Patents

Literature

185 results about "Contact reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

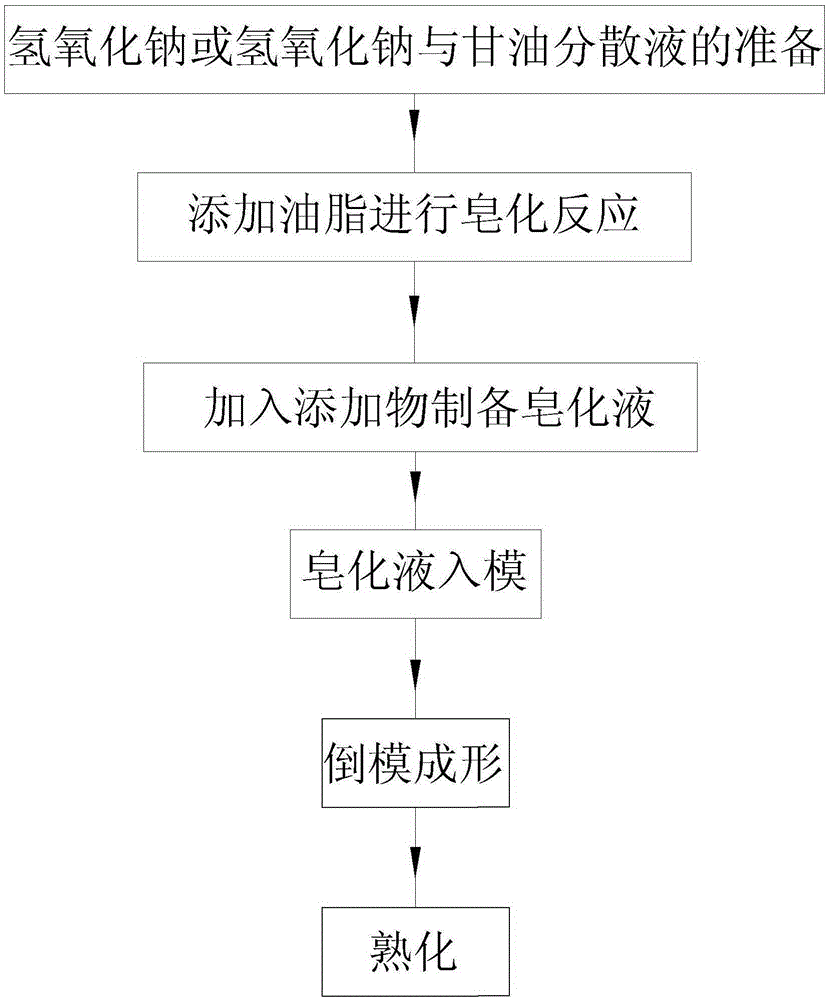

Preparation method of cold-formed soap

ActiveCN105400617AAvoid contact reactionsGive full play to effective functionsShaping soapAlkali/ammonium soap compositionsCold formedReaction rate

The invention relates to a preparation method of a cold-formed soap. The method has simple process steps, and substitutes traditional aqueous solution of sodium hydroxide with sodium hydroxide or a dispersion of sodium hydroxide and glycerol; sodium hydroxide is completely soluble in glycerol but disperses in glycerol, so as to avoid fast reaction after mixing of sodium hydroxide solution with oil too, reduce the initial reaction rate of saponification, and effectively control saponification reaction rate; along with the saponification reaction, the reaction product of glycerol continuously increases to help more fully dispersion of sodium hydroxide, accelerate the reaction rate of sodium hydroxide and the remaining oil. Since the method employs an anhydrous formula, water evaporation process is not needed after soap formation by liquid soap, and the production cycle is significantly shortened; and the nutrition substances are added in solid form powder to effectively prevent the contact reaction of non-alkali-resistant nutrients and alkali hydroxide molecules, so as to retain the active nutrient ingredients in the soap and give full play to the role of skin care of the nutrients.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

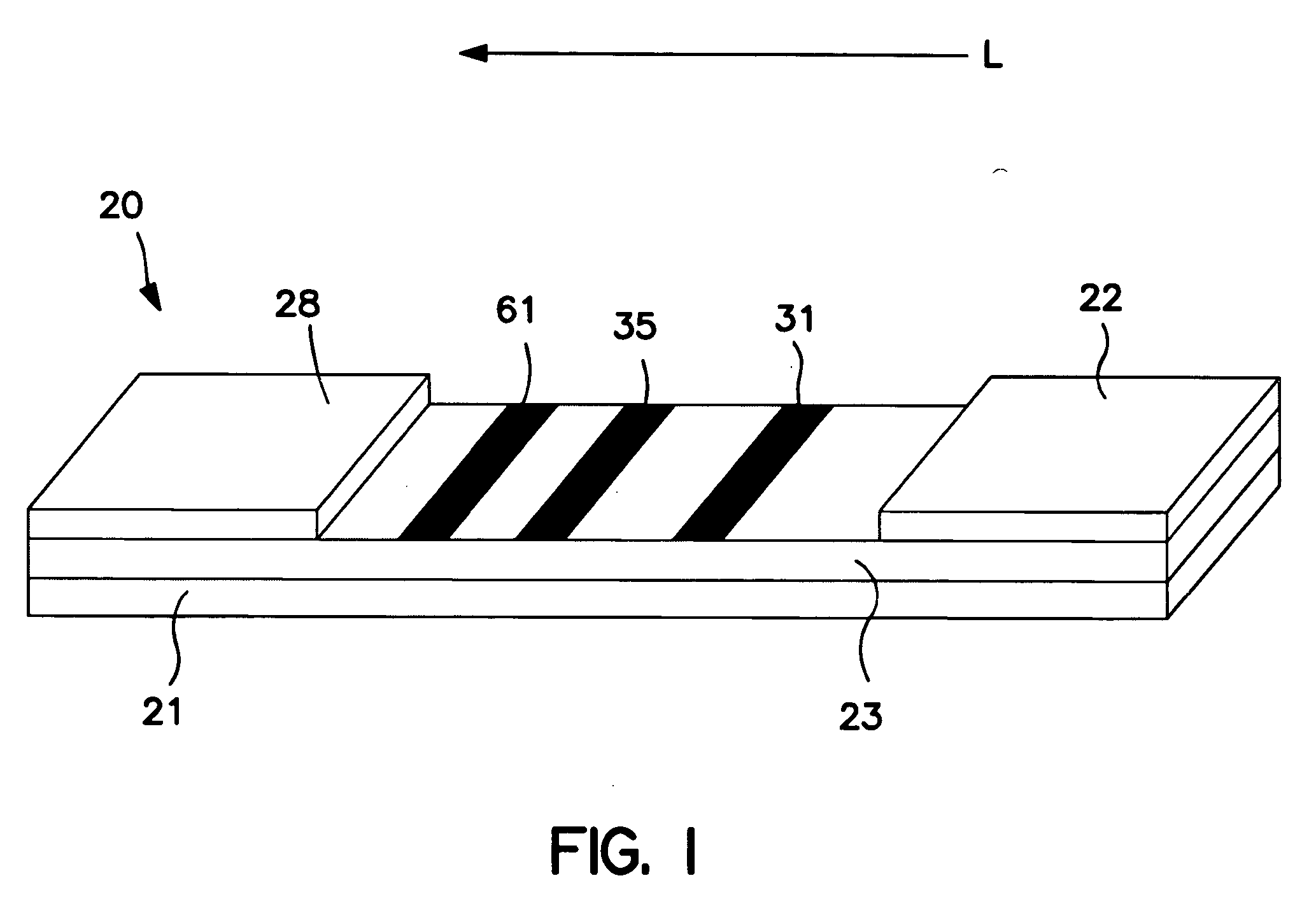

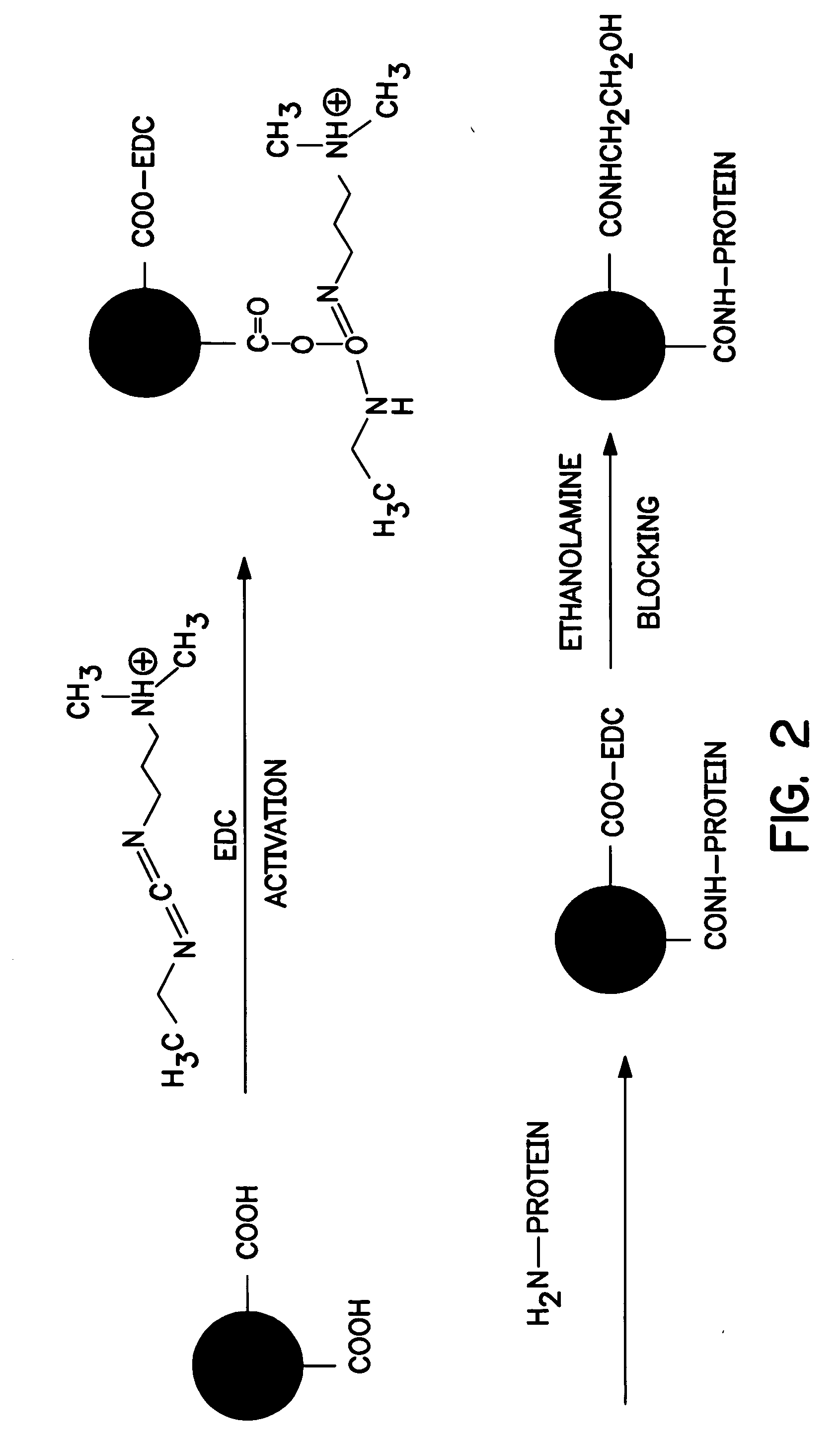

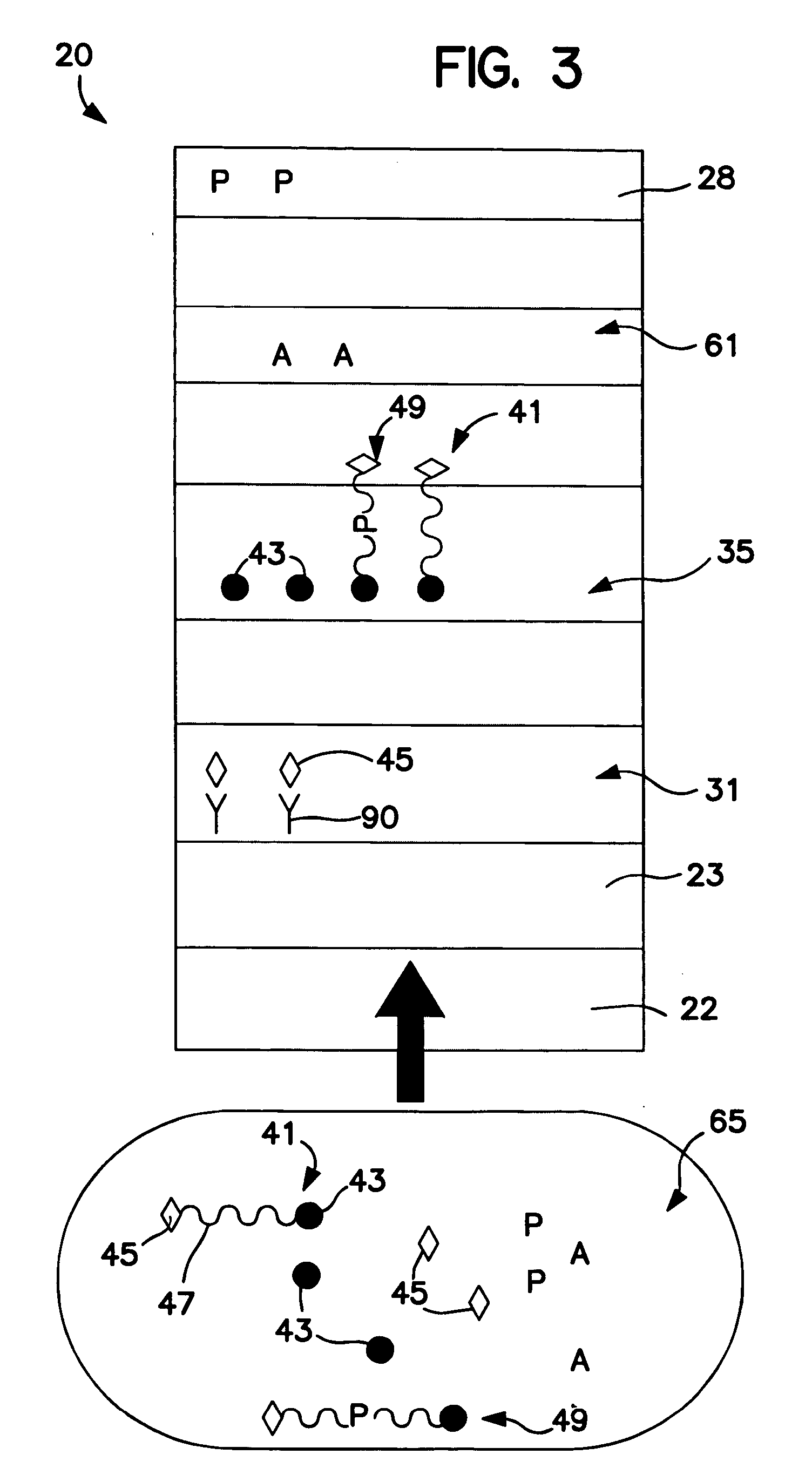

One-step enzymatic and amine detection technique

InactiveUS20060003336A1Bioreactor/fermenter combinationsBiological substance pretreatmentsChemical reactionDiagnostic test

A technique for detecting the presence or quantity of an enzyme (or enzyme inhibitor) and / or an amine within a test sample is provided. For example, in one embodiment, a diagnostic test kit is employed that utilizes reactive complexes that each includes a substrate joined (e.g., covalently bonded, physically adsorbed, etc.) to a reporter and a separation species. Upon contacting the reactive complexes, enzymes may cleave the substrate and release the reporter. Moreover, the test kit may also employ a chemichromic dye, i.e., a dye that exhibits a detectable color change upon chemical reaction with one or more functional groups, such as amino groups. The signal generated (directly or indirectly) by the reporter and chemichromic dye may then be used to indicate the presence or quantity of an enzyme (or enzyme inhibitor) and amine, respectively, within the test sample.

Owner:KIMBERLY-CLARK WORLDWIDE INC

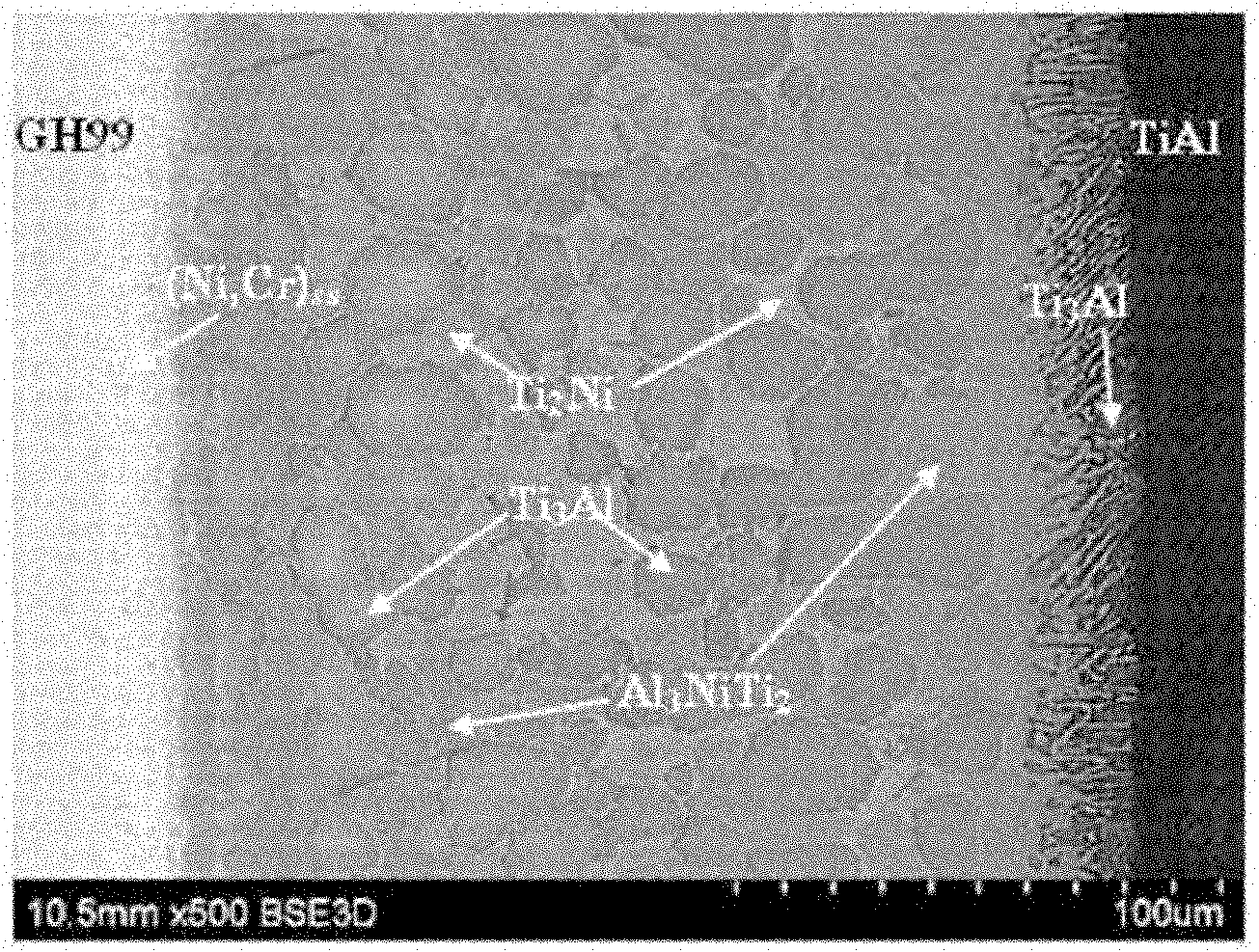

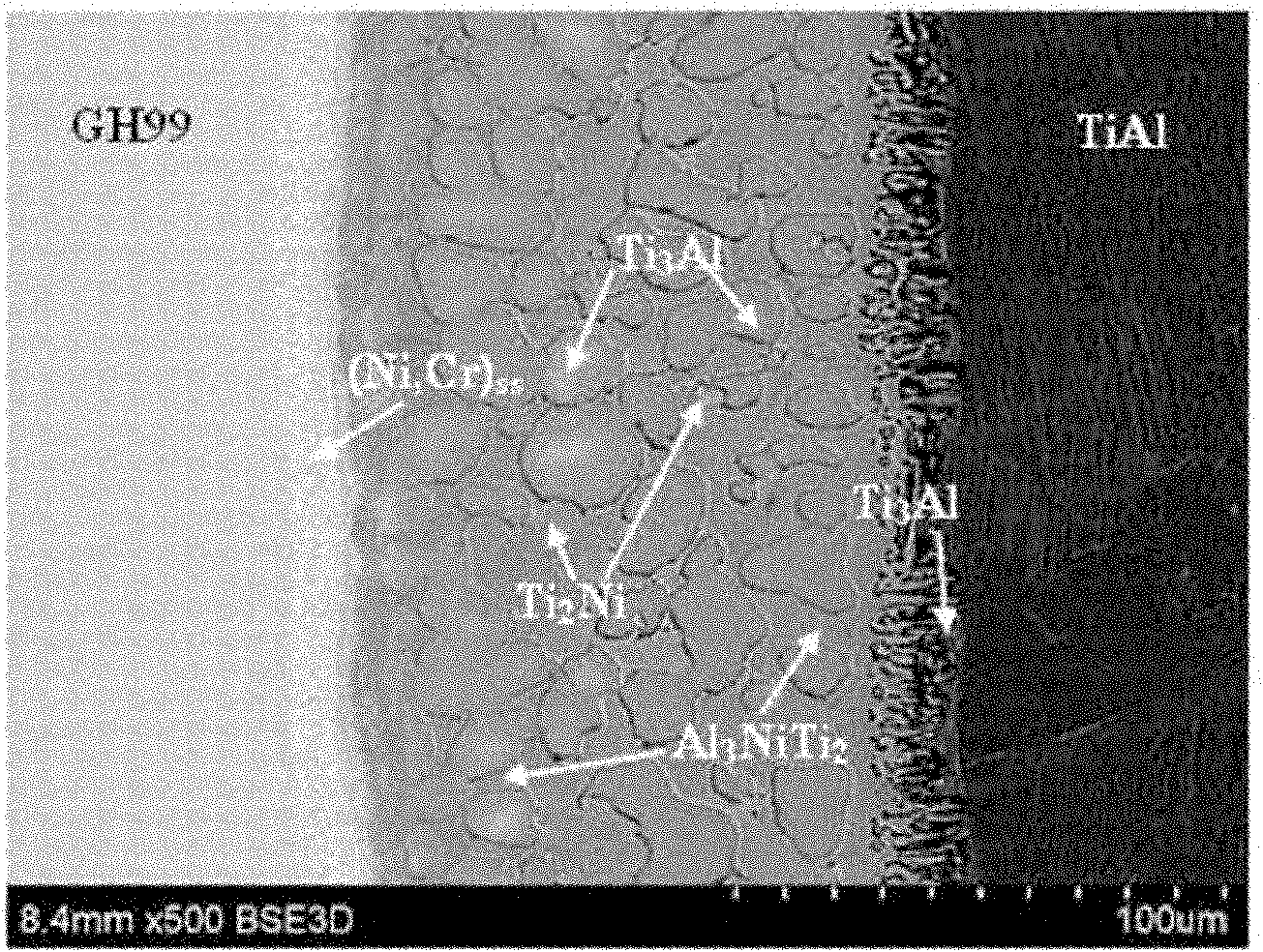

Contact reaction brazing connection method for TiAl based alloy and Ni based high-temperature alloy

ActiveCN101972877AAchieving a soldered connectionSimple processSoldering apparatusContact reactionsSuperalloy

The invention discloses a contact reaction brazing connection method for TiAl based alloy and Ni based high-temperature alloy, relating to a welding method for the TiAl based alloy and the Ni based high-temperature alloy and solving the problems of the traditional diffusion connection method for the TiAl based alloy and the Ni based high-temperature alloy that the process is complicated, the cost is high, the connection thermal cycle period is long, the efficiency is low, the requirement on the to-be-welded surface of a weldment is high, a silver brazing joint is not resistant to high temperature, and the brittle phase of high-temperature brazing is easy to aggregate and grow. The method comprises the steps of: treating the to-be- surface of a Ti foil, the TiAl based alloy and the Ni based high-temperature alloy, placing the Ti foil between the TiAl based alloy and the Ni based high-temperature alloy to form a weldment to be welded, and welding the weldment to be welded in a vacuum brazing furnace. The joint obtained in the invention has high shear strength up to 240-300MPa, and the shear strength is 180-210MPa at the high temperature of 800 DEG C, and the joint can be used as a hot end part for aerospace under high-temperature environment.

