Patents

Literature

106 results about "Palm fruit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

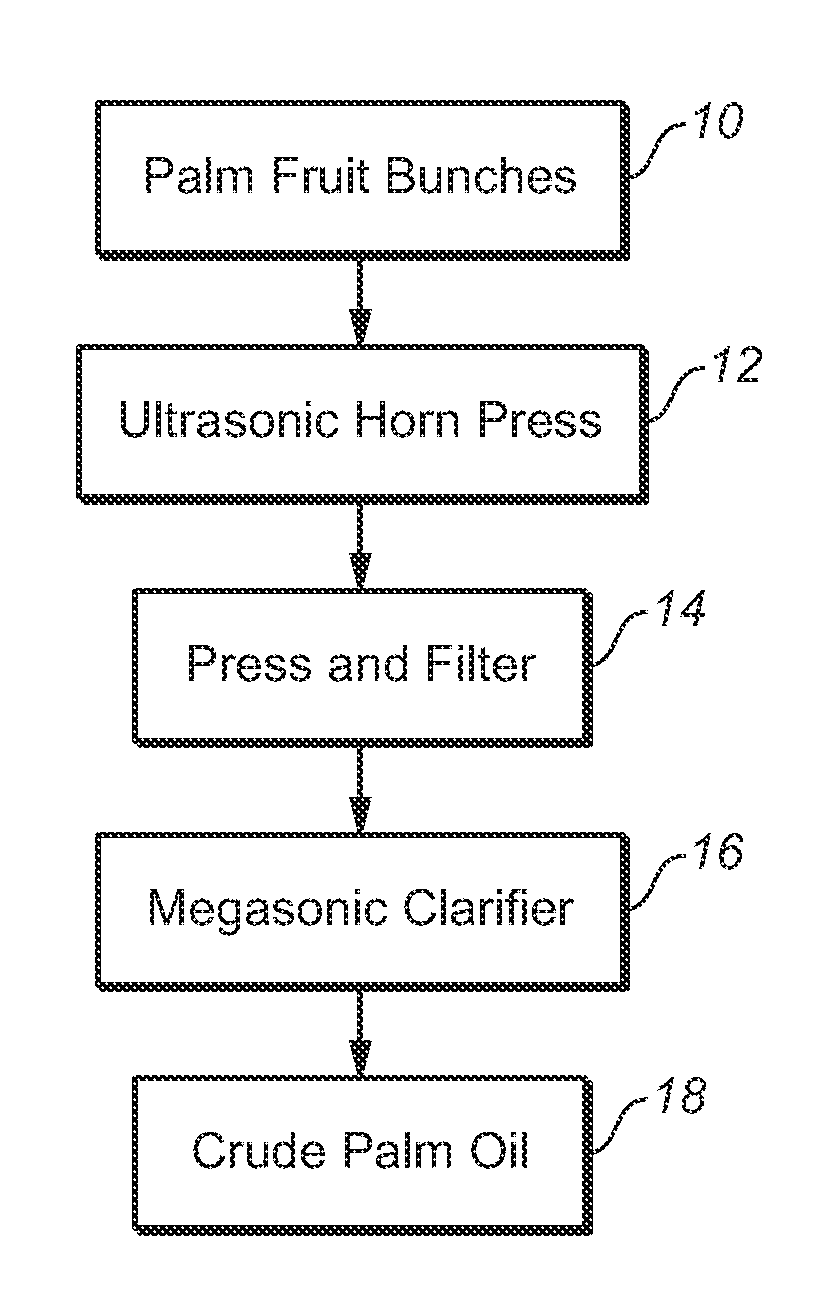

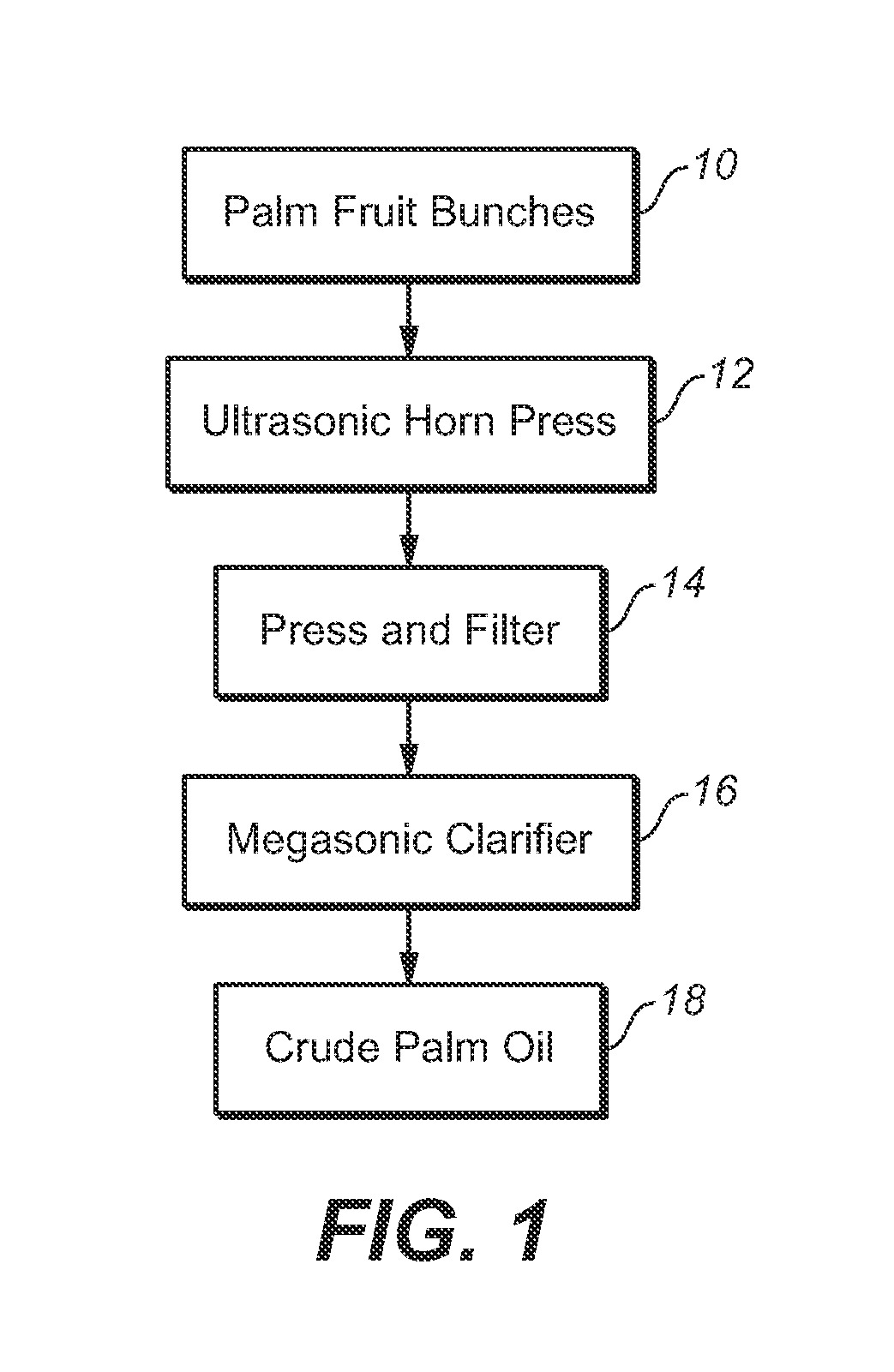

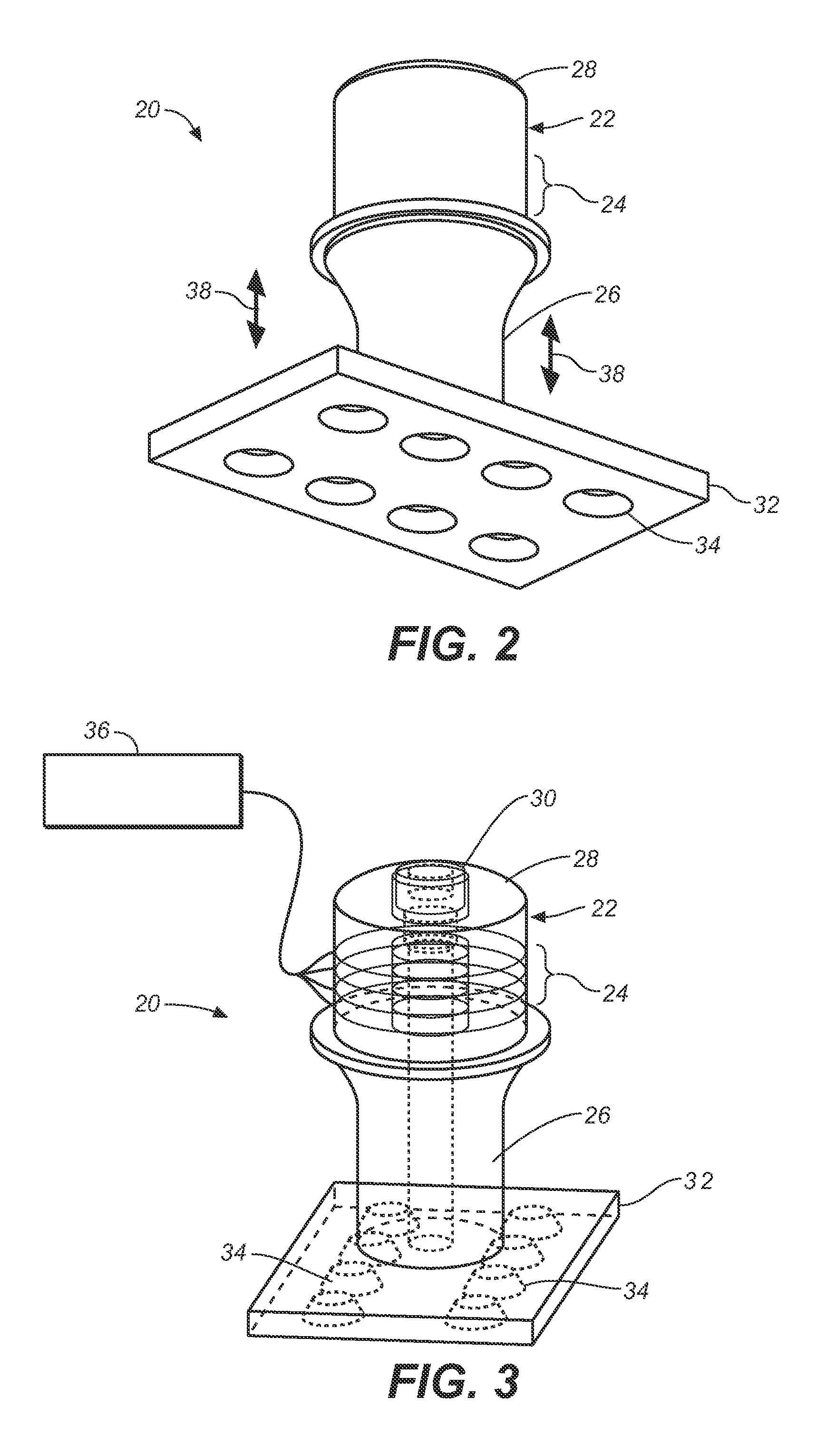

Ultrasonic and megasonic method for extracting palm oil

ActiveUS9388363B2Fatty-oils/fats productionCarboxylic compound separation/purificationPalm fruitUltrasonic vibration

A process for extracting palm oil includes an ultrasonic horn press and a megasonic clarifier. The ultrasonic horn press uses ultrasonic vibrations to rupture the palm fruit. After pressing and filtering the palm oil from the ultrasonic horn press, the megasonic clarifier applies megasonic vibrations to clarify the palm oil. The ultrasonic horn press and megasonic clarifier significantly reduce the use of water and minimizes pollution as compared to conventional processes.

Owner:MEGASONIC SWEEPING INC

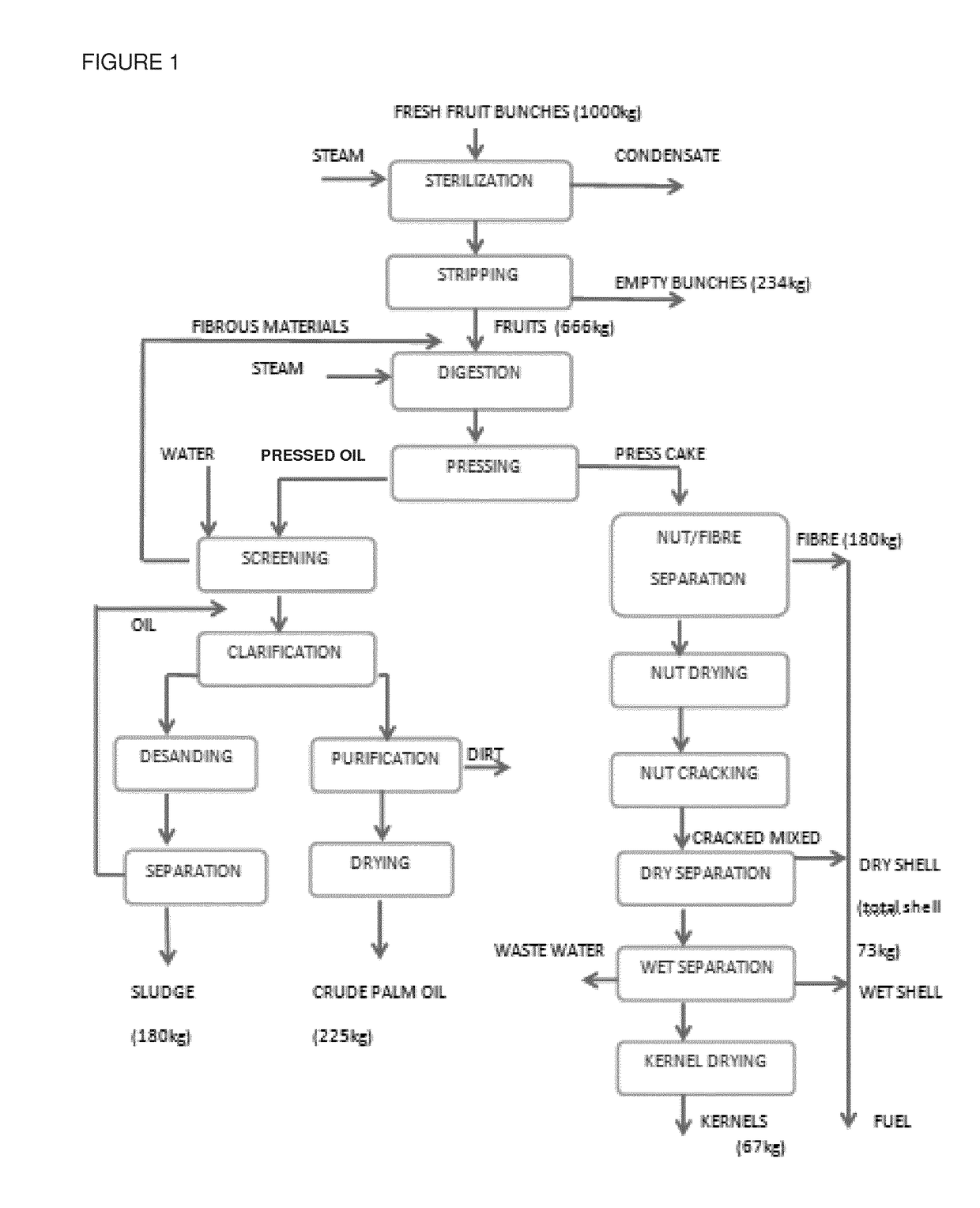

Integrated Methods for Processing Palm Fruit Bunches

ActiveUS20100167351A1Fatty oils/acids recovery from wasteFatty acid esterificationBiotechnologyCellulose

This invention is directed to an integrated method for the processing of palm fruit bunches to oil and other products. The method comprises inter alia separating palm fruit carrying bunches into fruits and lignocellulosic empty fruit bunches, processing the fruits to form palm oil, and at least one lignocellulosic processing coproduct; generating an aqueous stream; producing a non-oil, non-alcohol, non-fatty acid ester third product from the oil, the lignocellulosic processing coproduct, the aqueous stream or from a combination thereof; processing at least a portion of the lignocellulosic empty fruit bunches, lignocellulosic processing coproduct or a combination thereof into a fourth product and optionally producing at least one fifth conversion product from the fourth product; and using at least a portion of the fourth product or a product of its conversion or a combination thereof.

Owner:EYAL RES CONSULTANTS

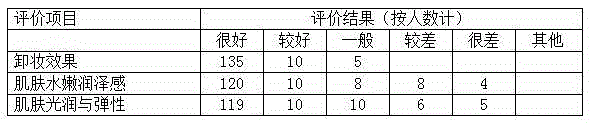

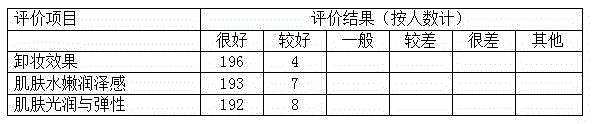

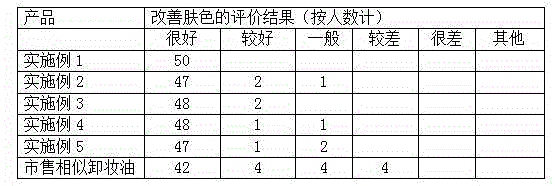

Cleansing oil, preparation method thereof and application thereof

The invention provides a cleansing oil. The cleansing oil comprises the following components in percentage by weight: 40 to 50 percent of olive fruit oil, 15 to 20 percent of isononyl isononanoate, 8 to 13 percent of simmondsia chinensis seed oil, 8 to 13 percent of grape seed oil, 8 to 13 percent of PEG (polyethylene glycol)-30 sorbitan tetraoleate, 2 to 8 percent of PEG-20 glyceryl triisostearate, 0.5 to 2 percent of tea extract, 0.5 to 1 percent of Moriche Palm fruit oil, 0.2 to 0.8 percent of citrus fruit extract and 0.2 to 0.6 percent of lotus extract. The invention also provides a preparation method and the application of the cleansing oil. The cleansing oil provided by the invention is mild in nature and has a very good cleansing effect, dirt deeply hidden in trichopore can be clearly cleaned, and the cleansing oil has the effects of moisturizing and tendering skin.

