Apparatus for clearing coating fluorescent layer and method of the same

A coating removal and lamp tube technology, which is applied to discharge tube coatings, coatings, and devices for coating liquids on the surface, etc., can solve the problems of residual phosphors and long processing time of phosphors, and achieve the effect of effective removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

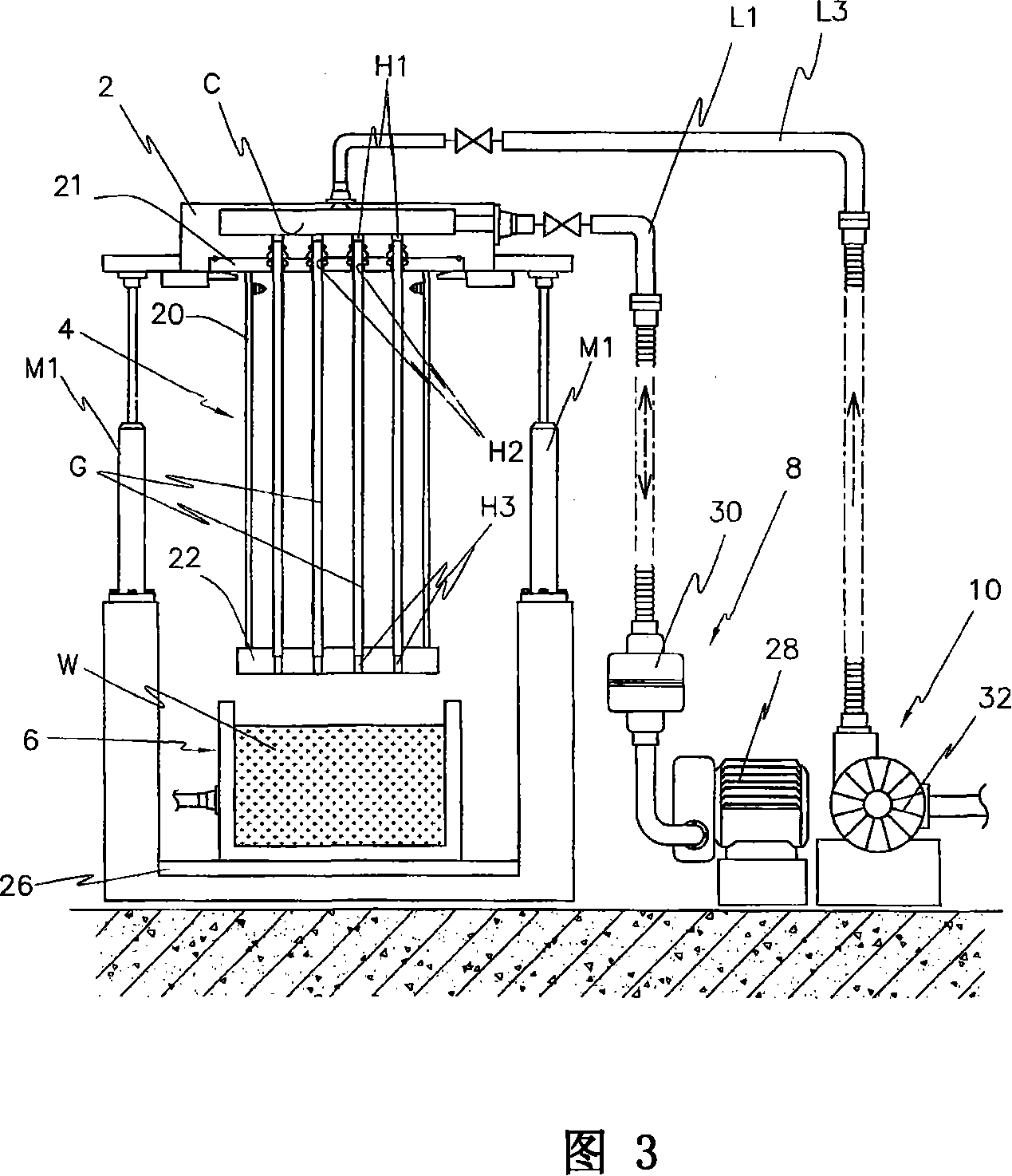

[0021] Hereinafter, preferred embodiments of the present invention will be described in more detail with reference to the accompanying drawings.