Owner:HARBIN INST OF TECH

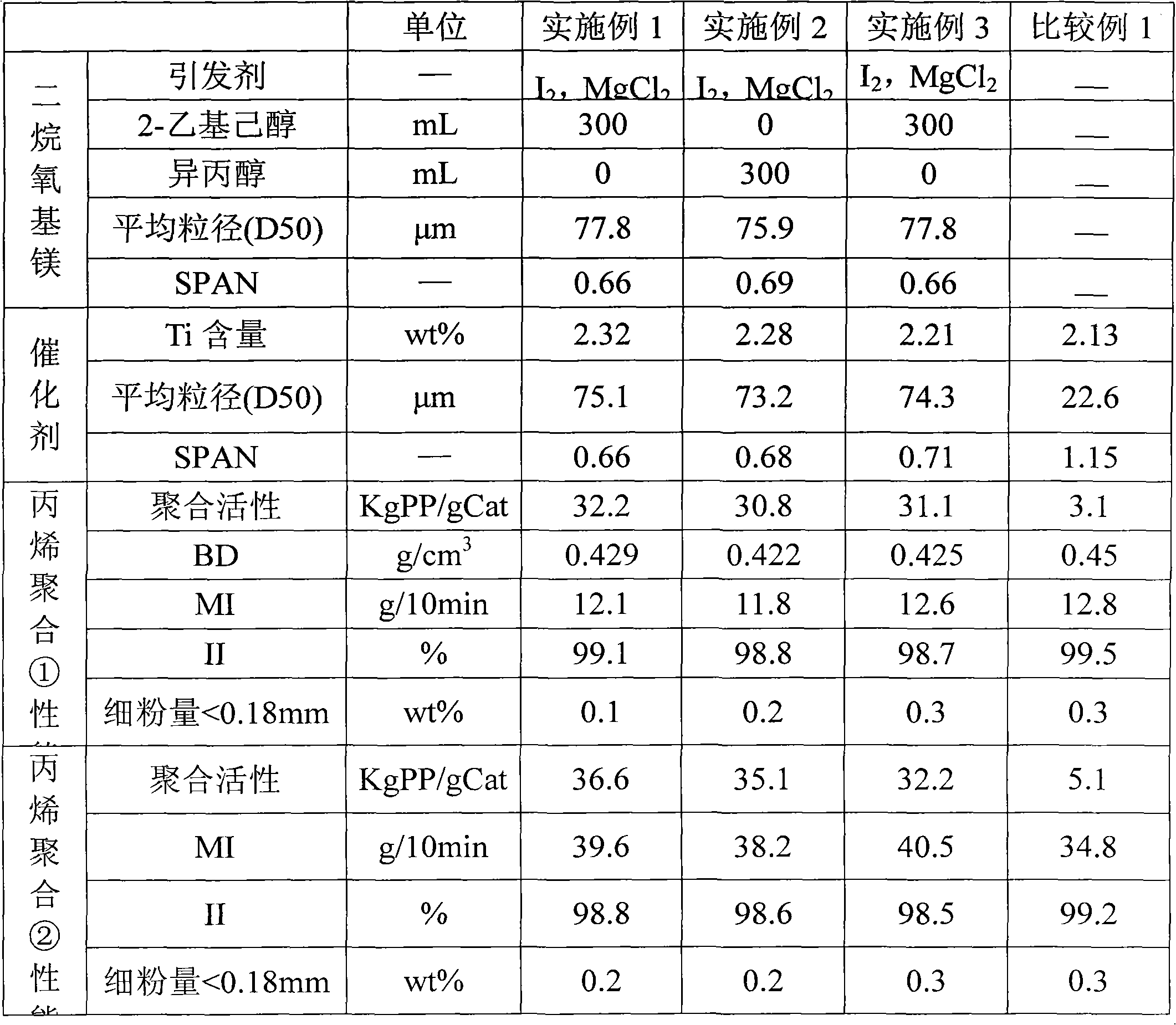

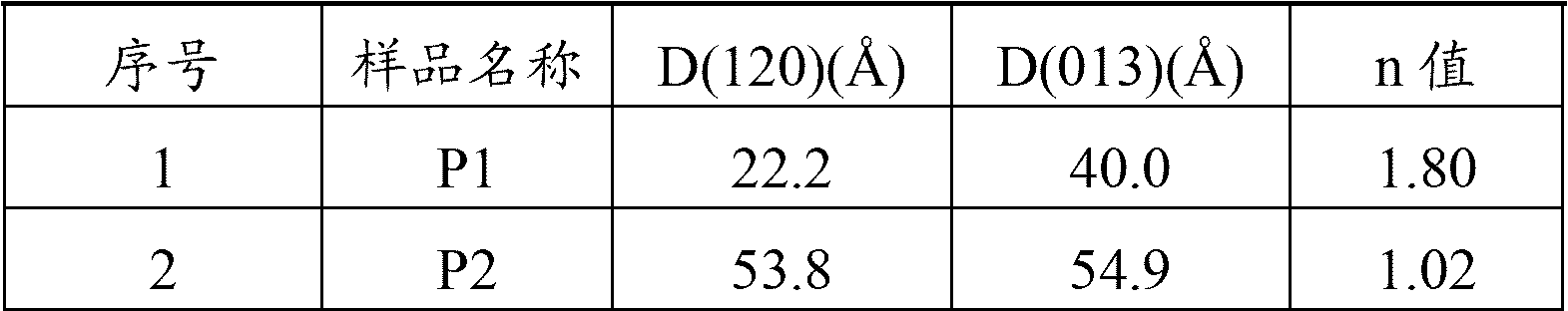

Catalyst component for high temperature olefin polymerization, and preparation method thereof

The present invention relates to a catalyst component for high temperature olefin polymerization. According to the present invention, metal magnesium and an alcohol are adopted and are subjected to a reaction in the presence of a halogenating agent to prepare a spherical dialkyloxy magnesium carrier with an excellent performance; then the carrier, a titanium compound and an electron donor compound are subjected to a contact reaction in an inert diluent agent to obtain a high temperature polymerization solid catalyst component; and the solid catalyst component is adopted as a main catalyst, an organic aluminum compound is adopted as an auxiliary catalyst, and an organosilicon compound is adopted as a stereo orientation agent, wherein the resulting catalyst component is particularly suitable for propylene homopolymerization or copolymerization of propylene and other olefins. Polymerization results show that the catalyst of the present invention provides higher activity than the conventional catalyst, and the resulting polymer has characteristics of high melt index, high isotacticity, and low fine powder content. With the present invention, high performance resin products can be developed, and broad application prospects are provided.

Owner:CHINA PETROLEUM & CHEM CORP +1

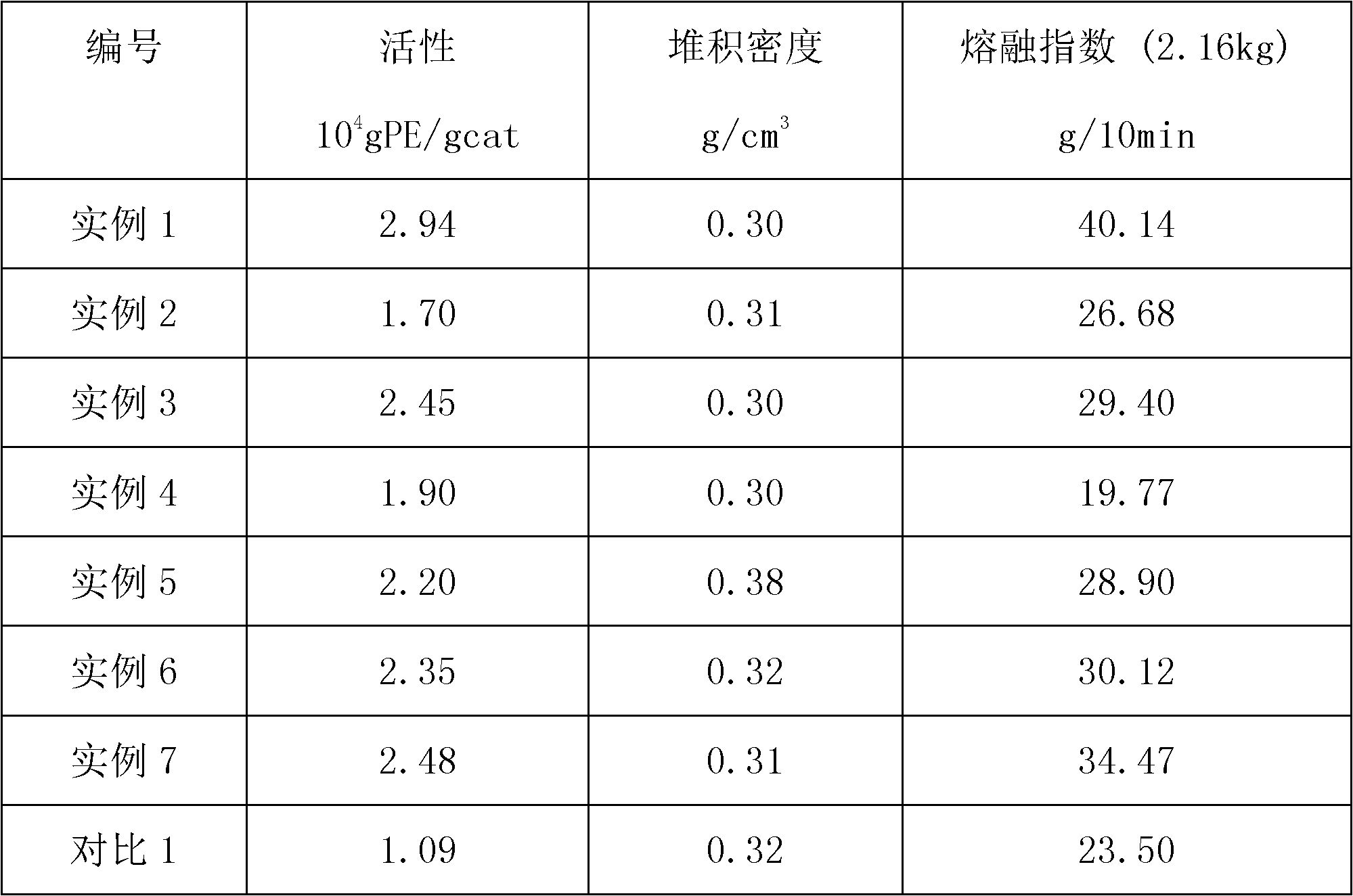

Preparation method of catalyst component for ethylene polymerization or copolymerization and catalyst thereof

InactiveCN102875707AHigh catalytic activityNarrow particle size distributionSolid componentOrganotitanium compound

The invention relates to a preparation method of a catalyst component for ethylene polymerization or copolymerization and a catalyst thereof. The method comprises the following steps: (1) at a temperature of 50-90DEG, dissolving magnesium halide in a solvent system containing an organic epoxy compound and an organic phosphorus compound to form a uniform solution; adding an organic alcohol compound during or after the solution formation and leaving them to react for certain time so as to obtain a reaction solution; (2) in the presence of an organic titanium compound and at a temperature of -30DEG C-0DEG C, subjecting the solution and a titanium compound to a contact reaction, or adding the organic titanium compound after the contact reaction of the solution obtained in step (1) and the titanium compound, and raising the temperature of the mixture slowly to 50-120DEG C, leaving solids to precipitate gradually and form particles, after certain period of reaction, removing the unreacted material and the solvent, and conducting washing with an inert diluent so as to obtain a solid component; and (3) suspending the solid component in certain amount of the inert diluent, performing a contact reaction with an organic aluminium compound under a temperature of 0DEG C-50DEG C, and after certain reaction time, removing the inert diluent, thus obtaining the catalyst component. The catalyst provided in the invention has high catalytic activity and good hydrogen response.

Owner:CHINA PETROLEUM & CHEM CORP +1

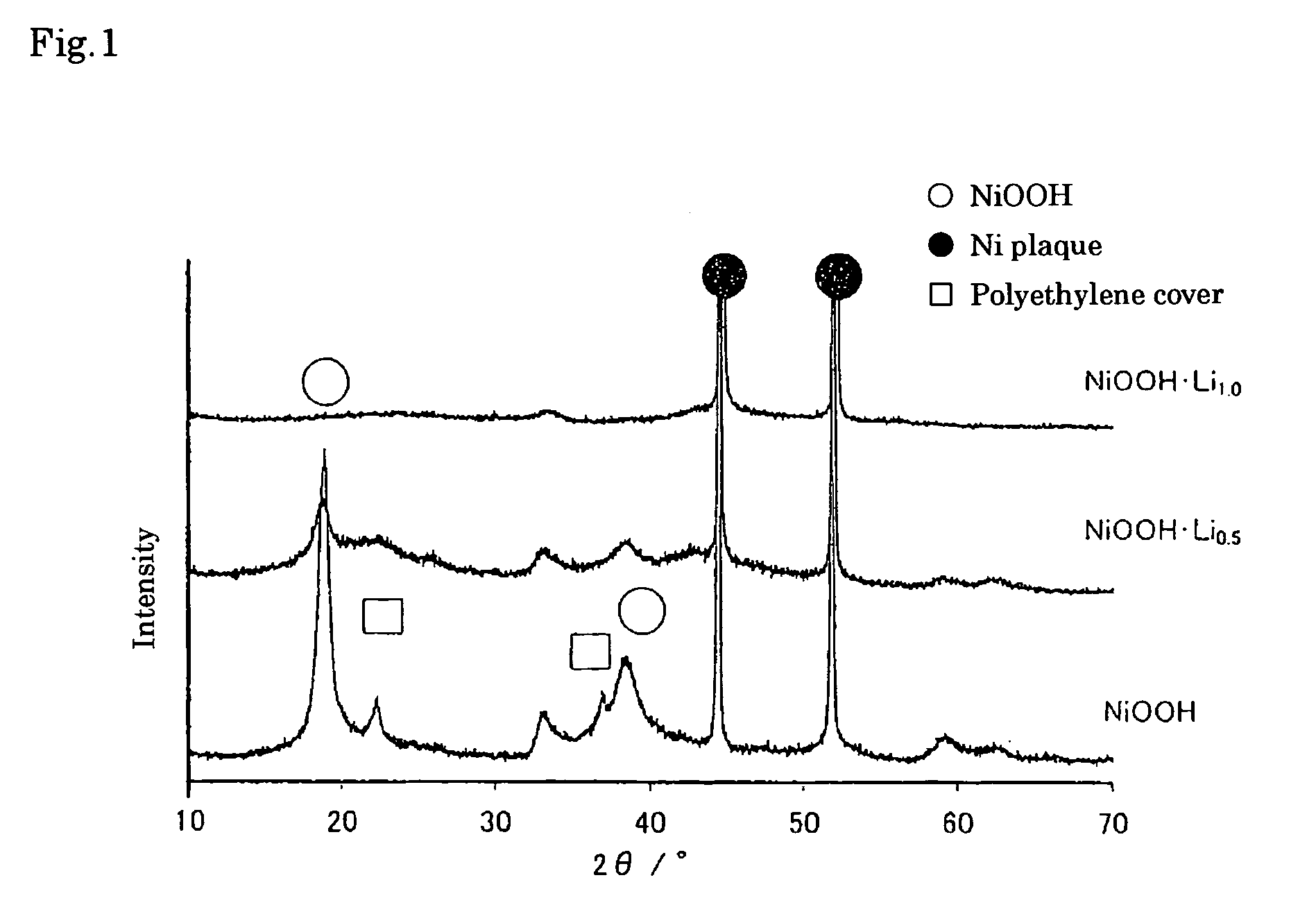

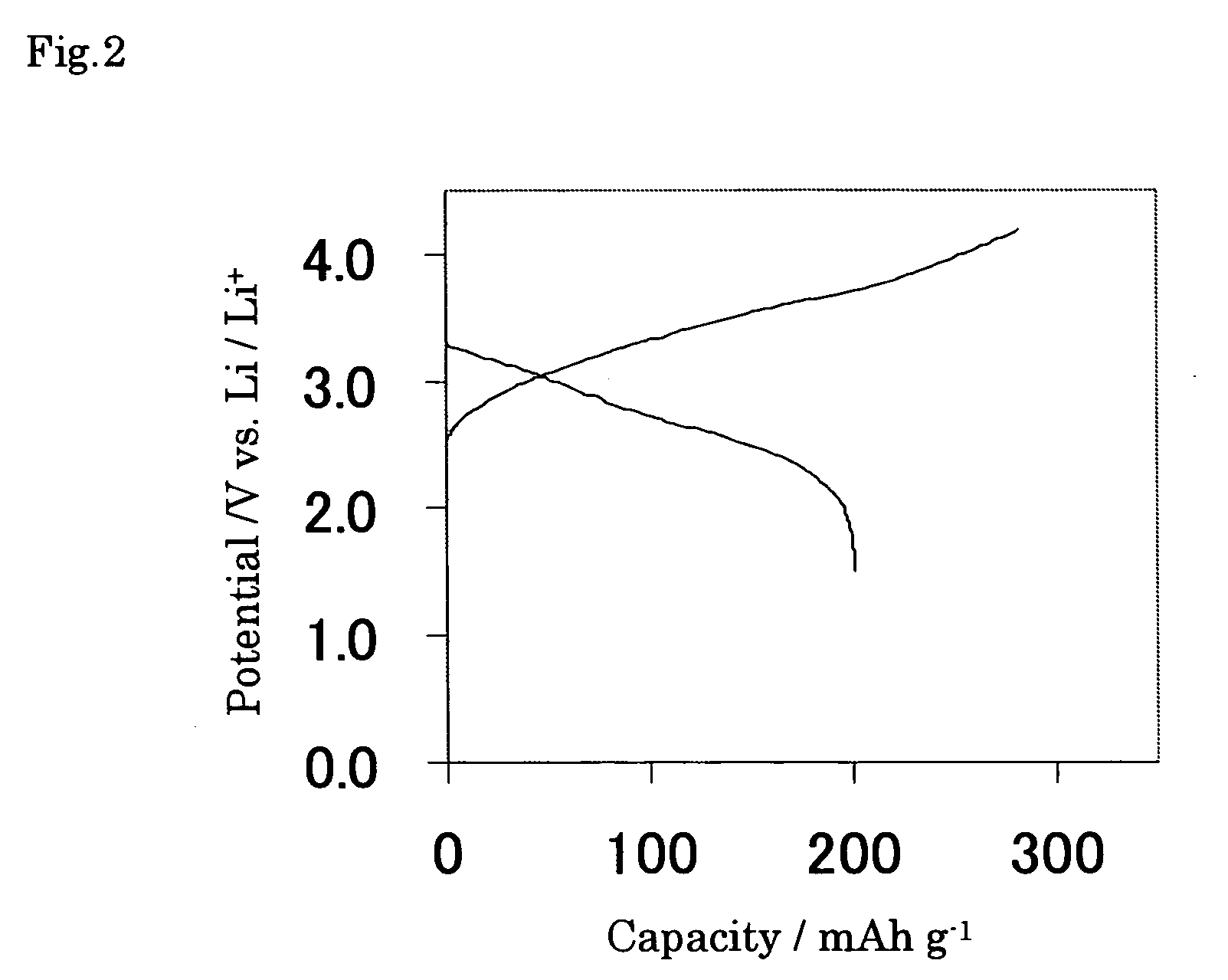

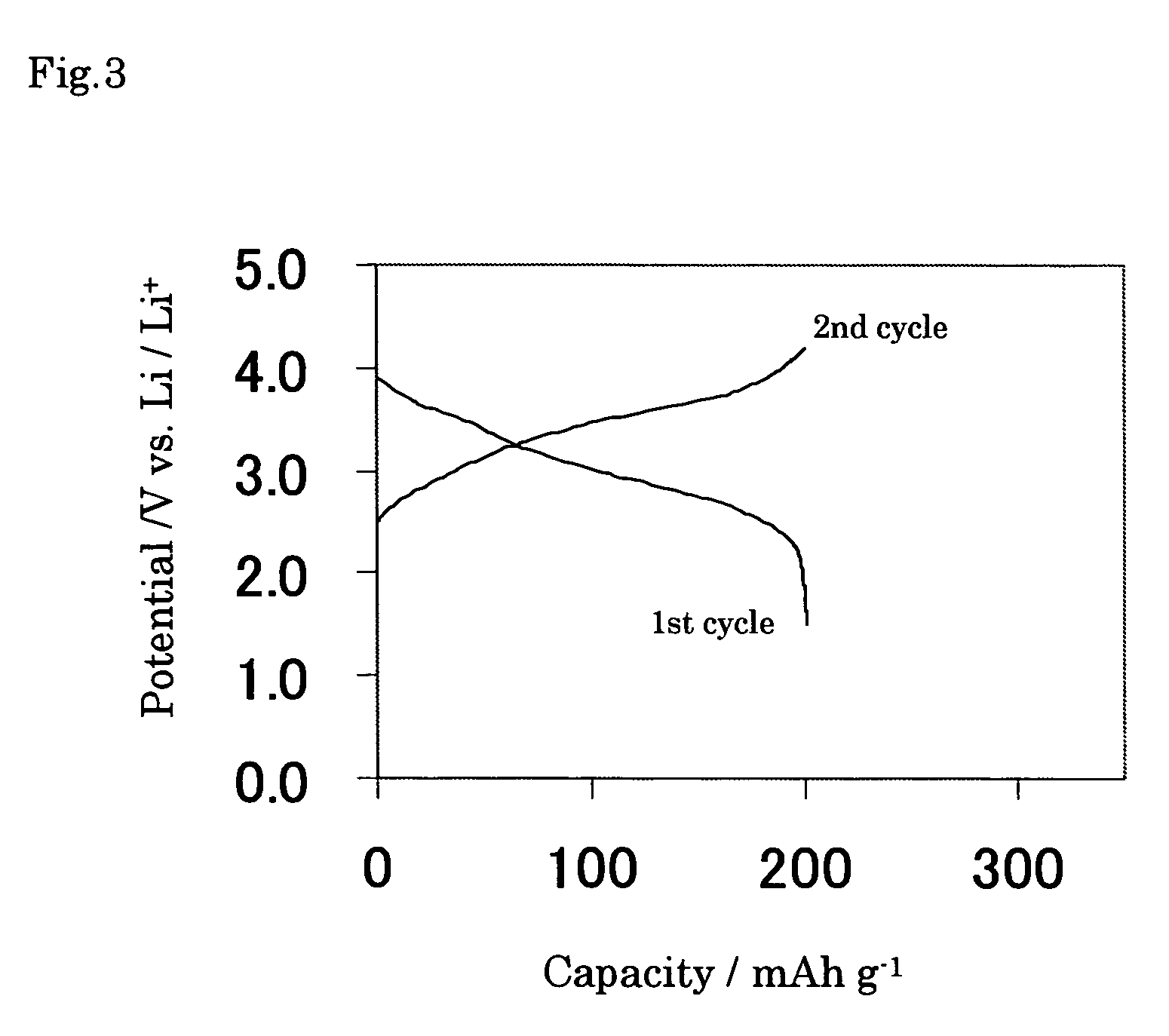

Manufacturing process of Li-contained nickel oxyhydroxide and nonaqueous electrolyte electrochemical cells with it

InactiveUS20050152830A1Non-aqueous electrolyte accumulatorsHybrid capacitor electrodesLithiumCompound (substance)

The present invention is concerned on the manufacturing process of Li-contained nickel oxyhydroxide obtained by a lithium absorption process with contact reaction between nickel oxyhydroxide and a solution obtained by dissolving metallic Li and polycyclic aromatic compounds in a solvent. Moreover, the nonaqueous electrolyte electrochemical cell using Li-contained nickel oxyhydroxide active material obtained by this manufacturing process is able to be high performance with a low manufacturing price by its simple process compared to the existing process by electrochemical process and so on.

Owner:GS YUASA CORP +1

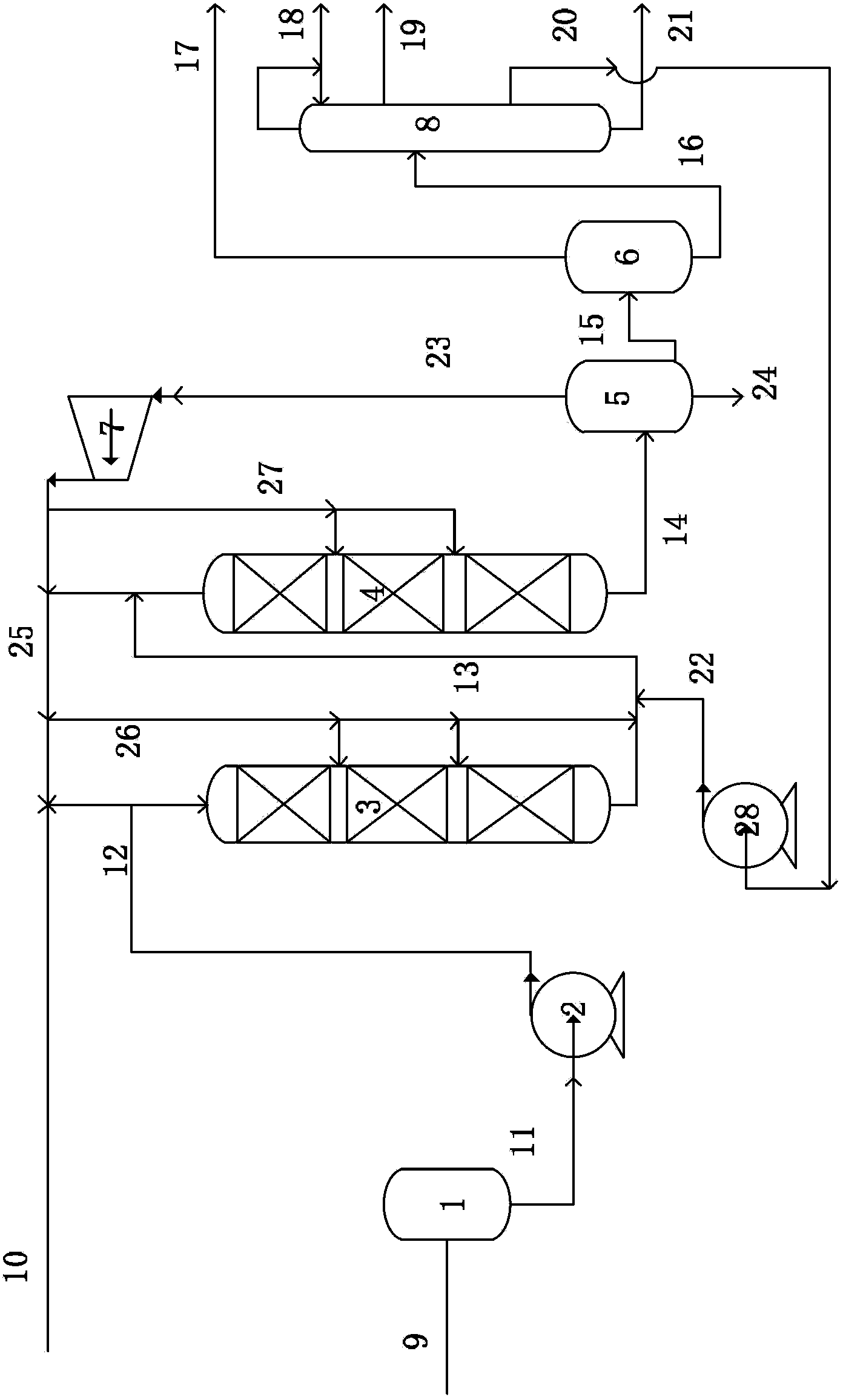

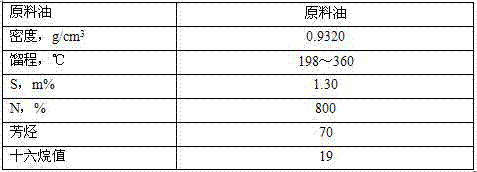

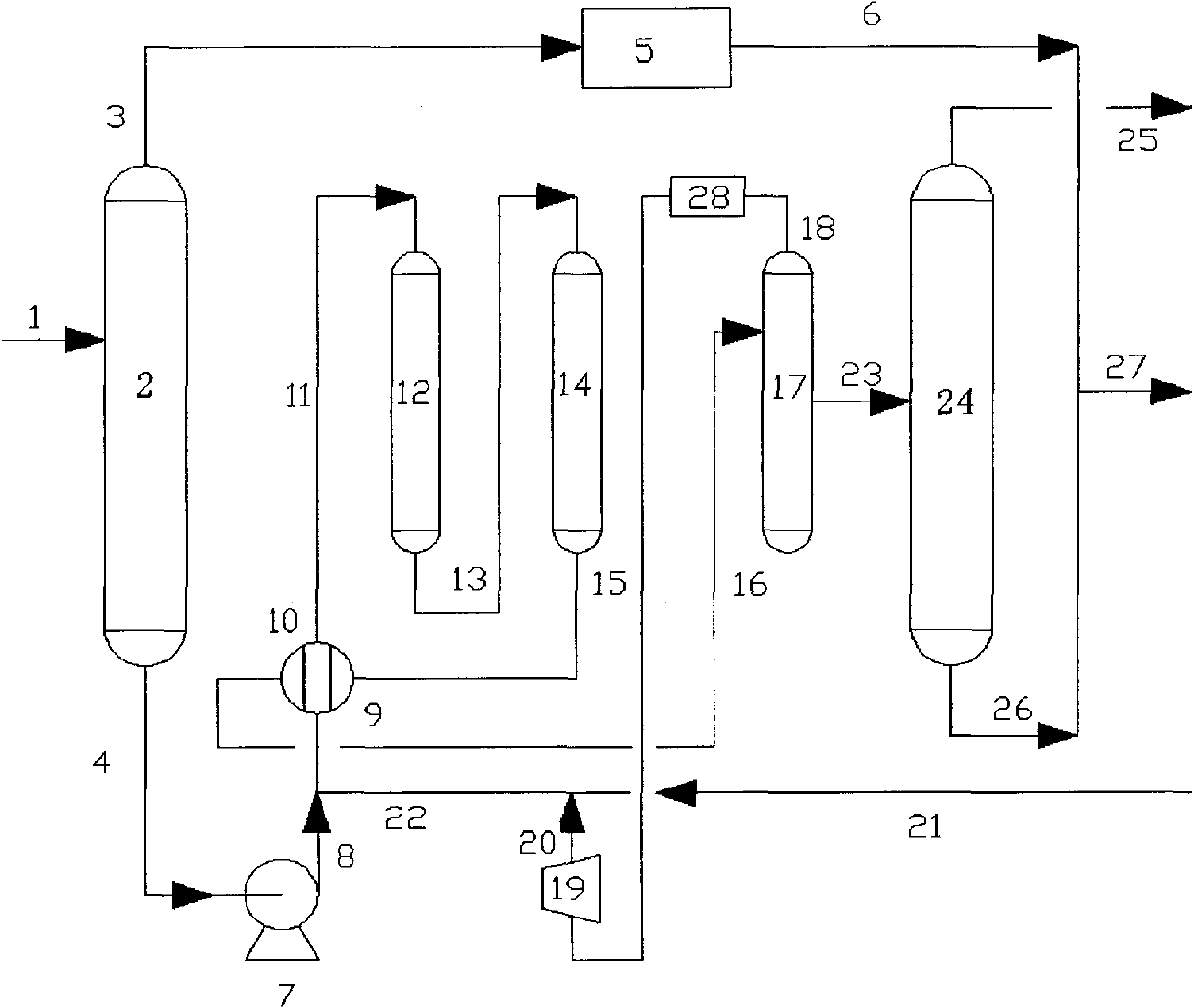

Hydrocracking method for catalytic cracking diesel

ActiveCN103773487ASimple compositionHigh yieldTreatment with hydrotreatment processesHydrogenNaphtha

