Structure-improved window shutter in hollow glass

A louver and hollow technology, which is applied in the field of louver structure improvement, can solve the problems of increasing the difficulty of operation, restricting the turning of the inner slider, and the inability to lift the louver blades, etc., and achieves the effects of low production cost, fast lifting, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Through the applicant's description of the embodiments, it will be more helpful to understand the present invention, and make the positive effects of the present invention more manifest, but the embodiments should not be regarded as limiting the solution of the present invention.

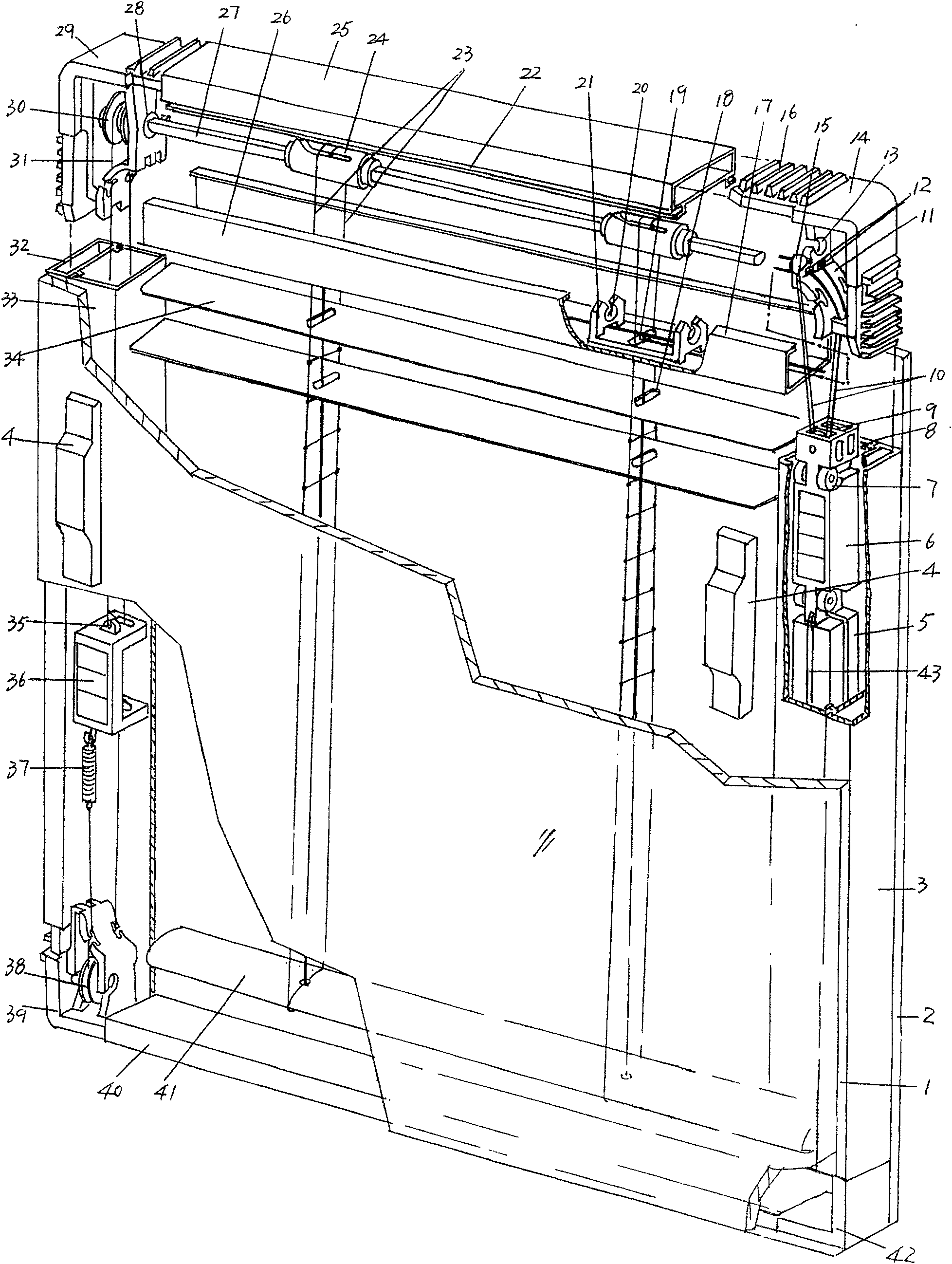

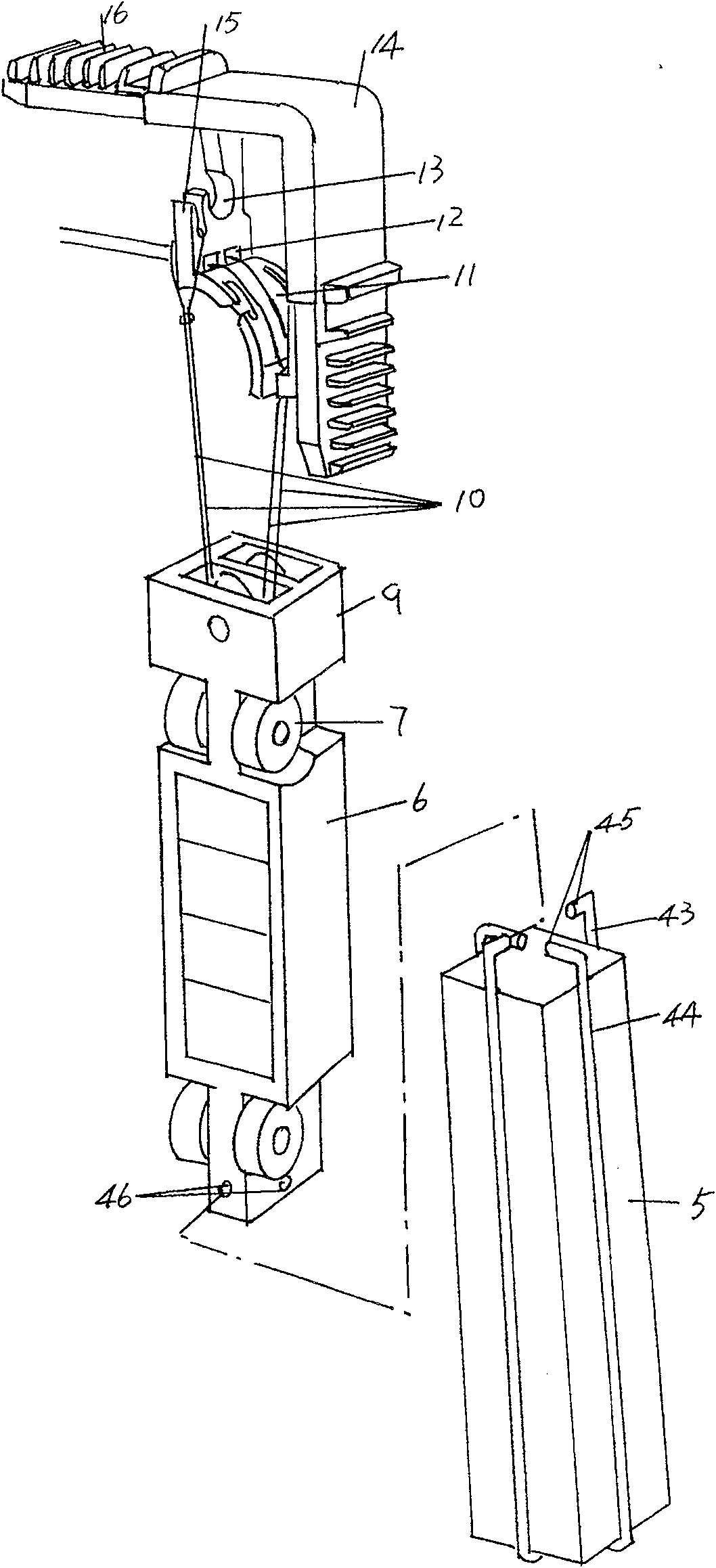

[0021] See figure 1 , the front and rear glass 1,2 of the louver of the present invention generally can be selected toughened safety glass, have certain sound insulation, heat insulation and anti-collision performance, the surroundings of the front and rear glass 1,2 are bonded to the frame of the louver by sealant On, it can realize the full sealing of insulating glass. The frame of the shutter is formed by surrounding the upper, lower, left and right window frames 25, 40, 32, 3 and the first, second, third and fourth corner joints 14, 29, 39, 42 at the corners, Specifically, the first, second, third, and fourth corner joints 14, 29, 39, and 42 are respectively connected to the upper, lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com