Graphene-containing lubricating oil and preparation method thereof

A technology of graphene and lubricating oil, which is applied in the field of graphene-containing lubricating oil and its preparation, can solve the problems of exhaust gas, pollutants, and environmental pollution, and achieve the effects of prolonging service life, reducing environmental pollution, and improving technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

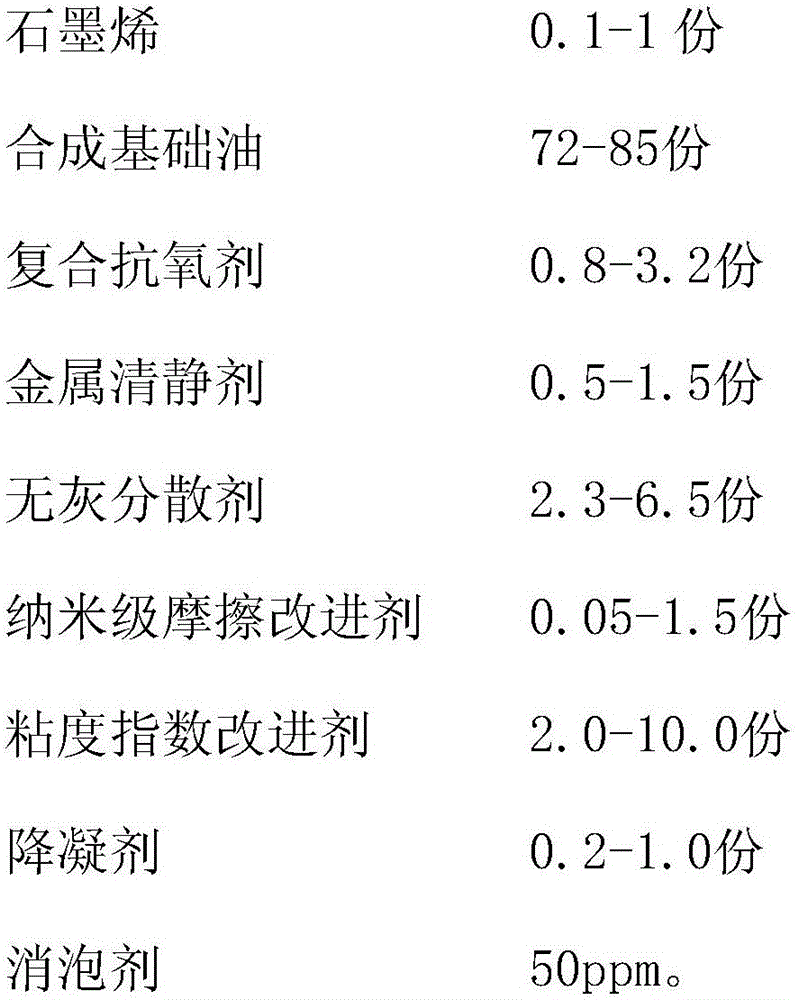

[0026] The invention provides a graphene lubricating oil and a preparation method thereof. The components of the graphene lubricating oil are composed of: a synthetic base oil, a composite antioxidant, a metal cleaner, an ashless dispersant, and a nanoscale friction modifier , Viscosity index improver, pour point depressant, defoamer, the content of each component includes: 0.1-1 part of graphene, 72-85 parts of synthetic base oil, 0.8-3.2 parts of composite antioxidant , Metal tranquilizer 0.5-1.5 parts, ashless dispersant 2.3-6.5 parts, nano-scale friction modifier 0.05-1.5 parts, viscosity index improver 2.0-10.0 parts, pour point depressant 0.2-1.0 parts, defoamer 50ppm.

