Patents

Literature

71results about "Discharge tube coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

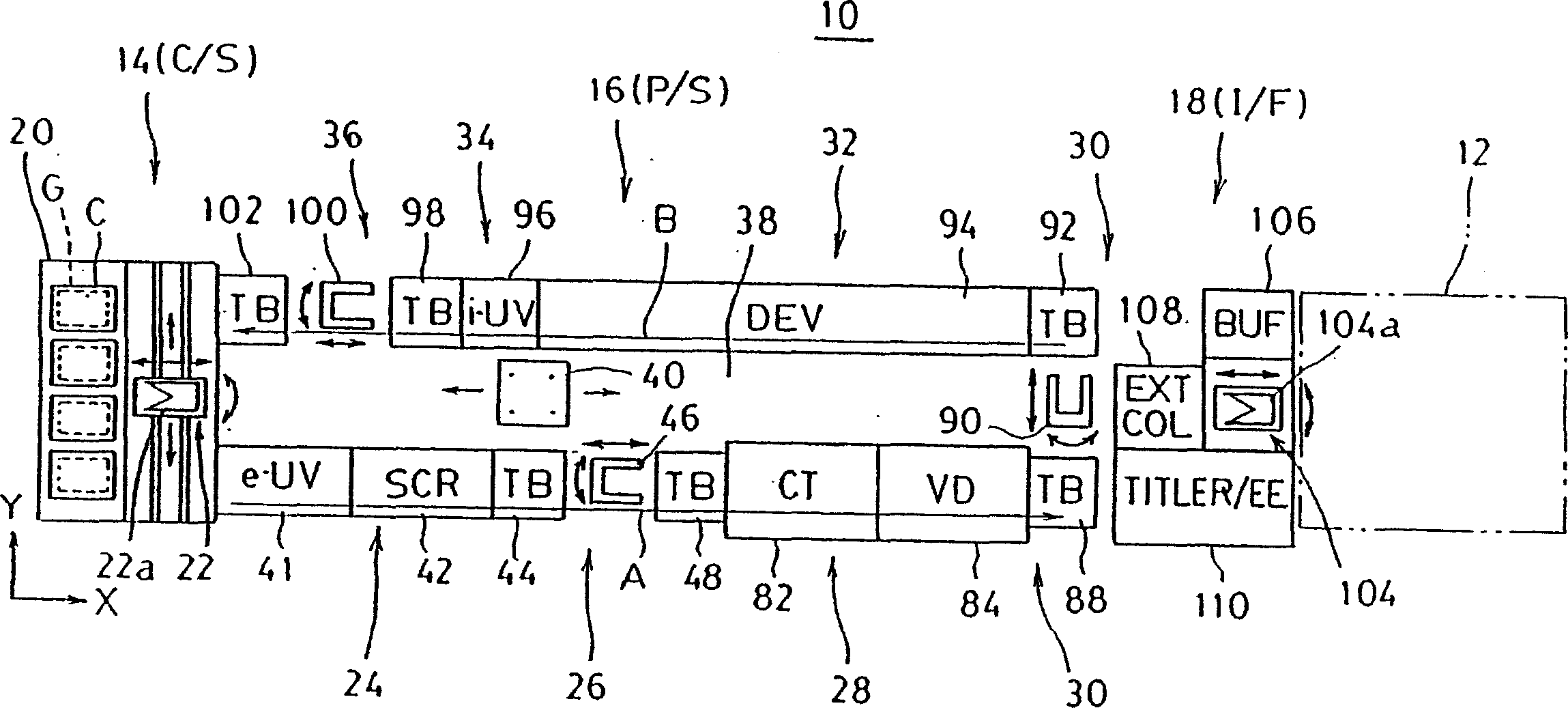

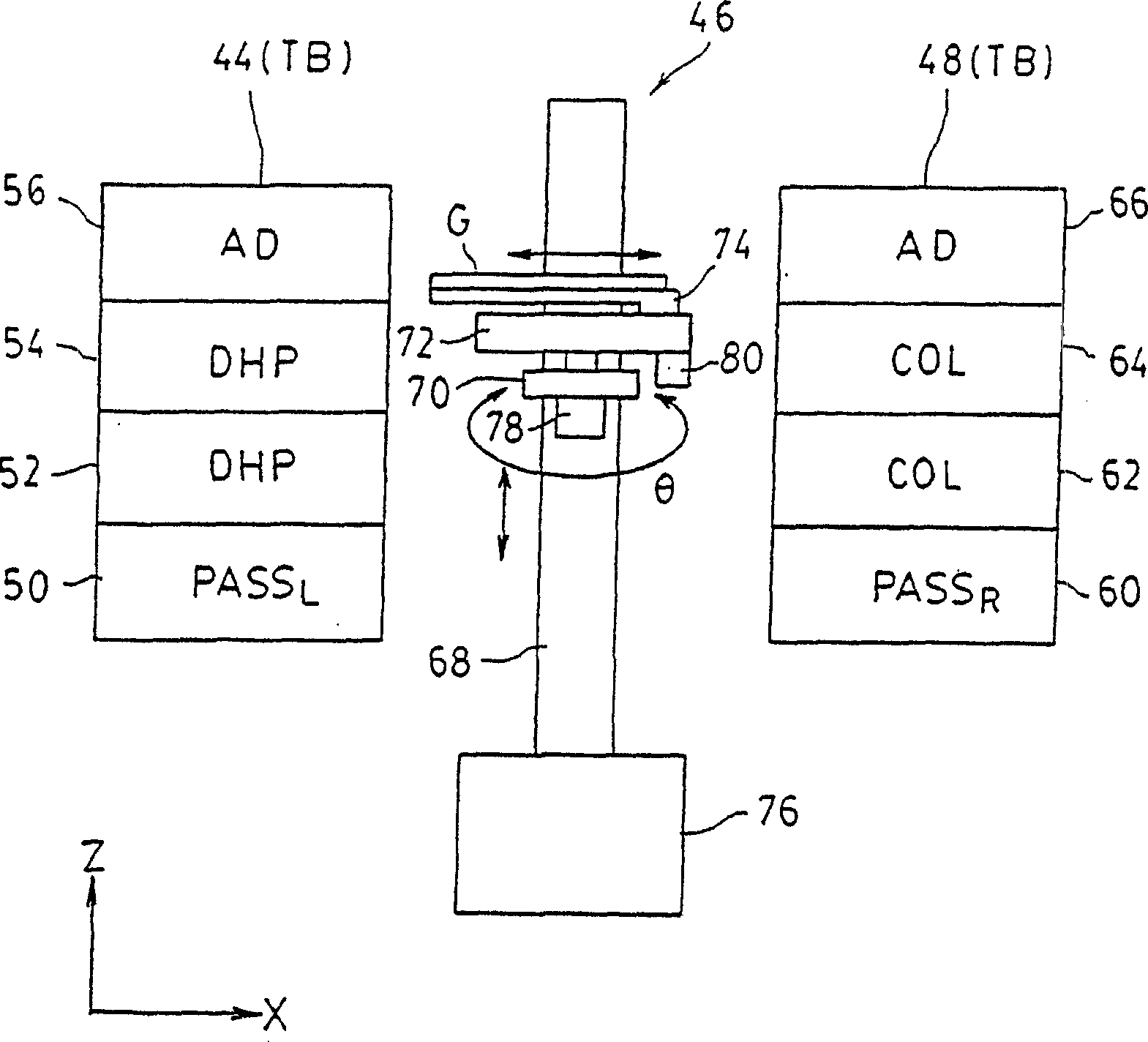

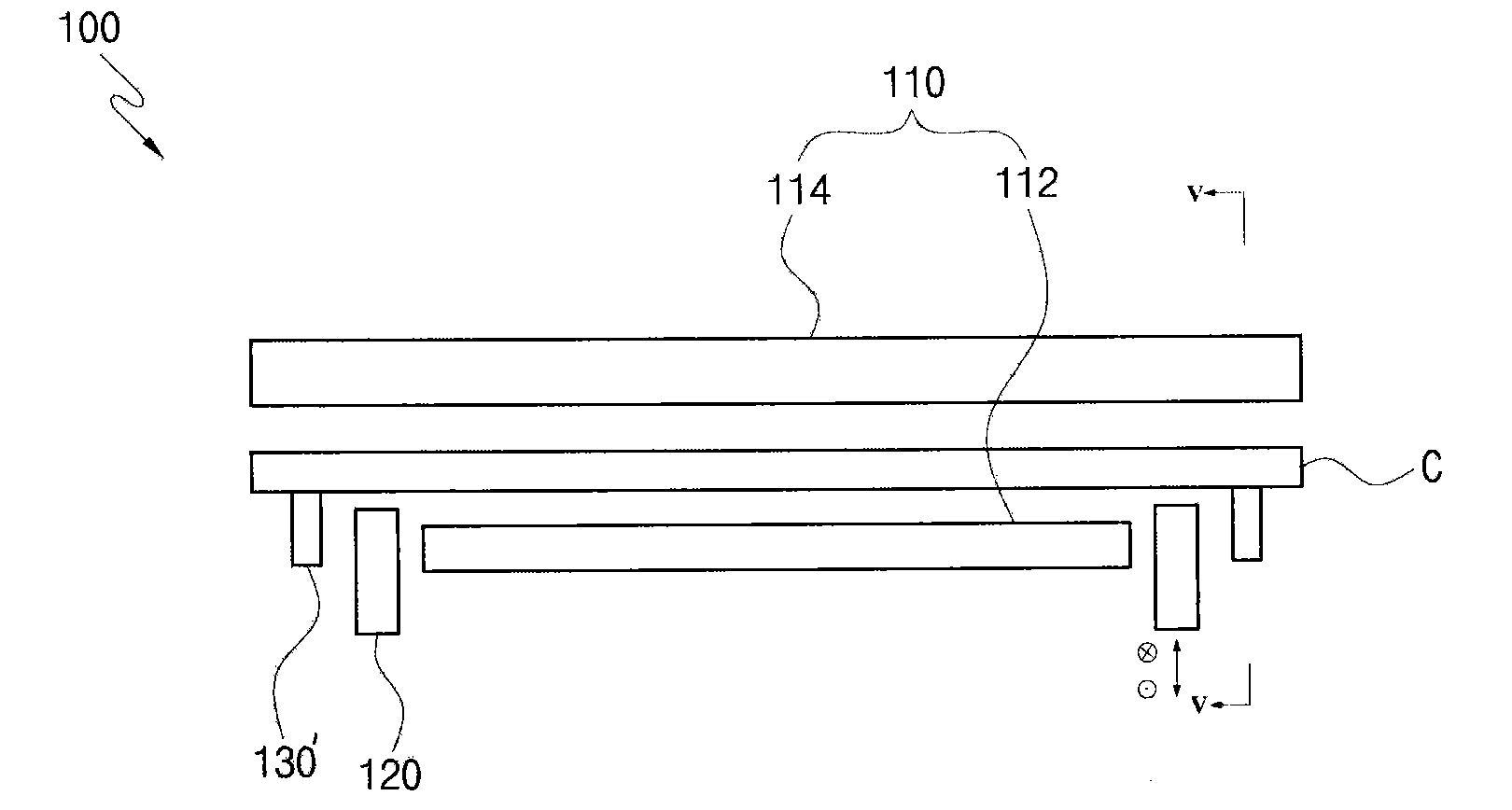

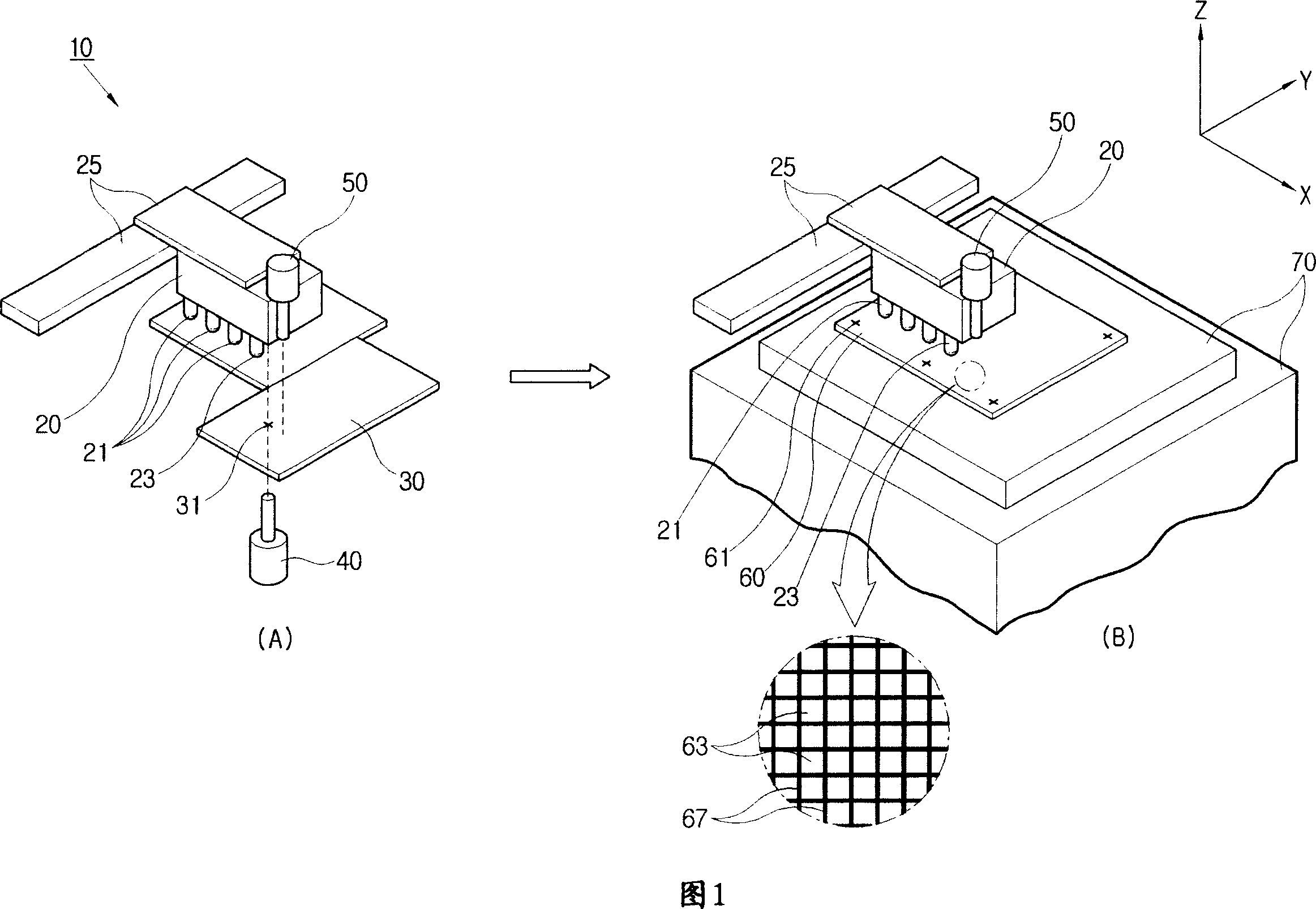

Substrate processing apparatus and substrate positioning device

Owner:TOKYO ELECTRON LTD

Method for coating a carbon substrate or a non-metallic containing carbon

InactiveUS6113991ALow costStrong adhesionLiquid surface applicatorsMolten spray coatingIridiumRhenium

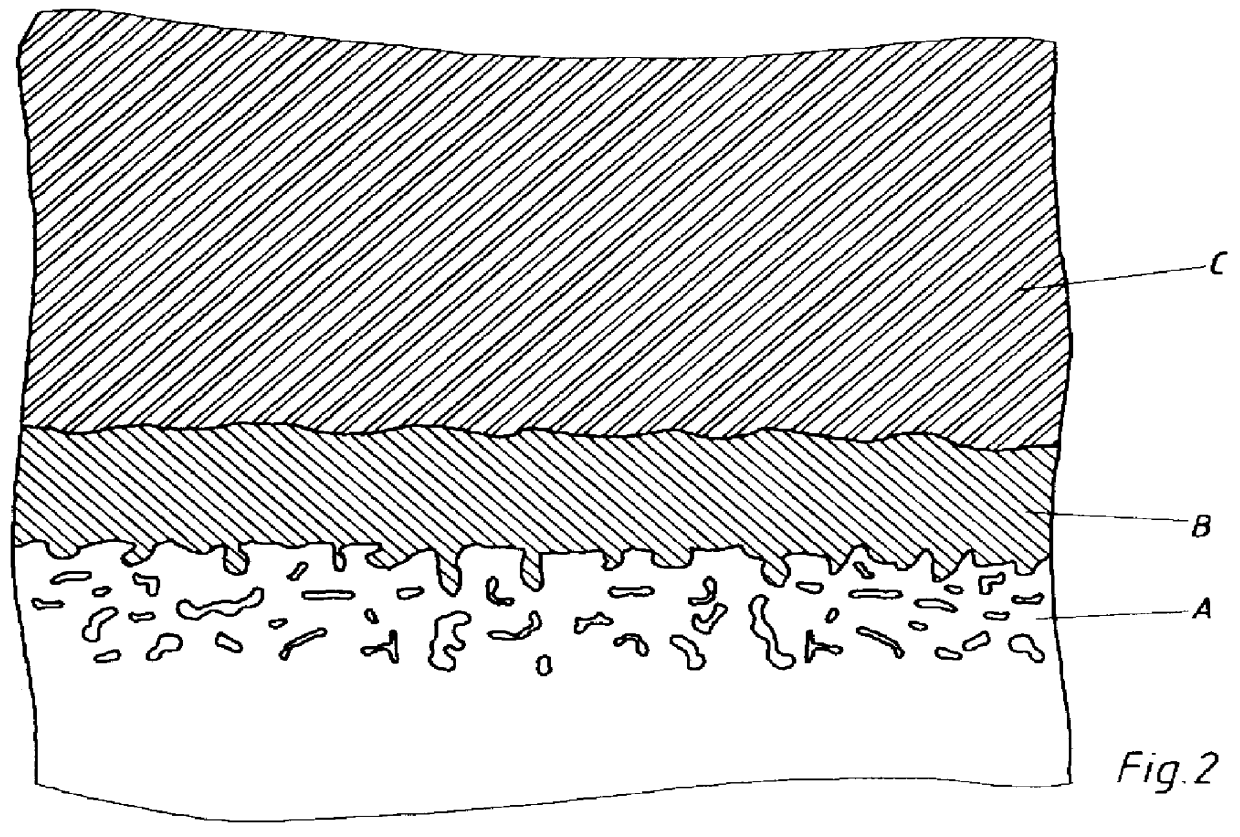

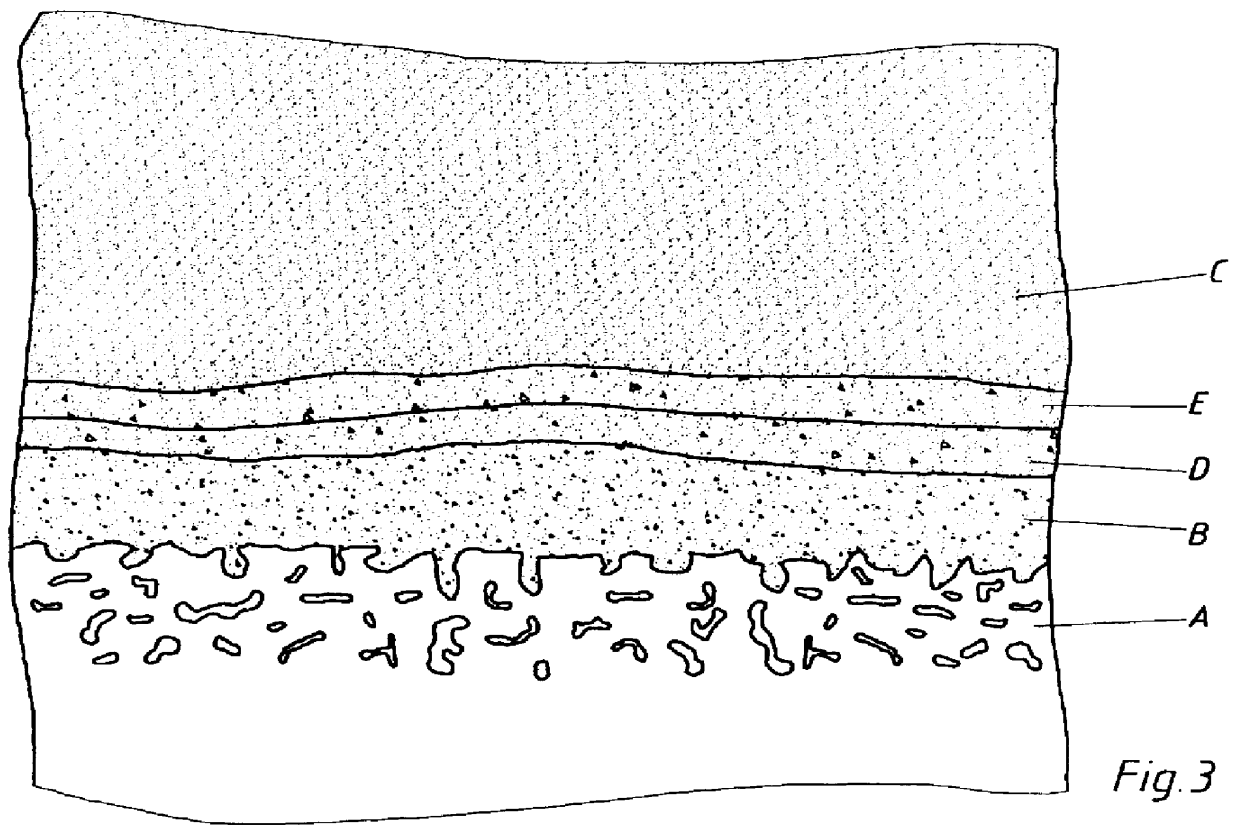

To provide a substrate consisting of carbon or non-metallic materials containing carbon with a layer of a metal having a high melting point, first an undercoat layer is applied to the substrate by plasma spraying in an inert atmosphere. The undercoat layer predominantly consists of rhenium, molybdenum, zirconium, titan, chrome, niobium, tantalum, hafnium, vanadium, platinum, rhodium or iridium. Onto that undercoat layer, a covering layer can be applied, by plasma spraying as well. In order to reduce the thermo-mechanical stress and to improve the adhesion of the undercoat layer on the surface of the substrate, the substrate is preheated prior to applying the undercoat layer. By means of such a method, carbon-containing substrates can be provided with an undercoat layer and, if required, with a covering layer quickly and reliably at low costs.

Owner:SULZER METRO AG

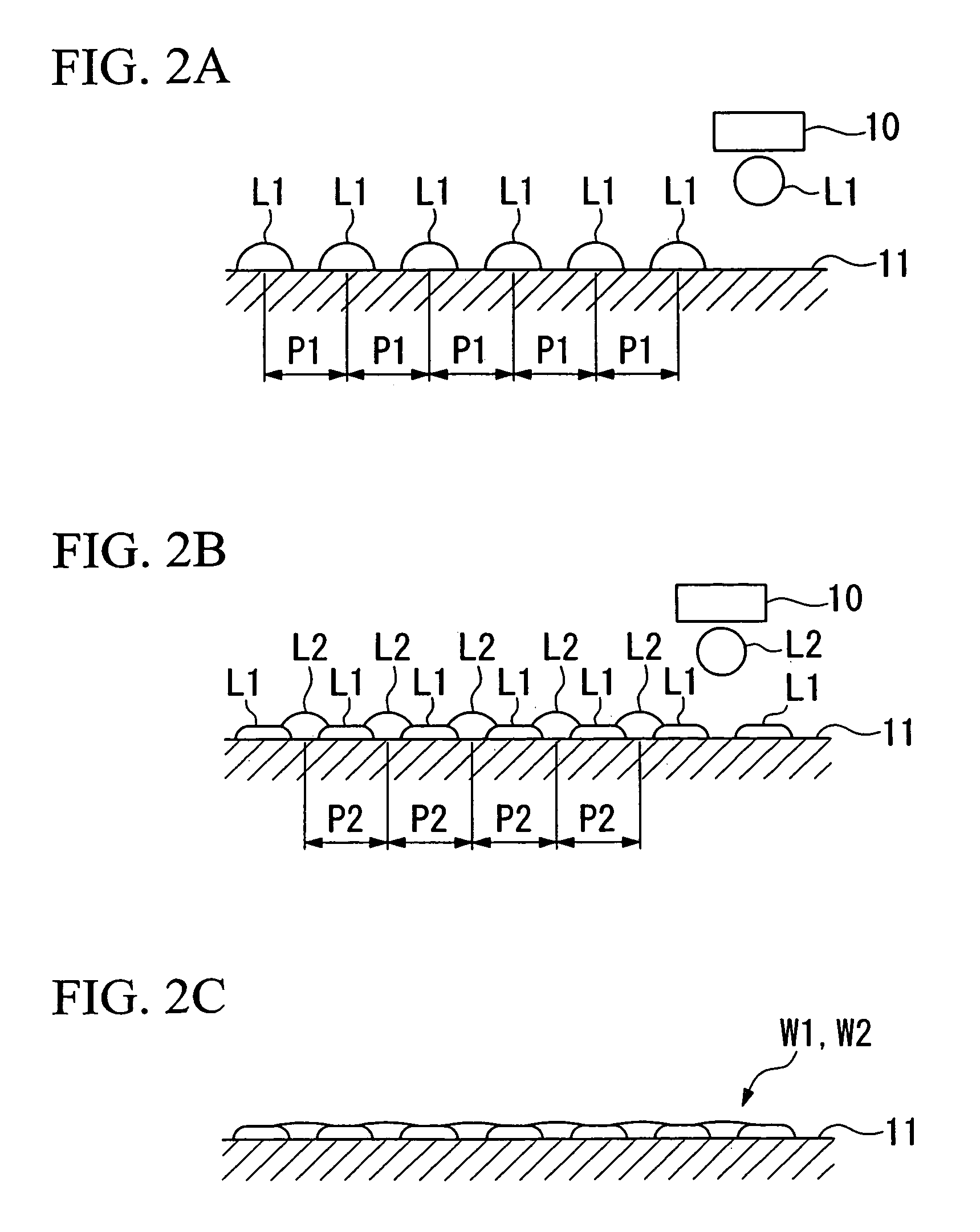

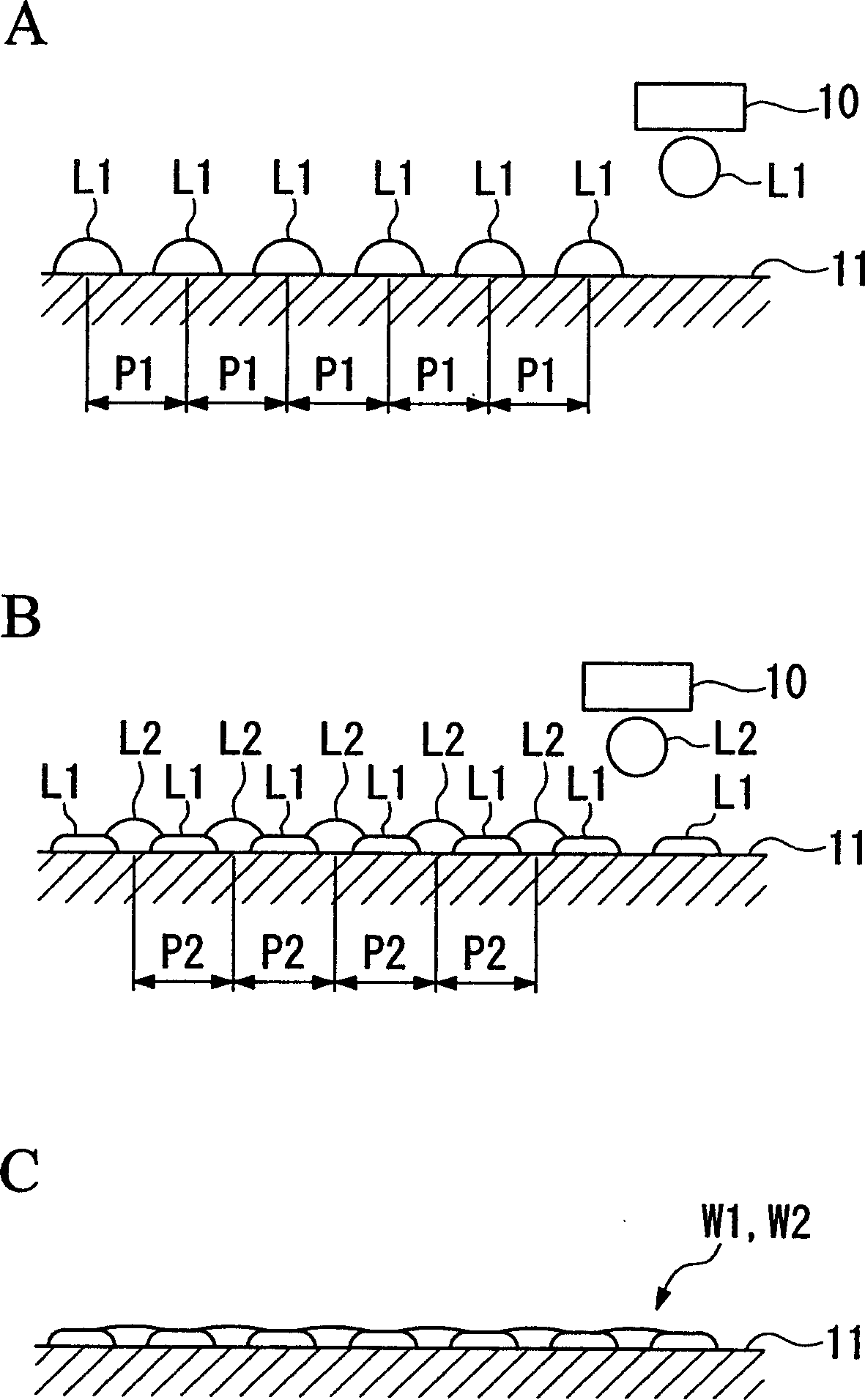

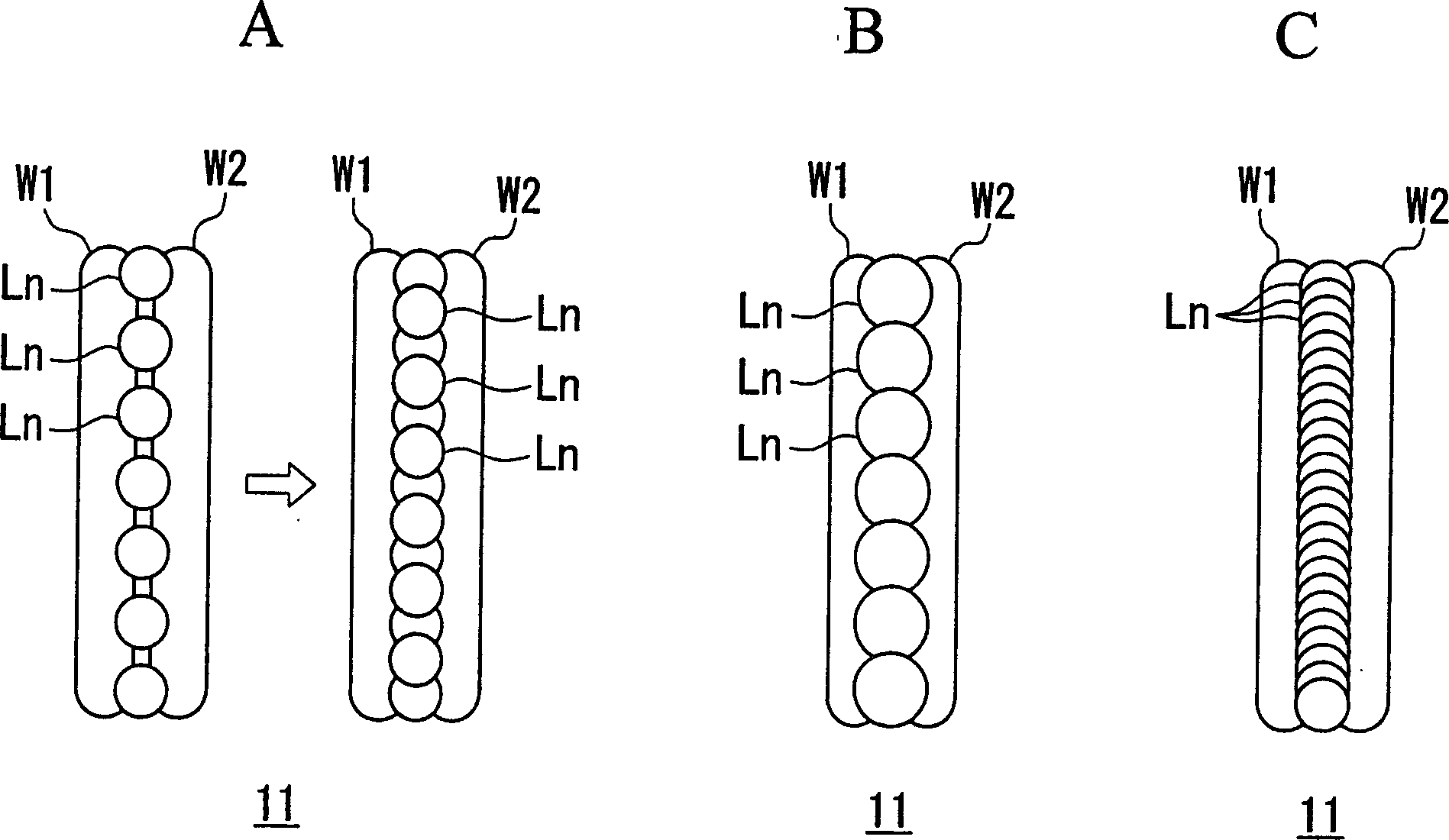

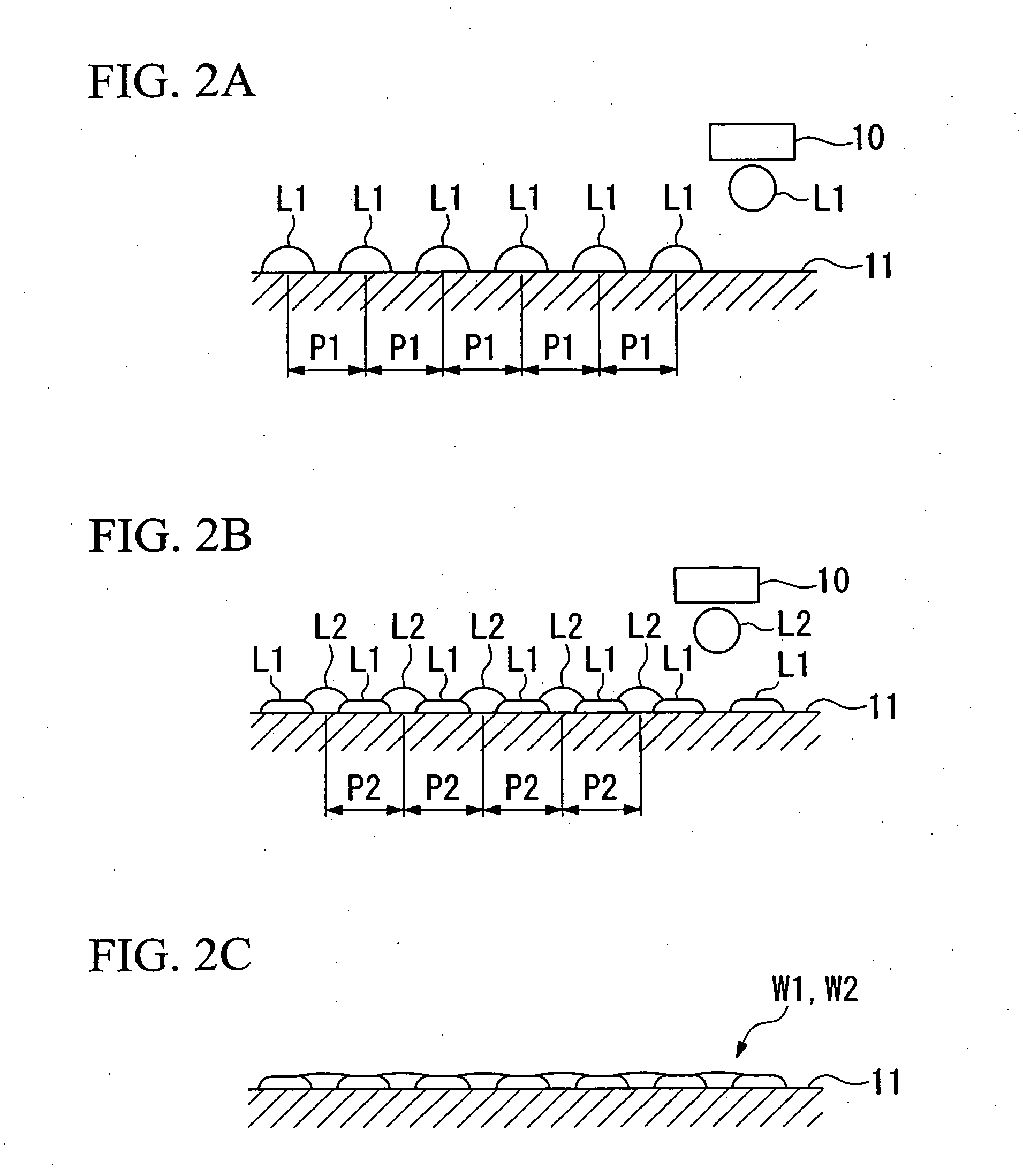

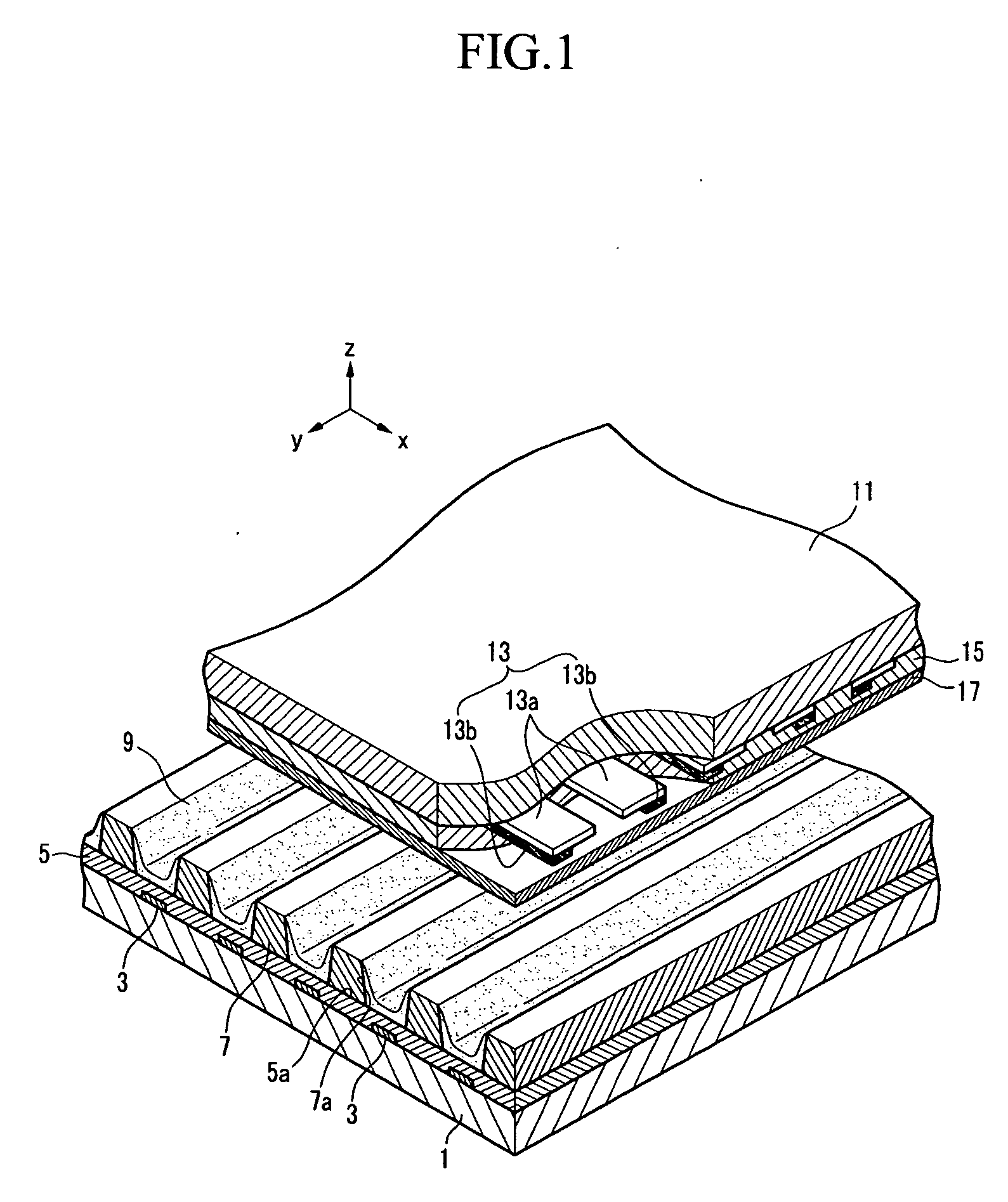

Method for fabricating pattern, apparatus for fabricating pattern, conductive film wiring, method for fabricating device, electro-optical apparatus, and electronic apparatus

