Filter element

A filter element and filter medium technology, applied in the filter field, can solve the problems of automatic transmission failure, increased channel resistance, shortened product life, etc., and achieve the effects of preventing pressure loss, suppressing the increase of pressure loss, and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described below with reference to the drawings.

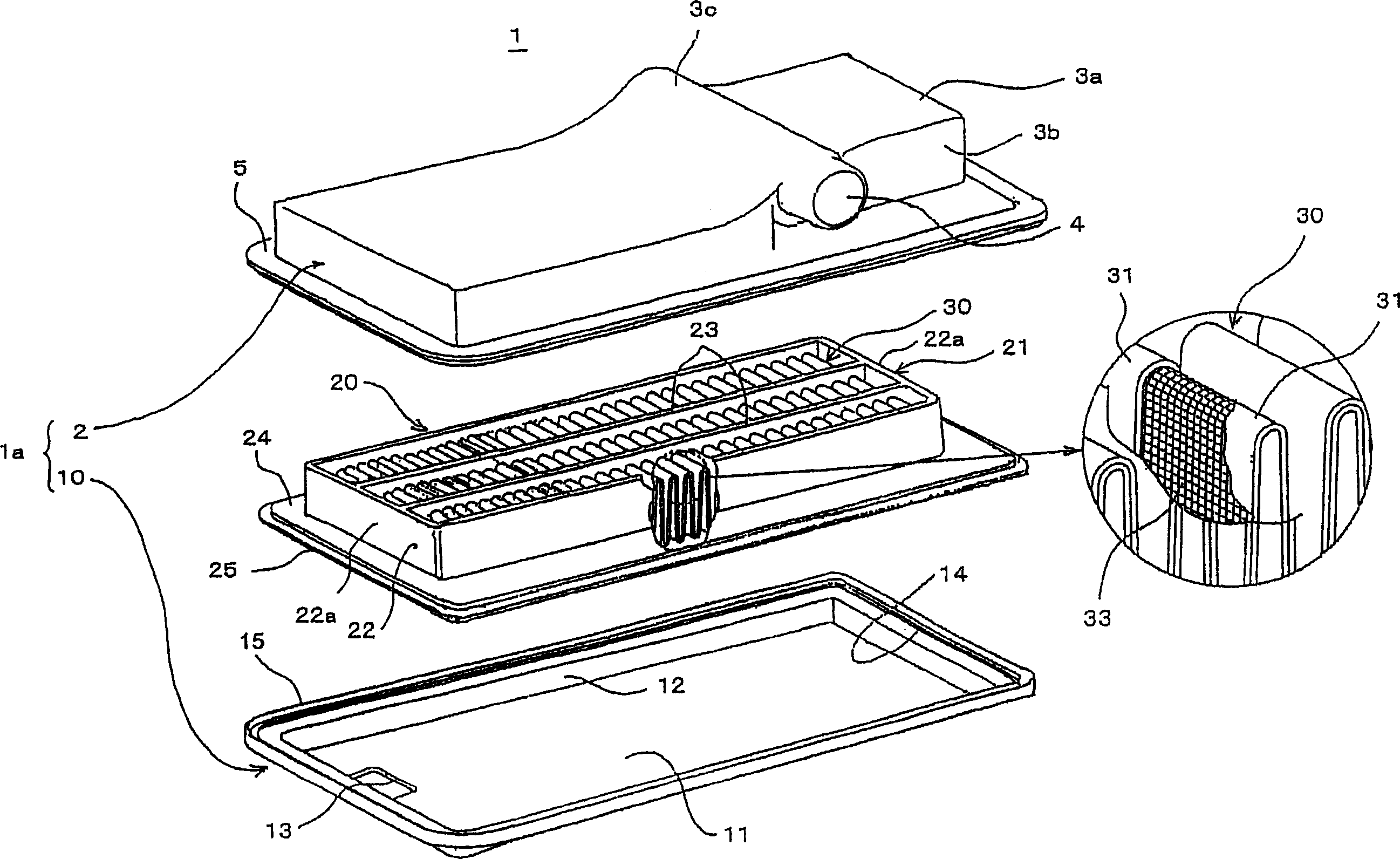

[0020] figure 1 A state is shown in which a filter element 20 according to an embodiment of the present invention is used for an oil filter 1 of an automatic transmission.

[0021] The oil filter 1 has a housing 1a forming its housing, in which a filter element 20 is accommodated. The housing 1 a is constituted by a lower case 10 having an opening 14 formed in an upper portion, and a cover 2 for closing the opening 14 of the lower case 10 .

[0022] The lower case 10 has a rectangular shape formed by a bottom surface 11 and a peripheral wall surface 12 surrounding the periphery of the bottom surface 11 . The bottom surface 11 is formed with an inflow port 13 which allows oil to flow into the housing 1a. At the upper end of the peripheral wall surface 12 forming the opening 14, a support flange 15 is formed on the entire peripheral edge and protrudes outward with a fixed dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com