An ozone catalytic decomposition device

A technology of ozone catalysis and catalytic devices, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of easy heating and combustion of activated carbon method, high processing cost, etc., achieve high energy utilization rate, avoid deactivation, The effect of solving long-term utilization problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

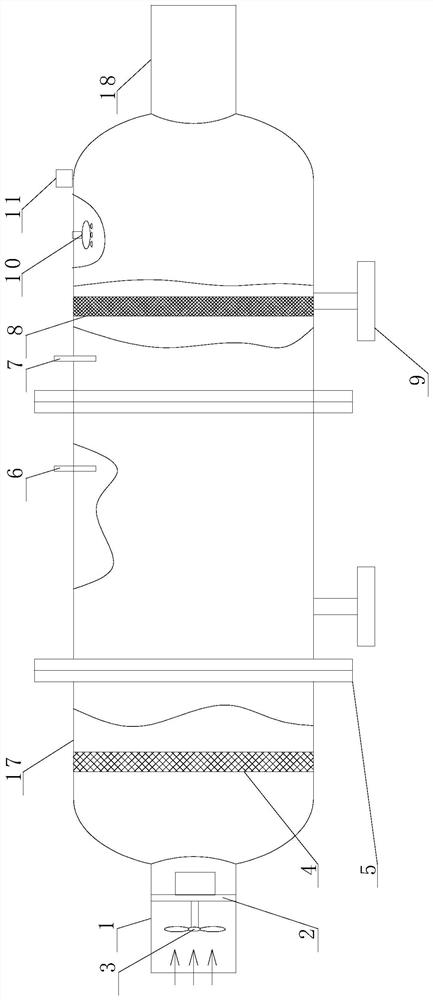

[0045] Such as Figure 1 to Figure 3 As shown, the present embodiment provides a catalytic ozone decomposition device, including a treatment tank 17, an air inlet 1 arranged on the treatment tank 17, an air outlet 18 arranged on the treatment tank 17, located in the treatment tank 17 and interposed In the ozone treatment part between the air inlet 1 and the gas outlet 18, the treatment tank 17 includes a middle section and two head sections, the middle section is cylindrical, and each end of the middle section is connected by a connection method. Lan 5 is fixed with a head section, the air inlet 1 is installed on one of the head sections, and the air outlet 18 is installed on the other head section;

[0046] Described ozone treatment part comprises the catalytic device 8 that is loaded with ozone treatment catalyst, the light source 10 that is contained in the processing tank 17, and light source 10 is arranged near catalytic device 8; 4, and the drying device 4 is located be...

Embodiment 2

[0055] Such as Figure 1 to Figure 3 Shown, this embodiment is further limited on the basis of embodiment 1:.

[0056] As a complete set of equipment design, it also includes a desiccant loaded on the drying device 4, and the desiccant is anhydrous calcium chloride. This desiccant can be used at an ambient temperature of -5°C to 90°C and can be regenerated at the same time.

