Palm fruit yeast killing technology

A palm fruit bunch and process technology, which is applied in the production of fat, fat oil/fat, etc., can solve the problems such as the difficulty of discharging the fruit ear bridge, the poor steam injection channel, and the poor effect of fermenting and cooking the fruit. The effect of small area, simple structure and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

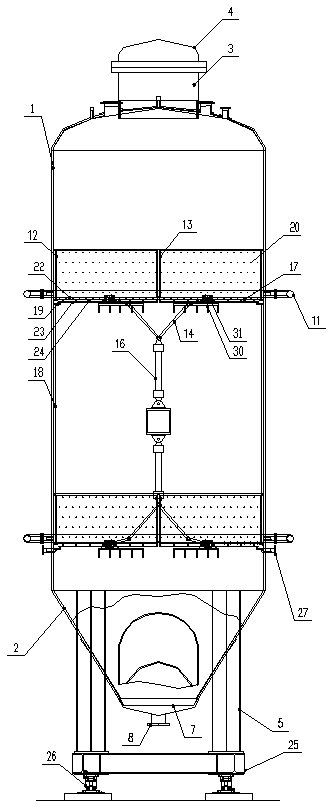

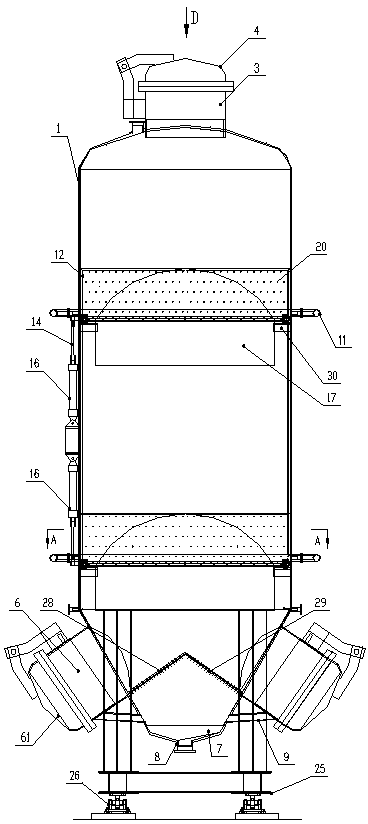

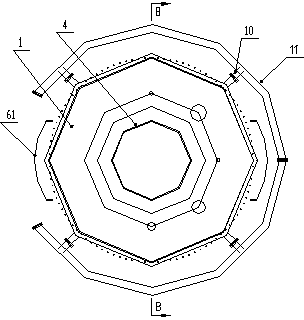

[0030] Embodiment 1: The palm fruit bundle braking fermentation process comprises the following steps: a, close the discharge port and quickly open the door, open the feed inlet and quickly open the door, close the movable flap, and feed the material from the feed port; b, the weighing module sends the first Secondary loading completion signal, that is, the upper movable flap is finished loading, open the upper and lower movable flaps to make the material fall to the bottom of the tank, or make the material fall to the lower movable flap first, and then fall to the tank Bottom: close the upper and lower movable flaps, continue to feed materials from the feed port to the weighing module to send the second loading completion signal, that is, the upper movable flap is loaded, and then open the upper movable flap to make the material fall to The lower movable flap; c. Close the upper movable flap, continue feeding from the feed port to the weighing module to send the third loading ...

Embodiment 2

[0039] Embodiment 2: the palm fruit bunch braking fermentation process comprises the following steps: a, close the discharge port and quickly open the door, open the feed inlet and quickly open the door, close the movable flap, and feed the material from the feed port; b, the weighing module sends the first Secondary loading completion signal, that is, the upper movable flap is finished loading, open the upper and lower movable flaps to make the material fall to the bottom of the tank, or make the material fall to the lower movable flap first, and then fall to the tank Bottom: close the upper and lower movable flaps, continue to feed materials from the feed port to the weighing module to send the second loading completion signal, that is, the upper movable flap is loaded, and then open the upper movable flap to make the material fall to The lower movable flap; c. Close the upper movable flap, continue feeding from the feed port to the weighing module to send the third loading c...

Embodiment 3

[0042] Embodiment 3: palm fruit bunch braking fermentation process comprises the following steps: a, close the discharge port quick-open door, open the feed inlet quick-open door, close the movable flap, feed from the feed port; b, the weighing module sends the first Secondary loading completion signal, that is, the upper movable flap is finished loading, open the upper and lower movable flaps to make the material fall to the bottom of the tank, or make the material fall to the lower movable flap first, and then fall to the tank Bottom: close the upper and lower movable flaps, continue to feed materials from the feed port to the weighing module to send the second loading completion signal, that is, the upper movable flap is loaded, and then open the upper movable flap to make the material fall to The lower movable flap; c. Close the upper movable flap, continue feeding from the feed port to the weighing module to send the third loading completion signal, close the feed port and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com