Owner:广州科玛生物科技股份有限公司

Method for extracting fiber from oil palm fruit bundle and fiber obtained thereby

The invention discloses a method for extracting fiber yarns from palm fruit clusters of oil palm. The palm fruit clusters of the oil palm are cooked by steam with a temperature of between 100 and 200 DEG C for 0.5 to 1.5 hours, oil palm fruit pericarps are separated to obtain empty fruit clusters, then the empty fruit clusters are extruded and torn to obtain fiber blocks, the fiber blocks are washed and then are extruded to ensure that the water content of the fiber blocks is between 30 and 80 percent, then the selection is performed, the selected fiber blocks are subjected to silk fetching treatment to obtain the fiber yarns, and then the fiber yarns are dried, screened and bagged. The applicator aims at the requirement on an elastic material to process and select the fiber yarns in the palm fruit clusters so as to be suitable to process natural oil palm silk mattresses. Natural fiber yarns of the palm fruit clusters obtained by the method can substitute mountain palm fiber yarns to produce various natural palm mattresses, cushions, and products such as fiberboards and sound insulation boards for buildings and so on.

Owner:GUIZHOU DAZIRAN TECH

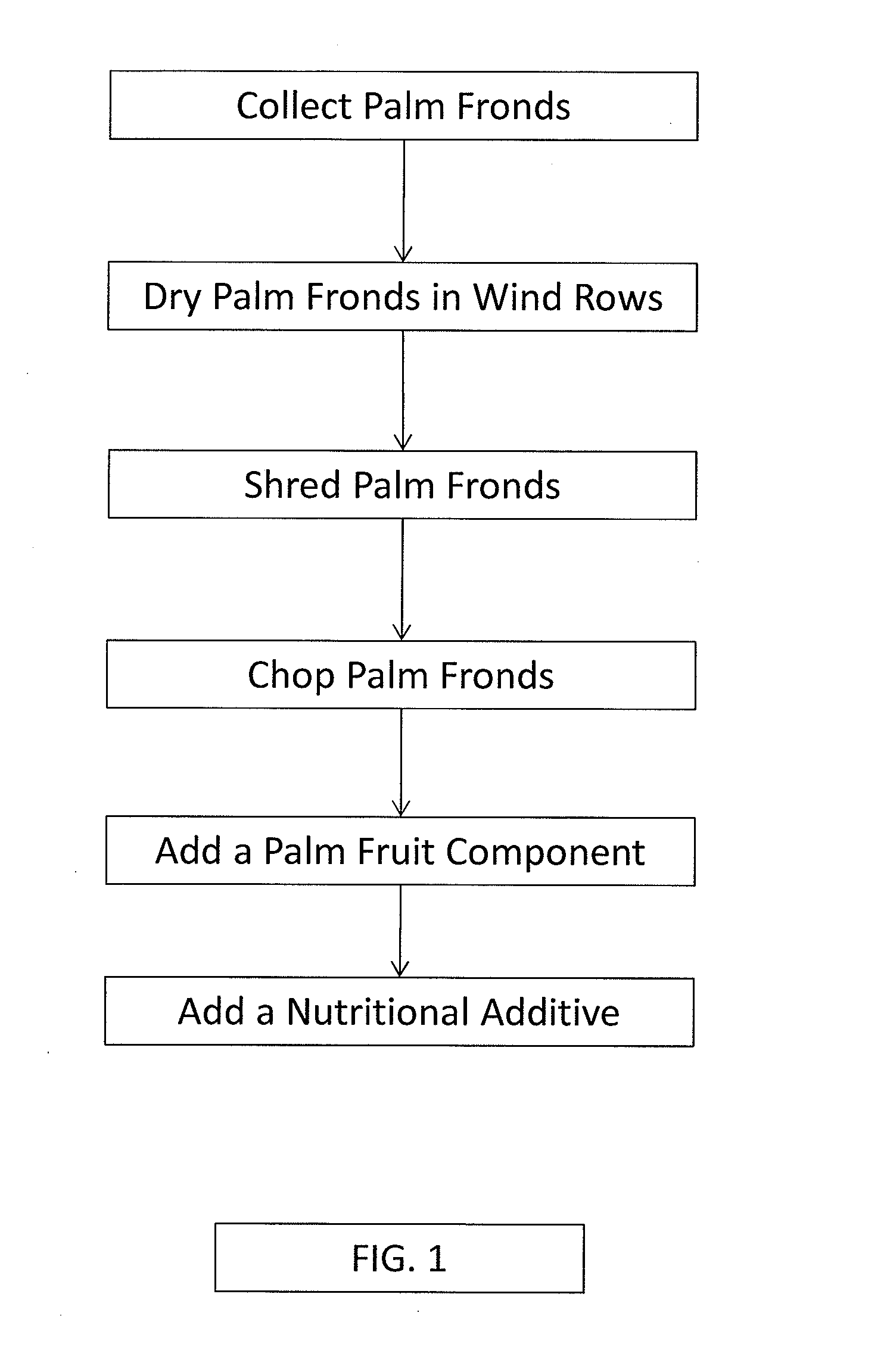

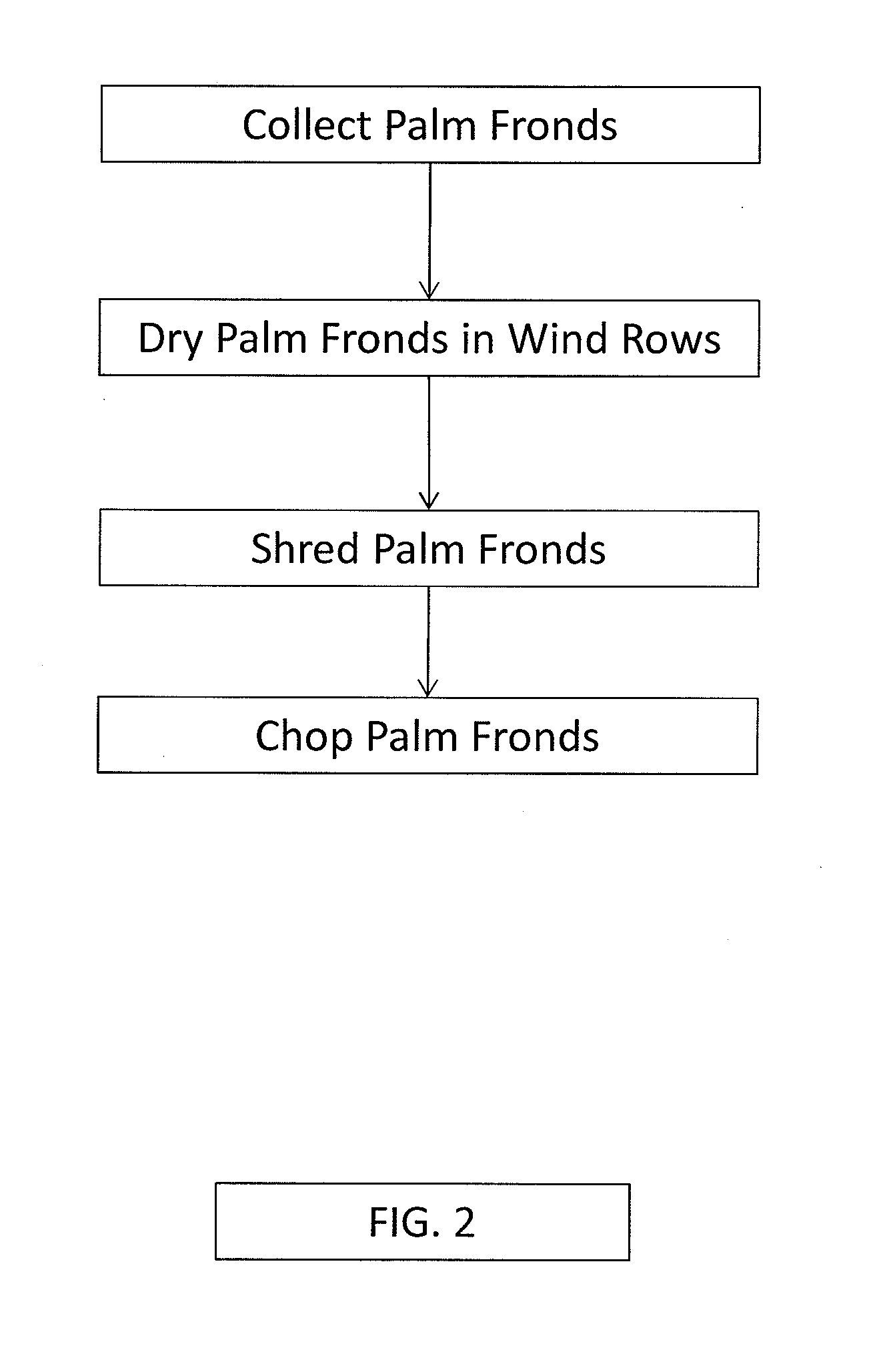

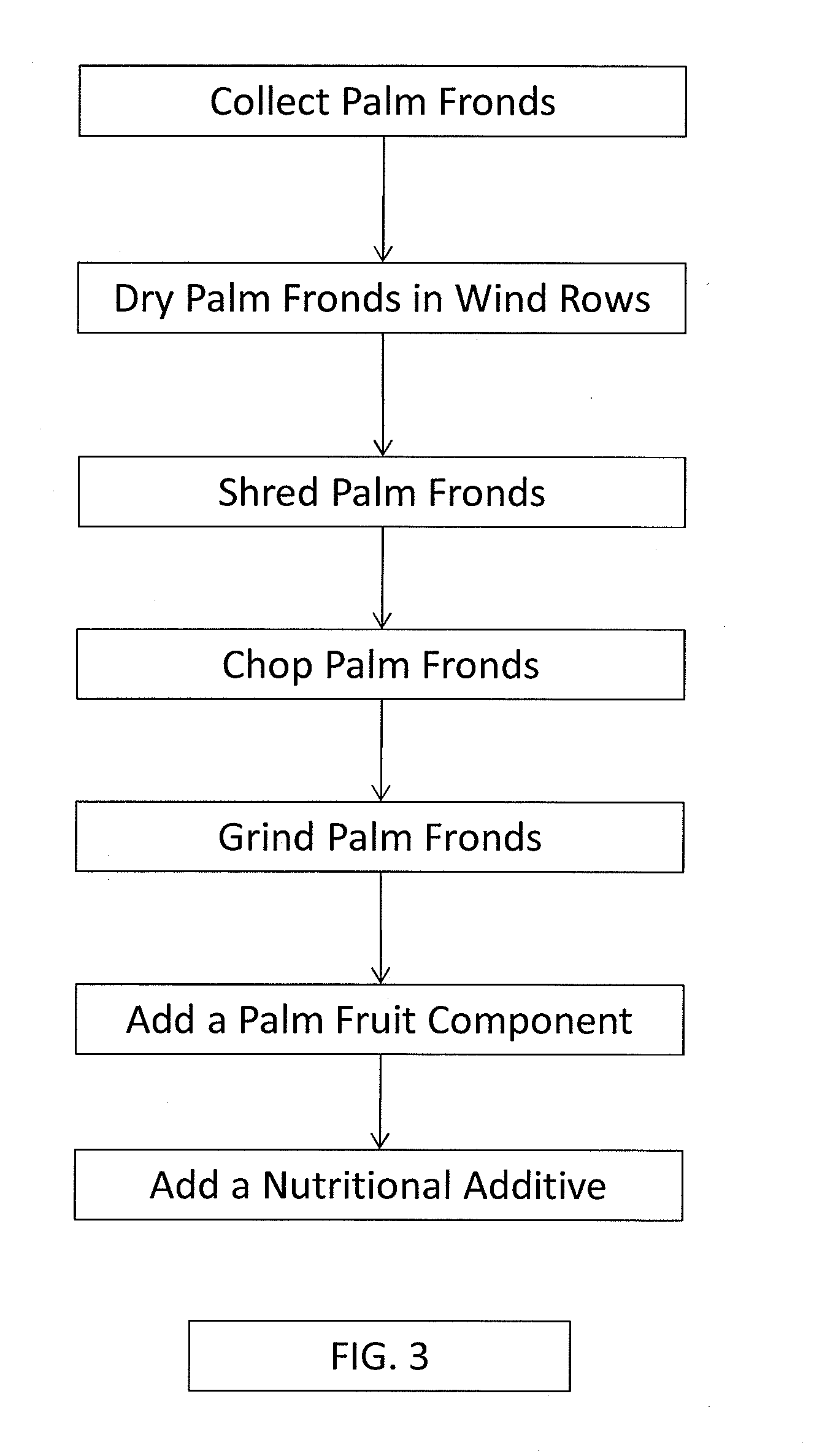

Palm-based animal feed

Animal feed formed with a base of palm fronds and combined with palm fruit, such as dates, is a sustainable and affordable feed product that can be developed in hot climates. Palm fronds with a desired moisture content are shredded, chopped, and / or ground, and mixed with palm fruit. Additives such as urea can increase the nutritional content. Feeds with palm fronds, palm fruit, and / or additives can serve as a base feed for other components. Palm fronds can also serve as a base feed for other components. Animal feeds with a variety of bases can have palm fruit added. Animal feeds with a variety of bases, including palm fronds, can include a variety of other components added.

Owner:PALM SILAGE INC

Hair-growing, hair-fixing and hair-care nutrient solution and preparation proces thereof

InactiveCN109260038AExcellent hair careReasonable formulaCosmetic preparationsHair cosmeticsPropolisPalm fruit

The invention discloses a hair growth, hair fixation and hair care nutrient solution, the composition and mass fraction of which are as follows: SD ethanol 40-B 9-15 parts, butanediol 5-10 parts, azelaic diglycine potassium 3-8 parts, purslane extract 5-7 parts, camphor 4-9 parts, zinc sulfate 3-10 parts, pyridoxine hydrochloride 2-6 parts, panthenol 5-7 parts, sawn leaf palm fruit extract 4-8 parts, glycerin 6-9 parts, nicotinamide 4-8 parts, allantoin 6-9 parts, biotin 3-10 parts, PEG-60 hydrogenate castor oil 7-9 parts, hydrolyzed yeast protein 3-8 parts, polysorbate-20 2-6 parts, phenoxyethanol 6-10 parts, menthol 1-5 parts, hydroxybenzyl methyl ester 1-3 parts, folium Camelliae sinensis extract 8-13 parts, root extract of Glycyrrhiza glabra 11-13 parts, propolis extract 9-14 parts, azelaic diglycine potassium 7-5 parts, tripeptide-1 copper 5-8 parts, tocopherol acetate 1-3 parts, water 80-100 parts. The hair growth, hair fixation and hair care nutrient solution provided by the invention has excellent hair care effect, in particular, obvious effect on damaged hair quality, can effectively improve damaged hair quality, and can keep the hair soft and elastic.

Owner:南京新生医疗科技有限公司

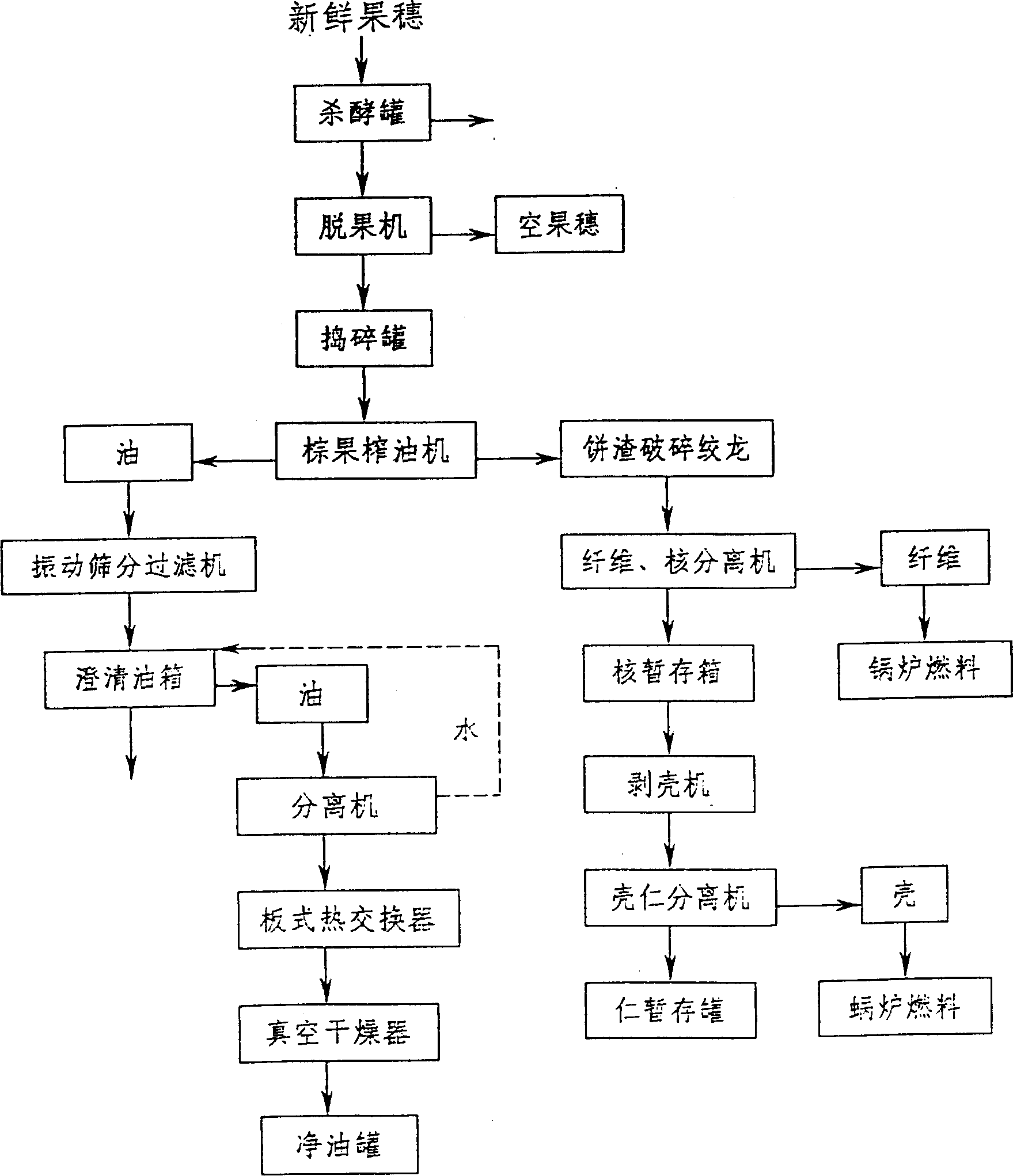

Method and system for extracting palm oil from fresh palm fruit

InactiveCN1847379AEfficient separationEfficient use ofFatty-oils/fats productionPalm fruitEngineering

The present invention relates to method and system for extracting palm oil from fresh palm fruit. The extraction process includes the following steps: treating fresh palm fruit with pressurized steam to deactivate, shelling and stamping, squeezing in an oil press to obtain crude palm oil, filtering and purifying palm oil, and heating and vacuum drying the purified palm oil to obtain palm oil product. The present invention can separate and utilize fully the fruit, kernel and stone of fresh fruit, and is suitable for industrial production.

