A kind of blueberry anthocyanin separation and purification method

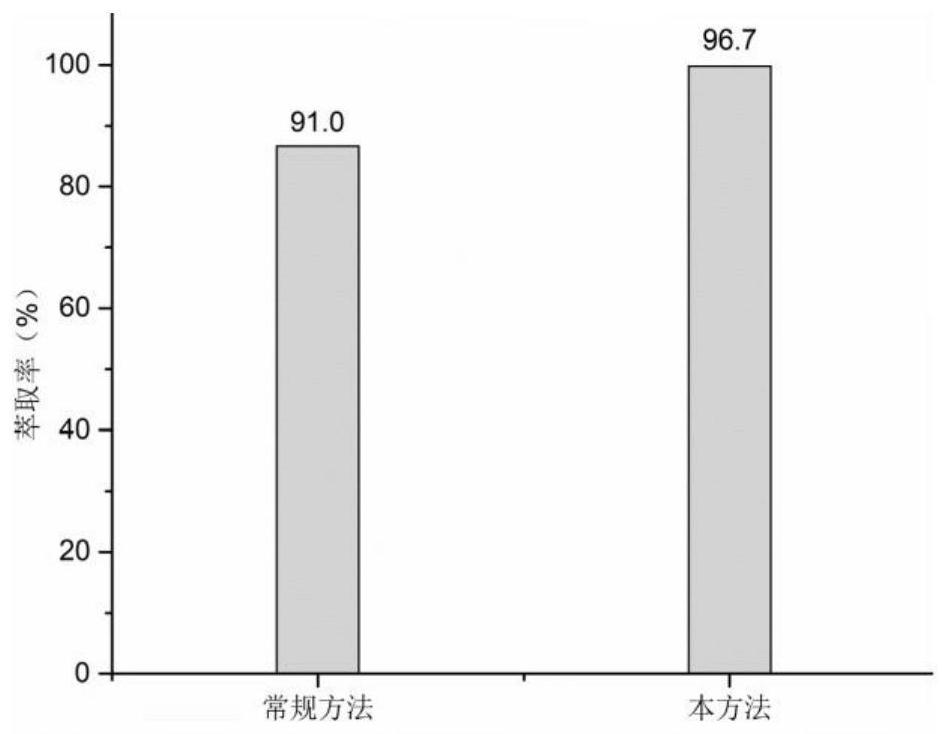

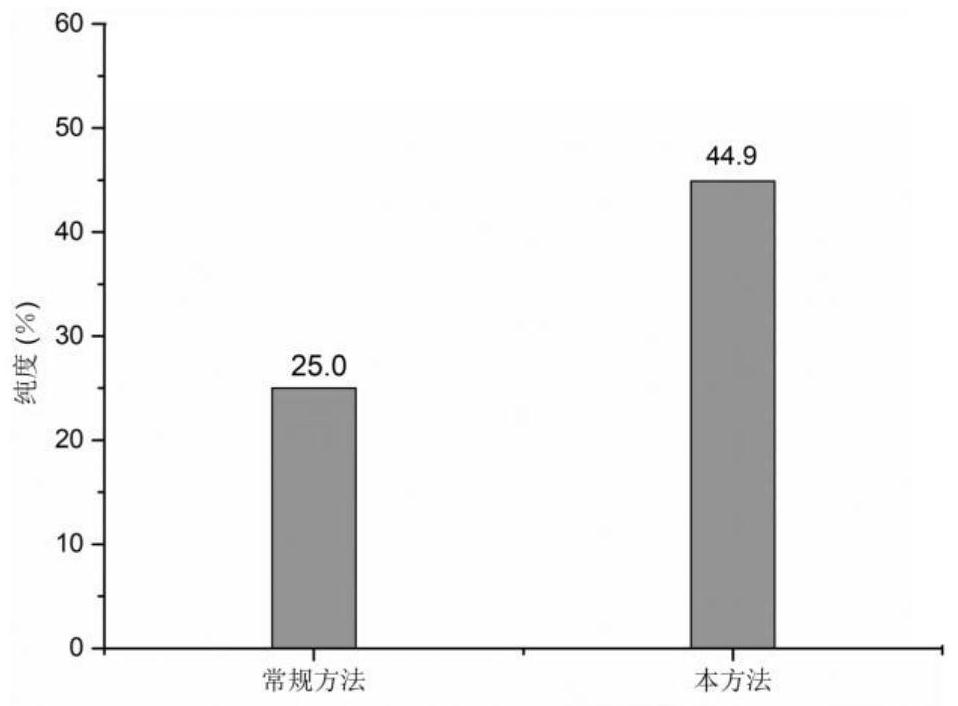

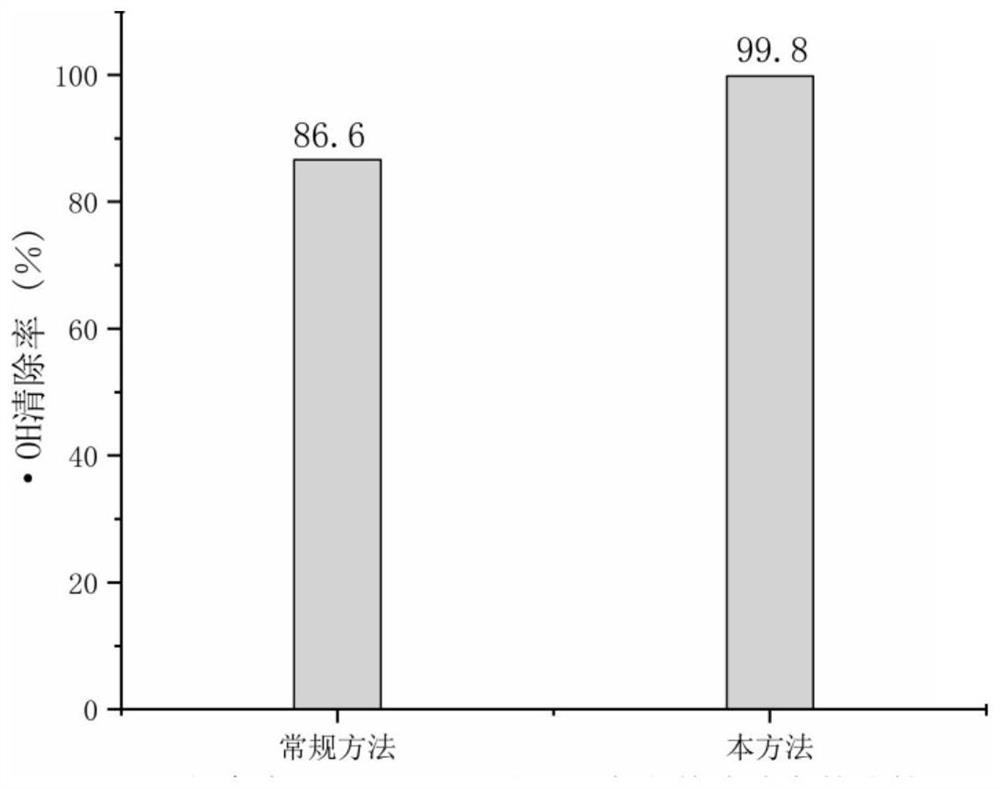

A technology for the separation and purification of blueberry anthocyanins, applied in the field of separation and purification of blueberry anthocyanins, can solve the problems of easy deactivation, low extraction rate and low purity of blueberry anthocyanins, and achieve the effect of increased purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1. Method for separation and purification of blueberry anthocyanins.

[0030] 1) Take 1000 g of blueberry fruit, crush it with a high-speed crusher, and crush it with a particle size of 100 mesh to obtain pulp, then add cellulase with an activity unit of 1000 U / g, and the addition amount is 0.1 g / kg pulp, at pH 4.5 , the temperature is 45° C., the rotational speed of the stirring paddle is 20 rpm, and the enzymatic hydrolysis is carried out by stirring for 40 minutes to obtain a cellulase enzymatic hydrolysis solution.

[0031] 2) Then add ethanol with a volume fraction of 60% at a ratio of 1 g:4 mL of material to liquid, and put it into a horizontal grinding bead extraction equipment for grinding and extraction to obtain an extract. The diameter of the grinding beads is 2.0 mm, the loading of the grinding beads is 30% of the volume of the grinding kettle, the stirring revolution is 20 times / min, and the extraction time is 40 min. During the extraction process,...

Embodiment 2

[0034] Example 2. Blueberry anthocyanin separation and purification method.

