Patents

Literature

54results about How to "Solve the clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exhaust gas dedusting, denitration and desulfuration method for thermal power plant

InactiveCN102393023AHigh strengthImprove flame retardant performanceDispersed particle filtrationCombustion processAir preheaterWhole body

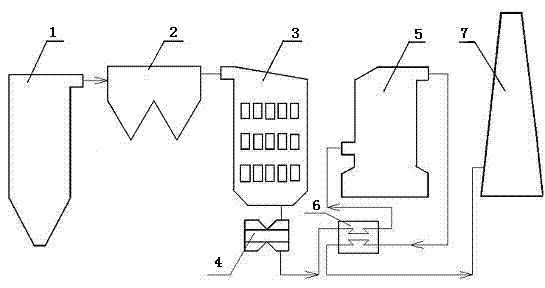

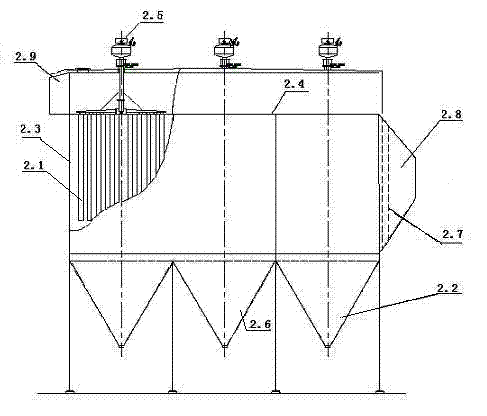

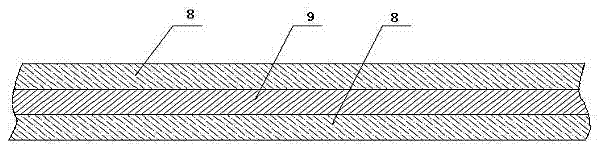

The invention relates to an exhaust gas dedusting, denitration and desulfuration method for a thermal power plant. According to the invention, after being dedusted firstly by a bag-type dust collector, high-temperature raw exhaust gas is introduced in an SCR (selective catalytic reduction) reactor for performing SCR for realizing denitration, and then, the exhaust gas subjected to denitration passes through an air preheater and a heat exchanger in sequence to be cooled to 90-100 DEG C, and then is subjected to wet desulfuration in a desulfurizer; and the exhaust gas subjected to desulfuration and discharged from the desulfurizer is heated to 100-105 DEG C by the heat exchanger and then enters a chimney to be discharged. In the bag-type dust collector, filter cloth in a filter bag has base cloth which is PBO (Poly-p-phenylenebenzobisthiazole) fiber woven cloth and has two surface layers referring to composite fibrofelts formed by cross-laying of PBO fiber nets and basalt fiber nets, the base cloth is sandwiched between the two surface layers and sewed up into a whole body, the whole body is subjected to hot rolling, singeing and heat shaping, Teflon dipping and drying to finally form high-temperature resistant filter cloth. By the adoption of the high-temperature resistant filter bag, the raw exhaust gas can be dedusted firstly at a high temperature and then is subjected to denitration, therefore, ash fouling of subsequent equipment and damages to a catalyst can be reduced, and the effects of low catalyst consumption and high denitration efficiency can be achieved; and since the catalytic reaction does not need additional heat, the effects of energy saving and emission reduction are achieved.

Owner:NANJING LONGYUAN ENVIRONMENTAL CO LTD

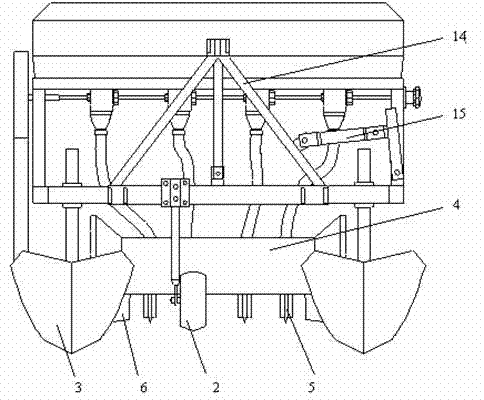

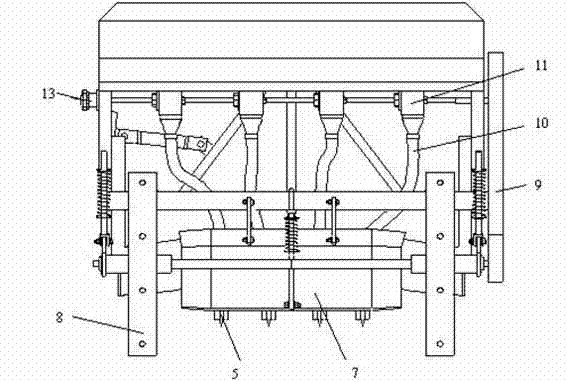

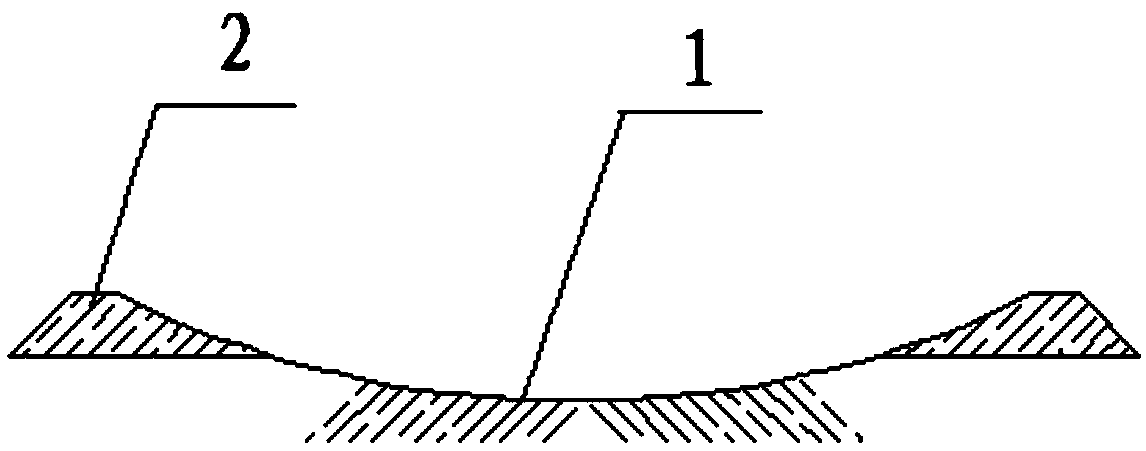

Wheat crop ridge seeding machine

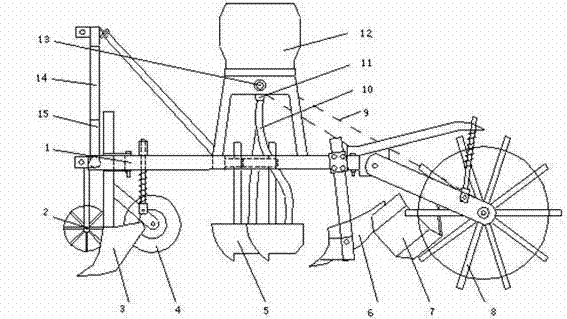

The invention provides a wheat crop ridge seeding machine, relating to the technical field of agricultural machinery, in particular to a wheat crop seeding machine. A frame of the wheat crop ridge seeding machine is connected with a traction locomotive by virtue of a suspension traction frame at the front end, a driving wheel is arranged at the rear end of the frame, a seed storage tank is arranged at the upper part of the frame, a seed sowing device is arranged on the seed storage tank, and the driving wheel is connected with the seed sowing device and drives the seed sowing device by virtue of a transmission chain; the lower part of the frame is sequentially provided with a depth limiting wheel, a single-winged ridging plough, a ridging compacting machine, a seed opener, a ditch cleaning shovel and a ridge reshaping device; and the seed opener is connected with the seed sowing device by virtue of a seed drop tube. A suspension traction system, a ridge body moulding system and a precision drilling system of the seeding machine ensure earthing of a seeding trench to be uniform and ridge trench and ridge surface to be uniform, thus multiple processes such as ridging, sowing and the like can be completed at the same time, and agricultural requirements of high ridging quality, uniform seed discharging and consistent sowing depth can be met.

Owner:INST OF SOIL FERTILIZER & WATER SAVING AGRI GANSU ACAD OF AGRI SCI

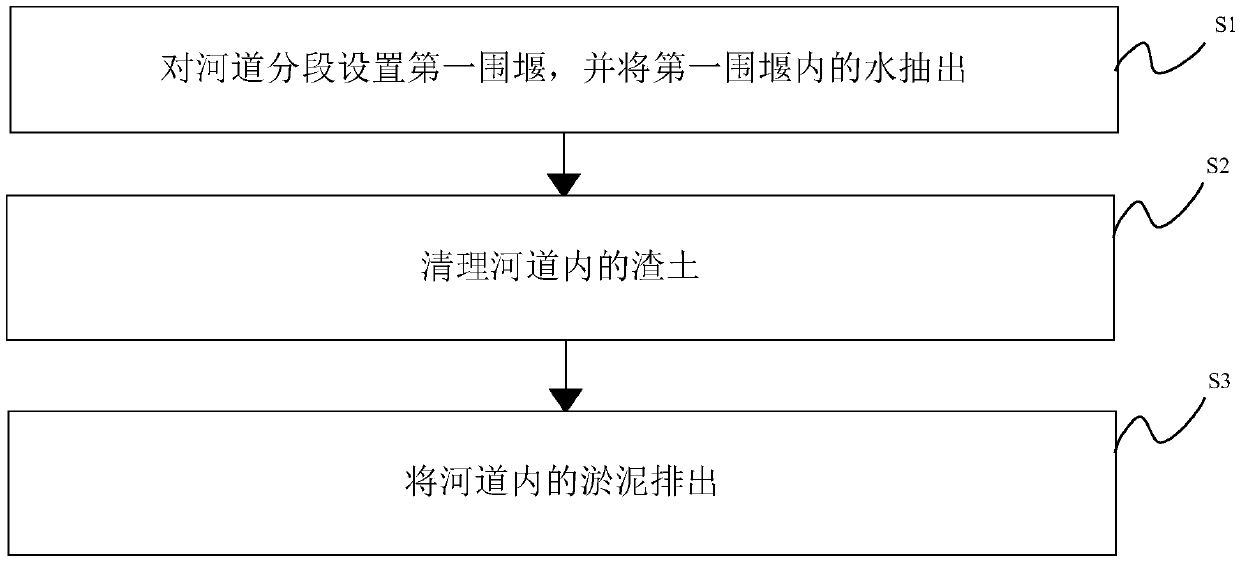

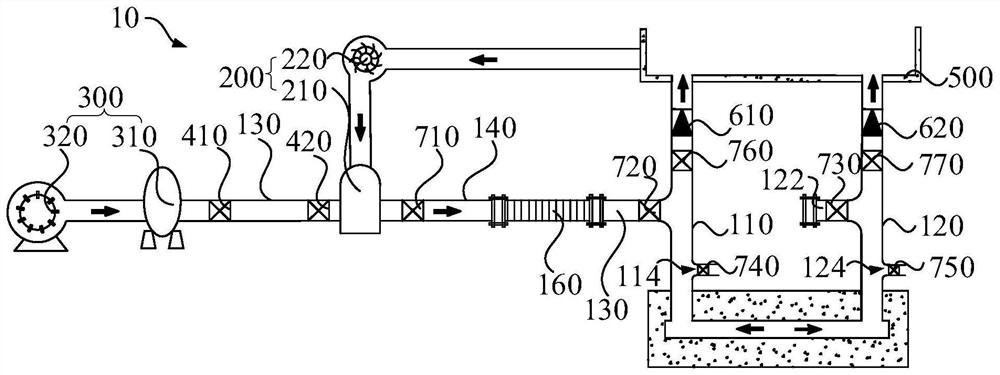

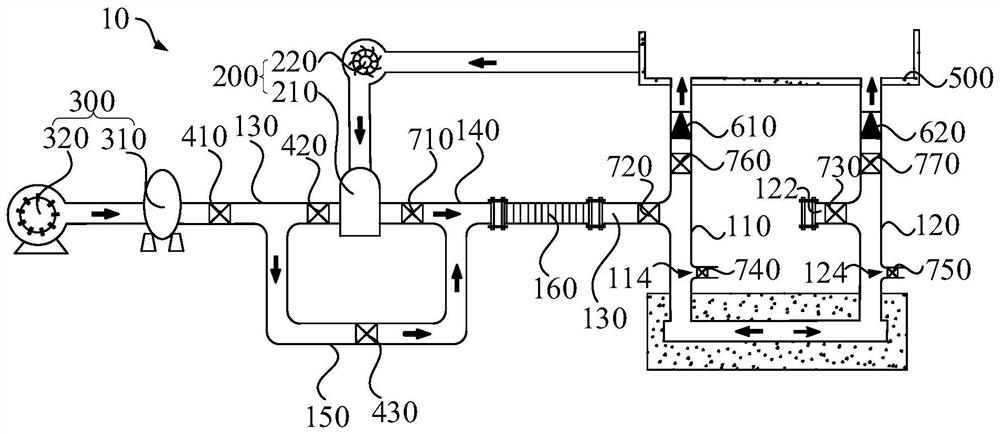

River dredging method

InactiveCN109056761ASolve the cloggingSoil-shifting machines/dredgersFoundation engineeringRiver routingSludge

The invention discloses a river dredging method. The method comprises the following steps of: step S1, setting a first cofferdam to the river section, and extracting the water in the first cofferdam;step S2, cleaning the muck in the river; step S3, discharging the sludge in the river. The method disclosed by the invention comprises: firstly, setting a first cofferdam to the river section, and extracting the water in the first cofferdam; next, cleaning the muck in the river; finally, discharging the sludge in the river. The method disclosed by the invention can discharge the sludge in the river, and solve the problem of clogging of the river.

Owner:SHANGHAI BAOYE GRP CORP

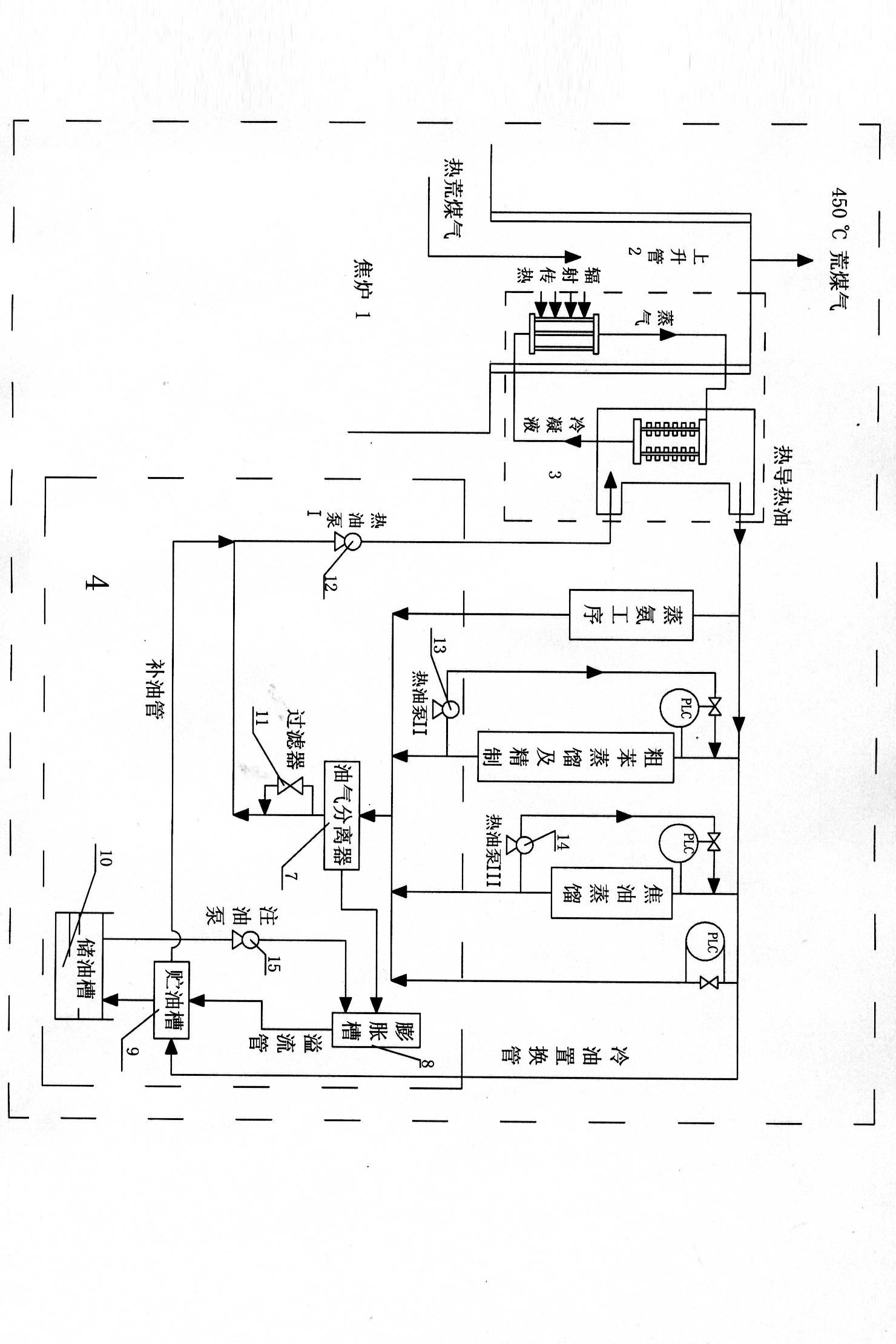

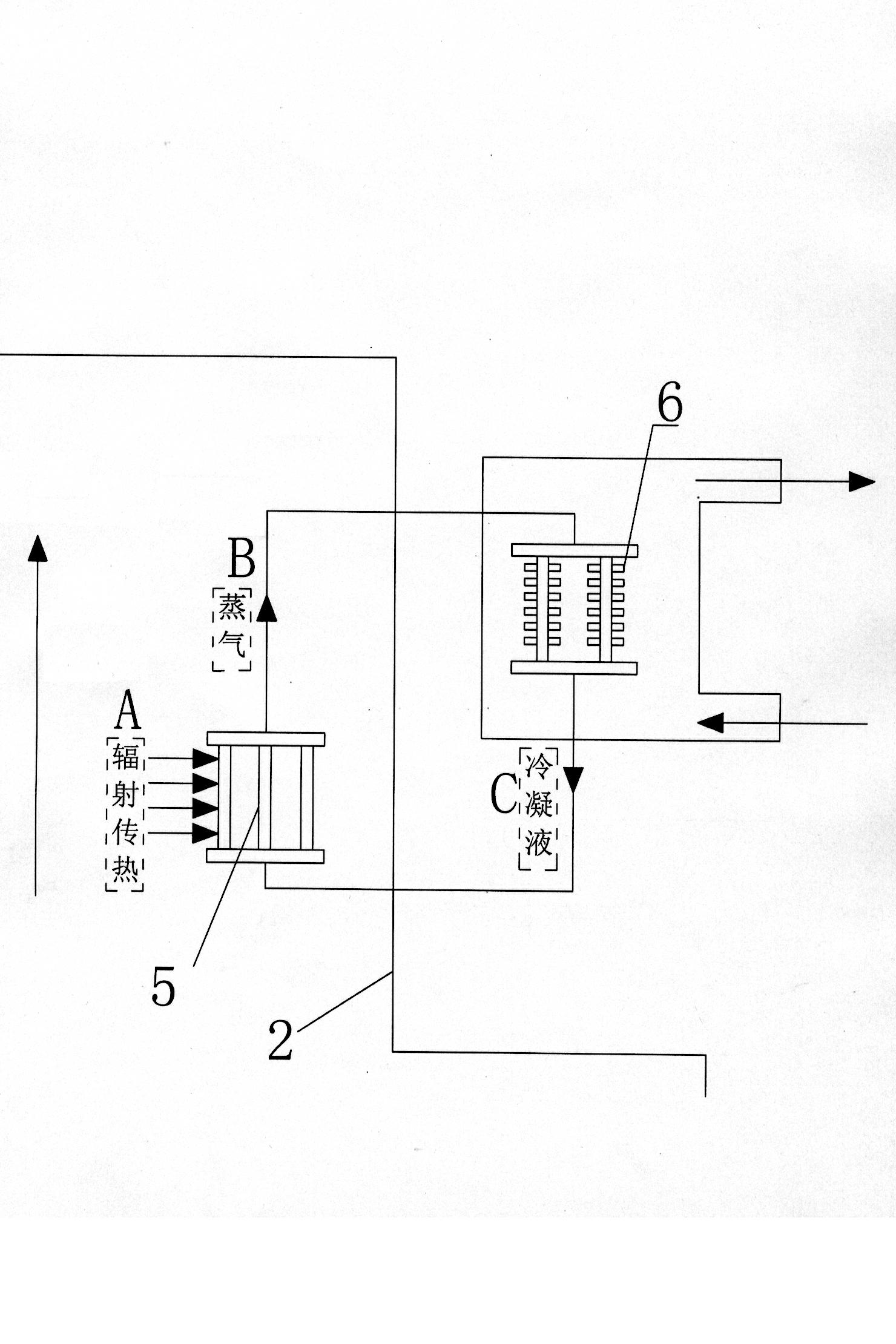

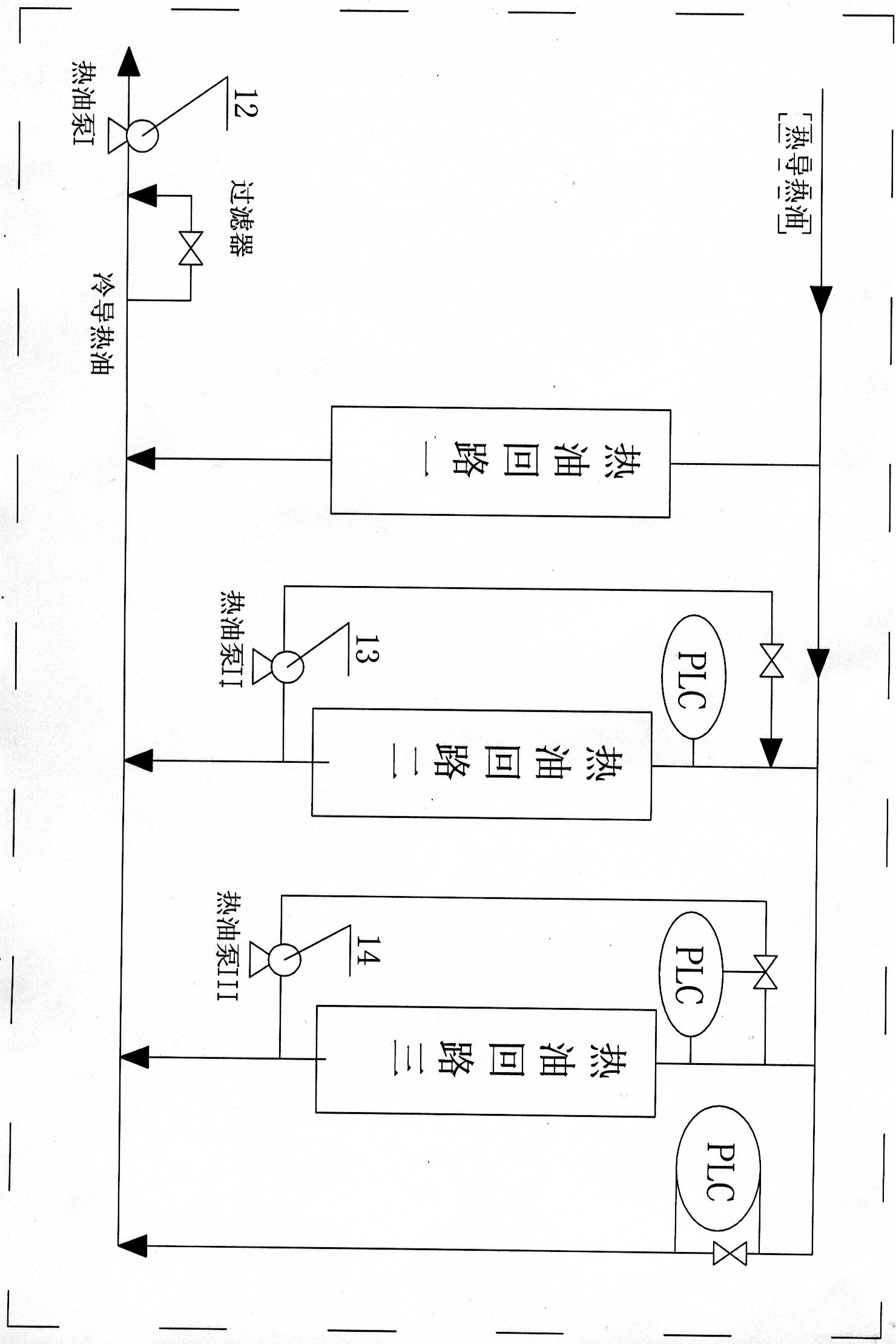

Integrated technique and special equipment for raw gas waste heat recovery and steam replacement with heat transfer soil