Owner:HUBEI BISHAN MACHINERY CO LTD

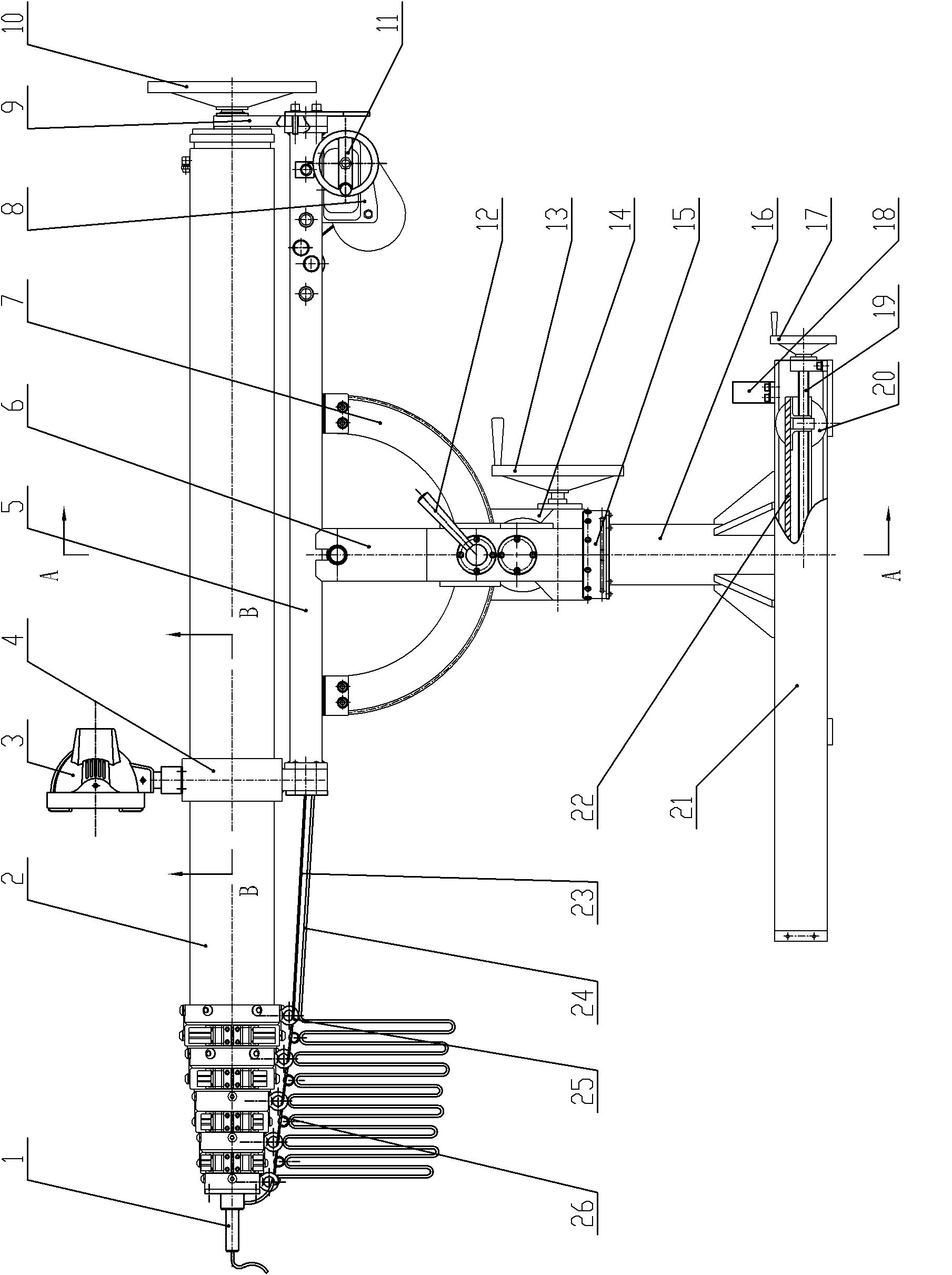

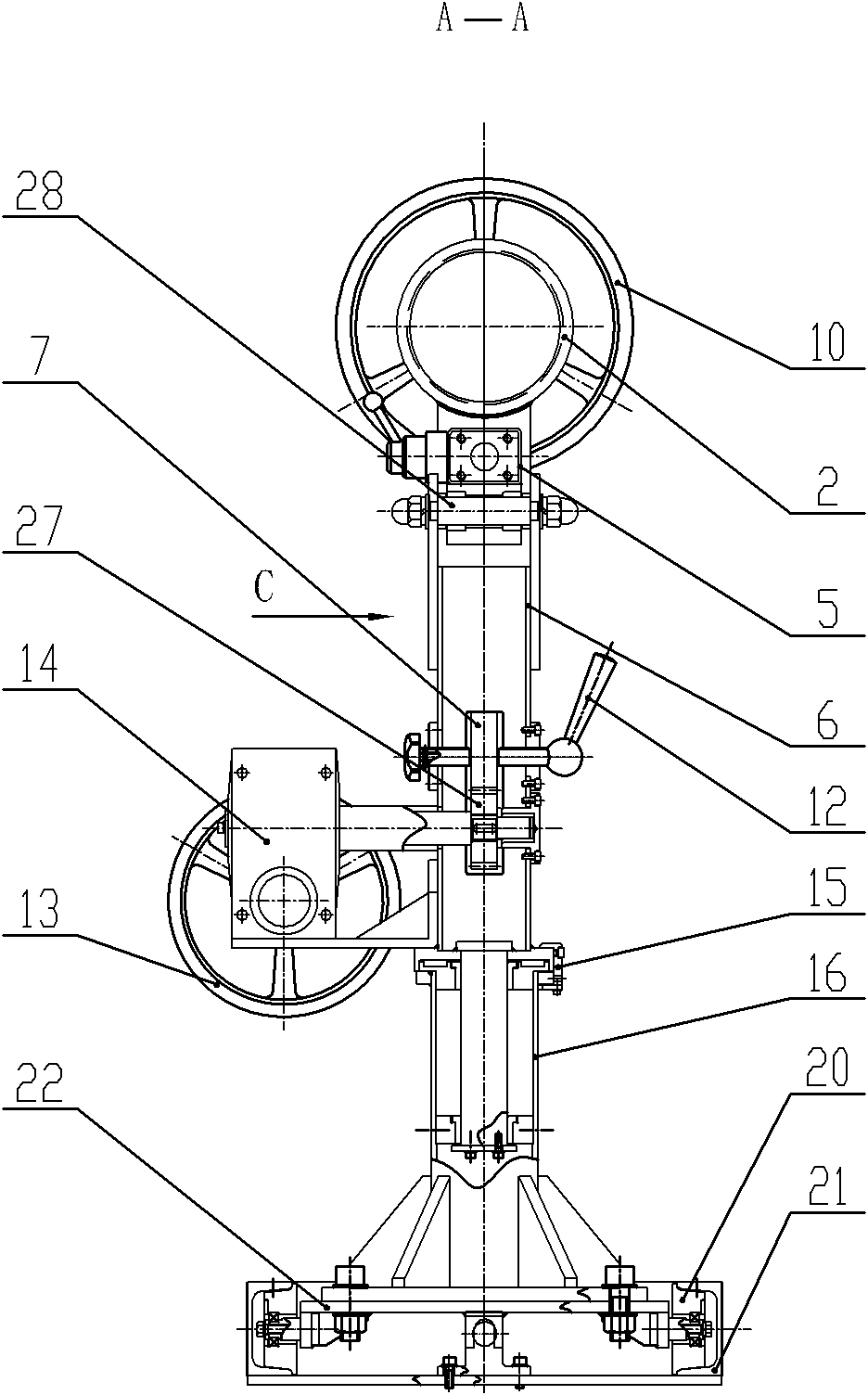

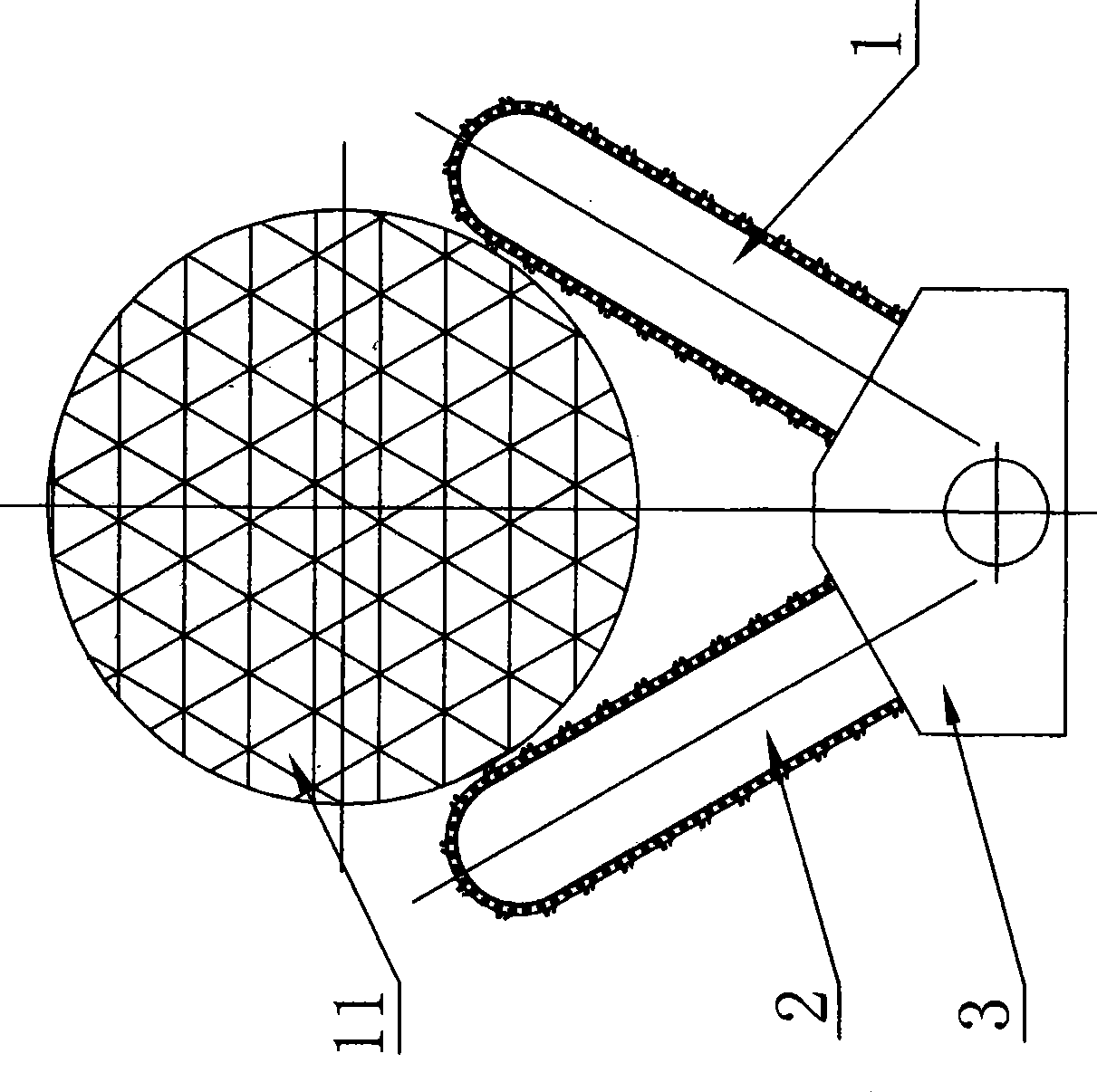

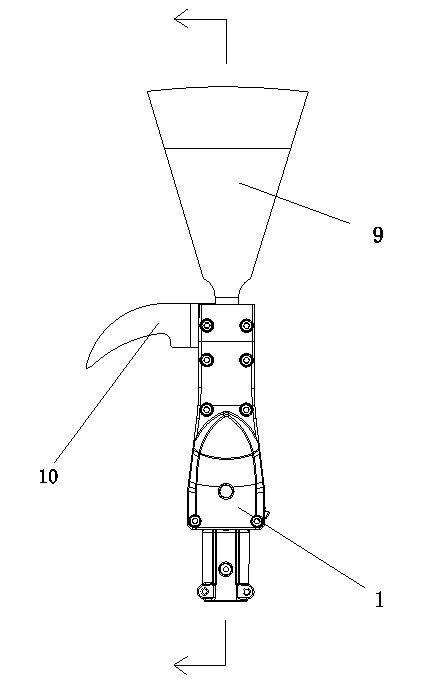

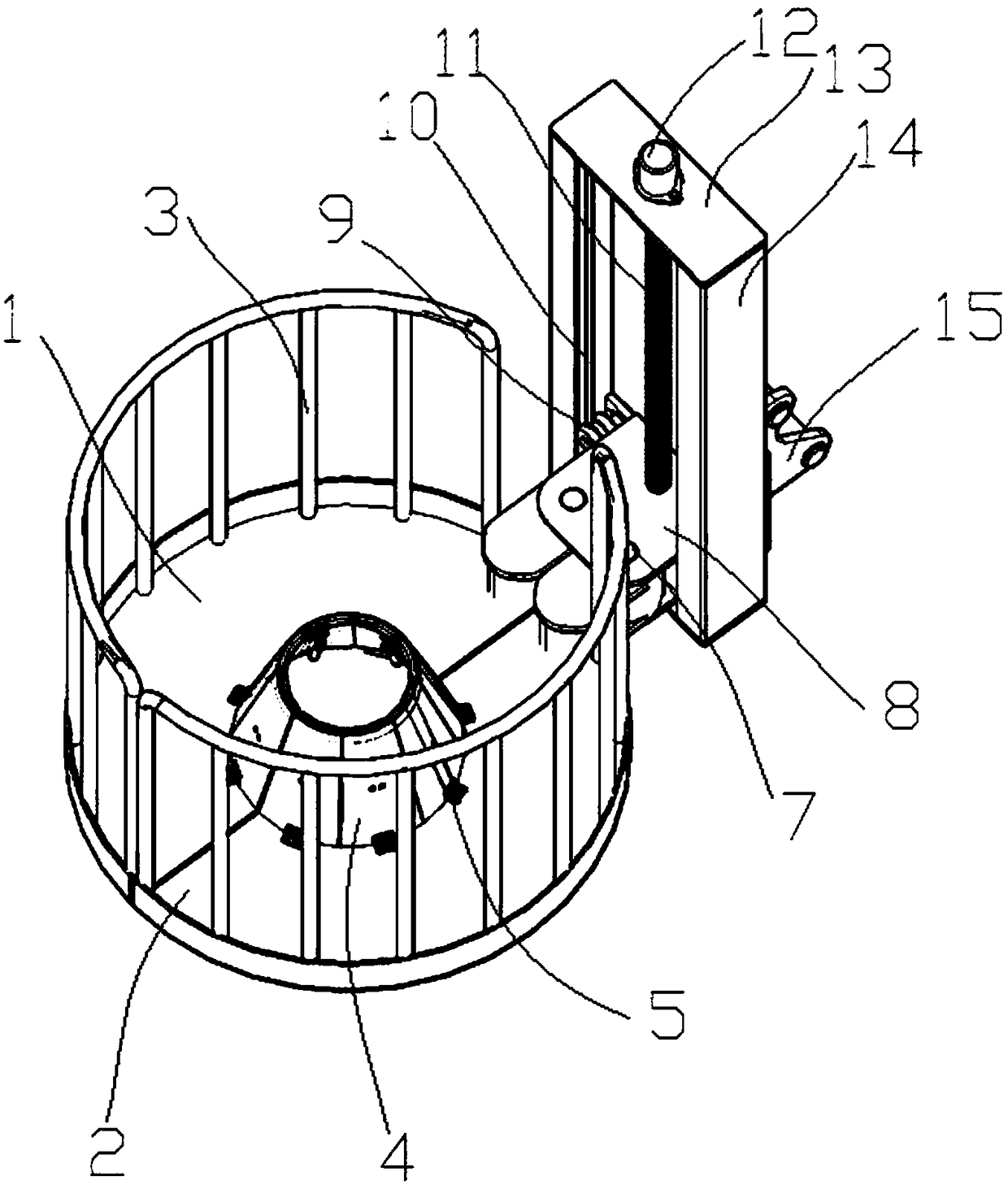

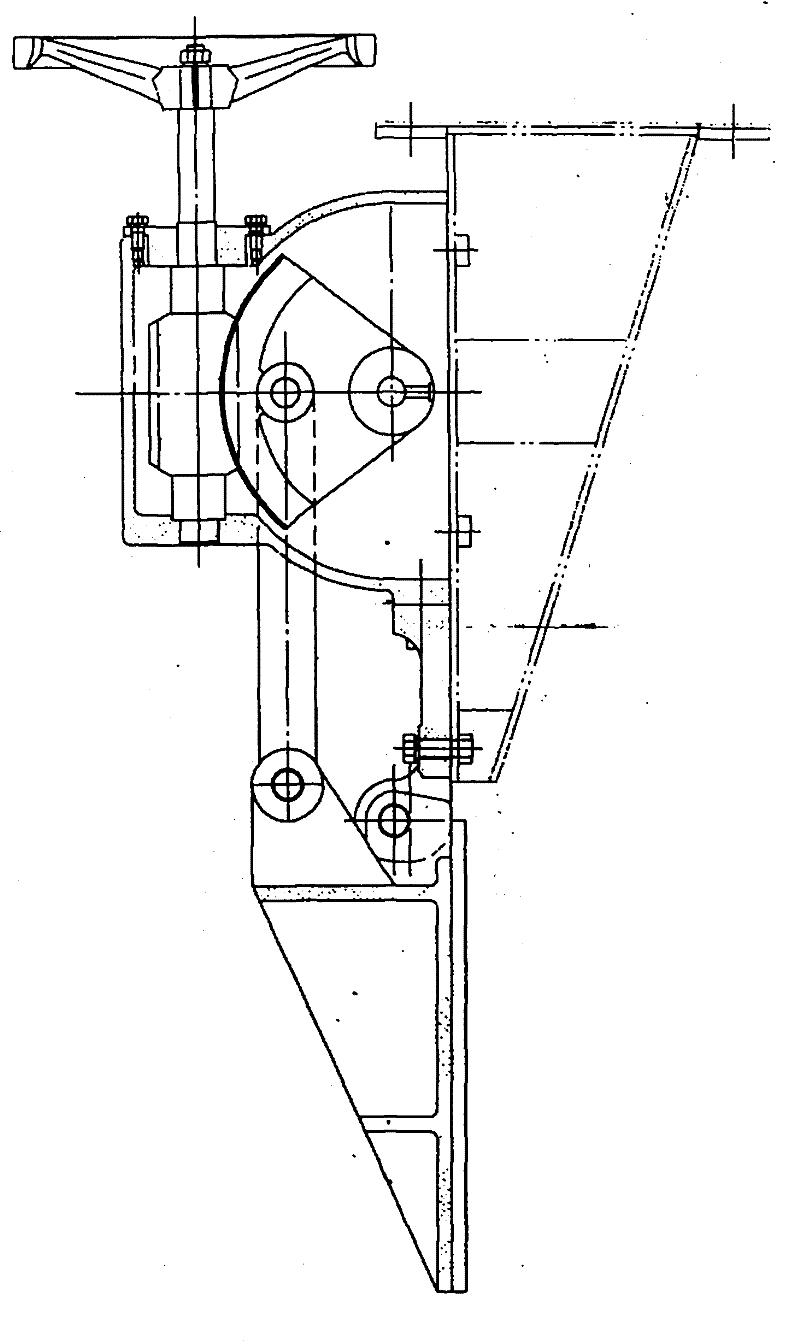

Mechanical arm of palm fruit picking machine

InactiveCN102138385AEasy to achieve picking operationsSimple structureManipulatorPicking devicesPalm fruitEngineering

The invention relates to a mechanical arm of a palm fruit picking machine, which comprises a chassis, wherein a lower supporting column is fixedly connected with the chassis; an upper supporting column capable of rotating horizontally is connected with the lower supporting column; a mast mounting frame is hinged on the upper supporting column; a mast pitching mechanism is arranged between the mast mounting frame and the upper supporting column; a pneumatic elevating mast is supported on the mast mounting frame in a rotating manner; a mast rotating hand wheel is arranged at the rear end of the pneumatic elevating mast; and a cutter connector is arranged at the front end of the pneumatic elevating mast. In the invention, as the pneumatic elevating mast and the corresponding mechanism are adopted, five-dimensional movement functions such as the advance and retreat, pitching, expansion and retraction, horizontal rotation, axial rotation and the like of the mechanical arm are realized, and the picking operation of palm fruit can be easily realized; moreover, the mechanical arm has the advantages of adopting simple structure, needing low cost, being convenient to operate, having low labor intensity and high production efficiency, being safe and reliable and the like.

Owner:无锡市华鹰移动照明有限公司

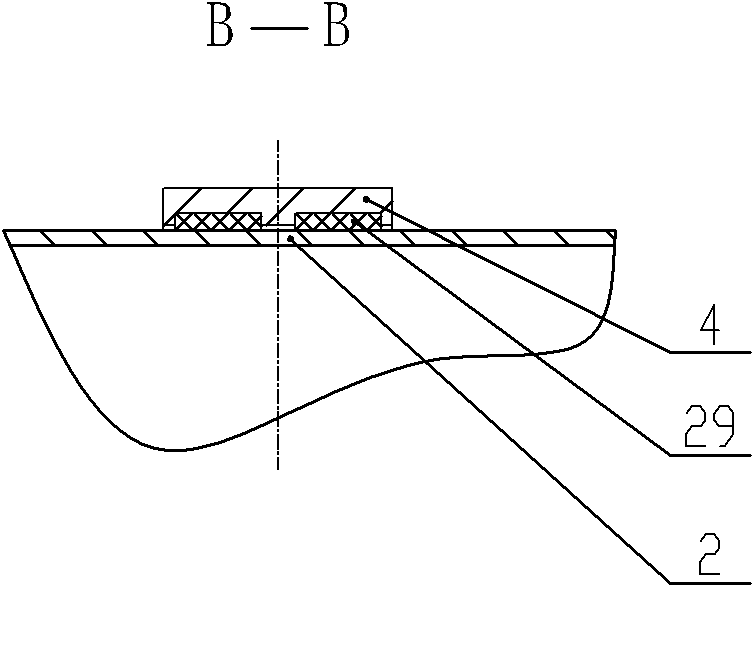

Betel palm food

The invention relates to food and a preparation method thereof, in particular to betel palm food and a preparation method thereof. The betel palm food comprises dried betel palm fruit sheets and dried fruit blocks with thickness smaller or equal to 5 mm and / or betel palm fiber with length smaller or equal to 5 mm. The betel palm food effectively avoids oral damage caused by sharp tips and rouse and hard fiber of traditional betel palms, improves the taste of betel palms and the table manner of people, can shorten the product production period and improve the production automation degree. Ingredients are very easy to add, are fully tasty, are easy to adjust different flavor characteristics and functional types, can be prepared into various shapes of food, and ensure normal shape, uniform size and stable quality.

Owner:罗正湘 +1

Device for harvesting palm fruit

InactiveCN101473732AImprove the efficiency of fruit pickingFlexible operationCuttersCutting implementsPalm fruitCoupling

The invention relates to a palm fruit harvesting device, comprising a chain knife-I, a chain knife-II, a gear case, a fluid motor, a function lever, a high-pressure oil tube, a gear oil pump, a gasoline engine and a base, wherein an output shaft of the gasoline engine and a butt-muff coupling of the gear oil pump are connected and fixed at the base together; the gear oil pump is connected with the fluid motor in the gear case by the high-pressure oil tube, and gears of the output shaft of the fluid motor is engaged with gears in the gear case; the chain knife-I and the chain knife-II are driven by the fluid motor by a gear pair and are movably connected on the gear case in a 'Y' shape in a horizontal direction; and the high-pressure oil tube is sheathed in the function lever, and the gear case is fixed at the top end of the function lever. The palm fruit harvesting device has the advantages of flexible operation, simple and light structure and high reliability and automation degree, avoids the counterforce in the horizontal direction to a great extent, labor conditions are obvious improved, and the efficiency of operators in picking fruits is improved.

Owner:ZHEJIANG UNIV

Palm fruit bundle transfer method

InactiveCN101469291AReduce in quantityShorten the lengthFatty-oils/fats productionConveyor partsPush and pullPalm fruit

The invention belongs to the technical field of oil preparation in palm fruit (FFB) squeezing plants, and in particular to a method for transporting palm fruit bunches, which comprises: firstly, the palm fruit bunches are discharged to a feeding scraper by utilizing a slope, and are conveyed into an empty fruit cage vehicle of a movable transporting dumper; secondly, a push and pull mechanism of the movable transporting dumper pushes the fruit cage vehicle filled with the fruit bunches into a fermentation tank along a rail for fermentation treatment; thirdly, the push and pull mechanism of the movable transporting dumper pulls the fruit cage vehicle out of the fermentation tank and pushes the fruit cage vehicle into the movable transporting dumper after fermentation is over; fourthly, the movable transporting dumper is moved to a determined position along the rail by virtue of a travel mechanism and turns over for discharging, and the next procedure begins; and fifthly, the empty fruit cage vehicle is recharged by the feeding scraper, and circular production is performed. The method is used for oil preparation in the palm fruit (FFB) squeezing plants, saves equipment, reduces floor occupation and the investment cost, shortens the transportation period, and can realize automatic operation and reduce labor intensity and production management cost.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Health-care oil capable of reinforcing kidney and tonifying yang and containing rubus idaeus

