Fluorescent lamp fluorescent liquid coating device

A coating device and fluorescent liquid technology are applied to the surface coating liquid device, the application of luminous paint, and the components of gas discharge lamps, etc., which can solve the problems of difficulty in maintaining stable viscosity of fluorescent liquid and complicated manufacturing process, etc. Achieve the effect of improving coating quality, maintaining stable viscosity and preventing evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

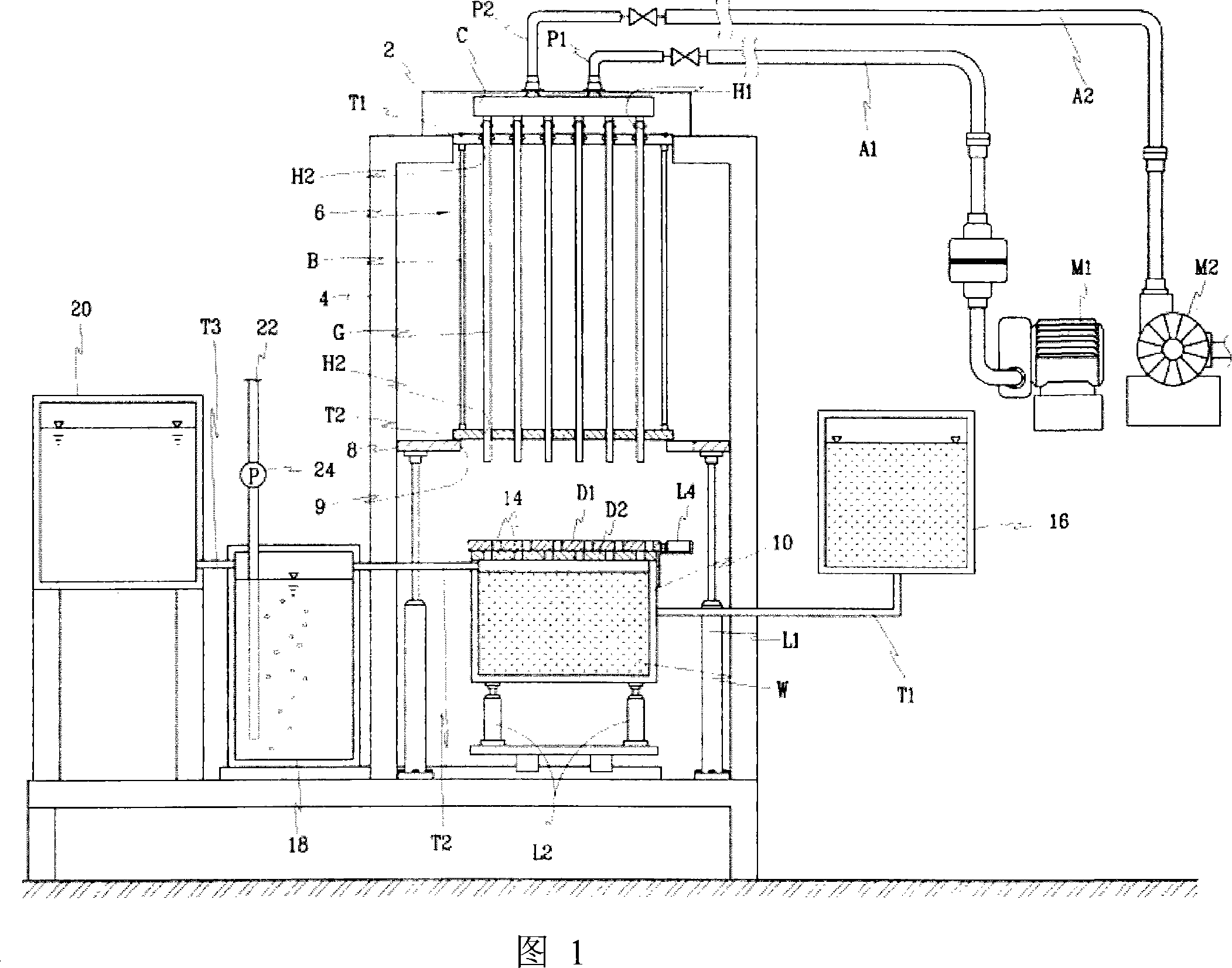

