Separated fluorescent light

A fluorescent lamp and separate technology, applied in the field of fluorescent lamps, can solve the problems of impossible recycling, increased manufacturing cost, use cost, increased energy consumption, material consumption and labor consumption, etc., to achieve the highest conversion efficiency, reduce the total burden, Effects that are easy to handle separately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiments are further described in detail below in conjunction with accompanying drawings

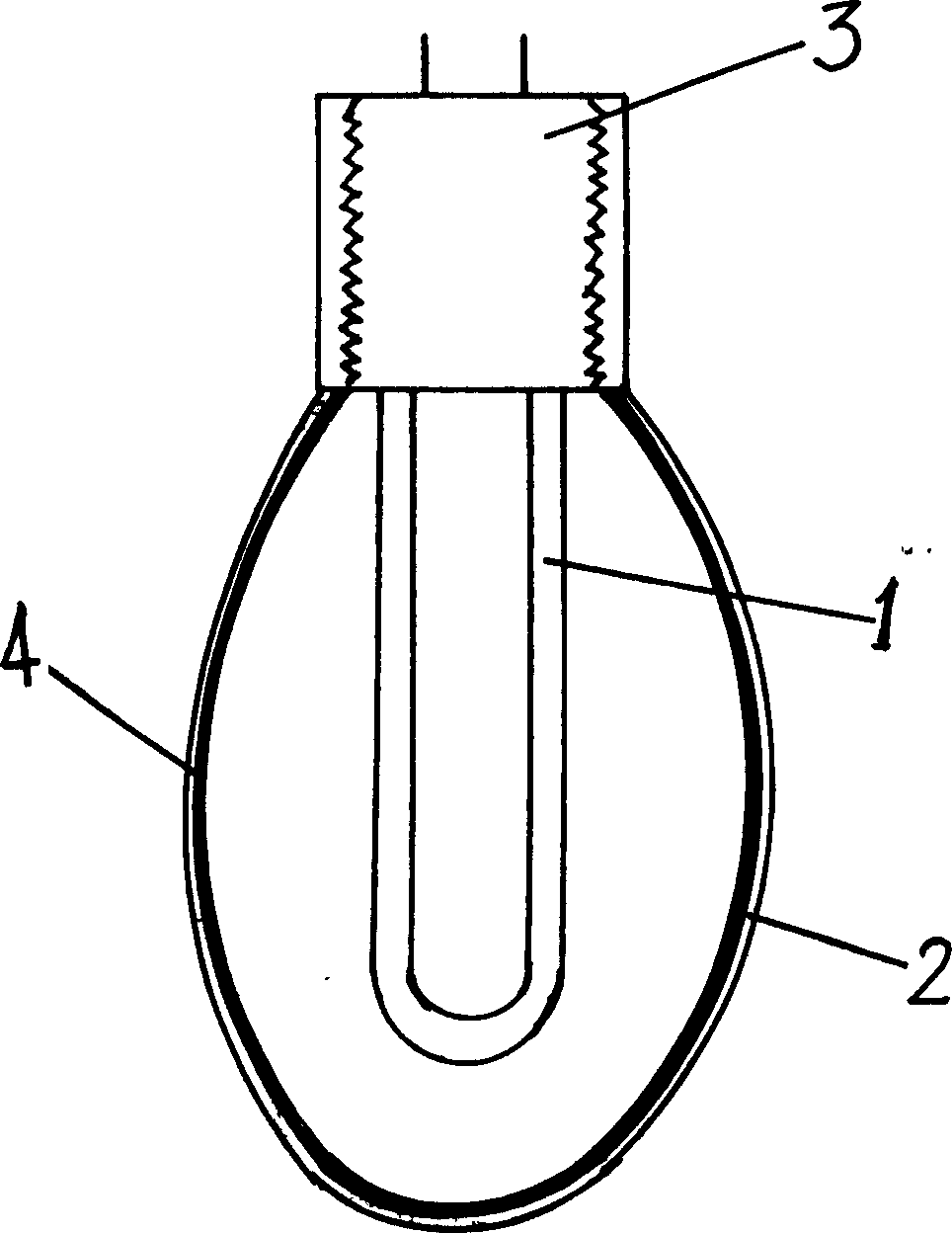

[0009] refer to figure 1 , 1-ultraviolet generating device; 2-visible light conversion device; 3-lamp holder; 4-fluorescent adhesion layer. As shown in the figure, the ultraviolet generating device (1) is composed of a closed quartz glass tube with good ultraviolet permeability. There is an extractable solid metal core (usually a copper core) in the tube, and the inner core of the tube is connected with a filament with electronic powder. The outer core end of the tube is electrically connected to the output end of the ballast, and the end of the ultraviolet generating device (1) is fixedly connected to the lamp holder (3); the tube is filled with a certain amount of metal mercury, and the quartz tube is vacuumed and injected with an appropriate amount of inert gas. Produces large amounts of intense UV light. The ultraviolet light passes through the wall of the quartz tube and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com