Patents

Literature

50results about How to "Improve continuous operation capability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

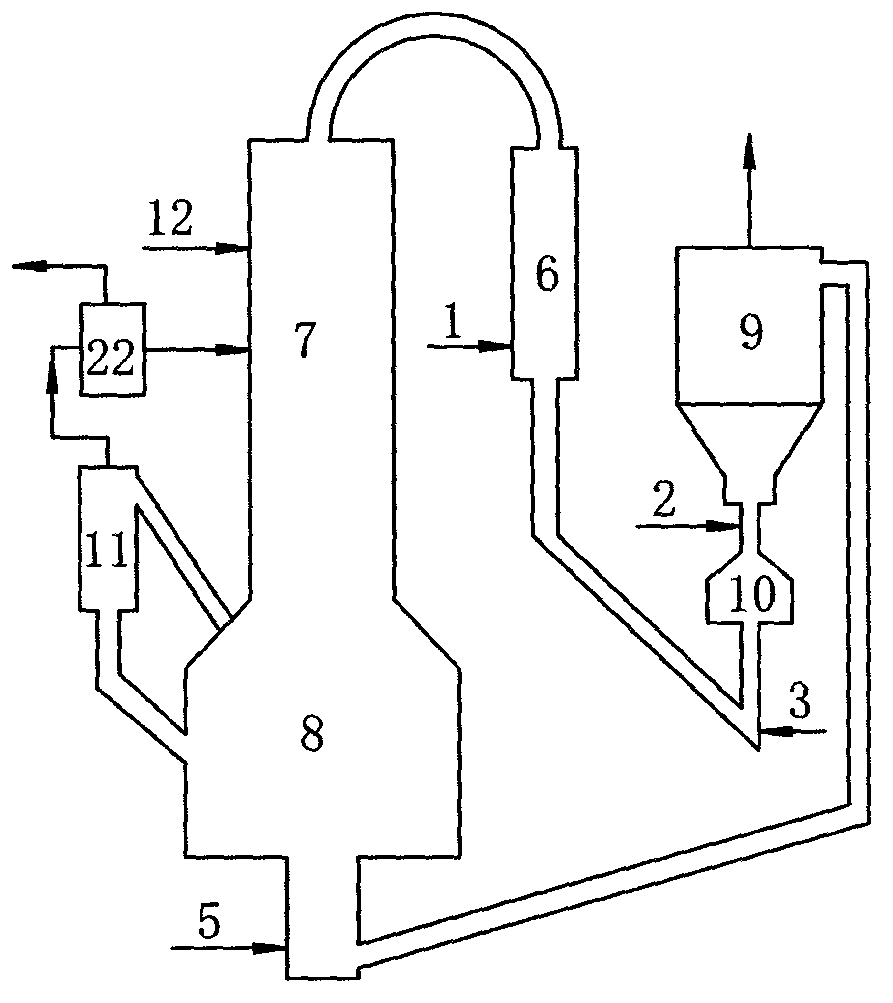

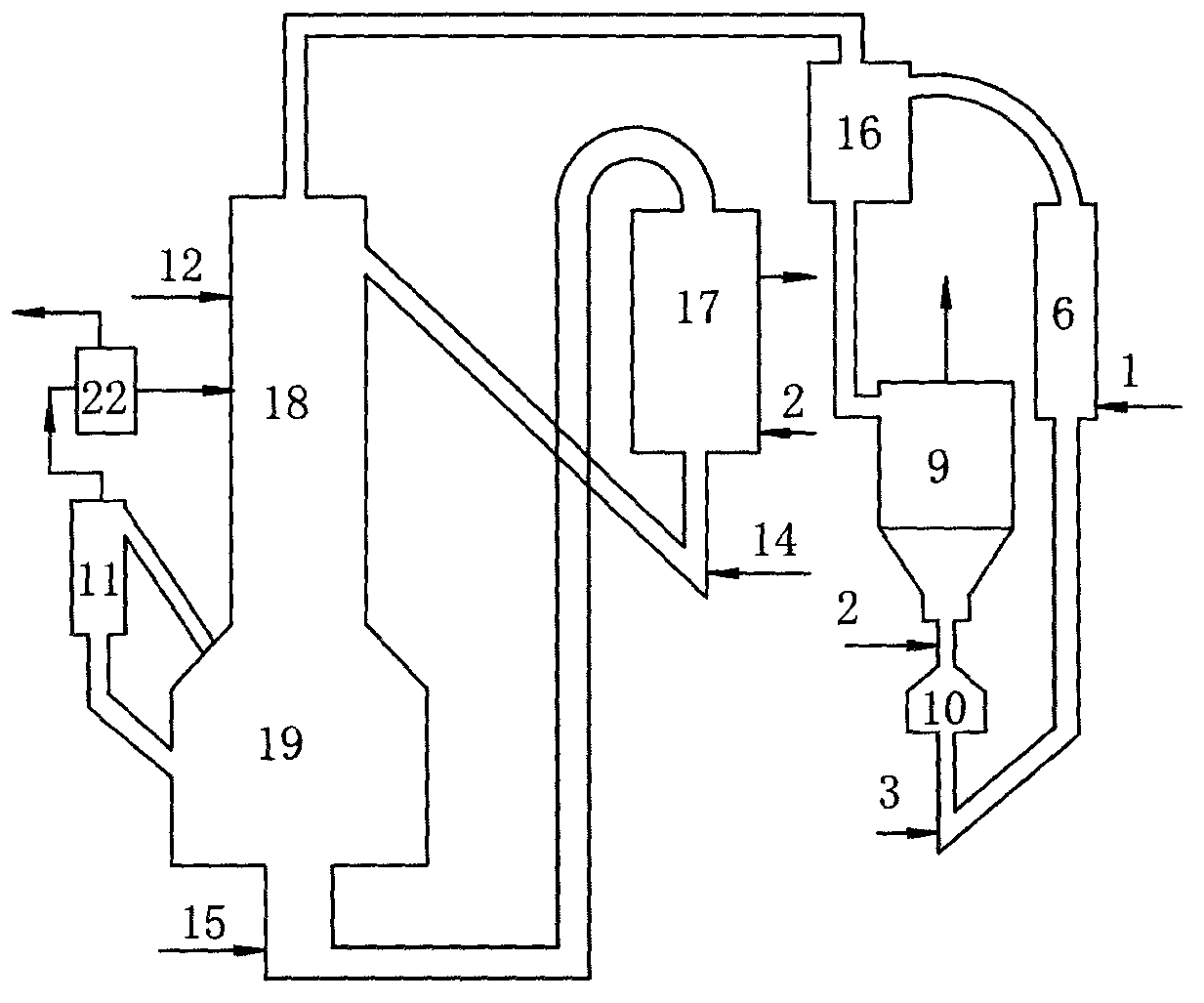

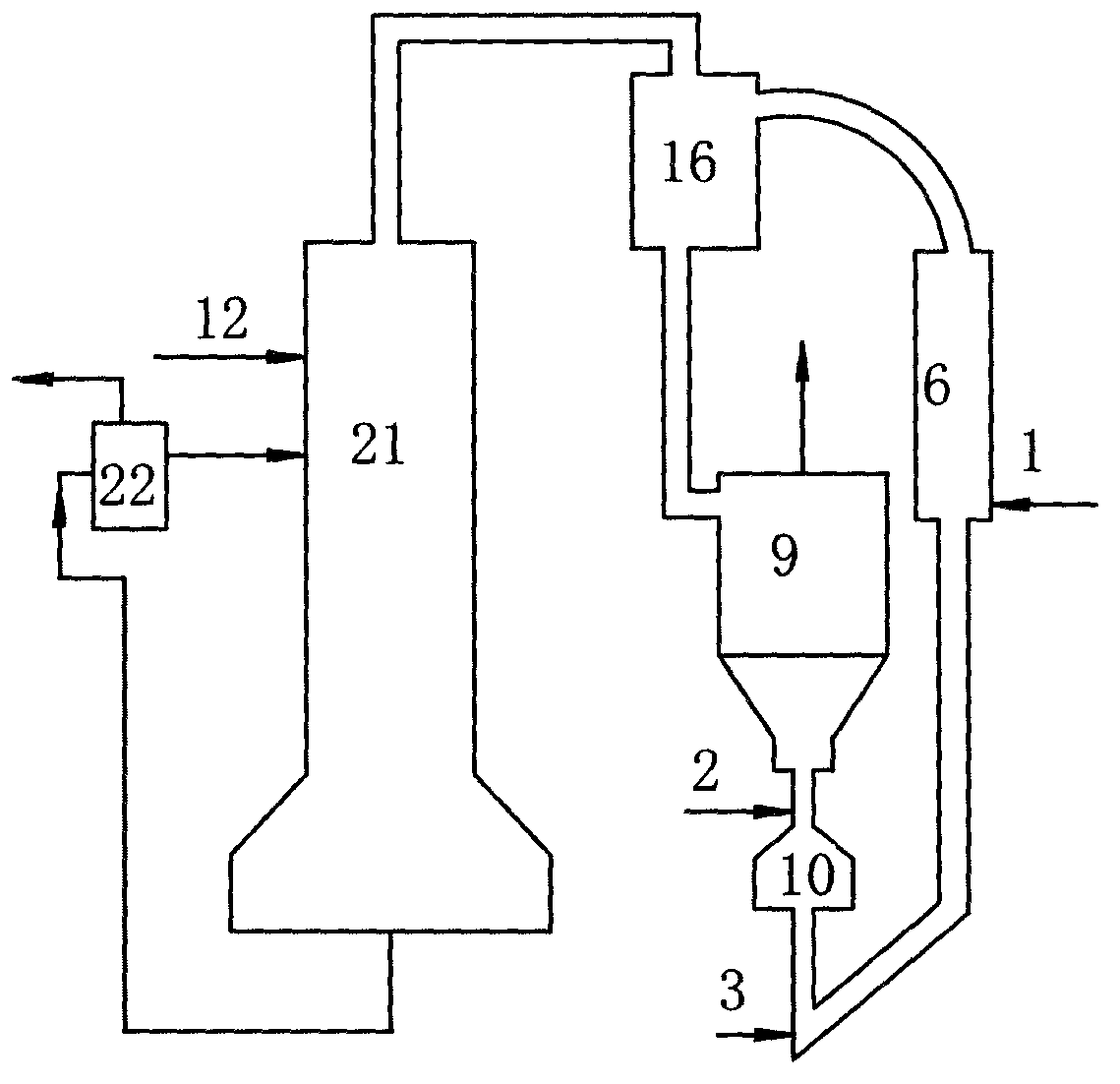

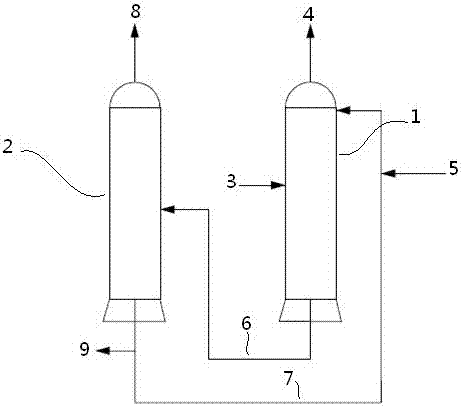

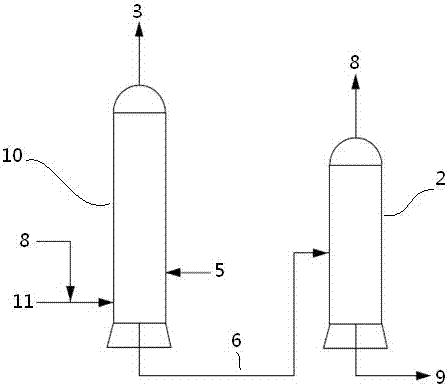

Method for preparing aromatic hydrocarbons from methanol with low carbon olefin as byproduct, and apparatus thereof

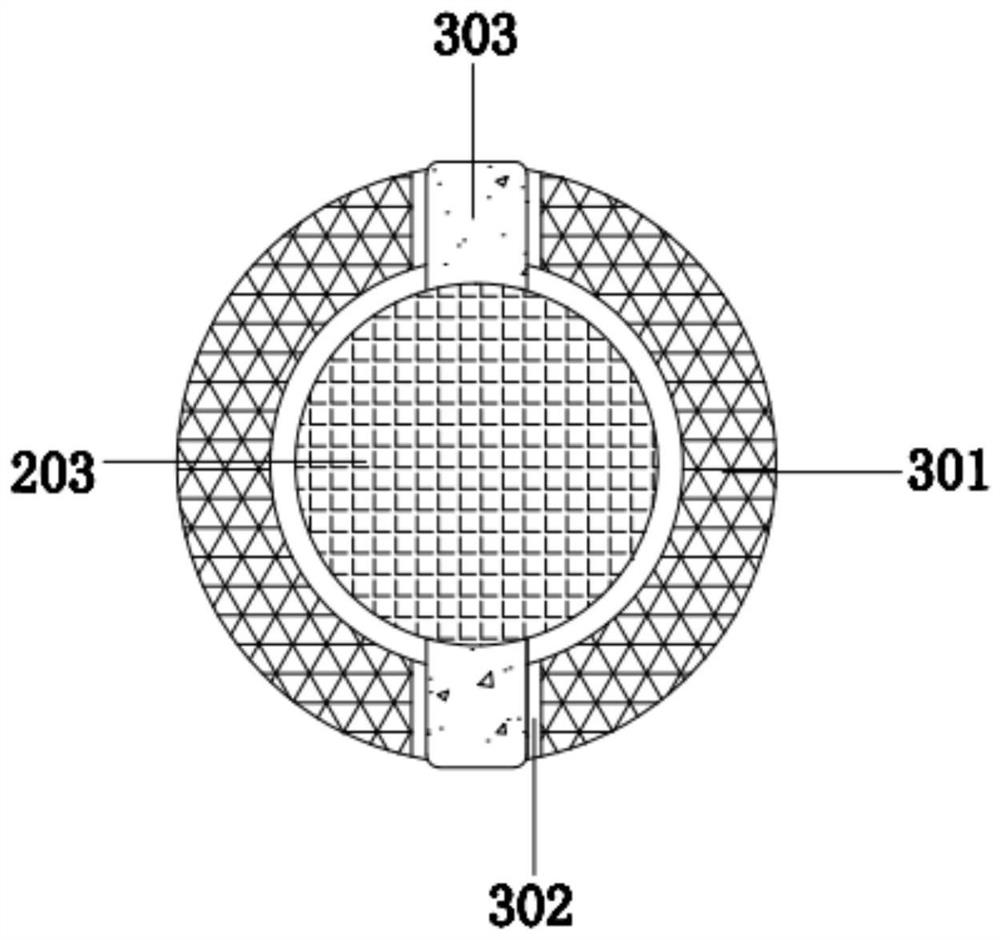

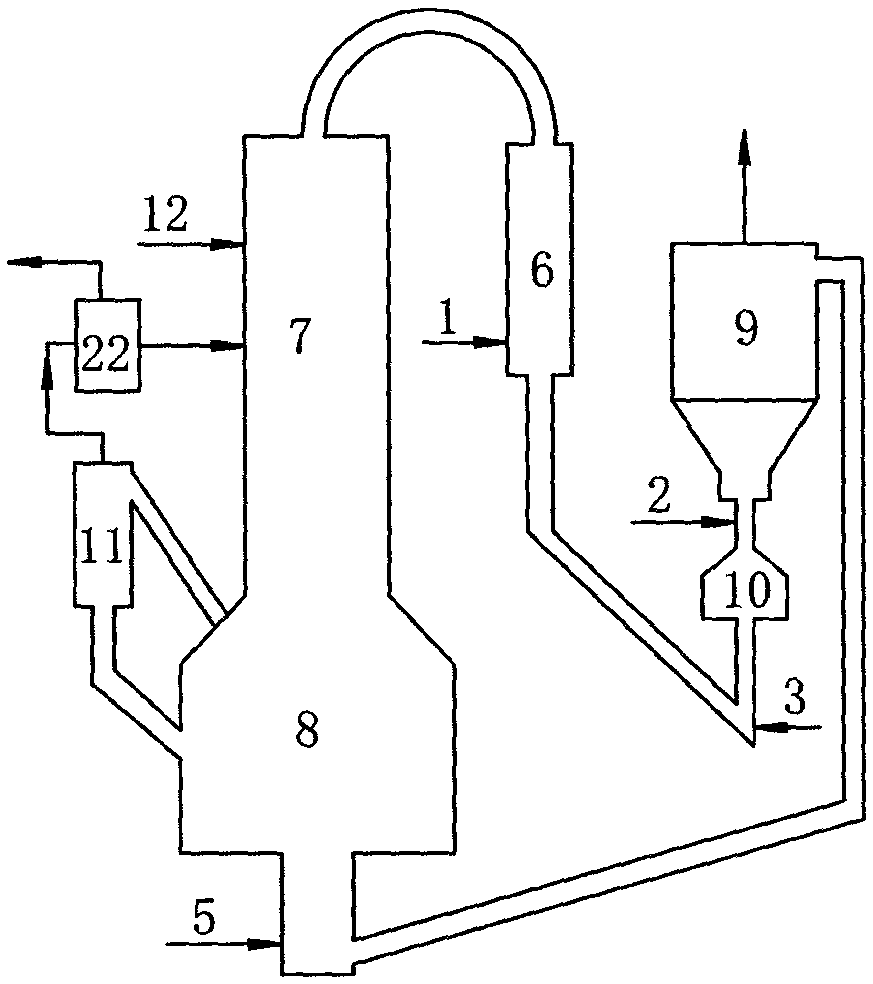

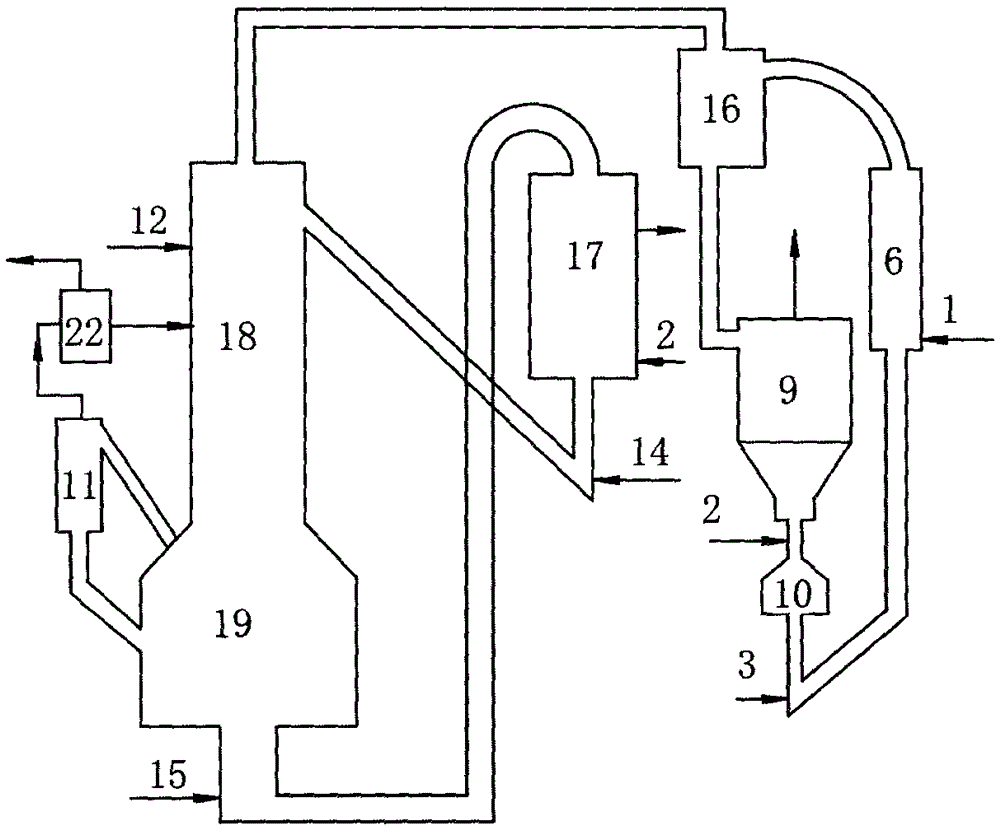

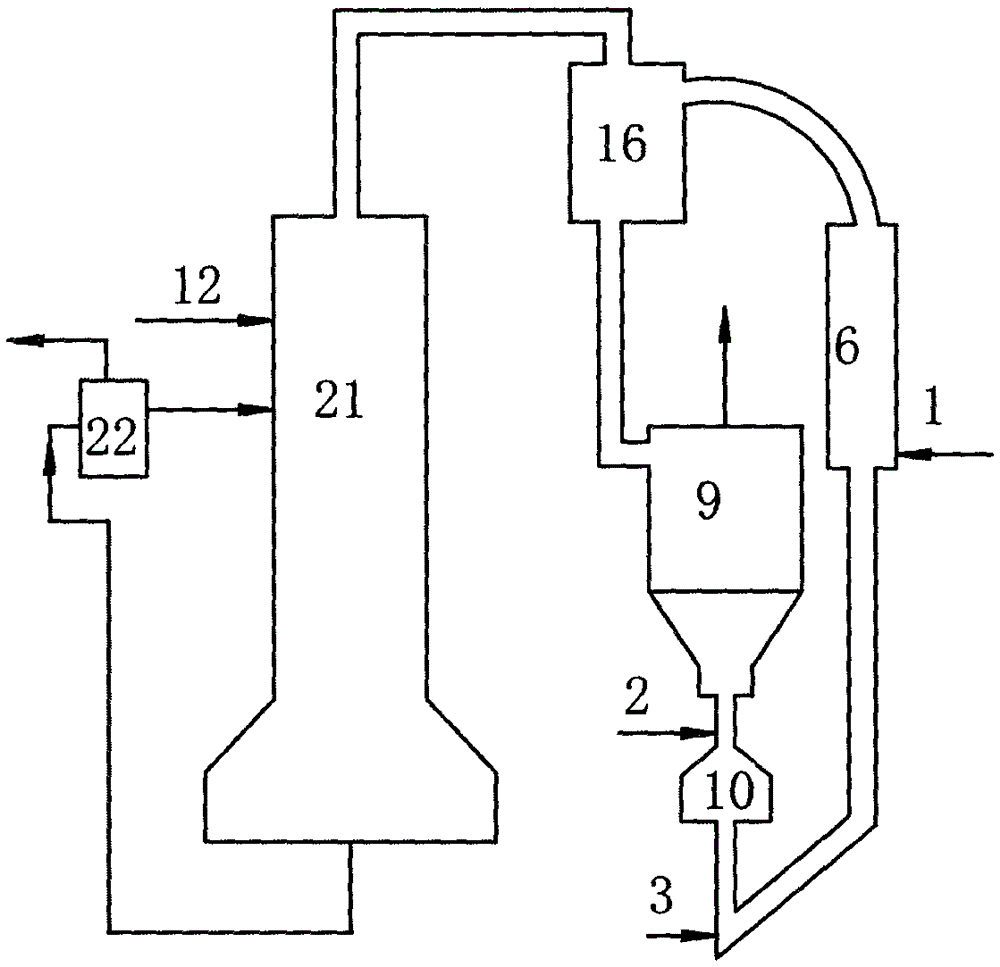

ActiveCN104250183AResolve inactivationImprove continuous operation capabilityHydrocarbon from oxygen organic compoundsEthylene productionFluidized bedFixed bed

