Non-centrosymmetrical H-shaped finned tube and finned tube heat exchange tube bundle

A non-centrosymmetric, finned tube technology, used in tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of blockage of heat exchange equipment, dust accumulation, low thermal conductivity, etc., to reduce volume and steel consumption. , The effect of reducing the total manufacturing cost and improving the heat exchange performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

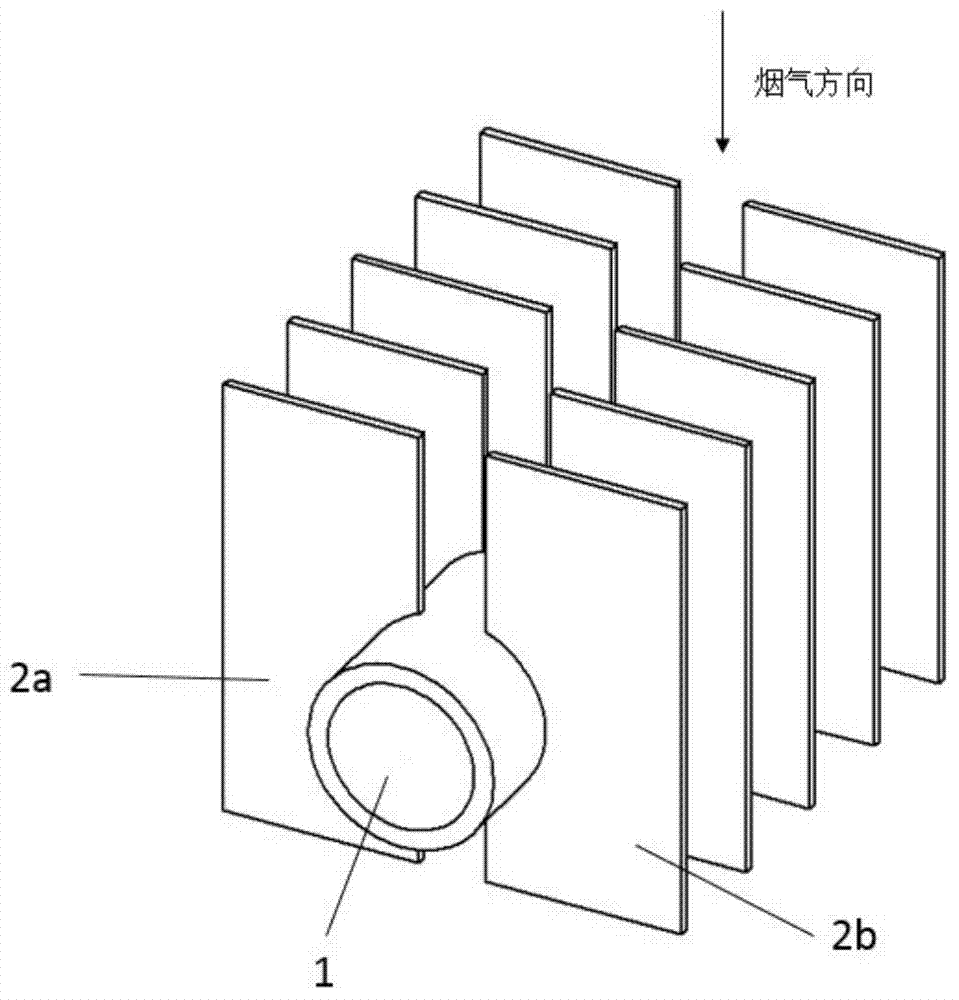

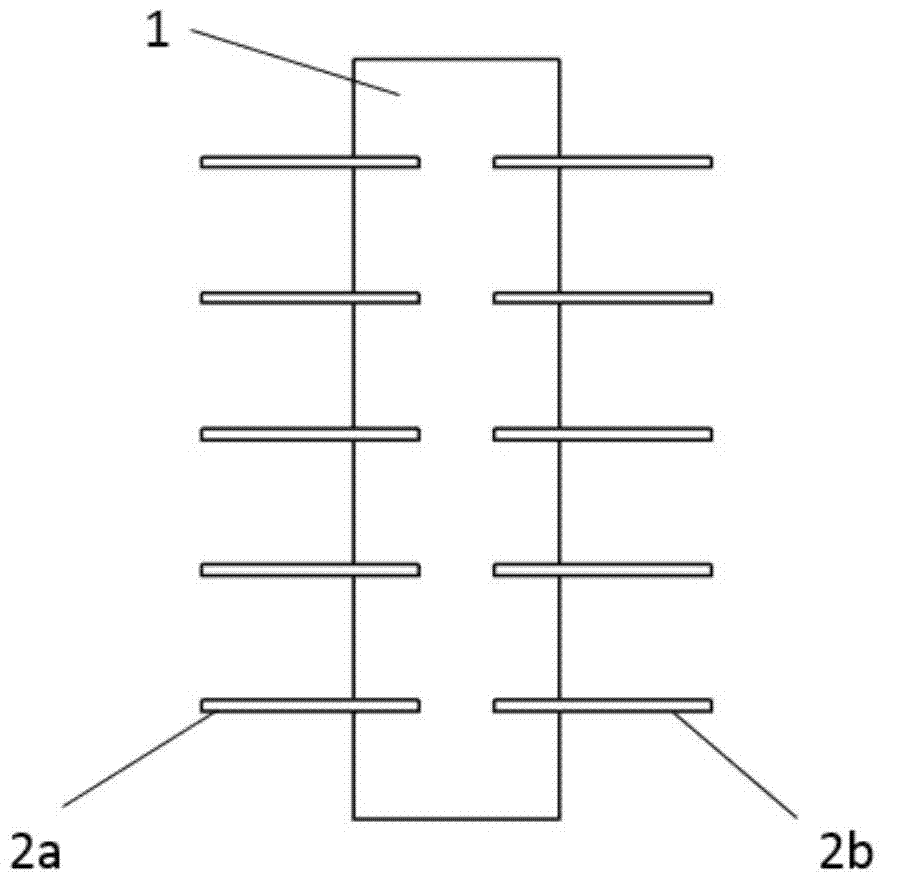

[0036] figure 1 It is a schematic structural diagram of Embodiment 1 of the present invention, the shape of the fins is rectangular, and the number of base tubes is one.

[0037] like figure 1 As shown, the non-centrosymmetric H-shaped finned tube includes a base tube portion 1 and a finned portion 2 . There is a flowing heat exchange working medium in the base pipe part 1 . The fin part 2 includes a plurality of fin groups composed of left quadrilateral fins 2a and right quadrilateral fins 2b, and the fin groups are arranged parallel to each other on the outer wall of the base pipe part 1 along the axial direction of the base pipe part 1 at a certain interval. superior.

