops, two groups of clamping assemblies and two groups of gluing assemblies are arranged on the rack; and one thread cutting assembly is arranged between the cloth guide assembly and one group of gluing assemblies. During first cloth inspection, firstly, silk threads bypass all cloth guide rollers in turn and are glued to one winding roller; cloth and the silk threads are clamped through the clamping assemblies and the silk threads are wound to make the cloth move through the winding roller; and after the clamping assemblies move and pass through the thread cutting assemblies, the silk threads are cut off through the thread cutting assemblies. During second cloth inspection and subsequent cloth inspection, the silk threads on the thread cutting assemblies are glued to another new winding roller through the gluing assemblies, and then new cloth and the silk threads in the silk thread loops are clamped through the clamping assemblies, so that cloth inspection and winding operations of the new cloth can be carried out. Accordingto the high-efficiency cloth inspection machine, the cloth inspection efficiency is greatly improved.

Owner:杭州高氏箱包布业有限公司

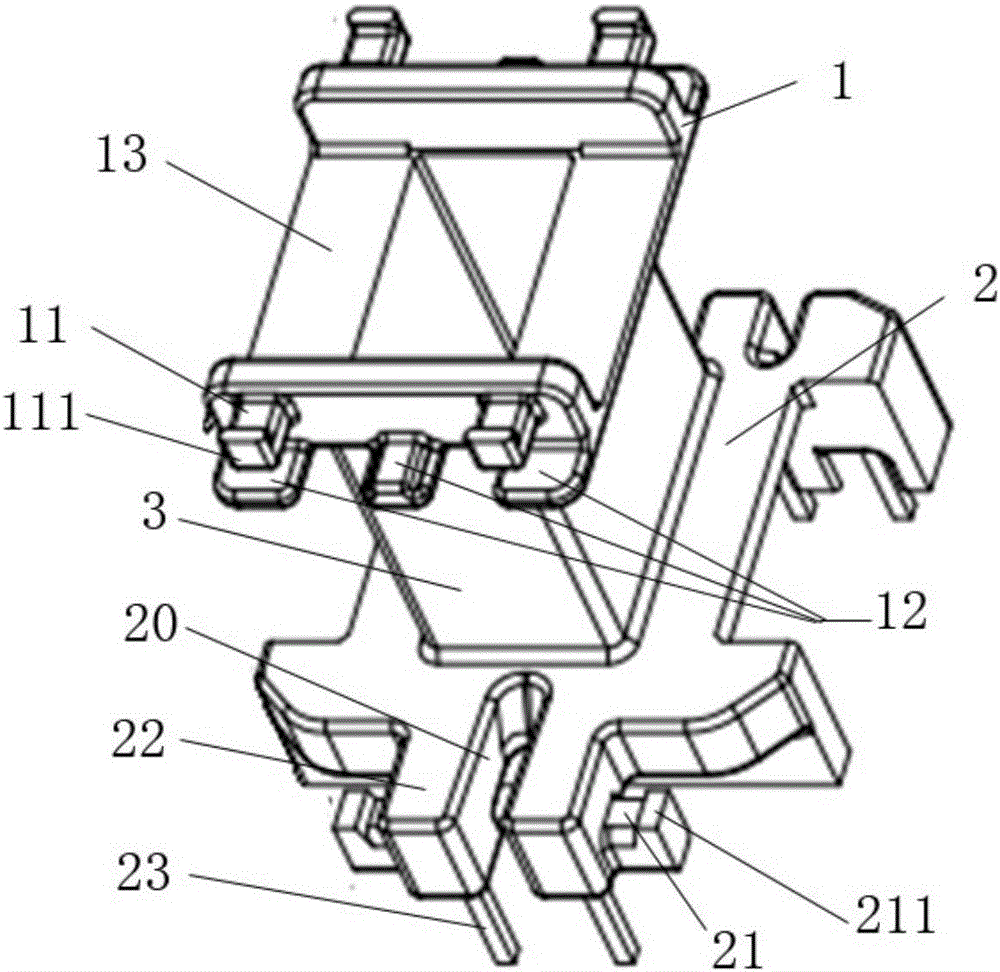

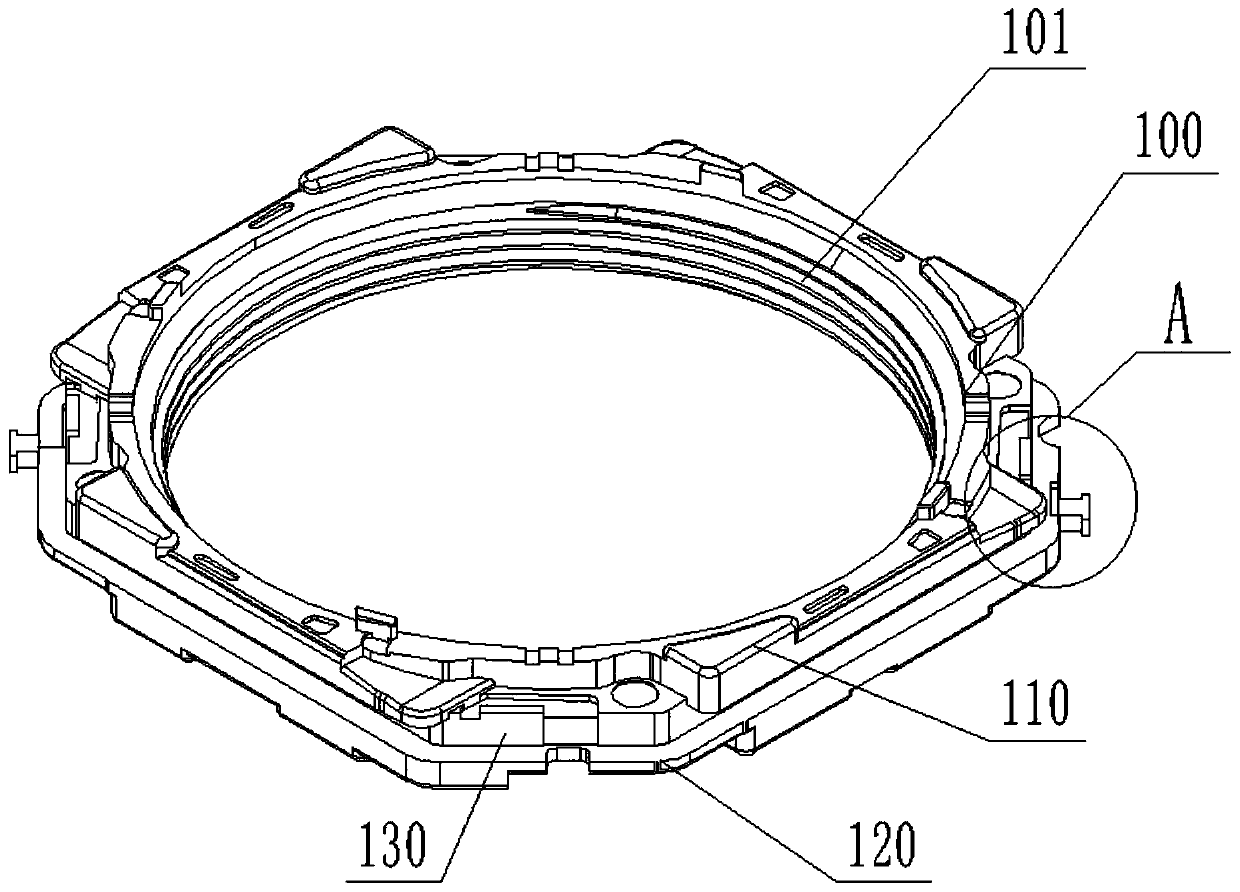

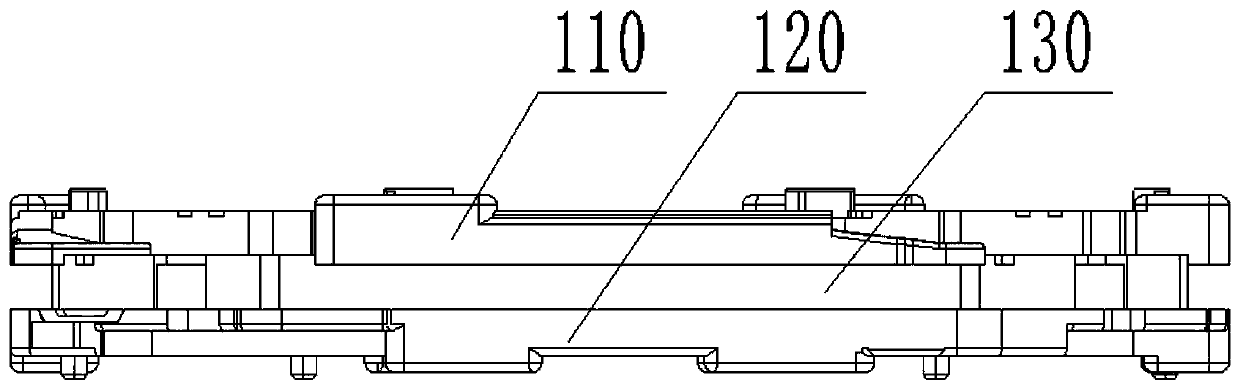

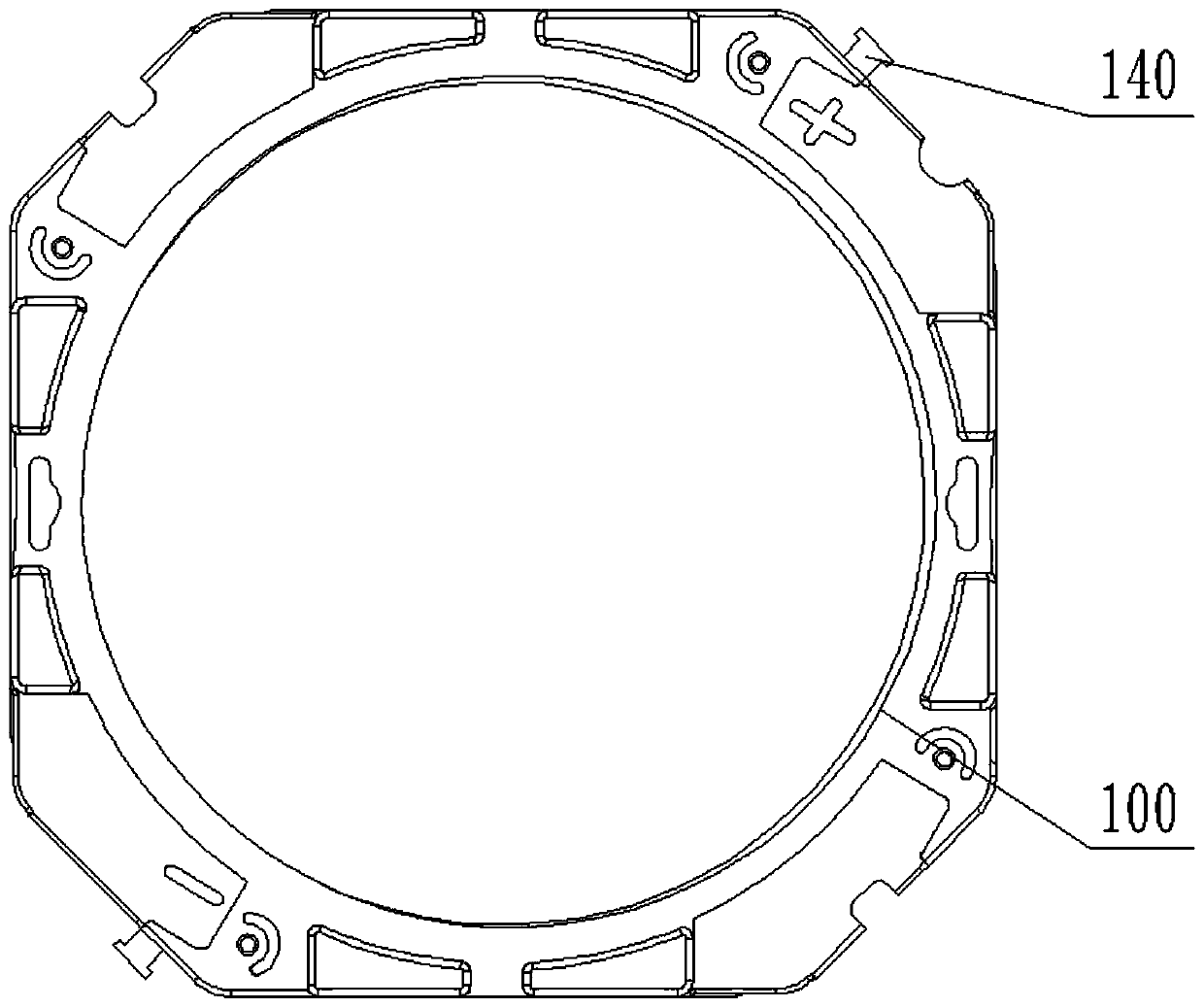

Lens support, lens driving device, camera and electronic equipment