The invention relates to the field of health-care food, in particular to health-care oil capable of reinforcing kidney and tonifying yang and containing rubus idaeus. The health-care oil comprises the following raw materials in parts by weight: 1400-1550 parts of palm fruits, 25-30 parts of camellia seed, 25-28 parts of walnut kernel, 25-28 parts of olive, 12-15 parts of ganoderma lucidum, 12-15 parts of panax quinquefolius, 8-10 parts of rubus idaeus, 10-12 parts of Chinese chive seed, and 15-18 parts of radix polygonati officinalis. The manufacturing process of the health-care oil adopts a carbon dioxide subcritical extraction technology, is simple and easy to implement, the extraction temperature is low, active ingredients in the raw materials cannot be broken, the raw materials with relatively high oil extraction rate such as palm fruits and the camellia seeds are used as carriers, and volatile oils, liposoluble constituents and the like of the traditional Chinese medicines such as the ganoderma lucidum, the panax quinquefolius and the rubus idaeus are extracted into the oil according to the principle of like dissolves like, so that the edibleness of the oil is increased; the health-care oil provided by the invention integrates the health care effects of the conventional health-care oil and the raw materials such as the ganoderma lucidum, the panax quinquefolius and the rubus idaeus, has the effects of tonifying yang, securing essence, and warming and nourishing liver and kidney, is simple in extraction process, reduces the cost, and has high market competitiveness.

Owner:安徽大平油脂有限公司

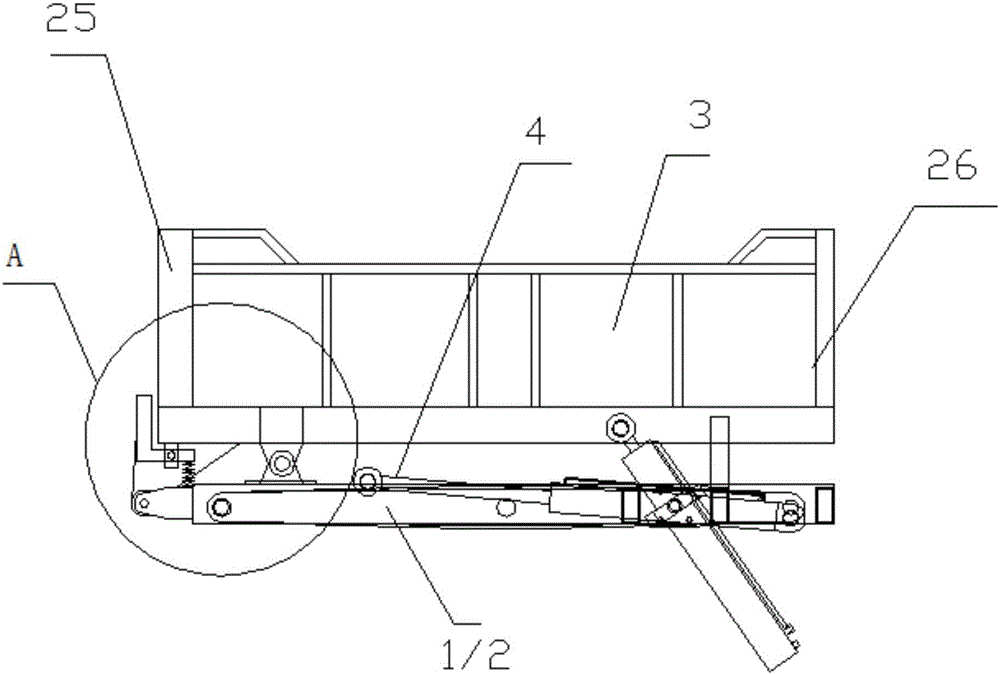

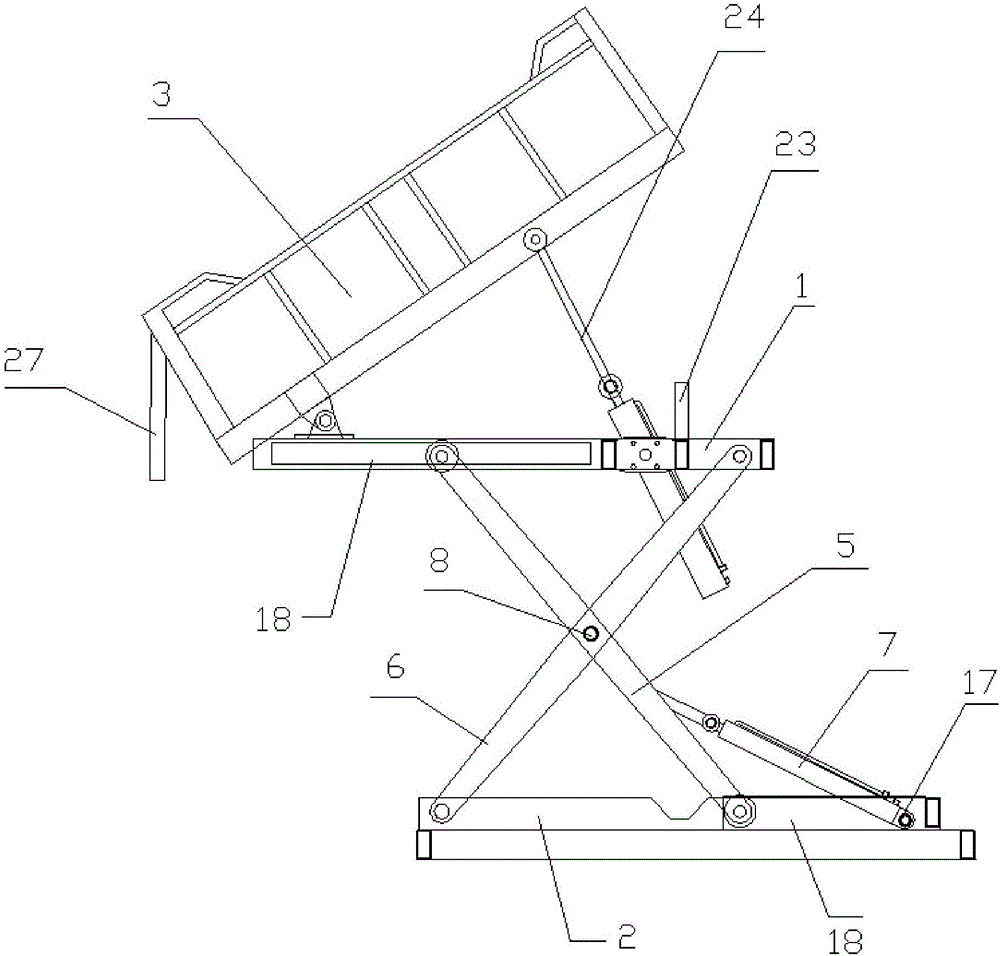

Fruit discharging mechanism for automatic fruit picking machine

InactiveCN106416616AEasy to operateImprove work efficiencyPicking devicesPalm fruitMechanical engineering

The invention relates to a fruit discharging mechanism for an automatic fruit picking machine. The fruit discharging mechanism comprises an upper base, a lower base, a bearing box and a lifting mechanism. The lifting mechanism comprises two first adjusting mechanisms, two second adjusting mechanisms, a first oil cylinder and a first rotating shaft. The second adjusting mechanisms are arranged between two first adjusting rods of the first adjusting mechanisms and are connected through a first rotating shaft to form a cross structure, the bearing box is fixed to the upper base and used for bearing palm fruits which fall from trees due to cutting and transferring the palm fruits into a transfer vehicle, and the fruit discharging mechanism is convenient to operate, economic and practical, improves working efficiency and reduces cost.

Owner:ZHENJIANG SHEN WARD MACHINERY CO LTD

Method for preparing chemical-mechanical pulp for fluting medium by using fresh empty fruit bunches

ActiveCN103103864ASimple pulping processLess investmentPretreatment with water/steamPulp beating/refining methodsPalm fruitPalm fiber

The method discloses a method for preparing chemical-mechanical pulp for fluting medium by using fresh empty fruit bunches, mainly aiming at the characteristics that the water content of the fresh empty fruit bunches is high, hard impurities such as residual palm fruit granules, sands and the like are carried in the fruit bunches and the palm silk surfaces of the empty fruit bunches contain more non-fiber surfaces; and on the basis of the technology process and the equipment configuration, the processing steps of granule removing, slicing, extruding, washing with water, pre-steaming, chemical soaking, pulping, washing and the like are performed gradually to materials. Before the pulp is formed, the non-fiber parts such as non-fiber surfaces with higher content on the fiber surface and the carried palm fruit granules in the EFP (empty fruit bunches) fiber raw materials are effectively removed as much as possible in the whole process and are used. The dosage of chemical product needed in the pulping process and the pollution load generated by pulping are effectively reduced, the paper pulp prepared by refining the palm fibers has the advantages of less dust, high strength and the like and is suitable for blending of the fluting medium; and by adopting the method, the clean and high-efficiency comprehensive utilization of the EFP raw materials in pulping and paper making is achieved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Qualitative of beta-sitosterol in sabal fruit extraction and its quantitative detecting method

The invention provides a qualitative and quantitative detection method for beta-sitosterol in saw leaf palm fruit extracts. The invention uses thin layer scanning method, the character is: the testing liquid and contrast liquid are produced through weighing, dissolving, refluence, extracting and drying and dissolving process to the saw leaf palm fruit extracts, uses developing agent to develop them on the preprocessed silica gel plate, they are detected under the ultraviolet after being dried and heated. Then carries on scan with fluorescence mode or visible light mode, it can acquire the content.

