Patents

Literature

553 results about "Venetian blinds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

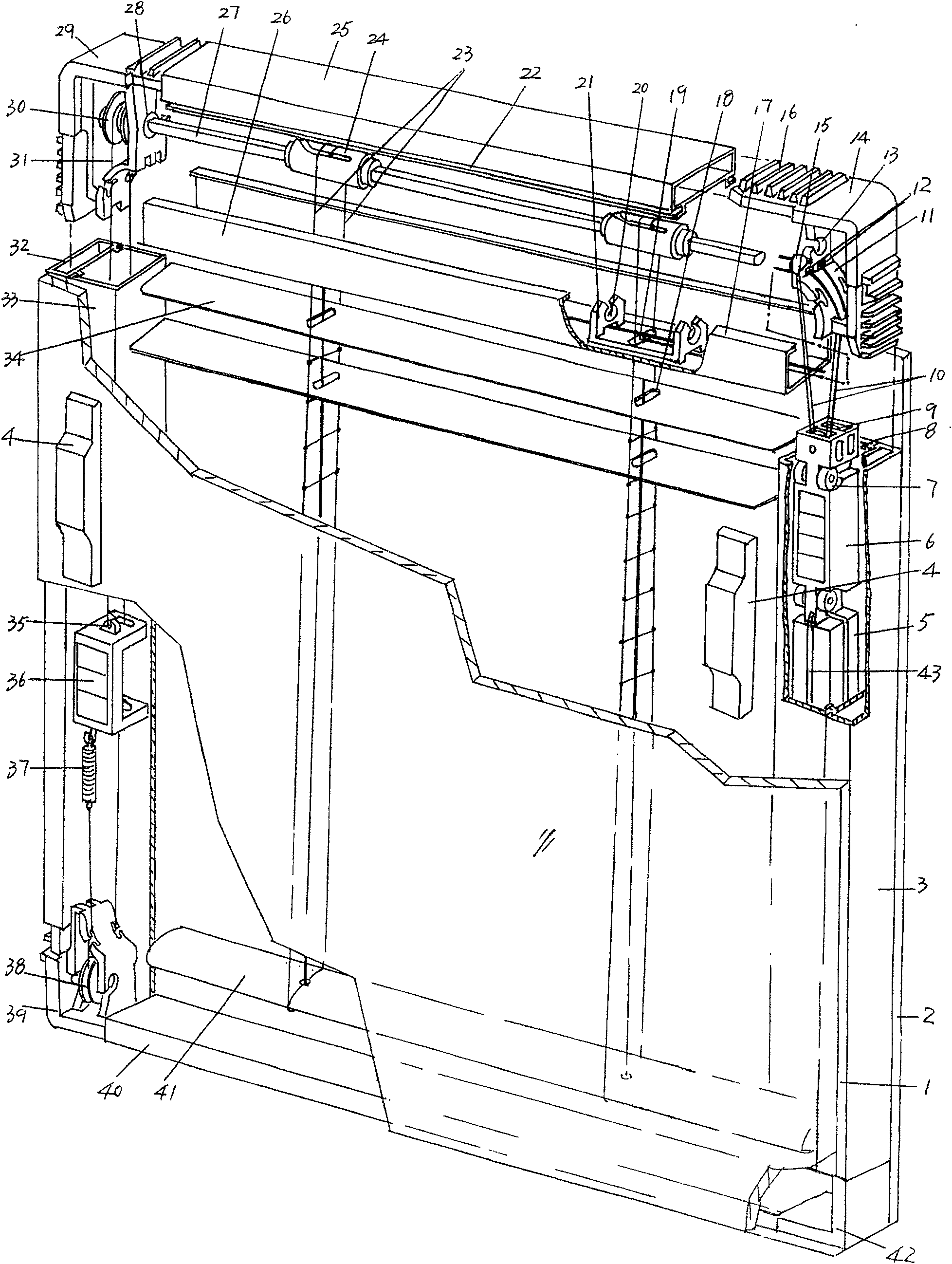

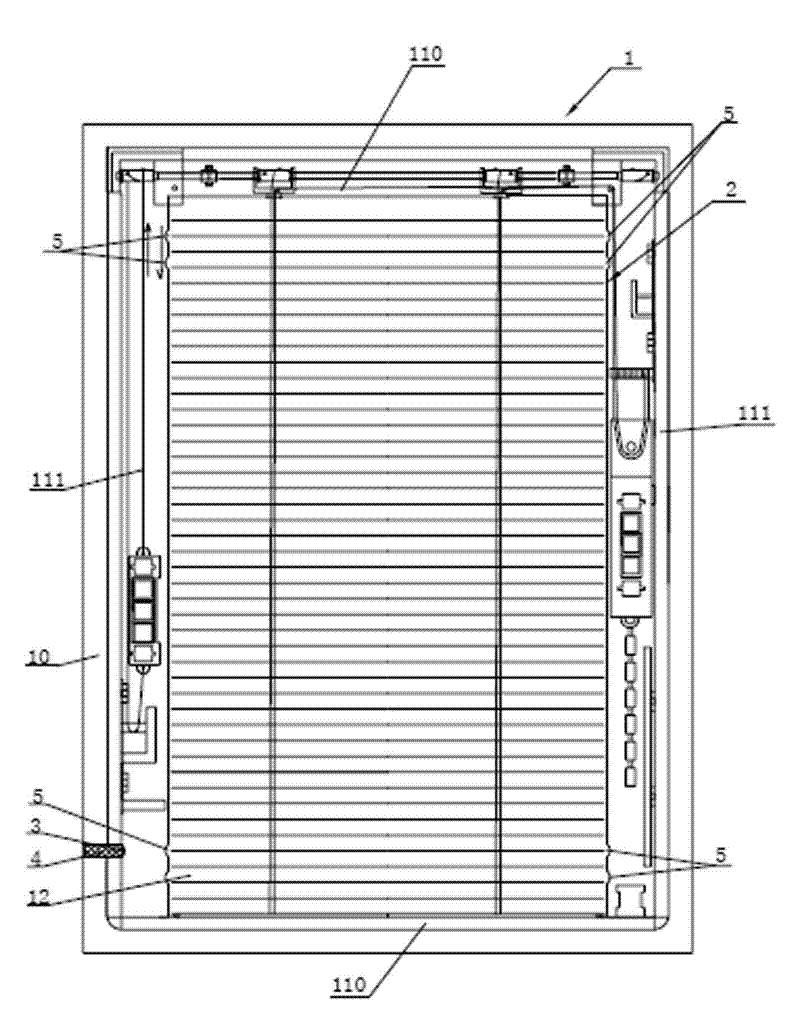

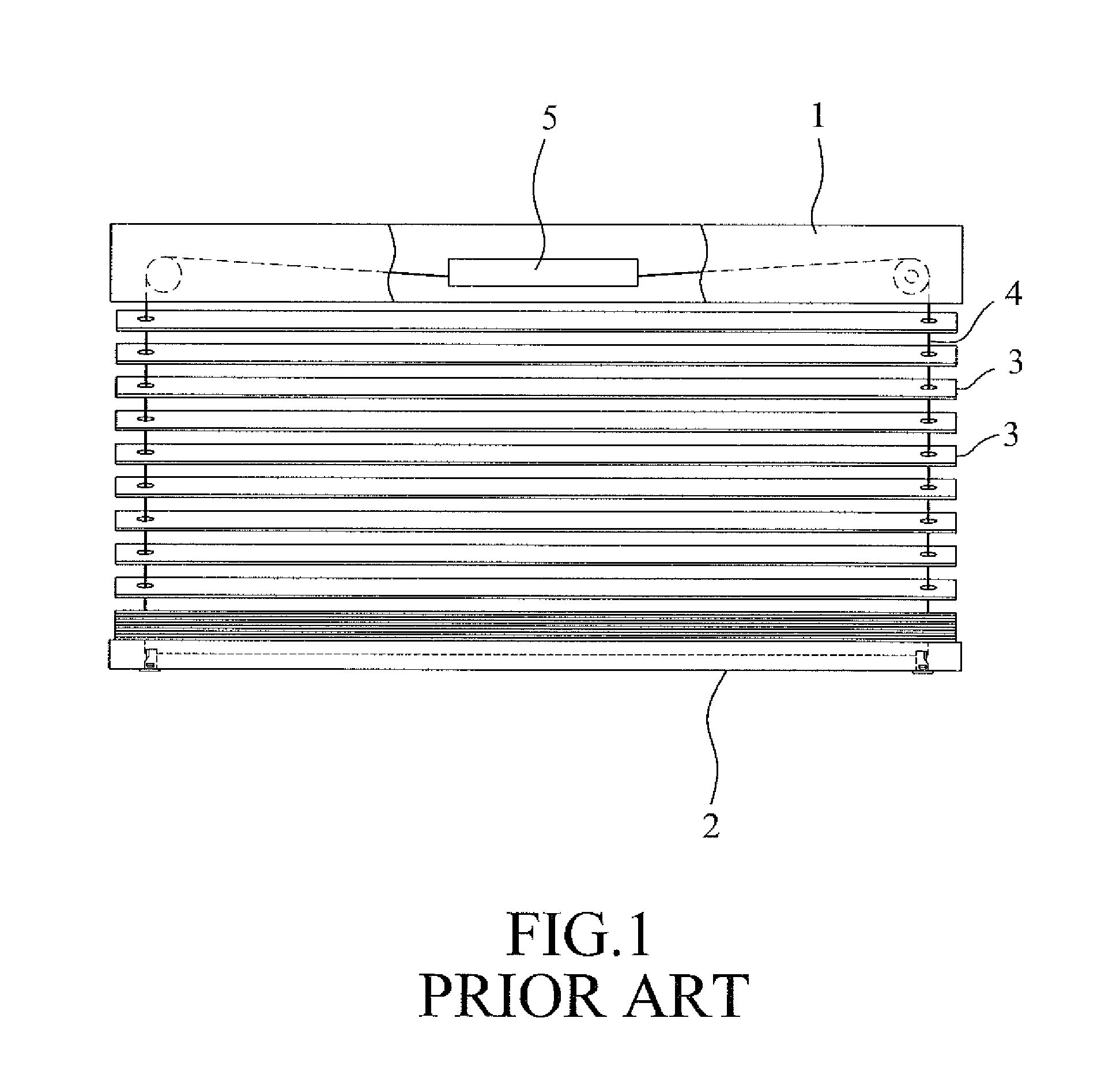

Structure-improved window shutter in hollow glass

ActiveCN100535378CImplement the flipping actionReduce manufacturing costLight protection screensWindow shutterEngineering

Owner:江苏中诚建材集团有限公司

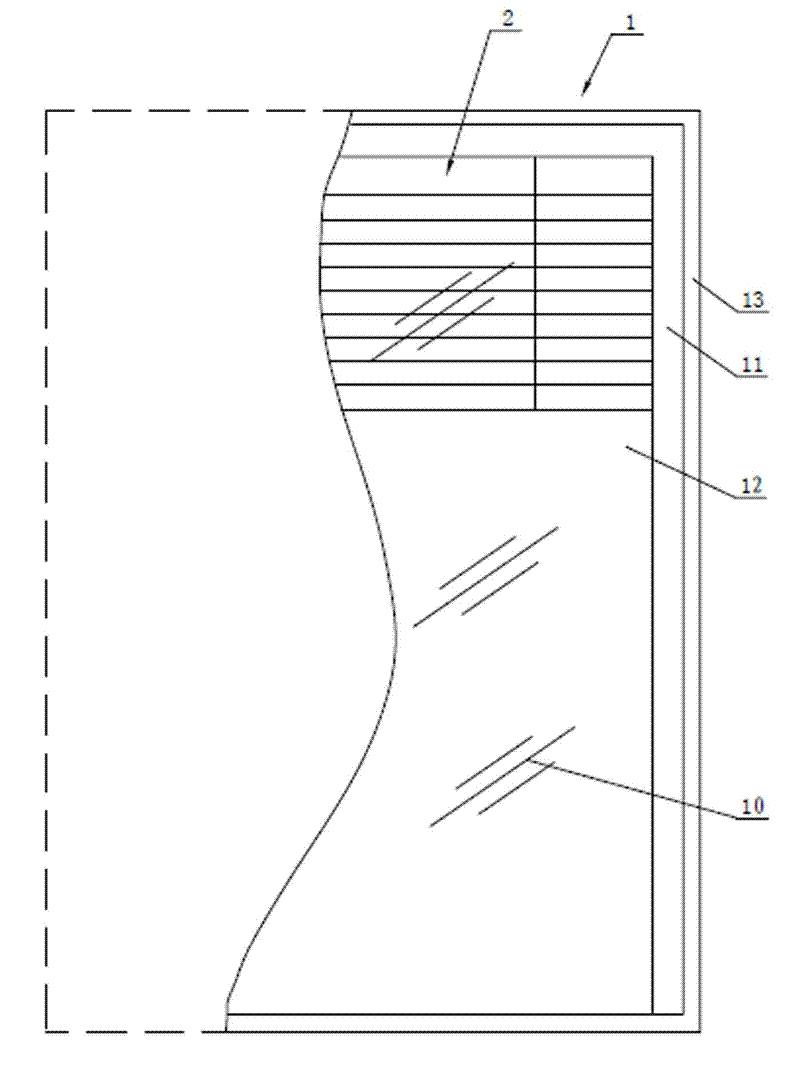

Internally-arranged sun-shading hollow shutter

InactiveCN102444372AExtended service lifePrevent oxidationDoor/window protective devicesClimate change adaptationWindow shutterEngineering

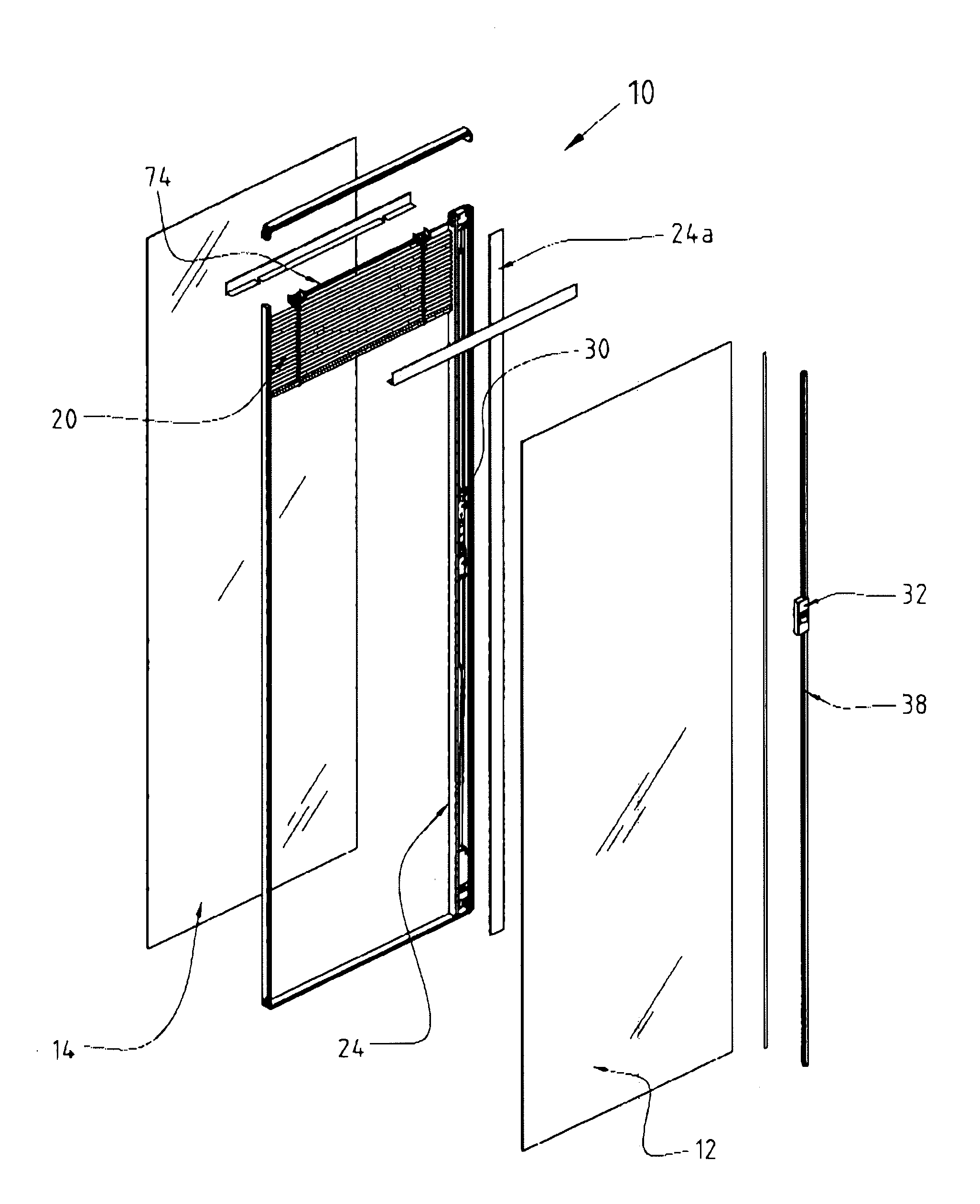

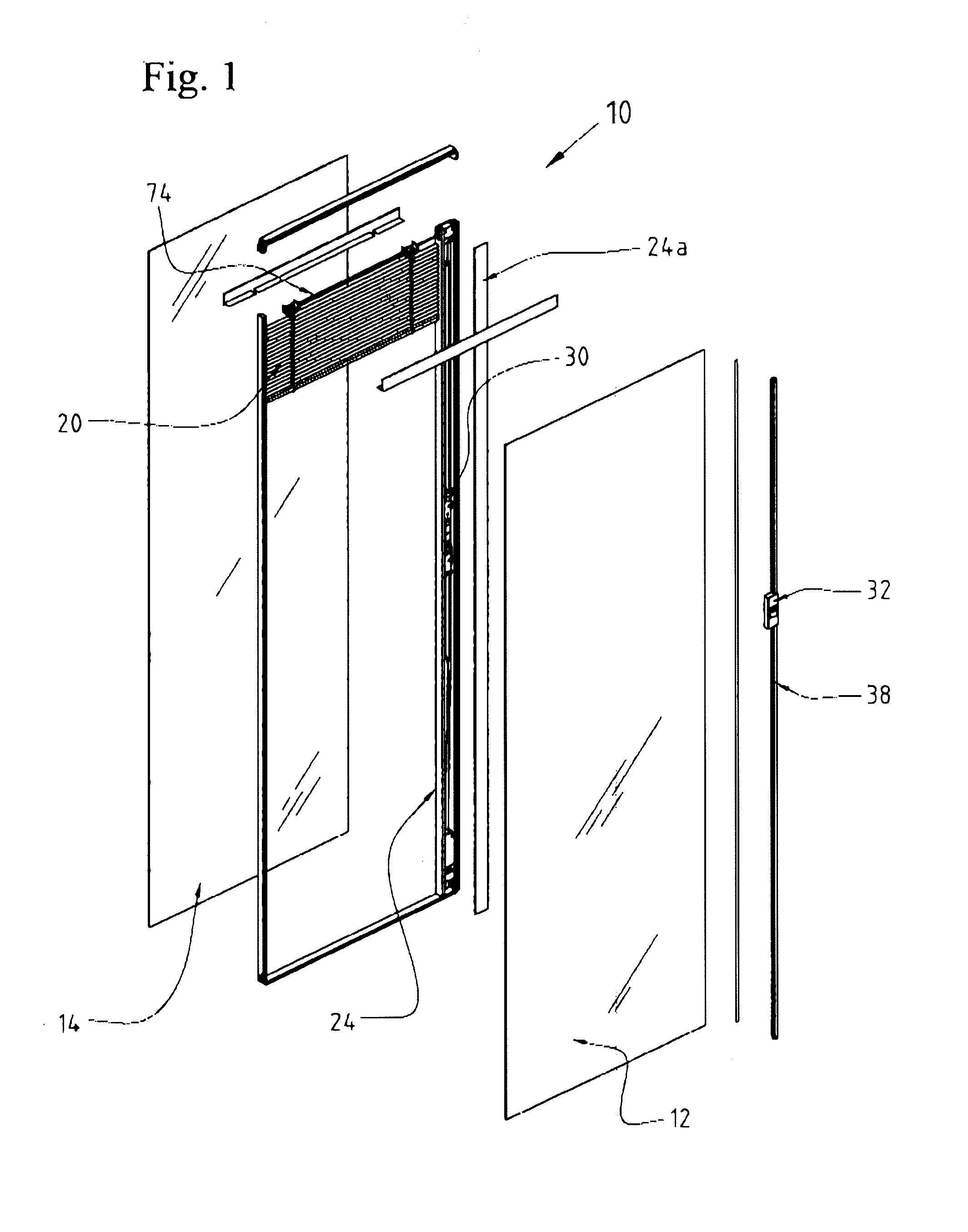

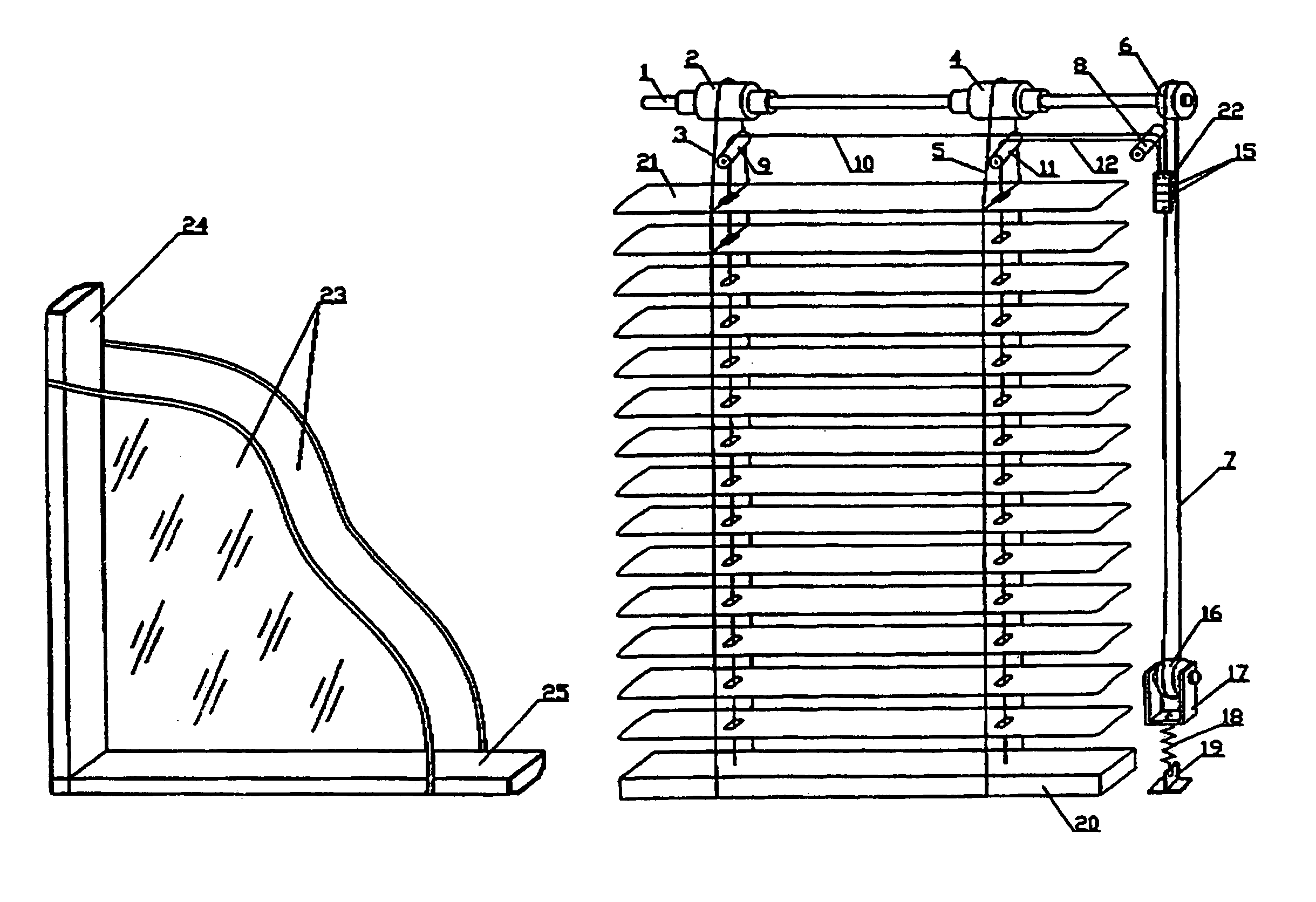

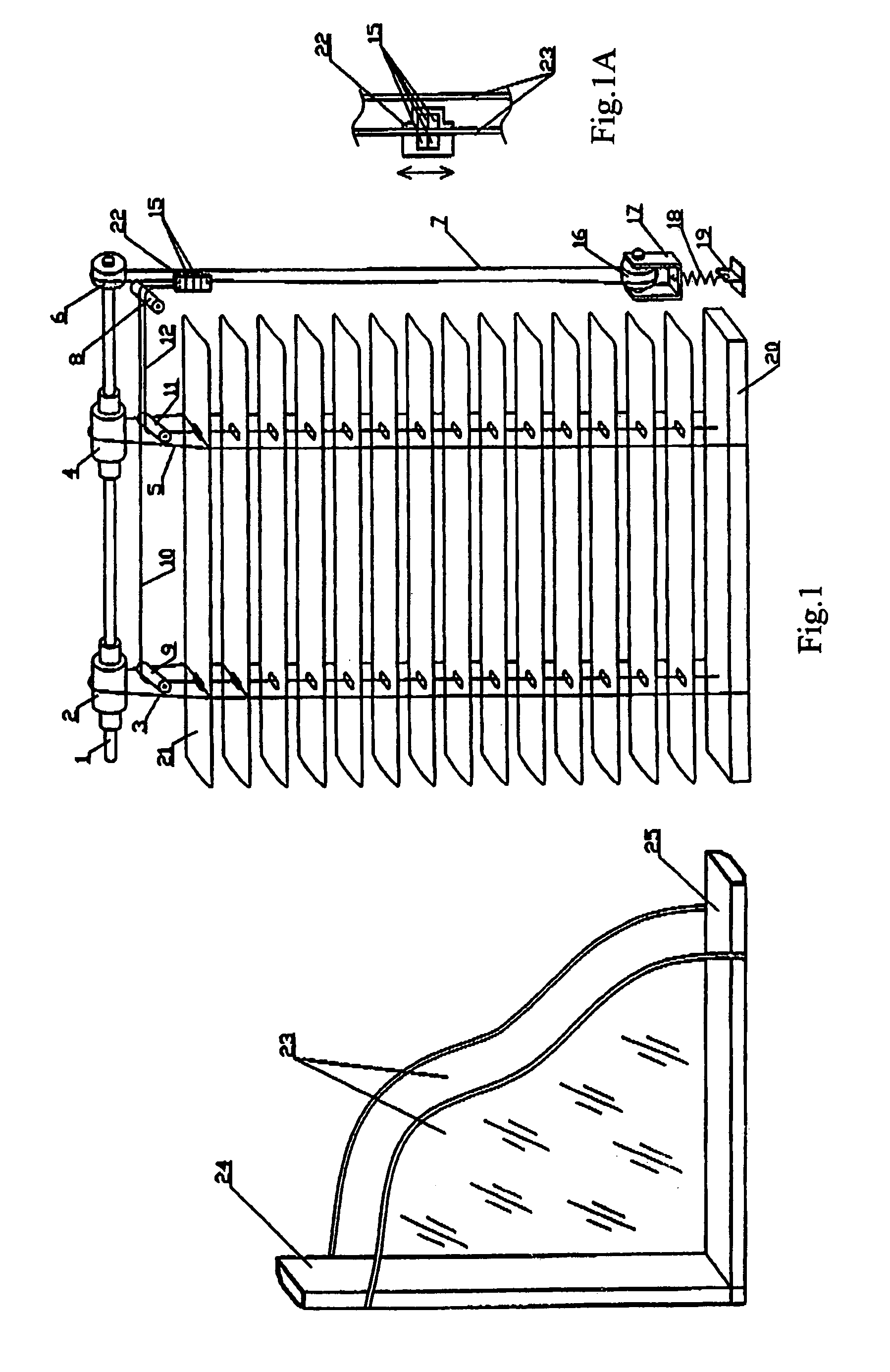

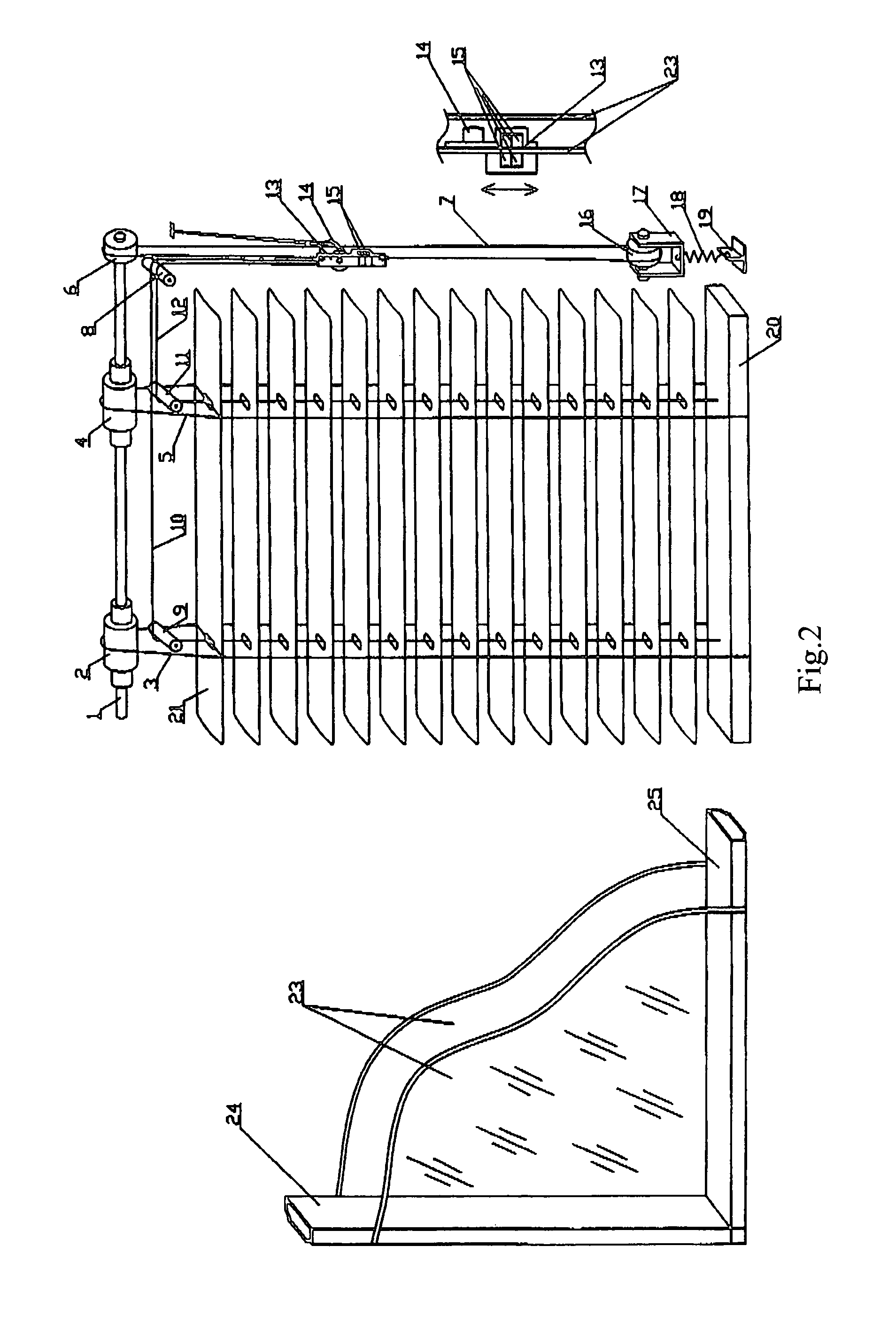

The invention relates to an internally-arranged sun-shading hollow shutter, which comprises hollow glass, a shutter curtain and a control mechanism. The hollow glass comprises a two glass original sheets which are parallel to each other, a metal hollow frame clamped between the two glass original sheets, a hollow portion enclosed by the two glass original sheets and the metal hollow frame, and sealing glue. The shutter curtain is arranged in the hollow portion. The internally-arranged sun-shading hollow shutter further comprises a port arranged on the outer lateral side of the metal hollow frame and a sealing plug for sealing the port. The inner lateral side of the metal hollow frame is provided with an air vent hole for communicating the metal hollow frame and the hollow portion, wherein the hollow portion is filled with inertia gas. The port can be connected with a vacuumizing device to vacuumize the inside of the hollow portion, the inertia gas is delivered into the hollow portion through the port, and inertia gas environment can prevent parts such as a pull rope and a ladder rope in the hollow glass from being oxidized so as to prolong service life of the internally-arranged sun-shading hollow shutter.