InactiveUS7146910B2Preferable shapeSufficient resistance against breaking of wireLiquid surface applicatorsPlaten pressesEngineeringElectron

Owner:SEIKO EPSON CORP

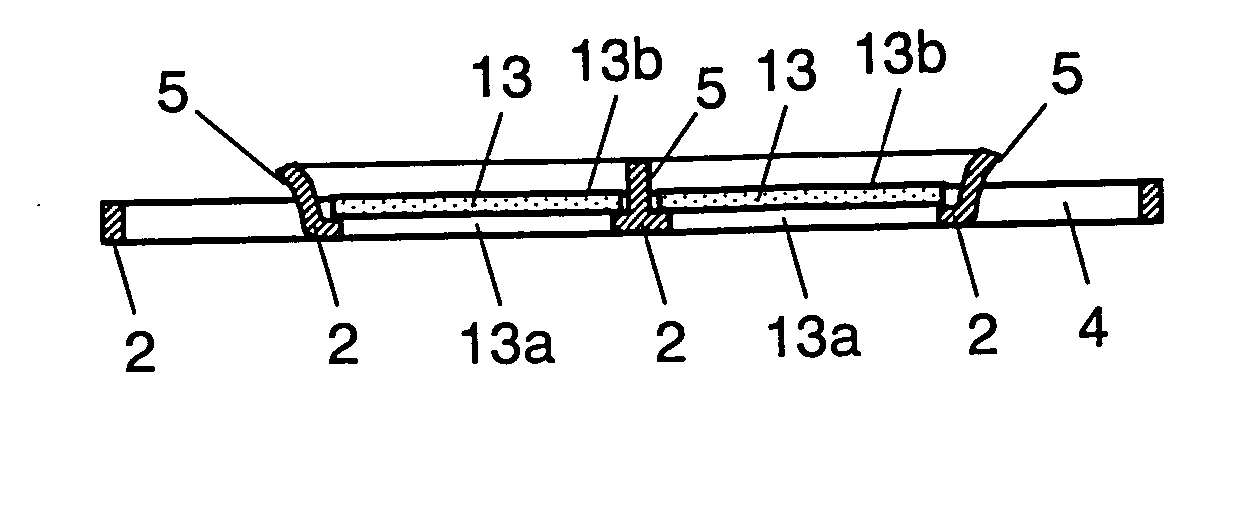

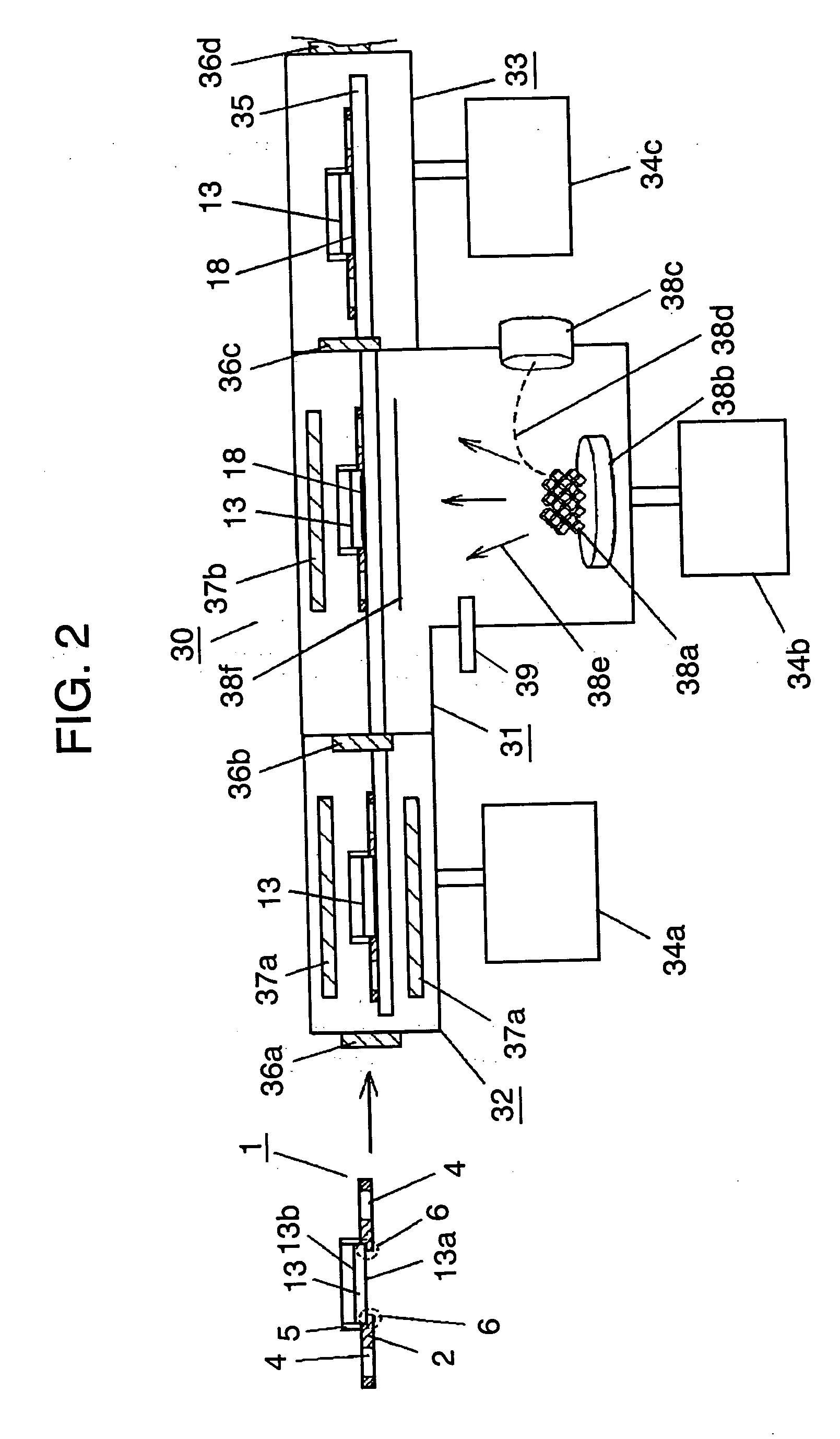

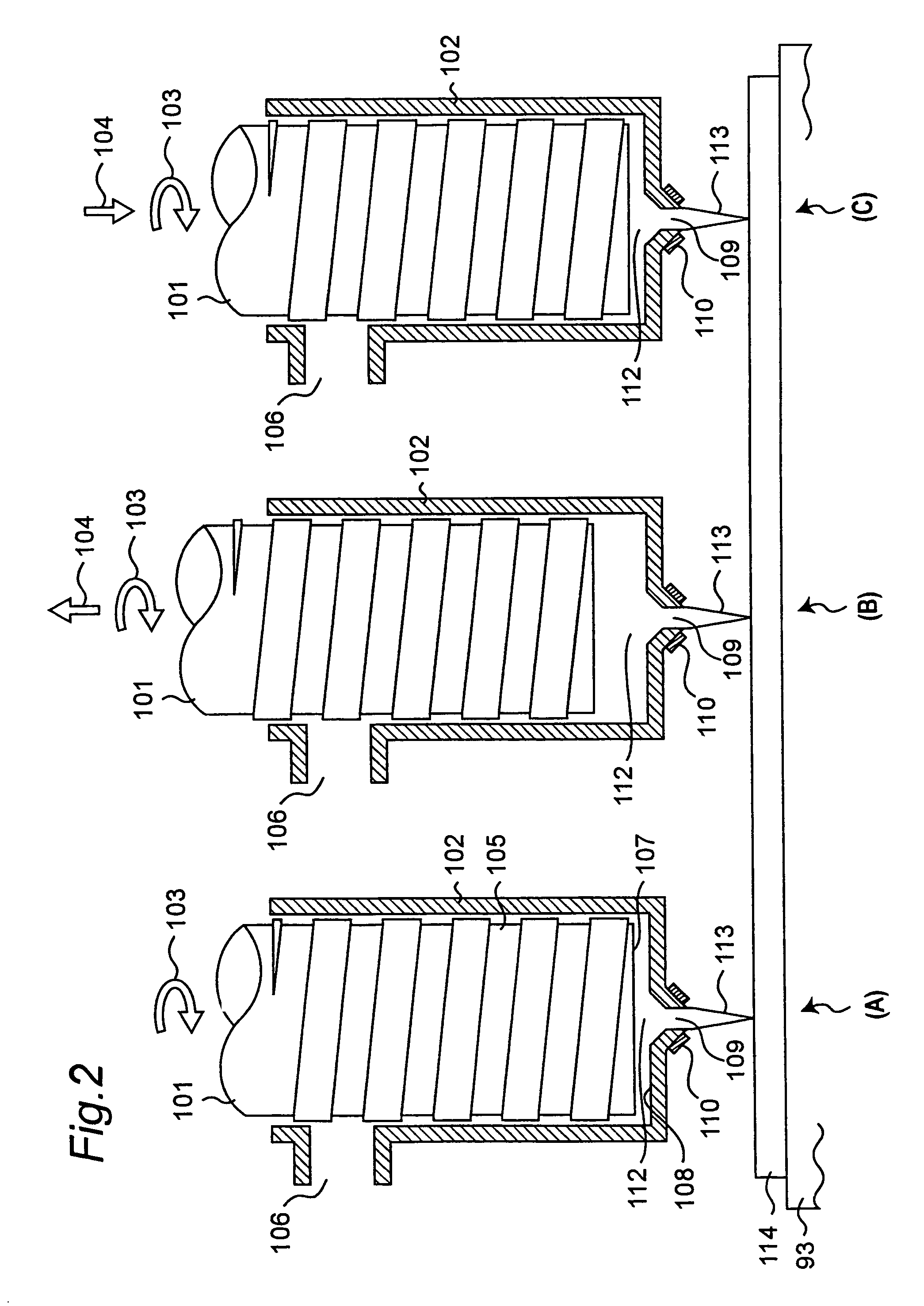

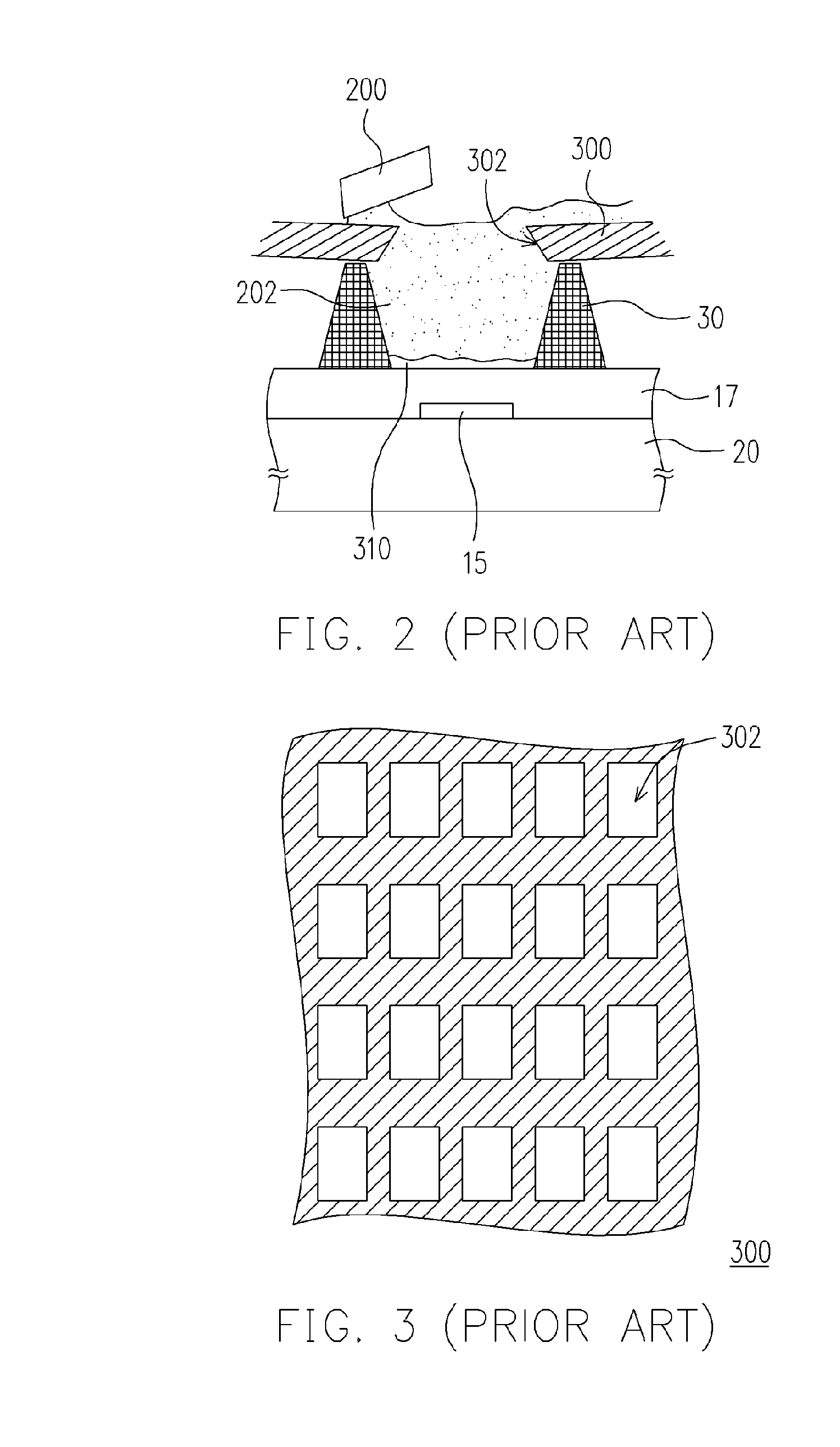

Method for manufacturing plasma display panels

InactiveUS20060068084A1Tube/lamp screens manufactureVacuum evaporation coatingEngineeringPlasma display

A method of manufacturing plasma display panels using a substrate holder for deposition on a substrate of the plasma display panel. The substrate holder is configured with plural frames, and the substrate of the plasma display panel is held by its periphery with at least one of these frames. A frame holding the substrate has a protrusion extending to a non-deposition face of the substrate held in such a way as to surround the substrate. Since the protrusion acts as a blocking sheet, attachment of a deposition material passing through an opening on the substrate holder and reaching onto the non-deposition face of the substrate is suppressed.

Owner:PANASONIC CORP

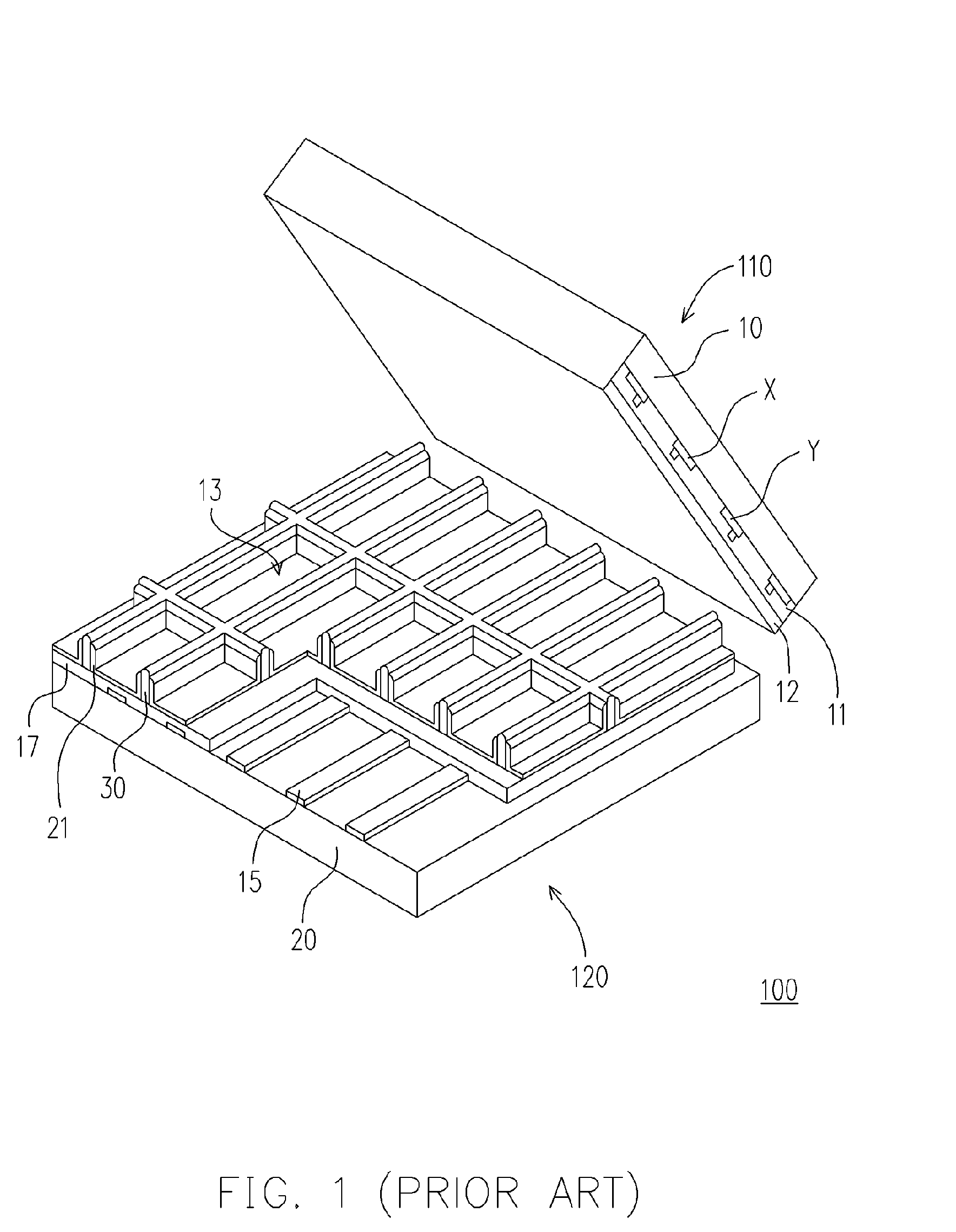

Device and method for fabricating display panel having ink-jet printing applied thereto

InactiveUS6997990B2Reduce manufacturing costThe process steps are simpleTube/lamp screens manufactureLiquid surface applicatorsManufacturing cost reductionDisplay board

Owner:LG ELECTRONICS INC

Method for forming metal oxide film and method for forming secondary electron emission film in gas discharge tube

According to the present invention, there is provided a method for forming a metal oxide film comprising, when a metal oxide film is formed by conducting a thermal treatment on a coating film containing an organic metal compound formed on an inner wall of a tube, performing an ultraviolet irradiation treatment or an ozone treatment on the coating film prior to or simultaneously with the thermal treatment.

Owner:SHINODA PLASMA

Pattern forming apparatus and method, mfg. method of conducting film wiring and electronic device

InactiveCN1459372AEasy to shapeAchieve wideningLiquid surface applicatorsSolid-state devicesElectronElectrical and Electronics engineering

Owner:SEIKO EPSON CORP

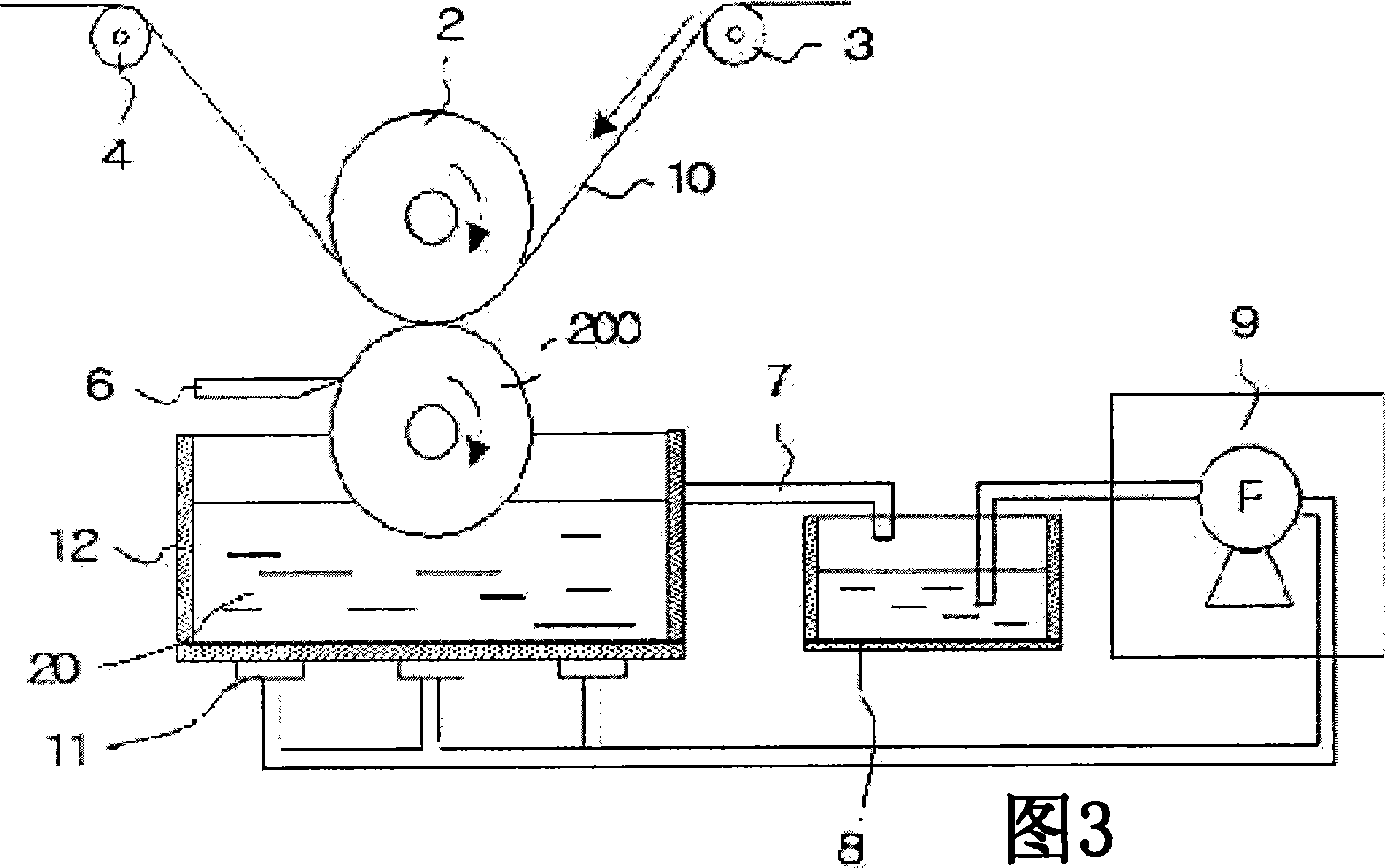

Coating device using roller with double blades, and method for producing optical film by using the same

InactiveCN101428262AGood lookingUniform coatingLiquid surface applicatorsElectric discharge tubesPulp and paper industryKnife blades

The invention relates to a roller coating apparatus with double knife blades and a method for manufacturing optical films by using the same. In order to reduce the product loss and defect ratio, another rear knife blade is arranged in a common gravure coating apparatus to remove coating liquid air bubbles which is produced in a long time continuous production and is transferred on the gravure roller, thereby remaining the stability of the production process for a long time and obtaining an even coating and a favorable appearance. The coating apparatus according to the invention comprises a gravure coating liquid transfer roller for transferring the coating liquid in a liquid disk to films and rotating the roller when a third of the roller is dipped in the coating liquid in the liquid disk; a fore knife blade arranged in front of the gravure roller for scraping redundant coating liquid and leaving given quantity of coating liquid to be transferred by the gravure roller; and the rear knife blade arranged on the back side of the gravure roller for preventing the bubbles from generating on the gravure roller surface.

Owner:TORAY SAEHAN

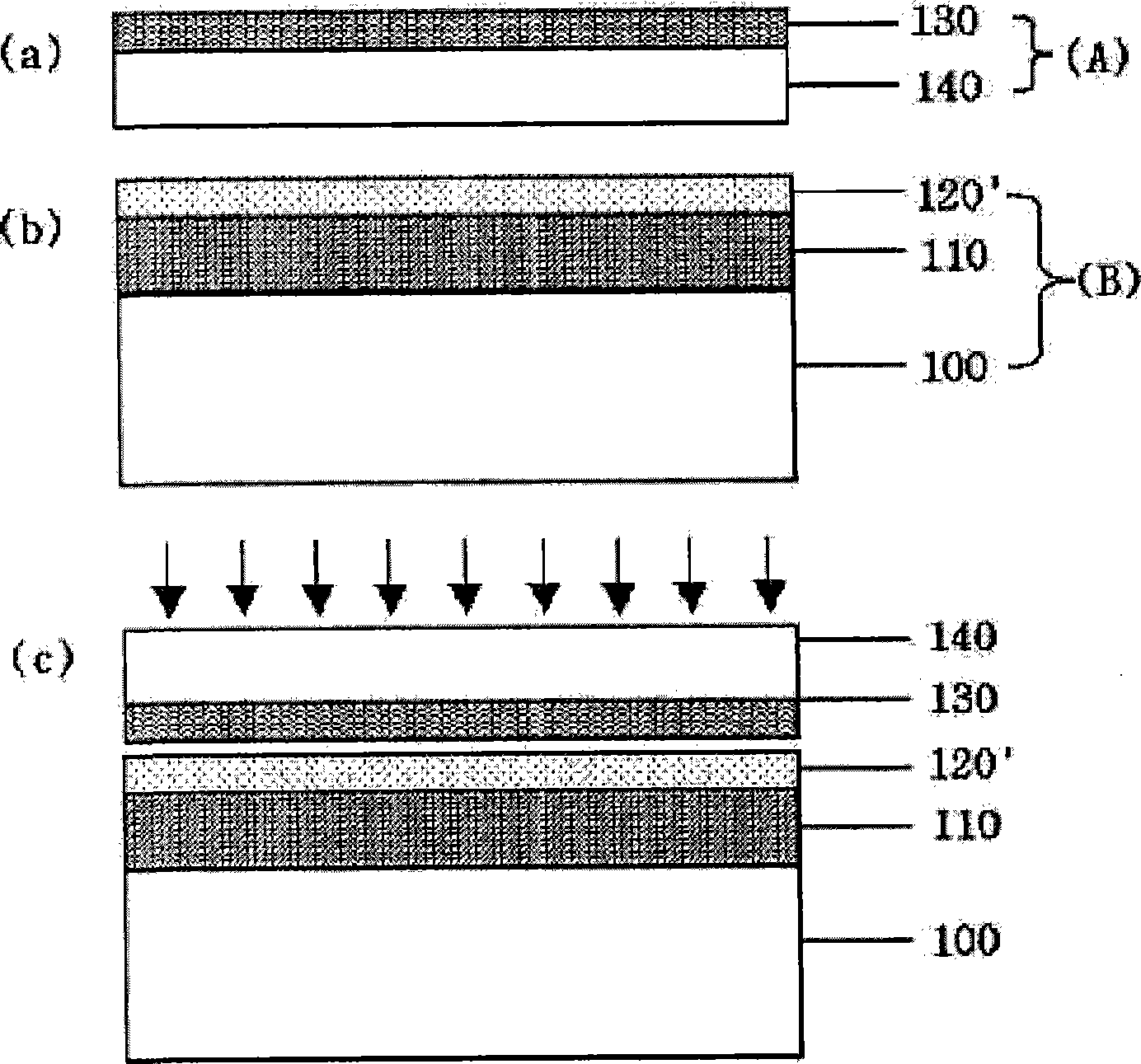

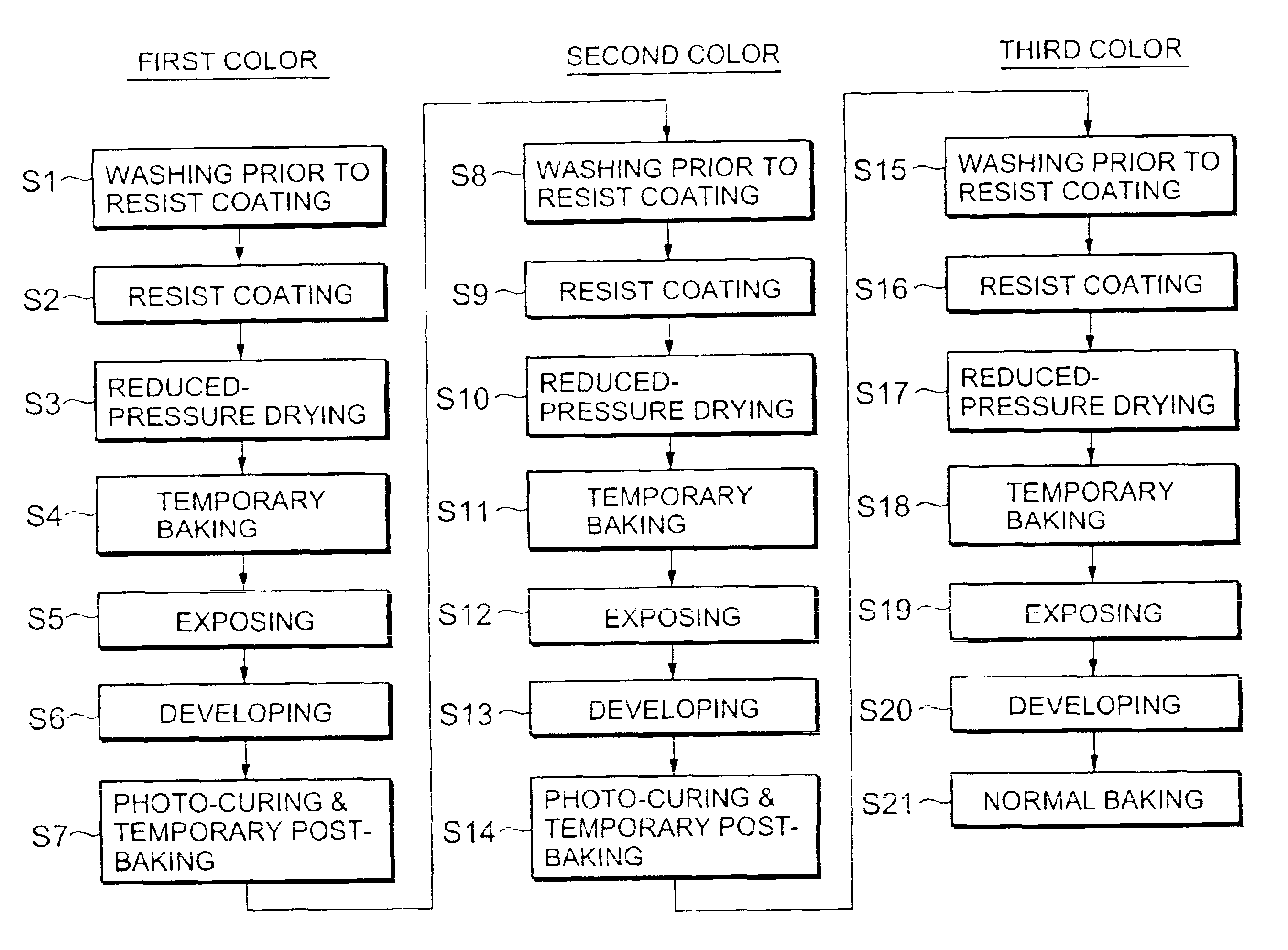

Color layer forming method

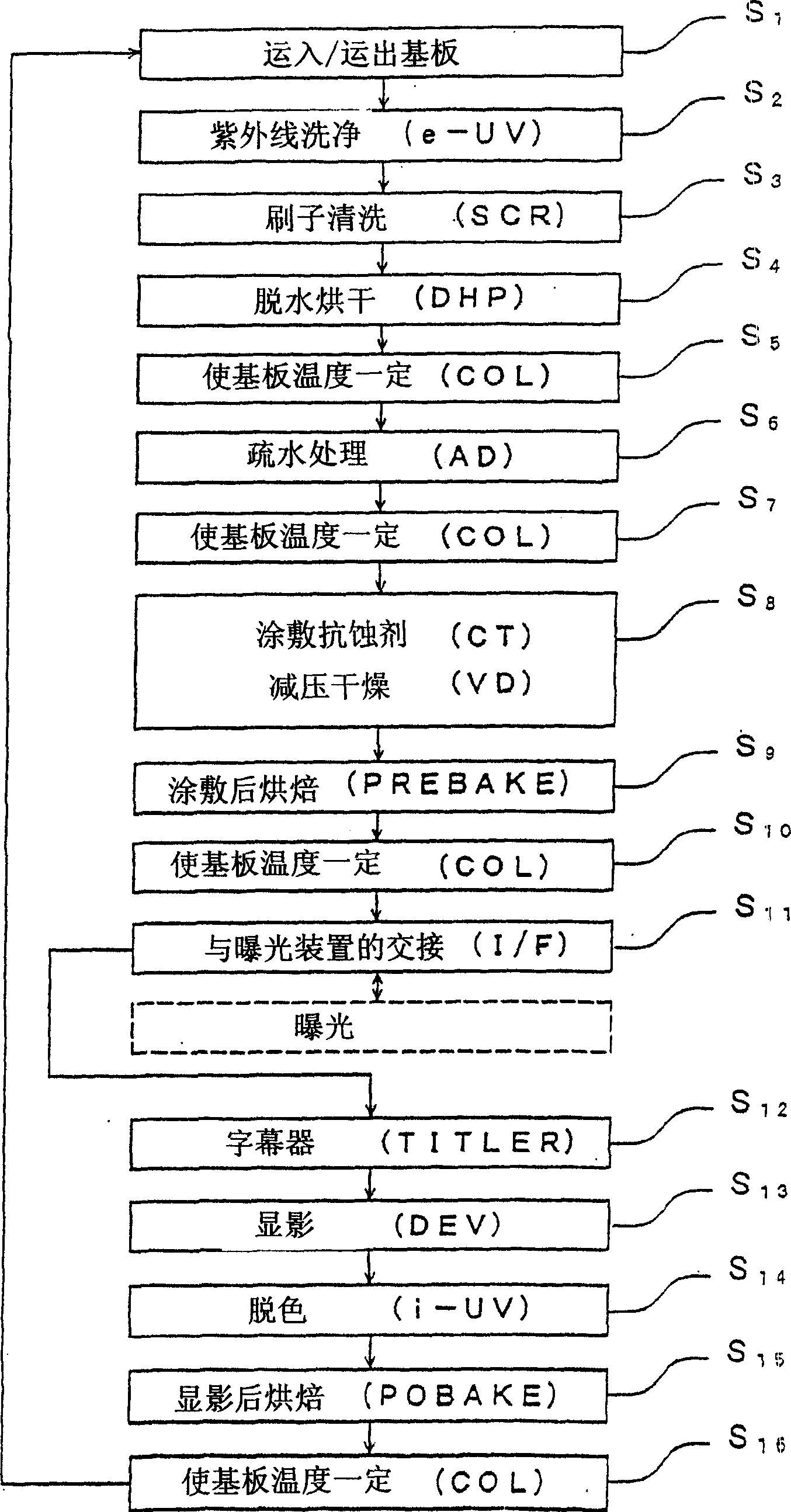

InactiveUS6866972B2Shorten the timeImprove productivityTube/lamp screens manufactureOptical filtersResistCooking & baking

For each of colored resists, a resist coating step of coating a washed substrate with the colored resist, a reduced-pressure drying and temporary baking step of evaporating solvent contained in the colored resist, an exposing step of printing a pattern in the colored resist, a developing the printed pattern and a photo-curing and temporary post-baking step of hardening a surface portion of the resist to a hardness level, in which there is no defect of the printed colored resist pattern occurs in a coating step and a developing step, which are performed later, are repeated. In forming a last colored resist, a normal baking step of simultaneously hardening all of the coated colored resist patterns is performed, instead of the photo-curing and temporary post-baking step.