The invention discloses a method for preparing aromatic hydrocarbons from methanol with low carbon olefin as a byproduct, and an apparatus thereof. The problems of low yield of the aromatic hydrocarbons, large output of dry gas and liquefied gas, and the like in the prior art are solved in the invention. The method comprises the following steps: preheating the raw material methanol to 350-500DEG C, adding the preheated methanol to a riser reactor, carrying out a contact reaction on the preheated methanol and a catalyst in the riser reactor for 0.8-4.0s, allowing the reaction product of the riser reactor to enter a deep catalysis reactor (such as a fluidized bed, moving bed or fixed bed reactor) to carry out a reaction, returning C2-C5 alkanes in the reaction products of the deep catalysis reactor to the deep catalysis reactor in order to re-process the C2-C5 alkanes, and discharging other products from the apparatus, wherein the catalyst is a ZSM-5 / SAPO-34 catalyst modified by Ga, Zn, P and Ag.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP +1

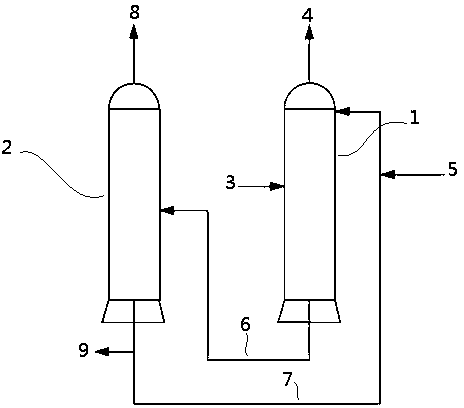

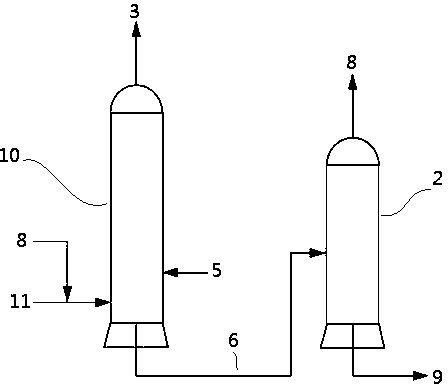

Method used for producing silane and trichlorosilane via reactive distillation

The invention discloses a method used for producing silane and trichlorosilane via reactive distillation. The method comprises a step that in a reactive distillation device, silane or trichlorosilane is prepared via chlorosilane disproportionation reaction or reverse-disproportionation reaction; and is characterized in that a liquid catalyst obtained via mixing of an alicyclic amine and an aromatic amine is used for the disproportionation reaction or the reverse-disproportionation reaction. According to the method, pretreatment of the liquid catalyst is not necessary, catalyst displacement is convenient, blocking of a subsequent system is not caused, recovery of inactive catalyst is simple, no liquid waste or solid water is generated, the method is clean and friendly to the environment, conversion rate of the disproportionation reaction or the reverse-disproportionation reaction is high, and operation of production processes is simple.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV

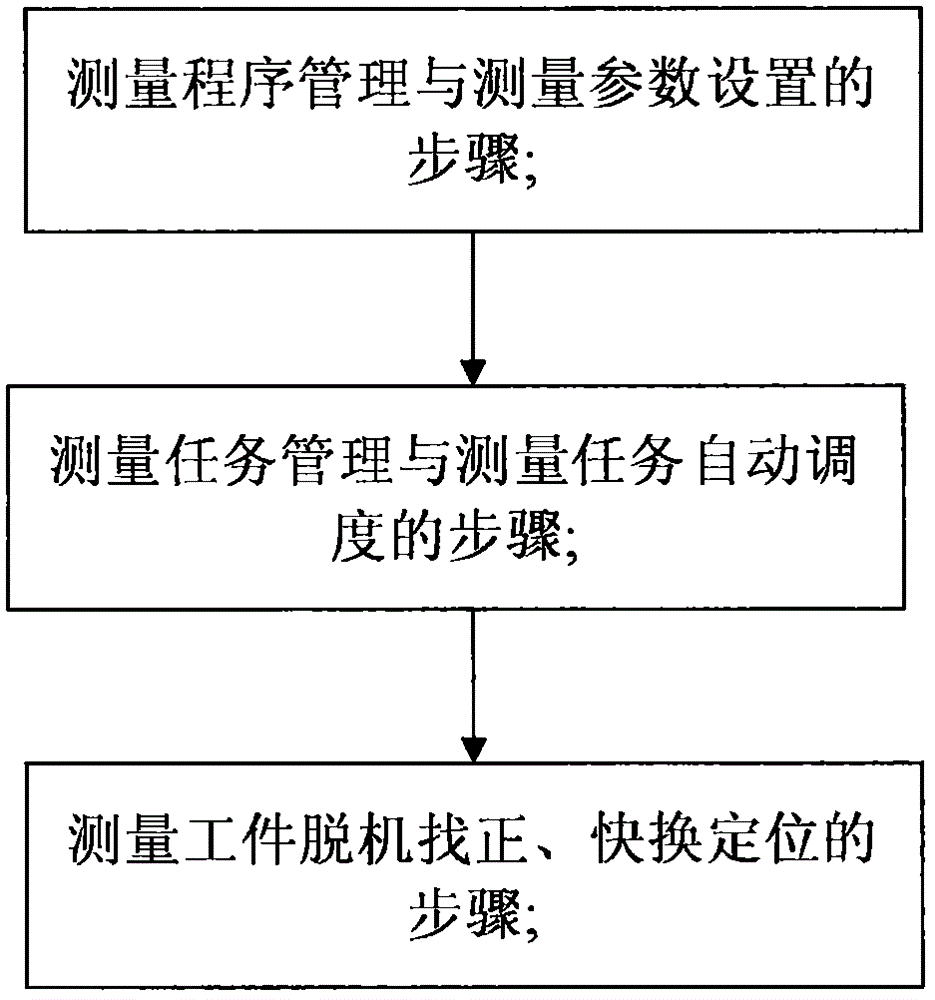

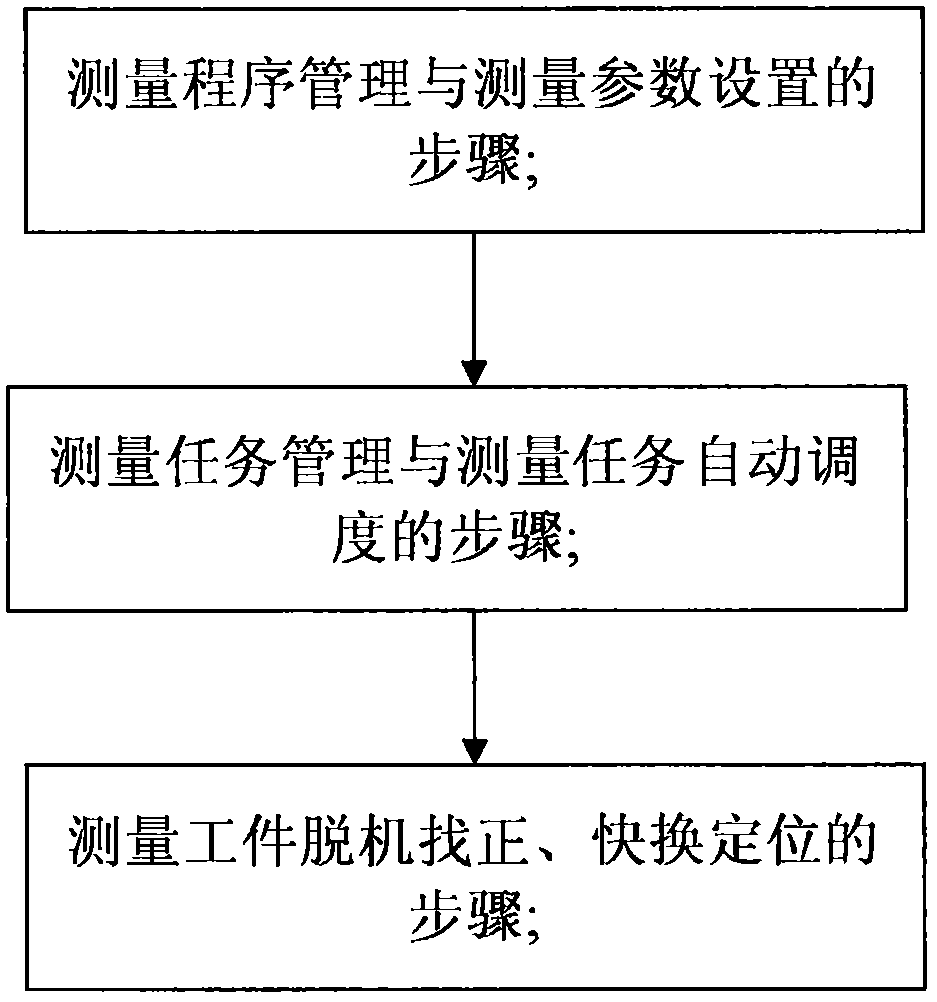

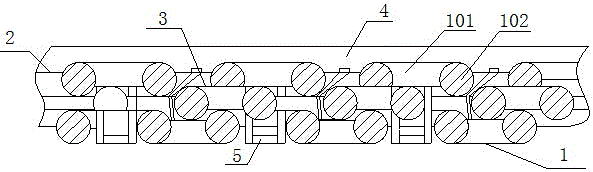

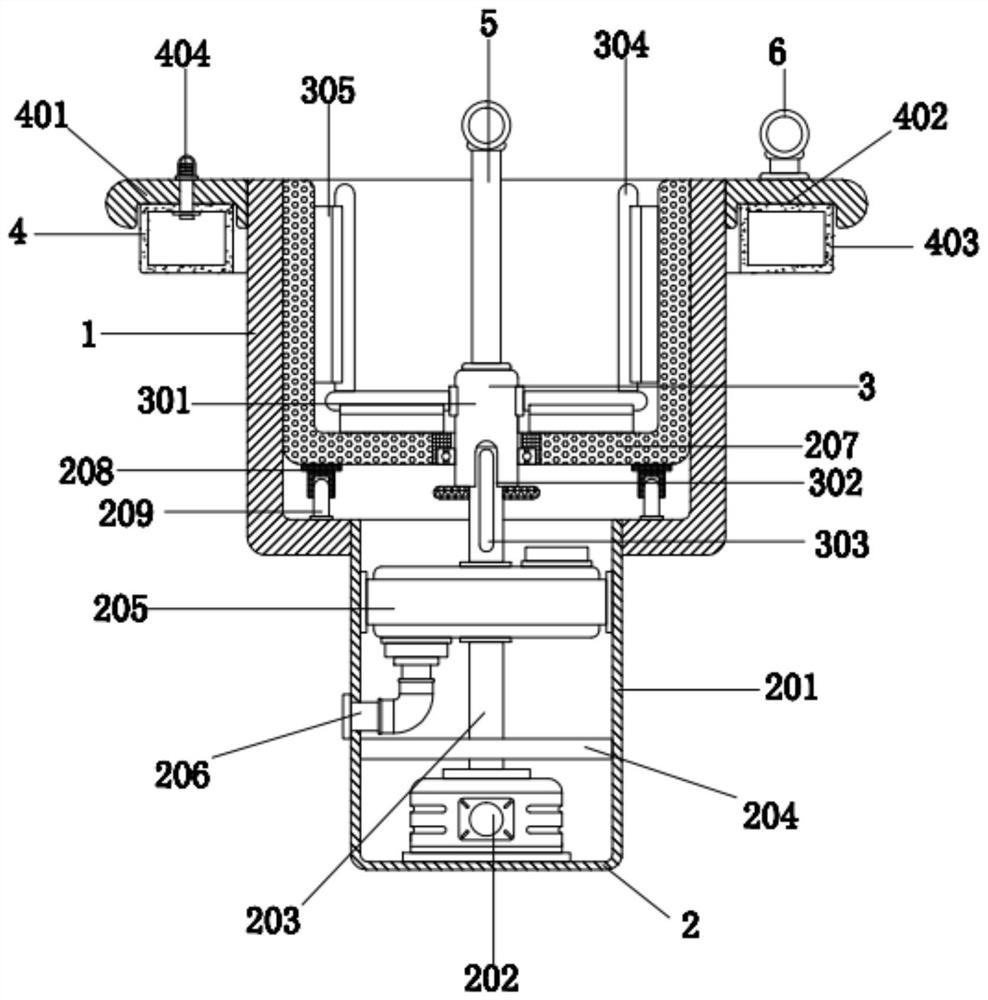

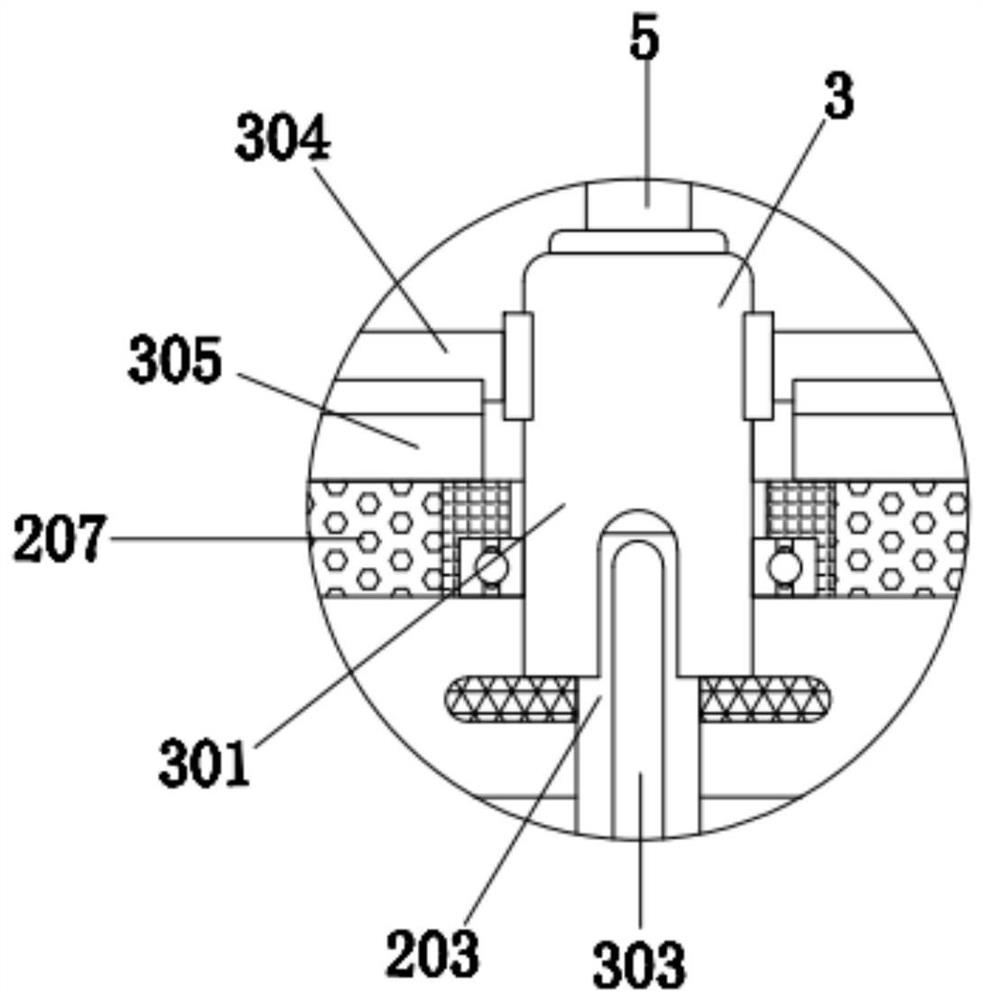

Three-coordinate measuring machine workpiece continuous measurement method

ActiveCN105910563AGuaranteed uptimeImprove continuous operation capabilityMechanical measuring arrangementsContinuous measurementProgram management

The invention discloses a three-coordinate measuring machine workpiece continuous measurement method which comprises the steps of a step of measurement program management and measurement parameter setting, a step of measurement task management and measurement task automatic scheduling, and a step of measurement workpiece offline centering and quick change positioning. Tasks such as measurement program switching, report storing, uploading and measurement timing are automatically scheduled and finished by a system. A plurality of workpieces can be simultaneously loaded for realizing combined measurement. A manually established coordinate system and automatic operation are integrated. Measurement personnel do not require high-frequency operation of a computer and a measurement machine, thereby reducing measurement time and workload of the measurement personnel, so that the measurement personnel have more energy for performing offline loading and workpiece alignment. When the measurement machine automatically operates through controlling of a scheduling system, the measurement personnel performs offline loading for alignment of a next workpiece. The measurement machine and a person perform parallel operation, thereby reducing waiting time of the person and the machine, ensuring continuous operation of the measurement machine, and improving integral measurement efficiency and utilization rate of the measurement machine.

