Mud-and-water auto-separating pipeline apparatus

A pipeline device and self-separation technology, applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve the problems of high energy consumption, unsuitable water for crop irrigation, complex structure, etc., and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

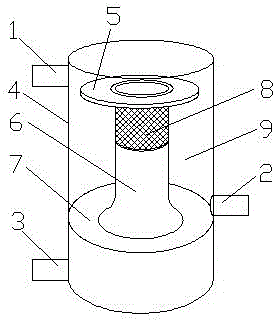

[0041] see figure 1, a mud-water self-separation pipeline device, including a water inlet pipe 1, an outlet pipe 2 and a sewage pipe 3, and also includes a mud-water self-separation component, and the mud-water self-separation component includes a cylindrical pipe body 4, and the inner side of the cylindrical pipe body 4 An annular step 5 is arranged on the wall, and an inner fixing seat 6 is arranged below the annular step 5, and an annular groove 7 is formed between the inner fixing seat 6 and the inner side wall of the cylindrical pipe body 4, and an annular groove 7 is arranged on the annular step 5. Filter screen 8, the upper end of the annular filter screen 8 is connected with the annular step 5, the lower end of the annular filter screen 8 is connected with the inner fixing seat 6, the inner side wall of the cylindrical pipe body 4 and the outer side wall of the annular filter screen 8 form a clear water chamber 9, the outlet pipe 2 communicates with the clear water cha...

Embodiment 2

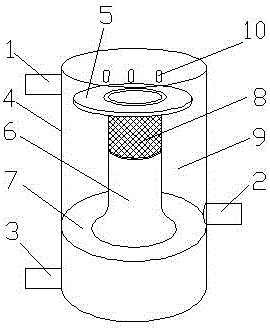

[0044] see figure 2 , a mud-water self-separation pipeline device, including a water inlet pipe 1, an outlet pipe 2 and a sewage pipe 3, and also includes a mud-water self-separation component, and the mud-water self-separation component includes a cylindrical pipe body 4, and the inner side of the cylindrical pipe body 4 An annular step 5 is arranged on the wall, and an inner fixing seat 6 is arranged below the annular step 5, and an annular groove 7 is formed between the inner fixing seat 6 and the inner side wall of the cylindrical pipe body 4, and an annular groove 7 is arranged on the annular step 5. Filter screen 8, the upper end of the annular filter screen 8 is connected with the annular step 5, the lower end of the annular filter screen 8 is connected with the inner fixing seat 6, the inner side wall of the cylindrical pipe body 4 and the outer side wall of the annular filter screen 8 form a clear water chamber 9, the outlet pipe 2 communicates with the clear water c...

Embodiment 3

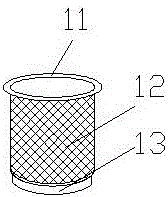

[0049] see Figure 2-Figure 4 , a mud-water self-separation pipeline device, including a water inlet pipe 1, an outlet pipe 2 and a sewage pipe 3, and also includes a mud-water self-separation component, and the mud-water self-separation component includes a cylindrical pipe body 4, and the inner side of the cylindrical pipe body 4 An annular step 5 is arranged on the wall, and an inner fixing seat 6 is arranged below the annular step 5, and an annular groove 7 is formed between the inner fixing seat 6 and the inner side wall of the cylindrical pipe body 4, and an annular groove 7 is arranged on the annular step 5. Filter screen 8, the upper end of the annular filter screen 8 is connected with the annular step 5, the lower end of the annular filter screen 8 is connected with the inner fixing seat 6, the inner side wall of the cylindrical pipe body 4 and the outer side wall of the annular filter screen 8 form a clear water chamber 9, the outlet pipe 2 communicates with the clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com