Patents

Literature

60results about How to "Reduce desulfurization operating costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

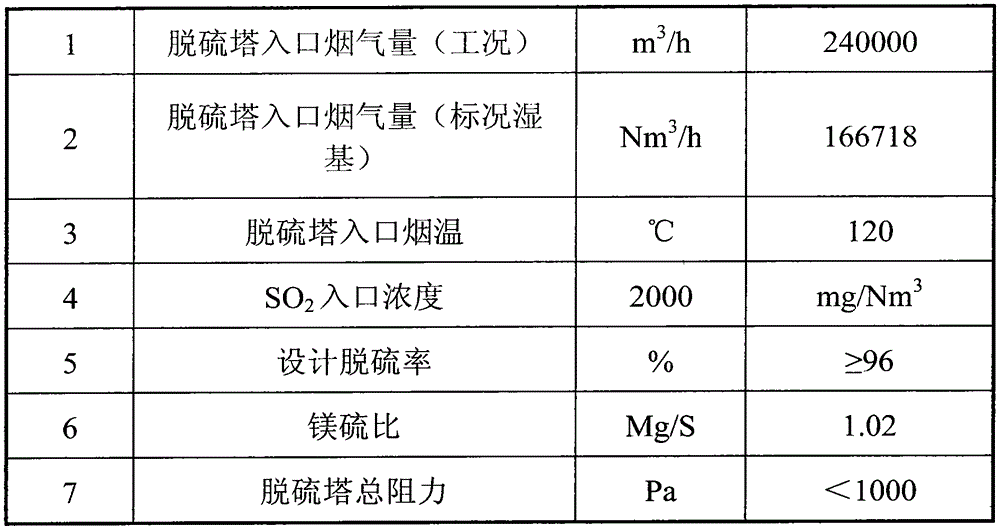

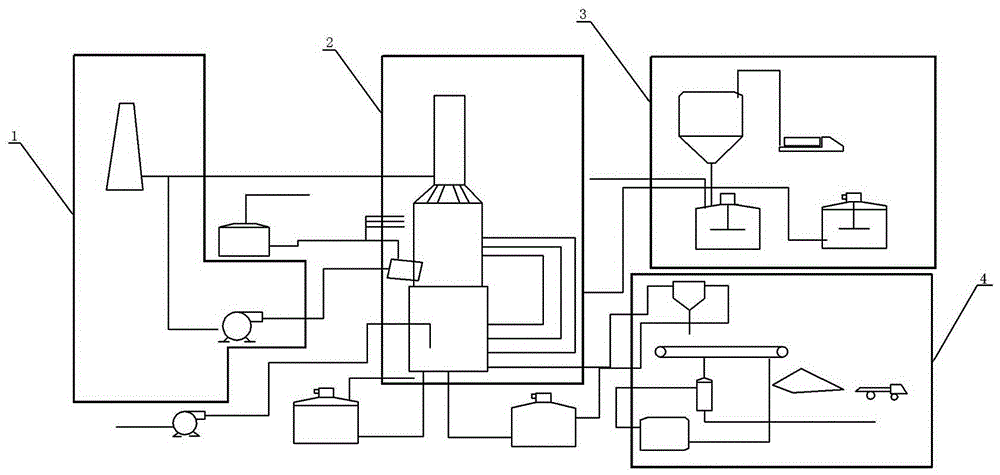

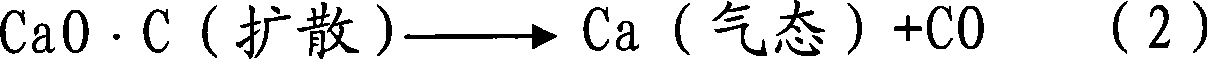

System device and method for recycling sulfur dioxide from fume to prepare sulfur

InactiveCN103303872AEmission reductionImprove performanceEnergy inputSulfur preparation/purificationCooling towerSulfur product

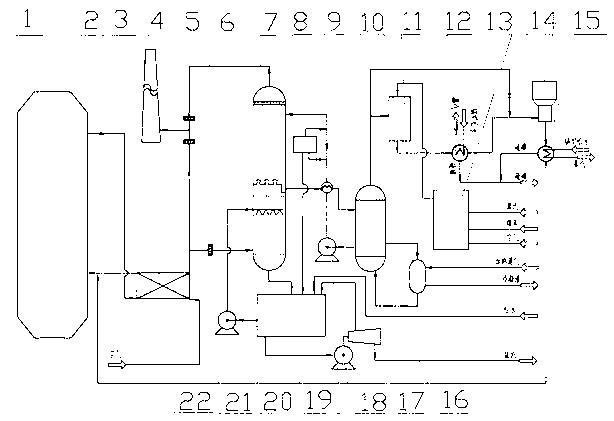

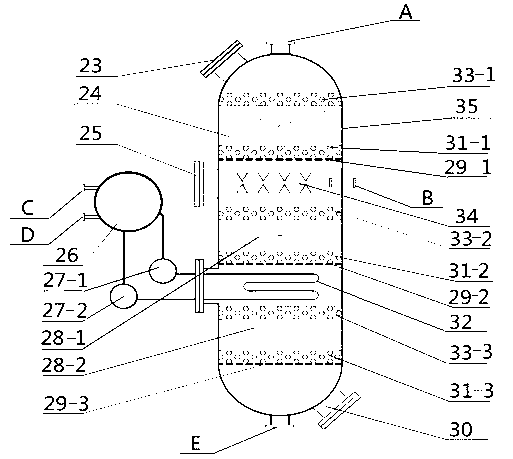

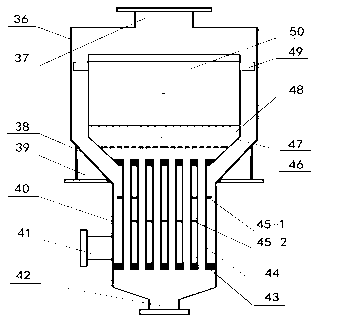

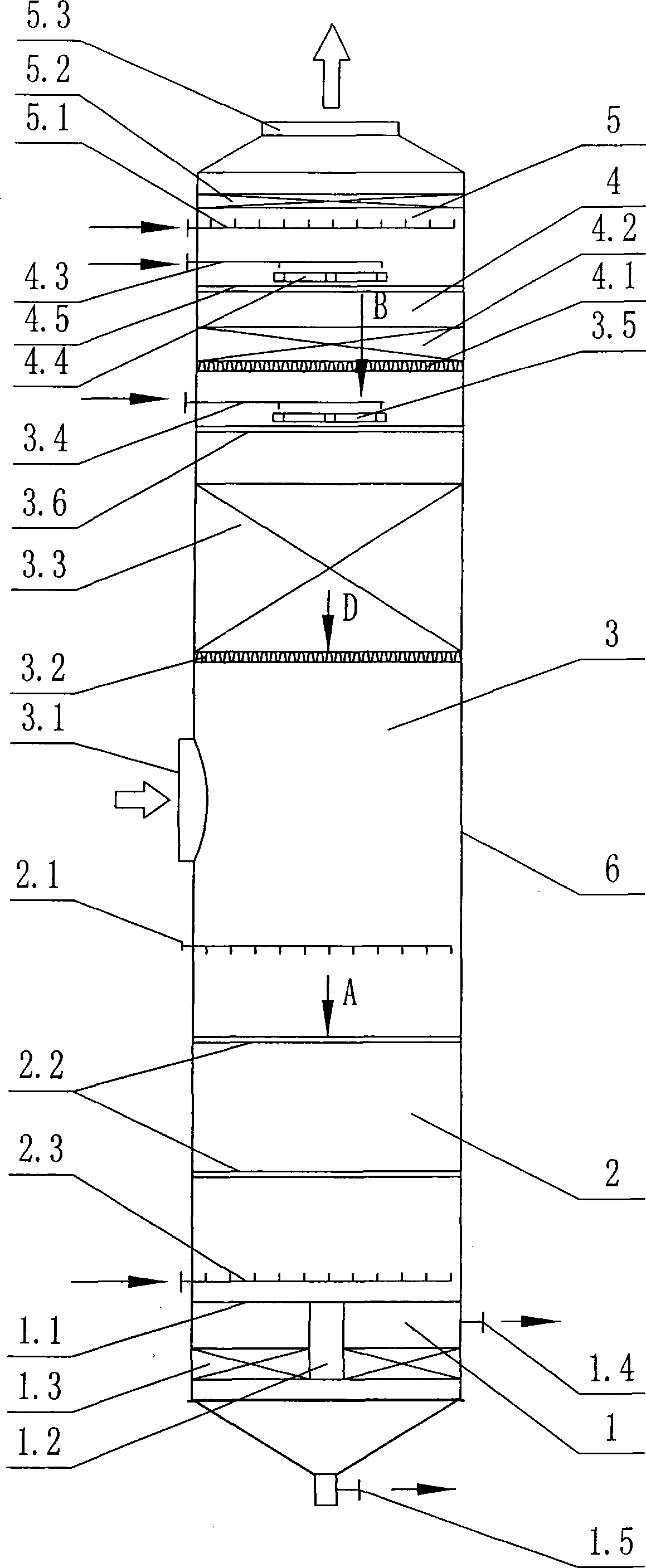

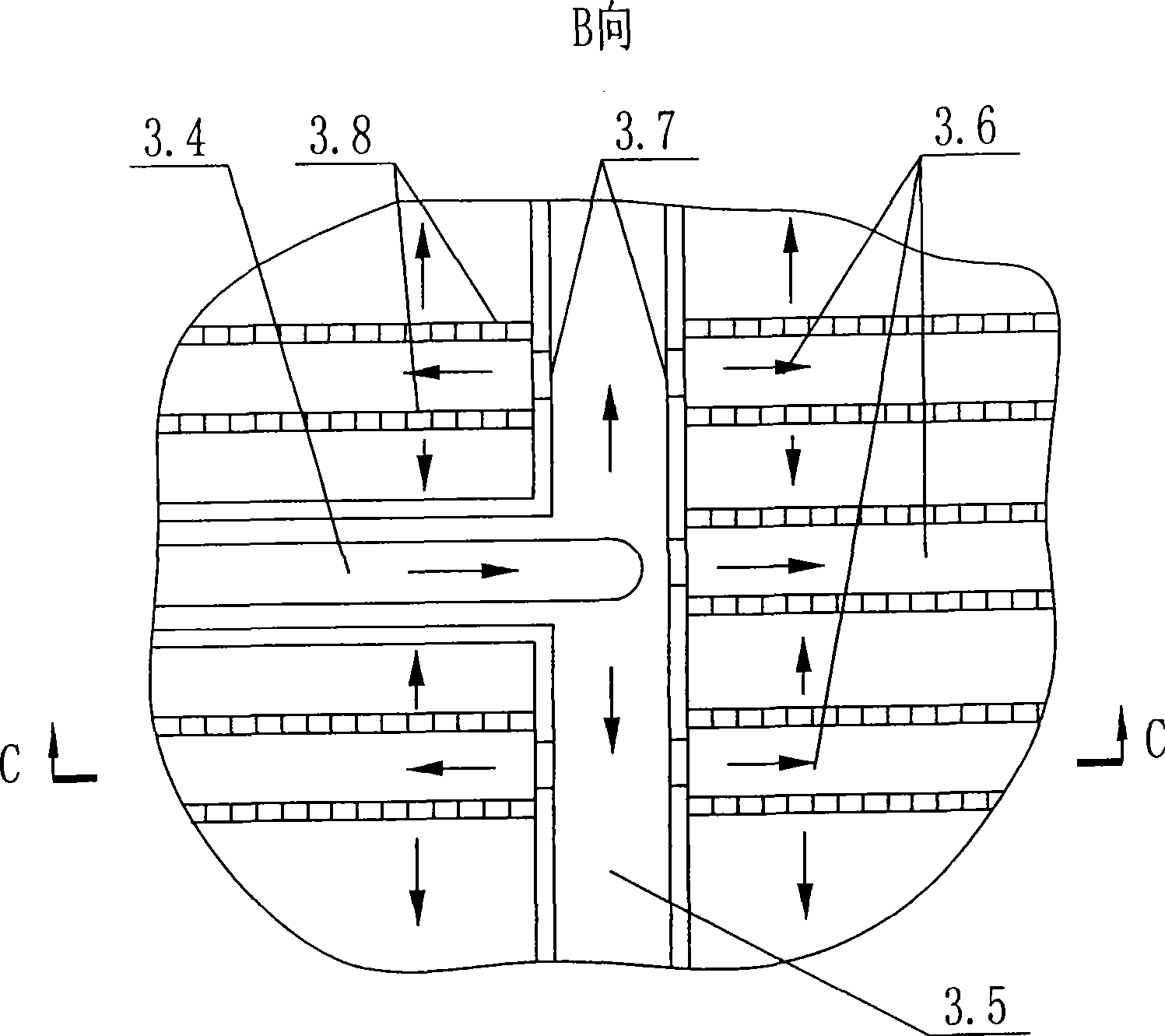

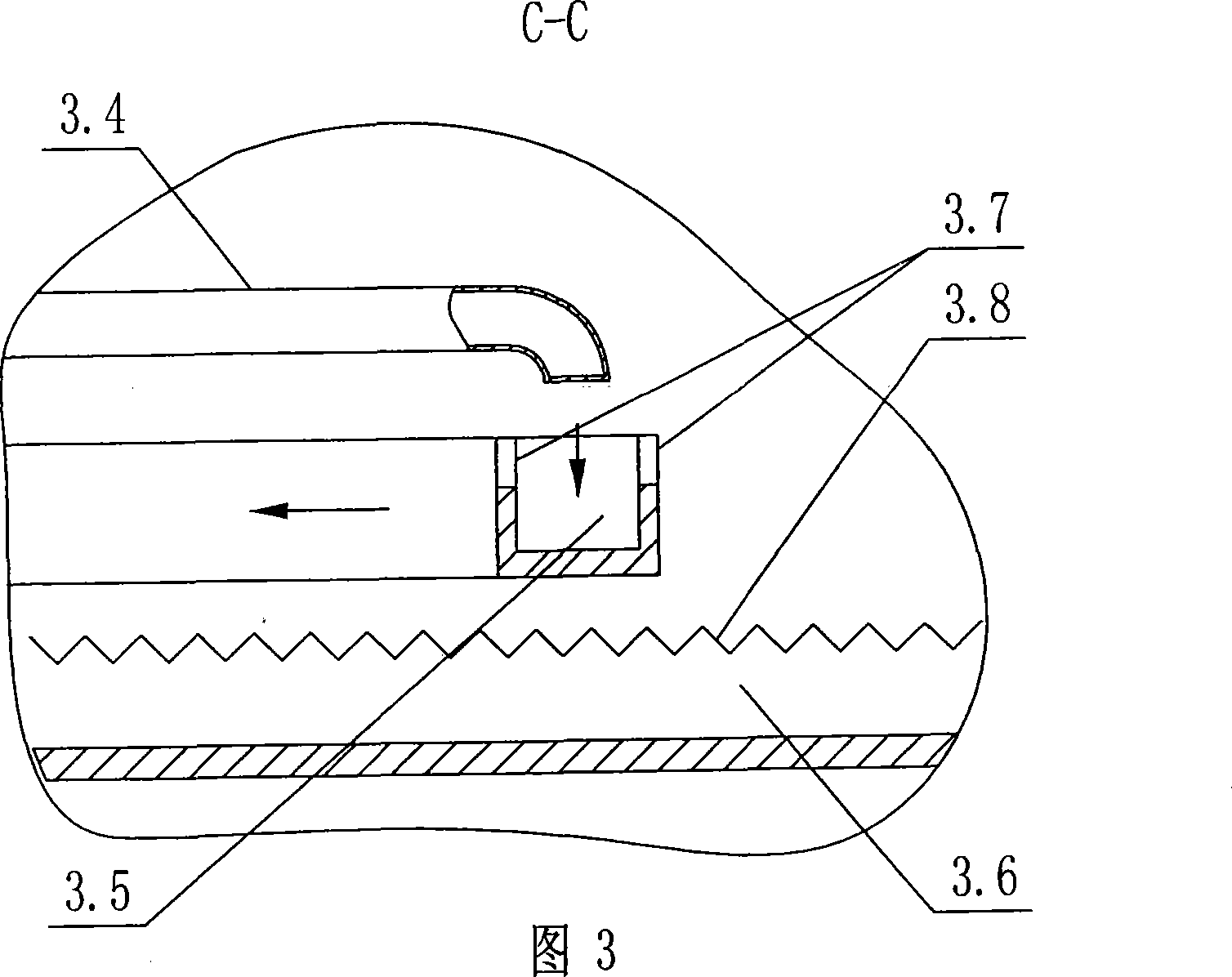

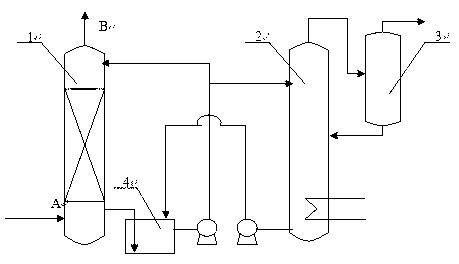

The invention discloses a system device and a method for recycling sulfur dioxide from fume to prepare sulfur. The device comprises three units of an absorption and pyrolysis unit, a reduction unit and a krauss unit, wherein the absorption and pyrolysis unit mainly consists of a cooling tower, an absorbing tower, a purifier, a circulation pump, a regeneration pyrolysis tank and a rich and lean liquid heat exchanger; the reduction unit mainly consists of a mixed gas generation system, a reduction reactor and a sulfur condenser; the krauss unit mainly consists of a krauss reactor and a sulfur condenser. The method comprises the steps that the absorption and pyrolysis unit absorbs and pyrolyzes the fume so as to obtain a pure sulfur dioxide gas, and the reduction unit converts the sulfur dioxide into elementary sulfur through catalysis reaction, wherein the conversion per pass is not less than 95%, and the total conversion is greater than 99.5%. The sulfur dioxide content that the fume is completely discharged is not greater than 50 milligrams per normal cubic meter. The sulfur dioxide is converted into national best grade sulfur products which are stable in property and convenient to store and transport, with high efficiency and low cost, the desulfuration operation cost is lower than the value of a recycled product, and the products can be widely applied to chemistry and thermal power industry.