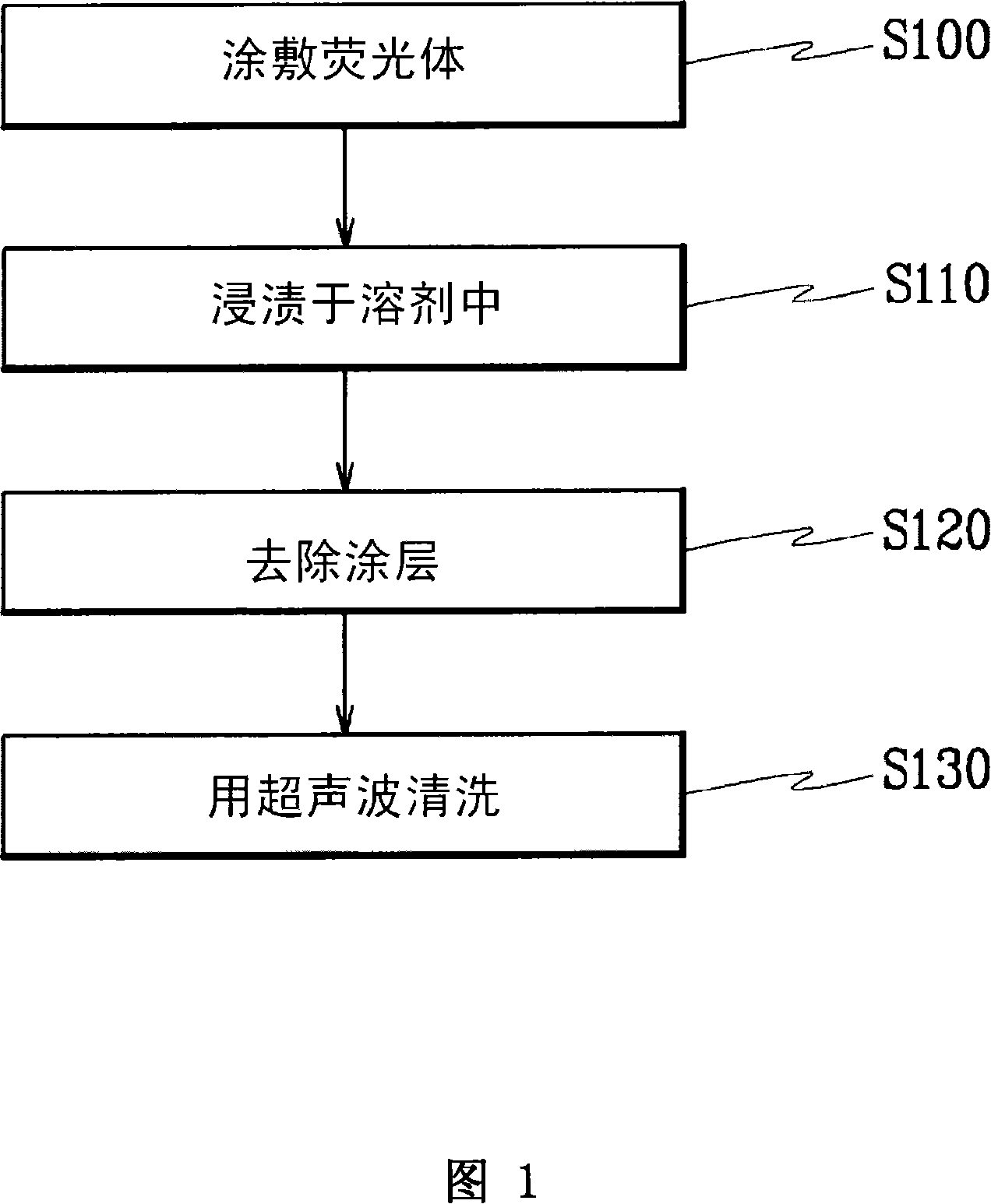

[0022] As shown in Fig. 1, the method for removing the coating of the lamp tube according to the present invention includes: a step S100 of applying phosphor inside the fluorescent lamp G (Fig. 2) by using a coating removal device capable of forming and removing the coating; The above-mentioned coating removal device, the step S110 of immersing the end of the fluorescent lamp G coated with phosphor in the coating step S110 in a solvent; injecting dry air into the fluorescent lamp G dipped in the dipping step S110 to squeeze The solvent is removed to remove the phosphor in the coating removal step S120.

