Patents

Literature

471results about How to "Reduce dust accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cooling devices and systems

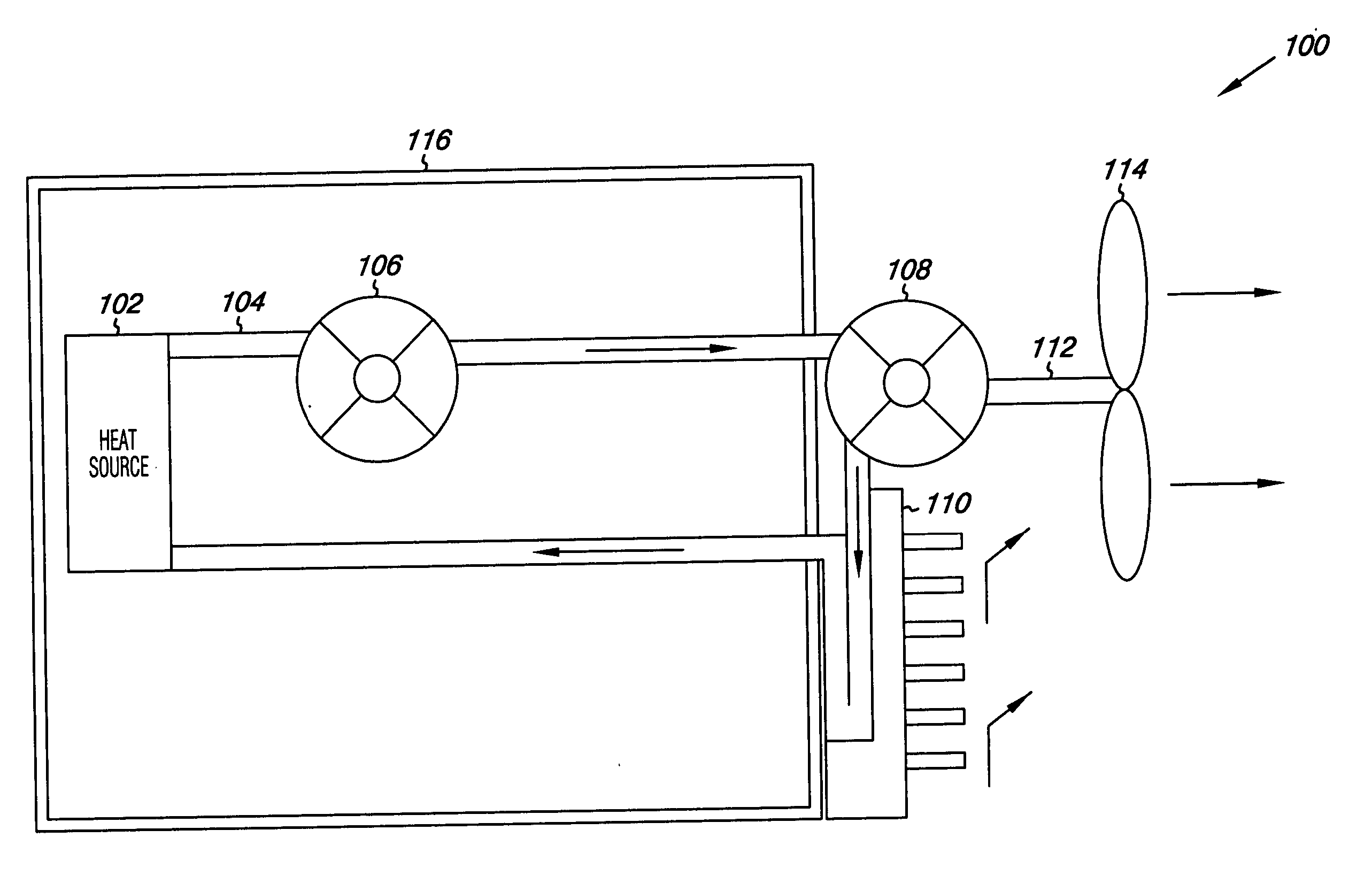

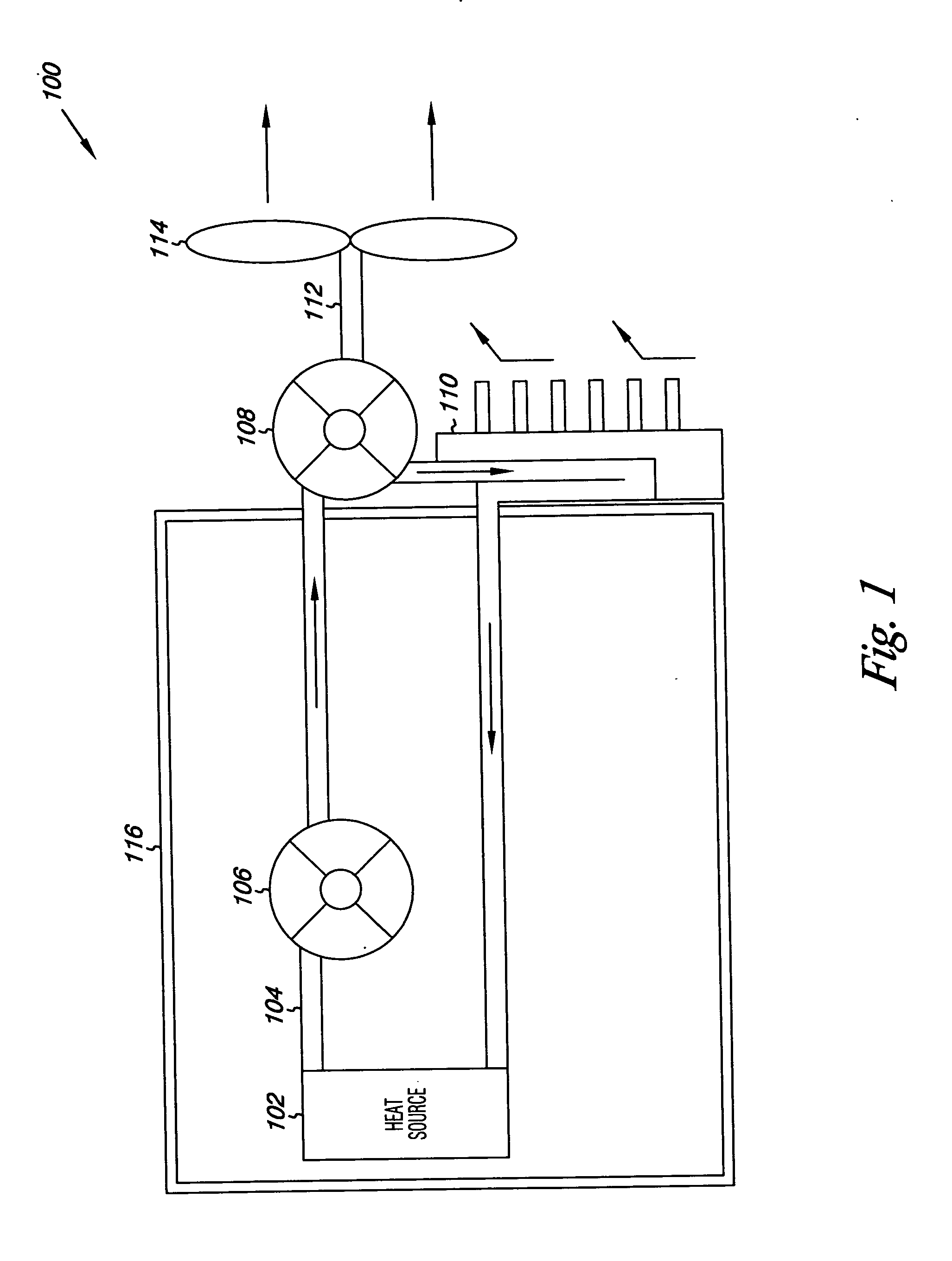

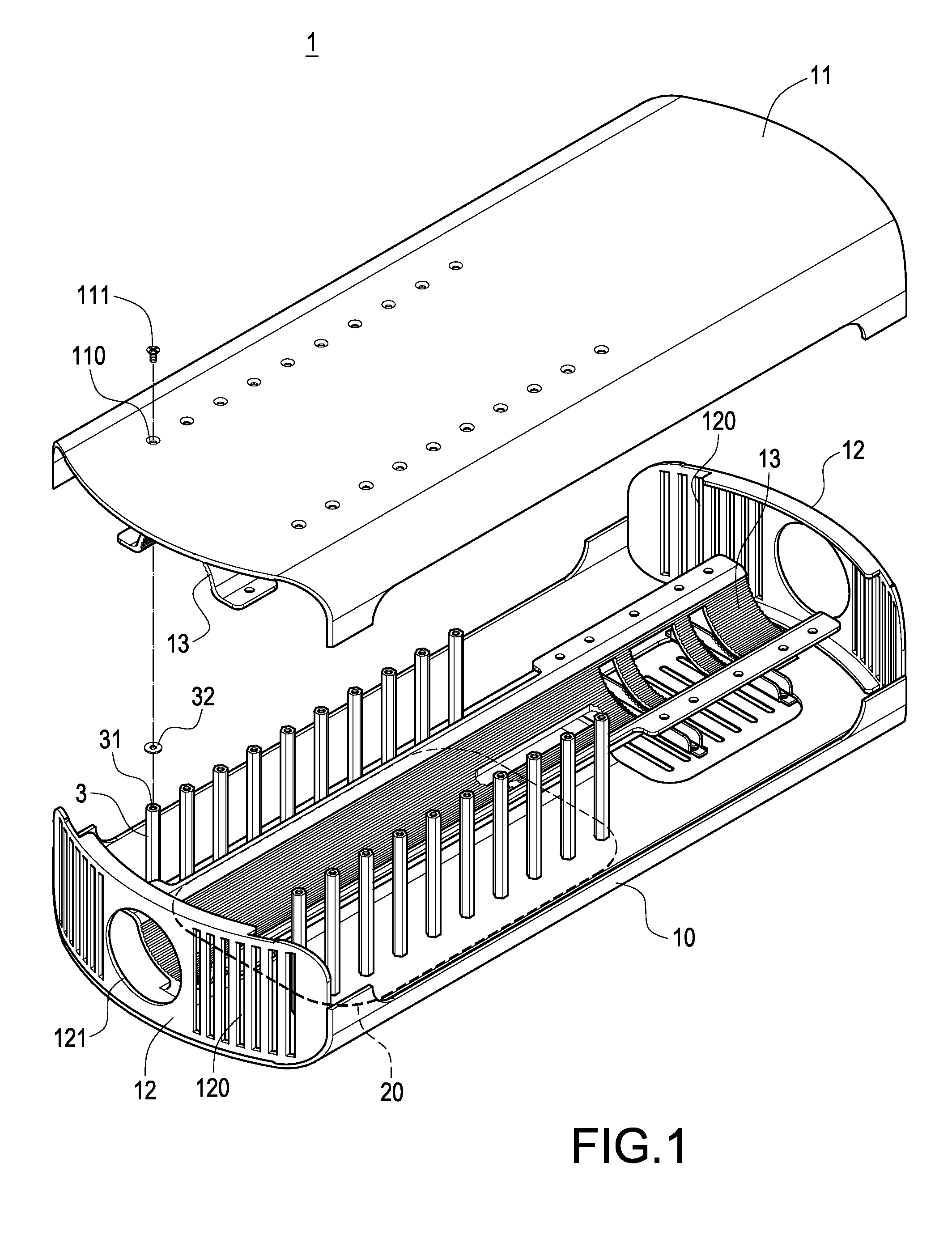

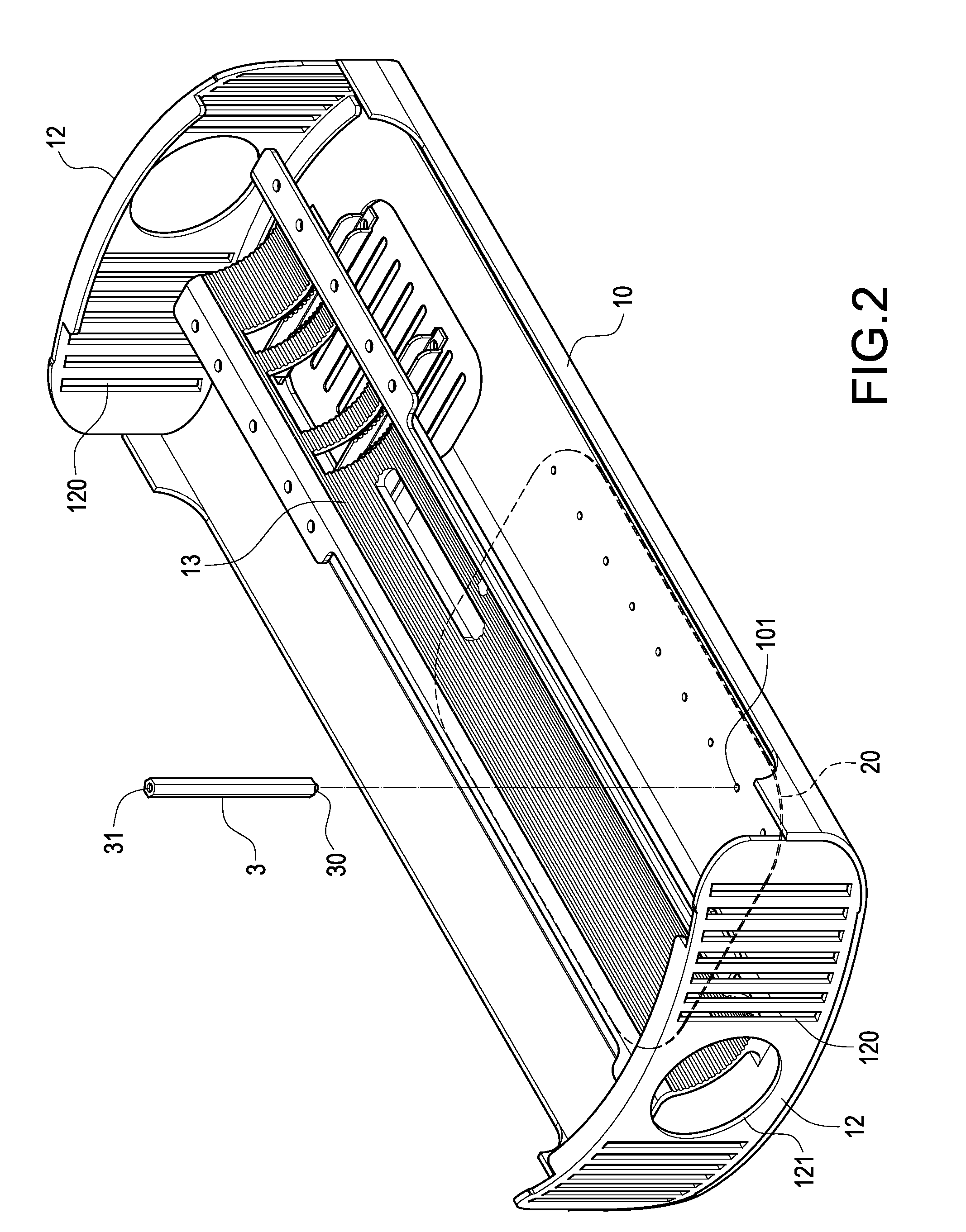

InactiveUS20060056994A1Reduce dust accumulationEasy to passSemiconductor/solid-state device detailsSolid-state devicesEngineeringTurbine

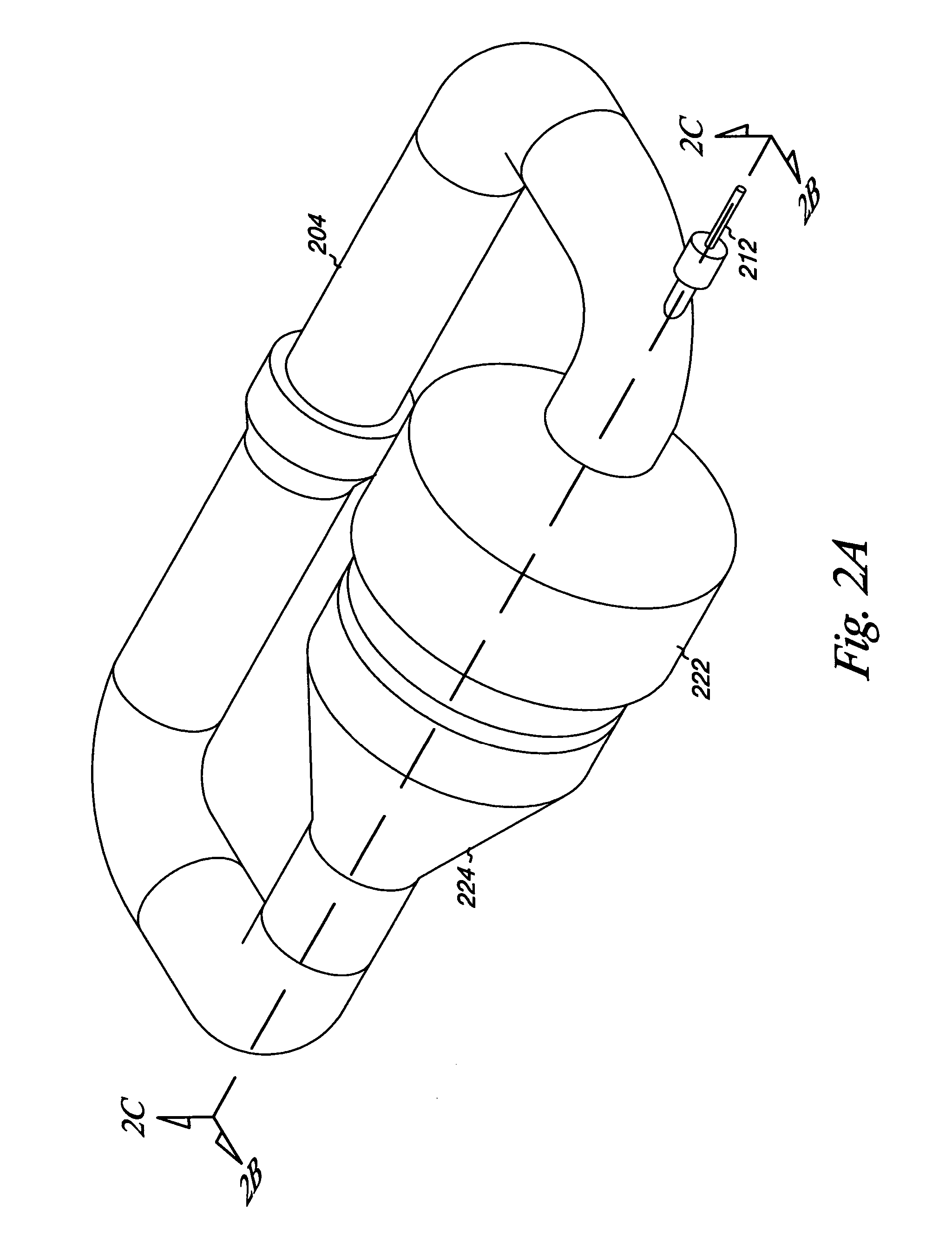

Methods, systems, and devices are provided for cooling a heat source. One apparatus embodiment includes a housing, a fluid conduit, a pump within the housing and in communication with the fluid conduit for conveying fluid through the fluid conduit, and a turbine in communication with the fluid conduit to be driven by the fluid as it passes through the fluid conduit.

Owner:LOCKHEED MARTIN CORP

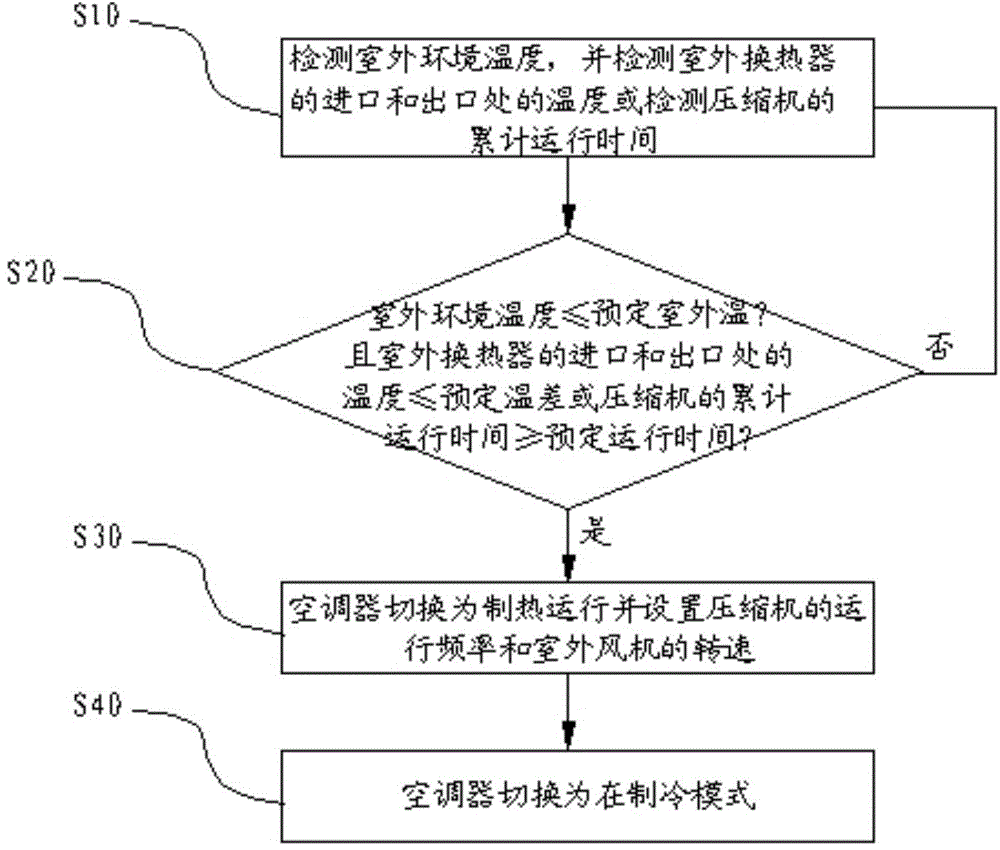

Self-cleaning control method for air conditioners

ActiveCN104949261AImprove heat transfer effectReduce dust accumulationMechanical apparatusSpace heating and ventilation safety systemsFrostTemperature difference

The invention discloses a self-cleaning control method for air conditioners. The self-cleaning control method includes enabling the air conditioners to detect outdoor environmental temperatures, detecting the temperatures of inlets and outlets of outdoor heat exchangers or detecting the cumulative run time of compressors; enabling the air conditioners to carry out heating running to allow frost to condense on the outdoor heat exchangers when the outdoor environmental temperatures are lower than or equal to preset outdoor temperatures and temperature difference between the inlets and the outlets of the outdoor heat exchangers is lower than or equal to preset temperature difference or the cumulative run time of the compressors is longer than or equal to preset run time; switching the air conditioners into a refrigerating mode. The self-cleaning control method for the air conditioners has the advantages that the air conditioners carry out heating running to allow the frost to condense on the outdoor heat exchangers and then are switched into the refrigerating mode to defrost the outdoor heat exchangers, accordingly, dust accumulated on the outdoor heat exchangers can be cleaned by condensed water generated after the outdoor heat exchangers are defrosted and can be effectively reduced, heat exchange effects of the air conditioners can be effectively improved, and energy consumption can be reduced.