Owner:陕西华锐迪橡胶科技有限公司

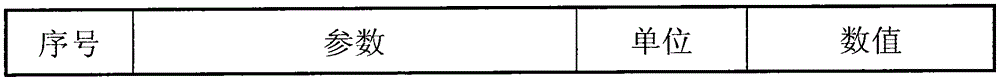

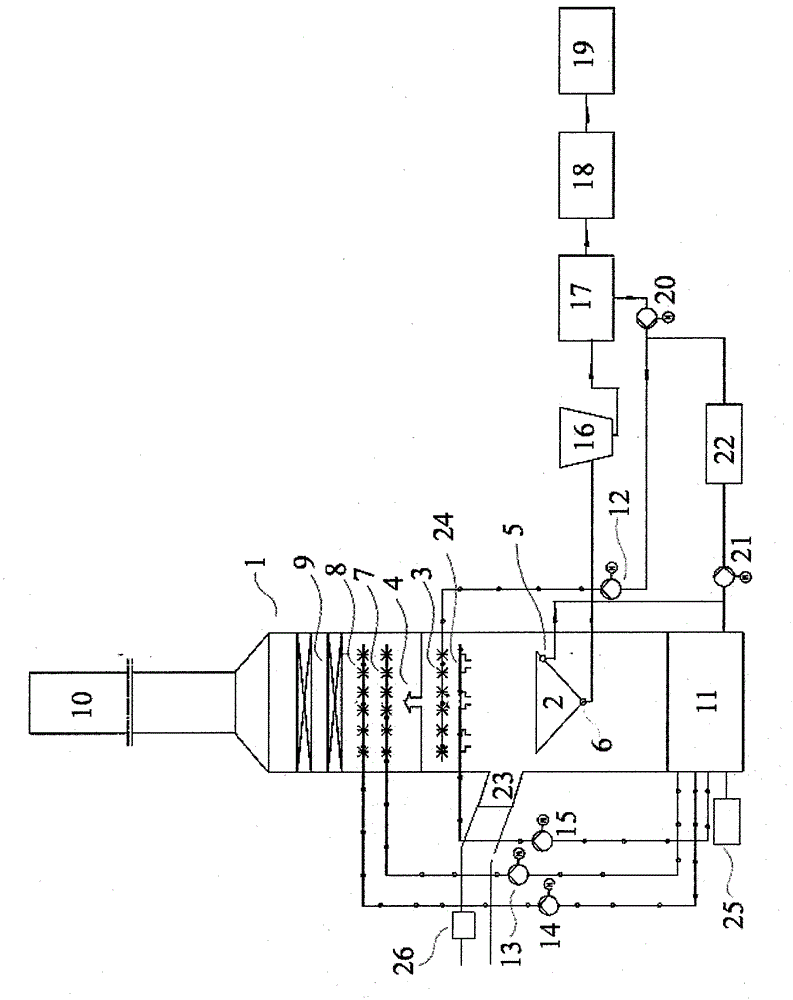

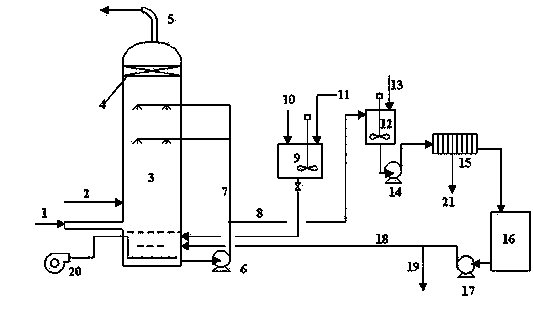

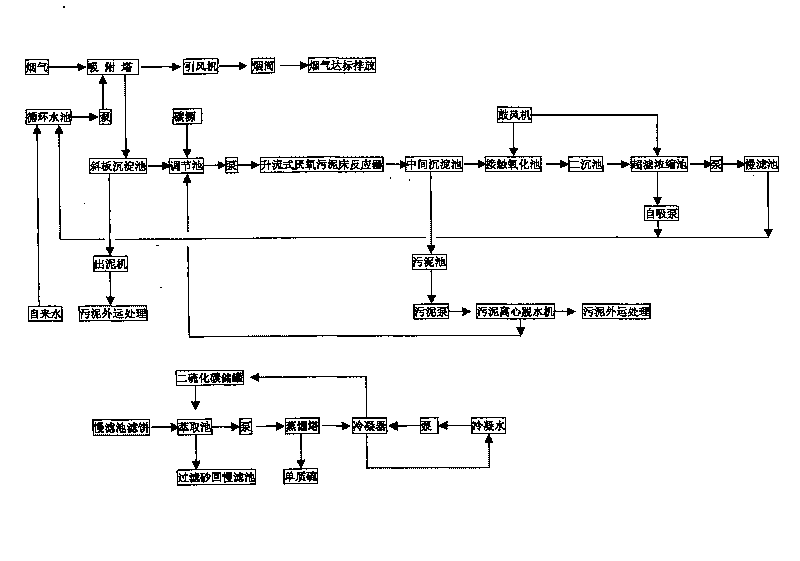

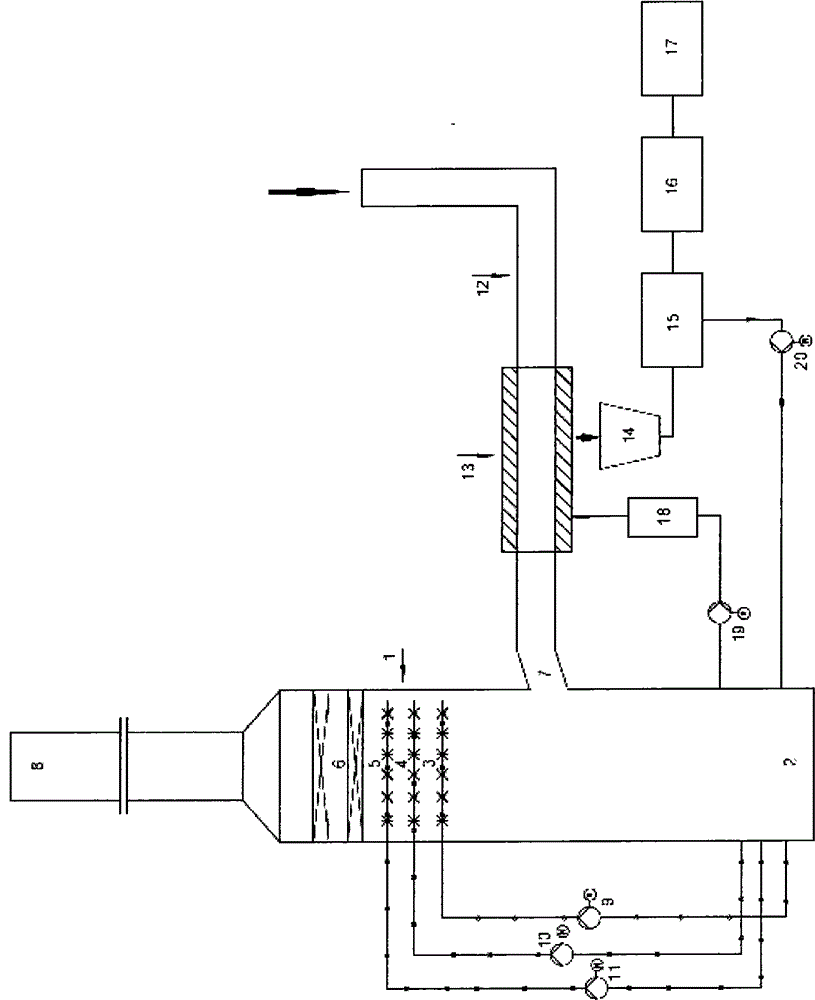

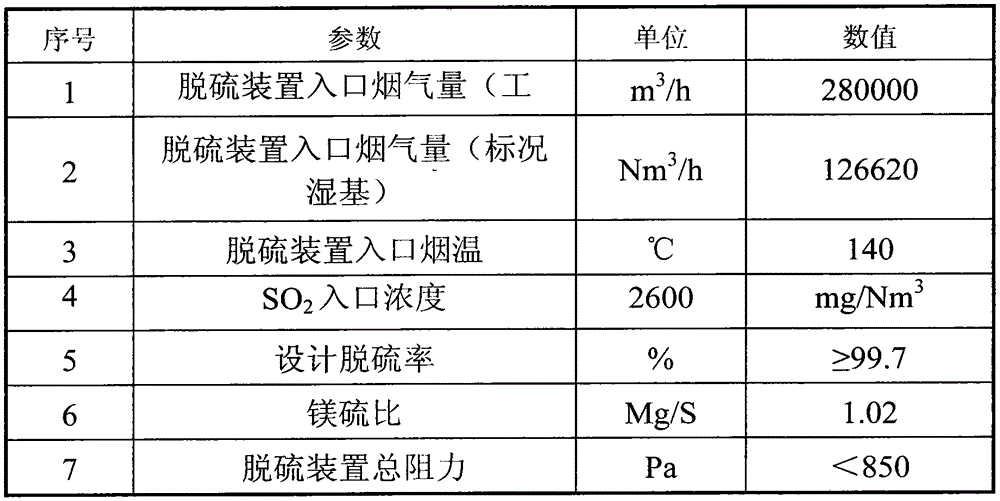

Magnesium sulfate production device and method by flue gas desulfurization

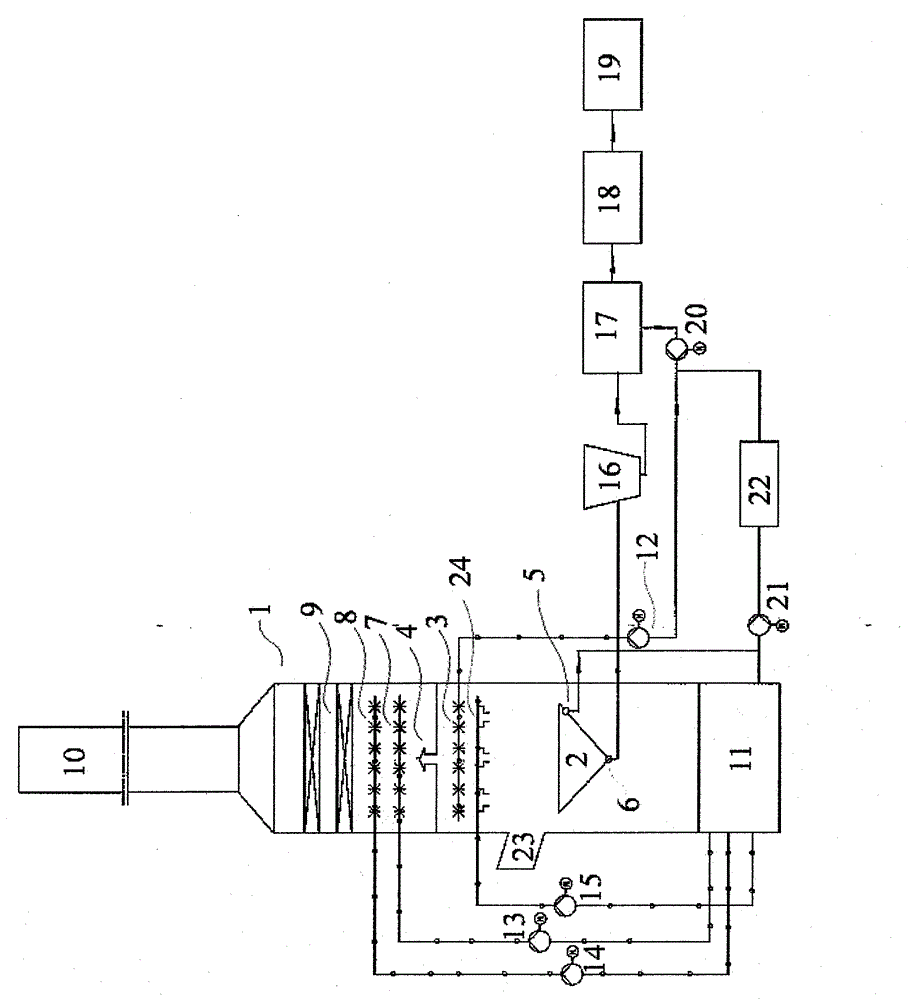

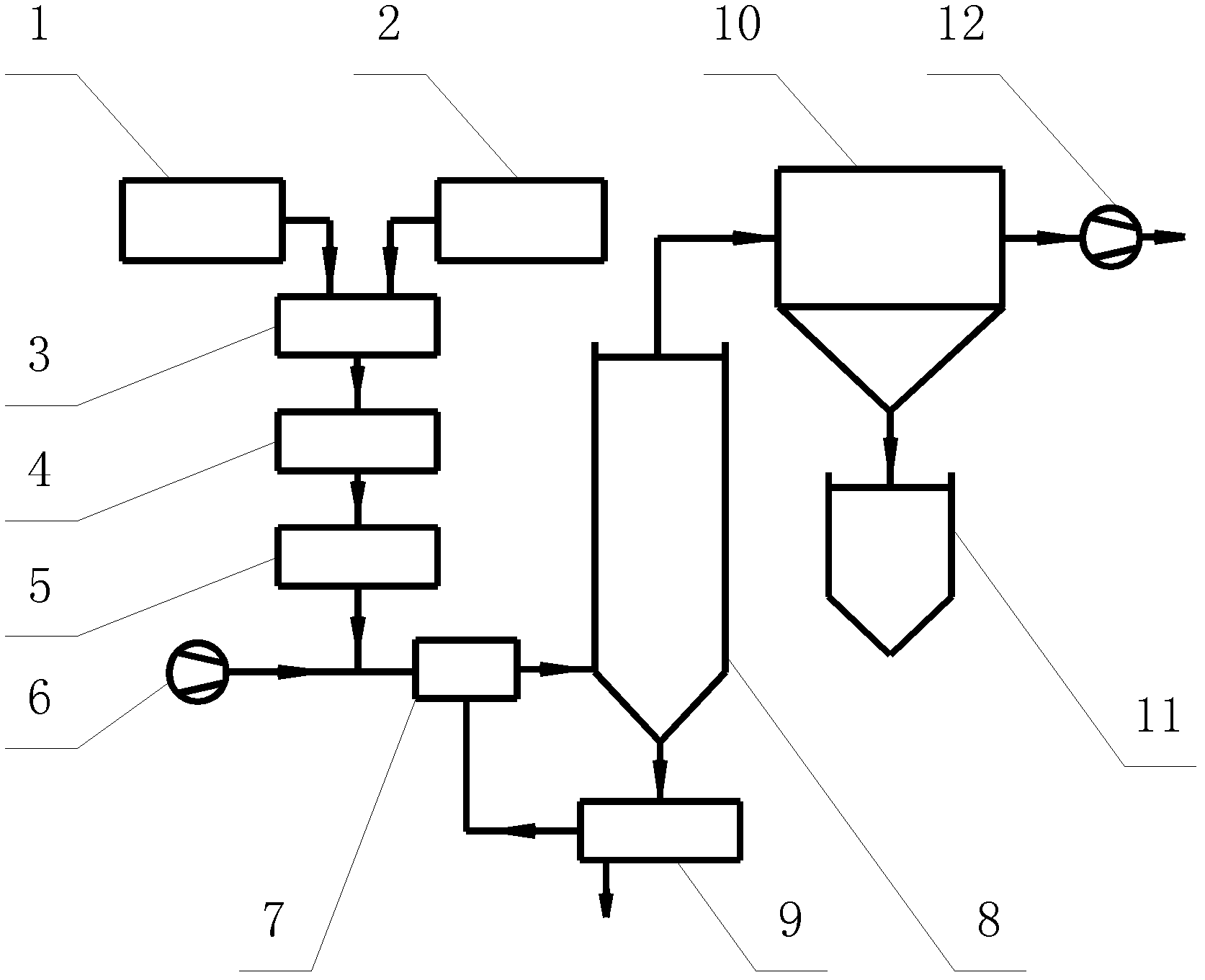

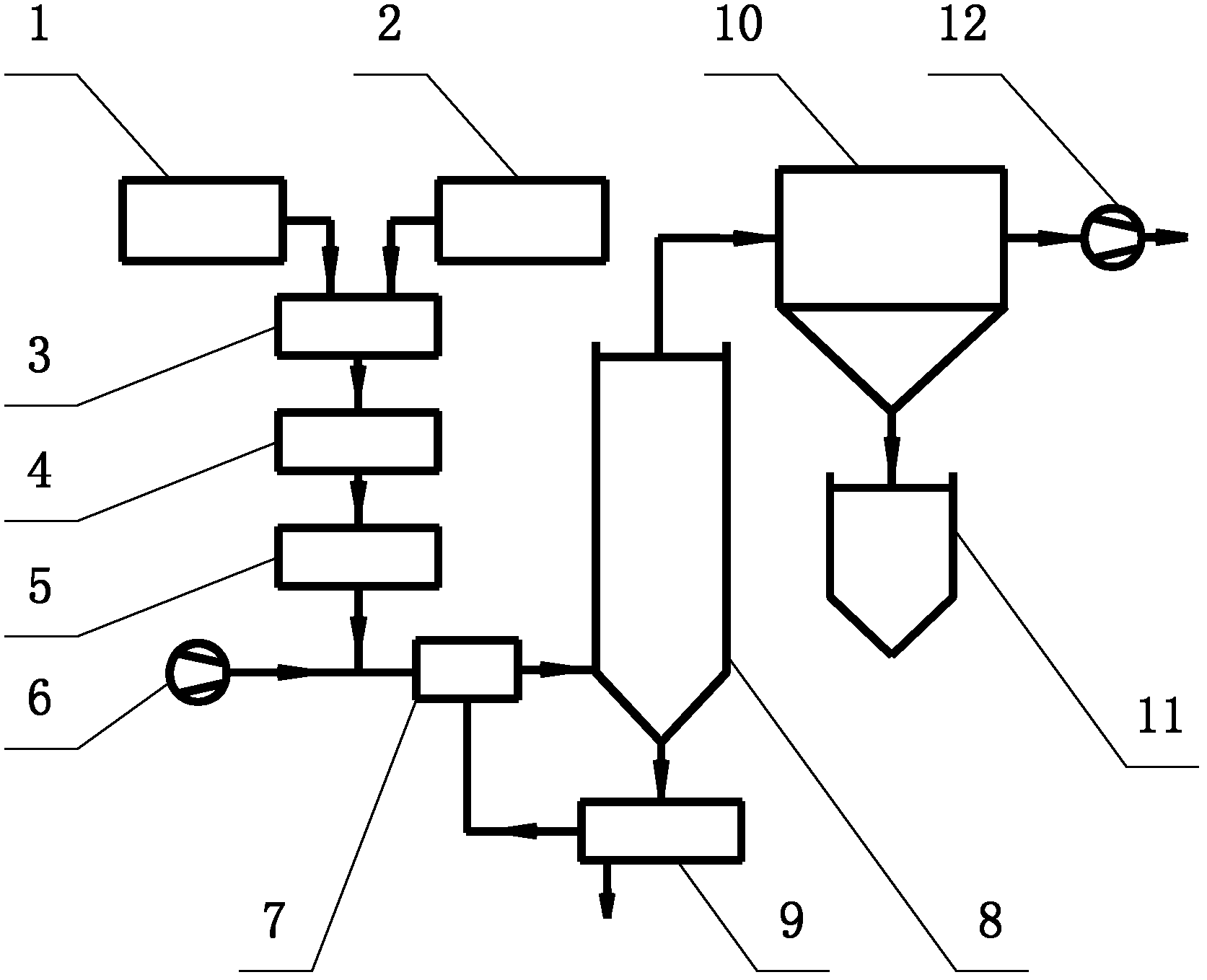

The invention a magnesium sulfate production device and method by flue gas desulfurization, particularly a device and method for producing magnesium sulfate by direct crystallization in a magnesium-oxide-process desulfurization waste liquid tower. The device comprises a flue gas desulfurization apparatus, a slurry circulating tank, an evaporative concentration region, a circulating settling apparatus, a crystallizing apparatus, a centrifugal apparatus, a drying apparatus and the like. The device and method provided by the invention can solve the problems of high steam consumption, higher production cost per ton of ores, and higher desulfurization operating cost when the magnesium-process desulfurization waste liquid is used for producing magnesium sulfate at present.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

Device and method for producing magnesium sulfate by using flue gas of coal-fired boiler

ActiveCN104477952AReduce power consumptionReduce consumptionGas treatmentMagnesium sulfitesEvaporationSlurry

The invention provides a device and a method for producing magnesium sulfate by using flue gas of a coal-fired boiler, and particularly provides a device and a method for producing the magnesium sulfate by direct crystallization in a magnesium oxide-process waste desulfurization liquid tower by using the flue gas, low in oxygen content, of the coal-fired boiler. The device comprises oxygenation equipment, flue gas desulfurization equipment, slurry circulating equipment, evaporation and concentration equipment, cyclic sedimentation equipment, oxidization equipment, crystallization equipment, centrifugation equipment, drying equipment and the like. By adopting the device and the method disclosed by the invention, the desulfurization efficiency and the quality of a side product magnesium sulfate can be guaranteed under a condition that the wind power consumption and steam consumption of an oxidization fan are greatly reduced, the operating cost of a magnesium sulfate production system is greatly lowered, and the desulfurization operation cost is lowered.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

Attapulgite flue gas desulfurizer and preparation method thereof

InactiveCN103736460AGood adsorption performanceReduce dosageOther chemical processesDispersed particle separationIon exchangeChemistry

An attapulgite flue gas desulfurizer is prepared from the following raw materials by weight: 100-120 parts of attapulgite, 40-45 parts of active carbon, 20-24 parts of magnesium chloride, 4-5 parts of zinc oxide, 25-28 parts of calcium oxide, 6-8 parts of sodium carbonate. 20-24 parts of wild chrysanthemum flowers, 10-12 parts of cordate houttuynia, 35-40 parts of monazite powder, 5-7 parts of sodium metasilicate, 3-4 parts of coconut fatty acid monoethanolamide, 4-5 parts of auxiliary agents, and a proper amount of water. By using attapulgite and monazite powder, the desulfurizer of the invention has adsorption decoloration and ion exchange effects, has good adsorption effect on sulfur dioxide, decreases the using amount of active carbon, and reduces the cost; by using wild chrysanthemum flowers and cordate houttuynia, the desulfurizer of the invention not only has adsorption effect, but also has antibacterial effect after carbonization; by using a plurality of basic metal oxides, rapid desulfurization is realized; the desulfurizer of the invention is high in porosity, large in adsorption quantity, easy to regenerate, and simple in production process, and can greatly reduce the operation cost of dry-method desulfurization.

Owner:WUHU ZHONGLU IND

Continuous concentration purification method for desulfurization by-product magnesium sulfate solution