The invention provides a hydrocracking method for catalytic cracking diesel. According to the method, a mixture of the diesel material and hydrogen is in contact reaction with a hydrorefining catalyst in a hydrorefining reactor, liquid efflux from the hydrorefining reactor is not separated and then enters a hydrocracking reactor to be in contact and react with a hydrocracking catalyst, the reaction efflux from the hydrocracking reactor is subjected to separation and fractional distillation to obtain hydrogen-rich gas, then light naphtha fraction, gasoline fraction, recycle fraction and diesel fraction are performed, in the distillation range of the recycle fraction, the temperature is 190 DEG C to 300 DEG C, and the recycle fraction returns to an inlet of the hydrocracking reactor. The method provided by the invention improves the composition of feed hydrocarbon of the hydrocracking reaction region, and the yield and the octane value of the gasoline fraction are effectively increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

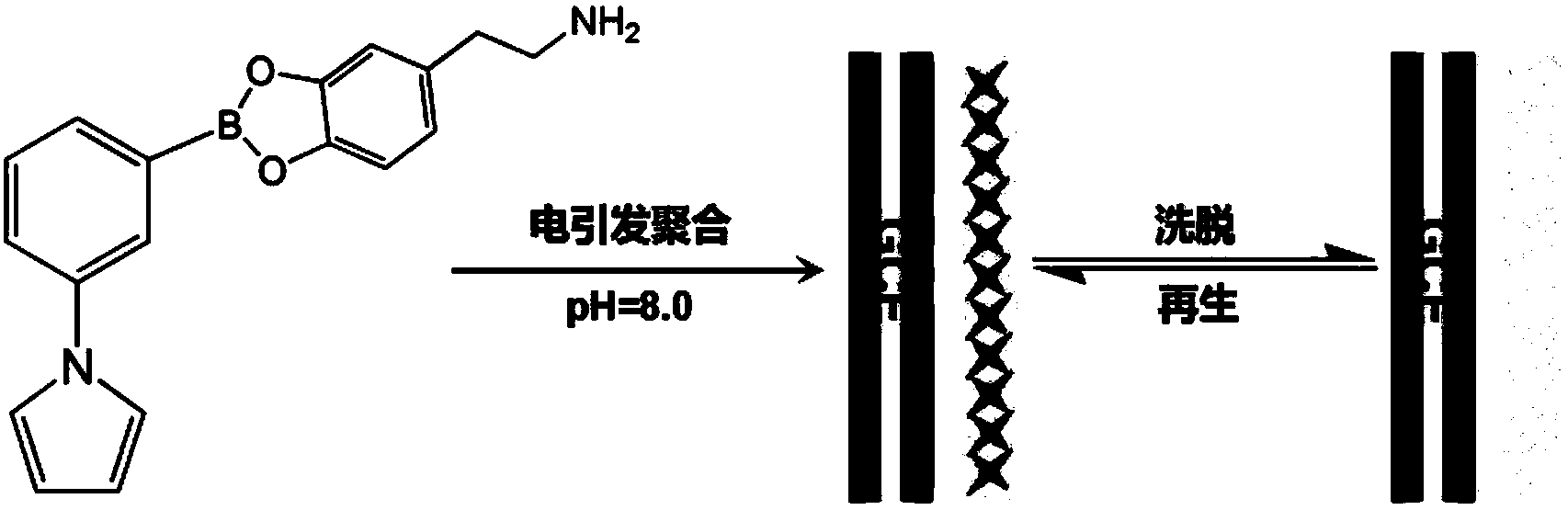

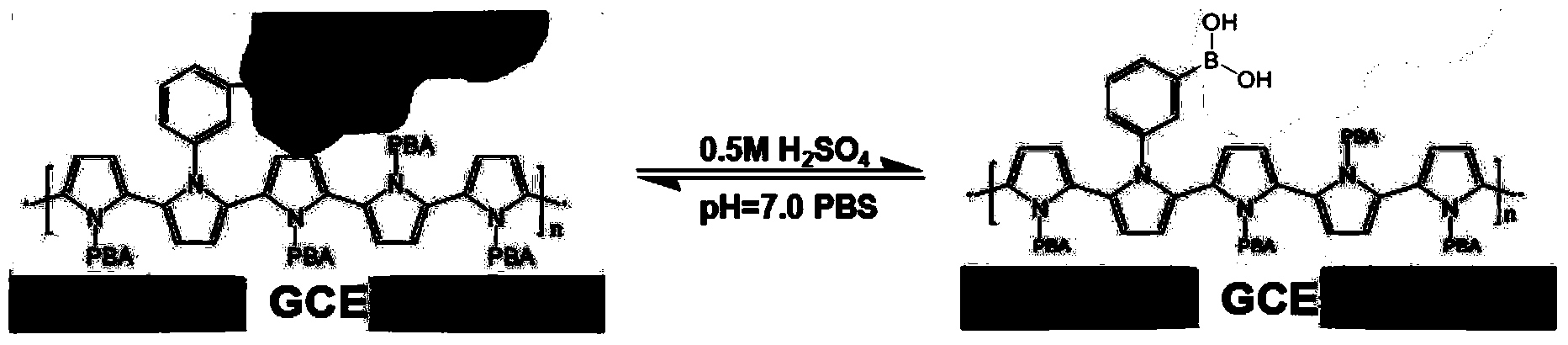

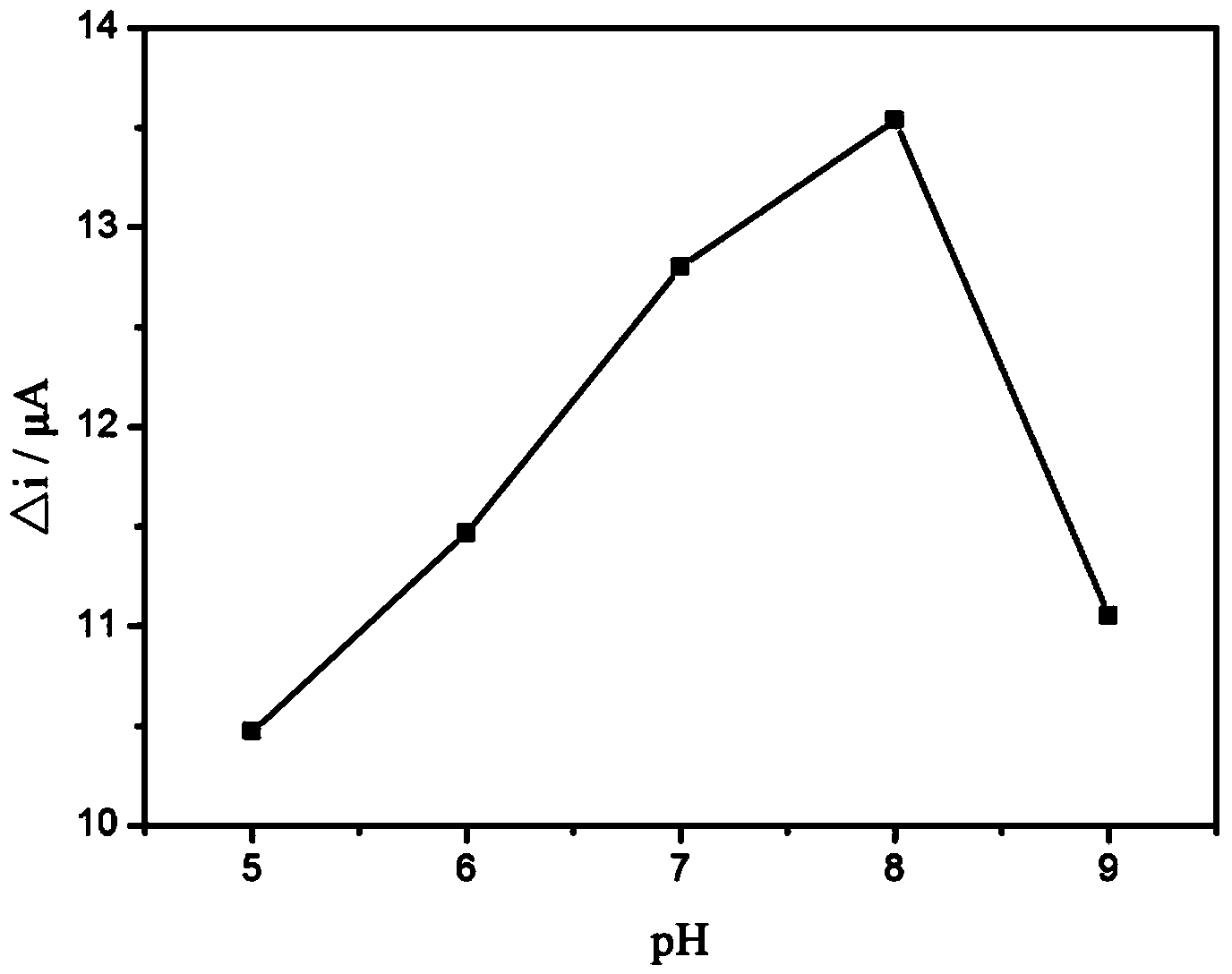

Double recognition dopamine imprinting electrochemical sensor and preparation method and application thereof

InactiveCN104020195AImprove specific recognition abilityImprove anti-interference abilityMaterial electrochemical variablesFuranAcetic acid

The invention discloses a double recognition dopamine imprinting electrochemical sensor and a preparation method and application thereof. The method comprises the following steps: (1) conducting contact reaction on 3-amino boronic acid, 2,5-dimethoxy furan and acetic acid to prepare functional monomers; (2) in the presence of a buffer solution, mixing the functional monomers and dopamine to form a polymerization liquid, placing a glassy carbon electrode in the polymerization liquid, and conducting scanning preparation of a polymer film modified electrode in the polymerization liquid in accordance with the a cyclic voltammetry; and (3) placing the polymer film modified electrode in an acidic solution for electrochemical elution, so as to prepare the double recognition dopamine imprinting electrochemical sensor. The electrochemical sensor provided by the invention has excellent specificity recognition ability and anti-interference ability for the detection of dopamine.

Owner:ANHUI NORMAL UNIV

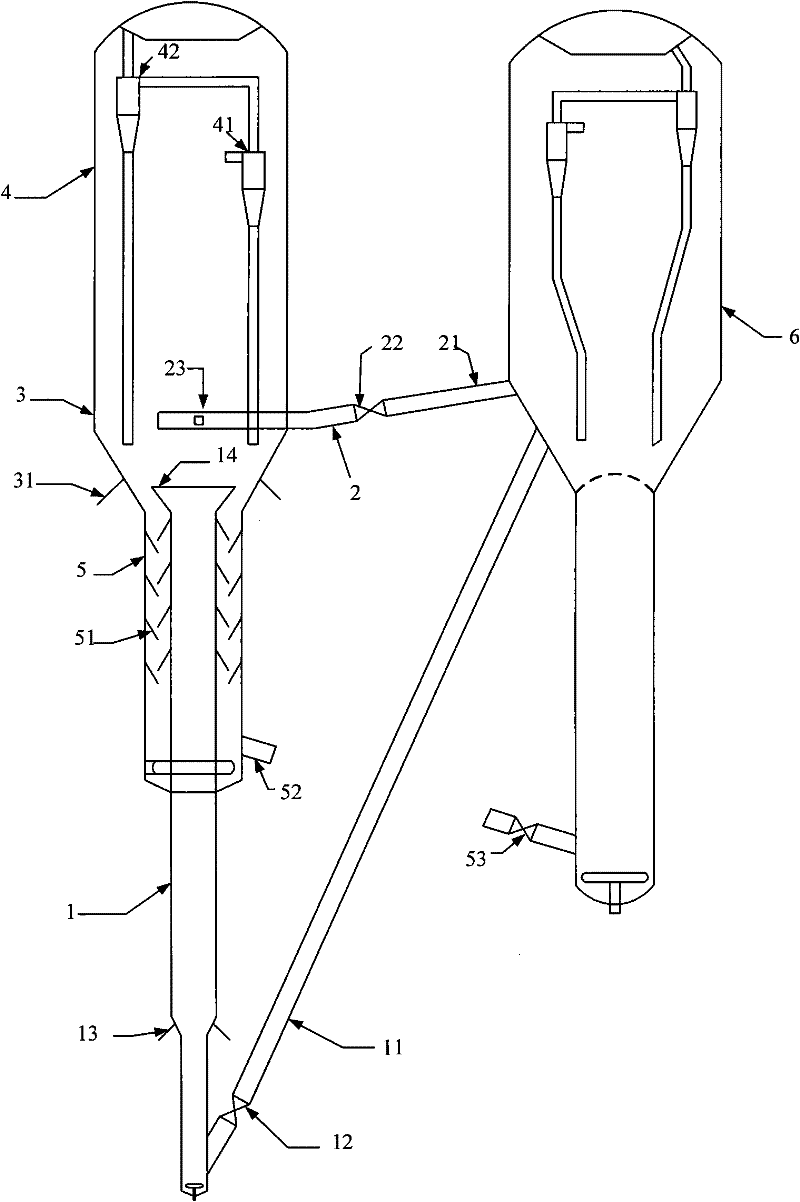

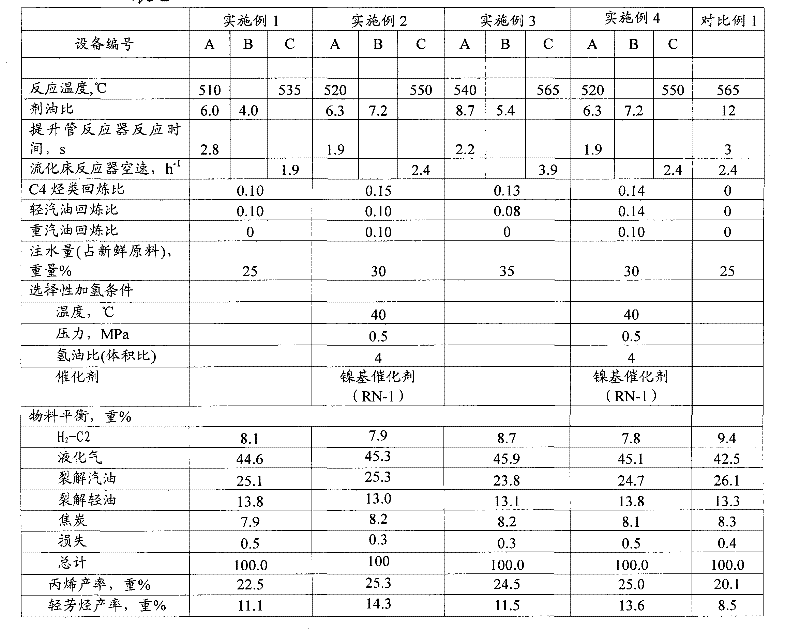

A method for catalytic conversion of hydrocarbons to produce propylene and light aromatics

ActiveCN102286294AImprove conversion rateHigh yieldTreatment with plural serial stages onlyTreatment with hydrotreatment processesFluidized bedFractionation

The invention provides a method for producing propylene and light arenes by catalytic conversion of hydrocarbons, and the method comprises: carrying out contact reaction on a hydrocarbon raw material and a first regenerated catalyst in a first reactor under a catalytic cracking condition; then introducing a fluidized bed reactor connected with the first reactor in series for reaction; after the reaction is finished, introducing oil vapor into a fractionation device for fractionation; and introducing a spent catalyst into a stripper, wherein a second regenerated catalyst is introduced into the fluidized bed reactor and the spent catalyst contains modified beta zeolite. The method provided by the invention has higher yields of propylene and light arenes, and is suitable for the production of propylene and light arenes by the catalytic conversion of the hydrocarbon raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing corrosion inhibition waterborne aluminum pigment

InactiveCN105482514AImprove stabilityGood sustained release effectPigment flushingPigment treatment with organosilicon compoundsContact reactionsElution

The invention discloses a method for preparing a corrosion inhibition waterborne aluminum pigment. The method comprises the following steps: a step (1) of aluminum powder surface elution treatment; a step (2) of surface hydroxylation treatment; and a step (3) of mixing coating treatment. The method for preparing the corrosion inhibition waterborne aluminum pigment is simple and convenient to operate and easy to implement. According to the method, through aluminum powder surface elution treatment, hydroxylation treatment, slow release treatment and coating treatment, the coating stability of the aluminum pigment surface is improved effectively, the aluminum pigment is prevented from being in contact reaction with water or an air medium, the slow release performance of the aluminum pigment is improved remarkably, and the prepared aluminum pigment is high in stability, good in glossiness and wide in application prospect.

Owner:常熟市环虹化工颜料厂

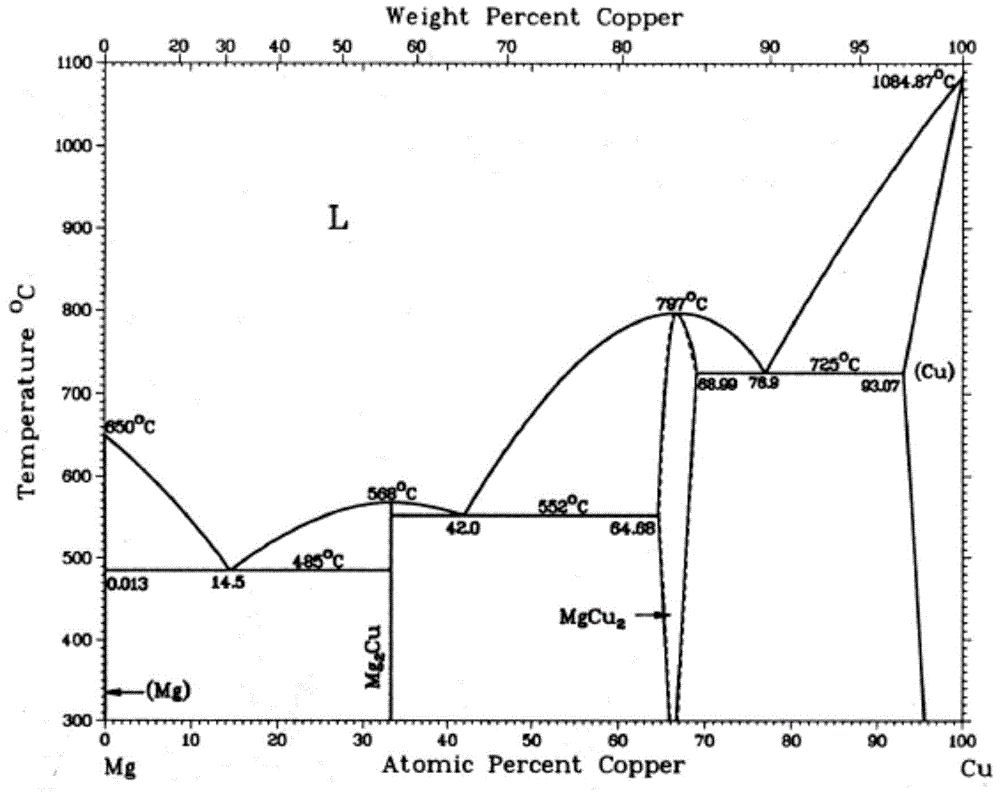

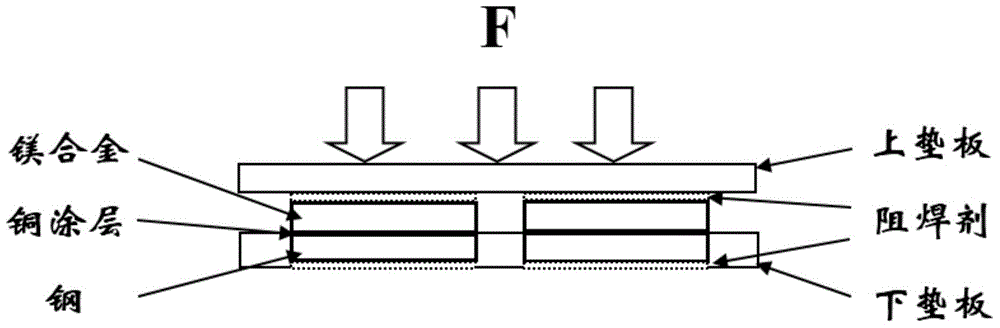

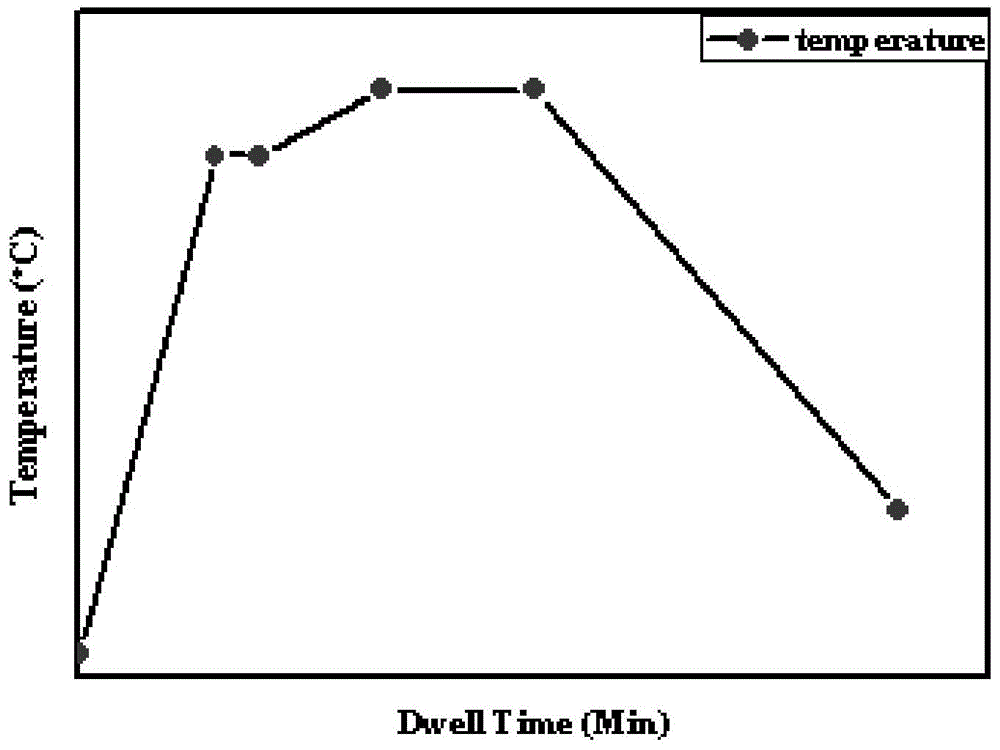

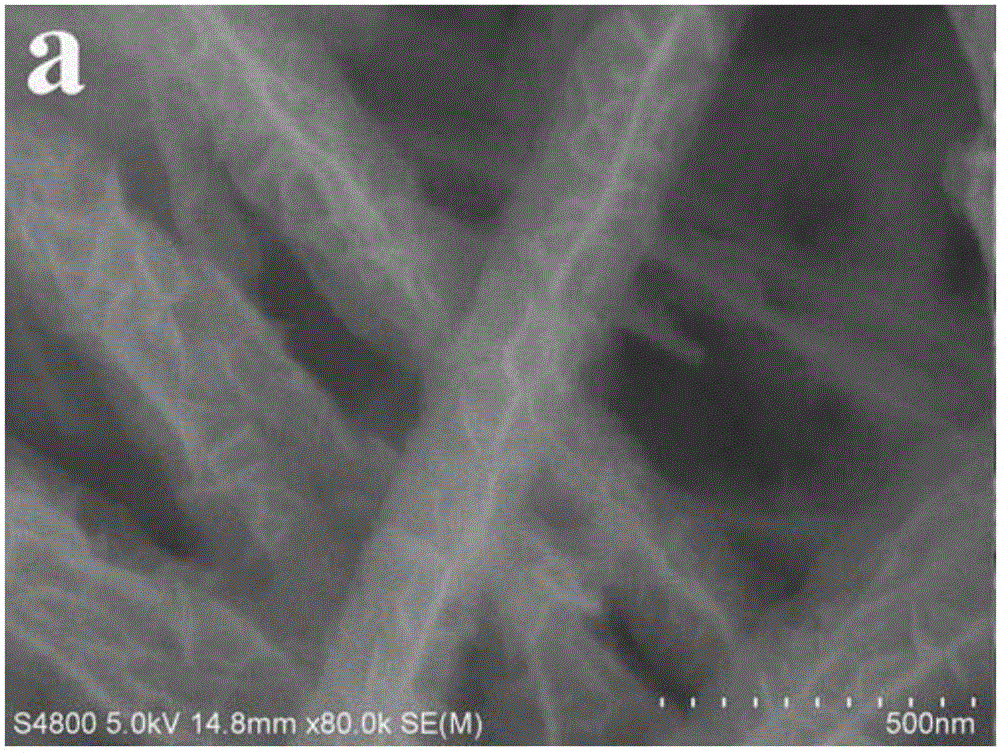

Diffusion brazing connecting method for contact reaction of magnesium alloy and steel

InactiveCN104084658AHigh strengthPrevent oxidationSoldering apparatusWelding/soldering/cutting articlesContact reactionsCopper

The invention discloses a diffusion brazing connecting method for a contact reaction of magnesium alloy and steel, and belongs to the field of dissimilar material connection. The melting point of the magnesium alloy is 650 DEG C only, and the magnesium alloy is sensitive to the welding temperature. Magnesium and steel are dissimilar materials. Particularly, the melting points and the linear expansion coefficients of the two dissimilar materials remarkably differ from each other, so that the welding difficulty of the magnesium and the steel is increased. The diffusion brazing connecting method comprises the steps that an intermediate pure copper layer is manufactured on the surface of the magnesium alloy, so that the magnesium alloy / Cu / steel brazing structure is formed in a combined mode; the magnesium alloy / Cu / steel brazing structure is fixedly arranged inside a vacuum diffusion furnace, the pressure of junction surfaces ranges from 0.0375 MPa to 0.2 MPa, the magnesium alloy / Cu / steel brazing structure is heated, the temperature of the magnesium alloy / Cu / steel brazing structure is kept constant, then, the magnesium alloy / Cu / steel brazing structure is reheated, the temperature of the magnesium alloy / Cu / steel brazing structure is kept constant, heating is stopped, the magnesium alloy / Cu / steel brazing structure is cooled with the furnace until the temperature of the magnesium alloy / Cu / steel brazing structure is smaller than 150 DEG C, and diffusion brazing connection of the contact reaction of the magnesium alloy and the steel is achieved. According to the diffusion brazing connecting method, the welding temperature is lower, the influence on the parent metal is small, no brazing filter metal is needed, the large surrounding and small surrounding phenomena are avoided, the aim that no defects (relative fusion welding) exist in brazing joints of welding of the magnesium alloy and the dissimilar metal is achieved to a certain degree, and the shearing strength of the brazing joints at indoor temperature can reach 39.6 MPa.