Owner:张家港市虹壹玻璃制品有限公司

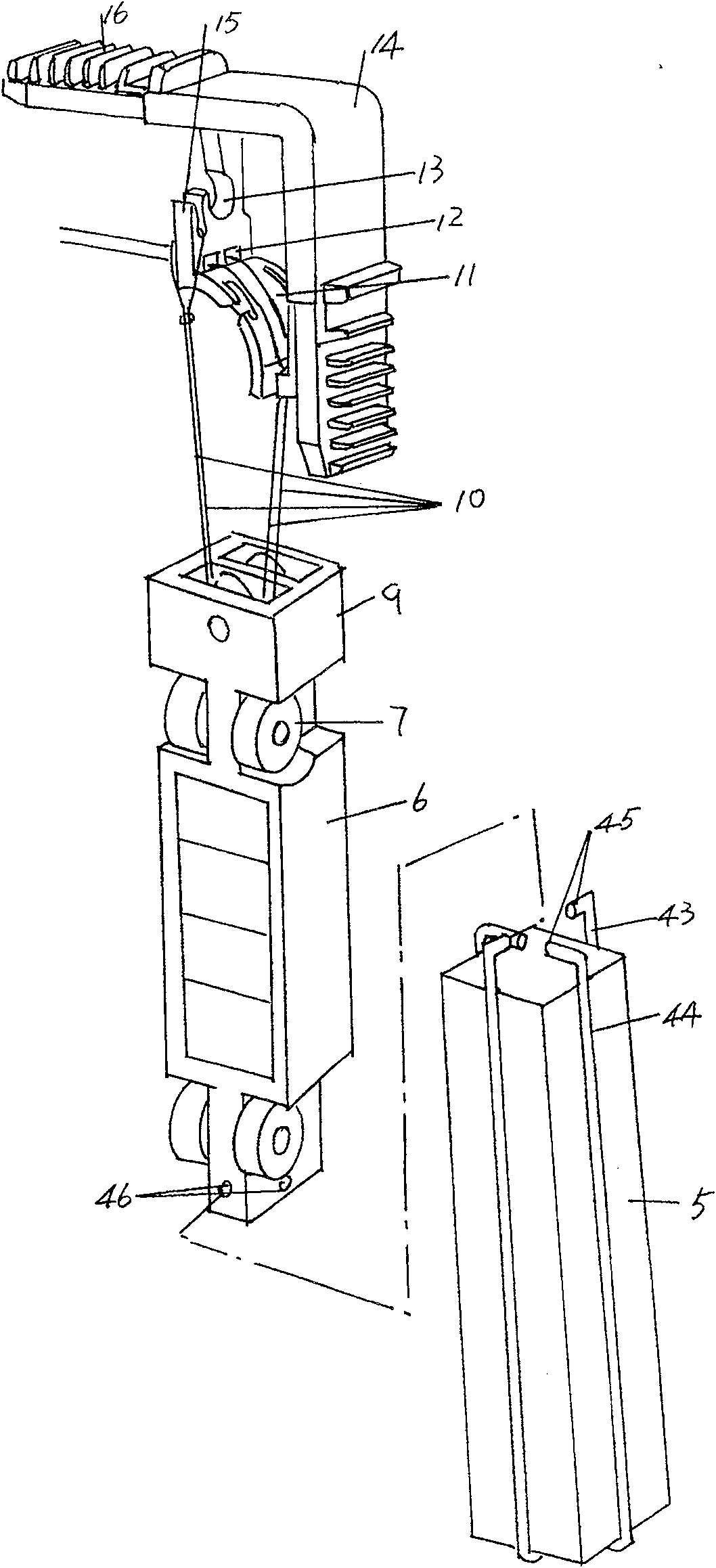

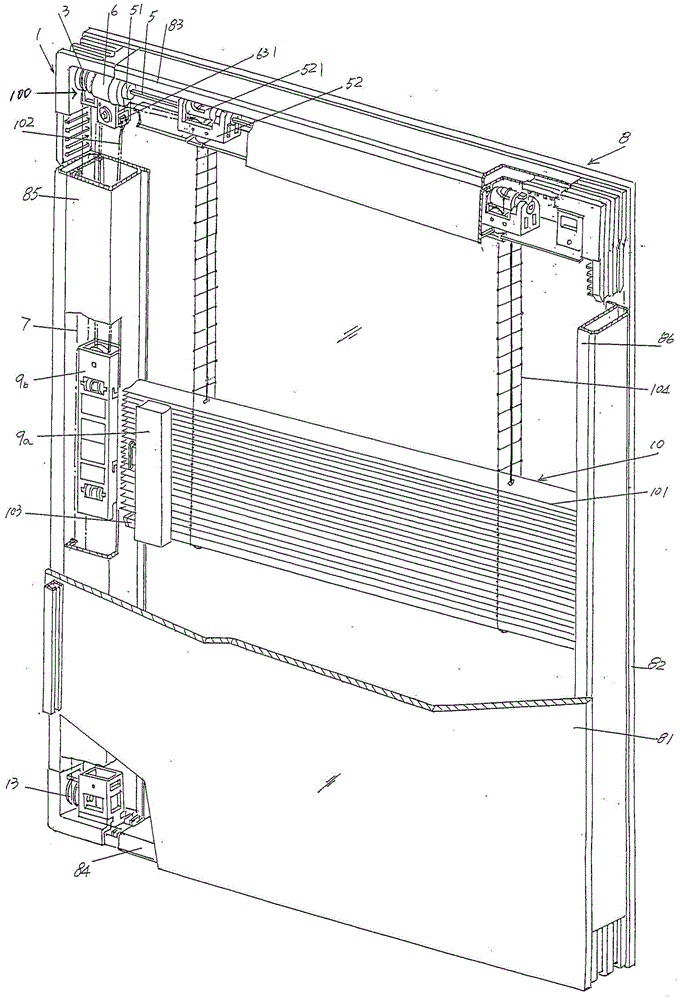

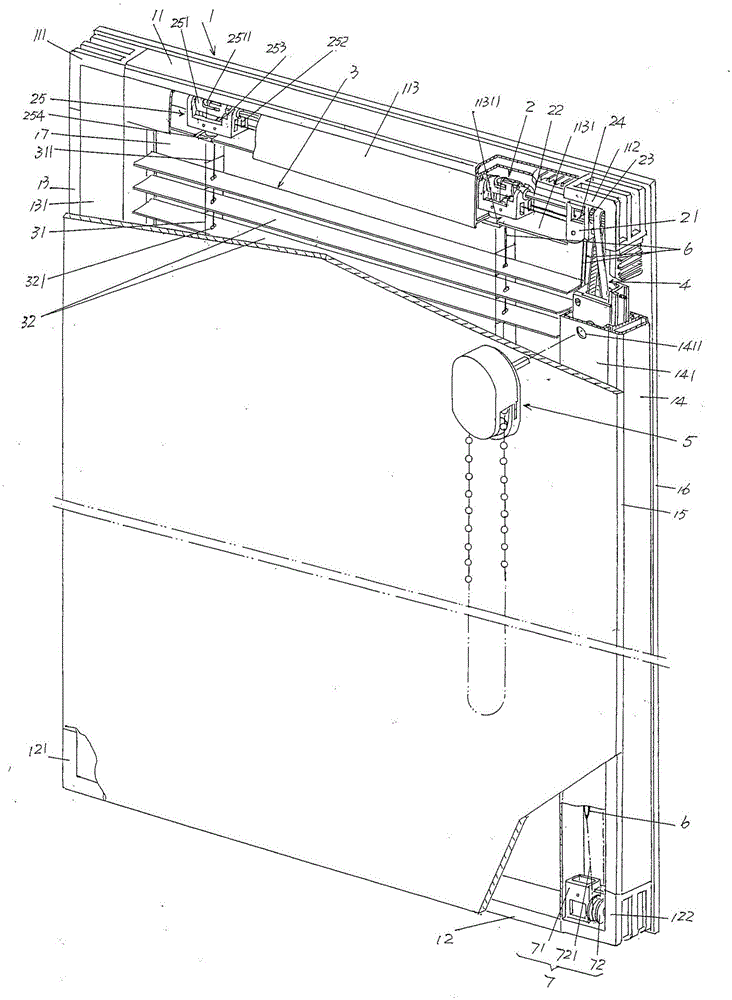

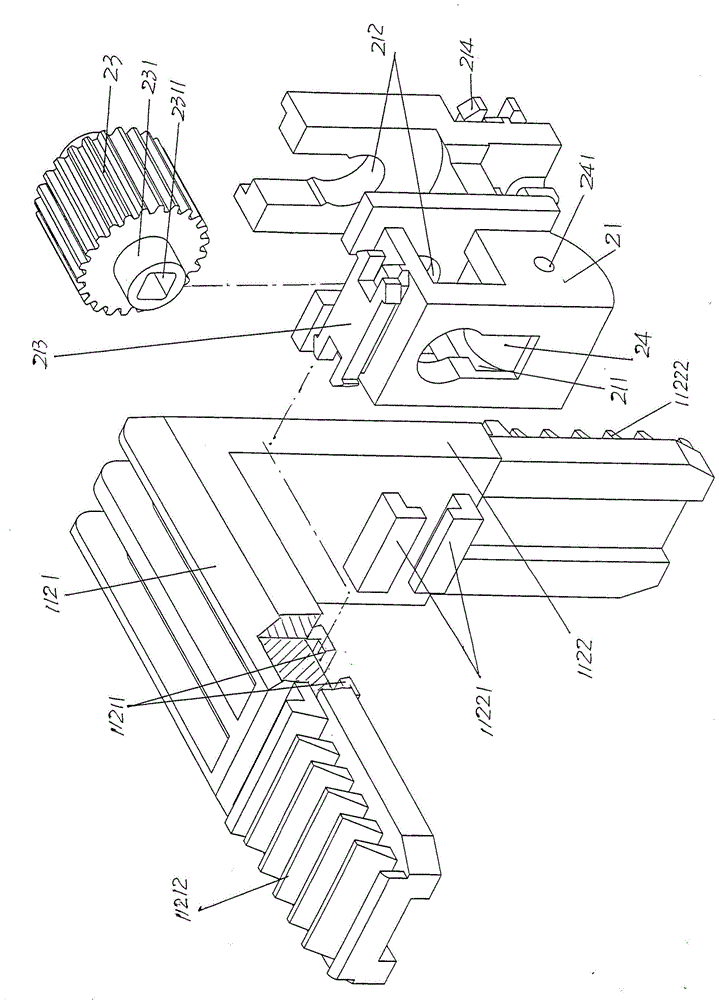

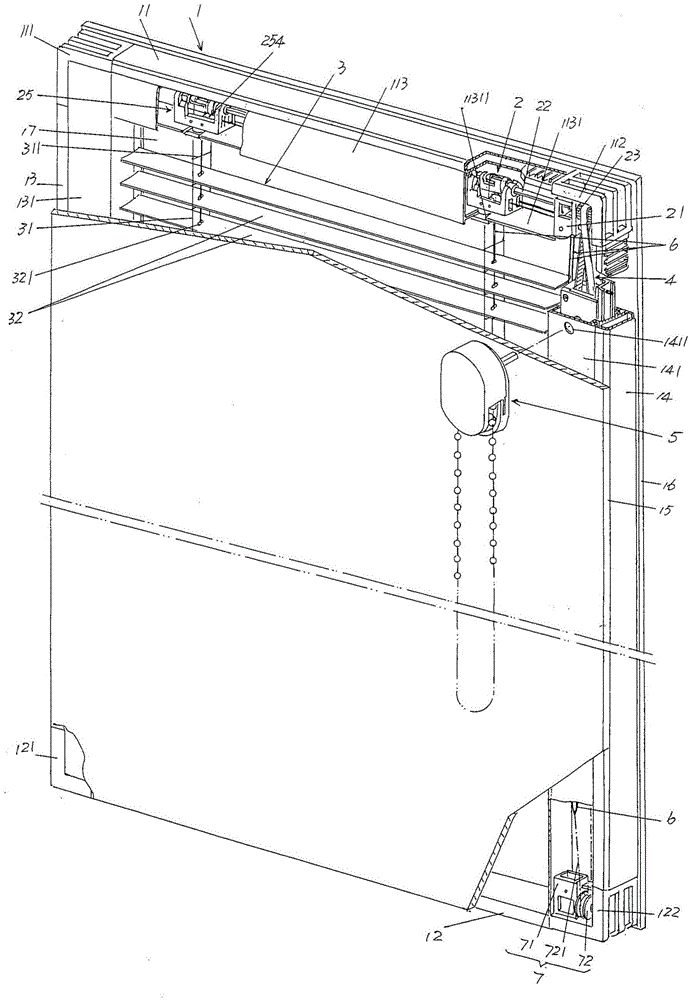

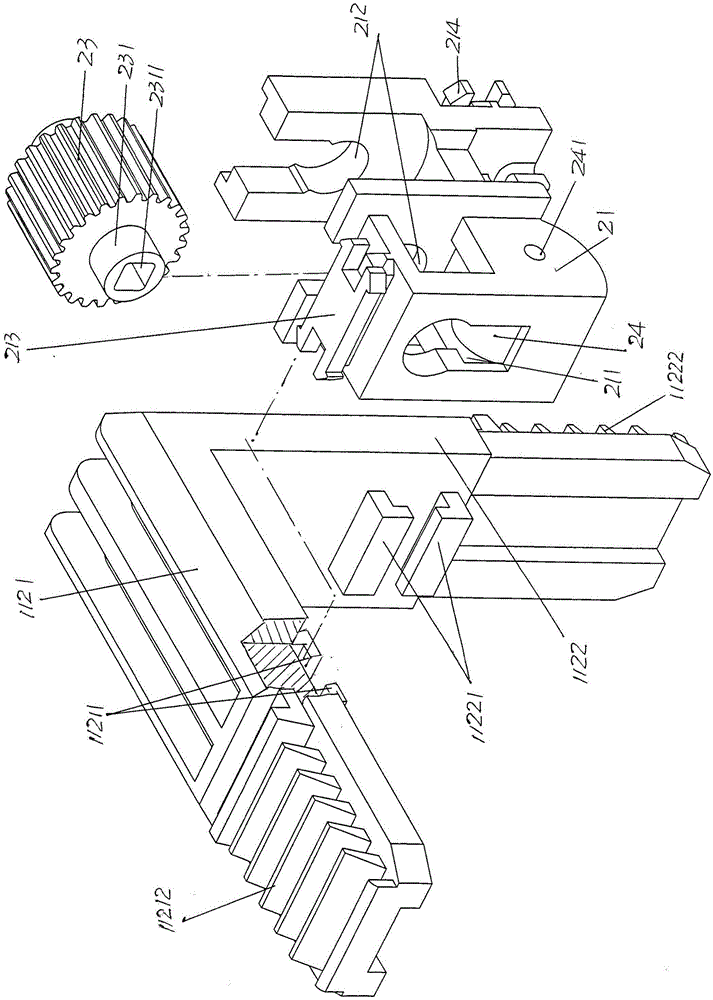

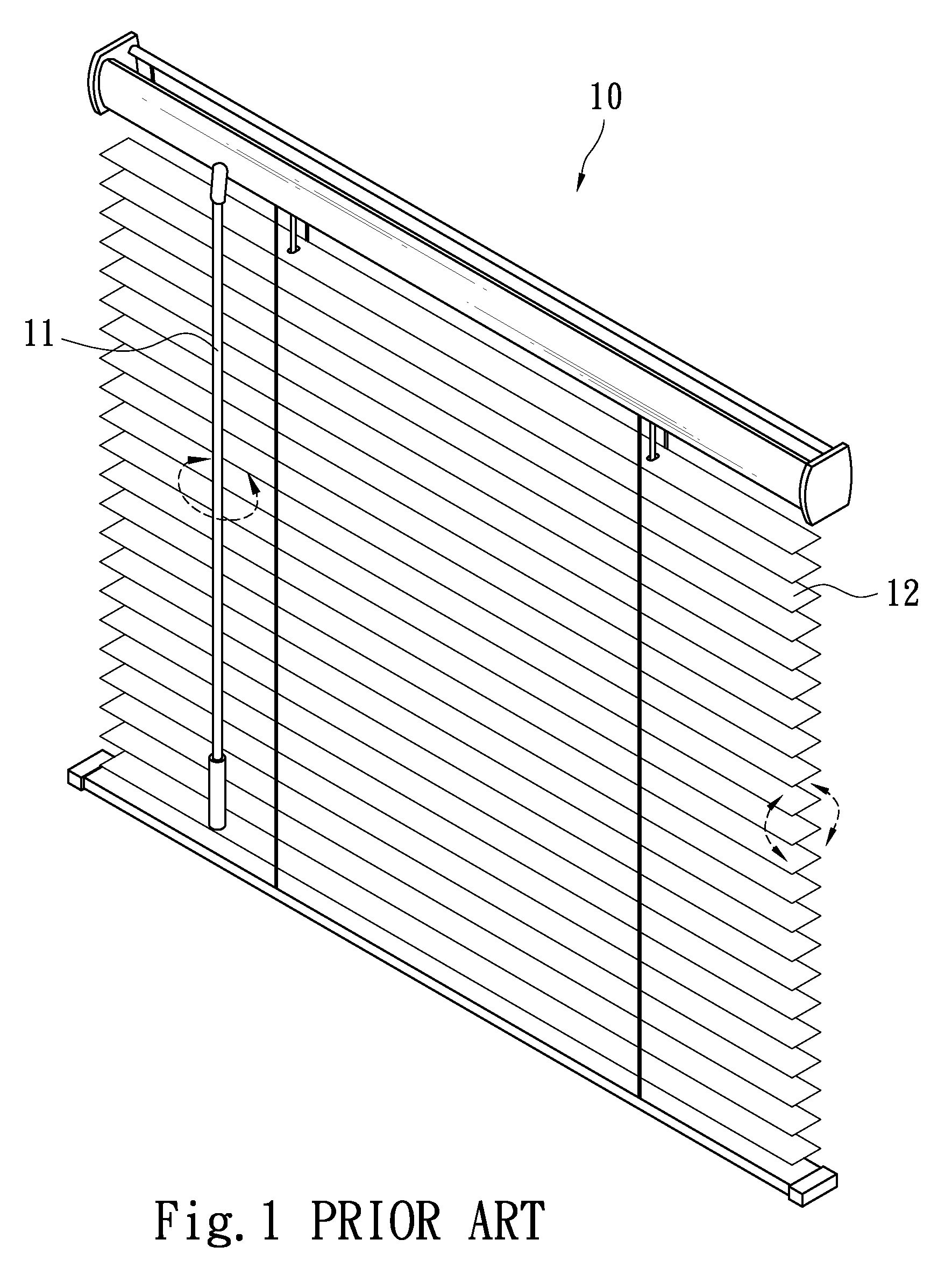

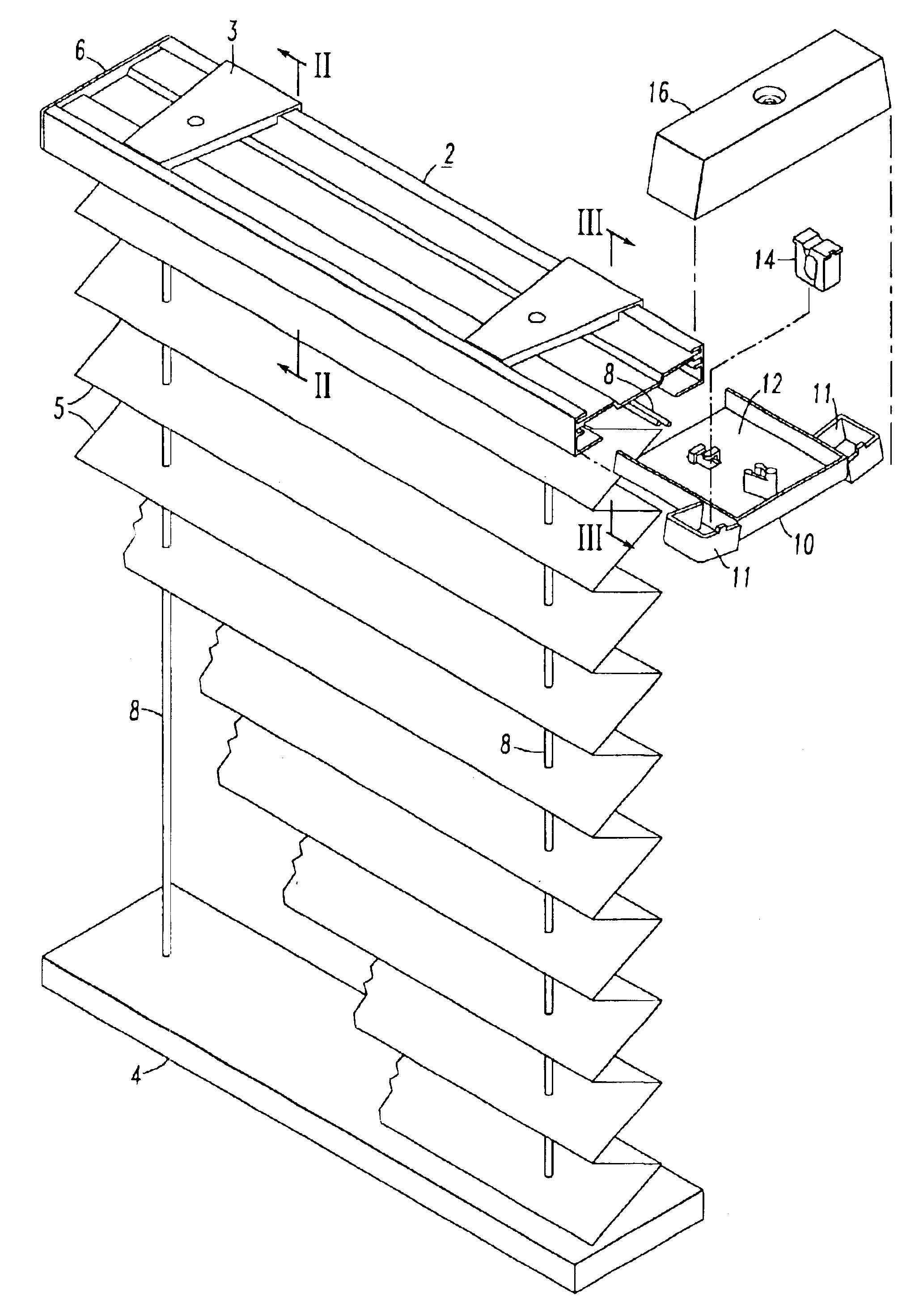

Single-operated double-glazed insulating glass with built-in shutters

ActiveCN105064896BAvoid frictional damageAvoid damageLight protection screensEngineeringVenetian blinds

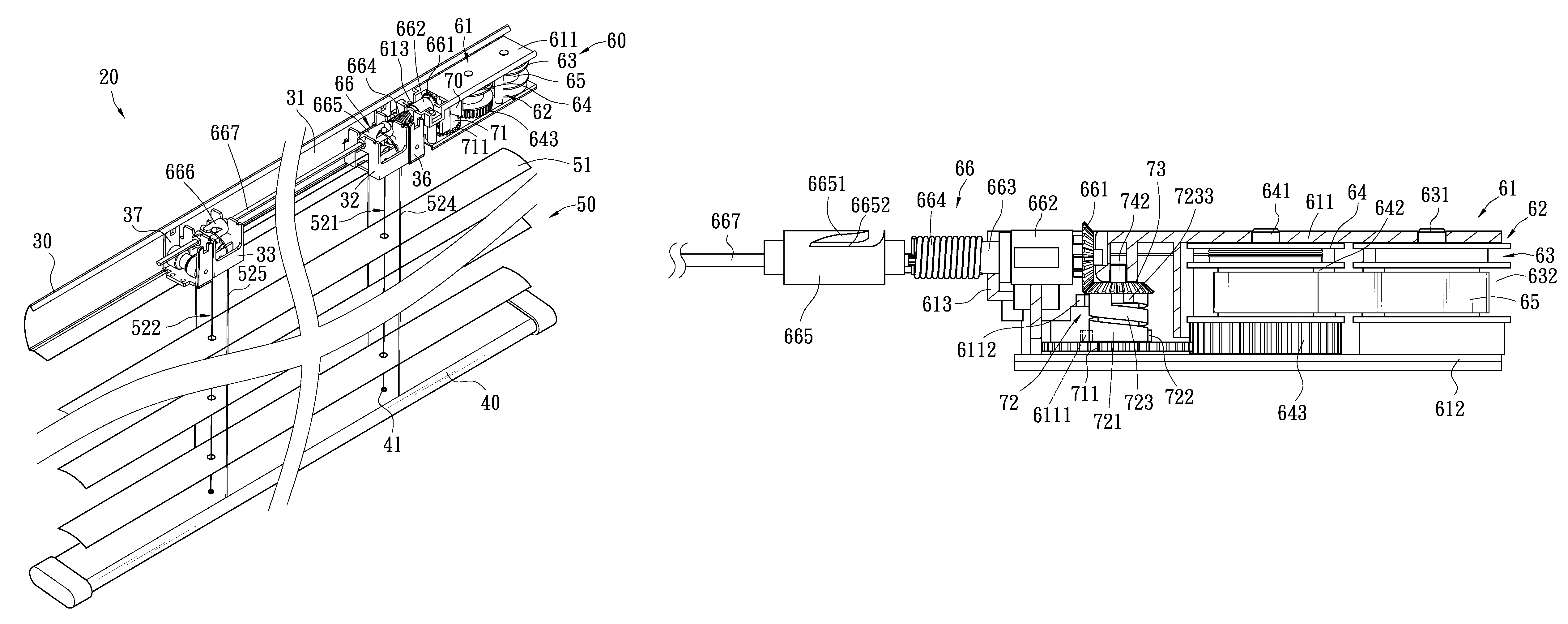

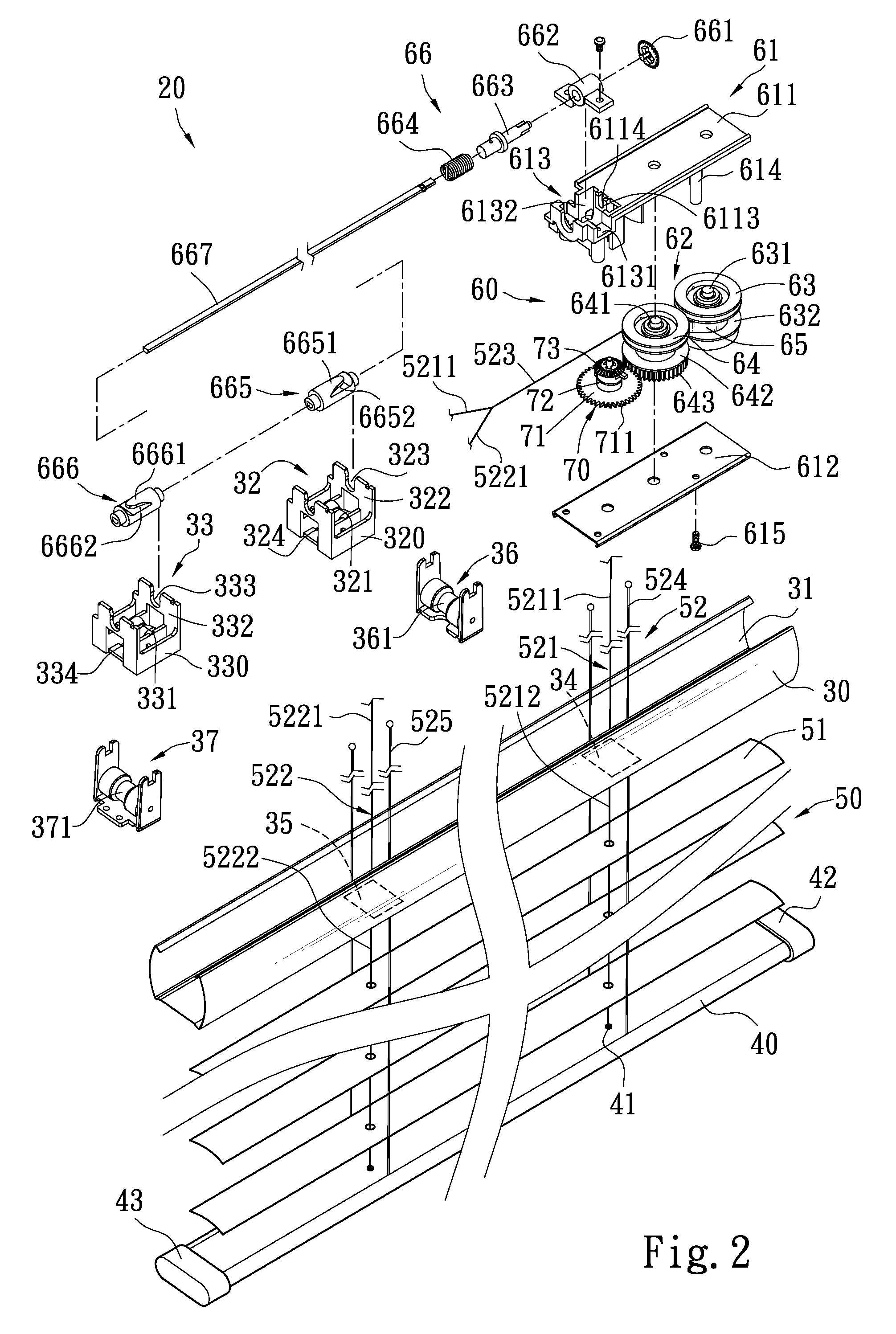

The invention provides a blind window with built-in single-control double-layer hollow glass, and belongs to the technical field of sunshade hollow glass products. The blind window with the built-in single-control double-layer hollow glass comprises a window body and venetian blind blade overturning devices, wherein the window body comprises inner glass, outer glass, an upper transverse frame strip, a lower transverse frame strip, a left longitudinal frame strip and a right longitudinal frame strip; and the venetian blind blade overturning devices are arranged on connectors of corners of a frame of the window body. The blind window with the built-in single-control double-layer hollow glass is characterized in that each venetian blind blade overturning device comprises a supporting mechanism, a blade overturning wheel, a clutch mechanism, a blade overturning shaft and a clutch shielding mechanism; each supporting mechanism is arranged on the connector of the corresponding corner of the frame of the window body; each blade overturning wheel is fixed on a corresponding blade overturning wheel shaft; each clutch mechanism is arranged on the corresponding supporting mechanism; each blade overturning shaft is connected with the right end of a corresponding blade overturning shaft sleeve; and each clutch shielding mechanism is matched with the corresponding supporting mechanism. When each clutch mechanism is connected with the right end of the corresponding blade overturning wheel shaft, each blade overturning wheel drives the corresponding blade overturning wheel shaft; and when blades of a venetian blind are overturned to be closed, the blade overturning wheels rotate independently, movement resistance of a blade overturning traction rope is reduced obviously, the blade overturning traction rope is prevented from being rubbed and damaged, and the blade overturning wheels are prevented from being damaged.

Owner:CHANGSHU ZHONGQIN BUILDING MATERIAL

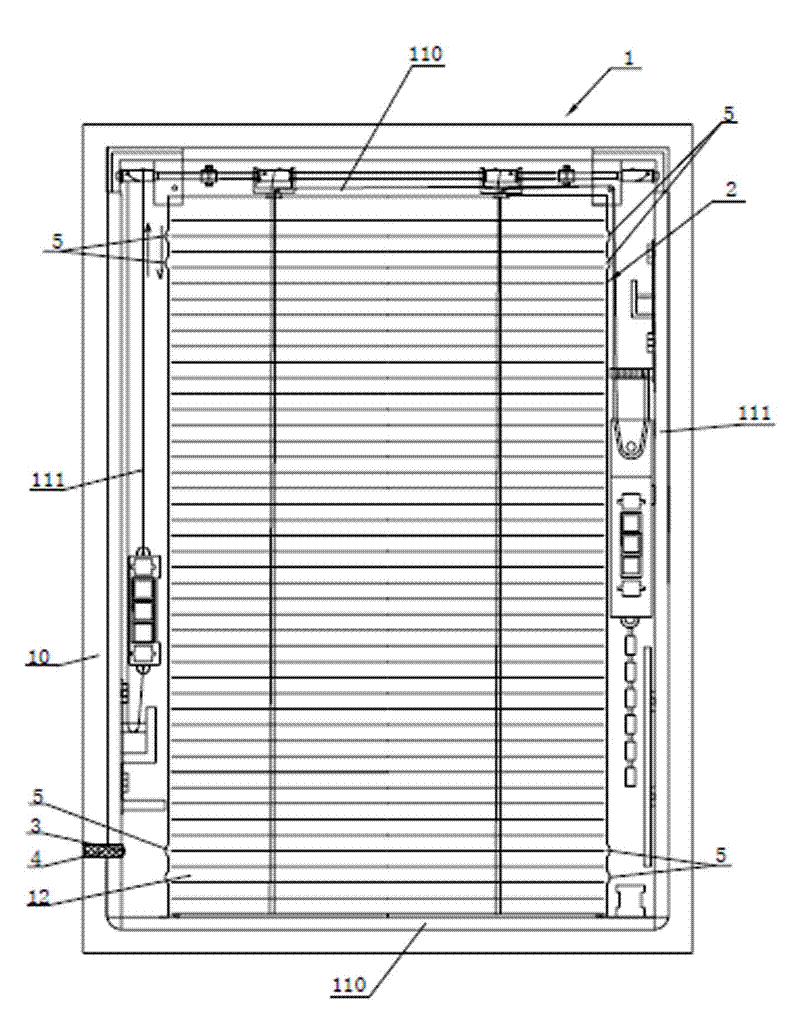

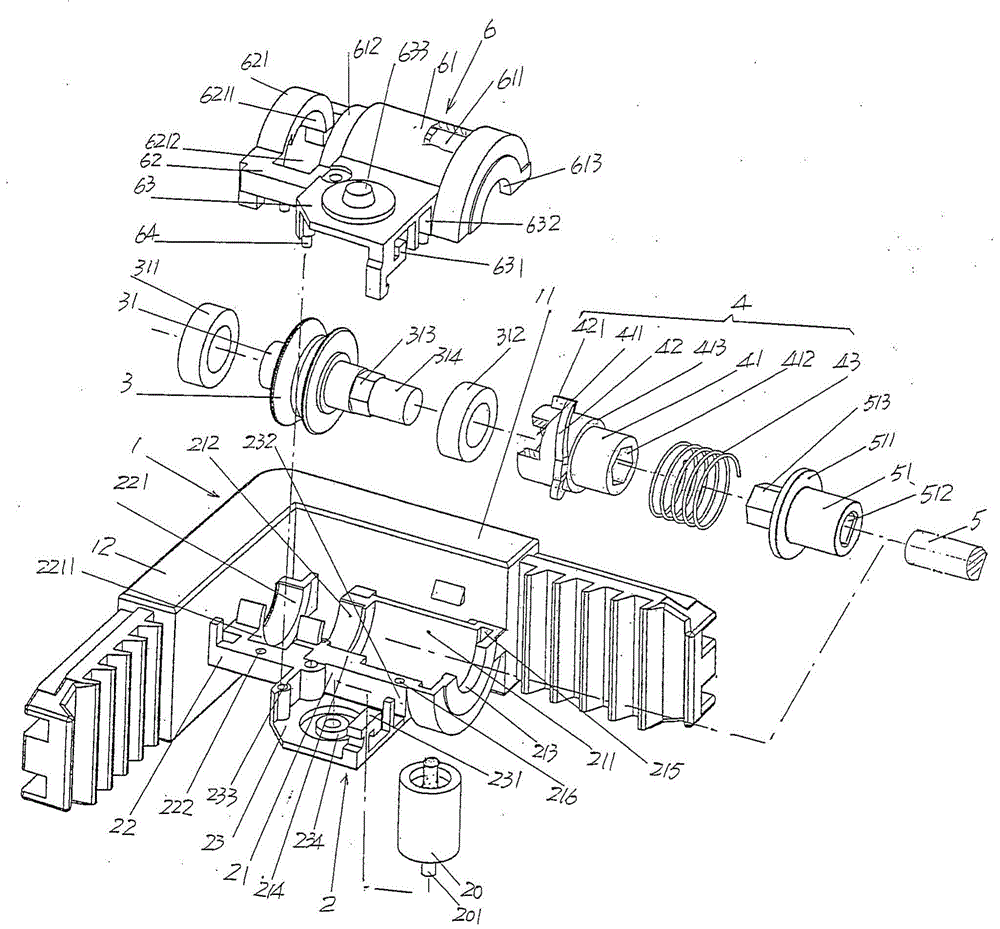

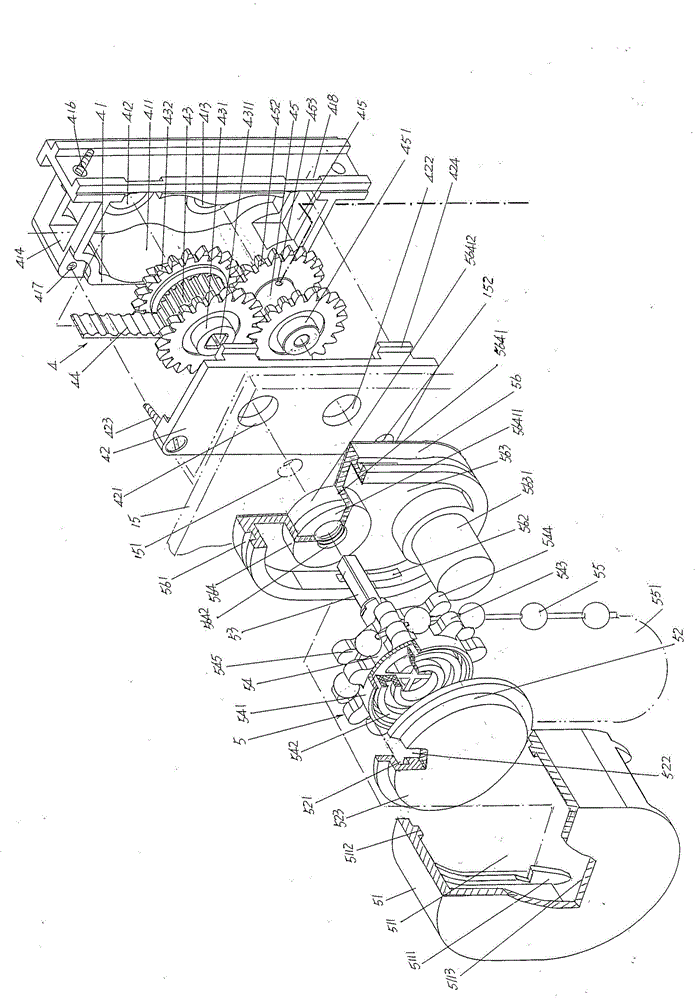

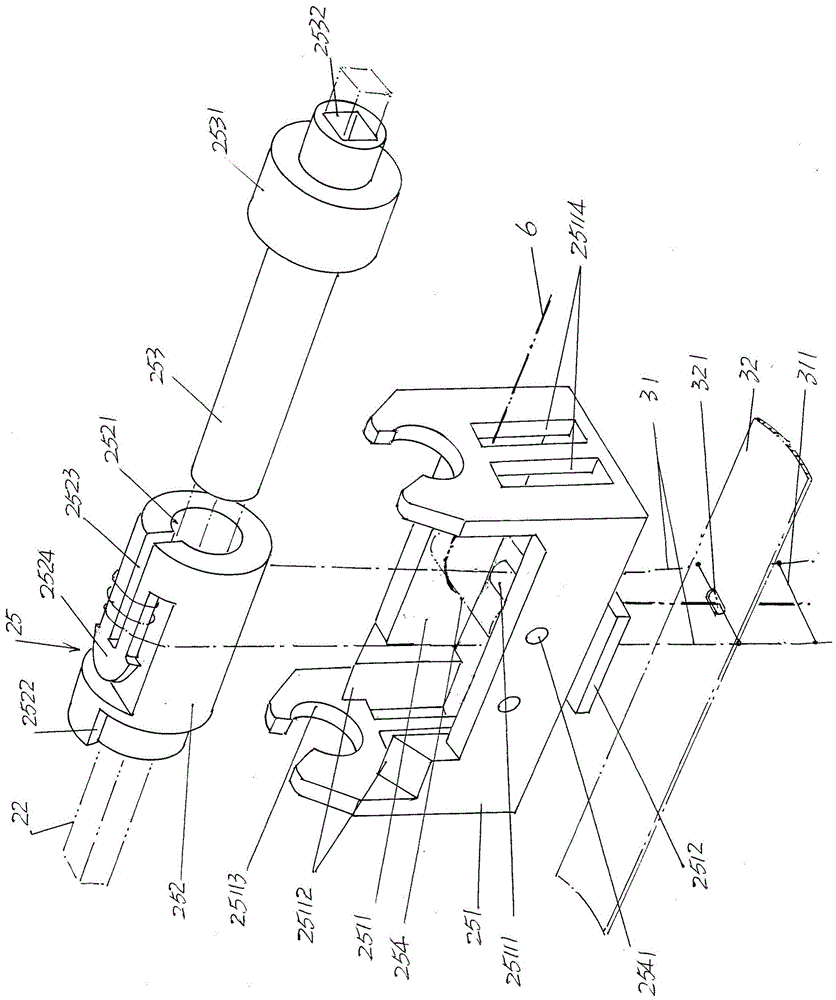

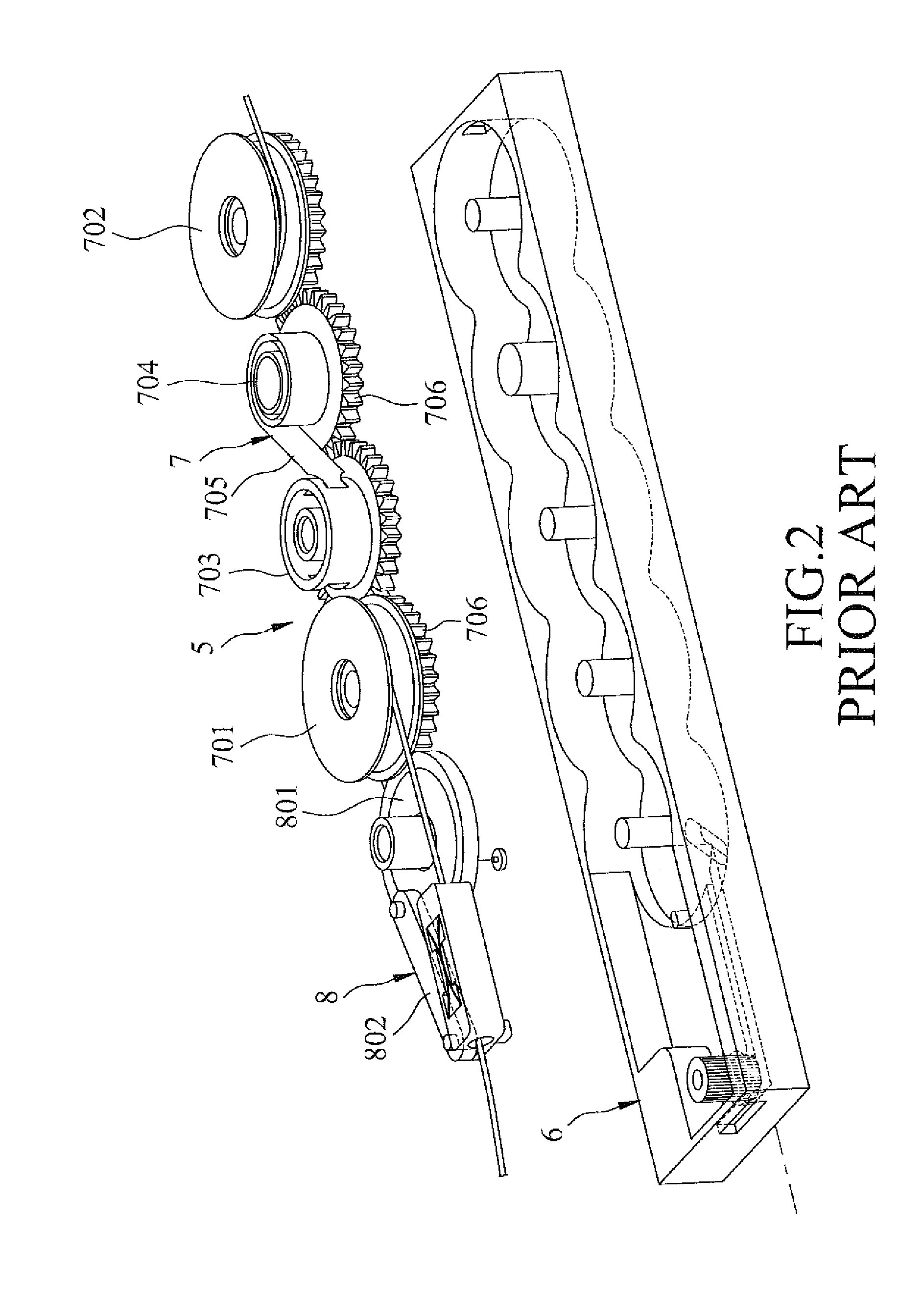

Non-magnet driven double-glazed built-in shutters

ActiveCN105041170BMeet the use requirementsSave resourcesLight protection screensWindow shutterEngineering

The invention discloses a non-magnetic driven type blind window with internally-installed double-layer hollow glass, and belongs to the technical field of sunshade hollow glass products. The non-magnetic driven type blind window with the internally-installed double-layer hollow glass comprises a window body which comprises inner glass and outer glass, a blind sheet turning mechanism, a venetian blind, an internal manipulation mechanism, an external manipulation mechanism and a venetian blind lifting pulling rope. The non-magnetic driven type blind window with the internally-installed double-layer hollow glass is characterized in that the internal manipulation mechanism comprises a case body, a case cover, a synchronous pulley, a synchronous belt and a lifting pulling rope driving wheel, the case body is arranged in a hollow cavity and fixed with the window body, the synchronous pulley is located above the case body cavity, one end of a synchronous pulley shaft is supported on the case cover, and the other end of the synchronous pulley shaft is supported on the cavity bottom wall of the case body cavity; one end of the synchronous belt is arranged on the blind sheet turning mechanism in a sleeving mode, and the other end of the synchronous belt is arranged on the synchronous pulley in a sleeving mode; the lifting pulling rope driving wheel is arranged in the case body cavity of the case body and located on the lower portion of the case body cavity; the external manipulation mechanism comprises a shield, a friction disc, a bead chain wheel shaft, a bead chain wheel hub, a bead chain and a bead chain wheel shaft seat; one end of the lifting pulling rope of the venetian blind is connected with the lifting pulling rope driving wheel. Therefore, resources are saved, the cost is reduced, and the labor is saved in operation.

Owner:CHANGSHU ZHONGQIN BUILDING MATERIAL

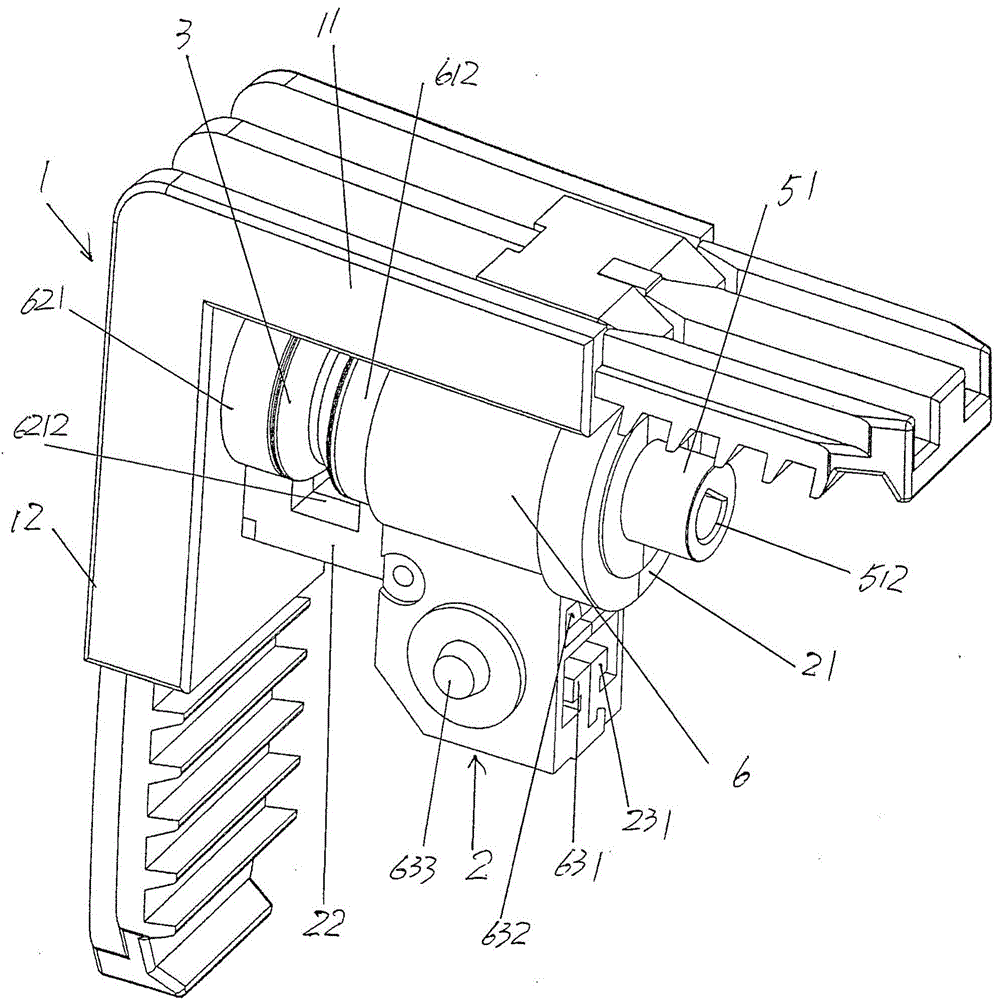

Bead-chain driven double-glazed built-in shutters

ActiveCN105041172BMeet the use requirementsReduce manufacturing costLight protection screensManufacturing cost reductionWindow shutter

The invention discloses a bead chain driving type double-layer hollow glass built-in louver and belongs to the technical field of sunshade hollow glass products. The louver comprises a window body, a curtain piece turning mechanism, a venetian blind, an inner control mechanism, an outer control mechanism and a venetian blind lifting traction rope. The window body comprises an upper window body transverse tube, a lower window body transverse tube, a left window body longitudinal tube, a right window body longitudinal tube, inner glass and outer glass. The louver is characterized in that the inner control mechanism comprises a box body, a box cover, a synchronous belt pulley, a synchronous belt and a lifting traction rope driving wheel. The outer control mechanism comprises a protective cover, a friction plate, a bead chain wheel shaft, a bead chain wheel shaft hub, a bead chain and a bead chain wheel shaft base. The protective cover forms a protective cover cavity. The friction plate is arranged in the protective cover cavity. The bead chain wheel shaft hub is supported by a shaft hub cavity. The bead chain wheel shaft is arranged in the middle of the bead chain wheel shaft hub. One end of the bead chain is arranged on the bead chain wheel shaft hub in a sleeving mode. The other end of the bead chain forms a suspending end. The bead chain wheel shaft base is matched with the protective cover. One end of the venetian blind lifting traction rope is in driving connection with a lifting traction rope driving wheel. Manufacturing cost is reduced; labor is saved during operation; service life is long, and the using effect is good; resource-saving economy is reflected.