ActiveCN102519285AIncrease the heat exchange areaReduce convection heat transfer thermal resistanceEnergy industryIndirect heat exchangersHeating systemDistillation

The invention relates to an integrated technique and special equipment for raw gas waste heat recovery and steam replacement with heat transfer soil. The integrated technique and the special equipment are mainly characterized in that high-temperature separation heat pipes are used to recover latent heat of high-temperature raw gas from a coking chamber, the recovered heat is transmitted to heat transfer oil, the heated transfer oil supplies required heat to various coking procedures of chemical production operational units (an ammonia evaporation procedure, crude benzene distillation and refining procedures, a coke distillation procedure), the heat transfer oil in a whole chemical production system cycles in closed loops, and temperature and flow are regulated and controlled according different requirements of the units on operational heat sources. Compared with the prior art, the integrated technique and the special equipment can be used for efficiently recovering high-quality waste heat of raw coke oven gas, energy consumption of the coking procedure is reduced, consumption of circulating ammonia water in spraying is reduced, heat transfer oil heating systems for the chemical production operational units and addition heat required by the heat transfer oil heating systems are omitted, and closed-loop circulation of the heat transfer soil and cascade use of the waste heat are achieved.

Owner:NORTHEASTERN UNIV

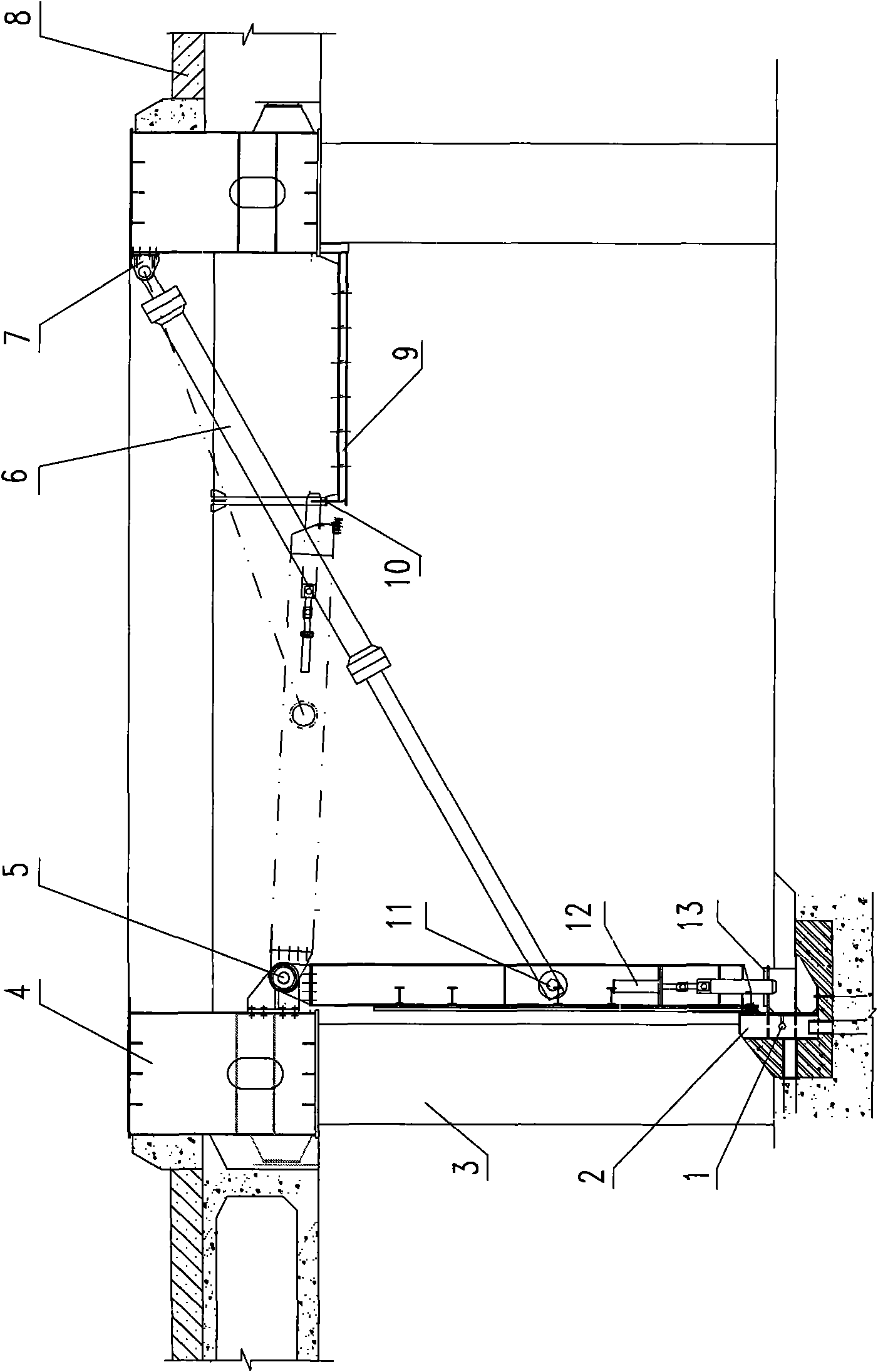

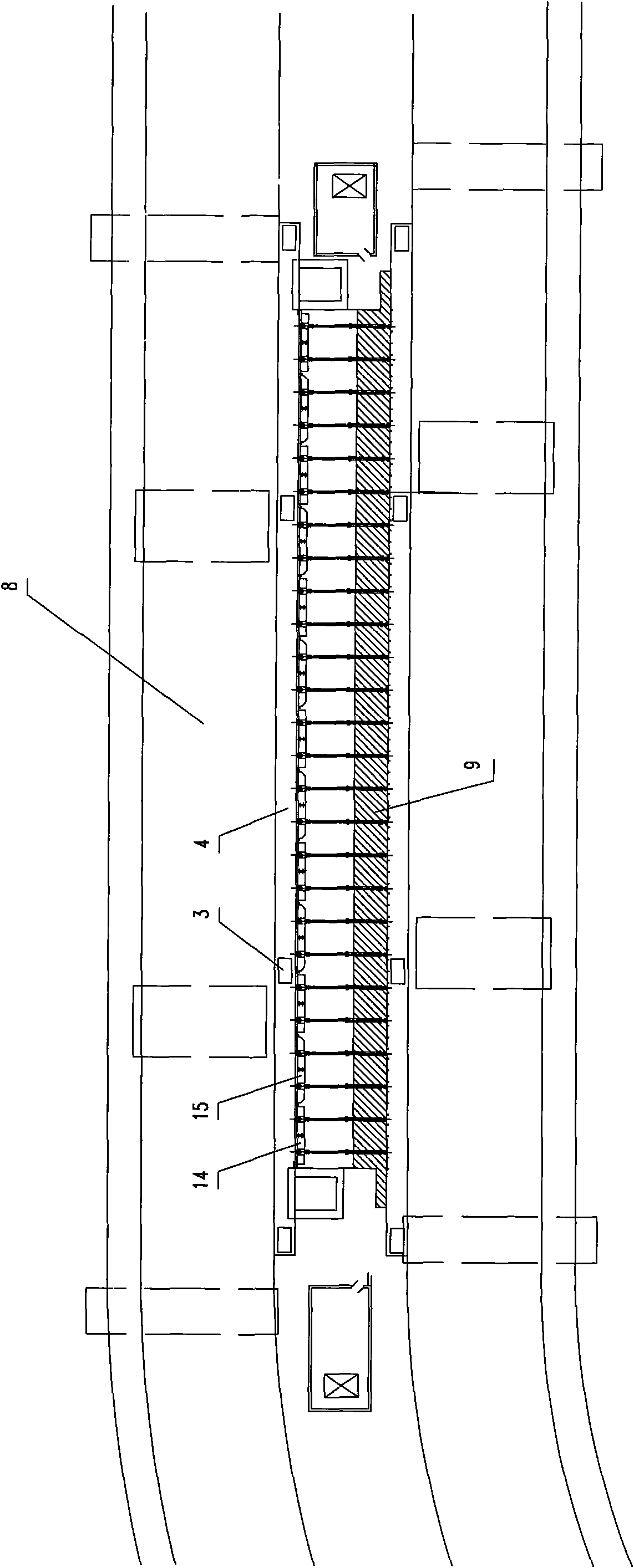

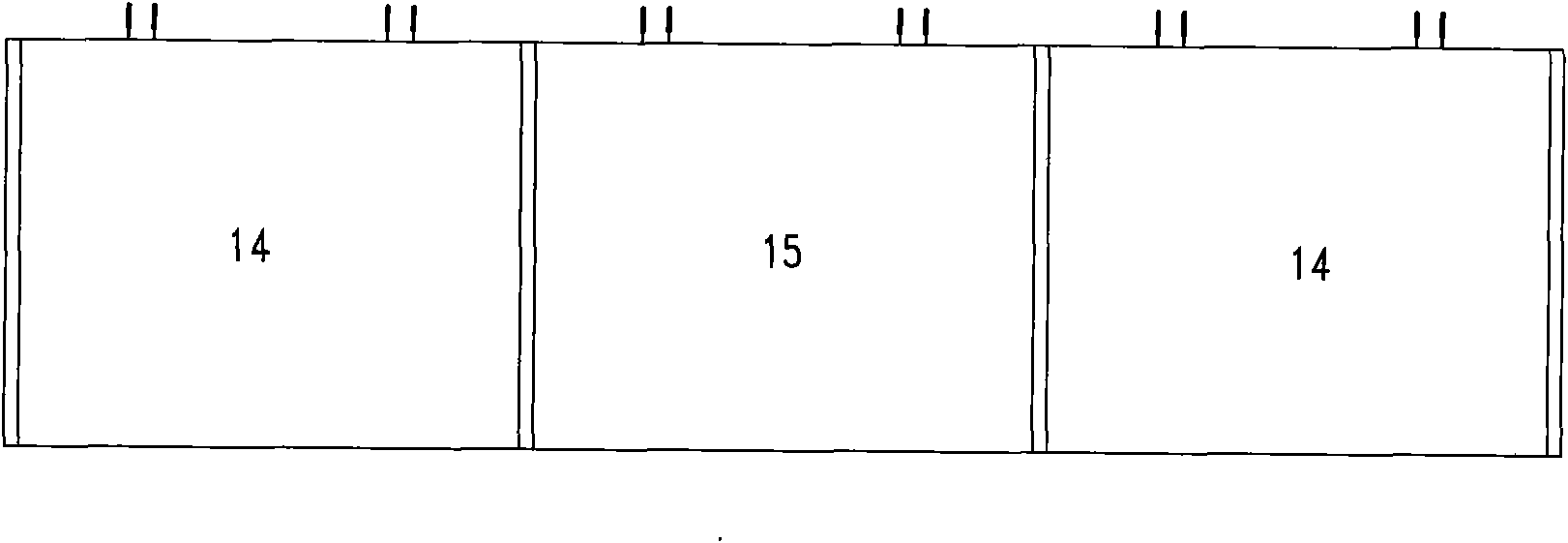

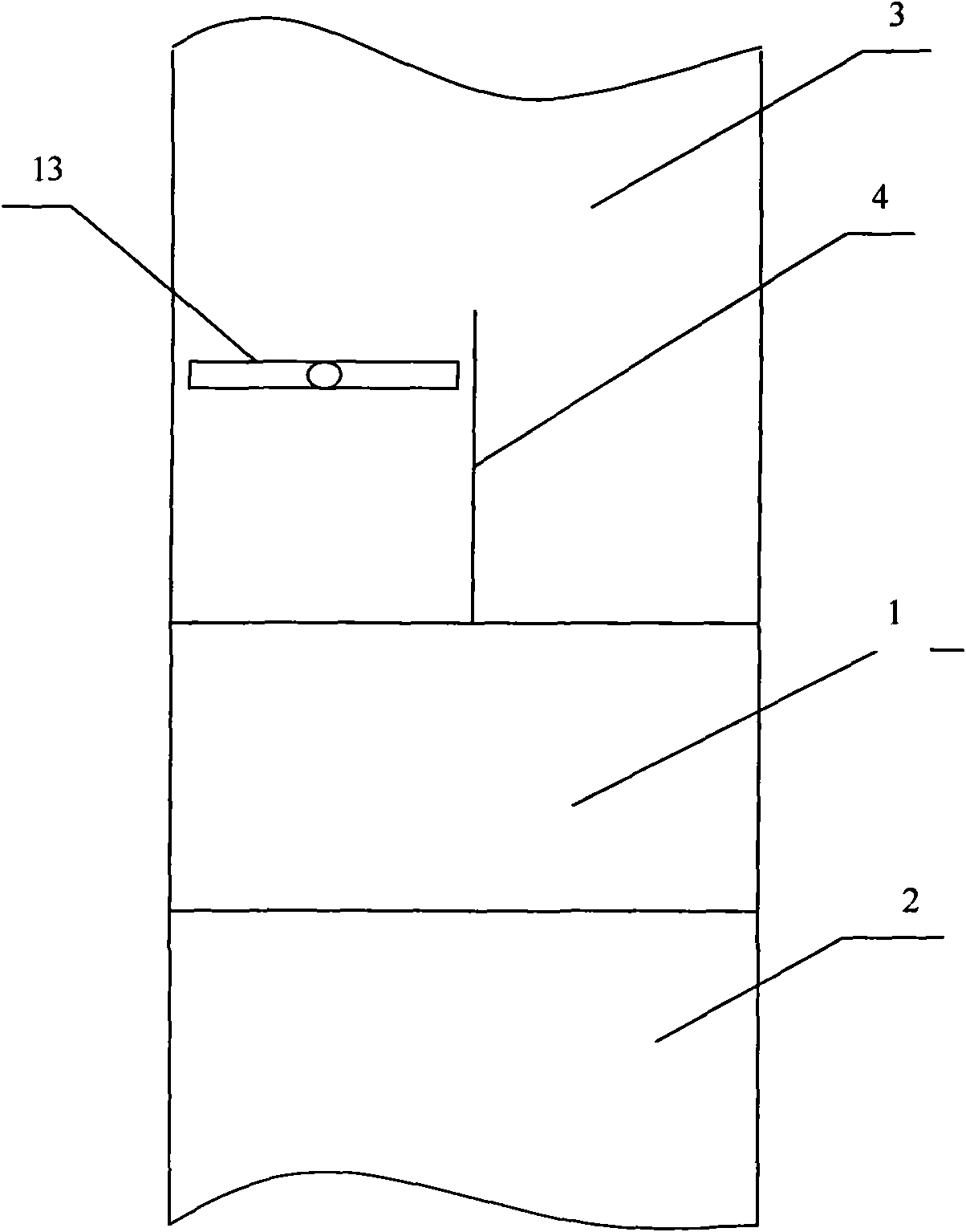

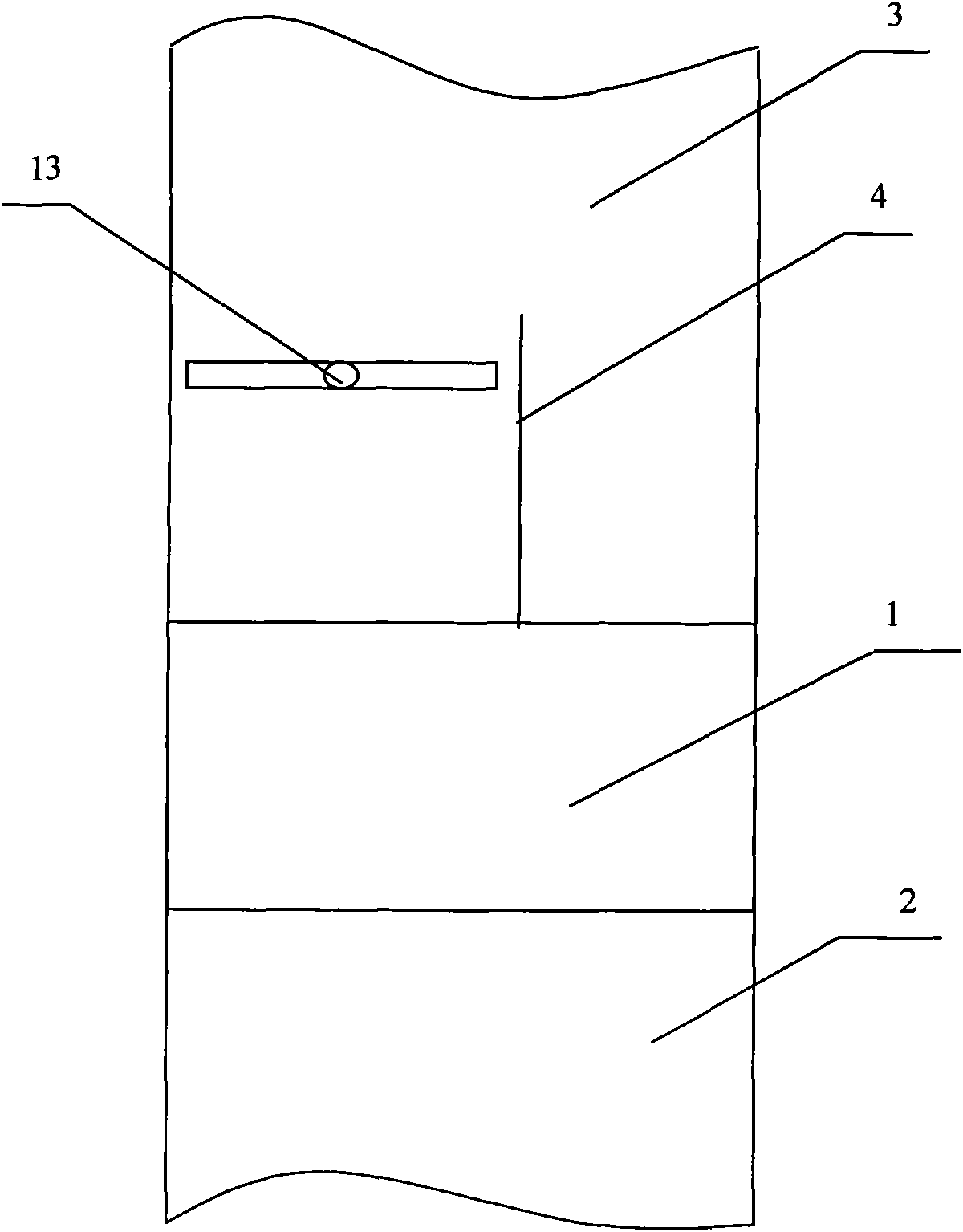

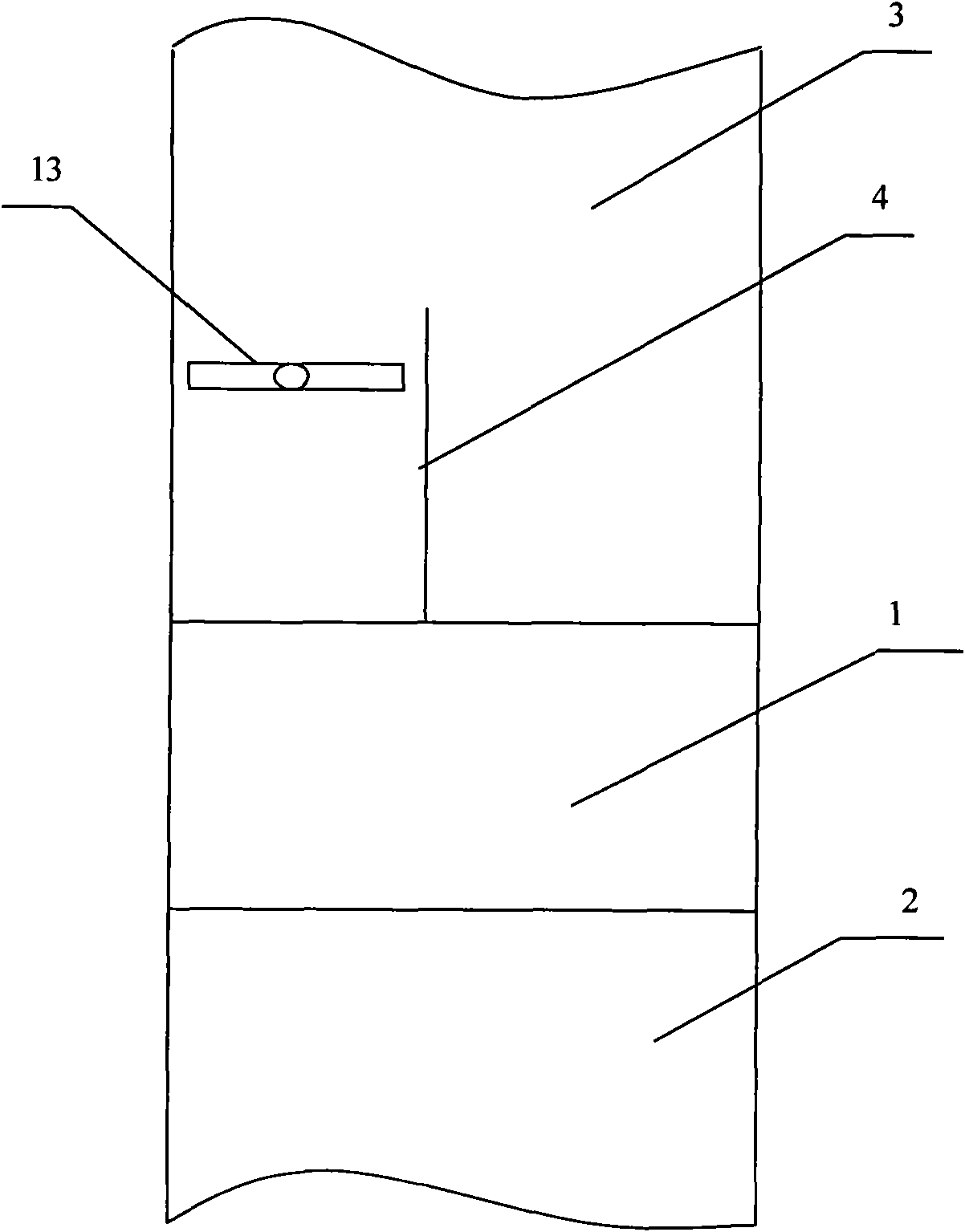

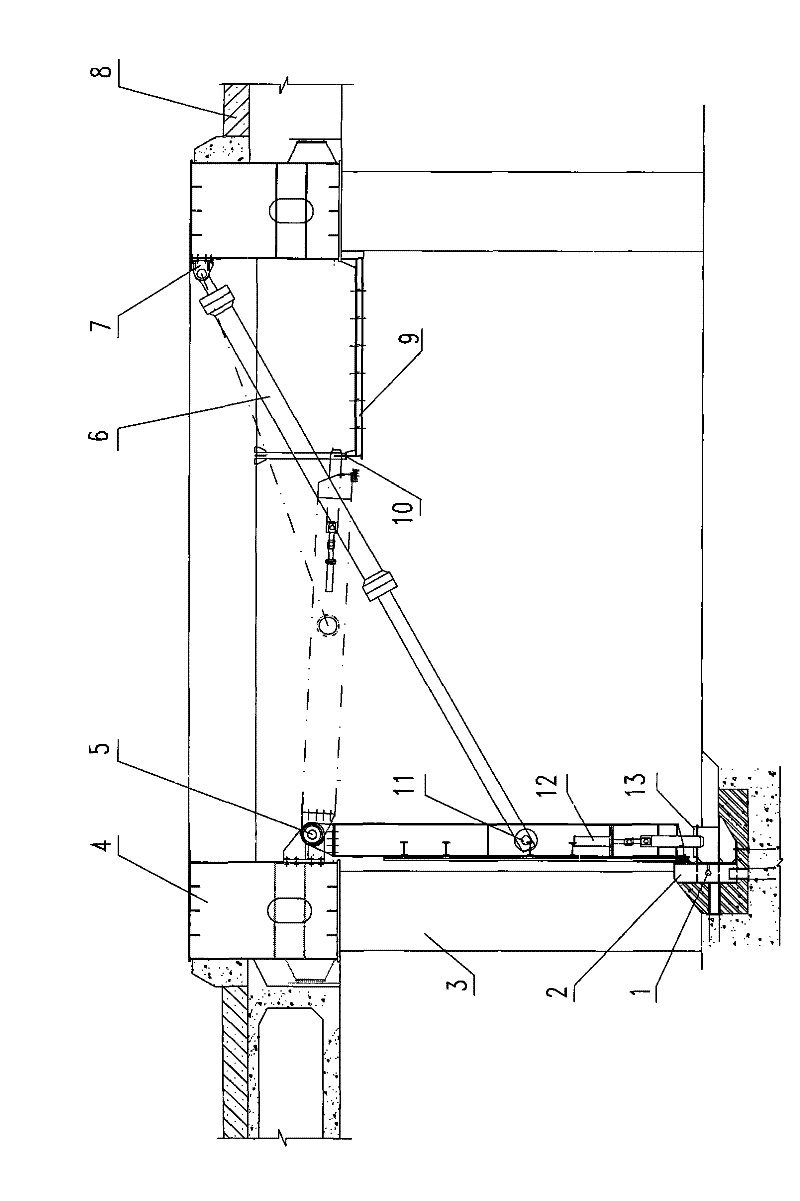

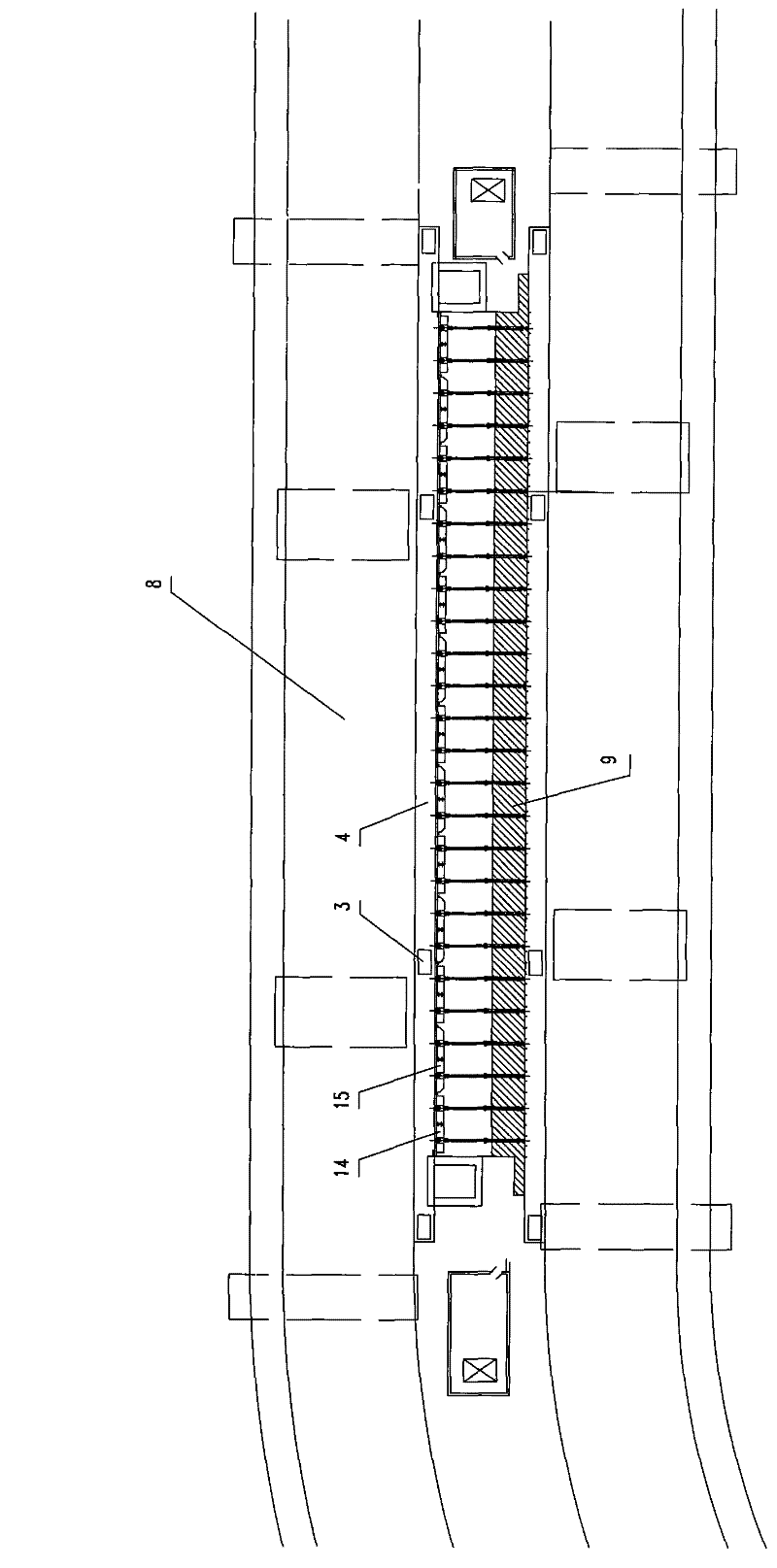

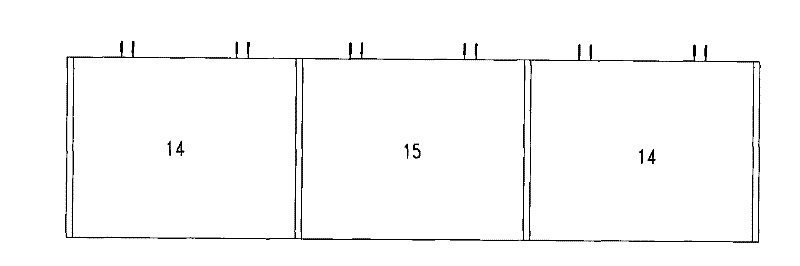

Hydraulic upward turnover type gate

ActiveCN101666076ASave spaceEasy maintenance and repairBarrages/weirsAgricultural engineeringControl room

The invention discloses a hydraulic upward turnover type gate comprising a gate, a hydraulic hoist, a hydraulic power unit and a control room, wherein the gate comprises three or more unit gates whichare arranged transversely, the odd unit gates are A type gates, the even unit gates are B type gates, each of the A type gates and the B type gates as well as an upper hoisting head of an oil cylinder of the hydraulic hoist are respectively hung on opposite sides of two box-type structural steel beams additionally arranged on the upstream and the downstream of an isolation strip between double-margined bridges, and the middle of each of the A type gates and the B type gates is respectively connected with each lower hoisting head of the oil cylinder of the hydraulic hoist through a trunnion; side seal rubbers at two sides of each B type gate are pressed on a gate leaf of the A type gate adjacent to the B type gate and bottom seal rubbers at the rear side of the bottom of each of the A typegates and the B type gates are pressed on the side of a sill so as to form a side and bottom sealing structure. The invention has the advantages of large-scale gate building, no influence to landscape, simple process, simple and convenient installation and lower cost.

Owner:YELLOW RIVER ENG CONSULTING

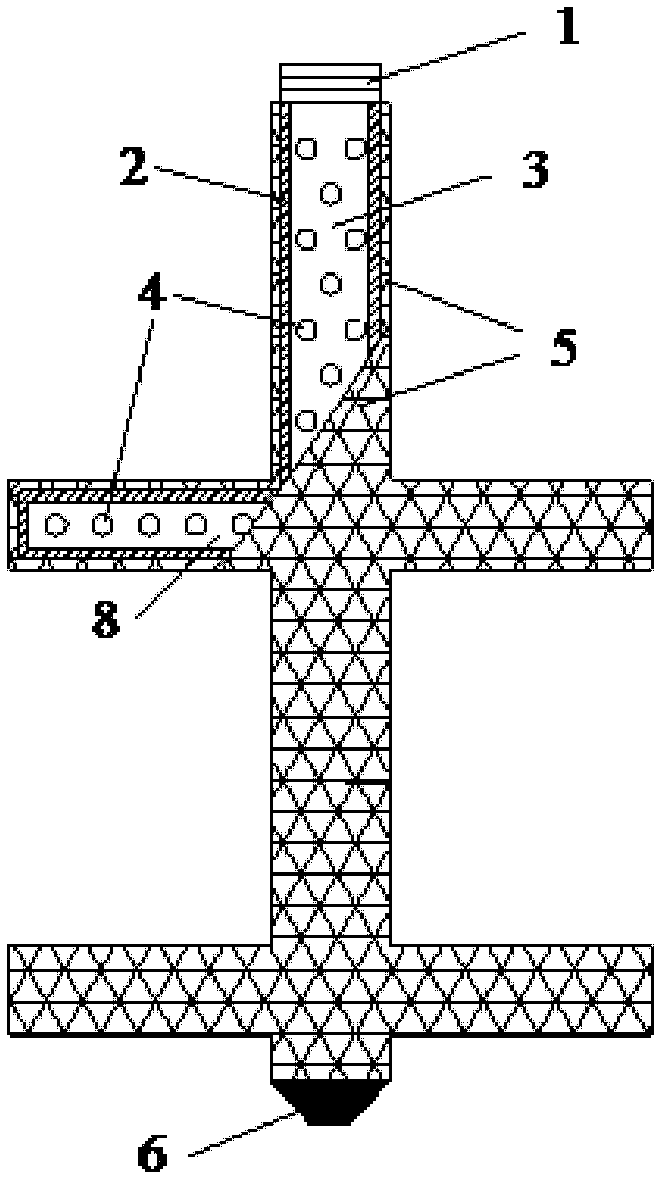

Clogging preventing method for drainage channel based on underground high-flow-capacity drainage system