Owner:刘玉芳

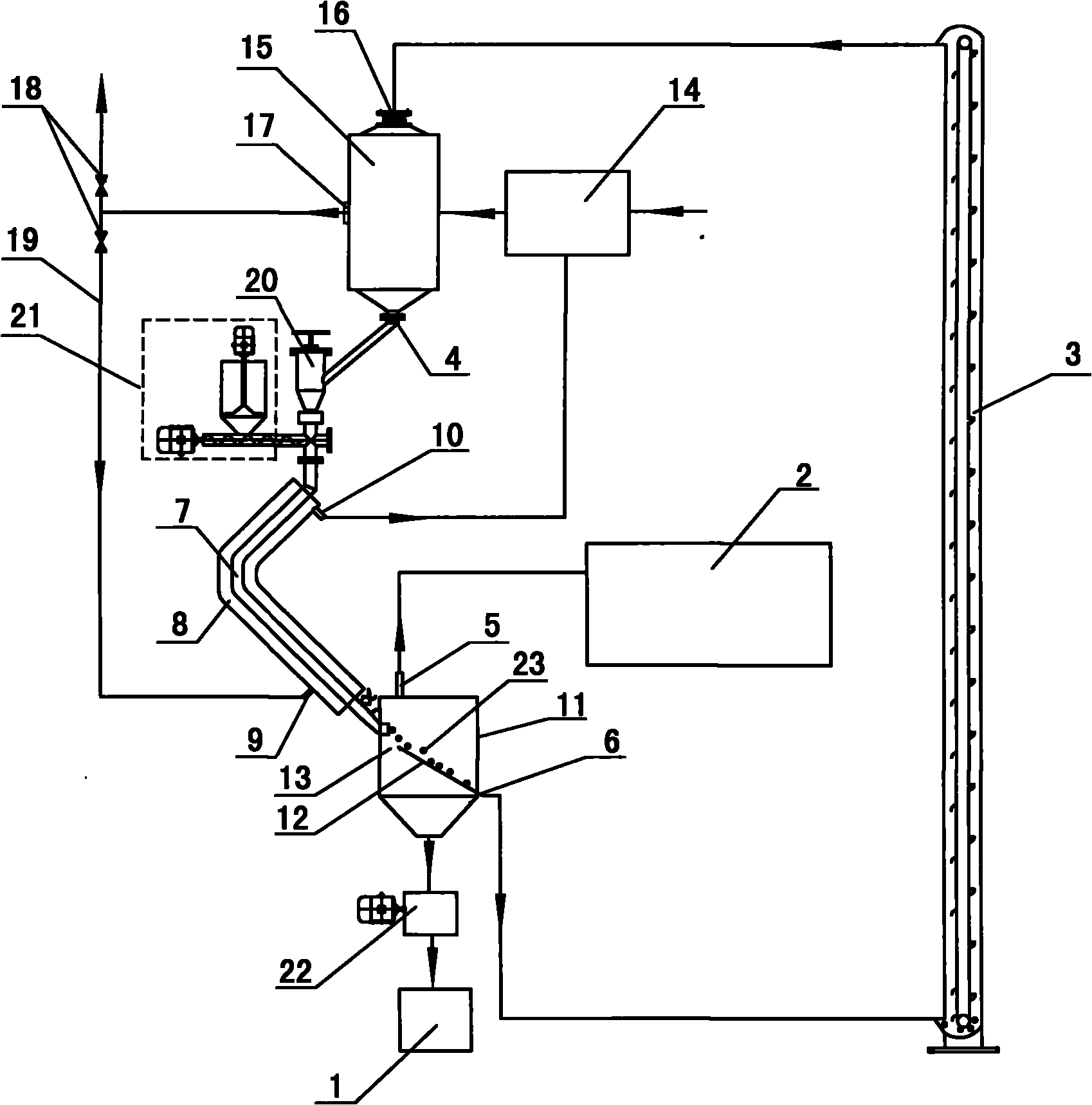

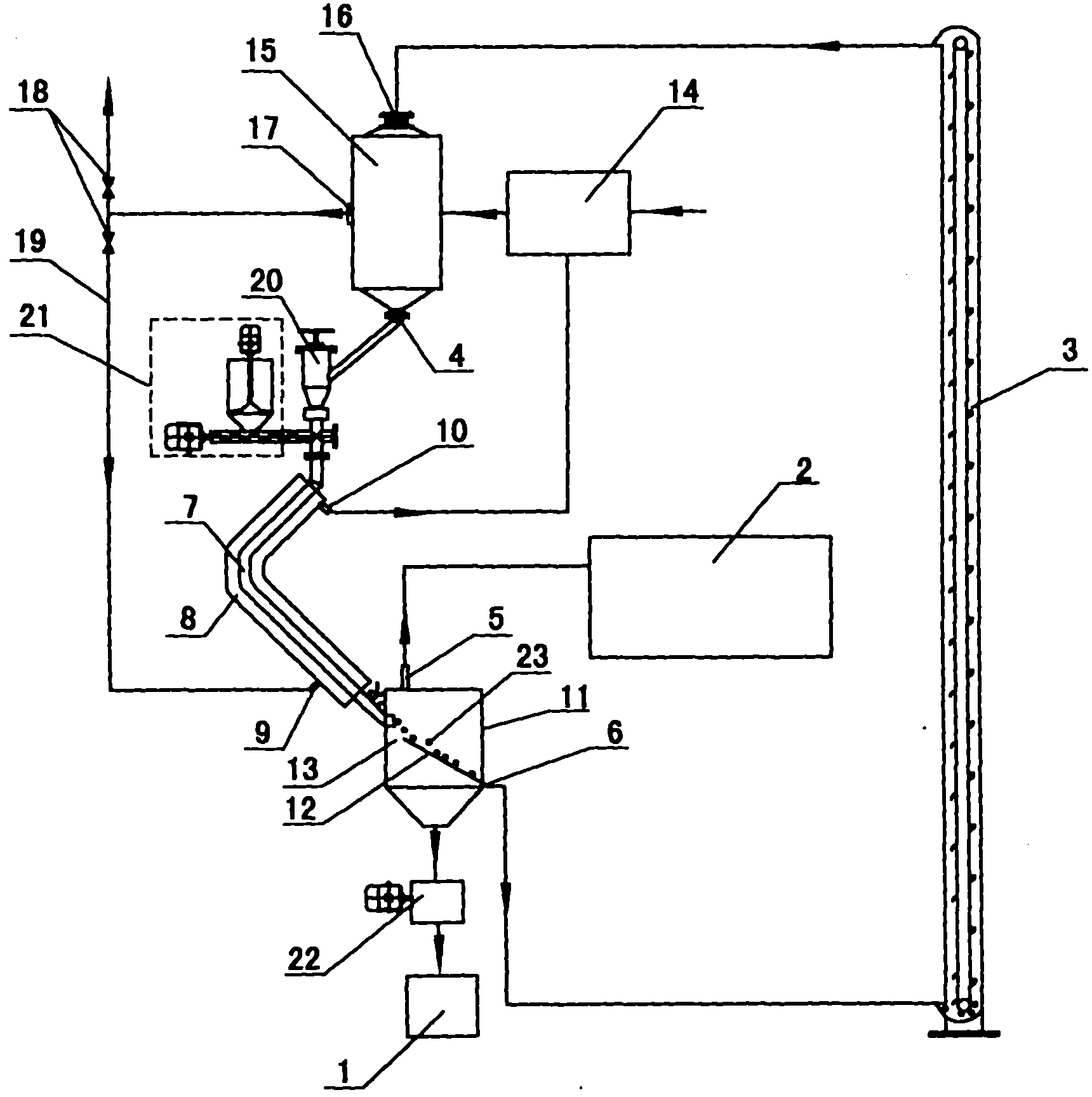

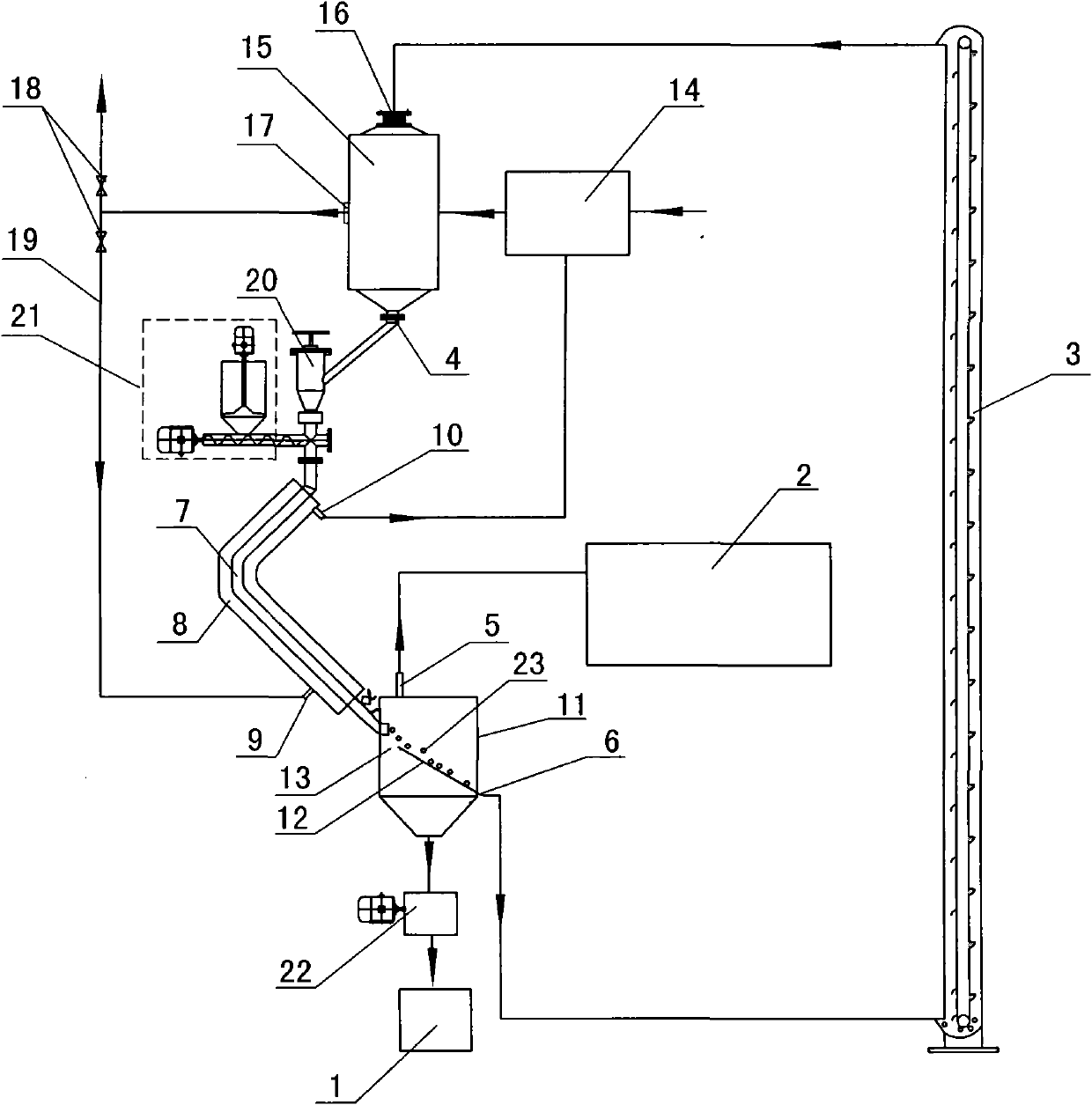

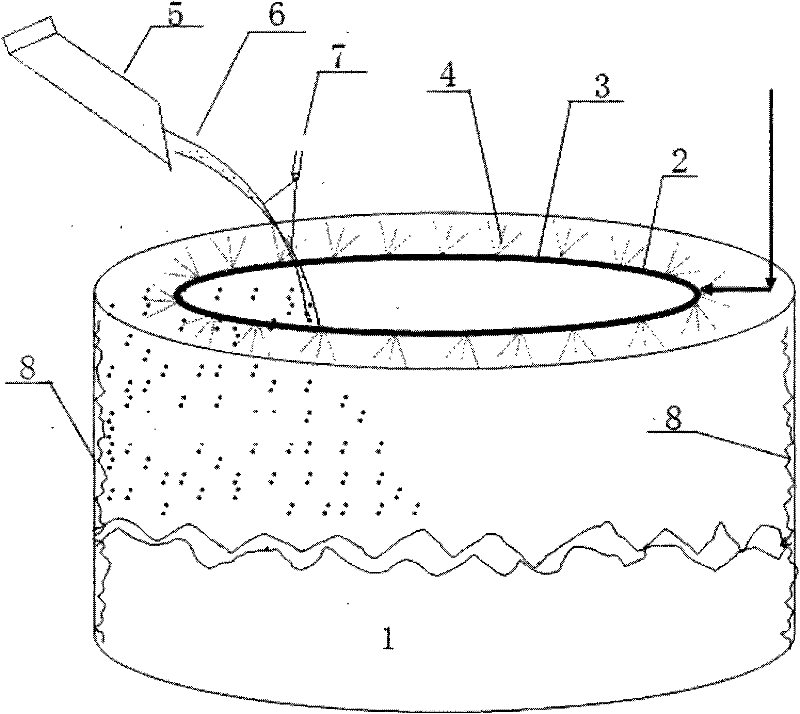

Pyrolysis and liquidation system for heating biomass by using solid heat storage ball

ActiveCN102206496AReduce energy consumptionImprove continuous operation capabilityDirect heating destructive distillationBiofuelsBiomassContinuous operation

The invention provides a pyrolysis and liquidation system for heating biomass by using a solid heat storage ball. In the system, an outlet of a heat storage ball heating device is communicated with a feed inlet of a reactor through a feeding device; a feed outlet of the reactor is communicated with a separation device; the bottom of the separation device is connected with an ash box, and the top of the separation device is connected with a pyrolysis gas treatment device; and a second heat storage ball outlet on the side wall at the lower end of the separation device is connected with the heat storage ball heating device through a heat storage ball lifting device. The system is characterized in that: the reactor is a sleeve-type reactor and comprises an inner pipe and an outer pipe which are coaxially sleeved with each other; the two ends of the inner pipe are communicated with the feeding device and the separation device respectively; a hot air outlet and a hot air inlet of the outer pipe are communicated with the heat storage ball heating device respectively; the separation device comprises a separation box and a sieve plate which is obliquely arranged in the separation box and is tilted along the direction of an outlet at the bottom of the inner pipe; and the lower end of the sieve plate is connected with the outlet of the second heat storage ball, and the upper end of the sieve plate and the side wall of the separation box forms a carbon ash falling opening. The device reduces energy consumption and has high continuous operation capability, high liquid conversion rate and high working performance.

Owner:SHANDONG UNIV OF TECH

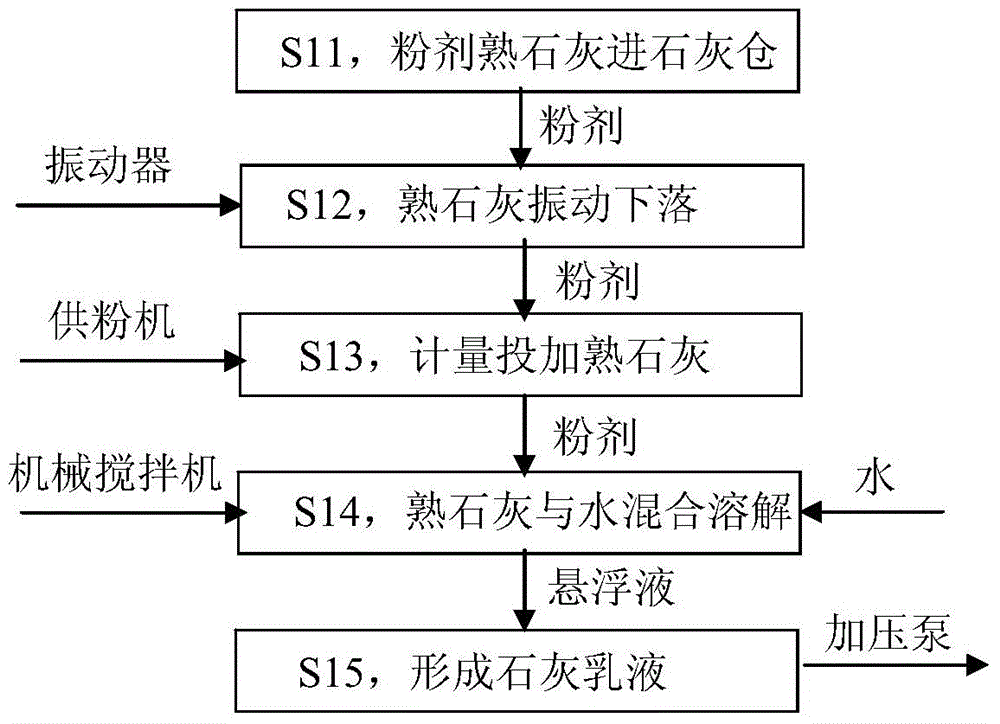

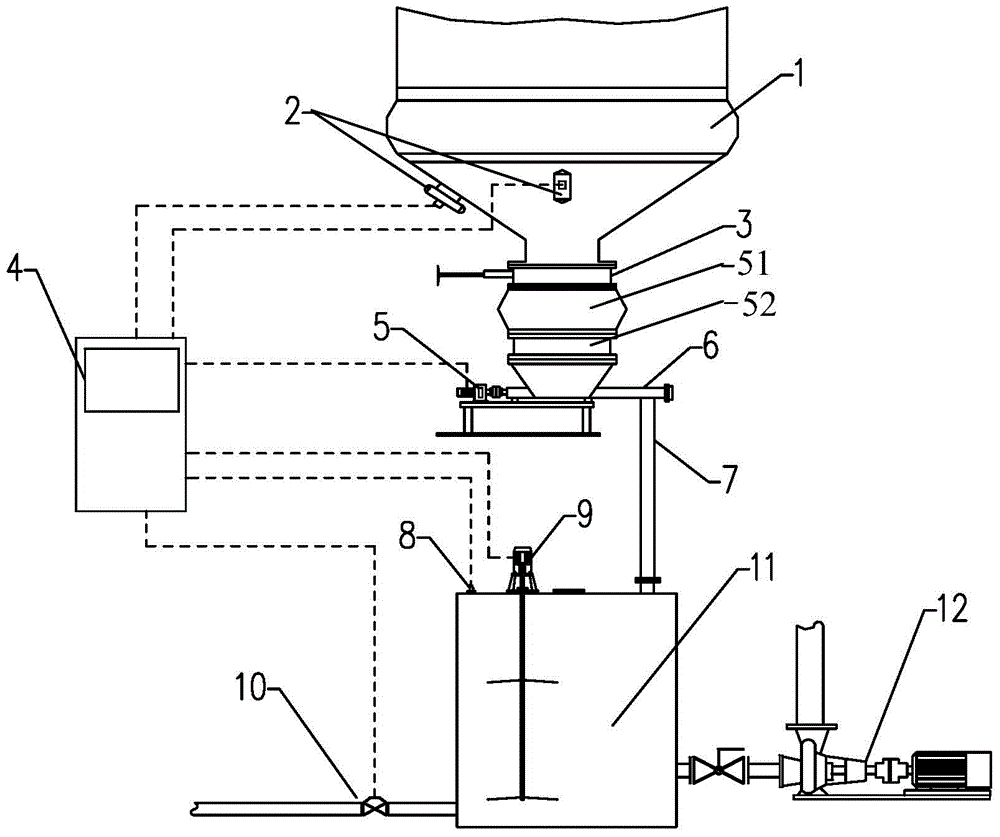

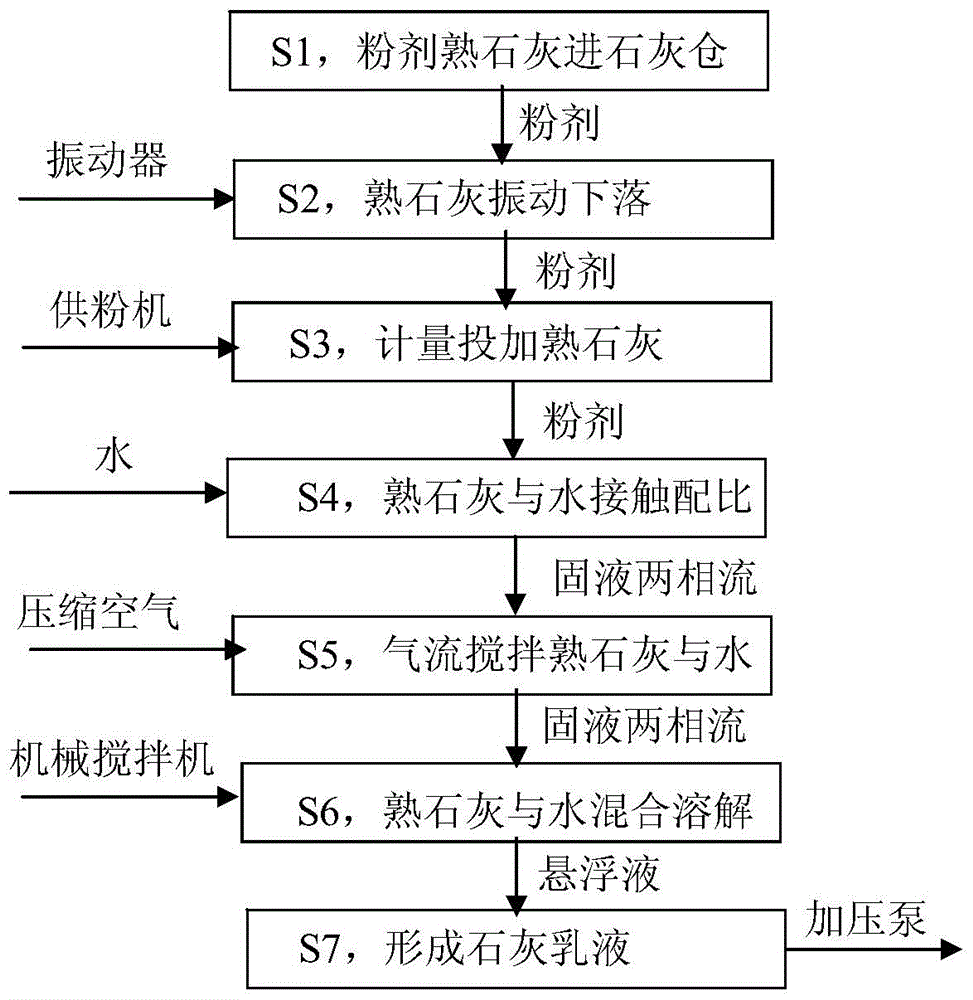

Preparation method of slaked lime emulsion for wastewater treatment and apparatus thereof

InactiveCN105435666AIncrease profitImprove mixing efficiencyTransportation and packagingMixing methodsEmulsionSprayer

The invention provides a preparation method of slaked lime emulsion for wastewater treatment and an apparatus thereof, and relates to an industrial wastewater treatment apparatus. The invention solves the problems in prior art, such as many faults and a large amount of dust. The method comprises the following steps: slaked lime powder is added into a lime cabin; the slaked lime is vibrated and falls into a mixer; the slaked lime is metered and added; water is added through a sprayer for contacting the slaked lime in the mixer according to a ratio; the slaked lime and the water are stirred by air-flow; the slaked lime is mixed and dissolved with the water; the lime emulsion is formed and is added into each process point of waste water treatment by a pressure pump. The sprayer and the mixer are used for contacting and proportioning the slaked lime and the water, lower water inlet is changed into upper water inlet for arranging lime, so that mixing time is increased; with the effect of a water film of the sprayer, dust pollution of pulverized limestone is reduced, and blocking rate of a downcomer of lime is reduced. Air-flow stirring of the air-flow stirrer is used for improving mixing efficiency of lime and water, so that utilization rate of the slaked lime is improved, and capability of continuous operation of the apparatus is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Pyrolysis and liquidation system for heating biomass by using solid heat storage ball

ActiveCN102206496BReduce energy consumptionImprove continuous operation capabilityDirect heating destructive distillationBiofuelsProcess engineeringContinuous operation

The invention provides a pyrolysis and liquidation system for heating biomass by using a solid heat storage ball. In the system, an outlet of a heat storage ball heating device is communicated with a feed inlet of a reactor through a feeding device; a feed outlet of the reactor is communicated with a separation device; the bottom of the separation device is connected with an ash box, and the top of the separation device is connected with a pyrolysis gas treatment device; and a second heat storage ball outlet on the side wall at the lower end of the separation device is connected with the heat storage ball heating device through a heat storage ball lifting device. The system is characterized in that: the reactor is a sleeve-type reactor and comprises an inner pipe and an outer pipe which are coaxially sleeved with each other; the two ends of the inner pipe are communicated with the feeding device and the separation device respectively; a hot air outlet and a hot air inlet of the outer pipe are communicated with the heat storage ball heating device respectively; the separation device comprises a separation box and a sieve plate which is obliquely arranged in the separation box and is tilted along the direction of an outlet at the bottom of the inner pipe; and the lower end of the sieve plate is connected with the outlet of the second heat storage ball, and the upper end of the sieve plate and the side wall of the separation box forms a carbon ash falling opening. The device reduces energy consumption and has high continuous operation capability, high liquid conversion rate and high working performance.