Owner:山东高熵金属科技有限公司

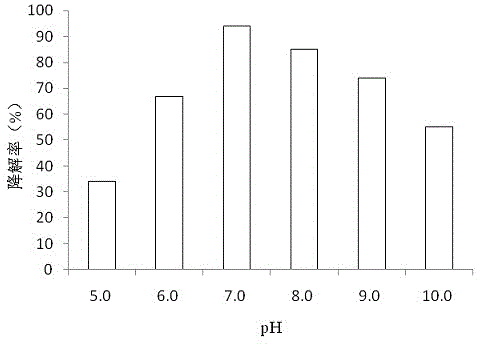

Pollution-depth degradation method of high-concentration chloronitrobenzene in soil by combination of solubilization and fenton oxidation of mixed surface active agent

ActiveCN103624074AImprove efficiencyReduce adsorption lossContaminated soil reclamationHigh concentrationSurface-active agents

The invention discloses a pollution-depth degradation method of high-concentration chloronitrobenzene in soil by combination of solubilization and fenton oxidation of a mixed surface active agent. The pollution-depth degradation method comprises the following steps: preparing and mixing aqueous solution of sodium dodecyl benzene sulfonate of an anionic surface active agent with certain concentration and a non-ionic surface active agent Tween -80 aqueous solution, putting polluted soil into the solution of the mixed surface active agent, and separating and discharging the solution of the mixed surface active agent after full contact reaction; adding a certain amount of water into the polluted soil after solubilizing treatment, mixing uniformly to prepare soil turbid liquid, and adjusting the pH value of the soil turbid liquid to be acid; adding ferrous sulfate for complete dissolving, then adding hydrogen peroxide slowly for stirring reaction, and after the reaction is finished, standing and discharging the upper-layer aqueous solution after the soil particles are completely sunk to the bottom layer. With the adoption of the surface active agent for solubilization, the pollution-depth degradation method disclosed by the invention has the advantages that high-concentration organic pollution can be economically removed, and the pollutant removing effect can be further optimized by the subsequent fenton oxidation. The pollution-depth degradation method is simple and easy and is suitable for large-scale production and use.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES

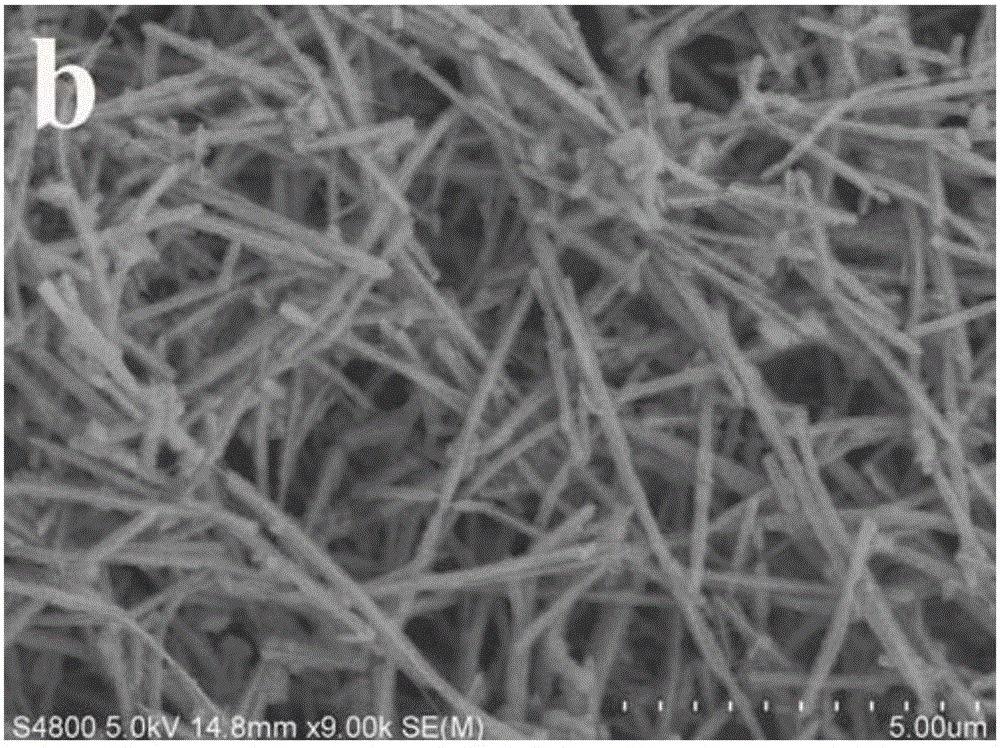

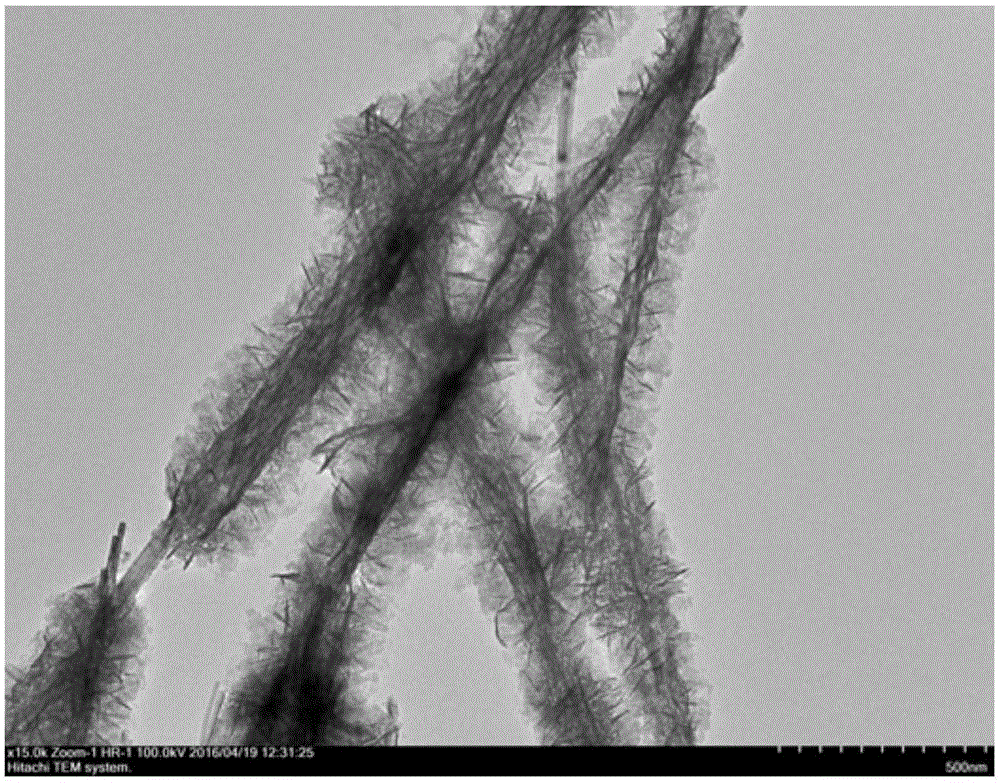

One-dimensional MnO2@NiMoO4 core shell heterojunction composite material and preparation method and application thereof

ActiveCN105914051AEasy post-processingEasy to controlHybrid capacitor electrodesHybrid/EDL manufactureHeterojunctionCapacitance

The invention discloses a one-dimensional MnO2@NiMoO4 core shell heterojunction composite material and a preparation method and an application thereof. The preparation method comprises the steps of: 1) preparing a MnO2 nano-wire monomer; and 2) carrying out contact reaction on urea, soluble nickel salt, soluble molybdate and the MnO2 nano-wire monomer in water so as to prepare the one-dimensional MnO2@NiMoO4 core shell heterojunction composite material. By adopting the method, the MnO2@NiMoO4 composite material with good specific capacitance and circulation stability is obtained, the composite material is capable of serving as an electrode material of an electrochemical capacitor, and the preparation method is simple to operate, low in cost, mild in condition, and green and environmental-friendly.

Owner:ANHUI NORMAL UNIV

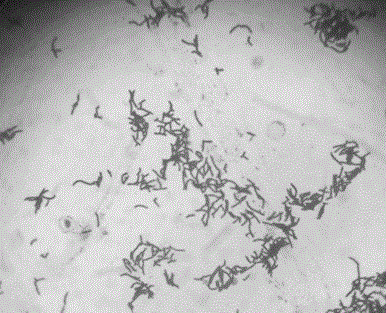

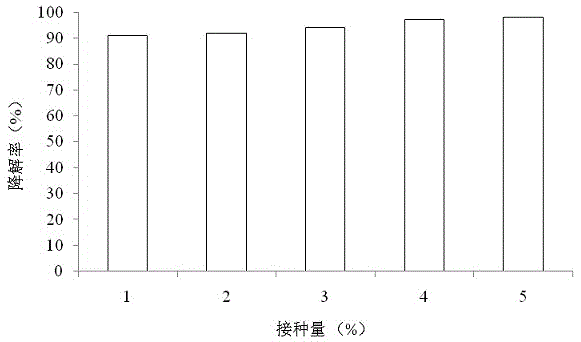

Rhodococcus ruber YMHL-1 capable of degrading nicosulfuron and applications thereof

ActiveCN106591168AResidue reductionReduce production and use costsBacteriaWater contaminantsAntibiotic YBiology

The invention discloses rhodococcus ruber YMHL-1 capable of degrading nicosulfuron and applications thereof. The invention provides a strain namely rhodococcus ruber YMHL-1 capable of degrading residual nicosulfuron in wastewater, and the identification shows that the strain belongs to Rhodococcus. The strain is preserved in China General Microbiological Culture Collection Center, CGMCC in February 9th, 2015; and the preservation number is CGMCC No. 10542. The main biological characteristics are as follows: the Gram staining reaction is negative; the bacterial colony is in an orange yellow color, is in a round shape, and is opaque, the surface of the bacterial colony is rough and dry; the cell is in a sphere shape or short bar shape, does not have any flagellum, is motionless, and does not generate any spore; the strain is aerobic and chemoheterotrophic and cannot liquefy gelatin and hydrolyze starch; the enzyme contact reaction is positive, the V.P. reaction is positive, the methyl red reaction is negative; the strain cannot degrade casein, cannot reduce nitrates; and the strain can produce acids from glucose, can utilize glucose, fructose, and citrates, cannot utilize mannose, arabinose, and raffinose, and can reduce more than 90% of antibiotics in water through direct application.

Owner:JIANGSU NANZI ENVIRONMENTAL PROTECTION SCI & TECH

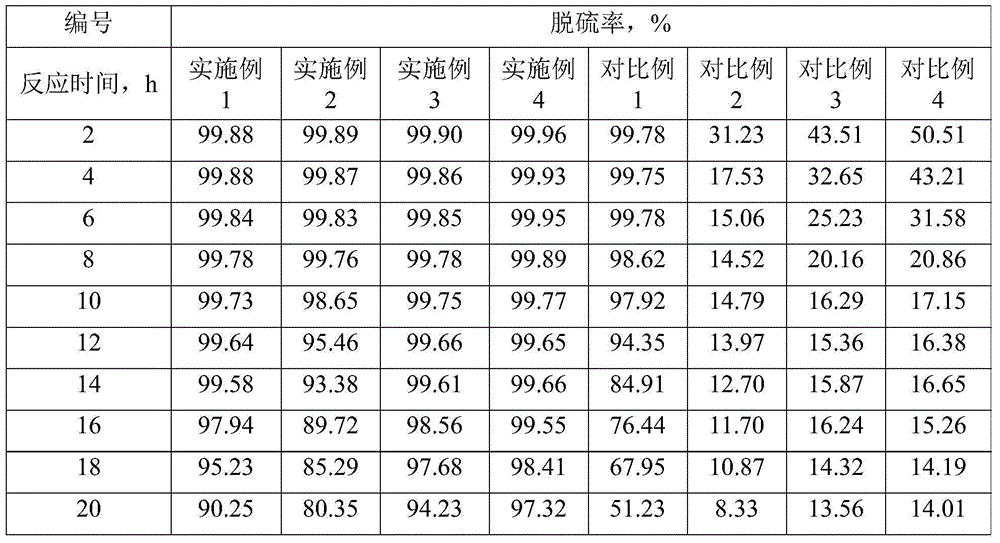

Adsorption desulfurization method

ActiveCN104560123AImprove the stability of desulfurization activityImprove utilization efficiencyHydrocarbon oils refiningHydrocarbon oils treatmentSilicon oxideCopper oxide

The invention provides an adsorption desulfurization method. The method comprises the step of carrying out contact reaction on sulfur-containing hydrocarbon oil, a hydrogen donor, a desulfurizer adsorbent and an adsorption desulfurization assistant, wherein the adsorption desulfurization assistant contains a metal oxide component which contains an adsorption desulfurization assistant carrier and is loaded on the adsorption desulfurization assistant carrier; the adsorption desulfurization assistant carrier is a mixture of aluminum oxide and silicon oxide; and the metal oxide component is selected from one or more of sodium oxide, potassium oxide, magnesium oxide, calcium oxide, titanium oxide, vanadium oxide, chromic oxide, manganese oxide, iron oxide, copper oxide, zinc oxide, zirconium oxide, lanthanum oxide, cerium oxide, praseodymium oxide and neodymium oxide. The desulfurization method provided by the invention has an excellent desulfurization effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

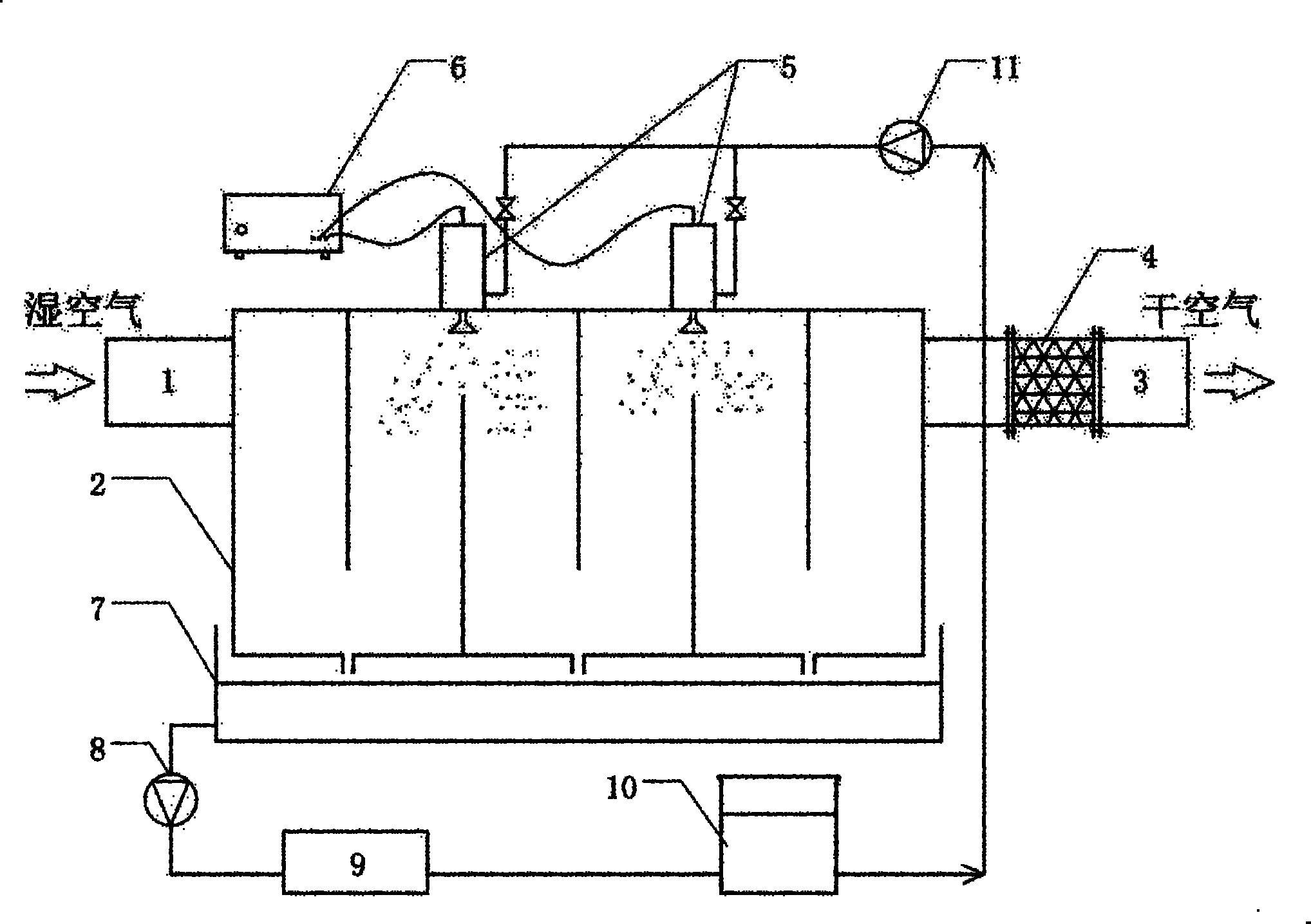

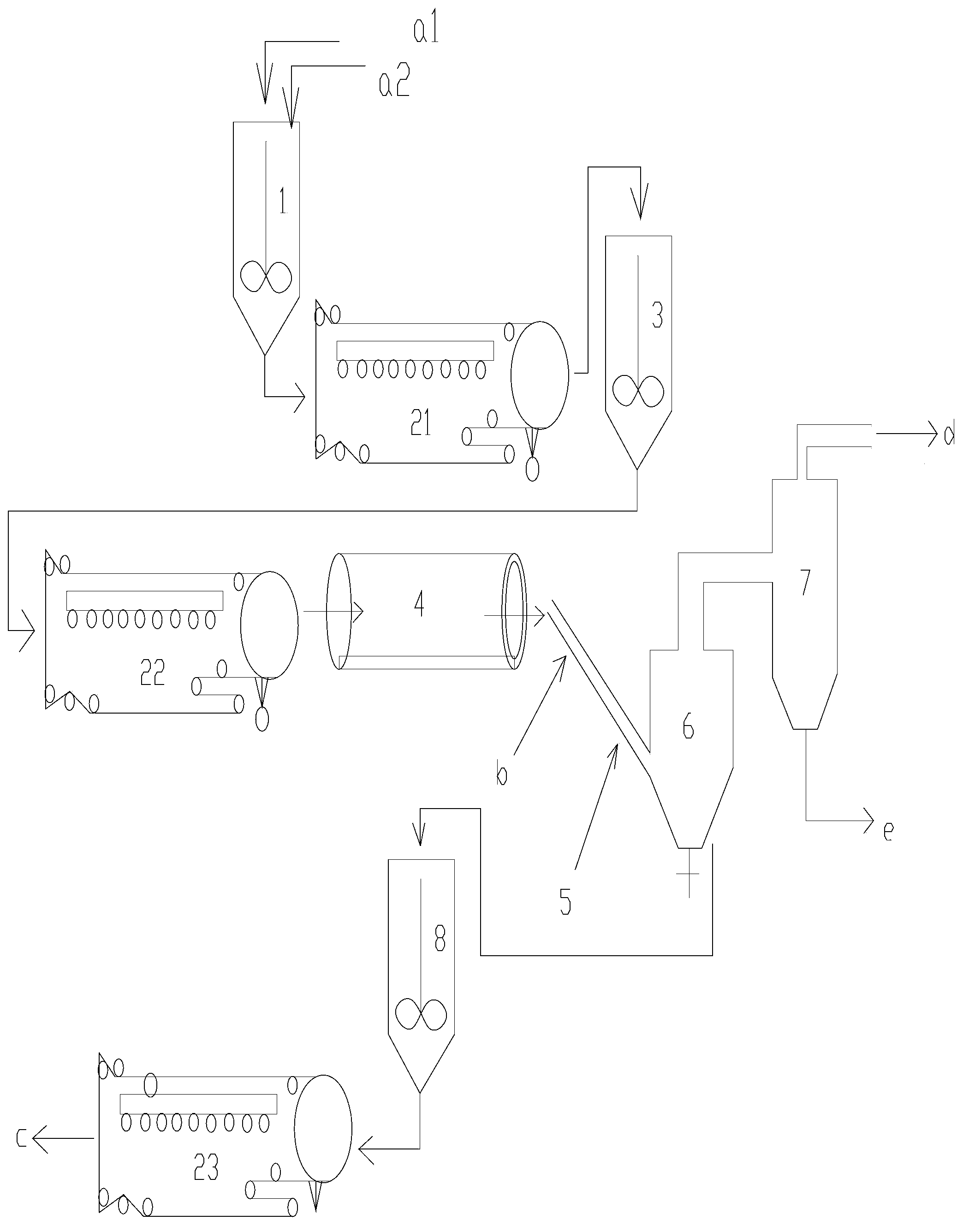

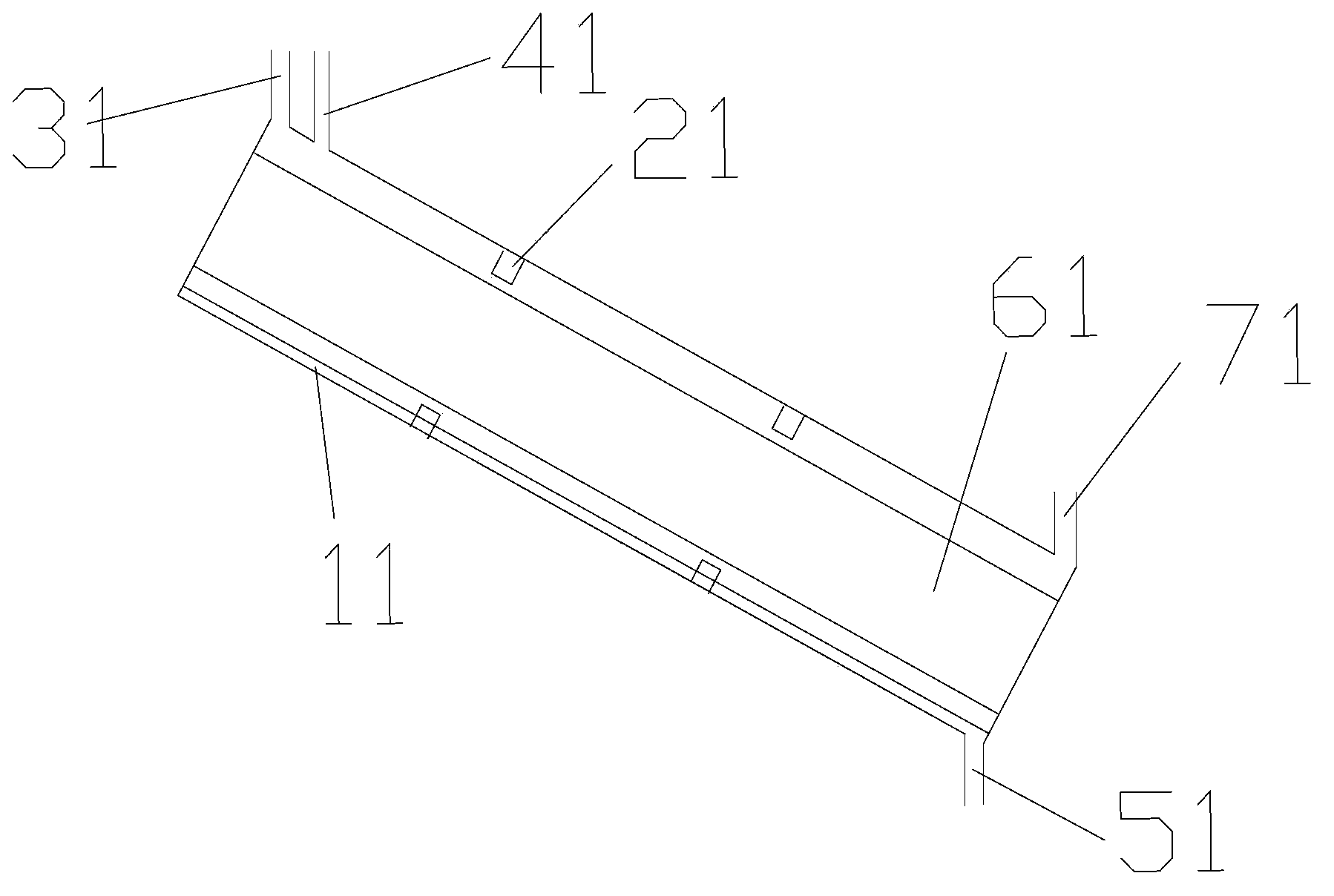

Multi-stage M-shaped air way liquid desiccant dehumidification air-conditioning system utilizing ultrasonic atomization technology

InactiveCN102052715AImprove dehumidification efficiencyDecrease in solid phase resistanceLighting and heating apparatusAir conditioning systemsEngineeringAir conditioning

Multi-stage M-shaped air way liquid desiccant dehumidification air-conditioning system utilizing the ultrasonic atomization technology belongs to the field of air-conditioning energy saving technology. The system changes the traditional liquid desiccant dehumidifier structure and adopts a multi-stage M-shaped air way to replace dehumidifying filling materials. Salting liquid is atomized by utilizing the ultrasonic technology, and humid air to be processed is in full contact with atomized salting liquid granules in a dehumidification air-conditioning box before heat and mass transfer is carried out. Due to the adoption of the M-shape air way structure, building space is fully utilized, air-liquid contact reaction time is prolonged, and meanwhile, the air-liquid contact area is increased due to the ultrasonically atomized salting liquid granules. Compared with the traditional filling material type dehumidification air-conditioning system, the invention has the major advantages that the building pace utilization rate is high, system resistance force is small, meanwhile, the air-liquid contact area and the air-liquid reaction time are increased, and the liquid desiccant dehumidification rate is improved. Therefore, the air conditioning energy consumption is remarkably reduced.