A clogging preventing method for drainage channel based on an underground high-flow-capacity drainage system comprises connecting the upper opening of a high-flow-capacity drainage body with a flexible water permeable pipe, and pressing into to-be-treated super-soft soil until reaching a design depth or hard shell course while reserving a section of the flexible water permeable pipe above the ground; connecting the flexible water permeable pipe with a drainage branch pipe, connecting the drainage branch pipe in a centralized way to a drainage main pipe, connecting the drainage main pipe to the water inlet of a sediment box and connecting the water outlet of the sediment box to another section of drainage main pipe and further to a pump and a drainage pipe; arranging a seal film and pressing a groove in the region where the drainage body is arranged; starting up the pump for evacuation; and choosing the time for stopping evacuation according to the super-soft soil surface settlement rate and predicted treatment effects. The invention can satisfy the requirement for construction period and strength uniformity of soil mass after drainage consolidation treatment, and realizes clogging preventing and treatment based on fine particle dredging.

Owner:HOHAI UNIV

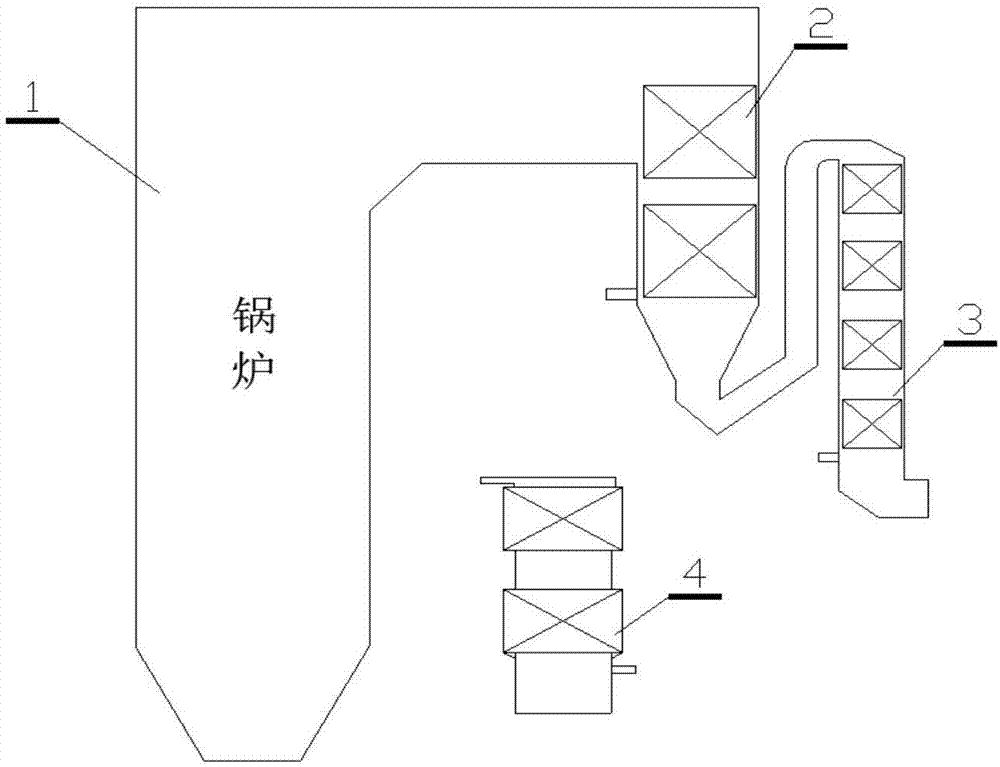

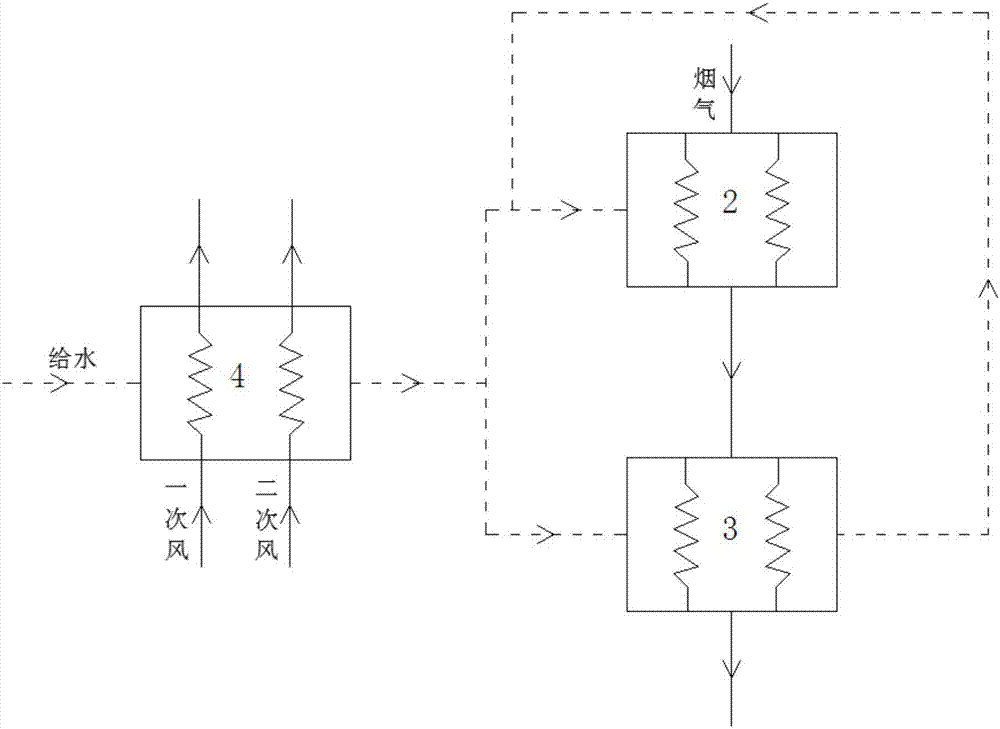

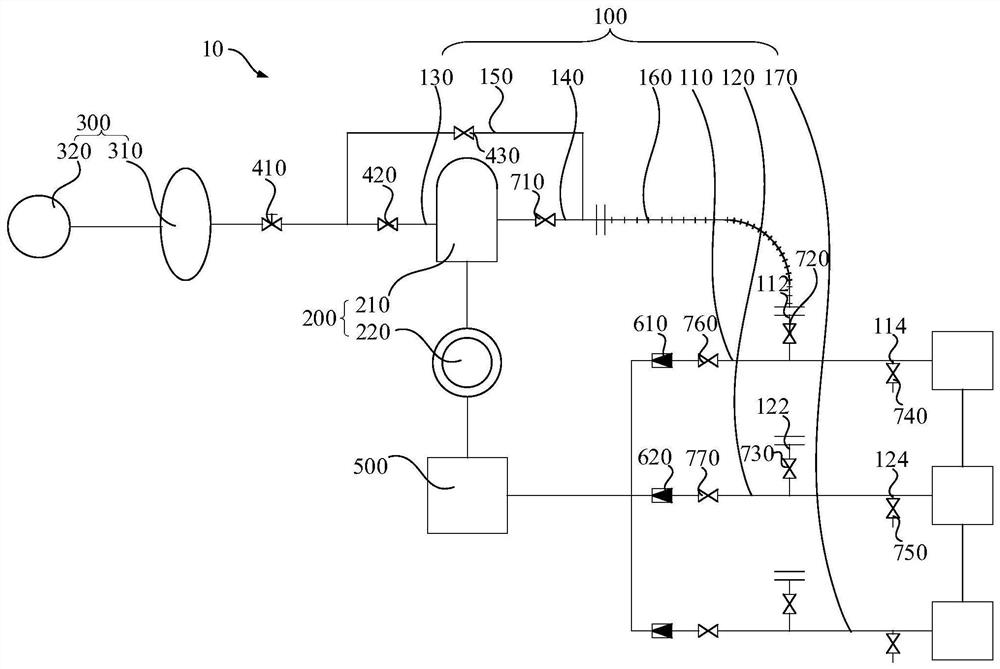

Part control phase change air preheating system and air preheating method

InactiveCN103115377AImprove securityImprove adaptabilityCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention relates to a part control phase change air preheating system and an air preheating method. The part control phase change air preheating system and the air preheating method well solve the coupling problem of traditional air preheater low temperature corrosion and heat efficiency, an operating method of the air preheating system can be timely adjusted according to actual operation parameters, adjusting capability is greatly increased, and not only is economy and high efficiency of a thermal circulation system guaranteed, but also security and adaptability of the air preheating system can be improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

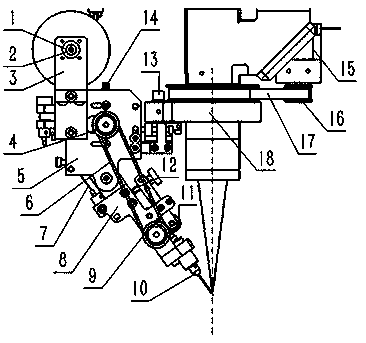

Automatic tin wire feeding device for laser welding

PendingCN109365936ASolve stress deformationSolve the cloggingSolder feeding devicesEngineeringArc welding

The invention discloses an automatic tin wire feeding device for laser welding. The automatic tin wire feeding device comprises a wire feeding mechanism and a welding rotating mechanism, wherein the wire feeding mechanism is formed by connecting a tin wire fixing device, a tin wire transmission device, a tin wire guide device, and a tin wire pressing regulating device; the welding rotating mechanism is fixedly connected with the wire feeding mechanism through a lifting mechanism; after the welding head centre line of the welding rotating mechanism is superposed with the centre line of a seconddriven wheel, the welding rotating mechanism and a wire feeding nozzle outlet are positioned on the same welding position. In this way, when the wire feeding mechanism has an angle of deflection, thewire outlet position is ensured to be kept consistent with a laser welding spot all the time; and moreover, wire feeding resistance can be prevented from being too great, stress deformation generatedby a tin wire during wire feeding is avoided, and a wire blocking phenomenon further can be prevented.

