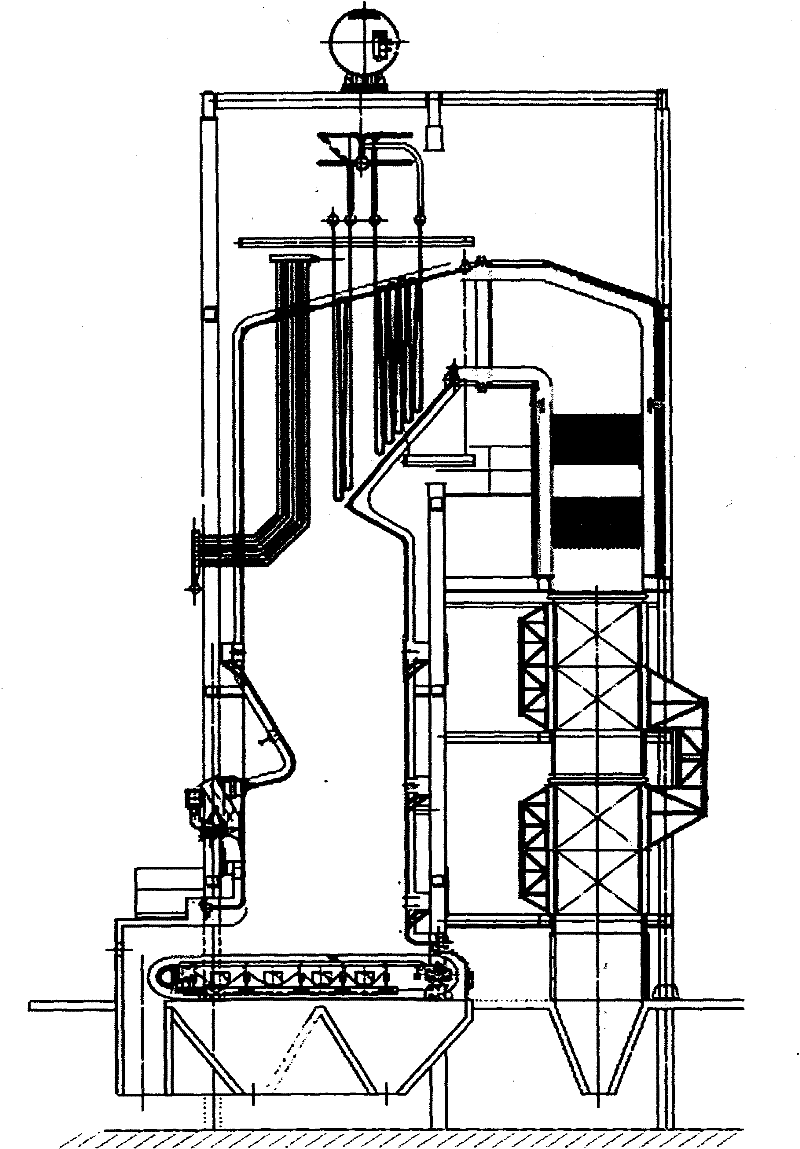

High-moisture-content biomass fuel boiler

A high moisture content, biomass fiber technology, applied in fuel supply, combustion method, combustion equipment, etc., can solve the problem of high price of power generation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

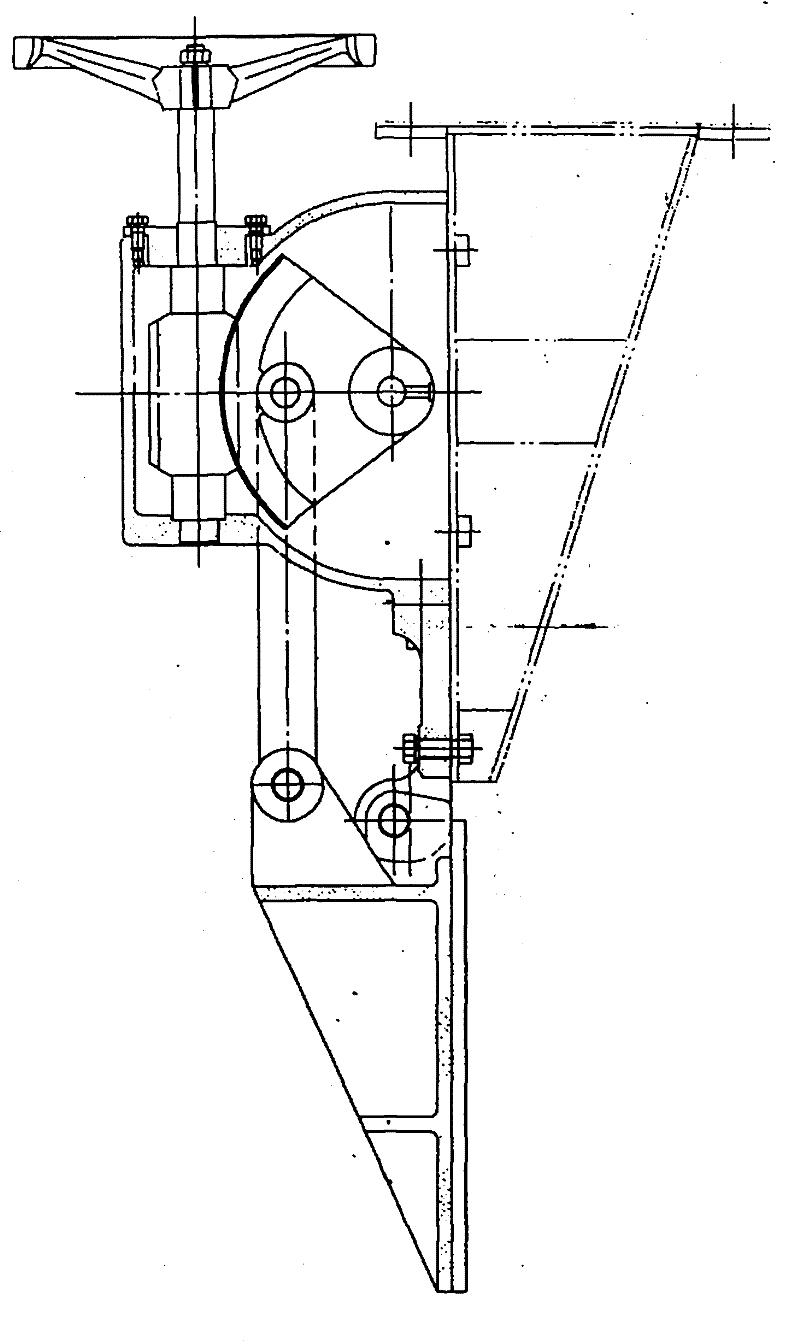

[0018] In October 2008, signed a contract with Malaysia POLAR VERTIX SDN BHD Co., Ltd. to provide two palm fiber biomass fuel boilers with a specification of 40t / h; At the end of the month, all complete sets of equipment will be sent to Malaysia. The technicians have been dispatched to start the equipment installation locally. It is estimated that the equipment installation will be completed by the end of November 2010. From December 2010 to March 2011, the equipment will be debugged and tested. In April 2011, it officially started power generation and heating. Palm fiber and husk string wastes from palm oil processing plants in Southeast Asian countries are very rich and concentrated, and cannot be processed. There is an urgent need for cost-effective biomass combustion boilers that turn waste into treasure. With the official operation of power generation and heat supply in Malaysia in April 2011, this product will be recognized in the Southeast Asian market because of its g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com