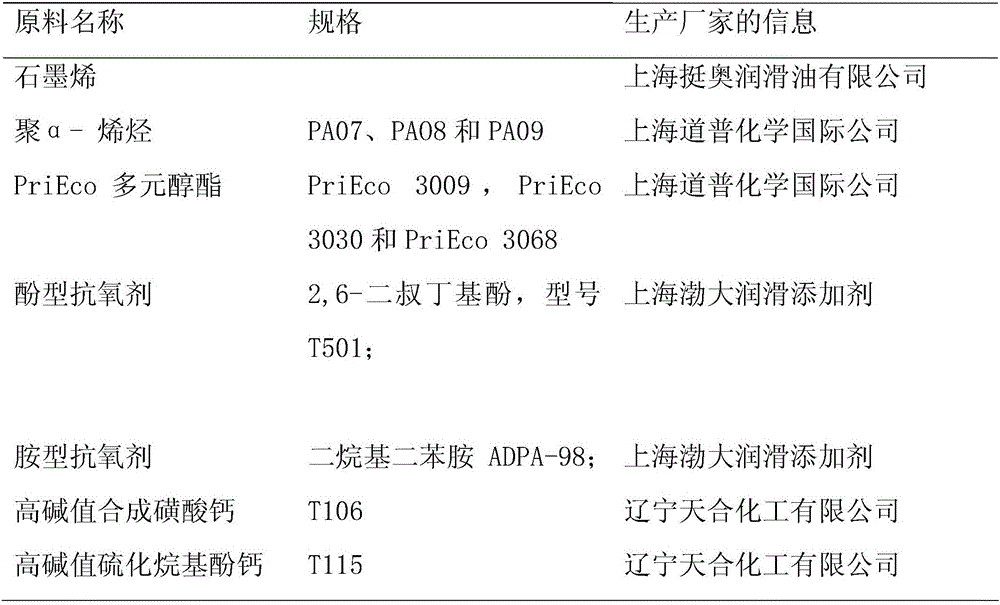

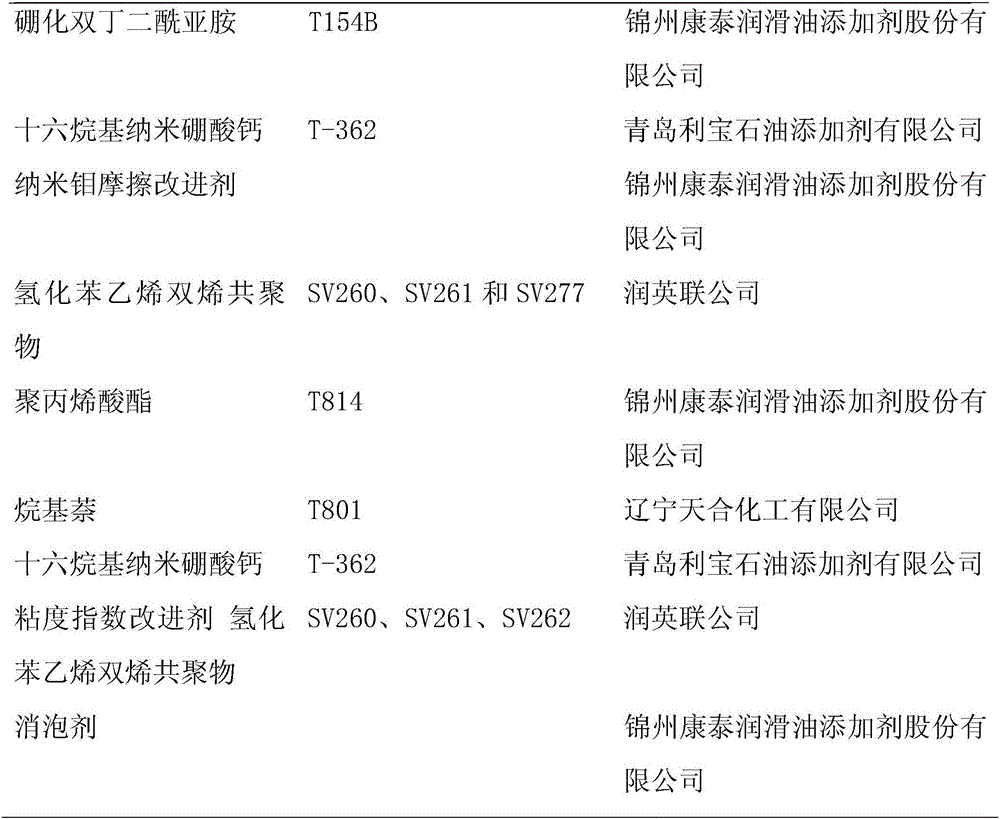

[0027] Wherein, the synthetic base oil proportioning by weight is: polyalphaolefin: PriEco polyol ester=5~10:5~10, wherein polyalphaolefin is at least one in PAO7, PAO8, PAO9, PriEco polyol The ester is at least one of PriEco 3030 and PriEco3030 polyol ester, provided by Shanghai Daopu Chemical Internati...

Embodiment 1

[0035] Recipe composition:

[0036]

[0037]

[0038] The preparation steps are as follows: add PAO8 60% and 14.2% of PriEco 3030 polyol ester at room temperature, and heat; under stirring at 62°C, add T814 0.5%, SV260 10.2%, and high alkali value sulfurized alkylphenate calcium 1.4%, T106 4.0%, stir evenly, add hexadecyl nano-calcium borate (T-362) 1.1%; friction modifier nano-organic molybdenum 0.2%, stir evenly, keep the original temperature and stir evenly, let it settle for 1 hour, That is the finished product.

Embodiment 2

[0040] Recipe composition:

[0041]

[0042]

[0043] The preparation steps are as follows: add PAO9 40%, PAO7 24.2% and 10% pentaerythritol ester at room temperature, and heat; while stirring at 64°C, add alkylnaphthalene T801 0.5%, SV261 10.1%, and perbasic alkanes successively. Calcium salicylate 1.2%, T106 4.0%, stir evenly, add 1.1% of nano-cerium naphthenate; friction modifier nano-organic molybdenum 0.2%; stir evenly, keep the original temperature, stir evenly, and let it settle for 1.5 hours to obtain finished product.

[0044] Chemical performance testing and simulation bench test, the main performance indicators are as follows:

[0045]

[0046] The test results are as follows:

[0047]A kind of green energy-saving gasoline engine oil disclosed by the present invention has passed three different types of models (Roewe sedan, BYD sedan and Great Wall off-road vehicle), and the actual driving test of 25,000 kilometers under different road conditions has foun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com