Patents

Literature

44results about How to "Reduce devitrification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

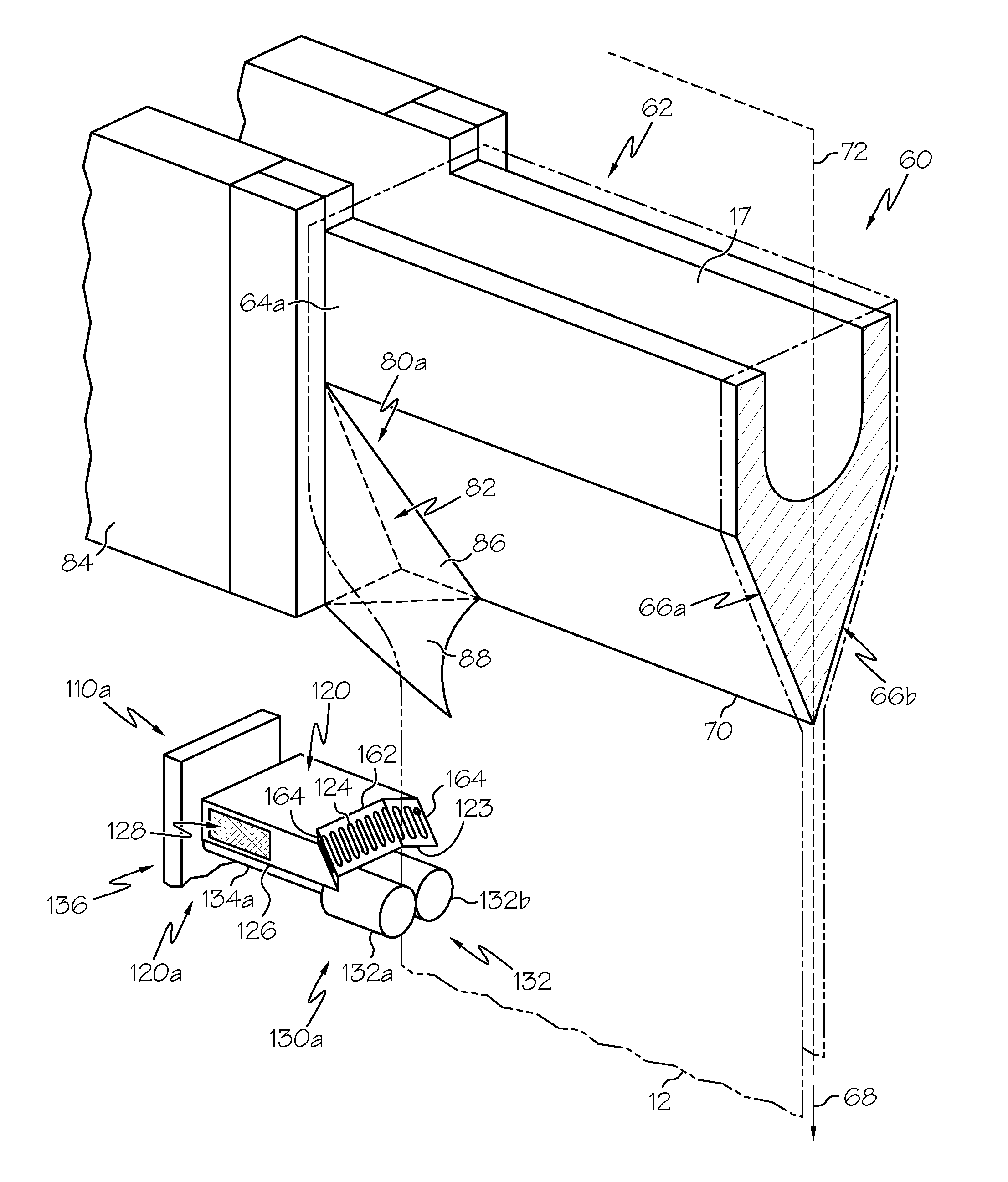

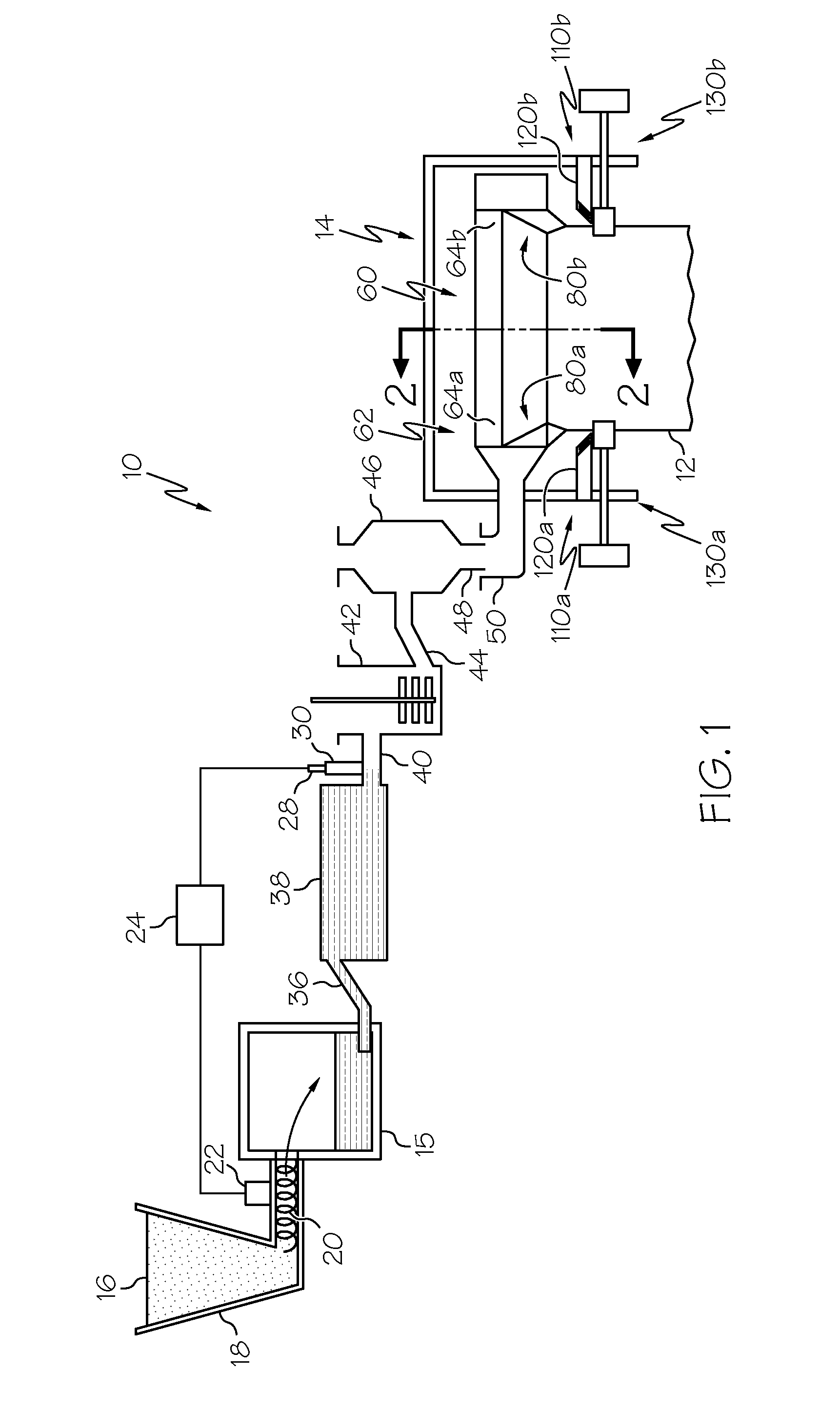

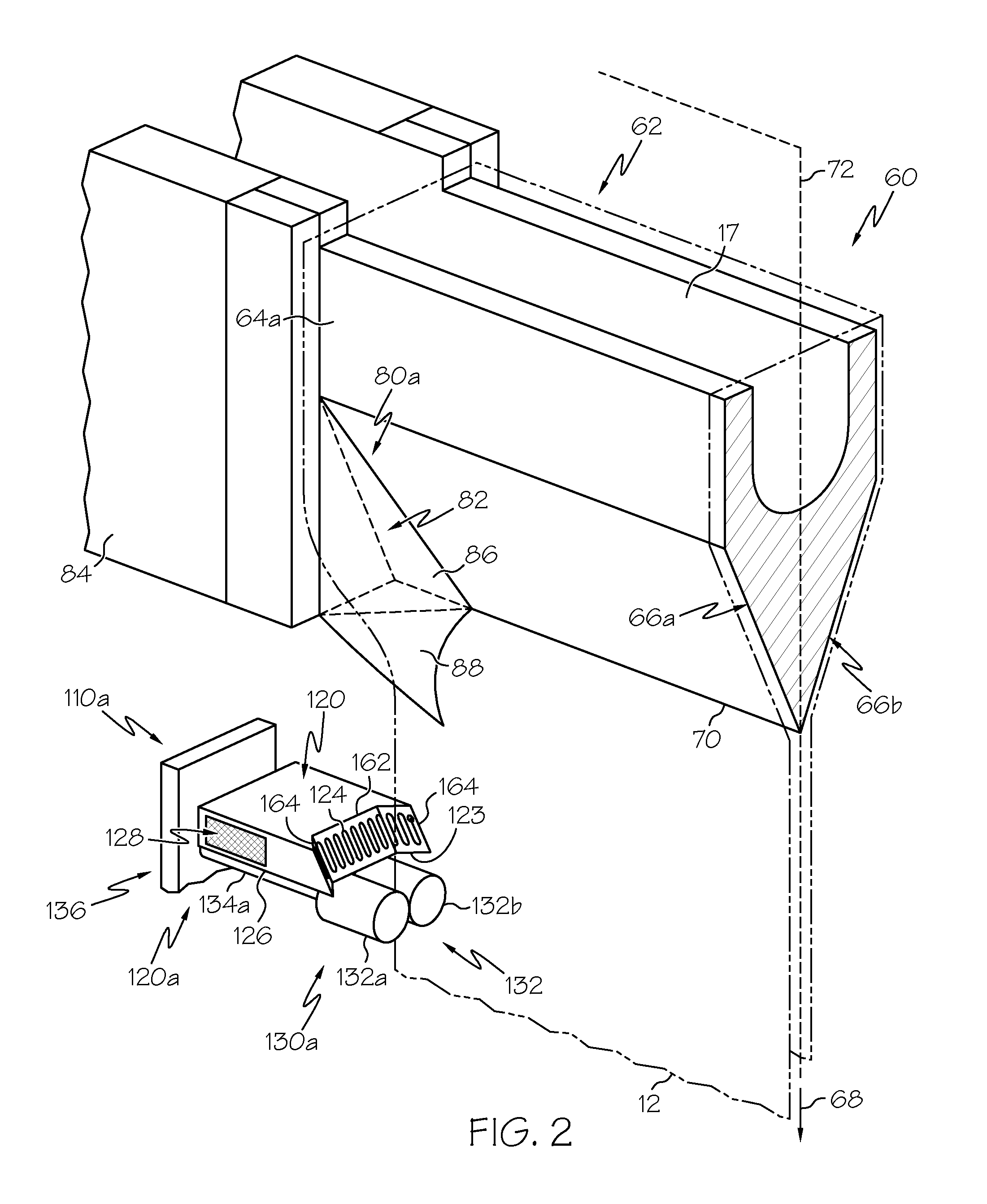

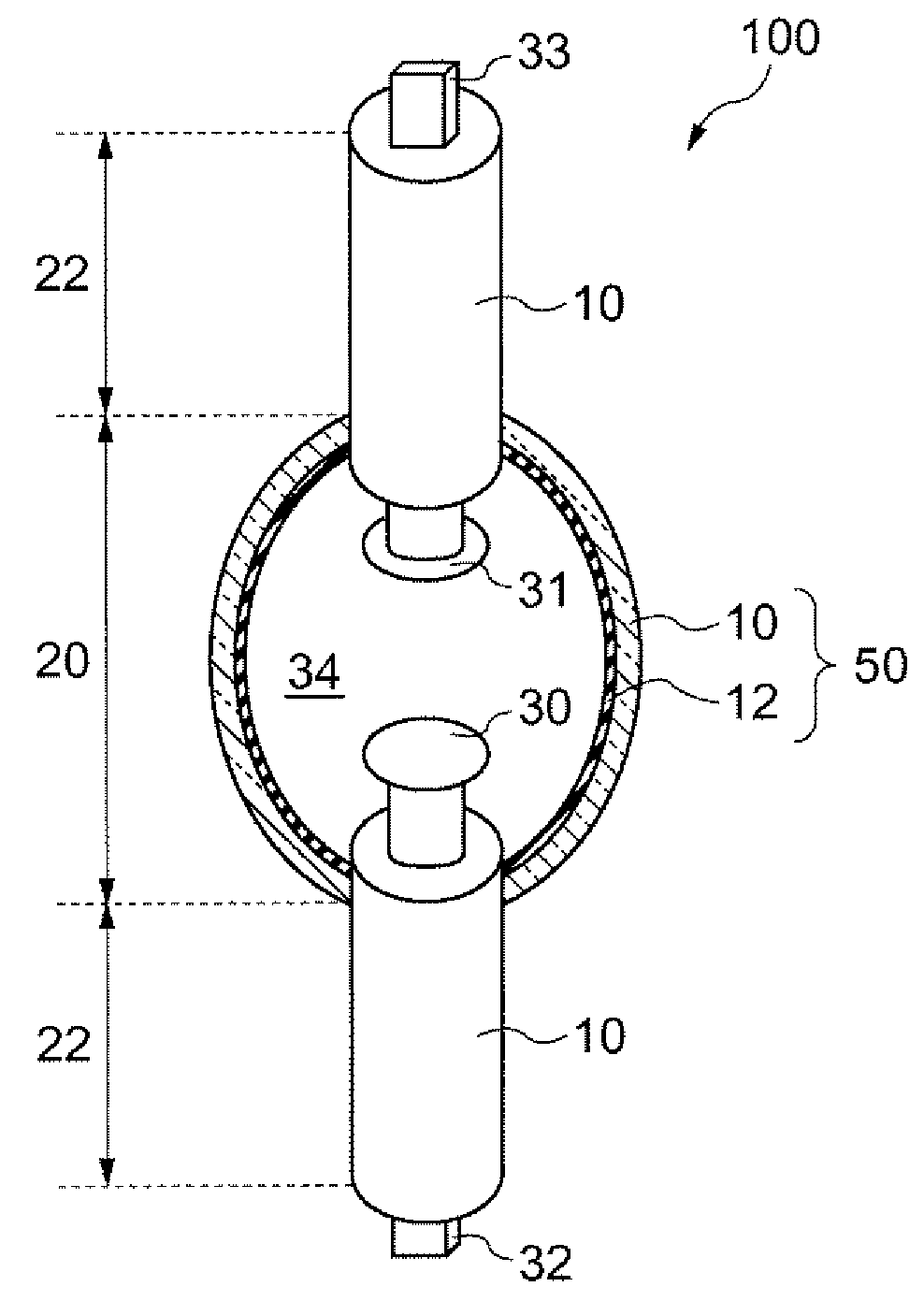

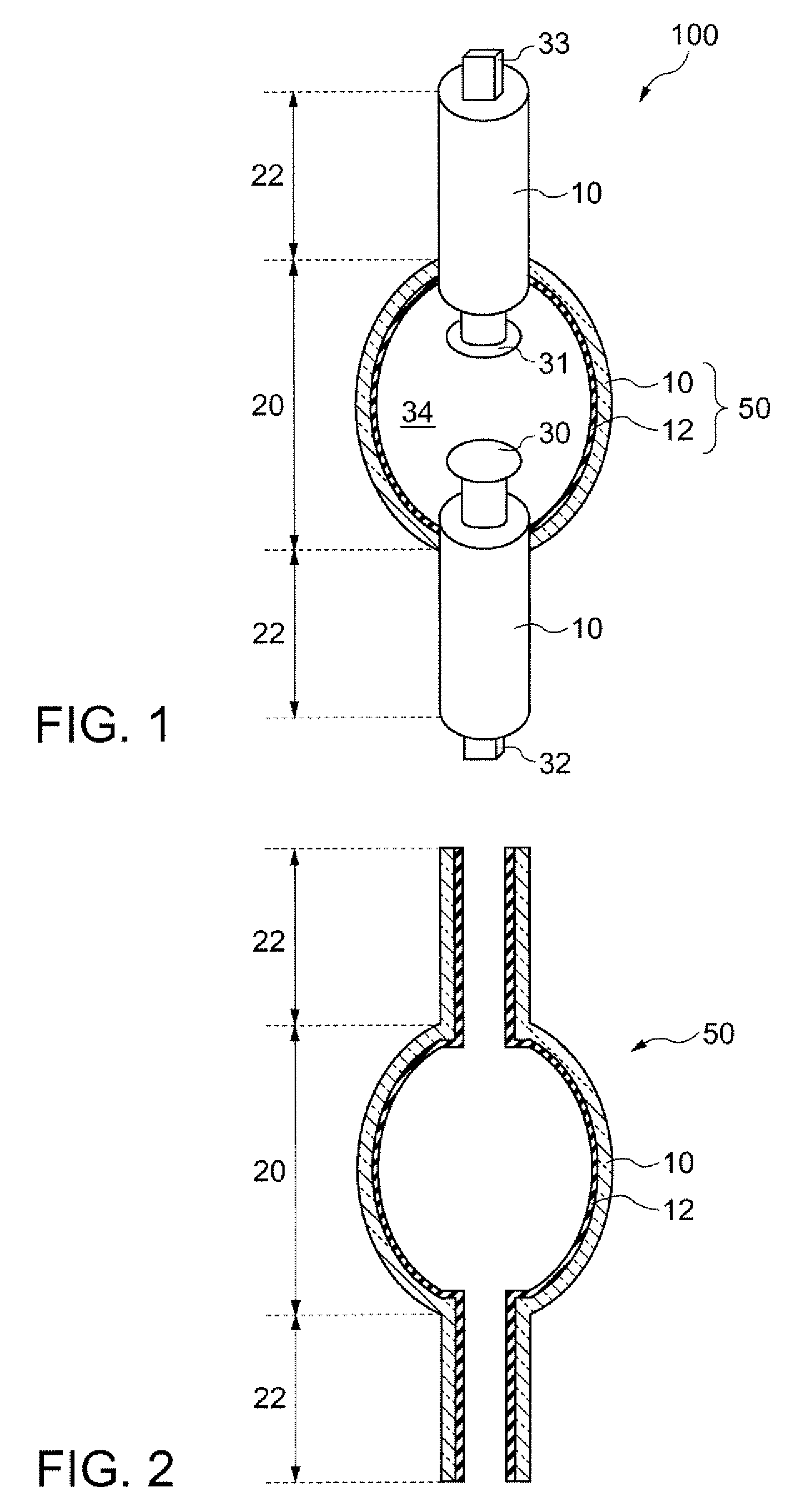

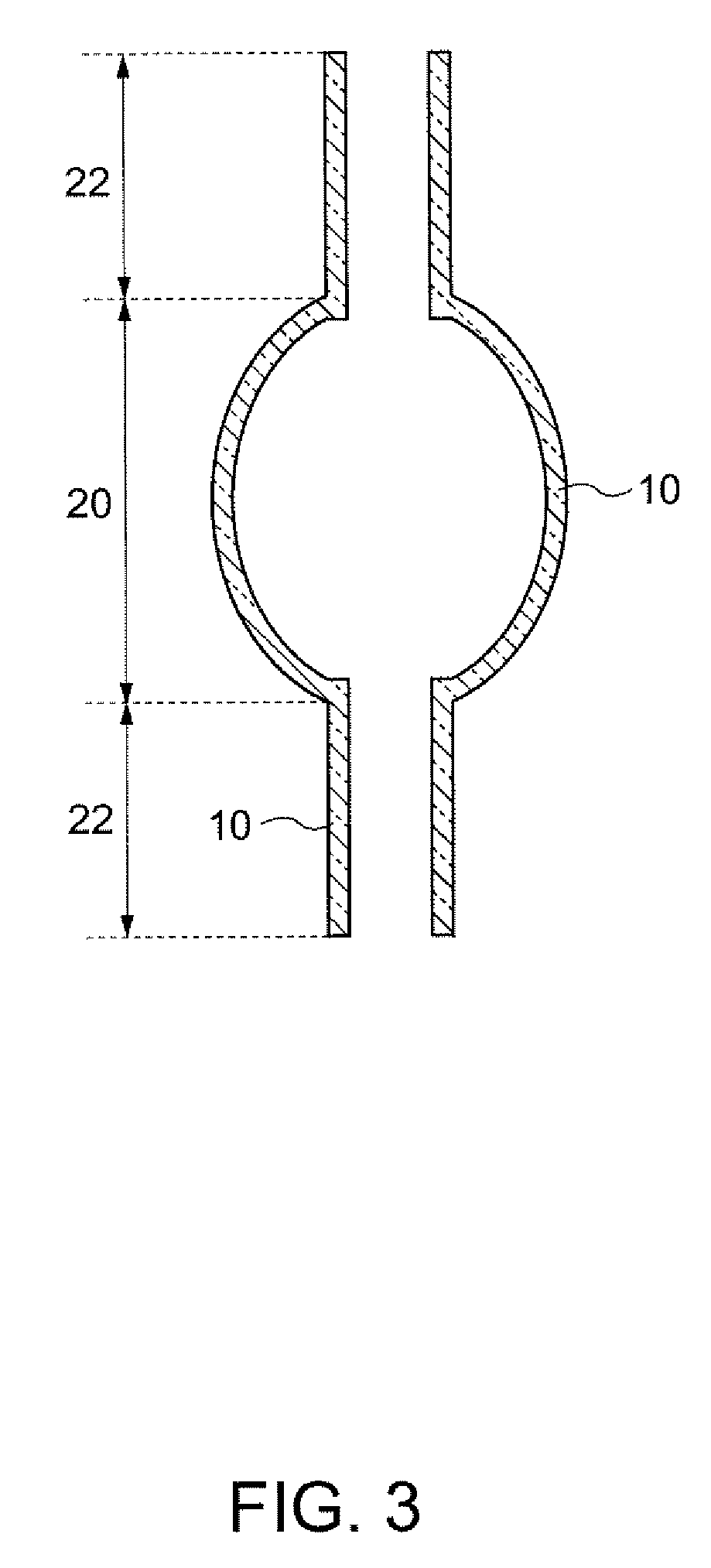

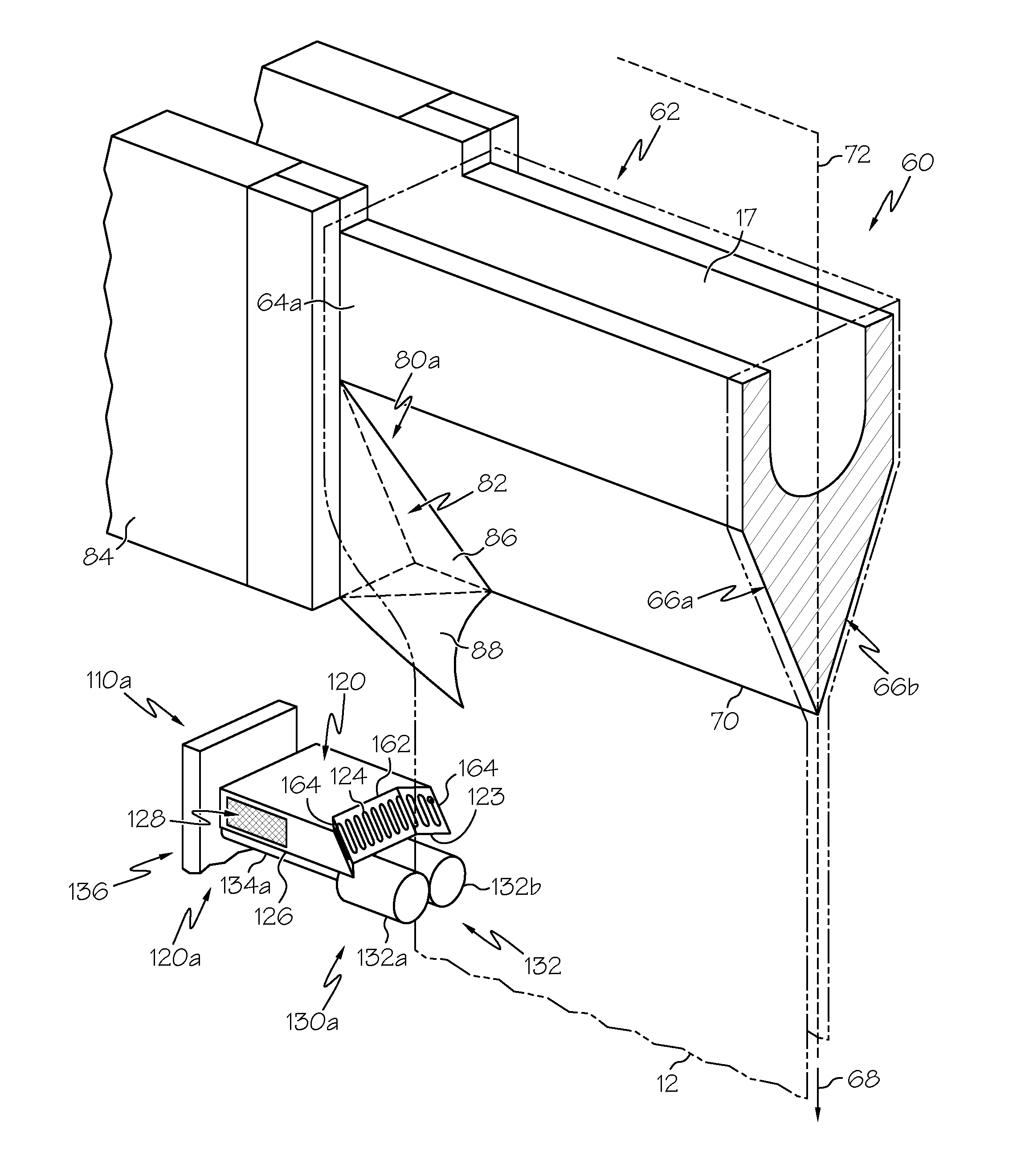

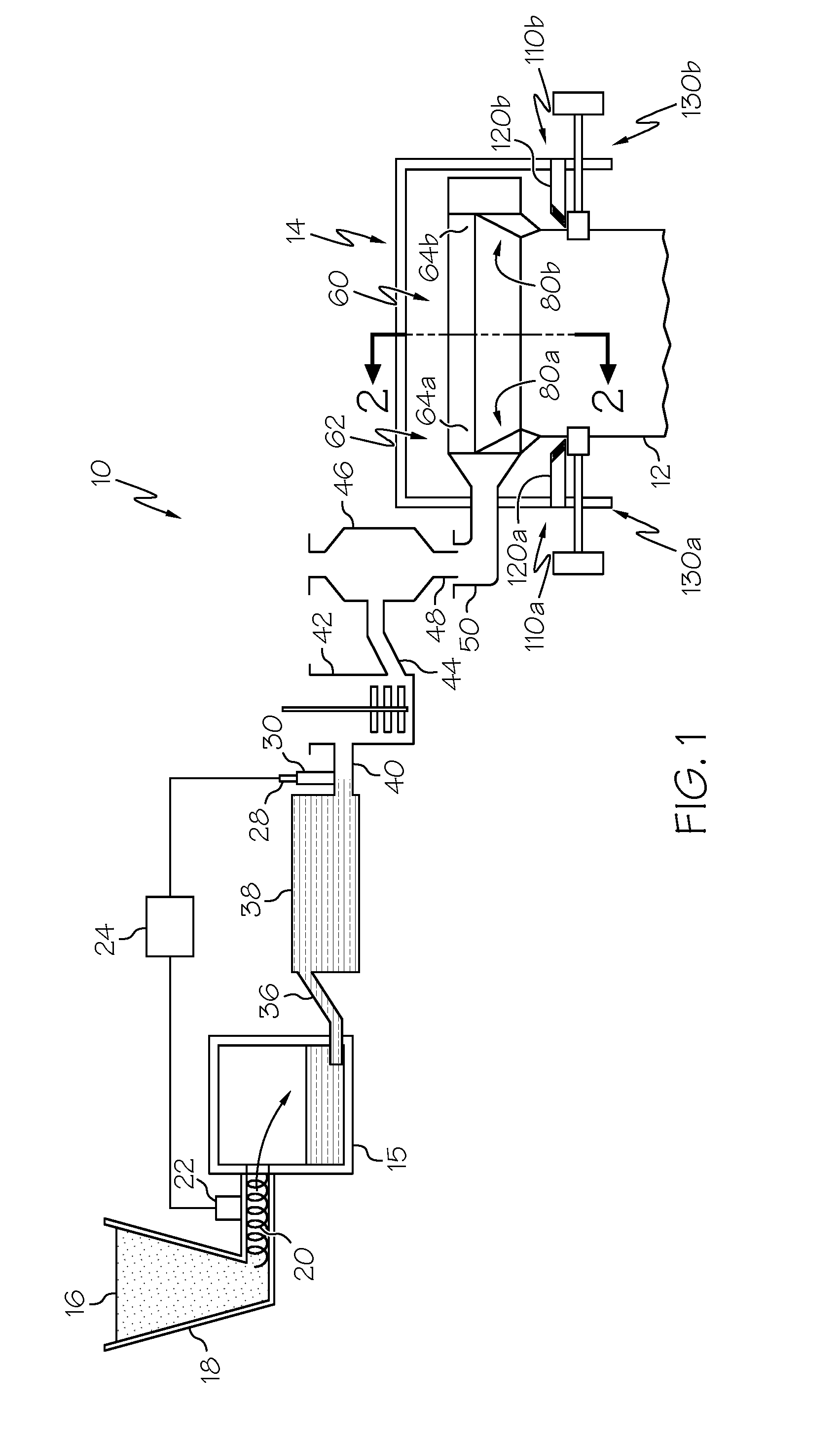

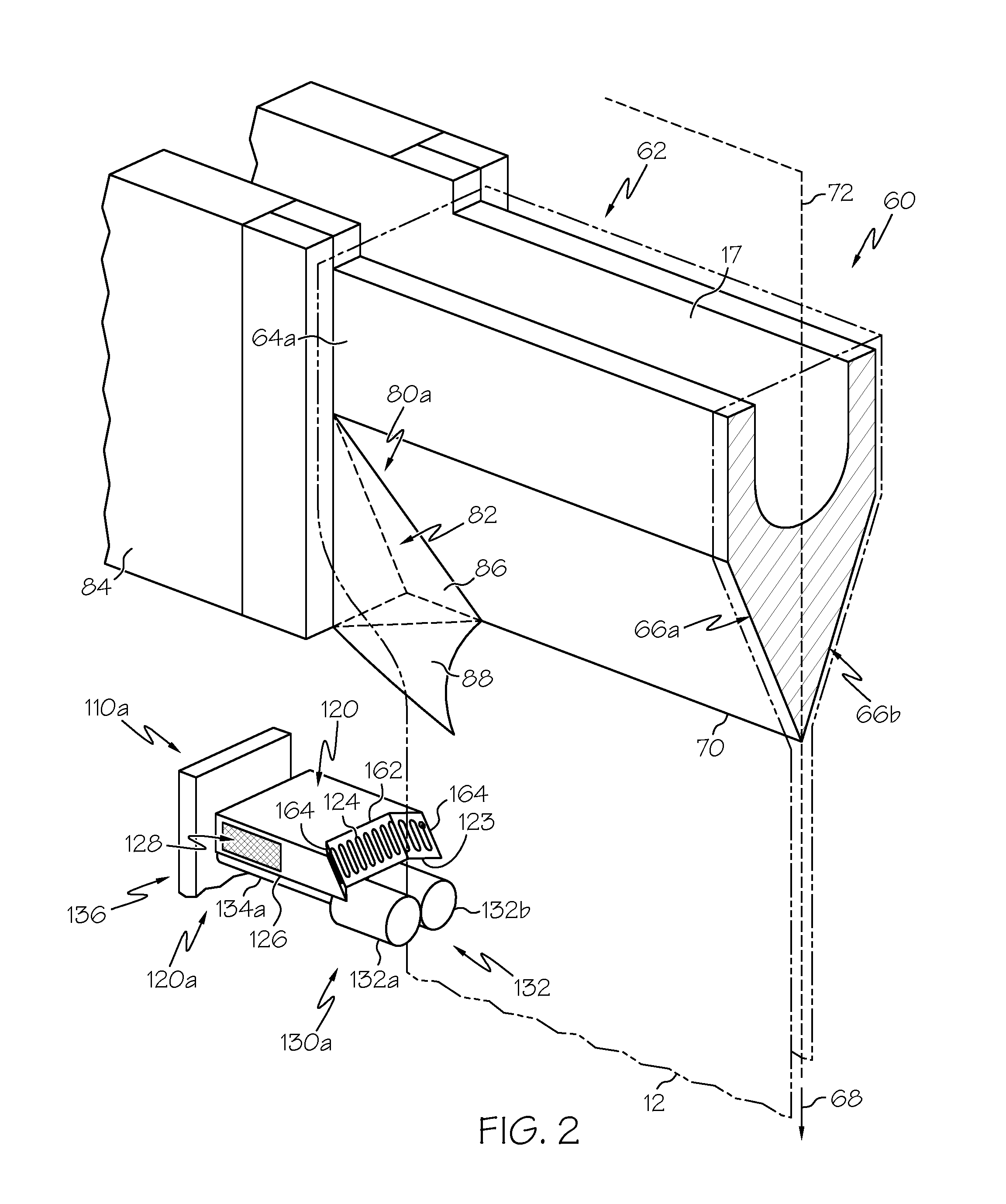

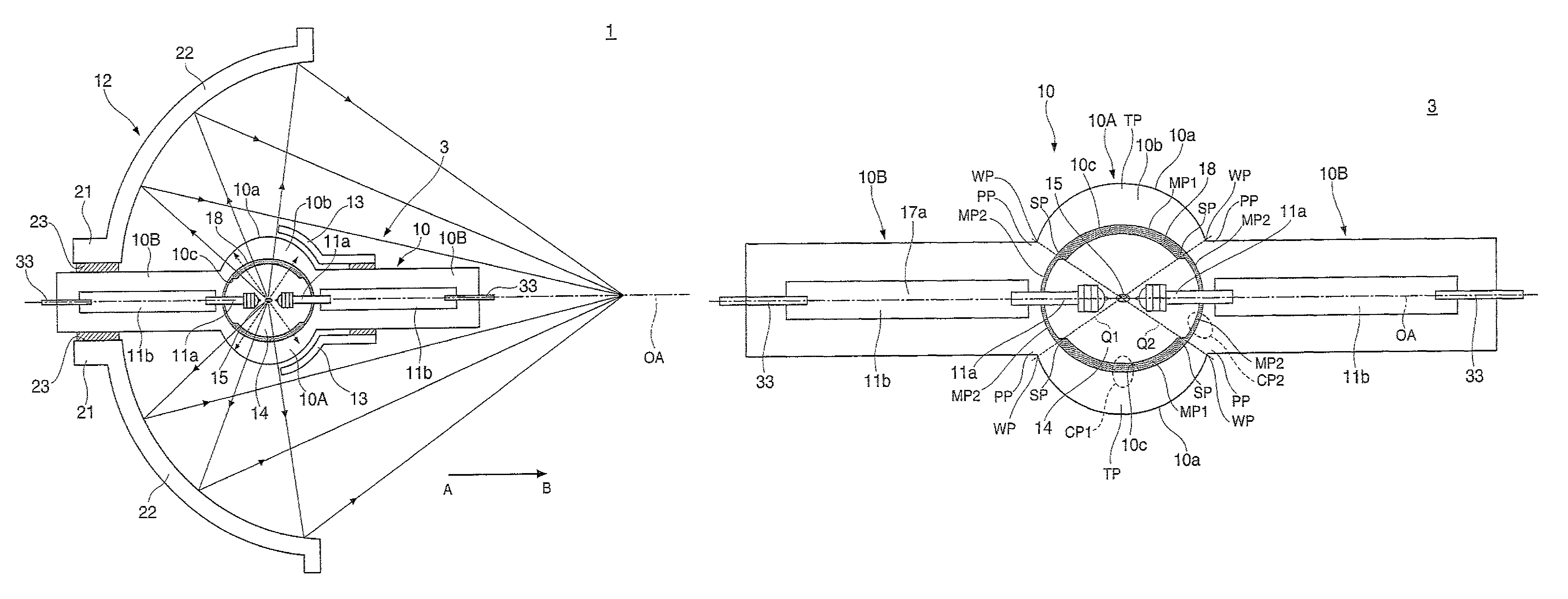

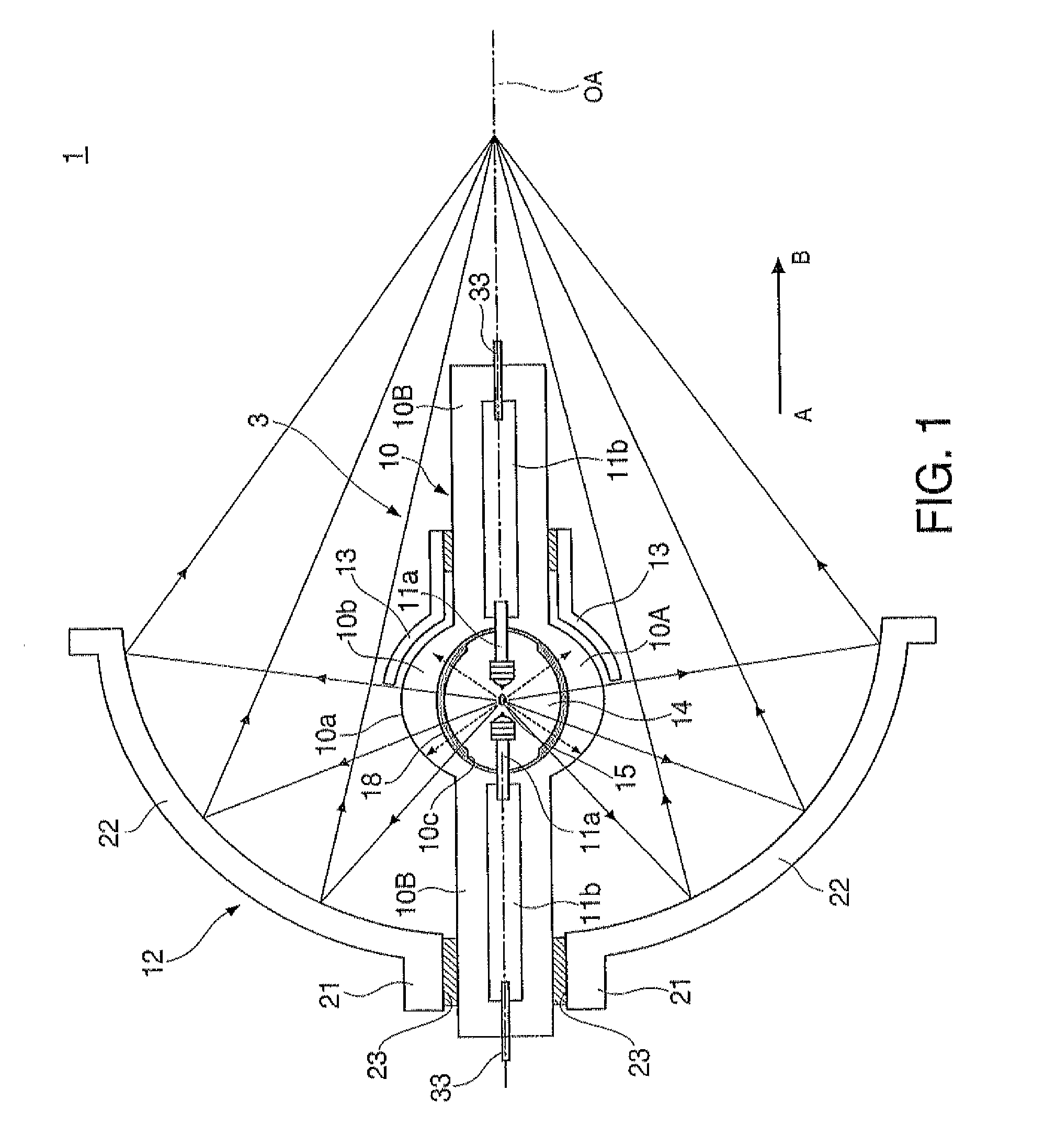

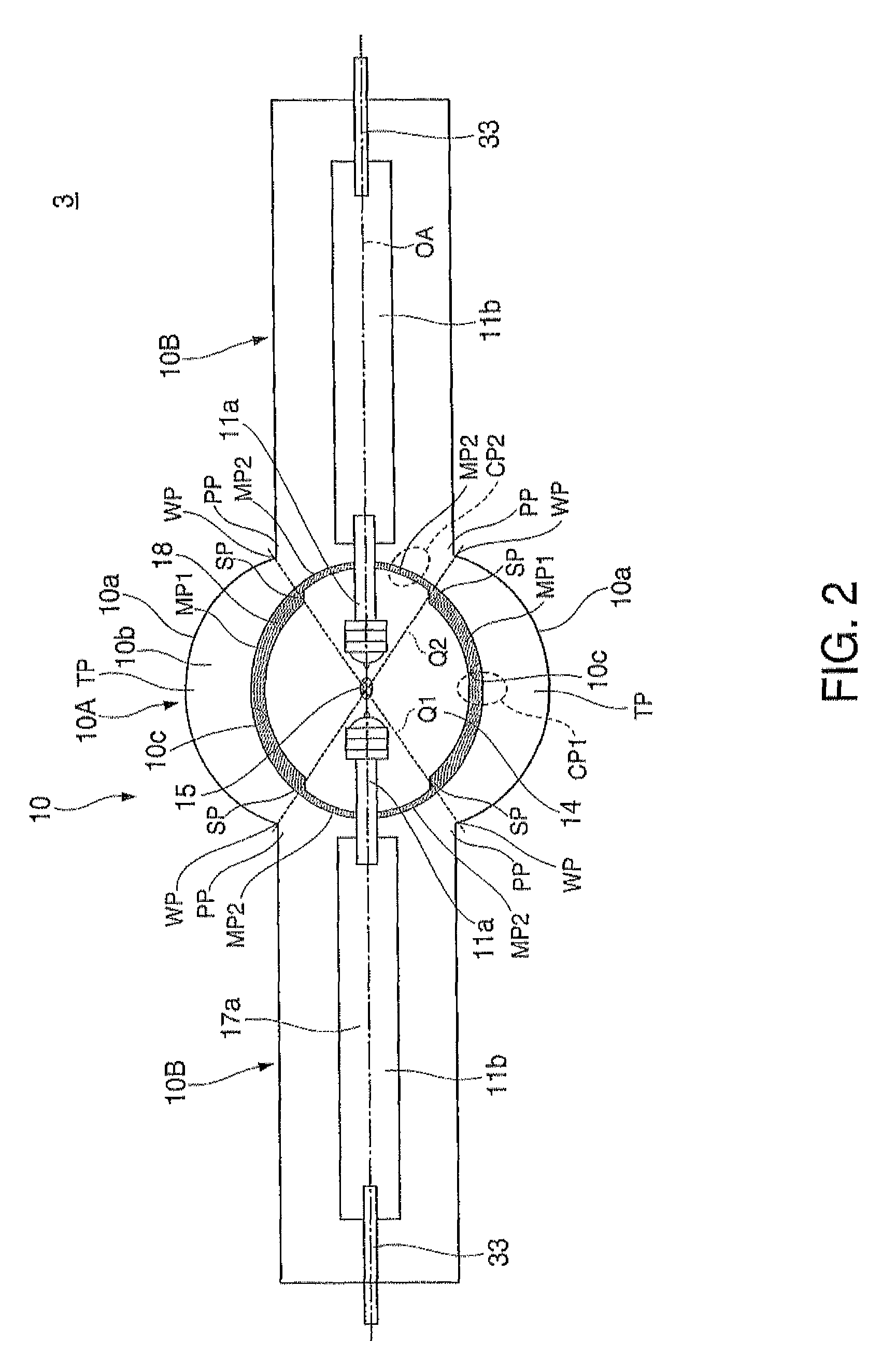

Methods and apparatuses for reducing heat loss from edge directors