The invention discloses a lens support, a lens driving device, a camera and electronic equipment. The lens support comprises a lens support body, the upper end and the lower end of the lens support body are respectively provided with an upper flange part and a lower flange part, a coil winding part is arranged between the upper flange part and the lower flange part, and a coil is wound on the coilwinding part; a protruding part is arranged on the outer edge of the lower flange part, the protruding part is in a rectangular column shape, a rectangular blocking part is arranged at the tail end of the protruding part, the blocking part is used for preventing a lead wound on the protruding part from disengaging, and a lead groove is formed in the position, close to the protruding part, of thelower flange part. According to the lens support with the lead wire groove, the coil can be wound more orderly, the height of the coil winding part can be reduced on the premise that the lens supportwith the lead wire groove in the scheme obtains the same using effect, and the size of the whole lens driving device can be reduced.

Owner:NEW SHICOH MOTOR CO LTD

Winding device for punched nickel-plated steel strip

ActiveCN113460764ANeatly coiledRealize winding operationWebs handlingDrive shaftStructural engineering

The invention discloses a winding device for a punched nickel-plated steel strip. The winding device comprises a material placement mechanism, a winding mechanism, a guiding mechanism and a lifting mechanism, the material placement mechanism is arranged on one side of the upper end of a workbench, the workbench is arranged at the upper end of a box body, a plurality of supporting legs are arranged at the bottom of the box body, the material placement mechanism is used for placing the punched nickel-plated steel strip to be wound, the winding mechanism is arranged on the other side of the upper end of the workbench and used for winding the punched nickel-plated steel strip, the guiding mechanism is arranged at the upper end of the workbench between the material placement mechanism and the winding mechanism and is used for carrying out limiting and guiding on the punched nickel-plated steel strip in the winding process, the lifting mechanism is arranged in the interior of the box body, the lifting mechanism is used for driving a driven shaft and a driving shaft to move up and down, the driven shaft is arranged in the material placement mechanism, and the driving shaft is arranged in the winding mechanism. According to the winding device for the punched nickel-plated steel strip, feeding and discharging are convenient, the working efficiency is high, and winding is neat.

