Method for preparing aromatic hydrocarbons from methanol with low carbon olefin as byproduct, and apparatus thereof

A low-carbon olefin and methanol technology, which is applied in the direction of hydrocarbon production from oxygen-containing organic compounds, ethylene production, bulk chemical production, etc., can solve the problems of low yield of aromatics, large output of dry gas and liquefied gas, etc. Increased efficiency, improved continuous operability, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

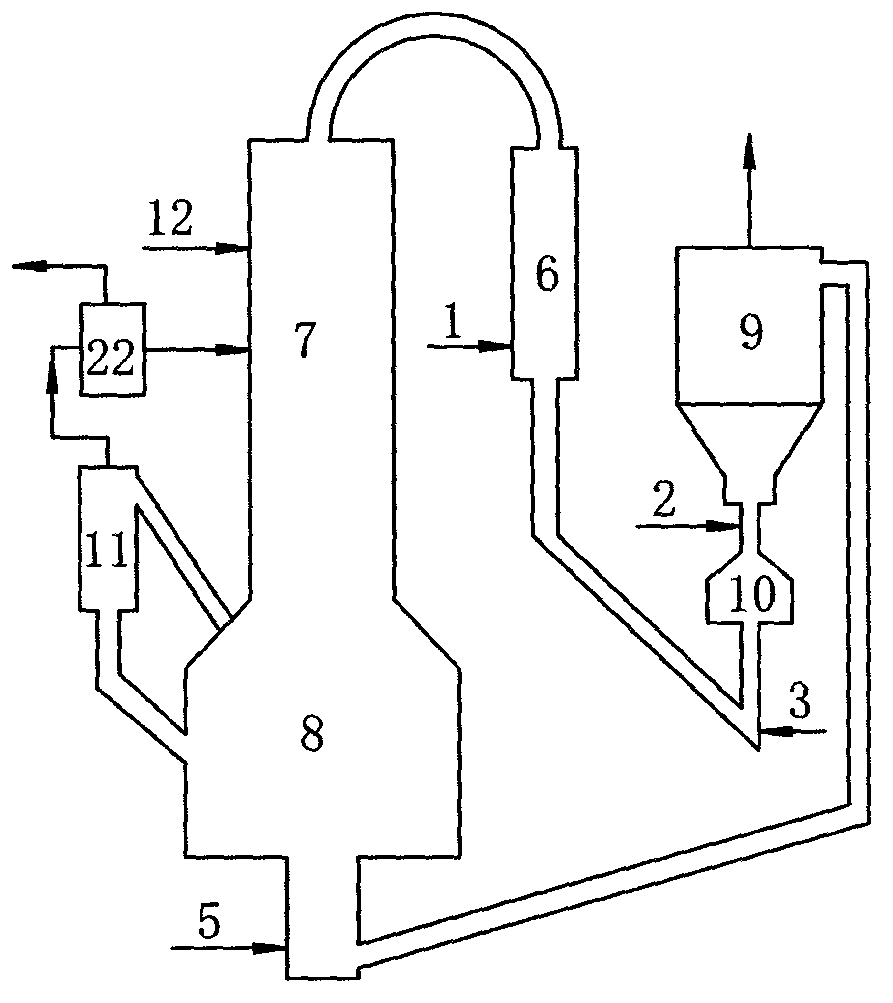