Owner:VISTA PEAK VENTURES LLC

Device and method for fabricating display panel having ink-jet printing applied thereto

InactiveUS20060073268A1Reduce manufacturing costThe process steps are simpleTube/lamp screens manufactureOptical filtersManufacturing cost reductionEngineering

Owner:LG ELECTRONICS INC

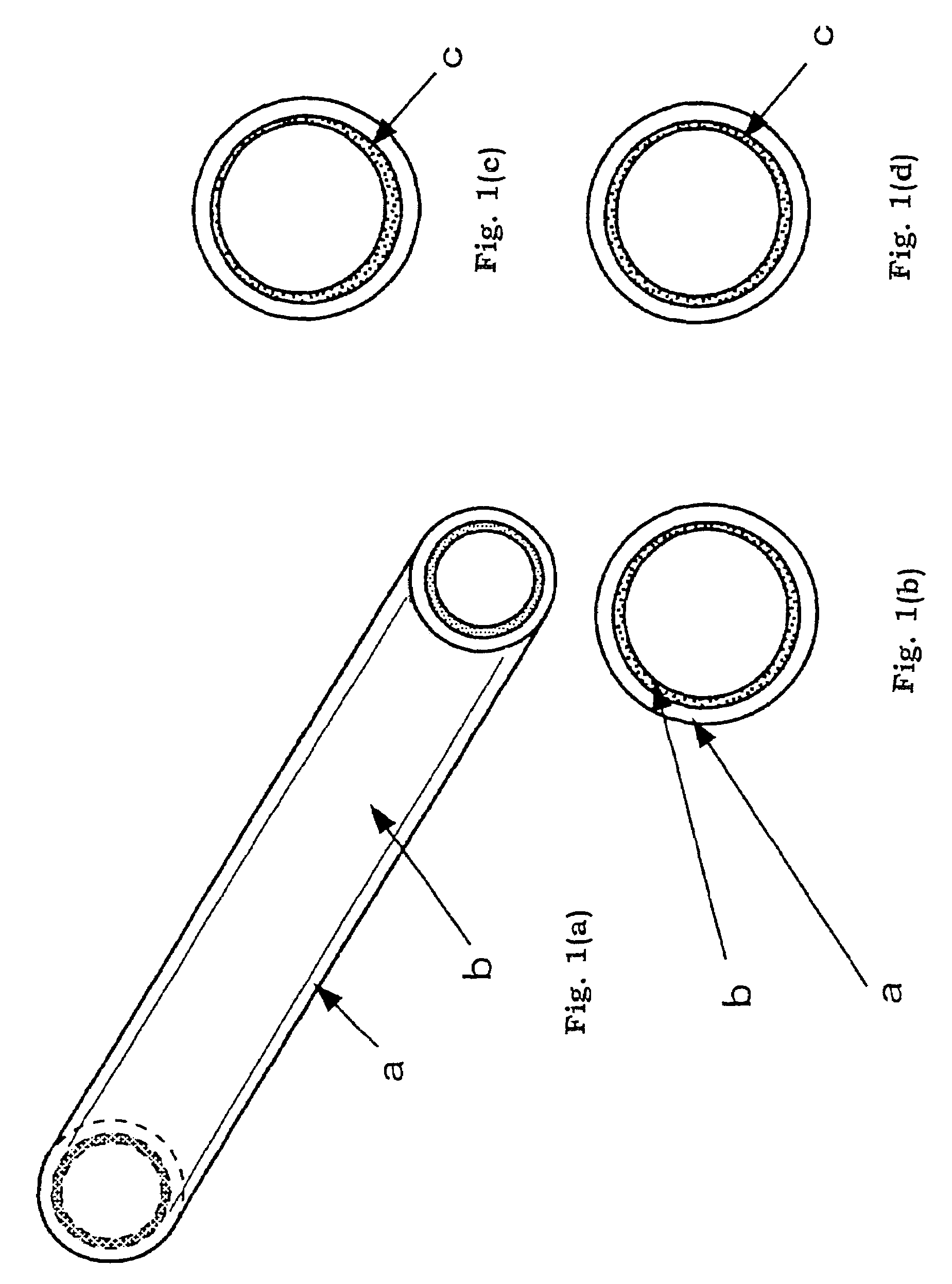

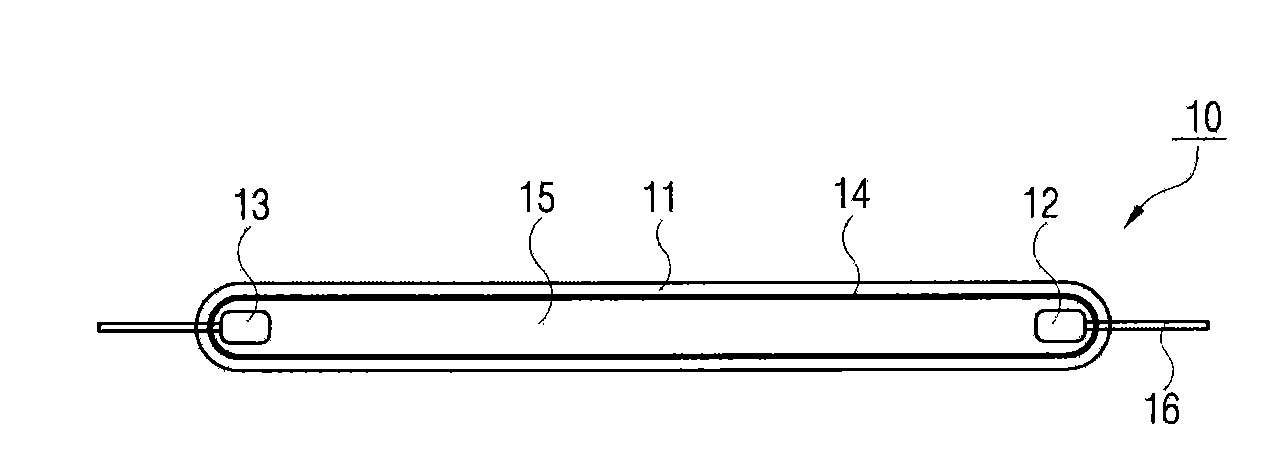

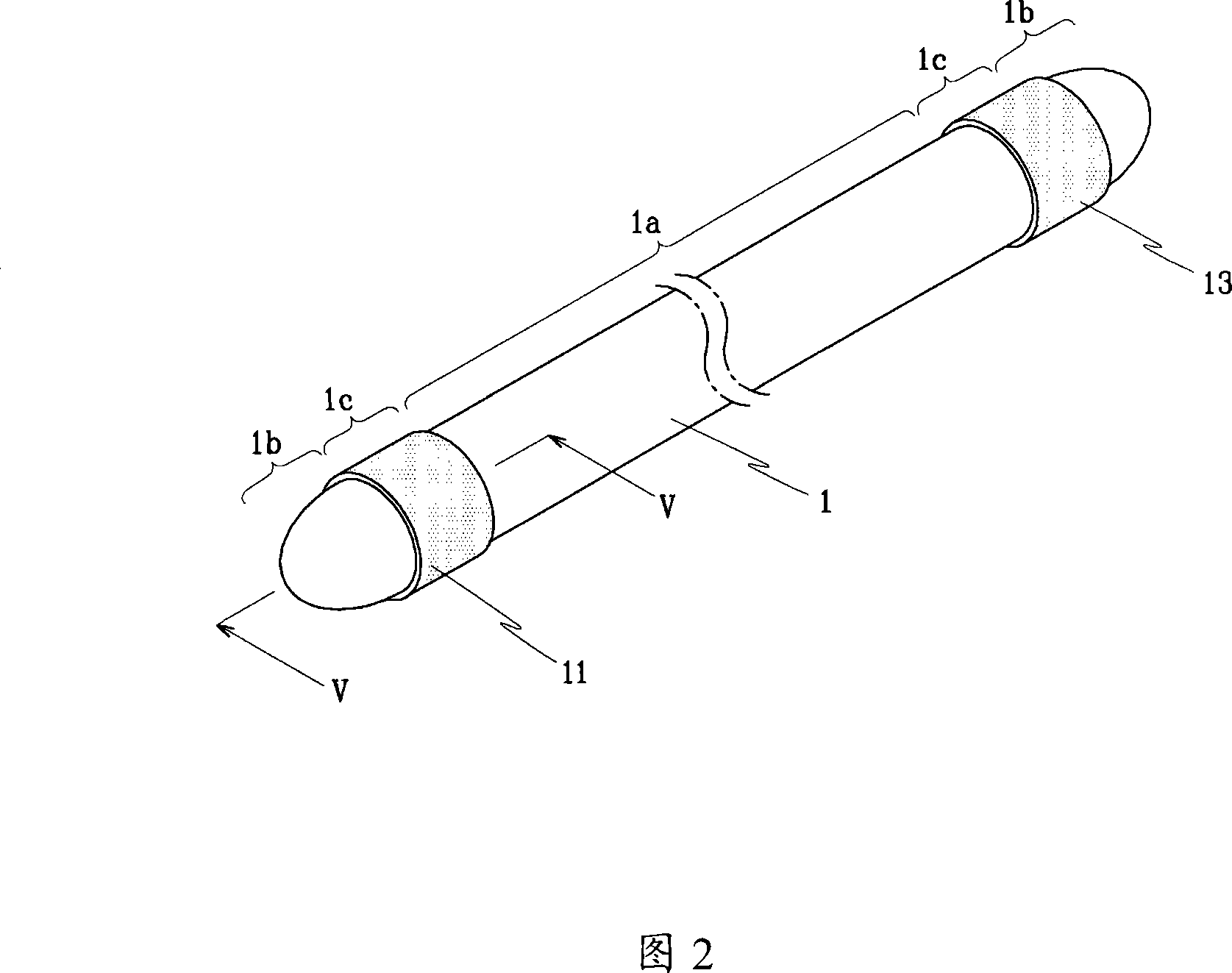

Glass tubes for lamps, method for manufacturing the same, and lamps

InactiveUS20070210714A1Extended service lifeAvoid impuritiesTube/lamp screens manufactureDischarge tube coatingEngineeringLight emission

A glass tube for lamp includes: a tubular glass section having open ends; and a ceramics film that covers at least a portion of an inner surface of the glass section in an area that forms a light emission section of the lamp.

Owner:SEIKO EPSON CORP

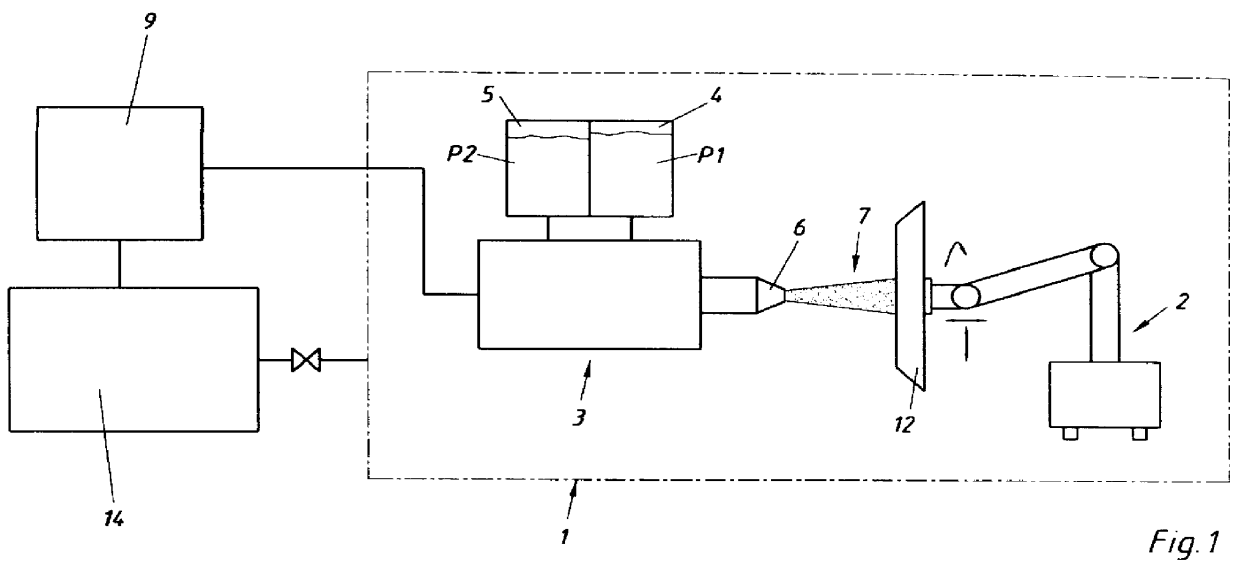

Fluorescent lamp fluorescent liquid coating device

InactiveCN101170036APrevent evaporationIncrease viscosityLiquid surface applicatorsLuminescent coatings applicationEvaporationEngineering

The invention relates to a fluorescent liquid coat device of fluorescent lamp which comprises a storage device used for storing and coating the fluorescent liquid in the wall of the glass tube, a saturated vapour supply device used for supplying vapor to the storage device, to apply pressure on the fluorescent liquid fluid level of the storage device, thereby preventing the evaporation of the fluorescent liquid and the flow of outer water or air. The fluorescent liquid coat device of fluorescent lamp applies pressure on the stored fluorescent liquid level through filling saturated vapour in the storage groove, thereby preventing the evaporation of the fluorescent liquid, keeping stability of the viscocity of fluorescent liquid and improving the coating quality of the fluorescent lamp.

Owner:WEIHAI DMS OPTICAL ELECTROMECHANICAL CO LTD

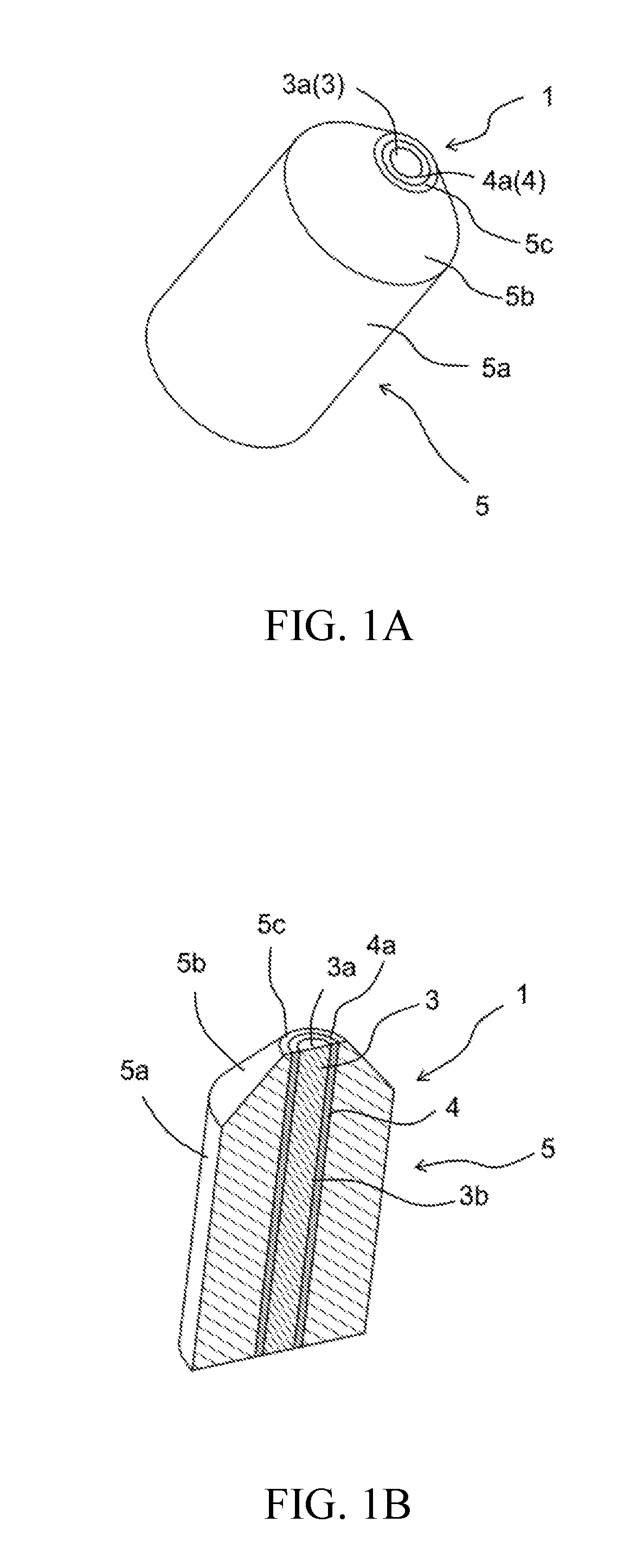

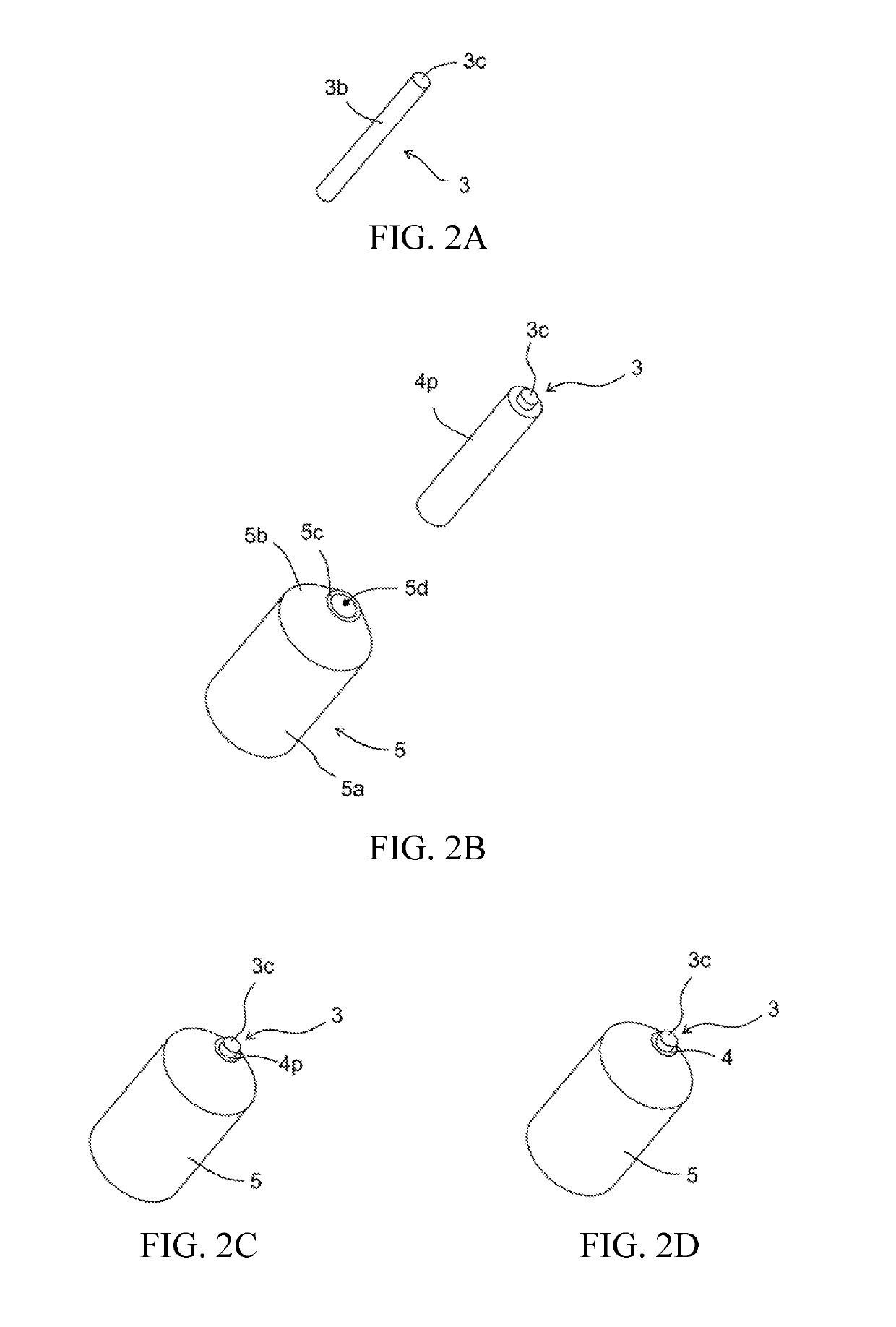

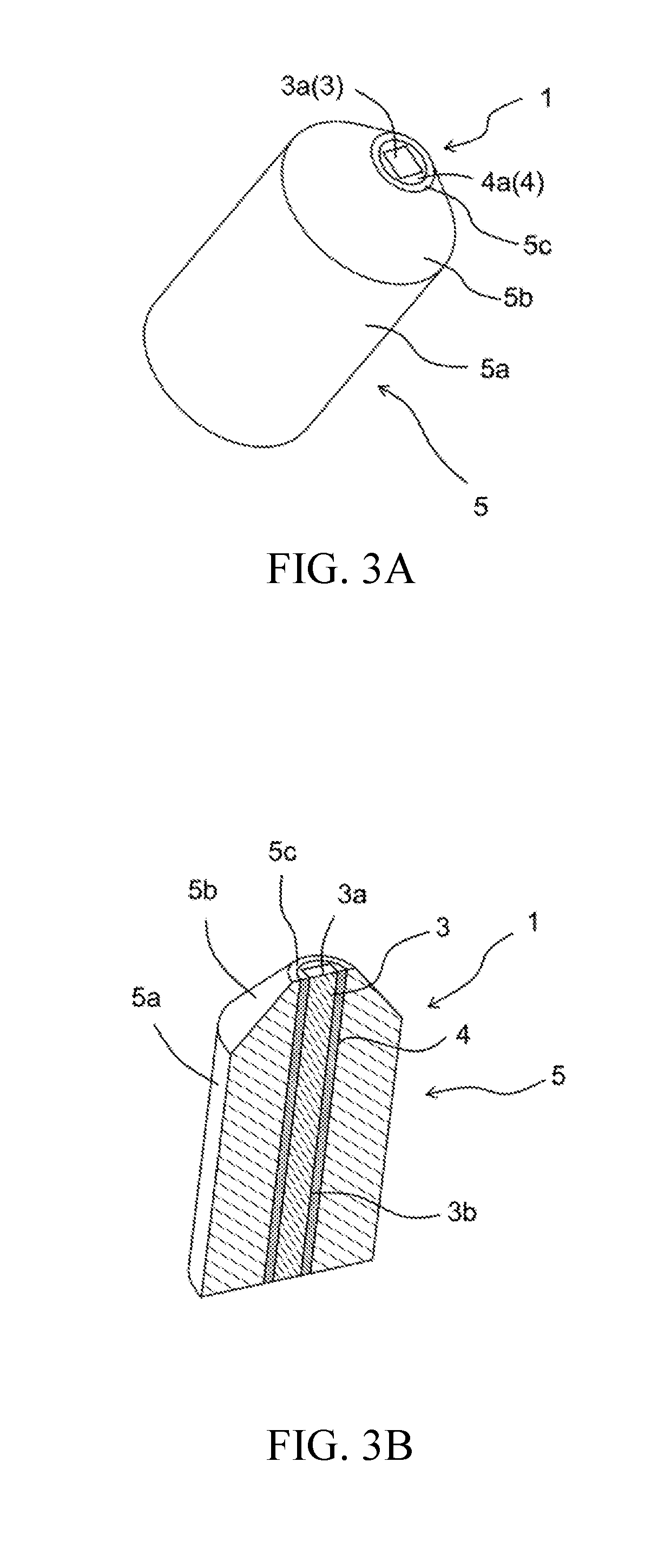

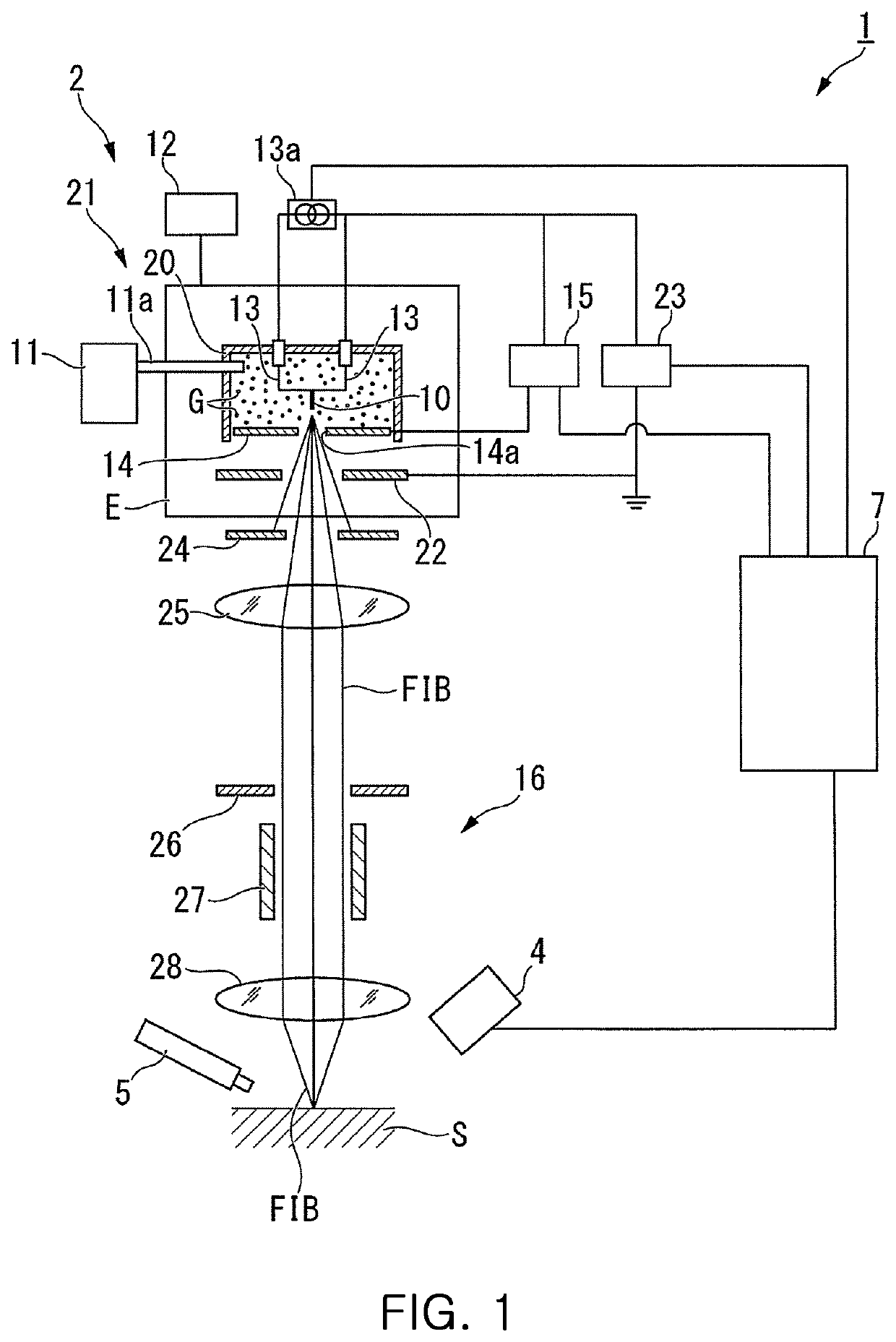

Electron source and production method therefor

ActiveUS20190221399A1Consumption of the electron emission material can be suppressedElectric discharge tubesDischarge tube/lamp detailsElectron sourceEmissivity

An electron source capable of suppressing consumption of an electron emission material is provide. The present invention provides an electron source including: an electron emission material; and, an electron emission-suppressing material covering a side surface of the electron emission material, wherein a work function of the electron emission-suppressing material is higher than that of the electron emission material, and a thermal emissivity of the electron emission-suppressing material is lower than that of the electron emission material.

Owner:DENKA CO LTD

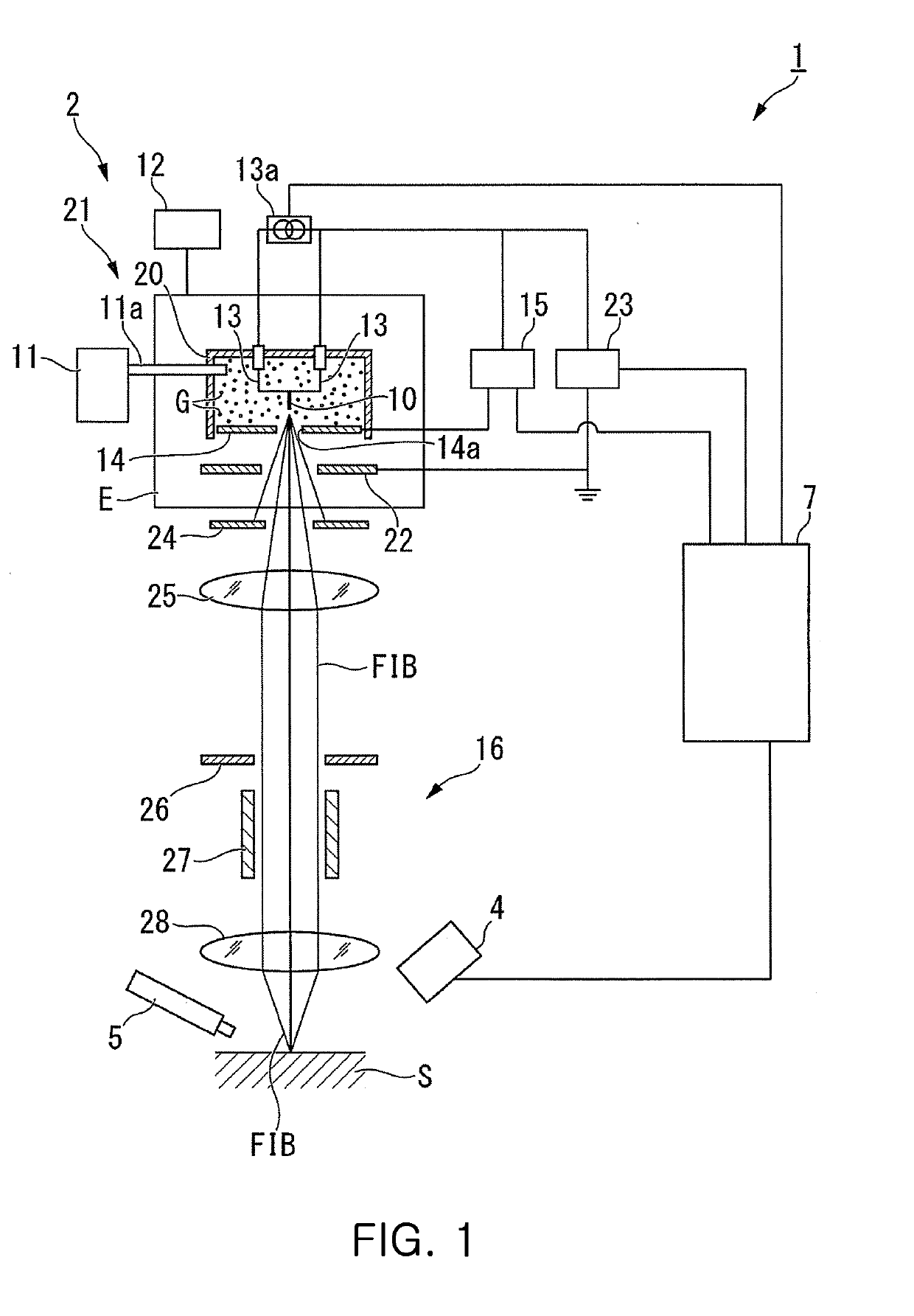

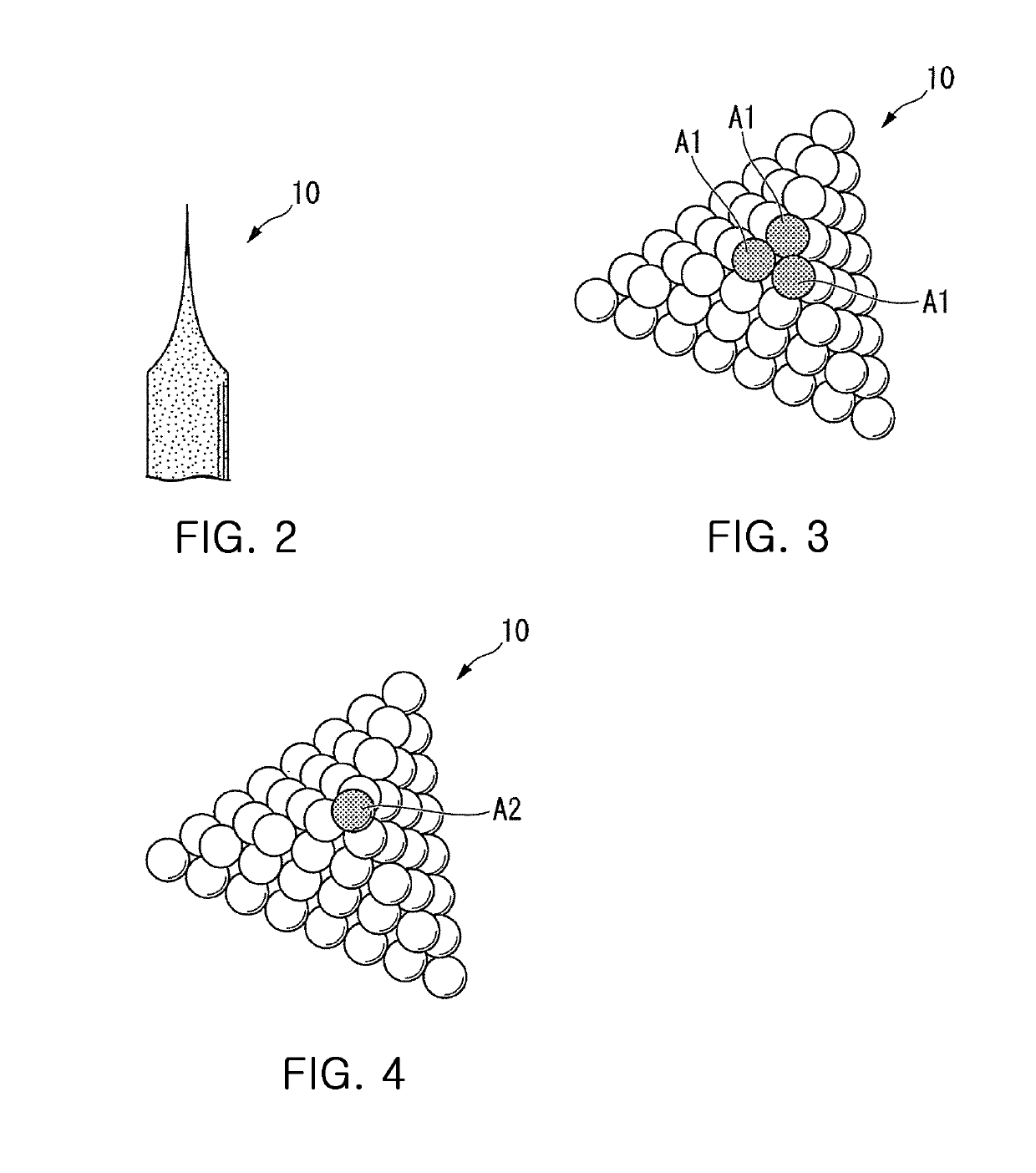

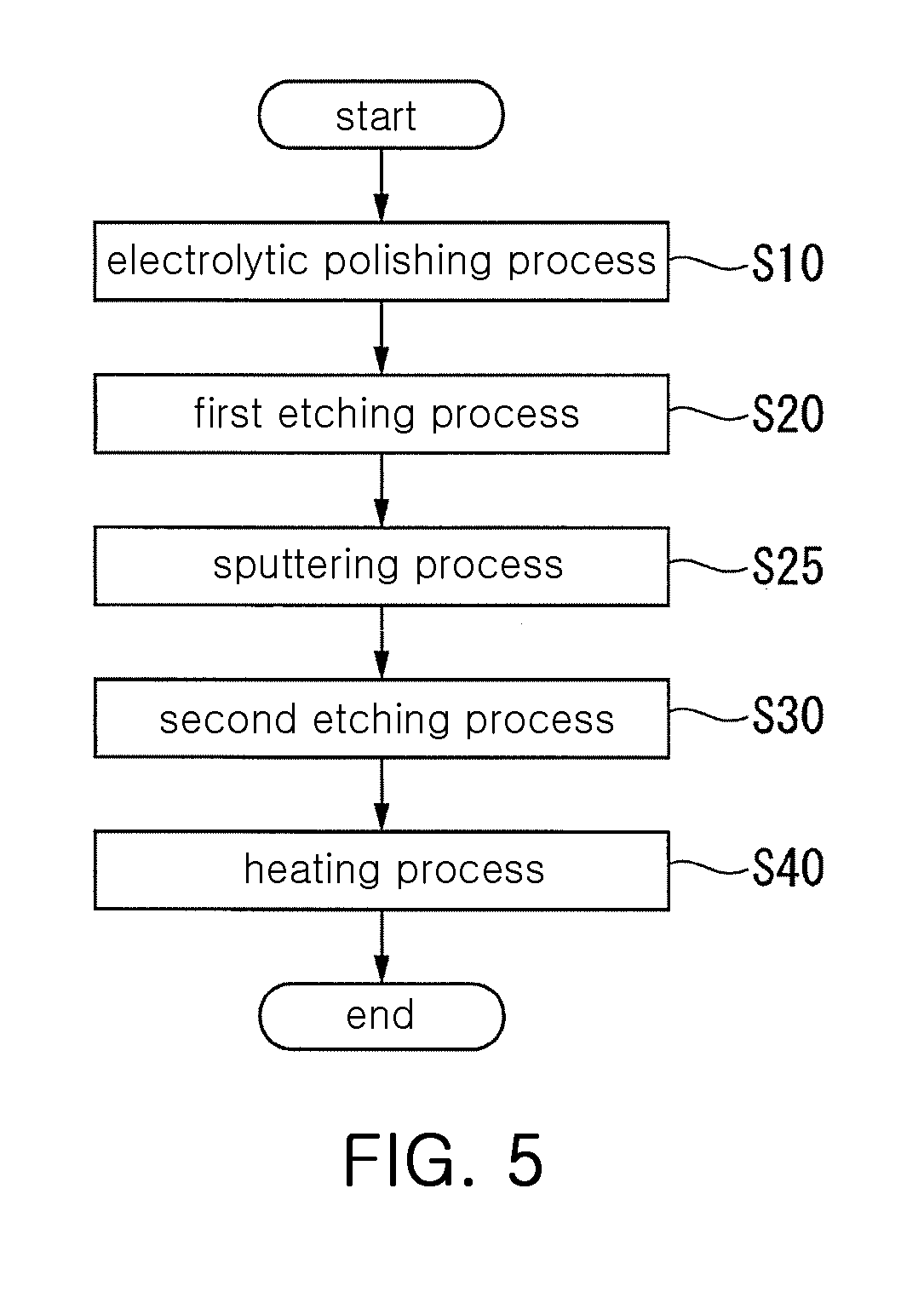

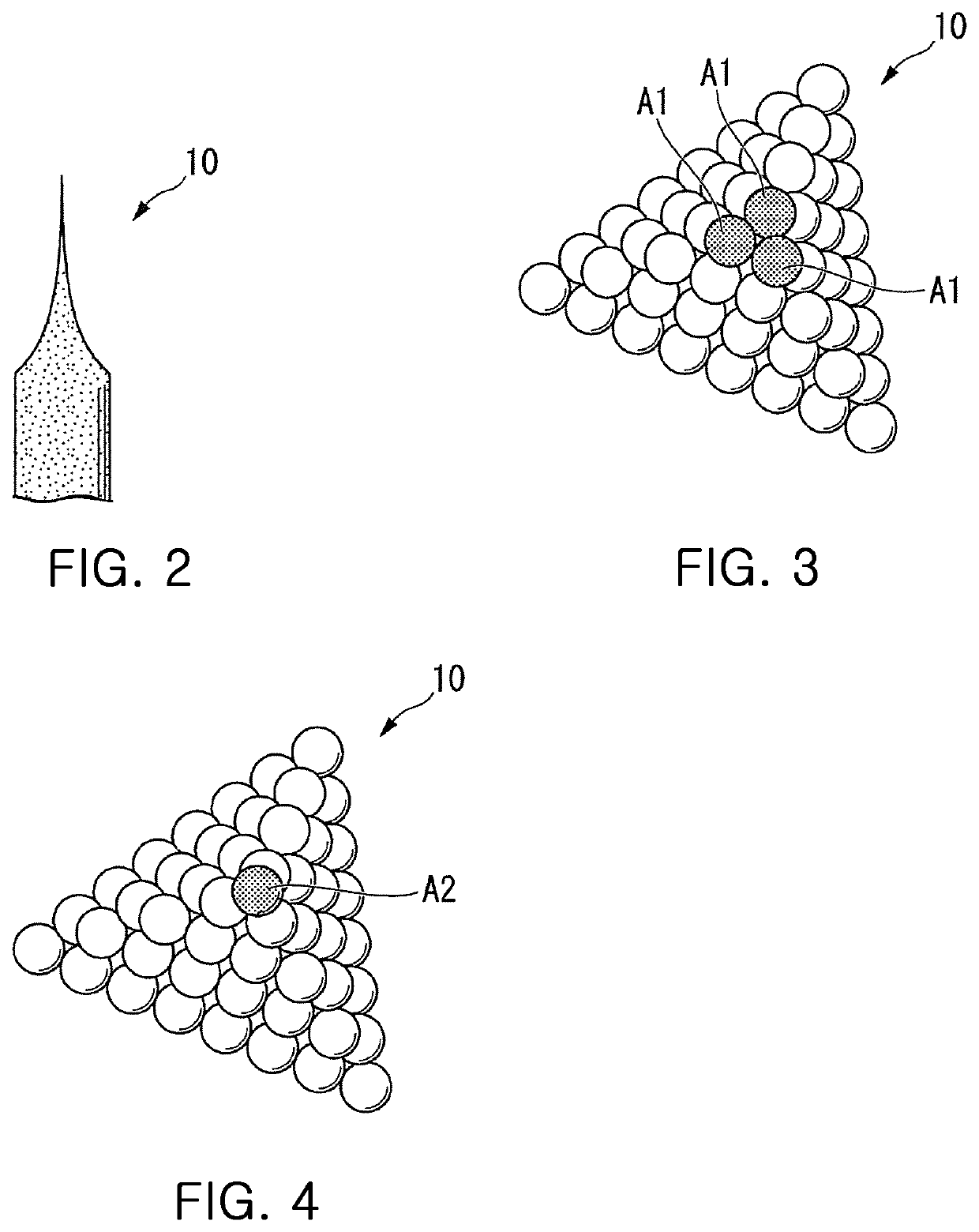

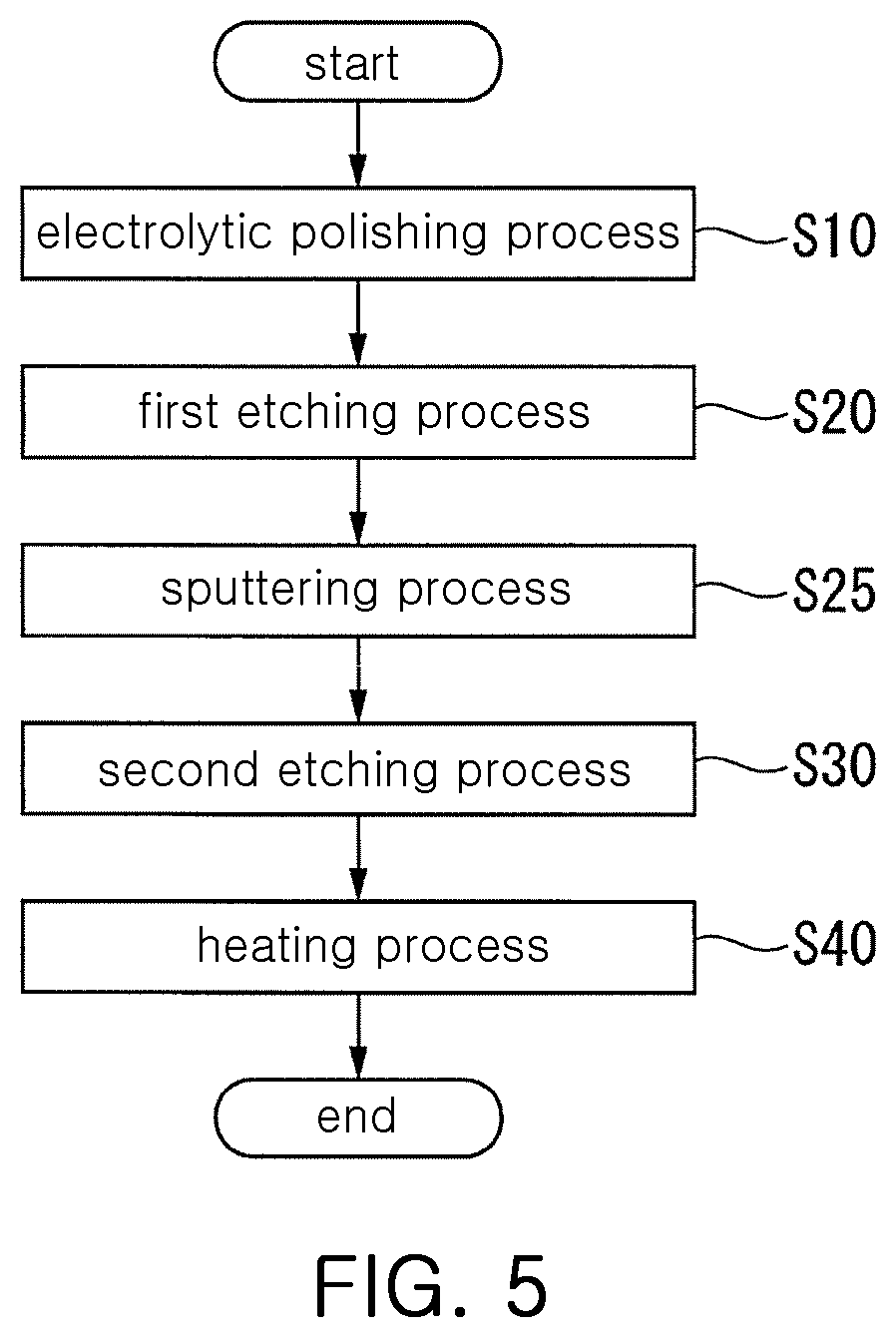

Method of manufacturing emitter

ActiveUS20190267208A1Desire shapeElectric discharge tubesDischarge tube/lamp detailsEtchingCrystal structure

Disclosed is a method of manufacturing an emitter in which the tip of the emitter can be formed into a desired shape even when various materials are used for the emitter. The method includes performing an electrolytic polishing process of polishing a front end of a conductive emitter material so that a diameter of the front end is gradually reduced toward a tip; performing a first etching process by irradiating a processing portion of the emitter material processed by the electrolytic polishing process with a charged particle beam; performing a sputtering process by irradiating the pointed portion formed by the first etching process with a focused ion beam; and performing a secondary etching process of further sharpening the tip by an electric field induced gas etching processing while observing a crystal structure of the tip of the pointed portion processed by the sputtering process using a field ion microscope.