Owner:MIDEA GRP CO LTD

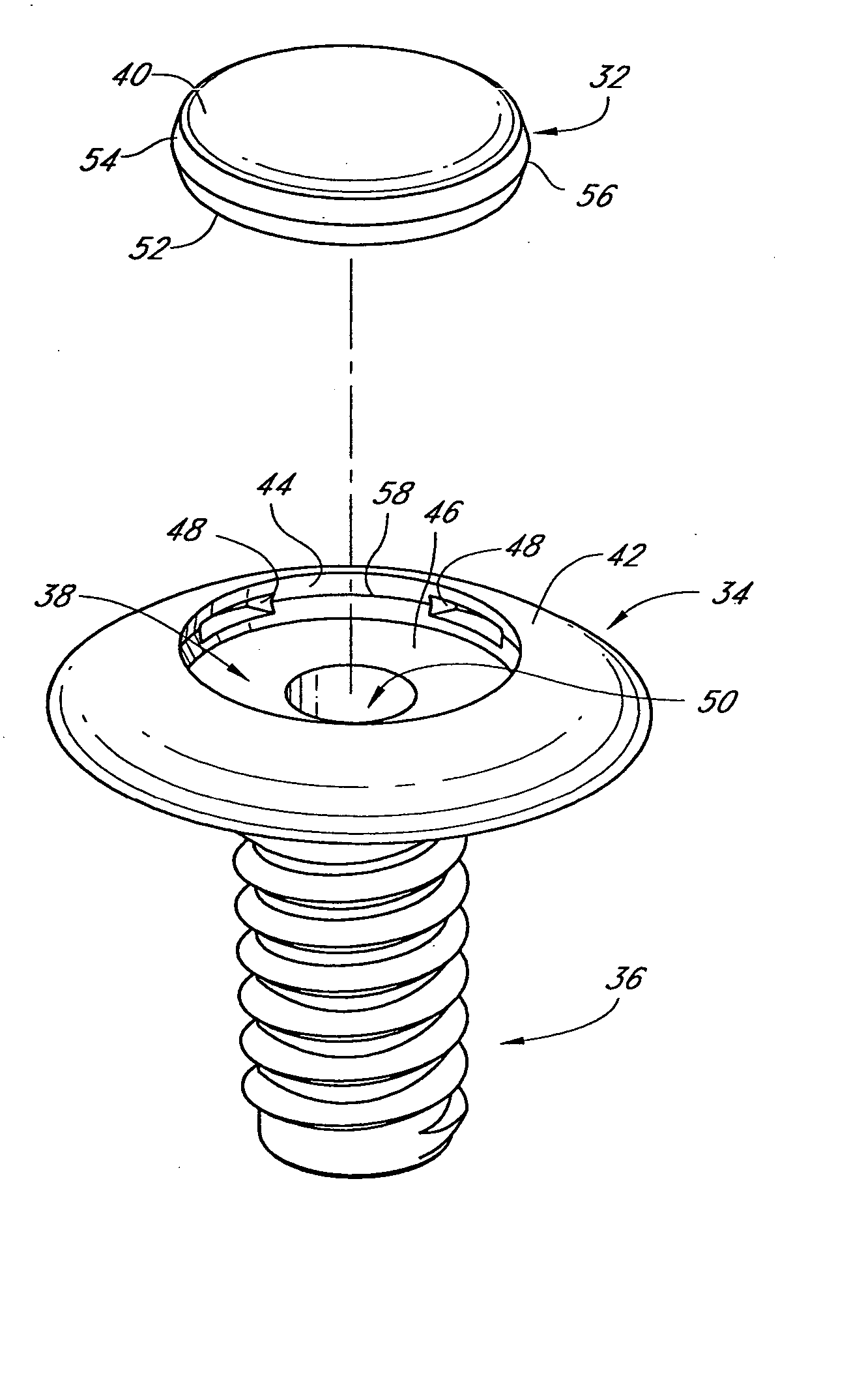

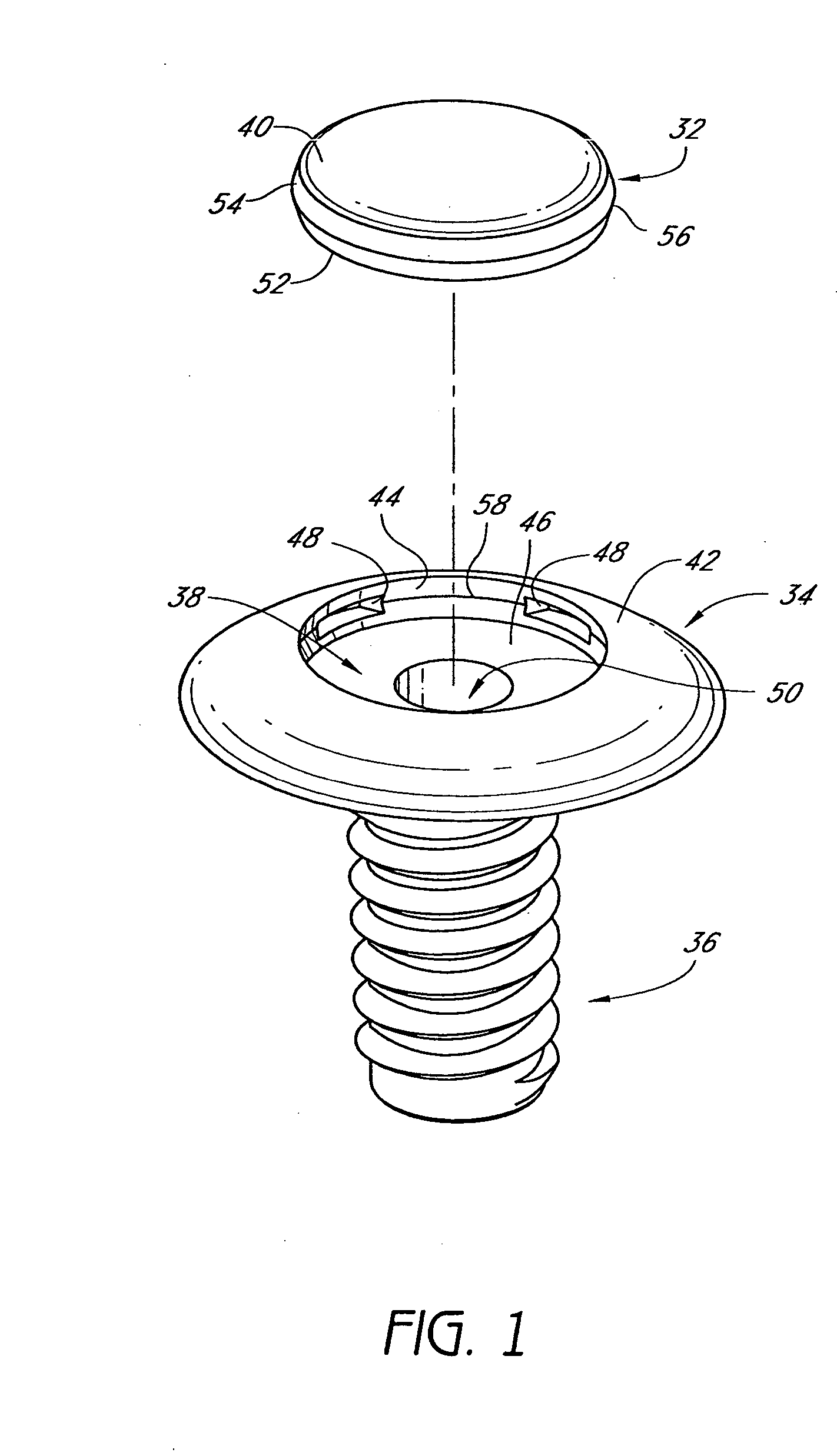

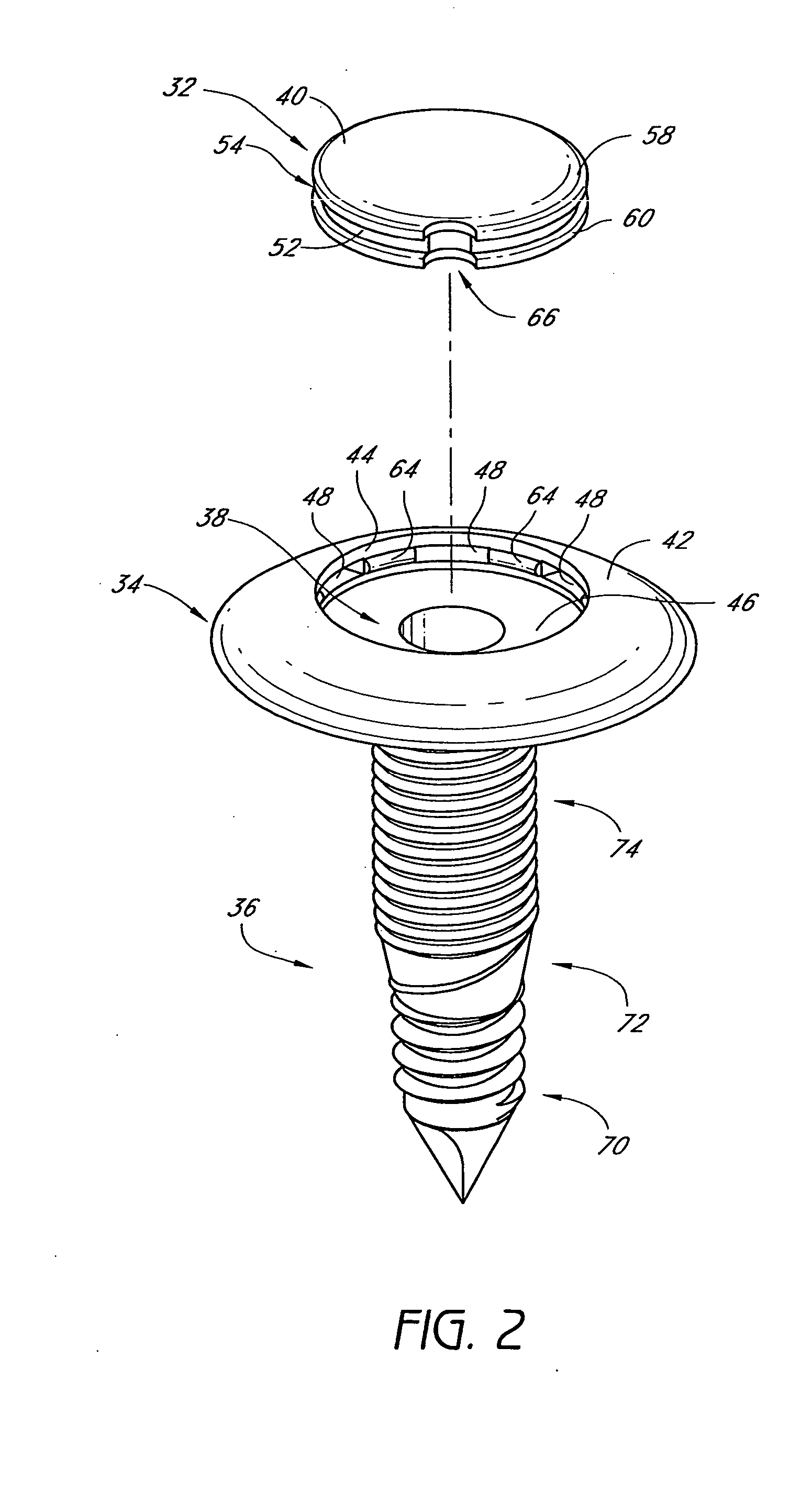

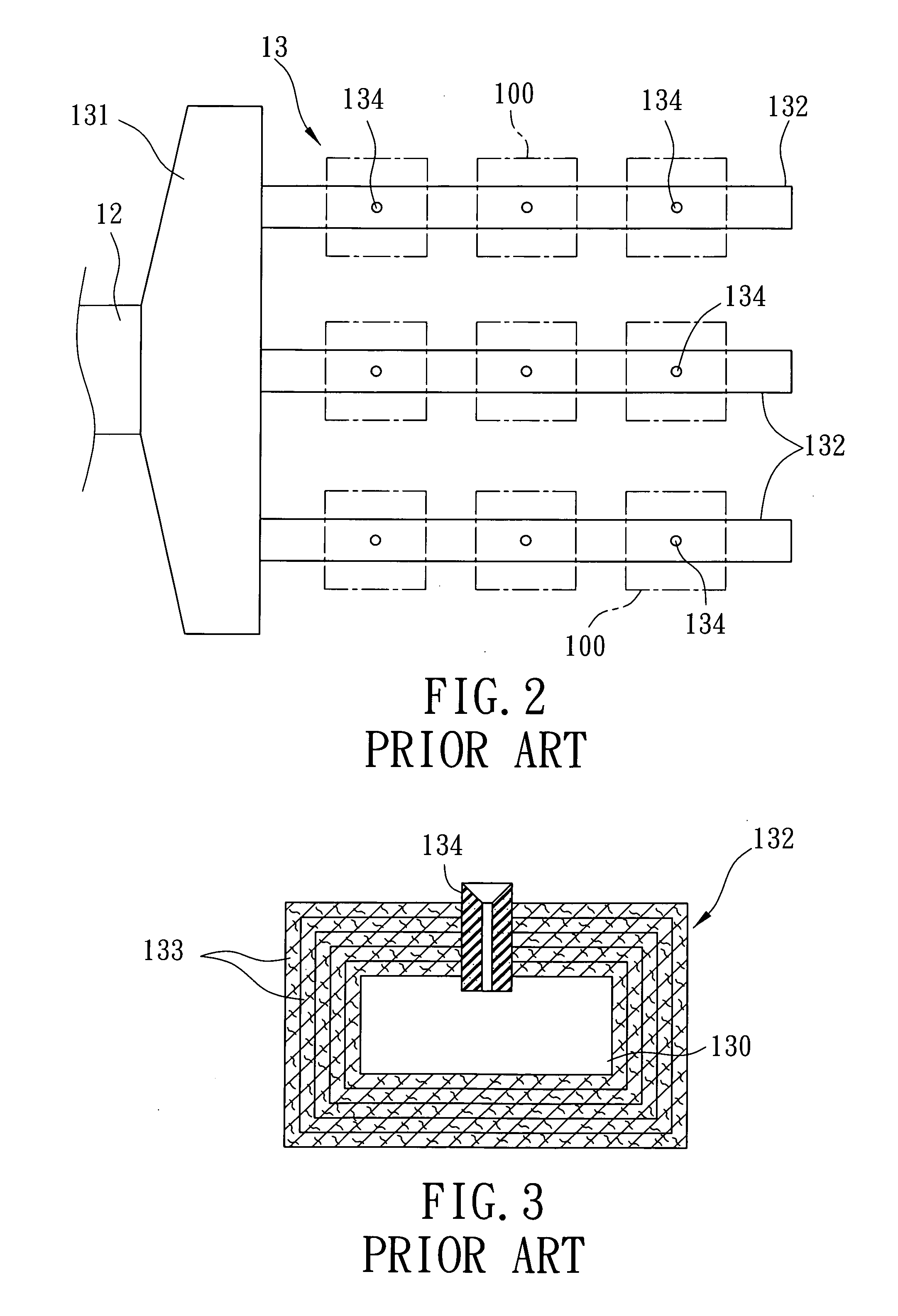

Low profile fastening system

Described herein are embodiments of fastening systems that can provide easily removed and reapplied fasteners and that provide a hindrance to those that might tamper with the fasteners. In some embodiments, fasteners are also described that are configured to reduce the accumulation of dust and dirt inside the fasteners. In further embodiments, fasteners are provided for improving the aerodynamics of the fastener, and some embodiments describe provision of commercial advertising or other messages on the fastener.

Owner:MONDAY JOHN S +1

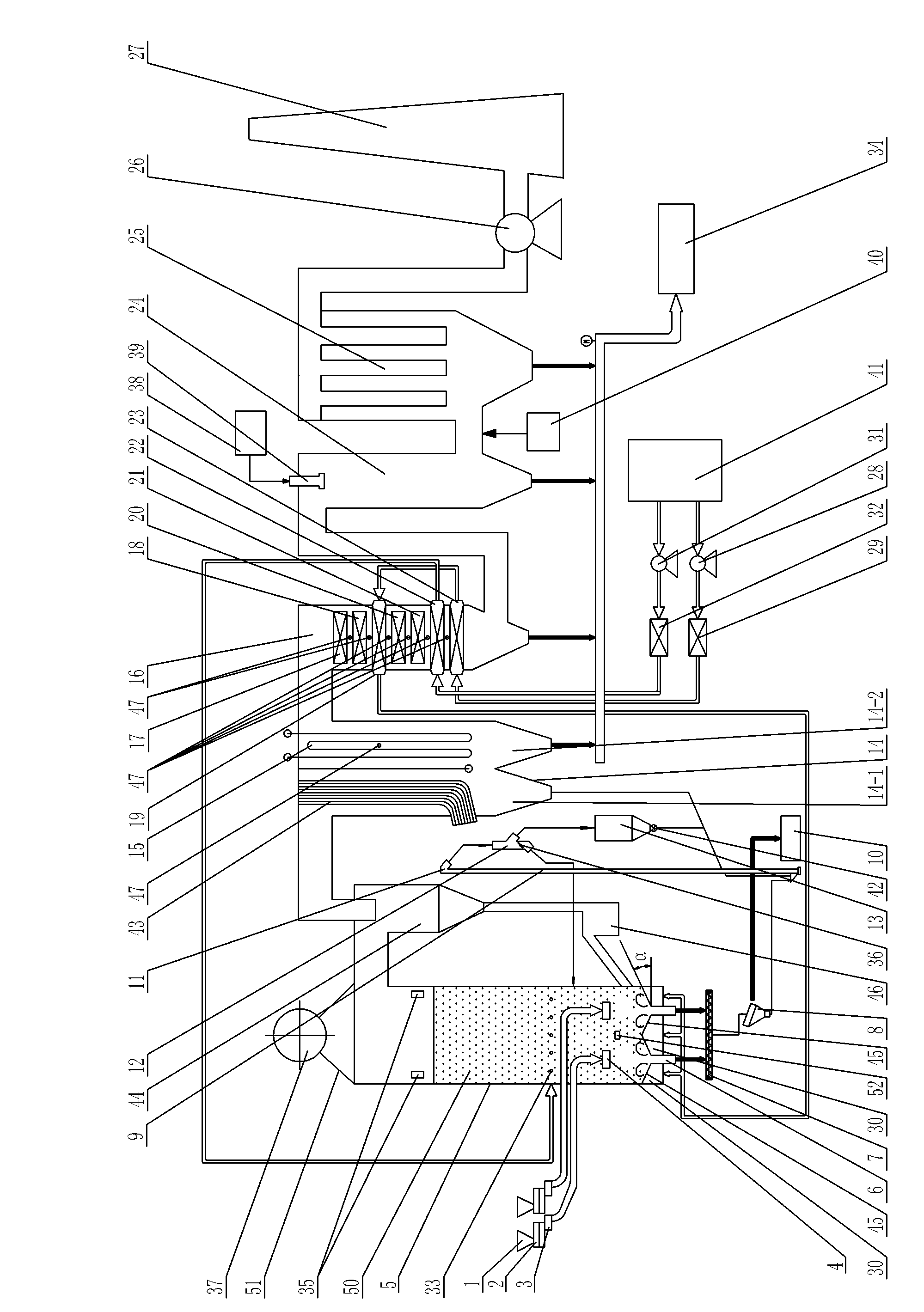

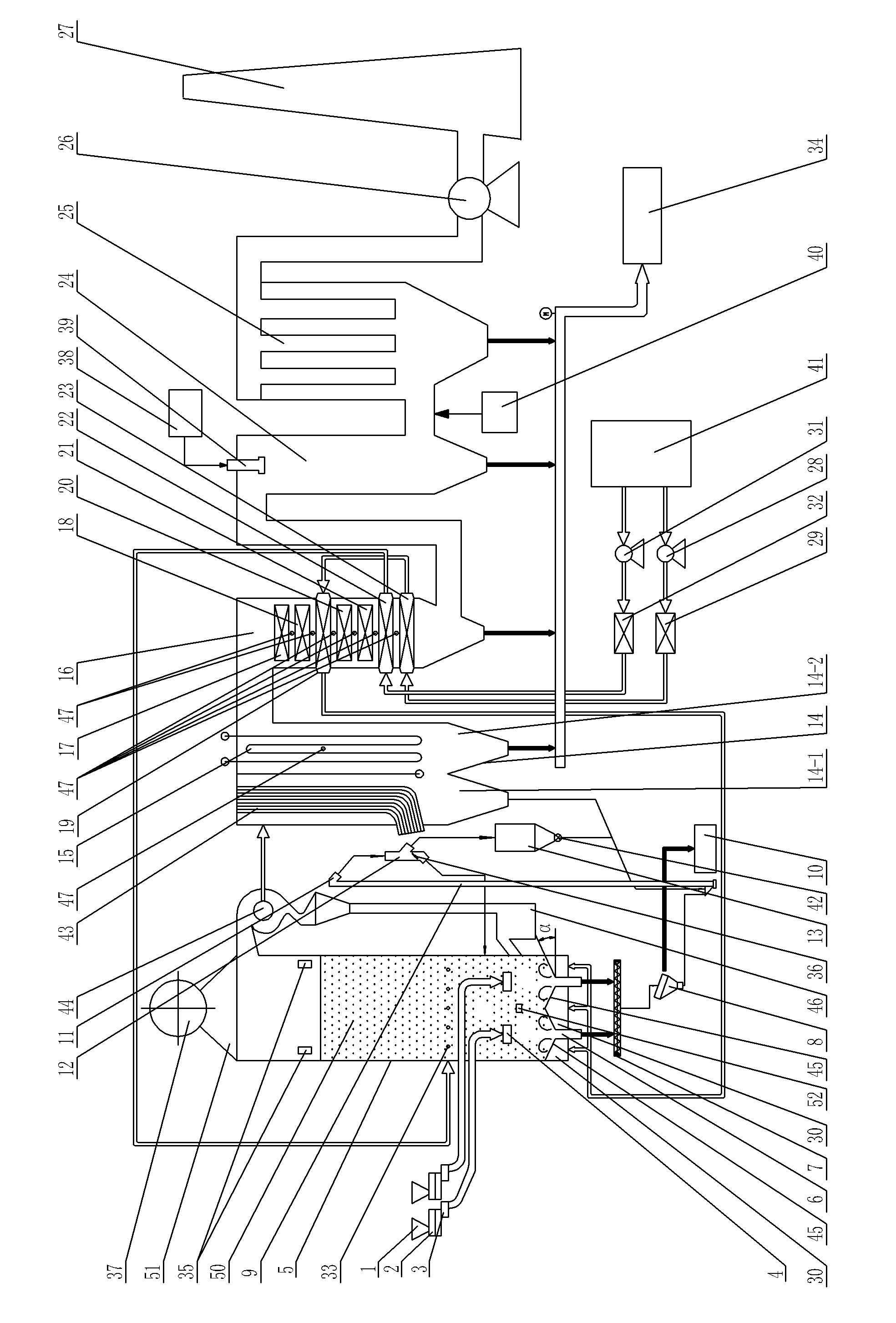

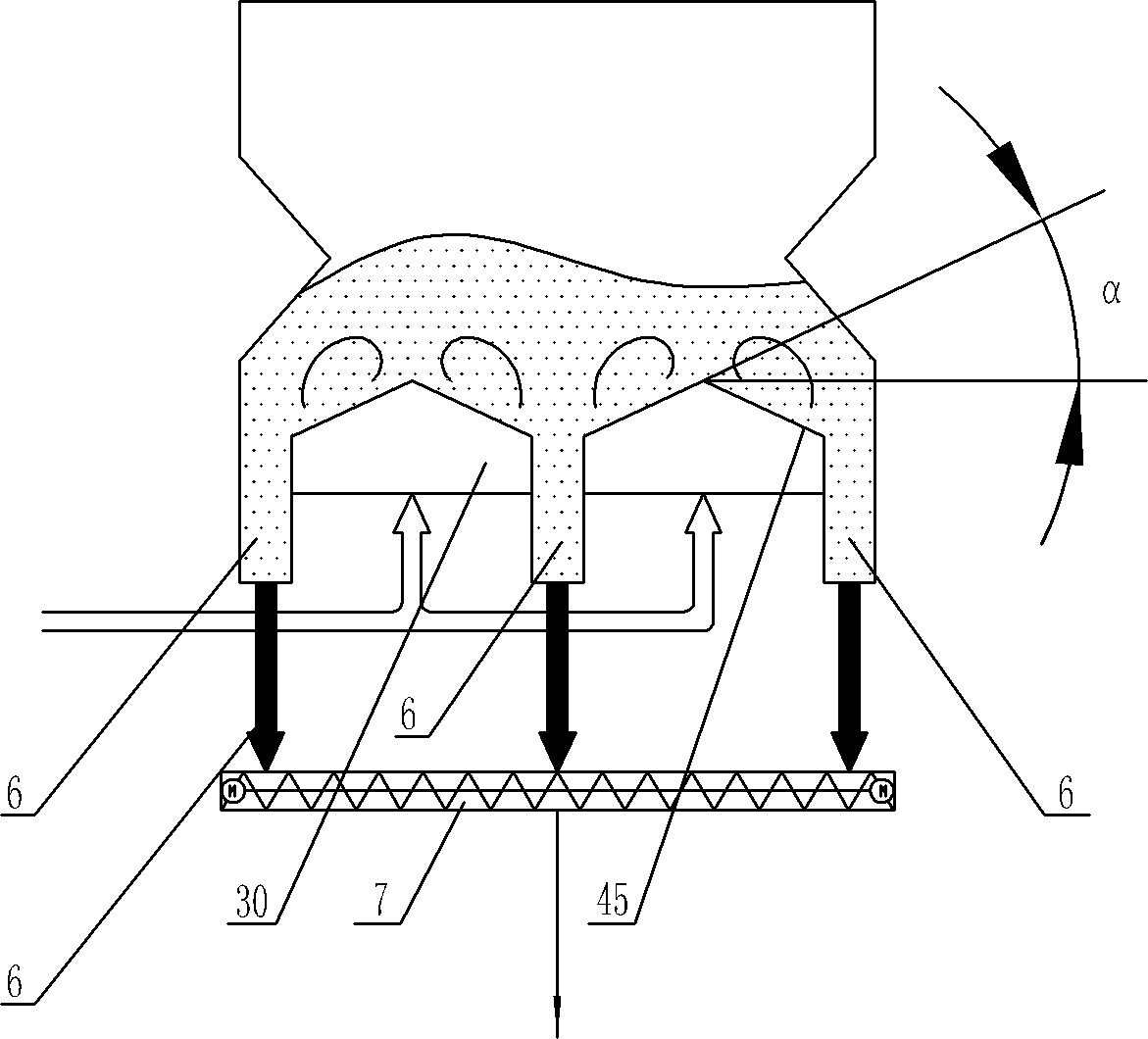

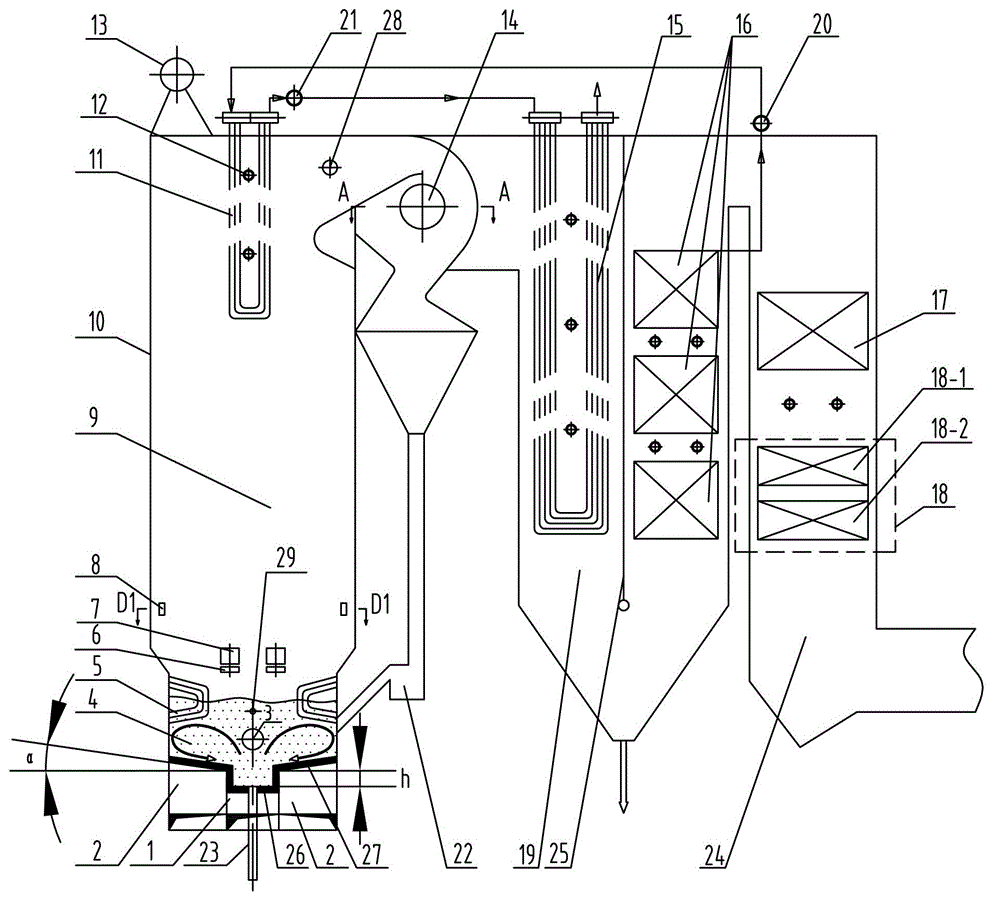

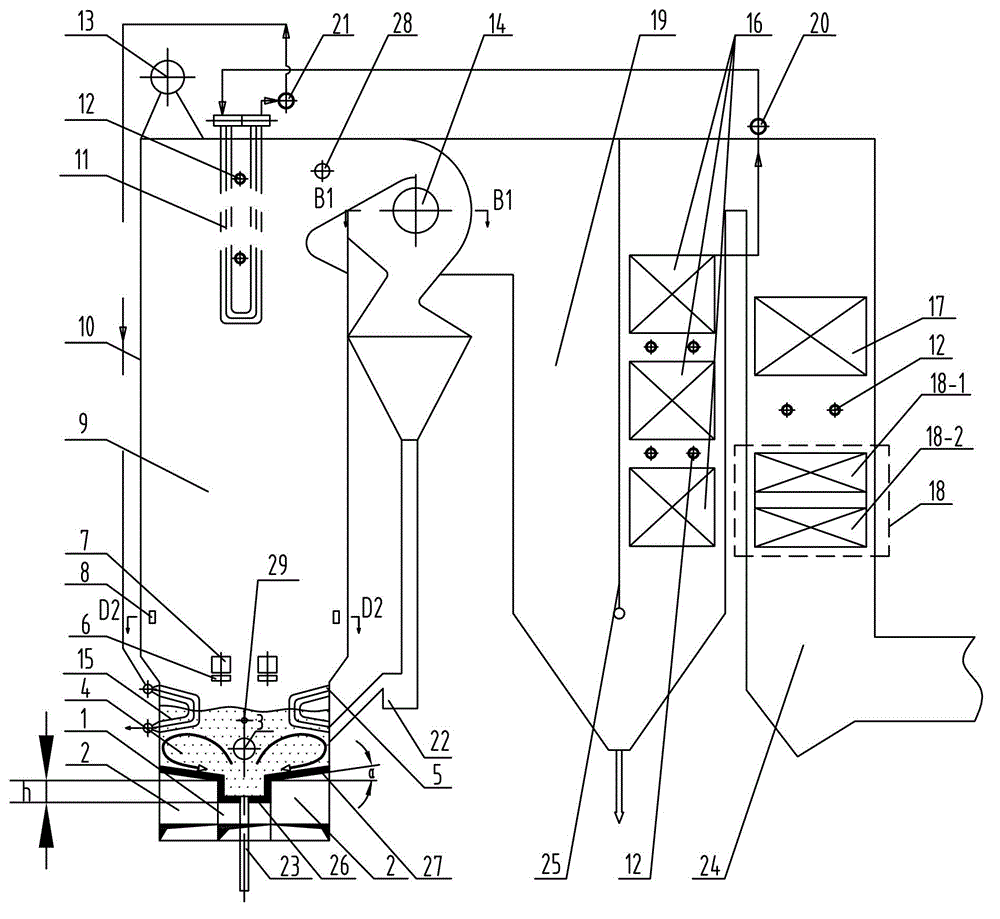

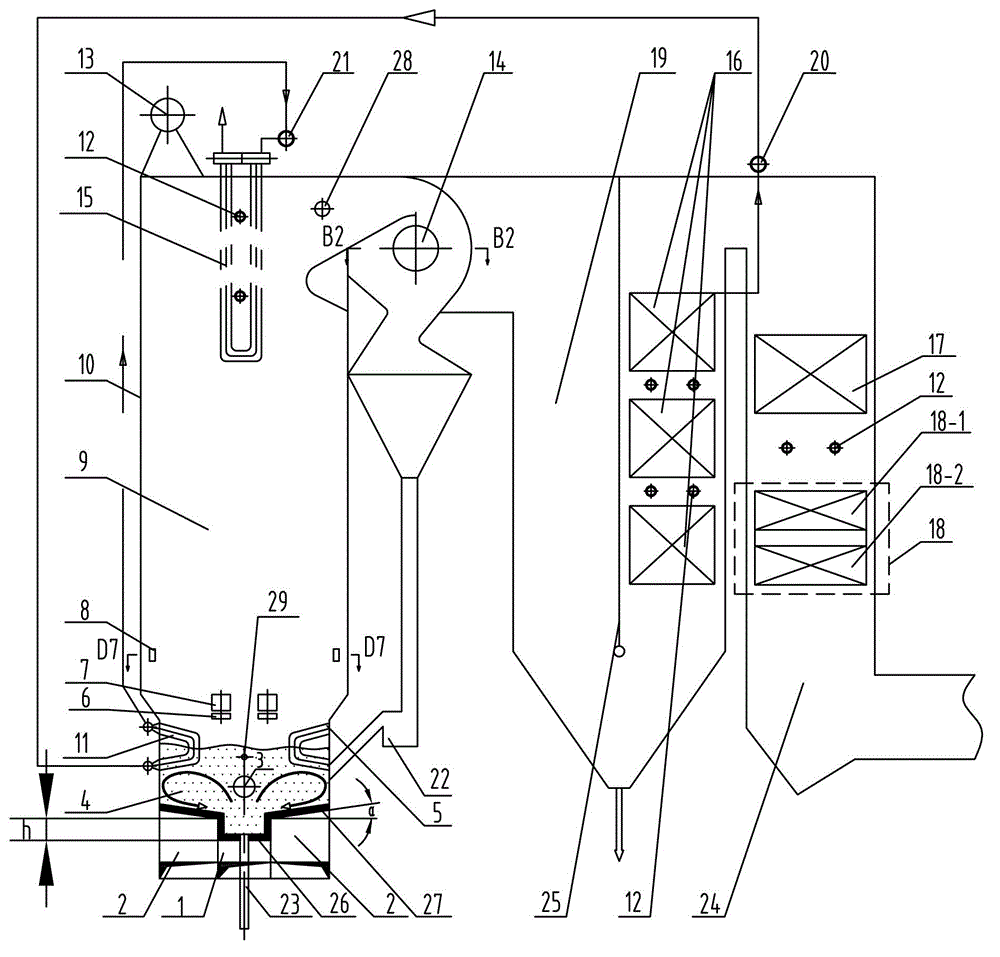

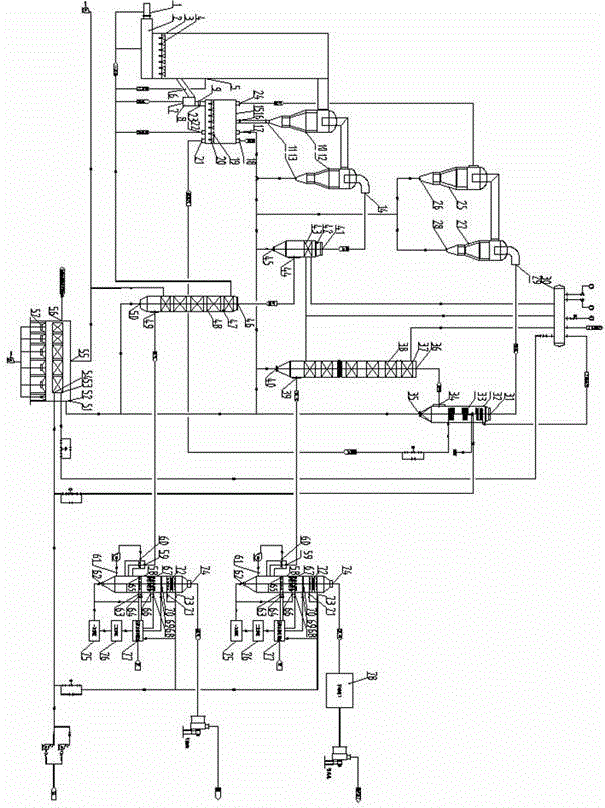

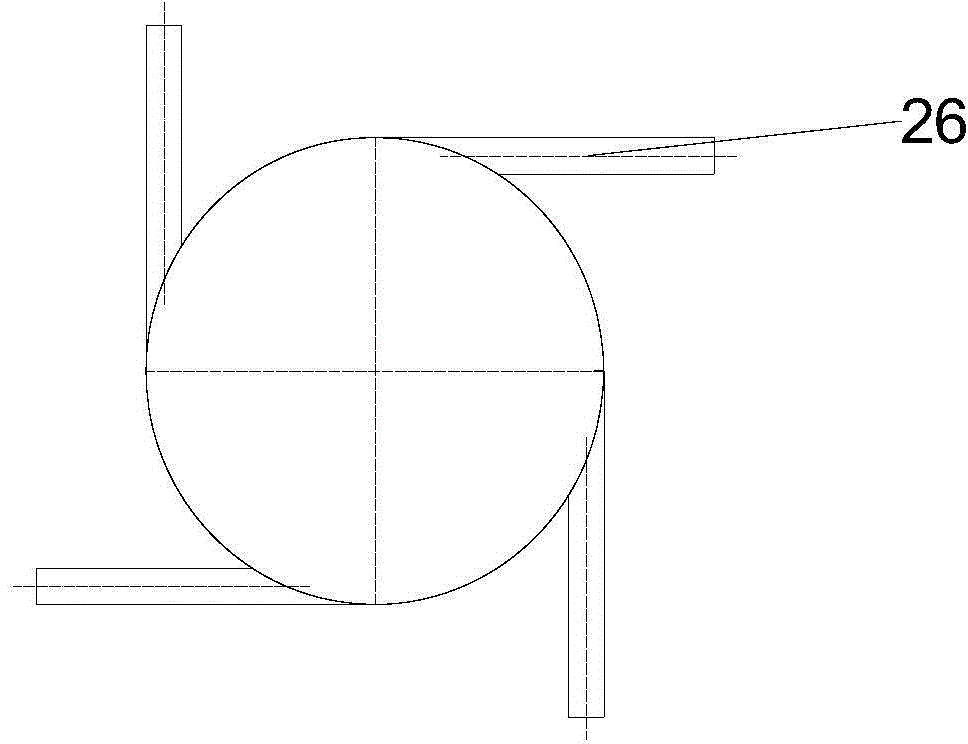

Circulating fluidized bed garbage incineration boiler and pollution control system with same