Owner:CHANGSHU ZHONGQIN BUILDING MATERIAL

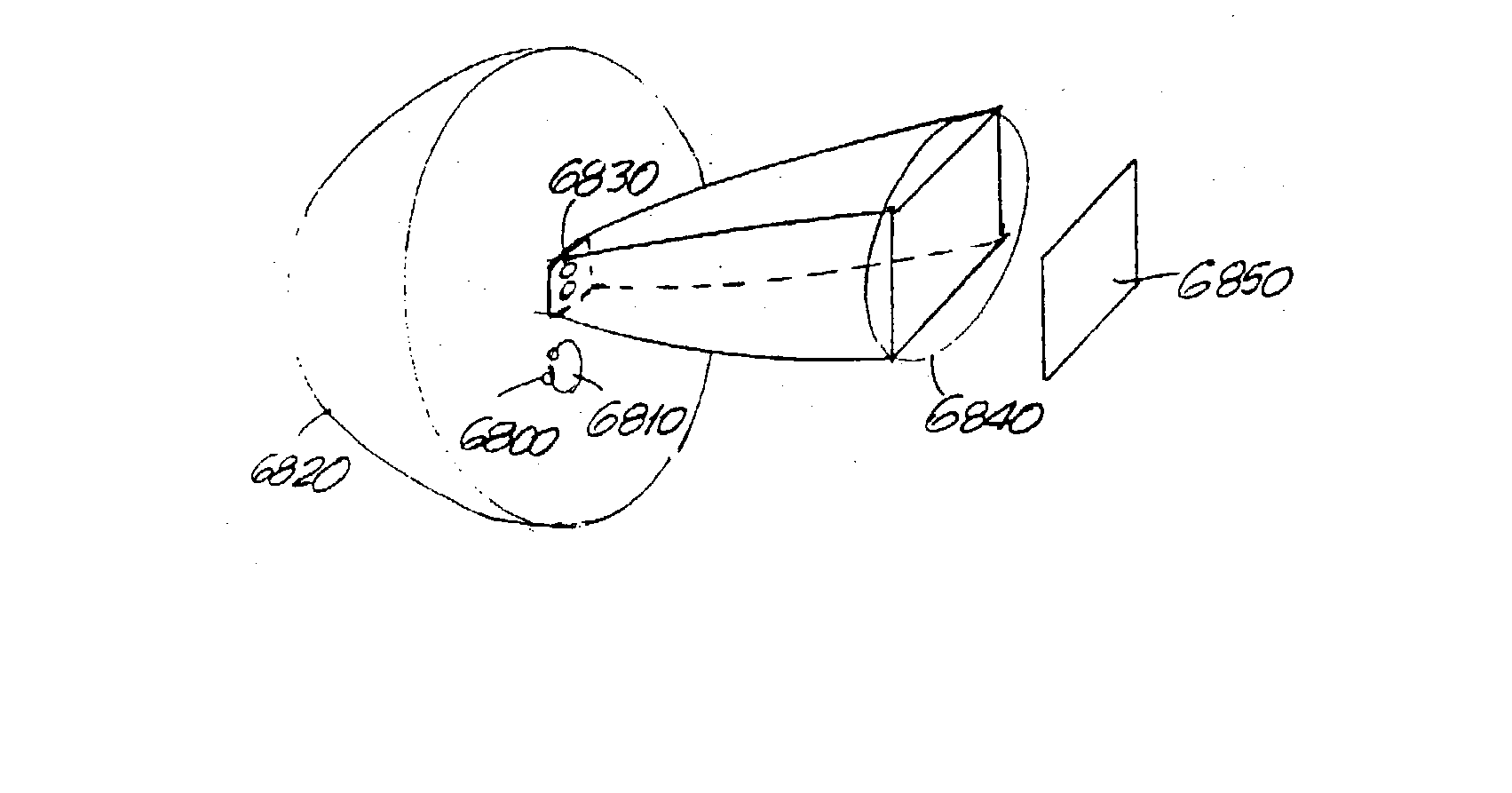

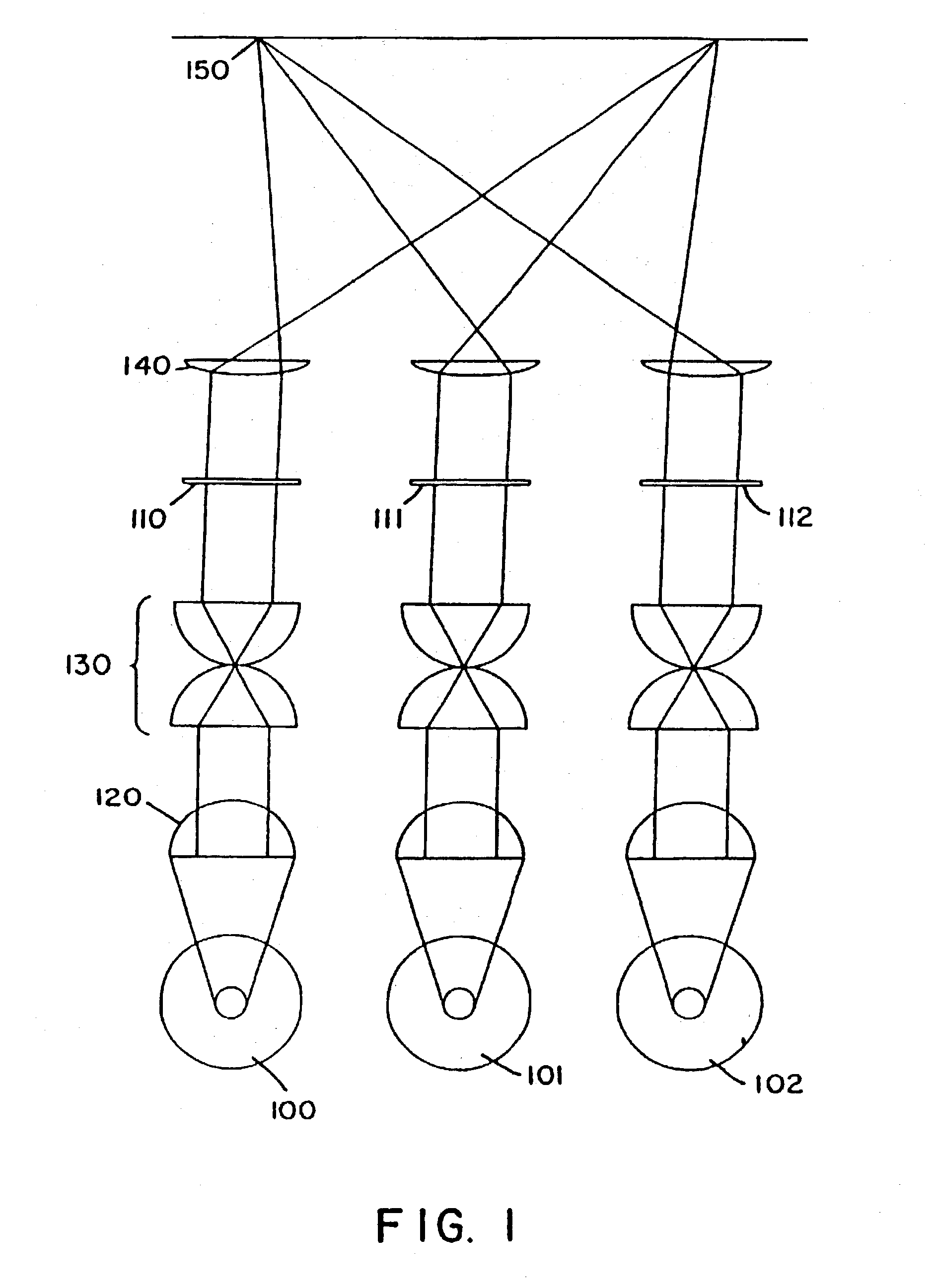

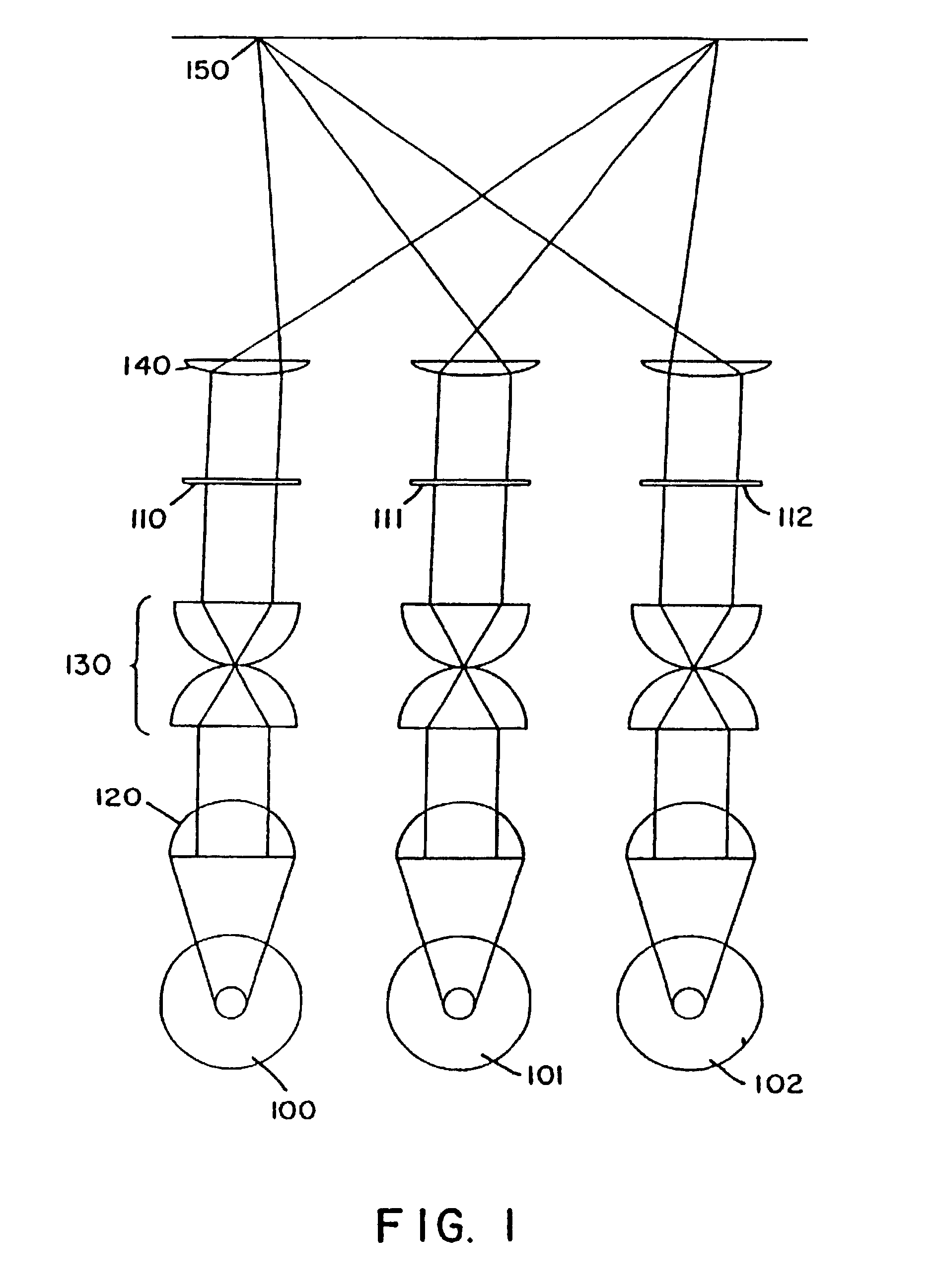

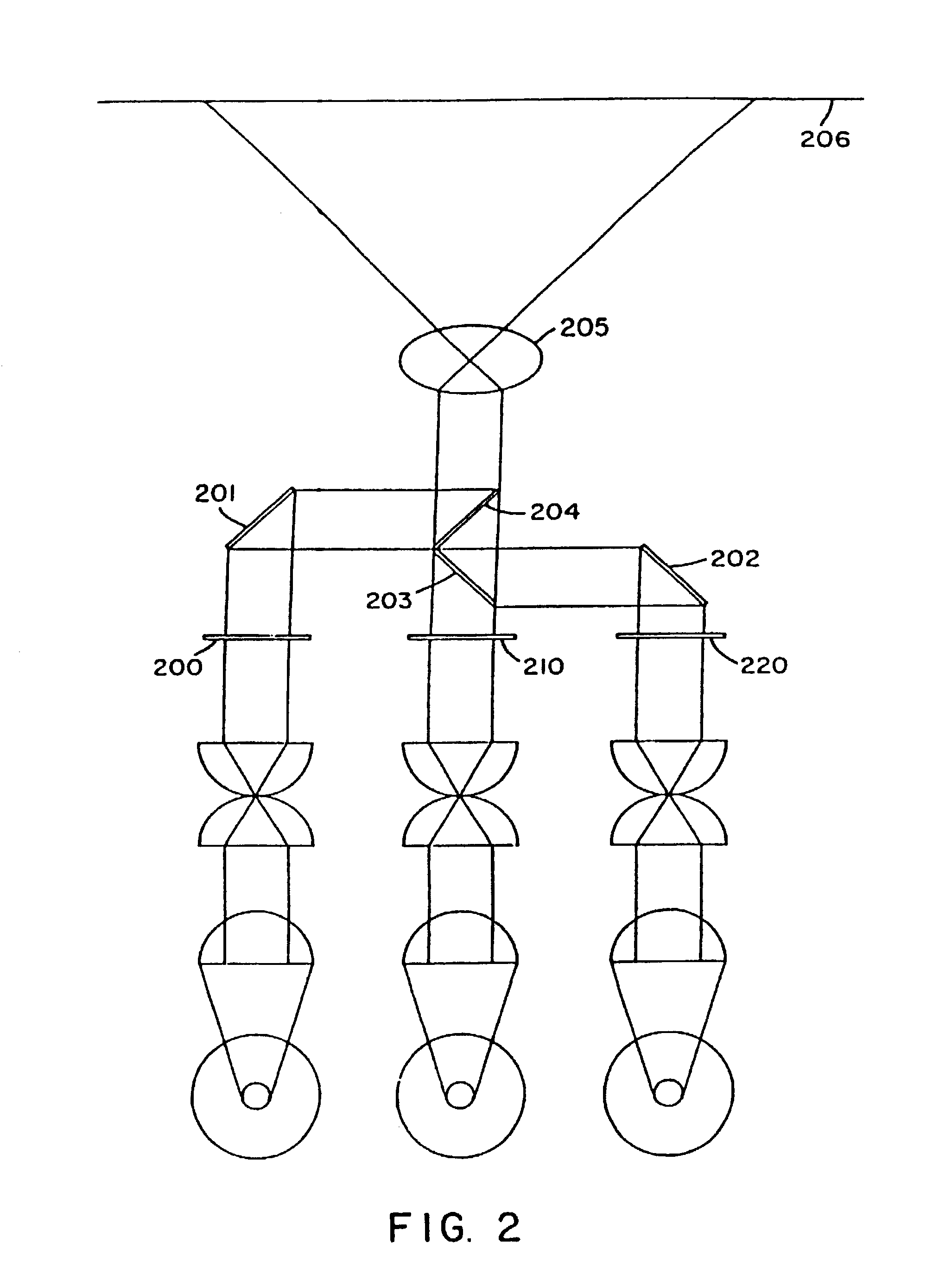

Optical element to reshape light with color and brightness uniformity

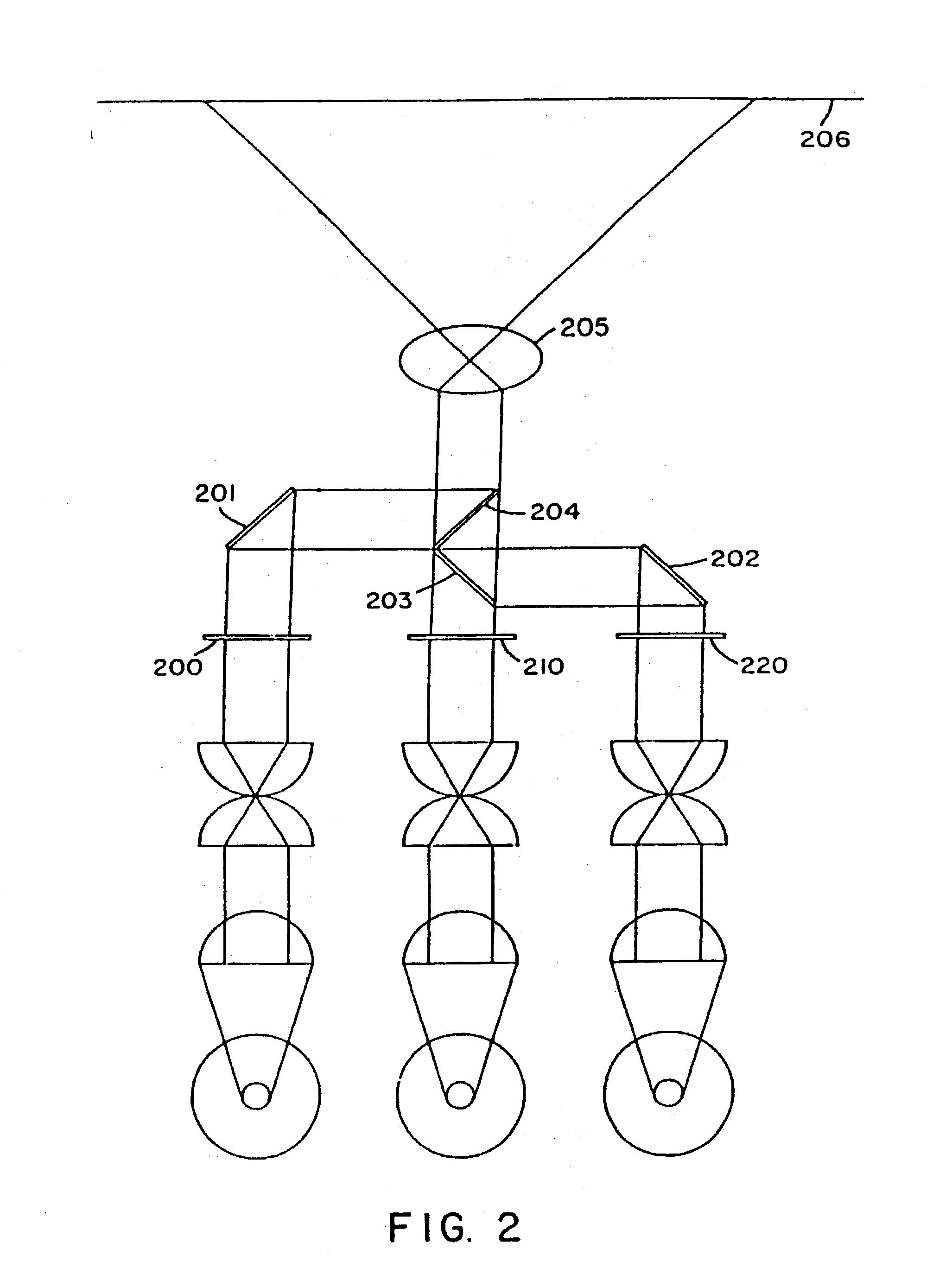

InactiveUS20030076423A1High resolutionIncrease contrastTelevision system detailsPicture reproducers using projection devicesContrast levelActive matrix

A light valve such as an active matrix LCD between crossed polarizers, utilizing, for instance, individual transistors to control each "pixel area" of the LCD and storage elements to store video signal data for each pixel, with optically shielded "dead spaces" between pixels to eliminate electric field cross-talk and non-information-bearing light bleed-through, is illuminated with a bright independent light source which creates a video image projected via specialized projection optics onto an internal or external screen without distortions, regardless of the angle of projection onto the screen. Use of heat sinks, IR reflective coatings, heat absorbing optics, optional fluid and a thermistor controlled pixel transistor bias voltage injection servo circuit stabilizes image performance, maintaining accurate color and contrast levels as the LCD changes temperature. In one embodiment of the invention, use of a multi-color LCD with a stepped cavity, producing different thicknesses of LCD for the different wavelengths that pass through it, allows a linear correspondence between the wavelengths passing through the LCD to produce true black, high contrast and CRT-like color rendition. A dichroic mirror arrangement is used to overlap differently colored pixels in the projected image. Use of striped mirrors duplicate pixels, where necessary, eliminating spaces between pixels, creating a continuous image with no apparent stripes or dots. A special venetian-blind type of screen is also disclosed and methods for using the system to view three-dimensional video are also explained.