InactiveCN103990360AReduce desulfurization operating costsDispersed particle separationMagnesium sulfatesPurification methodsSulfur

The invention relates to a resource treatment technology of flue gas pollutants, and aims to provide a continuous concentration purification method for a magnesium oxide desulfurization by-product magnesium sulfate solution. The method is as below: leading out part of magnesium sulfate solution from a desulfurization circulation absorption liquid, adding a filter aid and filtering; returning the filtered solution to a desulfurization tower, vaporizing water in diluted magnesium sulfate solution by using the adiabatic evaporation of high temperature flue gas, so as to concentrate the magnesium sulfate solution; when the concentration of magnesium sulfate reaches above 20-25%, subjecting a part of the magnesium sulfate solution to conventional cooling crystallization or evaporation crystallization; and separating to obtain magnesium sulfate heptahydrate with purity above 99%. The method realizes the resource of sulfur element and reduces the cost of magnesium oxide desulfurization process.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Smoke alkali-free adsorption type biological desulphurization technology

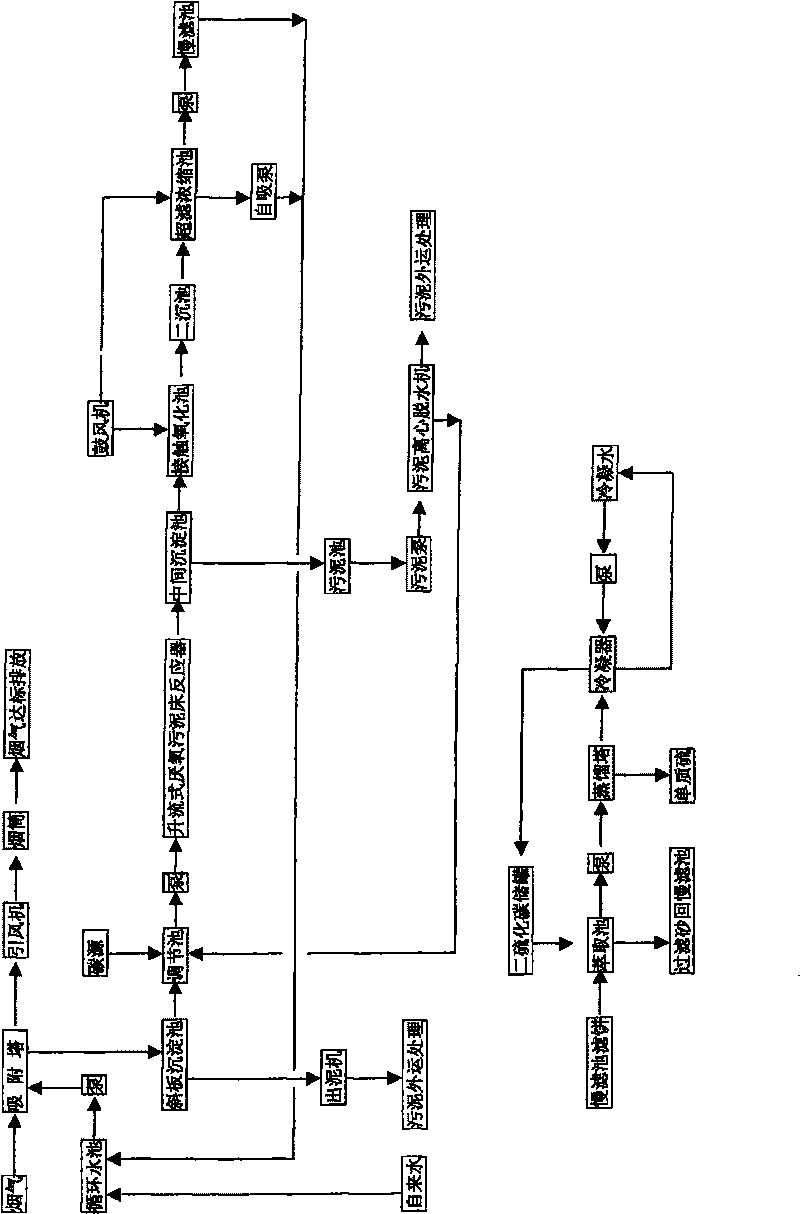

InactiveCN101703866AReduce desulfurization operating costsEliminate secondary pollutionDispersed particle separationTreatment with aerobic and anaerobic processesAlkali freeUltrafiltration

The invention discloses a smoke alkali-free adsorption type biological desulphurization technology which mainly comprises the following steps: alkali does not need to be added into absorption liquid in an adsorption tower; desulphurization of desulfurated waste water is completed by an technology of adopting an oblique plate sedimentation tank, an adjusting tank, a carbon adding source, an up-flow sludge bed reactor, a middle sedimentation tank, a contact oxidation tank and a secondary sedimentation tank; the adjusting tank is divided into 10 small adjusting tanks and adopts a plug flow structure, so that the temperature of the desulfurated waste water is gradually decreased; and the water which flows out of the secondary sedimentation tank is filtered by a falling curtain type ultrafiltration membrane to concentrate simple substance sulphur-containing water. The technology reduces the operation cost of the desulphurization of the smoke, eliminates the secondary pollution of secondary products caused by the desulphurization, and coverts sulfur dioxide and sulfur trioxide in the smoke into the simple substance sulphur under the function of microorganism.

Owner:张动科

Device and method for removing sulfur dioxide in fume by using carbide slag

ActiveCN106178858AAchieve the effect of meeting emission standardsRealize resource utilizationGas treatmentDispersed particle separationSlagCarbide

The invention discloses a device and a method for removing sulfur dioxide in fume by using carbide slag. The method for removing sulfur dioxide in boiler fume by using waste carbide slag generated in a paper-making alkali recovery process as a doctor solution comprises the following steps: firstly, detecting the content of calcium carbonate in causticized carbide slag, and adding water to stir the causticized carbide slag so as to obtain 20% carbide slag slurry; conveying the prepared carbide slag to a slurry preparation tank for storage through a pipeline by using a high-lift carbide slag pump, conveying the slurry to a nozzle of a desulfurizer spraying layer by using a lime slurry pump, enabling the nozzle to eject out the slurry to sufficiently contact fume which is discharged upwards, thereby removing the sulfur dioxide in the fume through a chemical absorption reaction. The device and the method are applicable to the situation that a great deal of waste carbide slag is generated in a paper-making plant and a wet desulphurization device is needed, and is low in operation cost, stable and reliable and remarkable in desulfurization effect.

Owner:湖南湘牛环保实业有限公司

Activated carbon diatomite particles with well-developed pores and low cost and method for preparing activated carbon diatomite particles with well-developed pores and low cost.