Owner:HITACHI HIGH TECH SCI CORP

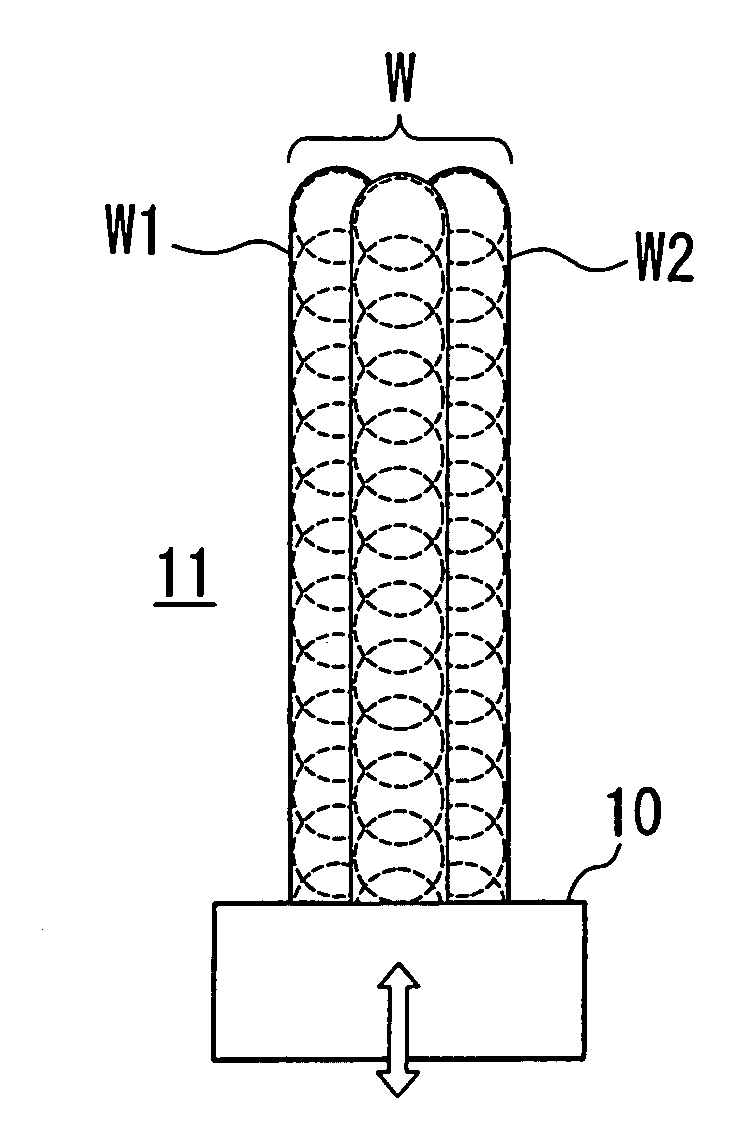

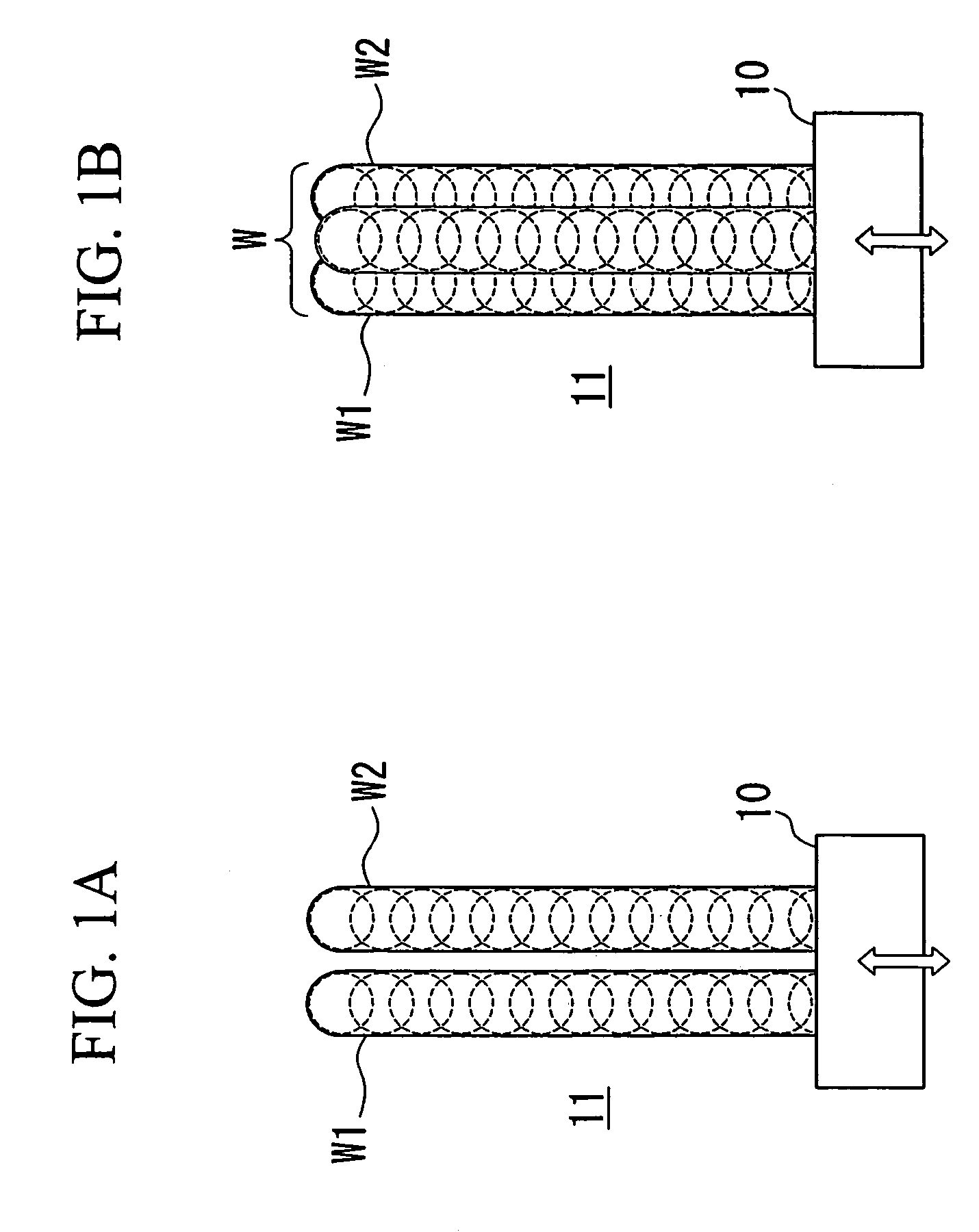

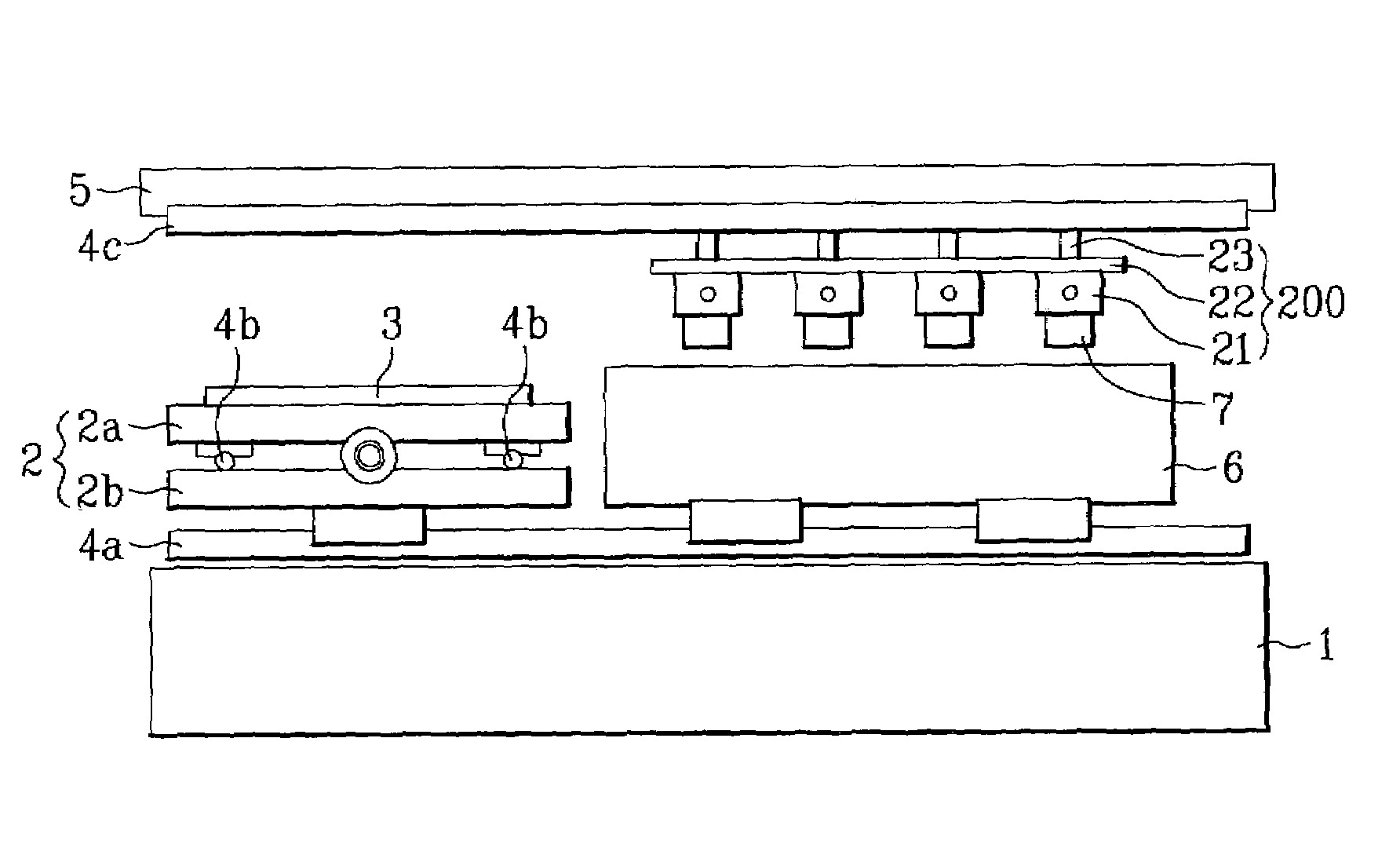

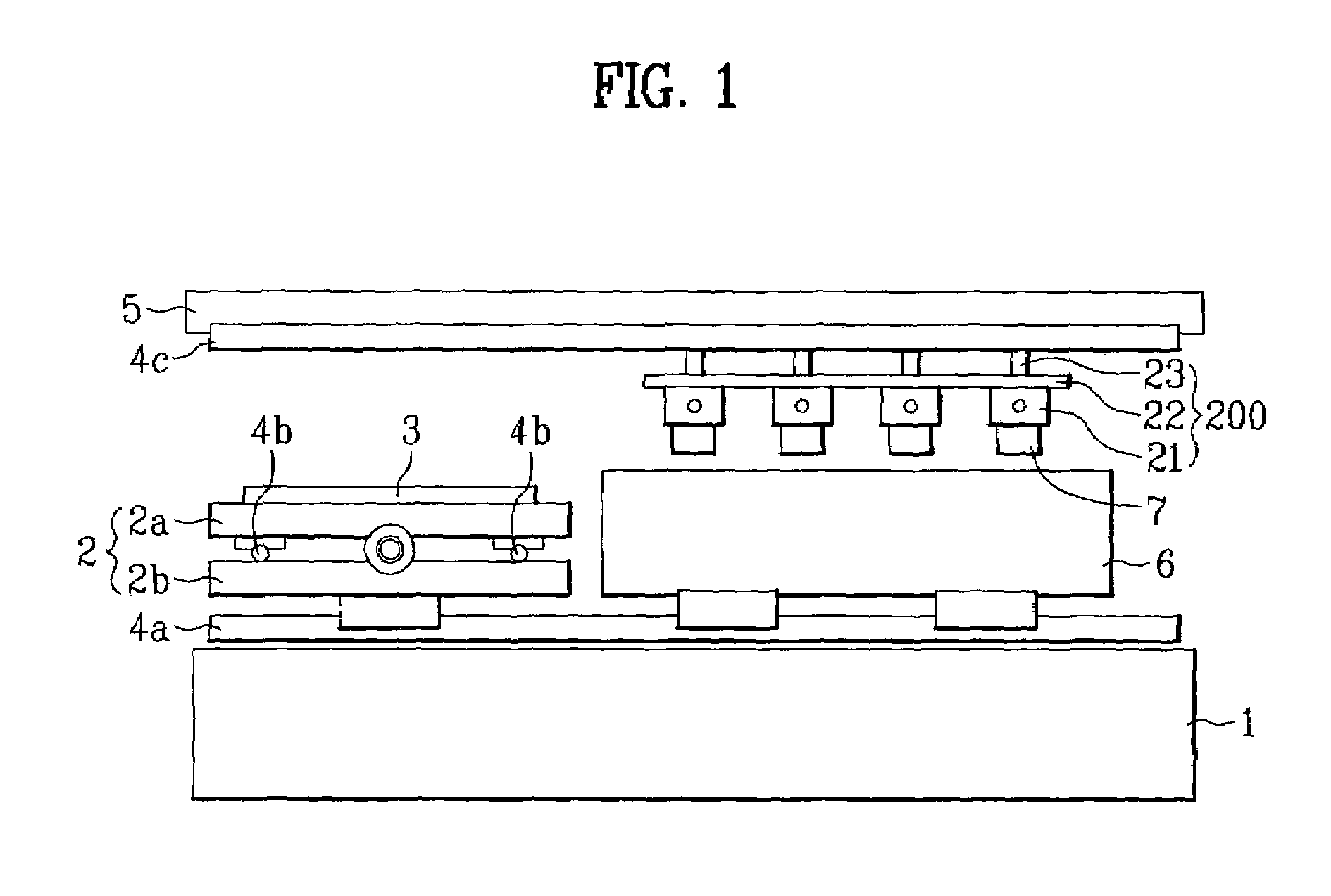

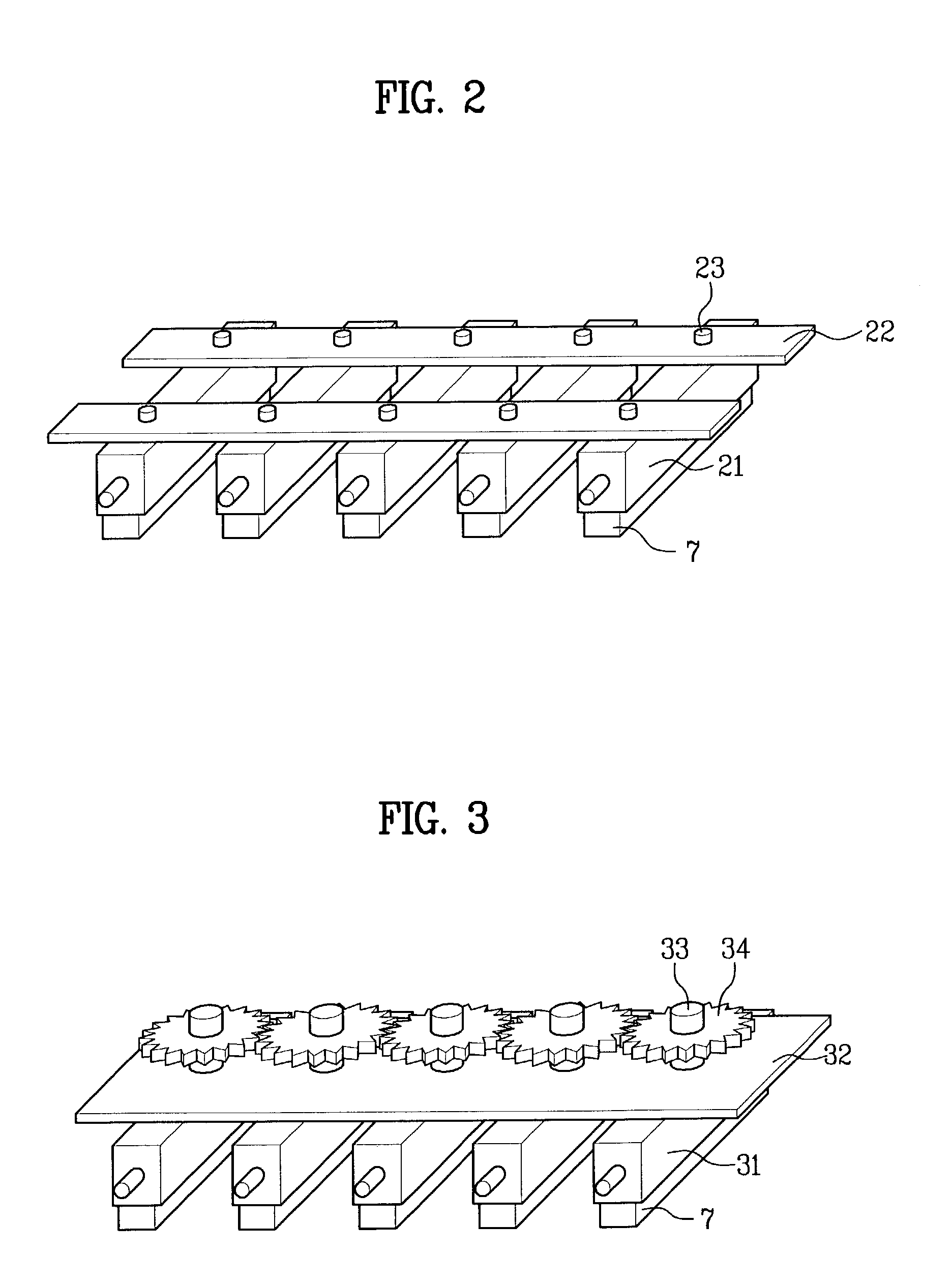

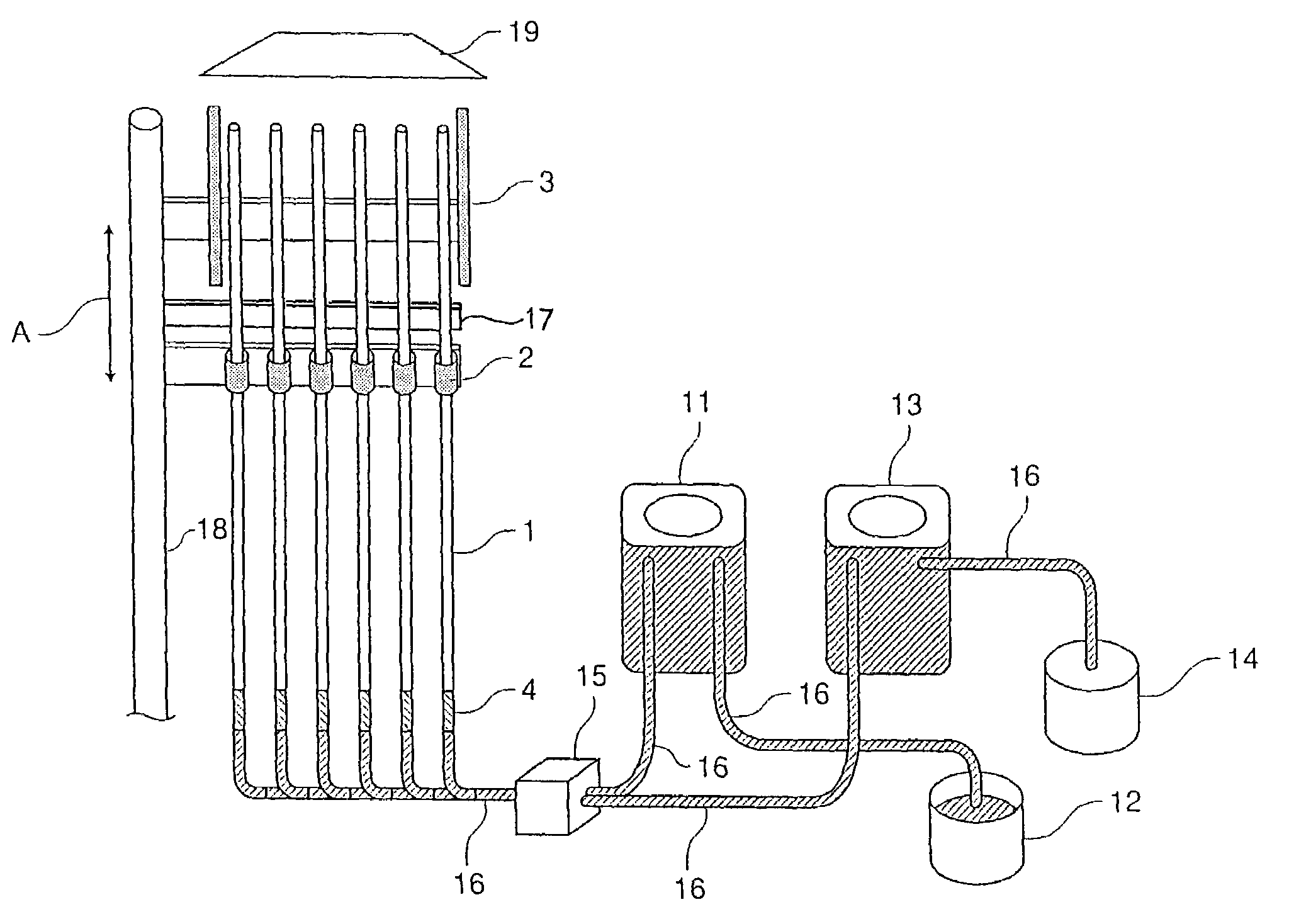

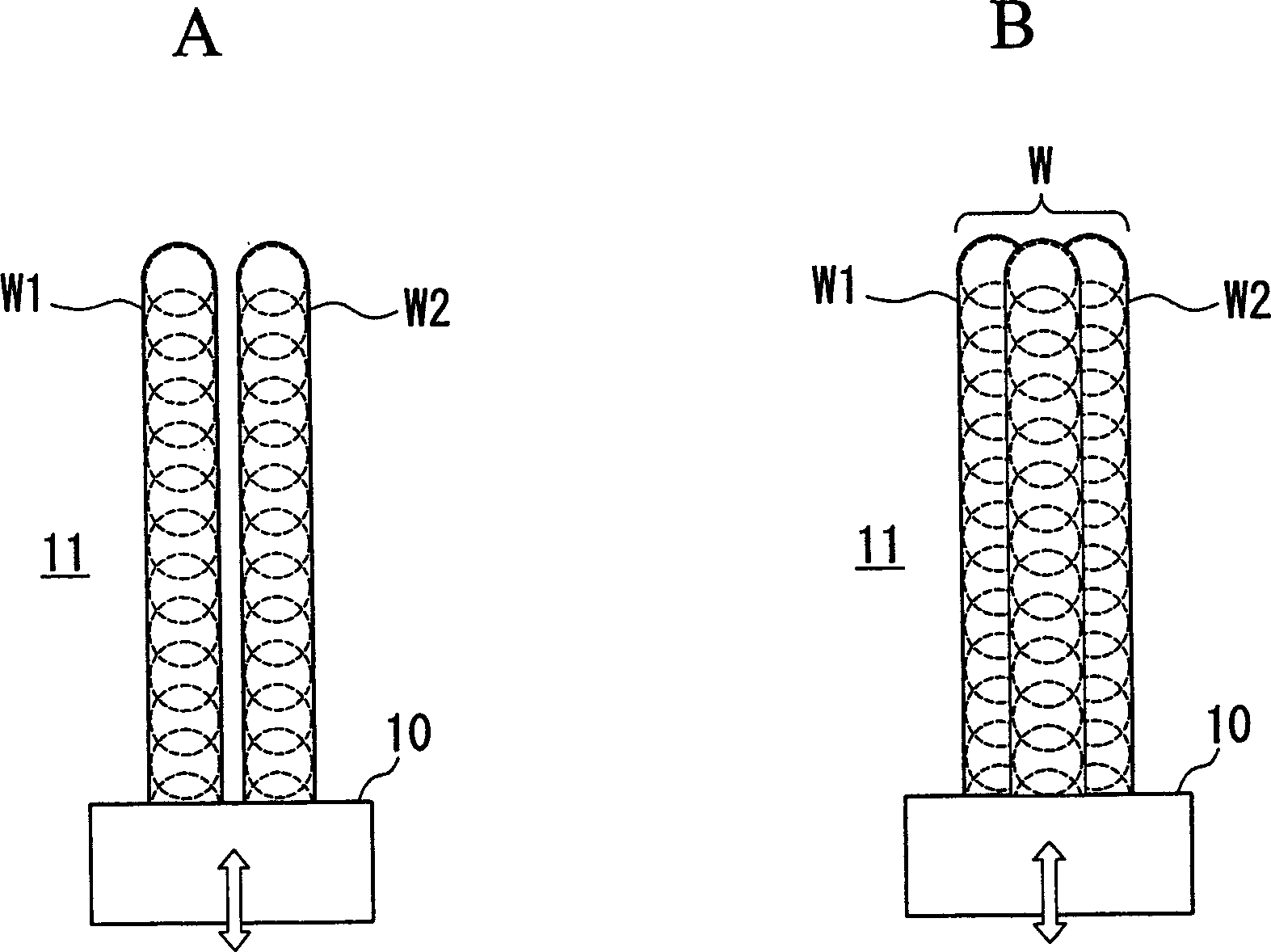

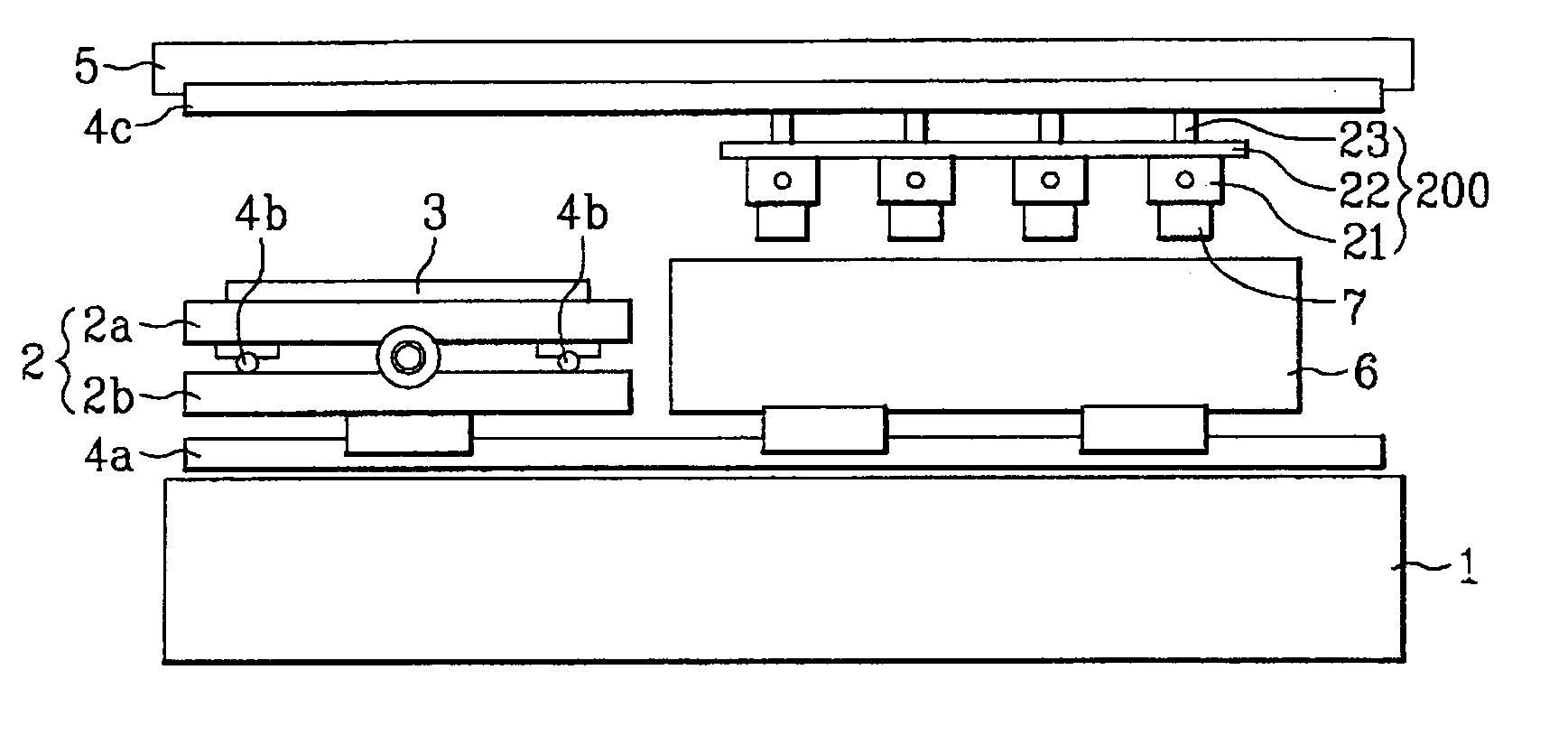

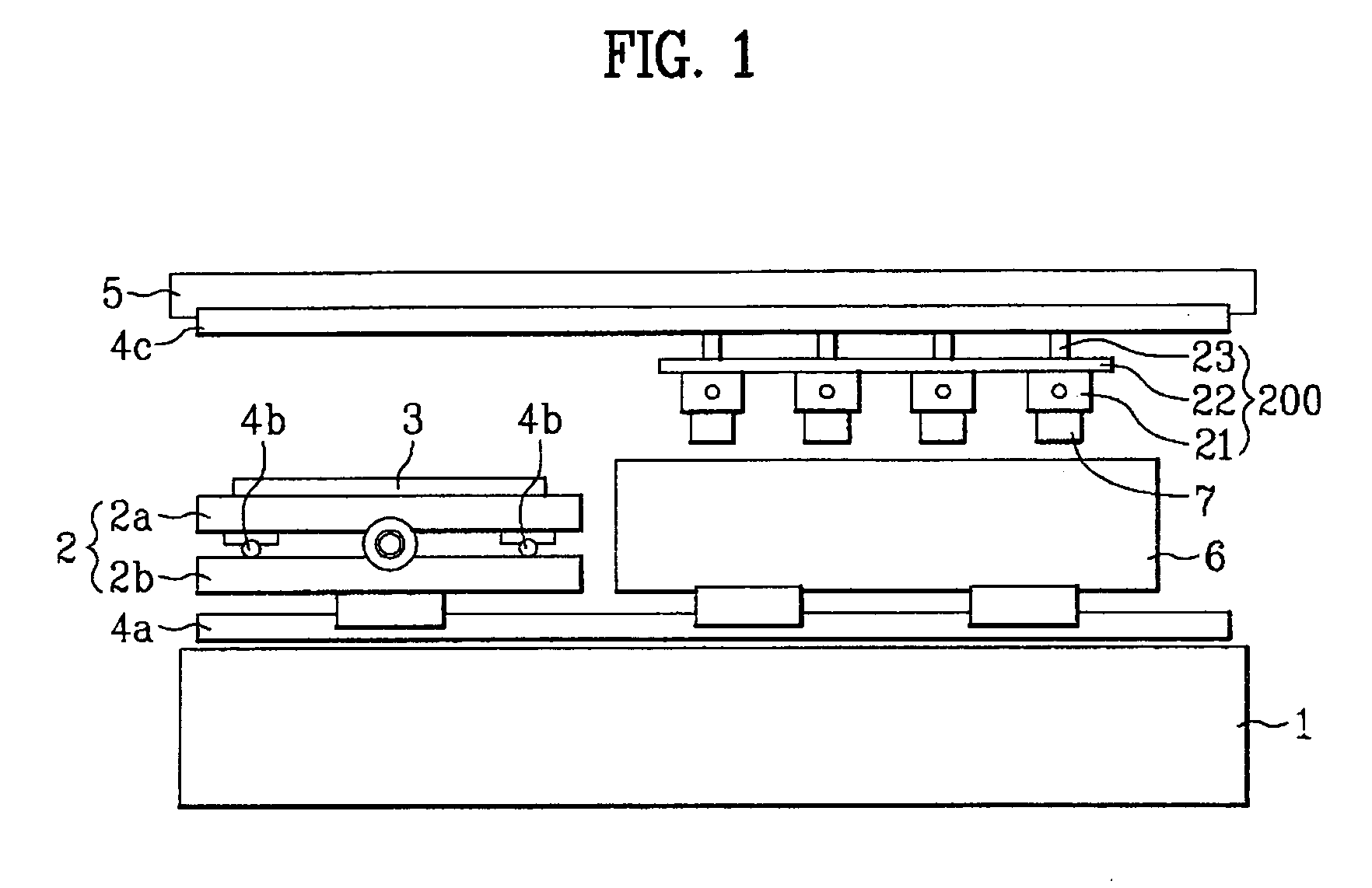

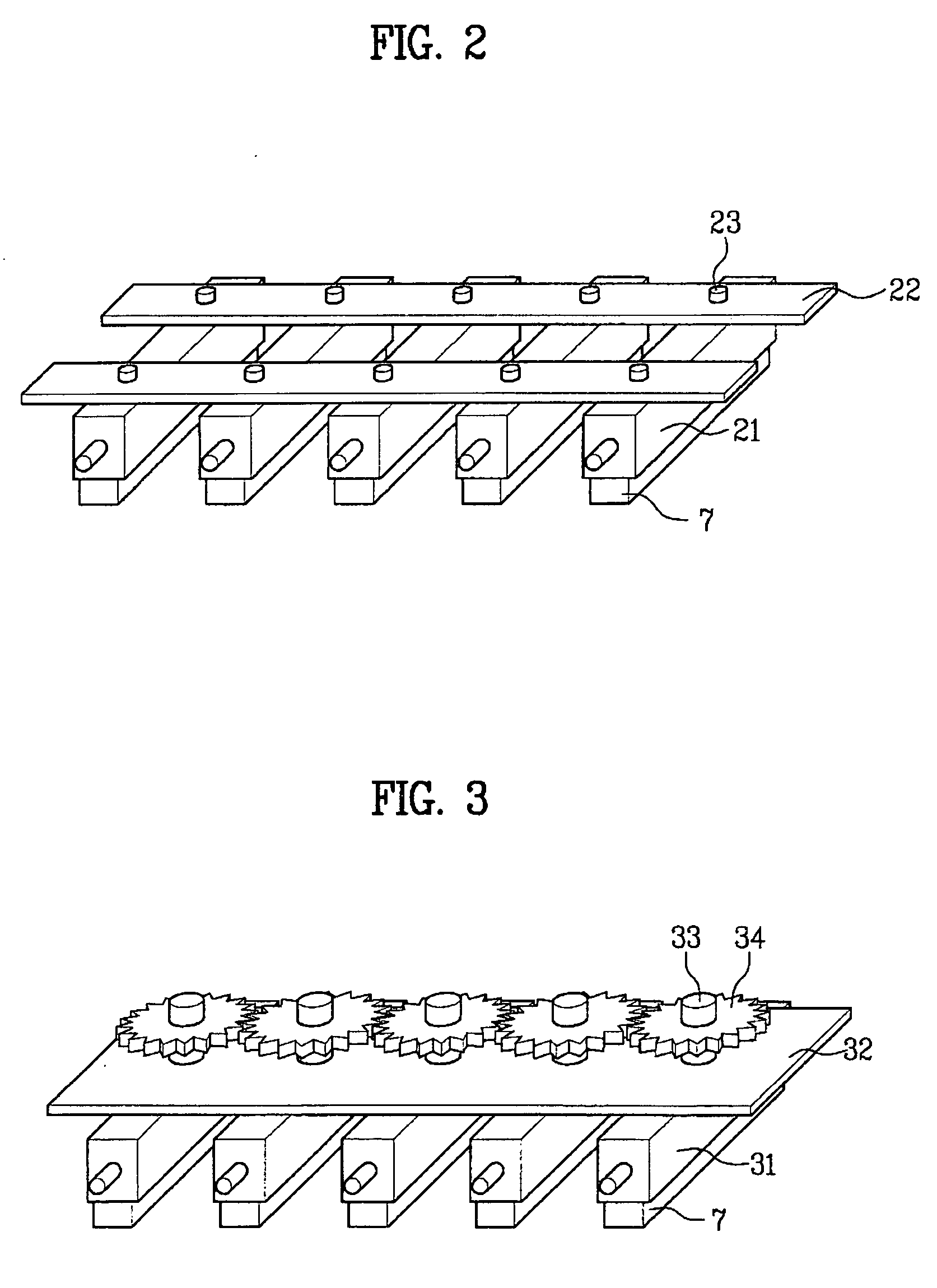

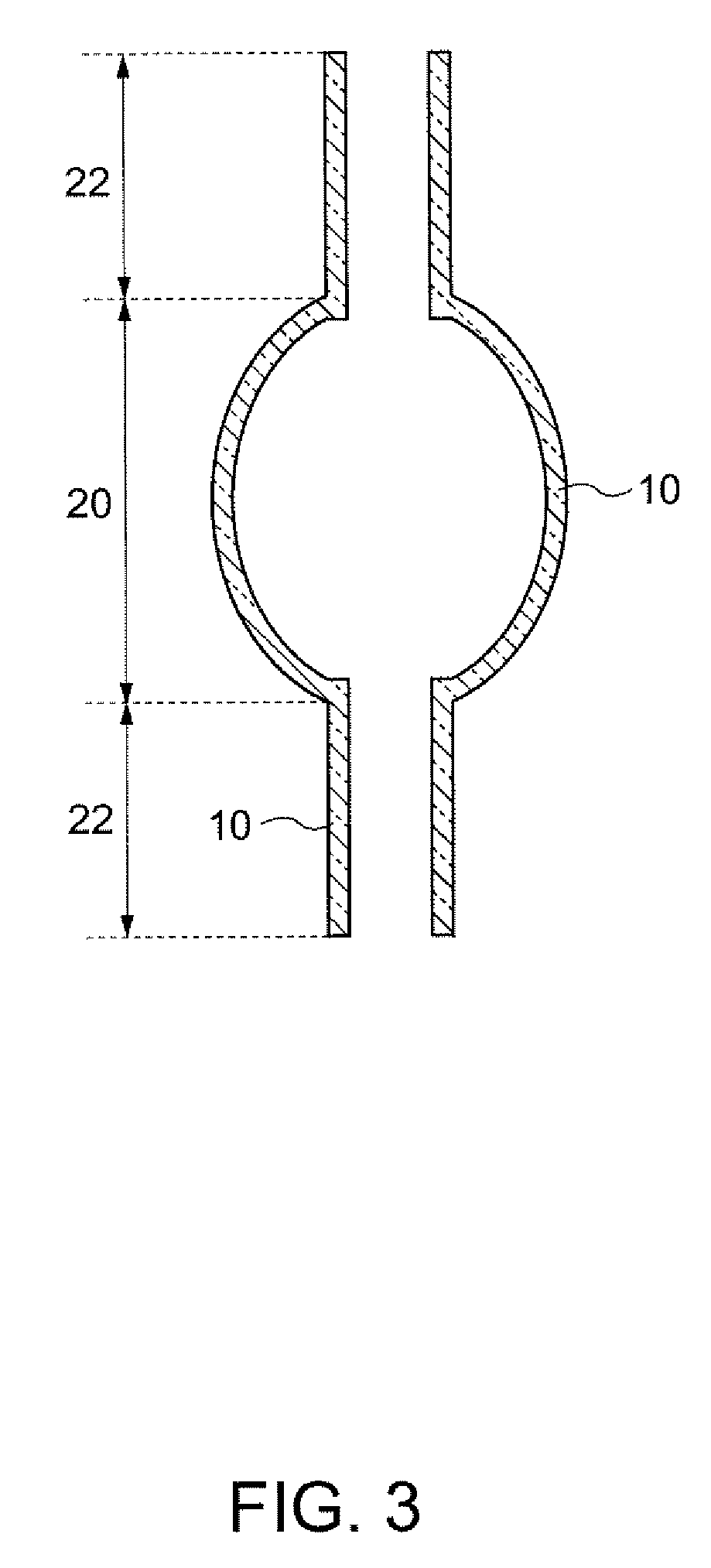

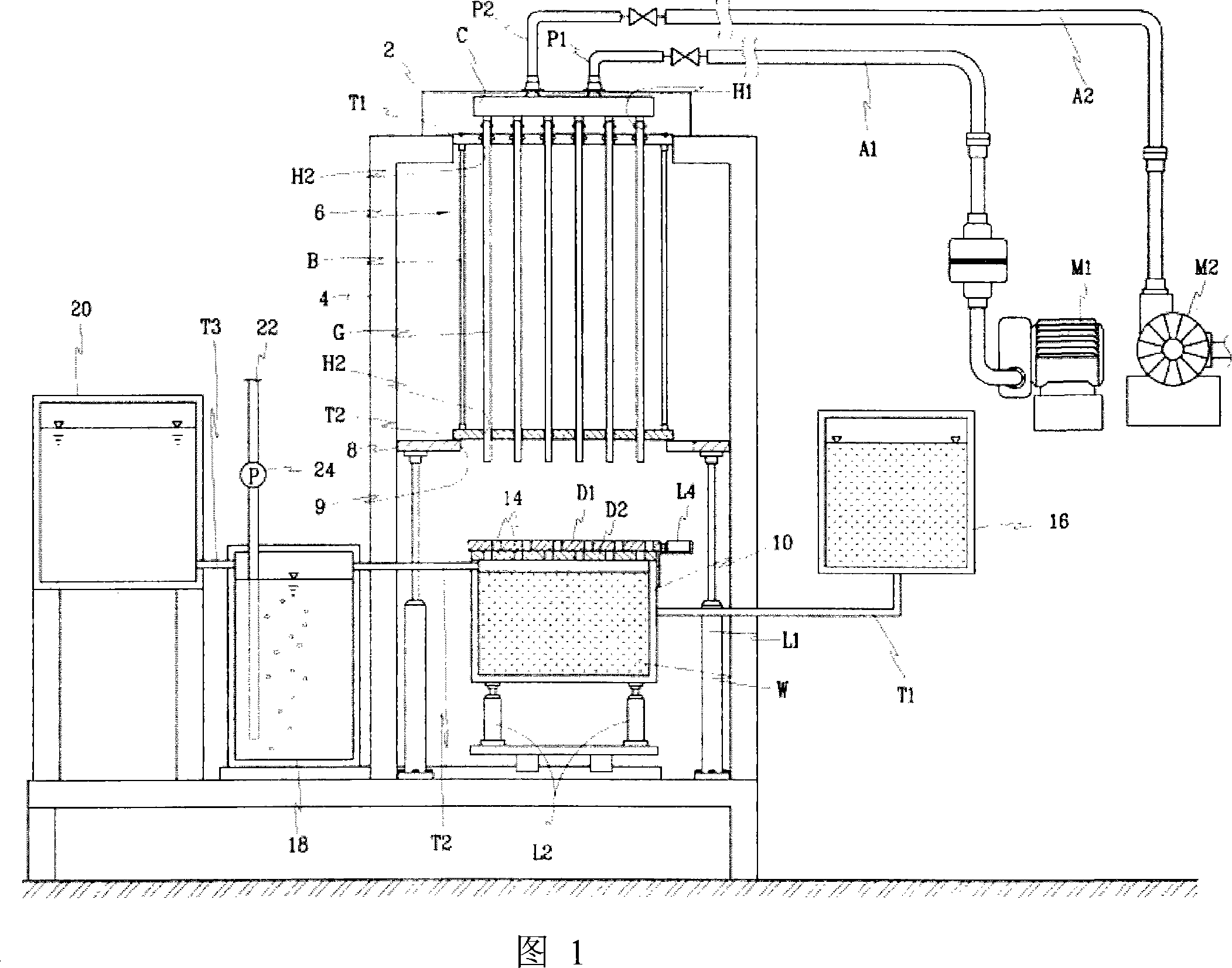

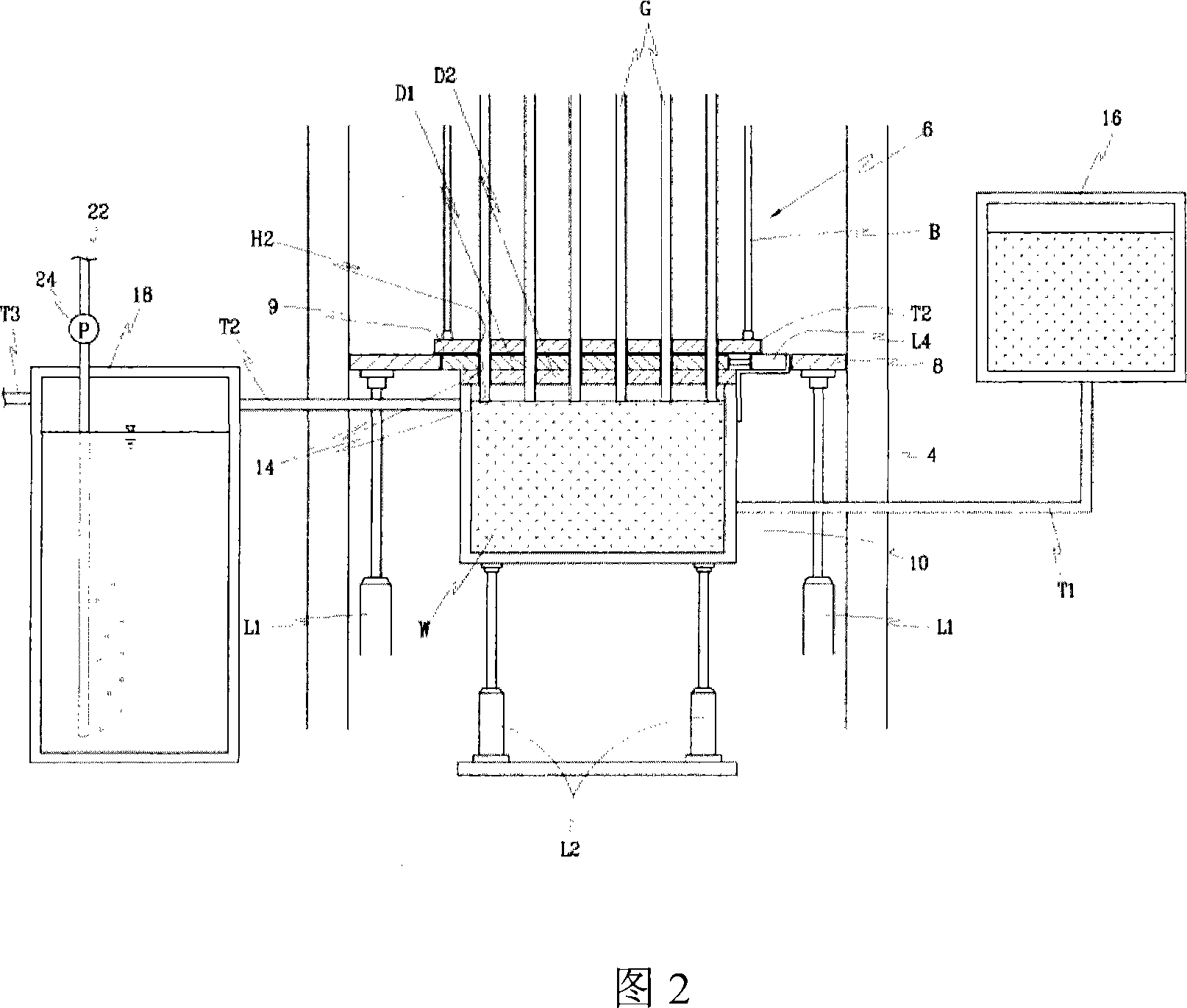

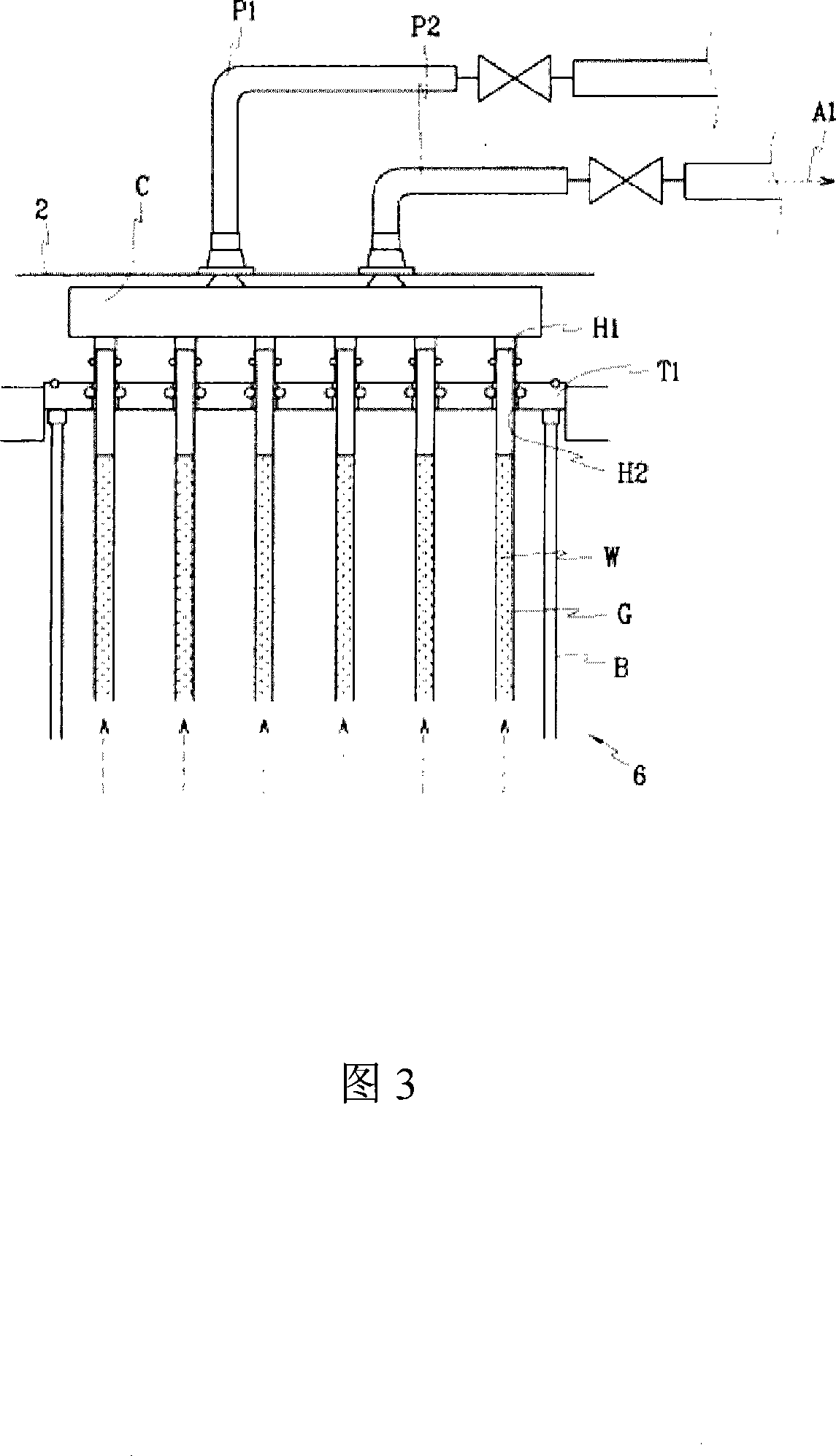

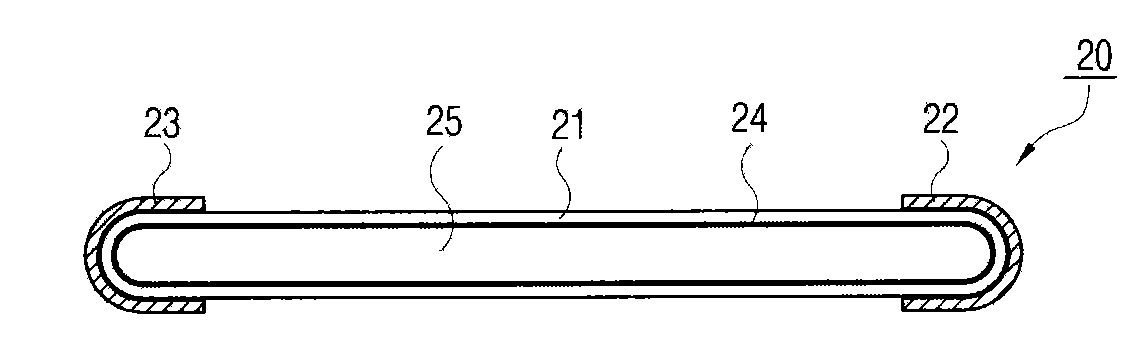

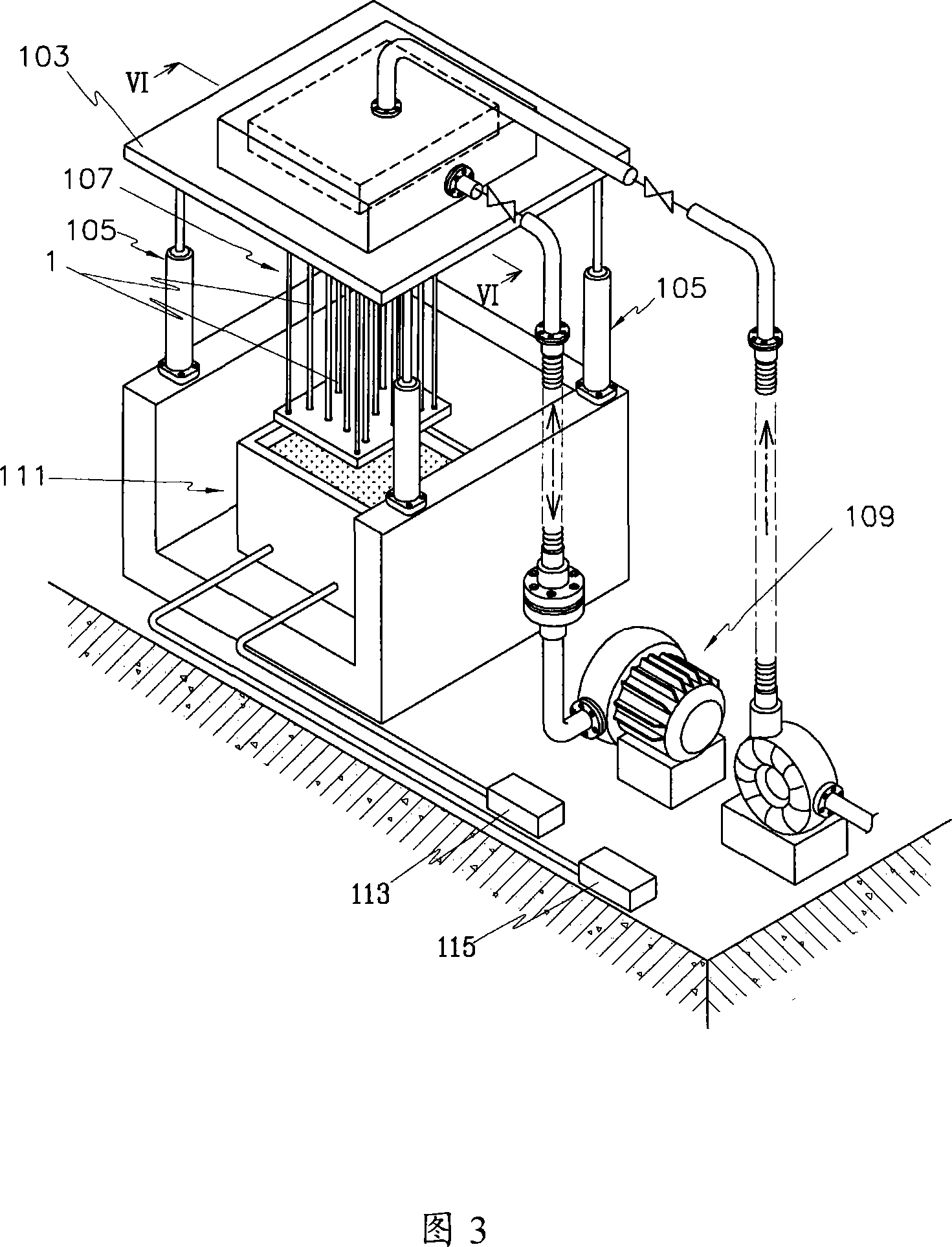

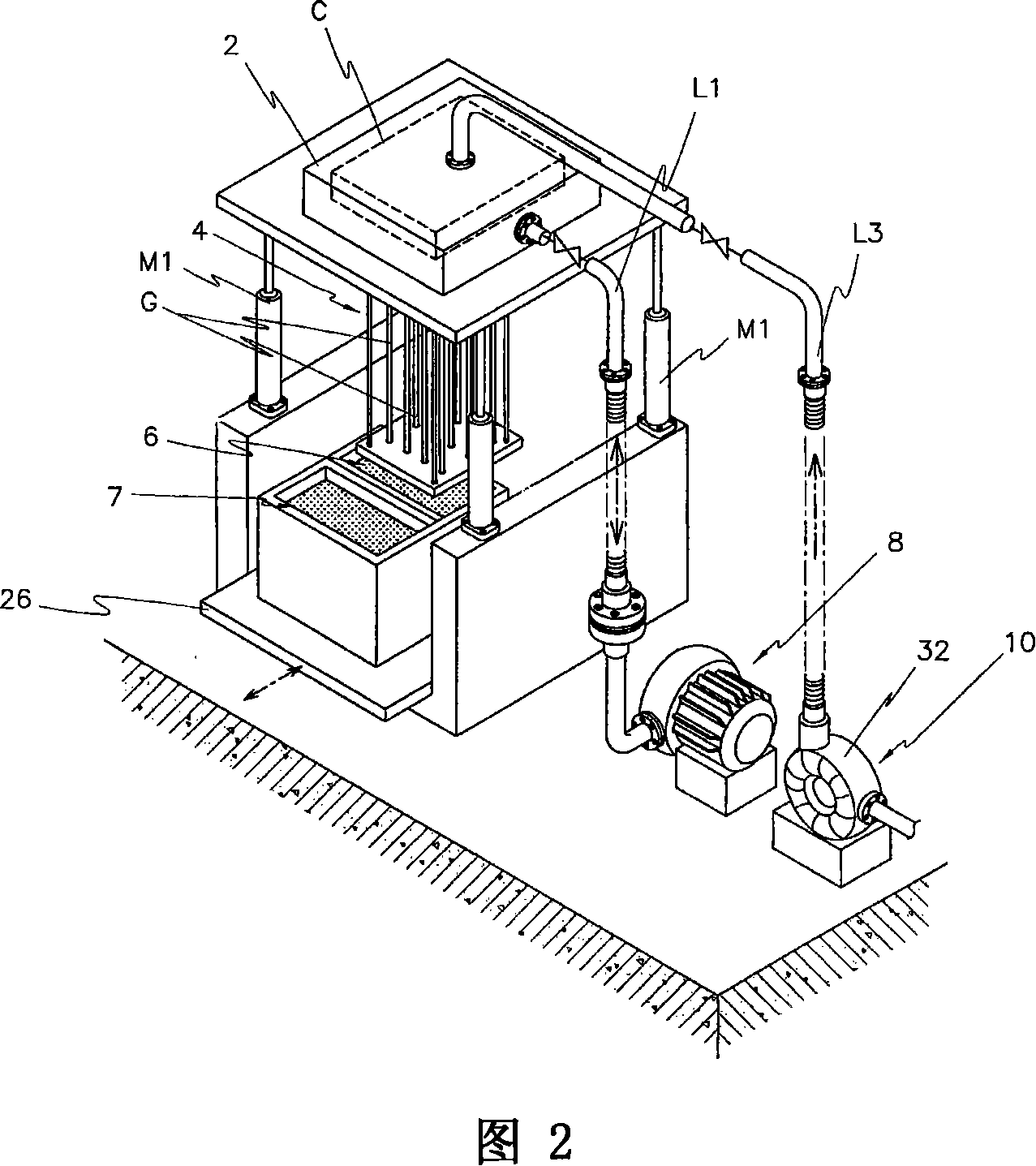

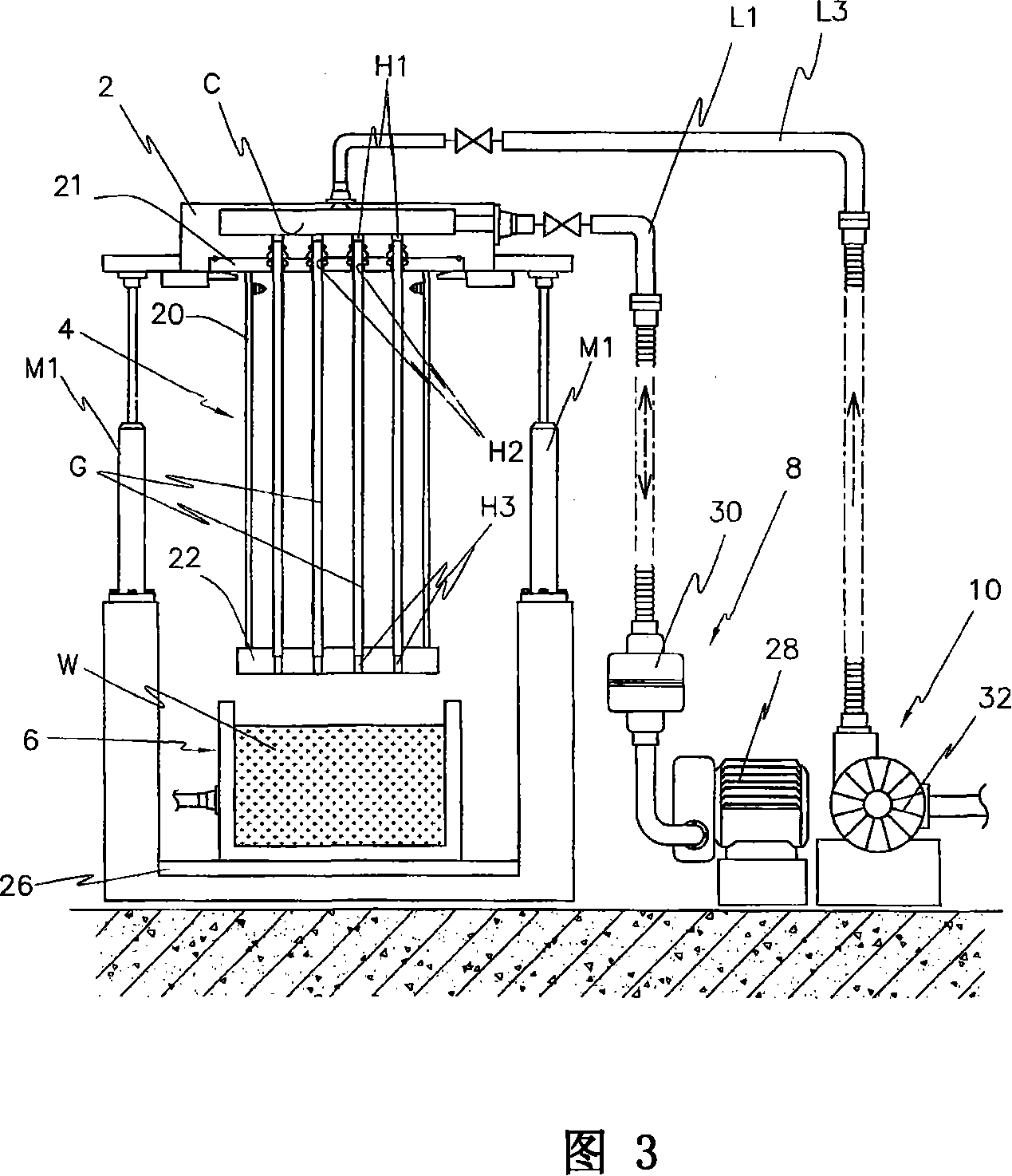

Apparatus and method for baking fluorescent lamp

This disclosure relates to an apparatus and a method for making or baking a fluorescent lamp. An apparatus for baking a fluorescent lamp includes a heater to heat a plurality of quartz tubes. Each tube has a fluorescent lamp provided therein. A plurality of rollers rotates the quartz tubes placed thereon, and a transfer block has a plurality of auxiliary rollers. The transfer block is configured to move in a first direction to transfer the plurality of quartz tubes from the plurality of rotating rollers to the plurality of auxiliary rollers. A process for heating at least one fluorescent lamp includes a step of providing a plurality of quartz tubes on a plurality of rotating rollers, at least one quartz tube having a fluorescent lamp provided therein, heating the plurality of quartz tubes while being rotated on the plurality of rollers, and transferring the plurality of quartz tube using a transfer block having a plurality of auxiliary rollers.