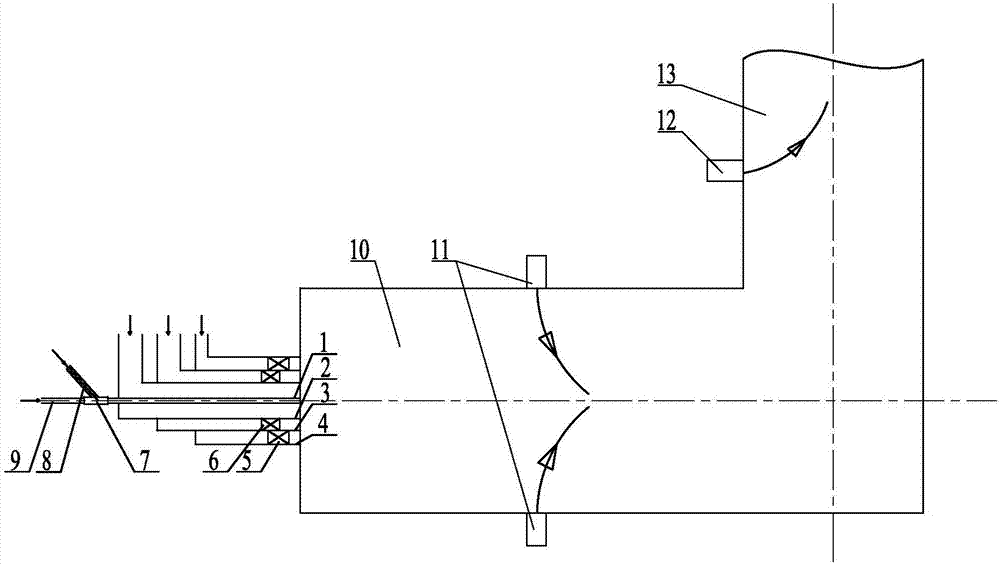

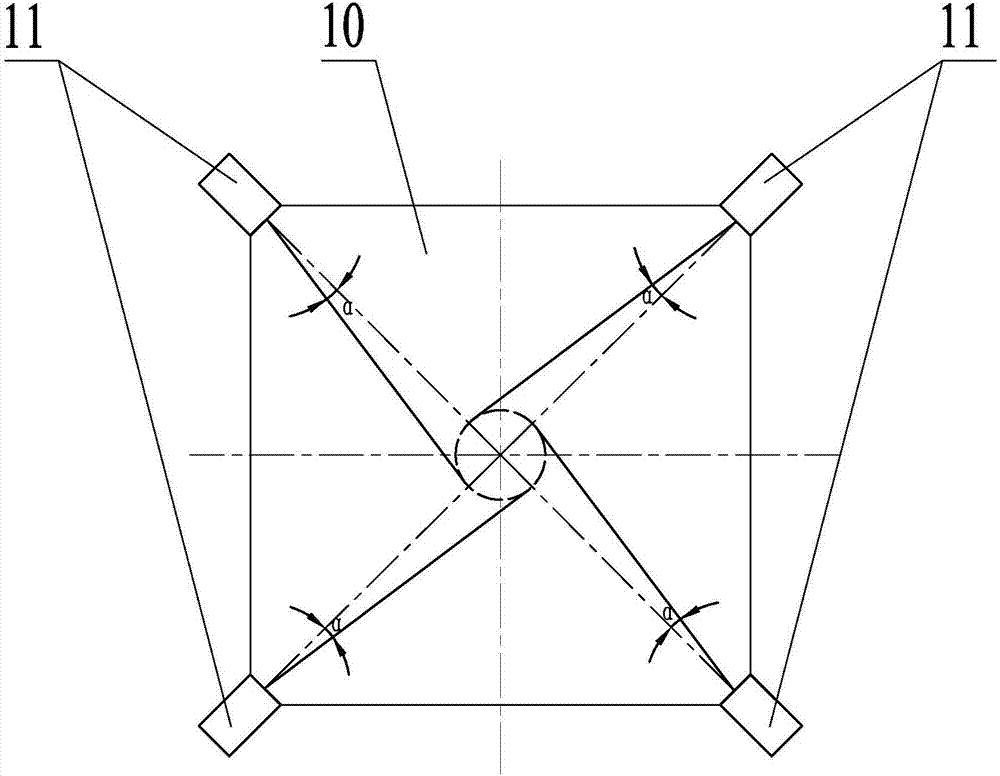

The invention discloses a circulating fluidized bed garbage incineration boiler and a pollution control system with the same, which relate to a garbage incineration boiler and a pollution control system with the same, and aim to solve the problems that the conventional circulating fluidized bed garbage incineration furnace difficultly discharges slag and is required to be stopped regularly to remove the slag and the economy of a garbage incineration plant is influenced. According to the scheme I, a circulating fluidized bed and double V-shaped wind distributing plates are arranged in a boiler body, the boiler body, a separator, a flue gas cooling chamber and a tail flue are communicated in sequence, an upper level low-temperature superheater, a lower level low-temperature superheater, a primary wind air preheater, a secondary wind air preheater, an upper level primary wind economizer, a lower level primary wind economizer, an upper level secondary wind economizer and a lower level secondary wind economizer are arranged in the tail flue, and the separator is communicated with the boiler body by a U-shaped valve; different from the scheme I, the scheme III is characterized in that: double inverted V-shaped wind distributing plates are adopted; different from the scheme III, the scheme V is characterized in that: an inverted V-shaped wind distributing plate is adopted; and according to the scheme II, the scheme IV and the scheme VI, a semidry reaction tower, a bag-type dust collector, an induced draft fan, a chimney, a fly ash cabin, a lime slurry preparation system, a rotary atomizer and an active carbon injecting device are added on the basis of the scheme I, the scheme III and the scheme V. The circulating fluidized bed garbage incineration boiler and the pollution control system with the same are used for incinerating garbage, and pollutant emission can be controlled.

Owner:无锡光核新能源建设有限公司

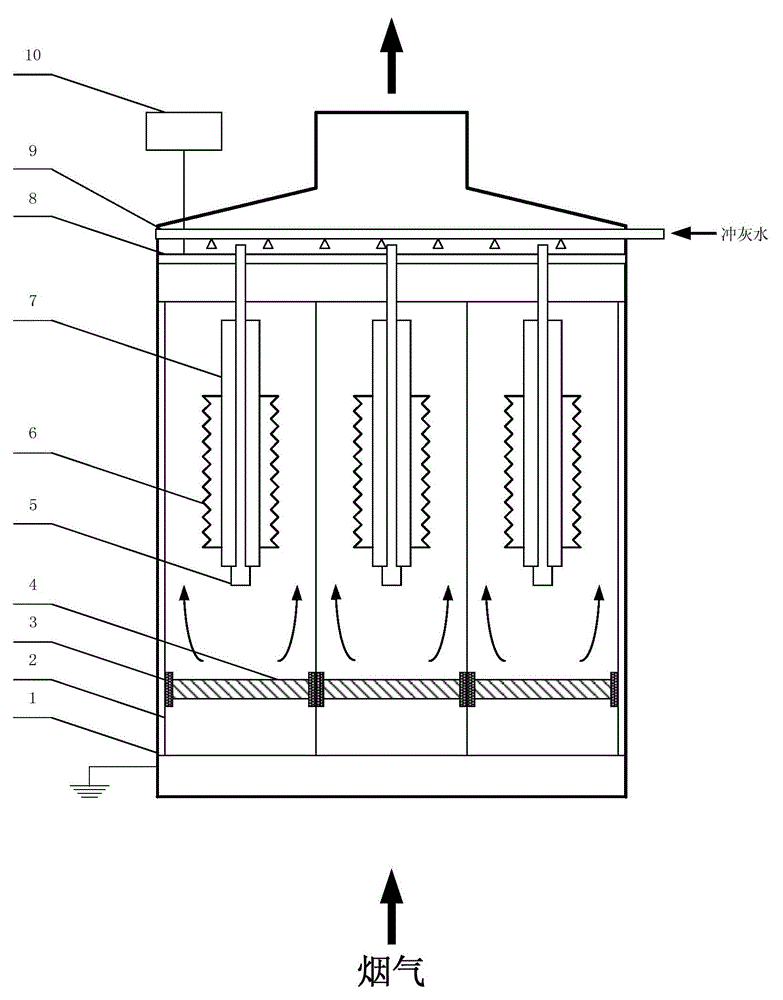

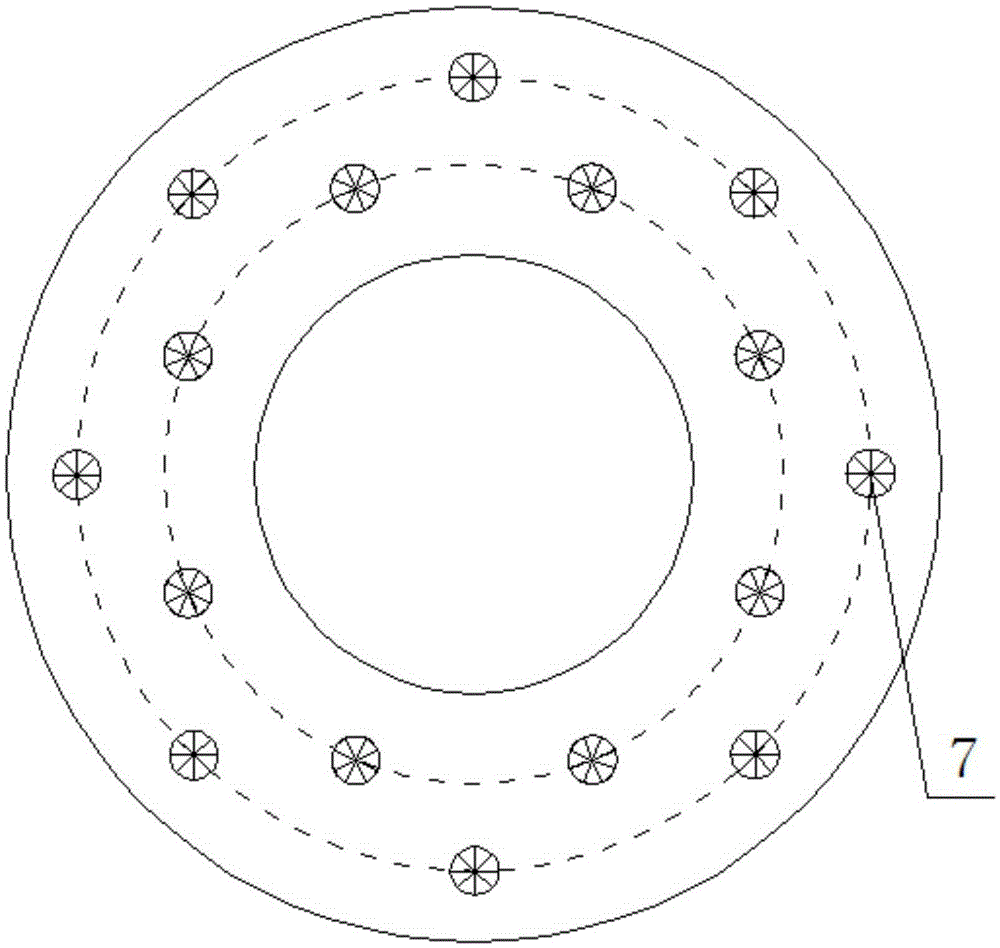

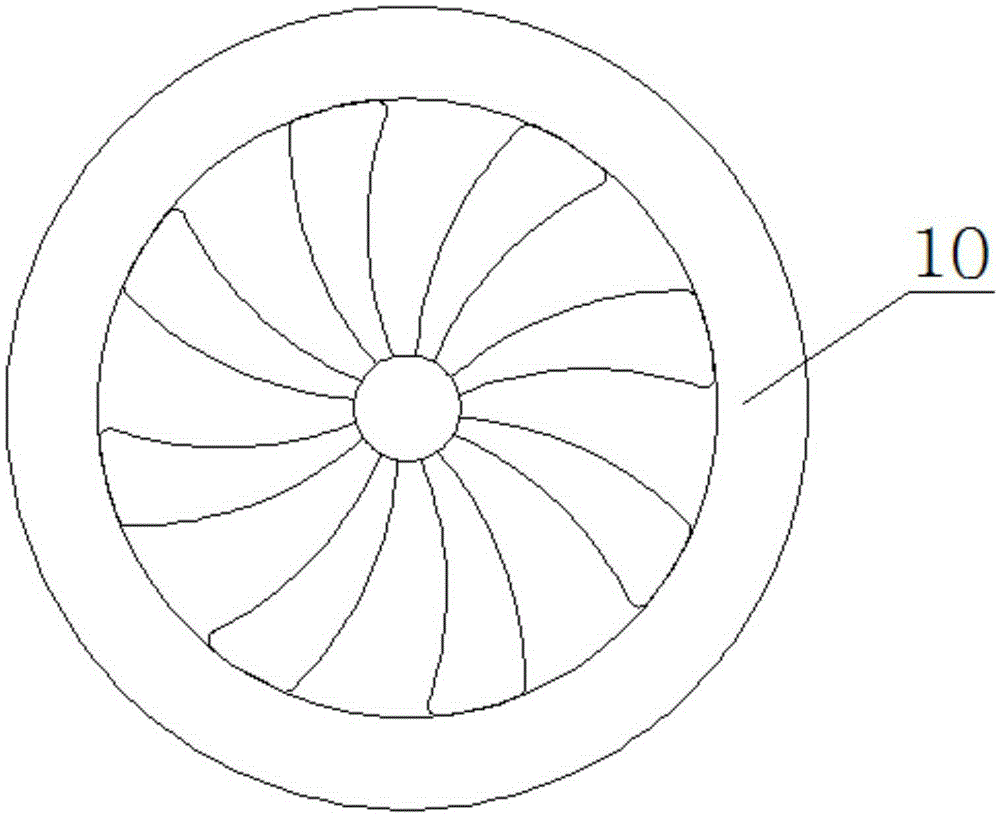

Cyclonic and electrostatic coupling high-efficiency dust and mist removal apparatus and its application

ActiveCN104307634AImprove removal efficiencyIncreased turbulenceExternal electric electrostatic seperatorElectrode constructionsCycloneFlue gas

The invention relates to a cyclonic and electrostatic coupling high-efficiency dust and mist removal apparatus and its application. The apparatus includes a shell (1), a cyclonic and electrostatic dust and mist removal unit, a discharge electrode fixing plate (8), an ash washing water tube (9) and a high voltage direct current power supply (10), the cyclonic and electrostatic dust and mist removal unit is arranged in the shell (1), the discharge electrode fixing plate (8) is arranged above the cyclonic and electrostatic dust and mist removal unit, the ash washing water tube (9) is arranged above the discharge electrode fixing plate (8), and the high voltage direct current power supply (10) is connected with the cyclonic and electrostatic dust and mist removal unit. Compared with apparatuses in the prior art, the apparatus combining an inward injection plate, a bottom cyclone plate and a spraying technology substantially improves the purifying degree of flue gas.

Owner:SHANGHAI JIAO TONG UNIV

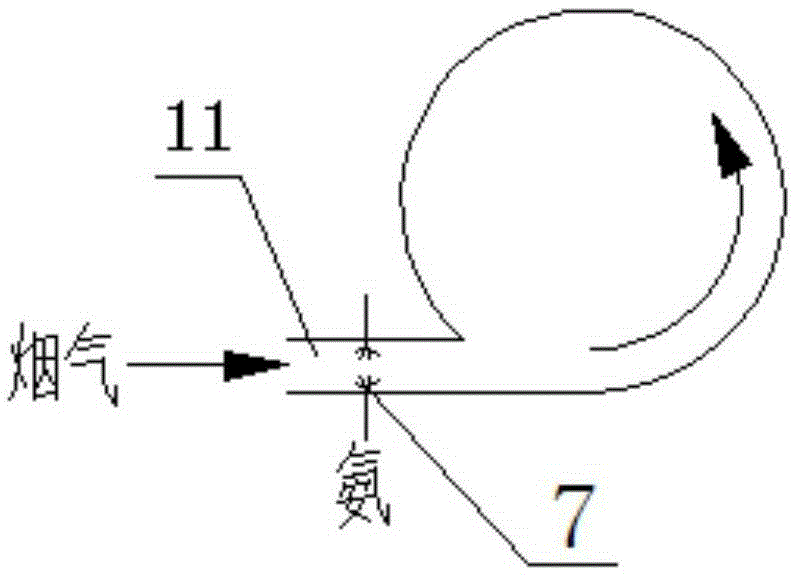

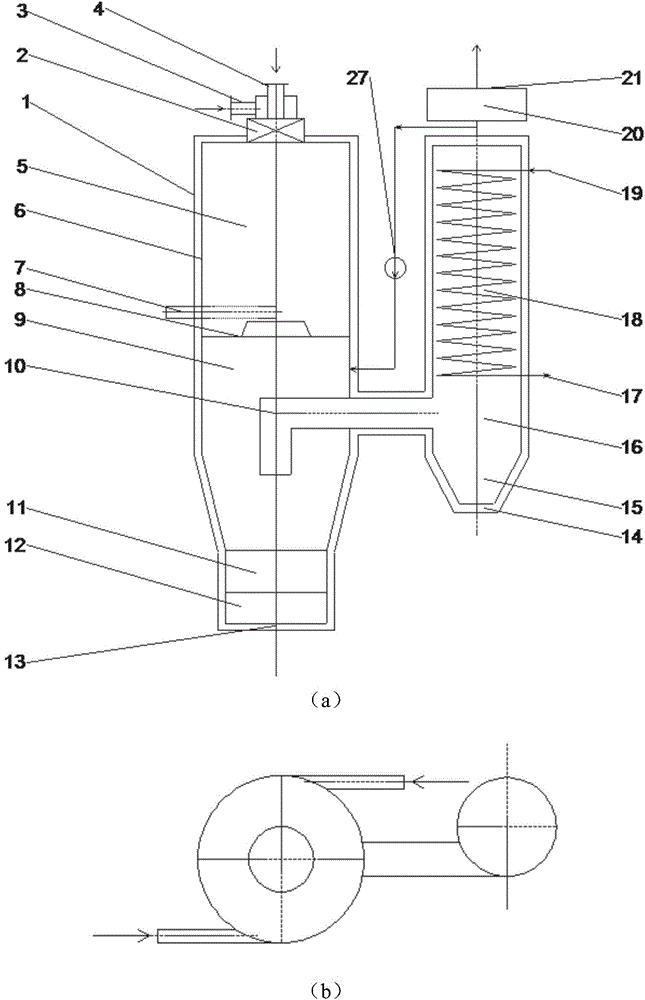

Double-rotation SCR denitration method and apparatus thereof

ActiveCN105289301AImprove denitrification efficiencyIncrease contact timeDispersed particle separationCycloneFlue gas

The invention discloses a double-rotation SCR denitration method and an apparatus thereof. According to the invention, a first eddy flow catalytic reaction chamber and a second eddy flow catalytic reaction chamber are arranged along a denitrating tower body; a flue gas introduction pipeline is arranged on a sidewall of the denitrating tower body; several eddy flow atomizing nozzles are respectively arranged on inner periphery of the flue gas introduction pipeline and the inner periphery at top of the first eddy flow catalytic reaction chamber; when flue gas is introduced into the flue gas introduction pipeline, the flue gas and ammonia gas injected by the eddy flow atomizing nozzle are mixed, and a mixture enables spiral sinking along circumference of the first eddy flow catalytic reaction chamber from up to down in a tangent circle mode, under effect of a cyclone, and then the mixture enable spiral rise along circumference of the second eddy flow catalytic reaction chamber from down to up in the tangent circle mode. Under prerequisite that high efficiency denitration is ensured, catalyst amount is less, operation of technical means is simple and easy, compared with the prior art, a denitrating tower structure is simple, cost of the apparatus is low, denitration efficiency is high, energy consumption is low, escapement ratio of ammonia is reduced, denitration cost is greatly reduced, and economic benefit is obviously increased.