Owner:方芳

Nutritive date palm fruit milk and preparation method thereof

The invention relates to nutritive date palm fruit milk and a preparation method thereof, belonging to the technical field of health beverages. The nutritive date palm fruit milk is prepared from the following raw materials in parts by weight: 45-60 parts of palm date, 15-30 parts of seedless cherry, 10-20 parts of fig, 10-15 parts of purslane, 4-8 parts of astragalus membranaceus, 2-5 parts of ginseng, 2-5 parts of white atractylodes rhizome, 4-8 parts of dried tangerine or orange peel, 3-6 parts of Chinese angelica, 6-8 parts of Chinese date, 5-7 parts of rhizoma nardostachyos, 3-5 parts of elecampane and 180-300 parts of milk. The nutritive date palm fruit milk provided by the invention is rich in protein, dietary fiber, ferrum, magnesium, potassium, phosphorus, carotene, vitamin C, vitamin B1, vitamin B2 and other nutrient elements, is low in fat and cholesterin, not only can strengthen the middle warmer and benefit vital energy, relieve a cough and moisten lung and resolve sputum and relieve asthma, but also can expel toxin, recover and strengthen intestines function, and is a function beverage suitable for various people.

Owner:崔子扬

Buckwheat tea paste with mango flavor and preparation method thereof

The invention discloses a buckwheat tea paste with mango flavor. The buckwheat tea paste is made from the following raw materials by weight: 160-170 parts of buckwheat kernel, 20-25 parts of glutinous rice, 5-6 parts of sweet scented osmanthus, 10-13 parts of large leaf type of tea seed oil, 9-12 parts of white beans, 2-4 parts of ginseng flower, 1-3 parts of glossy privet fruit, 6-9 parts of puffing Chinese yam powder, 4-6 parts of chocolate powder, 1-2 parts of Uncaria, 1-3 parts of Acacia leaves, 6-7 parts of jasmine buds, 4-5 parts of pickled cabbage stem, 2-3 parts of lavender, 9-11 parts of vegetable fat powder, 14-16 parts of mango juice, 11-13 parts of palm fruit, 7-9 parts of black bone chicken bones, 15-17 parts of an auxiliary agent and a proper amount of water. The tea paste provided by the invention uses tartary buckwheat kernel as the main raw material, also contains glutinous rice with effects of supplementing vacuity, enriching blood, invigorating spleen and warming the stomach, Chinese yam powder capable of improving hearing, brightening eyesight, benefiting the five internal organs, and strengthening bones and muscles, and fruit juice rich in nutrient and the extraction of traditional Chinese medicine; therefore, the tea paste has the advanategs of good taste, rich nutrition and good health preserving practicality.

Owner:ZONGYANG COUNTY XINCHANGHE FOOD DEV

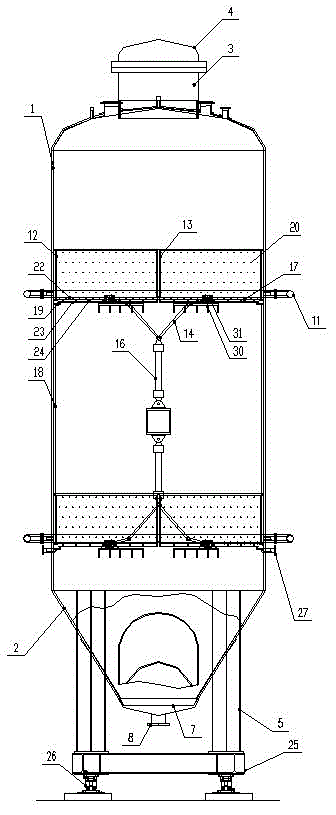

Palm fruit yeast killing technology

InactiveCN102746942AReduce stack heightAvoid high-speed vertical fallsFatty-oils/fats productionYeastPalm fruit

The invention discloses a palm fruit yeast killing technology. The technology comprises the following steps: 1, feeding a material from a material inlet; 2, opening a movable turnover plate after completing the first material feeding to enable the material to fall into a tank under the movable turnover plate, continuously feeding the material from the material inlet, and closing the movable turnover plate after completing the second material feeding; 3, continuously feeding the material from the material inlet, and closing the fast opening door of the material inlet after completing the third material feeding; 4, letting steam in the tank until the pressure reaches 0.05-0.35MPa and the temperature reaches 120-350DEG C, and waiting for 3-30min; 5, opening a steam discharge valve, waiting for 3-30min, closing the steam discharge valve, and repeatedly step 4 until yeast killing requirements are reached; 6, opening the steam discharge valve, waiting until the pressure in the tank returns to zero, opening a water discharge valve, and waiting until a deposition liquid in the lower part of the tank is evacuated; and 7, sequentially opening the fast opening doors of material outlets and the movable turnover plate, and closing the movable turnover plate after completing the first material discharge and the second material discharge. According to the technology, the material feeding and the material discharge are carried out in a grading and batch mode, so material bridging and caking are avoided, material unloading is convenient, and destructive impact of the material to the bottom of the tank is prevented.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Edible fungus culture material made from palm by-products and its making method

The invention belongs to the technical field of cultivation of mushrooms, in particular relates to an edible fungus culture medium, and further relates to a manufacturing method of the edible fungus culture medium. The edible fungus culture medium disclosed by the invention is characterized by comprising the following components: corncobs, palm kernel meal, palm leaves, palm fruit shells, palm shells, palm pulp residue, lime, cottonseed hull, sugar, light calcium carbonate, needle mushroom roots, and manganese. After being cultured by adopting the edible fungus culture medium disclosed by the invention, the edible fungus is rapid in fungus raising, vigorous in hypha growth and low in infectious microbe pollution rate; the produced edible fungus has all kinds of quality and nutritional characteristics of the edible fungus produced by utilizing ordinary culture mediums; furthermore, the biological conversion ratio is high. Due to the edible fungus culture medium disclosed by the invention, the use amounts of saw dust and cottonseed hull are obviously reduced, the environmental disruption caused by deforestation is effectively reduced, and the cost is reduced, therefore, the edible fungus culture medium disclosed by the invention is worthy of being popularized.

Owner:SHANDONG YOUHE BACTERIA IND CO LTD

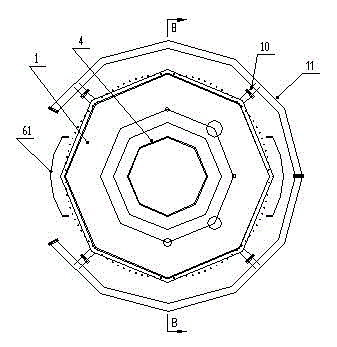

Non-palm shortening and preparation method thereof

The present invention provides a preparation method of low-trans fatty acids non-palm shortening oil composition with characteristics of palm shortening, wherein the method does not use palm oil or palm kernel oil as a starting material, and a non-palm shortening produced by the method. Specifically, the method uses vegetable oil which is not derived from palm fruit, and prepares a vegetable shortening by the processes of hydrogenation, transesterification and deployment. The vegetable shortening has similar solid fat content and melting point as a common palm shortening and can replace the palm shortening for usage.

Owner:COFCO NUTRITION & HEALTH RES INST +1

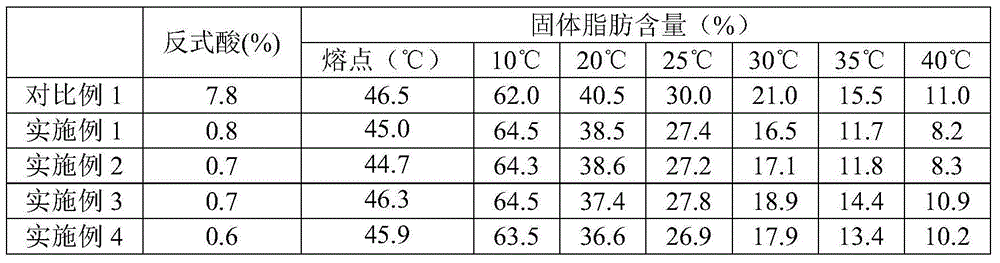

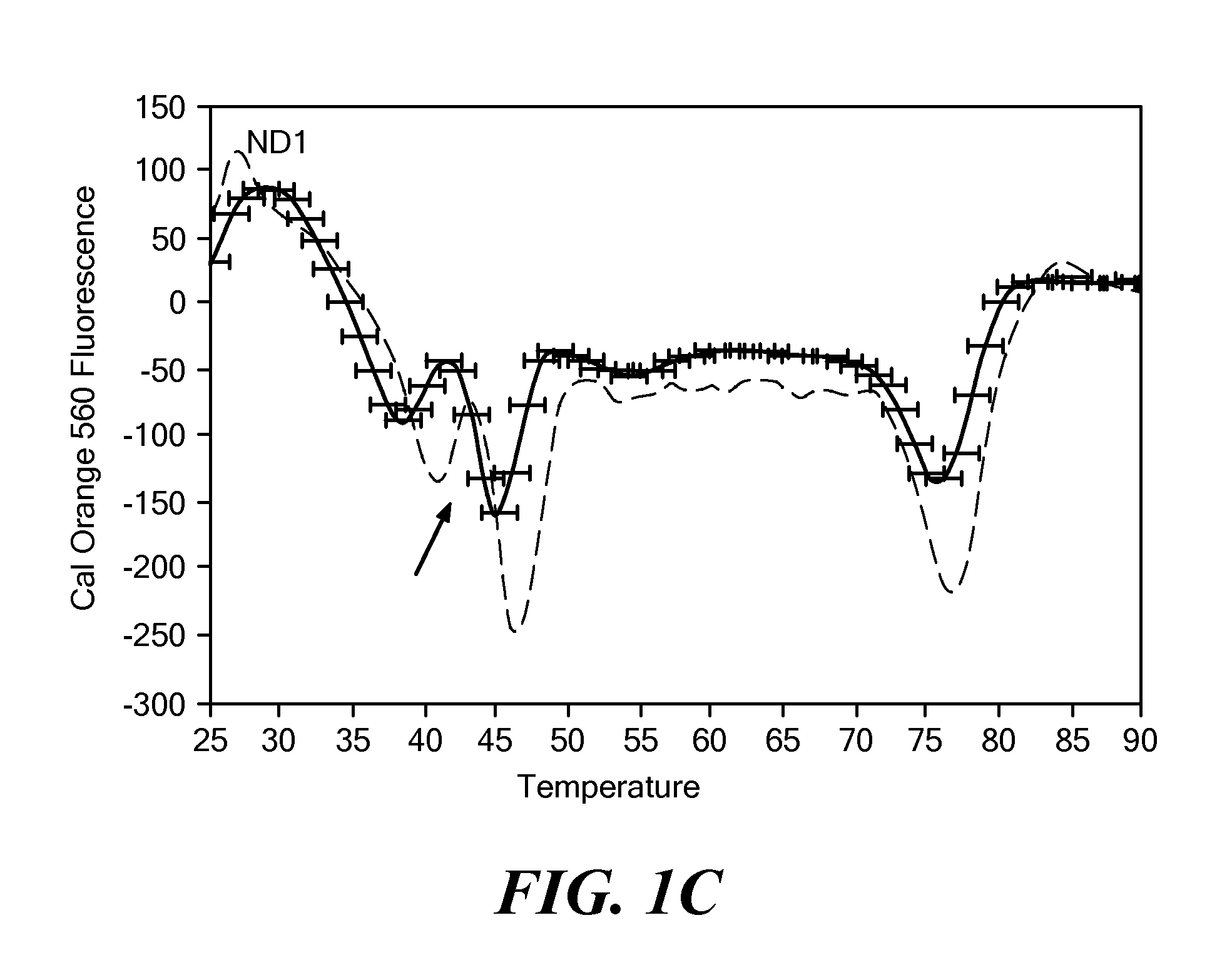

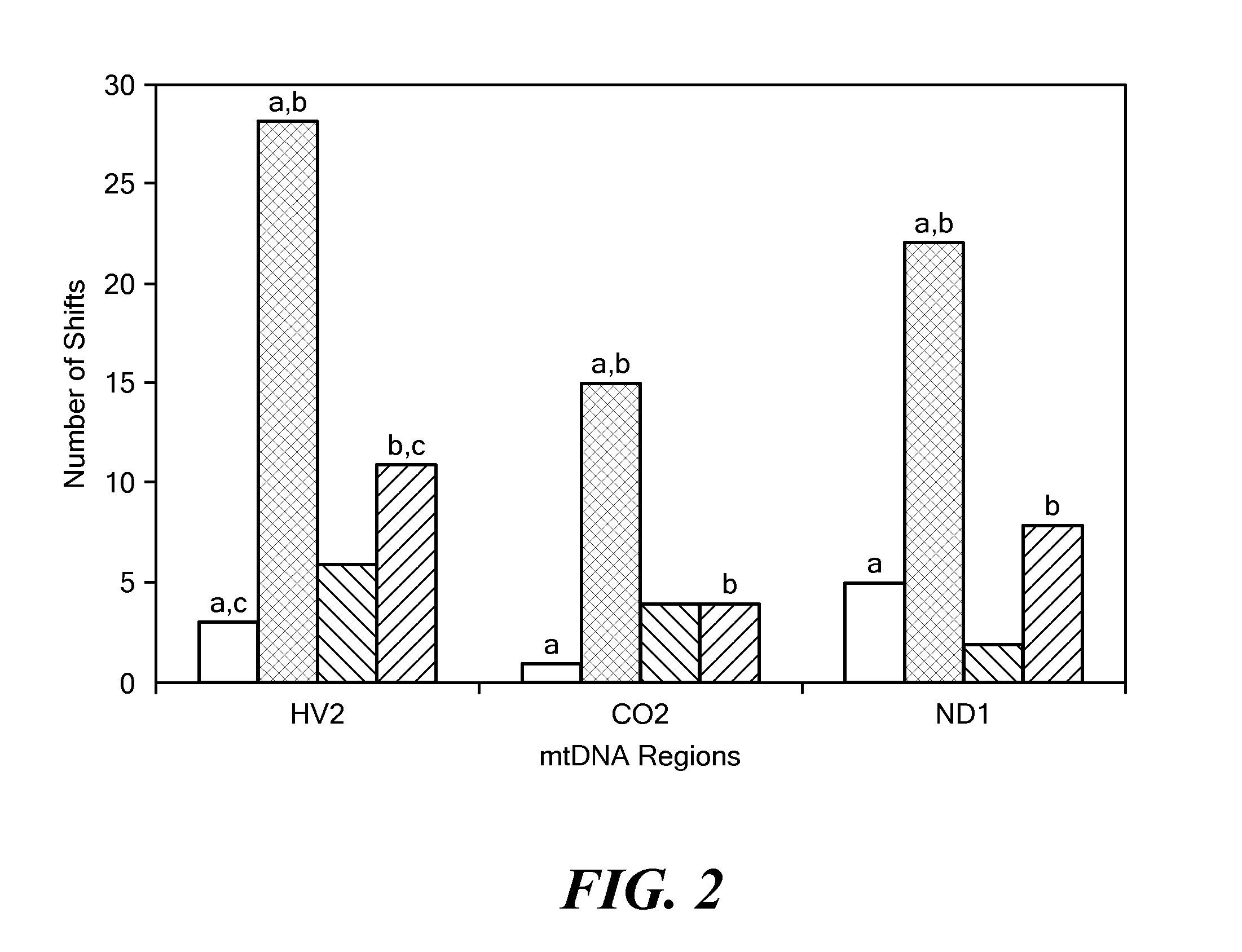

Treatment of DNA damage and mitochondrial dysfunction using palm fruit juice

ActiveUS20160000854A1Antibacterial agentsOrganic active ingredientsNucleoside Reverse Transcriptase InhibitorPalm fruit

Methods, compositions and kits for the prevention and treatment of mitochondrial dysfunction, mitochondrial DNA damage and genomic DNA damage are provided. The methods use the administration of palm fruit juice and / or compositions containing phenolic compounds present in palm fruit juice. The methods, compositions, and kits can be used to reduce DNA damage in subjects being treated with nucleoside reverse transcriptase inhibitors, such as patients having HIV or AIDS.

