Patents

Literature

35results about How to "Good effect of desulfurization and dust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

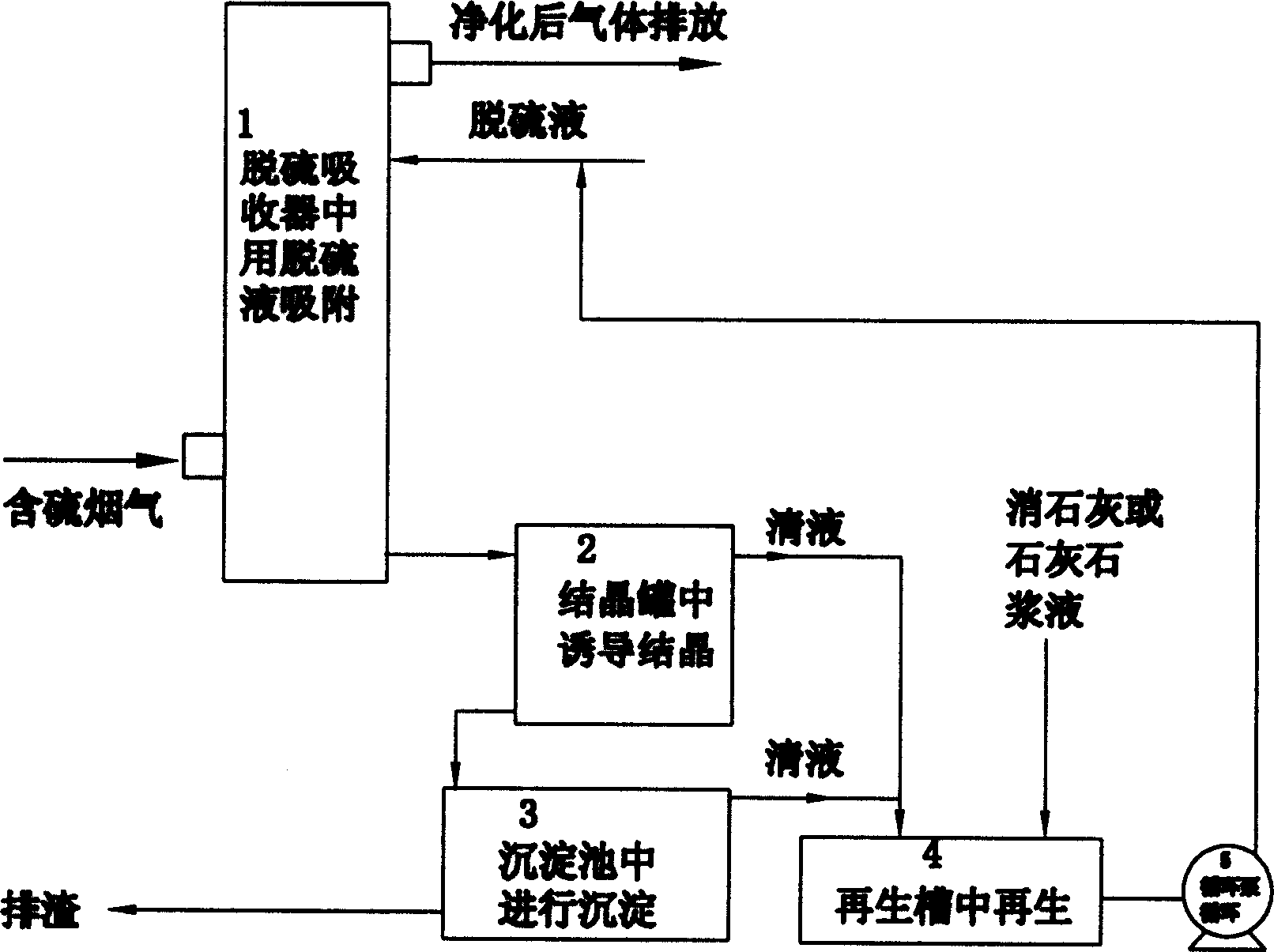

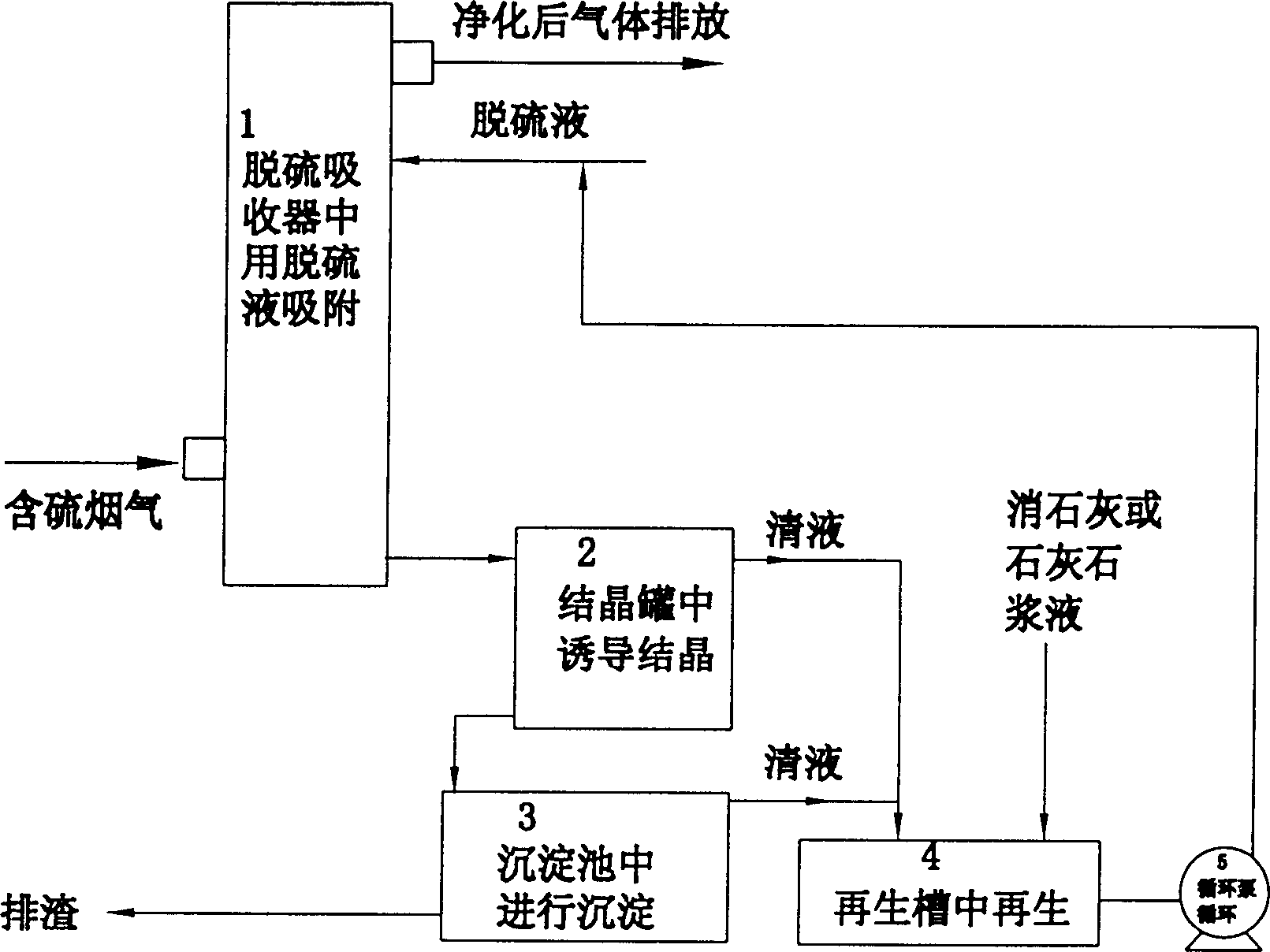

Flue desulfuriznig and dust collecting induction and crystallization process for reuse by concentrated slurry double alkali method

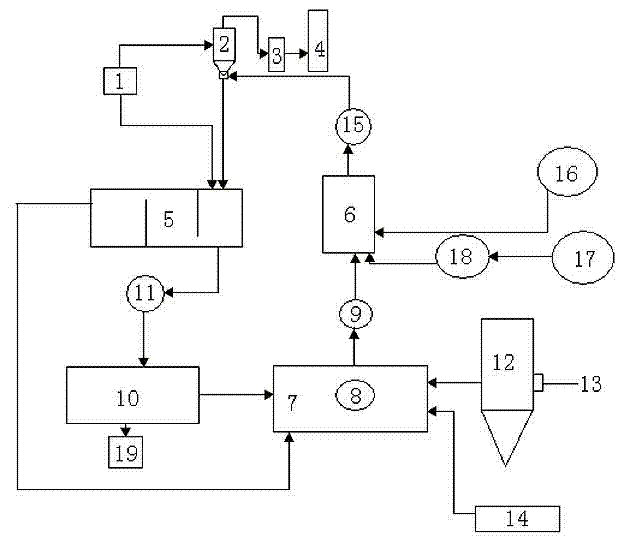

A concentrated slurry and dual-alkali process for desulfurizing, dusting and reclaming fume includes such steps as removing SO2 and dust from fume by the desulfurizing liquid, exhausting clean fume, returning part of resultant liquid base to desulfurizing liquid, pumping its rest in crystallizer, crystallizing, flowing the most of slurry in regenerator while flowing the rest in deposition pool, taking the supernatant from deposition pool and delivering it to regenerator, discharging deposit, and adding lime / lime stone and sodium alkali to said slurry in regenerator for regeneration.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

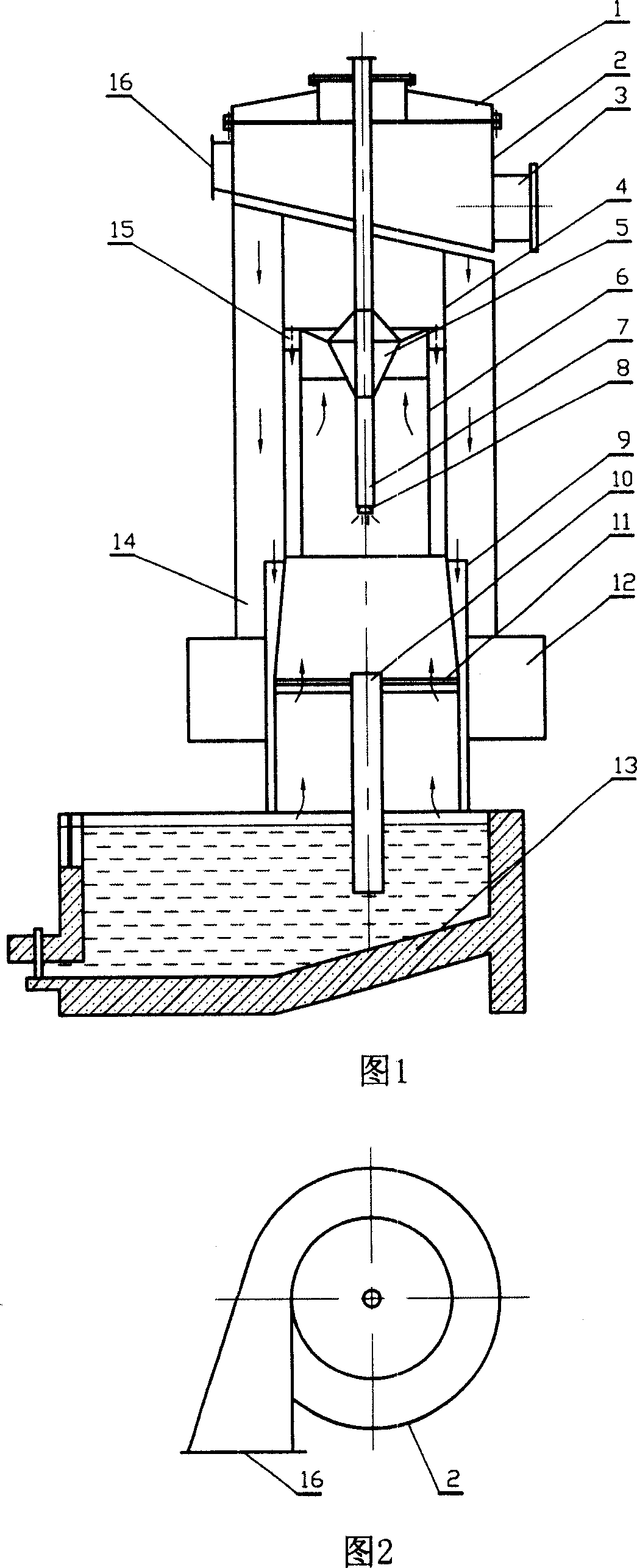

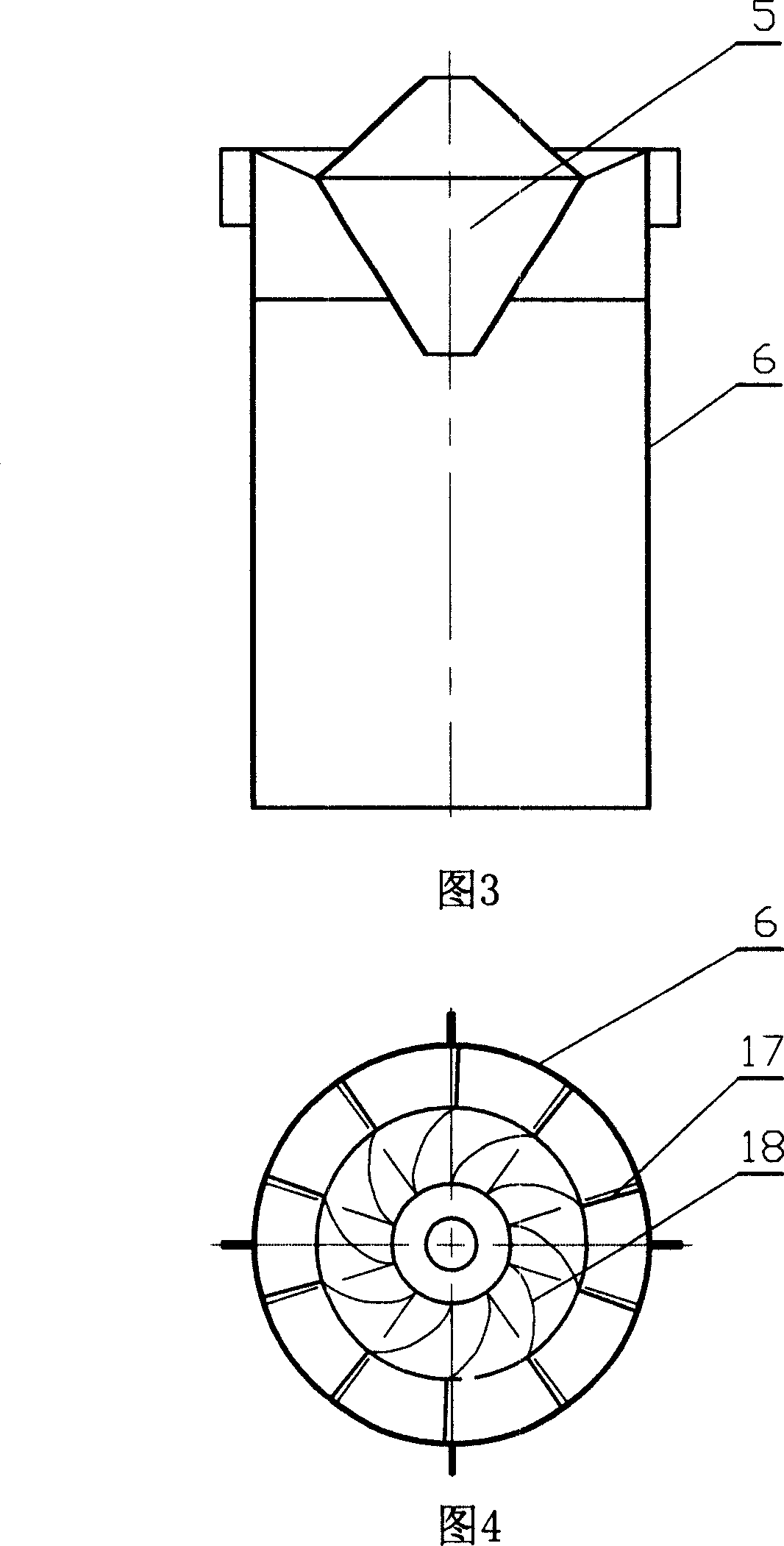

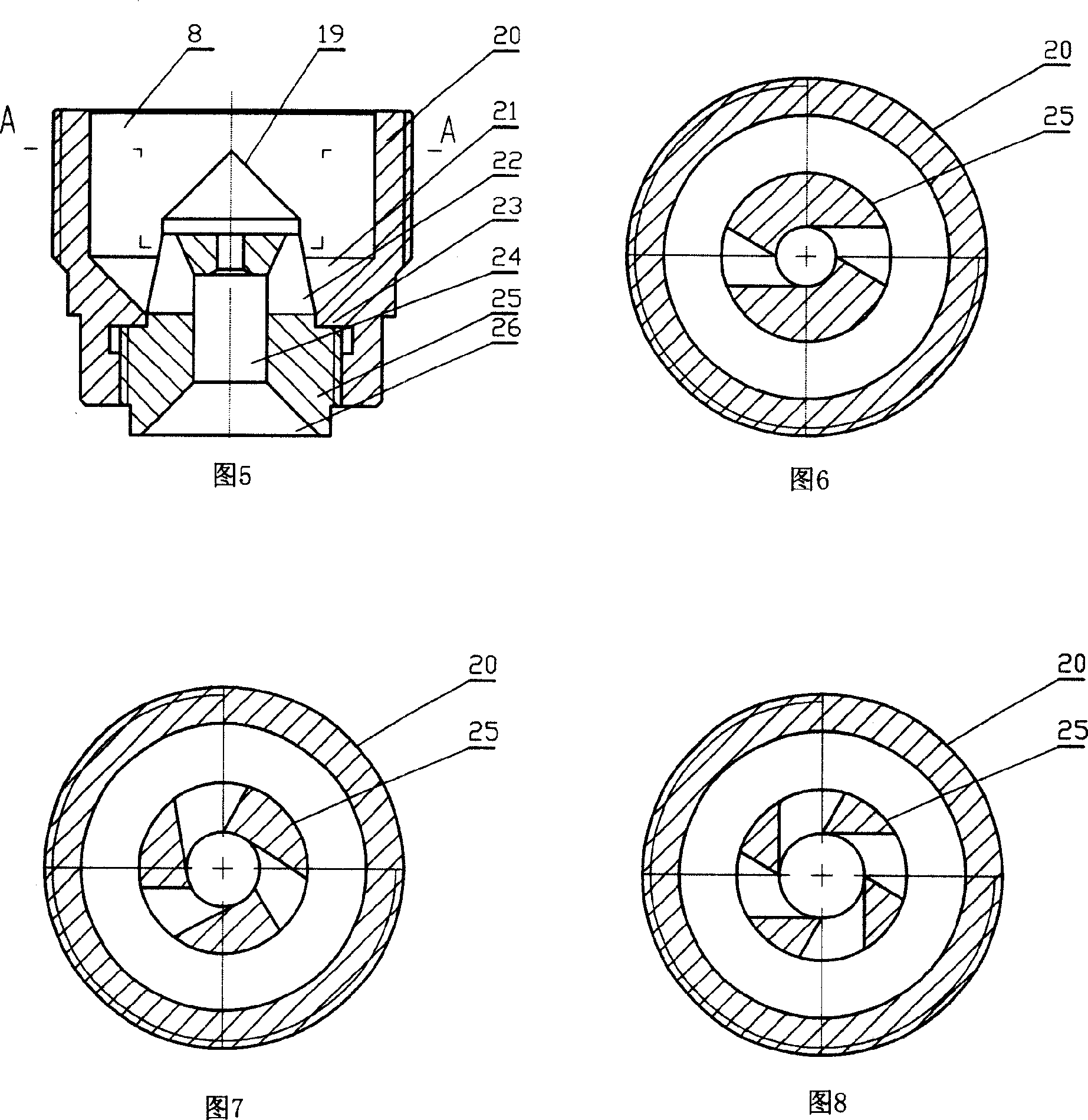

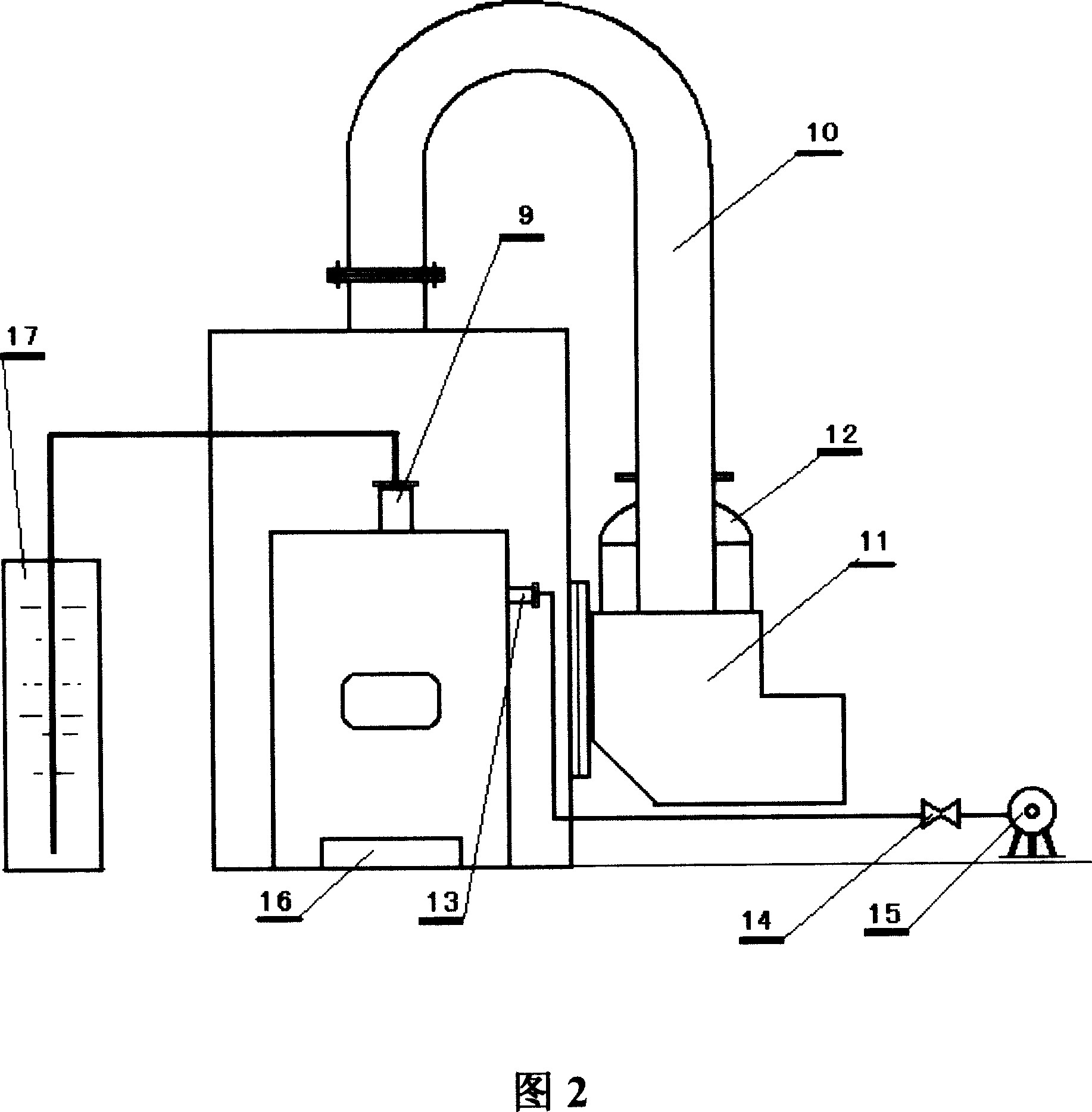

Integration dust-removing and desulfurizing device

InactiveCN101099920ACompact structureReasonable designUsing liquid separation agentSmall footprintEngineering

The present invention relates to integrated dedusting and desulfurizing apparatus and process. The integrated dedusting and desulfurizing apparatus one outer cylinder and one inner cylinder to form one sandwich with tangent air inlet and one air outlet, one sandwiched sleeve connected coaxially to the lower part of the inner cylinder and communicated to the sandwich between the outer cylinder and the inner cylinder, one water tank communicated to the sandwiched sleeve, one dewatering unit coaxially fixed inside the inner cylinder and with one axial water pipe, and one horizontal sieve plate in the middle part inside the sandwiched sleeve. The present invention has well combined cyclonic dedusting and spray dedusting and desulfurizing, possesses high dedusting and desulfurizing efficiency, and is suitable for purifying fume of small boiler.