Owner:SOUTH CHINA UNIV OF TECH

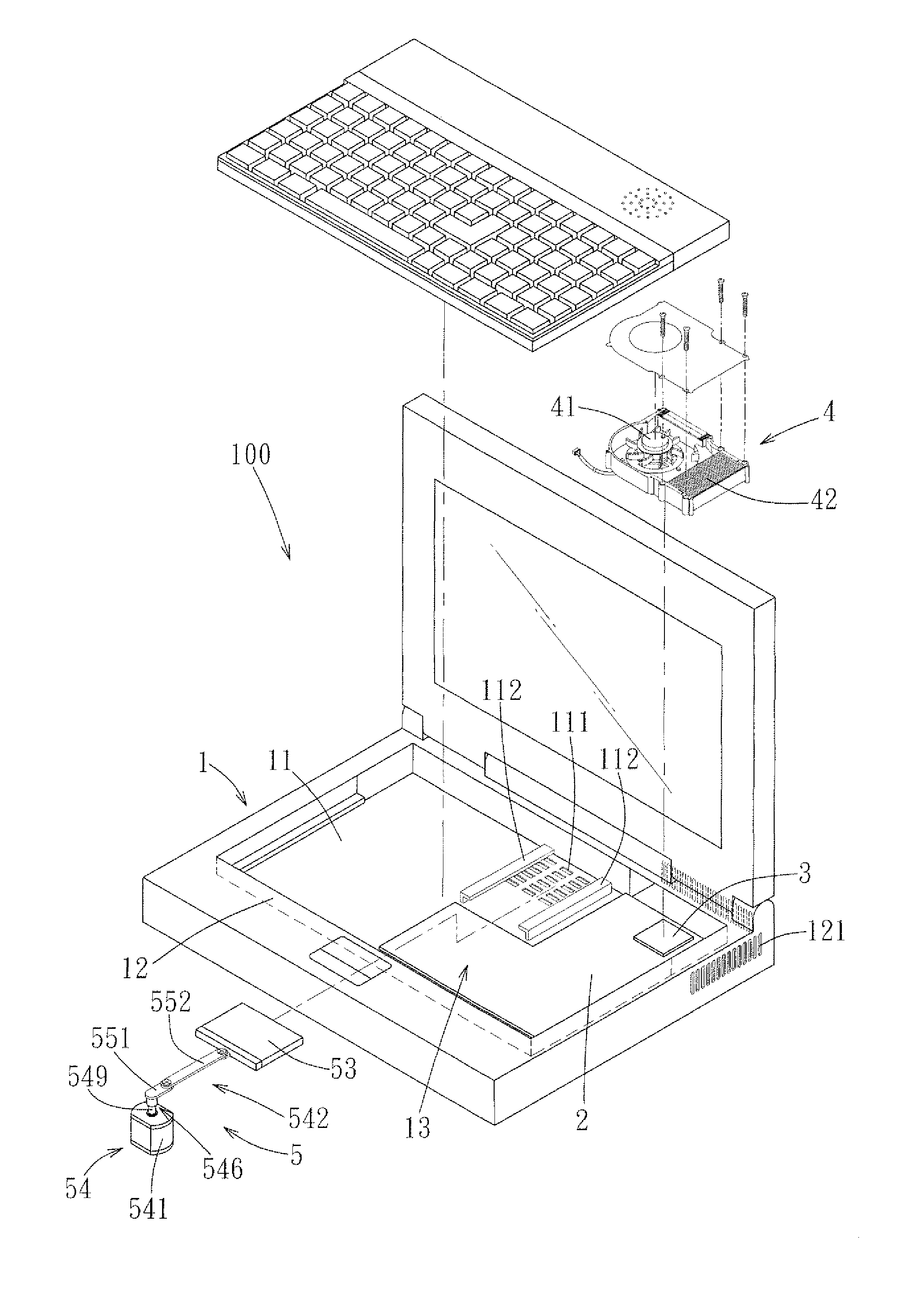

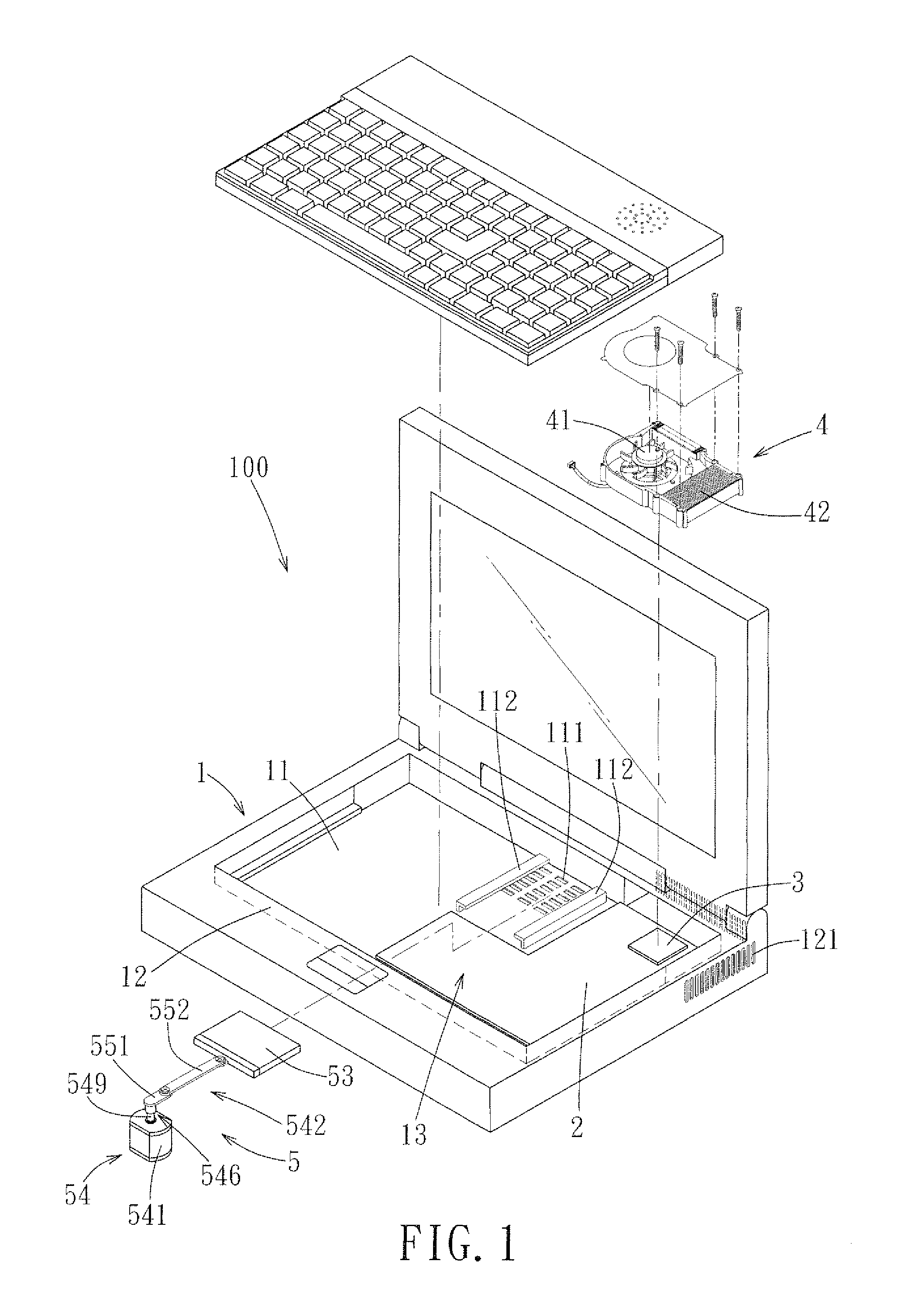

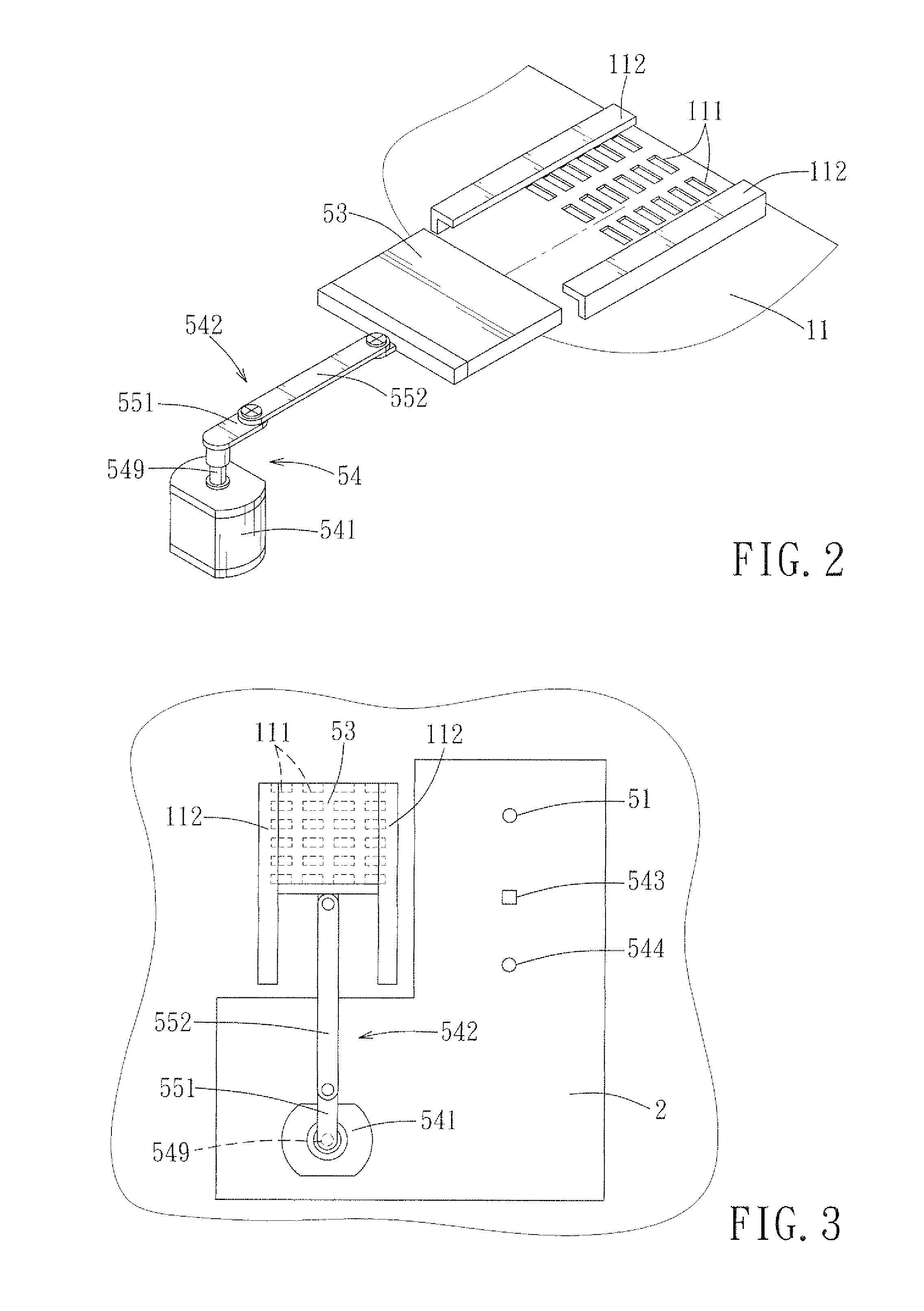

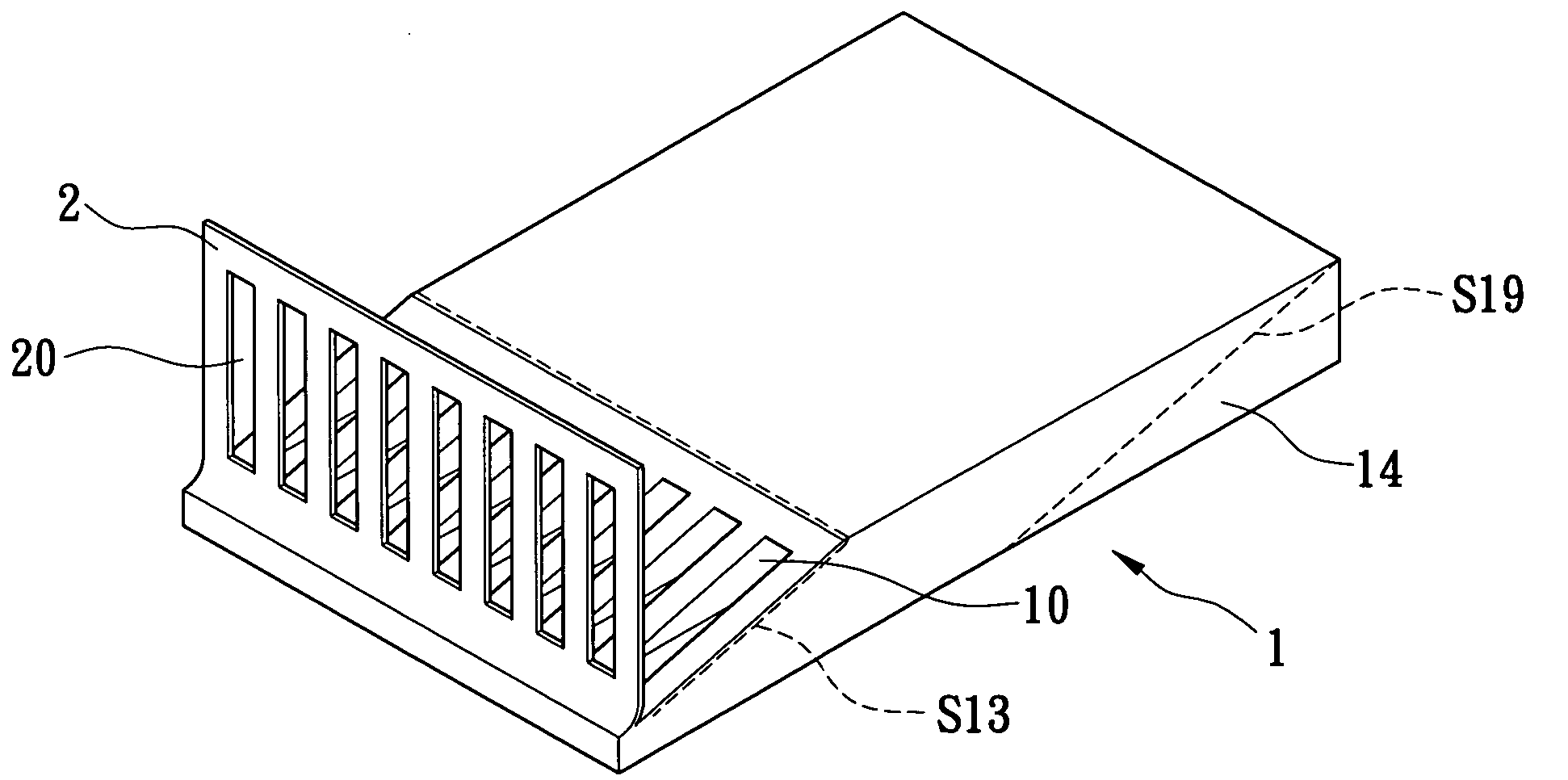

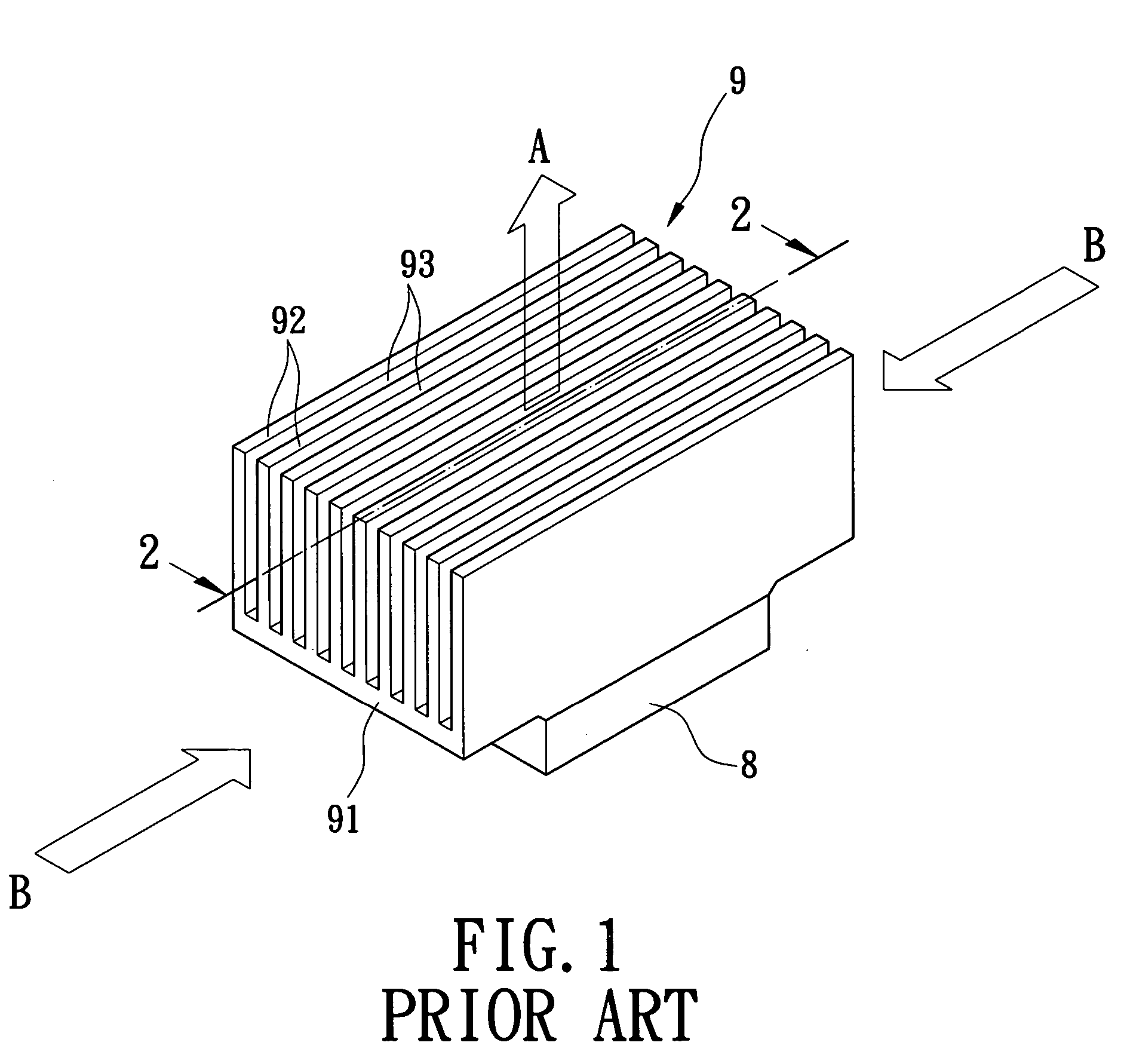

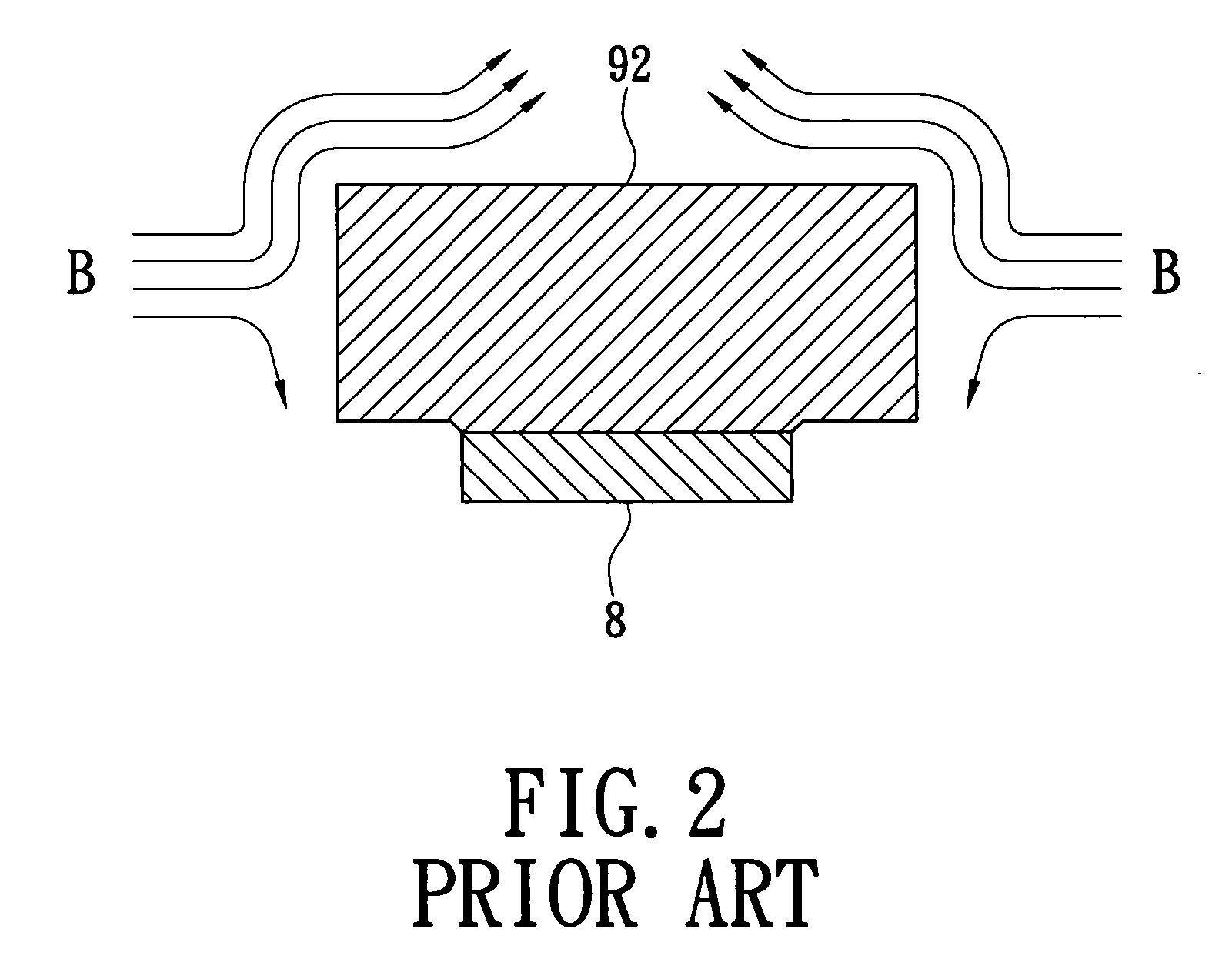

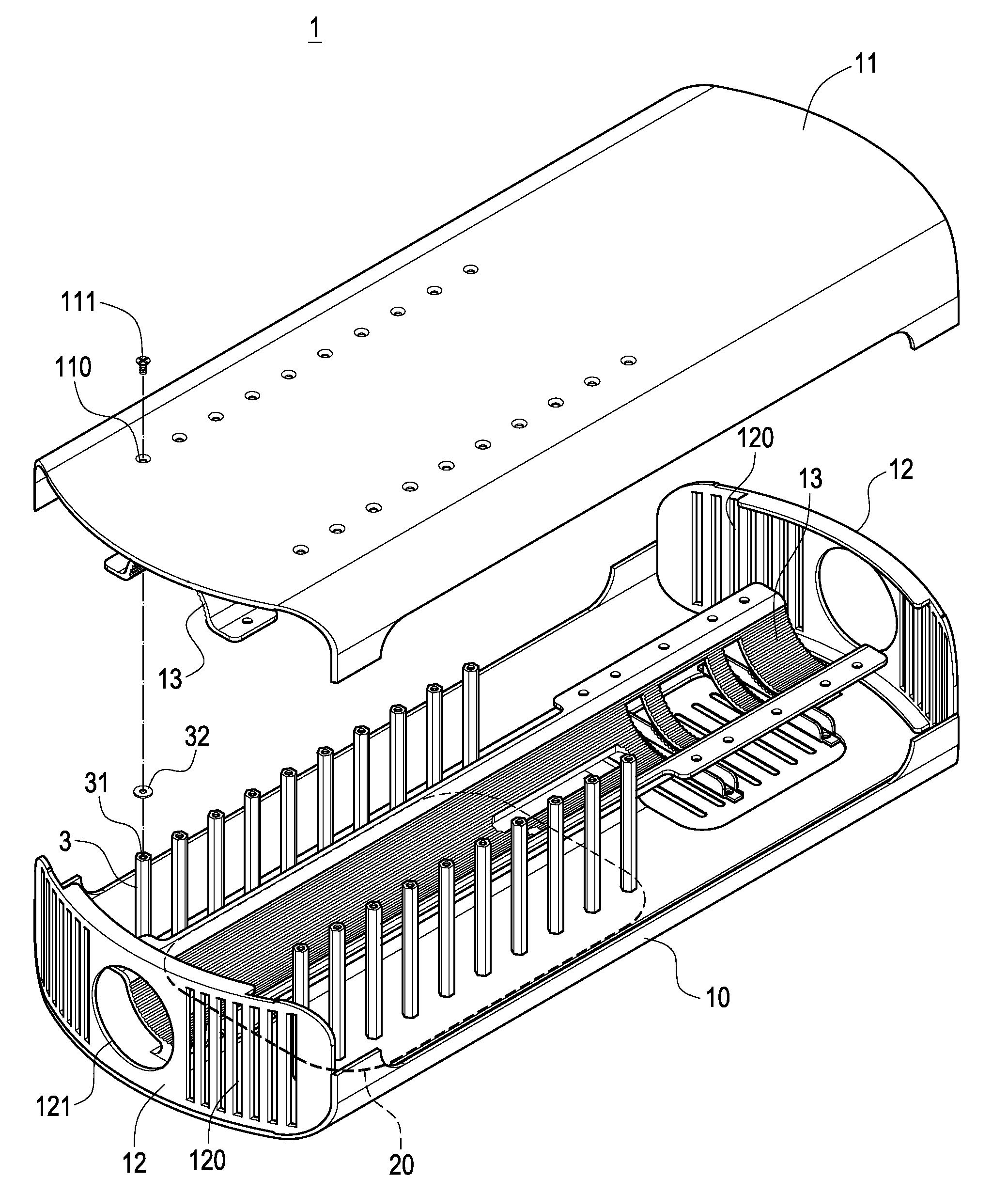

Dust-proofing method for an electronic device, and the electronic device

InactiveUS20100182748A1Reduce dust accumulationImprove cooling efficiencyDigital data processing detailsCooling/ventilation/heating modificationsElectrical and Electronics engineeringElectronic equipment

Owner:WISTRON CORP

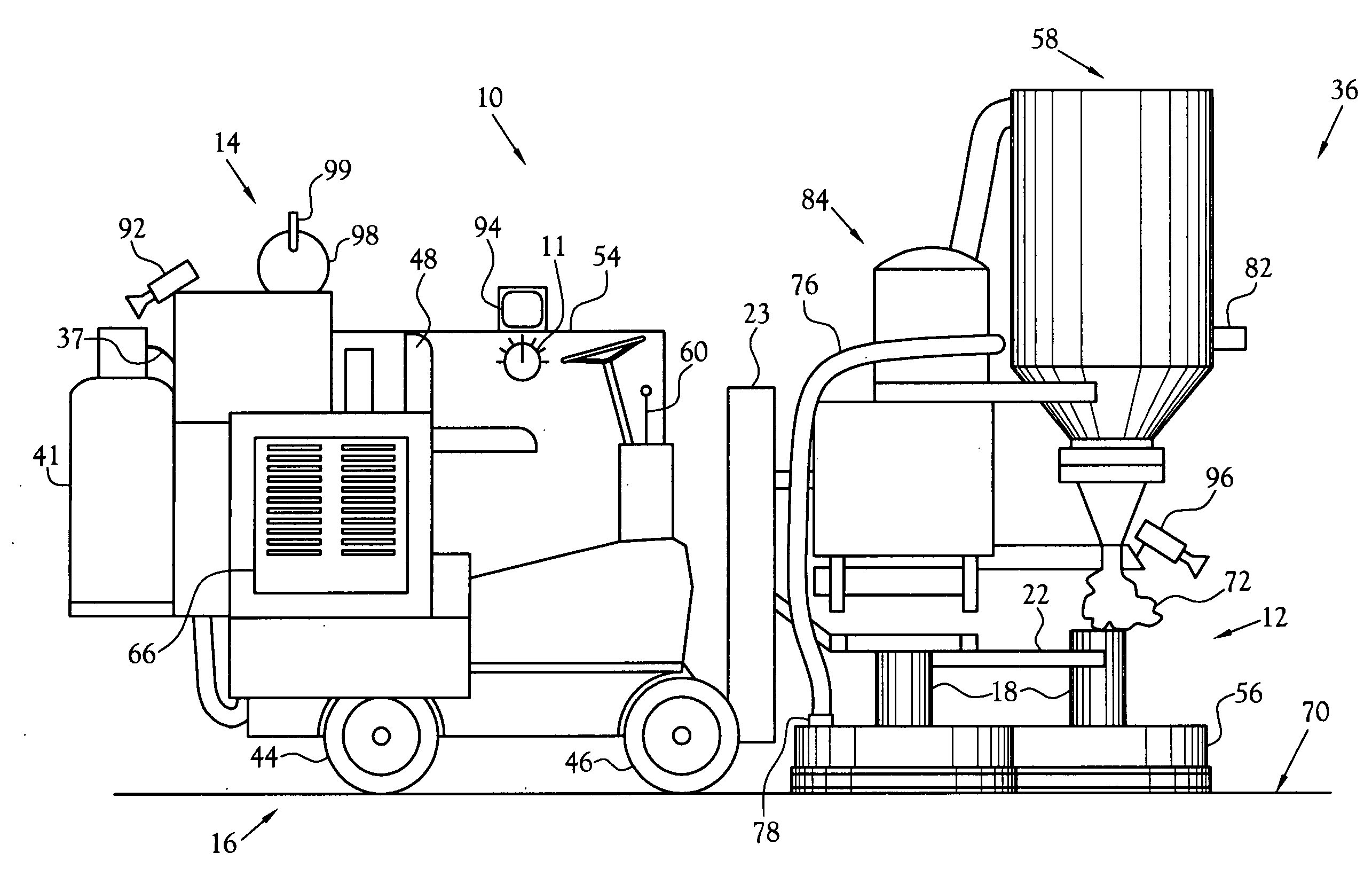

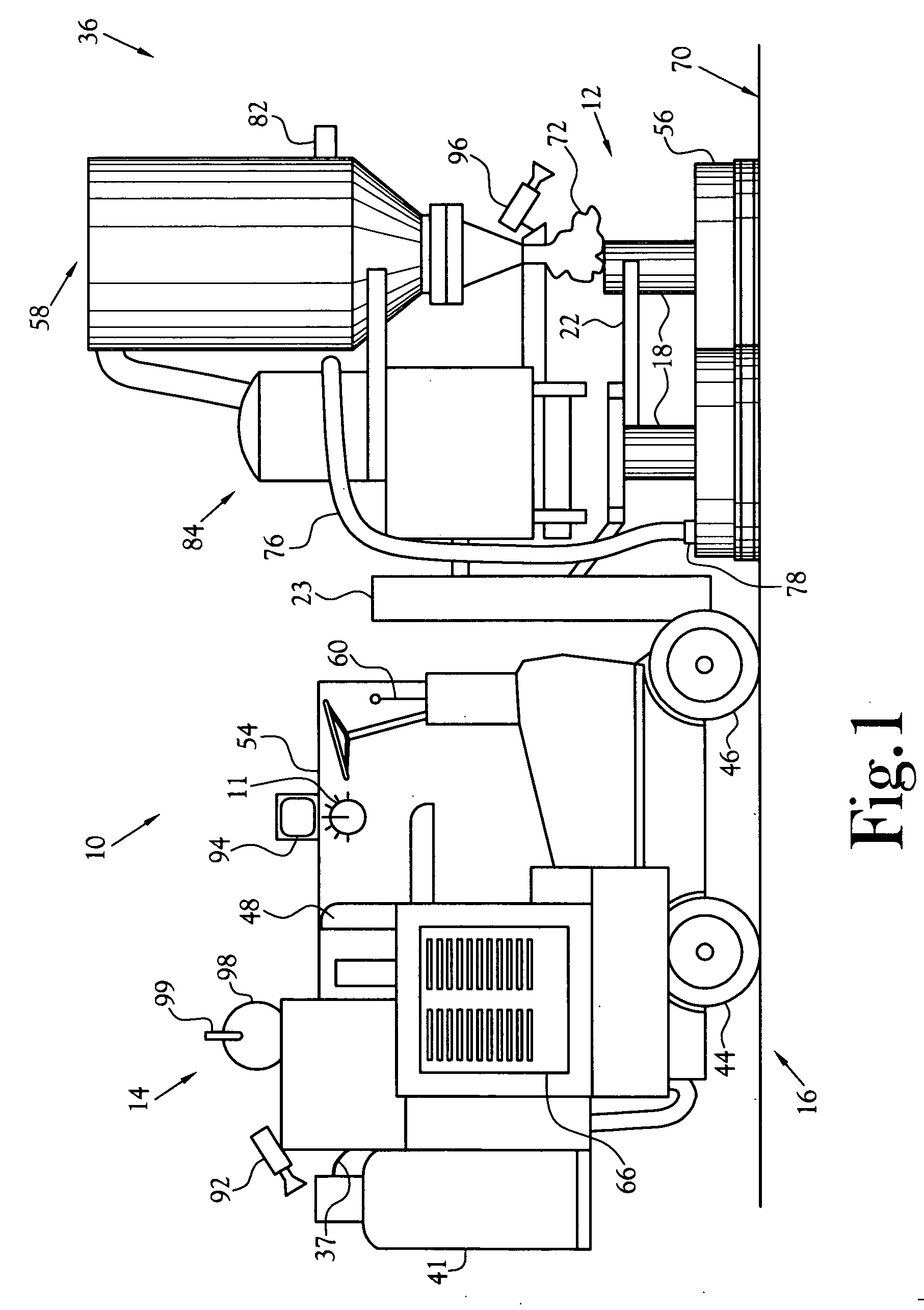

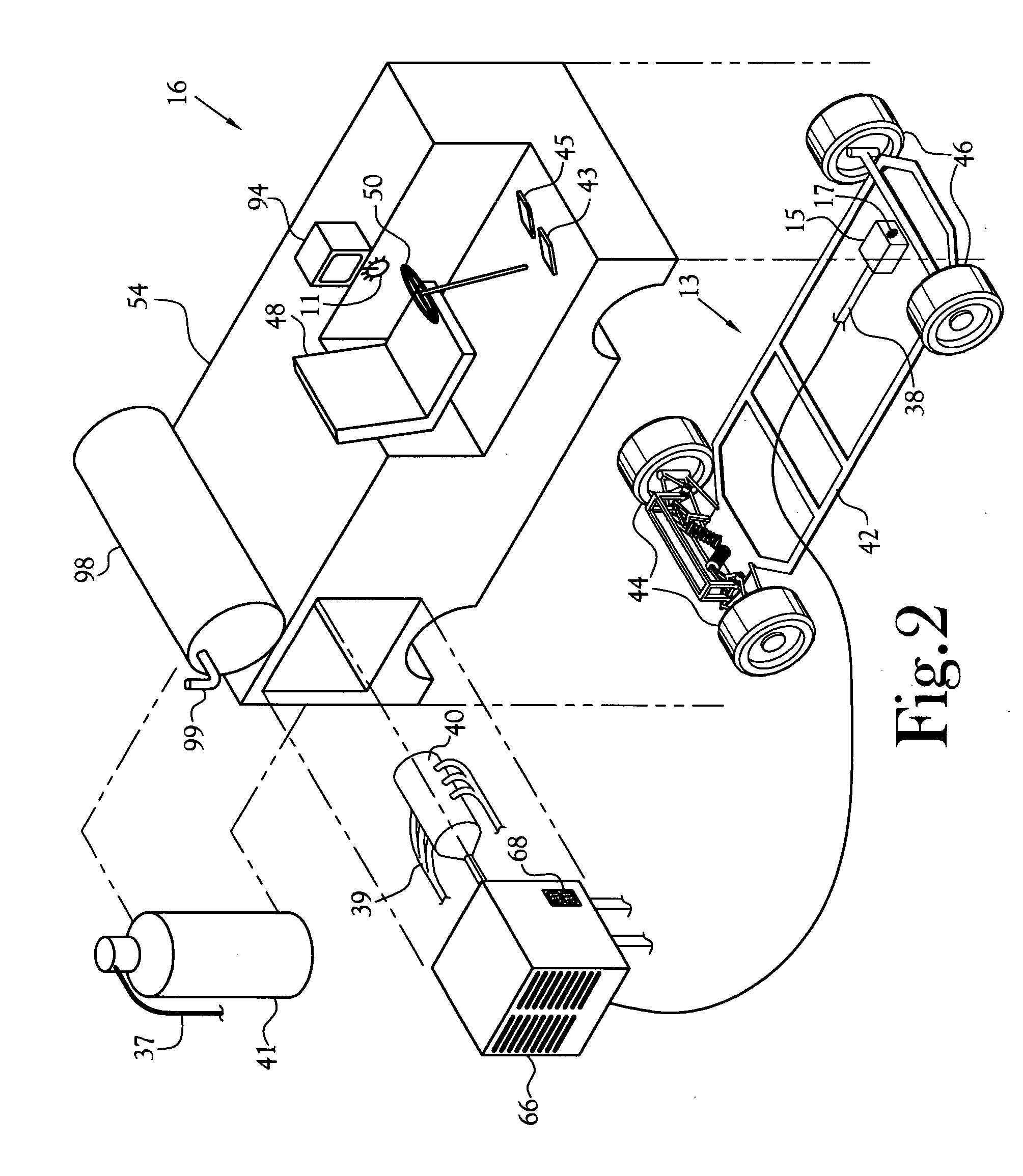

Riding floor polishing machine

InactiveUS20070155285A1Reduce dust accumulationReduce exhaust emissionsCarpet cleanersFloor cleanersHead partsWorking environment

A riding floor polishing machine with dust and exhaust filtering apparatus is disclosed. The riding floor polishing machine provides a vehicle-driven surface processing apparatus capable of performing a large scale surface polishing operation in an indoor setting with reduced dust accumulation and reduced exhaust emission to the working environment. The riding floor polishing machine includes generally a grinder assembly, an exhaust control device, and a dust collection device, each carried by a vehicle. The grinder assembly includes a plurality of planetary polishing heads carried by a frame. The frame is movably attached to the vehicle such that the planetary polishing heads can be moved in either lateral or vertical directions proximate the vehicle. The vehicle provides mobility to the riding floor polishing machine and includes a power source to provide power for operating the various functions of the grinder assembly, the exhaust control device, and the dust collection device.