Owner:SHANGHAI JIAO TONG UNIV

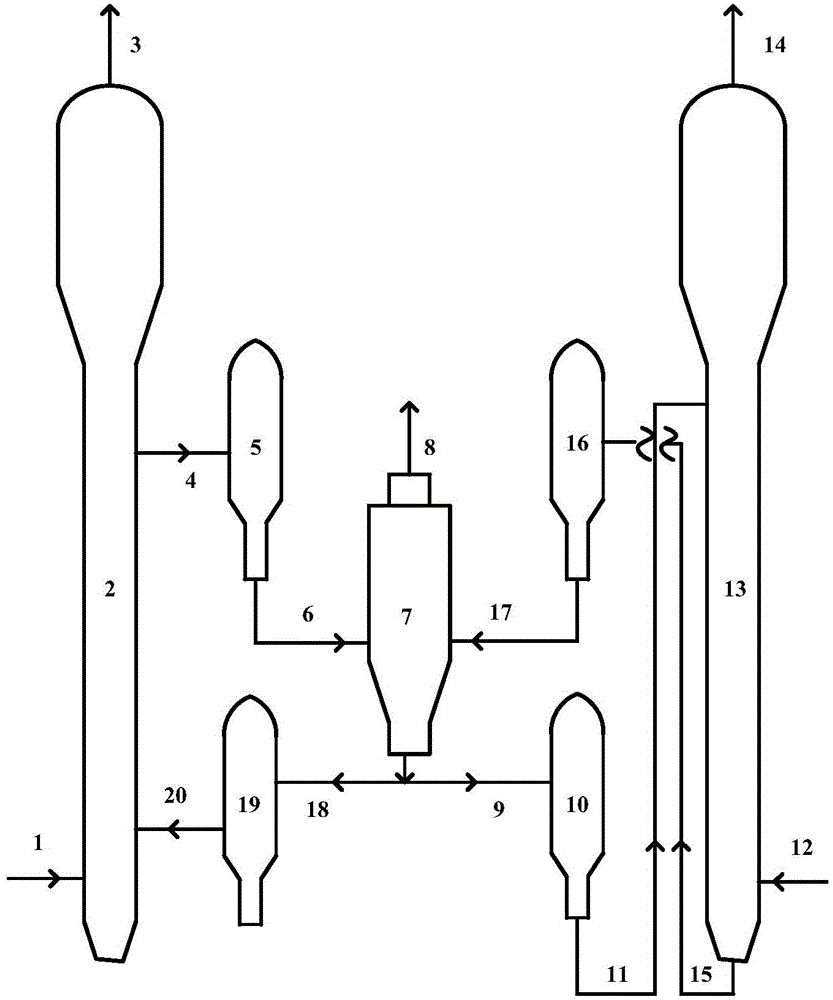

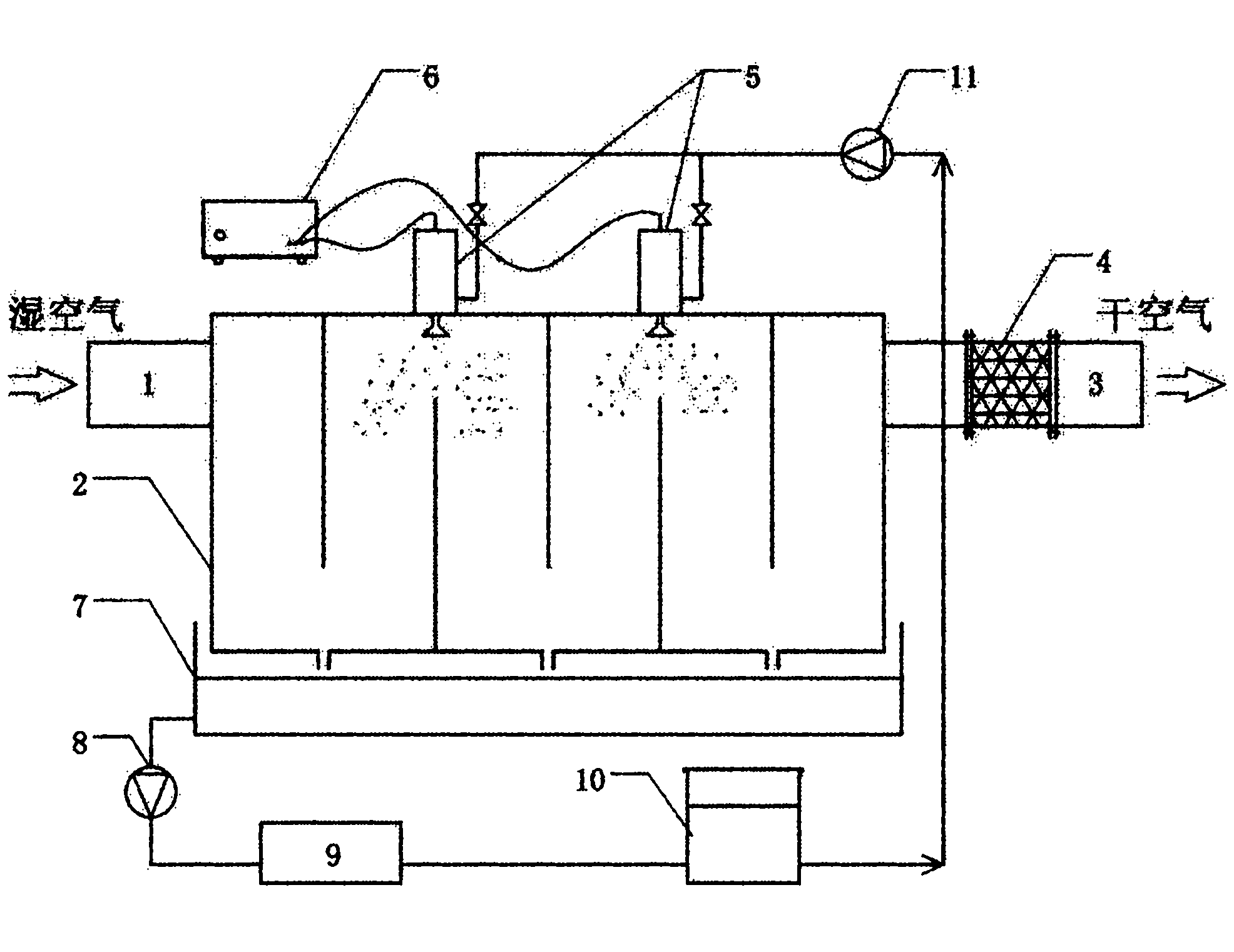

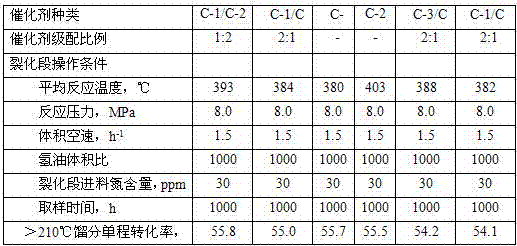

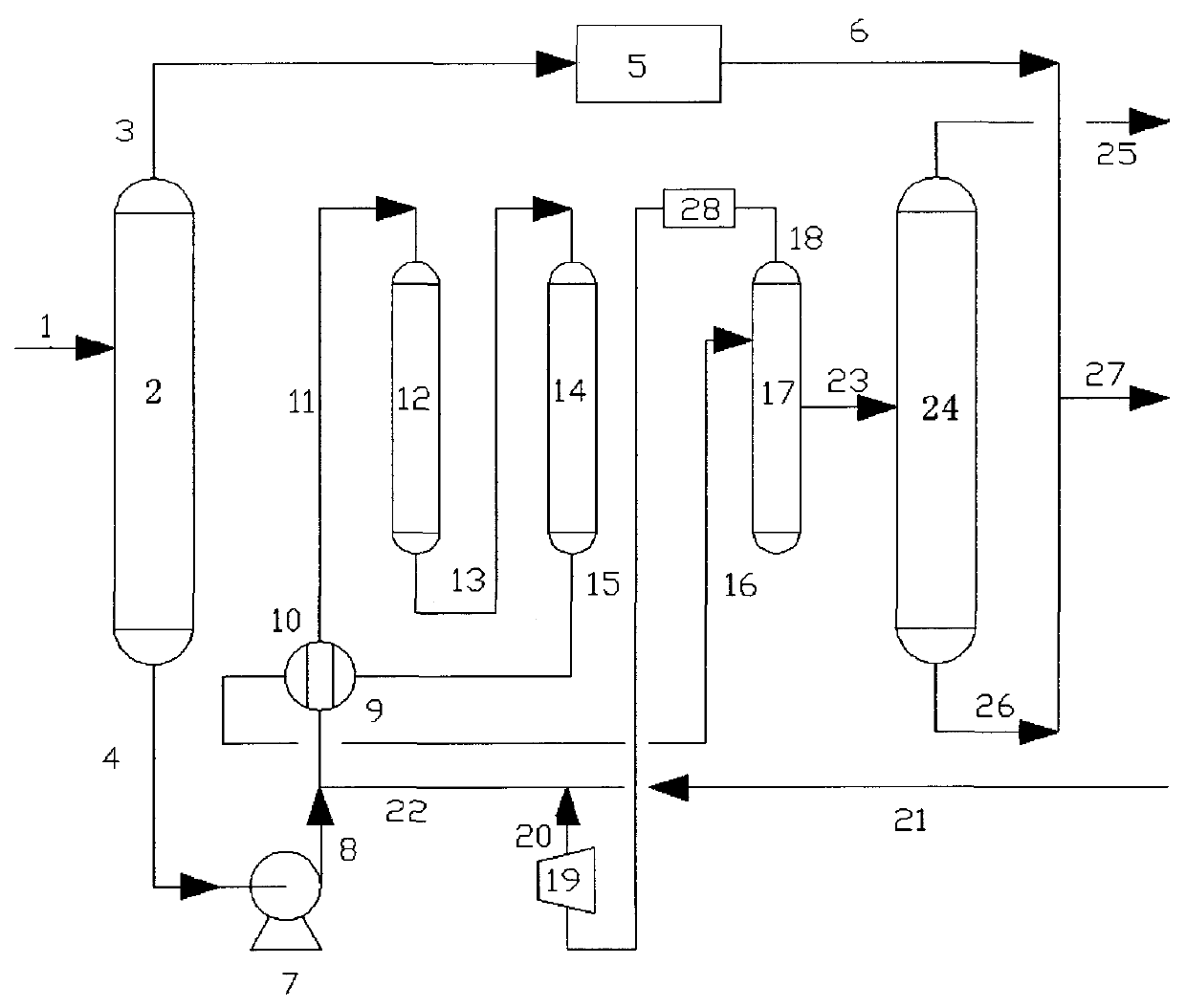

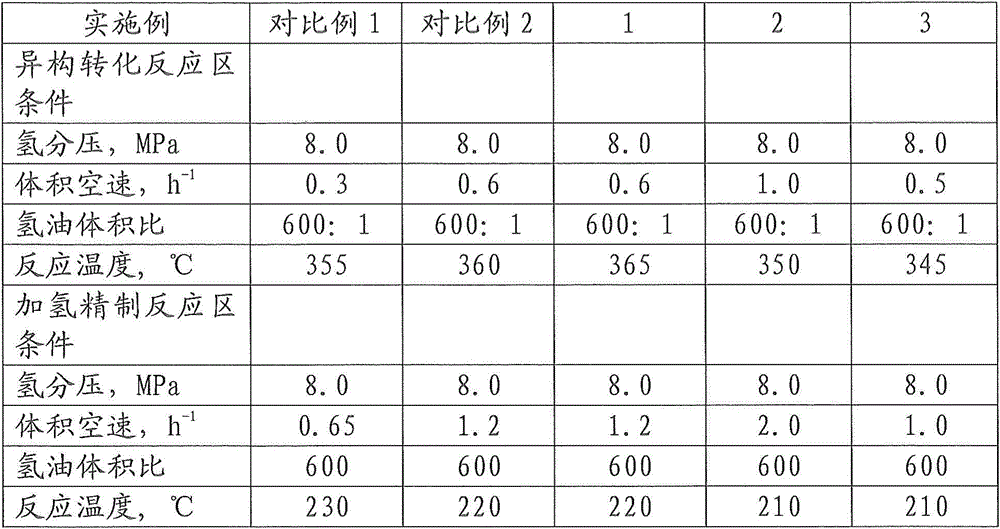

Technical method for grading catalyst in conversion process of catalytic diesel oil

ActiveCN107304375AReduce saturationBoost octaneMolecular sieve catalystsTreatment with hydrotreatment processesNaphthaHydrogenation reaction

The invention discloses a technical method for grading a catalyst in a conversion process of catalytic diesel oil. The method comprises the following steps: (1) firstly, putting a mixture of catalytic diesel oil and hydrogen into a hydrogenation reactor and performing hydrofining reaction; (2) guiding the hydrofining reaction effluent to directly enter a cracking reactor and generating contact reaction with hydrocracking catalyst layers filled in the cracking reactor, wherein the hydrocracking catalyst taking Mo-Co as active metal components is used on the upper layer of the two hydrocracking catalyst layers in the hydrocracking reactor and the hydrocracking catalyst taking Mo-Ni or W-Ni as active metal components is used on the lower layer; (3) separating and fractionally distilling the hydrocracking reaction effluent, thereby acquiring a naphtha component and a diesel oil component. The method disclosed by the invention can increase the device liquid yield, can reduce the hydrogenation saturation of the generated gasoline component and can increase the octane value of the gasoline component under the condition of meeting the requirement for the conversion rate of catalytic diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

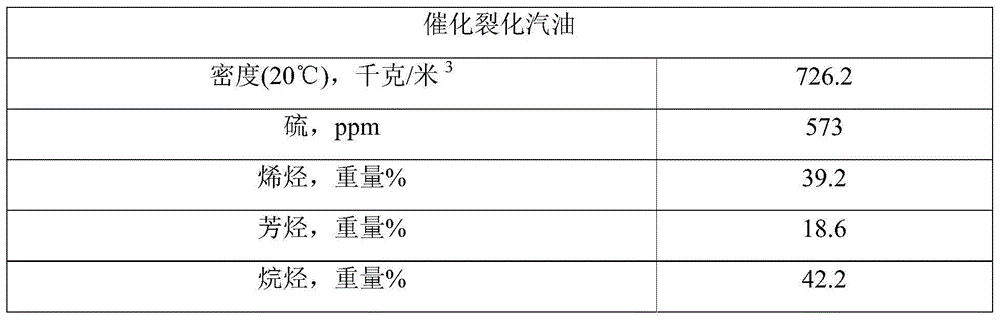

Process method for reducing olefins by hydrogen desulfurization of catalytic gasoline

InactiveCN102199448AReduce contentBoost octaneTreatment with hydrotreatment processesIsomerizationHydrodesulfurization

The invention relates to a process method for reducing olefins by the hydrogen desulfurization of catalytic gasoline, which comprises the following steps of: cutting gasoline into a light distillate and a heavy distillate at the cutting point of between 60 and 80 DEG C; contacting the heavy distillate and hydrogen with an octane value restoration catalyst to perform an isomerization reaction, an aromatization reaction and a building-up reaction; and contacting reaction effluents which are not separated with a selective hydrogen desulfurization catalyst to perform a hydrogen desulfurization reaction, and separating hydrogenated generation oil to obtain light hydrocarbons and gasoline distillates, wherein hydrogen-enriched gas is recycled, the octane value restoration catalyst is used for loading one or two VIB or VIII group metal as active ingredients by taking one or more of aluminum oxides or molecular sieves as a carrier, an aid is one or two oxides in IIB groups or lanthanide series, the selective hydrogen desulfurization catalyst takes the aluminum oxides as the carrier, Mo and Co as active metal and one or more of Ce, Mg, K, P and F as the aid, the olefin content is less than 20 volume percent, the sulfur content is less than 50 micrograms / gram, and research octane number (RON) is improved by 1.5 to 2 units.

Owner:PETROCHINA CO LTD

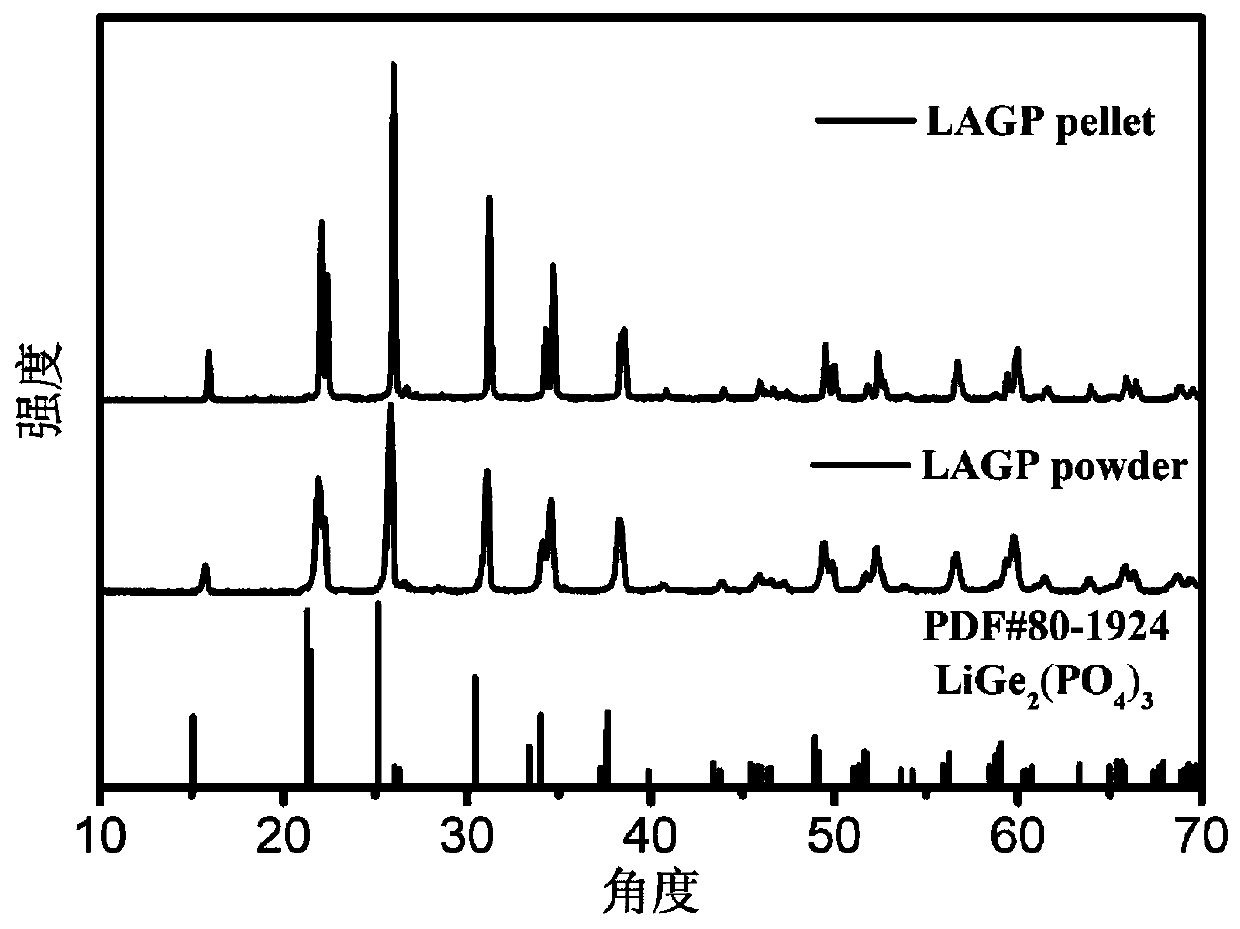

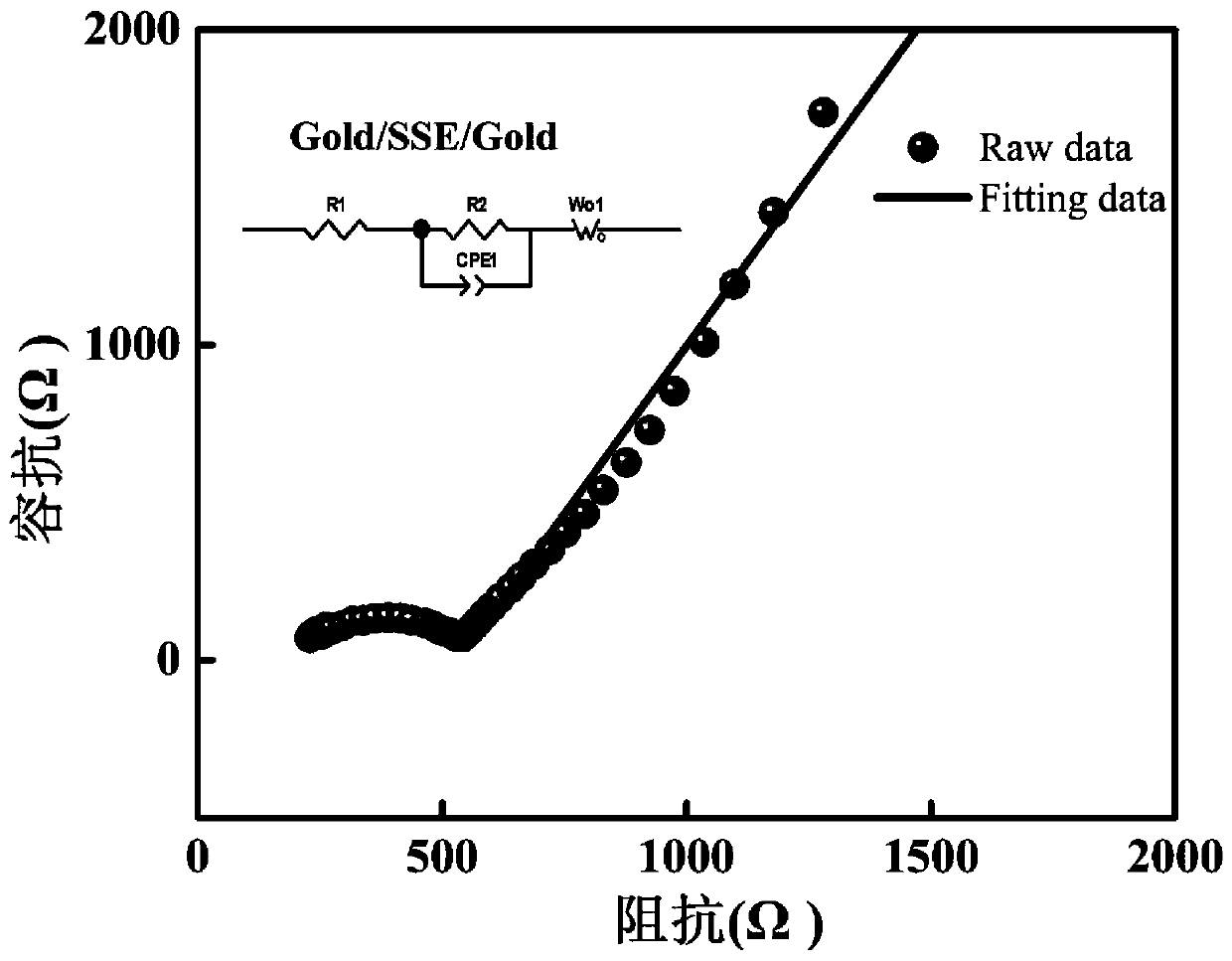

Method for improving solid-state battery interface stability by polymer electrolyte

InactiveCN110233285ALow reaction temperatureLow costFinal product manufactureNon-aqueous electrolyte accumulator electrodesSolid state electrolytePolymer electrolytes

A method for improving solid-state battery interface stability by a polymer electrolyte belongs to the technical field of solid batteries. A prepared hierarchical porous polymer electrolyte film is used as a buffer layer material and is placed between an electrode material and a solid-state electrolyte to form favorable contact with a positive electrode material, an electrolyte material and metallithium, the interface impedance is effectively reduced, direct contact reaction between the solid-state electrolyte and the metal lithium can be reduced, and the all-solid-state battery has relatively good cycle stability.