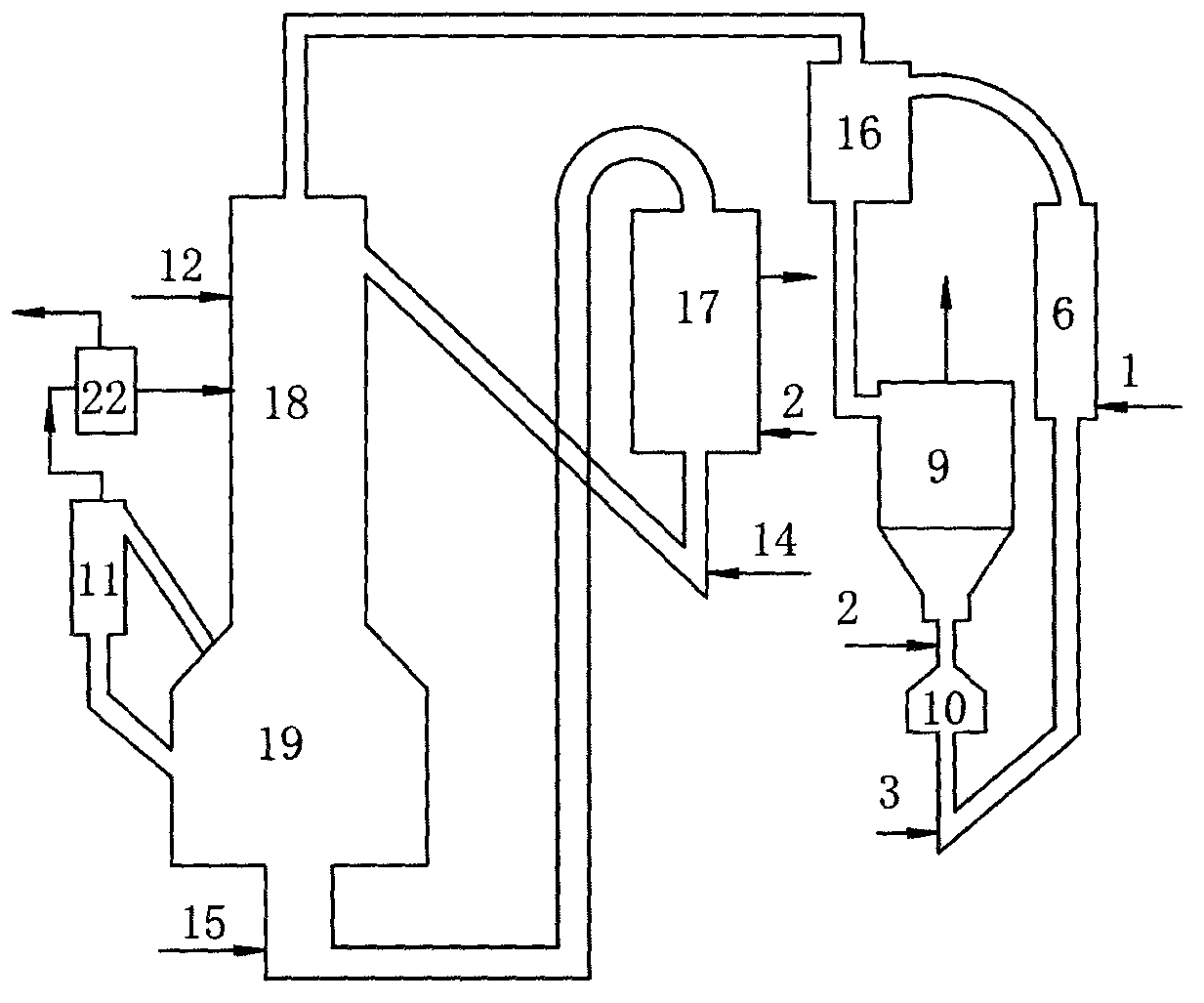

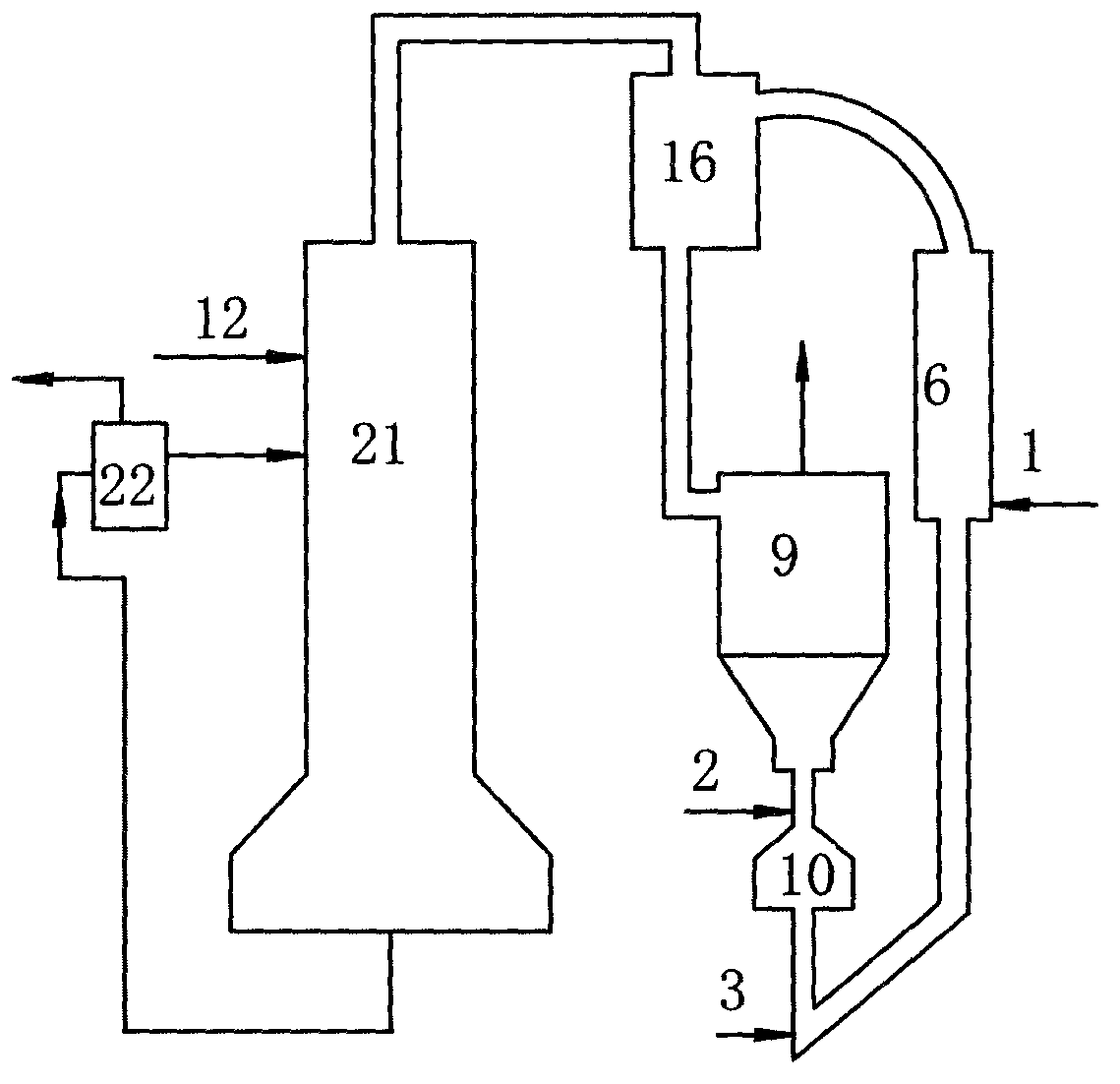

[0046] Such as figure 1 Shown is a simple schematic flow chart of a methanol-to-aromatics process with by-product light olefins. The device for producing aromatics from methanol and by-producting low-carbon olefins includes a riser reactor 6 and a fluidized bed reactor 7, the top of the riser reactor 6 is connected to the top of the fluidized bed reactor 7, and the fluidized bed reactor 7 The lower part is the separation tank 8 at the bottom of the fluidized bed reactor, and the upper part of the separation tank 8 at the bottom of the fluidized bed reactor is communicated with the upper part of the fluidized bed reactor 7 through the cyclone separator 11 and the separation device 22, and the bottom of the fluidized bed reactor is separated The bottom of the tank 8 is connected to the top of the charring tank 9 , and the bottom of the charring tank 9 is connected to the bottom of the riser reactor 6 . Or the bottom of the coke tank 9 is connected to the bottom of the riser rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com