Owner:王国华

High efficiency wet desulfuration and dust-removing device

InactiveCN1391978AWell mixedFull desulfurization and dust removalUsing liquid separation agentFlue gasEngineering

The efficient wet desulfurizing and dusting device especially for coal burning boiler in power plant has one vertical tower with inner tower in its center, tangent flue gas inlet pipe and flue gas outlet pipe, lime water and cinder output pipe, tangent chemical nozzle and water retaining ring. It features the inwards protruding ring set over the flue gas inlet pipe to make fluid passage turned first to tower center and then upwards, and one overflowing unit in the center of the tower to overflow downwards the showing chemical liquid. The present invention has high desulfurizing and dusing effect.

Owner:ZHEJIANG BOHUA ENVIRONMENTAL TECH & ENG

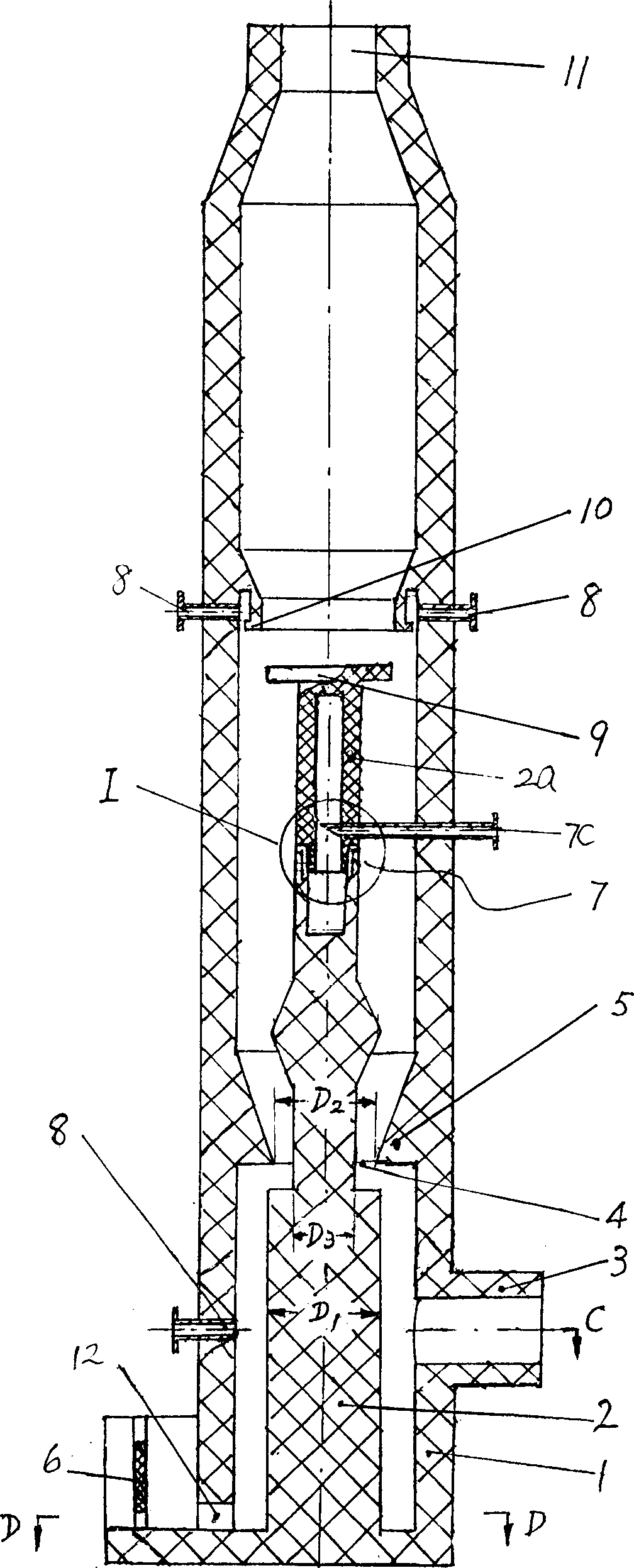

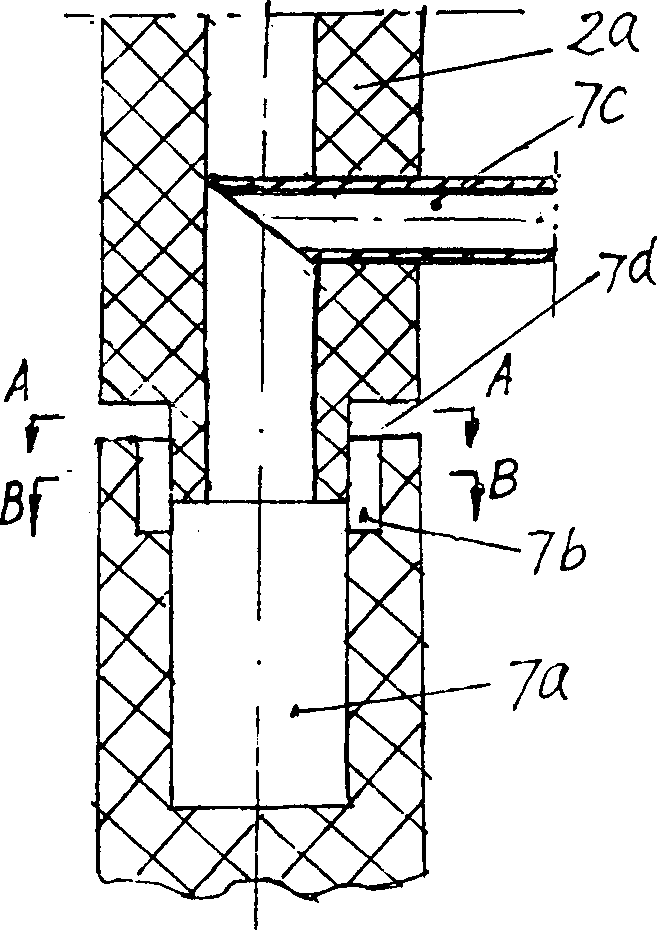

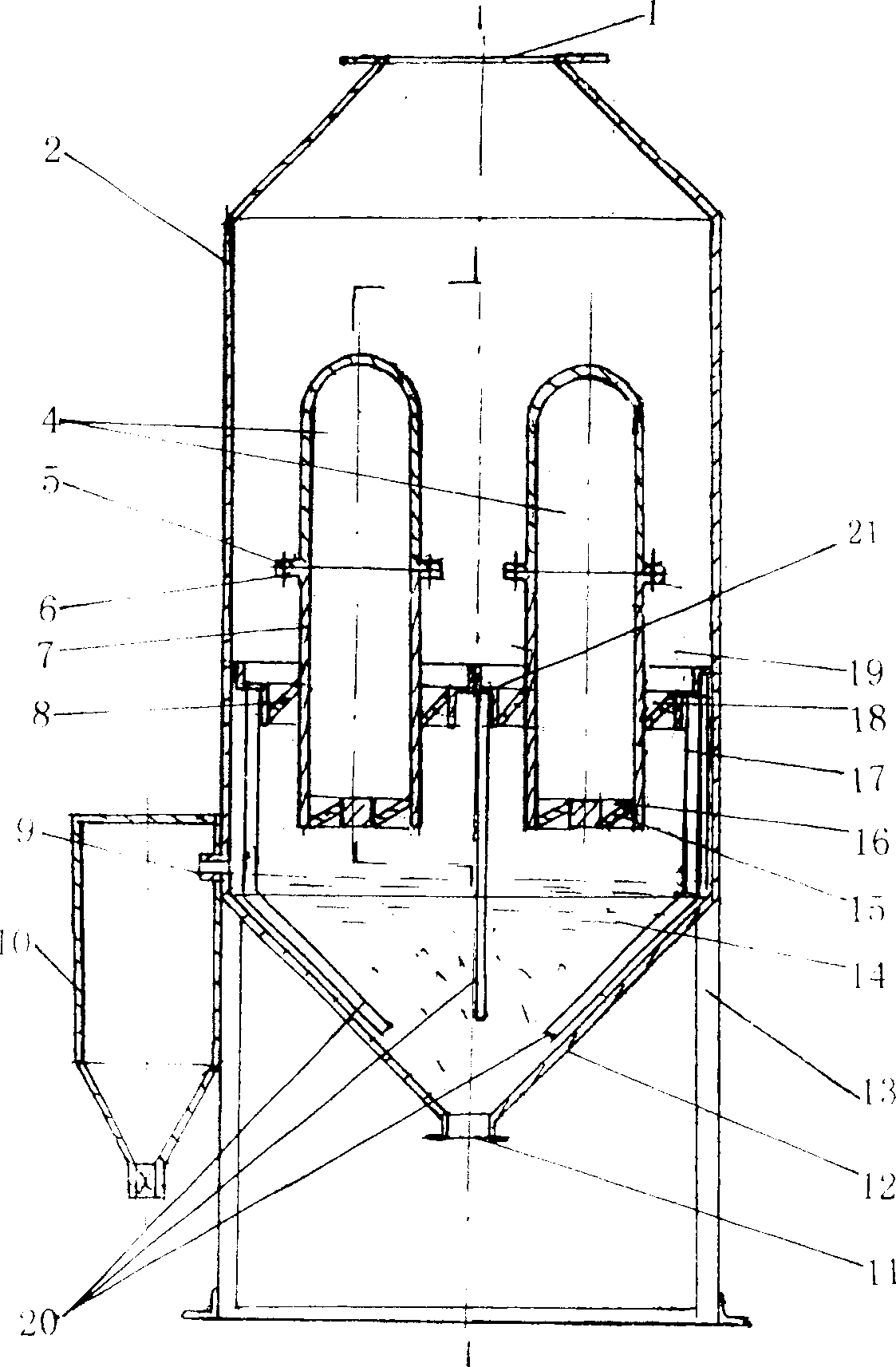

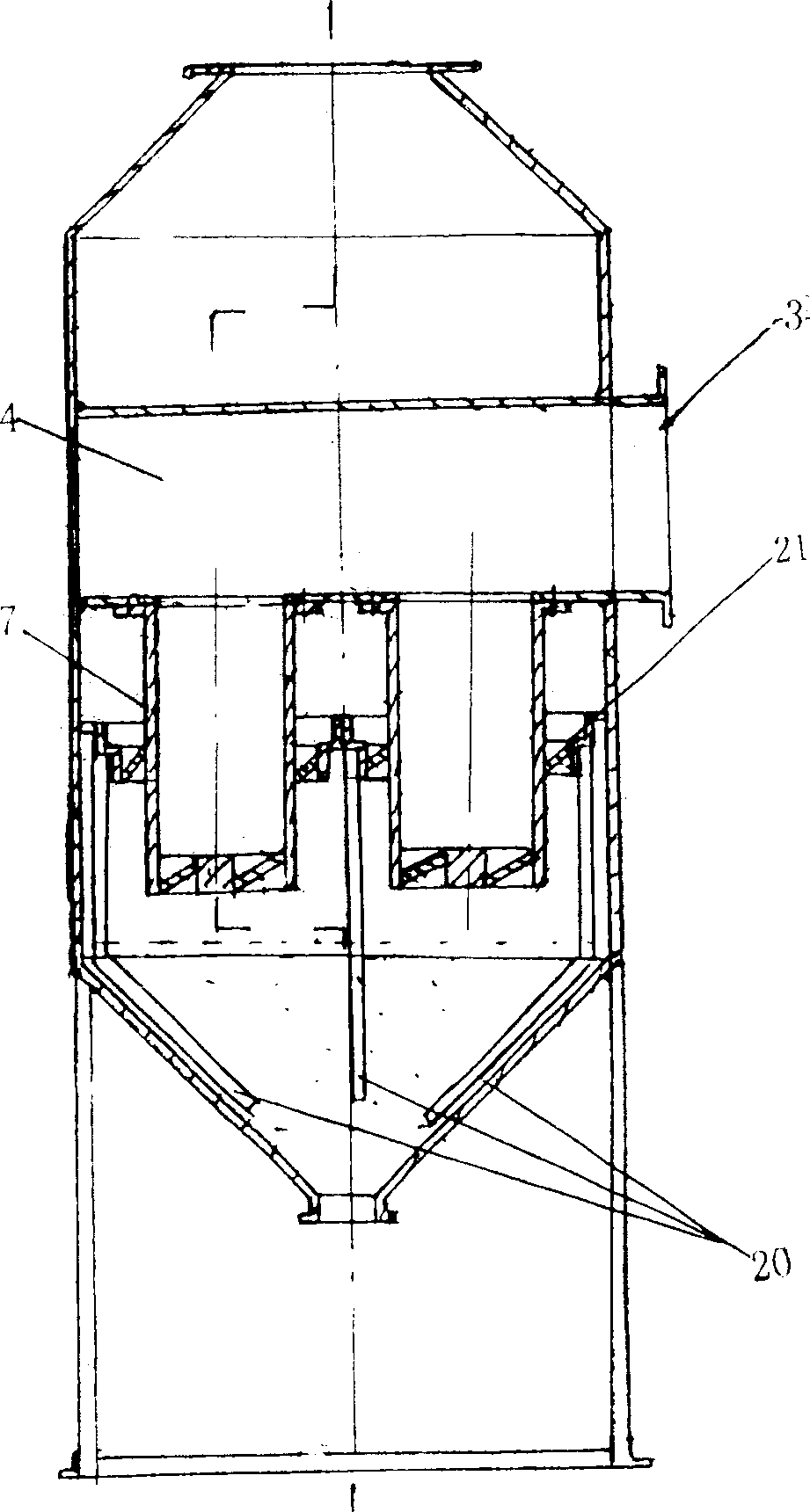

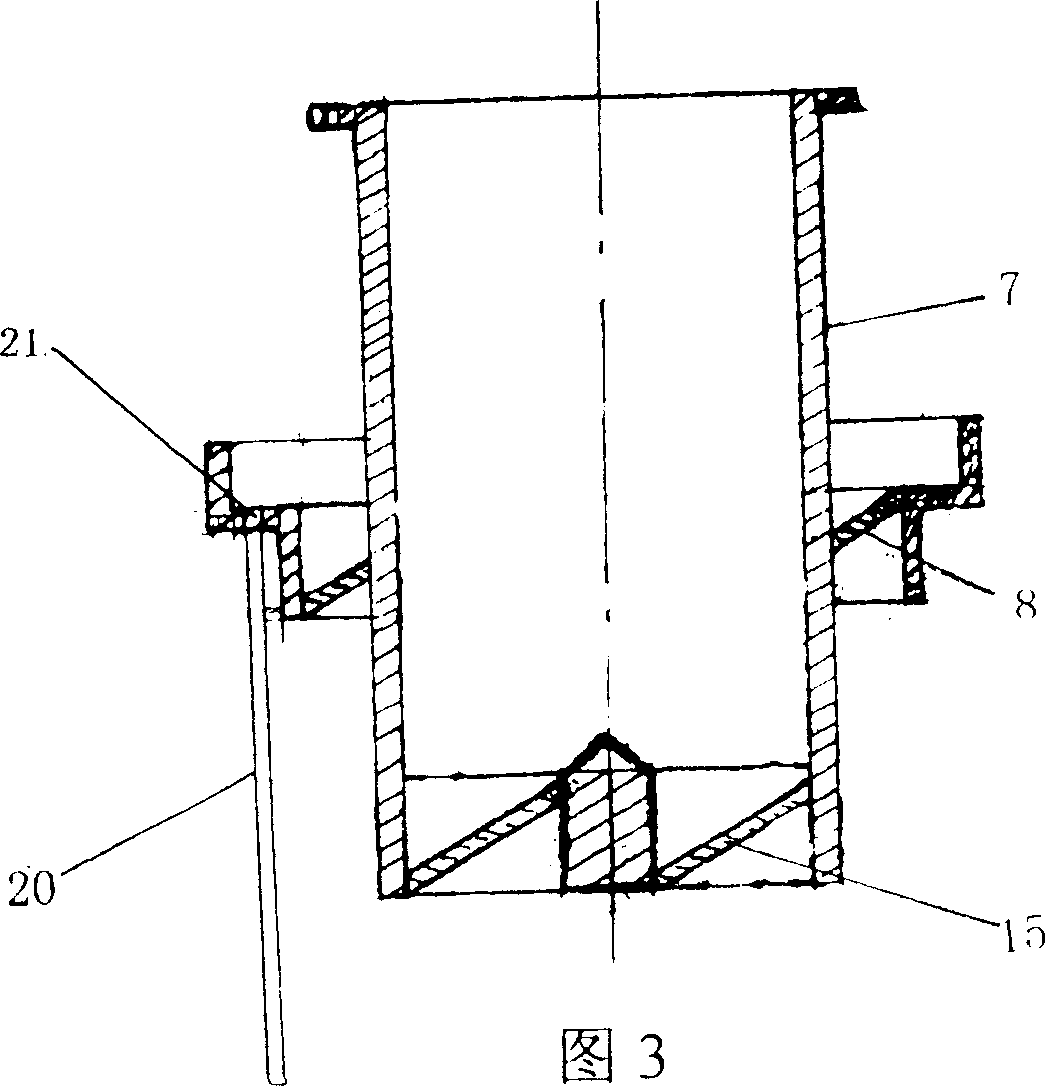

Dust removal and desulphurization device of roasting kiln

InactiveCN102019130AFully contactedComplete contact hydrationUsing liquid separation agentSlagFlue gas

TThe invention discloses a dust removal and desulphurization device of a roasting kiln, which comprises a flue gas dust removal tower, a desulphurization tower, a circulating neutralizing tank, an overflow pipe, a slag discharge pipe, an air blower, a high-pressure circulating pump and an annular dust hood, wherein the upper part of the desulphurization tower is provided with a fresh air discharge outlet, and the lower part of the desulphurization tower is provided with an impact bathing tank; the inner upper part of the flue gas dust removal tower is provided with a central spray header, and the inside of the tower is provided with a plurality of obconical liquid collecting boards; the flue gas dust removal tower is sheathed into the desulphurization tower; the upper and lower parts of a space between the inner wall of the desulphurization tower and the outer wall of the flue gas dust removal tower are respectively provided with a gas-liquid separator and a packing layer, and peripheral spray headers are arranged below the gas-liquid separator and the packing layer; the impact bathing tank is provided with the slag discharge pipe and the overflow pipe, the slag discharge pipe is connected with the circulating neutralizing tank, and the overflow pipe is connected with the slag discharge pipe; the air blower is connected with the fresh air discharge outlet, the water inlet of the high-pressure circulating pump is connected with the circulating neutralizing tank, and the water outlet of the high-pressure circulating pump is respectively connected with the central spray header and the peripheral spray headers by water pipes; and the annular dust hood is arranged at the top of the roasting kiln, and is connected to the top of the flue gas dust removal tower through a flue gas inlet pipe.