Owner:BEIJING UNIV OF CHEM TECH

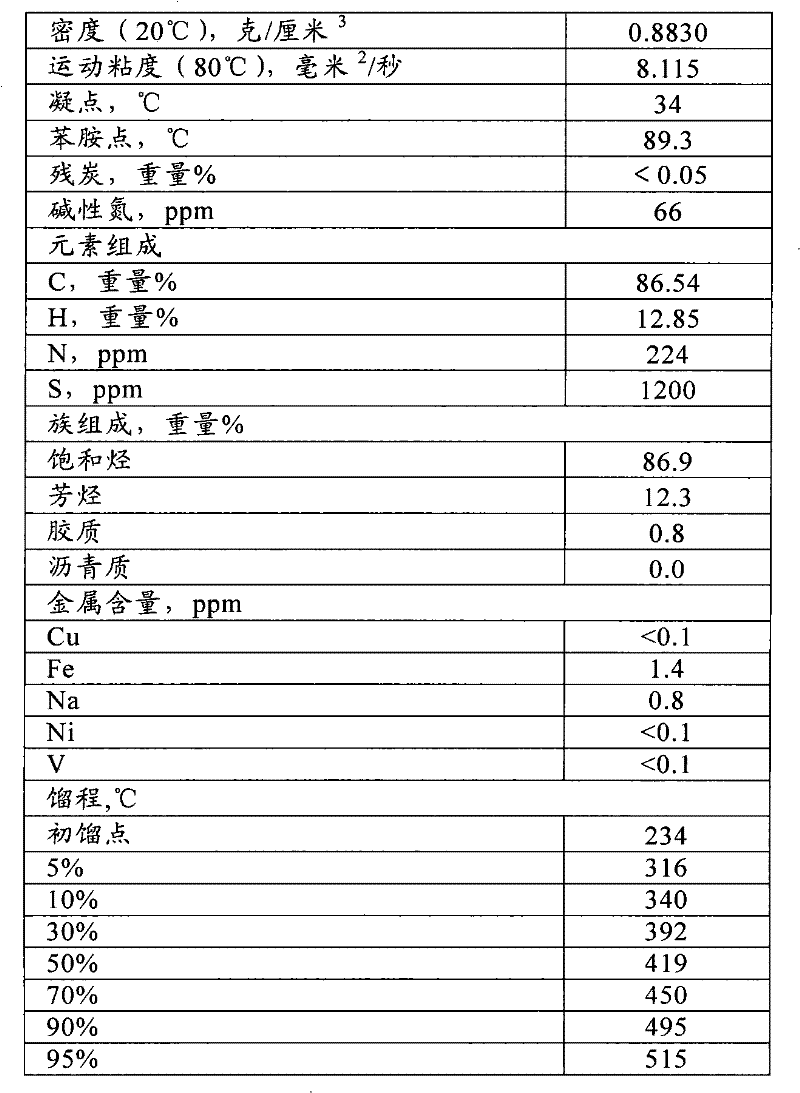

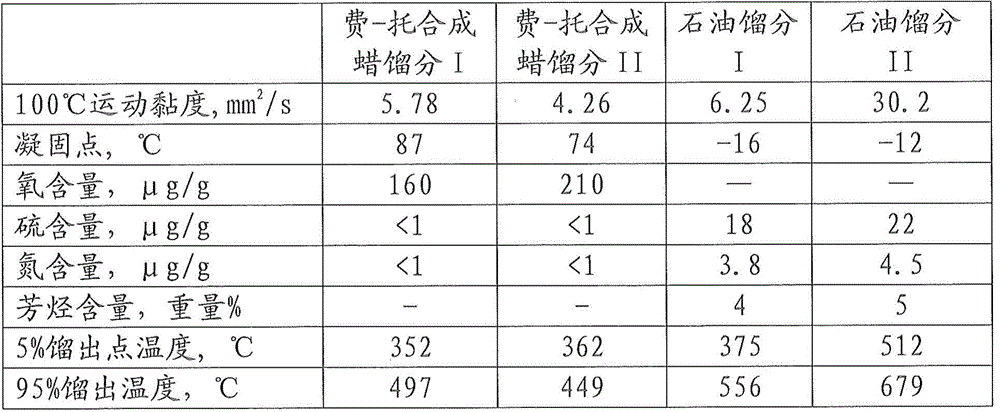

Method of producing ultrahigh-viscosity-index lubricant base oil

ActiveCN105316036AHigh yieldDistillation range unchangedTreatment with hydrotreatment processesBase-materialsWaxHydrogen

A method of producing ultrahigh-viscosity-index lubricant base oil comprises the following steps: (1) performing contact reactions to Fischer-Tropsch synthetic wax fraction material successively with a wax hydroisomerization conversion catalyst and a hydrorefining catalyst in the presence of hydrogen gas to prepare a mixture being subjected to the wax hydroisomerization conversion and the hydrorefining reactions; and (2) separating the mixture obtained in the step (1) to obtain the lubricant base oil, wherein the Fischer-Tropsch synthetic wax fraction material is a mixture composed of a Fischer-Tropsch synthetic wax fraction and a high-boil-point petroleum fraction. The Fischer-Tropsch synthetic wax fraction is 350-500 DEG C in distillation range. Compared with the prior art, the method can significantly increase the yield of the lubricant base oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified ordered mesoporous organosilicon material, preparation method and application thereof

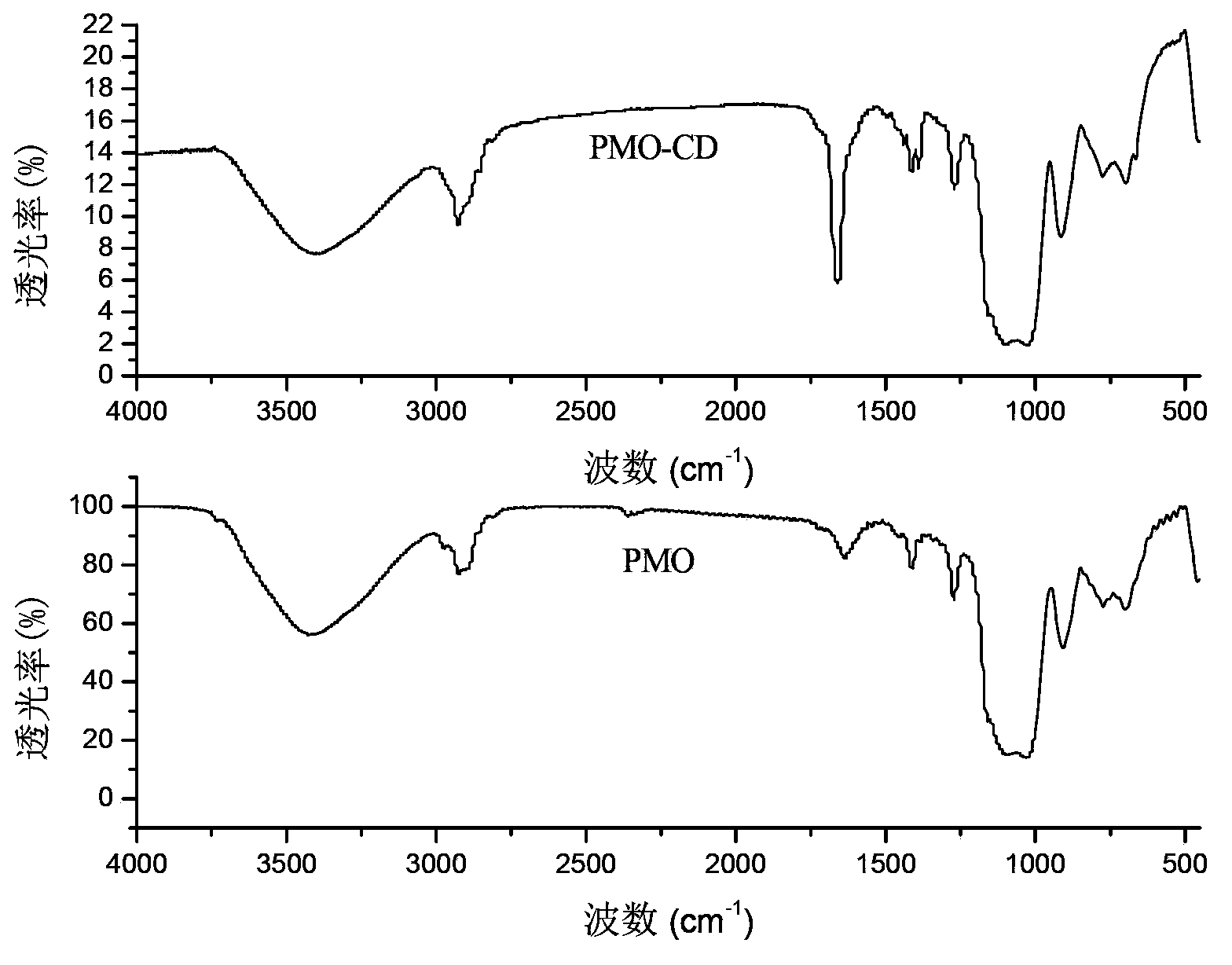

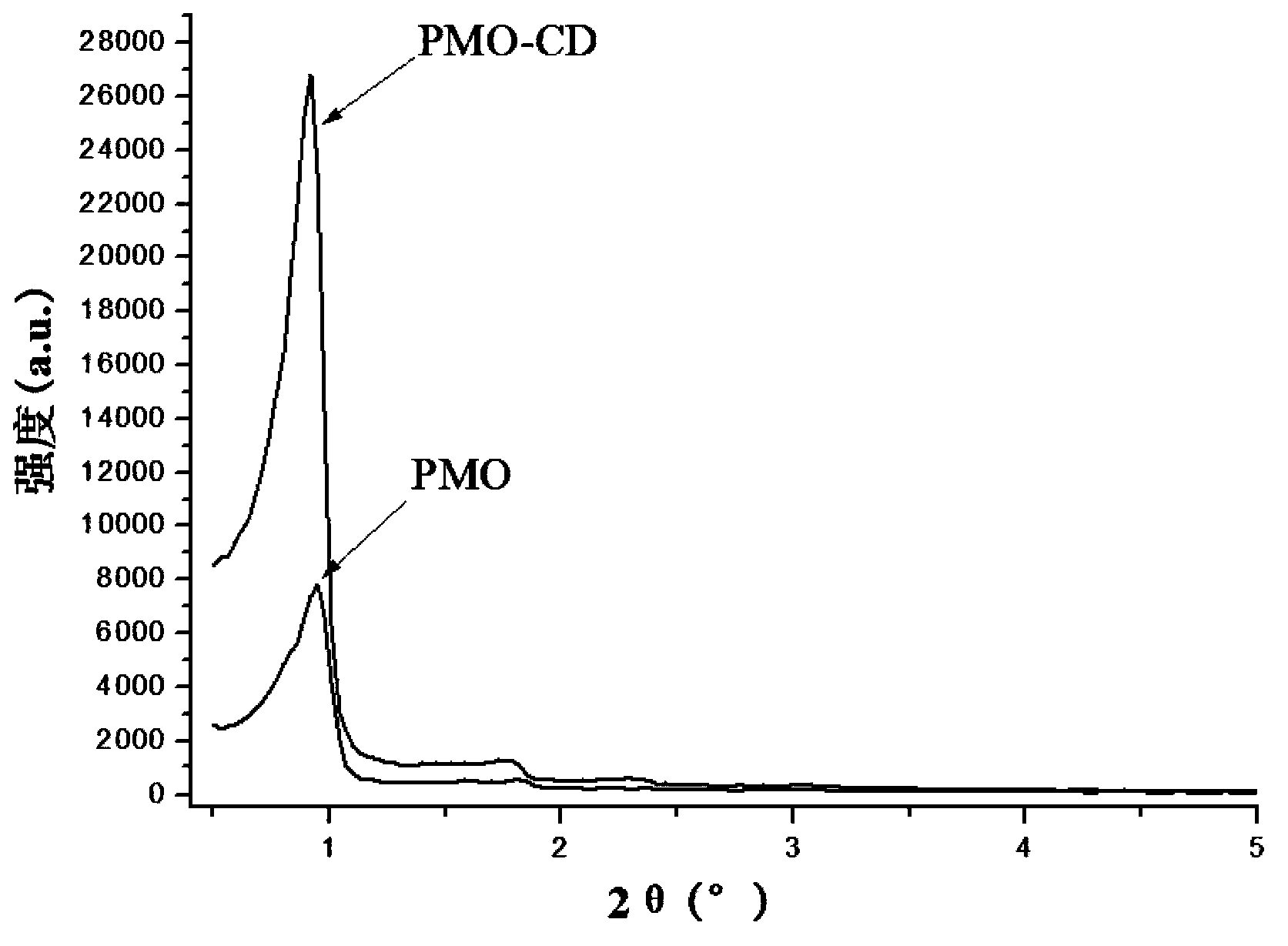

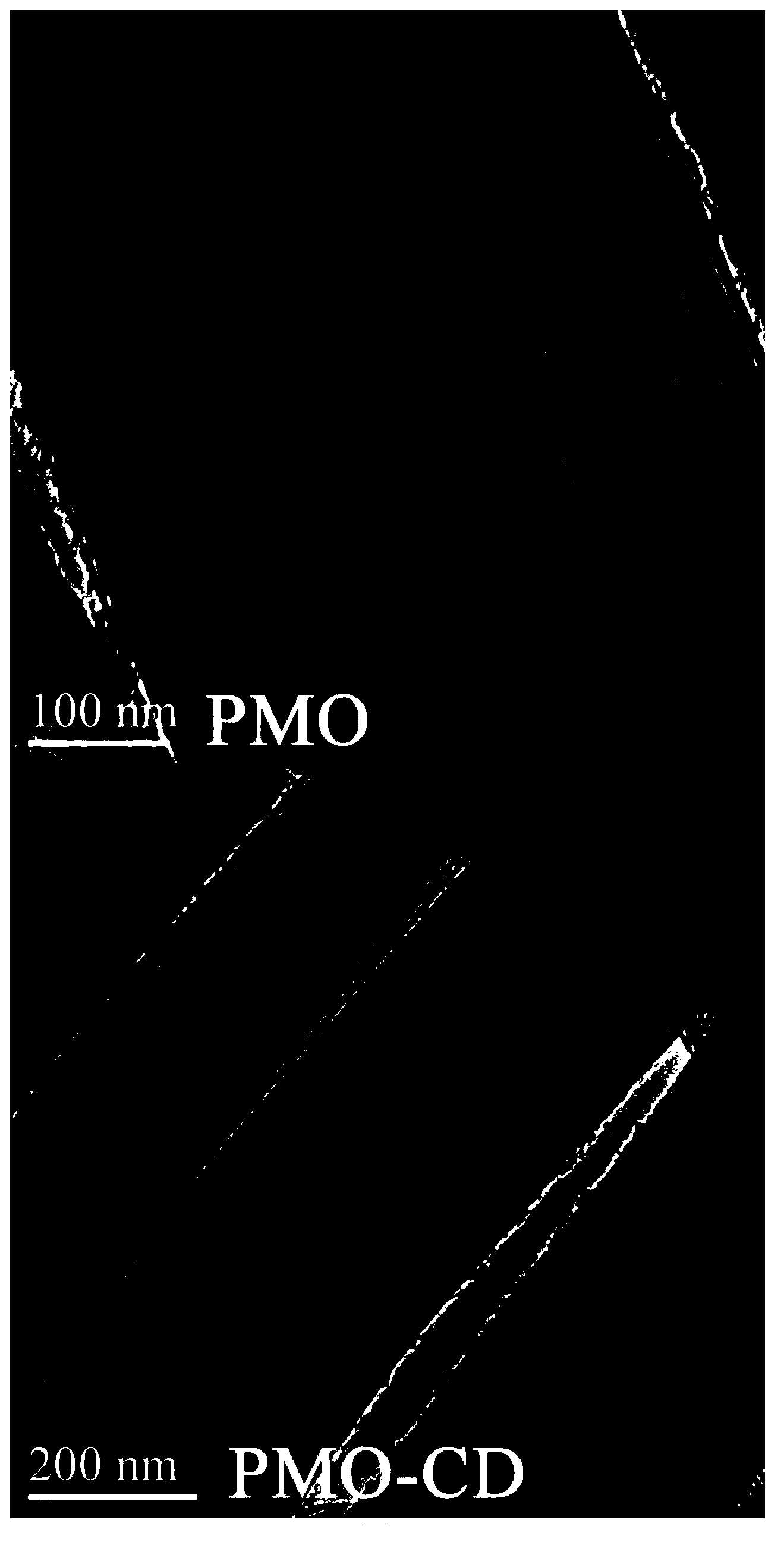

ActiveCN103772707AImprove adsorption capacityImprove hydrophobicityOther chemical processesPolymer scienceOligomer

The present invention discloses a modification method for an ordered mesoporous organosilicon material. The method comprises that: a cyclic oligomer and a coupling agent are subjected to a first contact reaction, and then the product obtained after the reaction and an ordered mesoporous organosilicon material are subjected to a second contact reaction, wherein the cyclic oligomer has hydroxyl, the general formula of the coupling agent is O=C=N-R1-Si-(OR2)3, R1 is C1-C10 alkylidene, and R2 is C1-C10 alkyl. The modified ordered mesoporous organosilicon material prepared according to the method has the excellent absorption performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