Owner:赣州市中金高能电池材料股份有限公司

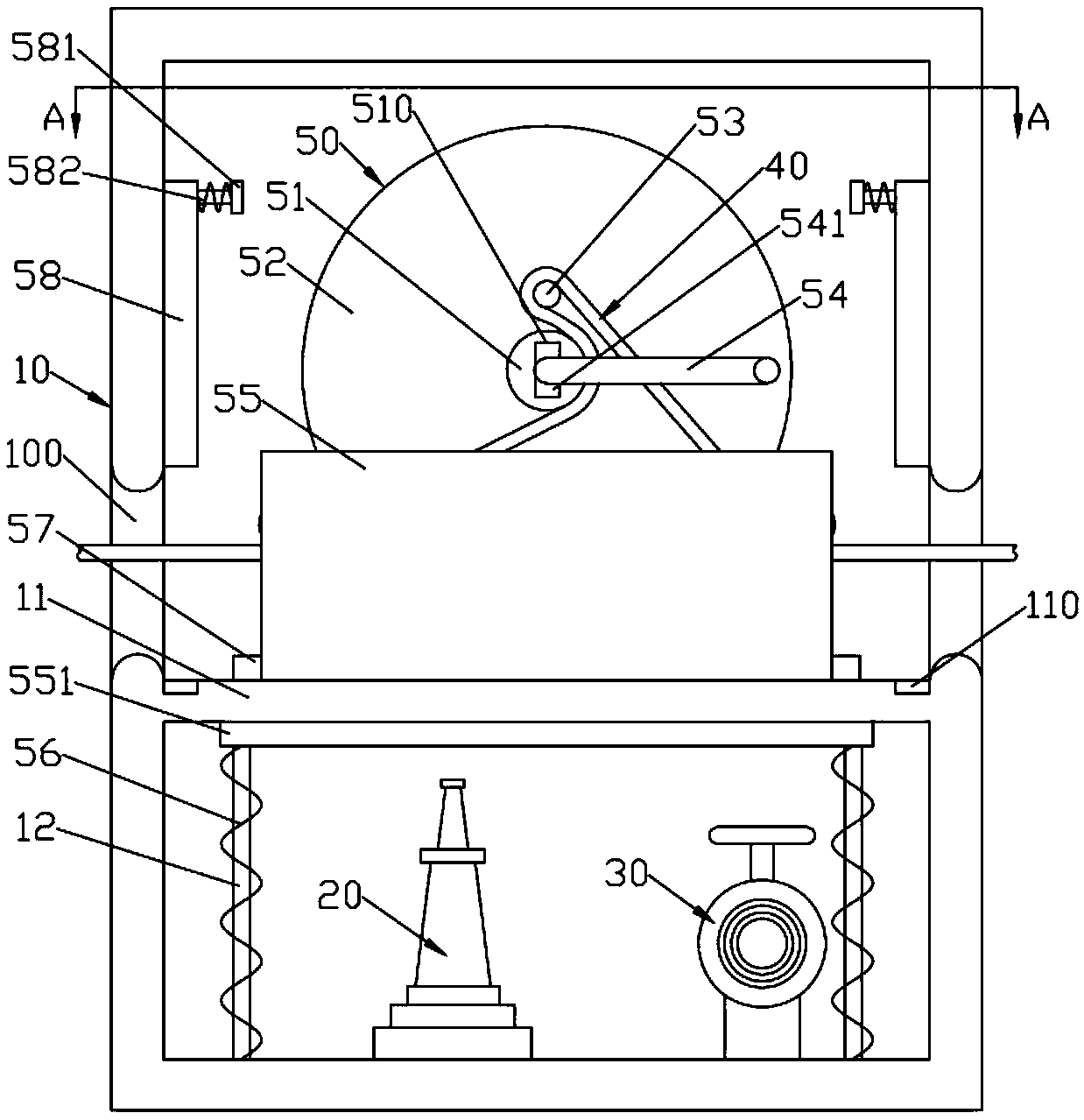

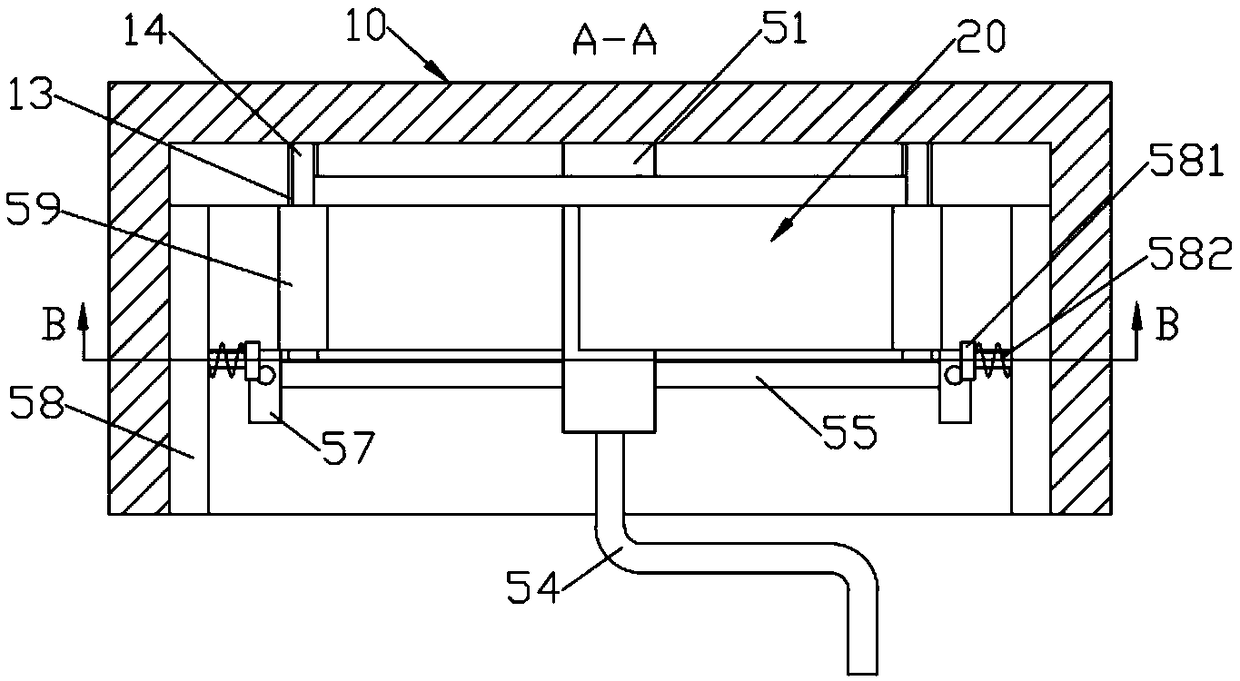

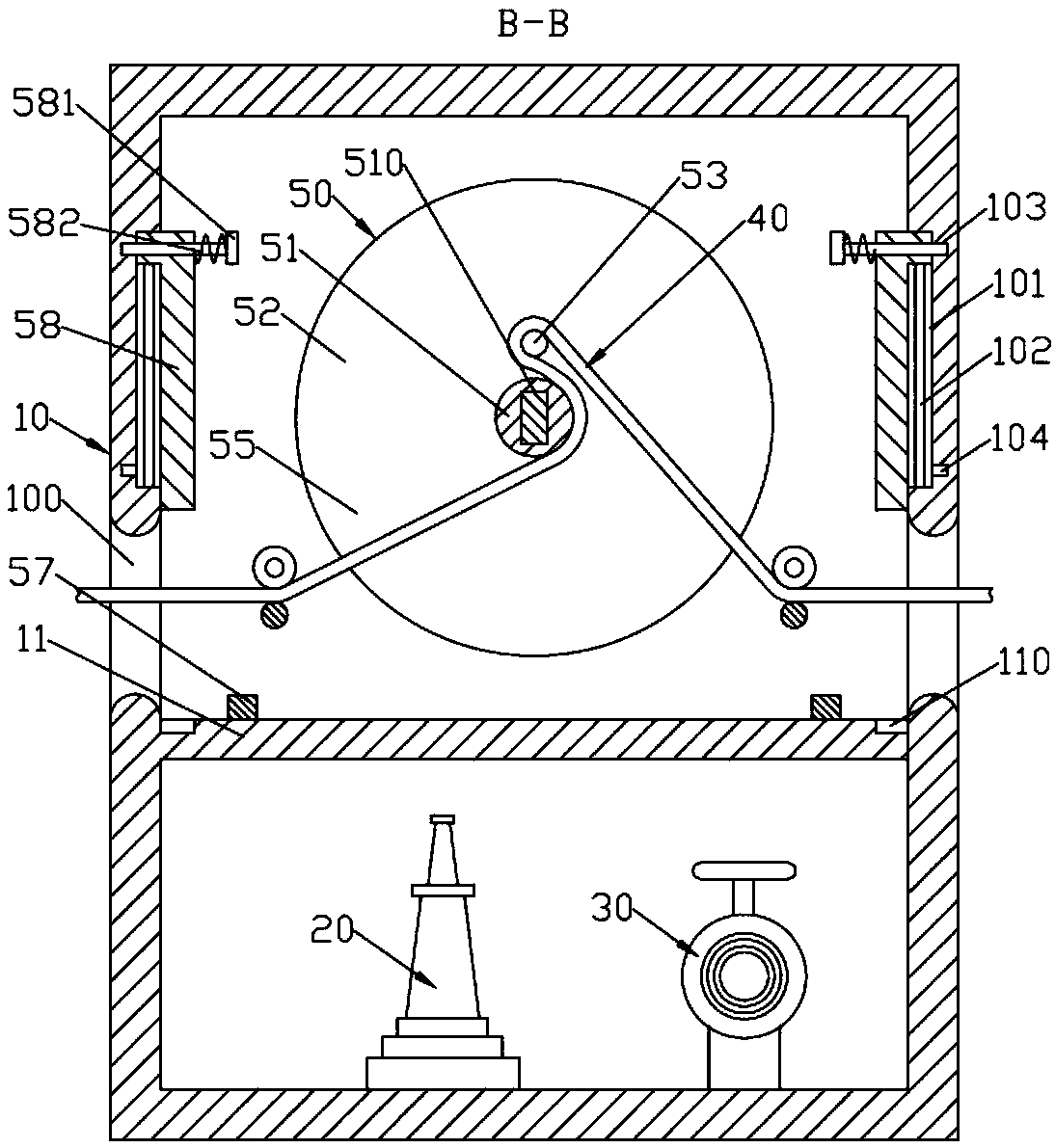

Fire hydrant cabinet with water hose convenient to wind

The invention discloses a fire hydrant cabinet with a water hose convenient to wind. The fire hydrant cabinet comprises a cabinet body and a water hose winding device. The water hose winding device comprises a winding center shaft which is in vertical pivot joint to the rear side wall of the cabinet body; a rear blocking disk is fixed to the rear part of the winding center shaft; a center partition column and a pair of roller center columns which are evenly distributed up and down are formed at the position, on the lower right portion of the rear blocking disk, of the rear side wall of the cabinet body; the pair of roller center columns are arranged in a longitudinal symmetry mode with respect to the center partition column; a penetrating hole which is through left and right is formed in the position, right facing the center partition column and the pair of roller center columns, of the right side wall of the cabinet body; the front end of the penetrating hole is not sealed; a left supporting plate and a right supporting plate which are in bilateral symmetry are formed at the middle parts of the left side wall and the right side wall of the cabinet body; a front blocking plate is arranged slidable front-and-back between the left supporting plate and the right supporting plate; and when the front blocking plate is placed at the forefront end, the front blocking plate is hinged between the left supporting plate and the right supporting plate. The fire hydrant cabinet is simple in structure and convenient to operate, and the water hose is wound neatly.