Owner:任建利

High-efficiency smoke desulfurizing, dedusting and purifying device

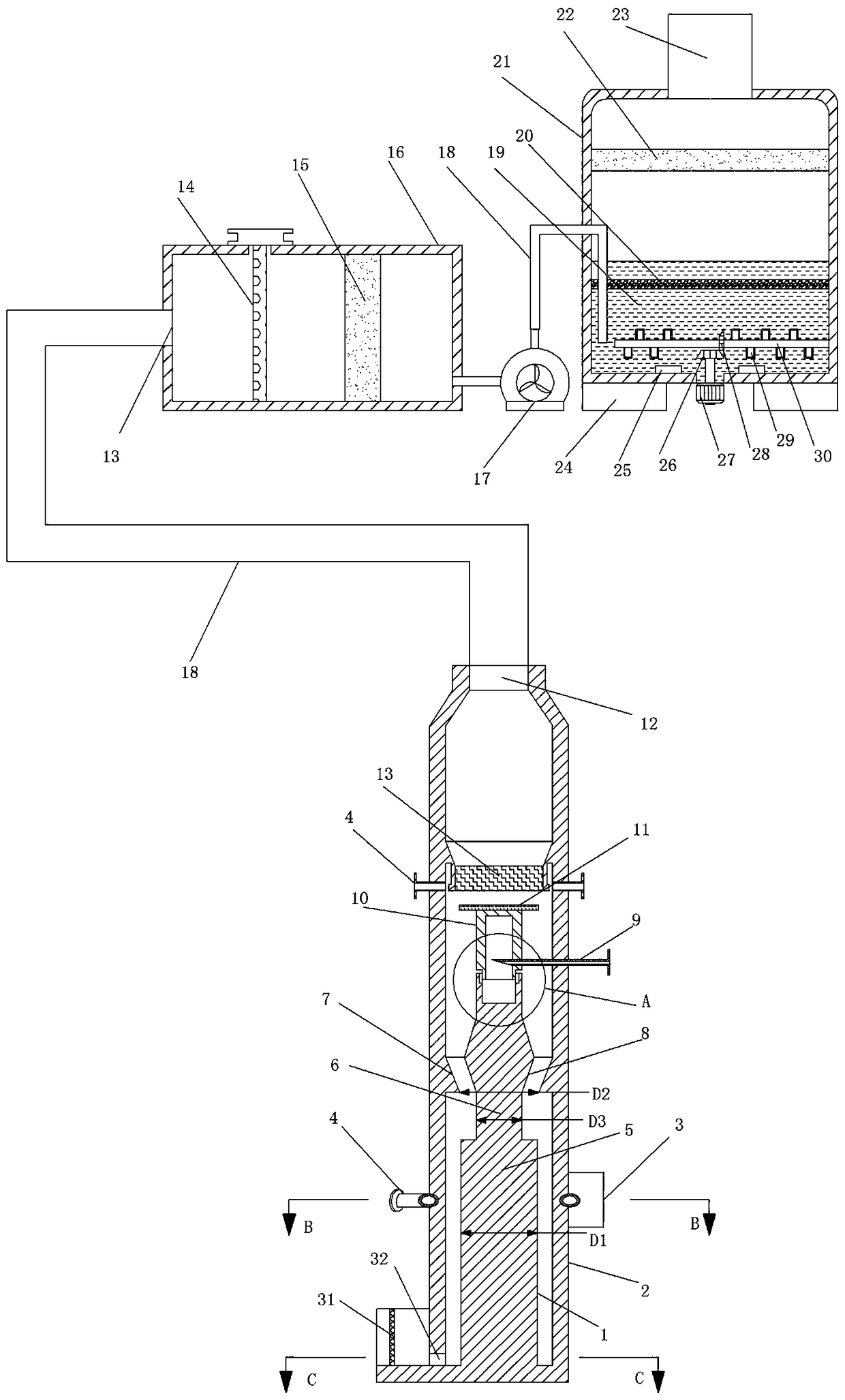

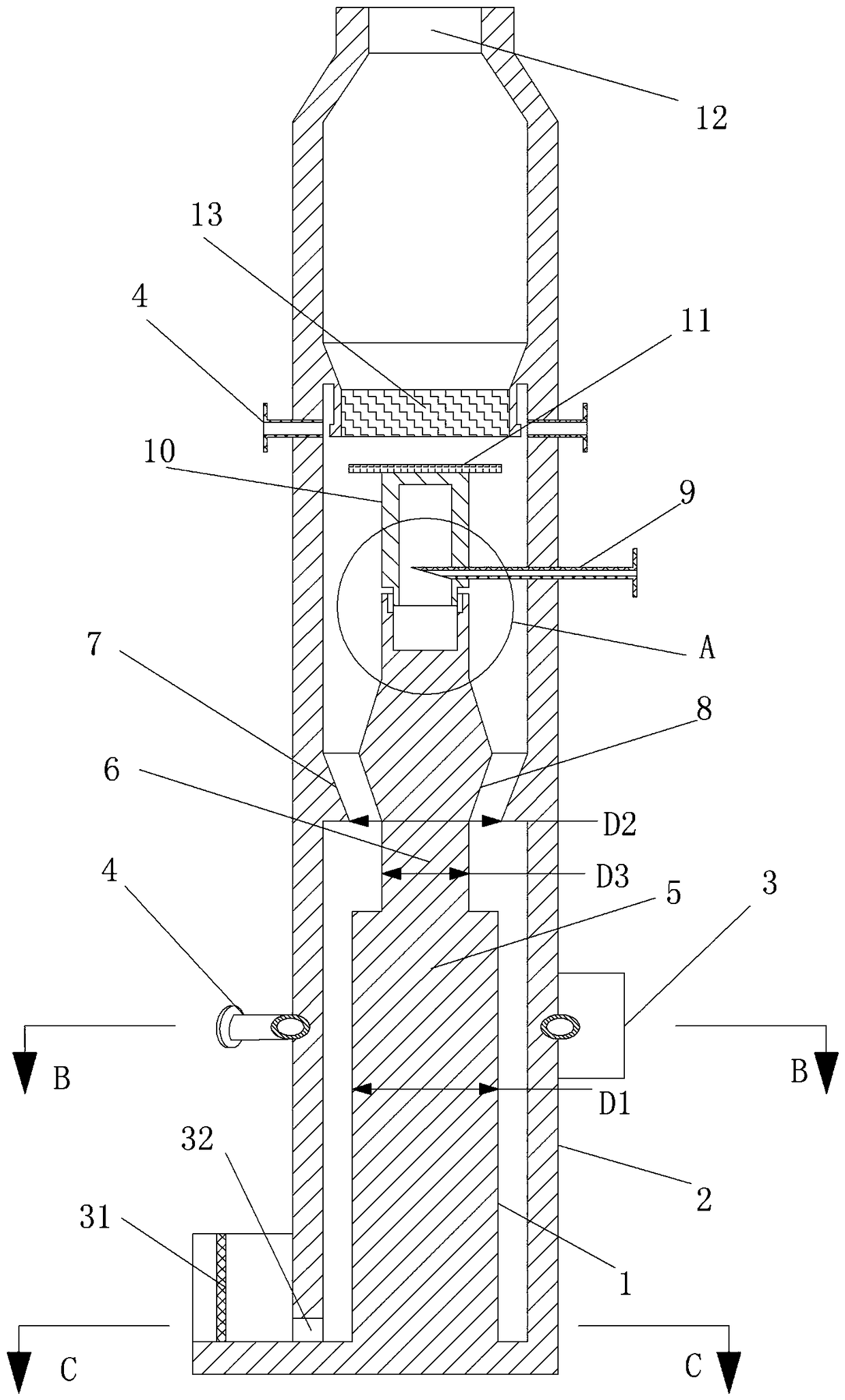

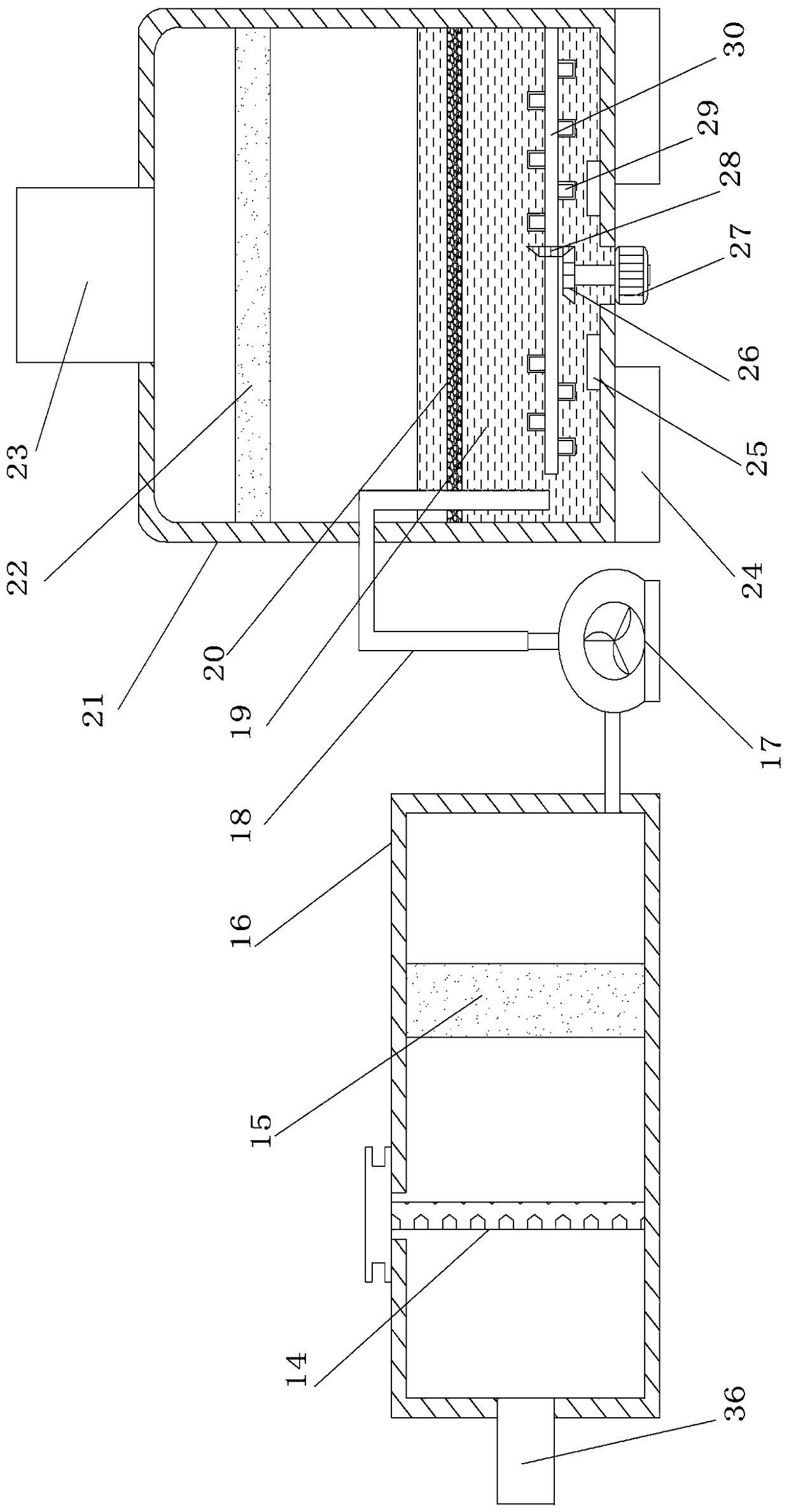

PendingCN108554151AWell mixedComplete contact reactionCombination devicesGas treatmentActivated carbonParticulates

The invention relates to a high-efficiency smoke desulfurizing, dedusting and purifying device. The device comprises a desulfurization tower, a dedusting box and a purifying box, smoke enters the desulfurization tower, the smoke and a chemical liquid flow in the desulfurization tower in the same direction and undergo a desulfurization reaction and rotation in order to achieve preliminary dedusting, radial interlacing mixing is performed on a stop channel, and a fluid infusion is obtained in the central area of the tower, so full air and liquid mixing, complete contact reaction and good desulfurizing and dedusting effects are achieved; the arrangement of a filter plate and an activated carbon adsorption layer makes waste gas filtered and adsorbed and some large particulate impurities in air filtered out, the waste gas in the dedusting box is conveyed into the purifying box through an exhaust fan and a conveying tube, the contact between an air filter screen and the chemical liquid makes the waste gas in full contact with the chemical liquid at the bottom of the inner chamber of the purifying box in order to chemically react the waste gas, and a stirrer in the purifying box can stir the chemical liquid to improve the reaction efficiency of the waste gas and the chemical liquid and improve the waste gas purifying effect.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

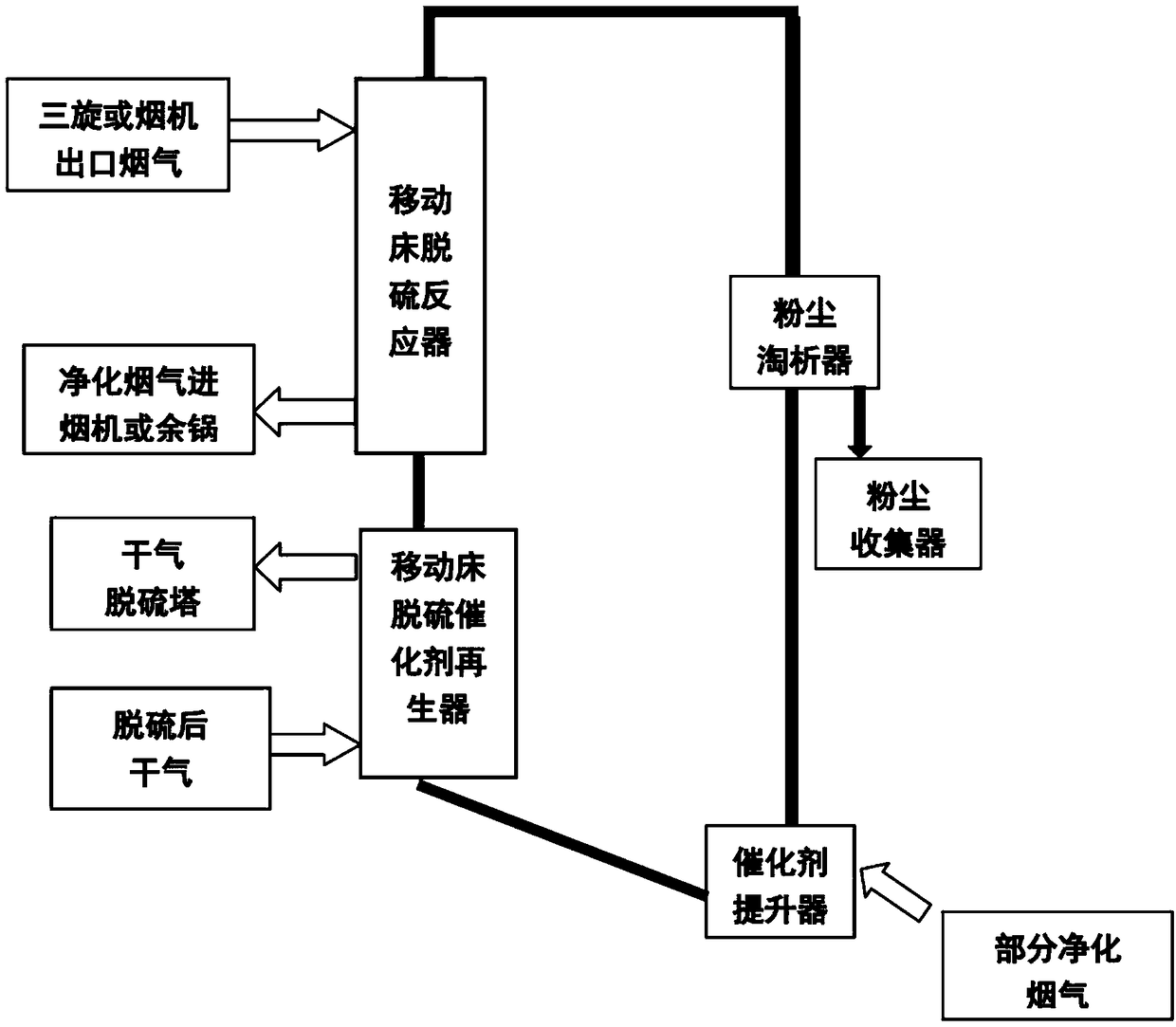

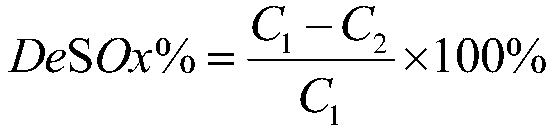

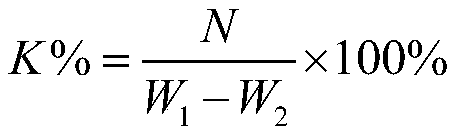

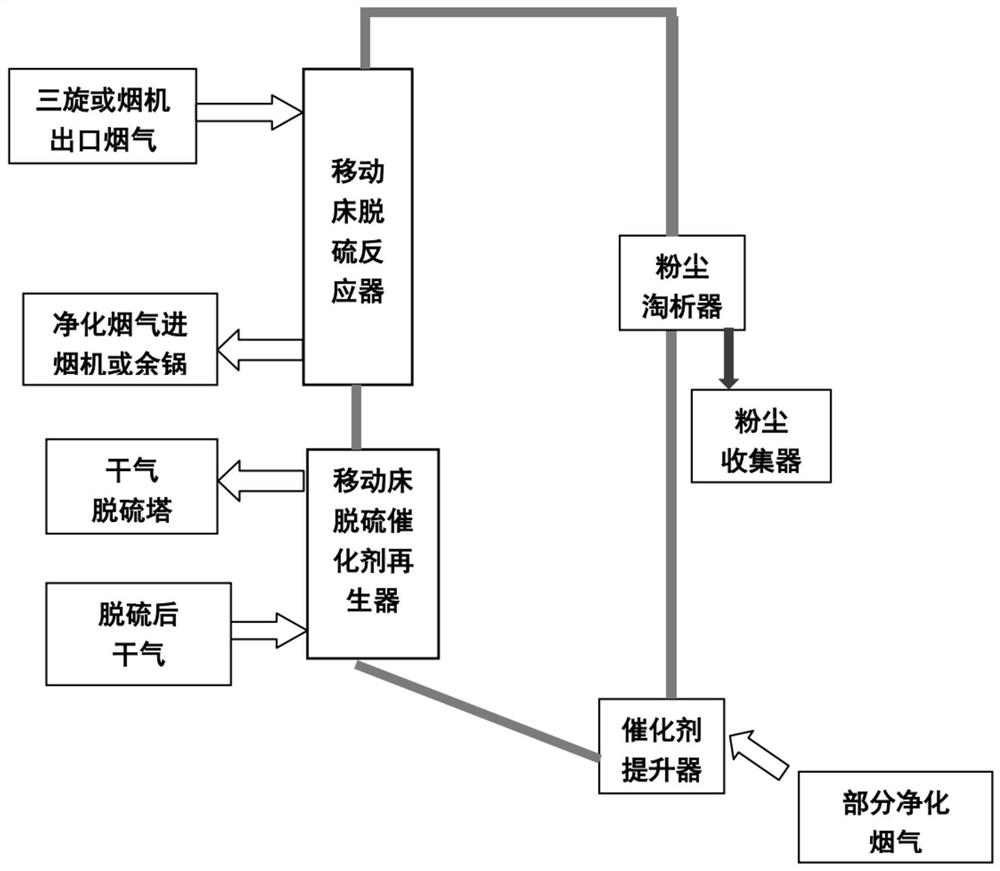

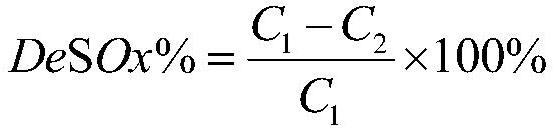

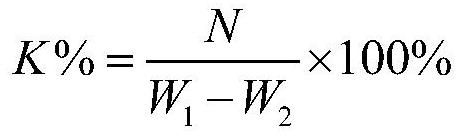

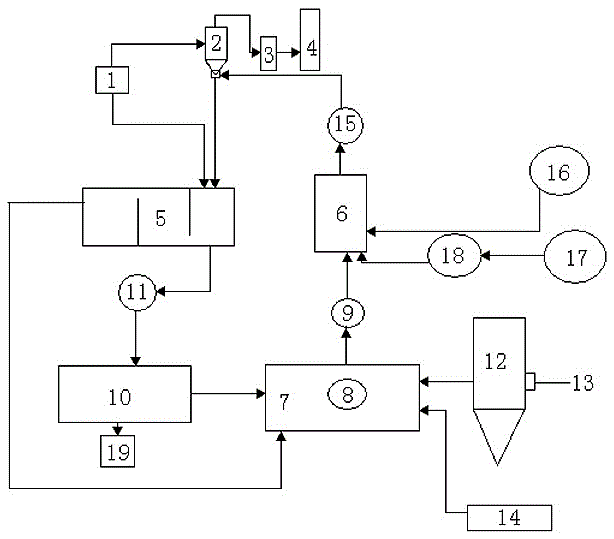

Dry desulfurization dust removing technology method for catalytic cracking regenerated flue gas

ActiveCN109351183AImprove purification efficiencyAvoid emissionsHeterogenous catalyst chemical elementsDispersed particle separationFlue gasElutriation

The invention provides a dry desulfurization dust removing technology method for catalytic cracking regenerated flue gas. The method comprises the steps that catalytic cracking flue gas is introducedin a moving bed desulfuration reactor, the catalytic cracking flue gas and a loaded desulfurization catalyst are subjected to the desulfurization reaction, oxysulfide in the flue gas is subjected to the catalytic reaction to produce metal sulfate, and the metal sulfate is adsorbed on the desulfurization catalyst; the desulfurization catalyst containing the metal sulfate is conveyed to a desulfurization catalyst reproducer, reductive regeneration gas is introduced in the reproducer, and after the metal sulfate on the desulfurization catalyst is reduced to metallic oxide, a part of purified fluegas is utilized for lifting the regenerated desulfurization catalyst into a dust elutriating apparatus through a catalyst lifter, and after dust is recovered through elutriation, desulfurization catalyst is conveyed into moving bed desulfuration reactor for recycling; regenerated acid gas containing hydrogen sulfide is introduced in a dry gas desulfurizer to produce sulphur. According to the method, the desulfuration and dust removal of the catalytic cracking flue gas can be effectively achieved, and the desulfurization rate reaches 99% or above.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Pre-charge spraying desulfurization and dust removal device

InactiveCN103480263ASync removalGood effect of desulfurization and dust removalCombination devicesSulfur dioxideEngineering

The invention discloses a pre-charge spraying desulfurization and dust removal device which is applied to the technical field of coal-fired flue gas desulfurization and dust removal. The pre-charge spraying desulfurization and dust removal device comprises a tower body, wherein the bottom of the tower body is connected with a gas inlet pipe and a liquid outlet pipe, and the top of the tower body is connected with a gas exhaust pipe correspondingly; a plurality of spraying heads are arranged in the tower body; a pre-charge needle is arranged at the front end of each spraying head and is connected with a high-voltage power supply through a cable; a high-pressure air pipeline is connected to a spraying pipe of the spraying heads and is connected with a high-pressure air compressor; the spraying heads are connected with an absorption liquid pipeline; a valve is arranged on the absorption liquid pipeline and is connected with an absorption liquid conveying pump; the absorption liquid conveying pump is connected with an absorption liquid preparation pool through a pipeline; a demister is arranged above the spraying heads. The pre-charge spraying desulfurization and dust removal device can be used for synchronously removing sulfur dioxide and fine particulate matters in coal-fired flue gas, and is high in efficiency and low in cost.

Owner:JIANGSU OU CHAO ENVIRONMENTAL TECH

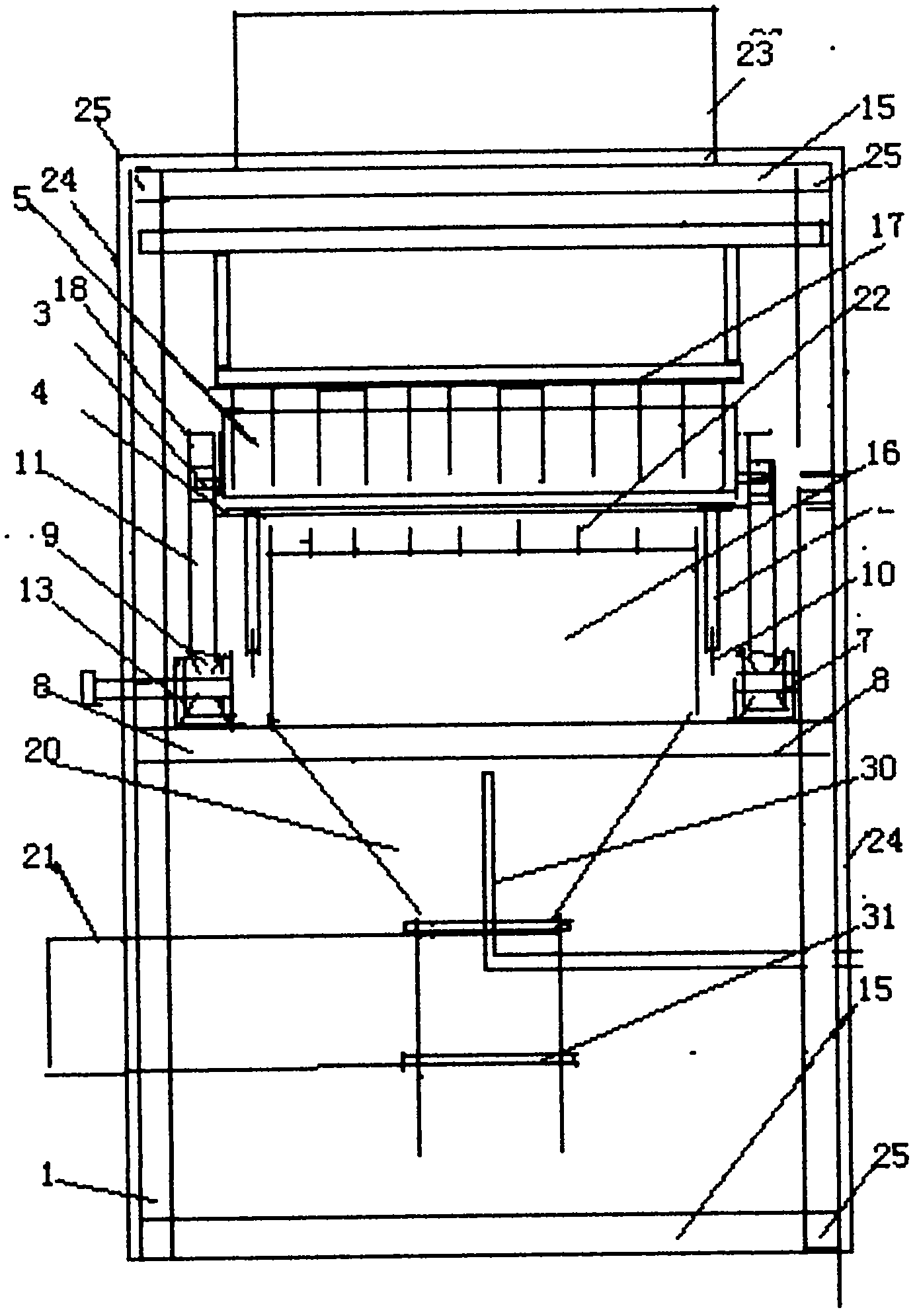

Device and technology for wet-type double-alkali method-based desulphurization and dedusting

ActiveCN103691294ATo achieve the effect of not expellingGuaranteed uptimeDispersed particle separationFlue gasWastewater

The invention belongs to the technical field of desulphurization and dedusting and discloses a device and a technology for wet-type double-alkali method-based desulphurization and dedusting. The invention solves the problem that the existing desulphurization technology is nonstandard and backward, has a high cost, wastes a desulphurization agent, and produces waste gas which does not satisfy discharge standards. The top of a desulfurization tower is connected to a chimney, the bottom of the desulfurization tower is connected to the top of a three-grade sedimentation basin, the bottom of the three-grade sedimentation basin is connected to an automatic timing filter press, the bottom of a desulfurizer pulping pool is connected to the automatic timing filter press, the top of the desulfurizer pulping pool is connected to the bottom of a pH adjustment tank, the top of the pH adjustment tank is connected to the desulfurization tower, and the desulfurizer pulping pool is connected to an ash storage bin and an automatic water-supplementing system. The device can operate stably and has desulphurization efficiency above 99%, dedusting efficiency above 98.5% and a low operation cost. The method has advanced and mature processes, realizes no discharge of waste water, effectively utilizes three wastes, utilizes local material quicklime as a desulfurizer, has a low cost, is accepted by users at present and is suitable for desulphurization and dedusting on flue gas produced in various large / medium-sized production processes.

