Dynode structure and arc dynode electron multiplier based on the same

A technology of electron multipliers and dynodes, which is applied in the direction of electron multiplier dynodes, electron multiplier details, dynodes, etc., can solve the problem of insufficient performance of process materials, unstable performance of dynodes, and inconsistent process consistency Advanced problems, to achieve high secondary electron emission efficiency, good uniformity and compactness, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

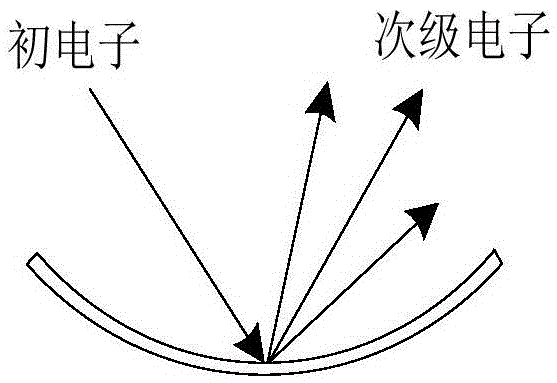

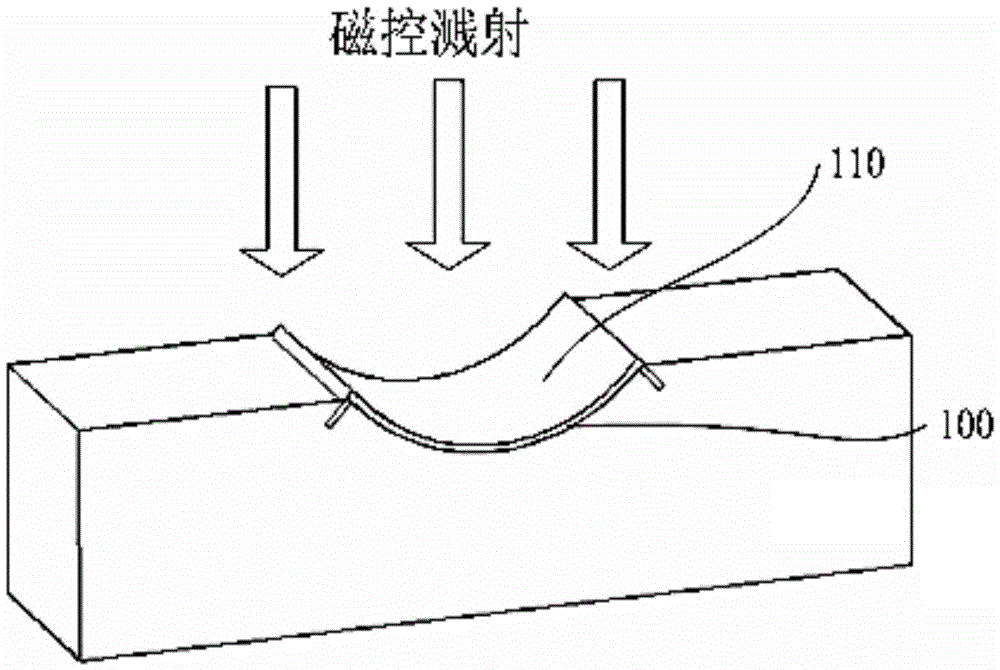

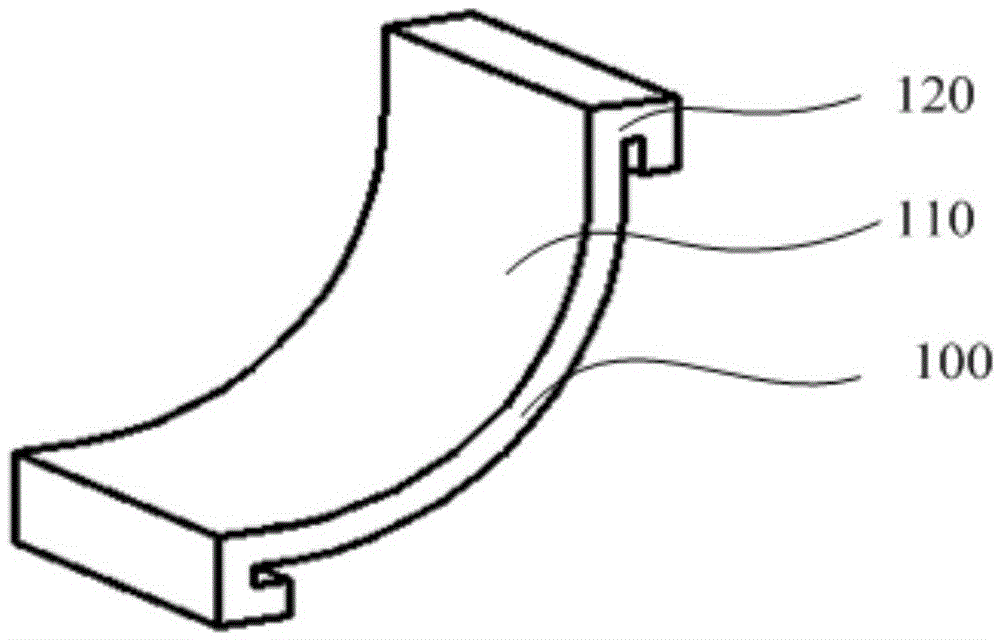

[0025] The dynode structure described in the present invention is an oxide film 110 grown on the upper surface of the metal substrate 100 by magnetron sputtering.

[0026] The arc-shaped dynode electron multiplier of the present invention includes a pedestal box body 130, a grid electrode 140 and a metal base 100; the pedestal box body 130 is a quarter cylindrical structure, wherein the pedestal box body 130 includes a base plate, a first side plate and a second side plate, the first side plate and the second side plate are respectively connected to the two sides of the base plate, the metal base 100 is fixed on the upper part of the base plate, and the upper surface of the metal base 100 and the base plate The upper surfaces of the metal base 100 are all concave arc surfaces, and a layer of oxide film 110 is grown on the upper surface of the metal base 100 by magnetro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com