Coating device using roller with double blades, and method for producing optical film by using the same

A coating device, double-blade technology, applied to the surface coating liquid device, optics, optical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention and accompanying drawings will be described in detail.

[0026] It will be apparent to those skilled in the art that these embodiments are intended to explain the present invention in more detail, but not to limit the scope of the present invention.

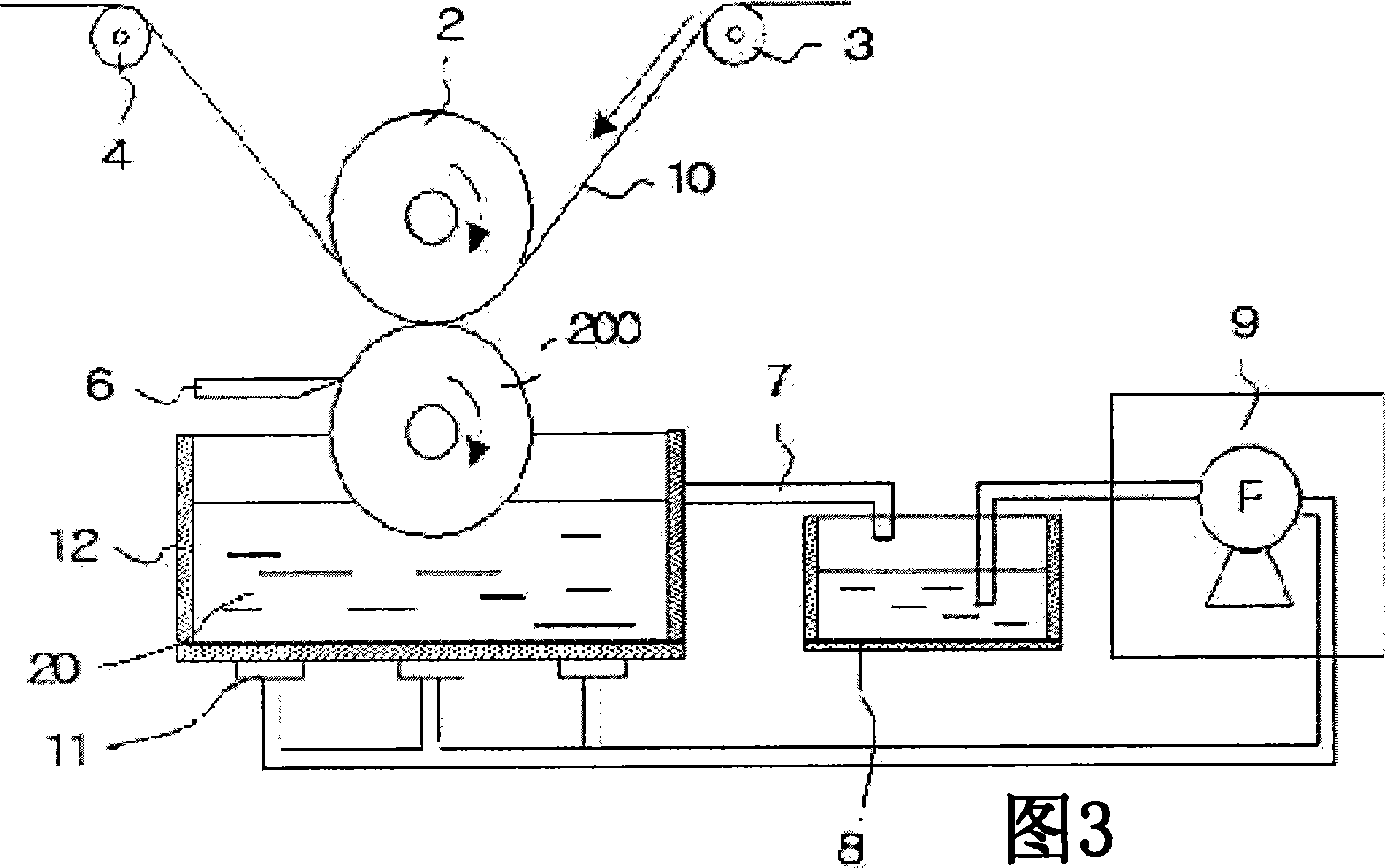

[0027] Figure 3 illustrates a conventional gravure coating apparatus with rolls. A method of producing an optical film using a conventional coating device with a roll will now be described with reference to FIG. 3 . First, the liquid pan 12 contains the coating liquid 20 . In the liquid pan 12, the lower end 1 / 3 of a mesh roll 200 as a coating liquid transfer roll is dipped in the coating liquid, which is rotated. The anilox roll 200 as a coating liquid transfer roll contacts the back roll 2 and is rotated. The film 10 is transferred through the gap between the roll 2 and the roll 200 . The coating liquid 20 contained in the liquid pan 12 overflows out of the liquid pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com