Owner:山西海云星环保科技有限公司

Novel double-tower type efficient desulfuration dust collector

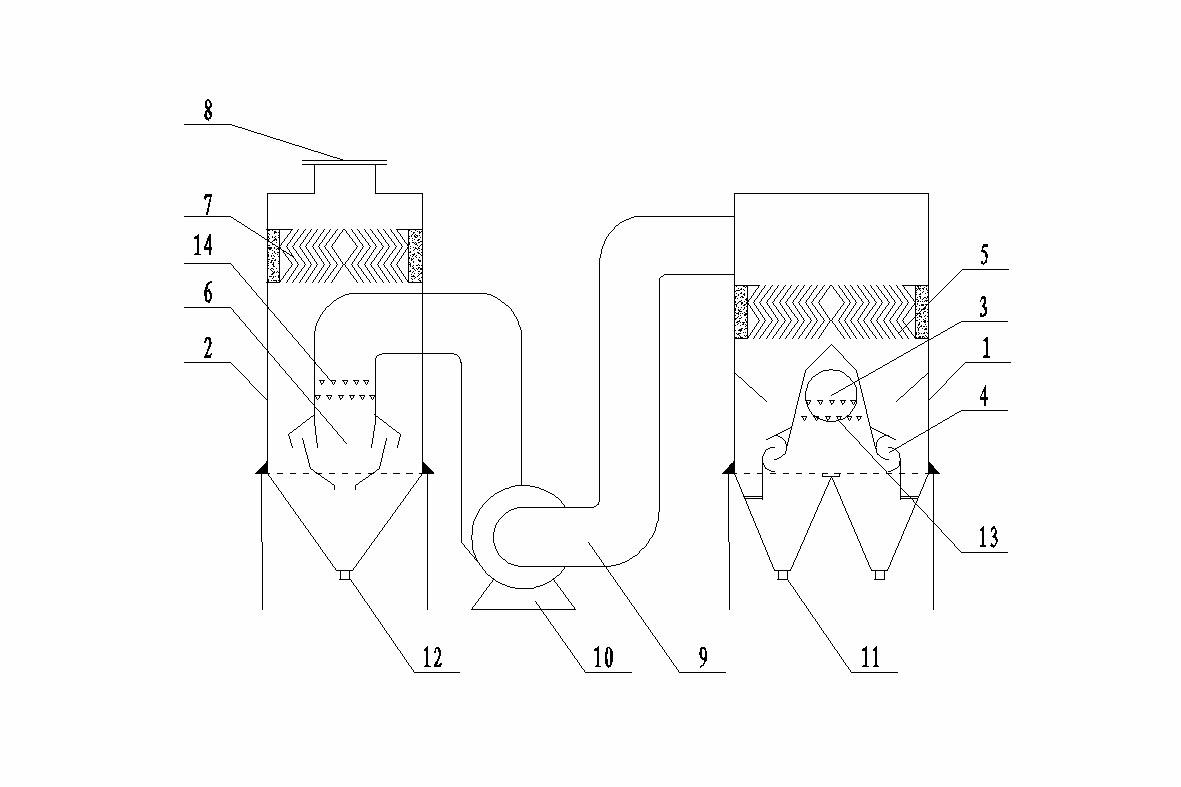

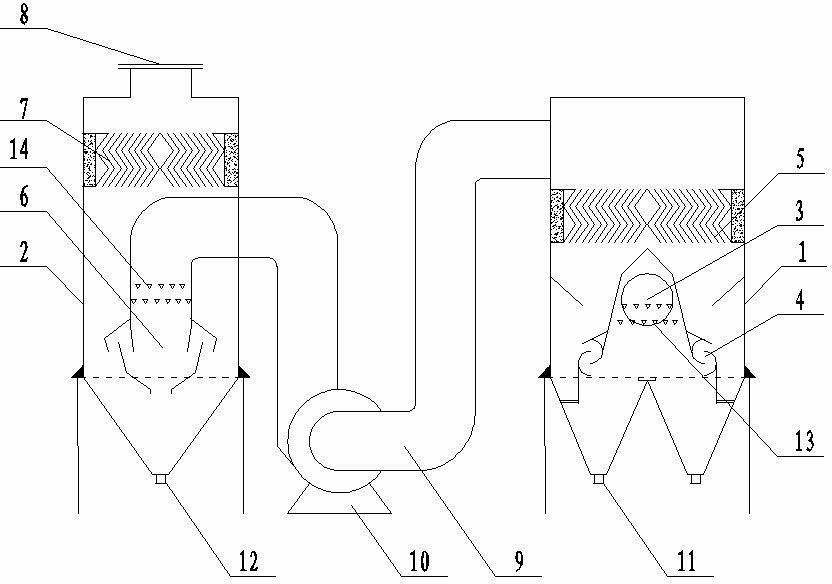

InactiveCN102553415AEfficient desulfurizationEfficient desulfurization and dust removalCombination devicesFlue gasEngineering

The invention relates to a novel double-tower type efficient desulfuration dust collector, belonging to an improvement for the structure of desulfuration dust-removing equipment. The structure of the novel double-tower type efficient desulfuration dust collector is as follows: an S-bend rotating type desulfuration dust-removing tower is connected with an impact turbulence-type desulfuration dust-removing tower by a flue; the flue is provided with a fan; the tower body of the S-bend rotating type desulfuration dust-removing tower is provided with a smoke inlet and a plurality of atomizing nozzles; the two sides of the smoke inlet in the S-bend rotating type desulfuration dust-removing tower are respectively provided with an S-shaped vortex channel; a baffle I is arranged on the middle upper part of the tower body of the S-bend rotating type desulfuration dust-removing tower, and an ash bucket I is arranged at the bottom of the tower body of the S-bend rotating type desulfuration dust-removing tower; an air outlet is arranged on the top of the tower body of the impact turbulence-type desulfuration dust-removing tower, and an ash bucket II is arranged at the bottom of the tower body of the impact turbulence-type desulfuration dust-removing tower; the tail end of the flue is positioned in the tower body of the impact turbulence-type desulfuration dust-removing tower and is provided with a plurality of atomizing nozzles; a flue gas impact body is arranged at the exit of the flue; and a baffle II is arranged on the middle upper part of the tower body of the impact turbulence-type desulfuration dust-removing tower. The novel double-tower type efficient desulfuration dust collector integrates the functions of desulfuration and dust removal, and the aim of efficient desulfuration without smoke and dust is achieved by using a two-stage desulfuration dust-removing tower.

Owner:尤凯军

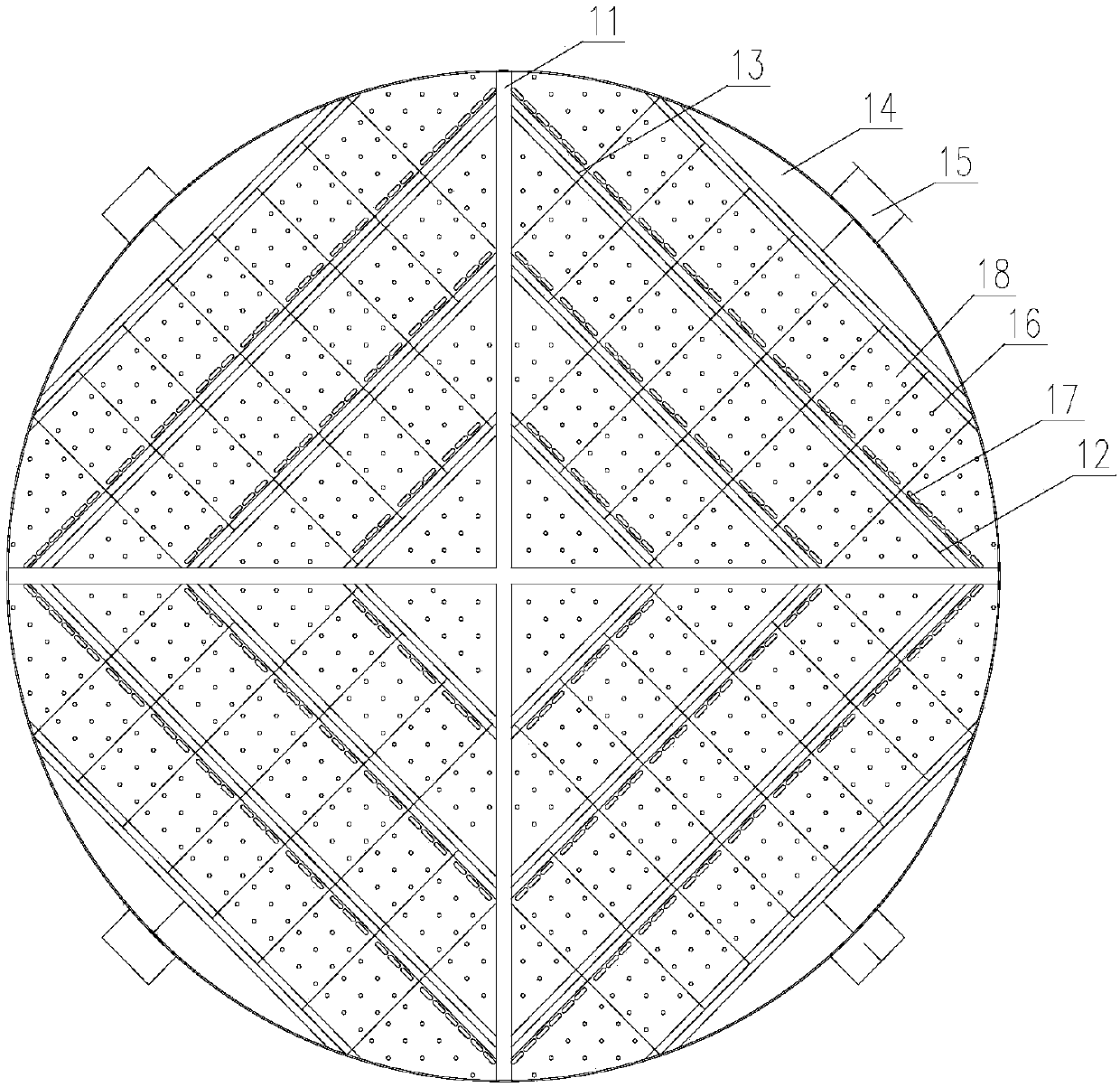

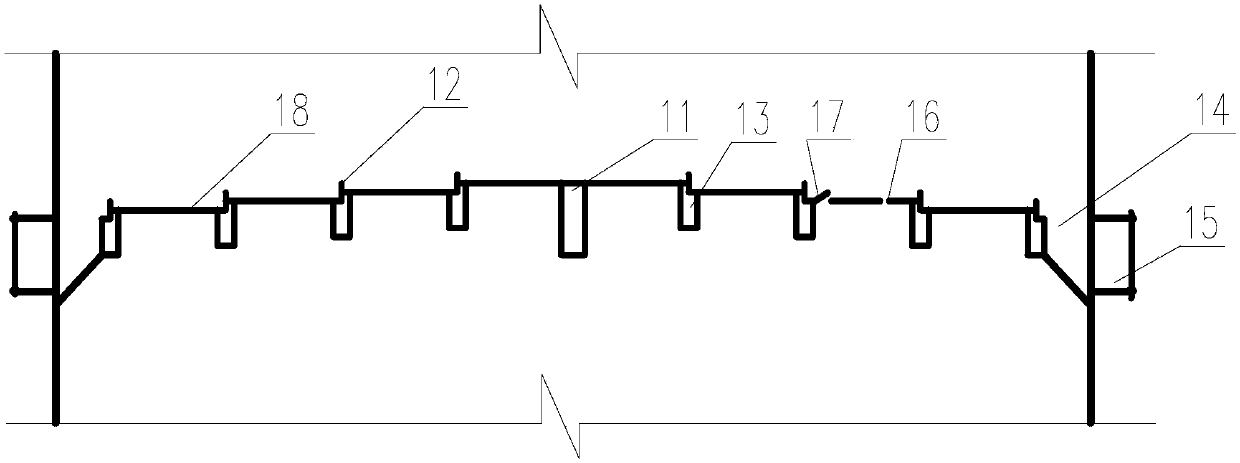

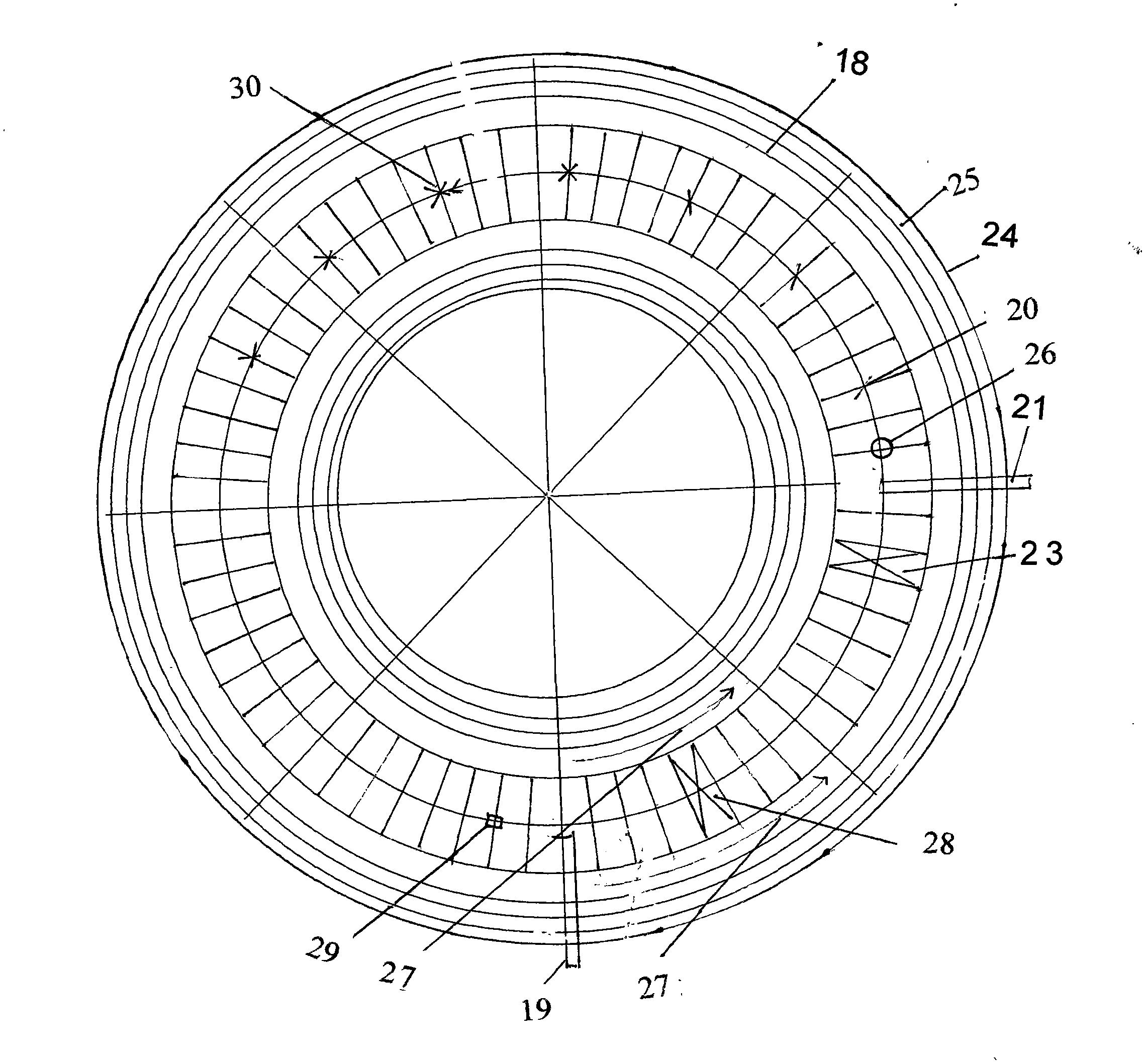

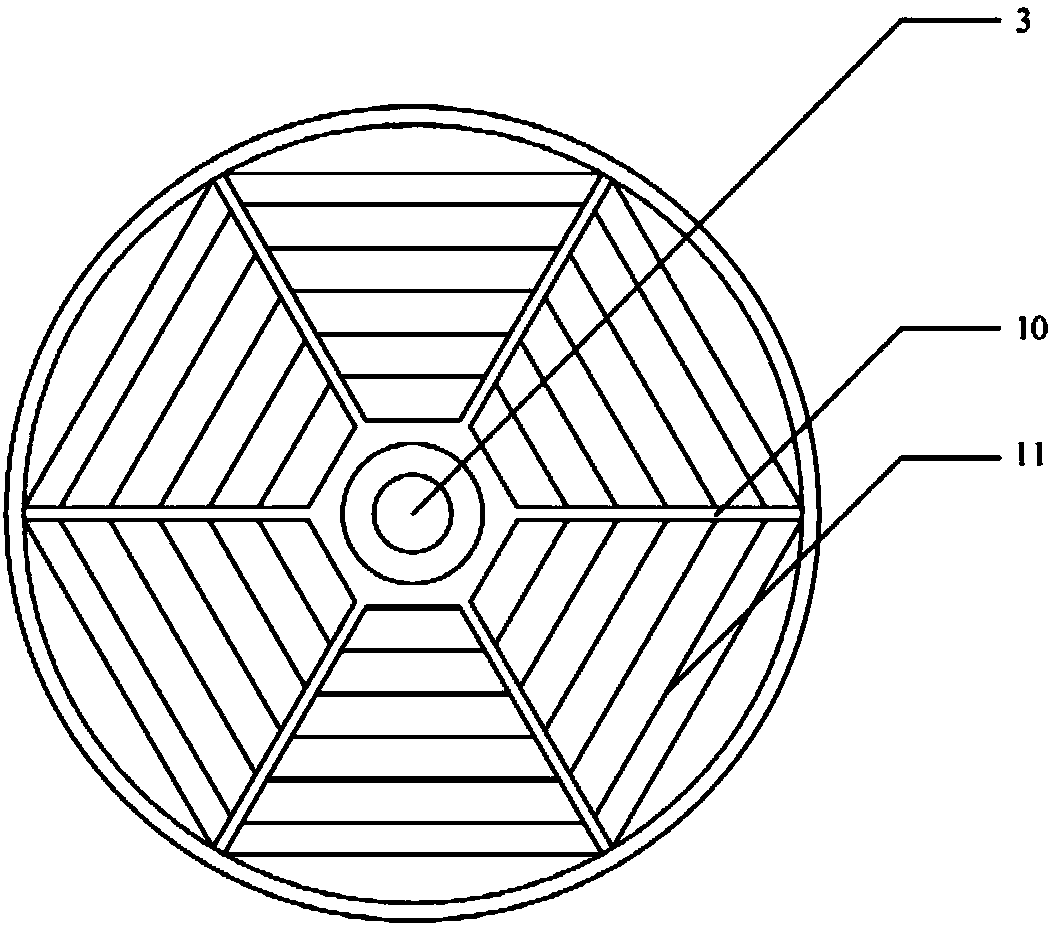

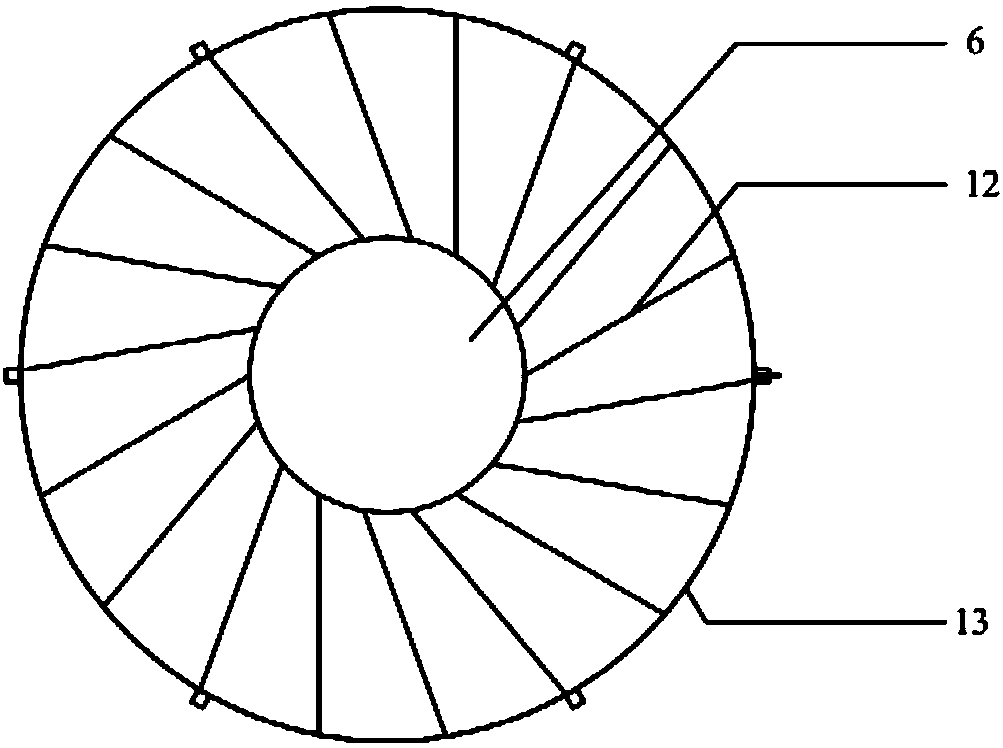

Two-stage flue gas desulfurization tower and ladder-level flow equalization and collection device thereof

PendingCN107789972AReduce headEnhanced two-phase mass transferGas treatmentDispersed particle separationFlue gasSlurry

The invention relates to a two-stage flue gas desulfurization tower and a ladder-level flow equalization and collection device thereof. The ladder-level flow equalization and collection device comprises a girder which is arranged along a radial direction of a flue gas desulfurization tower and is used for dividing the cross-section of the flue gas desulphurization tower into a number of fan-shapedregions, a plurality of small sub-beams are arranged in each one of the fan-shaped regions in parallel at intervals, the heights of the tops of the small sub-beams are decreased step by step from inside to outside, each two adjacent small sub-beams in the same region are connected through a liquid collection plate, the liquid collection plate is provided with sieve pores for gas flow equalizationand inclined spray holes, the liquid collection plate at the outermost side is provided with a liquid falling tank and the liquid falling tank is communicated with a return port on the wall of the desulphurization tower. The flow equalization and collection device has a small absorption tower height space so that the lift of a circulating pump in the second absorption stage is greatly reduced andthe two-stage flue gas desulfurization tower only needs one absorption tower slurry tank.