Owner:DOLGOFF GENE

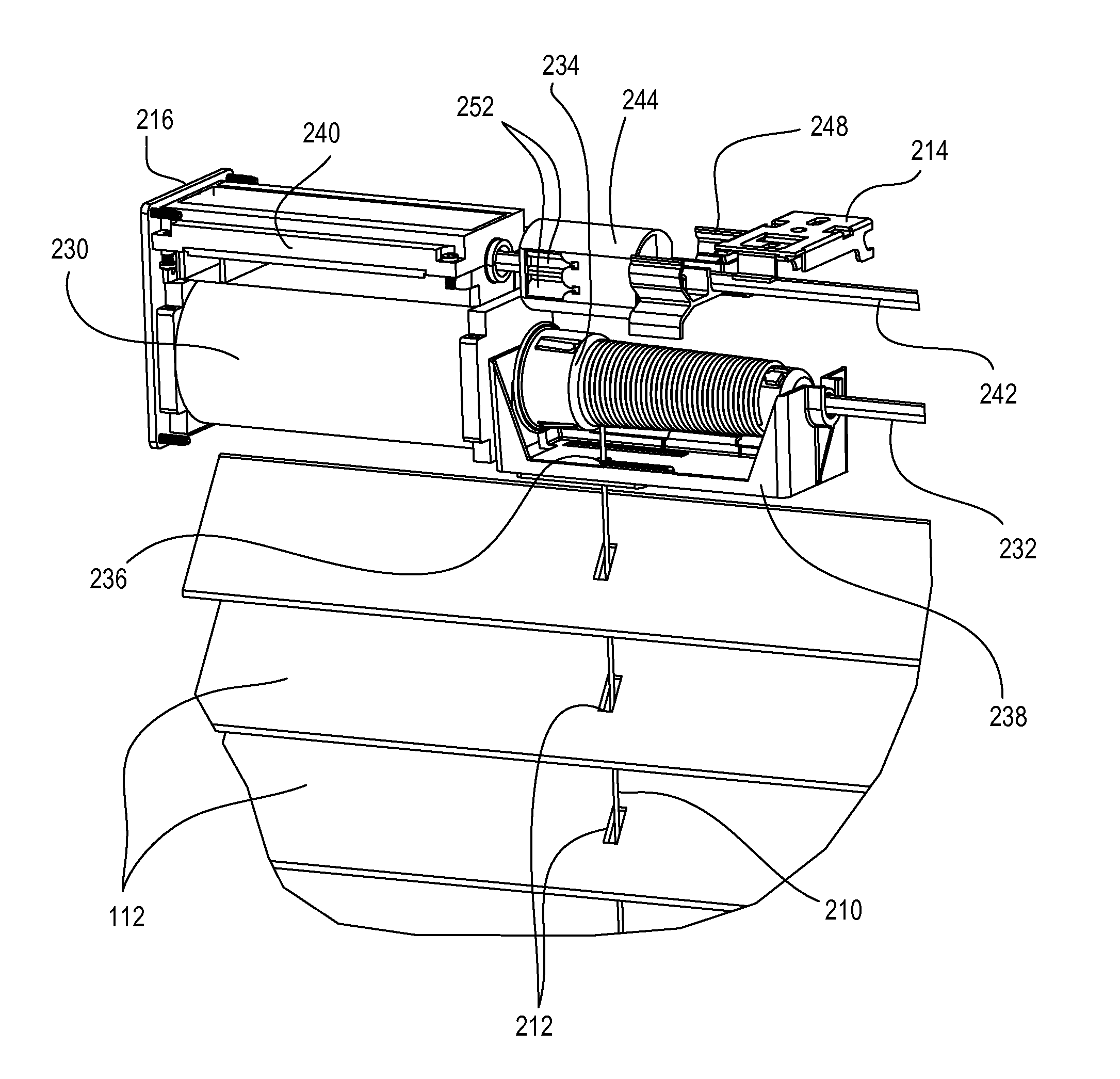

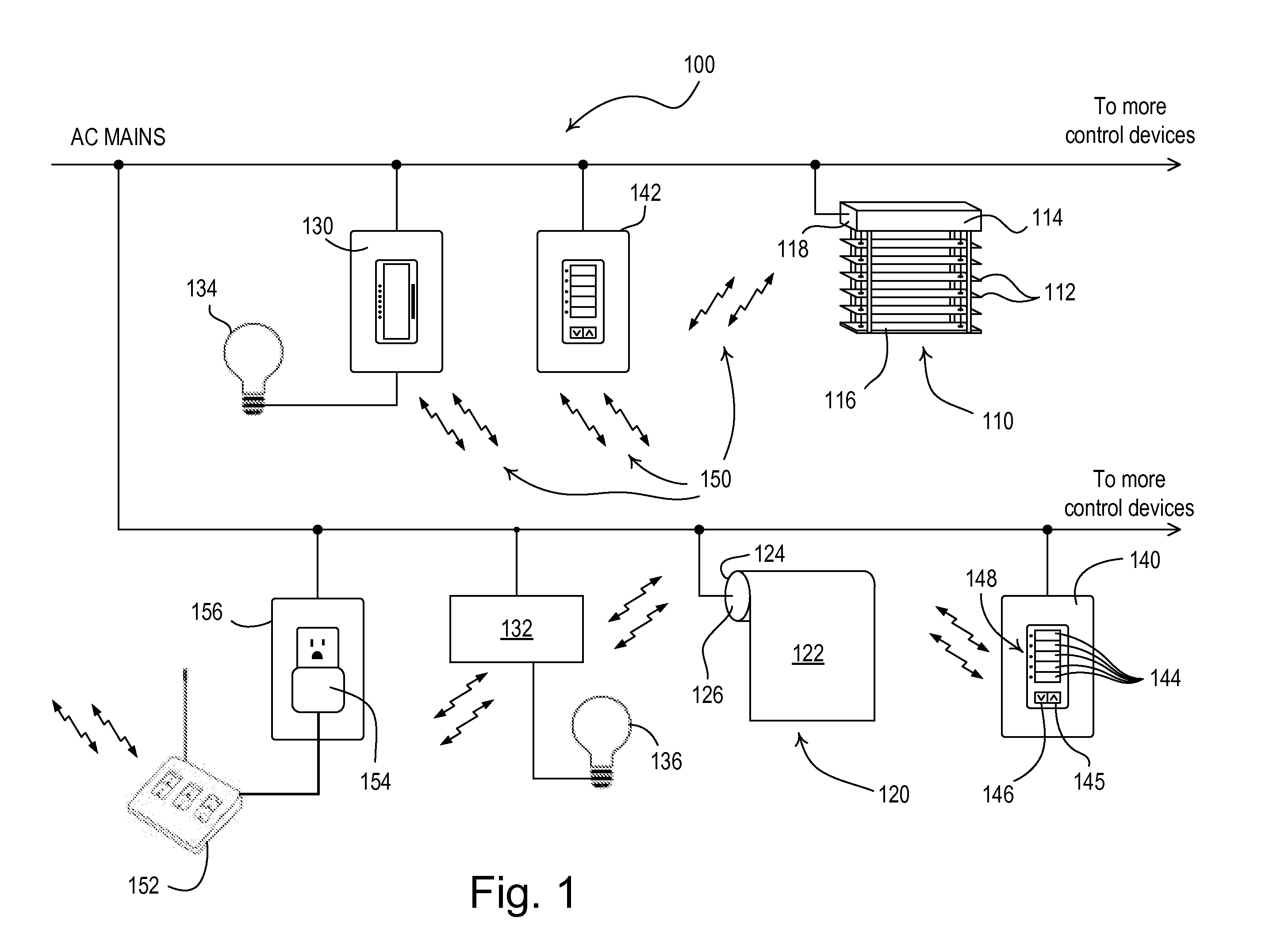

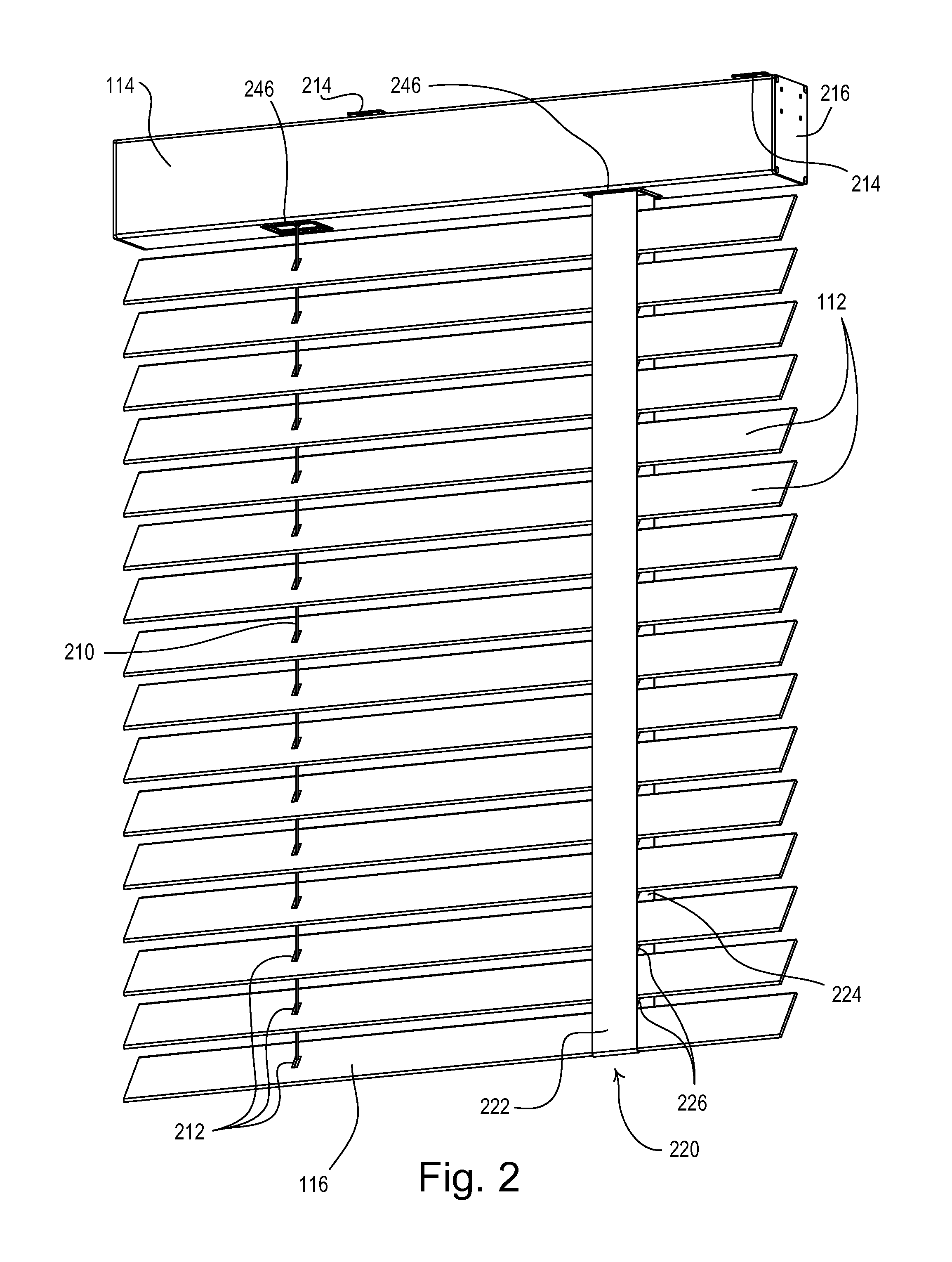

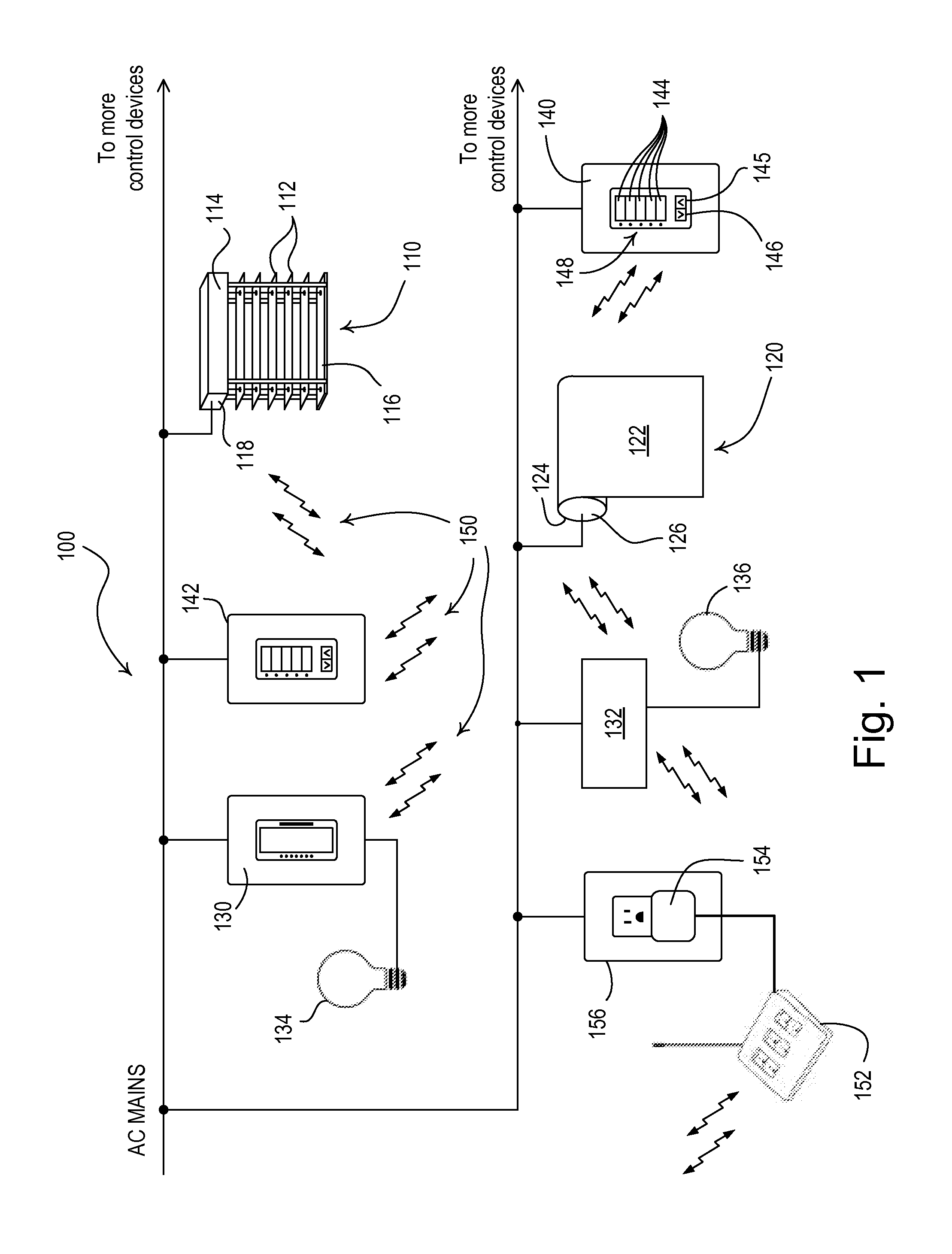

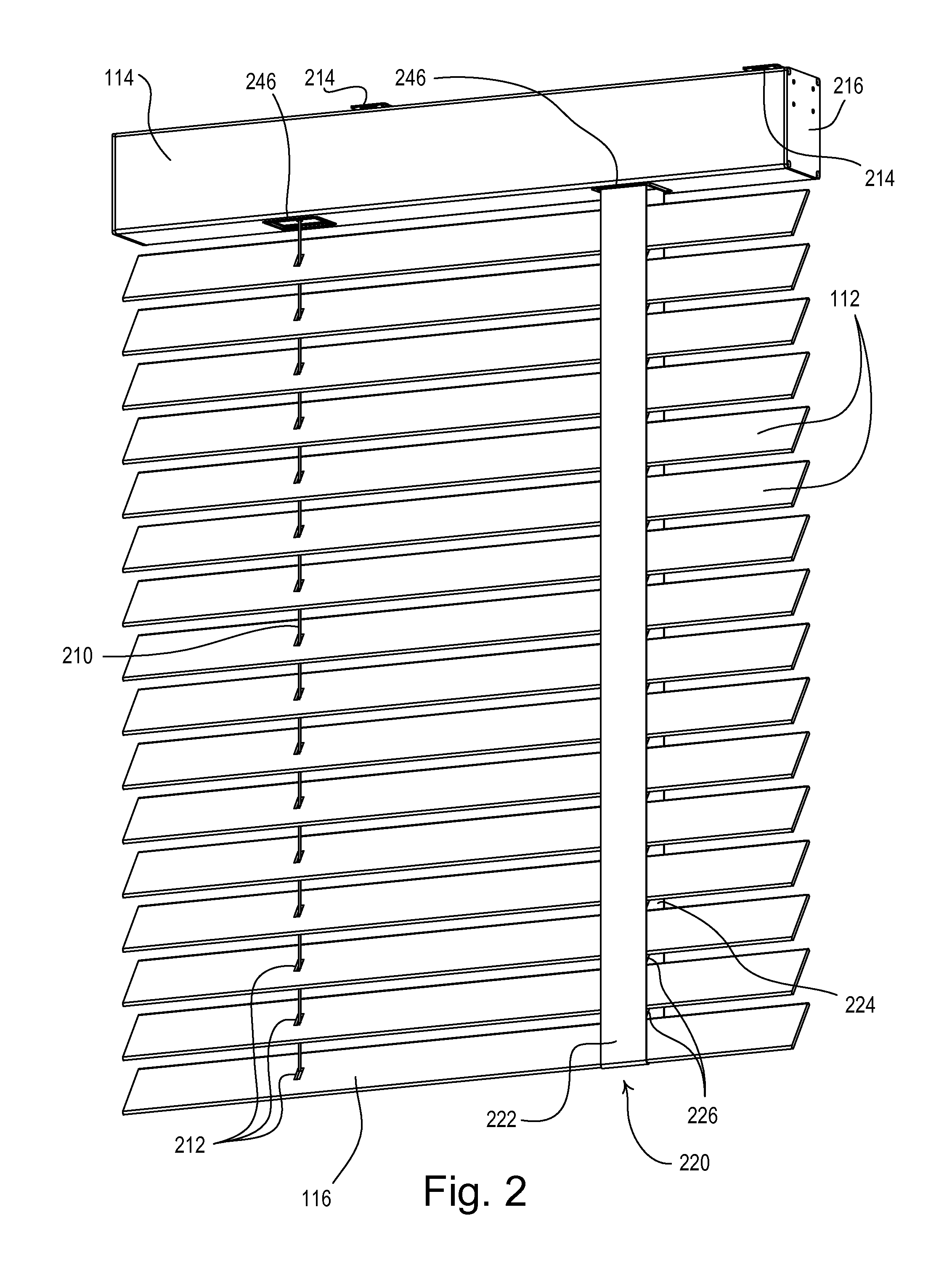

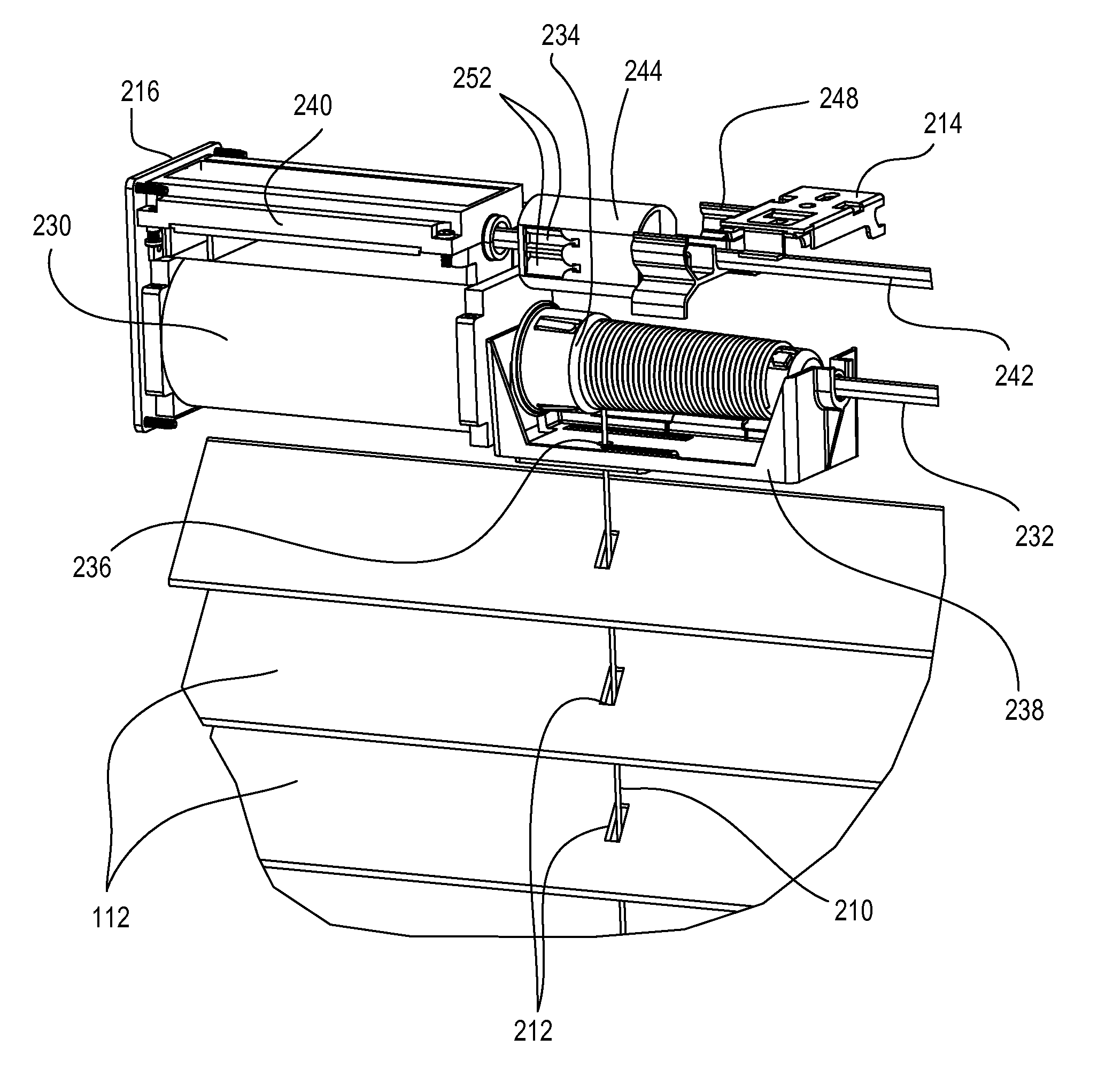

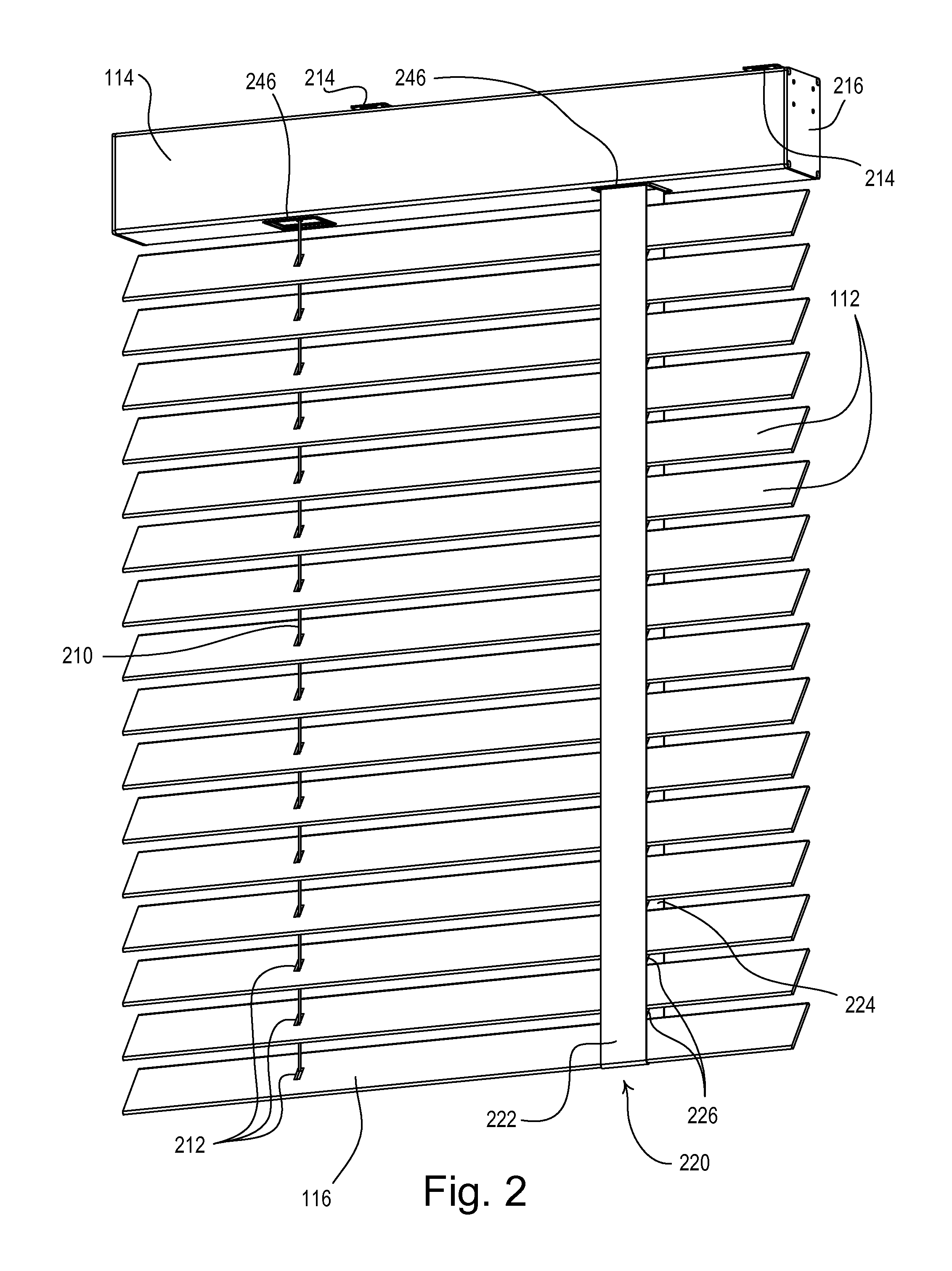

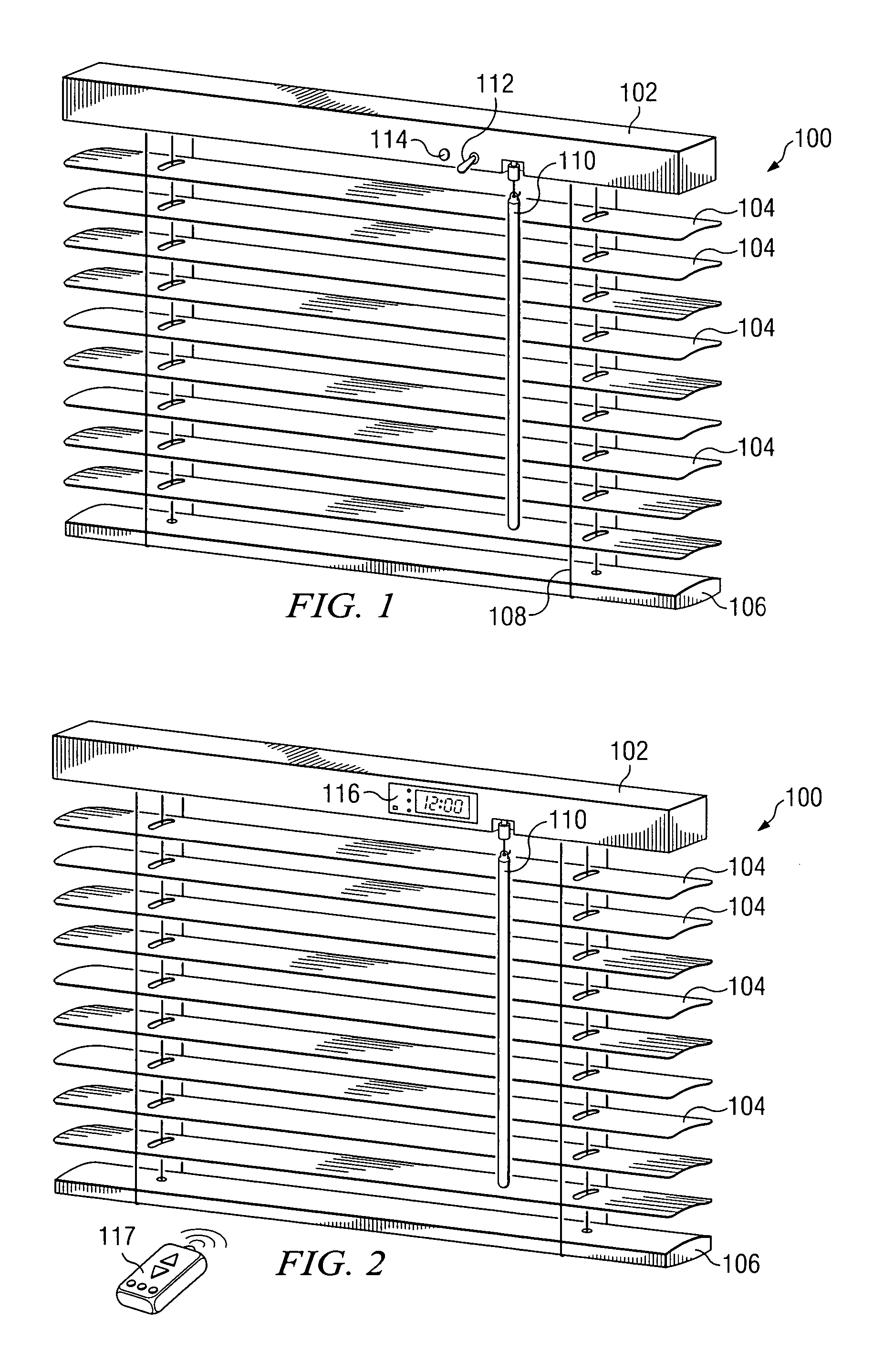

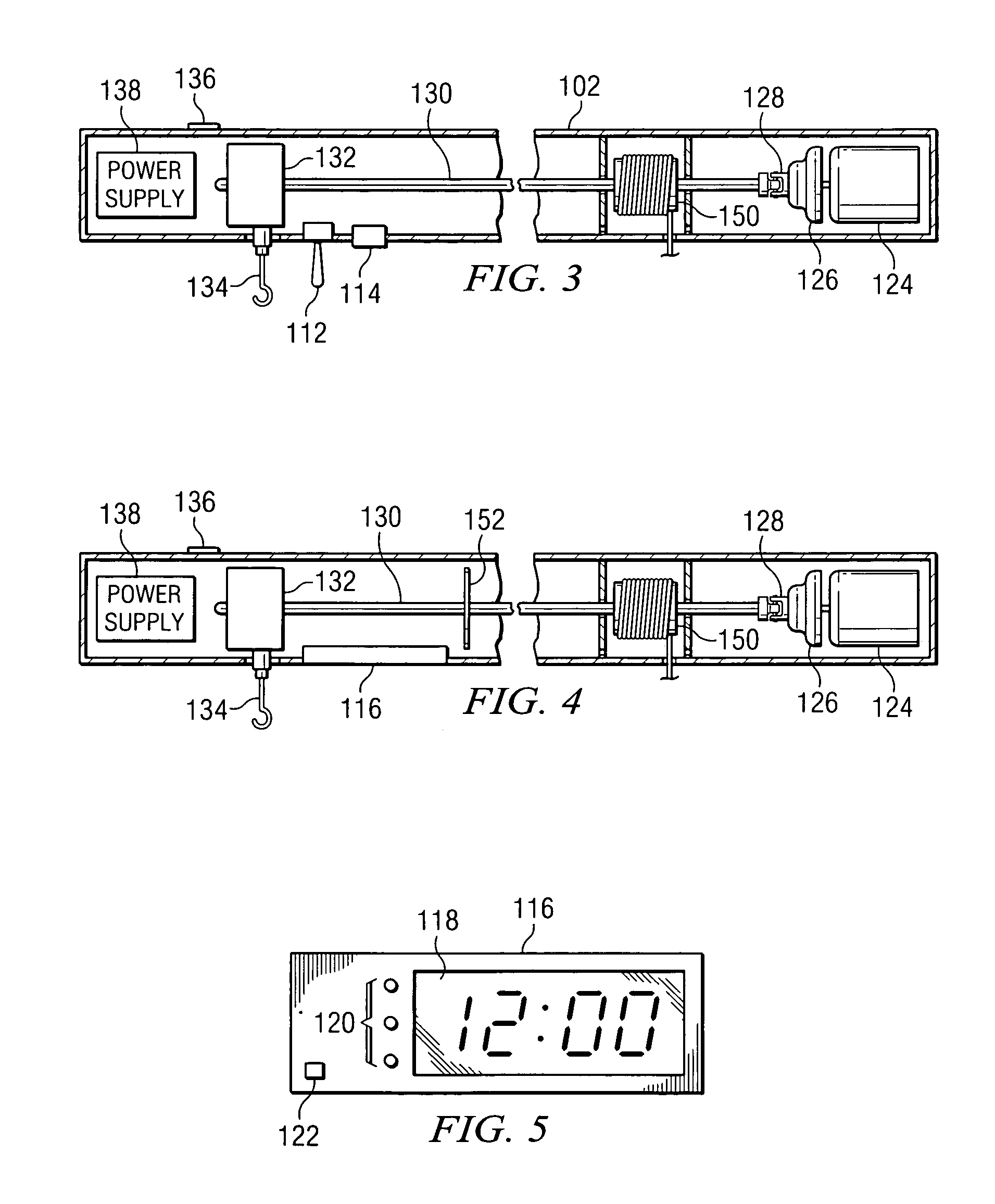

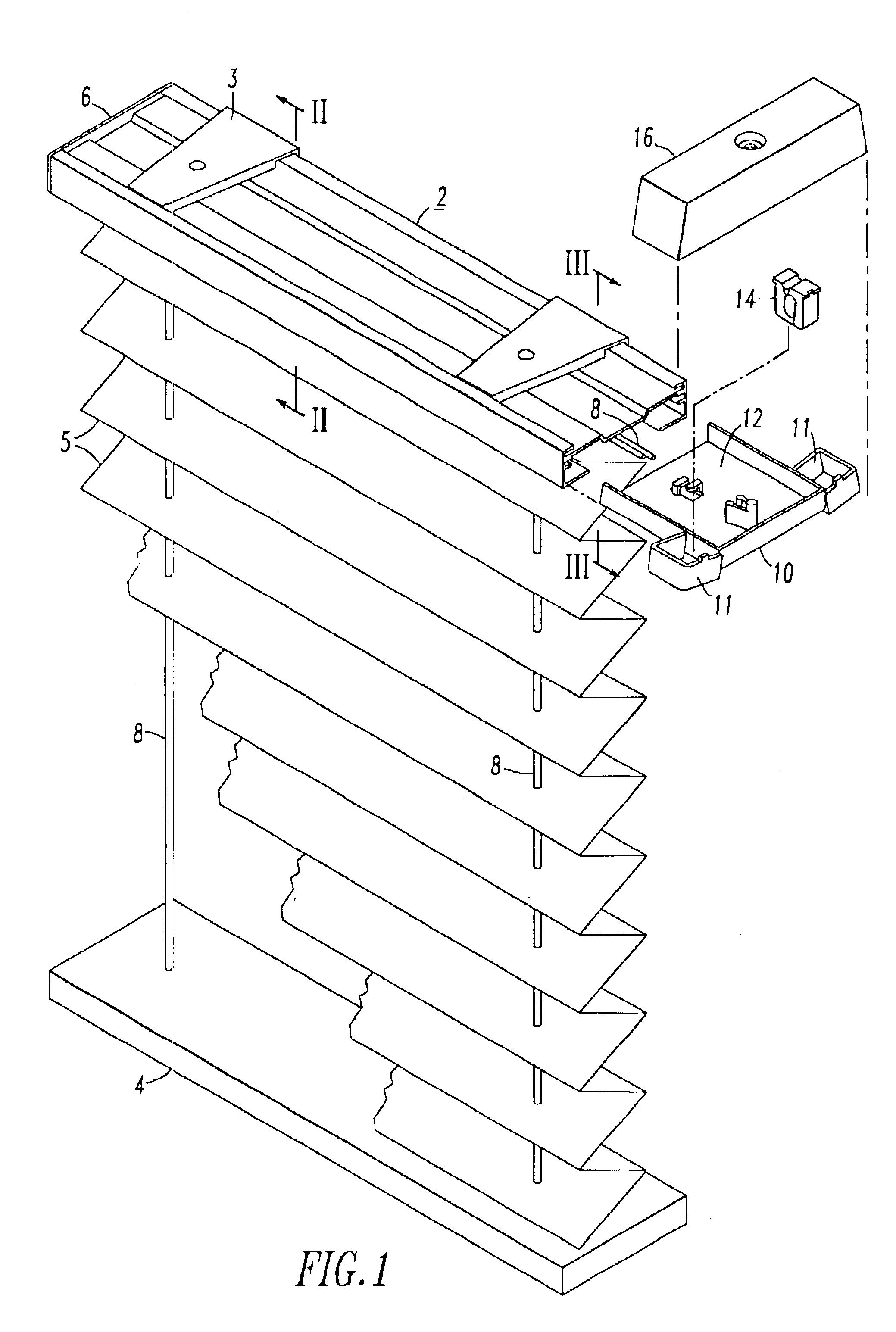

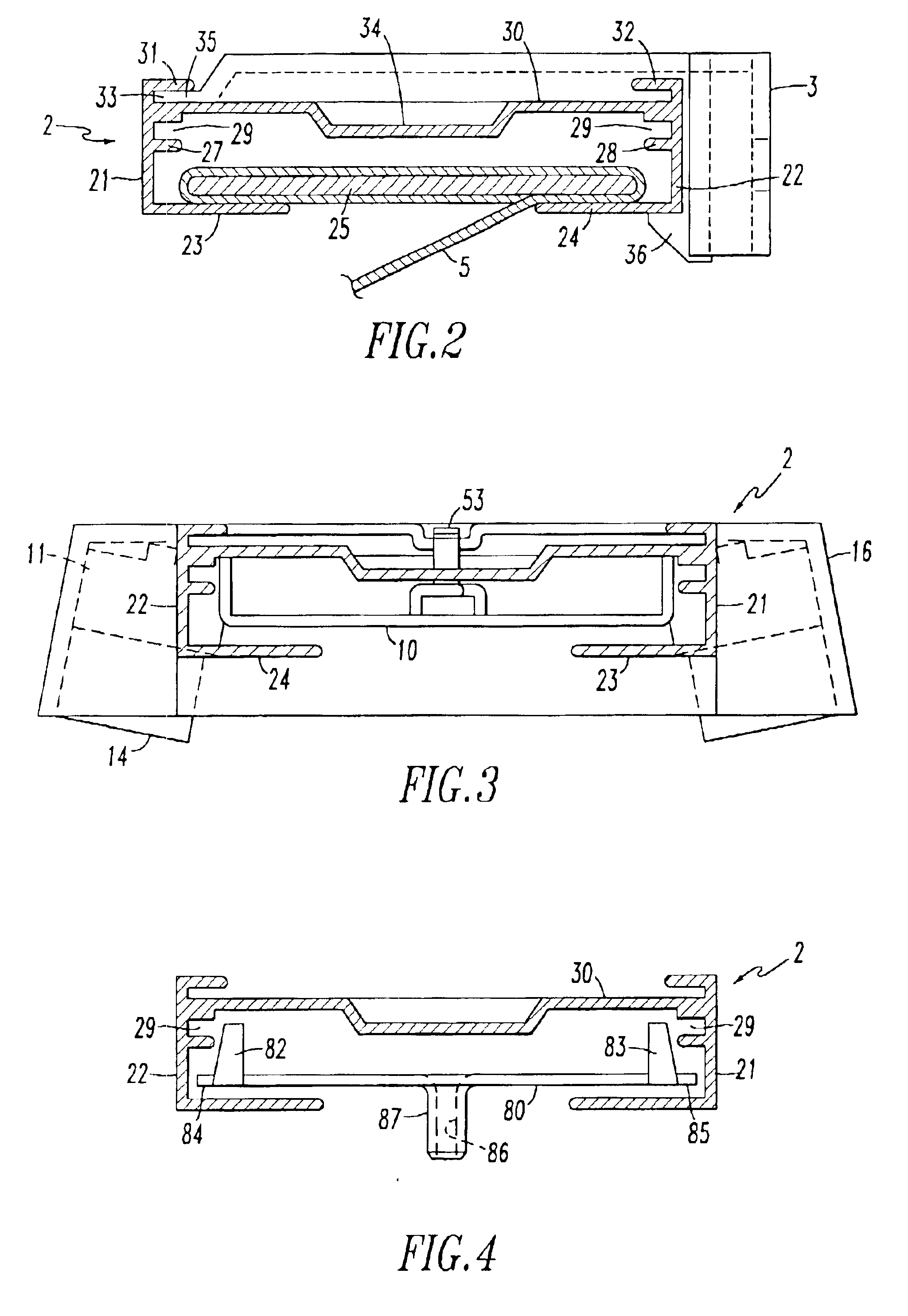

Motorized Venetian Blind System

InactiveUS20120073765A1Extensible doors/windowsShutters/ movable grillesVenetian blindsElectrical and Electronics engineering

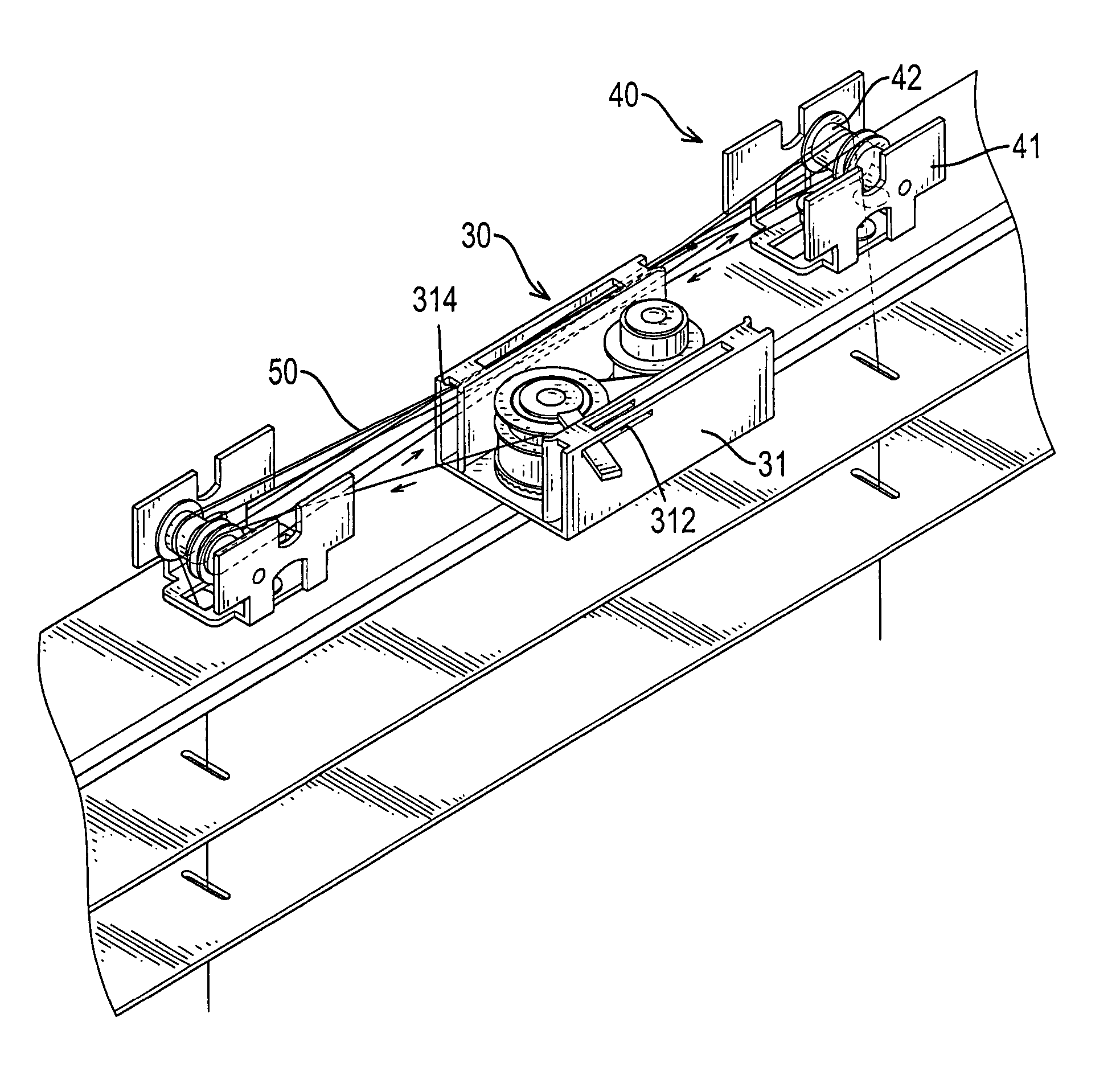

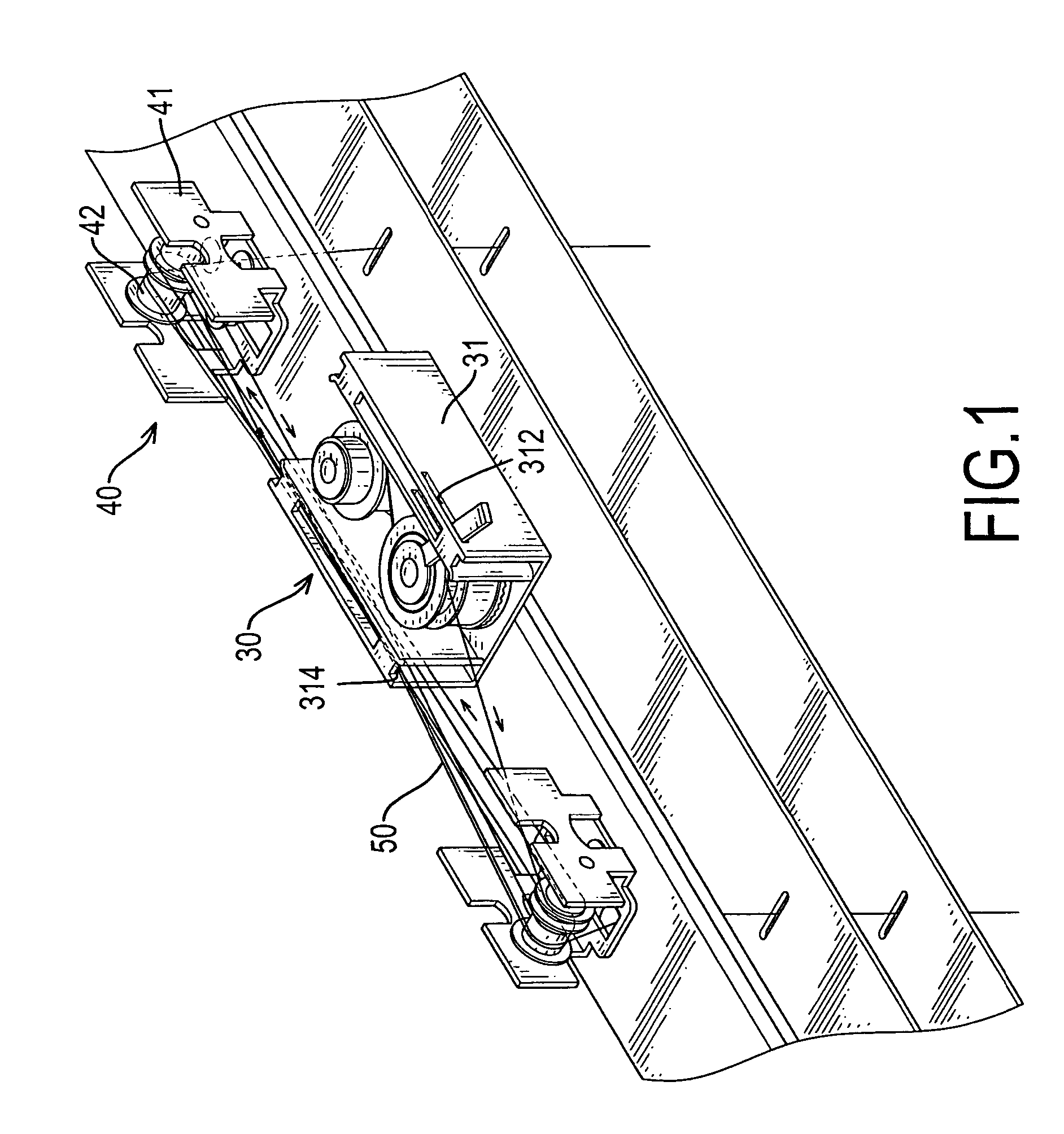

A motorized venetian blind system for covering a window of a space comprising a blind drive unit having two motors to provide for independent control of a position of a bottom rail via a lift cord and a tilt angle of a plurality of slats of the blind system. The blind drive unit has a headrail with a side panel and at least one of the motors is between between the side panel and the lift cord. The blind drive unit also has a spring-wrap brake. The blind drive unit is operable to adjust the position of the bottom rail to a preset position, and to adjust the tilt angle of the slats to a preset angle in response to receiving a single digital message (e.g., a preset command).

Owner:LUTRON TECH CO LLC

Motorized venetian blind system

Owner:LUTRON TECH CO LLC

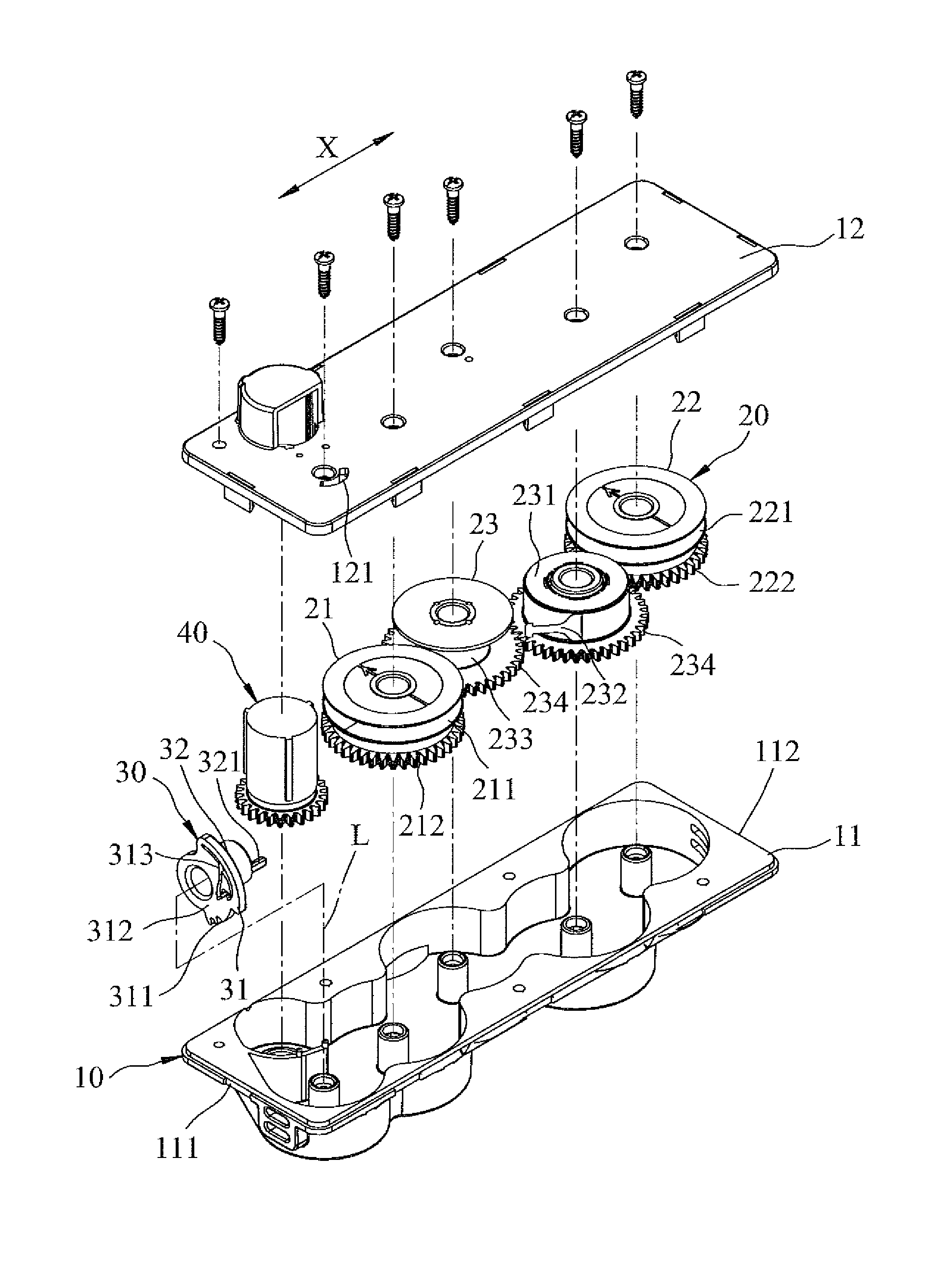

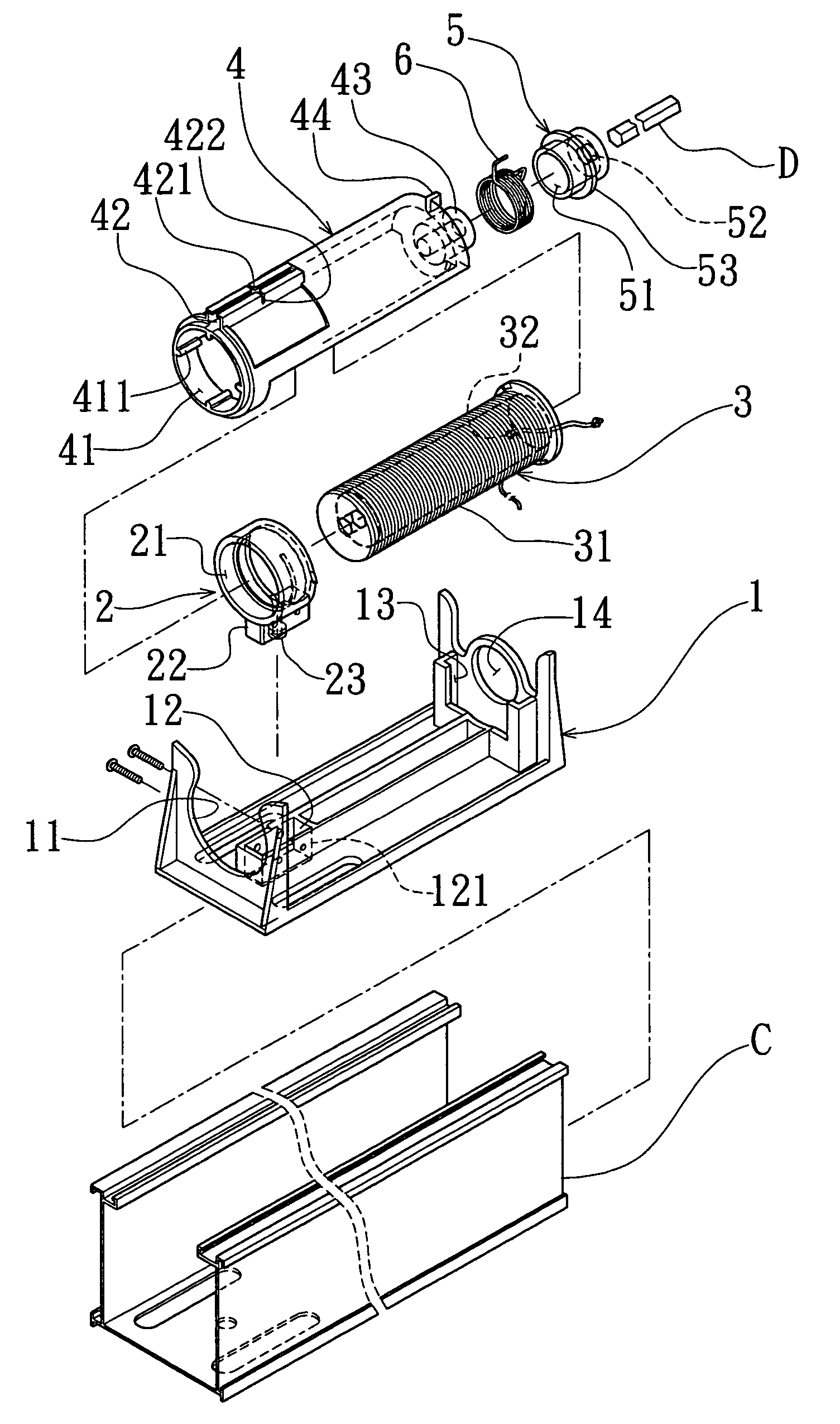

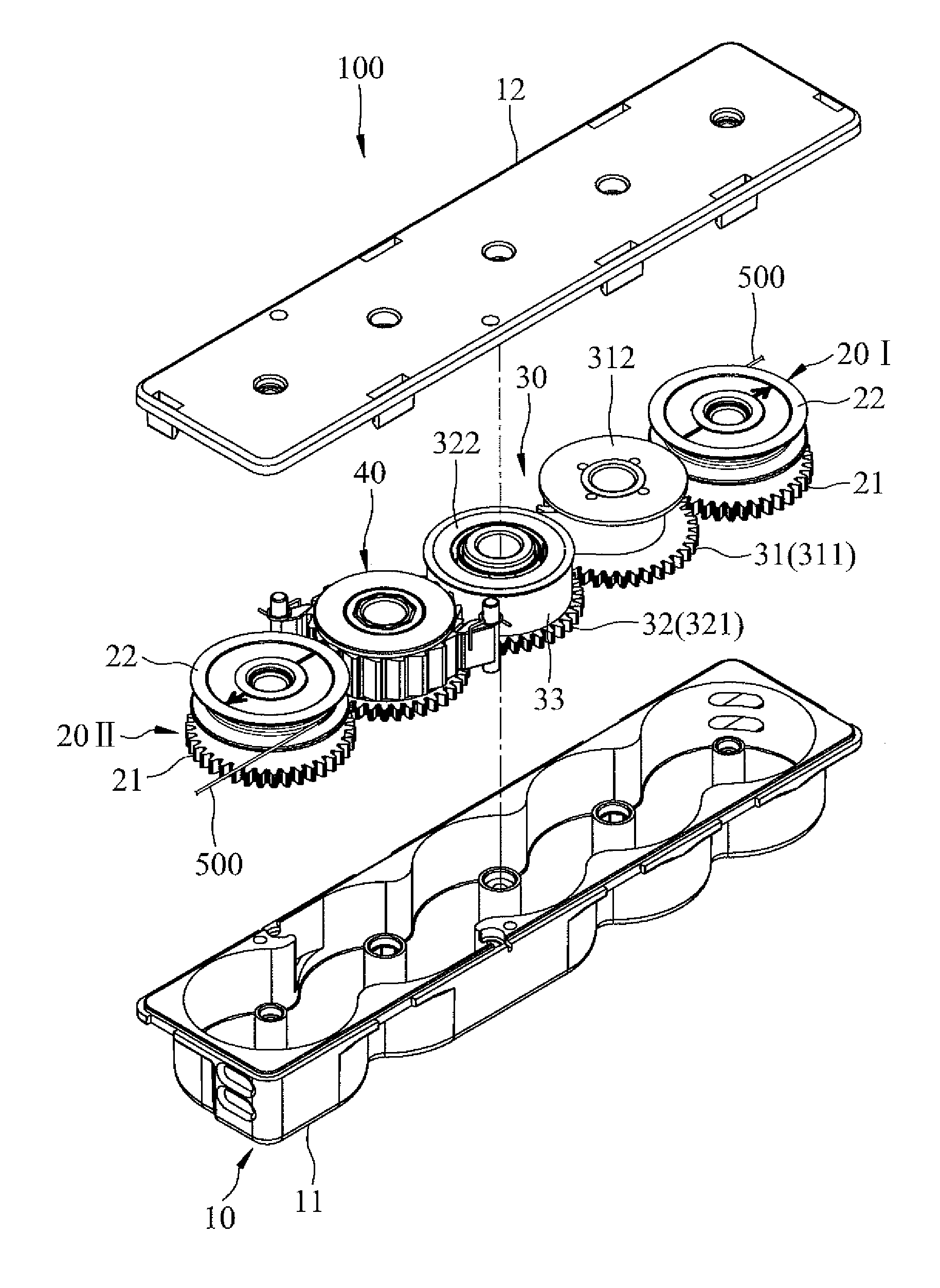

Cord-winding device for venetian blind

ActiveUS20150136336A1Improve securitySimple structureLight protection screensEngineeringVenetian blinds

Owner:TAICANG KINGFU PLASTIC MFG

Motorized Venetian Blind System

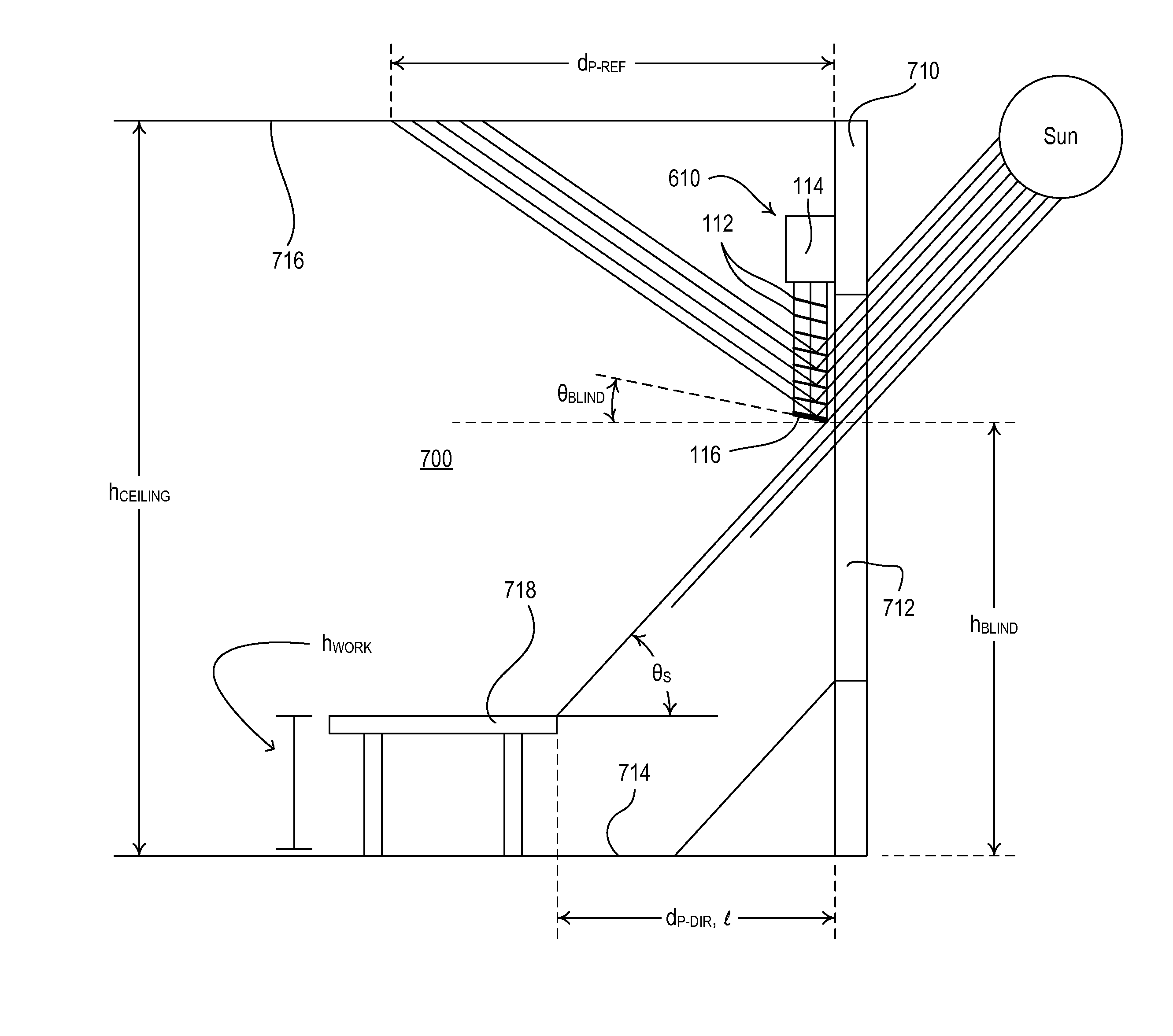

ActiveUS20120125543A1Minimize distractionProgramme controlSampled-variable control systemsWindow shutterAngular degrees

A motorized venetian blind system for covering a window of a space comprising a blind drive unit having two motors to provide for independent control of a position of a bottom rail and a tilt angle of a plurality of slats of the blind system. The blind drive unit is operable to adjust the position of the bottom rail to a preset position, and to adjust the tilt angle of the slats to a preset angle in response to receiving a single digital message (e.g., a preset command). The blind drive unit is operable to automatically adjust the position of the bottom rail and the tilt angle of the slats to limit a direct sunlight penetration distance in the space to a maximum direct sunlight penetration distance, and to maximum a reflected sunlight penetration distance on a ceiling of the space, while minimizing occupant distractions.