ActiveCN104289195ASufficient raw materialsWell-developed poresOther chemical processesAlkali metal oxides/hydroxidesChemistryActivated carbon

The invention discloses activated carbon diatomite particles with well-developed pores and low cost. The activated carbon diatomite particles are characterized by being prepared from the following raw materials in parts by weight: 95-105 parts of fruit shell activated carbon, 30-35 parts of diatomite, 18-22 parts of traditional Chinese medicine residues, 22-26 parts of tung seed shells, 6-9 parts of kaoline, 1-2 parts of a silane coupling agent kh560, 3-4 parts of sodium sulfate, 4-6 parts of limestone powder, 2.5-3.5 parts of vitrified microspheres, 3.5-5 parts of silicon micro-powder, 3-5 parts of clay, 3-5 parts of active aluminum oxide, 4-6 parts of an absorbent additive and an appropriate amount of water. According to the method for preparing the activated carbon diatomite particles with the well-developed pores and the low cost, the materials such as the traditional Chinese medicine residues, and the tung seed shells are reused, dried, crushed and then added into the activated carbon and the diatomite, and the particles have sufficient sources of raw materials, the well-developed pores, the high absorption ability and the excellent property; the absorbent additive gives the special porosity of the particles and increases the contact time between gas and each particle; the particles prepared according to the method have the good desulfurization dedusting effect and the high porosity, and is low in cost and simple in production process, and therefore, the operation cost of dry desulfurization is greatly reduced.

Owner:广州大津健康建筑技术有限公司

Device and method for producing magnesium sulfate

ActiveCN104445306ALow production costGuaranteed desulfurization efficiencyEnergy inputMagnesium sulfatesFlue gasSystem maintenance

The invention provides a device and a method for producing magnesium sulfate and specifically provides a device and method for producing the magnesium sulfate by use of waste heat of flue gas outside a magnesium oxide process-based desulfurization waste solution tower. The device comprises a desulfurizing tower, a flue, a heat exchanger, a crystallizer and a dryer; the heat exchanger is located at the periphery of at least one section of the flue to evaporate and concentrate a magnesium sulfate-containing solution from the desulfurizing tower under the action of the waste heat of flue gas. According to the device and the method for producing magnesium sulfate, concentration and crystallization are realized without consuming steam in the byproduct production process, and therefore, the byproduct production cost is reduced, the desulfurization operating cost is saved and the system maintenance difficulty is reduced under the premise that the normal desulfurization efficiency is guaranteed.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

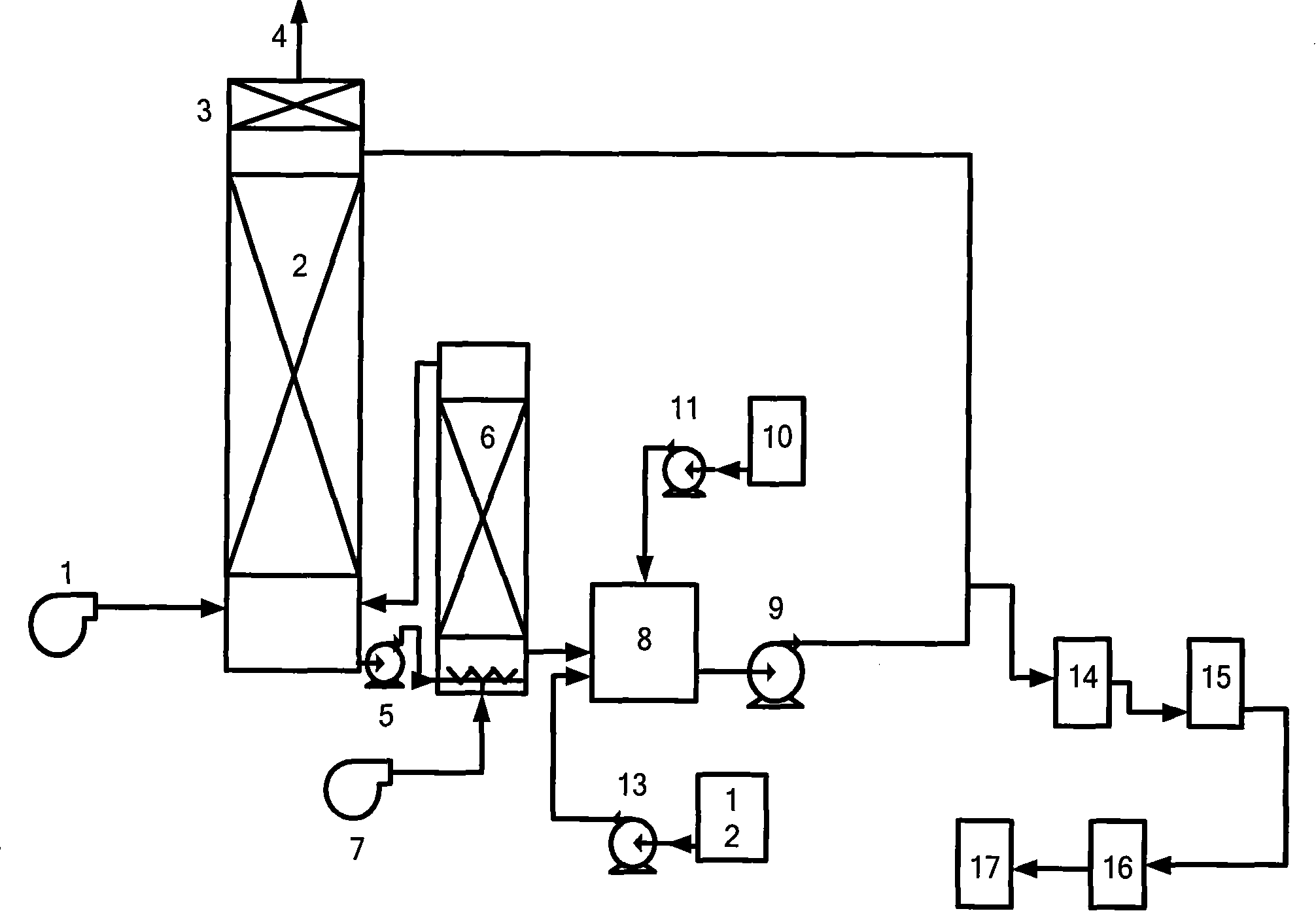

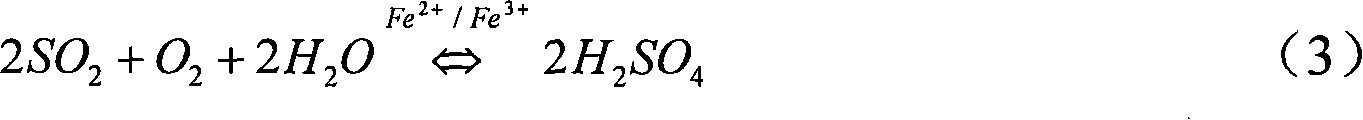

Technique of catalytic oxidation flue gas desulfurization and hydrocarbonylation by-product polymerization iron sulfate

InactiveCN101134154ALow costReduce usageDispersed particle separationIron carbonylsIron sulfateCatalytic oxidation

The catalytically oxidizing process for desulfurizing fume and co-producing polyferric sulfate includes: absorbing and dissolving SO2 from fume in a desulfurizing tower with ferrous sulfate solution as desulfurizing absorbent, catalytically oxidizing sulfite radical into sulfuric acid in the presence of O2 and iron ion as catalyst, reacting sulfuric acid and ferrous sulfate to co-produce liquid polyferric sulfate, and drying to obtain solid polyferric sulfate. The process has cheap desulfurizer, no waste discharge and obvious economic benefit, and is suitable for desulfurizing fume in boilers and other advantages.

Owner:DALIAN UNIV OF TECH

Liquid-phase oxidation catalyst for fire coal flue gas desulfurization

InactiveCN101195097AGood physical and chemical stabilityReduce desulfurization operating costsOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationOperational costsMass ratio

The invention discloses a liquid phase oxidation catalyst which is used to desulphurize fire coal flue gas. The invention comprises a surface active agent, M2+1, M3+2 and industrial-grade urea, wherein the mass ratio between the surface active agent and the industrial grade urea is 1:40-1:60, the solution mass concentration ratio between the M2+1and the M3+2 is 10:1-30:1, the mass ratio between the surface active agent and the M2+1 is 1:80-1:90, and M is Mn or Fe or Mg. The oxidative catalyst of the invention is very easy to be dissolved in water, and water solution is weakly-acidic. Density range is 2.75-2.93*103kg.m-3, and physiochemical stability is comparatively good. The invention only has catalytic oxidative effect in the process of flue gas desulphurization and no consumption theoretically, and can be used in circulation. The oxidative catalyst of the invention is adopted to desulphurize the fire coal flue gas, desulphurizing efficiency can be increased, simultaneously a desulphurizing process can be simplified (without an oxidation draught fan process), the operational cost of the flue gas desulphurization can be lowered greatly, and the invention has great practical applicable value and wide applicable foreground.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