ActiveUS20150329401A1Reduce devitrificationGlass drawing apparatusGlass forming apparatusHeat lossesEngineering

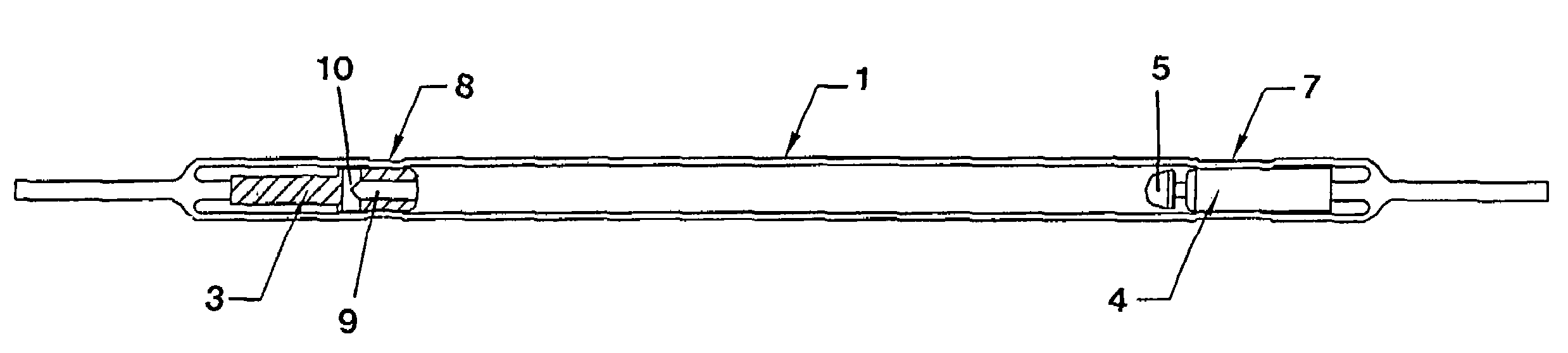

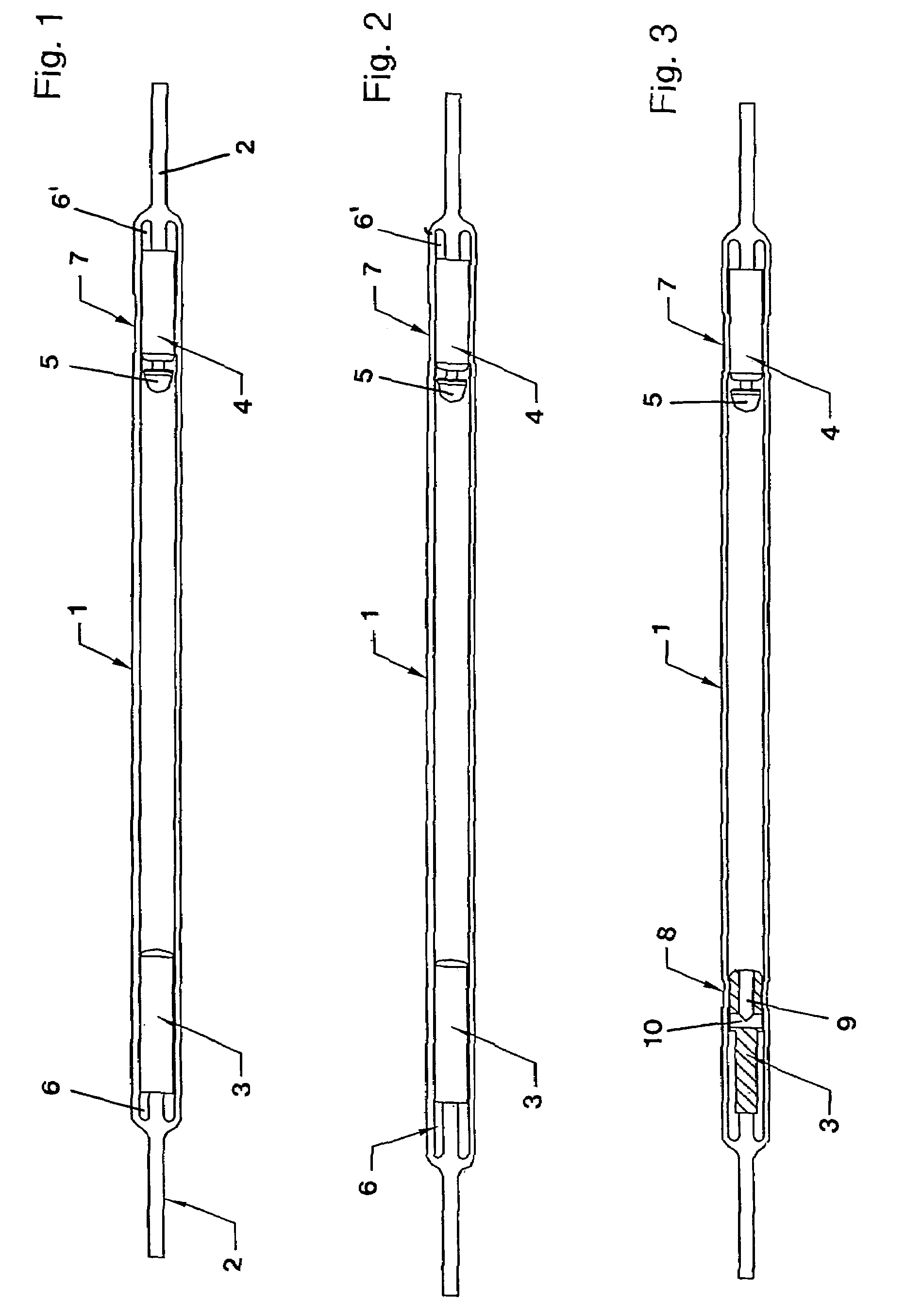

An apparatus and methods for making a glass ribbon includes a forming wedge with a pair of inclined forming surface portions converging along a downstream direction to form a root. The apparatus further includes an edge director intersecting with at least one of the pair of downwardly inclined forming surface portions, and a replaceable heating cartridge configured to direct heat to the edge director and thermally shield the edge director from heat loss. A replaceable heating cartridge is also provided for directing heat to the edge director and thermally shielding the edge director from heat loss.

