Axially through H-type finned tube and heat exchange tube bundle thereof

A technology of heat exchange tube bundles and finned tubes, which is applied in the field of H-shaped finned tubes, can solve the problems of not much change in the general structure, reduced heat transfer and anti-fouling performance, and insufficient normal height of the fins. Achieve the effects of eliminating the initial area of ash accumulation, good heat transfer and anti-fouling characteristics, and strong industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

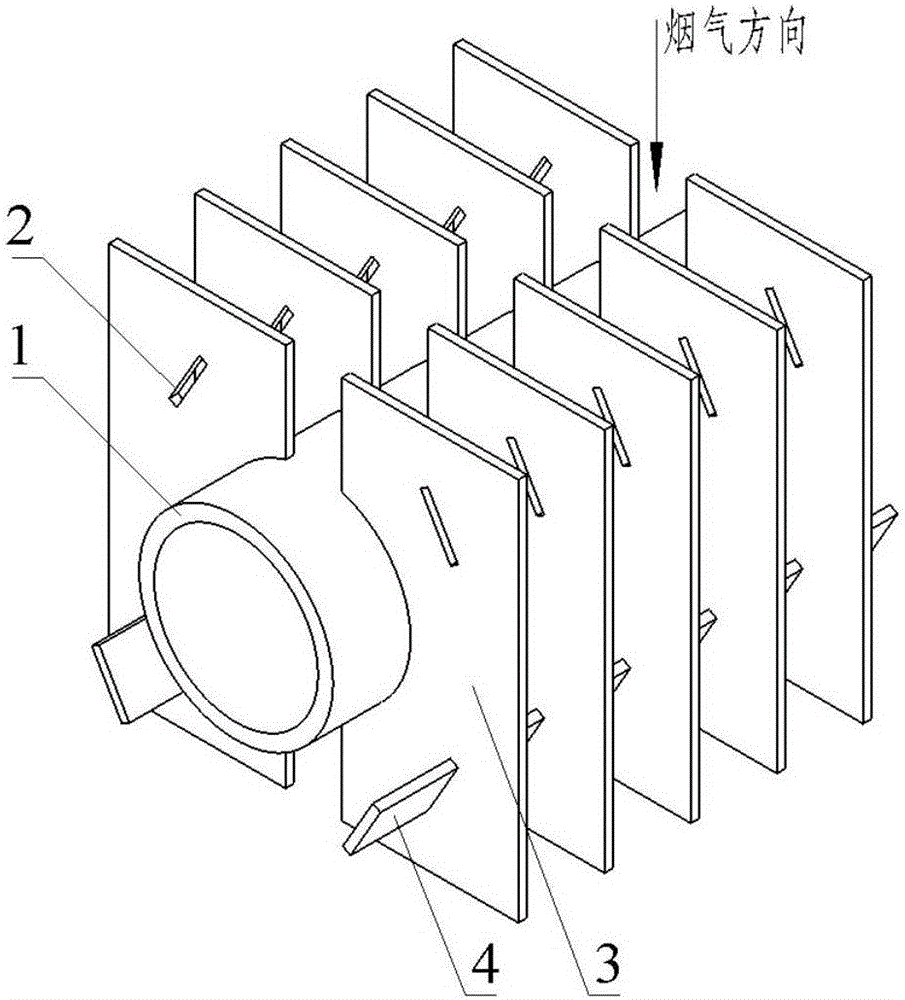

[0036] figure 1 It is a schematic diagram of a conventional H-shaped finned tube with a rectangular deflector in Embodiment 1 of the present invention.

