A kind of regeneration method of the catalyst that handles Fischer-Tropsch reaction synthetic water

A Fischer-Tropsch reaction and catalyst technology, which can be used in catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., and can solve problems such as catalyst deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

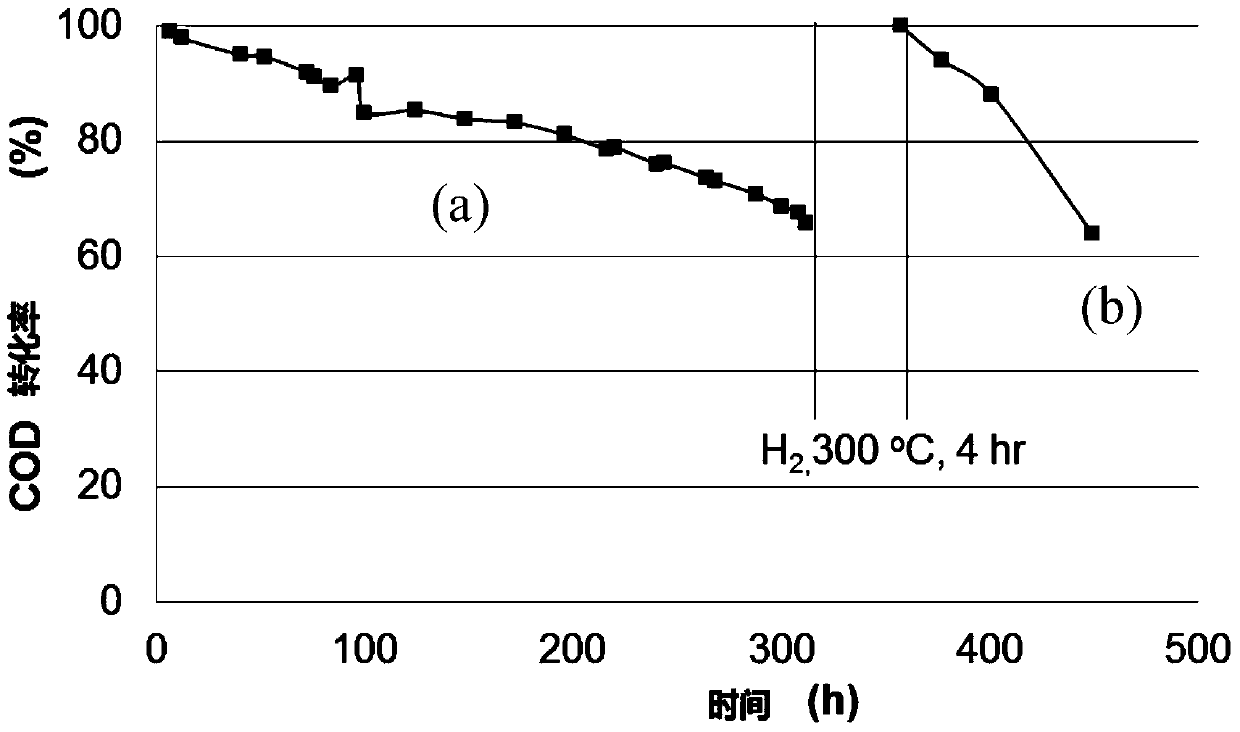

[0042] This example illustrates the regeneration method of the deactivated catalyst of the present invention.