Owner:ADVANCED DISPLAY PROCESS ENG

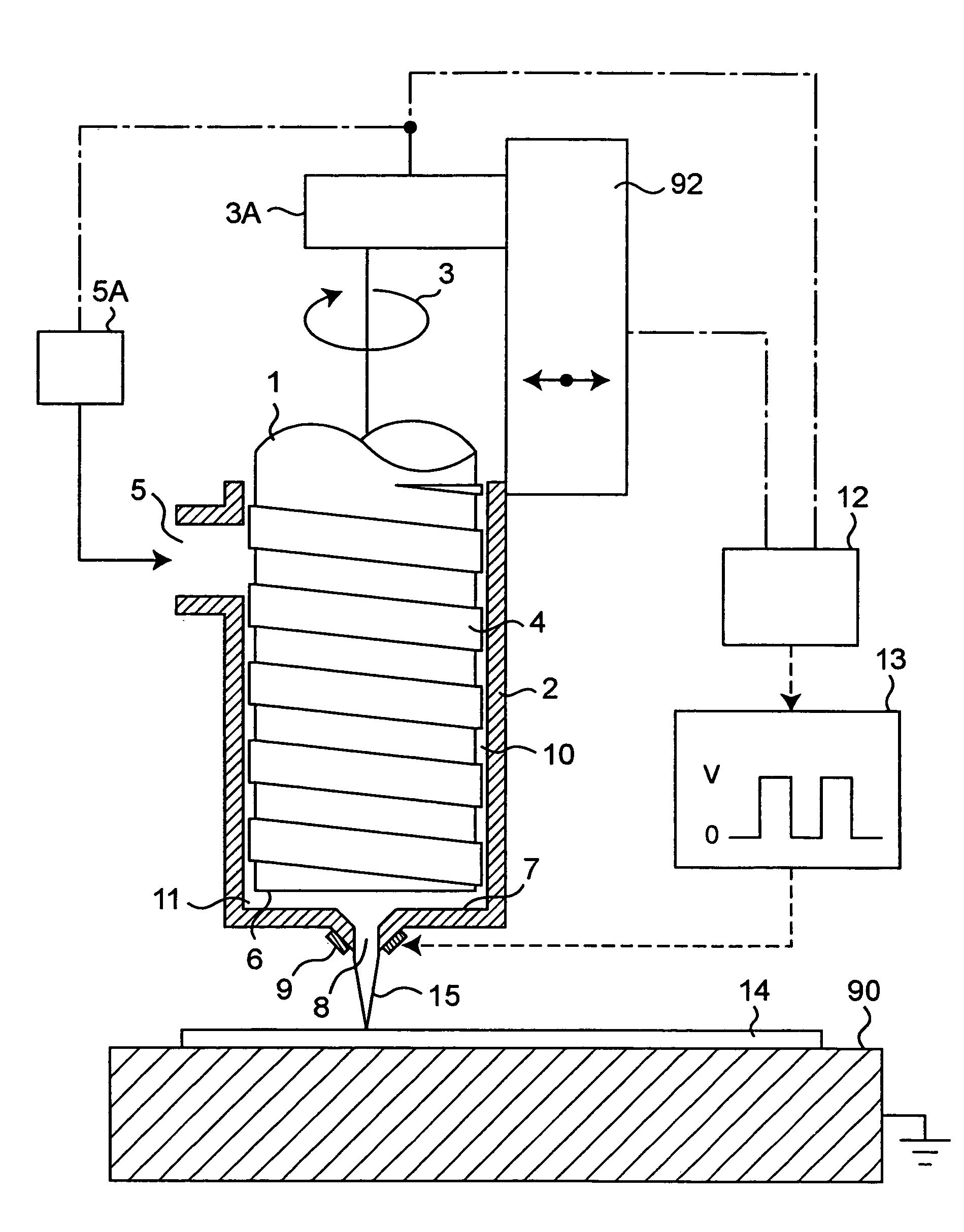

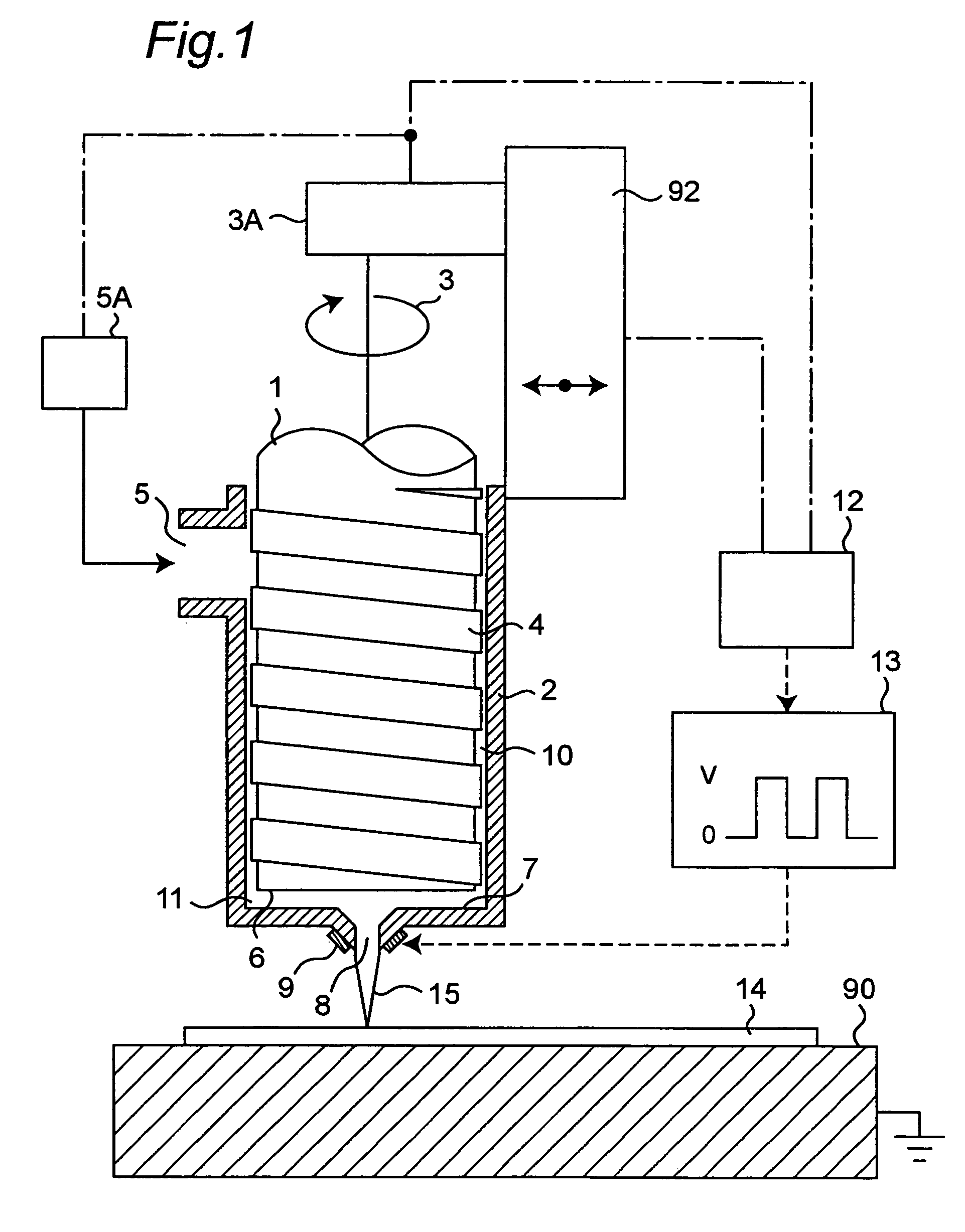

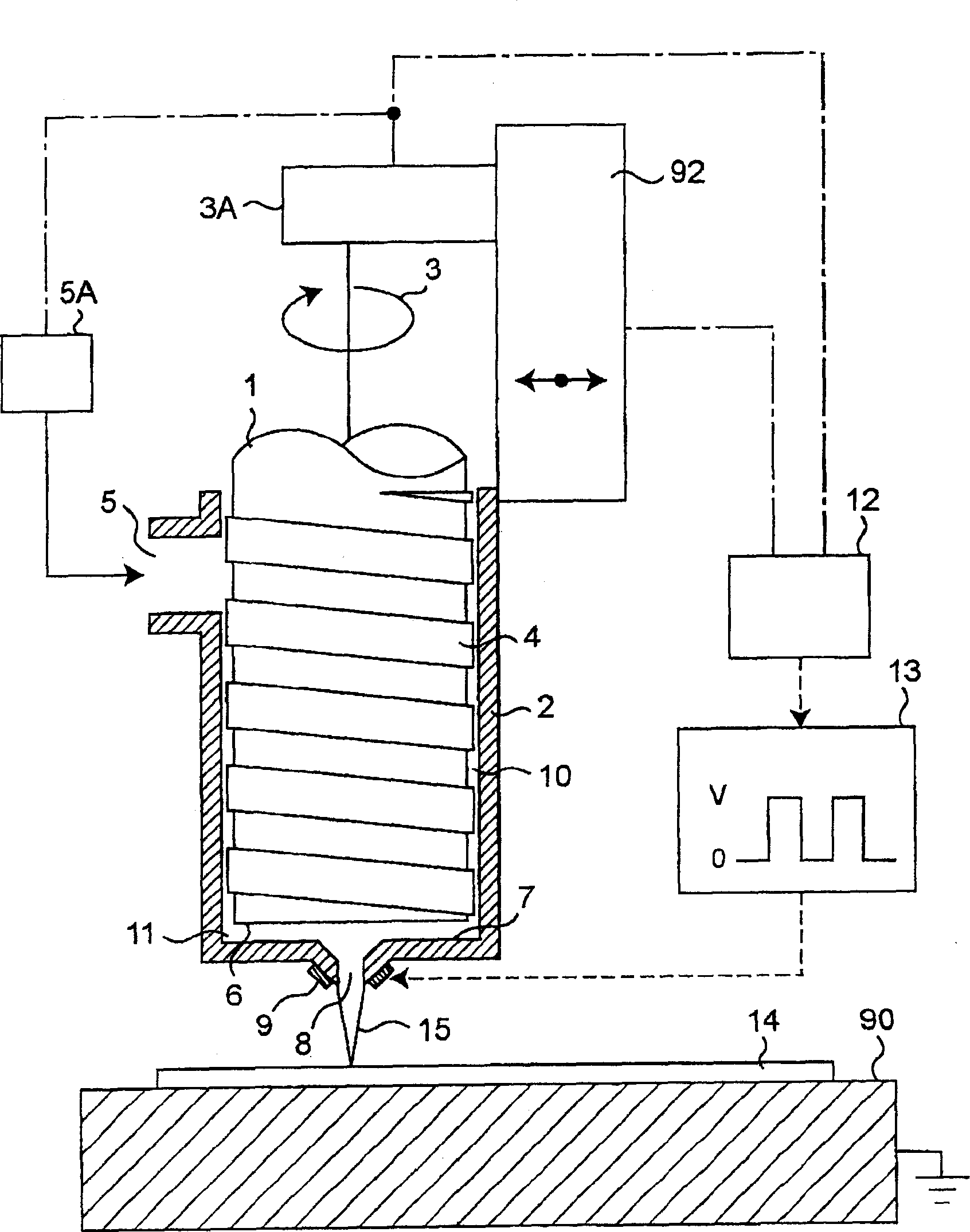

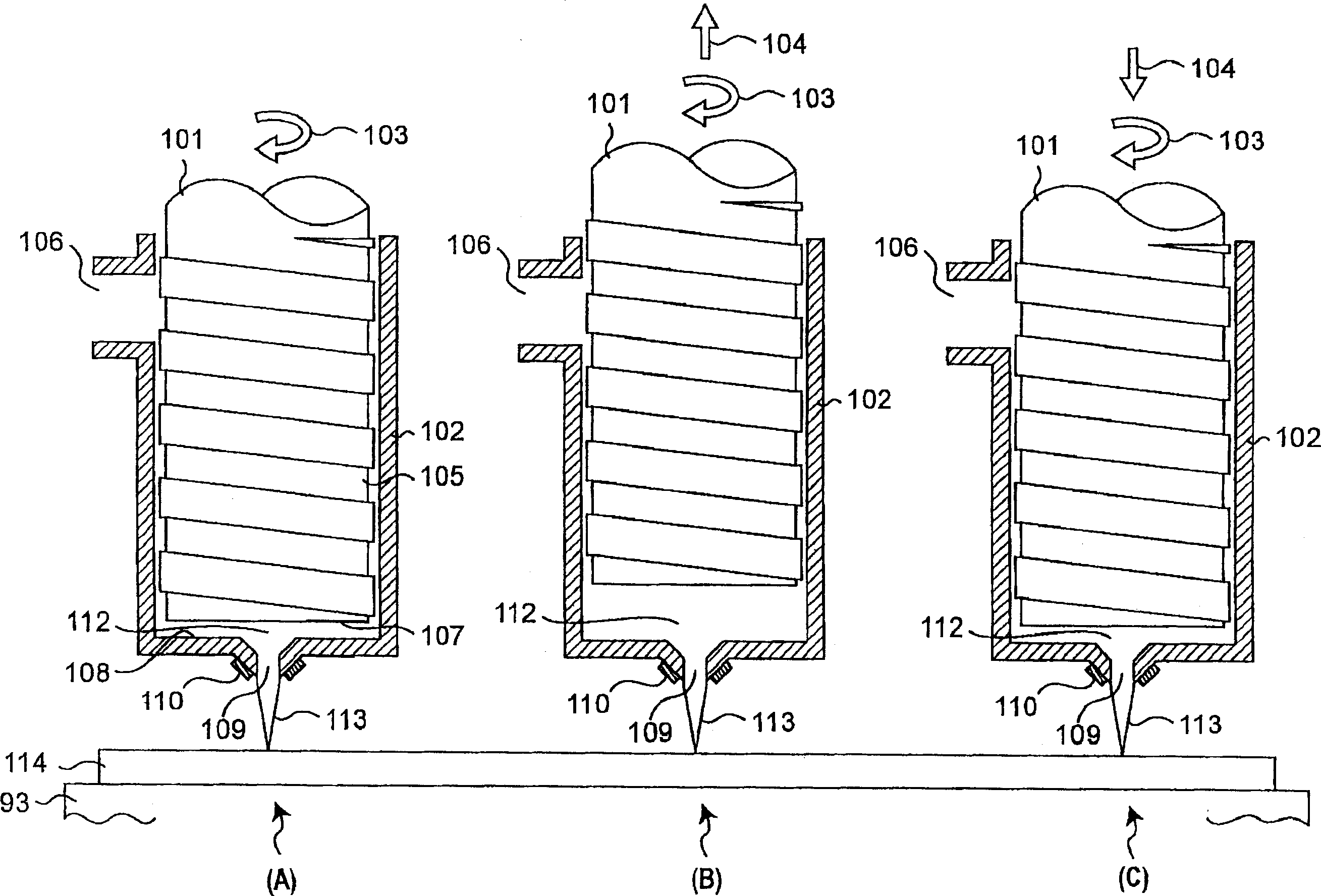

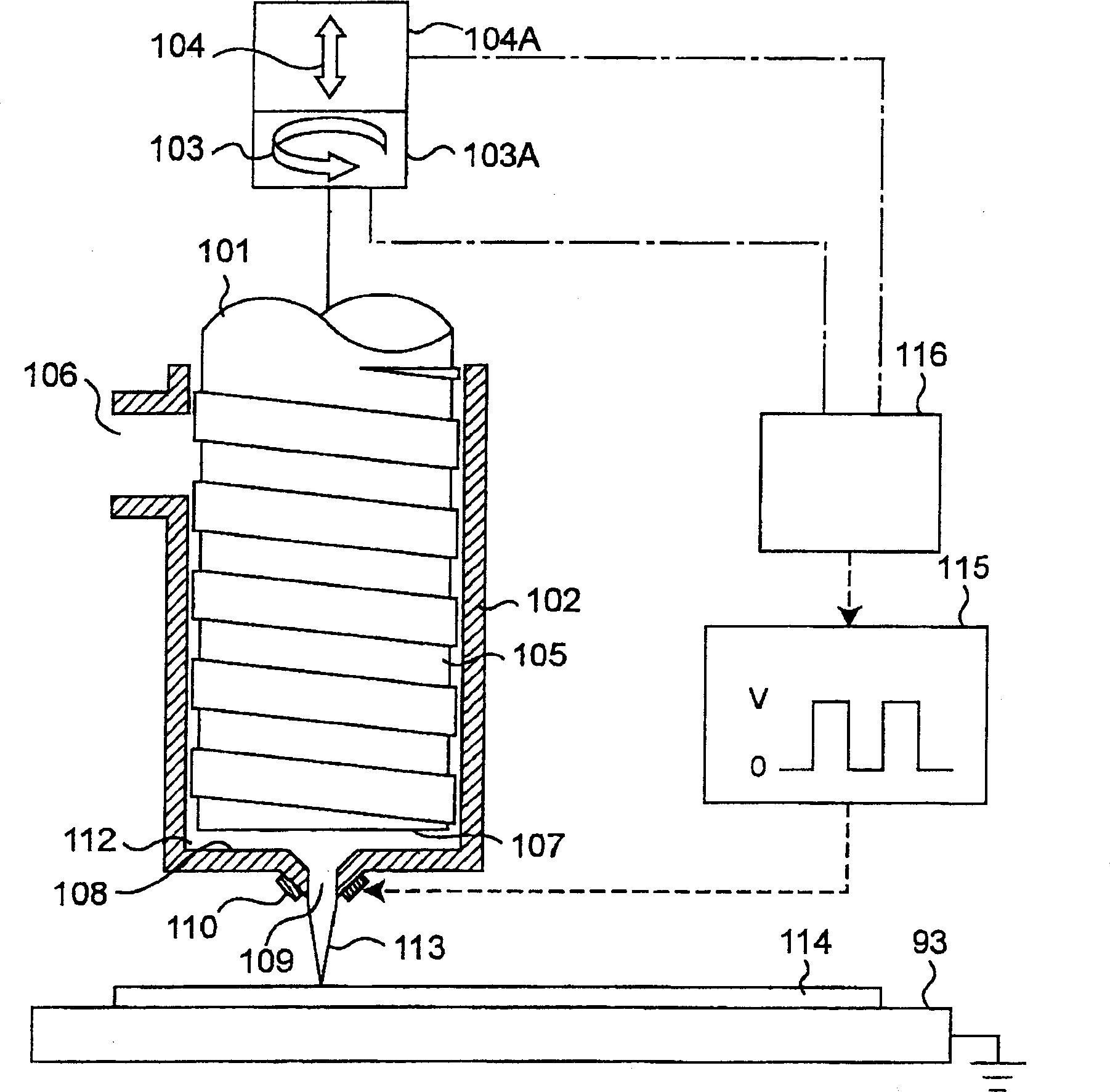

Fluid applying apparatus

InactiveUS7520967B2Increased and decreasedIncrease or decrease pressureLiquid surface applicatorsMovable measuring chambersPump chamberEngineering

A meniscus of applying fluid is controlled by applying a voltage to a discharge-nozzle side electrode and a counter electrode placed downstream of the discharge nozzle and by increasing or decreasing fluid pressure inside a pump chamber with use of a mechanism for rotational motion or rectilinear motion.

Owner:PANASONIC CORP

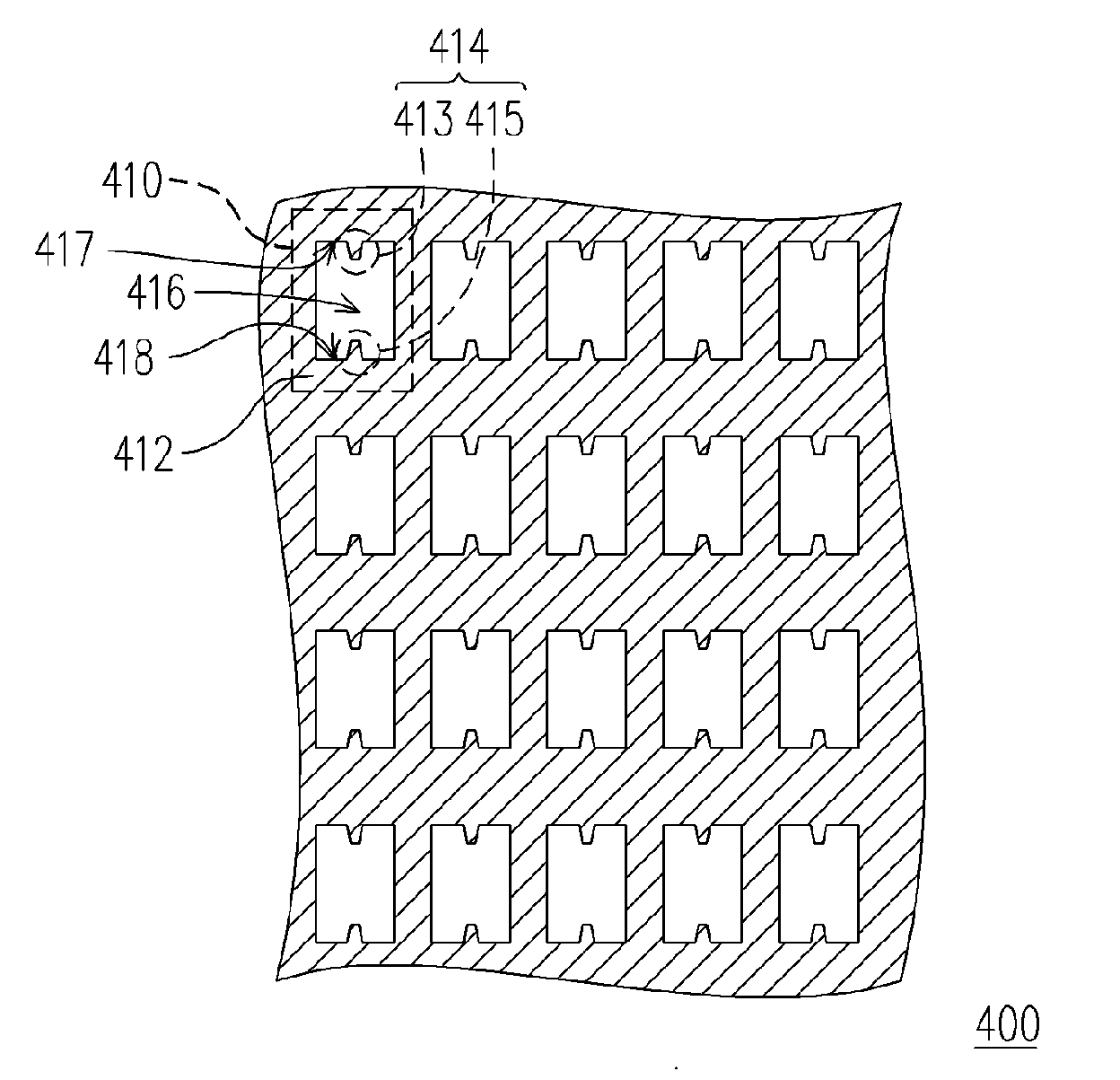

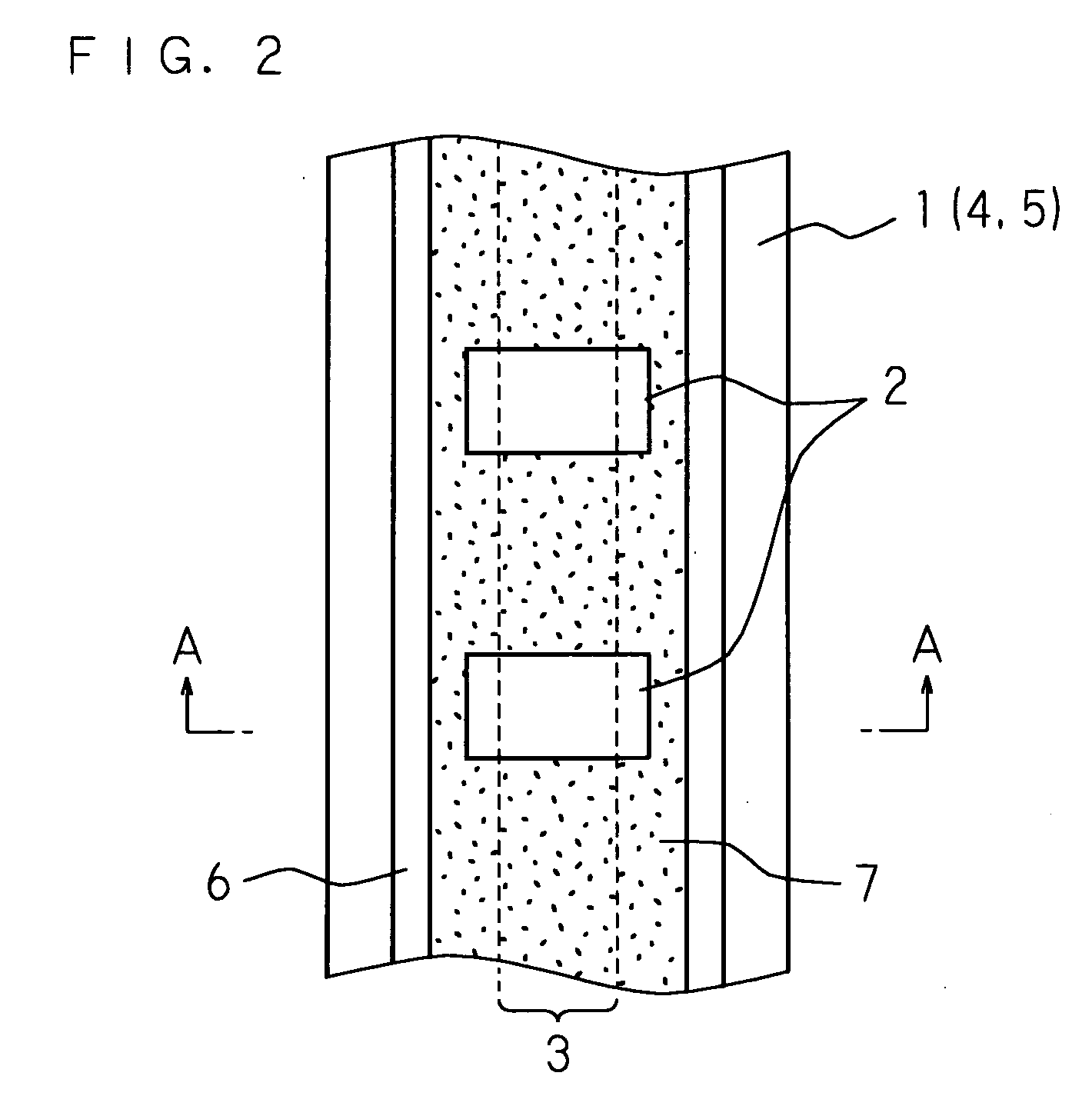

Printing screen, printing process and method for improving side-bottom ratio

ActiveUS20060113884A1Improve side-bottom ratioImprove luminous efficiencyCathode ray tubes/electron beam tubesAlternating current plasma display panelsEngineeringPlasma display

A printing screen, printing process and method for improving side-bottom ratio are provided. The printing screen mainly comprises a plurality of printing units, wherein each of the printing units comprises a body and a protrusion structure. The body has an ink aperture, and the protrusion structure extends from a surface of the body into the ink aperture. The printing process of a fluorescent layer in a plasma display panel utilizing the said printing screen can enhance the uneven film thickness of the fluorescent layer on the bottom of a discharge chamber, and further improve the side-bottom ratio of the fluorescent layer in a plasma display panel.

Owner:CPT TECH GRP

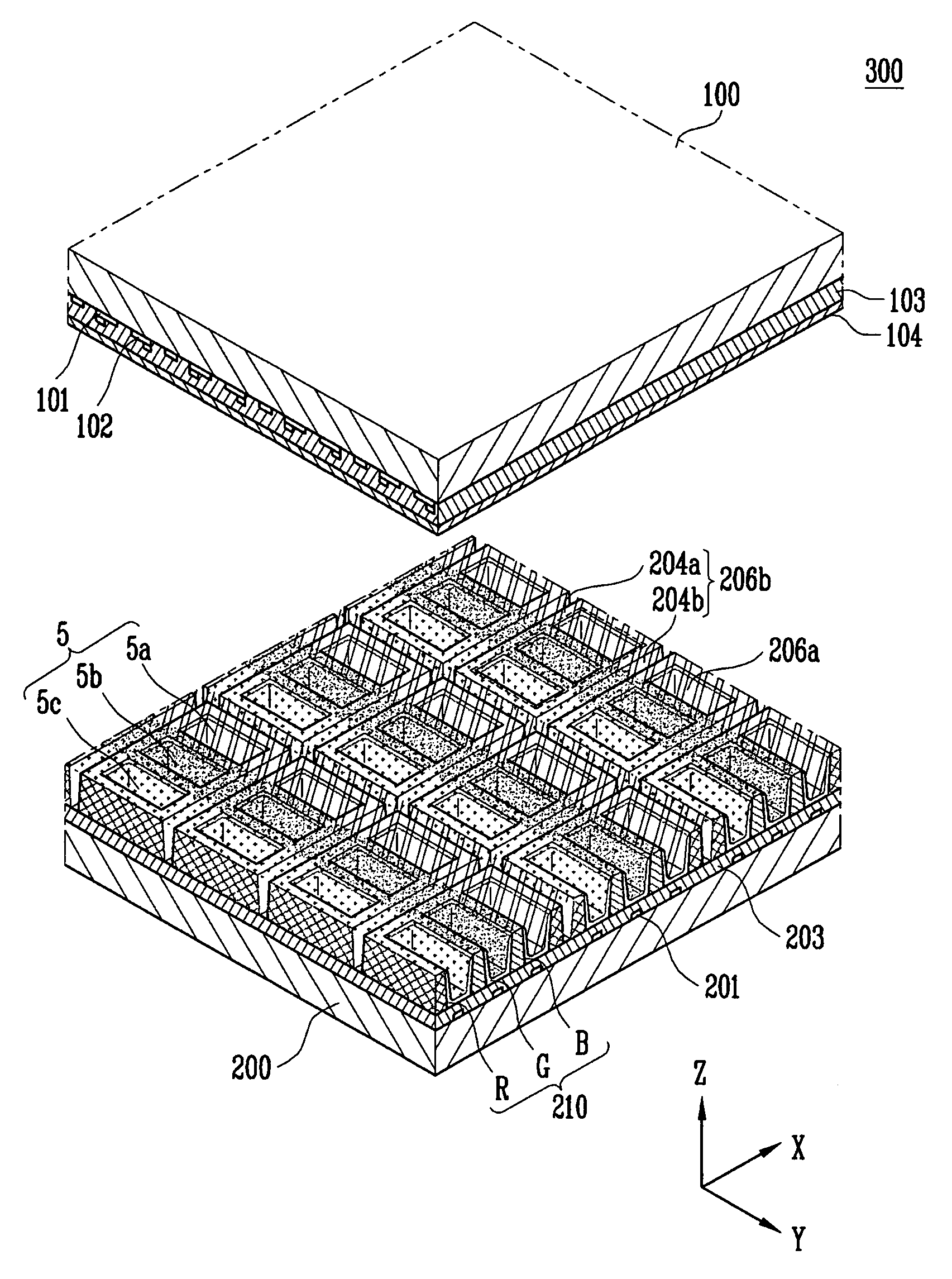

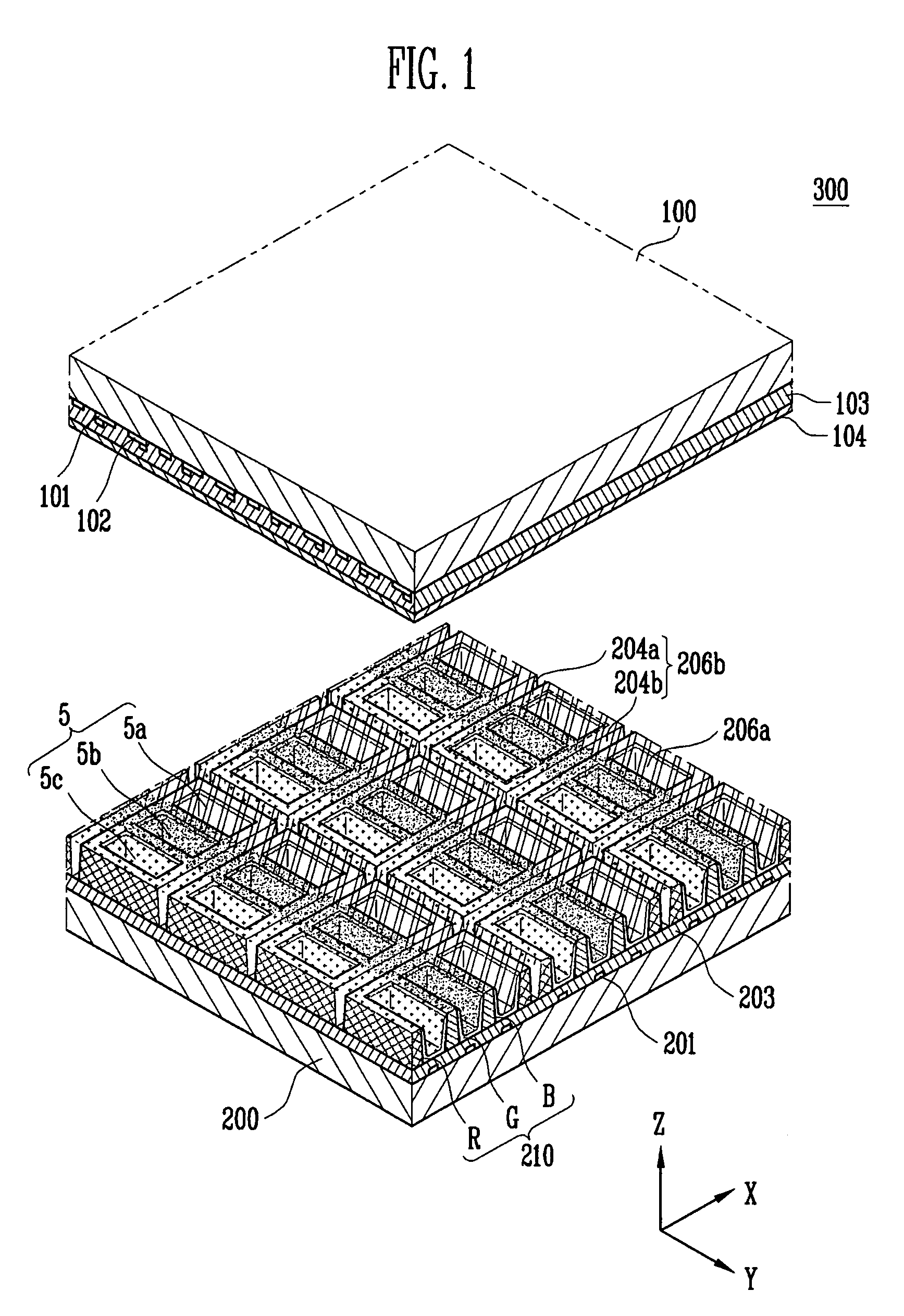

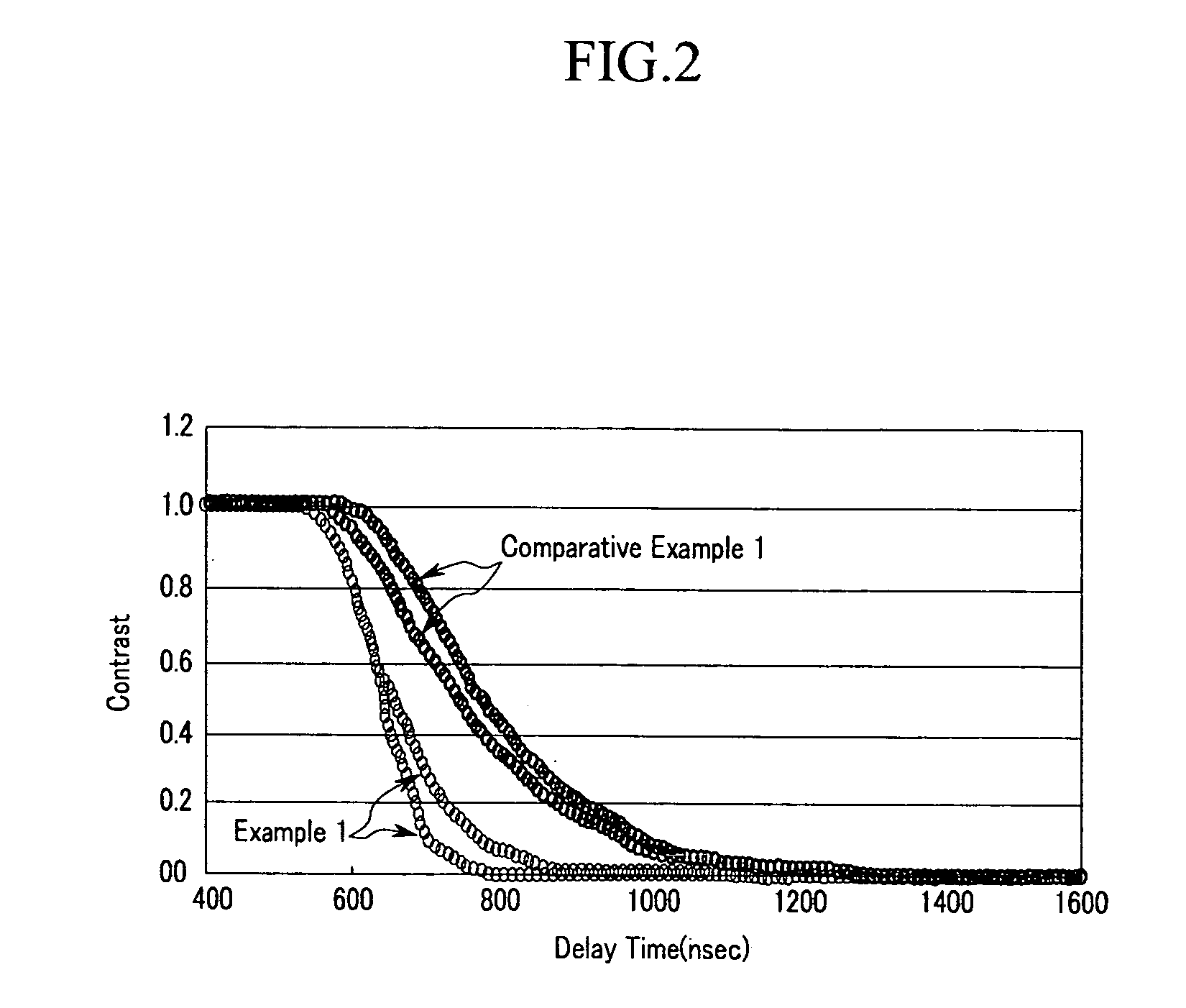

Plasma display panel and method of fabricating the same

InactiveUS20080197774A1Increased dark portionImprove Bright Room ContrastAlternating current plasma display panelsVessels or leading-in conductors manufacturePhotoluminescencePlasma display

A plasma display panel (PDP), includes first and second substrates facing each other, a plurality of first and second electrodes along a first direction between the first and second substrates, a plurality of third electrodes along a second direction between the first and second substrates, barrier ribs between the first and second substrates, the barrier ribs defining a plurality of pixels and exhaust areas between the pixels, and photoluminescent layers, the photoluminescent layers being in the pixels, on the barrier ribs, and in the exhaust areas.

Owner:SAMSUNG SDI CO LTD

Filming solution and method for forming a filming layer on a cathode ray tube

A filming solution contains a copolymerized emulsion having more than 70 wt % of butyl methacrylate and more than one species of monomer, and more than one species of additive. Preferably, the monomer is selected from the group consisting of acrylic acid derivative, methacrylic acid derivative, styrene, acrylamide, and acrylonitrile.