Owner:CORNING INC

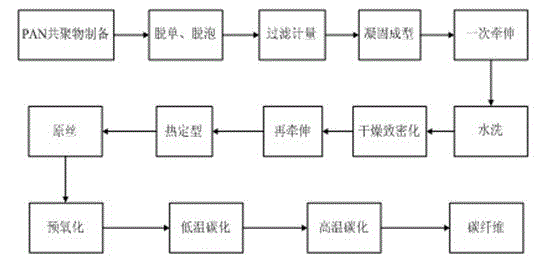

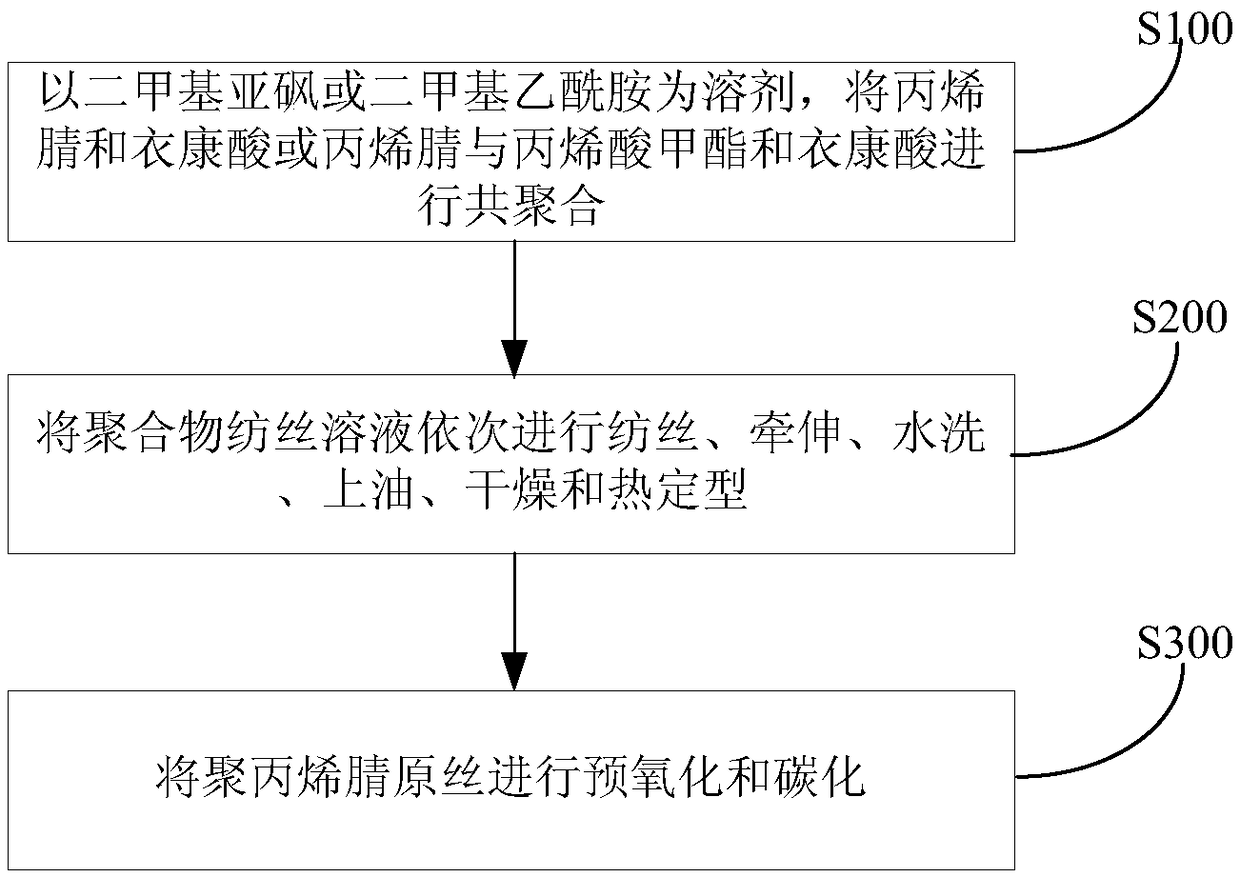

Preparation method of wet-process high-strength polyacrylonitrile-based carbon fiber

InactiveCN103952797AReduce exposureSimple structureFibre chemical featuresDevitrificationCarbon fibers

The invention relates to a preparation method of a wet-process high-strength polyacrylonitrile-based carbon fiber. The preparation method sequentially comprises the following steps: step1. preparing a PAN (Polyacrylonitrile) copolymer; step 2. removing monomers and removing foams; step 3. filtering and metering; step 4. carrying out consolidation forming; step 5. carrying out primary-drafting, washing, drying and compacting, re-drafting and thermally setting to prepare precursor fibers; and step 6. carrying out pre-oxidizing, low-temperature carbonizing and high-temperature carbonizing to finally obtain carbon fibers, wherein the coagulating bath system used in the step 4 consists of a good solvent of polyacrylonitrile, precipitator water and water soluble low carbon fatty amine. According to the preparation method provided by the invention, contact between the polymer and the precipitator water is alleviated by means of the appetency of the low carbon fatty amine and the polymer component to accelerate the solution trickle to precipitate with a slow speed phase so as to effectively reduce hole defects and skin cores of the precursor fibers in the conventional wet-process solidification forming process, so that the shape structure of the precursor fibers is improved, devitrification and non-uniformity of the precursor fibers are reduced, radial solidification and dispersion uniformity of the solution trickle are expanded and strands far from the bath are compact and transparent.

Owner:BEIJING UNIV OF CHEM TECH +1

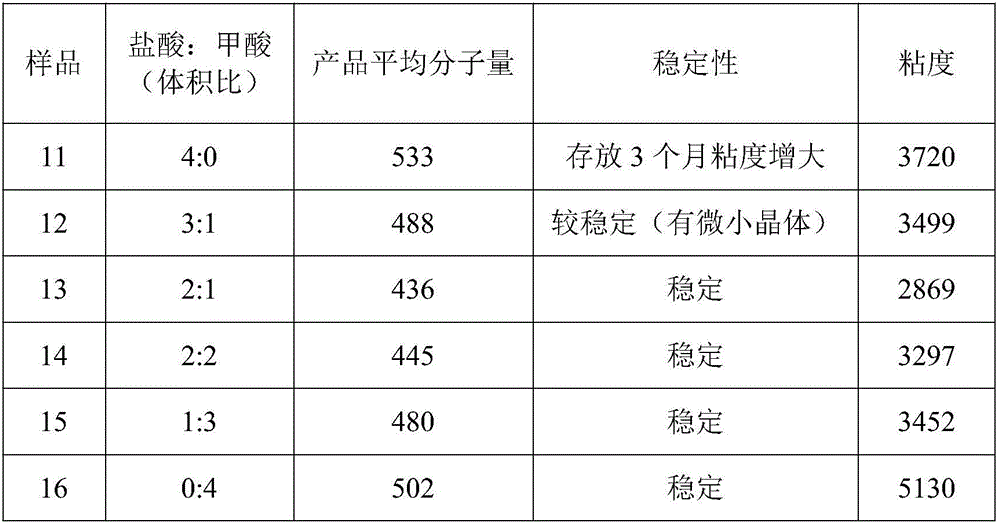

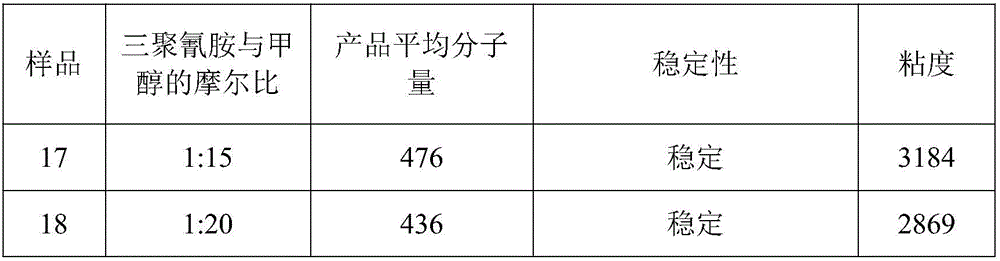

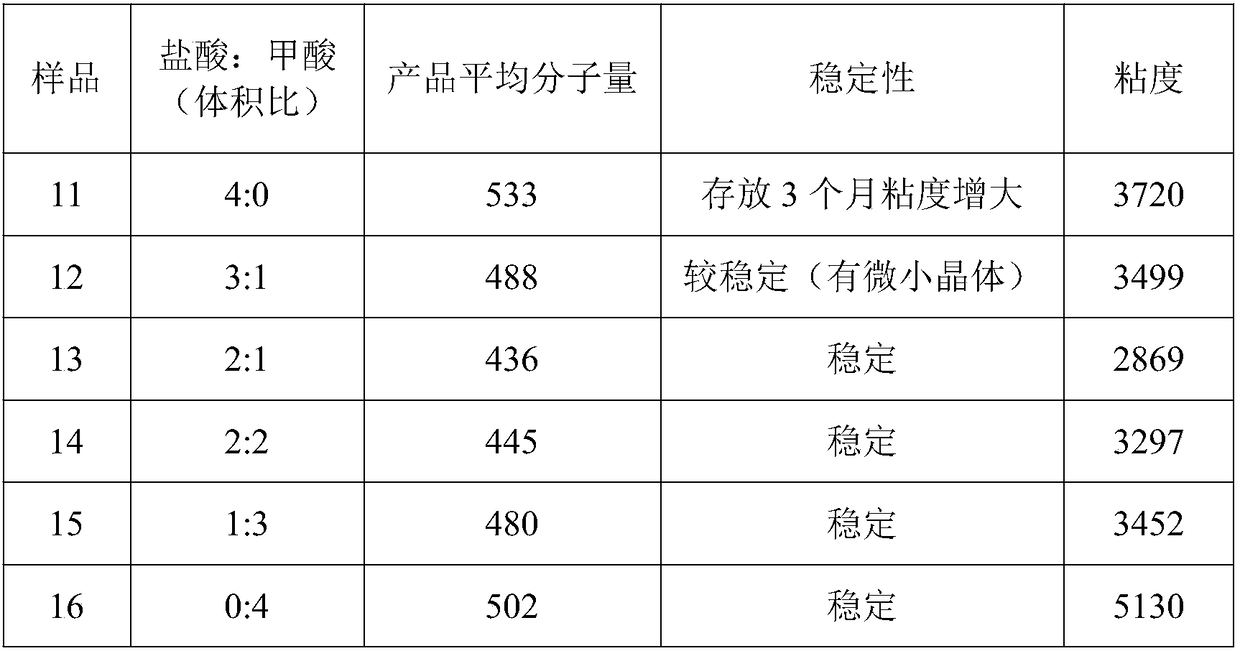

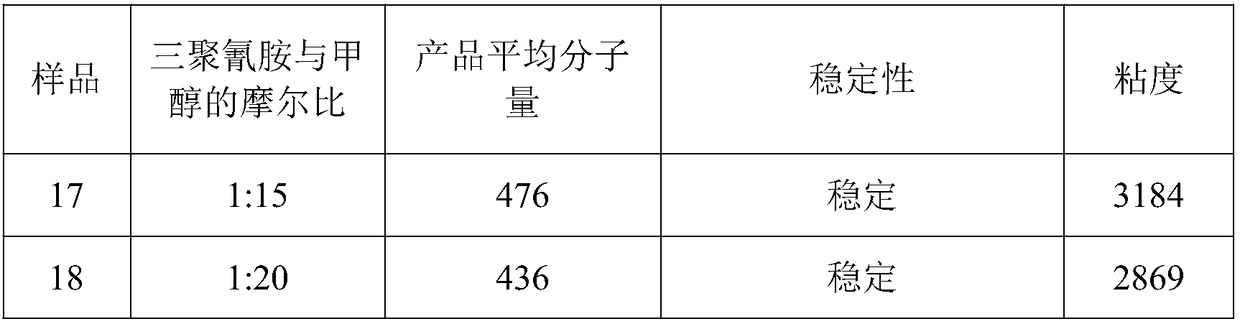

Preparation method of high-imido and high-methoxylation melamine resin capable of being cured at low temperature

The invention discloses a preparation method of a high-imido and high-methoxylation melamine resin capable of being cured at low temperature. According to the method, the high-imido and high-methoxylation melamine resin capable of being cured at low temperature is obtained by reacting melamine, a formaldehyde solution and methanol, paraformaldehyde is not required to be added, the step of synthesis of hydroxymethylation melamine as an intermediate product is omitted, preparation costs are reduced, links of crystallization, drying and the like of the intermediate product are omitted, energy consumption is low, a technological process is simple, the methanol only needs to be added at one step in reaction, and the preparation method is easy to control. In addition, a mixture of hydrochloric acid and formic acid is used as an etherification catalyst, and the effect of the obtained product is better than that of a single acid catalyst.

Owner:重庆建峰新材料有限责任公司

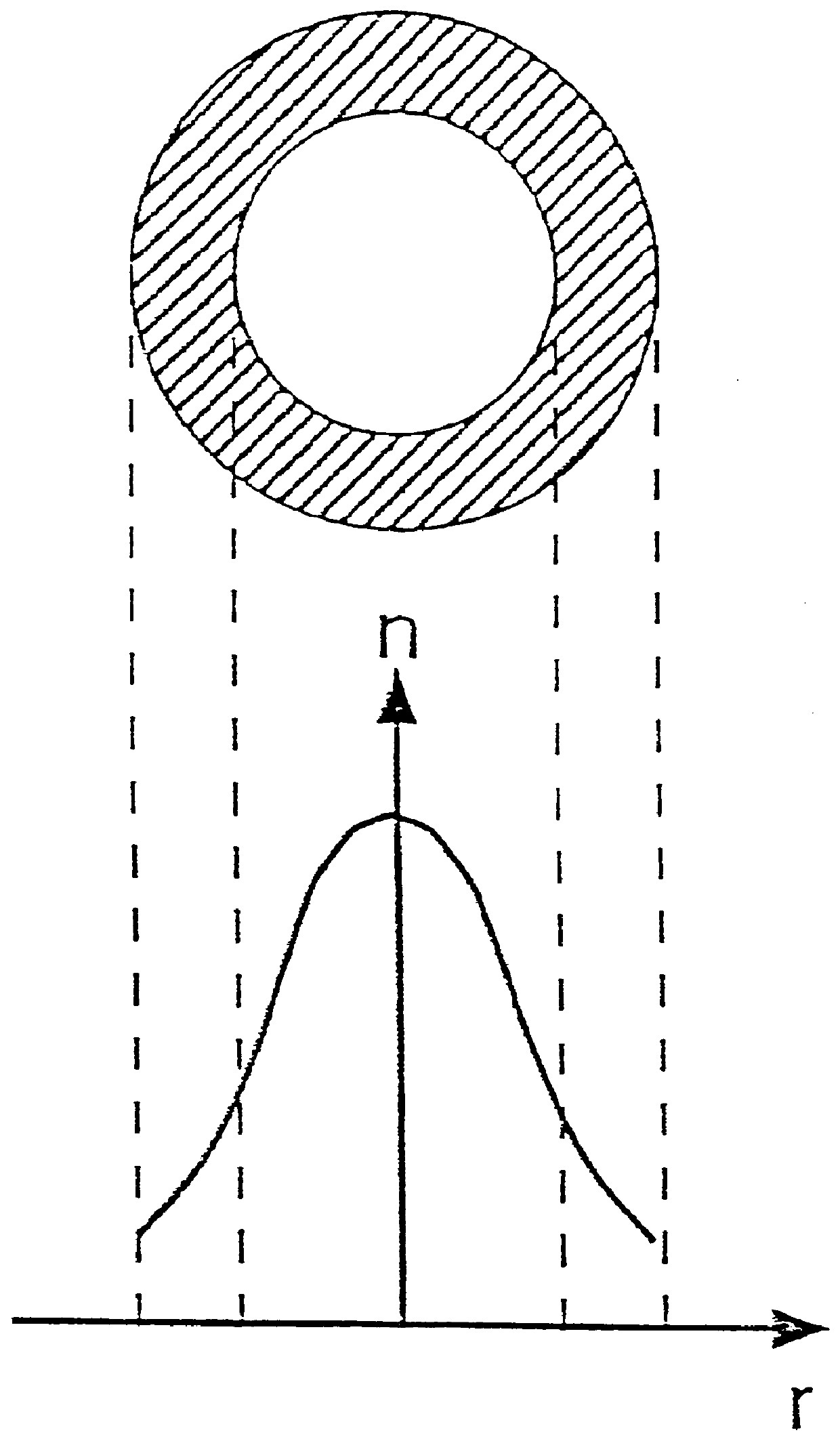

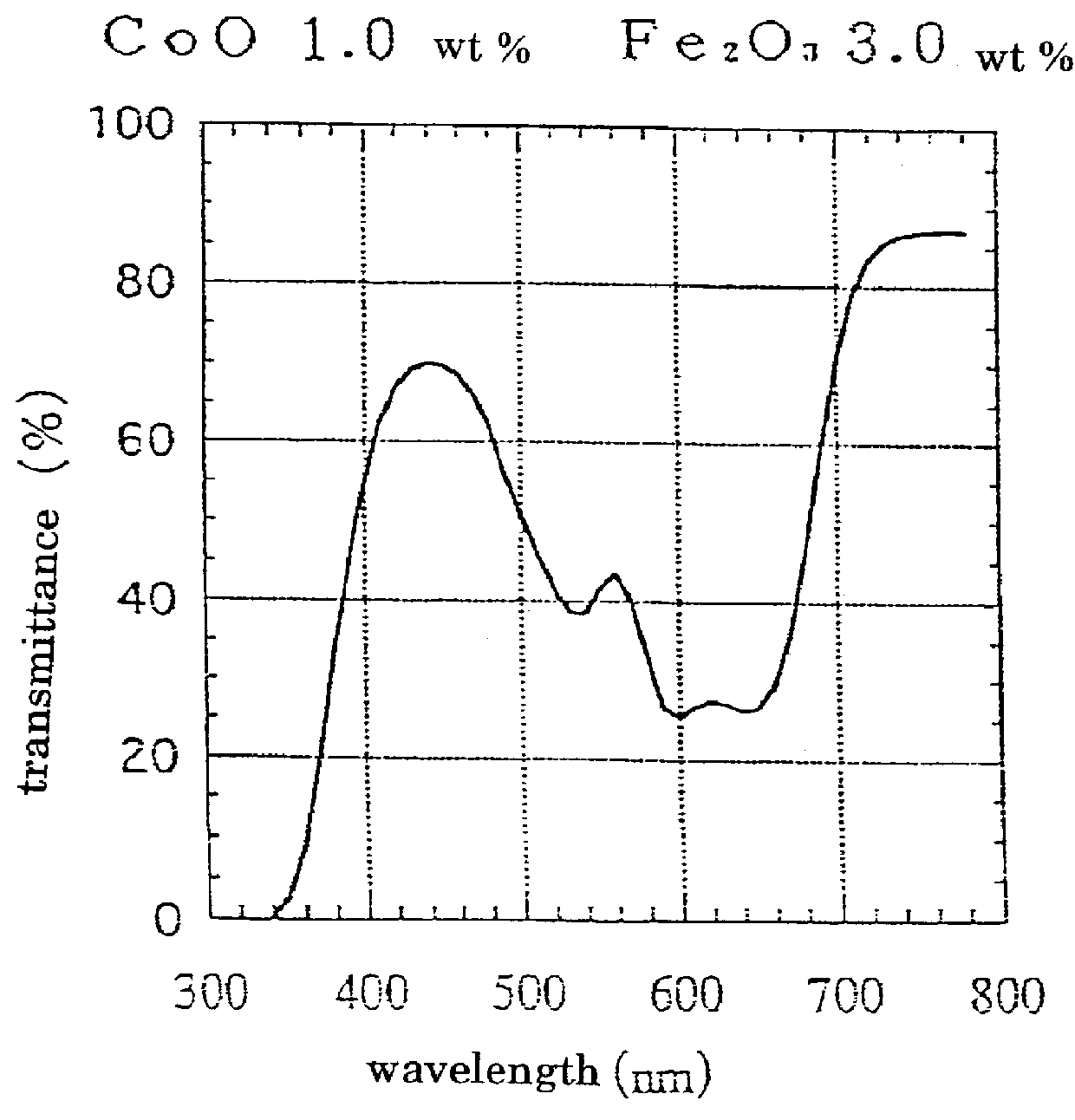

Refractive index distribution type optical element and refractive index distribution type rod lens array

InactiveUS6141155AHigh resolutionPrevented from deterioration of optical propertyOptical fibre with graded refractive index core/claddingOptical waveguide light guideOptical propertyImage resolution

A refractive index distribution type optical element has a core / cladding structure produced with the ion exchange method. The element includes colorant of metal oxides in cladding glass thereof. The cladding glass consists of base glass and the colorant of the metal oxides comprising: 0.3 to 4.0 wt. % CoO; 1.0 to 12.0 wt. % Fe2O3; 0.0 to 2.0 wt. % NiO; and 0.0 to 0.2 wt. % Cr2O3 when the total amount of the base glass except for the colorants is taken as 100 wt. %. The refractive index distribution type optical element is prevented from deterioration of the optical properties occurring at portions having the refractive index departing the regular parabolic distribution and also is prevented from entrance of the flare light. The element is provided with good resolution even when employed for an optical device using a white light, and a rod lens array formed with the refractive index distribution type optical element is provided.

