High-efficiency smoke desulfurizing, dedusting and purifying device

A technology for desulfurization and dust removal and purification devices, which is applied in the direction of combined devices, gas treatment, chemical instruments and methods, etc., can solve problems such as high manufacturing and installation costs, difficulties in popularization and application, and unsatisfactory desulfurization and dust removal effects, so as to improve efficiency and effect Good, the effect of complete contact reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

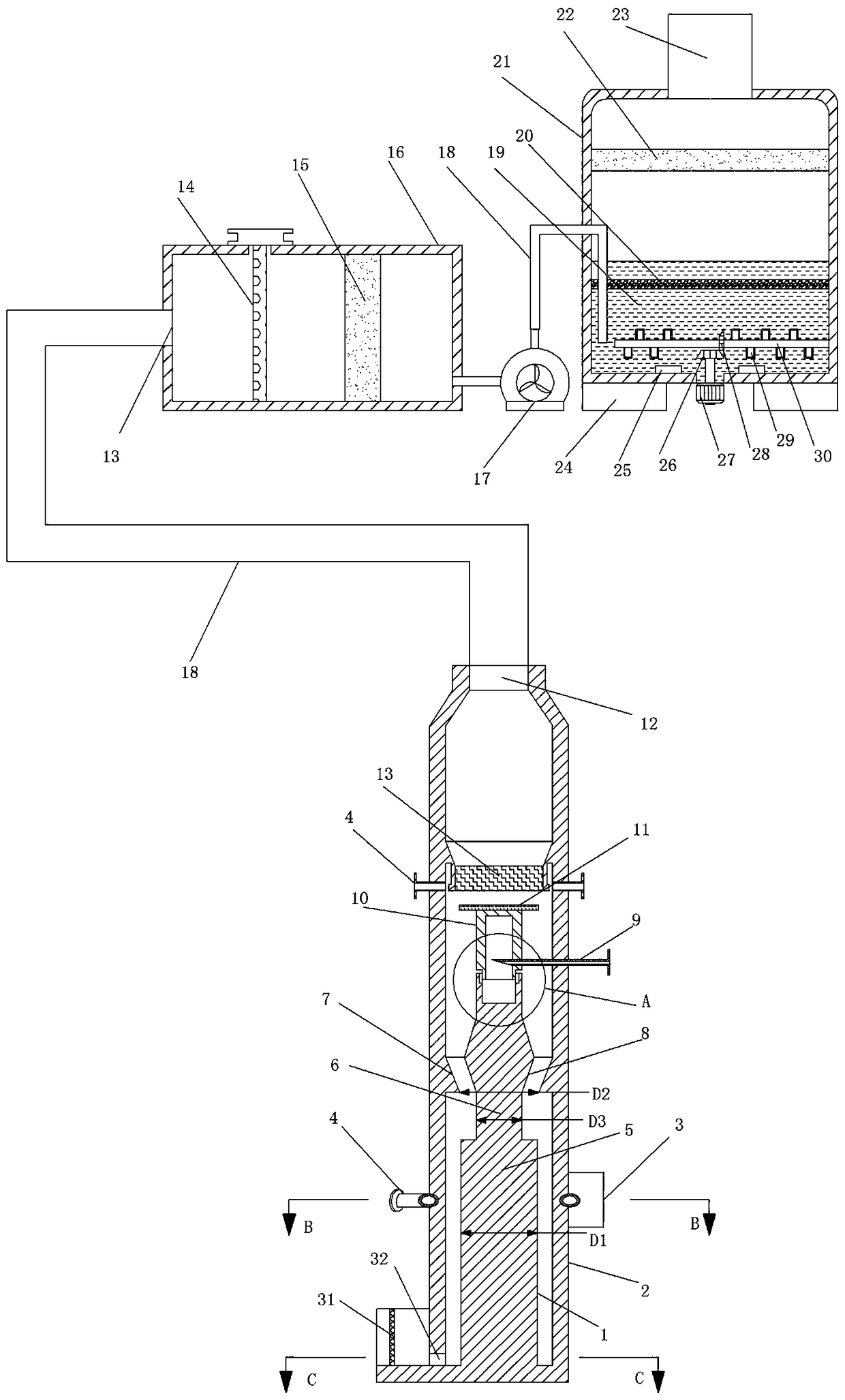

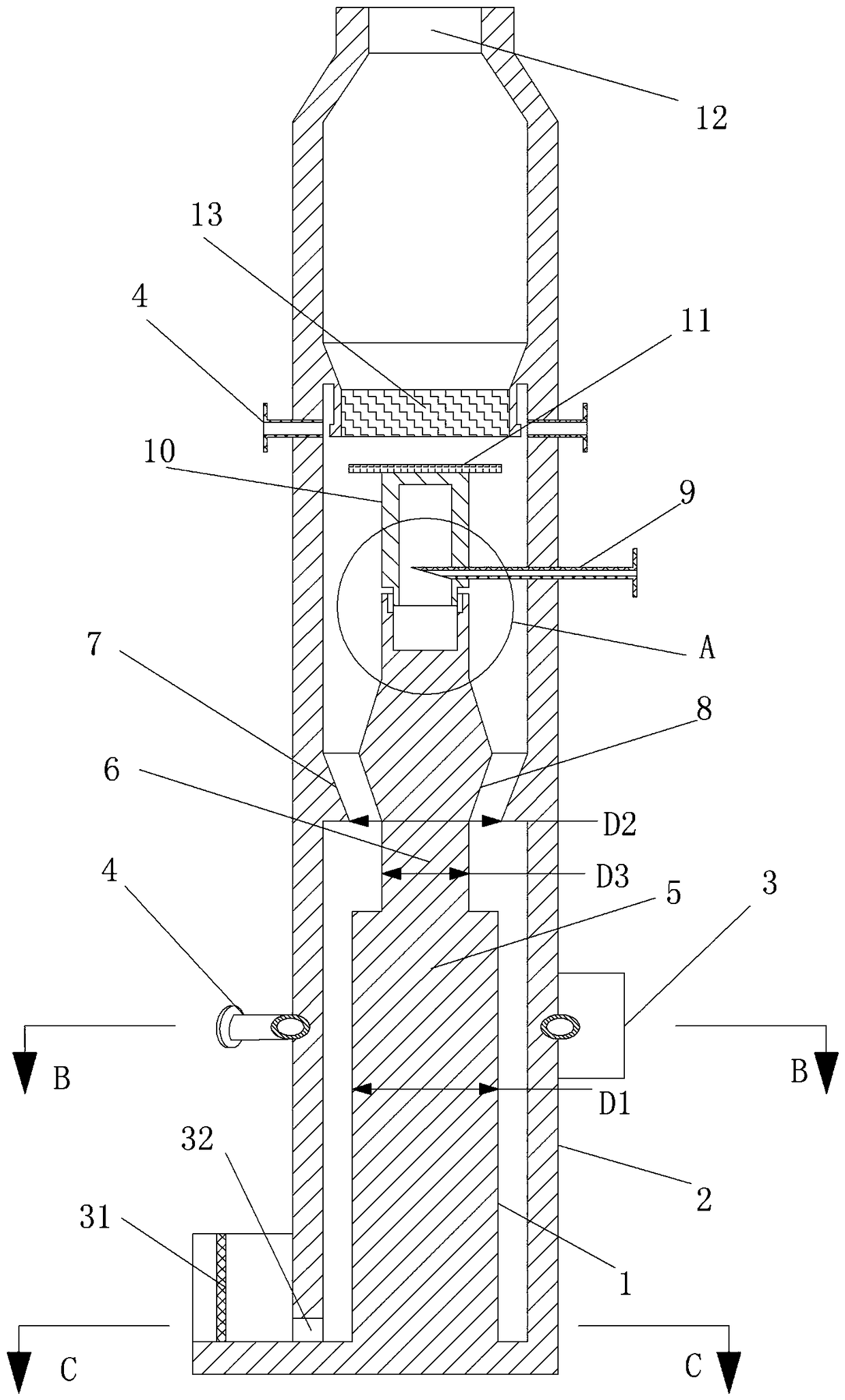

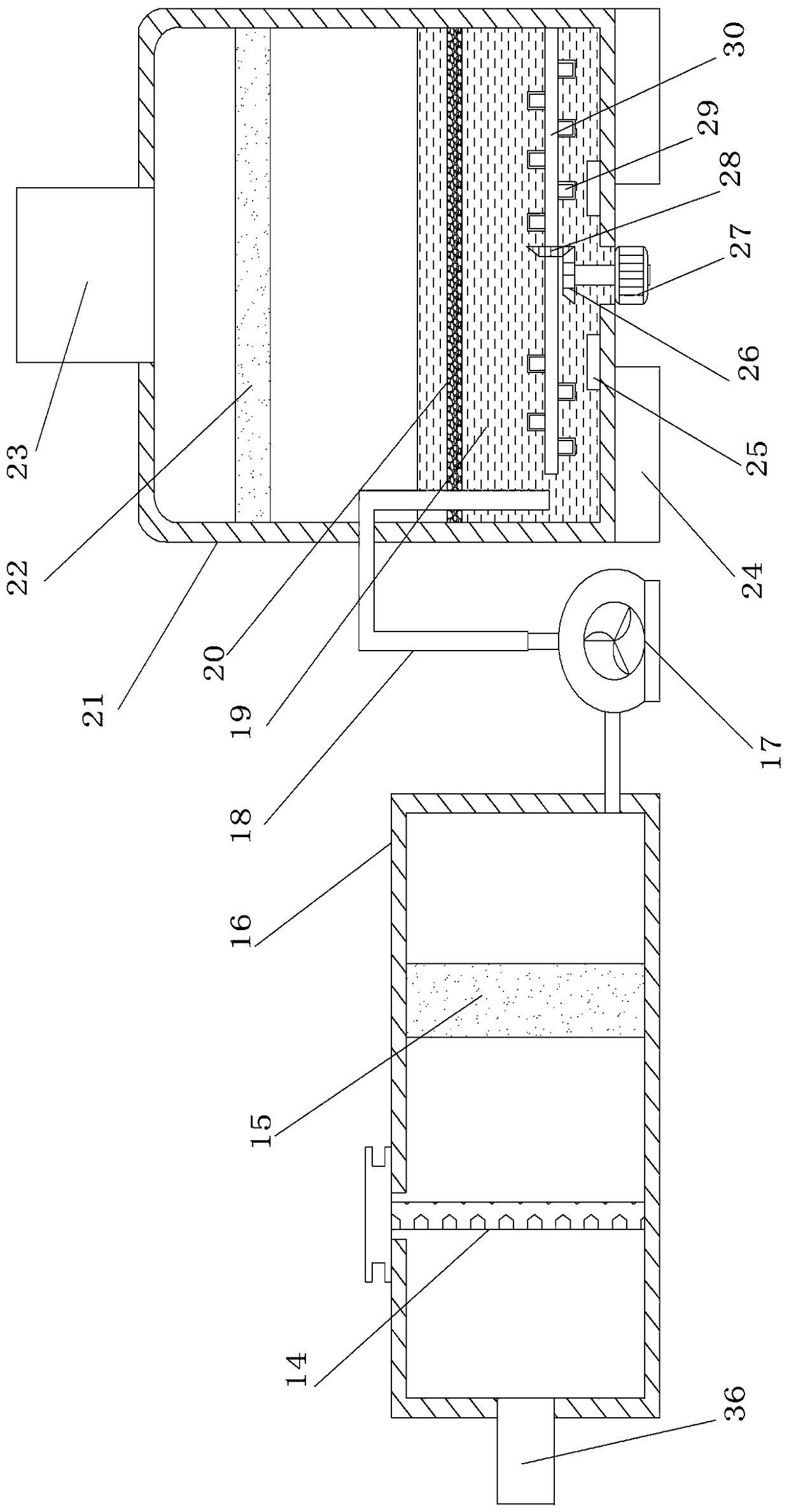

[0029] see Figure 1-7 , a high-efficiency flue gas desulfurization and dust removal purification device, the device includes a desulfurization tower, a dust removal box and a purification box, characterized in that the desulfurization tower includes an inner tower and an outer tower;

[0030] The outer tower is cylindrical, and the outer tower is provided with a flue gas inlet along the tangent direction of the tower wall and penetrating the tower wall. The direction of the tangent of the four liquid nozzles on the outer tower wall is the same as the tangent direction of the flue gas inlet, and the installation position of the liquid nozzle here is equal to the center line of the flue gas inlet. It is conducive to the full mixing and contact of the liquid medicine and the flue gas; the inner surface of the outer tower wall is provided with an inverted conical wall that protrudes toward the center of the outer tower, and the inverted conical wall is located above the flue gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com