[0035] 1) Take 1000g of blueberry fruit, crush it with a high-speed crusher, and crush the particle size of 100 mesh to obtain pulp, then add cellulase with an activity unit of 1000U / g, and the addition amount is 0.2g / kg pulp, at pH: 5 -6, the temperature is 50°C, the rotational speed of the stirring paddle is 25 revolutions / min, and the enzymatic hydrolysis is carried out by stirring for 50 minutes to obtain a cellulase enzymatic hydrolysis solution.

[0036] 2) Then add ethanol with a volume fraction of 60% at a material-to-liquid ratio of 1 g:6 mL, and put it into a horizontal grinding bead extraction kettle for grinding and extraction to obtain an extract. The diameter of the grinding beads is 1.0 mm, and the loading amount of the grinding beads is 50% of the volume of the grinding kettle. The stirring revolution was 30 times / min. The extraction time was 30 min. During the extraction process, ...

Embodiment 3

[0039] Example 3. Method for separation and purification of blueberry anthocyanins.

[0040] 1) Take 1000g of blueberry fruit, crush it with a high-speed crusher, and crush the particle size of 100 mesh to obtain pulp, and then add cellulase with an activity unit of 1000U / g, and the addition amount is 0.2g / kg pulp, at pH: 6.5 , the temperature is 55 ℃, the rotation speed of the stirring paddle is 20 rpm, and the stirring is carried out for 50 minutes to carry out enzymatic hydrolysis to obtain a cellulase enzymatic hydrolysis solution.

[0041] 2) Then add ethanol with a volume fraction of 60% at a material-to-liquid ratio of 1 g:5 mL, and put it into a horizontal grinding bead extraction kettle for grinding and extraction to obtain an extract. The diameter of the grinding beads is 3.0 mm, the loading of the grinding beads is 50% of the volume of the grinding kettle, the stirring revolution is 30 times / min, and the extraction time is 45 min. During the extraction process, coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com