Owner:NIPPON SHEET GLASS CO LTD

Purification method for quartz sand

InactiveCN106082238AReduce devitrificationImprove thermal propertiesSilicaPurification methodsQuenching

The invention discloses a purification method for quartz sand. The purification method comprises the following steps: crushing raw quartz ore, adding water, carrying out blending, then adding a grinding aid and successively carrying out ball milling, magnetic separation and drying so as to obtain a material A; subjecting the material A to heating, heat preservation, chlorination water and quenching and then carrying out filtering and drying so as to obtain a material B; and adding the material B into a mixed acid solution, carrying out ultrasonic treatment at 35 to 65 DEG C for 3 to 8 h and then successively carrying out filtering, washing until a pH value is 7, and drying so as to obtain purified quartz sand. The purification method for quartz sand is simple in steps, and the obtained quartz sand is high in purity and good in stability and can be applied to a plurality of fields.

Owner:安徽晶晶石英科技有限公司

Superfine lead-free glass powder for electrode slurry of solar battery, and preparation method thereof

The invention discloses superfine lead-free glass powder for the electrode slurry of a solar battery and a preparation method thereof. Lead-free glass comprises 20% to 30% of SiO2, 40% to 70% of Bi2O3, 2% to 15% of B2O3, 1% to 10% of Sb2O3, 1 to 3% of ZnO and 1 to 3% of ZrO2. The preparation method comprises the following steps: (1) weighing of a mixture according to the above-mentioned proportion and addition of a pore forming agent (C and PVA); (2) melting of the mixture; (3) water quenching; and (4) planetary ball milling (sieving). The superfine glass powder is prepared through ball milling of environment-friendly lead-free porous glass powder by using this method; and compared with conventional products, the prepared lead-free superfine glass powder has the advantages of short ball milling time, low energy consumption, a small particle size and high activity. A high photoelectric conversion rate is obtained when the lead-free superfine glass powder is used for photovoltaic positive electrode slurry; after electrode silver slurry is sintered, low volume resistance is obtained, bonding strength between an electrode silver layer and Si is improved, and sintering temperature of silver slurry is reduced.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

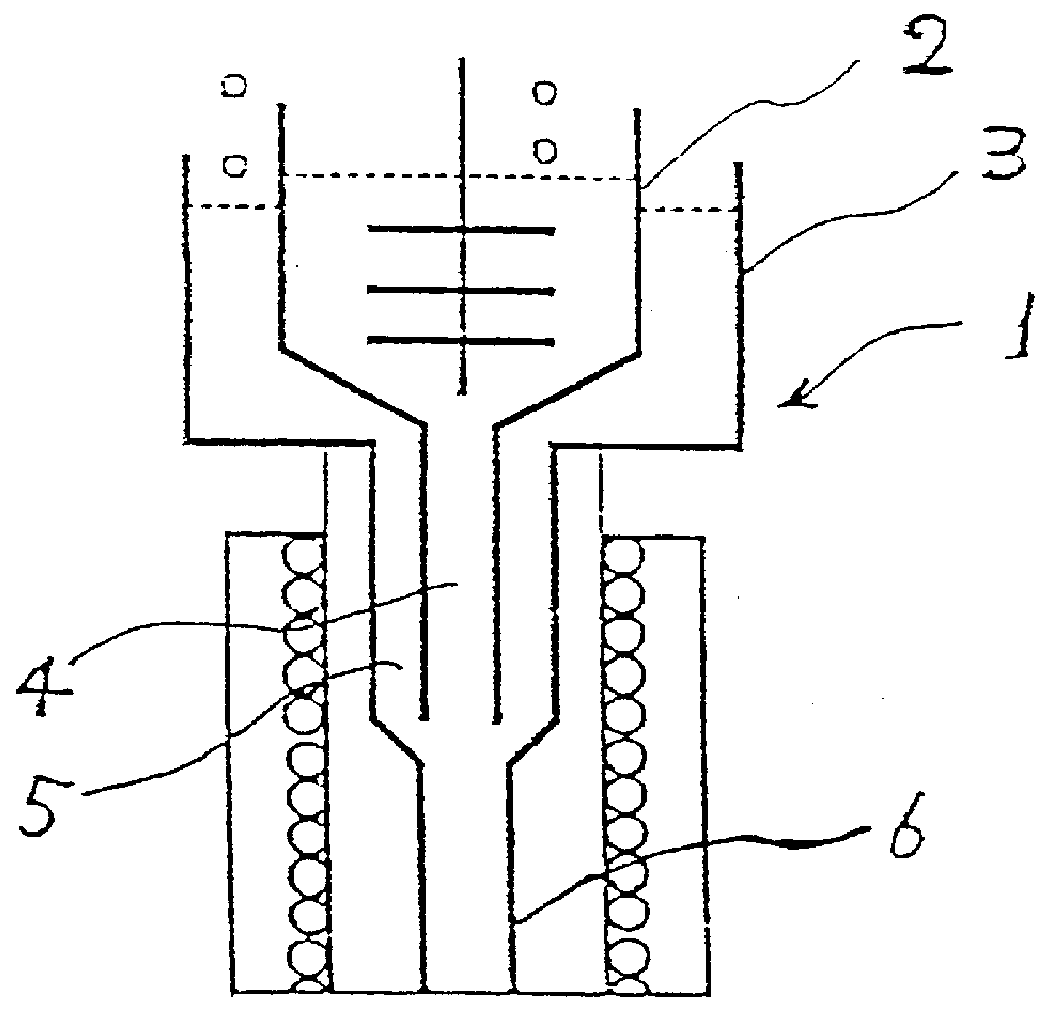

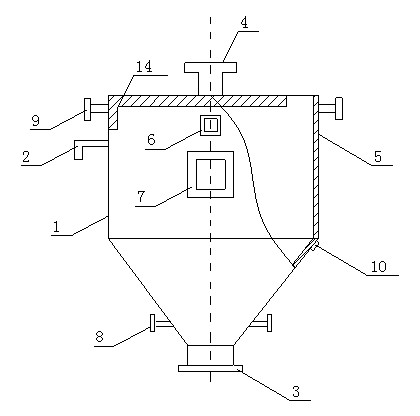

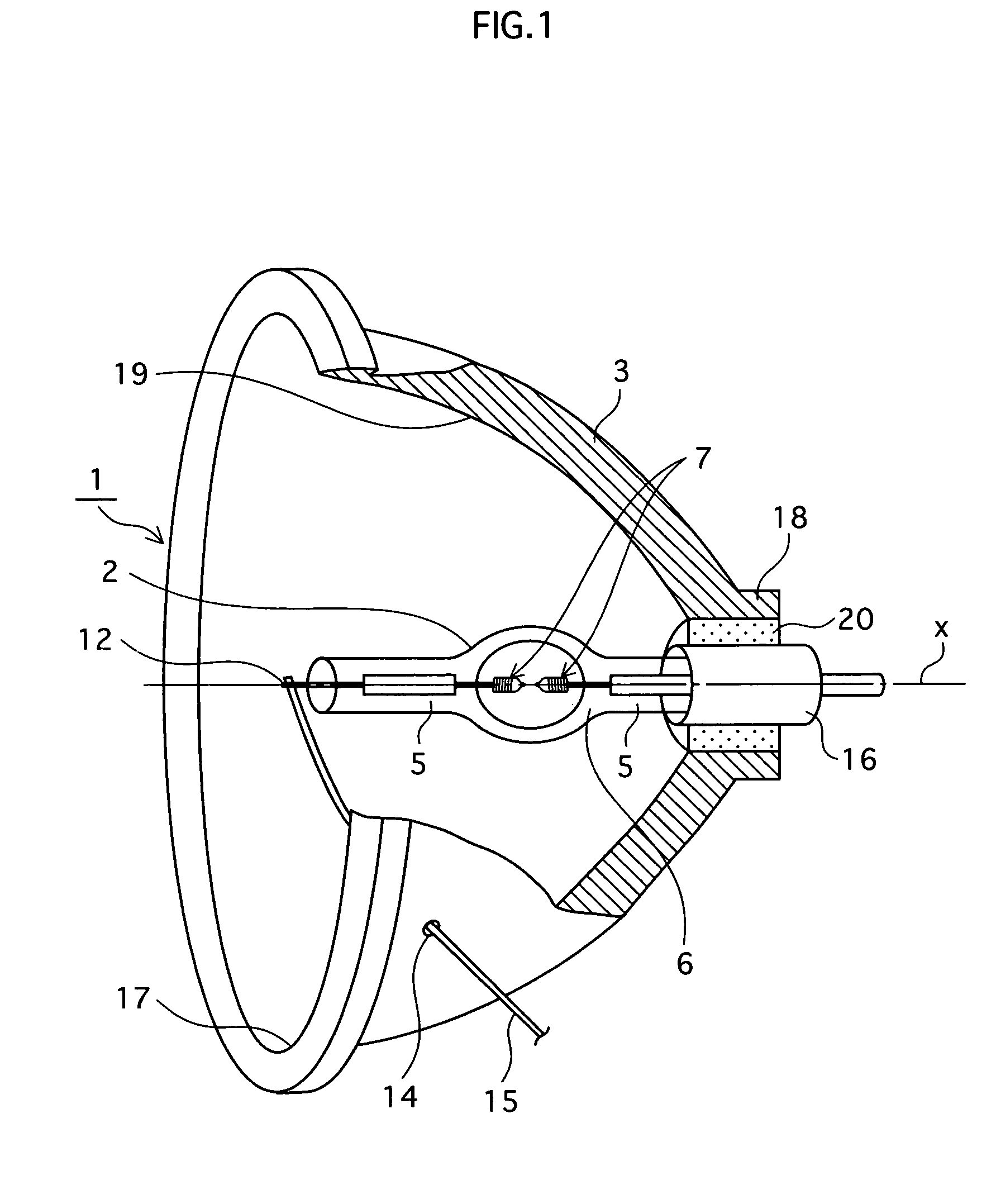

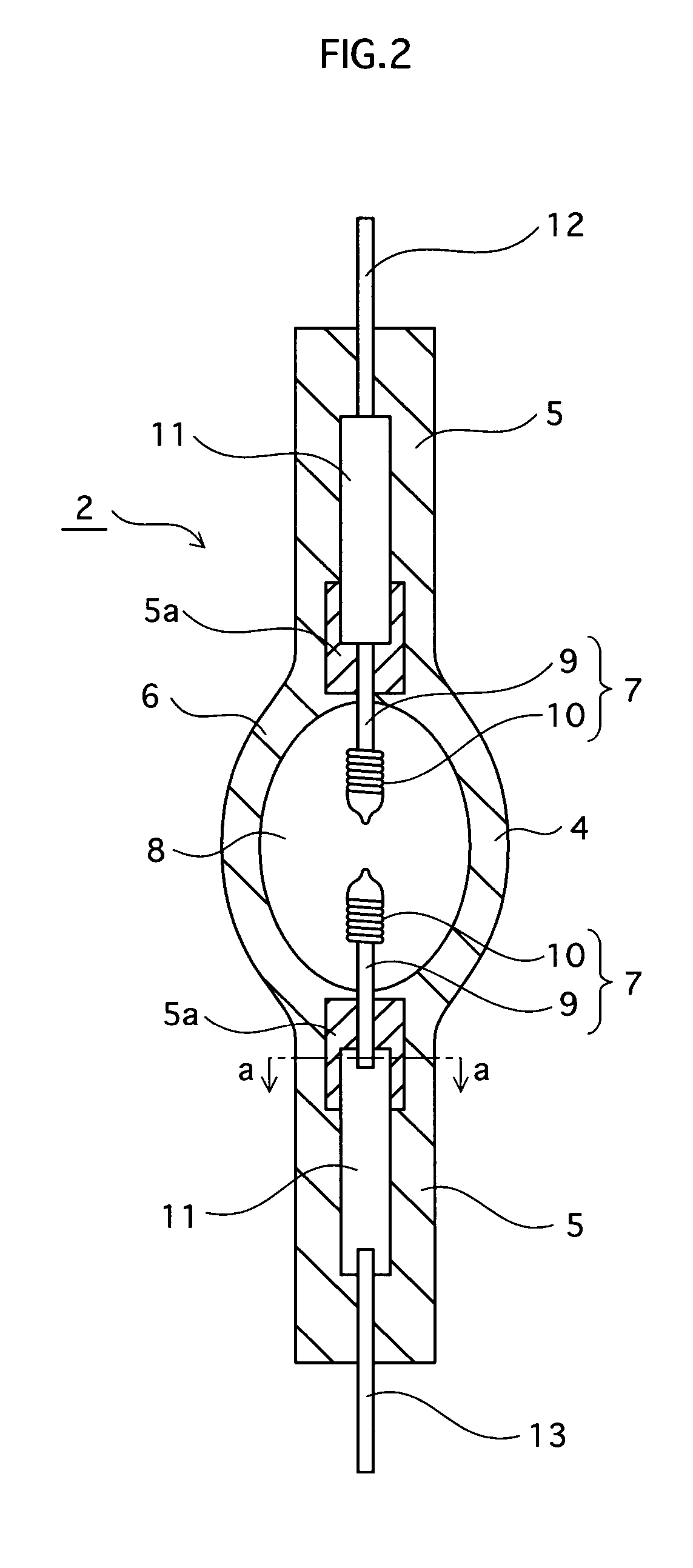

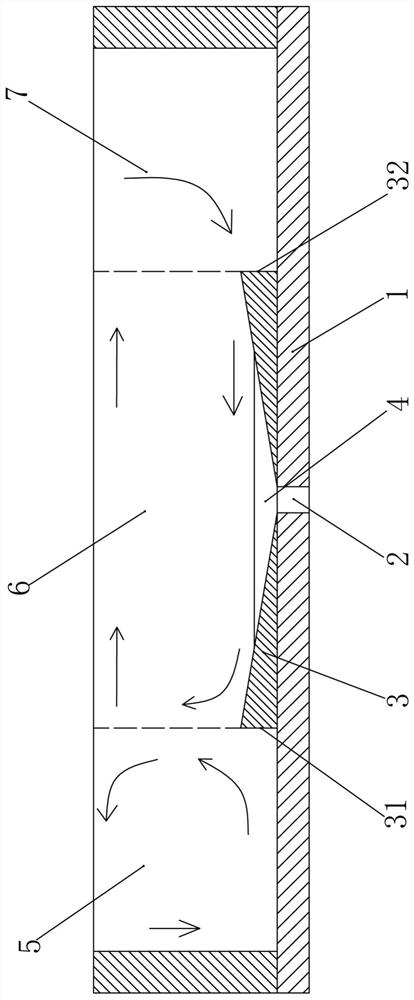

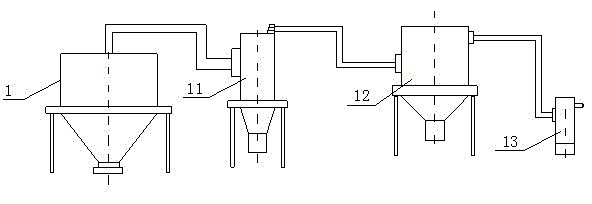

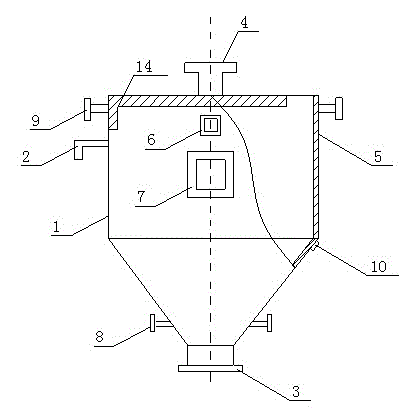

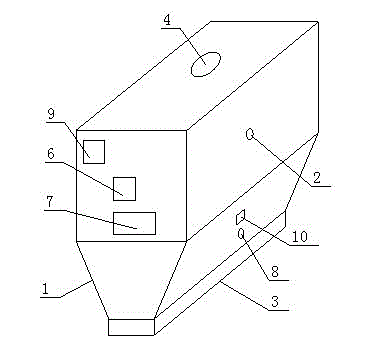

Glass microballoon manufacturing device and preparation method thereof

InactiveCN102417291APrevent molten buildupReduce devitrificationGlass shaping apparatusGlass productionDevitrificationCombustor

The invention discloses a glass microballoon manufacturing device comprising a furnace body (1) and a waste gas treatment device, wherein the furnace body (1) is formed by air-tight connection of an upper part and a lower part, the upper part of the furnace body is of a cubic shape, a waste gas emission port (4) is arranged at the top of the upper part, one or more injection-type burners (2) are horizontally installed on the side of the upper part, a preheating air pipe (14) is arranged in the upper part, the lower part of the furnace body is of a square conical shape, and one or more microballoon collectors (3) are arranged at the bottom of the lower part. According to the glass microballoon manufacturing device and the preparation method thereof provided by the invention, the furnace body which adopts the cubic structure enlarges the cooling space; the horizontally installed injection-type burners and the preheating air pipe arranged in the furnace body can give full play to the heat value of fuel, thus reducing energy source waste, saving energy and reducing emission; TiO2 and Al2O3 with relatively lower costs are adopted, the refractive index of the product is greater than or equal to 1.93; and the glass microballoon manufacturing device and the preparation method thereof have the advantages of reducing devitrification, improving the cooling velocity, having good product quality, improving the utilization ratio of raw material, being capable of large-scale production, and the like.

Owner:SICHUAN ZHONGKE BETTER TECH

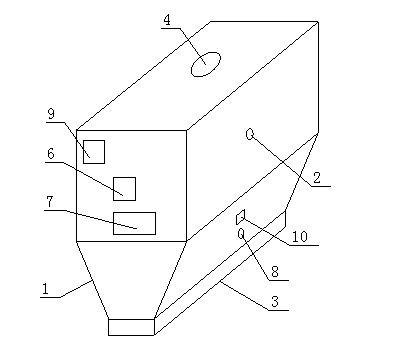

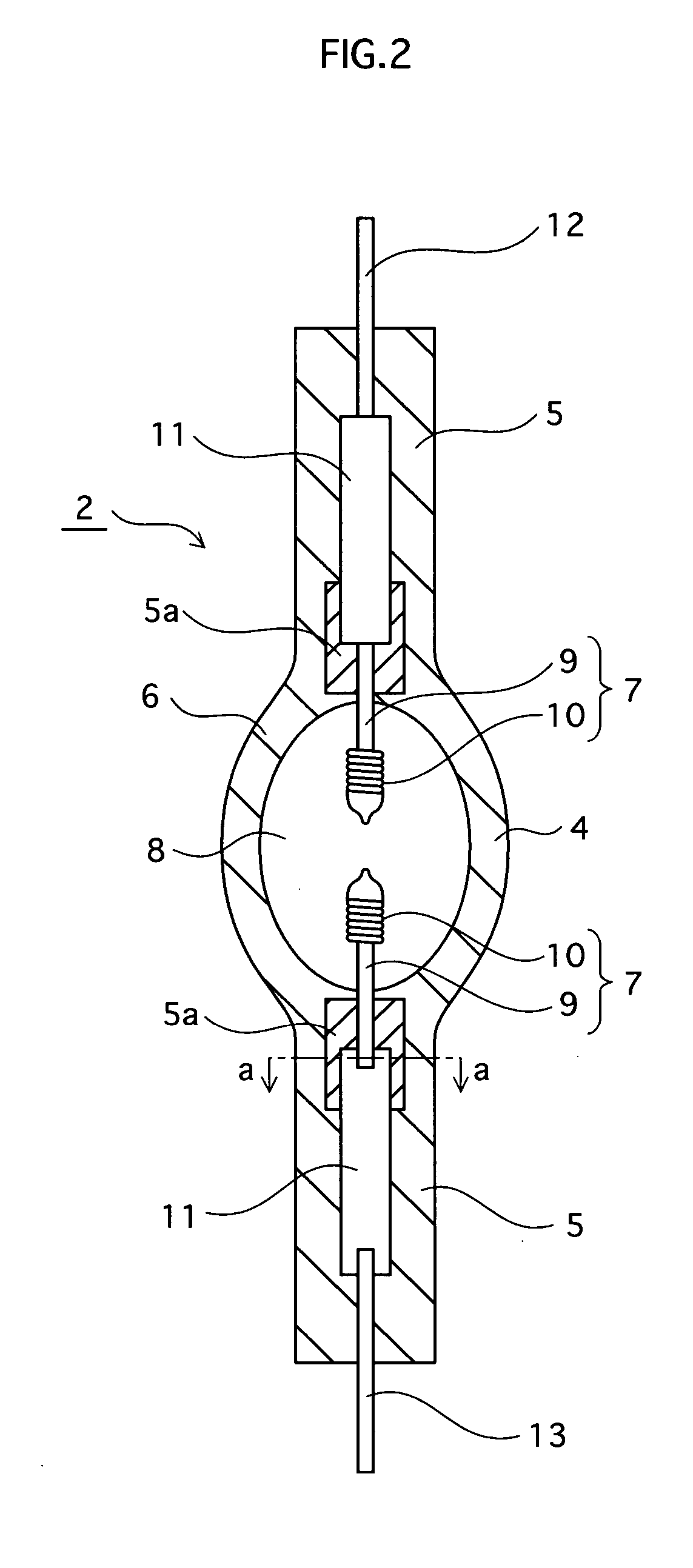

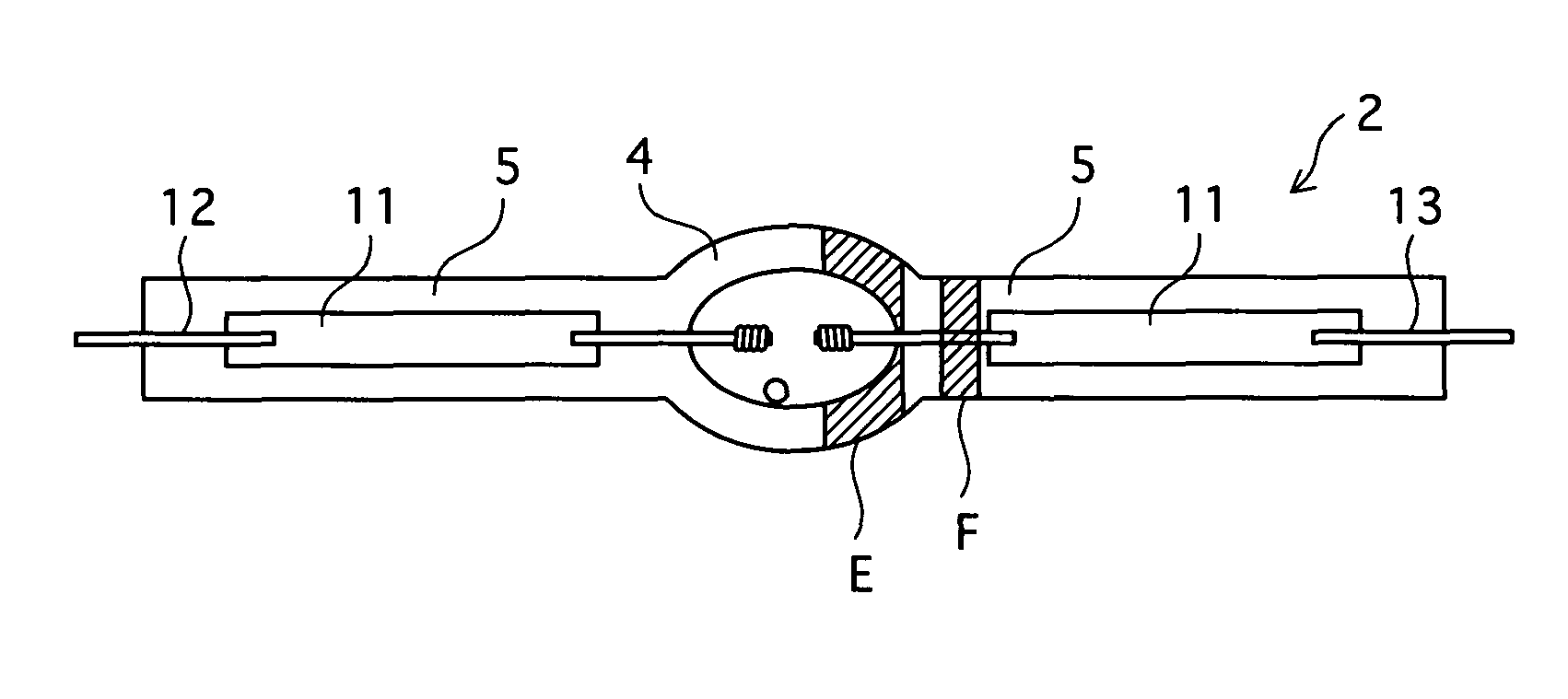

Manufacturing method of high-pressure discharge lamp, high-pressure discharge lamp, lamp unit using high-pressure discharge lamp, and image display apparatus using high-pressure discharge lamp

ActiveUS20070052365A1Reduce devitrificationAvoid darkeningDischarge tube luminescnet screensElectric lighting sourcesEngineeringHigh pressure

A manufacturing method of a high-pressure mercury lamp includes an electric field application step in which an electric field is applied to at least a light emission part (4) with the high-pressure mercury lamp being kept at a high temperature. This can reduce impurities such as hydrogen and alkali metals in a discharge space (8) and glass forming the light emission part (4). As a consequence, blackening and devitrification of the high-pressure mercury lamp while the lamp is lit can be reduced.