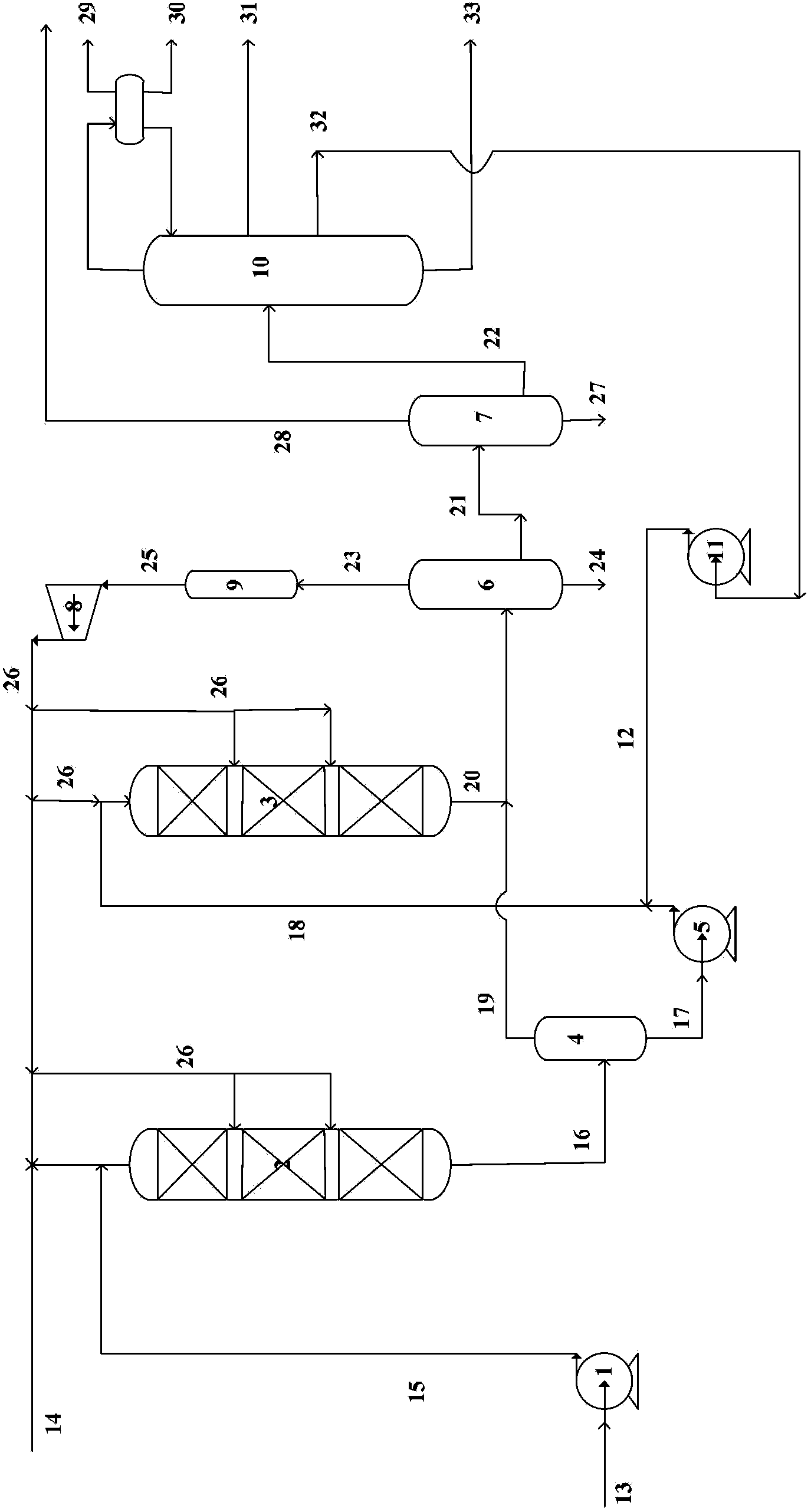

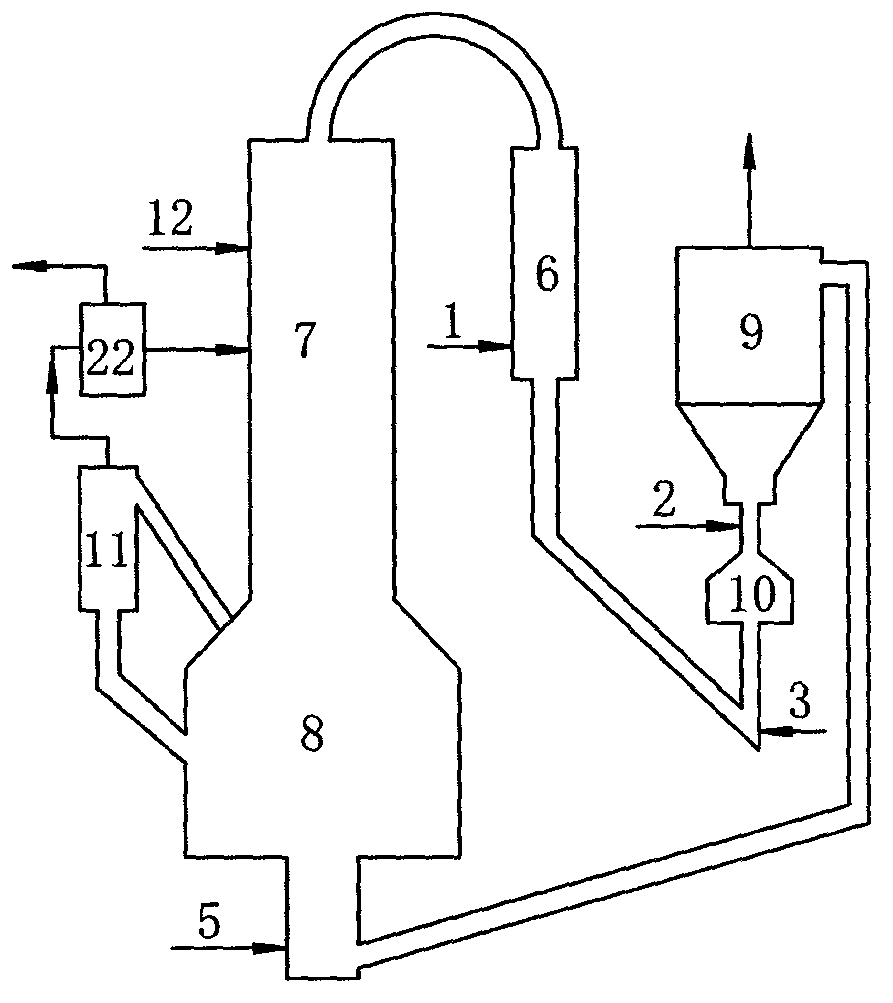

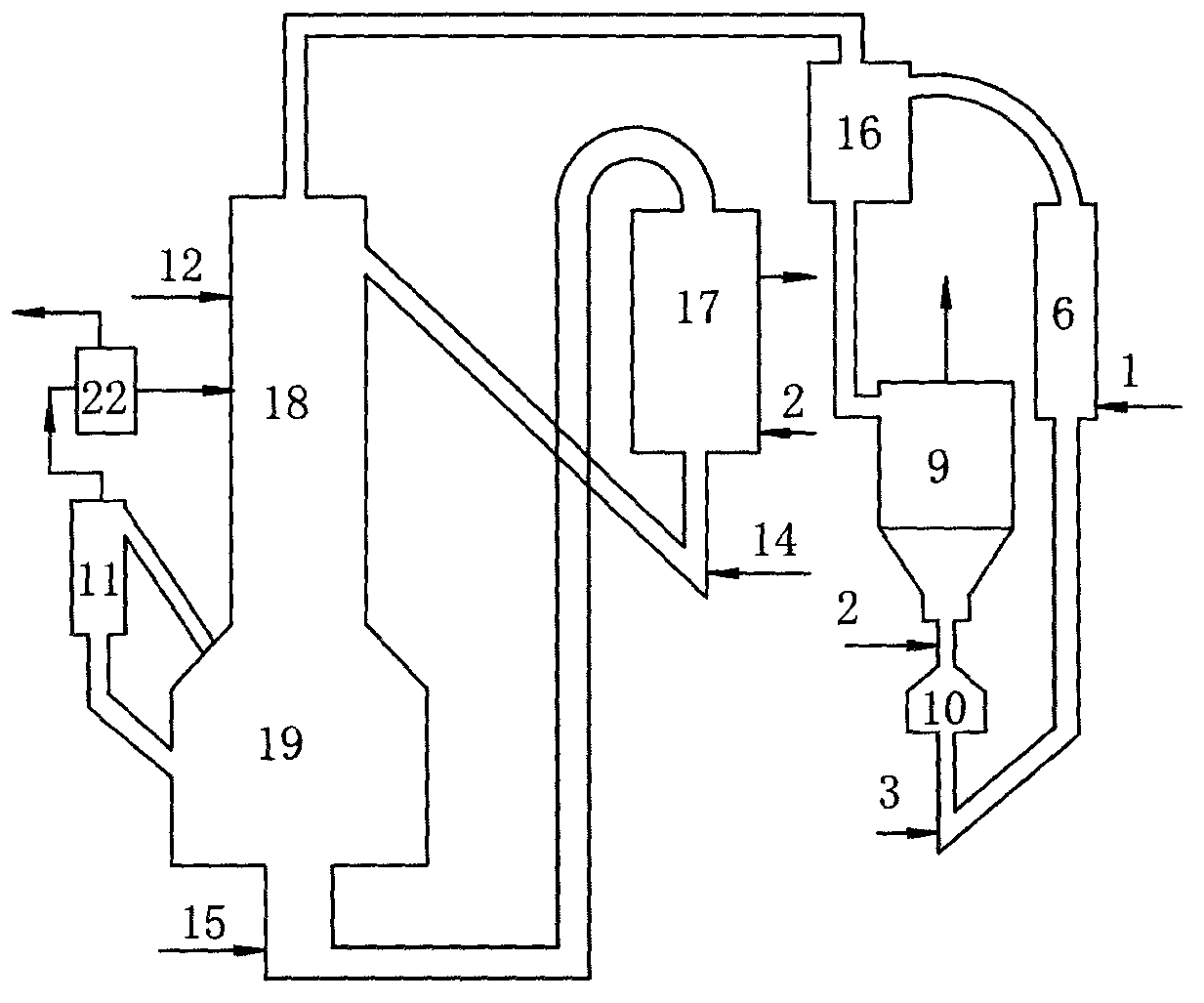

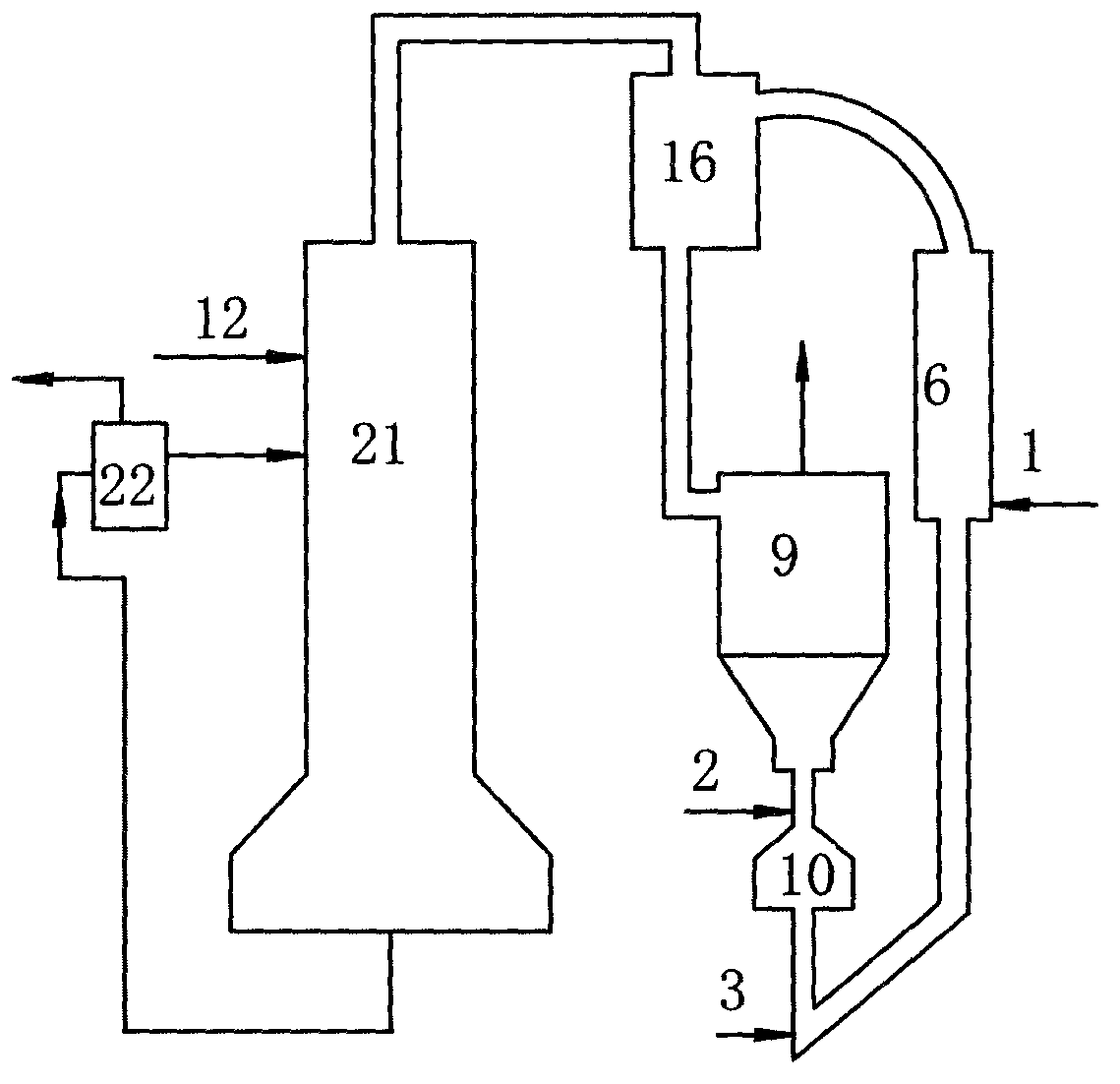

Molecular sieve production apparatus

ActiveCN103787353AFull residence timeFull contact timeCrystalline aluminosilicate zeolitesMolecular sieveCooking & baking

The invention relates to a molecular sieve production apparatus, which comprises a NaY molecular sieve exchange device, a baking furnace, a gas phase ultra-stable reactor and a gas-solid separation device, wherein the gas phase ultra-stable reactor comprises a molecular sieve inlet, a molecular sieve outlet and a silicon tetrachloride inlet. According to the present invention, with the gas phase ultra-stable reactor, the molecular sieve can move to the molecular sieve outlet of the gas phase ultra-stable reactor from the molecular sieve inlet of the gas phase ultra-stable reactor in the case of no requirement of conveying of the molecular sieve through carrier gas, and the molecular sieve and gas phase silicon tetrachloride can be subjected to a contact reaction in the gas phase ultra-stable reactor; and the apparatus can be used for continuous production of the high silicon molecular sieve, and further has characteristics of process simplifying, no requirement of molecular sieve fluidization carrier gas, and substantial silicon tetrachloride consumption reduction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing aromatic hydrocarbons from methanol with low carbon olefin as byproduct, and apparatus thereof

ActiveCN104250183AResolve inactivationImprove continuous operation capabilityHydrocarbon from oxygen organic compoundsEthylene productionFluidized bedFixed bed

The invention discloses a method for preparing aromatic hydrocarbons from methanol with low carbon olefin as a byproduct, and an apparatus thereof. The problems of low yield of the aromatic hydrocarbons, large output of dry gas and liquefied gas, and the like in the prior art are solved in the invention. The method comprises the following steps: preheating the raw material methanol to 350-500DEG C, adding the preheated methanol to a riser reactor, carrying out a contact reaction on the preheated methanol and a catalyst in the riser reactor for 0.8-4.0s, allowing the reaction product of the riser reactor to enter a deep catalysis reactor (such as a fluidized bed, moving bed or fixed bed reactor) to carry out a reaction, returning C2-C5 alkanes in the reaction products of the deep catalysis reactor to the deep catalysis reactor in order to re-process the C2-C5 alkanes, and discharging other products from the apparatus, wherein the catalyst is a ZSM-5 / SAPO-34 catalyst modified by Ga, Zn, P and Ag.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP +1

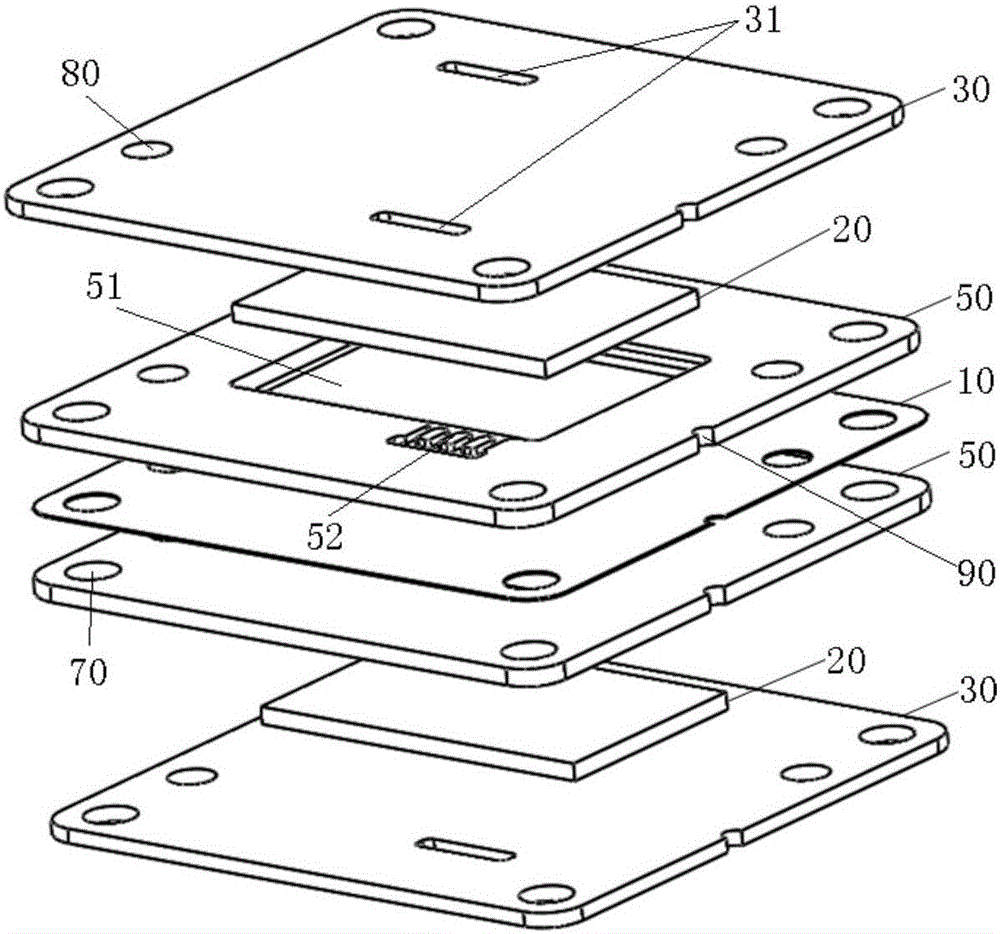

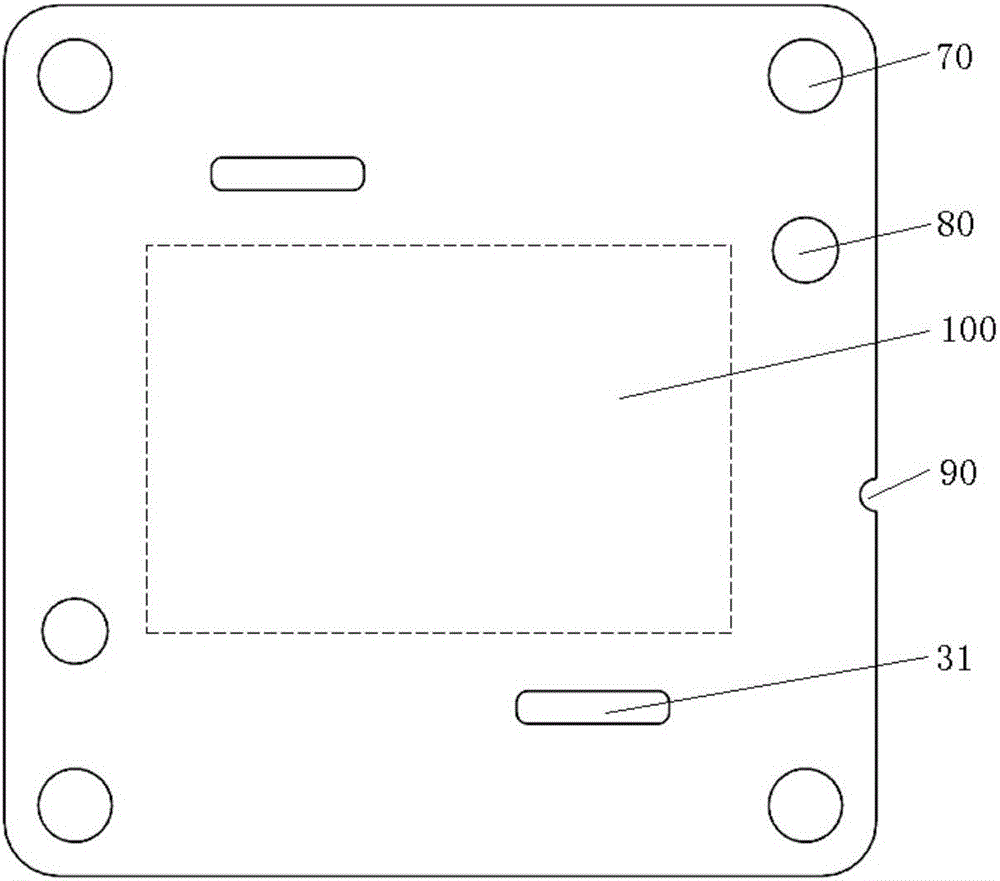

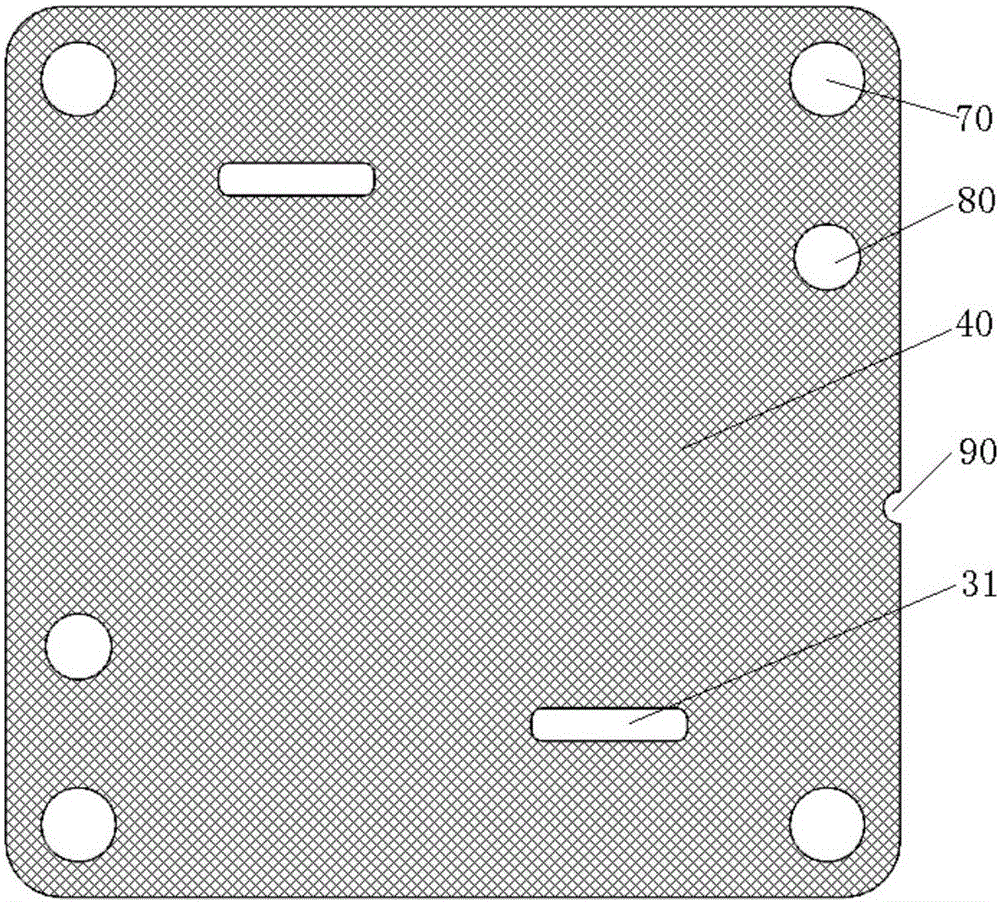

Flow battery

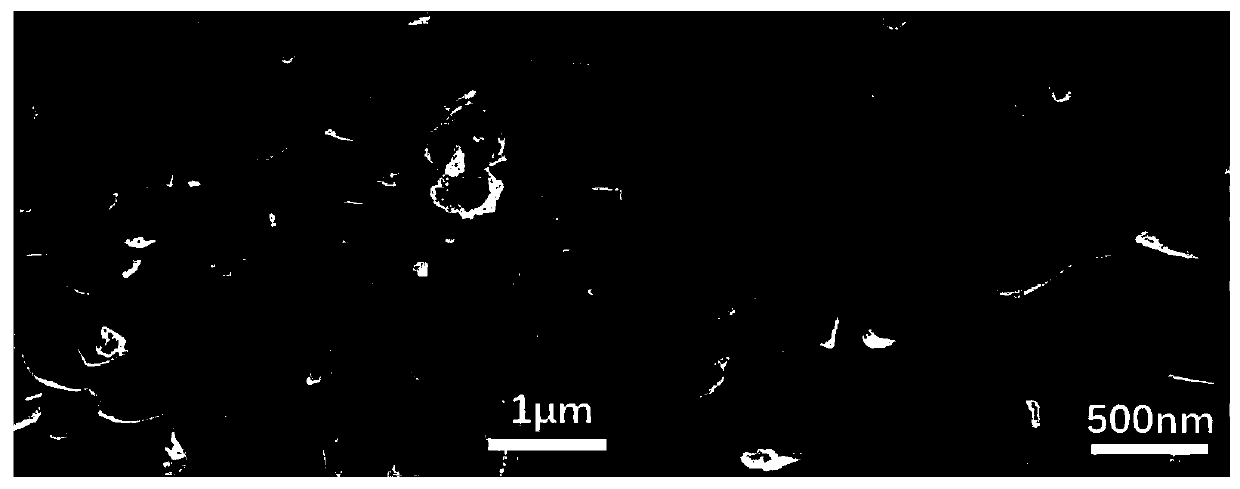

ActiveCN105810987AChange surface propertiesReduction of reactive activation polarizationRegenerative fuel cellsFuel cell detailsMicrometerContact reactions

The invention provides a flow battery. The flow battery comprises an ion exchange membrane, a plurality of electrodes and at least two current collection plates, wherein one electrode is arranged on each of the two sides of the ion exchange membrane, the at least two current collection plates are clamped between the electrodes and the two sides of the ion exchange membrane, a processing region is arranged on a surface, facing one side of each electrode, of each of the current collection plate, at least one part of the processing region is in contact reaction with the electrodes, and the surface roughness of the processing region is greater than or equal to 6.4 micrometers but smaller than or equal to 50 micrometers. By the flow battery, the problem of excessive high electrode polarization of the flow battery in the prior art is solved.

Owner:DONGFANG ELECTRIC (CHENGDU) HYDROGEN FUEL CELL TECH CO LTD

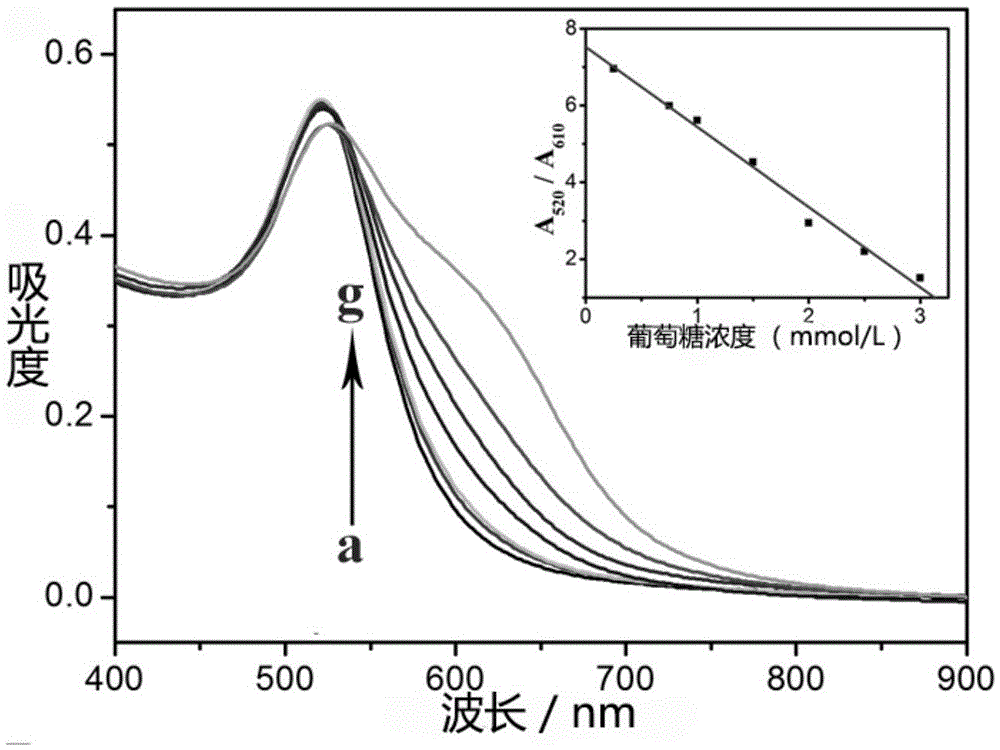

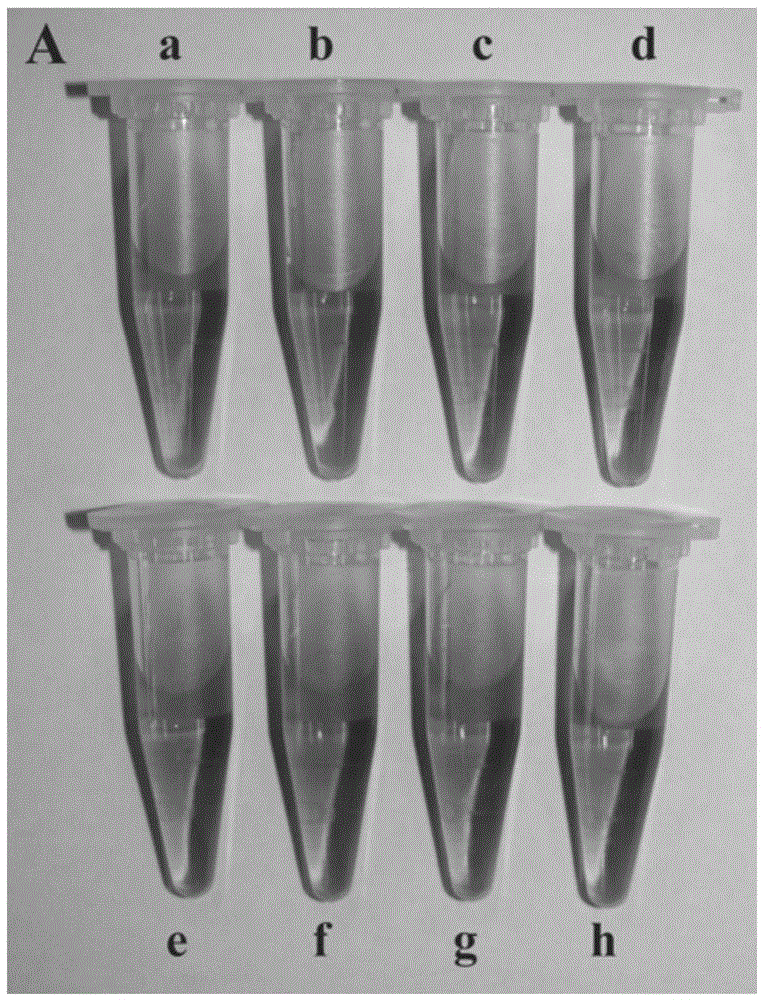

Gold nanoparticle-containing glucose visual detection sensor and its preparation method and use

ActiveCN105548153AHigh sensitivityGood choiceMaterial analysis by observing effect on chemical indicatorGlucose sensorsRead through

The invention discloses a gold nanoparticle-containing glucose visual detection sensor and its preparation method and use. The preparation method comprises that 1, chloroauric acid and trisodium citrate undergo a contact reaction in a solvent to produce a colloidal gold solution, and 2, pH of the colloidal gold solution is adjusted to 6.0-7.5 and 3-aminophenylboronic acid (APBA) and amino-terminated poly(N-isopropylacrylamide) (PNIPAM-NH2) are added into the colloidal gold solution for electrostatic interaction so that the gold nanoparticle-containing glucose visual detection sensor is obtained. The sensor has good sensitivity, selectivity and ion interference resistance in the glucose detection. The preparation method can be operated simply and easily and the detection result can be read through naked eyes.