Owner:YONKER ENVIRONMENTAL PROTECTION

Low-cost activated carbon kieselguhr particles with developed pores, and preparation method of kieselguhr particles

InactiveCN104437399AGood effect of desulfurization and dust removalHigh porosityGas treatmentOther chemical processesPorosityActivated carbon

The invention discloses low-cost activated carbon kieselguhr particles with developed pores. The activated carbon kieselguhr particles are characterized by being prepared from the following raw materials in parts by weight: 95-105 parts of nut shell activated carbon, 30-35 parts of kieselguhr, 18-22 parts of Chinese medicine residue, 22-26 parts of tung shell, 6-9 parts of kaolin, 1-2 parts of a silane coupling agent kh560, 3-4 parts of sodium sulfate, 4-6 parts of limestone powder, 2.5-3.5 parts of glass beads, 3.5-5 parts of silica powder, 3-5 parts of clay, 3-5 parts of activated aluminum oxide, 4-6 parts of an absorption auxiliary agent and a proper amount of water. According to the activated carbon kieselguhr particles, the resources such as Chinese medicine residue, tung shell are reused and are fed into the activated carbon and the kieselguhr after being dried and ground; the activated carbon kieselguhr particles are sufficient in raw materials, developed in pores, high in absorption and excellent in performances; the absorption auxiliary agent is fed into the activated carbon kieselguhr particles, so that the activated carbon kieselguhr particles have special porosity, and the contact time of the activated carbon kieselguhr particles with air can be prolonged; the activated carbon kieselguhr particles have good desulfurization and dust-removal effects, are high in porosity, low in cost and simple in production technology, and are capable of greatly lowering the operating cost of dry desulfurization.

Owner:ANHUI PHOENIX INT CO LTD

Method for absorbing SO2 in smoke and removing dust from coal boiler

InactiveCN1862092ASatisfy the absorption reaction processSolve pollutionLighting and heating apparatusDispersed particle separationRed mudPollutant emissions

The invention includes the following steps of first removing the dust from the smoke exhaust when firing the coal in the boiler via a dust preremover; loading the dust-removed smoke into a desulfurizing tower with the Bayer red mud inside; desulfurizing after making contact of the smoke led into the desulfurizing tower with the Bayer red mud; then removing the dust from the desulfurizing smoke led into the second-stage dust-remover and at last discharging the smoke treated by desulfurizing and dust-removing from the chimney.

Owner:GUIYANG AL-MG DESIGN & RES INST

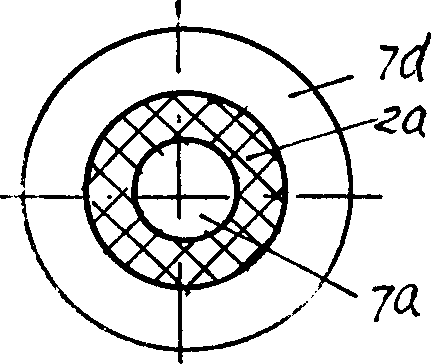

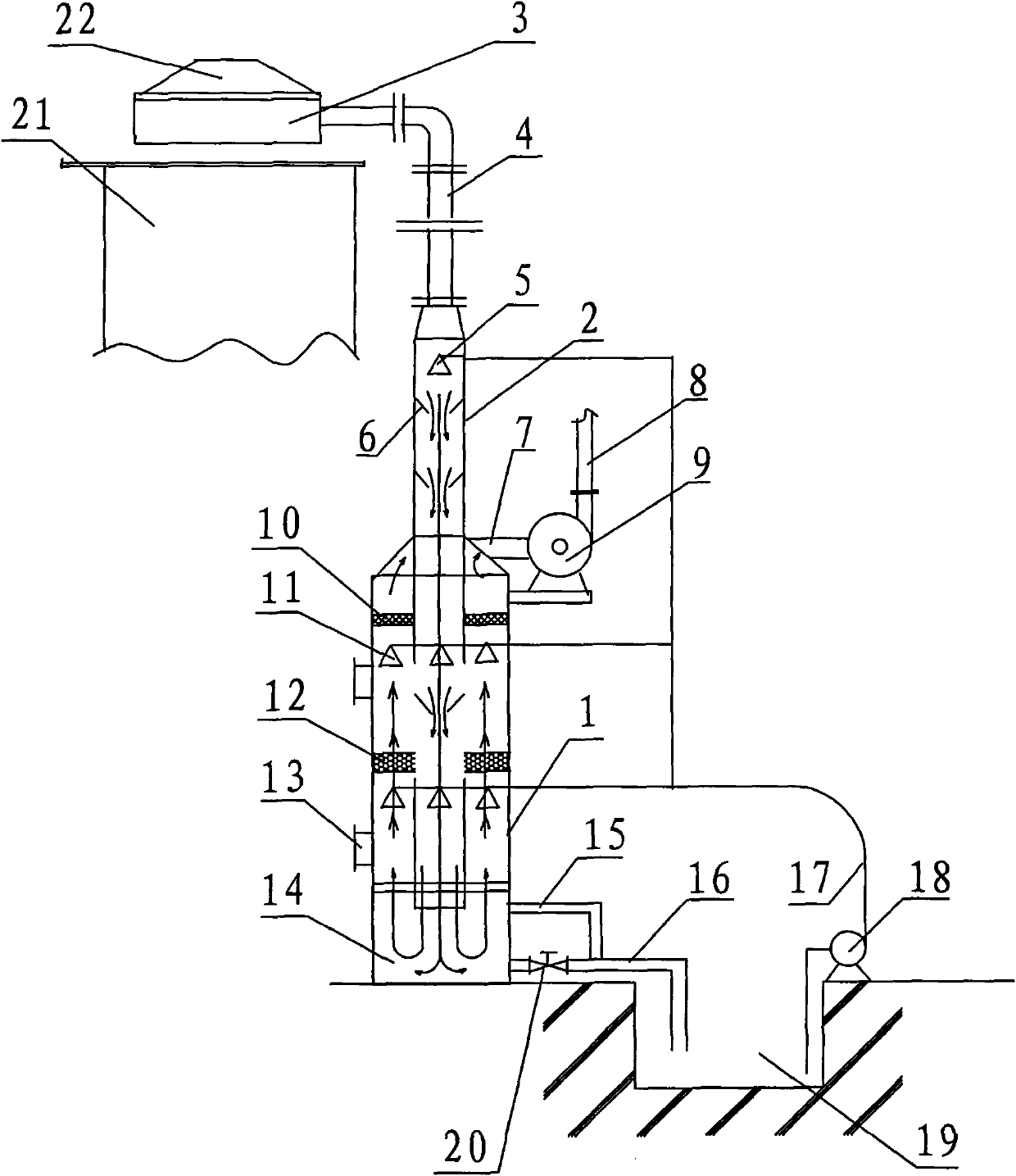

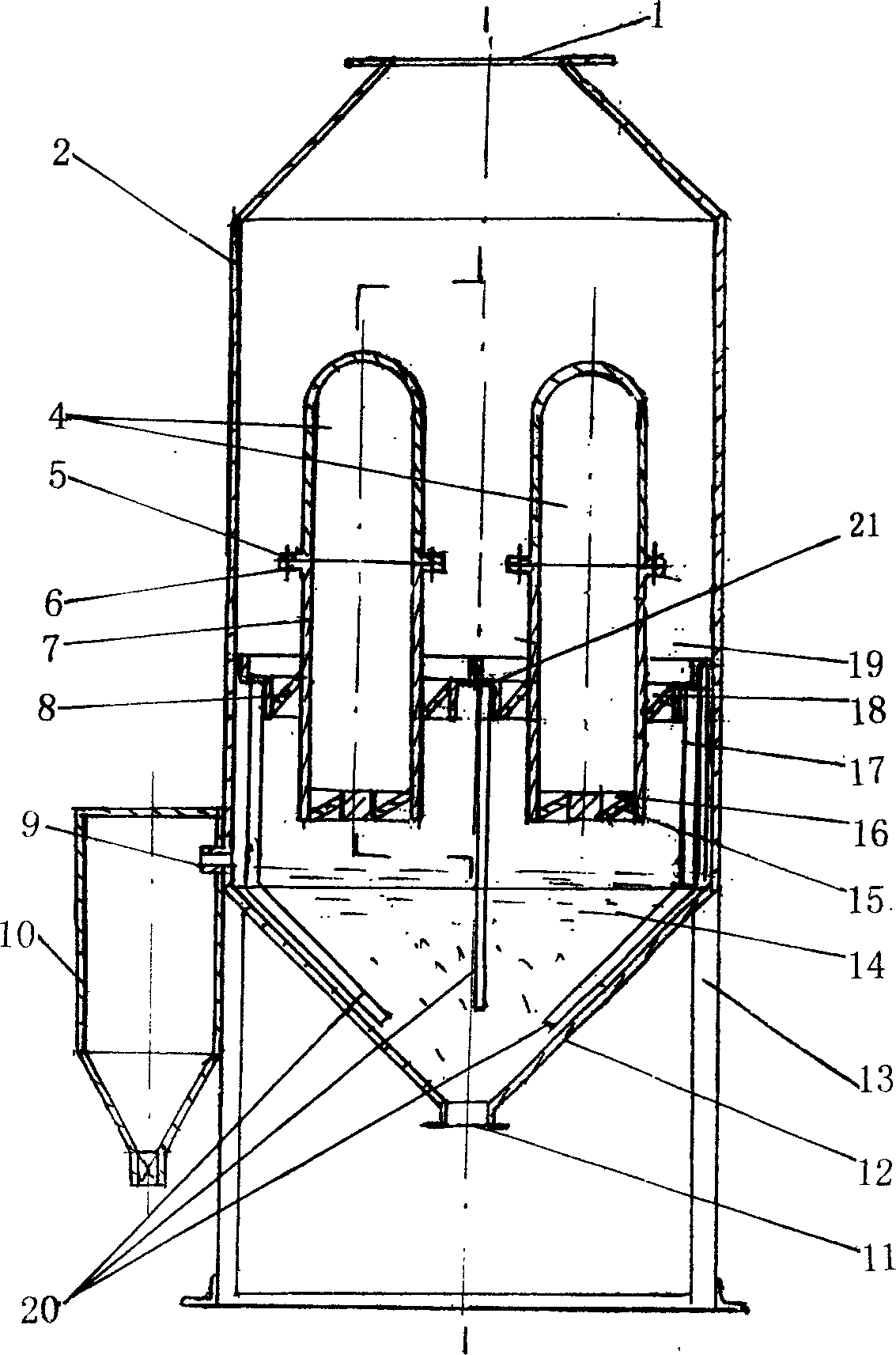

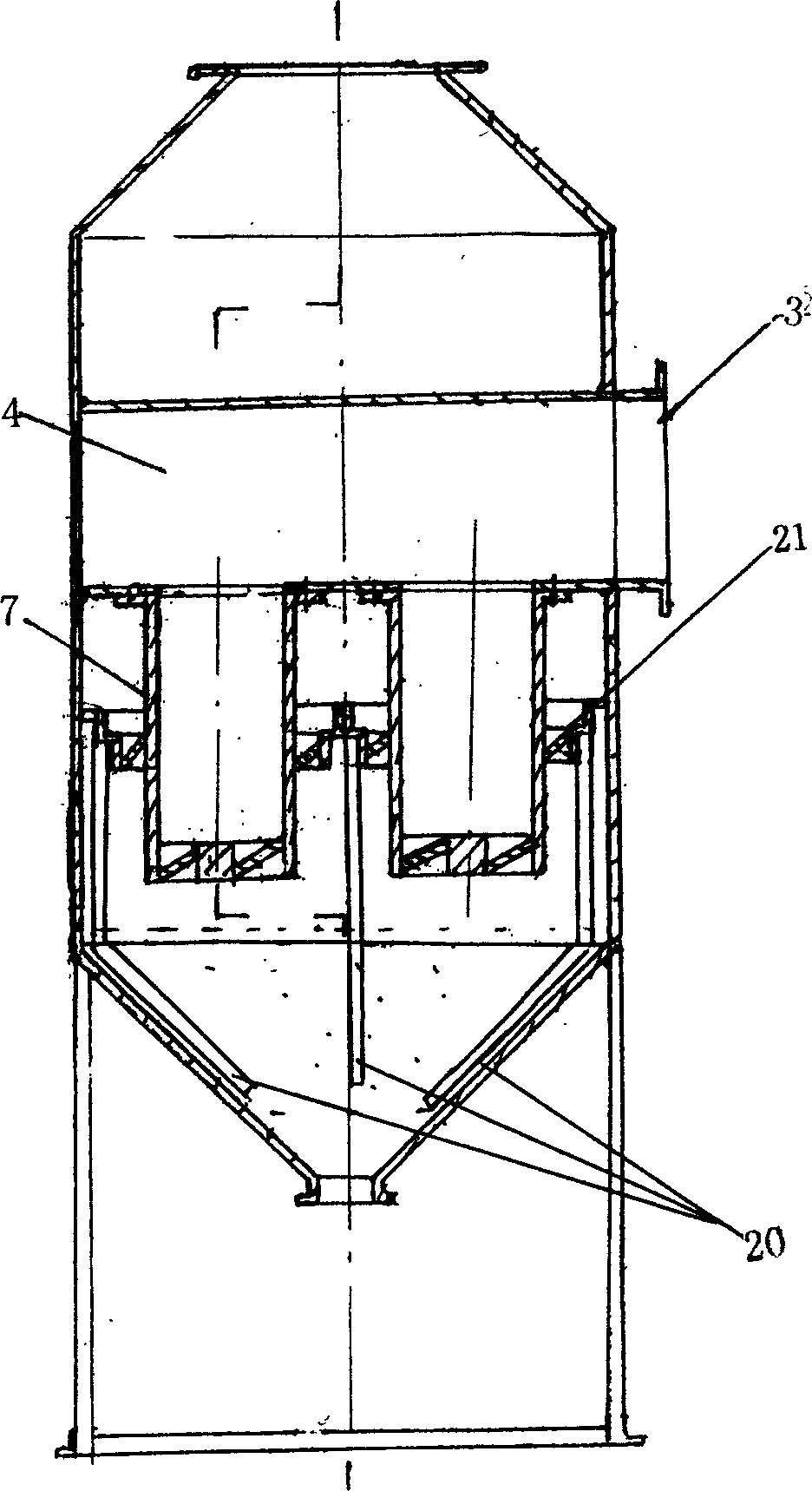

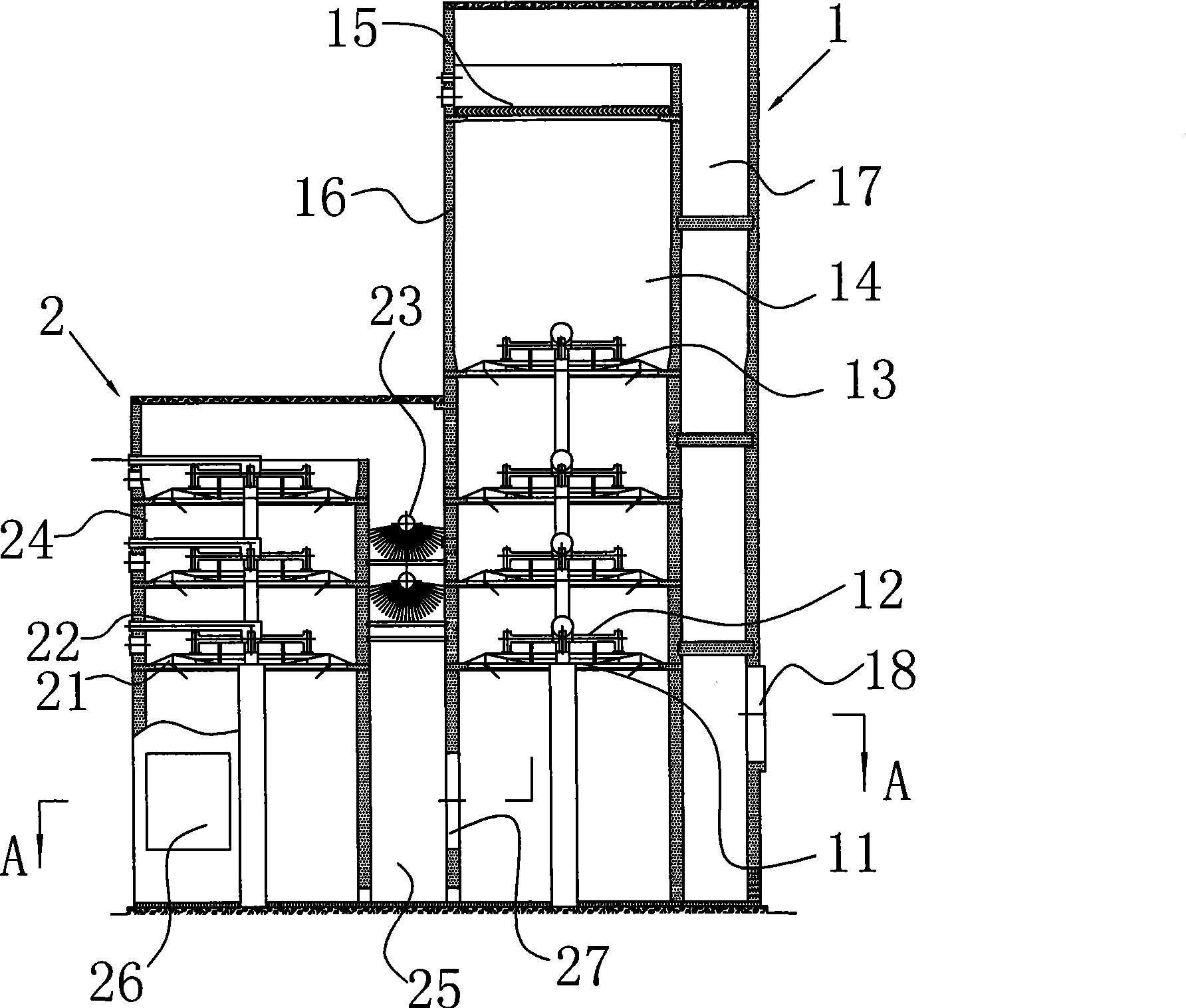

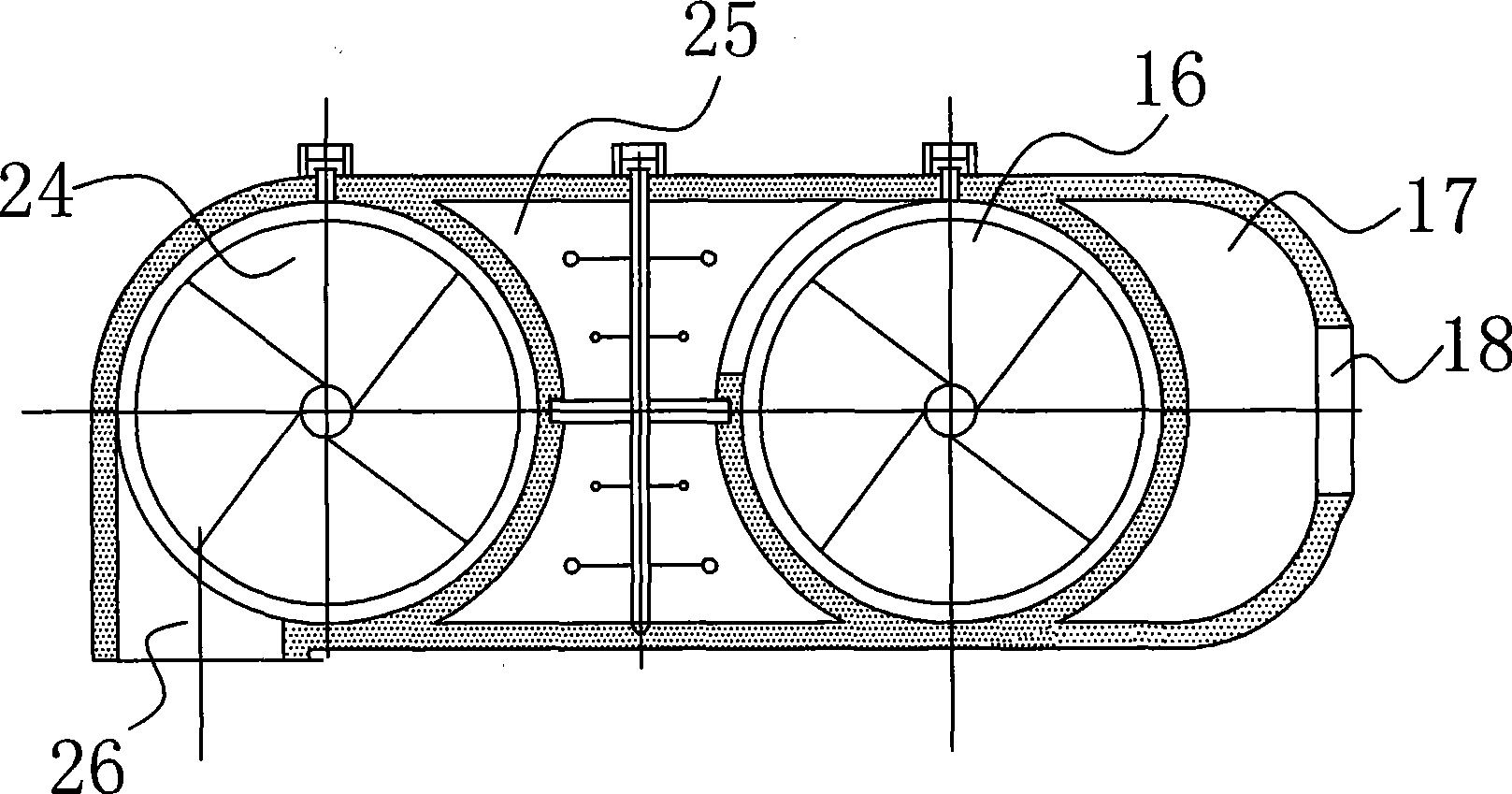

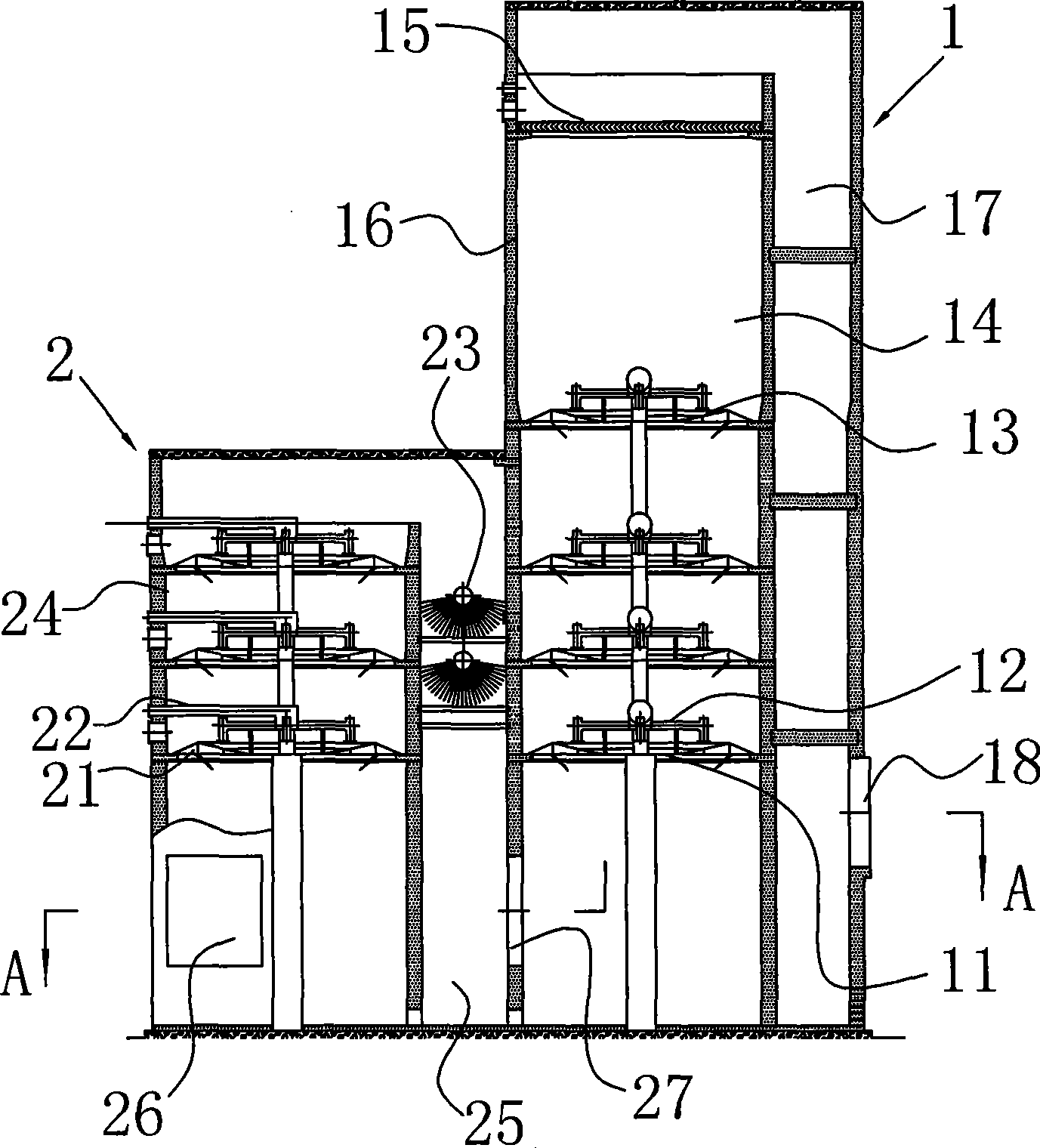

Multistage rotation impact wet desulfurizing and dust-removing equipment

InactiveCN1460537ALow running costGood effect of desulfurization and dust removalCombination devicesFlue gasEngineering

