Three-dimensional internal and external finned tube integrated air preheater and processing method thereof

An air preheater, three-dimensional technology, applied in combustion methods, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve the problems of large space occupation, acid corrosion, large floor area, etc., to save equipment space, reduce The effect of small equipment volume and reduced equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

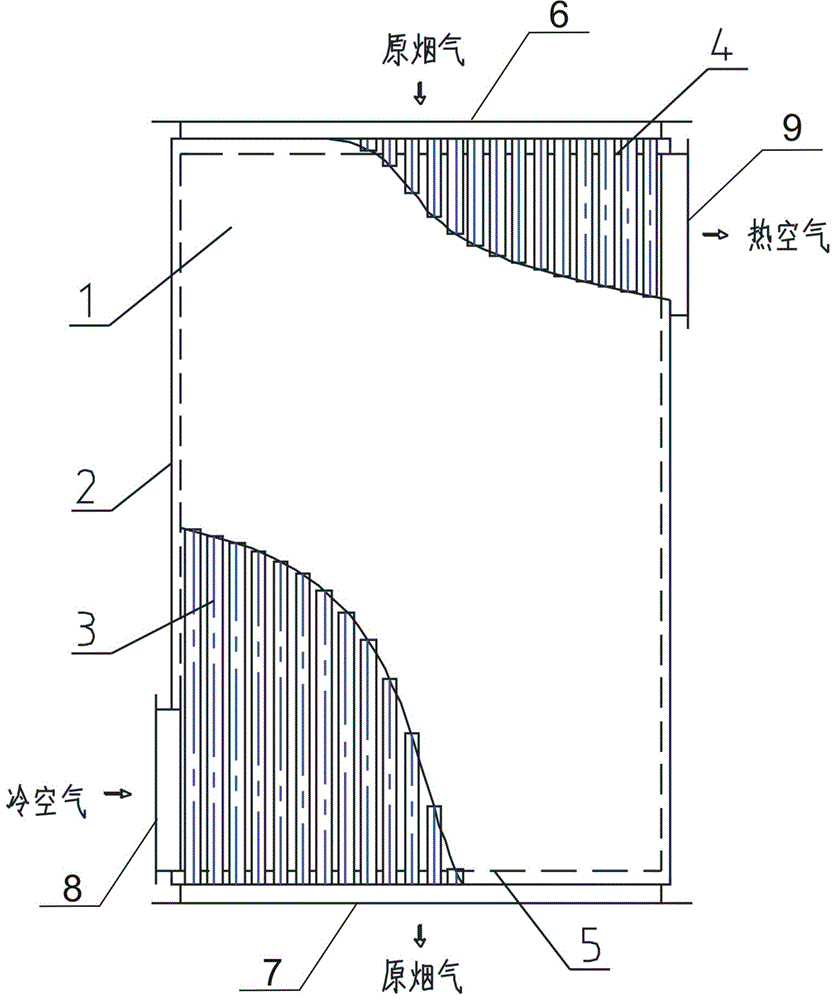

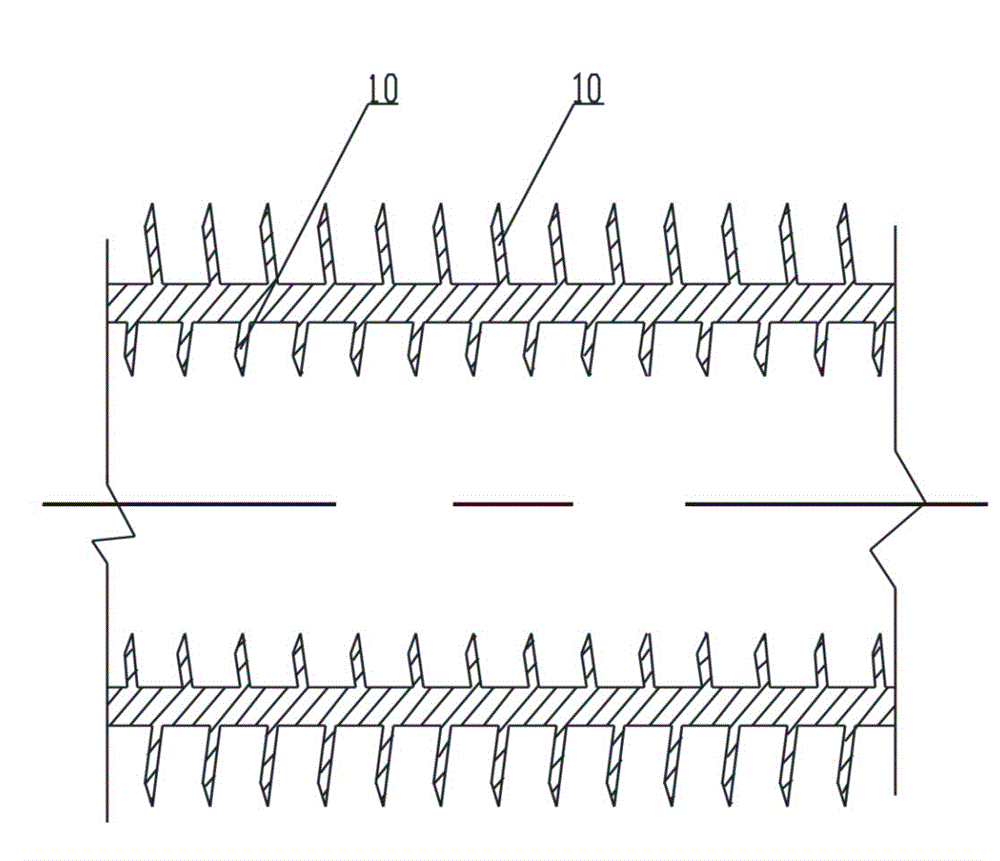

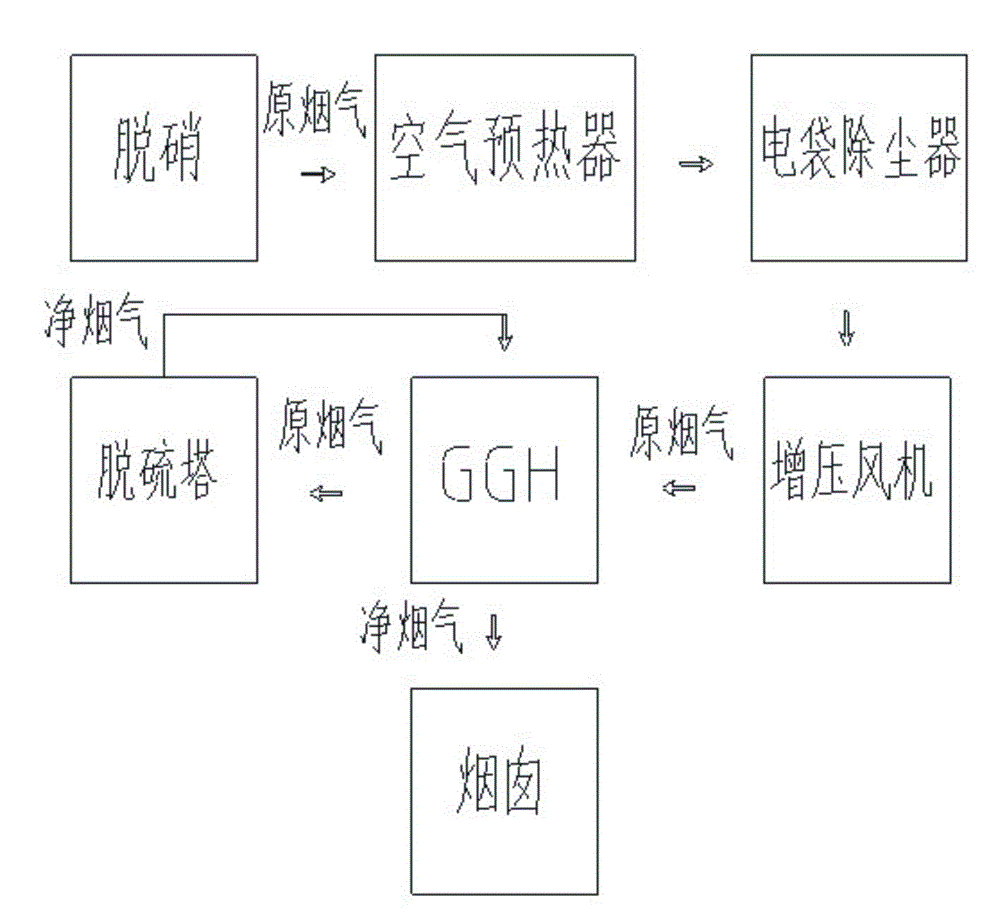

[0018] Example: such as figure 1 As shown, the integrated air preheater, its main body is a three-dimensional box, the upper end of the box is provided with a flue inlet, the lower end is provided with a flue outlet, and an upper tube plate closed box is arranged in the box near the smoke inlet. The box body of the smoke outlet is provided with a lower tube plate closed box body, which isolates the inside of the box body from the outlet and inlet of the flue. A plurality of installation holes are arranged on the tube plate, and a three-dimensional internal and external ribbed tube is inserted into each installation hole. The three-dimensional inner and outer ribbed tubes are expanded and welded on the tube plates at the upper and lower ends, and fixed in the box body, and the nozzles of the three-dimensional inner and outer ribbed tubes are located in the flue mouth. There is an air inlet on one side of the box, which is located on the side plate of the box inside the tube pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com