Owner:威克锐光电科技(苏州)有限公司

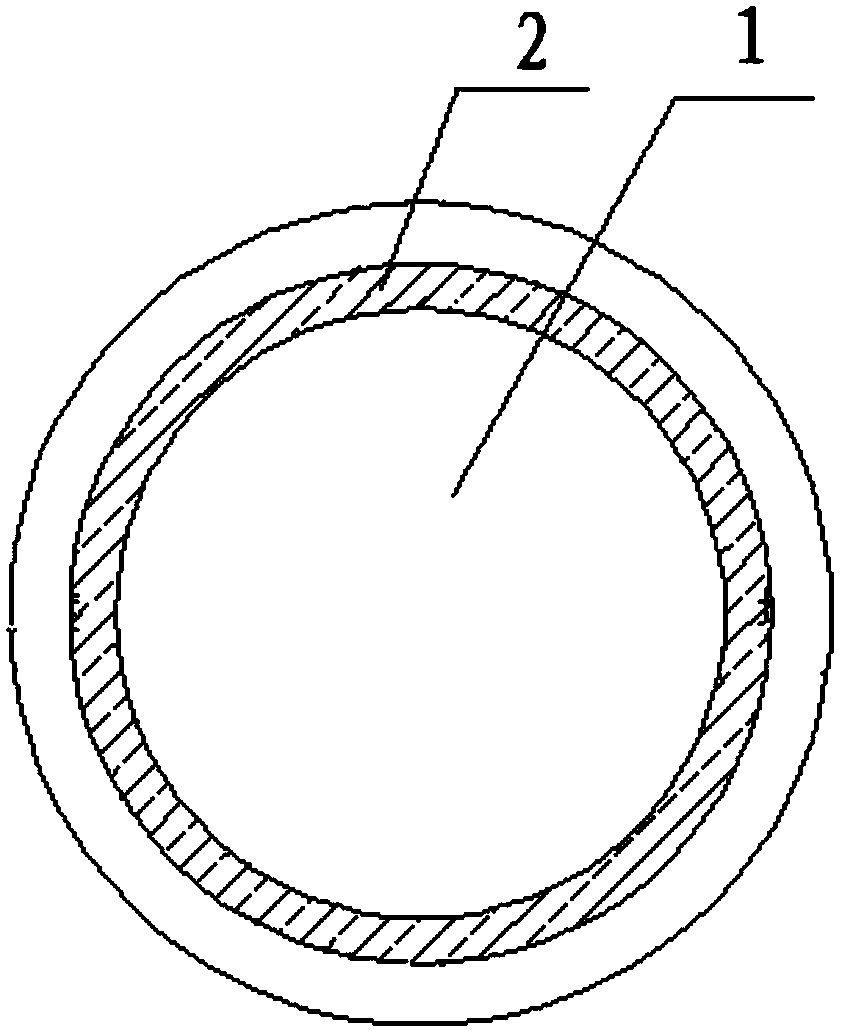

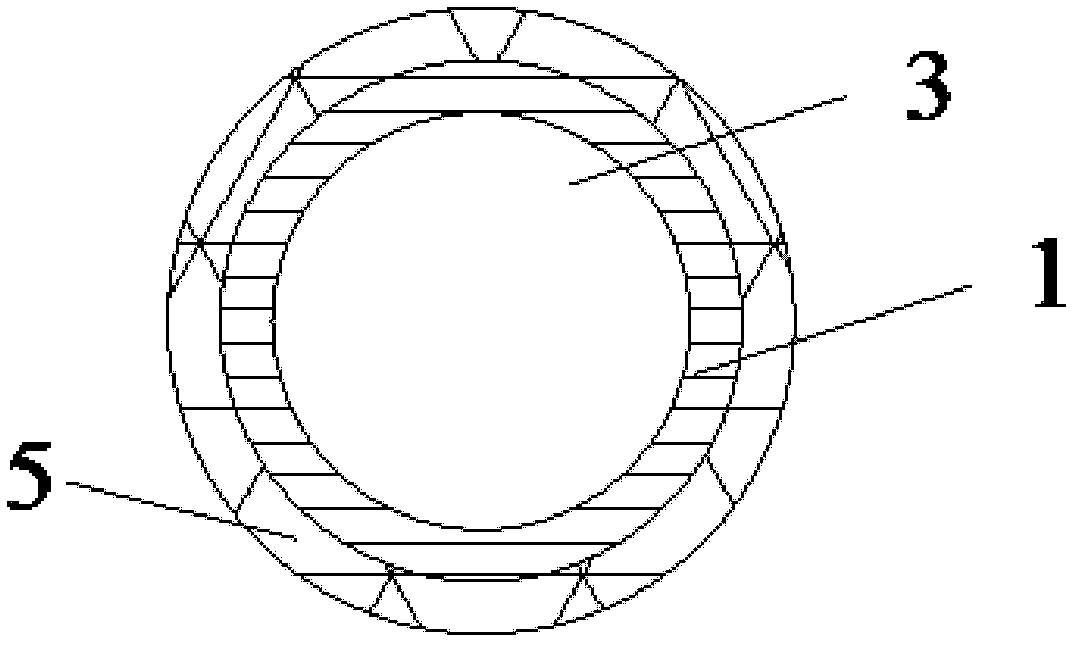

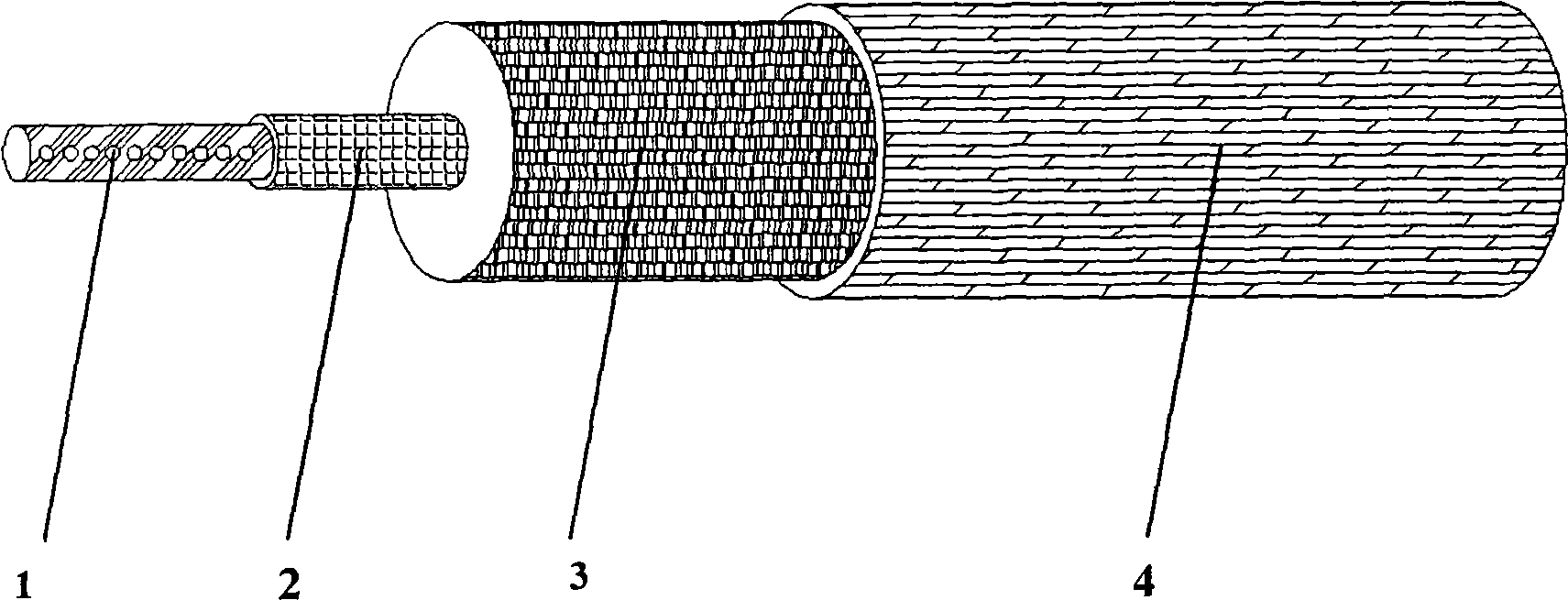

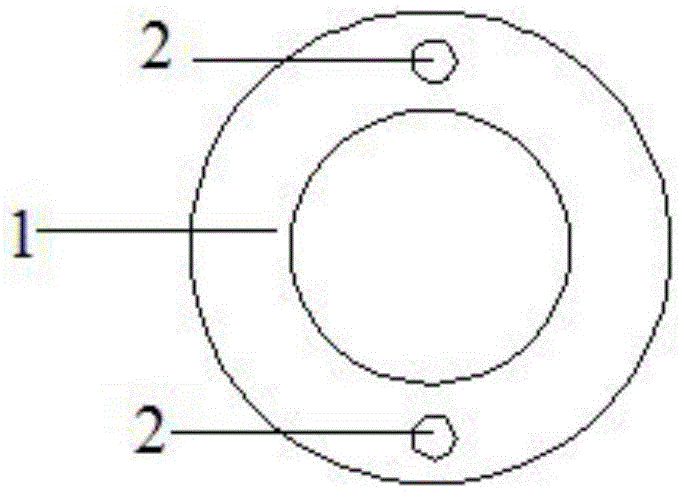

Ventilated anti-blocking composite filter tube structure and method for banding the same

InactiveCN101496969ALow priceLow costSoil drainageStationary filtering element filtersFilling materialsComposite structure

The invention relates to an air permeable anti-clogging composite filter tube structure and a seizing method. The air permeable anti-clogging composite filter tube structure has the following four layers from inside to outside: a low flow admittance inner tube, a water filtration layer, an air permeable porous filling material, and a high water permeability enwrapping material. The seizing method comprises the following steps: coating the low flow admittance inner tube which is evenly punched in advance with a layer of the water filtration layer material; sleeving the seized low flow admittance inner tube and the water filtration layer into the cylindrical high water permeability enwrapping material which is formed in advance; filling up the air permeable porous filling material between the water filtration layer and the high water permeability enwrapping material; and connecting the two ends of the whole composite structure with an exhaust pipe and a vent pipe respectively, and sealing the interfaces. The invention has the advantages that the invention solves the clogging problem which is frequently encountered during high water content sludge dredging; and an air permeable vacuum rapid sludge water separation method reaches an optimal effect in the project. The air permeable anti-clogging composite filter tube structure has easily-purchased raw materials, low price, convenient use, simple structure, simple process, and easy generalization and application.

Owner:HOHAI UNIV

Refuse landfill leachate guide and drainage pipe dredging device

PendingCN106948471ASolve the cloggingAvoid cloggingSewer cleaningSteel woolEnvironmental engineering

The invention relates to the technical field of environment geotechnical engineering, in particular to a refuse landfill leachate guide and drainage pipe dredging device. One end of a traction rope is connected onto an active roller; the other end of the traction rope passes through a leachate guide and drainage pipe to be connected onto the fixed pulley; a plurality of steel wire fuzzy balls are fixed on the traction rope. When the refuse landfill leachate guide and drainage pipe dredging device is used, a windlass starts, so that a steel wire fuzzy balls fixed on the traction rope can move to and fro in the leachate guide and drainage pipe; a pattern hole starts to be dredged; a residue structure remained in the leachate guide and drainage pipe is disordered, floats up, flows along with the leachate in the leachate guide and drainage pipe, and flows out to a discharging opening of the leachate guide and drainage pipe. The problems of blockage of the patterned hole of the refuse landfill leachate guide and drainage pipe and blockage of the leachate guide and drainage pipe are solved. The refuse landfill leachate guide and drainage pipe dredging device has the advantages that the structure is simple; safety and reliability are realized; the investment cost is low.

Owner:SHENZHEN GAD ENVIRONMENTAL TECH

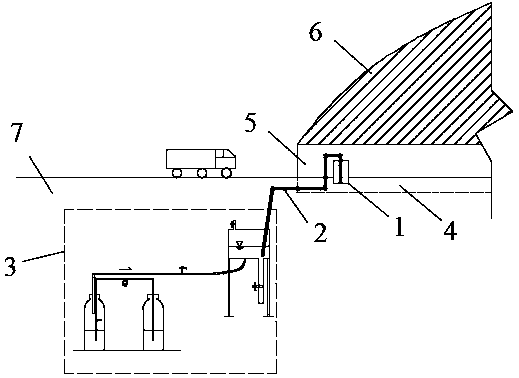

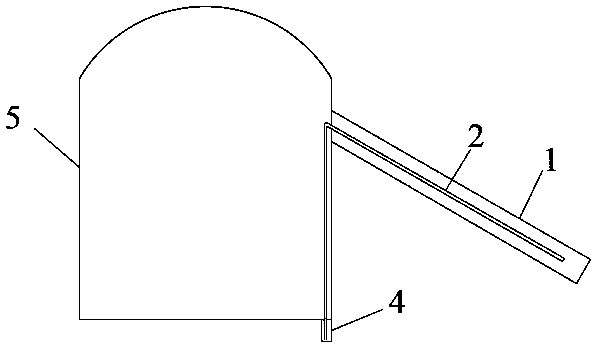

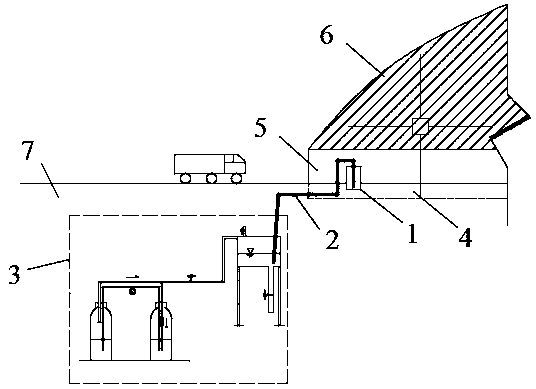

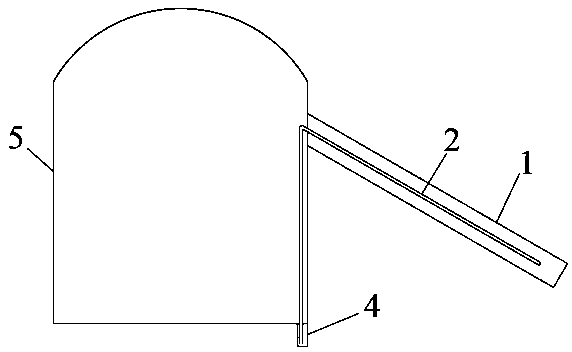

Tunnel drainage system and method thereof

ActiveCN108547662ASolve accumulationSolve the problem of sediment cloggingDrainageSiphonWater leakage

The invention provides a tunnel drainage system. According to the tunnel drainage system, the problems that the water leakage defect of a tunnel is a difficult problem disturbing tunnel operation andmaintenance, a tunnel lining is eroded and destroyed due to long-time water leakage of the tunnel, tunnel surrounding rock is also softened due to water leakage, the strength of the surrounding rock is reduced, and consequently the surrounding rock is destabilized and damaged are solved. The tunnel drainage system comprises a drill hole, a side ditch, a gas water pressing device and the like. High-pressure gas is filled into a water tank for reverse water pressing so as to start siphoning, the problems of siphon air accumulation and silt plugging are solved, the tunnel drainage system does notneed help of other electrical equipment and is simple and reliable, materials are simple and easy to obtain, and the tunnel drainage system is not disturbed by other external conditions and is wide in application range and suitable for wild mountain tunnels in remote areas.

Owner:滨州高新高端装备制造产业园有限公司

Flue gas system for unbalance control of flue gas flow

InactiveCN101566351ASolve corrosiveSolve the cloggingCombustion processIndirect carbon-dioxide mitigationAir preheaterFlue gas

The invention relates to a flue gas system for unbalance control of flue gas flow, which comprises an air preheater, an air preheater outlet flue and an air preheater inlet flue which are communicated with the air preheater. N partition boards are arranged in the air preheater inlet flue to partition the air preheater inlet flue into N+1 small flue gas passages in which N adjusting doors are arranged. By adjusting the flue gas flow through the adjusting doors, the flue gas flow flowing through the air preheater forms certain deviation according to the metal temperature variation of a heat storage plate, namely when the metal temperature of the heat storage plate is lower, the heat transfer temperature pressure with the flue gas is larger, and the flue gas flow flowing through the surface of the air preheater is relatively large; and when the metal temperature of the heat storage plate is raised in the flue gas passage along with the rotation of the air preheater, the flue gas flow flowing through the surface of the air preheater is relatively reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

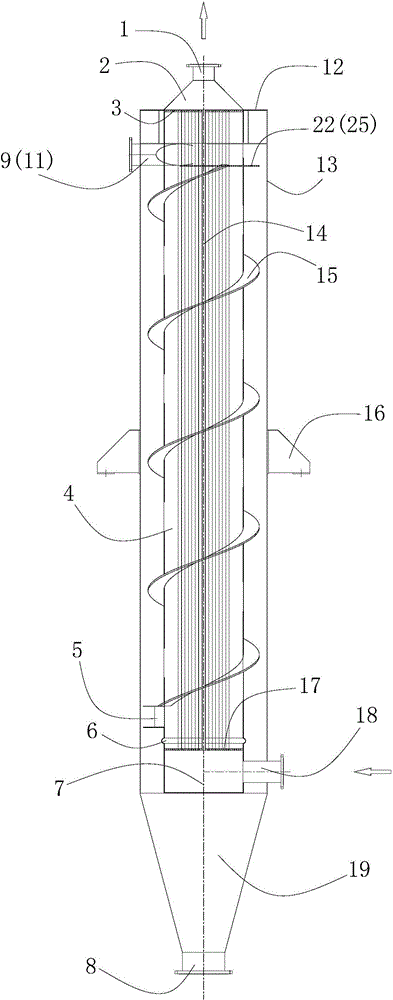

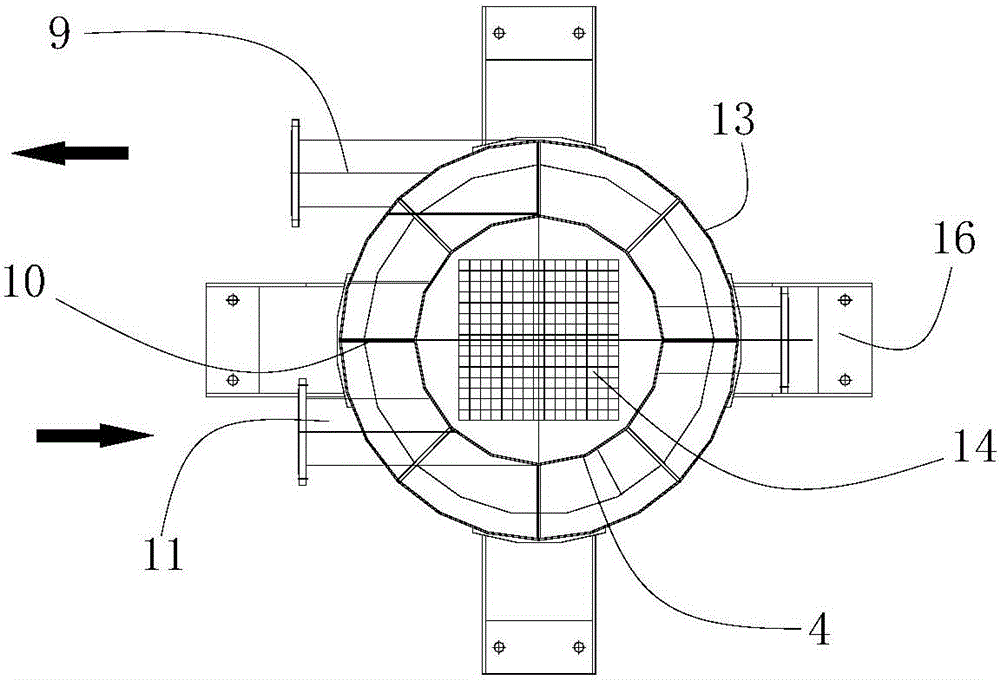

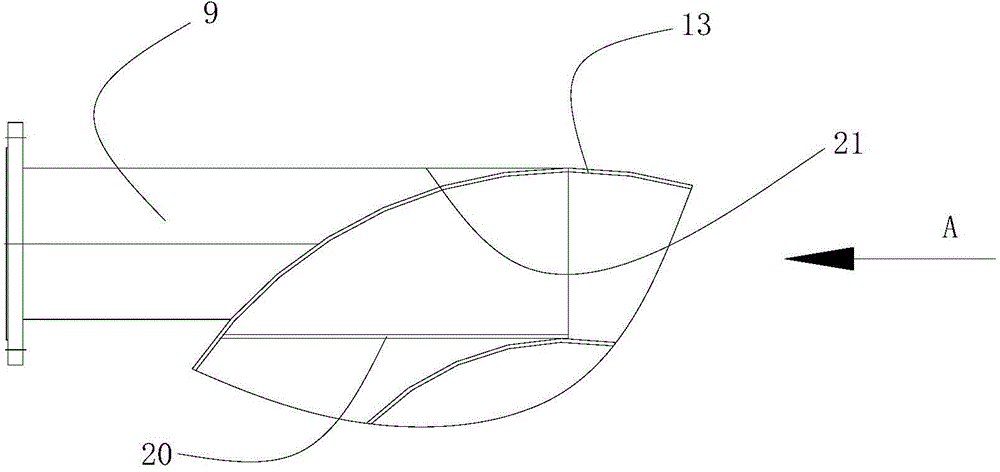

Efficient dehaze waste heat recovery energy-saving emission reduction device

InactiveCN105783013AImprove heat recovery efficiencyLower exhaust gas temperatureCorrosion preventionHeat exchanger casingsFriction lossEngineering