Owner:嘉兴市大众丝绸印花有限责任公司

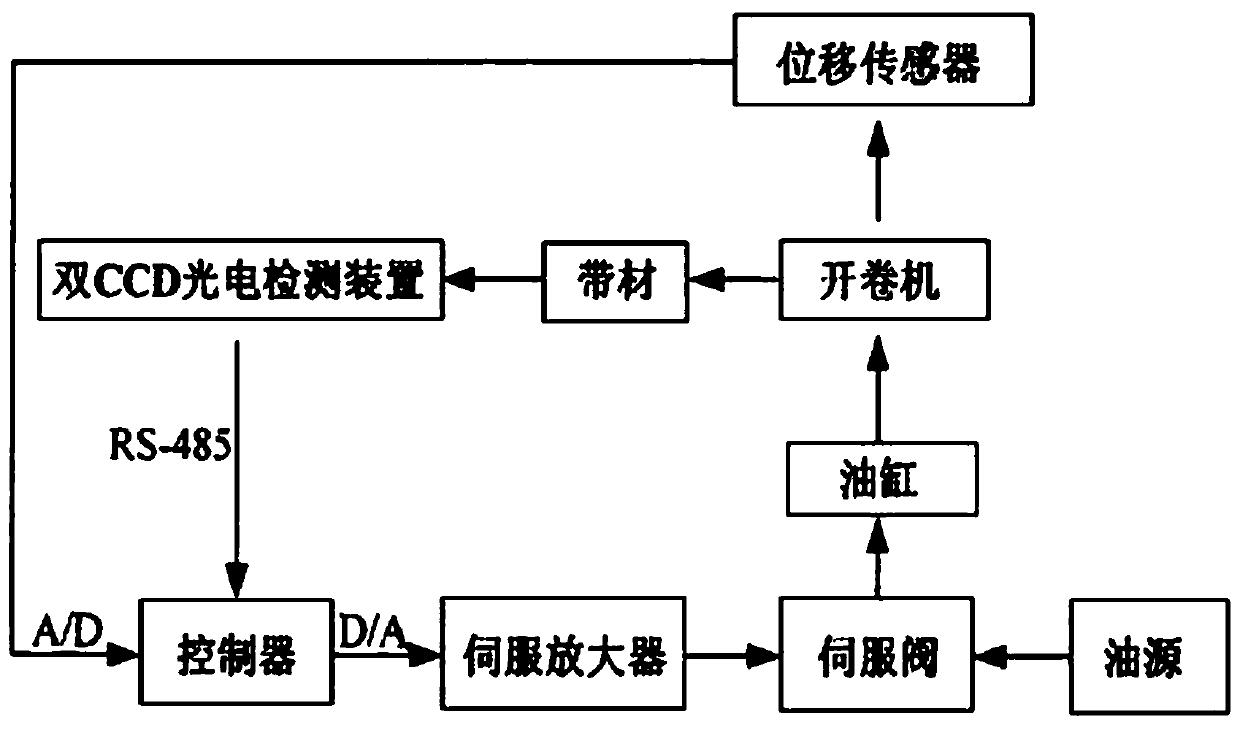

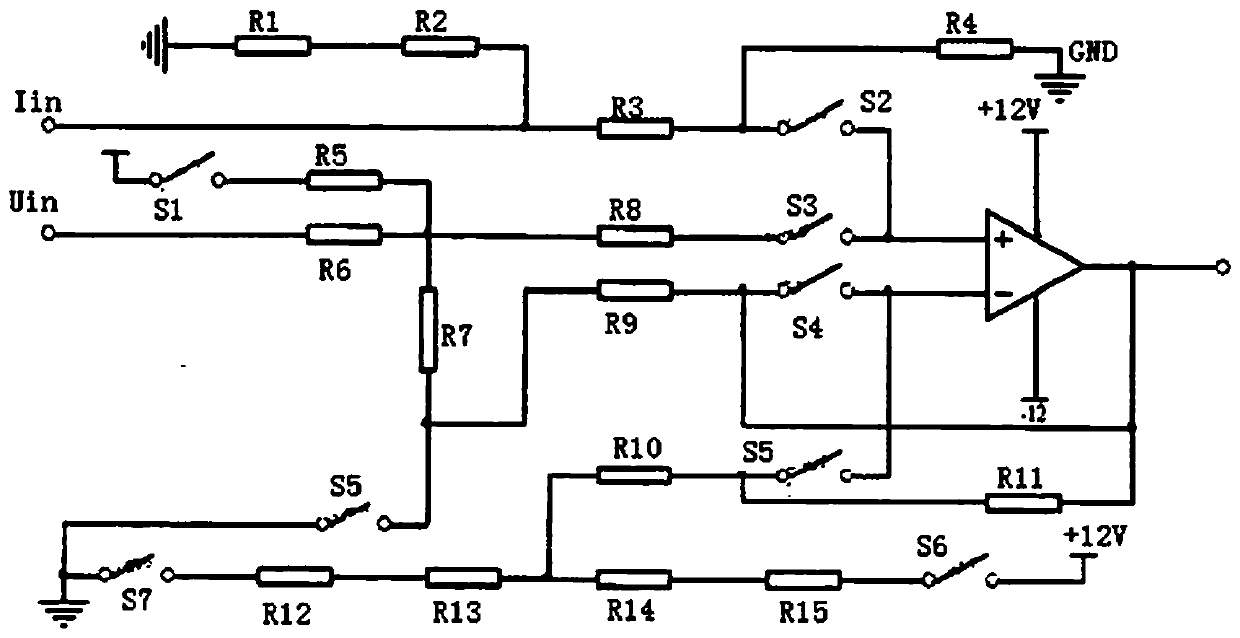

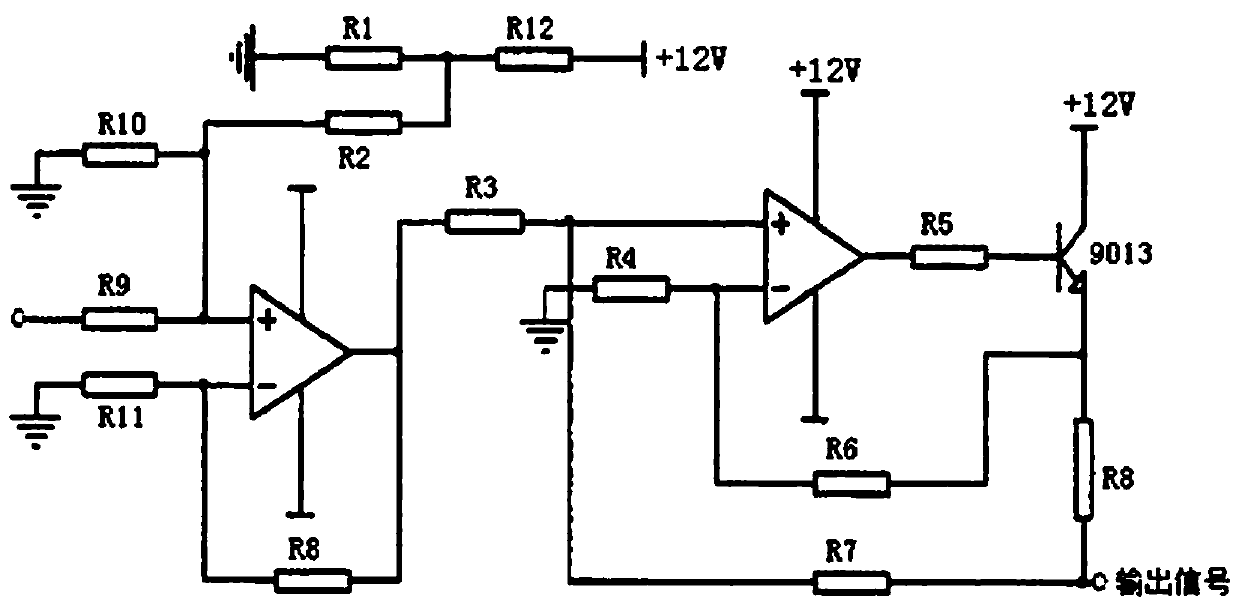

Automatic correction control system for strips

InactiveCN108097727AHigh precisionWork in real timeGuiding/positioning/aligning arrangementsRoll mill control devicesMicrocontrollerMicrocomputer

An automatic correction control system for strips is suitable for the field of production and manufacturing. The automatic correction control system is mainly composed of an A / D conversion front signal processing circuit, a current signal processing circuit and an RS-485 communication circuit. The control system is composed of a CCD photoelectric detection device, a displacement sensor, a correction controller, an electro-hydraulic servo control system and the like. The electro-hydraulic servo control system is composed of a servo amplifier, a servo valve, an oil cylinder, an oil source and the like. By the adoption of the system, a single chip microcomputer development system is adopted, the accuracy of a conversion circuit is improved, the cost is reduced, it is guaranteed that the automatic correction control system accurately and intelligently operates in real time, the response speed is increased, the system operates stably, the high anti-interference and reliability are achieved,and regular material winding and slitting in the production process can be guaranteed.

Owner:刘冰飞

Belt core formation device for conveying belts

ActiveCN105313431AIn line with the status quo of the production enterpriseIn line with the status quoLamination ancillary operationsLaminationMechanical engineeringCore formation

The invention relates to production equipment of rubber conveying belts, in particular to a belt core formation device for the conveying belts. The belt core formation device comprises a coiled material uncoiling device, a padding cloth trimming device and a padding cloth coiling device, and further comprises an upper conveyer belt and a lower conveyer belt, wherein a cutting device I is arranged at the inlet position of the upper conveyer belt; a plurality of fitted pressure roller groups are arranged on the upper conveyer belt and before the cutting device I; height rack devices and a height adjusting rack device are