Owner:SHANDONG UNIV OF TECH

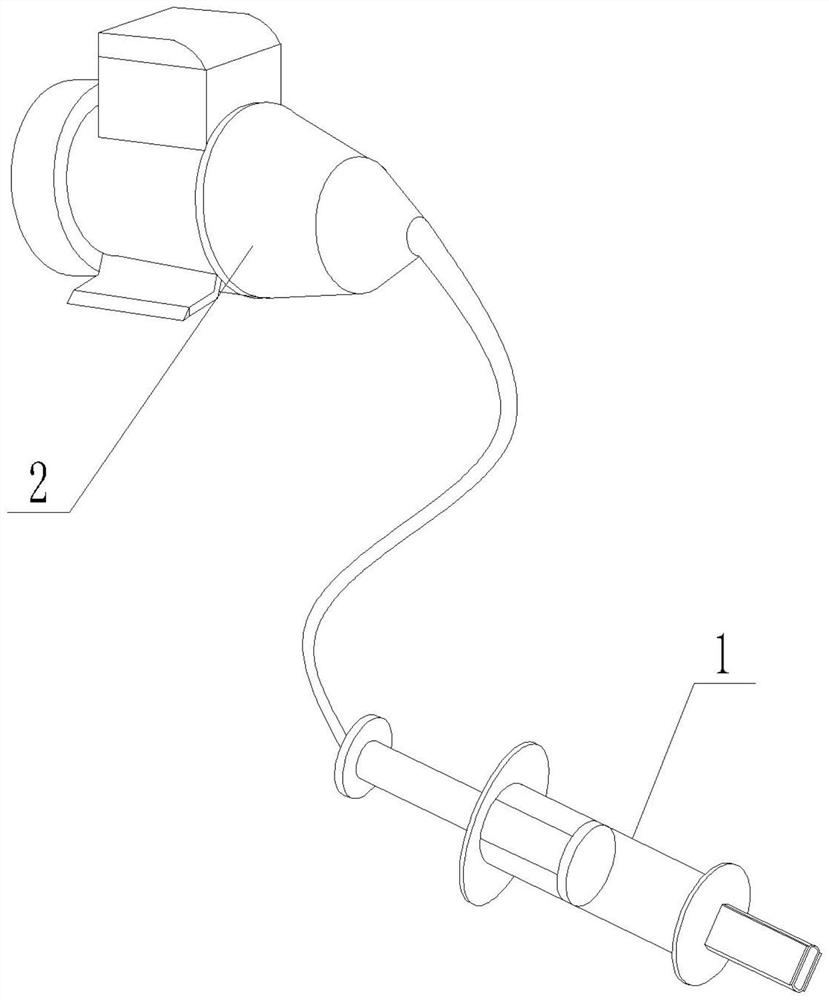

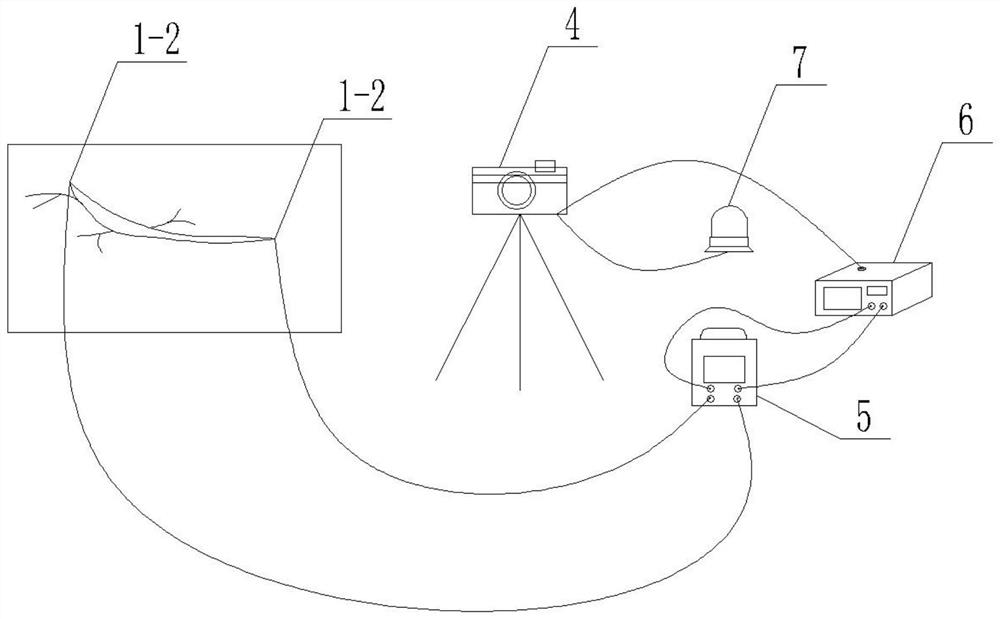

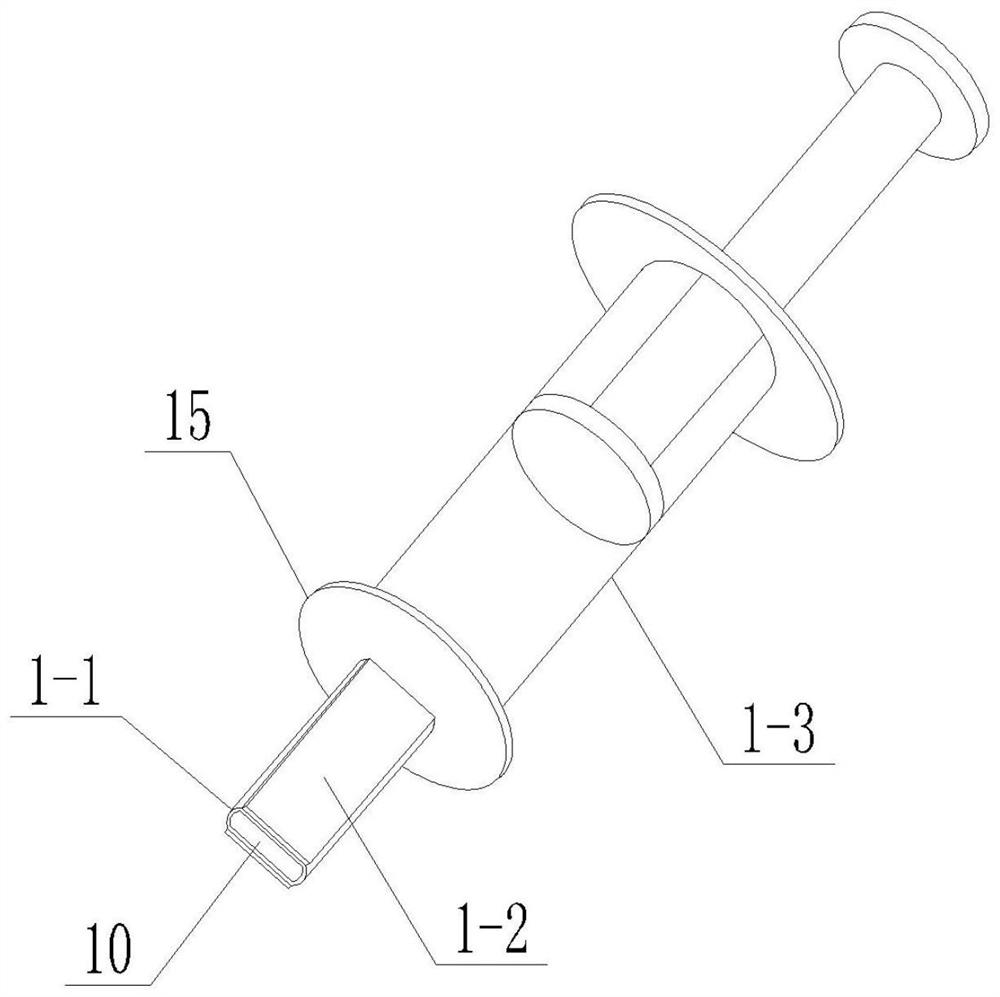

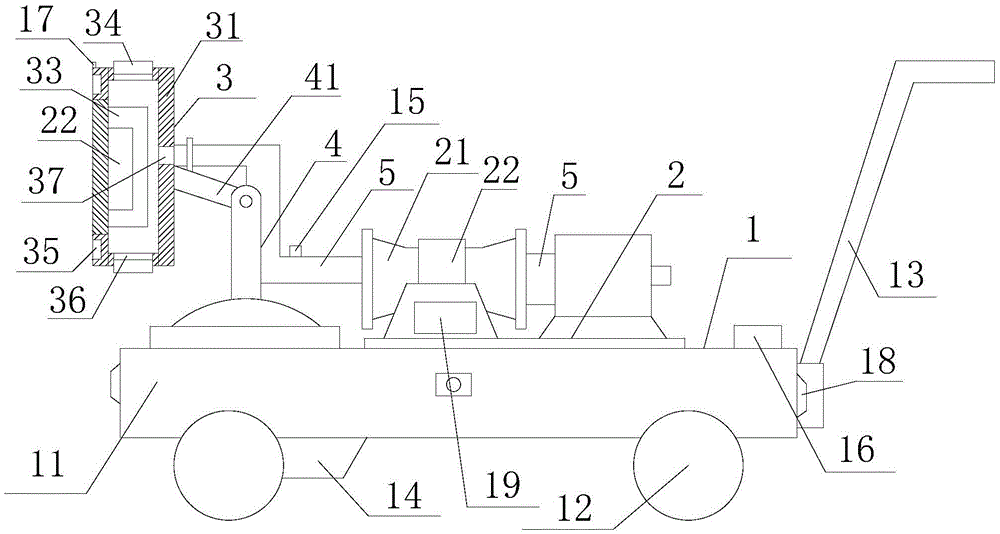

Filling type maintenance device and method for concrete crack repairing in winter in cold regions

ActiveCN112727139AEasy to useAvoid the defect of incoherent maintenance effectUnderground chambersBuilding repairsTemperature controlContinuous use

The invention discloses a filling type maintenance device and method for concrete crack repairing in winter in cold regions. The device and the method aim to overcome the defects that after a concrete structure is cracked in winter in a cold region, an existing method cannot achieve rapid repairing on site, and great problems are brought to continuous use of the structure. According to the filling type maintenance device, each electrode type injector of comprises a flat needle head, electrode plates and an injection body; the flat needle head is detachably connected to the discharging end of the injection body, a feeding port communicating with the discharging end of the injection body is machined in one end of the flat needle head, and a discharging port is machined in the other end of the flat needle head; and the electrode plates are arranged on the outer wall of the flat needle head, the injection body is filled with conductive concrete, the two electrode plates of the two electrode type injectors are electrically connected with a voltage regulator, the voltage regulator is connected with a thermal infrared imager through a temperature control switch, and the thermal infrared imager is further provided with an alarm in a matched mode. The filling type maintenance device is used for rapid repairing of the cracking part of the concrete structure in winter in the cold region.

Owner:HARBIN INST OF TECH

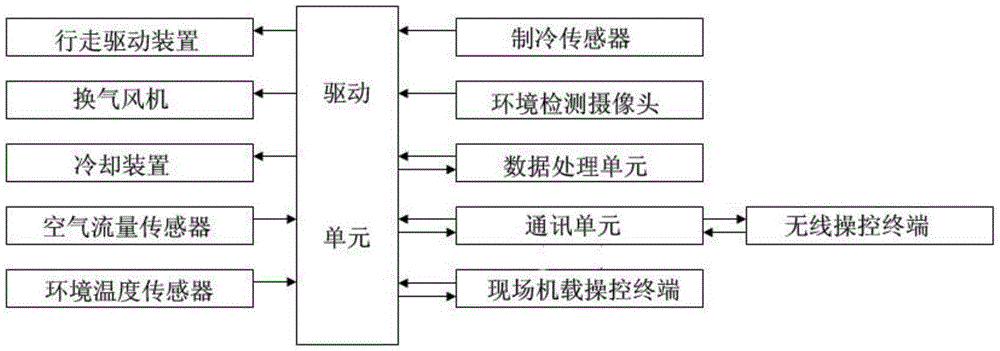

Emergent cooling and refrigerating device for large internet servers

ActiveCN105658034AImprove continuous operation capabilityImprove the operating environmentCooling/ventilation/heating modificationsControl systemAir filter

The invention relates to an emergent cooling and refrigerating device for large internet servers. The emergent cooling and refrigerating device comprises a mobile platform, an air forced-ventilation device, a cooling plate, a supporting arm, an air guiding pipe and a control system, wherein the air forced-ventilation device is arranged on the mobile platform and is communicated with the cooling plate by the air guiding pipe; the cooling plate is also hinged with the mobile platform by the supporting arm; the mobile platform comprises a working platform, traveling wheels and a pushing handle; the air forced-ventilation device comprises an air-exchange fan and a cooling device; and the cooling plate comprises a supporting frame, a cooling device, a heat exchange plate, radiating fin plates and an air filter. The emergent cooling and refrigerating device has good mobility and refrigerating and cooling performances, and can be flexibly applied to emergent cooling and forced cooling operation of multiple types of large internet servers, so that on the one hand, the emergent cooling and refrigerating device is conductive to enhancing the continuous operation capability of the internet servers, and on the other hand, the emergent cooling and refrigerating device is also conductive to improving the operation environment of the internet servers and increasing the operation performance of the internet server equipment.

Owner:STATE GRID CORP OF CHINA +1

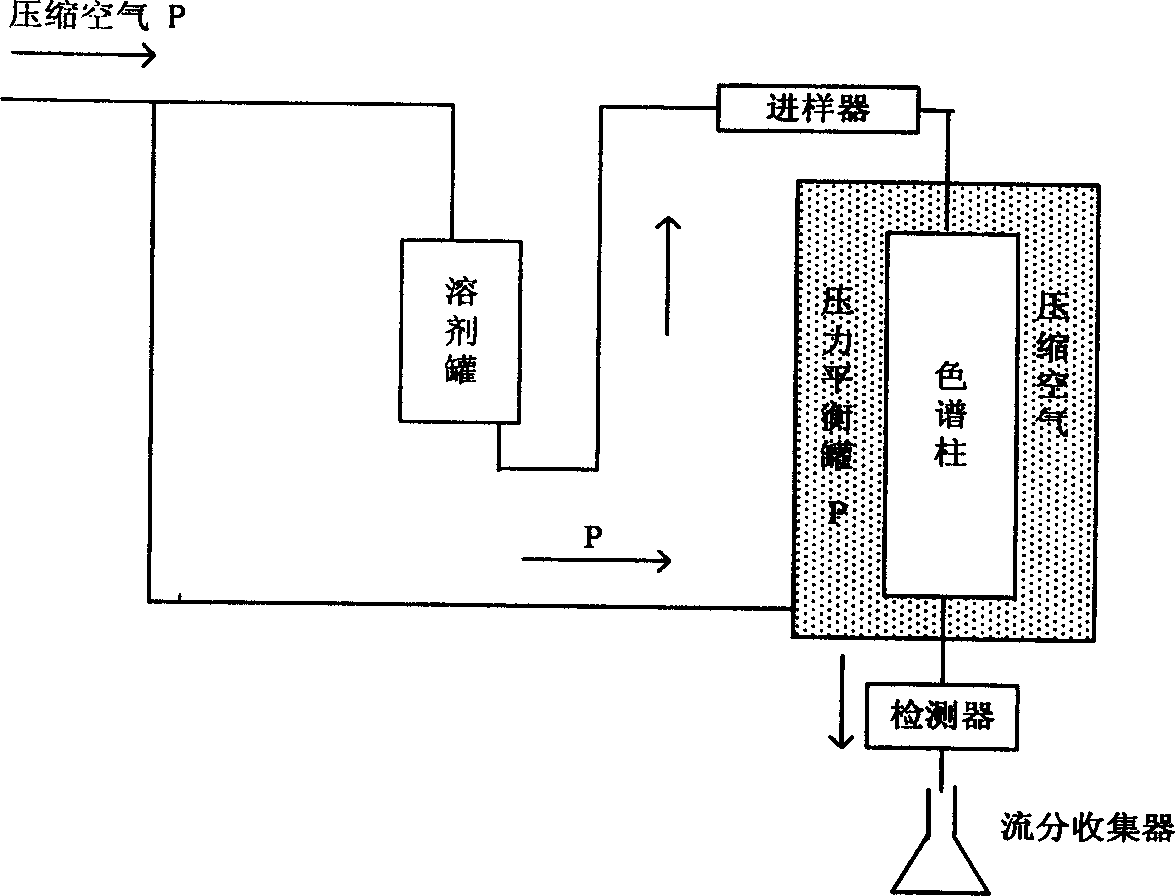

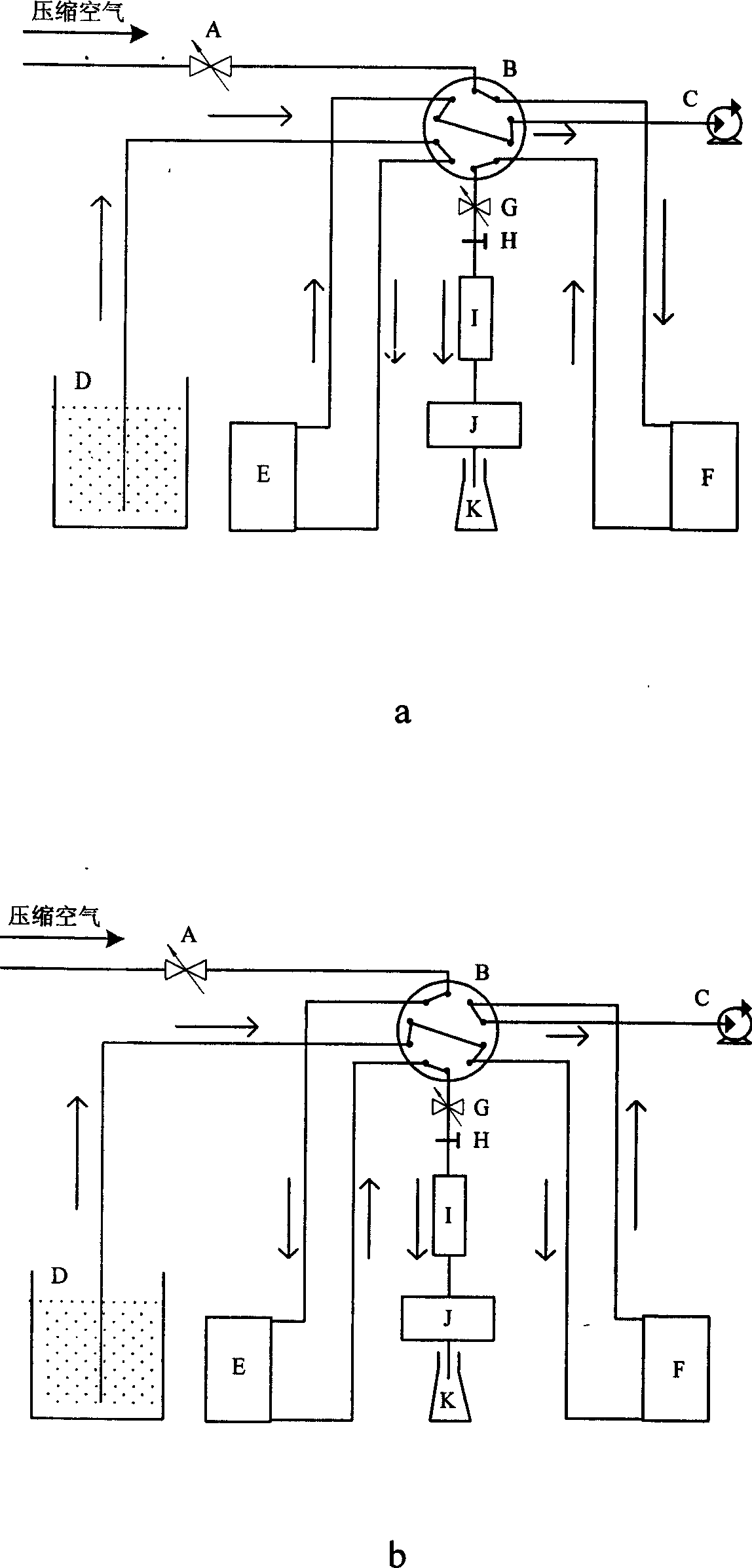

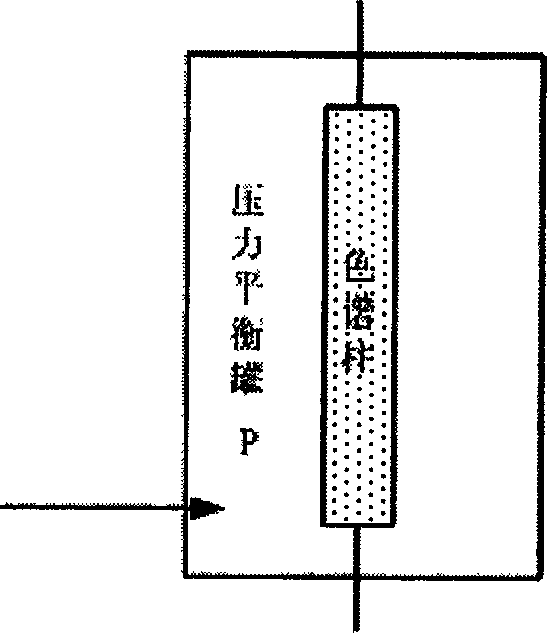

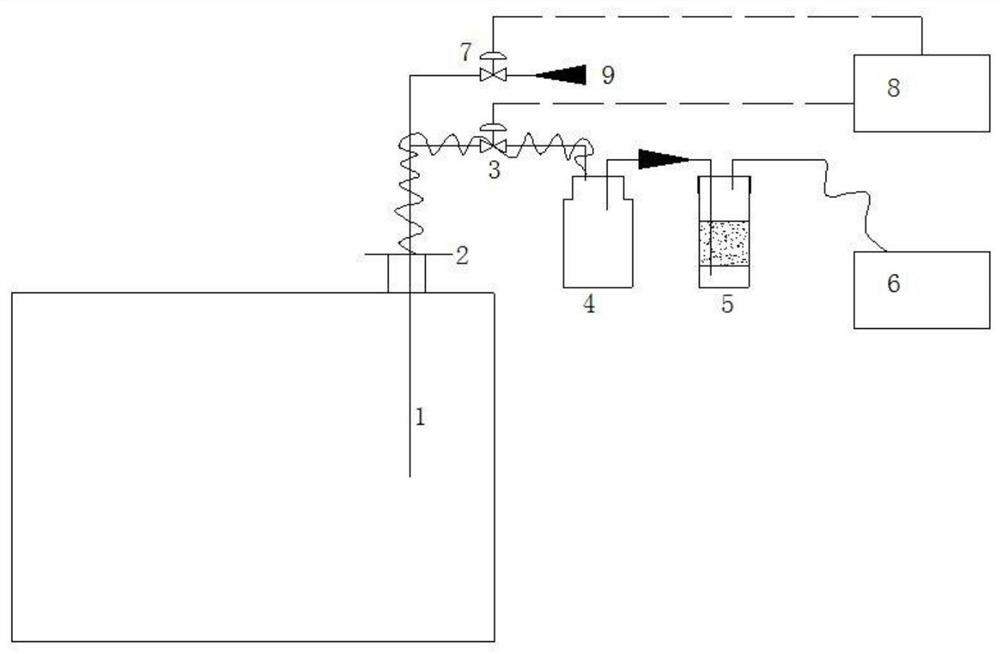

Fast pneumatic system for preparing columnar chromatograph and its utilization

InactiveCN1895717AContinuous operation performanceSimple installationIon-exchange process apparatusIon-exchanger regenerationSolventChromatographic column

A pneumatic fast column chromatography system is composed of a negative-pressure unit for filling flowing phase and a medium-pressure unit for eluting the flowing phase. Its application method is also disclosed. When a 10-way valve is in the first state, the flowing phase is filled from an open solvent tank into a sealed one under negative pressure while the chromatographic column is eluted by the flowing phase from the second sealed solvent tank via medium-pressure channel. When the flowing phase in the second tank is consumed off, it is switched to the second state, the flowing phase is filled from the open solvent tank into the second sealed one and the chromatographic column is eluted by the first sealed one.

Owner:天津奥秘科技有限公司

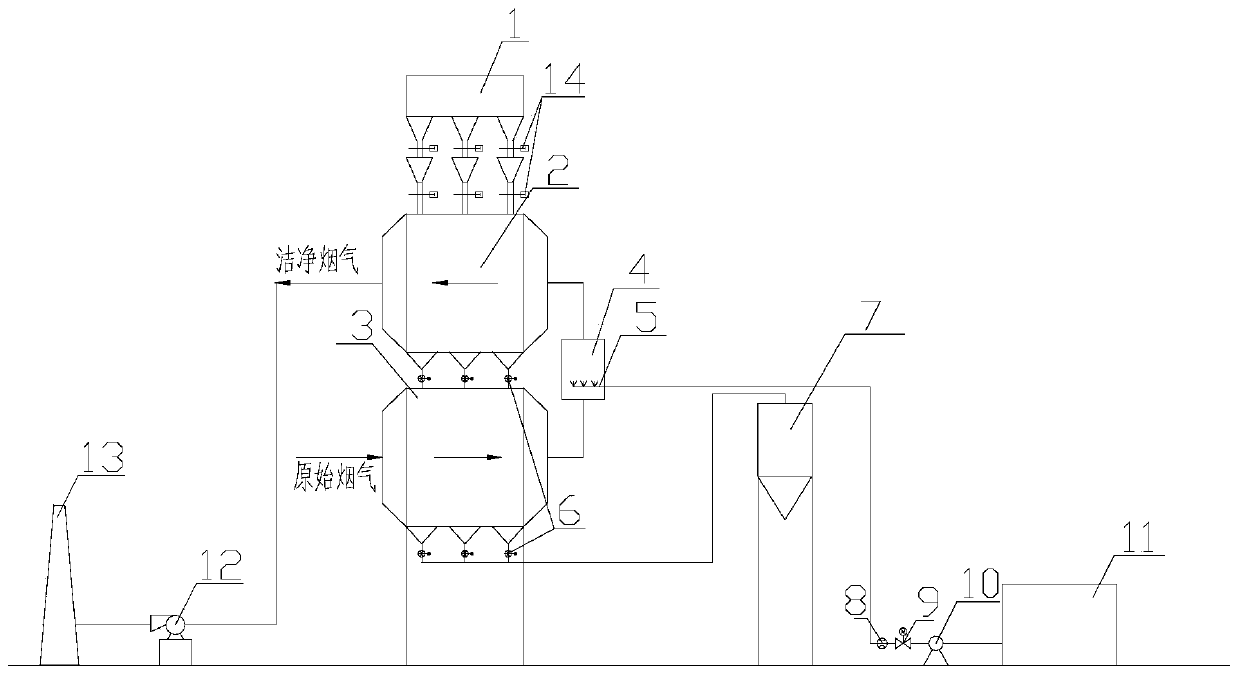

Activated coke flue desulfurization and denitrification integrated treating system

PendingCN110292847ATake advantage ofAchieve desulfurizationGas treatmentDispersed particle separationHandling systemStorage tank

The invention discloses an activated coke flue desulfurization and denitrification integrated treating system. The system mainly includes a desulfurization and denitrification integrated reactor, an ammonium hydroxide storage tank, an ammonia spraying and mixing tower, an ammonium hydroxide pump, a waste coke cabin and an induced draft fan. Original flue from a boiler enters a desulfurization module of the reactor through a desulfurization inlet of the desulfurization and denitrification integrated reactor, the flue is in contact with activated coke inside the reactor, SO2 in the flue is adsorbed by the activated coke inside the reactor to be removed, desulfurized flue enters the ammonia spraying and mixing tower to be fully mixed with ammonium hydroxide in the ammonium hydroxide storage tank and then enters a denitrification module of the reactor, NOx in the flue reacts with ammonia inside the reactor to be reduced into N2 through low-temperature catalysis of the activated coke, cleanflue obtained after desulfurization and denitrification is conveyed into a chimney through the induced draft fan to be discharged, and waste coke generated in the reactor is conveyed into the waste coke cabin. The activated coke flue desulfurization and denitrification integrated treating system has the advantages of being low in investment and running cost, simple in structure and reliable during running.