Owner:LUTRON TECH CO LLC

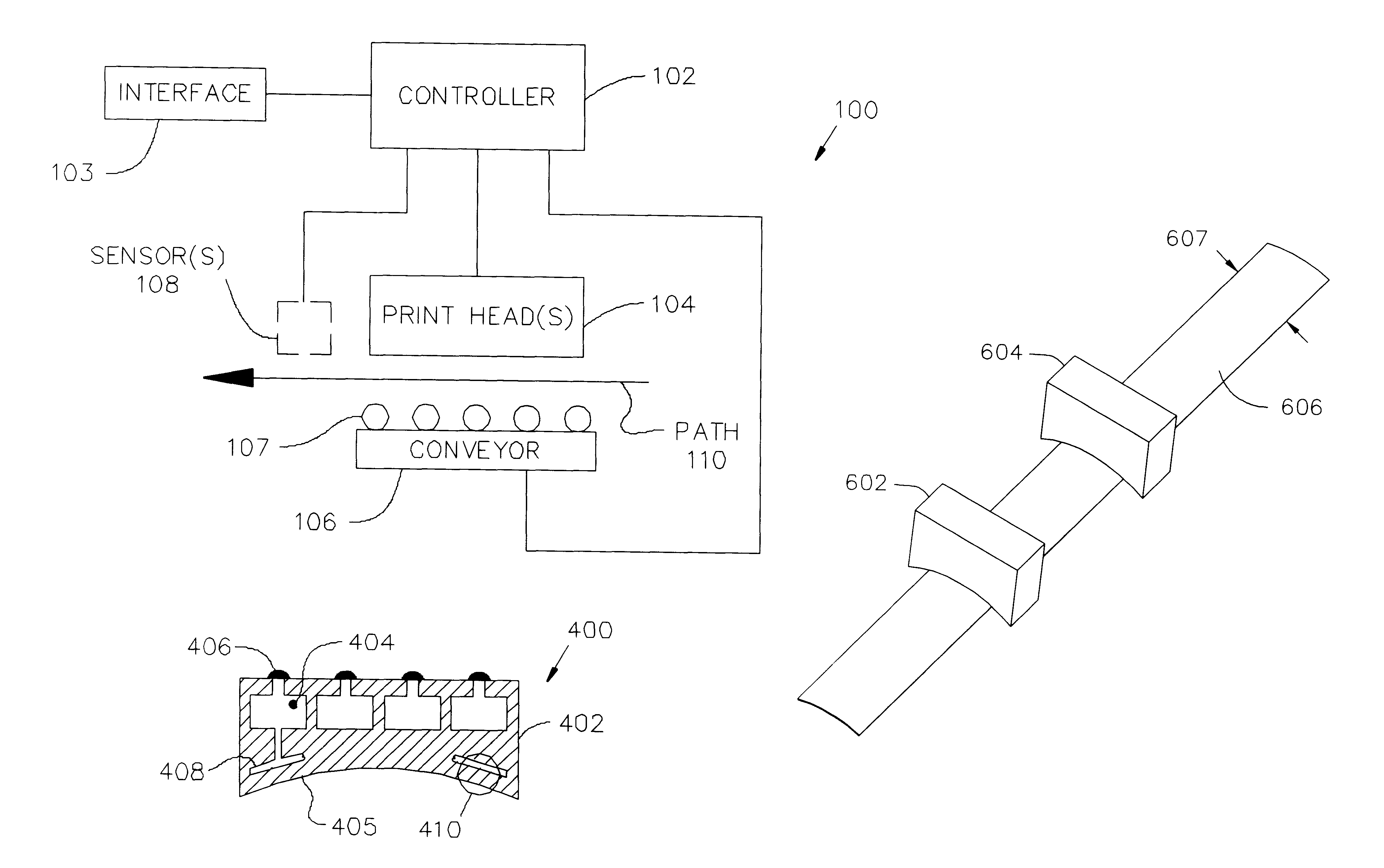

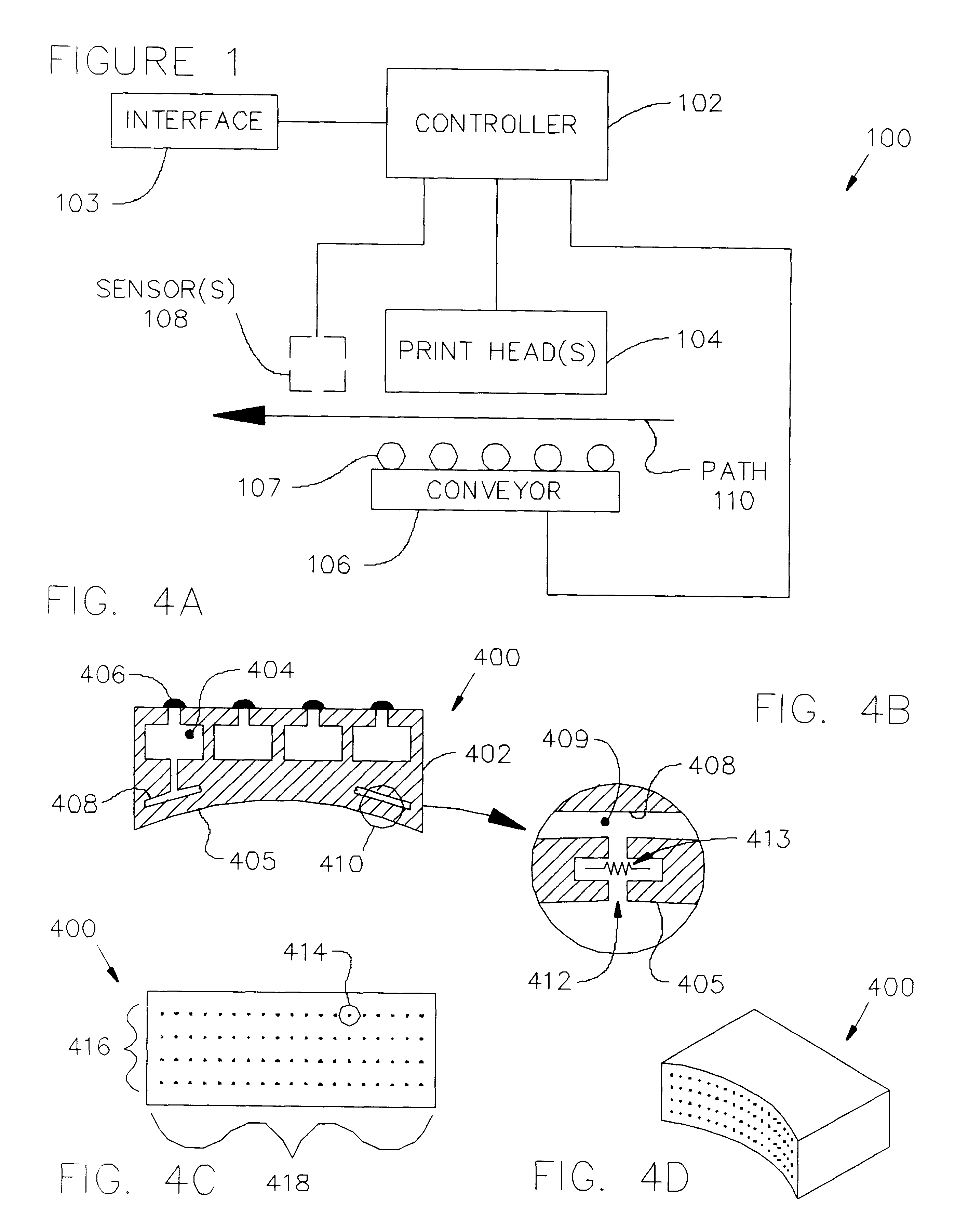

Venetian blind printing system

Print heads with arcuate printing surfaces are used to apply images to elongated, laterally curved slats prior to their assembly into Venetian blinds. Each print head includes a print head casing having a concave or convex printing surface forming an arc shape. The print heads are distributed in series along a slat path, which is defined by a conveyor. One or more ink wells are coupled to the print head casing; each ink well may contain a separate color of ink. Many print jet orifices are evenly distributed along the printing surface, and may be arranged in an array with multiple rows and columns, for example. Each print jet orifice is coupled to one of the ink wells by a supply path. During the printing process, slats are longitudinally advanced along the slat path past the print heads. A controller regulates the slat's position relative to the print heads, and controls the position using the conveyor. At selected times, depending upon the slat's position, the controller activates selected ink jets of selected print heads to eject ink upon the curved slat, and thereby imprint a desired image upon the slat. The images imprinted on individual slats are coordinated to provide a desired, overall image spanning the Venetian blinds.

Owner:RIDGWAY PAUL ANTHONY

Cord retaining device for non-cord venetian blind

InactiveUS6948546B2Improve securityEasy and fast mannerSnap fastenersRopes and cables for vehicles/pulleyAdhesiveCoupling

A cord retaining device for non-cord Venetian blinds include two sheltering caps, two snap members, two fixing seats, and two double-sided adhesive pieces wherein the sheltering cap has a registration cavity defined at the bottom side therein, and a through hole disposed at the top thereon. The snap member, shaped in form conforming to that of the registration cavity of the sheltering cap, has a support piece with a cord passage protruding at the top thereon, and an arc-shaped retaining cavity with an outwardly extended guide arc indented at the bottom side therein. The fixing seat has a solid coupling ball block extending at the top surface of a base thereon in match to the retaining cavity thereof, and the double-sided adhesive piece is shaped like the base of the fixing seat thereof. In assembly, retaining cords are tied up to the support pieces of the snap members by the bottom ends thereof before the snap members are registered with the ball blocks of the fixing seats that are mounted on top of the double-sided adhesive pieces fastened to both lateral sides of a windowsill. Thus, in case children curiously extending their heads out of the windowsill get caught by the retaining cords, the retaining cords pulled by the children struggling to get free there-from will draw upwards the snap members therewith and detach the retaining cavities thereof off from the ball blocks of the fixing seats in the first moment of emergency, efficiently preventing children from getting cut or strangled by the retaining cords to protect the safety of the family.

Owner:NIEN LESLIE

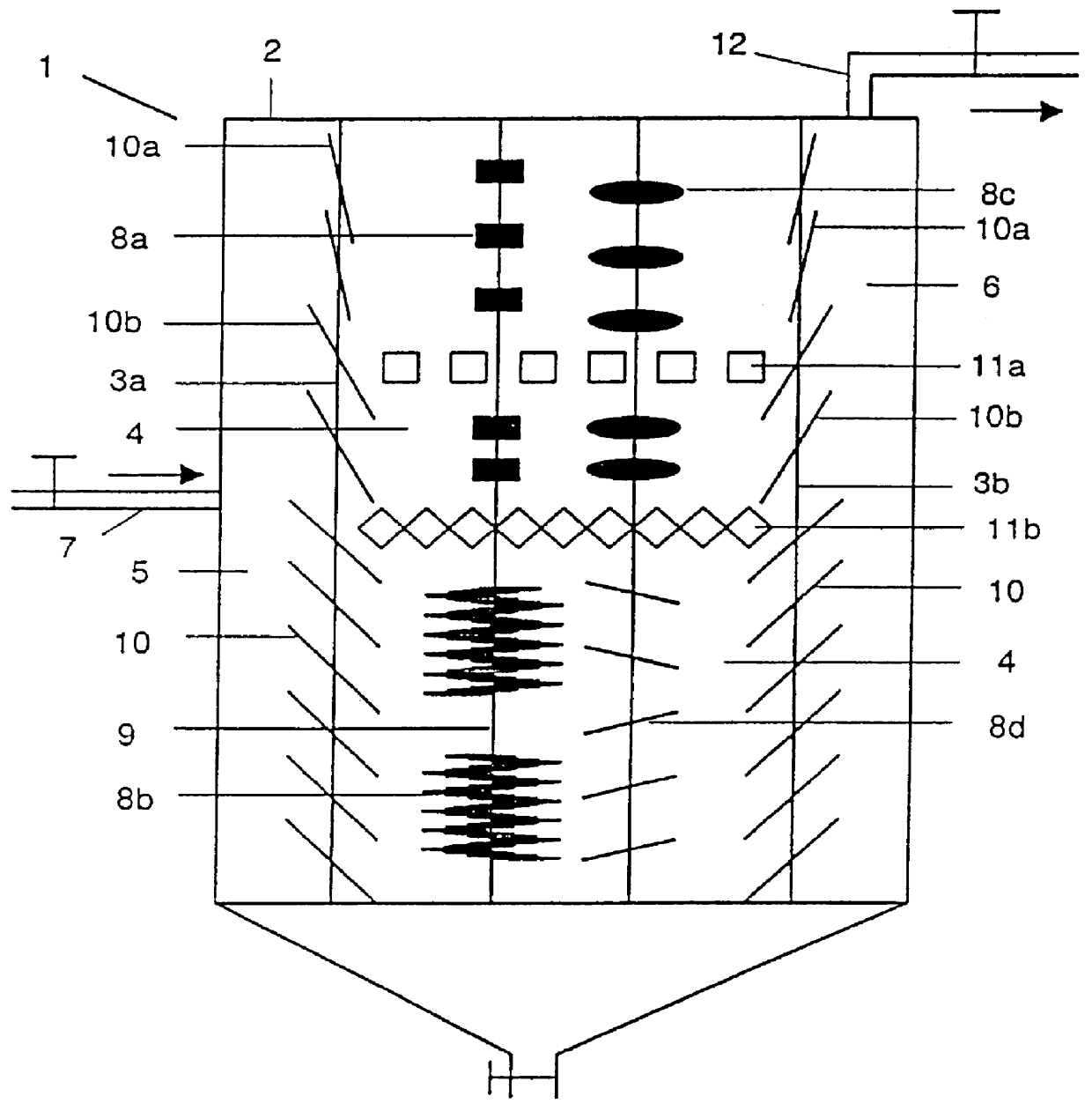

Device and process for the aerobic treatment of organic substances

InactiveUS6065224ABio-organic fraction processingDrying solid materials with heatEngineeringVenetian blinds

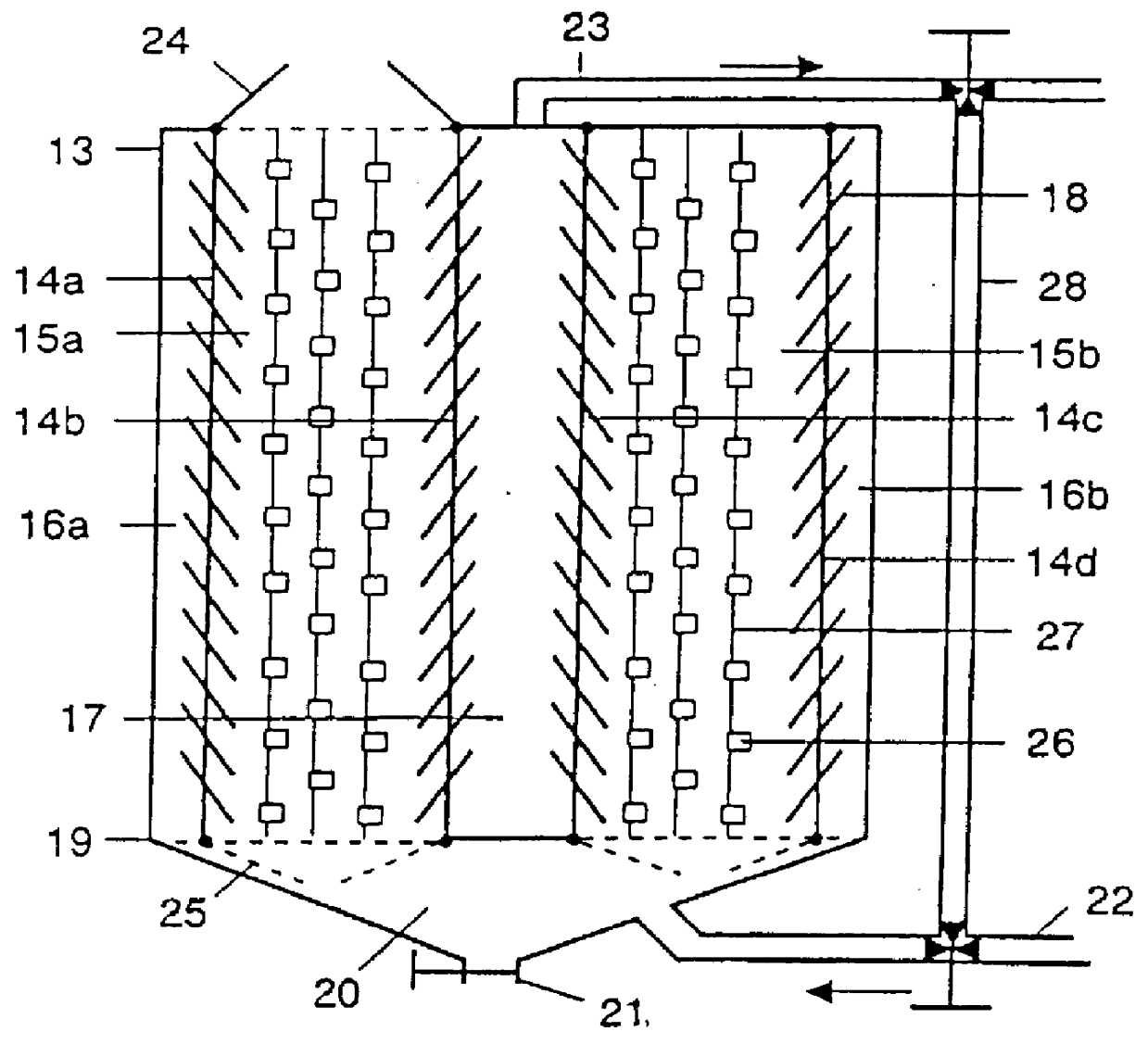

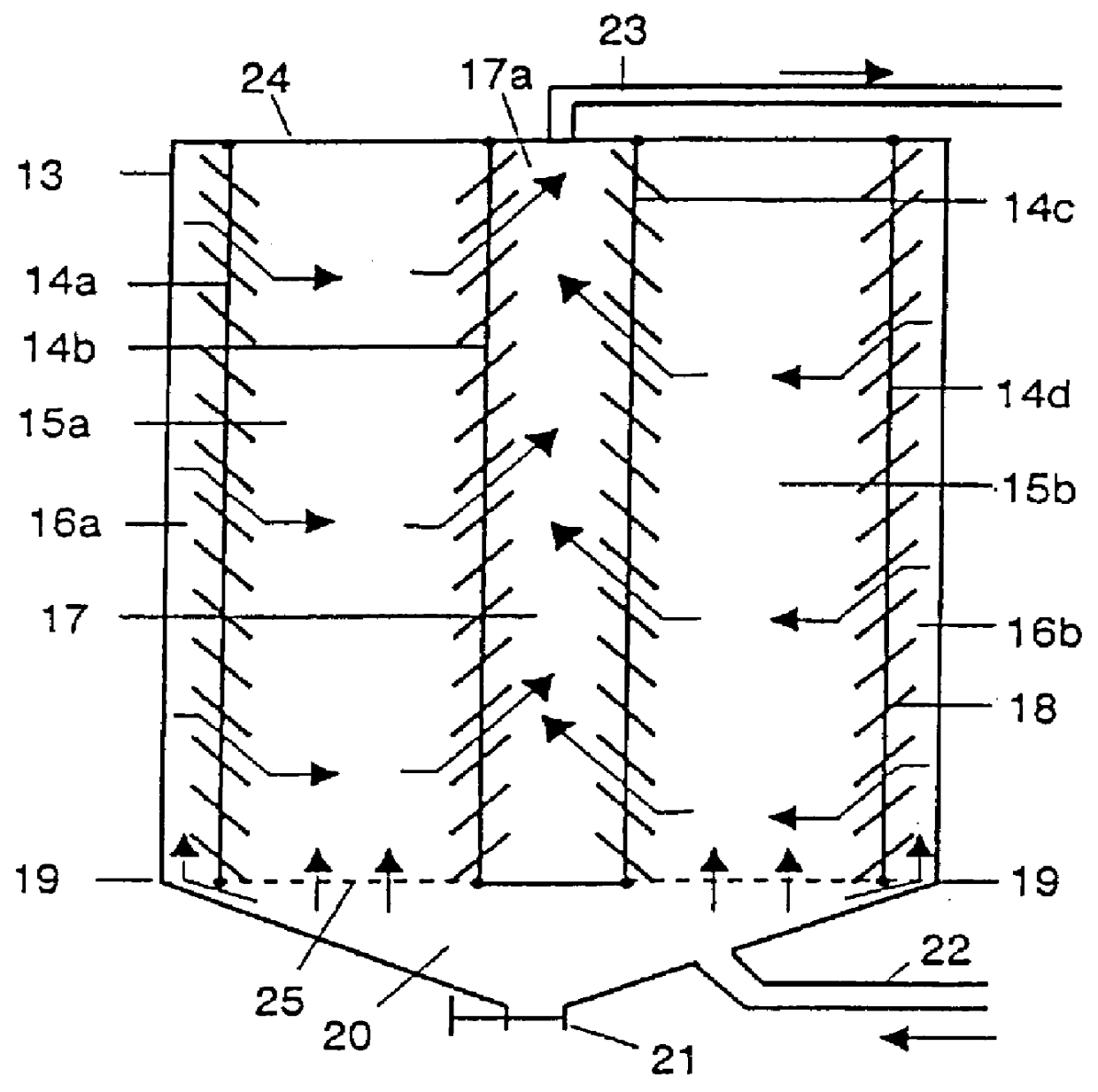

PCT No. PCT / EP96 / 00110 Sec. 371 Date Jul. 10, 1998 Sec. 102(e) Date Jul. 10, 1998 PCT Filed Jan. 11, 1996 PCT Pub. No. WO97 / 25295 PCT Pub. Date Jul. 17, 1997A device for the aerobic treatment, conditioning and / or drying of moist, substantially solid or paste-like, at least partly organic material, has a vessel containing paired, Venetian-blind-like walls, with adjustable blades, forming at least one reaction chamber, at least one air inlet chamber and at least one air discharge chamber, and containing supports which are in spatially staggered array inside the reaction chamber in such a way that they provide the best possible pressure relief for the filling. The invention also relates to a process using said device.

Owner:INTERLICENSE DEN HAAG

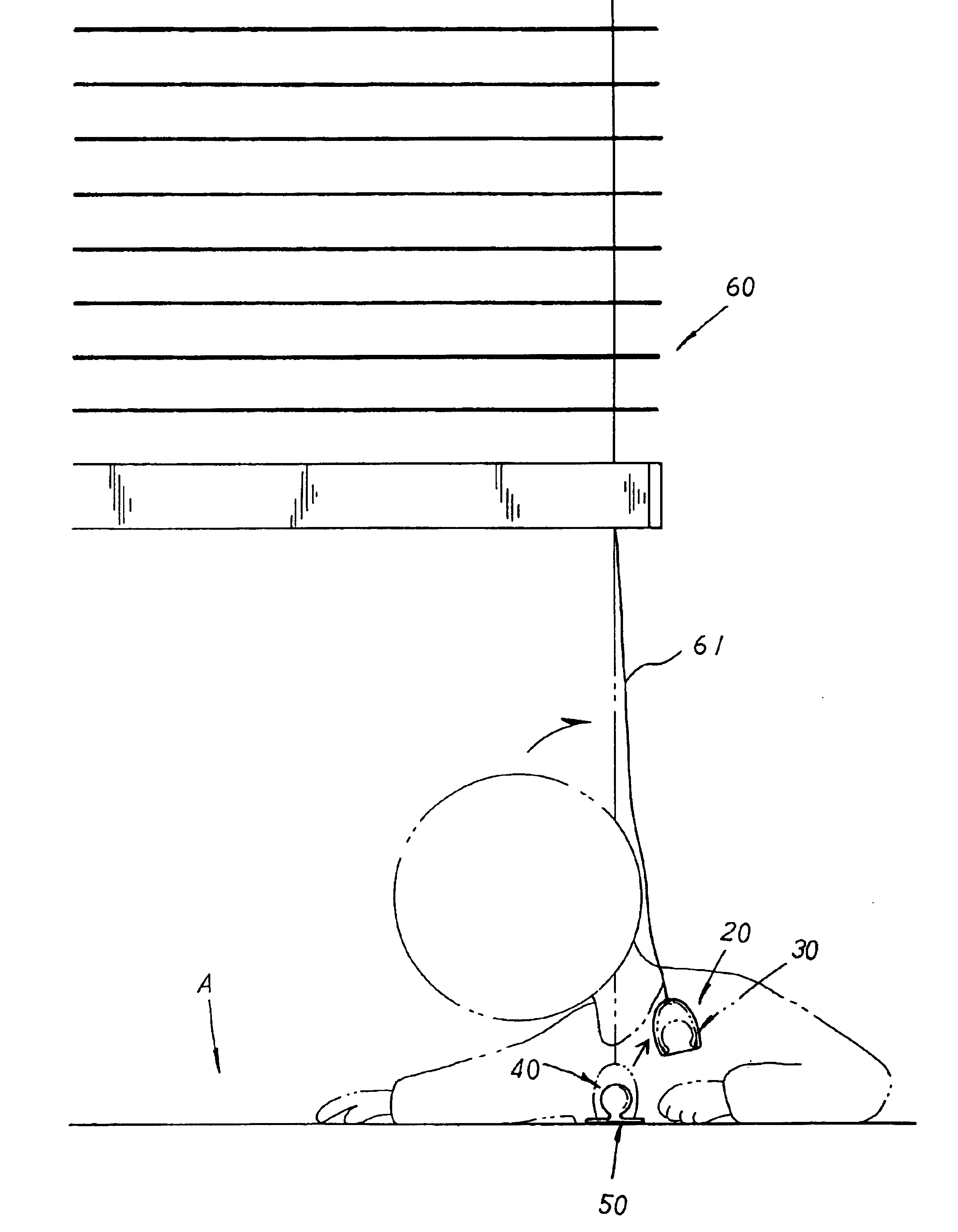

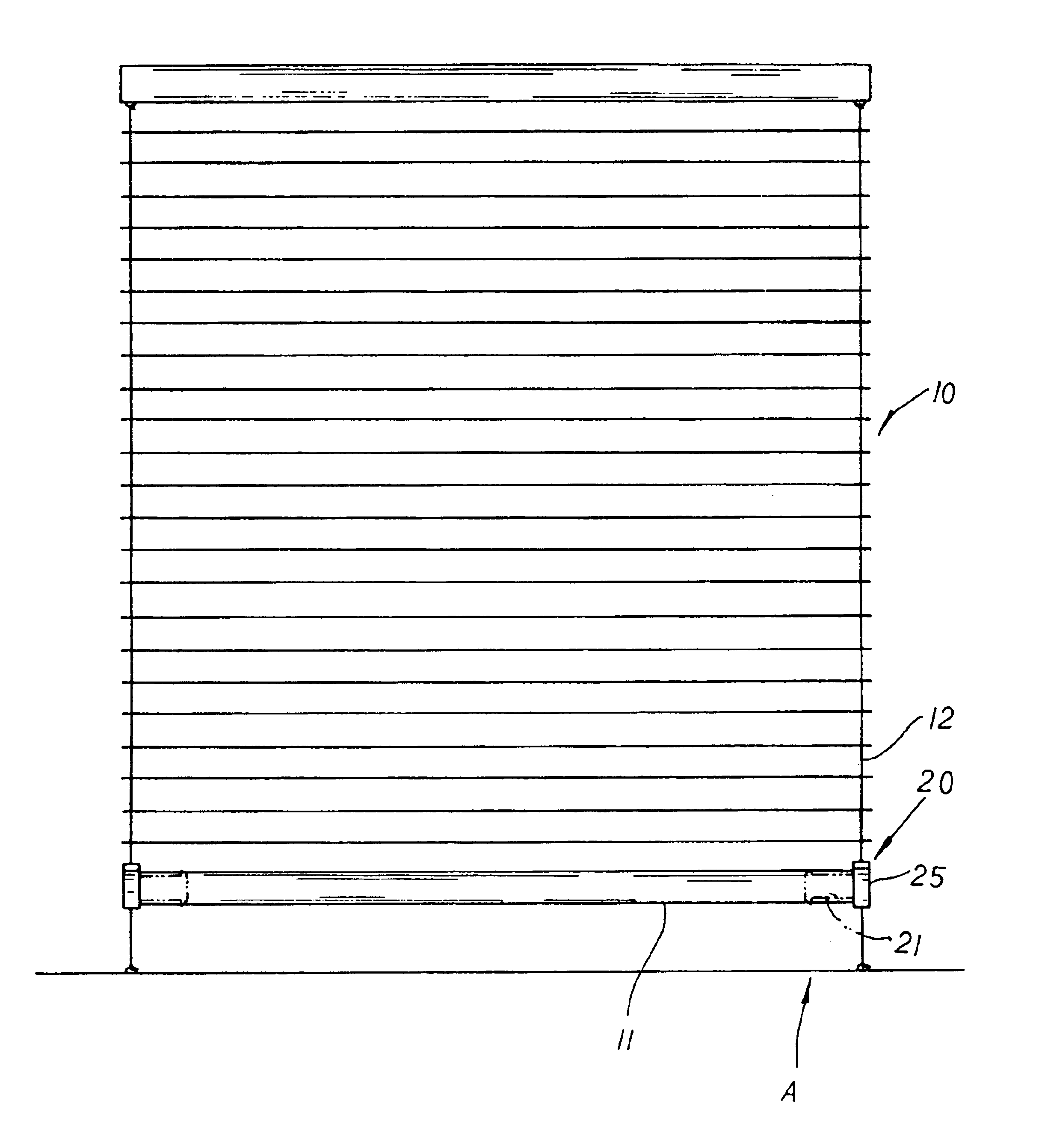

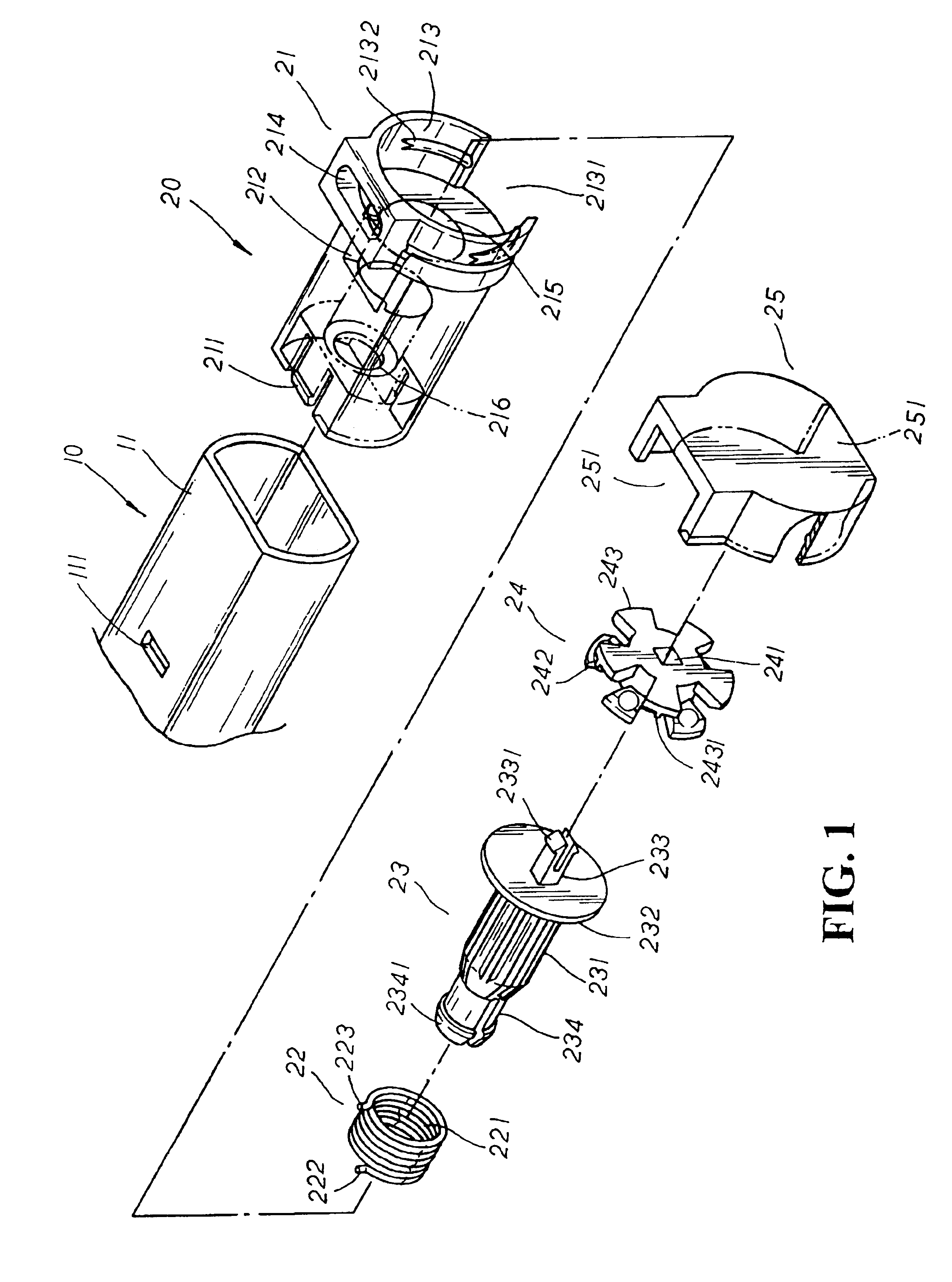

Cordless activating device for a venetian blind

Owner:CHEN CHIN FU

Tilt and lift device for adjusting tilt angle and height of slats of a Venetian blind

