Fluorescent body coating method of fluorescent lamp

A technology for phosphors and fluorescent lamps, which is applied in the application of luminescent coatings, parts and coatings of gas discharge lamps, etc., can solve the problems of reducing production efficiency and increasing processes, so as to improve production efficiency, reduce equipment costs, and improve coating. The effect of the application process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

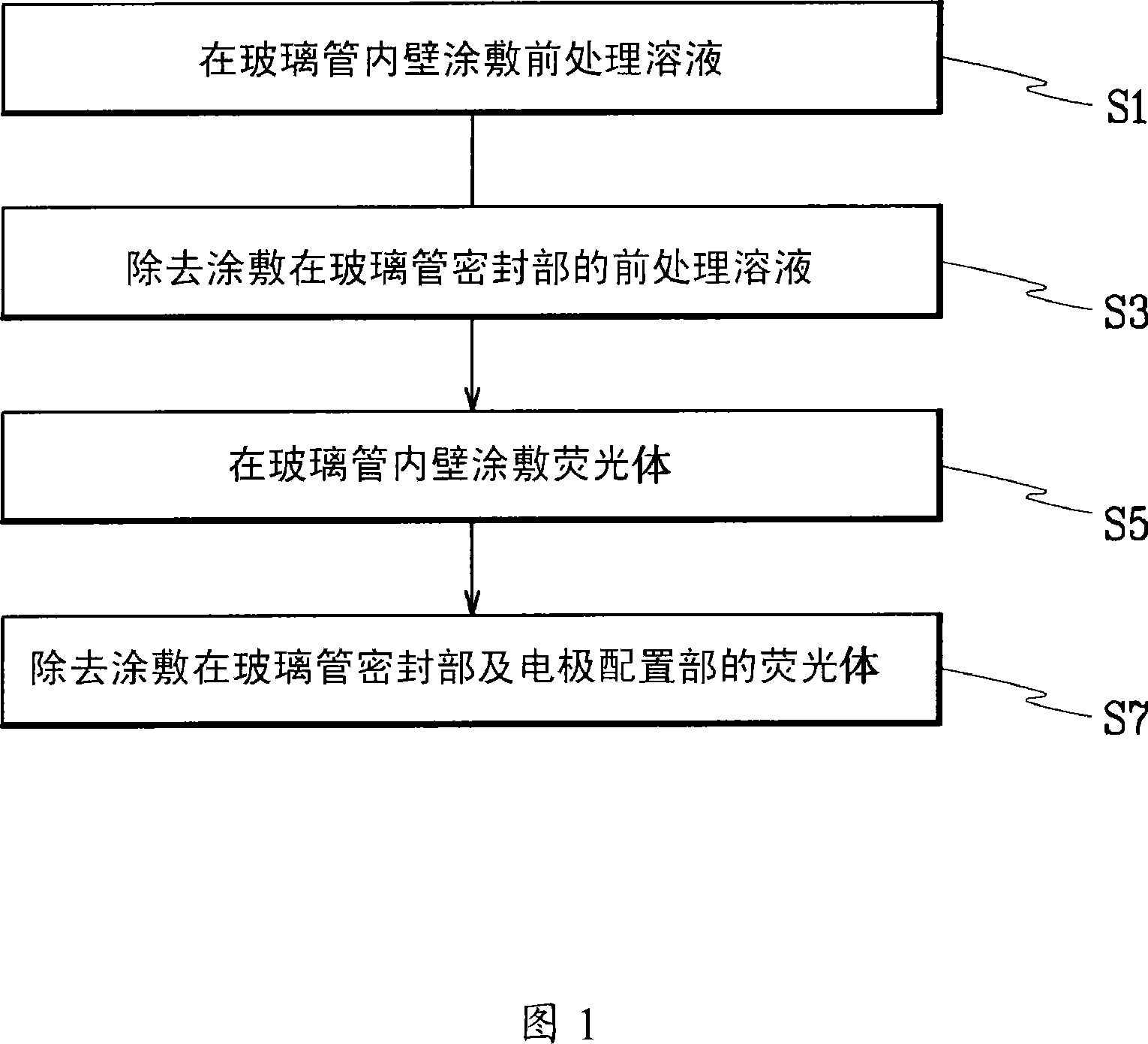

[0023] Figure 1 is a process flow diagram for illustrating an embodiment of the present invention. FIG. 1 sequentially shows a phosphor coating method for a fluorescent lamp. Fluorescent lamp phosphor coating method of the present invention, at first in glass tube 1 inner wall coating pretreatment solution, forms pretreatment solution layer (S1), utilizes isopropanol solution to remove the pretreatment solution that is coated on glass tube 1 sealing part afterwards layer (S3), and then apply phosphor on the inner wall of the glass tube (S5), and then use butyl acetate solution to remove the phosphor coated on the sealing part of the glass tube and the electrode arrangement part (S7).