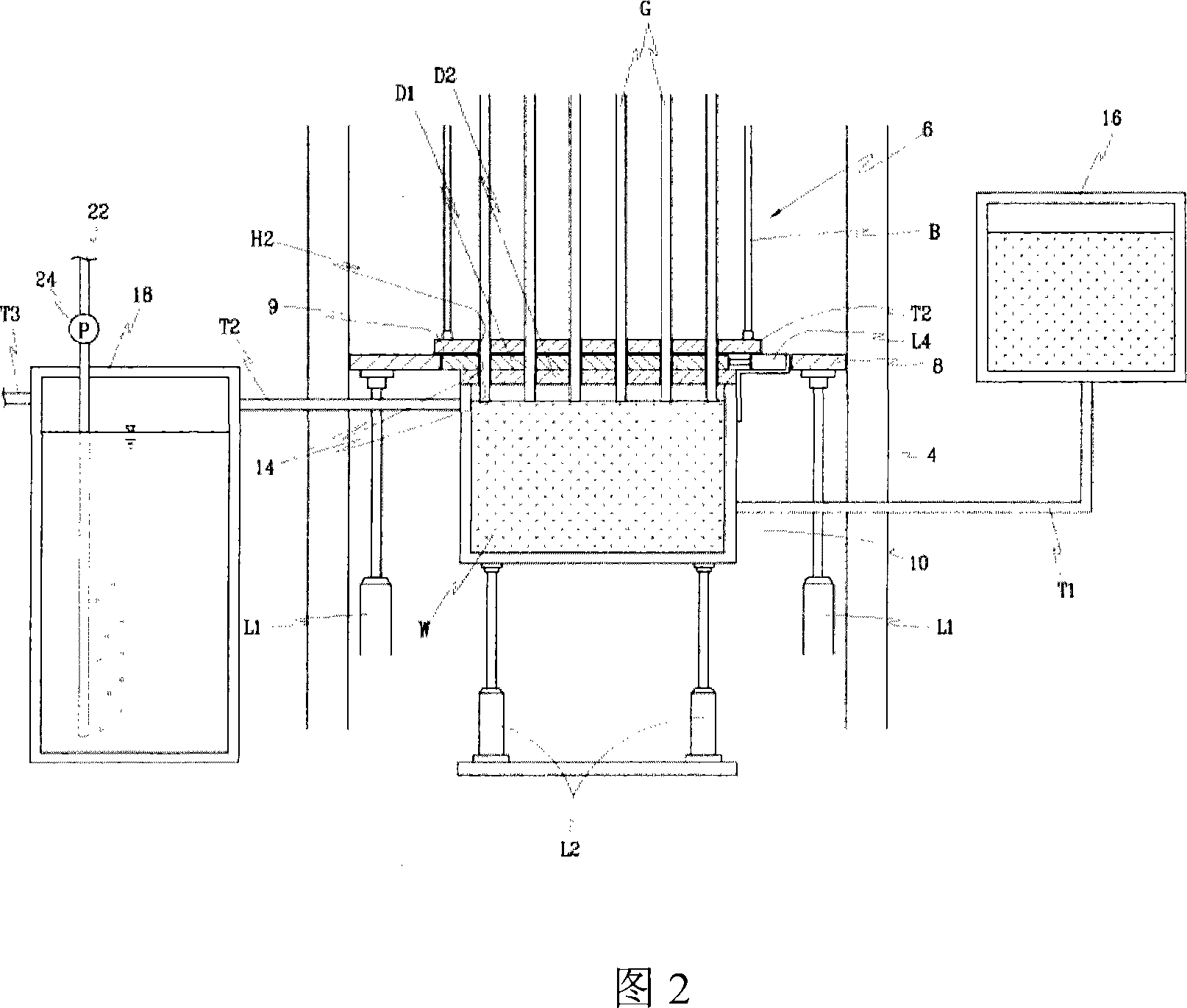

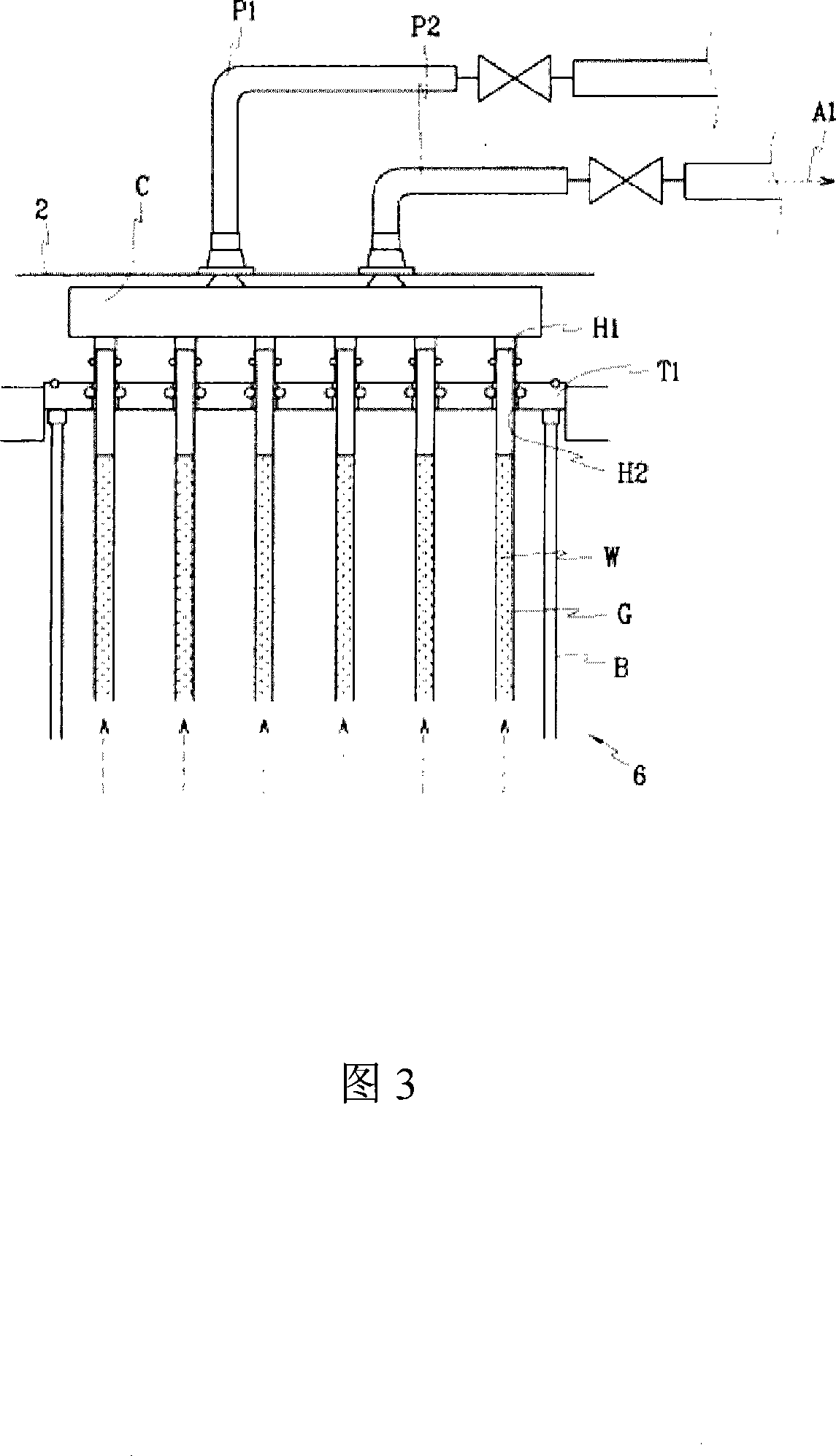

[0022] Next, the configuration of a fluorescent liquid application device for a fluorescent lamp according to a preferred embodiment of the present invention will be described with reference to the drawings.

[0023] As shown in Fig. 1, the fluorescent liquid coating device of the fluorescent lamp provided by the present invention includes: a chamber C; a loading box 6, which is used to carry the glass tube G combined with the chamber C; a negative pressure generating device M1 , which is connected with the chamber C, and generates negative pressure by changing the internal pressure of the chamber C, so as to coat the fluorescent liquid on the inner wall of the glass tube G; the drying device M2, which is connected with the chamber C is connected to supply dry gas into the chamber C, thereby drying the fluorescent liquid inside the glass tube G; a storage device, which is used to store the fluorescent liquid, so that when the negative pressure generating device M1 is driven , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com