Owner:LIN GWO TSAIR

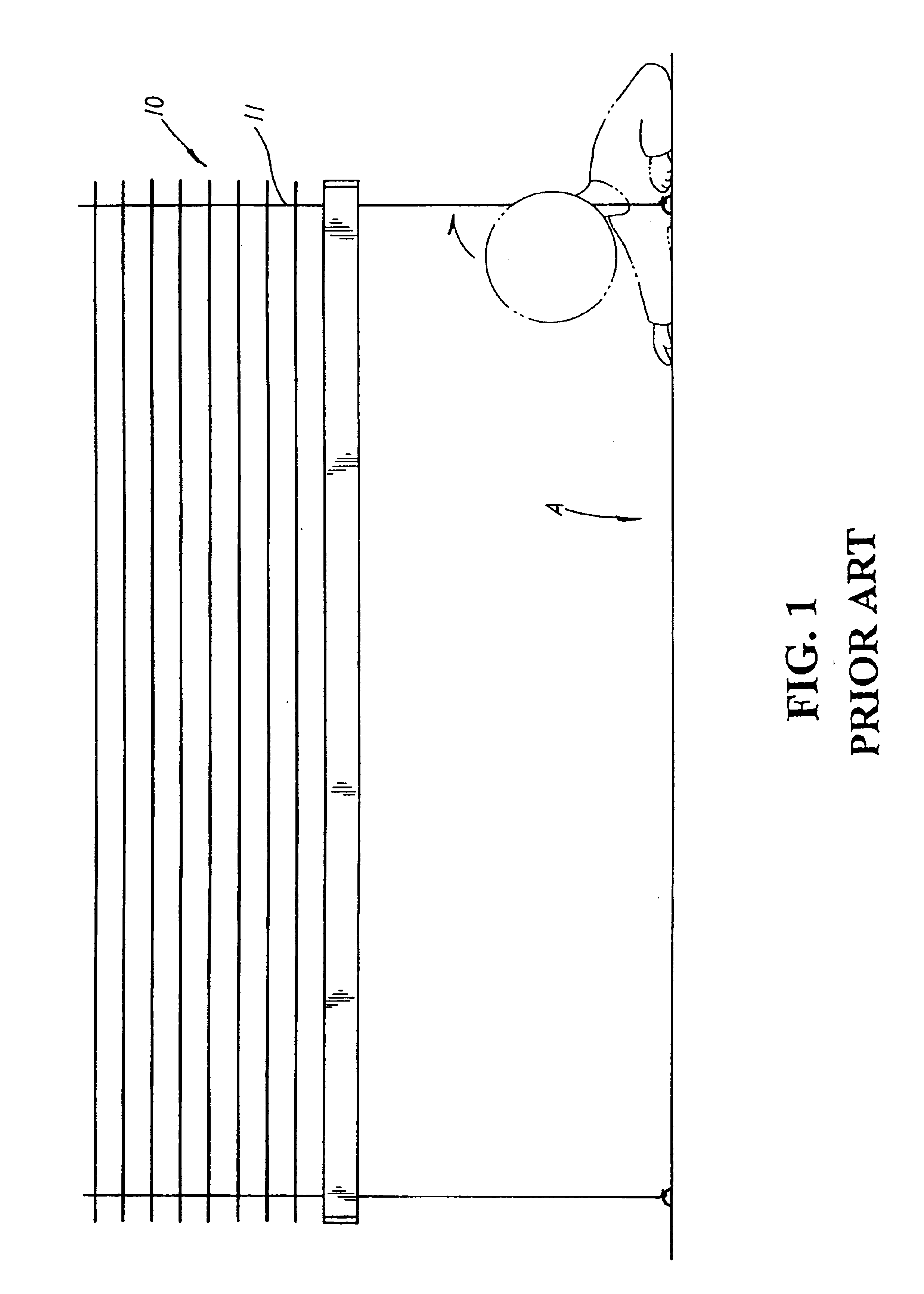

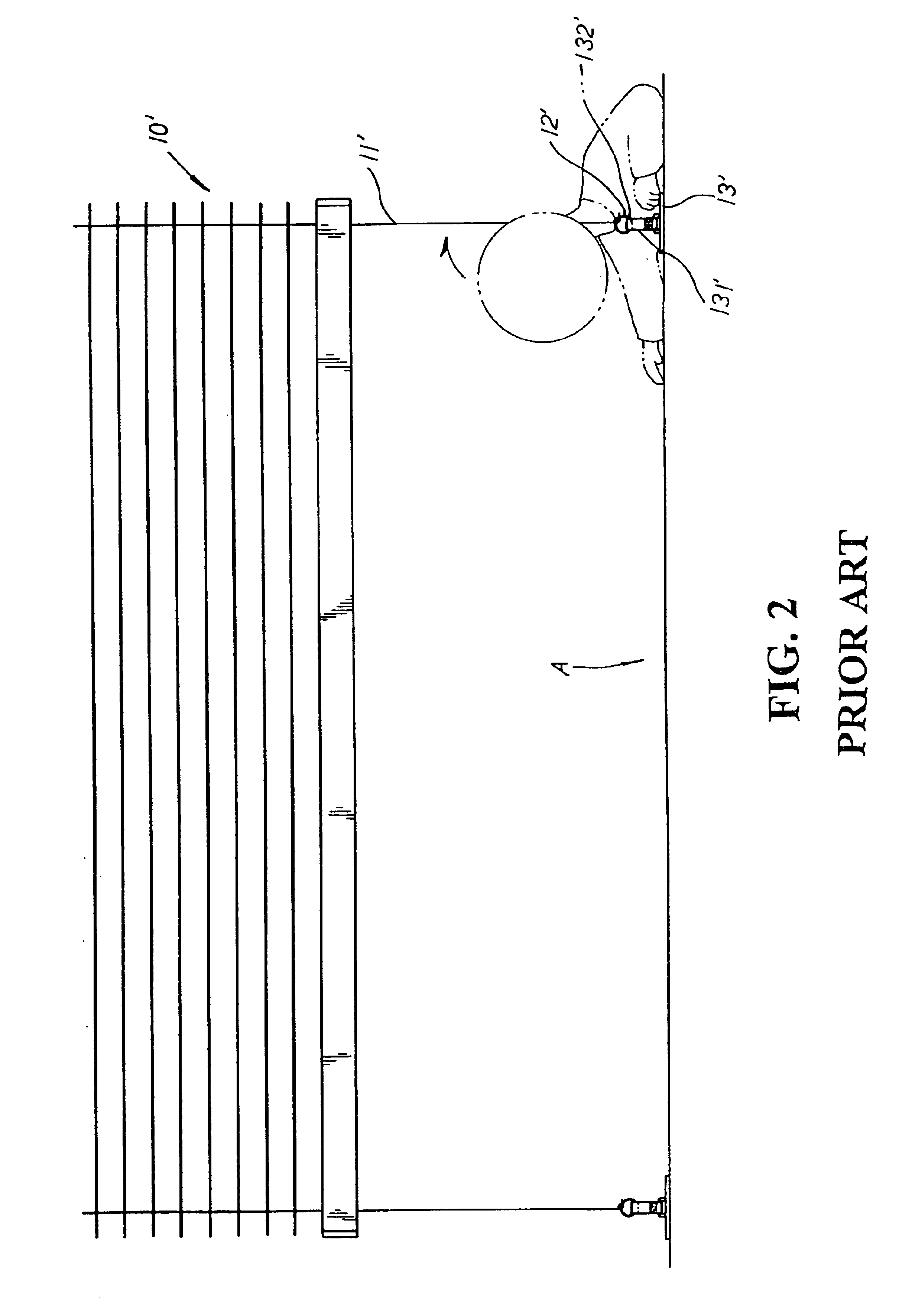

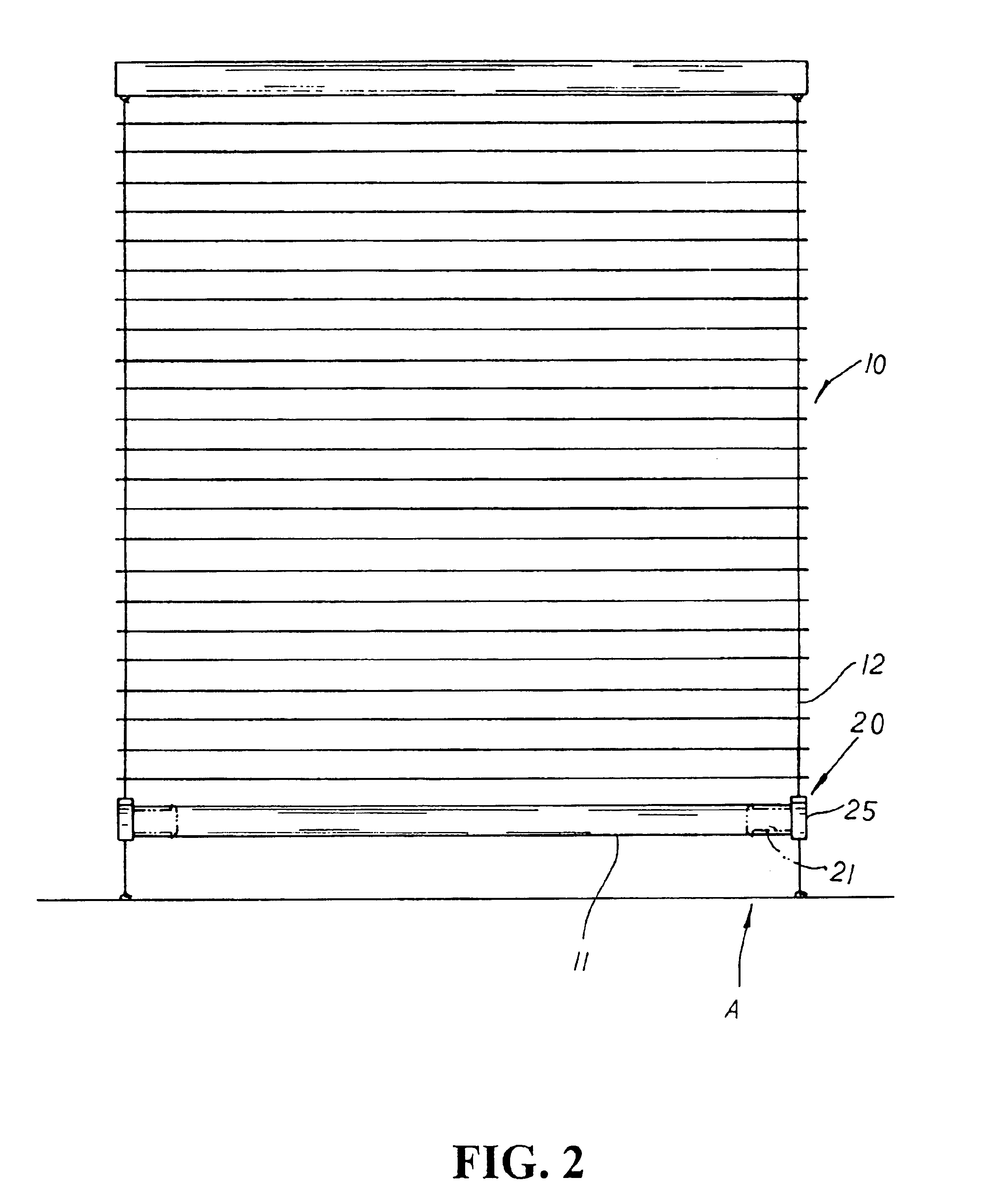

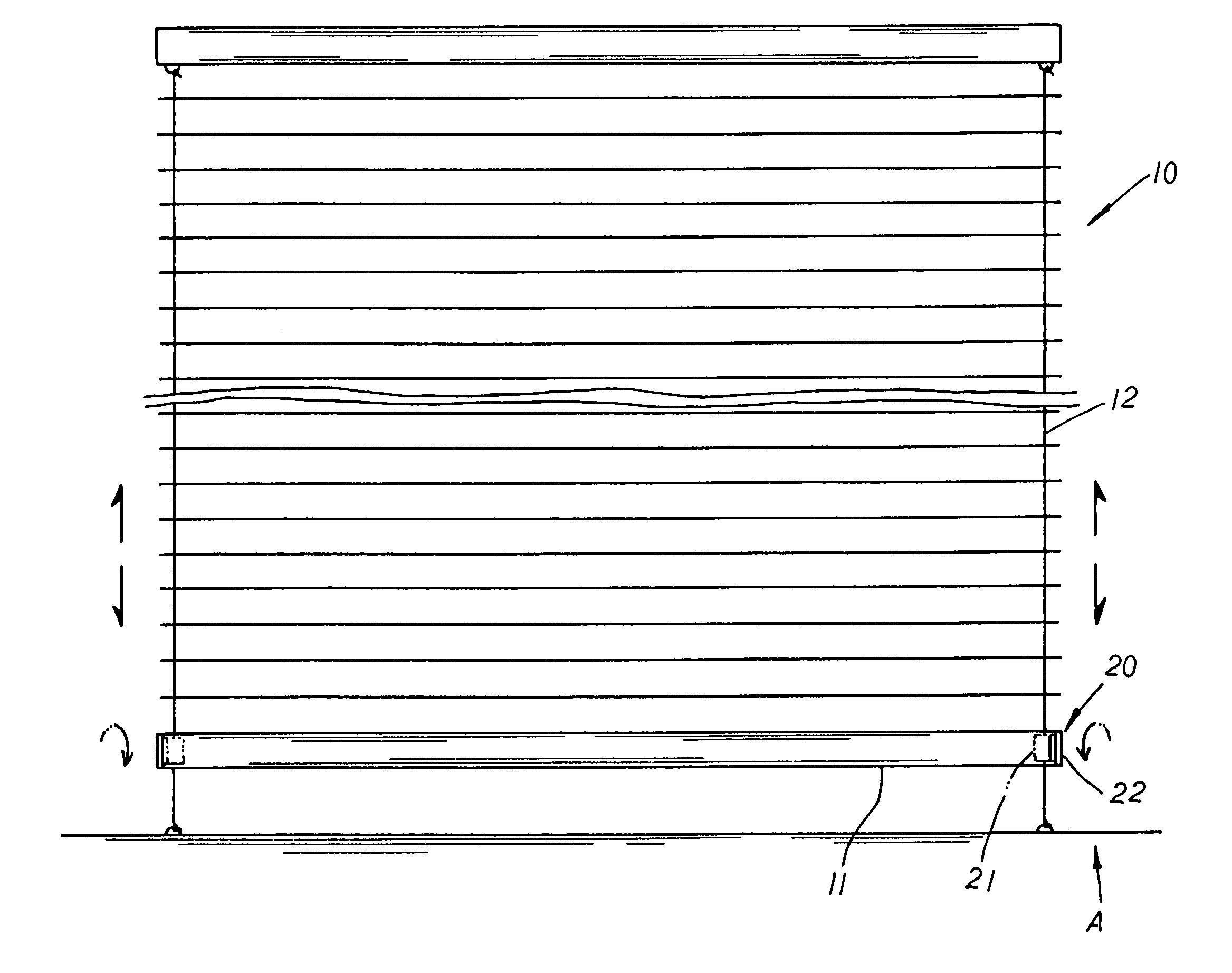

Non-pull cord operable venetian blind

InactiveUS6918425B2Move preciselyEnsure safetyCurtain accessoriesShutters/ movable grillesEngineeringVenetian blinds

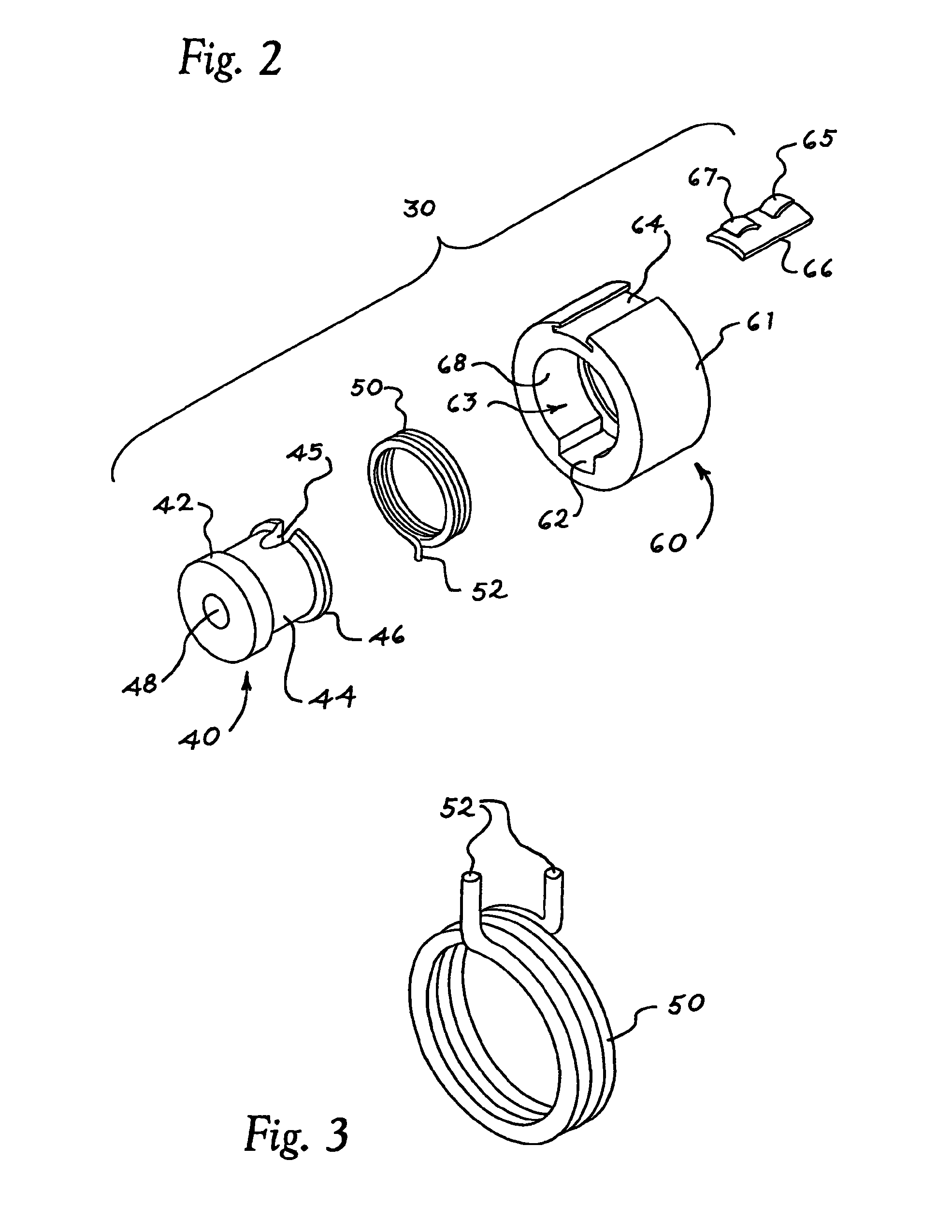

A non-pull cord operable Venetian blind includes a retaining device located at each end of a lower beam of a Venetian blind therein in working with a retaining cord. The retaining device is made up of a holding sleeve, a driven member adapted at the holding sleeve therein, a limiting spring joined to one side of the driven member with a pair of left and right stop legs protruding at a limiting hole of the holding sleeve, a rotary member to activate the driven member therewith, and an outer cap applied at the outer side of the holding sleeve. The retaining cord is wound through alternative left and right blades of the rotary member and clamped by abutting ribs of the holding sleeve before led straight downwards to be securely located at a windowsill at the bottom end thereof. Via the guidance of the retaining cord, the rotary member of the retaining device is rotated either counter-clockwise when the lower beam is pushed upwards to gather up the Venetian blind, or clockwise when the lower beam is drawn downwards to unfold the Venetian blind thereof. Meanwhile, three layers of frictional resistance are formed therewith in operation, ensuring the smooth and precise movements of the Venetian blind without any other pull cords applied thereon so as to keep the safety of children in the household.

Owner:NIEN LESLIE

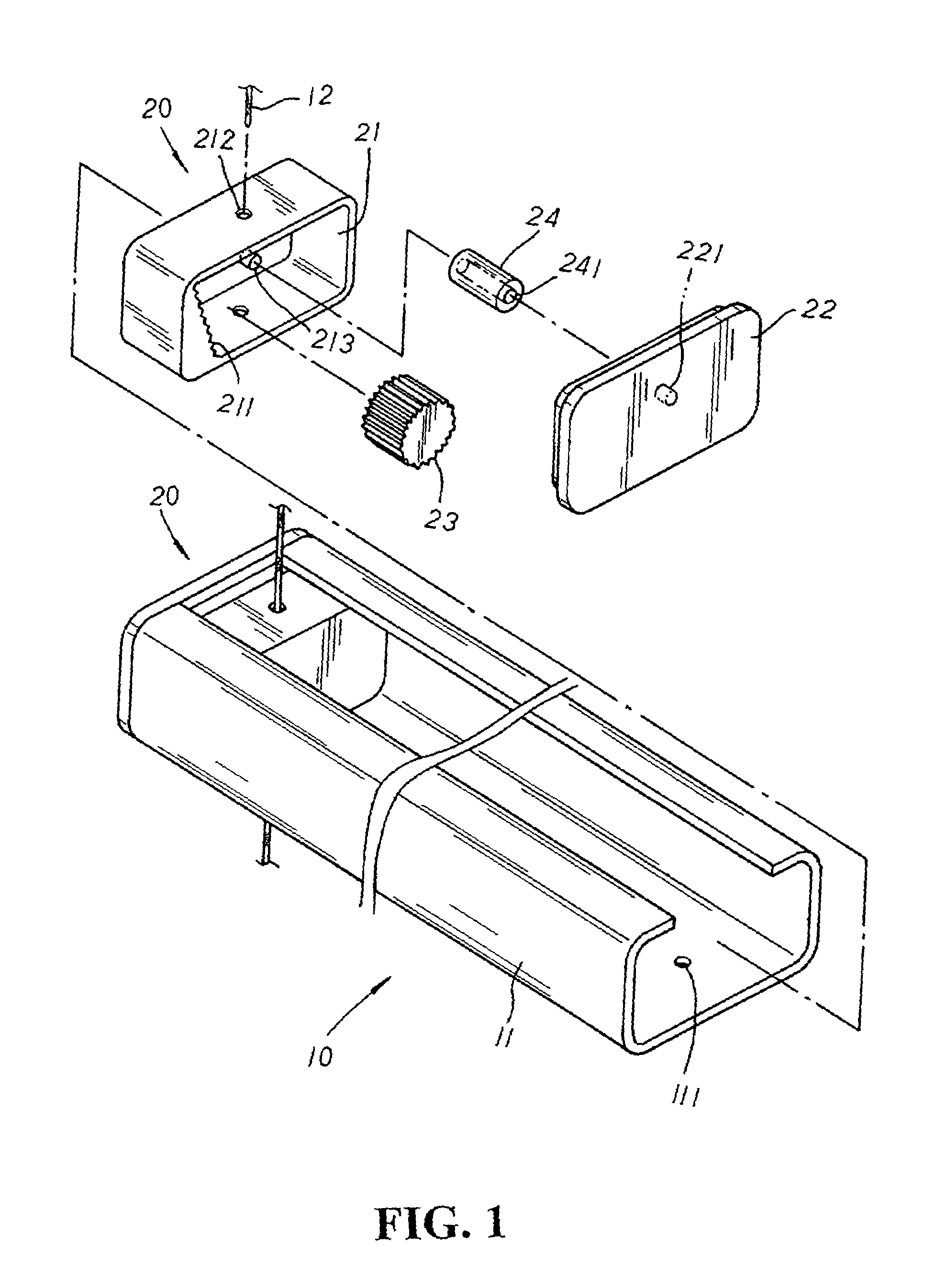

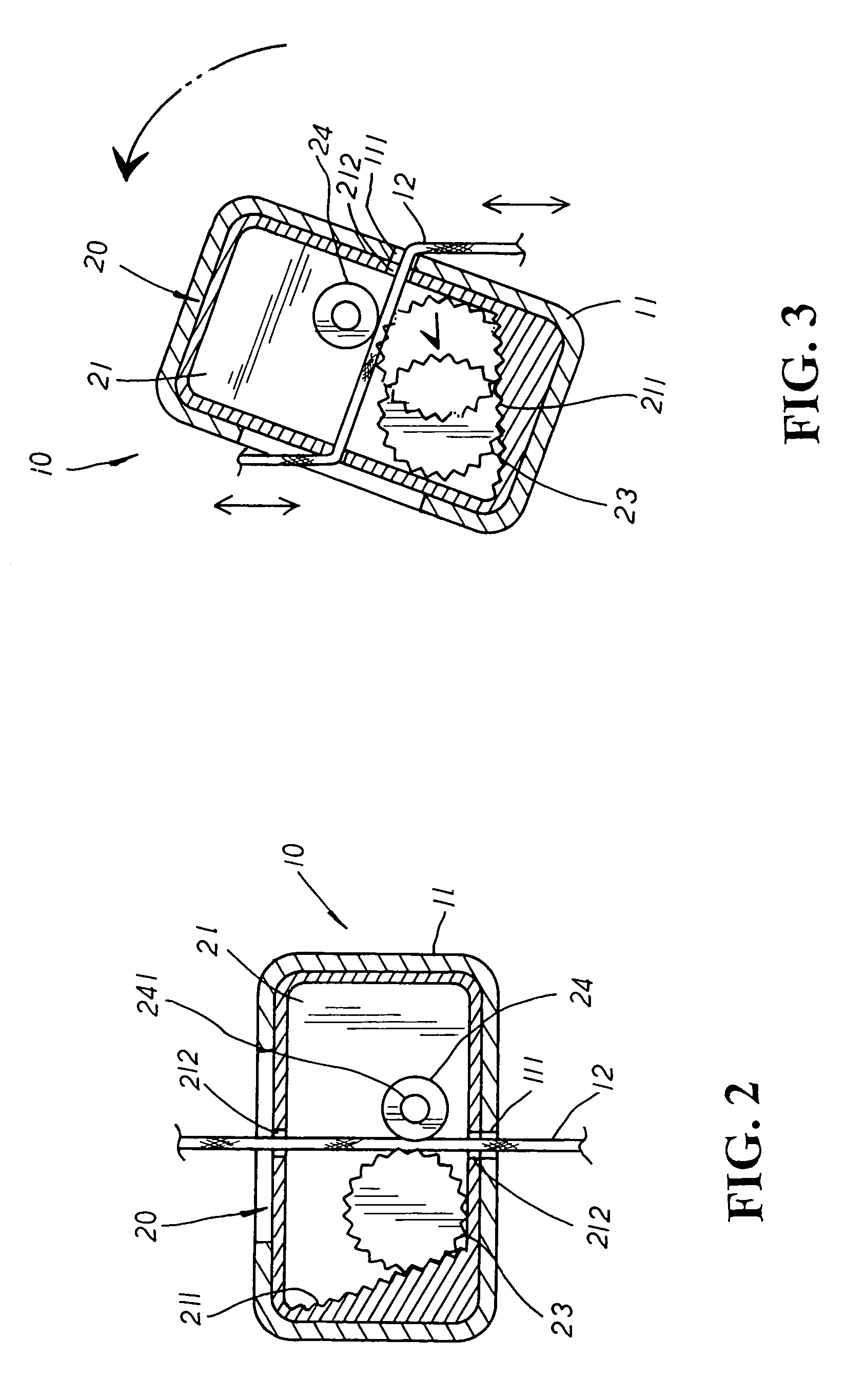

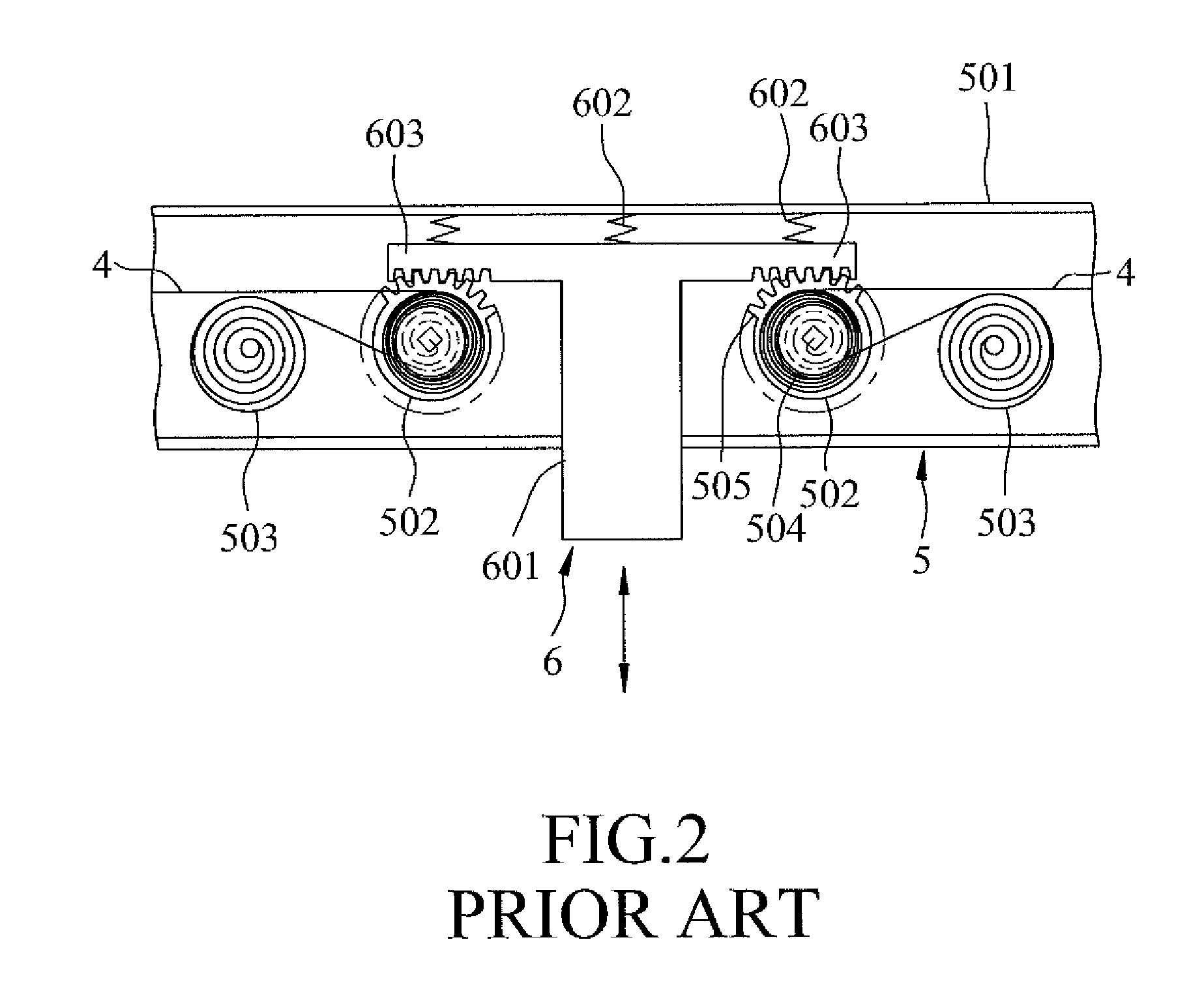

Venetian blind operated with non-pull cord structure

A Venetian blind operated with a non-pull cord structure includes a blind embodiment, a lower beam having a pivot hole disposed at the bottom side of each end thereon, and a control unit and a sealing cap to be sequentially adapted to each end of the lower beam thereof wherein the control unit has a housing cavity indented at one side thereof to which the sealing cap is joined at one side in sealing engagement therewith. At one inner side of the housing cavity thereof is disposed a sloped and serrated guiding face correspondingly matched to a retaining gear element which is abutted against a retaining shaft adapted to a coupling rod and a fixing rod of the housing cavity and the sealing cap thereof respectively to clamp tight a left / right retaining cord of the blind embodiment there-between before the left / right retaining cord is led through the pivot hole of the lower beam and fixed to a windowsill at the bottom end thereof. In operation, the lower beam is tilted upwards at one side to detach the left / right retaining cord from the clamping location thereof so that the blind embodiment can be adjusted upwards or downwards before the lower beam is horizontally set right to clamp tight the left / right retaining cord via the control unit thereof and relocate the blind embodiment at an adjusted position thereby, precisely gathering up or unfolding the blind embodiment in an easy and fast manner without any pull cords applied thereon so as to protect the safety of children in the household.