Owner:ANHUI NORMAL UNIV

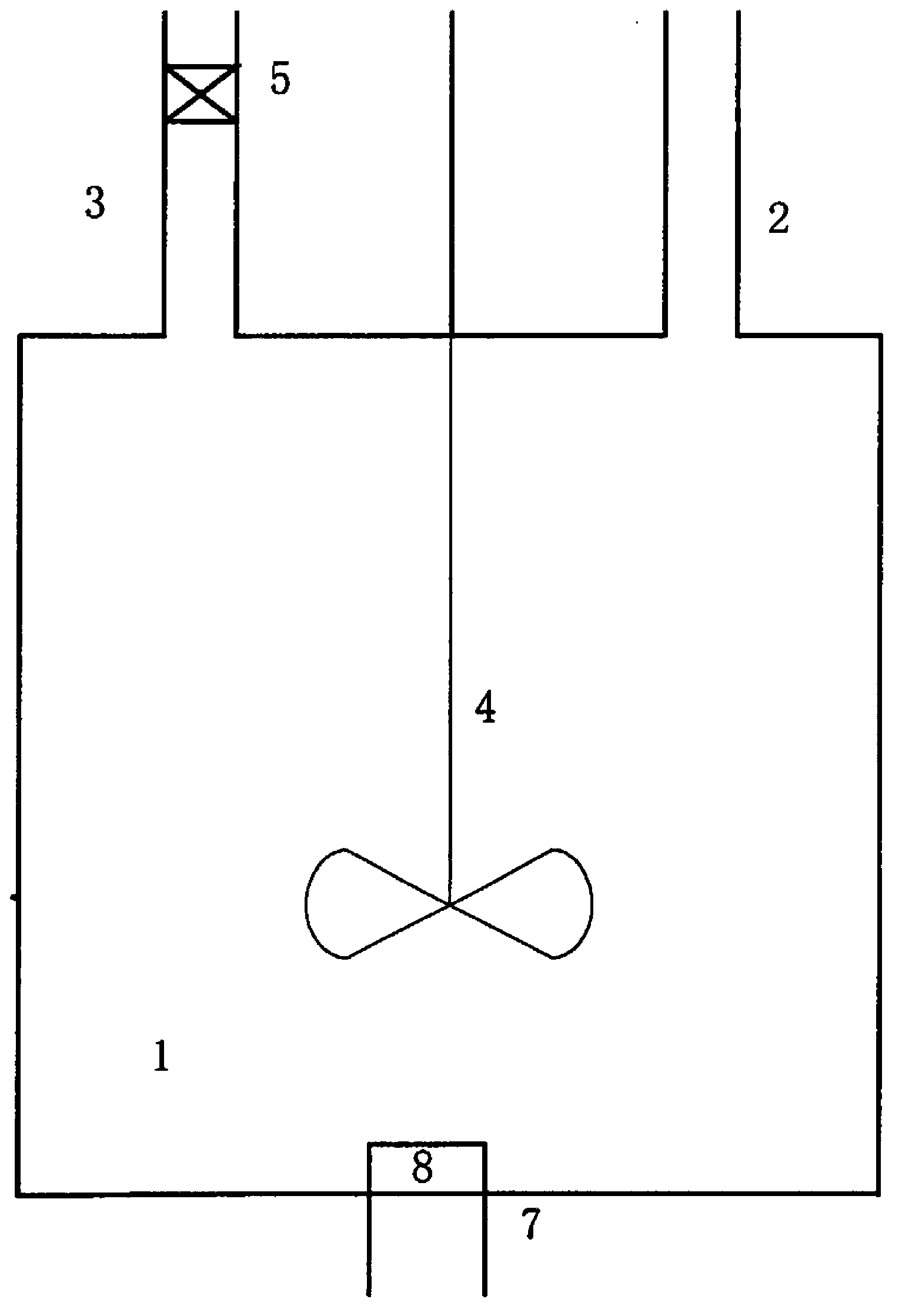

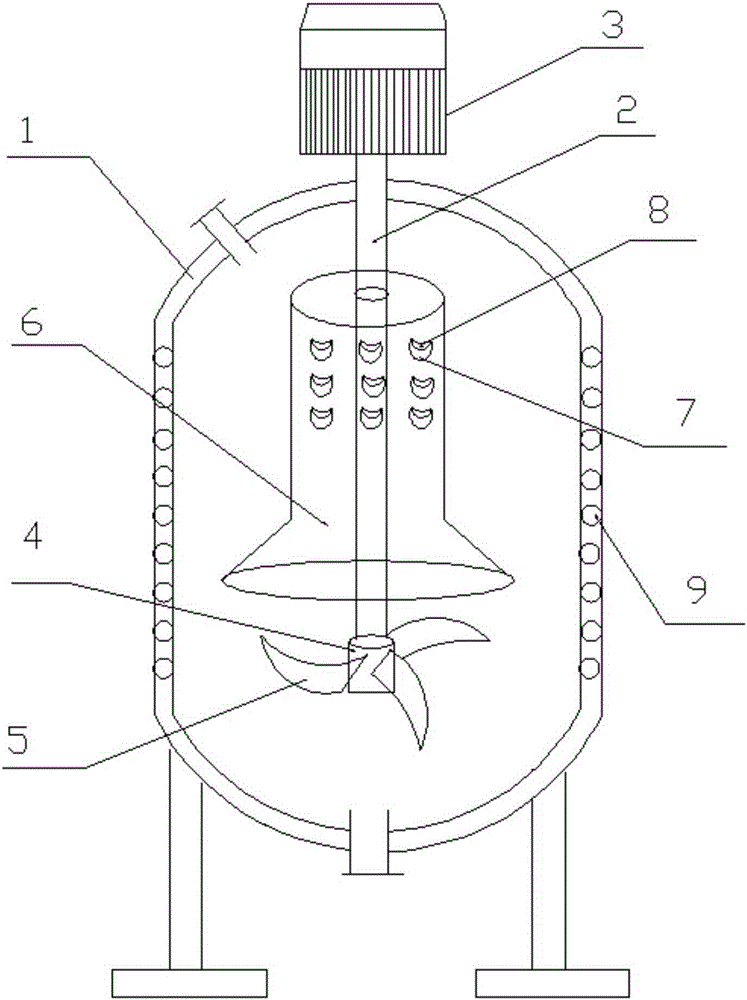

Stirring type reaction kettle

InactiveCN105214590ASmall particle sizeGood dispersionChemical/physical/physico-chemical stationary reactorsReaction rateContact reactions

The invention discloses a stirring type reaction kettle. The stirring type reaction kettle comprises a barrel body, wherein a stirring shaft is mounted in the barrel body, the top end of the stirring shaft is connected with a motor, the lower end of the stirring shaft is sleeved with a shaft sleeve, 3-4 stirring blades are uniformly distributed on the circumference of the shaft sleeve, the rotating directions of the root parts of the stirring blades are inclined for 30-45 degrees relative to the axial direction of the shaft sleeve, and the width of each stirring blade is gradually reduced from the root part to the tip; the reaction kettle further comprises a guide cover arranged on the stirring shaft in a sleeving manner, the upper part of the guide cover is in a hollow barrel shape, the diameter of the lower part is gradually increased, the top of the guide cover is clamped and fixed at the upper part of the stirring shaft, the lower part of the guide cover is open and is not contacted with the bottom wall of the barrel body, multiple guide holes are formed in the upper part of the guide cover, and the upper edge of each guide hole bulges and extends outwards to form a downwards inclined guide cap. According to the stirring type reaction kettle, the reaction materials can be circularly crushed in a large range and have the contact reaction, accordingly, solid-liquid or liquid-liquid reactions are more rapid and more uniform, and the reaction rate and the yield are both increased.

Owner:南京通用化工设备技术研究院有限公司

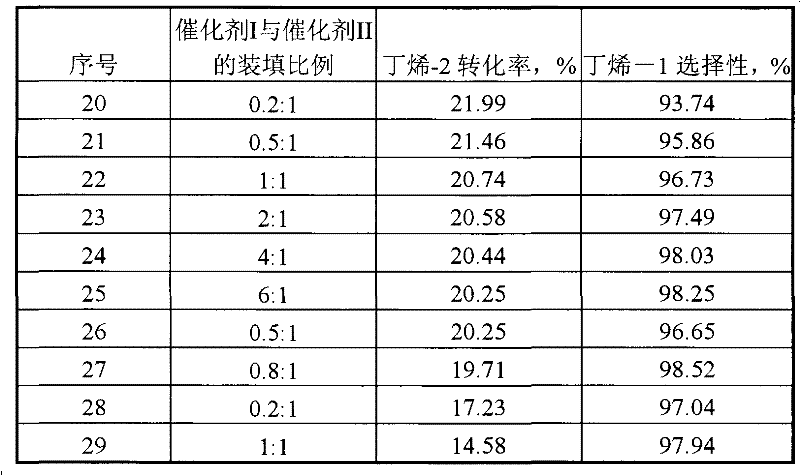

Method for double bond isomerization of butene

ActiveCN102649672AActivity unchangedImprove technical effectHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationReaction temperature

The invention relates to a method for double bond isomerization of butene, and mainly solves the technical problem in the prior art that the reaction product selectivity is low, and the active period of a catalyst is short. Through the adoption of the technical scheme that under the conditions that the reaction temperature is 100 to 450 DEG C, the reaction pressure is -0.08 to 10 MPa, the weight space velocity is 0.1 to 100 hours<-1>, a raw material containing butene is in contact reaction with a catalyst I and a catalyst II in a composite-bed reactor in sequence to generate an effluent containing butene-1 and butene-2 mol ratio close to a thermodynamic equilibrium value, wherein the catalyst I is made of magnesium oxide or silicon oxide, the catalyst is a ZSM molecular sieve with SiO2 / AL2O3 mol ratio being 100 to 2,000, and the weight filling ratio of the catalyst I and the catalyst II is (0.1 to 8) : 1. Therefore, the invention solves the problems well, and can be used in the industrial production of double bond isomerization of butene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polymer melt strength modifier and preparation method and application thereof, polypropylene composition and polypropylene material and preparation method thereof

The invention relates to the field of polymers, and particularly provides a polymer melt strength modifier and a preparation method and application thereof. The preparation method comprises the following steps: performing a contact reaction on polar monomer grafted polypropylene and an amine-containing substance, performing extrusion granulation, and then drying, wherein a polar monomer can chemically react with the amine-containing substance, the amine-containing substance comprises a compound A and a compound B, the compound A is an organic substance containing amido groups, ether bonds andaryl groups, and the compound B is polyamine. The invention provides a polypropylene composition and a polypropylene material and a preparation method thereof. The polymer melt strength modifier can achieve improvement on the melt strength of polymers such as polypropylene according to a relatively small addition amount by a physical blending method.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

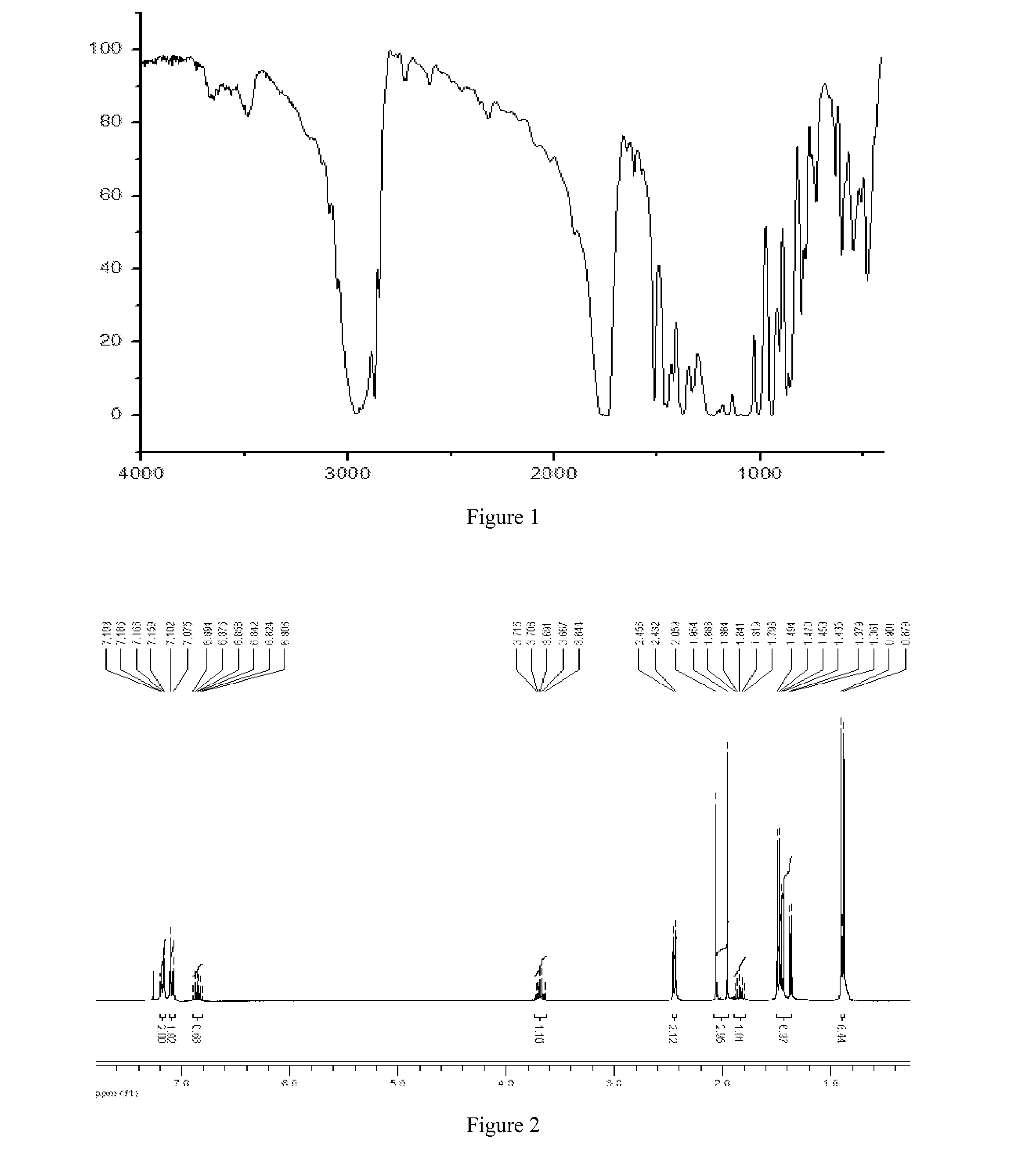

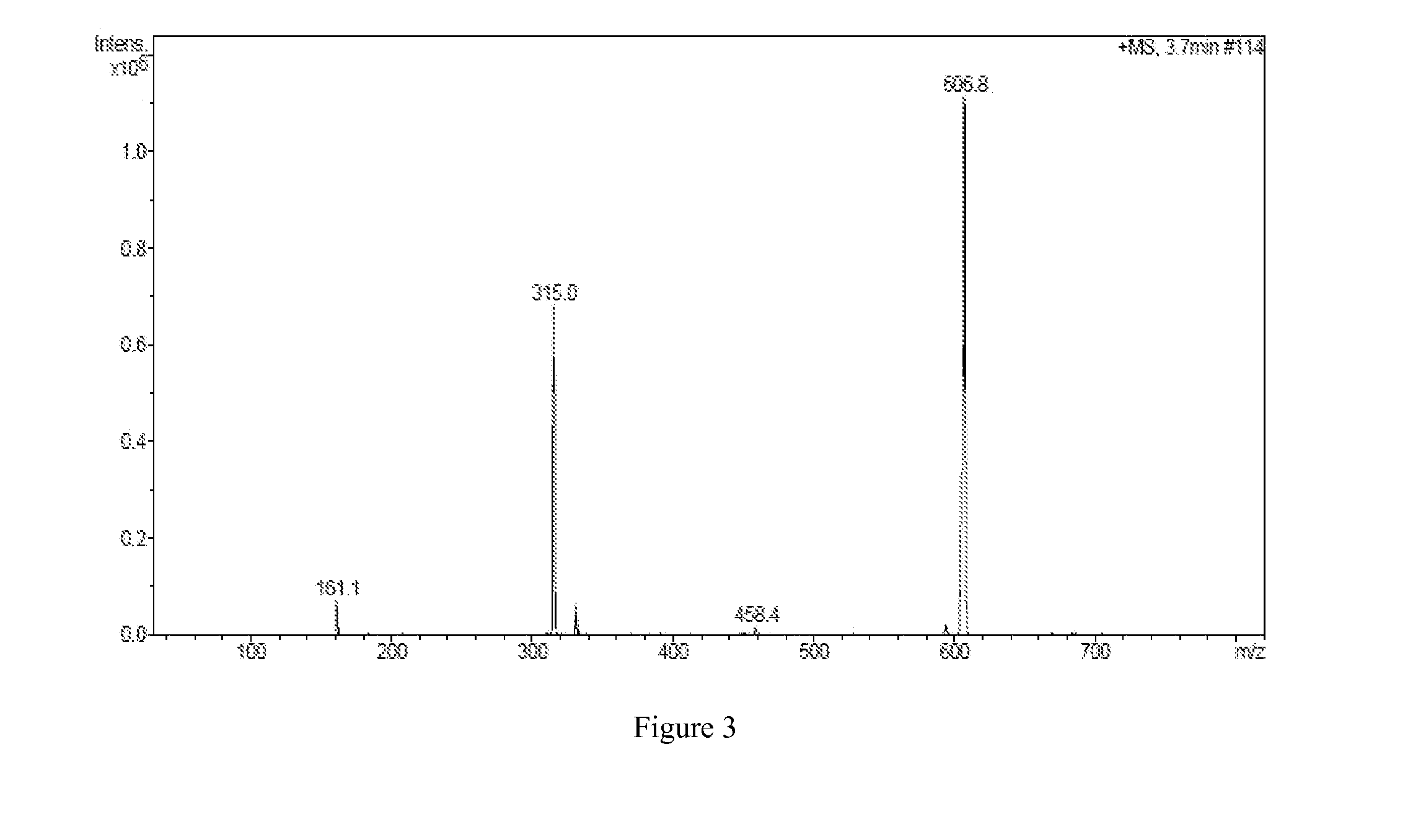

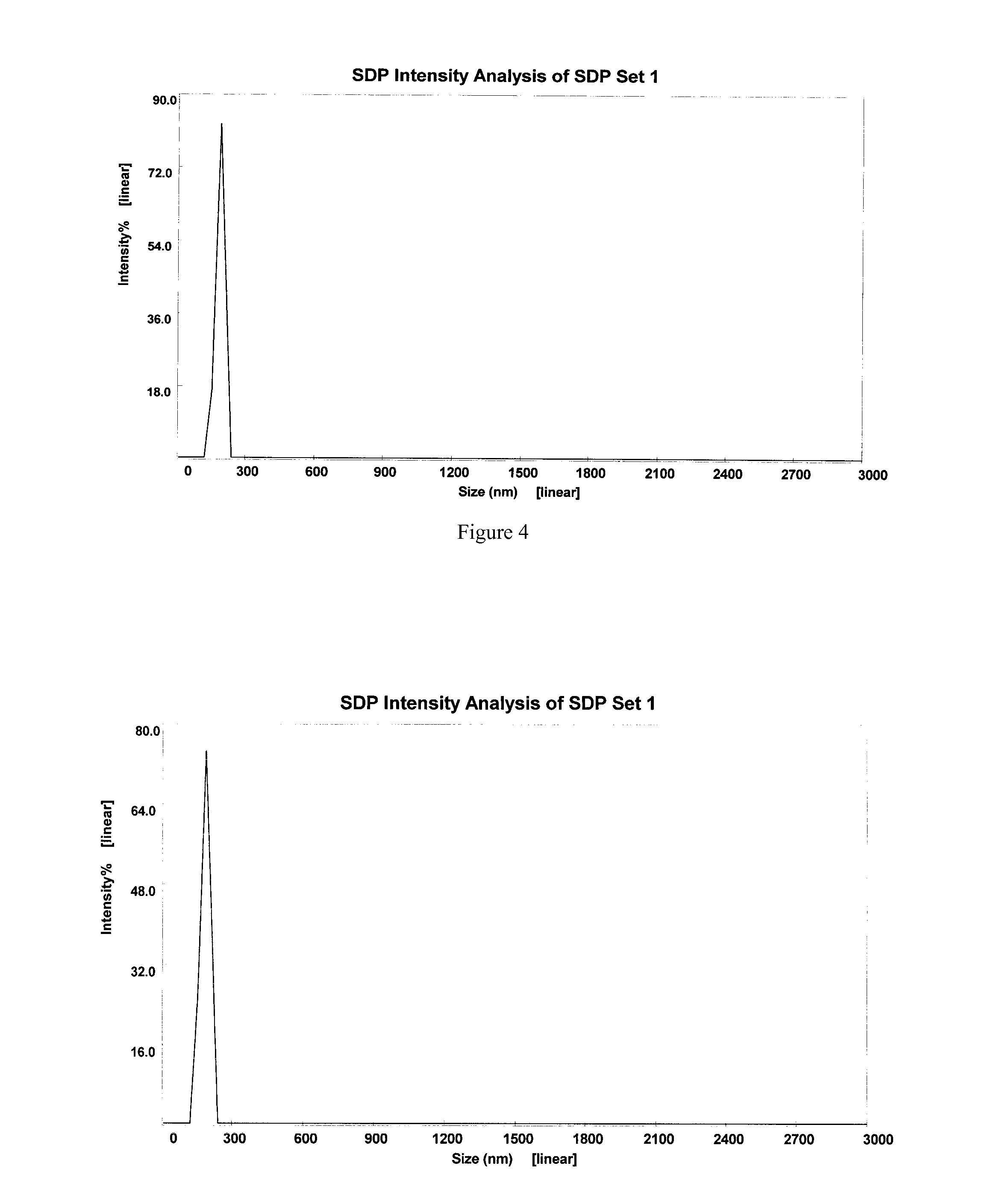

Ibuprofen-based compound, preparation method, use, and formulation of the same

InactiveUS20140112978A1Increase fat solubilityLong action timeOrganic active ingredientsBiocideOrganic acidPropanoic acid

Disclosed are compounds based on ibuprofen, their preparation methods, uses and pharmaceutical preparation. The compounds have structures shown as formula (1), wherein, m, n are integers and fulfill the requirements of 0≦n≦6, 0≦m≦6, respectively. The preparation methods for the compounds based on ibuprofen are as follows: contacting and reacting 2-(4-isobutyl-phenyl) propionic acid to have contact reaction with a solution of an organic acid ester in the presence of a catalyst under substitution reaction conditions The present compounds can be used to prepare nonsteroidal anti-inflammatory drugs. The preparation can be preparation of fat emulsion, liposome, and dried emulsion and so on.

Owner:HEILONGJIANG BAOQINGLONG BIOTECH

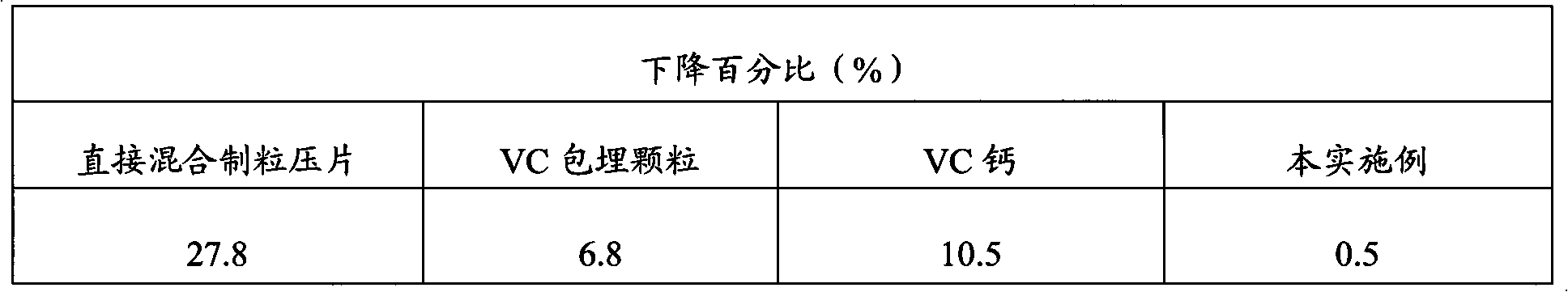

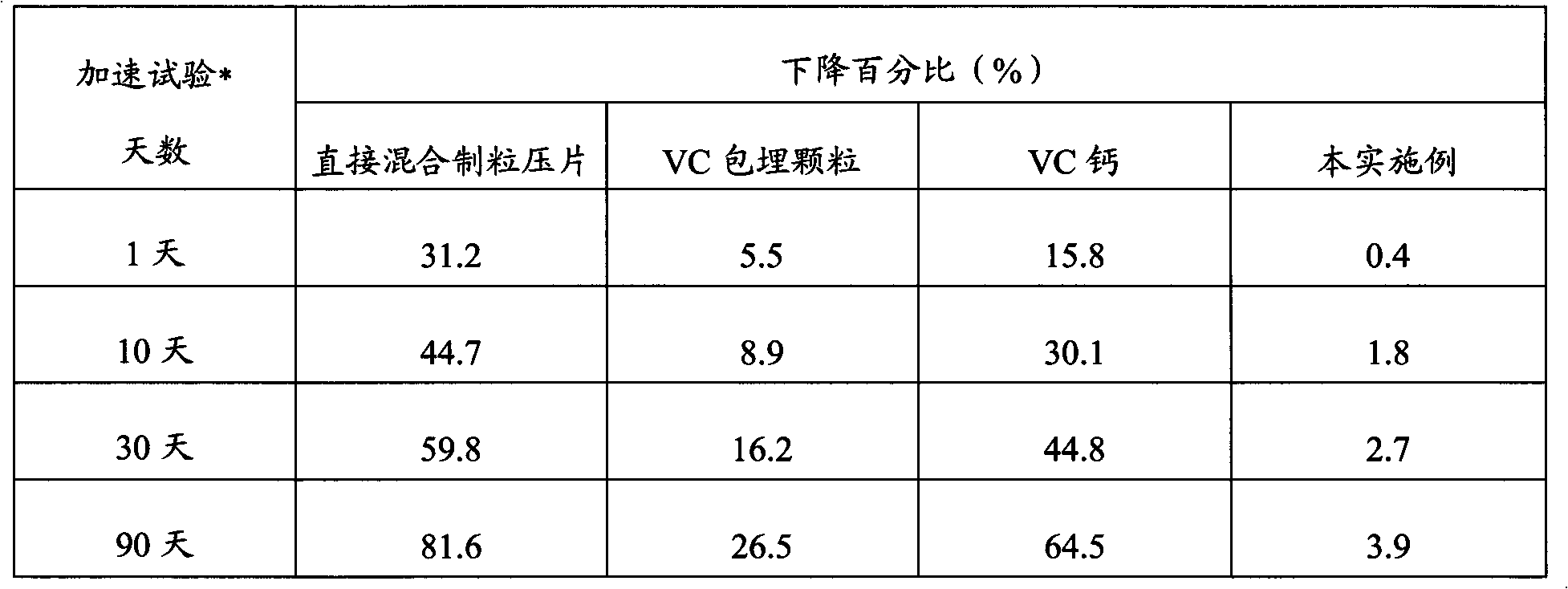

Multivitamin mineral preparation

ActiveCN102512445AEffective isolation of contactsProtection stabilityHeavy metal active ingredientsHydroxy compound active ingredientsElemental compositionVitamin C

The invention relates to the field of nutrition and health care and discloses a multivitamin mineral preparation. The multivitamin mineral preparation consists of enteric iron and selenium-embedded granules, multiple vitamins including vitamin C, and multiple mineral elements, wherein the enteric iron and for the selenium-embedded granules, iron and selenium are embed by a proper embedding agent, so that the iron and selenium can be effectively isolated from the vitamin C and other multiple vitamins, and multiple mineral elements which are added into the multivitamin mineral preparation. The stability of the vitamin C in the multivitamin mineral preparation is improved; most importantly, the loss of the vitamin C caused by contact reaction of the vitamin C with iron, selenium and other elements when the multivitamin mineral preparation is disintegrated after being eaten by a human body can be effectively prevented, and the absorption and utilization ratio of the vitamin C in the human body can be improved.

Owner:杭州海王生物工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com