Owner:MALASIAN PALM OIL BOARD +1

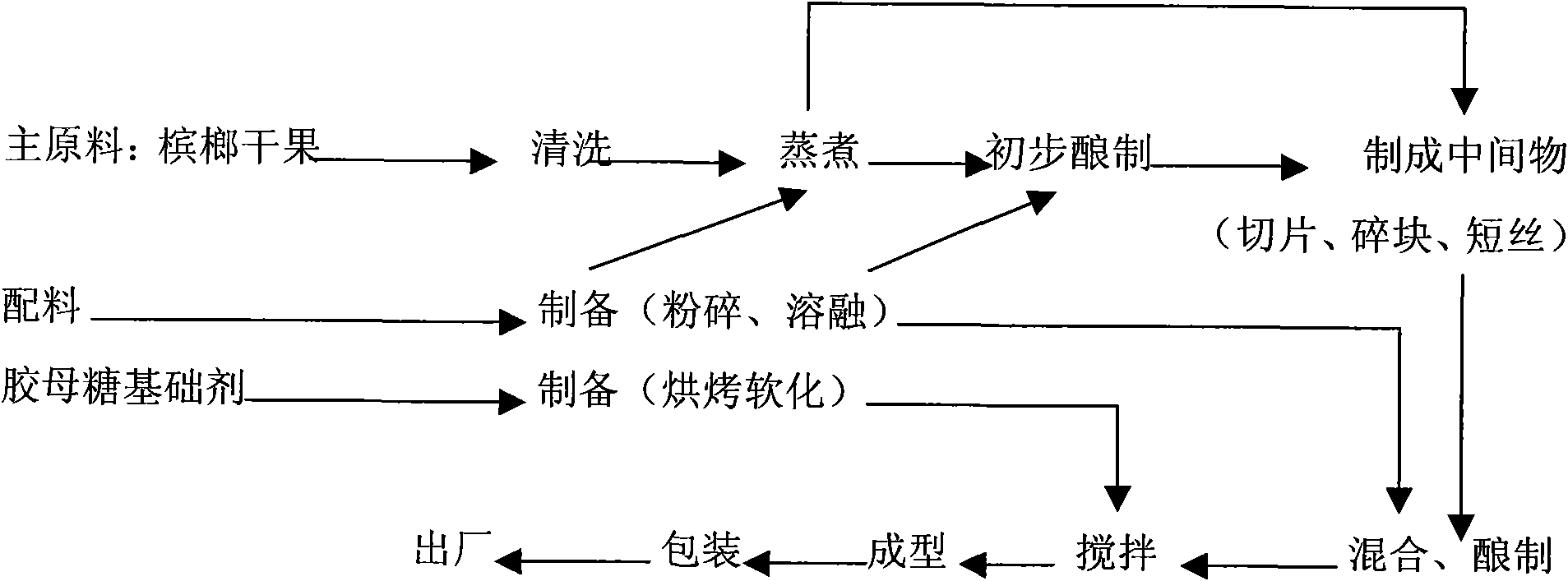

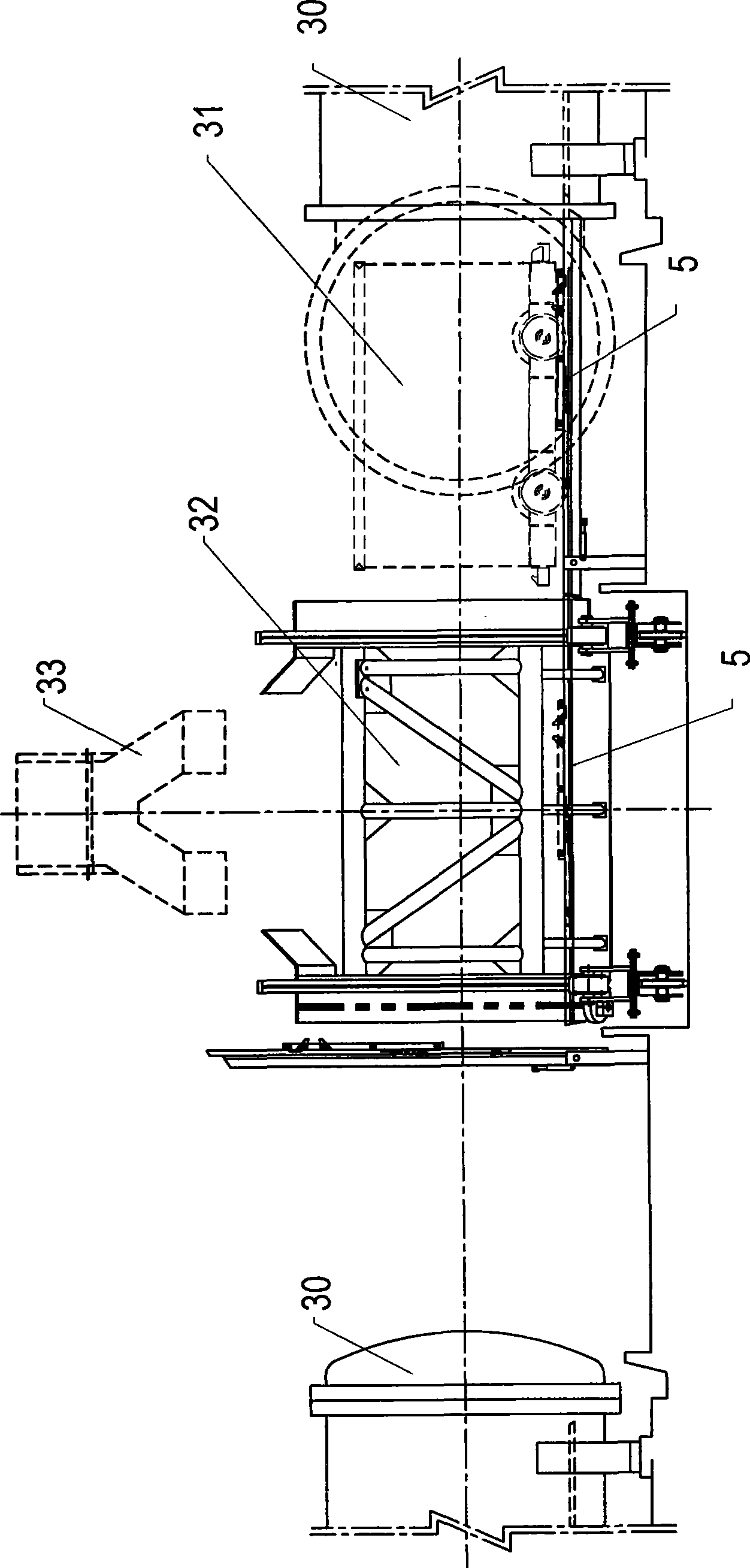

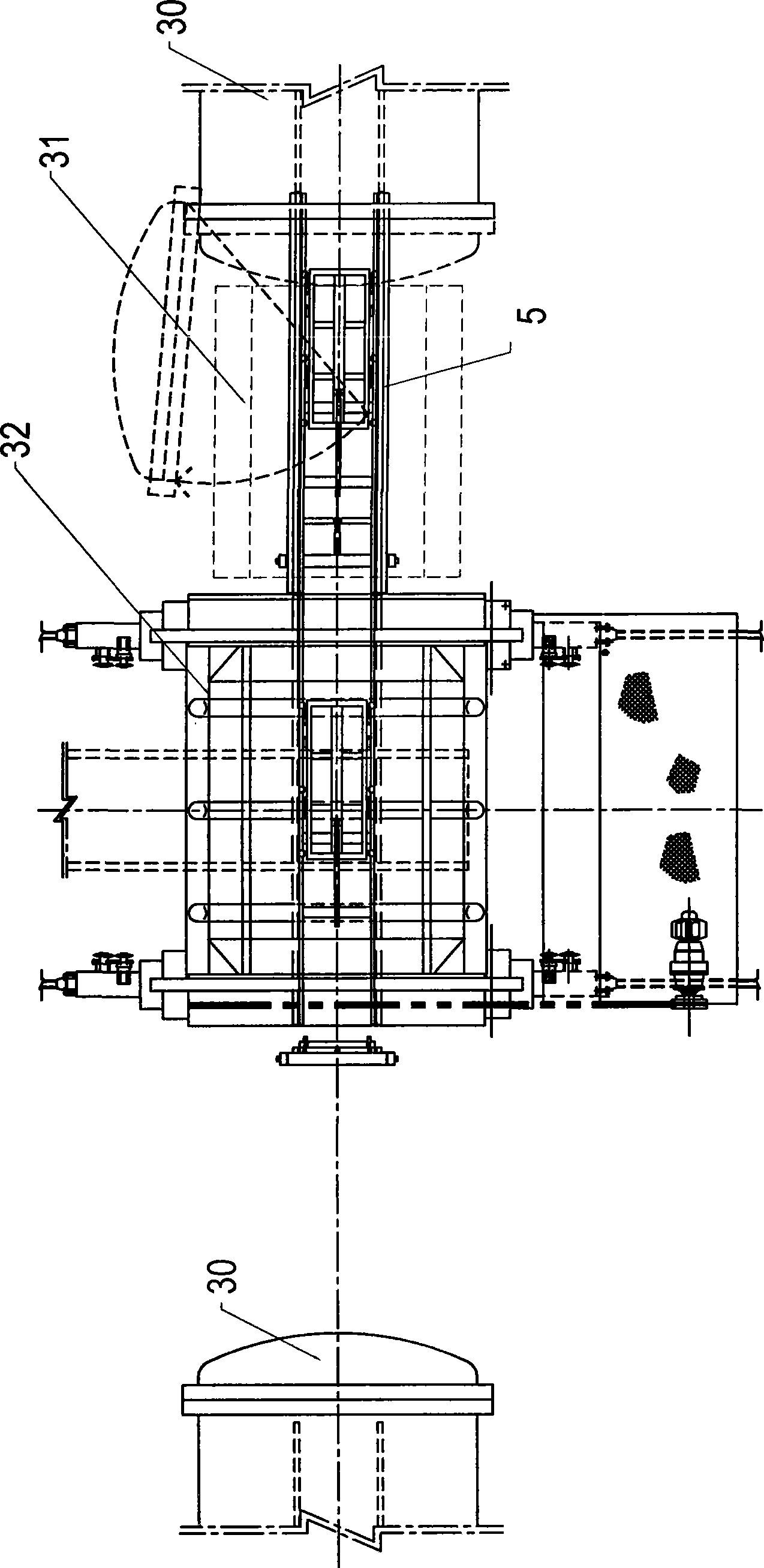

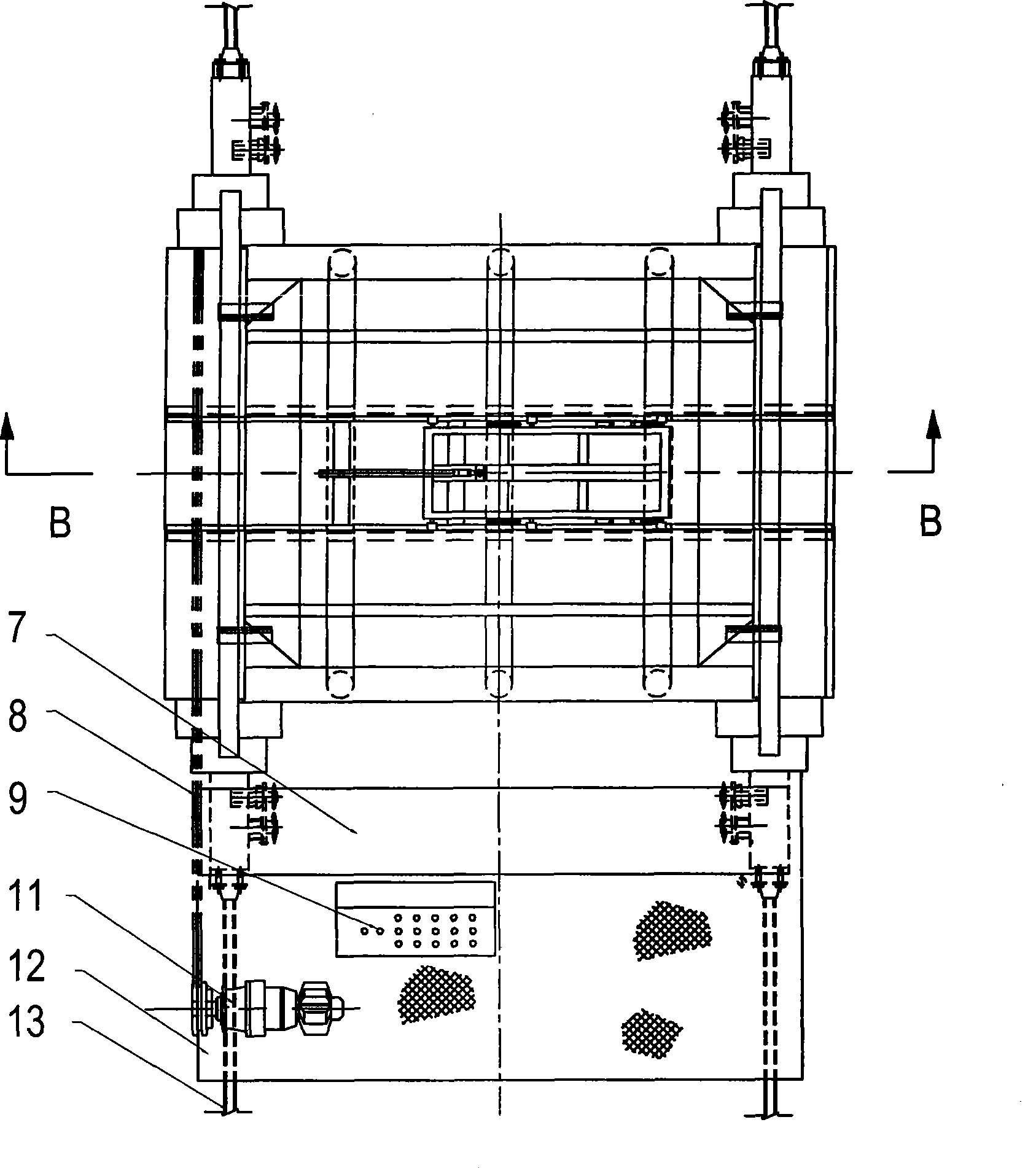

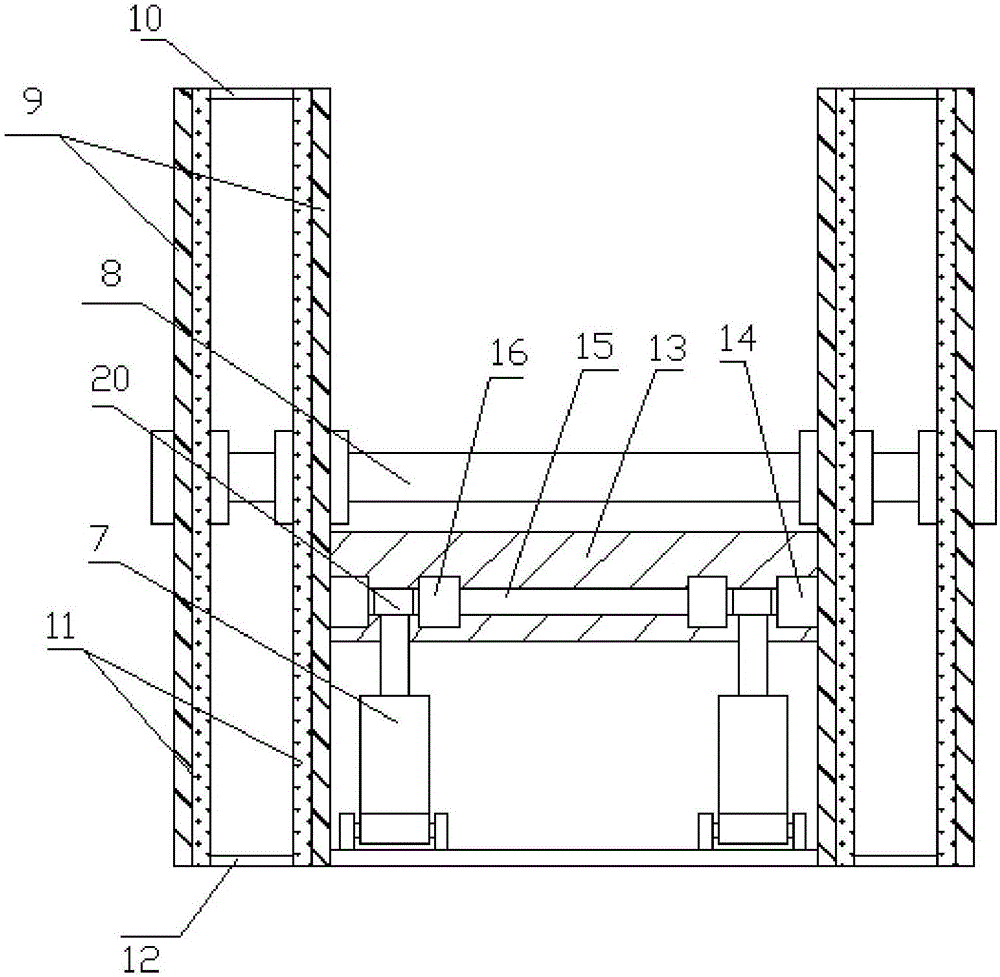

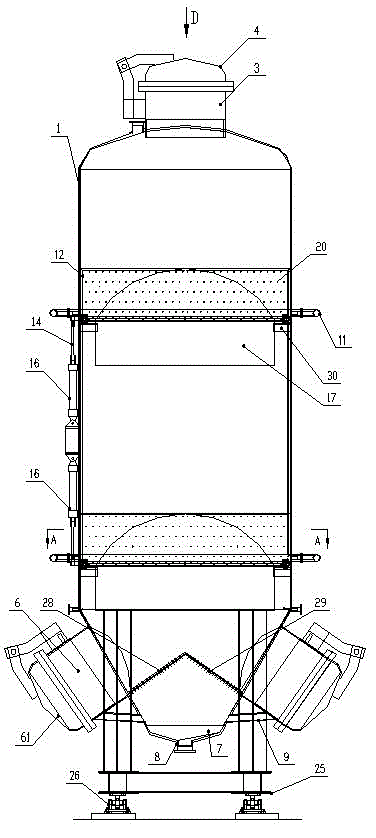

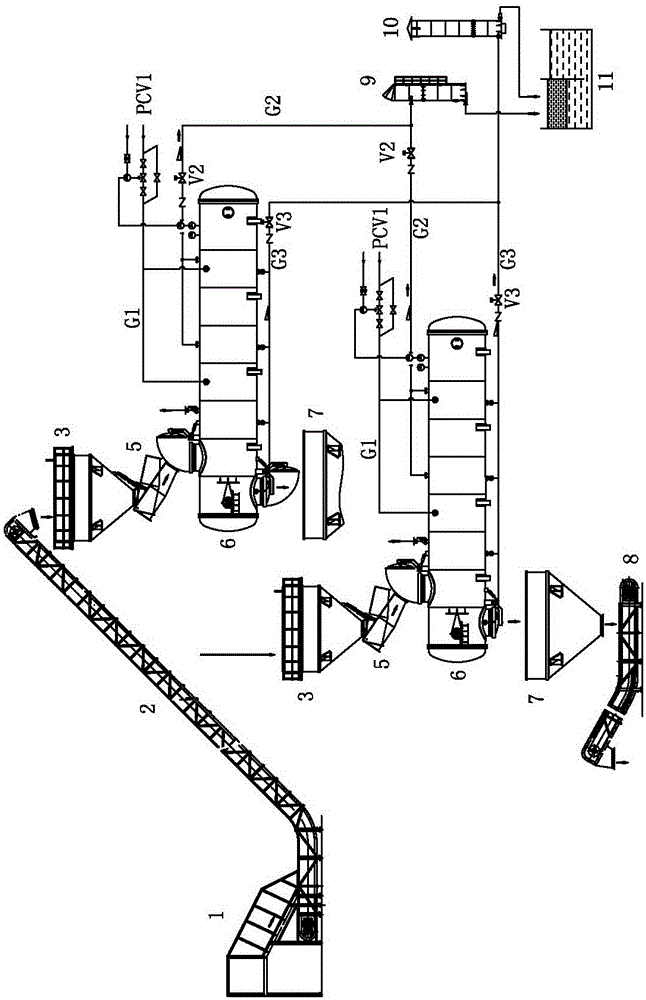

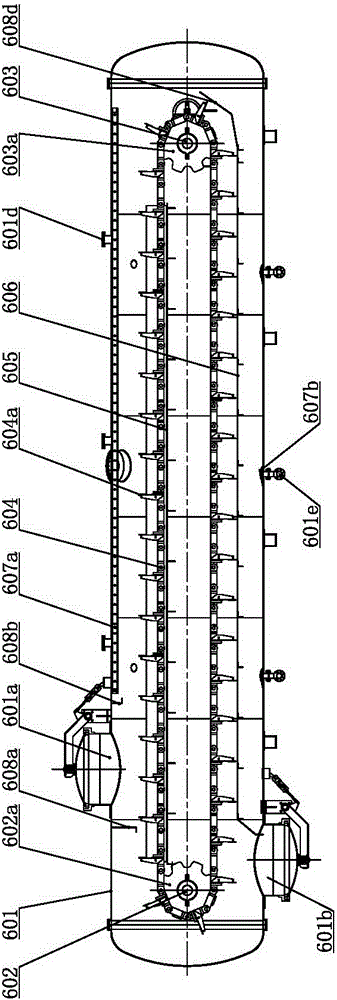

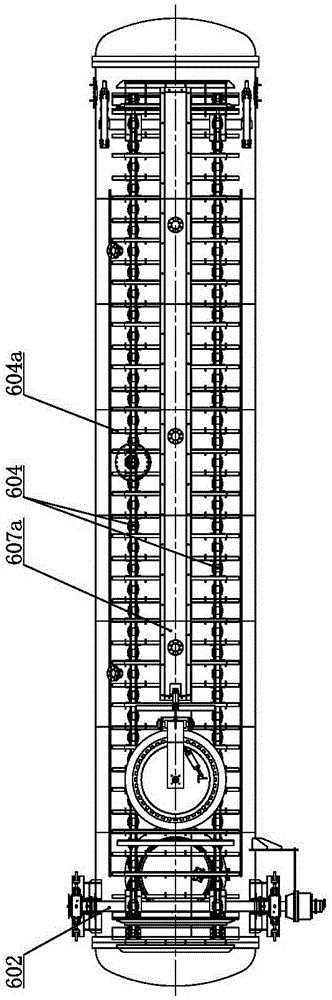

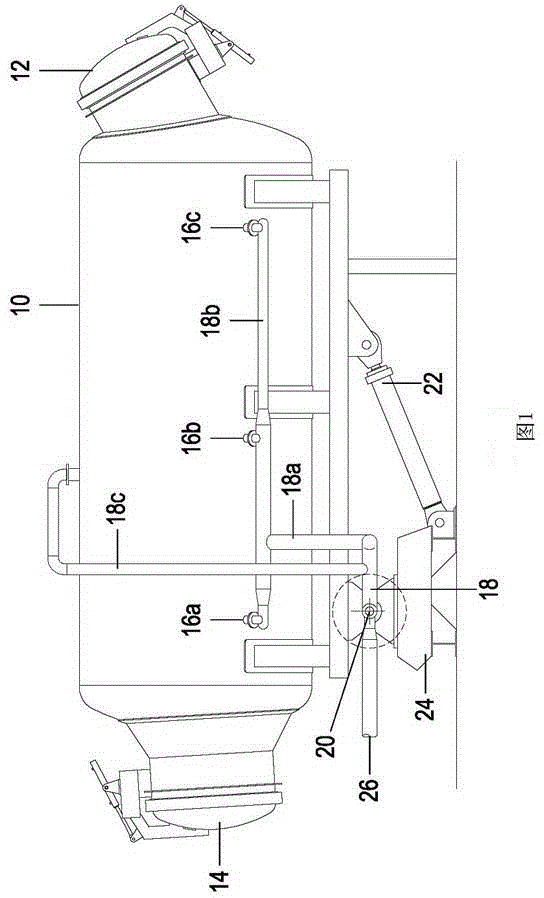

Palm fruit sterilization system

ActiveCN105154210AImprove securityImprove reliabilityFatty-oils/fats productionAgricultural sciencePalm fruit

The invention relates to a palm fruit sterilization system. The palm fruit sterilization system comprises a fresh fruit bunch ramp, a fresh fruit scraper conveyor, fresh fruit temporary storage feeding devices, palm fruit sterilizers, cooked fruit hoppers and a cooked fruit scraper conveyor. An outlet of the fresh fruit bunch ramp is connected with an inlet of the fresh fruit scraper conveyor, an outlet of the fresh fruit scraper conveyor is connected with inlets of the fresh fruit temporary storage feeding devices, outlets of the fresh fruit temporary storage feeding devices are connected with feeding ports of the palm fruit sterilizers, and discharging ports of the palm fruit sterilizers are connected with inlets of cooked fruit hoppers. Each palm fruit sterilizer comprises a horizontal round barrel, wherein a feeding door is arranged on the upper portion of the head end of the barrel, a discharging door is arranged on the lower portion of the head end of the barrel, a driving shaft and a driving chain wheel are arranged at the head end in an inner cavity of the barrel, a driven shaft and a driven chain wheel are arranged at the tail end, a chain is wound around the driving chain wheel and the driven chain wheel and evenly provided with sterilizer scrapers, and sieve plates are arranged below the upper layer sterilizer scrapers and the lower layer sterilizer scrapers respectively. The sterilization system is small in investment, high in production efficiency and equipment use ratio and capable of cooking a shallow material layer at high pressure.

Owner:江苏迈安德智能装备有限公司

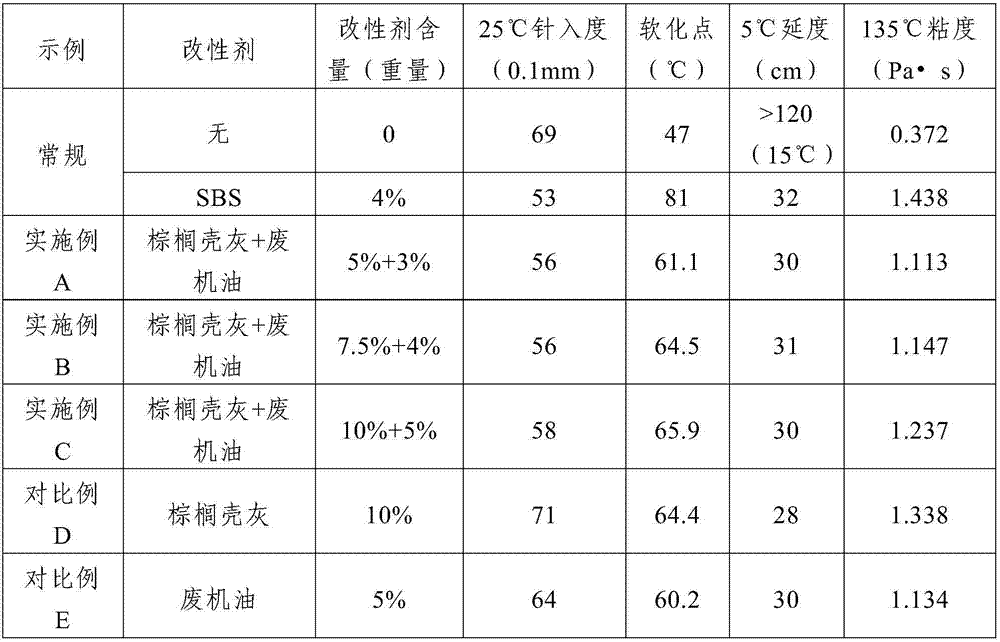

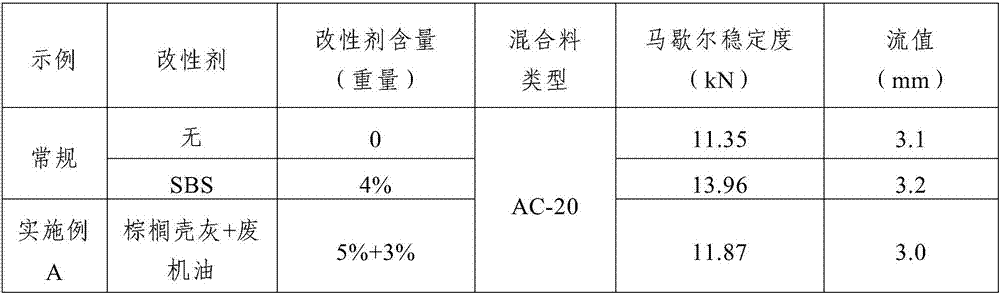

Modified asphalt

InactiveCN106916462AReduce in quantityImprove continuityBuilding insulationsSocial benefitsPalm fruit

Modified asphalt is provided. The modified asphalt includes matrix asphalt and a modifier. The modifier includes palm fruit shell ash and waste engine oil. The palm fruit shell ash is ash generated after palm fruit shell is combusted. The waste engine oil is engine oil wasted after vehicle maintenance. A large amount of palm fruit shell is adopted, thus providing a beneficial supplement for the flourishing palm oil industry at present, reducing pollution caused by secondary treatment of the palm fruit shell ash and the waste engine oil, reducing the fuel using amount during modified asphalt production, and meeting the social requirements of energy conservation and emission reduction at present. A construction process is convenient, the cost is low, and the effective utilization rate is increased. The modified asphalt can be widely used in highway and building projects, and has significant economic benefit and social benefit.

