Vertical turnover star wheel clamp and conveyer line

A technology of star wheels and turning plates, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of insufficient cleaning and disinfection time, residual impurities and bacteria in bottles, and remaining bottles, so as to solve the problem of cleaning and disinfection time too short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Canned or canned beverages that are common in daily life need to be cleaned and disinfected before filling the beverages. However, in the prior art, when cleaning the bottles, the bottles need to be turned over during cleaning. This part of the process takes up part of the cleaning time, resulting in insufficient cleaning and disinfection time for the bottle, and there are impurities and bacteria in the bottle, which will be mixed with bacteria and impurities when the beverage is injected, causing consumers to suffer from intestinal diseases after drinking. .

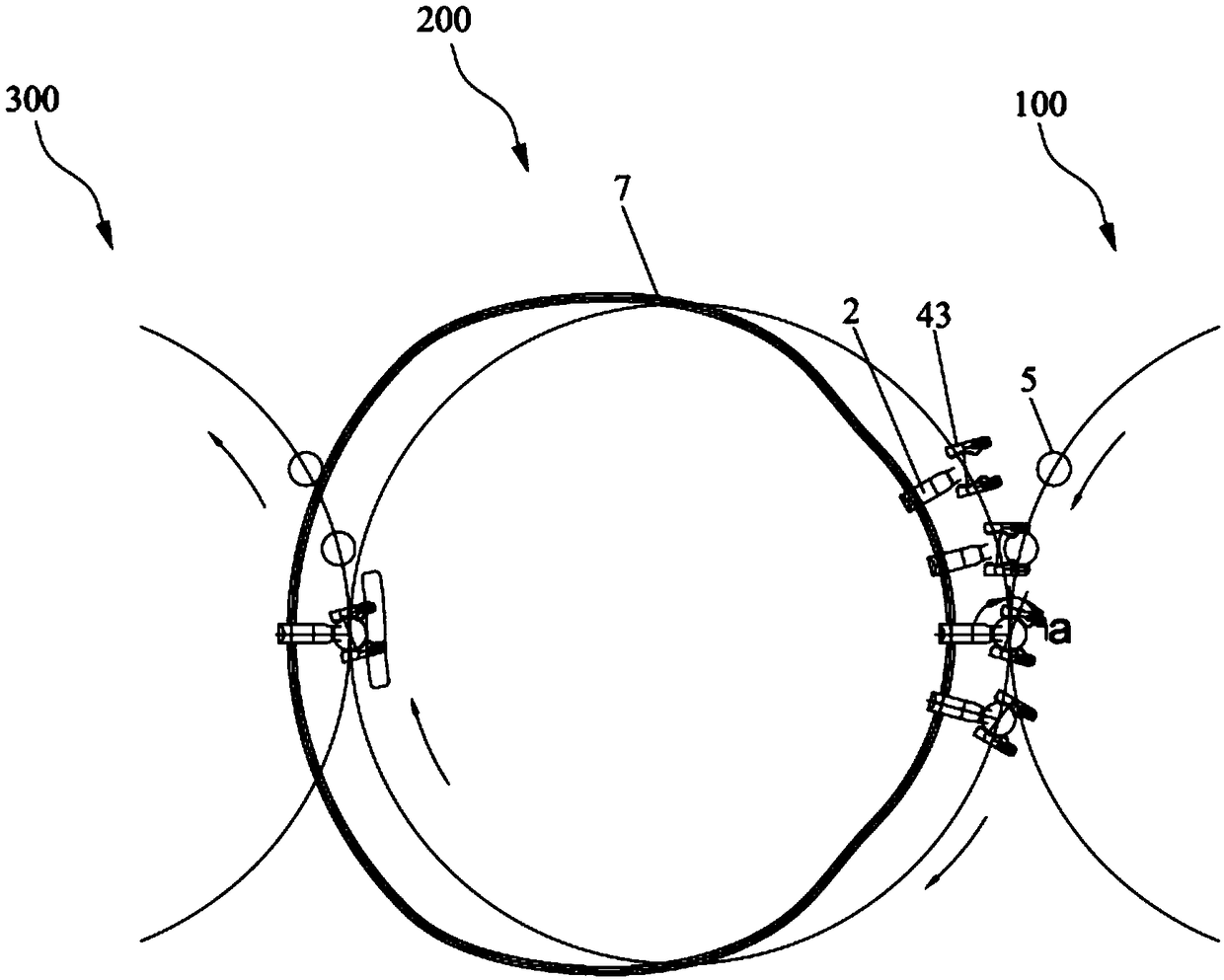

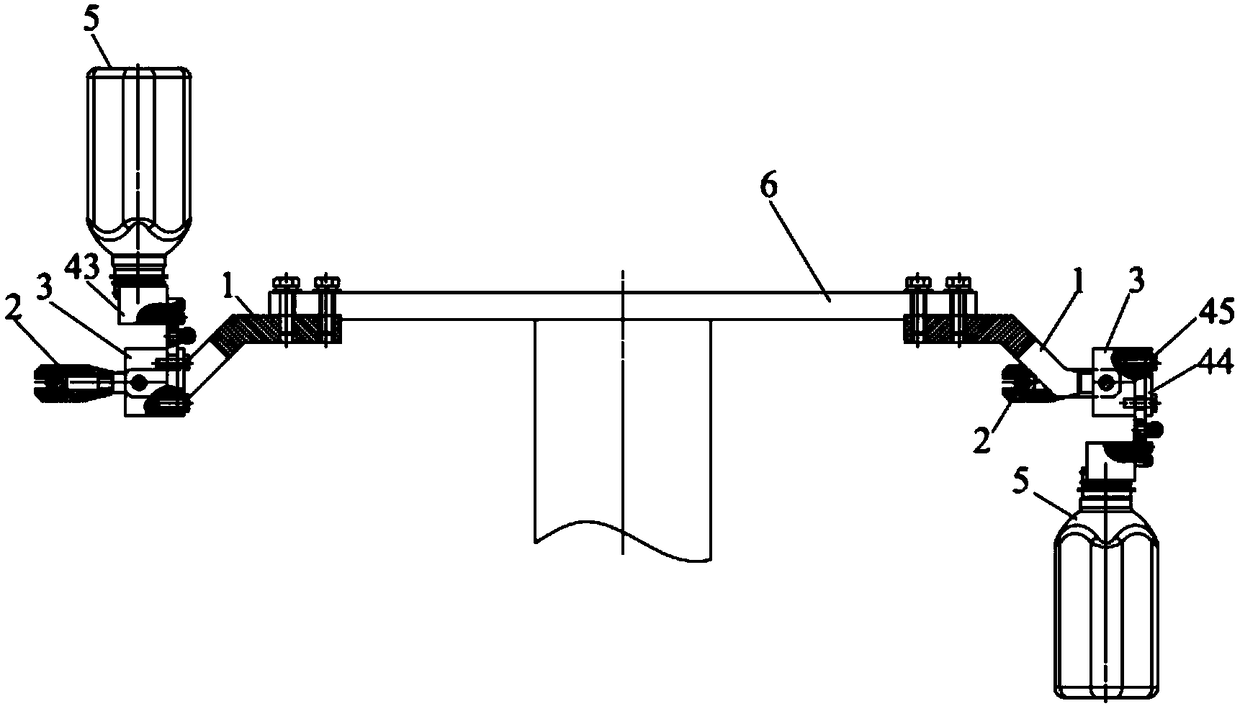

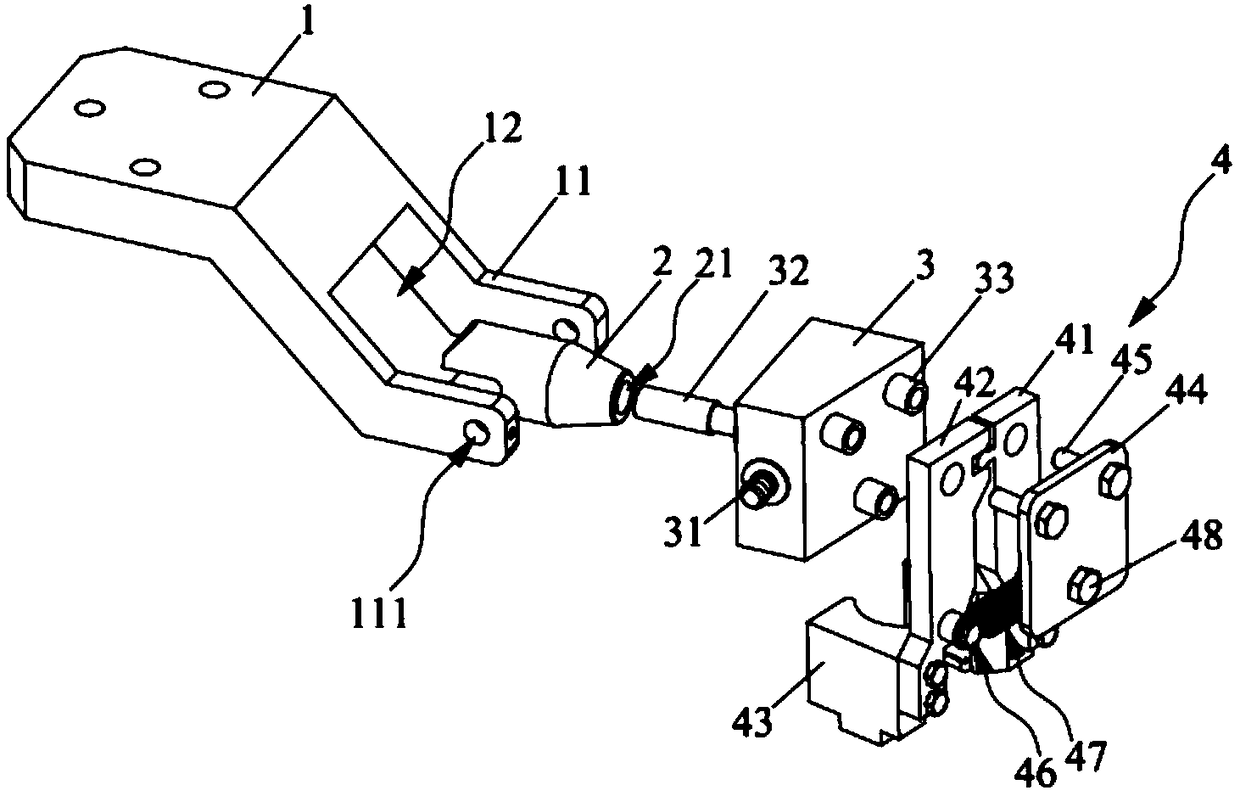

[0045] Therefore, the present embodiment provides a conveying line, which is arranged before the cleaning equipment and is responsible for turning over the bottles in advance, so as to increase the cleaning and disinfection time of the turned over bottles. Specifically, such as figure 1 with figure 2 As shown, the conveying line includes a first conveying mechanism 100, a second conveying mechanism 200 and a t...

Embodiment 2

[0058] Figure 9 A second embodiment is shown, in which parts identical or corresponding to those of the first embodiment are provided with corresponding reference numerals to those of the first embodiment. For simplicity, only the differences between the second embodiment and the first embodiment will be described.

[0059] The difference is that, in this embodiment, a connection portion 401 is provided between the two clamps 43, and the connection portion 401 is connected to the first installation surface 34 through the fixing portion 402, and is the same as in Embodiment 1, the two clamps The inclination angle of 43 is consistent with that of the first mounting surface 34 . Specifically, the connecting portion 401 is made of elastic memory metal, that is, when the bottle 5 is snapped into the two chucks 43, the opening of the connecting portion 401 becomes larger, and as the bottle 5 is snapped in, the opening gradually decreases. Moreover, the elastic force of the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com