Owner:HUANENG CLEAN ENERGY RES INST

Preparation process of p-phenylenediamine

InactiveCN113135826ALow costSimple processOrganic compound preparationCarboxylic acid amides preparationDistillationReaction temperature

The invention discloses a preparation process of p-phenylenediamine, and belongs to the technical field of polymer synthesis. The process method comprises two stages: firstly, in the first stage, one or more terephthalic acid polyesters react with ammonia with the water content of not more than 15% by controlling the reaction temperature to be 50-250 DEG C and the pressure to be 10-300 atmospheric pressure; in the second stage, the product obtained in the first stage reacts with pypocholoride, the ratio of pypocholoride to diamine is controlled to be 2:1-3:1, the temperature is controlled to be 0-30 DEG C, p-phenylenediamine with high purity is obtained; and finally, the product is extracted with chloroform, and drying and distillation are conducted, wherein the highest yield of p-phenylenediamine can reach 94%. The process is simple in flow, low in raw material cost, simple in device structure, low in investment cost, high in continuous operation performance and easy to realize in industrial production.

Owner:AFCHINA CORP CO LTD

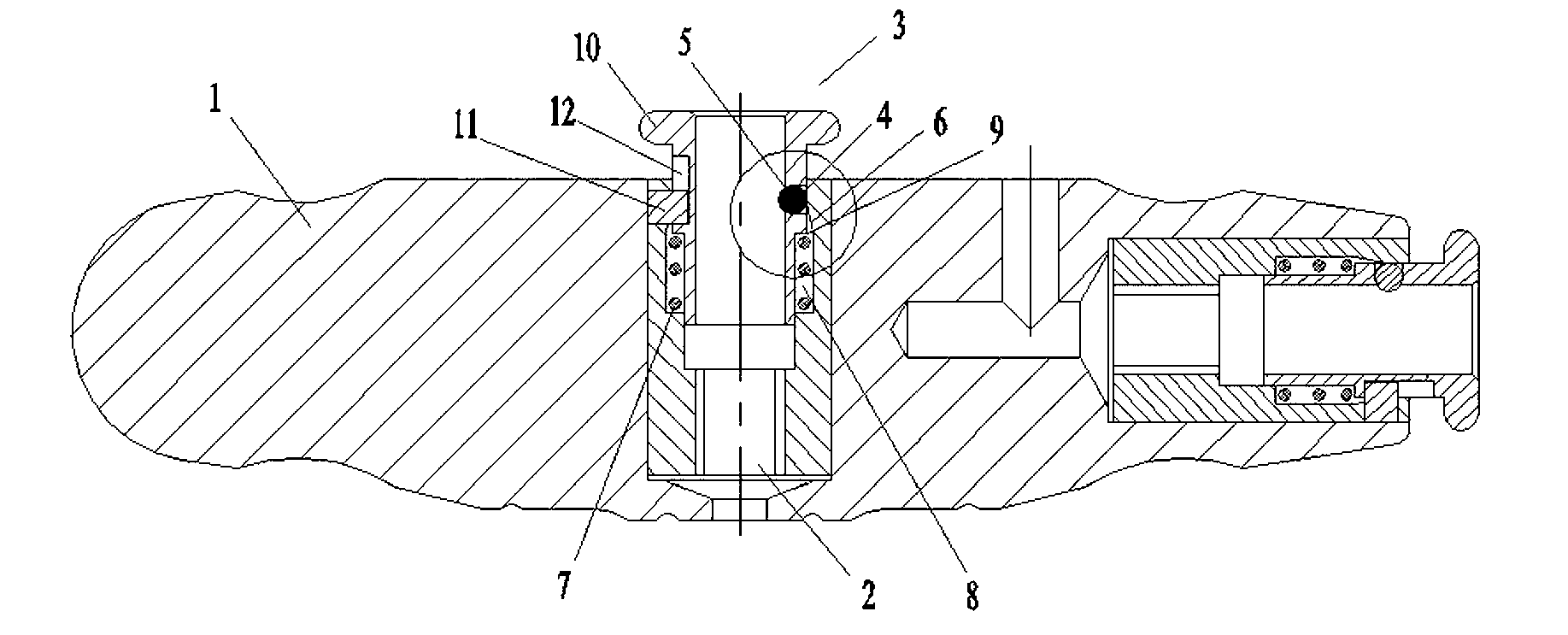

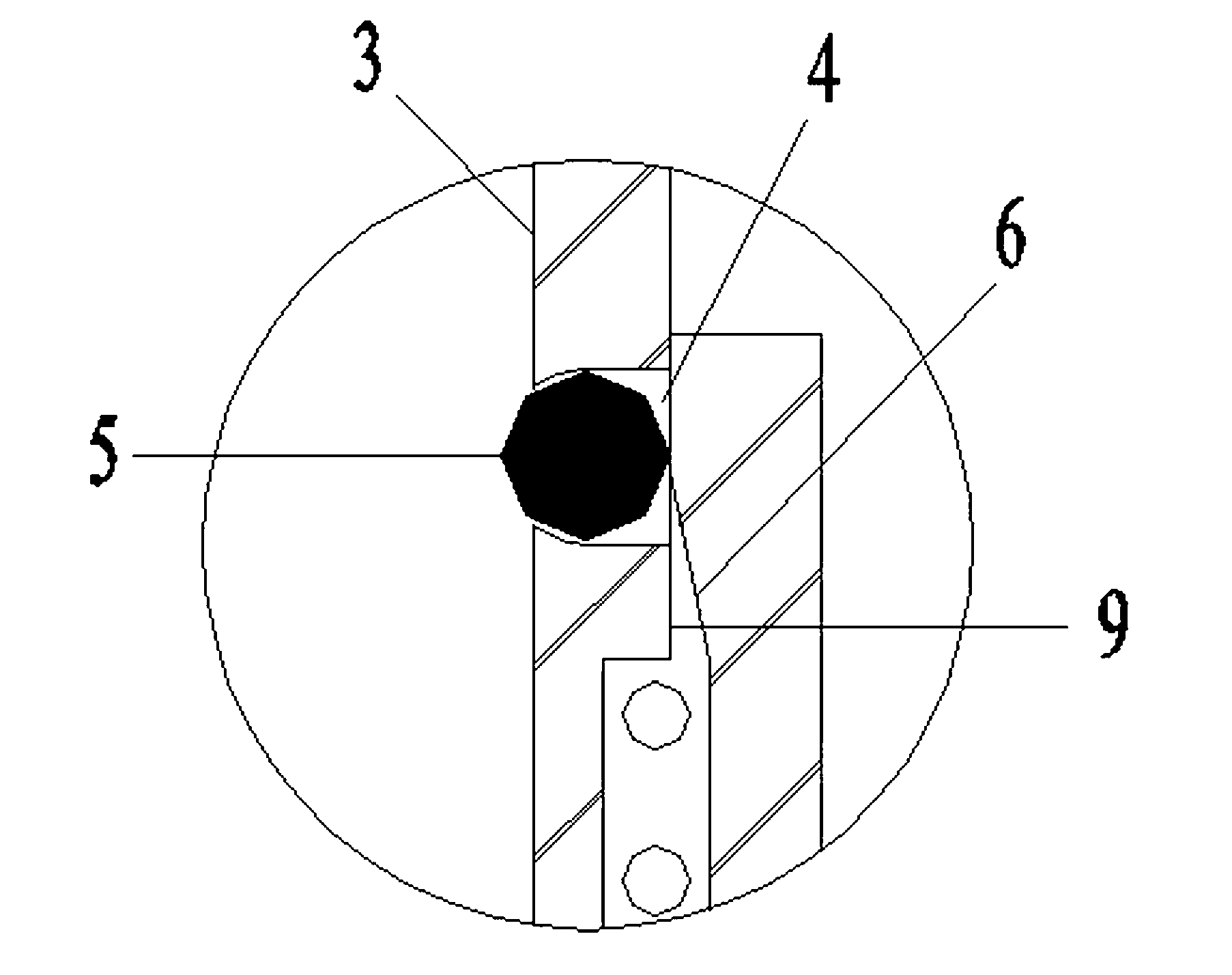

Rapid connection handle

ActiveCN103156673AWon't slipImprove continuous operation capabilitySurgeryMetal-working hand toolsSteel ballEngineering

The invention discloses a rapid connection handle. The rapid connection handle comprises a holding handle and an inserting connection sleeve formed in the holding handle. The rapid connection handle is characterized by further comprising a movable sleeve. The movable sleeve is arranged in the inserting connection sleeve and is connected with the inserting connection sleeve in a sliding mode. A horizontal through hole is formed in the side wall of the movable sleeve. A steel ball is arranged in the horizontal through hole. A diameter of the steel ball is larger than a diameter of the horizontal through hole. A sloping surface is formed on the side wall of the inserting connection sleeve. The sloping surface faces towards the bottom of the inserting connection sleeve. The position of the sloping surface corresponds to the position of the horizontal through hole. The movable sleeve is connected with the inserting connection sleeve through a spring in a sliding mode. The rapid connection handle has the advantages of being simple in structure and convenient to manufacture. The movable sleeve does not need to be pressed in advance when the rapid connection handle is used. A thin long rod can be directly inserted into the movable sleeve and locked automatically. The rapid connection handle is tightening in connection, convenient to operate and convenient to use. Continuous operation ability of the surgery is greatly improved. The surgery time is saved.

Owner:JIANGSU HOPE MEDICAL INSTR

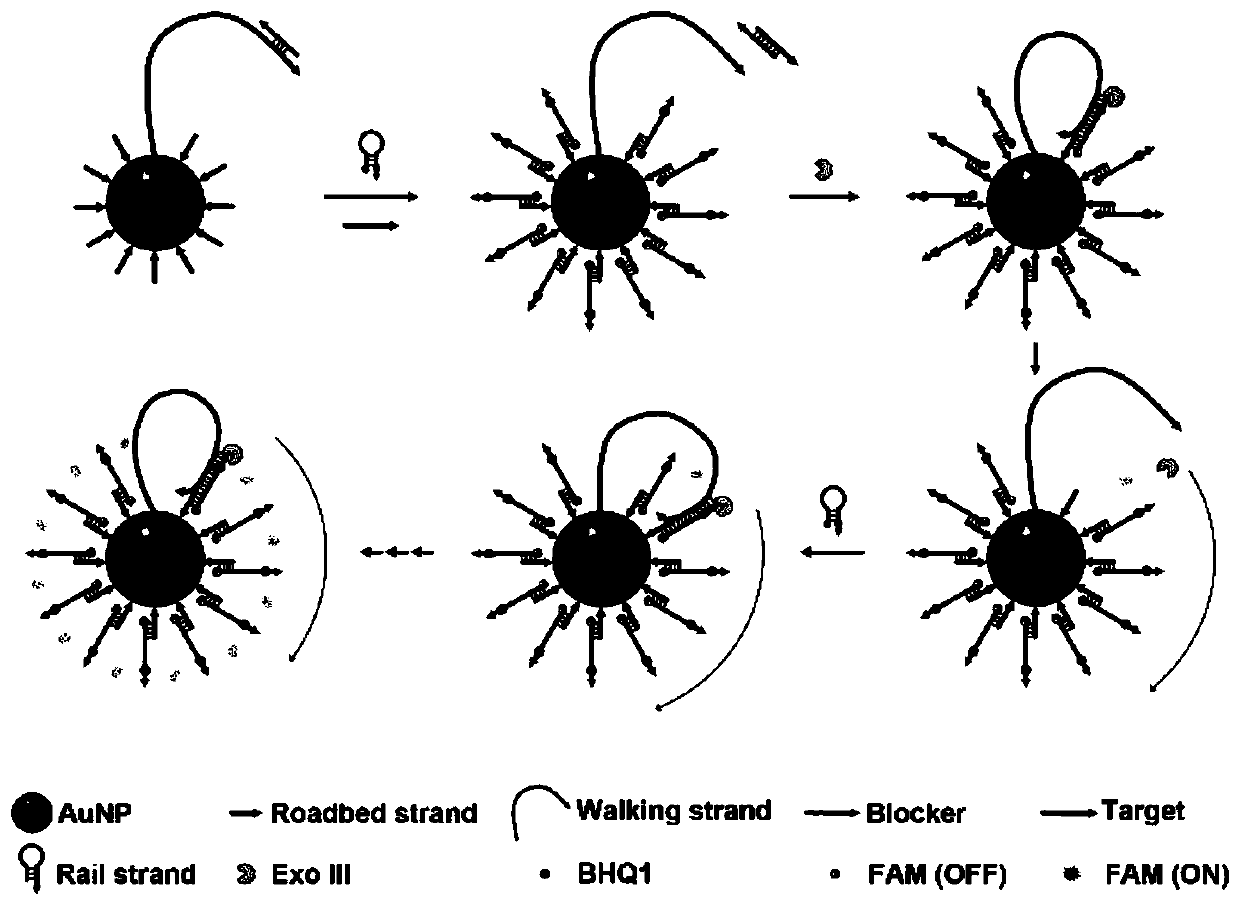

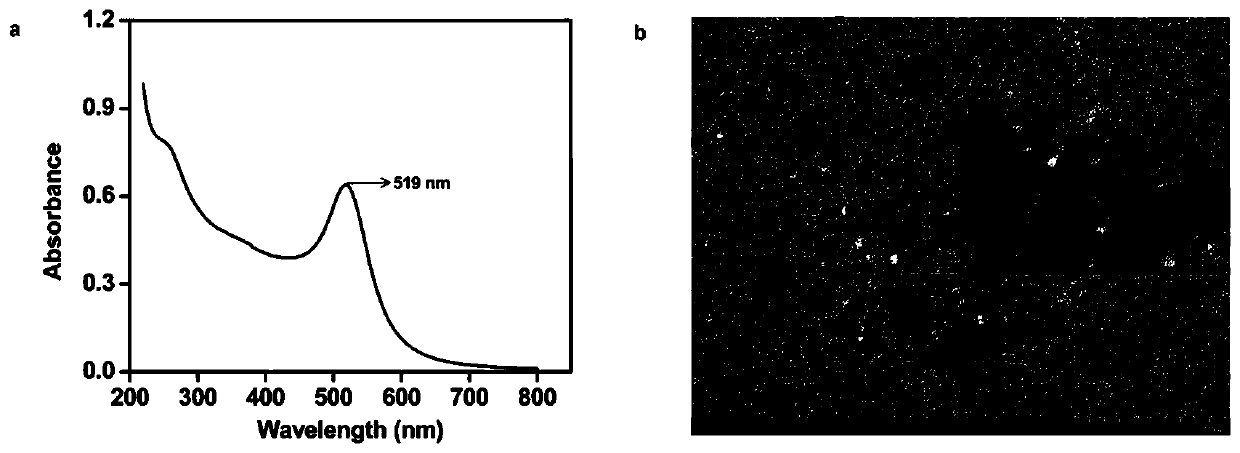

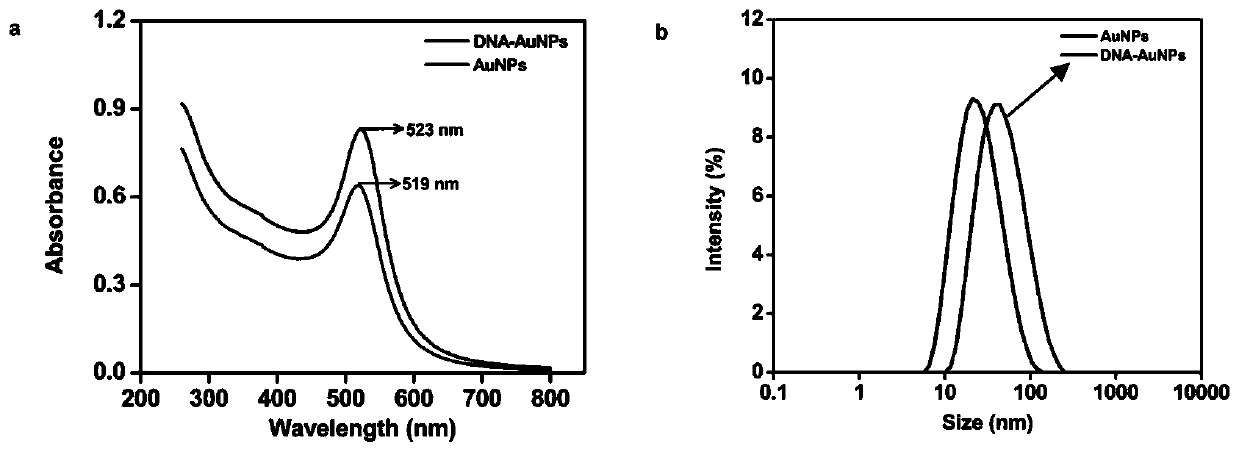

Track regeneration type DNA walker and application thereof

ActiveCN110904100AAchieve regenerationCut thoroughlyMicrobiological testing/measurementDNA/RNA fragmentationTrackwayNanoparticle

The invention belongs to the technical field of construction of DNA walkers, and particularly relates to a track regeneration type DNA walker and an application thereof. The concept of the track regeneration type DNA walker is provided and verified. The walker adopts a separable track consisting of a roadbed and a track. The roadbed chain of the walker is functionalized on gold nanoparticles, anda large number of track chains are dissociated in a solution and are hybridized with the roadbed chain to construct the track. As the walker walks along the track, the track chain is digested and releases the roadbed chain at the same time, and the released roadbed chain can be continuously combined with the track chain in the solution to form a new track. The continuous supply of the track enables the walker to keep walking. The walker has great advantages in the aspect of signal enrichment, so that the walker can be used for sensitive detection of Ebola virus gene segments in serum.