Owner:CAREX POWER TECH

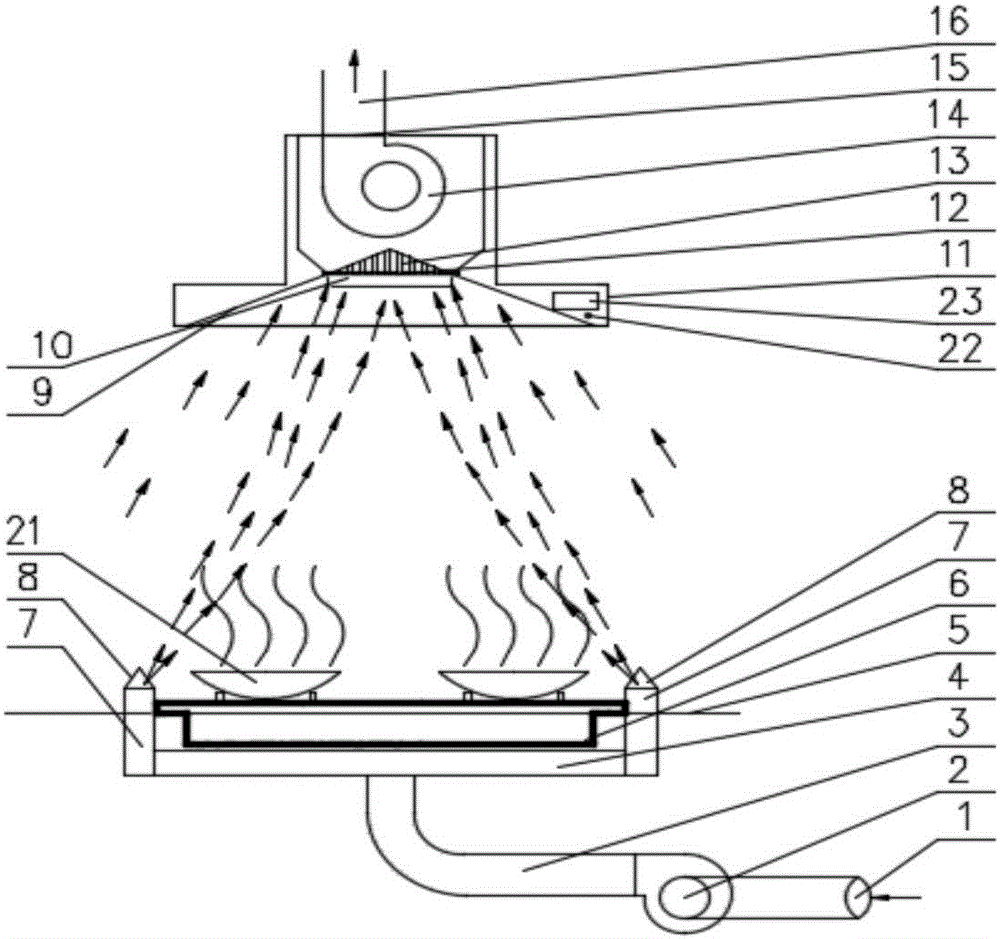

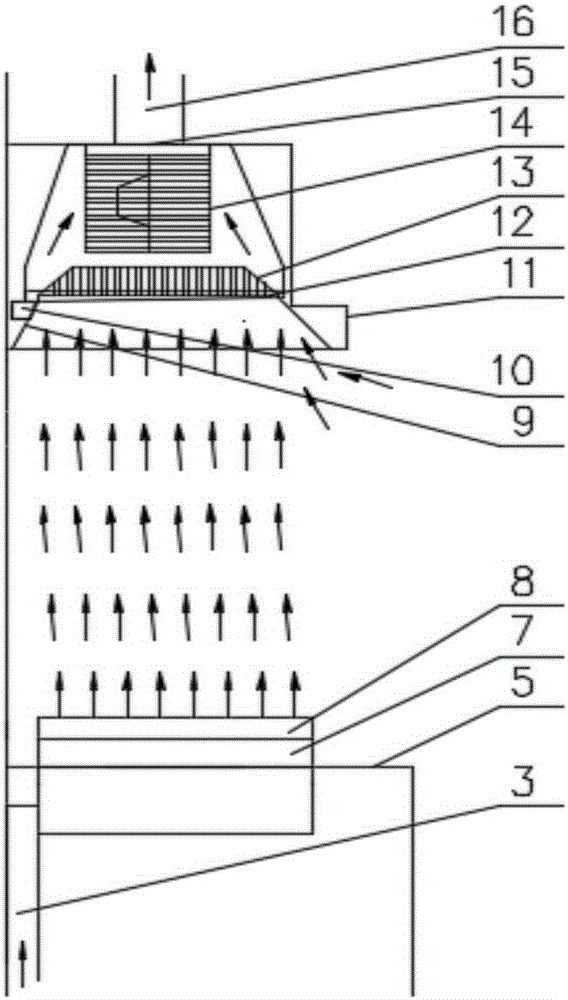

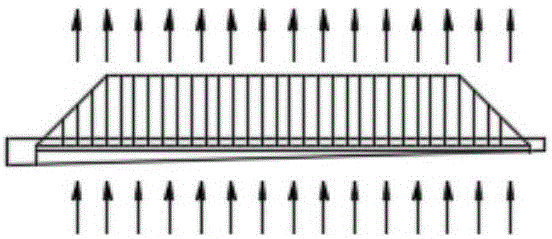

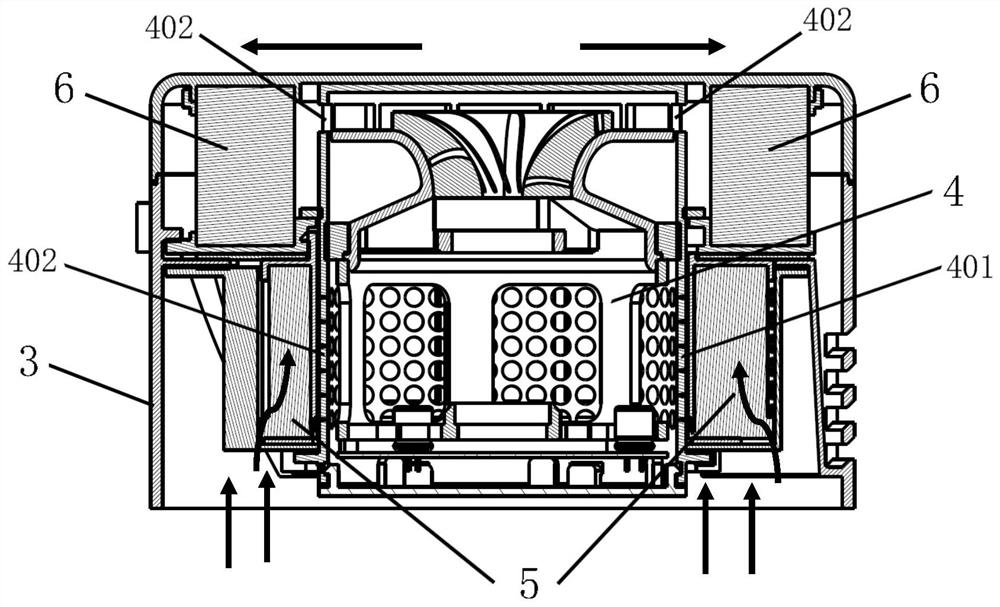

Combined blowing and drawing kitchen ventilator

ActiveCN106123078AImprove entrainment capacityAccelerated exclusionDomestic stoves or rangesLighting and heating apparatusGas stovesOil filter

The invention discloses a combined blowing and drawing kitchen ventilator, which comprises a kitchen ventilator shell and a cooking bench air supplement device. An inner shell is arranged in the kitchen ventilator shell at an interval; a smoke collecting cavity is arranged on an air drawing port of the inner shell; an oil filter screen is arranged in the inner shell on the top part of the smoke collecting cavity; the bottom face and the horizontal face of an oil collecting groove of the oil filter screen are arranged in an inclined way; an oil cup is slidably inserted into one groove on the side face of the smoke collecting cavity; an air outlet is formed in the top part of the kitchen ventilator shell; a smoke exhaust fan is arranged in the kitchen ventilator shell; and air outlet of the smoke exhaust fan communicates with an inlet of an air outlet pipeline penetrating through the air outlet; the cooking bench air supplement device comprises a still pressure box for supporting a gas stove; air curtain vertical pipes are fixed to the left side and the right side of the still pressure box along a vertical direction; the two air curtain vertical pipes respectively communicate with the still pressure box; and a plurality of side clearance air outlets are formed on the top parts of the air curtain vertical pipes. The device can be used for quickly discharging pollutants to outdoor.

Owner:TIANJIN UNIV

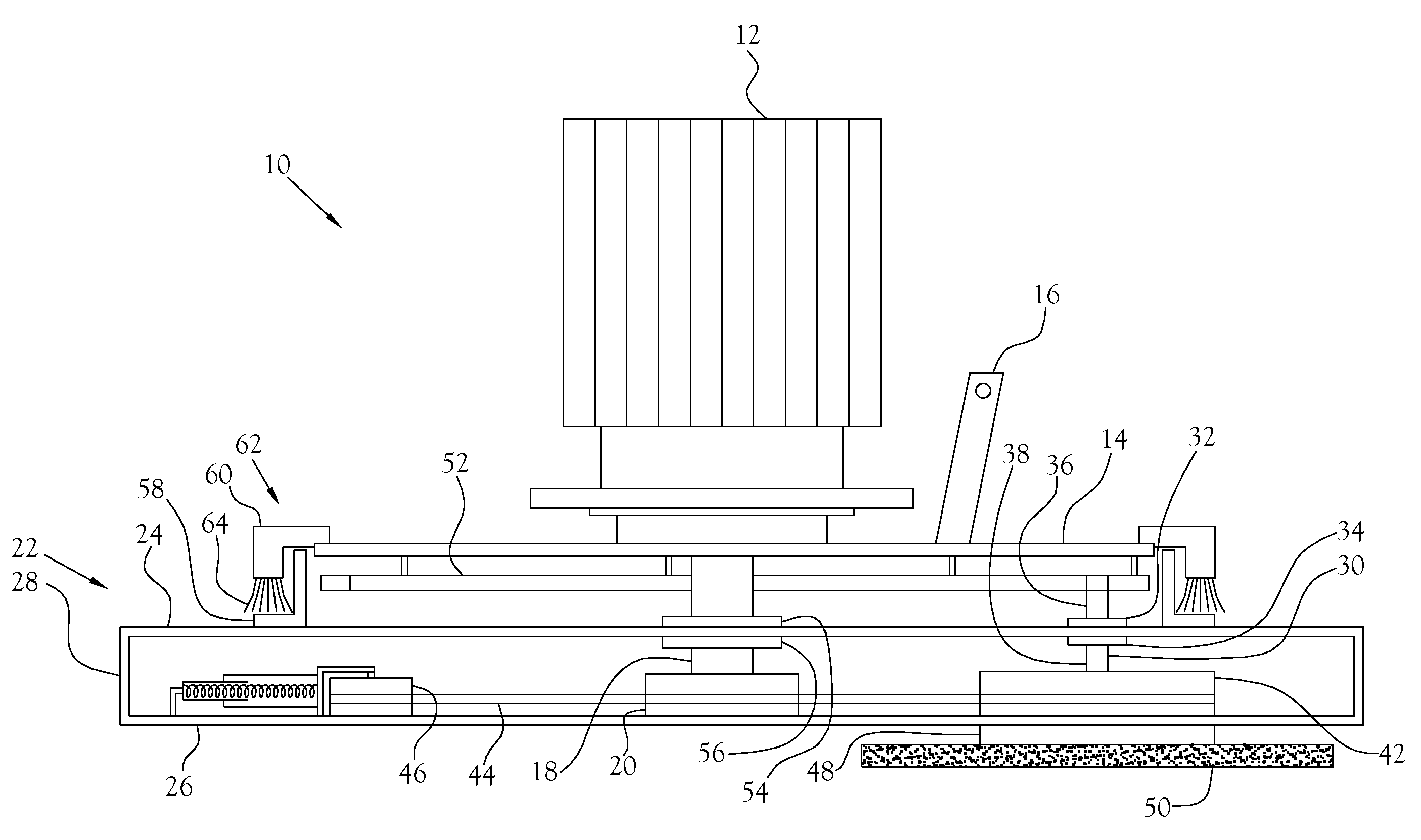

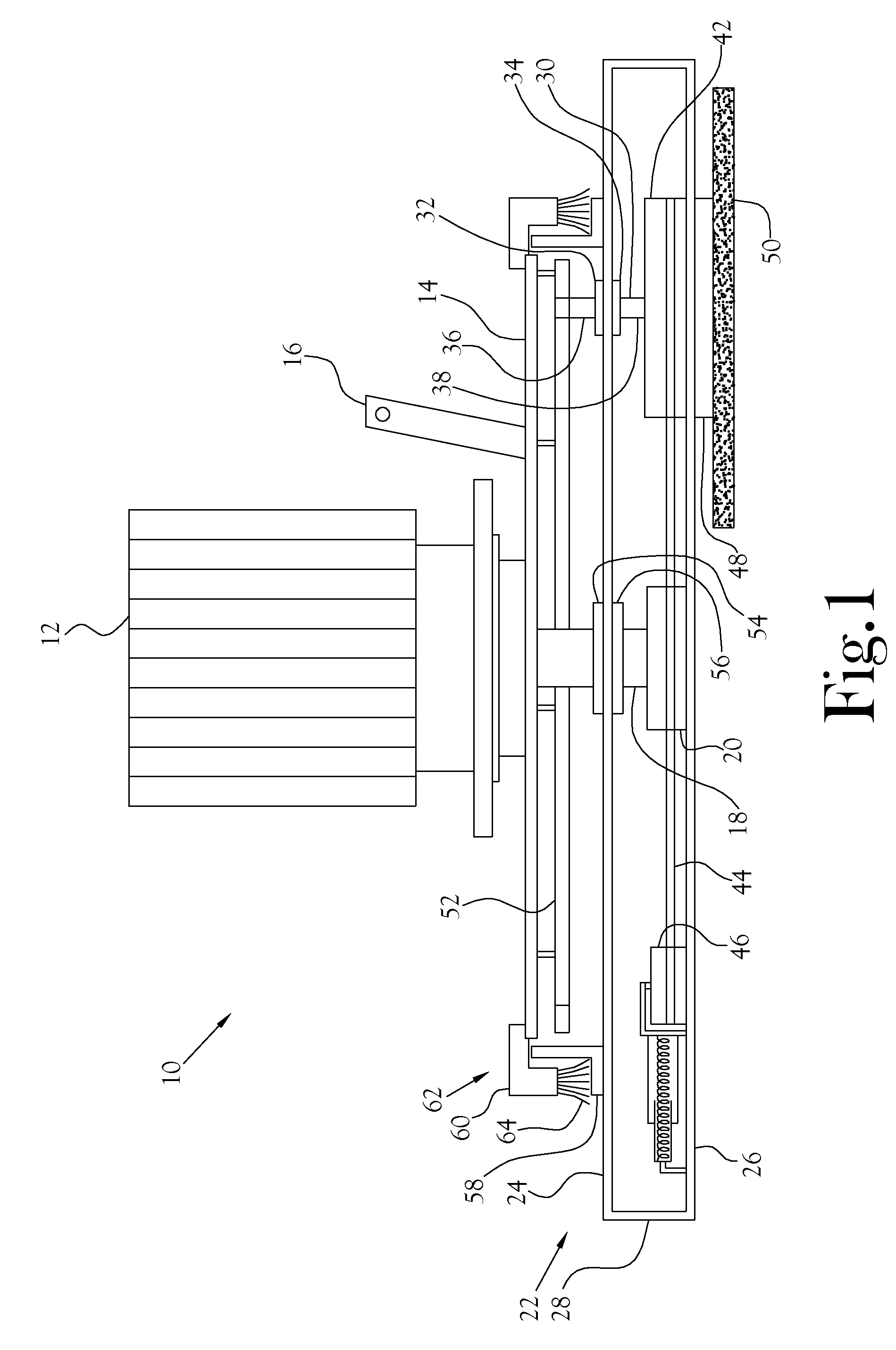

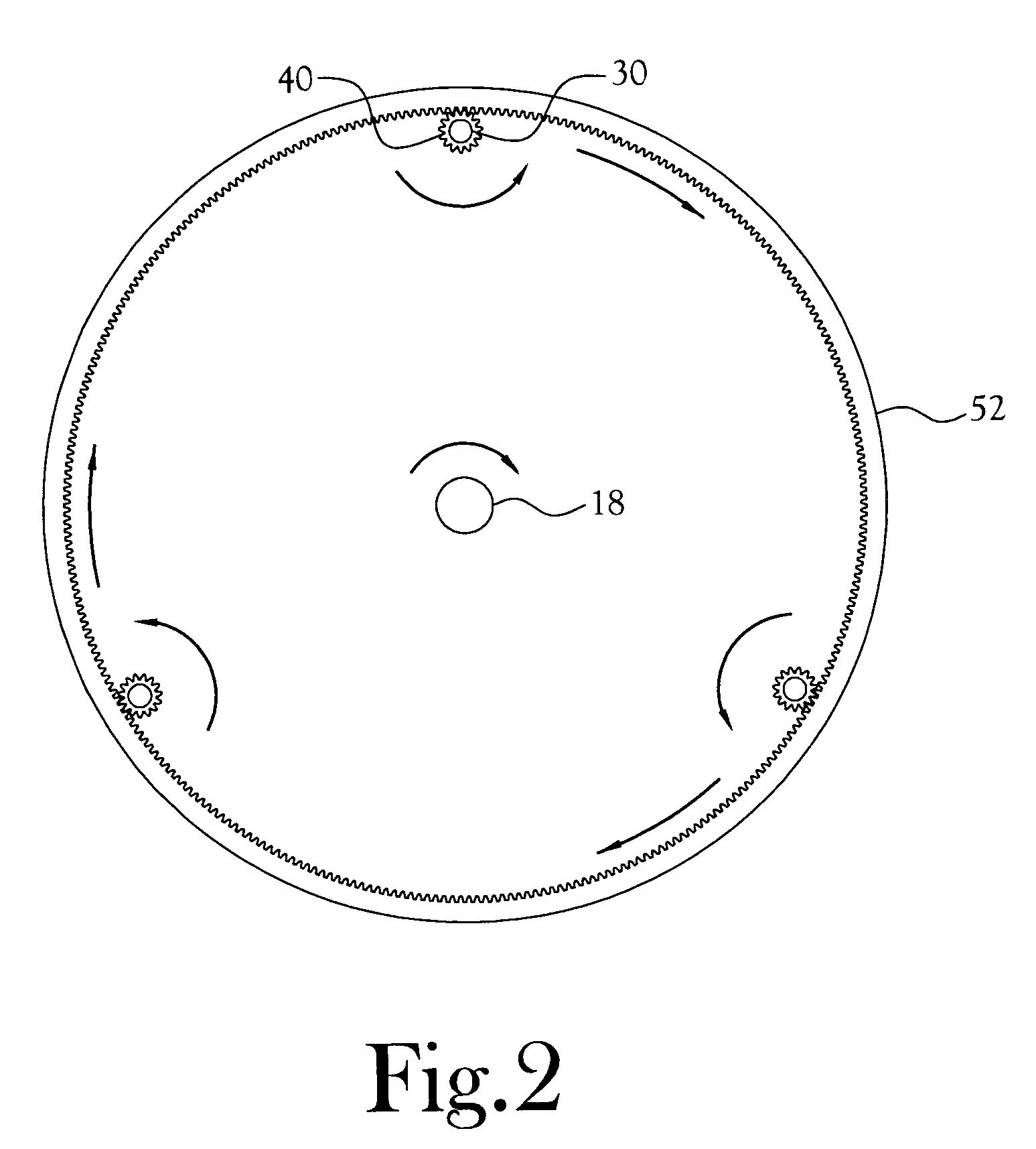

Walk behind polisher

InactiveUS7226347B1Reduce dust accumulationImproved directional stabilityCarpet cleanersFloor cleanersGear wheelEngineering

An improved walk behind polisher and grinder is disclosed. The improved walk behind polisher and grinder provides a surface polishing machine capable of operation with increased directional stability and reduced dust accumulation to the essential internal components of the machine. The improved walk behind polisher and grinder includes a drive motor mounted on a frame. The drive motor rotates a central shaft, and the central shaft supports a belt pulley and a rotary housing. The belt pulley mechanically communicates with at least one pinion shaft through an endless drive. Each pinion shaft is mechanically engaged by an internal gear such that rotation of the central shaft causes the pinion shaft to rotate about their own axes in a given direction and to revolve around the central shaft in the opposite direction.

Owner:CAREX POWER TECH

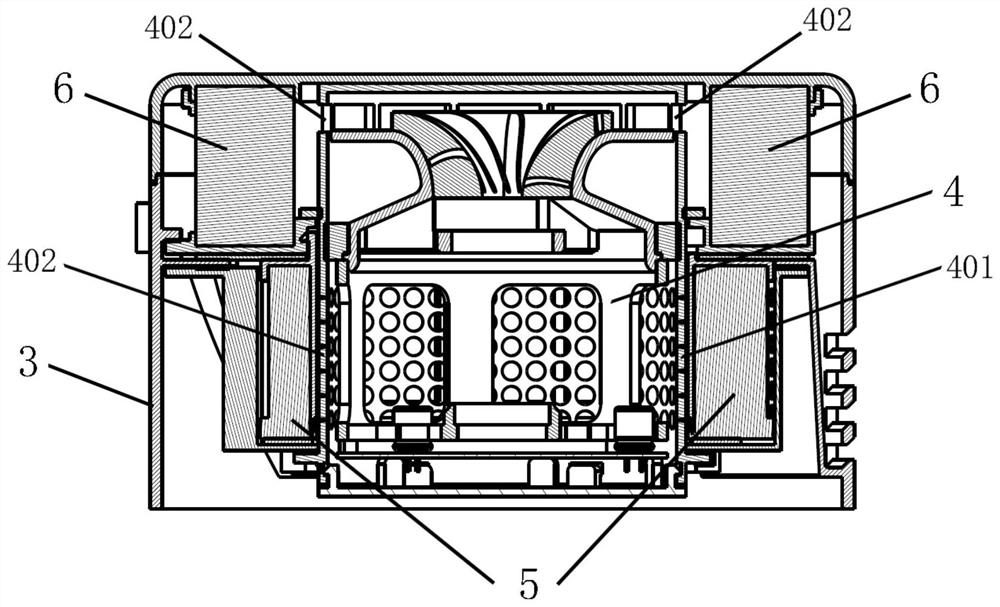

Dust cleaning mechanism and cleaning equipment

PendingCN112043203AReduce stepsImprove user experienceCleaning filter meansEnvironmental engineeringMechanical engineering

The invention discloses a dust cleaning mechanism and cleaning equipment. The dust cleaning mechanism comprises a driving mechanism, a transmission mechanism and a dust scraping mechanism, wherein thetransmission mechanism comprises a gear box, and the gear box is connected with the driving mechanism through an input shaft and is connected with the dust scraping mechanism through an output shaft;the dust scraping mechanism comprises a dust scraping body, and the output shaft is in transmission connection with the dust scraping body to drive the dust scraping body to move; and a first dust scraping strip and / or a second dust scraping strip are / is arranged on the dust scraping body. The cleaning equipment comprises a dust barrel, a dust barrel cover, the dust cleaning mechanism and a coveropening mechanism; and when a rack of the transmission mechanism moves to a preset position in the axial direction of the dust barrel, the cover opening mechanism is pushed to move, and therefore a locking state of the dust barrel cover relative to the dust barrel is relieved. According to the dust cleaning mechanism, after dust on the inner wall surface of the dust barrel and a filter screen iseffectively cleaned, the dust barrel cover at the bottom of the dust barrel is automatically opened, so that the dust is released through self gravity, the user operation is reduced, and the use experience is improved.

