Preparation method of slaked lime emulsion for wastewater treatment and apparatus thereof

A wastewater treatment and preparation device technology, applied in mixing methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems that the lime concentration cannot meet the process requirements, the lime cannot be decomposed, and the lime utilization rate is low. Achieve the effects of reducing lime dust pollution, improving dust pollution, and improving capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

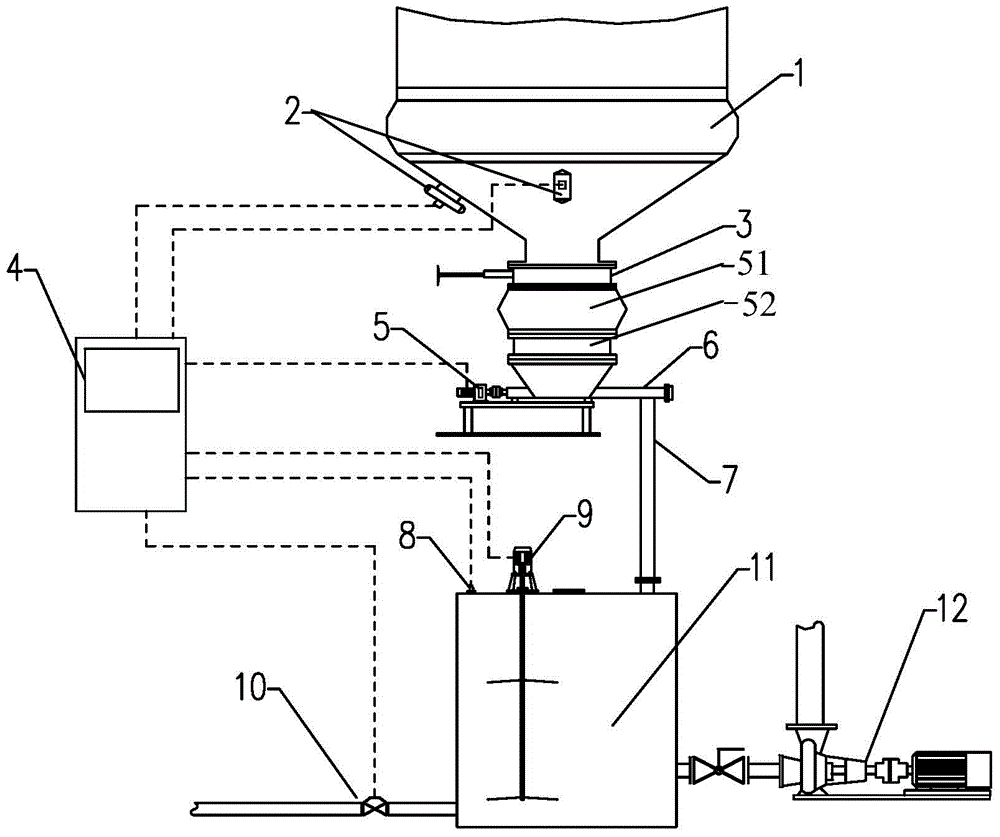

[0083] The specific implementation of the present invention will be described in detail below in conjunction with the drawings of the embodiments.