The invention discloses an efficient dehaze waste heat recovery energy-saving emission reduction device. The device comprises an SP heat exchange pipe, an upper tube plate, a lower tube plate, an inner barrel, a spiral plate and an outer barrel. The inner barrel is provided with a smoke inlet tube orifice and an inner barrel smoke outlet tube orifice. The lower tube plate is connected with a lower tube box provided with an air inlet tube orifice. The upper tube plate is connected with an upper tube box provided with an air outlet tube orifice. The spiral plate is spirally arranged on the outer wall of the inner barrel. The upper end of the inner barrel and the upper end of the outer barrel are connected through closure plates and reinforcing rib plates. The upper end of the outer barrel is provided with an outer barrel smoke outlet tube orifice, and the lower end of the outer barrel is connected with a dust hopper provided with a dust removing opening. The device has high heat exchange efficiency and can prolong the structure time of equipment, dust in smoke can be efficiently separated and removed, the emission amount of CO2, NOX and the like is effectively reduced, and resistance loss of the device is smaller than equipment of the same type under the same working condition. The size of the device is small, heat exchange, dust removal and dehazing are achieved, and the smoke temperature is lowered.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

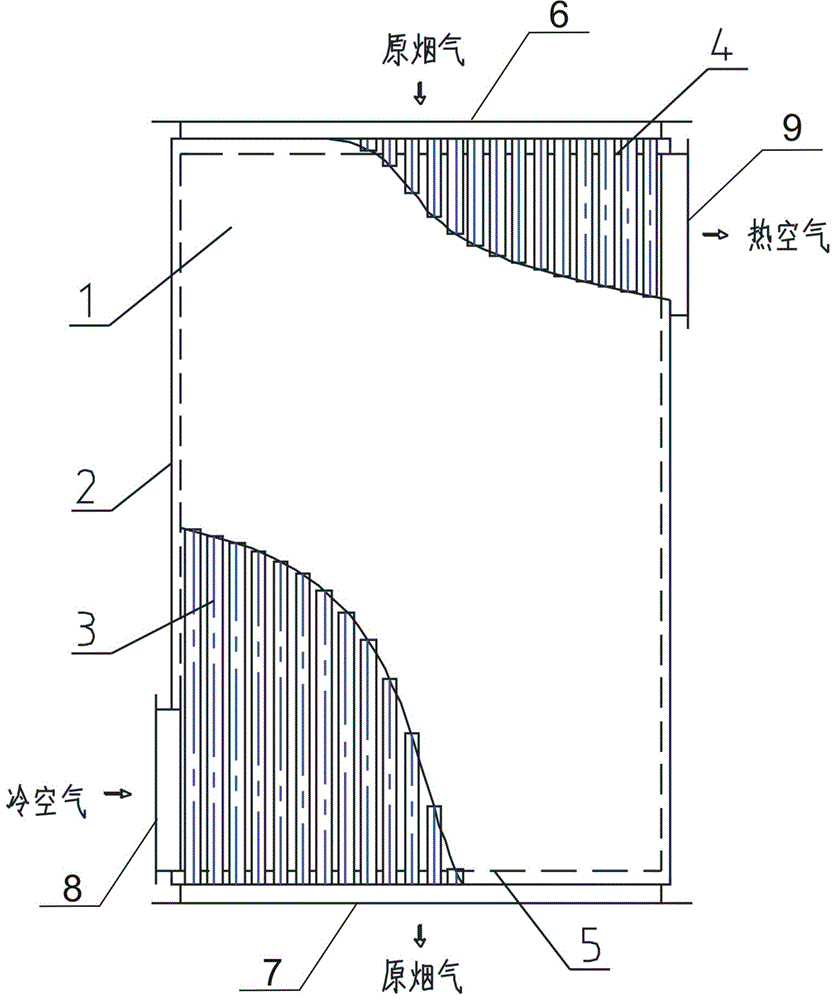

Anti-blocking segmented arrangement system for air pre-heaters

PendingCN106996577AImprove the operating environmentSolve the problem of cloggingCombustion processIndirect carbon-dioxide mitigationFlueElectrostatic precipitator

An anti-blocking segmented arrangement system for air pre-heaters comprises a high-temperature air pre-heater arranged behind a selective catalytic reduction (SCR) denitration device of a flue at the tail of a boiler; flue gas at the outlet of the high-temperature air pre-heater enters a high-temperature electrostatic precipitator through a flue; flue at the outlet of the high-temperature electrostatic precipitator enters a low-temperature air pre-heater through the flue for heat exchange; cold primary air enters the low-temperature air pre-heater through a cold primary air duct; supplied air enters the low-temperature air pre-heater through an air supply pipe; and the cold primary air and the supplied air absorb flue gas heat in the low-temperature air pre-heater and then enter a primary air side inlet and a supplied air side inlet of the high-temperature air pre-heater through an intermediate-temperate primary air pipeline and an intermediate-temperate air supply pipeline respectively. With the system, the problem of clogging of the air pre-heaters can be solved fundamentally, so that the temperature of the discharged flue gas can be effectively reduced, the temperature of the primary air and the temperature of secondary air can be increased, and the heat efficiency of the boiler can be improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

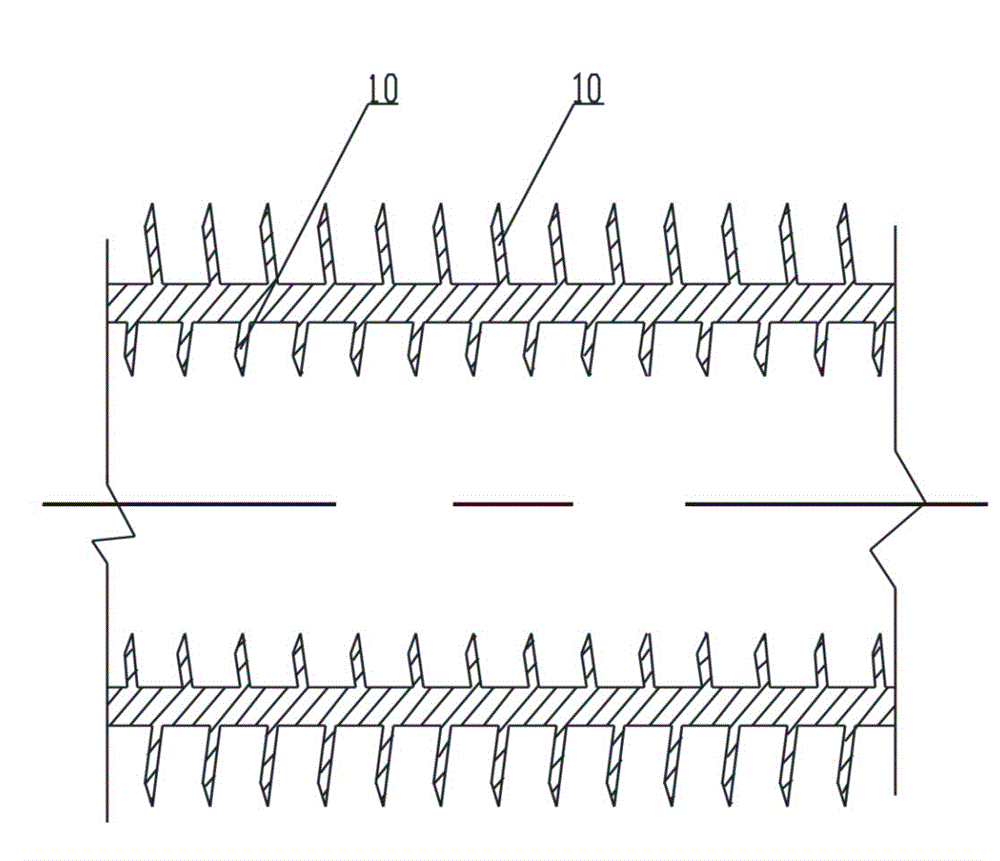

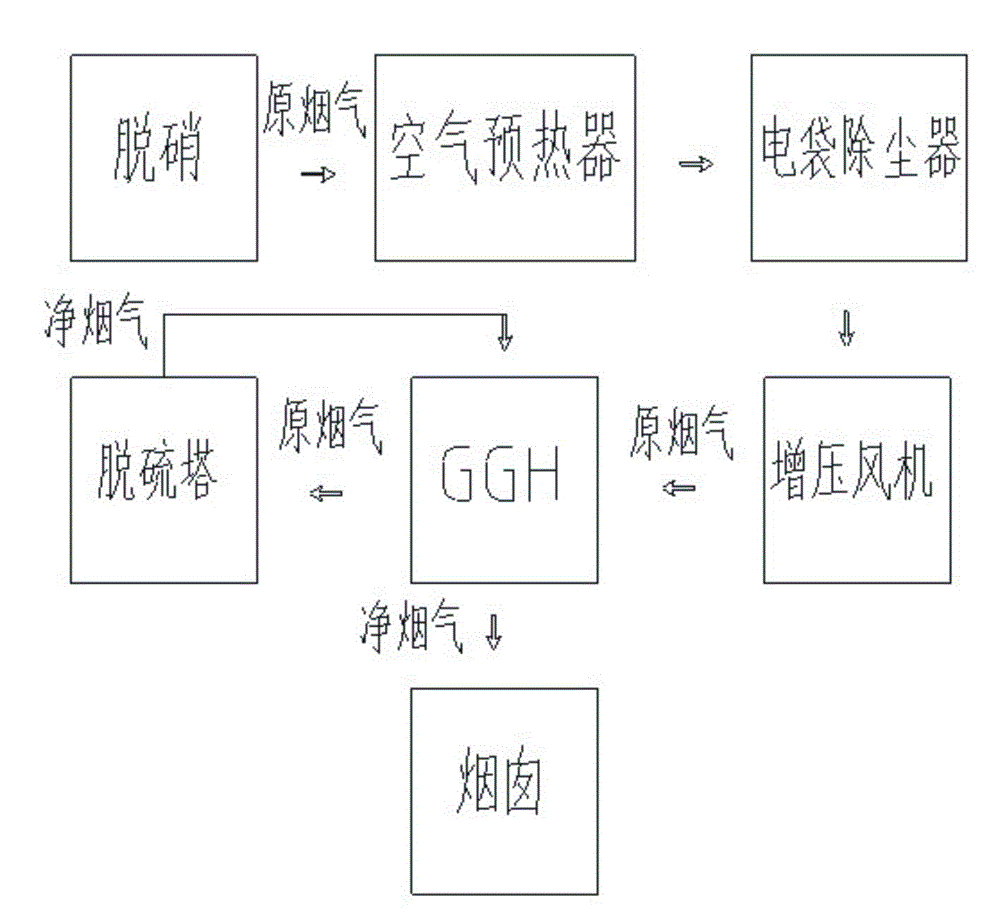

Three-dimensional internal and external finned tube integrated air preheater and processing method thereof

InactiveCN104421955AImprove heat transfer coefficientReduce volumeCombustion processIndirect carbon-dioxide mitigationAir preheaterCombustion

The invention discloses a three-dimensional internal and external finned tube integrated air preheater and a smoke processing method thereof. The three-dimensional internal and external finned tube integrated air preheater comprises a vertical case, the upper end and the lower end of the case are provided with flue ports including an flue inlet and a flue outlet respectively; the inside of the case close to the flue ports is provided with tube plates to close the case and separate the inside and the flue ports; a plurality of three-dimensional internal and external finned tubes are welded to the tube plates at the upper end and the lower end in an expanded mode and fixed inside the case; the orifices of the three-dimensional internal and external finned tubes are arranged inside the flue ports; one side of the case is provided with an air inlet, and the other side of the case is provided with an air outlet. The three-dimensional internal and external finned tube integrated air preheater integrates an air preheater and a GGH (gas-gas heater) into a whole, thereby reducing equipment investment, saving equipment space, achieving integration and solving the problems of low heat exchange efficiency, heat transfer surface acid corrosion, scale formation, clogging and the like of existing devices. Most of preheated high-temperature air is applied to combustion of a boiler, the other part of the high-temperature air is mixed with purified flue gas flowing out of a desulfurizing tower, and the temperature of the mixed purified flue gas can be up to environment protecting emission standard.

Owner:CHONGQING SHANGSHUN HEAT TRANSFER EQUIP

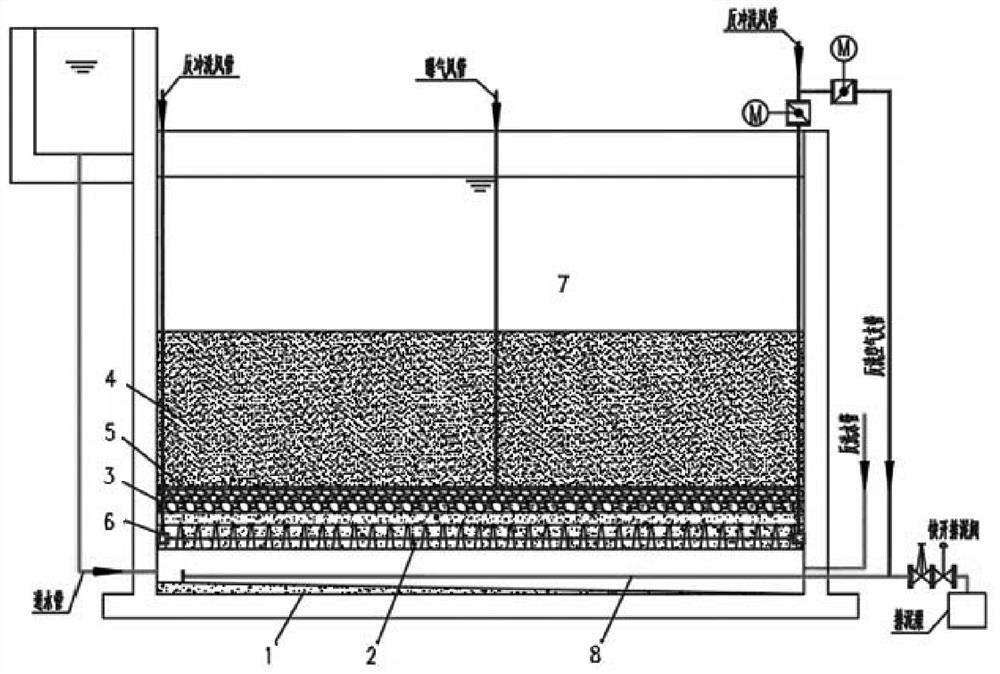

Upward flow novel biological aerated filter adopting filter with filter bricks

PendingCN112174302AStable structureFirmly connectedTreatment using aerobic processesSpecific water treatment objectivesAmmoniacal nitrogenSludge

The invention discloses a upward flow novel biological aerated filter adopting filter with filter bricks. The novel biological aerated filter is sequentially provided with a water distribution gallery, a backwashing gas distribution pipe, a T-shaped filter brick, a single-pore membrane aerator, a filter bed supporting layer, a filter bed filter material layer and a perforated sludge discharge pipefrom bottom to top; the perforated sludge discharge pipe is located in the water distribution gallery, the backwashing gas distribution pipe is located in an inner cavity of the T-shaped filter brick, and the water distribution gallery is located at the bottom of the filter body. According to the biological filter, the specially-made filter bricks are adopted for water distribution and gas distribution, gas and water flow upwards in the same direction, backwashing water distribution and gas distribution are more uniform, blockage is avoided, and the filter bricks are free of vulnerable partsand do not need to be maintained or replaced; a perforated sludge discharge pipe and a slope are arranged in the water distribution gallery, the sludge discharge pipe is connected with a backwashing air branch pipe, and flushing and sludge discharge are carried out regularly, so that the problem of sludge accumulation possibly caused by long-time operation of the water distribution gallery and thebottom of the filter tank is solved; upward flow filtration continuously provides a positive pressure condition at the whole height of the filter tank, air and water flow flow in the same direction,and the fluid is completely and uniformly distributed, so that the biomass is greatly improved, the quantity and activity of dominant organisms are improved, and the function of removing pollutants such as ammonia nitrogen and organic compounds is enhanced.

Owner:四川欧美华环境工程有限公司

Traditional Chinese medicine composition for preventing cancers

InactiveCN106377751ASolve the cloggingUnobstructed detox channelBird material medical ingredientsAluminium/calcium/magnesium active ingredientsDiseaseChinese drug

The invention discloses a traditional Chinese medicine composition for preventing cancers. The traditional Chinese medicine composition is prepared from raw materials comprising a composition capable of soothing liver and regulating qi, a composition capable of strengthening body resistance and a composition capable of eliminating evil. According to the traditional Chinese medicine composition, used medicines are moderate and have the effects of clearing, regulating and nourishing; the traditional Chinese medicine composition has the effects of regulating and correcting a normal operation rule of internal organs and a metabolism function is realized, so that the traditional Chinese medicine composition has capabilities of preventing the cancers, resisting the cancers and defending the external evil, and the cancers have no growth conditions. The traditional Chinese medicine composition is applicable to all people to use, and medical and disease theories and a medicine utilization skill are traditional treasures; clinical cases of generations are utilized and are beneficial.

Owner:时艳丽

Hydraulic upward turnover type gate

The invention discloses a hydraulic upward turnover type gate comprising a gate, a hydraulic hoist, a hydraulic power unit and a control room, wherein the gate comprises three or more unit gates which are arranged transversely, the odd unit gates are A type gates, the even unit gates are B type gates, each of the A type gates and the B type gates as well as an upper hoisting head of an oil cylinder of the hydraulic hoist are respectively hung on opposite sides of two box-type structural steel beams additionally arranged on the upstream and the downstream of an isolation strip between double-margined bridges, and the middle of each of the A type gates and the B type gates is respectively connected with each lower hoisting head of the oil cylinder of the hydraulic hoist through a trunnion; side seal rubbers at two sides of each B type gate are pressed on a gate leaf of the A type gate adjacent to the B type gate and bottom seal rubbers at the rear side of the bottom of each of the A type gates and the B type gates are pressed on the side of a sill so as to form a side and bottom sealing structure. The invention has the advantages of large-scale gate building, no influence to landscape, simple process, simple and convenient installation and lower cost.

Owner:YELLOW RIVER ENG CONSULTING

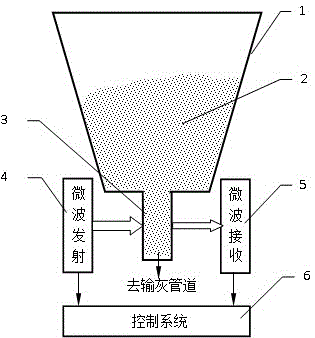

Sampling-free detection method applied to microwave carbon examination and carried out at dust outlet of dry collector

InactiveCN105115990ASolve the cloggingEliminate distractionsMaterial analysis using microwave meansMicrowave methodWorking environment

The invention relates to a sampling-free detection method applied to on-line monitoring of unburned carbon in fly ash of a large coal-fired boiler. According to the method, the operation is carried out on the dust outlet of a dry collector of a boiler unit, and the method is suitable for a detection device adopting a microwave method testing principle. The method is characterized in that monitoring points are moved to an outlet below a dust hopper of a primary dry collector through a flue. A pair of microwave transmitting and receiving devices is mounted on the opposite sides of a cross section of a dust outlet channel, so that microwave beams pass through the cross section of the dust outlet channel, while the flue dust which flows through the cross section and intercepted by the dust collector is taken as a tested object. With the adoption of the method, the problems of dust blockage, influences on the detection result by various factors, poor representativeness of a dust sample, and the like are solved; the arrangement, operation and maintenance of the detection device are convenient; and meanwhile, due to the improvement on the work environment, the reliability of the device is greatly improved, and the service life of the device is greatly prolonged.