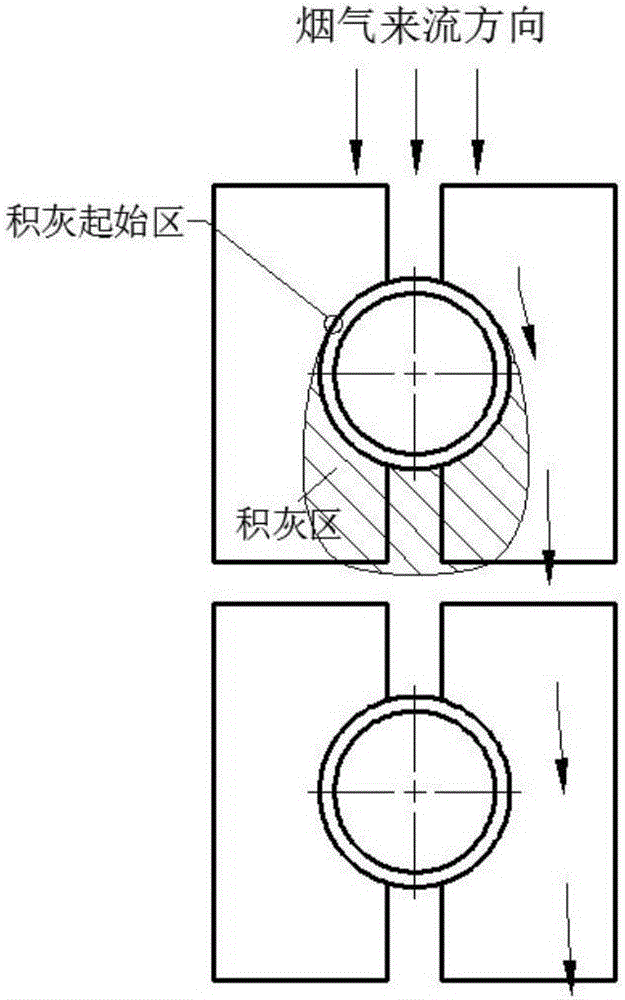

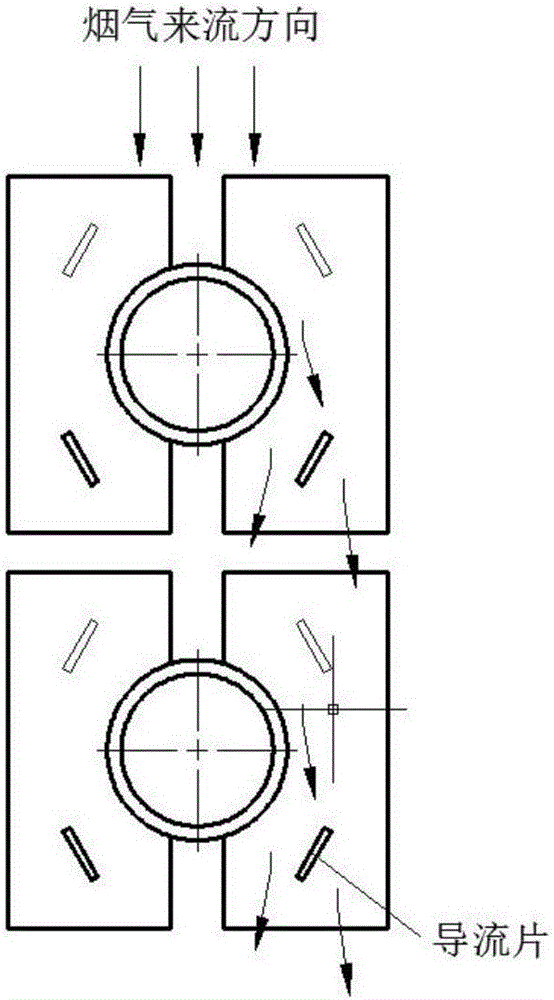

[0037]The structure includes a base tube part, a fin part and a through part, the base tube part includes at least one base tube 1; the fin part is a plurality of parallel fins arranged along the axis of the base tube and connected to the outer wall of the base tube 1 group, wherein the fin group includes two fins 3 symmetrically arranged on both sides of the base tube, the two fins are regularly arranged according to a certain pitch, and the inner side of each fin has a groove matching the outer wall of the base tube; through The part includes a through-slot 2 that is partially processed on the surface of the fin along the flow direction of the flue gas and arranged relative to the base pipe, and a guide vane 4 is provided on the side where the flue gas flows out to pass through all the through-slots 2 on the side where the ...

Embodiment 2

[0042] image 3 It is a schematic diagram of fin structures with different through-slot shapes under the same fin surface shape in Embodiment 2 of the present invention. In this embodiment, the same symbols are assigned to the same structures as in the first embodiment, and the same descriptions are omitted.

[0043] Such as image 3 As shown, in the axially penetrating H-shaped finned tube of the present invention, the through groove 2 is not limited to the rectangular groove in the first embodiment, and the shape of the through groove 2 can also be arc-shaped or circular. For rectangular slots, the rectangular long side of the flue gas flow side is used as the slotting reference direction, and the angle of attack between the slotting direction and the gas flow direction is 10° to 80°; for arc-shaped slots, the flue gas flow side The secant line where the arc of the groove is located is taken as the reference direction of the groove, which is 10°-80° from the gas flow direc...

Embodiment 3

[0045] 4 is a schematic surface view of H-shaped finned tubes with rectangular deflectors under different fin surface shapes in Embodiment 3 of the present invention. In this embodiment, the same symbols are assigned to the same structures as in the first embodiment, and the same descriptions are omitted.

[0046] As in Figure 4 Figure 4a and Figure 4b As shown, the surface shape of the fin 3 is not limited to the rectangle in the first embodiment, and may also be a parallelogram, trapezoid or other irregular quadrilateral.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com