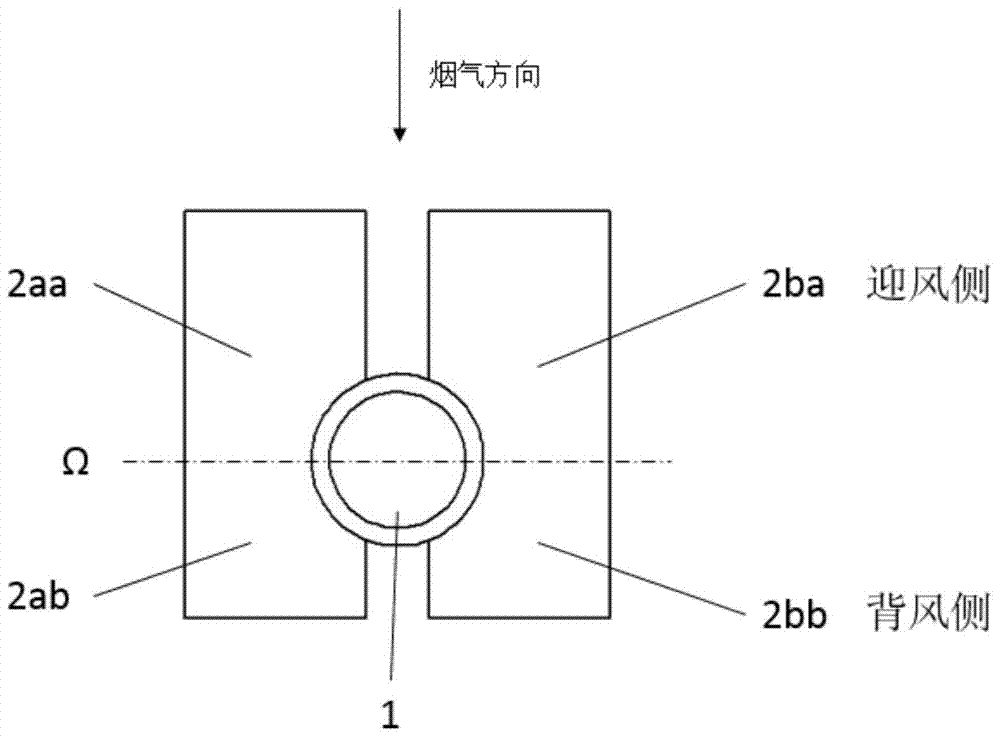

[0038] figure 2 It is the front view of Embodiment 1 of the present invention.

[0039] Taking the plane Ω passing through the axis of the base pipe 1 and perpendicular to the direction of flue gas flow as the interface, the left quadrilateral fin 2a is divided into the left windward side part 2aa and ...

Embodiment 2

[0044] Figure 5 It is a schematic structural diagram of Embodiment 2 of the present invention, the shape of the fins is trapezoidal, Image 6 It is the front view of Embodiment 2 of the present invention. The short side of the fins and the incoming flow direction of the flue gas vary in the range of 45° to 90°.

Embodiment 3

[0046] Figure 7 It is a schematic structural diagram of Embodiment 3 of the present invention, and the shape of the fins is a right-angled trapezoid, Figure 8 It is the front view of Embodiment 3 of the present invention. The fins are located on the short side of the windward side and the direction of the flue gas flow varies from 45° to 90°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com