Owner:XIAN UNIV OF SCI & TECH

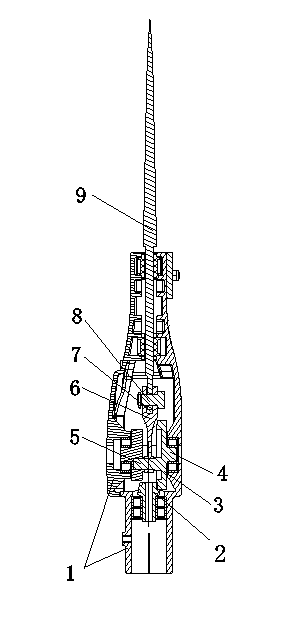

Shock axe for trimming palm leaves and harvesting palm fruits

The invention discloses a shock axe for trimming palm leaves and harvesting palm fruits, and belongs to the field of mechanical equipment for planting and harvesting palms. The shock axe comprises a gear box (1) and is characterized in that a driving bevel gear (2) and a driven bevel gear (3) are mounted in the gear box (1), a bevel gear pair comprises the driving bevel gear (2) and the driven bevel gear (3), an eccentric shaft (5) is arranged on the driven bevel gear (3) and is eccentric relative to a driven bevel gear shaft (4), a connecting rod (6) is mounted on the eccentric shaft (5), the upper end of the connecting rod (6) is provided with a U-shaped groove (7), a shaft (8) is mounted in the U-shaped groove (7), and a shoveling axe (9) is movably mounted on the shaft (8) through a hole at the lower end. The shock axe has the advantages that the shock axe is convenient to use, high in safety and efficiency and large in impact force, the palm fruits and the palm leaves are easily taken out, palm leaf trimming and palm fruit harvesting effects are fine, and the shock axe can be hung on the palms when operation pauses as the shock axe is provided with a hook.

Owner:YONGKANG WEILI GARDEN MACHINERY

Integrated methods for processing palm fruit bunches

This invention is directed to an integrated method for the processing of palm fruit bunches to oil and other products. The method comprises inter alia separating palm fruit carrying bunches into fruits and lignocellulosic empty fruit bunches, processing the fruits to form palm oil, and at least one lignocellulosic processing coproduct; generating an aqueous stream; producing a non-oil, non-alcohol, non-fatty acid ester third product from the oil, the lignocellulosic processing coproduct, the aqueous stream or from a combination thereof; processing at least a portion of the lignocellulosic empty fruit bunches, lignocellulosic processing coproduct or a combination thereof into a fourth product and optionally producing at least one fifth conversion product from the fourth product; and using at least a portion of the fourth product or a product of its conversion or a combination thereof.

Owner:EYAL RES CONSULTANTS

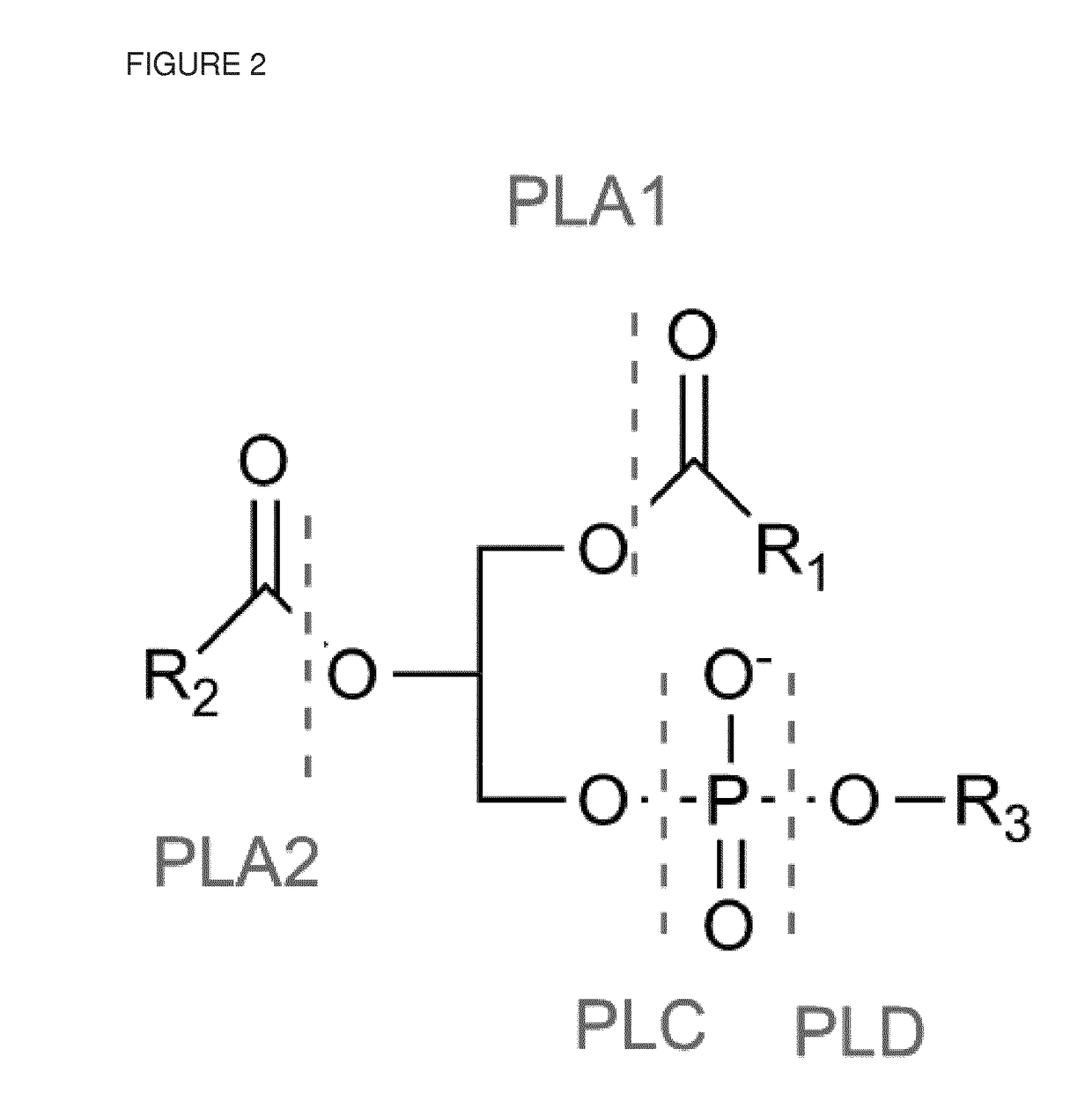

Method for increasing crude palm oil yields

InactiveUS20170121741A1Improve oil yieldEasy to separateFatty-oils/fats productionFermentationPalm fruitSludge

A method for improving crude palm oil yields or separating the crude palm oil from the sludge or a combination thereof in palm fruit processing comprising: admixing a palm fruit or a portion thereof or a palm fruit extract and an enzyme, which enzyme degrades a phospholipid present in said palm fruit or portion thereof or palm fruit extract; and incubating the admixture at about 45° C. to about 95° C. for about 15 minutes to about 6 hours. Also included are uses of an enzyme which degrades a phospholipid.