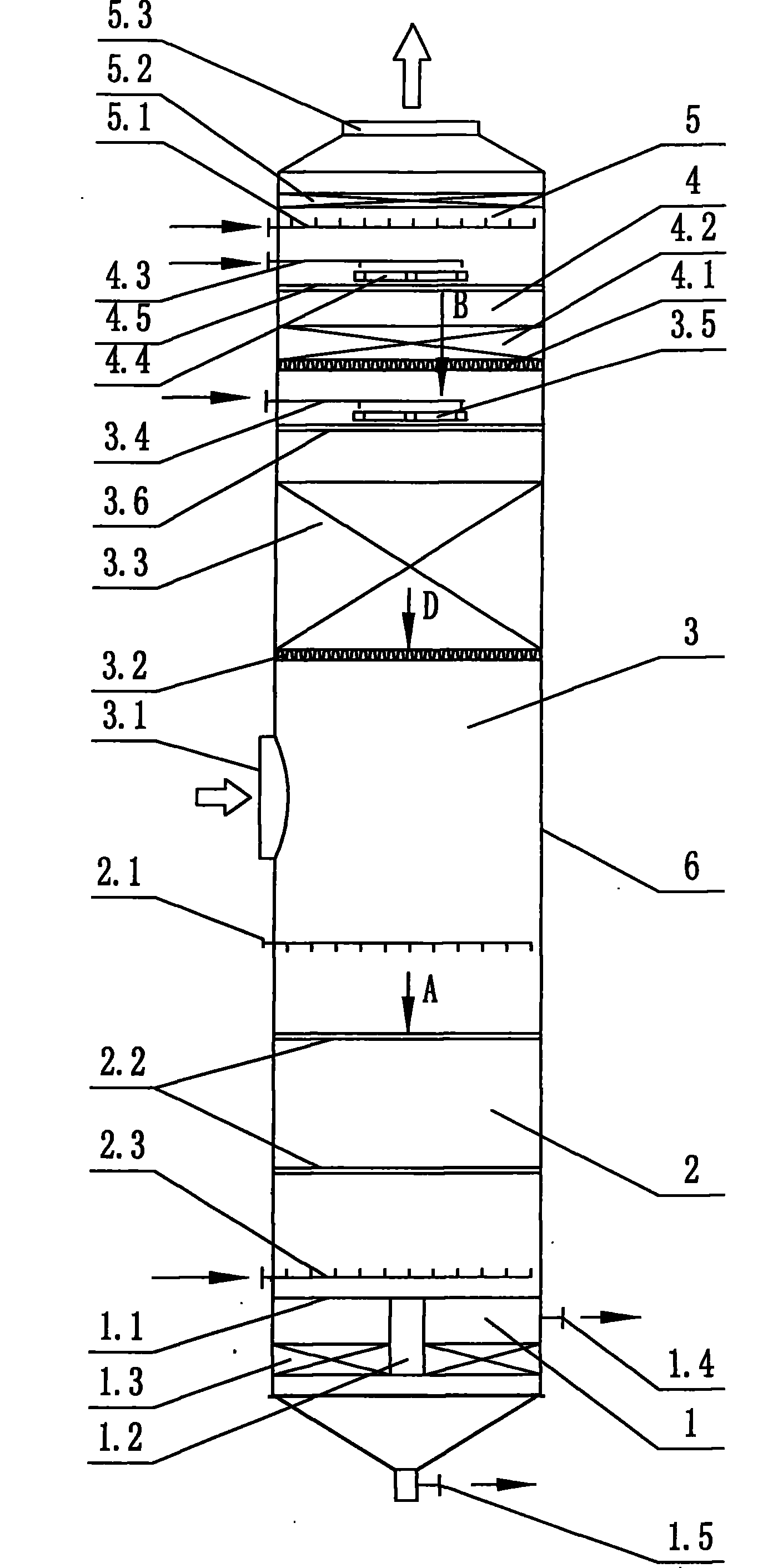

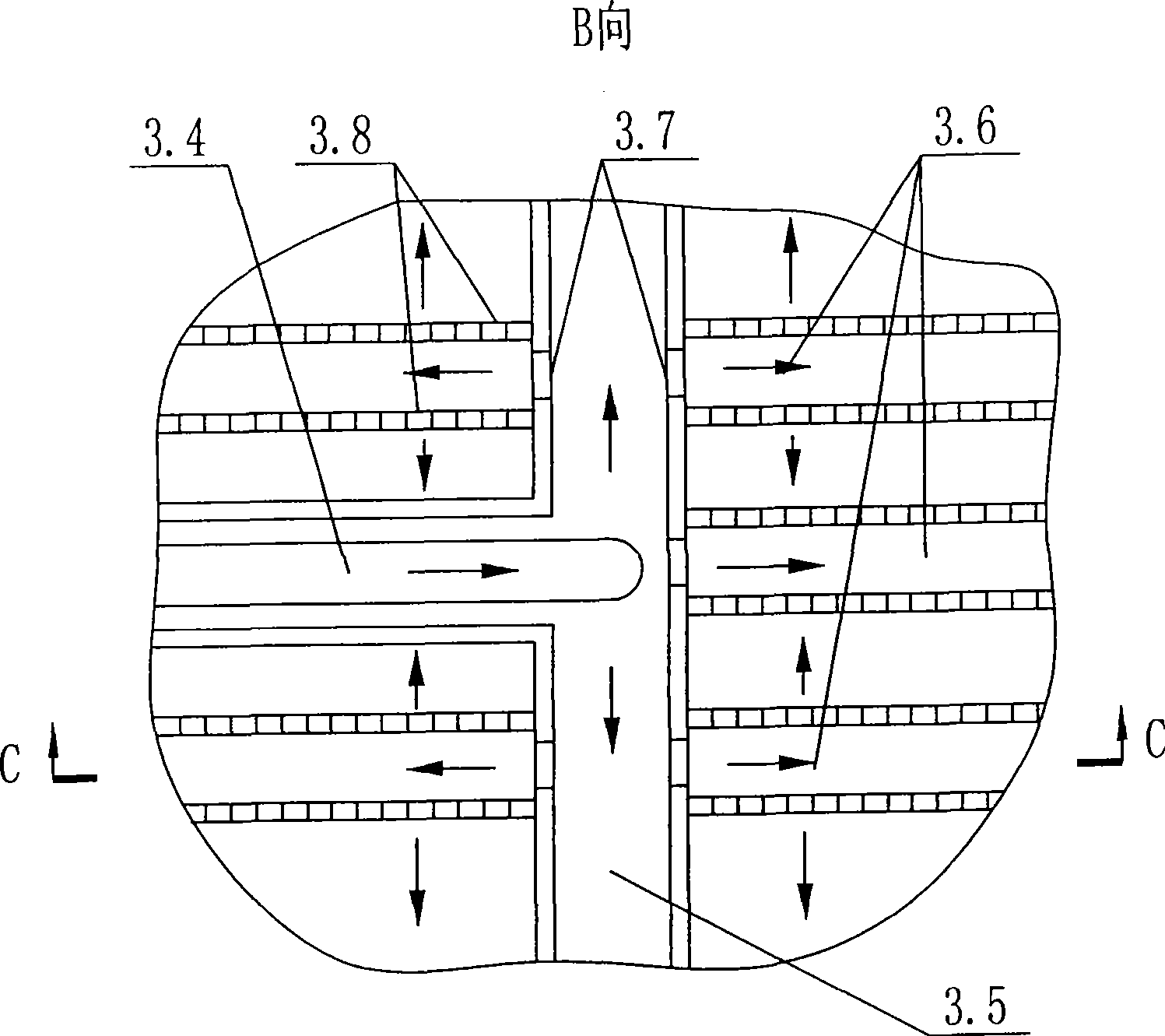

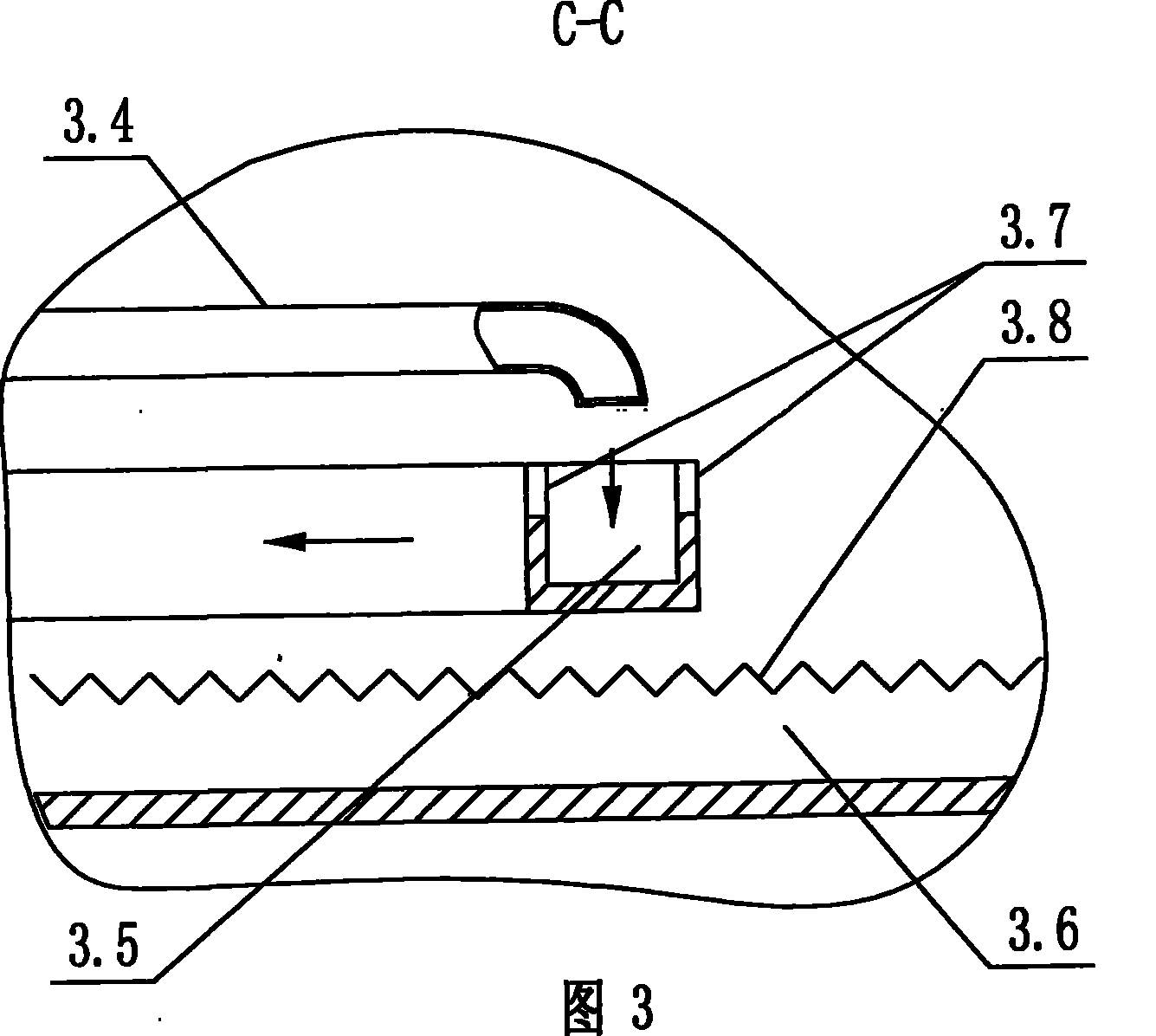

Desulphurizing tower for desulphurizing with seawater soda-residue emulsion

InactiveCN101444698AVersatileSimplified desulfurization processDispersed particle separationSeawaterOperating cost

The invention discloses a desulphurizing tower for desulphurizing with seawater soda-residue emulsion. A defogging section, a seawater absorption section, a seawater soda-residue emulsion absorption section, an oxidation section and a clarification section are sequentially arranged inside the tower from top to bottom. A flue gas inlet is arranged on the side of the tower positioned between the seawater soda-residue emulsion absorption section and the oxidation section, a flue gas outlet is arranged at the top of the tower, a sediment outlet is arranged at the bottom of the tower, and a clarified liquid outlet is arranged on the side of the tower positioned on the upper part of the clarification section. The desulphurizing tower has multiple functions including absorption, oxidation, clarification and fog removal, so as to simplify desulphurizing process; and the flue gas exhaust and water drainage both achieve National Standard. The desulphurizing tower also has the advantages of low equipment investment, small floor area, low operating cost, convenient operation, and high flue gas desulphurizing efficiency (up to 95%); realizes simultaneous treatment of soda-residue and sulfur dioxide in flue gas; and is suitable for flue gas desulphurization in boilers of large-sized, middle-sized and small-sized thermal power stations of ammonia-soda process soda ash production plants in a coastal area, as well as industrial boilers and kilns in industrial and mining establishments.

Owner:QINGDAO SODA ASH IND DEV CO LTD +1

Preparation method for desulfurizing agent

InactiveCN103157431AThe principle is simpleReasonable workmanshipOther chemical processesDispersed particle separationActivated carbonPorosity

The invention discloses a preparation method for a desulfurizing agent. The preparation method for a desulfurizing agent comprises the following steps of: taking attapulgite as a raw material, and drying the raw material after alkali modification and activation treatments; grinding the raw material into powder, sieving, granulating and forming; then performing roasting activation; and finally sieving the powder into a spherical attapulgite desulfurizing agent finished product. The attapulgite desulfurizing agent obtained by the preparation method disclosed by the invention is good in alkali modification effect, rough and hard in the surfaces of spherical particles, not easy to break, large in specific surface area, high in porosity, good in adsorptive property for sulfur dioxide, easy to regenerate, simple in production process, low in cost, capable of being used for replacing active carbon (coke) to perform flue gas desulfurization, and greatly reducing the running cost of dry desulfurization, and also capable of being used for sewage treatment and other occasions.

Owner:JIANGSU DONGDA THERMAL ENERGY MACHINERY MFG

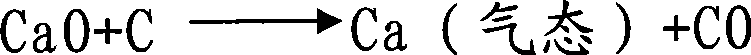

Method of desulfuration using powder dust and flue gas from calcium carbide stove

InactiveCN101411964AEliminate pollutionExtended maintenance cycleDispersed particle separationCalcium carbideSlagHearth

The invention provides a method for utilizing calcium carbide furnace dust and flue gas for desulfurization,and belongs to a coal fired boiler desulfurization method. Furnace gases containing dust and flue gases, which are generated during the production of the calcium carbide furnace, are transferred to a furnace hearth above a grate of the coal fired boiler, calcium oxide in the dust makes the over reaction with sulfur dioxide generated when coal burns, and the generated calcium sulfate is discharged along with slag; and, calcium steam in the flue gas enters a boiler flue and undergoes over reaction with sulfur dioxide in the flue, and the generated crystal is removed from the flue gas by an electric dust removing device in the flue. The desulfurization method not only eliminates the pollution of the dust and flue gas generated in the process of producing calcium carbide, but also uses the dust and flue gas to desulfurize the coal fired boiler, so that the method has the advantages of realizing the combat-pollutant-with-pollutant, having good desulfurization effect, and having low desulfurization operation cost, and the desulfurization efficiency is more than 90 percent; moreover, because the dust and flue gas are high in temperature and contain a large amount of coke powder and carbon monoxide, and the dust and flue gas are cofired with coal, the coal is saved.

Owner:WUDI XINXING THERMOELECTRICITY

System device and method for recycling sulfur dioxide from fume to prepare sulfur

InactiveCN103303872BEmission reductionImprove performanceEnergy inputSulfur preparation/purificationCooling towerSulfur product

The invention discloses a system device and a method for recycling sulfur dioxide from fume to prepare sulfur. The device comprises three units of an absorption and pyrolysis unit, a reduction unit and a krauss unit, wherein the absorption and pyrolysis unit mainly consists of a cooling tower, an absorbing tower, a purifier, a circulation pump, a regeneration pyrolysis tank and a rich and lean liquid heat exchanger; the reduction unit mainly consists of a mixed gas generation system, a reduction reactor and a sulfur condenser; the krauss unit mainly consists of a krauss reactor and a sulfur condenser. The method comprises the steps that the absorption and pyrolysis unit absorbs and pyrolyzes the fume so as to obtain a pure sulfur dioxide gas, and the reduction unit converts the sulfur dioxide into elementary sulfur through catalysis reaction, wherein the conversion per pass is not less than 95%, and the total conversion is greater than 99.5%. The sulfur dioxide content that the fume is completely discharged is not greater than 50 milligrams per normal cubic meter. The sulfur dioxide is converted into national best grade sulfur products which are stable in property and convenient to store and transport, with high efficiency and low cost, the desulfuration operation cost is lower than the value of a recycled product, and the products can be widely applied to chemistry and thermal power industry.

Owner:陕西华锐迪橡胶科技有限公司

Low-cost activated carbon kieselguhr particles with developed pores, and preparation method of kieselguhr particles

InactiveCN104437399AGood effect of desulfurization and dust removalHigh porosityGas treatmentOther chemical processesPorosityActivated carbon

The invention discloses low-cost activated carbon kieselguhr particles with developed pores. The activated carbon kieselguhr particles are characterized by being prepared from the following raw materials in parts by weight: 95-105 parts of nut shell activated carbon, 30-35 parts of kieselguhr, 18-22 parts of Chinese medicine residue, 22-26 parts of tung shell, 6-9 parts of kaolin, 1-2 parts of a silane coupling agent kh560, 3-4 parts of sodium sulfate, 4-6 parts of limestone powder, 2.5-3.5 parts of glass beads, 3.5-5 parts of silica powder, 3-5 parts of clay, 3-5 parts of activated aluminum oxide, 4-6 parts of an absorption auxiliary agent and a proper amount of water. According to the activated carbon kieselguhr particles, the resources such as Chinese medicine residue, tung shell are reused and are fed into the activated carbon and the kieselguhr after being dried and ground; the activated carbon kieselguhr particles are sufficient in raw materials, developed in pores, high in absorption and excellent in performances; the absorption auxiliary agent is fed into the activated carbon kieselguhr particles, so that the activated carbon kieselguhr particles have special porosity, and the contact time of the activated carbon kieselguhr particles with air can be prolonged; the activated carbon kieselguhr particles have good desulfurization and dust-removal effects, are high in porosity, low in cost and simple in production technology, and are capable of greatly lowering the operating cost of dry desulfurization.

Owner:ANHUI PHOENIX INT CO LTD

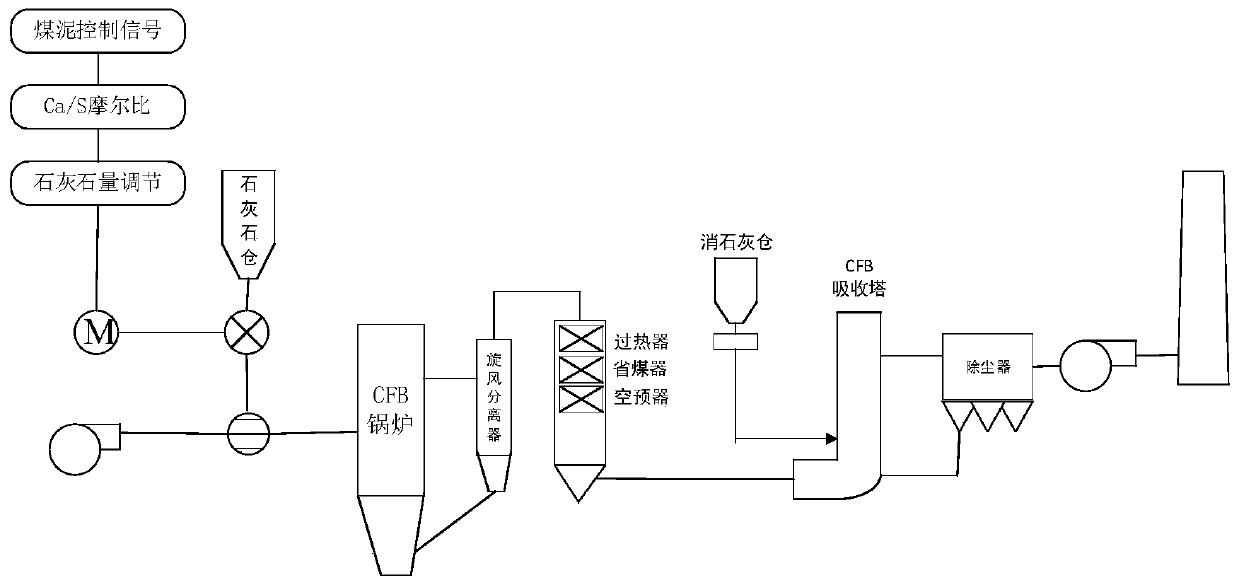

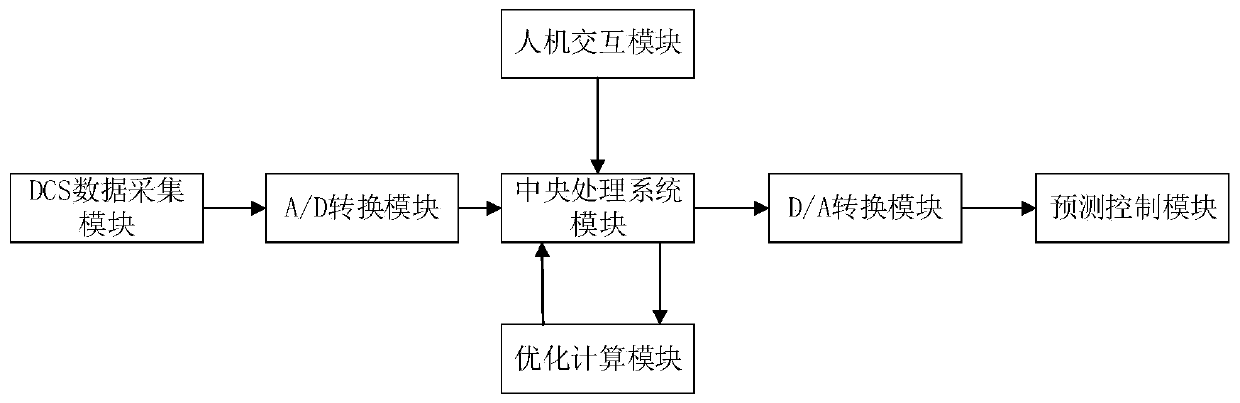

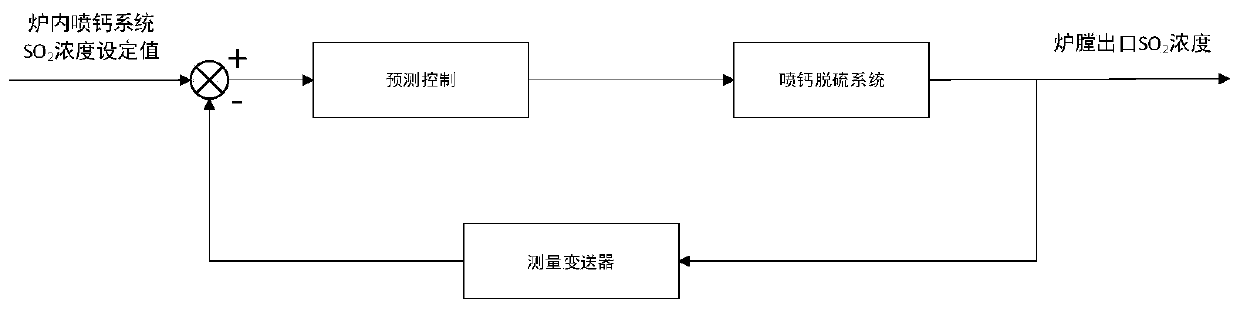

Coal slime fluidized bed boiler desulfurization collaborative optimization operation method

ActiveCN111461391ALow running costImprove operating conditionsDispersed particle separationForecastingFluidized bedData acquisition

The invention relates to the field of SO<2> pollutant treatment of coal-fired power plants. The invention aims to solve the problem of high SO<2> emission after desulfurization in the prior art. The invention discloses a coal slime fluidized bed boiler desulfurization collaborative optimization operation method. A desulfurization collaborative optimization operation system comprises the followingmodules: a DCS data acquisition module, an A / D and D / A conversion module, a central processing system module, a prediction control module, a man-machine interaction module and an optimization calculation module. The invention provides the coal slime fluidized bed boiler desulfurization collaborative optimization operation method. According to the method, modeling and optimization calculation are carried out on the process of the whole desulfurization system, and the SO<2> concentration value after optimization calculation is subjected to predictive control, so that the operation cost of the whole desulfurization system is minimized, and the result after optimization solution is subjected to predictive control to obtain the lowest operation cost, thereby realizing the economic and stable operation of SO<2> removal and improving the economic benefits of enterprises.

