Pyrolysis and liquidation system for heating biomass by using solid heat storage ball

A technology of biomass pyrolysis and solid heat storage, which is applied in the direction of biofuel, direct heating dry distillation, preparation of liquid hydrocarbon mixture, etc., can solve the problems of low heat utilization rate and low carbon powder collection rate, and achieve excellent working performance , Good separation effect, and the effect of improving continuous operation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

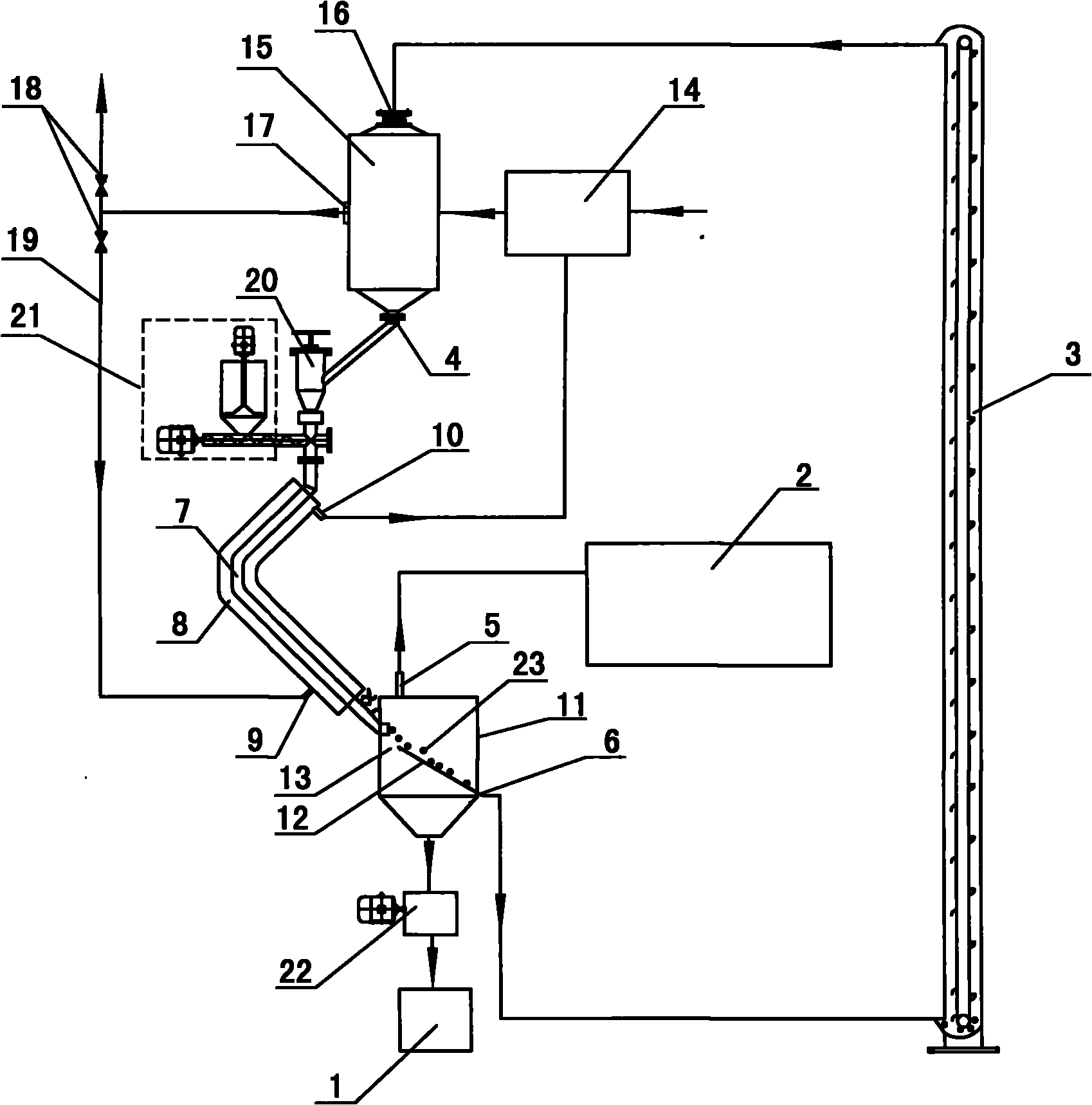

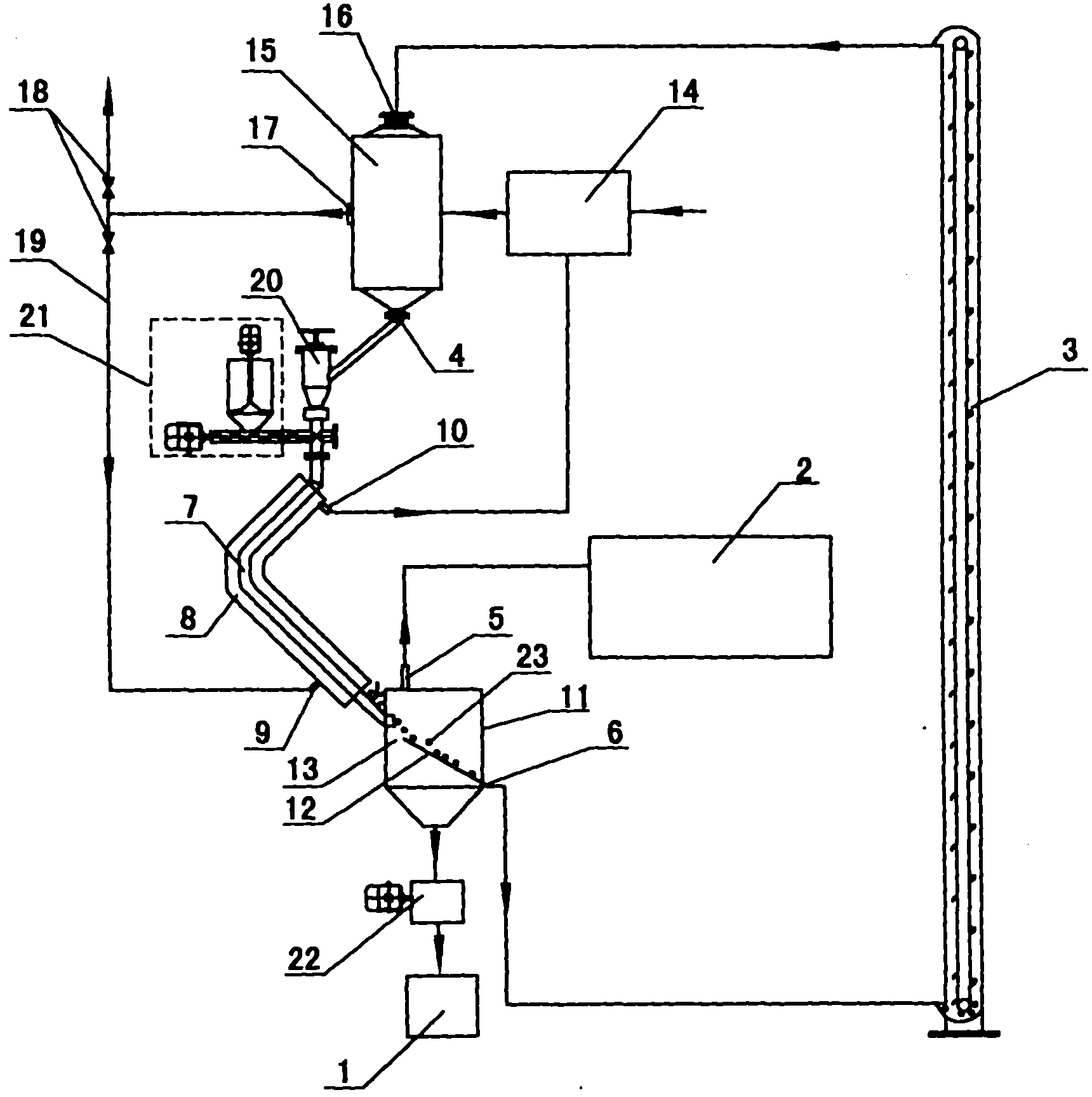

[0017] exist figure 1 In the shown embodiment: the reactor adopts a sleeve-type reactor, including an inner tube 7 and an outer tube 8 coaxially set, wherein the two ends of the inner tube 7 are open, respectively connected to the outlet of the feeding device and the separation device The two ends of the outer tube 8 are closed, the side wall at the upper end of the outer tube 8 is provided with a hot air outlet 10, and the side wall at the lower end of the outer tube 8 is provided with a hot air inlet 9; the reactor is divided into three parts from top to bottom along the axial direction: An inclined straight pipe part, an arc transition part and an inclined straight pipe part, wherein the axes of the two inclined straight pipe parts are 90 degrees.

[0018] The separation device comprises a separation box 11 and a sieve plate 12 obliquely arranged in the separation box 11, wherein the bottom of the inner pipe 7 penetrates into the separation box 11 at an angle α from the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com