Owner:PANASONIC CORP

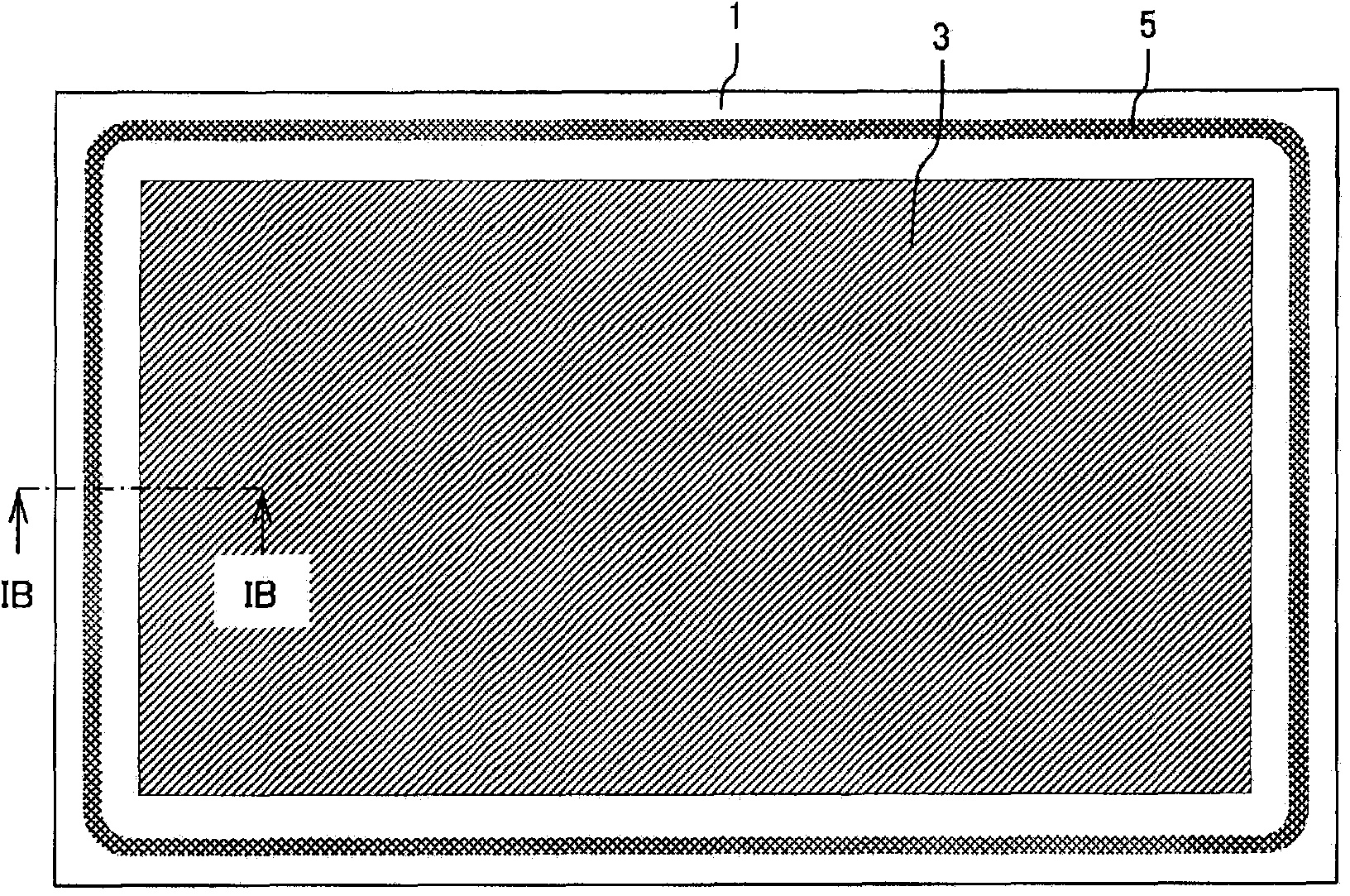

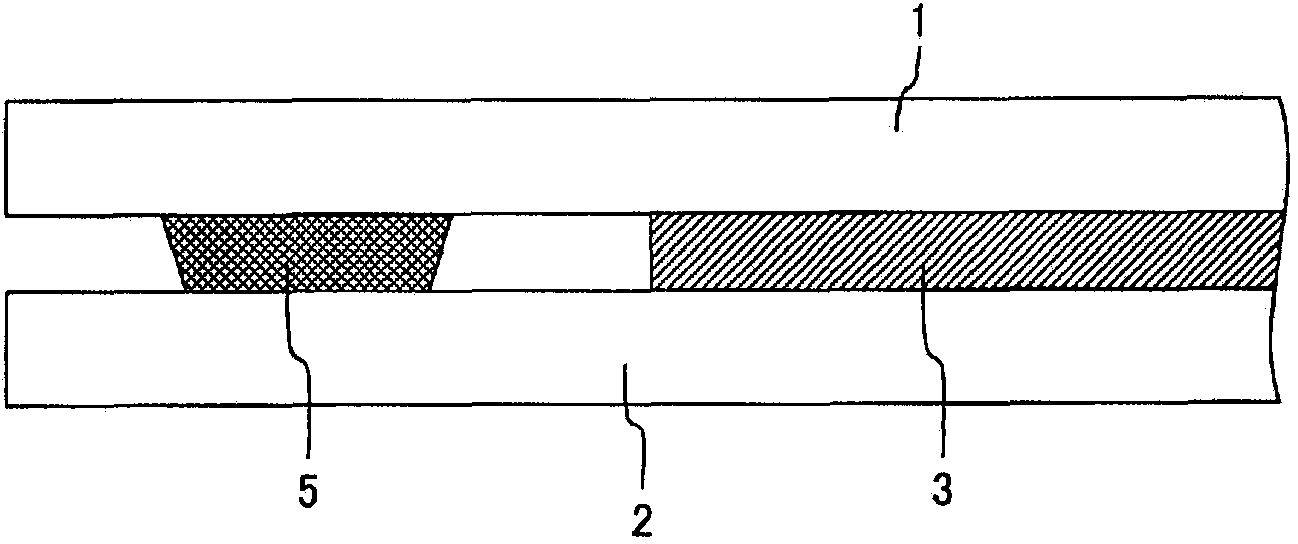

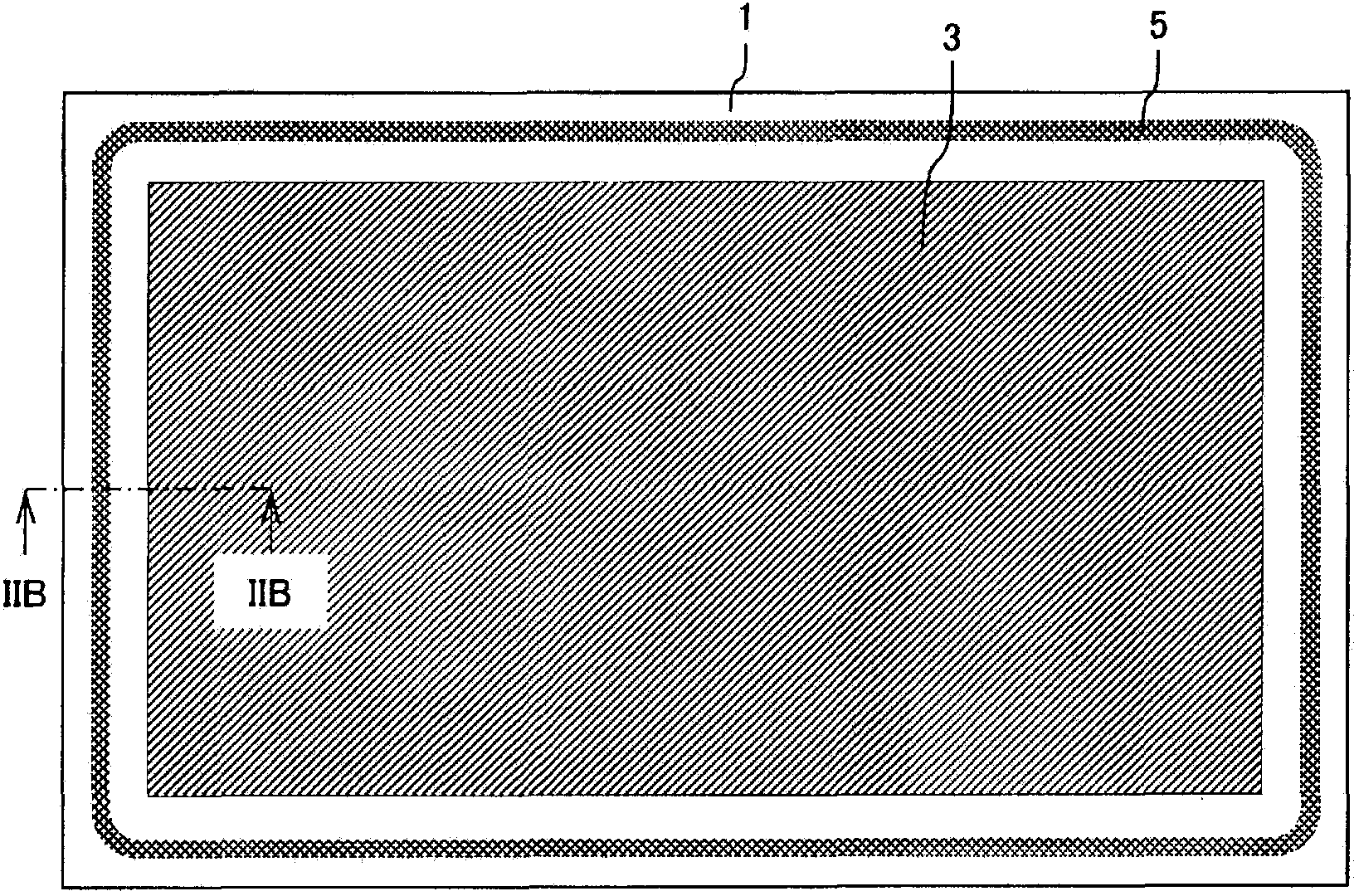

Electronic component, production method therefor, and sealing material paste used therein

InactiveCN104081877AReduce heat damageReduce devitrificationFinal product manufactureElectroluminescent light sourcesElectronic componentVanadium oxide

The invention relates to an electronic component, production method therefor, and sealing material paste used therein. The electronic component has an organic member (3) between two transparent substrates (1, 2). The outer peripheral sections of the two transparent substrates (1, 2) are bonded using a sealing material (5) that comprises low-melting-point glass. The low-melting-point glass comprises vanadium oxide (V2O5), tellurium oxide (TeO2), phosphorus oxide (P2O5), and iron oxide (Fe2O3), and in terms of oxide content, corresponds to the following: V2O5+TeO2+P2O5+Fe2O3>=75 mass%, and V2O5>TeO2>P2O5>Fe2O3 (in mass%).

Owner:HITACHI CHEM CO LTD

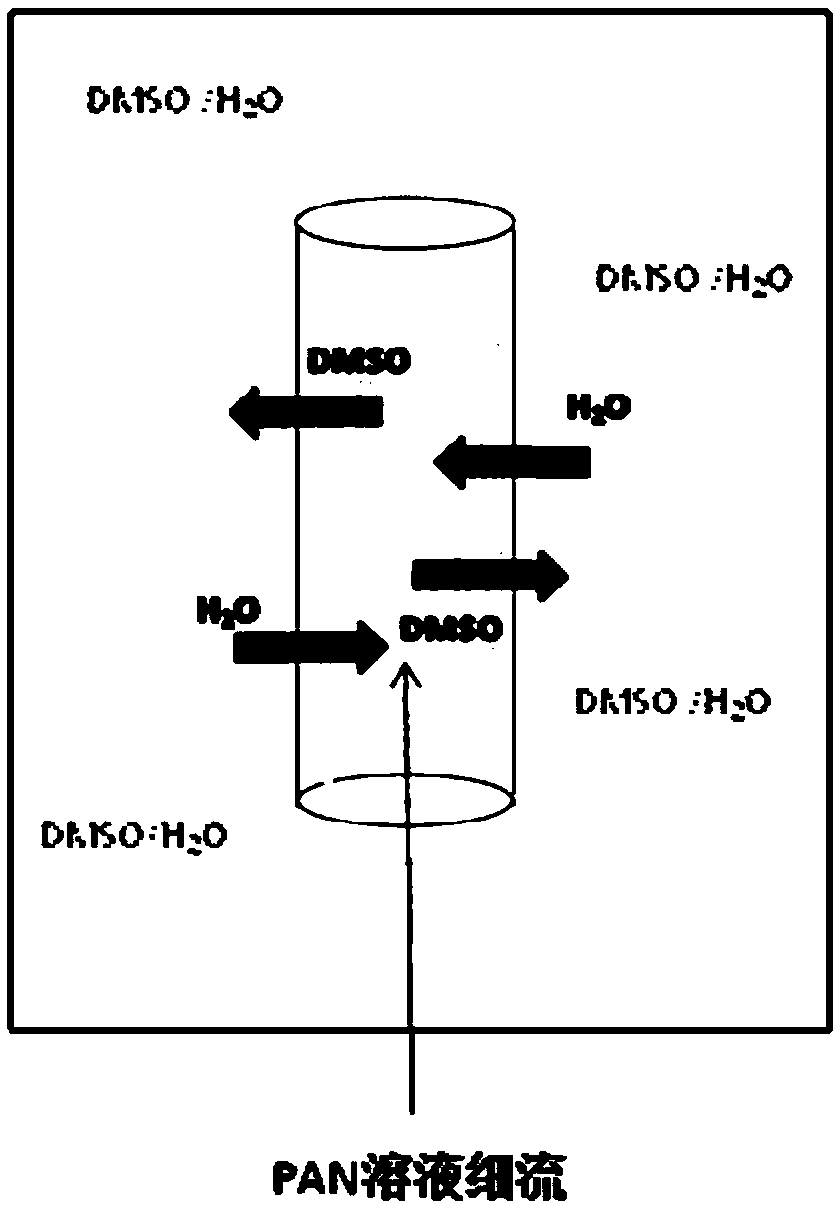

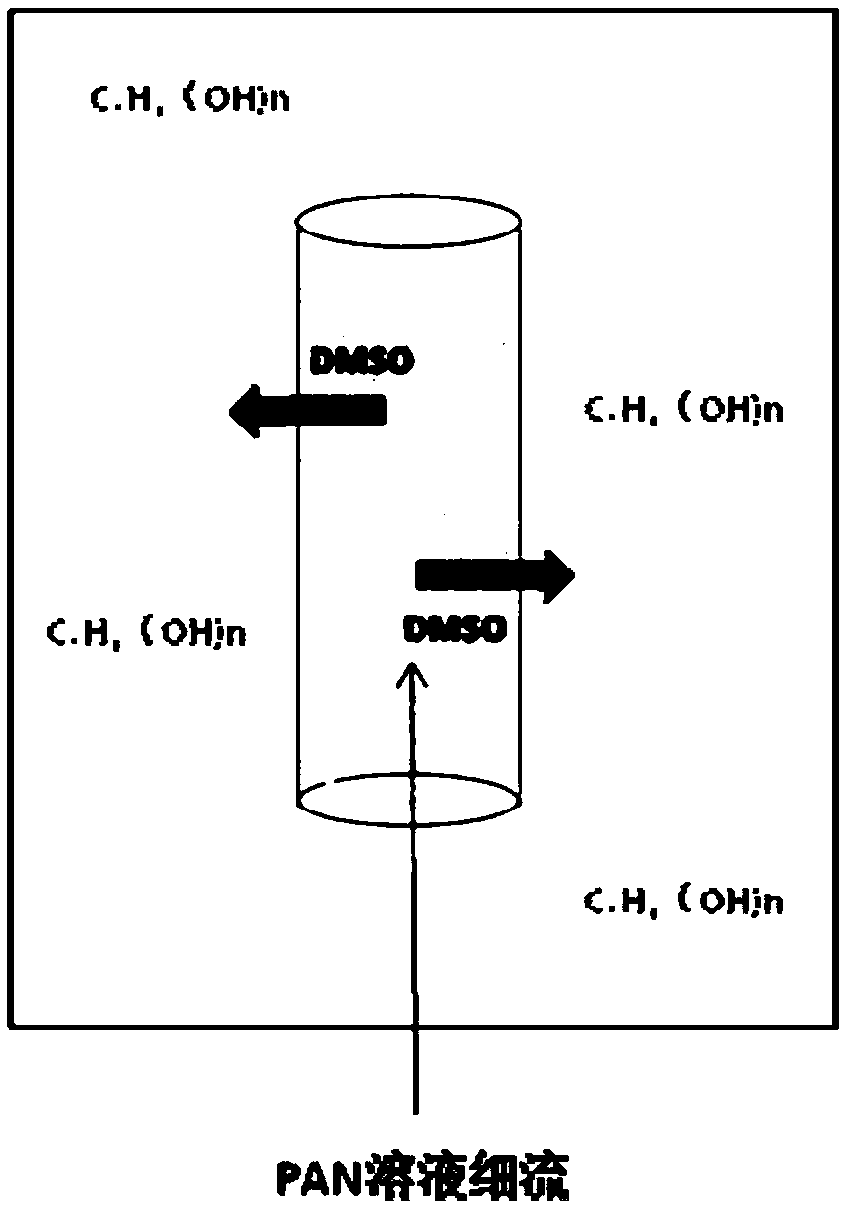

Ultra-high strength and middle high-modulus polyacrylonitrile carbon fibers as well as preparation method thereof

ActiveCN109023594AReduce defectsReduce devitrificationFibre chemical featuresPolymer scienceCarbon fibers

The invention discloses an ultra-high strength and middle high-modulus polyacrylonitrile carbon fibers as well as preparation method thereof. The method comprises the following steps: (1) using dimethyl sulfoxide or dimethylformacetamide as a solvent, and performing copolymerization on acrylonitrile and itaconic acid or acrylonitrile, methyl acrylate and itaconic acid; (2) spinning, drafting, washing, oiling, drying, and heat setting a polymer spinning solution in sequence; (3) performing pre-oxidation and carbonization on polyacrylonitrile strand to obtain ultra-high strength, middle high-modulus carbon fiber. The components of the coagulation bath system in a spinning process cannot penetrate into a spinning stream formed by the polymer spinning solution, and the solvent in the spinningstream formed by the polymer spinning solution can diffuse into the coagulation bath system.According to the method provided by the invention, a raw wire hole defect and a skin and core structure inhomogeneity defect formed by a traditional wet or dry-wet solidification molding process can be reduced; highly oriented raw silkstrand can be easily obtain from a fiber initial structure; the raw silkstrand is used to obtain carbon fiber with tensile strength of 5,500-7,000 MPa and tensile modulus 310-390 GPa.

Owner:BEIJING UNIV OF CHEM TECH

Glass tubes for lamps, method for manufacturing the same, and lamps

InactiveUS20070210714A1Extended service lifeAvoid impuritiesTube/lamp screens manufactureDischarge tube coatingEngineeringLight emission

A glass tube for lamp includes: a tubular glass section having open ends; and a ceramics film that covers at least a portion of an inner surface of the glass section in an area that forms a light emission section of the lamp.