arranged on the upper conveyer belt at intervals; a plurality of clamping roller groups are arranged at the tail end of the upper conveyer belt; a cutting device II is arranged between two of the clamping roller groups; a belt core coiling device and a padding cloth uncoiling device are arranged on the outer side at the tail end of the upper conveyer belt. Due to matched arrangement of the height rack devices and the height adjusting rack device, the belt core formation device has the advantages that production of relatively longer belt cores can be realized; no joints is formed in the production process.

Owner:ZHEJIANG DOUBLE ARROW RUBBER

Cloth winding machine capable of automatically adjusting tightness degree to avoid wrinkles

The invention discloses a cloth winding machine capable of automatically adjusting the tightness degree to avoid wrinkles. The cloth winding machine capable of automatically adjusting the tightness degree to avoid the wrinkles comprises a winding machine body, a winding cavity is formed in the winding machine body in a left-right penetrating mode, a winding device is arranged in the winding cavity, and the winding device comprises limiting cavities which are symmetrical front and back and communicate with the front wall and the rear wall of the winding cavity; a first supporting block is rotationally arranged between the upper wall and the lower wall of the limiting cavity in the front side, a second supporting block is arranged in the limiting cavity in the rear side, a first rotating shaft is rotationally arranged between the first supporting block and the second supporting block, an induction device is arranged between a driven rotating drum and a driving rotating drum, and a linkage device is arranged in the induction device. In the process of rewinding cloth before warehousing, the position of the driven rotary drum can be automatically adjusted to tension the cloth accordingto the tightness state of the cloth when the cloth is wound, the situation that the wrinkles exist in the cloth winding process due to the fact that one side of the cloth is inclined and loosened is avoided, and the adjustment does not need to be conducted through cloth switching and other modes, and the winding efficiency before warehousing is improved.