Owner:HANGZHOU DIANZI UNIV

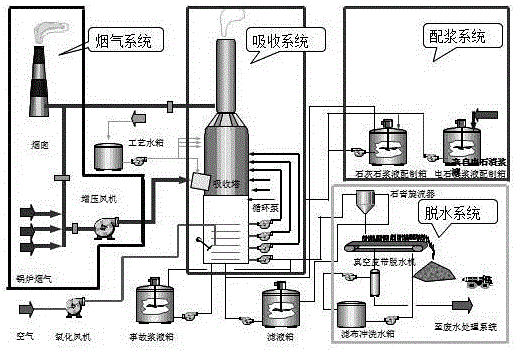

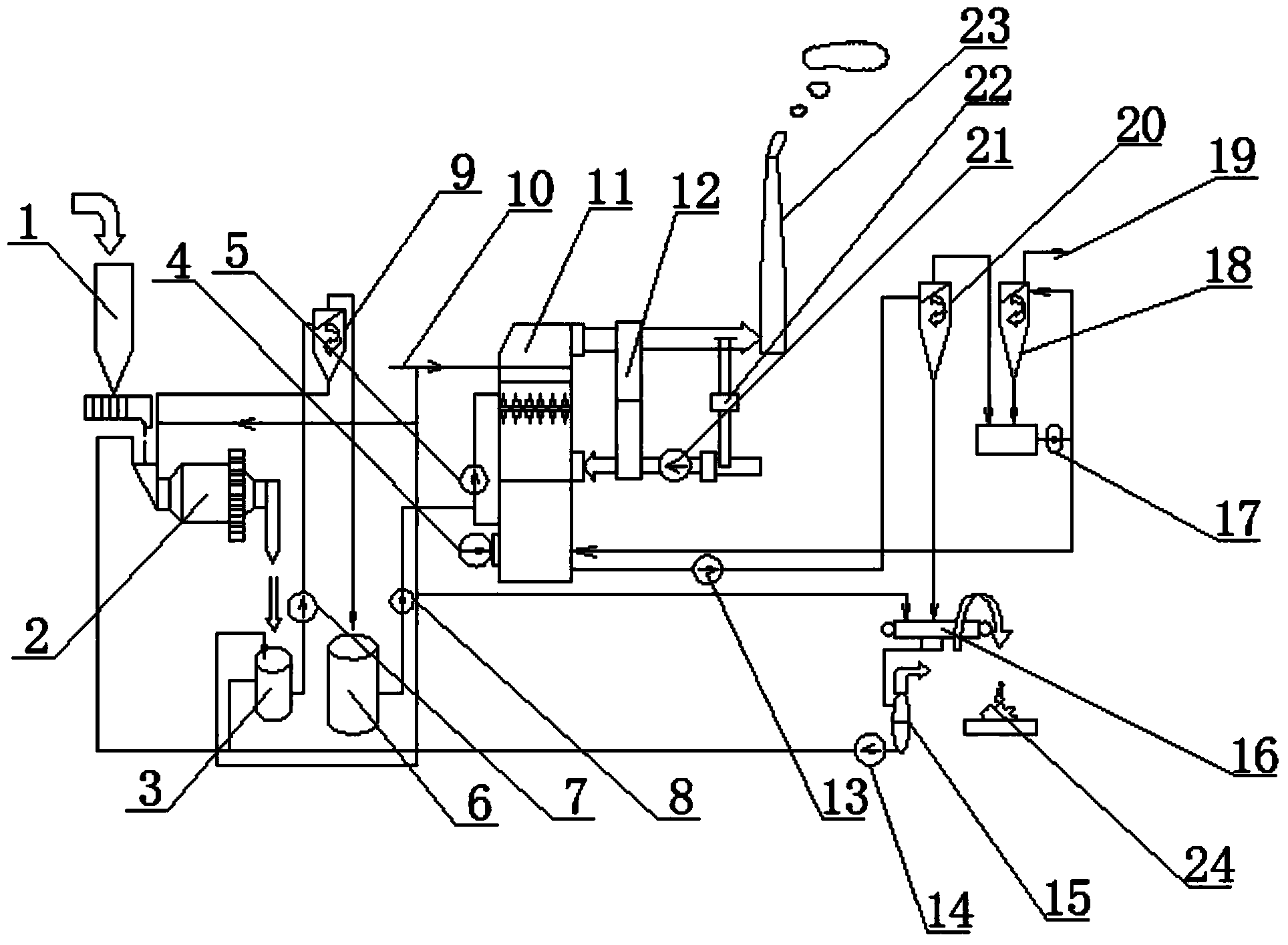

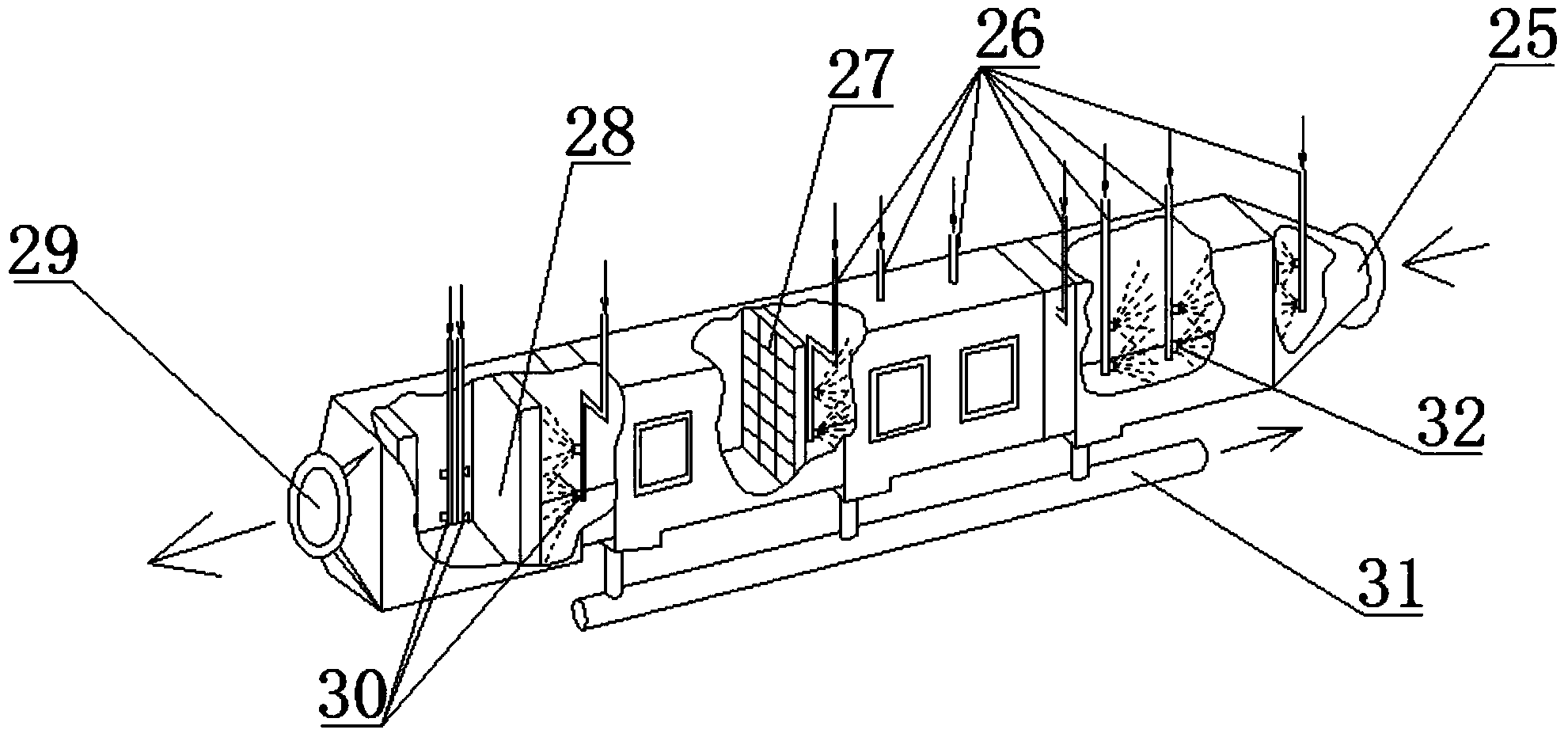

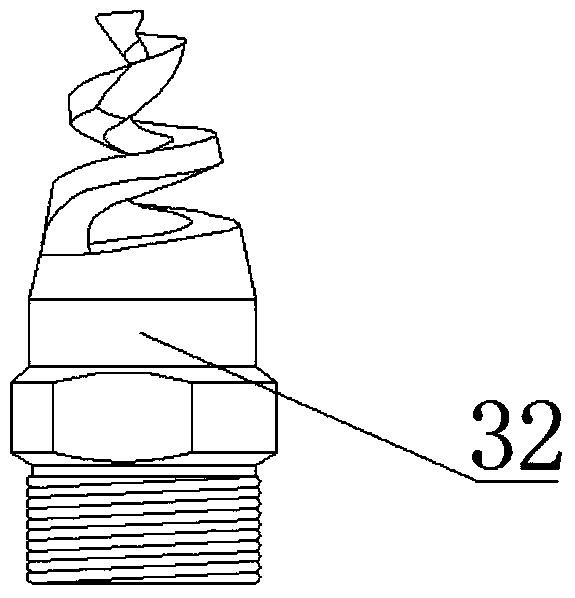

Horizontal spraying and desulfurizing device and method for aluminum electrolysis fume

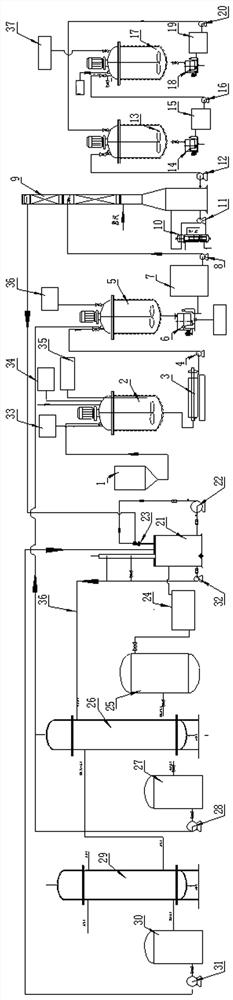

ActiveCN104226102AEfficient desulfurization and dust removalLow investment costDispersed particle separationCycloneElectrolysis

The invention discloses a horizontal spraying and desulfurizing device and method for aluminum electrolysis fume. The horizontal spraying and desulfurizing device comprises a limestone silo, a wet ball mill, a limestone slurry coarse material barrel, an oxidation fan, a circulation slurry pump, a limestone slurry fine material barrel, a limestone vortex pump, a limestone slurry pump, a limestone slurry cyclone, a horizontal absorption tower, a heat exchanger, a gypsum slurry pump, a filtered water pump, a vacuum device, a vacuum belt dewaterer, a water distribution vortex slurry pump, a waste water cyclone, a gypsum cyclone, a booster fan, a bypass baffle door and a chimney. Dehydrate gypsum is generated in the horizontal absorption tower, and SO2 is removed. Gypsum slurry expelled by the absorption tower is dewatered by the dewaterer to be recycled, and the desulfurized fume is exhausted. The r aluminum electrolysis fume has low-concentration SO2, efficient, economic and safety-management new process and new method and matched equipment are obtained, and the purposes of efficiently desulfurizing and removing dust, reducing investment cost, reducing desulfurization operation cost and improving the safety performance of aluminum electrolysis fume purification equipment and operation sites are achieved.

Owner:YUNNAN RUNXIN ALUMINUM

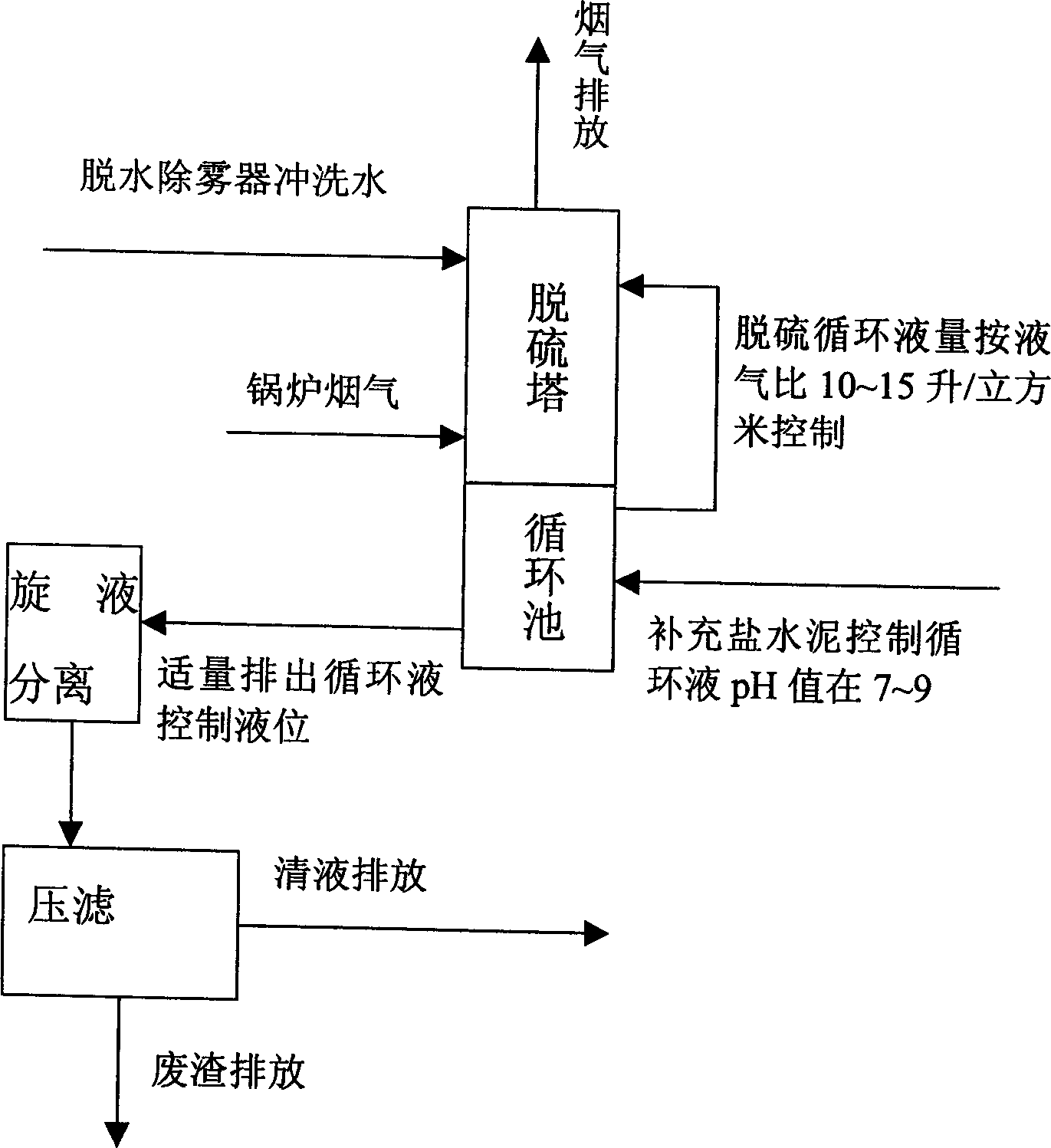

Method of liquid column spray tower desulfurization with salt cement

InactiveCN1554471ALess investmentReduce desulfurization operating costsDispersed particle separationSpray towerSalt water

The method of using salt cement in desulfurizing in liquid column spraying tower includes the following steps: leading fume into liquid column spraying desulfurizing tower while feeding the mixed slurry of salt cement and circulating slurry into the liquid column spraying desulfurizing tower for mixing to desulfurizing; and exhausting the desulfurized fume while circulating partial slurry and exhausting the other. The mixed slurry in the desulfurizing tower has pH 5-9, and the liquid / gas ratio inside the tower is 1-3 vol%. Compared with available technology, the present invention has the advantages of low investment in desulfurizing apparatus, low desulfurizing cost, expanded application range of salt cement, etc.