Owner:SHANDONG UNIV

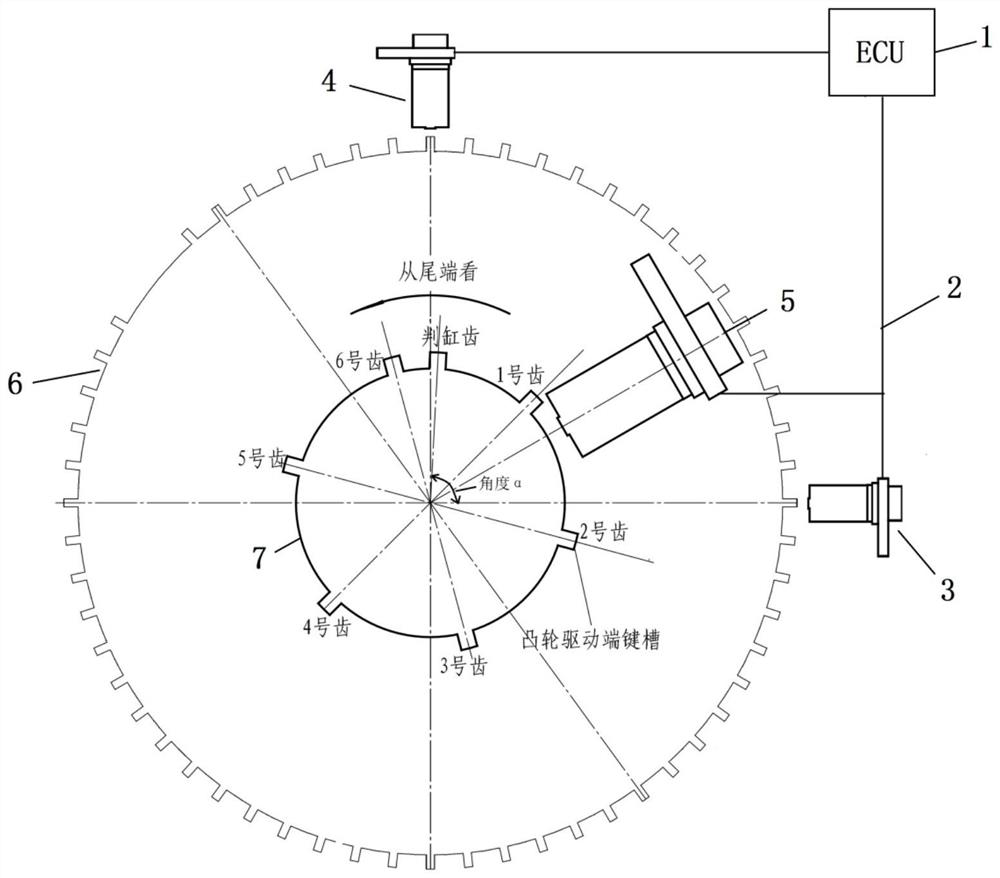

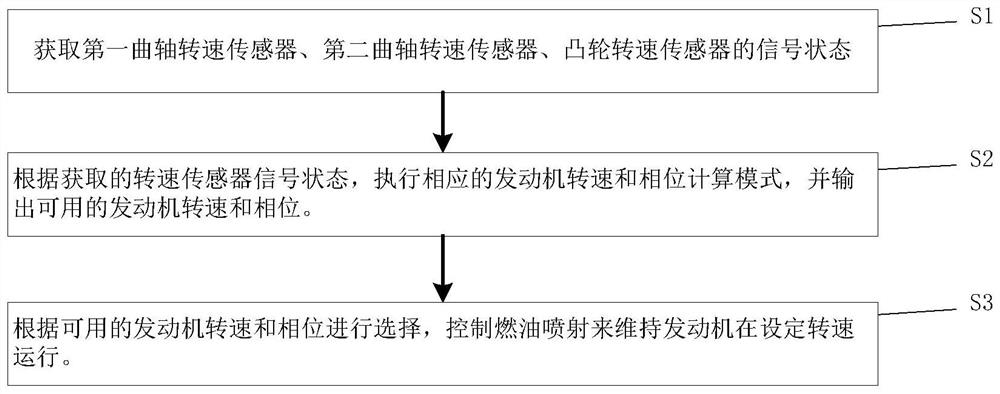

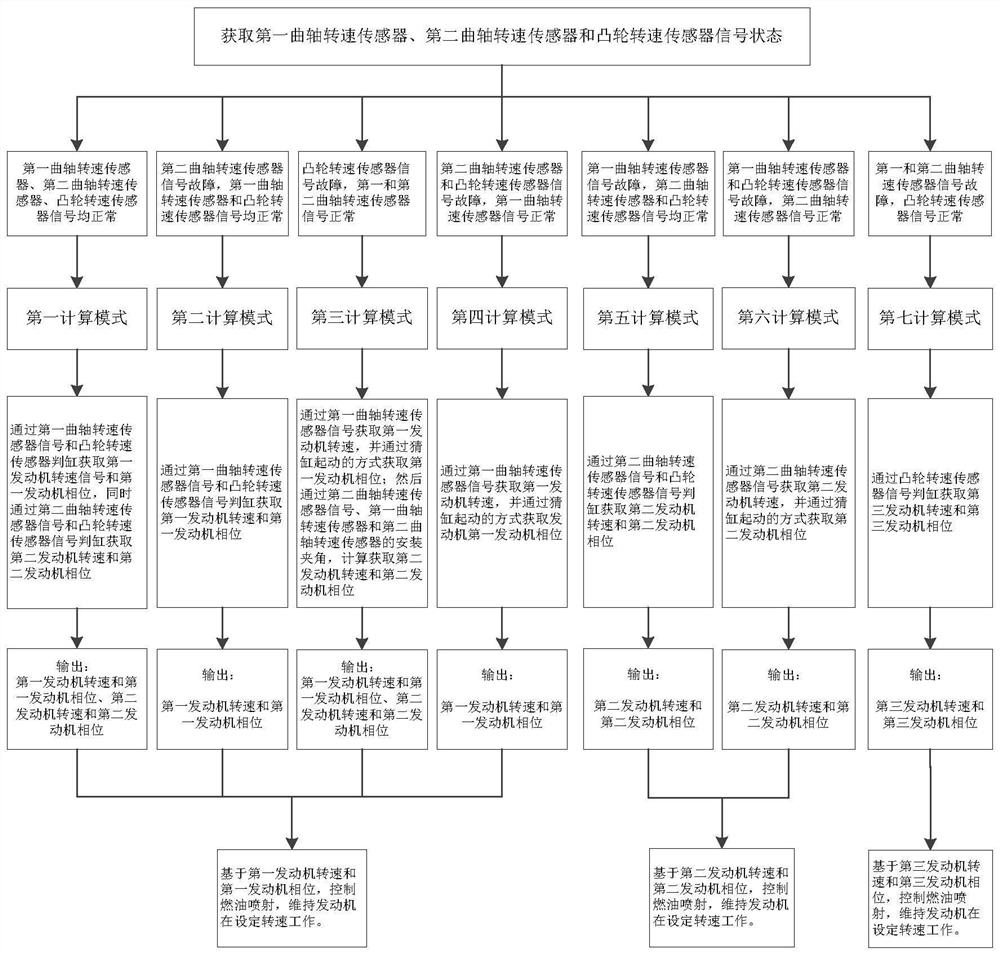

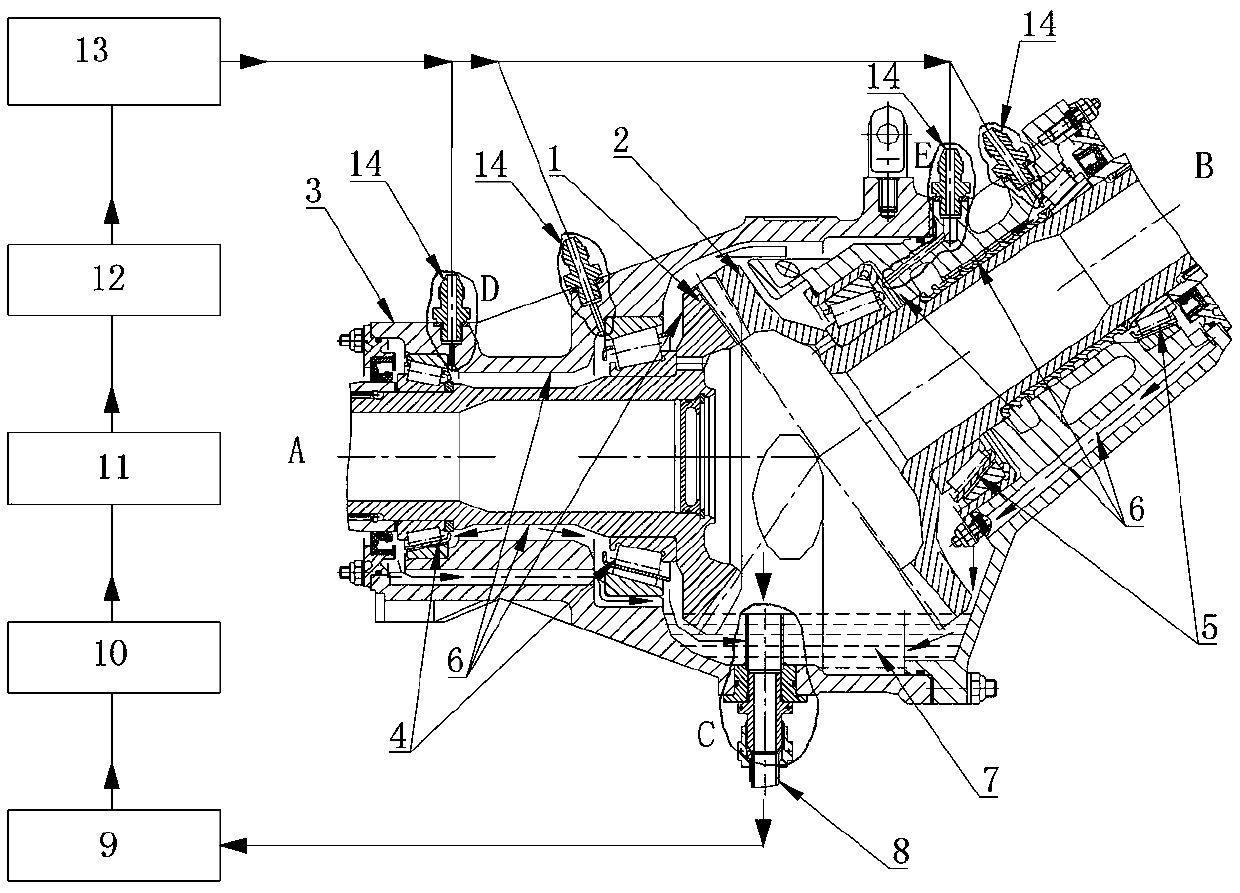

Redundant engine rotating speed control device and control method

PendingCN114087082AGuaranteed normal operationImprove continuous operation capabilityElectrical controlMachines/enginesElectric controlCam

The invention relates to the technical field of engines, and particularly discloses a redundant engine rotating speed control device which comprises an electric control unit, a first crankshaft rotating speed sensor, a second crankshaft rotating speed sensor, a cam rotating speed sensor, a crankshaft signal panel and a cam signal panel; the first crankshaft rotating speed sensor and the second crankshaft rotating speed sensor are used for collecting rotating speed signals of the crankshaft signal panel; the cam rotating speed sensor is used for collecting rotating speed signals and phase signals of the cam signal panel; and the electronic control unit is used for carrying out corresponding engine rotating speed and phase calculation according to the signal states of the first crankshaft rotating speed sensor, the second crankshaft rotating speed sensor and the cam rotating speed sensor, outputting the available engine rotating speed and phase, and determining the engine rotating speed and phase according to the available engine rotating speed and phase so as to carry out fuel injection control. The invention further discloses a redundant engine rotating speed control method. The redundant engine rotating speed control device is simple, reliable and low in cost.

Owner:WUXI WEIFU HIGH TECH CO LTD

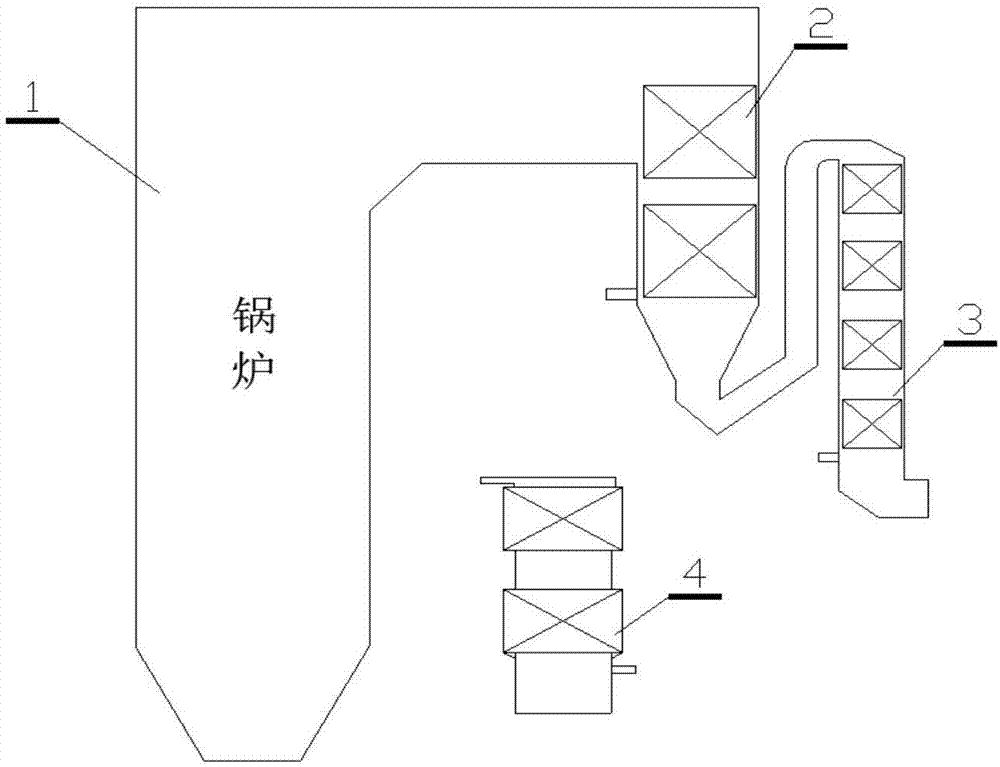

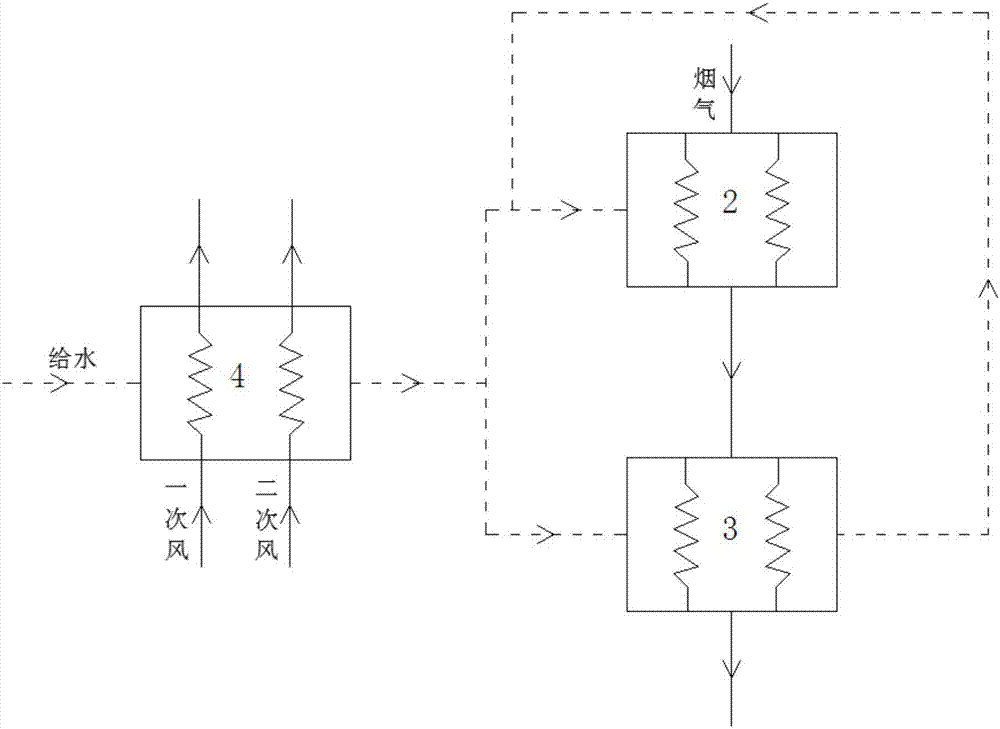

Smoke waste heat recovery system and method for biomass circulating fluidized bed boiler

The invention discloses a smoke waste heat recovery system and method for a biomass circulating fluidized bed boiler. The smoke waste heat recovery system for the biomass circulating fluidized bed boiler comprises a high-temperature economizer, a low-temperature economizer and an air preheater. The smoke waste heat recovery system for the biomass circulating fluidized bed boiler is characterized in that the air preheater is independently arranged below a horizontal flue of the boiler; primary air and secondary air are guided in from the space below the air preheater through cold air ducts correspondingly and exchange heat with supplied water flowing in the air preheater, and hot air obtained after heat exchange is guided out from the upper portion of the air preheater and enters a hearth. The smoke waste heat recovery system and method for the biomass circulating fluidized bed boiler have the beneficial effects that the problems of collision and ash blockage of the air preheater and the economizers are solved while the exhaust smoke temperature and the exhaust smoke loss are not increased, the service life of the air preheater on the tail is prolonged, the continuous operating capacity of the biomass boiler is improved, heat pollution is reduced, and the environment is protected.

Owner:SHANDONG QIQUAN ENERGY TECH CO LTD

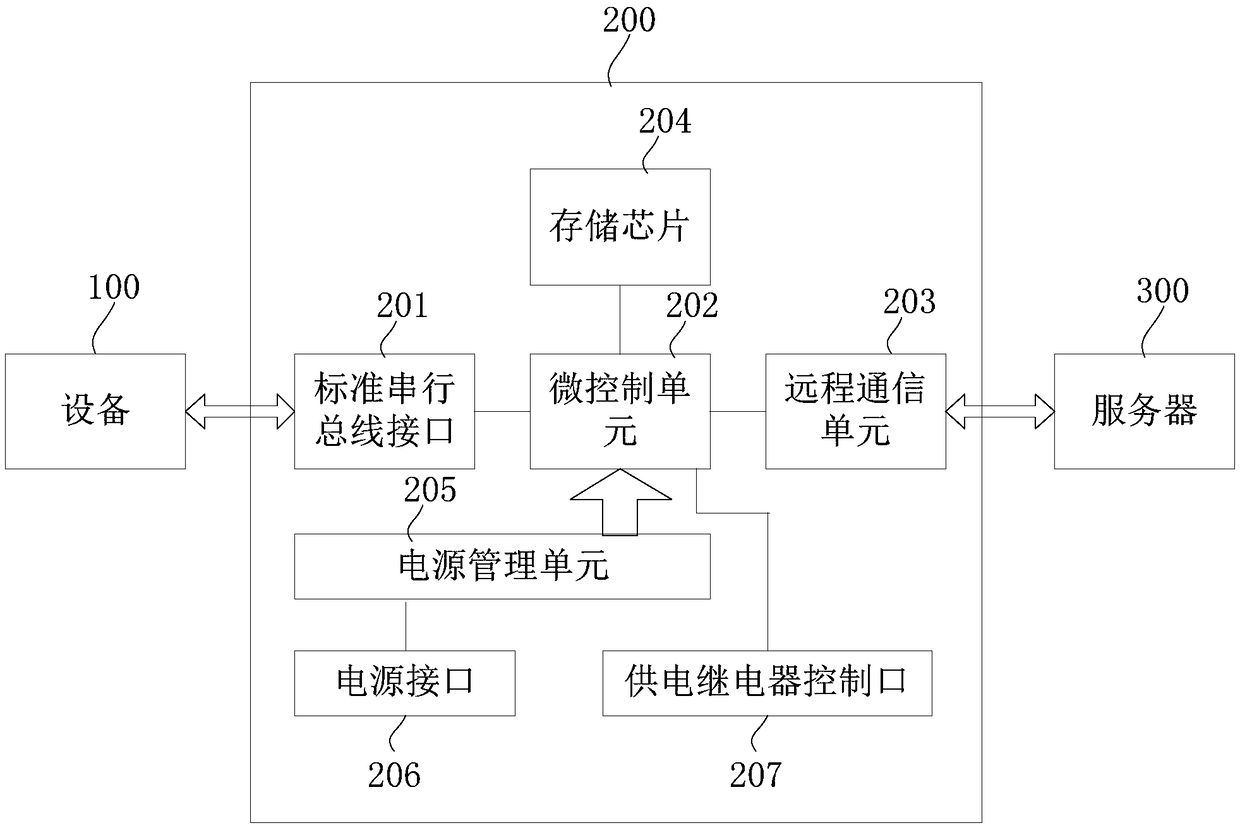

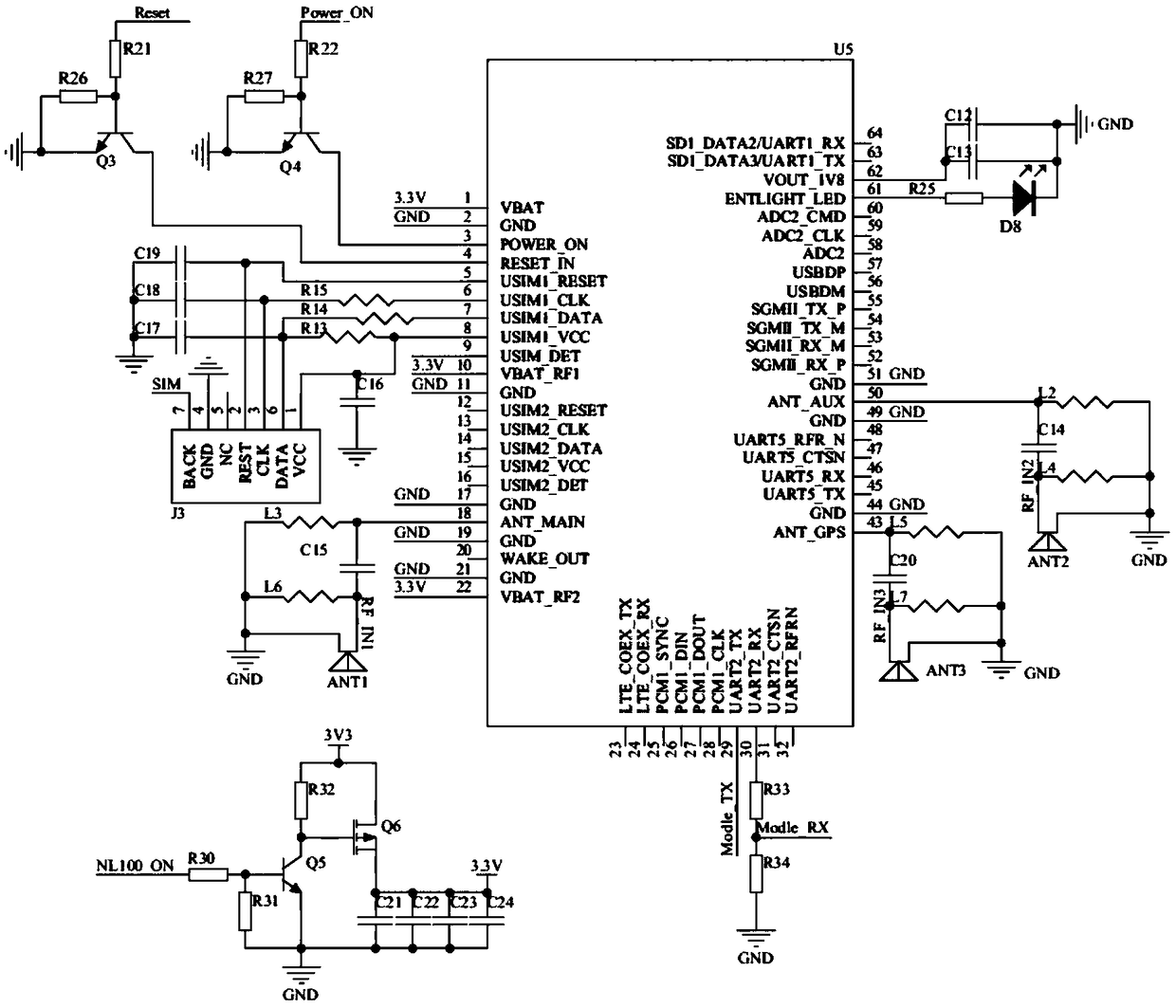

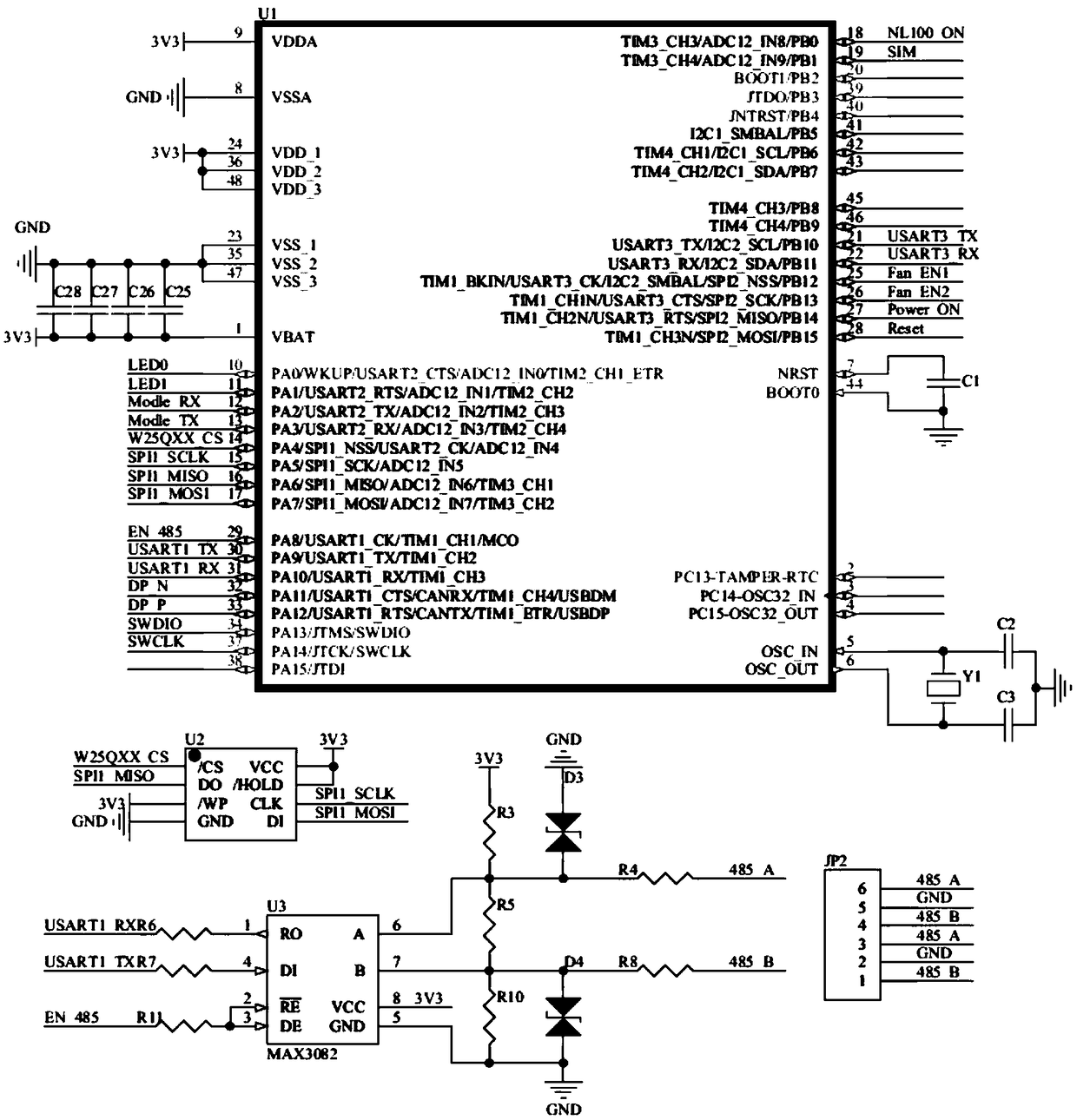

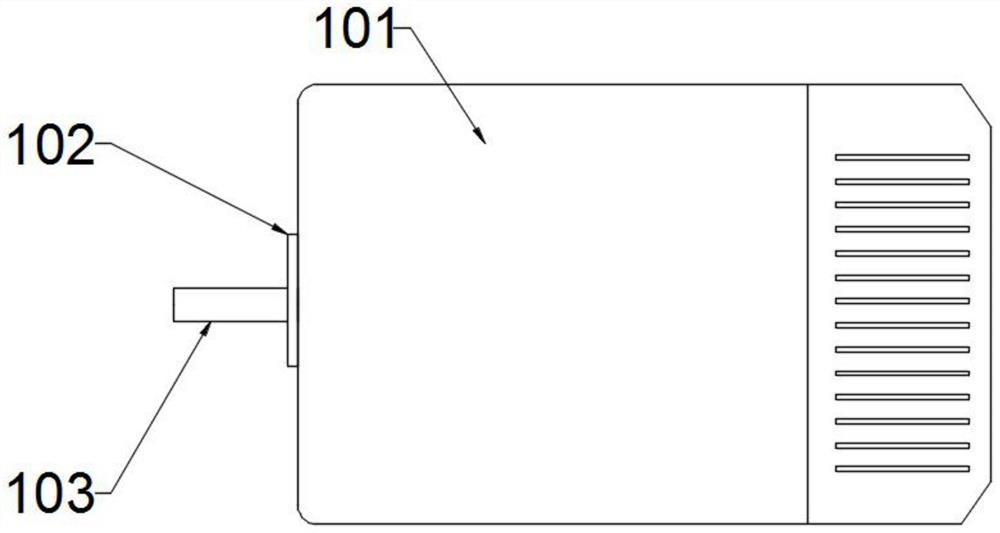

Communication module

InactiveCN109379100ADevelopment design and test docking is simple and fastImprove continuous operationTransmissionBus interfaceTimer