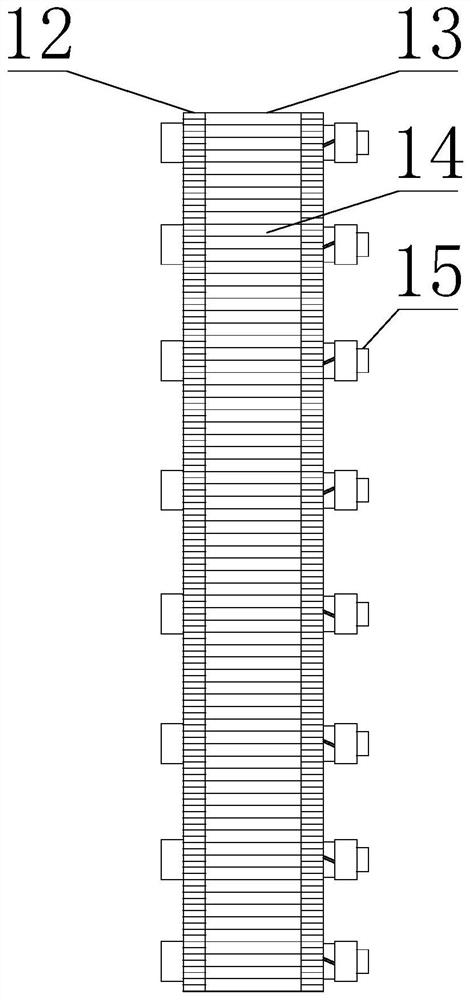

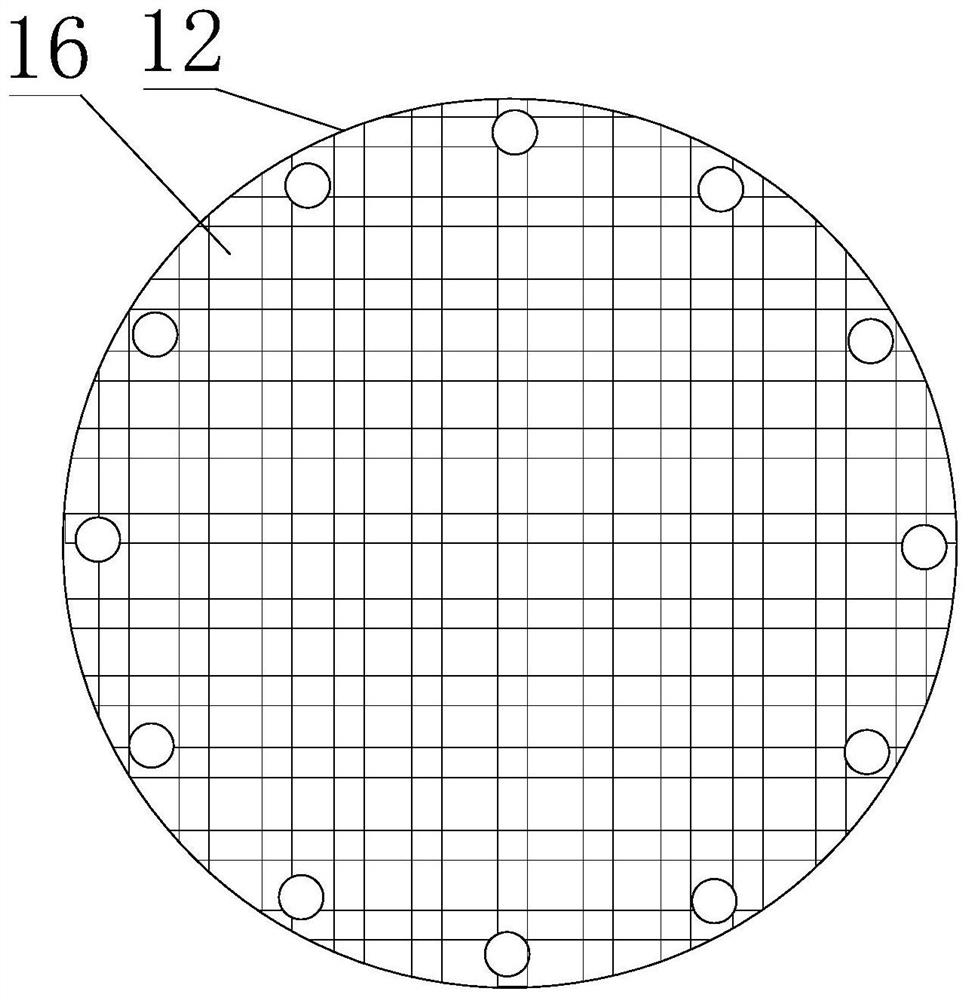

[0057] As a specific implementation of the drying device 4 and the catalytic device 8, the drying device 4 and the catalytic device 8 all include a carrier plate 13 and two end plates 12 for loading the carrier, and the carrier plate 13 is provided with A plate-shaped structure of a plurality of carrier holes 14, and each carrier hole 14 is a through hole through both sides of the carrier plate 13, the carrier hole 14 is used to accommodate the carrier, and the end plate 12 is a mesh-like structure;

[0058] On the drying device 4 or the catalytic device 8 , an end plate 12 is fixed on each side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com