The multistage rotary impact wet desulfurization dust-removing equipment includes a shell body mounted on a supporting frame, the lower portion of the shell body is equipped with an ash bucket with blowdown hole, and the upper portion of the shell body is equipped with cleaned gas outlet. Several flue gas channels are transversely parallelly-mounted in the upper portion of the shell body, and the bottom portion of the flue gas channel is equipped with connecting hole which can be connected with gas inlet of multistage tornadotron. Besides, said equipment also includes the components of cyclone flow-guiding blade, dust-removing device, gas-cleaning chamber, desulfurizing chamber, sewage discharging pipe and overflow pipe.

Owner:郑龙和

Desulfuration and dust-removal purifying device

InactiveCN102091521ALarge amount of processingIncrease contact areaUsing liquid separation agentInlet channelFlue gas

The invention discloses a desulfuration and dust-removal purifying device which comprises a gas inlet channel connected with a flue gas pipeline, wherein the gas inlet channel is connected with a flue gas treating pipeline, an outlet of the flue gas treating pipeline is connected with a gas outlet channel, a gas distributing cone with two thin ends and thick middle are fixedly suspended in the flue gas treating pipeline, a flue gas washing cavity is arranged between the wall of the flue gas treating pipeline and the wall of the gas distributing cone, the inner side of the wall of the gas distributing cone is provided with a washing solution inner cavity, a washing solution outer cavity sealed with the wall of the flue gas treating pipeline is arranged outside the wall of the flue gas treating pipeline, a liquid feeding channel is arranged on the washing solution outer cavity, a cavity communicating channel used for communicating the washing solution inner cavity with the washing solution outer cavity in a sealing manner is arranged between the wall of the flue gas treating pipeline and the wall of the gas distributing cone in a sealing manner, the washing solution inner cavity andthe washing solution outer cavity are filled with washing solutions, and washing solution spraying holes are arranged on the wall of the flue gas treating pipeline and the wall of the gas distributing cone.

Owner:黄官禹

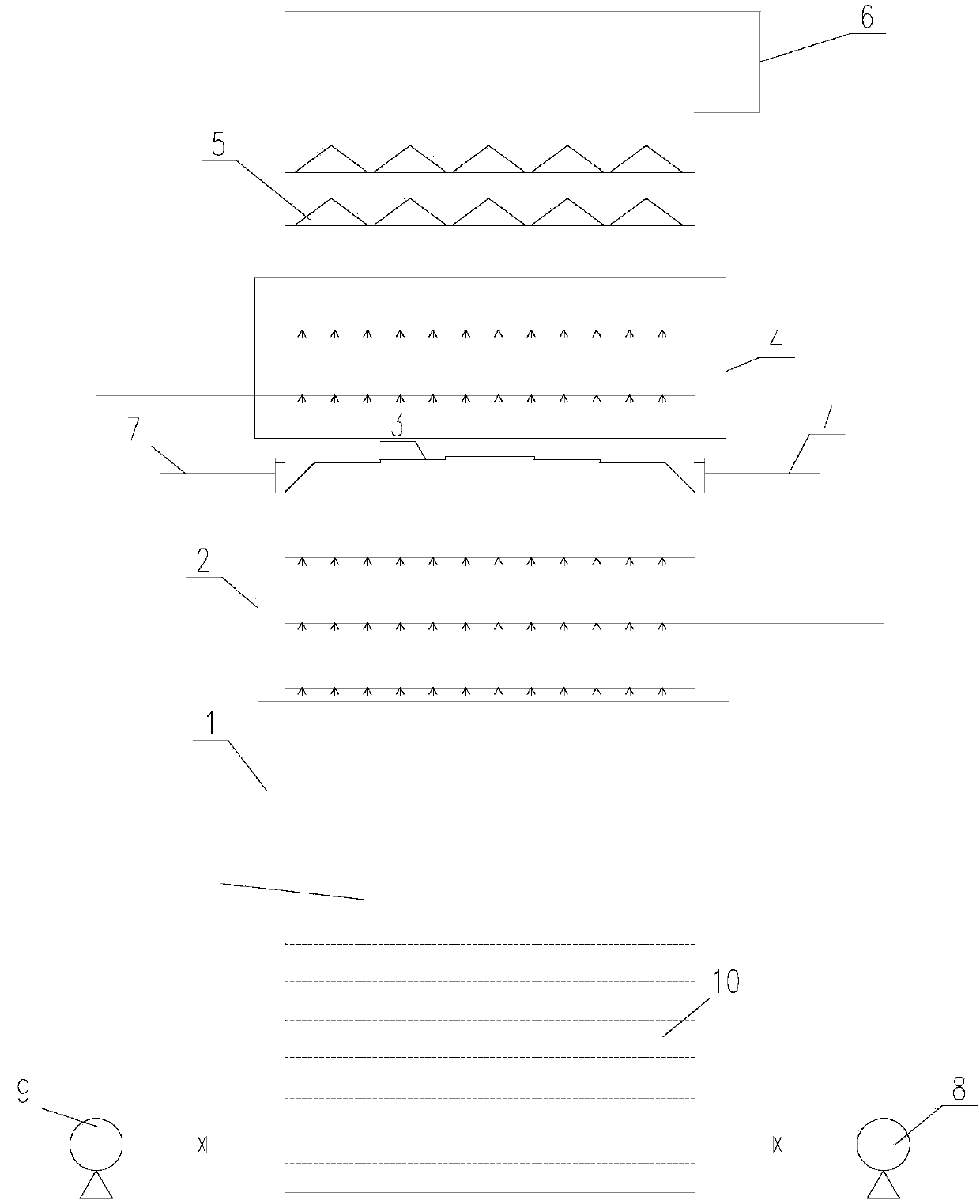

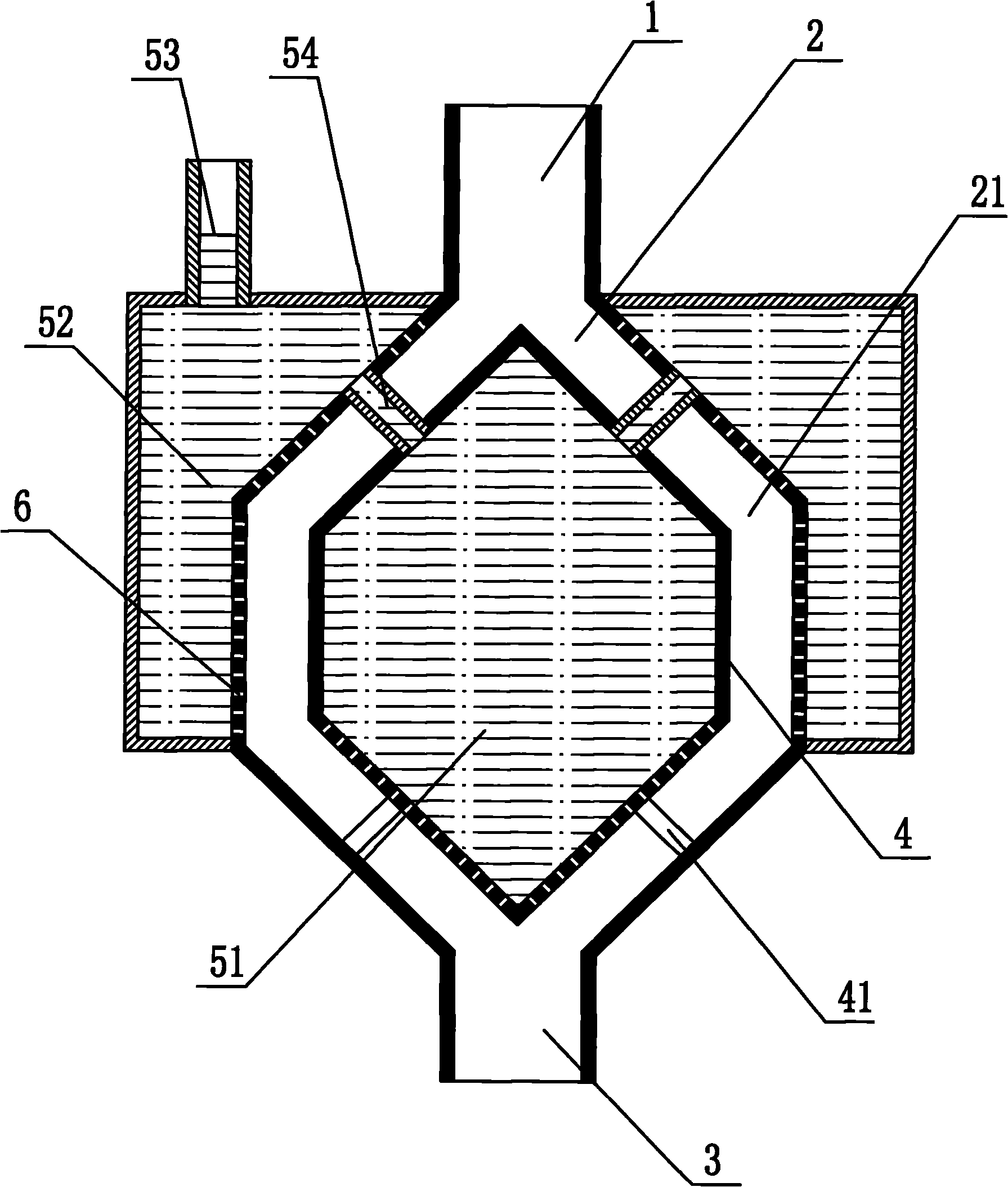

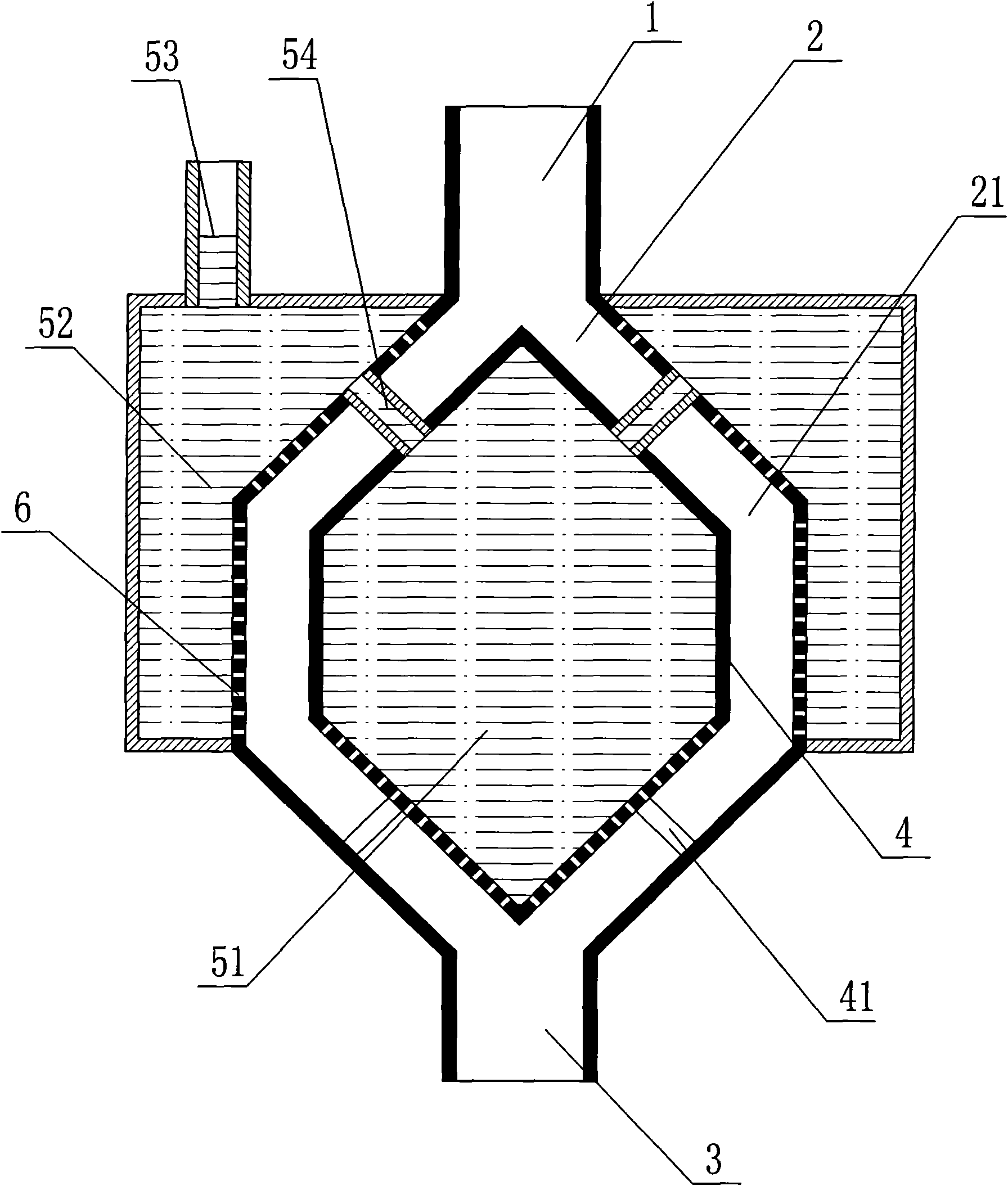

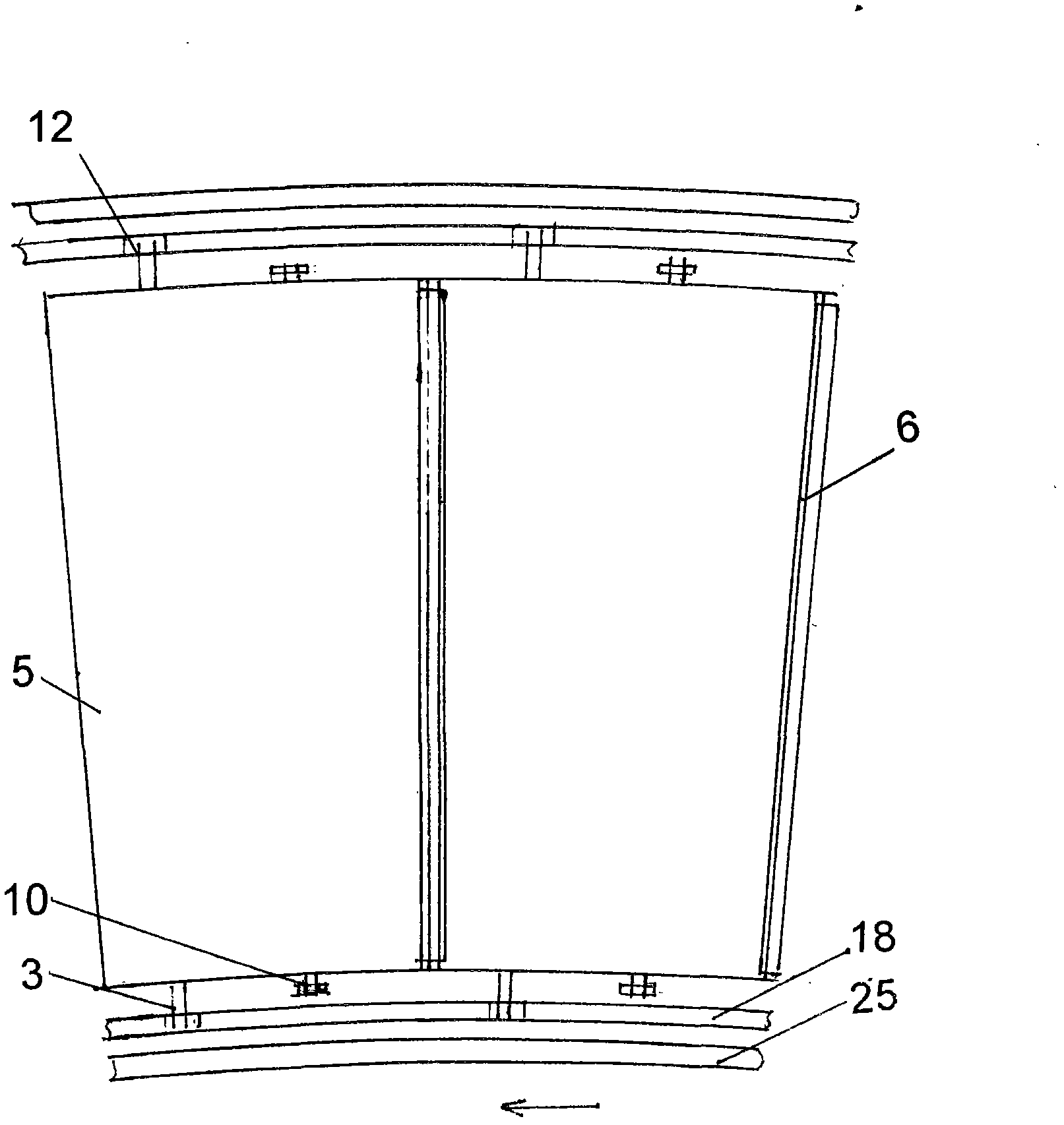

Large boiler low-temperature flue gas purification waste heat drying bed

InactiveCN102401547ATake advantage ofSimple structureDrying solid materials with heatDispersed particle separationOperating costCorrosion

The invention relates to a large boiler low-temperature flue gas purification waste heat drying bed, and belongs to the technical field of boiler low-temperature flue gas waste heat deep utilization. The drying bed is characterized by comprising a framework crossbeam positioned at the middle position of an annular bed body, wherein the upper part of the framework crossbeam bears a ceramic flue; two sides of the framework crossbeam are provided with riding wheels; two ends of the framework crossbeam are connected with framework upright posts, the framework crossbeam and longitudinal and horizontal struts form unit frames, and the unit frames are connected through connecting plates to form a steel structure framework; the flue has a ceramic combination mode, and the traditional desulfurization and dedusting processes are carried out in the ceramic flue; through the corrosion resistance of ceramics, the corrosion of the dew point of the low-temperature flue gas on main parts of a boiler is avoided; and the flue gas can be well cleaned, equipment investment and operating cost are saved, and the low-temperature flue gas waste heat can be deeply utilized. The drying bed has the characteristics that: an annular self-discharging device is utilized; the drying bed is concise in structure, reasonable in design, economic in operation and convenient to maintain and saves land; and a key technology for realizing low-grade flue gas waste heat utilization and developing power station boiler flue gas waste heat integrated utilization is provided.

Owner:张咸民 +1

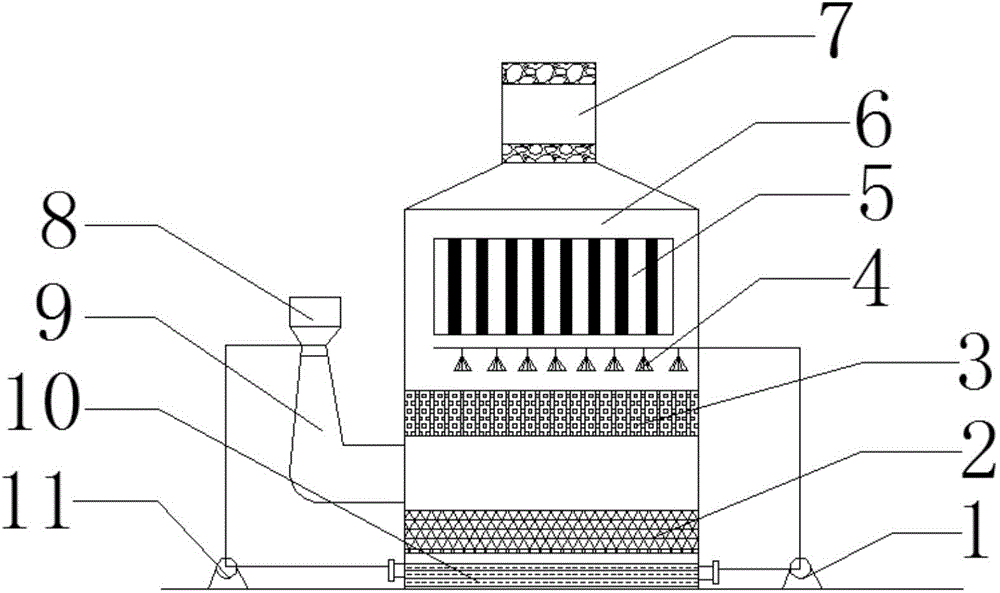

Environment-friendly desulfurization and dust collection tower

InactiveCN104941360ASimple structureGood effect of desulfurization and dust removalLighting and heating apparatusUsing liquid separation agentSulfur dioxideEngineering

The invention discloses an environment-friendly desulfurization and dust collection tower. A Venturi dust remover is arranged on the lower portion of the left side of a tower body, a smoke inlet is connected with the top of the Venturi dust remover, and a first water pump is arranged at the left side of the bottom of the tower body and connected with the Venturi dust remover through a pipeline. A sulfur dioxide neutralizing device is arranged on the upper portion of the interior of the tower, an alkaline filler layer is arranged in the middle of the interior of the tower, and a sprinkling device is arranged between the sulfur dioxide neutralizing device and the alkaline filler layer. A water tank is arranged on the bottom of the tower body, a sewage purifying device is arranged above the water tank, a discharge pipe is arranged on the top of the tower body, a second water pump is connected with the sprinkling device through a pipeline, and both the first pump and the second pump are connected with the water tank through pipelines. The environment-friendly desulfurization and dust collection tower is simple in structure, good in desulfurization and dust collection effect, and capable of saving energy and protecting the environment.