Owner:解海龙

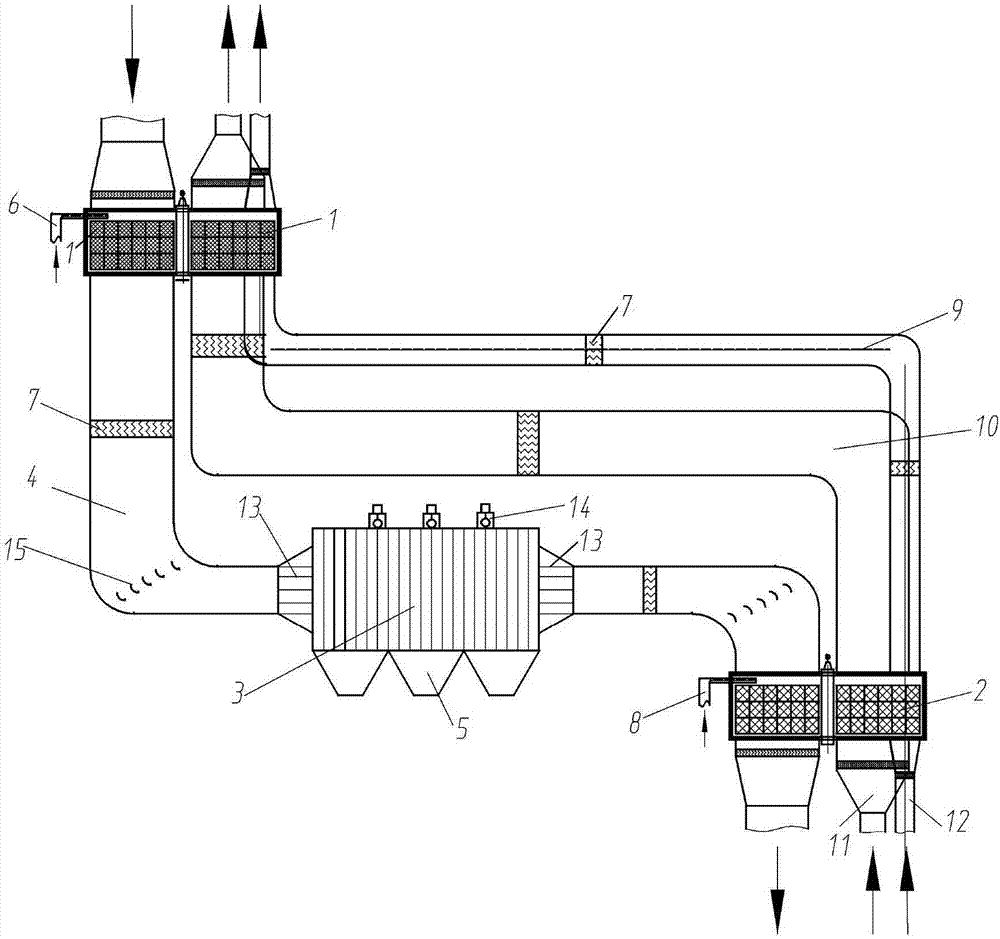

Smoke waste heat recovery system and method for biomass circulating fluidized bed boiler

The invention discloses a smoke waste heat recovery system and method for a biomass circulating fluidized bed boiler. The smoke waste heat recovery system for the biomass circulating fluidized bed boiler comprises a high-temperature economizer, a low-temperature economizer and an air preheater. The smoke waste heat recovery system for the biomass circulating fluidized bed boiler is characterized in that the air preheater is independently arranged below a horizontal flue of the boiler; primary air and secondary air are guided in from the space below the air preheater through cold air ducts correspondingly and exchange heat with supplied water flowing in the air preheater, and hot air obtained after heat exchange is guided out from the upper portion of the air preheater and enters a hearth. The smoke waste heat recovery system and method for the biomass circulating fluidized bed boiler have the beneficial effects that the problems of collision and ash blockage of the air preheater and the economizers are solved while the exhaust smoke temperature and the exhaust smoke loss are not increased, the service life of the air preheater on the tail is prolonged, the continuous operating capacity of the biomass boiler is improved, heat pollution is reduced, and the environment is protected.

Owner:SHANDONG QIQUAN ENERGY TECH CO LTD

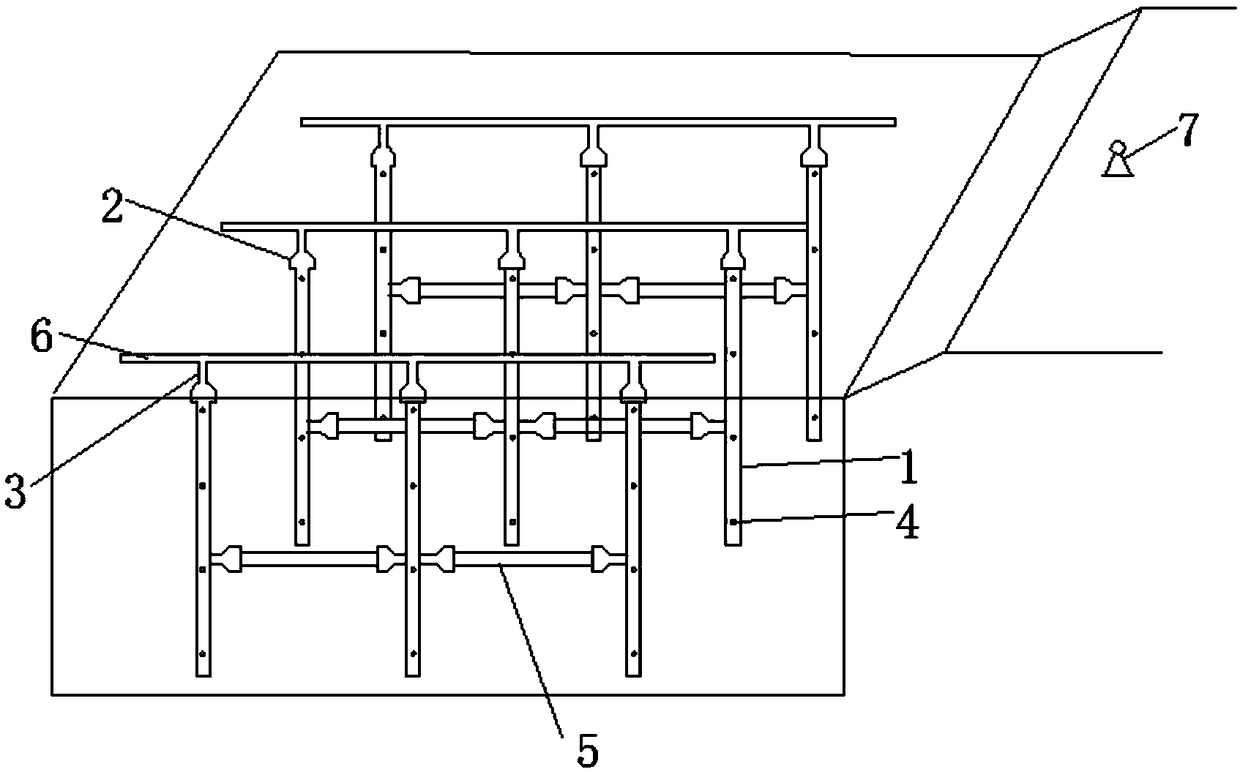

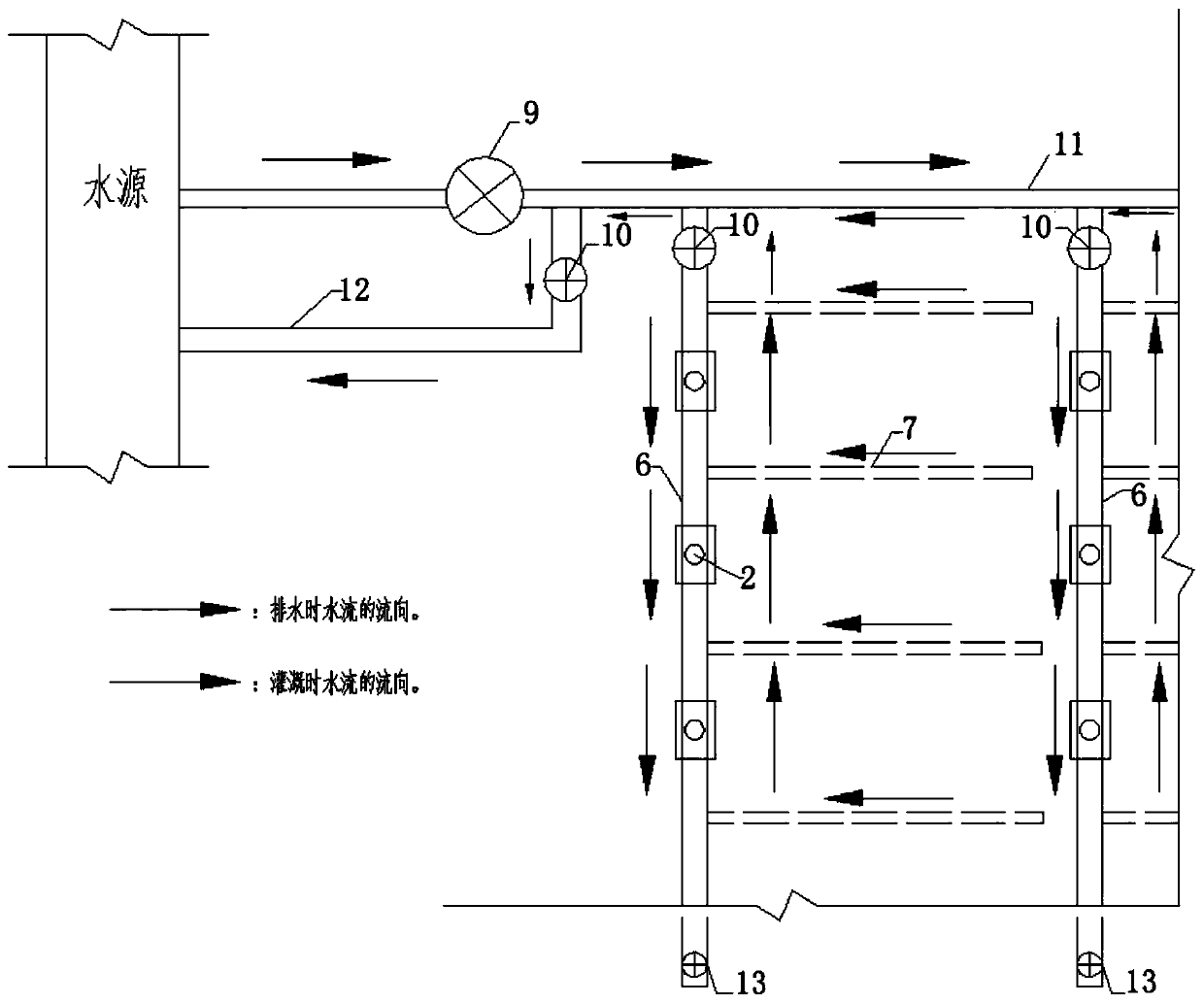

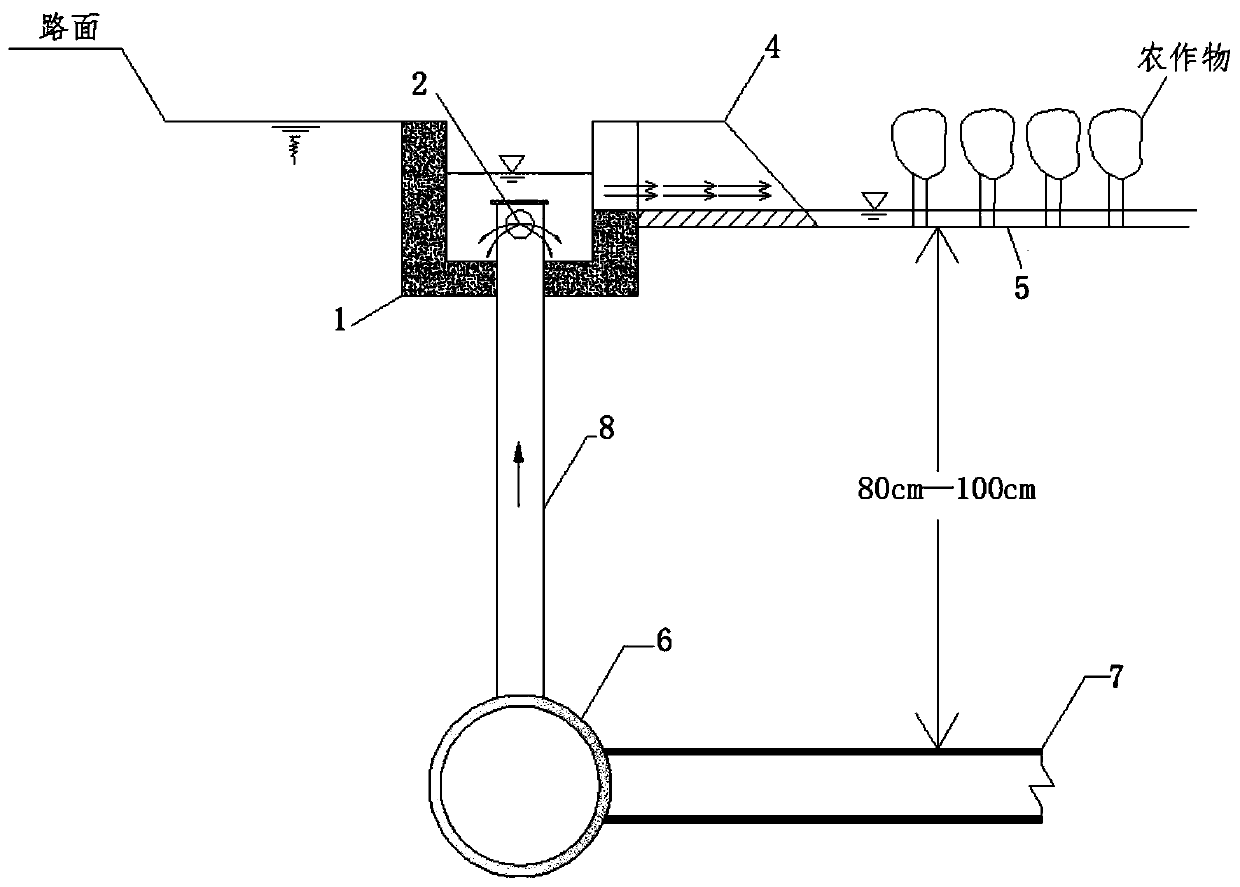

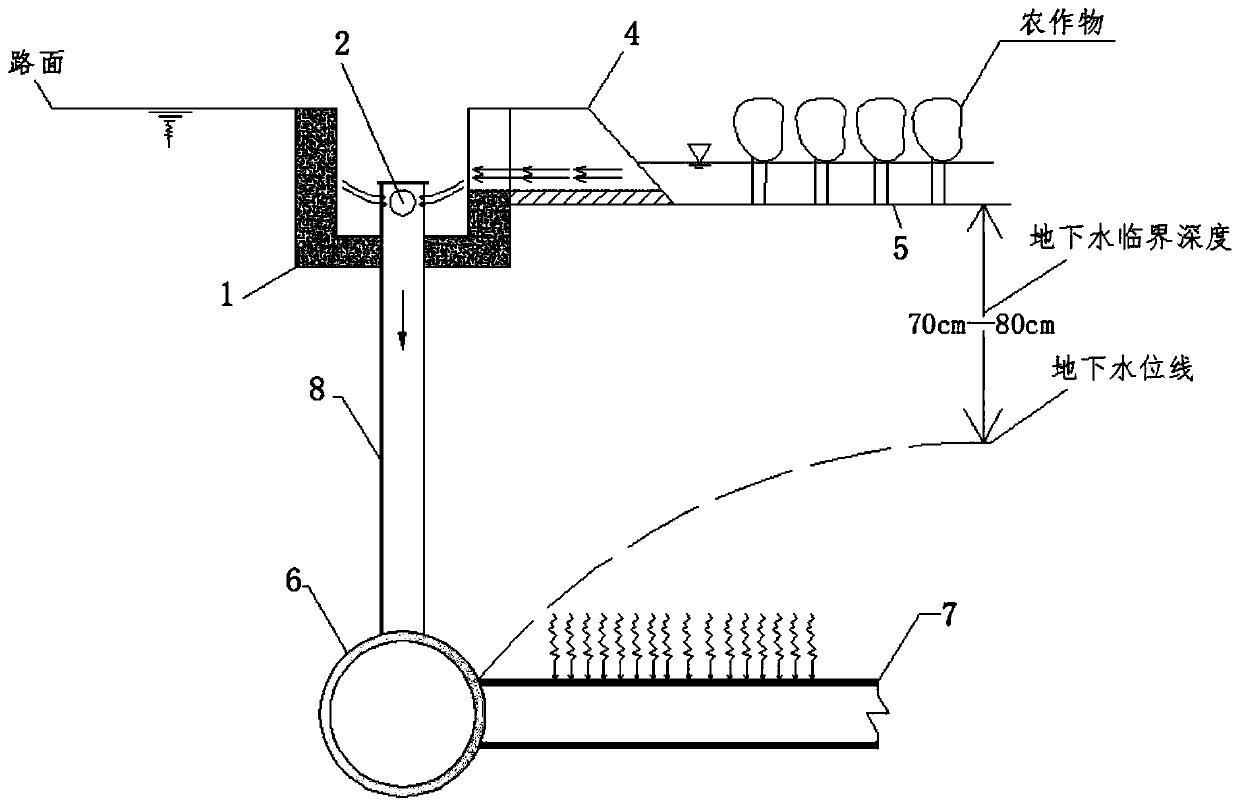

Blind ditch flushing system and flushing method

ActiveCN113599888ASolve the cloggingImprove drainage efficiencySewer cleaningSustainable biological treatmentWater useEnvironmental engineering

The invention discloses a blind ditch flushing system and flushing method. The flushing system for a blind ditch comprises a communication assembly, a liquid supply device and an air supply device. The communication assembly comprises a first pipeline for water inflow and a second pipeline for water drainage, the first pipeline communicates with one end of the blind ditch, and the second pipeline communicates with the other end of the blind ditch; the liquid supply device communicates with the blind ditch through a first pipeline and is used for providing water for flushing the blind ditch; and the air supply device communicates with the liquid supply device so that air-dissolved water used for flushing the blind ditch can be generated in the liquid supply device. High-pressure air provided by the air supply device is introduced into the liquid supply device to form high-pressure air-dissolved water, the high-pressure air-dissolved water enters the blind ditch through a first guide pipe and impacts the blind ditch from inside to outside, a filter cake layer on the outer surface of the blind ditch is broken through shearing force of the air-dissolved water, a water seepage channel of the blind ditch is dredged, and the water permeability of the blind ditch is improved. The blind ditch flushing method can effectively solve the problem of blind ditch clogging, and the drainage efficiency and the service life of the blind ditch are remarkably improved.

Owner:广州市设计院集团有限公司

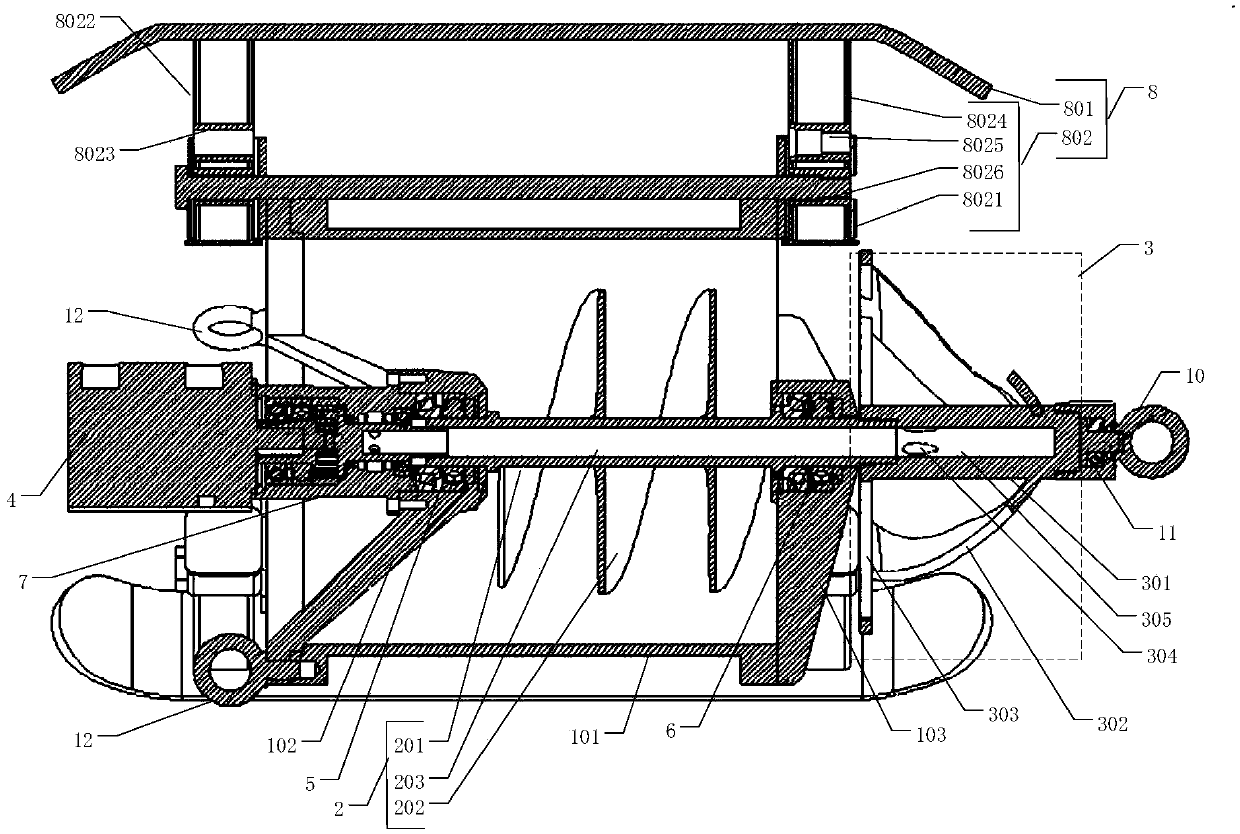

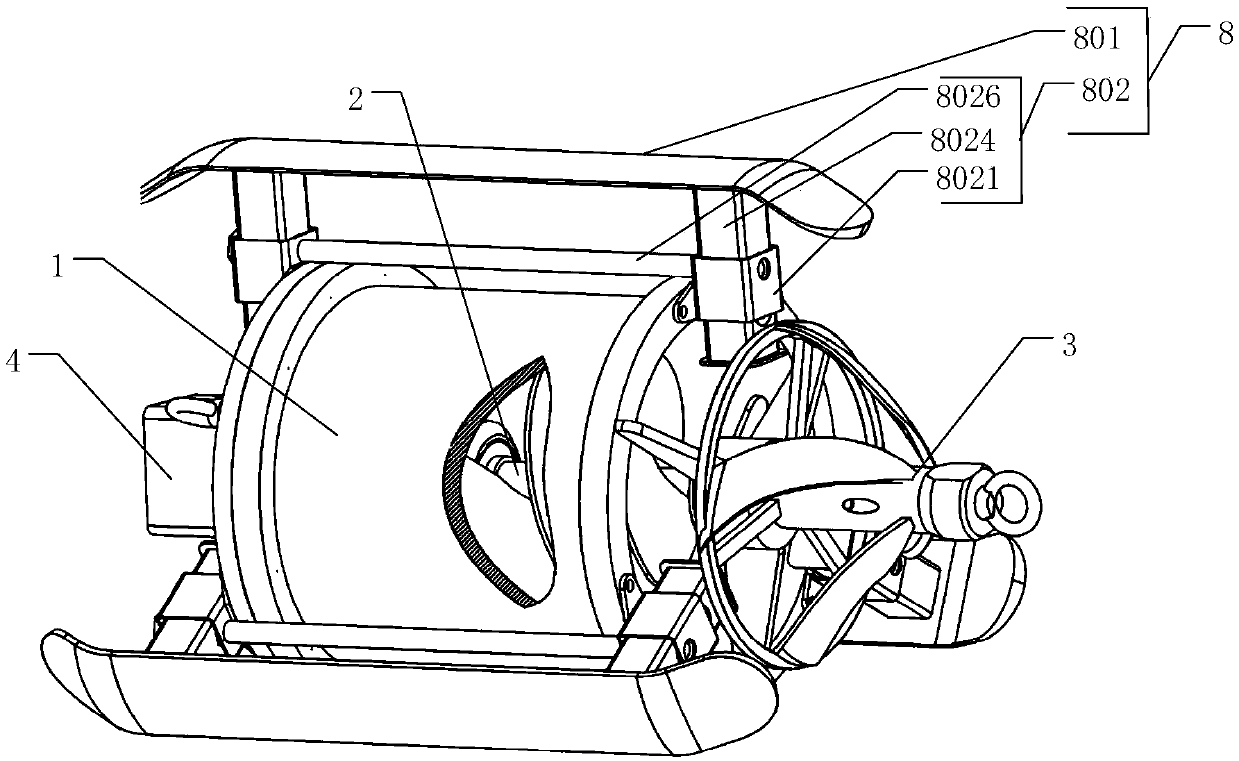

Cutter suction desilting device

PendingCN111456213ASolve the cloggingAvoid damageSewer cleaningControl engineeringStructural engineering