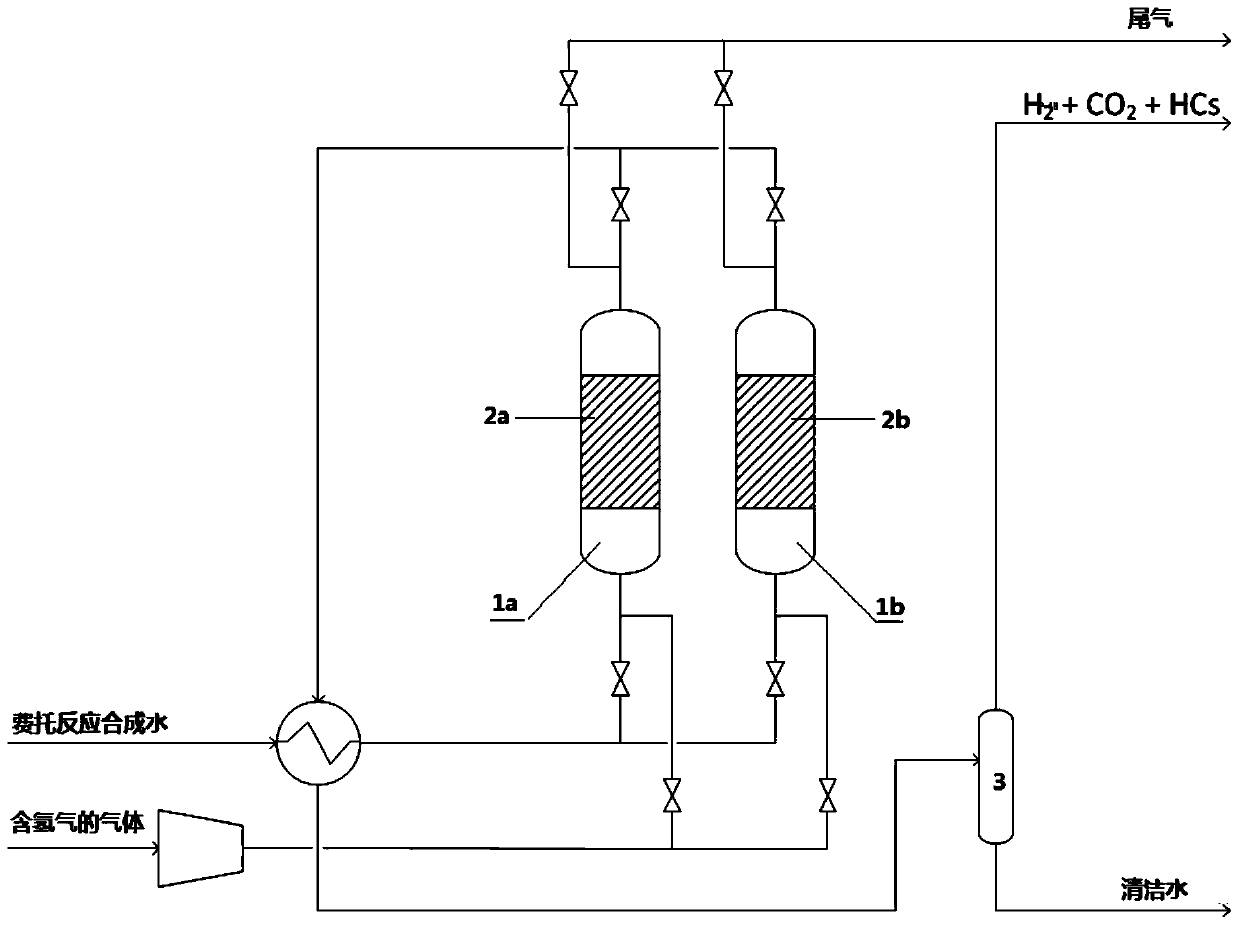

[0043] (1) Treatment of Fischer-Tropsch reaction synthetic water: figure 1 As shown, equal amounts of the same catalyst 2a, 2b (composition 5wt% Ru / 95wt% AC) were charged in two aqueous phase reforming reactors 1a, 1b, respectively. The water phase reforming reactor 1b is closed, and the Fischer-Tropsch reaction synthesis water (oxygenated organic matter content 4.7% by weight, COD is 82705mg / L, and the specific composition is shown in Table 1) is sent into the water phase reforming reactor 1a. The liquid mass space velocity of the whole reaction is 10h -1 , the temperature of the aqueous phase reforming reaction is 250° C., and the pressure is 52 atm.

[0044] The reaction product is sent to the gas-liquid separation tank to obtain clean water.