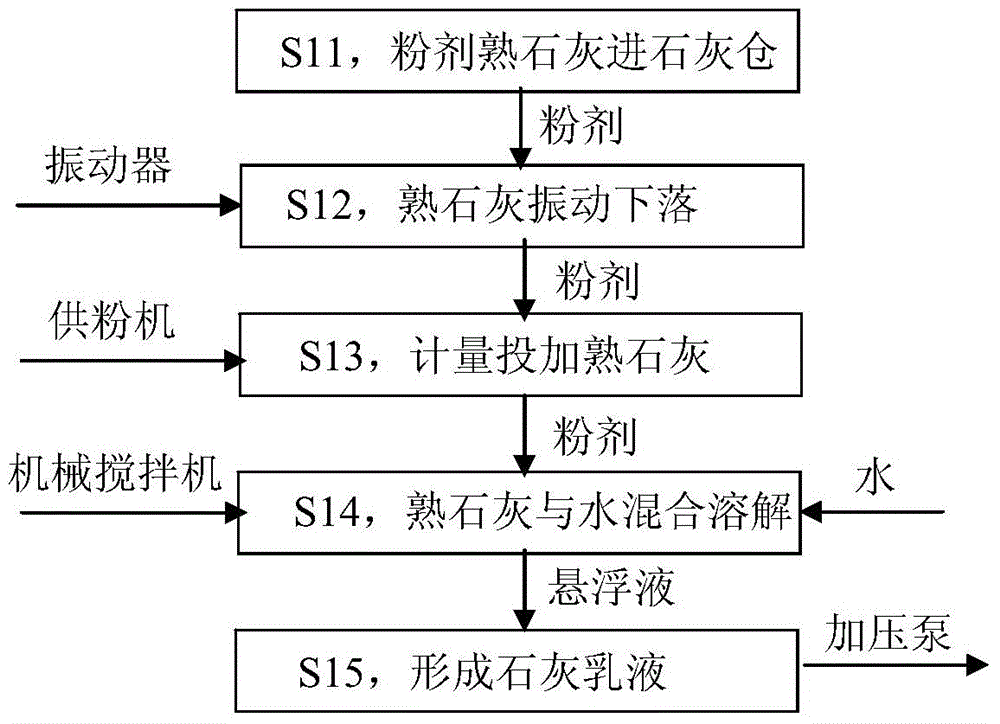

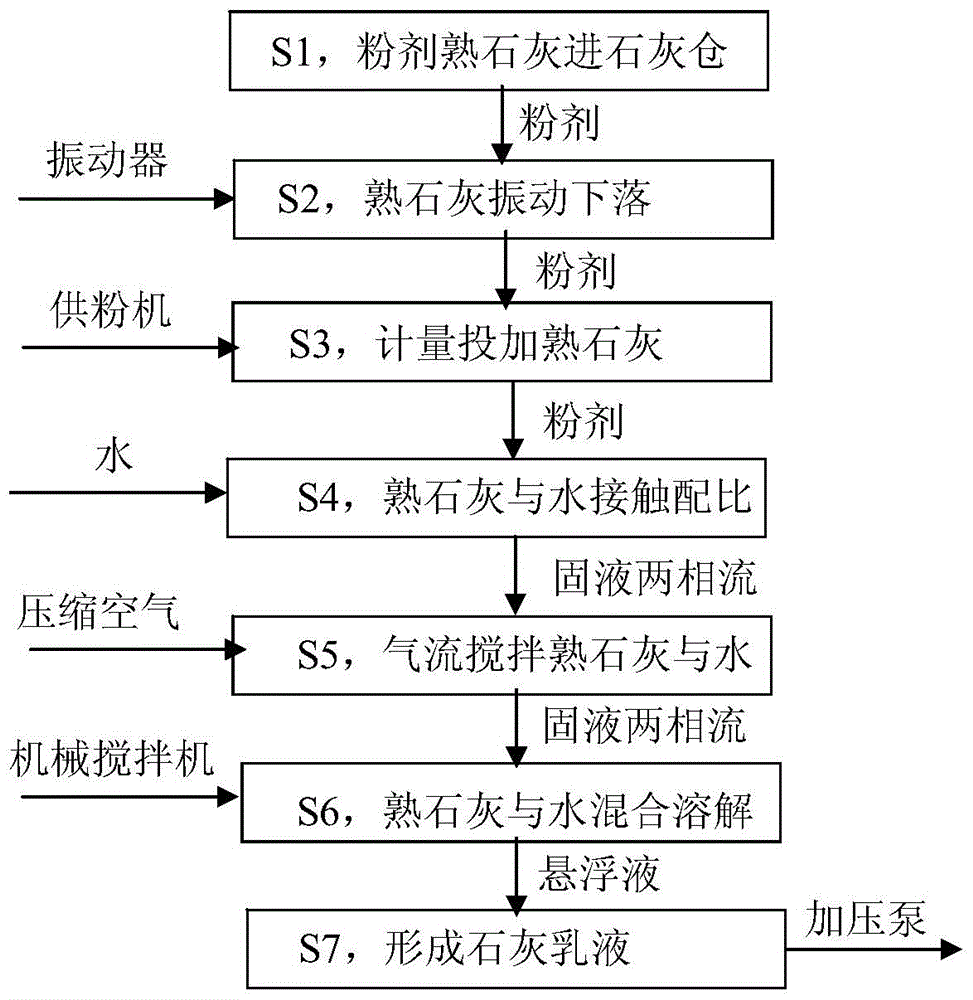

[0084] The key to solving the existing technical problems is to improve the mixing efficiency of water and lime, which is to improve the fineness and distribution of lime particles in the water. The mixing efficiency can be improved by increasing the mixing time and mixing degree. For this reason, the direction of entry of lime and water in the dissolution tank can be changed, so that their mixing time can be prolonged, and air flow is added to stir, so that the lime is crushed into fine particles before entering the dissolution tank, and the degree of mixing with water increases. It can be fully dissolved in the dissolving tank, and finally a lime emulsion with uniform concentration is formed.

[0085] The preparation method and device of the slaked lime emulsion for wastewater treatment of the present invention will be described in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com