Owner:SAMSUNG SDI CO LTD

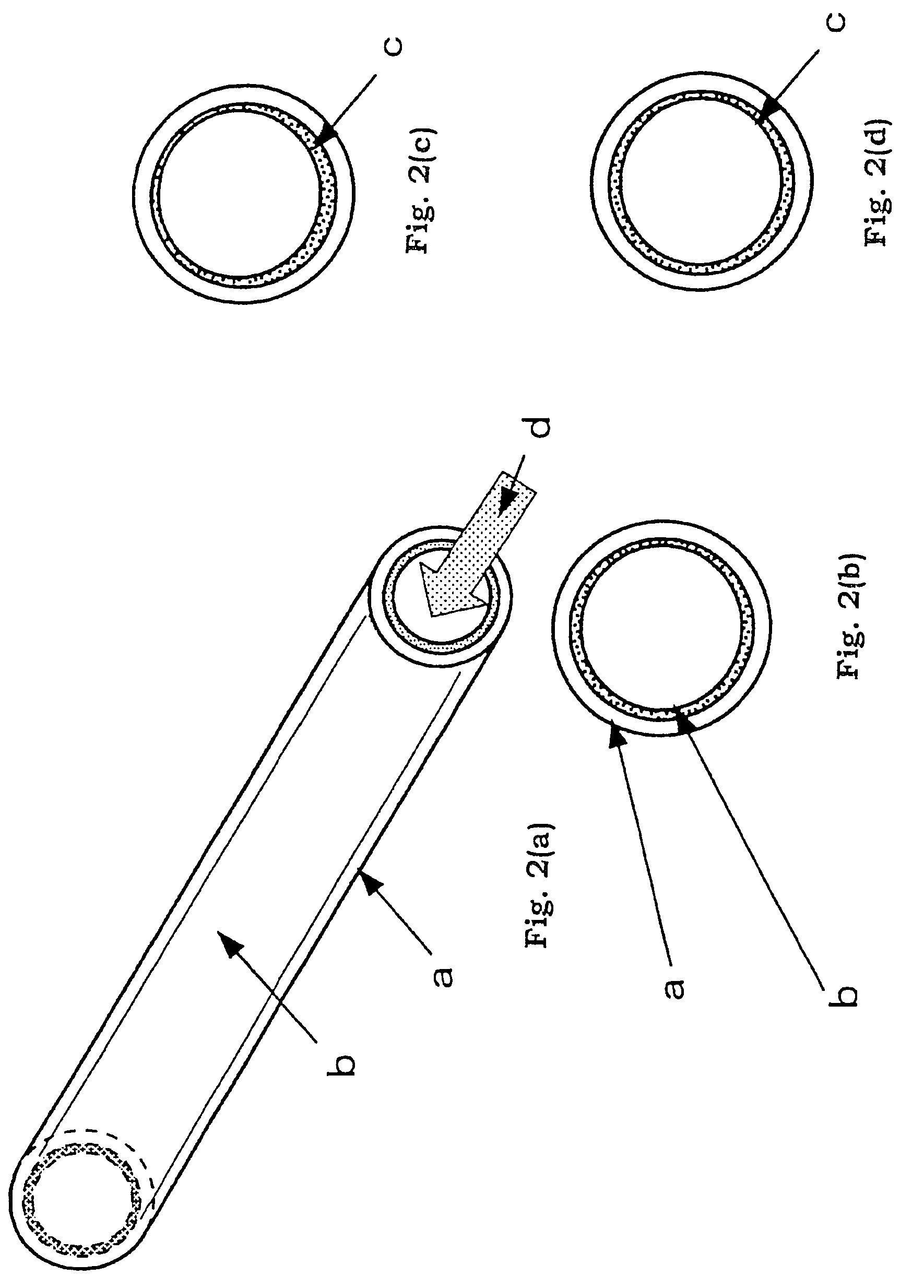

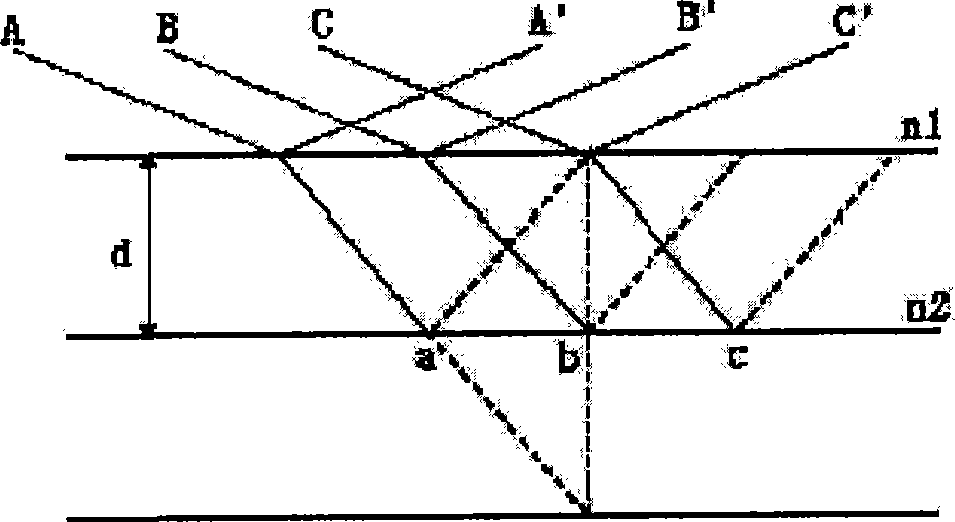

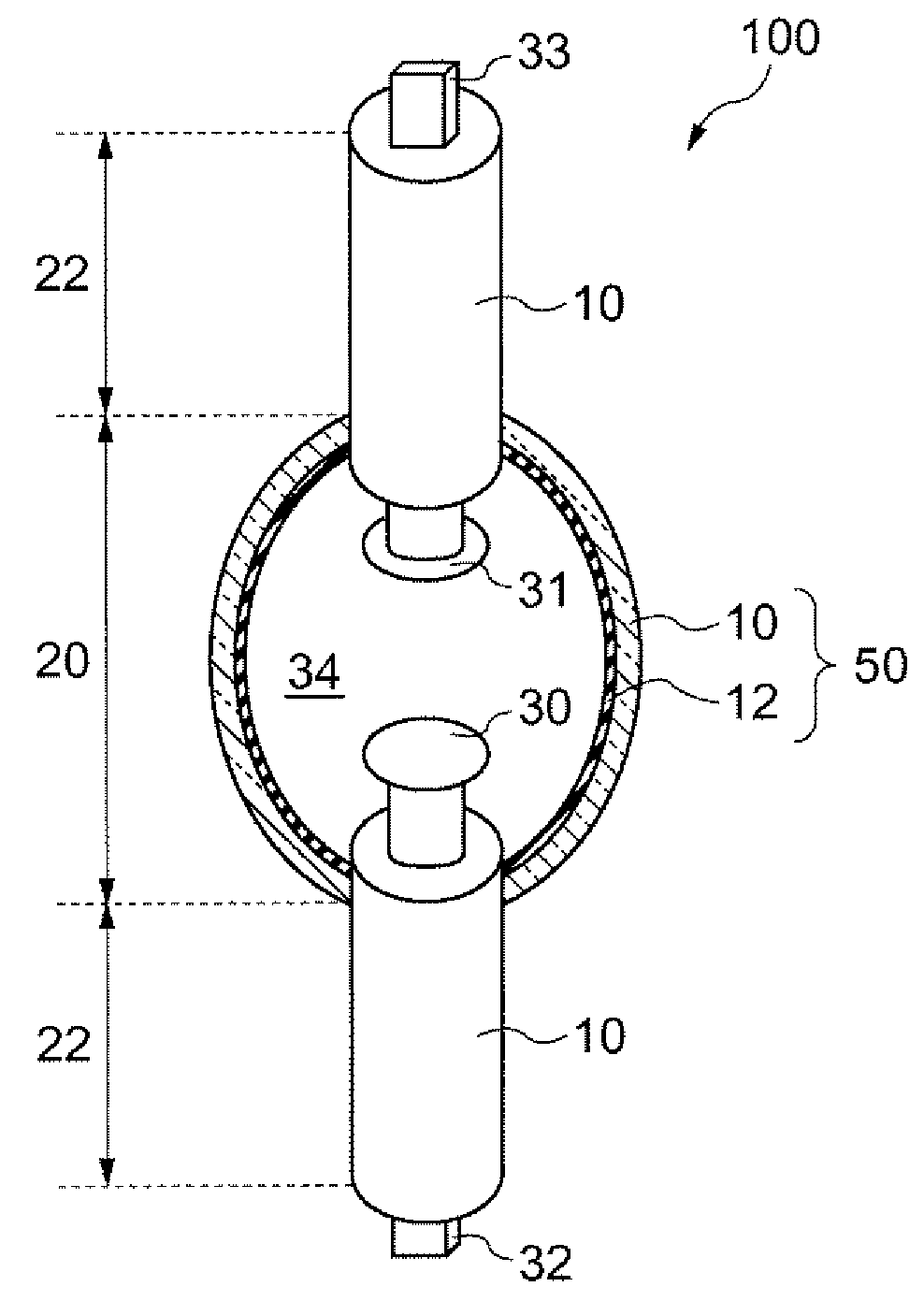

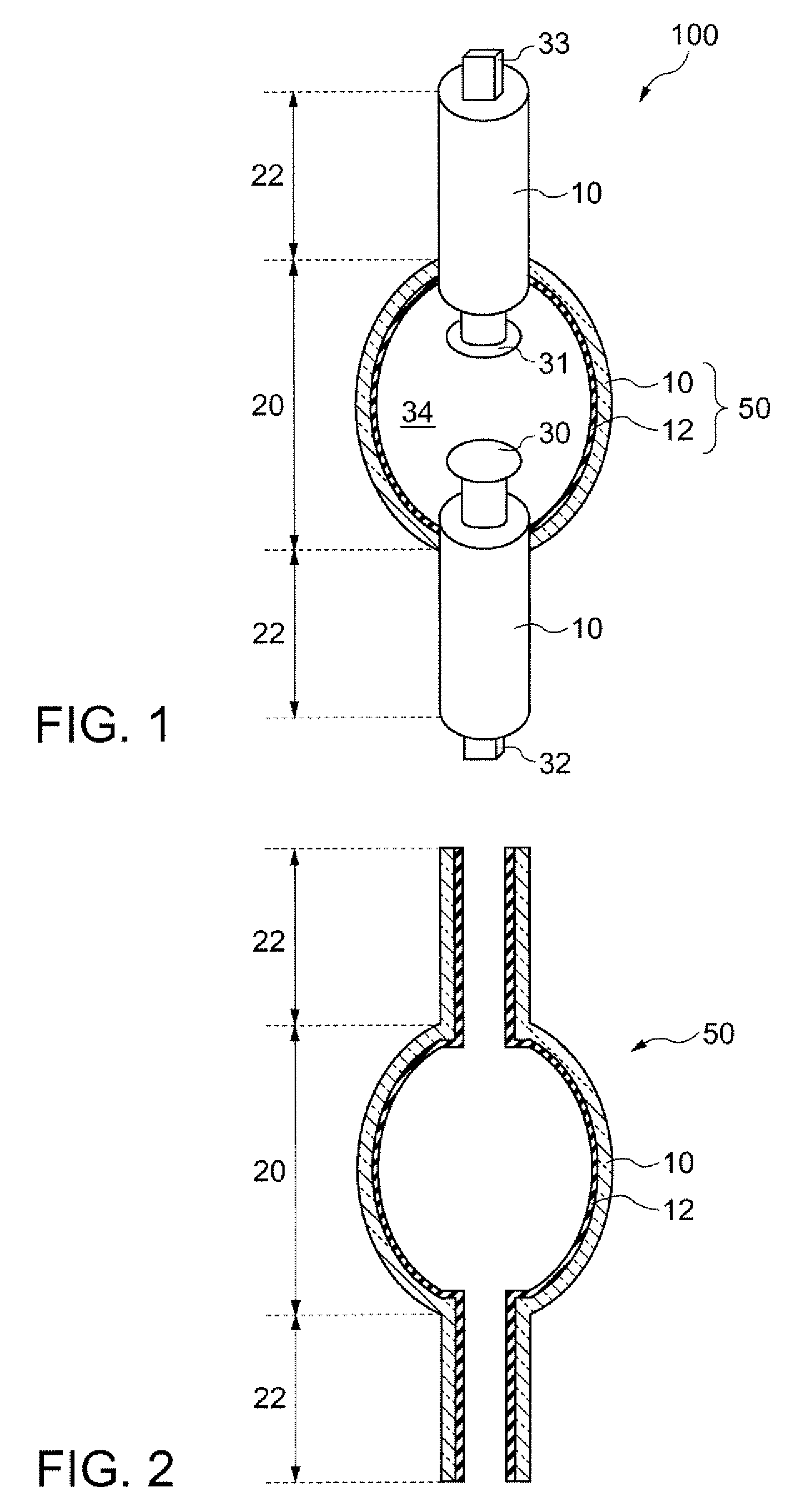

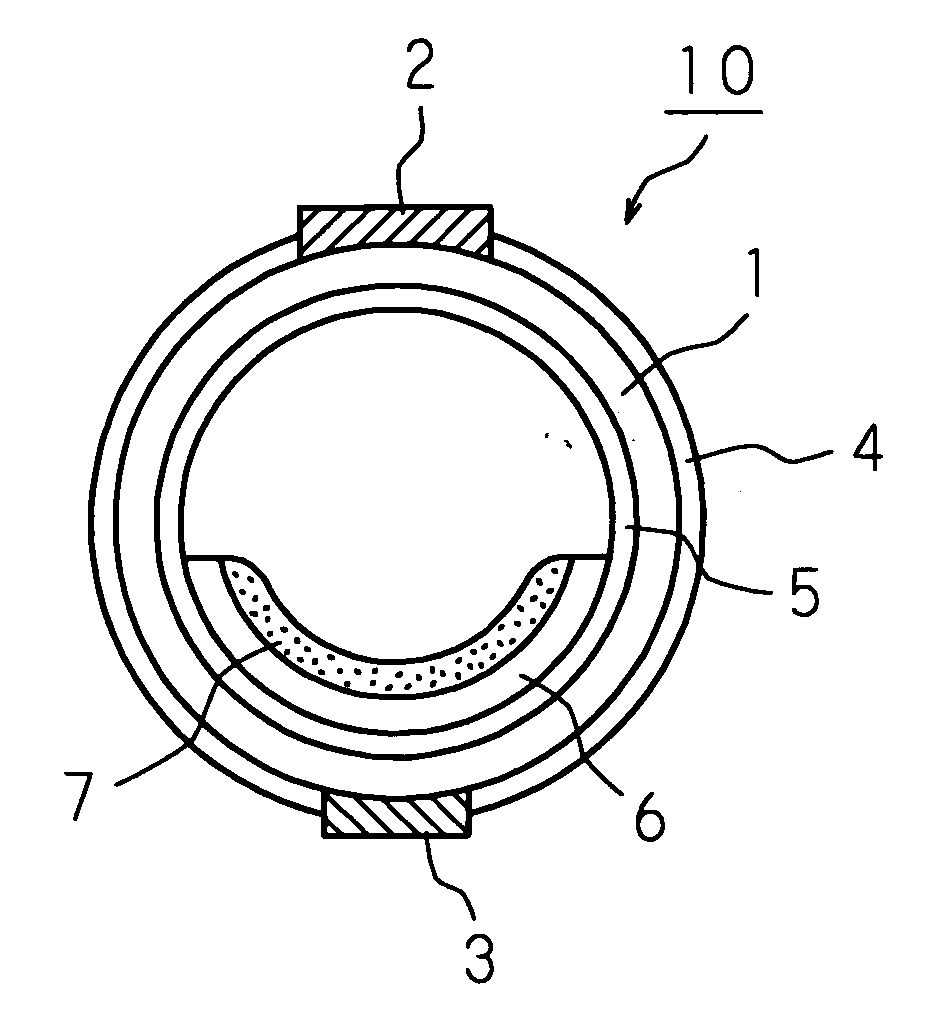

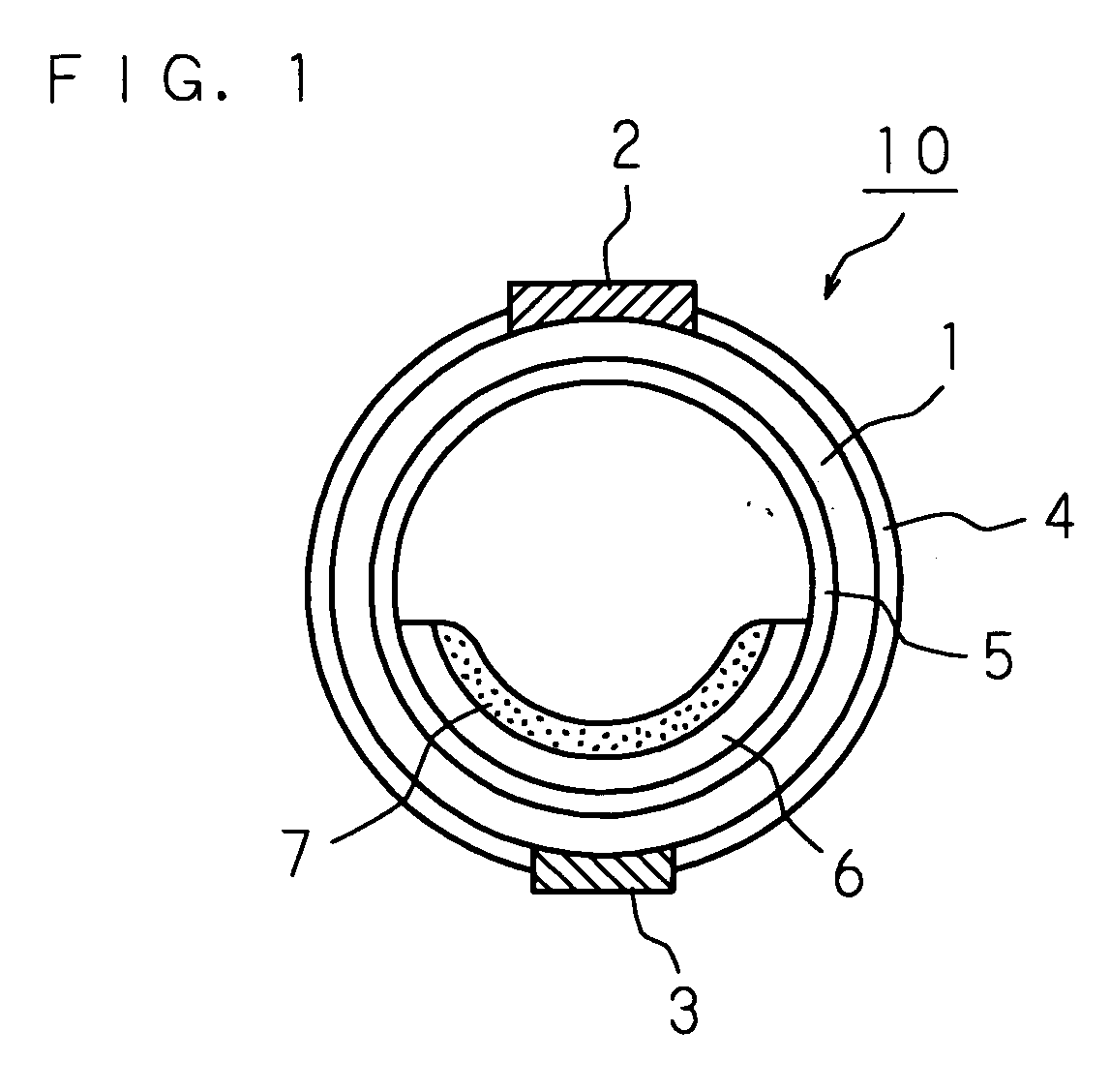

Light-emitting discharge tube, method of fabricating the same, and protective film forming apparatus

InactiveUS20060175972A1Simple structureImprove yieldTube/lamp screens manufactureGas-filled discharge tubesTectorial membraneOrganic film

A light-emitting discharge tube in which an outer wall surface of a glass tube is made less susceptible to flaws by forming a protective film on the outer wall surface of the glass tube, a method of fabricating the light-emitting discharge tube, and a protective film forming apparatus are provided. The light-emitting discharge tube defines light-emitting discharge regions by a plurality of external electrodes. The outer wall surface of the light-emitting discharge tube (the glass tube) is coated with the protective film (a metal film, a conductive metal oxide film, an insulating metal oxide film, or an organic film).

Owner:SHINODA PLASMA

Fluid coating device,fluid coating method and plasma display panel

InactiveCN1551279ALiquid surface applicatorsAlternating current plasma display panelsPump chamberEngineering

A meniscus of applying fluid is controlled by applying a voltage to a discharge-nozzle side electrode and a counter electrode placed downstream of the discharge nozzle and by increasing or decreasing fluid pressure inside a pump chamber with use of a mechanism for rotational motion or rectilinear motion.

Owner:PANASONIC CORP

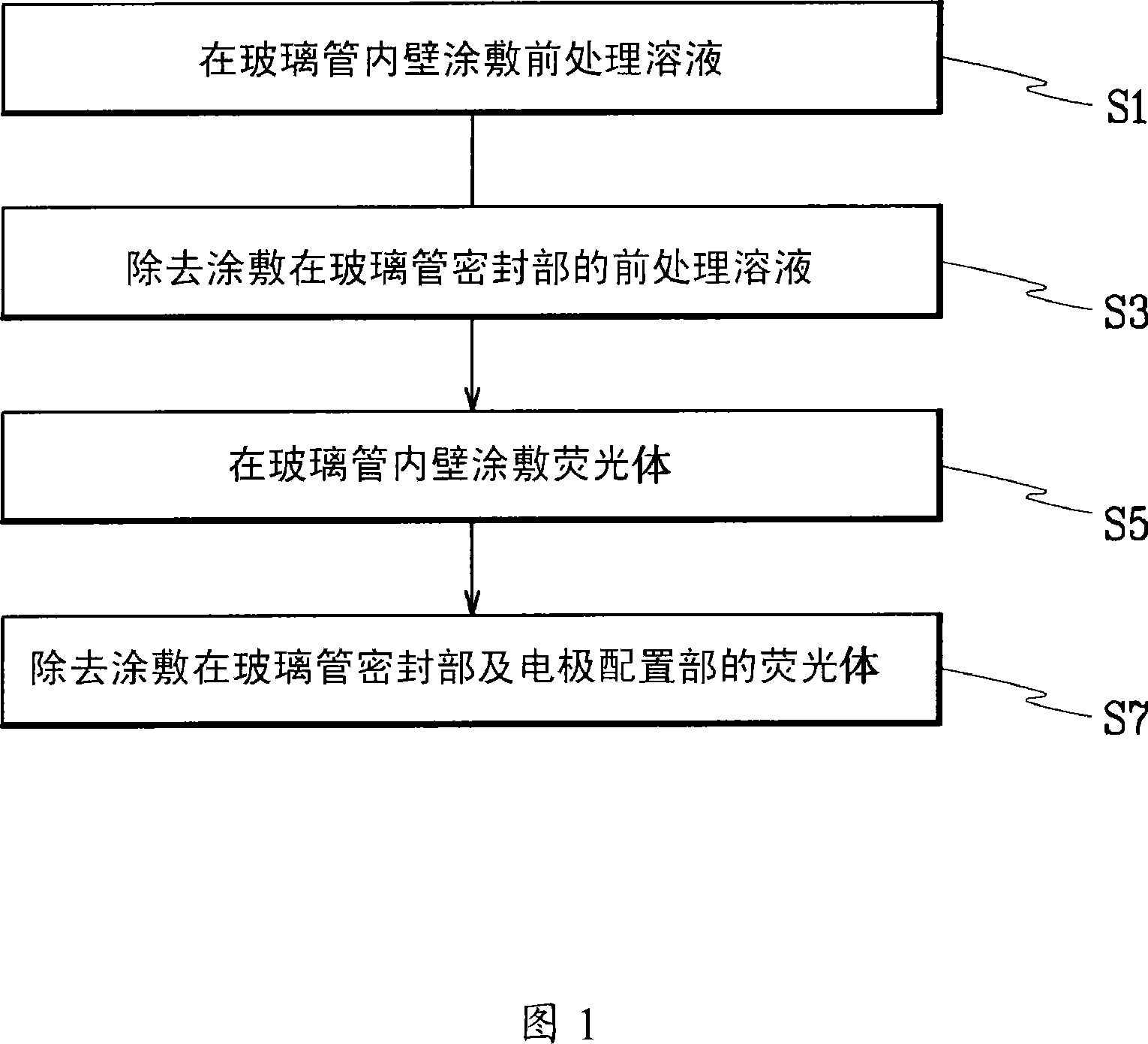

Fluorescent body coating method of fluorescent lamp

InactiveCN101174529AImprove coating processShorten the production linePretreated surfacesLuminescent coatings applicationSolventFluorescent lamp

The invention relates to a fluophor coating method for a fluorescent lamp, in particular to a fluophor coating method which can reduce the operation procedures in the technique of manufacturing the fluorescent lamps through coating the fluophor in the fluorescent lamp. The invention includes the following procedures: treating a solvent before the coating to the inner wall of a glass tube; utilizing the solvent to clear a pre-treated solvent layer coated on a sealing part of the glass tube, after the treatment of the solvent before the coating; coating the inner wall of the glass tube with fluophors after the clearing o f the pre-treated solvent layer on the sealing part of the glass tube; utilizing the solvent to clear the fluophors adhered to the sealing part of the glass tube and an electrode arrangement part, after the coating of the fluophors.

Owner:WEIHAI DMS OPTICAL ELECTROMECHANICAL CO LTD

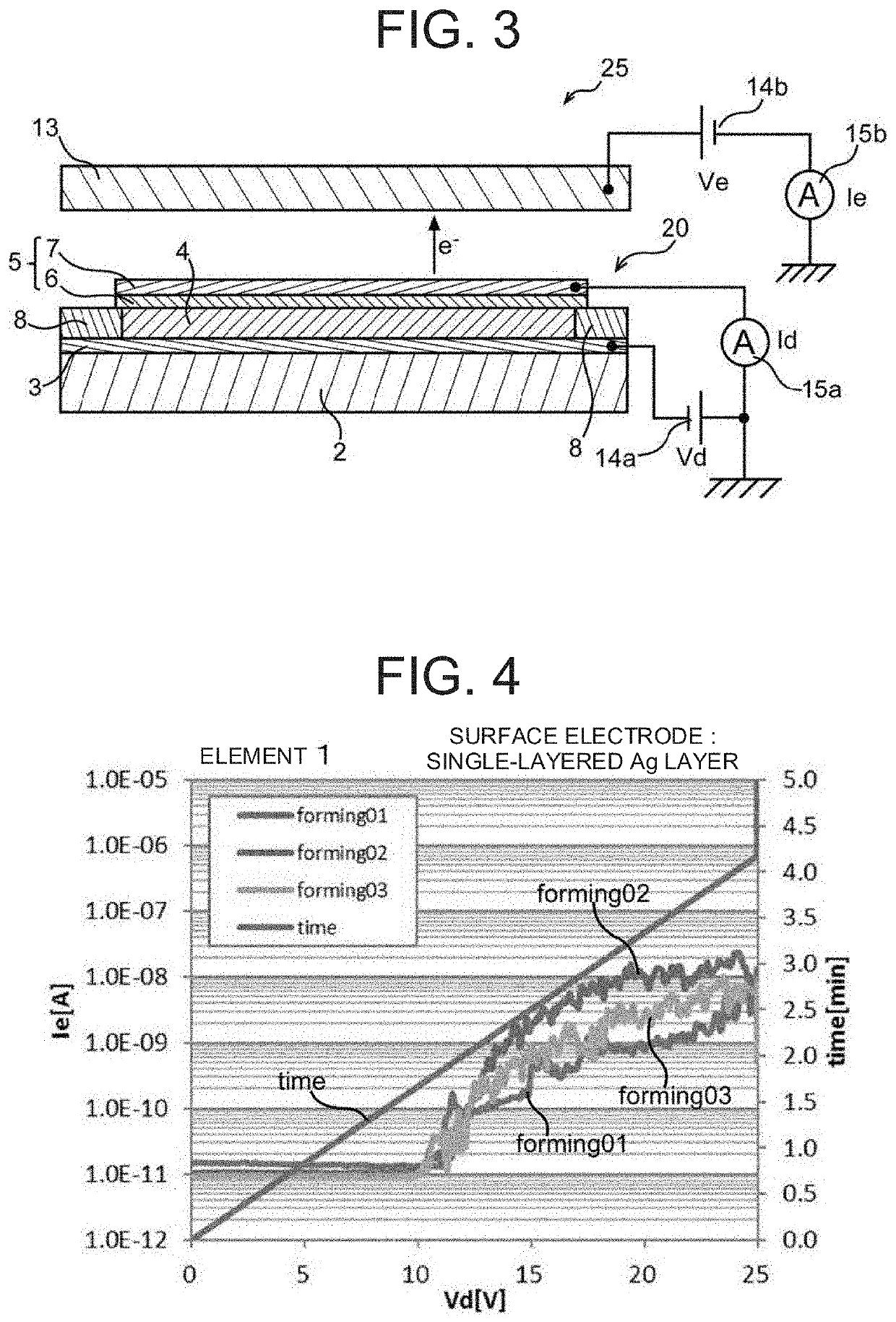

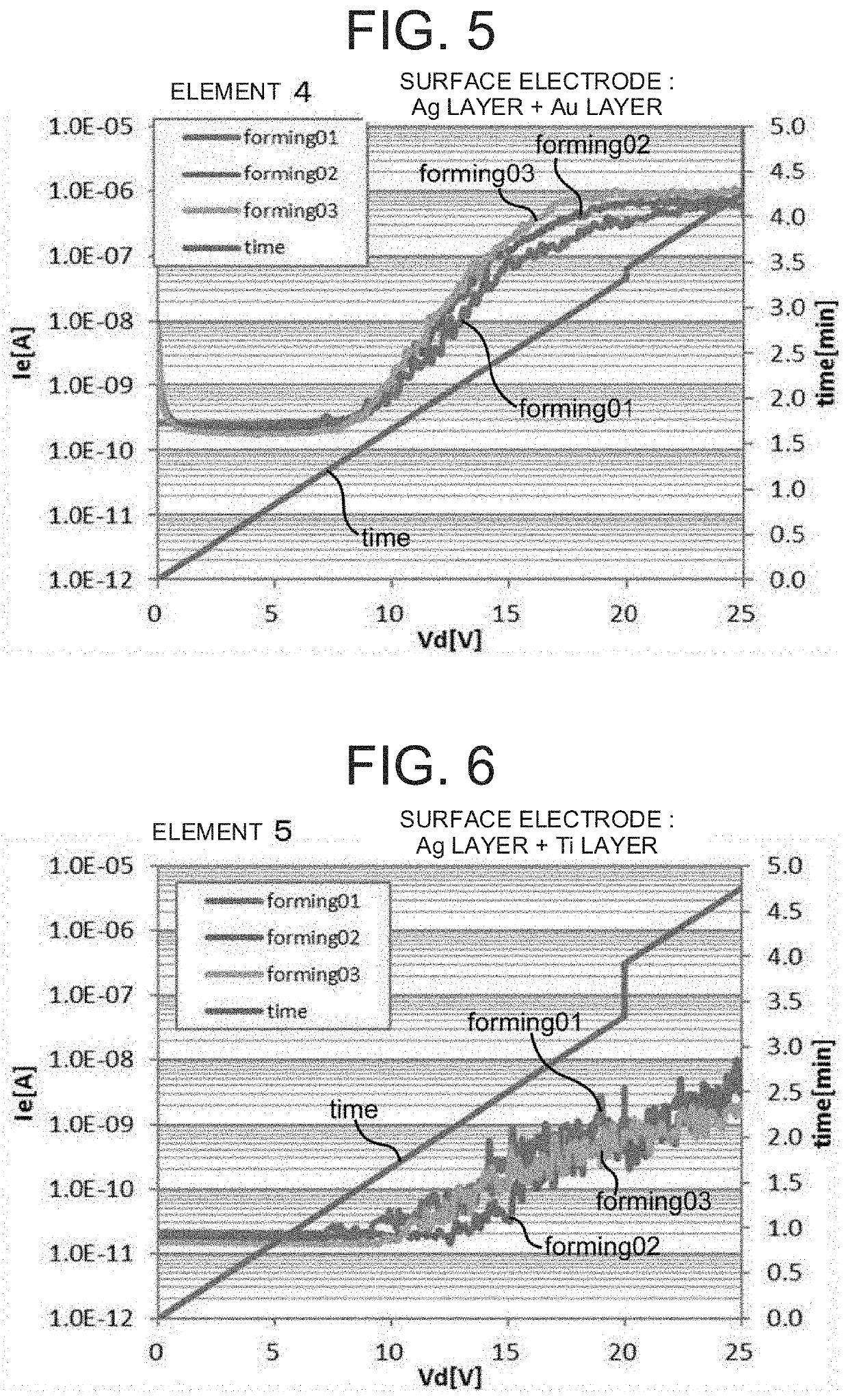

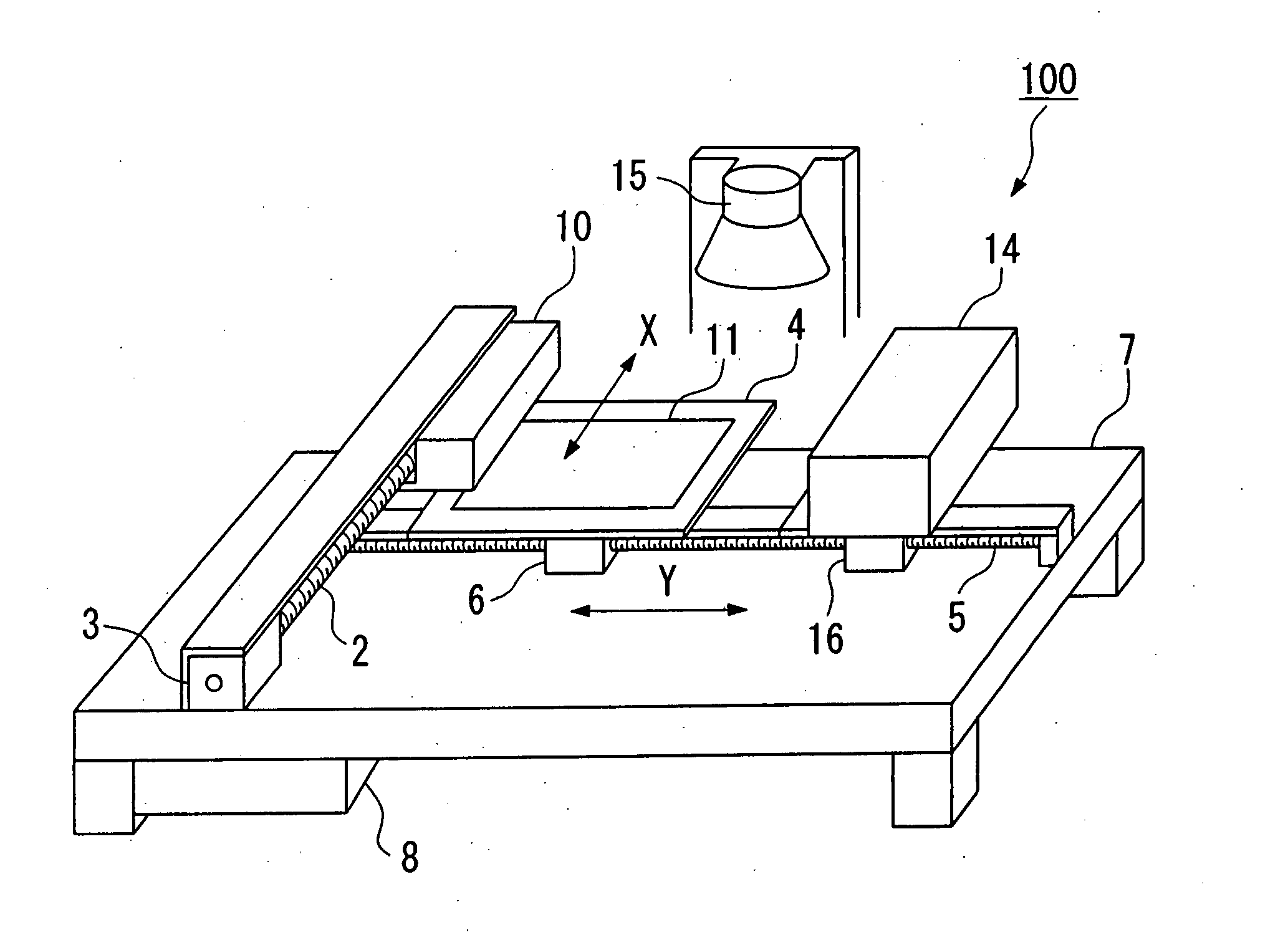

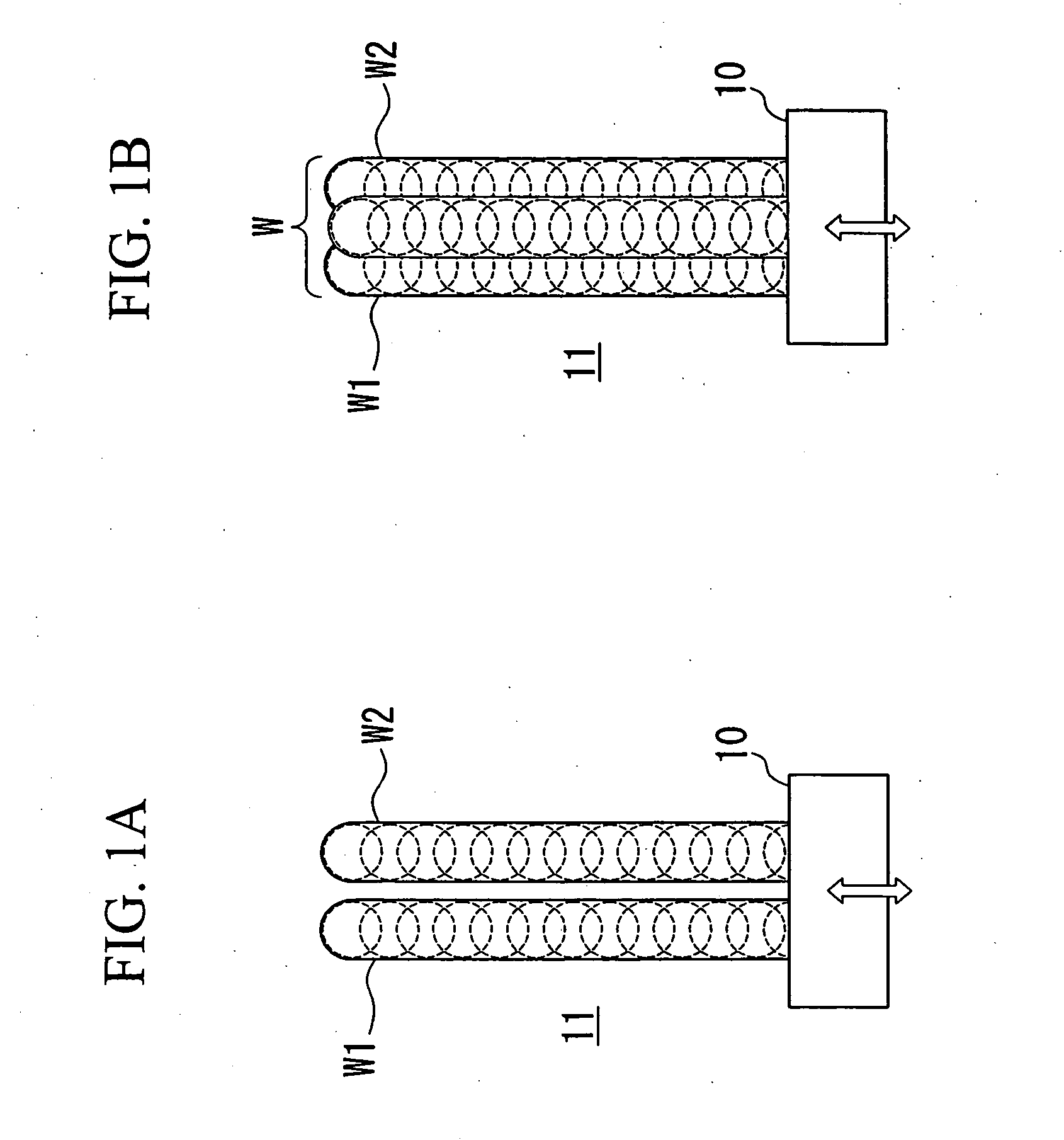

Electron emission element and method for manufacturing same

ActiveUS20210175039A1Suppress sudden breakdownProlong lifeDischarge tube cold cathodesDischarge tube coatingQuantum electrodynamicsAtomic physics

An electron emission element of the present invention includes a lower electrode, a surface electrode, and a silicone resin layer disposed between the lower electrode and the surface electrode, wherein the surface electrode includes a silver layer, and the silver layer is in contact with the silicone resin layer.

Owner:SHARP KK

Method for fabricating pattern, apparatus for fabricating pattern, conductive film wiring, method for fabricating device, electro-optical apparatus, and electronic apparatus

InactiveUS20050034622A1Preferable shapeSufficient resistance against breaking of wireLiquid surface applicatorsPlaten pressesEngineeringElectron

Owner:SEIKO EPSON CORP

Method of manufacturing emitter

Disclosed is a method of manufacturing an emitter in which the tip of the emitter can be formed into a desired shape even when various materials are used for the emitter. The method includes performing an electrolytic polishing process of polishing a front end of a conductive emitter material so that a diameter of the front end is gradually reduced toward a tip; performing a first etching process by irradiating a processing portion of the emitter material processed by the electrolytic polishing process with a charged particle beam; performing a sputtering process by irradiating the pointed portion formed by the first etching process with a focused ion beam; and performing a secondary etching process of further sharpening the tip by an electric field induced gas etching processing while observing a crystal structure of the tip of the pointed portion processed by the sputtering process using a field ion microscope.

Owner:HITACHI HIGH TECH SCI CORP

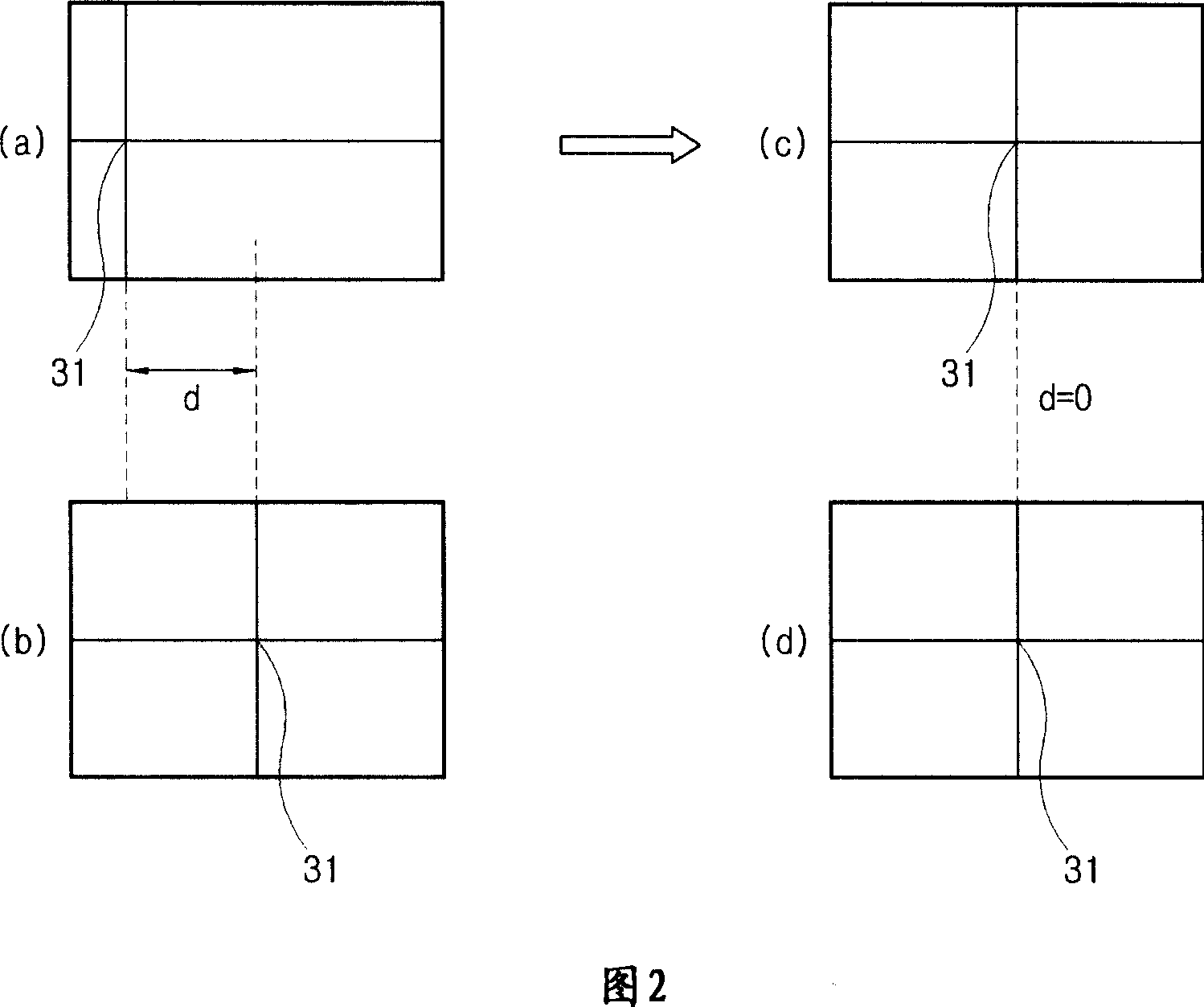

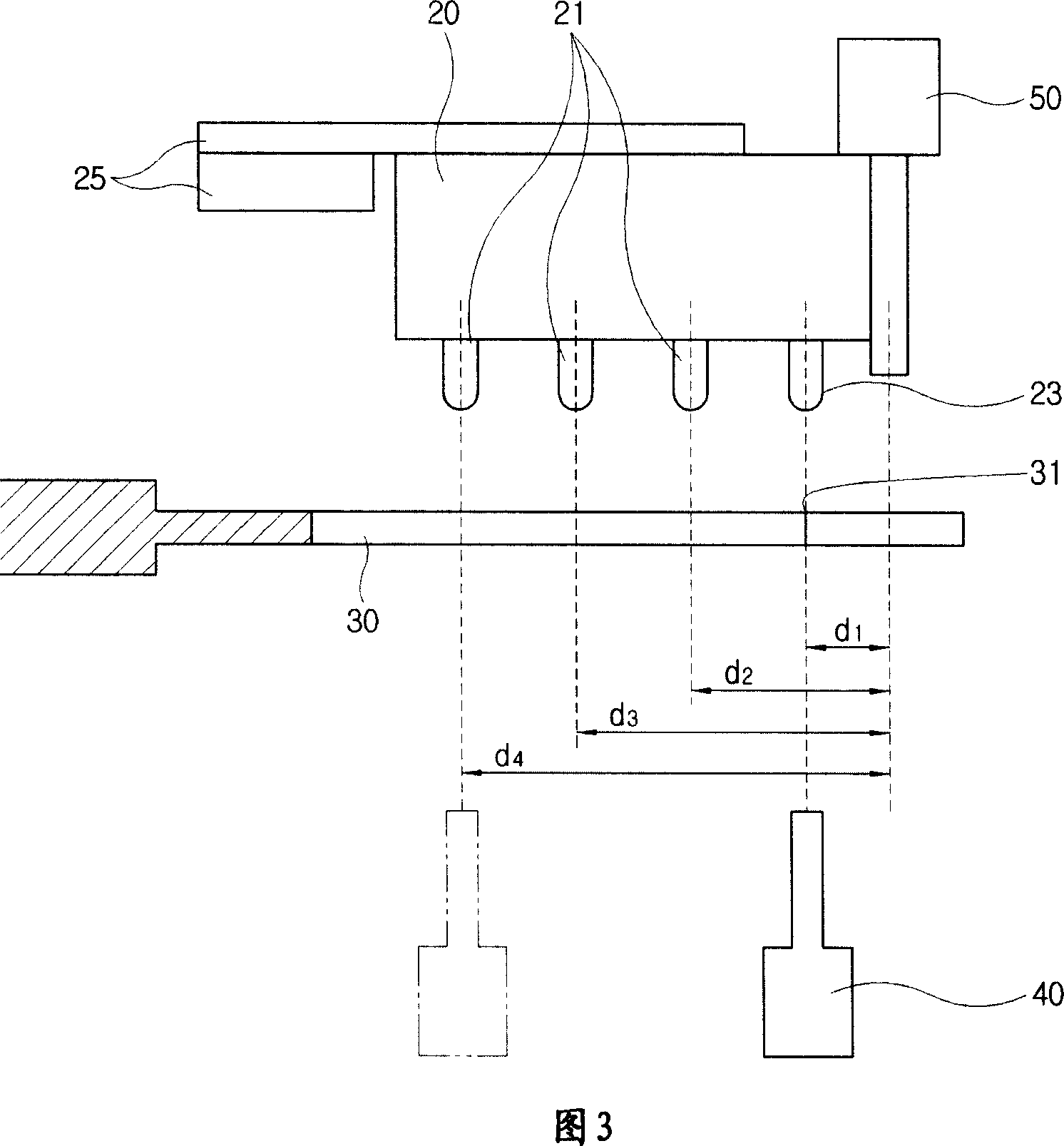

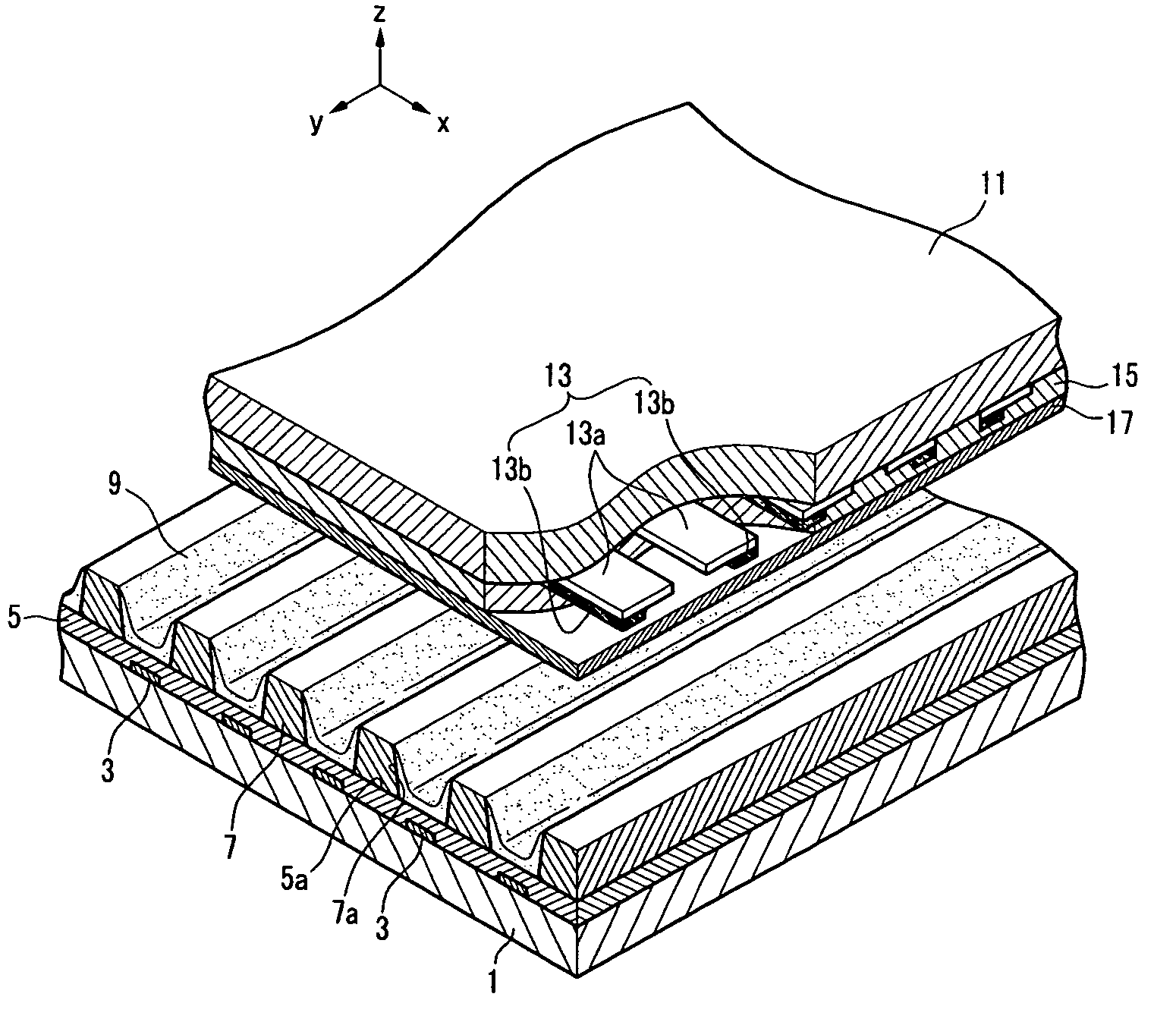

Alignment apparatus and method thereof

ActiveCN1963617AEasy alignmentSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringNozzle

Owner:SAMSUNG ELECTRONICS CO LTD

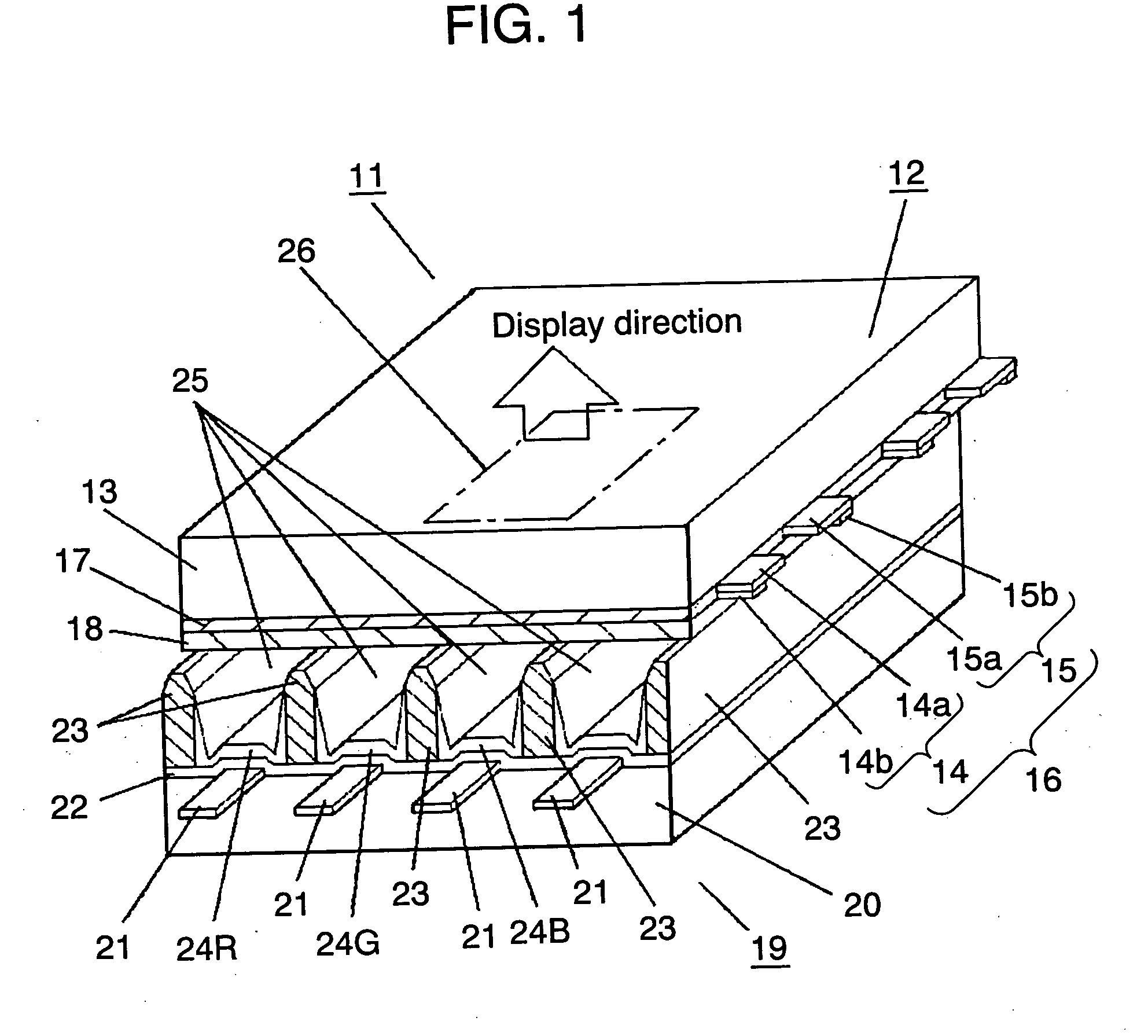

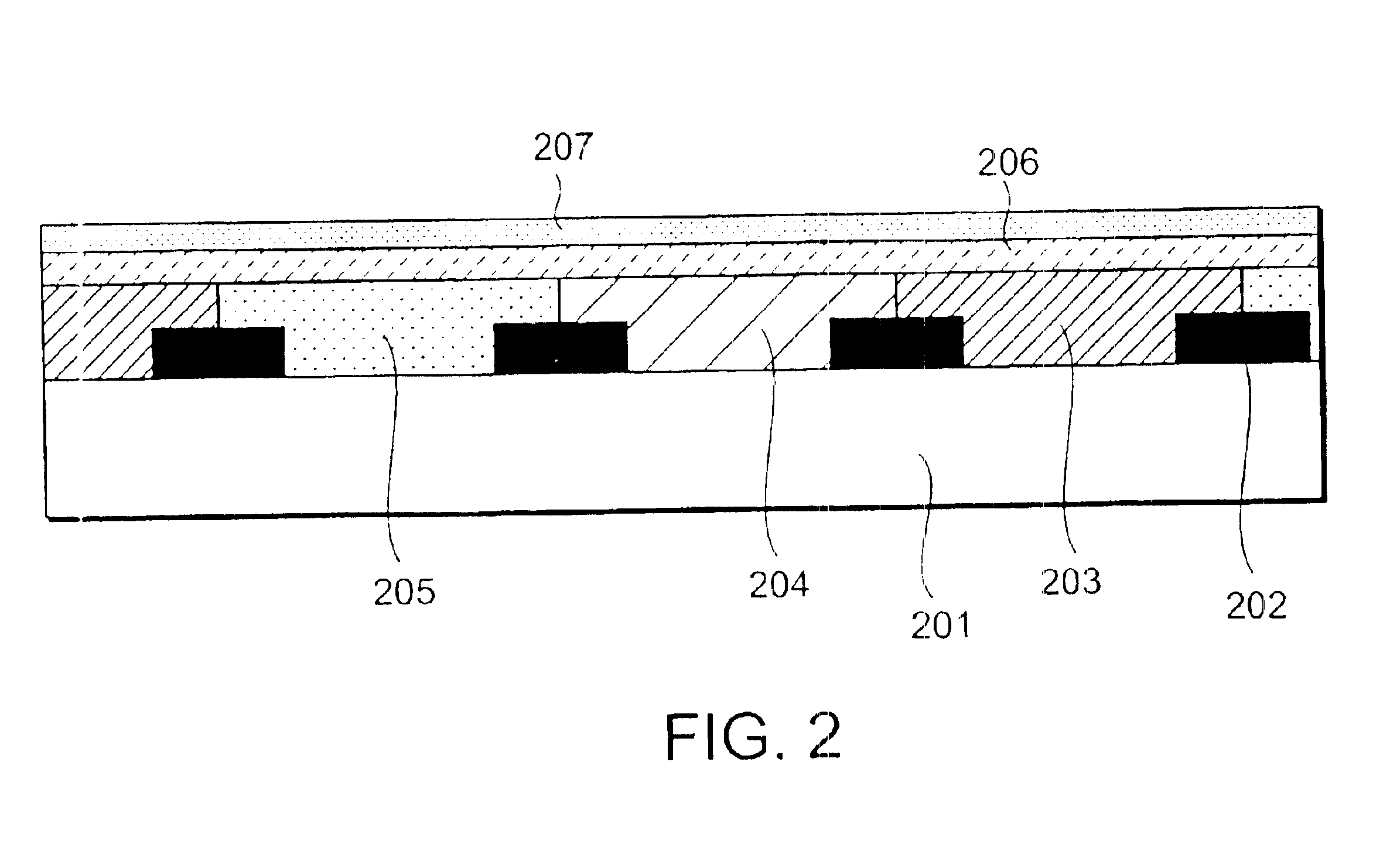

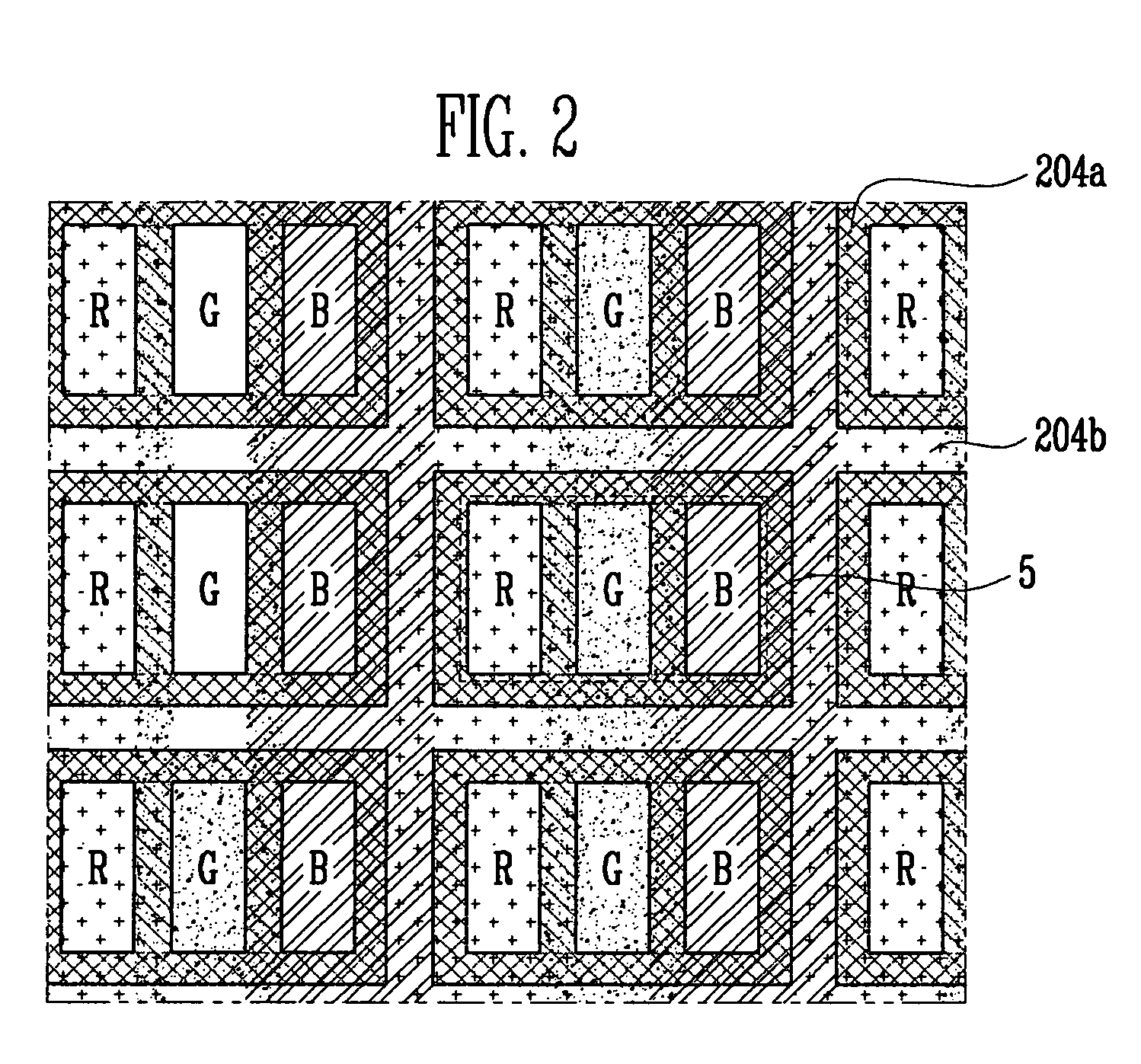

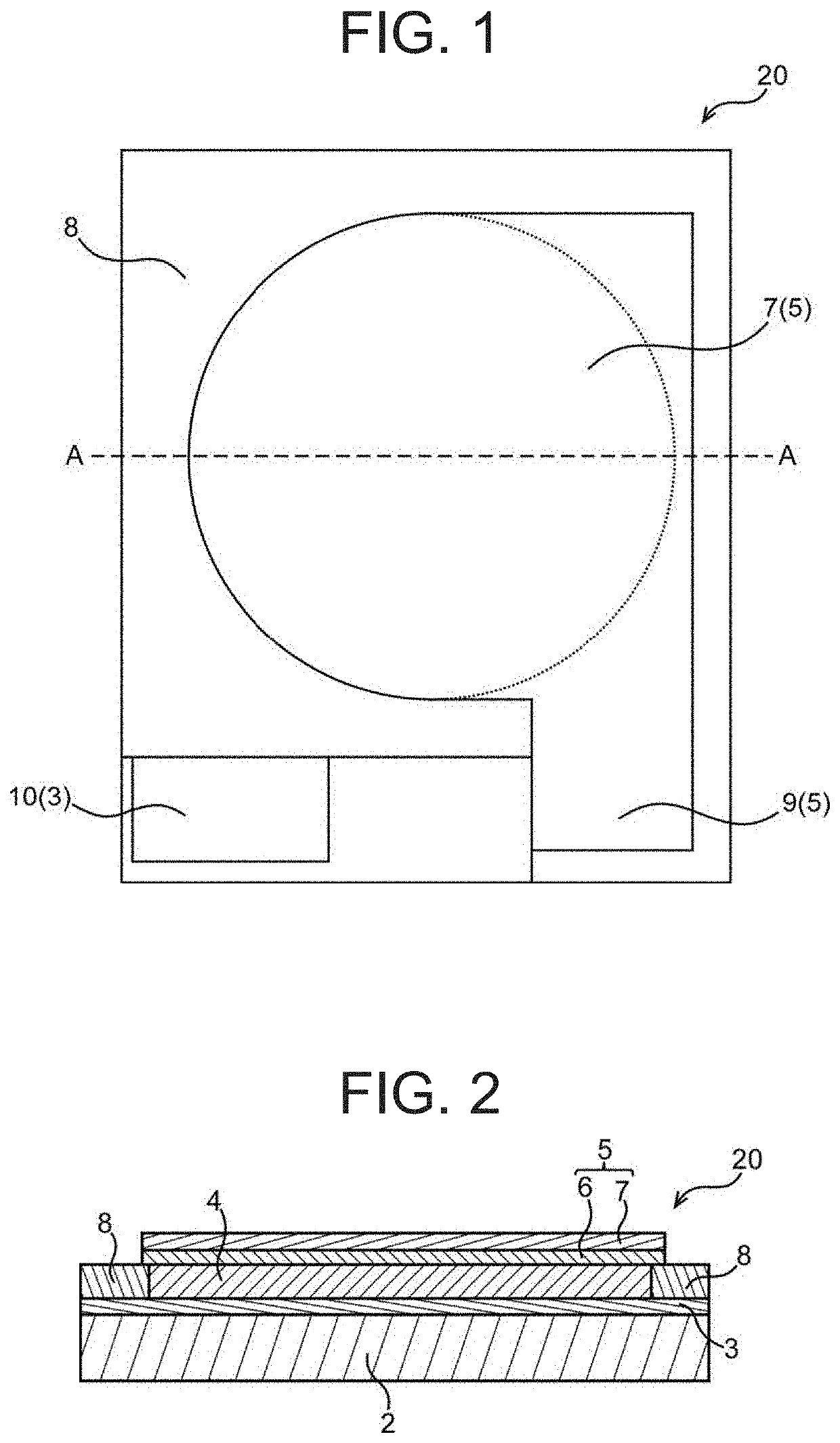

Plasma display panel

InactiveUS20070120489A1Improve display qualityTube/lamp vessel fillingAlternating current plasma display panelsPhosphorThird generation

A plasma display panel (PDP) according to one embodiment includes: a first substrate and a second substrate that are disposed substantially in parallel with each other with a predetermined distance therebetween; a plurality of address electrodes disposed on the first substrate; a first dielectric layer disposed on an entire surface of the first substrate while covering the address electrodes; a plurality of barrier ribs having a predetermined height from the first dielectric layer and disposed in a space between the first substrate and the second substrate to partition the space into discharge spaces of a predetermined size; a phosphor layer disposed in the discharge spaces; a plurality of display electrodes disposed on one side of the second substrate facing the first substrate in a direction crossing the address electrodes; a second dielectric layer disposed on an entire surface of the second substrate to cover the display electrodes; and a protective layer disposed to cover the second dielectric layer. The protective layer includes MgO having a crystalline grain size ranging from 100 to 500 nm and has a membrane density of less than or equal to 3.3 g / cm3.

Owner:SAMSUNG SDI CO LTD

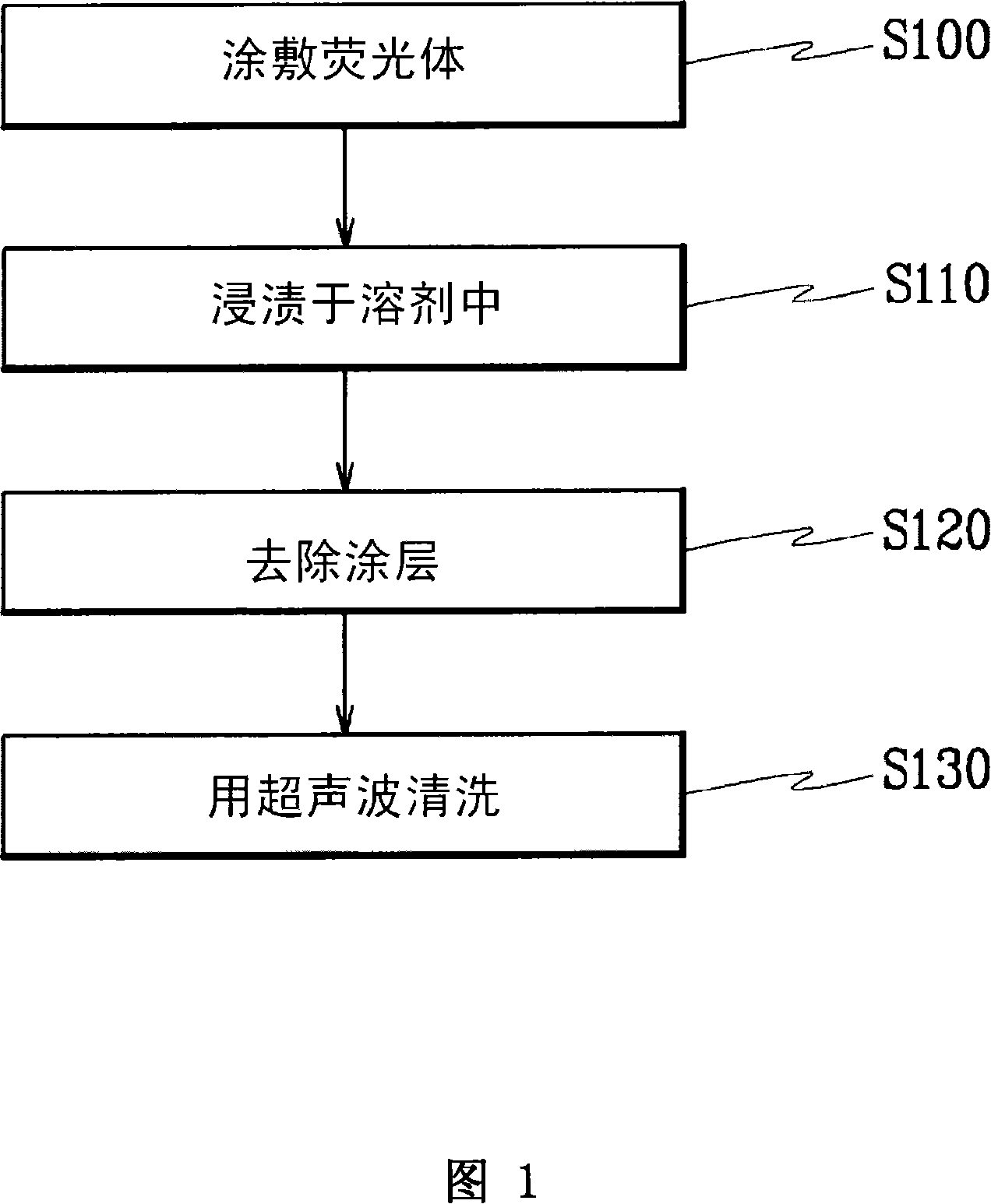

Apparatus for clearing coating fluorescent layer and method of the same

InactiveCN101140843AEfficient removalPretreated surfacesVessels or leading-in conductors manufactureChemical treatmentMegasonic cleaning

The present invention relates to a device for removing coating layers of a light tube and a method thereof. The method for removing coating layers of a light tube comprises the steps of coating a fluorophor inside a light tube through a coating layer removing mechanism which is capable of forming and removing coating layers, dipping the end of the light tube coated with the fluorophor through the coating step into a solvent through the coating layer removing mechanism; and then injecting dry air into inside the light tube dipped in the dipping step to extrude the solvent out to remove the coating layers of the fluorophor.In the chemical treatment manner, the method for removing coating layers of light tubes is capable of effectively removing fluorophor maintained in the light tube after the coating operation.In addition, after the coating layer removing step is completed, a step of ultrasonic cleaning is executed to remove coating layers of a fluorescent lamp more effectively.

Owner:WEIHAI DMS OPTICAL ELECTROMECHANICAL CO LTD

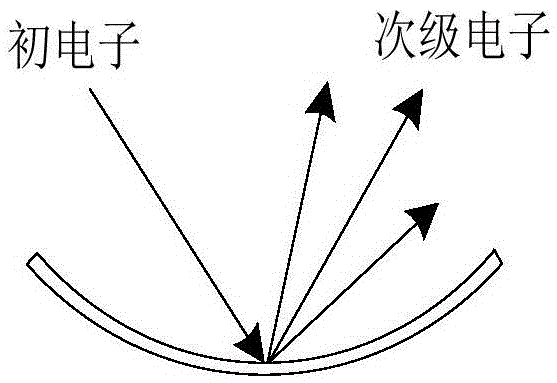

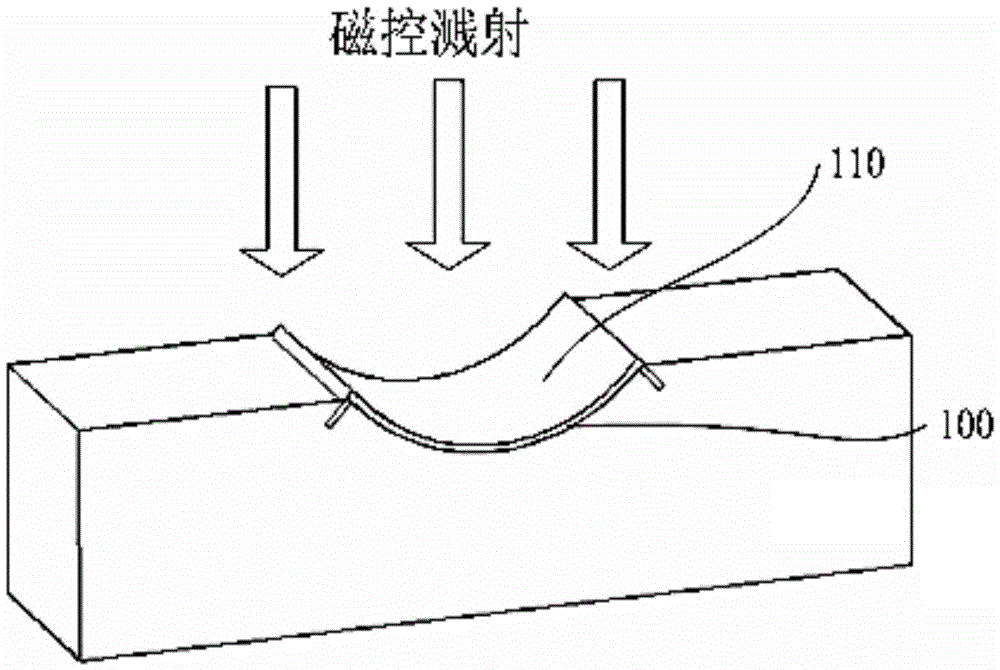

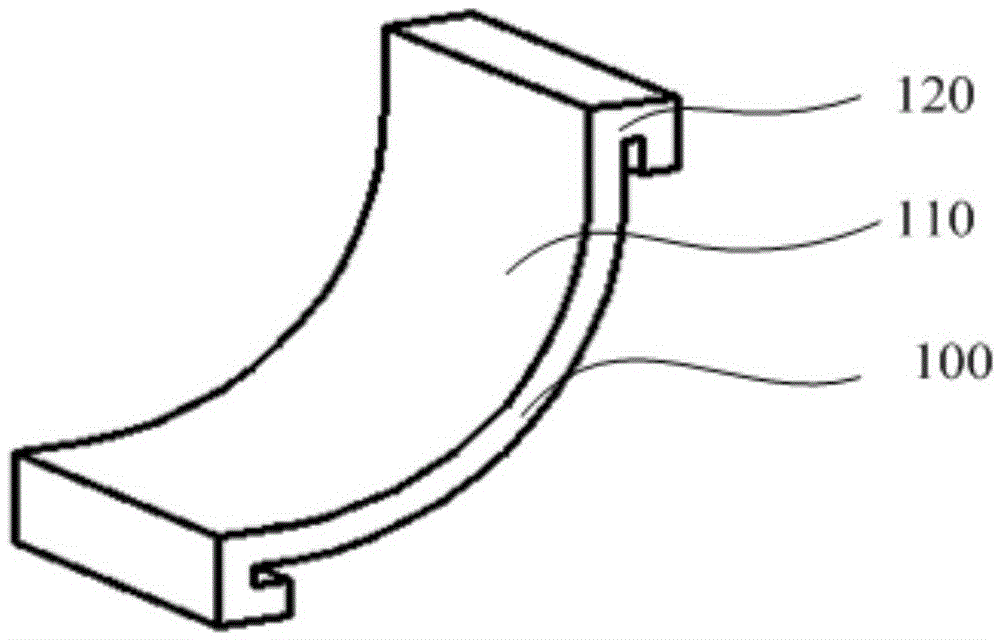

Dynode structure and arc dynode electron multiplier based on the same

InactiveCN105470092AImprove uniformityImprove compactnessDischarge tube coatingMultiplier dynodesThin oxideDynode

The invention discloses a dynode structure and an arc dynode electron multiplier based on the same. The electron multiplier comprises a base frame box body, a gate electrode and a metal substrate. The base frame box body having a quarter cylinder structure consists of a base plate, a first side plate, and a second side plate; the base plate has an arc structure; and the first side plate and the second side plate are connected with the two sides of the base plate. The metal substrate is fixed on the base plate and the upper surface of the metal substrate is an internally-recessed arc surface; a thin oxide film grows on the upper surface of the metal substrate by using a magnetron sputtering method; and the metal substrate is arranged between the first side plate, the second side plate, and the base plate and an incident electron is accelerated by the gate electrode and then enters the thin oxide film. The dynode of the electron multiplier has a uniform structure; the transmitting efficiency of the secondary electron is high; the service life is long; and installation becomes simple and convenient.

Owner:XI AN JIAOTONG UNIV

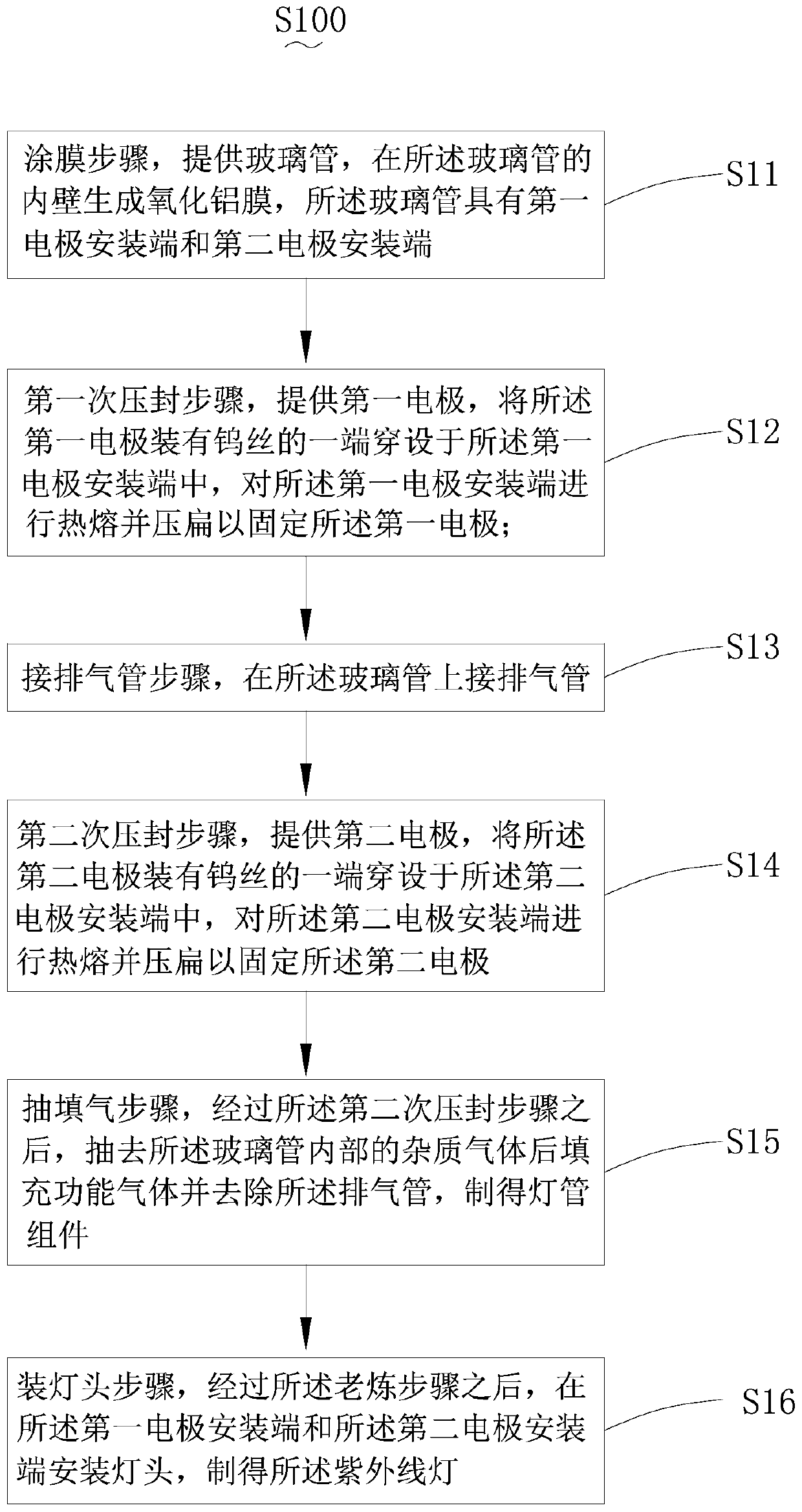

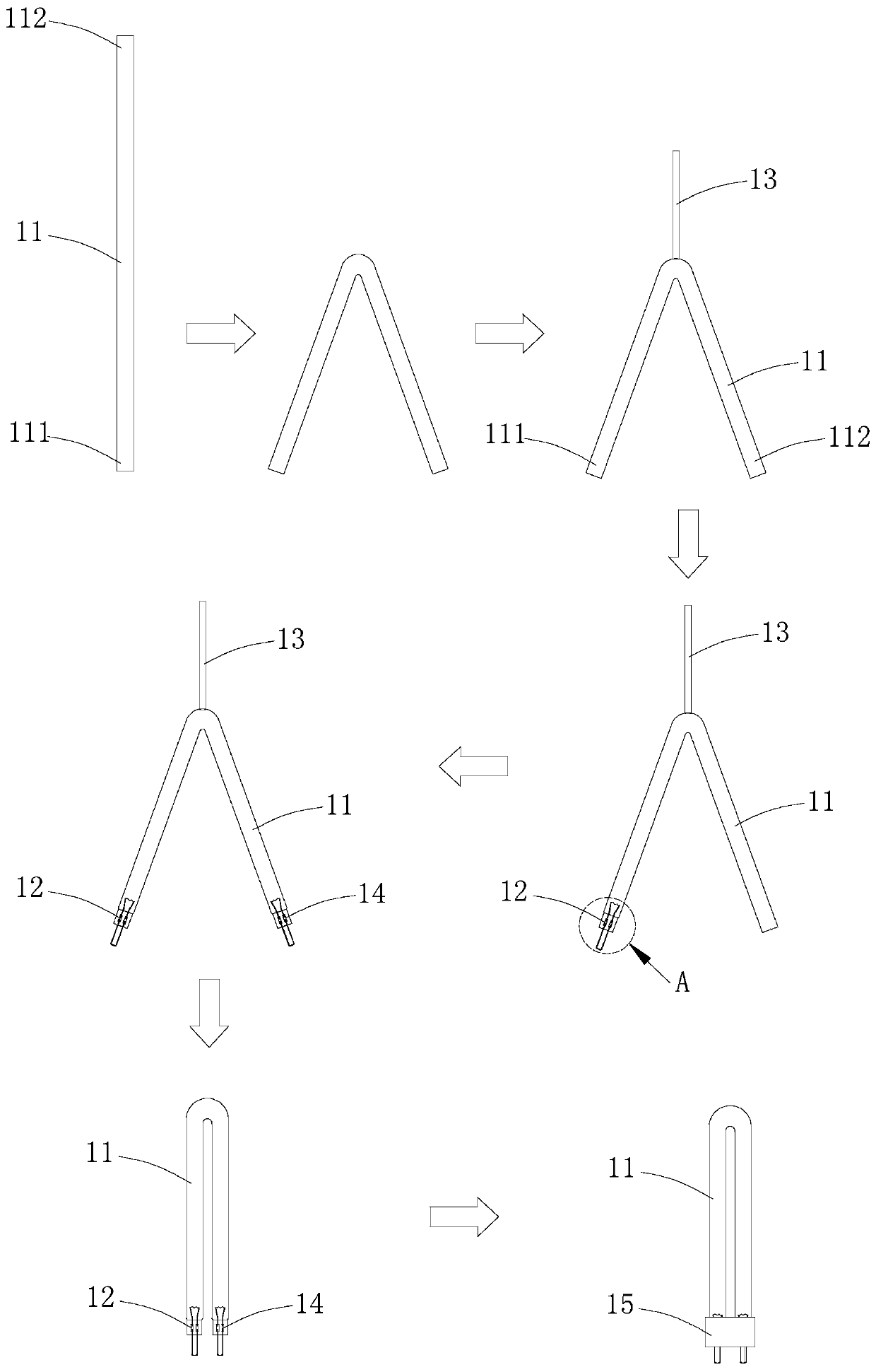

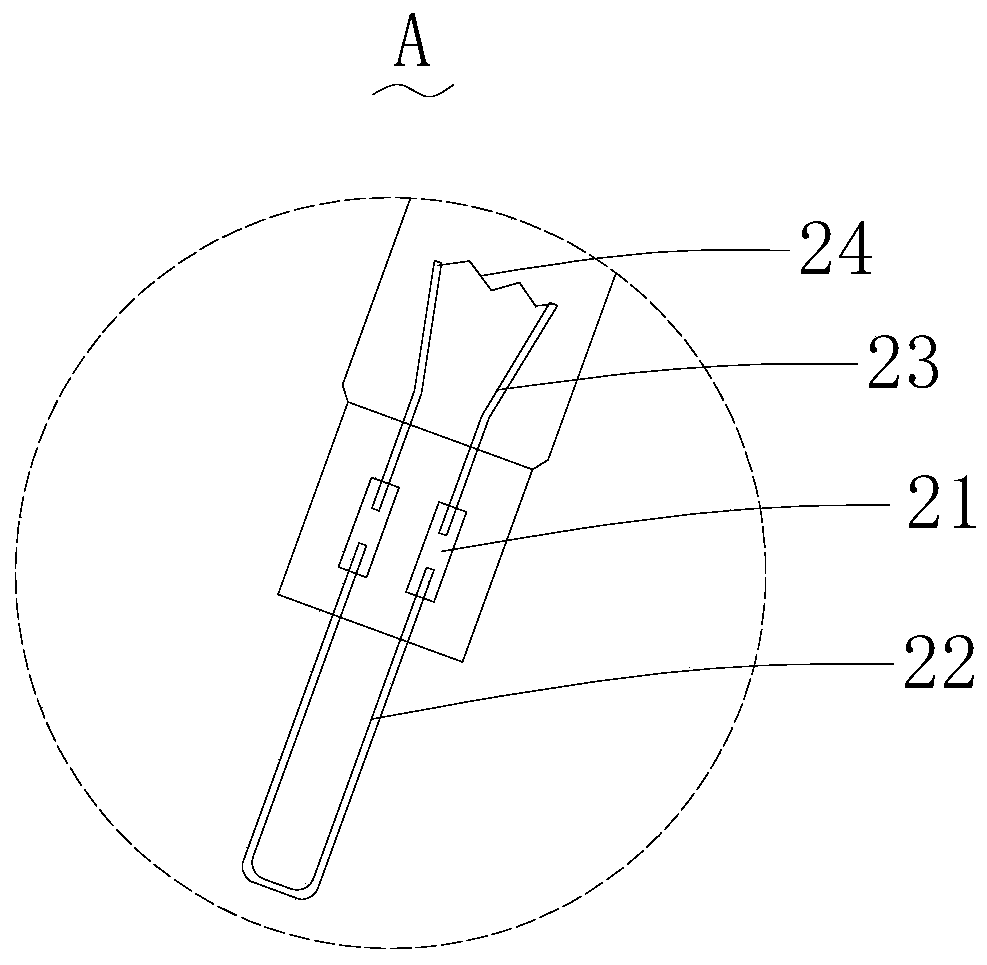

Ultraviolet lamp production process

PendingCN110828258AExtended service lifeTo satisfy the market's needsTube/lamp vessel fillingVessels or leading-in conductors manufactureUltraviolet lightsEngineering

The invention discloses an ultraviolet lamp production process, which comprises a film coating step, a first press-sealing step, an exhaust pipe connecting step, a second press-sealing step, a gas pumping and filling step and a lamp holder mounting step. In the film coating step, an aluminum oxide film is generated on the inner wall of a glass pipe. In the first press-sealing step, one end of a first electrode is arranged in a first electrode mounting end in a penetrating manner, and the first electrode mounting end is subjected to hot melting and flattening to fix the first electrode. In theexhaust pipe connecting step, an exhaust pipe is connected to the glass pipe. In the second press-sealing step, one end of a second electrode is arranged in a second electrode mounting end in a penetrating manner, and the second electrode mounting end is subjected to hot melting and flattening to fix the second electrode. In the gas pumping and filling step, foreign gas in the glass pipe is pumpedout, the glass pipe is then filled with functional gas, the exhaust pipe is removed, and a lamp tube assembly is manufactured. In the lamp holder mounting step, lamp holders are mounted at the firstelectrode mounting end and the second electrode mounting end. The ultraviolet lamp production process disclosed by the invention has the advantage that the service life of an ultraviolet lamp can be prolonged.

Owner:惠州市百欧森环保新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com