Owner:SEIKO EPSON CORP

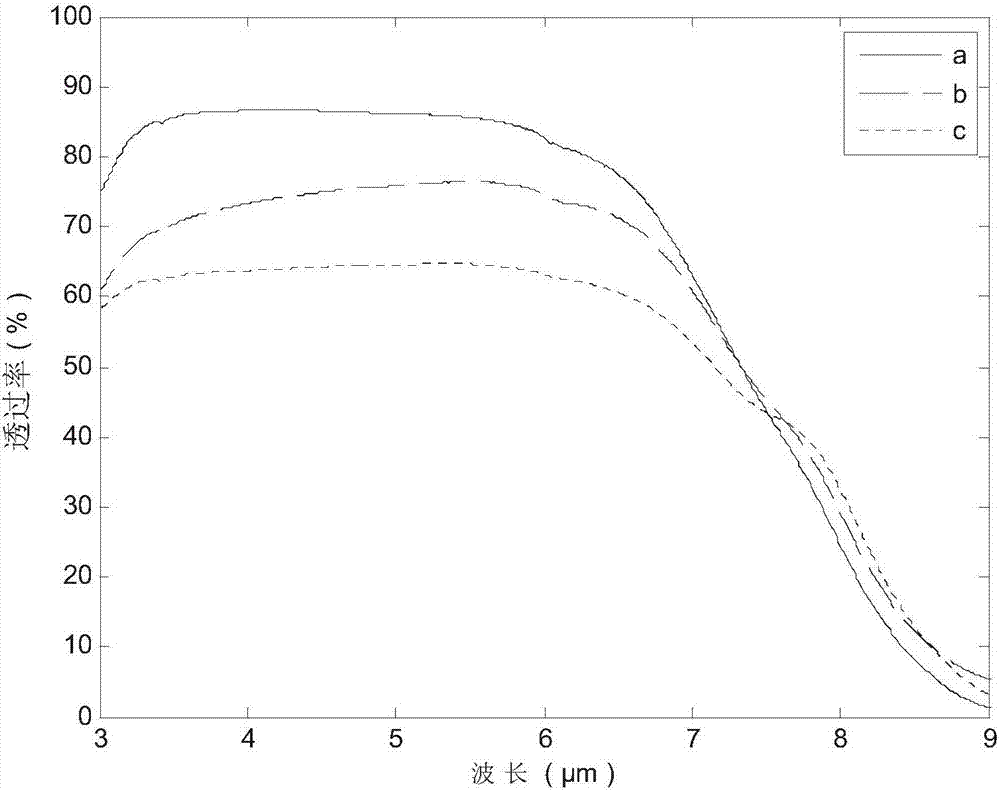

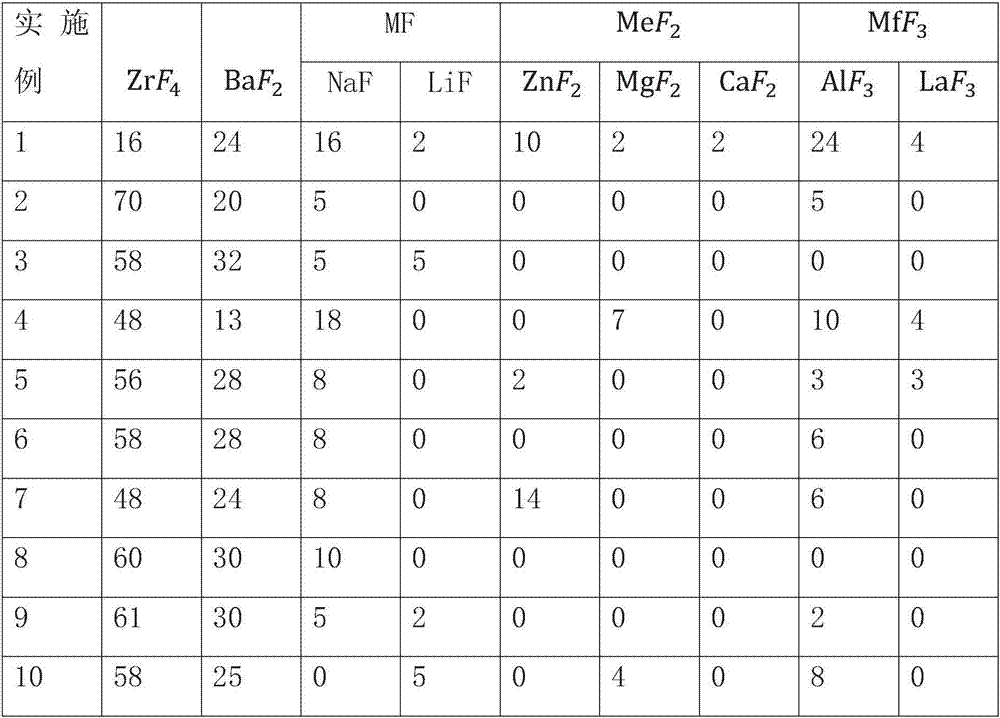

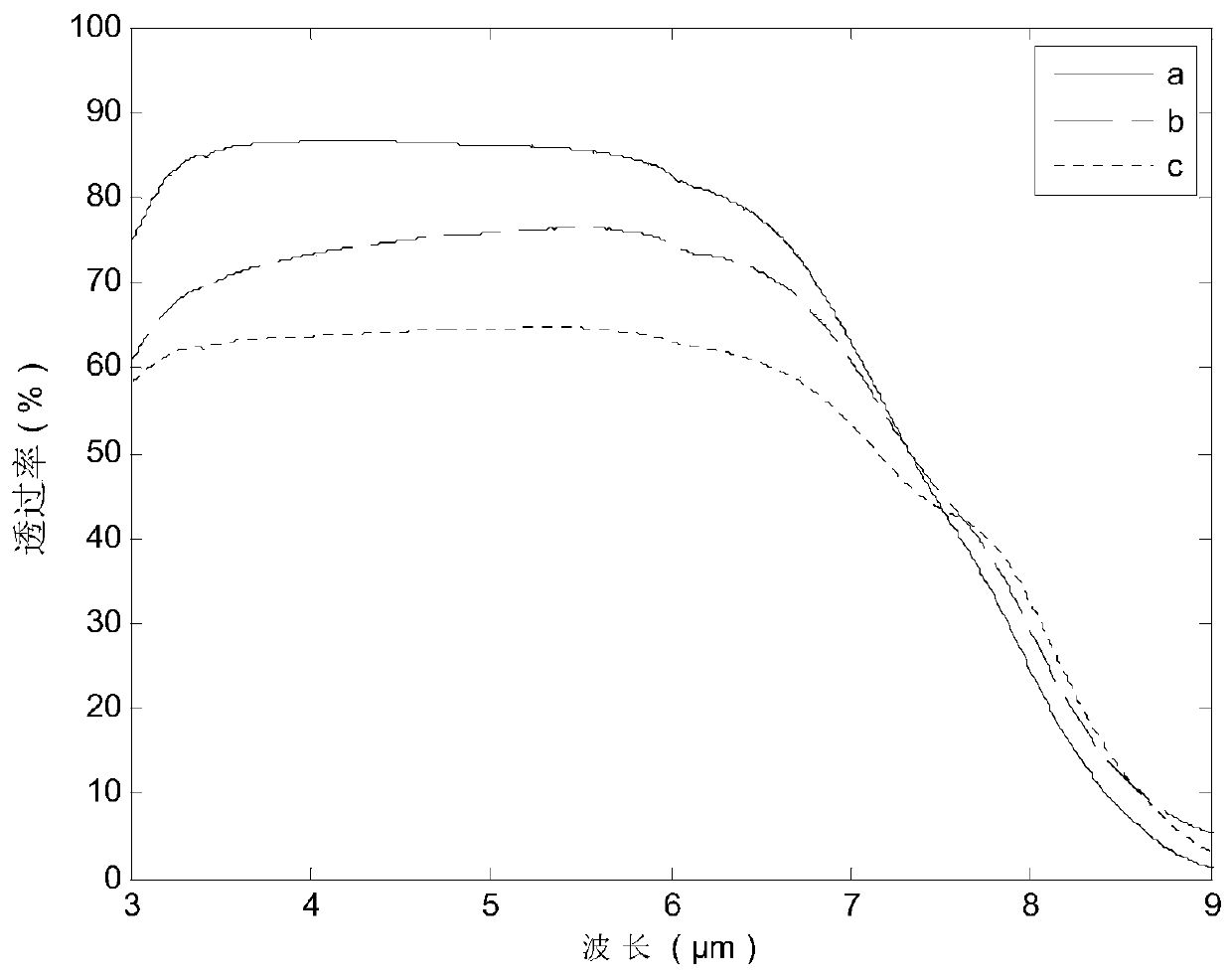

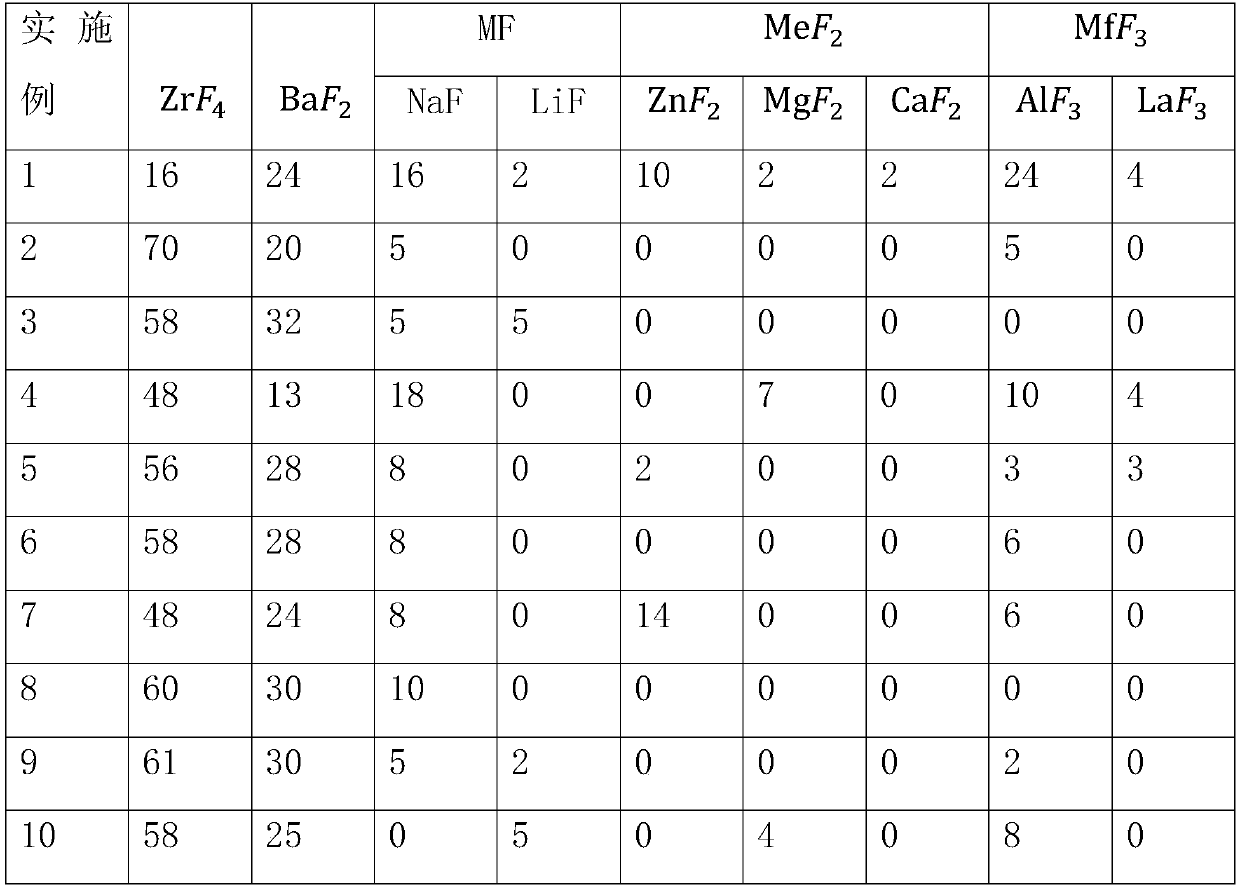

Fluoride glass and a preparing method thereof

Fluoride glass and a preparing method thereof are disclosed. The fluoride glass includes, in mole percentages, 16-70% of ZrF4, 13-32% of BaF2, 5-18% of MF, 0-14% of MeF2 and 0-28% of MfF3, wherein the M is one or two selected from Na and Li, the Me is one or more selected from Zn, Mg and Ca, and the Mf is one or two selected from Al and La. The fluoride glass has a low cost and is suitable for applications in optical windows of near ultraviolet to middle-infrared wavebands. The cutoff wavelength of the prepared glass is greater than 6 [mu]m. The glass has good glass forming capacity, and is suitable for preparing matrix glass of infrared laser fibers and fiber optic amplifiers and other optical materials. The glass has good glass forming capacity, good chemical stability, and low theoretical loss and is suitable for preparing matrixes of low-loss fluoride fibers and doped fibers.

Owner:HUAZHONG UNIV OF SCI & TECH

Methods and apparatuses for reducing heat loss from edge directors

ActiveUS20160311716A1Reduce devitrificationGlass forming apparatusGlass productionHeat lossesElectrical and Electronics engineering

An apparatus and methods for making a glass ribbon includes a forming wedge with a pair of inclined forming surface portions converging along a downstream direction to form a root. The apparatus further includes an edge director intersecting with at least one of the pair of downwardly inclined forming surface portions, and a replaceable heating cartridge configured to direct heat to the edge director and thermally shield the edge director from heat loss. A replaceable heating cartridge is also provided for directing heat to the edge director and thermally shielding the edge director from heat loss.

Owner:CORNING INC

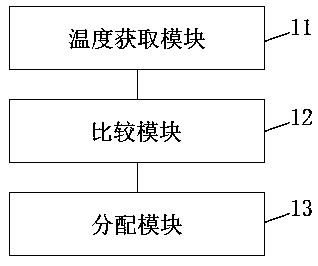

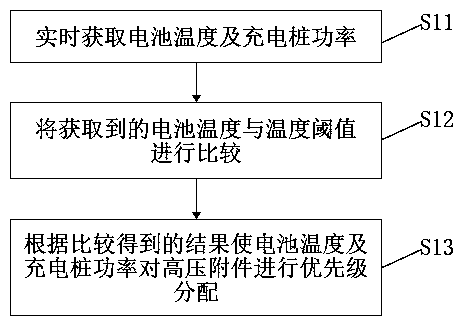

System and method for low-temperature charging management of electric vehicle

InactiveCN111071106AReduce lossImprove low temperature charging speedAir-treating devicesCharging stationsElectrical batteryElectric vehicle

The invention discloses a system and a method for low-temperature charging management of an electric automobile. The system for low-temperature charging management of the electric vehicle comprises atemperature obtaining module which is used for obtaining the temperature of a battery and the power of a charging pile in real time, a comparison module which is used for comparing the acquired battery temperature with a temperature threshold value, and a distribution module which is used for performing priority distribution on high-voltage accessories according to the comparison result and the battery temperature and the charging pile power. The low-temperature charging speed is increased, and the battery is protected.