Owner:DUPONT NUTRITION BIOSCIENCES APS

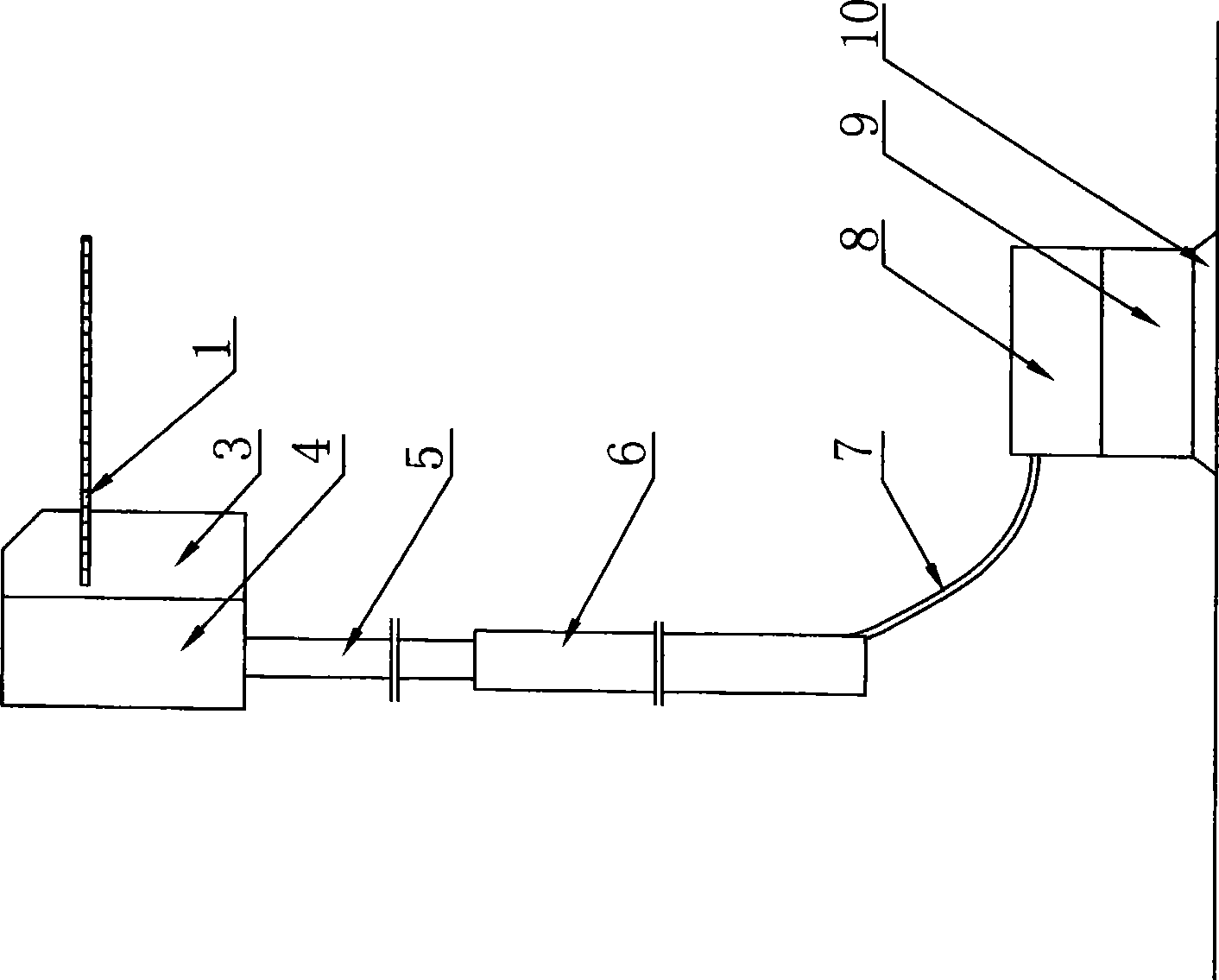

Palm berry fruit picking platform

The invention provides a palm berry fruit picking platform. The top end of a worm is connected to a hydraulic motor; the worm penetrates through a lifting base; the lifting base is fixedly arranged onthe worm through a threaded tooth sleeve, and up-and-down moves on the worm along with the rotation of the worm; pulleys are arranged on two sides of the lifting base through an installation base, and are arranged in sliding rails arranged on two lifting stand columns in a matching way; a left platform base and a right platform base are arranged on the lifting base through rotary pins, are in semi-circular ring shapes and surround to form a complete circular ring; one end of a hydraulic oil cylinder is fixed to the bottom surface of the left platform base; the other end of the hydraulic oil cylinder is fixed to the bottom surface of the right platform base; multiple surrounding plates are arranged; the bottom ends of the surrounding plates are arranged on edges of inner circles of the left platform base and the right platform base; and the top ends of the surrounding plates arranged on the left platform base and the right platform base surround to form a complete circle. The palm berry fruit picking platform provided by the invention can be adjusted according to the heights and the thicknesses of palm trees so as to carry out high-altitude picking operation, so that the picking efficiency is improved.

Owner:HUBEI FUYI AGRI MACHINERY MFG

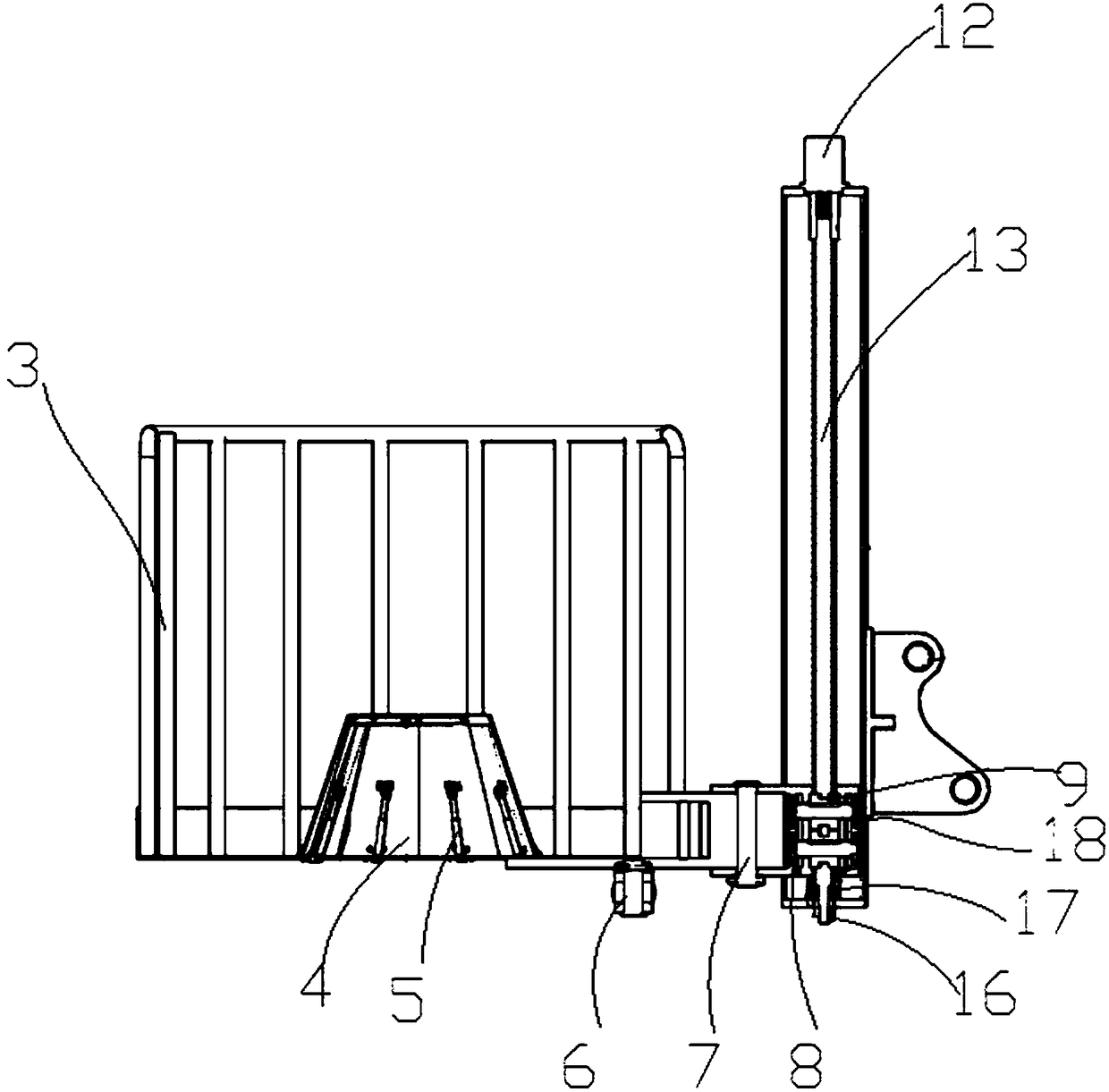

Installation for treatment of oil palm fruits

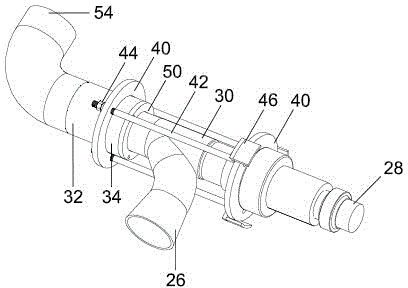

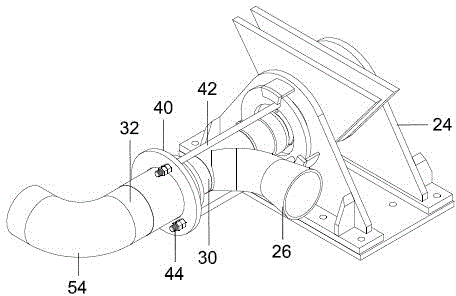

An installation for treatment of harvested palm fruits using pressurized steam comprises a sterilizer unit and a steam supply unit working in combination. The sterilizer unit includes a vessel (10) having inlet (12) for charging in fruits, steam openings (16a, 16b, 16c)) for receiving steam, outlet (14) for dispensing treated fruits and a pivot (20) for tilting the vessel to various orientations. The steam supply unit includes a shaft (28) fixedly mounted onto the pivot (20), a pipeline (30) connected to end of the shaft and used for supplying steam, a housing (32) connected to and rotatable about the pipeline, a flange (38) to retain the housing in position, and an elbow (54) connected to the housing such that the elbow can supply steam to the vessel from a fixed location.

Owner:廖升汶

Macadimia nut oil lipstick

InactiveCN107997997AIncrease moistureImprove ductilityCosmetic preparationsToilet preparationsPalm fruitVegetable oil

The invention discloses a macadimia nut oil lipstick. The lipstick is prepared from, by weight, 8-10 parts of macadimia nut oil, 18-21 parts of other natural plant oil, 9-11 parts of natural wax, 0.2-0.6 part of antioxidant and 1-3 parts of additives, wherein the other natural plant oil is any one or more of avocado oil, castor oil, palm fruit oil and olive oil, the natural wax is any one or moreof beewax, carnauba wax, castor wax, candelilla wax, and the antioxidant is any one or more of vitamin E, vitamin C, catechinic acid and oryzanol. The lipstick is ideal in expandability, permeability,breathability, nourishing effect and moisturizing effect.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

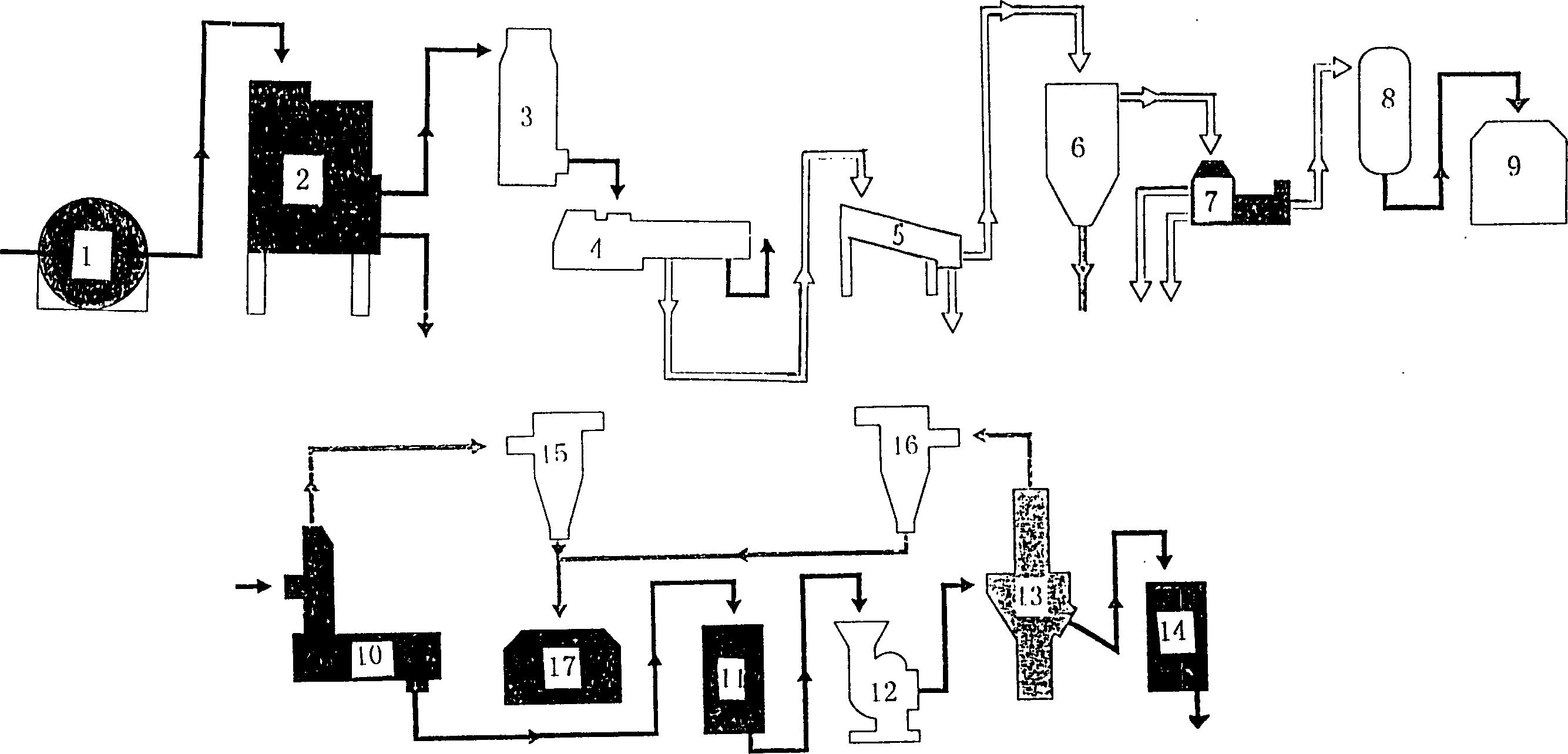

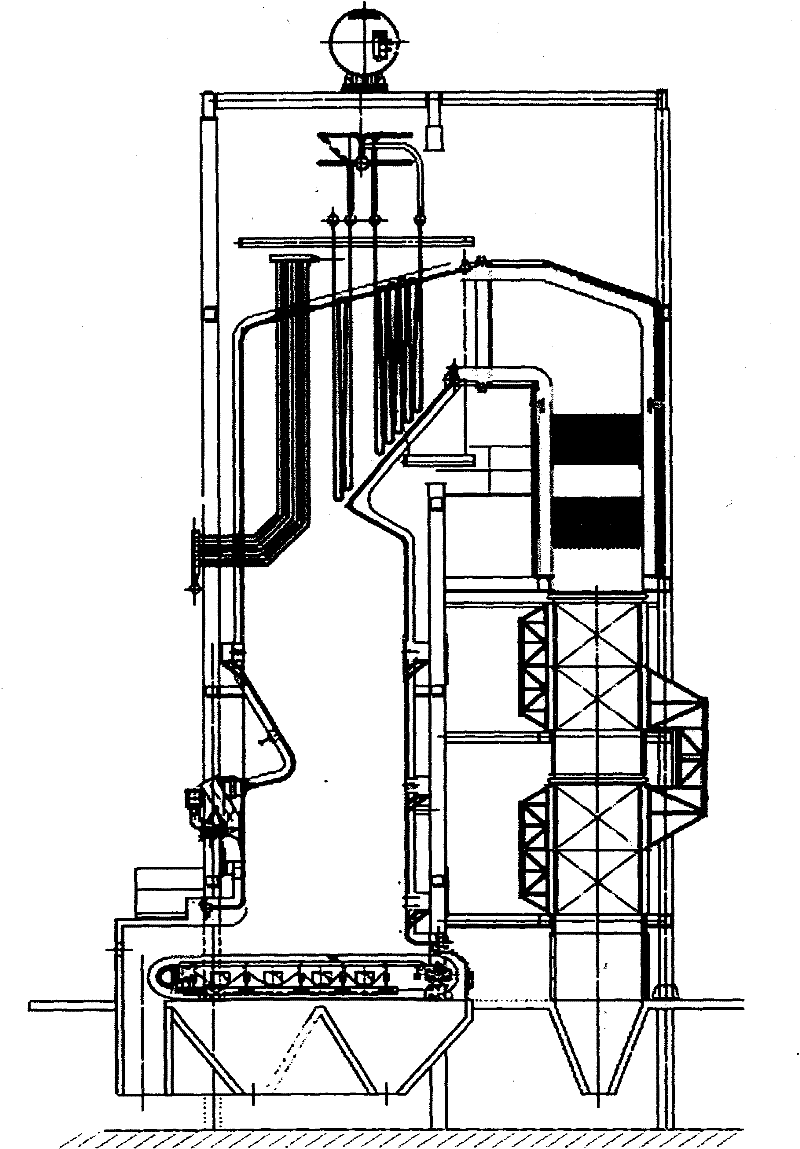

High-moisture-content biomass fuel boiler

InactiveCN102345875AEnough time to stayReduce accidentsLump/pulverulent fuel feeder/distributionFiberPalm fruit

The invention relates to a boiler, which is characterized in that high-moisture-content biomass fuels such as palm fruit shells, fibers, bran coats, bagasse and the like generate steam through a specific combustion method for electricity generation and steam supply. The boiler adopts a wind dispersal mode, and a layer combustion mode by using the suspension combustion in a furnace as a main means and using a rotating fire grate or a water cooling fixing fire grate as an auxiliary means is adopted. The boiler comprises main components such as a feeding machine, a spraying device, the fire grate, a multi-stage wind supply device, a diaphragm type water cooling wall hearth, a water cooling screen, an overheater, a water spraying temperature reducer, a coal economizer with fins and the like and is shown as Figure 1. In the boiler, the high-moisture-content biomass is pretreated and processed and is then directly dispersed by wind to the hearth by the variable-frequency speed-regulation feeding machine through high-pressure head wind, and medium and short fibers are rapid dried, fired and completely combusted in a high-temperature smoke gas environment in the furnace. Long fibers fall in the middle or back position of the fire grate, the fire grate rotates from the back end to the grate front, the detention time of the biomass fuels on the fire grate is effectively prolonged, the complete combustion is favorably realized, the probability of the coking on the fire grate is greatly reduced, and the operation reliability is improved.

Owner:SHANGHAI PUHAO PULP MAKING PAPER MAKING ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com