The invention discloses a communication module. The module includes: a standard serial bus interface, which is used for accessing equipment; a remote communication unit, which is used for establishingremote communication connection with a server, and is responsible for data interaction of the equipment and the server; and a micro control unit, which is respectively connected with the standard serial bus interface and the remote communication unit, and is used for converting instructions issued by the server into instructions which can be executed by the equipment, starting a first timer is toacquire running status data in real time from the equipment and the communication module, encapsulating the acquired data into a format specified in a communication protocol of the remote communication unit, and then uploading the same to the server. The module can be compatible with various types of equipment, and overcomes the defects of communication distance and communication quantity of an existing solution of a wifi communication module cooperating with a 4G wireless-router; further, the remote communication unit uses a standard wiring method and the standard communication protocol, anddevelopment, designing, testing and butt-joint connection are enabled to be simpler and faster; and erasable flash is added, and remote upgrading of code can be realized.

Owner:深圳数位科技有限公司

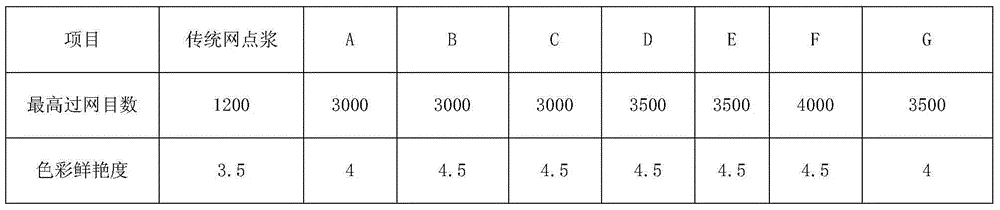

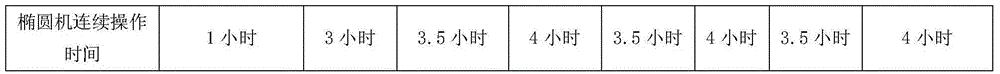

Preparation method of novel modified resin used as digital ink

The invention discloses novel modified resin used as digital ink. The novel modified resin comprises the following components in parts by weight: 10 to 30 parts of polyester polyol, 4 to 12 parts of diisocyanate, 0.5 to 5 parts of hydroxymethyl propionate, 0.05 to 0.1 part of catalyst, 10 to 20 parts of methacrylate monomer, 4 to 15 parts of low-molecular polyalcohol, 1 to 4 parts of hydroxylated acrylic, 0.5 to 2 parts of neutralizing agent, 30 to 70 parts of deionized water, 0.5 to 5 parts of diamine and 0.5 to 1.5 parts of initiator. The invention also discloses a preparation method of the novel modified resin. The digital-like ink produced by utilizing the novel modified resin is high in over-net mesh number which can reach 4000-mesh gauze, high in screentone clarity and bright in color, and the printed pattern effect can be comparable with the digital printed product.

Owner:江门市珍图新材料有限公司

Protecting device of dissolving tank inner wall of alkali recovery furnace

ActiveCN101746781BAvoid corrosionPrevent long-term corrosionPulp liquors combustionAlkali metal oxides/hydroxidesDissolutionContinuous operation

Owner:GUIZHOU CHITIANHUA PAPERS

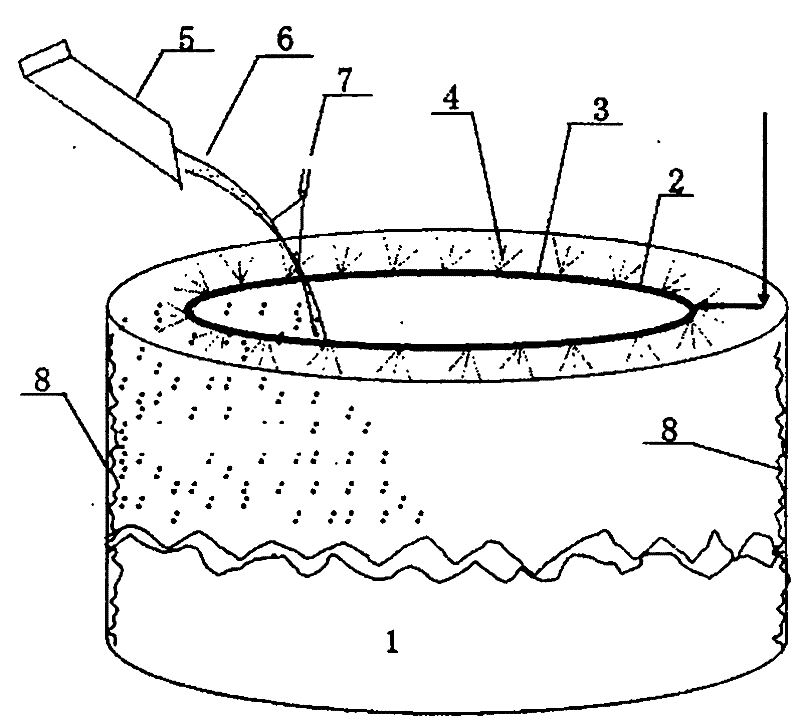

Automatic electrolyte sampling device of medium-temperature electrolytic fluorine production equipment

InactiveCN112665919AEliminate the possibility of contactImprove securityWithdrawing sample devicesAutomatic controlHazardous substance

The invention belongs to the technical field of electrolytic fluorine production, and particularly relates to an automatic electrolyte sampling device of medium-temperature electrolytic fluorine production equipment, the device comprises a sampling pipe, a connecting flange, a pneumatic valve A, a pneumatic valve B, a sampling bottle, a safety bottle, a vacuum machine, an automatic control system and nitrogen. By means of the device, operators can operate remotely, the possibility that the operators make contact with poisonous and harmful substances such as hydrogen fluoride and electrolyte is eradicated, and the safety capacity of the system is improved. Sampling can be completed without cutting off current, the stability of continuous operation of the electrolytic cell is improved, and the continuous operation performance of the electrolytic cell is improved. The electrolyte is not contacted with metal and air in the sampling process, so that the accuracy of the sample is improved.

Owner:中核二七二铀业有限责任公司

Method for producing silane and trichlorosilane by reactive distillation

The invention discloses a method for producing silane and trichlorosilane by reactive distillation, which includes the step of preparing silane or trichlorosilane through disproportionation or anti-disproportionation of chlorosilane in a reactive distillation device, and is characterized in that the disproportionation Or the anti-disproportionation reaction uses a liquid catalyst mixed with aliphatic amines and aromatic amines. By adopting the method of the present invention, the liquid catalyst does not need to be pretreated, and the catalyst replacement is convenient, and it will not cause blockage to the subsequent system. The recovery of the invalid catalyst is simple, and no liquid waste or solid waste is generated, which is clean and environmentally friendly; catalytic disproportionation or reaction The conversion rate of disproportionation is high, and the production process is easy to operate.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV

Furnace pressure control method during continuous annealing of stainless steel

ActiveCN104571170BHigh precisionImprove continuous operation capabilityFluid pressure control using electric meansProduction lineHuman–machine interface

The invention discloses a furnace pressure control method during continuous annealing of stainless steel, which can improve the hearth pressure detection accuracy, ensure the safety of equipment, and improve the continuous operation capability of the production line, wherein the furnace pressure control method comprises the following steps: step one, installing pressure transmitters on a working side and a driving side of a last hearth; step two, transmitting 4-20mA signals sent by the pressure transmitters to a PLC (Programmable Logic Controller) analog input module of an annealing furnace by a signal cable; step three, obtaining three pressure values as follows: a hearth pressure PT01 on the working side, a hearth pressure PT02 on the driving side and an average PT03 of PT01 and PT02, by PLC program conversion and calculation; and step four, compiling a PLC program and HMI (Human Machine Interface) software. The furnace pressure control method during continuous annealing of stainless steel has the advantages that the furnace detection accuracy is improved, the pressure detection value is closer to the actual furnace pressure due to two-point sampling and averaging, and the safety of the equipment is enhanced.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

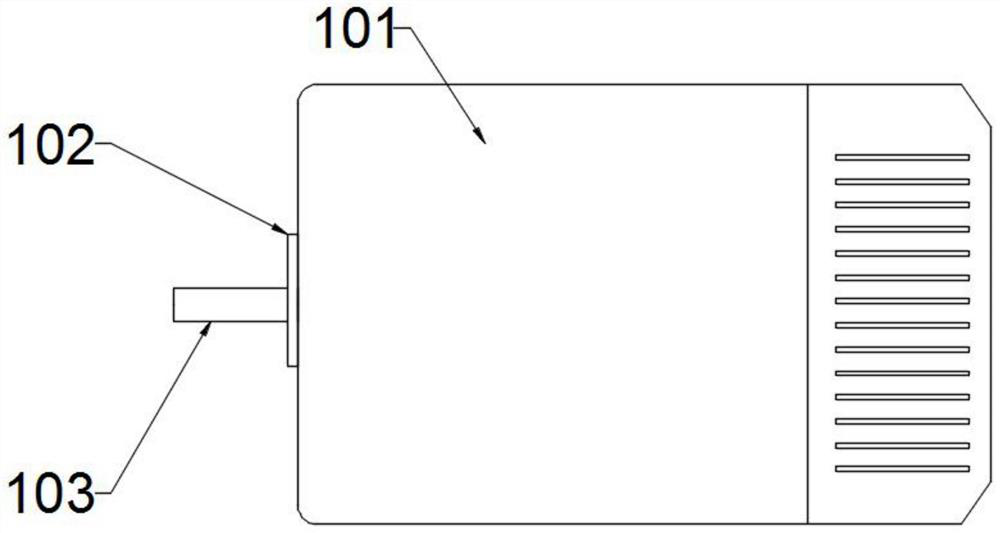

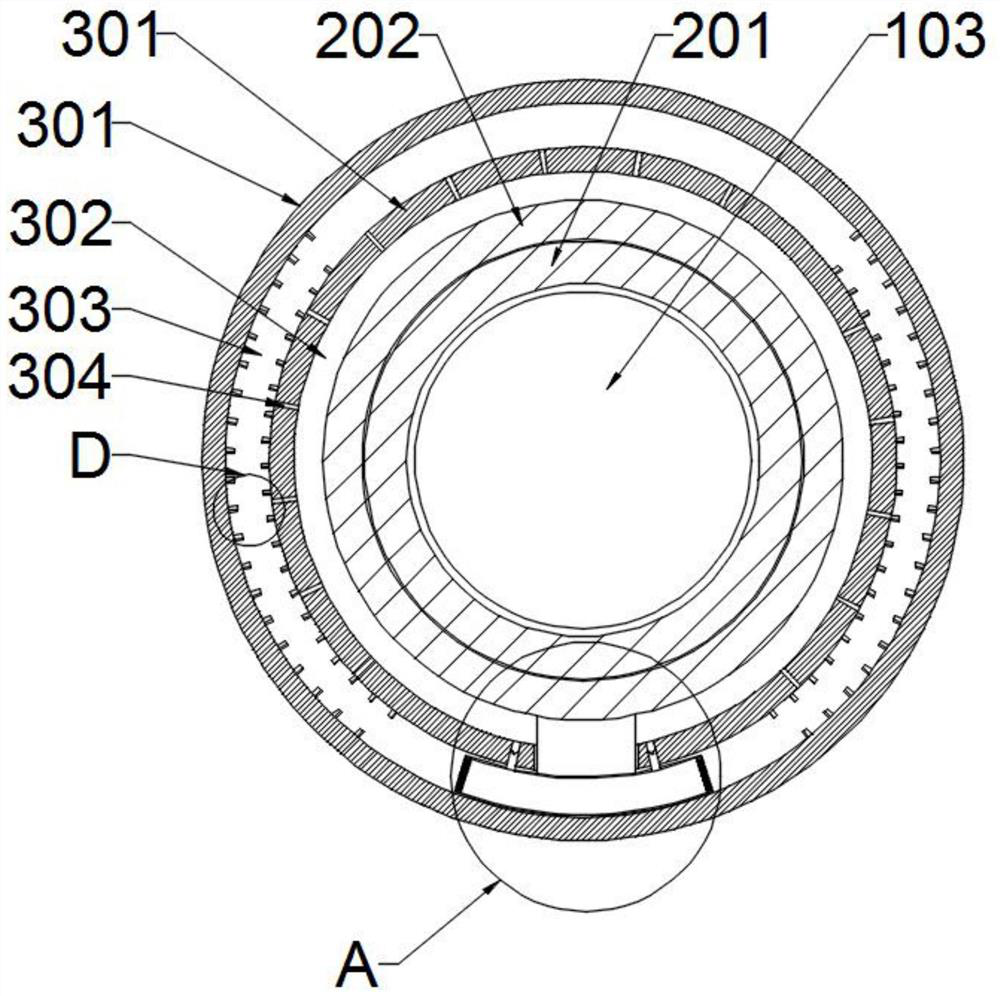

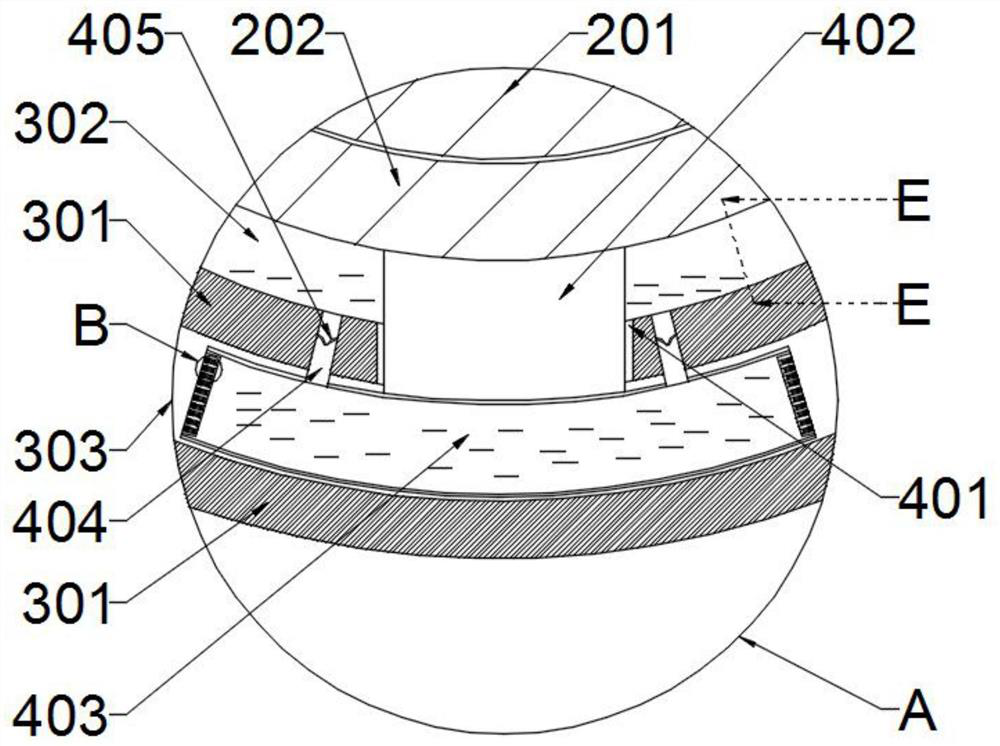

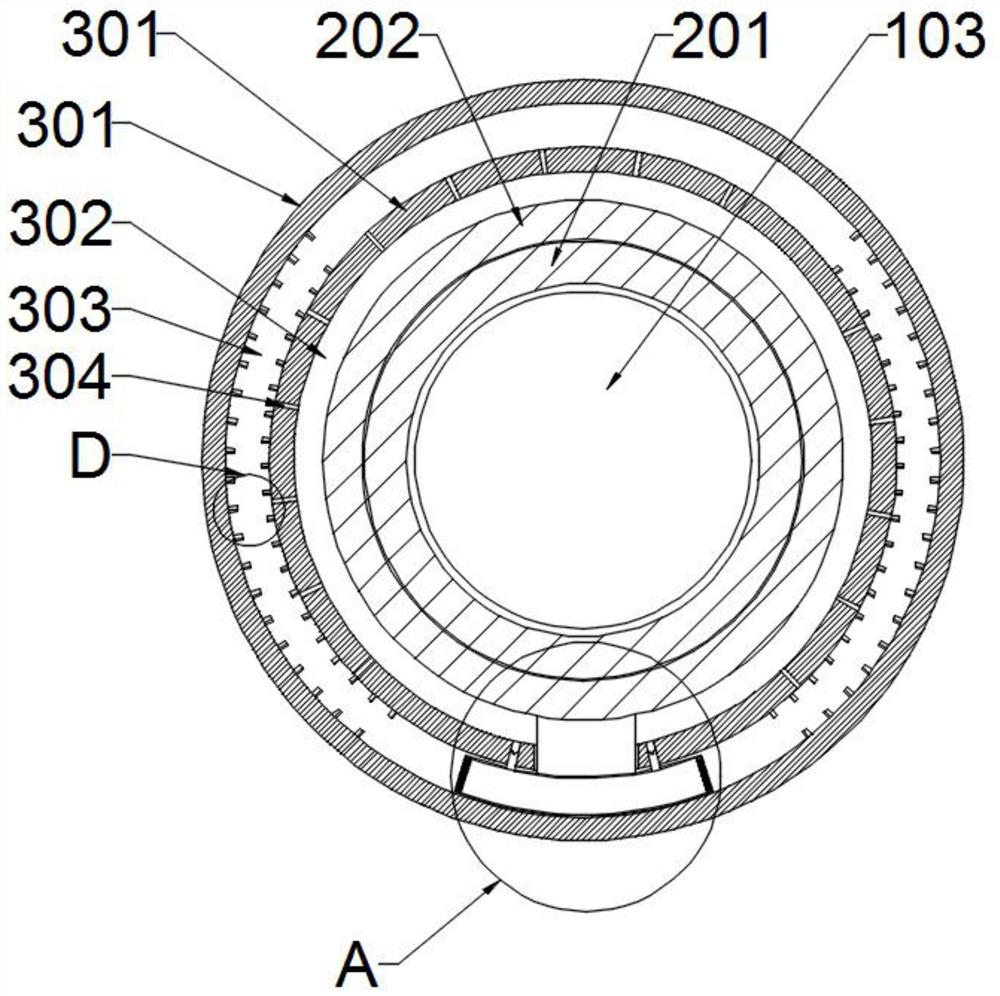

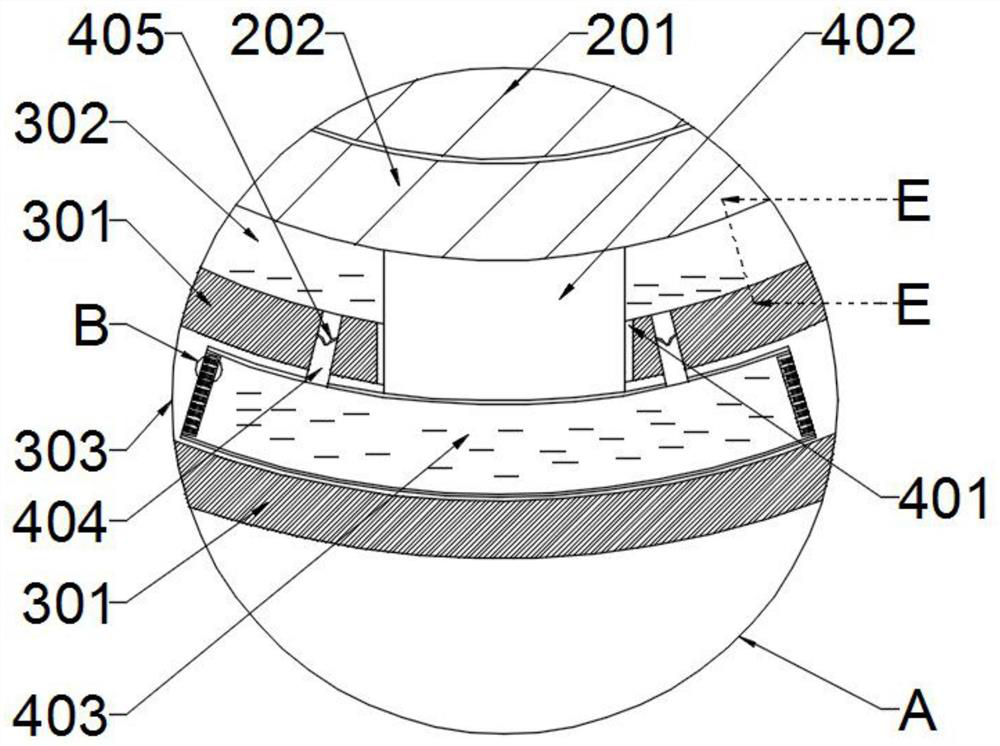

Motor with anti-shake and damping functions

ActiveCN111864971AGood vibration resistanceGood vibration reduction effectSupports/enclosures/casingsPhysicsDamping function

The invention discloses a motor with anti-shake and damping functions. The motor comprises a base assembly, a bearing assembly and a pressure stabilizing shaft assembly, wherein the basic assembly islocated in the middle of the whole device, the bearing assembly is arranged on one side of the base assembly, the pressure stabilizing shaft assembly is arranged in the bearing assembly, mist in a pressure stabilizing tank can be slowly accumulated at the bottom of the pressure stabilizing tank under the action of gravity, water molecules are atomized through the water flow atomization assembly toform circulation of the water molecules, and the aerial fog mixture can effectively cool down a motor transmission shaft area while vibration isolation, and improve the continuous operation performance of the device.. The motor can effectively avoid the characteristics of poor vibration reduction and shock absorption effect of pure gas, low flow rate of pure liquid vibration reduction, easiness in accumulation and poor flexibility, can further avoid characteristics of poor stability of spring vibration reduction and easiness in driving surrounding objects to swing due to aftershock of the spring, and is stable in vibration reduction effect.