Owner:HOZON NEW ENERGY AUTOMOBILE CO LTD

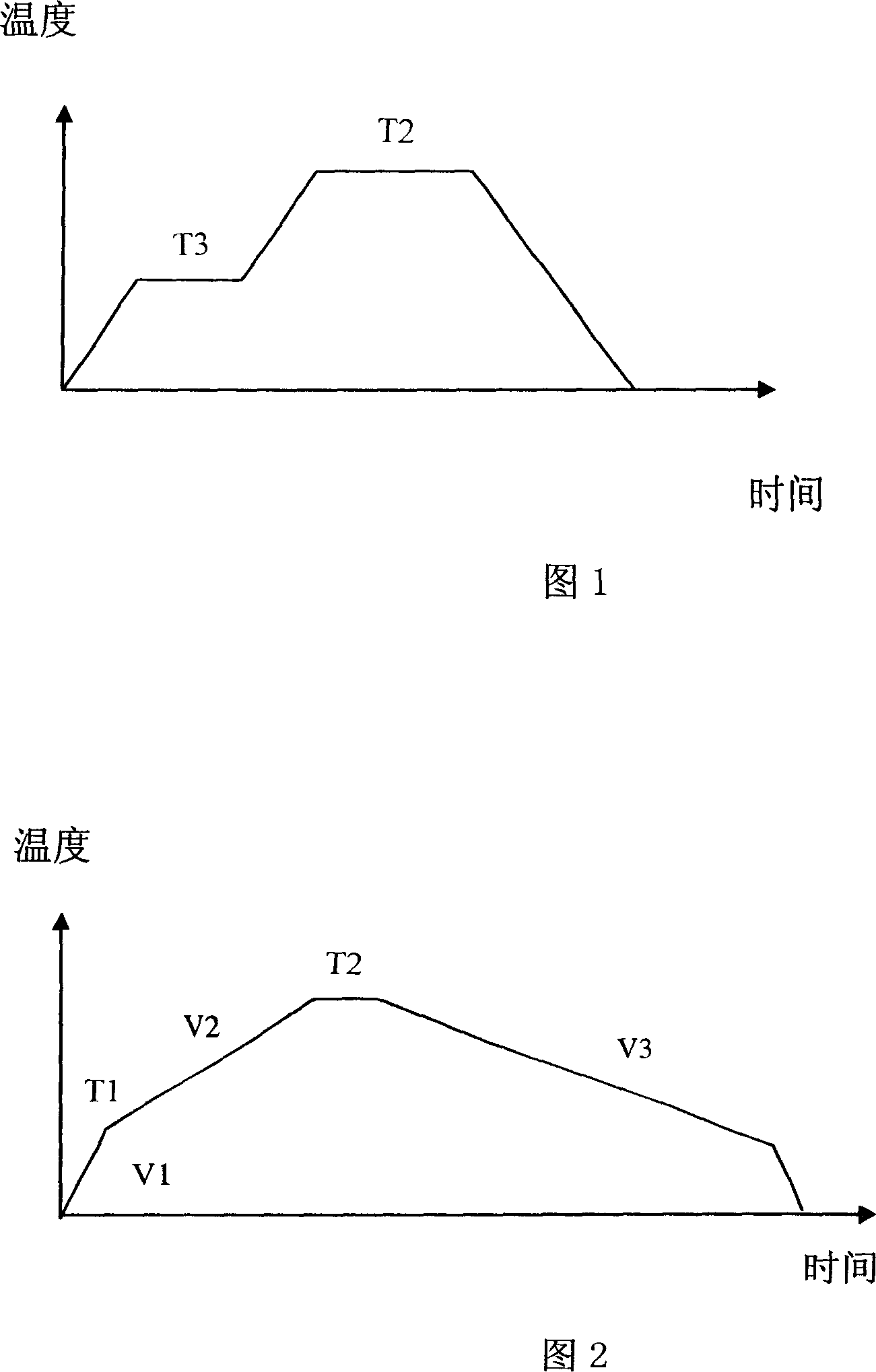

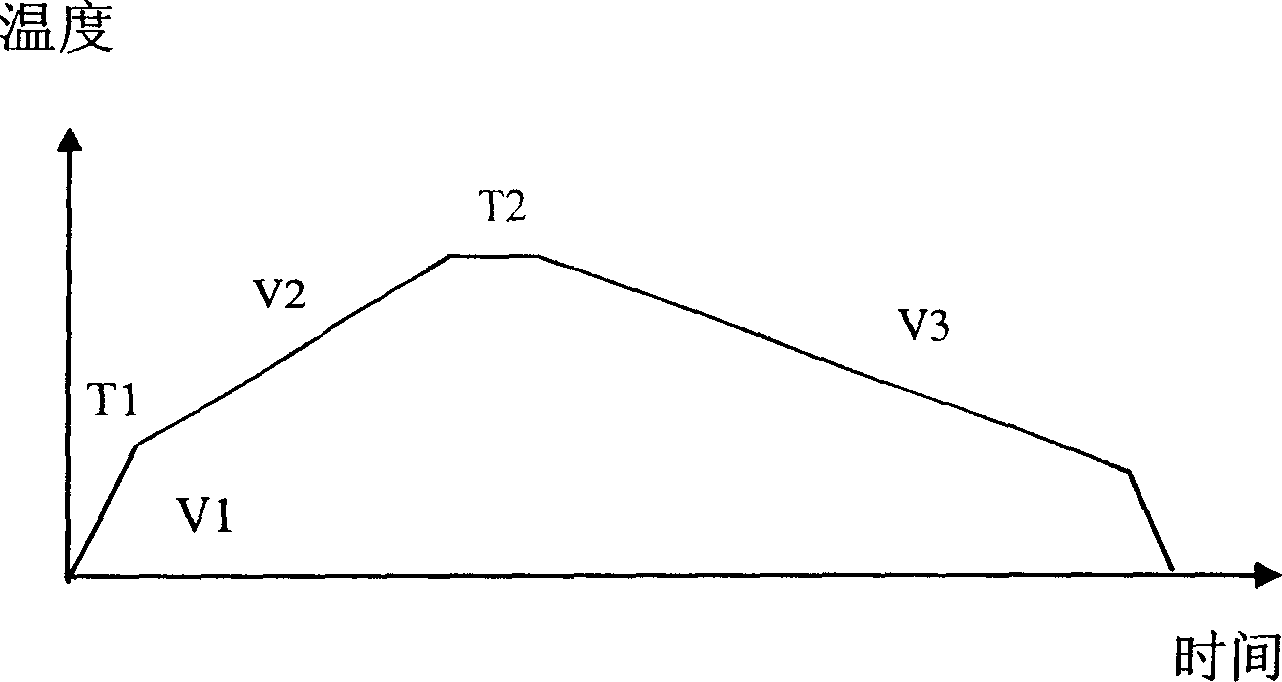

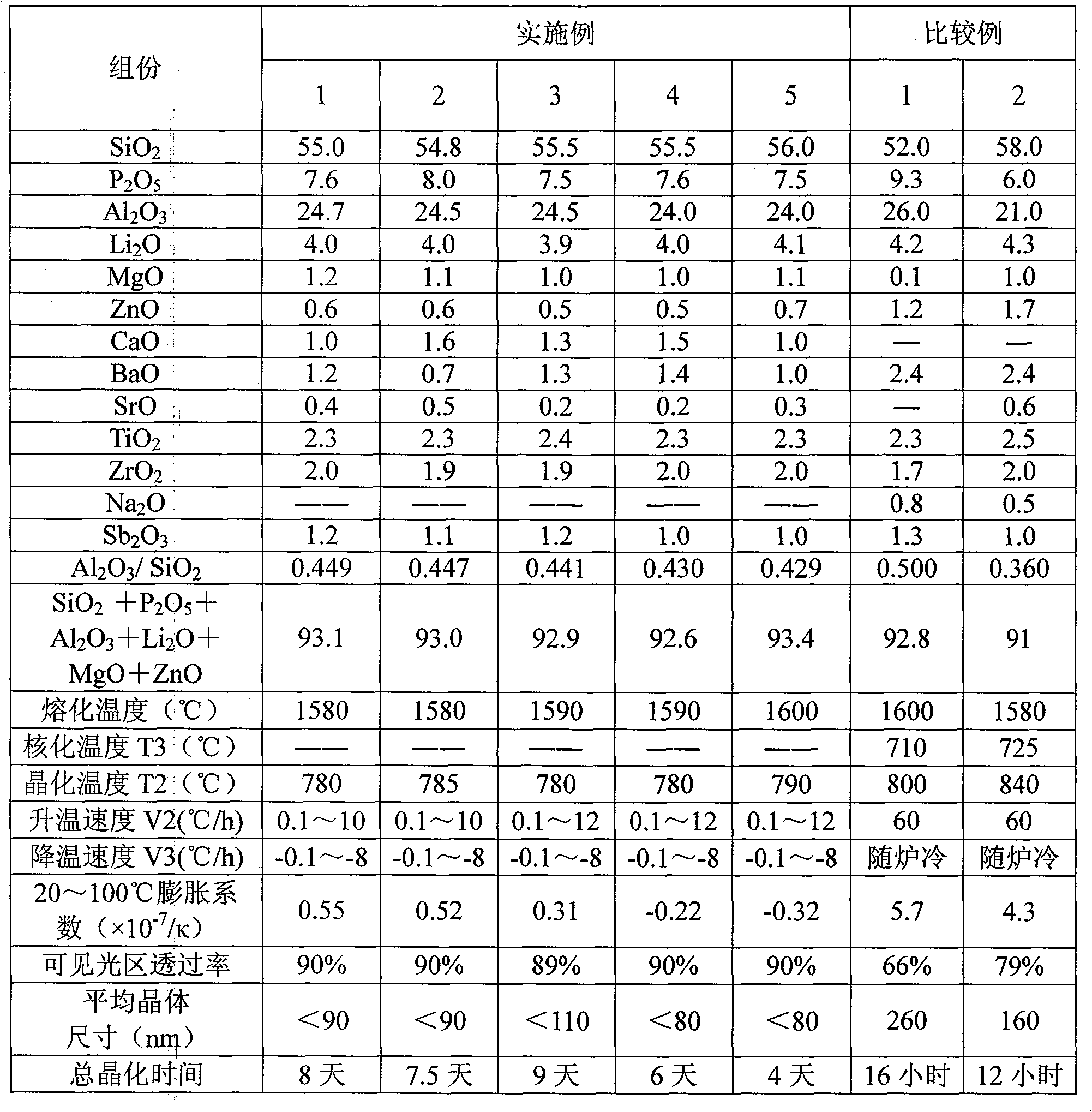

Low expansion coefficient micro crystal glass and its heat processing method

Owner:CDGM OPTICAL GLASS

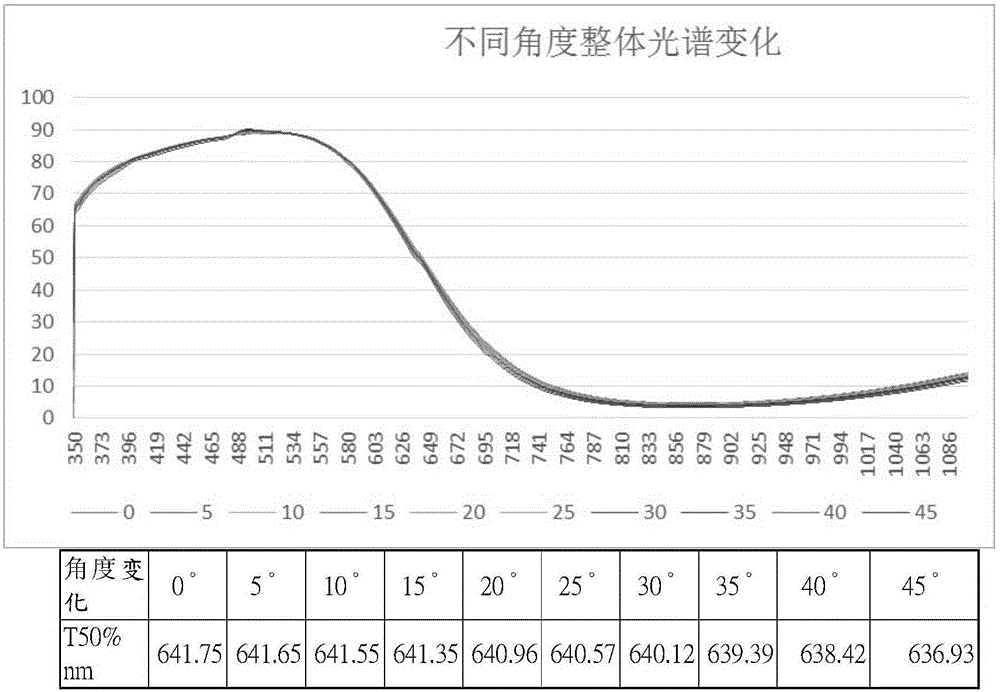

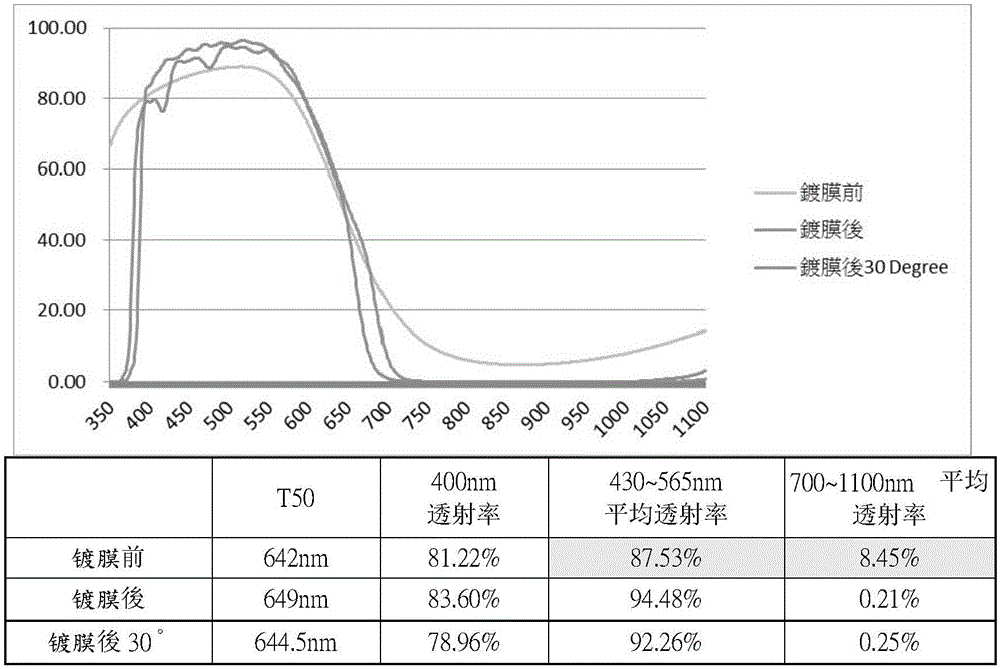

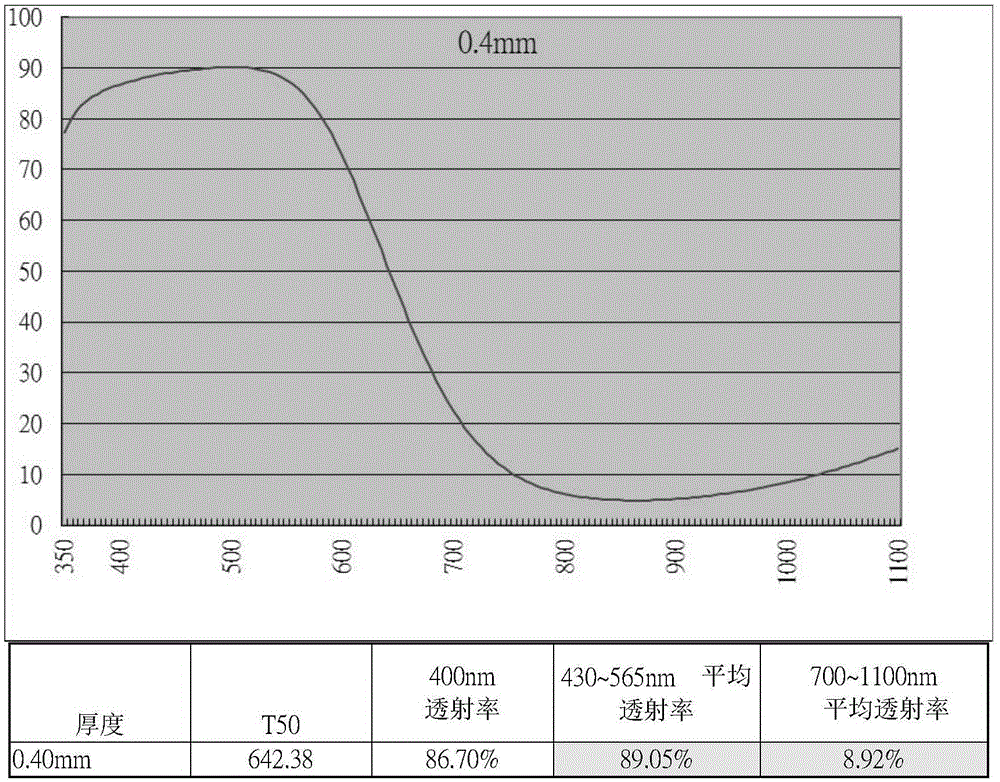

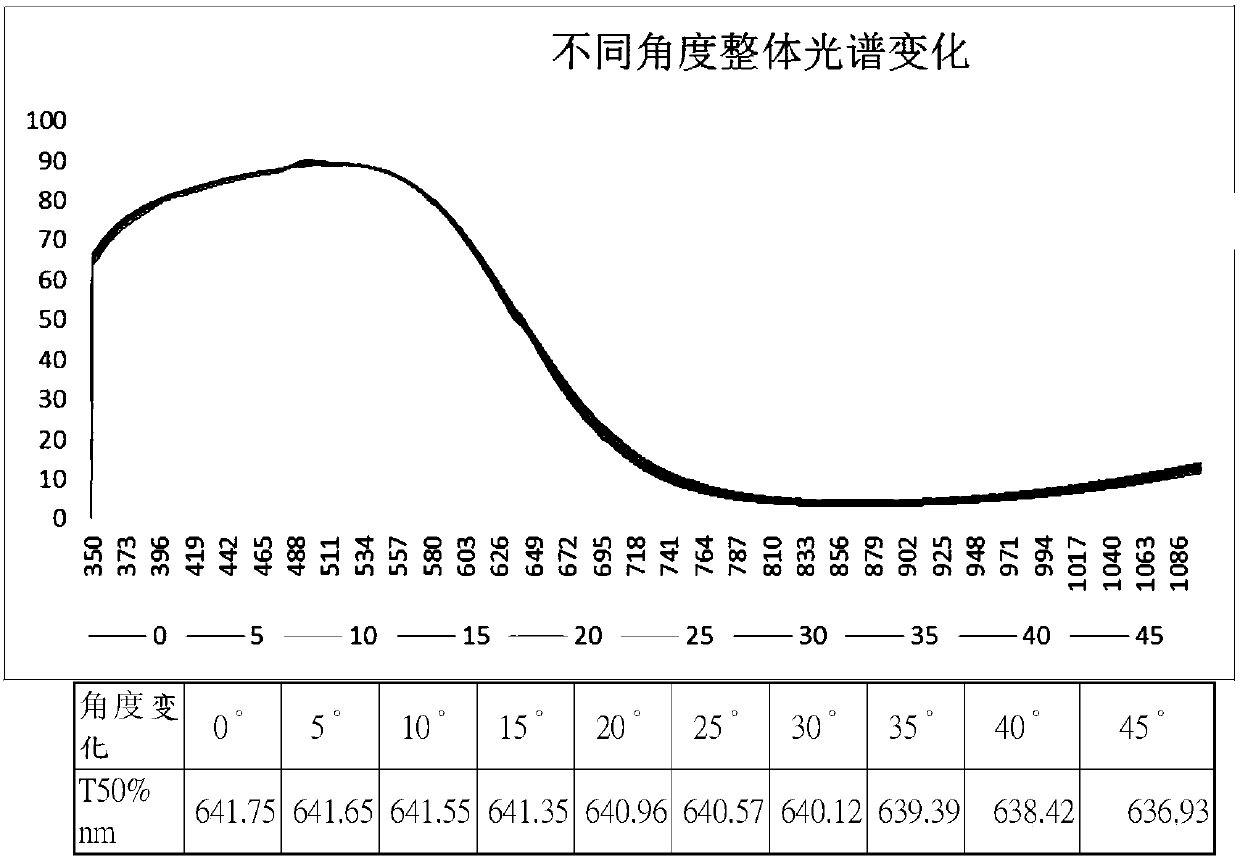

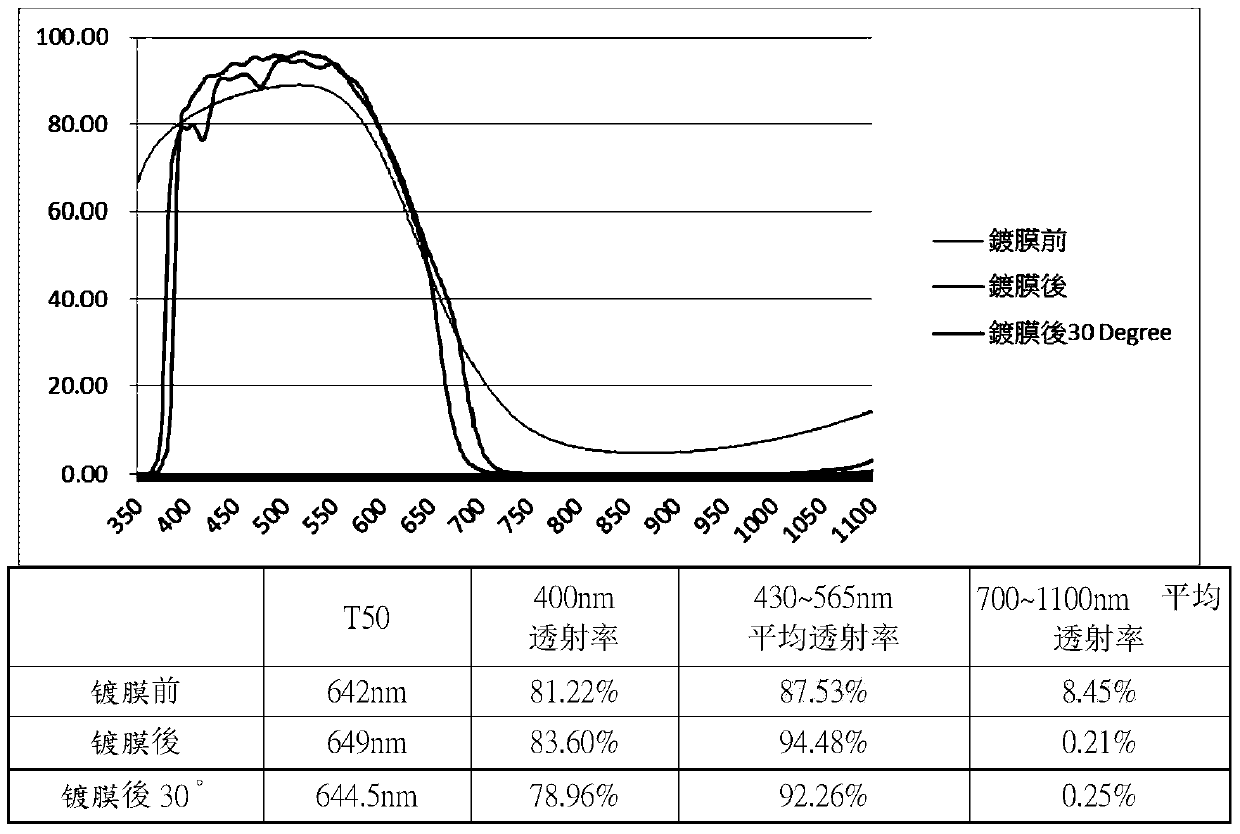

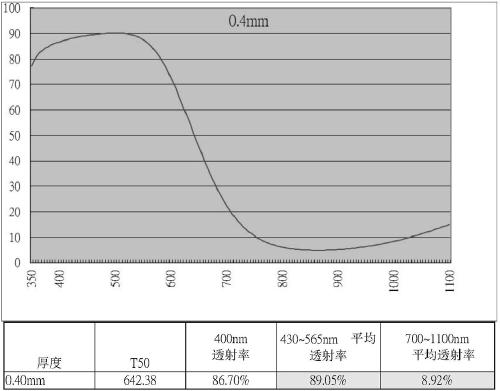

Improved near infrared ray filter glass

The invention provides improved near infrared ray filter glass which comprises a glass substrate with the thickness of 0.19 mm-0.4 mm. The center wavelength of the glass substrate is in a range of 640 nm-650 nm; the glass substrate comprises, by the molar percentage, 35%-45% of Al(PO3)3, 10%-25% of P2O5, 3%-7% of SrO and 6%-15% of CuO. The improved near infrared ray filter glass has excellent chemical stability and high penetration rate, has the molding temperature reduced, and can be resistant to severe high temperature and high humidity environments.

Owner:CO TECH DEV CORP

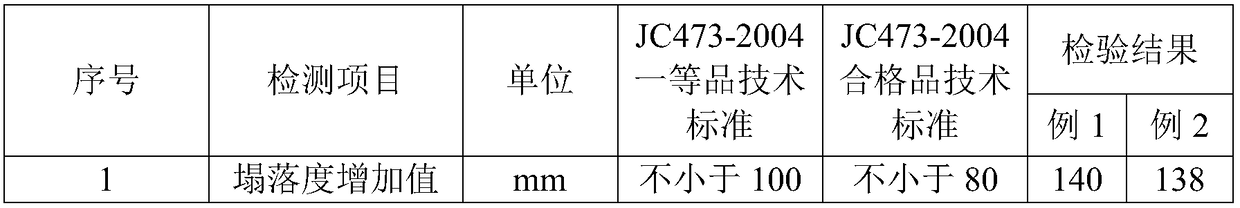

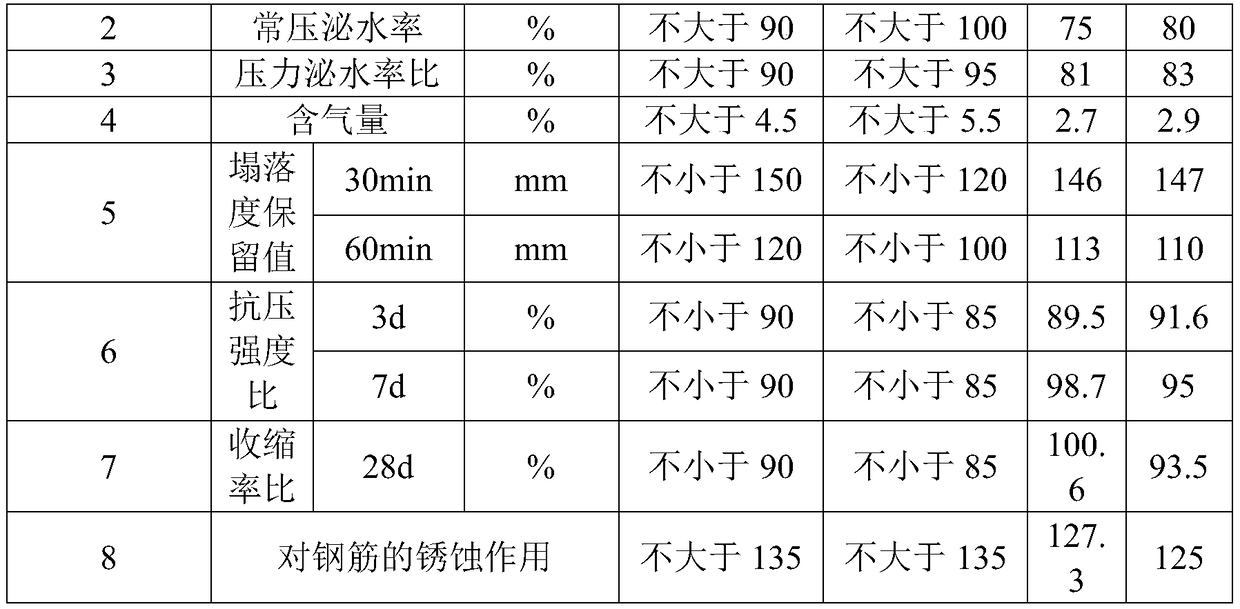

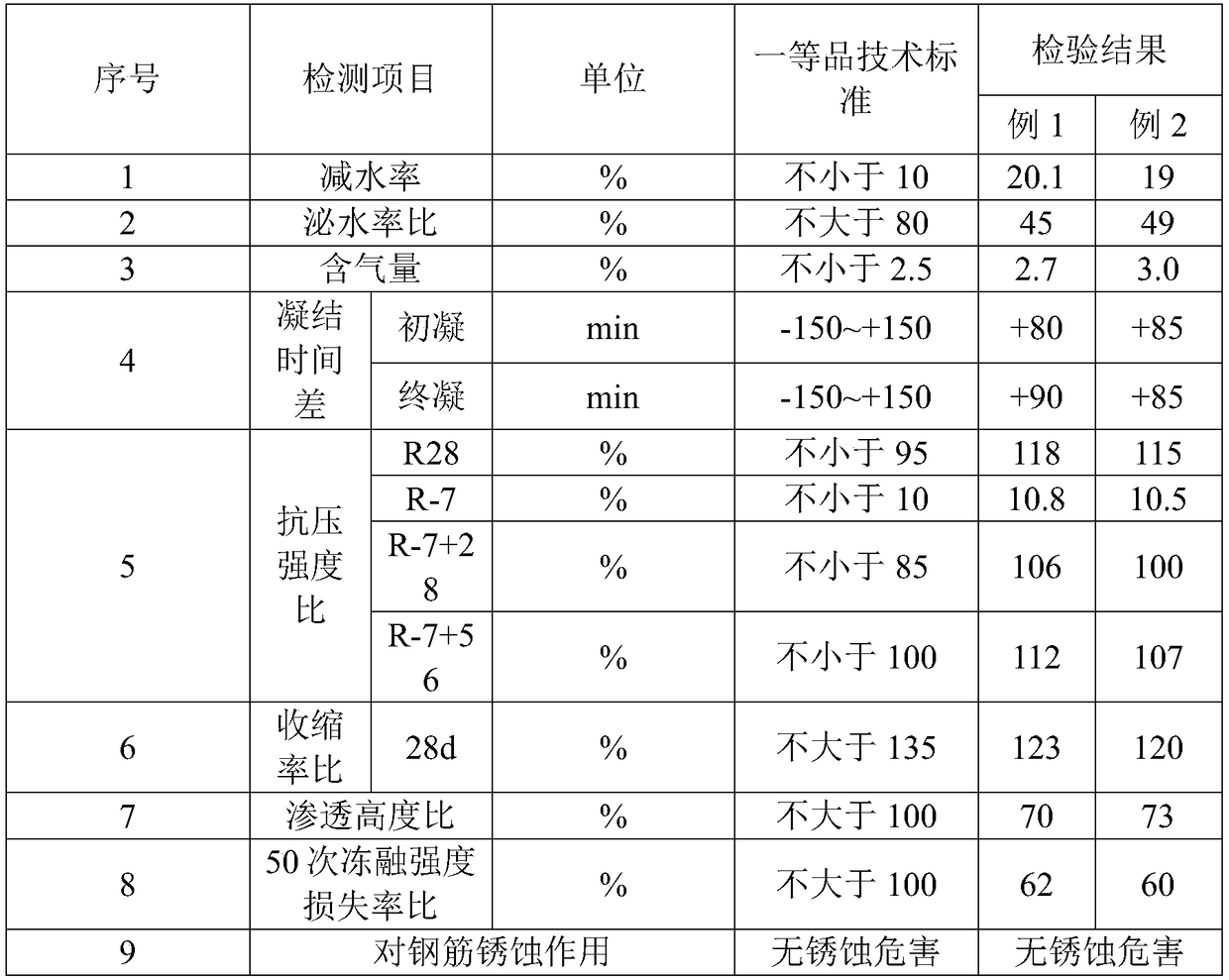

Compound type liquid anti-freezing pumping agent and preparation method thereof

The invention discloses a compound type liquid anti-freezing pumping agent and a preparation method thereof. The compound type liquid anti-freezing pumping agent is prepared from the following components in parts by mass: (30 to 35) parts of a polycarboxylic type high efficiency water-reducing agent, (5 to 6) parts of alkyl succinimide, (2 to 3) parts of dioctyl phthalate, (1.5 to 2) parts of sodium gluconate, (8 to 10) parts of magnesium acetate, (0.3 to 0.4) part of sodium dodecylbenzene sulfonate, (1.3 to 1.5) parts of isopropyl alcohol, (1 to 1.5) parts of fragilaria crotonensis anti-freezing protein, (0.005 to 0.007) part of polyethylene glycol, (0.0025 to 0.003) part of beta-cyclodextrin, (0.0075 to 0.008) part of dimethyl diallyl ammonium chloride and (45 to 50) parts of water. Theanti-freezing pumping agent has small crystallization amount at low temperature, high cohesive force, relatively small slump loss and no pollution and the preparation method is simple.

Owner:CHANGAN UNIV

A kind of preparation method of low-temperature curable high-imino high-etherified melamine resin

The invention discloses a preparation method of a high-imido and high-methoxylation melamine resin capable of being cured at low temperature. According to the method, the high-imido and high-methoxylation melamine resin capable of being cured at low temperature is obtained by reacting melamine, a formaldehyde solution and methanol, paraformaldehyde is not required to be added, the step of synthesis of hydroxymethylation melamine as an intermediate product is omitted, preparation costs are reduced, links of crystallization, drying and the like of the intermediate product are omitted, energy consumption is low, a technological process is simple, the methanol only needs to be added at one step in reaction, and the preparation method is easy to control. In addition, a mixture of hydrochloric acid and formic acid is used as an etherification catalyst, and the effect of the obtained product is better than that of a single acid catalyst.