[0045] From the beginning of the reaction, take samples at regular intervals, extract the clean water obtained from th...

Embodiment 2

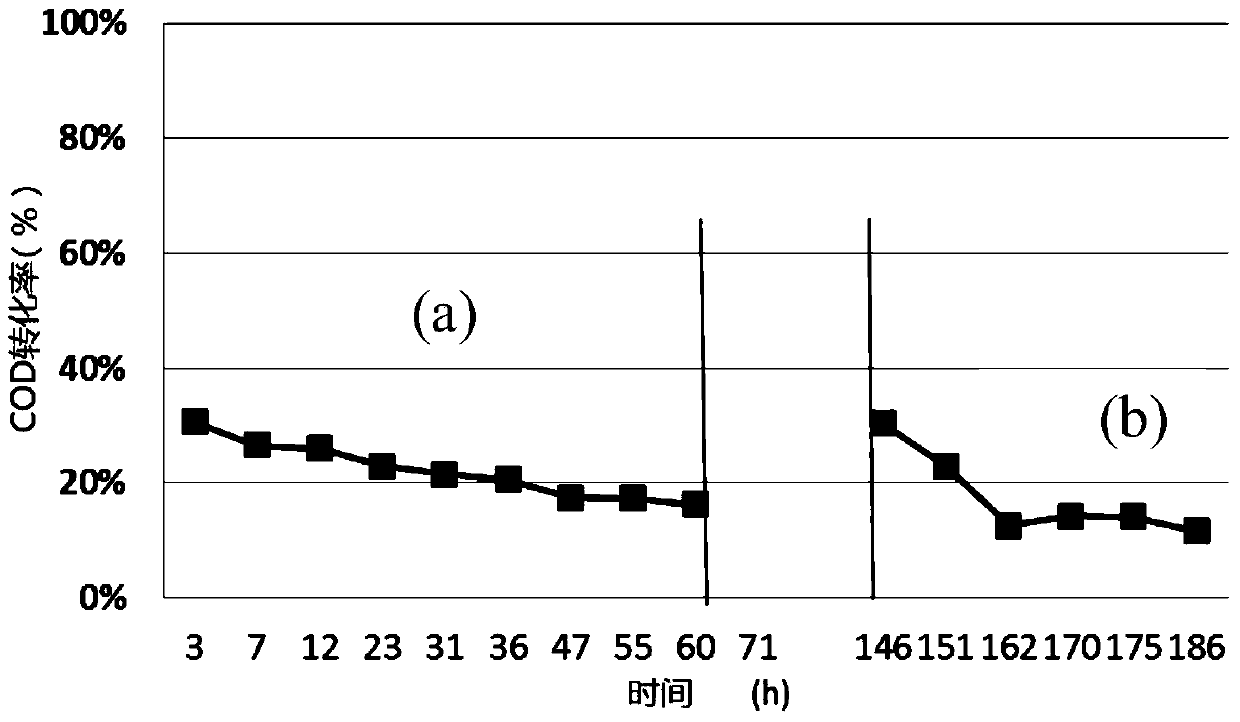

[0054] This example illustrates the regeneration method of the deactivated catalyst of the present invention.

[0055] (1) Treatment of Fischer-Tropsch reaction synthetic water: figure 1 As shown, equal amounts of the same catalyst 2a, 2b (composition 5wt% Ru / 95wt% AC) were charged in two aqueous phase reforming reactors 1a, 1b, respectively. The water phase reforming reactor 1b is closed, and the Fischer-Tropsch reaction synthesis water (the content of oxygen-containing organic matter is 4.7% by weight, COD is 82705mg / L) is sent into the water phase reforming reactor 1a, the quality of the water phase reforming reaction Airspeed is 10h -1 . The temperature of the aqueous phase reforming reaction is 220° C., and the pressure is 31 atm.

[0056] The reaction product is sent to the gas-liquid separation tank to obtain clean water.

[0057] From the beginning of the reaction, take samples at regular intervals, extract the clean water obtained from the reaction, measure the CO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com