Lens support, lens driving device, camera and electronic equipment

A technology of lens driving device and lens bracket, which is applied in the field of camera and electronic equipment, lens bracket, and lens driving device. It can solve the problems of uneven coil winding and untidy arrangement of lead wires, etc., and achieve the effect of neat coil winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

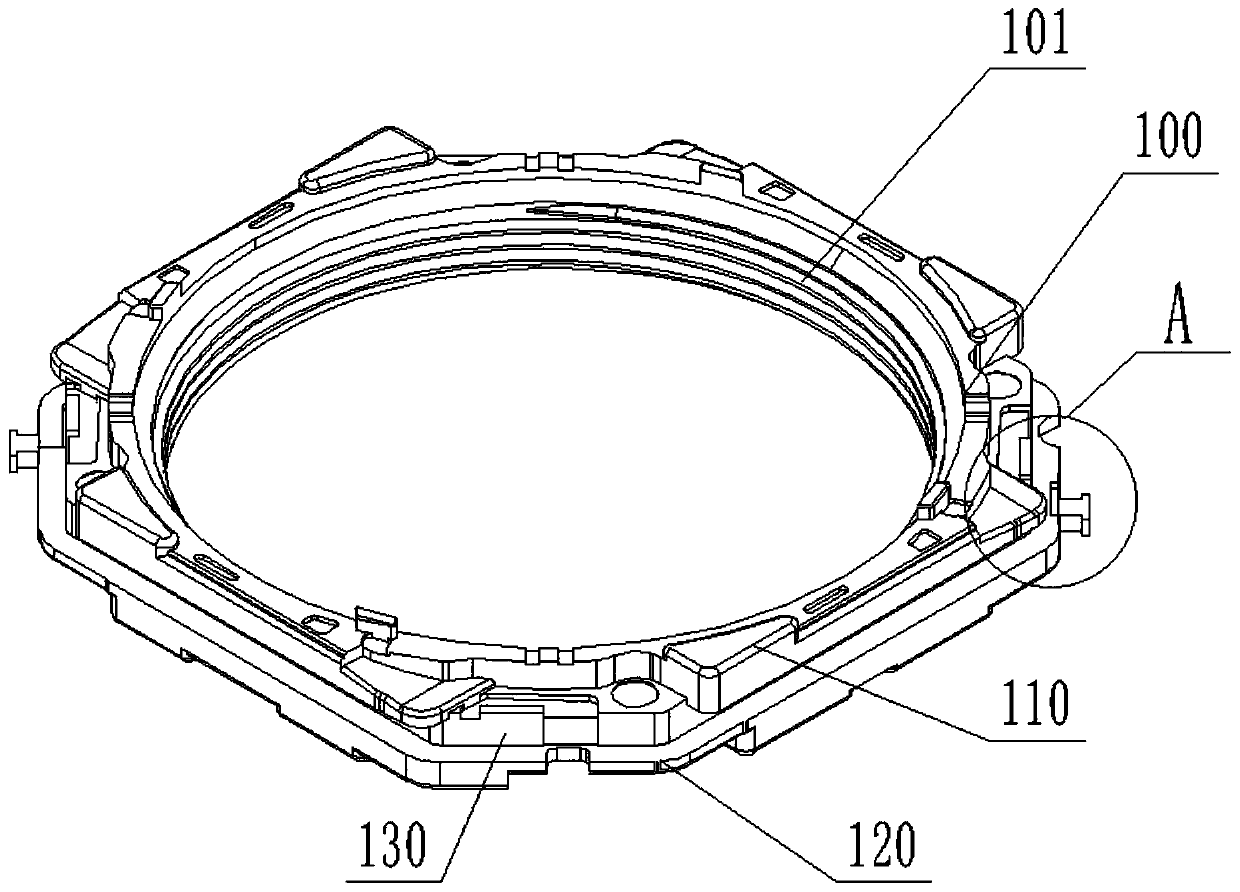

[0042] Example 1, please refer to Figure 1-6 , a lens holder, comprising a lens holder body 100,