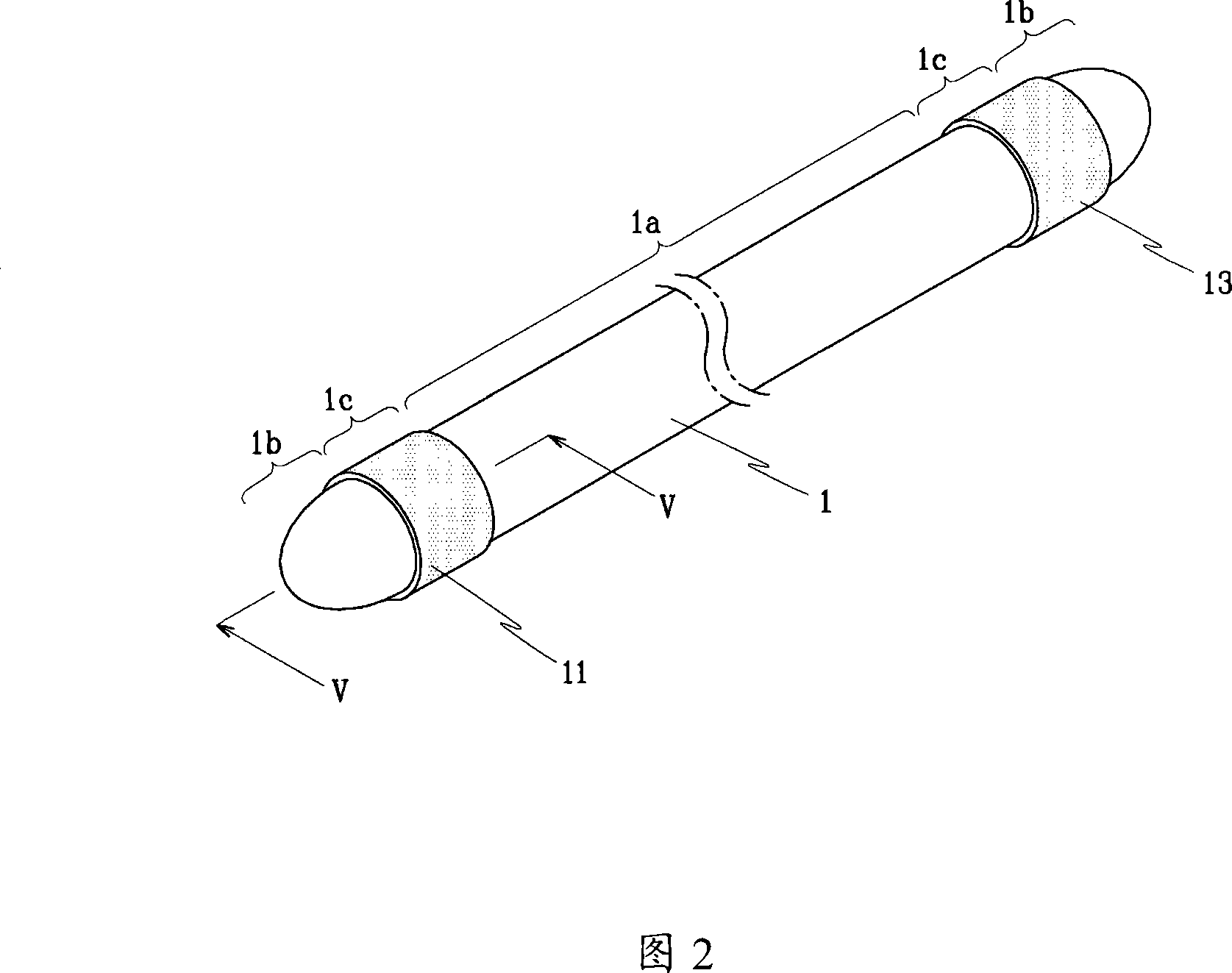

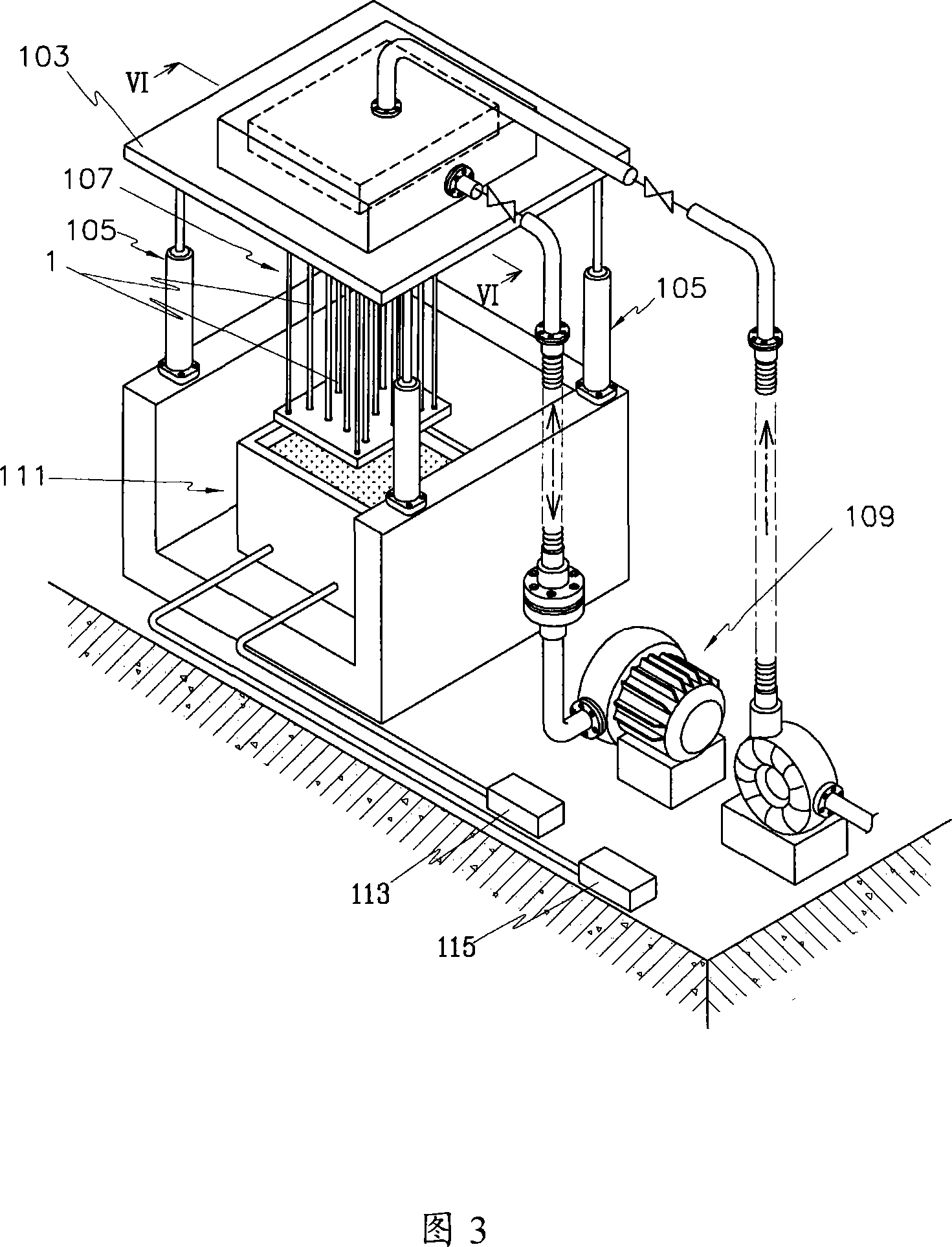

[0024] Fig. 2 is a perspective view illustrating the appearance and structure of a fluorescent lamp in an embodiment of the present invention, Fig. 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com