Owner:黄浩

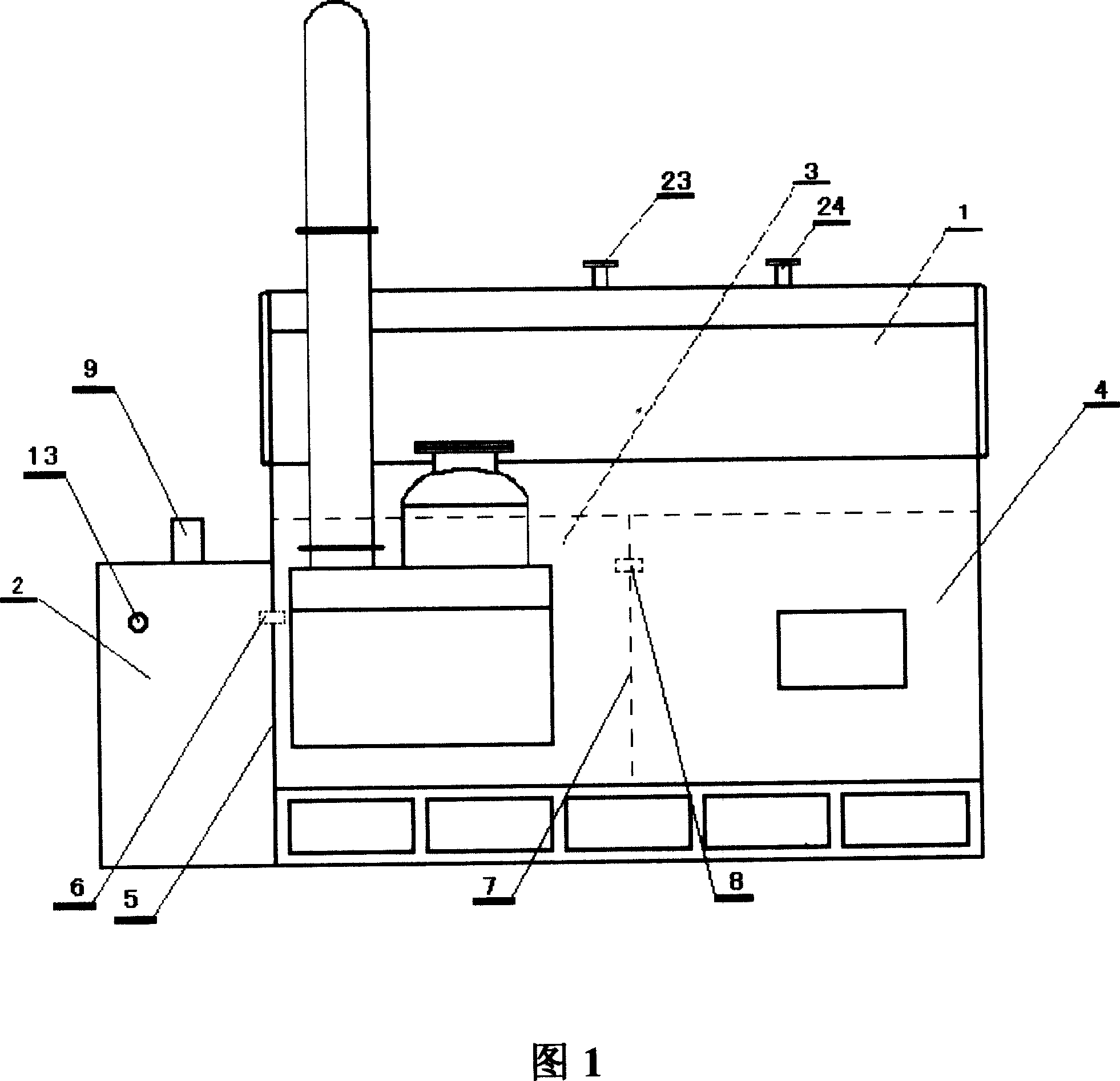

Fire coal gasfication atmospheric water heating horizontal boiler

InactiveCN101063552AAdvanced technologyReasonable structural designSolid fuel combustionWater heatersCombustion chamberSlag

The invention relates to a coal gasification normal atmosphere water heating horizontal boiler, comprising a boiler body, an air blaster, an air guide device, a desulfurization and dust collecting device, a coal gas generating area, an open fire igniting area, the upper part of the boiler body is a sleeve water-jacket pipe hot water circulating device, the lower part is arranged with a sealed slag removing pool, the coal gas generating area is arranged with an anti-explosion coal gas guide pipe above and it is communicated with the adequate water sealed place of the water sealed groove, the coal gas generating area is arranged on the front outer place of the boiler body, a sealed separating arch is arranged between the coal gas generating area and the open fire igniting area, the arch is arranged with one or two smoke via burning holes above. The open fire igniting area is arranged at the front of the boiler body and it is separated from the burning room, and a round or elliptical or square flame spraying hole is provided. The invention makes the coal gasified to burn, therefore it is burned more sufficiently and the efficiency is improved with energy saved, the operation is easy and the desulfurization and dust collecting effect is extinctive.

Owner:刘伟义

A dry desulfurization and dust removal process for catalytic cracking regenerated flue gas

ActiveCN109351183BImprove purification efficiencyAvoid emissionsHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystFlue gas

The invention provides a dry desulfurization dust removing technology method for catalytic cracking regenerated flue gas. The method comprises the steps that catalytic cracking flue gas is introducedin a moving bed desulfuration reactor, the catalytic cracking flue gas and a loaded desulfurization catalyst are subjected to the desulfurization reaction, oxysulfide in the flue gas is subjected to the catalytic reaction to produce metal sulfate, and the metal sulfate is adsorbed on the desulfurization catalyst; the desulfurization catalyst containing the metal sulfate is conveyed to a desulfurization catalyst reproducer, reductive regeneration gas is introduced in the reproducer, and after the metal sulfate on the desulfurization catalyst is reduced to metallic oxide, a part of purified fluegas is utilized for lifting the regenerated desulfurization catalyst into a dust elutriating apparatus through a catalyst lifter, and after dust is recovered through elutriation, desulfurization catalyst is conveyed into moving bed desulfuration reactor for recycling; regenerated acid gas containing hydrogen sulfide is introduced in a dry gas desulfurizer to produce sulphur. According to the method, the desulfuration and dust removal of the catalytic cracking flue gas can be effectively achieved, and the desulfurization rate reaches 99% or above.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

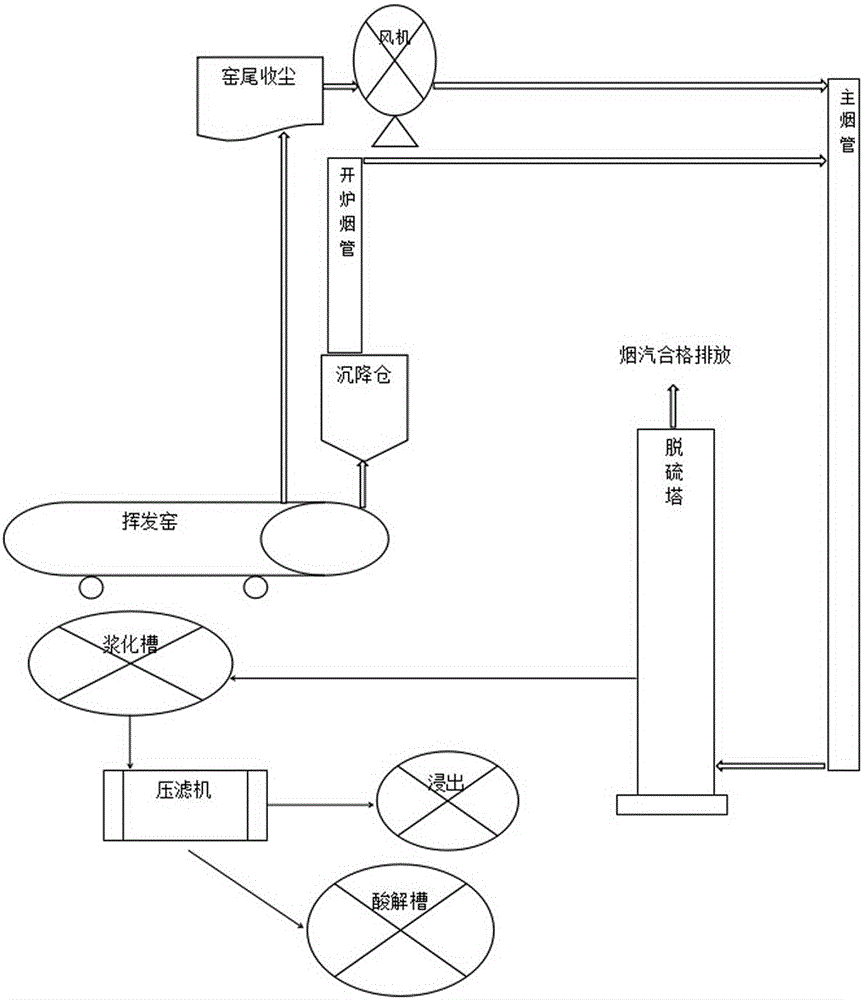

Kiln-opened flue gas treatment process in zinc-leaching residue volatilization kiln

InactiveCN106310876AImproving the efficiency of processing flue gas from kiln openingImprove processing efficiencyCombination devicesGas treatmentActivated carbonIndium

The invention relates to a kiln-opened flue gas treatment process in a zinc-leaching residue volatilization kiln. The process comprises the following steps: preparing kiln-opened flue gas in the volatilization kiln, removing dust in the kiln-opened flue gas of the volatilization kiln, transferring dust removal gas in a kiln tail dust collection bag, transferring dust removal gas in a settling bin, treating kiln-opened flue gas in a main flue pipe volatilization kiln and treating kiln-opened flue gas of the volatilization kiln which is adsorbed by a desulfurization tower. According to the process disclosed by the invention, diesel oil serves as auxiliary fuel, so that the kiln-opened flue gas in the volatilization kiln carries diesel flue gas, the diesel flue gas is capable of well absorbing the dust in the kiln-opened flue gas of the volatilization kiln, the efficiency of treating the kiln-opened flue gas in the volatilization kiln is improved, and the energy is effectively saved; the kiln-opened flue gas is simultaneously subjected to dust removal treatment by utilizing the kiln tail dust collection bag and the settling bin, so that the treatment efficiency of the kiln-opened flue gas is improved, and the equipment failure occurrence rate is reduced; and moreover, after activated carbon is added into a desulfurization dust catcher, valuable metals such as zinc, lead, silver, indium, cadmium and the like and sulfur dioxide gas in the kiln-opened flue gas of the volatilization kiln can be effectively recovered by the desulfurization dust catcher.

Owner:黄婧

Multistage rotation impact wet desulfurizing and dust-removing equipment

InactiveCN1244394CGood effect of desulfurization and dust removalEasy maintenanceCombination devicesFlue gasEngineering

The multistage rotary impact wet desulfurization dust-removing equipment includes a shell body mounted on a supporting frame, the lower portion of the shell body is equipped with an ash bucket with blowdown hole, and the upper portion of the shell body is equipped with cleaned gas outlet. Several flue gas channels are transversely parallelly-mounted in the upper portion of the shell body, and the bottom portion of the flue gas channel is equipped with connecting hole which can be connected with gas inlet of multistage tornadotron. Besides, said equipment also includes the components of cyclone flow-guiding blade, dust-removing device, gas-cleaning chamber, desulfurizing chamber, sewage discharging pipe and overflow pipe.

Owner:郑龙和

Double alkali method flue desulfurizing and dust collecting induction and crystallization process for reuse

A concentrated slurry and dual-alkali process for desulfurizing, dusting and reclaming fume includes such steps as removing SO2 and dust from fume by the desulfurizing liquid, exhausting clean fume, returning part of resultant liquid base to desulfurizing liquid, pumping its rest in crystallizer, crystallizing, flowing the most of slurry in regenerator while flowing the rest in deposition pool, taking the supernatant from deposition pool and delivering it to regenerator, discharging deposit, and adding lime / lime stone and sodium alkali to said slurry in regenerator for regeneration.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

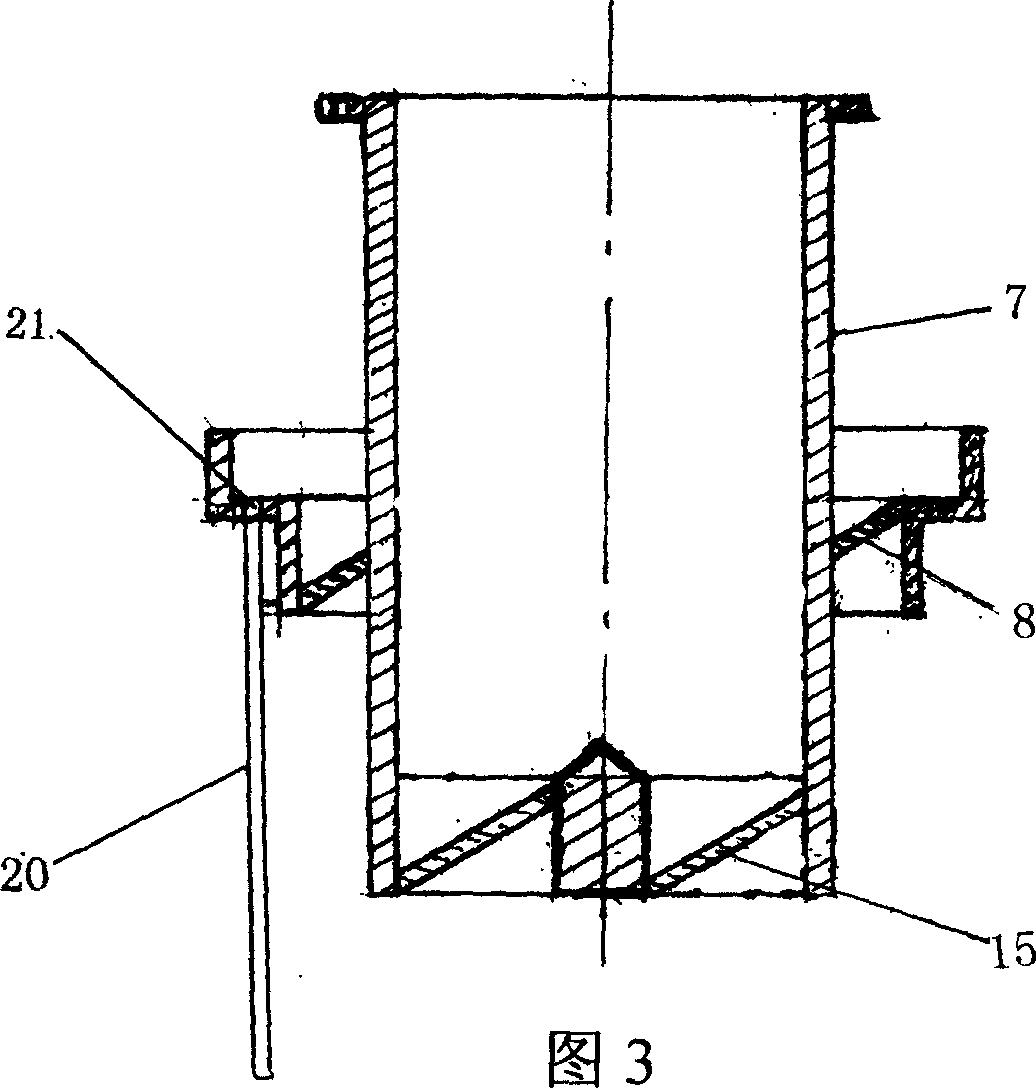

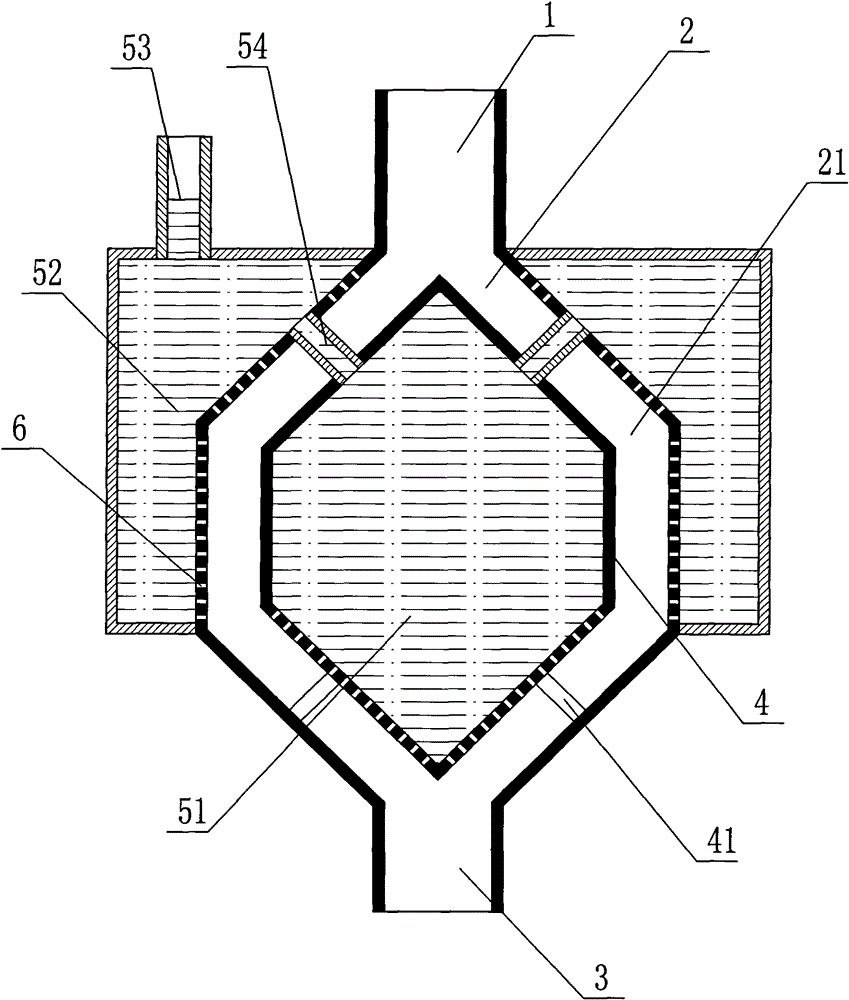

A swirl coupling deep desulfurization strengthening module

ActiveCN105617847BGood effect of desulfurization and dust removalAchieve the goal of energy saving and emission reductionGas treatmentUsing liquid separation agentSulfurEngineering

The invention relates to a novel rotational flow coupling deep desulfurization intensifying module which is arranged at the lower part of a spraying layer of a desulfurizer and comprises an outer barrel, a slit conical bottom cover, an outward ejection rotational flow plate and an inward ejection confluence plate, wherein the upper and lower ends of the outer barrel are opened; the slit conical bottom cover, the outward ejection rotational flow plate and the inward ejection confluence plate are arranged in sequence from bottom to top; a slit hole through which air flows is formed in a side wall of the slit conical bottom cover; a blind plate is arranged in the center of the outward ejection rotational flow plate; a downcomer for leading a doctor solution into the blind plate is arranged in the center of the inward ejection confluence plate. Compared with the prior art, the novel rotational flow coupling deep desulfurization intensifying module is simple and compact in overall structure, desulfuration synergism can be achieved on premise that the height of the desulfurizer is not increased, the spraying layer of the desulfurizer is not increased and the liquid-gas ratio of the desulfurizer is not increased, under the condition that the slurry circulation volume is not changed, the energy consumption can be reduced, the ultralow emission requirement of sulfur can be met, the operation cost can be lowered, and good application prospects can be achieved.

