Condensing gas boiler

A gas-fired boiler, condensing technology, applied in the field of gas-fired boilers and condensing gas-fired boilers, can solve the problems of hindering heat exchange, large area, burner extinguishing, etc., to ensure heat exchange efficiency, small footprint, sufficient heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

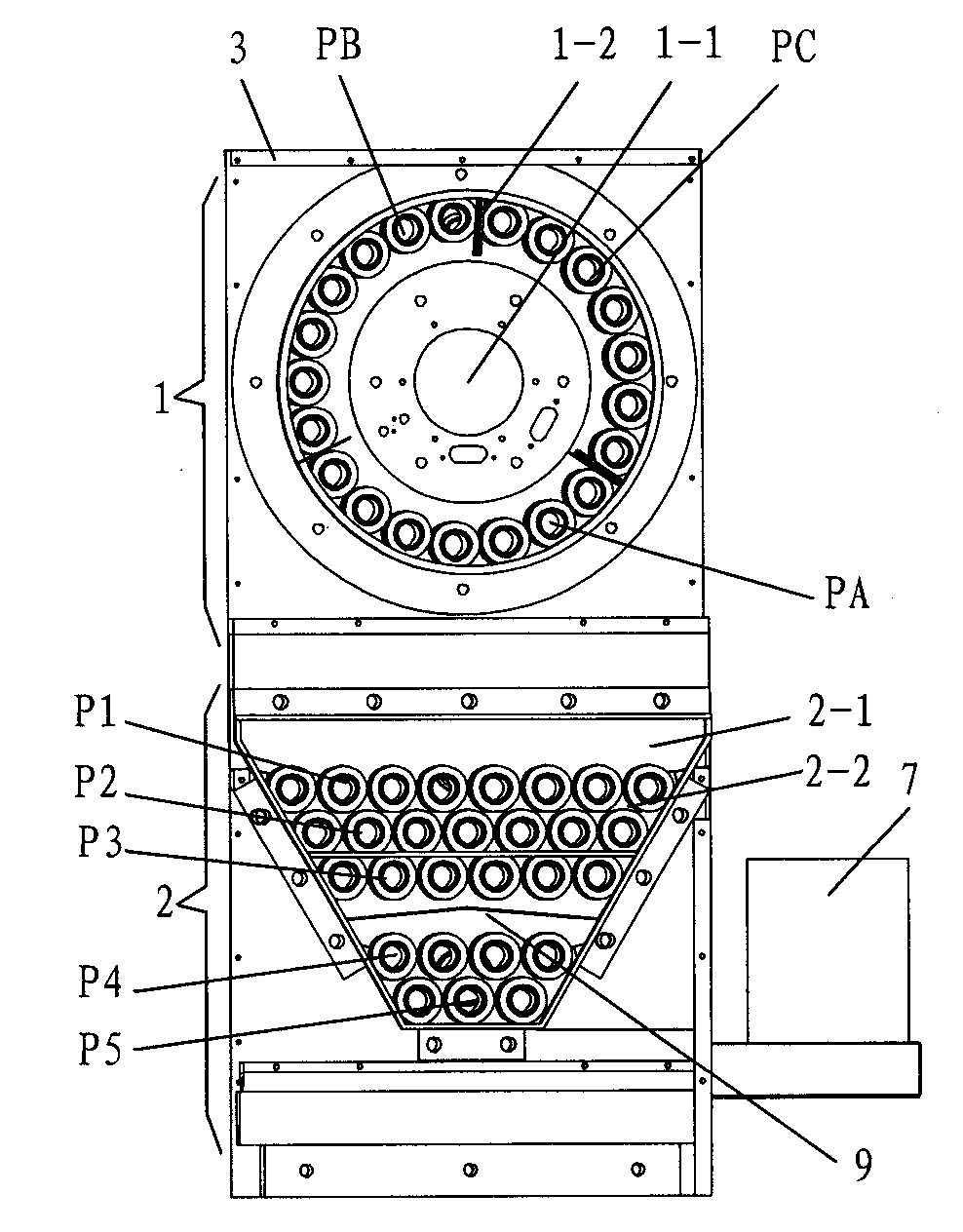

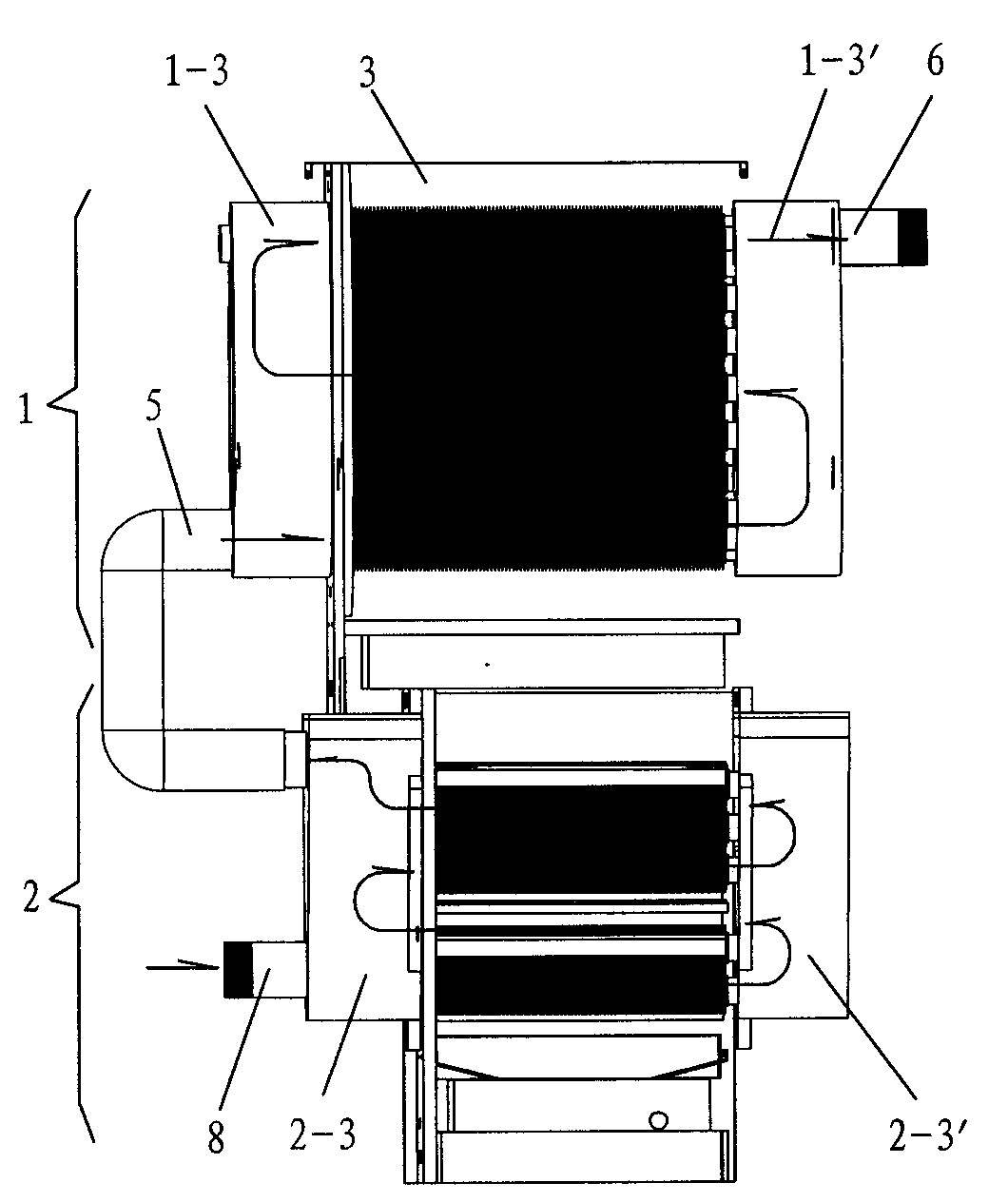

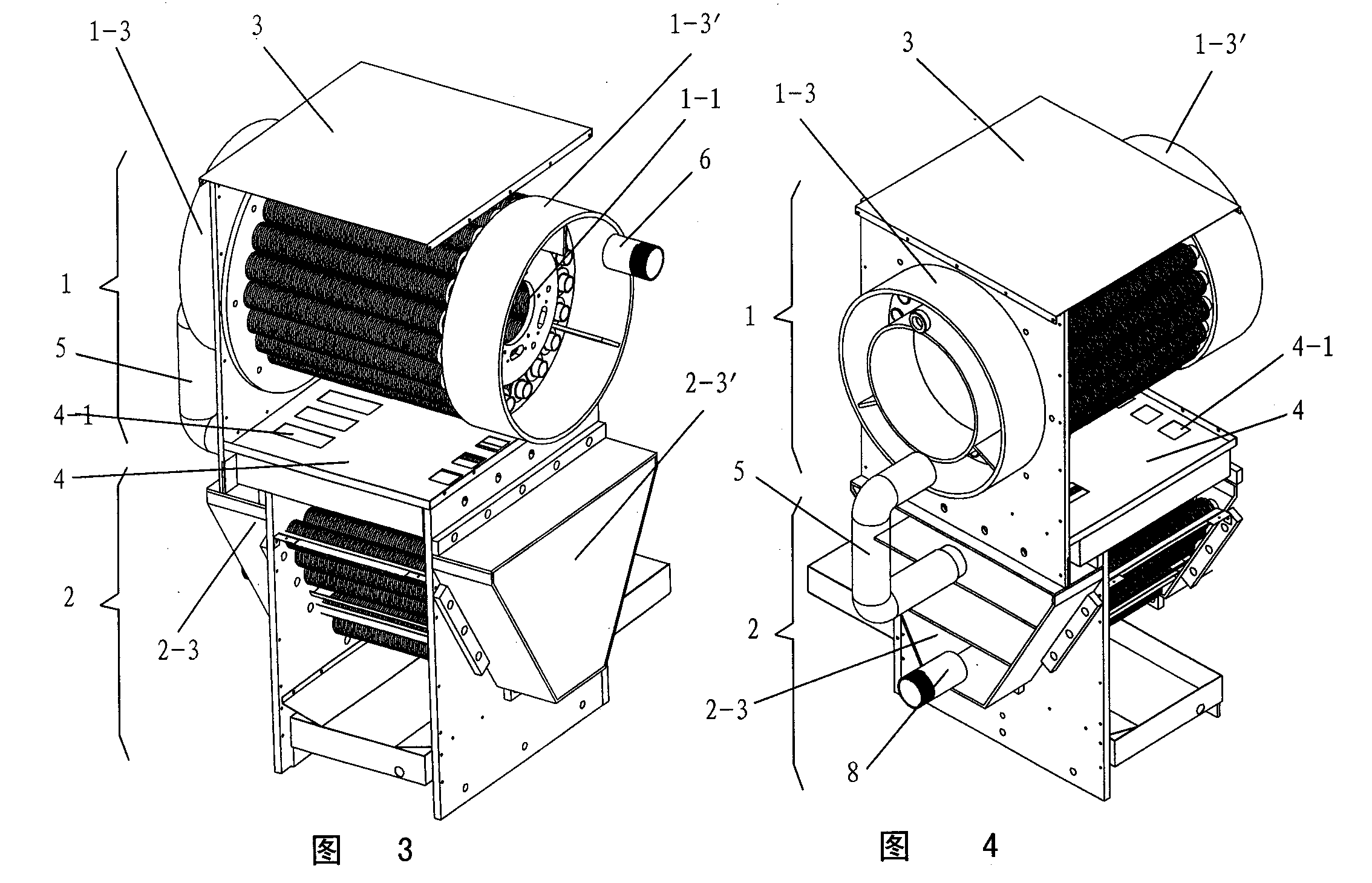

[0016] The condensing gas boiler of this preferred embodiment is as Figure 1 to Figure 4 As shown, it is mainly composed of a burner (not shown in the figure) and a heat exchange device with flue gas and water flow channels. The heat exchange device includes an upper annular horizontal heat exchanger 1 and a lower V-shaped heat exchanger 2 located in the casing 3 and connected in series. The circumference of the annular horizontal heat exchanger 1 is distributed with a first group of water pipes forming a roundabout flow channel, and the middle part is a cylindrical combustion chamber 1-1. A burner is installed at the front end of the cylindrical combustion chamber 1-1, and the V-shaped flue gas flow channel 2 of the V-shaped heat exchanger 2 passes through the exhaust holes 4-1 facing downwards at both ends of the mesh plate 4 separating the two heat exchangers. -1 connectivity.

[0017] The V-shaped flue gas flow channel 2-1 is equipped with a second group of water pipes ...

Embodiment 2

[0026] The condensing gas boiler of the present embodiment is as Figure 5 , Figure 6 As shown, the difference from Embodiment 1 is that the horizontal heat exchanger is located on one side of the V-shaped heat exchanger, and communicates with each other through a series of flues; its working principle and main advantages are the same as Embodiment 1 , without further details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com