The embodiment of the invention provides a cutter suction desilting device. The device comprises a protection mechanism, a transmission conveying mechanism, a cutter suction mechanism and a power mechanism, wherein a containing space is formed in the protection mechanism; the transmission conveying mechanism is installed on the protection mechanism, the first part of the transmission conveying mechanism is arranged in the containing space, and the second part of the transmission conveying mechanism extends out of the containing space; the cutter suction mechanism is arranged outside the protection mechanism and fixedly connected with the second part; the power mechanism is installed on the protection mechanism and fixedly connected with the first part; and the power mechanism drives the transmission conveying mechanism to rotate, the transmission conveying mechanism drives the cutter suction mechanism to rotate, and the cutter suction mechanism can scrape matter outside the protectionmechanism. According to the technical scheme, the power mechanism drives the transmission conveying mechanism to rotate and drives the cutter suction mechanism to rotate, silt and / or sundries in a horizontal well are scraped, crushed and conveyed to a vertical well, the problem that the horizontal well is difficult to clean is solved, and then the blockage problem of a drainage pipe network is solved.

Owner:河北三维普润环保科技有限公司

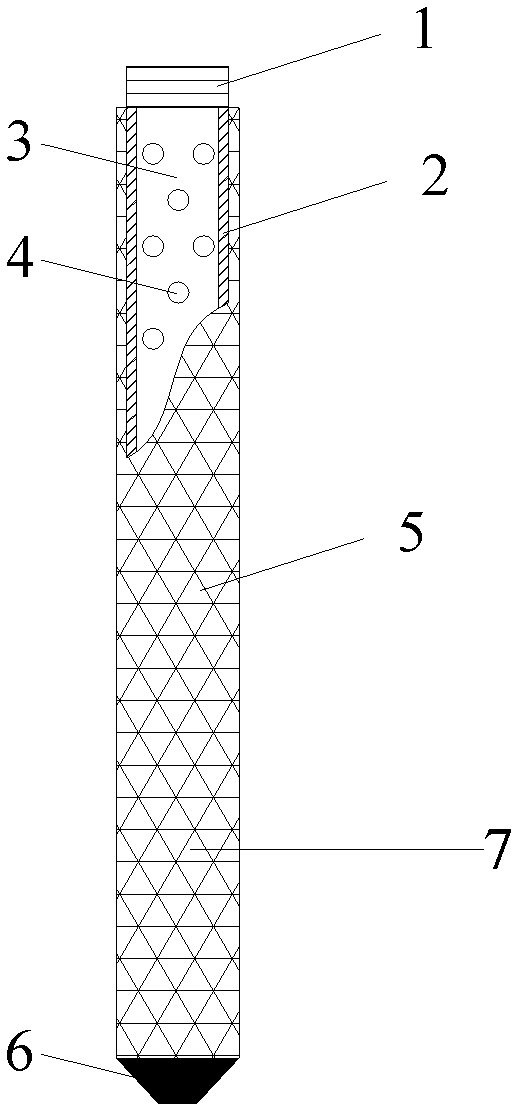

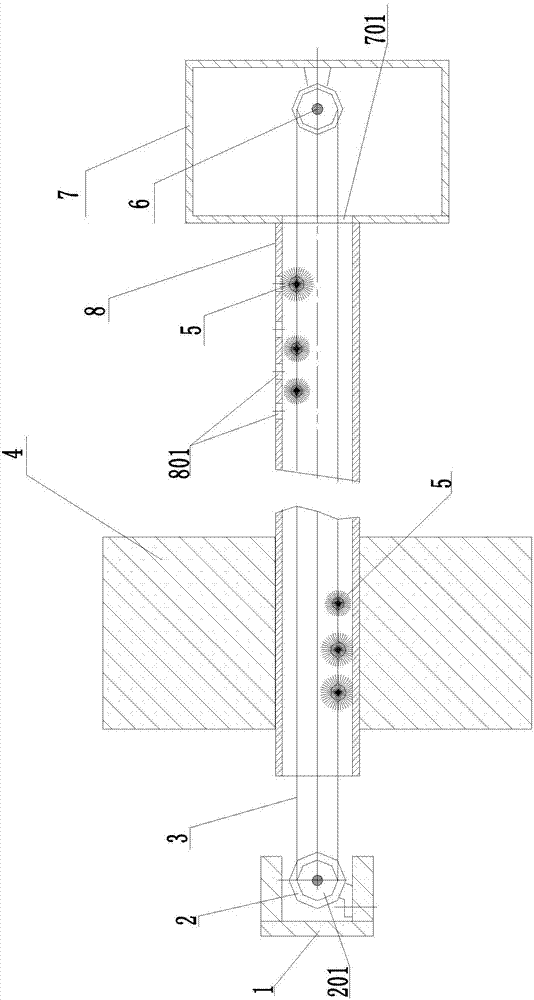

Reinforcing device for variable pressure and vacuum pumping of soft soil and application method thereof

PendingCN109162272AMake up for the lack of diffusion vacuumSolve the cloggingSoil preservationVacuum pumpingEngineering

The invention provides a reinforcing device for variable pressure and vacuum pumping of soft soil and an application method thereof. The reinforcing device for variable pressure and vacuum pumping ofthe soft soil comprises a vacuum pumping drainage mechanism arranged in silt, wherein the vacuum pumping drainage mechanism comprises drainage pipes horizontally arranged, first plastic drainage plates vertically arranged and a vacuum pump. The first plastic drainage plates are cavities which are formed by core plates located in the middle part and filter membranes coated on the outer sides of thecore plates, and the upper potion and the lower portion of the cavity are opened. The vacuum pump communicates with the upper ends of a plurality of first plastic drainage plates in a cavity shape through the drainage pipes, and a plurality of vacuum degree monitoring reflector are distributed on the core plates at height. According to the reinforcing device for variable pressure and vacuum pumping of the soft soil and the application method thereof, the problem that the pre-pressing vacuum degree is inadequate, the drainage plates is silted and blocked, and the drainage rate is too low can be solved.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T

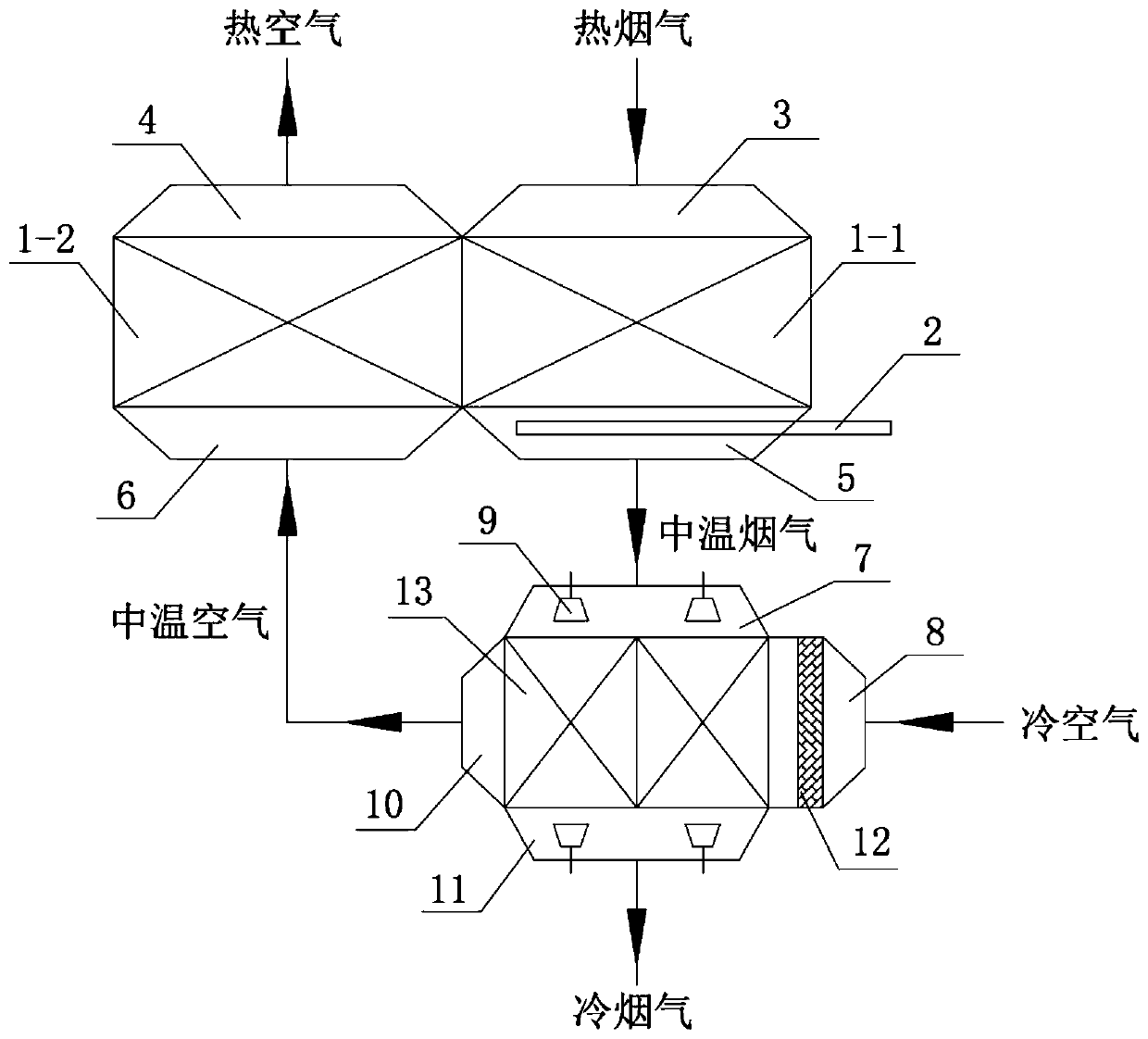

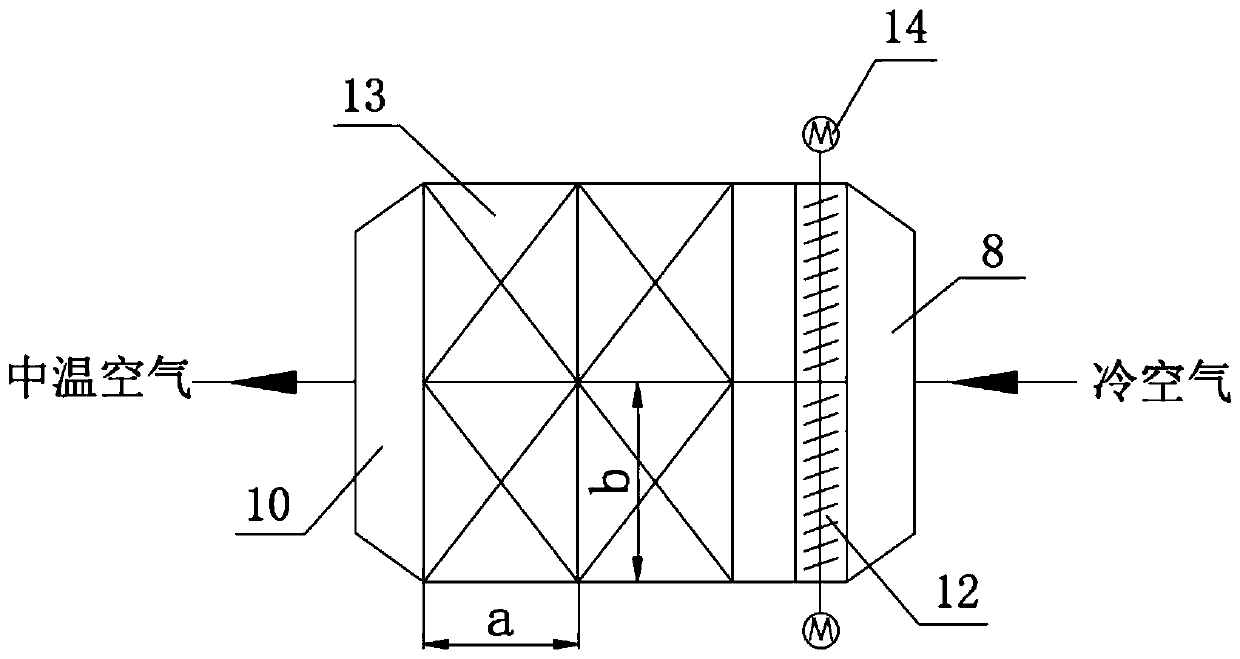

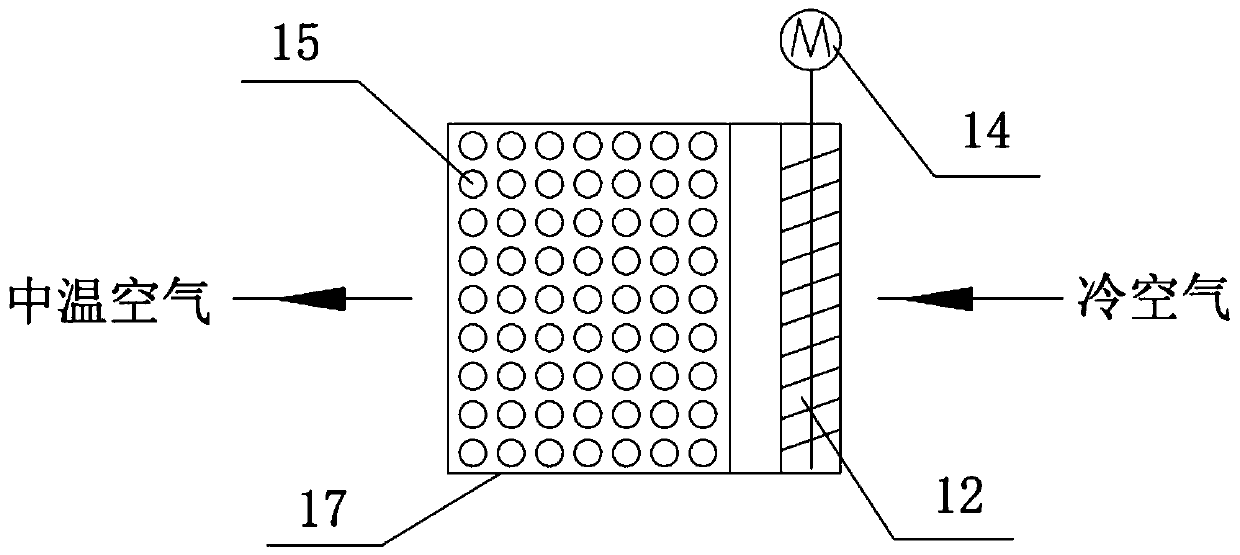

Combined air preheater

PendingCN111457417ARaise the exhaust gas temperatureImprove securityIndirect carbon-dioxide mitigationFlush cleaningAir preheaterCold air

The invention discloses a combined air preheater. A hot flue gas inlet flue communicates with a cold flue gas outlet flue through a flue gas side rotary air preheater, a medium-temperature flue gas outlet flue, a medium-temperature flue gas inlet flue and a heat release side of a tubular air preheater system. A cold air inlet air flue communicates with a hot air outlet air flue through a heat absorption side of the tubular air preheater system, a medium-temperature air outlet air flue, a medium-temperature air inlet air flue and an air side rotary air preheater. The combined preheater can effectively increase the temperature of outlet exhausted smoke of the rotary air preheater, solves the problem that ammonium bisulfate ash clogging influences the rotary air preheater, and is high in safety and stability.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD

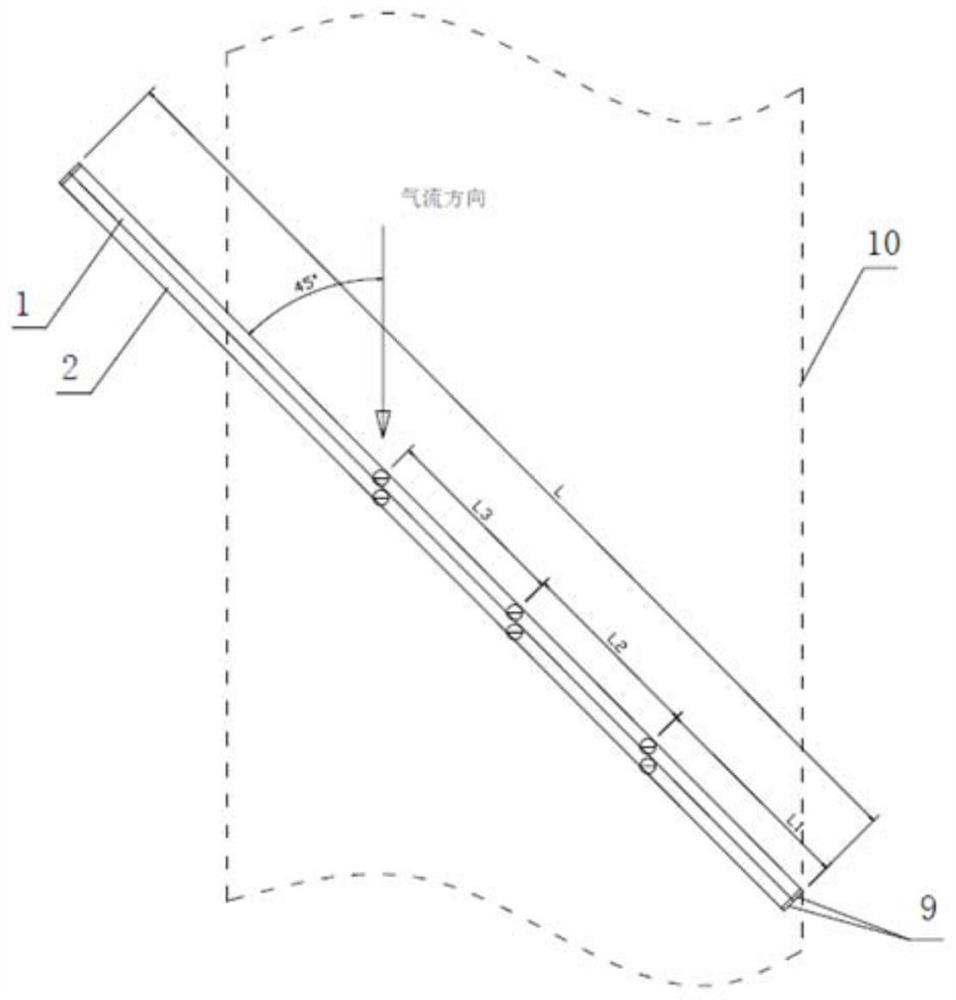

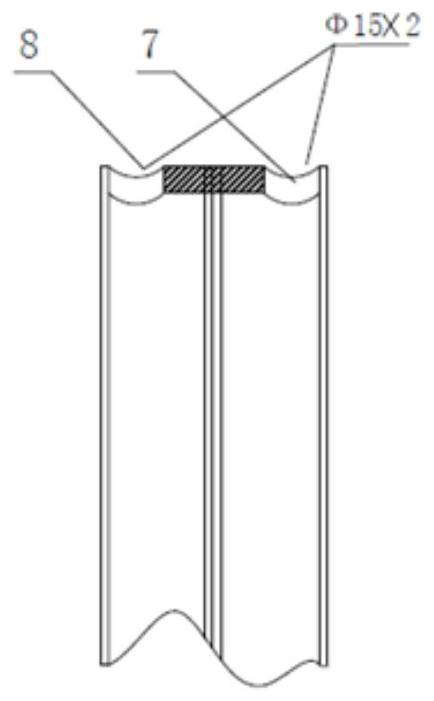

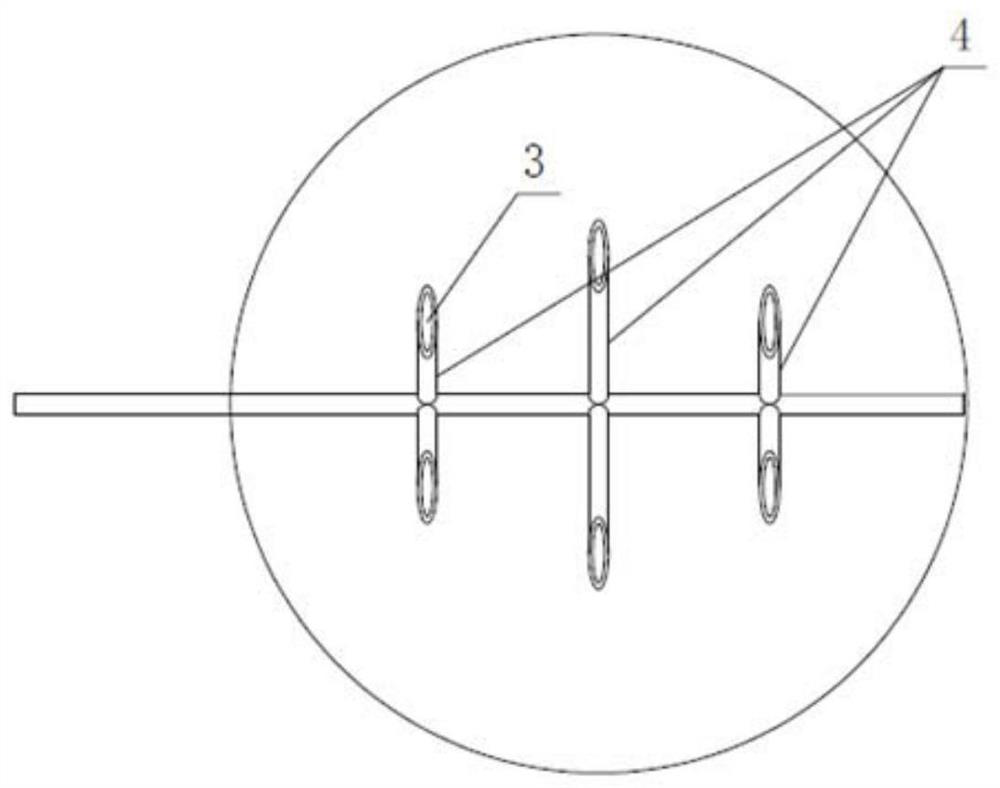

Large vertical flue gas, air and pulverized coal pipeline array type flow measuring device