Owner:SHANGHAI JIAO TONG UNIV

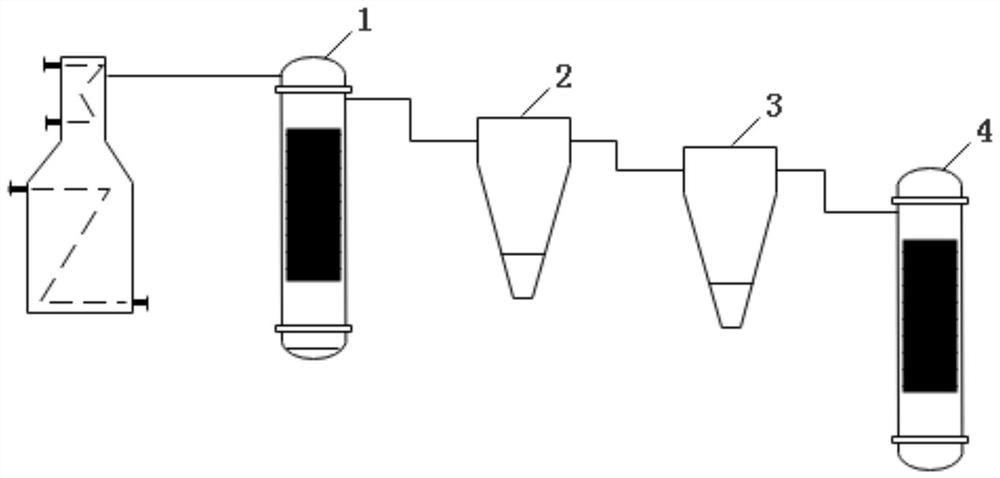

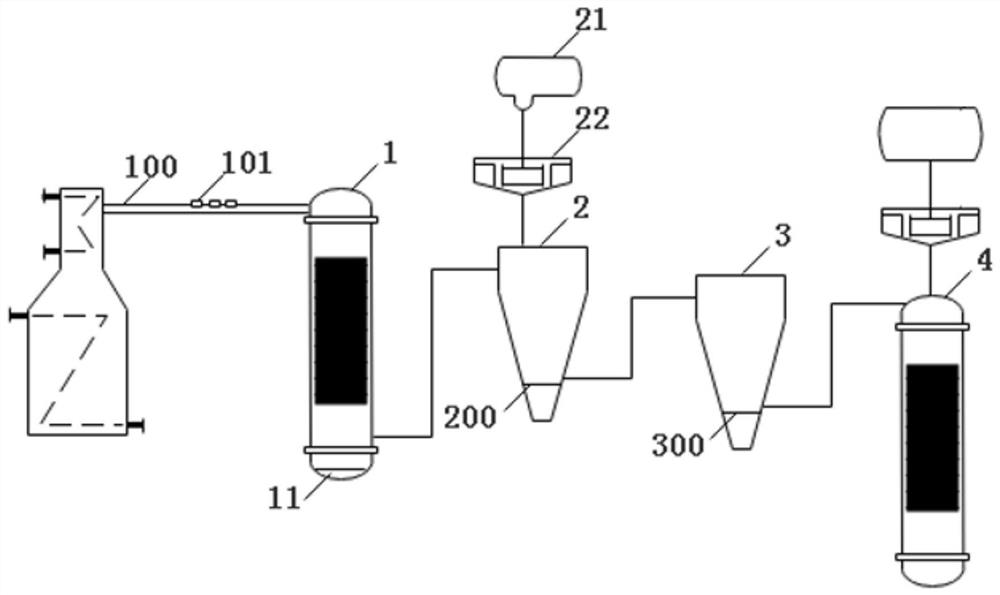

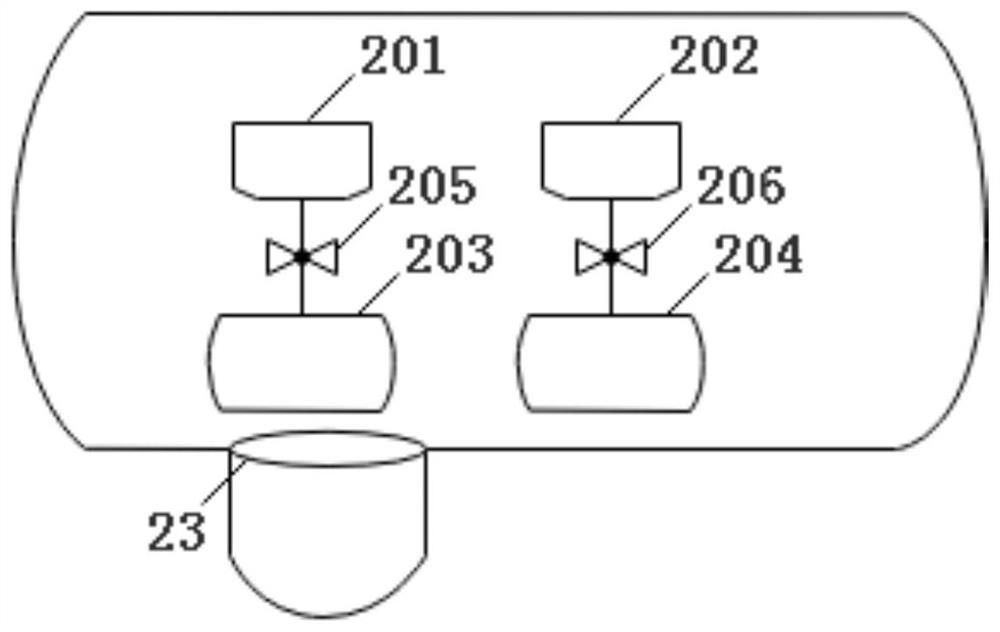

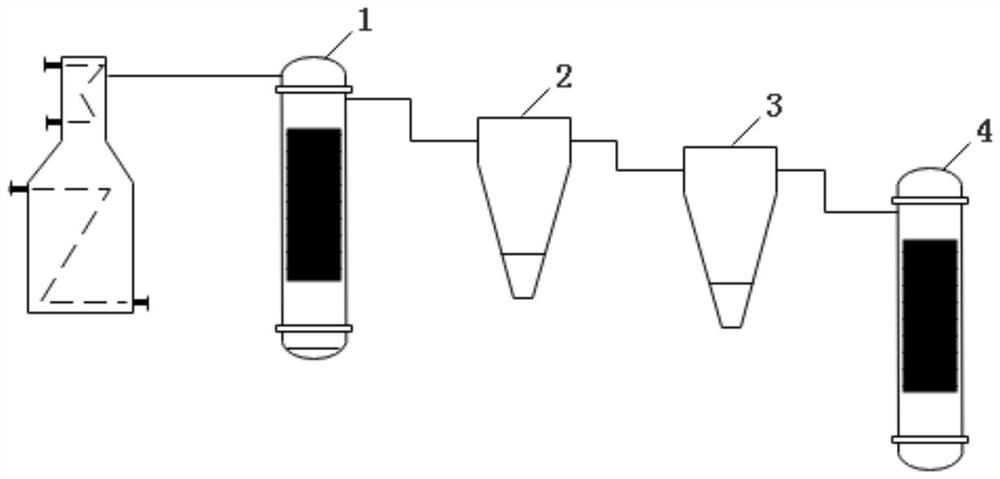

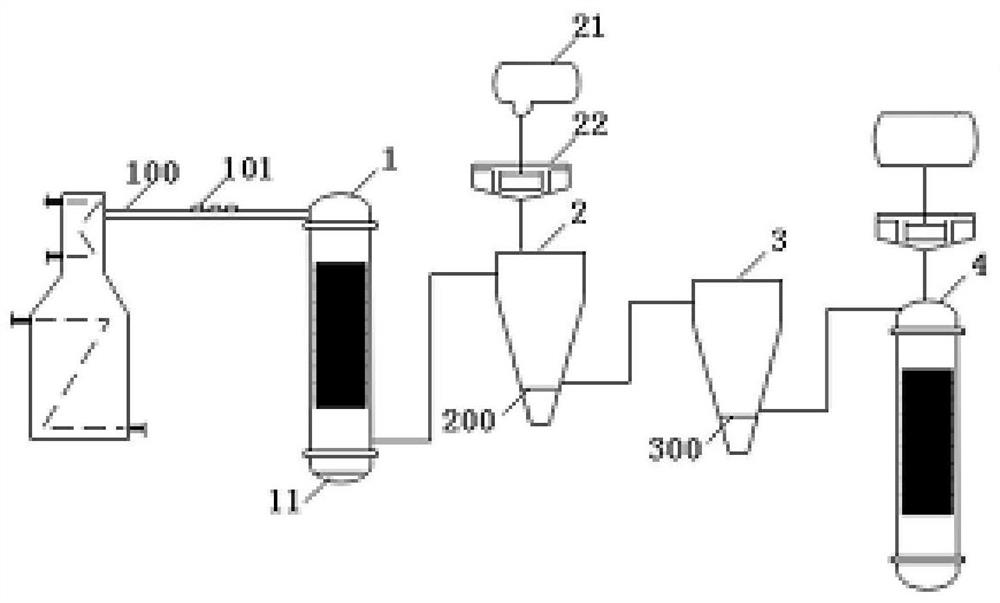

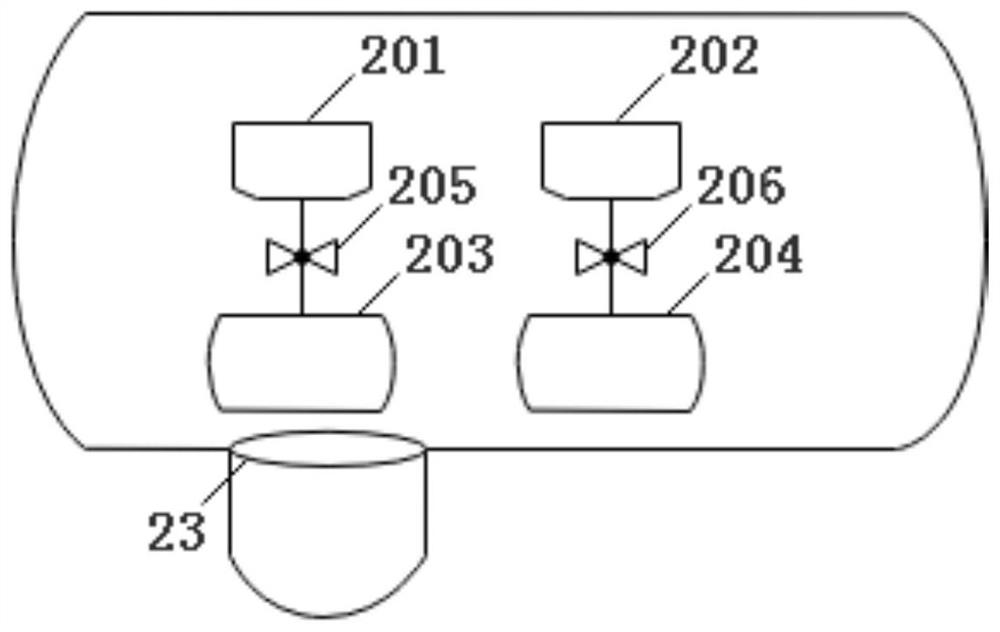

A scr processing system

ActiveCN109011932BRealize automated manufacturingHigh desulfurization and dust removal efficiencyUsing liquid separation agentThermodynamicsPtru catalyst

The present invention provides an SCR treatment system, the system includes a first desulfurizer, a first dust remover, a second dust remover and a second desulfurizer, the first desulfurizer, the first dust remover, the second dust remover and The second desulfurizer is connected sequentially. The second desulfurizer can also communicate with a preset SCR denitrification device, so as to denitrify the flue gas. The SCR denitrification device includes a catalyst injector for injecting powder catalyst into the flue flow passage. The powder catalyst may be a catalyst that catalyzes the selective catalytic reduction reaction SCR for denitration. A deceleration plate with a porous structure may also be provided at the passage, and the deceleration plate is used to prolong the residence time of the powder catalyst and increase the catalytic efficiency. The invention can better realize the purposes of desulfurization, dust removal and stock removal based on the multi-channel continuous process.

Owner:YANCHENG LANFENG ENVIRONMENTAL ENG TECH

Wet double alkali method desulfurization and dust removal device and process

ActiveCN103691294BTo achieve the effect of not expellingGuaranteed uptimeDispersed particle separationFlue gasWastewater

The invention belongs to the technical field of desulphurization and dedusting and discloses a device and a technology for wet-type double-alkali method-based desulphurization and dedusting. The invention solves the problem that the existing desulphurization technology is nonstandard and backward, has a high cost, wastes a desulphurization agent, and produces waste gas which does not satisfy discharge standards. The top of a desulfurization tower is connected to a chimney, the bottom of the desulfurization tower is connected to the top of a three-grade sedimentation basin, the bottom of the three-grade sedimentation basin is connected to an automatic timing filter press, the bottom of a desulfurizer pulping pool is connected to the automatic timing filter press, the top of the desulfurizer pulping pool is connected to the bottom of a pH adjustment tank, the top of the pH adjustment tank is connected to the desulfurization tower, and the desulfurizer pulping pool is connected to an ash storage bin and an automatic water-supplementing system. The device can operate stably and has desulphurization efficiency above 99%, dedusting efficiency above 98.5% and a low operation cost. The method has advanced and mature processes, realizes no discharge of waste water, effectively utilizes three wastes, utilizes local material quicklime as a desulfurizer, has a low cost, is accepted by users at present and is suitable for desulphurization and dedusting on flue gas produced in various large / medium-sized production processes.

Owner:山西海云星环保科技有限公司

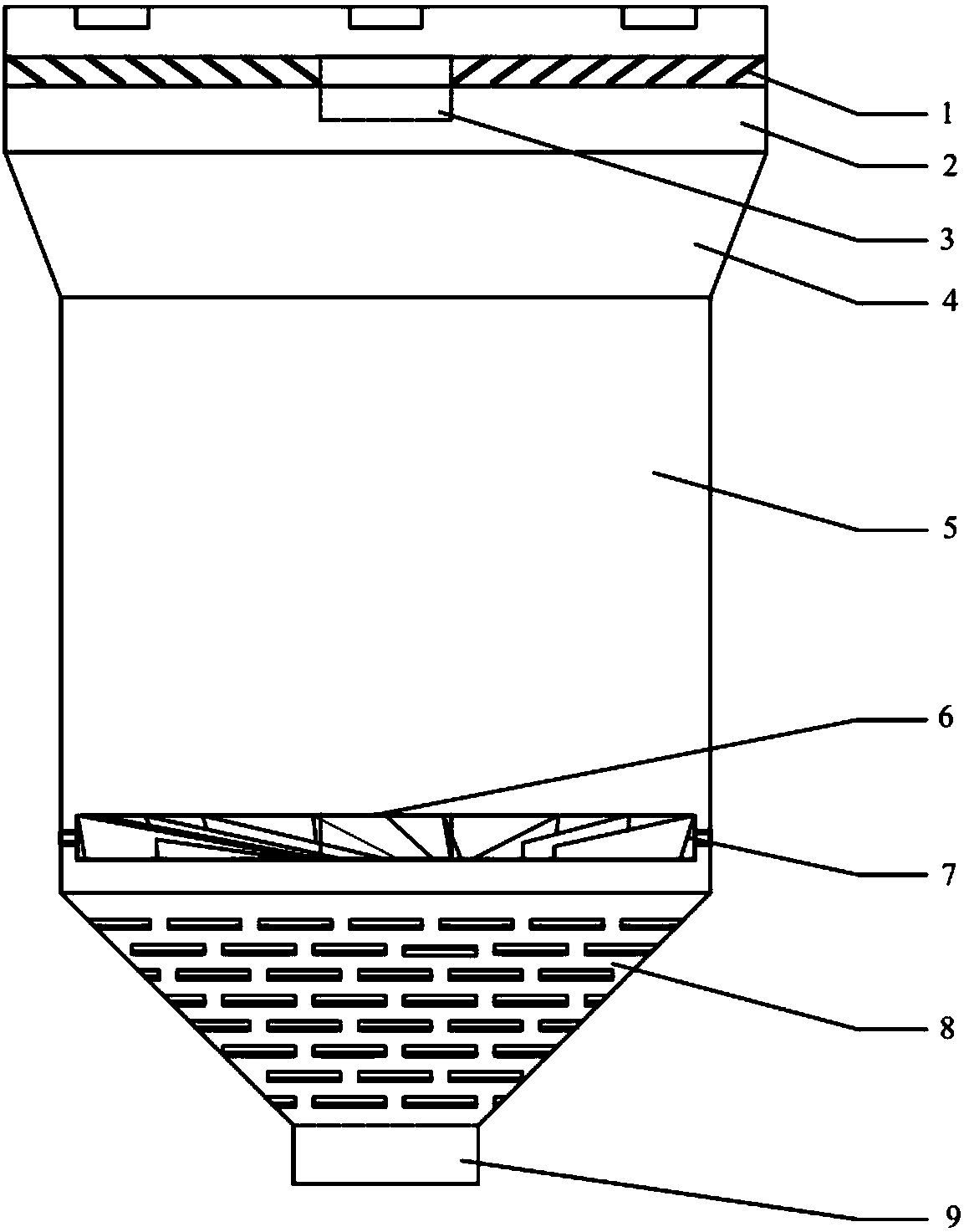

An integrated equipment for desulfurization, denitrification and dust removal

ActiveCN109011931BRealize automated manufacturingHigh desulfurization and dust removal efficiencyUsing liquid separation agentThermodynamicsFlue gas

The invention provides a desulfurization, denitration and dedusting integrated system. The integrated system comprises a first desulfurizer, a first deduster, a second deduster and a second desulfurizer which are communicated in order, the second desulfurizer can also be connected to a preset SCR denitration device to facilitate denitration of the flue gas, the first deduster and the second deduster are connected by a fence baffle plate, and the first deduster and the second deduster are both funnel-shaped dedusters. The integrated system can better achieve the purpose of desulfurization, denitration and dedusting based on the multi-pass continuous process. A plurality of desulfurizing agents and various dedusting agents are used in the whole process, and the automatic preparation of a dedusting agent as well as the automation of desulfurization and dedusting are realized, the efficiency of desulfurization and dedusting is improved, and the desulfurization and dedusting effect is alsobetter.

Owner:YANCHENG LANFENG ENVIRONMENTAL ENG TECH

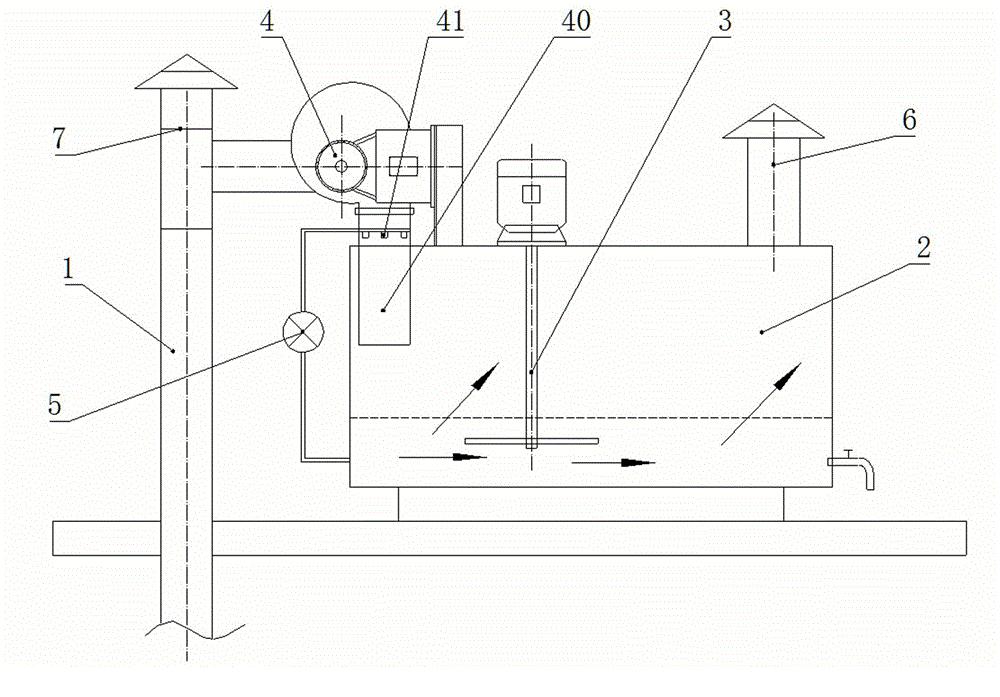

Special tail gas desulfurization and dust removal equipment for tobacco drying and baking barn

InactiveCN104801168AReduce use costGood effect of desulfurization and dust removalUsing liquid separation agentExhaust gasSpray nozzle

The invention provides special tail gas desulfurization and dust removal equipment for a tobacco drying and baking barn. The special tail gas desulfurization and dust removal equipment comprises a chimney, a desulfurization and dust removal box and a stirrer, wherein a stirring paddle of the stirrer extends to below the liquid level of the desulfurization and dust removal box; an induced draft fan is arranged between the chimney and the desulfurization and dust removal box; a plurality of spray nozzles are arranged in an air outlet duct of the induced draft fan; the desulfurization and dust removal box and the plurality of spray nozzles are connected by water pump pipelines; a secondary chimney is also arranged on the desulfurization and dust removal box. The special tail gas desulfurization and dust removal equipment has the advantages of good desulfurization and dust removal effect, capability of realizing clean discharge, small occupied area, low cost, safety and reliability.

Owner:ANHUI ZHONGKE AUTOMATION

SCR processing system

ActiveCN109011932ARealize desulfurization and destockingTo achieve the purpose of dust removalUsing liquid separation agentFlue gasEngineering

The invention provides a SCR processing system. The SCR processing system comprises a first desulfurizer, a first precipitator, a second precipitator, and a second desulfurizer, and the first desulfurizer, the first precipitator, the second precipitator and the second desulfurizer are communicated in order. The second desulfurizer can also be in communication with a preset SCR denitration device to facilitate denitration of the flue gas. The SCR denitration device includes a catalyst injector for injecting a powdered catalyst into a flue gas flowing channel. The powdered catalyst can be a catalyst for catalyzing a selective catalytic reduction reaction SCR for denitration. A deceleration plate having a porous structure is also disposed at the channel, and the deceleration plate is used toprolong the stay time of the powdered catalyst and increase the catalytic efficiency. The SCR processing system can better achieve the purpose of desulfurization, dust removal and denitration based onmultiple continuous processes.

Owner:YANCHENG LANFENG ENVIRONMENTAL ENG TECH

A kind of activated carbon diatomite particles with developed pores and low cost and preparation method thereof

ActiveCN104289195BGood effect of desulfurization and dust removalHigh porosityOther chemical processesAlkali metal oxides/hydroxidesPorosityHigh absorption

The invention discloses activated carbon diatomite particles with well-developed pores and low cost. The activated carbon diatomite particles are characterized by being prepared from the following raw materials in parts by weight: 95-105 parts of fruit shell activated carbon, 30-35 parts of diatomite, 18-22 parts of traditional Chinese medicine residues, 22-26 parts of tung seed shells, 6-9 parts of kaoline, 1-2 parts of a silane coupling agent kh560, 3-4 parts of sodium sulfate, 4-6 parts of limestone powder, 2.5-3.5 parts of vitrified microspheres, 3.5-5 parts of silicon micro-powder, 3-5 parts of clay, 3-5 parts of active aluminum oxide, 4-6 parts of an absorbent additive and an appropriate amount of water. According to the method for preparing the activated carbon diatomite particles with the well-developed pores and the low cost, the materials such as the traditional Chinese medicine residues, and the tung seed shells are reused, dried, crushed and then added into the activated carbon and the diatomite, and the particles have sufficient sources of raw materials, the well-developed pores, the high absorption ability and the excellent property; the absorbent additive gives the special porosity of the particles and increases the contact time between gas and each particle; the particles prepared according to the method have the good desulfurization dedusting effect and the high porosity, and is low in cost and simple in production process, and therefore, the operation cost of dry desulfurization is greatly reduced.

Owner:广州大津健康建筑技术有限公司

Desulfuration and dust-removal purifying device

InactiveCN102091521BLarge amount of processingIncrease contact areaUsing liquid separation agentInlet channelFlue gas

The invention discloses a desulfuration and dust-removal purifying device which comprises a gas inlet channel connected with a flue gas pipeline, wherein the gas inlet channel is connected with a flue gas treating pipeline, an outlet of the flue gas treating pipeline is connected with a gas outlet channel, a gas distributing cone with two thin ends and thick middle are fixedly suspended in the flue gas treating pipeline, a flue gas washing cavity is arranged between the wall of the flue gas treating pipeline and the wall of the gas distributing cone, the inner side of the wall of the gas distributing cone is provided with a washing solution inner cavity, a washing solution outer cavity sealed with the wall of the flue gas treating pipeline is arranged outside the wall of the flue gas treating pipeline, a liquid feeding channel is arranged on the washing solution outer cavity, a cavity communicating channel used for communicating the washing solution inner cavity with the washing solution outer cavity in a sealing manner is arranged between the wall of the flue gas treating pipeline and the wall of the gas distributing cone in a sealing manner, the washing solution inner cavity andthe washing solution outer cavity are filled with washing solutions, and washing solution spraying holes are arranged on the wall of the flue gas treating pipeline and the wall of the gas distributing cone.

Owner:黄官禹

Composite desulfuration dust removing device

InactiveCN101422694BGood effect of desulfurization and dust removalImprove desulfurization efficiencyUsing liquid separation agentFlue gasProcess engineering

The invention discloses a duplex type desulfurizing and dedusting device which comprises at least one high tower that comprises a pneumatic diverting device, a spraying device, a flue gas dehydrating device and a dry section, and further comprises at least one low tower that only comprises a pneumatic diverting device and a spraying device; the low tower comprises a forestage tower and a sprayingtower, the pneumatic diverting device and the spraying device are arranged inside the forestage tower, a flue gas inlet is arranged on the forestage tower, the spraying tower has a spraying device inside, the forestage tower and the spraying tower are communicated at the tops thereof, and the spraying tower and the high tower are serially connected at the lower parts thereof. The duplex type desulfurizing and dedusting device has great desulfurizing and dedusting effects, can reach the desulfurizing efficiency up to 99 percent and the dedusting efficiency up to 99.6 percent which are detected, thus being much higher than the nation required indexes and having remarkable improvement on the desulfurizing and dedusting efficiency compared with the prior art.

Owner:HUNAN JIAYU ENVIRONMENT PROTECTION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com