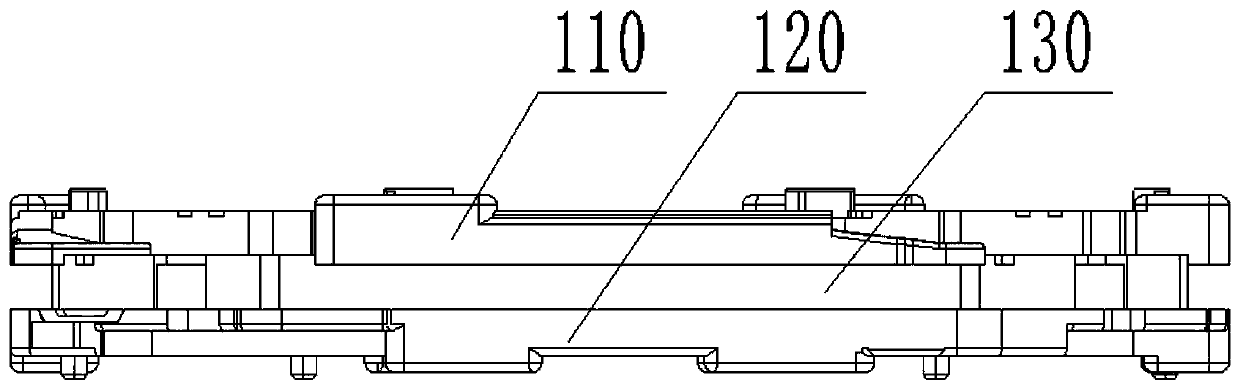

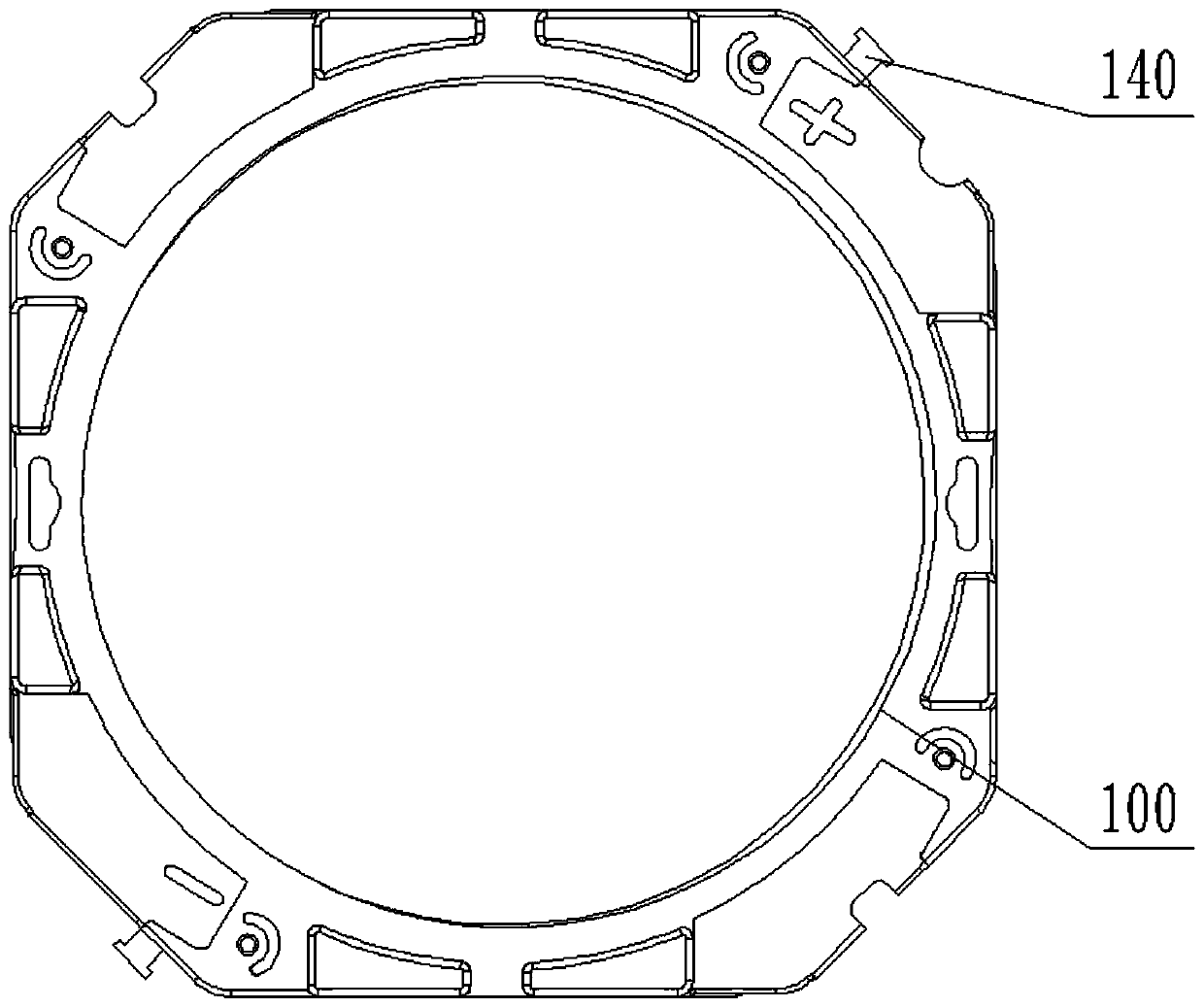

[0043] The lens holder body 100 is flat and cylindrical, and the axis of the lens holder body 100 is provided with a circular lens mounting hole 101 for installing the lens 700. The extension of the lens holder body 100 is octagonal,

[0044] The upper and lower ends of the lens holder body 100 are respectively provided with an upper flange part 110 and a lower flange part 120, between the upper flange part 110 and the lower flange part 120 is a coil winding part 130, and the coil winding part 130 A coil is wound on it;

[0045] The extension of the lower flange part 120 is provided with a protruding part 140, which is used to fix the lead wire of the coil. on the edge of

[0046] The protruding portion 140 is in the shape of a rectangular column, and the end of the protruding portion 140 is provided with a rectangular blocking portion 141, the blocking portion 141 is used to...

Embodiment 2

[0051] Example 2, please refer to Figure 7-15 , a lens driving device, including a frame 300, a housing 400, a lower elastic piece 500 and an upper elastic piece 600; the housing 400 and the lower elastic piece 500 are installed on the frame 300, the frame 300 is approximately in the shape of a rectangular plate, and the frame The center card of 300 is provided with a through hole for light to pass through;

[0052] The housing 400 is approximately in the shape of a square box with an opening at the bottom. The top axis of the housing 400 is provided with a through hole for passing light, and the bottom opening of the housing 400 is fixedly buckled on the frame 300 on the outer edge of the

[0053] The four corners of the frame 300 are provided with guide pillars 301, and the outer sides of the guide pillars 301 are arranged in an arc-shaped transition, while the four corners of the inner wall of the housing 400 are also arranged in an arc-shaped transition. The four corners ...

Embodiment 3

[0062] Embodiment 3, a camera including the above-mentioned lens driving device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com