Owner:TIANJIN BOHUA YONGLI CHEM IND

Technology for removing SO2 in smoke through recovery method

InactiveCN103203171AReactive desulfurization reaction is rapidGuaranteed uptimeDispersed particle separationRecovery methodResource recovery

The invention discloses a technology for removing SO2 in a smoke through a recovery method. Zinc sulfite reacts with SO2 in the smoke in an aqueous solution in a desulfurization tower as a desulfurization agent to generate a soluble zinc salt in order to absorb SO2 in the smoke and purify the smoke. A rich solution after SO2 absorption is heated to generate ZnSO3 and release SO2. The regenerated ZnSO3 is reused for the SO2 absorption, and released SO2 is trapped and recovered, and is used for producing sulfuric acid or an industrial SO2 gas in order to realize resource recovery.

Owner:BEIJING UNIV OF CHEM TECH

Apparatus and method for preparing high-activity calcium hydroxide by using carbide slag alkali residue

ActiveCN102423624ALarge specific surface areaReduce consumptionSolid waste disposalDispersed particle separationCalcium hydroxideSodium bicarbonate

The invention discloses an apparatus used for preparing high-activity calcium hydroxide by using carbide slag alkali residue. The apparatus comprises a sodium bicarbonate metrical adding apparatus, a carbide slag adding apparatus, and sequentially connected components of a mixing tank, a carbide slag delivering screw conveyor, a drier, a crusher, an air separator, a deduster, and a collection chamber. The sodium bicarbonate metrical adding apparatus and the carbide slag adding apparatus are both connected with the mixing tank. The invention also relates to a method used for preparing high-activity calcium hydroxide by using the carbide slag alkali residue. According to the invention, sodium bicarbonate and the carbide slag are stirred in the mixing tank; the mixture is processed by using the drier, the crusher, and the air separator; and a calcium hydroxide finished product can be collected by using the deduster. The apparatus and the method provided by the invention are advantaged inthat: an advanced micro-porous structure is formed in the calcium hydroxide particles, such that the specific surface area of calcium hydroxide is increased, and the reaction activity is improved. When calcium hydroxide is applied as a desulphurization absorbent, the desulphurization efficiency can be improved by 5-10%, such that the consumption amount of absorbent can be reduced, and the cost ofdesulphurization operation can be reduced.

Owner:浙江菲达脱硫工程有限公司 +1

Removal method for impurity ions in organic amine desulfurized solution

InactiveCN107930399AEfficient removalImprove cleanlinessDispersed particle separationChemical industryImpurity ions

The invention belongs to the field of chemical industry, and specifically relates to a removal method for impurity ions in an organic amine desulfurized solution. The invention is to solve a technicalproblem of providing the removal method for the impurity ions in the organic amine desulfurized solution. The removal method comprises the following steps: allowing an organic amine desulfurized richliquor to pass through a cation resin exchange column of chelated resin so as to adsorb Fe3+ and Cu2+ ions, allowing the obtained organic amine desulfurized rich liquor to enter a regeneration tower,carrying out SO2 regeneration so as to obtain a poor liquor, allowing the poor liquor to pass through an anionic resin exchange column of macroporous weakly basic resin so as to remove Cl-, and allowing the obtained poor liquor to enter a freezing crystallization system so as to remove SO4<2->. The method provided by the invention can purify a used organic amine desulfurizer, reduces poisoning ofthe desulfurizer, stabilizes the effect of desulfurization, reduces the operation cost of desulfurization, and guarantees normal and stable operation of a desulfurization system.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for preparing solid desulfurizer

InactiveCN107866198AThe principle is simpleReasonable workmanshipGas treatmentOther chemical processesPorosityActivated carbon

A method for preparing a solid desulfurizer, using attapulgite as a raw material, drying after alkali modification and activation treatment, grinding and sieving, granulating and forming, roasting and activating, and finally sieving into spherical attapulgite desulfurizer finished products . The attapulgite desulfurizer of the present invention has good alkali modification effect, spherical particle surface is rough and hard, not easily broken, large specific surface area, high porosity, good adsorption performance for sulfur dioxide, easy regeneration, simple production process, low cost, and can replace activated carbon (Coking) for flue gas desulfurization can greatly reduce the operating cost of dry desulfurization, and can also be used in sewage treatment and other occasions.

Owner:合肥果成科技有限公司

Regeneration method and regeneration equipment for waste salt produced in flue gas desulfurization

PendingCN111760457AHigh activityImprove desulfurization efficiencyGas treatmentDispersed particle separationFlue gasEnvironmental engineering

The invention relates to treatment of waste salt produced in flue gas desulfurization and discloses a regeneration method and regeneration equipment for waste salt produced in flue gas desulfurization, belonging to the technical field of treatment of coke oven flue gas. The regeneration method for waste salt produced in flue gas desulfurization in the invention comprises the following steps: (1) dissolving waste salt produced in flue gas desulfurization, carrying out flocculation for impurity removal, preparing a sodium sulfate saturated solution from the waste salt produced in flue gas desulfurization, an ammonium bicarbonate solution and a sodium sulfate solid, maintaining a temperature at 36-42 DEG C, and conducting centrifuging to obtain sodium bicarbonate and a mother solution I; (2)decomposing ammonium bicarbonate in the mother solution I through an ammonium bicarbonate tower to obtain ammonia gas, carbon dioxide and sodium sulfate, feeding the ammonia gas and the carbon dioxideinto an ammonium bicarbonate recovery device for generating an ammonium bicarbonate solution, and conducting centrifuging to obtain a sodium sulfate solid and a mother solution II; and (3) producingan ammonium sulfate fertilizer from the mother solution II by using an ammonium sulfate generation system. The regeneration method and the regeneration equipment in the invention can greatly reduce the operation cost of dry desulfurization of flue gas, improve the desulfurization efficiency and increase the utilization rate of sodium bicarbonate, and has important and positive practical significance for optimizing environmental conditions.

Owner:山西长林能源科技有限公司

Cement performance adjusting method for power plant gypsum production

The invention relates to the technical field of power plant gypsum, and discloses a cement performance adjusting method for power plant gypsum production. The method comprises the following steps: proper amounts of lime milk, soda ash, PFS and PAM are sequentially added to reclaimed water of an urban sewage treatment plant according to the quality of water coming from the urban sewage treatment plant in order to deeply treat the reclaimed water, the dosages of above reagents are correspondingly adjusted according to the quality of water coming from the urban sewage treatment plant and water treatment requirements, a mud-water mixture is subjected to mud-water separation through a variable-pore V-shaped filter tank, and clear water is conveyed to a clear water tank. The clinker components,admixture varieties, admixture use amounts, seasons and air temperatures during cement production, mill grinding working conditions and the like in the cement production process affect the quality andhe performances of produced cement, and adjustment of the ratio of the power plant gypsum, comprising an optimized formula of the gypsum and other raw materials, is carried out to timely correspondingly adjusting the formula in order to produce the stable high-strength and high-performance cement, so the method achieves an excellent effect.

Owner:SICHUAN XINGCHUANCHENG CEMENT CO LTD

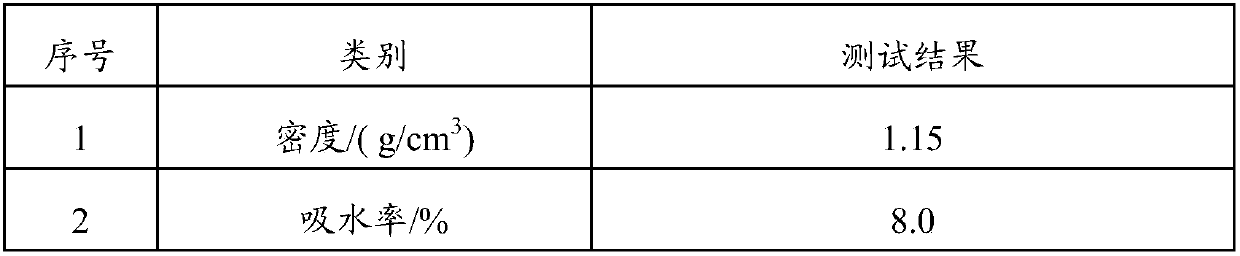

Fiber cement product and production method thereof

InactiveCN107805030AGuarantee high-efficiency operationSolve processing problemsGas treatmentDispersed particle separationIndustrial wasteMagnesium

The invention discloses a fiber cement product and a production method thereof. The production method includes following steps: (1), adopting a desulfurizing agent to absorb sulfur dioxide in flue gasthrough a wet process so as to form flue gas treatment paste, wherein the desulfurizing agent is size formed by magnesium oxide and industrial wastewater; (2), mixing the flue gas treatment paste, solid waste, magnesium oxide, fiber and additive to form a mixture, wherein a weight ratio of the flue gas treatment paste, the solid waste, the magnesium oxide, the fiber and the additive of 50-80:25-38:3-25:5-20:0.1-15; (3), subjecting the mixture to blank making and maintaining to obtain the fiber cement product. By the method, pollutants like sulfur dioxide in flue gas can be eliminated, and theproblem of treating industrial wastewater and the problem of recycling industrial waste residue and building waste can be solved.

Owner:中晶蓝实业集团有限公司

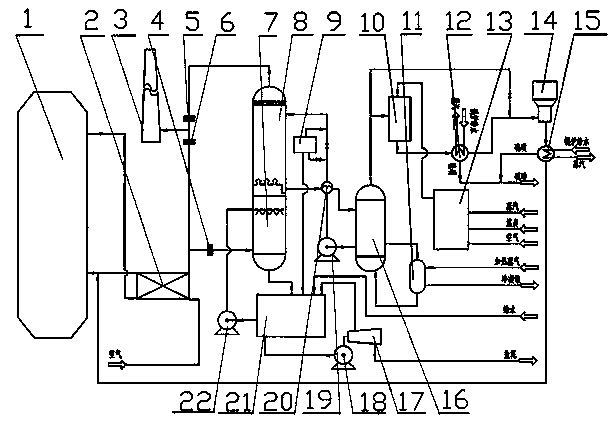

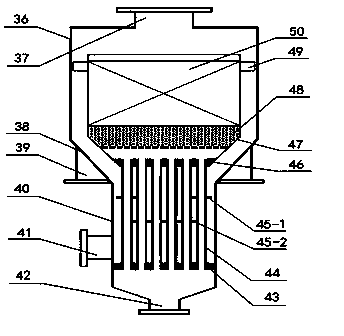

Efficient condensation absorption tower

ActiveCN111013373AGood condensation absorptionReduce frequencyGas treatmentDispersed particle separationEngineeringSlurry

The invention discloses an efficient condensation absorption tower. The efficient condensation absorption tower is characterized in that the efficient condensation absorption tower comprises a tower body; a slurry tank is arranged at the inner side of the lower part of the tower body; the left lower part of the tower body is connected with a flue gas inlet pipe; the joint of the flue gas inlet pipe and the tower body is higher than the liquid level of the slurry tank; the flue gas inlet pipe is obliquely arranged; one end, connected with the tower body, of the flue gas inlet pipe is lower thanthe other end; the upper part of the tower body is connected with a flue gas outlet pipe; and a condensation tray, a spraying area and four layers of demisters are sequentially arranged above the slurry tank in the tower body from bottom to top. According to the invention, exhaust gas temperature can be reduced, part of liquid water is recovered from saturated wet flue gas, and evaporation of water in the absorption tower is reduced, so water replenishment of a wet desulphurization system is reduced.