Owner:NIEN LESLIE

Magnetic tilt and raise/lower mechanisms for a venetian blind

Owner:MASONITE CORP

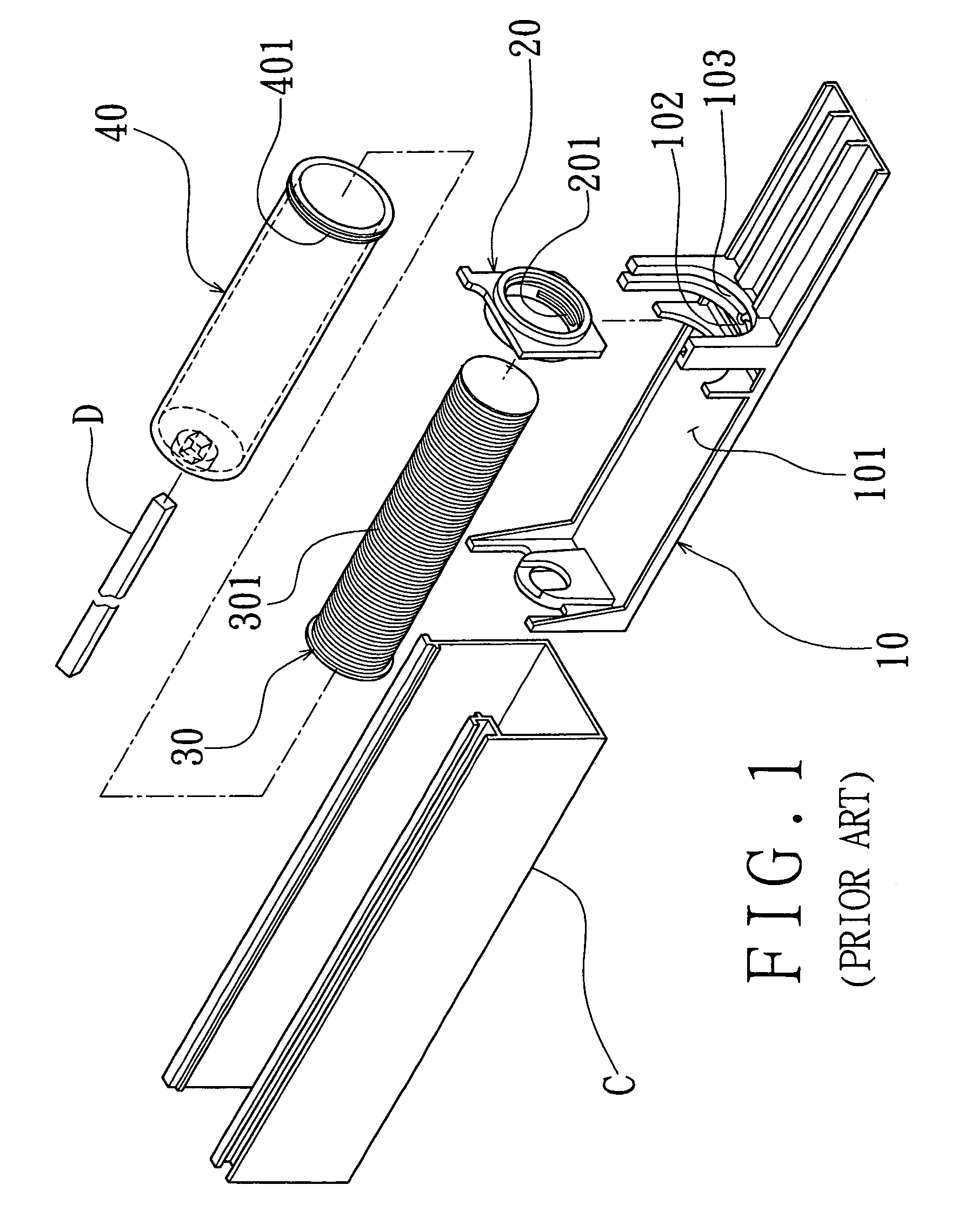

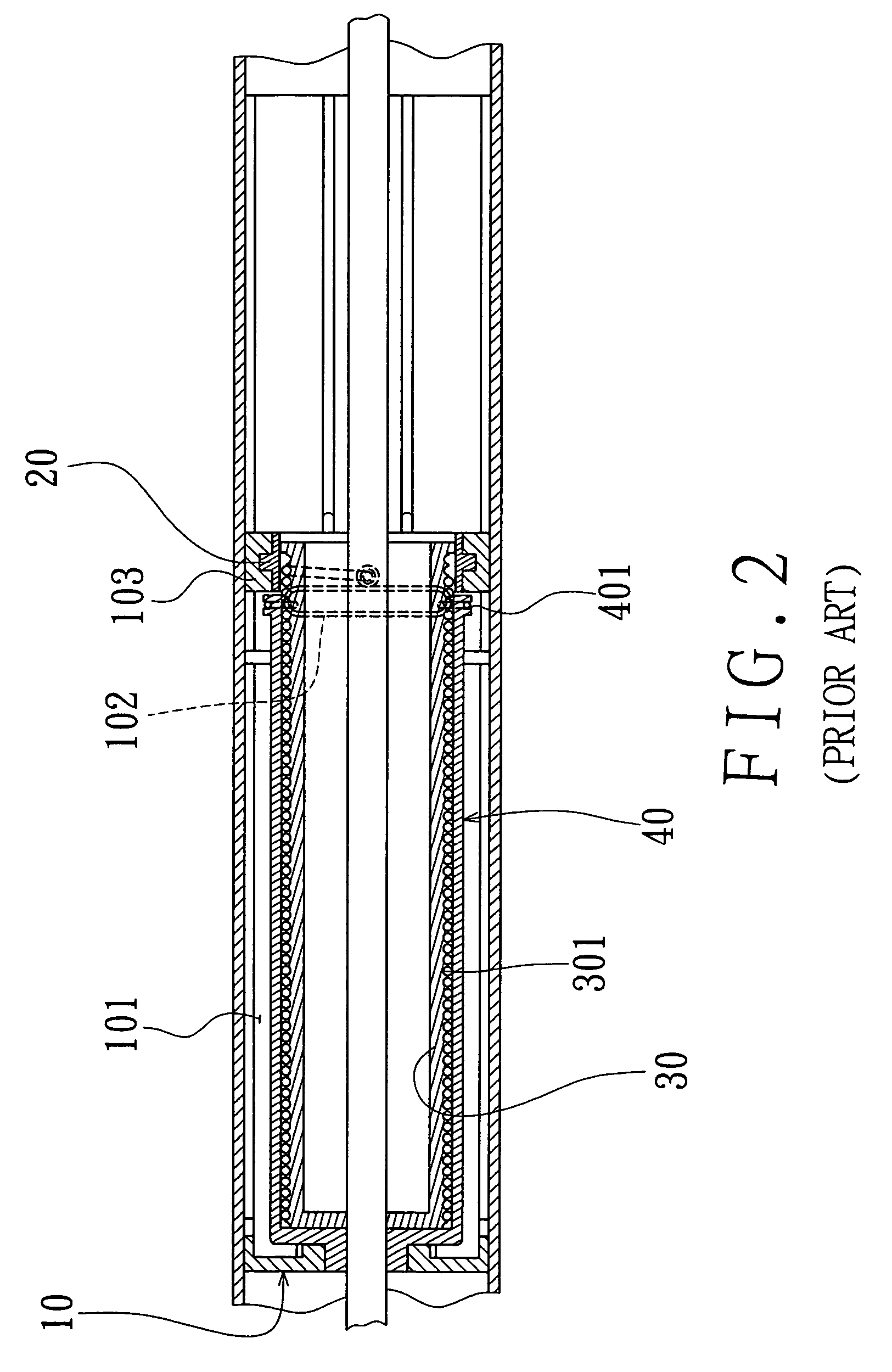

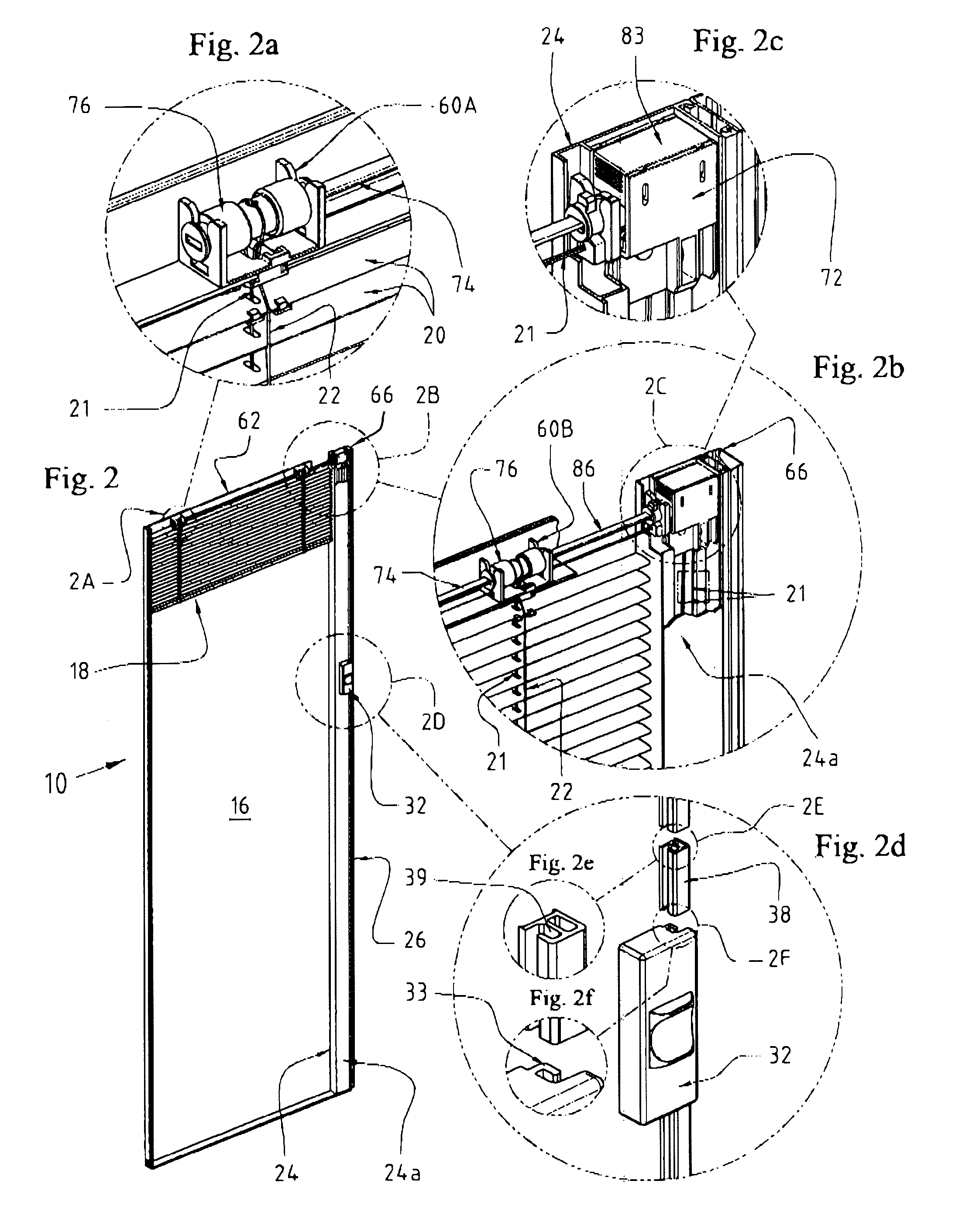

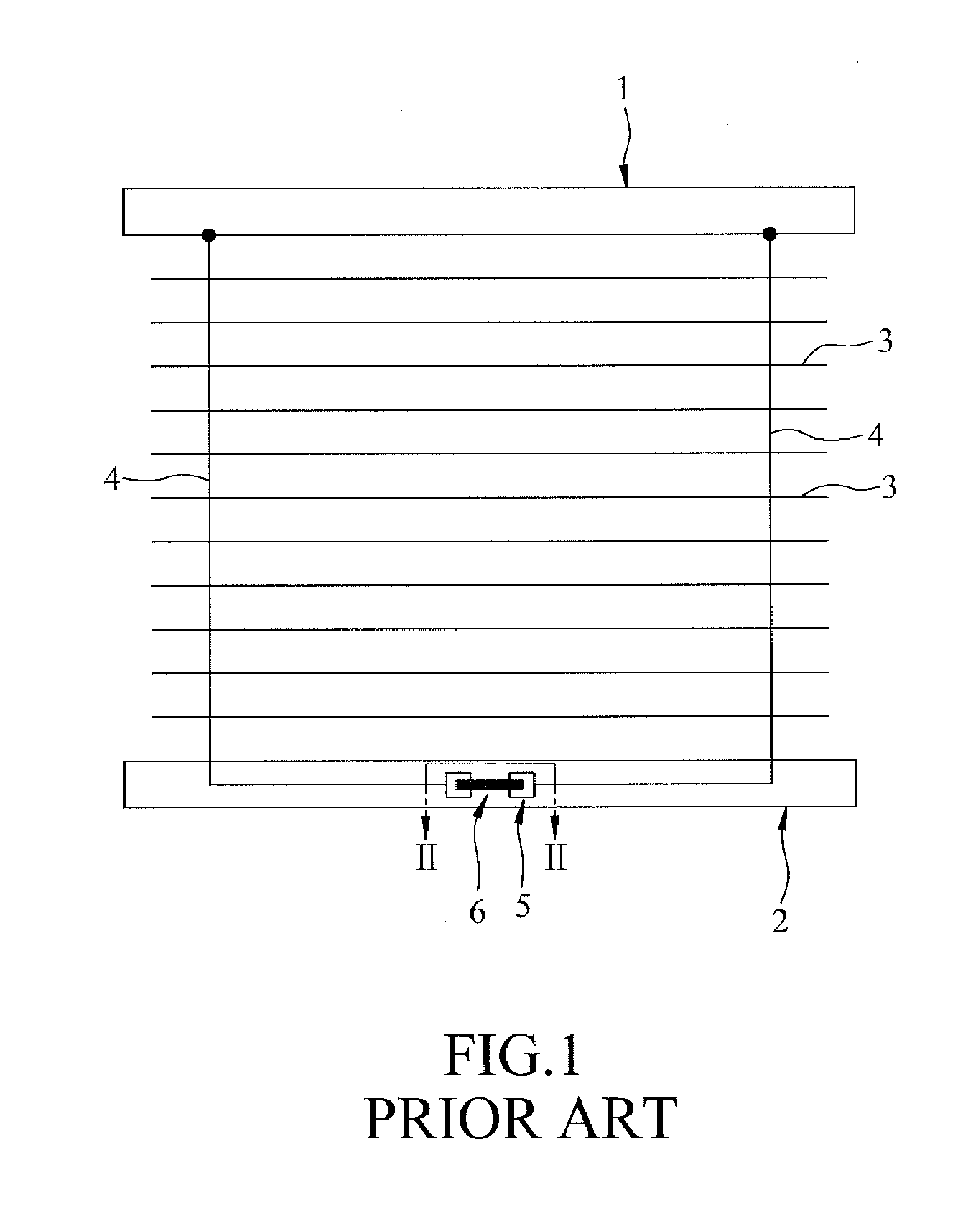

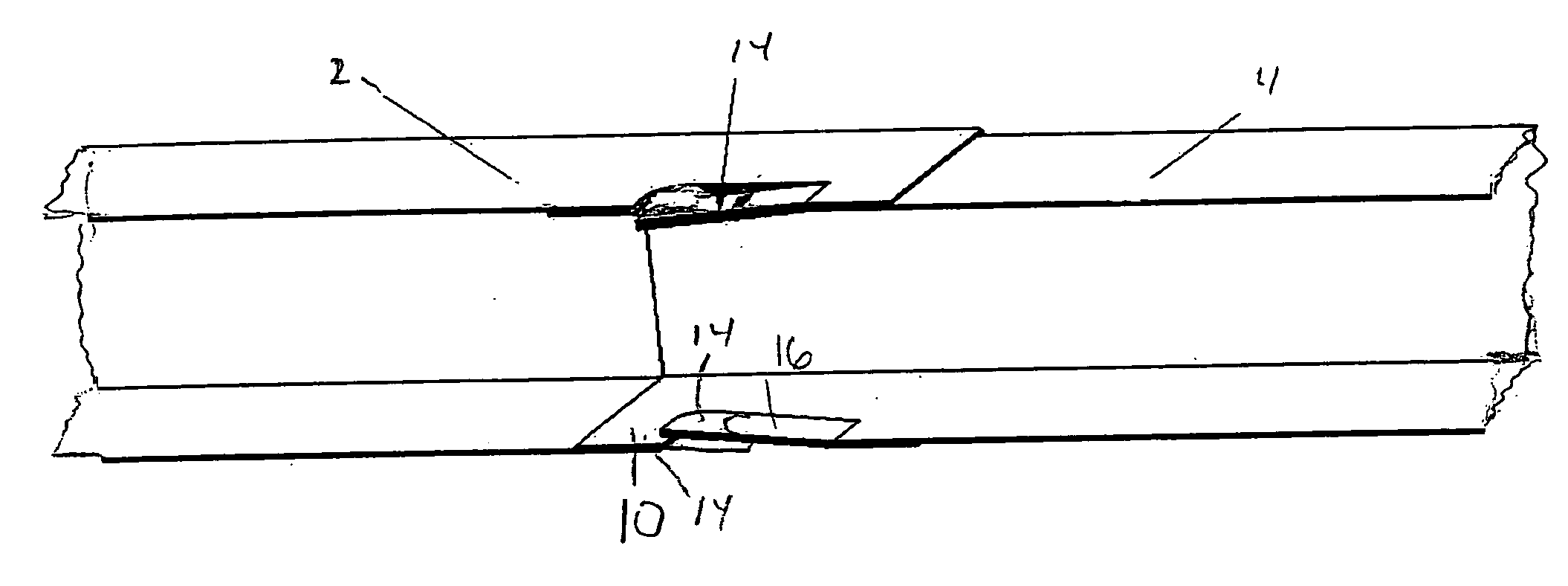

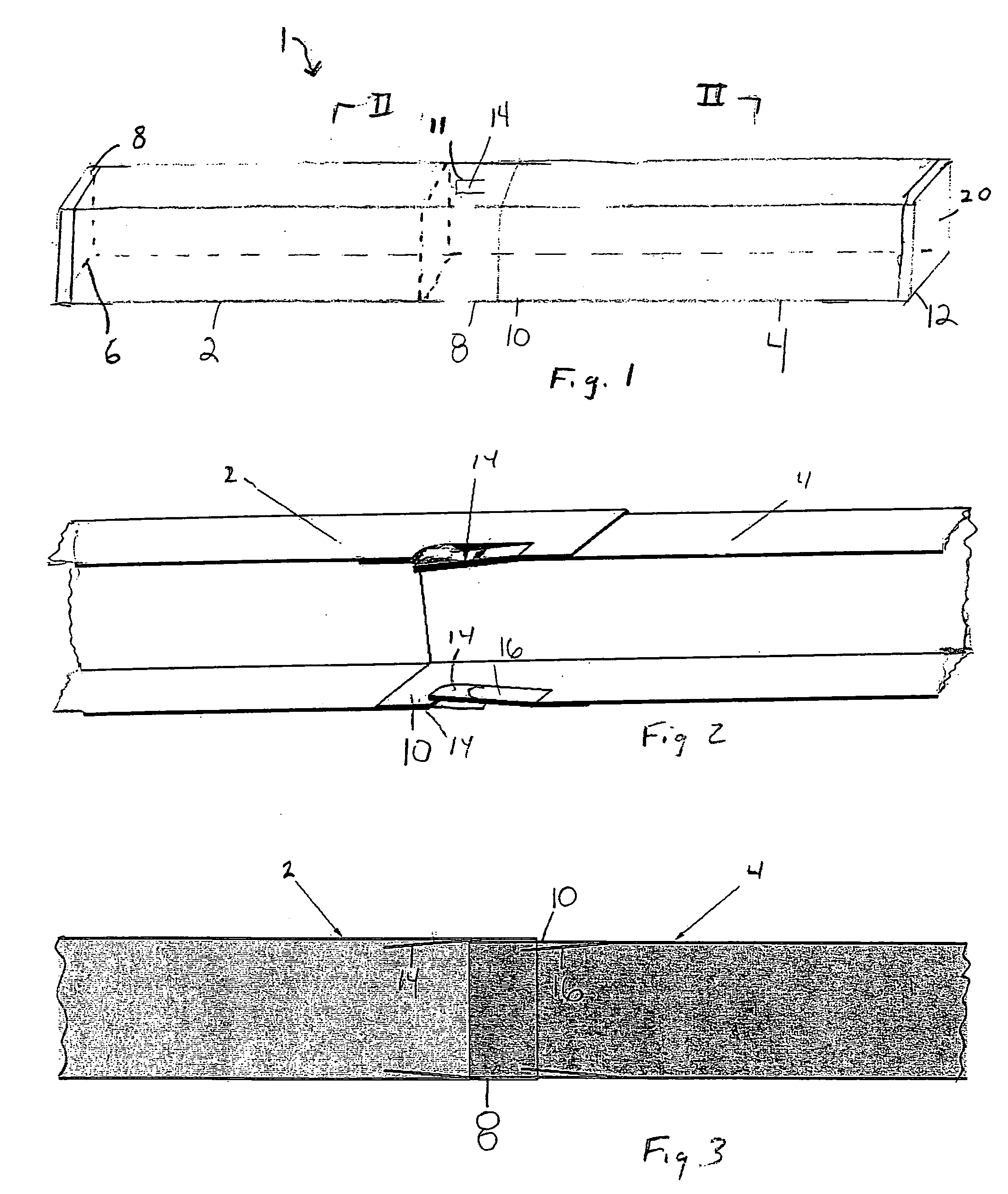

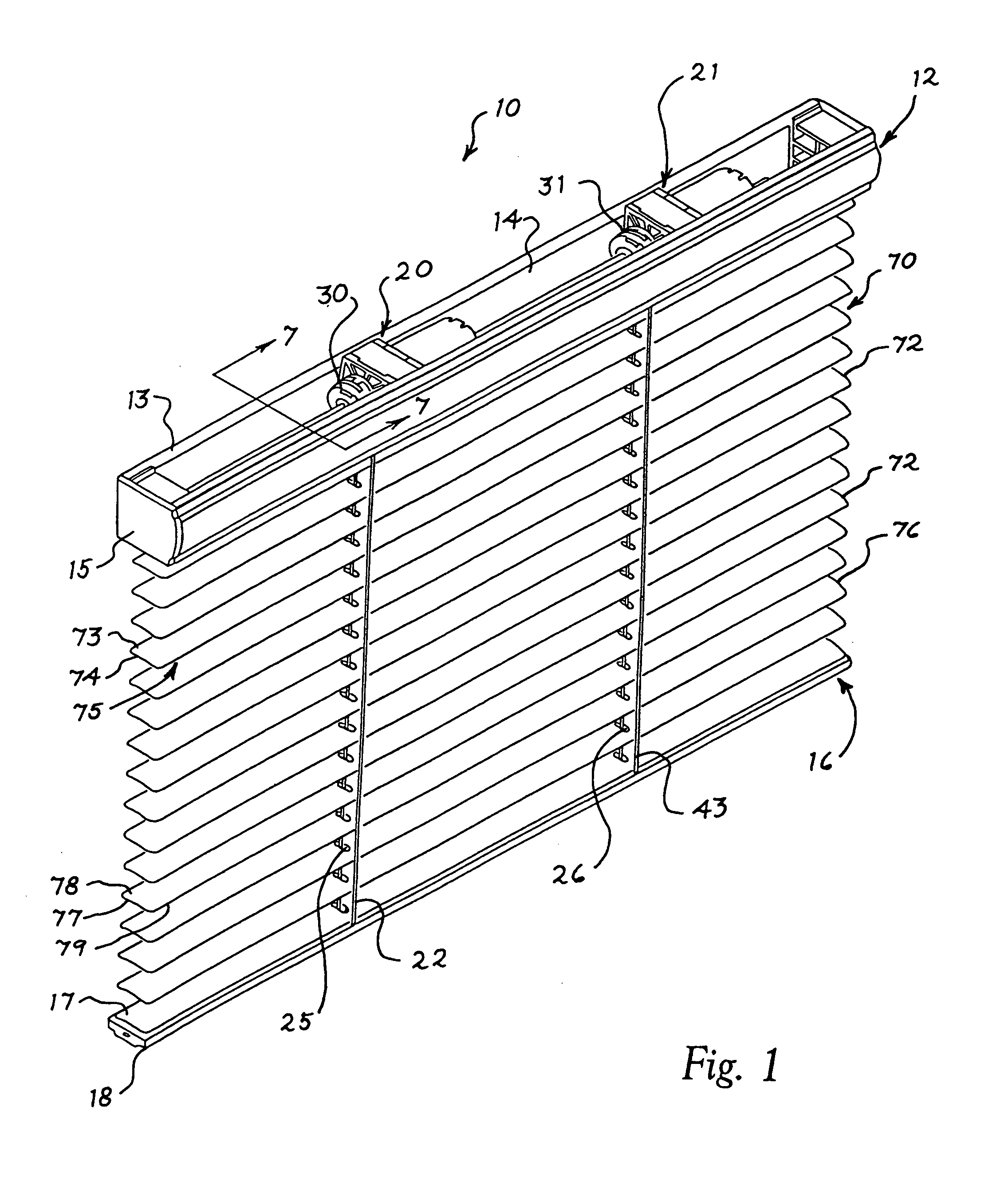

Venetian blind mounted in double glazing unit and a sliding block therefor

ActiveUS7124803B2Simple structureEasy to operateCurtain suspension devicesLight protection screensWindow shutterLong axis

A venetian blind provided in double glazing unit, which is mounted in a space defined by two sheets of glass, side frames, a top frame and a bottom frame, the venetian blind comprising a blind body composed of a counterweight, a long axis and a plurality of leaves, a driving unit, and two magnets, one of which being fixed to said sliding block and the other one being located outside the double glazing unit. The venetian blind could be lifted and deflect by the linear movement or rotation of the two magnets, one of which is inside the double glazing unit and the other one is outside the double glazing unit in the case that the double glazing unit is completely sealed. The venetian blind of the present invention is simple in structure and convenient for operating.

Owner:CHANGSHU HIGH TECH CONSTR ENERGY SAVING TECH +1

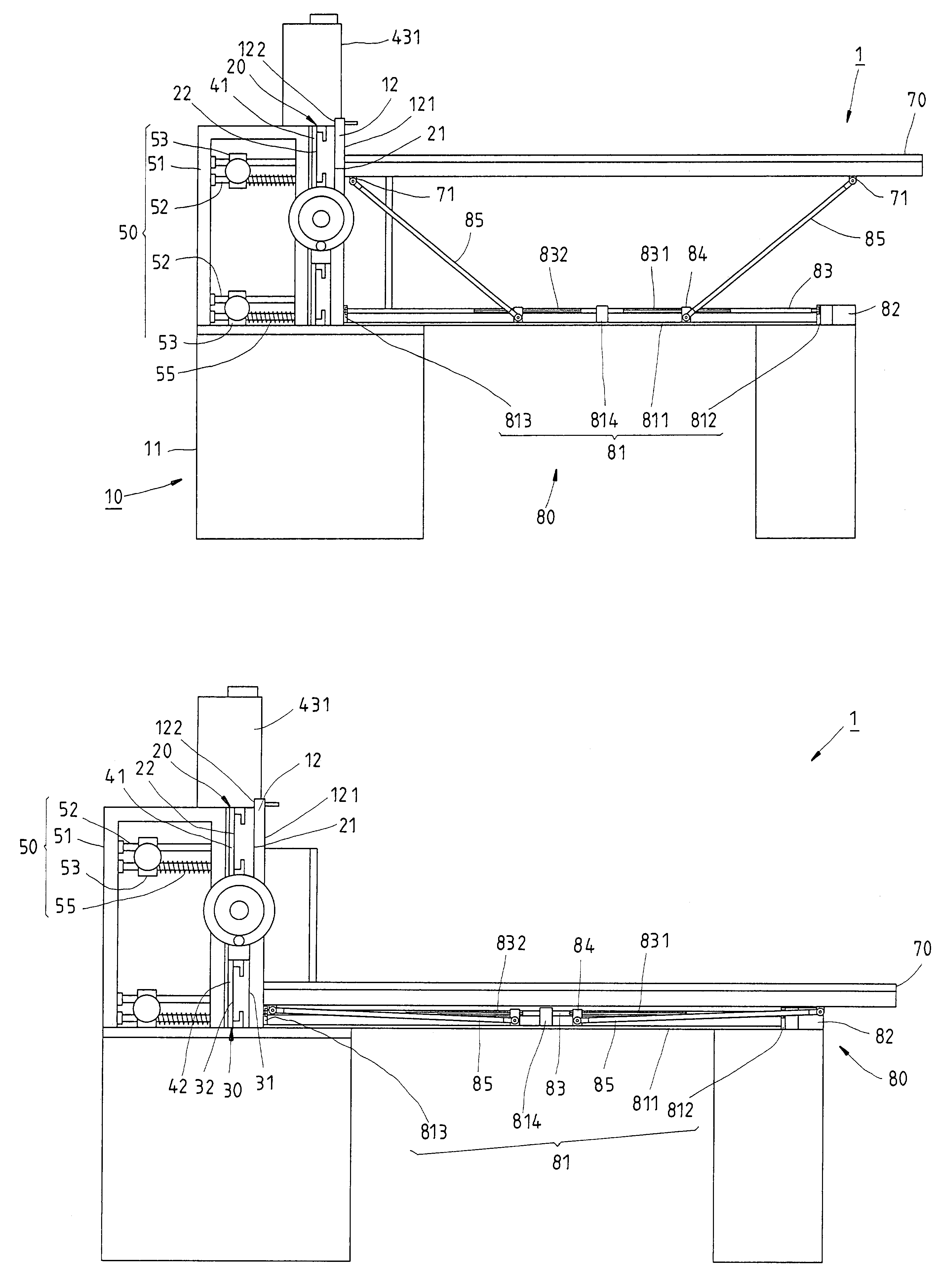

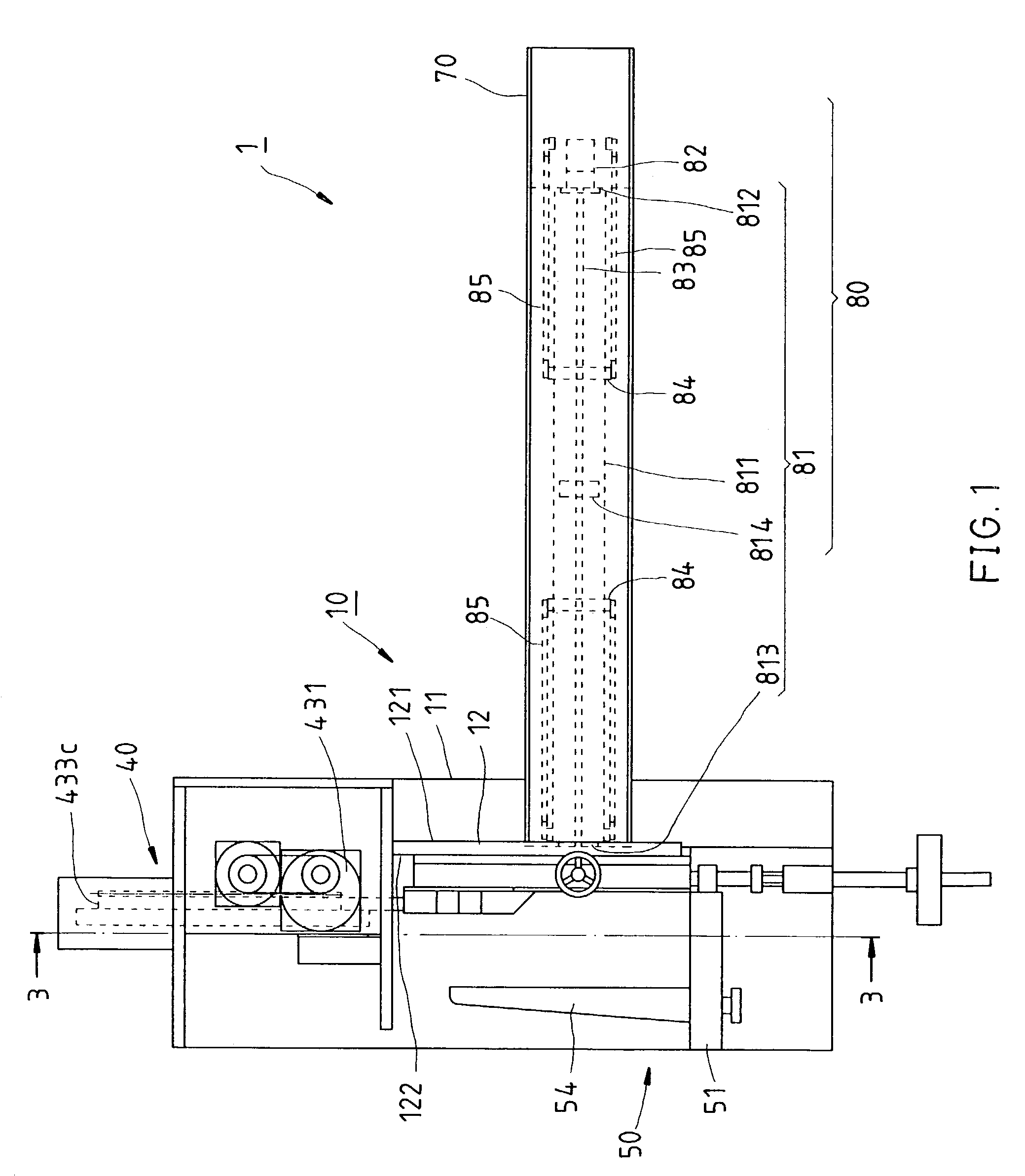

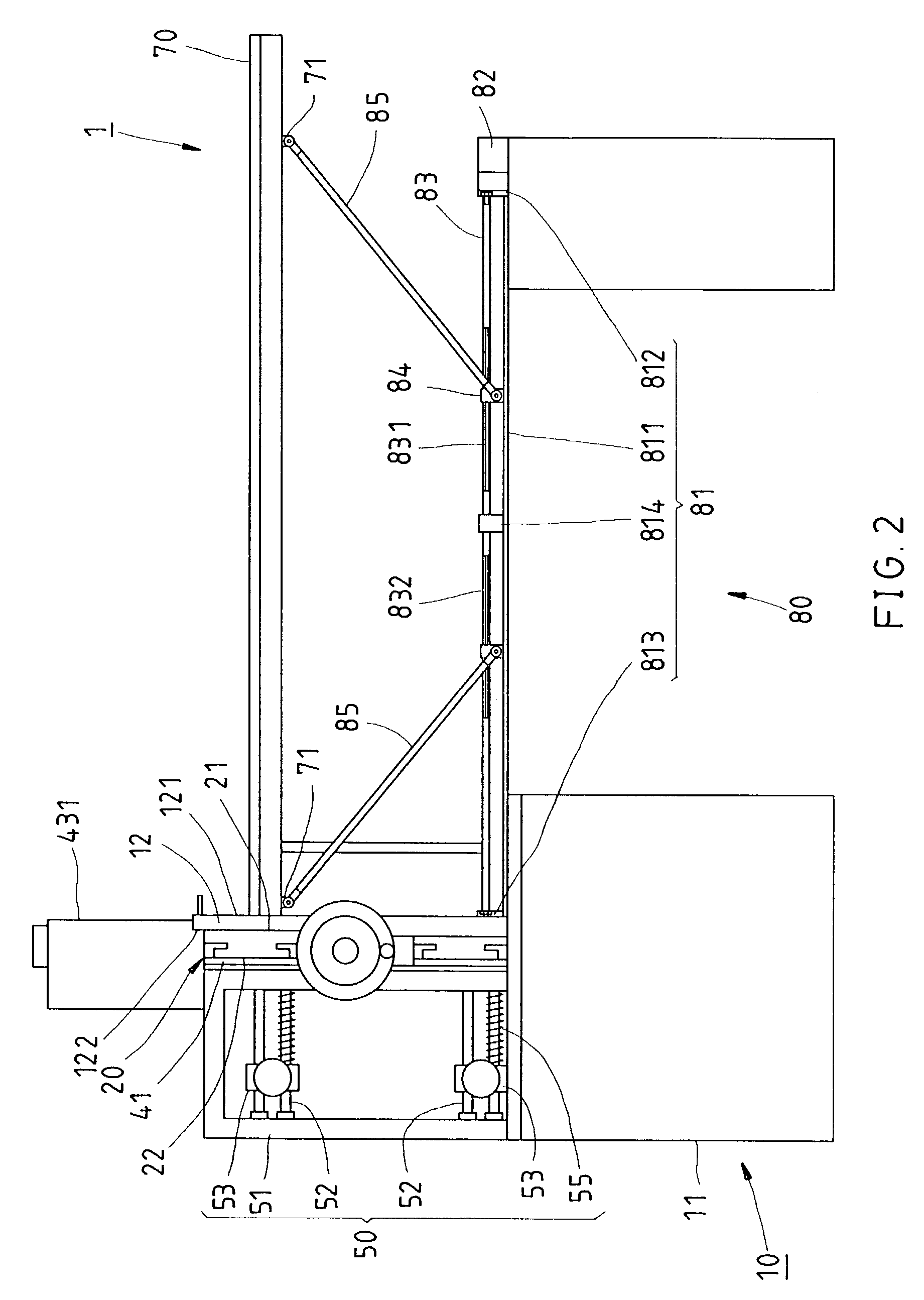

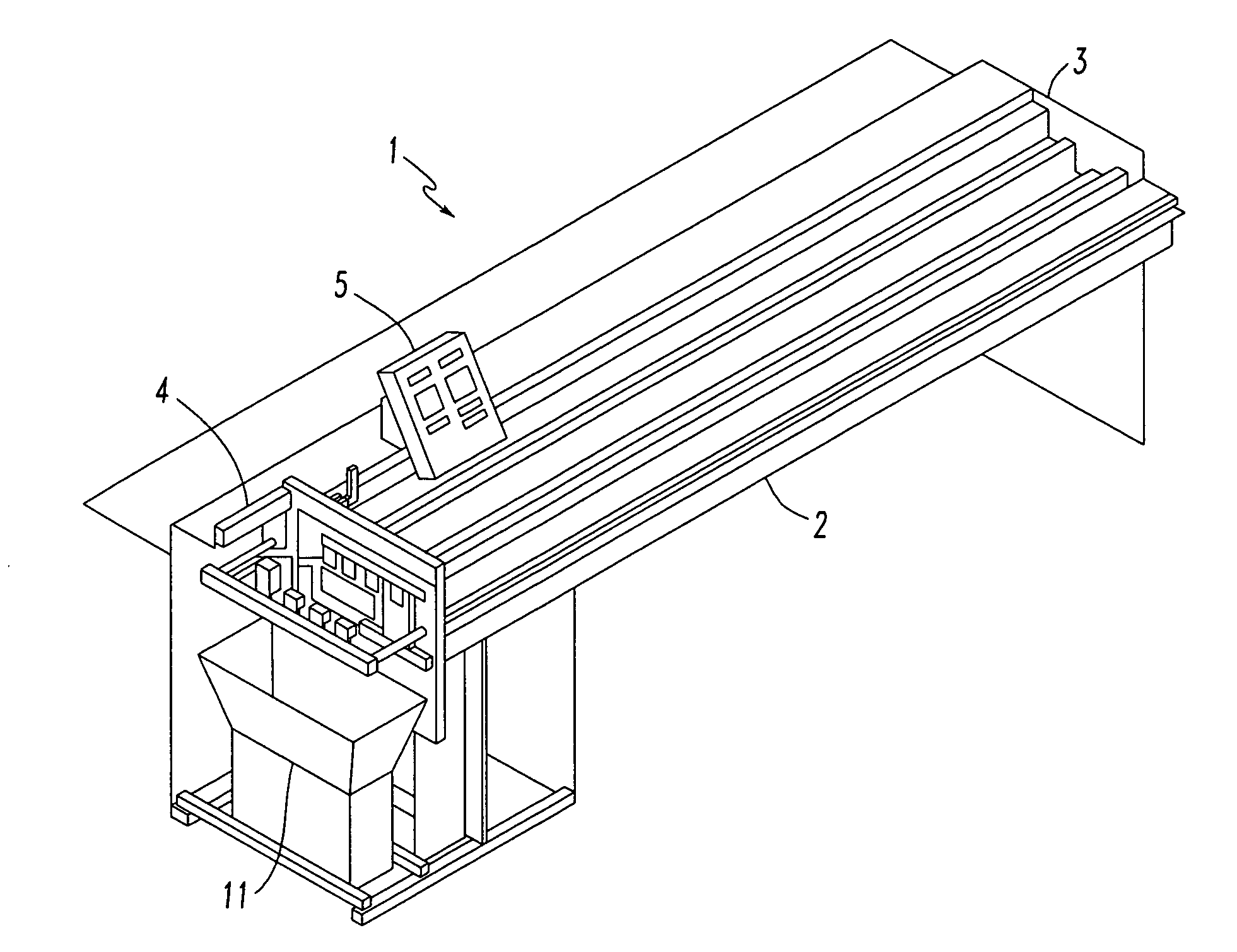

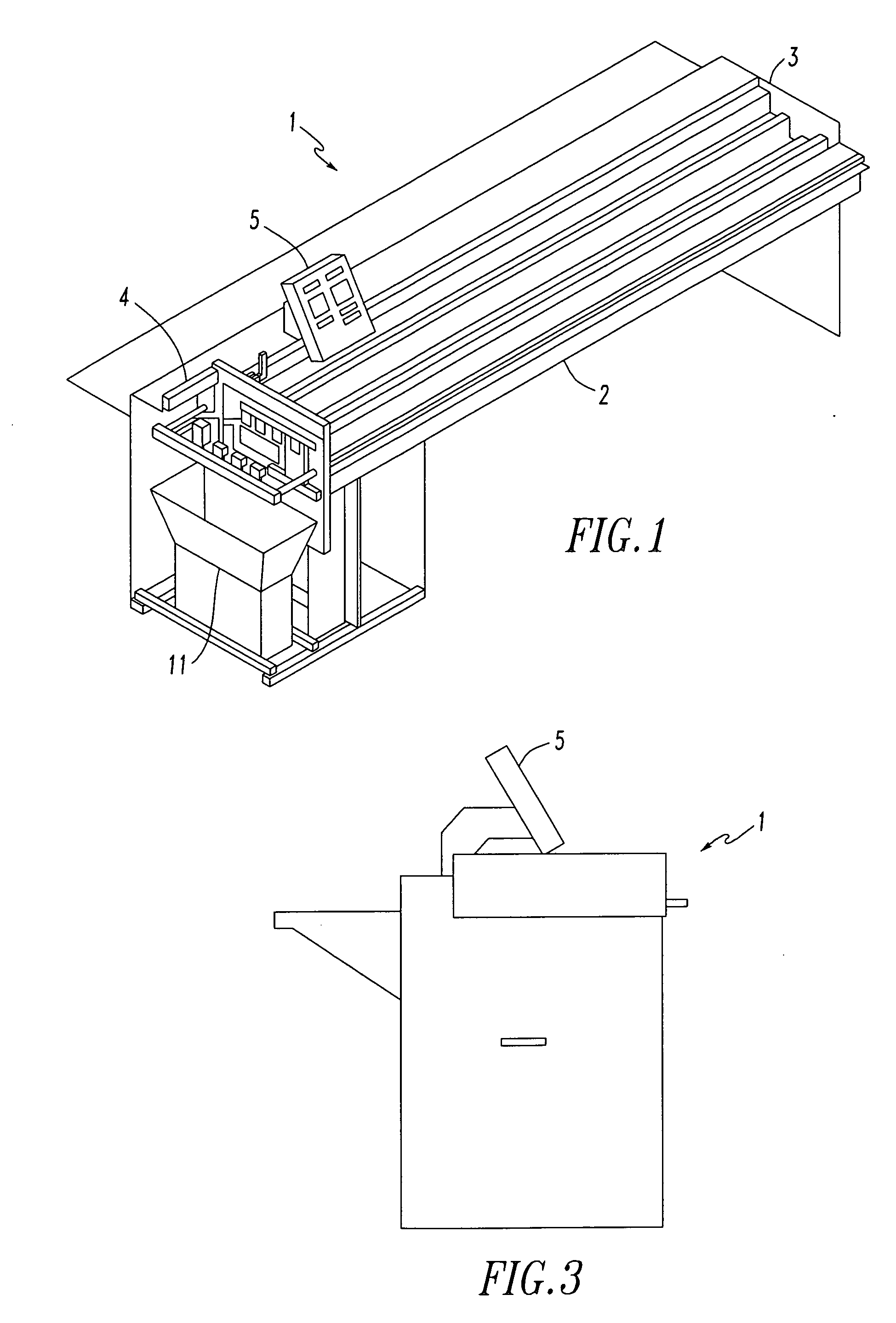

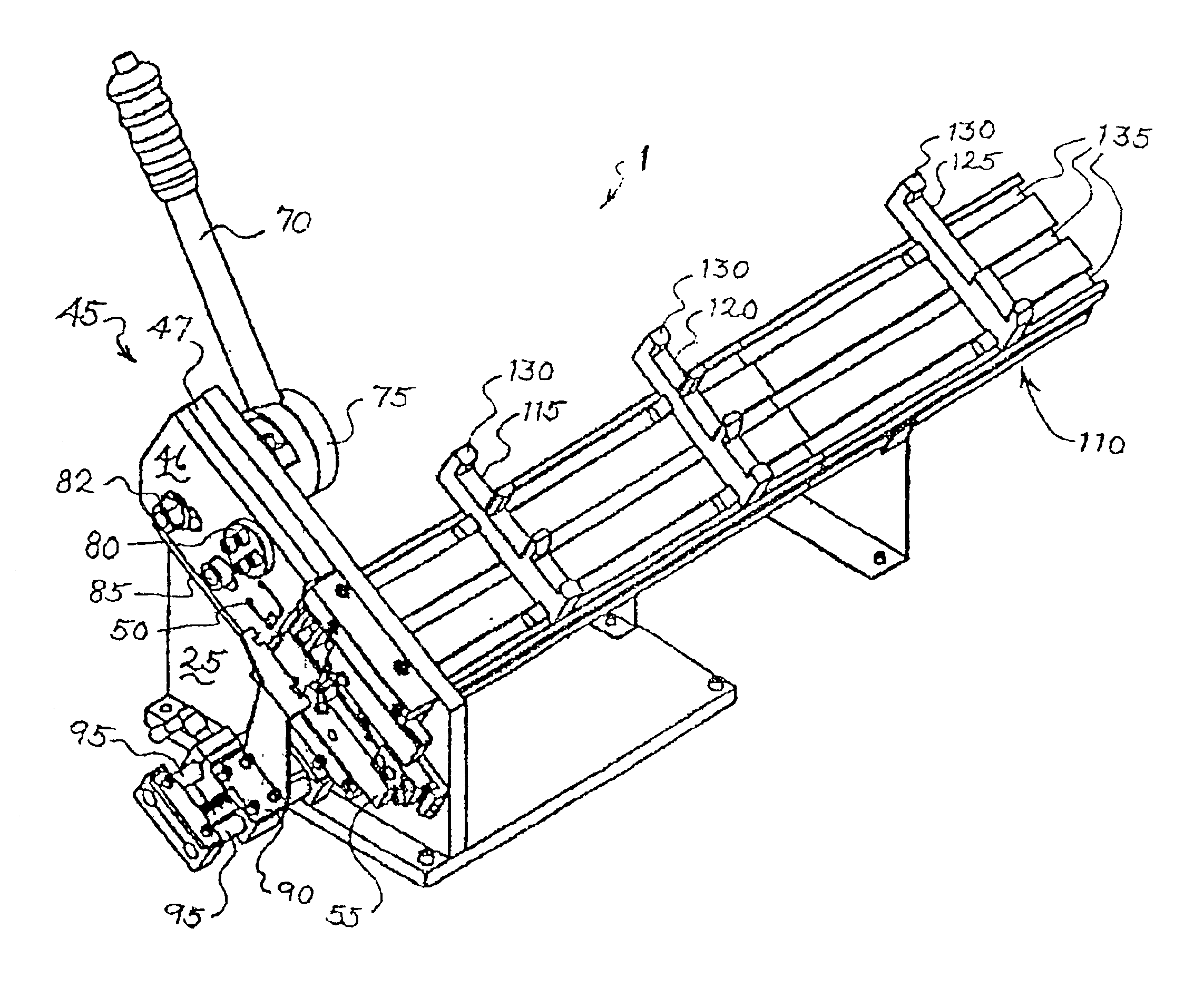

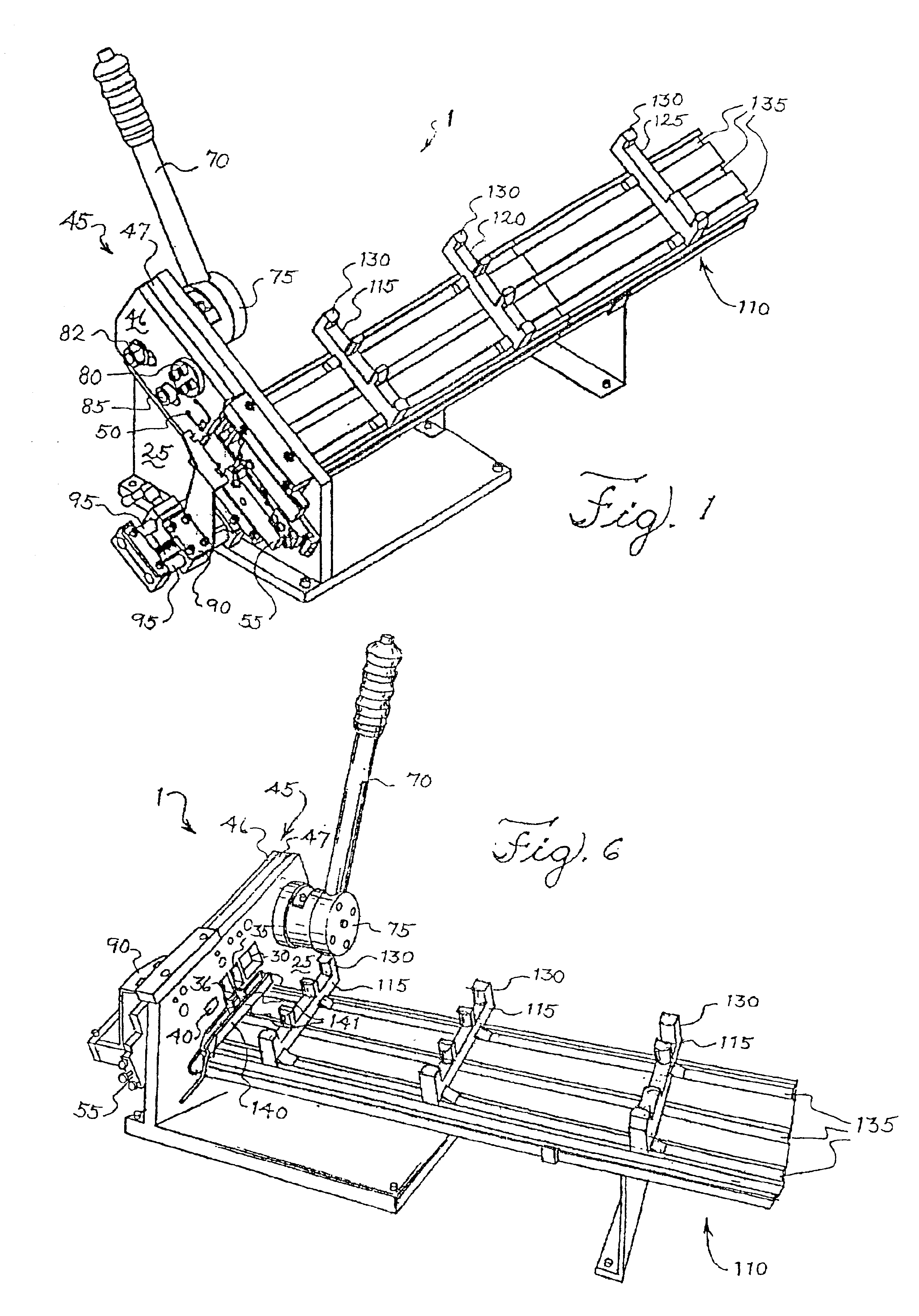

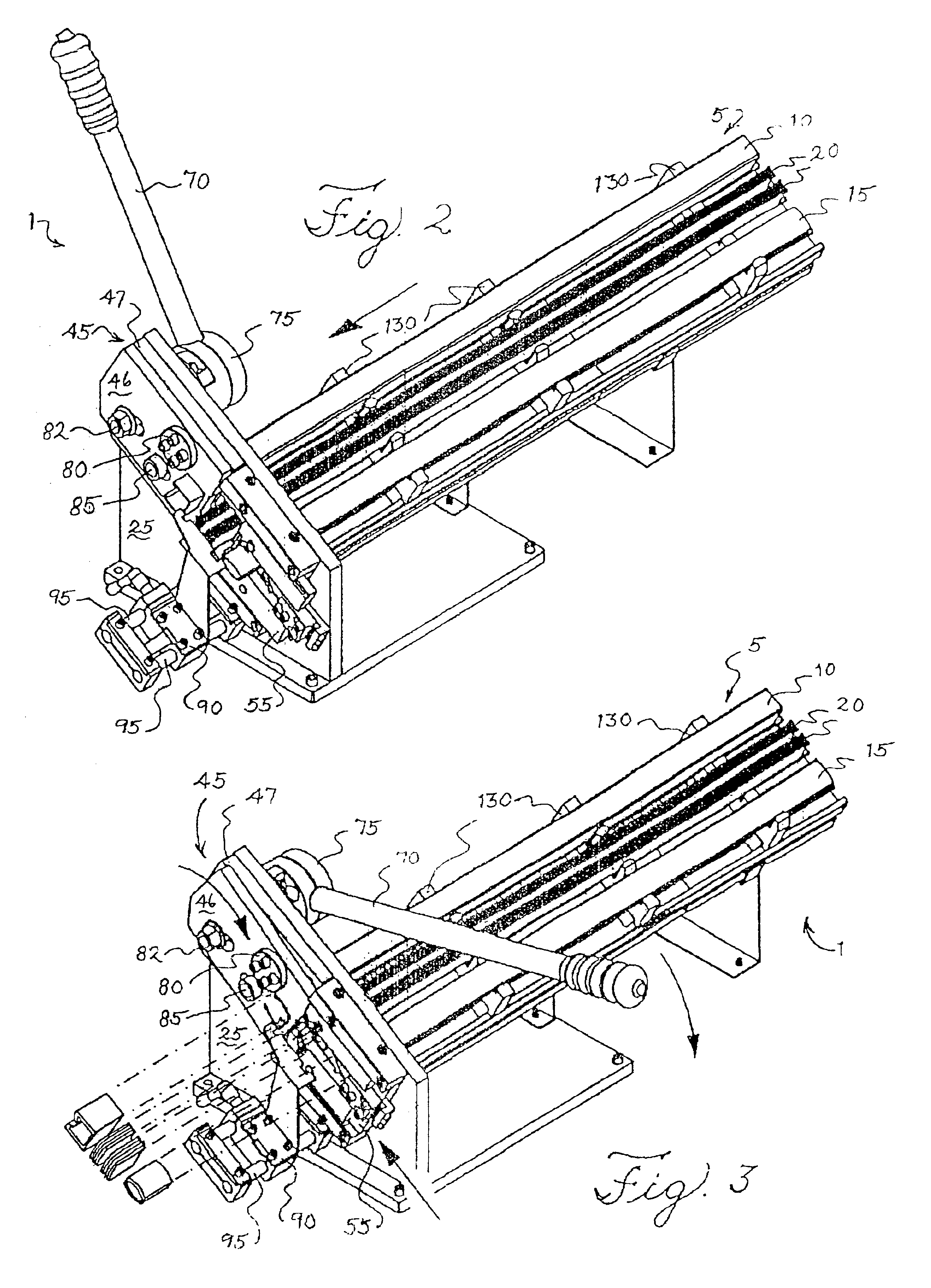

Venetian blind cutting machine

InactiveUS6971296B2Increase spaceLift/lower the blind carriageDoor/window protective devicesGang saw millsEngineeringVenetian blinds

A Venetian blind cutting machine is constructed to include a machine base, two blind locating modules mounted on the machine base at different elevations, each of which having a set of through holes for supporting component parts of a Venetian blind to be cut, a blind carriage adapted to carry the Venetian blind to be cut, a carriage for moving the blind carriage to the elevation of one of the blind locating modules for enabling the Venetian blind to be cut to be put in the selected blind locating module for cut, a cutter provided at the other side of the blind locating modules, and a cutter drive adapted to move the cutter across the imaginary axis passing through each of the through holes of the blind locating modules to cut the component parts of the loaded Venetian blind and then to return the cutter after cutting.

Owner:IND TECH RES INST +1

Automated venetian blinds

An automated blind assembly is disclosed including a shaft connected to a rotatable slat and a motor connected to the shaft. The motor operates to rotate the shaft and thereby rotate the rotatable slat.

Owner:WHITING GREG

Cord-winding device for a venetian blind

A cord-winding device for a Venetian blind includes: a first reel; a driving unit including a driving wheel and a spring-winding wheel; and a brake unit including a driven gear, a driving member, a ratchet wheel sleeved on the driving member, a plurality of friction members disposed between the driving member and the ratchet wheel, and at least pawl biased to engage the ratchet wheel. When the driven gear is driven by the first reel to rotate in a direction, rotation of the ratchet wheel is stopped by the pawl so that the driving member drives the friction members to rotate, and when the driven gear is driven by the driving wheel to rotate in an opposite direction, the driving member drives rotation of the friction members and, thus, the ratchet wheel.

Owner:TAICANG KINGFU PLASTIC MFG

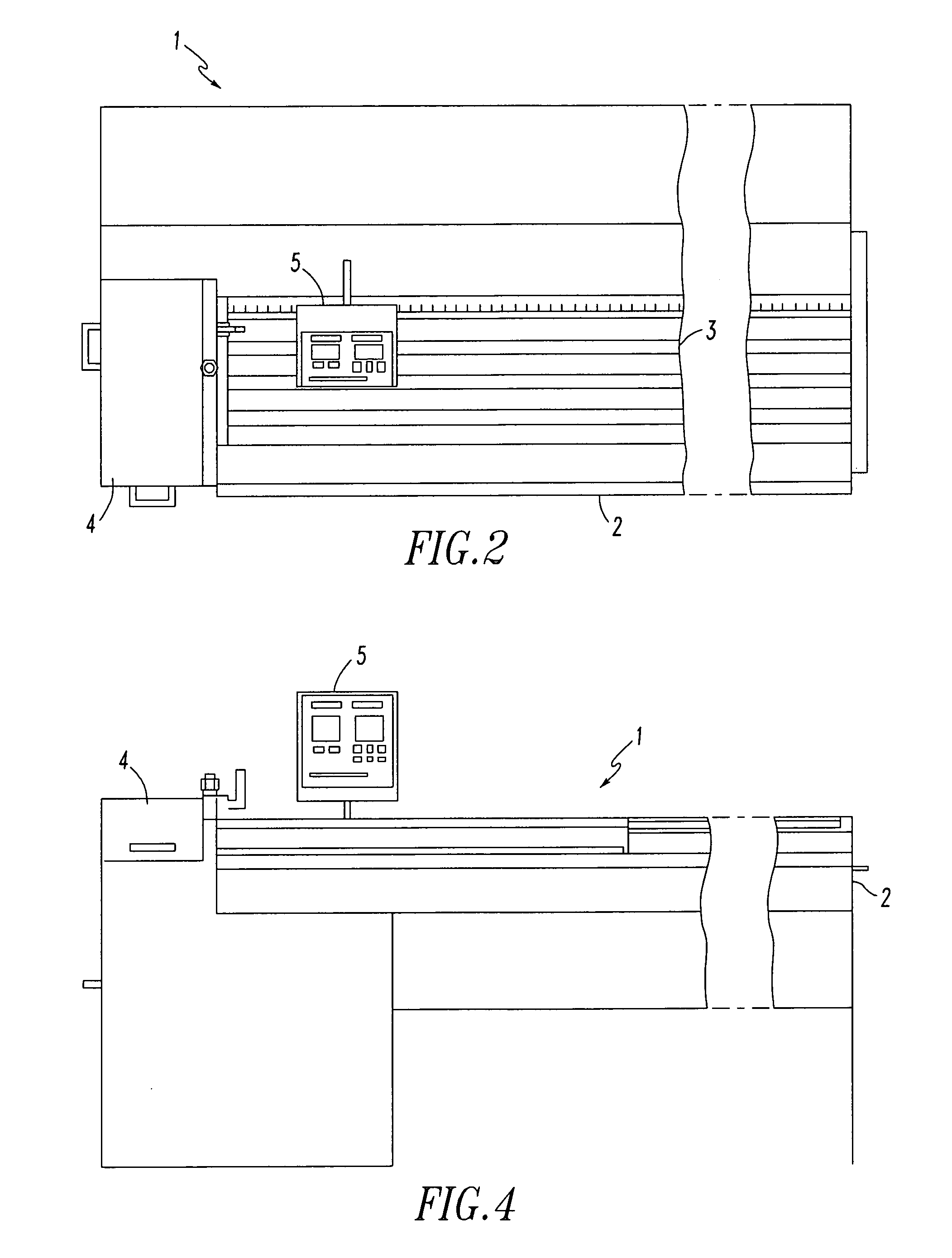

Cutting machine for blinds

ActiveUS20070000363A1Door/window protective devicesStock shearing machinesHorizontal axisVenetian blinds

In a cutting machine for cutting down Venetian blinds a headrail cutter and a bottom rail cutter are provided which move along a horizontal axis. After the headrail and bottom rail are trimmed a slat cutter moves in a vertical axis, up or down to cut the slats. The cutting machine enables one to cut down a venetian blind while the opposite end of the blind remains in the packing box. Preferably, a spacer or collar is provided on the blind prior to packaging so that the headrail, window covering material and bottom rail will be spaced apart from one another a desired amount. That spacing should be the same spacing as the openings in the cutting machine so that when one end of the blind is removed from the package that end of the blind can be readily inserted into the cutting mechanism.