PendingCN112964315ASolve dust accumulationSolve the cloggingVolume/mass flow by differential pressureEngineeringFlue gas

The invention discloses a large vertical flue gas, air and pulverized coal pipeline array type flow measuring device which is characterized in that a front end of a dynamic pressure expansion buffer pipe and an upper end of a static pressure expansion buffer pipe are obliquely inserted into a flue gas, air and pulverized coal pipeline, and a lower end of the dynamic pressure expansion buffer pipe and a lower end of the static pressure expansion buffer pipe are closed; wedge type dynamic pressure sensors are communicated with the dynamic pressure expansion buffer pipe, parallel static pressure sensors are communicated with the static pressure expansion buffer pipe, the wedge type dynamic pressure sensors and the parallel static pressure sensors are all located in a flue gas, air and pulverized coal pipeline, a dynamic pressure sampling hole is formed in an upper end of the dynamic pressure expansion buffer pipe, a static pressure sampling hole is formed in an upper end of the static pressure capacity expansion buffer pipe, the wedge type dynamic pressure sensors directly face the airflow direction in the flue gas, air and pulverized coal pipeline, the opening direction of the parallel static pressure sensors is parallel to the airflow direction in the flue gas, air and pulverized coal pipeline, and the device can effectively solve a problem of measurement of airflow with pulverized coal in a large vertical flue gas, air and pulverized coal pipeline.

Owner:XIAN THERMAL POWER RES INST CO LTD

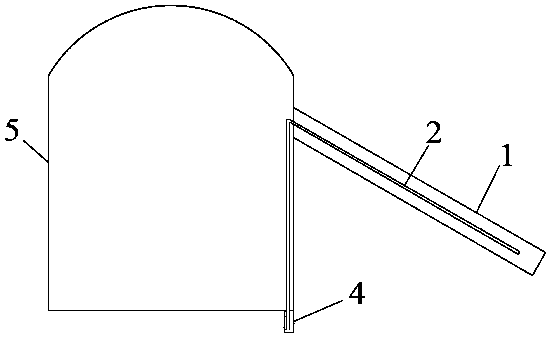

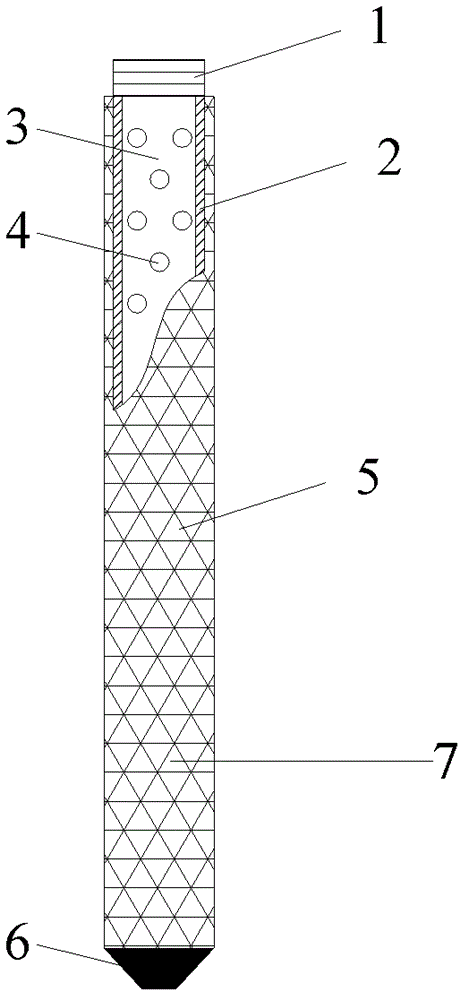

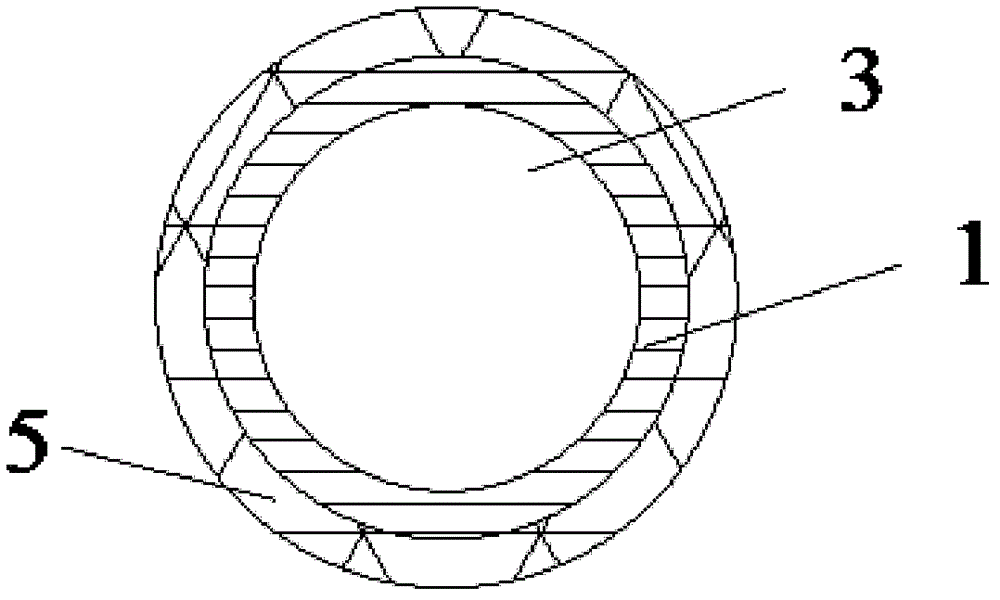

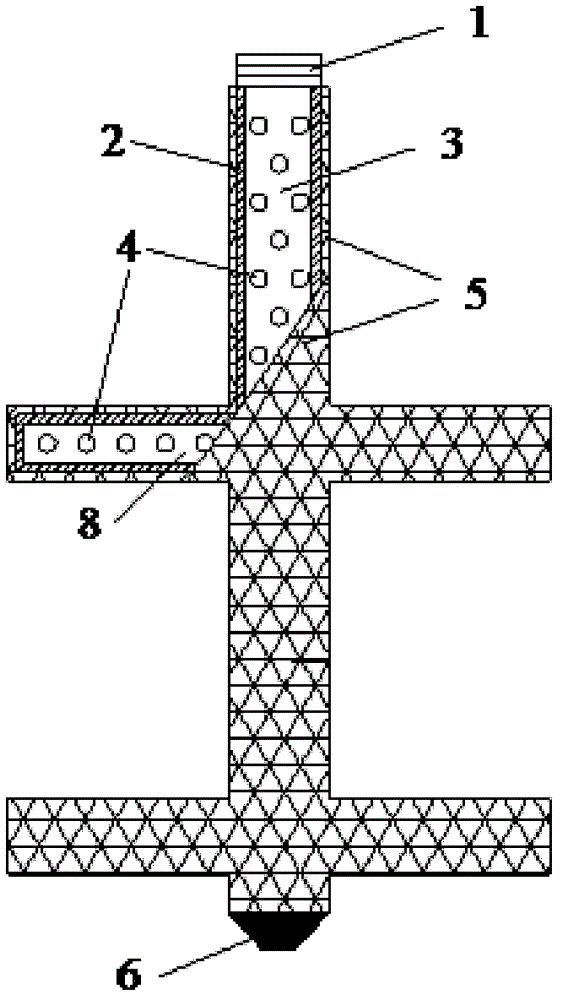

A plastic electrode tube for electroosmotic drainage

ActiveCN104088272BAvoid easy cloggingEvenly distributedSoil preservationDischarge efficiencyEngineering

The invention discloses a plastic electrode tube for electroosmotic drainage, which is characterized in that it comprises: a conductive plastic tube, a metal wire and a conductive geotextile filter layer, and the conductive plastic tube wall is provided with axial or radial There are at least two metal wires, the metal wires are distributed in the wall of the conductive plastic pipe and axially run through the entire conductive plastic pipe, the conductive geotextile filter layer wraps the conductive plastic pipe, and the conductive geotextile Drainage holes are evenly spaced on the outer wall of the plastic pipe. The invention has the advantages of simple structure, corrosion resistance, large drainage space, good mechanical properties, anti-silting and high drainage efficiency.

Owner:武汉谦诚环境技术有限公司

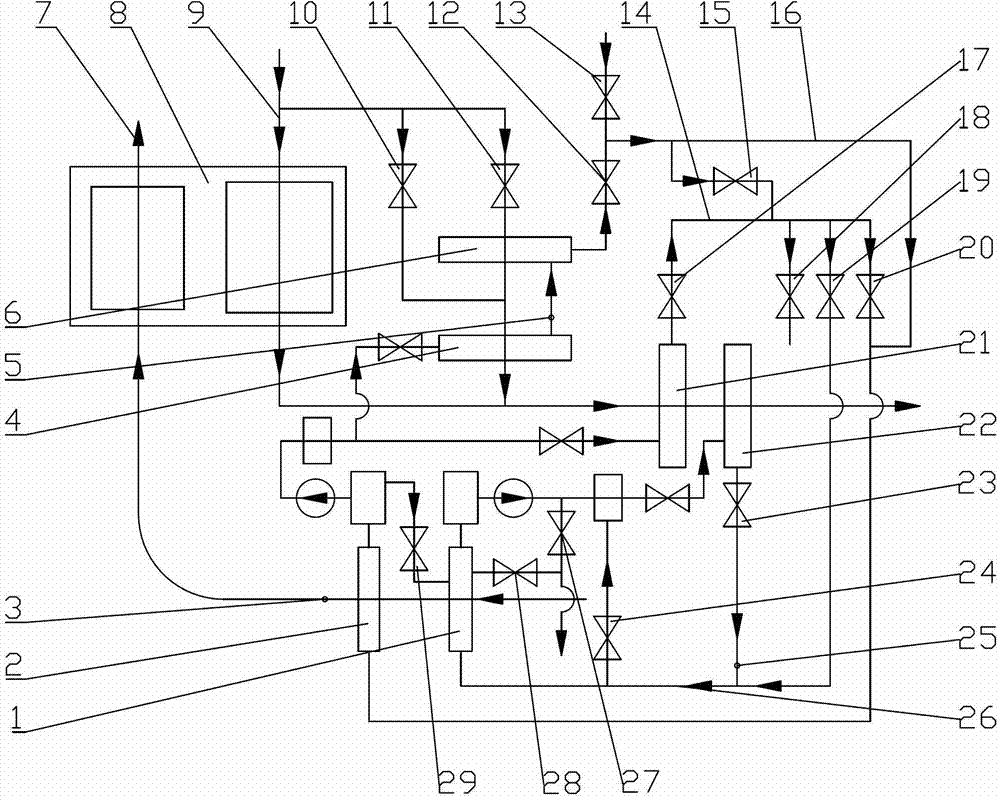

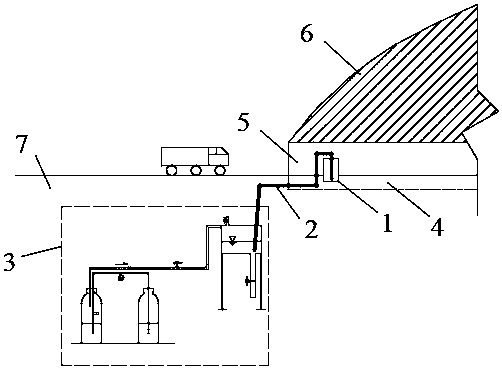

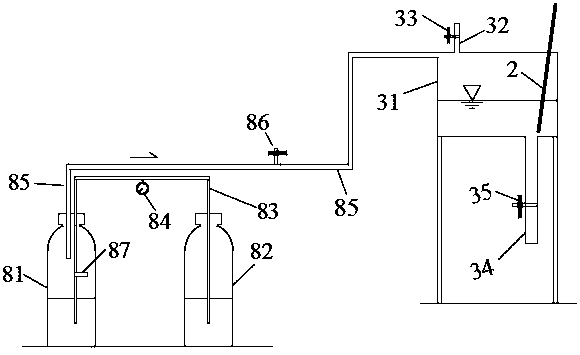

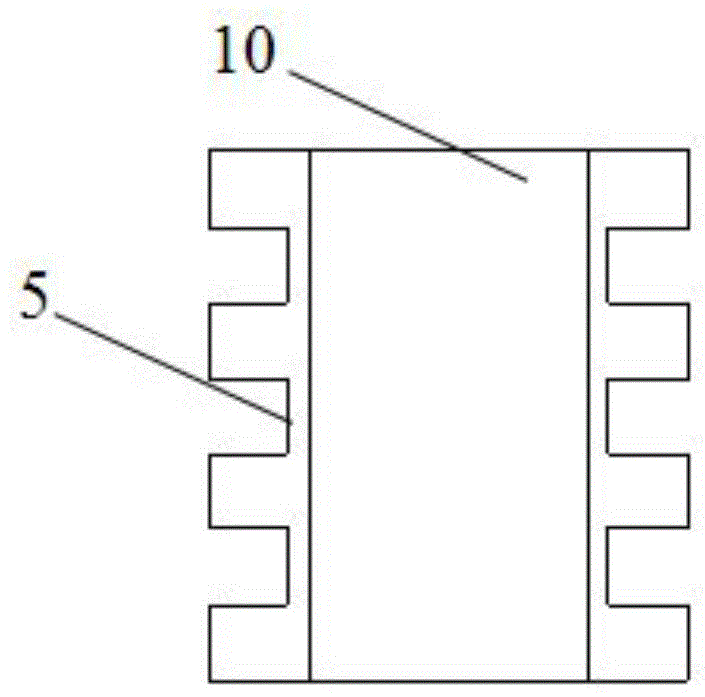

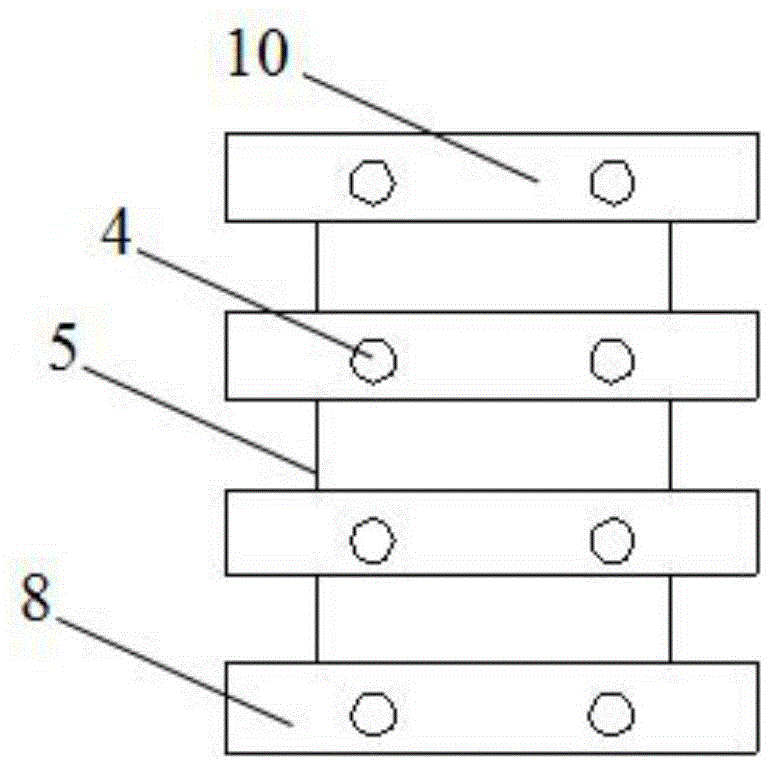

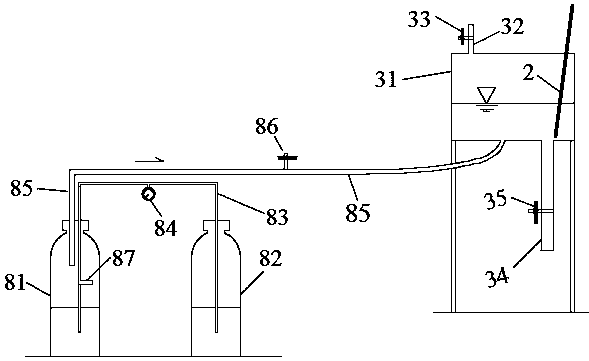

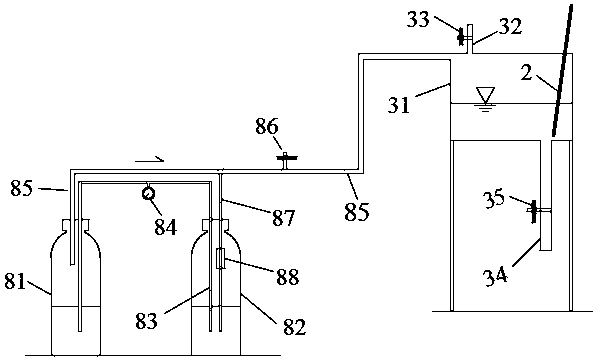

Air inflation start type tunnel drainage system and method

PendingCN108316972ASolve air accumulation and sediment cloggingWide range of applicationsDrainageDrill holeDrill bit

The invention provides an air inflation start type tunnel drainage system which comprises a drill hole, a siphon, a side ditch and an air inflation start device, wherein the drill bit is formed on a position needing drainage in tunnel surrounding rock; a water inlet of the siphon is formed in the drill hole; a water outlet of the siphon is formed in a closed water tank; the air inflation start device comprises a water tank, an exhaust pipe, a valve A, a drainage pipe, a valve B, a gas cylinder A, a gas cylinder B, a diversion pipe, a branch pipe, a pressure gauge, a gas pipe and a valve C; thegas cylinder A contains a sodium bicarbonate solution; the gas cylinder B contains a citric acid solution; the gas cylinder A and the gas cylinder B are connected through the diversion pipe; the pressure gauge is arranged at the middle of the diversion pipe; the branch pipe is connected to the diversion pipe; an entrance end of the gas pipe is arranged in the gas cylinder A; an exit end of the gas pipe is connected with the bottom of the water tank; the valve C is mounted on the gas pipe; the exhaust pipe is mounted at the top of the water tank; the valve A is mounted on the exhaust pipe; anentrance end of the drainage pipe is connected with the bottom of the water tank; and the valve B is mounted at an exit of the drainage pipe.

Owner:范云鹤

Clogging preventing method for drainage channel based on underground high-flow-capacity drainage system

The anti-silting method for drainage channels based on the underground large-flow drainage system is characterized in that it includes the following steps: After connecting the upper opening of the large-flow drainage body with a soft permeable pipe, press it into the ultra-soft soil to be treated until the design depth or the hard shell layer , reserve a section of soft permeable pipe higher than the ground; connect the soft permeable pipe to the drainage branch pipe, and connect the drainage branch pipe to the main drainage pipe, then connect the main drainage pipe to the water inlet of the sedimentation box, and the water outlet of the sedimentation box to connect The other section of the drainage main pipe is connected to the pump and the drainage pipe; and the sealing film and pressure groove are laid in the area where the drainage body is laid; the pump is turned on to vacuumize; according to the supersoft soil surface settlement rate and the expected treatment effect, choose the time to stop vacuuming . It can meet the requirements of the construction period and the uniformity of soil strength after drainage consolidation treatment, and realize the anti-silting treatment under the new idea of "fine particle dredging".

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com