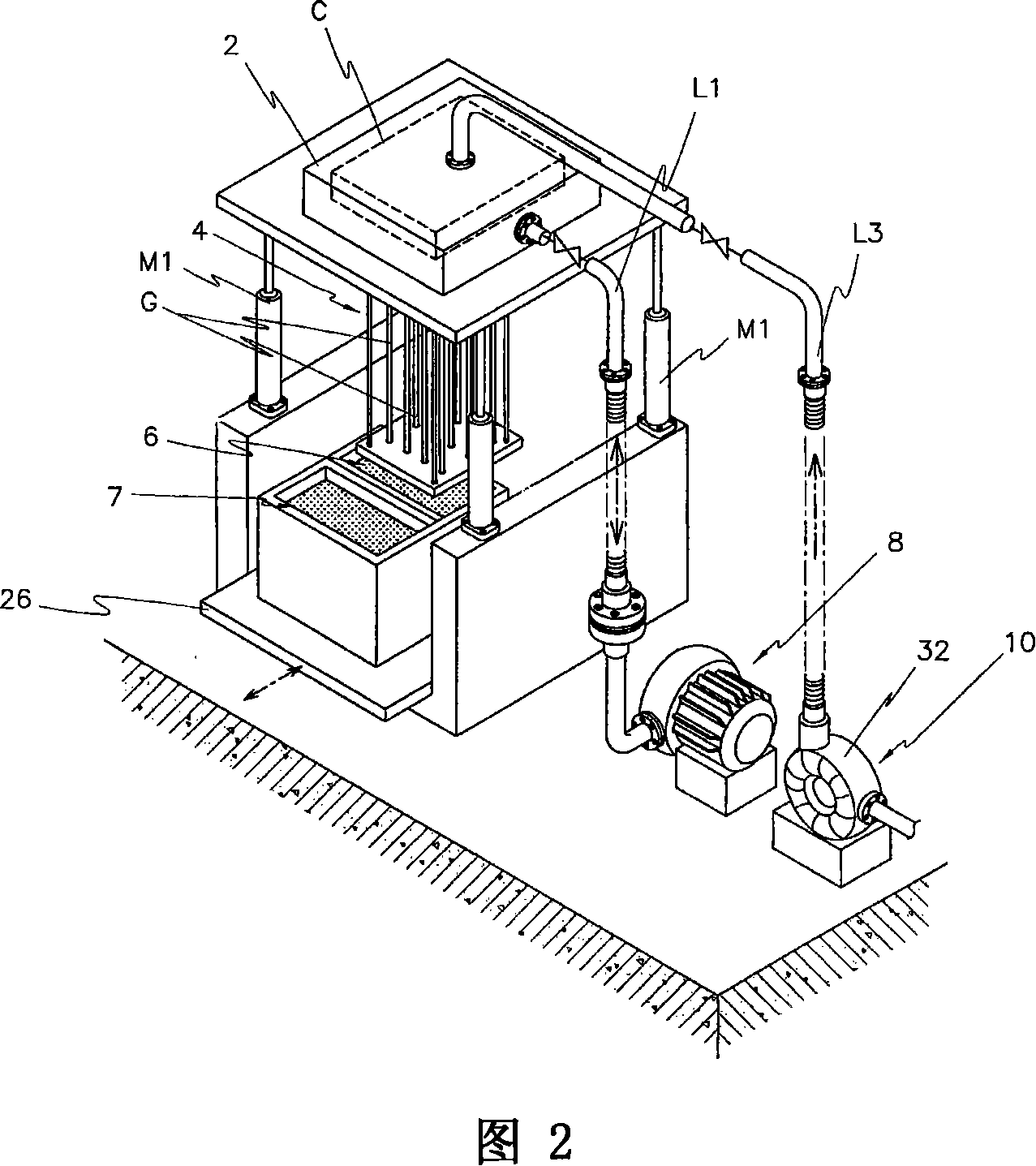

[0023] In such a fluorescent lamp coating method, the coating step S100 is performed before the fluorescent lamp G coating removal step is performed. The coating step S100 is accomplished by the coating removal device shown in FIG....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com