Owner:BEIJING ROCKROBO TECH CO LTD

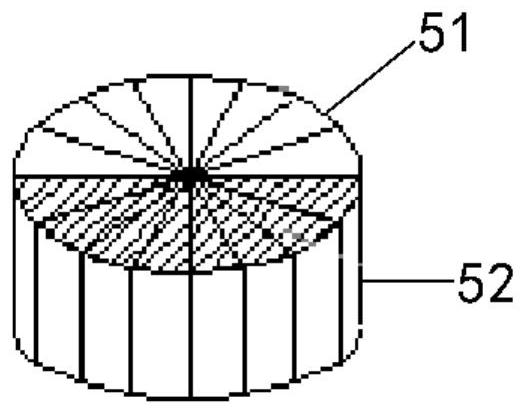

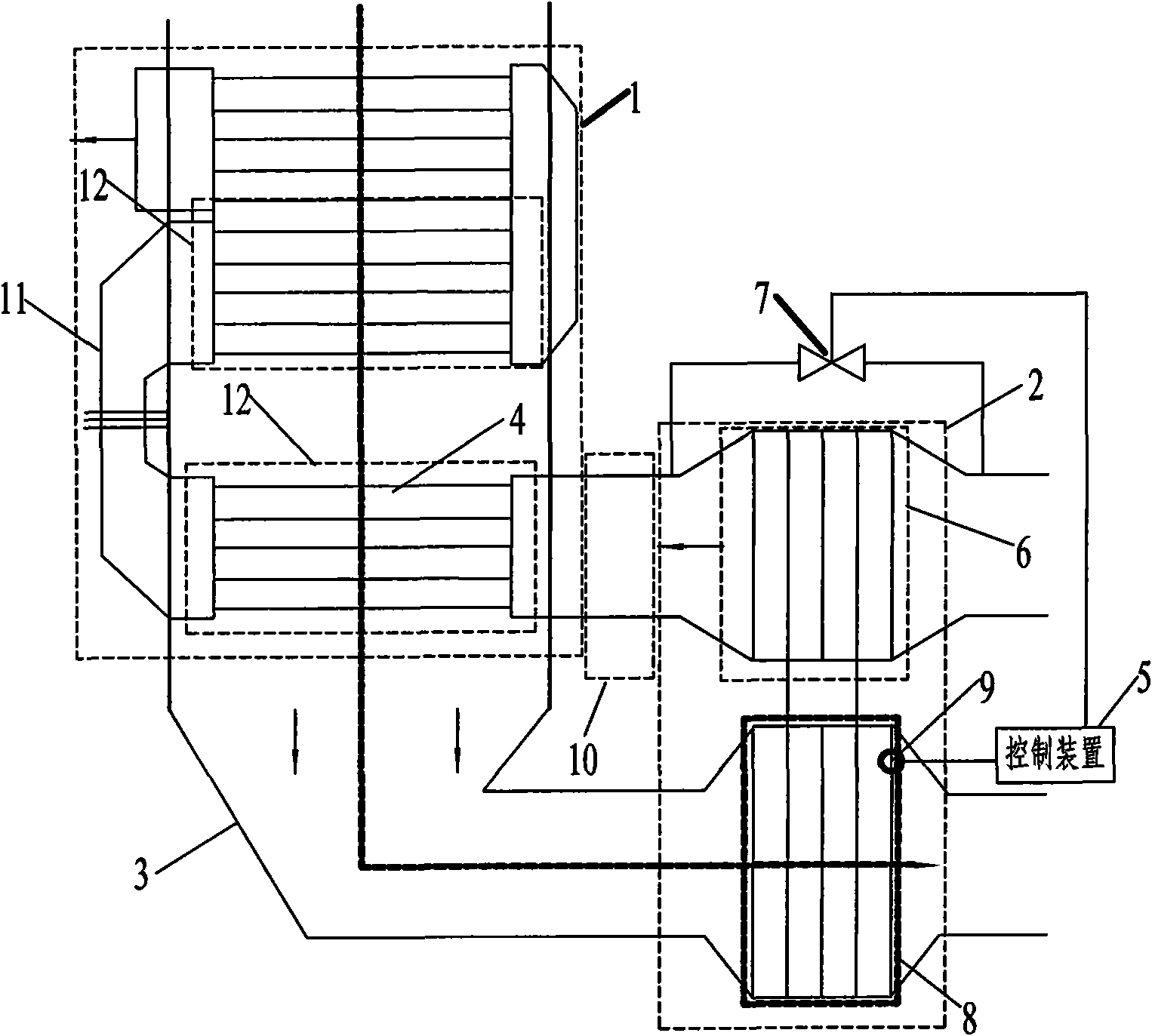

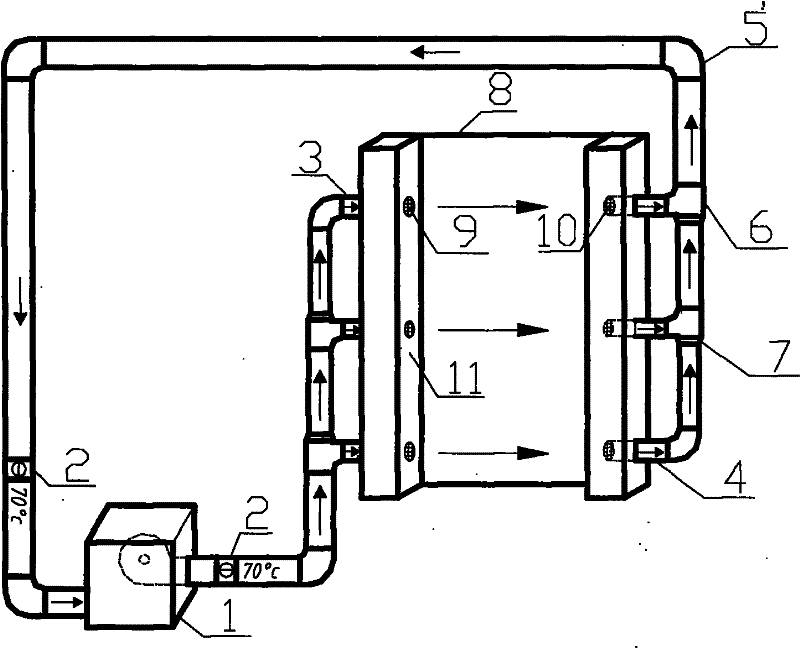

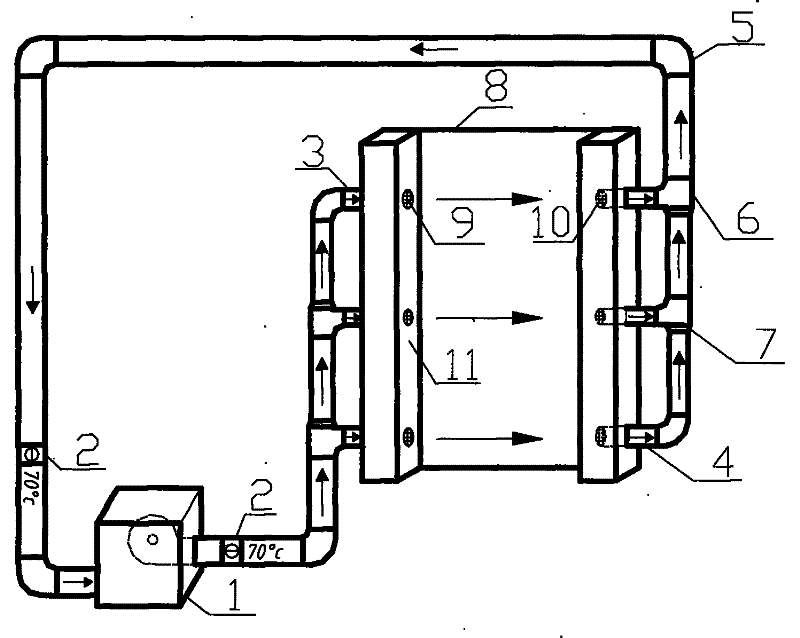

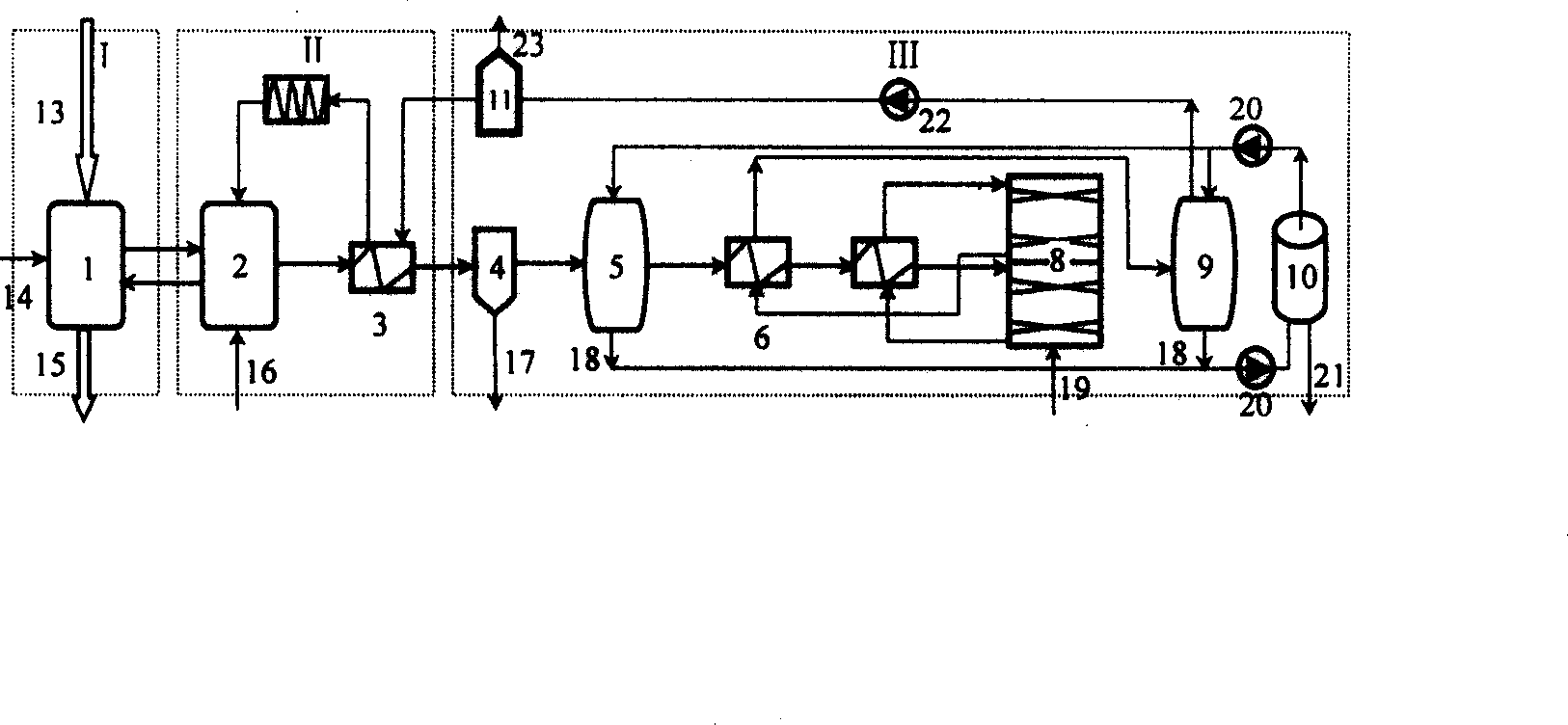

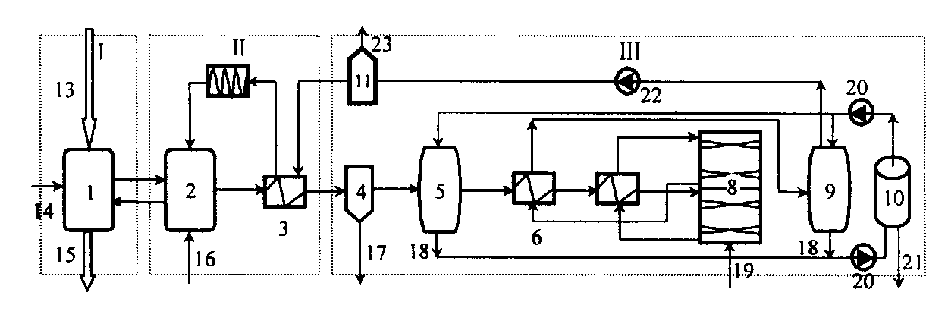

Phase transition combined air preheater

InactiveCN102141253AImprove anti-corrosion performanceReduce dust accumulationCombustion processIndirect carbon-dioxide mitigationAir preheaterElectricity

The invention provides a phase transition combined air preheater, which is suitable for the field of recycling of boiler waste heat. The phase transition combined air preheater comprises a tubular air preheater and a phase transition heat exchanger, wherein the tubular air preheater is connected with the upper section of the phase transition heat exchanger through an air duct; a flow valve which is used for controlling the flow passing through the phase transition heat exchanger by using a control device is arranged on the upper section of the phase transition heat exchanger; the lower section of the phase transition heat exchanger is connected with a gas duct on the tail part of a boiler; a temperature acquisition module which is electrically connected with the control device is arranged on the lower section tube wall of the phase transition heat exchanger; and the control device is used for controlling the open degree of the flow valve according to wall temperatures acquired by the temperature acquisition module. On the one hand, the wall temperature of a heat exchange tube is 10 to 30 DEG C higher than the tube wall temperature of a vertical tubular air preheater, and the corrosion prevention of the heat exchange tube is facilitated; and on the other hand, flow media in the heat exchange tube is air, so that less accumulated dust is generated in the heat exchange tube.

Owner:深圳中兴节能环保股份有限公司

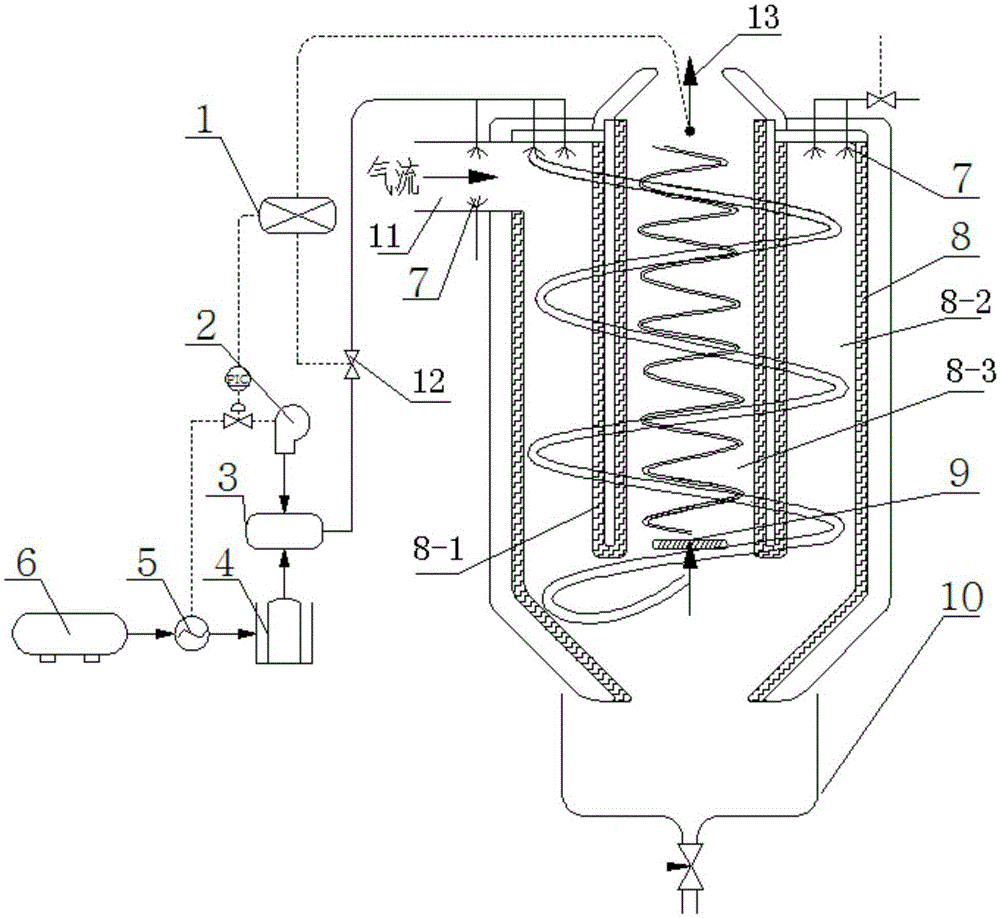

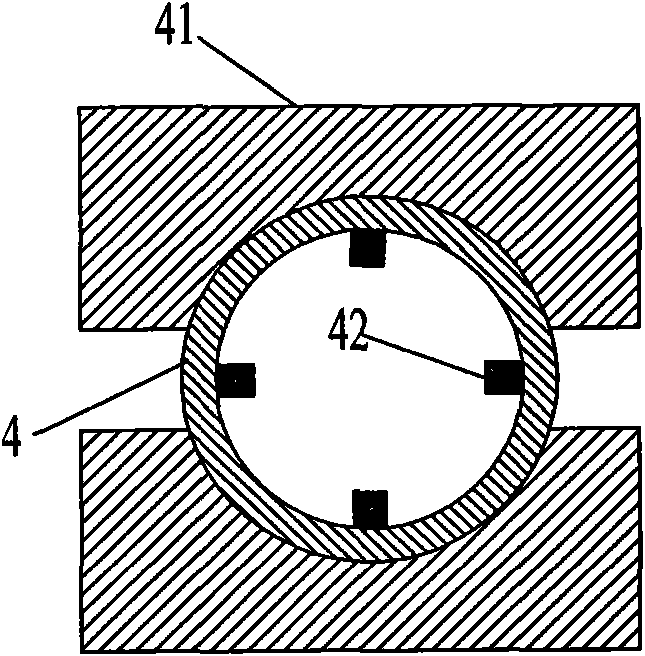

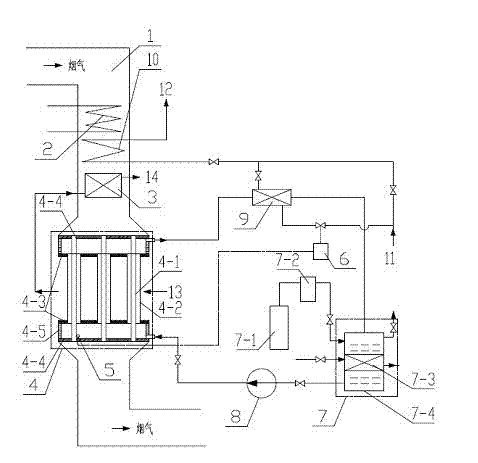

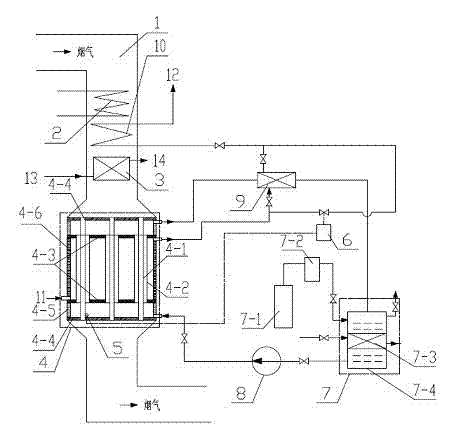

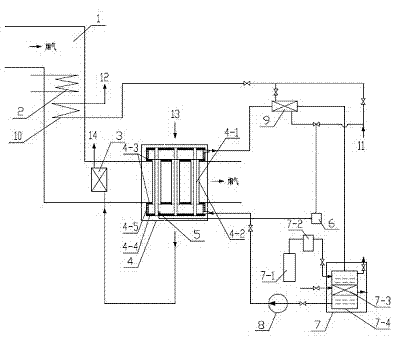

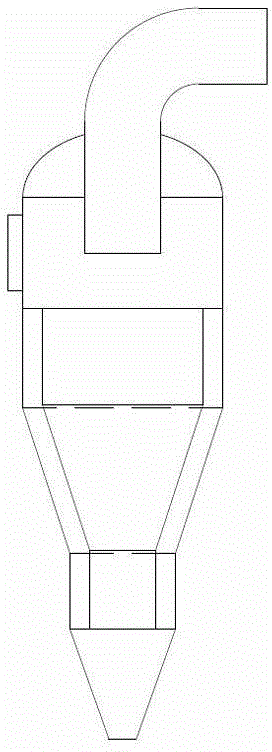

Low-ratio biomass circulating fluidized bed with cooling chamber and pollutant control method thereof

ActiveCN102913900AReduce wearReduce dust accumulationFluidized bed combustionDispersed particle separationSuperheaterCirculating fluidized bed boiler

The invention relates to a low-ratio biomass circulating fluidized bed with a cooling chamber and a pollutant control method thereof and solves the problem that existing grate-fired furnaces and circulating fluidized beds cause grate slag bonding and bed material coking in biomass combustion and especially causes soot formation and high-temperature corrosion in combustion of low ash fusion point biomass. A smoke cooling chamber is disposed behind a cyclone separator and used to lower smoke temperature from 800 DEG C to within 650 DEG C, so that soot formation and corrosion of a superheater are relieved greatly. By in-furnace denitration and limestone desulfuration, denitration efficiency can reach 50-70% when mole ratio of NH3 to NOX is 1.0-1.1, denitration efficiency can reach 70-80% when mole ratio of Ca to S is 2.0-2.5, and emission concentration of SO2 and NOx can be effectively controlled within 100mg / m<3>. The low-ratio biomass circulating fluidized bed with the cooling chamber and the pollutant control method thereof are used to control biomass combustion and pollutants.