Owner:SUZHOU SAIRONG CONSTITUTION&DECORATION ENG CO LTD

A motor with anti-shake and shock-absorbing functions

ActiveCN111864971BMake the most of the effectsWell mixedSupports/enclosures/casingsPressure stabilizationDrive shaft

The invention discloses a motor with anti-vibration and shock absorbing functions, which includes a base assembly, a bearing assembly, and a pressure-stabilizing shaft assembly. A pressure stabilizing shaft assembly is arranged inside the assembly. The mist in the pressure stabilizing tank of the present invention will slowly accumulate at the bottom of the pressure stabilizing tank under the action of gravity, and is atomized by the water flow atomizing component to form a cycle of water molecules, and the aerosol mixture is in the At the same time of vibration isolation, it can effectively cool down the area of the motor drive shaft and improve the continuous operation performance of the device. The invention can effectively avoid the characteristics of poor vibration damping effect of pure gas, and avoid the low flow rate and easy accumulation of pure liquid vibration damping The characteristics of poor flexibility can avoid the poor stability of spring vibration reduction, and the characteristics of spring aftershocks are easy to drive the surrounding objects to swing, and the vibration reduction effect is stable.

Owner:SUZHOU SAIRONG CONSTITUTION&DECORATION ENG CO LTD

Lubricating and cooling structure for high-power durability test of gear

PendingCN110715048AImproving the Efficiency of High Power Fatigue TestingReduce the amount of premature exception wearToothed gearingsGear lubrication/coolingThermodynamicsGear wheel

The invention discloses a lubricating and cooling structure for a high-power durability test of a gear. The lubricating and cooling structure comprises an oil well pump, a radiator, an oil storage tank, a conveying pump and a jet lubricating device which are sequentially connected, wherein the oil well pump communicates with an oil storage area at the bottom of a casing and is used for pumping lubricating oil; the jet lubricating device communicates with an oil path at the upper part of the casing; the lubricating oil in the oil storage area is pumped into the radiator by the oil well pump forcooling; and the cooled lubricating oil is conveyed to the jet lubricating device by the conveying pump and is jetted to a first bearing group or a second bearing group. The lubricating and cooling structure has the advantages that the temperature of the oil in the casing can be reduced, and the high-power fatigue test efficiency of the gear is improved.

Owner:ZHONGNAN TRANSMISSION MACHINERY FACTORY CHANGSHAAVIATION IND

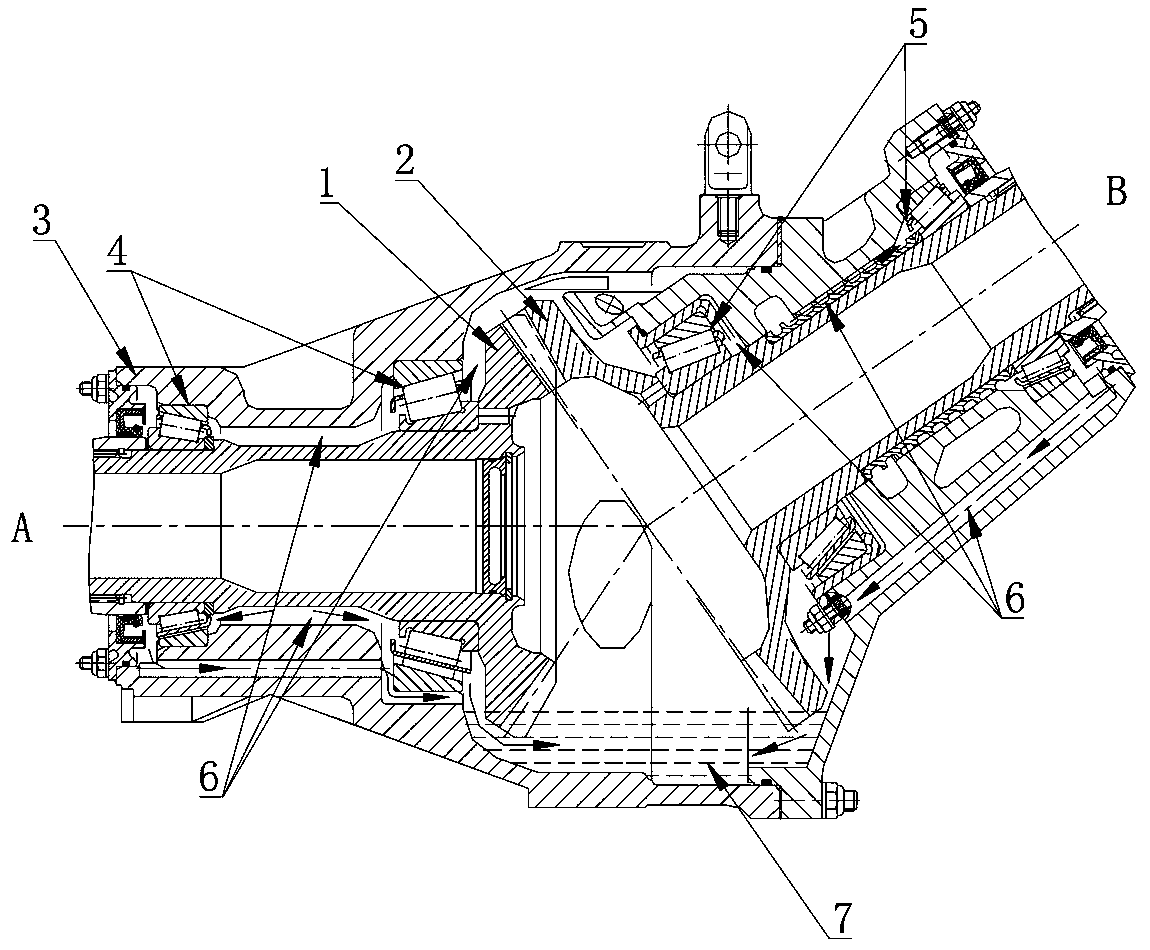

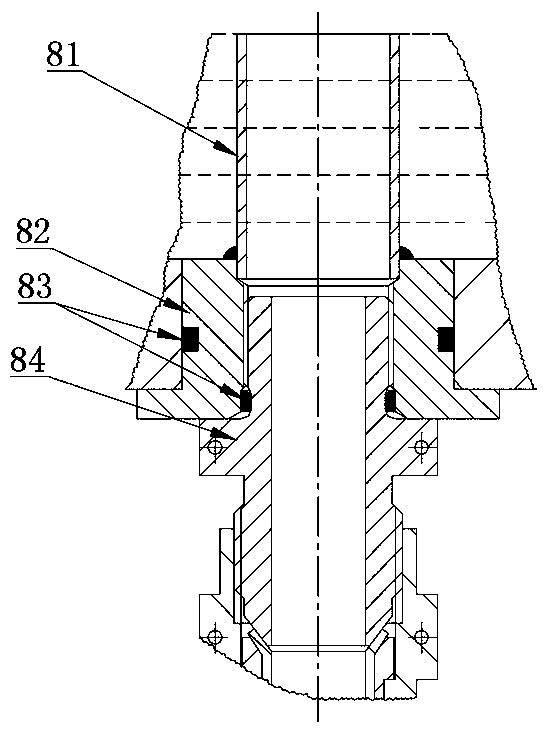

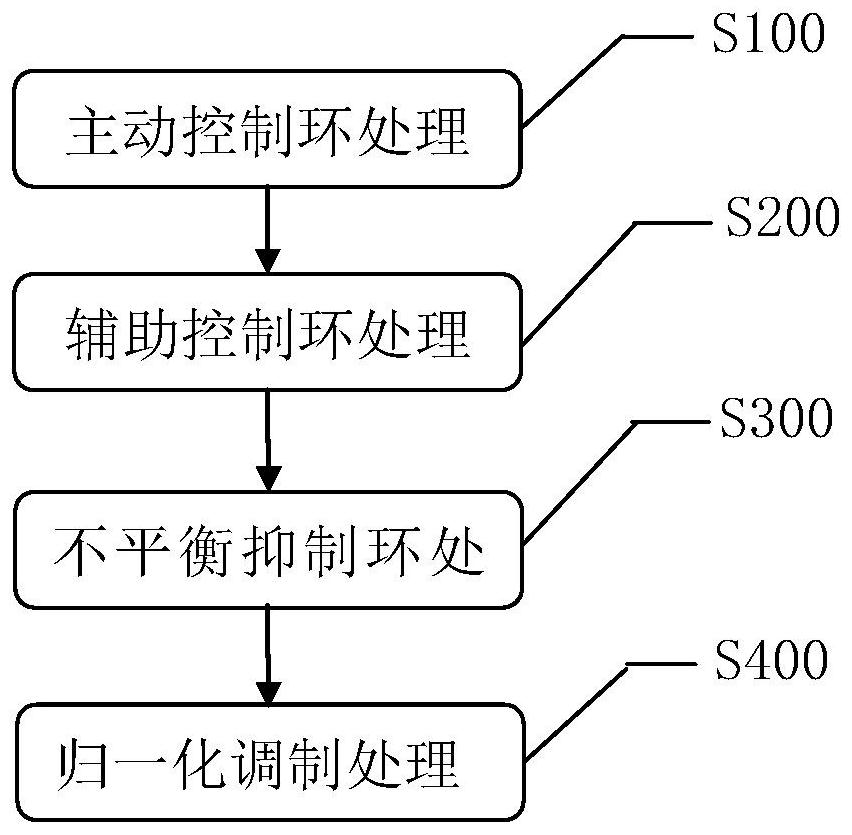

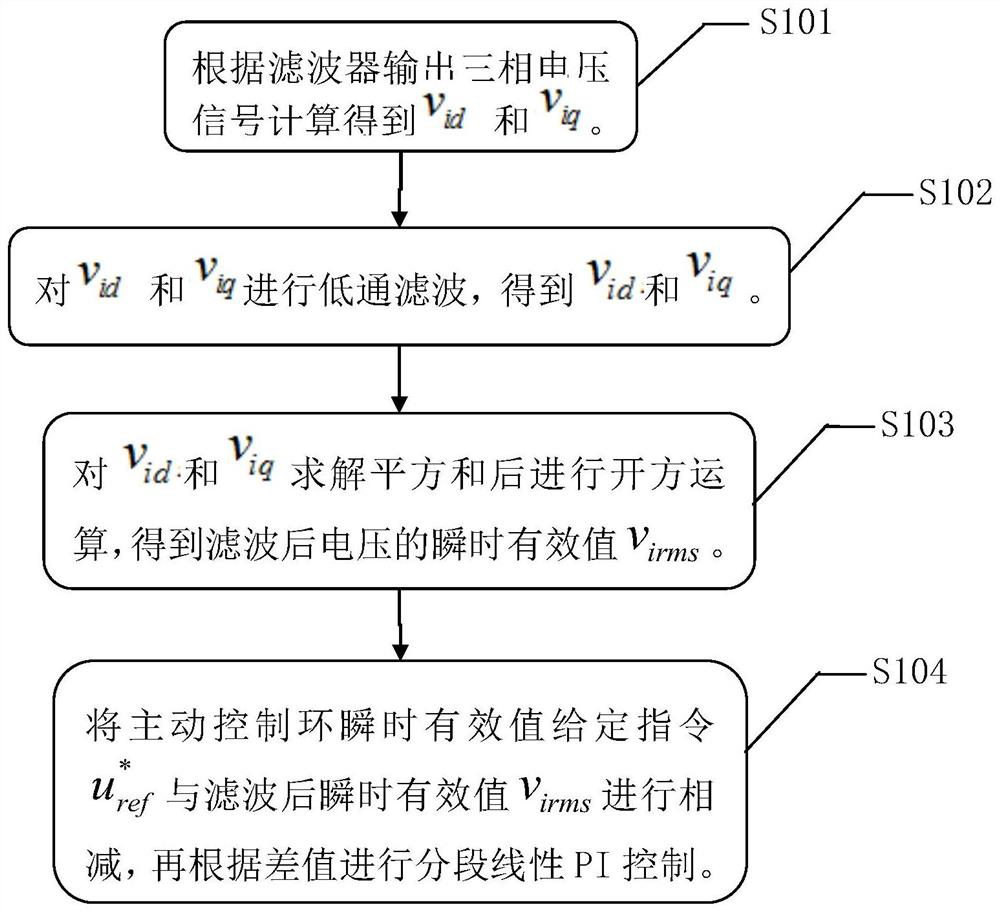

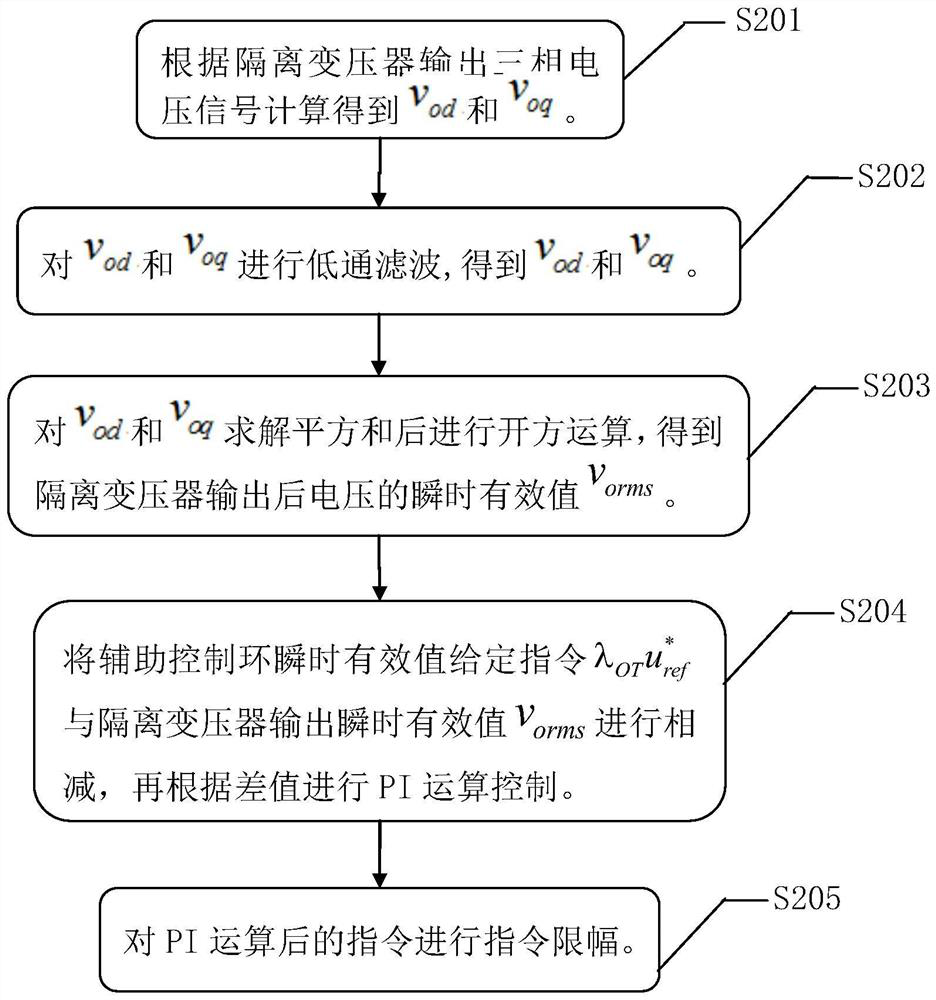

A control method for railway purification power supply to improve continuous operation ability under inrush current

ActiveCN112350557BReduce the probability of protective actionReduce control difficultyAc-dc conversionPhase currentsControl engineering

The invention relates to a control method for improving the continuous operation capability of a railway purification power supply under an impact current, including active control loop processing, auxiliary control loop processing, unbalance suppression loop processing, and normalized modulation processing. Through the active control loop processing, the control gain is increased when the current is small and large, and the tracking speed is improved. Under the impact current, the control gain is reduced, and the voltage change rate is reduced to reduce the probability of the drive device turning off the IGBT; through the auxiliary control loop processing, the increase The control accuracy of the output voltage is improved; the output voltage of each phase is adjusted to suppress the unbalanced voltage when the three-phase currents are inconsistent through the unbalanced suppression loop processing; the DC voltage is normalized through the normalized modulation processing, so that the engineering Modulation processing; therefore, the control method of the present invention can realize stable control under various currents, especially under the impact current, reduce the probability of driver protection action, and improve the ability of continuous operation.

Owner:ZHUHAI WANLIDA ELECTRICAL AUTOMATION

Riverway environment restoration structure

ActiveCN112695717AClear Energy ReductionImprove efficiencyWater resource protectionWater cleaningVertical tubeSuction force

The invention discloses a riverway environment restoration structure. The riverway environment restoration structure comprises a vertical cylinder, an impurity removing mechanism is arranged below the vertical cylinder, the impurity removing mechanism comprises a vertical tube, a machine box, a rotating rod, a circular plate, a water pumping box, a water discharging pipe, a filter cylinder, a groove block and a protruding rod, and the vertical tube is located at the bottom end of the vertical cylinder. According to the riverway environment restoration structure, through cooperation of the vertical cylinder and the impurity removing mechanism, the rotating rod can rotate to provide moving kinetic energy for the water pumping tank, the top end of the vertical cylinder can generate suction force to suck in floating objects floating on the water surface of a riverway, the filter cylinder can filter the sucked floating objects, reciprocating shuttling above the riverway is not needed, and the floating objects above the riverway can automatically flow into the vertical cylinder under the action of the water flow generating suction force, so that the energy consumption for removing the floating objects above the riverway is reduced, the efficiency is improved, and the practical performance is improved.

Owner:苏州恒誉环保科技有限公司

A method for continuous measurement of three-coordinate measuring machine workpieces

ActiveCN105910563BGuaranteed uptimeImprove continuous operation capabilityMechanical measuring arrangementsContinuous measurementProgram management

The invention discloses a three-coordinate measuring machine workpiece continuous measurement method which comprises the steps of a step of measurement program management and measurement parameter setting, a step of measurement task management and measurement task automatic scheduling, and a step of measurement workpiece offline centering and quick change positioning. Tasks such as measurement program switching, report storing, uploading and measurement timing are automatically scheduled and finished by a system. A plurality of workpieces can be simultaneously loaded for realizing combined measurement. A manually established coordinate system and automatic operation are integrated. Measurement personnel do not require high-frequency operation of a computer and a measurement machine, thereby reducing measurement time and workload of the measurement personnel, so that the measurement personnel have more energy for performing offline loading and workpiece alignment. When the measurement machine automatically operates through controlling of a scheduling system, the measurement personnel performs offline loading for alignment of a next workpiece. The measurement machine and a person perform parallel operation, thereby reducing waiting time of the person and the machine, ensuring continuous operation of the measurement machine, and improving integral measurement efficiency and utilization rate of the measurement machine.

Owner:刘玉芳

Composite industrial filtration fabric structure with high resistance

ActiveCN106192526AImprove quality and efficiencyImprove molding efficiencyLayered productsMachine wet endHigh resistanceFiltration

The invention discloses a composite industrial filtration fabric structure with high resistance. The structure comprises a forming layer making contact with paper pulp, a positioning layer making contact with a paper making machine, an adsorption transition layer used for connecting the forming layer and the positioning layer and guide weft used for guiding, wherein the forming layer, the positioning layer and the adsorption transition layer are distributed in parallel; the adsorption transition layer is located between the forming layer and the positioning layer and is abutted against the forming layer and the positioning layer; multiple pieces of the guide weft are distributed in parallel and are in weaving connection with the upper surface of the positioning layer, and the forming layer, the positioning layer and the adsorption transition layer are connected through strengthening threads. The surface quality and the forming efficiency of a papermaking product can be effectively improved, besides, the continuous operation capability of equipment can be effectively improved, and the routine maintenance of the equipment and the part replacement cost are reduced.

Owner:SICHUAN VANOV TECH FABRIC

A kind of river environment restoration structure

ActiveCN112695717BClear Energy ReductionImprove efficiencyWater resource protectionWater cleaningSuction forceRiver routing

The invention discloses a river channel environment restoration structure, which comprises a vertical tube, and a cleaning mechanism is arranged under the vertical tube, and the cleaning mechanism includes a vertical tube, a cabinet, a rotating rod, a circular plate, a pumping tank, a drainage pipe, A filter cartridge, a groove block and a protruding rod, the vertical cylinder is located at the bottom end of the vertical cylinder. The river environment restoration structure, through the cooperation between the vertical cylinder and the cleaning mechanism, can make the rotating rod rotate to provide running kinetic energy for the pumping box, and can make the top of the vertical cylinder generate suction, and the floating objects floating on the water surface of the river can be removed. During suction, the filter cartridge can filter the inhaled floating objects without reciprocating above the river channel, and the floating objects above the river channel will automatically flow into the vertical cylinder under the suction flow, reducing the energy consumption of the floating objects above the river channel And the efficiency can be improved, and the practical performance can be improved.

Owner:苏州恒誉环保科技有限公司

A method and device for producing aromatics from methanol and producing low-carbon olefins by-product

ActiveCN104250183BResolve inactivationImprove continuous operation capabilityHydrocarbon from oxygen organic compoundsEthylene productionAlkanePtru catalyst

The invention discloses a method for preparing aromatic hydrocarbons from methanol with low carbon olefin as a byproduct, and an apparatus thereof. The problems of low yield of the aromatic hydrocarbons, large output of dry gas and liquefied gas, and the like in the prior art are solved in the invention. The method comprises the following steps: preheating the raw material methanol to 350-500DEG C, adding the preheated methanol to a riser reactor, carrying out a contact reaction on the preheated methanol and a catalyst in the riser reactor for 0.8-4.0s, allowing the reaction product of the riser reactor to enter a deep catalysis reactor (such as a fluidized bed, moving bed or fixed bed reactor) to carry out a reaction, returning C2-C5 alkanes in the reaction products of the deep catalysis reactor to the deep catalysis reactor in order to re-process the C2-C5 alkanes, and discharging other products from the apparatus, wherein the catalyst is a ZSM-5 / SAPO-34 catalyst modified by Ga, Zn, P and Ag.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com