Owner:LUMINO

Telescoping container for venetian blinds

InactiveUS20060108078A1Small sizePrevented from expandingLight protection screensLocking mechanismEngineering

A clear tubular container consisting of two sections, one slightly smaller than the other, that can telescope to a smaller size. A flexible tab locking mechanism prevents the tubular structure from increasing in length beyond its original size but allows the structure to easily telescope to a smaller size. Removable caps are mounted at each end. The caps can be removed and the container telescoped to a smaller size to allow the window blinds to be trimmed without removing them from the container. The container's length can be easily varied by changing the placement of the tab and window.

Owner:LUMINO

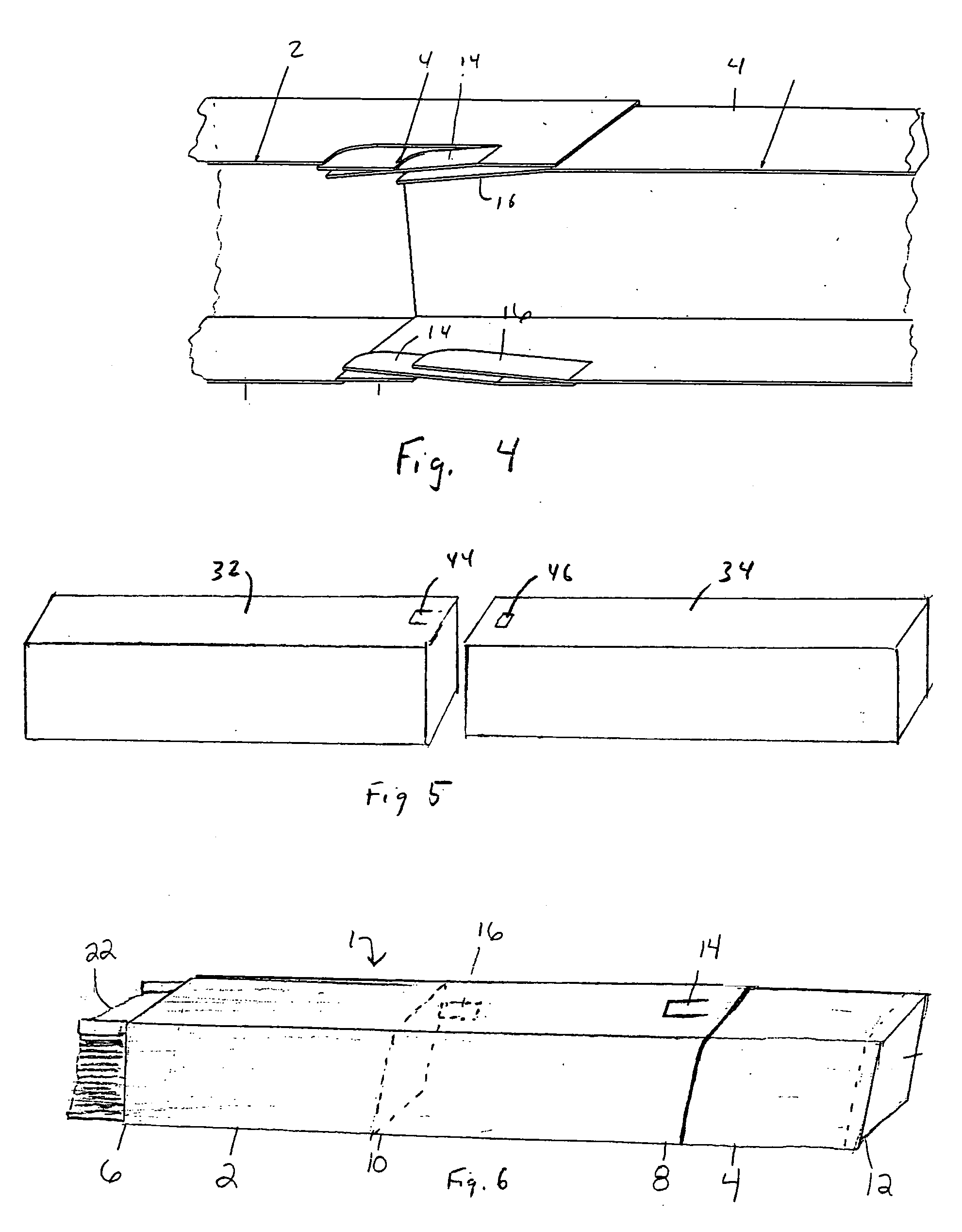

Cutting apparatus and method for venetian blinds

InactiveUS6877409B2Reduce the amount requiredEasily interchangeableLight protection screensStock shearing machinesEngineeringVenetian blinds

A cutting machine for a Venetian blind comprising a head rail, a bottom rail, and a plurality of blind slats. The cutting machine comprises a body defining a head rail opening, a bottom rail opening, and at least one blind slat opening, a plate for cutting the head rail, a blade assembly for cutting the bottom rail the blind slats, and a drive mechanism. The drive mechanism is operatively connected to the plate and the blade assembly causing the plate to cut the head rail while, at the same time, causing the blade assembly to cut the bottom rail and the blind slats.

Owner:TEH YOR CO LTD

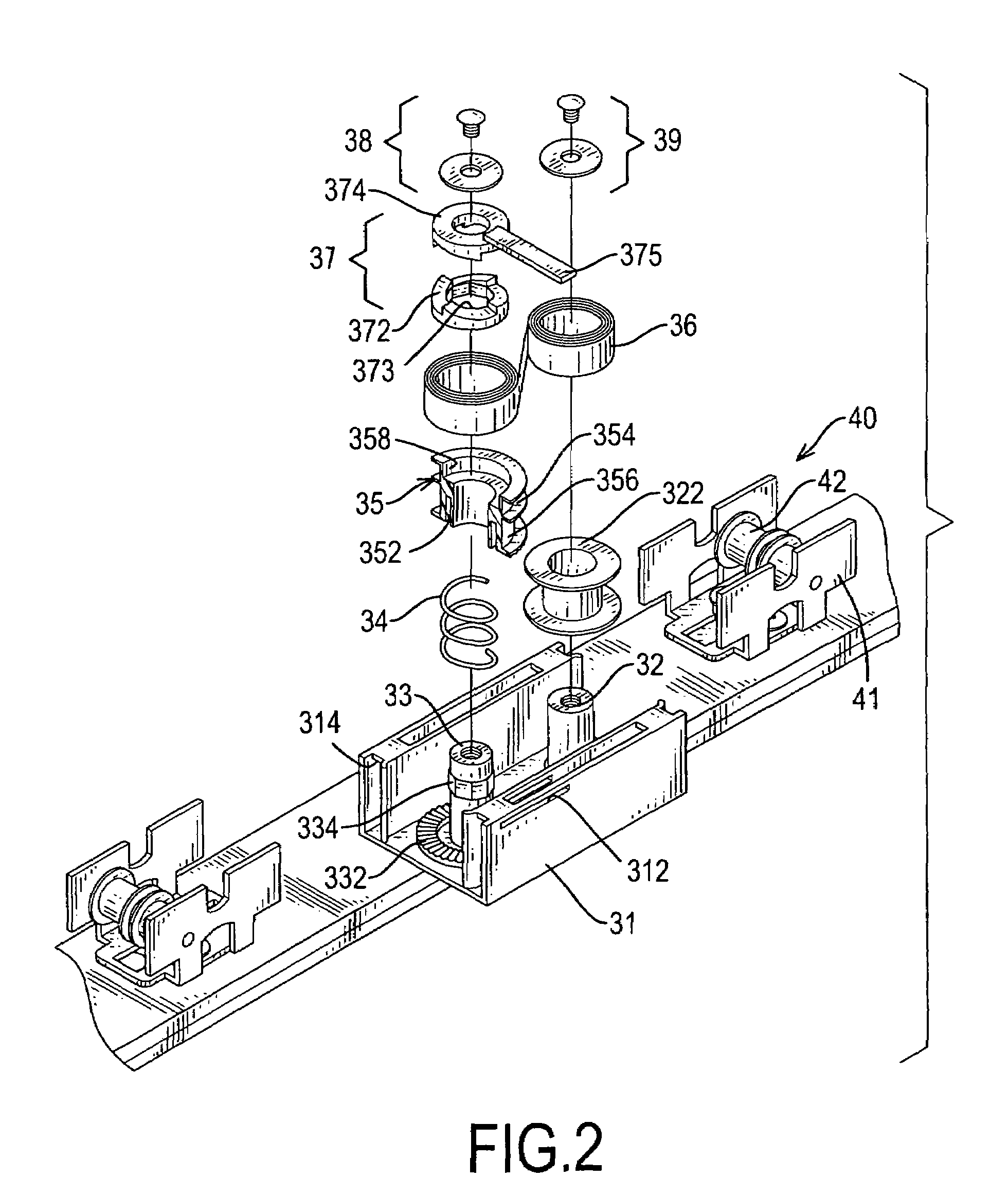

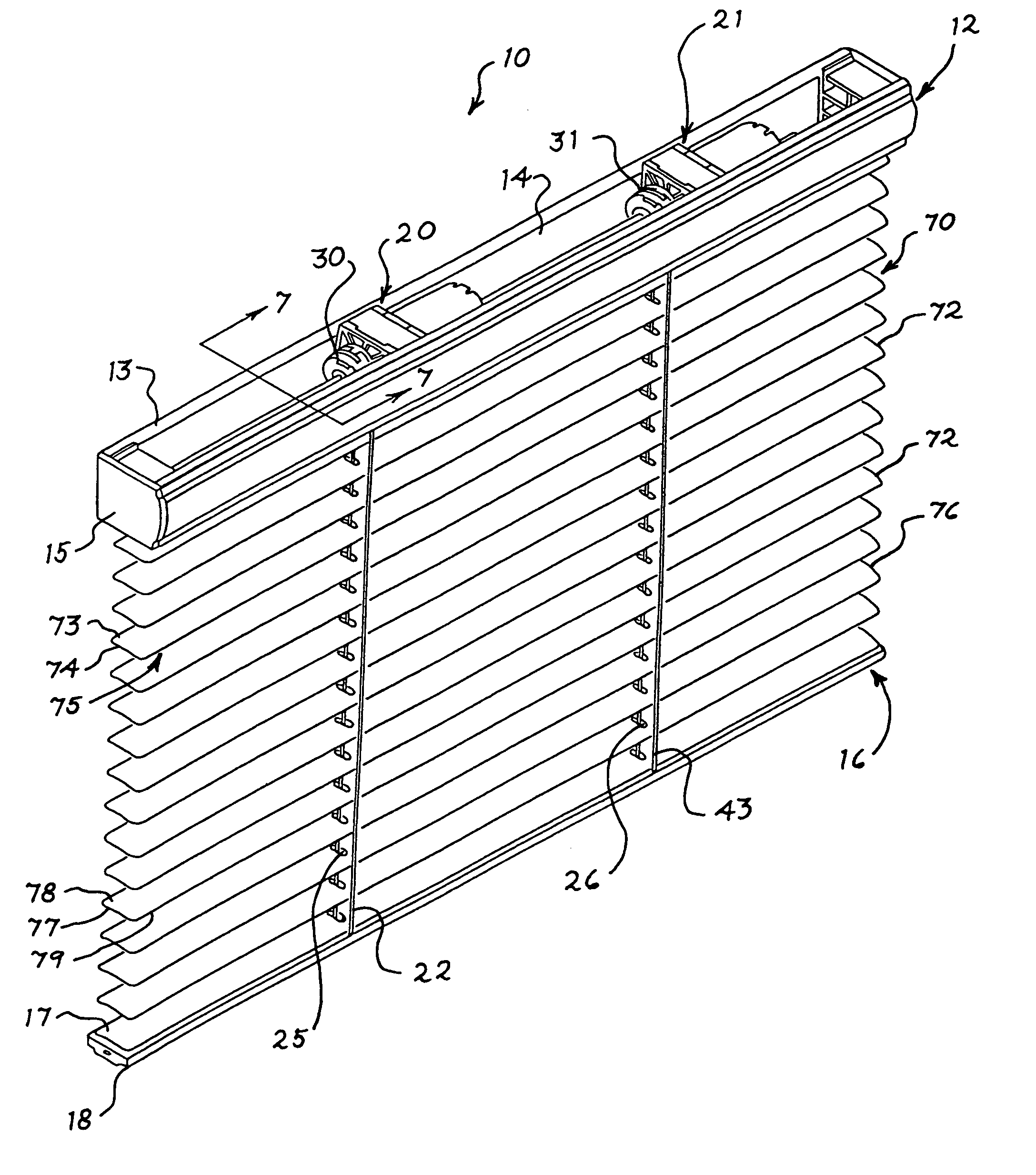

Actuator mechanism for venetian blinds

ActiveUS8281843B2High strengthIncrease engagementCurtain suspension devicesLight protection screensVenetian blindsActuator

An actuator mechanism for window coverings, such as, Venetian blinds that eliminates the use of pull cords and tilting wands is provided. The actuator mechanism includes a stop member engageable with at least one of the slats to stop tilting movement thereof and a clutch arrangement between a drive axle and a tilt control mechanism, responsive to the stop member engaging at least one of the slats, to disengage the tilting force applied to a ladder cord supporting the slats.

Owner:TEH YOR CO LTD

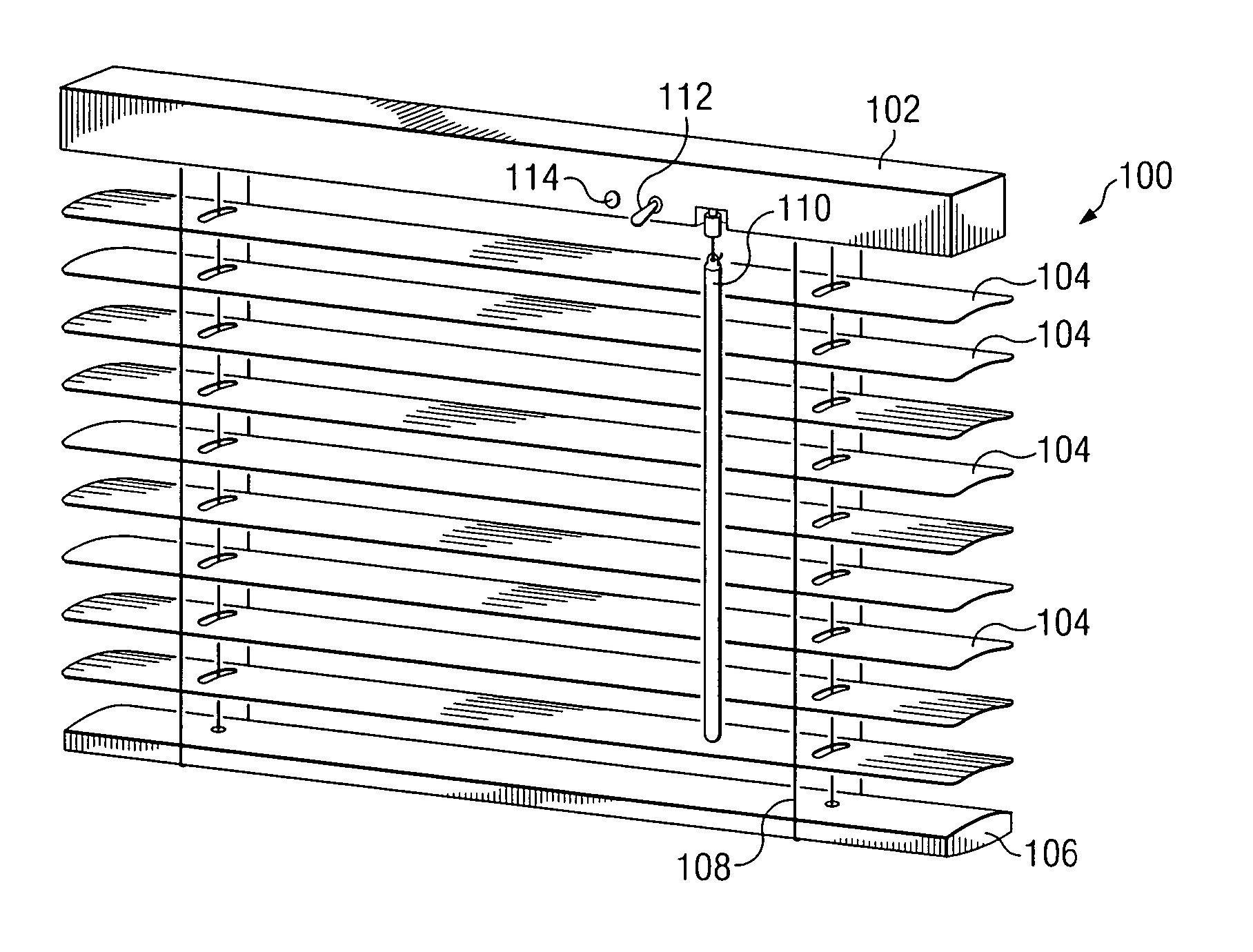

Venetian blind

InactiveUS8002012B2Easy to operateSimple and consistent mannerLight protection screensVenetian blindsMechanical engineering

A Venetian blind includes an upper rail, a lower rail, a slat assembly, an automatic retraction means and a slat opened / closed control means equipped with an adjustment member. The automatic retraction means is installed on one side of the upper rail which has a first cord wheel set and a second cord wheel set near two sides to direct a first lift cord and a second lift cord. The automatic retraction means has a retaining set to pivotally couple a transmission set inside that has a first transmission wheel and a second transmission wheel. The first transmission wheel and second transmission wheel are linked by an elastic element which provides an elastic force to drive the transmission set. The second transmission wheel controls the slat opened / closed control means. When the lower rail is pulled downwards or pushed upwards, the slat assembly can be opened or closed at different angles.

Owner:CHENG LI MING

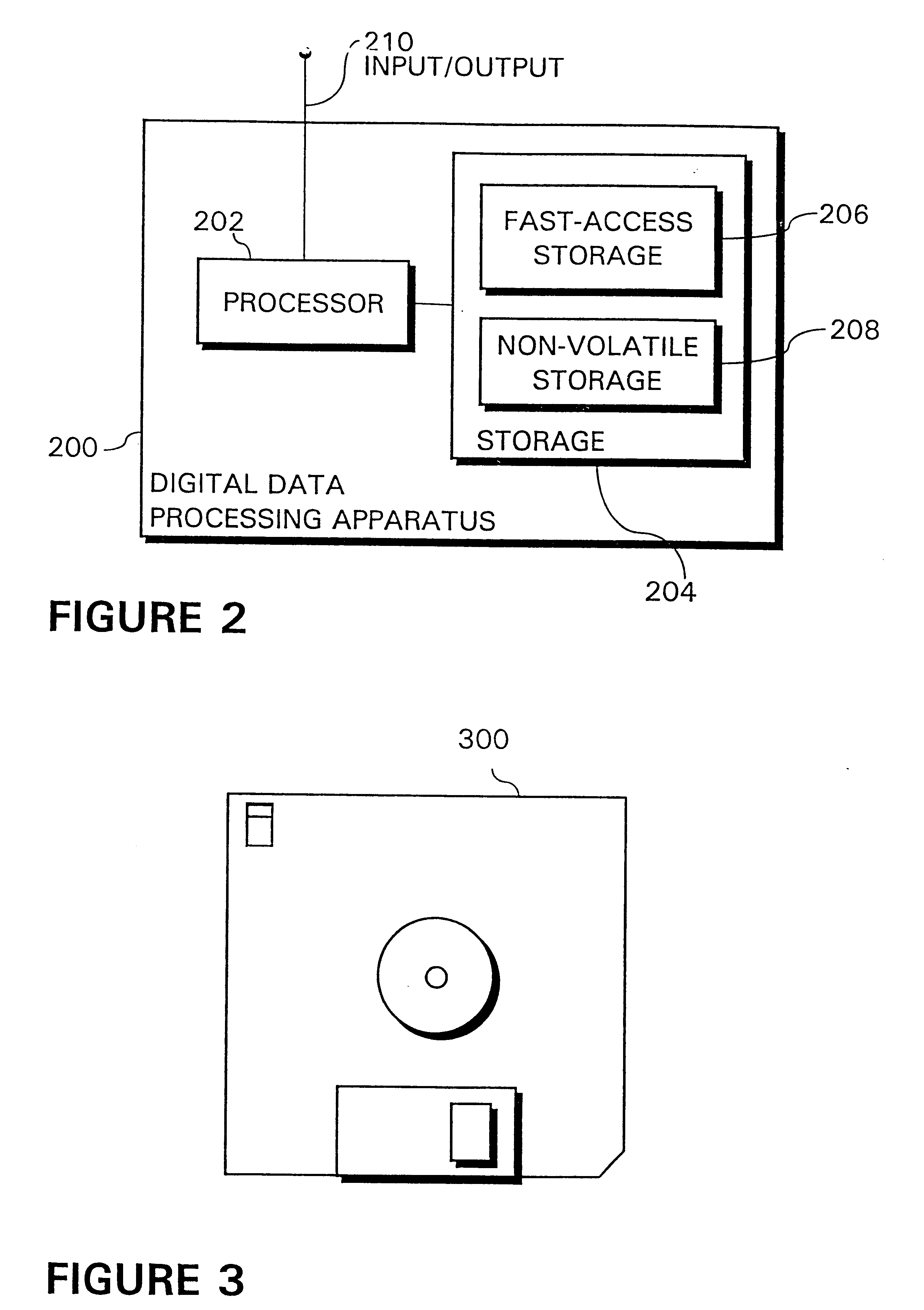

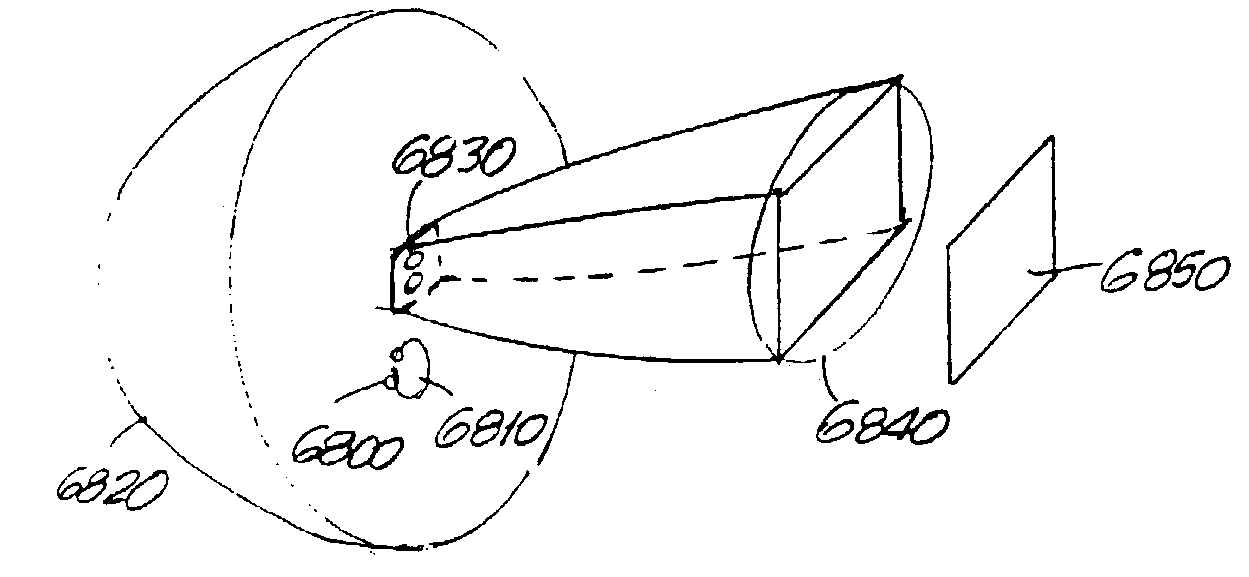

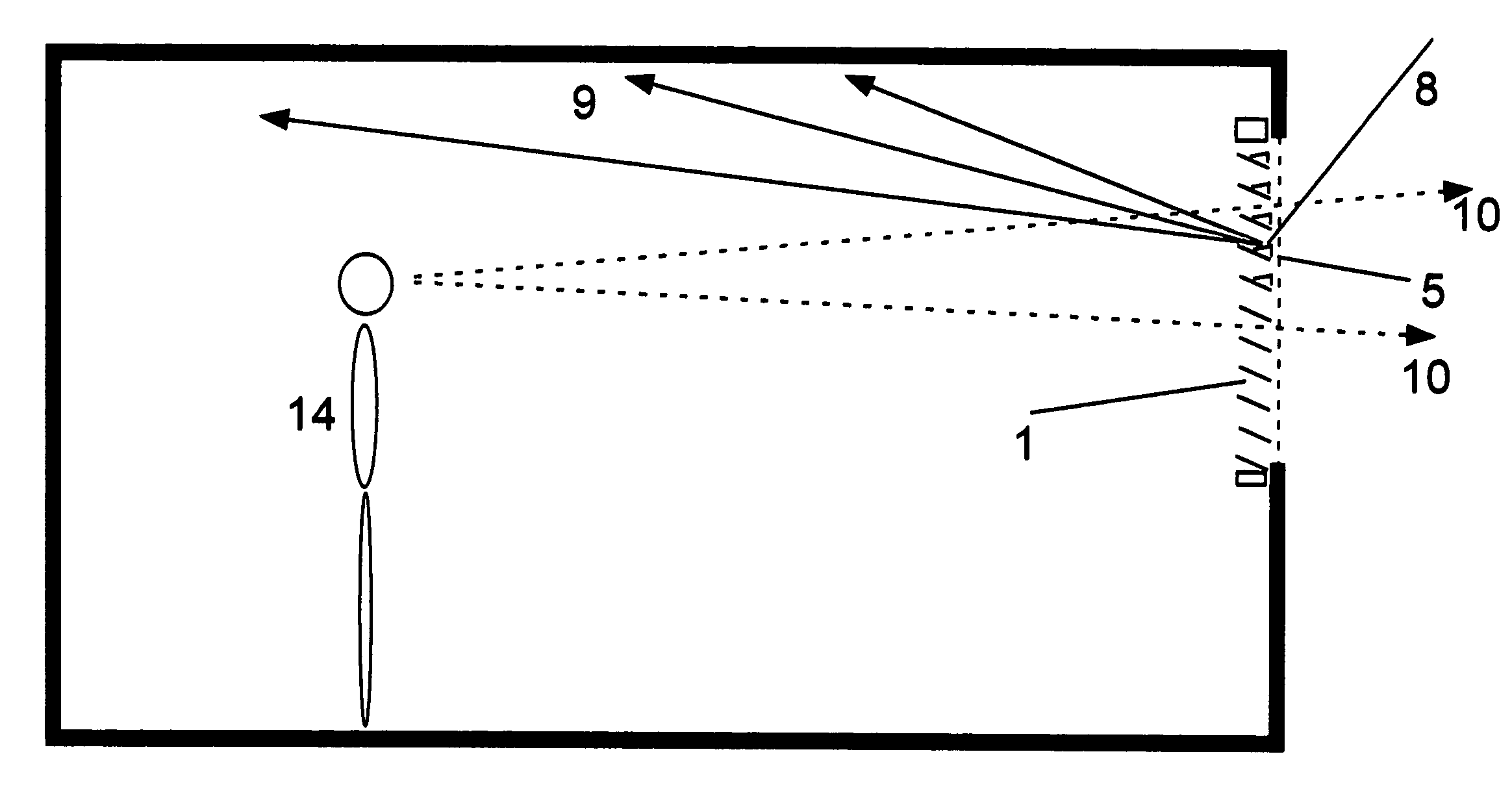

High-efficiency display system utilizing an optical element to reshape light with color and brightness uniformity

InactiveUS7688347B2Improve light throughput efficiency and qualityImprove efficiencyTelevision system detailsPicture reproducers using projection devicesContrast levelActive matrix

A light valve such as an active matrix LCD between crossed polarizers, utilizing, for instance, individual transistors to control each “pixel area” of the LCD and storage elements to store video signal data for each pixel, with optically shielded “dead spaces” between pixels to eliminate electric field cross-talk and non-information-bearing light bleed-through, is illuminated with a bright independent light source which creates a video image projected via specialized projection optics onto an internal or external screen without distortions, regardless of the angle of projection onto the screen. Use of heat sinks, IR reflective coatings, heat absorbing optics, optional fluid and a thermistor controlled pixel transistor bias voltage injection servo circuit stabilizes image performance, maintaining accurate color and contrast levels as the LCD changes temperature. In one embodiment of the invention, use of a multi-color LCD with a stepped cavity, producing different thicknesses of LCD for the different wavelengths that pass through it, allows a linear correspondence between the wavelengths passing through the LCD to produce true black, high contrast and CRT-like color rendition. A dichroic mirror arrangement is used to overlap differently colored pixels in the projected image. Use of striped mirrors duplicate pixels, where necessary, eliminating spaces between pixels, creating a continuous image with no apparent stripes or dots. A special venetian-blind type of screen is also disclosed and methods for using the system to view three-dimensional video are also explained.

Owner:DOLGOFF GENE

Headrail with reversible cord lock position

InactiveUS6899156B2Easy to disassembleEasy to switchClosuresCurtain suspension devicesEngineeringMechanical engineering

Owner:ITA

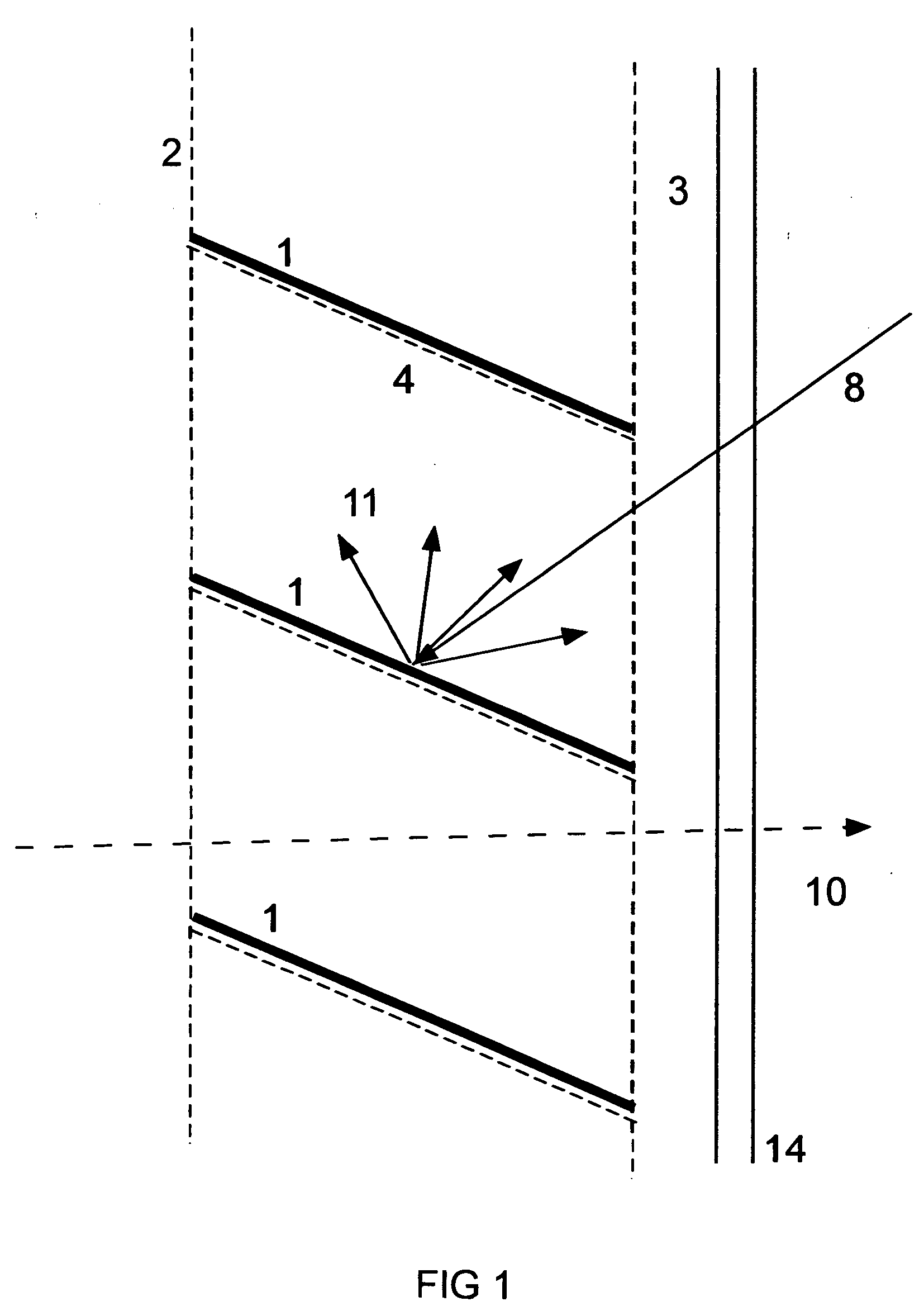

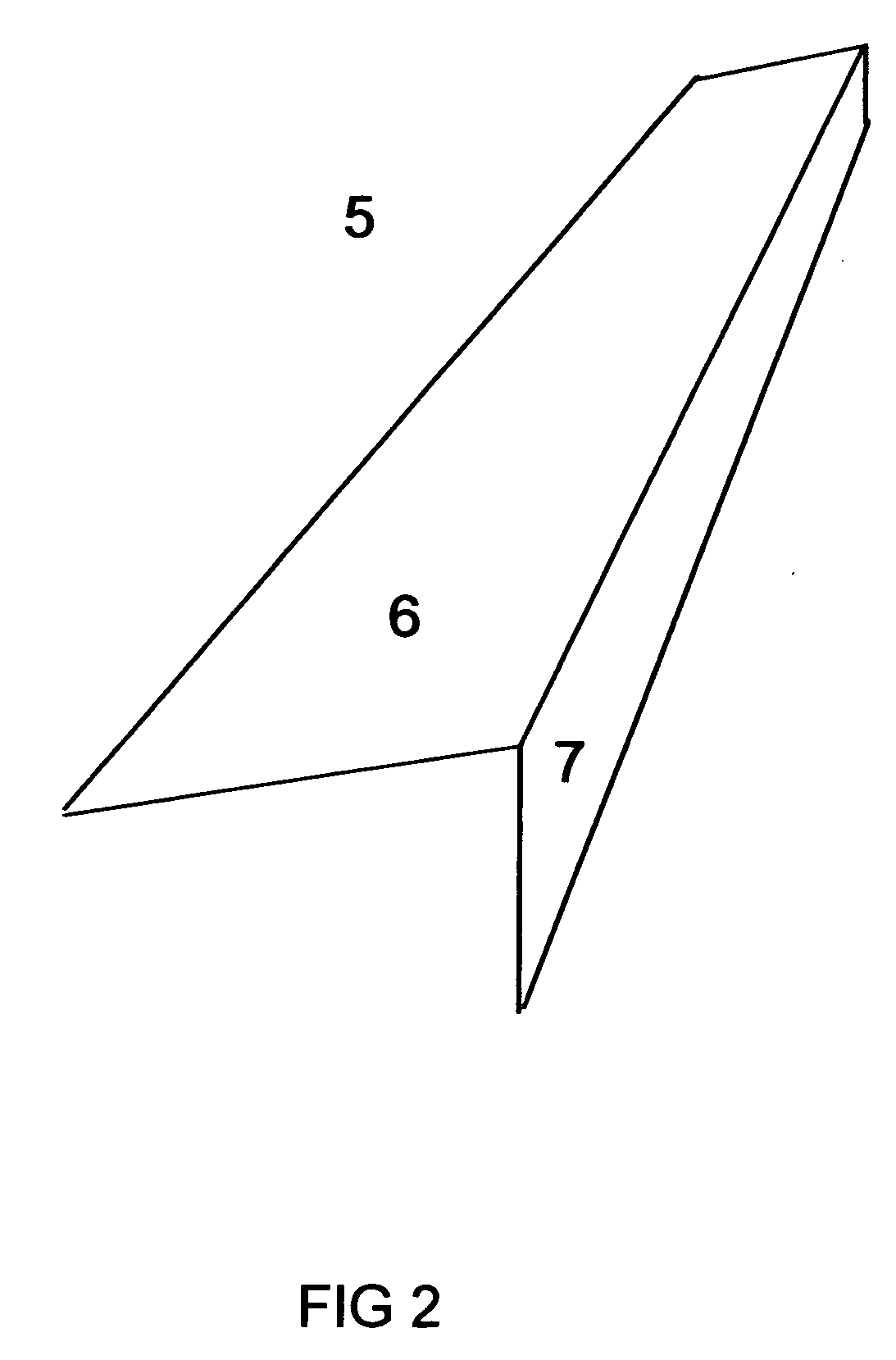

Daylighting system comprising light re-direction elements in a Venetian blind

A daylighting system comprising one or more light redirecting elements and a horizontal slat Venetian blind. The light redirecting elements are inserted between the slats of the Venetian blind and are supported between the slats and the outer strings of the Venetian blind. Each light redirecting element is a thin strip of reflective material formed into an angle section. The upper arm of the angle section reflects sunlight upwards through the Venetian blind and deeply into the interior of the building. The side arm of the angle section reflects sunlight back out of the window. The reflecting surface of an upper arm of a light redirecting element is treated to reflect light diffusely into a narrow angular range. The reflecting surface of a side arm of a light redirecting element is treated to reflect light diffusely into a wide angular range. The daylighting system is installed in the window of a building to redirect sunlight on to the ceiling of the building to improve natural illumination in the building.

Owner:EDMONDS IAN ROBERT

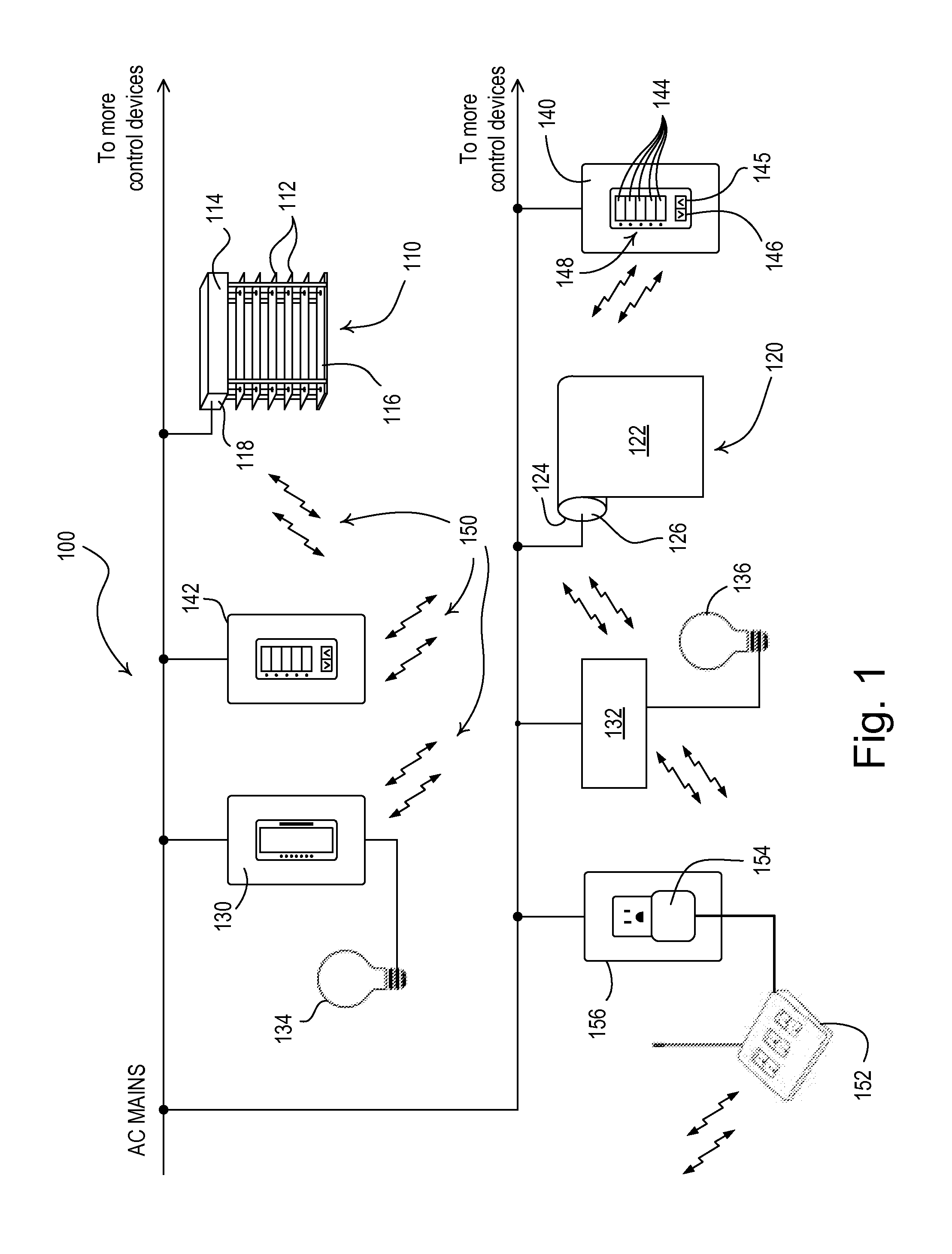

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com