Owner:海宁源茂针织股份有限公司

A fire hydrant box with convenient coiling operation

The invention discloses a fire hydrant cabinet with a water hose convenient to wind. The fire hydrant cabinet comprises a cabinet body and a water hose winding device. The water hose winding device comprises a winding center shaft which is in vertical pivot joint to the rear side wall of the cabinet body; a rear blocking disk is fixed to the rear part of the winding center shaft; a center partition column and a pair of roller center columns which are evenly distributed up and down are formed at the position, on the lower right portion of the rear blocking disk, of the rear side wall of the cabinet body; the pair of roller center columns are arranged in a longitudinal symmetry mode with respect to the center partition column; a penetrating hole which is through left and right is formed in the position, right facing the center partition column and the pair of roller center columns, of the right side wall of the cabinet body; the front end of the penetrating hole is not sealed; a left supporting plate and a right supporting plate which are in bilateral symmetry are formed at the middle parts of the left side wall and the right side wall of the cabinet body; a front blocking plate is arranged slidable front-and-back between the left supporting plate and the right supporting plate; and when the front blocking plate is placed at the forefront end, the front blocking plate is hinged between the left supporting plate and the right supporting plate. The fire hydrant cabinet is simple in structure and convenient to operate, and the water hose is wound neatly.

Owner:嘉兴市大众丝绸印花有限责任公司

Fire-hydrant cabinet with hose transversely penetrating through cabinet body

Owner:湖州达立智能设备制造有限公司

Warp-direction winding inspecting machine

ActiveCN111377277AImprove winding efficiencyNot easy to shake and shiftLiquid surface applicatorsInspecting textilesElectric machineryDrive motor

The invention relates to a warp-direction winding inspecting machine. The warp-direction winding inspecting machine comprises a machine frame, a plurality of cloth guiding rollers, a driving roller and a driving motor. An output shaft of the driving motor is fixedly connected to the driving roller. The machine frame is provided with a moving frame and a pushing part, and the moving frame is provided with a rotating roller and a rotating motor. When the pushing part drives the moving frame to be away from the driving roller, a falling cavity is formed by enclosing the driving roller and the rotating roller; and the machine frame is further provided with a storage box, a feeding inlet and a discharging outlet are separately formed in the upper side and the lower side of the storage box, thestorage box is further provided with a closing plate and a driving part. When a paper cylinder wound with cloth needs to be discharged, firstly the moving frame is driven to move through the pushing part, so that the paper cylinder wound with the cloth falls from the falling cavity to the lower part; then the moving frame is driven to move and reset through the pushing part, and the driving part drives a closing plate to move, so that the paper cylinder is discharged through the discharging outlet; and the paper cylinder located on the lowermost side of inside of the storage box moves throughthe closing plate and falls onto the driving roller and the rotating roller. The winding efficiency of the cloth is greatly improved.

Owner:杭州高氏箱包布业有限公司

Constant speed woven belt winding machine

The invention discloses a constant speed woven belt winding machine. The constant speed woven belt winding machine is characterized by comprising a base, wherein a left bracket and a right bracket are arranged on the base; a transmission shaft is arranged between the left bracket and the right bracket; a friction wheel is mounted on the transmission shaft between the left bracket and the right bracket; an inclined friction surface is manufactured on one side of the friction wheel; a compression ring and a paper roll are arranged on the outer wall of the transmission shaft on the outer side of the right bracket at intervals; a compression nut is arranged at the end part of the transmission shaft; the compression nut compresses the compression ring and the paper roll; a fixing block is arranged on one side of the right bracket; an inclined slide rail is arranged on the fixing block; a sliding block is arranged on the inclined slide rail; the sliding block and the inclined slide rail are in sliding fit; a fixing rack is arranged on the sliding block; a motor is arranged on one side of the fixing rack; an output shaft of the motor is connected with a driving wheel manufactured through a rubber material; the driving wheel is in frictional contact with the inclined friction surface of the friction wheel; a rotating pin is manufactured on the other side of the fixing rack; a belt pressing wheel is arranged outside the rotating pin; and the belt pressing wheel is in contact with a woven belt on the outer wall of the paper roll.

Owner:沈传良

Numerical control automatic winding equipment for door and window brush seal

PendingCN110015585AReduce shakingImprove tape qualityMeasurement devicesWebs handlingNumerical controlBristle

The invention discloses numerical control automatic winding equipment for a door and window brush seal, and belongs to the technical field of brush seal winding. The equipment comprises a control cabinet, a feeding device, a meter counting device, a laser detection device, an arranging device and a winding device, wherein the feeding device is used for providing conveying power of the brush seal,the meter counting device is used for metering the conveying length of the brush seal, the laser detection device is used for detecting the feeding state of the brush seal, the arranging device is used for adjusting discharging of the brush seal, and the winding device is used for winding the brush seal; a discharging end of a discharging guide groove of the arranging device is fixedly provided with a discharging mold, the discharging mold comprises a mounting block portion and a limiting block portion fixedly connected with the bottom of the mounting block portion, the limiting block portionis provided with a limiting opening which penetrates through the limiting block portion and communicates with the discharging end of the discharging guide groove, the matching clearance between the limiting opening and the brush seal in the width direction is 0.5 mm-3 mm, an outward convex transition arc surface is formed on the side surface, towards the discharging end of the discharging guide groove, of the limiting block portion along the side edge of the limiting opening towards the side edge of the limiting block portion; the brush seal is wound in order, the situation of bristle pressing, bristle staggering and the like in the winding process is greatly reduced, and the winding quality is improved.

Owner:兴国县迪佳建筑装饰材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com