Owner:ZHEJIANG TUNA ENVIRONMENTAL SCI & TECH

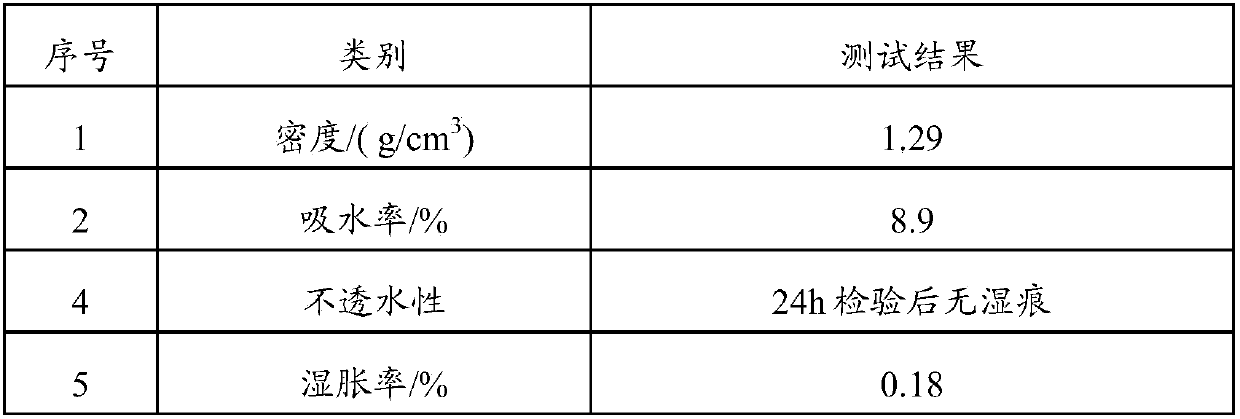

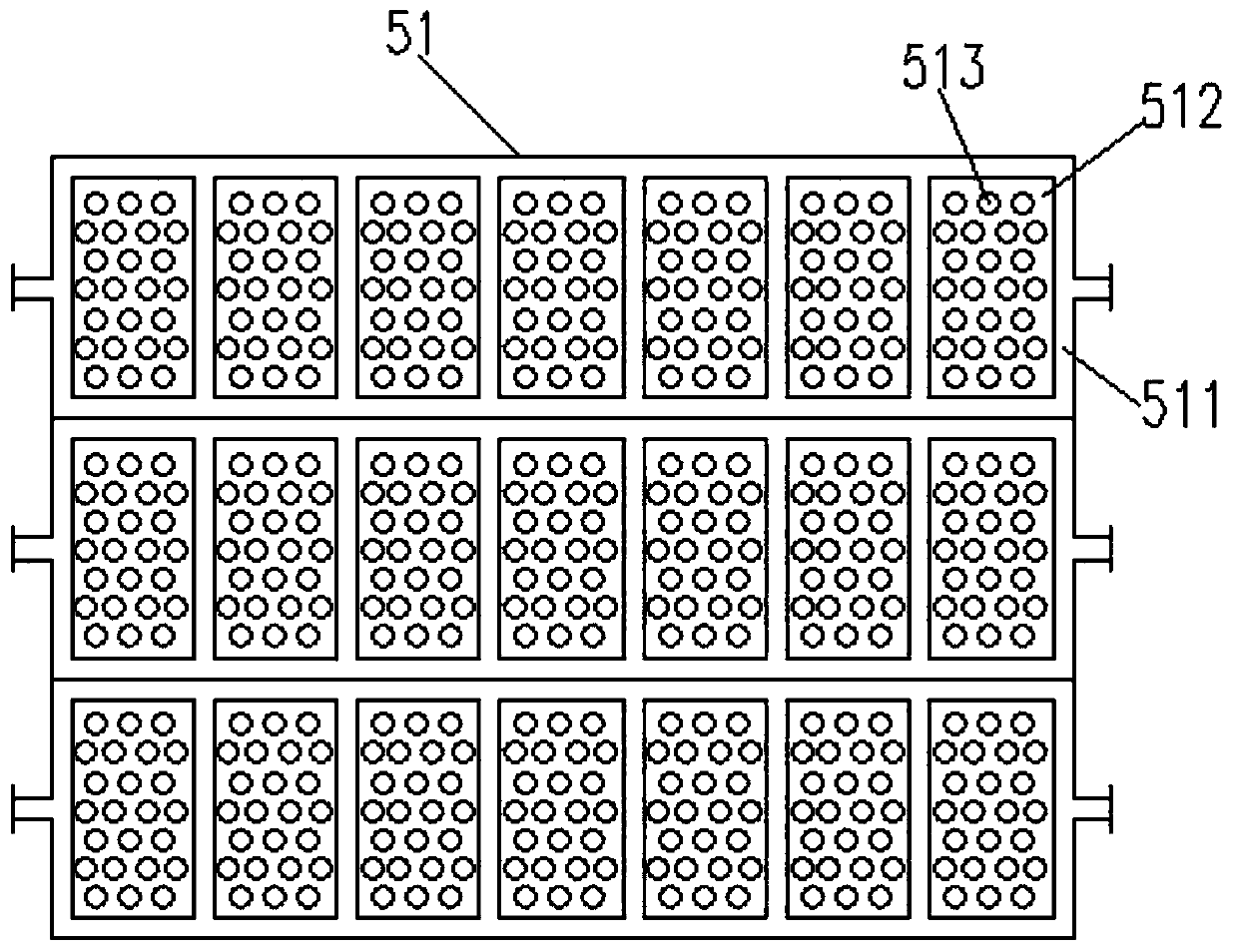

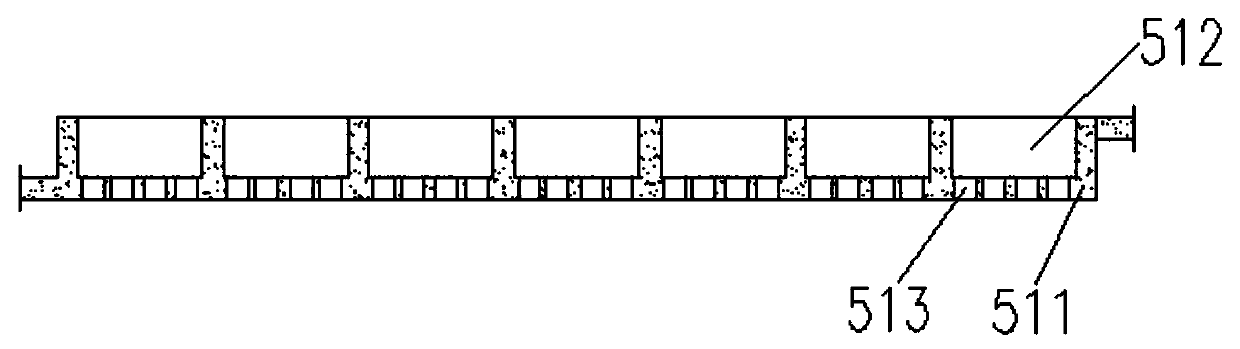

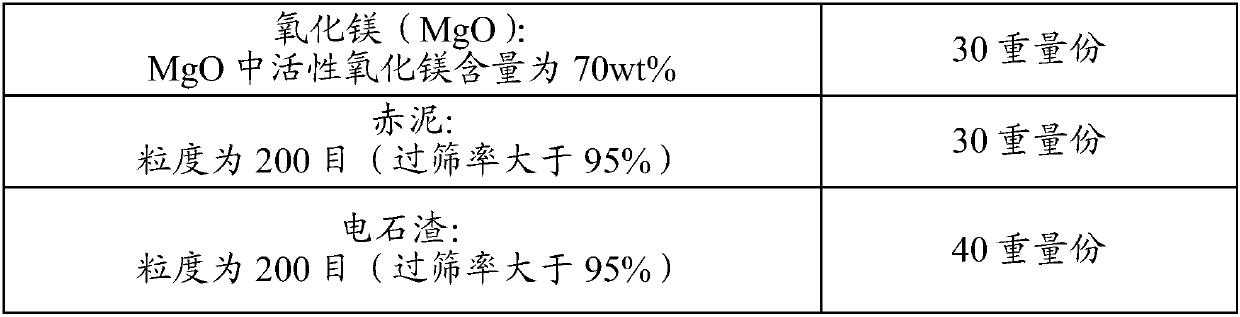

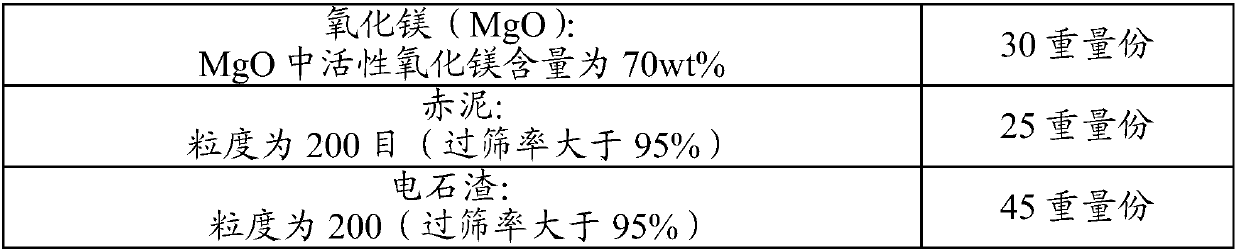

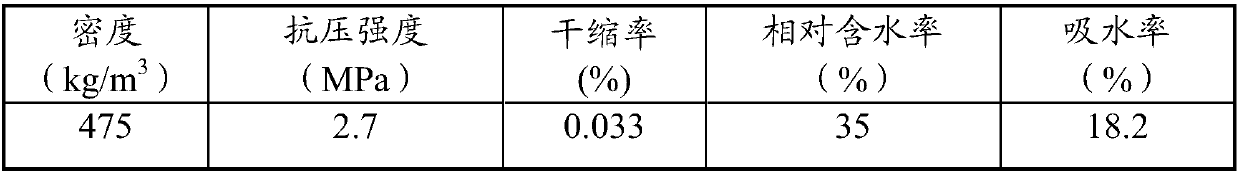

Method for producing lightweight concrete product based on calcium carbide slag desulphurization

InactiveCN107673725ALess investmentReduce desulfurization operating costsSolid waste managementSlagRed mud

The invention discloses a method for producing a lightweight concrete product based on calcium carbide slag desulphurization. The method comprises the following steps: adding a desulfurizer composed of calcium carbide slag, magnesium oxide and red mud in alkaline industrial wastewater to prepare a desulfurizer slurry; contacting the desulfurizer slurry and specific flue gas; discharging the slurrywhen the pH value of an absorption slurry reaches a scope of 5.3-6.8 to obtain a desulphurization slurry; sieving a light aggregate by sieves having 5 mm meshes and 10 mm meshes, taking the sieved light aggregate with a size being less than 5 mm as a fine aggregate, and taking the sieved light aggregate with the size being larger than 5 mm and less than 10 mm as a coarse aggregate; mixing the fine aggregate, the desulphurization slurry, magnesium oxide and industrial solid waste, and then adding the coarse aggregate for further mixing to obtain a mixture; moulding the mixture, and maintainingthe mixture to obtain the lightweight concrete product. The method can solve the problem of atmosphere pollution due to sulfur dioxide, and can use the industrial solid waste to obtain the qualifiedlightweight concrete product.

Owner:ZHONGJING ECO IND CO LTD

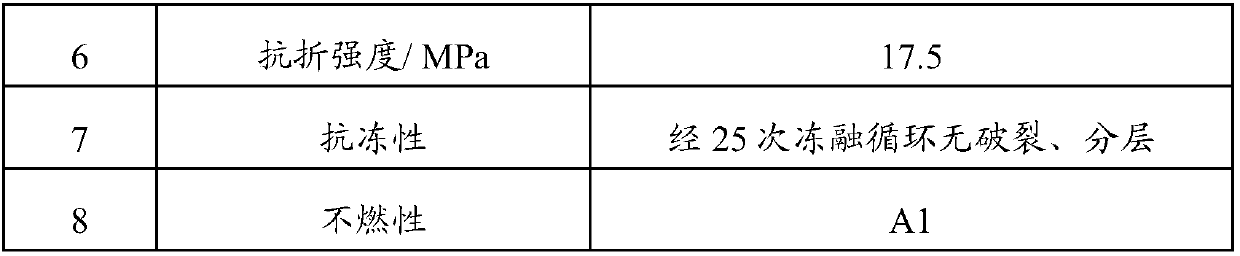

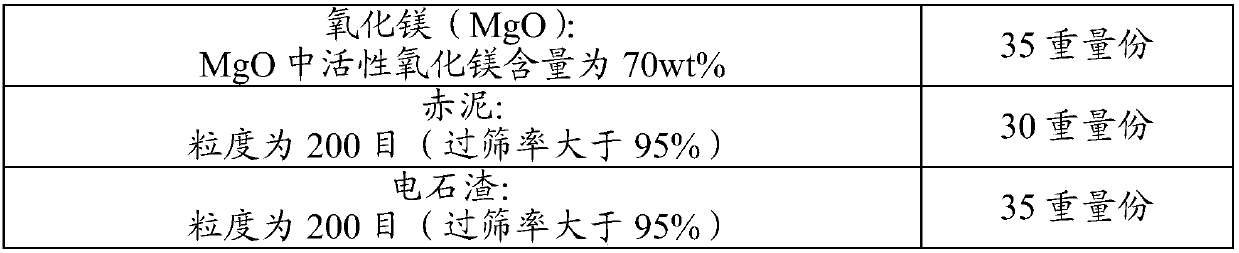

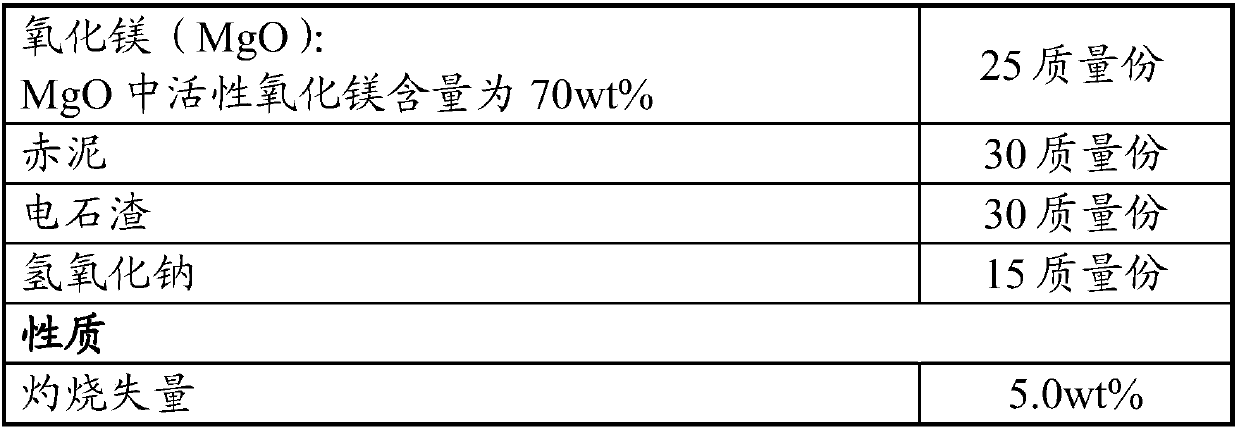

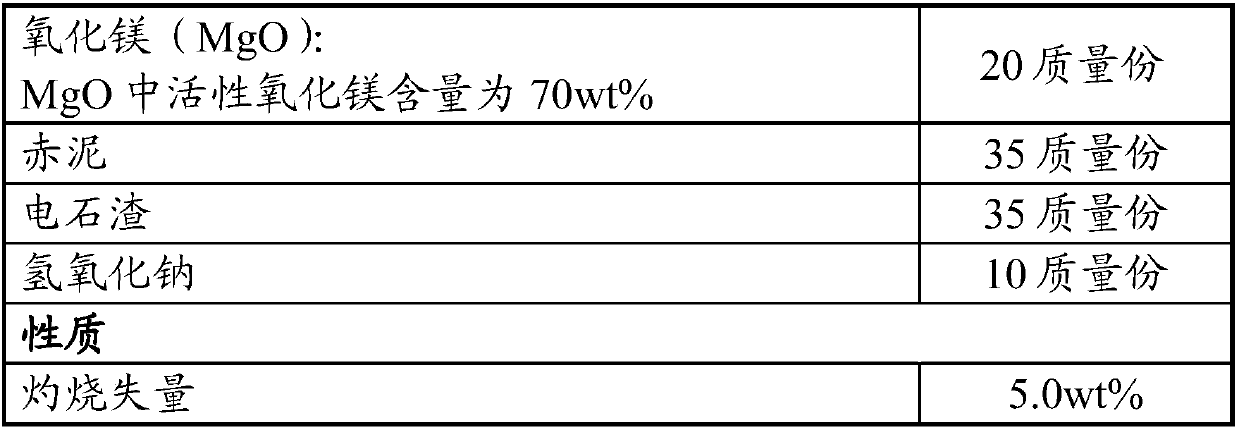

Method for producing lightweight concrete product by flue gas desulfurization based on red mud

InactiveCN107746243AReduce desulfurization operating costsGuaranteed uptimeGas treatmentSolid waste managementRed mudSlag

The invention discloses a method for producing a lightweight concrete product by flue gas desulfurization based on red mud. The method comprises the steps: (1) making flue gas desulfurizing agent slurry be in contact with flue gas, and removing sulfur dioxide in the flue gas by using a wet process to form desulfurized slurry, wherein the desulfurizing agent slurry is formed by adding water into adesulfurizing agent, and the desulfurizing agent contains 20-70 parts by weight of red mud, 20-70 parts by weight of carbide slag, 5-40 parts by weight of magnesium oxide and 5-30 parts by weight of sodium hydroxide; (2) when the pH of the desulfurized slurry is reduced to be 6.5-7.5, mixing raw materials containing the desulfurized slurry, magnesium oxide, lightweight aggregates, industrial solidwastes and additives to form a mixed material; and (3) carrying out pouring molding on the mixed material, and carrying out curing to obtain the lightweight concrete product. By using the method disclosed by the invention, industrial wastes can be effectively utilized on the basis of flue gas desulfurization, and the qualified lightweight concrete product can be produced.

Owner:ZHONGJING ECO IND CO LTD

Desulphurizing tower for desulphurizing with seawater soda-residue emulsion

InactiveCN101444698BVersatileSimplified desulfurization processDispersed particle separationSeawaterOperating cost

Owner:QINGDAO SODA ASH IND DEV CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com