Owner:HARBIN INST OF TECH

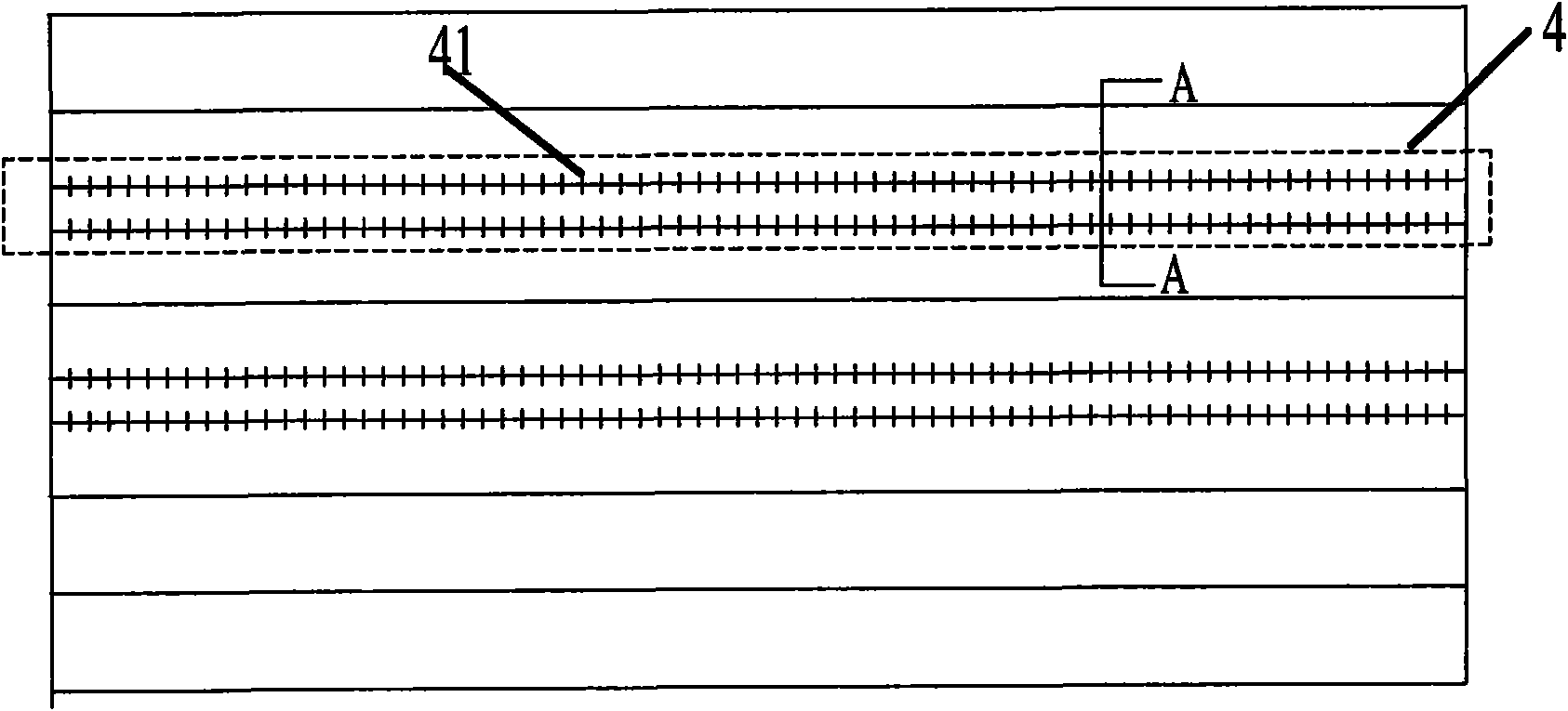

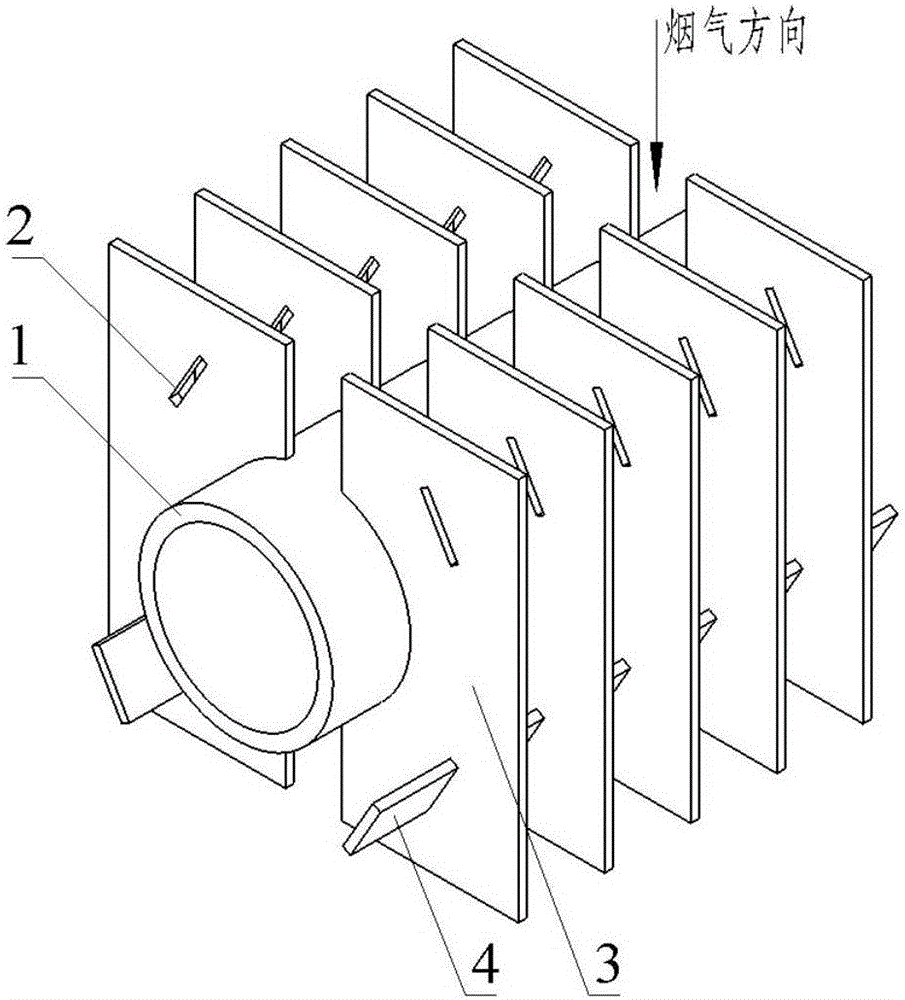

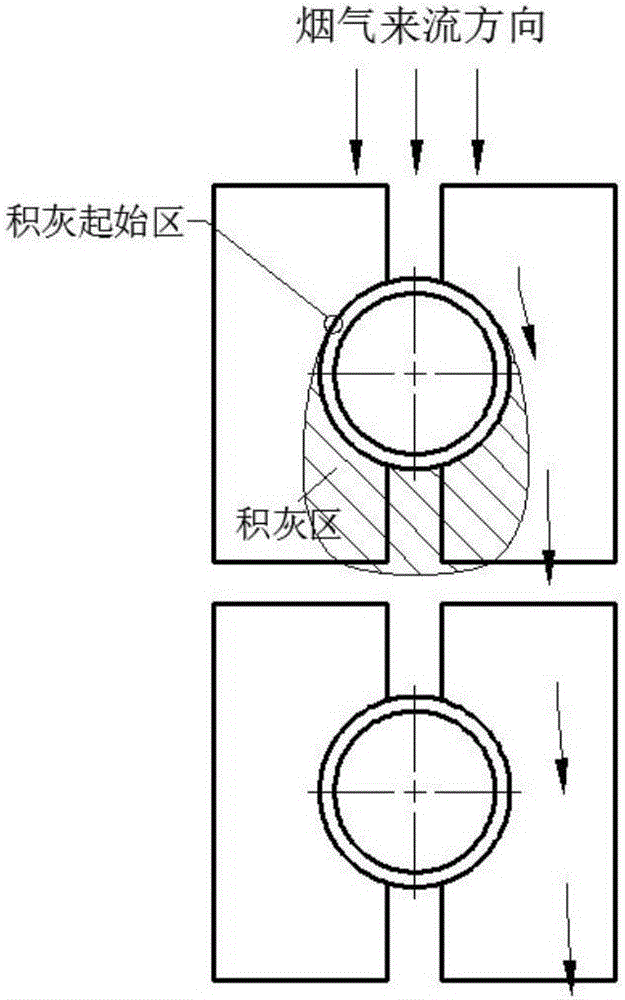

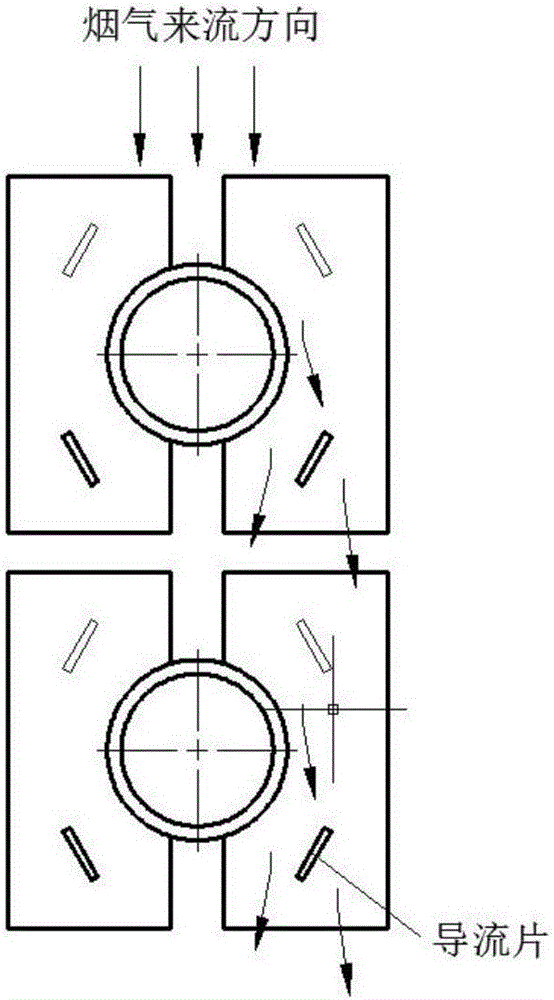

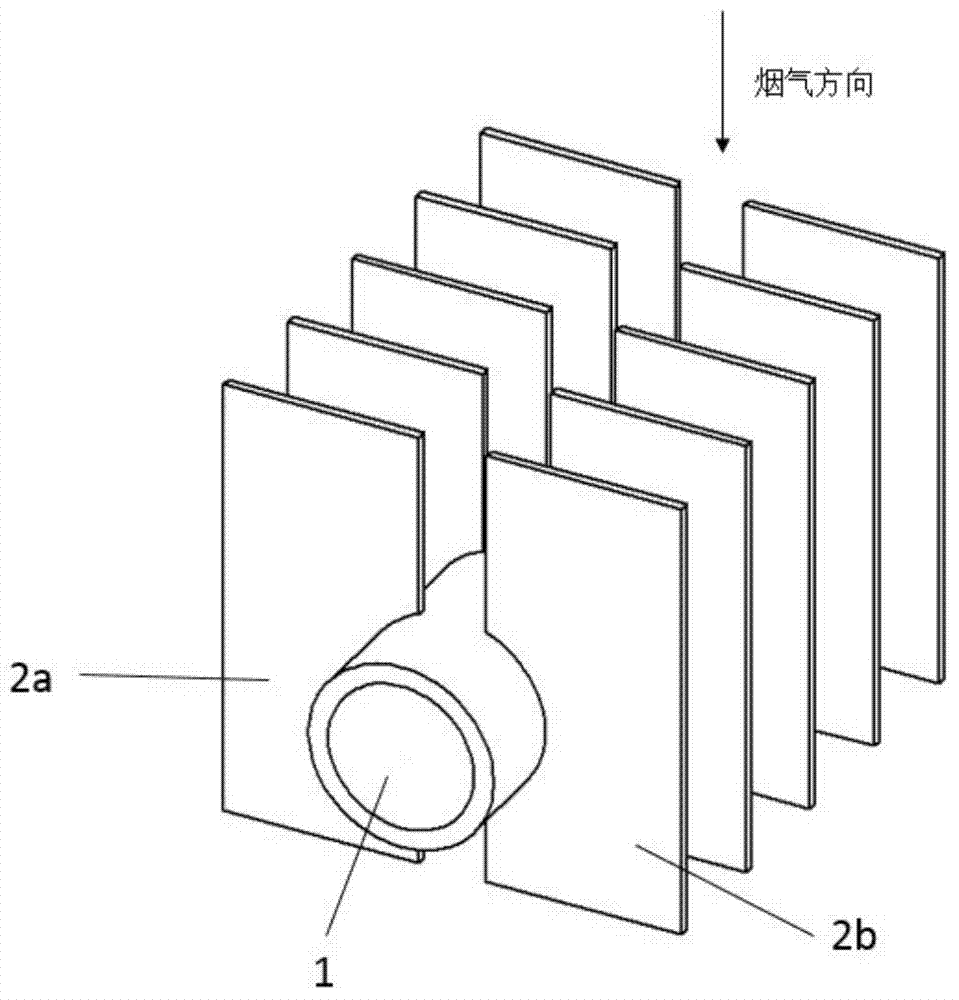

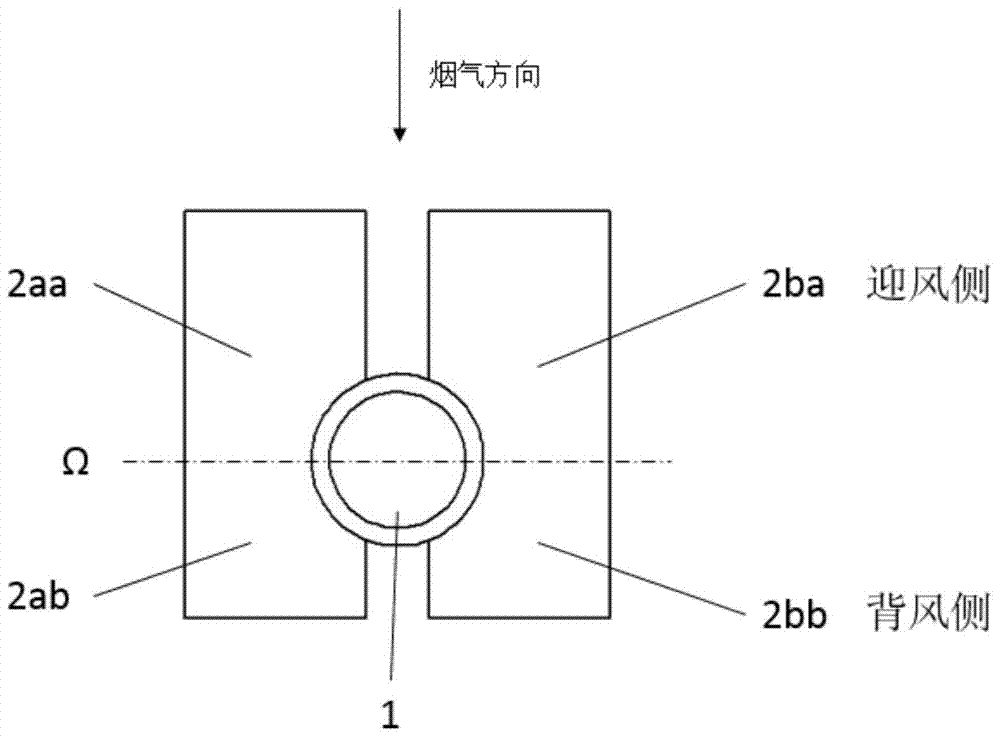

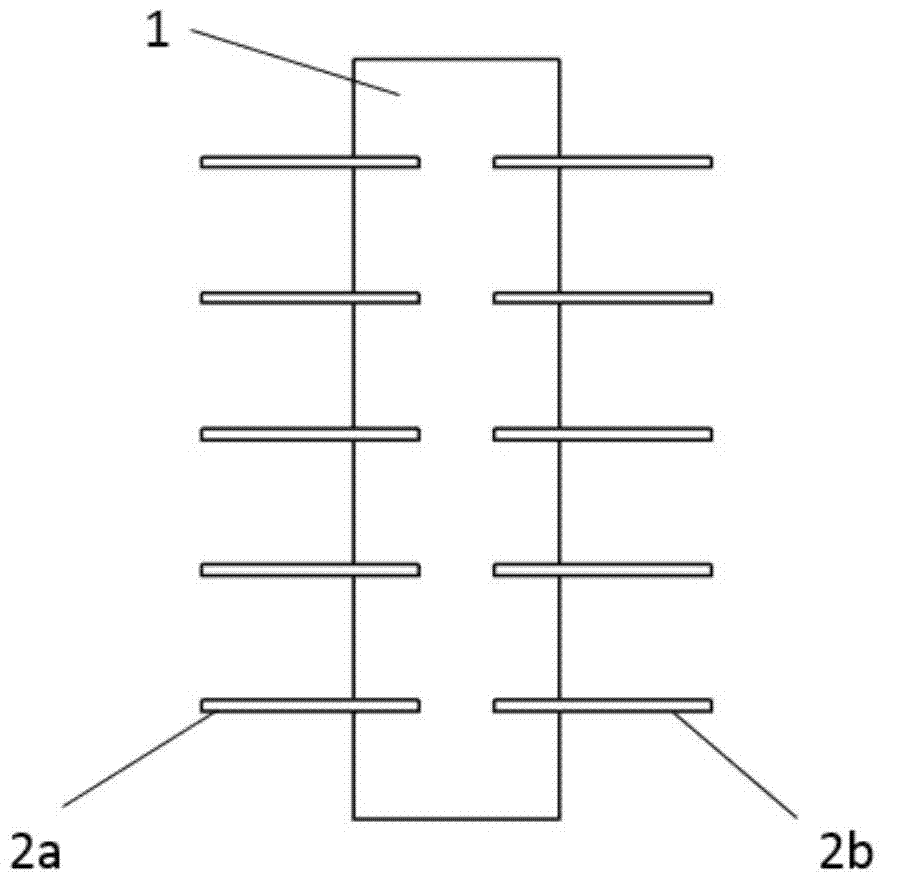

Axially through H-type finned tube and heat exchange tube bundle thereof

InactiveCN106091782AEliminate the starting area of dust accumulationReduce dust accumulationStationary conduit assembliesTubular elementsEngineeringHeat transfer

The invention relates to an axially through H-type finned tube and a heat exchange tube bundle thereof. The H-type finned tube comprises a base tube part, a fin part and a through part, wherein the base tube part comprises at least one base tube; the fin part comprises a plurality of parallel fin groups which are arranged in the axial direction of the base tube and connected with the outer wall of the base tube; each fin group comprises two fins which are symmetrically arranged on two sides of the base tube and regularly arranged according to a certain pitch; a groove matched with the outer wall of the base tube is formed in the inner side of each fin; the through part comprises through grooves that are processed in parts of the surfaces of the fines in a smoke flowing direction and arranged relative to the base tube; and flow deflectors passing through the corresponding through grooves are arranged on a smoke outlet side and connect the fin groups in series in the axial direction of the base tube to change the axial cross section of the H-type finned tube from a plane into a three-dimensional structure. According to the axially through H-type finned tube and the heat exchange tube bundle thereof, an initial region of ash deposition can be effectively eliminated, a flow stagnation region on the leeward side of the finned tube is obviously reduced, and ash deposited on the side surfaces of the fins and the base tube in the flow stagnation region is greatly reduced; meanwhile, the heat transfer effect of the H-type finned tube is effectively enhanced; and the through grooves can be formed by punching, so that automatic production can be realized easily.

Owner:XI AN JIAOTONG UNIV

Novel wind-curtain device for refrigerator

InactiveCN102374602AShort rangeReduce energy consumptionLighting and heating apparatusAir currents for screeningStore foodEngineering

The invention relates to a novel wind-curtain device for a refrigerator. The device comprises a fan set, a fireproof valve, a wind-supplying pipe, a wind-returning pipe, a bend, a three-way pipe, an increasing pipe, a PVC (Poly Vinyl Chloride) curtain, a wind-supplying opening grid, a wind-returning opening grid and a curtain wall. The PVC curtain and an air curtain of the device can perform the double heat-insulating actions for the refrigerator, and meanwhile, a door curtain can be used for blocking the air curtain from being directly contacted with an external environment, thereby the probability of garbage entering a wind pipe is decreased. Mosquitoes, flies, insects and mice are effectively prevented from entering the refrigerator from the side of the air curtain with a smaller wind speed through uniform air flows formed at a refrigerator door by a wind-supplying and returning system, thereby the storage safety of the refrigerator is improved, and the uniform wind speed is favorable to blocking the penetration of cold wind. The device can be used for sufficiently blocking the penetration of the cold wind in the refrigerator, and insect prevention and dust prevention are achieved. A wind curtain disclosed by the invention has the characteristics of energy saving, high efficiency, cleanliness, simple structure, low cost and the like and is particularly suitable for large refrigerators for storing foods.

Owner:SHANGHAI OCEAN UNIV

Composite phase change heat exchanger for flue gas heat recovery of boiler

InactiveCN102410527AEasy to operateOptimize layoutCombustion processIndirect carbon-dioxide mitigationFlue gasEngineering

The invention discloses a composite phase change heat exchanger for flue gas heat recovery of boiler, comprising an original coal saving device and an air pre-heater of the boiler, a fluid heater disposed in the flue, a composite phase change heat exchanger, and a temperature adjustor disposed outside the flue, a heat exchanger, a frequency modulation water pump, a pipeline and an instrument valve which are matched; the composite phase change heat exchanger is a three-process integrated structure composed of an inner heat exchange pipe process, a sleeve pipe process between the inner heat exchange pipe process and the sleeve pipe and a shell process outside the sleeve pipe. The composite phase change heat exchanger of the invention has a compact structure, which can be conveniently disposed in a vertical, horizontal or oblique flue; simultaneously, the adjustment is flexible, which can effectively avoid low-temperature corrosion, so that the boiler can be operated economically, safely and efficiently. Compared to the technology of the composite phase change heat exchanger developed by Mr. Yang Benluo, the composite phase change heat exchanger of the invention equals to the second-generation technology of the composite phase change heat exchanger.

Owner:王海波

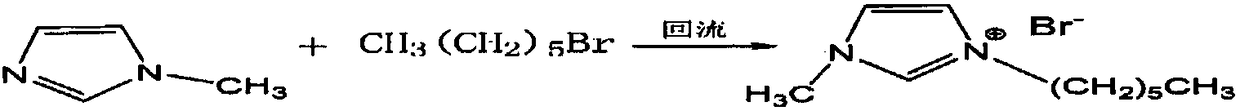

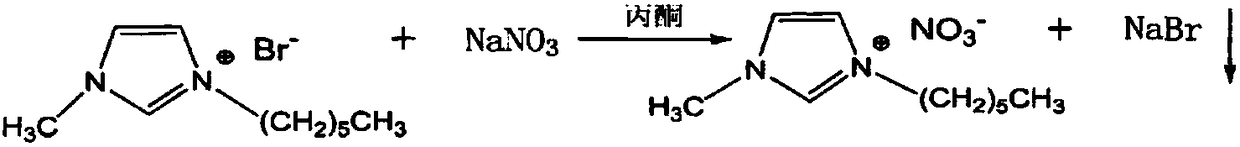

Ultralow temperature ash-free antiwear incombustible ester type hydraulic oil, production technology and application thereof

InactiveCN108641792AImprove oxidation stabilityStable molecular structureLubricant compositionFire retardantLubrication

The invention discloses ultralow temperature ash-free antiwear incombustible ester type hydraulic oil, a production technology and application thereof. The ultralow temperature ash-free antiwear incombustible ester type hydraulic oil is prepared from a viscosity index improver, a pour point reducer, an emulsion breaker, a defoaming agent, an antiwear reagent at extreme pressure, an ash-free detergent dispersant, an antirust agent, an antioxidant, a fire retardant and base oil. The ultralow temperature ash-free antiwear incombustible ester type hydraulic oil has the advantages that firstly, theoil has the extremely stable molecular structure, and the good oxidation stability; secondly, the oil has the extremely good lubricating performance and antiwear performance, and can effectively prolong the life of an engine; thirdly, the oil has the low temperature fluidity so that the engine can be easily started; fourthly, the oil has the good high temperature high shearing performance, the volatile loss at a high temperature is less, and the oil film tenacity and strength of an oil product at the high temperature are ensured; fifthly, the viscocity and the lubrication of the oil can be maintained after a ultralong driving process; sixthly, the oil has the good detergent dispersing performance, and the dust deposition amount is less after the oil is used for a long time; seventhly, theoil has the good biodegradability; and eighthly, the oil has low condensation point and can be widely applied to bad working environments such as low temperature and cold.

Owner:冠仕(上海)新能源科技有限公司

Decoking agent

The invention relates to a decoking agent capable of reducing or removing coked blocks and deposited dust in coal-fired boilers and industrial boilers. The components and weight percentage of each component of the decoking agent are as follows: 10-20 of borax, 10-25 of active metal powder, 10-25 of a combustion-supporting material and 10-30 of a high-melting point material. The basic material-borax can lower bonding strength of slag, is easy to produce volatile gas, and makes coked slag loosen; the combustion-supporting material can generate a lot of oxygen atoms under a high temperature, and directly promotes the combustion of coal powder. Besides, metal ions such as manganese ions and copper ions in reaction products can catalyze the combustion of oxydic coal powder and increases combustion efficiency, thereby reducing coke and the deposited dust; the active metal powder can form a dense high-melting point material oxide film under high temperature, protects the heating surface from washing of corrosion and smoke, and prolongs service life.

Owner:SNTO TECH GRP

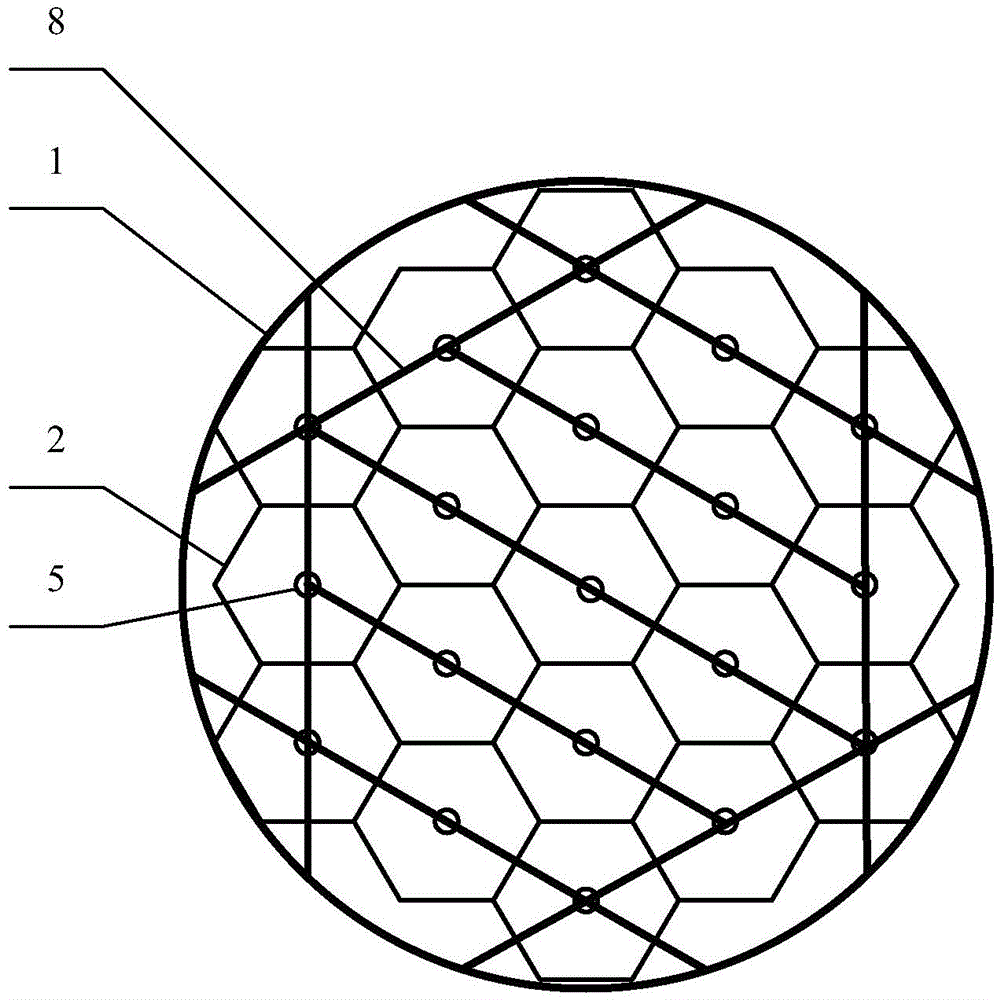

Rotational flow plate type SCR denitration tower and denitration method thereof

ActiveCN105289300AExtended stayThe catalytic reduction reaction is fullyDispersed particle separationFlue gasEscape rate

The invention discloses a rotational flow plate type SCR denitration tower and a denitration method thereof. The denitration tower comprises a denitration tower body and a corrugated plate type catalyst layer arranged along the inner circumference face of the denitration tower body, and the corrugated plate type catalyst layer forms a flue gas channel. A plurality of layers of rotational flow atomizing nozzles performing jetting in the contact circle direction are distributed on the circumference face of the corrugated plate type catalyst layer from bottom to top. When flue gas enters the flue gas channel from the bottom of the denitration tower body, and the flue gas encounters ammonia gas jetted by the whirlwind atomizing nozzles, the flue gas and the ammonia gas are mixed in an entrainment mode and spirally raises in the inner circumference direction of the flue gas channel in a contact circle mode because the ammonia gas is jetted in a rotational flow mode in the contact circle direction. On the premise that efficient denitration is guaranteed, the catalyst use amount of the denitration tower is small, the technical means is easy and convenient to use. Compared with the prior art, the denitration tower is simple in structure, low in manufacturing cost, high in denitration efficiency and low in energy consumption, reduces the ammonia escape rate, makes denitration cost greatly reduced, and remarkably improves economic benefits.

Owner:SOUTH CHINA UNIV OF TECH

Gasification process system for fine particle biomass or solid fossil fuel

ActiveCN104449872AWell mixedReduce dust accumulationEnergy inputGasification processes detailsCyclonic separationSeparation technology

The invention discloses a gasification process system for fine particle biomass or solid fossil fuel. A combustion system adopts a circulating fluidized bed combustion technology and an efficient cyclone separation technology of the fine particle biomass or solid fossil fuel. The fine-particle circulating fluidized bed combustion technology adopts a flat-plate directional wind cap, so that refining combustion of coal particles is achieved; a fluidized bed gasification reactor system of the fine particle biomass or solid fossil fuel adopts a fine-particle gasification technology, and the fine-particle gasification technology adopts the flat-plate directional wind cap, so that the problems of low gas production rate and low gas production heat value in an existing coal gasification process system are solved; by virtue of an afterheat utilization system, the heat carried in the gasification process is transformed into steam, and is supplied to the fluidized bed gasification reaction system of the fine particle biomass or solid fossil fuel, so that the cost is reduced by using self-energy sources; and the gasification process system also comprises an ash treatment system and a gasification process gas purification system, so that the problem of waste of the heat carried in ash, and the problem that sulfide and dust carried in the gasification process are not thoroughly treated are solved.

Owner:大连科林能源工程技术开发有限公司

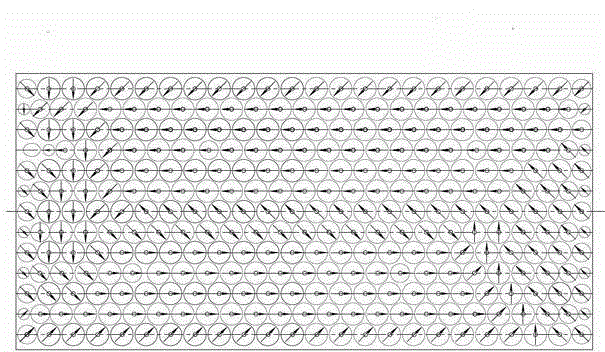

Non-centrosymmetrical H-shaped finned tube and finned tube heat exchange tube bundle

ActiveCN104501639AImprove heat transfer performanceReduce dust accumulationTubular elementsAirflowEngineering

The invention discloses a non-centrosymmetrical H-shaped finned tube and a finned tube heat exchange heat tube bundle. The finned tube comprises a base pipe portion and a fin portion, wherein the base pipe portion comprises at least one base pipe, the fin portion comprises a plurality of fin groups welded on the outer walls of the base pipes by preset distance along the axial direction of the base pipes, each fin group comprises two quadrilateral fins arranged on two sides of the base pipes, each fin is connected with the outer walls of the base pipes through grooves in the inner side, and the fins are arranged on the same plane and reserve gaps larger than or equal to zero or are connected. The area of the windward sides of the quadrilateral fins are arranged is larger than that of the leeward sides. Since heat exchange performance of the fins on the windward sides is more excellent than that of the leeward sides, airflow separation, eddy and dust accumulation on the windward sides are less than those on the leeward sides. The non-centrosymmetrical H-shaped finned tube has the advantages that the integral heat exchange performance is improved, dust accumulation on the windward sides cannot be generated, total amount of the dust accumulation on the leeward sides is reduced, the non-centrosymmetrical H-shaped finned tube is applicable to heat exchange enhancement of smoke of oil and gas firing and more suitable for enhancing heat transfer of dust-contained flowing smoke.