Owner:重庆建峰新材料有限责任公司

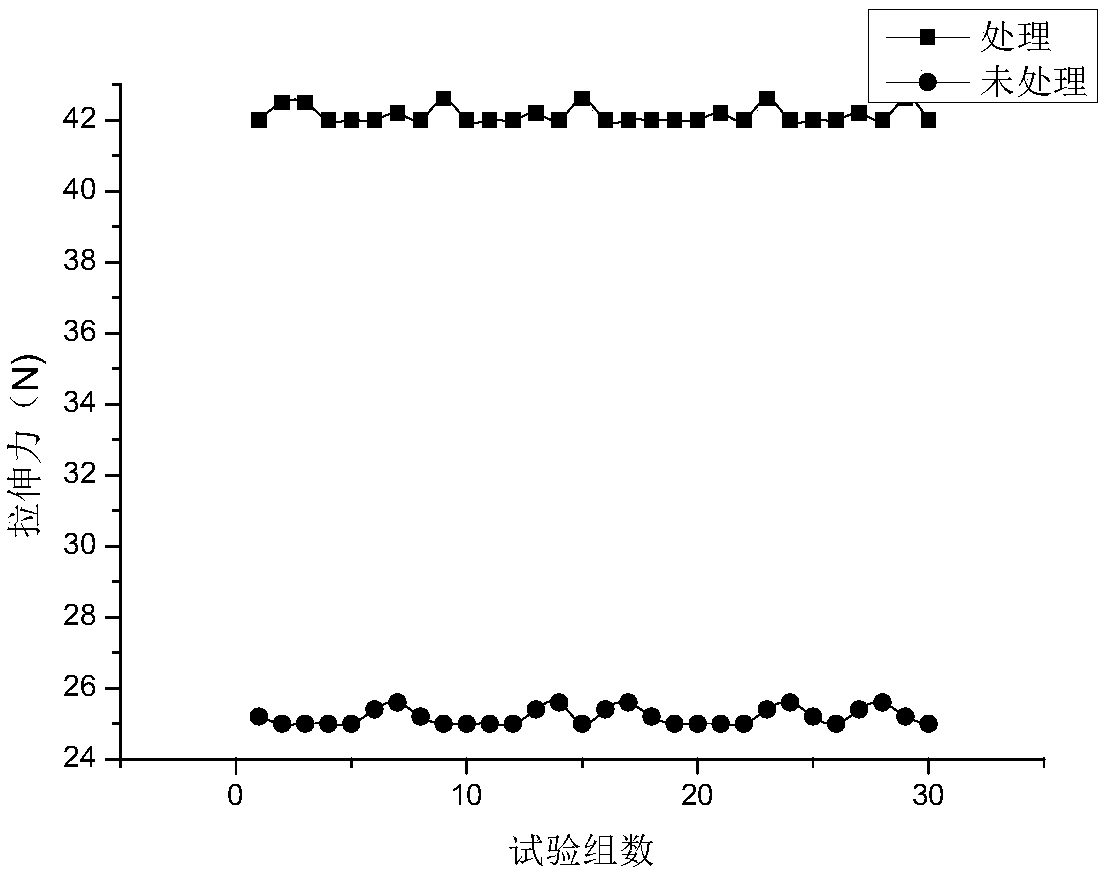

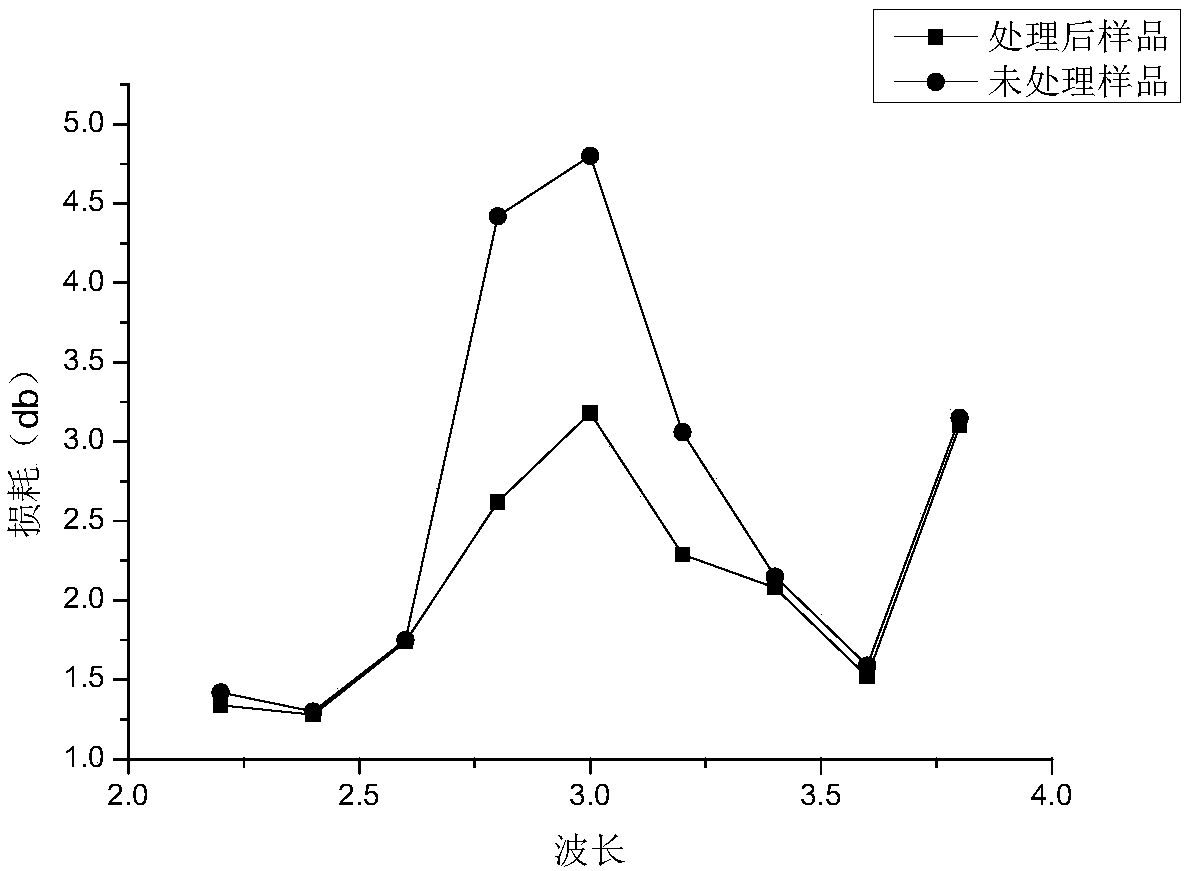

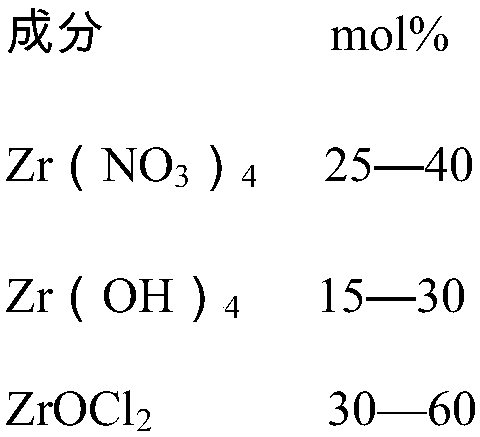

Non-water treatment agent used for surface enhanced treatment of fluorozirconate glass optical fiberpreform rod and treatment method

The invention discloses a non-water treatment agent used for surface enhanced treatment of a fluorozirconate glass optical fiber preform rod and a treatment method. The non-water treatment agent is formed by an acid part, a zircon salt part and an organic solvent part at a certain matching ratio, wherein the acid part comprises HCl, H3PO4 and CH3COOH at a certain proportion; the zircon salt part comprises Zr(NO3)4, Zr(OH)4 and ZrOCl2 at a certain proportion; the organic solvent comprises CH3CH2OH, THF and CH3COCH3 at a certain proportion. According to the non-water treatment agent and the treatment method provided by the invention, surface defects (microcracks), surface impurities and a surface layer with non-uniform chemical composition of the fluorozirconate glass optical fiber preform rod can be effectively removed, so that the risk of crystallization or devitrification in an optical fiber drawing process of the optical fiber preform rod is greatly lowered. An optical fiber drawn bythe fluorozirconate glass optical fiber preform rod treated by the non-water treatment agent and the treatment method has the characteristics of being higher in strength and less in loss.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Manufacturing method of high-pressure discharge lamp, high-pressure discharge lamp, lamp unit using high-pressure discharge lamp, and image display apparatus using high-pressure discharge lamp

ActiveUS8106585B2Reduce devitrificationAvoid darkeningDischarge tube luminescnet screensLamp detailsDevitrificationHydrogen

A manufacturing method of a high-pressure mercury lamp includes an electric field application step in which an electric field is applied to at least a light emission part (4) with the high-pressure mercury lamp being kept at a high temperature. This can reduce impurities such as hydrogen and alkali metals in a discharge space (8) and glass forming the light emission part (4). As a consequence, blackening and devitrification of the high-pressure mercury lamp while the lamp is lit can be reduced.

Owner:PANASONIC CORP

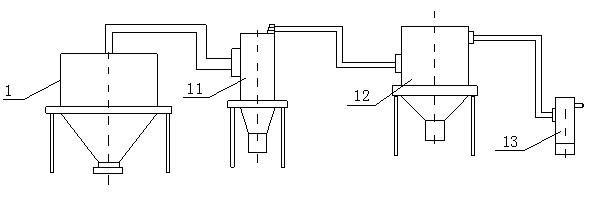

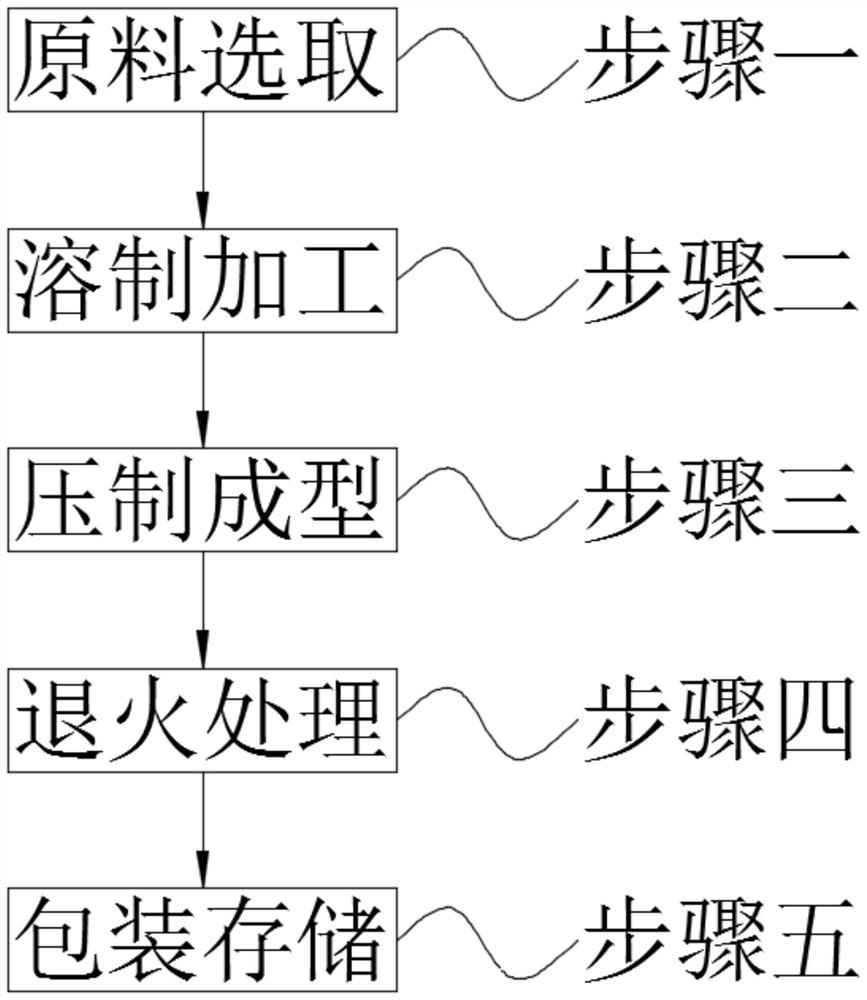

Low-dielectric sealing glass granulation powder and preparation method thereof

PendingCN114315160AHigh strengthReduce devitrificationGlass shaping apparatusSpray GranulationCompression molding

The invention discloses a low dielectric sealing glass granulation powder and a preparation method thereof, the sealing glass comprises the following components by mole percentage based on oxide: 68.2% to 72.3% of SiO2, 20.7% to 24.8% of B2O3, 1% to 2% of Al2O3, 2% to 3% of Na2O, 0.5% to 1% of K2O, 0.5% to 1% of CaO, and 0.5% to 1% of Bi2O3. The preparation method comprises the following steps: uniformly mixing the raw materials corresponding to the components, melting at 1600-1650 DEG C, quenching to obtain glass slag, carrying out ball milling on the glass slag, pulping, and carrying out spray granulation to obtain granulation powder with certain particle size and sphericity. And preparing the granulated powder into a glass blank with a required shape by compression molding, and placing the glass blank at a certain temperature for glue removal and vitrification to obtain the prefabricated glass bead for sealing. The sealing glass prepared by the method is relatively low in high-temperature viscosity after being melted, and glass residues are easy to recover; and meanwhile, the granulation powder has better sphericity and flowability, and the formed glass blank is transparent and white after glue removal and vitrification. Meanwhile, the dielectric constant and dielectric loss of the sealing glass are small, the dielectric constant is 3.9-4.2 under the frequency of 1 MHz, the dielectric loss is 1 * 10 <-3 >-4 * 10 <-3 >, and the sealing temperature is 840-900 DEG C.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

A kind of fluoride glass and preparation method thereof

ActiveCN107285627BReduce usageFew ingredientsGlass shaping apparatusFiber amplifierChemical stability

Fluoride glass and a preparing method thereof are disclosed. The fluoride glass includes, in mole percentages, 16-70% of ZrF4, 13-32% of BaF2, 5-18% of MF, 0-14% of MeF2 and 0-28% of MfF3, wherein the M is one or two selected from Na and Li, the Me is one or more selected from Zn, Mg and Ca, and the Mf is one or two selected from Al and La. The fluoride glass has a low cost and is suitable for applications in optical windows of near ultraviolet to middle-infrared wavebands. The cutoff wavelength of the prepared glass is greater than 6 [mu]m. The glass has good glass forming capacity, and is suitable for preparing matrix glass of infrared laser fibers and fiber optic amplifiers and other optical materials. The glass has good glass forming capacity, good chemical stability, and low theoretical loss and is suitable for preparing matrixes of low-loss fluoride fibers and doped fibers.

Owner:HUAZHONG UNIV OF SCI & TECH

Glass kiln clarification part pool bottom structure convenient for discharging

PendingCN113387543AEasy to gatherReduce outputGlass furnace apparatusMining engineeringMechanical engineering

The invention discloses a glass kiln clarification part pool bottom structure convenient for discharging in the technical field of glass kiln pool bottom structures. The glass kiln clarification part pool bottom structure comprises: a pool bottom layer, wherein a discharging opening is formed in the pool bottom layer, and a first slope pavement layer arranged on the pool bottom layer in the length direction of the pool bottom layer, wherein the slope surface of the first slope pavement layer faces the discharging opening, so that the inferior molten glass at the pool bottom of the clarification part flows to the discharging opening. According to the invention, the first slope pavement layer and the discharging opening are arranged on the pool bottom layer of the clarification part, and the inferior molten glass at the pool bottom is drained through the slope surface, facing the discharge port, of the first slope pavement layer, so that the inferior molten glass is gathered at the discharging opening and discharged.

Owner:CHINA TRIUMPH INT ENG +1

Glass microballoon manufacturing device and preparation method thereof

InactiveCN102417291BPrevent molten buildupReduce devitrificationGlass shaping apparatusGlass productionDevitrificationCombustor

The invention discloses a glass microballoon manufacturing device comprising a furnace body (1) and a waste gas treatment device, wherein the furnace body (1) is formed by air-tight connection of an upper part and a lower part, the upper part of the furnace body is of a cubic shape, a waste gas emission port (4) is arranged at the top of the upper part, one or more injection-type burners (2) are horizontally installed on the side of the upper part, a preheating air pipe (14) is arranged in the upper part, the lower part of the furnace body is of a square conical shape, and one or more microballoon collectors (3) are arranged at the bottom of the lower part. According to the glass microballoon manufacturing device and the preparation method thereof provided by the invention, the furnace body which adopts the cubic structure enlarges the cooling space; the horizontally installed injection-type burners and the preheating air pipe arranged in the furnace body can give full play to the heat value of fuel, thus reducing energy source waste, saving energy and reducing emission; TiO2 and Al2O3 with relatively lower costs are adopted, the refractive index of the product is greater than or equal to 1.93; and the glass microballoon manufacturing device and the preparation method thereof have the advantages of reducing devitrification, improving the cooling velocity, having good product quality, improving the utilization ratio of raw material, being capable of large-scale production, and the like.

Owner:SICHUAN ZHONGKE BETTER TECH

Improved near-infrared filter glass

The invention provides improved near infrared ray filter glass which comprises a glass substrate with the thickness of 0.19 mm-0.4 mm. The center wavelength of the glass substrate is in a range of 640 nm-650 nm; the glass substrate comprises, by the molar percentage, 35%-45% of Al(PO3)3, 10%-25% of P2O5, 3%-7% of SrO and 6%-15% of CuO. The improved near infrared ray filter glass has excellent chemical stability and high penetration rate, has the molding temperature reduced, and can be resistant to severe high temperature and high humidity environments.

Owner:CO TECH DEV CORP

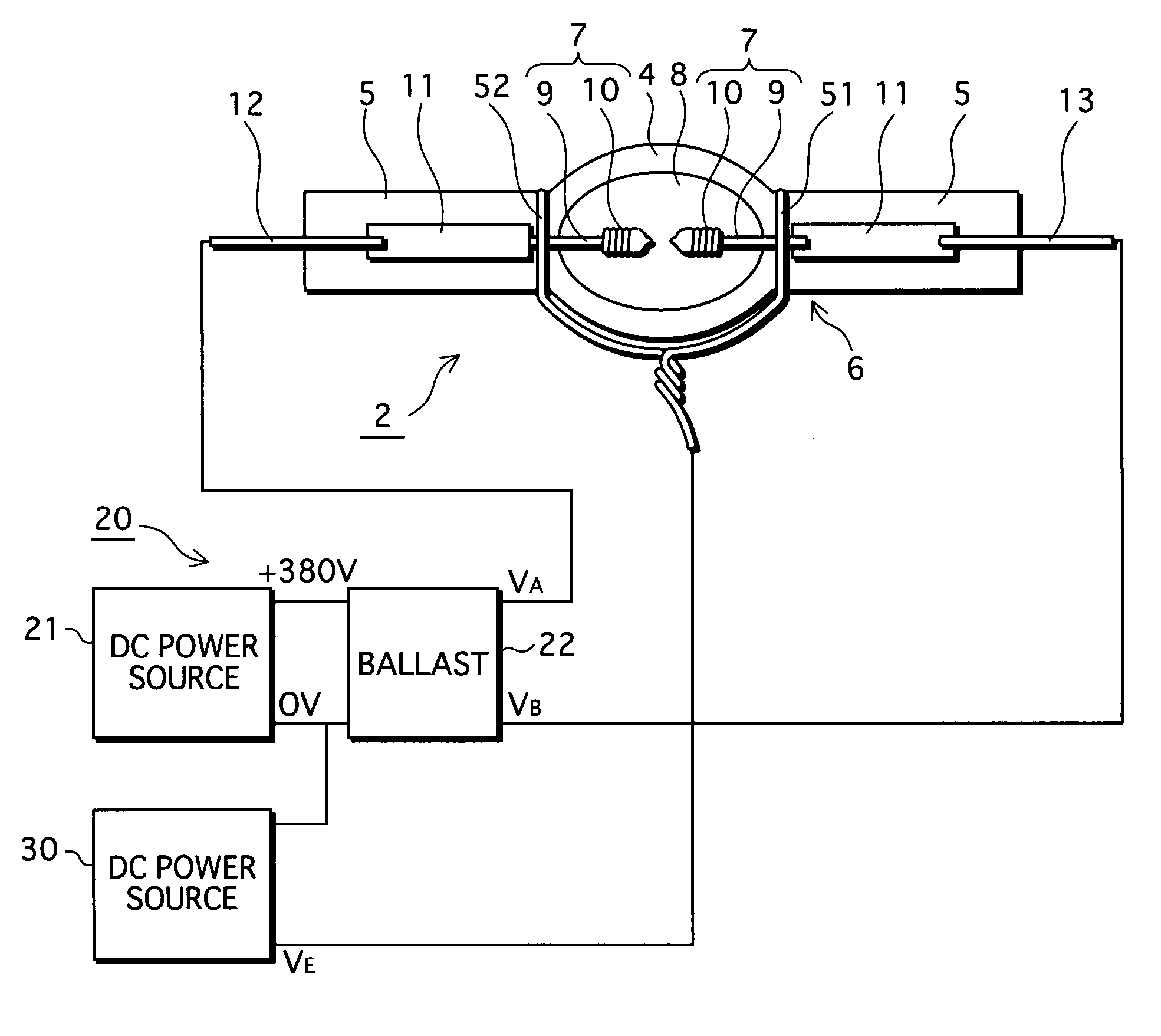

Discharge lamp, light source device and projector

ActiveUS9152026B2Extend lamp lifeReduce devitrificationIncadescent screens/filtersPoint-like light sourceProtection layerQuartz

A discharge lamp includes a pair of electrodes for discharge and a discharge container having an inner space formed by quartz glass for separately placing the pair of electrodes and enclosing a discharge medium therein, a bulging part that surrounds the inner space, a pair of sealing parts that extend from ends of the bulging part and respectively support the pair of electrodes, an inner protective layer provided from a top portion opposed to a center of the pair of electrodes to a peripheral portion located at sides of the pair of sealing parts on an inner surface of the bulging part and having a thickness of the peripheral portion thinner than that of the top portion.

Owner:SEIKO EPSON CORP

High-pressure discharge lamp

InactiveUS7489078B2Extended service lifeReduce devitrificationDischarge tube luminescnet screensLamp detailsHigh pressureElectrode

A high-pressure discharge lamp has a pressure chamber with two opposite end regions and delimited by a cylindrical envelope made of glass. An electrode is provided at each of the two end regions, the electrodes projecting into the pressure chamber and being arranged in the pressure chamber as anode and cathode. A discharge chamber is formed between the electrodes. The two end regions of the pressure chamber are designed differently at least outside of the discharge chamber.

Owner:HERAEUS NOBLELIGHT LTD

High-refractive-index watch glass for watch outer cover and production process of high-refractive-index watch glass

InactiveCN112250300AReduce devitrificationImprove stabilityGlass pressing apparatusCompression moldingWatch glass

The invention discloses high-refractive-index watch glass for a watch outer cover and a production process of the high-refractive-index watch glass. The high-refractive-index watch glass is prepared from silicon dioxide, aluminum oxide, borax, calcium carbonate, zinc oxide, dolomite, sodium carbonate, a clarifying agent and an initiator. The mass percentage of each component is as follows: 20-30%of silicon dioxide, 15-25% of aluminum oxide, 15-25% of borax, 10-20% of calcium carbonate, 2-4% of zinc oxide, 10-20% of dolomite, 1-3% of sodium carbonate, 5-10% of a clarifying agent and 2-5% of aninitiator. The glass is safe and reliable, silicon dioxide, aluminum oxide, borax, calcium carbonate, zinc oxide and dolomite are adopted as raw materials and subjected to dissolving processing and then compression molding, the glass crystallization phenomenon is reduced, the stability and strength of the watch glass are improved, the glass absorbs short-wavelength rays, the refractive index anddispersion of the watch glass are improved, the process is simple and rigorous, the raw materials are cheap, and the cost is low; machining is convenient, the production cost is greatly saved, and machining and production are facilitated.

Owner:DONGGUAN JINGSHI OPTICAL CO LTD

Lead-free colored glass and its melting process

PendingCN106064886AOvercome the disadvantage of discoloration and darkeningReduce devitrificationGlass furnace apparatusMicrowaveHigh energy

The invention discloses lead-free colored glass and its melting process. The glass is composed of the following raw material components: SiO2, B2O3, BaO, MgO, Na2O, Al2O3 and colorant; the melting steps of the glass are as follows: 1), select raw materials, mix raw materials according to the weight percentage, 2), microwave the mixed raw materials, and after heat treatment, obtain luminous glass; Disadvantages of discoloration and darkening under high-energy radiation, reducing ultraviolet radiation, no crystallization during glass production, stable luminous performance, energy saving in microwave melting process, and easy control of melting process parameters.

Owner:西安亚岱新能源科技有限公司

Dry spinning process of making bright polyacrylic fibre

InactiveCN100445433CHigh glossIncrease brightnessMonocomponent synthetic polymer artificial filamentDry spinning methodsEngineeringDraw ratio

A method for making dry-spun acrylic fiber with large gloss. By improving the original spinning and forming post-treatment process, in the process of washing and drawing, the washing temperature is increased to control at 96°C to 100°C, and the draw ratio control is reduced. At 2.65-4.5 times, reduce the drawing speed to 230-360m / min, and at the same time increase the drying temperature and steam flow in the process of water washing and drying after drawing, which not only ensures that the molecular chain has enough stretching time, but also avoids causing molecular damage. Chain damage, thereby reducing the roughness and damage of the fiber surface, and improving the smoothness and densification of the fiber, making the fiber shiny and bright, which meets the requirements of the domestic fur, clothing and other industries for fiber brightness. It can completely replace imported products.

Owner:浙江金甬腈纶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com