Desulfurizing technology and system with regenerable metal oxide as desulfurizing agent

A technology for regenerating metals and oxides, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of desulfurization by-products that are difficult to reuse, secondary pollution, large waste water, etc., to reduce desulfurization operating costs, reduce The effect of desulfurization cost and auxiliary power consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Enumerate the embodiment of the present invention below:

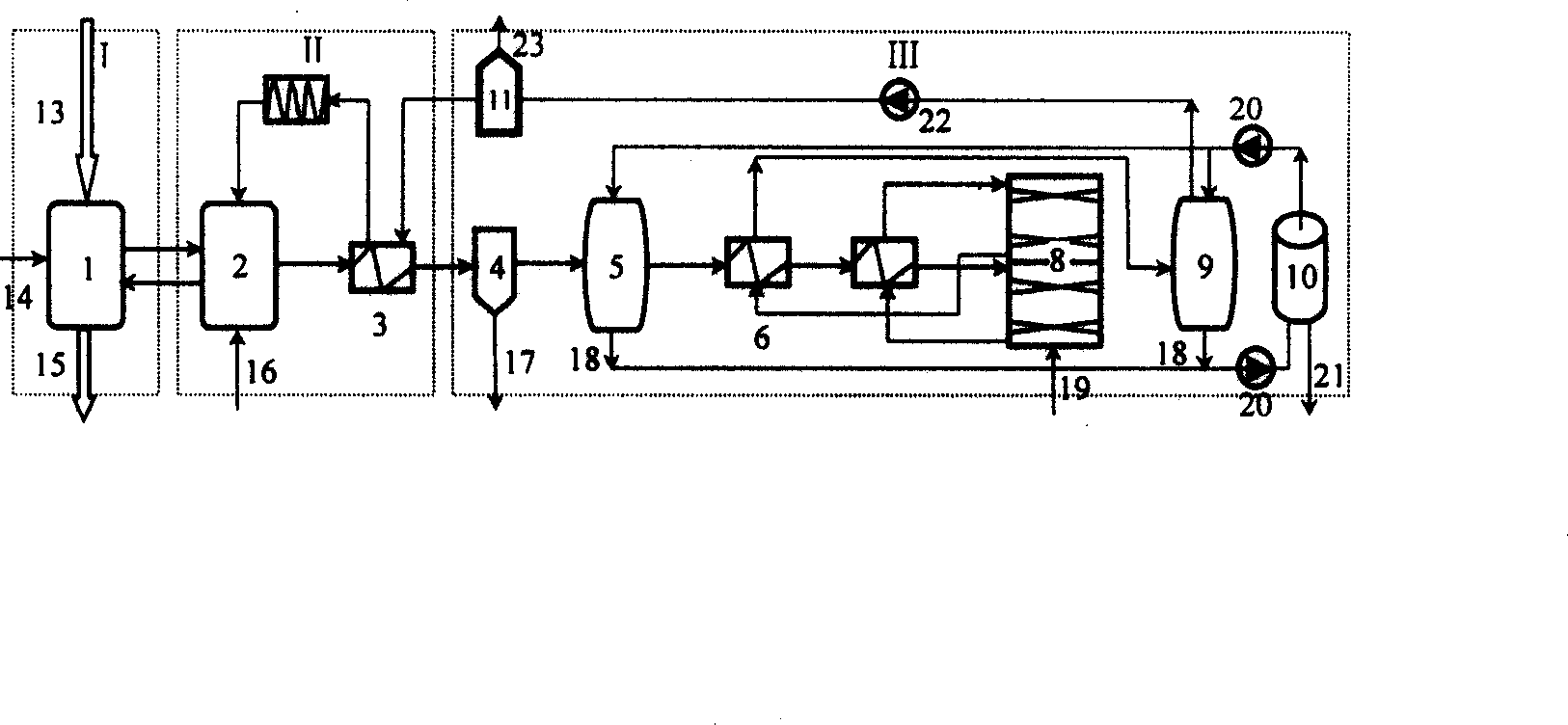

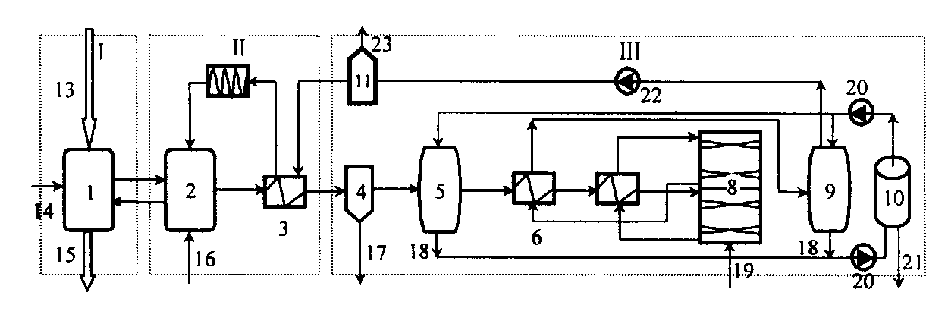

[0025] Set up a thermal test bench in the laboratory, and refer to the accompanying drawings for the system. Simulated flue gas was used for desulfurization experiments, wherein the volume ratio of each component was: 6% oxygen, 5% water vapor, 2000ppm, 1500ppm and 1000ppm sulfur dioxide, and the rest was nitrogen. Flue gas components before and after desulfurization were measured by a flue gas analyzer (Master2000 Gas Analyzer) and chemical titration. The desulfurization reactor, regeneration reactor, and catalytic conversion tower all use electric heating tube furnaces to maintain a stable reaction temperature.

[0026] The desulfurizer of the present invention adopts the DS01 and DS02 desulfurizers proposed in the "Renewable Metal Oxide Desulfurizer and Its Preparation" patent that the applicant applied for at the same time. Adsorb a lot of SO 2 After the gas reaches saturation, it is transferred to the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com