Owner:XI AN JIAOTONG UNIV

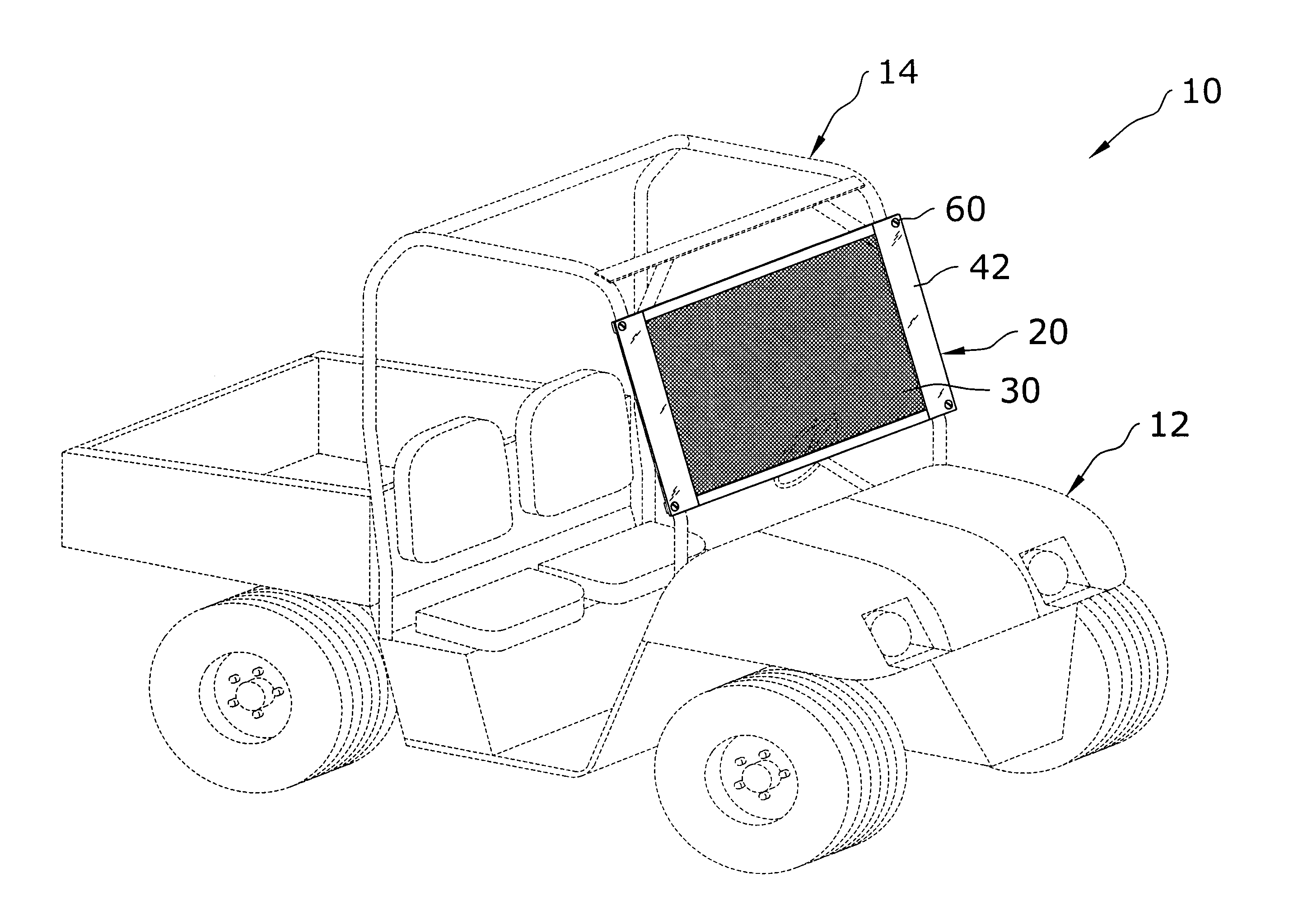

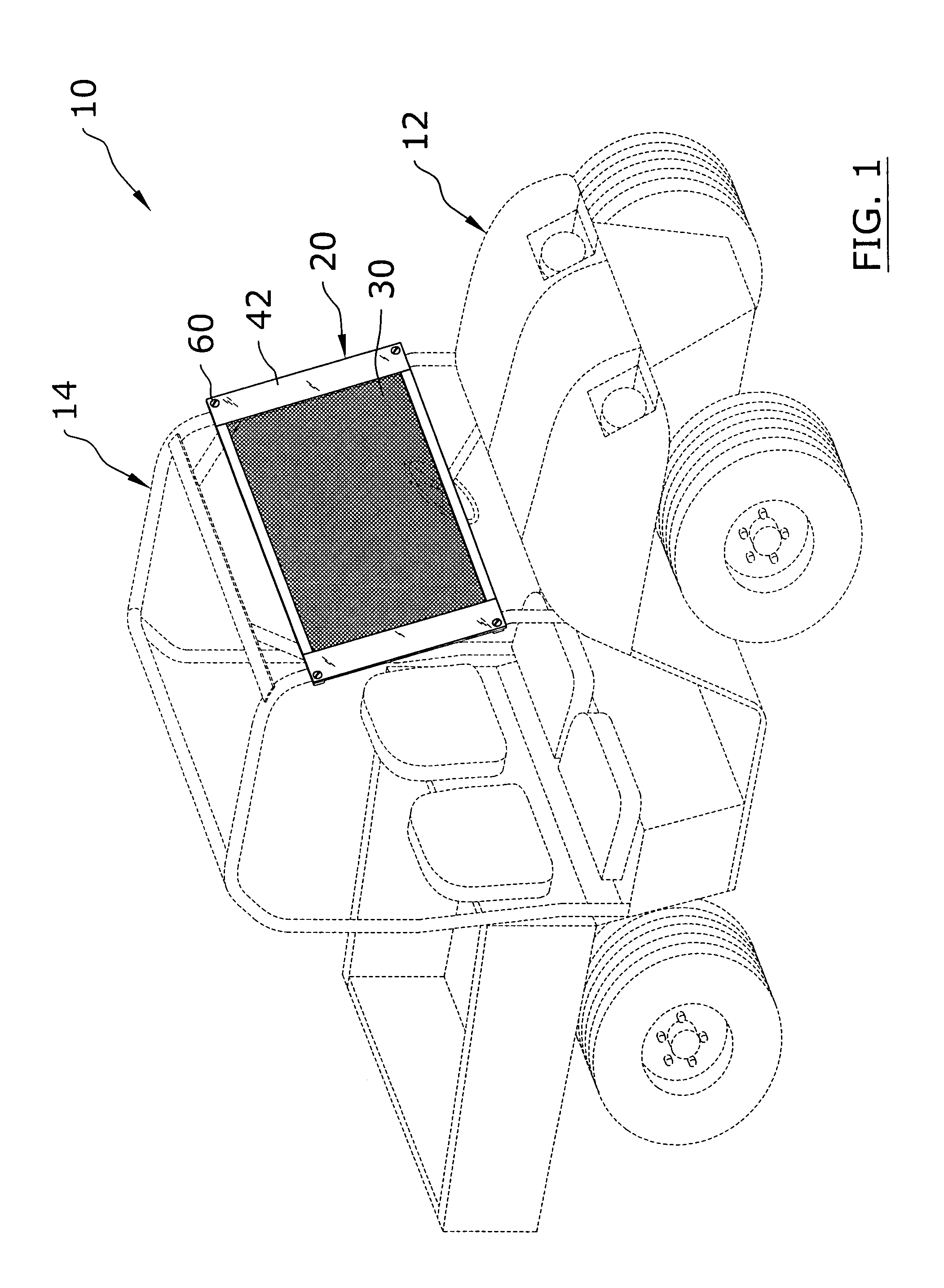

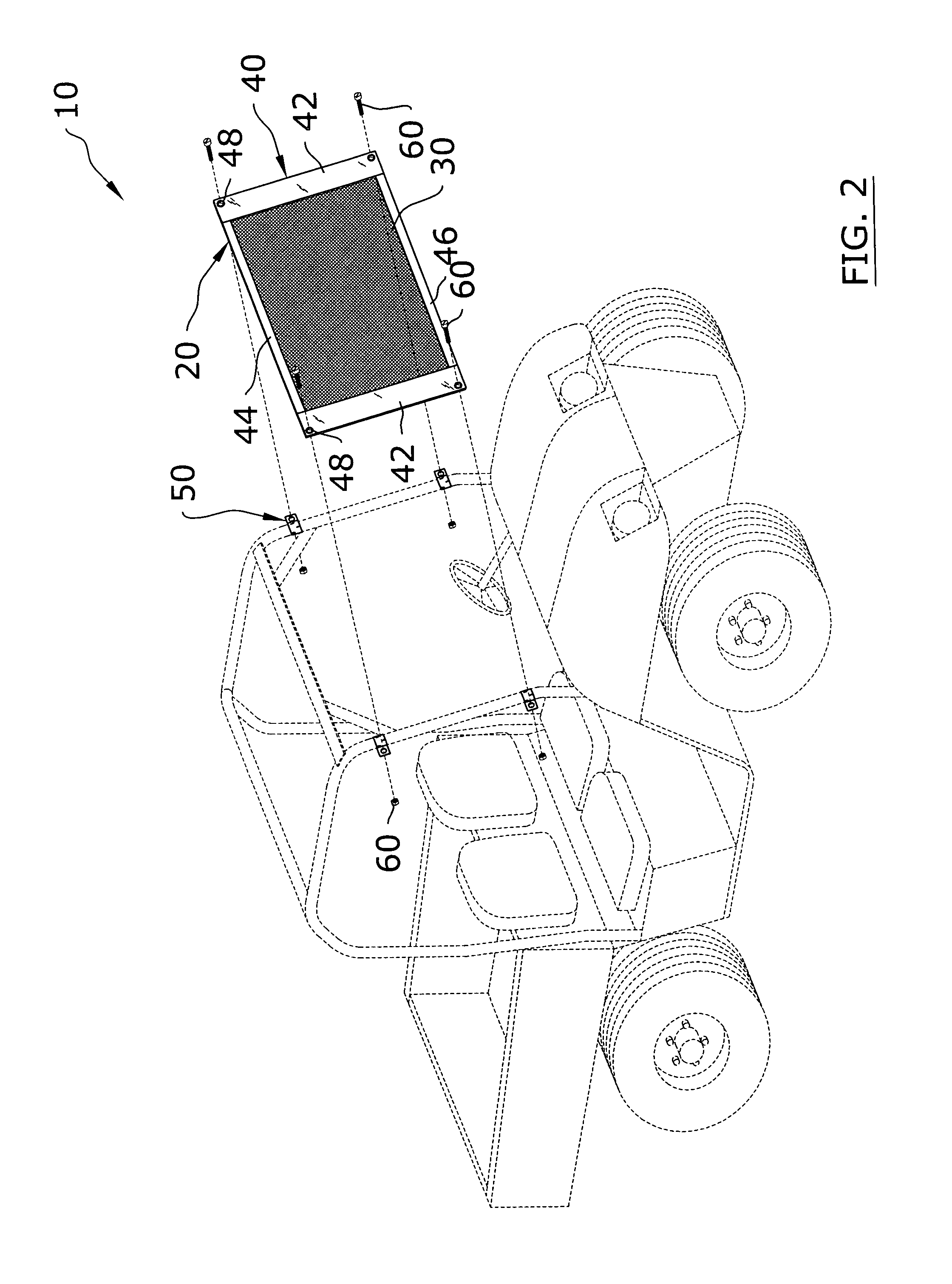

Utility vehicle windscreen system

InactiveUS7007999B1Provide protectionReduce dust accumulationWindowsVehicle arrangementsDriver/operatorVehicle driving

A utility vehicle windscreen system for providing protection from debris to a utility vehicle driver while allowing airflow into the cab area. The utility vehicle windscreen system includes a windscreen and a plurality of brackets. The brackets are attached to the front portion of the roll cage of the utility vehicle and the windscreen is attached to the brackets to provide protection to the driver and passengers from debris.

Owner:SCHNELLER DANIEL P

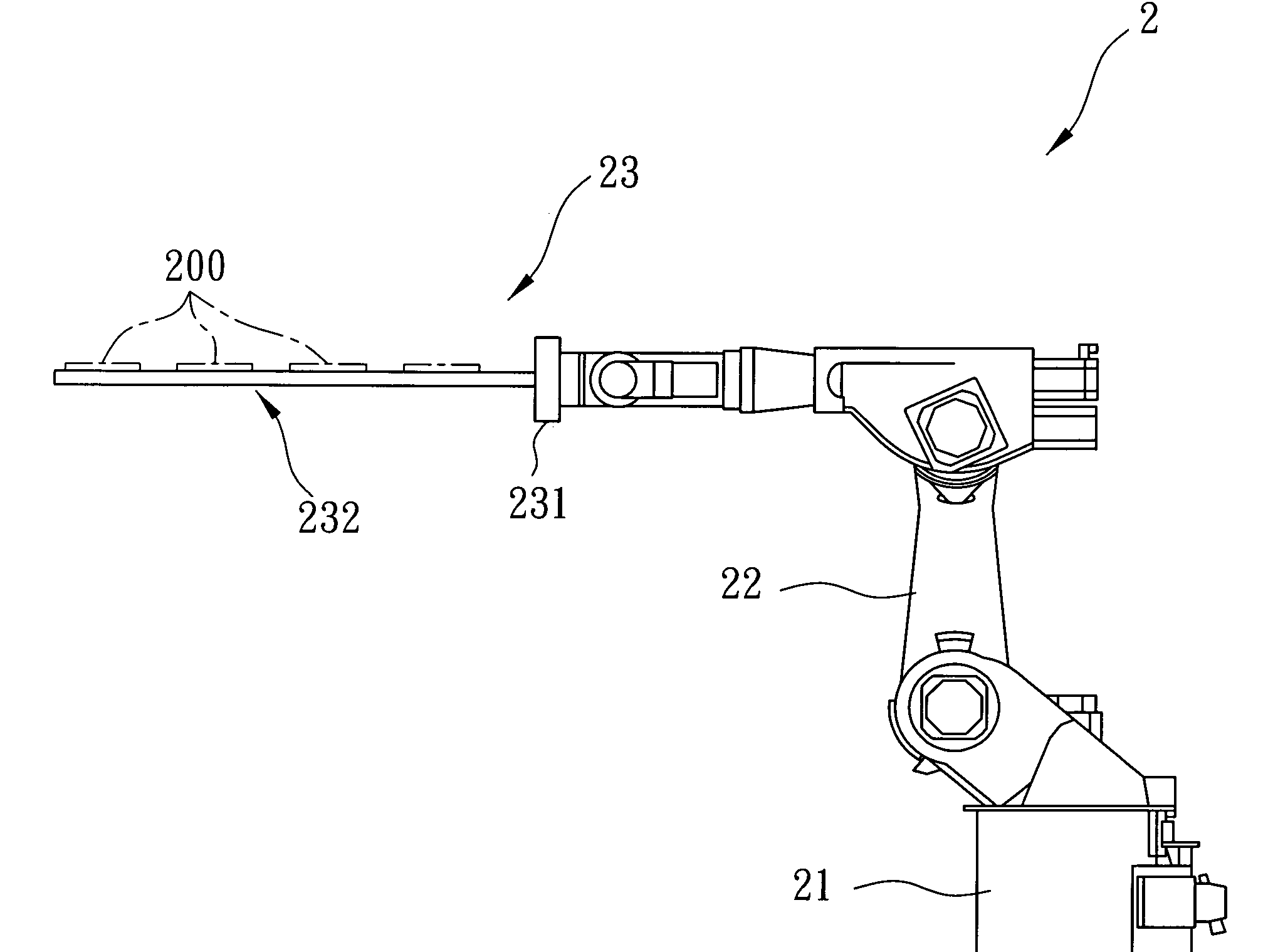

Robot arm

InactiveUS20090293663A1Reduce dust accumulationReduce the possibilityProgramme-controlled manipulatorJointsGlass fiberEngineering

A robot arm includes a working arm member, a workpiece placement unit, and a driving device. The workpiece placement unit includes a base seat coupled to the working arm member, and a hollow supporting rod with a suction unit. The supporting rod extends from the base seat, is adapted for supporting a workpiece thereon, and defines a passage therethrough. The supporting rod is made of a composite material including a hollow rod structure having at least one fibrous layer that is made of resin-impregnated carbon prepreg, and an outer covering layer made of fiberglass material and covering an outer surface of the hollow rod structure. The driving device is coupled to the working arm member, is operable to drive the working arm member for moving the workpiece placement unit, and is further operable for extracting air from the passage so that the workpiece supported by the supporting rod is held in position by the suction unit.

Owner:ADVANCED INT MULTITECH CO LTD

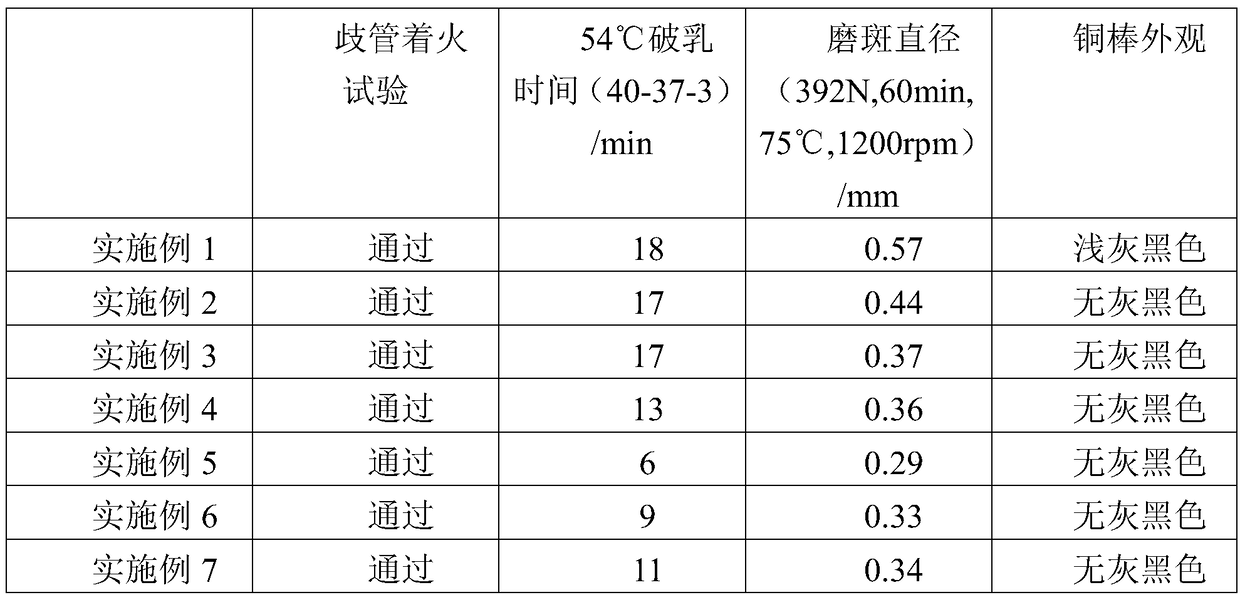

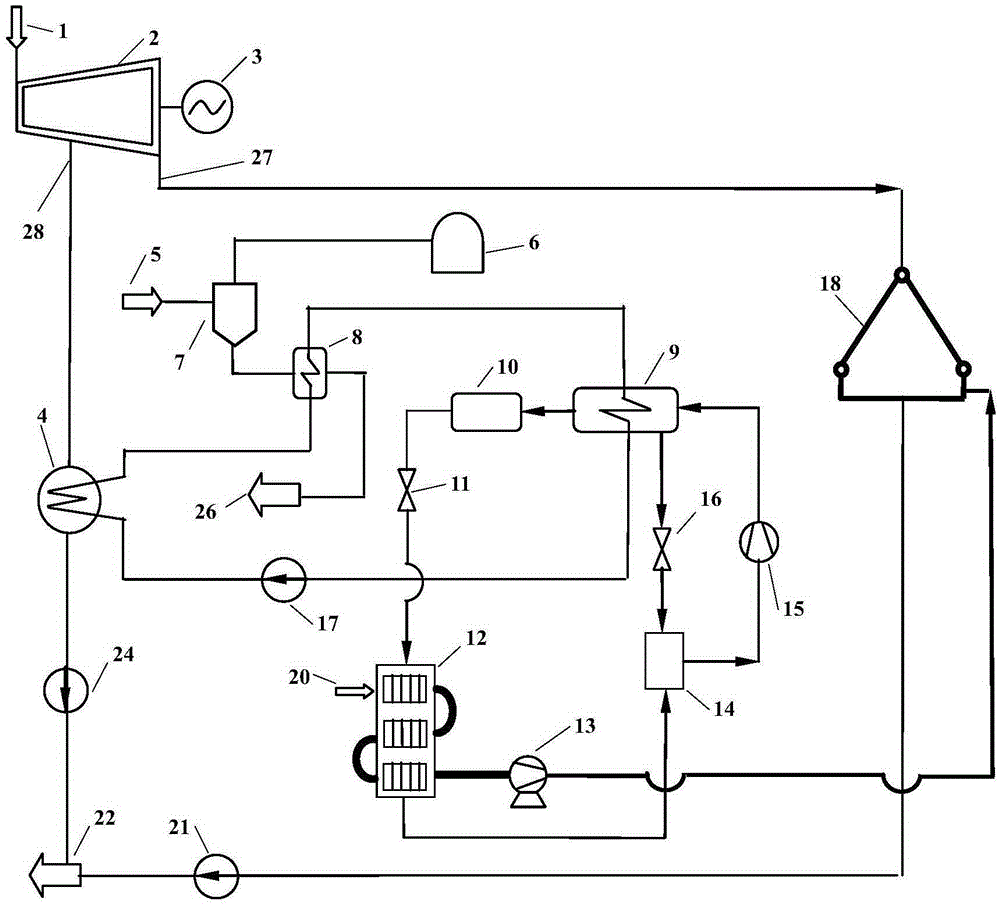

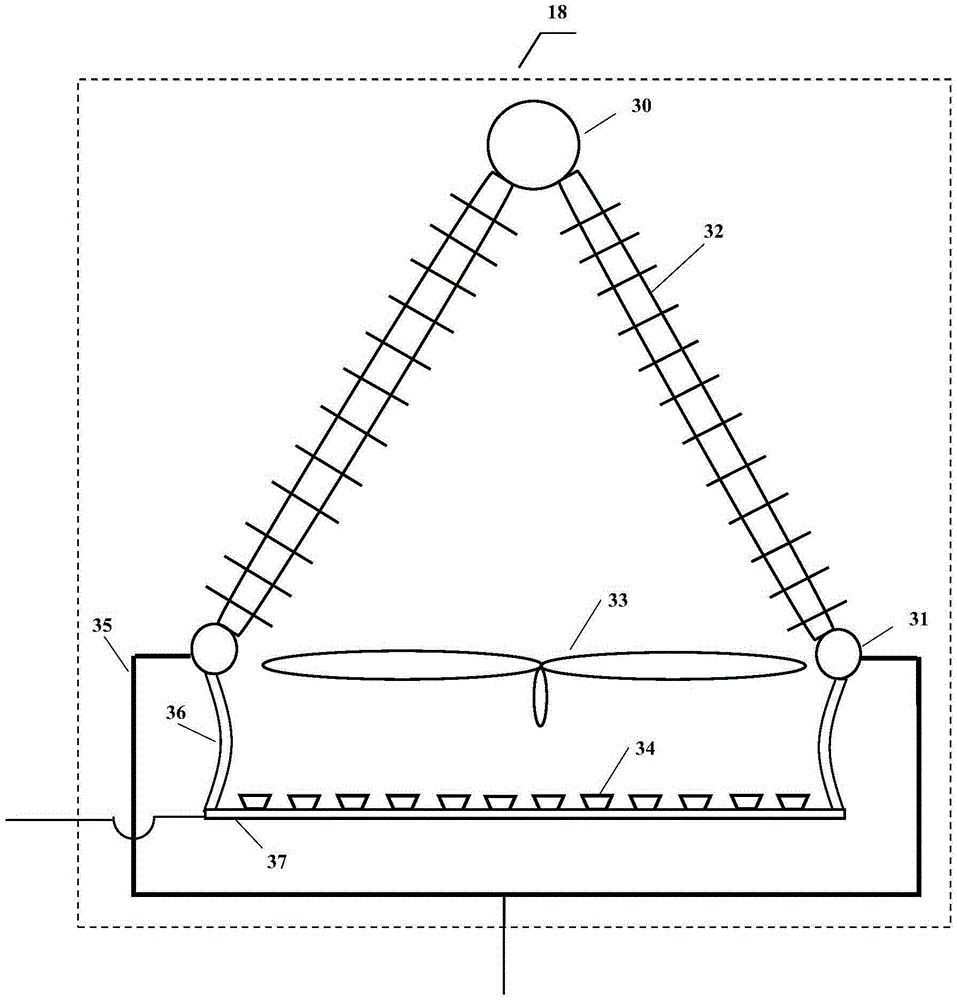

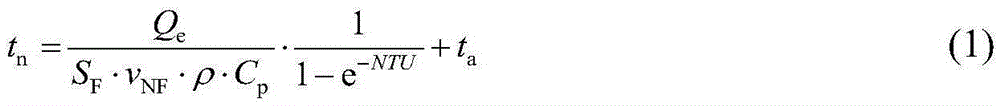

Power station air cooling system adopting combined refrigeration with shaft seal steam leakage of steam turbine and continuous blow-down waste heat of boiler as well as method for predicting heat-transfer coefficient of air-cooling condenser

ActiveCN105423772AReduce dust accumulationLower condensation temperatureHeat pumpsFeed water supplyEngineeringSuperheater

The invention discloses a power station air cooling system adopting combined refrigeration with shaft seal steam leakage of a steam turbine and continuous blow-down waste heat of a boiler. The system is characterized in that the steam turbine is communicated with a steam source, the steam turbine is connected with an electric generator, and the steam turbine is sequentially communicated with an air-cooling condenser, a condensate pump and boiler feedwater; the steam turbine is sequentially communicated with a steam leakage condenser, a steam leakage condensate pump and the boiler feedwater; boiler blow-down water is sequentially communicated with a flash tank, a deaerator, a working medium superheater and a drainage ditch; the steam leakage condenser is sequentially communicated with the working medium superheater, and a generator is communicated with the steam leakage condenser through a working medium circulating pump; the generator is sequentially communicated with a condenser, a first throttling valve and an evaporator, the evaporator is communicated with an absorber, and the generator is sequentially communicated with a second throttling valve, the absorber, a solution pump and a generator; and air is sequentially communicated with the evaporator, an induced draft fan and the air-cooling condenser. A method for predicting a heat-transfer coefficient of the air-cooling condenser is further provided.

Owner:NORTHEAST DIANLI UNIVERSITY

Heat dissipation device and manufacturing method thereof

InactiveUS20050230081A1Reduce weightImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesHeat sinkMetal

A heat dissipation device is made by skived-fin technology and has a thermal conductive portion and a plurality of fins. The fins are integrally formed with the thermal conductive portion. Each of the fins has a plurality of through holes, a top portion, and a bottom portion. The bottom portion of each fin connects with the thermal conductive portion with a curve. The thermal conductive portion, which is disposed on the bottom of the heat dissipation device, is integrally formed with the fins in one metal board.

Owner:VIA TECH INC

Lamp holder of LED streetlamp with heat-conducting and heat-dissipating capability

InactiveUS20100254140A1Improve cooling effectReduce dust accumulationMechanical apparatusPoint-like light sourceEdge surfaceHeat conducting

A lamp holder of a LED streetlamp includes a lamp cover, a LED unit and a plurality of heat-conducting posts. The LED unit is provided below the lamp cover. A transparent lamp cover covers outside the LED unit. Further, the heat-conducting posts are arranged upright in the lamp cover and separated from each other by a distance. Each of the heat-conducting posts is connected to the inner edge surface of the lamp cover opposite to the LED unit and extends toward the top edge of the lamp cover to be located between the top and bottom of the lamp cover. On both sides of the lamp cover laterally facing the heat-conducting posts, venting holes are provided to form an open structure, thereby allowing outside air to enter the lamp cover and flow among the heat-conducting posts.

Owner:GEM SUN TECH

Liquid coke inhibitor

InactiveCN102329676AReduce dust accumulationHas cleaning effectFuel additivesBULK ACTIVE INGREDIENTOxygen

The invention discloses a liquid coke inhibitor, and belongs to the technical field of clean coal combustion. Main active ingredients of the liquid coke inhibitor are an organic surfactant and nitrate. When the organic surfactant is at high temperature, an organic polymer compound has a dirt cleaning effect, and the organic polymer compound is reacted at high temperature to generate a large number of air bubbles so as to make coke blocks loose. The nitrate can generate microexplosion and release oxygen at high temperature, can continuously release oxygen in a range from low temperature to high temperature to make soot formation and carbon deposition layers on different parts loose and contribute to more fully combusting pulverized coal; metal ions in the nitrate can promote low melting point compounds in a coke layer to be converted into loose high melting point compounds, which can contribute to removing a coking layer and prevent high temperature corrosion.

Owner:SNTO TECH GRP

Desulfurizing technology and system with regenerable metal oxide as desulfurizing agent

InactiveCN1348830AReduce desulfurization costImprove system economyDispersed particle separationFossil fuelOxide

The present invention relates to regenerable metallic oxide sulfur removal technology and system, said system includes desulfurization part, regeneration part and by product treatment part. The desulfurizing agent is prepared by using regenerable metallic oxide active component as absorbent and assisted by catalyst, to remove SO2 in smoke in desulfurization reactor, the SO2 saturated desulfurizing agent is regenerated in regenerator to produce mixed gas containing high concentration SO2, SO3, which is then catalyzed, transferred and absorbed to obtain concentrated sulfuric acid by product with concentration higher than 92%. The sulfur removal efficiency can be higher than 88%, the sulfurizing agent can be cyclically reused, it is low in cost and has no secondary pollution.

Owner:孙学信 +1

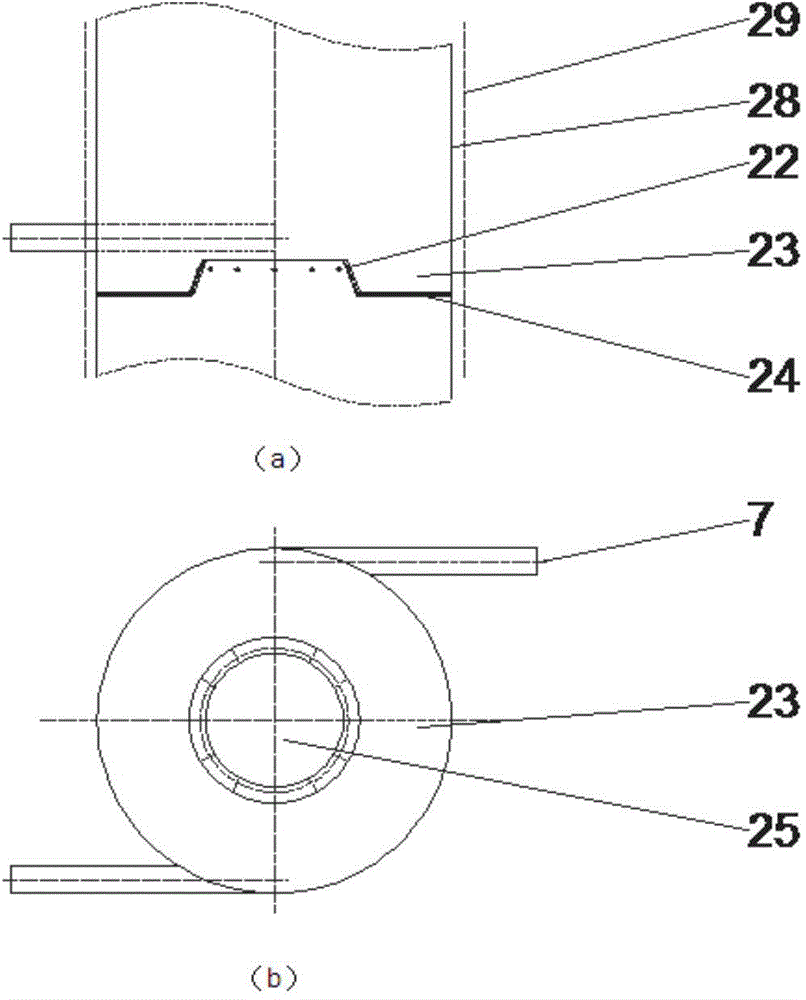

Industrial pulverized coal boiler burning device used for spraying ammonia in center of burner

ActiveCN107477573AEmission reductionImprove reducibilityPulverulent fuel combustion burnersCombustion apparatusCombustorEngineering

The invention provides an industrial pulverized coal boiler burning device used for spraying ammonia in the center of a burner, and relates to the technical field of industrial pulverized coal boilers. The problems that according to an existing horizontal industrial pulverized coal boiler, the NOx emission amount is high, the NOx emission reduction cost is high, the burnout condition of pulverized coal is poor, the adjusting capacity for load change is poor, the boiler thermal efficiency is low, and slagging is severe are solved. The burning device comprises a primary air pipe, a direct flow secondary air pipe, a rotational flow inner secondary air pipe, a rotational flow outer secondary air pipe, a mixer, an amino reducing agent conveying pipe, a concentrated pulverized coal conveying pipe, a hearth and a two-stage over-fire air system. The primary air pipe, the direct flow secondary air pipe, the rotational flow inner secondary air pipe and the rotational flow outer secondary air pipe are sequentially arranged from inside to outside. The amino reducing agent conveying pipe and the concentrated pulverized coal conveying pipe are connected with the inlet end of the mixer. The outlet end of the mixer is connected with the inlet end of the primary air pipe. The two-stage over-fire air system is arranged on the wall of the hearth. The burning device is used for an industrial pulverized coal boiler.

Owner:HARBIN INST OF TECH

Coal gasifier for slag granulation and coal gas preparation process

ActiveCN104593085AReduce oxygen concentrationReduce the temperatureCombined combustion mitigationGranular/pulverulent flues gasificationCoal waterSlag

The invention discloses a coal gasifier for slag granulation and a coal gas preparation process. The coal gasifier is mainly composed of a pressure-bearing housing, a slag film gasification device, an annular chamber structure slag basin, a quenching chamber, a conduit, a convection cooling section and the like. The process comprises the following steps: with pulverized dry coal or coal water slurry as a raw material, feeding the raw material to a gasification chamber to burn and gasify together with a gasifying agent from a vortex gasification burner; enabling formed liquid slag to collide with the wall surface of the gasification chamber under the vortex action, and flowing from bottom to top under the action of gravity; feeding to the slag basin of the annular chamber structure, carrying out further gasification reaction together with oxygen fed from the upper part of the slag basin, and discharging from a slag discharge hole; feeding coal gas main airflow to the quenching chamber together with liquid drops, cooling to a specific temperature, and then conveying to the convection cooling section to further lower temperature through the conduit; finally removing dust, purifying and then outputting. The liquid slag drops penetrating through the slag basin are cooled to form solid particles and are collected by a dry slag collector; and the heat is recovered by a slag cooler.

Owner:XI AN JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com